Exhibit 10.20

Certain portions of the exhibit have been omitted pursuant to Regulation S-K Item 601 because they are both (i) not material to investors and (ii) likely to cause competitive harm to the Company if publicly disclosed, and had been marked with “[***]” to indicate where omissions have been made.

Statement of Work:

LaaS Tech Center Design & Implementation

[***]

Berkshire Grey, Inc.

Proposal # 1907101330, Rev. 2

August 8, 2019

| Confidential Information | 1 | © Berkshire Grey, Inc. 2019 |

THIS STATEMENT OF WORK (“SOW”) is made a part of and wholly incorporated into the Technology Acceleration Agreement dated June 6, 2019 by and between Berkshire Grey, Inc., a Delaware corporation (“Berkshire Grey”) whose principal place of business is located at 10 Maguire Road, Building 4, Suite 190, Lexington, MA 02421 and SoftBank Robotics Corp., a Japanese Corporation whose principal address is located at 1-9-2 Higashi-shimbashi,Minato- ku,Tokyo JAPAN (“SoftBank”). ”) and is effective as of the date last signed by both parties hereto (“SOW Effective Date”). In the event of a conflict of terms and conditions the following order of precedence will apply: (i) the Technology Acceleration Agreement, and (ii) the SOW. Any capitalized terms not defined in this SOW will have the same meaning as in the Agreement.

This SOW defines the project scope, clarifies the roles and responsibilities associated with the project, and serves as the Parties’ agreement to begin work hereunder. The work provided for will be governed by the terms of the Agreement and this SOW. This SOW is used to communicate the project commitments and objectives to Berkshire Grey and to set out each Party’s roles and responsibilities. Signature of this SOW constitutes acceptance of the terms defined herein.

The work covered hereunder includes, but is not necessarily limited to, a) the Equipment, Software, and the System as a whole, and b) related professional services outlined herein. The work will be performed within the provided timeframe and under the terms contained both herein and in the Agreement. The work provided by Berkshire Grey will include:

| 2.2 | Additional Technology Acceleration |

| 2.2.2 | Picking from Tote Subdivisions |

| 2.2.3 | Alternate Robot Integration |

| 2.2.4 | SKU Enrollment Process |

It is mutually understood that business requirements, resources and dates may change upon mutual consent of the Parties. Customer is responsible for revising the estimated Project plans and requesting changes to the requirements for Equipment or the Services. Changes to the Equipment or the Services described in this SOW will be subject to mutual written agreement of the parties. Berkshire Grey will not commence work on any such change unless and until the change has been agreed to in writing by both Parties.

| Confidential Information | 2 | © Berkshire Grey, Inc. 2019 |

IN WITNESS WHEREOF, each party warrants that its respective signatory whose signature appears below is duly authorized by all necessary and appropriate corporate action to execute this SOW on behalf of such party.

| BERKSHIRE GREY, INC | | SoftBank Robotics Corp. |

| | | |

| By: | /s/ Tom Wagner | | By: | /s/ Kenichi Yoshida |

| Print Name: | Tom Wagner | | Print Name: | Kenichi Yoshida |

| Title: | CEO | | Title: | Chief Business Officer |

| | | | | |

| Date: | | | Date: | |

| Confidential Information | 3 | © Berkshire Grey, Inc. 2019 |

Legal Information and Confidentiality

All information contained herein (the “Proposal”) and disclosed to SoftBank by Berkshire Grey (the “Parties”) is subject to the confidentiality provision in the Technology Acceleration Agreement (TAA) between SoftBank and Berkshire Grey dated June 7, 2019.

| Confidential Information | 4 | © Berkshire Grey, Inc. 2019 |

[***]

With our unique automation technology, we aim to give SoftBank an essential lever in the virtuous cycle: improving operational efficiency. Labor is the biggest cost factor in order fulfillment today and changing demographics across the globe will increase the cost of labor. Automated unit handling will free SB’s LaaS business from the need for a vast workforce, which has cascading effects. Labor independence enables operations closer to population centers where labor markets are tighter. Inventory closer to customers cuts transportation costs and gives a competitive advantage in shipping times. Efficiency lowers costs, improves the customer experience, and attracts more LaaS clients, continuing the cycle.

We propose a partnership – a Technology Acceleration Agreement (TAA) – through which BG will fast-track the development of further capabilities that will ensure customer satisfaction in automated e-commerce and unlock even greater operational efficiency.

[***]

| Confidential Information | 5 | © Berkshire Grey, Inc. 2019 |

Table of Contents

| 1 | Executive Summary | 5 |

| 2 | Introduction | 7 |

| | 2.1 | | Background and Rationale | 7 |

| | 2.2 | | Objectives | 8 |

| | 2.3 | | Benefits and Impacts | 8 |

| | 2.4 | | Overall Approach | 8 |

| 3 | Technology Acceleration Program | 9 |

| | 3.1 | | [***] | 9 |

| | | 3.1.1 | | | Methodology | 9 |

| | | 3.1.2 | | | [***] | |

| | | 3.1.3 | | | [***] | |

| | | 3.1.4 | | | Larger Solution Space | 10 |

| | | 3.1.5 | | | Key Performance Indicators | 10 |

| | 3.2 | | Additional Technology Acceleration | 10 |

| | | 3.2.1 | | | Tote Consolidation | 10 |

| | | 3.2.2 | | | Picking from Tote Subdivisions | 10 |

| | | 3.2.3 | | | Alternate Robot Integration | 10 |

| | | 3.2.4 | | | SKU Enrollment Process | 11 |

| | | 3.2.5 | | | Cost Reduction Activities | 11 |

| | | 3.2.6 | | | Proposed Schedule of Activities | 11 |

| 4 | Facilities and Equipment | 12 |

| | 4.1 | | Integrated System Test | 13 |

| | 4.2 | | Lab Space | 13 |

| | 4.3 | | Prototyping Space | 14 |

| 5 | | Commercial | 14 |

| | 5.1 | | Pricing & Pricing Validity | 14 |

| | | 5.1.1 | | | Pricing for Technology Acceleration Program | 14 |

| | | 5.1.2 | | | Pricing Exclusions | 14 |

| | 5.2 | | Payment Invoices & Payment Schedule | 14 |

| Confidential Information | 6 | © Berkshire Grey, Inc. 2019 |

| 2.1 | Background and Rationale |

The purpose of this work is to accelerate the development of new capabilities that can be integrated into the various pick cells needed [***]. In our proposal Robotic Picking Cells Design & Implementation [***] we have proposed to integrate multiple instances of these three cell types into [***] operations, with the goal of automating order fulfillment at reduced labor and operational costs. The three cell types support the flow of goods through the distribution center: Induction Cells transfer items from AS/RS-delivered inventory totes to trays destined for a [***] pack items directly from inventory totes into a single shipping container; and [***] pack items delivered on trays [***] into a shipping container.

[***]

In addition to these [***] these other capabilities are of importance to SB:

| ● | Picking from tote subdivisions |

| ● | Tote consolidation at, e.g., Induction Cells |

| ● | Robot cells based on other robot arm vendors [***]. |

| ● | Development of SKU enrollment procedures. |

| ● | Define cost out activities based on SBR volume commits and future engineering design changes. |

Tote subdivisions and tote consolidation are tools to increase the cube utilization of the AS/RS – they increase the utilization of space within totes. Robotic picking from subdivided totes and consolidation will support cube utilization.

| Confidential Information | 7 | © Berkshire Grey, Inc. 2019 |

Our primary goal is to accelerate the development of the capabilities described above so that they can support SB’s efforts to create a successful LaaS business – achieving high customer satisfaction, and lower operational costs compared with manual operations. This primary goal translates to several objectives:

| (1) | Enable pick cells to handle a high proportion of units [***]. |

| (2) | Integrate the above capabilities into the three pick cell types destined for [***]. |

| (3) | Improve field maintainability in future cells in Japan. |

The proposed capabilities in Berkshire Grey’s approach have several key benefits:

| ● | Robotic unit picking with a white-glove level of care for goods provides SB’s LaaS business with a unique capability that both saves on labor costs and keeps customers coming back. |

| ● | Automated operations are less subject to fluctuations in personnel over the course of a day (no lunch, no bathroom breaks, no shift changes) and year (no need to ramp up labor for peak). |

Our program is intentionally structured to focus on delivering these technologies as quickly as possible:

| ● | Accelerated development is necessarily closed-loop in nature. We build out minimum viable solutions, continually measure progress towards our goals, and re-vector when needed. [***] for Packing, tied to objectives (1) and (2), respectively. |

[***]

| ● | The heart of the Tech Center is an integrated test facility. We are not developing isolated components, but complete solutions. We test them as such in an integrated facility that simulates the flow of goods through the DC. This helps catch and mitigate integration problems earlier rather than later. Around the tech center, we include lab space and rapid prototyping equipment to give engineers the space and tools they need to do things faster. |

¥ [***]

| Confidential Information | 8 | © Berkshire Grey, Inc. 2019 |

| ● | Progress towards goals and any issues, will be updated on a 6-week cadence. BG will also provide intermittent, informal updates as development progresses. |

| 3 | Technology Acceleration Program |

Over the past several months, we have been thinking carefully about the how to solve the challenges faced by operationalizing a white-glove level of service and the ability to place items for packing. The sections ahead describe a prudent and pragmatic approach to building this capability.

Operational efficiency cannot compromise quality. Product and packaging integrity are essential aspects of quality for the Japanese consumer who will reject dented, bent, punctured or crushed goods. Rejections are expensive to handle and create a poor customer experience that can send customers to competitors. Our aim in this thrust is to reduce rates of damage that may occur to products or their packaging when they are being picked and placed by robot, with the greater goal of ensuring customer satisfaction.

We start from a position of strength in both coverage of SKUs and in limited rates of damage to SKUs. BG automation was tested against human performance in a blind test of product damage. In that test, more items were found to be damaged after human handling than after automated handling. Damage, though, can occur and the most common causes of damage on products are two-fold: blisters forming on packaging due to vacuum; and products becoming dented because the gripper is too forceful picking them up, placing them or dropping them.

We adopt an engineering methodology that uses data to inform development, investigates root causes and maps out interdependencies, and employs objective surrogates to improve efficiency of testing:

[***]

| Confidential Information | 9 | © Berkshire Grey, Inc. 2019 |

These points highlight an approach to [***] that concentrates efforts on the simplest possible solutions to the biggest problems. The examples that follow illustrate root cause analysis, quick experimentation to verify hypotheses, and some outcomes of aligned testing.

[***]

| 3.1.4 | Larger Solution Space |

Our approach to the problem is set out in section 3.1.1 – this governs a process by which we evaluate gaps and assess potential solutions to address those gaps. We expect to draw from a set of solutions that include software, hardware and mechatronics. They may include but are not limited to:

[***]

We view each of these solutions as having potential impact in different phases of the pick, transfer and place operation. The following table illustrates some of the potential solutions above and their potential impacts relative to three major categories where damage can occur, namely large heavy objects, items with sensitive package wrapping, and items with fragile packing containers or contents.

[***]

| 3.1.5 | Key Performance Indicators |

In order to measure progress towards a [***] capability, we employ the following key performance indicators (KPIs):

[***]

Each of these measures are based on an agreed upon SKU test set, which we have a recommended a process for deriving in the separately delivered Recommended Methodology for SKU Set Selection.

| 3.2 | Additional Technology Acceleration |

[***]

| 3.2.2 | Picking from Tote Subdivisions |

[***]

| 3.2.3 | Alternate Robot Integration |

[***]

| Confidential Information | 10 | © Berkshire Grey, Inc. 2019 |

| 3.2.4 | SKU Enrollment Process |

Berkshire Grey will work with SoftBank to develop a SKU enrollment process. This includes defining what characteristics should be manually entered (e.g. with a user interface) and automatically acquired (e.g. with Cubiscan-type devices) when SKUs are enrolled. It also includes the definition of database schemas for recording acquired data.

| 3.2.5 | Cost Reduction Activities |

Berkshire Grey will work with SoftBank to target reduce costs for future RPC units based on SBR volume commits and engineering “cost out” activities.

The overall cost reduction schedule for the [***] after execution of the distribution agreement for the System between the parties is outlined in the table below:

The parties hereby agree that further details of the terms and conditions of the cost reduction activities shall be set forth in the distribution agreement of the System (defined in the TAA) to be executed between the parties.:

| # RPC Units |

| 1-14 | | | 15-49 | | | | 50-99 | | | | 100-249 | | | | 250-749 | | | | 750-1999 | | | | 2000+ | |

[***]

| 3.2.6 | Proposed Schedule of Activities |

The table below provides an outline of activities for phasing in the tech acceleration needed for [***] and additional technology acceleration as described in Section 3. It may be necessary to move dates from time to time. Date changes will be discussed with SBR.

Berkshire Grey will coordinate validation and review events with SBR such that SBR can join the validation event.

| Title | | Estimated Start | | Estimated End |

| [***] | | [***] | | [***] |

| [***] and Experiments | | [***] | | [***] |

| Pre-Grasp | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| Grasp | | [***] | | [***] |

| Confidential Information | 11 | © Berkshire Grey, Inc. 2019 |

| Title | | Estimated Start | | Estimated End |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| Transfer | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| Place | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| | | [***] | | [***] |

| Additional Tech | | [***] | | [***] |

| Picking from Subdivisions | | [***] | | [***] |

| Picking from Subdivisions MVP | | [***] | | [***] |

| SKU Classification | | [***] | | [***] |

| Initial Definition | | [***] | | [***] |

| Implementation | | [***] | | [***] |

| SKU Classification Tool MVP Released | | [***] | | [***] |

| Tote Consolidation | | [***] | | [***] |

| Tote Consolidation MVP Released | | [***] | | [***] |

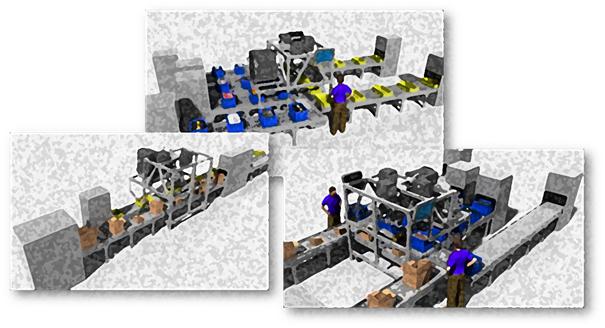

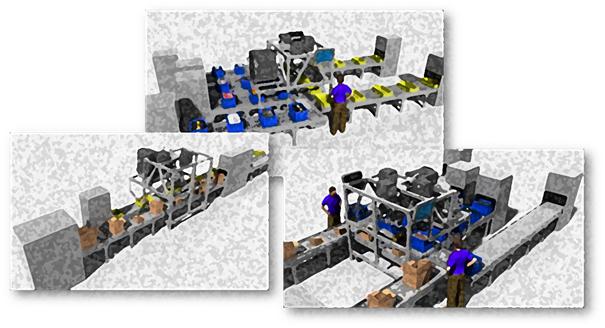

| 4 | Facilities and Equipment |

A dedicated space with the purpose of collocating the development team with hardware and equipment to speed development will be built out. The space will contain three principal areas:

[***]

Depending on timing of signed SOW and signed lease for lab space, Berkshire Grey may start some development work in our existing workspace. In that case we cannot guarantee the lab

| Confidential Information | 12 | © Berkshire Grey, Inc. 2019 |

space is only for SBR. However, we can guarantee that the SBR work will be in a private area where BG visitors will not have access to that equipment or see the work.

Access to most Berkshire Grey space is controlled via access card and only approved BG personnel will have access to the area.

The figure below shows the relative space utilization of the facility and highlights some of the major capabilities.

[***]

| 4.1 | Integrated System Test |

The Integrated System Testing area is critical to the development and verification of our performance metrics and goals. This system allows us to test, measure, and inspect our picking performance and quality throughout the process flow including inspecting items after they are fully packed. A conceptual system flow is shown in the diagram below.

[***]

The flow of material mimics on a much smaller scale the flow of goods within the [***] DC. The facility simulates the entire process of retrieval from mock inventory to outbound box shipping with quality checks in between and after each cell to verify system performance:

[***]

This end-to-end test facility allows full system functionality to be observed and tested as well as the system KPIs to be benchmarked against software and hardware improvements.

The lab space will be the first part of the tech center stood up for testing. The Development RPCs will be used to understand and rapidly iterate software and hardware toward our developments in [***]. The pick cells will have the ability to have new features added and removed quickly to facilitate active development.

| Confidential Information | 13 | © Berkshire Grey, Inc. 2019 |

There will be a section of the floor devoted to Quality Assurance to document and quantify product integrity and packing efficiency as development progresses. Lastly, there will be a storage space for curating various test SKUs.

SBR visits to the Lab Space must be coordinated with BG in advance. Due to the proprietary nature of this work and other work in our lab, BG may decline a visit request and ask SBR to adjust visit date, duration or members..

The prototyping space will house equipment to enable rapid development of new hardware solutions to support our research thrusts. A 3D printer will allow unique gripper designs to be designed printed and tested in the same day allowing rapid hardware maturity to be developed. A material property testing station will allow live testing of important subsystems and enable more detailed measurements to be taken for product integrity on the [***]. General assembly stations will support prototypes sub-system and system assembly. Lastly, other rapid prototyping equipment may be procured as necessary to support the project and deliveries. These include but are not limited to a laser cutter and milling machine.

| 5.1 | Pricing & Pricing Validity |

| 5.1.1 | Pricing for Technology Acceleration Program |

This agreement covers the work set out in the above SOW, in improved handling to reduce damage, packing boxes for e-commerce order fulfillment, enabling picking from subdivisions, integration of other robot vendors, work towards consolidation at cells, and SKU compatibility determination. The total price for the Technology Acceleration Program is outlined as below:

[***]

Scope items specifically excluded are totes, LaaS boxes and LaaS test product. It is assumed that SoftBank would provide these items in necessary quantities.

| 5.2 | Payment Invoices & Payment Schedule |

Berkshire Grey will invoice SoftBank per the schedule below. Invoices will be payable by SoftBank to Berkshire Grey [***] (as agreed in Section 8.2 of the signed MPLA). The payment milestone structure for the Technology Acceleration Center is as follows:

| Invoice Amount | | Invoice Items | | Invoice Date |

| [***] | | [***] | | [***] |

| [***] | | [***] | | [***] |

| Confidential Information | 14 | © Berkshire Grey, Inc. 2019 |