The initial assay method for Au utilizes a trace method fire-assay where 30 grams of pulp is fused in a lead collection fire assay. The prill is digested in aqua-regia and the gold content determined by AAS. The range of this technique is 0.002 to 1ppm. Over-range values are re-analyzed using an ore-grade method. The range of the ore-grade analysis is 0.01 to 100ppm. The assay for base metals uses a 48-element suite (ME-MS61). A sub-sample of the pulp is digested using a HF/multi acid ‘Near-Total’ digest. Analytes tested are: Ag, Al, As, Ba, Be, Bi, Ca, Cd, Ce, Co, Cr, Cs, Cu, Fe, Ga, Ge, Hf, In, K, La, Li, Mg, Mn, Mo, Na, Nb, Ni, P, Pb, Rb, Re, S, Sb, Sc, Se, Sn, Sr, Ta, Te, Th, Ti, Tl, U, V, W, Y, Zn & Zr. An ‘‘Ore Grade’’ OG62 analysis is used to re-assay samples for Cu, for samples assaying higher than 0.4% Cu in the method outlined above. This technique is also a four-acid digest, with ICP-AES or AAS finish. Assay results are reported electronically to Northparkes via email. Where re-assaying due to failed quality assurance and quality control occurred, the laboratory is required to report the whole batch to Northparkes (including the samples not re-assayed). QA/QC data are reviewed and monitored on a continuous basis.

A comprehensive independent quality control program is implemented by Northparkes as a standard part of each drilling program, which includes standards, blanks and duplicate samples. A suite of matrix-matched Northparkes standards are utilized. Each standard is selected by the logging geologist to match the appropriate level of Cu, Au, and As. Standards are inserted into sample batches at a minimum rate of 1:20. Blanks are also inserted into batches at the rate of 1:20 and consist of locally sourced basalt gravel. Duplicate samples are taken at various stages of sample preparation to assess sampling error; these comprise coarse field duplicates splits of RC samples (1:10); duplicate samples collected after crushing and pulverizing (1:20); internal laboratory repeats (1:20) of samples from the same pulp packet and within the same sample batch; and half core duplicates (1:100).

Dry bulk density is measured using two different methods on the same sample — the caliper method (diametric) and a water displacement (immersion) method. Measurements are generally taken at 20 m intervals downhole on diamond drill core. Samples are prepared by cutting 20 cm cylinders of core, rejecting those where substantial chipping occurred when cutting the ends. Samples are weighed after drying in air and then oven dried overnight (~12 hrs.) at around 105°C. The oven dried samples are then cooled and weighed to determine the dry sample weight. Caliper bulk density measurements are compared with water displacement measurements as a verification step. In the case of samples where the absolute percentage difference between the two methods is more than 5%, the method closest to 2.68 t/m3 (the average value) is selected as the preferred method, effectively rejecting any erroneous values. For estimation, density values less than 2.40 t/m3 are excluded and values greater than 3.00 t/m3 are cut to 3.00 t/m3.

Mineral Processing and Metallurgical Testing

Metallurgical testwork is performed for each new deposit area as part of the technical studies that are conducted prior to developing a new deposit or cave lift. Metallurgical studies are focused on assessing the ore treatment characteristics of the respective mining area in the Northparkes processing circuit and assessing options to optimize throughput and recovery. Northparkes ore tends to exhibit consistent and predictable metallurgical characteristics and are well understood and characterized. Metallurgical testwork typically includes detailed mineralogical characterization, comminution testwork (including grindability and abrasivity), locked- cycle floatation on composite samples and dewatering tests.

Arsenic and fluorine are the main penalty elements for Northparkes concentrates and certain offtakers also penalize aluminium (from mica) and magnesium (from carbonates). Northparkes is able to blend its ore sources to manage deleterious elements to minimize penalties and the increasing balance of E26 and E22 ore will positively impact arsenic levels.

Mineral Resource and Mineral Reserve Estimates

Mineral Resources and Mineral Reserves are reported as at December 31, 2022. The Mineral Resource and Mineral Reserve estimates are completed using the latest approved block models, economic factors, reconciled mining production figures, processing and mining recoveries, and dilution. The estimates have been prepared by Competent Persons in accordance with guidelines and principles of the JORC Code 2012. All Mineral Resources and Mineral Reserves are reported on a 100% attributable basis to Northparkes.

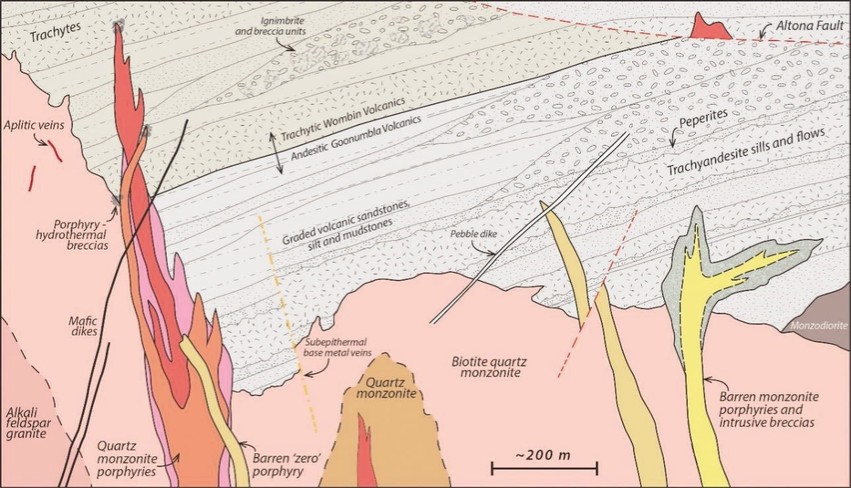

Validated raw drilling data was composited to top-down, 4 m run-length composites for all data, respecting key geological boundaries, which include: base of oxidation, ‘‘zero’’ porphyry, ‘‘half’’ porphyry and the Altona fault zone. Statistical analysis is conducted for each deposit and domain; grade distributions are not particularly skewed, with co-variances generally less than 2.0, with the exception of arsenic. Limited capping of high grades is required for copper, gold and silver. Variograms are developed for major and minor elements and bulk density for each deposit and domain. Block models are developed which appropriately account of the different lithologies.