Boa Esperança Project

NI 43-101 Technical Report on

Feasibility Study Update

Southern Pará State, Brazil

Effective Date: 31 August 2021

Prepared for: Ero Copper Corp.

1050 – 625 Howe Street, Vancouver, Canada

Prepared by: Ausenco Engineering Canada Inc.

1050 West Pender, Vancouver, Canada

List of Qualified Persons: Kevin Murray, P. Eng., Ausenco; Erin L. Patterson, P.E., Ausenco; Scott Elfen, P. Eng., Ausenco; Emerson Ricardo Ré, MAusIMM (CP), Ero Copper Corp.; Carlos Guzman, FAusIMM RM CMC, NCL.

CERTIFICATE OF QUALIFIED PERSON

Kevin Murray, P. Eng.

I, Kevin Murray, P.Eng., certify that:

1.I am employed as a Manager Process Engineering with Ausenco Engineering Canada Inc. (“Ausenco”), with an office address of 1050 West Pender Street, Suite 1200, Vancouver, BC Canada, V6E 3T4.

2.This certificate applies to the technical report titled “Boa Esperança Project NI 43-101 Technical Report on Feasibility Study Update,” that has an effective date of August 31, 2021, (the “Technical Report”).

3.I graduated from the University of New Brunswick, Fredericton NB, in 1995 with a Bachelor of Science in Chemical Engineering. I am a member in good standing of Engineers and Geoscientists British Columbia, License# 32350.

4.I have practiced my profession for 21 years. I have been directly involved in all levels of engineering studies from preliminary economic analysis to feasibility studies. I have been directly involved with test work and flowsheet development from preliminary testing through to detailed design and construction.

5.I have read the definition of “Qualified Person” set out in the National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that by virtue of my education, affiliation to a professional association and past relevant work experience, I fulfill the requirements to be a “Qualified Person” for those sections of the Technical Report that I am responsible for preparing.

6.I have not visited the Boa Esperança Project.

7.I am responsible for sections 1.2, 1.8, 1.13, 1.16, 1.17, 1.20, 1.21, 2, 3, 13, 17, 21.1 - 21.1.6, 21.1.8 - 21.1.11, 21.2.1, 21.2.3 -21.2.5, 25.5, 25.10, 25.14, 25.15, 25.17-25.17.1.1, 25.17.2 - 25.17.2.1, 25.18, 25.2, 25.3, 25.4, 25.6, 26 and 27 of the Technical Report.

8.I am independent of Ero Copper Corp., as independence is defined in Section 1.5 of NI 43-101. I have had no previous involvement with Boa Esperança Project.

9.I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument.

10.As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the Technical Report not misleading.

Dated this 12th day of November of 2021.

“Signed and sealed”

Kevin Murray, P.Eng.

CERTIFICATE OF QUALIFIED PERSON

Erin L. Patterson, P. E.

I, Erin L. Patterson, P.E., certify that:

1.I am employed as a Senior Study Manager with Ausenco Engineering USA South Inc. (“Ausenco USA”), an affiliate of Ausenco Engineering Canada Inc., with an office address of 4701 Port Chicago Highway, Suite 120, Concord, CA 94520.

2.This certificate applies to the technical report titled “Boa Esperança Project NI 43-101 Technical Report on Feasibility Study Update,” that has an effective date of August 31, 2021, (the “Technical Report”).

3.I am a graduate of the University of Arizona and received a Bachelor of Science in Chemical Engineering in 2005.

4.I am a registered professional Engineer in the state of Arizona, License No. 54243.

5.I have practiced my profession for 16 years. I have been directly involved in all levels of engineering studies from conceptual studies to feasibility studies as well as mineral projects in the construction and operation stages. The works I have been directly involved in include the mineral commodities copper, nickel, gold, and silver. I have been directly involved with process design, including testwork interpretation and flowsheet development, design specifications, cost estimating, and execution of mineral projects.

6.I have read the definition of “Qualified Person” set out in the National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that by virtue of my education, affiliation to a professional association and past relevant work experience, I fulfill the requirements to be a “Qualified Person” for those sections of the Technical Report that I am responsible for preparing.

7.I have not visited the Boa Esperança Project.

8.I am responsible for sections 1.18, 1.19, 2, 3, 22, 24, 25.16, 25.17-25.17.1.1, 25.17.2 - 25.17.2.1, 25.18, 26, and 27 of the Technical Report.

9.I am independent of Ero Copper Corp., as independence is defined in Section 1.5 of NI 43-101. I have had no previous involvement with Boa Esperança Project.

10.I have read NI 43-101 and Form 43-101F1, and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument and form.

11.As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the Technical Report not misleading.

Dated this 12th day of November, 2021.

“Signed and sealed”

Erin L. Patterson, P.E.

CERTIFICATE OF QUALIFIED PERSON

Scott C. Elfen, P.E.

I, Scott C. Elfen, P.E., do hereby certify that:

1.I am the Global Lead Geotechnical and Civil Services of Ausenco Engineering Canada Inc., 855 Homer Street, Vancouver, BC V6B 2W2, Canada.

2.This certificate applies to the technical report titled “Boa Esperança Project NI 43-101 Technical Report on Feasibility Study Update” that has an effective date of August 31, 2021 (the “Technical Report”).

3.I graduated from the University of California, Davis with a Bachelor of Science degree in Civil Engineering (Geotechnical) in 1991.

4.I am a Registered Civil Engineer in the State of California (No. C56527) by exam since 1996 and I am also a member of the American Society of Civil Engineers (ASCE), Society for Mining, Metallurgy & Exploration (SME) that are all in good standing.

5.I have practiced my profession continuously for 24 years and have been involved in geotechnical, civil, hydrological, and environmental aspects for the development of mining projects, including feasibility studies on numerous underground and open pit base metal and precious metal deposits in North America, Central and South America, Africa and Australia.

6.I have read the definition of “Qualified Person” set out in National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that by virtue of my education, affiliation with a professional association (as defined in NI 43-101) and past relevant work experience, I fulfill the requirements to be a “Qualified Person” for those sections of the Technical Report that I am responsible for preparing.

7.I have not visited Boa Esperança Project Site.

8.I am responsible for sections 1.11, 1.14, 2, 3, 15.2.4, 18, 25.8, 25.11, 25.17 - 25.17.1.1, 25.17.1.3, 25.17.2 - 25.17.2.1, 25.17.2.3, 25.18, 26.2.1, 26.5 and 27 of the Technical Report.

9.I am independent of Ero Copper Corp. as independence is defined in Section 1.5 of NI 43-101.

10.I have had no prior involvement with the Boa Esperança Project.

11.I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument.

12.As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the Technical Report not misleading.

Dated this 12th day of November of 2021.

“Signed and Sealed”

_____________________________________

Scott C. Elfen, P.E.

CERTIFICATE OF QUALIFIED PERSON

Emerson Ricardo Re, MAusIMM (CP)

I, Emerson Ricardo Re, MAusIMM (CP), certify that I am employed as a Resources Manager of Ero Copper Corp., with an office address of 625 Howe Street, Suite 1050, Vancouver – BC, Canada. This certificate applies to the technical report titled, “Boa Esperança Project NI 43-101 Technical Report on Feasibility Study Update,” that has an effective date of 31 August 2021, (the “Technical Report”).

I graduated from São Paulo State University with a degree in geology in 1999 and received a master’s in mining engineering at Polytechnic School - São Paulo University in 2002. I am a chartered professional by MAusIMM (CP) (No. 305892) and by the Chilean Mining Commission (No. 0138). I have practiced my profession for 22 years. I have been directly involved in the mineral sector as I have worked directly in management of mineral resources, generating the organic growth of mineral reserves, ensuring the health of the mineral enterprise through the implementation of strategic exploration routines (Life of Exploration ) and mining plan integrated with the production plan and customer requirements.

With experience in open pit and underground projects and operations, I was involved in the development of projects in the embryonic stage, feasibility and operation restructuring which I can cite as examples:

–Guaju Mine - Titanium (Millennium) - Open pit

–Morro do Ouro - Ouro (Kinross Gold) - Open pit

–Jacobina Mine - Gold (Yamana Gold) – Underground

–San Andres Mine - Gold (Yamana Gold, Honduras) - Open pit

–Chapada Mine - Copper and Gold (Yamana Gold) - Open pit

–Fazenda Brasileiro Mine - Ouro (Brio Gold) - Open pit and Underground

–Caraíba Mine - Copper (Ero Copper) - Open pit and Underground

–Boa Esperança Project - Copper (Ero Copper) - Open pit

I highlight the multidisciplinary team management and implementation of ESG procedures as the basis for the actions taken that culminated in the success achieved in the projects listed above.

I have read the definition of “Qualified Person” set out in the National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that by virtue of my education, affiliation to a professional association and past relevant work experience, I fulfill the requirements to be a “Qualified Person” for those sections of the Technical Report that I am responsible for preparing.

I visited the Boa Esperança Project between 29 September to 1 October 2020 for a visit duration of 3 days. I am responsible for sections 1.1, 1.3, 1.4, 1.5, 1.6, 1.7, 1.9, 1.15, 2, 3 - 12, 14, 19, 20, 23, 25.1, 25.2 – 25.4, 25.6, 25.12, 25.13, 25.17 - 25.17.1.1, 25.17.2 - 25.17.2.1, 25.18, 26, and 27 of the Technical Report.

I am not independent of the Company as defined by Section 1.5 of NI 43-101.

I have had prior involvement with the property that is the subject of this Technical Report in my role at the Company since September 2019 .

I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the Technical Report not misleading.

Dated this 12th day of November, 2021.

“Signed and sealed”

Emerson Ricardo Re,

Resources Manager of the Ero Copper Corp.

MAusIMM (CP) (No. 305892)

Chilean Mining Commission (No. 0138)

CERTIFICATE OF QUALIFIED PERSON

Carlos Guzmán, FAusIMM RM CMC

I, Carlos Guzmán, FAusIMM RM CMC, certify that I am employed as Principal and Project Director with NCL Ingeniería y Construcción SpA (“NCL”), with an office address of General del Canto 230, of 401, Providencia, Santiago, Chile. This certificate applies to the technical report titled “Boa Esperança Project, NI 43-101 Technical Report on Feasibility Study” that has an effective date of August 31, 2021. (the “Technical Report”).

I graduated from Universidad de Chile with a degree in Mining Engineering. I am a FAusIMM of the Australasian Institute of Mining and Metallurgy (229036) and a RM CMC of the Chilean Mining Commission (0119). I have practiced my profession for 26 years. I have been directly involved in reviews and reports as a consultant on numerous explorations, mining operation and projects around the world for due diligence and regulatory requirements and have extensive experience in mining engineering.

I have read the definition of “Qualified Person” set out in the National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that by virtue of my education, affiliation to a professional association and past relevant work experience, I fulfill the requirements to be a “Qualified Person” for those sections of the Technical Report that I am responsible for preparing.

I have not visited the Boa Esperança Project. I am responsible for Sections 1.10, 1.12, 2, 3, 15, 16, 21.1.7, 21.2.2, 25.7, 25.9, 25.17 - 25.17.1.2, 25.17.2 - 25.17.2.2, 25.18 and 26.1 of the Technical Report.

I am independent of Ero Copper Corp. as independence is defined in Section 1.5 of NI 43-101. I have had no previous involvement with the Boa Esperança Project.

I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument. As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make those sections of the Technical Report not misleading.

Dated this 12th day of November, 2021.

“Signed and sealed”

Carlos Guzmán

Mining Engineer, FAusIMM (229036), RM CMC (0119)

Important Notice

This report was prepared as National Instrument 43-101 Technical Report for insert Ero Copper (Ero Copper) by Ausenco Engineering Canada Inc. (Ausenco). The quality of information, conclusions, and estimates contained herein is consistent with the level of effort involved in Ausenco’s services, based on i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report. This report is intended for use by Ero Copper subject to terms and conditions of its contract with Ausenco. Except for the purposed legislated under Canadian provincial and territorial securities law, any other uses of this report by any third party is at that party’s sole risk.

Table of Contents

| | | | | |

1 Summary | |

1.1 Introduction | |

1.1.1 Key Outcomes | |

1.2 Terms of Reference | |

1.3 Property Description and Location | |

1.4 Ownership | |

1.5 Geology and Mineralization | |

1.6 Exploration | |

1.7 Data Verification | |

1.8 Metallurgical Testing | |

1.9 Mineral Resource Estimation | |

1.10 Mineral Reserve Estimation | |

1.11 Open Pit Geotechnical | |

1.12 Mining Methods | |

1.13 Recovery Methods | |

1.14 Project Infrastructure | |

1.14.1 Accessibility | |

1.14.1.1 Road | |

1.14.1.2 Rail | |

1.14.1.3 Air | |

1.14.2 Power | |

1.14.3 Accommodation | |

1.14.4 Waste Rock Facility | |

1.14.5 Low-Grade Stockpile | |

1.14.6 Tailings Storage Facilities | |

1.14.7 Water Management | |

1.14.8 Water Supply | |

1.14.9 Environmental and Social Considerations | |

1.14.10 Closure and Reclamation Considerations | |

1.14.11 Social Considerations | |

1.15 Markets and Contracts | |

1.16 Capital Cost Estimates | |

1.17 Operating Cost Estimates | |

1.18 Economic Analysis | |

1.19 Sensitivity Analysis | |

1.20 Interpretation and Conclusions | |

1.21 Recommendations | |

| | | | | |

| Boa Esperança Project | Page i |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

2 Introduction | |

2.1 Introduction | |

2.2 Terms of Reference | |

2.3 Qualified Persons | |

2.4 Site Visits and Scope of Personal Inspection | |

2.5 Effective Dates | |

2.6 Previous Technical Reports | |

2.7 Abbreviations | |

3 Reliance on other experts | |

3.1 Introduction | |

3.2 Property Agreements, Mineral Tenure, Surface Rights and Royalties | |

3.3 Environmental, Permitting, Closure, and Social and Community Impacts | |

3.4 Taxation | |

3.5 Markets | |

4 Property description and location | |

4.1 Property Description and Location | |

4.2 Mineral Title | |

4.3 Land Access and Surface Rights | |

5 Accessibility, climate, local resources, infrastructure, and physiography | |

5.1 Topography, Elevation and Vegetation | |

5.1.1 Air | |

5.2 Climate and Length of Operating Season | |

5.3 Local Resources & Infrastructure | |

6 History | |

6.1 Mapping and Sampling (Codelco) | |

6.2 Geophysical Surveys (Codelco) | |

6.3 Surveys and Investigations | |

6.4 2017 Mineral Resource and Mineral Reserve Estimates | |

6.5 2017 Mineral Reserve Estimate | |

7 geological Setting and Mineralization | |

7.1 Regional Geology | |

7.2 Local Geology | |

7.3 Deposit Geology | |

7.3.1 Lithologies | |

7.3.2 Mineralization | |

8 Deposit Types | |

8.1 Introduction | |

8.2 Geological Model | |

| | | | | |

| Boa Esperança Project | Page ii |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

9 Exploration | |

10 Drilling | |

10.1 Drilling by CODELCO (2003-2006) | |

10.1.1 Drilling Methodology | |

10.1.2 Drillhole Deviation | |

10.1.3 Core Logging Procedures | |

10.1.4 Core Storage | |

10.2 Drilling by MCSA (2008-2013) | |

10.2.1 Drilling Methodology | |

10.2.2 Drillhole Deviation | |

10.2.3 Core Logging Procedures | |

10.2.4 Core Storage | |

11 Sample Preparation, Analyses, and Security | |

11.1 Methods | |

11.2 Security Measures | |

11.3 Sample Preparation | |

11.4 Analysis | |

11.5 Quality Assurance and Quality Control Programs | |

11.6 QP Comments | |

12 Data verification | |

12.1 Procedures | |

12.2 Verification of Analytical Quality Control Data | |

12.3 Data Adequacy | |

13 Mineral Processing and Metallurgical Testing | |

13.1 Introduction | |

13.2 Sample Selection | |

13.3 Mineralogy | |

13.4 Head Grade Analysis | |

13.5 Sample Characteristics | |

13.5.1 Crushability and Grindability | |

13.6 Pre-Concentration Test | |

13.6.1 2015 SGS Geosol Jigging Test | |

13.7 Flotation Testwork | |

13.7.1 Flotation Condition Tests | |

13.7.1.1 Primary Grind Size | |

13.7.1.2 Rougher Flotation pH | |

13.7.1.3 Rougher Kinetics | |

13.7.1.4 Cleaner Kinetics | |

| | | | | |

| Boa Esperança Project | Page iii |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

13.7.2 Rougher Variability Flotation Tests | |

13.7.3 Open Circuit Cleaner Flotation Tests | |

13.7.4 Locked-Cycle Flotation Tests | |

13.7.4.1 LCT General Flowsheet | |

13.7.4.2 LCT Test Conditions | |

13.7.4.3 LCT Test Results | |

13.8 Magnetic Separation Test | |

13.9 Concentrate Quality | |

13.9.1 Copper Concentrate Quality | |

13.9.2 Pyrite Concentrate Quality | |

13.9.3 Iron Concentrate Quality | |

13.10 Thickening and Filtration | |

13.10.1 Copper Concentrate Thickening and Filtration Tests | |

13.10.2 Final Tailings and Pyrite Concentrate Thickening Tests | |

13.11 Pre-Concentration Assessment | |

13.12 Copper Recovery Projections | |

14 Mineral resource estimates | |

14.1 Introduction | |

14.2 Modeling Coordinate System | |

14.3 Drillhole Data Analysis | |

14.4 Topography | |

14.5 Geologic Model | |

14.6 Exploration Data Analysis | |

14.7 Contact Analysis | |

14.8 Specific Gravity | |

14.9 Variogram Analysis and Modeling | |

14.10 Block Model | |

14.11 Estimation Methodology | |

14.12 Model Validation | |

14.13 Resource Classification | |

14.14 Mineral Resource Statement | |

14.15 Mineral Resource Sensitivity | |

15 Mineral Reserve Estimates | |

15.1 Block Model | |

15.2 Open Pit Assumptions and Considerations | |

15.2.1 Block Size Analysis | |

15.2.2 Topography | |

15.2.3 Design Criteria | |

15.2.4 Geotechnical Considerations | |

| | | | | |

| Boa Esperança Project | Page iv |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

15.2.5 Geotechnical Program | |

15.2.6 Geotechnical Work plan | |

15.2.7 Pit Slope Analysis | |

15.2.8 Recommended Pit Slope Configuration | |

15.3 Cut-off Grades | |

15.3.1 Mining Loss and Dilution | |

15.4 Pit Limit Analysis | |

15.4.1 Pit Limit Sensitivities | |

15.5 Mineral Reserves Statement | |

15.6 Factors that May Affect the Mineral Reserves | |

16 Mining Methods | |

16.1 Overview | |

16.2 Pit Design | |

16.2.1 Geotechnical Considerations | |

16.2.2 Design Parameters | |

16.2.3 Mining Phases and Final Pit Designs | |

16.3 Production Schedule | |

16.4 Mining Equipment | |

16.4.1 General | |

16.4.2 Time Definition | |

16.4.3 Drilling Equipment | |

16.4.4 Loading Equipment | |

16.4.5 Hauling Equipment | |

16.4.5.1 Haulage Profile Estimation | |

16.4.5.2 Haul Truck Speeds | |

16.4.5.3 Fixed Time | |

16.4.6 Ancillary and Support Equipment | |

16.4.7 Total Mine Fleet Requirement | |

17 Recovery methods | |

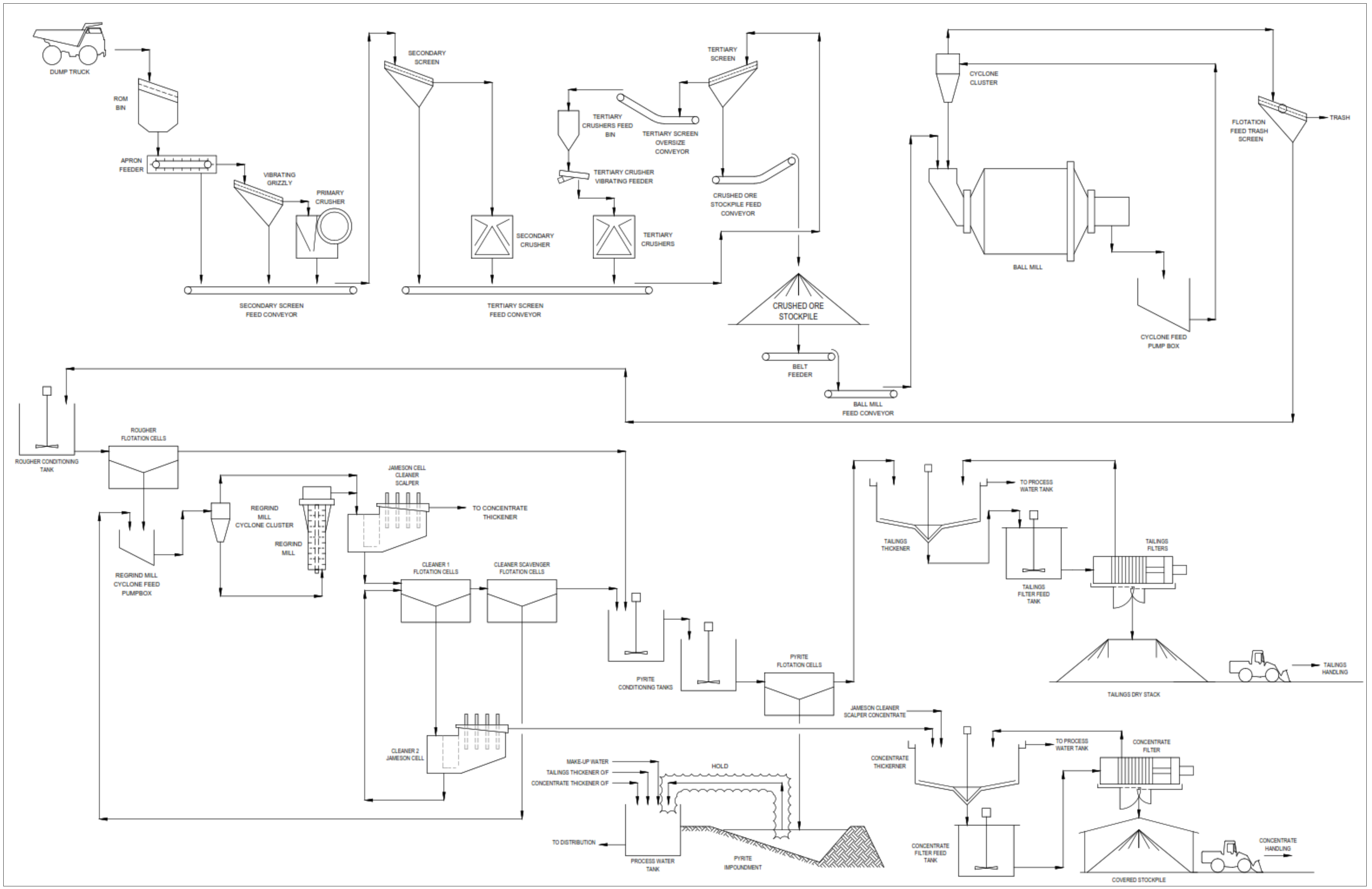

17.1 Overview | |

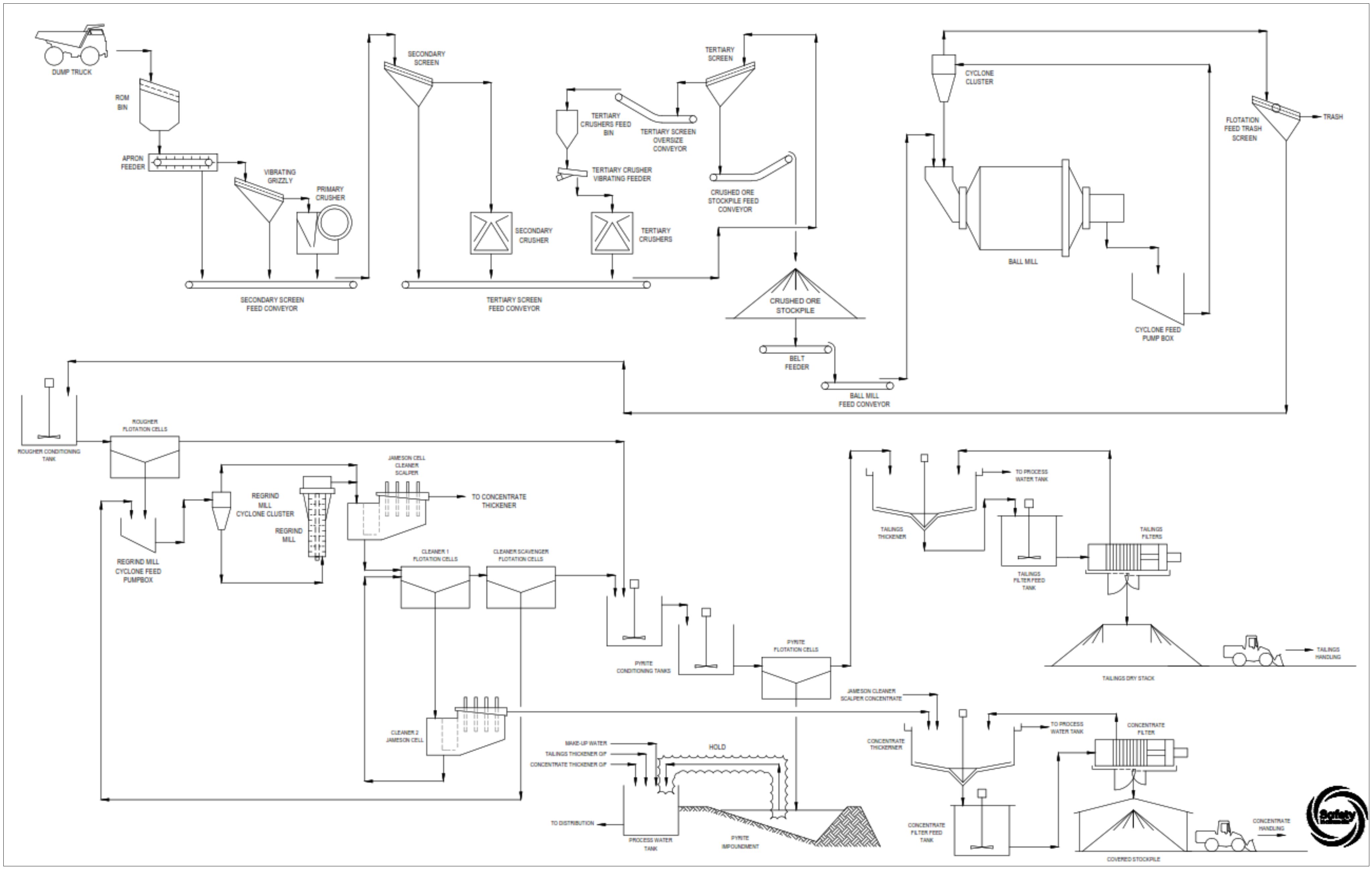

17.2 Process Flow Sheet | |

17.3 Plant Design Criteria | |

17.4 Unit Process Description | |

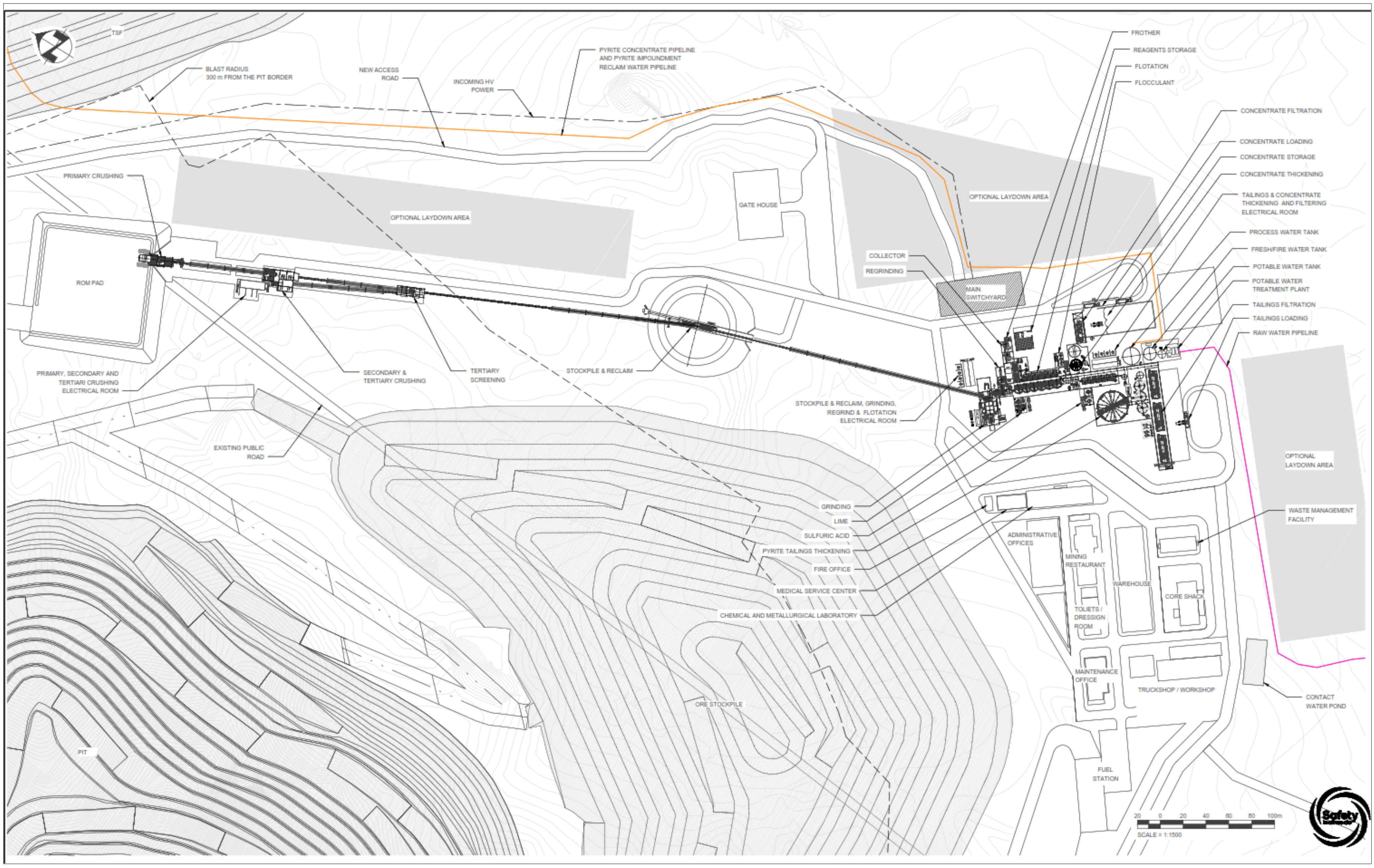

17.4.1 ROM Ore Handling and Crushing | |

17.4.2 Crushed Ore Stockpile | |

17.4.3 Ball Mill Grinding | |

17.4.4 Flotation | |

17.4.4.1 Copper Flotation | |

17.4.4.2 Pyrite Flotation | |

| | | | | |

| Boa Esperança Project | Page v |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

17.4.5 Concentrate Regrind | |

17.4.6 Concentrate Dewatering | |

17.4.7 Concentrate Storage and Load Out | |

17.4.8 Pyrite Tailings Dewatering | |

17.4.9 Pyrite Concentrate Pond Water Reclaim | |

17.4.10 Reagents and Consumables | |

17.5 Sampling and Metallurgical Laboratory | |

17.6 Plant Services | |

17.6.1 Water Supply and Distribution | |

17.6.1.1 Raw Water | |

17.6.1.2 Fire Water | |

17.6.1.3 Potable Water | |

17.6.1.4 Process Water | |

17.6.2 Air Supply and Distribution | |

17.7 Process Control System | |

18 Project infrastructure | |

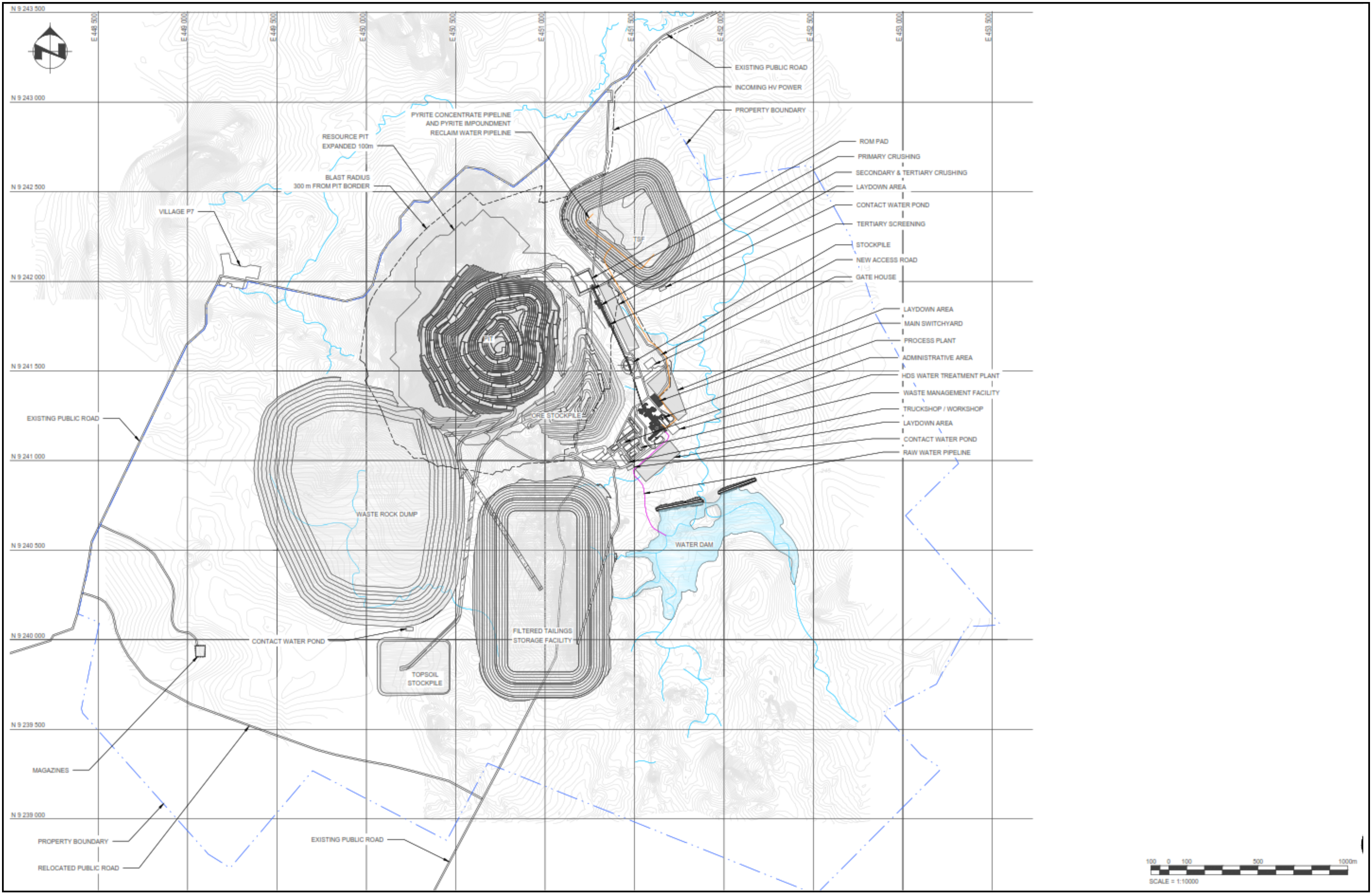

18.1 Project Infrastructure | |

18.2 Power | |

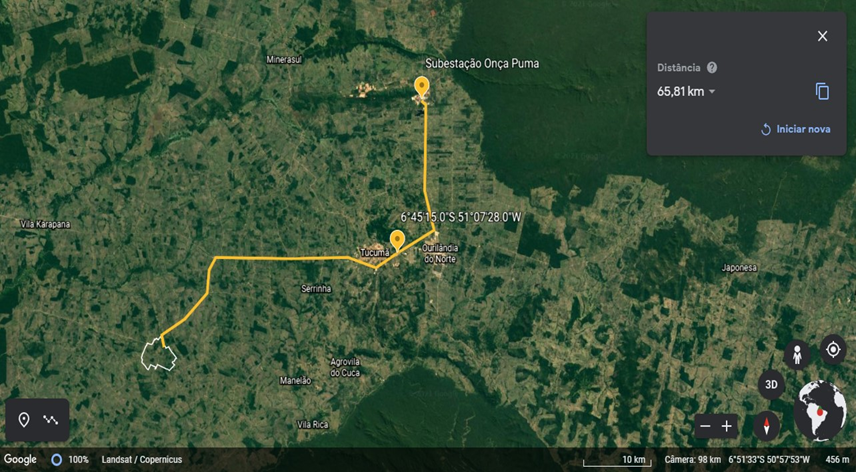

18.2.1 Electrical Power Demand | |

18.2.2 Electrical Power Source | |

18.2.3 Main Substation | |

18.2.4 Electric Power Distribution | |

18.3 Process Plant Water Consumption | |

18.4 Ancillary Buildings and Facilities | |

18.4.1 Administration Building and Offices | |

18.4.2 Laboratory | |

18.4.3 Warehouse and Yard Storage | |

18.4.4 Process Operations Workshop | |

18.4.5 Mine Dry | |

18.4.6 Mine Equipment Maintenance Shop (Truck Shop) | |

18.4.7 Truck Wash | |

18.4.8 Explosive Storage Magazine | |

18.4.9 Gatehouse and Weight-Scale | |

18.4.10 Core Shed | |

18.4.11 First Aid Clinic and Fire Protection Building | |

18.4.12 Fire Protection | |

18.4.13 Canteen | |

18.4.14 Sewage Treatment | |

18.4.15 Refuse Storage | |

| | | | | |

| Boa Esperança Project | Page vi |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

18.4.16 Communications | |

18.5 Water Management Plan | |

18.5.1 Climate | |

18.5.2 Topography | |

18.5.3 Mine Facilities - Footprints | |

18.5.3.1 Run-off and Capture Coefficients | |

18.5.4 Water Balance | |

18.5.4.1 Contact Water Estimate | |

18.5.5 Facilities | |

18.5.5.1 Open Pit | |

18.5.5.2 Waste Rock Facility | |

18.5.5.3 TSF | |

18.5.5.4 Dry-Stack Filtered Tailings Facility | |

18.5.5.5 Stockpile, Administrative and Process Plant Area | |

18.5.6 Hydrogeology | |

18.5.6.1 Groundwater Setting | |

18.5.6.2 Pit Inflow | |

18.5.6.3 Numerical Groundwater Modelling | |

18.5.7 Schematics | |

18.5.8 Treatment Plant Selection | |

18.6 Water Supply | |

18.7 Tailings Storage Facilities | |

18.7.1 Hazard Classification | |

18.7.2 Design Criteria | |

18.7.3 Dry-Stack Tailings Storage Facility and Pyrite Tailings Storage Facility Study | |

18.7.4 Geotechnical Field and Laboratory Investigation | |

18.7.5 Non-Pyrite Dry Stack Tailings Facility Design and Operation | |

18.7.6 Pyrite Tailings Storage Facility Design and Operation | |

18.7.7 Stability Analysis of Dry-Stack Tailings Storage Facility and Pyrite Tailings Storage Facility | |

18.7.8 Waste Rock Facility and Stockpiles | |

18.7.9 Closure and Post-Closure of the Tailings Storage Facilities | |

18.7.9.1 Closure of the Tailing Storage Facility | |

18.7.9.2 Closure of the Dry Stack Tailing Facility | |

18.8 Concentrate Transport Logistics | |

18.9 Built Infrastructure (Access Road) | |

19 Market studies and contracts | |

19.1 Market Studies | |

19.2 Contracts | |

20 Environmental Studies, Permitting, and Social or Community Impact | |

| | | | | |

| Boa Esperança Project | Page vii |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

20.1 Environmental Laws and Licensing | |

20.1.1 Reclamation of Degraded Areas | |

20.2 Environmental Licenses | |

20.3 Physiography, Flora and Fauna | |

20.3.1 Soil Types | |

20.3.2 Local Hydrography | |

20.3.3 Water Availability | |

20.3.4 Flora and Fauna | |

20.4 Environmental Studies | |

20.4.1 Classification of Areas of Influence | |

20.4.2 Agrarian Reform Areas | |

20.5 Environmental Impact Issues | |

20.5.1 Water Quality | |

20.5.2 Acid Rock Drainage | |

20.6 Environmental Compensation | |

20.7 Stakeholder Communications | |

20.7.1 Program for the Monitoring of Socio-Economic Indicators | |

20.7.2 Social Communication Program | |

20.7.3 Education, Job Training & Employment | |

20.7.4 Environmental Education | |

20.7.5 Labor Jobsite Hiring | |

20.8 Mining Closure and Reclamation | |

21 Capital and operating costs | |

21.1 Capital Costs | |

21.1.1 Basis of Estimate | |

21.1.2 Summary | |

21.1.3 Definition of Costs | |

21.1.4 General Methodology | |

21.1.5 Exchange Rates | |

21.1.6 Market Availability | |

21.1.7 Mine Capital Costs | |

21.1.8 Processing Capital Costs | |

21.1.9 Tailings/Reclaim Facilities | |

21.1.10 On-Site Infrastructure | |

21.1.11 Off-Site Infrastructure | |

21.2 Operating Cost Estimate | |

21.2.1 Summary | |

21.2.2 Mining Costs | |

21.2.3 Processing | |

| | | | | |

| Boa Esperança Project | Page viii |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

21.2.3.1 Power | |

21.2.3.2 Consumables | |

21.2.3.3 Maintenance Consumables | |

21.2.3.4 Labour | |

21.2.4 General and Administration | |

21.2.5 Dry Stack Tailings Facility | |

22 Economic analysis | |

22.1 Cautionary Statement | |

22.2 Methodology Used | |

22.3 Financial Model Parameters | |

22.3.1 Taxes | |

22.3.2 Royalties | |

22.3.3 Working Capital | |

22.3.4 Closure Costs | |

22.4 Economic Analysis | |

22.5 Sensitivity Analysis | |

22.6 QP Comments on “Item 22: Economic Analysis” | |

23 Adjacent properties | |

24 Other relevant data and information | |

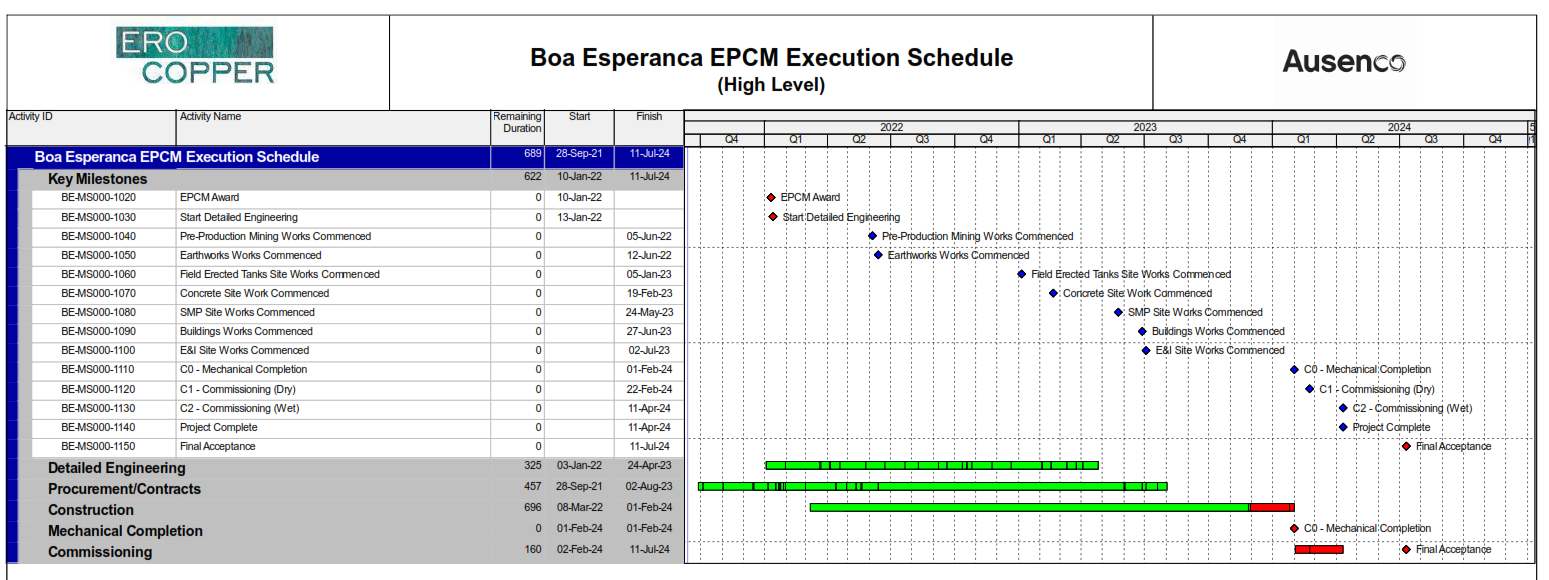

24.1 Project Execution Plan | |

24.1.1 Project Milestones | |

24.1.2 Scope, Approach and Objectives | |

24.1.3 Access Road | |

24.1.4 Mining | |

24.1.5 Process Plant and Infrastructure | |

24.1.6 Camp Facilities | |

24.1.7 Power Generation | |

24.1.8 Schedule | |

25 Interpretation and conclusions | |

25.1 Introduction | |

25.2 Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements | |

25.3 Geology and Mineralization | |

25.4 Exploration, Drilling and Analytical Data Collection in Support of Mineral Resource Estimation | |

25.5 Mineral Processing and Metallurgical Testing | |

25.6 Mineral Resource Estimates | |

25.7 Mineral Reserve Estimates | |

25.8 Open Pit Geotechnical | |

25.9 Mine Plan | |

25.10 Recovery Plan | |

| | | | | |

| Boa Esperança Project | Page ix |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

25.11 Infrastructure – Tailings Storage Facilities | |

25.12 Environmental, Permitting and Social Considerations | |

25.12.1 Environmental Considerations | |

25.12.2 Closure and Reclamation Considerations | |

25.13 Markets and Contracts | |

25.14 Capital Cost Estimates | |

25.15 Operating Cost Estimates | |

25.16 Economic Analysis | |

25.17 Risks and Opportunities | |

25.17.1 Risks | |

25.17.1.1 General | |

25.17.1.2 Mining | |

25.17.1.3 Tailings Storage Facilities | |

25.17.2 Opportunities | |

25.17.2.1 General | |

25.17.2.2 Mining | |

25.17.2.3 Tailings Storage Facilities | |

25.18 Conclusions | |

26 Recommendations | |

26.1 Mineral Reserves | |

26.2 Mining | |

26.2.1 Open Pit Geotechnical | |

26.3 Geochemistry | |

26.4 Metallurgical Testing | |

26.5 Tailings Storage Facilities | |

27 References | |

List of Tables

| | | | | |

Table 1-1: Mineral Resource Statement as of 31 August 2021 | |

Table 1-2: Mineral Reserves Statement as of 31 August 2021 | |

Table 1-3: Pit Slope Geometry | |

Table 1-4: Key Production Parameters | |

Table 1-5: Mine Production Schedule (yearly) | |

Table 1-6: Plant Feed Schedule (yearly) | |

Table 1-7: Contact Water Estimate | |

Table 1-8: Capital Cost Estimate | |

| | | | | |

| Boa Esperança Project | Page x |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

Table 1-9: Forecast Average Annual Operating Cost Estimate Summary | |

Table 1-10: Summary, Projected LOM Cashflow Assumptions and Results | |

Table 2-1: FSU Sections and Parties Responsible | |

Table 2-2: Name Abbreviations | |

Table 2-3: Unit Abbreviations | |

Table 4-1: Boa Esperança Exploration Permit | |

Table 6-1: Summary of Historic Exploration Works | |

Table 6-2: 2017 Mineral Resource Estimate | |

Table 6-3: 2017 Mineral Reserve Estimate | |

Table 7-1: Boa Esperança Copper Deposit Rock Types | |

Table 7-2: Mineralization Types | |

Table 9-1: Gap Zone Drilling Results, Subsequent to Effective Date | |

Table 10-1: Summary of Codelco drilling programs | |

Table 10-2: Summary of MCSA drill programs | |

Table 11-1: Specifications of Standard Reference Materials Used by MCSA for the Boa Esperança Copper Project | |

Table 12-1: Summary of Analytical Quality Control Data Produced by MCSA on the Boa Esperança Copper Project | |

Table 13-1: 2012 SGS Geosol Sample Compositions Summary | |

Table 13-2: 2015 SGS Sample Compositions Summary | |

Table 13-3: Main Mineral Composition for Boa Esperança Test Composite | |

Table 13-4: Mass Mineralogical Composition of the Copper Sulphides | |

Table 13-5: Sample Head Assays | |

Table 13-6: Hardness and Abrasion Test Results | |

Table 13-7: 2015 SGS Jigging Test Results | |

Table 13-8: Summary of 2009 and 2012 Flotation Tests Results | |

Table 13-9: Flotation pH Condition Results – 2009 CIMM | |

Table 13-10: LCT Test Conditions For All Test Work Programs | |

Table 13-11: CIMM LCTs Test Results Summary | |

Table 13-12: SGS LCTs Test Results Summary – 2012 and 2015 | |

Table 13-13: Pilot Magnetic Separation Tests – SGS Geosol 2015 | |

Table 13-14: Copper Concentrate Chemical Elemental Assays – SGS 2012 and 2015 | |

Table 13-15: Pyrite Concentrate Chemical Elemental Assays – SGS 2015 | |

Table 13-16: Iron Concentrate Chemical Elemental Assays – SGS 2015 (MAG CLN L8) | |

Table 13-17: Concentrate Chemical Elemental Assays | |

Table 13-18: Copper Recovery and Grade Projections | |

Table 14-1: Drillhole Statistics | |

| | | | | |

| Boa Esperança Project | Page xi |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

Basic statistics for coper and the assay interval length are shown in Table 14-2. The lithology codes and a description of the codes are shown in Table 14-3. Sulfide intervals were broken down based on the relative abundance of chalcopyrite and pyrite as shown in Table 14-6. | |

Table 14-4: Statistics for copper and assay interval length | |

Table 14-5: Lithology codes | |

Table 14-6: Mineralization codes | |

Table 14-7: Statistics of assay data within the wireframes | |

Table 14-8: Statistics of Composite Data within the Wireframes | |

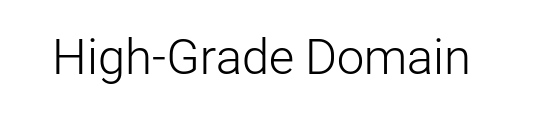

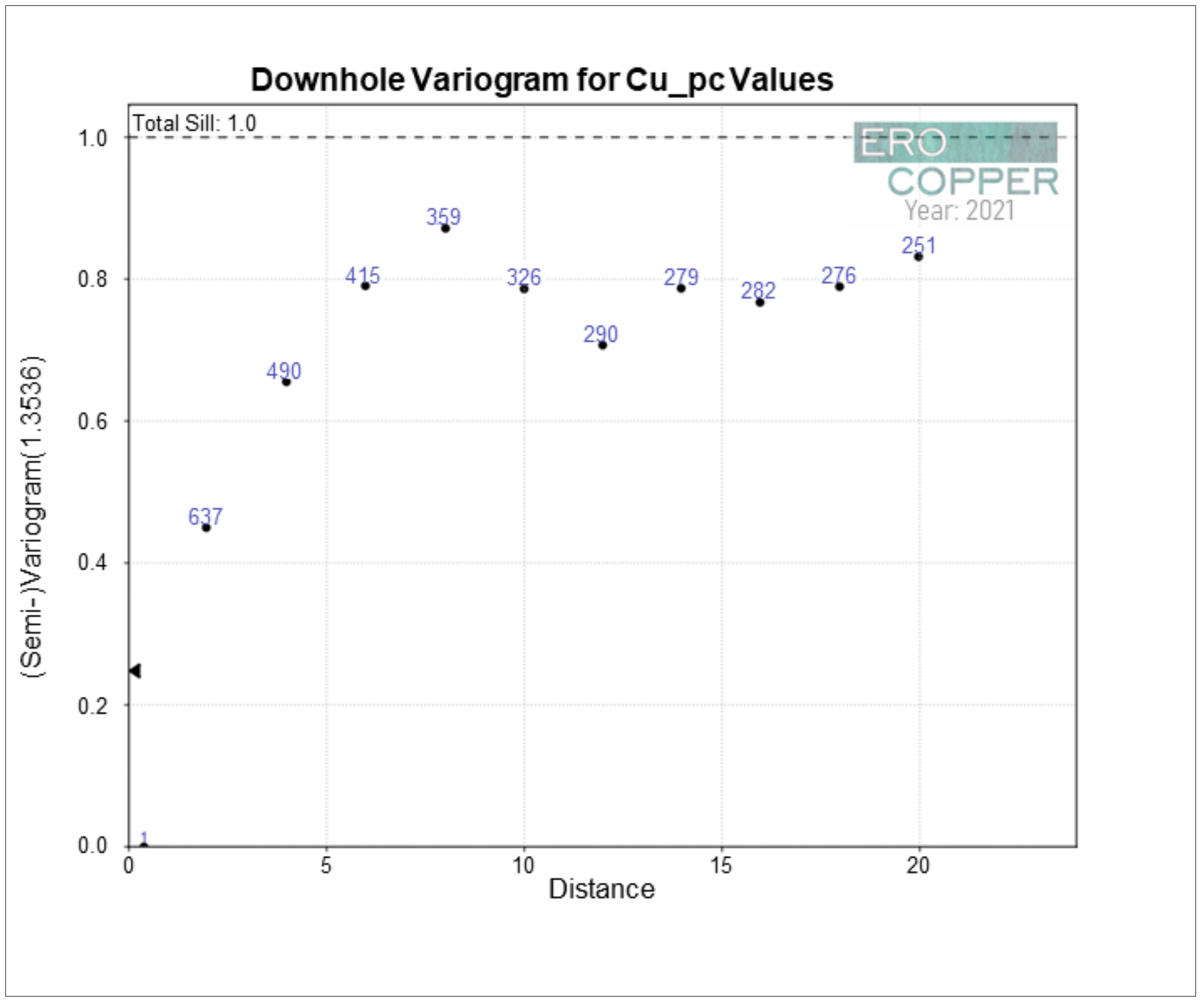

Table 14-9: Variogram Parameters for Copper (High Grade) | |

Table 14-10: Variogram Parameters for Copper (Low Grade) | |

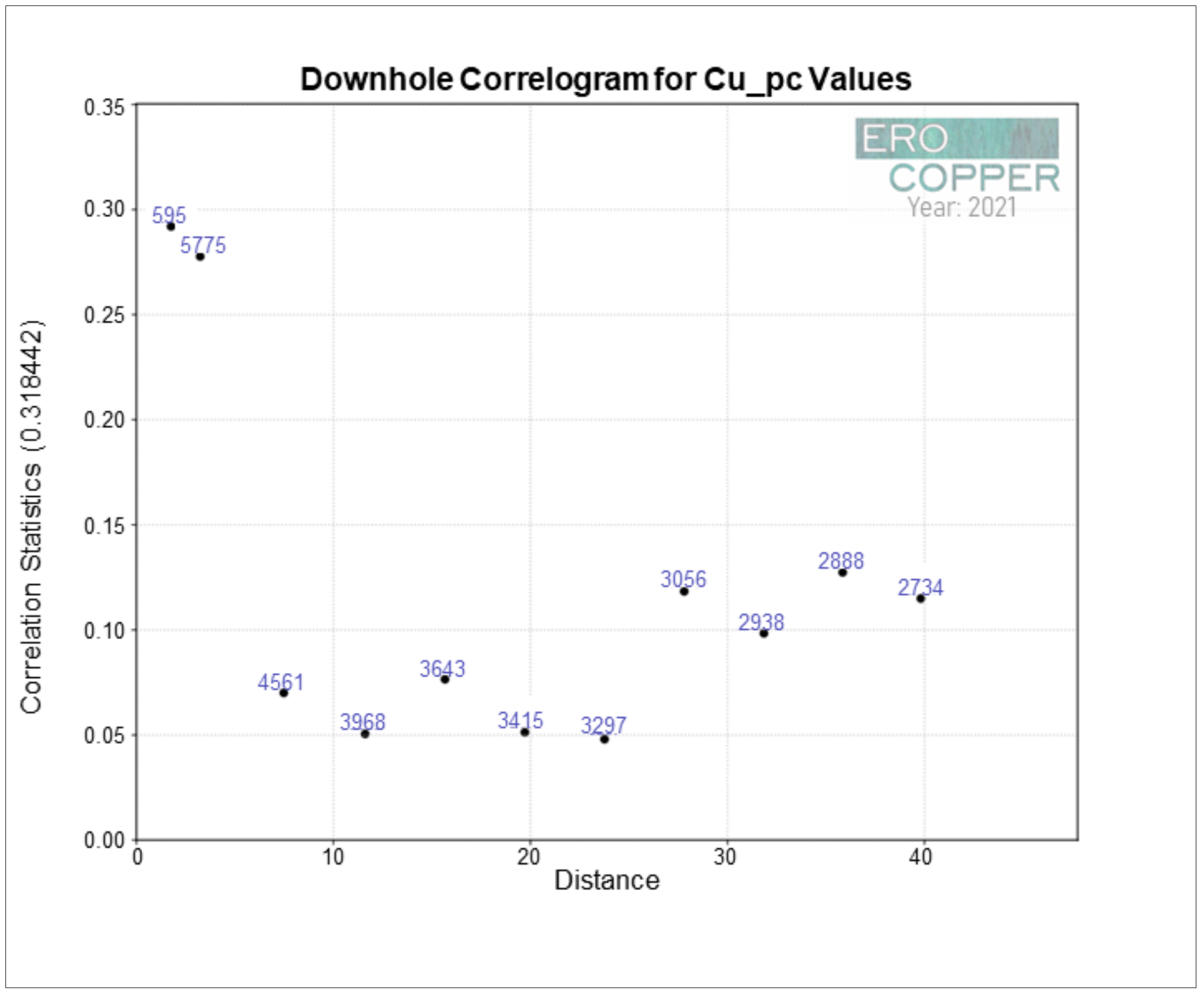

Table 14-11: Variogram Parameters for Iron (High Grade) | |

Table 14-12: Variogram Parameters for Iron (Low Grade) | |

Table 14-13: Block Model Summary | |

Table 14-14: Summary of Estimation Parameters for Copper and Iron | |

Table 14-15: Comparison between composite and block Cu grades (High-Grade and Low-Grade Domains) | |

Table 14-16: Stope Optimization Summary | |

Table 14-17: Mineral Resource Statement, Boa Esperança Copper Project, Pará State, Brazil, Ero Copper, August 31, 2021 | |

Table 15-1: Pit Optimisation Design Criteria | |

Table 15-2: Pit Slope Geometry | |

Table 15-3: Overall Dilution and Losses | |

Table 15-4: Mineral Reserves Statement as of 31 August 2021 | |

Table 16-1: Key Proposed Production Parameters | |

Table 16-2: Bench Configuration for Mine Design | |

Table 16-3: In-Pit Tonnages and Grades per Mining Phase | |

Table 16-4: Whittle pit vs Mine Design | |

Table 16-5: Planned Processing Plant Ramp-up | |

Table 16-6: Proposed Mine Schedule Summary (Yearly) | |

Table 16-7: Proposed Mine Schedule Summary (Quarterly) | |

Table 16-8: Proposed Mine Schedule Summary (Quarterly) – Material Movements by Mining Phase | |

Table 16-9: Proposed Plant Feed Summary (Quarterly) | |

Table 16-10: Proposed Plant Feed Summary (Yearly) | |

Table 16-11: Proposed Plant Feed Summary by Ore Type (Quarterly) | |

Table 16-12: Proposed Plant Feed Summary by Ore Type (Yearly) | |

Table 16-13: Proposed Operating Time and Index Definition | |

Table 16-14: Proposed Drilling Patterns | |

Table 16-15: Proposed Material Densities | |

Table 16-16: Proposed Haul Truck Speeds | |

Table 16-17: Total Proposed Mine Fleet Requirement | |

| | | | | |

| Boa Esperança Project | Page xii |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

Table 17-1: Boa Esperança Process Design Criteria | |

Table 18-1: Facility Footprints | |

Table 18-2: Runoffs Coefficient | |

Table 18-3: Contact Water Estimate | |

Table 18-4: Expected Water Treatment Demand | |

Table 18-5: Design Criteria TSF and DSTF | |

Table 20-1: Closure & reclamation activities and estimated costs, presented in BRL and USD, millions | |

Table 21-1: Estimate Summary Level 1 Major Facility | |

Table 21-2: Estimate by Major Discipline | |

Table 21-3: Assumed Equipment Prices and Life | |

Table 21-4: Projected Mine Capital Costs | |

Table 21-5: Projected Ore Handling and Processing Plant Costs | |

Table 21-6: Direct Tailings/Reclaim Capital Costs | |

Table 21-7: Projected On-Site Infrastructure Costs | |

Table 21-8: Projected Off-Site Infrastructure Costs | |

Table 21-9: Forecast Average Annual Operating Cost Estimate Summary | |

Table 21-10: Forecast Diesel Consumption Rates (L/h) | |

Table 21-11: Forecast Explosives Prices | |

Table 21-12: Proposed Mine Workforce | |

Table 21-13: Forecast Total Operating Expenses (‘000 US$) | |

Table 21-14: Forecast Unit Mine Operating Cost | |

Table 21-15: Forecast Capitalized Waste | |

Table 21-16: Forecast Total Operating Expenses Excluding Capitalized Waste (US$ x 1,000) | |

Table 21-17: Unit Mine Operating Cost excluding Capitalized Waste | |

Table 21-18: Processing Costs – Power, Consumables and Labour | |

Table 21-19: Forecast Processing Reagents and Consumable Costs | |

Table 21-20: Forecast Costs for Liners and Media | |

Table 21-21: Forecast Reagent Costs | |

Table 21-22: Labour Costs | |

Table 21-23: Forecast Dry Stack Tailings Facility Cost Summary | |

Table 22-1: Summary, Projected LOM Cashflow Assumptions and Results | |

Table 22-2: Projected Cashflow on an Annualized Basis | |

Table 22-3: Pre- and Post-Tax Sensitivity (base case is highlighted) | |

Table 24-1: Boa Esperança Milestones | |

| | | | | |

| Boa Esperança Project | Page xiii |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

List of Figures | | | | | |

Figure 1-1: Overall Process Flowsheet | |

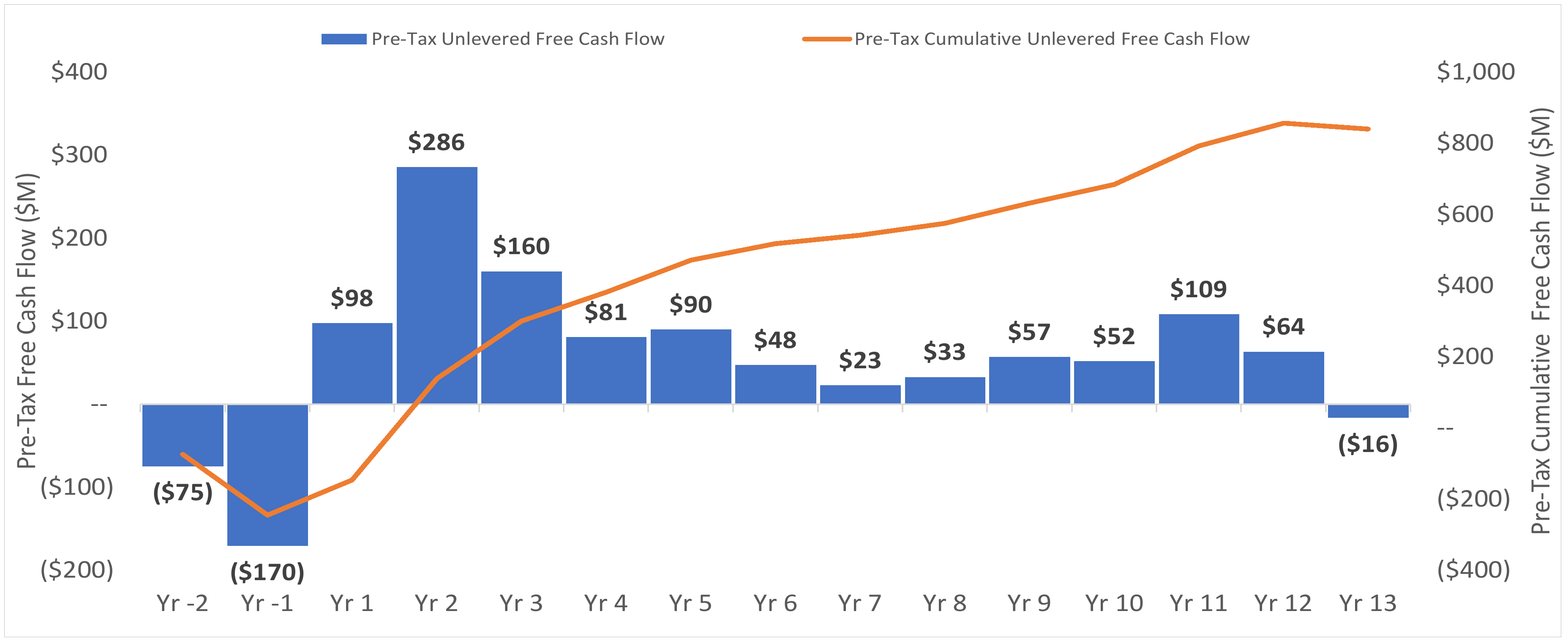

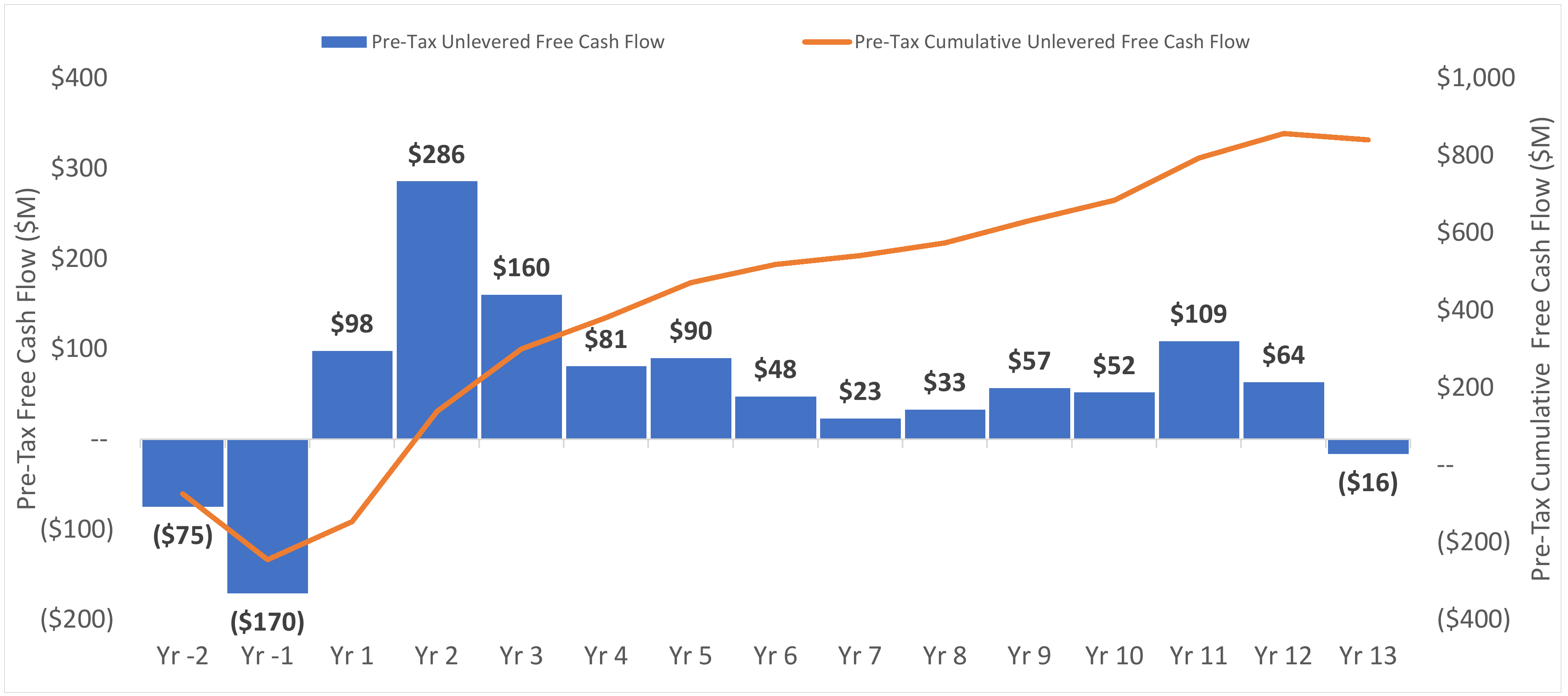

Figure 1-2: Projected LOM Pre-Tax Cashflow | |

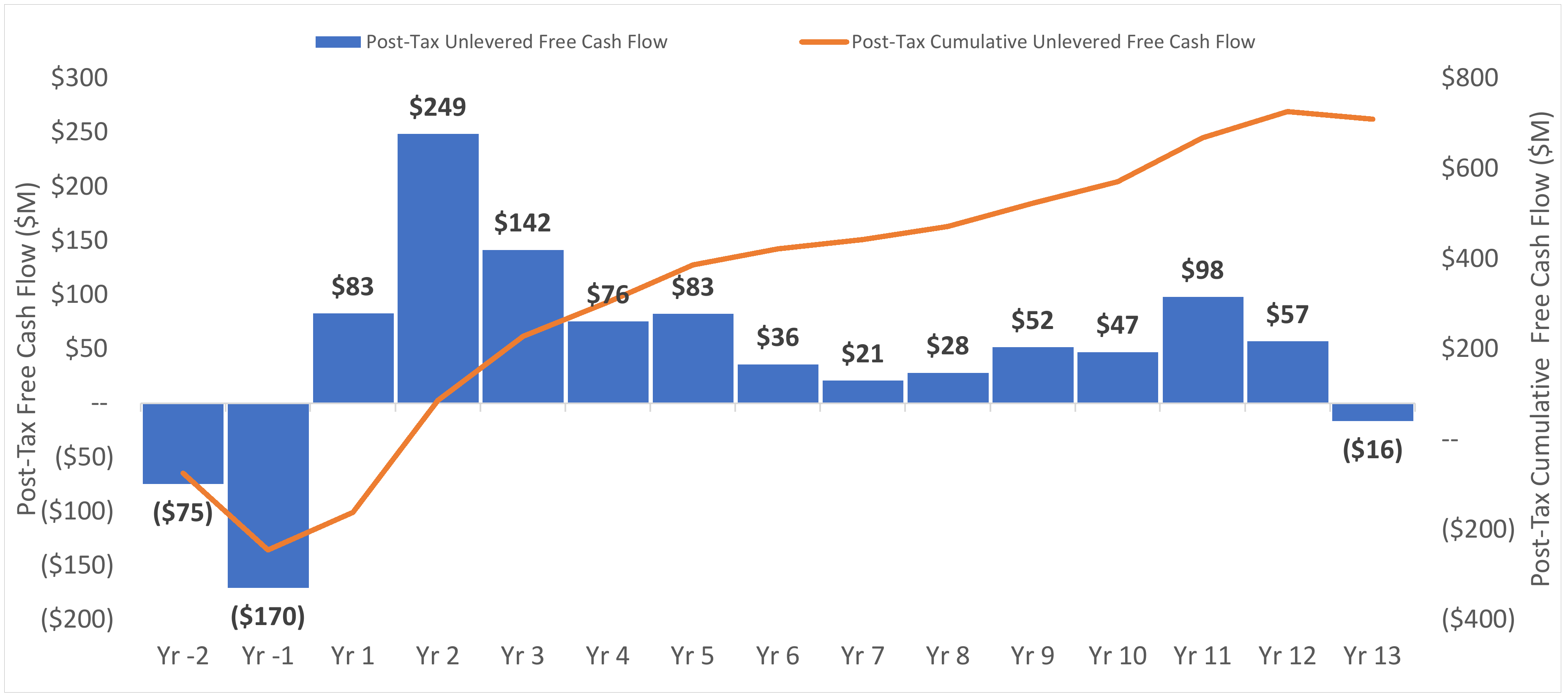

Figure 1-3: Projected LOM Post-Tax Cashflow | |

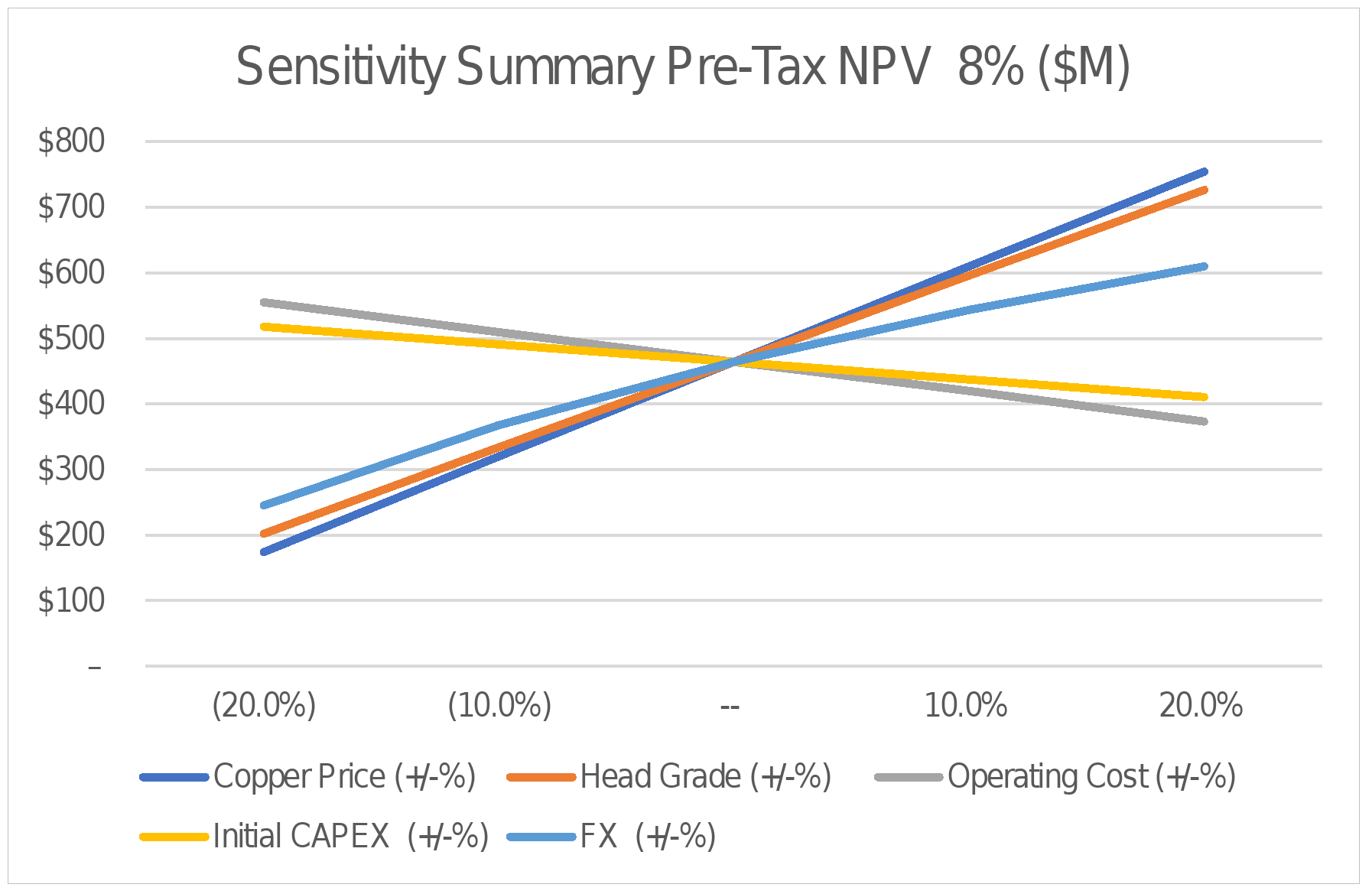

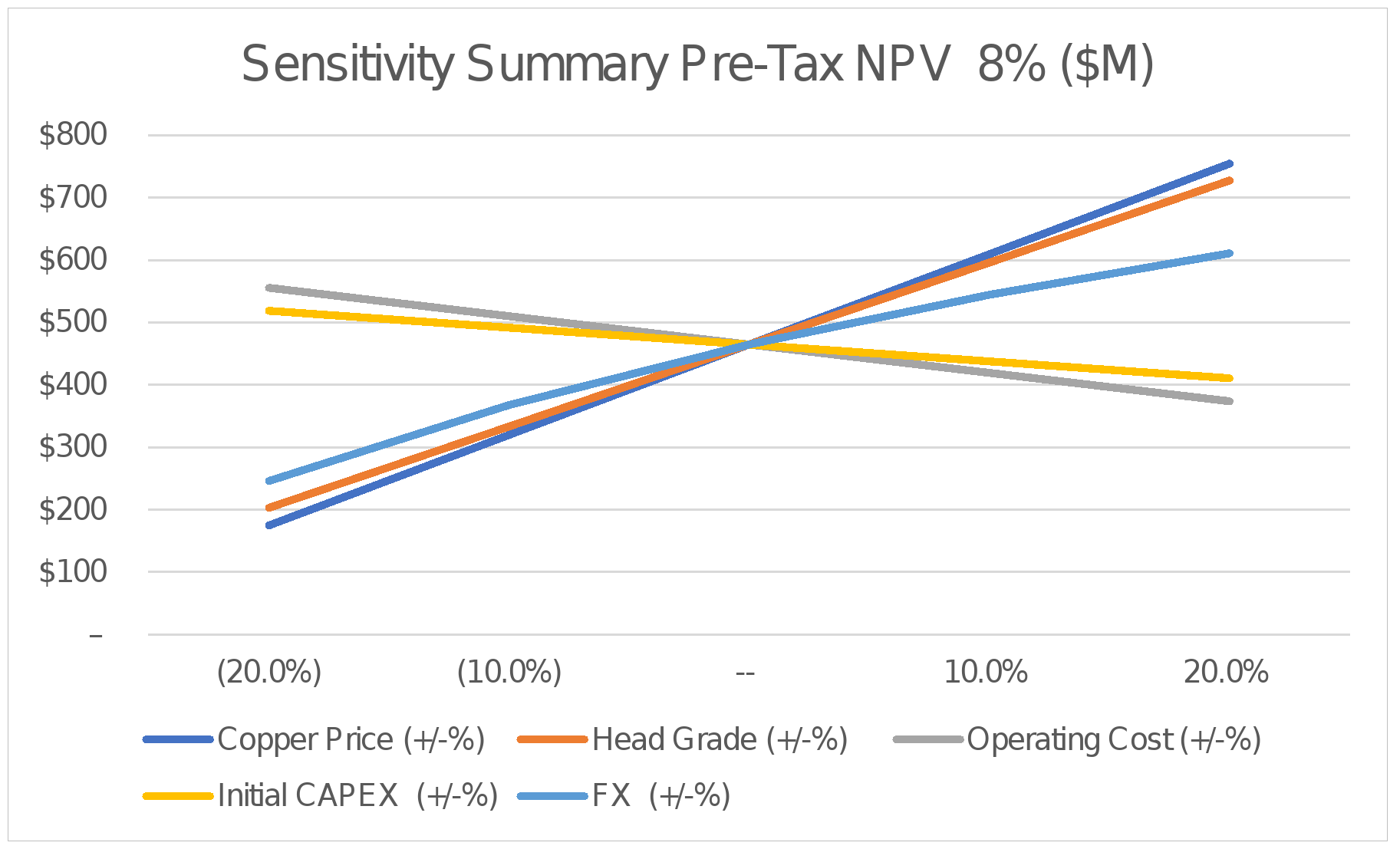

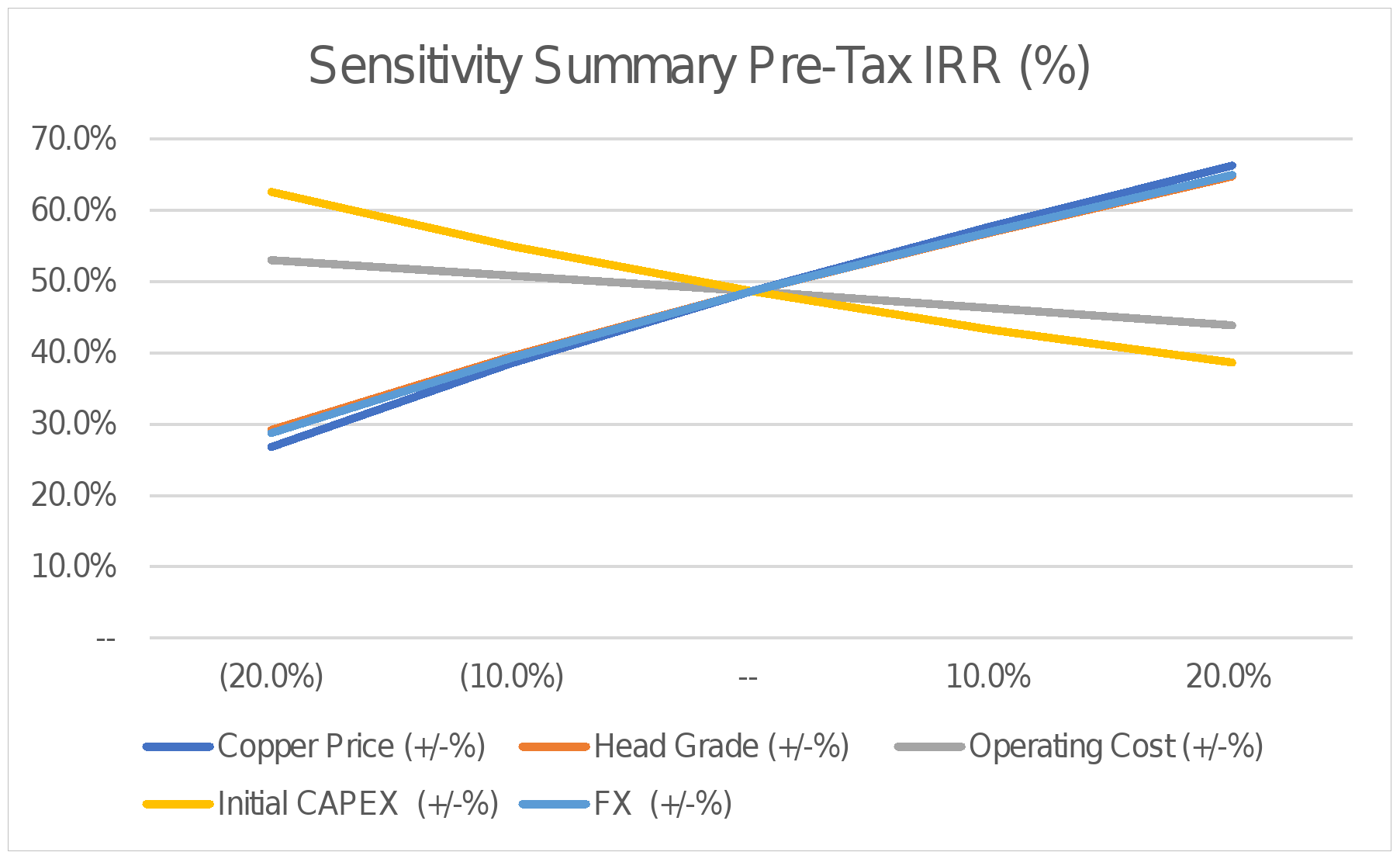

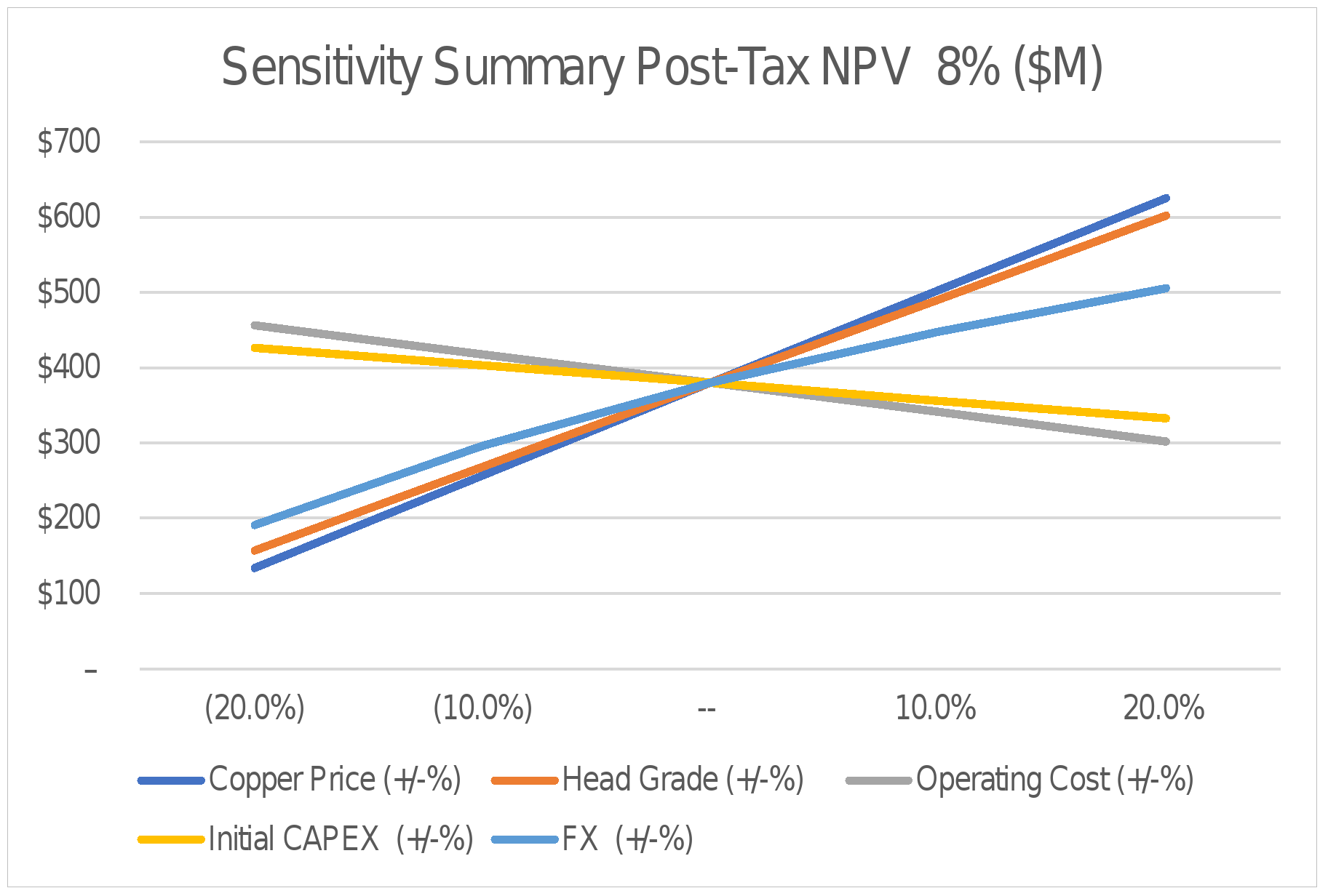

Figure 1-4: NPV & IRR Sensitivity Results | |

Figure 4-1: Location of the Boa Esperança Project | |

Figure 6-1: Soil Sampling Coloured by Copper Grade (ppm). Yellow contours are wireframes of the modelled lower grade mineralization at elevation 350 m above sea level | |

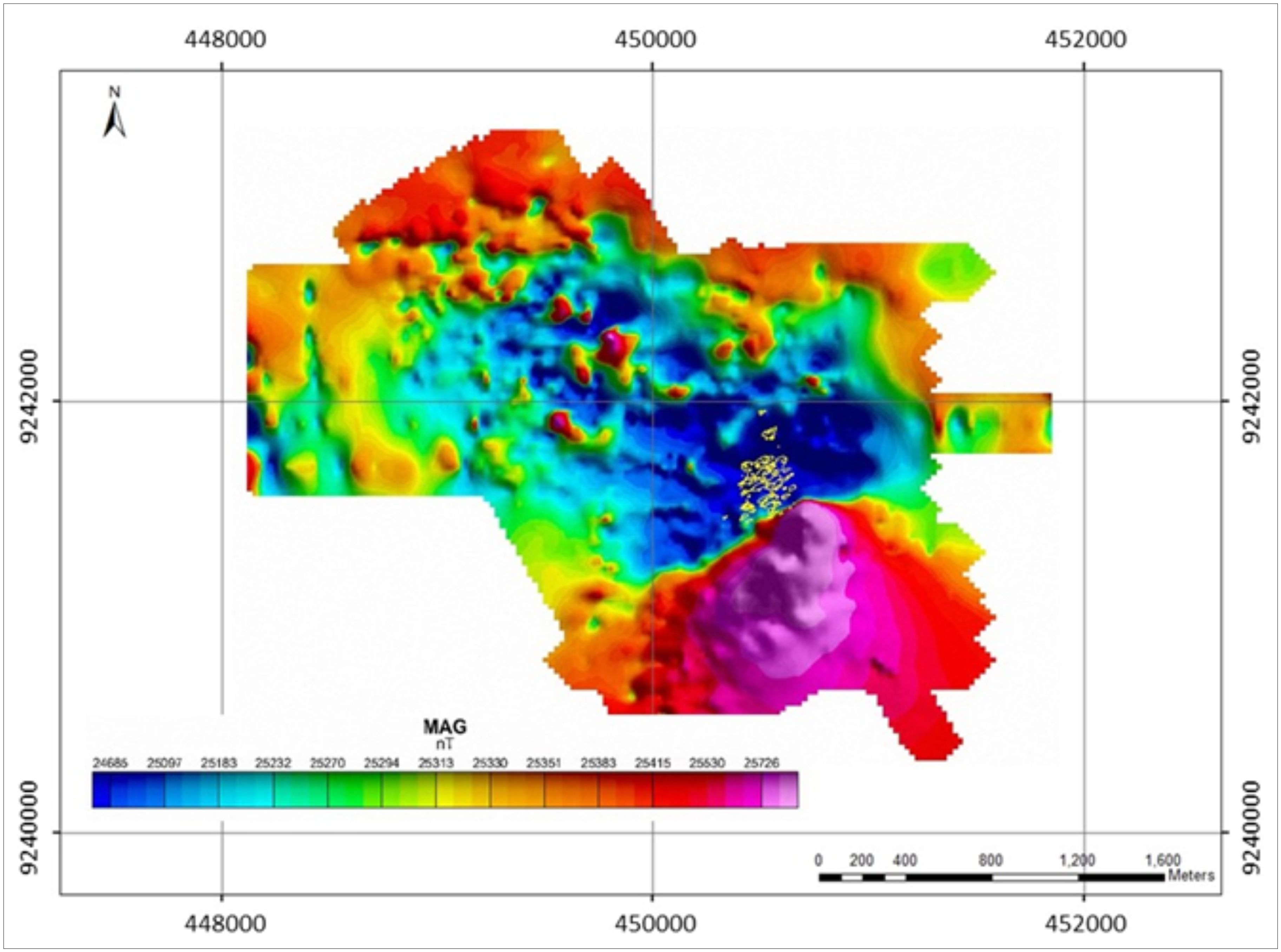

Figure 6-2: Total Magnetic Intensity Map of Boa Esperança Project. | |

Figure 7-1: Geologic Map of the Carajás and Rio Maria Domains, with the Main Tectonostratigraphic Units and Volcano Sedimentary Cover | |

Figure 7-2: Summarized Lithostratigraphic Column of the Carajás Domain after Teixeira et al. (2021) | |

Figure 7-3: General Overview Boa Esperança hill (looking NW) | |

Figure 7-4: Detailed Geology of the Boa Esperança Deposit | |

Figure 7-5: Granite Outcrop Cut by Anastomosed Breccia Veins | |

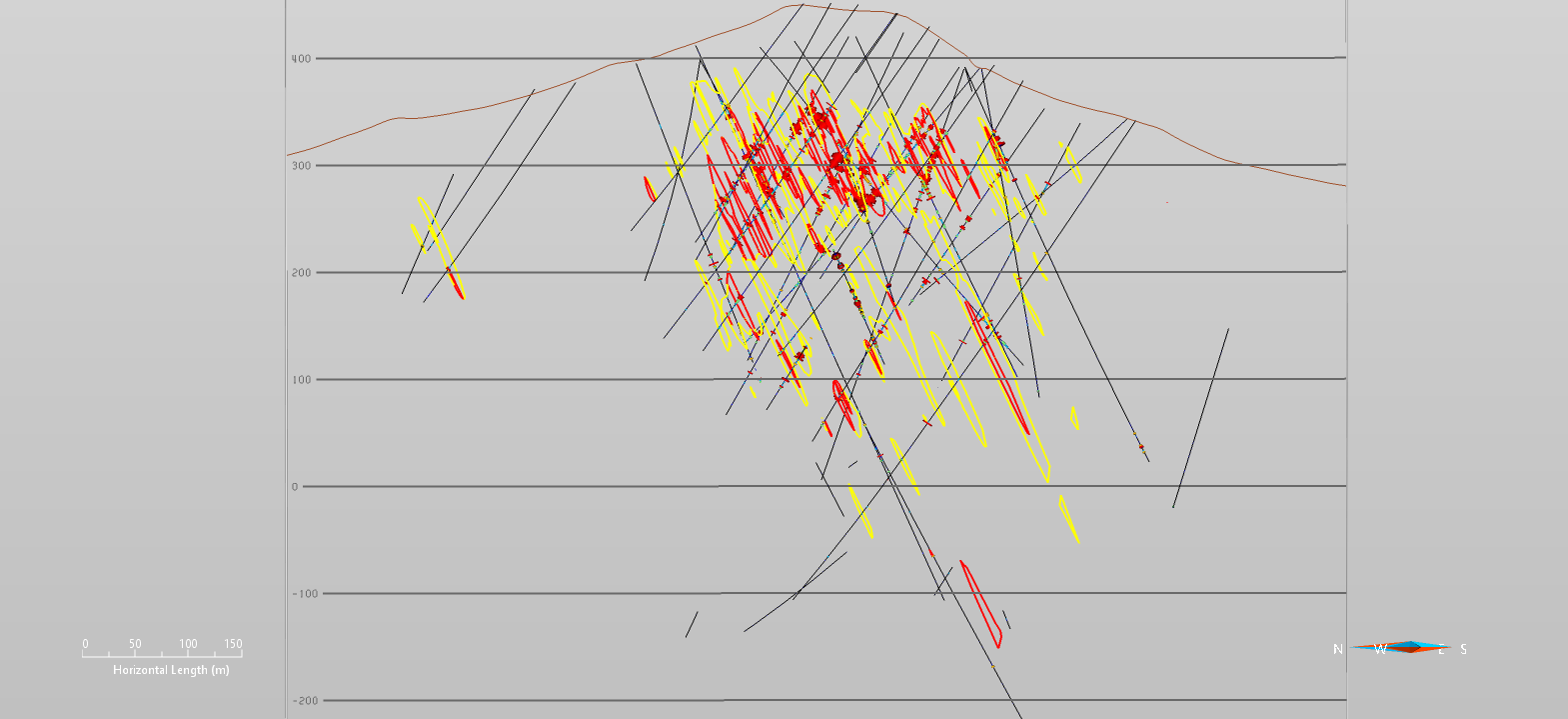

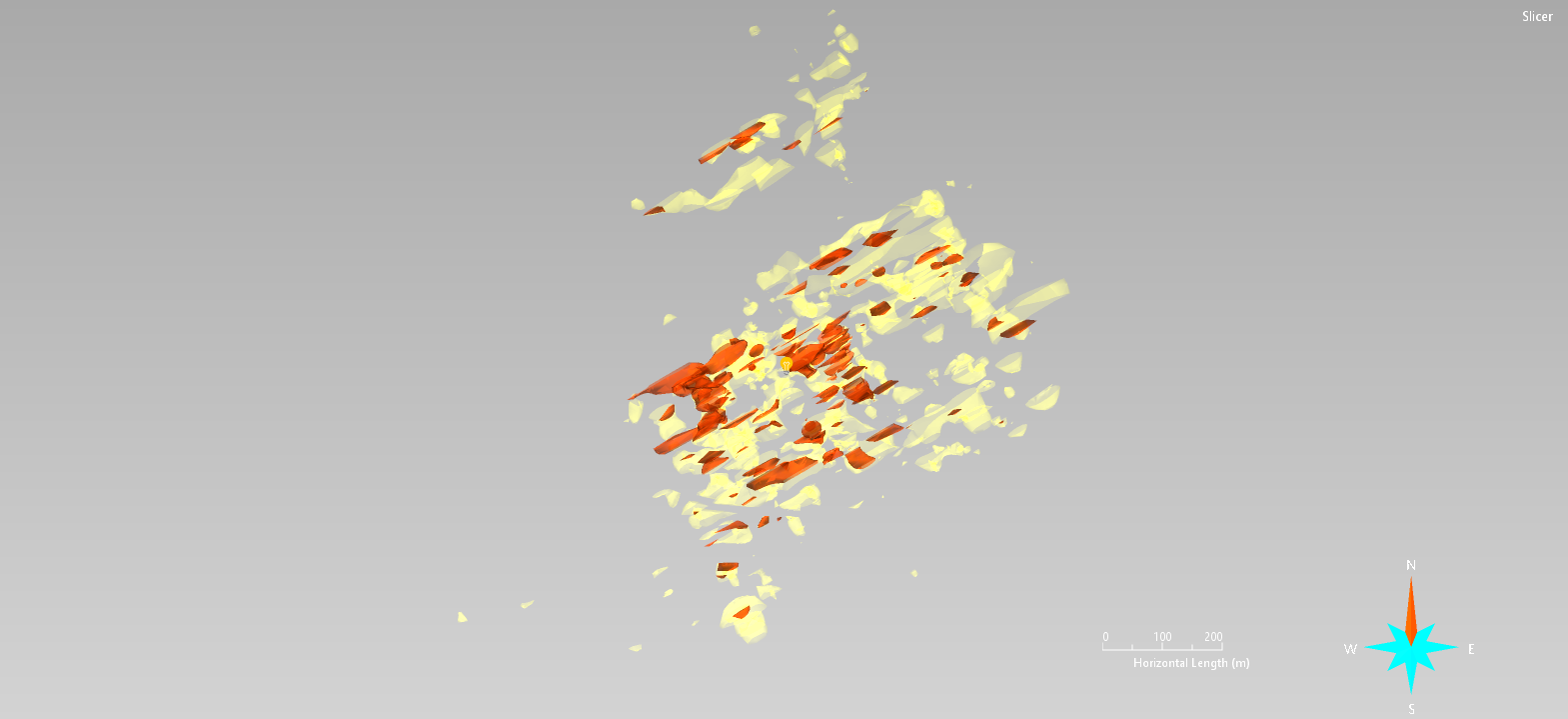

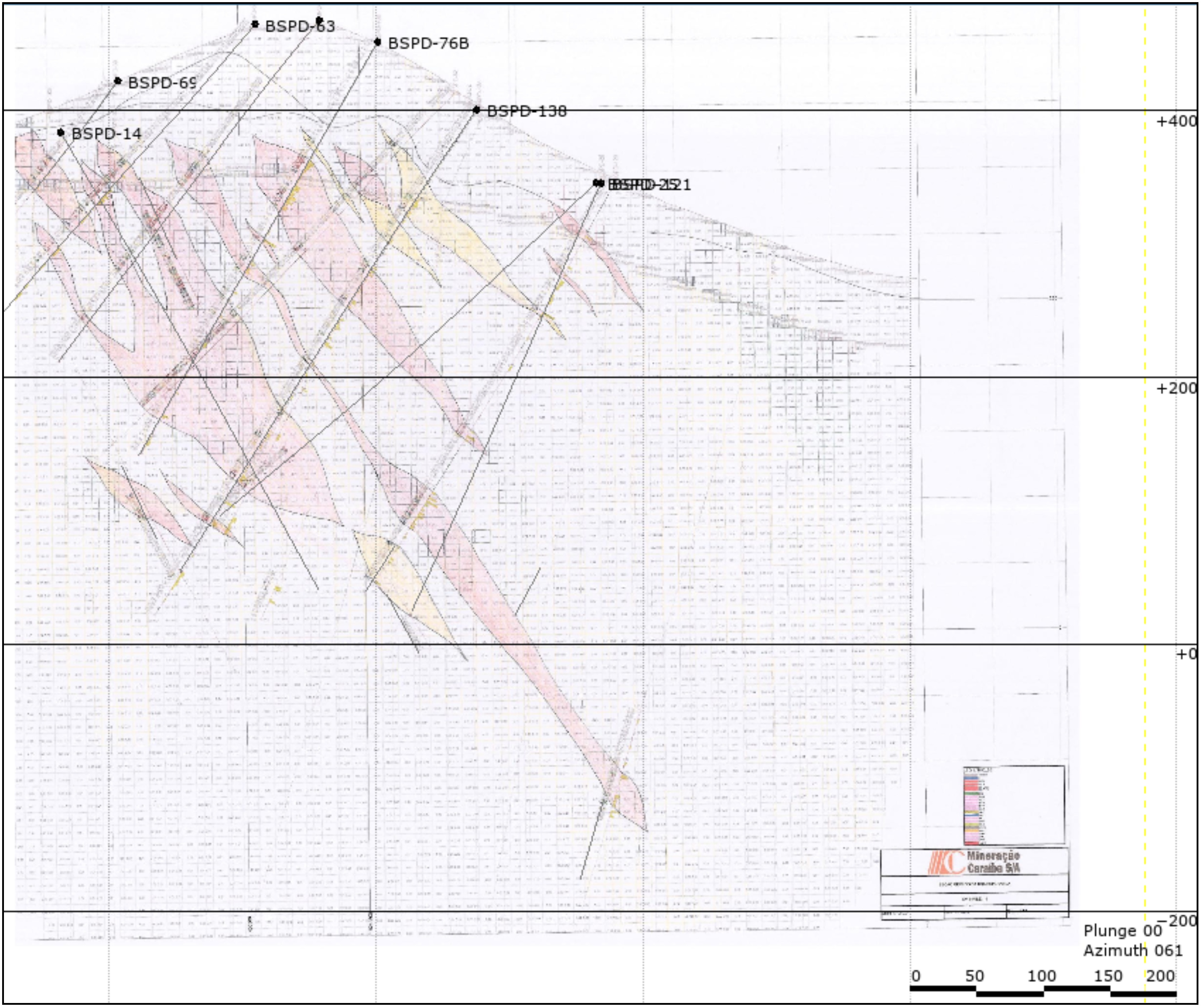

Figure 7-6: Vertical Section 10,000 High-Grade (in red) and Low-Grade (in yellow) Zones view looking North | |

Figure 7-7: Plan View at 150 m Showing the High Grade (in red) and Low Grade (in yellow) Zones | |

Figure 7-8: A - Chalcopyrite-pyrite ore from drillhole BSPD-162 (99.50 to 103.20 m); B - Pyrite-chalcopyrite ore in quartz magnetitic breccia from drillhole BSPD-162 (109.00 m). | |

Figure 7-9: Intrusive Volcanic Dike from Drillhole BSPD-59 | |

Figure 7-10: Top of Mineralized Zone, Leached Material Composed of Quartz Magnetitic Breccia | |

Figure 7-11: Detail of the Quartz Magnetitic Breccia Leached at Top | |

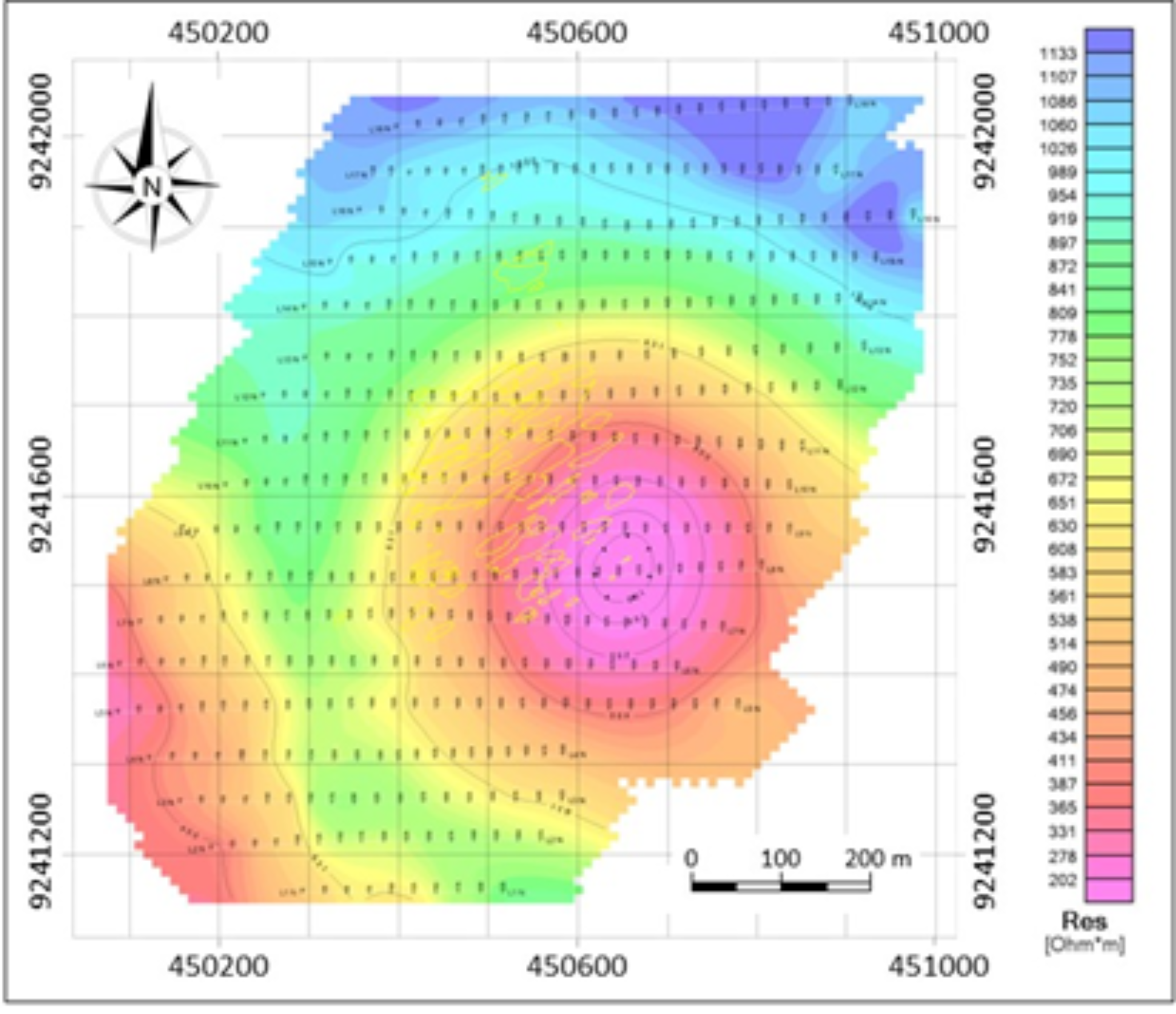

Figure 9-1: Resistivity map of the mise-à-la-masse survey. Yellow contours are wireframes of the modelled lower grade mineralization at elevation 350 m above sea level | |

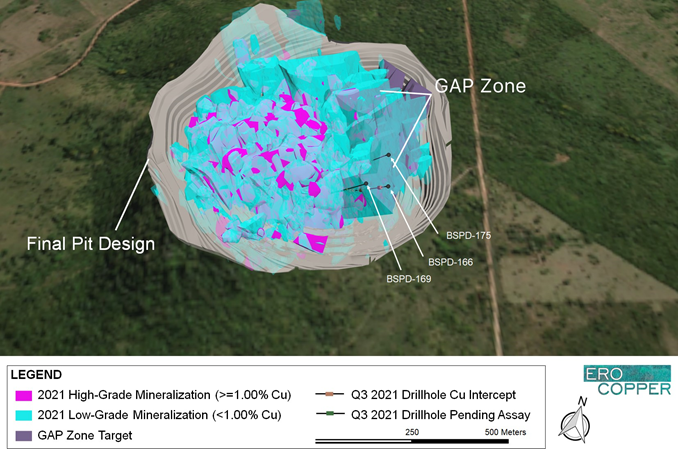

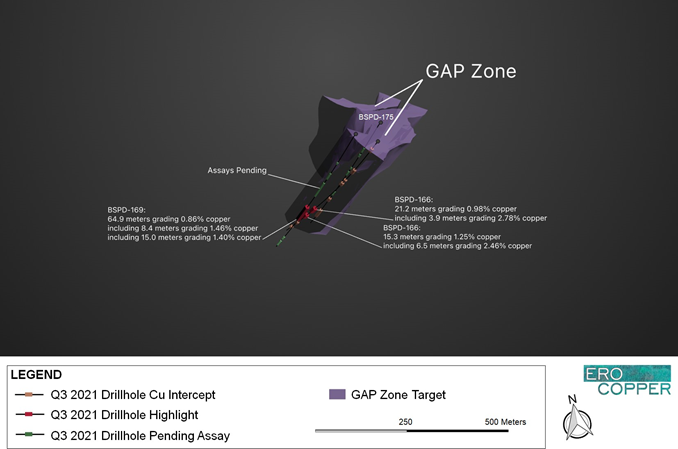

Figure 9-2: Boa Esperança, Plan View looking North | |

Figure 9-3: Boa Esperança VRIFY 3D Model, Gap Zone Results, view looking North | |

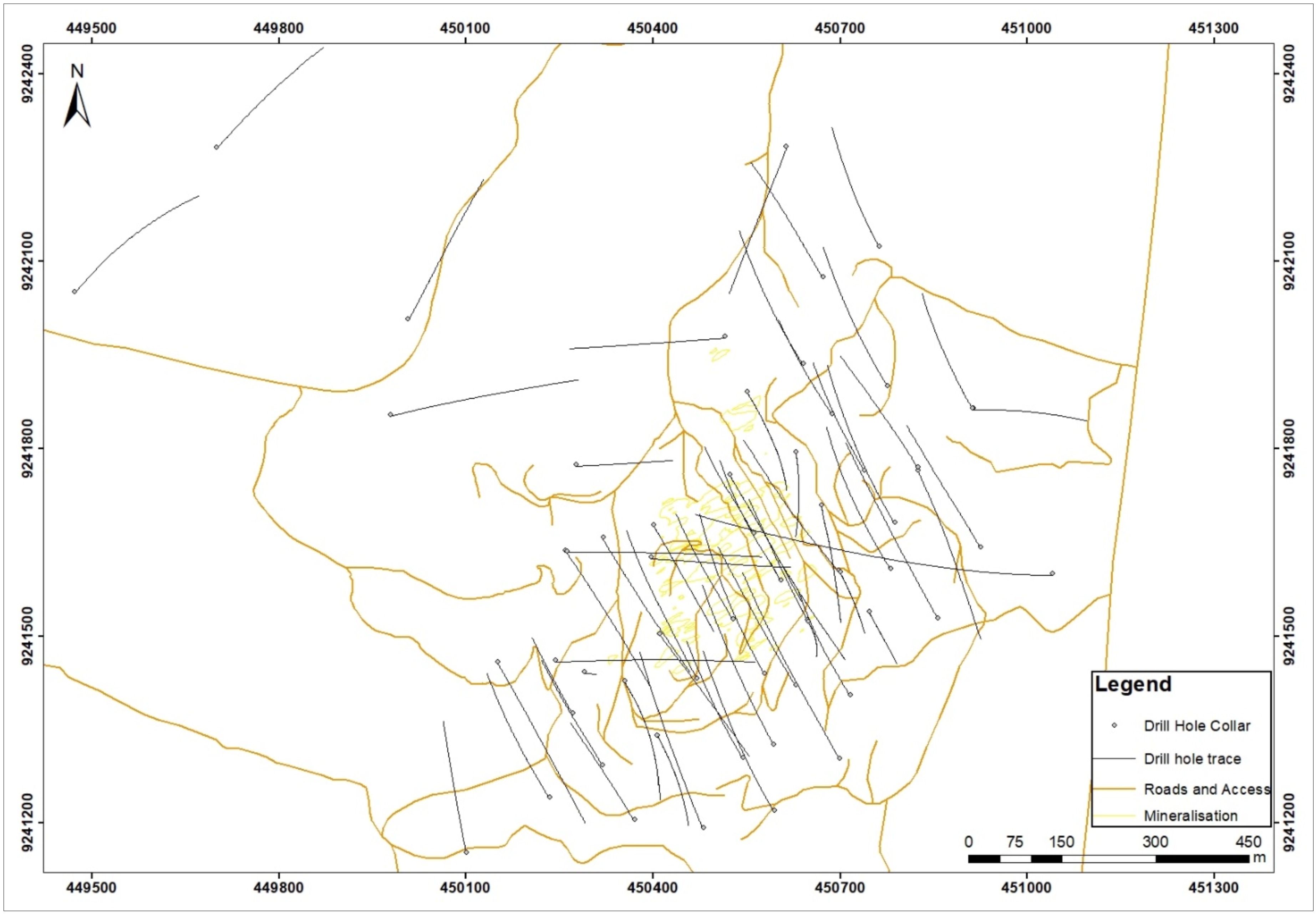

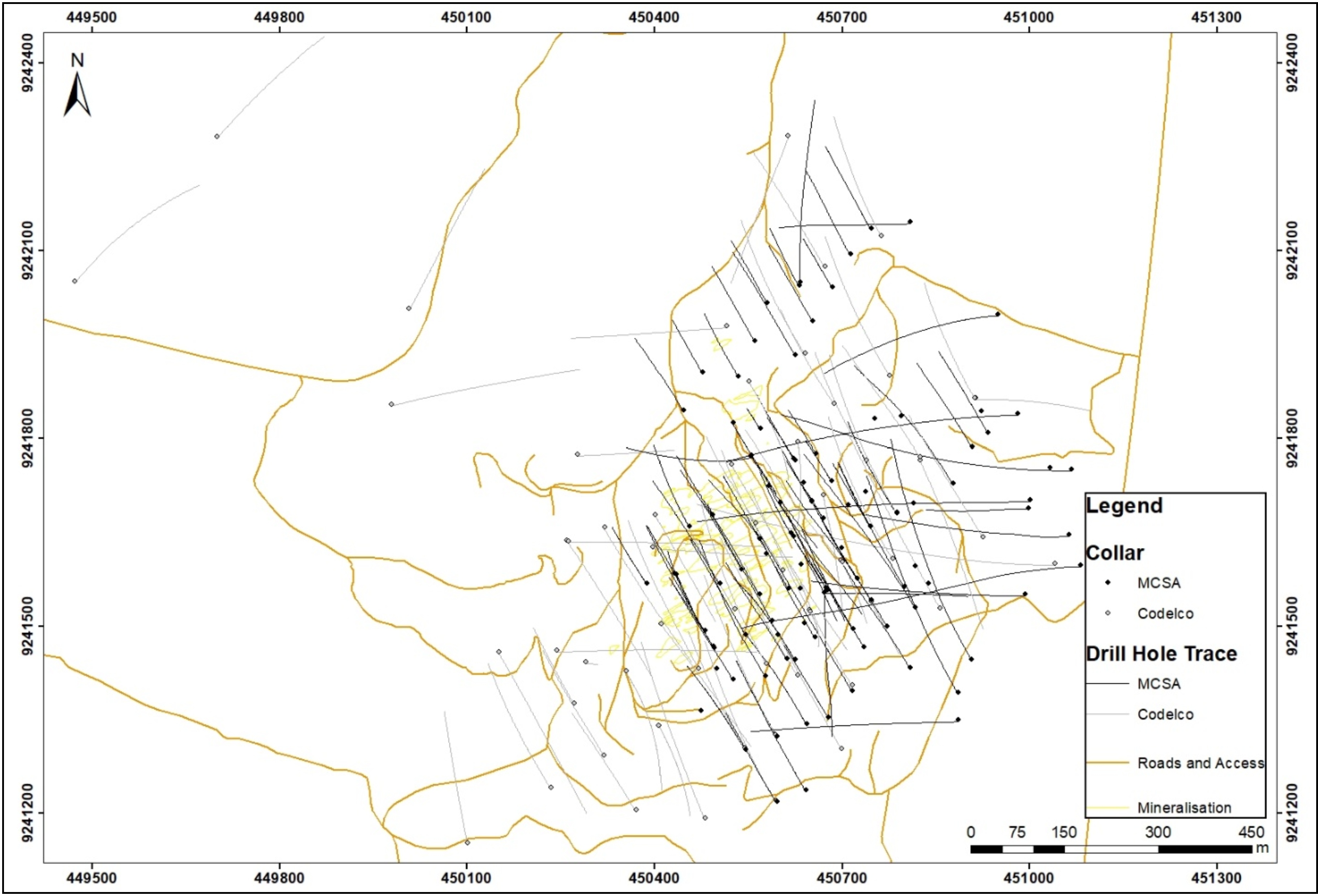

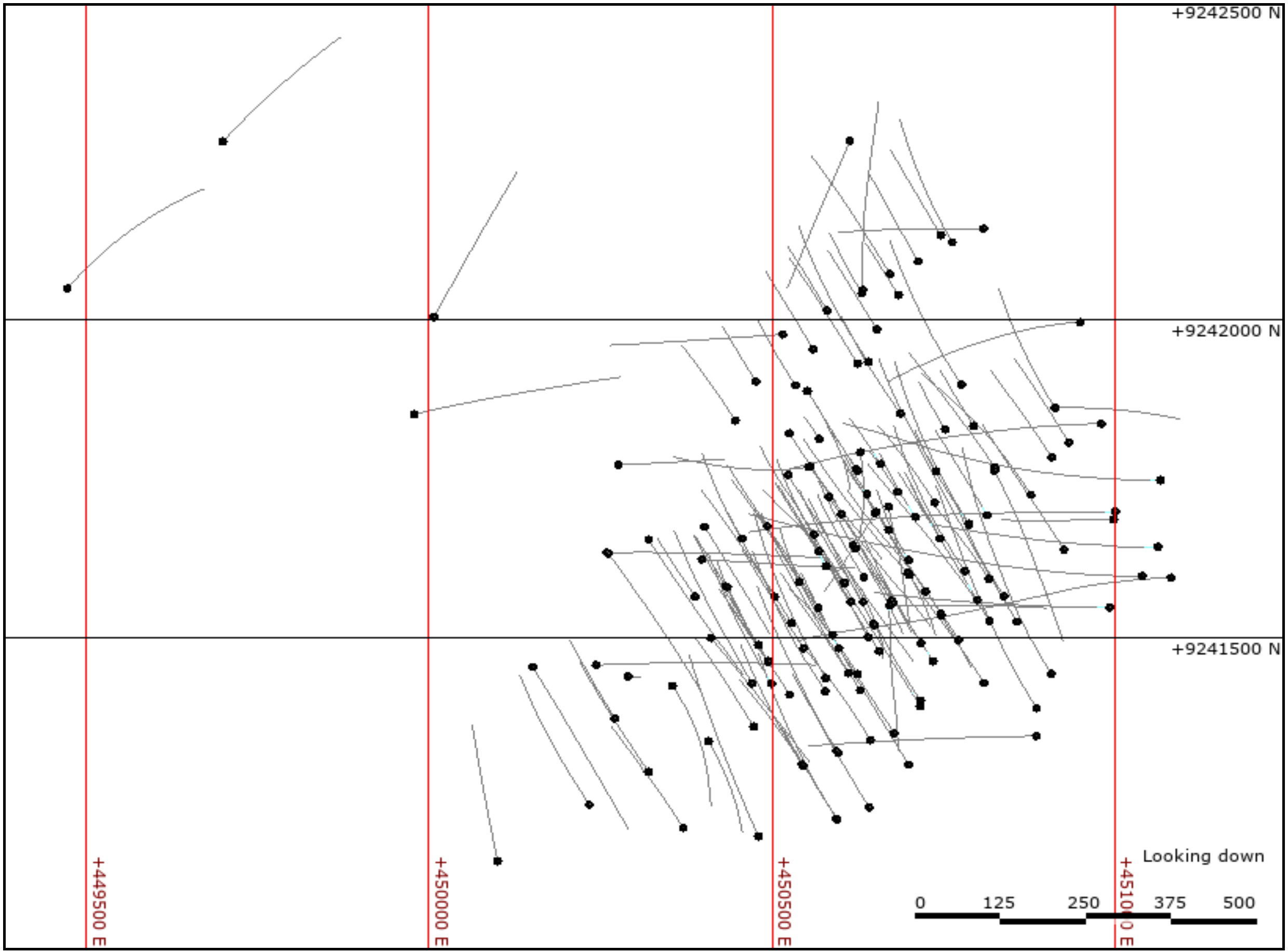

Figure 10-1: Surface map of drill holes on the Boa Esperança Project | |

Figure 10-2: Surface map of drill holes by MCSA (black) and Codelco (grey) on the Boa Esperança Project | |

Figure 13-1: 2012 SGS Geosol Rougher Copper Recovery and Grade | |

Figure 13-2: 2009 CIMM Rougher Kinetics | |

Figure 13-3: 2012 SGS Geosol Rougher Kinetics with 25%+106 µm Master Sample | |

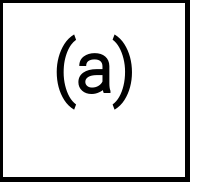

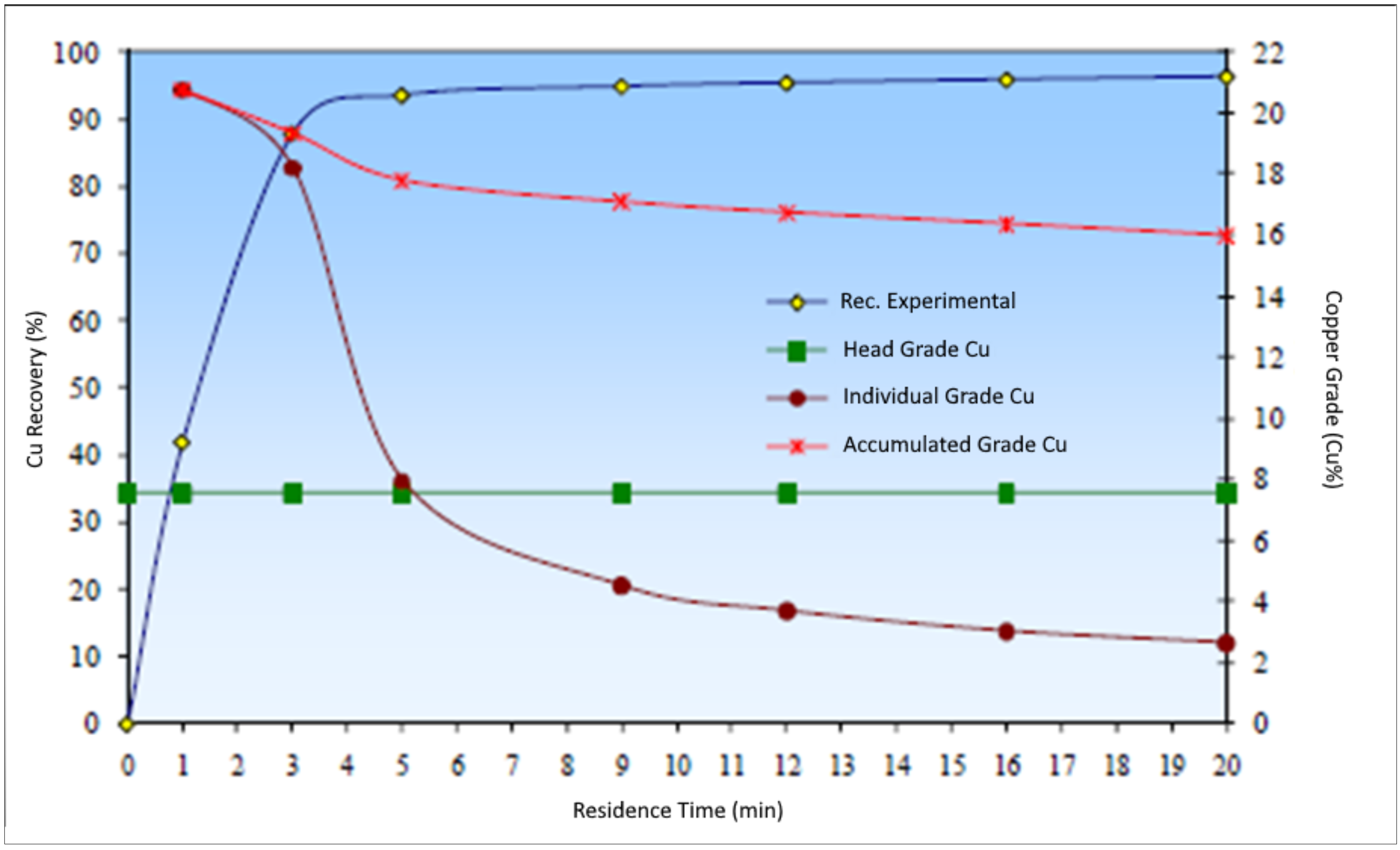

Figure 13-4: Cleaner Flotation Kinetics (a) reground rougher concentrate samples with regrind (b) reground rougher concentrate samples without regrind | |

Figure 13-5: Locked Cycle Flotation Test Flowsheet During The 2012 SGS Test Program | |

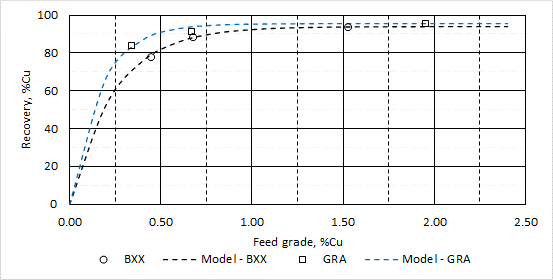

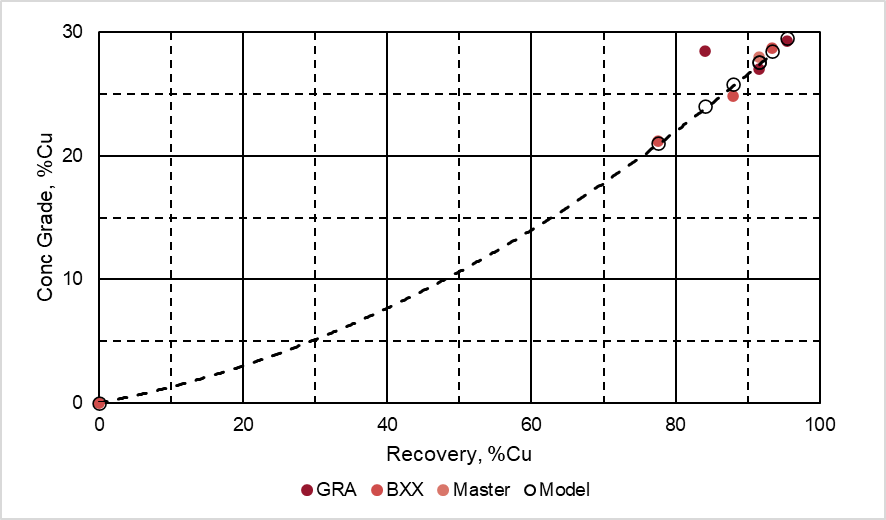

Figure 13-6: Copper Recovery vs. Copper Feed Grade | |

Figure 13-7: Copper Recovery and Copper Concentrate Grade | |

Figure 14-1: Drillhole Location Map, Drilling Used in Mineral Resource Estimation | |

Figure 14-2: Illustrative digitization of hand-drawn vertical section SV_NWSE_14 used for geological model interpretation. Mineralized material is represented in pink and yellow colours | |

| | | | | |

| Boa Esperança Project | Page xiv |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

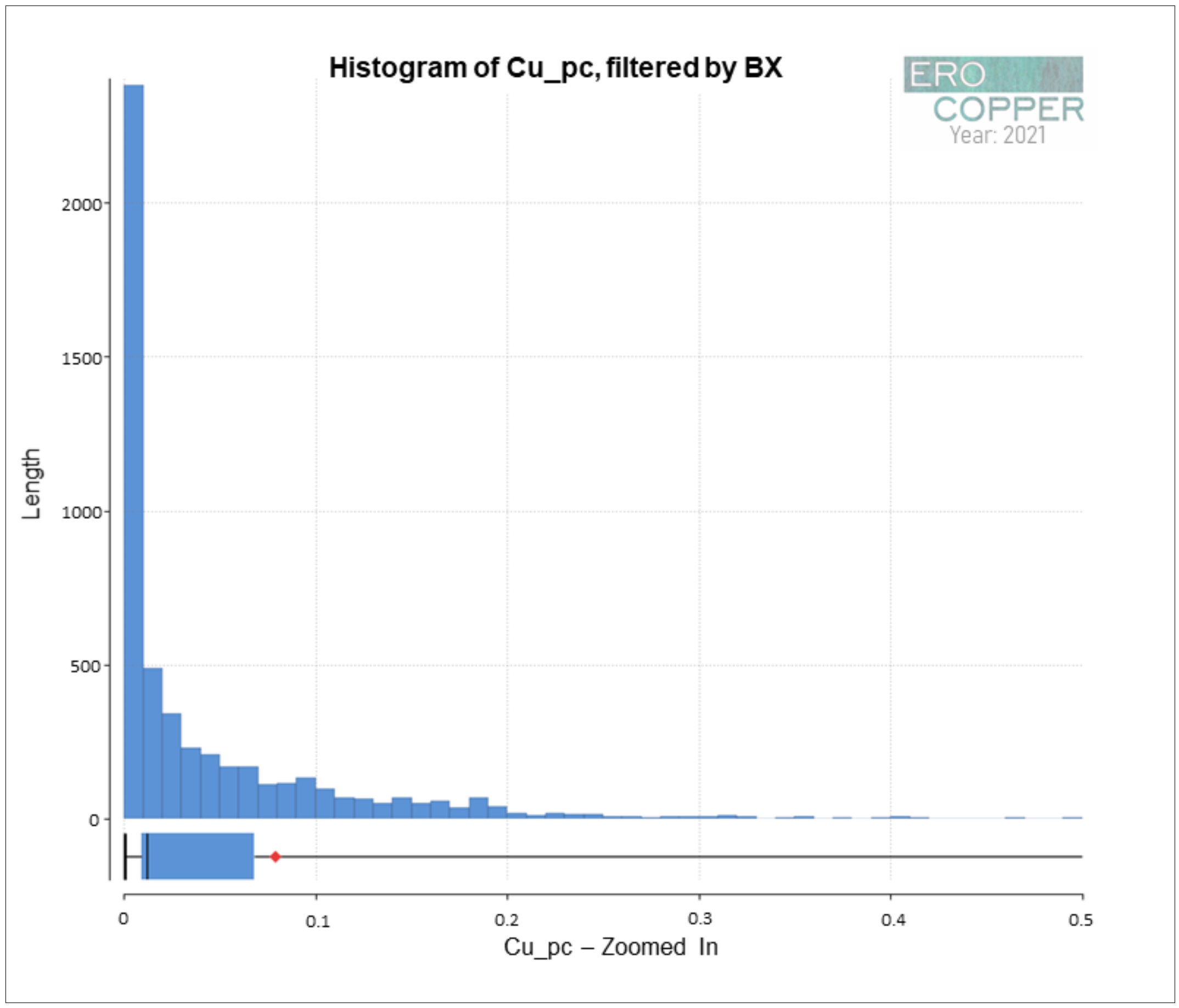

Figure 14-3: Histogram of Cu_pc, filtered by BX | |

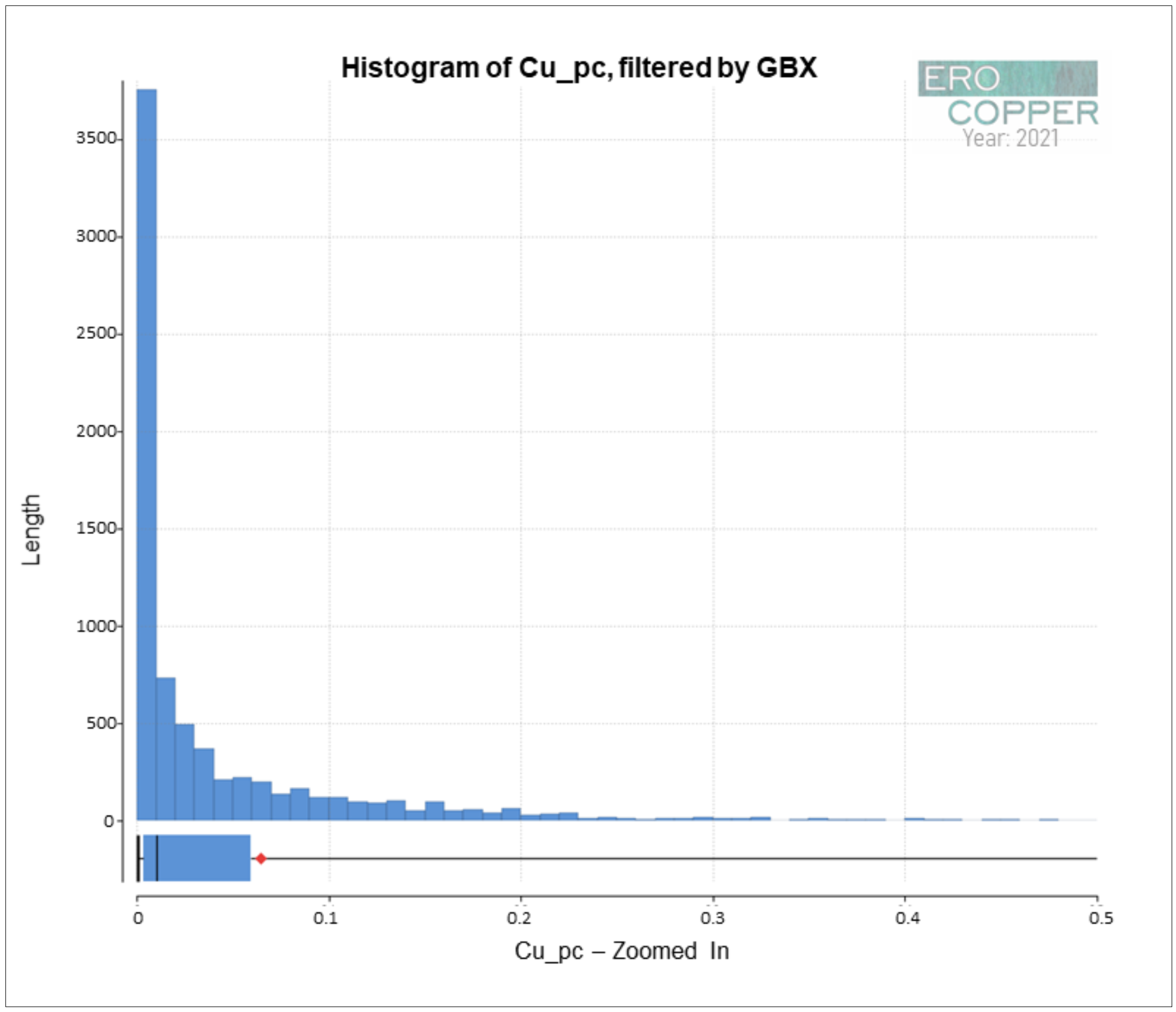

Figure 14-4: Histogram of Cu_pc, filtered by GBX | |

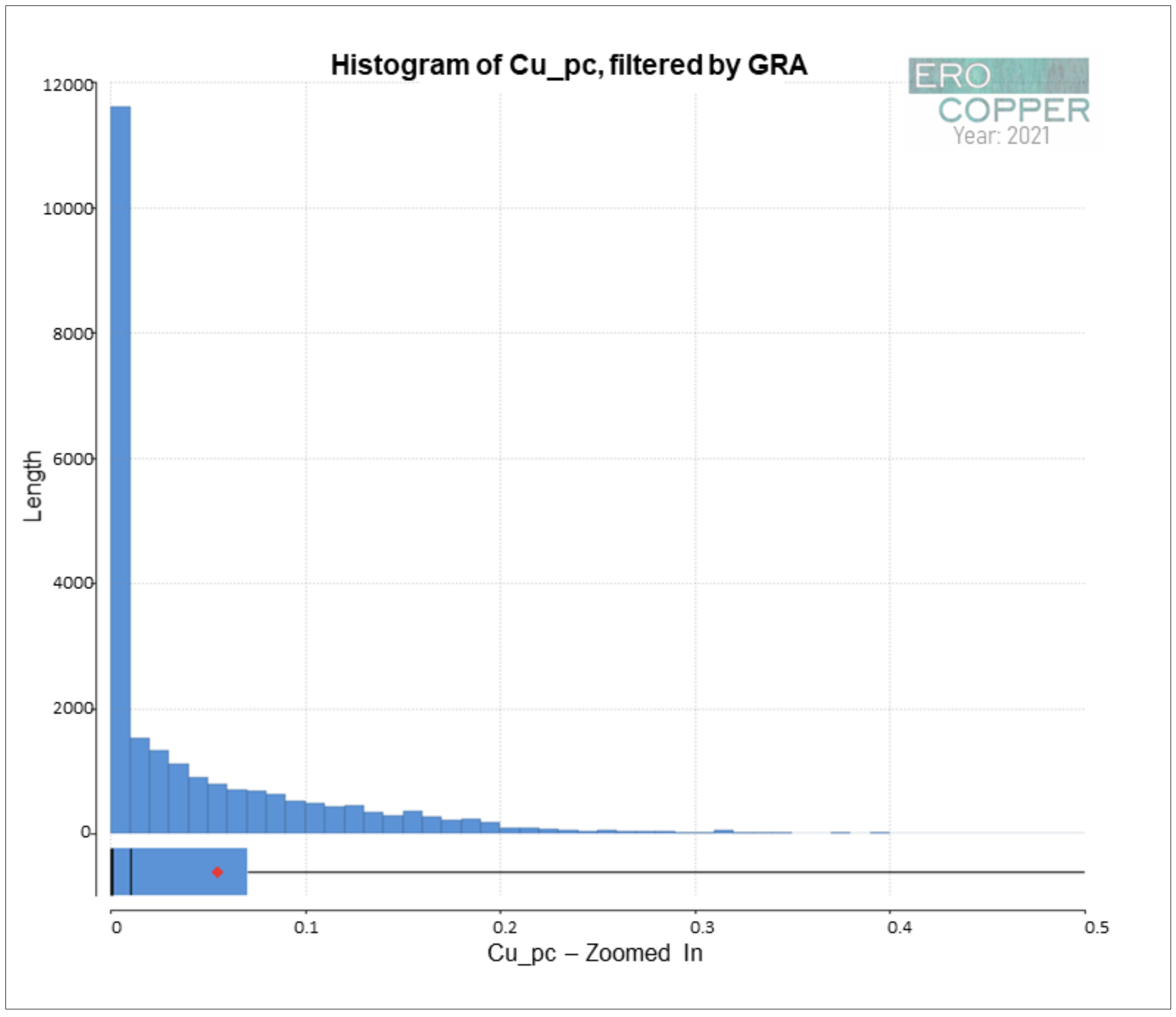

Figure 14-5: Histogram of Cu_pc, filtered by GRA | |

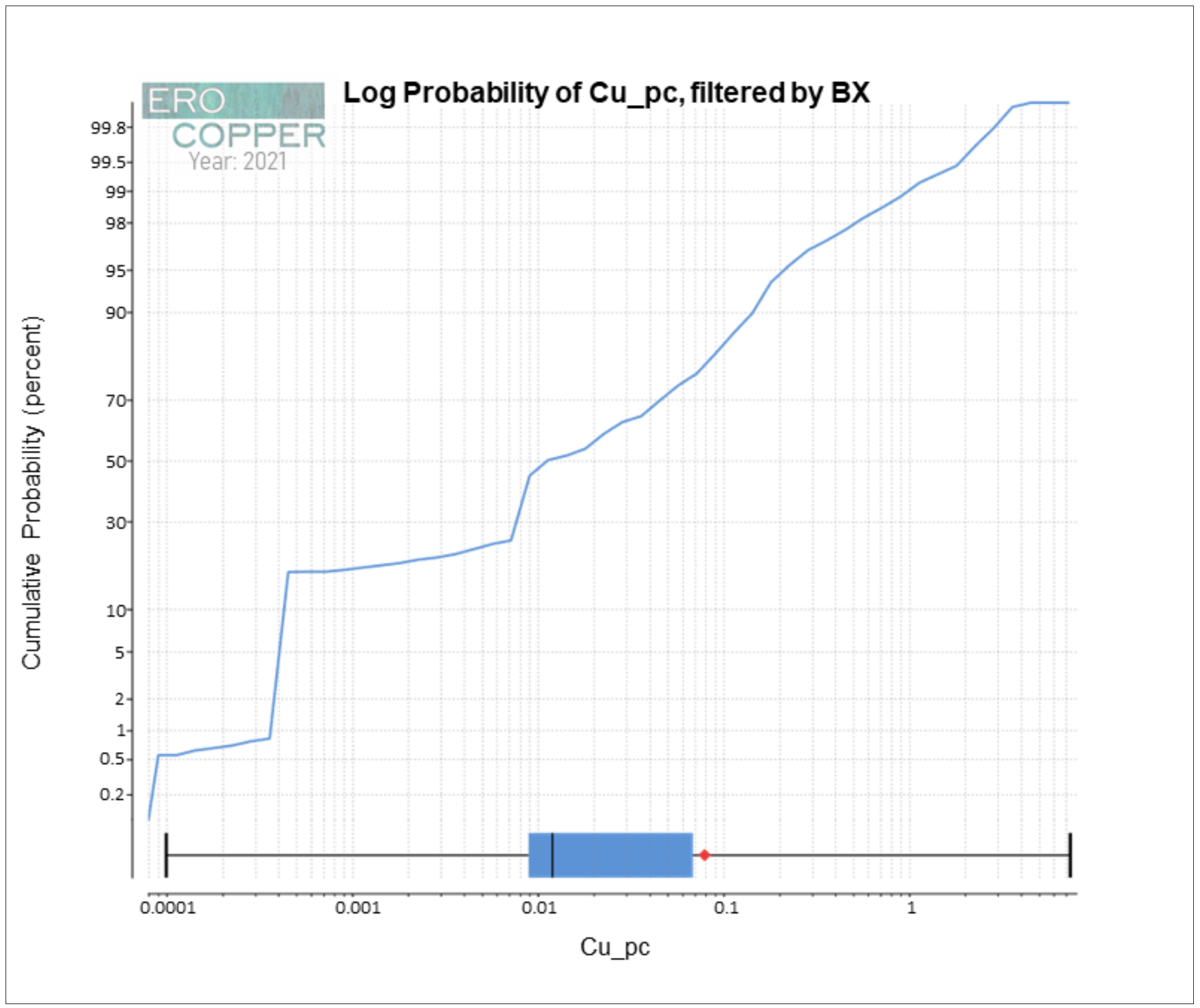

Figure 14-6: Log Probability of Cu_pc, filtered by BX | |

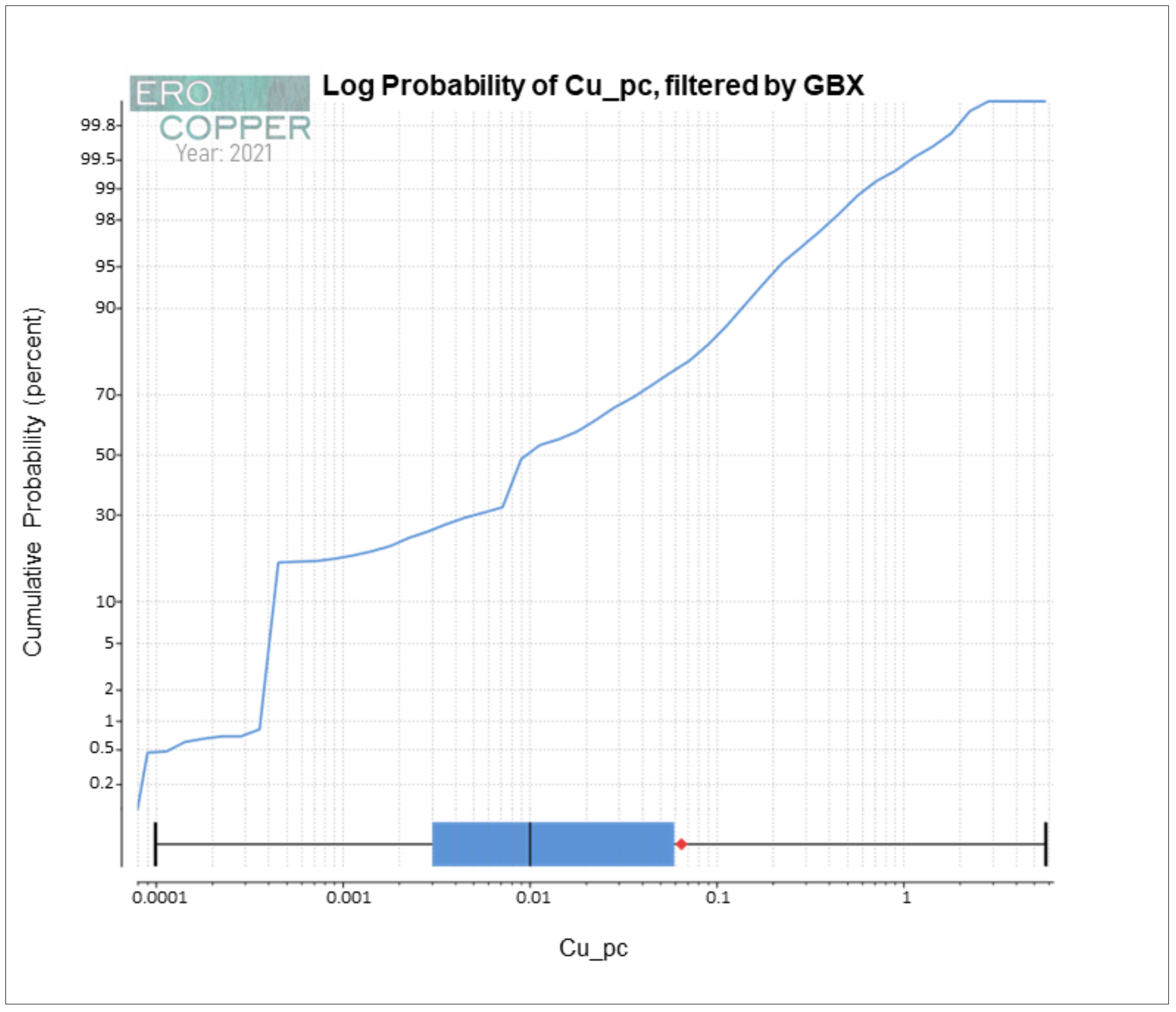

Figure 14-7: Log Probability of Cu_pc, filtered by BX | |

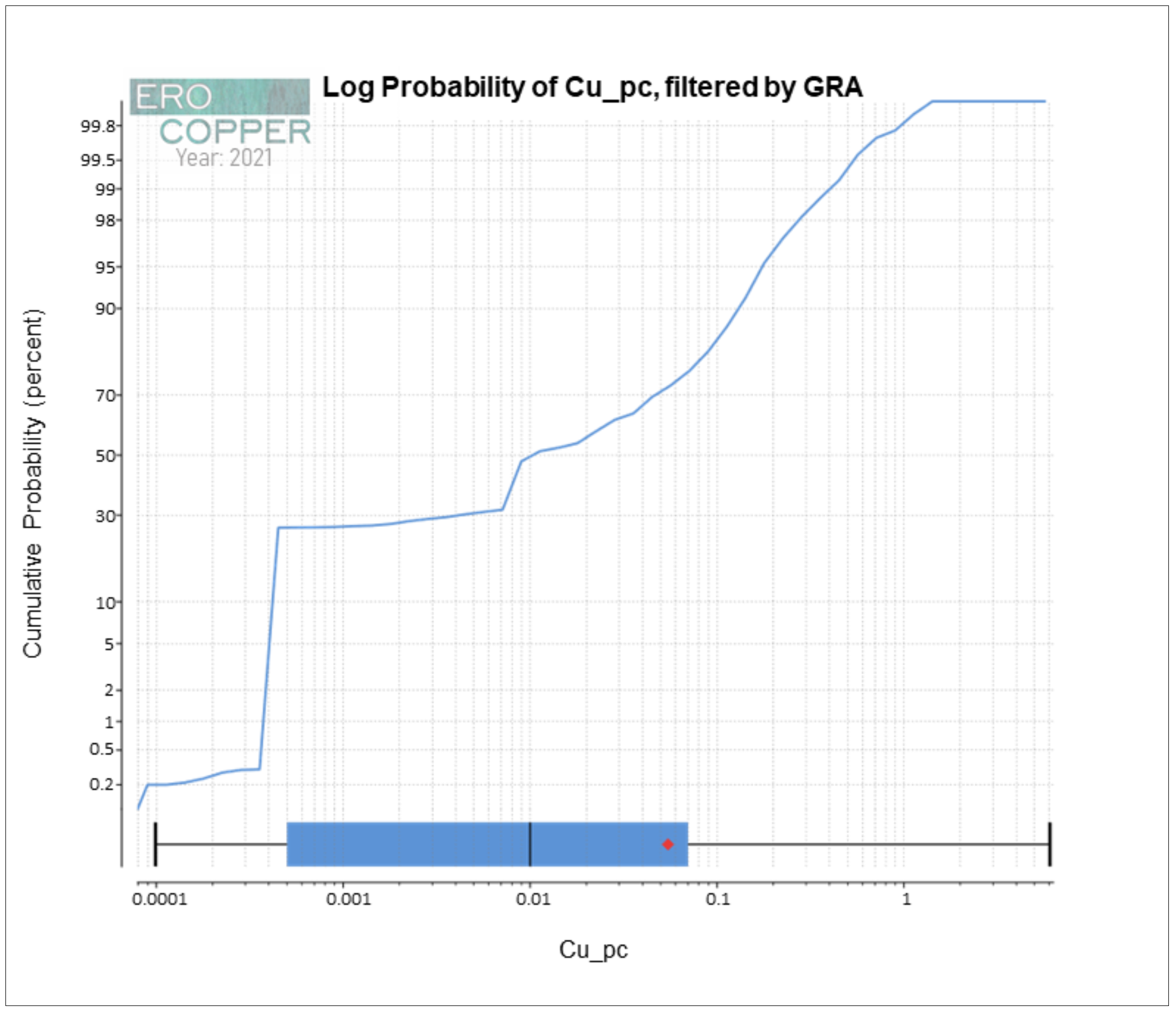

Figure 14-8: Log Probability of Cu_pc, filtered by GRA | |

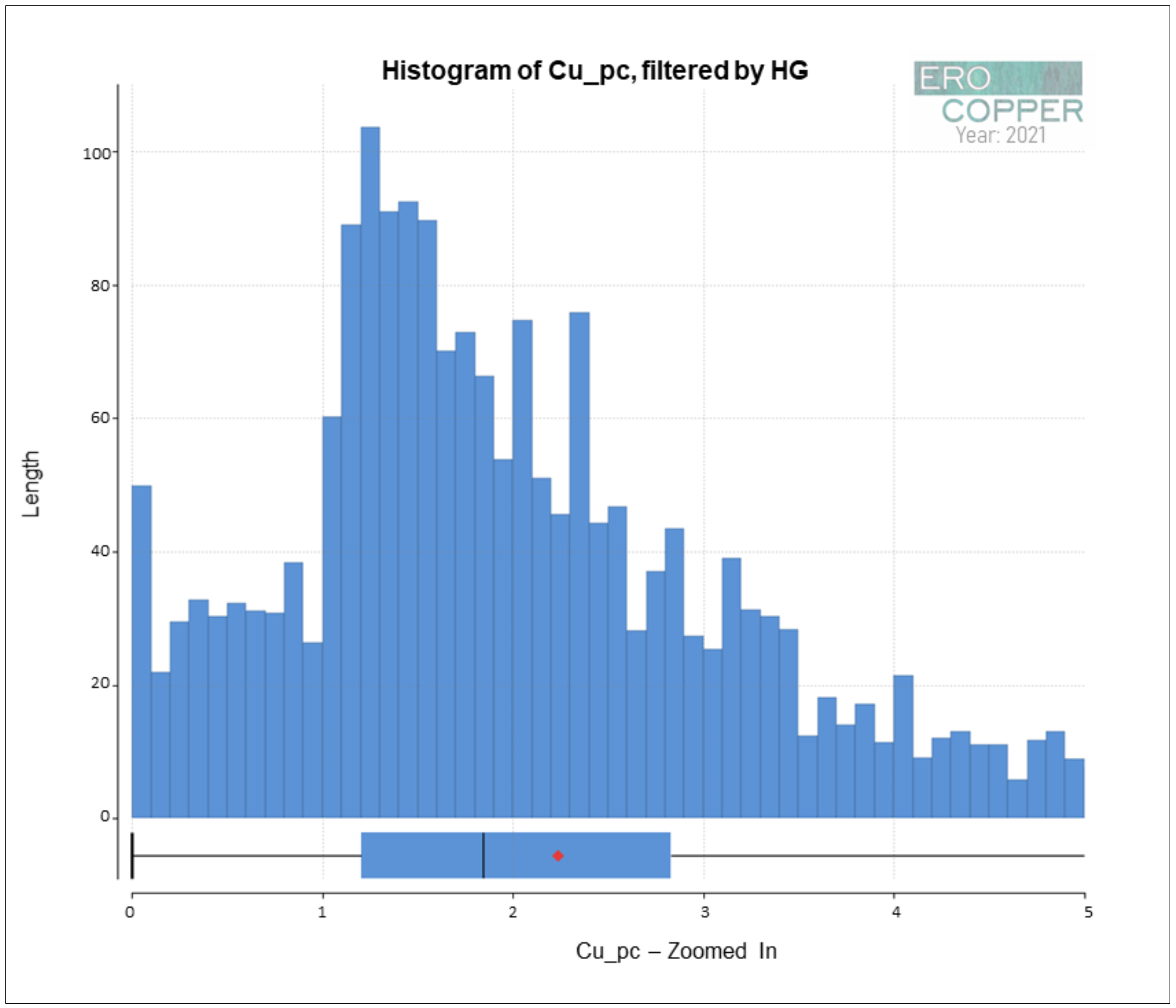

Figure 14-9: Histogram of Cu_pc, filtered by HG | |

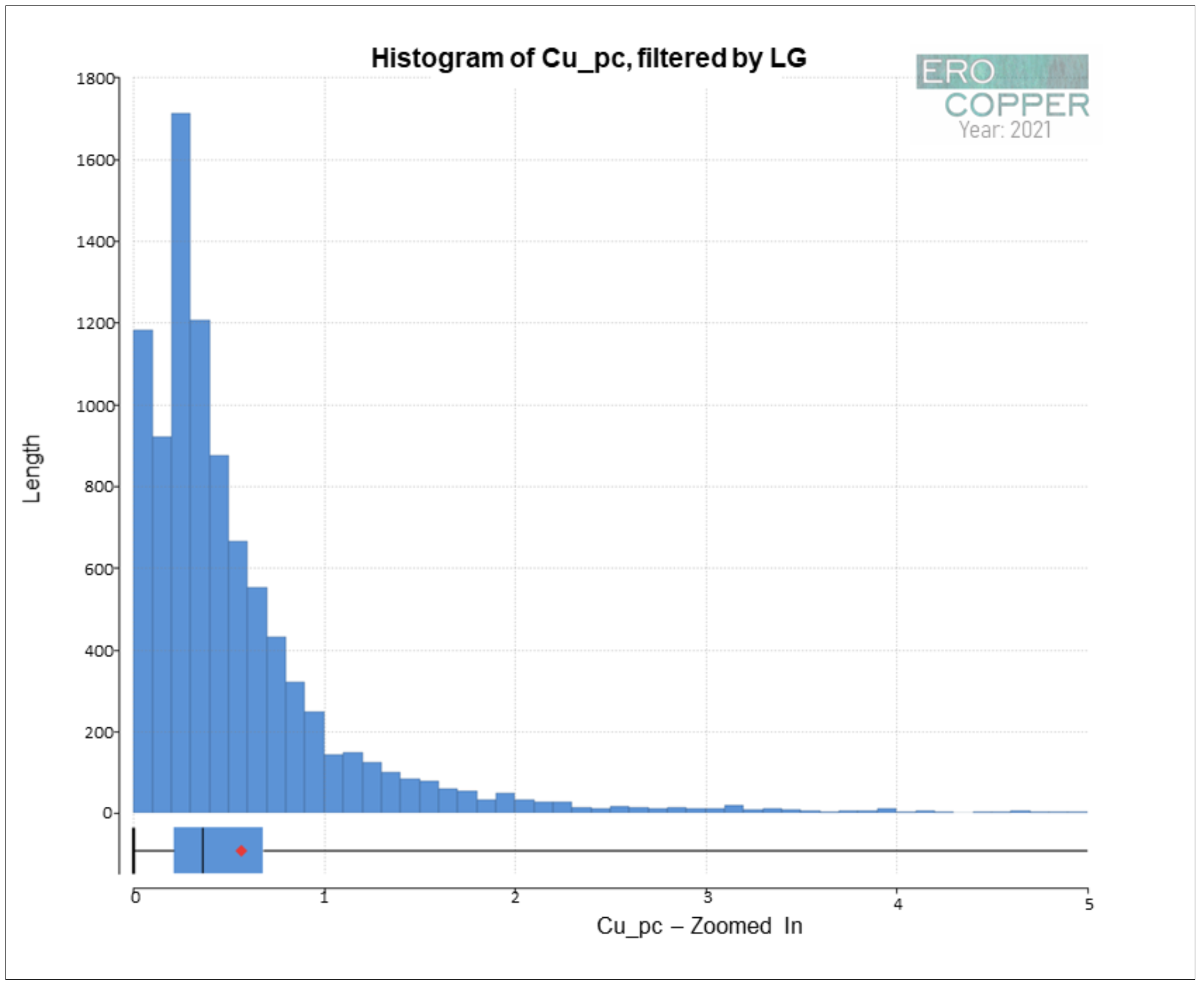

Figure 14-10: Histogram of Cu_pc, filtered by LG | |

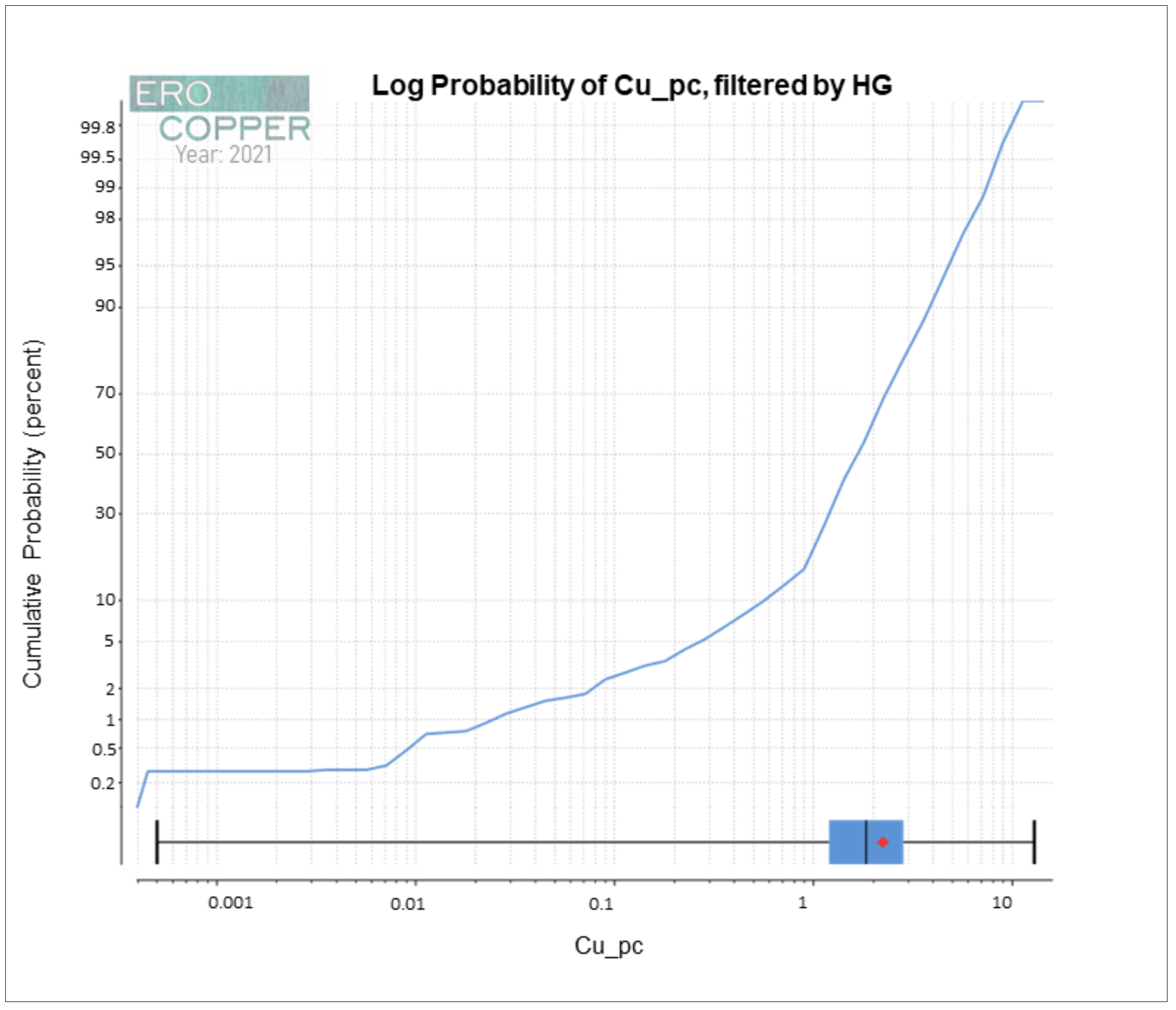

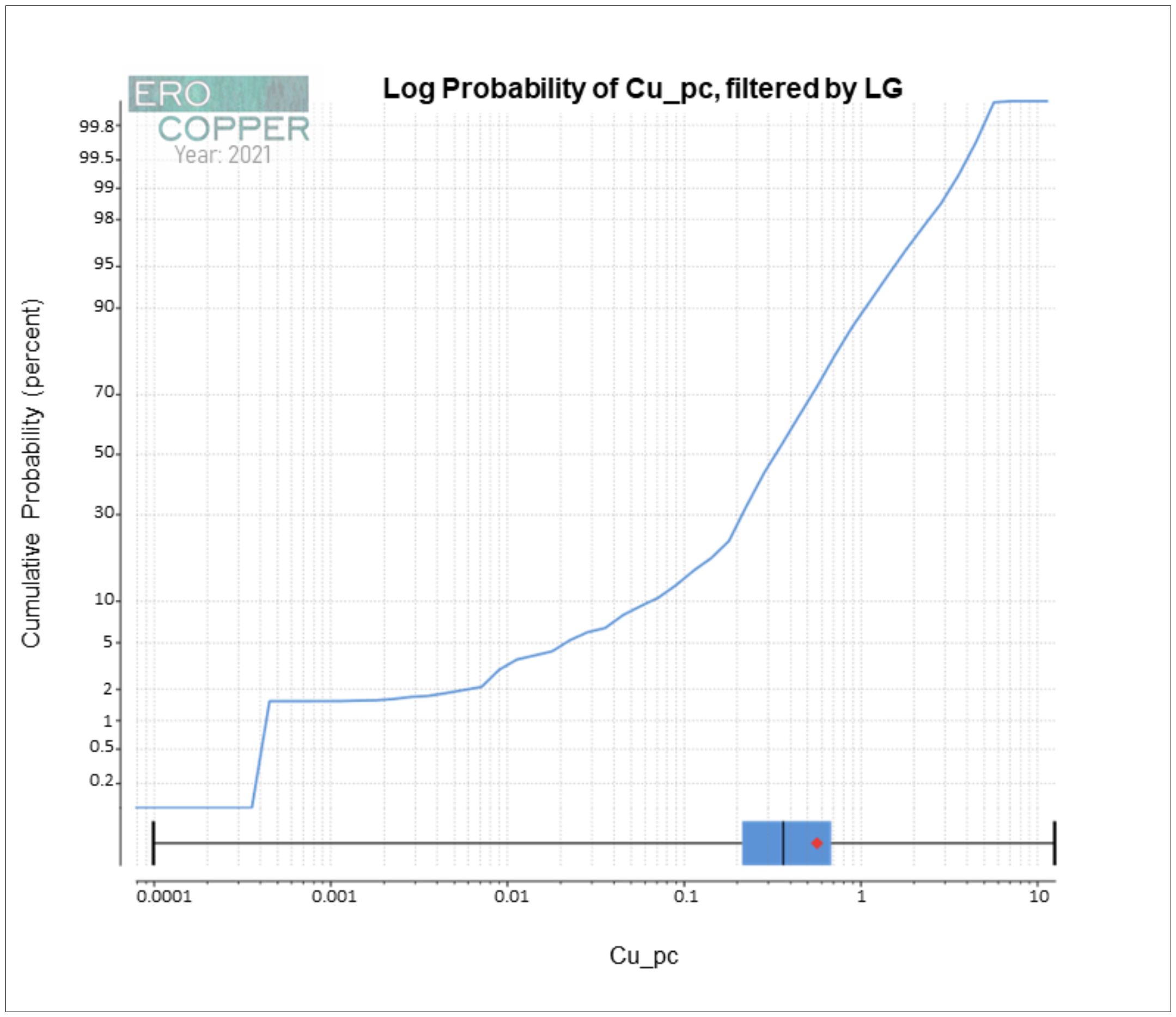

Figure 14-11: Log Probability of Cu_pc, filtered by HG | |

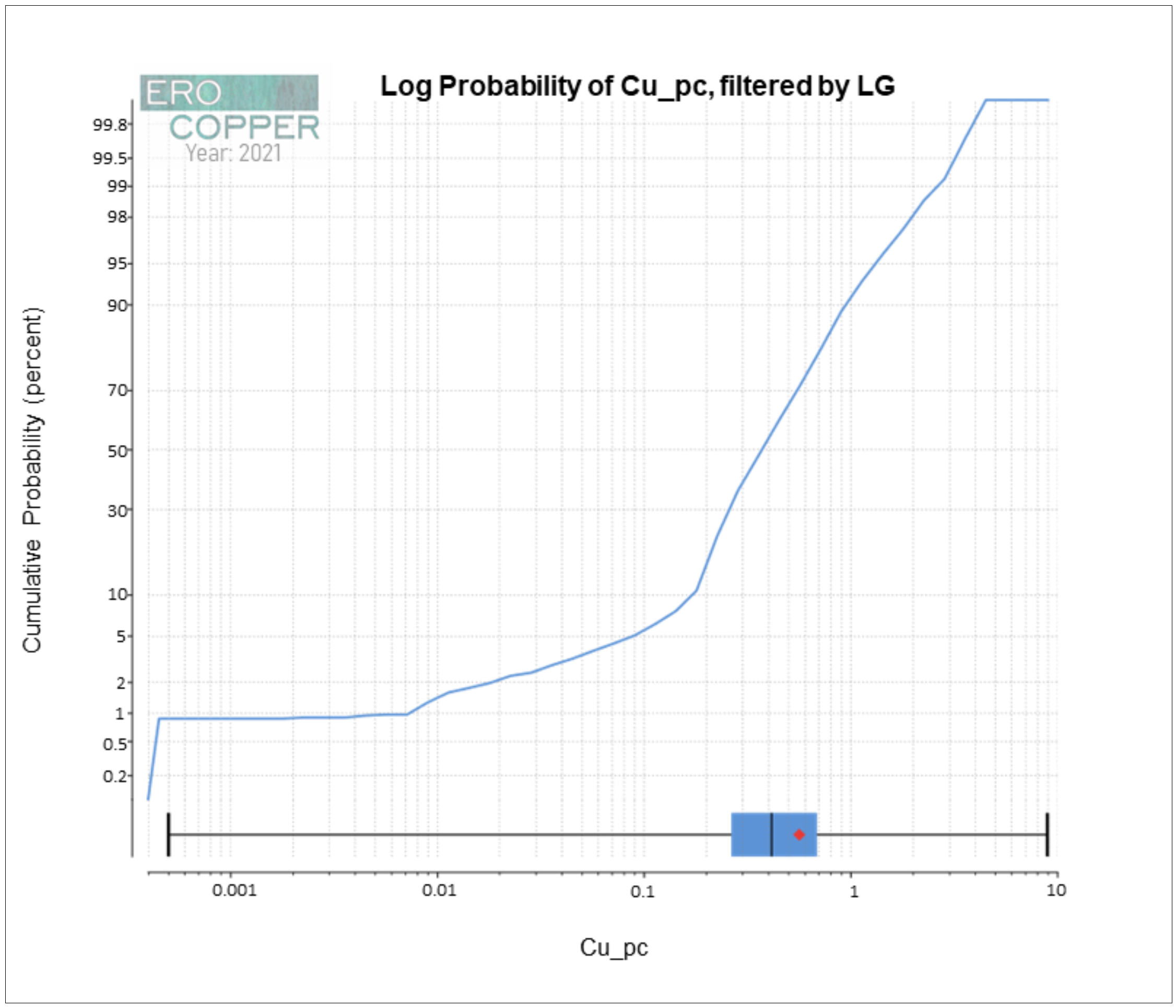

Figure 14-12: Log Probability of Cu_pc, filtered by LG | |

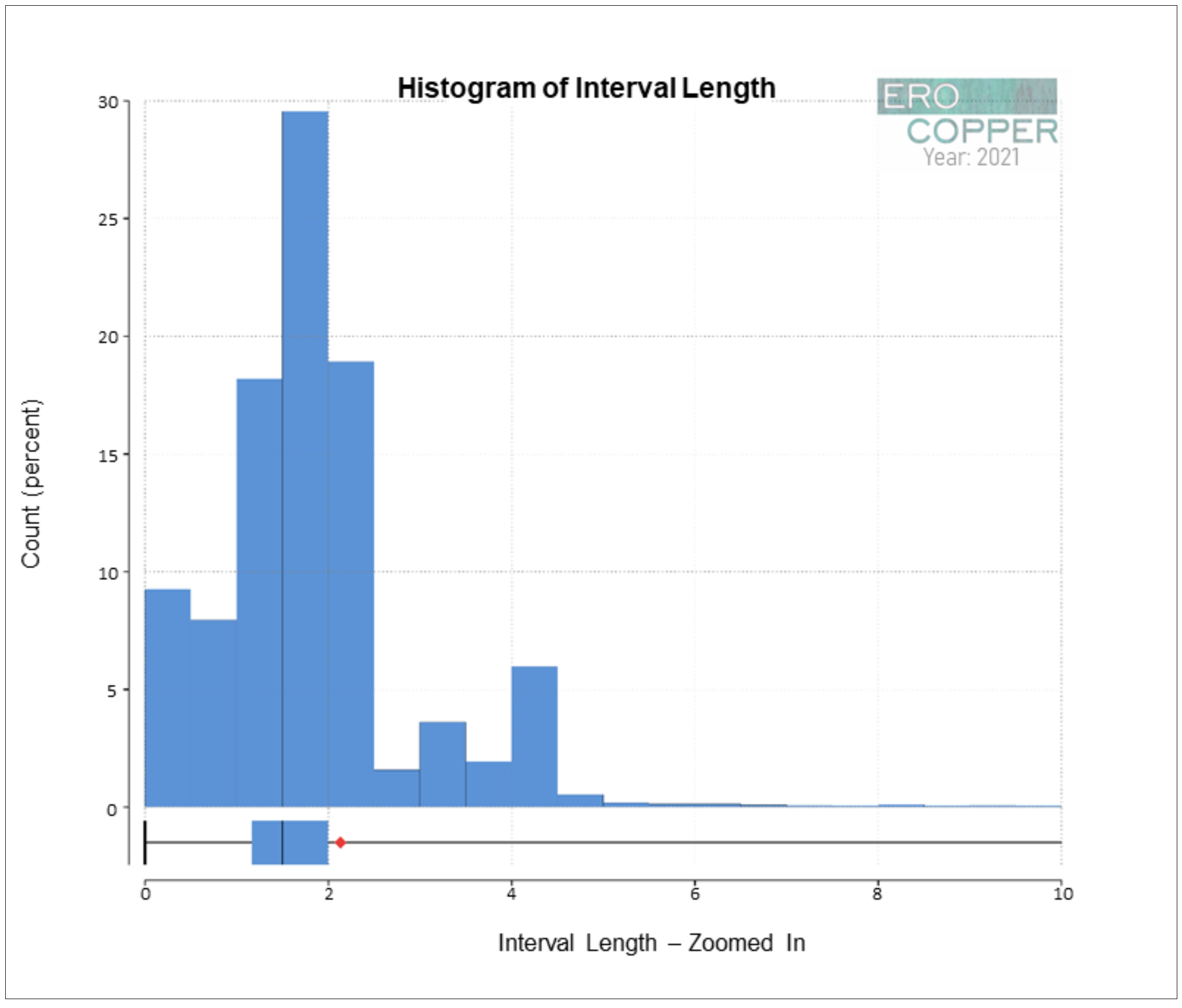

Figure 14-13: Length Histogram Graph from Raw Assay Data | |

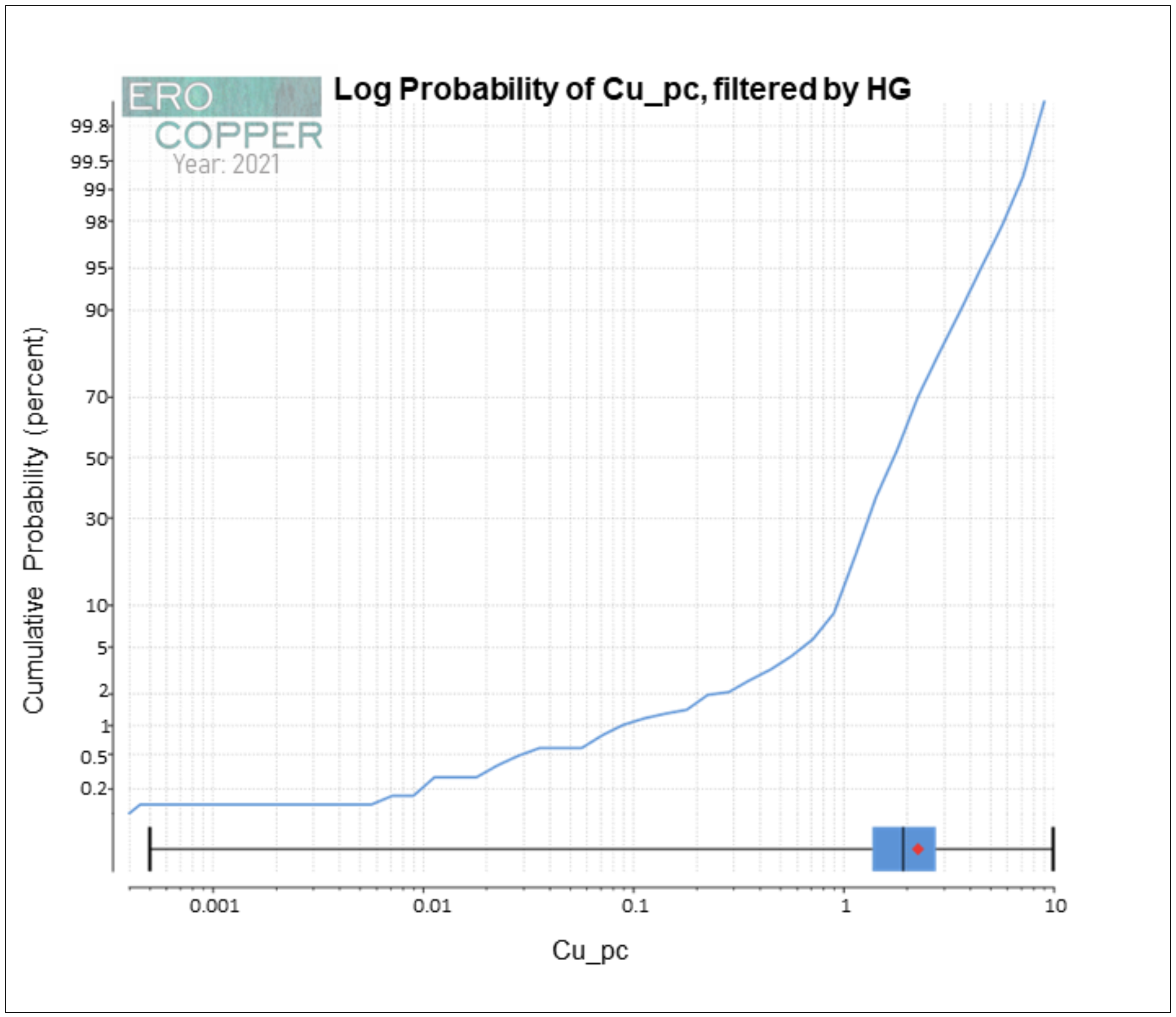

Figure 14-14: Log Probability of Cu_pc, filtered by HG | |

Figure 14-15: Log Probability of Cu_pc, filtered by LG | |

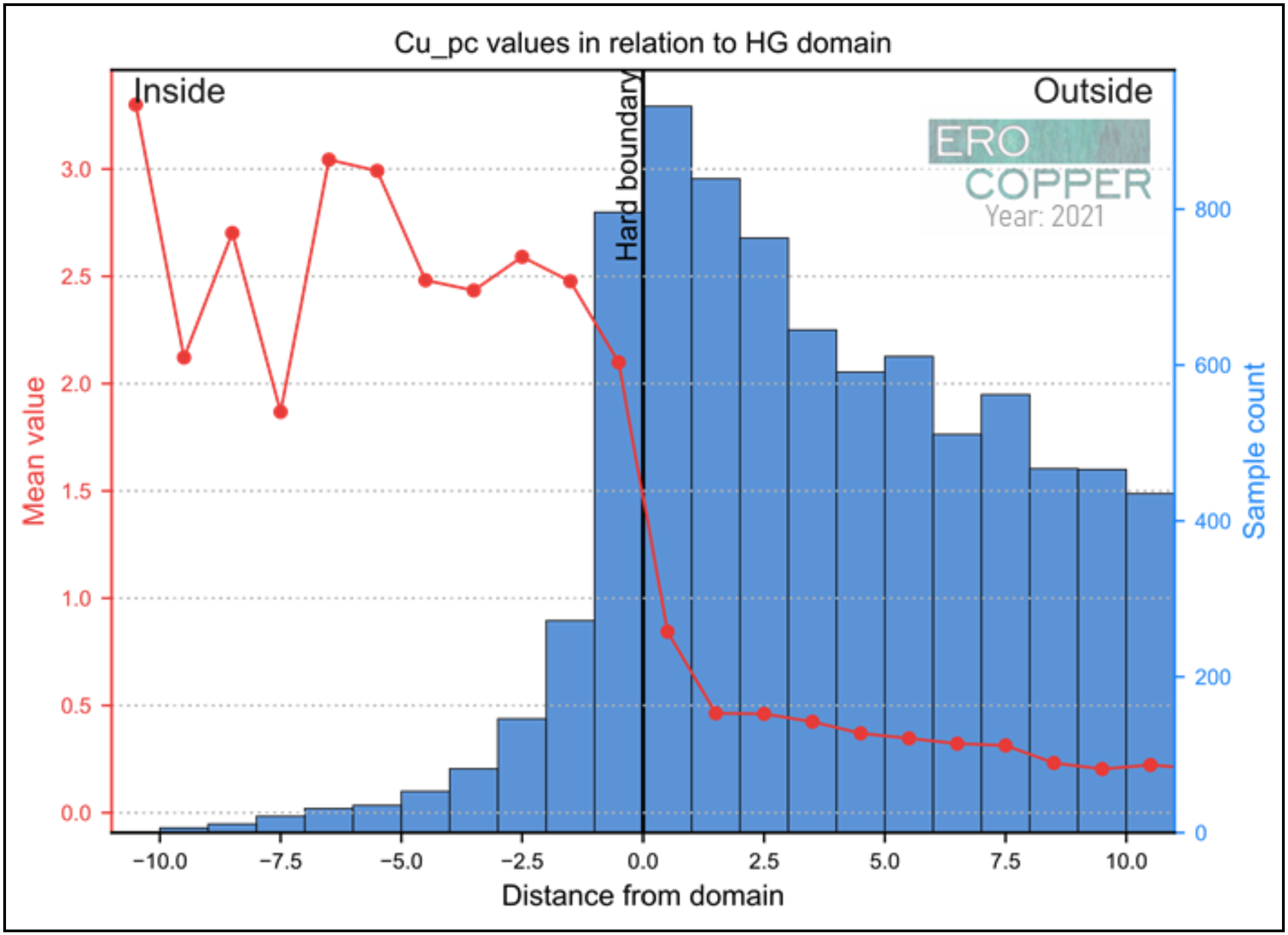

Figure 14-16: Cu_pc values in relation to HG domain | |

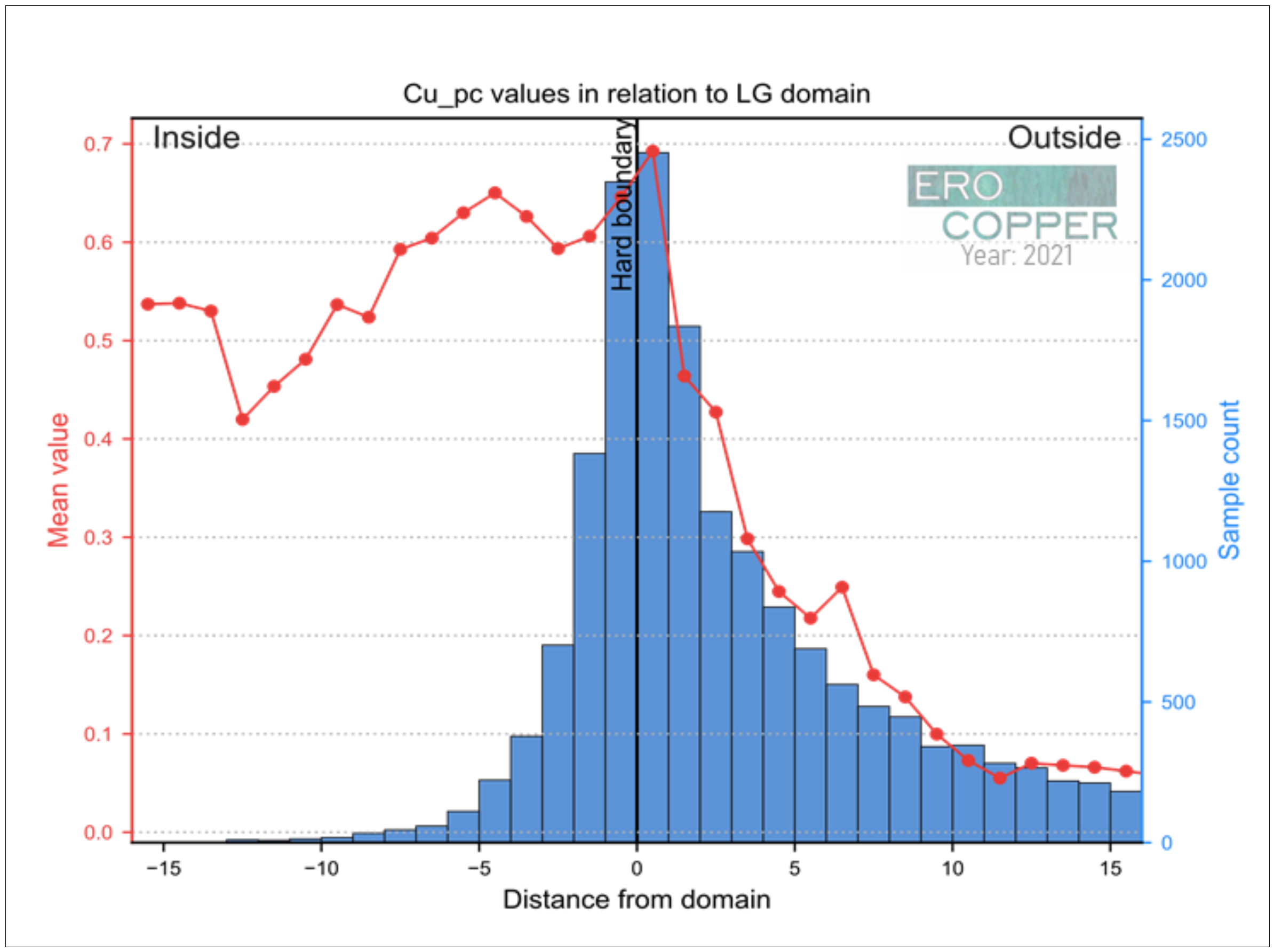

Figure 14-17: Cu_pc values in relation to LG domain | |

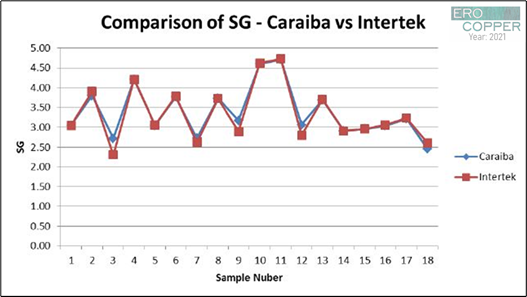

Figure 14-18: Comparison of SG results – MCSA vs. Intertek | |

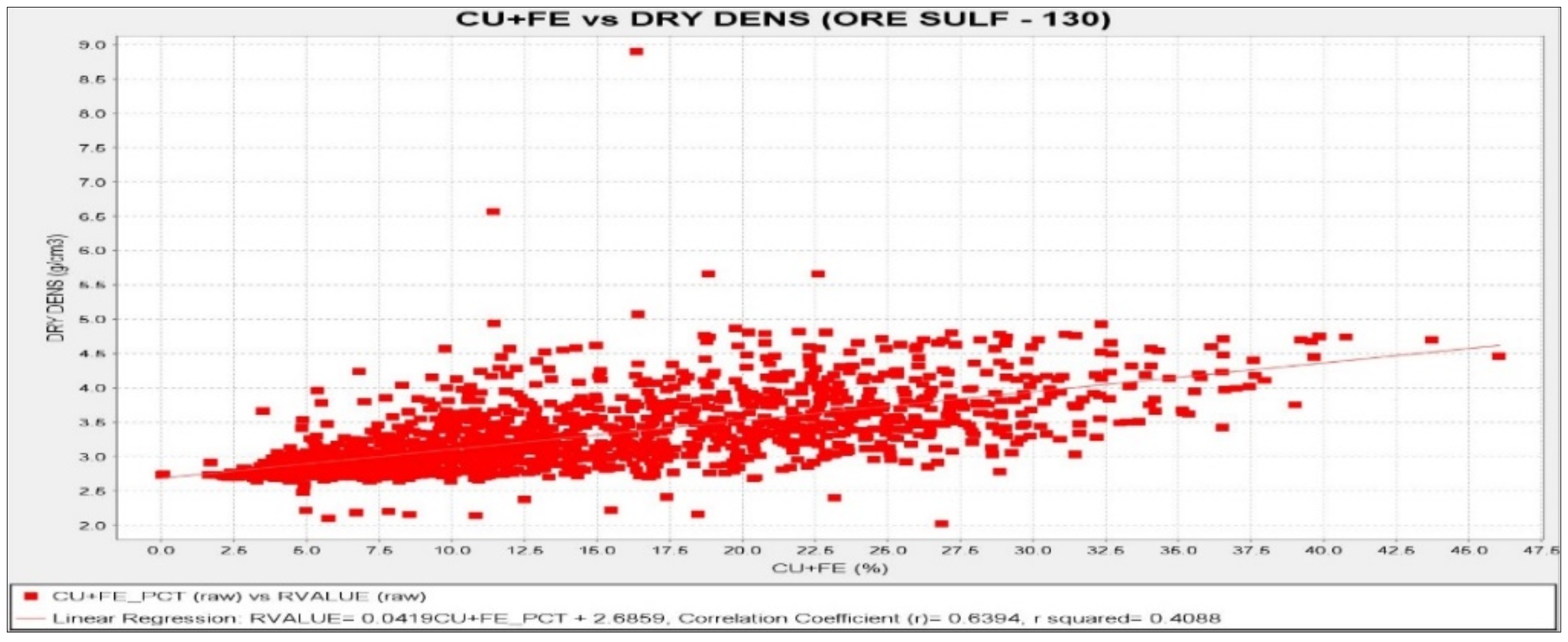

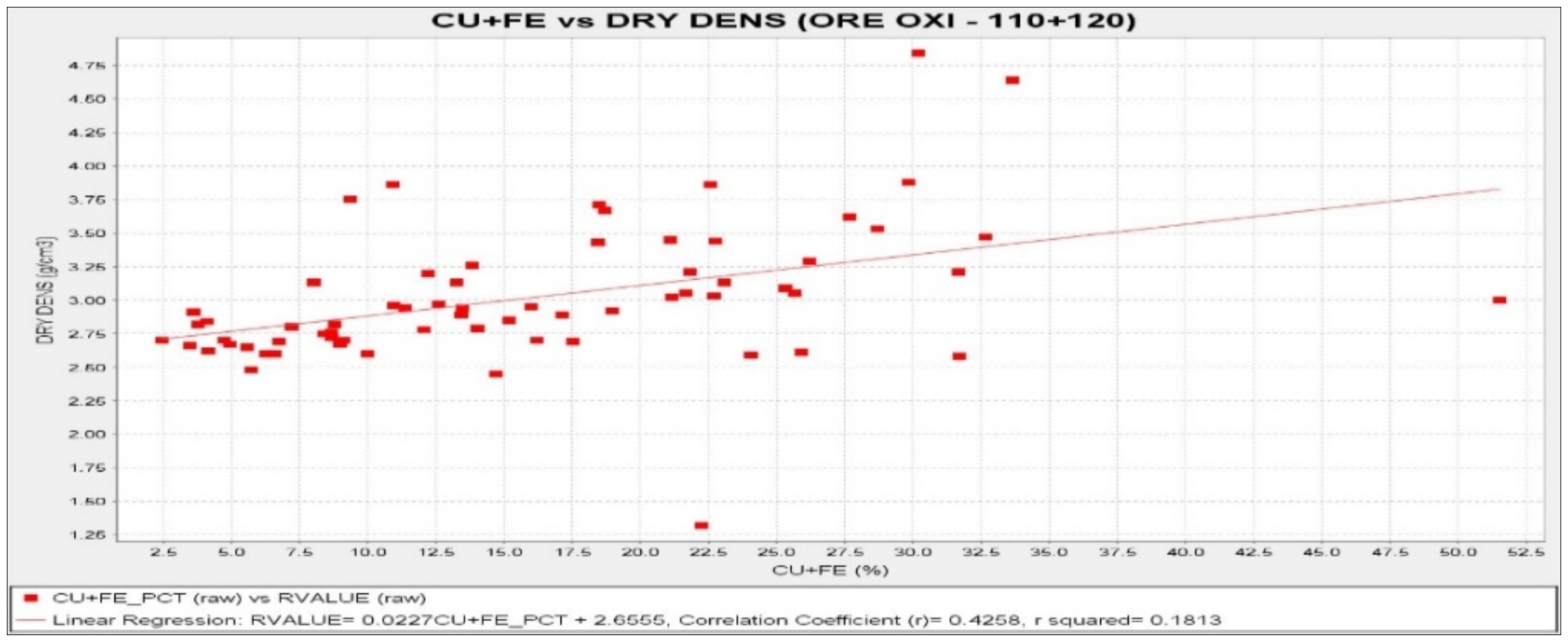

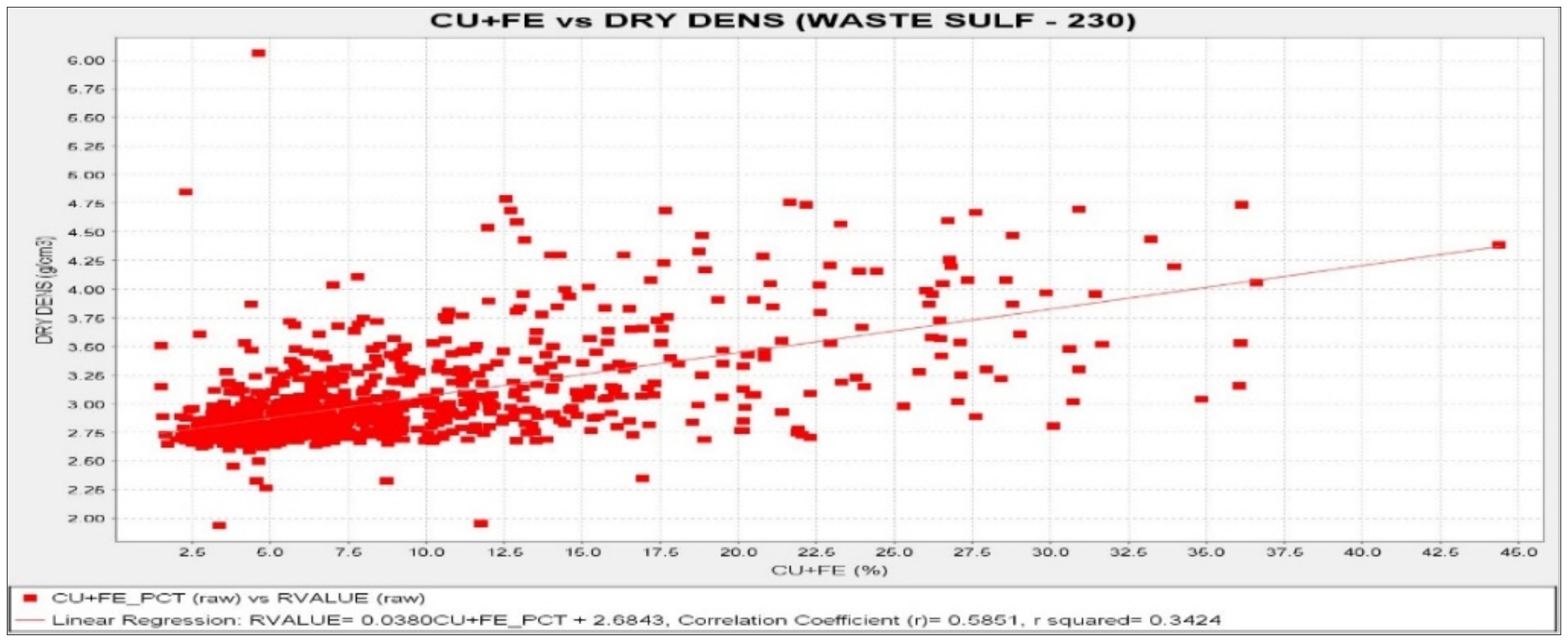

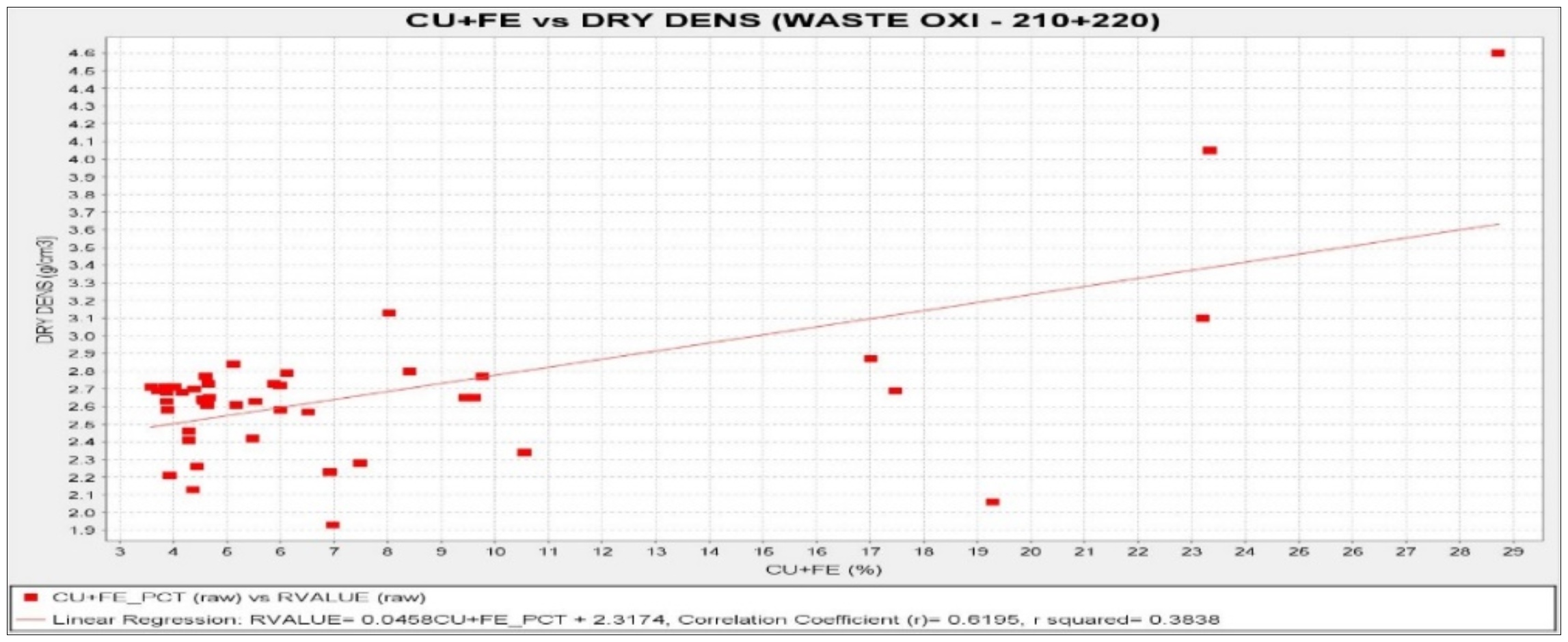

Figure 14-19: Scatter plots of SG vs. Cu + Fe | |

Figure 14-20: Downhole Variogram for Cu_pc Values | |

Figure 14-21: Downhole Correlogram for Cu_pc Values | |

Figure 14-22: Down hole Variogram for Fe_pc Values | |

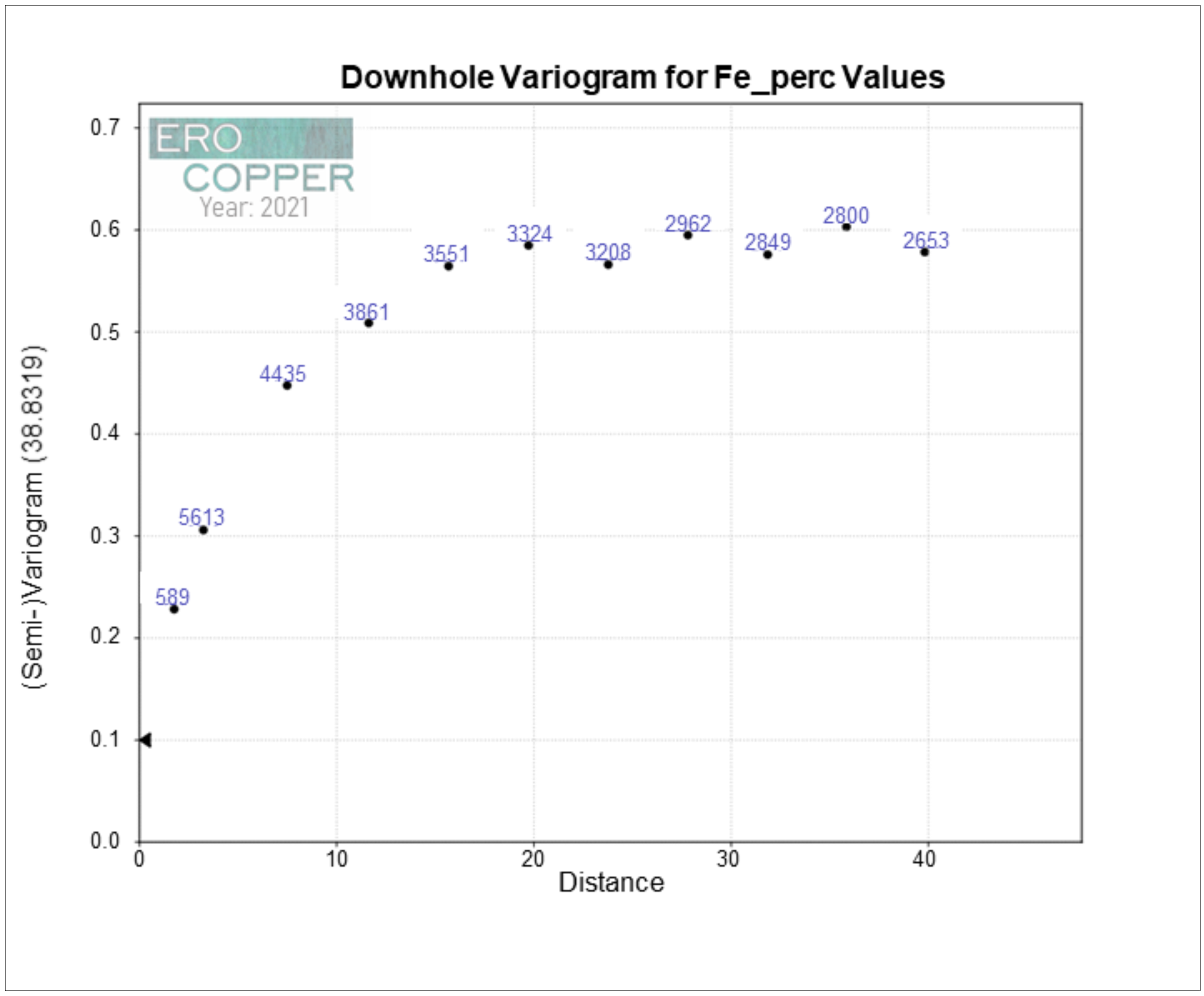

Figure 14-23: Downhole Variogram for Fe_pc Values | |

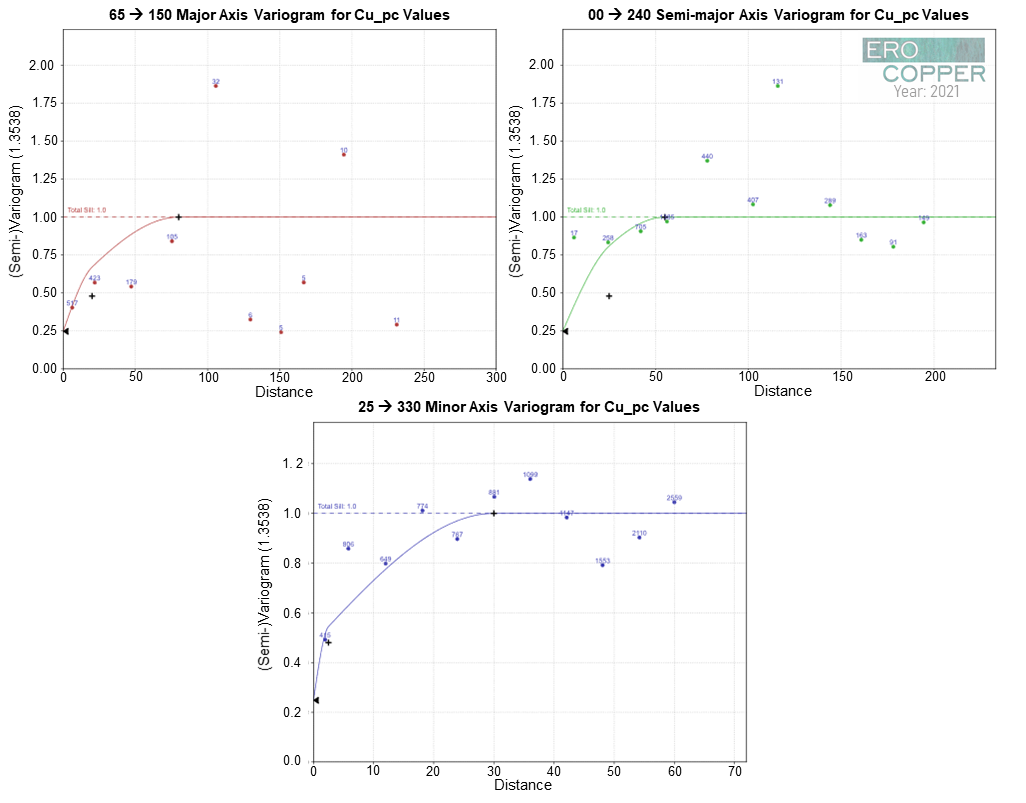

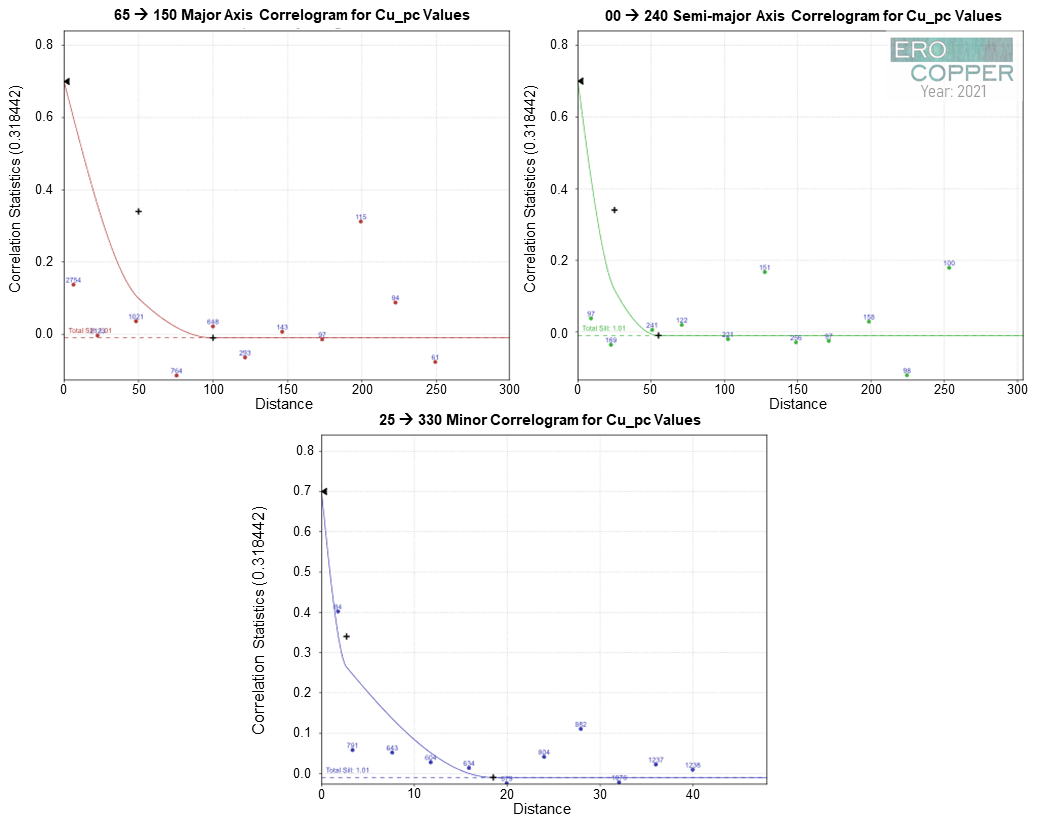

Figure 14-24: Directional Variogram for Copper (high-grade domain) | |

Figure 14-25: Directional Variogram for Copper (low-grade domain) | |

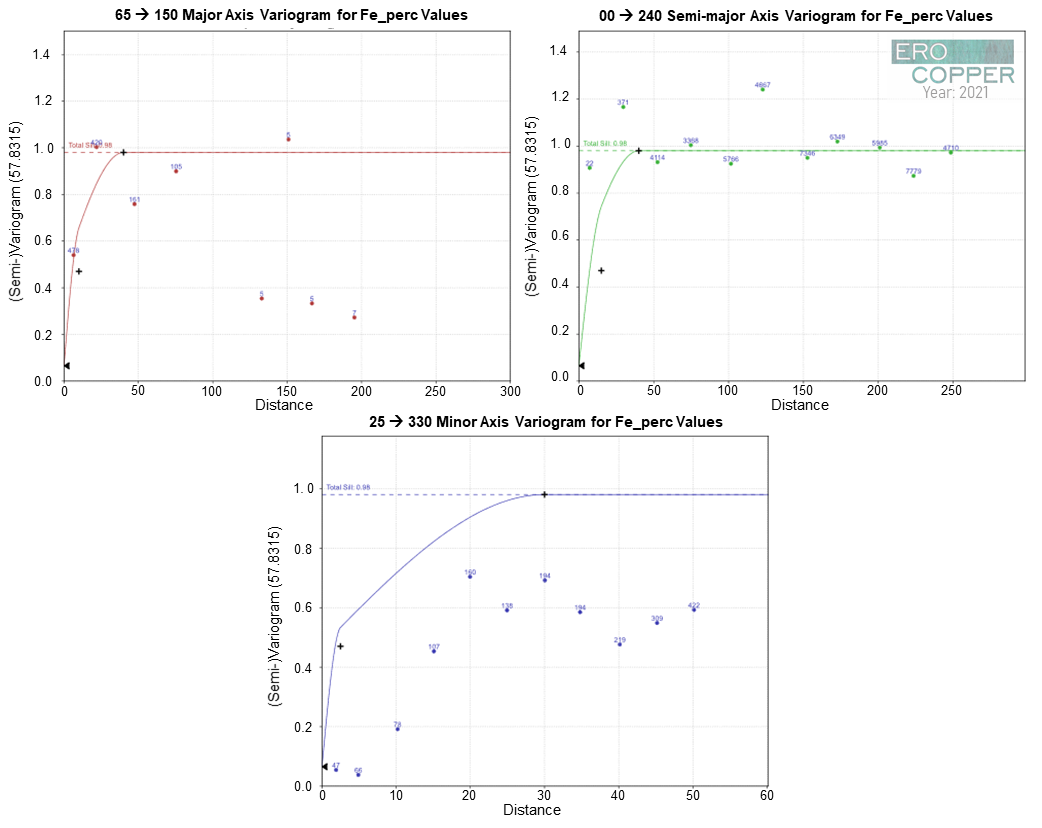

Figure 14-26:�� Directional Variogram for Iron (high-grade domain) | |

Figure 14-27: Directional Variogram for Iron (low-grade domain) | |

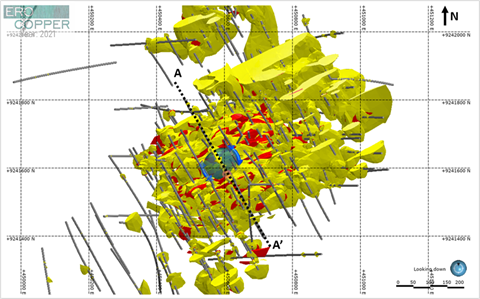

Figure 14-28: Copper Search Ellipses (blue) for high-grade (red) and low-grade (yellow) Domains | |

Figure 14-29: Wireframes With Block Model Outline in Section View | |

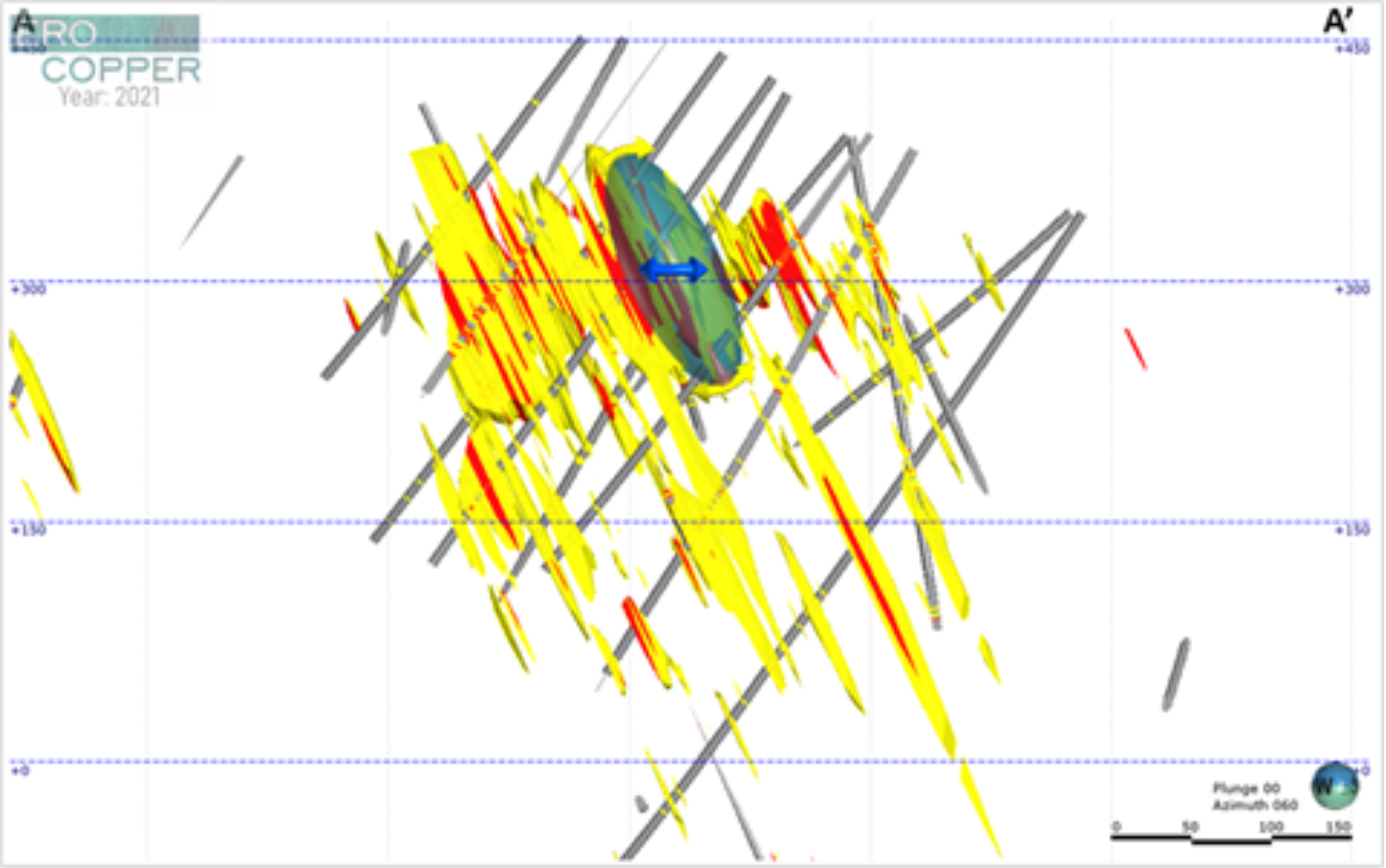

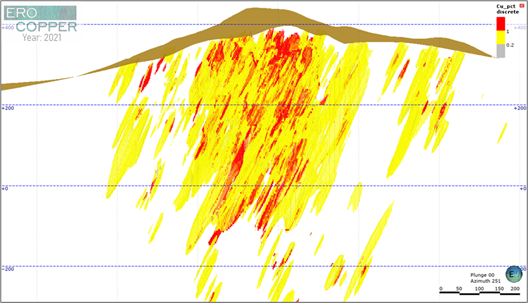

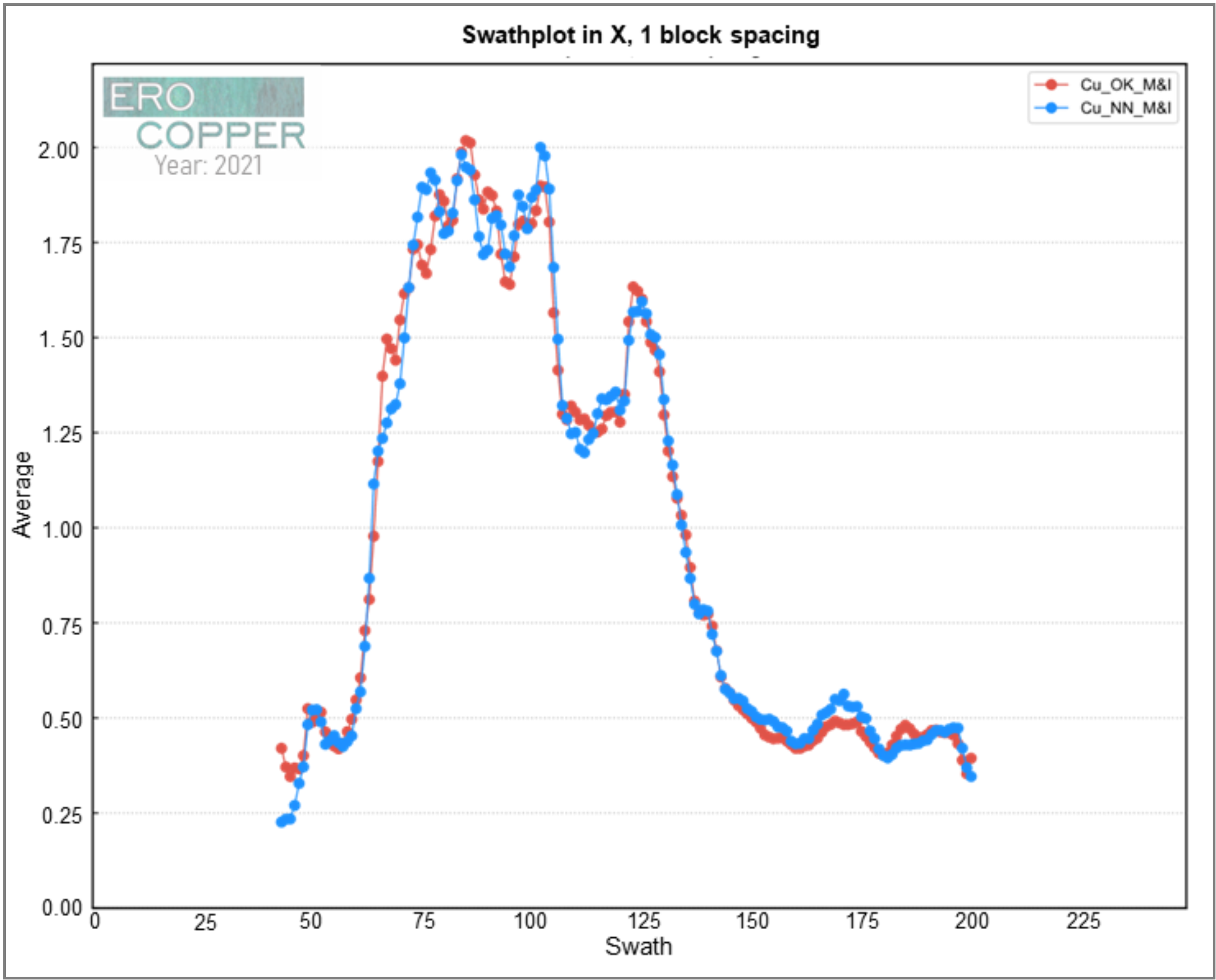

Figure 14-30: Swath plot in X, 1 block spacing | |

Figure 14-31: Swath plot in Y, 1 block spacing | |

Figure 14-32: Swath plot in Z, 1 block spa | |

Figure 14-33: Comparison between block model and composites in vertical section. | |

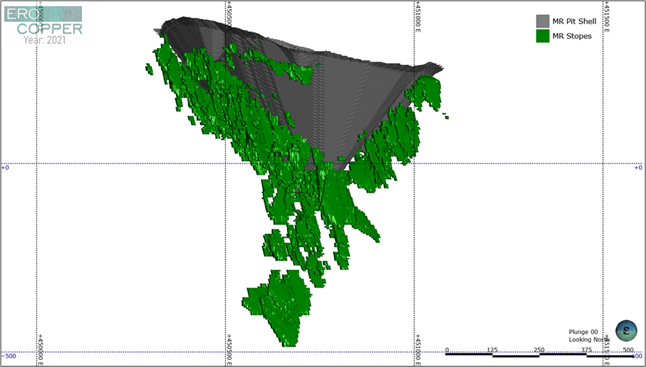

Figure 14-34: Mineral Resources Open Pit Shell and Stope Optimizer Rounds | |

Figure 14-35: Mineral Resources Within Open Pit Shell and Stopes | |

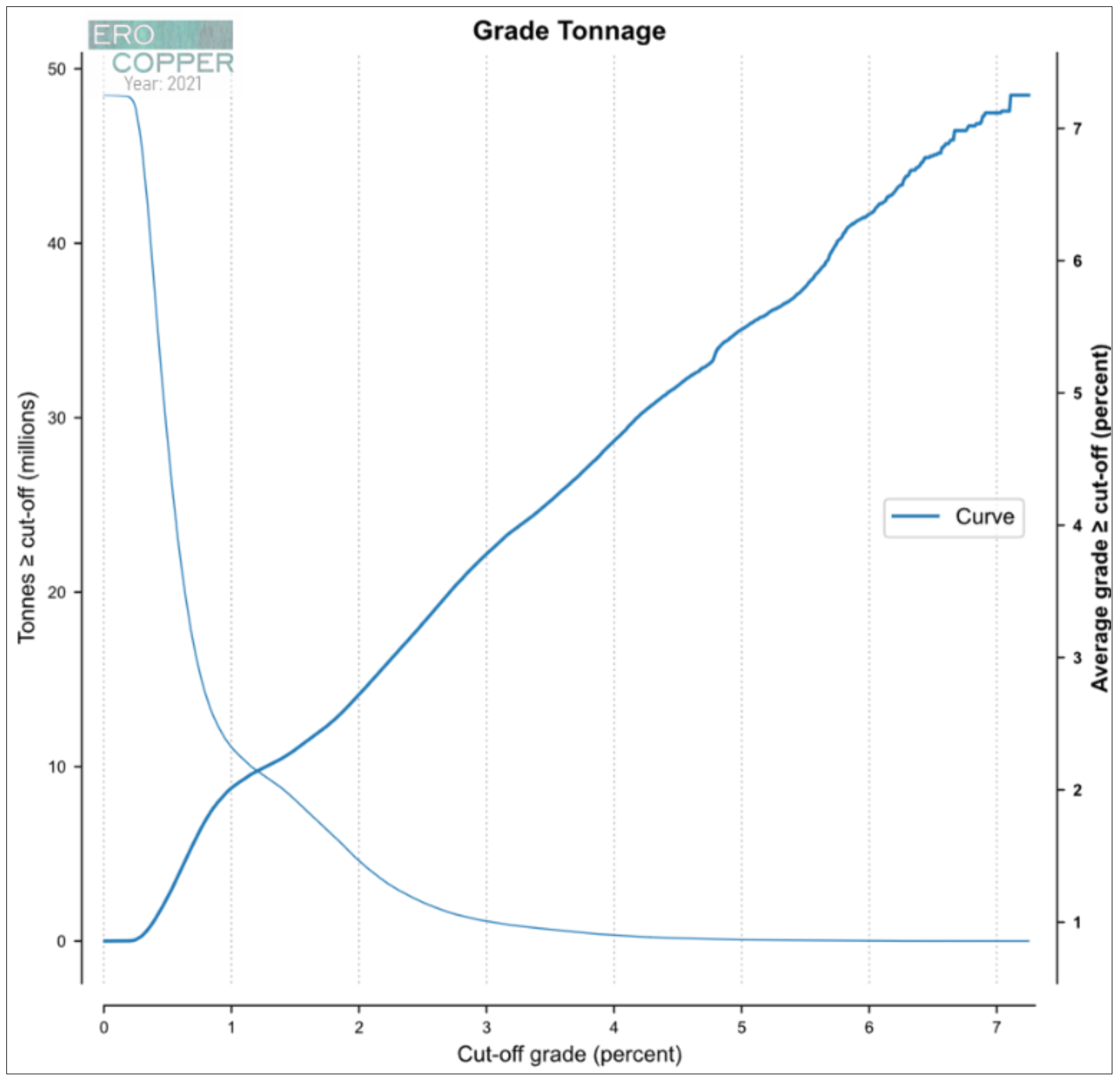

Figure 14-36: Grade Tonnage Sensitivity to Cut-off Grade, Measured & Indicated Resource | |

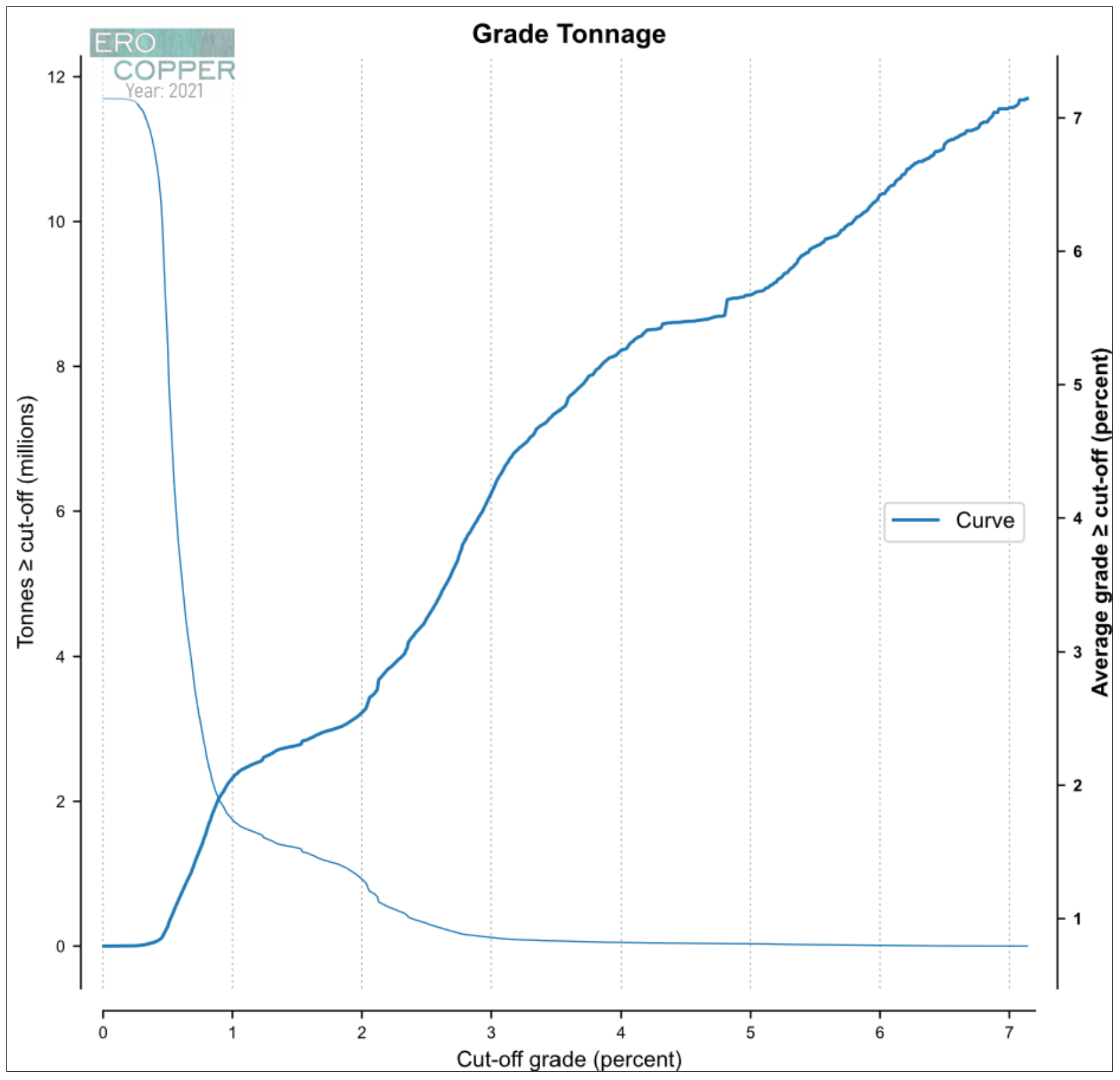

Figure 14-37: Grade – Tonnage Sensitivity to Cut=off Grade, Inferred Resource | |

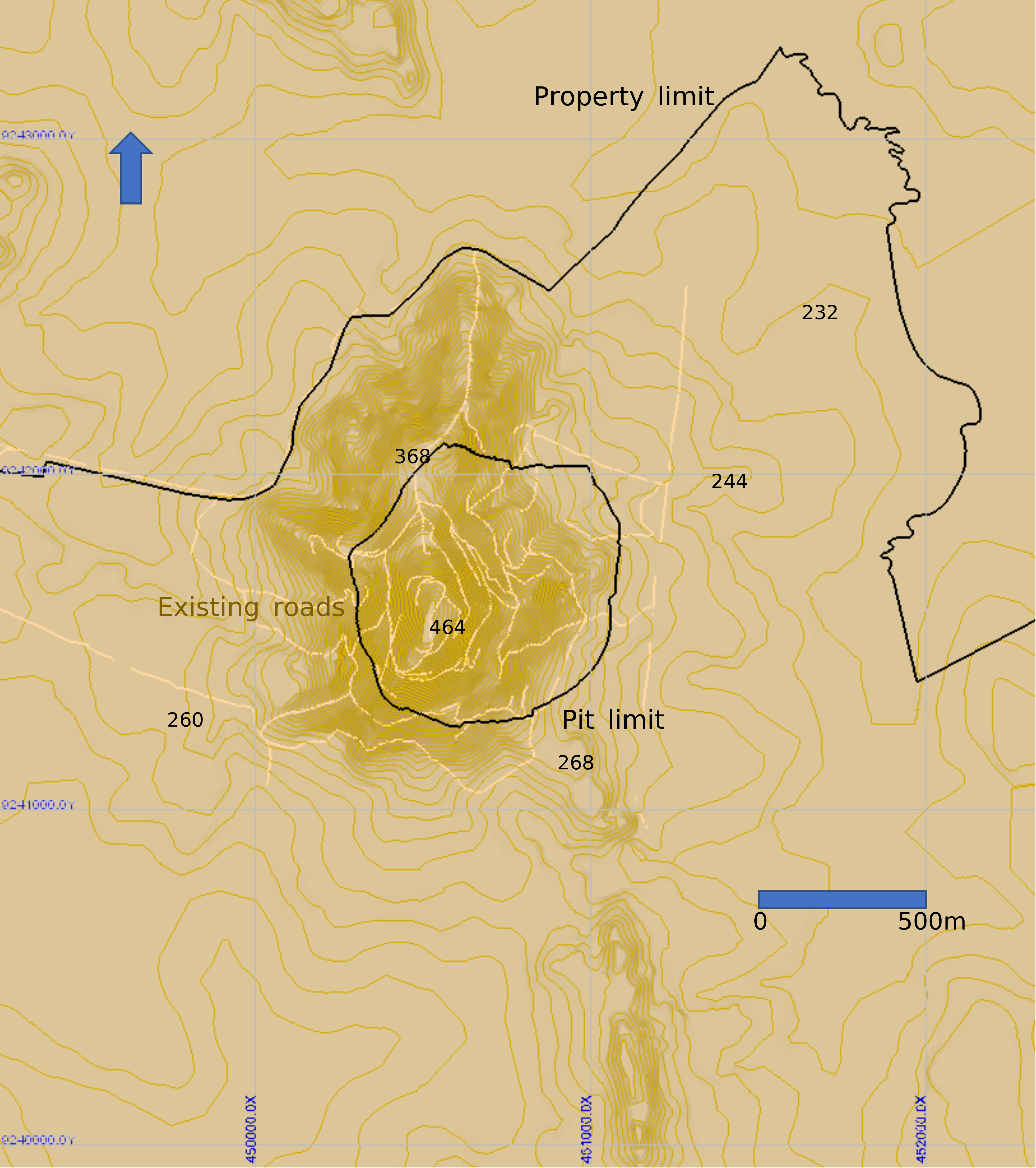

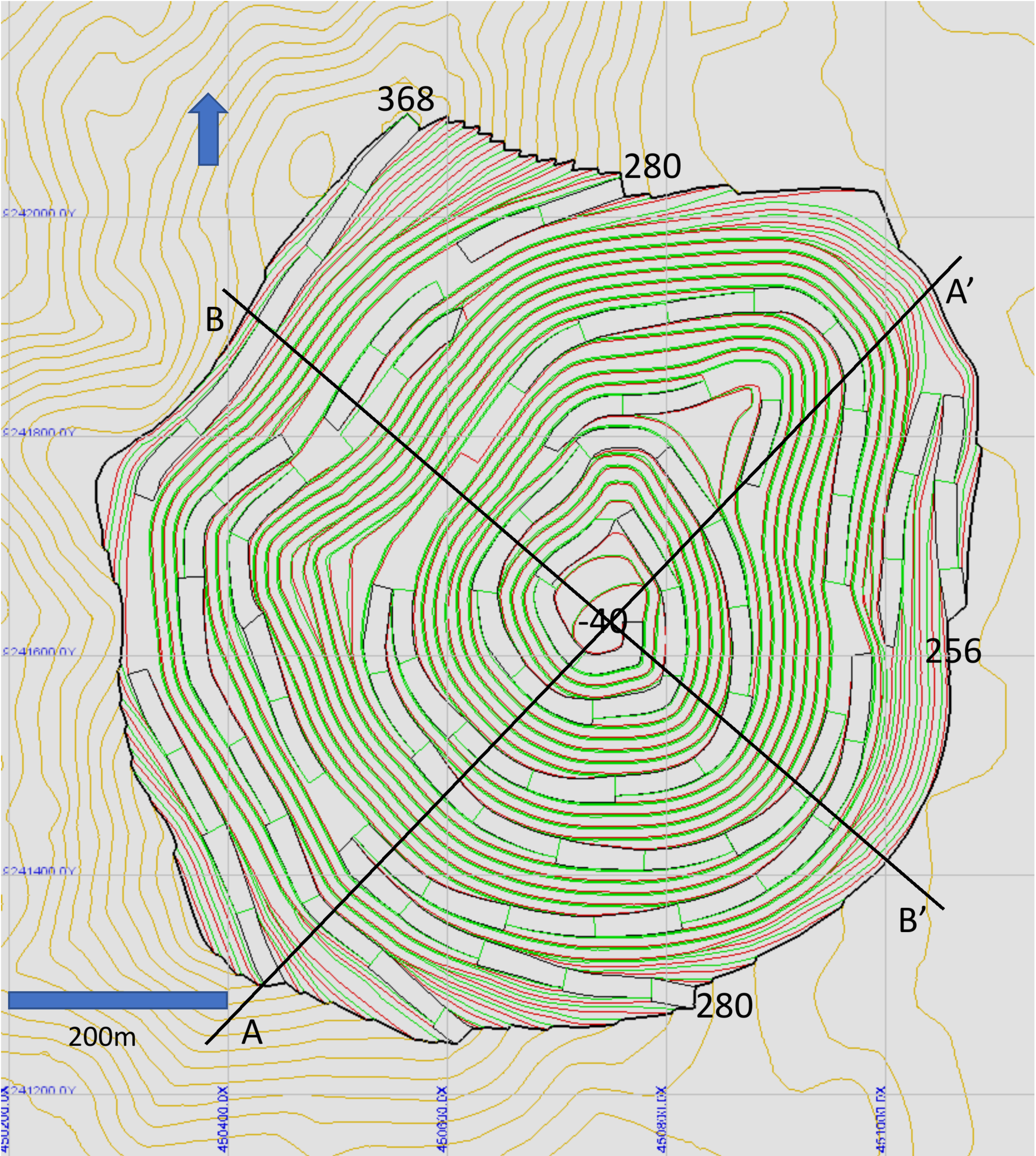

Figure 15-1: Boa Esperança Surface Topography | |

Figure 15-2: Mining Shapes Results for Selected Bench | |

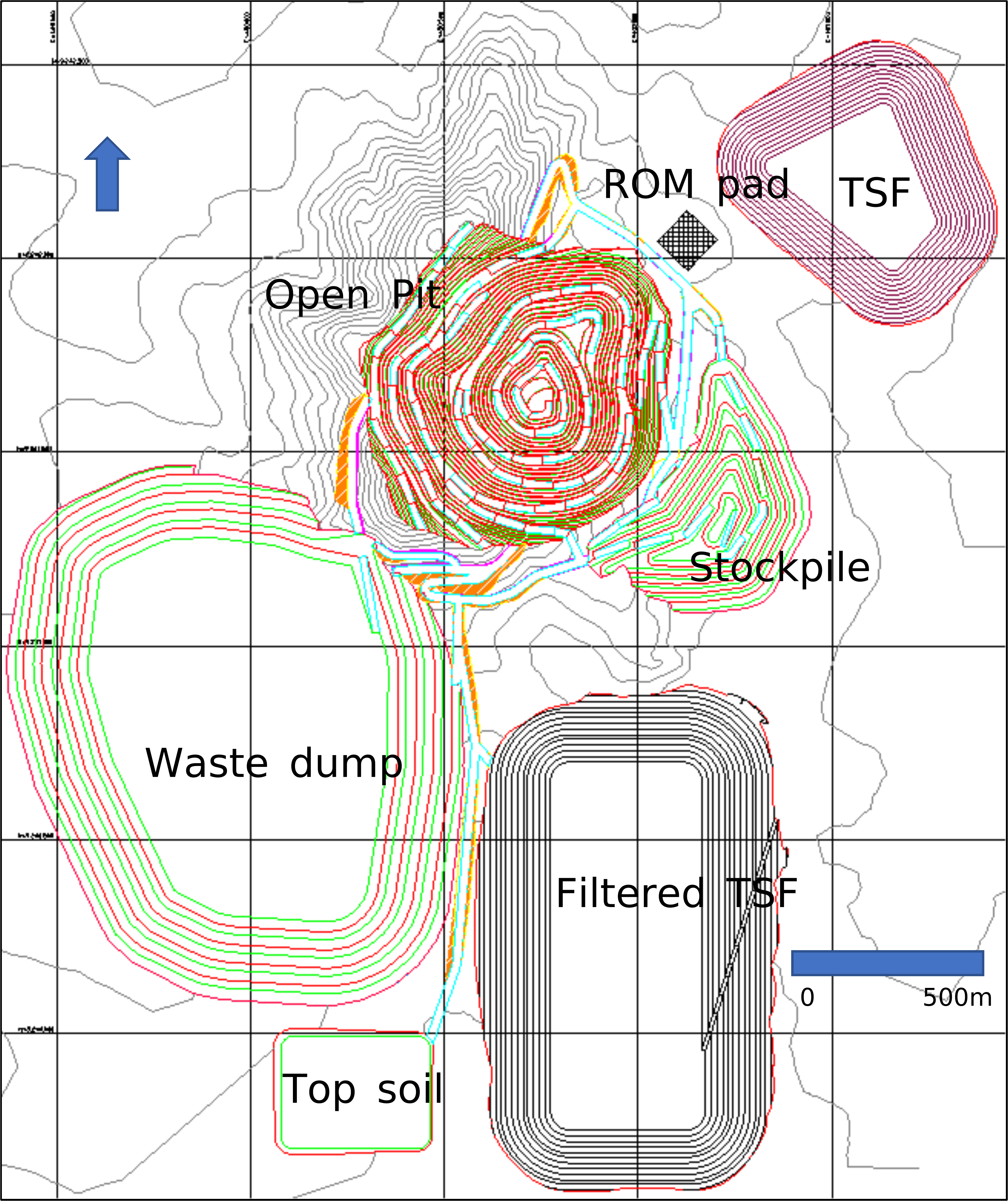

Figure 16-1: Planned General Mine Layout | |

| | | | | |

| Boa Esperança Project | Page xv |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

| | | | | |

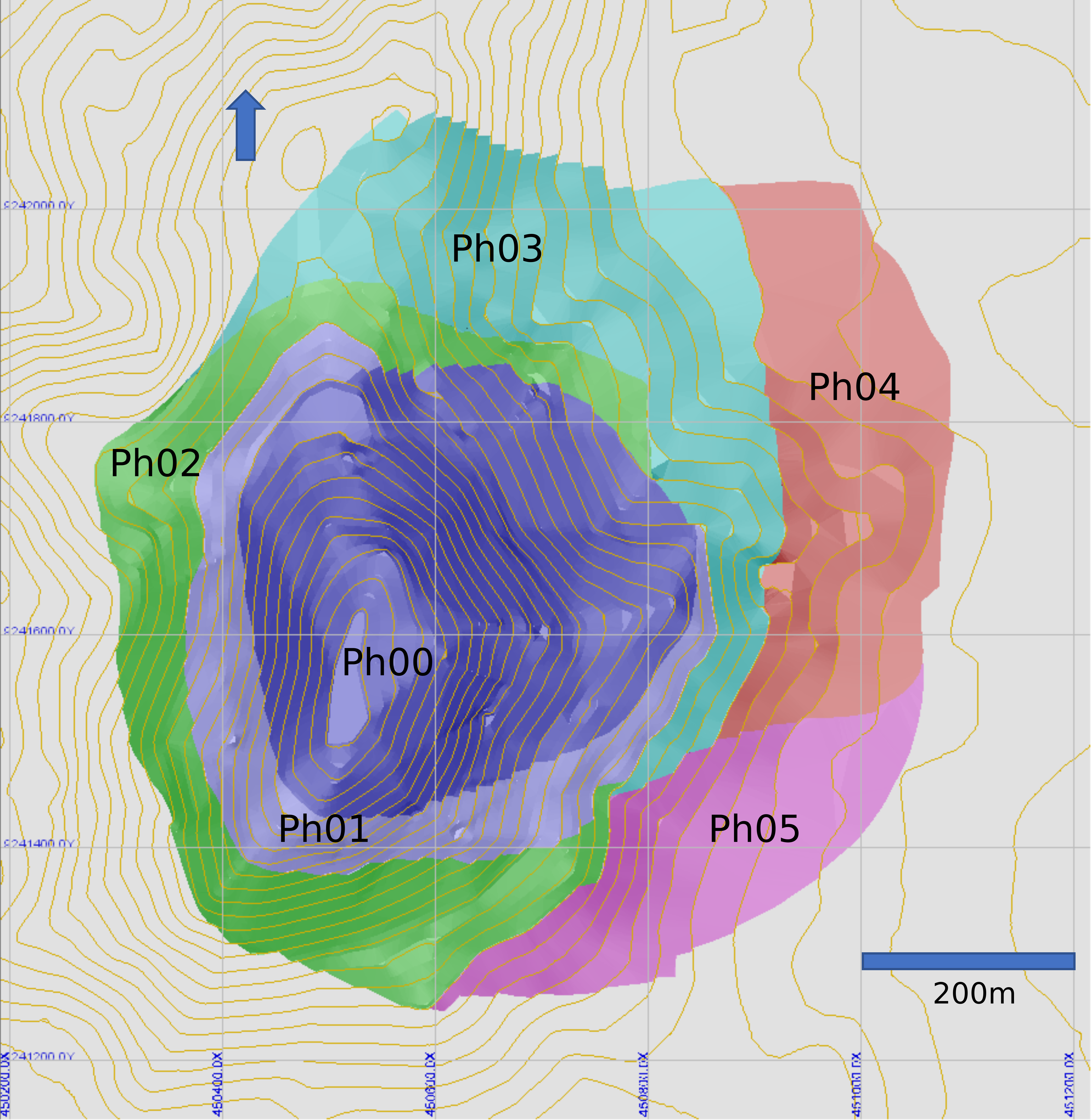

Figure 16-2: Phase Designs – Plan View Projection | |

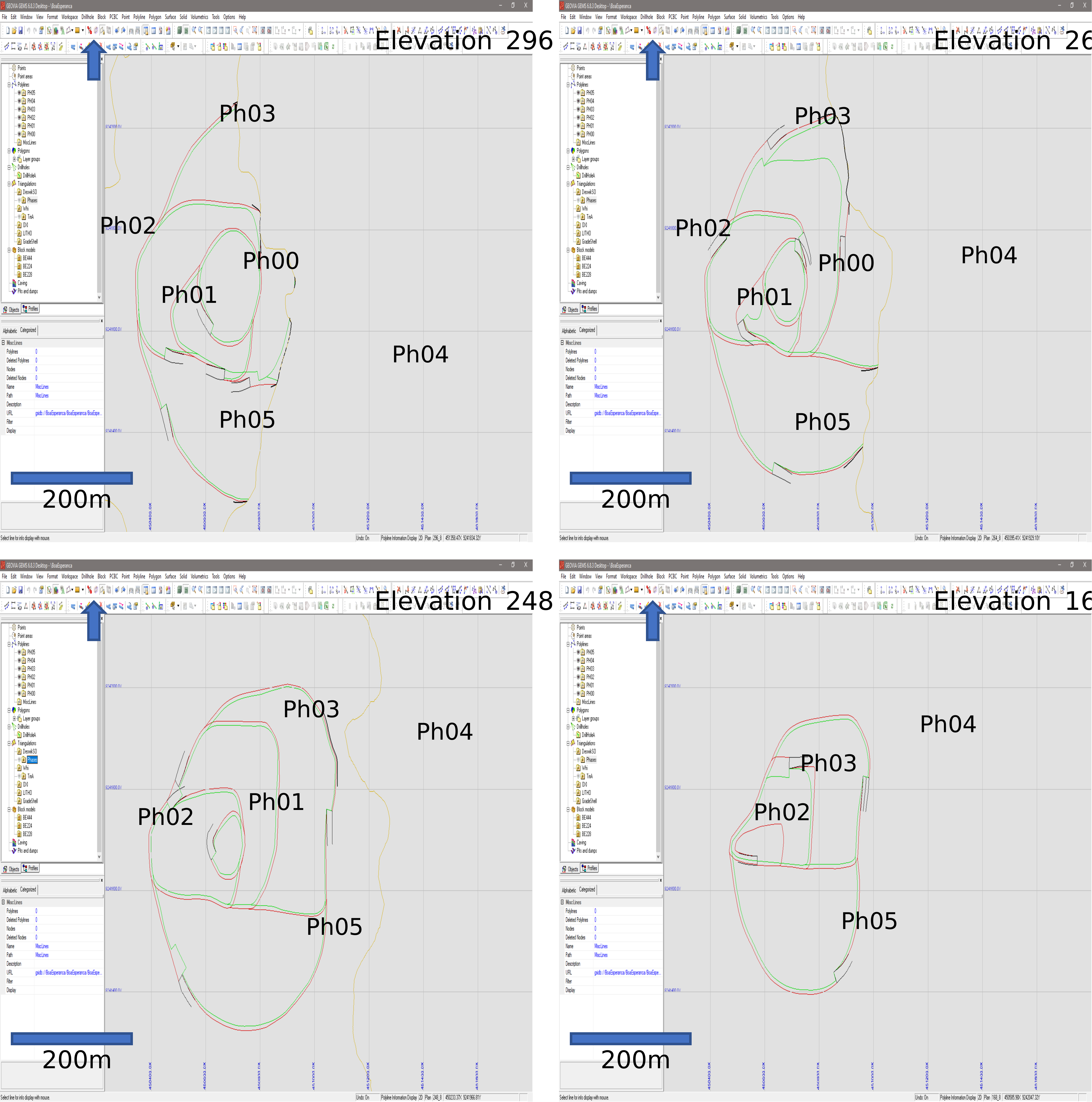

Figure 16-3: Phases Designs at Selected Elevations | |

Figure 16-4: Final Pit | |

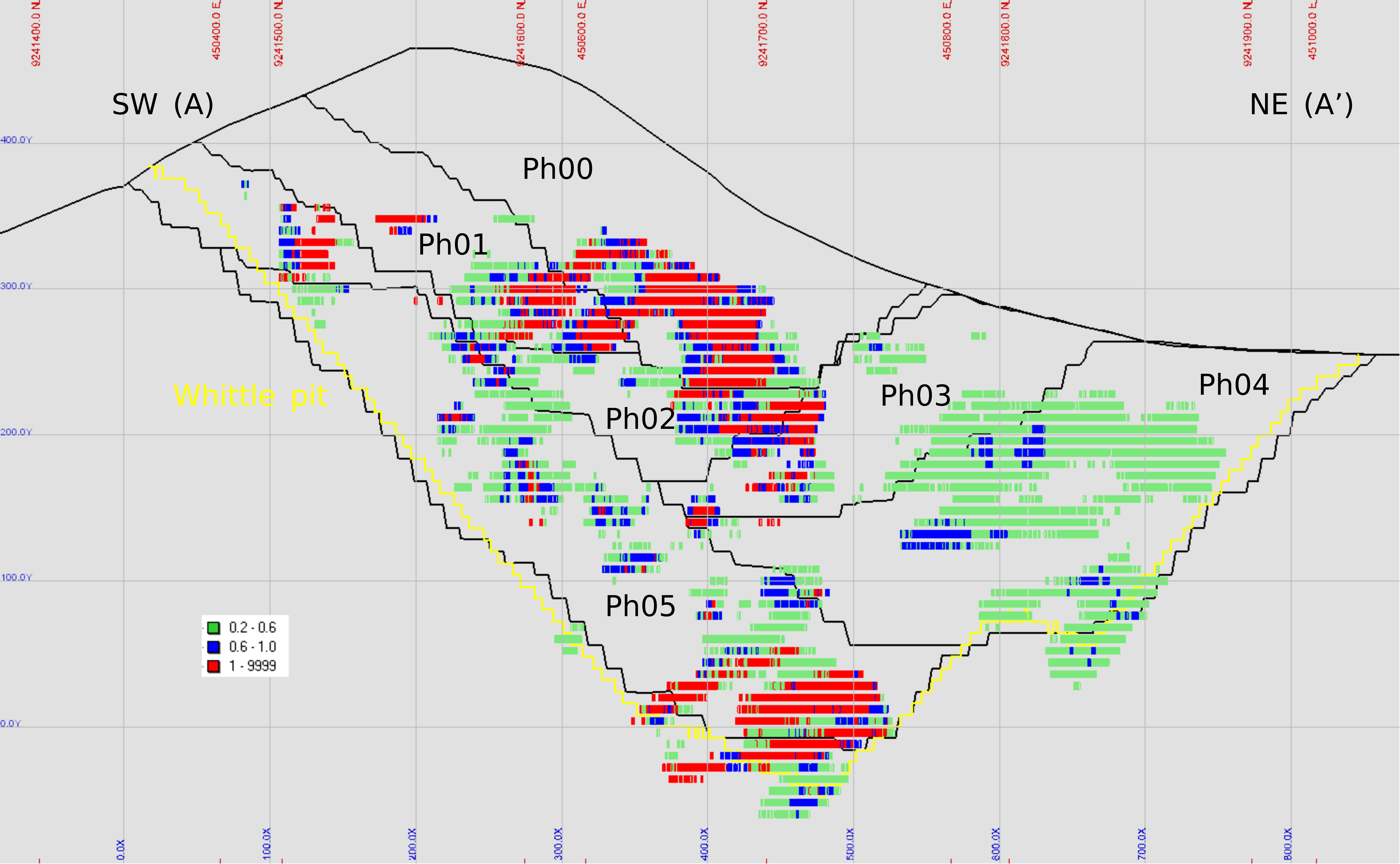

Figure 16-5: Phases designs and Whittle pit - Cross Section (A-A') | |

Figure 16-6: Phases designs and Whittle pit - Cross Section (B-B') | |

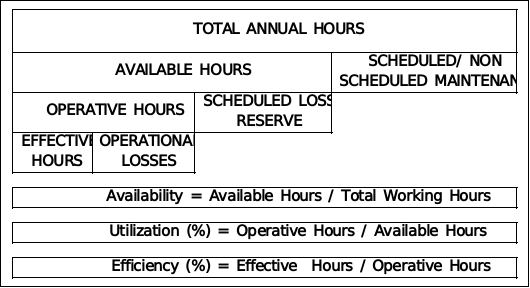

Figure 16-7: Operating Time and Index Definition | |

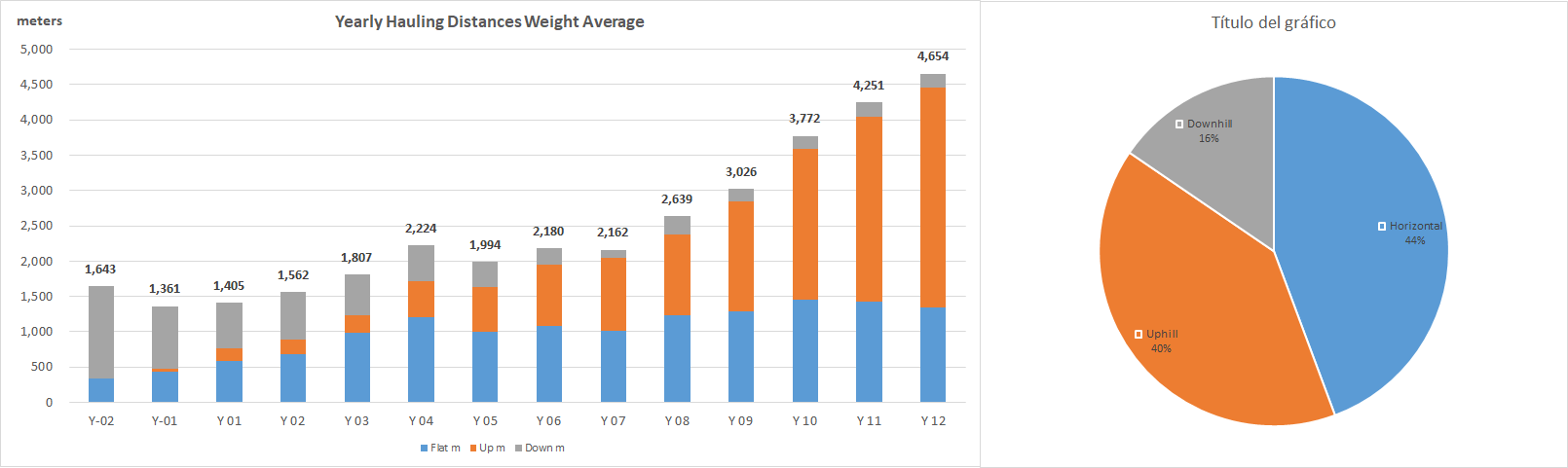

Figure 16-8: Proposed Hauling Distances Summary | |

Figure 17-1: Overall Process Flowsheet | |

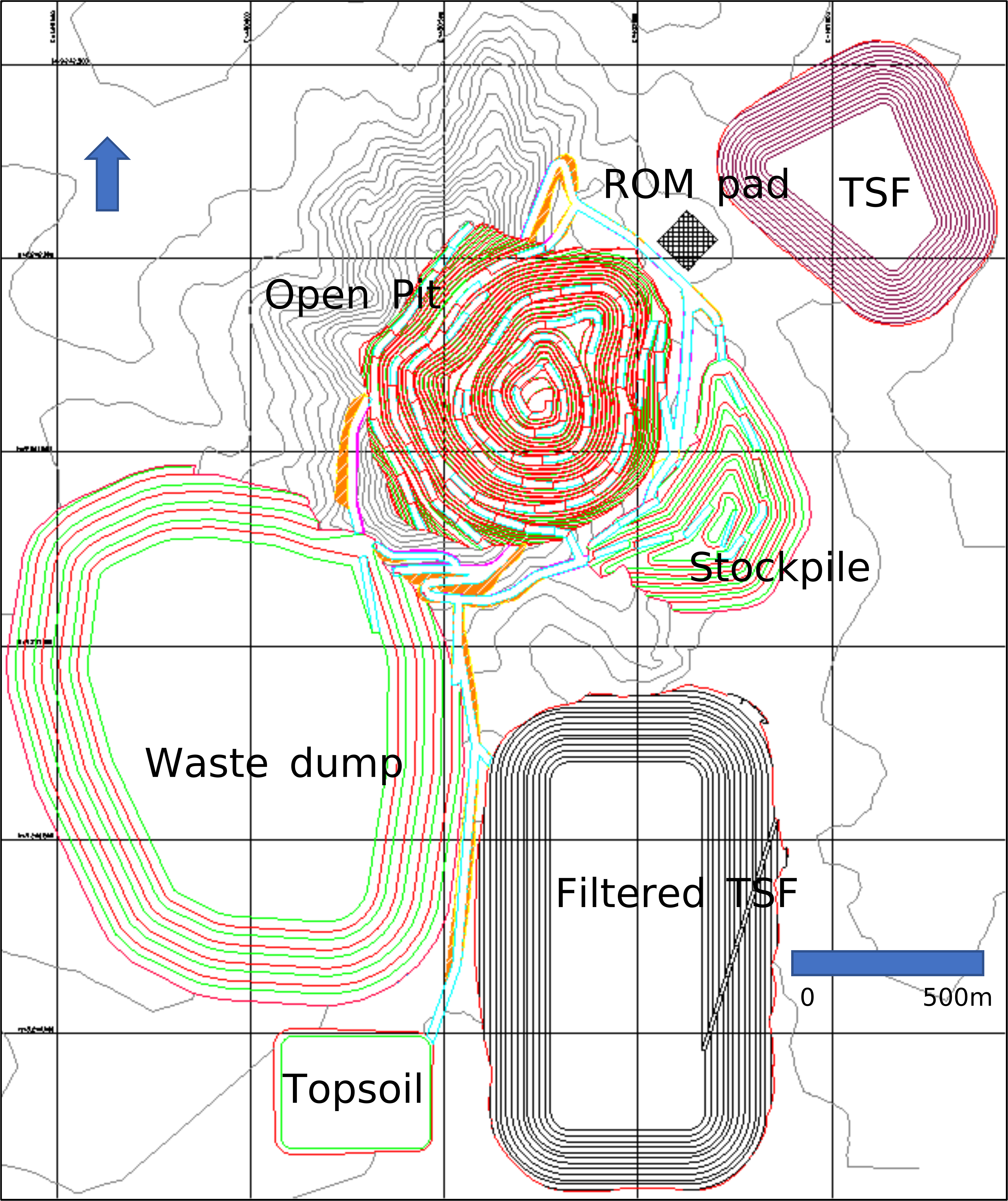

Figure 18-1: Project Area Layout | |

Figure 18-2: Proposed Plant Site Layout (Ausenco 2021) | |

Figure 18-3: Preliminary Power Transmission Line Route to Project Site | |

Figure 18-4: Pluviometric data (1975-2020) | |

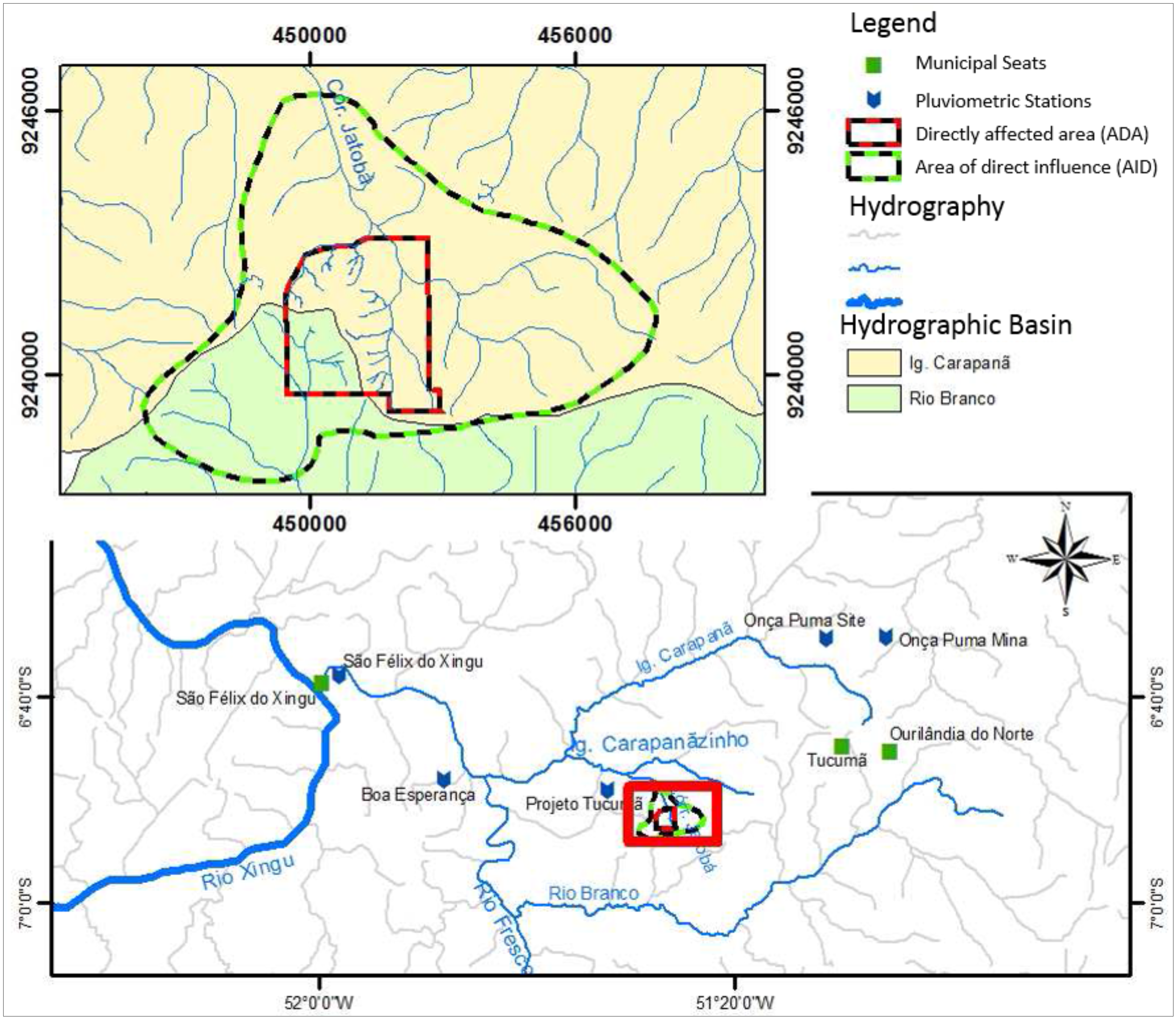

Figure 18-5: Location Map, Proposed Mine Site Facilities in Relation To Existing Water Courses | |

Figure 18-6: Intercepted Water as Contact Water, by Season | |

Figure 18-7: Water Balance Schematic (start-up) | |

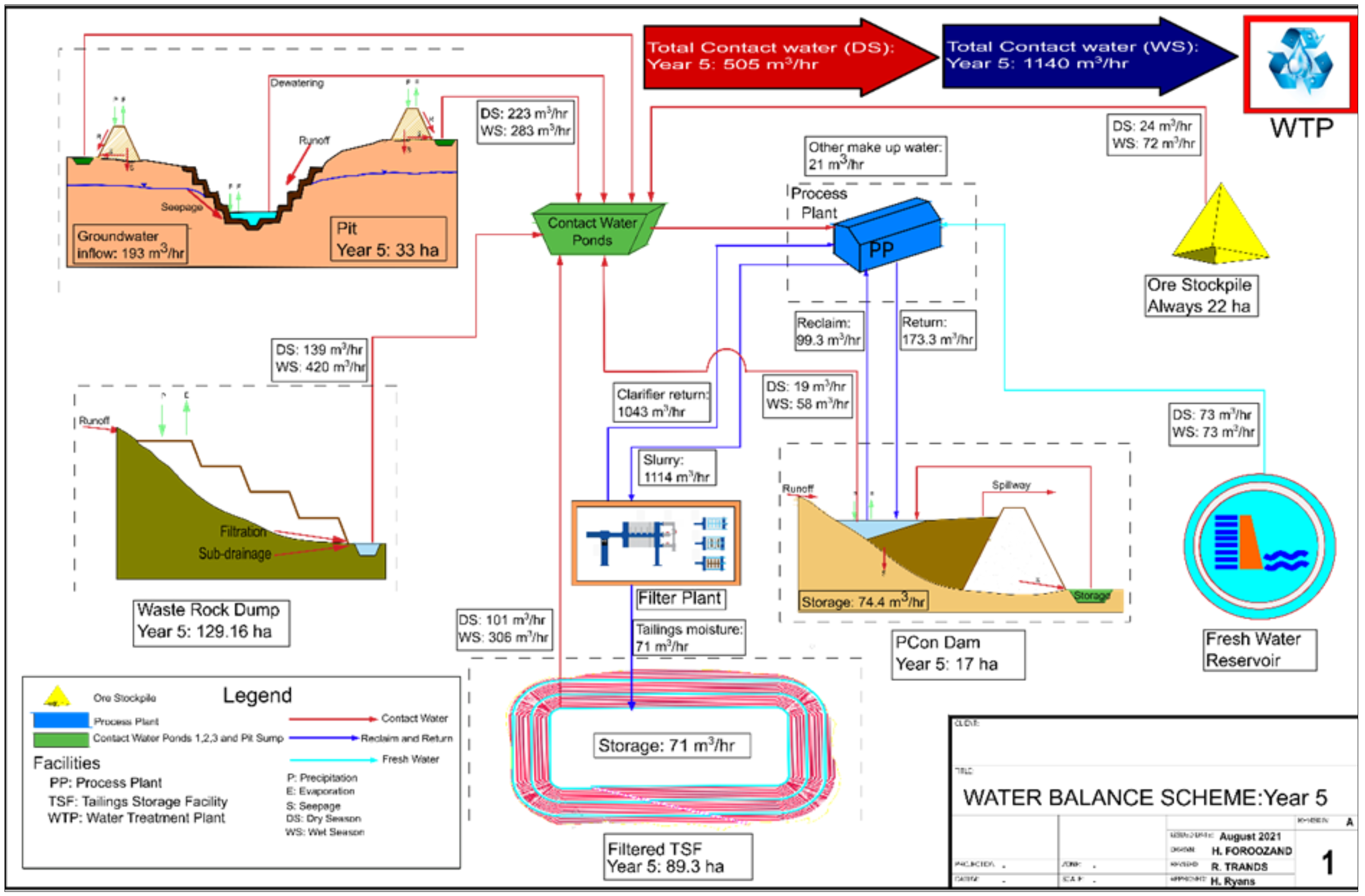

Figure 18-8: Water balance schematic (year 5) | |

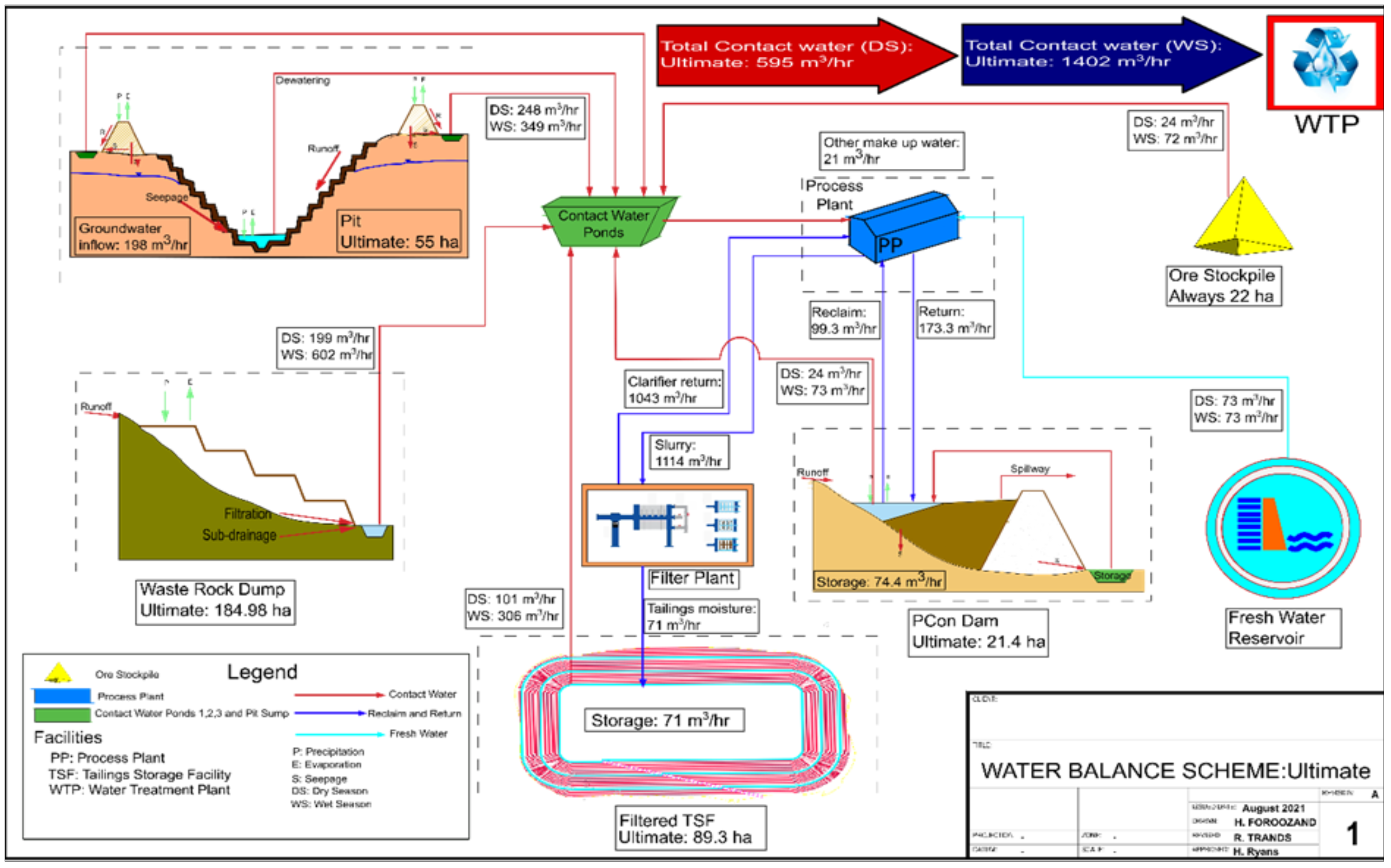

Figure 18-9: Water Balance Schematic (ultimate) | |

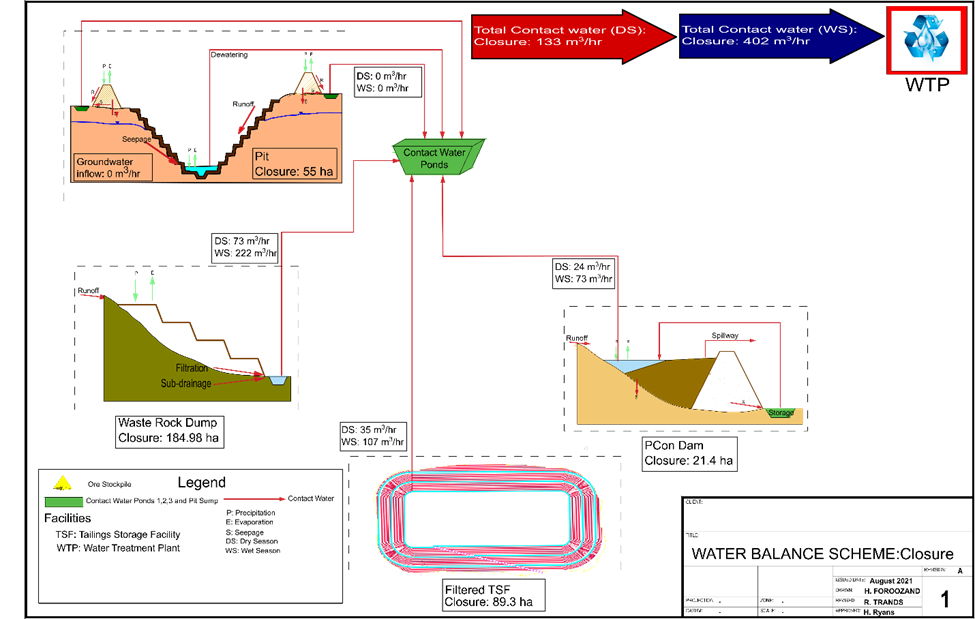

Figure 18-10: Water Balance Schematic (closure) | |

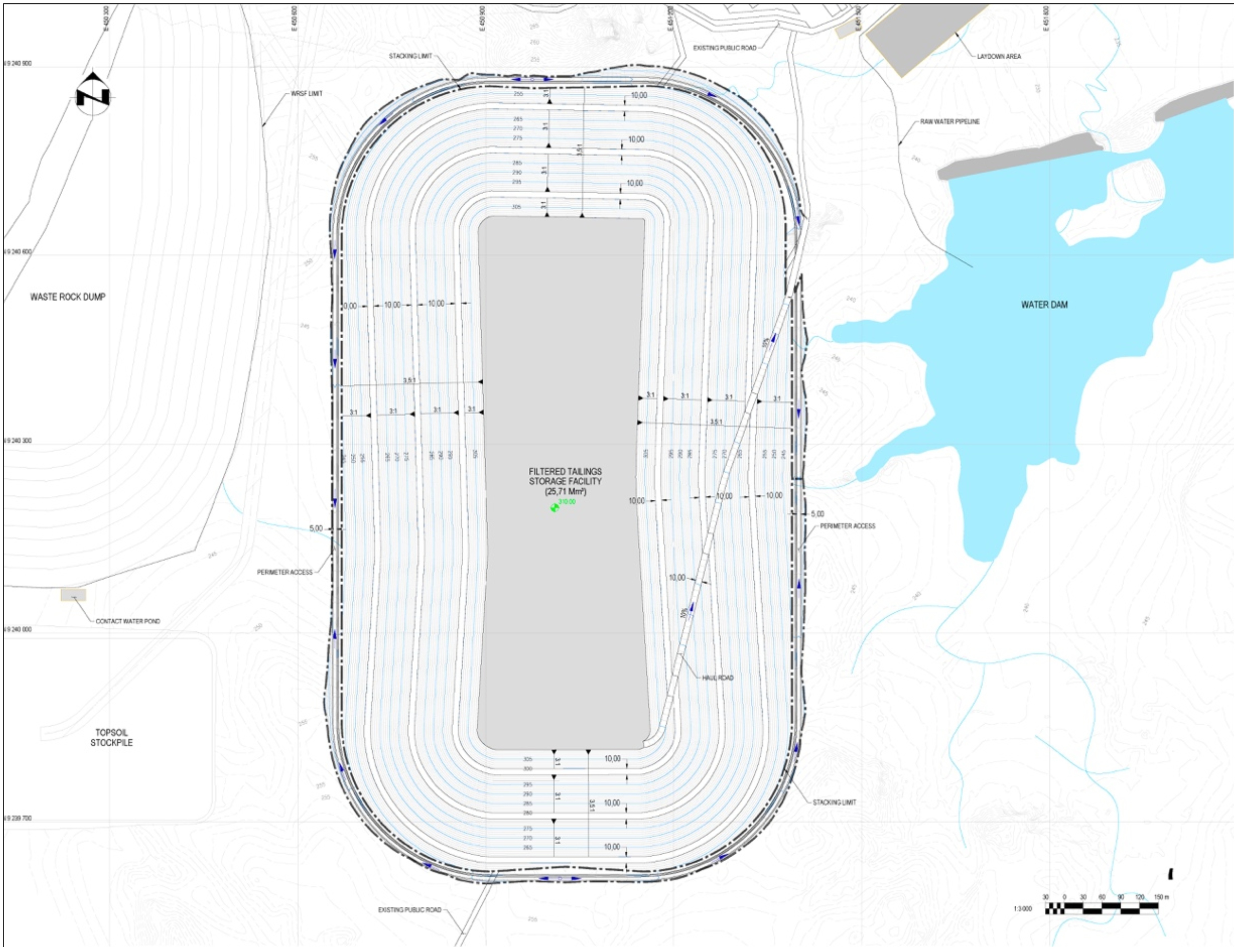

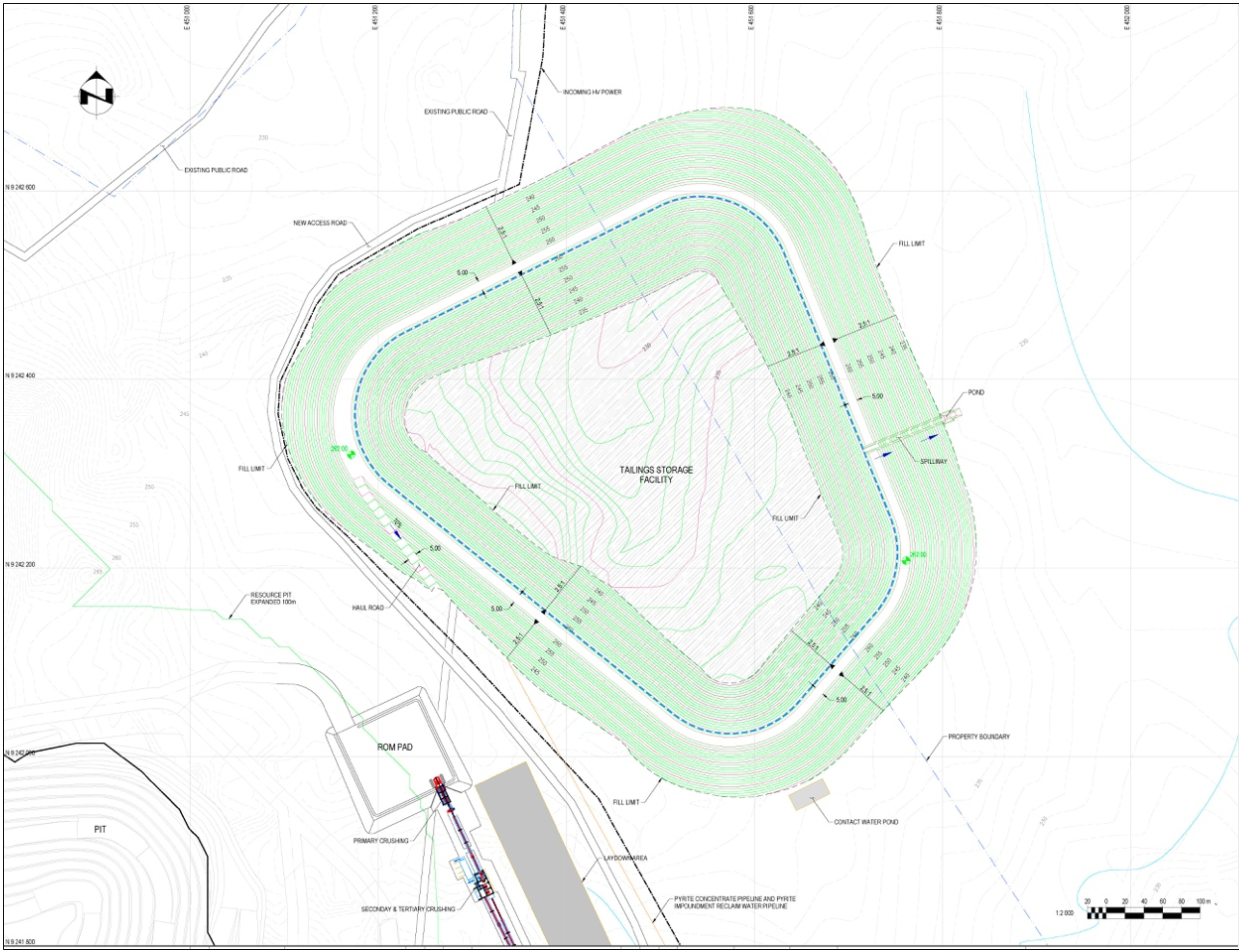

Figure 18-11: Non-Pyrite DSTF and Pyrite TSF | |

Figure 18-12: Proposed Non-Pyrite Dry Stack Tailings Facility Layout | |

Figure 18-13: Pyrite Tailings Storage Facility | |

Figure 18-14: Final Pit, Waste Rock Facility and Stockpile Configuration | |

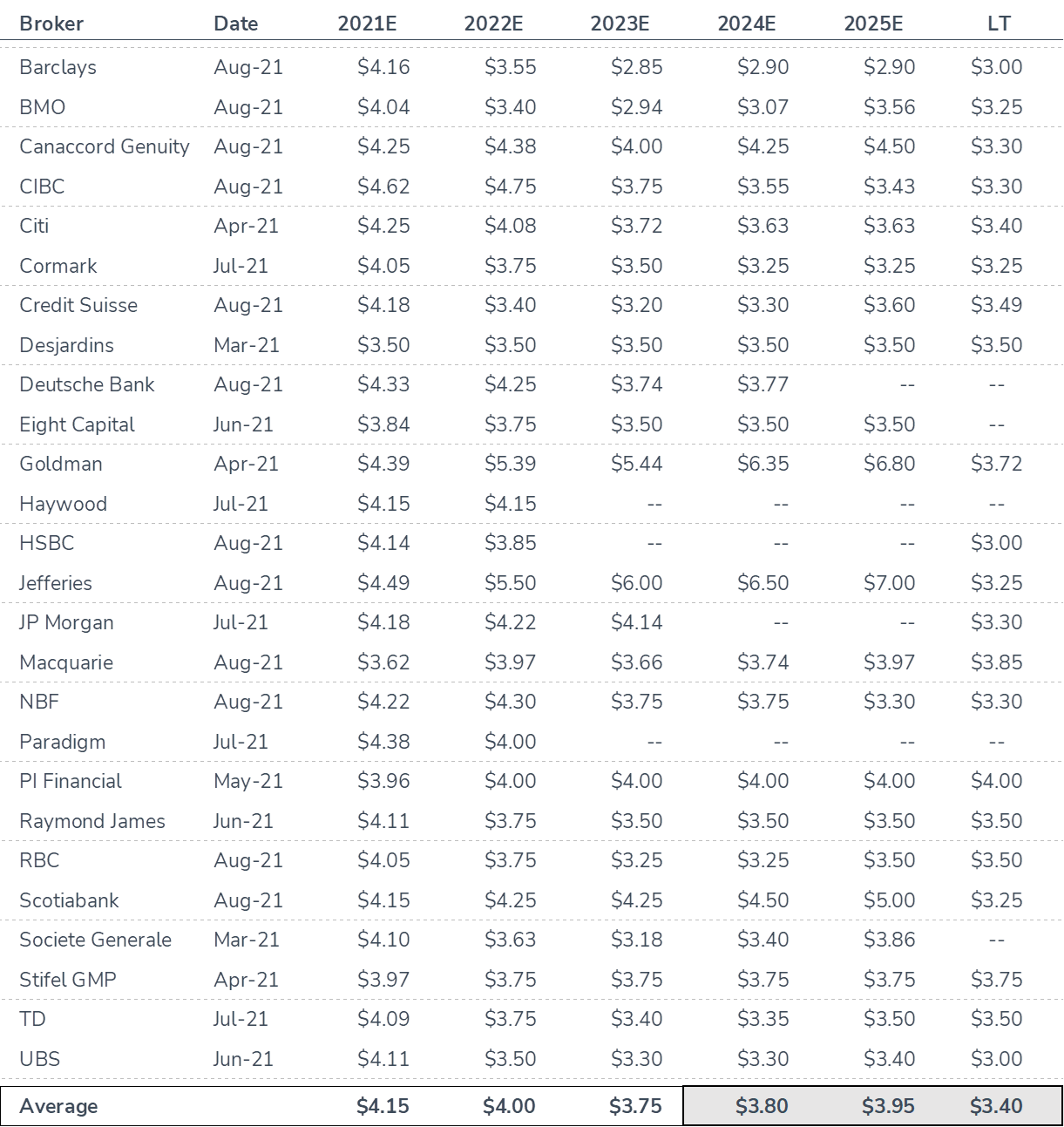

Figure 19-1: Analyst Consensus Copper Price Outlook | |

Figure 20-1: Local and Regional Drainage Network | |

Figure 22-1: Projected LOM Pre-Tax Cashflow | |

Figure 22-2: Projected LOM Post-Tax Cashflow | |

Figure 22-3: NPV & IRR Sensitivity Results | |

Figure 24-1: High Level Project Execution Schedule | |

| | | | | |

| Boa Esperança Project | Page xvi |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

1SUMMARY

1.1Introduction

Ero Copper Corp. (Ero) commissioned Ausenco Engineering Canada Inc. (Ausenco) to compile a Technical Report (the Report) for a Feasibility Study Update (FSU) on the Boa Esperança deposit, part of the Boa Esperança Project (the Project) in the Southern Pará State of Brazil.

1.1.1Key Outcomes

The Project demonstrates the financial outcomes (US dollars) summarized below based on Cu prices of $3.80/Ib in 2024, $3.95/Ib in 2025 and $3.40/Ib in 2026+:

•Pre-tax

•NPV of $464.6 million at an 8% discount rate

•IRR of 48.6%

•Payback period of 1.3 years

•Post-tax

•NPV of $379.6 million at an 8% discount rate

•IRR of 41.8%

•Payback period of 1.4 years

•Total capital costs of $507 million, comprised of:

•Initial capital cost of $294 million

•Sustaining capital cost of $196 million

•Closure cost of $24 million

•Salvage value of $7 million

•Total operating costs of $801 million

| | | | | |

| Boa Esperança Project | Page 1 |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

1.2Terms of Reference

The Report supports disclosure by Ero Copper Corp. in the news release dated September 28, 2021, entitled, “Ero Copper Announces Results of Optimized Feasibility Study for Boa Esperança Project – Longer Mine Life and Higher Annual Copper Production.”

The firms, companies and consultants who are providing Qualified Persons (QPs) responsible for the content of this Report, which is based on the Feasibility Study Update completed in 2021 (the 2021 FSU or FSU) and supporting documents prepared for the 2021 FSU, are, in alphabetical order: Ausenco Engineering Canada Inc. (Ausenco); Ero Copper Corp. (Ero), and NCL Ingeniería y Construcción SpA. (NCL).

The Report presents Mineral Resource and Mineral Reserve estimates for the Project, and an economic assessment based on open pit mining operations and a conventional processing circuit that would produce copper concentrate.

All units of measurement in this Report are metric, unless otherwise stated. The monetary units are in US dollars, unless otherwise stated.

1.3Property Description and Location

The Boa Esperança copper deposit is in the municipality of Tucumã, Pará State, Brazil. The site is located approximately 40 km to the southwest of the town. Tucumã can be accessed by state highway PA-279, which connects the town of Xinguara to the town of São Felix do Xingu, along a stretch of road that runs for approximately 160 km. The junction of PA-279 with federal highway BR-155 is in Xinguara, which is the main highway leading to the city of Marabá, situated approximately 220 km north of Xinguara.

1.4Ownership

Mineração Caraíba S.A. (MCSA) acquired the Boa Esperança copper deposit concession from Corporación Nacional del Cobre (Codelco) in 2007 and became the legal owner of the mineral rights to the Boa Esperança copper deposit. In December 2016, Ero acquired approximately 85.0% interest in MCSA. In June 2017, Ero acquired an additional 14.5% by subscribing for shares from treasury for a total interest in MCSA of approximately 99.5%.In December 2017, the Company acquired additional shares of MCSA, increasing its ownership interest in MCSA to approximately 99.6%.

The legal status of MCSA’s mining rights is as follows:

•The Final Exploration Report was presented to the Agência Nacional de Mineraçãoor (ANM) on April 10, 2008 and was approved by the ANM on July 30, 2009;

•MCSA applied for a Mining Concession by filing an Economic Exploitation Plan (Plano de Aproveitamento Econômico or PAE) with the ANM on May 5, 2010;

•The preliminary environmental license was filed with the ANM on March 22, 2012;

•The PAE technical analysis was completed and considered suitable for granting on July 30, 2013;

•Ero received the Installation License (LI) on August 30, 2021, which will allow for the commencement of surface and civil construction activities

| | | | | |

| Boa Esperança Project | Page 2 |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

•A formal request with the Para State environmental agency, Secretaria de Estado de Meio Ambiente e Sustentabilidade (SEMAS) will be made to incorporate changes in the Project's scope as outlined in the FSU.

•SEMAS is the agency responsible for approval of the Operating License (LO) for the Project, which is planned to be issued at the time of commercial production; and

•The estimated Mineral Resources and Mineral Reserves disclosed in this Report are completely contained within the Boa Esperança mineral rights held by MCSA. MCSA is the holder of required surface rights for the envisioned operations. It is expected that full title to the land will be transferred to MCSA after conclusion of an administrative procedure with the National Institute of Colonization and Land Reform (INCRA) to clear such surface rights from its prior classification as a resettlement area.

The site is free and clear of any environmental liabilities, and all required permits for construction activities are encompassed by the Installation License issued on August 30, 2021.

1.5Geology and Mineralization

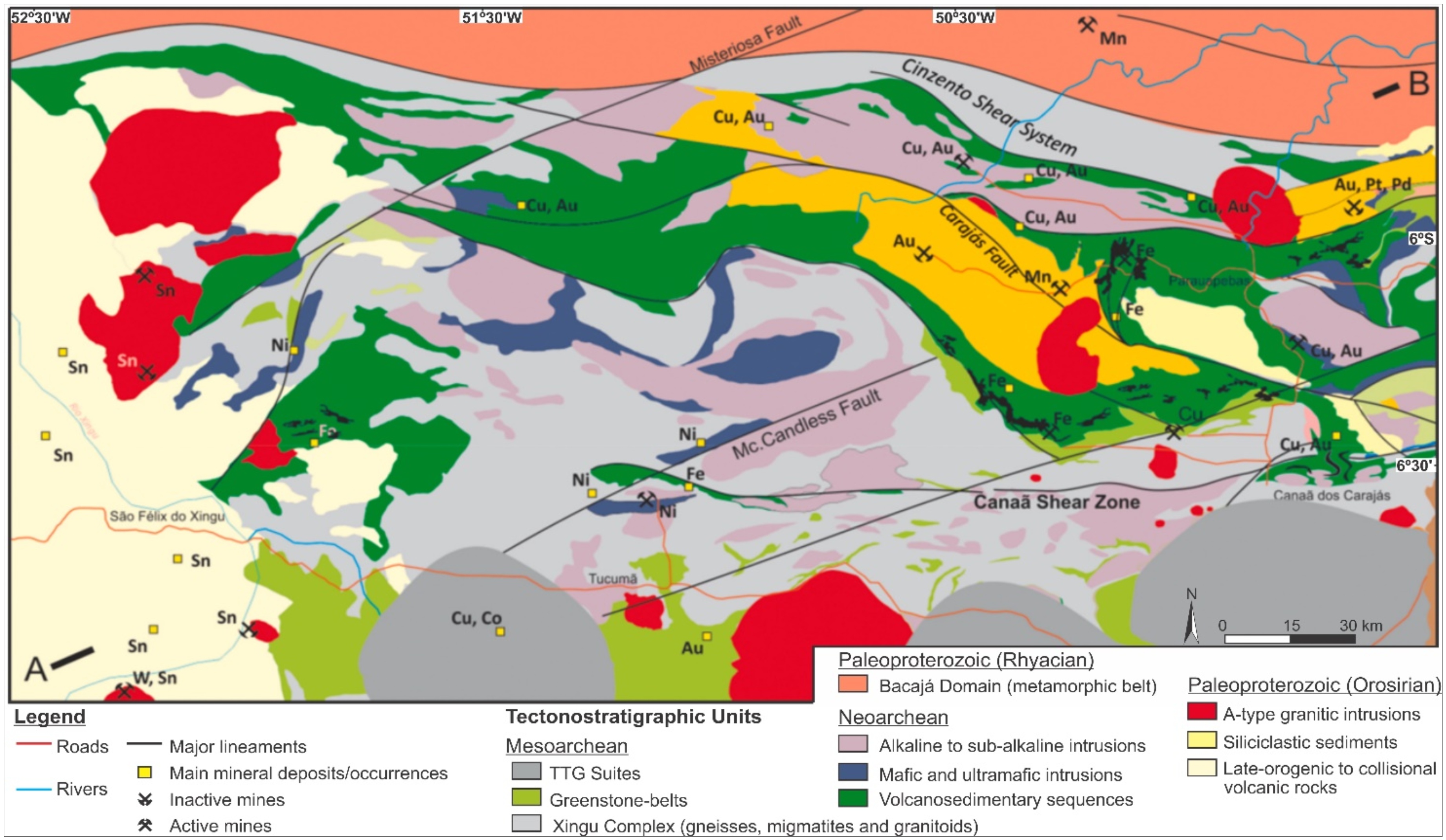

The Carajás Mineral Province, where the Boa Esperança copper deposit is located, is on the east side of the Amazon Craton and is considered one of the most important mineral provinces in Brazil. It is a region of high economic importance, as it hosts the world’s largest known high-grade Fe deposits, as well as world-class Cu-Au deposits, such as Salobo, Sossego, 118, Cristalino and Igarapé Bahia-Alemão. Deposits of Mn, Ni, Cr, Al and Zn have also been identified in the province. The existence of high-grade significant deposits elsewhere in the region provides no assurance regarding the size, extent, grade, or value of any deposits or prospective deposits within the area of the Boa Esperanҫa Project.

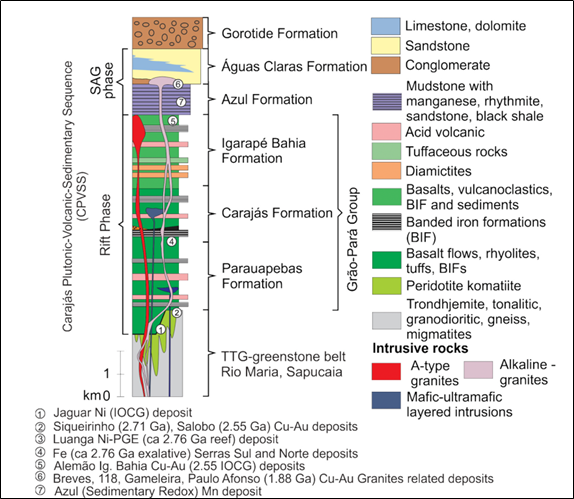

The Carajás Mineral Province encompasses two distinct tectonic domains, both Archean in age. The South Block, which is the older of the two (3.0 to 2.86 Ga) and where the Boa Esperança deposit is located, is called the Rio Maria Block, and contains a typical granite-greenstone belt terrain. The North Block, which is the younger domain (2.8 to 2.5 Ga), is called Carajás and is composed of volcano-sedimentary rocks and granitoids, which host the large Fe, Cu-Au, Mn, Ni and Zn deposits in the province. These two blocks are products of the juxtaposition of volcanic island arcs and plutonic-like Andes environments, associated with an intra-continental mantle plume.

The Boa Esperança copper deposit occurs within an isolated hill, which is elongated in an NNE direction and located 38km SW following a straight line from the town of Tucumã. The topographic high is mainly comprised of breccias composed of quartz and magnetite, which cut the Neoarchean biotite-granite (2.78 Ga), the host of the copper mineralization. The Neoarchean biotite granite intrudes into the Mesoarchean Rio Maria granodiorite (2.85 Ga).

Mineralization consists of a series of brecciated zones, which are aligned N60°-70°E and incline in a SE direction (60°-70°SE).

1.6Exploration

Over the years, Project exploration has consisted of multiple campaigns of ground geological mapping and sampling, soil geochemistry, ground geophysical surveys and exploration drilling conducted by both Codelco, MCSA, and more recently Ero. Available exploration datasets used in the FSU include detailed topography surveys, soil geochemistry surveys, geological mapping, magnetic surveys, induced polarization (IP) surveys, as well as a drill core database totalling approximately 58,000 meters of drilling, petrographic studies, and radiometric dating drilling and sampling.

| | | | | |

| Boa Esperança Project | Page 3 |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

Between 2003 and 2013 a total of 165 core drill holes totaling approximately 57,972 m were completed. Drilling was executed by Codelco over four drillhole campaigns in 2003–2004, 2005 and 2006, consisting of 62 core drillholes, totaling 21,956.12 m on a 200 x 200 m drilling grid that was infill drilled to 100 x 100 m. MCSA completed 103 core holes between 2008–2013, totaling 36,016.13 m. Infill drilling was completed to approximately 50 and 25 m centers for the core of the deposit in support of the Project. In 2021, Ero commenced an exploration program to further extend the known limits of the deposit. There were no results available from the 2021 exploration program to incorporate into the FSU.

All exploration drilling was conducted using l core methods. Holes were drilled at an HQ size (63.5 mm core diameter) through soil, saprolite and weathered rock and were reduced to NQ size (47.6 mm) upon reaching fresh rock. Average drill core recoveries were reported as exceeding 98%.

Sampling intervals were identified and marked in the core boxes according to the sampling plan, thus providing a physical register of sample identification and location. The core was split in half using a diamond saw and then quartered, with one quarter sent for analysis and the remaining three quarters stored for future reference. At the end of the sampling process the identifying description on each sample bag was verified by comparing the description in the core boxes to the corresponding location. If correct, the sample was sealed in the bag for dispatch.

Codelco used the SGS Geosol laboratory in Parauapebas, Pará, Brazil (SGS Parauapebas) to prepare all samples from the 2003–2006 drilling campaigns. MCSA used the same laboratory to prepare all samples from the 2008–2009, 2012 and 2013 drilling campaigns. Sample analyses were carried out by SGS Geosol in Vespasiano, Minas Gerais, Brazil (SGS Vespasiano) for these campaigns. SGS Geosol is an internationally recognized mineral testing laboratory and is independent of the Company.

MCSA used the Intertek laboratory in Parauapebas, Pará, Brazil (Intertek) to prepare all samples from the 2010 drilling campaign. Intertek is an internationally recognized mineral testing laboratory and is independent of the Company.

1.7Data Verification

MCSA provided Ausenco with external analytical control data containing the assay results of the quality control samples from the Boa Esperança copper project. All data was provided in Microsoft Excel spreadsheets. Control samples (blank and standard reference materials) were summarized in time-series plots to highlight their performance. Paired data (pulp duplicates) were analysed using bias charts, quantile-quantile plots, and relative precision plots. The external quality control data produced for this project represent approximately 5% of the total number of samples assayed.

MCSA used one standard reference material (High-Grade) during the 2008/2009 campaign. In more recent years, three standard reference materials (Low-Grade, Medium-Grade and High-Grade) were used.

SGS and Intertek delivered consistent Cu results, mostly within two standard deviations. The results for the High-Grade (HG) standard reference material shows consistently lower values than expected in all drilling campaigns. This shows that there is a negative bias for the HG standard reference material.

Paired assay data examined by Ausenco show that assay results can be reproduced by the SGS Geosol and Intertek laboratories from duplicate pulp with high confidence. In general, Ausenco considers the analytical quality control data delivered by the laboratories used by MCSA and reviewed by Ausenco to be sufficiently reliable for the purpose of resource estimation.

MCSA is currently including the use of certified blank samples and certified standard reference materials in its quality control programs.

| | | | | |

| Boa Esperança Project | Page 4 |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

1.8Metallurgical Testing

Boa Esperança copper deposit is considered as a variant of an Iron Oxide Copper Gold (IOCG) deposit type, with the presence of higher sulphur minerals and a high quartz content, the absence of pervasive hydrothermal alterations of the host rock, and the absence of gold. Granite (GRA) and breccia (BXX) are two main rock types recognized from the deposit.

A series of metallurgical test programs were performed between 2007 and 2015 to assess the metallurgical responses of the mineral samples from the deposit. In the tests reviewed, master composite samples were constructed as a blend of 50% GRA and 50% BXX, while variability composite samples were prepared to represent the individual GRA and BXX rock types.

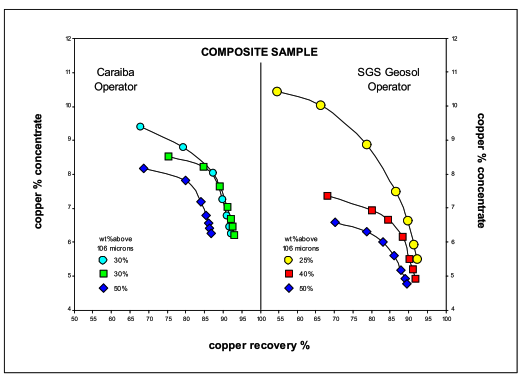

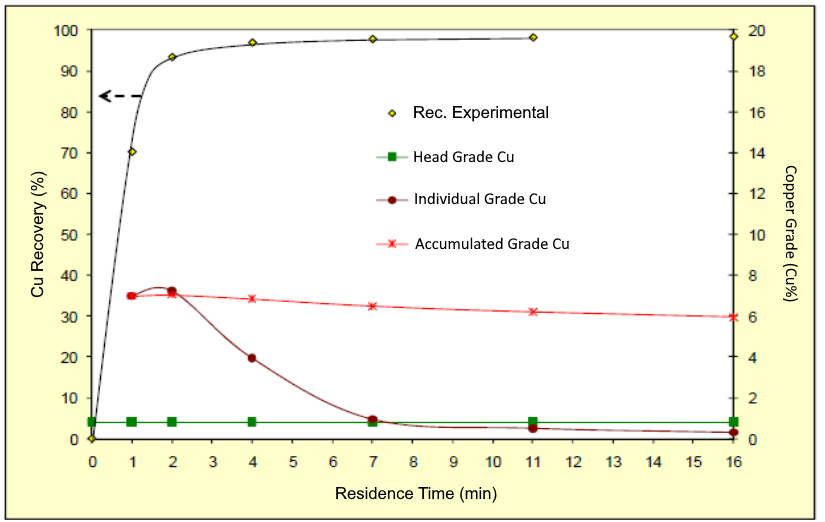

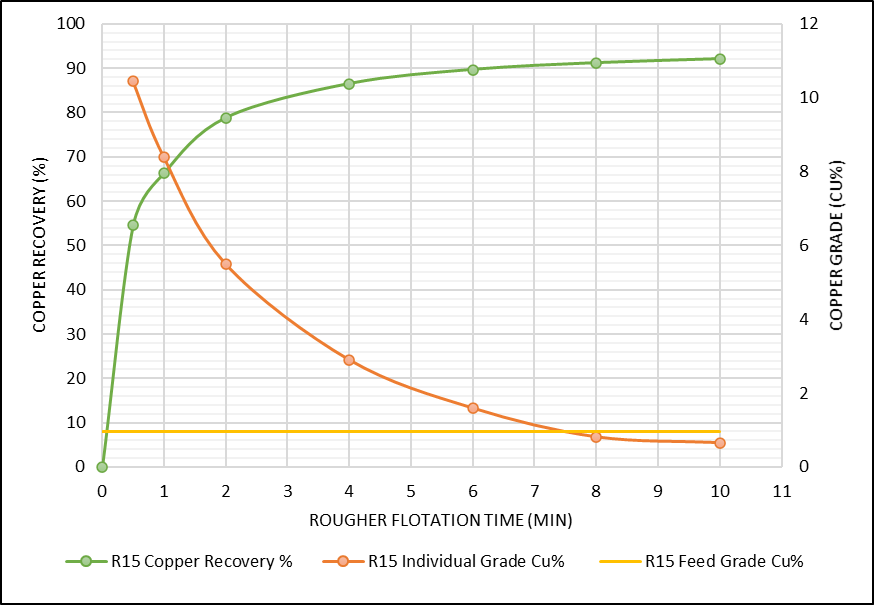

The initial test programs by Centro de Investigation’s Minero Metalúrgicas (CIMM) were conducted with one master sample which confirmed the selection of a sequential flotation flowsheet. In 2012, SGS Geosol (SGS) verified the flowsheet by using variability samples. Later in 2015, SGS investigated the amenability of a jigging pre-concentration step, and conducted subsequent flotation tests on the pre-concentrated samples, as well as the treatment of the flotation tailings. The main observations from the tests are shown as follows:

•Copper concentrate grade assaying at 28% Cu or higher were achieved from master samples. The 2015 SGS test program with a pre-concentration stage produced the highest concentrate grade of 28.9% Cu.

•Copper recovery to the head feed of 95.5% and 91.5% were achieved in the CIMM and 2012 SGS test work programs, respectively. The 2015 SGS tests produced a lower recovery of 85.1% to the head feed because of the pre-concentration stage, even though a similar copper stage recovery of 91.7% was achieved.

•Copper recovery and copper concentrate grade achieved from tests on variability samples in the 2012 SGS test program varied significantly. Copper grade ranged between 21.2 and 29.3% Cu while copper recovery varied between 77.5 and 95.4%.

•Copper concentrate samples present only trace-level deleterious elements.

Additional test programs were performed by equipment suppliers to determine the crushability and grindability of the ore samples, as well as the dewatering characteristics of the flotation concentrate and tailings samples. A fast-settling rate was observed for both copper concentrate and final tailings. The copper concentrate filtration can achieve a moisture level between 8 – 10%; no filtration tests were performed on tailings samples.

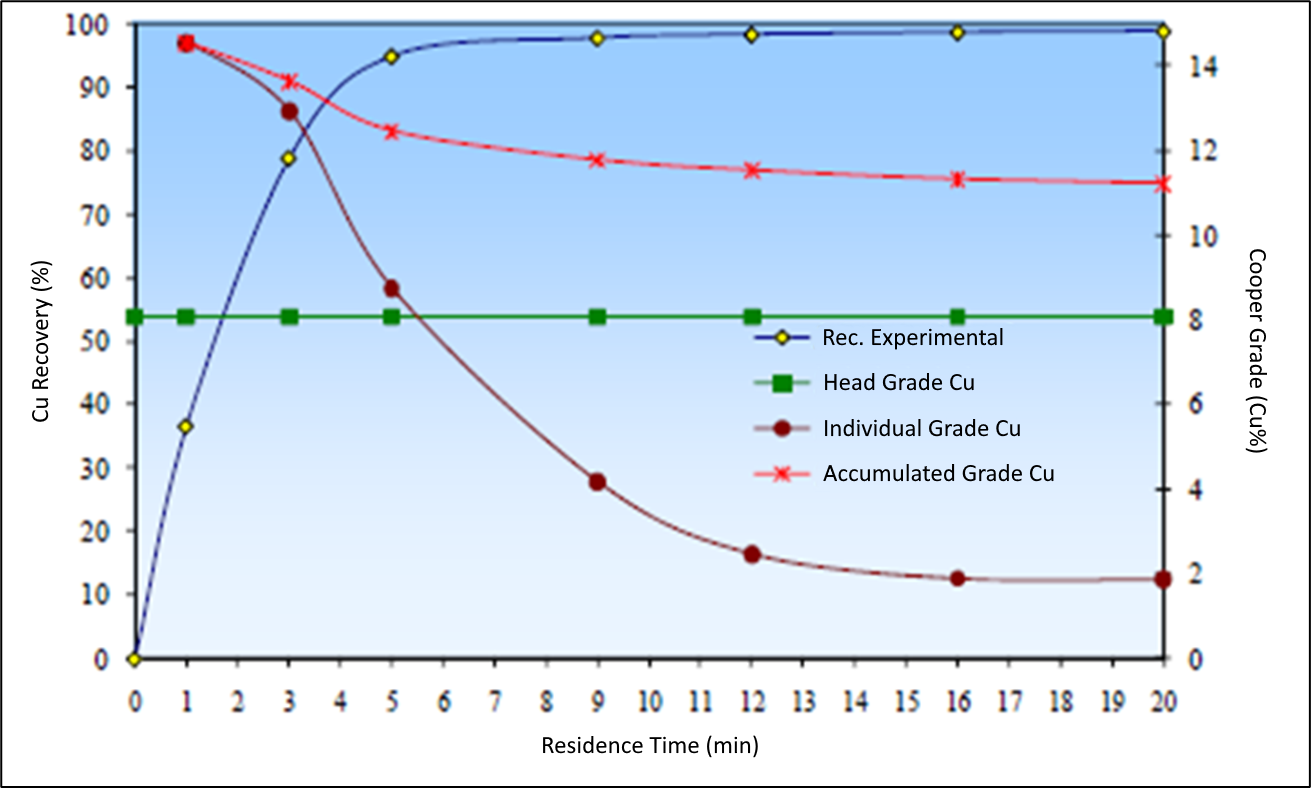

As part of this study, Ausenco completed a circuit review to determine the viability of including jigging pre-concentration. The evaluation indicates that the mass rejection in the jigging circuit does not result in significant reduction of the downstream plant and the associated capital cost requirements. The copper contained in the pre-concentration tailings can add significant value to the project when recovered to the final copper concentrate. As a result, a sequential flotation process with no pre-concentration stage is selected for the project. This flowsheet as well as the relevant locked cycle flotation test results comprise the basis for the copper recovery projection.

1.9Mineral Resource Estimation

Mineral Resources are detailed in Table 1-1 and have an effective date of 31 August 2021; they are presented inclusive of Mineral Reserves. Mineral Resources that are not Mineral Reserves have no demonstrated economic viability.

| | | | | |

| Boa Esperança Project | Page 5 |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

The mineral resource estimates were prepared in accordance with the Canadian Institute of Mining, Metallurgy and Petroleum (“CIM”) Definition Standards for Mineral Resources and Mineral Reserves, adopted by the CIM Council on May 10, 2014 (the “CIM Standards”), and the CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines, adopted by CIM Council on November 23, 2003 (the ‘CIM Guidelines”), using geostatistical and/or classical methods, plus economic and mining parameters appropriate to the deposit.

Block model tonnage and grade estimates for the Boa Esperança Project were classified according to the CIM Standards and the CIM Guidelines by Mr. Emerson Ricardo Re, RM CMC (0138) and MAusIMM (CP) (305892), Ero Resource Manager and QP as defined under NI 43-101.

A 3D geologic model was developed for the Boa Esperança Project. Geologically constrained grade shells were developed using various copper cut-off grades to generate a 3D mineralization model of the Boa Esperança Project. Within the grade shells, mineral resources were estimated using ordinary kriging within a 2.0 m by 2.0 m by 4.0 m block size. Within the optimized resource open pit limits, a cut-off grade of 0.20% copper was applied based upon a copper price of US$6,400 per tonne, net smelter return ("NSR") of 94.53%, average metallurgical recoveries of 90.7%, mining recovery of 91.0%, dilution of 5.0%, mining costs of US$3.10 per tonne mined run of mine ("ROM"), processing and costs of US$5.65 per tonne ROM, and G&A costs of US$5.65 per tonne ROM. Unconstrained inferred mineral resources have been stated at a cut-off grade of 0.51% copper with a marginal cut-off grade of 0.32% copper based upon a copper price of US$6,400 per tonne, NSR of 94.53%, mining recovery of 100%, average metallurgical recoveries of 90.7%, mining costs of US$14.71 per tonne ROM, processing and costs of US$5.70 per tonne ROM, and G&A costs of US$2.60 per tonne ROM. Stated mineral resources estimates are inclusive of mineral reserves.

Table 1-1: Mineral Resource Statement as of 31 August 2021

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Boa Esperança Copper Project | Measured Resources | Indicated Resources | Measured and Indicated Resources | Inferred Resources |

| Tonnes | Grade | Contained | Tonnes | Grade | Contained | Tonnes | Grade | Contained | Tonnes | Grade | Contained |

| (000's) | (%) | (000's) | (000's) | (%) | (000's) | (000's) | (%) | (000's) | (000's) | (%) | (000's) |

| Open Pit High-Grade | 7,117 | 2.16 | 153.65 | 1,661 | 2.27 | 37.63 | 8,778 | 2.18 | 191.3 | 40.5 | 2.69 | 1.09 |

| Open Pit Low-Grade | 25,476 | 0.60 | 152.00 | 13,433 | 0.51 | 68.43 | 38,909 | 0.57 | 220.4 | 514.4 | 0.49 | 2.51 |

| Subtotal Mineral Resources | 32,593 | 0.94 | 305.65 | 15,095 | 0.70 | 106.06 | 47,687 | 0.86 | 411.7 | 554.8 | 0.65 | 3.60 |

| Underground High-Grade | | | | | | | | | | 1,354 | 2.24 | 30.38 |

| Underground Low-Grade | | | | | | | | | | 9,681 | 0.60 | 58.24 |

| Subtotal Mineral Resources | | | | | | | | | | 11,035 | 0.80 | 88.62 |

| Total Copper Mineral Resources | 32,593 | 0.94 | 305.65 | 15,095 | 0.70 | 106.06 | 47,687 | 0.86 | 411.71 | 11,590 | 0.80 | 92.22 |

Notes to Accompany Mineral Resource Estimate:

•Mineral Resources have an effective date of 31 August 2021 and were prepared by Emerson Ricardo Re, MSc, MBA, MAusIMM (CP) (No. 305892), Registered Member (No. 0138) (Chilean Mining Commission), Resource Manager of Ero and a QP as such term is defined under NI 43-101.

•Tonnes and grade are rounded to reflect approximation.

•Open Pit Mineral Resources are stated at a cut-off grade of 0.20% Cu and are fully contained within an optimized pit shell.

•Underground Mineral Resources are stated within an optimized stopes below the pit shell. A cut-off grade of 0.51% Cu and a marginal cut-off grade of 0.32% Cu were applied in the stope optimization.

•Stated Mineral Resources are inclusive of Mineral Reserves.

•Mineral Resources that are not Mineral Reserves and have not demonstrated economic viability. Mineral Resource estimates do not account for mineability, selectivity, mining loss and dilution. These Mineral Resource estimates include Inferred Mineral Resources that are normally considered too geologically speculative to allow for the application of economic considerations that would see them categorized as Mineral Reserves. There is

| | | | | |

| Boa Esperança Project | Page 6 |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

also no certainty that these Inferred Mineral Resources will be converted to Measured and Indicated categories through further drilling or into Mineral Reserves once economic considerations have been applied.

1.10Mineral Reserve Estimation

Mineral Reserves are detailed in Table 1-2 and have an effective date of 31 August 2021. These are based on the 2021 FSU production schedule, which was constrained by a designed pit. Measured and Indicated Mineral Resources were used to support the statement of Proven and Probable Mineral Reserves. Measured Resources were converted to Proven Mineral Reserves, and Indicated Mineral Resources were converted into Probable Mineral Reserves. These are reported as delivered to the mill and are therefore fully diluted.

Table 1-2: Mineral Reserves Statement as of 31 August 2021

| | | | | | | | | | | | | | | | | |

| Reserves Category | Tonnage t '000 | Copper %Cu | Contained Copper t ‘000 | |

| Proven Reserves | 30,674 | 0.89 | 273.2 | |

| Probable Reserves | 12,378 | 0.67 | 83.4 | |

| Total Mineral Reserves | 43,052 | 0.83 | 356.6 | |

| Notes to Accompany Mineral Reserves Estimate: | |

1.Mineral Reserves have an effective date of 31 August 2021 and were prepared by Mr. Carlos Guzman, RM CMC (0119) and FAusIMM (229036), an employee of NCL and a QP as such term is defined under NI 43-101. 2.Mineral Reserves are reported as constrained within Measured and Indicated pit designs and are supported by a mine plan featuring a constant throughput rate and cut-off optimization. The pit designs and mine plan were optimized using the following economic and technical parameters: copper price of US$3.00/lb; average recovery to concentrate is 91.3%; copper concentrate logistics costs of US$108.2/wmt; transport losses of 0.2%; copper concentrate treatment charges of US$59.5/dmt, U$0.0595/lb of copper refining charges; copper payability of 96.3%; average mining cost of US$2.47/t-mined; process cost of US$7.74/t-processed and G&A costs of US$3.83/t-processed; average pit slope angles that range from 30º to 50º and 2% royalty. 3.Mineral Reserves estimate considered an SMU of 2m x 2m x 8m, an overall dilution of 3.3% and a metal loss of 0.3%. 4.Rounding as required by reporting guidelines may result in apparent summation differences between tonnes, grades, and metal content. 5.Tonnage measurements are in metric units. Copper grades are reported as percentages and payable copper as tonnes. | |

Mineral Reserves were derived by incorporating modifying factors into the Mineral Resource model. Design and production scheduling were then undertaken within mine planning software. This process incorporated appropriate modifying factors and the application of cut-off policies and economic analysis. These results were then incorporated into the 2021 FSU, which supports the statement of Mineral Reserves at the project.

Previously stated Mineral Reserves as of June 1, 2017, were 19.5 Mt at 0.95 %Cu. (refer to Chapter 6.0 for further detail). The increase of the current estimate to almost double the contained copper is mainly because of the increased throughput, higher metallurgical recoveries as a result of removing the jigging unit operation, and the Mineral Resource modelling technique, which applied a more selective approach and with less added in-situ dilution than used in 2017.

| | | | | |

| Boa Esperança Project | Page 7 |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

1.11Open Pit Geotechnical

Geotechnical investigations for previous feasibility studies for the Boa Esperança project were completed in 2012 and 2017. The overall objective of the evaluation was to determine the pit slope geometries. Design recommendations for the pit slope angles were provided.

A field data collection program was designed and carried out for the Project with the primary objective of rock mass characterization and discontinuity orientation to serve as the basis of geotechnical model development. Geotechnical logging, point load testing, and orientation of discontinuities intersected by core recovered from four boreholes were conducted by MCSA geologists to support this investigation. Rock quality designation (RQD) data for a total of 109 previous resource and condemnation drillholes was also analysed and used in the development of the geotechnical model and subsequent analyses.

Geomechanical testing was conducted on rock core samples obtained from the two geotechnical drillholes to determine strength characteristics for the in-situ materials. The overall laboratory program consisted of direct shear, uniaxial and triaxial compressive strength, direct tensile strength tests, and measurements of unit weight and elastic properties. A total of 56 laboratory tests were conducted on samples selected to represent the range of the rock conditions observed in the two geotechnical holes.

In addition to the rock core testing program, two relatively undisturbed block samples of saprolite were obtained from within the open pit area and tested by Pattrol Laboratory, located in Belo Horizonte, Brazil. The saprolite testing program included triaxial shear strength and classification testing.

At Boa Esperança, three distinct domains of rock quality exist, i.e., the upper, saprolite and weathered rock (Saprock) and the fresh granitic rock below (Fresh Rock). The depth of the saprolite and weathered rock zone varies across the site from approximately 15 m around the outer edges of the deposit, up to 125 m in the Boa Esperança hill in the central portion of the deposit. The saprolite materials logged generally classify as completely weathered rock to residual soils.

Below the Saprolite and Saprock Zones, the bedrock is generally fresh, showing few signs of oxidation and minimal fracturing resulting in a very competent rock mass. Rock mass ratings (RMR) for the fresh rock ranged between 49 and 80 with an average value of 69 according to the Bieniawski (1989) criteria. Hydrothermal breccia structures and rhyodacite dikes within the rock mass are generally well healed and expected to be of similar competency as the granitic host rock and consequentially have been included within the Fresh Rock domain.

In addition to the granitic rock, a schist unit exists at the surface to the north and east, potentially outcropping in the upper final north pit wall. Currently, the schist unit is poorly understood with very few actual drill core intercepts. The few drillhole intercepts with this unit at depth suggest a rock mass similarly competent to the granite host rocks, without strong cleavage or well-developed foliation.

Based on the oriented core data, the primary discontinuity sets at Boa Esperança are sub-vertical, northeast, and northwest striking and sub-horizontal. A secondary, moderately northwest dipping set also appears but relatively infrequent compared to the other sets.

To optimize the slope design at Boa Esperança, both global and bench scale stability for the proposed open pit were performed. Overall slopes were analysed with limit equilibrium methods using the Hoek-Brown (2002) rock mass shear strength criteria for the Fresh Rock and Mohr-Coulomb criteria for the highly weathered Saprolite Zone. Saprolite slopes were considered to be drained and conservatively high groundwater surfaces were used in the Fresh Rock.

| | | | | |

| Boa Esperança Project | Page 8 |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

Overall and high inter-ramp slopes were analyzed using commercially available geotechnical modelling software packages Slide 6.0 and Phase2. The limit equilibrium analysis results for the current final feasibility pit design showed a very low probability of failure and relatively high factors of safety (average of 2.1) for even the conservatively high phreatic surface assumed (10 to 25 m behind pit face). A safety factor of 1.7 was also demonstrated with Phase2 using the mean rock mass parameter values. This confirms that stable slopes at Boa Esperança, within the Fresh Rock, will be controlled primarily by geologic structure below the oxide boundary and not by rock mass strength. Stable slopes within the saprolite zone are anticipated to be controlled primarily by groundwater pressures which will be relieved with horizontal drain holes.

Slope kinematics were evaluated with a qualitative risk assessment for each pit sector. The purpose of the assessment was to judge the risk or likelihood of plane shear and wedge type failures occurring in a given pit sector. Based on the wall orientations of the current pit design and the steep dip angle of the primary structures at Boa Esperança, all sectors were identified as having very low to low risk of structural instabilities.

Table 1-3 shows the pit slope geometry proposed by Ausenco for each material type.

Table 1-3: Pit Slope Geometry

| | | | | | | | | | | |

| Saprolite | Saprock | Fresh Rock |

| Bench Height (m) | 8 | 8 | 16 |

| Minimum Bench Width (m) | 6 | 6 | 8 |

Bench Face Angle (O) | 50 | 65 | 81 |

Maximum Inter-ramp Angle (O) | 35 | 45 | 56 |

Maximum Overall Slope Angle (O) | - | 40 | 50 |

| Maximum Slope Height (m) | 50 | 100 | 200 |

1.12Mining Methods

A mine plan was developed by NCL. The plan is focused on a single mine area, mined through consecutive mining phases or pushbacks. The mill throughput assumption is based on an economic assessment study, resulting in an average throughput of 4.0 Mt per year of sulphide ore and a ramp-up period of 12 months that assumes a production rate of 3.2 Mt in the first year of production. Plan production (ramp-up) starts after commissioning during the second quarter of Year 1 to avoid the rainy season.

The required pre-stripping amounts to 13.2 Mt, and activities have been scheduled over 24 months. The mining schedule requires a maximum mine extraction of 20 Mt per year. The mine movement decreases from Year 10 until the mining operations are completed in Year 12. The production parameters for the Boa Esperança Project are summarised in Table 1-4.

| | | | | |

| Boa Esperança Project | Page 9 |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

Table 1-4: Key Production Parameters

| | | | | |

| Parameter | Quantity |

| Proven and Probable Mineral Reserves | 43.1 Mt at 0.83 %Cu |

| LOM production | Copper: 717.9 M lb (Year 1 - Year 12) |

| Pre-stripping | 13.2 Mt (24 months) |

| Maximum material movement | 20 Mt/anuum (without rehandling) |

| Mine life | 12 years |

The adopted mining operation strategy for this study corresponds to contract mining from pre-stripping through Year 5 of operation and transition to Owner mining in Year 6 to the life of mine. The preferred timing of the transition to Owner mining will be analyzed in future studies.

The mine is scheduled to work on a 7-days-a-week, three 8-hour shift basis, 365 days a year and 12 lost days per year due to weather conditions. The operation will include normal drilling, blasting, loading with 5.2 m3 / 3.9 m3 (waste/ore) backhoe configured excavator and 38 t conventional trucks over an 8-m bench height (double bench of 16 m in fresh rock in interim and final slopes). Mining will be performed on a sub-bench or flitch basis. All mining processes in the ore areas will apply processes commensurate with selective mining to mitigate ore dilution and losses. Mining will include supporting functions such as ancillary activities, dewatering, grade control, and equipment maintenance. Table 1-5 and Table 1-6 summarise the mine and plant feed production schedules.

| | | | | |

| Boa Esperança Project | Page 10 |

| NI 43-101 Technical Report Feasibility Study Update | October 2021 |

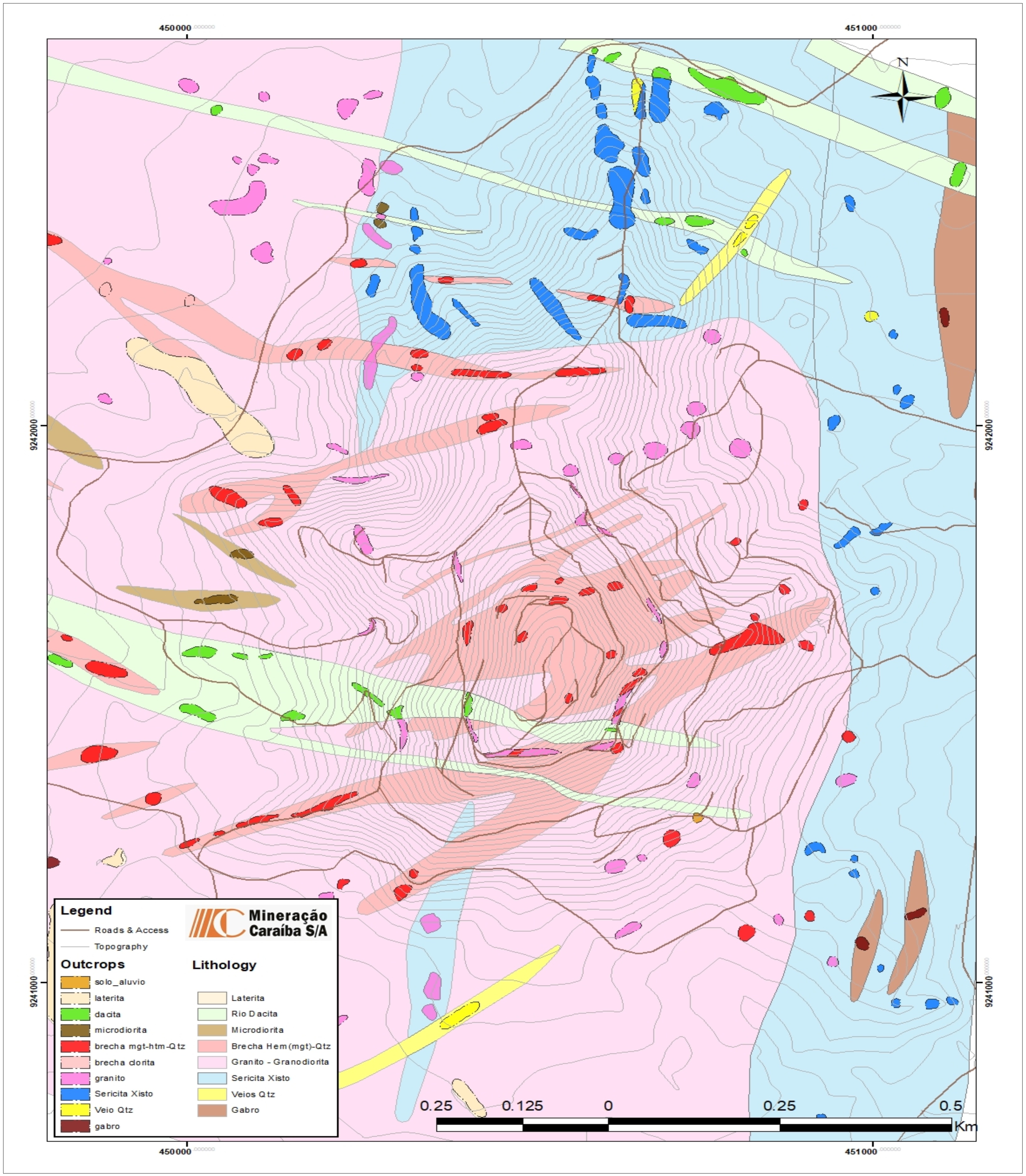

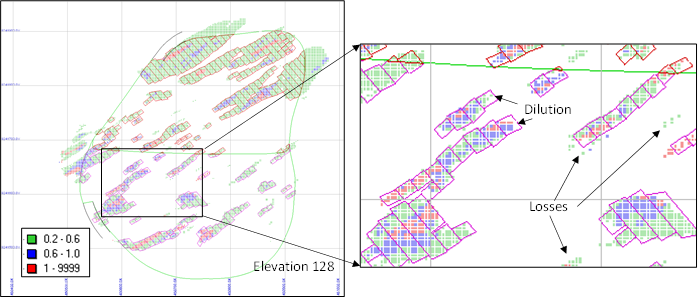

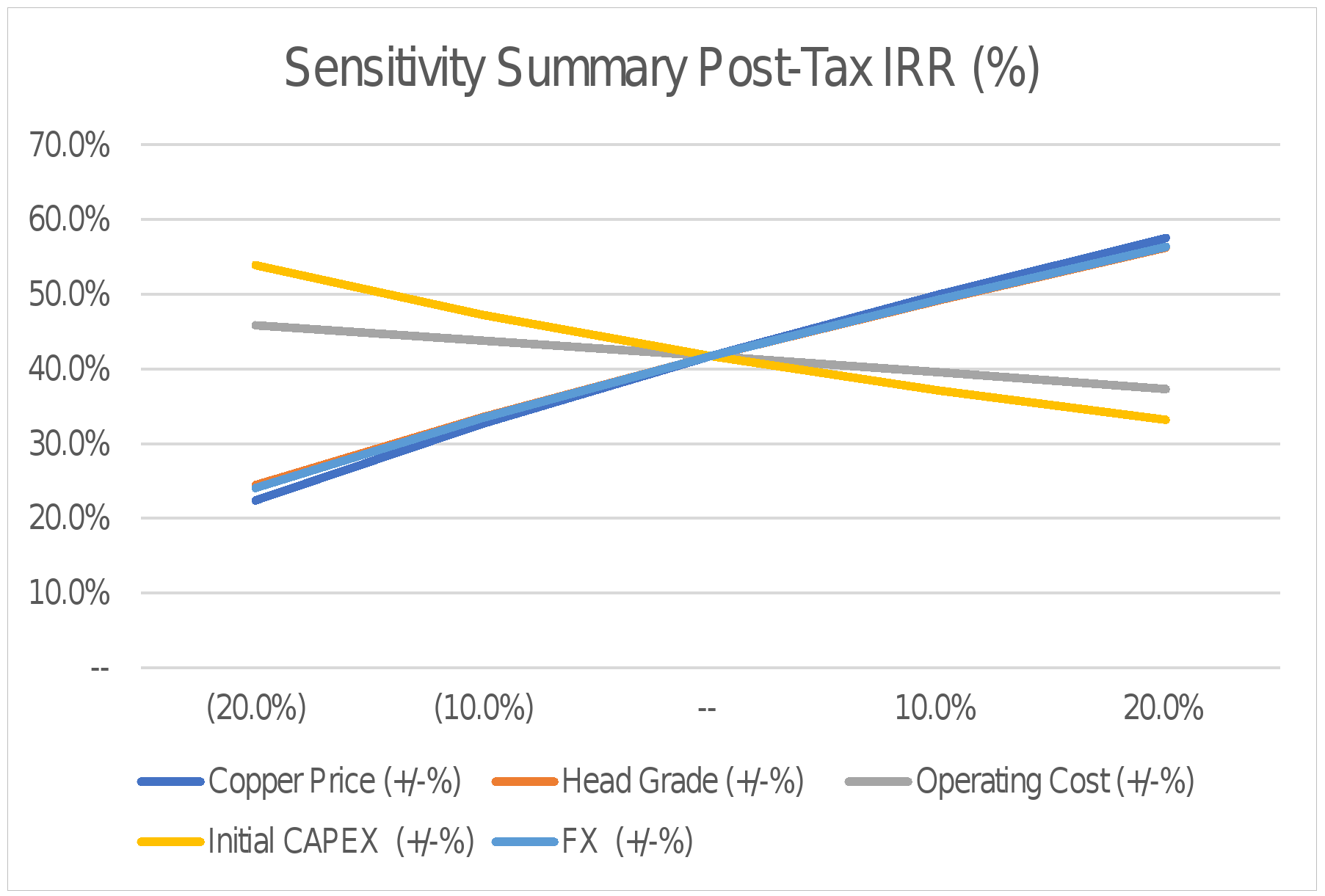

Table 1-5: Mine Production Schedule (yearly)