During the second quarter, we introduced and started deliveries of the second generation R1 vehicles. Our new R1 vehicles have hundreds of design, engineering, and performance upgrades, including:

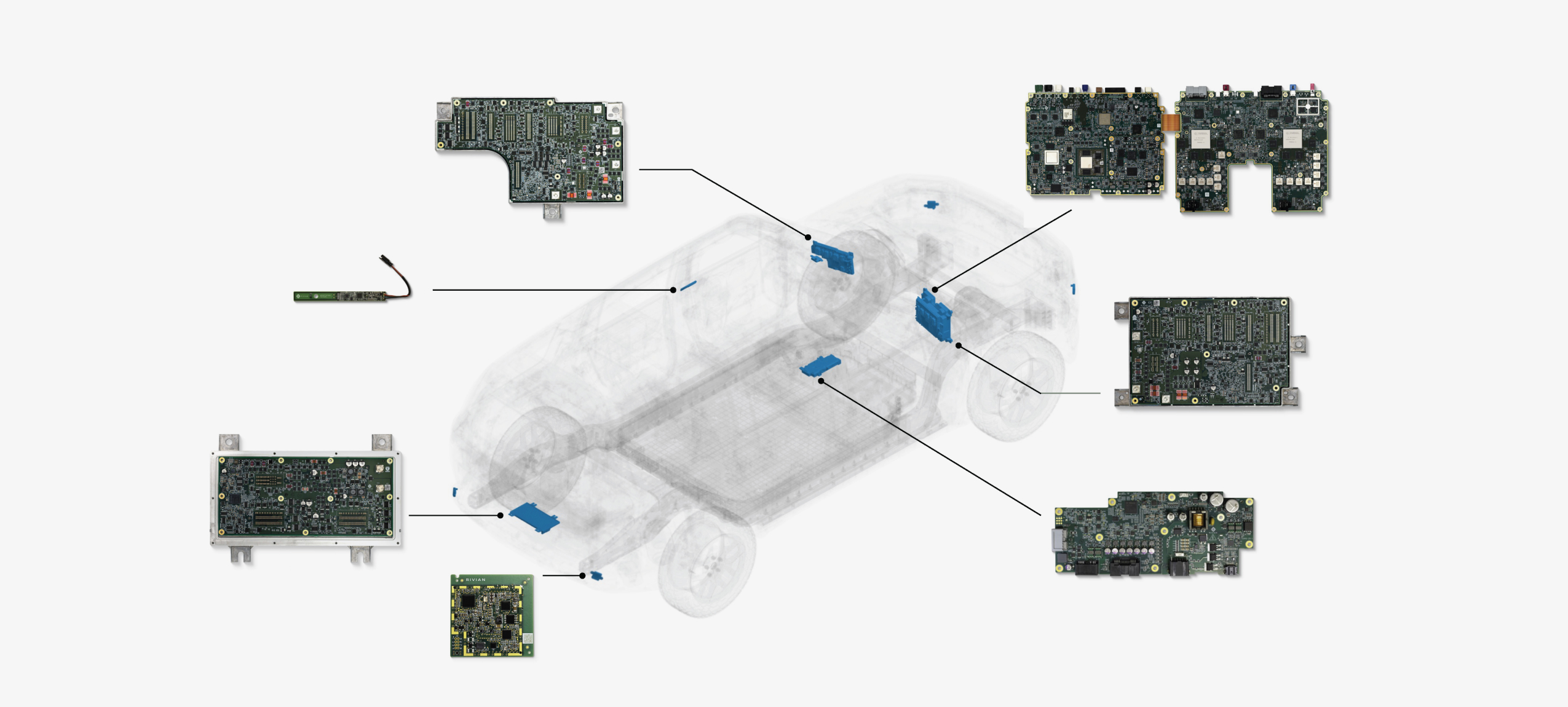

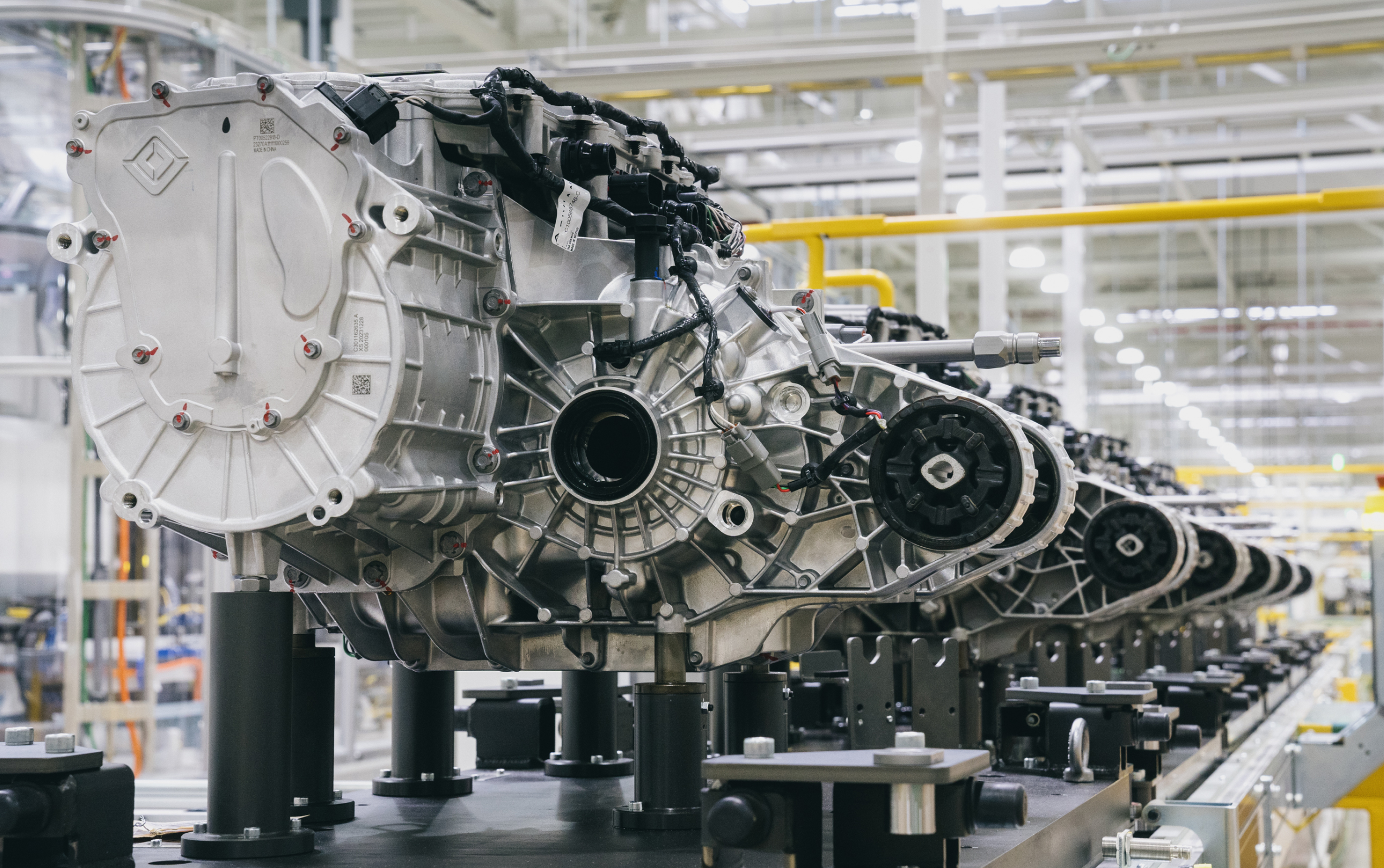

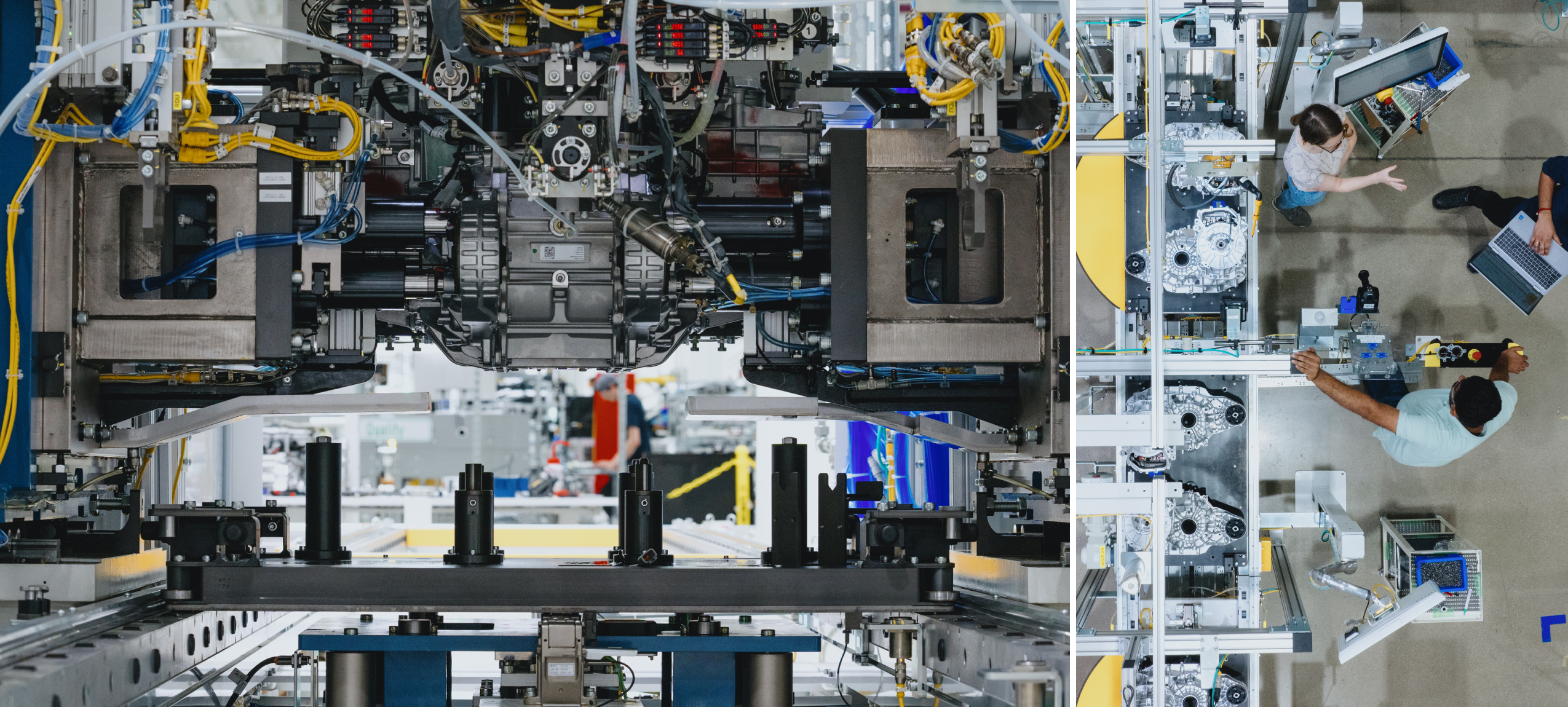

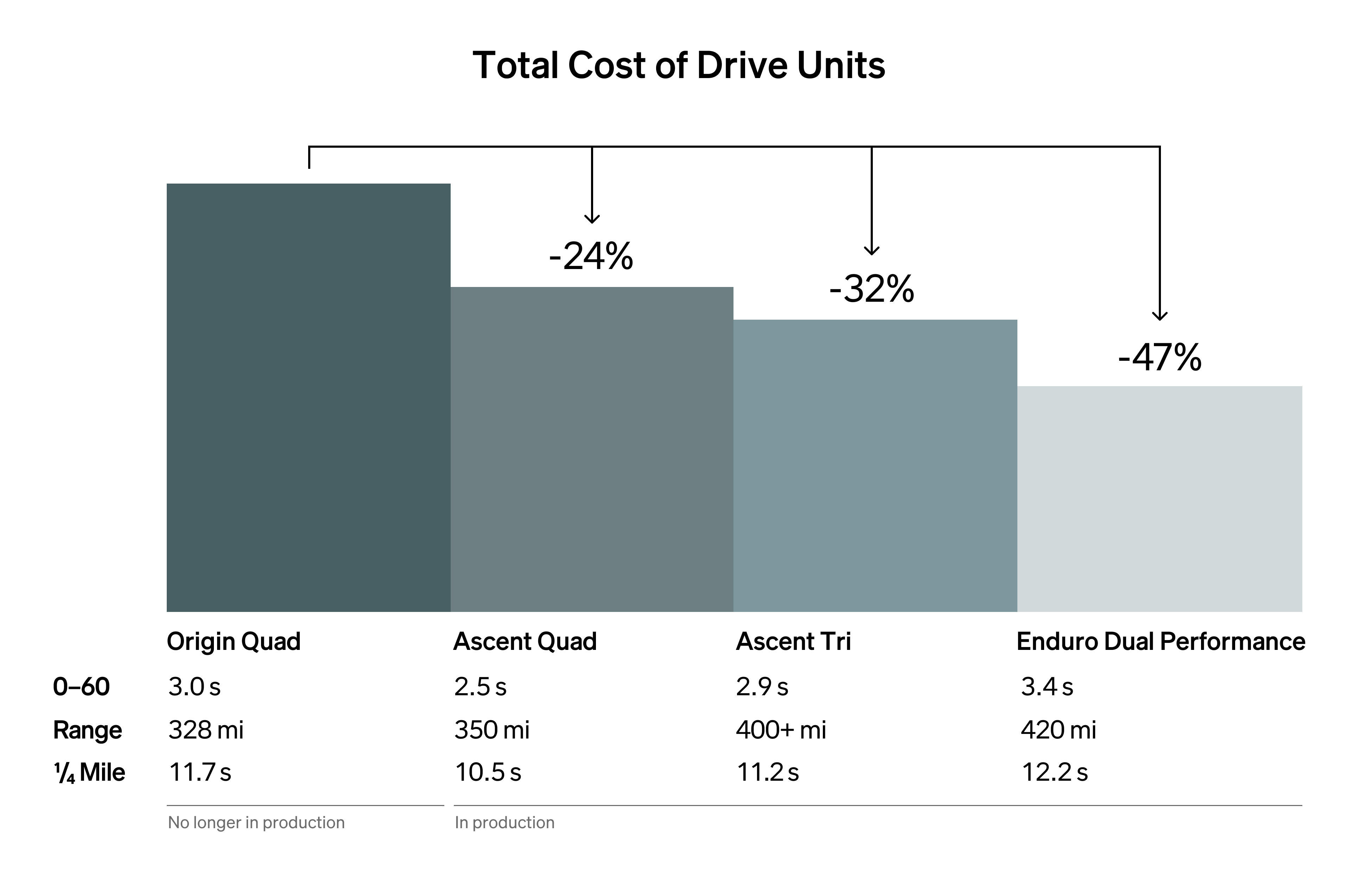

•Entirely new electrical network architecture •Entirely new compute and autonomy platforms •Two new in-house drive systems, Tri-Motor and Quad-Motor •Re-engineered suspension system •Two new premium interior options •Several new design options, including new exterior paint, new wheel choices, and electronically tinted glass roof and more •New exterior and interior lighting systems •New ultra-wideband access capabilities •New digital interfaces including our unique cel shading designs

These upgrades were made while also realizing significant cost improvements throughout the vehicle, which we believe positions the platform for long term profitability. The introduction of the second generation R1 platform combined with commercial cost improvements and commodity tail winds are expected to enable a 20% material cost reduction when comparing an R1 Dual-Motor with Large Pack produced in Q1 2024 versus the same vehicle produced in Q4 2024. In addition, we expect to realize a 30% efficiency in the R1 production line rate by the end of 2024.

To achieve this, significant design optimizations were made throughout the R1 vehicles. For example, the front crossmember of our battery pack has been reduced from 17 parts with high-pressure die casting enabling a 47% piece cost reduction. By moving to a zonal electrical architecture, we moved from having 17 in-house ECUs to 7, allowing us to remove 1.6 miles of harness length and significant cost in the electrical system cost.

Many of the new technologies introduced into the R1 platform will serve as the foundation for our MSP expected to launch in the first half of 2026 and give us increased confidence in our timelines associated with that platform.

|