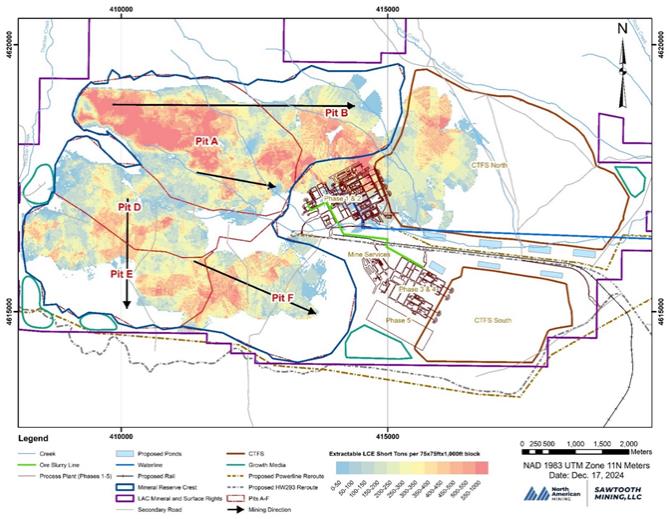

The Mineral Resource Estimate is based on a cutoff grade analysis, an optimized pit shell, and drill hole spacing based on geostatistical analysis. The Mineral Resource was also assessed where it was estimated under major infrastructure such as waste piles and the plant.

Mineral Reserve Estimates

This section contains forward-looking information related to the Mineral Reserves estimates for the Thacker Pass deposit. The material factors that could cause actual results to differ from the conclusions, estimates, designs, forecasts, or projections include geological modeling, grade interpolations, bulk density values, lithium price estimates, mining cost estimates, and final pit shell limits such as more detailed exploration drilling or final pit slope angle. The reference point at which the Mineral Reserves are defined is at the point where the ore is delivered to the run-of-mine feeder. Reductions attributed to plant losses have not been included in the Mineral Reserve estimate.

The Mineral Reserve estimate relies on the resource block model prepared by the QP responsible for the relevant section in the Reports.

Geological Block Model

The Mineral Reserve estimate relies on the resource block model prepared by the relevant QP. The block model had geological domains applied based on lithological type and grade. The domains in the block model include Alluvium, Smectite - S1 and S2, Illite - I1, I2 and I3, Hot Pond Zone, Tuff, and Basalt. The smectite and illite clay and ash zones are the Lithium rich domains within the Thacker Pass deposit and were the domains included in the Mineral Resource estimate. The waste zones include Alluvium, Hot Pond Zone, Tuff, and Basalt.

The block model was generated in Maptek’s geological software package and includes fields for geological domain, Mineral Resource classification, density, moisture, elemental values, in situ tonnages and volumes, ROM tonnages, extractable tonnages, and metallurgical recovery. The extractable tonnages and metallurgical recovery are based on recovery equations developed by LAC through material testing at the LiTDC. All equations have been applied to the entire block model and take into consideration the individual block’s elemental values, ash values and lithology.

Extractable Lithium and Metallurgical Recovery Factors

LAC used a set of equations to estimate the metallurgical recovery of lithium based on ash content, magnesium grade, and lithium grade, extractable lithium tonnage, and other important factors for determining waste tonnages. Imperial and Metric tonnages and volumes were carried in the block model along with wet and dry tonnages to allow for the flexible reporting for the mine plan schedule (imperial), metallurgical recovery processes (metric), and project cost model (metric).

Cut-off Grade

The Mineral Reserve pit is substantially larger than the pit utilized for the previous technical report. This change in size is due primarily to the LAC business decision to allow for the 2024 Mineral Reserves to extend outside of the currently permitted pit. In determining where the pit would be allowed to extend, a cut-off grade analysis, pit optimization routines, stripping ratio maps, waste tonnage amounts per pit area, and planned infrastructure locations were considered.

Two types of cutoff grades for the pit optimization were utilized in order to create the ultimate pit that will be utilized for the mine plan and Mineral Reserves. The two cutoff factors are:

| | • | | Economic Cutoff Grade of Lithium ppm |

| | • | | Kilogram of Extracted LCE per Leach Ore Tonne |

The lithium cutoff grade is the same as the Mineral Resource cutoff grade of 858 ppm Li. A second cutoff factor was based on the pit optimization analysis. This resulted in the application of the cutoff factor of 15 Kilograms of Extracted LCE per Leach Ore for pit optimization. In the 2022 Reports, the cut-off factor utilized Extracted Lithium and ROM Total Feed. However, in the current Mineral Reserve estimate, the Kilograms of Extracted LCE per tonne of Leach Ore cutoff factor was utilized to evaluate the blocks. The 2024 cut-off factor is based on how much LCE could be produced per Leach Ore tonne. With the 2024 factor, utilizing the LCE recovered allowed for the incorporation of the Metallurgical Recovery into the cut-off factor considerations. Which allows the equation to focus on the material quantities after Attrition Scrubbing.