- PHG Dashboard

- Financials

- Filings

-

Holdings

- Transcripts

- ETFs

- Insider

- Institutional

- Shorts

-

SD Filing

Koninklijke Philips (PHG) SDConflict minerals disclosure

Filed: 12 May 15, 12:00am

Exhibit 1.01

Philips Conflict Minerals Report

This Conflict Minerals Report for Koninklijke Philips N.V. (hereafter “Philips”, “we”, “us” or “our”) covers the reporting period from January 1st to December 31st, 2014, and is presented in accordance with the Securities Exchange Act of 1934, Rule 13p-1 (the “conflict minerals law”) and the requirements of Form SD.

This Conflict Minerals Report is filed as Exhibit 1.01 to our Specialized Disclosure Report on Form SD and is also posted on the Philipsconflict minerals website.1

Contents

1. | Introduction | 2 | ||||

2. | Philips conflict-free minerals program | 3 | ||||

| Philips | 3 | |||||

| Supply chain characteristics for 3TG | 3 | |||||

| Philips due diligence program | 4 | |||||

| OECD Step 1: Company Management system | 4 | |||||

| OECD Step 2: Risk identification and assessment | 5 | |||||

| OECD Step 3: Strategy to respond to identified risks | 6 | |||||

| OECD Step 4: Audits of smelter due diligence practices | 7 | |||||

| OECD Step 5: Report annually on supply chain due diligence. | 7 | |||||

3. | Reasonable Country of Origin Inquiry results | 7 | ||||

4. | Due diligence framework & measures2 | 9 | ||||

| Framework | 9 | |||||

| Measures | 9 | |||||

5. | Due diligence outcomes | 10 | ||||

6. | Determination | 11 | ||||

7. | Steps to improve future due diligence | 12 | ||||

8. | List of smelter facilities | 12 | ||||

9. | Independent private sector audit | 19 | ||||

10. | Data sources used | 19 | ||||

11. | Abbreviations | 19 | ||||

Exhibit A | 20 | |||||

| 1 | KPMG will verify that this Conflict Minerals Report is filed as Exhibit 1.01 to Philips Specialized Disclosure Report on Form SD and is also posted on the Philips conflict minerals website. |

| 2 | The due diligence framework and measures, as set forth in Section 4 of this report have been audited by KPMG, our independent private sector auditor. The audit report is set forth as Exhibit A in this Conflict Minerals Report. |

| 1. | Introduction |

The Democratic Republic of the Congo (DRC) and its adjoining countries have significant reserves of tin, tantalum, tungsten and gold (known as “3TG” or “conflict minerals”). All of these minerals are commonly used in the manufacturing of products for the consumer and professional markets. Various parties, including the United States Congress, have concerns that the exploitation and trade of conflict minerals by armed groups is helping to finance conflict in the DRC region and is contributing to an emergency humanitarian crisis. The DRC produces 19% of the world tantalum production and less than 2% of the world production for tin, tungsten and gold (source: U.S. Geological Survey – Minerals Commodity Summaries 2014).

In 2010, the Dodd-Frank Wall Street Reform and Consumer Protection Act (the “Act”) was enacted. Section 1502 of the Act specifically relates to conflict minerals and, as implemented by Rule 13p-1 under the Securities and Exchange Act 1934,requires registrants (issuers of securities that are required to file annual and quarterly reports with the United States Securities and Exchange Commission (SEC)) to make disclosures, for each calendar year, if conflict minerals are necessary to the functionality or production of a product manufactured by the registrant or contracted by the registrant to be manufactured. If the registrant determines, for a calendar year, that conflict minerals are necessary to the functionality or production of a product manufactured by the registrant or contracted by the registrant to be manufactured, the SEC registrant is required to file a Form SD with the SEC for that calendar year. If, after conducting a good faith, reasonable country of origin inquiry, the SEC registrant determines, or has reason to believe, that any of the 3TG used in connection with the products for which it is responsible may have originated in the Democratic Republic of Congo or an adjoining country, or did not come from recycled or scrap sources, the registrant is required to conduct due diligence on the source and chain of custody of its conflict minerals, following a nationally or internationally recognized framework. If, based on this due diligence, the registrant determines that, or is unable to determine whether, its conflict minerals originated from the Democratic Republic of Congo or an adjoining country, then the registrant is also required to file a Conflict Minerals Report.

Philips has concluded, in good faith, that:

| • | Philips has manufactured and contracted to manufacture products as to which conflict minerals are necessary to the functionality or production of our products; and |

| • | Based on our reasonable country of origin inquiry, Philips knows or has reason to believe that a portion of its necessary conflict minerals originated or may have originated from the Democratic Republic of Congo or an adjoining country and knows or has reason to believe that those minerals may not be solely from recycled or scrap sources. |

2

| • | Based on our due diligence measures on the source and chain of custody of those necessary conflict minerals, Philips is unable to determine whether its conflict minerals originated from the Democratic Republic of Congo or an adjoining country. |

As a result, Philips is filing this Conflict Minerals Report with our Form SD to comply with the requirements ofRule 13p-1 of the Securities and Exchange Act 1934.

| 2. | Philips conflict-free minerals program |

Philips

Koninklijke Philips N.V. (NYSE: PHG, AEX: PHIA) is a diversified technology company, focused on improving people’s lives through meaningful innovation in the areas of Healthcare, Consumer Lifestyle and Lighting. The company is a leader in cardiac care, acute care and home healthcare, energy efficient lighting solutions and new lighting applications, as well as male shaving and grooming and oral healthcare. Philips business groups cover a wide product portfolio, including thousands of different products for the professional and consumer markets. In 2014 the company was organized around the following three sectors and business groups:

| – | For the sector Healthcare: Imaging Systems, Customer Services, Healthcare Informatics, Solutions & Services, and Patient Care & Monitoring Solutions |

| – | For the sector Consumer Lifestyle: Personal Care, Domestic Appliances, and Health & Wellness |

| – | For the sector Lighting: Light Sources & Electronics, Consumer Luminaires, Professional Lighting Solutions, Automotive Lighting, and Lumileds3 |

Supply chain characteristics for 3TG

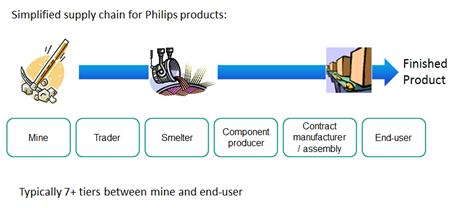

The supply chain for 3TG consists of many tiers. Before reaching Philips’ direct suppliers, 3TG typically will go from mines to traders, exporters, smelters or refiners (collectively referred to in this report as smelters), alloy producers and component manufacturers, and sometimes intermediate suppliers. One or more of the 3TG metals are contained in the vast majority of Philips products, typically in small quantities. The majority of Philips suppliers also use these metals in their products. Philips sources products and components from approximately 10,000 first tier suppliers globally. First tier suppliers are those suppliers that Philips selected and with whom we have a direct business relationship. These first tier suppliers select their suppliers (second tier suppliers), which in turn have their own group of suppliers (third tier), and so on. In a typical case, there may be seven or more tiers in the supply chain between a 3TG mine and Philips’ first tier suppliers. Philips works with and through its first tier suppliers to investigate the deeper levels of our supply chain, in an effort to determine the origin of 3TG contained in Philips products.

| 3 | As of April 1st 2015 the combined businesses of Lumileds and Automotive Lighting are discontinued operations. In this 2014 conflict minerals report the businesses of Lumileds and Automotive are still included. |

3

Philips due diligence program

Due to Philips’ position in the supply chain and limited insight in and leverage over the deeper levels of the supply chain, we engage and actively cooperate with other industry members. As encouraged in the second edition of theOrganization for Economic Co-operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas(including its supplements on 3TG, referred to in this report as “OECD Guidance”), the internationally recognized standard on which our company’s system is based, we support an industry initiative that uses an independent third-party audit to identify smelters and refiners that have systems in place to assure sourcing of only conflict-free materials. That industry initiative is theEICC and GeSI’s Conflict-Free Sourcing Initiative (CFSI).

The data on which we relied for certain statements in this report was obtained through our membership in the CFSI, using the CFSI Reasonable Country of Origin Inquiry report4 (CFSI membership number “PHIL”). We use the tools and programs developed by the CFSI, especially theConflict Minerals Reporting Template (CMRT) and theConflict Free Smelter Program (CFSP).

Philips designed its conflict minerals supply chain due diligence program with reference to the OECD Guidance and the five steps described in the supplements on 3TG.

OECD Step 1: Company Management system

Philips adopted aPosition paper on responsible sourcing in relation to conflict minerals5, posted it on the company website and communicated it to all priority suppliers (see below section “OECD Step 2” for definition of priority suppliers). Philips has committed not to purchase raw materials, subassemblies, or supplies which we know contain conflict minerals that directly or indirectly finance or benefit armed groups in the DRC or an adjoining country. Philips program goals as described in the position paper are to encourage the development of European Union initiatives that would:

| 4 | This list provides country of origin information for smelting and refining facilities that are validated through the Conflict-Free Smelter Program. This data is based on the results of the independent third-party audits is available to CFSI member companies only. The audit standard is developed according to global standards including the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas and the U.S. Dodd-Frank Wall Street Reform and Consumer Protection Act. |

| 5 | The content of any website referred to in this Conflict Minerals Report is included for general information only and is not incorporated by reference in the Conflict Minerals Report or Form SD |

4

| • | Minimize the trade in conflict minerals from mines that directly or indirectly finance or benefit armed groups anywhere in the world. |

| • | Enable legitimate minerals from the region to enter global supply chains, thereby supporting the Congolese economy and the local communities that depend on these exports. |

Philips created an internal conflict minerals team to manage the implementation and progress of our due diligence efforts. The internal team consists of representatives from Procurement at group and sector level, Sustainability, Finance and Control, Legal and the Ethics Office.

Philips established a system of controls and transparency over its 3TG supply chains by creating a process to engage a group of first tier priority suppliers (as defined below) and request them to submit information to Philips using the CMRT. The CMRT is a survey tool developed by the CFSI to standardize collection of due diligence information in the supply chain. The information submitted by priority suppliers includes information gathered by those suppliers about the smelters identified in their own supply chains. The information was used by Philips to assess due diligence efforts implemented by suppliers, and to identify smelters.

The PhilipsSupplier Sustainability Declaration (SSD) includes a provision about conflict minerals. The SSD is part of the general conditions of purchase, and of the purchasing agreements signed with suppliers. It requires suppliers to have a policy to reasonably assure that their 3TG does not directly or indirectly finance or benefit armed groups that are perpetrators of serious human rights abuses in the DRC or an adjoining country, and to exercise due diligence on the source and chain of custody.

For first tier suppliers in risk-countries Philips has a supplier sustainability audit program in place, in which implementation of the SSD is assessed. Conflict minerals is one of the topics reviewed in these audits. In case non-conformances are identified during the audit, suppliers are requested to make a corrective action plan and Philips monitors the implementation of this plan until the non-conformance is closed.

Multiple communication channels exist to serve as grievance mechanisms for early-warning risk awareness. Internally, Philips has a hotline available to its personnel to report anonymously possible violations of Philips General Business Principles and other policies. Externally, concerns can be reported via the Philips website and via existing industry grievance mechanisms like ITRI’s Tin Supply Chain Initiative (iTSCi).

OECD Step 2: Risk identification and assessment

Given the size and diversity of our supplier base, we choose to focus our efforts on a group of first tier priority suppliers and work with them to identify the smelters in our supply chain. Priority suppliers are selected based on:

5

| • | Purchasing spend |

The selected priority suppliers cover the top 80% spend of the commodity groups identified by Philips as relevant. Philips uses a system to classify suppliers in commodity groups, for example plastics, packaging, and metals. Philips excluded from the set of “relevant commodity groups” any suppliers in commodity groups for which it is unlikely that one or more of the 3TGs is contained in the products, for example, software suppliers and packaging suppliers.

| • | Usage of 3TG |

Suppliers with products that contain a high quantity of 3TG were selected as priority suppliers regardless of the purchasing spend with these suppliers. For example solder suppliers: since the main component of solder is tin, all solder suppliers are selected as priority suppliers.

All identified priority suppliers receive a letter formally requesting them to:

| - | Adopt a policy to reasonably assure that the 3TG in their products does not directly or indirectly finance or benefit armed groups in the DRC or an adjoining country |

| - | Identify all 3TG smelters in their supply chain |

| - | Report back to Philips by filling in the CMRT |

A Philips conflict minerals helpdesk is available to increase awareness amongst priority suppliers and to help them meet our expectations. Different background materials, a list of frequently asked questions and trainings are made available to suppliers. Webinars are organized for suppliers in both English and Chinese.

Philips reviews all received supplier CMRTs and assesses whether it meets our acceptance criteria related to completeness, whether supplier has adopted a conflict-free policy, data collection from next tier suppliers, and smelter identification and disclosure. Suppliers with a CMRT that does not meet the acceptance criteria are requested to take corrective actions and update their CMRT accordingly.

We review the supplier CMRTs to determine if there are any findings that indicate a need to conduct further due diligence and gather more detailed information. An example of such a finding is when suppliers indicate that their 3TG metals originate from the DRC or adjoining countries.

Philips evaluates the smelters identified in the supplier CMRTs based on the information available. Philips uses the CFSP compliant smelter list (CFSP recognizes and includes smelters from other lists such as the London Bullion Metal Association (LBMA) and Responsible Jewelry Council (RJC) lists for gold). If available, we will also use other sources of information to assess potential risk, for example, publicly available reports and direct information that Philips may have about a smelter’s sourcing practices.

Philips relies on industry programs like the CFSP to carry out smelter assessments, and we rely on the CFSP compliant smelter list to determine whether smelters performed due diligence.

6

OECD Step 3: Strategy to respond to identified risks

Progress and findings of the supply chain risk assessment are reported to senior management quarterly and monthly. The risk management plan adopted by Philips is in accordance with its policy to ultimately discontinue doing business with any supplier found to be purchasing tungsten, tantalum, tin or gold material which directly or indirectly finances or benefits armed groups in the DRC or adjoining countries, after attempts at corrective actions are not successful.

To monitor and track performance of risk management efforts, Philips relies on supplier CMRTs and updates of the CFSP compliant smelter list. The status is discussed internally in monthly reviews with the conflict minerals team and reported to senior management.

We request priority suppliers to update and resend their CMRT when additional information becomes available. When updates are received, the CMRT review step as described above is repeated to assess and mitigate risks.

OECD Step 4: Audits of smelter due diligence practices

The fourth step in the OECD guidance is to carry out independent third-party audits of supply chain due diligence at identified points in the supply chain. Philips relies on information provided by the CFSI for this step, and uses the CFSI RCOI report to identify the minerals country of origin and conflict-free status of smelters.

Philips contributes to the CFSI as a member company, and encourages smelters to participate in the CFSP through direct communication and smelter outreach communication, as well as by signing on to industry letters that are sent to smelters.

OECD Step 5: Report annually on supply chain due diligence.

Since 2014, Philips reports annually on supply chain due diligence by filing with the SEC a Form SD and Conflict Minerals Report. Philips has been including certain disclosures about the use of conflict minerals since 2009, even before the SEC’s rules first became effective. A dedicated conflict minerals website with information for consumers, customers and suppliers is available. In 2012 Philips was the first company to publish its smelter list, and will continue to regularly update this list as more information becomes available.

3. Reasonable Country of Origin Inquiry results

As described above, if, after conducting a good faith, reasonable country of origin inquiry, the SEC registrant determines, or has reason to believe, that any of the 3TG used in connection with the products for which it is responsible may have originated in the Democratic Republic of Congo or an adjoining country, or did not come from recycled or scrap sources, the registrant is required to conduct due diligence on the source and chain of custody of its conflict minerals, following a nationally or internationally recognized framework.

Philips identified 411 priority suppliers and used the data provided by these suppliers in their CMRTs to identify the smelters in the Philips supply chain and that therefore may have been used to process 3TG metals contained in Philips products.

7

92% of the priority suppliers submitted a CMRT and 81% were meeting or exceeding the Philips 2014 minimum acceptance criteria. Names of 3,432 different entities were provided to us by priority suppliers as part of their smelter lists.

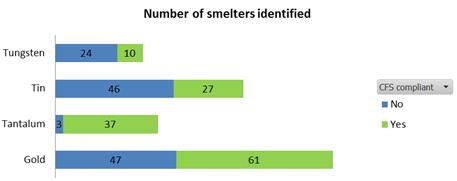

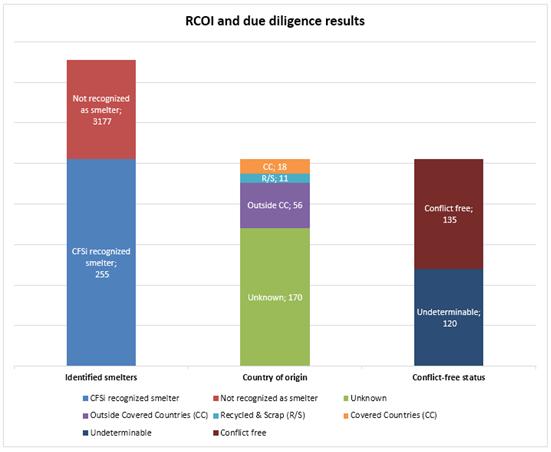

However, not all of those entities named by the priority suppliers in fact appear to be smelters. We used the “CFSI smelter reference list” as a reference to determine whether these named entities are recognized as smelters. Out of the names identified to us, we have identified a total of 255 recognized smelters in the supply chain. The remaining 3,177 entities named to us were not recognized as smelters. A number of these 3,177 entities clearly were not smelters (for example, in some cases, home supply stores were named) but in other cases, we were unable to identify the entity at all. A majority of the suppliers reported that they use metals from multiple smelters, and the average number of entities that suppliers reported on their smelter lists was 104.

Below, we provide information about the 255 recognized smelters. All entities that were not recognized as smelters on the CFSI smelter reference list have been excluded.

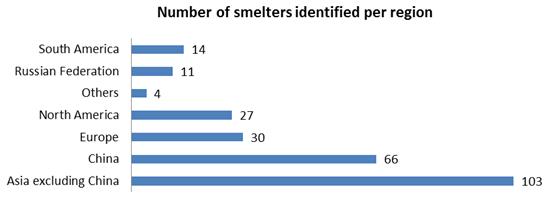

The majority of the smelters identified by our priority suppliers are located in Asia, with 66 smelters in China, followed by Indonesia (42) and Japan (28).

Results RCOI (Reasonable Country of Origin Inquiry)

| Gold | Ta | Tin | Tungsten | Sum | ||||||||||||||||

Smelters known to source from the DRC | 0 | 10 | 1 | 0 | 11 | |||||||||||||||

Smelters known to source from the DRC adjoining countries (not from the DRC itself) | 0 | 4 | 1 | 2 | 7 | |||||||||||||||

Smelters known to process onlyrecycled or scrap materials | 3 | 7 | 1 | 0 | 11 | |||||||||||||||

Smelters known to source from outside the DRC or adjoining countries | 8 | 16 | 24 | 8 | 56 | |||||||||||||||

Smelters that disclosed mineral country of origin to auditors only | 50 | 0 | 0 | 0 | 50 | |||||||||||||||

Smelters withunknown mineral origin | 47 | 3 | 46 | 24 | 120 | |||||||||||||||

|

|

|

|

|

|

|

|

|

| |||||||||||

Total | 108 | 40 | 73 | 34 | 255 | |||||||||||||||

|

|

|

|

|

|

|

|

|

| |||||||||||

8

For the 255 identified smelters, we used the CFSI Reasonable Country of Origin Inquiry report. This country of origin data is available for smelters that successfully completed a CFSP audit and chose to disclose their sourcing countries to the CFSI. 50 of the identified CFSP compliant smelters – all gold smelters – chose to disclose their mineral country of origin to the auditors only andnot make it available for CFSI members. The table below shows the results of our RCOI.

In the CMRTs received, 147 suppliers indicated that their products contain 3TG metals that originated from the DRC or adjoining countries. We requested these suppliers to disclose to us which smelters were supplying the related minerals, and to provide additional information to confirm the conflict-free status of their supply chains. Several suppliers stated that they had received information from next-tier suppliers that certain minerals originated from the covered countries, without disclosing the related smelters. By April 2015:

| – | 143 suppliers disclosed the names of all smelters known to them to process the 3TG originating from the DRC or adjoining countries, and all these smelters were CFSP compliant. |

| – | 4 suppliers did not identify the smelters sourcing from the DRC or adjoining countries |

| 4. | Due diligence framework & measures6 |

Framework

Our conflict minerals due diligence measures for the reporting period of calendar year 2014 have been designed to conform to the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, Second Edition (2013), as applicable for downstream companies.

Measures

Below is a description of the measures we performed to exercise due diligence on the source and chain of custody of the necessary conflict minerals contained in our products.

| – | Philips adopted theposition paper on responsible sourcing in relation to conflict minerals |

| – | The conflict minerals team met once a month to review progress and results of supplier data collection, supplier due diligence and smelter identification |

| – | In total 9 progress reports were shared with senior management and the main topics addressed included: |

| • | Progress of CMRT collection from priority suppliers |

| • | Status of supplier CMRTs meeting our acceptance criteria |

| • | Observed bottlenecks and resolution paths in getting suppliers to meet our CMRT acceptance criteria |

| 6 | The due diligence framework and measures, as set forth in Section 4 of this report have been audited by KPMG, our independent private sector auditor. The audit report is set forth as Exhibit A in this Conflict Minerals Report. |

9

| – | We reached out to priority suppliers via a supplier letter, explaining our expectations and requesting suppliers to fill out the CMRT. The supplier letter is posted on the companyconflict minerals website5 and was communicated to all priority suppliers. |

| – | We invited all priority suppliers to attend webinar trainings that we provided in English and Chinese. The goal of the webinars was to raise awareness, explain Philips’ expectations towards suppliers regarding conflict minerals, and help suppliers in setting up their own conflict minerals program. |

| – | We requested priority suppliers to investigate their supply chain and report back to Philips using the CMRT. When lack of progress was observed in supplier CMRT collection we followed-up with suppliers and sent out multiple reminders via email and phone. |

| – | We reviewed all received supplier CMRTs to evaluate whether it met our acceptance criteria related to completeness, adoption of a conflict-free policy, data collection from next tier suppliers, and smelter identification and disclosure. Suppliers with a CMRT that did not meet the acceptance criteria did not provide complete information or provided information that was potentially inaccurate, were requested to take corrective actions and update their CMRT accordingly. |

| – | We reviewed the received supplier CMRTs to determine if there were any findings that indicated a need to conduct further due diligence and gather more detailed information. |

| – | We compared smelters identified in supplier CMRTs against the list of smelters that have received a “conflict free” designation from the CFSP or other independent third party audit program. |

| – | As a member of the CFSI, we leveraged the due diligence conducted on smelters by the CFSI’s Conflict-Free Smelter Program (CFSP). This program uses independent third-party auditors to audit the source and chain of custody of the conflict minerals used by smelters that agree to participate in the CFSP. |

| – | We contacted smelters and refiners that had not received a “conflict free” designation to encourage their participation in the CFSP or other independent third party audit program |

| – | We published the “Philips Conflict Minerals Declaration” on the company’sconflict minerals website5, including a list of all smelters identified by our first tier suppliers during 2014. |

| – | We filed with the SEC our Conflict Minerals Report (and the Exhibits thereto) for the reporting period 2013 and 2014 as Exhibit 1.01 to Form SD and made the report available on ourconflict minerals website5. |

| 5. | Due diligence outcomes |

To the best of our knowledge, none of the smelters identified in our supply chain are known to source minerals that benefit armed groups in the DRC. Philips did not discontinue business with suppliers because we did not have a reason to believe that any of our suppliers was purchasing 3TG which directly or indirectly finances or benefits armed groups in the DRC or adjoining countries.

10

135 (53%) of the identified smelters successfully passed the CSFP or equivalent audit, thereby confirming their conflict-free status under those standards. The remaining 120 identified smelters did not complete an independent third party audit to confirm their conflict-free status. Accordingly, the conflict-free status of these 120 un-audited smelters is reported in this conflict minerals report as undeterminable.

| 6. | Determination |

We have not been able to confirm the identification of and conflict-free status under the CFSP standards for all smelters used in our supply chain. None of the smelters identified in our supply chain is known to us as sourcing 3TG that directly or indirectly finances or benefits armed groups in the DRC or adjoining countries.

11

As a result of the due diligence measures performed, Philips provides below the known smelter facilities that may have been used to process 3TG metals contained in Philips products, and their conflict-free status. The conflict-free status is based on the CFSI RCOI report which the CFSI provides to its members. Below list of smelter facilities includes all 255 entities that were recognized as smelters.

This conflict minerals report covers Philips’ entire product portfolio. Given Philips’ large product portfolio and extensive supplier base, Philips does not have component level information from all of our 10,000 first tier suppliers, and we therefore do not report for each of the many specific Philips products. Our approach is to conduct supply chain due diligence and report on the company level for our entire product portfolio, which allows us to focus our efforts on building, maintaining, and improving a robust due diligence program that makes a difference for the communities in the DRC or adjoining countries.

| 7. | Steps to improve future due diligence |

For the next reporting year, Philips plans to

| • | Continue our engagement with industry programs and groups to encourage further adoption, improvement and reliability in relevant programs, tools and standards. |

| • | Continue to reach out to smelters that are not yet CFSP compliant, with the aim of increasing the number of smelters on the list of CFSP compliant smelters. |

| • | Continue our work with priority suppliers to |

| • | help them understand and satisfy Philips conflict-free expectations |

| • | investigate their supply chain and identify smelters |

| • | confirm the conflict-free status of identified smelters |

| • | Communicate to priority suppliers our expectation that they steer their supply chain towards CFSP compliant smelters only |

| • | For priority suppliers using tantalum, request them to confirm that they source from conflict-free tantalum smelters only. In case they are unable to confirm this, we will request these suppliers to develop, share and implement a mitigation plan to source from conflict-free smelters only in the future. |

As sufficient number of tantalum smelters has been audited (CFSP or equivalent) as conflict-free, therefore we can start to implement this requirement now for tantalum. It is our intention to do this for the other metals as well, as soon as sufficient validated smelters become available.

| 8. | List of smelter facilities |

The table below represents a consolidated list of smelters (255 in total) identified by Philips’ priority suppliers. The results are based on:

| • | Information provided by our priority suppliers in their CMRTs |

| • | RCOI report provided by the CFSI – version February 28th 2015 |

12

List of known smelter facilities processing conflict minerals for DRC Conflict Undeterminable Products | ||||

Metal | Facility Name | Conflict-Free Status7 | ||

| Gold | Advanced Chemical Company | Undeterminable | ||

| Gold | Aida chemical industries Co.,LTD. | Undeterminable | ||

| Gold | Allgemeine Gold-und Silberscheideanstalt A.G. | Conflict-free | ||

| Gold | Almalyk Mining and Metallurgical Complex (AMMC) | Undeterminable | ||

| Gold | AngloGold Ashanti Córrego do Sítio Minerção | Conflict-free | ||

| Gold | Argor-Heraeus SA | Conflict-free | ||

| Gold | Asahi Pretec Corporation | Conflict-free | ||

| Gold | Asaka Riken Co.,Ltd. | Undeterminable | ||

| Gold | Atasay Kuyumculuk Sanayi Ve Ticaret A.S. | Conflict-free | ||

| Gold | Aurubis AG | Conflict-free | ||

| Gold | Bangko Sentral ng Pilipinas (Central Bank of the Philippines) | Undeterminable | ||

| Gold | Bauer Walser AG | Undeterminable | ||

| Gold | Boliden AB | Conflict-free | ||

| Gold | C. Hafner GmbH + Co. KG | Conflict-free | ||

| Gold | Caridad | Undeterminable | ||

| Gold | CCR Refinery – Glencore Canada Corporation | Conflict-free | ||

| Gold | Cendres & Métaux SA | Undeterminable | ||

| Gold | Chimet S.p.A. | Conflict-free | ||

| Gold | China National Gold Group Corporation | Undeterminable | ||

| Gold | Chugai Mining | Undeterminable | ||

| Gold | Colt Refining | Undeterminable | ||

| Gold | Daejin Indus Co. Ltd | Undeterminable | ||

| Gold | Daye Non-Ferrous Metals Mining Ltd. | Undeterminable | ||

| Gold | Do Sung Corporation | Undeterminable | ||

| Gold | Doduco | Undeterminable | ||

| Gold | Dowa | Conflict-free | ||

| Gold | ECO-SYSTEM RECYCLING CO., LTD. | Conflict-free | ||

| Gold | FSE Novosibirsk Refinery | Undeterminable | ||

| Gold | Gansu Seemine Material Hi-Tech Co Ltd | Undeterminable | ||

| Gold | Guangdong Jinding Gold Limited | Undeterminable | ||

| Gold | Hangzhou Fuchunjiang Smelting Co., Ltd. | Undeterminable | ||

| Gold | Heimerle + Meule GmbH | Conflict-free | ||

| Gold | Heraeus Ltd. Hong Kong | Conflict-free | ||

| Gold | Heraeus Precious Metals GmbH & Co. KG | Conflict-free | ||

| 7 | This categorization is based on the CFSP standards. All CFSP compliant smelters are listed here as conflict-free. |

13

| Gold | Hunan Chenzhou Mining Industry Group | Undeterminable | ||

| Gold | Hwasung CJ Co., Ltd | Undeterminable | ||

| Gold | Inner Mongolia Qiankun Gold and Silver Refinery Share Company Limited | Undeterminable | ||

| Gold | Ishifuku Metal Industry Co., Ltd. | Conflict-free | ||

| Gold | Istanbul Gold Refinery | Conflict-free | ||

| Gold | Japan Mint | Conflict-free | ||

| Gold | Jiangxi Copper Company Limited | Undeterminable | ||

| Gold | Johnson Matthey Inc | Conflict-free | ||

| Gold | Johnson Matthey Ltd | Conflict-free | ||

| Gold | JSC Ekaterinburg Non-Ferrous Metal Processing Plant | Conflict-free | ||

| Gold | JSC Uralectromed | Undeterminable | ||

| Gold | JX Nippon Mining & Metals Co., Ltd | Conflict-free | ||

| Gold | Kazzinc Ltd | Conflict-free | ||

| Gold | Kennecott Utah Copper LLC | Conflict-free | ||

| Gold | Kojima Chemicals Co., Ltd | Conflict-free | ||

| Gold | Korea Metal Co. Ltd | Undeterminable | ||

| Gold | Kyrgyzaltyn JSC | Undeterminable | ||

| Gold | L’ azurde Company For Jewelry | Conflict-free | ||

| Gold | Lingbao Gold Company Limited | Undeterminable | ||

| Gold | Lingbao Jinyuan Tonghui Refinery Co. Ltd. | Undeterminable | ||

| Gold | LS-Nikko Copper Inc | Conflict-free | ||

| Gold | Luoyang Zijin Yinhui Metal Smelt Co Ltd | Undeterminable | ||

| Gold | Materion | Conflict-free | ||

| Gold | Matsuda Sangyo Co. Ltd | Conflict-free | ||

| Gold | Metalor Technologies (Hong Kong) Ltd | Conflict-free | ||

| Gold | Metalor Technologies (Singapore) Pte. Ltd. | Conflict-free | ||

| Gold | Metalor Technologies SA | Conflict-free | ||

| Gold | Metalor USA Refining Corporation | Conflict-free | ||

| Gold | Metalurgica Met-Mex Peñoles, S.A. | Conflict-free | ||

| Gold | Mitsubishi Materials Corporation | Conflict-free | ||

| Gold | Mitsui Mining and Smelting Co., Ltd. | Conflict-free | ||

| Gold | MMTC-PAMP India Pvt. Ltd. | Conflict-free | ||

| Gold | Moscow Special Alloys Processing Plant | Undeterminable | ||

| Gold | Nadir Metal Rafineri San. Ve Tic. A.Ş. | Conflict-free | ||

| Gold | Navoi Mining and Metallurgical Combinat | Undeterminable | ||

| Gold | Nihon Material Co. LTD | Conflict-free | ||

| Gold | Ohio Precious Metals, LLC | Conflict-free | ||

| Gold | Ohura Precious Metal Industry Co., Ltd | Conflict-free | ||

| Gold | OJSC “The Gulidov Krasnoyarsk Non-Ferrous Metals Plant” (OJSC Krastvetmet) | Conflict-free | ||

| Gold | OJSC Kolyma Refinery | Undeterminable | ||

| Gold | PAMP SA | Conflict-free | ||

14

| Gold | Penglai Penggang Gold Industry Co Ltd | Undeterminable | ||

| Gold | Prioksky Plant of Non-Ferrous Metals | Undeterminable | ||

| Gold | PT Aneka Tambang (Persero) Tbk | Conflict-free | ||

| Gold | PX Précinox SA | Conflict-free | ||

| Gold | Rand Refinery (Pty) Ltd | Conflict-free | ||

| Gold | Royal Canadian Mint | Conflict-free | ||

| Gold | Sabin Metal Corp. | Undeterminable | ||

| Gold | Samduck Precious Metals | Undeterminable | ||

| Gold | SAMWON METALS Corp. | Undeterminable | ||

| Gold | Schone Edelmetaal | Conflict-free | ||

| Gold | SEMPSA Joyería Platería SA | Conflict-free | ||

| Gold | Shandong Zhaojin Gold & Silver Refinery Co., Ltd | Conflict-free | ||

| Gold | So Accurate Group, Inc. | Undeterminable | ||

| Gold | SOE Shyolkovsky Factory of Secondary Precious Metals | Undeterminable | ||

| Gold | Solar Applied Materials Technology Corp. | Conflict-free | ||

| Gold | Sumitomo Metal Mining Co., Ltd. | Conflict-free | ||

| Gold | Tanaka Kikinzoku Kogyo K.K. | Conflict-free | ||

| Gold | The Great Wall Gold and Silver Refinery of China | Undeterminable | ||

| Gold | The Refinery of Shandong Gold Mining Co. Ltd | Conflict-free | ||

| Gold | Tokuriki Honten Co., Ltd | Conflict-free | ||

| Gold | Tongling nonferrous Metals Group Co.,Ltd | Undeterminable | ||

| Gold | Torecom | Undeterminable | ||

| Gold | Umicore Brasil Ltda | Conflict-free | ||

| Gold | Umicore Precious Metals Thailand | Conflict-free | ||

| Gold | Umicore SA Business Unit Precious Metals Refining | Conflict-free | ||

| Gold | United Precious Metal Refining, Inc. | Conflict-free | ||

| Gold | Valcambi SA | Conflict-free | ||

| Gold | Western Australian Mint trading as the Perth Mint | Conflict-free | ||

| Gold | YAMAMOTO PRECIOUS METAL CO., LTD. | Undeterminable | ||

| Gold | Yokohama Metal Co Ltd | Undeterminable | ||

| Gold | Yunnan Copper Industry Co Ltd | Undeterminable | ||

| Gold | Zhongyuan Gold Smelter of Zhongjin Gold Corporation | Undeterminable | ||

| Gold | Zijin Mining Group Co. Ltd | Undeterminable | ||

| Tantalum | Changsha South Tantalum Niobium Co., Ltd. | Conflict-free | ||

| Tantalum | Conghua Tantalum and Niobium Smeltry | Conflict-free | ||

| Tantalum | Duoluoshan | Conflict-free | ||

| Tantalum | Exotech Inc. | Conflict-free | ||

| Tantalum | F&X Electro-Materials Ltd. | Conflict-free | ||

| Tantalum | Global Advanced Metals Aizu | Conflict-free | ||

| Tantalum | Global Advanced Metals Boyertown | Conflict-free | ||

| Tantalum | Guangdong Zhiyuan New Material Co., Ltd. | Conflict-free | ||

15

| Tantalum | H.C. Starck Co., Ltd. | Conflict-free | ||

| Tantalum | H.C. Starck GmbH Goslar | Conflict-free | ||

| Tantalum | H.C. Starck GmbH Laufenburg | Conflict-free | ||

| Tantalum | H.C. Starck Hermsdorf GmbH | Conflict-free | ||

| Tantalum | H.C. Starck Inc. | Conflict-free | ||

| Tantalum | H.C. Starck Ltd. | Conflict-free | ||

| Tantalum | H.C. Starck Smelting GmbH & Co.KG | Conflict-free | ||

| Tantalum | Hengyang King Xing Lifeng New Materials Co., Ltd. | Conflict-free | ||

| Tantalum | Hi-Temp | Conflict-free | ||

| Tantalum | Jiujiang Jinxin Nonferous Metals Co., Ltd | Conflict-free | ||

| Tantalum | Jiujiang Tanbre Co., Ltd. | Conflict-free | ||

| Tantalum | Kemet Blue Metals | Conflict-free | ||

| Tantalum | KEMET Blue Powder | Conflict-free | ||

| Tantalum | King-Tan Tantalum Industry Ltd | Undeterminable | ||

| Tantalum | LSM Brasil S.A. | Conflict-free | ||

| Tantalum | Metallurgical Products India (Pvt.) Ltd. | Conflict-free | ||

| Tantalum | Mineração Taboca S.A. | Conflict-free | ||

| Tantalum | Mitsui Mining & Smelting | Conflict-free | ||

| Tantalum | Molycorp Silmet A.S. | Conflict-free | ||

| Tantalum | Ningxia Orient Tantalum Industry Co., Ltd. | Conflict-free | ||

| Tantalum | Phoenix Metal Ltd | Undeterminable | ||

| Tantalum | Plansee SE Liezen | Conflict-free | ||

| Tantalum | Plansee SE Reutte | Conflict-free | ||

| Tantalum | QuantumClean | Conflict-free | ||

| Tantalum | RFH Tantalum Smeltry Co., Ltd | Conflict-free | ||

| Tantalum | Shanghai Jiangxi Metals Co. Ltd | Undeterminable | ||

| Tantalum | Solikamsk Metal Works | Conflict-free | ||

| Tantalum | Taki Chemicals | Conflict-free | ||

| Tantalum | Telex | Conflict-free | ||

| Tantalum | Ulba | Conflict-free | ||

| Tantalum | Yichun Jin Yang Rare Metal Co., Ltd | Conflict-free | ||

| Tantalum | Zhuzhou Cement Carbide | Conflict-free | ||

| Tin | Alpha | Conflict-free | ||

| Tin | China Rare Metal Materials Company | Undeterminable | ||

| Tin | CNMC (Guangxi) PGMA Co. Ltd. | Undeterminable | ||

| Tin | Cooper Santa | Undeterminable | ||

| Tin | CV Gita Pesona | Undeterminable | ||

| Tin | CV JusTindo | Undeterminable | ||

| Tin | CV Makmur Jaya | Undeterminable | ||

| Tin | CV Nurjanah | Undeterminable | ||

| Tin | CV Serumpun Sebalai | Undeterminable | ||

16

| Tin | CV United Smelting | Conflict-free | ||

| Tin | Dowa | Conflict-free | ||

| Tin | EM Vinto | Undeterminable | ||

| Tin | Estanho de Rondônia S.A. | Undeterminable | ||

| Tin | Fenix Metals | Undeterminable | ||

| Tin | Gejiu Kai Meng Industry and Trade LLC | Undeterminable | ||

| Tin | Gejiu Non-FerrousMetal Processing Co.Ltd. | Conflict-free | ||

| Tin | Gejiu Zi-Li | Undeterminable | ||

| Tin | Guangxi China Tin Group Co., LTD | Undeterminable | ||

| Tin | Huichang Jinshunda Tin Co. Ltd | Undeterminable | ||

| Tin | Jiangxi Nanshan | Undeterminable | ||

| Tin | Linwu Xianggui Smelter Co | Undeterminable | ||

| Tin | Magnu’s Minerais Metais e Ligas LTDA | Conflict-free | ||

| Tin | Malaysia Smelting Corporation Berhad | Conflict-free | ||

| Tin | Melt Metais e Ligas S/A | Conflict-free | ||

| Tin | Metallo Chimique | Undeterminable | ||

| Tin | Mineração Taboca S.A. | Conflict-free | ||

| Tin | Minsur | Conflict-free | ||

| Tin | Mitsubishi Materials Corporation | Conflict-free | ||

| Tin | Novosibirsk Integrated Tin Works | Undeterminable | ||

| Tin | O.M. Manufacturing (Thailand) Co., Ltd. | Undeterminable | ||

| Tin | O.M. Manufacturing Philippines, Inc. | Undeterminable | ||

| Tin | OMSA | Conflict-free | ||

| Tin | PT Alam Lestari Kencana | Undeterminable | ||

| Tin | PT Artha Cipta Langgeng | Undeterminable | ||

| Tin | PT ATD Makmur Mandiri Jaya | Conflict-free | ||

| Tin | PT Babel Inti Perkasa | Conflict-free | ||

| Tin | PT Babel Surya Alam Lestari | Undeterminable | ||

| Tin | PT Bangka Kudai Tin | Undeterminable | ||

| Tin | PT Bangka Putra Karya | Conflict-free | ||

| Tin | PT Bangka Timah Utama Sejahtera | Undeterminable | ||

| Tin | PT Bangka Tin Industry | Conflict-free | ||

| Tin | PT Belitung Industri Sejahtera | Undeterminable | ||

| Tin | PT BilliTin Makmur Lestari | Undeterminable | ||

| Tin | PT Bukit Timah | Conflict-free | ||

| Tin | PT DS Jaya Abadi | Conflict-free | ||

| Tin | PT Eunindo Usaha Mandiri | Conflict-free | ||

| Tin | PT Fang Di MulTindo | Undeterminable | ||

| Tin | PT HP Metals Indonesia | Undeterminable | ||

| Tin | Pt Inti Stania Prima | Undeterminable | ||

| Tin | PT Karimun Mining | Undeterminable | ||

17

| Tin | PT Koba Tin | Undeterminable | ||

| Tin | PT Mitra Stania Prima | Undeterminable | ||

| Tin | PT Panca Mega Persada | Undeterminable | ||

| Tin | PT Pelat Timah Nusantara Tbk | Undeterminable | ||

| Tin | PT Prima Timah Utama | Conflict-free | ||

| Tin | PT Rajwa International | Undeterminable | ||

| Tin | PT Refined Banka Tin | Conflict-free | ||

| Tin | PT Sariwiguna Binasentosa | Conflict-free | ||

| Tin | PT Seirama Tin investment | Undeterminable | ||

| Tin | PT Stanindo Inti Perkasa | Conflict-free | ||

| Tin | PT Sumber Jaya Indah | Undeterminable | ||

| Tin | PT Supra Sukses Trinusa | Undeterminable | ||

| Tin | PT Tambang Timah | Conflict-free | ||

| Tin | PT Timah (Persero), Tbk | Conflict-free | ||

| Tin | PT Tinindo Inter Nusa | Undeterminable | ||

| Tin | PT Tommy Utama | Undeterminable | ||

| Tin | PT Yinchendo Mining Industry | Undeterminable | ||

| Tin | Rui Da Hung | Undeterminable | ||

| Tin | Soft Metals Ltda | Undeterminable | ||

| Tin | Thaisarco | Conflict-free | ||

| Tin | White Solder Metalurgia e Mineração Ltda. | Conflict-free | ||

| Tin | Yunnan Chengfeng Non-ferrous Metals Co.,Ltd | Undeterminable | ||

| Tin | Yunnan Tin Company Limited | Conflict-free | ||

| Tungsten | A.L.M.T. Corp. | Undeterminable | ||

| Tungsten | Chenzhou Diamond Tungsten Products Co., Ltd. | Undeterminable | ||

| Tungsten | Chongyi Zhangyuan Tungsten Co Ltd | Undeterminable | ||

| Tungsten | Dayu Weiliang Tungsten Co., Ltd. | Undeterminable | ||

| Tungsten | Fujian Jinxin Tungsten Co., Ltd. | Undeterminable | ||

| Tungsten | Ganxian Shirui New Material Co., Ltd. | Undeterminable | ||

| Tungsten | Ganzhou Huaxing Tungsten Products Co., Ltd. | Conflict-free | ||

| Tungsten | Ganzhou Jiangwu Ferrotungsten Co., Ltd. | Conflict-free | ||

| Tungsten | Ganzhou Nonferrous Metals Smelting Co Ltd. | Undeterminable | ||

| Tungsten | Ganzhou Seadragon W & Mo Co., Ltd. | Conflict-free | ||

| Tungsten | Global Tungsten & Powders Corp. | Conflict-free | ||

| Tungsten | Guangdong Xianglu Tungsten Industry Co., Ltd. | Undeterminable | ||

| Tungsten | H.C. Starck Smelting GmbH & Co.KG | Undeterminable | ||

| Tungsten | HC Starck GmbH | Undeterminable | ||

| Tungsten | Hunan Chenzhou Mining Group Co | Undeterminable | ||

| Tungsten | Hunan Chun-Chang Nonferrous Smelting & Concentrating Co., Ltd. | Conflict-free | ||

| Tungsten | Japan New Metals Co Ltd | Conflict-free | ||

| Tungsten | Jiangxi Gan Bei Tungsten Co., Ltd. | Undeterminable | ||

18

| Tungsten | Jiangxi Minmetals Gao’an Non-ferrous Metals Co., Ltd. | Undeterminable | ||

| Tungsten | Jiangxi Richsea New Materials Co., Ltd. | Undeterminable | ||

| Tungsten | Jiangxi Tonggu Non-ferrous Metallurgical & Chemical Co., Ltd. | Undeterminable | ||

| Tungsten | Jiangxi Xinsheng Tungsten Industry Co., Ltd. | Undeterminable | ||

| Tungsten | Jiangxi Yaosheng Tungsten Co., Ltd. | Undeterminable | ||

| Tungsten | Kennametal Fallon | Undeterminable | ||

| Tungsten | Kennametal Huntsville | Undeterminable | ||

| Tungsten | Malipo Haiyu Tungsten Co., Ltd. | Conflict-free | ||

| Tungsten | Nui Phao H.C. Starck Tungsten Chemicals Manufacturing LLC | Undeterminable | ||

| Tungsten | Tejing (Vietnam) Tungsten Co., Ltd. | Undeterminable | ||

| Tungsten | Vietnam Youngsun Tungsten Industry Co., Ltd | Conflict-free | ||

| Tungsten | Wolfram Bergbau und Hütten AG | Undeterminable | ||

| Tungsten | Wolfram Company CJSC | Undeterminable | ||

| Tungsten | Xiamen Tungsten (H.C.) Co., Ltd. | Conflict-free | ||

| Tungsten | Xiamen Tungsten Co., Ltd | Conflict-free | ||

| Tungsten | Xinhai Rendan Shaoguan Tungsten Co., Ltd. | Undeterminable | ||

Known Countries of origin for the minerals processed by above smelters |

| Angola, Argentina, Australia, Austria, Belgium, Bolivia, Brazil, Burundi, Canada, Central African Republic, Chile, China, Colombia, Côte D’Ivoire, Czech Republic, Djibouti, Egypt, Estonia, Ethiopia, France, Germany, Guyana, Hungary, India, Indonesia, Ireland, Israel, Japan, Kazakhstan, Kenya, Laos, Luxembourg, Madagascar, Malaysia, Mongolia, Mozambique, Myanmar, Namibia, Netherlands, Nigeria, Peru, Portugal, Republic of Congo, Russia, Rwanda, Sierra Leone, Singapore, South Africa, South Sudan, Suriname, Switzerland, Taiwan, Tanzania, Thailand, Uganda, United Kingdom, United States of America, Vietnam, Zambia, Zimbabwe. |

9. Independent private sector audit

We obtained an independent private sector audit of whether the design of our due diligence framework (as described in section 4) conforms to a recognized due diligence framework and whether our description of the due diligence in the Conflict Minerals Reports (as described in section 4) is consistent with the due diligence measures we undertook. This report is set forth in Exhibit A to this report.

10. Data sources used

| • | CFSI Reasonable Country of Origin Inquiry report – version February 28th 2015 |

| • | CMRTs received from priority suppliers until April 2015 |

| • | CFSI smelter reference list, as included in the CMRT – version 3.02 (November 7th, 2014) |

19

11. Abbreviations

Abbreviation | Term | |

| 3TG | Tin, tantalum, tungsten, and gold | |

| CFSI | Conflict Free Sourcing Initiative | |

| CFSP | Conflict Free Smelter Program | |

| CMRT | CFSI Conflict Minerals Reporting Template | |

| EICC | Electronics Industry Citizenship Coalition | |

| Form SD | Specialized Disclosure Form | |

| GeSI | Global e-Sustainability Initiative | |

| OECD | Organization for Economic Cooperation and Development | |

| RCOI | Reasonable Country of Origin Inquiry | |

| SEC | Securities and Exchange Committee | |

| SSD | Supplier Sustainability Declaration | |

Exhibit A

Independent Accountants Report

To the Supervisory Board and Shareholders of Koninklijke Philips N.V.:

We have examined:

| • | whether the design of Koninklijke Philips N.V (the “Company”) due diligence framework as set forth in paragraph “Framework” of section 4 Due diligence framework & measures of the Conflict Minerals Report for the reporting period from January 1 to December 31, 2014, is in conformity, in all material respects, with the criteria set forth in the Organisation of Economic Co-Operation and DevelopmentDue Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, Second Edition 2013 (“OECD Due Diligence Guidance”), and |

| • | whether the Company’s description of the due diligence measures it performed, as set forth in paragraph “Measures” of section 4 Due diligence framework & measures of the Conflict Minerals Report for the reporting period from January 1 to December 31, 2014, is consistent, in all material respects, with the due diligence process that the Company undertook. |

Management is responsible for the design of the Company’s due diligence framework and the description of the Company’s due diligence measures set forth in the Conflict Minerals Report, and performance of the due diligence measures. Our responsibility is to express an opinion on the design of the Company’s due diligence framework and on the description of the due diligence measures the Company performed, based on our examination.

Our examination was conducted in accordance with attestation standards established by the American Institute of Certified Public Accountants and the standards applicable to attestation engagements contained inGovernment Auditing Standards, issued by the Comptroller General of the United States, and, accordingly, included examining, on a test basis, evidence about the design of the Company’s due diligence framework and the description of the due diligence measures the Company performed, and performing such other procedures as we considered necessary in the circumstances. We believe that our examination provides a reasonable basis for our opinion.

20

Our examination was not conducted for the purpose of evaluating:

| • | The consistency of the due diligence measures that the Company performed with either the design of the Company’s due diligence framework or the OECD Due Diligence Guidance; |

| • | The completeness of the Company’s description of the due diligence measures performed; |

| • | The suitability of the design or operating effectiveness of the Company’s due diligence process; |

| • | Whether a third party can determine from the Conflict Minerals Report if the due diligence measures the Company performed are consistent with the OECD Due Diligence Guidance; |

| • | The Company’s reasonable country of origin inquiry (RCOI), including the suitability of the design of the RCOI, its operating effectiveness, or the results thereof; or |

| • | The Company’s conclusions about the source or chain of custody of its conflict minerals, those products subject to due diligence, or the DRC Conflict Free status of its products. |

Accordingly, we do not express an opinion or any other form of assurance on the aforementioned matters or any other matters included in any section of the Conflict Minerals Report other than section 4 Due diligence framework & measures.

In our opinion,

| • | the design of the Company’s due diligence framework with respect to the reporting period from January 1 to December 31, 2014, as set forth in paragraph ���Framework” of section 4 Due diligence framework & measures of the Conflict Minerals Report is in conformity, in all material respects, with the criteria set forth in the OECD Due Diligence Guidance that the Company used, and |

| • | the Company’s description of the due diligence measures it performed as set forth in paragraph “Measures” of section 4 Due diligence framework & measures of the Conflict Minerals Report with respect to the reporting period from January 1 to December 31, 2014, is consistent, in all material respects, with the due diligence process that the Company undertook. |

Amsterdam, The Netherlands

May 12, 2015

/s/ KPMG Accountants N.V.

21