NEWS RELEASE

EL GALLO METALLURGICAL RESULTS

DEMONSTRATE EXCELLENT SILVER RECOVERY

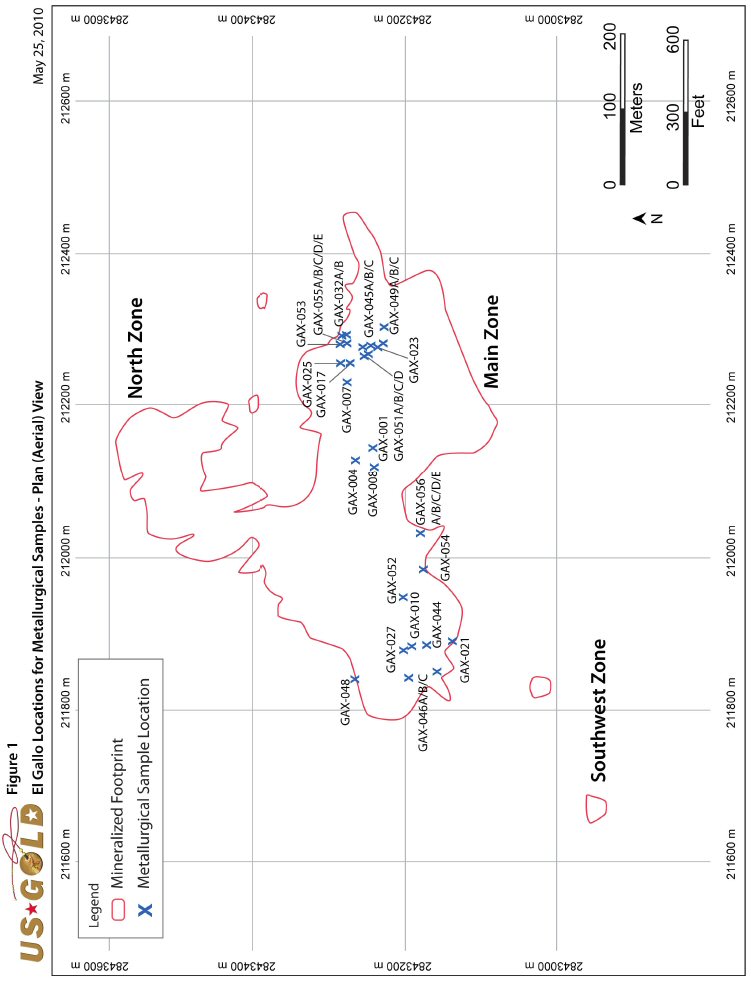

TORONTO, ONTARIO (May 25, 2010) US GOLD CORPORATION (NYSE Amex: UXG) (TSX: UXG) is pleased to announce the results of metallurgical testing at El Gallo that demonstrates excellent silver recovery. Two types of tests were performed 1) bottle rolls tests to establish silver recoveries under a milling scenario, which is the primary process method being considered and 2) column leach tests, a secondary process that is being studied to treat low grade mineralization. The average recovery from the bottle rolls and column tests were 87% and 54%, respectively. These results will be incorporated into El Gallo’s initial resource estimate and Preliminary Economic Assessment.

Tests were supervised by Juvencio Mireles Ortiz, Metallurgy Manager, SGS de México S.A. de C.V. located in Durango, Mexico, along with consultation services provided by Richard Addison, P.E., Principal Process Engineer, Pincock Allen & Holt of Denver, Colorado.

1) BOTTLE ROLL TESTING – MILL PROCESSING

(Table 1)

The objective of the bottle roll tests was to determine potential silver recoveries under a milling scenario and assist with the projects economics. A total of 28 new samples spaced across El Gallo’s Main Zone were collected from HQ-size drill core (2.5 inch or 6.4 cm diameter). To date, 38 bottle roll tests have been completed (Table 3). US Gold is very pleased with these results. Average recovery, grade, sodium cyanide and lime consumption are listed below.

Table 1. Average Recovery 38 Bottle Tests | |

| Calculated | Calculated | Silver | Sodium Cyanide | Lime |

| Head Grade | Head Grade | Recovery | Consumption | Consumption |

| (Silver opt) | (Silver gpt) | (%) | (kg/t) | (kg/t) |

| 25.0 | 855.9 | 87.2 | 2.3 | 5.7 |

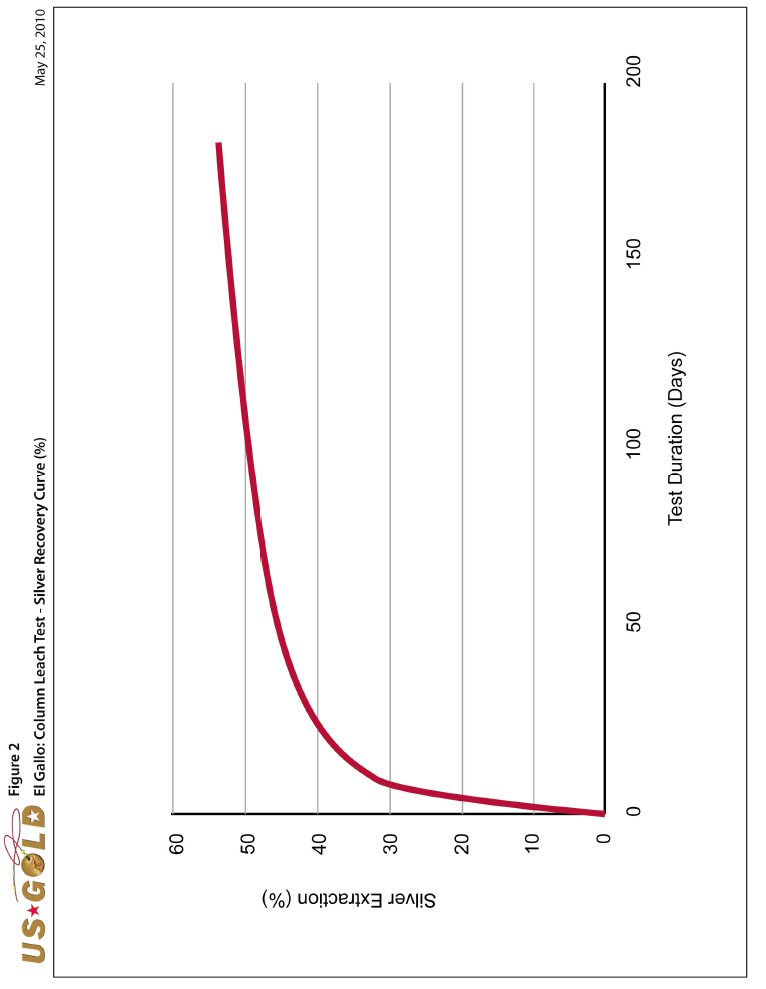

2) COLUMN LEACH TESTING – HEAP LEACH PROCESSING

Metallurgical work also consisted of three column leach tests using samples from HQ-size drill core (2.5 inch or 6.4 cm diameter) with a -¼ inch crush size. US Gold performed these tests to help evaluate the feasibility of mining lower grade mineralization using a heap leach recovery process. Although additional work is required, initial results are encouraging.

The average silver recovery during the 180 day test cycle was 54% with 45% being recovered within the first 30 days (Fig 2). Based on the rate of the recovery when the tests were concluded, US Gold, in consultations with Pincock Allen & Holt, believe the average recovery could reach 60% if the tests were continued for 2 years (Fig 2). The averages from the three columns are listed below.

US Gold – May 25, 2010 News Release

1

Table 2. Average Recovery 3 Column Tests at 180 days | |

| Calculated | Calculated | Silver | Sodium Cyanide | Lime |

| Head Grade | Head Grade | Recovery | Consumption | Consumption |

| (Silver opt) | (Silver gpt) | (%) | (kg/t) | (kg/t) |

| 2.1 | 71.3 | 53.5 | 0.6 | 9.1 |

ABOUT US GOLD (www.usgold.com)

US Gold Corporation is a Colorado incorporated company that explores for gold and silver. It has a strong treasury, no debt and two significant land holdings, one in Nevada next to Barrick Gold's multi-million ounce Cortez project, and the other in Mexico where it has made an exciting high-grade silver discovery and is currently conducting a 330,000 ft (100,000 m) exploration drill program that is expected to provide news throughout the year. US Gold’s goal is to qualify for inclusion in the S&P 500 within the next 5 years. US Gold's shares trade on the NYSE Amex and the Toronto Stock Exchange under the symbol UXG. US Gold has good market liquidity, trading 1.0 million shares daily, and is included in S&P/TSX and Russell indices.

QUALIFIED PERSON

This news release has been viewed and approved by John Read, Consulting Geologist, who is a Qualified Person as defined by National Instrument 43-101 and is responsible for program design and quality control of the metallurgical testing undertaken by the Company at its El Gallo Project.

Samples for bottle roll metallurgical testing were chosen as nominal 3 kg composites of individual adjacent drill samples based on parameters of grade and oxidation characteristics. Samples were taken from either HQ core or bulk rejects from the corresponding core sample intervals. In the case of core composites, entire intervals of core were taken, leaving nominal representative pieces in the core box. For seven of the bottle roll tests, bulk rejects were utilized by compositing the entire reject. Samples for column testing were composed of 120 kg composites of individual HQ drill core samples from low to medium grade intercepts Composites were sent to SGS de Mexico S.A. de C.V. in Durango, Mexico for testing under the direction of Juvencio Mireles Ortiz, Manager of Metallurgy.

Certain statements contained herein and subsequent oral statements made by and on behalf of the Company may contain “forward-looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995. Such forward-looking statements may be identified by words such as “intends,” “anticipates,” “believes,” “expects” and “hopes” and include, without limitation, statements regarding the Company’s results of exploration, plan of business operations, potential contractual arrangements, receipt of working capital, anticipated revenues and related expenditures. Factors that could cause actual results to differ materially include, among others, those set forth in the Company’s Annual Report on Form 10-K for the fiscal year ended December 31, 200 9 and other filings with the Securities and Exchange Commission, under the caption “Risk Factors”. Most of these factors are outside the control of the Company. Investors are cautioned not to put undue reliance on forward-looking statements. Except as otherwise required by applicable securities statutes or regulations, the Company disclaims any intent or obligation to update publicly these forward looking statements, whether as a result of new information, future events or otherwise.

For further information contact: | |

Ian J. BallVP, MexicoTel: (647) 258-0395Toll Free: (866) 441-0690Fax: (647) 258-0408 | Mailing Address99 George Street, 3rd FloorToronto, ON M5A 2N4E-mail: info@usgold.com |

US Gold – May 25, 2010 News Release

2

| Table 3El Gallo Bottle Roll Test Results | May 25, 2010 |

| |

| Phase I | Particle Size | Sodium | Test | Calculated | Calculated | Silver | Sodium | Lime |

| Samples | | Cyanide | Duration | Head Grade | Head Grade | Recovery | Cyanide | Consumption |

| | | Concentration | | | | | Consumption | |

| | | (ppm) | Hours | (Silver opt) | (Silver gpt) | (%) | (kg/t) | (kg/t) |

| GAX001 | 80% passing/-200 mesh | 1500 | 96 | 10.6 | 363 | 96.6 | 2.2 | 13.3 |

| GAX004 | 80% passing/-200 mesh | 750 | 144 | 3.4 | 118 | 95.8 | 1.3 | 8.0 |

| GAX007 | 80% passing/-200 mesh | 750 | 144 | 3.4 | 118 | 97.0 | 1.3 | 5.6 |

| GAX008 | 80% passing/-200 mesh | 1500 | 96 | 39.4 | 1350 | 96.2 | 3.3 | 4.0 |

| GAX010 | 80% passing/-200 mesh | 1000 | 96 | 6.0 | 207 | 85.7 | 1.7 | 11.5 |

| GAX017 | 70% passing/-200 mesh | 1500 | 96 | 11.3 | 389 | 88.2 | 1.6 | 4.9 |

| GAX021 | 70% passing/-200 mesh | 750 | 96 | 18.9 | 649 | 88.2 | 1.4 | 3.6 |

| GAX027 | 80% passing/-200 mesh | 750 | 96 | 2.6 | 89 | 94.5 | 1.3 | 7.2 |

| GAX032-A | 80% passing/-200 mesh | 1500 | 96 | 7.8 | 266 | 83.9 | 1.8 | 11.2 |

| GAX032-B | 80% passing/-200 mesh | 1500 | 96 | 10.1 | 346 | 77.8 | 1.9 | 11.6 |

| Phase II | Particle Size | Sodium | Test | Calculated | Calculated | Silver | Sodium | Lime |

| Samples | | Cyanide | Duration | Grade Head | Head Grade | Recovery | Cyanide | Consumption |

| | | Concentration | | | | | Consumption | |

| | | (ppm) | Hours | (Silver opt) | (Silver gpt) | (%) | (kg/t) | (kg/t) |

| GAX044 | 80% passing/-200 mesh | 1000 | 144 | 2.6 | 90 | 86.4 | 0.90 | 3.30 |

| GAX045-A | 80% passing/-200 mesh | 1000 | 144 | 14.7 | 505 | 90.1 | 1.50 | 3.87 |

| GAX045-B | 80% passing/-200 mesh | 1000 | 144 | 53.7 | 1842 | 92.1 | 3.30 | 2.97 |

| GAX045-C | 80% passing/-200 mesh | 1000 | 144 | 12.4 | 425 | 88.5 | 1.70 | 3.87 |

| GAX046-A | 80% passing/-200 mesh | 1000 | 144 | 3.0 | 103 | 79.3 | 0.7 | 11.50 |

| GAX046-B | 80% passing/-200 mesh | 1000 | 144 | 1.5 | 51 | 86.3 | 0.97 | 4.37 |

| GAX046-C* | 80% passing/-200 mesh | 5000 | 144 | 320.6 | 10991 | 95.9 | 16.60 | 2.20 |

| GAX048 | 80% passing/-200 mesh | 1000 | 144 | 1.5 | 53 | 80.6 | 0.70 | 17.40 |

| GAX049-A | 80% passing/-200 mesh | 1000 | 144 | 1.7 | 58 | 91.1 | 1.42 | 3.31 |

| GAX049-B | 80% passing/-200 mesh | 1000 | 144 | 2.4 | 82 | 75.0 | 1.43 | 3.17 |

| GAX049-C | 80% passing/-200 mesh | 1000 | 144 | 8.5 | 291 | 91.6 | 1.53 | 3.73 |

| GAX051-A | 80% passing/-200 mesh | 1000 | 144 | 16.7 | 572 | 74.8 | 1.87 | 3.34 |

| GAX051-B | 80% passing/-200 mesh | 1000 | 144 | 9.8 | 335 | 60.9 | 1.62 | 4.94 |

| GAX051-C | 80% passing/-200 mesh | 1000 | 144 | 1.8 | 62 | 90.0 | 1.25 | 2.95 |

| GAX051-D | 80% passing/-200 mesh | 1000 | 144 | 1.9 | 64 | 90.3 | 1.32 | 3.39 |

| GAX052 | 80% passing/-200 mesh | 1000 | 144 | 13.1 | 448 | 78.4 | 2.27 | 4.17 |

| GAX053 | 80% passing/-200 mesh | 1000 | 144 | 0.8 | 26 | 92.1 | 1.17 | 4.56 |

| GAX054 | 80% passing/-200 mesh | 1000 | 144 | 1.5 | 50 | 86.5 | 1.37 | 3.95 |

| GAX055-A | 80% passing/-200 mesh | 1000 | 144 | 1.9 | 65 | 89.8 | 1.00 | 8.07 |

| GAX055-B | 80% passing/-200 mesh | 1000 | 144 | 84.4 | 2893 | 85.8 | 5.72 | 1.84 |

| GAX055-C | 80% passing/-200 mesh | 1000 | 144 | 71.8 | 2462 | 73.1 | 4.97 | 1.82 |

| GAX055-D | 80% passing/-200 mesh | 1000 | 144 | 34.3 | 1175 | 80.1 | 2.25 | 2.52 |

| GAX055-E | 80% passing/-200 mesh | 1000 | 144 | 3.5 | 120 | 95.5 | 1.08 | 3.39 |

| GAX-56-A | 80% passing/-200 mesh | 1000 | 144 | 5.3 | 180 | 93.6 | 0.95 | 6.06 |

| GAX056-B | 80% passing/-200 mesh | 1000 | 144 | 3.3 | 113 | 91.2 | 0.82 | 9.44 |

| GAX056-C | 80% passing/-200 mesh | 1000 | 144 | 7.1 | 245 | 84.7 | 1.17 | 8.95 |

| GAX056-D | 80% passing/-200 mesh | 1000 | 144 | 44.1 | 1511 | 93.1 | 3.45 | 2.52 |

| GAX056-E | 80% passing/-200 mesh | 1000 | 144 | 111.4 | 3818 | 93.2 | 8.17 | 2.52 |

| Average | | | | 25.0 | 855.9 | 87.2 | 2.3 | 5.7 |

| * Aggressive leaching conditions because of extreme high grade. | | | | | |

US Gold - May 25, 2010 News Release

3