Scotia Howard Weil 2018 Energy Conference March 2018 Robert Drummond President and Chief Executive Officer Exhibit 99.1

Safe-Harbor Language This presentation contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Statements that are not historical in nature or that relate to future events and conditions are, or may be deemed to be, forward-looking statements. These statements are only predictions and are subject to substantial risks and uncertainties and are not guarantees of performance. Future actions, events and conditions and future results of operations may differ materially from those expressed in these statements. Often, but not always, “forward-looking statements” are identified by words such as “expects,” “believes,” “anticipates” and similar phrases. Important factors that may affect Key’s expectations, estimates or projections include, but are not limited to, the following: conditions in the oil and natural gas industry, especially oil and natural gas prices and capital expenditures by oil and natural gas companies; volatility in oil and natural gas prices; Key’s ability to implement price increases or maintain pricing on its core services; risks that Key may not be able to reduce, and could even experience increases in, the costs of labor, fuel, equipment and supplies employed in Key’s businesses; industry capacity; asset impairments or other charges; the periodic low demand for Key’s services and resulting operating losses and negative cash flows; Key’s highly competitive industry as well as operating risks, which are primarily self-insured, and the possibility that its insurance may not be adequate to cover all of its losses or liabilities; significant costs and potential liabilities resulting from compliance with applicable laws, including those resulting from environmental, health and safety laws and regulations, specifically those relating to hydraulic fracturing, as well as climate change legislation or initiatives; Key’s historically high employee turnover rate and its ability to replace or add workers, including executive officers and skilled workers; Key’s ability to incur debt or long-term lease obligations; Key’s ability to implement technological developments and enhancements; severe weather impacts on Key’s business, including from hurricane activity; Key’s ability to successfully identify, make and integrate acquisitions and its ability to finance future growth of its operations or future acquisitions; Key’s ability to achieve the benefits expected from disposition transactions; the loss of one or more of Key’s larger customers; Key’s ability to generate sufficient cash flow to meet debt service obligations; the amount of Key’s debt and the limitations imposed by the covenants in the agreements governing its debt, including its ability to comply with covenants under its debt agreements; an increase in Key’s debt service obligations due to variable rate indebtedness; Key’s inability to achieve its financial, capital expenditure and operational projections, including quarterly and annual projections of revenue and/or operating income and its inaccurate assessment of future activity levels, customer demand, and pricing stability which may not materialize (whether for Key as a whole or for geographic regions and/or business segments individually); Key’s ability to respond to changing or declining market conditions, including Key’s ability to reduce the costs of labor, fuel, equipment and supplies employed and used in its businesses; Key’s ability to maintain sufficient liquidity; adverse impact of litigation; and other factors affecting Key’s business described in “Item 1A. Risk Factors” in its most recent Annual Report on Form 10-K, recent Quarterly Reports on Form 10 Q, recent Current Reports on Form K and its other filings with the SEC. Given these risks and uncertainties, readers are cautioned not to place undue reliance on forward-looking statements. Unless otherwise required by law, Key disclaims any obligation to update its forward-looking statements.

Q1 2018 Update First quarter 2018 consolidated revenues expected to increase 5 to 7 percent from fourth quarter 2018 US Rig Services revenues expected to increase 5 to 7 percent from fourth quarter 2018 Coiled Tubing Services revenues expected to increase 20 to 25 percent from fourth quarter 2018 The Company expects first quarter 2018 Adjusted EBITDA margins to be impacted by 200 to 250 bps due to employment taxes, as compared to the fourth quarter of 2017, along with anticipated and additional start-up costs and inefficiencies during the first two months of the quarter Additional start-up costs are expected to offset the incremental margin from higher than expected revenues in the first quarter of 2018 The Company expects high-single-to-double-digit Adjusted EBITDA margins in the second quarter of 2018, driven by realized price increases in the first quarter of 2018 and reduction in start-up inefficiencies Included in the Company’s planned $30 to $35 million of 2018 capital expenditures: The Company will add an additional 2 5/8” coiled tubing unit in the second quarter of 2018 bringing its total large diameter coiled tubing fleet to 14 units The Company will be assembling 8 additional Class 5 well service rigs from exiting component inventories at less than half of current new build cash outlay The Company expects its liquidity to be approximately $75 million at the end of the first quarter of 2018 due to the timing of certain annual payments, then improving over the balance of 2018

Company Overview

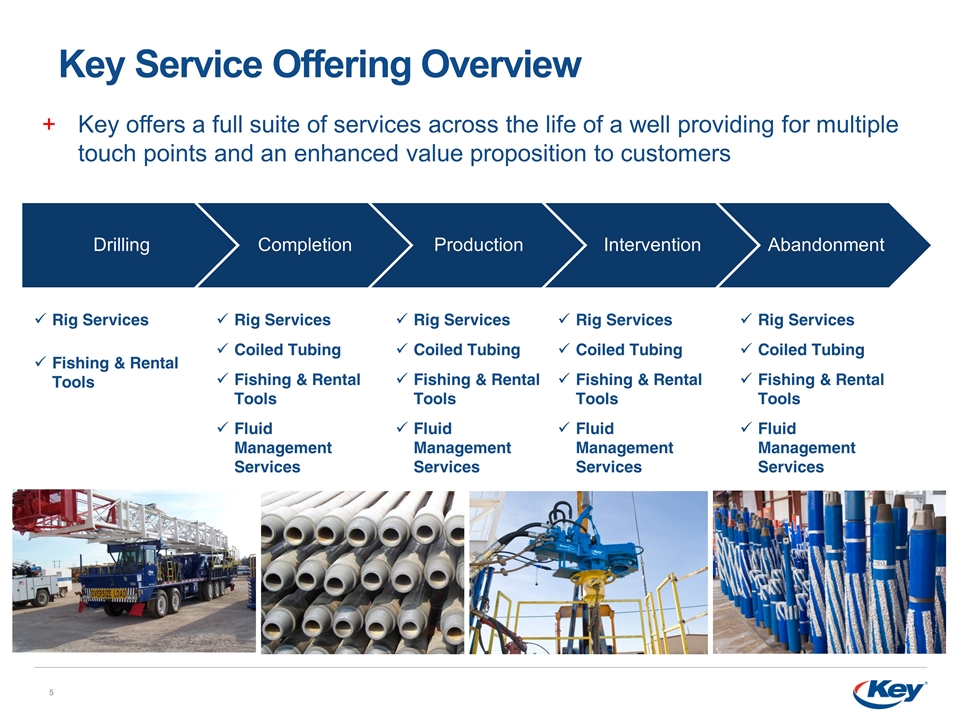

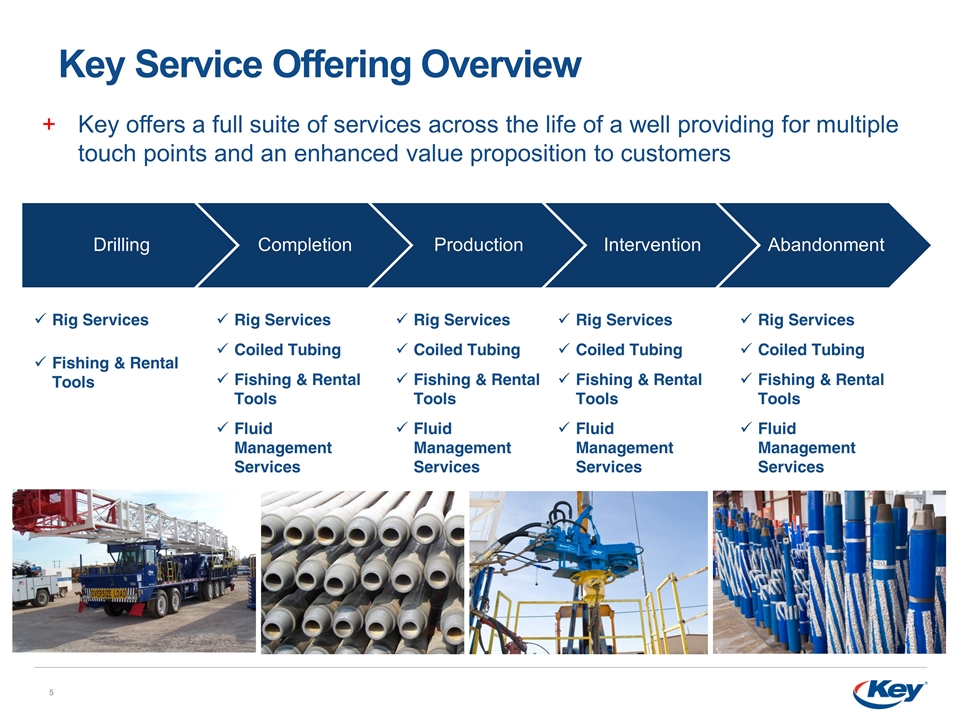

Key Service Offering Overview Rig Services Fishing & Rental Tools Rig Services Coiled Tubing Fishing & Rental Tools Fluid Management Services Rig Services Coiled Tubing Fishing & Rental Tools Fluid Management Services Rig Services Coiled Tubing Fishing & Rental Tools Fluid Management Services Rig Services Coiled Tubing Fishing & Rental Tools Fluid Management Services Key offers a full suite of services across the life of a well providing for multiple touch points and an enhanced value proposition to customers Drilling Completion Production Intervention Abandonment

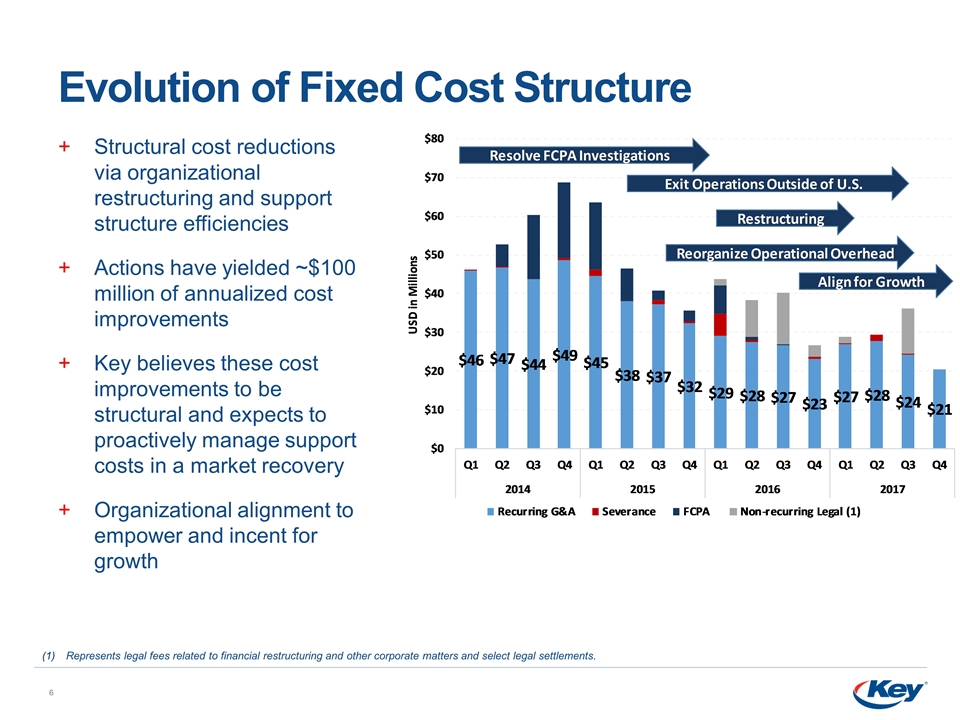

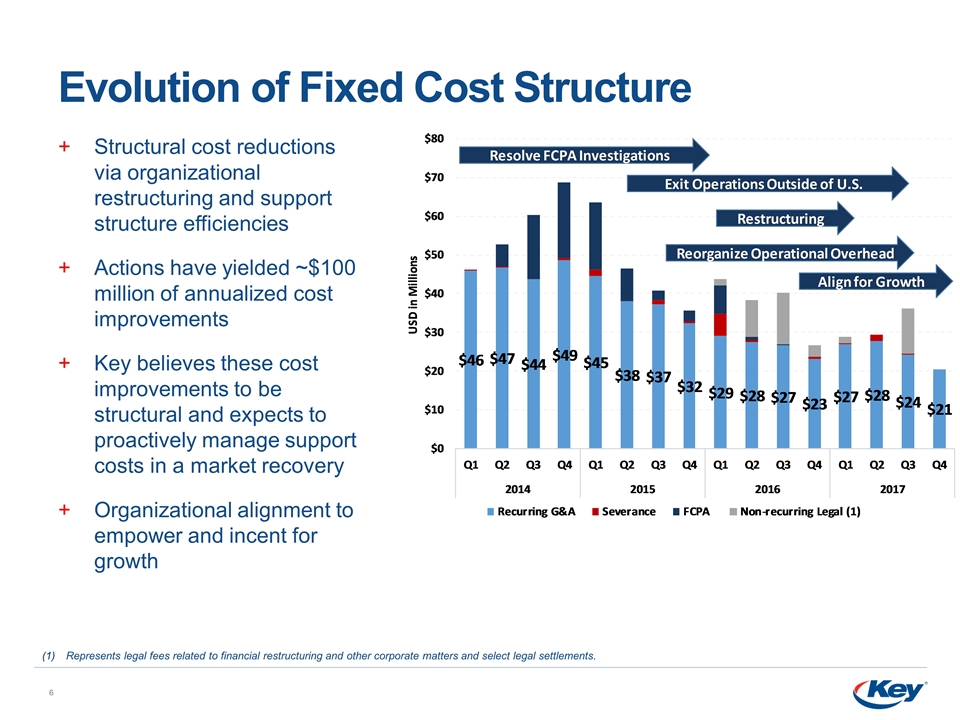

Evolution of Fixed Cost Structure Structural cost reductions via organizational restructuring and support structure efficiencies Actions have yielded ~$100 million of annualized cost improvements Key believes these cost improvements to be structural and expects to proactively manage support costs in a market recovery Organizational alignment to empower and incent for growth Represents legal fees related to financial restructuring and other corporate matters and select legal settlements.

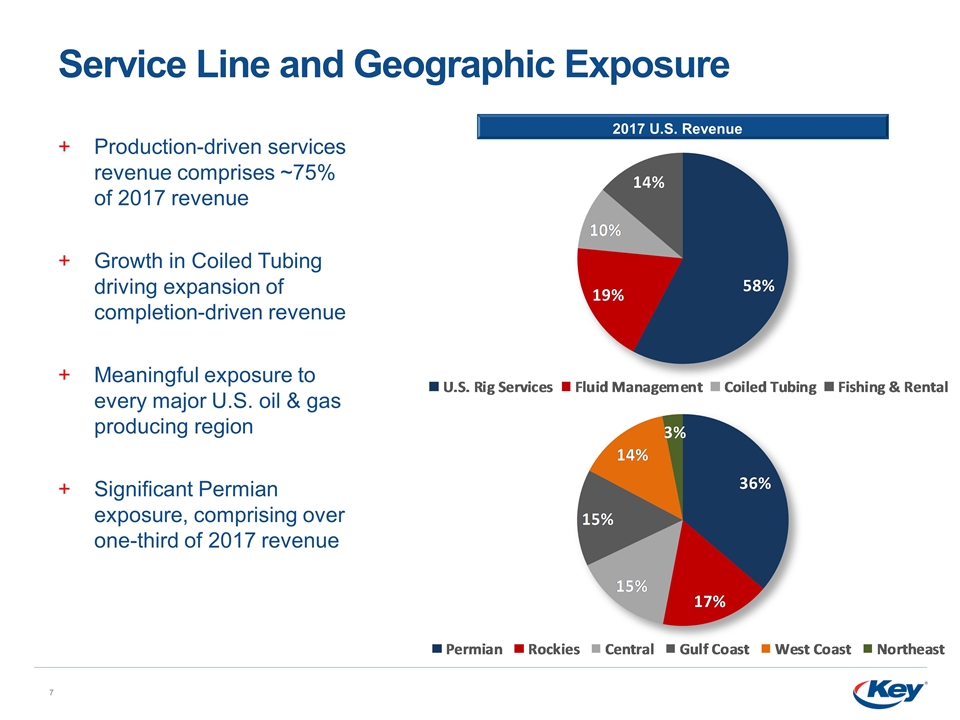

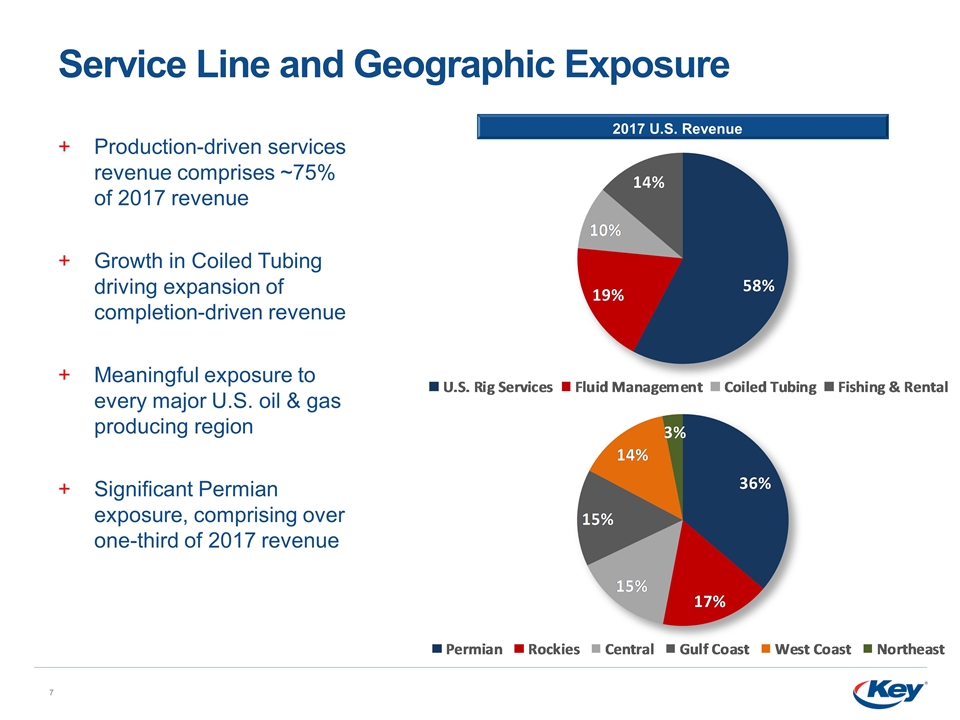

Service Line and Geographic Exposure Production-driven services revenue comprises ~75% of 2017 revenue Growth in Coiled Tubing driving expansion of completion-driven revenue Meaningful exposure to every major U.S. oil & gas producing region Significant Permian exposure, comprising over one-third of 2017 revenue 2017 U.S. Revenue

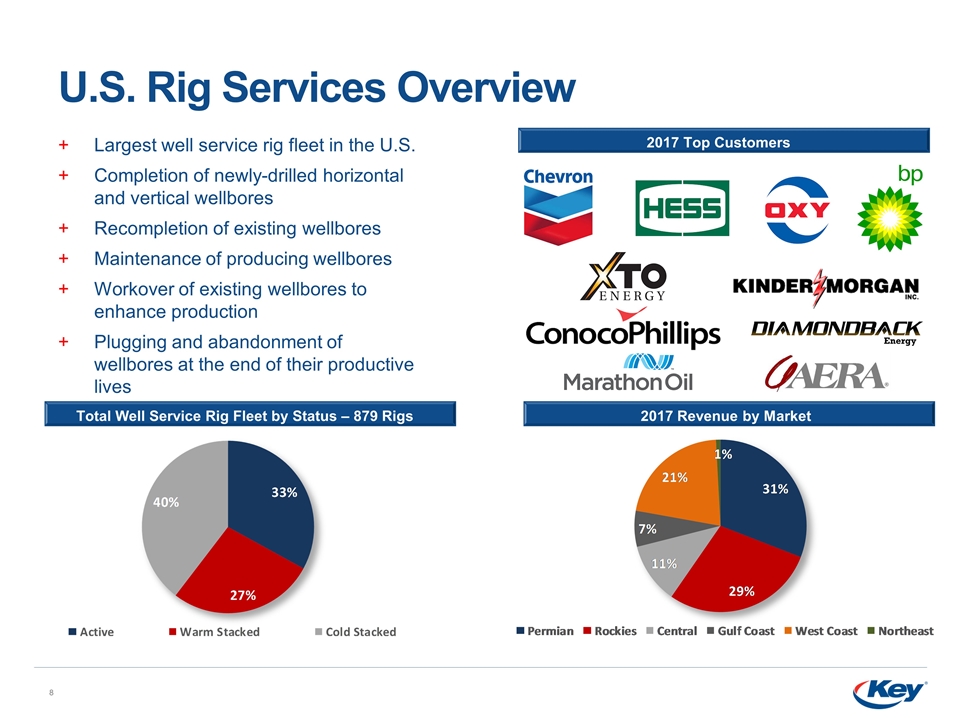

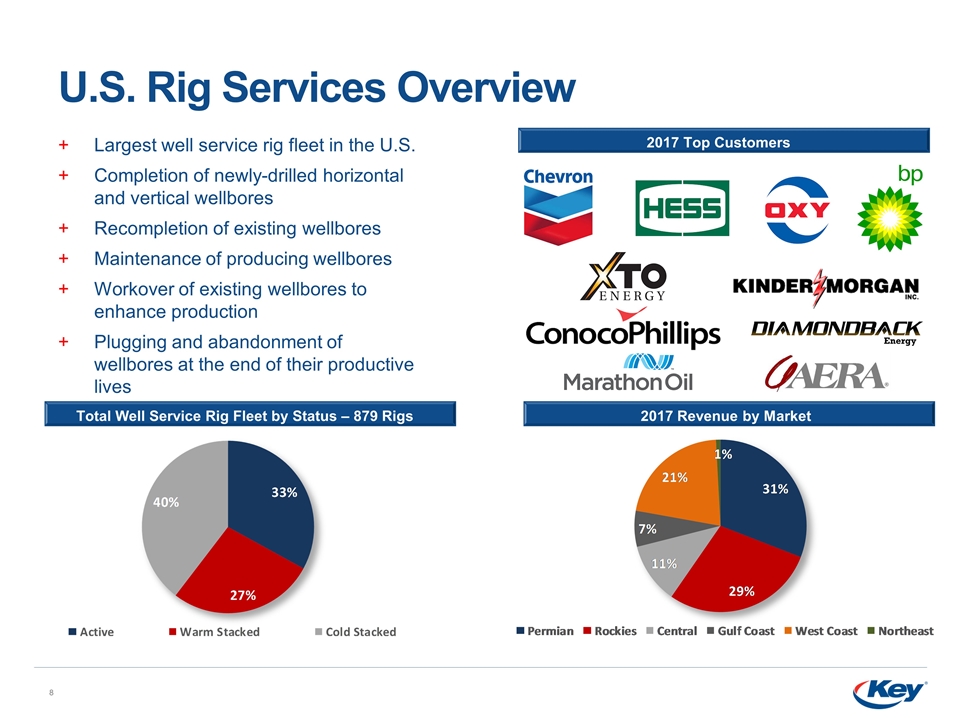

U.S. Rig Services Overview Largest well service rig fleet in the U.S. Completion of newly-drilled horizontal and vertical wellbores Recompletion of existing wellbores Maintenance of producing wellbores Workover of existing wellbores to enhance production Plugging and abandonment of wellbores at the end of their productive lives 2017 Top Customers 2017 Revenue by Market Total Well Service Rig Fleet by Status – 879 Rigs

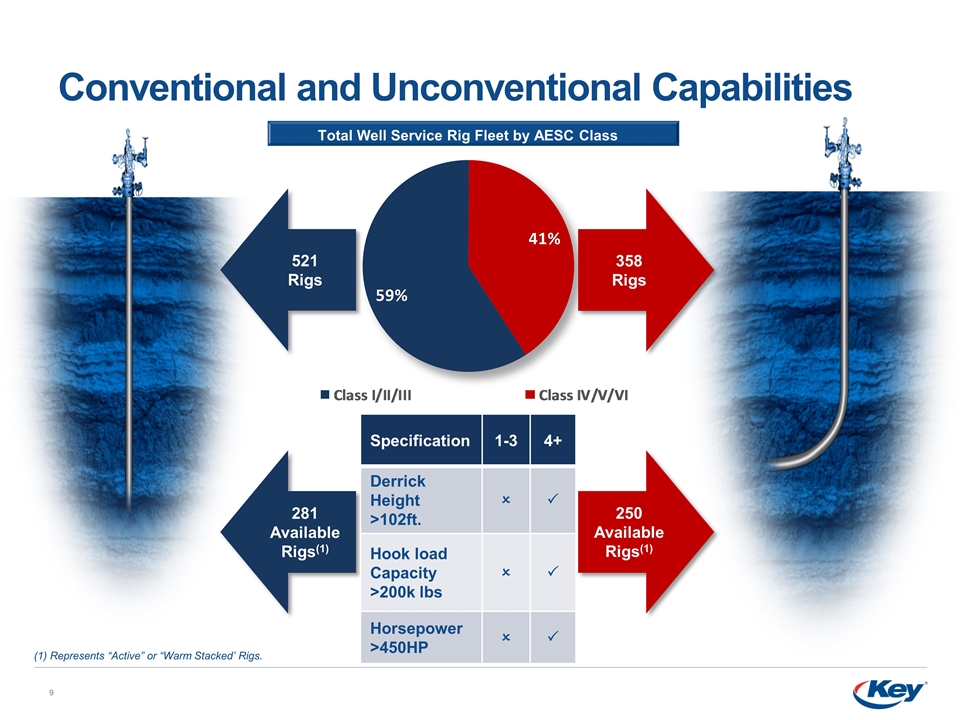

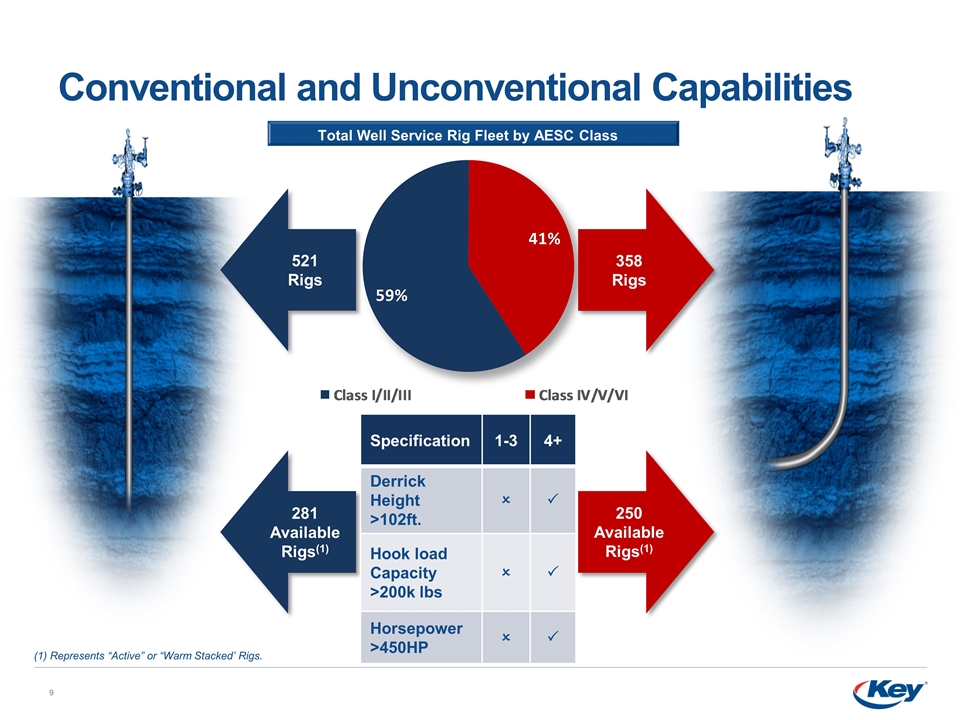

Conventional and Unconventional Capabilities (1) Represents “Active” or “Warm Stacked’ Rigs. 358 Rigs 521 Rigs 250 Available Rigs(1) 281 Available Rigs(1) Specification 1-3 4+ Derrick Height >102ft. O P Hook load Capacity >200k lbs O P Horsepower >450HP O P Total Well Service Rig Fleet by AESC Class

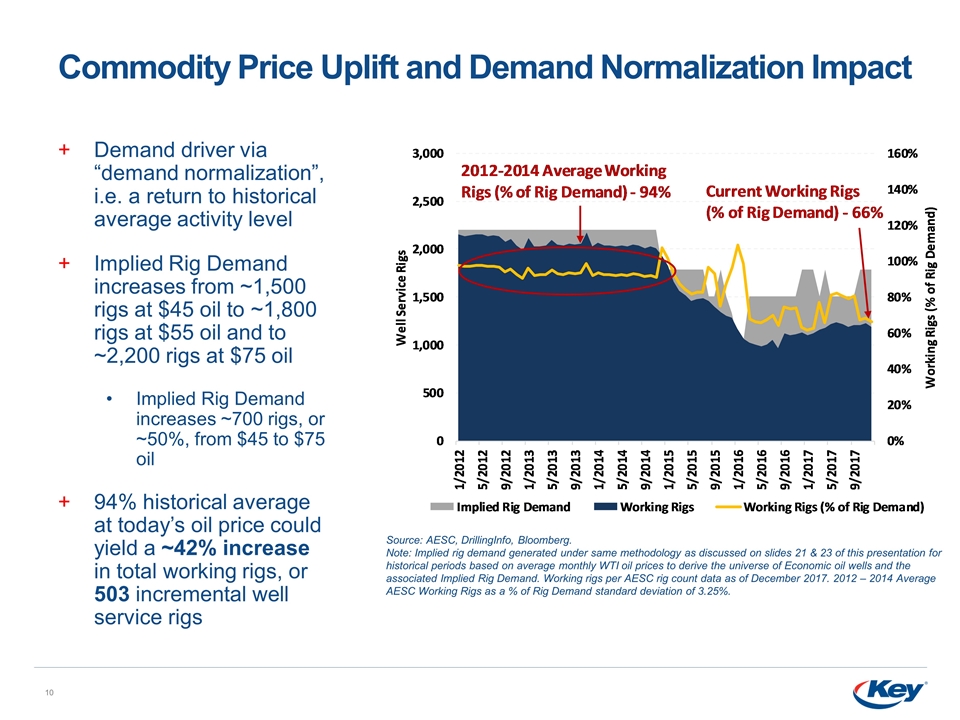

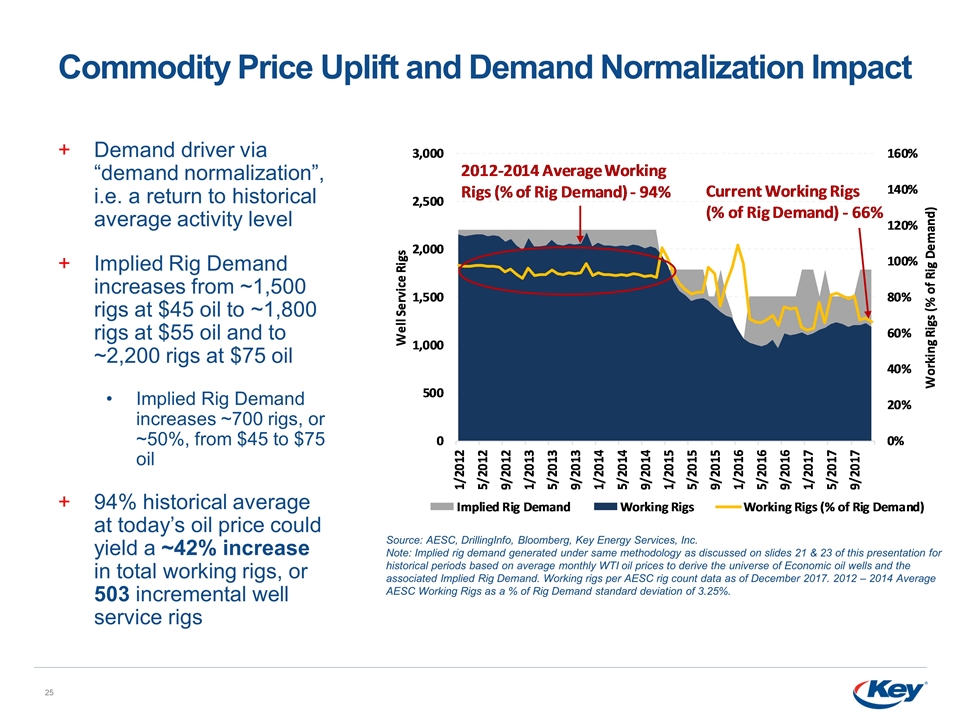

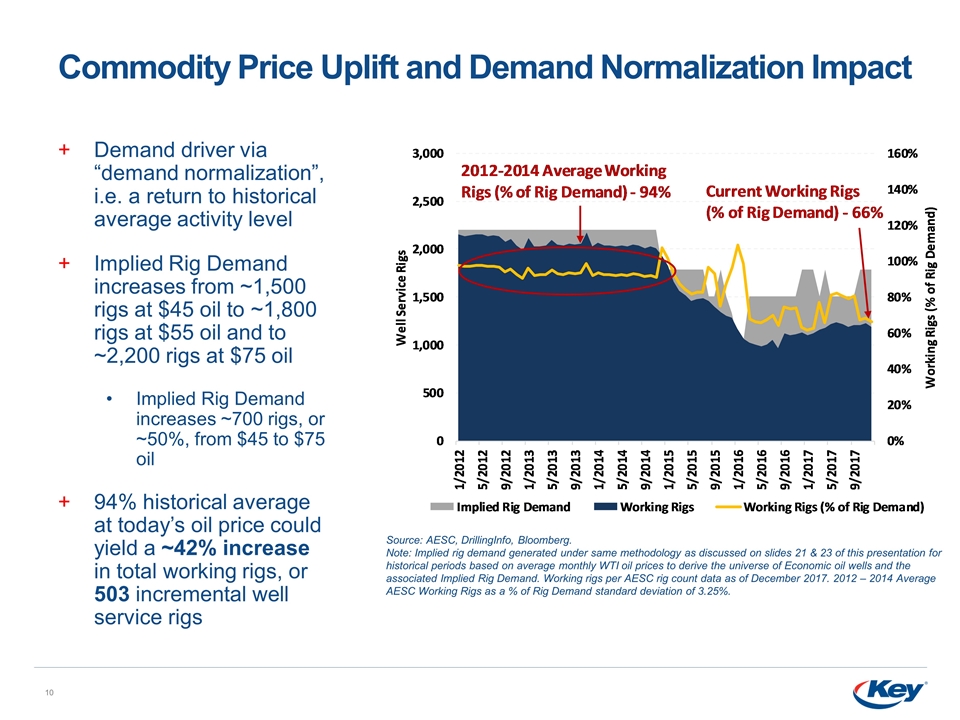

Commodity Price Uplift and Demand Normalization Impact Demand driver via “demand normalization”, i.e. a return to historical average activity level Implied Rig Demand increases from ~1,500 rigs at $45 oil to ~1,800 rigs at $55 oil and to ~2,200 rigs at $75 oil Implied Rig Demand increases ~700 rigs, or ~50%, from $45 to $75 oil 94% historical average at today’s oil price could yield a ~42% increase in total working rigs, or 503 incremental well service rigs Source: AESC, DrillingInfo, Bloomberg. Note: Implied rig demand generated under same methodology as discussed on slides 21 & 23 of this presentation for historical periods based on average monthly WTI oil prices to derive the universe of Economic oil wells and the associated Implied Rig Demand. Working rigs per AESC rig count data as of December 2017. 2012 – 2014 Average AESC Working Rigs as a % of Rig Demand standard deviation of 3.25%.

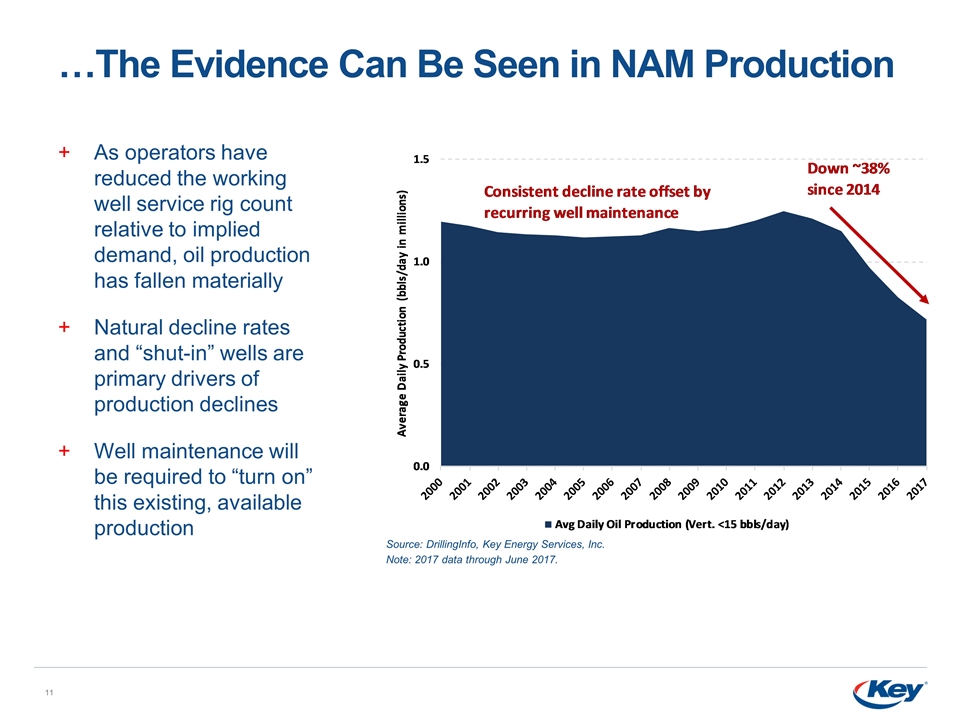

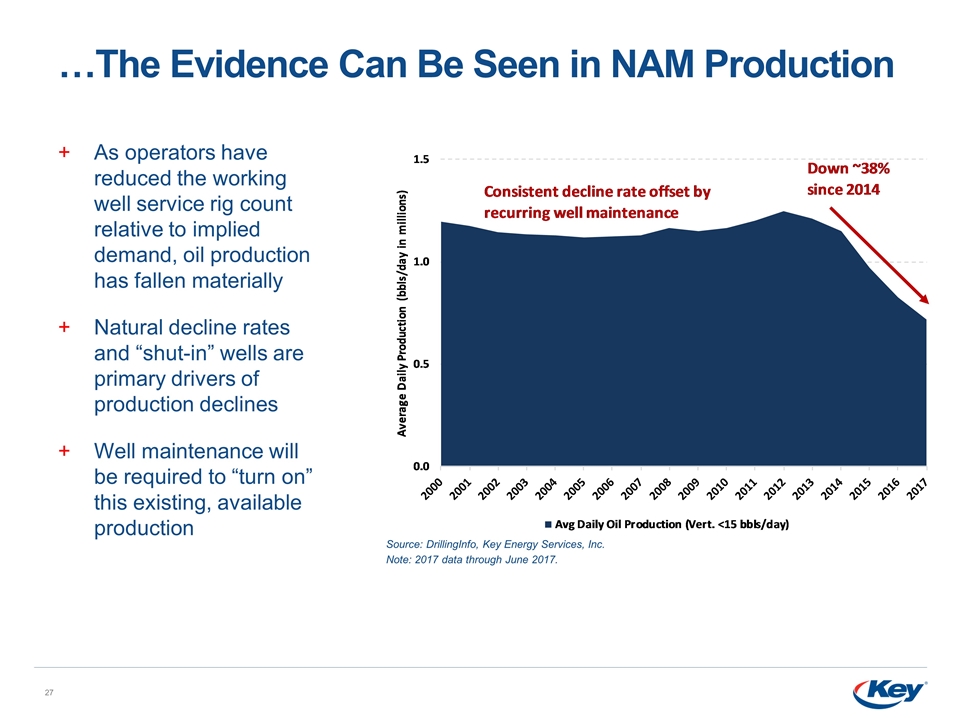

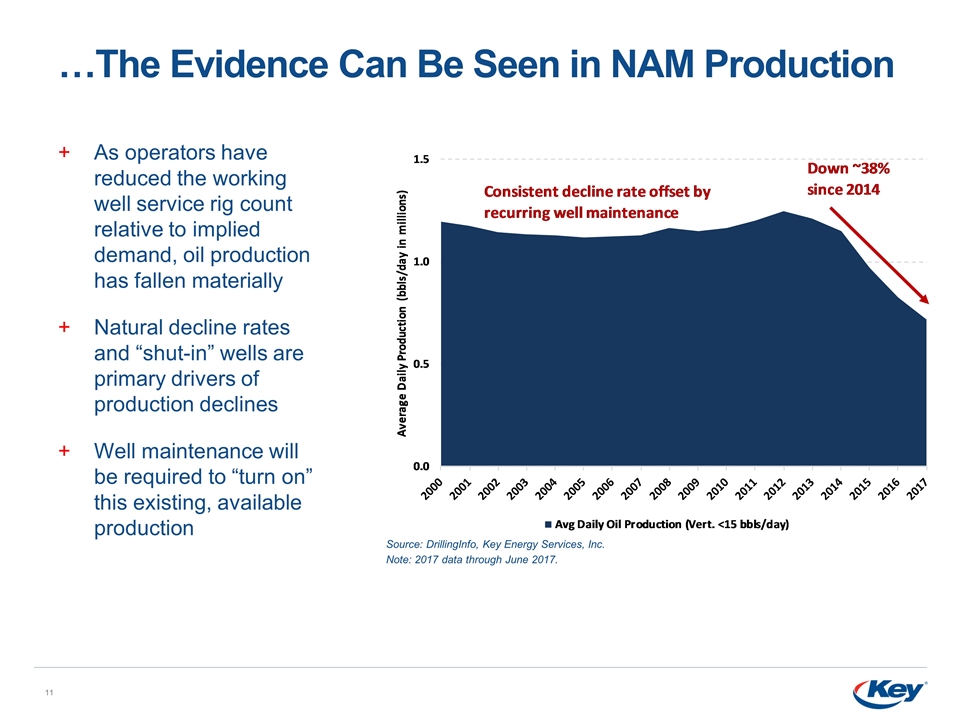

…The Evidence Can Be Seen in NAM Production Source: DrillingInfo, Key Energy Services, Inc. Note: 2017 data through June 2017. As operators have reduced the working well service rig count relative to implied demand, oil production has fallen materially Natural decline rates and “shut-in” wells are primary drivers of production declines Well maintenance will be required to “turn on” this existing, available production

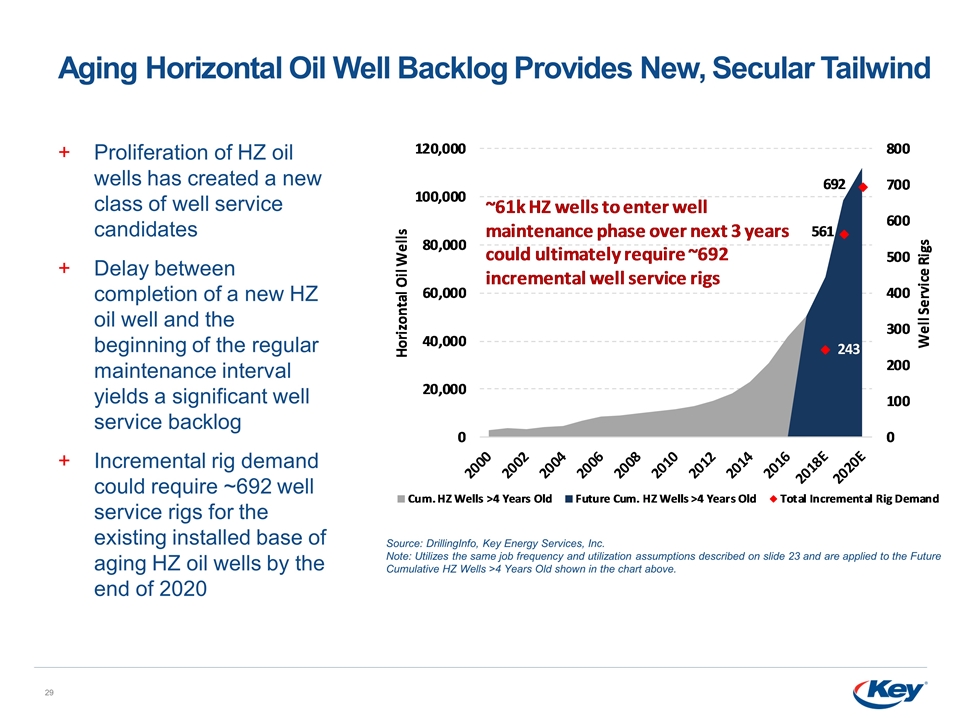

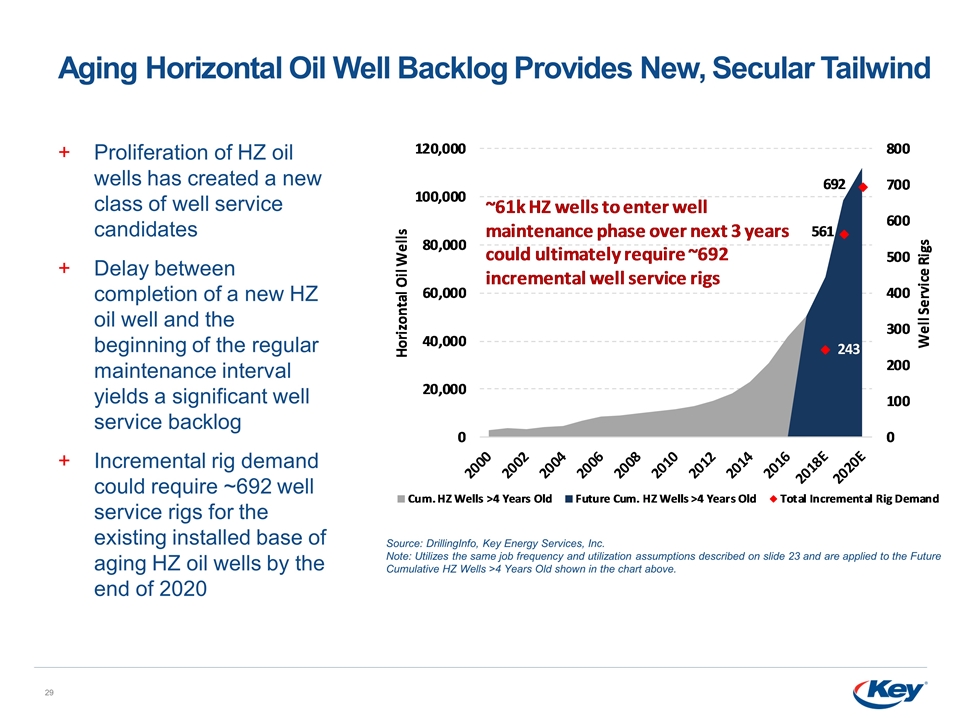

Aging Horizontal Oil Well Backlog Provides New, Secular Tailwind Source: DrillingInfo. Note: Utilizes the same job frequency and utilization assumptions described on slide 23 and are applied to the Future Cumulative HZ Wells >4 Years Old shown in the chart above. Proliferation of HZ oil wells has created a new class of well service candidates Delay between completion of a new HZ oil well and the beginning of the regular maintenance interval yields a significant well service backlog Incremental rig demand could require ~692 well service rigs for the existing installed base of aging HZ oil wells by the end of 2020

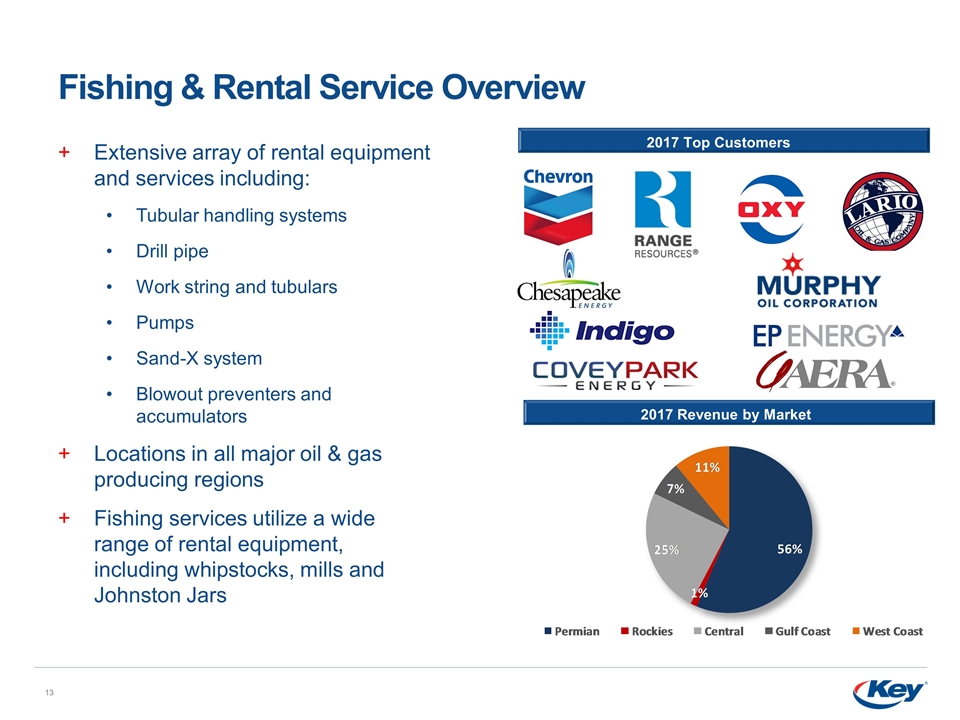

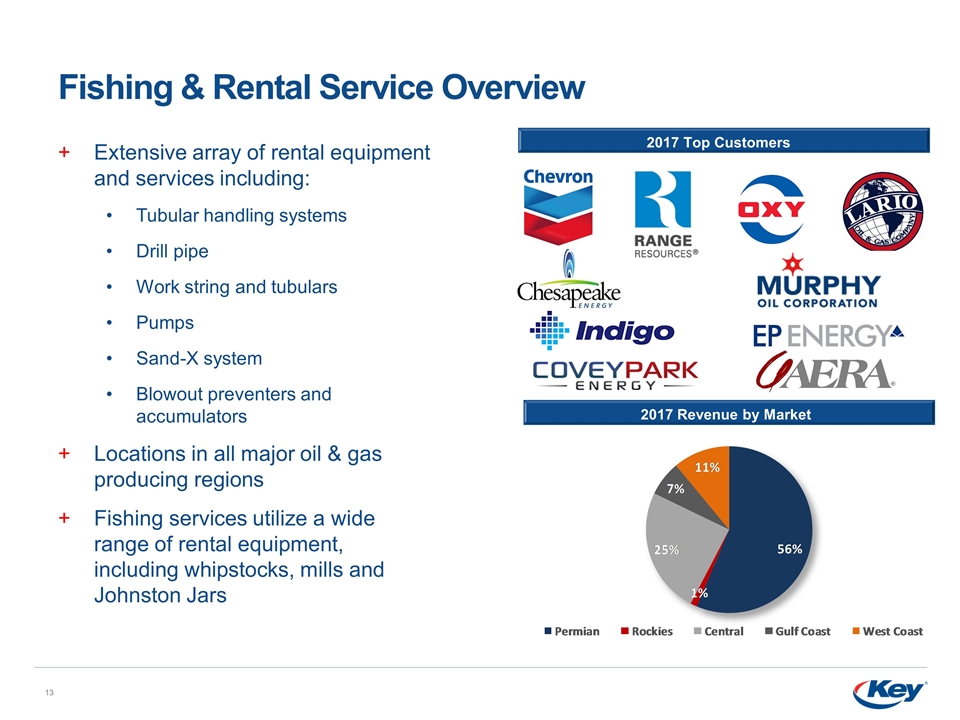

Fishing & Rental Service Overview Extensive array of rental equipment and services including: Tubular handling systems Drill pipe Work string and tubulars Pumps Sand-X system Blowout preventers and accumulators Locations in all major oil & gas producing regions Fishing services utilize a wide range of rental equipment, including whipstocks, mills and Johnston Jars 2017 Top Customers 2017 Revenue by Market

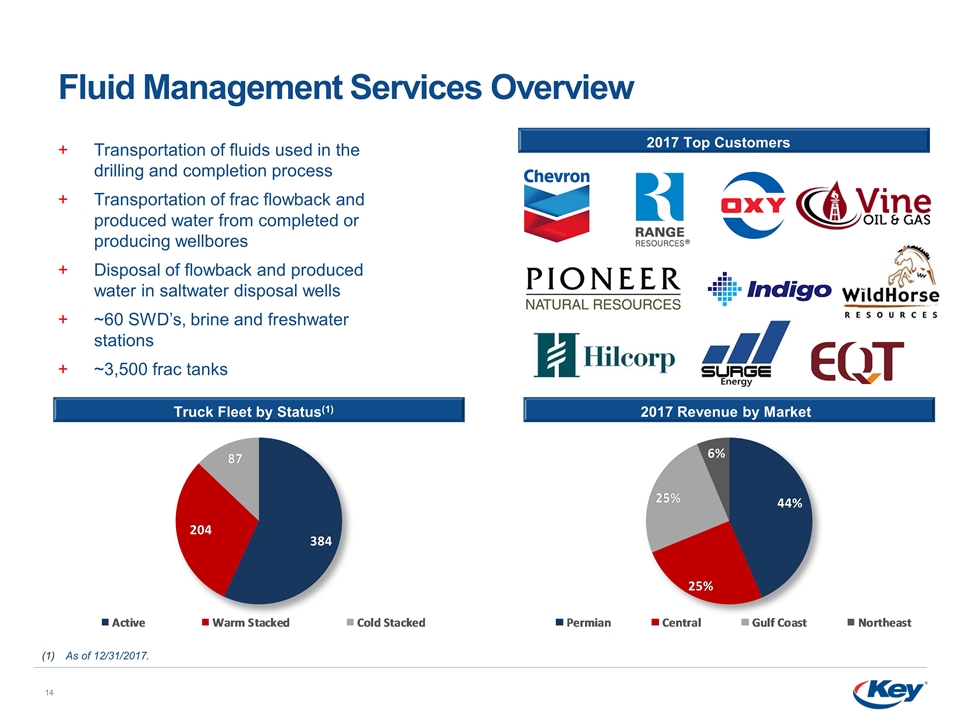

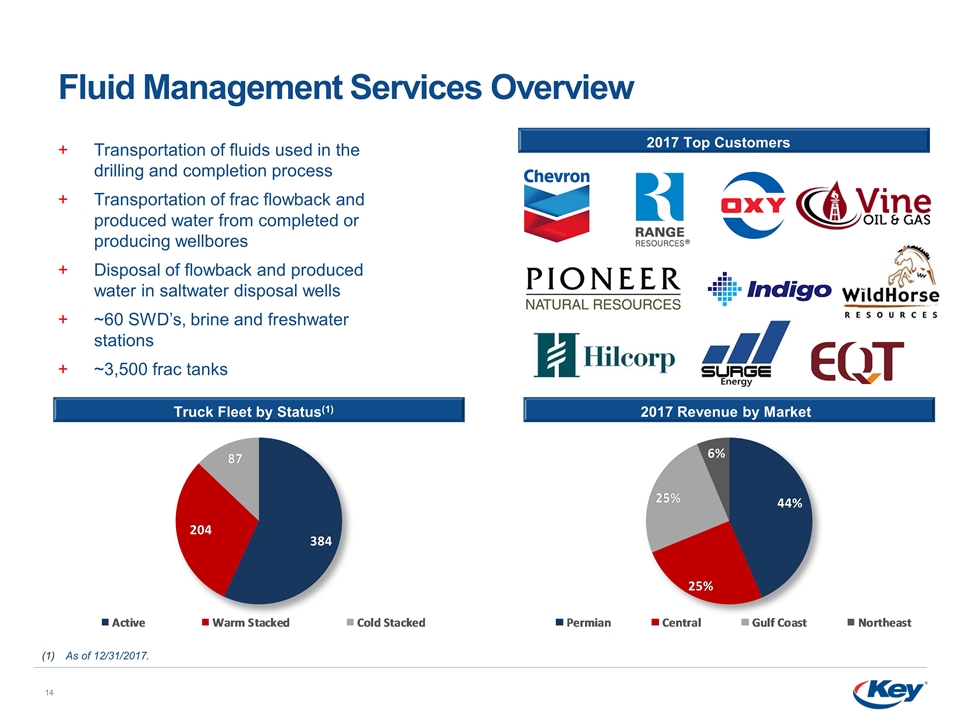

Fluid Management Services Overview Transportation of fluids used in the drilling and completion process Transportation of frac flowback and produced water from completed or producing wellbores Disposal of flowback and produced water in saltwater disposal wells ~60 SWD’s, brine and freshwater stations ~3,500 frac tanks 2017 Top Customers 2017 Revenue by Market As of 12/31/2017. Truck Fleet by Status(1)

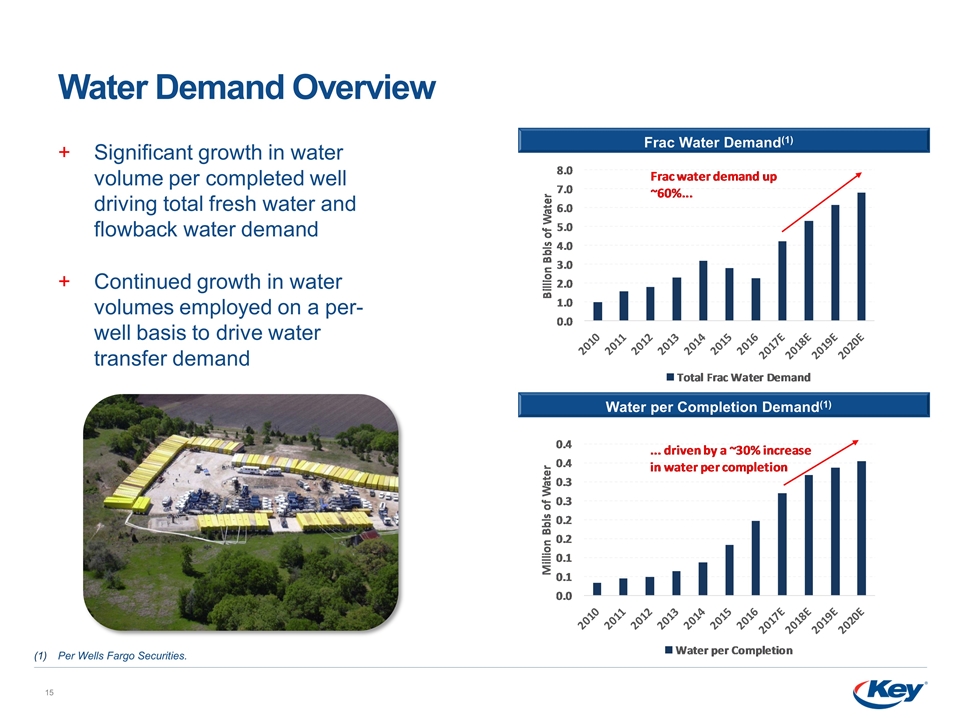

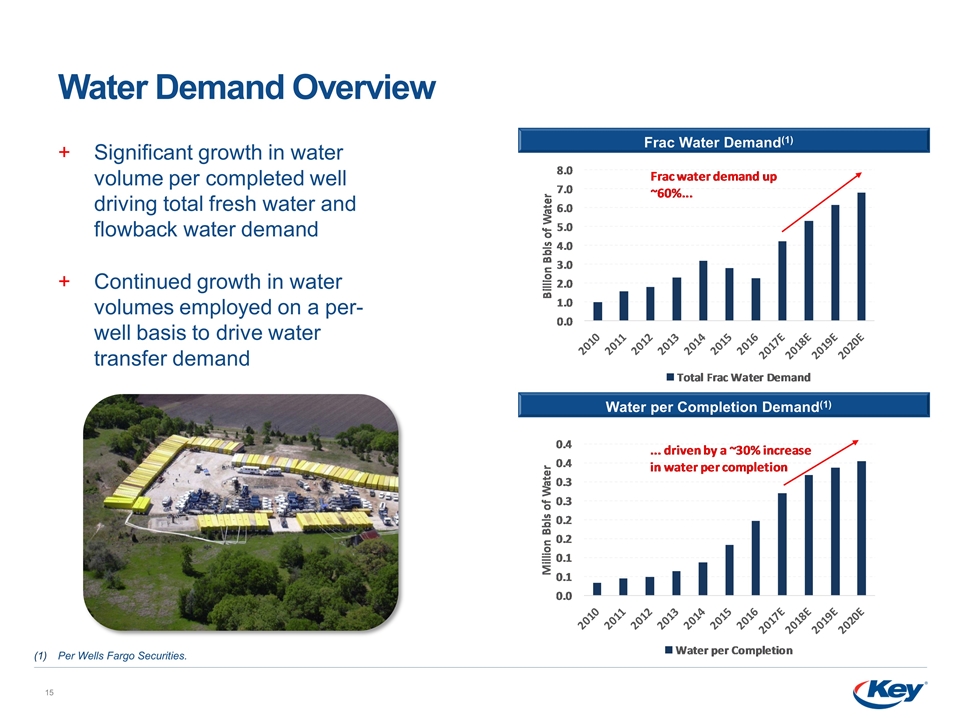

Water Demand Overview Significant growth in water volume per completed well driving total fresh water and flowback water demand Continued growth in water volumes employed on a per-well basis to drive water transfer demand Frac Water Demand(1) Per Wells Fargo Securities. Water per Completion Demand(1)

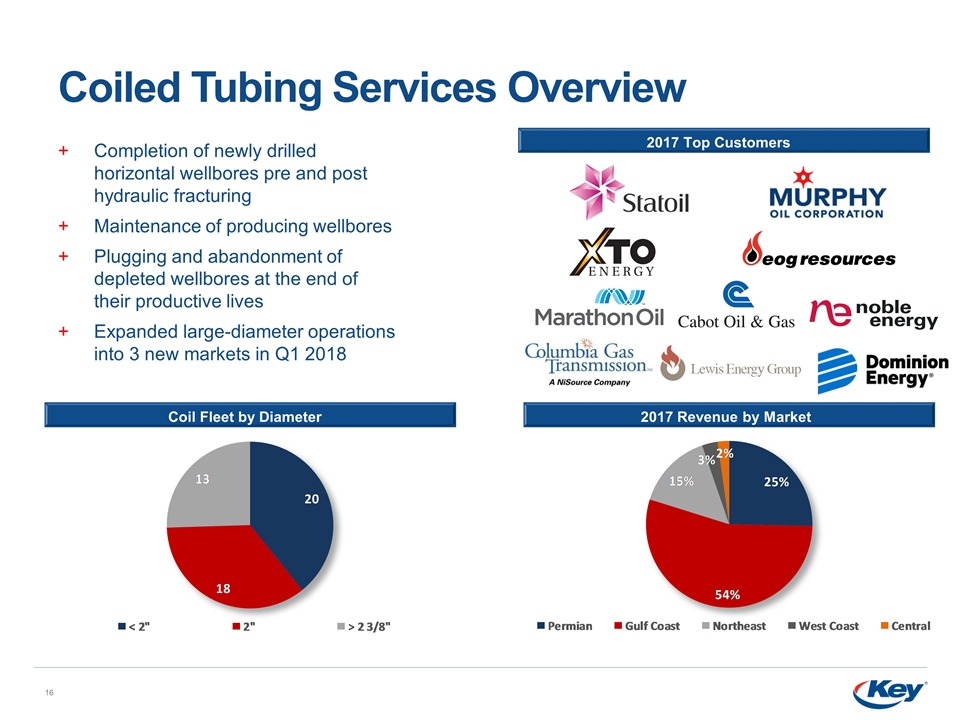

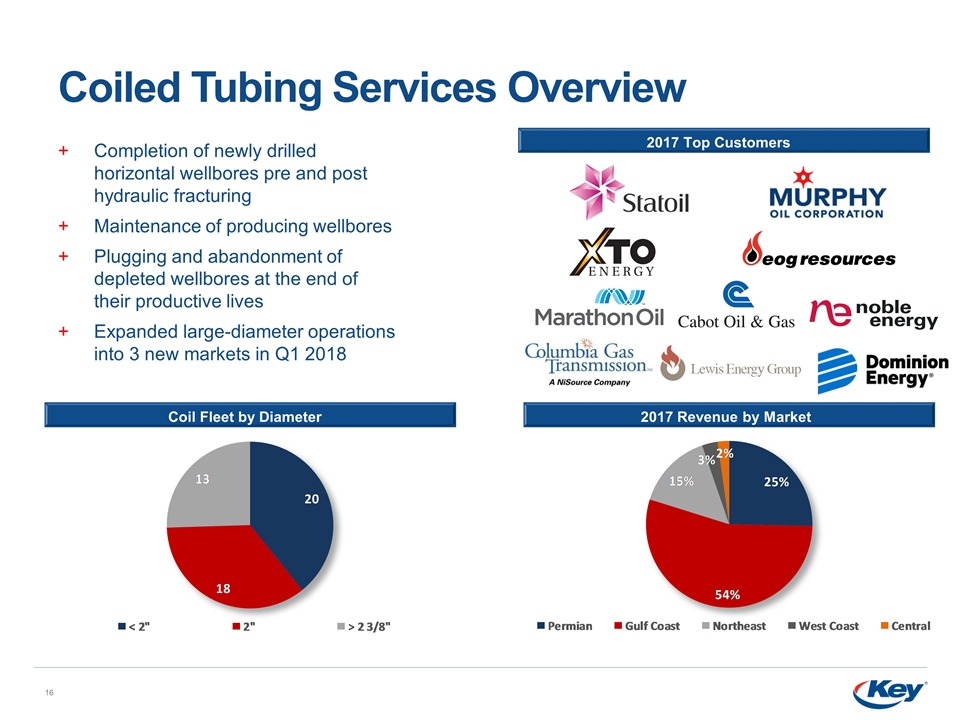

Coiled Tubing Services Overview Completion of newly drilled horizontal wellbores pre and post hydraulic fracturing Maintenance of producing wellbores Plugging and abandonment of depleted wellbores at the end of their productive lives Expanded large-diameter operations into 3 new markets in Q1 2018 2017 Top Customers 2017 Revenue by Market Coil Fleet by Diameter

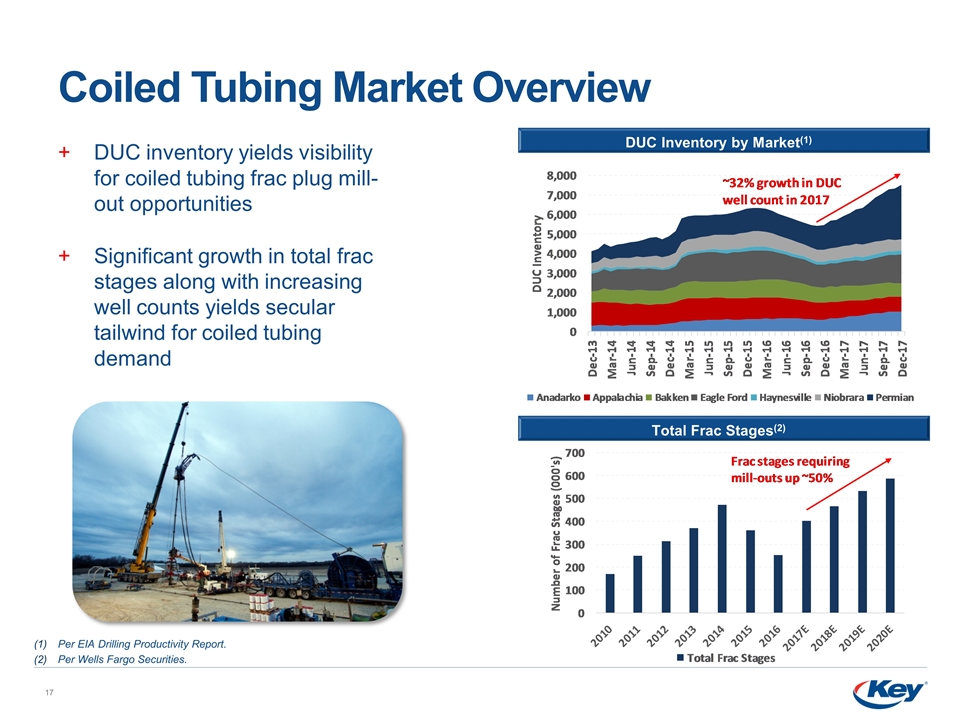

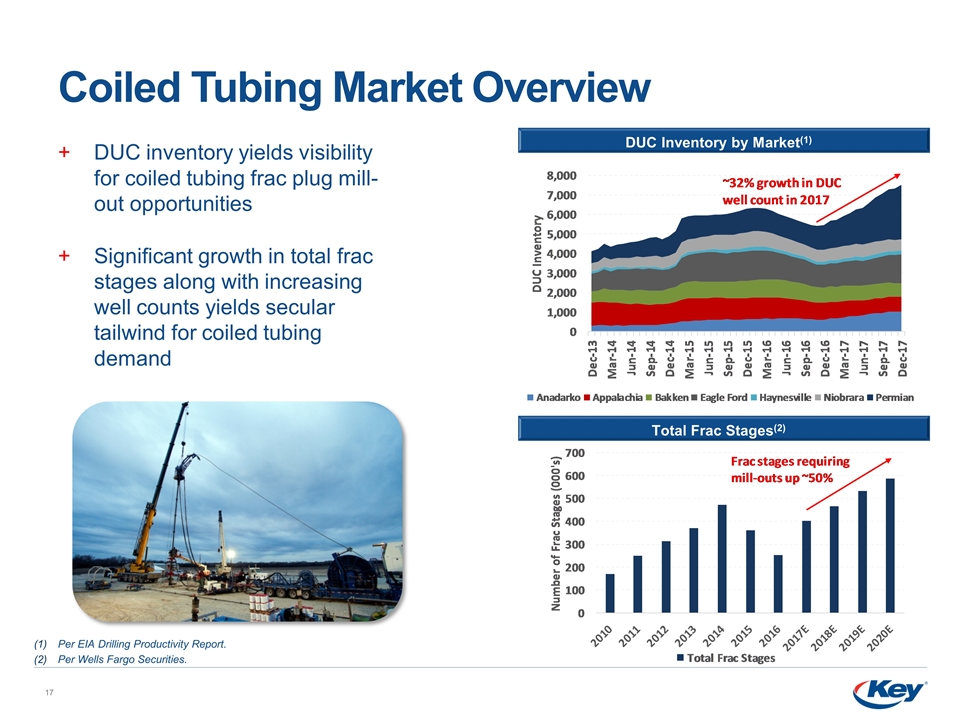

Coiled Tubing Market Overview DUC Inventory by Market(1) Total Frac Stages(2) DUC inventory yields visibility for coiled tubing frac plug mill-out opportunities Significant growth in total frac stages along with increasing well counts yields secular tailwind for coiled tubing demand Per EIA Drilling Productivity Report. Per Wells Fargo Securities.

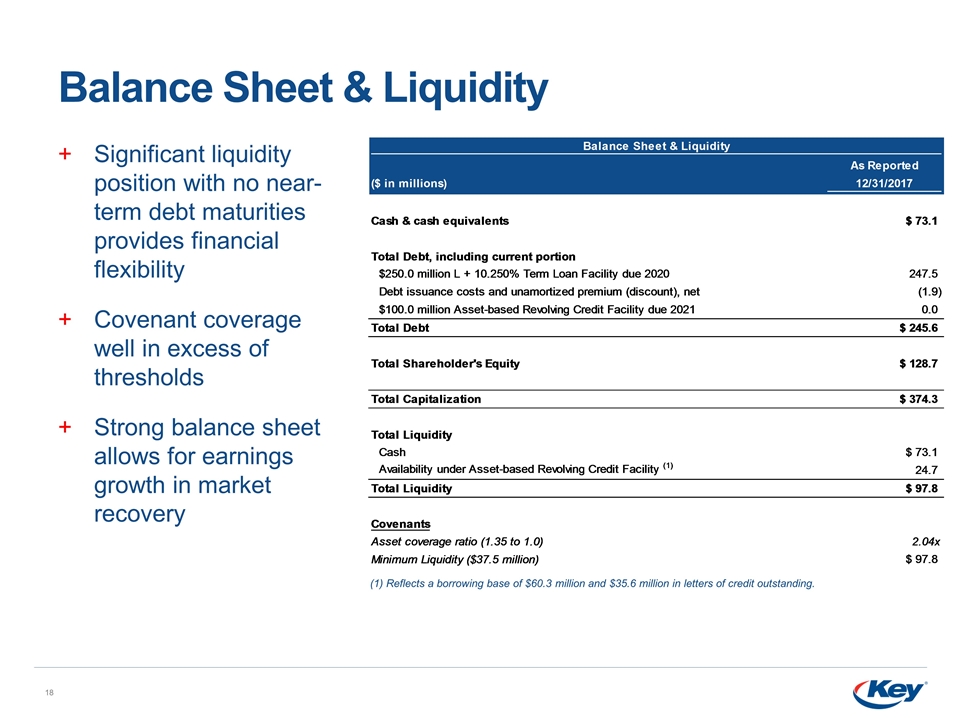

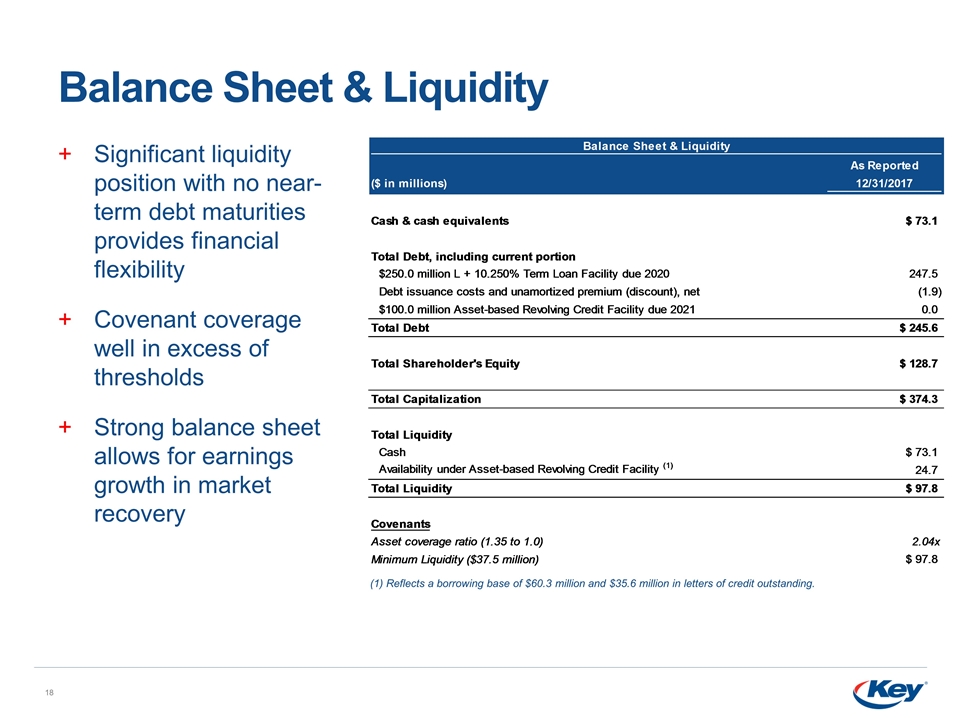

Balance Sheet & Liquidity Significant liquidity position with no near-term debt maturities provides financial flexibility Covenant coverage well in excess of thresholds Strong balance sheet allows for earnings growth in market recovery (1) Reflects a borrowing base of $60.3 million and $35.6 million in letters of credit outstanding.

Final Thoughts Well positioned for future growth through exposure to secular growth and cyclical recovery Completions driving demand for Coiled Tubing, Fluid Management and U.S. Rig Services Growing population of aging horizontal wells to provide new, incremental demand for production services Recovery in oil prices to provide for cyclical recovery in production services Strong geographical footprint with significant Permian Basin exposure Meaningful presence in all major U.S. oil & gas producing regions Provides exposure to regional secular and cyclical demand dynamics Poised to benefit from market recovery and growth via significant operating leverage Limited capital needs to reactivate assets to achieve 2014 activity levels Structural changes to cost structure allow for enhanced financial performance Focused on delivering value to shareholders

Appendix

Market and Service Demand Overview

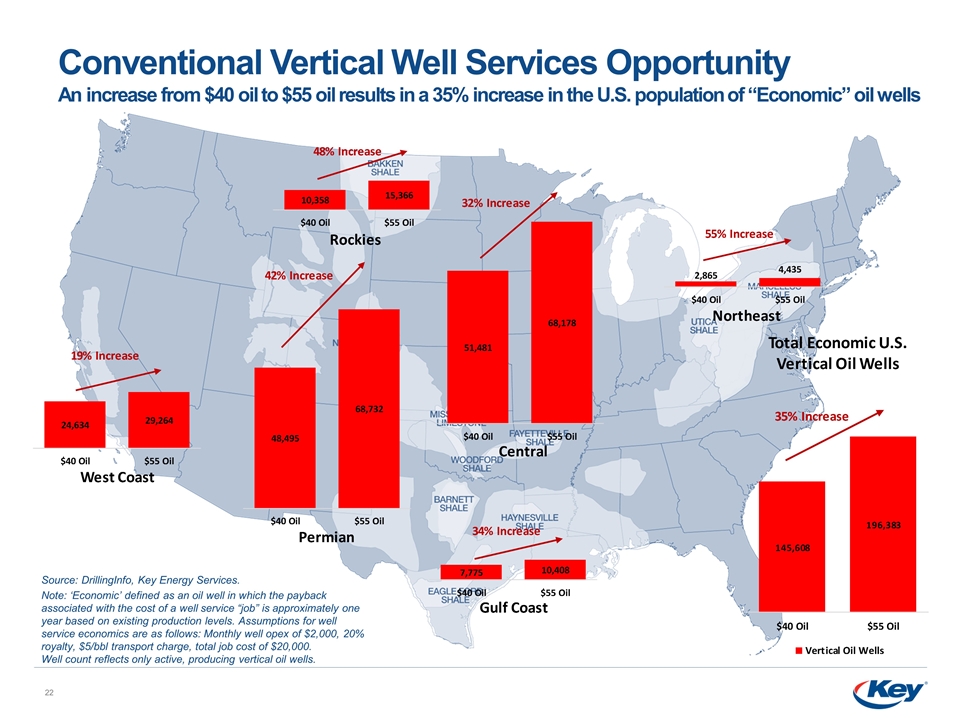

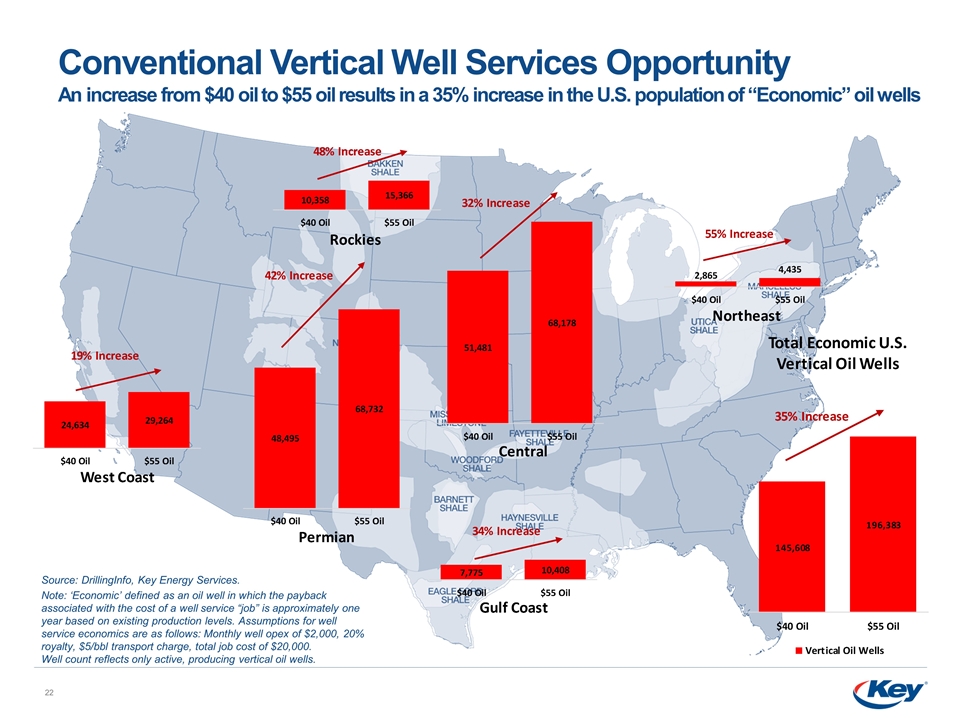

Conventional Vertical Well Services Opportunity An increase from $40 oil to $55 oil results in a 35% increase in the U.S. population of “Economic” oil wells Source: DrillingInfo, Key Energy Services. Note: ‘Economic’ defined as an oil well in which the payback associated with the cost of a well service “job” is approximately one year based on existing production levels. Assumptions for well service economics are as follows: Monthly well opex of $2,000, 20% royalty, $5/bbl transport charge, total job cost of $20,000. Well count reflects only active, producing vertical oil wells.

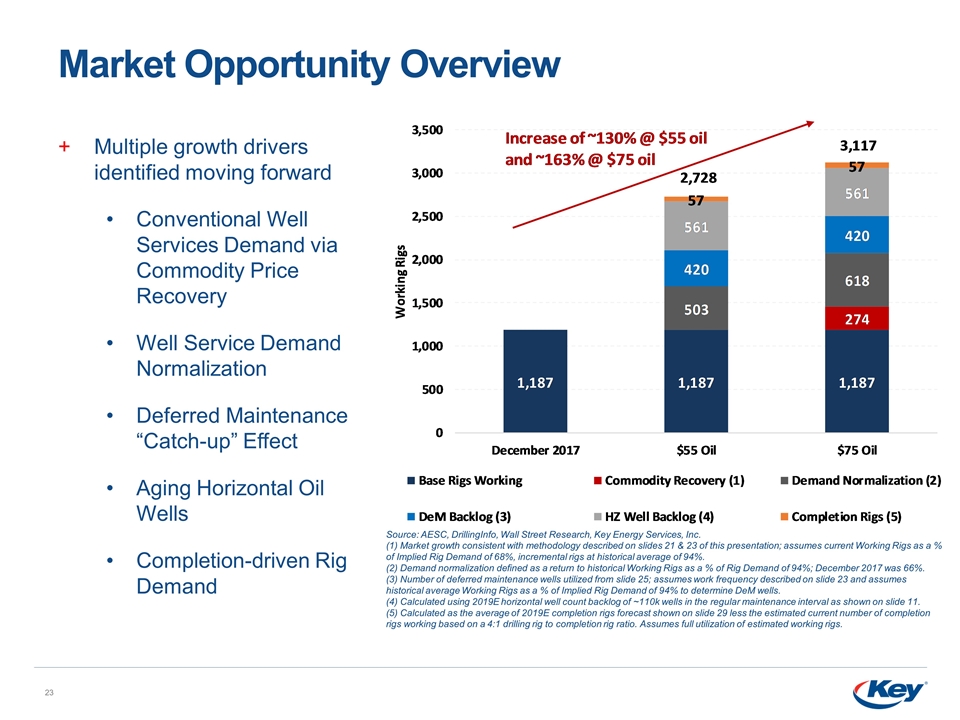

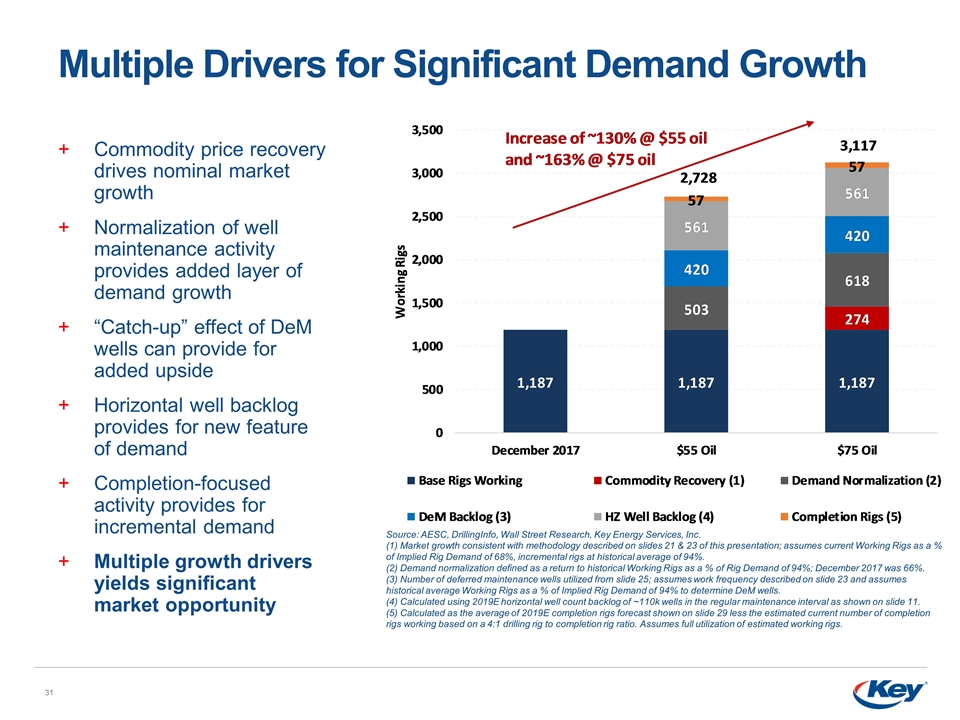

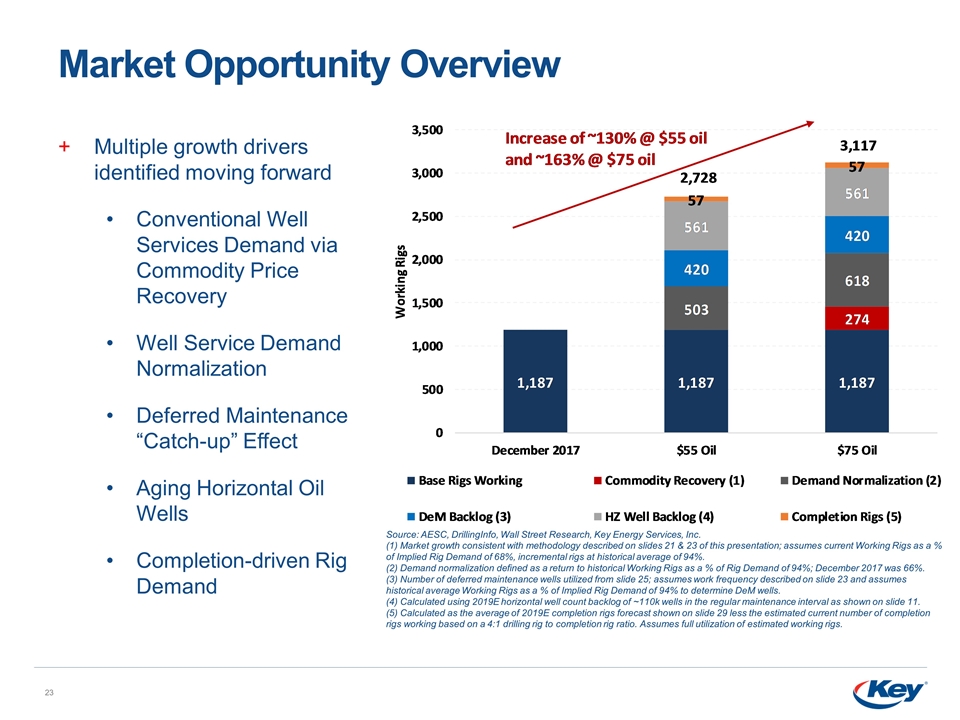

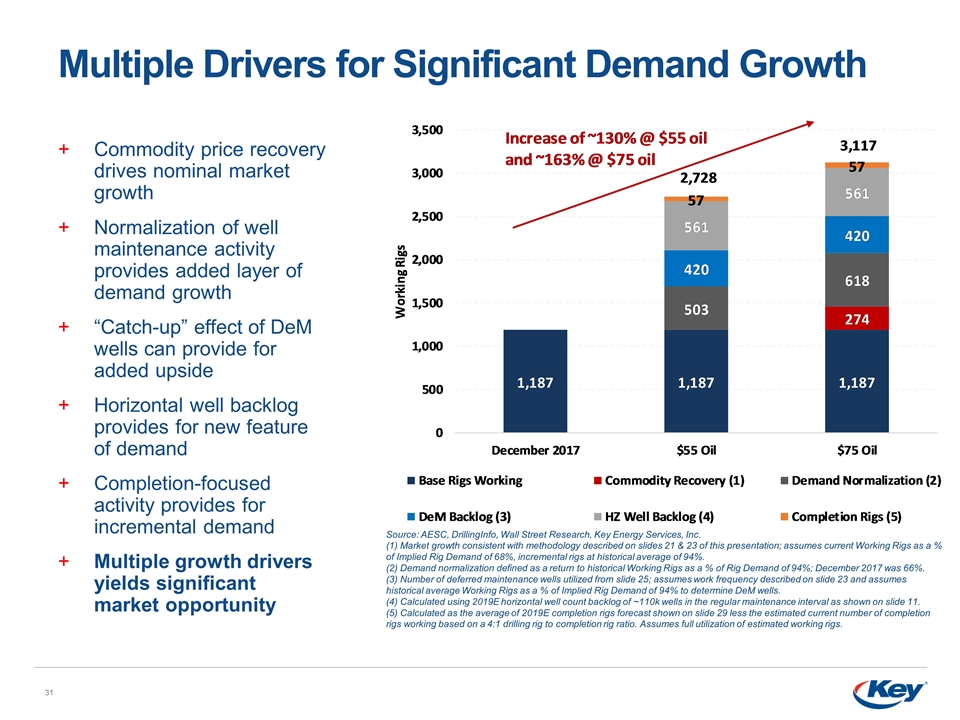

Market Opportunity Overview Multiple growth drivers identified moving forward Conventional Well Services Demand via Commodity Price Recovery Well Service Demand Normalization Deferred Maintenance “Catch-up” Effect Aging Horizontal Oil Wells Completion-driven Rig Demand Source: AESC, DrillingInfo, Wall Street Research, Key Energy Services, Inc. (1) Market growth consistent with methodology described on slides 21 & 23 of this presentation; assumes current Working Rigs as a % of Implied Rig Demand of 68%, incremental rigs at historical average of 94%. (2) Demand normalization defined as a return to historical Working Rigs as a % of Rig Demand of 94%; December 2017 was 66%. (3) Number of deferred maintenance wells utilized from slide 25; assumes work frequency described on slide 23 and assumes historical average Working Rigs as a % of Implied Rig Demand of 94% to determine DeM wells. (4) Calculated using 2019E horizontal well count backlog of ~110k wells in the regular maintenance interval as shown on slide 11. (5) Calculated as the average of 2019E completion rigs forecast shown on slide 29 less the estimated current number of completion rigs working based on a 4:1 drilling rig to completion rig ratio. Assumes full utilization of estimated working rigs.

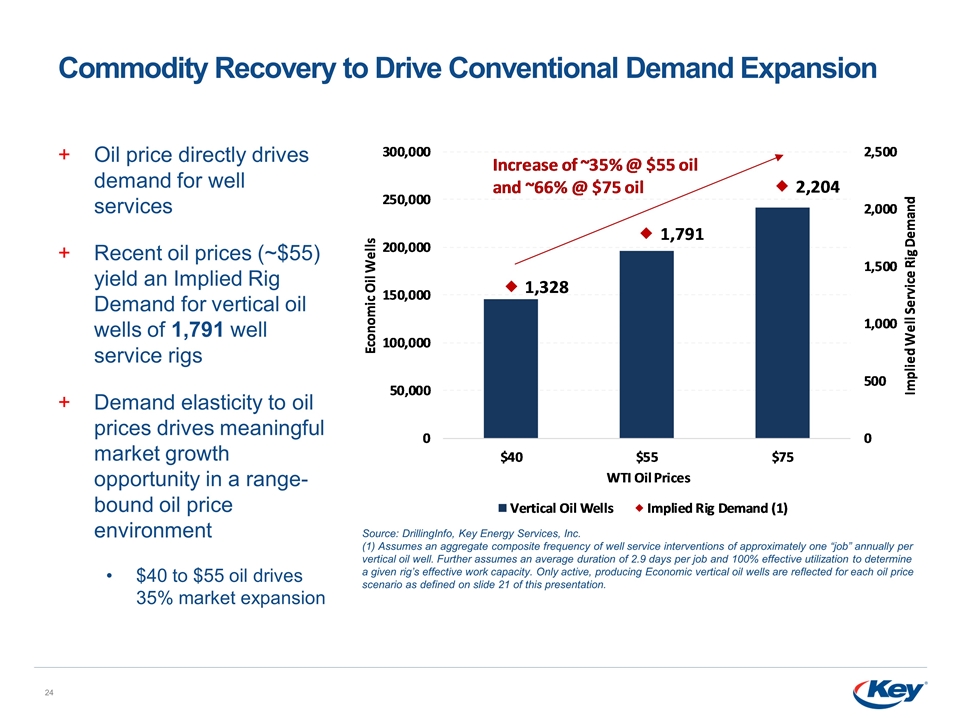

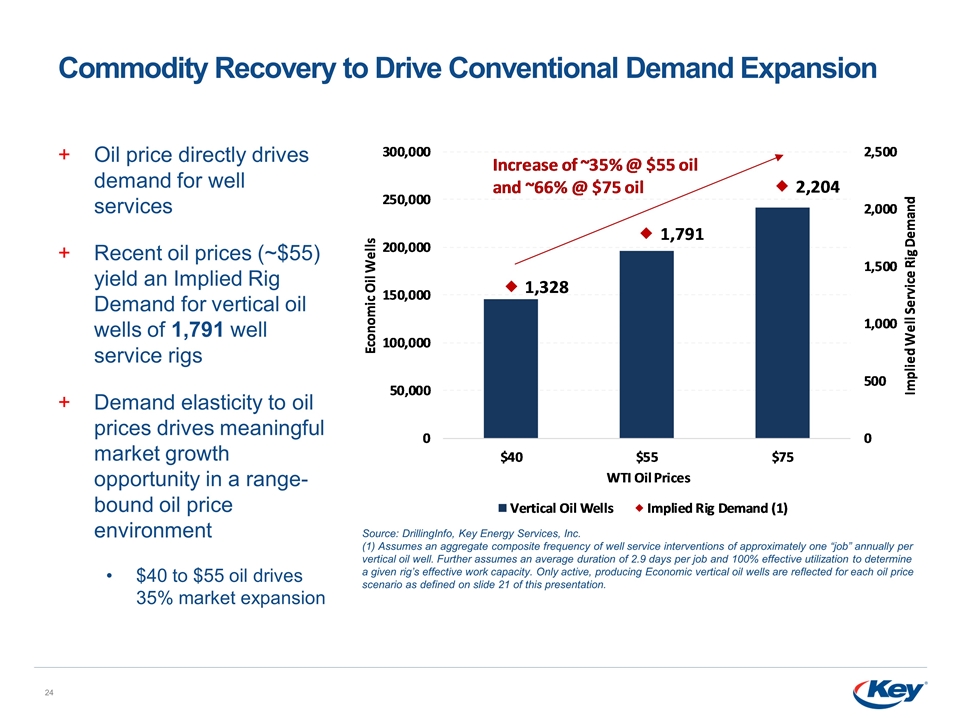

Commodity Recovery to Drive Conventional Demand Expansion Oil price directly drives demand for well services Recent oil prices (~$55) yield an Implied Rig Demand for vertical oil wells of 1,791 well service rigs Demand elasticity to oil prices drives meaningful market growth opportunity in a range-bound oil price environment $40 to $55 oil drives 35% market expansion Source: DrillingInfo, Key Energy Services, Inc. (1) Assumes an aggregate composite frequency of well service interventions of approximately one “job” annually per vertical oil well. Further assumes an average duration of 2.9 days per job and 100% effective utilization to determine a given rig’s effective work capacity. Only active, producing Economic vertical oil wells are reflected for each oil price scenario as defined on slide 21 of this presentation.

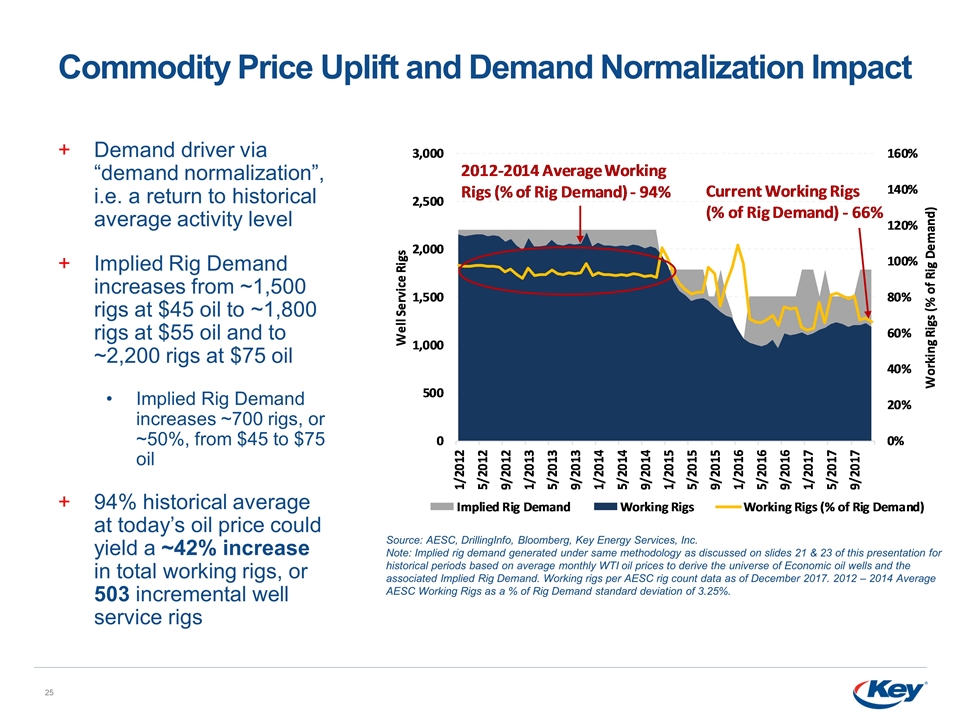

Commodity Price Uplift and Demand Normalization Impact Demand driver via “demand normalization”, i.e. a return to historical average activity level Implied Rig Demand increases from ~1,500 rigs at $45 oil to ~1,800 rigs at $55 oil and to ~2,200 rigs at $75 oil Implied Rig Demand increases ~700 rigs, or ~50%, from $45 to $75 oil 94% historical average at today’s oil price could yield a ~42% increase in total working rigs, or 503 incremental well service rigs Source: AESC, DrillingInfo, Bloomberg, Key Energy Services, Inc. Note: Implied rig demand generated under same methodology as discussed on slides 21 & 23 of this presentation for historical periods based on average monthly WTI oil prices to derive the universe of Economic oil wells and the associated Implied Rig Demand. Working rigs per AESC rig count data as of December 2017. 2012 – 2014 Average AESC Working Rigs as a % of Rig Demand standard deviation of 3.25%.

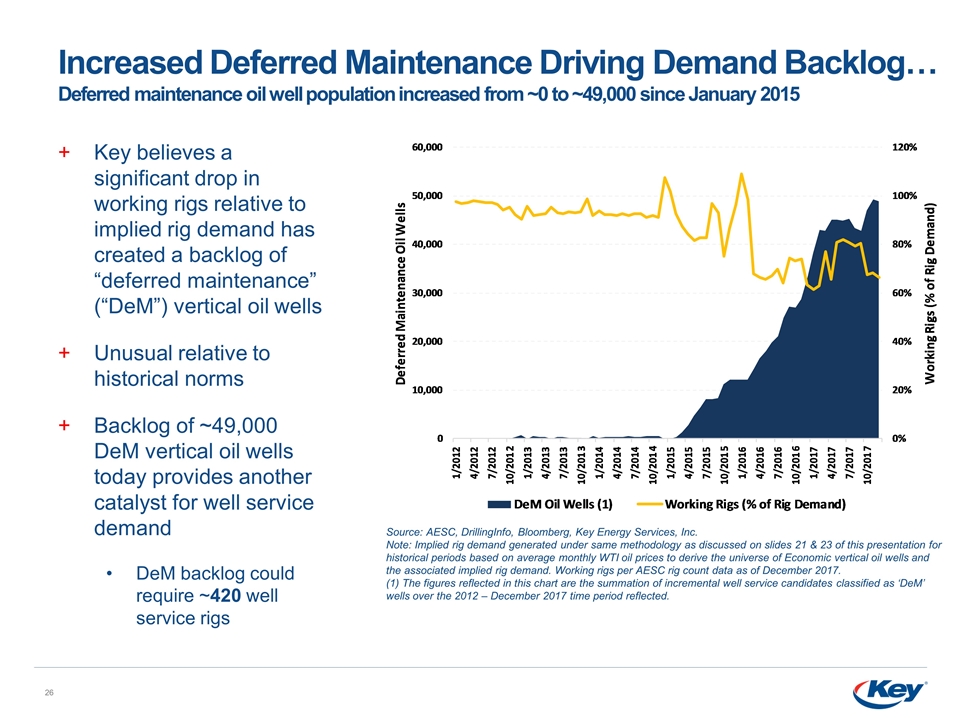

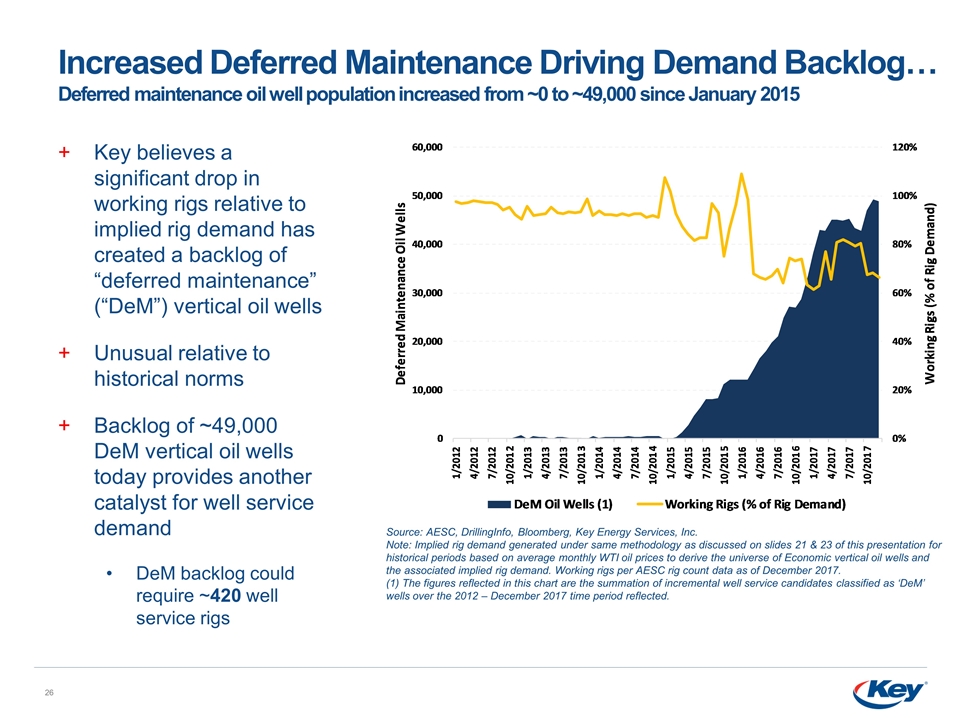

Increased Deferred Maintenance Driving Demand Backlog… Deferred maintenance oil well population increased from ~0 to ~49,000 since January 2015 Key believes a significant drop in working rigs relative to implied rig demand has created a backlog of “deferred maintenance” (“DeM”) vertical oil wells Unusual relative to historical norms Backlog of ~49,000 DeM vertical oil wells today provides another catalyst for well service demand DeM backlog could require ~420 well service rigs Source: AESC, DrillingInfo, Bloomberg, Key Energy Services, Inc. Note: Implied rig demand generated under same methodology as discussed on slides 21 & 23 of this presentation for historical periods based on average monthly WTI oil prices to derive the universe of Economic vertical oil wells and the associated implied rig demand. Working rigs per AESC rig count data as of December 2017. (1) The figures reflected in this chart are the summation of incremental well service candidates classified as ‘DeM’ wells over the 2012 – December 2017 time period reflected.

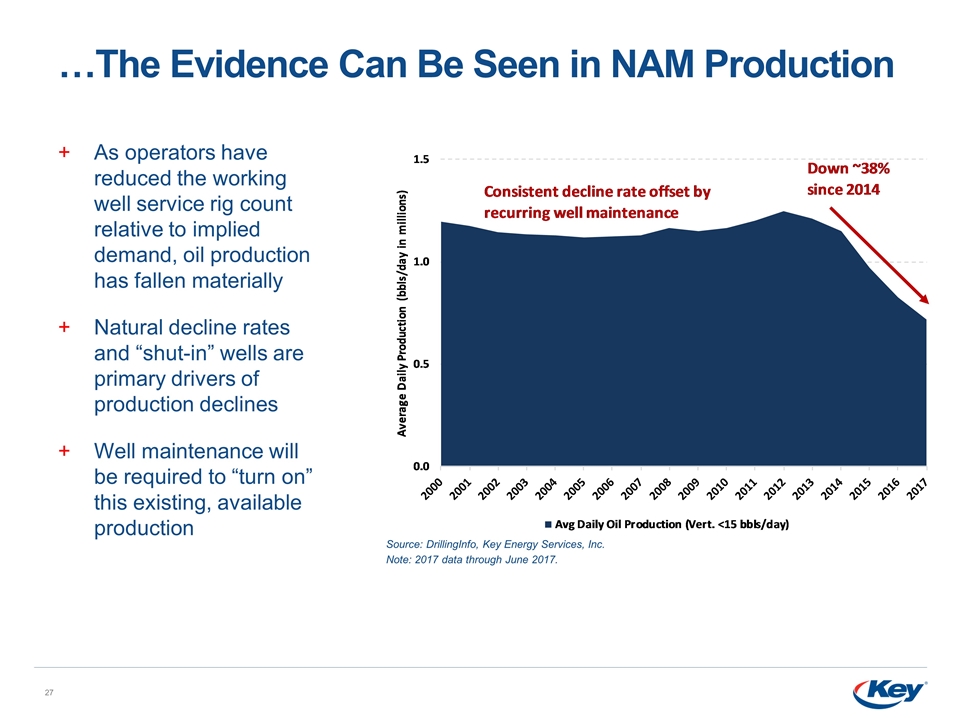

…The Evidence Can Be Seen in NAM Production Source: DrillingInfo, Key Energy Services, Inc. Note: 2017 data through June 2017. As operators have reduced the working well service rig count relative to implied demand, oil production has fallen materially Natural decline rates and “shut-in” wells are primary drivers of production declines Well maintenance will be required to “turn on” this existing, available production

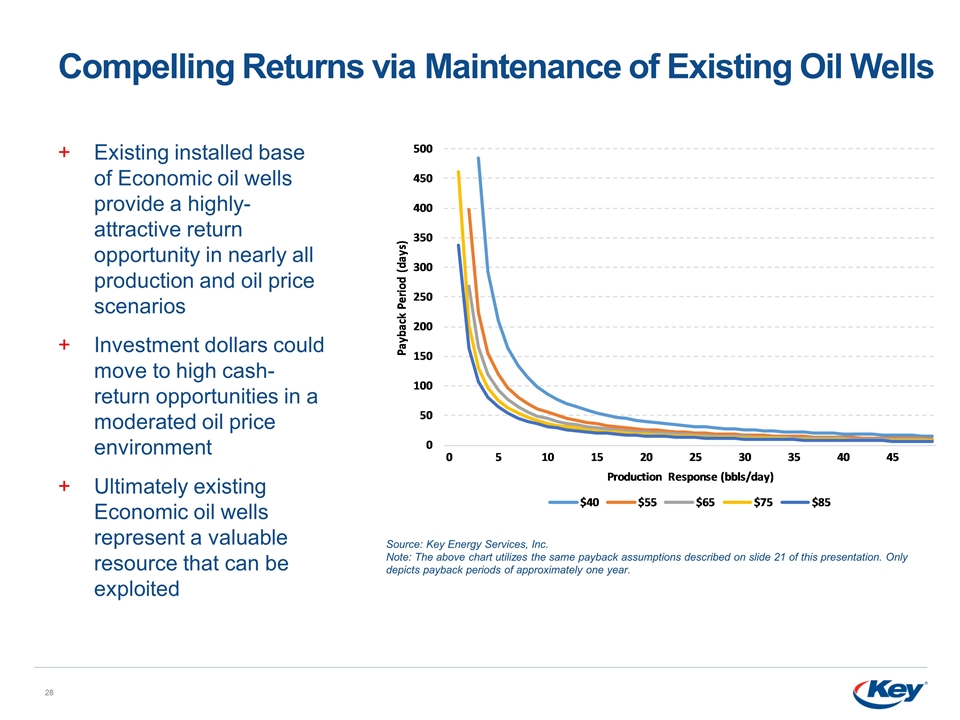

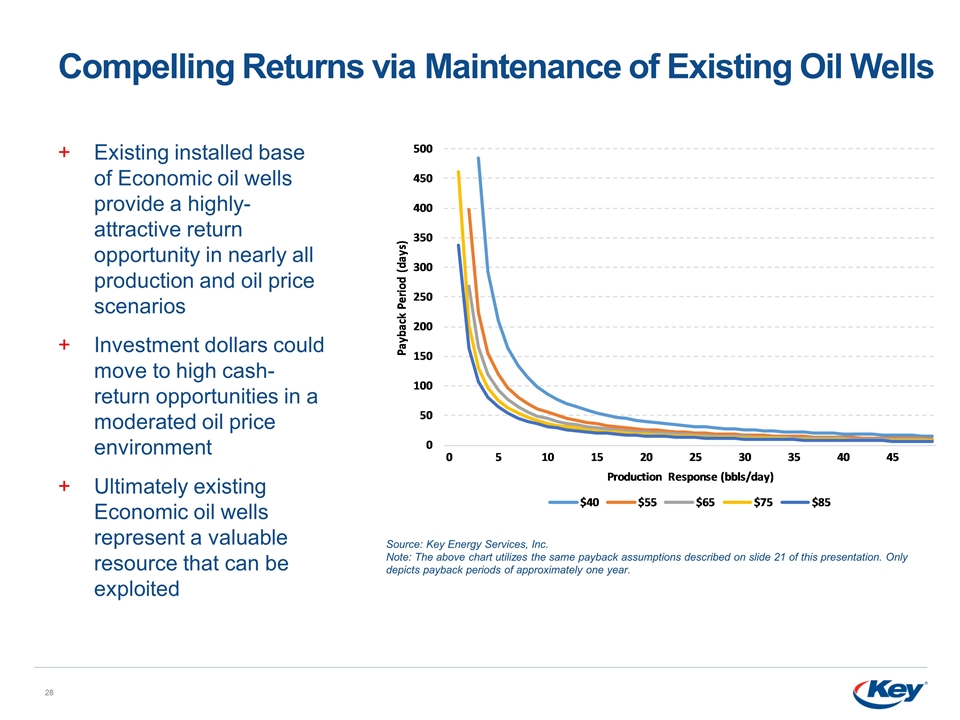

Compelling Returns via Maintenance of Existing Oil Wells Source: Key Energy Services, Inc. Note: The above chart utilizes the same payback assumptions described on slide 21 of this presentation. Only depicts payback periods of approximately one year. Existing installed base of Economic oil wells provide a highly-attractive return opportunity in nearly all production and oil price scenarios Investment dollars could move to high cash-return opportunities in a moderated oil price environment Ultimately existing Economic oil wells represent a valuable resource that can be exploited

Aging Horizontal Oil Well Backlog Provides New, Secular Tailwind Source: DrillingInfo, Key Energy Services, Inc. Note: Utilizes the same job frequency and utilization assumptions described on slide 23 and are applied to the Future Cumulative HZ Wells >4 Years Old shown in the chart above. Proliferation of HZ oil wells has created a new class of well service candidates Delay between completion of a new HZ oil well and the beginning of the regular maintenance interval yields a significant well service backlog Incremental rig demand could require ~692 well service rigs for the existing installed base of aging HZ oil wells by the end of 2020

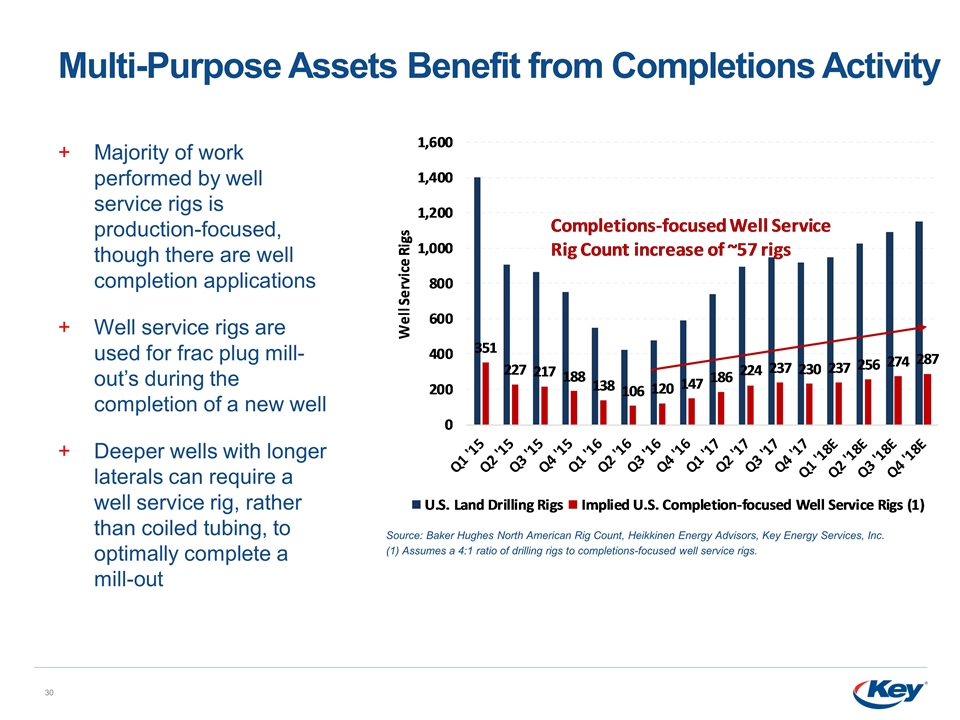

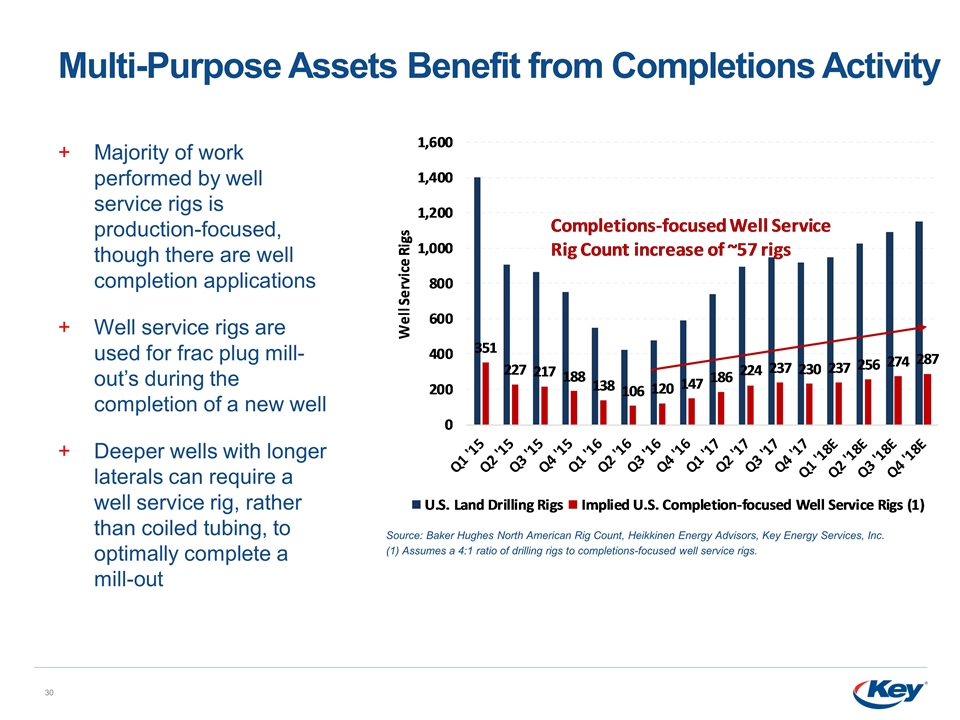

Multi-Purpose Assets Benefit from Completions Activity Source: Baker Hughes North American Rig Count, Heikkinen Energy Advisors, Key Energy Services, Inc. (1) Assumes a 4:1 ratio of drilling rigs to completions-focused well service rigs. Majority of work performed by well service rigs is production-focused, though there are well completion applications Well service rigs are used for frac plug mill-out’s during the completion of a new well Deeper wells with longer laterals can require a well service rig, rather than coiled tubing, to optimally complete a mill-out

Multiple Drivers for Significant Demand Growth Commodity price recovery drives nominal market growth Normalization of well maintenance activity provides added layer of demand growth “Catch-up” effect of DeM wells can provide for added upside Horizontal well backlog provides for new feature of demand Completion-focused activity provides for incremental demand Multiple growth drivers yields significant market opportunity Source: AESC, DrillingInfo, Wall Street Research, Key Energy Services, Inc. (1) Market growth consistent with methodology described on slides 21 & 23 of this presentation; assumes current Working Rigs as a % of Implied Rig Demand of 68%, incremental rigs at historical average of 94%. (2) Demand normalization defined as a return to historical Working Rigs as a % of Rig Demand of 94%; December 2017 was 66%. (3) Number of deferred maintenance wells utilized from slide 25; assumes work frequency described on slide 23 and assumes historical average Working Rigs as a % of Implied Rig Demand of 94% to determine DeM wells. (4) Calculated using 2019E horizontal well count backlog of ~110k wells in the regular maintenance interval as shown on slide 11. (5) Calculated as the average of 2019E completion rigs forecast shown on slide 29 less the estimated current number of completion rigs working based on a 4:1 drilling rig to completion rig ratio. Assumes full utilization of estimated working rigs.