Exhibit 10.3

Execution Copy

ENGINEERING, PROCUREMENT AND CONSTRUCTION SERVICES AGREEMENT

for

PRELIMINARY WORK

for the

CORPUS CHRISTI LNG RECEIVING,

STORAGE AND REGASIFICATION TERMINAL

by and between

CORPUS CHRISTI LNG, LLC

as Owner

and

LA QUINTA LNG PARTNERS, LP

as Contractor

Dated as of the 13th Day of April, 2006

TABLE OF CONTENTS

RECITALS | 1 | |||

ARTICLE 1 | DEFINITIONS | 1 | ||

ARTICLE 2 | RELATIONSHIP OF OWNER, CONTRACTOR AND SUBCONTRACTORS | 9 | ||

2.1 | Status of Contractor | 9 | ||

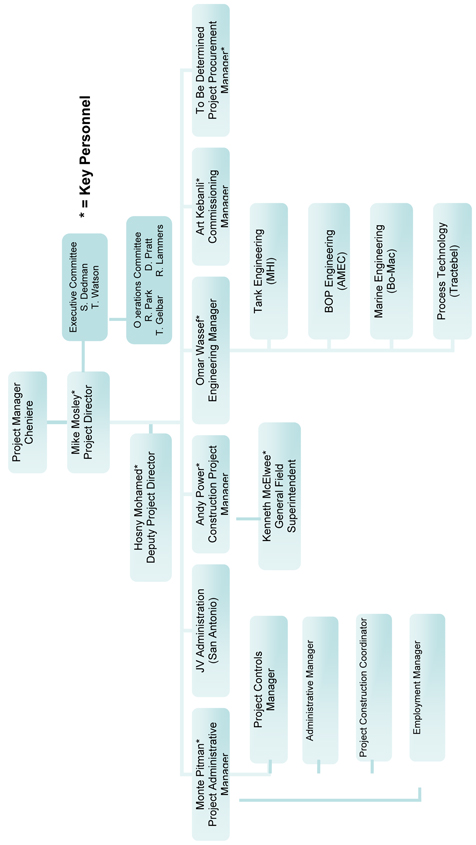

2.2 | Key Personnel, Organization Chart and Contractor Representative | 9 | ||

2.3 | Subcontractors | 10 | ||

2.4 | Subcontracts | 10 | ||

ARTICLE 3 | CONTRACTOR’S RESPONSIBILITIES | 12 | ||

3.1 | Scope of Work | 12 | ||

3.2 | Applicable Law | 12 | ||

3.3 | Changes in Applicable Codes and Standards Not Constituting a Change in Law | 13 | ||

3.4 | Design and Engineering Work | 13 | ||

3.5 | Environmental Regulations and Environmental Compliance | 14 | ||

3.6 | Construction Equipment | 14 | ||

3.7 | Employment of Personnel | 14 | ||

3.8 | Clean-Up | 15 | ||

3.9 | HSE Plan; Security | 15 | ||

3.10 | Emergencies | 16 | ||

3.11 | Contractor Permits | 16 | ||

3.12 | Assistance with Owner Permits | 16 | ||

3.13 | Books, Records and Audits | 17 | ||

3.14 | Tax Accounting and Auditing | 17 | ||

3.15 | Temporary Utilities, Roads, Facilities and Storage | 17 | ||

3.16 | Reports | 18 | ||

3.17 | Payment | 18 | ||

3.18 | Commercial Activities | 18 | ||

3.19 | Title to Materials Found | 18 | ||

3.20 | Survey Control Points and Layout | 19 | ||

3.21 | Cooperation with Others | 19 | ||

3.22 | Responsibility for Property | 19 | ||

3.23 | Equipment Quality | 19 | ||

3.24 | Excusable Delay | 20 | ||

3.25 | Nondiscrimination | 20 | ||

3.26 | Rights of Way and Easement Agreements | 20 | ||

ARTICLE 4 | OWNER’S RESPONSIBILITIES | 20 | ||

4.1 | Payments | 20 | ||

4.2 | Owner Permits | 20 | ||

4.3 | Access to the Site | 20 | ||

4.4 | Sales and Use Tax Matters | 21 | ||

- i -

4.5 | Legal Description and Survey | 23 | ||

4.6 | Owner-Provided Items | 23 | ||

4.7 | Excusable Delay | 23 | ||

4.8 | Personal and Real Property Taxes | 23 | ||

4.9 | Waivers of Consequential Damages from Landowners | 23 | ||

ARTICLE 5 | COMMENCEMENT OF WORK AND SCHEDULING OBLIGATIONS | 23 | ||

5.1 | Commencement of Work | 23 | ||

5.2 | Work Order No. 1 | 23 | ||

5.3 | Work Schedules | 24 | ||

ARTICLE 6 | CHANGES AND CHANGE ORDERS | 24 | ||

6.1 | Changes | 24 | ||

6.2 | Adjustment Only Through Change Order | 24 | ||

ARTICLE 7 | COMPENSATION | 24 | ||

ARTICLE 8 | INVOICING AND PAYMENTS TO CONTRACTOR | 24 | ||

8.1 | Initial Payment | 24 | ||

8.2 | Subsequent Invoices for Progress Payments | 24 | ||

8.3 | Form and Content of Invoices | 25 | ||

8.4 | Cost of Work Estimate | 26 | ||

8.5 | Review and Payment by Owner | 27 | ||

8.6 | Progress Reports | 27 | ||

8.7 | Interim Lien and Claim Waivers | 27 | ||

8.8 | Final Payment | 28 | ||

8.9 | Payments During Default | 28 | ||

8.10 | Payments Not Acceptance of Work | 28 | ||

8.11 | Payments Withheld | 28 | ||

8.12 | Interest on Late Payments and Improper Collection | 29 | ||

8.13 | Offset | 29 | ||

8.14 | Payment Error | 29 | ||

8.15 | Reconciliation or True-Up of Payments | 30 | ||

ARTICLE 9 | TITLE AND RISK OF LOSS | 30 | ||

9.1 | Clear Title | 30 | ||

9.2 | Title to Work | 30 | ||

9.3 | Risk of Loss | 30 | ||

ARTICLE 10 | INSURANCE | 31 | ||

10.1 | Provision of Insurance | 31 | ||

10.2 | No Cancellation | 31 | ||

10.3 | Obligations Not Relieved | 31 | ||

10.4 | Failure to Provide Insurance | 31 | ||

10.5 | Unavailable Insurance | 31 | ||

- ii -

ARTICLE 11 | OWNERSHIP OF DOCUMENTATION | 32 | ||

11.1 | Work Product, Contractor’s Intellectual Property and Third Party Proprietary Work Product | 32 | ||

11.2 | Return of Work Product | 33 | ||

11.3 | Contractor’s Right to Use of Work Product | 34 | ||

11.4 | Owner Provided Documents | 34 | ||

ARTICLE 12 | WARRANTY AND CORRECTION OF WORK | 34 | ||

12.1 | Warranty | 34 | ||

12.2 | Defective Work | 35 | ||

12.3 | Extended Defect Correction Period for Corrective Work | 35 | ||

12.4 | Standards for Corrective Work | 35 | ||

12.5 | Assignability of Warranties | 36 | ||

12.6 | Waiver of Implied Warranties | 36 | ||

ARTICLE 13 | CONTRACTOR’S REPRESENTATIONS | 36 | ||

13.1 | Corporate Standing | 36 | ||

13.2 | No Violation of Law; Litigation | 36 | ||

13.3 | Licenses | 36 | ||

13.4 | No Breach | 36 | ||

13.5 | Corporate Action | 37 | ||

13.6 | Financial Solvency | 37 | ||

ARTICLE 14 | OWNER’S REPRESENTATIONS | 37 | ||

14.1 | Standing | 37 | ||

14.2 | No Violation of Law; Litigation | 37 | ||

14.3 | Licenses | 37 | ||

14.4 | No Breach | 37 | ||

14.5 | Corporate Action | 38 | ||

14.6 | Ability to Pay | 38 | ||

ARTICLE 15 | DEFAULT, TERMINATION AND SUSPENSION | 38 | ||

15.1 | Default by Contractor | 38 | ||

15.2 | Termination for Convenience by Owner | 40 | ||

15.3 | Suspension of Work | 40 | ||

15.4 | Suspension by Contractor for Owner’s Failure to Pay Undisputed Amounts | 41 | ||

15.5 | Contractor’s Right to Terminate | 41 | ||

ARTICLE 16 | INDEMNITIES | 41 | ||

16.1 | General Indemnification | 41 | ||

16.2 | Injuries to Contractor’s or Owner’s Employees | 42 | ||

16.3 | Damage to Contractor’s or Owner’s Property | 42 | ||

16.4 | Hazardous Materials Indemnification | 43 | ||

16.5 | Patent and Copyright Indemnification Procedure | 44 | ||

16.6 | Lien Indemnification | 44 | ||

16.7 | Legal Defense | 45 | ||

16.8 | Enforceability | 46 | ||

- iii -

ARTICLE 17 | DISPUTE RESOLUTION | 47 | ||

17.1 | Negotiation | 47 | ||

17.2 | Mediation | 47 | ||

17.3 | Arbitration | 48 | ||

17.4 | Continuation of Work During Dispute | 49 | ||

ARTICLE 18 | CONFIDENTIALITY | 49 | ||

18.1 | Contractor’s Obligations | 49 | ||

18.2 | Owner’s Obligations | 49 | ||

18.3 | Definitions | 50 | ||

18.4 | Exceptions | 50 | ||

18.5 | Equitable Relief | 50 | ||

18.6 | Term | 50 | ||

ARTICLE 19 | LIMITATION OF LIABILITY | 50 | ||

19.1 | Contractor Aggregate Liability | 50 | ||

19.2 | Consequential Damages | 51 | ||

19.3 | Consequential Damages with Respect to Landowners | 51 | ||

19.4 | Applicability | 51 | ||

ARTICLE 20 | MISCELLANEOUS PROVISIONS | 52 | ||

20.1 | Entire Agreement | 52 | ||

20.2 | Amendments | 52 | ||

20.3 | Joint Effort | 52 | ||

20.4 | Captions | 52 | ||

20.5 | Notice | 52 | ||

20.6 | Severability | 53 | ||

20.7 | Assignment | 53 | ||

20.8 | No Waiver | 54 | ||

20.9 | Governing Law | 54 | ||

20.10 | Successors and Assigns | 54 | ||

20.11 | Attachments and Schedules | 54 | ||

20.12 | Obligations | 54 | ||

20.13 | Further Assurances | 54 | ||

20.14 | Priority | 54 | ||

20.15 | Restrictions on Public Announcements | 55 | ||

20.16 | Hazardous Materials | 55 | ||

20.17 | Parent Guarantee | 56 | ||

20.18 | Foreign Corrupt Practices Act | 56 | ||

20.19 | Language | 56 | ||

20.20 | Counterparts | 56 | ||

20.21 | Joint and Several Liability | 56 | ||

20.22 | Survival | 56 | ||

- iv -

LIST OF ATTACHMENTS AND SCHEDULES

ATTACHMENT A | Scope of Work, Design Basis and Contractor Deliverables | |

SCHEDULE A-1 | Scope of Work for the Agreement | |

SCHEDULE A-2 | Design Basis | |

SCHEDULE A-3 | Contractor Deliverables | |

ATTACHMENT B | Permits | |

SCHEDULE B-1 | Contractor Permits | |

SCHEDULE B-2 | Owner Permits | |

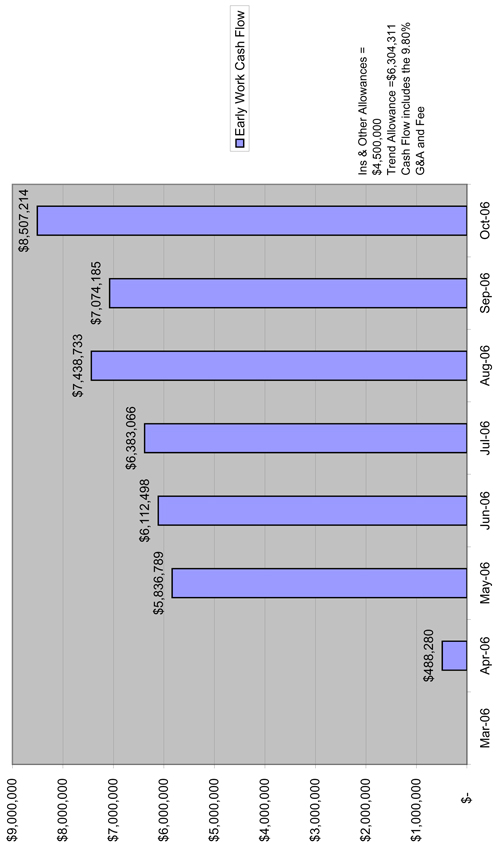

ATTACHMENT C | Payment Schedule | |

ATTACHMENT D | Form of Change Order | |

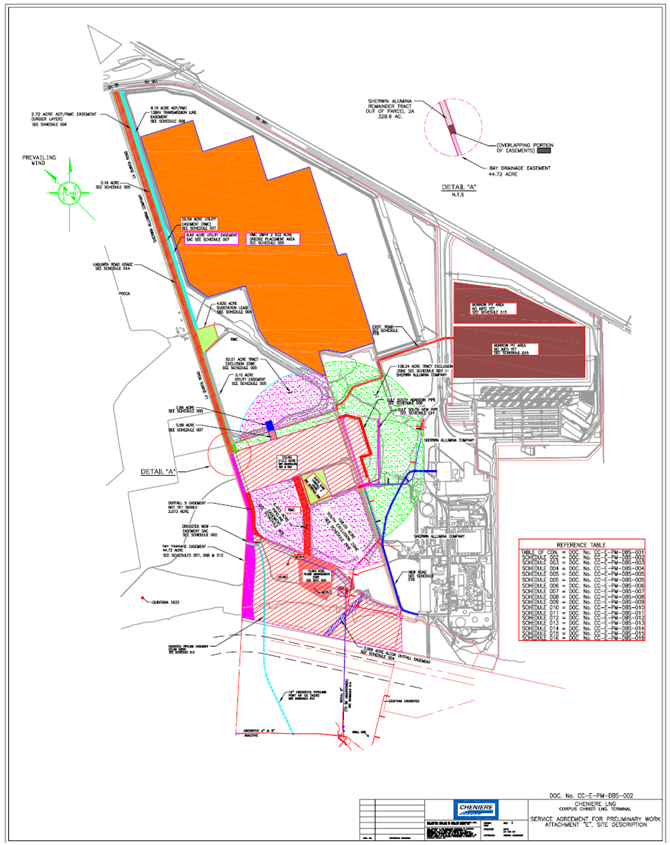

ATTACHMENT E | Site Description | |

ATTACHMENT F | Key Personnel and Contractor’s Organization | |

ATTACHMENT G | Approved Subcontractors | |

ATTACHMENT H | Form of Parent Guarantee | |

ATTACHMENT I | Form of Contractor’s Invoices | |

SCHEDULE I-1 | Form of Contractor’s Interim Invoice | |

SCHEDULE I-2 | Form of Contractor’s Final Invoice | |

ATTACHMENT J | Form of Lien and Claim Waivers | |

SCHEDULE J-1 | Contractor’s Interim Lien and Claim Waiver | |

SCHEDULE J-2 | Subcontractor’s Interim Lien and Claim Waiver | |

SCHEDULE J-3 | Contractor’s Final Lien and Claim Waiver | |

SCHEDULE J-4 | Subcontractor’s Final Lien and Claim Waiver | |

ATTACHMENT K | Owner-Provided Items and Responsibility | |

ATTACHMENT L | Insurance Requirements | |

ATTACHMENT M | Work Order No. 1 | |

ATTACHMENT N | Form of Work Order | |

- v -

SERVICES AGREEMENT for PRELIMINARY WORK

for the CORPUS CHRISTI LNG RECEIVING,

STORAGE AND REGASIFICATION TERMINAL

THIS ENGINEERING, PROCUREMENT AND CONSTRUCTION SERVICES AGREEMENT for PRELIMINARY WORK(this “Agreement”), dated as of the 13th Day of April, 2006 (the “Agreement Effective Date”), is entered into by and betweenCORPUS CHRISTI LNG, LLC, a Delaware limited liability company, having its principal place of business at 717 Texas Avenue, Suite 3100, Houston, Texas 77002 (“Owner”), andLA QUINTA LNG PARTNERS, LP, a Texas limited partnership, having an address at 527 Logwood, San Antonio, Texas 78224 (“Contractor” and, together with Owner, each a “Party” and together the “Parties”).

RECITALS

WHEREAS,the Parties contemplate that, from time to time, Owner will desire to engage Contractor to provide certain preliminary Work (as defined below) for the LNG receiving, storage and regasification terminal to be constructed and owned by Owner, located in San Patricio County and Nueces County near Portland, Texas (as more fully described below, the “Facility”); and

WHEREAS,Contractor, itself or through its vendors, suppliers, and subcontractors, desires to provide such preliminary Work, subject to the terms of one or more Work Orders (as defined below) to be mutually executed by the Parties;

NOW THEREFORE,in consideration of the mutual covenants herein contained and for other good and valuable consideration, the receipt and adequacy of which are hereby acknowledged, the Parties, intending to be legally bound, hereby agree as follows:

Article 1

DEFINITIONS

1.1 In addition to other defined terms used throughout this Agreement, when used herein, the following capitalized terms have the meanings specified in this Section 1.1.

“AAA” has the meaning set forth in Section 17.2.

“AAA Rules” has the meaning set forth in Section 17.2.

“Affiliate” means any Person that directly or indirectly, through one or more intermediaries, controls, is controlled by, or is under common control with a Party;provided, however, with respect to Contractor, the term “Affiliate” also includes Zachry and AMEC and with respect to Owner, the term “Affiliate” also includes Cheniere. For purposes of this definition, “control” (including, with correlative meanings, the terms “controlled by” and “under common control with”) means the possession, directly or indirectly, of the power to direct or cause the direction of the management and policies of a Person, whether through the ownership of voting securities or otherwise.

“Agreement” means this Agreement (including all Attachments and Schedules attached hereto), as it may be amended from time to time in accordance with this Agreement.

“Agreement Effective Date” has the meaning set forth in the preamble.

“AMEC” means AMEC E&C Services, Inc., a Georgia corporation, or any successor entity thereto.

“Applicable Codes and Standards” means any and all codes, standards or requirements applicable to the Work set forth or listed in a Work Order, in any Applicable Law, or which are set forth or listed in any document or Drawing listed in a Work Order, which codes, standards and requirements shall govern Contractor’s performance of the Work, as provided herein;provided that, with respect to Applicable Codes and Standards which are not set forth in any Applicable Law, any reference herein to Applicable Codes and Standards shall be deemed only to refer to such Applicable Codes and Standards in existence as of the applicable Work Order Effective Date.

“Applicable Law” means all laws, statutes, ordinances, orders, decrees, injunctions, licenses, Permits, approvals, rules and regulations, including any conditions thereto, of any Governmental Instrumentality having jurisdiction over all or any portion of the Site or the Facility or performance of all or any portion of the Work, or other legislative or administrative action of a Governmental Instrumentality, or a final decree, judgment or order of a court which relates to the performance of Work hereunder.

“Books and Records” has the meaning set forth in Section 3.13A.

“Business Day” means every Day other than a Saturday, a Sunday or a Day that is an official holiday for employees of the federal government of the United States of America.

“CAD” has the meaning set forth in Section 3.4E.

“Change in Law” means any amendment, modification, superseding act, deletion, addition or change in or to Applicable Law (excluding changes to Tax laws where such Taxes are based upon Contractor’s gross receipts, capital, income or profits/losses) that occurs and takes effect after the applicable Work Order Effective Date. A Change in Law shall include any official change in the interpretation or application of Applicable Law (including Applicable Codes and Standards set forth in Applicable Law),provided that such change is expressed in writing by the applicable Governmental Instrumentality.

“Change Order” means, after the execution of a Work Order, (i) a written instrument signed by both Parties in the form ofAttachment D, executed pursuant to the applicable provisions of Article 6; or (ii) a determination issued pursuant to Article 17 that authorizes an addition to, deletion from, suspension of, or any other modification or adjustment to the requirements of a Work Order.

“Cheniere” means Cheniere Energy, Inc.

“Confidential Information” has the meaning set forth in Section 18.3.

- 2 -

“Consequential Damages” has the meaning set forth in Section 19.2.

“Construction Equipment” means the equipment, machinery, structures, scaffolding, materials, tools, supplies and systems owned, rented or leased by Contractor or its Subcontractors for use in accomplishing the Work, but not intended for incorporation into the Facility.

“Contract Documents” means this Agreement and all Work Orders and Change Orders as they may be amended from time to time in accordance with this Agreement.

“Contractor” has the meaning set forth in the preamble hereto.

“Contractor Group” means (i) Contractor, Zachry, AMEC and each of their respective Affiliates and (ii) the respective directors, officers, agents, employees, representatives of each Person specified in clause (i) above.

“Contractor Representative” means that Person or Persons designated by Contractor in a written notice to Owner, and acceptable to Owner, who shall have (except for any limitations specified in such notice) complete authority to act on behalf of Contractor on all matters pertaining to the Contract Documents or the Work including giving instructions and making changes in the Work and executing Work Orders. Contractor designates Harold “Mike” Mosley, Jr. as the Contractor Representative. Notification of a change in Contractor Representative shall be provided in advance, in writing, to Owner.

“Contractor’s Confidential Information” has the meaning set forth in Section 18.2.

“Contractor’s Intellectual Property” has the meaning set forth in Section 11.1B.

“Corrective Work” has the meaning set forth in Section 12.2.

“Cost of Work” shall have the meaning set forth inAttachment C.

“Day” means a calendar day.

“Default” has the meaning set forth in Section 15.1A.

“Defect” or “Defective” has the meaning set forth in Section 12.1A.

“Defect Correction Period” means the period commencing upon completion of all Work under the Contract Documents and ending eighteen (18) months thereafter.

“Disclosing Party” has the meaning set forth in Section 18.3.

“Dispute” has the meaning set forth in Section 17.1.

“Dispute Notice” has the meaning set forth in Section 17.1.

“Drawings” means the graphic and pictorial documents showing the design, location and dimensions of the Facility, generally including plans, elevations, sections, details,

- 3 -

schedules and diagrams, which are prepared as a part of and during the performance of the Work.

“EPC Agreement” has the meaning set forth in Section 3.1C.

“Equipment” means any of the equipment, materials, supplies, software, licenses and systems required for the completion of and permanent incorporation into the Facility.

“Excusable Delay” means any act or event that is (i) beyond the reasonable control of the affected Party, not due to its fault or negligence and (ii) could not have been prevented or avoided by the affected Party through the exercise of due diligence. Excusable Delay may include acts of Third Parties, catastrophic storms or floods, lightning, tornadoes, hurricanes, a named tropical storm, earthquakes and other acts of God, wars, civil disturbances, revolution, acts of public enemy, acts of terrorism, credible threats of terrorism, revolts, insurrections, sabotage, riot, plague, epidemic, commercial embargoes, expropriation or confiscation of the Facility, fires, explosions, industrial action or strike (excluding industrial actions and strikes involving only the employees of Contractor or any of its Subcontractors at the Site) and actions, inactions, or delays of a Governmental Instrumentality that were not requested, promoted, or caused by the affected Party. For avoidance of doubt, Excusable Delay shall not include any of the following causes: (i) economic hardship; (ii) changes in market conditions; or (iii) nonperformance or delay by Contractor or its Subcontractors, unless otherwise caused by an Excusable Delay.

“Facility” means the LNG receiving, storage and regasification facilities that will be engineered, procured, constructed, pre-commissioned, commissioned and tested in accordance with the terms of this Agreement or the EPC Agreement, as applicable.

“Fee” has the meaning set forth inAttachment C.

“FERC” means the Federal Energy Regulatory Commission.

“Final Lien and Claim Waiver” means the waiver and release provided to Owner by Contractor and Subcontractors in accordance with the requirements of Section 8.8, which shall be in the form ofAttachment J,Schedules J-3 and J-4.

“GAAP” means generally accepted accounting principles.

“Geotechnical Reports” means the following reports provided by Owner to Contractor prior to the Agreement Effective Date: (i) Final Report, Geotechnical Investigation, LNG Tank Area, Corpus Christi, Texas, dated September 2003, prepared by Tolunay-Wong Engineers, Inc.; (ii) Final Report, Geotechnical Investigation, Process Area, Piperack and Waterline, Liquefied Natural Gas Terminal, Corpus Christi, Texas, dated September 2003, prepared by Tolunay-Wong Engineers, Inc; (iii) Final Report, Geotechnical Investigation, Berth Area, Liquefied Natural Gas Terminal, Corpus Christi, Texas, dated September 2003, prepared by Tolunay-Wong Engineers, Inc; (iv) Geological Technical Hazard Evaluation, Corpus Christi LNG Terminal, Ingleside, Texas, dated September 19, 2003, prepared by Tolunay-Wong Engineers, Inc.; and (v) Seismic Hazard Assessment of the Planned LNG Terminal Site in Corpus Christi, Texas, dated September 2003, prepared by ABS Consulting, Inc.

- 4 -

“Good Engineering and Construction Practices” or “GECP” means the generally accepted practices, skill, care, methods, techniques and standards employed by the international LNG industry at the time of the applicable Work Order Effective Date that are commonly used in prudent design, engineering, procurement and construction to safely design and construct LNG related facilities of similar size and type as the Facility, in accordance with Applicable Law and Applicable Codes and Standards.

“Governmental Instrumentality” means any federal, state or local department, office, instrumentality, agency, court, board or commission having jurisdiction over a Party or any portion of the Work, the Facility or the Site.

“Guarantor” means AMEC plc, a public limited company organized under the laws of the United Kingdom.

“Hazardous Materials” means any substance that under Applicable Law is considered to be hazardous or toxic or is or may be required to be remediated, including (i) any petroleum or petroleum products, radioactive materials, asbestos in any form that is or could become friable, urea formaldehyde foam insulation, transformers or other equipment that contain dielectric fluid containing polychlorinated biphenyls and processes and certain cooling systems that use chlorofluorocarbons, (ii) any chemicals, materials or substances which are now or hereafter become defined as or included in the definition of “hazardous substances,” “hazardous wastes,” “hazardous materials,” “extremely hazardous wastes,” “restricted hazardous wastes,” “toxic substances,” “toxic pollutants,” or any words of similar import pursuant to Applicable Law, or (iii) any other chemical, material, substance or waste, exposure to which is now or hereafter prohibited, limited or regulated by any Governmental Instrumentality, or which may be the subject of liability for damages, costs or remediation.

“HSE Plan” has the meaning set forth in Section 3.9.

“Indemnified Party” means any member of the Owner Group or the Contractor Group, as the context requires.

“Indemnifying Party” means Owner or Contractor, as the context requires.

“Initial Payment” has the meaning set forth in Section 8.1.

“Insolvency Event” in relation to any Party or Guarantor means the bankruptcy, insolvency, liquidation, administration, administrative or other receivership or dissolution of such Party or Guarantor, and any equivalent or analogous proceedings by whatever name known and in whatever jurisdiction, and any step taken (including the presentation of a petition or the passing of a resolution or making a general assignment or filing for the benefit of its creditors) for or with a view toward any of the foregoing. Notwithstanding the above definition, the Parties agree that a corporate reorganization of Guarantor shall not be considered an Insolvency Event, provided that any such reorganization of Guarantor does not create a material adverse change in the Guarantor’s financial condition.

- 5 -

“Interim Lien and Claim Waiver” means the waiver and release provided to Owner by Contractor and Subcontractors in accordance with the requirements of Section 8.7, which shall be in the form ofAttachment J,Schedules J-1 and J-2.

“Invoice” means Contractor’s request for a payment pursuant to Section 8.1, which invoice shall be in the form ofAttachment I.

“Key Personnel” or “Key Persons” has the meaning set forth in Section 2.2B.

“Landowner” means any Person with whom the Contractor must interface on the Site, such Persons being identified inAttachment E or within the applicable Work Order.

“Lender” means any entity or entities providing temporary or permanent debt financing to Owner for the Facility.

“LNG” means liquefied Natural Gas.

“Master Services Agreement” means the Master Services Agreement among Cheniere, Zachry and AMEC, dated October 14, 2005.

“Memorandum of Understanding” has the meaning set forth in Section 20.1.

“Mediation Request” has the meaning set forth in Section 17.2.

“Month” means a Gregorian calendar month; “month” means any period of thirty (30) consecutive Days.

“Monthly” means an event occurring or an action taken once every Month.

“Monthly Progress Reports” has the meaning set forth in Section 3.16A.8.

“Natural Gas” means combustible gas consisting primarily of methane.

“Owner” has the meaning set forth in the preamble hereto.

“Owner Default” has the meaning set forth in Section 15.5.

“Owner Group” means (i) Owner, its parent and each of their respective Affiliates and (ii) the respective directors, officers, agents, employees and representatives of each Person specified in clause (i) above.

“Owner Representative” means that Person or Persons designated by Owner in a written notice to Contractor, each of whom shall have (except for any limitations specified in such notice) complete authority to act on behalf of Owner on all matters pertaining to the Contract Documents or the Work, including giving instructions and making changes in the Work and executing Work Orders. Owner designates Ed Lehotsky and Carlos Macias as the Owner Representatives. Notification of a change in Owner Representative shall be provided in advance, in writing, to Contractor.

- 6 -

“Owner’s Confidential Information” has the meaning set forth in Section 18.1.

“P&ID’s” means piping and instrumentation diagrams.

“Parent Guarantee” has the meaning set forth in Section 20.17.

“Party” or “Parties” means Owner and/or Contractor and their successors and permitted assigns.

“Permit” means any valid waiver, certificate, approval, consent, license, exemption, variance, franchise, permit, authorization or similar order or authorization from any Governmental Instrumentality required to be obtained or maintained in connection with the Facility, the Site or the Work.

“Person” means any individual, company, joint venture, corporation, partnership, association, joint stock company, limited liability company, trust, estate, unincorporated organization, Governmental Instrumentality or other entity having legal capacity.

“Qualified Research Expenditures” means the costs funded by Owner under the Contract Documents that are incurred in connection with Work performed by Contractor and its Subcontractors which meet all of the requirements of Section 41(d)(1) of the Internal Revenue Code of 1986, as amended, and which are related to the development or improvement of a business component of the Facility.

“Receiving Party” has the meaning set forth in Section 18.3.

“Rights of Way and Easements” means the rights of way and easements listed inAttachment E, which shall, for the purposes of the Contract Documents, unless otherwise indicated in this Agreement, be considered part of the Site.

“Rights of Way and Easement Agreements” means the agreements between Owner or its Affiliates and Landowners with respect to the Rights of Way and Easements. The Rights of Way and Easement Agreements, which are incorporated herein by reference, are listed inAttachment E.

“Safety Standards” has the meaning set forth in Section 3.9.

“Scope of Work” means the description of Work to be performed by Contractor under this Agreement or as set forth in a particular Work Order, depending upon the context in which the term “Scope of Work” is used.

“SEC” means the Securities and Exchange Commission or any successor entity thereto.

“Site” means those areas shown in greater detail inAttachment E.

“Specifications” means those documents consisting of the written requirements for Equipment, standards and workmanship for the Work, which are prepared as a part of and during the performance of the Work.

- 7 -

“Subcontract” means a direct or indirect agreement by Contractor with a Subcontractor for the performance of any portion of the Work.

“Subcontractor” means any Person, of any tier who has a direct or indirect contract with Contractor to perform any portion of the Work.

“Taxes” means any and all taxes, assessments, levies, duties, fees, charges and withholdings of any kind or nature whatsoever and howsoever described, including value-added, sales and use taxes, gross receipts, license, payroll, environmental, profits, premium, franchise, property, excise, capital stock, import, stamp, transfer, employment, occupation, generation, privilege, utility, regulatory, energy, consumption, lease, filing, recording and activity taxes, levies, duties, fees, charges, imposts and withholding, together with any and all penalties, interest and additions thereto.

“Tax Exempt Equipment” is defined in Section 4.4A.2.

“Third Party” means any Person other than a member of (i) the Contractor Group, (ii) the Owner Group, or (iii) any Subcontractor or any employee, officer or director of such Subcontractor.

“Third Party Proprietary Work Product” has the meaning set forth in Section 11.1B.

“U.S. Dollars” or “U.S.$” means the legal tender of the United States of America.

“Warranty” or “Warranties” has the meaning set forth in Section 12.1A.

“Work” means the obligations, duties and responsibilities to be performed by or on behalf of Contractor in connection with certain preliminary design, engineering, procurement, pipeline dismantlement, removal and construction, road construction, and Site work, and the required related labor and materials and Equipment, all in accordance with the terms of the Contract Documents.

“Work Order” means an order for Work in substantially the form ofAttachment N, signed in writing by both Parties, which sets forth and describes Scope of Work for such Work Order and a Work Schedule.

“Work Order Effective Date” means the date on which the Parties execute the applicable Work Order.

“Work Order No. 1” is the Work Order mutually agreed to between Owner and Contractor and set forth inAttachment M, which describes an initial Scope of Work and Work Schedule to be performed by Contractor under the Work Order and pursuant to this Agreement.

“Work Product” has the meaning set forth in Section 11.1A.

“Work Schedule” means the schedule of the performance of Work by Contractor under a Work Order.

- 8 -

“Zachry” means Zachry Construction Corporation, a Delaware corporation, or any successor entity thereto.

1.2 The meanings specified in this Article 1 are applicable to both the singular and plural. As used in this Agreement, the terms “herein,” “herewith,” “hereunder” and “hereof” are references to this Agreement taken as a whole, and the terms “include,” “includes” and “including” mean “including, without limitation,” or variant thereof. Reference in this Agreement to an Article or Section shall be a reference to an Article or Section contained in this Agreement (and not in any Attachments or Schedules to this Agreement) unless expressly stated otherwise, and a reference in this Agreement to an Attachment or Schedule shall be a reference to an Attachment or Schedule attached to this Agreement unless expressly stated otherwise.

Article 2

RELATIONSHIP OF OWNER, CONTRACTOR AND SUBCONTRACTORS

2.1Status of Contractor. The relationship of Contractor to Owner shall be that of an independent contractor. Any provisions of the Contract Documents which may appear to give Owner or the Owner Representative the right to direct or control Contractor as to details of performing the Work, or to exercise any measure of control over the Work, shall be deemed to mean that Contractor shall follow the desires of Owner or the Owner Representative in the results of the Work only and not in the means by which the Work is to be accomplished, and Contractor shall have the complete right, obligation and authoritative control over the Work as to the manner, means or details as to how to perform the Work. Nothing herein shall be interpreted to create a master-servant or principal-agent relationship between Contractor, or any of its Subcontractors, and Owner. Nevertheless, Contractor shall comply with all provisions, terms and conditions of the Contract Documents, and the fact that Contractor is an independent contractor does not relieve it from its responsibility to fully, completely, timely and safely perform the Work in compliance with the Contract Documents.

2.2Key Personnel, Organization Chart and Contractor Representative.

A.Contractor Personnel. Contractor represents that it has adequate and fully qualified personnel and facilities within its organization to perform the Work required by the Contract Documents.

B.Key Personnel and Organization Chart.Attachment F sets forth Contractor’s organizational chart to be implemented for the Work and also contains a list of key personnel (“Key Personnel” or “Key Persons”) from Contractor’s organization who will be assigned to the Work. Key Personnel shall, unless otherwise expressly stated inAttachment F, be devoted full-time to the Work until completion of the Work, and Key Personnel shall not be removed or reassigned without Owner’s prior written approval. All requests for the substitution of Key Personnel shall include a detailed explanation and reason for the request and the resumes of professional education and experience for a minimum of two (2) candidates of equal or greater qualifications and experience. Should Owner approve of the replacement of a Key Person, Contractor shall, so far as reasonably practicable, allow for an overlap of at least one (1) week during which both the Key Person to be replaced and the Owner-approved new Key Person shall work together full time. The

- 9 -

additional cost of any replacement of such Key Personnel and overlap time shall be entirely at Contractor’s expense. Owner shall have the right, but not the obligation, at any time to require that Contractor replace any Key Person with another employee acceptable to Owner.

C.Contractor Representative. The Contractor Representative is a Key Person.

2.3Subcontractors. Owner acknowledges and agrees that Contractor intends to have portions of the Work accomplished by Subcontractors pursuant to written Subcontracts. All Subcontractors shall be reputable, qualified firms with an established record of successful performance in their respective professions performing identical or substantially similar work. All Subcontracts shall be consistent with the terms or provisions of the Contract Documents to the extent such terms and provisions are applicable to the Scope of Work of any applicable Work Order. In the event Contractor is unable to obtain consistent provisions in any Subcontract, or Owner’s written approval to deviate from the provisions of the Contract Documents within such Subcontract, Contractor will use commercially reasonable efforts to provide a substitute Subcontractor;provided, however, should Contractor, notwithstanding its use of commercially reasonable efforts, be unable to procure a substitute Subcontractor, Contractor shall not be deemed to be in default or breach of this Agreement. No Subcontractor is intended to be or shall be deemed a third-party beneficiary of this Agreement or any Work Order. Contractor shall be fully responsible to Owner for the acts and omissions of Subcontractors and of Persons directly or indirectly employed by any of them in the performance of the Work, as it is for the acts or omissions of Persons directly employed by Contractor. The work of any Subcontractor shall be subject to inspection by Owner to the same extent as the Work of Contractor. All Subcontractors and their respective personnel are to be instructed by Contractor in the terms and requirements of the Owner-approved safety and environmental protection regulations and policies and shall be expected to comply with such regulations. In the event that any personnel are not adhering to such regulations and policies, such personnel shall be removed by Contractor. In no event shall Contractor be entitled to any adjustment of any Work Schedule under any Work Order as a result of such personnel’s non-compliance with such regulations and policies set forth in the HSE Plan, or any removal of personnel necessitated by non-compliance. Nothing contained herein shall (i) create any contractual relationship between any Subcontractor and Owner, or (ii) obligate Owner to pay or cause the payment of any amounts to Subcontractor.

2.4Subcontracts.

A.Approved List. Subject to Section 2.4C,Attachment Gsets forth a list of contractors and suppliers that Contractor and Owner have agreed are approved for selection as Subcontractors for the performance of that portion of the Work specified inAttachment G. Following the Agreement Effective Date, Contractor and Owner may specify in a Work Order additional contractors and suppliers for selection as Subcontractors for performance of Work set forth in such Work Order. Approval by Owner of any Subcontractors does not relieve Contractor of any responsibilities under the Contract Documents.

- 10 -

B.Additional Proposed Subcontractors. In the event that Contractor is considering the selection of a Subcontractor not listed onAttachment G or in a Work Order, Contractor shall notify Owner of its proposed Subcontractor as soon as possible during the selection process and furnish to Owner all information requested by Owner with respect to Contractor’s selection criteria (including copies of bid packages furnished to prospective Subcontractors, responses to such bid packages, and the qualifications of the proposed Subcontractors). Contractor shall use best efforts to hire qualified, local Subcontractors. Owner shall have the discretion to reject any proposed Subcontractor not listed onAttachment G or in a Work Order for a Subcontract within ten (10) Days of Owner’s receipt of Contractor’s notice and proper documentation given pursuant to this Section 2.4. If Owner does not accept or reject a Subcontractor that is otherwise properly proposed by Contractor pursuant to this Section 2.4, then such Subcontractor shall be deemed approved by Owner, but such approval does not relieve Contractor of any responsibilities under the Contract Documents. Contractor shall not enter into any Subcontract with a proposed Subcontractor that is rejected by Owner in accordance with this Section 2.4. Even if Owner approves of a Subcontractor, Owner nevertheless has the right of approval with respect to the terms and conditions of any Subcontract.

C.Subcontracts.Owner shall have the right to approve any Subcontract exceeding Fifty Thousand U.S. Dollars (U.S.$50,000) prior to execution of such Subcontract by Contractor, but approval by Owner of any Subcontract shall not relieve Contractor of any of its obligations under this Agreement. The price in any Subcontract may be for a separated fixed price, on a cost-reimbursable basis or some other basis, in each case to be approved by Owner. Contractor shall furnish Owner with a copy of all Subcontracts ten (10) or more Days prior to the execution of each such Subcontract. Without limitation of the requirements in this Section 2.4, each Subcontract shall contain the following provisions:

1. the Subcontract may, upon termination of this Agreement or all or any part of the Work, and Owner’s written notice to such Subcontractor, be assigned to Owner without the consent of Subcontractor; and

2. unless otherwise agreed by Owner in writing, Subcontractor shall comply with and perform for the benefit of Owner all requirements and obligations of Contractor to Owner under the Contract Documents, as such requirements and obligations are applicable to the performance of the work under the Subcontract.

3. Subcontractor’s billings and change orders, if any, will separate charges/pricing for “skills and labor” from charges/pricing for taxable Equipment and taxable services re-sold to Owner.

- 11 -

Article 3

CONTRACTOR’S RESPONSIBILITIES

3.1Scope of Work.

A.Generally. The initial Work to be performed by Contractor under this Agreement is specified in Work Order No. 1, which is attached hereto asAttachment M. Any further Work to be performed by Contractor shall be mutually agreed upon between Owner and Contractor in subsequent Work Orders in the form ofAttachment N. All Work Orders shall be dated and numbered and shall include a Scope of Work and Work Schedule for such Work Order. The rights of Owner and Contractor under each Work Order shall be independent of those under all other Work Orders. Each Work Order shall be governed by the provisions of this Agreement and shall be deemed to incorporate by reference all terms and conditions of this Agreement and shall constitute a separate and binding contract between the Parties. Contractor shall perform the Work under each Work Order in accordance with GECP, Applicable Law, Applicable Codes and Standards, and all other terms and provisions of this Agreement and such Work Order. It is understood and agreed that the Work shall include any incidental work that can reasonably be inferred as necessary to complete any Scope of Work under any Work Order in accordance with GECP, Applicable Law, Applicable Codes and Standards, and all other terms and provisions of this Agreement, excluding only those items which Owner has specifically agreed to provide under the terms of this Agreement. SUBJECTTO WORK ORDER NO. 1,NOTHINGINTHIS AGREEMENTREQUIRES OWNERTOORDER WORKFROM CONTRACTORORREQUIRES CONTRACTORTOPROVIDE WORKTO OWNER,AND CONTRACTORSHALLBECOMPENSATEDONLYFORSUCH WORKAS CONTRACTORACTUALLYPERFORMSPURSUANTTOA WORK ORDEREXECUTEDINACCORDANCEWITHTHIS AGREEMENT.

B.Exception to Scope of Work. Contractor shall not be responsible for providing (i) the Permits that Owner is responsible for obtaining in accordance with Section 4.2; (ii) those requirements set forth under Sections 4.3 and 4.5; (iii) legal description of the Site and a survey of the Site showing the boundaries of the Site and one survey control point pursuant to Section 4.5; and (iv) any other obligations or requirements expressly set forth in the Contract Documents as required to be performed by Owner.

C.EPC Agreement.If the Parties enter into an agreement for the engineering, procurement, and construction of the Facility (the proposed “EPC Agreement”), then the Work performed under the Contract Documents shall become part of the EPC Agreement and the terms and conditions of the EPC Agreement shall govern the Work performed under the Contract Documents and shall control over any terms in the Contract Documents. THE PARTIESACKNOWLEDGETHATTHE CONTRACT DOCUMENTSDONOTIMPOSEANYOBLIGATIONON OWNERTOENTERINTOAN EPC AGREEMENTWITH CONTRACTORFORTHEENGINEERING,PROCUREMENTANDCONSTRUCTIONOFTHE FACILITY.

3.2Applicable Law. By signing any particular Work Order, Contractor represents that it has investigated to its satisfaction Applicable Law (including any Applicable Codes and Standards incorporated into Applicable Law) in existence as of the applicable Work Order Effective Date, and warrants that it can perform the Work in accordance with such Applicable Law. Contractor shall perform the Work in accordance with Applicable Law, whether or not such Applicable Law came into effect before such Work Order Effective Date or during the performance of the Work. Contractor shall advise Owner of any change in Applicable Law occurring after such Work Order Effective Date.

- 12 -

3.3Changes in Applicable Codes and Standards Not Constituting a Change in Law. Contractor shall provide notice to Owner on a timely basis, and no later than thirty (30) Days after such a change, of any change in Applicable Codes and Standards that does not constitute a Change in Law. Contractor shall inform Owner if compliance with a changed Applicable Code and Standard is mandatory to comply with GECP. In the event Owner, at its sole option, elects for Contractor to implement a change in Applicable Codes and Standards that does not constitute a Change in Law, Owner shall so inform Contractor in writing.

3.4Design and Engineering Work.

A.General. Contractor shall, as part of the Work, perform all design and engineering Work in accordance with the Contract Documents and cause the Work to meet and achieve the requirements of the Contract Documents.

B.Drawings and Specifications. The Drawings and Specifications shall be based on the requirements of the Contract Documents, including the Scope of Work of the Agreement and Design Basis as set out inAttachment A, GECP, Applicable Codes and Standards and Applicable Law.

C.Review Process.

1.Submission by Contractor. Contractor shall submit copies of the Drawings and Specifications to Owner for formal review, comment or disapproval in accordance with the requirements set forth in the applicable Work Order.

2.Review Periods. Owner shall have up to ten (10) Business Days from its receipt of Drawings and Specifications submitted in accordance with Section 3.4C.1 to issue to Contractor written comments, proposed changes and/or written disapprovals of the submission of such Drawings and Specifications to Contractor.

If Owner does not issue any comments, proposed changes or written disapprovals within such time periods, Contractor may proceed with the development of such Drawings and Specifications, but Owner’s lack of comments or disapproval, if applicable, shall in no event constitute an approval of the matters received by Owner.

In the event that Owner disapproves the Drawings or Specifications, Owner shall provide Contractor with a written statement of the reasons for such rejection within the time period required for Owner’s response, and Contractor shall provide Owner with revised and corrected Drawings and Specifications as soon as possible thereafter.

Owner’s lack of disapproval of or comments on, or any approval by Owner of, any Drawings and Specifications shall not in any way be deemed to limit or in any way alter Contractor’s responsibility to design and engineer the Facility and perform the Work in accordance with the requirements of the Contract Documents.

D.Design Licenses. Contractor shall perform all design and engineering Work in accordance with Applicable Law, and all Drawings and Specifications shall be

- 13 -

complete and fully coordinated and stamped by design professionals duly licensed in accordance with Applicable Law.

E.CAD Drawings. Drawings prepared by Contractor or its Subcontractors under the Contract Documents shall be prepared using computer aided design (“CAD”). Contractor shall provide Drawings in their native formats as set forth in the applicable Work Order along with six (6) hard copies.

F.Progress P&ID’s. During the progress of the Work, Contractor shall maintain and provide Owner with access to a marked, up-to-date set of P&ID’s maintained for and by Contractor.

G.Other Information. Contractor shall deliver to Owner copies of any and all Drawings, Specifications or other documents, as requested by Owner, within a reasonable time of such request.

3.5Environmental Regulations and Environmental Compliance. Without limitation of Section 3.1, Contractor shall perform the Work and shall design the Facility in compliance with Contractor’s HSE Plan. If applicable to the Work to be performed under the Contract Documents, Contractor shall dispose of all non-hazardous wastes and Hazardous Materials brought onto the Site by Contractor or any of its Subcontractors or produced as a by-product of Equipment, material or Construction Equipment brought onto the Site by Contractor or Subcontractors during performance of the Work, all of which shall be disposed in off-Site locations permitted to receive such non-hazardous wastes and Hazardous Materials. Contractor shall deliver to Owner (i) notice of any pending or threatened material environmental claim with respect to the Facility, and (ii) promptly upon their becoming available, copies of written communications with any Governmental Instrumentality relating to any such material environmental claim.

3.6Construction Equipment. Contractor shall furnish all Construction Equipment necessary and appropriate for the timely and safe completion of the Work in compliance with the Contract Documents. Notwithstanding anything to the contrary contained in this Agreement, Contractor shall be responsible for damage to or destruction or loss of, from any cause whatsoever, all such Construction Equipment. Subject to Section 3 ofSchedule L-1, Contractor shall require all insurance policies (including policies of Contractor and all Subcontractors) in any way relating to such Construction Equipment to include clauses stating that each underwriter will waive all rights of recovery, under subrogation or otherwise, against Owner and any Owner Affiliates.

3.7Employment of Personnel.

A. Contractor shall not employ, or permit any Subcontractor to employ, in connection with its performance under the Contract Documents, any Person who is demonstrably not skilled or qualified in the services or work assigned to such Person. Contractor agrees to promptly remove (or to require any Subcontractor to remove) from its services or work in connection with the Work any Person who does not meet the foregoing requirements. In addition, Contractor agrees that, after receipt of written notice from Owner, it shall promptly remove from the Work any employee or agent of Contractor or of

- 14 -

its Subcontractors who, in Owner’s opinion, is unsafe, incompetent, careless, unqualified to perform the Work assigned to such Person, creates an unsafe or hostile work environment, disregards the terms and conditions of the Contract Documents, or is interrupting, interfering with or impeding the timely and proper completion of the Work. NOTWITHSTANDINGTHEFOREGOING, OWNERSHALLHAVENOLIABILITYAND CONTRACTORAGREESTORELEASE,INDEMNIFY,DEFENDANDHOLDHARMLESSTHE OWNER GROUPFROMANDAGAINSTANYANDALLCLAIMS,CAUSESOFACTION,DAMAGES,LOSSES,COSTANDEXPENSES (INCLUDINGALLREASONABLEATTORNEYS’FEESANDLITIGATIONORARBITRATIONEXPENSES)ANDLIABILITIES,OFWHATSOEVERKINDORNATURE,WHICHMAYDIRECTLYORINDIRECTLYARISEORRESULTFROM CONTRACTORORANY SUBCONTRACTORCHOOSINGTOTERMINATETHEEMPLOYMENTOFANYSUCHEMPLOYEE (INCLUDINGANY KEY PERSON)ORREMOVESUCHEMPLOYEEFROMTHE WORKWHOFAILSTOMEETTHEFOREGOINGREQUIREMENTSFOLLOWINGAREQUESTBY OWNERTOHAVESUCHEMPLOYEEREMOVEDFROMTHE WORK. Any such employee shall be replaced at the cost and expense of Contractor or the relevant Subcontractor, as appropriate.

B. Contractor is responsible for maintaining labor relations in such manner that, so far as reasonably practicable, there is harmony among workers. Contractor and its Subcontractors shall conduct their labor relations in accordance with the recognized prevailing local area practices. Contractor shall inform Owner promptly of any labor dispute, anticipated labor dispute, request or demand by a labor organization, its representatives or members which may reasonably be expected to affect the Work. Contractor further agrees to inform Owner, before any commitments are made, during the negotiations of any agreements or understandings with local or national labor organizations.

3.8Clean-Up. If applicable to the Work to be performed under the Contract Documents, Contractor shall, to Owner’s satisfaction, at all times keep the Site free from all waste materials or rubbish caused by the activities of Contractor or any of its Subcontractors. As soon as practicable after final completion of the Work, Contractor shall remove all of its Construction Equipment and remove from the Site all waste material and rubbish that was caused by the activities of Contractor or any of its Subcontractors. The Site shall be restored in accordance with all Permits and the Contract Documents. In the event of Contractor’s failure to comply with any of the foregoing upon three (3) Days’ notice to do so, Owner may accomplish the same;provided, however, that Contractor shall be responsible for all reasonable costs associated with such removal and/or restoration, including costs associated with Taxes, permitting and transportation.

3.9HSE Plan; Security. Contractor recognizes and agrees that safety and physical security are of paramount importance in the performance of the Work and that Contractor is responsible for performing the Work in a safe and physically secure manner. Within sixty (60) Days after the Agreement Effective Date, Contractor shall submit to Owner for its review a health, safety and environmental plan (including a drug testing program) based upon Contractor’s standard safety and environmental policies, as modified to account for the particulars of the Work to be performed under this Agreement (the “HSE Plan”). Contractor shall revise the HSE Plan to incorporate comments, if any, provided by Owner during its review, which shall be conducted within ten (10) Days of receipt of the HSE Plan. Contractor further agrees to perform the Work in accordance with the health, safety and environmental rules and standards of Applicable Law,

- 15 -

GECP and the HSE Plan (collectively, the “Safety Standards”). Owner’s review of, or comments with respect to, the HSE Plan shall not in any way relieve Contractor of its obligations under this Agreement (including Contractor’s obligations to conduct the Work in accordance with the health, safety and environmental rules of Applicable Law and GECP). Contractor shall appoint one or more (as appropriate) safety representative(s) reasonably acceptable to Owner who shall have responsibility to correct unsafe conditions or unsafe acts associated with Work performed on the Site, act on behalf of Contractor on health, safety and environmental matters, and participate in periodic safety meetings with Owner. Contractor further agrees to provide or cause to be provided necessary training and safety equipment to its employees, Subcontractors, and to Owner personnel temporarily visiting the Site to ensure their compliance with the foregoing Safety Standards and enforce the use of such training and safety equipment. Contractor shall maintain all accident, injury and any other records required by Applicable Law or by Permit and shall furnish Owner a Monthly summary of injuries and labor hours lost due to injuries. Should Owner at any time observe Contractor, or any of its Subcontractors performing the Work at the Site in violation of the Safety Standards or in an unsafe manner, or in a manner that would, if continued, violate the Safety Standards or become unsafe, then Owner shall have the right (but not the obligation) to require Contractor to stop the affected Work until such time as the manner of performing such Work has been rendered safe. In connection with Work performed at the Site, Contractor shall be responsible for the security, fencing, guarding and lighting until all of the completion of such Work. In addition, for Work performed on Rights of Way and Easements, Contractor shall perform all Work in accordance with, and cause all Subcontractors to perform all Work in accordance with, the safety, health and environmental rules and policies required by the Landowners of such Rights of Way and Easements and provided in advance to Contractor in writing.

3.10Emergencies. In the event of any emergency endangering life or property in any way relating to the Work, whether on the Site or otherwise, Contractor shall take such action as may be reasonable and necessary to prevent, avoid or mitigate injury, damage, or loss and shall, as soon as reasonably possible, report any such incidents, including Contractor’s response thereto, to Owner. If Contractor fails to take such action and the emergency requires immediate action, then Owner, with or without notice to Contractor may, but shall be under no obligation to, take reasonable action as required to address such emergency. The taking of any such action by Owner, or Owner’s failure to take any action, shall not limit Contractor’s liability. Contractor shall reimburse Owner in an amount equal to the reasonable costs incurred by Owner in taking such action.

3.11Contractor Permits. Contractor shall be responsible for obtaining the Permits listed inSchedule B-1 and any other Permits to be issued in Contractor’s name as may be required to perform the Work under the Contract Documents. Contractor shall provide Owner with copies of such Permits as soon as reasonably practicable after they are obtained.

3.12Assistance with Owner Permits. Contractor shall provide assistance, information and documentation as requested by Owner to enable Owner to obtain any Permits that Owner is required to obtain in connection with the Section 4.2.

- 16 -

3.13Books, Records and Audits.

A. Contractor shall keep full and detailed books, records, daily reports, schedules, accounts, work logs, payroll records, receipts, statements, electronic files, correspondence and other pertinent documents as may be necessary for proper performance of the Work under the Contract Documents, as required under Applicable Law or the Contract Documents, and in any way relating to the Contract Documents (“Books and Records”). Contractor shall maintain all such Books and Records in accordance with GAAP and shall retain all such Books and Records for a minimum period of three (3) years after the earlier of the termination or expiration of this Agreement, or such greater period of time as may be required under Applicable Law.

B. Upon reasonable notice, Owner shall have the right to audit, or have audited by Owner’s third party auditors, Contractor’s Books and Records;provided, however, that such audit shall not extend to calculations of the internal composition of any compensation that is fixed in amount hereunder, including the composition of any agreed-upon multipliers, rates, burdens and markups reflected inAttachment C. When requested by Owner, Contractor shall provide Owner or its auditors with reasonable access to all such Books and Records, and Contractor’s personnel shall cooperate with Owner and such auditors to effectuate the audit or audits hereunder. Owner and its auditors shall have the right to copy all such Books and Records. Contractor shall endeavor to include audit provisions identical to this Section 3.13 in all Subcontracts. No access to Books and Records shall be granted to Owner’s auditors until such auditors have signed a confidentiality agreement with Contractor in accordance with the standard practice in the auditing industry for audits of this kind.

C. Contractor shall not, and shall provide that its Subcontractors and agents or employees of any of them shall not (i) pay any commissions or fees, or grant any rebates, to any employee or officer of Owner or its Affiliates, (ii) favor employees or officers of same with gifts or entertainment of a significant cost or value, or (iii) enter into any business arrangements with employees or officers of same.

3.14Tax Accounting and Auditing. Within a reasonable period of time following a request therefor by Owner, Contractor shall provide to Owner or its auditors any information (including Books and Records) regarding quantities and descriptions of any Equipment ordered for the Facility and any other information as Owner or its auditors may deem reasonably necessary in connection with the preparation of Owner’s tax returns (including information reasonably required to determine the amount of Qualified Research Expenditures incurred in connection with the Work) or other tax documentation in connection with the Work. Contractor shall be responsible for personal property Taxes on Construction Equipment.

3.15Temporary Utilities, Roads, Facilities and Storage. Until final completion of the Work, to the extent applicable, Contractor shall provide all temporary utilities (i.e., electricity, water, communication, cable, telephone, waste and sewer) necessary for the performance of the Work, including installation and usage costs. Subject to Section 4.3, Contractor shall construct and maintain temporary access and haul roads as may be necessary for the proper performance of the Contract Documents and the Work. If requested by Owner, Contractor shall provide Owner with sufficient office space at the time of Contractor’s mobilization at the Site to accommodate Owner’s Site representative and support staff at the Site. Contractor shall provide Owner with all

- 17 -

office space, construction trailers, utilities, storage and warehousing, security, telephones, furnishings, and other temporary facilities required for their oversight of the Work, as set forth in more detail in the applicable Work Order. Once title to Equipment has passed to Owner as set forth in Section 9.1, such Equipment shall, if stored at a location other than on the Site, be segregated from other goods, and shall be clearly marked as “Property of Corpus Christi LNG, LLC.”

3.16Reports.

A. Contractor shall provide Owner with an electronic copy of the following reports and other documentation:

1. minutes for all weekly status and other Work-related meetings with Owner within five (5) Business Days following such meeting;

2. safety incident reports within three (3) Business Days of the occurrence of any such incident; except for any safety incident involving a significant non-scheduled event such as fires, explosions, mechanical failures or major injuries which shall be provided to Owner within eight (8) hours of the occurrence of such incident;provided, however, notification shall be provided to Owner immediately if the incident is of significant magnitude to threaten public or employee safety, cause significant property damage or interrupt the Work;

3. productivity reports;

4. manpower reports;

5. cost reports;

6. reports with respect to Contractor and Subcontractor performance;

7. schedule reports; and

8. Monthly progress reports (“Monthly Progress Reports”) in form and content to be mutually determined by the Parties.

3.17Payment. Contractor shall timely make all payments required to be paid to Owner pursuant to the terms of this Agreement.

3.18Commercial Activities. Neither Contractor nor its employees shall establish any commercial activity or issue concessions or permits of any kind to Third Parties for establishing commercial activities on the Site or any other lands owned or controlled by Owner.

3.19Title to Materials Found. As between Owner and Contractor, the title to water, soil, rock, gravel, sand, minerals, timber and any other materials developed or obtained in the excavation or other operations of Contractor or any Subcontractor and the right to use said materials or dispose of same is hereby expressly reserved by Owner. Notwithstanding the foregoing, Contractor shall be permitted, without charge and with Owner’s approval, to use in the Work any such materials that comply with the requirements of the Contract Documents.

- 18 -

3.20Survey Control Points and Layout. If necessary for the performance of the Work, Contractor shall establish all survey control points and layout any such Work in accordance with the requirements of the Contract Documents, which shall be based on the survey control point established by Owner pursuant to Section 4.5. If Contractor or any of its Subcontractors or any of the representatives or employees of any of them move or destroy or render inaccurate the survey control point provided by Owner, such control point shall be replaced by Contractor at Contractor’s own expense.

3.21Cooperation with Others. Subject to the provisions of this Agreement, including Section 4.3, Contractor acknowledges that Owner or Owner’s other contractors or subcontractors may be working at the Site during the performance of the Contract Documents and Contractor’s Work or use of certain facilities may be interfered with as a result of such concurrent activities. Subject to Section 4.3, Contractor agrees to coordinate the performance of the Work with such other contractors or subcontractors performing work at the Site so as not to materially interfere with any of Owner’s other contractors or subcontractors performing work at the Site; provided, however,Contractor shall in all cases coordinate the Work with any Persons (other than Owner or Owner’s other contractors or subcontractors) on or using the Rights of Way and Easements, and Contractor shall adhere to the reasonable instructions provided by Owner or the applicable Landowner(s) in connection with Work performed within such Rights of Way and Easements.

3.22Responsibility for Property. Contractor shall plan and conduct its operations so that neither Contractor nor any of its Subcontractors shall (i) enter upon lands (other than the Site) or waterbodies in their natural state unless authorized by the appropriate owner or entity; (ii) close or obstruct any utility installation, highway, waterway, harbor, road or other property unless Permits are obtained and authorized by the appropriate entity or authority; or (iii) disrupt or otherwise interfere with the operation of any portion of any pipeline, telephone, conduit or electric transmission line, ditch, navigational aid, dock or structure unless otherwise specifically authorized in a Work Order or in writing by Owner. The foregoing includes damage arising from performance of the Work through operation of Construction Equipment or stockpiling of materials.

3.23Equipment Quality. Contractor shall furnish reasonable evidence as to the kind, quality, and quantity of all Equipment. Without prior written approval by Owner which specifically waives the requirements of this Agreement, where a Work Order specifies the procurement of certain Equipment as part of the Work, Contractor shall not procure any Equipment other than as specified in the Work Order. If Contractor wishes to modify the requirements with respect to any Equipment, then it shall make written application to Owner for Owner’s approval (such approval not to be unreasonably withheld), prior to procuring such Equipment. Such application shall (i) identify the requirements being modified, (ii) certify that the quality of the proposed substitute is equal to or better than that currently specified, and (iii) certify that the substitute is suited to the same use and capable of performing the same function as that specified. If the preceding requirements are not followed, then any substitution shall constitute a material failure by Contractor to comply with its obligations under the Contract Documents.

- 19 -

3.24Excusable Delay. If an Excusable Delay prevents the performance of any Work under a Work Order and causes Contractor to suspend performance of any such Work affected by an Excusable Delay, such suspension shall not be considered a Default,provided that Contractor uses all reasonable efforts to (i) mitigate the effects of such Excusable Delay and (ii) recommence such affected Work.

3.25Nondiscrimination. Contractor agrees that it shall conduct its activities without discrimination on account of race, creed, color, sex, national origin, age or disability and shall comply with Applicable Law relating thereto, including Executive Order 11246, as amended. Upon the request of Owner, Contractor shall provide Owner with copies of all plans or programs that Contractor uses to satisfy the requirements of this Section 3.25.

3.26Rights of Way and Easement Agreements. During the performance of the Work, Contractor shall comply with any obligations of the Rights of Way and Easement Agreements to the extent that such obligations apply to the Work being performed and provided that such Rights of Way and Easement Agreements are provided in advance of Contractor performing Work on such Rights of Way and Easement.

Article 4

OWNER’S RESPONSIBILITIES

Owner shall comply with the following provisions in a timely manner in accordance with the Work Schedule at no cost to Contractor:

4.1Payments. Owner shall timely make payments in accordance with the provisions of Article 8 hereof.

4.2Owner Permits. Owner shall be responsible for obtaining the Permits listed inSchedule B-2. Owner shall maintain and, to the extent applicable, renew such Permits. To the extent Owner has already obtained any such Permits as of the Agreement Effective Date, Owner shall provide copies of such Permits to Contractor on or before the Agreement Effective Date. The terms of all such Permits shall be compatible with Contractor’s performance of the Work, and Owner shall promptly notify Contractor of any changes to the terms of any such Permit that impacts Contractor’s performance of the Work under the Contract Documents. Owner shall provide information, assistance and documentation to Contractor as reasonably requested in connection with the Permits that Contractor is responsible for obtaining in accordance with Section 3.11.

4.3Access to the Site.

A. In accordance withAttachment K and subject to the terms of this Agreement, including Sections 3.21 and 4.3B, Owner shall provide Contractor with access to the Site,provided that Contractor’s access to Rights of Way and Easements shall be in accordance with the terms and conditions of the Rights of Ways and Easement Agreements.

B. Owner shall have access to the Site at all times.

- 20 -

4.4Sales and Use Tax Matters.

A.Sales and Use Tax Exemption Certificates on Tax Exempt Equipment.

1. For Texas state and local sales and use tax purposes, the Contract Documents shall be considered to be a separated contract for the construction of new non-residential real property as defined under Applicable Law, including 34 Tex. Admin Code Rule § 3.291(a)(12). Work Orders, all Change Orders, and Contractor’s Invoices will separate pricing/charges for “skills and labor” from pricing/charges for Equipment and taxable services re-sold to Owner. Contractor’s Invoices shall further separate Contractor’s pricing for taxable Equipment and taxable services re-sold to Owner from Contractor’s pricing/charges for Tax Exempt Equipment. Contractor shall invoice Owner Texas sales and use tax on Contractor’s sales price of the separated taxable Equipment and separated taxable services re-sold to Owner. Owner will pay Contractor Texas sales and use tax and Contractor will remit these taxes to the appropriate taxing authorities. Contractor shall ensure that all Subcontracts are separated for Texas state and local sales and use tax purposes. Contractor shall issue valid Texas re-sale certificates to Contractor’s Subcontractors for Subcontractor purchases of Equipment and taxable services re-sold to Owner.

2. Owner shall list in each Work Order and Change Order those items of Equipment to be permanently installed at the Facility in which Owner intends to claim a manufacturing, pollution control or other applicable exemption from the payment of Texas state and applicable local sales and use taxes under Applicable Law, including the governing law specified in Section 20.9 (“Tax Exempt Equipment”), which such list as set out in the Work Order may be adjusted by Owner at its sole discretion with written notice to Contractor on or before the completion of the Work and formalized by Change Order. In addition, Owner will update the list of Tax Exempt Equipment and taxable services re-sold to Owner in a Work Order (i) with respect to any additional items of Equipment and taxable services re-sold to Owner added by Change Order which are subject to a manufacturing, pollution control or other applicable exemption from the payment of Texas state and applicable local sales and use taxes, or (ii) should Owner determine that any Equipment previously designated as taxable Equipment and taxable services re-sold to Owner should be designated as Tax Exempt Equipment or tax exempt services. Owner shall provide Contractor with a valid Texas state and applicable local sales and use tax exemption certificates claiming the manufacturing and pollution control exemptions for the Tax Exempt Equipment (including Tax Exempt Equipment added to a Work Order by Change Order). The Owner-issued Texas sales and use tax exemption certification will be supported by the Owner-provided list included and incorporated into applicable Work Order.

3. Contractor shall maintain for Owner’s review copies of Texas state and applicable local sales and use tax exemption certificates and other similar documentation necessary to support all Texas state and applicable local sales and use tax exemptions that may be available to Owner, Contractor or any Subcontractor in connection with the Work.

- 21 -

4. Contractor shall reasonably cooperate with Owner to minimize any and all Texas state and applicable local sales and use taxes relating to the Facility and the Work. If Contractor or any Subcontractor incurs any Texas state and applicable local sales and use taxes on any items of Tax Exempt Equipment or taxable services re-sold to Owner listed in a Work Order, due to Contractor failing to follow such Owner provided listed in the Work Order, Contractor shall be responsible for the payment of such Texas state and applicable local sales and use taxes, penalties and interest, without reimbursement by Owner and CONTRACTORSHALLINDEMNIFY,DEFENDANDHOLDHARMLESS OWNER GROUPFROMANDAGAINSTANYCLAIMSBYA GOVERNMENTAL INSTRUMENTALITYFORSUCH TEXASSTATEANDAPPLICABLELOCALSALESANDUSETAXES. If the state of Texas increases or decreases the state or local option sales and use tax rates, the increase or decrease will be to the Owner’s account.

5. For clarification purposes, it is understood that Owner is solely responsible for the accuracy of the Owner-provided list in the Work Order regarding Tax Exempt Equipment and taxable services re-sold to Owner. If Contractor or any Subcontractor pays or incurs any Texas state and applicable local sales and use taxes on any items of Tax Exempt Equipment or taxable services re-sold to Owner attributable to the Owner’s failure to provide Contractor with a valid Texas state and applicable local sales and use tax exemption certificate for all or any portion of the Tax Exempt Equipment and taxable services resold to Owner included in the Owner-provided list in the applicable Work Order (including adjustments made to a Work Order due to Change Orders), Contractor shall be entitled to reimbursement in accordance with Article 7 in an amount equal to such Texas state and applicable local sales and use taxes, penalties and interest, if any, that are properly owed and paid by Contractor for such Tax Exempt Equipment and services improperly identified by Owner in the Owner-provided list included in the Work Order regarding Tax Exempt Equipment and taxable services re-sold to Owner, and OWNERSHALLINDEMNIFY,DEFENDANDHOLDHARMLESS CONTRACTOR GROUPFROMANDAGAINSTANYCLAIMSBYA GOVERNMENTAL INSTRUMENTALITYFORSUCH TEXASSTATEANDLOCALSALESANDUSETAXES.

B.Texas Sales and Use Tax on Taxable Equipment & Taxable Services Re-Sold to Owner. With each Invoice that includes any Equipment to be permanently installed in the Project (other than Tax Exempt Equipment) and taxable services resold to Owner including items such as real property services and non-Hazardous Materials removal services, Contractor shall separately list in the Invoice and bill Owner the Texas state and applicable local sales and use taxes with respect to such taxable Equipment and services. Contractor invoice charges for labor and skills will be separated from Contractor invoice charges for Equipment. In addition, Contractor will separate invoice charges for taxable Equipment from invoice charges for Tax Exempt Equipment and services. In no instance will “skills and labor”, service, fabrication labor or any other form of labor charge” be billed together with a charge for taxable Equipment. The Texas state and applicable local sales and use taxes charged to Owner shall be based on the prices listed inAttachment C and the schedule in the applicable Work Order. Texas sales and use tax amounts billed Owner will be subject to the provisions of Section 4.4A.4 and 4.4A5 (which

- 22 -

may be subject to Change Order or Work Order), which shall represent Owner’s maximum liability to Contractor for Texas state and applicable local sales and use taxes on taxable Equipment and services. Subject to other provisions of this Agreement, Owner shall remit to Contractor the payment of such Texas sales and use taxes within the time allowed for the payment of Invoices under this Agreement. Contractor shall be responsible for paying to the applicable Governmental Instrumentality all applicable Texas state and applicable local sales and use taxes owed under Applicable Law with respect to taxable Equipment and services. If the Owner elects to dispute the applicable Texas state and applicable sales and use taxes on any item, Owner shall bear the costs incurred in resolving such dispute.

4.5Legal Description and Survey. As of the Agreement Effective Date, Owner has provided to Contractor (i) the legal description of the Site as set forth inAttachment E and (ii) a survey of the Site showing the boundaries of the Site and one survey control point, prepared by Shiner Moseley and Associates, Inc., dated June 8, 2004. Contractor shall be entitled to rely upon the accuracy of this information. To the extent any existing structures or utilities are shown in the survey, Contractor shall independently verify the locations of such existing structures and utilities.

4.6Owner-Provided Items. Owner shall provide those items listed inAttachment K (within the times listed inAttachment K) or any other items specified in a Work Order as being Owner-provided items. The items already provided by Owner are listed inAttachment K. The Contractor shall be entitled to rely upon the accuracy and completeness of those items designated by Owner as “Rely Upon” within the Design Basis inSchedule A-2.

4.7Excusable Delay. Owner’s obligations under this Agreement, except for any obligation to pay monies due to Contractor as provided under this Agreement, shall be suspended to the extent that performance of such obligation is delayed or prevented by Excusable Delay.

4.8Personal and Real Property Taxes. Owner shall be responsible for personal and real property Taxes on the Facility and the Equipment that are stored or located on the Site on the applicable Tax assessment date provided for under Applicable Law.

4.9Waivers of Consequential Damages from Landowners. Unless otherwise agreed to in writing by Contractor, such agreement not to be unreasonably withheld, Owner is responsible for obtaining a written waiver of consequential damages from Landowners in favor of Contractor as a condition precedent to Contractor’s obligation to commence Work in those areas of the Site that cause Contractor to interface with such Landowner.

Article 5