Harbor Aluminum Conference Chicago, IL June 9, 2016 Exhibit 99.1

Cautions about forward-looking statements and other notices Cautionary Statement Regarding Forward-Looking Statements. This presentation contains forward-looking statements, which are based on our current expectations, estimates and projections about Real Industry, Inc. and its subsidiaries' (the “Company”) businesses and prospects, as well as management’s beliefs and certain assumptions made by management. Words such as “anticipates,” “expects,” “intends,” “plans,” “believes,” “seeks,” “estimates,” “may,” “should,” “will” and variations of these words are intended to identify forward-looking statements. Such statements speak only as of the date hereof and are subject to change. The Company undertakes no obligation to revise or update publicly any forward-looking statements for any reason. These statements include, but are not limited to, statements regarding estimated secondary aluminum demand in future periods; secondary aluminum outlook; scrap market outlook; automotive end use outlook as well as future performance, growth, operating results, financial condition and prospects of the Company. Such statements are not guarantees of future performance and are subject to certain risks, uncertainties, and assumptions that are difficult to predict. Accordingly, actual results could differ materially and adversely from those expressed in any forward-looking statements as a result of various factors. Important factors that may cause such a difference include, but are not limited to the Company’s ability to successfully identify, consummate and integrate acquisitions and/or other businesses; changes in business or other market conditions; the difficulty of keeping expense growth at modest levels while increasing revenues; the difficulty of making operating and cost improvements; the Company and its subsidiaries' ability to successfully defend against current and new litigation and indemnification matters, as well as demands by investment banks for defense, indemnity, and contribution claims; the Company’s ability to access and realize value from its federal net operating loss tax carryforwards; the Company’s ability to identify and recruit management; the Company’s ability to maintain the listing requirements of the NASDAQ; and other risks detailed from time to time in the Company’s SEC filings, including but not limited to the most recently filed Annual Report on Form 10-K and subsequent reports filed on Forms 10-Q and 8-K.

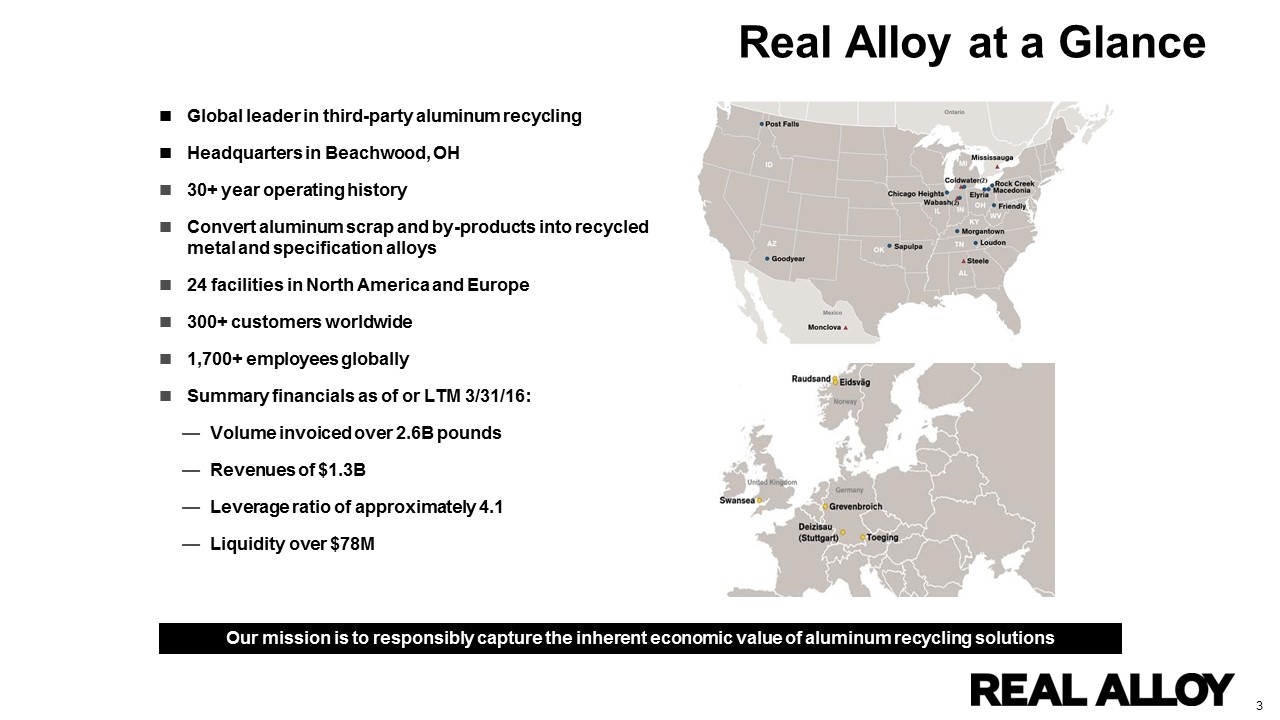

Real Alloy at a Glance Global leader in third-party aluminum recycling Headquarters in Beachwood, OH 30+ year operating history Convert aluminum scrap and by-products into recycled metal and specification alloys 24 facilities in North America and Europe 300+ customers worldwide 1,700+ employees globally Summary financials as of or LTM 3/31/16: Volume invoiced over 2.6B pounds Revenues of $1.3B Leverage ratio of approximately 4.1 Liquidity over $78M Our mission is to responsibly capture the inherent economic value of aluminum recycling solutions

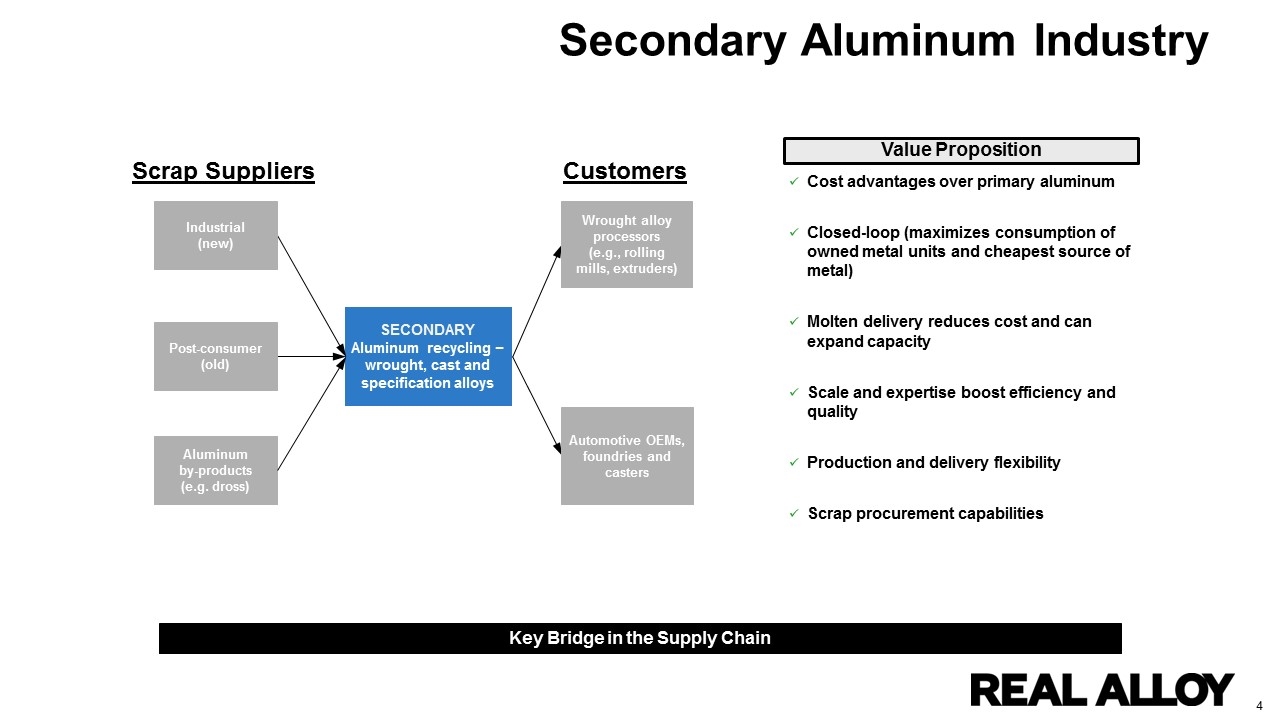

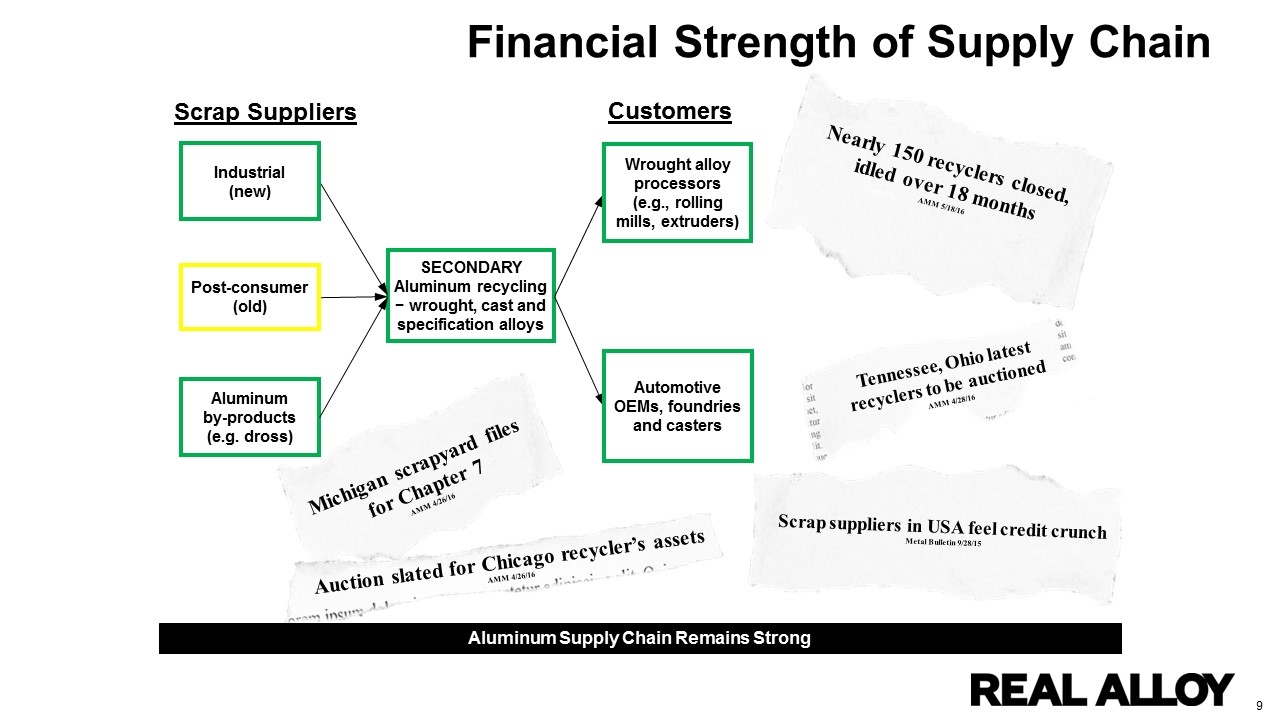

Value Proposition Cost advantages over primary aluminum Closed-loop (maximizes consumption of owned metal units and cheapest source of metal) Molten delivery reduces cost and can expand capacity Scale and expertise boost efficiency and quality Production and delivery flexibility Scrap procurement capabilities Scrap Suppliers Customers SECONDARY Aluminum recycling − wrought, cast and specification alloys Wrought alloy processors (e.g., rolling mills, extruders) Automotive OEMs, foundries and casters Industrial (new) Post-consumer (old) Aluminum by-products (e.g. dross) Secondary Aluminum Industry Key Bridge in the Supply Chain

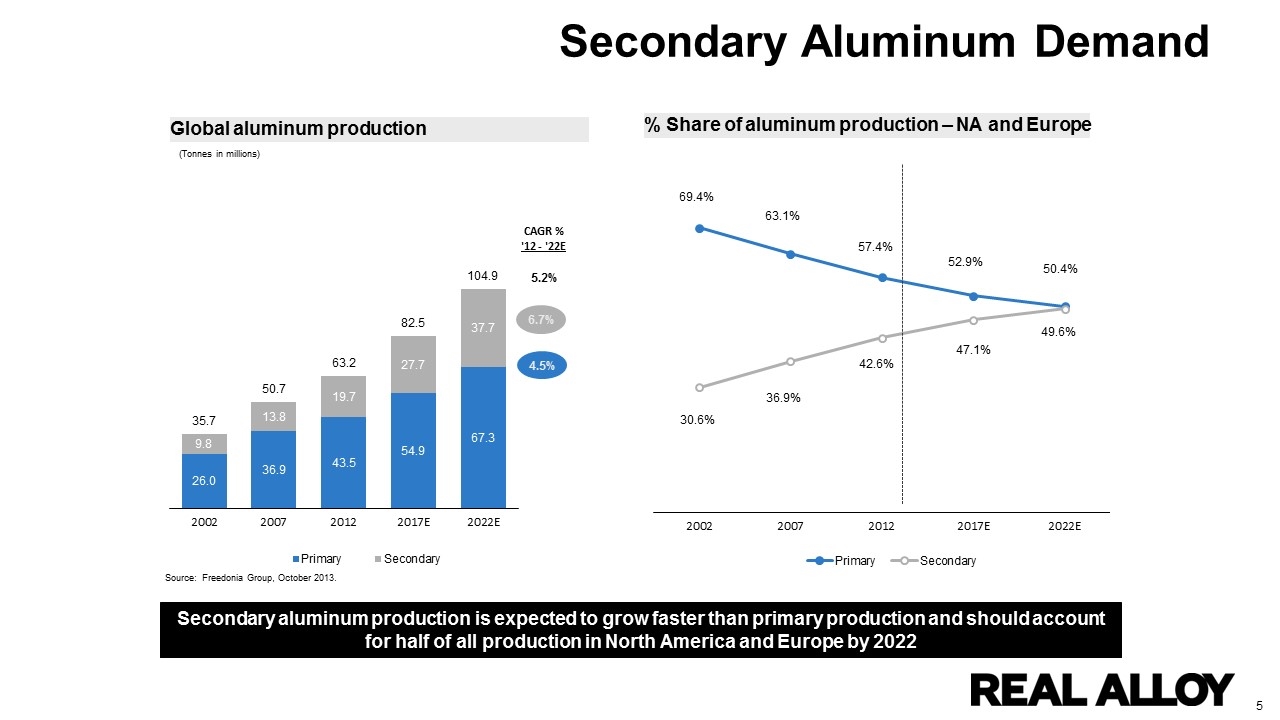

Secondary Aluminum Demand Global aluminum production % Share of aluminum production – NA and Europe Secondary aluminum production is expected to grow faster than primary production and should account for half of all production in North America and Europe by 2022 (Tonnes in millions) 6.7% 4.5% Source: Freedonia Group, October 2013.

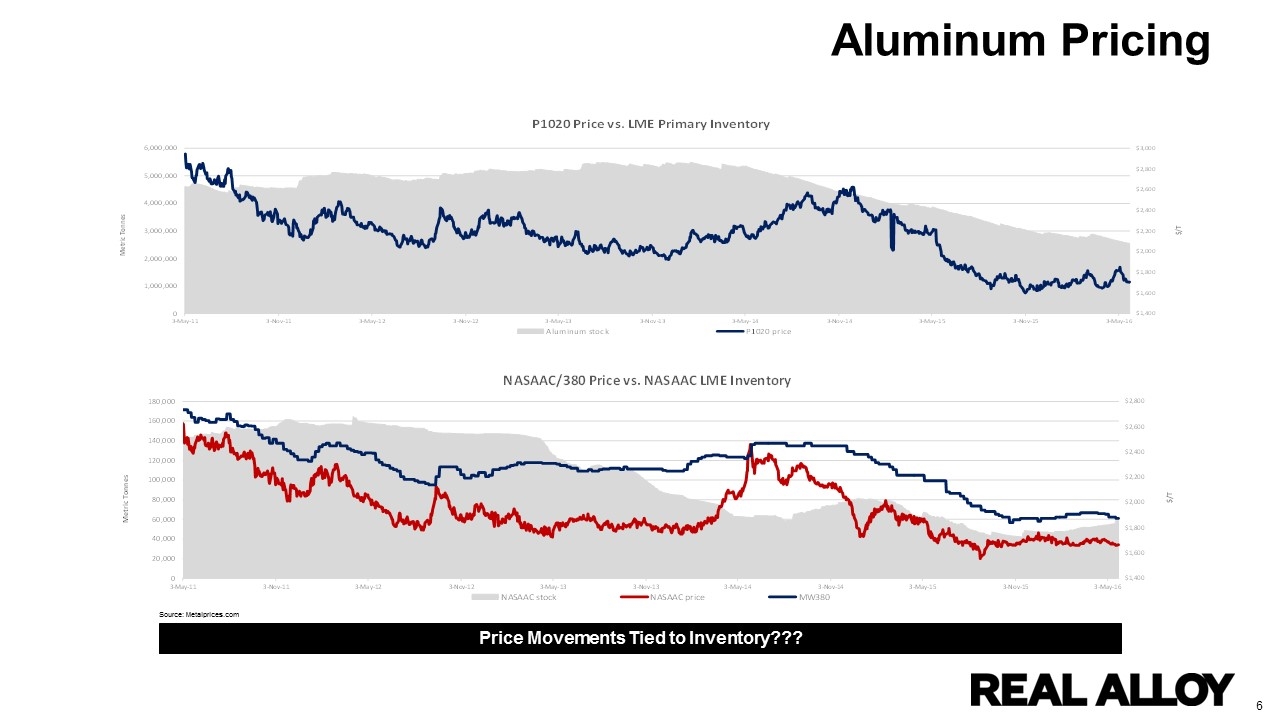

Aluminum Pricing Source: Metalprices.com Price Movements Tied to Inventory???

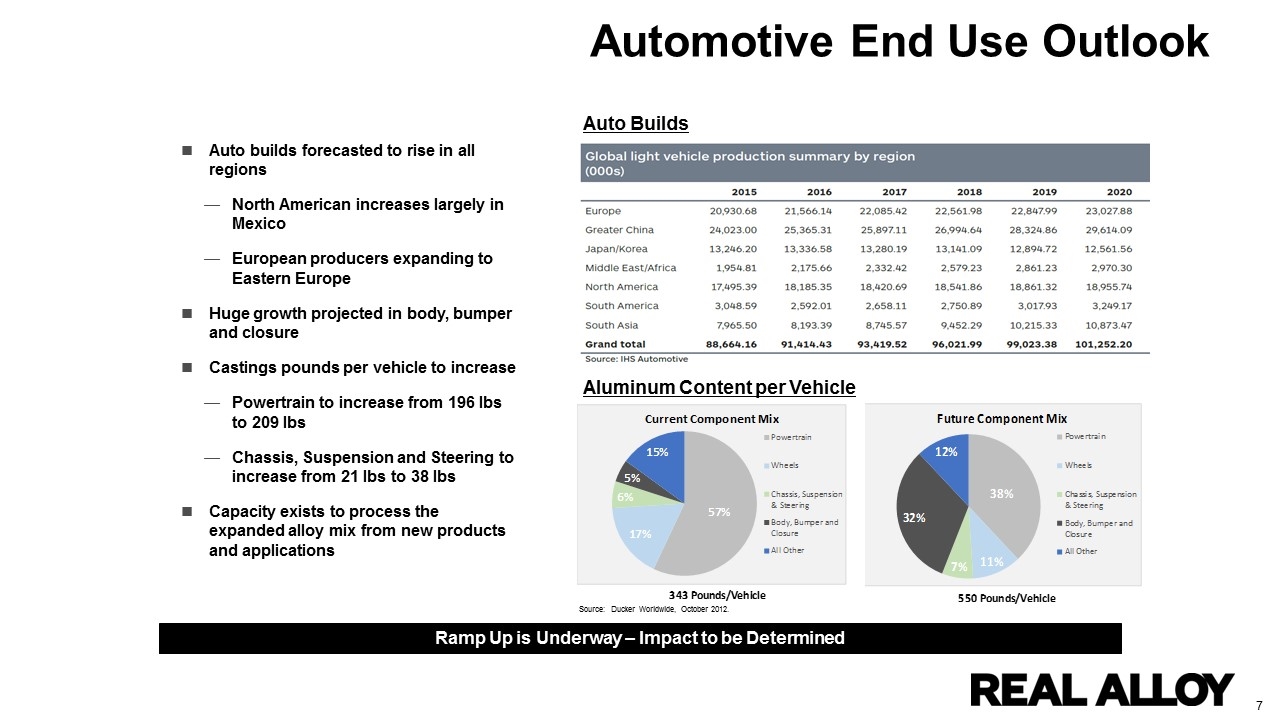

Automotive End Use Outlook Auto builds forecasted to rise in all regions North American increases largely in Mexico European producers expanding to Eastern Europe Huge growth projected in body, bumper and closure Castings pounds per vehicle to increase Powertrain to increase from 196 lbs to 209 lbs Chassis, Suspension and Steering to increase from 21 lbs to 38 lbs Capacity exists to process the expanded alloy mix from new products and applications Source: Ducker Worldwide, October 2012. Auto Builds Aluminum Content per Vehicle Ramp Up is Underway – Impact to be Determined

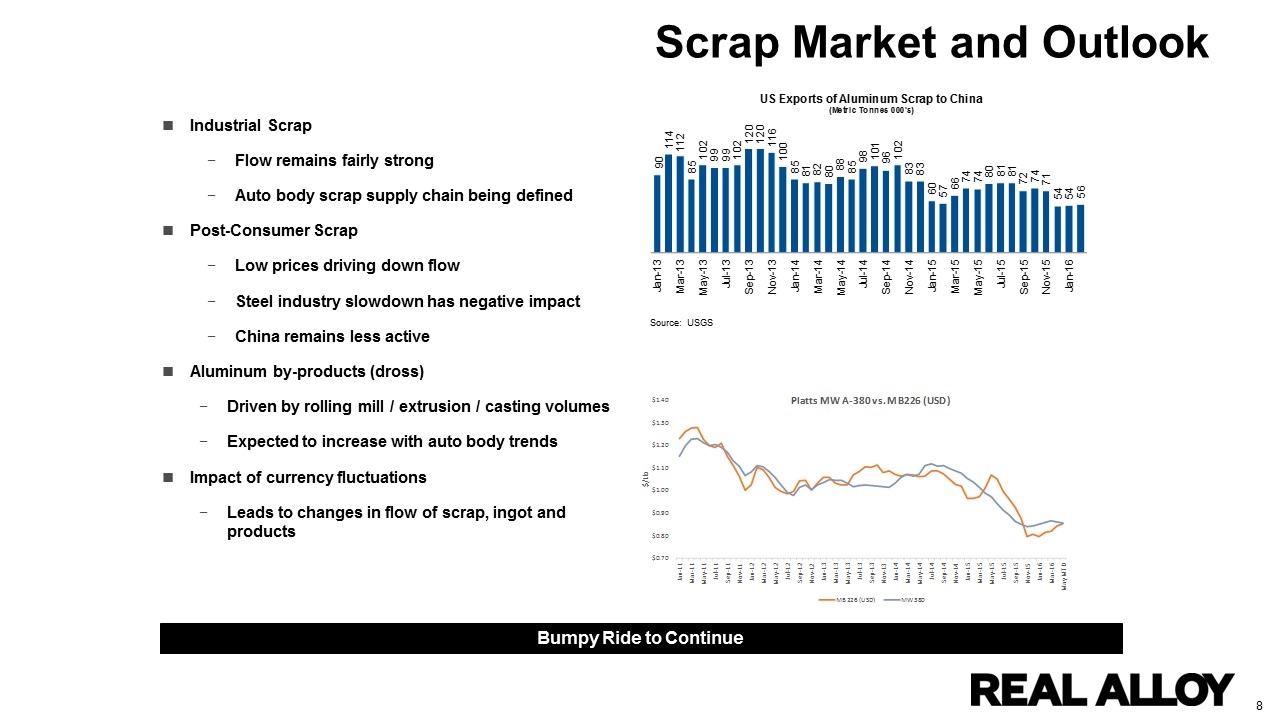

Scrap Market and Outlook Industrial Scrap Flow remains fairly strong Auto body scrap supply chain being defined Post-Consumer Scrap Low prices driving down flow Steel industry slowdown has negative impact China remains less active Aluminum by-products (dross) Driven by rolling mill / extrusion / casting volumes Expected to increase with auto body trends Impact of currency fluctuations Leads to changes in flow of scrap, ingot and products Source: USGS Bumpy Ride to Continue

Financial Strength of Supply Chain Scrap Suppliers Customers SECONDARY Aluminum recycling − wrought, cast and specification alloys Wrought alloy processors (e.g., rolling mills, extruders) Automotive OEMs, foundries and casters Industrial (new) Post-consumer (old) Aluminum by-products (e.g. dross) Nearly 150 recyclers closed, idled over 18 months AMM 5/18/16 Tennessee, Ohio latest recyclers to be auctioned AMM 4/28/16 Michigan scrapyard files for Chapter 7 AMM 4/26/16 Auction slated for Chicago recycler’s assets AMM 4/26/16 Scrap suppliers in USA feel credit crunch Metal Bulletin 9/28/15 Aluminum Supply Chain Remains Strong

Secondary Aluminum Outlook Increasing use of aluminum Global expansion of the industry Technology Demand for eco-friendly products Legislation Opportunities Risks Currency Relocation of production Financial health of industry Impact of low prices Global balance of prime and scrap Positive Outlook Despite Risks