2014

United States

Securities and Exchange Commission

Washington, D.C. 20549

Form 40-F

| ¨ | Registration Statement pursuant to section 12 of the Securities Exchange Act of 1934 |

| þ | Annual report pursuant to section 13(a) or 15(d) of the Securities Exchange Act of 1934 |

For the fiscal year ended December 31, 2014

Commission File Number: 001-04307

Husky Energy Inc.

(Exact name of Registrant as specified in its charter)

| | | | |

| Alberta, Canada | | 1311 | | Not Applicable |

(Province or other jurisdiction of incorporation or organization) | | (Primary Standard Industrial

Classification Code Number (if applicable)) | | (I.R.S. Employer Identification Number (if applicable)) |

707-8th Avenue S.W., P.O. Box 6525 Station D, Calgary, Alberta, Canada T2P 3G7

(403) 298-6111

(Address and telephone number of Registrant’s principal executive office)

CT Corporation System, 111 Eighth Avenue, New York, New York 10011

(877) 467-3525

(Name, address (including zip code) and telephone number (including area code)

of agent for service in the United States)

Securities registered or to be registered pursuant to Section 12(b) of the Act:

Title of Class: None

Securities registered or to be registered pursuant to Section 12(g) of the Act:

Title of Class: None

Securities for which there is a reporting obligation pursuant to Section 15(d) of the Act:

Title of Class: Common Shares

For annual reports, indicate by check mark the information filed with this Form:

| | |

| þ Annual information form | | þ Audited annual financial statements |

Number of outstanding shares of each of the issuer’s classes of capital or common stock as of the close of the period covered by the annual report:

983,738,062 Common Shares outstanding as of December 31, 2014

12,000,000 Cumulative Redeemable Preferred Shares, Series 1 outstanding as of December 31, 2014

10,000,000 Cumulative Redeemable Preferred Shares, Series 3 outstanding as of December 31, 2014

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Exchange Act during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports) and (2) has been subject to such filing requirements for the past 90 days.

þ Yes ¨ No

Indicate by check mark whether the Registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (s.232.405 of this chapter) during the preceding 12 months (or for such shorter period that the Registrant was required to submit and post such files).

¨ Yes ¨ No

The Annual Report on Form 40-F shall be incorporated by reference into or as an exhibit to, as applicable, the Registrant’s Registration Statement under the Securities Act of 1933: Form F-10 File (No. 333-191849); Form S-8 File No. (333-187135).

Principal Documents

The following documents have been filed as part of this Annual Report on Form 40-F:

| A. | Annual Information Form |

The Annual Information Form of Husky Energy Inc. (“Husky” or “the Company”) for the year ended December 31, 2014 is included as Document A of this Annual Report on Form 40-F.

| B. | Audited Annual Financial Statements |

Husky’s audited consolidated financial statements for the years ended December 31, 2014 and December 31, 2013, including the auditors’ report with respect thereto, is included as Document B of this Annual Report on Form 40-F.

| C. | Management’s Discussion and Analysis |

Husky’s Management’s Discussion and Analysis for the year ended December 31, 2014 is included as Document C of this Annual Report on Form 40-F.

Certifications

See Exhibits 31.1, 31.2, 32.1 and 32.2, which are included as Exhibits to this Annual Report on Form 40-F.

Supplemental Reserves Information

See Exhibit 99.1 for the Supplemental Reserves Information, which is included as an Exhibit to this Annual Report on Form 40-F.

Disclosure Controls and Procedures

See the section “Disclosure Controls and Procedures” in Husky’s Management’s Discussion and Analysis for the year ended December 31, 2014, which is included as Document C of this Annual Report on Form 40-F.

Management’s Annual Report on Internal Control Over Financial Reporting

The section “Management’s Annual Report on Internal Control over Financial Reporting” in Husky’s Management’s Discussion and Analysis, is included as Document C of this Annual Report on Form 40-F.

Attestation Report of the Registered Public Accounting Firm

The required disclosure is included in the “Report of Independent Registered Public Accounting Firm” that accompanies Husky’s audited consolidated financial statements for the year ended December 31, 2014, which is included as Document B of this Annual Report on Form 40-F.

Changes in Internal Control Over Financial Reporting

The required disclosure is included in the section “Disclosure Controls and Procedures” in Husky’s Management’s Discussion and Analysis for the year ended December 31, 2014, which is included as Document C of this Annual Report on Form 40-F.

Notice Pursuant to Regulation BTR

Not Applicable.

Audit Committee Financial Expert

The Board of Directors of Husky has determined that William Shurniak is an “audit committee financial expert” (as defined in paragraph 8(b) of General Instruction B to Form 40-F) serving on its Audit Committee. Pursuant to paragraph 8(a)(2) of General Instruction B to Form 40-F, the Board has applied the definition of independence applicable to the audit committee members of New York Stock Exchange listed companies, although the Company’s securities are not listed on a U.S. stock exchange. Mr. Shurniak is a corporate director and is independent under the New York Stock Exchange standards. For a description of Mr. Shurniak’s relevant experience in financial matters, see Mr. Shurniak’s history in the section “Directors and Officers” and in the section “Audit Committee” in Husky’s Annual Information Form for the year ended December 31, 2014, which is included as Document A of this Annual Report on Form 40-F.

Code of Business Conduct and Ethics

Husky’s Code of Ethics is disclosed in its Code of Business Conduct, which is applicable to its principal executive officer, principal financial officer, principal accounting officer or controller or persons performing similar functions and to all of its other employees, and is posted on its website atwww.huskyenergy.com. A copy of Husky’s Amended Code of Business Conduct is included as Exhibit 99.2 to this Annual Report on Form 40-F. In the fiscal year ended December 31, 2014, Husky has not granted a waiver, including an implicit waiver, from a provision of its Code of Ethics to any of its principal executive officer, principal financial officer, principal accounting officer or

controller or persons performing similar functions that relates to one or more of the items set forth in paragraph (9)(b) of General Instruction B to Form 40-F. In the event that, during Husky’s ensuing fiscal year, Husky:

| | i. | amends any provision of its Code of Business Conduct that applies to its principal executive officer, principal financial officer, principal accounting officer or controller or persons performing similar functions that relates to any element of the code of ethics definition enumerated in paragraph (9)(b) of General Instruction B to Form 40-F; or |

| | ii. | grants a waiver, including an implicit waiver, from a provision of its Code of Business Conduct to any of its principal executive officer, principal financial officer, principal accounting officer or controller or persons performing similar functions that relates to one or more of the items set forth in paragraph (9)(b) of General Instruction B to Form 40-F; |

Husky will promptly disclose such occurrences on its website following the date that such amendment or waiver is granted and will specifically describe the nature of any amendment or waiver, and in the case of a waiver, name the person to whom the waiver was granted and the date of the waiver, in each case as further described in paragraph (9) of General Instruction B to Form 40-F.

Principal Accountant Fees and Services

See the section “External Auditor Service Fees” in the Annual Information Form for the year ended December 31, 2014, which is included as Document A of this Annual Report on Form 40-F.

Off-Balance Sheet Arrangements

See the section “Off-Balance Sheet Arrangements” in Husky’s Management’s Discussion and Analysis for the year ended December 31, 2014, which is included as Document C of this Annual Report on Form 40-F.

Tabular Disclosure of Contractual Obligations

See the section “Cash Requirements” in Husky’s Management’s Discussion and Analysis for the year ended December 31, 2014, which is included as Document C of this Annual Report on Form 40-F.

Interactive Data File

Not applicable.

Mine Safety Disclosure

Not applicable.

Undertaking and Consent to Service of Process

Undertaking

Husky undertakes to make available, in person or by telephone, representatives to respond to inquiries made by the Commission staff, and to furnish promptly, when requested to do so by the Commission staff, information relating to: the securities in relation to which the obligation to file an annual report on Form 40-F arises; or transactions in said securities.

Consent to Service of Process

A Form F-X signed by Husky and its agent for service of process has been filed with the Commission together with Form F-10 (File No. 333-191849) in connection with its common shares registered on such form.

Any change to the name or address of the agent for service of process of Husky shall be communicated promptly to the Commission by an amendment to the Form F-X referencing the file number of Husky.

Signatures

Pursuant to the requirements of the Exchange Act, Husky Energy Inc. certifies that it meets all of the requirements for filing on Form 40-F and has duly caused this Annual Report to be signed on its behalf by the undersigned, thereto duly authorized.

Dated this 27th day of February, 2015

| | |

| | Husky Energy Inc. |

| |

| By: | | /s/ Asim Ghosh |

| | Name: Asim Ghosh |

| | Title: President & Chief Executive Officer |

| |

| By: | | /s/ James D. Girgulis |

| | Name: James D. Girgulis |

| | Title: Senior Vice President, General Counsel & Secretary |

Document A

Form 40-F

Annual Information Form

For the Year Ended December 31, 2014

Husky Energy Inc.

Annual Information Form

For the Year Ended December 31, 2014

February 27, 2015

TABLE OF CONTENTS

ADVISORIES

In this AIF, the terms “Husky” and “the Company” mean Husky Energy Inc. and its subsidiaries and partnership interests on a consolidated basis, including information with respect to predecessor corporations.

Unless otherwise noted, all financial information included and incorporated by reference in this AIF is determined using IFRS as issued by the International Accounting Standards Board.

Except where otherwise indicated, all dollar amounts stated in this AIF are Canadian dollars.

ABBREVIATIONS AND GLOSSARY OF TERMS

When used in this AIF, the following terms have the meanings indicated:

| | |

Units of Measure |

| bbl | | barrel |

| bbls | | barrels |

| bbls/day | | barrels per calendar day |

| bcf | | billion cubic feet |

| boe | | barrels of oil equivalent |

| boe/day | | barrels of oil equivalent per calendar day |

| GJ | | gigajoule |

| lt | | litres |

| lt/day | | litres per day |

| m | | meters |

| mbbls | | thousand barrels |

| mbbls/day | | thousand barrels per calendar day |

| mboe | | thousand barrels of oil equivalent |

| mboe/day | | thousand barrels of oil equivalent per day |

| mcf | | thousand cubic feet |

| mmbbls | | million barrels |

| mmboe | | million barrels of oil equivalent |

| mmbtu | | million British thermal units |

| mmcf | | million cubic feet |

| mmcf/day | | million cubic feet per calendar day |

| MW | | megawatts |

| tpy | | tons per year |

|

Acronyms |

| AER | | Alberta Energy Regulator |

| AIF | | Annual Information Form |

| API | | American Petroleum Institute |

| ARO | | Asset Retirement Obligations |

| ASC | | Alberta Securities Commission |

| ASP | | Alkaline Surfactant Polymer |

| BACT | | Best Available Control Technology |

| CAPP | | Canadian Association of Petroleum Producers |

| CEMA | | Cumulative Environmental Management Association |

| CEPA | | Canadian Energy Pipeline Association |

| CFA | | Canadian Fuels Association |

| CHOPS | | Cold Heavy Oil Production with Sand |

| CNOOC | | China National Offshore Oil Corporation |

| CO2 | | Carbon dioxide |

| CO2e | | Carbon dioxide equivalent |

| COGEH | | Canadian Oil and Gas Evaluation Handbook |

| CPF | | Central Processing Facility |

| CSA | | Canadian Securities Administrators |

| CSS | | Cyclic Steam Stimulation |

| EDGAR | | Electronic Data Gathering, Analysis, and Retrieval system |

| EIA | | Energy Information Administration |

| EL | | Exploration Licence |

| EOR | | Enhanced Oil Recovery |

| | |

| EPA | | Environmental Protection Agency |

| FASB | | Financial Accounting Standards Board |

| FEED | | Front End Engineering Design |

| FPSO | | Floating Production, Storage and Offloading Vessel |

| GHG | | Greenhouse Gas |

| GHGRP | | Greenhouse Gas Reporting Program |

| HOIMS | | Husky Operational Integrity Management System |

| HSB | | Husky Synthetic Blend |

| IFRS | | International Financial Reporting Standards |

| LARP | | Lower Athabasca Regional Plan |

| LNG | | Liquefied Natural Gas |

| MD&A | | Management’s Discussion And Analysis |

| MEG | | Monoethylene Glycol |

| NGL | | Natural Gas Liquids |

| NIT | | NOVA Inventory Transfer |

| NYMEX | | New York Mercantile Exchange |

| OPEC | | Organization of Petroleum Exporting Countries |

| PHMSA | | Pipeline and Hazardous Materials Safety Administration |

| PSC | | Production Sharing Contract |

| PTAC | | Petroleum Technology Alliance Canada |

| SAGD | | Steam Assisted Gravity Drainage |

| SEC | | Securities and Exchange Commission of the United States |

| SEDAR | | System for Electronic Document Analysis and Retrieval |

| UNFCC COP | | United Nations Framework Convention on Climate Change Conference of the Parties |

| U.S. | | United States |

| WCI | | Western Climate Initiative |

| WTI | | West Texas Intermediate |

| 2-D | | two-dimensional |

| 3-D | | three-dimensional |

The Company uses the term boe, which is calculated on an energy equivalence basis whereby one barrel of crude oil is equivalent to six thousand cubic feet of natural gas. Readers are cautioned that the term boe may be misleading, particularly if used in isolation. This measure is primarily applicable at the burner tip and does not represent a value equivalency at the wellhead.

Abandonment costs

Costs of abandoning a well, net of any salvage value, and disconnecting the well from the surface gathering system.

API° gravity

Measure of oil density or specific gravity used in the petroleum industry. The API scale expresses density such that the greater the density of the petroleum, the lower the degree of API gravity.

Barrel

A unit of volume equal to 42 U.S. gallons.

Bitumen

Bitumen is solid or semi-solid with a viscosity greater than 10,000 centipoise at original temperature in the deposit and atmospheric pressure.

Coal bed methane

The primary energy source of natural gas is methane. Coal bed methane is methane found and recovered from the coal bed seams. The methane is normally trapped in coal by water that is under pressure. When the water is removed the methane is released.

Delineation well

A well in close proximity to an oil or gas well that helps determine the aerial extent of the reservoir.

Development well

A well drilled within the proved area of an oil and gas reservoir to the depth of a stratigraphic horizon known to be productive.

Diluent

A lighter gravity liquid hydrocarbon, usually condensate or synthetic oil, added to heavy oil to improve the transmissibility of the oil through a pipeline.

Dry and abandoned well

A well found to be incapable of producing oil or gas in sufficient quantities to justify completion as a producing oil or gas well.

Enhanced oil recovery

The increased recovery from a crude oil pool achieved by artificial means or by the application of energy extrinsic to the pool. An artificial means or application includes pressuring, cycling, pressure maintenance or injection to the pool of a substance or form of energy but does not include the injection in a well of a substance or form of energy for the sole purpose of aiding in the lifting of fluids in the well, or stimulation of the reservoir at or near the well by mechanical, chemical, thermal or explosive means.

Exploration licence

A licence with respect to the Canadian offshore or the Northwest or Yukon Territories conferring the right to explore for, and the exclusive right to drill and test for, petroleum; the exclusive right to develop the applicable area in order to produce petroleum; and, subject to satisfying the requirements for issuance of a production licence and compliance with the terms of the licence and other provisions of the relevant legislation, the exclusive right to obtain a production licence.

Exploratory well

A well drilled to find a new field or to find a new reservoir in a field previously found to be productive of oil or gas, in another reservoir. Generally, an exploratory well is any well that is not a development well, a service well, an extension well, which is a well drilled to extend the limits of a known reservoir, or a stratigraphic test well as those terms are defined herein.

Field

An area consisting of a single reservoir or multiple reservoirs all grouped on or related to the same individual geological structural feature and/or stratigraphic condition. There may be two or more reservoirs in a field which are separated vertically by intervening impervious strata, or laterally by local geologic barriers, or by both.

Heavy crude oil

Crude oil measured between 10 API° and 22.3 API° and is liquid at original temperature in the deposit and atmospheric pressure.

Horizontal drilling

Drilling horizontally rather than vertically through a reservoir, thereby exposing more of the well to the reservoir and increasing production.

Infill well

A well drilled on an irregular pattern disregarding normal spacing requirements. These wells are drilled to produce from parts of a reservoir that would otherwise not be recovered through existing wells drilled in accordance with normal spacing.

Light crude oil

Crude oil measured at 31.1 API° or lighter.

Liquefied petroleum gas

Liquefied propanes and butanes, separately or in mixtures.

Medium crude oil

Crude oil measured between 22.3 API° and 31.1 API°.

Natural gas liquids

Those hydrocarbon components recovered from raw natural gas as liquids by processing through extraction plants, or recovered from field separators, scrubbers or other gathering facilities. These liquids include the hydrocarbon components ethane, propane, butanes and condensate or a combination thereof.

Oil sands

Sands and other rock materials that contain crude bitumen and include all other mineral substances in association therewith.

Production Sharing Contract

A contract for the development of resources under which the contractor’s costs (investment) are recoverable each year out of the production but with a maximum amount of production that can be applied to the cost recovery in any year. This annual allocation of production is referred to as cost oil; the remainder is referred to as profit oil and is divided in accordance with the contract between the contractor and the host government.

Reserve Replacement Ratio

The reserve replacement ratio represents the rate at which the Company replaces reserve volumes realized through current production for a given period. The ratio is calculated as the sum of: closing reserve volumes less opening reserve volumes plus production volumes divided by production volumes.

Secondary recovery

Oil or gas recovered by injecting water or gas into the reservoir to force additional oil or gas to the producing wells. Usually, but not necessarily, this is done after the primary recovery phase has passed.

Seismic survey

A method by which the physical attributes in the outer rock shell of the earth are determined by measuring, with a seismograph, the rate of transmission of shock waves through the various rock formations. The rate at which the waves are transmitted varies with the medium through which they pass.

Service well

A well drilled or completed for the purpose of supporting production in an existing field. Specific purposes of service wells include gas injection, water injection, steam injection, air injection, saltwater disposal, water supply for injection, observation or injection for in-situ combustion.

Significant discovery licence

A licence issued following the declaration of a significant discovery, which is indicated by the first exploration well that demonstrates by flow testing the existence of sufficient hydrocarbons in a particular geological feature to suggest potential for sustained production. A significant discovery licence confers the same rights as that of an exploration licence.

Specific gravity

The ratio between the weight of equal volumes of water and another liquid measured at standard temperature. The weight of water is assigned a value of one. However, the specific gravity of oil is normally expressed in degrees of API gravity as follows:

| | | | |

Degrees API = | | 141.5 | | -131.5 |

| Specific gravity @ F60 degrees | |

Spot price

The price for a one-time open market transaction for immediate delivery of a specific quantity of product at a specific location where the commodity is purchased “on the spot” at current market rates.

Steam assisted gravity drainage

An enhanced oil recovery method used to produce heavy crude oil and bitumen in-situ. Steam is injected via a horizontal well along a producing formation. The temperature in the formation increases and lowers the viscosity of the crude oil allowing it to fall to a horizontal production well beneath the steam injection well.

Stratigraphic test well

A drilling effort, geologically directed, to obtain information pertaining to a specific geologic condition. Such wells customarily are drilled without the intention of being completed for hydrocarbon production. This classification also includes tests identified as core tests and all types of expendable holes related to hydrocarbon exploration. Stratigraphic test wells are classified as (i) “exploratory-type,” if not drilled in a proved area, or (ii) “development-type,” if drilled in a proved area.

Synthetic oil

A mixture of hydrocarbons derived by upgrading heavy crude oils, including bitumen, through a process that reduces the carbon content and increases the hydrogen content.

Three-dimensional seismic survey

Three dimensional seismic imaging which uses a grid of numerous cables rather than a few lines stretched in one line.

Turnaround

Maintenance at a plant or facility which requires the plant or facility to be completely or partially shut down for the duration.

Two-dimensional seismic survey

A vertical section of seismic data consisting of numerous adjacent traces acquired sequentially.

Waterflood

One method of secondary recovery in which water is injected into an oil reservoir for the purpose of forcing oil out of the reservoir and into the bore of a producing well.

Wellhead

The structure, sometimes called the “Christmas tree,” that is positioned on the surface over a well and used to control the flow of oil or gas as it emerges from the subsurface casing head.

Working interest

An interest in the net revenues of an oil and gas property, which is proportionate to the share of exploration and development costs borne until such costs have been recovered, and which entitles the holder to participate in a share of net revenue thereafter.

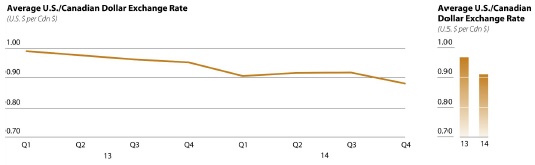

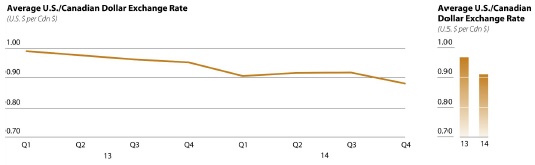

EXCHANGE RATE INFORMATION

The following table discloses various indicators of the Canadian dollar/U.S. dollar rate of exchange or the cost of a U.S. dollar in Canadian currency for the three years indicated.(1)(2)

| | | | | | | | | | | | |

| | | Year ended December 31, | |

(Cdn $ per U.S. $) | | 2014 | | | 2013 | | | 2012 | |

Year-end | | | 1.160 | | | | 1.064 | | | | 0.995 | |

Low | | | 1.059 | | | | 0.982 | | | | 0.964 | |

High | | | 1.167 | | | | 1.074 | | | | 1.044 | |

Average | | | 1.104 | | | | 1.030 | | | | 0.999 | |

| (1) | The year-end exchange rates were as quoted by the Bank of Canada for the noon buying rate. |

| (2) | The high, low and average rates were either quoted or calculated as at the last day of the relevant period. |

CORPORATE STRUCTURE

Husky Energy Inc.

Husky Energy Inc. was incorporated under theBusiness Corporations Act(Alberta) on June 21, 2000. The Company’s Articles were amended effective February 28, 2011 to permit the issuance of common shares as payment of stock dividends on the common shares and to authorize preferred shares to be issued in one or more series. The Company’s Articles were amended effective March 11, 2011 to create Cumulative Redeemable Preferred Shares, Series 1 (the “Series 1 Preferred Shares”) and Cumulative Redeemable Preferred Shares, Series 2 (the “Series 2 Preferred Shares”); and were amended effective December 4, 2014, to create Cumulative Redeemable Preferred Shares, Series 3 (the “Series 3 Preferred Shares”) and Cumulative Redeemable Preferred Shares, Series 4 (the “Series 4 Preferred Shares”).

Husky has its registered office and its head and principal office at 707, 8th Avenue S.W., P.O. Box 6525, Station D, Calgary, Alberta, T2P 3G7.

Intercorporate Relationships

The following table lists Husky’s significant subsidiaries and jointly controlled entities and their place of incorporation, continuance or organization, as the case may be, as at December 31, 2014.(1) All of the following companies and partnerships, except as otherwise indicated, are 100% beneficially owned or controlled or directed, directly or indirectly by Husky.

| | |

Name | | Jurisdiction |

| Subsidiary of Husky Energy Inc. | | |

| Husky Oil Operations Limited | | Alberta |

| |

| Subsidiaries and jointly controlled entities of Husky Oil Operations Limited | | |

| Husky Oil Limited Partnership | | Alberta |

| Husky Terra Nova Partnership | | Alberta |

| Husky Downstream General Partnership | | Alberta |

| Husky Energy Marketing Partnership | | Alberta |

| Husky Energy International Corporation | | Alberta |

| Sunrise Oil Sands Partnership (50%) | | Alberta |

| BP-Husky Refining LLC (50%) | | Delaware |

| Lima Refining Company | | Delaware |

| Husky Marketing and Supply Company | | Delaware |

| (1) | Principal operating subsidiaries exclusive of intercorporate relationships due to financing related receivables and investments. |

GENERAL DEVELOPMENT OF HUSKY

Three-year History of Husky

2012

On March 22, 2012, the Company issued U.S. $500 million of 3.95% senior unsecured notes due April 15, 2022 pursuant to the universal short form base shelf prospectus filed with the ASC and the SEC on June 13, 2011 and an accompanying prospectus supplement. The notes are redeemable at the option of the Company at a make-whole premium and interest is payable semi-annually. The notes are unsecured and unsubordinated and rank equally with all of the Company’s other unsecured and unsubordinated indebtedness.

On June 15, 2012, Husky repaid the maturing U.S. $400 million of 6.25% notes for U.S. $413 million, including U.S. $13 million of interest. The amount paid to note holders was equivalent to $410 million in Canadian dollars.

On December 14, 2012, Husky amended and restated both of its revolving syndicated credit facilities to allow the Company to borrow up to $1.5 billion and $1.6 billion in either Canadian or U.S. currency from a group of banks on an unsecured basis. The maturity date for the $1.5 billion facility was extended to December 14, 2016 and there was no change to the August 31, 2014 maturity date of the $1.6 billion facility.

On December 31, 2012, Husky filed a universal short form base shelf prospectus (the “Canadian Shelf Prospectus”) with applicable securities regulators in each of the provinces of Canada, other than Quebec, that enabled the Company to offer up to $3.0 billion of common shares, preferred shares, debt securities, subscription receipts, warrants and units in Canada up to and including January 30, 2015. This Canadian Shelf Prospectus replaced the universal short form base shelf prospectus filed in Canada during November 2010 which expired in December 2012.

During 2012, the Company continued to advance exploration and development projects on its oil resource land base. Heavy oil production commenced in the second quarter of 2012 ahead of schedule at both the Pikes Peak South and Paradise Hill heavy oil thermal projects and production ramped up to a combined average of 17,000 bbls/day exceeding the combined 11,500 bbls/day design rates. The Company advanced construction on the 3,500 bbls/day Sandall thermal development project and commenced initial drilling. Design and initial site work continued at the 10,000 bbls/day Rush Lake commercial project. Initial planning continued for three additional commercial thermal projects.

The Overall Development Plan for the Liwan Gas Project on Block 29/26 in the South China Sea was approved by the Government of China. The development project was more than 80% complete at the end of 2012. Approximately 90 kilometers of the two 79-kilometer deep water pipelines connecting the gas field to the central platform had been laid and approximately 190 kilometers out of 261 kilometers of shallow water pipeline had been laid from the central platform to the onshore gas plant. The completed jacket for the shallow water central platform was placed onto the ocean floor on August 30, 2012.

FEED for the development of the Liuhua 29-1 gas field was completed. Planning continued for the development of the single well Liuhua 34-2 field in 2012.

In December 2012, Husky signed a joint venture agreement with CPC Corporation, Taiwan, for an exploration block in the South China Sea. The exploration block is located 100 kilometers southwest of the island of Taiwan and covers approximately 10,000 square kilometers. Husky holds a 75% working interest during exploration, while CPC Corporation has the right to participate in the development program up to a 50% interest.

The 2012 exploration drilling program on the Madura Strait Block concluded in October 2012, with four new discoveries being made as a result of a five well exploration drilling program.

Husky and BP continued to advance the development of the Sunrise Energy Project in multiple stages. During 2012, drilling of the planned steam assisted gravity drainage horizontal well pairs for Phase I was completed and site construction and equipment installations were advanced. Development work continued on the next phase of the project, where regulatory approvals are in place for a total 200,000 bbls/day (100,000 bbls/day net).

Development continued at the White Rose field with the addition of an infill production well which was brought online in August 2012. At the end of 2012, a total of 22 wells, including nine producing wells, 10 water injectors, and three gas injectors were on production. A development plan amendment was filed with the regulator in October 2012 to facilitate development of resources at the South White Rose Extension satellite. At North Amethyst, development continued in 2012 with the addition of the fourth production well. At the end of 2012, four production and three water injection wells were online. An application to develop the deeper Hibernia formation at North Amethyst progressed through the regulatory review process. A water injection well to support the existing producing well for the West White Rose pilot project was completed and brought online during 2012. Evaluation of a wellhead platform to facilitate future development continued during 2012 and supporting regulatory filings were submitted for an environmental assessment of the concept.

Husky and Seadrill entered into a five-year contract for the use of Seadrill’s West Mira rig, a new harsh environment semi-submersible rig currently being built and expected to be completed in late 2015.

Exploration activity in the Atlantic Region included drilling of the Searcher prospect in the southern Jeanne D’Arc Basin. The well did not encounter commercial hydrocarbons and was expensed in 2012.

2013

During February 2013, the limit on the $1.5 billion revolving syndicated credit facility, allowing the Company to borrow in either Canadian or U.S. currency on an unsecured basis, was increased to $1.6 billion. There was no change to the maturity date of the facility. There continues to be no difference between the terms of the Company’s revolving syndicated credit facilities other than their maturity dates.

At the Liwan Gas Project, drilling and completion work continued in 2013, with all nine wells on the Liwan 3-1 gas field completed and made ready for production. During May 2013, the platform topsides were completed and transported approximately 2,500 kilometers from Qingdao, China, to the South China Sea and installed onto the jacket. In addition, the 261 kilometers of shallow water pipeline from the central platform to the gas plant and construction of the onshore gas plant was completed. Five major construction vessels and their support vessels were in operation during 2013, while construction continued on the deep water facilities. Despite encountering unusually difficult weather conditions during an extended typhoon season in late 2013, all piping to connect the individual wells to the manifolds and the manifolds to the connecting infield production flow lines was installed.

On June 5, 2013, Husky received regulatory approval for a development plan amendment for the South White Rose field, the third satellite extension at the White Rose field in the Atlantic Region. The amendment provided for gas injection, which will enhance oil production and provide additional storage for recovered gas. Installation of gas injection equipment to support the South White Rose Extension was completed at the end of 2013.

On October 31, 2013 and November 1, 2013, Husky filed a universal short form base shelf prospectus (the “U.S. Shelf Prospectus”) with the ASC and the SEC, respectively, that enables the Company to offer up to U.S. $3.0 billion of debt securities, common shares, preferred shares, subscription receipts, warrants and units of the Company in the United States up to and including November 30, 2015. The U.S. Shelf Prospectus replaced the shelf prospectus which was filed in June 2011 and expired in July 2013.

Husky and its partner made two significant discoveries in the year of a high-quality, light, sweet crude oil resource in the Flemish Pass Basin. The first discovery was made at the Harpoon O-85 well followed by a second discovery made at the Bay Du Nord prospect, both located approximately 500 kilometers offshore Newfoundland. The evaluation of well results at the Harpoon discovery is ongoing, with further appraisal drilling required to assess the potential of the prospect. The two discoveries made in the year bring the total number of significant discoveries in the region to three. The 2009 Mizzen discovery of slightly heavier oil has best estimate contingent resources estimated by Husky of 130 million barrels on a 100% working interest basis (46.1 million barrels net to Husky) as at December 31, 2014. Husky holds a 35% working interest in all three wells.

For the West White Rose Extension Project, Husky and its joint venture partners concluded a benefits agreement with the Government of Newfoundland and Labrador for the project and a development application to the Canada-Newfoundland and Labrador Offshore Petroleum Board was submitted. Construction of a graving dock commenced in Argentia, Newfoundland and detailed engineering and design in advance of a final investment decision is ongoing.

The North Amethyst G-25-9 multilateral well was completed and brought online in late November 2013, with average gross production of 20,000 bbls/day (14,000 bbls/day net to Husky). In addition, drilling commenced on the North Amethyst Hibernia well in the fourth quarter of 2013, targeting a secondary deeper zone below the main North Amethyst field.

At the 60,000 bbls/day (30,000 bbls/day net to Husky) Sunrise Energy Project, the CPF was more than 75% complete at December 31, 2013 with major equipment installed and field tanks and buildings for Plant 1A in place. Commissioning of the first six well pads commenced in 2013.

At December 31, 2013, construction was substantially complete at the 3,500 bbls/day Sandall heavy oil thermal development project, and steaming was underway.

In 2013, construction work continued at the 10,000 bbls/day Rush Lake commercial project with first production expected in the second half of 2015.

In 2013, the liquids-rich natural gas formations at Ansell in west central Alberta continued to be a key area of focus with 25 wells (gross) drilled and 30 wells (gross) completed. At December 31, 2013, the Company had drilled and completed over 300 (gross) wells at the play, which had an average production of 13,800 boe/day in 2013.

2014

Production commenced in early 2014 ahead of schedule at the Sandall heavy oil development with rates exceeding the 3,500 bbls/day design rate capacity throughout the year. Production at the end of 2014 was approximately 5,700 bbls/day.

On January 9, 2014, the Company sanctioned two new heavy oil thermal projects, Edam East and Vawn, in Saskatchewan, each of which is expected to deliver 10,000 bbls/day of production. Site clearing, detailed engineering and module fabrication work was completed during 2014 with first oil expected in the second half of 2016.

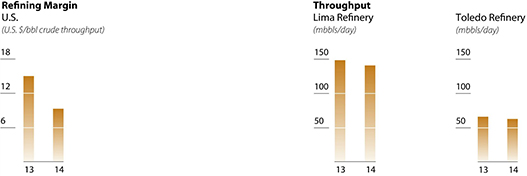

FEED on the feedstock flexibility project at the Company’s Lima Refinery was completed in 2014. The project is expected to give the refinery flexibility to take up to 40,000 bbls/day of Western Canadian heavy oil while overall nameplate capacity would remain unchanged at 160,000 bbls/day. The initial planned completion date has been deferred with the project now expected to be completed in the 2018-2019 time frame.

On March 17, 2014, the Company issued U.S. $750 million of 4.00% notes due April 15, 2024 pursuant to the U.S. Shelf Prospectus. The notes are redeemable at the option of the Company at any time, subject to a make whole premium unless the notes are redeemed in the three month period prior to maturity. Interest is payable semi-annually. The notes are unsecured and unsubordinated and rank equally with all of the Company’s other unsecured and unsubordinated indebtedness.

At the Liwan Gas Project, first gas from the deep water wells on the Liwan 3-1 gas field was achieved on March 30, 2014 with gas sales to the Guangdong market natural gas grid commencing on April 24, 2014. In addition, the tie-in of the Liuhua 34-2 field single production well into the Liwan 3-1 field deep water infrastructure was completed and commissioned with first gas production taking place in December of 2014. Total gas and NGL production averaged approximately 114.2 mmcf/day and 4.2 mbbls/day respectively in 2014.

On May 6, 2014, the Company sanctioned a 3,500 bbls/day thermal project at Edam West with first production expected in the second half of 2016.

On June 15, 2014, the Company repaid the maturing 5.90% notes issued under a trust indenture dated September 11, 2007. The amount paid to noteholders was U.S. $772 million, including U.S. $22 million of interest, equivalent to $839 million in Canadian dollars, including interest of $25 million.

On June 19, 2014, the $1.6 billion revolving syndicated credit facility was increased to $1.63. The maturity, previously set to expire on August 31, 2014, was extended to June 19, 2018. The Company also increased the limit on one of its operating facilities from $50 million to $100 million.

On September 15, 2014, the Company launched a commercial paper program in Canada. The program is supported by the Company’s syndicated credit facilities and the Company is authorized to issue commercial paper up to a maximum of $1.0 billion having a term not to exceed 365 days. The weighted average interest rate for commercial paper outstanding as at December 31, 2014 was 1.24 percent.

On December 9, 2014, the Company issued 10 million Cumulative Redeemable Preferred Shares, Series 3 (the “Series 3 Preferred Shares”) at a price of $25.00 per share for aggregate gross proceeds of $250 million under the Canadian Shelf Prospectus. Holders of the Series 3 Shares are entitled to receive a cumulative quarterly fixed dividend yielding 4.50 percent annually for the initial period ending December 31, 2019 as declared by Husky. Thereafter, the dividend rate will be reset every five years at the rate equal to the five-year Government of Canada bond yield plus 3.13 percent. Holders of Series 3 Preferred Shares will have the right, at their option, to convert their shares into Cumulative Redeemable Preferred Shares, Series 4 (the “Series 4 Preferred Shares”), subject to certain conditions, on December 31, 2019 and on every five years thereafter. Holders of the Series 4 Preferred Shares will be entitled to receive cumulative quarterly floating dividends at a rate equal to the 90-day Government of Canada Treasury Bill rate plus 3.13 percent.

On December 10, 2014, the Company announced the results of an independent assessment of its heavy oil resources in the Lloydminster region. The assessment has increased the Company’s overall working interest of total heavy oil initially in place which is now estimated at 17 billion barrels, of which 16 billion barrels are discovered heavy oil initially in place. The assessment conducted by Sproule Unconventional Limited has also estimated the Company’s working interest of best estimate contingent resources to be 1.9 billion barrels as of December 31, 2013, of which 54 percent, or 1 billion barrels, has the potential to be recovered using thermal technology.

At the Sunrise Energy Project, steaming commenced in December 2014. Phase 1 of the project is being developed with two processing plants. The first 30,000 bbls/day plant is expected to begin production towards the end of the first quarter of 2015. The second 30,000 bbls/day plant is expected to begin steaming in mid-2015, with production commencing in late 2015. Production is expected to ramp up to full capacity over a two-year period. Husky is the operator of the Sunrise Energy Project and has a 50 percent working interest in the project with BP Canada Energy Company, which operates the jointly-owned BP-Husky Toledo refinery.

In the Atlantic Region, development drilling commenced at the South White Rose Extension project with production from the project expected to commence in mid-year 2015. The project is expected to produce peak production volumes of approximately 15,000 bbls/day (net). The Company also commenced drilling in 2014 at the North Amethyst Hibernia formation which will target a secondary deeper zone below the main North Amethyst producing field. Production from the Hibernia formation is expected to start up in the second half of 2015 with peak production volumes expected to reach 5,000 bbls/day (net). In addition, the Company and its partner commenced an 18-month appraisal and exploration drilling program in the Flemish Pass offshore Newfoundland and Labrador, including the area of the Bay Du Nord discovery. Husky holds a 35 percent working interest in the Bay Du Nord discovery. Hearings for the public review of the application for a wellhead platform to facilitate full field development at West White Rose were held during 2014. Construction continued on the dry-dock in Argentia, Newfoundland and early site preparation was advanced, including construction of a graving dock. Husky has deferred a final investment decision on the project.

The liquids-rich gas formations at Ansell in west central Alberta continue to be a key area of focus, with 31 wells (gross) drilled and 23 wells (gross) completed in 2014. To date, the Company has drilled and completed over 350 (gross) wells at the play with average production of 17,500 boe/day in 2014, an increase of 27 percent when compared to 2013.

Husky completed a two-well pad in 2014 at the Duvernay liquids-rich natural gas resource play at Kaybob, Alberta. Results from the four-well pad drilled and completed in 2013 and the two-well pad completed in 2014 continue to be in-line with expectations.

Construction work continued at the 10,000 bbls/day Rush Lake heavy oil thermal development with first production expected in the third quarter of 2015. Site clearing, detailed engineering and module fabrication commenced at the two 10,000 bbls/day Edam East and Vawn developments in 2014 with first production expected in the second half of 2016.

Progress continued on the shallow water gas developments in the Madura Strait Block during 2014. Work related to the BD field engineering, procurement, installation and construction contract is ongoing and approximately 29 percent complete. The contract for the construction and lease of a FPSO vessel received final approval in the second quarter of 2014 and was signed in December 2014.

Tender plans for the MDA and MBH development projects were approved by SKK Migas, the Indonesia oil and gas regulator, and the tendering process is in progress. The Gas Sales Agreement for the first tranche of gas from this development is complete and awaiting final approval from the regulator. The development plan for the MDK field to tie into the MDA/MBH combined development was approved by SKK Migas in July 2014.

During 2014, Husky signed a PSC for the Anugerah contract area. The contract area covers approximately 8,215 square kilometres and is primarily offshore East Java, Indonesia, with water depths of up to 1,400 metres. The main prospective locations are in water depths of 800 to 1,300 metres. The contract area is located approximately 150 kilometres east of the Madura Strait Block. Under the PSC, Husky has an obligation to carry out seismic surveys to assess the petroleum potential of the exploration block within the first three years. Exploration work, including planning for a 3-D seismic survey covering the contract area, is in progress.

DESCRIPTION OF HUSKY’S BUSINESS

General

Husky is a publicly traded international integrated energy company headquartered in Calgary, Alberta, Canada.

Management has identified segments for the Company’s business based on differences in products, services and management responsibility. The Company’s business is conducted predominantly through two major business segments—Upstream and Downstream.

Upstream includes exploration for, and development and production of, crude oil, bitumen, natural gas and NGL (Exploration and Production) and marketing of the Company’s and other producers’ crude oil, natural gas, NGL, sulphur and petroleum coke, pipeline transportation, the blending of crude oil and natural gas, and storage of crude oil, diluent and natural gas (Infrastructure and Marketing). The Company’s Upstream operations are located primarily in Western Canada, offshore East Coast of Canada, offshore China and offshore Indonesia.

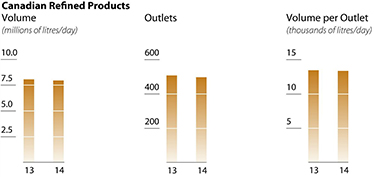

Downstream includes upgrading of heavy crude oil feedstock into synthetic crude oil (Upgrading), refining in Canada of crude oil and marketing of refined petroleum products including gasoline, diesel, ethanol blended fuels, asphalt and ancillary products, and production of ethanol (Canadian Refined Products) and refining in the U.S. of primarily crude oil to produce and market gasoline, jet fuel and diesel fuels that meet U.S. clean fuels standards (U.S. Refining and Marketing).

Social and Environmental Policy

Husky has a Health, Safety and Environment Policy that affirms its commitment to operational integrity. Operational integrity at Husky means conducting all activities safely and reliably so that the public is protected, impact to the environment is minimized, the health and wellbeing of employees are safeguarded, contractors and customers are safe, and physical assets (such as facilities and equipment) are protected from damage or loss.

The Health, Safety and Environment Committee of the Board of Directors is responsible for oversight of health, safety and environment policy, audit results and for monitoring compliance with the Company’s environmental policies, key performance indicators and regulatory requirements. The mandate of the Health, Safety and Environment Committee is available on the Husky website atwww.huskyenergy.com.

Husky Operational Integrity Management System

Husky approaches social responsibility and sustainable development by seeking a balance among economic, environmental and social factors while maintaining growth. Husky strives to find solutions to issues that do not compromise the needs of future generations. In 2008, Husky implemented HOIMS, which is followed by all Husky businesses. HOIMS is a systematic approach to anticipating, identifying and mitigating hazardous situations within the Company’s operations. The implementation of HOIMS has produced tangible business results, including improved performance, fewer incidents and enhanced business value. It incorporates best practices from across the industry, consistent with Husky’s commitment to excellence in operational integrity. HOIMS includes 14 fundamental elements; each element contains well defined objectives and expectations that guide Husky to continuously improve operational integrity. Resources are dedicated to the continued implementation and execution of HOIMS, and audits are conducted to help ensure that HOIMS is effectively integrated into daily operations.

The fundamental elements of HOIMS are:

| | 1. | Ensure all levels of management demonstrate leadership and commitment to operational integrity. Define and ensure appropriate accountability for HOIMS throughout the organization. |

| | 2. | Prevent incidents by identifying and minimizing workplace and personal health risks. Promote and reinforce all safe behaviours. |

| | 3. | Manage risks by performing comprehensive risk assessments to provide essential decision-making information. Develop and implement plans to manage significant risks and impacts to as low as reasonably practical levels. |

| | 4. | Be prepared for an emergency or security threat. Identify all necessary actions to be taken to protect people, the environment, the organization’s assets and reputation in the event of an emergency or security threat. |

| | 5. | Maintain operations reliability and integrity by use of clearly defined and documented operational, maintenance, inspection and corrosion programs. Seek improvements in process and equipment dependability by systematically eliminating defects and sources of loss. |

| | 6. | Provide assurance that personnel possess the necessary competencies, knowledge, abilities and behaviours to perform and demonstrate designated tasks and responsibilities effectively, efficiently and safely. |

| | 7. | Report and investigate all incidents. Learn from incidents and use the information to take corrective action and prevent recurrence. |

| | 8. | Operate responsibly to minimize the environmental impact of operations. Leave a positive legacy behind when operations cease. |

| | 9. | Ensure that risks and exposures from proposed changes are identified, evaluated and managed to remain at an acceptable level. |

| | 10. | Identify, maintain and safeguard important information. Ensure personnel can readily access and retrieve information. Promote and encourage constructive dialogue within the organization to share industry recommended practices and acquired knowledge. |

| | 11. | Ensure conformance with corporate policies and compliance with all relevant government regulations. Work constructively to influence proposed laws and regulations, and debate on emerging issues. |

| | 12. | Design, construct, commission, operate and decommission all assets in a healthy, safe, secure, environmentally sound, reliable and efficient manner. |

| | 13. | Ensure contractors and suppliers perform in a manner that is consistent and compatible with Husky’s policies and business performance standards. Ensure contracted services and procured materials meet the requirements and expectations of Husky’s standards. |

| | 14. | Confirm that HOIMS processes are implemented and assess whether they are working effectively. Measure progress and continually improve towards meeting HOIMS objectives, targets, and key performance indicators. |

Environmental Protection

Husky’s operations are subject to various environmental requirements under federal, provincial, state and local laws and regulations, as well as international conventions. These laws and regulations cover matters such as air emissions, wastewater discharge, non-saline water use, land disturbances and handling and disposal of waste materials. These regulatory requirements have grown in number and complexity over time, covering a broader scope of industry operations and products. In addition to existing requirements, Husky recognizes that there are emerging regulatory frameworks that may have a financial impact on the Company’s operations, including pending legislation on criteria regarding air contaminants and GHG emissions.

Husky is required by the Government of Canada to report GHG emissions for facilities that emit more than 50,000 tonnes of CO2e per year. Husky has implemented an Environmental Performance Reporting System that gathers, consolidates, and calculates information, generates reports and identifies trends regarding GHG and other air emissions, water use, as well as other environmental factors such as ARO.

Husky recognizes that the intensity of its GHG emissions is increasing driven by growth in the Company’s thermal oil business. As part of its efforts to manage GHG emissions performance, the Company is investing in technology to capture and utilize CO2 from its operations for EOR. The Company currently captures CO2 from its Lloydminster Ethanol Plant and is testing multiple commercial technologies for exhaust gas CO2 capture from steam generators at a thermal oil production facility. The captured CO2 is then injected into reservoirs in the Lloydminster area of Saskatchewan for EOR purposes. Husky is also focused on steam to oil ratio optimization, which impacts the GHG emissions intensity of thermal operations and has invested in vacuum insulated tubing as an example to reduce steam consumption. The Company has dedicated resources to identifying new ways of managing GHG emissions performance through technology and process improvements.

Directly and through joint venture partnerships, Husky is a member of several industry associations that collaborate to identify and implement best practices on environmental performance. IPIECA, the global oil and gas industry association for environmental and social issues, produces guidelines that Husky uses to improve its environmental practices, enhance its strategic planning, engage with regulators and enhance operations. Husky is also a member of the Integrated CO2 Action Network, which is working to improve deployment of carbon capture and storage technologies in Canada. As a member of Petroleum Technology Alliance Canada, Husky participates in technology research for energy efficiency and emissions reduction. In addition, as an active member of the In-situ Water Technology Development Centre, Husky is developing new technologies to reduce energy and water use. Husky dedicates teams to water management issues, with expertise in hydrogeology, surface water aquatics, hydrology, water treatment and drilling waste management. Husky continues to seek ways to conserve and recycle water, including looking at alternative water sources, recycling produced water and the use of ASP to increase water efficiency. At the Tucker Thermal Facility, produced water is recycled and make up water is sourced from very saline, non-potable groundwater. The Sunrise Energy Project will also recycle produced water, and will use process-affected water from a nearby oil sands operation, after it has been treated, to generate steam for oil recovery.

Ongoing remediation and reclamation work is occurring at approximately 5,300 well sites and facilities. In 2014, Husky spent approximately $167.4 million on ARO, and the Company expects to spend approximately $97.3 million in 2015 on environmental site closure activities, including abandonment, decommissioning, reclamation and remediation.

The Company completed a review of its ARO provisions, including estimated costs and projected timing of performing the abandonment and retirement operations. The results of this review have been incorporated into the estimated liability as disclosed in Note 16 of the Company’s 2014 audited consolidated financial statements.

At December 31, 2014, Husky had 490 retail locations in its light refined products operations, which consisted of 333 Husky controlled, owned or leased locations and 157 independent retailer locations. Husky is continually monitoring the owned and leased locations for environmental compliance and, where required, performing remediation including routine underground tank replacements. Husky has several “legacy” (inactive facility) sites which require remediation. These legacy sites range from refinery sites to retail locations.

It is not possible to predict with certainty the amount of additional investment in new or existing facilities required to be incurred in the future for environmental protection or to address regulatory compliance requirements, such as reporting. Although these costs may be significant, Husky does not expect that they will have a material adverse effect on liquidity and financial position over the long-term.

Upstream Operations

Description of Major Properties and Facilities

Husky’s portfolio of Upstream assets includes properties with reserves of light crude oil, medium crude oil, heavy crude oil, bitumen, NGL, natural gas and sulphur.

China

Liwan Gas Project

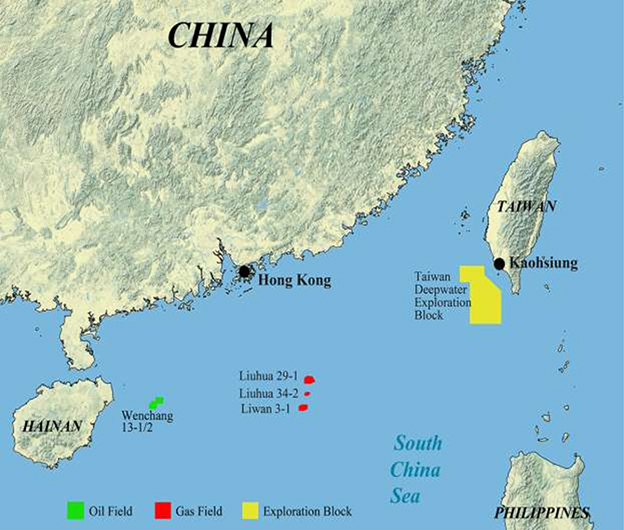

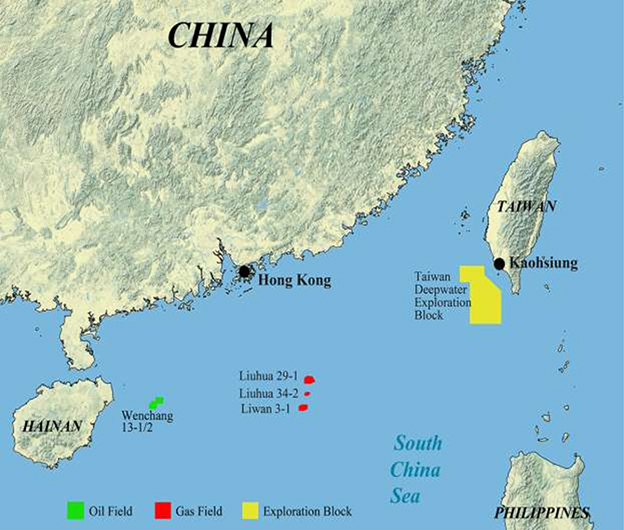

The Liwan Gas Project includes the natural gas discoveries at the Liwan 3-1, Liuhua 34-2 and Liuhua 29-1 fields within the Contract Area 29/26 exploration block located in the Pearl River Mouth Basin of the South China Sea, approximately 300 kilometers southeast of the Hong Kong Special Administrative Region.

In late 2010, Husky Oil China Ltd. signed a Heads of Agreement with CNOOC, which specified CNOOC’s election to participate in the development of the Block 29/26 discoveries to its maximum 51% working interest and key principles to fund, develop and operate the Liwan 3-1 deep water gas field. It was agreed that the project would be separated into deep water and shallow water development projects, with Husky acting as deep water operator and CNOOC acting as shallow water operator. The development plan includes tie-in of the Liuhua 34-2 and Liuhua 29-1 fields into the shallow water infrastructure and the three fields will share a subsea production system, subsea pipeline transportation and onshore gas processing infrastructure.

In 2013, Husky completed the deep water development of the Liwan 3-1 field. During the same period, CNOOC completed the shallow water central platform standing in approximately 120 meters of water. The CNOOC-operated shallow water development also includes a 261 kilometer 30 inch diameter pipeline running from the central platform to the onshore Gaolan Gas Plant. The gas plant includes liquids separation facilities, ten spherical NGL storage tanks, an export jetty, control facilities, as well as administrative and accommodation buildings.

The Liwan 3-1 field commenced production at the end of March 2014. The gas field is currently producing from 9 wells to the central platform and on through to the onshore Gaolan Gas Plant. The single production well, Liuhua 34-2 field was tied into the deep water facilities of the Liwan 3-1 field and commenced production in December 2014. Gas sales from Liwan were in the range of 180 to 250 mmcf/day (gross) in 2014. Husky’s share of natural gas production was 114.2 mmcf/day representing its 49% working interest share plus production allocated to Husky to recover past exploration costs. Husky’s share of production from the two fields including NGL was 23.3 mboe/day. Negotiations for the sale of the gas from the Liuhua 29-1 field are ongoing.

Wenchang

The Wenchang field is located in the western Pearl River Mouth Basin, approximately 400 kilometers south of the Hong Kong Special Administrative Region and 100 kilometers east of Hainan Island. Husky holds a 40% working interest in two oil fields, which commenced production in July 2002. The Wenchang 13-1 and 13-2 oil fields are currently producing from 32 wells in 100 meters of water into an FPSO stationed between fixed platforms located in each of the two fields. Husky’s share of production averaged 4.8 mbbls/day during 2014. The PSC is due to expire in 2017.

Taiwan

In December 2012, Husky signed a joint venture agreement with CPC Corporation, Taiwan, for an exploration block in the South China Sea. The exploration block is located 100 kilometers southwest of the island of Taiwan and covers approximately 10,000 square kilometers. Husky holds a 75% working interest during exploration, while CPC Corporation has the right to participate in the development program up to a 50% interest.

In 2013 and 2014, Husky completed the minimum 2-D seismic survey obligation required in the joint venture agreement and is currently processing the survey data to identify geological structures for 3-D seismic surveying to be considered in 2016. Husky has options to carry out three-dimensional seismic surveys and to drill at least one exploration well in subsequent exploration periods.

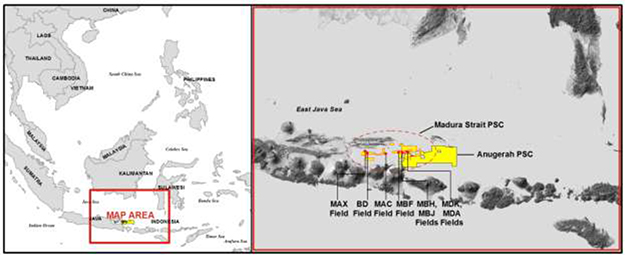

Indonesia

Madura Strait

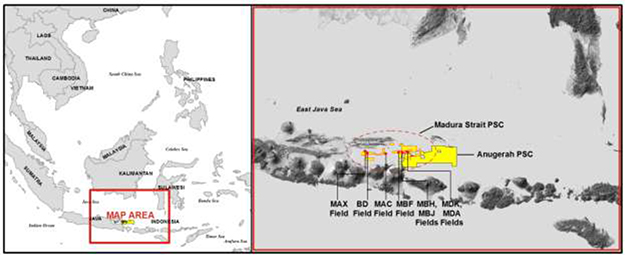

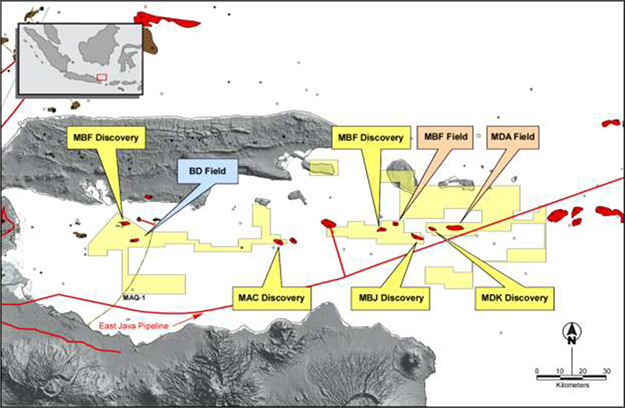

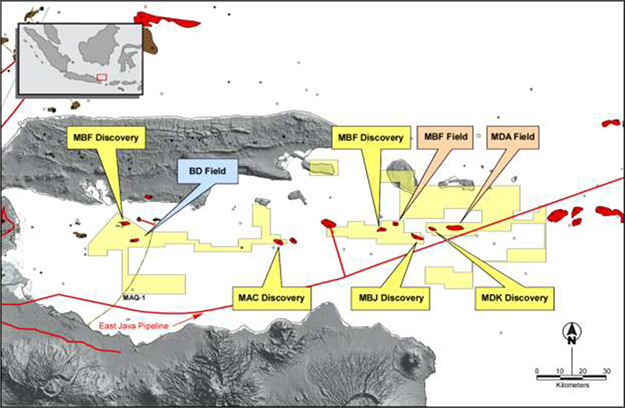

Husky has a 40% interest in approximately 621,700 acres (2,516 square kilometers) of the Madura Strait Block, located offshore East Java, south of Madura Island, Indonesia. Husky’s two partners are CNOOC, which is the operator and has a 40% working interest, and Samudra Energy Ltd., which holds the remaining 20% interest through its affiliate, SMS Development Ltd.

The BD gas field was granted commercial status and the Plan of Development was approved by the Indonesian state oil company in 1995. The field was to supply natural gas to a proposed independent power plant; however, construction of the power plant did not proceed due to economic issues that occurred in Indonesia at that time and as a result, the BD development was deferred. Market conditions became more favourable for the BD development to supply gas to meet the demand of the East Java region and an updated development plan was approved in 2008 by the Government of Indonesia.

In October 2010, the Government of Indonesia approved an extension of the PSC that was originally awarded in 1982. The approval provided a 20-year extension to the contract, which now runs until 2032. The BD field FEED was completed in the second quarter of 2010.

In 2011, CNOOC drilled an appraisal well that confirmed commercial quantities of hydrocarbons in the MDA field. An exploration well was also drilled in 2011 on the MBH field and a new gas field was discovered. The gas sales contracts for the BD field previously signed in 2010 with three gas buyers were amended in 2011. In November 2012, the functions of BP Migas, the then Indonesian oil and gas regulator, were temporarily transferred to the Energy and Mineral Resources Ministry and subsequently, a new body, SKK Migas, was established as the new industry regulator. As discussed and agreed with the new regulator, a re-tender for the BD field FPSO commenced.

In 2012, the exploration drilling program resulted in discoveries on the MAC, MAX, MDK and MBJ fields. The fields are being evaluated for commercial development potential.

In January 2013, the plan of development for a combined MDA and MBH development project was approved by SKK Migas. In July 2013, the BD field engineering, procurement, installation and commissioning contract was awarded and engineering/construction work under the contract commenced. The Government of Indonesia appointed a lead distributor for the major portion of the gas from the MDA and MBH fields and a Heads of Agreement has been signed. The Gas Sales Agreement for the first tranche of gas from this development is complete and awaiting final approval from the regulator. Exploration drilling on the block in 2013 resulted in an additional discovery at the MBF field.

In 2014, the tender plans for the combined development project for the MDA and MBH fields were approved by SKK Migas. The development plan for the MDK field to tie into the MDA/MBH combined development was approved by SKK Migas in July 2014. A contract for the lease of an FPSO for the BD field was signed in December.

First gas from the Madura Strait Block is anticipated in mid-2017.

North Sumbawa II

Husky executed a PSC in November 2008 with the Government of Indonesia for the North Sumbawa II contract area. Husky holds a 100% interest in the North Sumbawa II Block, which is located in the East Java Basin approximately 300 kilometers east of the Madura Strait block and covers an area of 937,300 acres (3,793 square kilometers). In August 2014, Husky gave notice to the Government of Indonesia of its intention to relinquish the PSC.

Anugerah

Husky executed a PSC in February 2014 with the Government of Indonesia for the Anugerah contract area. Husky holds a 100% interest in the Anugerah Block, which is located in the East Java Basin approximately 150 kilometers east of the Madura Strait Block and 220 km west of the North Sumbawa II Block. The block covers an area of 2,030,000 acres (8,215 square kilometers) with main prospective locations in water depths of 800 to 1,300 meters. The PSC requires the acquisition of 2-D and 3-D seismic data during the first three years of the contract. Planning is in progress for the seismic acquisition program to be carried out in 2015.

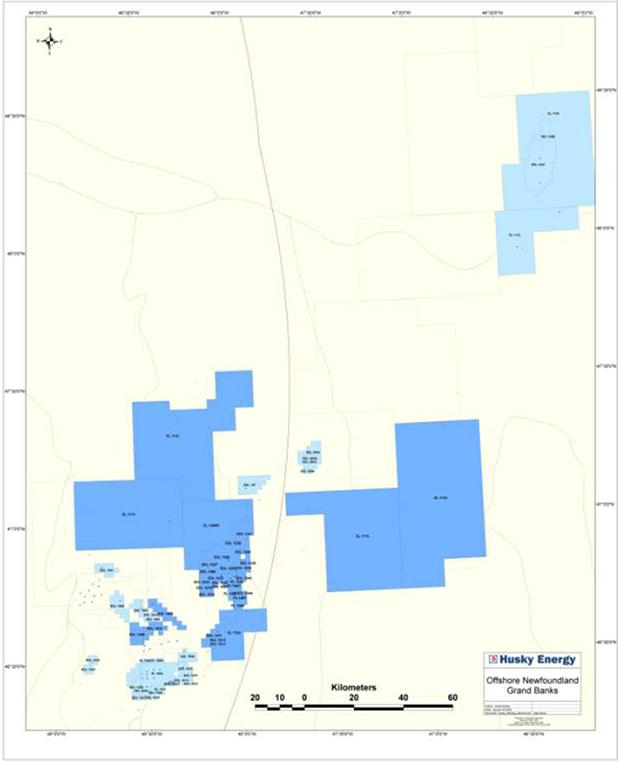

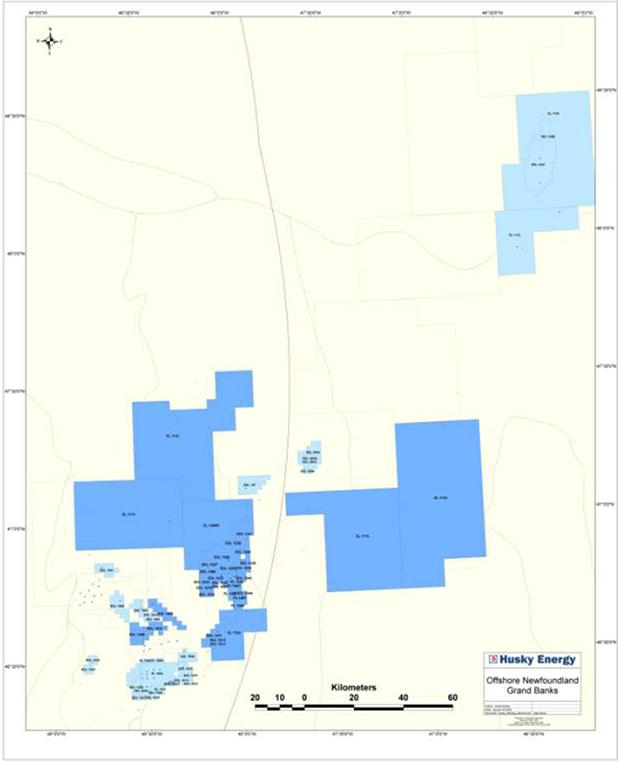

Atlantic Region

Husky’s offshore East Coast exploration and development program is focused in the Jeanne d’Arc Basin on the Grand Banks, which contains the Hibernia and Terra Nova fields, the White Rose field and satellite extensions, including North Amethyst, West White Rose and the South White Rose Extensions; and the Flemish Pass Basin, which contains the Mizzen, Bay du Nord and Harpoon discoveries. Husky is the operator of the White Rose field and satellite extensions, and holds an ownership interest in the Terra Nova field as well as in a number of smaller undeveloped fields. Husky also holds significant exploration acreage offshore Newfoundland and a portfolio of ELs offshore Greenland.

White Rose Oil Field

The White Rose oil field is located 354 kilometers off the coast of Newfoundland and Labrador and approximately 48 kilometers east of the Hibernia oil field on the eastern section of the Jeanne d’Arc Basin. Husky is the operator of the White Rose field and satellite tiebacks, including the North Amethyst, West White Rose and South White Rose Extensions. The Company has a 72.5% working interest in the core field and a 68.875% working interest in the satellite fields.

First oil was achieved at White Rose in November 2005. The White Rose field was the third oil field developed offshore Newfoundland and currently has nine production wells, 10 water injectors, and three gas injectors. During 2014, Husky’s production from the White Rose field was 6.5 mmbbls (17.7 mbbls/day).

On May 31, 2010, first oil was achieved from North Amethyst, the first satellite field extension for the White Rose field. The field is located approximately six kilometers southwest of the SeaRose FPSO. Production flows from North Amethyst to the SeaRose FPSO through a series of subsea flow lines. During 2014, Husky’s production from North Amethyst was 5.6 mmbbls (15.3 mbbls/day). As of December 31, 2014, the field had five production wells and four water injection wells, which completes the base plan for the field. A development plan amendment was approved by regulators in June 2013. In October 2013, Husky received regulatory approval to develop a second, deeper formation at North Amethyst utilizing existing infrastructure. A supporting water injector is already in place. The Company commenced drilling in 2014 at the North Amethyst Hibernia formation which will target a secondary deeper zone below the main North Amethyst producing field. Production from the Hibernia formation is expected to start up in the second half of 2015.

Initial production from West White Rose was achieved in September 2011 through a two-well pilot project. These wells have helped provide further information on the reservoir to refine development plans for the full West White Rose field. Husky’s share of production from this satellite field was 2.0 mmbbls (5.6 mbbls/day) during 2014.

Hearings for the public review of the application for a wellhead platform to facilitate full field development at West White Rose were held during 2014. Construction on the dry-dock in Argentia, Newfoundland and early site preparation was advanced, including construction of a graving dock. Husky has deferred a final investment decision on the White Rose Extension Project while it re-evaluates concept development plans.

Gas injection at the South White Rose Extension commenced in the first quarter of 2014, with oil production equipment installed in summer 2014. Drilling of the first oil production well is underway with production anticipated in mid-2015.

Terra Nova Oil Field

The Terra Nova oil field is located approximately 350 kilometers southeast of St. John’s, Newfoundland in 91 to 100 metres of water. The Terra Nova oil field is divided into three distinct areas, known as the Graben, the East Flank and the Far East. Production at Terra Nova commenced in January 2002. Husky’s working interest in the field increased to 13% effective December 1, 2010.

As at December 31, 2014, there were 14 development wells drilled in the Graben area, consisting of eight production wells, three water injection wells and three gas injection wells. In the East Flank area there were 14 development wells, consisting of eight production wells and six water injection wells. There is one extended reach producer and an extended reach water injection well in the Far East area. The Operator continues to progress delineation and development opportunities at Terra Nova.

Husky’s share of production in 2014 from the Terra Nova field was 2.2 mmbbls (6.0 mbbls/day). Production at Terra Nova was impacted by a 25-day turnaround associated with scheduled maintenance on the FPSO and coincided with the 2014 subsea program to replace a water injection tee and reinstate the second production flowline to the Northwest Drill Centre. Production from the field resumed on August 31, 2014.

East Coast Exploration

Husky believes that the Atlantic Region has exploration potential, and that the Company’s position there will provide growth opportunities for light crude oil and natural gas development in the medium to long-term. Husky presently holds working interests ranging from 5.8% to 73.125% in 23 significant discovery areas in the Jeanne d’Arc Basin, Flemish Pass Basin, offshore Newfoundland and Labrador and Baffin Island.

In November 2014, following the major discoveries made, Husky and its partner commenced an 18-month appraisal drilling program in the Northern Flemish Pass, beginning in the Bay du Nord area. Evaluation of well results at Bay du Nord have confirmed significant quantities of hydrocarbons with best estimate economic contingent resources estimated by Husky at 400 million barrels of crude oil on a 100% working interest basis (141.2 million net to Husky) as at December 31, 2014. The Bay du Nord prospect is south of the Mizzen discovery and west of the Harpoon discovery. Mizzen, discovered in 2009, holds best estimate economic contingent resources estimated by Husky at 130 million barrels of crude oil on a 100% working interest basis (46.1 million net to Husky) as at December 31, 2014. Evaluation of well results at Harpoon continues. Husky holds a 35% working interest in all three wells.

The Company plans to participate in additional exploration and delineation wells during 2015 in the southern Flemish Pass Basin and the Jeanne d’Arc Basin. Drilling of an exploration well on the Aster prospect in the Flemish Pass Basin commenced on December 19, 2014, and results are currently being evaluated.

Greenland

Husky is the operator of two ELs offshore the west coast of Disko Island, Greenland. Husky continues to evaluate its opportunities in the region.

Oil Sands

Sunrise Energy Project

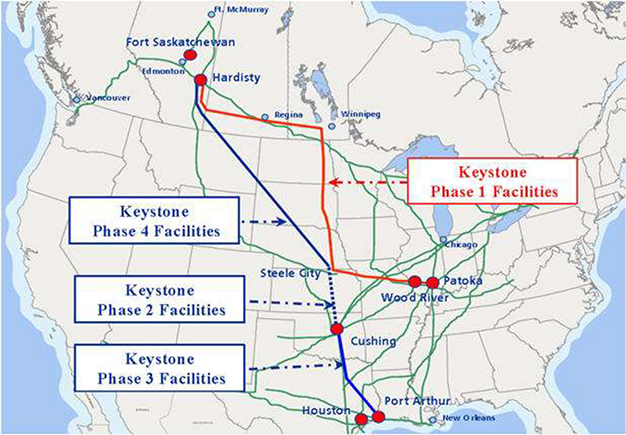

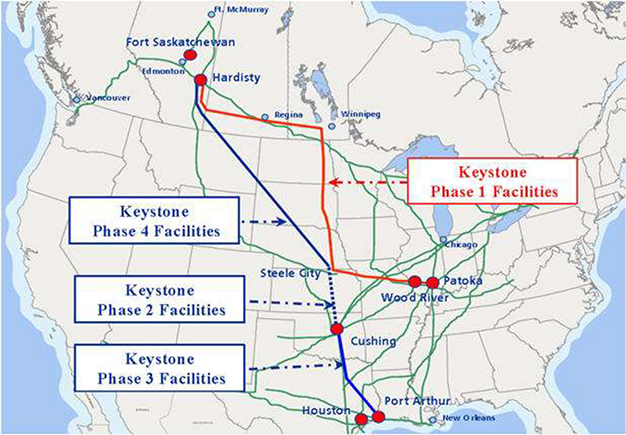

On March 31, 2008, Husky and BP completed a transaction that created an integrated North American oil sands business. The business is comprised of a 50/50 partnership to develop the Sunrise Energy Project, operated by Husky, and a 50/50 limited liability company for the BP-Husky Toledo Refinery, operated by BP.

The Sunrise Energy Project is an in-situ SAGD oil sands project located in the Athabasca region of northern Alberta. The project will be developed in multiple phases with Phase 1 consisting of two 30,000 bbls/day steam plants (Plants 1A and 1B). The project was sanctioned in 2010 and Husky awarded major engineering and construction contracts for the central processing and field facilities and the partnership reached an agreement on the movement of diluted bitumen to market and transportation of diluent to the Sunrise oil sands site. Development drilling of all planned SAGD horizontal well pairs for Phase 1 was completed in 2012. Construction of the central processing facilities and field facilities was substantially completed in 2014 and steaming from Plant 1A commenced in December 2014. First oil is expected towards the end of the first quarter of 2015. Plant 1B is scheduled to be completed and commence steaming in mid-2015.

Undeveloped Oil Sands Assets

Husky holds in excess of 550,000 acres in undeveloped oil sands leases and has a 100% working interest in all leases except in Athabasca South, in which it has a 50% working interest. The undeveloped oil sands leases include the Saleski asset covering more than 241,000 acres located north of Wabasca, Alberta. Saleski contains a best estimate economic contingent resource of 10 billion barrels of bitumen.

Tucker Oil Sands Project

Tucker is an in-situ SAGD oil sands project located 30 kilometers northwest of Cold Lake, Alberta that commenced production at the end of 2006. Husky has expanded the project through the development of the overlying Lower Grand Rapids formation with an initial six well pairs. Production at Tucker in 2014 was 10.8 mbbls/day. Several applications to the AER have been approved or are proceeding for additional drilling and field development through 2015.

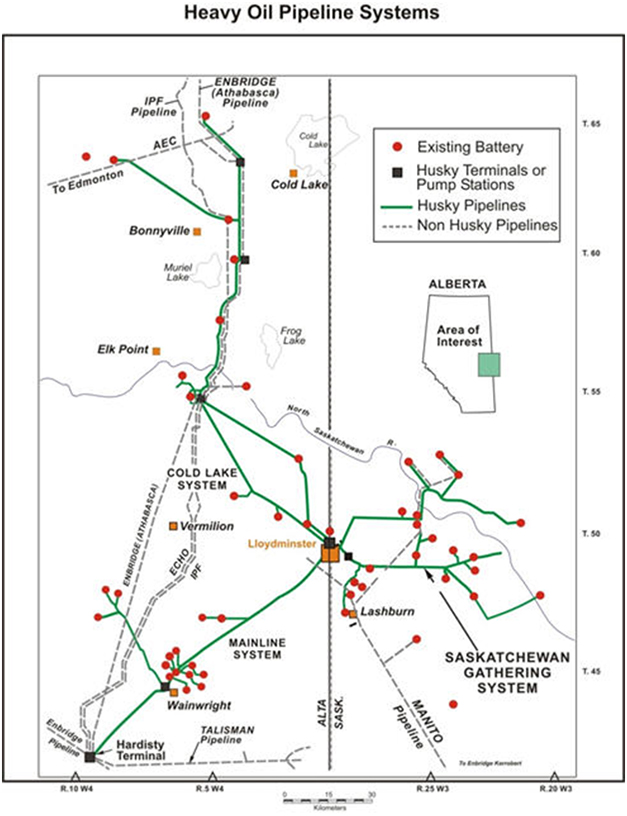

Heavy Oil

Lloydminster Heavy Oil and Gas

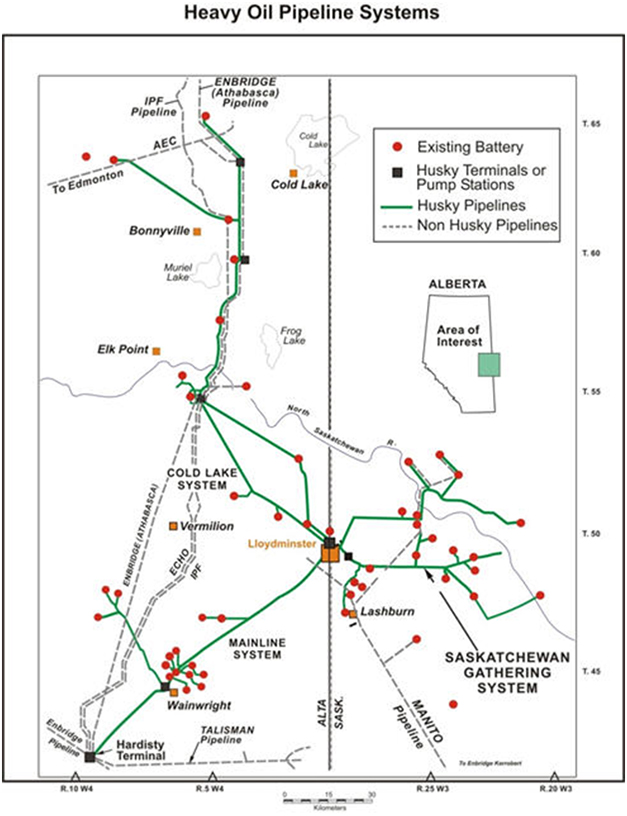

The majority of Husky’s heavy oil assets are located in the Lloydminster region of Alberta and Saskatchewan, with lands consisting of approximately two million acres. This extensive land position spans most of the productive oil fields in the area, all within 100 kilometers of the City of Lloydminster. The Company operates over 4,500 wells in the area, with a 100% working interest in the majority of these wells. Husky’s operations are supported by a network of Husky owned oil treating facilities and pipelines that transport heavy crude oil from the field locations to the Husky Lloydminster asphalt refinery, the Husky Lloydminster Upgrader and the third-party pipeline systems at Hardisty, Alberta, providing full integration with the Company’s Upstream Infrastructure and Marketing and Downstream businesses.

Production of heavy oil from the Lloydminster area uses a variety of techniques, including production methods, horizontal well technology, CSS and SAGD. Husky’s gross heavy and medium crude oil production from the area averaged 107.4 mbbls/day in 2014. Of the total crude oil produced, 61.8 mbbls/day was production of heavy crude oil, using CHOPS and horizontal technologies, 43.8 mbbls/day was from Husky’s thermal operations and 1.8 mbbls/day was from the medium gravity waterflooded fields in the Wainwright and Wildmere areas. Husky also produces natural gas from numerous small shallow pools in the Lloydminster region and recovers solution gas produced from heavy oil wells. During 2014, Husky’s gross natural gas production from the Lloydminster region averaged 17.7 mmcf/day.

Construction was completed at the 3,500 bbls/day Sandall thermal development project in the first quarter of 2014. Production commenced ahead of schedule and continues to be strong with oil rates averaging 5,600 bbls/day in the fourth quarter of 2014.

Design and construction is continuing at the 10,000 bbls/day Rush Lake commercial project with first production expected in the third quarter of 2015. Production performance from the two well pair pilot is in line with expectations.