SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

S ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 - For the fiscal year ended December 31, 2006

Commission file number 1-3919

Keystone Consolidated Industries, Inc. |

| (Exact name of Registrant as specified in its charter) |

Delaware | | 37-0364250 |

(State or other jurisdiction of Incorporation or organization) | | (IRS Employer Identification No.) |

5430 LBJ Freeway, Suite 1740, Three Lincoln Centre, Dallas, Texas | | 75240-2697 |

| (Address of principal executive offices) | | (Zip Code) |

Registrant’s telephone number, including area code: | (972) 458-0028 |

| | |

Securities registered pursuant to Section 12(b) of the Act: | None. |

Securities registered pursuant to Section 12(g) of the Act: | Title of each class |

| | Common Stock, $.01 par value |

Indicate by check mark:

If the Registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes £ No S

If the Registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes £ No S

Whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months and (2) has been subject to such filing requirements for the past 90 days. Yes S No £

If disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. S

Whether the Registrant is a large accelerated filer, an accelerated filer or a non-accelerated filer (as defined in Rule 12b-2 of the Act).

Large accelerated filer £ Accelerated filer £ Non-accelerated filer S.

Whether the Registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes £ No S

The aggregate market value of the 4,900,000 shares of voting stock held by nonaffiliates of the Registrant, as of June 30, 2006 (the last business day of the Registrant’s most-recently completed second fiscal quarter), was approximately $11,025,000.

Whether the Registrant has filed all documents and reports required to be filed by Section 12, 13 or 15(d) of the Securities Exchange Act of 1934 subsequent to the distribution of securities under a plan confirmed by a court. Yes S No £

As of March 28, 2007, 10,000,000 shares of common stock were outstanding.

Documents incorporated by reference

The information required by Part III is incorporated by reference from the Registrant’s definitive proxy statement to be filed with the Commission pursuant to Regulation 14A not later than 120 days after the end of the fiscal year covered by this report.

PART I

This Annual Report contains forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Statements in this Annual Report on Form 10-K that are not historical in nature are forward-looking and are not statements of fact. Statements found in this report including, but not limited to, statements found in Item 1 - "Business," Item 1A - "Risk Factors," Item 3 - "Legal Proceedings," Item 7 - "Management’s Discussion and Analysis of Financial Condition and Results of Operations" and Item 7A - "Quantitative and Qualitative Disclosures About Market Risk," are forward-looking statements that represent our beliefs and assumptions based on currently available information. In some cases you can identify these forward-looking statements by the use of words such as "believes," "intends," "may," "should," "could," "anticipates," "expected" or comparable terminology, or by discussions of strategies or trends. Although we believe the expectations reflected in such forward-looking statements are reasonable, we do not know if these expectations will be correct. Forward-looking statements by their nature involve substantial risks and uncertainties that could significantly impact expected results. Actual future results could differ materially from those predicted. While it is not possible to identify all factors, we continue to face many risks and uncertainties. Among the factors that could cause our actual future results to differ materially from those described herein are the risks and uncertainties discussed in this Annual Report and those described from time to time in our other filings with the Securities and Exchange Commission (“SEC”) including, but not limited to, the following:

| · | Future supply and demand for our products (including cyclicality thereof), |

| · | Customer inventory levels, |

| · | Changes in raw material and other operating costs (such as ferrous scrap and energy), |

| · | The possibility of labor disruptions, |

| · | General global economic and political conditions, |

| · | Competitive products and substitute products, |

| · | Customer and competitor strategies, |

| · | The impact of pricing and production decisions, |

| · | Environmental matters (such as those requiring emission and discharge standards for existing and new facilities), |

| · | Government regulations and possible changes therein, |

| · | Significant increases in the cost of providing medical coverage to employees, |

| · | The ultimate resolution of pending litigation, |

| · | International trade policies of the United States and certain foreign countries, |

| · | Operating interruptions (including, but not limited to, labor disputes, fires, explosions, unscheduled or unplanned downtime and transportation interruptions), |

| · | Our ability to renew or refinance credit facilities, and |

| · | Any possible future litigation. |

Should one or more of these risks materialize, if the consequences worsen, or if the underlying assumptions prove incorrect, actual results could differ materially from those currently forecasted or expected. We disclaim any intention or obligation to update or revise any forward-looking statement whether as a result of changes in information, future events or otherwise.

ITEM 1. BUSINESS.

Keystone Consolidated Industries, Inc. (“KCI”) is a leading manufacturer of steel fabricated wire products, welded wire reinforcement, coiled rebar, industrial wire and wire rod for the agricultural, industrial, construction, original equipment manufacturer and retail consumer markets, and we are one of the largest manufacturers of fabricated wire products in the United States based on tons shipped (112,000 tons in 2006). We are vertically integrated, converting substantially all of our fabricated wire products, welded wire reinforcement, coiled rebar and industrial wire from wire rod produced in our steel mini-mill. Our vertical integration has historically allowed us to benefit from the higher and more stable margins associated with fabricated wire products and welded wire reinforcement, as compared to wire rod, as well as from lower production costs of wire rod as compared to fabricators that purchase wire rod in the open market. Moreover, we believe our downstream fabricated wire products, welded wire reinforcement, coiled rebar and industrial wire businesses better insulate us from the effects of wire rod imports as compared to non-integrated wire rod producers.

Our operating segments are organized by our manufacturing facilities and include three reportable segments:

| · | Keystone Steel and Wire (“KSW”), located in Peoria, Illinois, operates an electric arc furnace mini-mill and manufactures and sells wire rod, industrial wire, nails, coiled rebar and fabricated wire products for agricultural, industrial, construction, commercial, original equipment manufacturers and retail consumer markets; |

| · | Engineered Wire Products (“EWP”), located in Upper Sandusky, Ohio, manufactures and sells welded wire reinforcement in both roll and sheet form that is utilized in concrete construction products including pipe, pre-cast boxes and applications for use in roadways, buildings and bridges; and |

| · | Keystone Wire Products (“KWP”), located in Sherman, Texas, manufactures and sells industrial wire and fabricated wire products for agricultural, industrial, construction, commercial, original equipment manufacturers and retail consumer markets. |

During the third quarter of 2006, we decided to relocate KWP’s industrial wire manufacturing process to KSW in order to eliminate duplicative costs. Additionally, we decided to discontinue our nail operations during the third quarter of 2006 as a result of lower cost foreign competition driving down selling prices, which eliminated the profitability of our nail business. By the end of the second quarter of 2007, all nail production should be phased out and the relocation of KWP’s industrial wire manufacturing operations should be complete.

For additional information about our segments see “Part II - Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations” and Note 3 to our Consolidated Financial Statements.

We are the successor to Keystone Steel & Wire Company, which was founded in 1889. Contran Corporation owns 51.0% of our outstanding common stock at December 31, 2006. Substantially all of Contran's outstanding voting stock is held by trusts established for the benefit of certain children and grandchildren of Harold C. Simmons (for which Mr. Simmons is the sole trustee) or is held directly by Mr. Simmons or other persons or companies related to Mr. Simmons. Consequently, Mr. Simmons may be deemed to control Contran and us.

Unless otherwise indicated, references in this report to "we", "us" or "our" refer to KCI and its subsidiaries, taken as a whole.

Manufacturing

Overview

Our manufacturing operations consist of an electric arc furnace mini-mill, a rod mill and three wire and wire product fabrication facilities as outlined in our segment discussion above. The manufacturing process commences at KSW where ferrous scrap is loaded into an electric arc furnace, converted into molten steel and then transferred to a ladle refining furnace where chemistries and temperatures are monitored and adjusted to specifications prior to casting. The molten steel is transferred from the ladle refining furnace into a six-strand continuous casting machine which produces five-inch square strands referred to as billets that are cut to predetermined lengths. These billets, along with any billets purchased from outside suppliers, are then transferred to the adjoining rod mill.

Upon entering the rod mill, the billets are brought to rolling temperature in a reheat furnace and are fed to the rolling mill, where they are finished to a variety of diameters and specifications. After rolling, the wire rod is coiled and cooled. After cooling, the coiled wire rod passes through inspection stations for metallurgical, surface and diameter checks. Finished coils are compacted and tied, and either further processed into industrial wire, welded wire reinforcement, nails, coiled rebar and fabricated wire products at our wire and wire product fabrication facilities or shipped to wire rod customers.

While we do not maintain a significant "shelf" inventory of finished wire rod, we generally have on hand approximately a one-month supply of industrial wire, welded wire reinforcement, coiled rebar and fabricated wire products inventory which enables us to fill customer orders and respond to shifts in product demand.

Raw Materials and Energy

The primary raw material used in our operations is ferrous scrap. Our steel mill is located close to numerous sources of high density automobile, industrial and railroad ferrous scrap, all of which are currently readily available. We believe we are one of the largest recyclers of ferrous scrap in Illinois. The purchase of ferrous scrap is highly competitive and its price volatility is influenced by periodic shortages, export activity, freight costs, weather, and other conditions beyond our control. The cost of ferrous scrap can fluctuate significantly and product selling prices cannot always be adjusted, especially in the short-term, to recover the costs of increases in ferrous scrap prices. We have not entered into any long-term contracts for the purchase or supply of ferrous scrap; therefore, we are subject to the price fluctuation of ferrous scrap.

Our manufacturing processes consume large amounts of energy in the form of electricity and natural gas. During 2004, 2005 and 2006, we purchased electrical energy for KSW from a utility under an interruptible service contract which provided for more economical electricity rates but allowed the utility to refuse or interrupt power to KSW. During the past three years, the utility exercised their rights under the contract and periodically interrupted our power, which resulted in decreased production and increased costs associated with the related downtime. This agreement expired on December 31, 2006.

Deregulation of electricity in Illinois occurred on January 1, 2007. For 2007 and 2008, we have a firm uninterruptible contract for delivery of power. Under this new contract, on a daily basis, we are required to notify the utility of the amount of electricity we expect to consume on the next day, and the price we pay for this electricity is determined when we provide such notification based on the forecasted hourly energy market rate for the next day. Any difference between our forecasted consumption and actual consumption will be settled based on the actual hourly market rate. However, to allow us to avoid pricing fluctuations, the contract allows us to purchase blocks of power in the forward markets at our discretion at prices negotiated at the time of purchase. Overall, we expect these changes will result in higher energy costs for us in the future.

Employment

As of December 31, 2006, we employed approximately 1,100 people, some of whom are covered under collective bargaining agreements as follows:

| · | 800 are represented by the Independent Steel Workers’ Alliance at KSW under an agreement expiring in May 2009, |

| · | 30 are represented by the International Association of Machinists and Aerospace Workers (Local 1570) at KWP under an agreement expiring in October 2008, and |

| · | 60 are represented by Local Union #40, an Affiliate to the International Brotherhood of Teamsters' Chauffeurs Warehousemen and Helpers of America, AFL-CIO at EWP under an agreement expiring in November 2009. |

Products, Markets and Distribution

The following table sets forth certain information with respect to our product mix in each of the last three years.

| | | Year Ended December 31, | |

| | | 2004 | | 2005 | | 2006 | |

Product | | Percent of Tons Shipped | | Percent Of Sales | | Percent of Tons Shipped | | Percent of Sales | | Percent of Tons Shipped | | Percent of Sales | |

| | | | | | | | | | | | | | |

| Fabricated wire products | | | 22.6 | % | | 31.4 | % | | 19.2 | % | | 30.1 | % | | 16.5 | % | | 26.6 | % |

| Welded wire reinforcement | | | 13.8 | | | 16.3 | | | 13.6 | | | 17.2 | | | 10.0 | | | 13.5 | |

| Nails | | | 5.4 | | | 5.8 | | | 3.2 | | | 3.4 | | | 2.6 | | | 2.8 | |

| Industrial wire | | | 16.0 | | | 16.1 | | | 13.7 | | | 14.4 | | | 11.2 | | | 12.6 | |

| Coiled rebar | | | - | | | - | | | - | | | - | | | 0.2 | | | 0.1 | |

| Wire rod | | | 38.9 | | | 29.6 | | | 44.9 | | | 32.4 | | | 51.6 | | | 40.1 | |

| Billets | | | 3.3 | | | .8 | | | 5.4 | | | 2.5 | | | 7.9 | | | 4.3 | |

| | | | 100.0 | % | | 100.0 | % | | 100.0 | % | | 100.0 | % | | 100.0 | % | | 100.0 | % |

| | | | | | | | | | | | | | | | | | | | |

Fabricated Wire Products. We are one of the leading manufacturers in the United States of agricultural fencing, barbed wire, stockade panels and a variety of woven wire mesh, fabric and netting for agricultural, construction and industrial applications. These products are sold to agricultural, construction, industrial, consumer do-it-yourself and other end-user markets which in our opinion are typically less cyclical than many steel consuming end-use markets such as the automotive, construction, appliance and machinery manufacturing industries. We serve these markets through distributors, agricultural retailers, building supply centers and consumer do-it-yourself chains such as Tractor Supply Co., Lowe's Companies, Inc., and Ace Hardware Corporation. We believe our ability to service these customers with a wide range of fabricated wire products through multiple distribution locations provides a competitive advantage in accessing these growing and less cyclical markets. As part of our marketing strategy, we design merchandise packaging, and supportive product literature for marketing many of these products to the retail consumer market.

We also manufacture products for residential and commercial construction, including rebar ty wire and stucco netting. The primary customers for these products are construction contractors and building materials manufacturers and distributors.

We believe our fabricated wire products are less susceptible to the cyclical nature of the steel business than nails, industrial wire, coiled rebar or wire rod because the commodity-priced raw materials used in such products, such as ferrous scrap, represent a lower percentage of the total cost of such value-added products.

Welded Wire Reinforcement. We manufacture a wide variety of wire mesh rolls and sheets used to form wire reinforcement in concrete construction projects such as pipe, precast boxes and other applications, including use in roadways, buildings, and bridges. Our welded wire reinforcement customers include pipe manufacturers, culvert manufacturers, rebar fabricators, and steel reinforcing distributors. Like our fabricated wire products, we believe our welded wire reinforcement products are also less susceptible to the cyclical nature of the steel business than nails, industrial wire, coiled rebar or wire rod because the commodity-priced raw materials used in such products, such as ferrous scrap, represent a lower percentage of the total cost of such value-added products when compared to wire rod or other less value-added products.

Nails. We manufacture bulk and packaged nails and sell these nails primarily to construction contractors, building manufacturers and distributors and do-it-yourself retailers. During 2006, we sold approximately 17% of our nails through PrimeSource, Inc., one of the largest nail distributors in the United States, under PrimesSource’s Grip-Rite® label.

During 2006, we decided to discontinue our nail operations and we anticipate all nail production will be phased out by the end of the second quarter of 2007, after which we plan to sell our nail production equipment. The results of operations of our nail business is not material.

Industrial Wire. We are one of the largest manufacturers of industrial wire in the United States. We produce custom-drawn industrial wire in a variety of gauges, finishes and packages for further consumption by our fabricated wire products operations or for sale to industrial fabrication and original equipment manufacturer customers, who are generally not our competitors. Our industrial wire is used by customers in the production of a broad range of finished goods, including nails, coat hangers, barbecue grills, air conditioners, tools, containers, refrigerators and other appliances.

Coiled rebar. Several sizes of coiled rebar are produced at KSW’s rod mill. The coils are typically used by fabricators who will process the material as straightened and cut to length bars or fabricated shapes for specific reinforcement applications such as building and road construction.

Wire Rod. We produce primarily low carbon steel wire rod at KSW’s rod mill. Low carbon steel wire rod, with carbon content of up to 0.38%, is more easily shaped and formed than higher carbon wire rod and is suitable for a variety of applications where ease of forming is a consideration. High carbon steel wire rod, with carbon content of up to 0.65%, is used for high tensile wire applications as well as for furniture and bedding springs. During 2006, approximately 42% of the wire rod that we manufactured was used internally to produce industrial wire, nails, welded wire reinforcement and fabricated wire products. The remainder of our wire rod production was sold directly to producers of construction products, fabricated wire products and industrial wire, including products similar to those manufactured by us.

Billets. KSW’s annual permitted billet production capacity is 820,000 tons. However, since KSW’s rod production is constrained by the 750,000 ton capacity of its rod mill, we sell excess billets to producers of products manufactured from low carbon steel.

Trademarks

Many of our fencing and related wire products are marketed under our RED BRAND label, a widely recognized brand name in the agricultural fencing and construction marketplaces for more than 80 years. RED BRAND sales represented approximately 85% of fabricated wire products net sales in 2006. We also maintain other trademarks for various products that have been promoted in their respective markets.

Customers

Our customers are primarily in the Midwestern, Southwestern and Southeastern regions of the United States. Customers vary considerably by product and we believe our ability to offer a broad range of products represents a competitive advantage in servicing the diverse needs of our customers.

Our fabricated wire products, welded wire reinforcement, industrial wire and wire rod business is not dependent upon a single customer or a few customers, the loss of any one, or a few, would not have a material adverse effect on our business. The percentage of sales related to our ten largest customers and the percentage of sales related to the only customer that accounted for more than 10% of our net sales during 2004, 2005 and 2006 is set forth in the following table. The customer that accounted for more than 10% of our net sales during 2005 and 2006 was a different customer from the customer that accounted for more than 10% of our net sales during 2004.

| | 2004 | | 2005 | | 2006 |

| | % of Sales |

| | | | | | |

Ten largest customers | 48% | | 43% | | 44% |

| | | | | |

Single customer | 12% | | 11% | | 14% |

Seasonality

Historically, we have experienced greater sales and profits during the first half of the year due to the seasonality of sales in principal wire products markets, including the agricultural and construction markets.

Backlog

Our backlog of unfilled cancelable fabricated wire products, welded wire reinforcement, nails, industrial wire, coiled rebar and wire rod purchase orders, for delivery generally within three months, approximated $52.9 million and $25.8 million at December 31, 2005 and 2006, respectively. We do not believe backlog is a significant factor in our business, and we expect all of the backlog at December 31, 2006 will be shipped during 2007.

Industry and Competition

The fabricated wire products, welded wire reinforcement, industrial wire, coiled rebar and wire rod businesses in the United States are highly competitive and are comprised primarily of several large mini-mill wire rod producers, many small independent wire companies and a few large diversified wire producers. We also face significant foreign competition. Lower wage rates and other costs in foreign countries have resulted in market prices that significantly reduce and sometimes eliminate the profitability of certain products, which resulted in our recent decision to exit the nail business.

We believe we are well positioned to compete effectively due to:

| · | the breadth of our fabricated wire products, welded wire reinforcement and industrial wire offerings; |

| · | our ability to service diverse geographic and product markets; and |

| · | the relatively low cost of our internal supply of wire rod. |

We believe our facilities are well located to serve markets throughout the continental United States, with principal markets located in the Midwestern, Southwestern and Southeastern regions. Close proximity to our customer base provides us with certain advantages over foreign and certain domestic competition including reduced shipping costs, improved customer service and shortened delivery times.

Fabricated Wire Products and Industrial Wire. Our principal competitors in the fabricated wire products and industrial wire markets are Leggett and Platt, Deacero, Oklahoma Steel and Wire and Davis Wire Corporation. Competition in the fabricated wire products and industrial wire markets is based on a variety of factors, including channels of distribution, price, delivery performance, product quality, service, and brand name preference. Our RED BRAND label has been a widely recognized brand name in the agricultural fencing and construction marketplaces for more than 80 years. Additionally, we believe higher transportation costs and the lack of local distribution centers tend to limit foreign producers' penetration of our principal fabricated wire products and industrial wire markets, but there can be no assurance this will continue to be the case.

Welded Wire Reinforcement. Our principal competitors in our welded wire reinforcement markets are Insteel Wire Products, Inc., of Mount Airy, NC and MMI Products, Inc., of Houston Texas. We also face competition from smaller regional manufacturers and wholesalers of welded wire reinforcement products. We believe EWP’s superior products, renowned customer service and industry leading sales force distinguish EWP from its competitors. In addition, we believe our vertical integration enhances EWP’s ability to compete more effectively in the market as EWP can rely on a more stable supply of wire rod. Competitors of EWP have at times faced raw material shortages that have negatively impacted their daily production capability and delivery reliability.

Coiled Rebar. The principal competitors for our assortment of coiled rebar include Gerdau Ameristeel, Rocky Mountain Steel, and Nucor Connecticut. The primary competitive factors of the coiled rebar business are delivered price, coil size and product quality. Due to our location, we believe we can effectively serve fabricators in the Midwestern region of the United States.

Wire Rod and Billets. Since wire rod and billets are commodity steel products, we believe the domestic market for these items is more competitive than the fabricated wire products and industrial wire markets, and price is the primary competitive factor. Among our principal domestic competitors in these markets are Gerdau Ameristeel and Rocky Mountain Steel. We also face significant foreign competition. The domestic steel industry continues to experience consolidation. During the last seven years, we and the majority of our major domestic competitors have either filed for protection under Federal bankruptcy laws and discontinued operations, were acquired, or reduced or completely shut-down their operations. We believe these shut-downs or production curtailments represent a significant decrease in estimated domestic annual capacity. However, worldwide overcapacity in the steel industry continues to exist and imports of wire rod in recent years have increased significantly.

Environmental Matters

Our production facilities are affected by a variety of environmental laws and regulations, including laws governing the discharge of water pollutants and air contaminants, the generation, transportation, storage, treatment and disposal of solid wastes and hazardous substances and the handling of toxic substances, including certain substances used in, or generated by, our manufacturing operations. Many of these laws and regulations require permits to operate the facilities to which they pertain. Denial, revocation, suspension or expiration of such permits could impair the ability of the affected facility to continue operations.

We record liabilities related to environmental issues at such time as information becomes available and is sufficient to support a reasonable estimate of a range of probable loss. If we are unable to determine that a single amount in an estimated range is more likely, the minimum amount of the range is recorded. Costs of future expenditures for environmental remediation obligations are not discounted to their present value due to the uncertain timeframe of payout. Recoveries of environmental remediation costs from other parties are recorded as assets when their receipt is deemed probable.

We believe our current operating facilities are in material compliance with all presently applicable Federal, State and local laws regulating the discharge of materials into the environment, or otherwise relating to the protection of the environment. Environmental legislation and regulations have changed rapidly in recent years and we may be subject to increasingly stringent environmental standards in the future.

Information in Note 9 to our Consolidated Financial Statements is incorporated herein by reference.

Acquisition and Restructuring Activities

We routinely compare our liquidity requirements against our estimated future cash flows. As a result of this process, we have in the past and may in the future seek to raise additional capital, refinance or restructure indebtedness, consider the sale of interests in subsidiaries, business units or other assets, or take a combination of such steps or other steps, to increase liquidity, reduce indebtedness and fund future activities. Such activities have in the past and may in the future involve related companies. From time to time, we and related entities also evaluate the restructuring of ownership interests among our subsidiaries and related companies and expect to continue this activity in the future and may in connection with such activities, consider issuing additional equity securities and increasing our indebtedness.

Acquisition and Amendment of Credit Facility in 2007

During the first quarter of 2007, we formed Calumet, which acquired substantially all of the real estate, equipment, and inventory of CaluMetals, Inc. CaluMetals, located in Chicago Heights, Illinois, is a manufacturer of merchant and special bar quality products and special sections in carbon and alloy steel grades, offering a broad range of value added products for use in agricultural, cold drawn, construction, industrial chain, service centers, and transportation applications. CaluMetals’ product mix consists primarily of angles, flats, channels, rounds and squares. CaluMetals’ sold approximately 17,000 tons of product during 2006 for $10.9 million. Calumetals’ primary raw material is billets. We expect to provide the majority of the acquired operations billet requirements from KSW, which has sufficient capacity to supply the needed billets. This acquisition will allow us to further enhance our vertical integration strategy by converting more of our current billet production into higher-margin products. We will report the results of the acquired operations in a new segment.

We also completed an amendment to our current credit facility during the first quarter of 2007, increasing the total committed facility amount from $80.0 million to $100.0 million, in part to finance the CaluMetals acquisition.

Restructuring

In an effort to reduce costs, in September 2006 we decided to relocate KWP’s industrial wire operations to KSW and to discontinue the production of nails at KSW. By the end of the second quarter of 2007, all nail production should be phased out and the relocation of KWP’s industrial wire manufacturing operations should be completed. We will continue to analyze the profitability of our operations and make operating decisions accordingly.

Bankruptcy

On February 26, 2004, we and five of our then direct and indirect subsidiaries filed for voluntary protection under Chapter 11 of the Federal Bankruptcy Code. We attributed the need to reorganize to weaknesses in product selling prices over the preceding several years, unprecedented increases in ferrous scrap costs, our primary raw material, and significant liquidity needs to service retiree medical costs. These problems substantially limited our liquidity and undermined our ability to obtain sufficient debt or equity capital to operate as a going concern.

We emerged from bankruptcy protection on August 31, 2005. Significant provisions of our plan of reorganization included greater employee participation in healthcare costs and a permanent reduction in healthcare related payments to retirees. Before the bankruptcy can be completely closed, all claims must be adjudicated. As of December 31, 2006, only two significant claims had not been adjudicated: (i) an environmental claim against Sherman Wire Company (“SWC”), one of our pre-petition wholly-owned subsidiaries, and (ii) an employment related claim against KCI.

Upon emergence from Chapter 11, certain operating assets and existing operations of SWC were sold at fair market value (fair market value and book value both approximated $2.0 million) to us, which were then used to form and operate KWP. SWC was also reorganized and the proceeds of the operating assets sold to us, liquidation of SWC’s remaining real estate assets (book value approximates $1.6 million), and other funds (including $4.0 million of proceeds from a settlement agreement with a former insurer received in the second quarter of 2006, as discussed in Notes 2 and 10 of our Consolidated Financial Statements) will be distributed, on a pro rata basis, to SWC’s pre-petition unsecured creditors when all claims have been finally adjudicated. The total amount ultimately distributed to SWC’s pre-petition unsecured creditors will be limited to the lesser of (i) the total of the claims granted by the U.S. Bankruptcy Court for the Eastern District of Wisconsin in Milwaukee (the “Court”) and (ii) the total funds available to be distributed.

Availability of Company Reports Filed with the SEC

Our fiscal year is 52 or 53 weeks and ends on the last Sunday in December. We will provide without charge copies of this Annual Report on Form 10-K for the year ended December 31, 2006, any copies of our Quarterly Reports on Form 10-Q for 2006 and any Current Reports on Form 8-K for 2005 and 2006, and any amendments thereto, upon written request. Such requests should be directed to the attention of the Corporate Secretary at our address on the cover page of this Form 10-K.

The general public may read and copy any materials we file with the SEC at the SEC’s Public Reference Room at 100 F Street, NE, Washington, DC 20549, and may obtain information on the operation of the Public Reference Room by calling the SEC at 1-800-SEC-0330. We are an electronic filer, and the SEC maintains an Internet website at www.sec.gov that contains reports, proxy and information statements, and other information regarding issuers that file electronically with the SEC, including us.

ITEM 1A. RISK FACTORS.

Listed below are certain risk factors associated with our businesses. In addition to the potential effect of these risk factors discussed below, any risk factor which could result in reduced earnings or operating losses, or reduced liquidity, could in turn adversely affect our ability to service our liabilities or adversely affect the quoted market prices for our publicly-traded securities.

Our leverage may impair our financial condition or limit our ability to operate our businesses. We currently have a significant amount of debt. As of December 31, 2006, our total consolidated debt was approximately $76.4 million. Our level of debt could have important consequences to our stockholders and creditors, including:

| · | making it more difficult for us to satisfy our obligations with respect to our liabilities; |

| · | increasing our vulnerability to adverse general economic and industry conditions; |

| · | requiring a portion of our cash flow from operations be used for the payment of interest on our debt, therefore reducing our ability to use our cash flow to fund working capital, capital expenditures, acquisitions and general corporate requirements; |

| · | limiting our ability to obtain additional financing to fund future working capital, capital expenditures, acquisitions and general corporate requirements; |

| · | limiting our flexibility in planning for, or reacting to, changes in our business and the industry in which we operate; and |

| · | placing us at a competitive disadvantage relative to other less-leveraged competitors. |

We are vulnerable to business downturns. We incur significant ongoing costs for plant and equipment and pay substantial benefits for both current and retired employees. As such, we remain vulnerable to business downturns and increases in costs.

Demand for, and prices of, certain of our products are cyclical and we may experience prolonged depressed market conditions for our products, which may result in reduced earnings or operating losses. A significant portion of our revenues are attributable to sales of products into the agricultural and construction industries. These two industries themselves are cyclical and changes in those industries’ economic conditions can significantly impact our earnings and operating cash flows. This may result in reduced earnings or operating losses. Events that could adversely affect the agricultural and construction industries include, among other things, short and long-term weather patterns, interest rates and embargos placed by foreign countries on U.S. agricultural products. Such events could significantly decrease our operating results and our business and financial condition could significantly decline.

We sell the majority of our products in mature and highly competitive industries and face price pressures in the markets in which we operate, which may result in reduced earnings or operating losses. The markets in which we operate our businesses are highly competitive. Competition is based on a number of factors, such as price, product quality and service. Some of our competitors may be able to drive down prices for our products because the competitors’ costs are lower than our costs. In addition, some of our competitors’ financial, technological and other resources may be greater than our resources, and such competitors may be better able to withstand changes in market conditions. Our competitors may be able to respond more quickly than we can to new or emerging technologies and changes in customer requirements. Further, consolidation of our competitors or customers in any of the industries in which we compete may result in reduced demand for our products. In addition, in some of our businesses new competitors could emerge by modifying their existing production facilities so they could manufacture products that compete with our products. The occurrence of any of these events could result in reduced earnings or operating losses.

Many of EWP’s products are ultimately used in infrastructure projects by local, State or Federal governments. Such projects are impacted by the availability of governmental funding for such projects. A decline in the availability of governmental funds for such projects could ultimately result in a decline in demand or selling prices of EWP’s products. Such a decline could result in reduced earnings or operating losses.

Wire rod imported into the U.S. continues at high levels. Global producers of wire rod are able to import their products into the U.S. with minimal tariffs and duties. Many of these global wire rod producers are able to produce wire rod at costs lower than us. As such, these wire rod imports are often able to be priced at lower levels than similar products manufactured by us. In addition, we believe certain foreign governments subsidize local wire rod producers. These events can adversely impact our shipment levels and pricing decisions and, as such, could result in reduced earnings or operating losses.

Higher costs or limited availability of ferrous scrap may decrease our liquidity. The number of sources for, and availability of, ferrous scrap, our primary raw material, is generally limited to the particular geographical region in which a facility is located. Should our suppliers not be able to meet their contractual obligations or should we be otherwise unable to obtain necessary ferrous scrap quantities, we may incur higher costs for ferrous scrap or may be required to reduce production levels, either of which may decrease our liquidity as we may be unable to offset such higher costs with increased selling prices for our products.

Our relationships with our union employees could deteriorate. At December 31, 2006, we employed approximately 1,100 persons in our various businesses of which approximately 78% are subject to collective bargaining or similar arrangements. A significant portion of these collective bargaining agreements are set to expire within the next three years. We may not be able to negotiate labor agreements with respect to these employees on satisfactory terms or at all. If our employees were to engage in a strike, work stoppage or other slowdown, we could experience a significant disruption of our operations or higher ongoing labor costs.

Our forecasted operating results for Calumet may not come to fruition. We believe a steady supply of billets, an upgrade of production equipment and a more intense selling initiative will result in operating income at Calumet. Although we believe the expectations used in our forecasts for Calumet are reasonable, forecasts by their nature involve substantial uncertainties that could significantly impact results. Actual results could differ materially from forecast resulting in operating losses at Calumet.

ITEM 1B. UNRESOLVED STAFF COMMENTS.

None.

ITEM 2. PROPERTIES.

Our principal executive offices are located in approximately 1,200 square feet of leased space at 5430 LBJ Freeway, Suite 1740, Dallas, Texas 75240-2697.

Our fabricated wire products, welded wire reinforcement, industrial wire, coiled rebar and wire rod production facilities utilize approximately 2.4 million square feet for manufacturing and office space, approximately 84% of which is located at our Peoria, Illinois facility.

The following table sets forth the location, size and general product types produced for each of our operating facilities, as of December 31, 2006, all of which are owned by us.

Facility Name | | Location | | Approximate Size (Square Feet) | | Products Produced | |

| | | | | | | | |

| Keystone Steel & Wire | | | Peoria, IL | | | 2,012,000 | | | Fabricated wire products, nails, industrial wire, coiled rebar and wire rod (1) | |

| Keystone Wire Products | | | Sherman, TX | | | 299,000 | | | Fabricated wire products and industrial wire (2) | |

| Engineered Wire Products | | | Upper Sandusky, OH | | | 79,000 | (3) | | Welded wire reinforcement | |

| | | | | | | | | | | |

| | | | | | | 2,390,000 | | | | |

(1) All nail production is expected to be phased out by the end of the second quarter of 2007.

(2) By the end of the second quarter of 2007, the relocation of KWP’s industrial wire manufacturing processes to KSW should be complete.

(3) During 2006, an expansion project at EWP commenced that will add 50,000 square feet of production facilities. The expansion project is expected to be completed during the second quarter of 2007.

We believe all of our facilities are well maintained and satisfactory for their intended purposes.

ITEM 3. LEGAL PROCEEDINGS.

On February 26, 2004, we and five of our then direct and indirect subsidiaries filed for voluntary protection under Chapter 11 of the Federal Bankruptcy Code. We filed our petitions in the U.S. Bankruptcy Court for the Eastern District of Wisconsin in Milwaukee. The Chapter 11 cases were consolidated for procedural purposes only and were jointly administered under the name FV Steel and Wire Company - Case No. 04-22421-SVK. Each of the filing companies continued to operate its business and manage its property as a debtor-in-possession. As a result of the Chapter 11 filings, litigation relating to pre-petition claims against the filing companies was stayed during the Chapter 11 proceedings. We emerged from Chapter 11 on August 31, 2005. Before the bankruptcy can be completely closed, all claims must be adjudicated. As of December 31, 2006, only two significant claims had not been adjudicated: (i) an environmental claim against SWC and (ii) an employment related claim against KCI.

We are also involved in various legal proceedings. Information required by this Item is included in Notes 2, 9 and 10 to our Consolidated Financial Statements, which information is incorporated herein by reference.

ITEM 4. SUBMISSION OF MATTERS TO A VOTE OF SECURITY HOLDERS.

None.

PART II

ITEM 5. MARKET FOR REGISTRANT'S COMMON EQUITY AND RELATED STOCKHOLDER MATTERS.

In connection with our emergence from Chapter 11, all of our outstanding common stock at August 31, 2005 was cancelled and we issued 10 million shares of a new issue of common stock. See Note 2 to our Consolidated Financial Statements. Prior to our emergence, our common stock was traded on the OTC Bulletin Board (Symbol: KESNQ.PK). Our common stock was not publicly traded from August 31, 2005 to June 23, 2006, on which date our common stock began trading again on the OTC Bulletin Board (Symbol: KYCN). As of March 27, 2007, we had approximately 1,146 holders of record of our common stock at a closing price of $17.50 according to Bloomberg. The following table sets forth the high and low closing per share sales prices for our common stock for the periods indicated, according to Bloomberg.

| | | High | | Low | |

| | | | | | |

Year ended December 31, 2006 | | | | | | | |

| | | | | | | | |

| First quarter | | | N/A | | | N/A | |

| Second quarter (April 1 to June 22) | | | N/A | | | N/A | |

| Second quarter (June 23 to June 30) | | $ | 2.25 | | $ | 2.00 | |

| Third quarter | | $ | 14.00 | | $ | 2.55 | |

| Fourth quarter | | $ | 18.50 | | $ | 11.70 | |

| | | | | | | | |

Year ended December 31, 2005 | | | | | | | |

| | | | | | | | |

| First quarter | | $ | .23 | | $ | .09 | |

| Second quarter | | $ | .17 | | $ | .08 | |

| Third quarter (July 1 to August 31) | | $ | .08 | | $ | .01 | |

| Third quarter (September 1 to September 30) | | | N/A | | | N/A | |

| Fourth quarter | | | N/A | | | N/A | |

| | | | | | | | |

We have not paid cash dividends on our common stock since 1977. Our current intention is to retain all earnings to fund working capital requirements, capital expenditures and scheduled debt repayments, and we do not anticipate paying divends on our common stock in the foreseeable future. In addition, we are subject to certain covenants under our primary credit facilities that restrict our ability to pay dividends, including a prohibition against the payment of cash dividends on our common stock without lender consent.

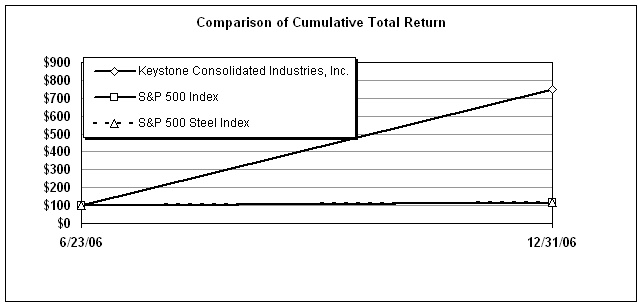

Performance Graph - Set forth below is a line graph comparing the change in our cumulative total stockholder return on our common stock against the cumulative total return of the S&P 500 Composite Stock Price Index and the S&P 500 Industrial Conglomerates Index for the period from June 23, 2006 through December 31, 2006. The graph shows the value at the December 31, 2006 assuming an original investment of $100 at June 23, 2006 and the reinvestment of dividends.

| | |

| | | June 23, 2006 | | December 31, 2006 | |

| | | | | | |

| Keystone common stock | | $ | 100 | | $ | 750 | |

| S&P 500 Index | | | 100 | | | 115 | |

| S&P Steel Index | | | 100 | | | 117 | |

ITEM 6. SELECTED FINANCIAL DATA.

The following selected consolidated financial data should be read in conjunction with our Consolidated Financial Statements and Item 7. "Management's Discussion And Analysis Of Financial Condition And Results Of Operations."

| | | Years ended December 31, | |

| | | 2002 | | 2003 | | 2004 | | 2005 | | 2006 | |

| | | (In thousands, except per share and per ton amounts) | |

| Statement of Operations Data: | | | | | | | | | | | | | | | | |

| Net sales | | $ | 334,835 | | $ | 306,671 | | $ | 364,335 | | $ | 367,545 | | $ | 440,540 | |

| Operating income (loss) | | | (7,699 | ) | | (31,446 | ) | | 26,641 | | | 22,718 | | | 80,963 | |

| | | | | | | | | | | | | | | | | |

| Defined benefit pension expense (credit) | | | (1,604 | ) | | 6,898 | | | (6,752 | ) | | (11,710 | ) | | (55,978 | ) |

| Other postretirement benefit expense (credit) | | | 14,260 | | | 17,503 | | | 20,909 | | | 8,885 | | | (8,297 | ) |

| Gain on cancellation of debt | | | - | | | - | | | - | | | 32,510 | | | - | |

| Gain on early extinguishment of debt | | | 54,739 | | | - | | | - | | | - | | | - | |

| Gain on legal settlement | | | - | | | - | | | 5,284 | | | - | | | - | |

| Reorganization costs | | | - | | | - | | | 11,158 | | | 10,308 | | | 679 | |

| Provision for income taxes | | | 21,622 | | | - | | | 1,379 | | | 430 | | | 17,055 | |

Cumulative effect of change in accounting principle (4) | | | 19,998 | | | - | | | - | | | - | | | - | |

| | | | | | | | | | | | | | | | | |

| Net income (loss) | | $ | 38,420 | | $ | (37,517 | ) | $ | 16,060 | | $ | 39,232 | | $ | 57,732 | |

Net income (loss) available for common shares (1) | | $ | 33,737 | | $ | (43,457 | ) | $ | 14,837 | | $ | 39,232 | | $ | 57,732 | |

| | | | | | | | | | | | | | | | | |

| Basic net income (loss) available for common shares per share | | $ | 3.35 | | $ | (4.32 | ) | $ | 1.47 | | $ | 4.12 | | $ | 5.77 | |

| Diluted net income (loss) available for common shares per share | | $ | 1.76 | | $ | (4.32 | ) | $ | .57 | | $ | 1.88 | | $ | 5.77 | |

Weighted average common and common equivalent shares outstanding (3): | | | | | | | | | | | | | | | | |

| Basic | | | 10,067 | | | 10,068 | | | 10,068 | | | 10,046 | | | 10,000 | |

| Diluted | | | 21,823 | | | 10,068 | | | 28,043 | | | 22,029 | | | 10,000 | |

Other Steel and Wire Products operating data: | | | | | | | | | | | | | | | | |

| Shipments (000 tons): | | | | | | | | | | | | | | | | |

| Fabricated wire products | | | 146 | | | 135 | | | 116 | | | 101 | | | 112 | |

| Welded wire reinforcement | | | 63 | | | 66 | | | 71 | | | 71 | | | 67 | |

| Nails | | | 74 | | | 53 | | | 28 | | | 17 | | | 18 | |

| Industrial wire | | | 96 | | | 91 | | | 82 | | | 72 | | | 75 | |

| Coiled rebar | | | - | | | - | | | - | | | - | | | 1 | |

| Wire rod | | | 287 | | | 252 | | | 200 | | | 236 | | | 349 | |

| Billets | | | 5 | | | 17 | | | 17 | | | 29 | | | 53 | |

| Total | | | 671 | | | 614 | | | 514 | | | 526 | | | 675 | |

Per-ton selling prices: | | | | | | | | | | | | | | | | |

| Fabricated wire products | | $ | 791 | | $ | 783 | | $ | 984 | | $ | 1,090 | | $ | 1,037 | |

| Welded wire reinforcement | | | 526 | | | 539 | | | 829 | | | 881 | | | 870 | |

| Nails | | | 592 | | | 558 | | | 759 | | | 742 | | | 692 | |

| Industrial wire | | | 448 | | | 452 | | | 709 | | | 731 | | | 726 | |

| Coiled rebar | | | - | | | - | | | - | | | - | | | 529 | |

| Wire rod | | | 304 | | | 314 | | | 539 | | | 503 | | | 500 | |

| Billets | | | 156 | | | 192 | | | 176 | | | 321 | | | 354 | |

| Steel and wire products in total | | | 482 | | | 479 | | | 707 | | | 696 | | | 645 | |

| | | | | | | | | | | | | | | | | |

| Average per-ton ferrous scrap purchase cost | | $ | 94 | | $ | 115 | | $ | 205 | | $ | 220 | | $ | 210 | |

| | | | | | | | | | | | | | | | | |

| Other Financial Data: | | | | | | | | | | | | | | | | |

Capital expenditures | | $ | 7,973 | | $ | 2,683 | | $ | 5,080 | | $ | 9,772 | | $ | 18,739 | |

| Depreciation and amortization | | | 17,396 | | | 16,461 | | | 15,812 | | | 15,745 | | | 15,222 | |

| | | As of December 31, | |

| | | 2002 | | 2003 | | 2004 | | 2005 | | 2006 | |

| | | (In thousands) | |

| Balance Sheet Data: | | | | | | | | | | | | | | | | |

Working capital (deficit) (2) | | $ | (41,790 | ) | $ | (90,210 | ) | $ | 11,910 | | $ | 36,373 | | $ | 31,776 | |

| Property, plant and equipment, net | | | 119,984 | | | 105,316 | | | 94,033 | | | 86,773 | | | 88,695 | |

Total assets(5) | | | 215,495 | | | 282,194 | | | 323,282 | | | 358,364 | | | 763,936 | |

| Total debt | | | 98,684 | | | 88,897 | | | 65,985 | | | 99,895 | | | 76,448 | |

Redeemable preferred stock (3) | | | 2,112 | | | 2,112 | | | 2,112 | | | - | | | - | |

Stockholders’ equity (deficit)(5) | | | (136,900 | ) | | (10,050 | ) | | 4,787 | | | 67,531 | | | 403,662 | |

| | (1) | Includes the effect of dividends on preferred stock of $4,683,000, $5,940,000 and $1,223,000 in 2002, 2003 and 2004, respectively. We discontinued accruing dividends on our preferred stock upon filing for Chapter 11 on February 26, 2004. |

| | (2) | Working capital (deficit) represents current assets minus current liabilities. |

| | (3) | All of our outstanding common and preferred stock at August 31, 2005 was cancelled in connection with our emergence from Chapter 11 on August 31, 2005, and at that time, we issued 10 million shares of a new issue of common stock. |

| | (4) | Upon adoption of Statement of Financial Accounting Standards (“SFAS”) No. 142, effective January 1, 2002, negative goodwill with a net book value of $20.0 million was eliminated as a cumulative effect of change in accounting principle. |

| | (5) | We adopted SFAS No. 158 effective December 31, 2006. See Note 14 to our Consolidated Financial Statements. |

ITEM 7. MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS.

RESULTS OF OPERATIONS

Business Overview

We are a leading domestic manufacturer of steel fabricated wire products, welded wire reinforcement, coiled rebar, industrial wire and wire rod for the agricultural, industrial, construction, original equipment manufacturer and retail consumer markets and we are one of the largest manufacturers of fabricated wire products in the United States based on tons shipped (112,000 tons in 2006). We are vertically integrated, converting substantially all of our fabricated wire products, welded wire reinforcement, coiled rebar and industrial wire from wire rod produced in our steel mini-mill. Our vertical integration has historically allowed us to benefit from the higher and more stable margins associated with fabricated wire products and welded wire reinforcement as compared to wire rod, as well as from lower production costs of wire rod as compared to wire fabricators that purchase wire rod in the open market. Moreover, we believe our downstream fabricated wire products, welded wire reinforcement, coiled rebar and industrial wire businesses better insulate us from the effects of wire rod imports as compared to non-integrated wire rod producers.

The domestic wire rod industry continues to experience consolidation. During the last seven years, the majority of our major domestic competitors have either filed for protection under Federal bankruptcy laws and discontinued operations, were acquired, or reduced or completely shut-down their operations. We believe these shut-downs or production curtailments represent a significant decrease in domestic annual capacity. However, worldwide overcapacity in the steel industry continues to exist and imports of wire rod, certain fabricated wire products and nails in recent years have increased significantly.

On February 26, 2004, we and five of our direct and indirect subsidiaries filed for voluntary protection under Chapter 11 of the Federal Bankruptcy Code. We attributed the need to reorganize to weaknesses in product selling prices over the preceding several years, unprecedented increases in ferrous scrap costs, our primary raw material, and significant liquidity needs to service retiree medical costs. These problems substantially limited our liquidity and undermined our ability to obtain sufficient debt or equity capital to operate as a going concern. We emerged from bankruptcy protection on August 31, 2005. Significant provisions of our plan of reorganization included greater employee participation in healthcare costs and a permanent reduction in healthcare related payments to retirees. We continue to incur substantial employee benefits for both current and retired employees and significant ongoing costs for plant and equipment. As such, we are vulnerable to business downturns and increases in costs, and accordingly, routinely compare our liquidity requirements and capital needs against our estimated future operating cash flows.

Our profitability is primarily dependent on sales volume, per-ton selling prices, per-ton ferrous scrap cost, and energy costs. Additionally, because pension and OPEB expense or credits are unrelated to the operating activities of our business, we measure our overall performance using operating income before pension and OPEB credit or expense. Operating income before pension and OPEB credit or expense is a non-GAAP measure of profitability that is not in accordance with accounting principles generally accepted in the United States of America (“GAAP”) and it shall not be considered in isolation or as a substitute for a measure prepared in accordance with GAAP. A reconciliation of operating income as reported to operating income adjusted for pension and OPEB expense or credit is set forth in the following table.

| | | Years ended December 31, | |

| | | 2004 | | 2005 | | 2006 | |

| | | (In thousands) | |

| Operating income as reported | | $ | 26,641 | | $ | 22,718 | | $ | 80,963 | |

| Defined benefit pension credit | | | (6,752 | ) | | (11,710 | ) | | (55,978 | ) |

| OPEB expense (credit) | | | 20,909 | | | 8,885 | | | (8,297 | ) |

| Operating income before pension/OPEB | | $ | 40,798 | | $ | 19,893 | | $ | 16,688 | |

The decrease in operating income before pension and OPEB from 2004 to 2005 was primarily due to the following factors:

| · | increased costs for ferrous scrap; |

| · | increased costs for natural gas; and |

| · | increased advertising and marketing expenses resulting from our efforts to recapture the portion of the market that we lost during bankruptcy. |

The decrease in operating income before pension and OPEB from 2005 to 2006 was primarily due to the net effect of the following factors:

| · | lower overall per-ton selling prices in 2006; |

| · | increased conversion costs in 2006 resulting from production interruptions due to operating issues with our wire rod mill reheat furnace; |

| · | an extra week of operations as 2006 was a 53-week year as compared to a 52-week year in 2005; |

| · | lower costs for ferrous scrap in 2006; and |

| · | lower costs for natural gas in 2006. |

Outlook for 2007

We currently believe 2007 operating income before pension and OPEB will be higher than 2006 due primarily to the net effect of the following factors:

| · | lower shipment volume due to a 52-week year in 2007 as compared to a 53-week year in 2006, the decision to discontinue our nail business and the use of a higher percentage of our billets and wire rod in our downstream businesses, partially offset by increased shipment volumes of fabricated wire products and welded wire reinforcement (resulting from an expansion project at EWP); |

| · | increased overall per-ton selling price; |

| · | lower ferrous scrap costs; |

| · | increased energy costs as a result of the deregulation of electricity in Illinois; |

| · | lower conversion costs as a result of the rod mill reheat furnace overhaul during the fourth quarter of 2006; |

| · | slightly higher depreciation expense related to the expansion project at EWP and the new reheat furnace at KSW; and |

| · | lower costs as a result of the relocation of KWP’s industrial wire manufacturing operations to KSW and the discontinuance of nail operations. |

Expected trends in 2007 non-operating costs as compared to 2006 are as follows:

| · | higher defined benefit pension credit in 2007; |

| · | increased interest expense in 2007 due, in part, to the additional financing obtained for the CaluMetals acquisition; and |

| · | a provision for income taxes that more approximates the statutory rate in 2007. |

See Note 14 to our Consolidated Financial Statements for the projected impact of recent accounting pronouncements on our financial position and results of operations.

During the first quarter of 2007, we formed Calumet, which acquired substantially all of the real estate, equipment, and inventory of CaluMetals, Inc. CaluMetals, located in Chicago Heights, Illinois, is a manufacturer of merchant and special bar quality products and special sections in carbon and alloy steel grades, offering a broad range of value added products for use in agricultural, cold drawn, construction, industrial chain, service centers, and transportation applications. CaluMetals’ product mix consists primarily of angles, flats, channels, rounds and squares. CaluMetals’ sold approximately 17,000 tons of product during 2006 for $10.9 million. Calumetals’ primary raw material is billets. We expect to provide the majority of the acquired operations billet requirements from KSW, which has sufficient capacity to supply the needed billets. This acquisition will allow us to further enhance our vertical integration strategy by converting more of our current billet production into higher-margin products. We will report the results of the acquired operations in a new segment.

Segment Operating Results

Our operating segments are organized by our manufacturing facilities and include three reportable segments:

| · | Keystone Steel and Wire (“KSW”), located in Peoria, Illinois, operates an electric arc furnace mini-mill and manufactures and sells wire rod, industrial wire, nails, coiled rebar and fabricated wire products for agricultural, industrial, construction, commercial, original equipment manufacturers and retail consumer markets; |

| · | Engineered Wire Products (“EWP”), located in Upper Sandusky, Ohio, manufactures and sells welded wire reinforcement in both roll and sheet form that is utilized in concrete construction products including pipe, pre-cast boxes and applications for use in roadways, buildings and bridges; and |

| · | Keystone Wire Products (“KWP”), located in Sherman, Texas, manufactures and sells industrial wire and fabricated wire products for agricultural, industrial, construction, commercial, original equipment manufacturers and retail consumer markets. |

In connection with our emergence from Chapter 11 on August 31, 2005, certain operating assets and existing operations of SWC were sold to us at fair market value. We then used these assets to form and operate KWP. As such, operating results of this segment prior to our emergence from Chapter 11 were operating results of Sherman. Operating results of this segment after our emergence from Chapter 11, were operating results of KWP. In accordance with our plan of reorganization, the remaining assets of SWC will eventually be liquidated.

During 2006, we decided to relocate KWP’s industrial wire manufacturing process to KSW. Certain of KWP’s industrial wire production equipment will be transferred to KSW. KWP recorded an impairment charge of $172,000 to write down the carrying value of the industrial wire production equipment to be sold to an estimated fair value of $130,000.

We also decided to discontinue our nail operations during 2006 and we anticipate all nail production will be phased out by the end of the second quarter of 2007, after which we plan to sell our nail production equipment. KSW recorded an impairment charge of $357,000 to write down the carrying value of the nail production equipment to be sold to an estimated fair value of $500,000. The sales and operating income or loss of our nail operations is not material to our operating results.

During 2006, because pension and OPEB expense or credits are unrelated to the operating activities of our business, we began measuring our segments’ profitability based on operating income before pension and OPEB. See Note 3 to our Consolidated Financial Statements for adjustments to the previously reported operating income by segment.

Our consolidated net sales, cost of goods sold, operating costs and operating income before pension and OPEB by segment are set forth in the following table.

| | | KSW | | EWP | | Sherman/ KWP | | Allocation differences/ eliminations(1) | | Total | |

| | | (In thousands) | |

| | | | | | | | | | | | |

| For the year ended December 31, 2004: | | | | | | | | | |

| | | | | | | | | | | | | | | | | |

| Net sales | | $ | 346,703 | | $ | 58,982 | | $ | 16,193 | | $ | (57,543 | ) | $ | 364,335 | |

| Cost of goods sold | | | 302,827 | | | 43,821 | | | 15,020 | | | (53,582 | ) | | 308,086 | |

| Gross margin | | | 43,876 | | | 15,161 | | | 1,173 | | | (3,961 | ) | | 56,249 | |

| | | | | | | | | | | | | | | | | |

| Selling and administrative expense | | | 9,877 | | | 4,345 | | | 878 | | | 351 | | | 15,451 | |

| Operating income (loss) before pension/OPEB | | $ | 33,999 | | $ | 10,816 | | $ | 295 | | $ | (4,312 | ) | $ | 40,798 | |

| | | | | | | | | | | | | | | | | |

| For the year ended December 31, 2005: | | | | | | | | | |

| | | | | | | | | | | | | | | | | |

| Net sales | | $ | 342,139 | | $ | 62,777 | | $ | 18,024 | | $ | (55,395 | ) | $ | 367,545 | |

| Cost of goods sold | | | 319,578 | | | 48,801 | | | 18,726 | | | (57,516 | ) | | 329,589 | |

| Gross margin | | | 22,561 | | | 13,976 | | | (702 | ) | | 2,121 | | | 37,956 | |

| | | | | | | | | | | | | | | | | |

| Selling and administrative expense | | | 12,440 | | | 4,277 | | | 1,135 | | | 211 | | | 18,063 | |

| Operating income (loss) before pension/OPEB | | $ | 10,121 | | $ | 9,699 | | $ | (1,837 | ) | $ | 1,910 | | $ | 19,893 | |

| | | | | | | | | | | | | | | | | |

For the year ended December 31, 2006: | | | | | | | | | |

| | | | | | | | | | | | | | | | | |

Net sales | | $ | 414,927 | | $ | 58,748 | | $ | 17,664 | | $ | (50,799 | ) | $ | 440,540 | |

Cost of goods sold | | | 393,871 | | | 45,397 | | | 17,937 | | | (51,486 | ) | | 405,719 | |

Gross margin | | | 21,056 | | | 13,351 | | | (273 | ) | | 687 | | | 34,821 | |

| | | | | | | | | | | | | | | | | |

Selling and administrative expense | | | 13,551 | | | 3,887 | | | 674 | | | 21 | | | 18,133 | |

Operating income (loss) before pension/OPEB | | $ | 7,505 | | $ | 9,464 | | $ | (947 | ) | $ | 666 | | $ | 16,688 | |

| | | | | | | | | | | | | | | | | |

(1)Allocation differences related to net sales and cost of goods sold are the elimination of intercompany profit or loss on ending inventory balances. Cost of goods sold allocation differences also include LIFO inventory reserve adjustments.

Keystone Steel & Wire

| | | | |

| | | 2004 | | % of sales | | 2005 | | % of sales | | 2006 | | % of sales | |

| | | ($ in thousands) | |

| | | | |

| Net sales | | $ | 346,703 | | | 100.0 | % | $ | 342,139 | | | 100.0 | % | $ | 414,927 | | | 100.0 | % |

| Cost of goods sold | | | 302,827 | | | 87.3 | | | 319,578 | | | 93.4 | | | 393,871 | | | 94.9 | |

| Gross margin | | | 43,876 | | | 12.7 | | | 22,561 | | | 6.6 | | | 21,056 | | | 5.1 | |

| | | | | | | | | | | | | | | | | | | | |

| Selling and administrative | | | 9,877 | | | 2.8 | | | 12,440 | | | 3.6 | | | 13,551 | | | 3.3 | |

| Operating income before pension/OPEB | | $ | 33,999 | | | 9.9 | % | $ | 10,121 | | | 3.0 | % | $ | 7,505 | | | 1.8 | % |

| | | | | | | | | | | | | | | | | | | | |

The primary drivers of sales, cost of goods sold, and the resulting gross margin are as follows:

| | | 2004 | | 2005 | | 2006 | |

| Sales volume(000 tons): | | | | | | | | | | |

| Fabricated wire products | | | 116 | | | 101 | | | 112 | |

| Nails | | | 28 | | | 17 | | | 18 | |

| Industrial wire | | | 75 | | | 64 | | | 69 | |

| Coiled rebar | | | - | | | - | | | 1 | |

| Wire rod | | | 295 | | | 325 | | | 422 | |

| Billets | | | 23 | | | 29 | | | 62 | |

| Total | | | 537 | | | 536 | | | 684 | |

| | | | | | | | | | | |

| | | | | | | | | | | |

| Per-ton selling prices: | | | | | | | | | | |

| Fabricated wire products | | $ | 984 | | $ | 1,090 | | $ | 1,037 | |

| Nails | | | 759 | | | 742 | | | 692 | |

| Industrial wire | | | 709 | | | 735 | | | 729 | |

| Coiled rebar | | | - | | | - | | | 529 | |

| Wire rod | | | 517 | | | 497 | | | 494 | |

| Billets | | | 236 | | | 321 | | | 359 | |

| All products | | | 645 | | | 635 | | | 599 | |

| | | | | | | | | | | |

| Average per-ton ferrous scrap purchase cost | | $ | 205 | | $ | 220 | | $ | 210 | |

| | | | | | | | | | | |

| Average electricity cost per kilowatt hour | | $ | 0.04 | | $ | 0.04 | | $ | 0.04 | |

| | | | | | | | | | | |

| Average natural gas cost per therm | | $ | 0.65 | | $ | 0.89 | | $ | 0.77 | |

The decrease in operating income before pension and OPEB from 2004 to 2005 was primarily due to higher shipment volumes of lower margin products, an increase in the cost of ferrous scrap and natural gas, an increase in wages and an increase in selling and administrative expenses. Net sales remained relatively constant from 2004 to 2005 as lower shipment volumes of higher-priced products offset increased shipment volumes of lower-priced products. The decrease in operating income before pension and OPEB from 2005 to 2006 was primarily due to higher shipment volumes of lower margin products and increased conversion costs caused by production interruptions related to operating issues of our rod mill reheat furnace, partially offset by a decrease in the cost of ferrous scrap and natural gas. The reheat furnace was overhauled during the fourth quarter of 2006 to avoid future production inefficiencies.

We believe lower shipment volumes of fabricated wire products, nails, and industrial wire in 2005 as compared to 2004 were primarily due to high customer inventory levels at the end of 2004. The higher shipment volumes of wire rod (in 2005 and 2006) and billets (in 2006) as compared to the respective prior year were primarily due to competitor production problems that are not expected to continue in 2007. In addition, due to the increased cost associated with exporting rod, foreign rod prices approximated domestic rod prices on a delivered basis in 2006 resulting in increased demand for domestic wire rod. The higher shipment volumes of all other products in 2006 as compared to 2005 was partially due to an extra week of operations as 2006 was a 53-week year.

The decrease in the overall per-ton selling price from 2004 to 2005 was primarily due to reduced demand for value-added finished products due to high customer inventory levels at the end of 2004. The lower per-ton selling prices on all products except billets during 2006 as compared to 2005 were due primarily to significantly lower ferrous scrap costs, as the price we sell our products is influenced in part by the market cost of ferrous scrap.

Our efforts to recapture the portion of the market that we lost during bankruptcy resulted in higher selling and administrative cost in 2005 as compared to 2004 primarily due to higher advertising and marketing expenses and in 2006 as compared to 2005 primarily due to an increased sales force. Additionally, personnel related costs were higher in 2006 as compared to 2005 due to annual compensation increases.

Engineered Wire Products

| | | 2004 | | % of sales | | 2005 | | % of sales | | 2006 | | % of sales | |

| | | ($ in thousands) | |

| | | | | | | | | | | | | | |

| Net sales | | $ | 58,982 | | | 100.0 | % | $ | 62,777 | | | 100.0 | % | $ | 58,748 | | | 100.0 | % |

| Cost of goods sold | | | 43,821 | | | 74.3 | | | 48,801 | | | 77.7 | | | 45,397 | | | 77.3 | |

| Gross margin | | | 15,161 | | | 25.7 | | | 13,976 | | | 22.3 | | | 13,351 | | | 22.7 | |

| | | | | | | | | | | | | | | | | | | | |

| Selling and administrative | | | 4,345 | | | 7.4 | | | 4,277 | | | 6.8 | | | 3,887 | | | 6.6 | |

Operating income before pension/OPEB | | $ | 10,816 | | | 18.3 | % | $ | 9,699 | | | 15.5 | % | $ | 9,464 | | | 16.1 | % |

| | | | | | | | | | | | | | | | | | | | |

The primary drivers of sales, cost of goods sold, and the resulting gross margin are as follows:

| | | 2004 | | 2005 | | 2006 | |

| Sales volume (000 tons) - | | | | | | | | | | |

| Welded wire reinforcement | | | 71 | | | 71 | | | 67 | |

| | | | | | | | | | | |

| Per-ton selling prices - | | | | | | | | | | |

| Welded wire reinforcement | | $ | 829 | | $ | 881 | | $ | 870 | |

| | | | | | | | | | | |

| Average per-ton wire rod purchase cost | | $ | 516 | | $ | 536 | | $ | 504 | |

| | | | | | | | | | | |

The decrease in operating income before pension and OPEB from 2004 to 2005 was primarily due to an increase in the cost of wire rod, EWP’s primary raw material, partially offset by an increase in sales due to an increase in selling price. The decrease in operating income before pension and OPEB from 2005 to 2006 was primarily due to a decrease in shipment volumes and selling price, partially offset by a decrease in the cost of wire rod and selling and administrative expenses.

We believe the lower shipment volume during 2006 as compared to 2005 was due to a decline in the construction of new homes which results in a decline of related infrastructure projects and consequently, in a decrease in the sales of welded wire reinforcement.

The higher per-ton selling prices for 2005 as compared to 2004 were due primarily to higher cost for wire rod, EWP’s primary raw material. Conversely, the lower per-ton selling prices for 2006 as compared to 2005 were due primarily to significantly lower cost for wire rod during 2006. EWP sources substantially all of its wire rod requirements from KSW at prices that we believe approximate market.

Selling and administrative expenses were lower in 2006 as compared to 2004 and 2005 primarily due to a decline in 2006 bonuses.

Sherman/KWP

| | | 2004 | | % of sales | | 2005 | | % of sales | | 2006 | | % of sales | |

| | | ($ in thousands) | |

| | | | | | | | | | | | | | |

| Net sales | | $ | 16,193 | | | 100.0 | % | $ | 18,024 | | | 100.0 | % | $ | 17,664 | | | 100.0 | % |

| Cost of goods sold | | | 15,020 | | | 92.8 | | | 18,726 | | | 103.9 | | | 17,937 | | | 101.5 | |

| Gross margin | | | 1,173 | | | 7.2 | | | (702 | ) | | (3.9 | ) | | (273 | ) | | (1.5 | ) |

| | | | | | | | | | | | | | | | | | | | |

| Selling and administrative | | | 878 | | | 5.4 | | | 1,135 | | | 6.3 | | | 674 | | | 3.8 | |

| Operating income (loss) before pension/OPEB | | $ | 295 | | | 1.8 | % | $ | (1,837 | ) | | (10.2 | )% | $ | (947 | ) | | (5.3 | )% |

| | | | | | | | | | | | | | | | | | | | |

The primary drivers of sales, cost of goods sold, and the resulting gross margin are as follows:

| | | 2004 | | 2005 | | 2006 | |

| Sales volume(000 tons): | | | | | | | | | | |

| Fabricated wire products | | | 10 | | | 11 | | | 12 | |

| Industrial wire | | | 8 | | | 9 | | | 8 | |

| Total | | | 18 | | | 20 | | | 20 | |

| | | | | | | | | | | |

| Per-ton selling prices: | | | | | | | | | | |

| Fabricated wire products | | $ | 942 | | $ | 1,003 | | $ | 968 | |

| Industrial wire | | | 708 | | | 698 | | | 678 | |

| | | | | | | | | | | |

| Average per-ton wire rod purchase cost | | $ | 331 | | $ | 439 | | $ | 443 | |

| | | | | | | | | | | |

The decrease in operating income (loss) before pension and OPEB from 2004 to 2005 was primarily due to an increase in the cost of wire rod, KWP’s primary raw material, higher costs for utilities and repairs and maintenance, and an increase in selling and administrative expenses, partially offset by an increase in shipment volumes and selling prices. The decrease in operating loss before pension and OPEB from 2005 to 2006 was primarily due to lower costs for utilities and repairs and maintenance, lower depreciation and employment related expenses in part due to our decision to relocate KWP’s industrial wire manufacturing process to KSW, and a decrease in selling and administrative expenses, partially offset by a decrease in selling prices and the $172,000 impairment charge related to the industrial wire production equipment that we plan to sell.

The higher per-ton selling prices of fabricated wire products in 2005 as compared to 2004 were primarily due to higher cost for wire rod while the decrease in per-ton selling prices of industrial wire in 2005 as compared to 2004 was primarily due to reduced demand as a result of high customer inventory levels at the end of 2004. The lower per-ton selling prices in 2006 as compared to 2005 were primarily due to lower cost for wire rod throughout most of 2006. KWP sources substantially all of its wire rod requirements from KSW at prices that we believe approximate market.

Selling and administrative expenses were higher in 2005 as compared to 2004 primarily due to an increase in 2005 personnel related costs. Selling and administrative expenses were lower in 2006 as compared to 2005 primarily due to a reduction in employment related expenses due in part to our decision to relocate KWP’s industrial wire manufacturing process to KSW.

Pension and Postretirement Benefit Expense or Credits, Interest Expense, Provision for Income Taxes, and Other Items