UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

(Mark One)

FORM 10-K

| | | | | |

| ☒ | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE

SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2024

or

| | | | | |

| ☐ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE

SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to .

Commission File Number 001-07845

LEGGETT & PLATT, INCORPORATED

(Exact name of registrant as specified in its charter)

| | | | | | | | | | | |

| Missouri | | 44-0324630 |

(State or other jurisdiction of

incorporation or organization) | | (I.R.S. Employer

Identification No.) |

| 1 Leggett Road | | |

| Carthage, | Missouri | | 64836 |

| (Address of principal executive offices) | | (Zip code) |

Registrant’s telephone number, including area code: (417) 358-8131

Securities registered pursuant to Section 12(b) of the Act: | | | | | | | | |

| Title of each class | Trading Symbol | Name of each exchange on which registered |

| Common Stock, $.01 par value | LEG | New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ☒ No ☐

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ☐ No ☒

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes ☒ No ☐

Indicate by check mark whether the registrant has submitted electronically every Interactive Data File required to be submitted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit such files). Yes ☒ No ☐

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, a smaller reporting company, or an emerging growth company. See the definitions of “large accelerated filer,” “accelerated filer,” “smaller reporting company” and “emerging growth company” in Rule 12b-2 of the Exchange Act. | | | | | | | | | | | | | | |

| Large accelerated filer | ☒ | | Accelerated filer | ☐ |

| | | |

| Non-accelerated filer | ☐ | | Smaller reporting company | ☐ |

| | | Emerging growth company | ☐ |

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. ☐

Indicate by check mark whether the registrant has filed a report on and attestation to its management's assessment of the effectiveness of its internal control over financial reporting under Section 404(b) of the Sarbanes-Oxley Act (15 U.S.C. 7262(b)) by the registered public accounting firm that prepared or issued its audit report. ☒

If securities are registered pursuant to Section 12(b) of the Act, indicate by check mark whether the financial statements of the registrant included in the filing reflect the correction of an error to previously issued financial statements. ☐

Indicate by check mark whether any of those error corrections are restatements that required a recovery analysis of incentive-based compensation received by any of the registrant’s executive officers during the relevant recovery period pursuant to §240.10D-1(b). ☐

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ☐ No ☒

The aggregate market value of the voting common stock held by non-affiliates of the registrant (based on the closing price of our common stock on the New York Stock Exchange) on June 28, 2024 was $1,505,582,000.

There were 134,733,672 shares of the registrant’s common stock outstanding as of February 20, 2025.

DOCUMENTS INCORPORATED BY REFERENCE

Parts of Item 10, and all of Items 11, 12, 13 and 14 of Part III, are incorporated by reference from the Company's definitive Proxy Statement for the Annual Meeting of Shareholders to be held on May 7, 2025.

LEGGETT & PLATT, INCORPORATED—FORM 10-K

FOR THE YEAR ENDED December 31, 2024

TABLE OF CONTENTS

| | | | | | | | |

| | Page

Number |

| |

| PART I |

| Item 1. | | |

| | |

| Item 1A. | | |

| | |

| Item 1B. | | |

| | |

| Item 1C. | | |

| | |

| Item 2. | | |

| | |

| Item 3. | | |

| | |

| Item 4. | | |

| | |

| Supp. Item. | | |

| PART II |

| Item 5. | | |

| | |

| Item 6. | | |

| | |

| Item 7. | | |

| | |

| Item 7A. | | |

| | |

| Item 8. | | |

| | |

| Item 9. | | |

| | |

| Item 9A. | | |

| | |

| Item 9B. | | |

| | |

| Item 9C. | | |

| PART III |

| Item 10. | | |

| | |

| Item 11. | | |

| | |

| Item 12. | | |

| | |

| Item 13. | | |

| | |

| Item 14. | | |

| PART IV |

| Item 15. | | |

| | |

| | |

| | |

| Item 16. | | |

| |

| |

Forward-Looking Statements

This Annual Report on Form 10-K, as well as the documents, or portion thereof, incorporated by reference herein, may contain “forward-looking” statements within the meaning of Section 27A of the Securities Act of 1933, as amended, and Section 21E of the Securities Exchange Act of 1934, as amended, including, but not limited to: projections of our revenue, income, earnings, capital expenditures, dividends, product demand, capital structure, cash flows, interest costs, the payment of cash dividends, metal margins, cash repatriation, tax impacts, effective tax rate, maintenance of commercial paper indebtedness, litigation expense, acquisition or disposition activity, collectability of receivables, ability to issue debt, cybersecurity protections and costs, cash expenditures, antidumping determinations, amortization expense, uses of cash, our technological competitiveness, compiling a GHG emissions inventory, hedge accounting treatment, unauthorized use of artificial intelligence, industry demand projections, impact of accounts receivable and payable programs, access to liquidity, compliance with debt covenants, raw material and parts availability and pricing, supply chain disruptions, labor, raw material and part shortages, inventory levels, climate-related targets and costs, goodwill or other asset impairment; possible plans, goals, objectives, prospects, strategies, or trends concerning future operations; statements concerning future economic performance; items related to the restructuring plan (the “2024 Restructuring Plan” or “2024 Plan”) such as estimates of the amounts, types, and timing of facility closures, restructuring-related costs (cash and non-cash including write-down of inventories) and impairment charges, sales reduction, proceeds from the sale of facilities, and EBIT benefit; and the underlying assumptions relating to forward-looking statements. These statements are identified either by the context in which they appear or by use of words such as “anticipate,” “believe,” “estimate,” “expect,” “guidance,” “intend,” “may,” “plan,” “project,” “should,” or the like. All such forward-looking statements, whether written or oral, and whether made by us or on our behalf, are expressly qualified by the cautionary statements described in this provision.

Any forward-looking statement reflects only the beliefs of Leggett & Platt or its management at the time the statement is made. Because all forward-looking statements deal with the future, they are subject to risks, uncertainties, and developments, which might cause actual events or results to differ materially from those envisioned or reflected in any forward-looking statement. Moreover, we do not have and do not undertake any duty to update or revise any forward-looking statement to reflect events or circumstances after the date on which the statement was made. For all of these reasons, forward-looking statements should not be relied upon as a prediction of actual future events, objectives, strategies, trends, or results.

Listed below and discussed elsewhere in further detail in this Annual Report on Form 10-K, including in Item 1A. Risk Factors herein, are some important risks, uncertainties, and contingencies that could cause actual events or results to differ materially from forward-looking statements. It is not possible to anticipate and list all of the risks, uncertainties, and contingencies which could cause actual events or results to differ from forward-looking statements. However, some of these risks and uncertainties include the following:

•potential changes to our 2024 Restructuring Plan, including estimates relating to cash and non-cash costs, EBIT benefit, sales attrition, and the sale of real estate; our ability to implement the 2024 Plan or sell real estate and obtain expected proceeds in a timely manner; the impact on relationships with employees, customers, and suppliers; and other restructuring and impairment costs in addition to the 2024 Plan;

•delays and non-delivery of raw materials, parts, and finished products in our supply chain from fire, explosion, terrorism, geopolitical conflicts, government action, labor strikes, delivery port shutdowns, trade tensions, trucking constraints, pandemics, vendor quality issues, and non-compliance with laws;

•our product demand, growth rates, and reduced opportunities in the industries in which we participate;

•consumer confidence, housing turnover, employment levels, interest rates, and trends in capital spending;

•the loss of business with customers;

•impairment of goodwill and long-lived assets;

•our ability to manage working capital;

•our ability to borrow under our credit facility and comply with restrictive covenants;

•our ability to simplify our portfolio through our strategic review;

•compliance with environmental and climate change laws, including the cost, market, technological, and reputational impacts;

•the direct and indirect physical effects of climate change, including severe weather-related events, natural disasters, and changes in climate patterns, on our markets, operations, supply chains, and results;

•inability to collect receivables due to customer financial difficulties or insolvency;

•inflationary and deflationary impacts on raw materials, wage rates and energy costs, and availability and pricing of steel scrap and rod, chemicals, and semiconductors;

•our market share in goods and services we sell or provide;

•our ability to pass along cost increases through increased selling prices;

•price and product competition from Asian, European, Mexican, and domestic competitors;

•our ability to maintain profit margins if our customers change the quantity and mix of our products;

•our ability to access the commercial paper market and debt markets and increased borrowing costs due to credit rating changes;

•changes in political risk, U.S. or foreign laws, regulations, or legal systems (including tax and trade laws);

•the realization of deferred tax assets and challenges to tax positions pursuant to ongoing or future audits;

•cash repatriation from foreign accounts;

•the enforcement of antidumping and countervailing duties on the import of innersprings, steel wire rod, and finished mattresses;

•tariffs imposed by the U.S. government resulting in increased costs of imported purchases;

•the disruption of the semiconductor industry and our global operations generally from conflict between China and Taiwan;

•the development of commercially viable and innovative products;

•the financial health and stability of domestic mattress manufacturers, along with their ability to purchase mattress components, which could result in a reduction in the overall demand for our products;

•volatility related to growth of Chinese EV manufacturers and potential declines in market share among multinational OEMs, which could result in a reduction in the overall demand for our Automotive products;

•the functioning of our internal business processes and information systems through technology failures;

•cybersecurity incidents on our business, financial results, supplier or customer relationships, cybersecurity protection and remediation costs, legal costs, insurance premiums, competitiveness, and reputation;

•the unauthorized use of artificial intelligence that could expose Company information, infringe intellectual property rights, violate privacy laws, and harm our reputation;

•the costs and risk exposure relating to sustainability matters, including sustainability issues, regulatory or legal requirements, and disparate stakeholder expectations;

•litigation risks including antitrust, intellectual property, personal injury, contract disputes, product liability and warranty, taxation, patent, climate change, environmental, and workers’ compensation;

•business disruptions to our steel rod mill or wire mills, including a lack of adequate supply of steel scrap;

•foreign operating risks, including credit, intellectual property rights, exchange rates, labor strikes, customs rates, asset seizure, business licensing, land use requirements, and inconsistent enforcement of laws;

•controls regarding the exportation of semiconductor chips and equipment to China;

•compliance with privacy and data protection regulations; and

•continuation of cash dividends on our common stock.

PART I

Item 1. Business.

Summary

Leggett & Platt, Incorporated ("Leggett & Platt," "Company," "we," "us," or "our"), a pioneer of the steel coil bedspring, is an international diversified manufacturer that conceives, designs, and produces a wide range of engineered components and products found in many homes and automobiles. As discussed below, our operations are organized into 15 business units, which are divided into seven groups under our three segments: Bedding Products; Specialized Products; and Furniture, Flooring & Textile Products.

Overview of Our Segments

Bedding Products Segment

| | |

| BEDDING GROUP |

| Steel Rod |

| Drawn Wire |

| U.S. Spring |

| Specialty Foam |

| Adjustable Bed |

| International Bedding |

| Machinery |

Our Bedding Products segment has its roots in the Company's founding in 1883 with the manufacture of steel coil bedsprings. Today, we support our customers' product needs from raw materials to components to finished mattresses and foundations and provide distribution and fulfillment capabilities. Our industry-leading innerspring and specialty foam technologies, innovative product development, and vertical integration allow us to create value for our customers at each step, from raw material to end consumer.

We operate a steel rod mill in the United States with annual capacity of approximately 500,000 tons. Approximately half of the rod mill's output is used internally by our wire mills to supply virtually all of the wire consumed by our domestic innerspring operations and other businesses. We also supply steel rod and wire to trade customers that operate in a broad range of markets. Our innerspring operations produce coils and semi-finished mattress products with internally designed and manufactured wire-forming machines.

In Specialty Foam, we blend polyols and chemical additives to enhance foam properties and pour and fabricate foam for use in bedding and furniture applications. We utilize our specialty foam capabilities to produce mattress accessories and private label boxed mattresses, which often also incorporate our innersprings in hybrid mattress designs.

We are a major supplier of adjustable beds, with North American manufacturing and distribution, and global sourcing capabilities. Internationally, primarily in Europe, we produce innersprings, specialty foam, and finished mattresses. We also produce machinery used by bedding manufacturers in the production and assembly of their finished products. Our range of products offers our customers a single source for many of their component and finished product needs.

These innovative proprietary products and our efficient vertical integration have made us one of the largest U.S.-based manufacturers in many of these businesses. We strive to understand what drives consumer purchases in our markets and focus our product development activities on meeting end-consumer needs. We believe we attain a cost advantage from efficient manufacturing methods, internal production of certain raw materials, large-scale production, and purchasing leverage. Sourcing components and finished products from us allows our customers to focus on designing, merchandising, and marketing their products.

PRODUCTS

Bedding Group

| | | | | | | | | | | |

| • | | Steel rod |

| • | | Drawn wire |

| • | | Innersprings (sets of steel coils, bound together, that form the core of a mattress) |

| • | | Specialty foam chemicals and additives |

| • | | Specialty foam for use primarily in bedding and furniture |

| • | | Semi-finished mattresses (a subassembly including innersprings and foam) |

| • | | Private label finished mattresses, often sold compressed and boxed |

| • | | Mattress accessories, such as pillows and toppers |

| • | | Static foundations |

| • | | Adjustable beds |

| • | | Machines that we use to produce innersprings; industrial sewing and quilting machines; mattress-packaging and glue-drying equipment |

CUSTOMERS

| | | | | | | | | | | |

| • | | We used more than 60% of our wire mill output to manufacture our own products in 2024, with the majority going to our U.S. innerspring operations |

| • | | Various industrial users of steel rod and wire |

| • | | Manufacturers of finished bedding (mattresses and foundations) |

| • | | Bedding brands and mattress retailers |

| • | | E-commerce retailers |

| • | | Big box retailers, department stores, and home improvement centers |

Specialized Products Segment

| | |

| AUTOMOTIVE GROUP |

| Automotive |

|

| AEROSPACE PRODUCTS GROUP |

| Aerospace Products |

|

| HYDRAULIC CYLINDERS GROUP |

| Hydraulic Cylinders |

Our Specialized Products segment designs, manufactures, and sells products including automotive comfort and convenience systems, tubing and fabricated assemblies for the aerospace industry, and hydraulic cylinders for the material handling and heavy construction industries. In our Automotive business, our technical capability and deep customer engagement allows us to compete on critical functionality, such as comfort, size, weight, and noise. We believe our reliable product development and launch capability, coupled with our global footprint, makes us a trusted supplier to our Tier 1 and Original Equipment Manufacturer (OEM) customers.

PRODUCTS

Automotive Group

| | | | | | | | | | | |

| • | | Mechanical and pneumatic lumbar support and massage systems for automotive seating |

| • | | Seat suspension systems |

| • | | Motors and actuators, used in a wide variety of vehicle power features |

| • | | Cables |

Aerospace Products Group

| | | | | | | | | | | |

| • | | Titanium, nickel, and stainless-steel tubing, formed tube, tube assemblies, and flexible joint components, primarily used in fluid conveyance systems |

Hydraulic Cylinders Group

| | | | | | | | | | | |

| • | | Engineered hydraulic cylinders |

CUSTOMERS

| | | | | | | | | | | |

| • | | Automobile Tier 1 suppliers and OEMs |

| • | | Aerospace OEMs and suppliers |

| • | | Mobile equipment OEMs, primarily serving material handling and heavy construction markets |

Furniture, Flooring & Textile Products Segment

| | |

| HOME FURNITURE GROUP |

| Home Furniture |

|

| WORK FURNITURE GROUP |

| Work Furniture |

|

| FLOORING & TEXTILE PRODUCTS GROUP |

| Flooring Products |

| Fabric Converting |

| Geo Components |

In our Furniture, Flooring & Textile Products segment, we design, manufacture, and distribute a wide range of components and finished products for residential and commercial markets, and select structural fabric and geo component markets. We supply components used by home and work furniture manufacturers to provide comfort, motion, and style in their finished products and manufacture select lines of private-label finished furniture. We produce carpet cushion and hard surface flooring underlayment for residential and commercial use. We convert fabrics into components used by bedding and furniture manufacturers and in other applications such as filtration, hospitality, automotive, and packaging. We also convert and distribute geo components for erosion control, subgrade stabilization, and storm water management.

PRODUCTS

Home Furniture Group

| | | | | | | | | | | |

| • | | Steel mechanisms and motion hardware (enabling furniture to recline, tilt, swivel, rock, and elevate) for reclining chairs, sofas, sleeper sofas, and lift chairs |

| • | | Springs and seat suspensions for chairs, sofas, and loveseats |

Work Furniture Group

| | | | | | | | | | | |

| • | | Components and private-label finished goods for collaborative soft seating |

| • | | Bases, columns, back rests, casters, and frames for office chairs, and control devices that allow chairs to tilt, swivel, and elevate |

Flooring & Textile Products Group

| | | | | | | | | | | |

| • | | Carpet cushion and hard surface flooring underlayment (made from bonded scrap foam, fiber, rubber, and prime foam) |

| • | | Structural fabrics for mattresses, residential furniture, and industrial uses |

| • | | Geo components (synthetic fabrics and various other products used in ground stabilization, drainage protection, erosion, and weed control) |

CUSTOMERS

| | | | | | | | | | | |

| • | | Manufacturers of upholstered and office furniture |

| • | | Flooring retailers and distributors, including big box retailers and home improvement centers |

| • | | Contractors, landscapers, road construction companies, retailers, and government agencies using or selling geo components |

| • | | Mattress and furniture producers |

| • | | Manufacturers of draperies, specialty packaging, filtration, and automotive upholstery |

2024 Restructuring Plan

In the first quarter of 2024, we committed to a restructuring plan, primarily associated with our Bedding Products segment and, to a lesser extent, our Furniture, Flooring & Textile Products segment (the “2024 Restructuring Plan” or “2024 Plan”), which is expected to be substantially complete by the end of 2025. The 2024 Plan was expanded in the second quarter of 2024 to include a restructuring opportunity within the Specialized Products segment and in the third quarter of 2024 to include general and administrative cost structure initiatives.

For more information about the 2024 Restructuring Plan, please see the discussion under Operational Risk Factors beginning on page 15 in Item 1A. Risk Factors, and in Item 7. Management's Discussion and Analysis of Financial Condition and Results of Operations on page 39.

Strategic Initiatives

We are evaluating the market attractiveness and competitive position of all our businesses and assessing opportunities for profitable, long-term growth. We are also determining which businesses are the best long-term fit for the company and as part of this review, we are currently exploring the potential sale of our Aerospace business. This business has not reached the criteria to be classified as held for sale.

Acquisitions

We did not acquire any businesses in 2024 or 2023.

In August 2022, we acquired two businesses. First, we acquired a small U.S. textiles business that converts and distributes construction fabrics for the furniture and bedding industries for a cash purchase price of $2 million. This acquisition became part of our Furniture, Flooring & Textile Products segment. Second, we acquired a global manufacturer of hydraulic cylinders for heavy construction equipment for a final purchase price of $88 million ($61 million cash plus additional contingent consideration). This business has manufacturing

locations in Germany and China and a distribution facility in the United States, and operates within the Specialized Products segment.

In early October and mid-December 2022, we acquired two Canadian distributors of products used for erosion control, stormwater management, and various other applications for a cash purchase price of $7 million and $13 million, respectively. These acquisitions became a part of our Furniture, Flooring & Textile Products segment and expanded the geographic scope of our Geo Components business unit.

For more information regarding our acquisitions, please refer to Note R on page 119 of the Notes to Consolidated Financial Statements. Divestitures

We did not have any divestitures of businesses in 2024 or 2023.

In February 2022, we sold our South African bedding innerspring operation for a cash purchase price of approximately $2 million. This business was reported in our Bedding Products segment.

Foreign Operations

The percentages of our trade sales related to products manufactured outside the United States were 35%, 39%, and 40% in 2022, 2023, and 2024, respectively. In comparison to our other two segments, our Specialized Products segment has a larger percentage of trade sales manufactured outside the United States, which ranged between 84% and 86% over the last three years.

Our international operations are principally located in Europe, China, Canada, and Mexico. Our products in these foreign locations primarily consist of:

Europe

| | | | | |

| • | Innersprings, specialty foam, and finished mattresses |

| • | Lumbar and seat suspension systems for automotive seating and actuators for automotive applications |

| • | Seamless and welded tubing and fabricated assemblies for aerospace applications |

| • | Select lines of private-label finished furniture |

| • | Hydraulic cylinders for material handling and heavy construction equipment |

| • | Machinery and equipment designed to manufacture innersprings for mattresses |

China

| | | | | |

| • | Lumbar and seat suspension systems for automotive seating |

| • | Cables, motors, and actuators for automotive applications |

| • | Recliner mechanisms and bases for upholstered furniture |

| • | Work furniture components, including chair bases and casters |

| • | Innersprings for mattresses |

| • | Hydraulic cylinders for heavy construction equipment |

Canada

| | | | | |

| • | Lumbar and seat suspension systems for automotive seating |

| • | Fabricated wire for the furniture and automotive industries |

| • | Work furniture chair controls and bases |

| • | Geo components |

Mexico

| | | | | |

| • | Lumbar and seat suspension systems for automotive seating |

| • | Motors and actuators for automotive applications |

| • | Adjustable beds |

| • | Select lines of private-label finished furniture |

Geographic Areas of Operation

As of December 31, 2024, we had 119 manufacturing facilities in 18 countries; 71 located in the United States and 48 located in foreign countries, as shown below. We also had various sales, warehouse, and administrative facilities. However, our manufacturing facilities are our most important properties.

| | | | | | | | | | | |

| Bedding Products | Specialized Products | Furniture, Flooring & Textile Products |

| North America | | | |

| Canada | | n | n |

| Mexico | n | n | n |

| United States | n | n | n |

| Europe | | | |

| Austria | | n | |

| Belgium | | n | |

| Croatia | n | | |

| Denmark | n | | |

| France | | n | |

| Germany | | n | |

| Hungary | | n | |

| Ireland | n | | |

| Poland | | | n |

| Switzerland | n | | |

| United Kingdom | n | n | |

| South America | | | |

| Brazil | n | | |

| Asia | | | |

| China | n | n | n |

| India | | n | |

| South Korea | | n | |

Dependence on Market Demand for Key Product Families

The following table shows our approximate percentage of trade sales by product family for the last three years, which indicates the degree of dependence upon market demand:

| | | | | | | | | | | | | | | | | | | | | | | | | | |

| Product Families | 2024 | | 2023 | | 2022 |

| Bedding Group | 40 | % | | 42 | % | | 46 | % |

| Flooring & Textile Products Group | 20 | | | 19 | | | 18 | |

| Automotive Group | 19 | | | 19 | | | 17 | |

| Home Furniture Group | 6 | | | 6 | | | 8 | |

| Work Furniture Group | 6 | | | 6 | | | 6 | |

| Hydraulic Cylinders Group | 5 | | | 5 | | | 3 | |

| Aerospace Products Group | 4 | | | 3 | | | 2 | |

| | | | | | | | |

We do not have a material amount of sales derived from government contracts subject to renegotiation of profits or termination at the election of any government. As such, our business is not materially dependent upon governmental customers.

Distribution of Products

We sell and distribute our products primarily through our own personnel. However, many of our businesses have relationships and agreements with outside sales representatives and distributors. We do not believe any of these agreements or relationships would, if terminated, have a material adverse effect on our consolidated financial condition, operating cash flows, or results of operations.

Sources and Availability of Raw Materials

The products we manufacture require a variety of raw materials. We believe that worldwide supply sources are available for all the raw materials we use, as explained below. Among the most important raw materials we use are:

| | | | | |

| • | Various types of steel, including scrap, rod, wire, sheet, and stainless |

| • | Chemicals used in foam production |

| • | Foam scrap |

| • | Woven and nonwoven fabrics |

| • | Titanium and nickel-based alloys and other high strength metals |

| • | Electronic systems (including semiconductors) |

We supply our own raw materials for many of the products we make. For example, we produce steel rod that we make into steel wire, which we then use to manufacture innersprings and static foundations for mattresses. Our domestic wire drawing mills purchase nearly all of their steel rod requirements from our rod mill. Our wire drawing mills supply nearly all of our U.S. requirements for steel wire.

Customer Concentration

We serve thousands of customers worldwide, sustaining many long-term business relationships. Our largest customer represented less than 8% of our 2024 consolidated revenue. Our top 10 customers accounted for approximately 32% of these consolidated revenues. The loss of one or more of these customers could have a material adverse effect on the Company and the respective segments in which the customer’s sales are reported.

Patents and Trademarks

As of December 31, 2024, we had 1,281 patents issued, 503 patents in process, 1,007 trademarks registered, and 57 trademarks in process. No single patent or group of patents, or trademark or group of trademarks, is material to our operations as a whole. A significant number of our patents relate to products manufactured in each of our three segments, while over half of our trademarks relate to products manufactured by the Bedding Products segment. The expiration of any single patent would not have a material negative effect on our results of operations or financial condition.

Some of the most significant trademarks used in our businesses include: | | | | | |

| • | ComfortCore®, Quantum®, Eco-Base®, CombiCoreTM, Nanocoil®, Softech®, Active Support Technology®, Mira-Coil®, and VertiCoil® (mattress innersprings) |

| • | Energex®, Coolflow®, ThermaGel®, EcoFlowTM, and Gorilla FoamTM (specialty foam products) |

| • | Semi-Flex® (box spring components and foundations) |

| • | Spuhl® (mattress innerspring manufacturing machines) |

| • | Wall Hugger® (recliner chair mechanisms) |

| • | No-Sag® (wire forms used in seating) |

| • | LPSense® (capacitive sensing) |

| • | Hanes® (fabric materials) |

| • | Schukra® (automotive seating products) |

| • | Gribetz® and Porter® (quilting and sewing machines) |

Product Development

One of our strongest performing product categories across the Company is ComfortCore®, our fabric-encased innerspring coils used in hybrid mattresses. ComfortCore® represented 70% of our U.S. innerspring units in 2024. Our ComfortCore® innersprings can be further enhanced with Quantum® Edge and Eco-Base® features. Quantum® Edge units are narrow-diameter, fabric-encased coils that form a perimeter around an innerspring set, replacing a rigid foam perimeter in a finished mattress. In 2024, over 40% of our ComfortCore® innersprings in the United States had the Quantum® Edge feature. In 2022, we launched two new products called the Quantum® Edge Enhanced Profile with Eco-Base® and Caliber Edge® Enhanced Profile with Eco-Base®. Our Eco-Base® products feature a robust polyester fabric attached to the bottom of a ComfortCore® unit, eliminating non-value-added base foam in a finished mattress and saving customers time and labor. To maintain mattress profile, innerspring coil height is increased by one inch.

Our Specialty Foam business formulates many of the chemicals and additives used in the production of specialty foams for the bedding and furniture industries. These branded, specialty polyols and additives enhance foam performance by reducing heat retention and improving mobility, support, and durability. Our innovations enable us to produce high-quality, differentiated compressed mattresses.

We are leveraging our innerspring and specialty foam technologies to develop unique products that meet end-consumer needs while streamlining mattress manufacturing for our customers by reducing labor constraints and simplifying supply chain and inventory requirements. In 2023, we launched CombiCoreTM, a semi-finished mattress featuring fabric-encased perimeter edge innerspring and specialty foam columns that minimize motion disturbance from a sleeping partner and improve airflow. In 2024, we launched our pre-foam encased product, which features foam rails automatically attached to an Eco-Base® innerspring set during the innerspring production process.

Our Automotive business designs and engineers lightweight components that help reduce overall vehicle weight and improve fuel efficiency (and thus reduce noise and greenhouse gas emissions), while maintaining performance, safety, and functionality. These products help auto manufacturers meet emission standards and their environmental goals for both internal combustion engines and electric vehicles.

Across our other businesses, we are engaged in product development activities to improve product quality, increase efficiency, support ongoing growth, and help our customers achieve their goals.

Human Capital Management

Our success depends on our ability to attract and retain talent, foster a culture of inclusion, respect, and equal opportunity, provide a safe and healthy work environment, train and develop our employees, and ensure productive succession planning efforts. The Board’s Human Resources and Compensation Committee has oversight of our human resources policies and programs, officer and director compensation, compensation plans, executive succession planning, and senior management leadership development. This oversight is designed to support our business objectives, to attract, retain, and develop high-quality leadership, and to link compensation with business performance.

Our Employees

At year-end 2024, we had approximately 17,700 employees, of which around 11,500 were engaged in production and around 10,200 were international employees. Of these employees, approximately 5,400 were in Bedding Products, 7,000 were in Specialized Products, and 4,500 were in Furniture, Flooring & Textile Products, with the remainder in other roles. Also, at year-end 2024, approximately 14% of our employees were represented by labor unions that collectively bargain for work conditions, wages, or other issues. We did not experience any material work stoppage related to labor contract negotiations during 2024, and we are not aware of circumstances likely to result in a material work stoppage during 2025. At year-end 2023, we had approximately 19,300 employees.

Our Ability to Attract, Recruit, and Retain Employees

We operate in competitive labor markets, and accordingly, we attract, recruit, and retain employees through competitive compensation and benefits, training and development programs that support career growth, and employee engagement initiatives designed to foster a strong, inclusive culture.

Compensation and Benefits. We offer cash compensation and benefits designed to attract and retain the talent needed to achieve our business objectives. Depending on location, we offer health, dental, and vision benefits; flexible spending plans and health savings accounts; retirement savings; disability, life, critical illness, accident, and travel insurance; well-being and employee assistance programs; vacation, personal time, and holidays; and a discount stock purchase plan. We also provide incentive programs for management employees based on performance. Finally, we offer part-time jobs, flexible hours, and remote and hybrid working, where applicable.

Training and Development Programs. Developing our talent continues to be part of our ongoing, long-term strategy, which is focused on growing talent, including technical/skilled positions, supervisory and management levels, and other future leaders. We believe that the first step toward achieving our long-term strategic business goals is to maintain a culture of employee development at all levels of the Company. In 2024, we engaged employees on a monthly basis in learning spotlights which included development programs regarding career growth, change management, collaboration, feedback, gratitude, professional growth, psychological safety, and other topics.

Employee Engagement and Satisfaction. We analyze employee satisfaction to better enhance engagement. At many of our locations, we collect data on employee satisfaction, feedback, and turnover through surveys, employee focus groups, and turnover analysis. From this data, we develop plans designed to improve engagement and reduce turnover.

We rely on a stable workforce to deliver our operating results. In 2024, our turnover rates in the United States were reasonably comparable to average voluntary turnover rates of the manufacturing industry in the United States.

At all locations, we also have an Ethics Hotline where employees can express concerns, confidentially and anonymously, regarding possible violations of ethics, law, or our policies. All reports received are promptly investigated, and appropriate action is taken based on the findings. Our Ethics Hotline helps ensure that the voices of our employees are heard.

Our Culture of Inclusion, Respect, and Equal Opportunity

We continue to foster a culture of inclusion in which everyone is respected, valued, and has an equal opportunity to contribute, grow, thrive, and advance. We strive to cultivate inclusive team environments that empower all employees to realize their full potential. We believe that it is important to appreciate people's differences and provide equal employment opportunities at all organizational levels, without regard to irrelevant factors such as sex, race, age, etc. Our commitment is to maintain our focus on building a workforce of qualified and talented individuals, who can best contribute to the Company's success. We are taking comprehensive actions to build on our foundational awareness, understanding, engagement, and skills to promote a culture of respect and equal opportunity.

Our Workforce Health and Safety

We are dedicated to the health and safety of our employees through prevention, education, and awareness with the objective of mitigating workplace injuries through accident investigation and process safety. Our dedicated staff of professionals supports health and safety management at our manufacturing facilities, including implementation of a comprehensive program called “SafeGuard.” The SafeGuard program develops relevant job hazard analyses, which are undertaken on many processes and used to develop comprehensive job procedures. This allows us to implement job-specific health and safety practices across our business.

Our manufacturing employees receive new hire and annual refresher safety training, weekly “tool box” talks regarding safety and training, job-specific safety training based on the job hazards analysis developed from our SafeGuard program, and safety stand-down training based on real-time identified and emerging risks, when needed.

Succession Development

We are committed to having strong managers and leadership in critical roles across the Company. Our values and culture guide our talent initiatives, which are designed to create a pipeline of strong, high performing leadership candidates to serve in progressively important roles throughout the Company. Our internal promotion rate over the last three years for corporate officer positions was 100%. We are building on our success in these areas and continue to develop our succession processes to allow us to adapt and grow.

Trends in Market Demand and Competition

Market Demand. Market demand (including product mix) is impacted by several economic factors, with housing turnover and consumer confidence being the most significant. Other important factors include disposable income levels, employment levels, and interest rates. All of these factors influence consumer spending on durable goods, and therefore affect demand for our products and components. Some of these factors also influence spending on infrastructure, facilities, and equipment, which has historically impacted approximately 25%-30% of our sales. The dynamic macroeconomic environment has pressured most of our end markets and negatively affected the demand for our products. As a result of these uncertainties, we expect 2025 overall demand to be down modestly from 2024 levels. For more information on our trends in market demand, see Market Demand in Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations on page 41. Competition. Many companies offer products that compete with those we manufacture and sell. The number of competing companies varies by product family, but many of the markets for our products are highly competitive. We tend to attract and retain customers through innovation, product quality, competitive pricing, and customer service. Many of our competitors try to win business primarily on price, but, depending upon the particular product, we experience competition based on quality and performance as well. In general, our competitors tend to be smaller, private companies.

Based on certain industry data, we believe we are a leading supplier, in terms of revenue, of the following:

| | | | | |

| • | Bedding components and private label finished goods |

| • | Automotive seat comfort and convenience systems |

| • | Home and work furniture components |

| • | Geo components |

| • | Flooring underlayment |

| • | Hydraulic cylinders for material handling and heavy construction applications |

| • | Aerospace tubing and fabricated assemblies |

We continue to face pressure from foreign competitors, as some of our customers source a portion of their components and finished products offshore. In addition to lower labor rates, foreign competitors benefit (at times) from lower raw material costs. They may also benefit from currency factors and more lenient regulatory climates. We typically compete in market segments that value product differentiation. When we do compete on cost, we typically remain price competitive in most of our business units, even versus many foreign manufacturers, as a result of our efficient operations, automation, vertical integration in steel rod and wire, logistics and distribution efficiencies, and large-scale purchasing of raw materials and commodities. To stay competitive with global steel costs, both contract and non-contract innerspring pricing was adjusted in the back half of 2023 and fully realized in 2024. We have also reacted to foreign competition in certain cases by developing new proprietary products that help our customers reduce total costs and by shifting production offshore to take advantage of lower input costs.

For information about antidumping duty orders regarding innerspring, steel wire rod, and mattress imports, please see Competition in Item 7. Management’s Discussion and Analysis of Financial Condition and Results of Operations on page 42. Seasonality

We generally experience some seasonality in our consolidated sales, earnings, and operating cash flows. Both sales and earnings are typically higher in the second and third quarters, primarily driven by our residential bedding and furniture businesses, as well as our geo components business. Also, historically, our operating cash flows have been stronger in the fourth quarter, primarily related to the timing of cash collections from customers and payments to vendors, and lower in the first quarter, when annual cash incentive payments are paid and as inventories typically increase. However, supply chain disruptions, inflation, and other macroeconomic factors have impacted seasonality in prior years.

Governmental Regulations

Our operations are subject to various federal, state, local, and international laws and regulations, including environmental regulations. We have policies intended to ensure that our operations are conducted in compliance with applicable laws and regulations. While we cannot predict policy changes by various regulatory agencies or unexpected operational or other developments, management expects that compliance with these laws and regulations will not have a material adverse effect on our capital expenditures (including those capital expenditures for environmental control facilities), earnings, and competitive position.

Internet Access to Information

We routinely post information for investors under the Investor Relations section of our website (www.leggett.com). Our annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and all amendments to those reports are made available, free of charge, on our website as soon as reasonably practicable after electronically filed with, or furnished to, the SEC. In addition to these reports, the Company’s Financial Code of Ethics, Code of Business Conduct and Ethics, and Corporate Governance Guidelines, as well as charters for the Audit, Human Resources and Compensation, and Nominating, Governance and Sustainability Committees of our Board of Directors, can be found on our website under the Governance section. Information contained on our website does not constitute part of this Annual Report on Form 10-K.

Industry and Market Data

Unless indicated otherwise, the information concerning our industries contained in this Annual Report is based on our general knowledge of and expectations concerning the industries. Our market share is based on estimates using our internal data, information from various industry analyses, internal research, and adjustments and assumptions that we believe to be reasonable. We have not independently verified data from industry analyses and cannot guarantee their accuracy or completeness.

Item 1A. Risk Factors.

Investing in our securities involves risk. Set forth below and elsewhere in this report are risk factors that could cause actual results to differ materially from the results contemplated by the forward-looking statements contained in this report. We may amend or supplement these risk factors from time to time by other reports we file with the SEC.

Operational Risk Factors

Supply chain disruptions and shortages impacting our ability to timely receive competitively priced raw materials and parts used in our products, or impacting our ability to timely deliver our finished products to customers, may adversely affect our manufacturing processes, financial condition, results of operations, and cash flows.

We have manufacturing facilities in 18 countries, primarily located in North America, Europe, and Asia. In our manufacturing processes, we source raw materials and parts from a global supply chain. We sell and deliver our finished products to customers all over the world. We rely on third parties to supply certain raw materials, components, and packaging products and to deliver our finished products. Any interruption or failure by our suppliers to meet their obligations on schedule could adversely affect our business and financial results. In recent years, we have experienced supply chain disruptions related to foam chemical shortages, semiconductor shortages, labor availability, and freight challenges, as well as higher costs associated with each of these issues. We have also experienced delays in delivery of materials, parts, and finished goods because of delivery port disruptions, trucking constraints, and inclement weather. At times, this has resulted in reduced volume and higher costs in many of our businesses, including our Automotive Group and Bedding Products segment.

We also bear the risk of delays or non-delivery from our suppliers or reduced demand from our customers because of natural disasters, fires, explosions, terrorism, pandemics, labor strikes, foreign government action including asset seizure, changed licensing, or land use requirements which restrict operations, or other reasons beyond our control or the control of our suppliers, all of which could impair our ability to timely manufacture and deliver our products.

Labor strikes or shutdowns at delivery ports, loss of or damage to raw materials, parts, or finished products while they are in transit or storage, losses due to tampering, third-party vendor issues with quality, failure by our suppliers to comply with applicable laws and regulations, potential tariffs or other trade restrictions, or similar problems could restrict or delay the supply of raw materials, parts, or finished products, resulting in harm to our business and reputation. Also, in late 2023 and early 2024, the conflict in the Red Sea caused delays with some of our shipments, while other shipments from China to the United States or Europe have been re-routed.

The aforementioned supply chain risks can materially adversely affect our manufacturing processes, financial condition, results of operations, and cash flows.

Our 2024 Restructuring Plan may not achieve its intended outcomes, and we may incur restructuring costs, restructuring-related costs, and impairments in addition to those anticipated to be incurred in connection with our announced 2024 Restructuring Plan.

2024 Restructuring Plan

In the first quarter of 2024, we committed to a restructuring plan (the “2024 Restructuring Plan” or “2024 Plan”). The 2024 Plan is primarily associated with our Bedding Products segment and, to a lesser extent, our Furniture, Flooring & Textile Products segment. The 2024 Plan was expanded in the second quarter of 2024 to include a restructuring opportunity within the Specialized Products segment and in the third quarter of 2024 to include the general and administrative cost structure initiatives. We expect to consolidate between 15 and 20 production and distribution facilities in the Bedding Products segment and a small number of production facilities in the Furniture, Flooring & Textile Products segment.

With respect to Bedding Products, we (i) consolidated 14 production and distribution facilities (ten in U.S. Spring, three in Specialty Foam, one in Adjustable Bed); (ii) consolidated all domestic innerspring production

into our four larger remaining spring production facilities; (iii) exited our Mexican innerspring operation; (iv) downsized our Chinese innerspring operation; and (v) sold two properties. With respect to Specialized Products, we launched restructuring activities in our Hydraulic Cylinders business to optimize manufacturing and improve operating efficiencies. With respect to Furniture, Flooring & Textile Products, we closed one facility each in the Home Furniture and Flooring Products business units. Finally, we reduced corporate general and administrative expenses, which are expected to be fully realized in 2025. In 2025, we expect to have further consolidations in Bedding Products (primarily in Specialty Foam), achieve full implementation of manufacturing efficiency improvement activities in Hydraulic Cylinders, and complete restructuring initiatives in Flooring Products.

Below is a table containing the 2024 Restructuring Plan costs, EBIT benefit, sales attrition, and proceeds from the sale of real estate incurred or realized in 2024, and our estimates for 2025 and thereafter:

| | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| (Dollar amounts in millions-all pretax) | | 2024

Actual | | | | Estimates for 2025 1 | | Total Plan Estimate 2, 3, 4 | | Total Plan Prior Estimate 3 |

| Plan activity: | | | | | | | | | | |

| Restructuring and restructuring-related costs: | | | | | | | | | | |

| Cash | | $ | 30 | | | | | $15 to $20 | | $45 to $50 | | $30 to $40 |

| Non-cash | | 18 | | | | | 15 to 20 | | 35 to 40 | | 35 to 45 |

| Total costs | | $ | 48 | | | | | $30 to $40 | | $80 to $90 | | $65 to $85 |

| | | | | | | | | | |

Pretax net cash from real estate 5 | | $ | 20 | | | | | $15 to $40 | | $60 to $80 | | $60 to $80 |

| | | | | | | | | | |

| Plan impacts: | | | | | | | | | | |

| Sales attrition | | $ | 15 | | | | | $ | 60 | | | $ | 80 | | | $ | 80 | |

| | | | | | | | | | |

| EBIT benefit | | $ | 22 | | | | | $55 to $60 | | $60 to $70 | | $50 to $60 |

1 Estimates for 2025 sales attrition and EBIT benefit include full year impacts of the actions completed in 2024 and additional actions expected to be completed in 2025.

2 Due to implementation timing of certain restructuring activities, we expect to have a small amount of incremental EBIT benefit and sales attrition in 2026. Additionally, due to the timing of listing properties, we expect the remainder of real estate sales to occur in 2026.

3 Estimates of annualized sales attrition and EBIT benefit are expected to be realized after the 2024 Plan is fully implemented in late 2025.

4 Increases in our total plan estimates for both cash costs and EBIT benefit are related to 2024 Plan activities in our Specialized Products segment and our general and administrative initiatives.

5 Pretax net cash from real estate is only related to the 2024 Plan and does not include the sale of idle real estate. The 2024 sale of real estate resulted in a pretax gain of $17 million. We estimate up to $37 million of pretax gains on the sale of real estate in 2025.

Total restructuring and restructuring-related costs, including 2024 Plan costs and costs to explore the potential sale of our Aerospace business, for the year ending December 31, 2024, were $51 million ($33 million cash and $18 million non-cash).

2024 Plan costs are expected to be substantially complete by the end of 2025.

Because of certain risks and uncertainties, the estimates of the number of facilities to be consolidated, EBIT benefit, sales attrition, proceeds from the sale of real estate, and the cash and non-cash costs and impairments associated with the 2024 Plan may change as our analysis develops and additional information is obtained. Also, we may not be able to implement the 2024 Plan in a timely manner that will positively impact our

financial condition and results of operations. Moreover, we may not be able to dispose of real estate pursuant to the 2024 Plan or obtain the expected proceeds in a timely manner. The 2024 Plan may also negatively impact our relationships with employees, customers, and vendors. Any failure to achieve the intended outcomes could materially adversely affect our business, financial condition, results of operations and cash flows, and liquidity. The 2024 Plan may not achieve its intended outcomes.

We continue to evaluate our businesses for further restructuring opportunities in addition to those activities included in the 2024 Plan. The execution of any of these opportunities may result in additional material restructuring costs, restructuring-related costs, or impairments.

Business disruptions to our steel rod mill or wire drawing mills, if coupled with an inability to purchase an adequate and/or timely supply of quality steel rod from alternative sources, could have a material negative impact on our Bedding Products segment and the Company's results of operations.

We purchase steel scrap from third-party suppliers and convert it into steel rod in our mill in Sterling, Illinois. Our steel rod mill has historically had annual output of approximately 500,000 tons, a majority of which has been used internally by our wire mills. Our two wire mills, located in Carthage, Missouri, and Kouts, Indiana, convert steel rod into drawn steel wire, which is used in the production of mattress innersprings and other products.

A disruption to the operation of, or supply of steel scrap to, our steel rod mill could require us to purchase steel rod from alternative supply sources, subject to market availability. Ongoing trade action by the U.S. government, along with the existence of antidumping and countervailing duty orders against multiple countries, could result in reduced market availability and/or higher cost of steel rod.

If we experience a disruption to our ability to produce steel rod in our mill, coupled with a reduction of adequate and/or timely supply from alternative market sources of quality steel rod, we could experience a material negative impact on our Bedding Products segment and the Company’s results of operations.

The physical effects of climate change could adversely affect our business, results of operations, and financial condition.

Direct Physical Effects

The acute and chronic physical effects of severe weather-related events, natural disasters, and/or significant changes in climate patterns, could have an increasingly adverse impact on our business and customers. At December 31, 2024, we had 119 manufacturing facilities in 18 countries, primarily located in North America, Europe, and Asia. We serve thousands of customers worldwide. In 2024, our customers were located in approximately 100 countries. Western states, including California and Washington, have historically experienced, and are projected to continue to experience, climate-related events (such as wildfires) at an increasing frequency. In early 2025, there were multiple wildfires in California, including unprecedented wildfires in the Los Angeles County area. We have production facilities located in California and Washington in each of our segments. To date, no facilities have suffered damage from these fires. However, because of lack of rain, higher temperatures, and unpredictable winds, we could experience potential adverse physical effects, including damage to our properties and disruption to our operations. Although our diverse geographical manufacturing footprint and our broad geographical customer base mitigates the potential physical risks of any local or regional severe weather-related event having a material effect on our operations and results, the increased frequency and severity of such weather-related events could result in potential damage to our physical assets, local infrastructure, transportation systems, water delivery systems, our customers’ or suppliers’ operations, as well as prolonged disruptions in our manufacturing operations (including, but not limited to, our steel rod mill and wire drawing mills), all of which could harm our business, results of operations, and financial condition.

Indirect Physical Effects

The physical effects of climate change could continue to have an adverse impact on our supply chain. In prior years, we experienced (due, in part, to severe weather-related impacts) supply shortages in chemicals, which restricted foam supply and constrained overall mattress production in the bedding industry. This reduced our production levels and increased the cost of chemicals and foam. Severe weather impacts could also reduce supply of other products in our supply chain that could result in higher prices for our products and the resources needed to produce them. If we are unable to secure an adequate and timely supply of products in our supply chain, or the cost of these products materially increases, it could have a negative impact on our business, results of operations, and financial condition.

In recent years, drought conditions lowered water levels of the Mississippi River and Panama Canal, reducing traffic through these waterways, which impacted some of our shipments. Although these issues did not have a material impact on our results of operations, additional logistical disruptions could result in additional costs and delays in our ability to deliver products timely to certain customers.

In addition, although the cost has not been material to our business, results of operations, and financial condition, severe weather-related incidents have resulted and may, in the future, result in increased costs of property insurance.

The market transition risks related to climate change could adversely affect our business, results of operations, and financial condition.

We are engaged in the manufacture of various automotive components, including lumbar supports and massage systems for seating, seat suspension systems, motors and actuators, and cables. For several decades, automotive manufacturers have sought lightweight components designed to increase fuel efficiency in the automobiles they manufacture. Replacing traditional steel components with lightweight alternative components can directly reduce the weight of a vehicle's body and chassis and therefore reduce a vehicle's fuel consumption. This increased fuel efficiency also indirectly reduces greenhouse gas (GHG) emissions.

These long-standing market transitions have negatively impacted our market share, although not materially because of our technological competitiveness. However, if we are unable to continue to react to changes in technology, successfully develop new and innovative products, or successfully respond to evolving business trends, including continuing to produce comparatively lightweight components, our share in these markets could be materially negatively impacted.

Global economic, political, legal, and business factors could adversely impact our business.

We operate in global markets. Approximately 40% of our sales in 2024 were generated outside the United States. In addition, as of December 31, 2024, 48 manufacturing facilities and approximately one-third of our tangible long-lived assets were located outside the United States. Our reliance on sales and manufacturing facilities outside the United States expose us to a number of risks, including price and currency controls; sanctions, export controls or trade restrictions, including import and export tariffs; extraterritorial effects of U.S. laws; expropriation of assets; war, civil uprisings; political instability; nationalization of private enterprises; hyperinflationary conditions; the necessity of governmental approvals for products and operations, currency conversion, cash repatriation; and laws and regulations that may be arbitrarily applied.

These factors could result in, or could continue to result in, among other things, supply chain or production disruptions, lower consumer demand, compressed profit margins, and unfavorable foreign currency exchange rates, any of which could materially negatively impact our business, results of operations, financial condition, and cash flows.

Geopolitical Risk Factors

Conflict between China and Taiwan could lead to trade sanctions, export controls, technology disputes, or supply chain disruptions, which could, in particular, impact the semiconductor industry, and our operations globally.

Our Automotive Group uses semiconductors in seat comfort products and, to a lesser extent, in motors and actuators. Our OEM and Tier customers also use semiconductors, or components containing semiconductors, in their manufacture of automotive components and/or vehicles. This supply could be challenged by any number of unexpected or unplanned events. According to certain market reports, Taiwan and, to a lesser extent, China are leading manufacturers of the world’s semiconductor supply. Conflict between China and Taiwan might lead to trade sanctions, export controls, technology disputes, or supply chain disruptions, which could, in particular, affect the semiconductor industry. If this were to occur, our Automotive Group’s ability to source an adequate supply of semiconductors may be reduced, which could adversely harm our business, financial condition, and results of operations. Such a conflict also could negatively impact our OEM and Tier customers' supply chains and production schedules. In addition, any outbreak of hostilities or conflict between China and Taiwan could harm our operations globally and the operations of our customers and suppliers.

Financial Risk Factors

Our borrowing costs and access to liquidity may be impacted by lower credit ratings.

Independent rating agencies evaluate our credit profile and have assigned ratings for our long-term and short-term debt. Recently, our credit ratings have been lowered and could be lowered further. These recent downgrades have resulted in slightly higher interest rates and could impact marketability. Lower credit ratings could adversely affect our sources of borrowing and our financial arrangements, including access to the commercial paper market, our lending agreements, and supply chain financing arrangements. If we are unable to meet our short-term borrowing needs in the commercial paper market, we may need to access our credit facility or other bank debt to fund short-term working capital needs at higher interest costs.

Our inability to collect receivables in accordance with their terms could negatively impact our earnings, liquidity, cash flow, and financial condition.

Some of our customers have suffered financial difficulty. As a result, some of our customers have been unable to pay their debts to us, have exhibited slow payments, have rejected their contractual obligations to us under bankruptcy laws or otherwise, or we have had to negotiate significant discounts and/or extend financing terms with these parties. These collection issues may continue.

We monitor our receivable portfolio closely and make reserve decisions based upon individual customer credit risk reviews, aging of customer accounts, historical loss experience, and general macroeconomic and industry trends that could impact the expected collectability of all customers or pools of customers with similar risks. Our bad debt expense has fluctuated over the last three years: $6 million expense in 2024, $(7) million benefit in 2023, and $3 million expense in 2022. As of December 31, 2024, our allowance for doubtful accounts for trade receivables was $14 million. If we are unable to collect receivables on a timely basis, larger provisions for bad debt may be required and may result in a negative impact on our earnings, liquidity, cash flow, and financial condition.

Our goodwill and other long-lived assets are subject to potential impairment which could negatively impact our earnings.

A significant portion of our assets consists of goodwill and other long-lived assets, the carrying value of which would be reduced if we determine that those assets are impaired. At December 31, 2024, goodwill and other intangible assets represented $935 million, or 26% of our total assets. In addition, net property, plant, and equipment, operating lease right-of-use assets, and sundry assets totaled $1,036 million, or 28% of total assets.

Goodwill Impairment

We test goodwill for impairment at the reporting unit level (the business groups that are one level below the operating segments) when triggering events occur or at least annually. We perform our annual goodwill impairment testing in the second quarter.

The 2024 annual goodwill impairment testing indicated that fair value had fallen below carrying value for three reporting units, and fair value exceeded carrying value by less than 100% for one reporting unit. We had 2024 impairments of $588 million, $44 million, and $44 million in our Bedding, Work Furniture, and Hydraulic Cylinders reporting units, respectively. The fair values of our reporting units in relation to their respective carrying values and significant assumptions used are presented in the tables in Note F to the Consolidated Financial Statements, beginning on page 96. In general, the fair values for these reporting units decreased versus prior year due to macroeconomic pressures, including low demand, particularly in residential end markets. The fair values of our reporting units were reconciled to our consolidated market capitalization, which decreased due to the significant decline in stock price during the second quarter of 2024. Our closing stock price per share was $26.17 on December 29, 2023, $19.15 on March 28, 2024, and $11.46 on June 28, 2024. We concluded that an impairment existed under generally accepted accounting principles in connection with the preparation and review of our second quarter financial statements filed on August 7, 2024 as part of the quarterly report on Form 10-Q.

While the Aerospace Products reporting unit did not incur impairment charges, fair value exceeded carrying value by 21% in our 2024 testing. Aerospace’s long-term forecasts continue to reflect demand improvements as industry recovery continues.

Long-lived Asset Impairment

Late in the fourth quarter of 2023, we had a triggering event to review long-lived assets and test for impairment when certain of our Elite Comfort Solutions (ECS) and Kayfoam customers notified us of efforts to improve their financial position by moving their business to or exploring alternative suppliers, which adversely impacted our future cash flow forecast. In early January 2024, we conducted an evaluation and determined that our sales and earnings forecasts should be reduced, and, as a result, we performed a recoverability test for these asset groups. Because the forecasted undiscounted cash flows had fallen below the carrying value for these asset groups, we tested for impairment by comparing the estimated fair value of long-lived assets to their carrying values. This resulted in a non-cash pretax charge of $444 million for long-lived asset impairments (primarily customer relationships, technology, and trademark intangibles) in the Bedding Products segment during the fourth quarter of 2023. This impairment was unrelated to the 2024 Restructuring Plan.

In evaluating the potential for impairment of goodwill and other long-lived assets, we make assumptions and estimates regarding future operating performance, business trends, and market and economic performance, including future sales, operating margins, growth rates, and discount rates. If actual results or the long-term outlook of any of our reporting units materially differ from the assumptions and estimates used in the goodwill and other long-lived assets valuation calculations, we could incur future non-cash impairment charges, which could have a material negative impact on our earnings.

If we do not comply with the restrictive covenants in our credit facility, we may not be able to borrow in the commercial paper market or under our credit facility and our outstanding debt instruments may default, all of which would adversely impact our liquidity.

Our credit facility is a multi-currency facility maturing in September 2026, providing us the ability, from time to time, to borrow, repay, and re-borrow up to $1.2 billion, subject to certain restrictive covenants and customary conditions. The credit facility serves as back-up for our commercial paper borrowing. Capitalized terms used in this section but not defined herein have the meanings set forth in the Credit Agreement.

To provide additional borrowing capacity and financial flexibility, we amended our credit agreement in March 2024 to increase the Leverage Ratio from 3.50 to 1.00 to 4.00 to 1.00. After the amendment, our credit facility contains restrictive covenants which include (a) an amended Leverage Ratio requiring us to maintain, as of the last day of each fiscal quarter, or when we borrow under the credit facility (i) Consolidated Funded Indebtedness minus the lesser of: (A) Unrestricted Cash, or (B) $750 million to (ii) Consolidated EBITDA for the four consecutive trailing quarters, such ratio not being greater than 4.00 to 1.00 as of March 31, 2024 through June 30, 2025, and not greater than 3.50 to 1.00 beginning September 30, 2025 through maturity, provided however, subject to certain limitations, if we make a Material Acquisition in any fiscal quarter after June 30, 2025, at our election, the maximum Leverage Ratio shall be 4.00 to 1.00 for the fiscal quarter during which such Material Acquisition is consummated and the next three consecutive fiscal quarters; (b) a limitation of the amount of total secured obligations to 15% of our total consolidated assets; and (c) a limitation on our ability to sell, lease, transfer, or dispose of all or substantially all of our assets and the assets of our subsidiaries, taken as a whole (other than accounts receivable sold in a Permitted Securitization Transaction, products sold in the ordinary course of business and our ability to sell, lease, transfer, or dispose of any of our assets or the assets of one of our subsidiaries to us or one of our subsidiaries, as applicable) at any given point in time.

If our earnings are reduced, the covenants in the credit facility will continue to reduce our borrowing capacity, both under the credit facility or through commercial paper issuances. Depending on the degree of earnings reduction, our liquidity could be materially negatively impacted. This covenant may also restrict our current and future operations, including (i) our flexibility to plan for, or react to, changes in our businesses and industries; and (ii) our ability to use our cash flows, or obtain additional financing, for future working capital, capital expenditures, acquisitions, or other general corporate purposes. If we are not in compliance with the restrictive covenants in our credit facility, and are not able to negotiate more lenient terms, we may not be able to access the commercial paper market or borrow under the credit facility.

Also, if we fail to comply with the covenants specified in the credit facility, we may trigger an event of default, in which case the lenders would have the right to: (i) terminate their commitment to provide loans under the credit facility; and (ii) declare all borrowings outstanding, together with accrued and unpaid interest and fees, to be immediately due and payable. Additionally, our senior notes contain cross-default provisions which could make outstanding amounts under the senior notes immediately payable in the event of an acceleration of amounts due under the credit facility following a material uncured default. If debt under the credit facility or

senior notes were to be accelerated, we may not have sufficient cash to repay this debt, which would have an immediate material adverse effect on our business, results of operations, and financial condition.

We may not be able to realize deferred tax assets on our balance sheet, depending upon the amount and source of future taxable income.

Our ability to realize deferred tax assets on our balance sheet is dependent upon the amount and source of future taxable income. As discussed in Note O of the Consolidated Financial Statements, we had $148 million of deferred tax assets (net of a $21 million valuation allowance) as of December 31, 2024. It is possible the amount and source of our taxable income could materially change in the future. This change may impact our underlying assumptions on which valuation allowances are established and negatively affect future period earnings and balance sheets. As a result, we may not be able to realize deferred tax assets on our balance sheet. There can be no assurance that we will continue to pay cash dividends on our common stock.

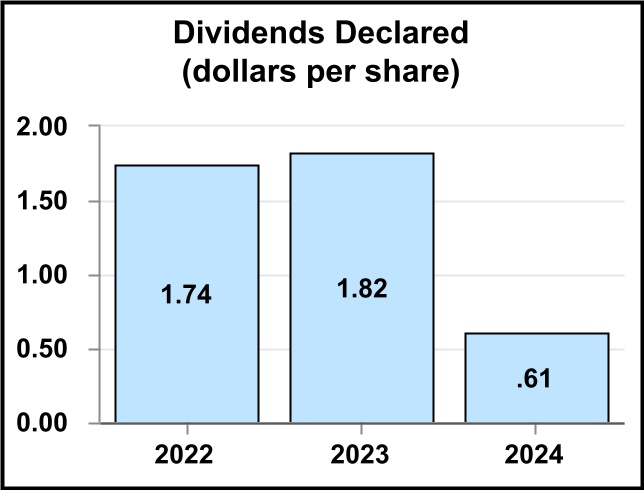

We recently reduced our quarterly cash dividend per share. Dividends on shares of common stock are declared at the discretion of the Board of Directors, which may decide to further reduce, suspend or terminate the dividend, based upon general economic conditions, our financial condition, operating results, cash flows, available cash and current and anticipated cash needs, capital requirements, strategic alternatives, compliance with contractual debt leverage ratios, and other factors.

Market Risk Factors

Costs of raw materials have negatively affected, and could continue to negatively affect, our profit margins and earnings.