Washington, D. C. 20549

LUFKIN INDUSTRIES, INC.

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See definitions of “large accelerated filer”, “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

The aggregate market value of the Company's voting stock held by non-affiliates as of the last business day of the Company’s most recently completed second fiscal quarter, June 30, 2010, was $1,168,182,314.

There were 30,423,702 shares of Common Stock, $1.00 par value per share, outstanding as of February 25, 2011.

The information called for by Items 10, 11, 12, 13 and 14 of Part III of this annual report on Form 10-K are incorporated by reference from the registrant’s definitive proxy statement for the 2011 Annual Meeting of Stockholders to be filed pursuant to Regulation 14A.

Lufkin Industries, Inc. (the “Company”) was incorporated under the laws of the State of Texas on March 4, 1902, and since that date has maintained its principal office and manufacturing facilities in Lufkin, Texas. The Company, a global supplier of oil field and power transmission products, is divided into two operating segments: Oil Field and Power Transmission.

On November 1, 2010 the Company completed the acquisition of the significant operating assets of Petro Hydraulic Lift Systems, LLC (“PHL”) and certain related companies, based in South Louisiana. PHL, specializes in the design, manufacture and leasing of hydraulic rod pumping units for oil and gas wells.

Financial information by industry segment and geographic area is incorporated herein by reference to Note 17 – “Business Segment Information” in the Notes to Consolidated Financial Statements set forth in Part II, Item 8 of this annual report on Form 10-K.

The Company employed approximately 3,000 people at December 31, 2010, including approximately 2,000 people that were paid on an hourly basis. Certain of the Company’s operations are subject to a union contract that expires in October 2011.

No customer represented over 10% of consolidated company sales as of December 31, 2010. An Oil Field customer and its related subsidiaries represented 11.0% and 15.4% of consolidated company sales in 2009 and 2008, respectively.

The Oil Field segment manufactures and services artificial lift products, including reciprocating rod lift, commonly referred to as pumping units, gas lift, plunger lift equipment and related products.

Oil Field purchases a variety of raw materials in manufacturing its products. The principal raw materials are structural and plate steel, round alloy steel and iron castings, which are purchased from both its own foundry and third-party foundries. Casting costs are subject to change, as a result of changes in raw material prices on scrap iron and pig iron in addition to changes in natural gas and electricity prices. Due to the many configurations of its products and thus sizes of raw material used, Oil Field does not enter into long-term contracts for raw materials but generally does not experience shortages of raw materials. During the period of 2008 through 2010, Oil Field did not experience any significant material shortages. During the first three quarters of 2008, raw material prices for steel and castings increased significantly but started declining in the fourth quarter of 2008 and through 2009. Raw material prices stayed relatively unchanged in 2010. As the global economy improves in 2011, raw material prices are expected to moderately increase. Raw material prices may continue to increase and availability may decrease with little notice.

The nature of the products manufactured and serviced by Oil Field generally requires skilled labor. Oil Field’s ability to increase capacity could be limited by its ability to hire and train qualified personnel. Also, the main U.S. manufacturing facilities are unionized, so any labor disruption could have a significant impact on Oil Field’s ability to maintain production levels. The current labor contract expires in October 2011.

Demand for artificial lift equipment primarily depends on the level of new onshore oil well and workover drilling activity as well as the depth and fluid conditions of that drilling. Drilling activity is driven by the available cash flow of the Company’s customers as well as their long-term perceptions of the level and stability of the price of oil. The higher energy prices experienced since 2004 have increased the demand for artificial lift equipment and related service and products from higher drilling activity, activation of idle wells and the upgrading of existing wells. During 2008, demand in the North American market increased significantly due to the impact of increased drilling in response to higher oil prices and recapturing certain market share from lower-priced imported equipment as customers reevaluated the total life - -cycle cost differences. In the fourth quarter of 2008, oil prices decreased significantly and stayed at reduced levels throughout 2009. As drilling activity reduced in response to lower oil prices, demand for artificial lift equipment and related service was also negatively impacted. Also, as raw material costs declined and surplus equipment increased, there was competitive pressure to lower selling prices. Lower selling prices combined with the negative impact of low capacity utilization in manufacturing facilities, caused gross margins to decline in 2009. Activity levels increased moderately during the second half of 2009 and early 2010. As the global economy began to recover in 2010 and oil prices and drilling activity rose, demand levels increased to near 2008 levels. This trend is expected to continue in 2011, with higher drilling activity and lower surplus equipment inventory driving demand for new artificial lift equipment. Longer-term, the demand for artificial lift equipment is also expected to con tinue to increase in international markets. While a majority of the segment’s revenues are in North America, international opportunities continue to increase as new drilling increases and existing fields mature, requiring increased use of artificial lift, especially in the South American, Russian and Middle Eastern markets.

The primary global competitor for artificial lift equipment is Weatherford International, but Chinese manufacturers of artificial lift equipment are also present in the market. Used pumping units are also an important factor in the North American market, as customers will generally attempt to satisfy requirements through used equipment before purchasing new equipment. While the Company believes that it is one of the larger manufacturers of artificial lift equipment in the world, manufacturers of other types of equipment like electric submersible pumps have a significant share of the total artificial lift market. While Weatherford International is the Company’s single largest competitor in the service market, small independent operators provide significant competitive pressures.

Because of the competitive nature of the business and the relative age of many of the product designs, price, delivery time, product quality and customer service are important factors in winning orders. To this end, the Company maintains strategic levels of inventories in order to ensure delivery times and invests in new capital equipment to maintain quality and price levels.

The Power Transmission segment designs, manufactures and services speed increasing and reducing gearboxes for industrial applications. Speed increasers convert lower speed and higher torque input to higher speed and lower torque output while speed reducers convert higher speed and lower torque input to lower speed and higher torque output. The Company produces numerous sizes and designs of gearboxes depending on the end use. While there are standard designs, the majority of gearboxes are customized for each application.

Power Transmission purchases a variety of raw materials in manufacturing its products. The principal raw materials are steel plate, round alloy steel, iron castings and steel forgings. Due to the customized nature of its products, Power Transmission generally does not enter into long-term contracts for raw materials. Though raw material shortages are infrequent, lead times can be long due to the custom nature of many of its orders. Raw material prices are not expected to decline significantly in the short-term and may continue to increase with little notice. Certain materials like steel round, steel plate, steel forgings and bearings have continued to experience price increases and longer lead times. Raw material and component part shortages are not expected in the short-term, but certain supplier lead-times have grown, especially bear ing suppliers.

The nature of the products manufactured and serviced by Power Transmission generally requires skilled labor. Power Transmission’s ability to increase capacity could be limited by its ability to hire and train qualified personnel. Also, the main U.S. manufacturing facilities are unionized, so any labor disruption could have a significant impact on Power Transmission’s ability to maintain production levels. The current labor contract expires in October 2011.

Power Transmission services many diverse markets, with high-speed gearing for markets such as petrochemicals, refineries, offshore production and transmission of oil and low-speed gearing for the gas, rubber, sugar, paper, steel, plastics, mining, cement and marine propulsion markets, each of which has its own unique set of drivers. Favorable conditions for one market may be unfavorable for another market. Generally, if general global industrial capacity utilizations are not high, spending on new equipment lags. Also impacting demand are government regulations involving safety and environmental issues that can require capital spending. Recent market demand increases have come from energy-related markets such as refining, petrochemical, drilling, coal, marine and power generation in response to higher global energy prices. RMT produc ts generally follow the market for high-speed gearboxes. During the latter part of 2008, energy prices decreased significantly, global growth slowed and large project financing became difficult to secure. New order booking declined in the first half of 2009, which negatively impacted sales starting in late 2009. Order levels increased in the first half of 2010 as energy markets recovered, translating into higher sales in the second half of 2010. The pace of bookings in 2011 is expected to remain at this higher level, which should translate in to overall higher sales in 2011 compared to 2010.

Despite the highly technical nature of the products in this segment, there are many competitors. While several North American competitors have de-emphasized the market, many European companies remain in the market. Competitors include Flender Graffenstaden, BHS, Renk, Rientjes, CMD, Philadelphia Gear and Horsburgh & Scott. While price is an important factor, proven designs, workmanship and engineering support are critical factors. Due to this, the Company outsources very little of the design and manufacturing processes.

The Company’s operations are subject to various federal, state and local laws and regulations, including those related to air emissions, wastewater discharges, the handling of solid and hazardous wastes and occupational safety and health. Environmental laws have, in recent years, become more stringent and have generally sought to impose greater liability on a larger number of potentially responsible parties. While the Company is not currently aware of any situation involving an environmental claim that would likely have a material adverse effect on its business, it is always possible that an environmental claim with respect to one or more of the Company’s current businesses or a business or property that one of our predecessors owned or used could arise that could have a material adverse effect. The Co mpany’s operations have incurred, and will continue to incur, capital and operating expenditures and other costs in complying with these laws and regulations in both the United States and abroad. However, the Company does not anticipate the future costs of environmental compliance will have a material adverse effect on its business, financial results or results of operations.

The Company makes available, free of charge, through the Company’s website, www.lufkin.com, its annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Exchange Act of 1934, as amended. Access to these electronic filings is available as soon as reasonably practicable after the Company files such material with, or furnishes it to, the Securities and Exchange Commission. You may also request printed copies of these documents free of charge by writing to the Company Secretary at P.O. Box 849, Lufkin, Texas 75902. Our reports filed with the SEC are also made available to read and copy at the SEC’s Public Reference Room at 100 F Street, N.E., Washington, D.C., 2 0549. You may obtain information about the Public Reference Room by contacting the SEC at 1-800-SEC-0330. Reports filed with or furnished to the SEC are also made available on the SEC’s website at www.sec.gov.

Item 1A. Risk Factors.

The risks described below are those which the Company believes are the material risks that it faces. Any of the risk factors described below could significantly and adversely affect its business, prospects, financial condition and results of operations.

A decline in domestic and worldwide oil and gas drilling activity would adversely affect the Company’s results of operations.

The Oil Field segment is materially dependent on the level of oil and gas drilling activity in North America and worldwide, which in turn depends on the level of capital spending by major, independent and state-owned exploration and production companies. This capital spending is driven by current prices for oil and gas and the perceived stability and sustainability of those prices. Oil and gas prices have been subject to significant fluctuation in recent years in response to changes in the supply and demand for oil and gas, market uncertainty, world events, governmental actions, and a variety of additional factors that are beyond the Company’s control, including:

Increases in the prices of our raw materials could adversely affect the Company’s margins and results of operations.

The Company uses large amounts of steel, iron and electricity in the manufacture of its products. The price of these raw materials has a significant impact on the cost of producing products. Steel and electricity prices have increased significantly in the last five years, caused primarily by higher energy prices and increased global demand. Since most of the Company’s suppliers are not currently parties to long-term contracts with us, the Company is vulnerable to fluctuations in prices of such raw materials. Factors such as supply and demand, freight costs and transportation availability, inventory levels of brokers and dealers, the level of imports and general economic conditions may affect the price of cast iron and steel. Raw material prices may increase significantly in the future.& #160; Certain items such as steel round, bearings and aluminum have continued to experience price increases, price volatility and longer lead times. If the Company is unable to pass future raw material price increases on to its customers, margins, results of operations, cash flow and financial condition could be adversely affected.

Interruption in the Company’s supply of raw materials could adversely affect its results of operations.

The Company relies on various suppliers to supply the components utilized to manufacture its products. The availability of the raw materials is not only a function of the availability of steel and iron, but also the alloy materials that are utilized by the Company’s suppliers. To date, these shortages have not caused a material disruption in availability or the Company’s manufacturing operations. However, material disruptions may occur in the future. Raw material shortages and allocations may result in inefficient operations and a build-up of inventory, which can negatively affect the Company’s working capital position. The loss of any of the Company’s suppliers or their inability to meet its price, quality, quantity and delivery requirements could have an adverse effe ct on the Company’s business and results of operations.

The inherent dangers and complexity of the Company’s products and services could subject it to substantial liability claims that may not be covered by insurance and that could adversely affect our results of operations.

The products that the Company manufactures and the services that it provides are complex, and the failure of this equipment to operate properly or to meet specifications may greatly increase customers’ costs. In addition, many of these products are used in inherently hazardous industries, such as the oil and gas drilling and production industry where an accident or product failure can cause personal injury or loss of life, damage to property, equipment, or the environment, regulatory investigations and penalties and the suspension of the end-user’s operations. If the Company’s products or services fail to meet specifications or are involved in accidents or failures, the Company could face warranty, contract, or other litigation claims for which it may be held responsible and its reputation for providing quality products may suffer.

The Company’s insurance may not be adequate in risk coverage or policy limits to cover all losses or liabilities that the Company may incur or for which the Company may be found responsible. Moreover, in the future, the Company may not be able to maintain insurance at levels of risk coverage or policy limits that it deems adequate or at premiums that it deems reasonable, particularly in the recent environment of significant insurance premium increases. Further, any claims made under the Company’s policies will likely cause its premiums to increase.

Any future damages deemed to be caused by the Company’s products or services that are assessed against it and that are not covered by insurance, or that are in excess of policy limits or subject to substantial deductibles, could have a material adverse effect on the Company’s results of operations and financial condition. Litigation and claims for which the Company is not insured can occur, including employee claims, intellectual property claims, breach of contract claims, and warranty claims.

The Company may not be able to successfully integrate future acquisitions, which will cause it to fail to realize expected returns.

The Company continually explores opportunities to acquire related businesses, some of which could be material to the Company. The ability to continue to grow, however, may depend upon identifying and successfully acquiring attractive companies, effectively integrating these companies, achieving cost efficiencies and managing these businesses as part of the Company. The Company may not be able to effectively integrate the acquired companies and successfully implement appropriate operational, financial and management systems and controls to achieve the benefits expected to result from these acquisitions. The Company’s efforts to integrate these businesses could be affected by a number of factors beyond its control, such as regulatory developments, general economic conditions and increased competition. � 60;In addition, the process of integrating these businesses could cause the interruption of, or loss of momentum in, the activities of the Company’s existing business. The diversion of management’s attention and any delays or difficulties encountered in connection with the integration of these businesses could negatively impact the Company’s business and results of operations. Further, the benefits that the Company anticipates from these acquisitions may not develop.

Labor dispute or the expiration of the Company’s current labor contract could have a material adverse effect on its business.

The Company’s main U.S. manufacturing facilities are unionized and the current labor contract with respect to those facilities expires in October 2011. The Company cannot assure that any disputes, work stoppages or strikes will not arise in the future. In addition, when the existing collective bargaining agreement expires, the Company cannot assure that it will be able to reach a new agreement with its employees or that any new agreement will be on substantially similar terms as the existing agreement. Future disputes with and labor concessions to the Company’s employees could have a material adverse effect upon its results of operations and financial position.

The inability to hire and retain qualified employees may hinder the Company’s growth.

The ability to provide high-quality products and services depends in part on the Company’s ability to hire and retain skilled personnel in the areas of management, product engineering, servicing and sales. Competition for such personnel is intense and competitors can be expected to attempt to hire the Company’s skilled employees from time to time. In particular, the Company’s business and results of operations could be materially adversely affected if it is unable to retain the customer relationships and technical expertise provided by the Company’s management team and professional personnel.

Significant competition in the industries in which the Company operates may result in its competitors offering new or better products and services or lower prices, which could result in a loss of customers and a decrease in revenues.

The industries in which the Company operates are highly competitive. The Company competes with other manufacturers and service providers of varying sizes, some of which may have greater financial and technological resources than it does. If the Company is unable to compete successfully with other manufacturers and service providers, it could lose customers and its revenues may decline. In addition, competitive pressures in the industry may affect the market prices of the Company’s new and used equipment, which, in turn, may adversely affect its sales margins, results of operations, cash flow and financial condition.

Disruption of the Company’s manufacturing operations or management information systems would have an adverse effect on its financial condition and results of operations.

While the Company owns numerous facilities domestically and internationally, its primary manufacturing facilities, located in and around Lufkin, Texas account for a significant percentage of its manufacturing output. An unexpected disruption in the Company’s production at these facilities or in its management information systems for any length of time would have an adverse effect on our business, financial condition and results of operations.

The Company has foreign operations that would be adversely impacted in the event of war, political disruption, civil disturbance, economic and legal sanctions and changes in global trade policies.

The Company has operations in certain international areas, including parts of the Middle East and South America, that are subject to risks of war, political disruption, civil disturbance, economic and legal sanctions (such as restrictions against countries that the U.S. government may deem to sponsor terrorism) and changes in global trade policies. The Company’s operations may be restricted or prohibited in any country in which these risks occur. In particular, the occurrence of any of these risks could result in the following events, which in turn, could materially and adversely impact the Company’s results of operations:

Results of operations could be adversely affected by actions under U.S. trade laws.

Although the Company is a U.S.-based manufacturing and services company, it owns and operates international manufacturing operations that support its U.S.-based business. If actions under U.S. trade laws were instituted that limited the Company’s access to these products, the Company’s ability to meet its customer specifications and delivery requirements would be reduced. Any adverse effects on the Company’s ability to import products from its foreign subsidiaries could have a material adverse effect on its results of operations.

The Company is subject to currency exchange rate risk, which could adversely affect its results of operations.

The Company is subject to currency exchange rate risk with intercompany debt denominated in U.S. dollars owed by its Canadian subsidiary. The Company cannot assure that future currency exchange rate fluctuations will not have an adverse affect on its results of operations.

The Company’s common stock has experienced, and may continue to experience, price volatility.

The trading price of the Company’s common stock has been and may continue to be subject to large fluctuations. The Company’s common stock price may increase or decrease in response to a number of events and factors, including:

Due to the recent financial and credit crisis, certain of the Company’s counterparties may be unable to meet their financial obligations to the Company or, alternatively, may be forced to postpone or otherwise cancel their contracts with the Company.

The recent credit crisis and the related turmoil in the global financial system have had an adverse impact on the Company’s business and financial condition and the business and financial condition of our counterparties. While the financial markets experienced improvement in 2010, the Company may face challenges if conditions in the financial markets do not continue to improve in 2011. The Company may be subject to increased counterparty risks whereby its counterparties may not be willing or able to meet their financial obligations to the Company or, alternatively, may be forced to postpone or otherwise cancel their contracts with the Company. To the extent a third-party is unable to meet its obligations to the Company, the earnings and results of operations of the Company could be negatively impacted in fut ure reporting periods. A sustained decline in the ability of the Company’s counterparties to meet their financial obligations to the Company would adversely affect its business, results of operations and financial condition.

Climate change legislation limiting and reducing greenhouse gas emissions through a “cap and trade” system of allowances and credits could result in increased operating costs and reduced demand for our products or services.

On June 26, 2009, the U.S. House of Representatives passed the American Clean Energy and Security Act of 2009, which would establish an economy-wide cap-and-trade program to reduce U.S. emissions of greenhouse gases, including carbon dioxide and methane. Although it is not possible at this time to predict if or when any future federal laws or implementing regulations addressing greenhouse gas emissions may be adopted, and such laws or regulations that may be adopted could require the Company to incur increased operating costs, could adversely impact customers’ operations or demand for customers’ products, or could adversely affect demand for the Company’s products or services.

An array of international climate change accords focused on limiting and reducing greenhouse gas emissions could result in increased operating costs and reduced demand for our products or services.

The Company services customers in numerous foreign countries. As such, we are subject not only to U.S. climate change legislation but may also be subject to certain international climate change accords. A variety of regulatory developments, proposals or requirements have been introduced and/or adopted in the international regions in which we operate that are focused on restricting the emission of carbon dioxide, methane and other greenhouse gases. Among these developments are the United Nations Framework Convention on Climate Change, also known as the “Kyoto Protocol, ” and the European Union Emissions Trading System (“EU ETS”), which was launched as an international “cap and trade” system on allowances for emitting greenhouse gases. These international regulatory developments may curtail production and demand for fossil fuels such as oil and gas in areas of the world where the Company and our customers operate and thus adversely affect future demand for the Company’s products and services, which may in turn adversely affect the Company’s future results of operations.

Climate change regulations restricting emissions of greenhouse gases could result in increased operating costs and reduced demand for our products or services.

On December 15, 2009, the U.S. Environmental Protection Agency (the “EPA”) officially published its findings that emissions of carbon dioxide, methane and other greenhouse gases present an endangerment to human health and the environment because emissions of such gases are, according to the EPA, contributing to warming of the Earth’s atmosphere and other climatic changes. These findings by the EPA allow the agency to proceed with the adoption and implementation of regulations that would restrict emissions of greenhouse gases under existing provisions of the federal Clean Air Act. In response to its endangerment findings, the EPA adopted regulations that require a reduction in emissions of greenhouse gases from motor vehicles. The EPA has asserted that the motor vehicle greenhouse gas emissions standards triggered the Clean Air Act construction and operating permit requirements for stationary sources, commencing when the motor vehicle standards took effect on January 2, 2011. The EPA also adopted rules which will lead to the imposition of greenhouse gas emission limitations in Clean Air Act permits for certain stationary sources. In addition, on September 22, 2009, the EPA issued a final rule requiring the reporting of greenhouse gas emissions from specified large greenhouse gas emission sources in the United States beginning in 2011 for emissions occurring in 2010. The adoption and implementation of any regulations imposing reporting obligations on, or limiting emissions of greenhouse gases from, our equipment and operations could require the Company to incur costs to reduce emissions of greenhouse gases associated with operations, could adversely impact customers’ operations or demand for customers’ products, or could adversely affect demand for the Company’s products or services.

Item 1B. Unresolved Staff Comments.

None

Item 2. Properties

The Company's major manufacturing facilities are located in and near Lufkin, Texas, are company-owned and include approximately 150 acres, a foundry, machine shops, structural shops, assembly shops and warehouses. The facilities by segment are:

| Oil Field: | |

| Pumping Unit Manufacturing | 240,000 sq. ft. |

| Foundry Operations | 687,000 sq. ft. |

| | |

| Power Transmission: | |

| New Unit Manufacturing | 458,000 sq. ft. |

| Repair Operations | 84,000 sq. ft. |

| | |

| Former Trailer Manufacturing | 388,000 sq. ft. |

| | |

| Corporate Facilities | 33,000 sq. ft. |

Through the acquisitions of ILS and RMT in 2009 and PHL in 2010, the Company added three leased manufacturing facilities:

| Lufkin ILS- Houston, TX | 50,000 sq. ft. |

| | |

| Lufkin RMT- Wellsville, NY | 23,500 sq. ft. |

Also, the Company has numerous service centers throughout the U.S. to support the Oil Field and Power Transmission segments. The majority of these locations are company-owned, with some leased. None of these leases qualify as capital leases.

Internationally, there are company-owned facilities for the production and servicing of pumping units and power transmission products. The facilities by segment are:

| Oil Field (Pumping unit manufacturing and repair): | |

| Nisku, Alberta, Canada | 66,000 sq. ft. |

| Comodoro Rivadia, Argentina | 125,000 sq. ft. |

| | |

| Power Transmission (New unit manufacturing and repair): | |

| Fougerolles, France | 377,000 sq. ft. |

Also, the Company has several international service centers to support the Oil Field segment. The majority of these locations are owned by the Company, with some leased. None of these leases qualify as capital leases.

Item 3. Legal Proceedings

On March 7, 1997, a class action complaint was filed against Lufkin Industries, Inc. (the “Company”) in the U.S. District Court for the Eastern District of Texas by an employee and a former employee of the Company who alleged race discrimination in employment. Certification hearings were conducted in Beaumont, Texas in February 1998 and in Lufkin, Texas in August 1998. In April 1999, the District Court issued a decision that certified a class for this case, which included all black employees employed by the Company from March 6, 1994, to the present. The case was administratively closed from 2001 to 2003 while the parties unsuccessfully attempted mediation. Trial for this case began in December 2003, and after the close of plaintiff’s evidence, the court adjourned and did not complete the trial until October 2004. Although plaintiff’s class certification encompassed a wide variety of employment practices, plaintiffs presented only disparate impact claims relating to discrimination in initial assignments and promotions at trial.

On January 13, 2005, the District Court entered its decision finding that the Company discriminated against African-American employees in initial assignments and promotions. The District Court also concluded that the discrimination resulted in a shortfall in income for those employees and ordered that the Company pay those employees back pay to remedy such shortfall, together with pre-judgment interest in the amount of 5%. On August 29, 2005, the District Court determined that the back pay award for the class of affected employees was $3.4 million (including interest to January 1, 2005) and provided a formula for attorney fees that the Company estimates will result in a total not to exceed $2.5 million. In addition to back pay with interest, the District Court (i) enjoined and ordered the Company to cease and desist all racially bia sed assignment and promotion practices and (ii) ordered the Company to pay court costs and expenses.

The Company reviewed this decision with its outside counsel and on September 19, 2005, appealed the decision to the U.S. Court of Appeals for the Fifth Circuit. On April 3, 2007, the Company appeared before the appellate court in New Orleans for oral argument in this case. The appellate court subsequently issued a decision on Friday, February 29, 2008 that reversed and vacated the plaintiff’s claim regarding the initial assignment of black employees into the Foundry Division. The court also denied plaintiff’s appeal for class certification of a class disparate treatment claim. Plaintiff’s claim on the issue of the Company’s promotional practices was affirmed but the back pay award was vacated and remanded for recomputation in accordance with the opinion. The District Court’s injunction was vacated and remanded with instructions to enter appropriate and specific injunctive relief. Finally , the issue of plaintiff’s attorney’s fees was remanded to the District Court for further consideration in accordance with prevailing authority.

On December 5, 2008, the U.S. District Court Judge Clark held a hearing in Beaumont, Texas during which he reviewed the 5th U.S. Circuit Court of Appeals class action decision and informed the parties that he intended to implement the decision in order to conclude this litigation. At the conclusion of the hearing Judge Clark ordered the parties to submit positions regarding the issues of attorney fees, a damage award and injunctive relief. Subsequently, the Company reviewed the plaintiff’s submissions which described the formula and underlying assumptions that supported their positions on attorney fees and damages. After careful review of the plaintiff’s submission to the court the Company continued to have significant differences regarding legal issues that materially impacted the plaintiff’s requests. As a result of these different results, the court requested further evidence from the parties regarding their positions in order to render a final decision. The judge reviewed both parties arguments regarding legal fees, and awarded the plaintiffs an interim fee, but at a reduced level from the plaintiffs original request. The Company and the plaintiffs reconciled the majority of the differences and the damage calculations which also lowered the originally requested amounts of the plaintiffs on those matters. Due to the resolution of certain legal proceedings on damages during first half of 2009 and the District Court awarding the plaintiffs an interim award of attorney fees and cost totaling $5.8 million, the Company recorded an additional provision of $5.0 million in the first half of 2009 above the $6.0 million recorded in fourth quarter of 2008. The plaintiffs filed an appeal of the District Court’s interim award of attorney fees with the U.S. Fifth Circuit Court of Appeals. The Fifth Circuit subsequently dismissed these appeals on August 28, 2009 on the basis that an appealable final judgment in this case had not been issued. The court commented that this issue can be reviewed with an appeal of final judgment.

On January 15, 2010, the U.S. District Court for the Eastern District of Texas notified the Company that it had entered a final judgment related to the Company’s ongoing class-action lawsuit. On January 15, 2010, the plaintiffs filed a notice of appeal with the U.S. Fifth Circuit Court of Appeals of the District Court’s final judgment. On January 21, 2010, the Company filed a notice of cross-appeal with the same court.

On January 15, 2010, in its final judgment, the Court ordered Lufkin Industries to pay the plaintiffs $3.3 million in damages, $2.2 million in pre-judgment interest and 0.41% interest for any post-judgment interest. The Company had previously estimated the total liability for damages and interest to be approximately $5.2 million. The Court also ordered the plaintiffs to submit a request for legal fees and expenses from January 1, 2009 through the date of the final judgment. The plaintiffs were required to submit this request within 14 days of the final judgment. On January 21, 2010, the Company filed a motion with the District Court to stay the payment of damages referenced in the District Court’s final judgment pending the outcome of the Fifth Circuit’s decision on both parties’ appeals. The District Court granted this motion to stay.

On January 29, 2010, the plaintiffs filed a motion with the U.S. District Court for the Eastern District of Texas for a supplemental award of $0.7 million for attorney’s fees, costs and expenses incurred between January 1, 2009 and January 15, 2010, as allowed in the final judgment. In the fourth quarter of 2009, the Company recorded a provision of $1.0 million for these legal expenses and accrual adjustments for the final judgment award of damages. On September 28, 2010, the District Court granted plaintiffs’ motion for supplemental attorney’s fees, costs and expenses in the amount of $0.7 million for the period of January 1, 2009 through January 15, 2010. In order to cover these cost, the Company recorded an additional provision of $1.0 million in September 2010 for anticipated costs through th e end of 2010.

On February 2, 2011 the United States Fifth Circuit Court of Appeals accepted the oral arguments from the plaintiffs and the Company on their respective appeals to the court. We anticipate the court’s decision before the end of the second quarter of 2011.

There are various other claims and legal proceedings arising in the ordinary course of business pending against or involving the Company wherein monetary damages are sought. For certain of these claims, the Company maintains insurance coverage while retaining a portion of the losses that occur through the use of deductibles and retention limits. Amounts in excess of the self-insured retention levels are fully insured to limits believed appropriate for the Company’s operations. Self-insurance accruals are based on claims filed and an estimate for claims incurred but not reported. While the Company does maintain insurance above its self-insured levels, a decline in the financial condition of its insurer, while not currently anticipated, could result in the Company recording additi onal liabilities. It is management’s opinion that the Company’s liability under such circumstances or involving any other non-insured claims or legal proceedings would not materially affect its consolidated financial position, results of operations, or cash flow.

Item 4. (Removed and Reserved)

PART II

Item 5. Market for Registrant's Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities

Common Stock Information

The Company's common stock is traded on the NASDAQ National Market under the symbol “LUFK.” As of January 31, 2011, there were approximately 379 record holders of the Company’s common stock. This number does not include any beneficial owners for whom shares of common stock may be held in “nominee” or “street” name. The following table sets forth, for each quarterly period during fiscal 2010 and 2009, the high and low sales price per share of the Company’s common stock and the dividends paid per share on the Company’s common stock.

| | | 2010 | | 2009 |

| | | Stock Price | | | Stock Price | |

| Quarter | | High | Low | Dividend | | High | Low | Dividend |

| | | | | | | | | |

| First | | $ 40.85 | $ 29.80 | $ 0.125 | | $ 20.63 | $ 13.48 | $ 0.125 |

| Second | | 45.10 | 35.13 | $ 0.125 | | 24.08 | 14.76 | $ 0.125 |

| Third | | 44.97 | 36.22 | $ 0.125 | | 26.91 | 18.19 | $ 0.125 |

| Fourth | | 63.50 | 42.63 | $ 0.125 | | 37.87 | 24.77 | $ 0.125 |

| | | | | | | | | |

The Company has paid cash dividends for 71 consecutive years. Total dividend payments were $15.0 million, $14.9 million and $14.8 million in 2010, 2009 and 2008, respectively.

Equity Compensation Plan Information

The following table sets forth securities of the Company authorized for issuance under equity compensation plans at December 31, 2010.

| Plan Category | Number of securities to be issued upon exercise of outstanding options, warrants and rights (a) | Weighted-average exercise price of outstanding options, warrants and rights (b) | Number of securities remaining available for future issuance under equity compensation plans (excluding securities reflected in column (a) |

| Equity compensation plans approved by security holders | 1,321,637 | | $ | 33.26 | | | | 1,135,936 | |

| | | | | | | | | | |

| Equity compensation plans not approved by security holders | - | | | - | | | | - | |

| | | | | | | | | | |

| Total | 1,321,637 | | $ | 33.26 | | | | 1,135,936 | |

300,000 shares were authorized for issuance pursuant to the 1996 Nonemployee Director Stock Option Plan and 3,800,000 shares were authorized for issuance pursuant to the Incentive Stock Compensation Plan 2000. Awards may be granted pursuant to the Incentive Stock Compensation Plan 2000 include options, restricted stock, performance awards, phantom shares, bonus shares and other stock-based awards.

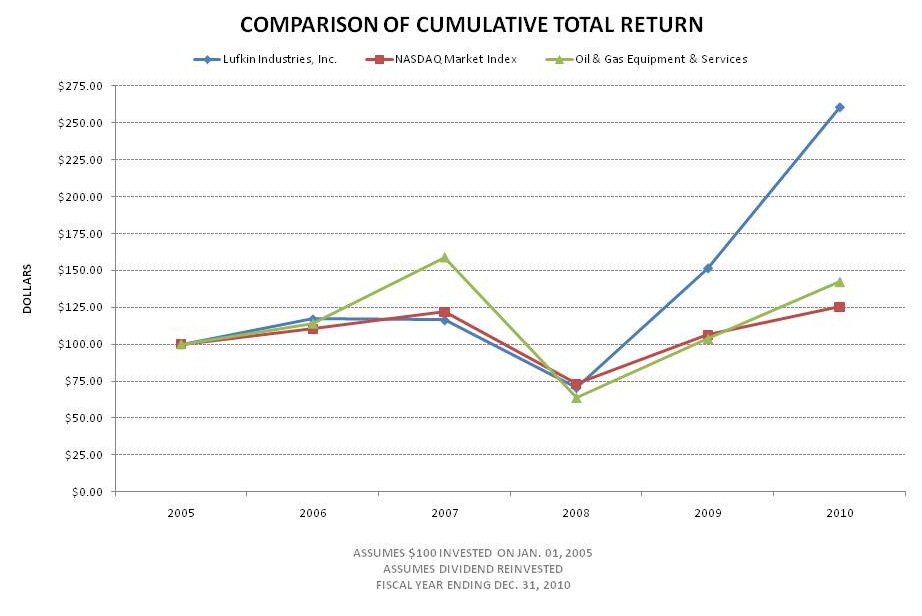

Performance Graph- Total Stockholder Return

The following is a line graph comparing the Company’s cumulative, five–year total shareholder return with that of a general market index (the NASDAQ Market Index) and a published industry index of oil and gas equipment/service providers (Hemscott Industry Group 124).

The graph shall not be deemed incorporated by reference by any general statement incorporating by reference this Form 10-K into any filing under the Securities Act of 1933, as amended, or the Securities Exchange Act of 1934, as amended, except to the extent that the Company specifically incorporates this information by reference, and shall not otherwise be deemed filed under such acts.

Item 6. Selected Financial Data

Five Year Summary of Selected Consolidated Financial Data

The following table sets forth certain selected historical consolidated financial data from continuing operations and should be read in conjunction with “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and the Consolidated Financial Statements and Notes thereto included elsewhere in this annual report on Form 10-K. The following information may not be indicative of future operating results.

| (In millions, except per share data) | | 2010 | | | 2009 | | | 2008 | | | 2007 | | | 2006 | |

| | | | | | | | | | | | | | | | |

| Sales | | $ | 645.6 | | | $ | 521.4 | | | $ | 741.2 | | | $ | 555.8 | | | $ | 526.1 | |

| | | | | | | | | | | | | | | | | | | | | |

| Earnings from continuing operations | | | 43.5 | | | | 22.5 | | | | 88.0 | | | | 71.8 | | | | 71.3 | |

| | | | | | | | | | | | | | | | | | | | | |

| Earnings per share from continuing operations: | | | | | | | | | | | | | | | | | | | | |

| Basic | | | 1.45 | | | | 0.76 | | | | 2.98 | | | | 2.41 | | | | 2.40 | |

| Diluted | | | 1.44 | | | | 0.76 | | | | 2.96 | | | | 2.38 | | | | 2.36 | |

| | | | | | | | | | | | | | | | | | | | | |

| Total assets | | | 621.1 | | | | 541.6 | | | | 530.7 | | | | 500.7 | | | | 409.1 | |

| | | | | | | | | | | | | | | | | | | | | |

| Cash dividends per share | | | 0.50 | | | | 0.50 | | | | 0.50 | | | | 0.44 | | | | 0.31 | |

| | | | | | | | | | | | | | | | | | | | | |

Item 7. Management's Discussion and Analysis of Financial Condition and Results of Operations

Overview

General

Lufkin Industries is a global supplier of oil field and power transmission products. Through its Oil Field segment, the Company manufactures and services artificial lift equipment and related products, which are used to extract crude oil and other fluids from wells. Through its Power Transmission segment, the Company manufactures and services high-speed and low-speed increasing and reducing gearboxes for industrial applications. While these markets are price-competitive, technological and quality differences can provide product differentiation.

The Company’s strategy is to differentiate its products through additional value-added capabilities. Examples of these capabilities are high-quality engineering, customized designs, rapid manufacturing response to demand through plant capacity, inventory and vertical integration, superior quality and customer service, and an international network of service locations. In addition, the Company’s strategy is to maintain a low debt-to-equity ratio in order to quickly take advantage of growth opportunities and pay dividends even during unfavorable business cycles.

In support of its strategy, the Company has made capital investments in the Oil Field segment to increase manufacturing capacity and capabilities in its two main manufacturing facilities in Lufkin, Texas and Argentina. These investments have reduced production lead times, improved quality and reduced manufacturing costs. Investments also continue to be made to expand the Company’s presence in automation products and international service. During the first quarter of 2009, the Company purchased International Lift Systems (“ILS”), which manufactures and services gas lift, plunger lift and completion equipment for the oil and gas industry and in November 2010 acquired the assets of Petro Hydraulic Lift Systems, which manufactured hydraulic pumping units. In July 2010, the Company announced its intention to construct a new multi-purpose manufacturing an d aftermarket facility in Ploiesti Romania to support market expansion efforts in the Eastern Hemisphere. This facility will manufacture products for both the Oil Field and Power Transmission segments, with an initial focus on oil field products. This facility, which is being built on an 82 acre site, will have an estimated aggregate gross cost of $126 million. When completed in 2012, the facility will initially employ just over 300 employees. The government of Romania, through the Ministry of Public Finance, has agreed to provide the Company with economic development incentives and financial assistance of 28 million Euros towards the construction costs, which accounts for approximately 30% of the total cost of the plant. The Company continues to look for investment opportunities to reduce manufacturing costs, expand geographically and add product offerings in the artificial lift space. On November 1, 2010 the Company completed the acquisition of the significant operating assets of Petr o Hydraulic Lift Systems, LLC (“PHL”) and certain related companies, based in South Louisiana. PHL, specializes in the design, manufacture and leasing of hydraulic rod pumping units for oil and gas wells.

In the Power Transmission segment, the Company continues to expand its gear repair network by opening and expanding facilities in various locations in the United States and Canada. The Company has made targeted capital investments in the United States and France to expand capacity, develop new product lines and reduce manufacturing lead times, in addition to certain capital investments targeting cost reductions. On July 1, 2009, the Company purchased Rotating Machinery Technology, Inc. (“RMT”), which specializes in the analysis, design and manufacture of precision, custom-engineered tilting-pad bearings and related components for high-speed turbo equipment operating in critical duty applications. RMT also services, repairs and upgrades turbo-expander process units for air and gas separation, both on-site with its skilled field service team and at its repair facility in Wellsville, New York. The Company intends to focus future capital investments for Oil Field and Power Transmission on international geographic expansion of manufacturing and service centers.

Trends/Outlook

Oil Field

Demand for the Company’s artificial lift equipment is primarily dependent on the level of new onshore oil wells, workover drilling activity, the depth and fluid conditions of such drilling activity and general field maintenance budgets. Drilling activity is driven by the available cash flow of the Company’s customers as well as their long-term perceptions of the level and stability of the price of oil. Increasing energy prices since 2004 increased the demand for pumping units and related service and products as a result of higher drilling activity, activation of idle wells and the upgrading of existing wells. In the fourth quarter of 2008, energy prices dramatically declined due to reductions in global demand. Planned new drilling and workover activity also reduced significantly as capital and operating budgets were reduced. These negative trends continue d into the first quarter of 2009, and worsened during the second quarter of 2009, as E&P companies deferred or cancelled drilling programs and reduced field spending in response to lower energy prices. This trend was more pronounced in North America than in international markets. Lower selling prices combined with the negative impact of low capacity utilization in manufacturing facilities caused gross margins to decline in 2009. In the second half of 2009, oil prices increased back to 2007 levels and drilling activity, especially for oil, increased.

During 2010, demand from North America increased steadily as the oil-directed rig count level surpassed 2008 levels. North America demand for artificial lift equipment has not increased as quickly as the oil-directed rig count due to fewer well completions per rig drilling due to the increased use of multi-stage horizontal frac technology, delays in completions due to unavailability of frac crews and improvements in drilling technology that extends the length of time wells remain free-flowing. Also, while order levels have continued to increase during 2010, the ability to raise prices remains a challenge. Most raw material prices have remained stable during 2010, but certain raw material associated with cast iron have recently increased. The Company expects 2011 demand to continue to increase over 2010 levels as these market issues are resolved and equipment sales st art to catch up to the prior oil-directed rig count increases.

While the oil market is cyclical, the Company continues to believe that there are long-term positive growth trends for artificial lift equipment, and as existing fields mature, the market will require an increased use of artificial lift, especially in the South American, European, Russian and Middle Eastern markets. For this reason, the Company announced its intentions to construct a new multi-purpose manufacturing and aftermarket facility in Romania to support these markets. The new facility will be operational in 2012 and will cost approximately $90 million net after Romanian government economic incentives. Additionally, the acquisitions of ILS and PHL were consistent with the Company’s long-term growth strategy of integrating strategic assets to leverage the Company’s position of industry leadership, providing an entry for Lufkin into the offshore mark et for artificial lift wells, including deepwater plays, and expanded reach into the artificial lift market.

Power Transmission

Power Transmission services many diverse markets, with high-speed gearing for markets such as petrochemicals, refineries, offshore production and transmission of oil and slow-speed gearing for the gas, rubber, sugar, paper, steel, plastics, mining, cement and marine propulsion markets, each of which has its own unique set of drivers. Generally, if global industrial capacity utilizations are not high, spending on new equipment lags. Also impacting demand are government regulations involving safety and environmental issues that can require capital spending. Recent market demand increases have come from energy-related markets such as refining, petrochemical, drilling, coal, marine and power generation in response to higher global energy prices. During the latter part of 2008, energy prices decreased significantly, global growth slowed and large project financing became difficult to secure. New order booking declined in the first half of 2009, which negatively impacted sales starting in late 2009. While sales remained at these lower levels throughout the first half of 2010, new order and quotation activity, especially from the energy markets, increased during 2010 over levels seen in 2009. The pace of bookings in 2011 is expected to remain at this higher level, which should translate in to overall higher sales in 2011 compared to 2010.

Discontinued Operations

During the second quarter of 2008, the Trailer segment was classified as a discontinued operation. In January 2008, the Company announced the decision to suspend its participation in the commercial trailer markets and to develop a plan to run-out existing inventories, fulfill contractual obligations and close all trailer facilities. During the second quarter of 2008, this plan was completed, with the majority of the remaining inventory and manufacturing equipment sold and all facilities closed.

Other

During 2010, 2009 and 2008, the Company booked pre-tax contingent liability provisions of $1.0 million, $6.0 million and $6.0 million, respectively, for its ongoing class-action lawsuit. For additional information, please see Part I, Item 3 “Legal Proceedings” of this annual report on Form 10-K.

Summary of Results

The Company generally monitors its performance through analysis of sales, gross margin (gross profit as a percentage of sales) and net earnings, as well as debt/equity levels, short-term debt levels, and cash balances.

Overall, sales for 2010 increased to $645.6 million from $521.4 million for 2009, or 23.8%. This increase in 2010 was primarily driven by higher sales of Oil Field products and services in the North American markets. In 2008, sales were $741.2 million.

Gross margin for 2010 increased to 24.6% from 21.6% for 2009, due primarily to the favorable impact of higher plant utilization on fixed cost coverage in the Oil Field segment. Gross margin in 2008 was 28.9%. Additional segment data on gross margin is provided later in this section.

Higher selling, general and administrative expenses negatively impacted net earnings, with these expenses increasing to $89.9 million during 2010 from $75.1 million during 2009 and $72.0 million during 2008. This increase in 2010 was primarily related to resources added from the ILS and RMT acquisitions, higher employee-related expenses in support of international expansion efforts and new product development. As a percentage of sales, selling, general and administrative expenses decreased to 13.9% during 2010 compared to 14.4% during 2009, but increased compared to 9.7% during 2008. Operating income was also impacted by a litigation reserve of $1.0 million during 2010, as compared to $6.0 million each during 2008 and 2009, related to its ongoing class-action lawsuit.

The Company reported net earnings from continuing operations of $43.5 million, or $1.44 per share (diluted), for 2010, compared to net earnings from continuing operations of $22.5 million, or $0.76 per share (diluted), for 2009, and net earnings from continuing operations of $88.0 million, or $2.96 per share (diluted), for 2008.

Debt/equity (long-term debt net of current portion as a percentage of total equity) levels were back to 0.0% as of December 31, 2010 from 0.3% as of December 31, 2009. Cash balances at December 31, 2010, were $88.6 million, down from $100.9 million at December 31, 2009.

Year Ended December 31, 2010 Compared to Year Ended December 31, 2009:

The following table summarizes the Company’s sales and gross profit by operating segment (in thousands of dollars):

| | | | | | | | | Increase/ | | | % Increase/ | |

| Year Ended December 31 | | 2010 | | | 2009 | | | (Decrease) | | | (Decrease) | |

| | | | | | | | | | | | | |

| Sales | | | | | | | | | | | | |

| Oil Field | | $ | 477,867 | | | $ | 349,168 | | | $ | 128,699 | | | | 36.9 | |

| Power Transmission | | | 167,776 | | | | 172,191 | | | | (4,415 | ) | | | (2.6 | ) |

| Total | | $ | 645,643 | | | $ | 521,359 | | | $ | 124,284 | | | | 23.8 | |

| | | | | | | | | | | | | | | | | |

| Gross Profit | | | | | | | | | | | | | | | | |

| Oil Field | | $ | 112,236 | | | $ | 65,510 | | | $ | 46,726 | | | | 71.3 | |

| Power Transmission | | | 46,282 | | | | 47,034 | | | | (752 | ) | | | (1.6 | ) |

| Total | | $ | 158,518 | | | $ | 112,544 | | | $ | 45,974 | | | | 40.8 | |

| | | | | | | | | | | | | | | | | |

Oil Field

Oil Field sales increased to $477.9 million, or by 36.9%, for the year ended December 31, 2010, from $349.2 million for the year ended December 31, 2009. New pumping unit sales of $254.4 million during 2010 were up $66.2 million, or 35.2%, compared to $188.2 million during 2009, primarily from higher U.S. demand. Pumping unit service sales of $104.1 million during 2010 were up $19.2 million, or 22.6%, compared to $84.9 million during 2009. Automation sales of $83.8 million during 2010 were up $32.4 million, or 62.9%, compared to $51.4 million during 2008. Commercial casting sales of $11.3 million during 2010 were up $1.9 million, or 20.4%, compared to $9.3 million during 2009. Sales from Lufkin ILS of $24.4 million during 2010 were up $9.1 million, or 62.9%, compared to $15.3 million in 2009, which represents 10 months of operations. Oil Field’s backl og increased to $131.4 million as of December 31, 2010, from $43.3 million at December 31, 2009. This increase was caused primarily by higher orders for new pumping units as U.S. and international customers increased production due to higher oil prices.

Gross margin (gross profit as a percentage of sales) for the Oil Field segment increased to 23.5% for year ended December 31, 2010, compared to 18.8% for the year ended December 31, 2009, or 4.7 percentage points. This gross margin increase was related to the positive impact of higher plant utilization on fixed cost coverage.

Direct selling, general and administrative expenses for Oil Field increased to $36.7 million, or by 37.4%, for the year ended December 31, 2010, from $26.7 million for the year ended December 31, 2009. This increase was due to higher employee-related and legal expenses. Direct selling, general and administrative expenses as a percentage of sales increased only 0.1% to 7.7% for the year ended December 31, 2010, from 7.6% for the year ended December 31, 2008.

Power Transmission

Sales for the Company’s Power Transmission segment decreased to $167.8 million, or by 2.6%, for the year ended December 31, 2010, compared to $172.2 million for the year ended December 31, 2009. New unit sales of $114.2 million during 2010 were down $17.6 million, or 13.3%, compared to $131.8 million during 2009. Repair and service sales of $48.8 million during 2010 were up $10.5 million, or 27.3%, compared to $38.4 million during 2009. Sales from Lufkin RMT increased to $4.7 million during 2010, up from $2.0 million during 2009. A portion of this increase is due to 2009 representing only 6 months of operations. Power Transmission backlog at December 31, 2010, increased to $101.6 million from $97.0 million at December 31, 2009, primarily from increased bookings of new units for the energy-related markets.

Gross margin for the Power Transmission segment increased to 27.6% for the year ended December 31, 2010, compared to 27.3% for the year ended December 31, 2009, or 0.3 percentage points. This gross margin increase was primarily from the favorable impact of higher production levels in manufacturing and repair on fixed cost coverage and an improved product mix.

Direct selling, general and administrative expenses for Power Transmission increased to $27.5 million, or by 17.0%, for the year ended December 31, 2010, compared to $23.5 million for the year ended December 31, 2009. Direct selling, general and administrative expenses as a percentage of sales increased to 16.4% for the year ended December 31, 2010, from 13.7% for the year ended December 31, 2009.

Corporate/Other

Corporate administrative expenses, which are allocated to the segments primarily based on budgeted sales levels, were $25.6 million for the year ended December 31, 2010, an increase of $0.7 million or 2.8%, from $24.9 million for the year ended December 31, 2009.

Interest income, interest expense and other income and expense for the year ended December 31, 2010, decreased to $.2 million of expense compared to $1.6 million of income for the year ended December 31, 2009, primarily from a decrease in gains of currency exchange and other interest from tax overpayments.

Pension expense, which is reported as a component of cost of sales, decreased to $7.9 million for the year ended December 31, 2010, compared to $10.7 million for the year ended December 31, 2009. This decrease in expense was primarily due to the impact of favorable demographic trends.

The net tax rate for the year ended December 31, 2010, was 35.5%, compared to 31.9% for the year ended December 31, 2009. The net tax rate in 2009 benefitted from adjustments to prior period tax filings in the U.S related to changes in tax laws.

Year Ended December 31, 2009 Compared to Year Ended December 31, 2008:

The following table summarizes the Company’s sales and gross profit by operating segment (in thousands of dollars):

| | | | | | | | | Increase/ | | | % Increase/ | |

| Year Ended December 31 | | 2009 | | | 2008 | | | (Decrease) | | | (Decrease) | |

| | | | | | | | | | | | | |

| Sales | | | | | | | | | | | | |

| Oil Field | | $ | 349,168 | | | $ | 551,814 | | | $ | (202,646 | ) | | | (36.7 | ) |

| Power Transmission | | | 172,191 | | | | 189,380 | | | | (17,189 | ) | | | (9.1 | ) |

| Total | | $ | 521,359 | | | $ | 741,194 | | | $ | (219,835 | ) | | | (29.7 | ) |

| | | | | | | | | | | | | | | | | |

| Gross Profit | | | | | | | | | | | | | | | | |

| Oil Field | | $ | 65,510 | | | $ | 153,673 | | | $ | (88,163 | ) | | | (57.4 | ) |

| Power Transmission | | | 47,034 | | | | 60,286 | | | | (13,252 | ) | | | (22.0 | ) |

| Adjustment* | | | - | | | | 115 | | | | (115 | ) | | | (100.0 | ) |

| Total | | $ | 112,544 | | | $ | 214,074 | | | $ | (101,530 | ) | | | (47.4 | ) |

| | | | | | | | | | | | | | | | | |

*Due to the discontinuation of the Trailer segment, certain items previously allocated to that segment in cost of sales have been reclassified to continuing operations. The adjustment is related to pension and postretirement charges associated with Trailer personnel that will continue to be a liability in future years.

Oil Field

Oil Field sales decreased to $349.2 million, or by 36.7%, for the year ended December 31, 2009, from $551.8 million for the year ended December 31, 2008. New pumping unit sales of $188.2 million during 2009 were down $153.9 million, or 45.0%, compared to $342.1 million during 2008, primarily from lower U.S. demand and pricing pressure. Pumping unit service sales of $84.9 million during 2009 were down $18.1 million, or 17.6%, compared to $103.0 million during 2008, from declines in the U.S. market. Automation sales of $51.4 million during 2009 were down $30.9 million, or 37.5%, compared to $82.4 million during 2008, from lower sales in the U.S and pricing pressure. Commercial casting sales of $9.3 million during 2009 were down $15.1 million, or 61.6%, compared to $24.4 million during 2008, from lower sales to the machine tool market. Sales from Lufkin ILS c ontributed $15.3 million during 2009. Oil Field’s backlog decreased to $43.3 million as of December 31, 2009, from $188.1 million at December 31, 2008. This decrease was caused primarily by lower orders for new pumping units as U.S. and international customers deferred or cancelled drilling programs in response to lower energy prices.

Gross margin (gross profit as a percentage of sales) for the Oil Field segment decreased to 18.8% for year ended December 31, 2009, compared to 27.8% for the year ended December 31, 2008, or 9.0 percentage points. This gross margin decrease was related to price reductions in response to material price decreases and lower customer demand and the negative impact of lower plant utilization on fixed cost coverage.

Direct selling, general and administrative expenses for Oil Field increased to $26.7 million, or by 18.2%, for the year ended December 31, 2009, from $22.6 million for the year ended December 31, 2008. The majority of this increase is related to higher international sales commissions as well as the resources added with the ILS acquisition. Direct selling, general and administrative expenses as a percentage of sales increased to 7.6% for the year ended December 31, 2009, from 4.1% for the year ended December 31, 2008.

Power Transmission

Sales for the Company’s Power Transmission segment decreased to $172.2 million, or by 9.1%, for the year ended December 31, 2009, compared to $189.4 million for the year ended December 31, 2008. New unit sales of $131.8 million during 2009 were down $13.1 million, or 9.0%, compared to $144.9 million during 2008. Repair and service sales of $38.4 million during 2009 were down $6.1 million, or 13.7%, compared to $44.5 million during 2008 as customers deferred spending on maintenance projects due to poor economic conditions. Sales from Lufkin RMT contributed $2.0 million during 2009. Power Transmission backlog at December 31, 2009, decreased to $97.0 million from $129.3 million at December 31, 2008, primarily from decreased bookings of new units for the energy-related and marine markets.

Gross margin for the Power Transmission segment decreased to 27.3% for the year ended December 31, 2009, compared to 31.8% for the year ended December 31, 2008, or 4.5 percentage points. This gross margin decrease was primarily from the unfavorable impact of lower production levels in manufacturing and repair on fixed cost coverage.

Direct selling, general and administrative expenses for Power Transmission remained at $23.5 million for the year ended December 31, 2009, compared to the year ended December 31, 2008. However, direct selling, general and administrative expenses as a percentage of sales increased to 13.7% for the year ended December 31, 2009, from 12.4% for the year ended December 31, 2008.

Corporate/Other

Corporate administrative expenses, which are allocated to the segments primarily based on budgeted sales levels, were $24.9 million for the year ended December 31, 2009, a decrease of $1.0 million or 4.0%, from $25.9 million for the year ended December 31, 2008.

Interest income, interest expense and other income and expense for the year ended December 31, 2009, increased to $1.6 million of income compared to $0.3 million of income for the year ended December 31, 2008, from currency gains offsetting reduced interest income and increased interest expense.

Pension expense, which is reported as an increase in cost of sales, increased to $10.7 million for the year ended December 31, 2009, compared to pension income of $1.3 million for the year ended December 31, 2008. This expense increase was primarily due to lower expected returns on asset balances and the amortization of previously deferred market losses out of other comprehensive income.

The net tax rate for the year ended December 31, 2009, was 31.9%, compared to 35.5% for the year ended December 31, 2008. The net tax rate in 2009 benefitted from adjustments to prior period tax filings in the U.S., the settlement of the 2006 IRS tax audit, revised 199 manufacturing deduction claims and R&E tax credit estimate adjustments.

Liquidity and Capital Resources

The Company has historically relied on cash flows from operations and third-party borrowings to finance its operations, including acquisitions, dividend payments and stock repurchases. The Company believes that its cash flows from operations and its available borrowing capacity under its credit agreements will be sufficient to fund its operations, including planned capital expenditures, dividend payments and stock repurchases, through December 31, 2011, and the foreseeable future.

The Company’s cash balance totaled $88.6 million at December 31, 2010, compared to $100.9 million at December 31, 2009. For the year ended December 31, 2010, net cash provided by operating activities was $59.5 million, net cash used in investing activities totaled $69.5 million and net cash used in financing activities amounted to $2.3 million. Significant components of cash provided by operating activities included net earnings from continuing operations, adjusted for non-cash expenses, of $75.0 million, partially offset by an increase in working capital of $15.5 million. This working capital increase was primarily due to an increase in trade receivables and inventory balances of $35.0 million and $5.0 million, respectively, due to increased sales volumes during 2010, partially offset by an increase in accounts payable and accrued liabilities of $27. 2 million. Net cash used in investing activities included net capital expenditures totaling $60.4 million and the ILS, RMT, and PHL acquisitions totaling $9.9 million. Capital expenditures in 2010 were primarily for new facilities to support geographical and product line expansions in the Oil Field and Power Transmission segments. Capital expenditures for 2011 are projected to increase over 2010 spending levels, primarily for the new Romanian manufacturing facility, other new manufacturing and service facilities to support geographical and product line expansions and equipment replacement for efficiency improvements in the Oil Field and Power Transmission segments and will be funded by operating cash flows. Significant components of net cash used by financing activities included dividend payments of $15.0 million, or $0.50, per share and debt repayments of $2.9 million. Proceeds from stock option exercises of $13.3 million partially offset financing cash outflows.

The Company has a three-year credit facility with a domestic bank (the “Bank Facility”) consisting of an unsecured revolving line of credit that provides up to $80.0 million of aggregate borrowing. This Bank Facility expires on December 31, 2013. Borrowings under the Bank Facility bear interest, at the Company’s option, at either the greater of (i) the prime rate, (ii) the base CD rate plus an applicable margin or (iii) the Federal Funds Effective Rate plus an applicable margin or the London Interbank Offered Rate plus an applicable margin, depending on certain ratios as defined in the Bank Facility. As of December 31, 2010, no debt was outstanding under the Bank Facility and the Company was in compliance with all financial covenants under the terms of the Bank Facility. Deducting outstanding letters of credit of $16.4 million, $63.6 million of borrowing capacity was available at December 31, 2010.

The following table summarizes the Company’s expected cash outflows from financial contracts and commitments as of December 31, 2010. Information on recurring purchases of materials for use in manufacturing and service operations has not been included. These amounts are not long-term in nature (less than six months) and are generally consistent from year to year.

| (In thousands of dollars) | | | | | Payments due by period | |

| | | | | | Less than | | | | 1 - 3 | | | | 3 - 5 | | | More than | |

| Contractual obligations | | Total | | | 1 year | | | years | | | years | | | 5 years | |

| | | | | | | | | | | | | | | | | | |

| Operating lease obligations | | $ | 10,885 | | | $ | 2,552 | | | $ | 2,575 | | | $ | 1,588 | | | $ | 4,170 | |

| Contractual commitments | | | | | | | | | | | | | | | | | | | | |

| for capital expenditures | | | 5,820 | | | | 5,820 | | | | - | | | | - | | | | - | |

| | | | | | | | | | | | | | | | | | | | | |

| Total | | $ | 16,705 | | | $ | 8,372 | | | $ | 2,575 | | | $ | 1,588 | | | $ | 4,170 | |

| | | | | | | | | | | | | | | | | | | | | |

Since the Company has no significant tax loss carryforwards, the Company expects to make quarterly estimated tax payments in 2011 based on taxable income levels. Also, the Company has various qualified retirement plans for which the Company has committed a certain level of benefit. The Company expects to make contributions to its pension plans of $6.4 million and to its post-retirement health and life plans of approximately $0.5 million in 2011. Contribution levels to these plans after 2011 will depend on participation in the plans, possible plan changes, discount rates and actual rates of return on plan assets.

As discussed in Note 17 – “Business Segment Information” in the Notes to Consolidated Financial Statements, set forth in Part II, Item 8 of this Form 10-K, the Consolidated Balance Sheet at December 31, 2010 includes approximately $1.8 million of liabilities associated with uncertain tax positions in the jurisdictions in which the Company conducts business. Due to the uncertain and complex application of tax regulations, combined with the difficulty in predicting when tax audits throughout the world may be concluded, Lufkin cannot make reliable estimates of the timing of cash outflows relating to these liabilities.

Off-Balance Sheet Arrangements

None.

Recently Issued Accounting Pronouncements

In September 2009, the Financial Accounting Standards Board (FASB) issued Accounting Standards Update (ASU) 2009-13, Revenue Recognition (Topic 605): Multiple – Deliverable Revenue Arrangements – a consensus of the FASB Emerging Issues Task Force, which changes the accounting for certain revenue arrangements. The new requirements change the allocation methods used in determining how to account for multiple payment streams and will result in the ability to separately account for more deliverables, and potentially less revenue deferrals. Additionally, ASU 2009-13 requires enhanced disclosures in financial statements. ASU 2009-13 is effective for revenue arrangements entered into or materially modified in fiscal years beginning after June 15, 2010 on a prospective basis, with early application permitted. The Company is currently evaluating the impact ASU 2009-13 will have on our financial statements.

Management believes the impact of other recently issued guidance, which is not yet effective, will not have a material impact on the Company's consolidated financial statements upon adoption.

Critical Accounting Policies and Estimates

The discussion and analysis of financial condition and results of operations are based upon the Company’s consolidated financial statements, which have been prepared in accordance with accounting principles generally accepted in the United States of America. The preparation of these financial statements requires the Company to make estimates and judgments that affect the reported amounts of assets, liabilities, revenues and expenses and related disclosure of contingent assets and liabilities. The Company evaluates its estimates on an ongoing basis, based on historical experience and on various other assumptions that are believed to be reasonable under the circumstances. Actual results may differ from these estimates under different assumptions or conditions. The Company believes the following critical accounting policies affect its more significant judgments an d estimates used in preparation of its consolidated statements.