UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10 – K

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the Fiscal Year Ended September 30, 2007

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

Commission File No. 0-3821

GENCOR INDUSTRIES, INC.

| | |

Incorporated in the State of Delaware | | I.R.S. Employer Identification No. 59-0933147 |

5201 North Orange Blossom Trail

Orlando, Florida 32810

Registrant’s Telephone Number, Including Area Code:

(407) 290-6000

SECURITIES REGISTERED PURSUANT TO SECTION 12(b) OF THE ACT:

None.

SECURITIES REGISTERED PURSUANT TO SECTION 12(g) OF THE ACT:

Common Stock ($.10 Par Value)

Indicate by check mark if the registrant is a well-known seasonal issuer, as defined in Rule 405 of the Securities Act ¨ Yes x No

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15 (d) of the Act ¨ Yes x No

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to filing requirements for the past 90 days. x Yes ¨ No

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer. See definition of “accelerated filer “and” large accelerated filer” in Rule 12b-2 of the Exchange Act (check one):

Large Accelerated Filer ¨ Accelerated Filer ¨ Non-Accelerated Filer x

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). ¨ Yes x No

The aggregate market value of the common equity held by non-affiliates computed by reference to the price at which the common equity was last sold as of the last business day of the most recently completed second fiscal quarter was $62,034,060.

Indicate the number of shares outstanding of each of the Registrant’s classes of Common Stock, as of the latest practicable date: 7,967,372 shares of Common Stock ($.10 par value) and 1,642,998 shares of Class B Stock ($.10 par value) as of November 27, 2007.

DOCUMENTS INCORPORATED BY REFERENCE

Part III of this Form 10-K is incorporated by reference from the Registrant’s 2008 Proxy Statement for the Annual Meeting of the Stockholders.

Introductory Note Caution Concerning Forward-Looking Statements

This Report on Form 10-K and our other communications and statements may contain “forward-looking statements,” including statements about our beliefs, plans, objectives, goals, expectations, estimates, projections and intentions. These statements are subject to significant risks and uncertainties and are subject to change based on various factors, many of which are beyond our control. The words “may,” “could,” “should,” “would,” “believe,” “anticipate,” “estimate,” “expect,” “intend,” “plan,” “target,” “goal,” and similar expressions are intended to identify forward-looking statements. All forward-looking statements, by their nature, are subject to risks and uncertainties. Our actual future results may differ materially from those set forth in our forward-looking statements. For information concerning these factors and related matters, see “Risk Factors” in Part I, Item 1A in this Report, and “Management’s Discussion and Analysis of Financial Condition and Results of Operations” in Part II, Item 7 in this Report. However, other factors besides those referenced could adversely affect our results, and you should not consider any such list of factors to be a complete set of all potential risks or uncertainties. Any forward-looking statements made by us herein speak as of the date of this Report. We do not undertake to update any forward-looking statement, except as required by law.

PART I

General

Gencor Industries, Inc. and its subsidiaries (the “Company”) is a leading manufacturer of heavy machinery used in the production of highway construction materials, synthetic fuels, and environmental control equipment. The Company’s products are manufactured in two facilities in the United States and one facility located in the United Kingdom. The Company’s products are sold through a combination of Company sales representatives and independent dealers and agents located throughout the world.

The Company designs and manufactures machinery and related equipment used primarily for the production of asphalt and highway construction materials. The Company’s principal core products include asphalt plants, combustion systems and fluid heat transfer systems. The Company’s technical and design capabilities, environmentally friendly process technology, and wide range of products have enabled it to become a leading producer of equipment worldwide. The Company believes it has the largest installed base of asphalt production plants in the United States.

Because the Company’s products are sold primarily to the highway construction industry, the business is seasonal in nature. The majority of orders for the Company’s products are received between October and February, with a significant volume of shipments occurring prior to May. The principal factors driving demand for the Company’s products are the level of government funding for domestic highway construction and repair, infrastructure development in emerging economies, the need for spare parts, and a trend towards larger plants resulting from industry consolidation.

In 1968, the foundation of the Company was formed by the merger of Mechtron Corporation with General Combustion, Inc. and Genco Manufacturing, Inc. The new entity reincorporated in Delaware in 1969 and adopted the name Mechtron International Corporation in 1970. In 1985, the Company began a series of acquisitions into related fields starting with the Beverley Group Ltd. in the United Kingdom. Hy-Way Heat Company, Inc. and the Bituma Group were acquired in 1986. In 1987, the Company changed its name to Gencor Industries, Inc. and acquired the Davis Line Inc. and its subsidiaries in 1988.

2

In January 1998, the Company finalized agreements with Carbontronics, LLC (“CLLC”) pursuant to which the Company sold, designed, manufactured, and installed four synthetic fuel production plants. These plants were subsequently sold by CLLC to a limited partnership (“LP”), Carbontronics Synfuels Investors, L.P., which is now the owner of the plants. The Company was paid in full for these plants in 1998. In addition to payment for the plants, per agreement, the Company received a member interest of 45% in CLLC. Future revenue to CLLC is based upon the production of these plants continuing to qualify for tax credits under Section 29 of the Internal Revenue Code, and the ability to economically produce and successfully market synthetic fuel produced by the plants. If the LP is successful in producing fuel which qualifies for tax credits, sells the synthetic fuel, sells the tax credits to investors, and has sufficient cash flow to cover all operating expenses, then the LP remits cash to CLLC as additional purchase price for the sale of the plants. CLLC generally distributes any cash receipts to its investors.

Also, the Company received a 25% partnership position in the General Partner (“GP”) of the LP and in Carbontronics II, LLC (“C2LLC”). C2LLC receives royalty payments from the LP only if the LP is successful in producing fuel which qualifies for tax credits, sells the synthetic fuel, sells the tax credits to investors, and has sufficient cash flow to cover all other operating expenses. The remaining interests in the GP, CLLC, and C2LLC are owned by other, unrelated entities. An administrative member of the GP, not the Company, is responsible for administration of the day-to-day affairs of the GP and LP. The Company is entitled to appoint only one of the three members of the GP Management Committee and has 1/3 of the voting rights thereof. As a part of the member positions in CLLC, C2LLC, and the GP, the Company has the potential for income subject to the performance of the LP. Future benefits realizable by the Company on the synthetic fuel production plants depend on whether the production from these plants will continue to qualify for tax credits under Section 29 of the Internal Revenue Code and the ability to economically produce and successfully market synthetic fuel produced by the plants.

3

On August 8, 2003, the Company was notified by its investee General Partner that the income tax returns for its synthetic fuel producing partnership were being audited. As previously reported the Limited Partners may declare a “Tax Event” and suspend further distributions indefinitely. The Company was informed that the Limited Partners had declared a “Tax Event” and therefore future distributions had ceased.

On December 12, 2003, the Company was notified by the General Partner that the IRS had issued rulings dated December 10, 2003 to the producing partnership concluding that, if the partnership adheres to the specified production methods and chemistry, the partnership would be entitled to the section 29 credit for the production of qualified fuel that is sold to unrelated persons.

Although the IRS advised us that it is satisfied with the chemical testing procedures, it nevertheless proceeded with a general IRS audit. Therefore the previously imposed Tax Event continued and the Limited Partners were not allowing revenue to be distributed to the Company until satisfactory conclusion of the audit.

On January 5, 2005, the Company was informed that the IRS had concluded its examination of the investees with no material adverse findings. As a result, distributions suspended since August 2003 resumed. The Company received $44.2 million during the fiscal year 2005. The Company recognized income of $14.5 million in 2006, for the distribution received less an accrual of $1 million for certain expenses associated with efforts by the Company as plaintiff in a matter against its synthetic fuels partners. The Company received $19.9 million of distributions in fiscal 2007. These distributions are subject to state and Federal income taxes.

Future distributions from these entities depend upon the production of these operations continuing to qualify for tax credits under Section 29 of the Internal Revenue Code and the ability to economically produce and market synthetic fuel produced by the plants. One of the contingencies related to future benefits from these entities is based on the average price of crude oil. Per a provision of Section 29, if the average price of crude oil reaches a certain level, the tax credits will terminate. The recent escalation in oil prices raises serious doubt on the continued availability of tax credits under Section 29 for the future. If oil prices remain at the current levels or increase, the tax credits could phase-out or terminate. Any one of the above eventualities may interrupt, reduce, or terminate further distributions.

On May 15, 2006, the Company received notification from the administrative partner of these investments that the limited partners gave notice that the plants should be “idled” until further notice. They indicated the operations will be curtailed until the earlier of: 1) a legislative change adjusting the determination of the phase-out price, or 2) a downward movement in oil prices signaling some improved expectation that the credit phase-out will still provide sufficient capital to support the continuation of operations. On October 6, 2006, the Company received notification that the synthetic fuel plants had resumed operation and on October 18, 2006, the Company received a cash distribution of $3.1 million.

The existing tax credit legislation is expiring at the end of calendar year 2007. Consequently, the four synthetic fuel plants are being decommissioned. The plants are in process of being sold or transferred to site owners in exchange for a release of all contracted liabilities related to the removal of plants from the sites. The administrative partner has informed the Company that there will be no operations in calendar 2008 and almost all of the partnership affairs will be finalized in early 2008. It is not possible to predict the amount, if any, of final distributions from the partnerships upon the final disposition and winding-up of operations.

Products

Asphalt Plants. The Company manufactures and produces hot-mix asphalt plants used in the production of asphalt paving materials. The Company also manufactures related asphalt plant equipment including hot mix storage silos, fabric filtration systems, cold feed bins and other plant components. The Company’s H&B (Hetherington and Berner) product line is the world’s oldest asphalt plant line, first manufactured in 1894. The Company’s subsidiaries, Bituma Corporation, formerly known as Boeing Construction Company, developed the continuous process for asphalt production, which has been adopted as the United States industry’s standard technology, as well as patented the counterflow technology, several adaptations of which have become the industry standard, which recaptures and burns emissions and vapors, resulting in a cleaner and more efficient process. The Company manufactures a very comprehensive range of fully mobile batch plants, as well as mobile shredders and trommel screens.

4

Combustion Systems and Industrial Incinerators. The Company manufactures combustion systems, which are large burners that can transform most solid, liquid or gaseous fuels into usable energy, or burn multiple fuels, alternately or simultaneously. Through its subsidiary General Combustion, the Company has been a significant source of combustion systems for the asphalt and aggregate drying industries since the 1950’s. The Company also manufactures soil decontamination machinery, as well as combustion systems for rotary dryers, kilns, fume and liquid incinerators, boilers and tank heaters. The Company believes maintenance and fuel costs are lower for its burners because of their superior design.

Fluid Heat Transfer Systems. The Company’s General Combustion subsidiaries in the USA and U.K. manufacture the Hy-Way heat and Beverley lines of thermal fluid heat transfer systems and specialty storage tanks for a wide array of industry uses. Thermal fluid heat transfer systems are similar to boilers, but use high temperature oil instead of water. Thermal fluid heaters have been replacing steam pressure boilers as the best method of heat transfer for storage, heating and pumping viscous materials (i.e., asphalt, chemicals, heavy oils, etc.) in many industrial and petrochemical applications worldwide. The Company believes the high efficiency design of its thermal fluid heaters can outperform competitive units in many types of process applications. Heaters are available for vertical, horizontal and underground tanks in steel, stainless steel, and other materials designed to meet large or small specific job requirements.

Product Engineering and Development

The Company is engaged in product engineering and development efforts to expand its product lines and to further develop more energy efficient and environmentally compatible systems.

Significant developments include the use of cost effective, non-fossil fuels, biomass (bagasse, municipal solid waste, sludge and wood waste), refuse-derived fuel, coal and coal mixtures, the economical recycling of old asphalt and new designs of environmentally compatible asphalt plants. Product engineering and development activities are directed toward more efficient methods of producing asphalt and lower cost fluid heat transfer systems. In addition, efforts are also focused on developing combustion systems that operate at higher temperatures and offer a higher level of environmental compatibility. The Company continues to evaluate opportunities in the energy field.

Sources of Supply and Manufacturing

Substantially all products sold by the Company and its subsidiaries are manufactured or assembled by the Company, except for procured raw materials and hardware. The Company purchases a large quantity of steel, raw materials and hardware used to manufacture its products from hundreds of suppliers and is not dependent on any single supplier. Periodically, the Company reviews the cost effectiveness of internal manufacturing versus outsourcing its product lines to independent third parties and currently believes it has the internal capability to produce the highest quality product at the lowest cost. This, however, may change from time to time.

5

Seasonality

The Company is concentrated in the asphalt-related business and subject to a seasonal slow-down during the third and fourth quarters of the calendar year. Traditionally, the Company’s customers do not purchase new equipment for shipment during the summer and fall months to avoid disrupting their peak season for highway construction and repair work. This slow-down often results in lower reported sales and earnings and/or losses during the first and fourth quarters of the Company’s fiscal year.

Competition

The markets for the Company’s products are highly competitive. Within a given product line, the industry remains fairly concentrated, with typically a small number of companies competing for the majority of a product line’s industry sales. The principal competitive factors include technology and overall product design, dependability and reliability of performance, brand recognition, pricing and after-the-sale customer support. Management believes its ability to compete depends upon its continual efforts to improve product performance and dependability, competitively price its products, and provide the best customer support and service in the industry.

Sales and Marketing

The Company’s products and services have been marketed internationally through a combination of Company-employed sales representatives and independent dealers and agents.

Sales Backlog

The Company’s manufacturing processes allow for a relatively short turnaround from the order date to shipment date of usually less than ninety (90) days. Therefore, the size of the Company’s backlog should not be viewed as an indicator of the Company’s annualized revenues or future financial results. The Company’s backlog was approximately $29 million and $28 million as of December 1, 2007 and December 1, 2006, respectively.

Financial Information about Geographic Areas

The Company has operations outside of the United States in the United Kingdom. For a geographic breakdown of revenues see the table captioned Reporting Segments in Note 1 in our consolidated financial statements in Item 8 below.

Licenses, Patents and Trademarks

The Company holds numerous patents covering technology and applications related to various products, equipment and systems, and numerous trademarks and trade names registered with the U.S. Patent and Trademark Office and in various foreign countries. In general, the Company depends upon technological capabilities, manufacturing quality control and application know-how, rather than patents or other proprietary rights in the conduct of its business. The Company believes the expiration of any one of these patents, or a group of related patents, would not have a material adverse effect on the overall operations of the Company.

6

Government Regulations

The Company believes its design and manufacturing processes meet all industry and governmental agency standards that may apply to its entire line of products, including all domestic and foreign environmental, structural, electrical and safety codes. The Company’s products are designed and manufactured to comply with Environmental Protection Agency regulations. Certain state and local regulatory authorities have strong environmental impact regulations. While the Company believes that such regulations have helped, rather than restricted its marketing efforts and sales results, there is no assurance that changes to federal, state, local, or foreign laws and regulations will not have a material adverse effect on the Company’s products and earnings in the future.

Environmental Matters

The Company is subject to various federal, state, local and foreign laws and regulations relating to the protection of the environment. The Company believes it is in material compliance with all applicable environmental laws and regulations. The Company does not expect any material impact on future operating costs as a result of compliance with currently enacted environmental regulations.

The Company has conducted environmental assessments consistent with recognized standards of due diligence on properties and businesses which it acquired. These assessments had not identified contamination resulting from acquired properties that would be reasonably likely to result in a material adverse effect on the Company’s business, results of operations, or financial condition.

Employees

As of September 30, 2007, the Company employed a total of 434 employees; there were 421 employees in the domestic U.S. operations and 13 employees in the U.K. operations. The Company has collective bargaining agreements covering production and maintenance employees at its Marquette, Iowa facilities. The remaining domestic employees are not represented by a labor union or collective bargaining agreement. The Company believes that its relationship with its employees is good.

The following risk factors and other information included in this Annual Report on Form 10-K should be carefully considered. The risks and uncertainties described below are not the only ones we face. Additional risks and uncertainties not presently known to us or that we presently deem less significant may also impair our business operations. If any of the following risks actually occur, our business operating results and financial condition could be materially adversely affected.

Our business is affected by the cyclical nature of the markets served by us. The demand for our products and service is dependent on general economic conditions and more specifically, the commercial construction industry. Adverse economic conditions may cause customers to forego or delay new purchases and rely more on repairing existing equipment thus negatively impacting our sales and profits. Rising gas and oil prices, increasing steel prices, and shortage of qualified workers can have adverse effects on us.

Our business is affected by the level of government funding for highway construction. In 2005, the Federal Government passed the SAFETEA-LU bill. This bill appropriated a multi-year guaranteed funding for federal highway, transit and safety programs. Many of our customers depend on funding by Federal and state agencies. Future legislation may increase or decrease government spending, which if decreased, could have a negative affect on our financial condition or results of operations.

Income from our investment in synthetic fuel partnerships is affected by the level of oil prices. The tax credits provided for the synthetic fuel industry under Section 29 of the Internal Revenue Code could phase-out or terminate if oil prices exceed certain levels. Other contingencies affecting the income from these investments include the ability to economically produce and successfully market synthetic fuel produced by these partnerships.

7

We face risks associated with our international business.We operate manufacturing and sales offices principally located in the United States and the United Kingdom. As a result, we are subject to business risks inherent in non-U.S. activities, including difficulty in staffing and managing foreign subsidiary operations, difficulty in managing distributors and dealers, adverse tax consequences, political and economic uncertainty and difficulty in accounts receivable collection. We are subject to the risks associated with the imposition of protective legislation and regulations, including those relating to import or export or otherwise resulting from trade or foreign policy. We cannot predict whether quotas, duties, taxes or other charges or restrictions will be implemented by the U.S. or any other country upon the import or export of our products. There can be no assurance that any of these factors, or the adoption of restrictive policies, will not have a material adverse effect on our business, financial condition and results of operations. In addition, we face market risk related to changes in interest rates and foreign currency exchange rates. Our principal currency exposure against the U.S. dollar is the British pound. Our foreign currency exposures generally are not hedged and there can be no assurance that our future results of operations and investments will not be adversely affected by currency fluctuations. Periodically, we use derivative financial instruments consisting primarily of interest rate hedge agreements to manage exposures to interest rate changes. If we have not adequately managed our exposure to fluctuating interest rates, our earnings and cash flow could be adversely affected.

We may encounter difficulties with future acquisitions. As part of our growth strategy, we intend to evaluate the acquisitions of other companies, assets or product lines that would complement or expand our existing businesses or broaden our customer relationships. Although we conduct due diligence reviews of potential acquisition candidates, we may not be able to identify all material liabilities or risks related to potential acquisition candidates. There can be no assurance that we will be able to locate and acquire any business, retain key personnel and customers of an acquired business or integrate any acquired business successfully. Additionally, there can be no assurance that financing for any acquisition, if necessary, will be available on acceptable terms, if at all, or that we will be able to accomplish our strategic objectives in connection with any acquisition. Although we periodically consider possible acquisitions, no specific acquisitions are probable as of the date of this Report on Form 10-K.

We could be harmed if we violate financial covenants contained in our credit facility. Our Revolving Credit and Security Agreement with PNC Bank, N.A., dated August 1, 2003, and amended July 31, 2006, imposes certain financial and operating covenants upon us, including, among others, restrictions on our ability to incur debt, or take certain other corporate actions. In addition, the credit facility requires that we maintain certain financial ratios and provides for limitations on capital expenditures. The foregoing covenants may restrict our ability to obtain additional funds, dispose of assets, or otherwise pursue our business strategies, and may impair our ability to obtain additional financing to fund future working capital requirements, capital expenditures, acquisitions and other general corporate purposes. Changes in economic or business conditions, results of operations or other factors could in the future cause a violation of one or more covenants in the credit facility, which could have a negative impact on our financial condition or results of operations.

Demand for our products is cyclical in nature. Orders for our products slow down during the summer and fall months since our customers generally do not purchase new equipment for shipment in their peak season for highway construction and repair work. In addition, demand for our products depends in part upon the level of capital and maintenance expenditures by the highway construction industry. The highway construction industry historically has been cyclical in nature and vulnerable to general downturns in the economy. Decreases in industry spending could have a material adverse effect upon demand for our products and negatively impact our business, financial condition and results of operations.

Our Marketable Securities are comprised of stocks and bonds invested through a professional investment advisor and are subject to various risks such as interest rates, markets, and credit. Due to the level of risk associated with certain investment securities and the level of uncertainty related to changes in the value of securities, changes in these risk factors could have a material adverse impact on our results of operations.

8

There are and will continue to be quarterly fluctuations of our operating results. Our operating results historically have fluctuated from quarter to quarter as a result of a number of factors, including the value, timing and shipment of individual orders and the mix of products sold. Revenues from certain large contracts are recognized using the percentage of completion method of accounting. We recognize product revenues upon shipment for the rest of our products. Our asphalt production equipment operations are subject to seasonal fluctuation, which may lower sales and result in possible losses in the first and fourth fiscal quarters of each year. Traditionally, asphalt producers do not purchase new equipment for shipment during the summer and fall months to avoid disruption of their activities during peak periods of highway construction.

If we are unable to attract and retain key personnel, our business could be adversely affected. The success of our business will continue to depend substantially upon the efforts, abilities and services of our management team and certain other key employees. The loss of one or more key employees could adversely affect our operations. Our ability to attract and retain qualified personnel, either through direct hiring, or acquisition of other businesses employing such persons, will also be an important factor in determining our future success.

We may be required to defend our intellectual property against infringement or against infringement claims of others. We hold numerous patents covering technology and applications related to various products, equipment and systems, and numerous trademarks and trade names registered with the U.S. Patent and Trademark Office and in various foreign countries. There can be no assurance as to the breadth or degree of protection that existing or future patents or trademarks may afford us, or that any pending patent or trademark applications will result in issued patents or trademarks, or that our patents, registered trademarks or patent applications, if any, will be upheld if challenged, or that competitors will not develop similar or superior methods or products outside the protection of any patents issued, licensed or sublicensed to us. Although we believe that none of our patents, technologies, products or trademarks infringe upon the patents, technologies, products or trademarks of others, it is possible that our existing patent, trademark or other rights may not be valid or that infringement of existing or future patents, trademarks or proprietary rights may occur. In the event that our products are deemed to infringe upon the patent or proprietary rights of others, we could be required to modify the design of our products, change the name of our products or obtain a license for the use of certain technologies incorporated into our products. There can be no assurance that we would be able to do any of the foregoing in a timely manner, upon acceptable terms and conditions, or at all, and the failure to do so could have a material adverse effect on us. In addition, there can be no assurance that we will have the financial or other resources necessary to enforce or defend a patent, registered trademark or other proprietary right, and, if our products are deemed to infringe upon the patents, trademarks or other proprietary rights of others, we could become liable for damages, which could also have a material adverse effect on us.

We may be subject to substantial liability for the products we produce. We are engaged in a business that could expose us to possible liability claims for personal injury or property damage due to alleged design or manufacturing defects in our products. We believe that we meet existing professional specification standards recognized or required in the industries in which we operate, and we have had no material product liability claims brought against us as of the date hereof. Although we currently maintain product liability coverage which we believe is adequate for the continued operation of our business, such insurance may prove inadequate or become difficult to obtain or unobtainable in the future on terms acceptable to us.

We are subject to extensive environmental laws and regulations, and our costs related to compliance with, or our failure to comply with, existing or future laws and regulations, could adversely affect our business and results of operations. Our operations are subject to federal, state, local and foreign laws and regulations relating to the protection of the environment. Sanctions for noncompliance may include revocation of permits, corrective action orders, administrative or civil penalties and criminal prosecution. Our business involves environmental management and issues typically associated with historical manufacturing operations. To date, our cost of complying with environmental laws and regulations has not been material, but the fact that such laws or regulations are changed frequently makes predicting the cost or impact of such laws and regulations on our future operations uncertain.

9

The loss of one or more of our raw materials supplies could cause production delays, a reduction of revenues or an increase in costs. The principal raw materials we use are steel and related products. We have no long-term supply agreements with any of our major suppliers. However, we have generally been able to obtain sufficient supplies of raw materials for our operations, and changes in prices of such materials historically have not had a significant affect on our operations. Although we believe that such raw materials are readily available from alternate sources, an interruption in our supply of steel and related products or a substantial increase in the price of any of these raw materials could have a material adverse effect on our business, financial condition and results of operations.

We are subject to significant government regulations. We are subject to a variety of governmental regulations relating to the manufacturing of our products. Any failure by us to comply with present or future regulations could subject us to future liabilities, or the suspension of production that could have a material adverse effect on our results of operations. Such regulations could also restrict our ability to expand our facilities, or could require us to acquire costly equipment or to incur other expenses to comply with such regulations. Although we believe we have the design and manufacturing capability to meet all industry or governmental agency standards that may apply to our product lines, including all domestic and foreign environmental, structural, electrical and safety codes, there can be no assurance that governmental laws and regulations will not become more stringent over time, imposing greater compliance costs and increasing risks and penalties associated with a violation. The cost to us of such compliance to date has not materially affected our business, financial condition or results of operations. There can be no assurance, however, that violations will not occur in the future as a result of human error, equipment failure or other causes. Our customers are also subject to extensive regulations, including those related to the workplace. We cannot predict the nature, scope or effect of governmental legislation, or regulatory requirements that could be imposed or how existing or future laws or regulations will be administered, or interpreted. Compliance with more stringent laws or regulations, as well as more vigorous enforcement policies of regulatory agencies, could require substantial expenditures by us and could adversely affect our business, financial condition and results of operations.

Our management has effective voting control. Our officers and directors beneficially own an aggregate of approximately 88.2% of the outstanding shares of our $.10 par value Class B stock. The Class B stock is entitled to elect 75% (calculated to the nearest whole number, rounding five-tenths to next highest whole number) of the members of our board of directors. Further, approval of a majority of the Class B stock is generally required to effect a sale of us and certain other corporate transactions. As a result, these stockholders can elect more than a majority of the board of directors and exercise significant influence over most matters requiring approval by our stockholders. This concentration of control may also have the effect of delaying or preventing a change in control.

The issuance of preferred stock may impede a change of control or may be dilutive to existing stockholders. Our Certificate of Incorporation, as amended, authorizes our Board of Director, without stockholder vote, to issue up to 300,000 shares of preferred stock in one or more series and to determine for any series the dividend, liquidation, conversion, voting or other preferences, rights and terms that are senior, and not available, to the holders of our common stock. Thus, issuances of series of preferred stock could adversely affect the relative voting power, distributions and other rights of the common stock. The issuance of preferred stock could deter or impede a merger, tender offer or other transaction that some, or a majority, of our common stockholders might believe to be in their best interest or in which our common stockholders might receive a premium for their shares over the then current market price of such shares.

We may be required to indemnify our directors and executive officers. We have authority under Section 145 of the Delaware General Corporation Law to indemnify our directors and officers to the extent provided in that statute. Our Certificate of Incorporation, as amended, provides that a director shall not be personally liable to us for breach of fiduciary duty as a director, except to the extent such exemption from liability or limitation thereof is not permitted under the Delaware General Corporation Law. Our Bylaws provide in part that we indemnify each of our directors and officers against liabilities imposed upon them (including reasonable amounts paid in settlement) and expenses incurred by them in connection with any claim made against them or any action, suit or proceeding to which they may be a party by reason of their being or having been a director or officer. We maintain officer’s and director’s liability insurance coverage. There can be no assurance that such insurance will

10

be available in the future, or that if available, it will be available on terms that are acceptable to us. Furthermore, there can be no assurance that the insurance coverage provided will be sufficient to cover the amount of any judgment awarded against an officer or director (either individually or in the aggregate). Consequently, if such judgment exceeds the coverage under the policy, we may be forced to pay such difference.

We enter into indemnification agreements with each of our executive officers and directors containing provisions that may require us, among other things, to indemnify them against certain liabilities that may arise by reason of their status or service as officers or directors (other than liabilities arising from willful misconduct of a culpable nature) and to advance their expenses incurred as a result of any proceeding against them as to which they could be indemnified. Management believes that such indemnification provisions and agreements are necessary to attract and retain qualified persons as directors and executive officers.

We do not expect to pay dividends for the foreseeable future.For the foreseeable future, we intend to retain any earnings to finance our business requirements, and we do not anticipate paying any cash dividends on our common stock or Class B stock. Any future determination to pay dividends will be at the discretion of our Board of Directors and will be dependent upon then existing conditions, including our financial condition and results of operations, capital requirements, contractual restrictions, business prospects, and other factors that the Board of Directors considers relevant.

| ITEM 1B. | UNRESOLVED STAFF COMMENTS |

None.

The following table lists the properties owned or leased by the Company as of September 30, 2007:

| | | | | | |

Location | | Owned

Acreage | | Building

Square

Footage | | Principal Function |

Billingshurst, West Sussex England | | 1.2 | | 5,000 | | Offices |

Marquette, Iowa (1 ) | | 72.0 | | 137,000 | | Offices and manufacturing |

Orlando, Florida (1) | | 27.0 | | 171,000 | | Corporate offices and manufacturing |

| (1) | These properties are owned and pledged as security under the Company’s credit agreement. |

See Note 3 to our consolidated financial statements in Item 8 below for more information about our properties.

The Company has various litigation and claims pending as of the date of this Form 10-K which have occurred in the ordinary course of business, and which may be covered in whole or in part by insurance. Management has reviewed all litigation matters arising in the ordinary course of business and, upon advice of counsel, has made provisions, not deemed material, for any estimable losses and expenses of litigation.

11

| ITEM 4. | SUBMISSION OF MATTERS TO A VOTE OF SECURITY HOLDERS |

There were no matters submitted during the fourth quarter of this fiscal year to a vote of security holders.

12

PART II

| ITEM 5. | MARKET FOR THE REGISTRANT’S COMMON EQUITY AND RELATED SHAREHOLDER MATTERS |

The Company’s stock is traded over the counter on the Pink Sheets and the OTC Electronic Bulletin Board under the symbol “GNCI.OB”. Following are the high and low per share bid prices for our common stock for the periods indicated:

| | | | | | |

| | | HIGH | | LOW |

2007 | | | | | | |

| | |

First Quarter | | $ | 12.85 | | $ | 9.20 |

| | |

Second Quarter | | $ | 12.25 | | $ | 9.00 |

| | |

Third Quarter | | $ | 11.00 | | $ | 9.00 |

| | |

Fourth Quarter | | $ | 10.25 | | $ | 9.00 |

| | |

2006 | | | | | | |

| | |

First Quarter | | $ | 8.25 | | $ | 6.20 |

| | |

Second Quarter | | $ | 10.00 | | $ | 7.30 |

| | |

Third Quarter | | $ | 9.95 | | $ | 9.05 |

| | |

Fourth Quarter | | $ | 9.50 | | $ | 9.10 |

As of November 27, 2007, there were 325 holders of Common Stock of record and seven holders of Class B Stock of record.

Dividend Policy

The Company has not paid any dividends during the last two fiscal years and there is no intention to pay cash dividends in the foreseeable future.

13

EQUITY COMPENSATION PLAN

In the following table is information about our common stock that may be issued upon exercise of options, warrants and rights under all of our existing equity compensation plans and arrangements as of September 30, 2007, including the 1997 Stock Option Plan.

| | | | | | | |

Plan Category | | Number of Securities

to be issued upon

exercise of

outstanding options,

warrants and rights | | Weighted- average

exercise price of

outstanding options,

warrants and rights | | Number of Securities

remaining available for future

issuance under equity

compensation plans

(excluding securities reflected

in second column) |

Equity compensation plans approved by security holders | | 30,000 | | $ | 9.32 | | 0 |

Equity compensation plans not approved by security holders | | 0 | | | 0 | | 0 |

| | | | | | | |

Total | | 30,000 | | $ | 9.32 | | 0 |

| | | | | | | |

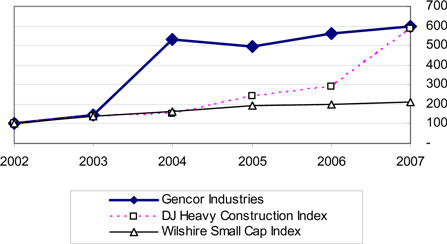

The following graph sets forth the cumulative total stockholder return (assuming reinvestment of dividends) to the Company’s stockholders during the five-year period ended September 30, 2007, as well as the Wilshire Small Capitalization Index and the Dow Jones Heavy Construction Index. The stock performance assumes $100 was invested on October 1, 2002.

14

Comparison of Cumulative Total Return Among Gencor Industries, Inc., the

Wilshire Small Capitalization Index and the Dow Jones Heavy Construction Index

| | | | | | | | | | | | |

With Base Year of 2002: | | 9/30/02 | | 9/30/03 | | 9/30/04 | | 9/30/05 | | 9/30/06 | | 9/30/07 |

Gencor Industries, Inc. | | 100.00 | | 142.42 | | 530.30 | | 493.94 | | 560.61 | | 600.00 |

| | | | | | |

DJ Heavy Construction Index | | 100.00 | | 140.32 | | 153.16 | | 243.91 | | 289.83 | | 584.36 |

| | | | | | |

Wilshire Small Cap Index | | 100.00 | | 139.22 | | 160.48 | | 192.20 | | 196.94 | | 208.66 |

Subsequent to June 1, 2000, the Company’s stock has traded on the “pink sheets” under the stock symbol “GRCX” until 2003 when the stock symbol was changed to “GNCI”. In January 2005, quotation on the Company’s stock commenced reporting on the OTC Electronic Bulletin Board under the symbol “GNCI.OB”.

On December 20, 2007, the Company’s stock will be available for trading on NASDAQ under the symbol “GENC”.

15

| ITEM 6. | SELECTED FINANCIAL DATA |

| | | | | | | | | | | | | | | | | |

| | | Years Ended September 30 | |

| | | 2007 | | 2006 | | 2005 | | | 2004 | | 2003 | |

| | | (in thousands, except per share data) | |

Net revenue | | $ | 75,286 | | $ | 67,107 | | $ | 48,140 | | | $ | 54,070 | | $ | 55,898 | |

| | | | | |

Operating income (loss) | | $ | 6,333 | | $ | 1,359 | | $ | (1,258 | ) | | $ | 4,171 | | $ | (1,173 | ) |

| | | | | |

Net Income | | $ | 18,495 | | $ | 11,587 | | $ | 31,307 | | | $ | 2,604 | | $ | 7,260 | |

| | | | | |

Per share data: | | | | | | | | | | | | | | | | | |

Basic: | | | | | | | | | | | | | | | | | |

Net Income | | $ | 1.91 | | $ | 1.17 | | $ | 3.50 | | | $ | 0.30 | | $ | 0.84 | |

| | | | | |

Diluted: | | | | | | | | | | | | | | | | | |

Net Income | | $ | 1.91 | | $ | 1.17 | | $ | 3.29 | | | $ | 0.27 | | $ | 0.82 | |

Cash dividends declared per common share | | $ | — | | $ | — | | $ | — | | | $ | — | | $ | — | |

| | | | | |

Selected balance sheet data: | | | | | | | | | | | | | | | | | |

| | | September 30, | |

| | | 2007 | | 2006 | | 2005 | | | 2004 | | 2003 | |

Current assets | | $ | 96,392 | | $ | 67,634 | | $ | 63,745 | | | $ | 22,195 | | $ | 19,331 | |

Current liabilities | | $ | 14,048 | | $ | 11,888 | | $ | 10,361 | | | $ | 18,437 | | $ | 16,518 | |

Total assets | | $ | 104,227 | | $ | 80,974 | | $ | 78,010 | | | $ | 42,812 | | $ | 40,634 | |

Long-term debt, less current maturities | | $ | — | | $ | — | | $ | — | | | $ | 5,701 | | $ | 5,321 | |

Shareholders’ equity | | $ | 83,781 | | $ | 63,043 | | $ | 51,435 | | | $ | 15,294 | | $ | 12,609 | |

16

| ITEM 7. | MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS |

“Forward-Looking” Information

This Form 10-K contains certain “forward-looking statements” within the meaning of Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”), which represent our expectations and beliefs, including, but not limited to, statements concerning gross margins, sales of our products and future financing plans, income from investees and litigation. These statements by their nature involve substantial risks and uncertainties, certain of which are beyond our control. Actual results may differ materially depending on a variety of important factors, including the financial condition of our customers, changes in the economic and competitive environments, whether or not the Company receives income from its investees, the performance of our investment portfolio and the demand for our products.

For information concerning these factors and related matters, see “Risk Factors” in Part I, Item 1A in this Report. However, other factors besides those referenced could adversely affect our results, and you should not consider any such list of factors to be a complete set of all potential risks or uncertainties. Any forward-looking statements made by us herein speak as of the date of this Report. We do not undertake to update any forward-looking statement, except as required by law.

Results of Operations

Year ended September 30, 2007 compared with the year ended September 30, 2006

Net sales for the years ended September 30, 2007 and 2006 were $75.3 million and $67.1million, respectively. Domestic sales during this period for 2007 and 2006 were $72.4 million and $63.1 million, respectively. Domestic sales were higher than the prior year due to the general improvement in the road-building industry, partially due to the passage of the Federal highway bill in the summer of 2005. Foreign sales decreased by $1.1 million due to one large order in 2006. Backlog was $24.5 million at September 30, 2007, compared to a backlog of only $5 million at September 30, 2006.

Gross margin for fiscal 2007 was $3.1 million higher than fiscal 2006 and as a percent of net sales was 26.4% in 2007 and 25.0% of sales for 2006. The increased volume in our manufacturing plants improved overhead absorption and improved margins. Domestic margins were negatively affected by $.7 million in 2007 and 2006 due to an increase in the LIFO reserve.

Product engineering and development costs increased $.5 million due to hiring of additional engineers. Selling and administrative expenses decreased $2.4 million during 2007 due to lower legal costs offset by $.7 million due to higher commissions and payroll costs resulting from the higher sales volume.

Operating income was $6.3 million in 2007 compared to $1.4 million in 2006. Operating income increased as a result of increased domestic business, higher gross margins in 2007, and reduced selling and administrative expenses.

During fiscal 2007, we sold land and buildings for $5,481 resulting in a loss of $1,633 after an adjustment of $1,905 for the cumulative translation adjustment related to the assets sold.

The increase in value of marketable securities is a result of additional net cash invested in marketable securities ($10 million) and the increase in the market value ($5.8 million) of the securities held in the portfolio.

We recognized income from investees of $19,937 in 2007 and $14,547 of income from investees in 2006. The operations of Carbontronics LLC consist of the receipt of contingent payments from the sales of the plants and the distribution thereof to its members. Carbontronics LLC has no other significant operations or assets. The operations of Carbontronics II, LLC consist of the receipt of royalty payments from the plants and the distribution thereof to its members. Carbontronics II, LLC has no other significant operations or assets. Any income arising from these investments is dependent upon tax credits (adjusted for operating losses at the fuel

17

plants) being generated as a result of synthetic fuel production, which will be recorded as received. These distributions are subject to state and Federal income taxes. Future distributions from these entities depend upon the production of these operations continuing to qualify for tax credits under Section 29 of the Internal Revenue Code and the ability to economically produce and market synthetic fuel produced by the plants. One of the contingencies related to future benefits from these entities is based on the average price of crude oil. Per a provision of Section 29, if the average price of crude oil reaches a certain level, the tax credits will terminate. The recent escalation in oil prices raises serious doubt on the continued availability of tax credits under Section 29 for the future. If oil prices remain at the current levels or increase, the tax credits could phase-out or terminate. Any one of the above eventualities may interrupt, reduce, or terminate further distributions.

The existing tax credit legislation is expiring at the end of calendar year 2007. Consequently, the four synthetic fuel plants are being decommissioned. The plants are in process of being sold or transferred to site owners in exchange for a release of all contracted liabilities related to the removal of plants from the sites. The administrative partner has informed the Company that there will be no operations in calendar 2008 and almost all of the partnership affairs will be finalized in early 2008. It is not possible to predict the amount, if any, of final distributions from the partnerships upon the final disposition and winding-up of operations.

Income taxes were 39.5% of pre-tax income for 2007 and 37% for 2006. The effective tax rate is higher than the Federal rate of 35% due to state income taxes and losses for foreign operations for which no tax benefit has been recognized.

Year ended September 30, 2006 compared with the year ended September 30, 2005

Net sales for the years ended September 30, 2006 and 2005 were $67.1 million and $48.1million, respectively. Domestic sales during this period for 2006 and 2005 were $63.1 million and $46.9 million, respectively. Domestic sales were higher than the prior year due to the improved economy and the passage of the Federal highway bill in the summer of 2005. Foreign sales increased by $2.7 million due to one large order. Backlog was only $5 million at September 30, 2006, however, it had increased to over $28 million as of December 1, 2006. This compares to a backlog of $24 million as of December 1, 2005.

Gross margin for fiscal 2006 was $5.8 million higher than fiscal 2005 and as a percent of net sales was 25.0% in 2006 and 22.7% of sales for 2005. The increased volume in our manufacturing plants improved overhead absorption and improved margins. Domestic margins were negatively affected by $.7 million in 2006 and $.5 million in 2005 due to an increase in the LIFO reserve.

Product engineering and development costs remained at comparable levels with 2005. Selling and administrative expenses increased $1.6 million during 2006 due to higher legal costs and $.5 million due to higher commissions and payroll costs resulting from the higher sales volume.

Operating income was $1.4 million in 2006 compared to a loss of ($1.3 million) in 2005. Operating income increased as a result of increased domestic and foreign business, higher gross margins in 2006, partially offset by the higher selling and administrative expenses.

The increase in value of marketable securities is a result of the net cash invested in marketable securities since the second quarter of fiscal 2005 and the increase in the market value of the securities held in the portfolio.

The Company recognized income from investees of $14,457 in 2006, for the distribution received less an accrual of $1 million for certain expenses associated with our efforts as plaintiff in a matter against its synthetic fuels partners. We received $44,238, during the fiscal year 2005. We received no distributions in fiscal 2004. The operations of Carbontronics LLC consist of the receipt of contingent payments from the sales of the plants and the distribution thereof to its members. Carbontronics LLC has no other significant operations or assets. The operations of Carbontronics II, LLC consist of the receipt of royalty payments from the plants and the distribution thereof to its members. Carbontronics II, LLC has no other significant operations or assets. Any income arising from these investments is dependent upon tax credits (adjusted for operating losses at the fuel

18

plants) being generated as a result of synthetic fuel production, which will be recorded as received. These distributions are subject to state and Federal income taxes. Future distributions from these entities depend upon the production of these operations continuing to qualify for tax credits under Section 29 of the Internal Revenue Code and the ability to economically produce and market synthetic fuel produced by the plants. One of the contingencies related to future benefits from these entities is based on the average price of crude oil. Per a provision of Section 29, if the average price of crude oil reaches a certain level, the tax credits will terminate. The recent escalation in oil prices raises serious doubt on the continued availability of tax credits under Section 29 for the future. If oil prices remain at the current levels or increase, the tax credits could phase-out or terminate. The existing tax credit legislation is scheduled to expire at the end of calendar year 2007. Any one of the above eventualities may interrupt, reduce, or terminate further distributions.

Income taxes were 37% of pre-tax income for 2006 and 31% for 2005. The tax provision in 2005 includes a reduction of $2.5 million (5.5%) in the tax contingency reserve as a result of resolution of prior year tax filings and expiration of the statute of limitations.

Liquidity and Capital Resources

We entered into a Revolving Credit and Security Agreement with PNC Bank, N.A. The Agreement established a three year revolving $20 million credit facility and was renewed through July 31, 2009. The facility provides for advances based on accounts receivable, inventory and real estate. The facility includes a $2 million limit on letters of credit. At September 30, 2007, we had $.7 million of letters of credit outstanding. The interest rate at September 30, 2007, is at LIBOR plus 2.00% and subject to change based upon the Fixed Charge Coverage Ratio. We are required to maintain a Fixed Charge Coverage Ratio of 1.1:1. There are no required repayments as long as there are no defaults and there is adequate eligible collateral. Substantially all of our assets are pledged as security under the Agreement. We had no long term debt outstanding at September 30, 2007 or 2006.

As of September 30, 2007, we had $3.7 million in cash and cash equivalents, and $51.8 million in marketable securities. The marketable securities are invested in stocks and bonds through a professional investment advisor. The securities may be liquidated at any time into cash and cash equivalents.

Inventories have increased from $23.0 million at September 30, 2006, to $34.7 million at September 30, 2007, as we have built inventory to meet the high demands for plant deliveries in early calendar 2008. This demand is reflected in the large backlog of $24.5 million at September 30, 2007, versus only $4.6 million in backlog at September 30, 2006.

Critical Accounting Policies, Estimates and Assumptions

We believe the following discussion addresses our most critical accounting policies, which are those that are most important to the portrayal of our financial condition and results of operations and require management’s most difficult, subjective, or complex judgments, often as a result of the need to make estimates about the effect of matters that are inherently uncertain. Accounting policies, in addition to the critical accounting policies referenced below, are presented in Note 1 to our consolidated financial statements, “Accounting Policies.”

Estimates and Assumptions

In preparing the consolidated financial statements, we use certain estimates and assumptions that may affect reported amounts and disclosures. Estimates and assumptions are used, among other places, when accounting for certain revenue (e.g. contract accounting), expense, and asset and liability valuations. We believe that the estimates and assumptions made in preparing the consolidated financial statements are reasonable, but are inherently uncertain and unpredictable. Assumptions may be incomplete or inaccurate and unanticipated events may occur. We are subject to risks and uncertainties that may cause actual results to differ from estimated results.

19

Revenues

Revenues from contracts for the design and manufacture of certain custom equipment are recognized under the percentage-of-completion method. Revenues from all other sales are recorded as the products are shipped or service is performed.

The percentage-of-completion method of accounting for long term contracts recognizes revenue in proportion to actual labor costs incurred as compared with total estimated labor costs expected to be incurred during the entire contract. All selling, general and administrative expenses are charged to operations as incurred. Provision is made for any anticipated contract losses in the period that the loss becomes evident.

Investment in Unconsolidated Investees

As of September 30, 2007, 2006, and 2005, we own a 45% interest in Carbontronics LLC and a 25% interest in Carbontronics Fuels LLC and Carbontronics II LLC. These interests were obtained as part of contracts to build four synthetic fuel production plants during 1998. We have no basis in these equity investments or requirement to provide future funding. Any income arising from these investments is dependent upon tax credits (adjusted for operating losses at the fuel plants) being generated as a result of synthetic fuel production, which will be recorded as received.

Inflation

The overall effects of inflation on our business during the periods discussed have not been significant. We monitor the prices we charge for our products and services on an ongoing basis and believe that we will be able to adjust those prices to take into account future changes in the rate of inflation.

Contractual Obligations

The following table summarizes our outstanding borrowings and long-term contractual obligations at September 30, 2007:

| | | | | | | | | | | | | | | |

| | | | | Less than | | | | 3 - 5 | | More than |

| | | Total | | 1 Year | | 1-3 Years | | Years | | 5 Years |

Long-term debt | | $ | — | | $ | — | | $ | — | | $ | — | | $ | — |

Operating leases | | $ | 142 | | $ | 67 | | $ | 75 | | $ | — | | $ | — |

| | | | | | | | | | | | | | | |

Total | | $ | 142 | | $ | 67 | | $ | 75 | | $ | — | | $ | — |

| | | | | | | | | | | | | | | |

The long-term debt facility matures in 2009. We also have $.7 million of letters of credit outstanding. The letters of credit are for one year and have been renewed annually.

Off-Balance Sheet Arrangements

None

| ITEM 7A. | QUANTITATIVE AND QUALITATIVE DISCLOSURES ABOUT MARKET RISK |

The Company operates manufacturing facilities and sales offices principally located in the United States and the United Kingdom. The Company is subject to business risks inherent in non-U.S. activities, including political and economic uncertainty, import and export limitations, and market risk related to changes in interest rates and foreign currency exchange rates. The Company’s principal currency exposure against the U.S. dollar is the British pound. Periodically, the Company will use derivative financial instruments consisting primarily of interest rate hedge agreements to manage exposures to interest rate changes. The Company’s objective in managing its exposure to changes in interest rates on its variable rate debt is to limit their impact on earnings and cash flow and reduce its overall borrowing costs.

20

At September 30, 2007 and 2006, the Company had no debt outstanding. Under the Revolving Credit and Security Agreement, substantially all of the Company’s borrowings will bear interest at variable rates based upon the prime rate or LIBOR.

The Company’s marketable securities are invested in stocks and bonds through a professional investment advisor. Investment securities are exposed to various risks such as interest rate, market and credit. Due to the level of risk associated with certain investment securities and the level of uncertainty related to changes in the value of securities, it is possible that changes in these risk factors could have an adverse material impact on the Company’s results of operations or equity.

The Company’s sensitivity analysis for interest rate risk excludes accounts receivable, accounts payable and accrued liabilities because of the short-term maturity of such instruments. The analysis does not consider the effect on other variables such as changes in sales volumes or management’s actions with respect to levels of capital expenditures, future acquisitions or planned divestures, all of which could be significantly influenced by changes in interest rates.

21

| ITEM 8. | FINANCIAL STATEMENTS AND SUPPLEMENTARY DATA |

INDEX TO FINANCIAL STATEMENTS AND FINANCIAL STATEMENT SCHEDULES

GENCOR INDUSTRIES, INC.

All other schedules are omitted because they are not applicable or the required information is shown in the consolidated financial statements or notes thereto.

22

REPORT OF INDEPENDENT REGISTERED PUBLIC ACCOUNTING FIRM

Board of Directors

Gencor Industries, Inc.

Orlando, Florida

We have audited the accompanying consolidated balance sheets of Gencor Industries, Inc. and subsidiaries as of September 30, 2007 and 2006, and the related consolidated statements of income, shareholders’ equity and cash flows for the years ended September 30, 2007, 2006 and 2005. Our audits also included the financial statement schedule listed in the accompanying index. These financial statements and financial statement schedule are the responsibility of the Company’s management. Our responsibility is to express an opinion on these financial statements and financial statement schedule based on our audits.

We conducted our audits in accordance with the standards of the Public Company Accounting Oversight Board (United States of America). Those standards require that we plan and perform the audit to obtain reasonable assurance about whether the financial statements are free of material misstatement. An audit includes examining, on a test basis, evidence supporting the amounts and disclosures in the financial statements. An audit also includes assessing the accounting principles used and significant estimates made by management, as well as evaluating the overall financial statement presentation. We believe that our audits provide a reasonable basis for our opinion.

In our opinion, the consolidated financial statements referred to above present fairly, in all material respects, the financial position of Gencor Industries, Inc. and subsidiaries as of September 30, 2007 and 2006, and the results of their operations and their cash flows for the years ended September 30, 2007, 2006 and 2005, in conformity with accounting principles generally accepted in the United States of America. Also, in our opinion, the financial statement schedule referred to above, when considered in relation to the basic consolidated financial statements taken as a whole, presents fairly in all material respects the information set forth therein.

MOORE STEPHENS LOVELACE, P.A.

Certified Public Accountants

Orlando, Florida

December 13, 2007

23

Part I. Financial Information

GENCOR INDUSTRIES, INC.

Consolidated Balance Sheets

(In thousands, except per share data)

| | | | | | | | |

| | | September 30 2007 | | | September 30 2006 | |

| ASSETS | | | | | | | | |

Current assets: | | | | | | | | |

Cash and cash equivalents | | $ | 3,707 | | | $ | 1,110 | |

Marketable securities at market value (Cost $42,000 at September 30, 2007 and $32,000 at September 30, 2006) | | | 51,780 | | | | 35,949 | |

Account receivable, less allowance for doubtful accounts of $1,685 ($1,440 at September 30, 2006) | | | 4,570 | | | | 5,372 | |

Other receivables | | | 288 | | | | 366 | |

Inventories, net | | | 34,694 | | | | 22,960 | |

Deferred income taxes | | | — | | | | 587 | |

Prepaid expenses | | | 1,353 | | | | 1,290 | |

| | | | | | | | |

Total current assets | | | 96,392 | | | | 67,634 | |

Property and equipment, net | | | 7,660 | | | | 12,949 | |

Other assets | | | 175 | | | | 391 | |

| | | | | | | | |

Total assets | | $ | 104,227 | | | $ | 80,974 | |

| | | | | | | | |

| | |

| LIABILITIES AND SHAREHOLDERS’ EQUITY | | | | | | | | |

Current Liabilities: | | | | | | | | |

Account payable | | $ | 4,132 | | | $ | 5,622 | |

Customer deposits | | | 1,414 | | | | 837 | |

Income and other taxes payable | | | 2,164 | | | | 600 | |

Accrued expenses | | | 6,338 | | | | 4,829 | |

| | | | | | | | |

Total current liabilities | | | 14,048 | | | | 11,888 | |

Long-term debt | | | — | | | | — | |

Deferred income taxes | | | 6,398 | | | | 6,043 | |

| | | | | | | | |

Total liabilities | | | 20,446 | | | | 17,931 | |

Commitments and contingencies | | | | | | | | |

Shareholder’s equity: | | | | | | | | |

Preferred stock, par value $.10 share; authorized 300,000 shares; none issued | | | — | | | | — | |

Common stock, par value $.10 per share; 15,000,000 shares authorized; 7,967,372 shares and 8,302,130 shares issued at September 30, 2007 and 2006, respectively | | | 797 | | | | 830 | |

Class B Stock, par value $.10 per share; 6,000,000 shares authorized;

1,642,998 shares issued at September 30,2007 and 2006 | | | 164 | | | | 164 | |

Unearned compensation | | | (135 | ) | | | (270 | ) |

Capital in excess of par value | | | 10,520 | | | | 10,273 | |

Retained earnings | | | 72,136 | | | | 53,641 | |

Accumulated other comprehensive income (loss) | | | 299 | | | | (1,595 | ) |

| | | | | | | | |

Total shareholder’s equity | | | 83,781 | | | | 63,043 | |

| | | | | | | | |

| | $ | 104,227 | | | $ | 80,974 | |

| | | | | | | | |

See accompanying notes to consolidated financial statements

24

GENCOR INDUSTRIES, INC.

Consolidated Statements of Income

(In thousands, except per share data)

| | | | | | | | | | | | |

| | | For the Years Ended

September 30, | |

| | | 2007 | | | 2006 | | | 2005 | |

Net revenue | | $ | 75,286 | | | $ | 67,107 | | | $ | 48,140 | |

Cost and expense: | | | | | | | | | | | | |

Production costs | | | 55,436 | | | | 50,348 | | | | 37,218 | |

Product engineering and development | | | 2,567 | | | | 2,075 | | | | 1,911 | |

Selling, general and administrative | | | 10,950 | | | | 13,325 | | | | 10,269 | |

| | | | | | | | | | | | |

| | | 68,953 | | | | 65,748 | | | | 49,398 | |

| | | | | | | | | | | | |

Operating income (loss) | | | 6,333 | | | | 1,359 | | | | (1,258 | ) |

| | | |

Other income (expense): | | | | | | | | | | | | |

Interest income | | | 159 | | | | 160 | | | | 92 | |

Interest expense | | | (48 | ) | | | (85 | ) | | | (161 | ) |

Income from investees | | | 19,937 | | | | 14,457 | | | | 44,238 | |

Loss on sale of assets | | | (1,633 | ) | | | — | | | | — | |

Increase in value of marketable securities | | | 5,831 | | | | 2,162 | | | | 1,787 | |

Miscellaneous | | | 6 | | | | 327 | | | | 386 | |

| | | | | | | | | | | | |

| | | 24,252 | | | | 17,021 | | | | 46,342 | |

Income before income taxes | | | 30,585 | | | | 18,380 | | | | 45,084 | |

Income taxes | | | 12,090 | | | | 6,793 | | | | 13,777 | |

| | | | | | | | | | | | |

Net income | | $ | 18,495 | | | $ | 11,587 | | | $ | 31,307 | |

| | | | | | | | | | | | |

Basic earnings per common share: | | | | | | | | | | | | |

Net income | | $ | 1.91 | | | $ | 1.17 | | | $ | 3.50 | |

| | | | | | | | | | | | |

Diluted earnings per common share: | | | | | | | | | | | | |

Net income | | $ | 1.91 | | | $ | 1.17 | | | $ | 3.29 | |

| | | | | | | | | | | | |

See accompanying notes to consolidated financial statements.

25

GENCOR INDUSTRIES, INC.

Consolidated Statements of Shareholders’ Equity

(In thousands)

For the Years Ended September 30, 2007, 2006 and 2005

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | Common Stock | | | Class B Stock | | | Unearned

Compensation | | | Capital in

Excess of

Par Value | | | Retained

Earnings

(Accumulated

Deficit) | | Comprehensive

Income (Loss) | | | Accumulated

Other

Comprehensive

Income (Loss) | | | Subscription

Receivable

From

Officer | | | Treasury Stock | | | Total

Shareholders’

Equity | |

| | | Shares | | | Amount | | | Shares | | | Amount | | | | | | | | | Shares | | | Cost | | |

September 30, 2004 | | 7,094 | | | $ | 709 | | | 1,878 | | | $ | 188 | | | $ | — | | | $ | 11,467 | | | $ | 10,747 | | | | | | $ | (6,018 | ) | | $ | (95 | ) | | | 179 | | | $ | (1,704 | ) | | $ | 15,294 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Net income | | — | | | | — | | | — | | | | — | | | | — | | | | — | | | | 31,307 | | $ | 31,307 | | | | — | | | | — | | | | — | | | | — | | | | 31,307 | |

Stock options exercised | | 1,103 | | | | 111 | | | — | | | | — | | | | — | | | | 192 | | | | — | | $ | — | | | | — | | | | — | | | | — | | | | — | | | | 303 | |

Collection of subscription | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | 95 | | | | — | | | | — | | | | 95 | |

Disposal of foreign assets | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | 4,347 | | | | | | | | | | | | | | | | 4,347 | |

Conversion of Class B Stock | | 143 | | | | 14 | | | (143 | ) | | | (14 | ) | | | — | | | | — | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Translation adj. | | — | | | | — | | | — | | | | — | | | | — | | | | — | | | | — | | | 89 | | | | 89 | | | | — | | | | — | | | | — | | | | 89 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Comprehensive income | | | | | | | | | | | | | | | | | | | | | | | | | | | $ | 31,396 | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

September 30, 2005 | | 8,340 | | | $ | 834 | | | 1,735 | | | $ | 174 | | | $ | — | | | $ | 11,659 | | | $ | 42,054 | | | | | | $ | (1,582 | ) | | $ | — | | | | 179 | | | $ | (1,704 | ) | | $ | 51,435 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Net income | | — | | | | — | | | — | | | | — | | | | — | | | | — | | | | 11,587 | | $ | 11,587 | | | | — | | | | — | | | | — | | | | — | | | | 11,587 | |

Stock options granted | | | | | | | | | | | | | | | | | (270 | ) | | | 270 | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Stock options exercised | | 49 | | | | 5 | | | — | | | | — | | | | — | | | | 29 | | | | — | | $ | — | | | | — | | | | — | | | | — | | | | — | | | | 34 | |

Retirement of treasury stock | | (87 | ) | | | (9 | ) | | (92 | ) | | | (10 | ) | | | — | | | | (1,685 | ) | | | — | | | | | | | — | | | | — | | | | (179 | ) | | | 1,704 | | | | — | |

Translation adj. | | — | | | | — | | | — | | | | — | | | | — | | | | — | | | | — | | | (13 | ) | | | (13 | ) | | | — | | | | — | | | | — | | | | (13 | ) |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Comprehensive income | | | | | | | | | | | | | | | | | | | | | | | | | | | $ | 11,574 | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

September 30, 2006 | | 8,302 | | | $ | 830 | | | 1,643 | | | $ | 164 | | | $ | (270 | ) | | $ | 10,273 | | | $ | 53,641 | | | | | | $ | (1,595 | ) | | $ | — | | | $ | — | | | $ | — | | | $ | 63,043 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Net income | | — | | | | — | | | — | | | | — | | | | — | | | | — | | | | 18,495 | | $ | 18,495 | | | | — | | | | — | | | | — | | | | — | | | | 18,495 | |

Amortization | | | | | | | | | | | | | | | | | 135 | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | 135 | |

Stock retired | | (335 | ) | | | (33 | ) | | — | | | | — | | | | — | | | | 247 | | | | — | | $ | — | | | | — | | | | — | | | | — | | | | — | | | | 214 | |

Disposal of foreign assets | | | | | | | | | | | | | | | | | — | | | | | | | | — | | | | | | | 1,905 | | | | — | | | | | | | | | | | | 1,905 | |

Translation adj. | | — | | | | — | | | — | | | | — | | | | — | | | | — | | | | — | | | (11 | ) | | | (11 | ) | | | — | | | | — | | | | — | | | | (11 | ) |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Comprehensive income | | | | | | | | | | | | | | | | | | | | | | | | | | | $ | 18,484 | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

September 30, 2007 | | 7,967 | | | $ | 797 | | | 1,643 | | | $ | 164 | | | $ | (135 | ) | | $ | 10,520 | | | $ | 72,136 | | | | | | $ | 299 | | | $ | — | | | $ | — | | | $ | — | | | $ | 83,781 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

See accompanying notes to consolidated financial statements.

26

GENCOR INDUSTRIES, INC.

Consolidated Statements of Cash Flows

In Thousands

| | | | | | | | | | | | |

| | | For the Years Ended September 30, | |

| | | 2007 | | | 2006 | | | 2005 | |

Cash flows from operations: | | | | | | | | | | | | |

Net income | | $ | 18,495 | | | $ | 11,587 | | | $ | 31,307 | |

Adjustments to reconcile net income to cash provided (used) by operations: | | | | | | | | | | | | |

Increase in Marketable securities | | | (10,000 | ) | | | (1,000 | ) | | | (31,000 | ) |

Increase in market value of marketable securities | | | (5,831 | ) | | | (2,162 | ) | | | (1,787 | ) |

Deferred income taxes | | | 2,714 | | | | (8,837 | ) | | | 14,824 | |