UNITED STATES SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

| | þ | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended June 30, 2012

OR

| | ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to

Commission File Number 0-07491

MOLEX INCORPORATED

(Exact name of registrant as specified in its charter)

| | |

| Delaware | | 36-2369491 |

(State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification No.) |

2222 Wellington Court, Lisle, Illinois 60532

(Address of principal executive offices)

Registrant’s telephone number, including area code:

(630) 969-4550

SECURITIES REGISTERED PURSUANT TO SECTION 12(b) OF THE ACT

| | |

Title of each class | | Name of each exchange on which registered |

Common Stock, par value $0.05 Class A Common Stock, par value $0.05 | | The Nasdaq Stock Market, LLC The Nasdaq Stock Market, LLC |

SECURITIES REGISTERED PURSUANT TO SECTION 12(g) OF THE ACT: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes þ No ¨

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No þ

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15 (d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes þ No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes þ No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (Section 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. þ

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

| | | | | | |

| Large accelerated filer þ | | Accelerated filer ¨ | | Non-accelerated filer ¨ | | Smaller reporting company ¨ |

| | | | (Do not check if a smaller reporting company) | | |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ¨ No þ

The aggregate market value of the voting and non-voting shares held by non-affiliates as of the last business day of the registrant’s most recently completed second fiscal quarter was approximately $2.6 billion (based on the closing price of these shares on the NASDAQ Global Select Market on December 31, 2011).

On July 25, 2012, the following numbers of shares of the Company’s common stock were outstanding:

| | | | |

Common Stock | | | 95,560,076 | |

Class A Common Stock | | | 80,873,472 | |

Class B Common Stock | | | 94,255 | |

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Proxy Statement for the Annual Meeting of Stockholders, to be held on October 26, 2012, are incorporated by reference into Part III of this annual report on Form 10-K.

TABLE OF CONTENTS

Molex Web Site

We make available through our web site at www.molex.com our annual report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and all amendments to those reports as soon as reasonably practicable after such material is electronically filed with the Securities and Exchange Commission (SEC).

Information relating to corporate governance at Molex, including our Code of Business Conduct and Ethics, information concerning executive officers, directors and Board committees (including committee charters), and transactions in Molex securities by directors and officers, is available on or through our web site at www.molex.com under the “Investors” caption.

We are not including the information on our web site as a part of, or incorporating it by reference into, this annual report on Form 10-K.

2

PART I

Molex Incorporated (together with its subsidiaries, except where the context otherwise requires, “we,” “us” and “our”) was incorporated in the state of Delaware in 1972 and originated from an enterprise established in 1938.

We are one of the world’s largest manufacturers of electronic connectors in terms of net revenue. Our net revenue was $3.5 billion for fiscal 2012. We operated 40 manufacturing locations in 16 countries, and employed 34,226 people in 42 countries as of June 30, 2012.

Our core business is the manufacture and sale of electronic components. Our products are used by a large number of leading original equipment manufacturers (OEMs) throughout the world. We design, manufacture and sell more than 100,000 products, including terminals, connectors, planar cables, cable assemblies, interconnection systems, backplanes, integrated products and mechanical and electronic switches.

The Connector Industry

The global connector industry is competitive and estimated to represent approximately $48 billion in net revenue for calendar year 2011. The industry has grown at a compounded annual rate of 5.4% over the past 20 years.

The connector industry is characterized by rapid advances in technology and new product development. These advances have been substantially driven by the increased functionality of applications in which our products are used. There is a constant demand for new product solutions and innovations in the technology industry. Our product life cycles tend to mirror the life span of our customers’ products although many of our products are designed into subsequent applications. Consumer and mobile products have relatively short product life cycles while automotive and industrial products are typically longer.

Industry trends that we deem particularly relevant include:

| | • | | Globalization. Synergistic opportunities exist for the industry to design, manufacture and sell electronic products in different countries around the world in an efficient and seamless process. For example, our customers’ products may be designed in Japan, manufactured in China and sold in multiple geographies. |

| | • | | Convergence of products. Traditionally separate products developed for consumer electronics, infotech and telecommunications markets are converging, resulting in electronic devices offering broad-based functionality. |

| | • | | Increasing electronics content. Consumer demand for advanced product features, convenience and connectivity is increasing electronic content in end devices. For example, electronic content in automobiles is increasing due to proliferation in infotainment, telematics and safety systems. |

| | • | | Increasing storage and bandwidth requirements. The global demand and use of streaming information such as audio and video require electronic components to have increased storage capacity and high-speed retrieval capabilities. Increasing internet traffic is taxing existing network infrastructure, resulting in equipment upgrades and capacity additions. |

| | • | | Product size reduction. High-density, micro-miniature technologies originally developed for consumer product applications are expanding to markets such as infotech and telecommunications, leading to smaller devices and greater mobility. |

| | • | | Consolidating supply base. Generally, global OEMs are consolidating their supply chain by selecting global companies possessing broad product lines for the majority of their connector requirements. |

3

| | • | | Price erosion. Due to rapidly evolving innovation in the technology industry, our customers’ experience pressure to reduce their prices to meet customer expectations. As a result, component suppliers are generally expected to lower prices. |

| | • | | Competitive market. There are a large number of competitors in the connector industry increasing the level of competition worldwide. We believe that the 10 largest connector suppliers, as measured by net revenue, represent approximately 54% of the worldwide market and exhibit a faster growth rate than their smaller competitors. |

| | • | | Rising input costs. Input costs, including commodity prices and employee costs in developing countries continue to increase and affect gross margin. |

Markets and Products

The approximate percentage of our net revenue by market for fiscal 2012 is summarized below:

| | | | |

| Markets | | Percentage of Fiscal 2012 Net Revenue | | Primary End Use Products Supported by Molex |

Telecommunications | | 23% | | Mobile phones, networking equipment, switches and transmission equipment |

Infotech | | 26% | | Desktop, tablet and notebook computers, peripheral equipment, servers and storage |

Consumer | | 18% | | Digital electronics, cameras, televisions, gaming systems, acoustics and major appliances |

Industrial | | 13% | | Factory automation, food and beverage equipment, alternative energy and electrical lighting and cables |

Automotive | | 17% | | Powertrain, body electronics, safety electronics, sensors, infotainment, telematics and lighting |

Other (includes Medical, Military and Aerospace) | | 3% | | Electronic and electrical devices for a variety of products |

Telecommunications. In the telecommunications market, we believe our key strengths include high-speed optical signal product lines, backplane connector systems and power distribution products. For mobile phones, we provide micro-miniature connectors, SIM and SD card sockets, keypads, electromechanical subassemblies and internal antennas.

We released several new products for the telecommunications market in fiscal 2012 including:

| | • | | NeoScale™ High-Speed Mezzanine System delivers the market’s cleanest signal integrity at 28+ Gbps and features a high-speed triad wafer design with Solder-Charge Technology™ for customized printed circuit boards routing in high-density system applications; |

| | • | | SC, SC/APC and Duplex Connectors, Adapters and Cable Assemblies were developed to meet the challenges of the infotech and telecommunications’ industries, including compatibility with many standard cable sizes and fiber types, adhering to industry mechanical and environmental standards; |

| | • | | DDR3 DIMM Sockets, DDR3 DIMM Memory Module Sockets increase data bandwidth and performance for demanding memory applications in desktop, personal and notebook computers, and servers; and |

4

| | • | | Milli-Grid™ is based on a 2.00mm by 2.00mm (.079” by .079”) grid pattern offering complete design flexibility for wire-to-board, board-to-board and cable-to-board connections in personal computers, entertainment, telecommunications and other electronic industries. |

Infotech. In the infotech market, our key strengths include our high-speed signal product line, storage input/output (I/O) products, standards committee leadership, global coordination and strong relationships with OEMs and contract manufacturers.

We manufacture power, optical and signal connectors and cables for fast end-to-end data transfer, linking disk drives, controllers, servers, switches and storage enclosures. For example, our family of small form-factor pluggable products offers end-users both fiber optic and copper connectivity and more efficient storage area network management. Our ongoing involvement in industry committees contributes to the development of new standards for the connectors and cables that transport data.

We hold a strong position in the infotech market with respect to the connectors used in servers, the segment of this market that accounts for the largest volume of our connector purchases. We offer a large variety of products for power distribution, signal integrity, processor and memory applications. We are also a leading designer in the industry for storage devices.

We participate in the tablet market with a wide range of customers, largely using wire-to-board, board-to-board and flexible printed circuit connectors developed for mobile phones and smartphones.

We released several new products for the infotech market in fiscal 2012 including:

| | • | | ZXP® zSFP+™ Interconnect System is the first complete ZXP® zSFP+™ Interconnect System for 25 Gbps serial channels, delivering signal integrity with electromagnetic interference protection for next-generation ethernet and Fibre Channel applications; |

| | • | | VersaBeam™ POD Cable Assemblies mates to Avago parallel optical modules, optimizing airflow and cable management for next generation applications in emerging high-speed data and computer markets and meets Telcordia GR-1435 specifications; |

| | • | | Impact™ 100 Ohm Orthogonal (Direct) Backplane Connector System improves system airflow and reduces performance constraints by eliminating backplane and midplane connections with our Impact™ Orthogonal Direct connector system, ideal for next-generation data and telecommunication equipment with rates up to 25 Gbps; and |

| | • | | Premo-Flex™ FFC and Etched Polyimide Jumpers, Premo-Flex™ FFC and etched polyimide jumpers, available in a variety of pitches, cable lengths and thicknesses and high-temperature ratings up to +105°C deliver durable, ultra flexible, competitively priced solutions for PCB connections in virtually any industry. |

Consumer. In the consumer market, we believe our key strengths include micro-miniature connector engineering and manufacturing capabilities, breadth of our high wattage product line and cable and wire application equipment.

We design and manufacture many of the world’s smallest connectors for home and portable audio, digital still and video cameras, DVD players and recorders, as well as devices that combine multiple functions. Our micro-miniature products support customer needs for increased power, speed and functionality, but with decreased weight and space requirements. We provide industry leadership with advanced interconnection products that help enhance the performance of video and still cameras, DVD players, portable music players, PDAs and hybrid devices that combine multiple capabilities into a single unit.

We are a leading connector source and preferred supplier to computer game makers. In addition, we provide components for gaming machines.

5

We released several new products for the consumer market in fiscal 2012 including:

| | • | | MobliquA™ antenna technology supports small-volume antenna designs without compromising efficiency and provides standard or custom solutions for an unlimited range of wireless applications and includes with superior bandwidth enhancing capability; |

| | • | | FFC-FPC (SMT), our microminiature SMT FFC/FPC connectors include features to meet a wide variety of space and application-specific needs; |

| | • | | micro-SIM Card Sockets, operate in push-push and push-pull styles that offer excellent electrical reliability and maximum space savings; and |

| | • | | SlimStack™ 0.40mm Pitch Board-to-Board Connectors, are low profile, ultra-narrow-width connectors manufactured in various stack heights for space savings and design flexibility, ideal for tight packaging applications such as mobile phones. |

Industrial. In the industrial market, we believe our key strengths include our industrial communications and networking technology, breadth of our power and signal product lines, distribution partnerships and global presence.

Our extensive industrial product line includes network interface cards, software for industrial networks and custom or industry standard cord sets. We offer a complete line of Woodhead® electrical solutions designed to support optimal worker safety and performance for today’s harsh duty environments. Our industry-leading solutions support the needs of industries such as factory automation, commercial construction, utility, petrochemical and food and beverage. In addition, we offer I/O connectors deployed in a variety of industrial production equipment on the factory floor, including:

| | • | | automated assembly equipment; |

| | • | | conveyors and material handling equipment; |

| | • | | packaging equipment; and |

We released several new products for the industrial market in fiscal 2012 including:

| | • | | Brad® Ultra-Lock® (M12) EX Connection System for Zone 2 Hazardous Locations achieve non-arcing connections in a one-step installation process with the Brad® Ultra-Lock® (M12) EX Connection System, designed for industrial automation use in Class I, Division 2 and Zone 2 hazardous areas; |

| | • | | Brad® Micro-Change® (M12) Connectors, Rugged Micro-Change® connectors and receptacles provide a high-pin-density M12 solution and can be used in harsh commercial and industrial environments; and |

| | • | | SolarSpec™ Junction Box and Cable Assemblies, Innovative SolarSpec™ products deliver solutions to the solar market and provide value to module manufacturers, installers and distributors. |

Automotive. In the automotive market, we believe our strengths include our wide range of products and extensive research and development capabilities that include rapid prototyping and high volume production support. Our automotive products are designed for every system in today’s connected vehicle: infotainment and navigation, powertrain, safety and chassis and body electronics. In addition to advanced electronics, we provide standard product offerings such as HSAutoLinkTM, MX150TM, STAC64TM, CMC, MX123TM and Squib.

We released several new products for the automotive market in fiscal 2012 including:

| | • | | Mini50™ Unsealed Connection Systems achieve space savings over traditional USCAR 0.64mm connectors with smaller terminals to fit more low-current electrical circuits in interior, unsealed, transportation-vehicle environments; |

6

| | • | | Mizu-P25™ Miniature Waterproof Connectors provides superior levels of dustproof and waterproof protection along with space savings; |

| | • | | Automotive Sensor Interconnects reduce the package size in automotive sensor applications which allow automakers to achieve greater competitive advantage; and |

| | • | | S8 Automotive Bulb Sockets simplify assembly and include a patented individual wire seal design that provides easy attachment during the crimping process. |

Other. Medical electronics is a growing market for our connectors, switch and assembly products. We provide both connectors and custom integrated systems for diagnostic and therapeutic equipment used in hospitals, including x-ray, magnetic resonance imaging and dialysis machines. Military electronics is also one of our focus markets. There is a range of electronic applications for our products in the commercial-off-the-shelf segment of this market. Products originally developed for the infotech, telecommunications and automotive markets are used in an increasing number of military applications. We are also expanding into non-connector markets, such as Solid State Lighting. Our Solid State Lighting business focuses on producing solutions that accelerate the adoption of LED lighting in general illumination, including LED holders and packaged LED/electronics products.

We released several new products for these other markets in fiscal 2012 including:

| | • | | MediSpec™ Hybrid Circular MT Cable Assemblies and Receptacles provide high-performance, mixed optical and electrical signaling to streamline the amount of connectors required in medical systems; |

| | • | | Tight-Jacketed Cable LC and SC Connectors reduce optical micro bends and fiber breakage and are designed for synchronized plug-and-cable movement in tight, outer-jacket cable commonly deployed in rugged military and industrial applications; and |

| | • | | LED Array Holder for Sharp Zenigata (COB) Arrays simplify the installation process for small-fixture applications and reduce installation time with compression contacts that eliminate hand soldering. |

Business Objectives and Strategies

One of our business objectives is to develop or improve our leadership position in each of our primary markets by increasing our overall position as a preferred supplier and improving our competitiveness on a global scale.

We believe that our success in achieving net revenue growth exceeding the connector market growth rate throughout our history is the result of the following key strengths:

| | • | | broad and deep technological knowledge of microelectronic devices and techniques, power sources, coatings and materials; |

| | • | | strong intellectual property portfolio that underlies many key products; |

| | • | | high product quality standards, backed with stringent systems designed to ensure consistent performance, that meet or surpass customers’ expectations; |

| | • | | strong technical collaboration with customers; |

| | • | | extensive experience with advanced development, engineering, and new product development processes; |

| | • | | broad geographical presence in developed and developing markets; |

| | • | | continuous effort to develop an efficient, low-cost manufacturing footprint; and |

| | • | | a broad range of products both for specific and standard applications. |

7

We serve our customers by continuing to focus on the following strategies:

| | • | | Concentrate on core markets. We focus on markets where we have the expertise, qualifications and leadership position to sustain a competitive advantage. We have been an established supplier of interconnect solutions for 73 years. We are a principal supplier of connector components to the telecommunications, infotech, consumer, industrial and automotive electronics markets. |

| | • | | Grow through the development and release of new products. We invest strategically in the tools and resources to develop and market new products and to expand existing product lines through innovation. New products are essential to enable our customers to advance their solutions and their market leadership positions. |

| | • | | Strategic investments in selected adjacencies. We continuously review and prioritize opportunities for adjacent markets for our technologies. A subset of these are becoming priorities for us and are pursued to expand our available market. |

| | • | | Optimize manufacturing and supply chain. We analyze the design and manufacturing patterns of our customers along with our own supply chain economics to help ensure that our manufacturing operations are of sufficient scale and are located strategically to minimize production costs and maximize customer service. |

| | • | | Leverage financial strength. We use our expected cash flow from operations and strong balance sheet to invest aggressively in new product development, to pursue synergistic acquisitions, to align manufacturing capacity with customer requirements and to pursue productivity improvements. We invested approximately 6.5% and 5.2% of fiscal 2012 net revenue in capital expenditures and research and development activities, respectively. |

Our global organizational structure consists of three product-focused divisions and one worldwide sales and marketing organization. The structure enables us to work effectively as a global team to meet customer needs as well as leverage our design expertise and our low-cost production centers around the world. The worldwide sales and marketing organization structure enhances our ability to sell any product, to any customer, anywhere in the world.

Competition

We compete with many companies in each of our product categories and global industries. These competitors include Amphenol Corporation, Delphi Automotive PLC, Hirose Electronic Co., Ltd, Hon Hai Precision Industry Co., Ltd., Japan Aviation Electronics Industry, Ltd., Japan Solderless Terminal Ltd. and TE Connectivity Ltd. We also compete with a significant number of smaller competitors who compete in specific geographies and industries. The identity and significance of competitors may change over time. We believe that the 10 largest connector suppliers, as measured by net revenue, represent approximately 54% of the worldwide market. Many of these companies offer products in some, but not all, of the markets and regions we serve.

Our products compete to varying degrees on the basis of quality, price, availability, performance and brand recognition. We also compete on the basis of customer service. Our ability to compete also depends on continually providing innovative new product solutions and worldwide support for our customers.

Customers and Sales Channels

We sell products directly to OEMs, contract manufacturers and distributors. Our customer base includes global companies and no single customer accounted for more than 10% of our net revenue in fiscal 2012, 2011 or 2010.

Many of our customers operate in more than one geographic region of the world and we have developed a global footprint to service these customers. We are engaged in significant operations in foreign countries. Our net revenue originating outside the United States was approximately 74% in fiscal 2012.

8

In fiscal 2012, the approximate share of net revenue by geographic region follows:

| | • | | 60% of net revenue originated in Asia-Pacific (China, including Hong Kong and Taiwan, India, Indonesia, Japan, Korea, Malaysia, the Philippines, Singapore and Thailand). Approximately 32% and 14% of net revenue in fiscal 2012 was derived from operations in China and Japan, respectively. |

| | • | | 26% of net revenue originated in the Americas. |

| | • | | 14% of net revenue originated in Europe. |

Most of our sales in international markets are made by foreign sales subsidiaries. In countries with low sales volumes, sales are made through various representatives and distributors. A discussion of market risk associated with changes in foreign currency exchange rates can be found in Management’s Discussion and Analysis of Financial Condition and Results of Operations and Risk Factors.

We sell our products primarily through our own sales organization with a presence in most major connector markets worldwide. To complement our own sales force, we work with a network of distributors to serve a broader customer base and provide a wide variety of supply chain tools and capabilities. Sales through distributors represented approximately 25% of our net revenue in fiscal 2012.

We seek to provide each customer one-to-one service tailored to their business needs. Our engineers work collaboratively with customers to develop products for specific applications. We provide customers the benefit of state-of-the-art technology for engineering, design and prototyping, supported by development centers throughout the world. In addition, most customers have a single Molex customer service contact and a specific field salesperson to provide technical product and application expertise.

Our sales force around the world has access to our global information systems to provide 24/7 visibility on orders, pricing, contracts, shipping, inventory and customer programs. We offer a self-service environment for our customers through our web site at www.molex.com, so that customers can access our entire product line, download drawings or 3D models, obtain price quotes, order samples and track delivery.

Information regarding our operations by reporting segment appears in Note 21 of the Notes to Consolidated Financial Statements.

Research and Development

We remain committed to investing in world-class technology development, particularly in the design and manufacture of connectors and interconnect systems. Our research and development activities are directed toward developing technology innovations, primarily high-speed signal integrity, miniaturization, higher power delivery, optical signal delivery and sealed harsh environment connectors that we believe will deliver the next generation of products. We continue to invest in new manufacturing processes, improve existing products and reduce costs. We believe that we are well positioned in the technology industry to help drive innovation and promote industry standards that will yield innovative and improved products for customers.

We incurred total research and development costs of $181.1 million in fiscal 2012, $170.1 million in fiscal 2011 and $154.0 million in fiscal 2010. We believe this investment, approximating 5.2% of net revenue, is among the highest levels relative to the largest participants in the industry and helps us achieve a competitive advantage.

We strive to provide customers with the most advanced interconnection products through intellectual property development and participation in industry standards committees. Our engineers are active in many of these committees, helping to give us a voice in shaping the technologies of the future. In fiscal 2012, we commercialized 229 new products and received 319 patents.

9

We perform a majority of our design and development of connector products in the United States and Japan, but have additional product development capabilities in various locations, including China, Germany, Ireland, Korea and Singapore.

Manufacturing

Our core manufacturing expertise includes molding, stamping, plating and assembly operations. We use state of the art plastic injection molding machines and metal stamping and forming presses. We have created new processes to meet the ongoing challenge of manufacturing smaller connectors. We continue to utilize our proprietary plated plastic technology, which provides excellent shielding performance while eliminating secondary manufacturing processes in applications such as mobile phone antennas.

We also have expertise in printed circuit card, flexible circuit and harness assembly for our integrated products operations, which build devices that leverage our connector content. We operate low-cost manufacturing centers in China, India, Malaysia, Mexico, Poland, the Philippines, Thailand and Vietnam to reduce our manufacturing costs and align our footprint with our customers’ needs.

Continuous improvements achieved through a global lean/six sigma program have reduced our manufacturing costs and improved our quality and delivery. Our trend of fewer but larger factories, such as our one million square foot facility in Chengdu, China, provides increasing economies of scale and efficiencies.

Raw Materials

The principal raw materials that we purchase for the manufacture of our products include plastic resins for molding, metal alloys (primarily copper based) for stamping and gold and palladium salts for use in the plating process. We also purchase molded and stamped components and connector assemblies. Most materials and components used in our products are available from several sources. To achieve economies of scale, we concentrate purchases from a limited number of suppliers, and therefore in the short term may be dependent upon certain suppliers to meet performance and quality specifications and delivery schedules. We use financial instruments to hedge the volatility of commodity material costs. We anticipate that our raw material expenditures as a percentage of sales may increase due to growth in our integrated products business and increases in certain commodity costs.

Backlog

The backlog of unfilled orders as of June 30, 2012 was approximately $416.4 million compared with backlog of $418.5 million as of June 30, 2011. Substantially all of these orders are scheduled for delivery within 12 months. The majority of orders are shipped within 30 days of acceptance.

Employees

As of June 30, 2012, we had 34,226 people working for us worldwide. Approximately 70% of these people were located in low labor cost countries. We believe that we have strong relations with our employees.

Acquisitions and Investments

Our strategy to provide a broad range of connectors requires a wide variety of technologies, products and capabilities. The rapid pace of technological development in the connector industry and the specialized expertise required in different markets make it difficult for a single company to organically develop all of the required products. Though a significant majority of our growth has come from internally developed products, we will seek to make future acquisitions or investments where we believe we can stimulate the development of, or acquire, new technologies and products to further our strategic objectives and strengthen our existing businesses. Information regarding our acquisitions appears in Note 5 of the Notes to Consolidated Financial Statements.

10

Intellectual Property

Patents, trade secrets and trademarks and other proprietary rights (collectively, Intellectual Property) are important to our business. We own an extensive portfolio of U.S. and foreign patents and trademarks. In addition, we are a licensee of various third-party patents and trademarks. We review third-party Intellectual Property in an effort to avoid infringements of third-party Intellectual Property rights and to identify desirable third-party Intellectual Property rights to license to advance our business objectives. We also review our competitors’ products to identify infringements of our Intellectual Property rights and to identify licensing opportunities for our Intellectual Property rights. We believe that our Intellectual Property is important to our business, but do not consider ourselves materially dependent upon any particular piece of Intellectual Property.

Environmental, Health & Safety (EHS) Matters

We are committed to achieving high standards of environmental quality and product safety, and strive to provide a safe and healthy workplace for our employees, contractors and the communities in which we do business. We have EHS policies and disciplines that are applied to our operations. We closely monitor the environmental laws and regulations in the countries in which we operate and believe we are in compliance in all material respects with federal, state and local regulations pertaining to environmental protection.

All major Molex manufacturing sites are certified to the International Organization for Standardization 14001 environmental management system standard, which requires that a broad range of environmental processes and policies be in place to minimize environmental impact, maintain compliance with environmental regulations and communicate effectively with interested stakeholders. In addition, many sites globally are Occupational Health and Safety Assessment Series 18001 certified Occupational Health and Safety Management Systems, which is intended to manage occupational health and safety risks and drive continual health and safety improvement within our operations. Our corporate social responsibility auditing program includes not only compliance components, but also modules on business risk, environmental excellence and management systems. We have internal processes that focus on minimizing and properly managing hazardous materials used in our facilities and products. We monitor regulatory and resource trends and set short and long-term targets to continually improve our environmental performance.

The manufacture, assembly and testing of our products are subject to a broad array of laws and regulations, including restrictions on the use of hazardous materials. We have a program for compliance with the European Union Restriction on Certain Hazardous Substances Directive (RoHS) and similar laws.

11

Executive Officers

Our executive officers as of July 27, 2012 are set forth in the table below.

| | | | | | | | | | |

Name | | Positions Held with Registrant During the Last Five Years | | Age | | | Year

Employed | |

Frederick A. Krehbiel(a) | | Co-Chairman (1999-present); Chief Executive Officer (2004-2005); Co-Chief Executive Officer (1999-2001). | | | 71 | | | | 1965(b | ) |

John H. Krehbiel, Jr.(a) | | Co-Chairman (1999-present); Co-Chief Executive Officer (1999-2001). | | | 75 | | | | 1959(b | ) |

Martin P. Slark | | Vice-Chairman and Chief Executive Officer (2005-present); President and Chief Operating Officer (2001-2005). | | | 57 | | | | 1976 | |

Liam McCarthy | | President and Chief Operating Officer (2005-present); Vice President of Operations, Europe (2000-2005). | | | 56 | | | | 1976 | |

David D. Johnson | | Executive Vice President, Treasurer and Chief Financial Officer (2005-present). | | | 56 | | | | 2005 | |

Graham C. Brock | | Executive Vice President (2005-present) and President, Global Sales & Marketing (2006-present) and Regional President, Europe (2005). | | | 58 | | | | 1976 | |

James E. Fleischhacker | | Executive Vice President (2001-present), Technology & Innovation (2012-present); President, Global Commercial Products Division (2009-2012); President Global Transportation Products Division

(2007-2009). | | | 68 | | | | 1984 | |

Katsumi Hirokawa | | Executive Vice President (2005-present) and President, Global Micro Products Division (2007-present); Vice President and President, Asia-Pacific North

(2005-2007). | | | 65 | | | | 1995 | |

J. Michael Nauman | | Executive Vice President and President, Global Integrated Products Division (2009-present); Senior Vice President and President, Global Integrated Products Division (2007-2009); President, Integrated Products Division, Americas Region (2005-2007). | | | 50 | | | | 1994 | |

Joseph Nelligan | | Senior Vice President, (2011-present); President, Commercial Products Division (2012-present); Vice President, Product Development and Commercialization, Commercial Products Division (2009-2011); Vice President, Global Industry Group — Datacom (2007-2009). | | | 48 | | | | 1984 | |

Gary J. Matula | | Senior Vice President, Information Systems and Chief Information Officer (2008-present); Vice President, Information Systems and Chief Information Officer (2004-2008). | | | 57 | | | | 1984 | |

Timothy I. Ruff | | Senior Vice President, Business Development and Corporate Strategy (2012-present); Vice President Sales and Marketing, Americas (2006-2011). | | | 47 | | | | 1988 | |

Ana G. Rodriguez | | Senior Vice President, Global Human Resources (2008-present); Vice President, Co-General Counsel and Secretary (2007-2008). | | | 44 | | | | 2005 | |

12

| (a) | John H. Krehbiel, Jr. and Frederick A. Krehbiel (the Krehbiel Family) are brothers. The members of the Krehbiel Family may be considered to be “control persons” of Molex. The other executive officers listed above have no relationship, family or otherwise, to the Krehbiel Family, Molex or each other. |

| (b) | Includes period employed by our predecessor company. |

Code of Business Conduct and Ethics

We have adopted a Code of Business Conduct and Ethics applicable to all employees, officers and directors. The Code of Business Conduct incorporates our policies and guidelines designed to deter wrongdoing and to promote honest and ethical conduct and compliance with applicable laws and regulations. We have also adopted a Code of Ethics for Senior Financial Management applicable to our Chief Executive Officer, Chief Financial Officer, Chief Accounting Officer and other senior financial managers. The Code of Ethics sets out our expectations that financial management produce full, fair, accurate, timely and understandable disclosure in our filings with the Securities and Exchange Commission (the SEC) and other public communications. We intend to post any amendments to or waivers from these codes of conduct on our web site.

The full text of these codes of conduct is published on the investor relations page of our web site at www.molex.com.

Available Information

We file with the SEC our annual report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and all amendments to those reports, proxy statements and registration statements. You may read and copy any material we file with the SEC at the SEC’s Public Reference Room at 100 F Street, NE, Washington, D.C. 20549. You may also obtain information on the operation of the Public Reference Room by calling the SEC at 1-800-SEC-0330. In addition, the SEC maintains an internet site at http://www.sec.gov that contains reports, proxy and information statements, and other information regarding issuers, including us, that file electronically. We make available free of charge on or through our website at www.molex.com our annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K and amendments to these reports filed or furnished pursuant to Section 13(a) or 15(d) of the Exchange Act as soon as reasonably practicable after we file these materials with the SEC.

Cautionary Statement Regarding Forward-Looking Statements

This Annual Report on Form 10-K and other documents we file with the SEC contain forward-looking statements that are based on current expectations, estimates, forecasts and projections about our future performance, business, beliefs, and management’s assumptions. In addition, we, or others on our behalf, may make forward-looking statements in press releases or written statements, or in our communications and discussions with investors and analysts in the normal course of business through meetings, web casts, phone calls, and conference calls. Words such as “expect,” “anticipate,” “outlook,” “forecast,” “could,” “project,” “intend,” “plan,” “continue,” “believe,” “seek,” “estimate,” “should,” “may,” “assume,” “potential,” variations of such words and similar expressions are intended to identify such forward-looking statements. These statements are not guarantees of future performance and involve certain risks, uncertainties, and assumptions that are difficult to predict. We describe our respective risks, uncertainties, and assumptions that could affect the outcome or results of operations below.

We have based our forward-looking statements on our management’s beliefs and assumptions based on information available to management at the time the statements are made. We caution you that actual outcomes and results may differ materially from what is expressed, implied, or forecast by our forward-looking statements. Reference is made in particular to forward-looking statements regard-

13

ing growth strategies, industry trends, global economic conditions, success of customers, cost of raw materials, value of inventory, availability of credit, currency exchange rates, labor costs, protection of intellectual property, cost reduction initiatives, acquisition synergies, manufacturing strategies, product development introduction and sales, regulatory changes, competitive strengths, natural disasters, unauthorized access to data, government investigations and outcomes of legal proceedings. Except as required under the federal securities laws, we do not have any intention or obligation to update publicly any forward-looking statements after the distribution of this report, whether as a result of new information, future events, changes in assumptions, or otherwise.

Risk Factors

You should carefully consider the risks described below. These risks are not the only ones facing our company. Additional risks and uncertainties not presently known to us or that we currently believe to be immaterial may also impair our business operations. If any of the following risks occur, our business, financial condition or operating results could be materially adversely affected.

Risks Relating to Our Business

We may be adversely affected by a prolonged economic downturn or economic uncertainty.

Our business and operating results have been and will continue to be affected by global economic conditions. When global economic conditions deteriorate or economic uncertainty increases, our customers or potential customers may experience deterioration of their businesses, which may result in the delay or cancellation of plans to purchase our products. Our sensitivity to economic cycles and any related fluctuation in the businesses of our customers or potential customers may have a material adverse effect on our financial condition, results of operations or cash flows.

We may see a negative effect on our business due to disruptions in financial markets.

Economic downturns and economic uncertainty generally affect global credit markets. Financial markets in the United States, Europe and Asia have been experiencing volatility in security prices, limited liquidity and credit availability, rating downgrades of certain investments and declining valuation of others. While these conditions have not yet impaired our ability to access credit markets and finance our operations, there is no assurance that there will not be deterioration in financial markets and confidence in developed economies. The tightening of credit in financial markets may adversely affect the ability of our customers and suppliers to obtain financing of significant purchases and operations and this can in turn have a material adverse effect on our business and results of operations.

We are dependent on the success of our customers.

We are dependent on the continued growth, viability and financial stability of our customers. Our customers generally are OEMs in the telecommunications, infotech, automotive, consumer and industrial markets. These markets are subject to rapid technological change, vigorous competition and short product life cycles and cyclical and reduced consumer demand patterns. When our customers are adversely affected by these factors, we may be similarly affected.

For example, the telecommunications market, which accounted for approximately 23% of our net revenue in fiscal 2012, has historically experienced periods of robust capital expenditure followed by periods of retrenchment and consolidation. The infotech market, which accounted for 26% of our net revenue in fiscal 2012, has fluctuated seasonally and is subject to variations in enterprise spending depending on current economic and credit conditions. Periodic downturns in our customers’ industries can significantly reduce demand for certain of our products, which could have a material adverse effect on our financial condition, results of operations and cash flows.

14

We are subject to continuing pressure to lower our prices.

Over the past several years, we have experienced, and we expect to continue to experience, pressure to lower our prices. In the last two years, we have experienced annual price erosion averaging from 2% to 3% of net revenue. In order to maintain our margins, we must continue to reduce our costs by similar amounts. Continuing pressure to reduce our prices could have a material adverse effect on our financial condition, results of operations and cash flows.

We face rising costs of commodity materials.

The cost and availability of certain commodity materials used to manufacture our products, such as plastic resins, copper-based metal alloys, gold and palladium salts, molded and stamped components and connector assemblies, are critical to our success. The prices of many of these raw materials, including copper and gold, has increased in recent years, and continues to fluctuate. Gold, which made up approximately 16% of our material cost in fiscal 2012, has increased in price approximately 52% since fiscal 2010. In addition, many of these commodity materials are produced in a limited number of regions around the world or are only available from a limited number of suppliers. Volatility in the prices and shortages of such materials may result in increased costs and lower operating margins if we are unable to pass such increased costs through to our customers. Some of our competitors may be less dependent on these commodity materials and have less exposure to these volatile commodity costs. Our results of operations, financial condition and cash flows may be materially and adversely affected if we have difficulty obtaining these commodity materials, the quality of available commodity materials deteriorates, or there are continued significant price increases for these commodity materials. We use financial instruments to hedge the volatility of commodity material costs. The success of our hedging program depends on accurate forecasting of transaction activity in the various commodity materials. We could experience unanticipated commodity materials or hedge gains or losses if these forecasts are inaccurate during periods of volatility.

We face intense competition in our markets.

Our markets are highly competitive and we expect that both direct and indirect competition will increase in the future. Our overall competitive position depends on a number of factors including the price, quality and performance of our products, the level of customer service, the development of new technology and our ability to participate in emerging markets. A relative decline in our competitive position in these areas could have a material adverse effect on our financial condition. Within each of our markets, we encounter direct competition from other electronic components manufacturers and suppliers ranging in size from large, diversified manufacturers to small, highly specialized manufacturers. Competition may intensify from various U.S. and non-U.S. competitors and new market entrants, some of which may be our current customers. Our markets have continued to become increasingly concentrated and globalized in recent years, and our major competitors have significant financial resources and technological capabilities. Moreover, our competitive position is increasingly dependent upon being a socially responsible citizen and any inability to meet our customers’ expectations may result in a loss of business and market share to competitors. Increased competition may result in price reductions, reduced margins or loss of market share, any of which could materially and adversely affect our business, operating results and financial condition.

We are dependent on new products.

We expect that a significant portion of our future net revenue will continue to be derived from sales of newly introduced products. Rapidly changing technology, evolving industry standards and changes in customer needs characterize the market for our products. If we fail to modify or improve our products in response to changes in technology, industry standards or customer needs, our products could rapidly become less competitive or obsolete. We must continue to make investments in research and development in order to timely develop new products, enhance existing products and achieve market acceptance for such products. As a result of our need to make these investments in research and

15

development, our operating results could be materially affected if our net revenue falls below expectations. Moreover, there is no assurance that development stage products will be successfully completed or, if developed, will achieve significant customer acceptance.

We may need to license new technologies to respond to technological change and these licenses may not be available to us on terms that we can accept or may materially change the gross profit margin that we are able to obtain on our products. We may not succeed in adapting our products to new technologies as they emerge. Development and manufacturing schedules for technology products are difficult to predict, and there is no assurance that we will achieve timely initial customer shipments of new products. The timely availability of these products in volume and their acceptance by customers are important to our future success.

We face manufacturing challenges.

The volume and timing of sales to our customers may vary due to: variation in demand for our customers’ products; our customers’ attempts to manage their inventory; design changes; changes in our customers’ manufacturing strategy; and consolidations among or acquisitions of customers. Due in part to these factors, many of our customers do not commit to long-term production schedules. Our inability to forecast the level of customer orders with certainty makes it difficult to schedule production and maximize utilization of manufacturing capacity.

Our industry must provide increasingly rapid product turnaround for its customers. We generally do not obtain firm, long-term purchase commitments from our customers and we continue to experience reduced lead-times in customer orders. Customers may cancel their orders, change production quantities or delay production for a number of reasons and such actions could negatively affect our operating results. In addition, we make significant operating decisions based on our estimate of customer requirements. The short-term nature of our customers’ commitments and the possibility of rapid changes in demand for their products reduce our ability to accurately estimate the future requirements of those customers.

We rely on third-party suppliers for the components used in our products, and we rely on third-party manufacturers to manufacture certain of our assemblies and finished products. Our results of operations, financial condition, and cash flows could be adversely affected if our third-party suppliers lack sufficient quality control or if there are significant changes in their financial or business condition. If our third-party suppliers fail to deliver products, parts, and components of sufficient quality on time and at reasonable prices, we could have difficulties fulfilling our orders, sales and profits could decline, and our commercial reputation could be damaged.

From time to time, we have underutilized our manufacturing lines. This excess capacity means we incur increased fixed costs in our products relative to the net revenue we generate, which could have an adverse effect on our results of operations, particularly during economic downturns. If we are unable to improve utilization levels for these manufacturing lines and correctly manage capacity, the increased expense levels will have an adverse effect on our business, financial condition and results of operations. In addition, some of our manufacturing lines are located in China or other foreign countries that are subject to a number of additional risks and uncertainties, including increasing labor costs and political, social and economic instability.

We are dependent on independent distributors to sell and market our products.

Sales through independent distributors accounted for approximately 25% of our net revenue in fiscal 2012. Although we have entered into written agreements with most of the distributors, the agreements are nonexclusive and generally may be terminated by either party upon written notice. The distributors are not within our control, are not obligated to purchase products from us, and may also sell other lines of products. We do not assure you that these distributors will continue their current relationships with us or that they will not give higher priority to the sale of other products, which could include products of competitors. A reduction in sales efforts or discontinuance of sales of our products

16

by the distributors would lead to reduced sales and could materially adversely affect our financial condition, results of operations and business. Selling through indirect channels such as distributors may limit our contact with the ultimate customers and our ability to assure customer satisfaction.

We face industry consolidation.

Many of the industries to which we sell our products, as well as many of the industries from which we buy materials, have become increasingly concentrated in recent years, including the telecommunications, infotech, automotive and consumer electronics industries. Consolidation of customers may lead to decreased product purchases from us. In addition, as our customers buy in larger volumes, their volume buying power has increased, and they may be able to negotiate more favorable pricing and find alternative sources from which to purchase. Our materials suppliers similarly have increased their ability to negotiate favorable pricing. These trends may adversely affect the profit margins of our products, particularly for commodity components.

We face the possibility that our gross margins may decline.

In response to changes in product mix, competitive pricing pressures, increased sales discounts, introductions of new competitive products, product enhancements by our competitors, increases in manufacturing or labor costs or other operating expenses, we may experience declines in prices, gross margins and profitability. To maintain our gross margins we must maintain or increase current shipment volumes, develop and introduce new products and product enhancements and reduce the costs to produce our products. If we are unable to accomplish this, our net revenue, gross profit and operating results may be below our expectations and those of investors and analysts.

We face risks associated with inventory.

The value of our inventory may decline as a result of surplus inventory, price reductions or technological obsolescence. The life cycles of some of our products can be very short compared with the development cycle, which may result in excess or obsolete inventory or equipment that we may need to write off. We must identify the right product mix and maintain sufficient inventory on hand to meet customer orders. Failure to do so could adversely affect our net revenue and operating results. However, if circumstances change (for example, an unexpected shift in market demand, pricing or customer defaults) there could be a material effect on the net realizable value of our inventory. We maintain an inventory valuation reserve account against diminution in the value or salability of our inventory. However, there is no guaranty that these arrangements will be sufficient to avoid write-offs in excess of our reserves in all circumstances.

We may encounter problems associated with our global operations.

For fiscal year 2012, approximately 74% of our net revenue came from international sales, including 32% and 14% in China and Japan, respectively. In addition, a significant portion of our operations consists of manufacturing activities outside of the United States, including approximately 21% and 30% in China and Japan, respectively. Our ability to sell our products and conduct our operations globally is subject to a number of risks. Local economic, political and labor conditions in each country could adversely affect demand for our products and services or disrupt our operations in these markets. We may also experience reduced intellectual property protection or longer and more challenging collection cycles as a result of different customary business practices in certain countries, including China where we do business. Additionally, we face the following risks:

| | • | | international business conditions including the relationships between the United States and other governments; |

| | • | | unexpected changes in laws, regulations, trade, monetary or fiscal policy, including interest rates, foreign currency exchange rates and changes in the rate of inflation in the United States and other foreign countries; |

17

| | • | | tariffs, quotas, customs and other import or export restrictions and other trade barriers; |

| | • | | difficulties in staffing and management; |

| | • | | language and cultural barriers, including those related to employment regulation; |

| | • | | disruption of our supply chain as a result of natural disasters; and |

| | • | | potentially adverse tax consequences. |

We are exposed to fluctuations in currency exchange rates.

We face substantial exposure to movements in non-U.S. currency exchange rates because a significant portion of our business is conducted outside the United States. This may harm our results of operations, and any measures that we may implement to reduce the effect of volatile currencies and other risks of our global operations may not be effective. Approximately 64% of our net revenue for fiscal year 2012 was invoiced in currencies other than the U.S. dollar, and we expect net revenue and manufacturing costs from non-U.S. markets to continue to represent a significant portion of our operating results. Price increases caused by currency exchange rate fluctuations may make our products less competitive or have an adverse effect on our margins. Our international net revenue and expenses generally are derived from sales and operations in currencies other than the U.S. dollar. Accordingly, when the U.S. dollar strengthens in relation to the currencies of the countries in which we sell our products, our U.S. dollar reported net revenue and income will decrease. Currency exchange rate fluctuations may also disrupt the business of our suppliers by making their purchases of raw materials more expensive and more difficult to finance. We mitigate a portion of our foreign currency exchange rate risk principally through the establishment of local production facilities in the markets we serve. This creates a “natural hedge” since purchases and sales within a specific country are both denominated in the same currency and therefore no exposure exists to hedge with a foreign exchange forward or option contract (collectively, “foreign exchange contracts”). Natural hedges exist in most countries in which we operate, although the percentage of natural offsets, as compared with offsets that need to be hedged by foreign exchange contracts, will vary from country to country. To reduce our exposure to fluctuations in currency exchange rates when natural hedges are not effective, we may use financial instruments to hedge U.S. dollar and other currency commitments and cash flows arising from trade accounts receivable, trade accounts payable and fixed purchase obligations.

If these hedging activities are not successful or we change or reduce these hedging activities in the future, we may experience significant unexpected expenses from fluctuations in exchange rates or financial instruments which become ineffective. The success of our hedging program depends on accurate forecasts of transaction activity in the various currencies. To the extent that these forecasts are over or understated during periods of currency volatility, we could experience unanticipated currency or hedge gains or losses.

We may find that our products have quality issues.

The fabrication of the products we manufacture is a complex and precise process. Our customers specify quality, performance and reliability standards. If flaws in either the design or manufacture of our products were to occur, we could experience a rate of failure in our products that could result in significant delays in shipment and product re-work or replacement costs. Although we engage in extensive product quality programs and processes, these may not be sufficient to avoid product failures, which could cause any of the following to occur and negatively affect our financial condition and results of operations:

| | • | | incur increased costs such as warranty expense and costs associated with customer support; |

| | • | | experience delays, cancellations or rescheduling of orders for our products; |

18

| | • | | experience increased product returns or discounts; or |

If we fail to manage our growth effectively or to integrate successfully any future acquisition, our business could be harmed.

We expect to continue to make investments in companies, products and technologies through acquisitions. While we believe that such acquisitions are an integral part of our long-term strategy, there are risks and uncertainties related to acquiring companies. Such risks and uncertainties include:

| | • | | successfully identifying and completing transactions; |

| | • | | difficulty in integrating acquired operations, technology and products or realizing cost savings or other anticipated benefits from integration; |

| | • | | retaining customers and existing contracts; |

| | • | | retaining the key employees of the acquired operation; |

| | • | | potential disruption of our or the acquired company’s ongoing business; |

| | • | | charges for impairment of long-term assets; |

| | • | | unanticipated expenses related to integration; and |

| | • | | potential unknown liabilities associated with the acquired company. |

In addition, if we were to undertake a substantial acquisition for cash, the acquisition would likely need to be financed in part through additional financing from banks, through public offerings or private placements of debt or equity securities, or other arrangements. This acquisition financing might decrease our ratio of earnings to fixed charges and adversely affect other leverage measures. Any necessary acquisition financing may not be available to us on acceptable terms if and when required. If we undertake an acquisition by issuing equity securities or equity-linked securities, the issued securities would have a dilutive effect on the interests of the holders of our stock.

We depend on our key employees and face competition in hiring and retaining qualified employees.

Our future success depends partly on the continued contribution of our key employees, including executive, engineering, sales, marketing, manufacturing and administrative personnel. We face intense competition for key personnel in several of our product and geographic markets. Our future success depends in large part on our continued ability to hire, assimilate and retain key employees, including qualified engineers and other highly skilled personnel needed to compete and develop successful new products. We may not be as successful as competitors at recruiting, assimilating and retaining highly skilled personnel.

We are subject to various laws and government regulations.

We are subject to a wide and ever-changing variety of U.S. and foreign laws and regulations, compliance with which may require substantial expense. Of particular note are laws and regulations restricting the use of certain chemical substances in the production of electronic equipment. Failure to comply with these requirements could result in fines or suspension of sales.

In addition, some environmental laws impose liability, sometimes without fault, for investigating or cleaning up contamination on or emanating from our currently or formerly owned, leased or operated property, as well as for damages to property or natural resources and for personal injury arising out of such contamination.

19

We rely on our intellectual property rights.

We rely on a combination of patents, copyrights, trademarks and trade secrets and confidentiality provisions to establish and protect our proprietary rights. To this end, we hold rights to a number of patents and registered trademarks and regularly file applications to attempt to protect our rights in new technology and trademarks. Even if approved, our patents or trademarks may be successfully challenged by others or otherwise become invalidated for a variety of reasons. Also, to the extent a competitor is able to reproduce or otherwise capitalize on our intellectual property, it may be difficult, expensive or impossible for us to obtain necessary legal protection.

Third parties may claim that we are infringing their intellectual property rights. Such claims could have an adverse effect on our business and financial condition. From time to time we receive letters alleging infringement of patents. Litigation concerning patents or other intellectual property is costly and time consuming. We may seek licenses from such parties, but they could refuse to grant us a license or demand commercially unreasonable terms. Such infringement claims could also cause us to incur substantial liabilities and to suspend or permanently cease the manufacture and sale of affected products.

Our Information Technology (“IT”) systems could be breached.

We face certain security threats relating to the confidentiality and integrity of our IT systems. Despite implementation of security measures, our IT systems may be vulnerable to damage from computer viruses, cyber attacks and other unauthorized access and these security breaches could result in a disruption to our operations. A material network breach of our IT systems could involve the theft of our and our customers’ intellectual property or trade secrets which may be used by competitors to develop competing products. To the extent that any security breach results in a loss or damage to data, or inappropriate disclosure of confidential or proprietary information, it could cause significant damage to our reputation, affect our customer relations, lead to claims against us, increase our costs to protect against future damage and could result in a material adverse effect on our business and financial position.

We could suffer significant business interruptions.

Our operations and those of our suppliers and customers may be vulnerable to interruption by natural disasters such as earthquakes, tsunamis, typhoons, or floods, or other disasters such as fires, explosions, acts of terrorism or war, disease or failures of our management information or other systems due to internal or external causes. If a business interruption occurs, our business could be materially and adversely affected.

A decline in the market value of our pension plans’ investment portfolios could adversely affect our results of operations, financial condition and cash flows.

Concerns about deterioration in the global economy, together with the credit crisis, have caused significant volatility in interest rates and equity prices, which could decrease the value of our pension plans’ investment portfolios. A decrease in the value of our pension plans’ investment portfolios could have an adverse effect on our results of operations, financial condition and cash flows.

We may have exposure to income tax rate fluctuations and to additional tax liabilities, which could negatively affect our financial position.

As a corporation with operations both in the United States and abroad, we are subject to income taxes in the United States and various foreign jurisdictions. Our effective tax rate is subject to significant fluctuation from one period to the next because the income tax rates for each year are a function of a number of factors, including the following:

| | • | | the effects of a mix of earnings among countries with a broad range of statutory tax rates; |

| | • | | changes in the valuation of deferred tax assets and liabilities; |

20

| | • | | changes in assessment of tax exposures; and |

| | • | | changes in tax laws or the interpretation of these laws. |

Changes in the mix of these items and other items may cause our effective tax rate to fluctuate between periods, which could have a material adverse effect on our results of operations and financial condition.

In addition, if we encounter a significant need for liquidity domestically or at a particular location that we cannot fulfill through borrowings, equity offerings, or other internal or external sources, we may experience unfavorable tax and earnings consequences due to cash transfers. These adverse consequences would occur, for example, if the transfer of cash into the United States is taxed and no offsetting foreign tax credit is available to offset the U.S. tax liability, resulting in lower earnings. Foreign exchange ceilings imposed by local governments and the sometimes lengthy approval processes that foreign governments require for international cash transfers may delay our internal cash transfers from time to time.

We are also subject to non-income taxes, such as payroll, sales, use, value-added, net worth, property and goods and services taxes, in both the United States and various foreign jurisdictions.

Significant judgment is required in determining our provision for income taxes and other tax liabilities. Although we believe our tax estimates are reasonable, we are regularly under audit by tax authorities with respect to both income and non-income taxes and may have exposure to additional tax liabilities as a result of these audits. Unfavorable audit findings and tax rulings may result in payment of taxes, fines and penalties for prior periods and higher tax rates in future periods, which may have a material adverse effect on our results of operations and financial condition.

An adverse outcome in a litigation proceeding may result in a material adverse effect on our financial position.

We are currently a party to various legal proceedings which may divert financial and management resources. If one or more unfavorable final outcomes were to occur, our financial position could be materially and adversely affected.

Covenants in our debt instruments may adversely affect us if we are determined not to be in compliance.

Our unregistered, private placement of debt (the Private Placement) and three-year revolving credit facility in the United States (the U.S. Credit Facility) contain representations and covenants with which we are required to be in compliance. Although we believe none of these covenants are restrictive to our operations, our ability to meet these representations and/or covenants can be affected by events beyond our control, and we do not assure you that we will continue to comply. A breach of any of these representations and/or covenants could result in a default giving the lender(s) the right to declare all amounts outstanding thereunder to be immediately due and payable and our lender(s) could terminate commitments to extend further credit. If the lender(s) accelerate the repayment of borrowings, we do not assure you that we will have sufficient assets to repay our affected indebtedness. In addition, acceleration of any debt obligation under any of our material debt instruments may permit the lender(s) under other material debt instruments to accelerate payment of amounts outstanding.

Our certificate of incorporation and bylaws include antitakeover provisions, which may deter or prevent a takeover attempt.

Some provisions of our certificate of incorporation and bylaws may deter or prevent a takeover attempt, including a takeover that might result in a premium over the market price for our Common Stock and Class A Common Stock. Our governing documents establish a classified board, require stockholders to give advance notice prior to the annual meeting if they want to nominate a candidate

21

for director or present a proposal, and contain a number of provisions subject to supermajority vote. In addition, the Board may issue up to 25,000,000 shares of preferred stock without action by our stockholders, which could be used to make it more difficult and costly to acquire our company.

| Item 1B. | Unresolved Staff Comments |

None.

We own and lease manufacturing, design, warehousing, sales and administrative space in locations around the world. The leases are of varying terms with expirations ranging from fiscal 2012 through fiscal 2021. The leases in aggregate are not considered material to the financial position of Molex.

As of June 30, 2012, we owned or leased a total of approximately 9.7 million square feet of facility space worldwide. We have vacated several buildings in France, Germany and Slovakia and are holding these buildings and related assets for sale. We own 91% of our manufacturing, design, warehouse and office space and lease the remaining 9%. Our manufacturing plants are equipped with machinery, most of which we own and which, in part, we developed to meet the special requirements of our manufacturing processes. We believe that our buildings, machinery and equipment are well maintained and adequate for our current needs.

Our principal executive offices are located at 2222 Wellington Court, Lisle, Illinois, United States of America. We own 40 manufacturing locations, of which 15 are located in North America and 25 are located in other countries. A listing of the locations of our principal manufacturing facilities by geographic region is presented below:

| | • | | Americas: Mexico and United States |

| | • | | Asia-Pacific: China, India, Japan, Korea, Malaysia, the Philippines, Singapore, Taiwan, Thailand and Vietnam |

| | • | | Europe: Ireland, Italy and Poland |

Currently, we are involved in a number of legal proceedings. For a discussion of contingencies related to legal proceedings, see Note 20 of the Notes to Consolidated Financial Statements, which is hereby incorporated by reference.

| Item 4. | Mining Safety Disclosures — Not Applicable |

22

PART II

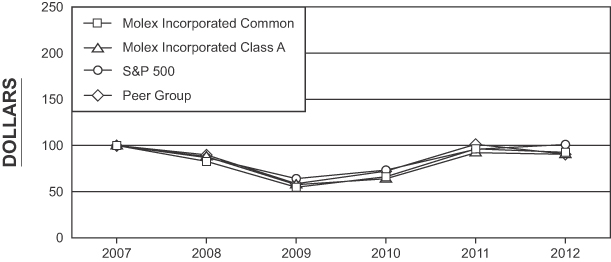

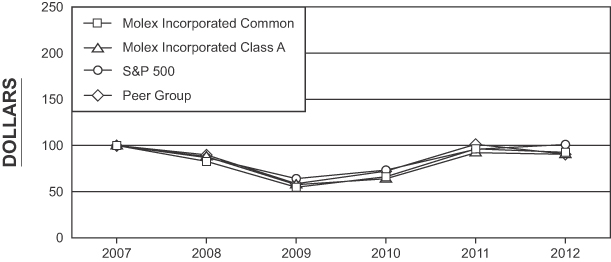

| Item 5. | Market for Registrant’s Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities |

Molex Incorporated is traded on the NASDAQ Global Select Market and on the London Stock Exchange and trades under the symbols MOLX for Common Stock and MOLXA for Class A Common Stock. Molex Class B Common Stock is not publicly traded.

The number of stockholders of record at June 30, 2012 was 1,883 for Common Stock, 5,150 for Class A Common Stock and 13 for Class B Common Stock.

The following table presents quarterly stock prices for the fiscal years ended June 30:

| | | | | | | | | | | | | | | | | | | | |

| | | | | | 2012 | | | 2011 | |

| | | Quarter | | | Low — High | | | Low — High | |

Common Stock | | | 1st | | | $ | 18.62 | | | $ | 26.63 | | | $ | 17.65 | | | $ | 21.10 | |

| | | 2nd | | | | 19.09 | | | | 25.88 | | | | 20.18 | | | | 23.02 | |

| | | 3rd | | | | 24.35 | | | | 28.38 | | | | 23.01 | | | | 28.22 | |

| | | 4th | | | | 22.19 | | | | 28.28 | | | | 24.22 | | | | 27.95 | |

| | | |

| | | | | | 2012 | | | 2011 | |

| | | Quarter | | | Low — High | | | Low — High | |