UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-K

| (Mark One) |

| S | Annual Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 |

| | For the fiscal year endedJune 30, 2013 |

| Or | |

| £ | Transition Report Pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934 |

| | For the transition period from ___________ to ____________ |

Commission file number0-12944

Zygo Corporation

(Exact name of registrant as specified in its charter)

| Delaware | | 06-0864500 |

| (State or other jurisdiction of | | (IRS Employer Identification Number) |

| incorporation or organization) | | |

| | Laurel Brook Road, Middlefield, Connecticut 06455-1291 | |

| | (Address of principal executive offices) (Zip Code) | |

| | | |

| | (860) 347-8506 | |

| | (Registrant’s telephone number, including area code:) | |

| | | |

| | Securities registered pursuant to Section 12(b) of the Act: | |

| | None | |

| | | |

| | Securities registered pursuant to Section 12(g) of the Act: | |

| | Common Stock, $.10 Par Value | |

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

YES£NOS

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act.

YES£NOS

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

YESS NO£

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

YESS NO£

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§ 229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K.S

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in rule 12b-2 of the Exchange act. (Check one):

| Large accelerated filer | £ | | | Accelerated filer S |

| Non-accelerated filer | £ | (Do not check if a smaller reporting company) | | Smaller reporting company£ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). YES£ NOS

The aggregate market value of the registrant’s Common Stock held by non-affiliates, based upon the closing price of the Common Stock on December 31, 2012, as reported by the NASDAQ National Market System, was $152,802,040. Shares of Common Stock held by each executive officer and director and by each person who owns 5% or more of the outstanding Common Stock, based on filings with the Securities and Exchange Commission, have been excluded since such persons may be deemed affiliates. This determination of affiliate status is not necessarily a conclusive determination for other purposes.

Indicate the number of shares outstanding of each of the registrant’s classes of Common Stock, as of the latest practicable date.

18,689,893 Shares of Common Stock, $.10 Par Value, at August 30, 2013

Documents incorporated by reference: Specified portions of the registrant’s Proxy Statement related to the registrant’s 2013 Annual Meeting of Stockholders, to be filed pursuant to Regulation 14A of the Securities Exchange Act of 1934 with the Securities and Exchange Commission, are incorporated by reference into Part III (Items 10-14) of this Annual Report on Form 10-K to the extent stated herein.

TABLE OF CONTENTS

As used in this Annual Report on Form 10-K, unless the context otherwise requires, the terms “we,” “us,” “our,” “Company,” and “Zygo” refer to Zygo Corporation, a Delaware corporation.

FORWARD-LOOKING STATEMENTS

All statements other than statements of historical fact included in this Annual Report regarding our financial performance, financial condition and operations and the business strategy, plans, anticipated revenues, bookings, market acceptance, growth rates, market opportunities and objectives of management of the Company for future operations are forward-looking statements. Forward-looking statements include, without limitation, statements under “Business,” “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and “Risk Factors.” Forward-looking statements provide management’s current expectations or plans for the future operating and financial performance of the Company based upon information currently available and assumptions currently believed to be valid. Forward-looking statements can be identified by the use of words such as “anticipate,” “believe,” “estimate,” “expect,” “intend,” “plan(s),” “strategy,” “project,” “should” and other words of similar meaning in connection with a discussion of current or future operating or financial performance. Actual results could differ materially from those contemplated by the forward-looking statements as a result of certain factors such as those disclosed under “Risk Factors.” Such statements reflect our current views with respect to future events and are subject to these and other risks, uncertainties and assumptions relating to the operations, results of operations and our growth strategy.

Any forward-looking statements included in this Annual Report speak only as of the date of this document. Zygo Corporation undertakes no obligation to publicly update or revise forward-looking statements to reflect events or circumstances occurring after the date of this Annual Report on Form 10-K, except as required by law.

PART I

Item 1. Business

OVERVIEW

Zygo Corporation (“Zygo,” “we,” “us,” “our,” or “Company”) designs, develops, and manufactures ultra-high precision measurement solutions and top-tier optical sub-systems and components for original equipment manufacturers (“OEM”) and end-user applications. We operate within two divisions. Our Metrology Solutions Division (also referred to herein as the “Metrology Solutions segment”) manufactures products to improve quality, increase productivity to improve our customers’ manufacturing yields, and decrease the overall cost of product development and manufacturing for high-technology companies. Our Optical Systems Division (also referred to herein as the “Optical Systems segment”) provides leading-edge product development and manufacturing services that leverage a variety of core technologies across semiconductor, defense, laser fusion research, life-sciences, and other industrial markets. The Metrology Solutions segment has manufacturing locations in Middlefield, Connecticut; Tucson, Arizona; Montreal, Canada; Shanghai, China, Germany and Tainan City, Taiwan. The Optical Systems segment has manufacturing locations in Middlefield, Connecticut; Tucson, Arizona; Costa Mesa, California; and Richmond, California.

We focus on markets around the world that are engaged in research and manufacture of high volume precision components used to support high technology applications in industries such as consumer electronics, automotive engineering, LED lighting, life-sciences, military and defense. We have expanded our geographic reach in recent years by continued investment in our joint venture in China and expansion of our office in Taiwan.

In May 2012, we purchased a 110,020 square-foot facility in Tucson, Arizona and essentially completed the renovation of the building and moved into the new location in July 2013.

In July 2012, we purchased the noncontrolling interest of our German subsidiary.

During the second quarter of fiscal 2011, we completed a transaction with ASML US, Inc. (“ASML”) where we purchased substantially all the assets of ASML’s Richmond, California operation, including a 55,300 square-foot manufacturing facility. In addition, we hired key management and employees working at the former ASML Richmond facility and formed our Extreme Precision Optics group (“EPO”), which is included in our Optical Systems segment. With this acquisition, we considerably expanded and improved our optical manufacturing capabilities. EPO’s highly symbiotic capabilities that address new applications in semiconductor, defense and the life-sciences strengthened our leadership position in metrology, large flat optics production and electro-optical design and manufacturing.

Zygo was incorporated in 1970 under the laws of the State of Delaware. The address of our principal executive office is Laurel Brook Road, Middlefield, Connecticut, 06455-1291. Our telephone number at this address is (860) 347-8506. Our website address is www.zygo.com. The information on our website is not part of this Annual Report on Form 10-K.

Business Segments & Products

The products and services in our two reportable segments are based on our core technologies, process knowledge and extensive experience in optical design, mechanical engineering, software and algorithms and optical fabrication. Most products are proprietary or incorporate proprietary technology in their design.

Metrology Solutions Segment

Our Metrology Solutions segment includes 3-dimensional surface metrology products, precision positioning systems and custom-engineered solutions. We offer a comprehensive line of metrology products and solutions to address requirements of precision manufacturing industries and advanced research. Our systems are commonly used to measure surface characteristics and critical parameters, including topography and roughness, shape, dimension, thickness, optical characteristics and defects.

Zygo metrology products provide precise measurements for quality control, process feedback and machine control. There are many applications in a variety of markets where precision and consistency are critical to the process or the enablement of advanced research and process development, including the automotive, consumer electronics, medical, defense/aerospace, materials research, optics, flat panel displays and semiconductor industries. The inherent precision, reliability and speed of Zygo’s metrology measurement technologies help to reduce cost of ownership, which is a significant factor for many users. Demand for our products is driven by advancement of next generation devices and technology, complex processing methods and tighter manufacturing tolerances across many industries.

The Metrology Solutions segment markets products under the Zygo and Zemetrics brand names. Each brand is targeted to a different customer segment, with the Zygo brand providing a high-end, feature-rich product offering and the Zemetrics brand addressing mid-level, industrial market needs. Products under the Zygo brand include New View™ andVeriFire™ family of products. Products under the Zemetrics brand include theZeGage™ andZeScope™ family of products. Both Zygo and Zemetrics products are often developed using common research and development and engineering resources. Both brands provide customers a progressive choice of products addressing their full range of metrology needs.

Zygo is considered to be a world leader in optical interferometry with a portfolio of approximately 470 patents issued worldwide, many of which are related to the broad field of interferometry. While there are numerous practical applications for our instruments in a wide variety of industries, the inherent precision involved in using the wavelength of light as our “ruler” has historically required our instruments to be placed in well-controlled environments. Much of our recent development efforts have focused on technology enhancements that allow our systems to move from the stable laboratory to the production floor. This provides our customers with real-time process feedback to reduce scrap/defects and improve productivity and yields.

For example, the newest member of theVeriFire™ laser interferometer family, the QPZ, was developed to bring high precision large aperture metrology to the production floor. By combining high speed acquisition with patented technology, the QPZ eliminates the effects of typical shop floor vibration and enables high precision metrology next to process equipment.

TheZeGage-2D-3D optical profiler family is designed to provide non-contact nanometer-level surface height measurements without requiring additional vibration isolation. The ZeGage provides unique capabilities designed for the industrial market segment using a combination of scanning white light interferometry and patent pending scanning methods to provide performance that is competitively positioned against contact stylus instruments traditionally used in the industrial machine tool market. The instrument also utilizesZeMaps™ software, and features a range of 2D and 3D surface parameters including form, step height and ISO/EN 25178 compliant surface roughness parameter standardization. The recently released motorized XY staging greatly expands the ZeGage profiler’s functionality by offering the ability to stitch adjacent images for evaluation over large areas/scan lengths. This product family is being marketed primarily to the industrial factory market, expanding the price range and customer base for the ZygoNewView™ line of products.

We also recently introduced theMini™ Compact Production Interferometer. Developed specifically to meet the growing demands of high volume, small optic manufacturing, theMini interferometer provides robust, quantitative optical surface metrology in a compact, industrial package. Traditionally, high volume optical manufacturing relied on qualitative, visual interpretation of surface quality. By combining patented and proprietary acquisition technology with a user-friendly touchscreen user interface, theMini interferometer eliminates the subjectivity of visual inspection and brings true process control capability to the production floor.

Markets

Automotive Industry

The automotive industry continually strives to improve fuel economy and decrease environmental pollution to meet customer demand and adhere to government regulation. Improving both requires more efficient engines, and our measurement-based process control and yield-enhancement systems are used in the development and high-precision manufacture of some of those engine components.

NewView™ Series 3D Optical Profilers

Our high precision metrology equipment is well suited for some engine components, which are ground or lapped to tolerances of one-hundred billionths of a meter. Our patented Fourier Domain Analysis data acquisition system for theNewView optical profiler meets these high-precision measurement requirements.

ZeGage™Optical Profiler

The ZeGage optical profiler addresses applications with the need to measure and visualize a wide variety of materials, including rubber, paper, metal, plastic and ceramics, further addressing the needs of the automotive market. We believe the ZeGage profiler price point has a broader appeal to first-time buyers of optical metrology.

Consumer Electronics

Consumer electronics, including tablets, smart phones, digital cameras, DVD and CD players, and optical computer drives, have significant optical content. Consumer electronics optics, which provide imaging and data storage, are manufactured in quantities in the hundreds of thousands to millions of components per year. These complex miniature optical systems require precise optical testing-from development to in-line process control, which our measurement-based process control and yield enhancement systems are designed to perform.

VeriFire™ Asphere System

TheVeriFire asphere system provides high resolution 3-dimensional surface metrology for aspheric-shaped surfaces using patented non-contact interferometric techniques for production and process control. Aspheres are important in consumer electronics products, cameras, military/defense optics, and commercial optics and represent a growing segment in the optics markets due to improved optical performance in these devices in comparison to traditional spherical lenses.

VeriFire™ Systems

The development of new optical systems for any application requires flexible and easy to use test equipment. The ZygoVeriFire systems are the latest products in our established product family that has improved optical testing and continues to evolve to meet changing requirements. Consumer electronics production applications for larger optics, greater than a 25 millimeter diameter, and research and development for any size application rely on these products for critical developmental data and process-control feedback in production. These products are widely used for Zygo’sMetroPro™ data analysis software and their configuration flexibility in hardware set ups.

Mini™ Compact Production Interferometer

The growing demands of high volume, small optic manufacturing require the need for production-floor measurement to be more timely and precise, eliminating the visual observation of surface quality. TheMiniinterferometer provides robust, quantitative optical surface metrology in a compact, industrial package designed for production floor use.

Defense/Aerospace

GPI™ and VeriFire™ Systems

Developing state-of-the-art optical designs and manufacturing technology for the defense/aerospace market also requires leading-edge metrology systems for manufacturing process control and development. Our VeriFire optical interferometers test the optical components as well as the systems for design compliance. Our VeriFire Asphere rapidly measures asphere-shaped optics in a production environment without the need for specialized tooling. OurVeriFire QPZ system continues our move to the production floor, providing laboratory-level results in a production environment. Using patented methods, theVeriFire QPZ system removes the degrading effects of vibration from the measurement without the need for additional expensive isolation hardware. This system is primarily used in qualification of optical elements during the production of military and commercial optics. We are also active in designing and manufacturing custom test systems for defense/aerospace applications, especially interferometers that operate at infrared wavelengths, which are unique to this market.

Semiconductor Products

The transistor and associated integrated circuit have transformed the way people work, live and play, creating several multi-billion dollar industries that thrive through innovation, technology, and ultra-large scale integration of micro/nano circuitry. These industries provide components used in everyday appliances, including the more modern mobile phones and wireless internet devices. State-of-the-art microprocessors may contain in excess of a billion transistors comprised of components that have physical dimensions as small as 22 nanometers.

Precision Positioning Systems

The layers of circuit patterns must overlay each other to nanometer precision during the wafer lithography process. Photolithography systems, mask and reticle writers and yield improvement metrology tools rely on displacement- measuring interferometers to provide precise feedback to control the position of the silicon wafer. Our Metrology Solutions segment’sZMI™ 7700 series precision positioning feedback systems are designed primarily for photolithography systems. They are also used in a broad range of semiconductor metrology and back-end process tools.

Printed Circuit Board Substrates

Printed circuit substrates interface integrated circuit flip chip packages to printed circuit boards. These substrates make the circuit connection via arrays of miniature solder bumps and balls, and Zygo manufactures several tools to measure these bump and ball arrays for process control and yield improvement. Several products serve this market, including theNano™ CSP2000 andNano2™ series, providing high-throughput, fully-automated 100% 2D/3D inspection of C4 bumps for chip scale packaging (CSPs) strips to support high-volume manufacturing and process yields.

Technology Development Projects

Photolithography scanners image the electronic circuit pattern through a precision projection lens. The optical performance of the lenses required for next-generation photolithography scanners often exceeds the capabilities of commercially available measurement systems. Our expertise in optical interferometer technology and the practical skills needed to apply this technology position us well to deliver custom solutions to leading photolithography equipment suppliers.

Optical Systems Segment

Zygo’s Optical Systems segment designs, develops and manufactures high precision optical components and electro-optical systems used in the semiconductor, defense/aerospace, life-sciences and research markets. Our optical components and systems are manufactured to high levels of precision and are intended to meet the demands of both internal and external customers. The primary value we bring to the market place is the ability to meet exacting specifications from our customers in a high volume production environment. Examples of our products include aspheric lenses, mirrors, objective assemblies, machined glass structures and windows used in applications ranging from semiconductor lithography to ophthalmic surgical devices to aerial reconnaissance. We provide products used across a broad spectral range including extreme ultra-violet (“EUV”), visible and mid-infrared that are fabricated from materials such as fused silica, sapphire, silicon, calcium fluoride and precision optical glasses. Representative programs and products include volume manufacturing of meter class laser fusion optics for the National Ignition Facility, development and manufacturing of high precision imaging lenses for military aerial reconnaissance and precision optics used in EUV semiconductor lithography equipment.

Markets

Defense/Aerospace

Defense and aerospace companies use optical technology in a broad range of applications that are often deemed mission critical and, therefore, have become a major component of military spending. Examples include tactical information gathering through the use of fixed wing and rotary aerial reconnaissance, fire-control systems used for targeting or threat detection and navigation systems necessary for all-weather combat readiness. We manufacture a variety of defense-related products, including lenses, windows, freeform optics and lens assemblies. These products have been integrated on several prominent platforms, including the Joint Strike fighter, Predator and Global Hawk drones, F/A-18C Distributed Mission Training system and the F16 Internal FLIR Targeting System. In addition to traditional defense applications, we are a leading manufacturer of meter class optical components used in high energy laser fusion development for the United States Department of Energy nuclear stockpile governance and a similar program for the French Atomic Energy Commission. We have become a major provider within this application space that consists of two of the largest optical programs ever created. We have also delivered electro-optical systems used in high resolution surveillance and protection of civilian targets, such as nuclear power reactors, airports and shipping ports.

Life-sciences

The life-sciences market continues to present a significant opportunity. Increased demand for high precision medical devices continues to be driven by an aging population and consumers’ desire to improve their quality of life. We address this demand with specialized design and assembly services tailored to producing high-precision research, diagnostic and surgical devices. Key application areas include ophthalmic, dental, diagnostics and DNA analysis. Product manufacturing strengths include high performance objectives used in laser delivery and fluorescent imaging systems, integration of full systems utilizing light sources, optics and detectors, and stand-alone medical devices built to customer specification. Examples of customer products include laser eye correction, cataract surgery and genomic analysis instruments. In addition, the group offers a variety of process control advantages considered critical to medical device customers. These include our ISO 13485:2003 and FDA registration as a medical-device manufacturer.

Semiconductor and Electronics

Semiconductor lithography demands, in many cases, the ultimate in optical manufacturing technology, a critical driver for meeting the industry demands of Moore’s law. With over 20 years of experience in extreme ultraviolet lithography and proceeding nodes, we routinely participate in the advancement and deployment of new lithographic platforms. As a supplier to the world’s leading semiconductor lithography companies and consortiums, we provide custom components and assemblies used in high precision stages, illumination optics and objectives. Our products are typically used in the manufacture of semiconductor chips for deployment in all types of computer-driven equipment. Zygo is currently developing and manufacturing EUV lithography optics for the fifth-generation micro-exposure tool (“MET-5”) at the State University of New York at Albany’s College of Nanoscale Science & Engineering’s (“CNSE”) Albany NanoTech Complex.

The MET-5 program is managed by the SEMATECH consortium, whose members and partners include leading semiconductor manufacturing companies worldwide, that performs research and development to advance chip manufacturing. The program is intended to extend semiconductor lithography resolution capability to less than 16 nanometers.

Our key manufacturing strengths include high precision machining used in the production of reticle and wafer stages, advanced polishing methods such as ion beam figuring of off-axis mirrors, and metrology necessary to meet specifications down to one nanometer in accuracy. In addition to semiconductor lithography, we also support customers involved in semiconductor metrology and electronics through the production of high precision objective assemblies and laser sub systems. These systems are often developed in collaboration with our customers who rely heavily on our optical engineering capabilities to achieve both performance and cost objectives.

Manufacturing Technology and Processes

Our strategic advantages in the market place derive heavily from the development of unique manufacturing technology and processes. Key areas of focus include deterministic polishing, high precision machining and grinding, coating, opto-mechanical assembly and metrology. Within these areas we have developed highly refined processes and equipment for the manufacture of meter class plano windows and mirrors, aspheric and free-form lenses, complex ceramic machining up to one meter and large aperture coating. The unique nature of our capabilities requires much of the equipment used in our manufacturing to be developed or modified internally. Our ability to provide accurate metrology in the final inspection, as well as for in-process control, is strategic to our success in manufacturing. In this regard, the Optical Systems segment works closely with the Metrology Solutions segment to produce unique metrology tools that improve the quality and yield of our products.

Sales, Marketing and Service

We market our full range of products throughout the United States and in most foreign markets. Our revenues are largely generated through our direct worldwide sales force, as well as through independent agents and distributors. We have sales and service centers positioned close to our major customers and business opportunities throughout the Americas, Europe and Asia. We believe that our business relationships with the major customers in all of our key markets are generally favorable, and that we are in a good position to respond promptly to customer requirements and technology trends.

We require our sales representatives to have technical expertise and a thorough understanding of the businesses of our customers and our prospective customers. In a typical sale process, one of our representatives will provide a potential customer with information about our products, including specifications and performance data, as well as a product demonstration using samples for testing and demonstration provided by the customer. The sales cycle for our systems typically ranges from three to twelve months, but can be longer for complex systems or when our customers are evaluating new applications of our technology.

Our products are supported by a global service organization of factory-trained technicians and engineers, and generally backed by a standard twelve month warranty. We also offer service contracts for our products of one year or more in duration after expiration of any warranty.

Competition

We participate in markets that are highly dynamic and globally competitive across all our segments. Additionally, many of the markets for our products are subject to constant change, due largely to evolving customer needs. As we attempt to respond to this change, the competitive landscape as well as the specific strategies of competitors may change. Moreover, one or more of our competitors might achieve a technological advancement that could put us at a competitive disadvantage.

Although there are no firms that compete with us across our full range of product lines and services, we face competition in each business segment in domestic and foreign markets. Certain of our competitors have substantially greater resources than we do, or may be smaller regional producers with lower overhead costs and profit requirements, particularly in Asia. Our strategy is to offer technologically advanced products that are price competitive in our markets, and to link the product offerings with market knowledge and customer service. We believe this serves to differentiate our products in many markets. Due to the critical mass necessary to support our large installed base of systems, as well as the highly specialized nature of our products, competition can be more limited in our service business.

Our overall focus is typically on niche and value-added segments where we can differentiate our products from our competition’s products through technological and product value advantage. The following further discusses the competitive landscape in each of our strategic business segments.

Metrology Solutions Segment

Our principal competitors for the sale of metrology products and services include Bruker Corporation, Ametek, Agilent, KLA-Tencor and 4D Technology. We believe the key competitive factors are performance, range of features, reliability, price and service. We believe that we are competitive with respect to each of these factors, although we have faced increasing pressure on purchase price due to aggressive pricing practices of competitors. Our ability to remain competitive depends in part upon our success in developing new and enhanced systems, leveraging our intellectual property and introducing these systems at competitive prices on a timely basis. Intense price competition in the sale of metrology products in the past has adversely affected our profit margins.

Our Metrology Solutions segment offers products that we believe are leaders in most of the markets served, including semiconductor, flat panel displays, precision machining, research and optics. A key strategy in this segment is to continue to develop and produce precise 3D surface metrology products that are technology leaders in the markets where they participate, particularly as the demand increases for more advanced application use, and where adoption and volume is continuously growing. On a regional basis, this segment participates in North America, Europe and Asia. It faces competition in each of these locations from a wide variety of companies, from very large multinational manufacturers to much smaller, regional companies. Similar to our optical systems segment, this segment must address the continual threat of commoditization, particularly with respect to products that have matured in their life cycle.

Optical Systems Segment

Our Optical Systems segment offers precision optical products and integrated electro-optical systems that serve the critical needs of the defense/aerospace, medical and semiconductor markets. We have a strong reputation and presence worldwide, particularly in North America and Europe. Our business also includes government contract and consulting work. We have multiple competitors across our served markets. We typically compete on price, delivery and technology, as well as quality and service. Our experience in design and manufacture of complex optical systems is a core competence, and we are committed to protecting our intellectual property and designs, particularly in regions where such laws are not as strictly enforced. We also strive to continuously differentiate our product offerings, to help avoid commoditization of certain products. Competitors include, but are not limited to, L-3 Tinsley, Exotic Electro-Optics, Sagem, JenOptik and Berliner Glas.

Research and Development

We maintain our position as a market leader in metrology and optics through continuous and focused investment in research and development of new technology, products and applications. Research and development activities constitute an important and vital part of our overall business strategy, as the markets we serve are typically characterized by rapid technological changes and advances. Accordingly, the success of our strategy depends in part on our ability to develop market-leading products and solutions, which is primarily driven by close relationships with our customers, together with efforts in research and development.

Through continual investment in research and development, we seek to expand our leadership position in metrology products and optical sub-systems. In order to remain as a market leader in our core market segments, Zygo works with our customers to address their current needs, as well as their evolving requirements, so that we remain designed into their products during the entire product lifecycle. In addition, as part of our development efforts, we focus on lowering the production costs of our products.

We hold approximately 470 active patents worldwide and have additional patent applications on file related to both business segments. The patents are of varying duration and provide some protection from competition. Although we vigorously defend our patents, we believe that our patents are most valuable when combined with our products, technology, competencies and customer-focused, value-added solutions. On occasion, we also engage in joint research and development projects with some of our customers and other parties. We also own a number of registered and unregistered trademarks and have acquired certain technology that we believe to be of importance to our business. We believe that continued enhancement, development, and commercialization of new and existing products and systems are essential to maintaining and improving our position in the markets in which we operate.

Patents and Other Intellectual Property

Our success and ability to compete depend substantially on our technology. We have been developing a portfolio of intellectual property for over 40 years, and we rely on a combination of patent, copyright, trademark and trade secret laws and license agreements to establish and protect the proprietary rights for our products.

Since we introduced the first optical interferometer in 1972, we have had over 590 United States and foreign patents issued, of which approximately 470 are currently active. We also have approximately 120United States and foreign patent applications pending. In addition, we have a number of registered and unregistered trademarks. While we rely on patent, copyright, trademark, and trade secret laws to protect our technology, we also believe that the technological and creative skills of our personnel, new product developments, frequent product enhancements, and reliable product maintenance are essential to establishing and maintaining a technology leadership position. We do not expect the expiration in the near future of various of our active patents to have a material effect on our business.

BACKLOG AND BOOKINGS

Backlog at June 30, 2013 was $89.8 million, an increase of $21.8 million compared with $68.0 million at June 30, 2012, of which $44.6 million, or 50%, was in the Metrology Solutions segment and $45.2 million, or 50%, was in the Optical Systems segment. Bookings for the fiscal year ended June 30, 2013 were $172.3 million and consisted of $116.6 million, or 68%, in the Metrology Solutions segment and $55.7 million, or 32%, in the Optical Systems segment. We expect to fill all orders.

Marketing and Sales

Our sales and marketing strategy is to establish and/or solidify strategic relationships with leading OEMs and end-users in targeted sectors within our markets. The selling process for our products is performed through our worldwide sales organization operating out of regional sales and service offices in California and Connecticut, Canada, China, Germany, Japan, Singapore and Taiwan. Supporting this core sales team are business development, marketing and engineering specialists representing our various optics and metrology units in Connecticut, Arizona, California and Canada. Product promotion is through trade shows, printed and e-business advertising and industry technical organizations.

The following table sets forth the percentage of our total revenue by region (based on shipping destination, including sales delivered through distributors) during the past three years:

| | | Fiscal Year Ended June 30, |

| | | 2013 | | | 2012 | | | 2011 | |

| Americas | | | 53 | % | | | 54 | % | | | 54 | % |

| Japan | | | 18 | % | | | 16 | % | | | 21 | % |

| China | | | 12 | % | | | 13 | % | | | 6 | % |

| Europe | | | 12 | % | | | 12 | % | | | 12 | % |

| Pacific Rim | | | 5 | % | | | 5 | % | | | 7 | % |

| Total | | | 100 | % | | | 100 | % | | | 100 | % |

Customer service is an essential part of our business, since product up-time is critical given its effect on our customers’ production efficiency. As of June 30, 2013, our global sales, customer support and service organization consisted of 89 people skilled in sales, marketing, optical and electronic component repair, software, application and system integration, diagnostics and problem-solving capabilities.

Manufacturing, Raw Materials and Sources of Supply

Our principal manufacturing activities are conducted at our facilities in Middlefield, Connecticut; Richmond, California; and Tucson, Arizona. We also perform manufacturing activities in our Costa Mesa, California; Canada; Taiwan; German; and China facilities.

We maintain an advanced optical components manufacturing facility in Middlefield, Connecticut, specializing in the fabrication, polishing and coating of plano, or flat, optics for sales to third parties, as well as the manufacture of a wide variety of optics that are used in our metrology products. Our manufacturing activities for metrology products consist primarily of assembling and testing components and sub-assemblies supplied by us and third-party vendors, then integrating these components and sub-assemblies into our finished products.

Our optical assembly manufacturing activities are conducted in our Costa Mesa, California; Richmond, California; and Tucson, Arizona facilities. We integrate our optics, optics from third party vendors and mechanical sub-systems utilizing our metrology in these facilities.

Certain components and sub-assemblies incorporated into our systems are obtained from a limited group of suppliers. We routinely monitor limited-source supply parts, and we endeavor to ensure that adequate inventory is available to maintain manufacturing schedules should the supply of any part be interrupted. Although we seek to reduce our dependence on limited source suppliers, we have not qualified a second source for some of these products, and the partial or complete loss of certain of these sources could have a negative impact on our results of operations and damage customer relationships.

AVAILABLE INFORMATION

We make available free of charge through our website,www.zygo.com, our Annual Reports on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K, proxy statements and all amendments to those reports as soon as reasonably practicable after such material is electronically filed with the Securities and Exchange Commission (“SEC”). These reports may also be obtained without charge by contacting Investor Relations, Zygo Corporation, Corporate Headquarters, Laurel Brook Road, Middlefield, Connecticut 06455-1291, phone: (860) 347-8506. Our internet website and the information contained therein or incorporated therein are not intended to be incorporated into this Annual Report on Form 10-K. In addition, the public may read and copy any materials we file with the SEC at its Public Reference Room at 100 F Street, NE, Room 1580, Washington, DC 20549 or may obtain information by calling the SEC at 800-SEC-0330. Moreover, the SEC maintains an internet website that contains reports, proxy and information statements, or other information regarding reports that we file electronically with them at http://www.sec.gov.

Employees

At June 30, 2013, we employed 637 people worldwide of which 17 were temporary or independent contractors. We employed 302 in manufacturing, 149 in research and development, 89 in sales and marketing and 80 in management and administration. Our employees are not represented by a labor union or a collective bargaining agreement. We regard our employee relations as good to excellent.

EXECUTIVE OFFICERS OF THE REGISTRANT

Chris L. Koliopoulos - age 60 - Chairman, President and Chief Executive Officer

Dr. Koliopoulos joined our Company in January 2010 and serves as our Chairman, President and Chief Executive Officer. Previously he served as President and CEO of ADE Corporation from 2002 to 2006 and as a private investor, director and advisor to Zemetrics, Inc. from 2007 to 2010.

John P. Jordan - age 67 - Vice President, Chief Financial Officer and Treasurer

Mr. Jordan joinedour Company in February 2011 andserves as our Vice President, Chief Financial Officer and Treasurer. Prior to joining Zygo, Mr. Jordan spent four years with Baldwin Technology Company, Inc., a manufacturer of accessories, controls and consumables for the printing industry, as Vice President, Chief Financial Officer and Treasurer.

John M. Stack - age 48 - President, Optical Systems Division

Mr. Stackjoined our Company in November 2006 andhas served as President of the Optical Systems Division since December 2006. Previously he spent 18 years with Edmund Optics Inc., a supplier of optics and optical components, where his most recent position was President and Chief Operating Officer from 2001 to 2006.

Anthony Allan - age 48 - Senior Vice President, Worldwide Operations

Mr. Allan has served asSenior Vice President, Worldwide Operations since February 2013. Prior to Joining Zygo, Mr. Allan served as Chief Operating Officer of Masimo Corporation, a medical technology manufacturer from 2010 to 2013. Prior to that, Mr. Allan had been Vice President - Global Business Units, Instrumentation and Medical Sector, with Jabil Inc., an electronic manufacturing services and solutions company from 1995 to 2010.

John A. Tomich - age 55 - Vice President, General Counsel and Secretary

Mr. Tomich joined our Company in August 2010 as Vice President and General Counsel. In November 2010, Mr. Tomich was also appointed the Corporate Secretary of the Company. Prior to joining Zygo, Mr. Tomich was Vice President, General Counsel and Secretary for Doctors Research Group, Inc., a medical device manufacturer, from 2008 to 2010, and Assistant Clinical Professor of Law and Supervising Patent Attorney for the University of Connecticut, School of Law from 2006 to 2008. Prior to teaching, Mr. Tomich was General Counsel and Secretary for CUNO Incorporated.

David F. Basila - age 54 - Vice President, Business Development

Mr. Basila has served as Vice President of Business Development since February 2010. Previously he served as Vice President of ADE Corporation from 2002 to 2006, and as a private investor and director of Zemetrics, Inc. from 2007 to 2010.

William H. Bacon - age 63 - Vice President, Corporate Quality and Support Services

Mr. Bacon has served as Vice President, Corporate Quality and Support Services since March 2003. Previously he served as our Vice President, Manufacturing from April 2002 to March 2003, Vice President, Metrology Manufacturing from April 2000 to April 2002 and Vice President, Corporate Quality from January 1996 to April 2000. From November 1993 to January 1996, Mr. Bacon was Director of Total Quality and also served as Manager of Instrument Manufacturing from June 1987 to November 1993.

Michael M. Vehlies - age 52 - Corporate Controller

Mr. Vehlies has served as Corporate Controller since June 2002. Prior to joining Zygo, Mr. Vehlies served as the Chief Financial Officer for Gunther International, Ltd from 1998 to 2002.

Under the by-laws, executive officers serve for a term of one year and until their successors are chosen and qualified unless earlier removed.

Item 1A. Risk Factors

We are subject to numerous known and unknown risks, many of which are described below and elsewhere in this Annual Report. Any of the events or conditions described below could have a material adverse effect on our business, financial condition and results of operations.

Integration of manufacturing facilities may entail certain operational risk.

We regularly review our manufacturing operations to maximize the effectiveness and cost benefit of those operations. As our business evolves, it becomes necessary to rationalize our manufacturing facilities requirements. Securing additional manufacturing facilities or integrating existing manufacturing facilities involve certain risks. These risks include substantial cash expenditures and capital expenditures, potentially in excess of budgeted amounts; difficulties in assimilating or moving existing operations; loss of orders or customers due to the failure to obtain all necessary permits and regulatory approvals, including those that may be required by our customers; diverting management’s attention away from other business concerns; and disruption of manufacturing schedules and forecasted revenue which could adversely affect our results of operations. We are in the process of transitioning our existing Tucson operations into a recently purchased facility in Tucson.

General economic conditions and the related deterioration in the global business environment could have a material adverse effect on our business, operating results and financial condition.

Global consumer confidence has eroded amid concerns over, among other things, declining asset values, inflation, volatility in energy costs, geopolitical issues, the availability and cost of credit, high unemployment and the stability and solvency of financial institutions, financial markets, businesses and sovereign nations. These concerns have slowed global economic growth in numerous countries, including many of those in North America, Europe and Asia, where the Company does substantially all of its business. In addition, the on-going European debt crisis and the downgrade of the United States’ long term sovereign credit rating have negatively affected the financial markets and could continue to weigh on the global business environment. As these economic conditions continue to persist, or if they worsen, a number of negative effects on our business could result, including customers or potential customers reducing or delaying orders, the insolvency of key suppliers which could result in production delays, the inability of customers to obtain credit and the insolvency of one or more customers, certain of which we have already experienced. Any of these effects could impact our ability to effectively manage inventory levels and collect receivables, create unabsorbed costs due to lower net revenues and ultimately decrease our net revenues and profitability, as well as cause us to write-down certain of our assets.

Zygo is dependent on the semiconductor industry which, as a whole, is volatile.

Our business is somewhat dependent on capital expenditures and component requirements for manufacturers in the semiconductor industry. This industry is cyclical and has historically experienced periods of oversupply, resulting in significantly reduced demand for capital equipment, including the products manufactured and marketed by us. For the foreseeable future, our operations will continue to be dependent on the capital expenditures in this industry, which in turn is largely dependent on the market demand in the semiconductor markets.

Zygo could suffer significant business interruptions.

Our customers, suppliers and operations may be vulnerable to interruption by natural disasters such as earthquakes, tsunamis, typhoons, or floods, or other disasters such as fires, explosions, acts of terrorism or war, disease or failures of our management information or other systems. If a business interruption occurs, our business could be materially and adversely affected.

Zygo is subject to environmental laws and regulations and may have liabilities arising from environmental matters.

Zygo is subject to a variety of environmental regulations relating to the use, storage, discharge and disposal of hazardous chemicals used during our manufacturing processes. Any failure by us to comply with applicable regulations could subject us to future liabilities or the suspension of production. We are aware of certain levels of contamination on our property which is below reportable levels. In addition, we are aware of certain contamination on an adjacent property that we formerly owned. The future effect of environmental matters, including potential liabilities, is often difficult to estimate. We are unable to determine or reasonably estimate the amount of cost, if any, that we might incur or for which we may potentially be responsible to remediate the situation or for damages which may have resulted or result from the situation. In addition, environmental regulations could restrict our ability to expand our facilities or could require us to acquire costly equipment or to incur other significant expenses to comply with such regulations.

Zygo is subject to changes in senior management that could affect the operation of the Company.

Unforeseen or anticipated changes in senior management could adversely impact the Company due to a lack of historical knowledge and familiarity with all aspects of the Company’s business and operations by new senior management.

Zygo has been dependent on sales to two large customers; the loss of or a reduction in bookings from these customers would materially affect our revenue and profitability.

During fiscal 2013, 2012 and 2011, sales to Canon Inc., one of our largest customers in each of those periods, accounted for 9%, 10%, and 13% of our net revenues, respectively. We expect that sales to Canon will continue to represent a significant percentage of our net revenues for the near future. Canon is an original investor in our Company, the owner at June 30, 2013 of approximately 7% of outstanding shares of our common stock, and is a distributor of certain of our products in the Japanese market. During fiscal 2013, sales to another large customer accounted for 9% of our net revenues. A reduction or delay in orders from these customers, including reductions or delays due to market, economic, or competitive conditions in the industries which we or our customer serve, could have a material adverse effect upon our results of operations. Our customers, including these two customers, generally do not enter into long-term agreements obligating them to purchase our products.

Our substantial international revenues are subject to risk.

Zygo sells products internationally, primarily to customers in Japan, China and Europe. Net revenue from customers outside the United States accounted for approximately 47% of our net revenue in fiscal 2013 and 46% of our net revenue in each of the fiscal years ended June 30, 2012 and 2011 and are expected to continue to account for a substantial percentage of our net revenue.

International revenue and foreign operations are subject to inherent risks. These risks include the economic conditions in various foreign countries and their trading partners, political instability, longer payment cycles, potential difficulty in accounts receivable collection, compliance with foreign laws, changes in regulatory requirements, tariffs or other barriers, difficulties in obtaining export licenses, staffing and managing foreign operations, exposure to currency exchange fluctuations, transportation delays and potentially adverse tax consequences.

Our revenue and costs are negotiated and paid primarily in U.S. dollars. However, changes in the values of foreign currencies relative to the value of the U.S. dollar can render our products comparatively more expensive to the extent locally produced alternative products are available. Such conditions could negatively affect international revenues of our products and foreign operations, as would changes in the general economic conditions in those markets. Revenues that are recorded in local currency are exposed to foreign exchange fluctuations from the time customers are invoiced in local currency until collection occurs. For fiscal 2013, approximately 24% of our revenues were denominated in foreign currencies. We hedge certain intercompany transactions by entering into forward contracts to reduce the impact of adverse fluctuations on earnings associated with foreign currency exchange rate changes. We do not enter into any derivative transactions for speculative purposes. In some cases, we design hedges such that they qualify for hedge accounting treatment. These contracts are entered into for periods consistent with the currency transaction exposures, generally three to fifteen months. Any gains and losses on the fair value of these contracts are expected to be largely offset by gains and losses on the underlying transactions unless they are qualify for hedge accounting treatment in which case the change in fair value will be charged to accumulated other comprehensive income.There can be no assurance that risks inherent in international revenues and foreign operations will not have a material adverse effect on our results of operations in the future.

Zygo may have additional tax liabilities.

Zygo is subject to income taxes in the United States and many foreign jurisdictions. Significant judgment is required in determining our worldwide provision for income taxes. In recent years we recorded a valuation allowance on substantially all of our deferred tax assets, including federal net operating loss carryforwards in the United States. We no longer record a valuation allowance against the federal net operating loss carryforwards and substantially all of the deferred tax assets in the United States. Although we believe our tax estimates are reasonable, the final determination of tax audits and any related tax liabilities could be materially different from our income tax provisions and accruals. The results of audits could have a material effect on our financial statements in the period or periods for which that determination is made. In previous years, we incorrectly recorded deferred tax asset balances. Tax planning strategies could be affected if our deferred tax assets or income tax provisions are misstated.

Zygo earns a significant amount of operating income from outside the United States, and any repatriation of funds currently held in foreign jurisdictions may result in higher effective tax rates for the company. A change in the mix of product sold into various jurisdictions or a change in the revenue or profit from foreign jurisdictions could have an adverse effect on the Company’s effective tax rate. In addition, there have been proposals to change U.S. tax laws that would significantly impact how U.S. multinational corporations are taxed on foreign earnings. Although we cannot predict whether or in what form any proposed legislation may pass, if enacted it could have a material adverse impact on our tax expense and cash flow.

Acquisitions may entail certain operational and financial risks.

Our growth strategy includes expanding our products and services, and we may seek acquisitions or make internal investments to strategically expand our business. We regularly review potential acquisitions of businesses, technologies, or products complementary to our business and periodically engage in discussions regarding such possible acquisitions. Acquisitions involve numerous risks, including some or all of the following: substantial cash expenditures and capital investments; potentially dilutive issuance of equity securities; incurrence of debt and contingent liabilities; amortization of certain intangible assets; difficulties in assimilating the operations and products of the acquired companies; diverting management’s attention away from other business concerns; risks of entering markets in which we have limited or no direct experience; the inability to manage the growth expected for various acquisitions; potential loss of key employees of the acquired companies in the process of integrating personnel with disparate business backgrounds; and combining different corporate cultures. In addition, we may spend considerable effort and resources to review potential acquisition candidates, which we may elect not to pursue, or we may not actually consummate the transaction.

We cannot provide assurance that any acquisition, including the acquisitions of Zemetrics, Solvision, Inc. and the assets of the ASML Inc. Richmond, California operation will result in long-term benefits to us, or that our management will be able to effectively manage the acquired businesses. We may also incorrectly judge the value or worth of an acquired company or business or of a line of business to which we devote internal resources and funding. We have previously disposed of or divested several companies or lines of business that previously were acquired by us or in which we internally invested at a significant net loss to us.

Our quarterly operating results fluctuate and may continue to fluctuate in the future.

Our quarterly and annual operating results have varied in the past and may vary significantly in the future depending on factors such as: budgeting cycles of our customers; the size, timing and recognition of revenue from significant orders; increased competition; our ability to develop innovative products; the timing of new product releases by us or our competitors; market acceptance of our products; changes in our and our competitors’ pricing policies; changes in operating expenses and personnel changes; the effect of our acquisitions and consequent integration; changes in our business strategy; and general economic factors.

Due to these and other factors, we believe that quarter-to-quarter comparisons of our operating results may not be meaningful. Our results for one quarter should not be relied upon as an indication of our future performance. In future periods, our operating results may be below the expectations of public market analysts or investors. If this occurs, the price of our common stock would likely decrease. Current conditions in the domestic and global economies are uncertain. As a result, it is difficult to estimate the level of growth for the economy as a whole or of capital expenditures in the markets we serve, including the semiconductor capital equipment, industrial, bio-medical and scientific markets. Because various components of our budgeting and forecasting are dependent on estimates of spending within these markets, the prevailing economic uncertainty renders estimates of future revenue and expenses more difficult to make.

Our scheduled backlog may not result in future revenues.

We schedule the production of our systems based in part upon order backlog. Due to possible customer changes in delivery schedules and cancellations of bookings, our backlog at any particular date is not necessarily indicative of actual revenues for any succeeding period. There can be no assurance that amounts included in our backlog will ultimately result in future revenues. We have experienced push-outs and cancellations in the semiconductor capital equipment and electro-optics sectors. A reduction in backlog during any particular period, or the failure of our backlog to result in future revenues could adversely affect our results of operations.

Our lengthy revenue cycle could affect our manufacturing schedule and cause us to incur expenses without realizing sales.

Our lengthy and variable qualification and sales cycle makes it difficult to predict the timing of a sale or whether a sale will be made, which may cause us to have excess manufacturing capacity or inventory and negatively affect our operating results. As is typical in the industry, our customers generally expend significant efforts in evaluating and qualifying our products and manufacturing process. This evaluation and qualification process frequently results in a lengthy sales cycle, typically ranging from three totwelve months, but it can be longer for complex systems sales. While our customers are evaluating our products and before they place an order with us, we may incur substantial sales, marketing and research and development expenses, expend significant management efforts, increase manufacturing capacity and order long-lead-time supplies prior to receiving an order. Even after this evaluation process, it is possible that a potential customer will not purchase our products. In addition, product purchases are frequently subject to unplanned processing and other delays, particularly with respect to larger customers for whom our products represent a very small percentage of their overall purchasing activity.

If we increase capacity and order supplies in anticipation of an order that does not materialize, our gross margins may be negatively impacted, and we may have to carry or write off excess inventory. Even if we receive an order, the additional manufacturing capacity that we add to service the customer’s requirements may be underutilized in a subsequent quarter. Either situation could cause our results of operations to be adversely affected. Our long sales cycles also may cause our revenues and operating results to vary significantly and unexpectedly from quarter to quarter and make us more susceptible to the effects of general economic downturns.

Zygo is exposed to significant delays and additional costs if we do not receive adequate or timely supplies of raw materials and other supplies upon which we depend.

Zygo is dependent on suppliers for raw materials and various electrical, mechanical and optical supplies. Although we enter into purchase orders with our suppliers either directly or through our contract manufacturers based on our forecasts, we do not have any guaranteed supply arrangements with these suppliers. Moreover, as our demand for supplies increases, we may not be able to obtain these supplies in a timely manner. If any relationship with a key supplier is terminated or if a supplier fails or is unable to provide reliable services or equipment and we are unable to reach suitable alternative solutions quickly, we may experience significant delays and additional costs in the manufacture of our products. If our key suppliers cease manufacturing the supplies we require, if their manufacturing operations are interrupted for any significant period of time, or if they are unable or unwilling to supply us for any other reason, including capacity constraints, then we may be at least temporarily unable to obtain these supplies, thus exposing us to significant delays and additional costs. Currently there are only a limited number of companies that are capable of supplying optical materials in the quantity and of the quality we require. Although we seek to reduce our dependence on limited source suppliers, we may not have qualified a second source for some of these products, and the partial or complete loss of certain of these sources could have a negative impact on our results of operations and damage customer relationships.

We face risks associated with manufacturing forecasts.

If we fail to predict our manufacturing requirements accurately, we could incur additional costs or experience manufacturing delays, which could cause us to lose orders or customers and result in lower net revenues. We currently use a rolling 12-month forecast based primarily on our anticipated product orders and our product order history to help determine our requirements for components and materials. It is very important that we accurately predict both the demand for our products and the lead-time required to obtain the necessary components and raw materials. Lead times for materials and components that we order vary significantly and depend on factors such as the specific supplier, the size of the order, contract terms and demand for each component at a given time. If we underestimate our requirements, we may have inadequate manufacturing capacity or inventory, which could interrupt manufacturing of our products and result in delays in shipments and net revenues. If we overestimate our requirements, we could have excess inventory of parts. In addition, delays in the manufacturing of our products could cause us to lose orders or customers.

Our stock price may fluctuate significantly due to a variety of risks.

We believe that factors such as the announcement of new products or technologies by us or our competitors, market conditions in the semiconductor and industrial markets and quarterly fluctuations in financial results can be expected to cause the market price of our common stock to vary substantially. Further, our net revenues or results of operations in future quarters may be below the expectations of public market securities analysts and investors. In such event, the price of our common stock would likely decline. In addition, the stock market has historically experienced price and volume fluctuations that have particularly affected the market prices for many high technology companies; these variations have often been unrelated to the operating performance of such companies. The market volatility may adversely affect the market price of shares of our common stock. Furthermore, our common stock trading price may be more susceptible to market fluctuations due to the relatively small public float and trading volume of our stock and our dependence on a limited number of industries.

We operate in a highly competitive industry.

We face competition from a number of companies in all our markets, many of which have greater manufacturing and marketing capabilities and greater financial, technological and personnel resources. In addition, we compete with the internal development efforts of our current and prospective customers, some of which may attempt to become vertically integrated. Our competitors can be expected to continue to improve the design and performance of their products and to introduce new products with competitive price/performance characteristics. Competitive pressures may necessitate price reductions, which can adversely affect results of operations. Although we believe that we have certain technical and other advantages over some of our competitors, maintaining such advantages will require a continued high level of investment by our Company in research and development and sales, marketing and service. There can be no assurance that we will have sufficient resources to continue to make such investments or that we will be able to make the technological advances necessary to maintain such competitive advantages. In addition, due to historical relationships and possible prior investments by potential customers in competitive product lines, it may be more difficult for us to realize certain of our growth strategies and initiatives. There can be no assurance that the basis of competition in the industries in which we compete will not shift.

Our inability to anticipate and keep pace with rapidly changing technological developments in the markets in which we operate could have a material adverse effect on our business.

The market for our products is characterized by rapidly changing technology. Our future success will continue to depend upon our ability to enhance our current products and to develop and introduce new products that keep pace with technological developments and evolving industry standards, respond to changes in customer requirements and achieve market acceptance. The development of new technologically advanced products is a complex and uncertain process requiring high levels of innovation, as well as the accurate anticipation of technological and market trends. With continuing advances in technology, potential product advancements require an increasing allocation of resources, including potentially more resources than we then would have available.

We commit significant financial and personnel resources on a continuous basis to redesign and enhance our instruments, systems and components and upgrade the proprietary software technology incorporated in our products. Any failure to anticipate or respond adequately to technological developments and customer requirements, or any significant delays in product development or introduction, could have a material adverse effect on our business and impact our relationships with customers. This could have an impact on customers’ willingness to share proprietary information about their requirements and participate in collaborative efforts with us. There can be no assurance that our customers will continue to provide us with timely access to such information, that we will be successful in developing and marketing new products and services or product and service enhancements on a timely basis, or respond effectively to technological changes or new product announcements by others. In addition, there can be no assurance the new products and services or product enhancements, if any, which we developed will achieve market acceptance.

We may be unable to enforce or defend our ownership and use of proprietary technology.

Our success is heavily dependent upon our proprietary technology. There can be no assurance that the steps we take to protect our proprietary technology will be adequate to prevent misappropriation of our technology by third parties or will be adequate under the laws of some foreign countries; those laws may not protect our proprietary rights to the same extent as do laws of the United States. We have been experiencing an increased level of revenue in China and other foreign countries which historically have created concerns for various companies. In addition, the possibility remains that others will “reverse engineer” our products in order to determine their method of operation and introduce competing products, or that others will independently develop competing technology. Any such circumstances could have a material adverse effect on our results of operations.

Our business depends on management and technical personnel who are in great demand.

Our success depends in large part upon the continued services of many of our highly skilled personnel involved in management, research, development and engineering, sales and marketing, manufacturing and support and upon our ability to attract and retain additional highly qualified employees. Our employees may voluntarily terminate their employment with us at any time. At times, competition for these individuals from a variety of employers, including our competitors and companies in computer or technology-related industries, is intense. We cannot provide assurance that we will be able to retain our existing personnel or attract and retain additional personnel.

Our products may contain defects that are undetected until after our products are installed, which may lead to a loss of reputation and customers.

Our products are deployed in large and complex systems and may contain defects that are not detected until after our products have been installed, which could damage our reputation and cause us to lose customers. We design some of our products for deployment in large and complex optical networks. Because of the nature of these products, they can only be fully tested for reliability when deployed in networks for long periods of time. Our customers may discover defects in our products only after they have been fully deployed and operated under peak stress conditions. In addition, our products are combined with products from other vendors. As a result, should problems occur, it could be difficult to identify the source of the problem. These conditions increase the risk that we could experience, among other things: loss of customers; damage to our brand reputation; failure to attract new customers or achieve market acceptance; diversion of development and engineering resources; and legal actions by our customers. The occurrence of any one or more of the foregoing factors couldhave a negative impact on our financial condition and results of operations, and damage customer relationships.

Item 1B. Unresolved Staff Comments

We have received no written comments regarding our periodic or current reports from the staff of the SEC that were issued 180 days or more preceding the end of our fiscal year 2013 that remain unresolved.

Item 2. Properties

We own our principal manufacturing facility and corporate headquarters, which is located on Laurel Brook Road in Middlefield, Connecticut. This facility consists of one 153,500 square-foot building on approximately 13 acres. In addition we own a 55,300 square-foot manufacturing facility, acquired as part of the ASML Richmond asset acquisition in fiscal 2011. In May 2012, we purchased a 110,020 square-foot facility in Tucson, Arizona, which will function as the manufacturing site for our Tucson operation. The following table sets forth information with respect to our facilities which are used by both of our operating segments, except as identified otherwise below:

| | | Square Footage | | | Owned / Leased |

| Operation/Location | | Manufacturing | | | Total | | | Expiration Date |

| Corporate Headquarters, Eastern Regional Sales Office and Metrology and Optics Manufacturing | | | | | | | | | | |

| Middlefield, Connecticut | | | 96,049 | | | | 153,500 | | | Owned |

| | | | | | | | | | | |

| Zygo Extreme Precision Optics Group | | | | | | | | | | |

| Richmond, California | | | 44,274 | | | | 55,300 | | | Owned |

| Richmond, California | | | 0 | | | | 13,230 | | | Leased - 07/31/15 |

| | | | | | | | | | | |

| Zygo - Optical Systems | | | | | | | | | | |

| Tucson, Arizona | | | 25,300 | | | | 110,020 | | | Owned |

| Tucson, Arizona- (1) | | | 14,560 | | | | 22,560 | | | Leased - 10/31/13 |

| | | | | | | | | | | |

| Zygo-Texas | | | | | | | | | | |

| Texas Office | | | 0 | | | | 519 | | | Leased - 09/30/14 |

| | | | | | | | | | | |

| Zygo-Massachusetts | | | | | | | | | | |

| Massachusetts Office | | | 0 | | | | 400 | | | Leased - 06/30/15 |

| | | | | | | | | | | |

| Zygo Lamda | | | | | | | | | | |

| China | | | 3,552 | | | | 12,206 | | | Leased - 09/16/15 |

| China | | | 1,292 | | | | 1,292 | | | Leased - 06/30/13 |

| | | | | | | | | | | |

| Zygo Canada, Inc. | | | | | | | | | | |

| Canada | | | 3,000 | | | | 7,026 | | | Leased - 07/31/16 |

| | | | | | | | | | | |

| Zygo - Optical Systems | | | | | | | | | | |

| Costa Mesa, California | | | 6,500 | | | | 13,714 | | | Leased - 04/30/14 |

| | | | | | | | | | | |

| Western Regional Sales Office and R&D Center | | | | | | | | | | |

| Santa Clara, California | | | 0 | | | | 4,000 | | | Leased - 06/30/16 |

| | | | | | | | | | | |

| Zygo - Laser Technology Metrology (R&D) | | | | | | | | | | |

| Watsonville, California | | | 0 | | | | 1,452 | | | Leased - 03/31/14 |

| | | | | | | | | | | |

| Zygo PTE Ltd | | | | | | | | | | |

| Singapore | | | 0 | | | | 2,174 | | | Leased - 12/31/15 |

| | | | | | | | | | | |

| Zygo Taiwan | | | | | | | | | | |

| Sales and Service Office - Taiwan Branch | | | 0 | | | | 992 | | | Leased - 04/30/14 |

| Taiwan Co., Ltd | | | 0 | | | | 18,937 | | | Leased - 04/30/14 |

| | | | | | | | | | | |

| ZygoLOT | | | | | | | | | | |

| Germany | | | 0 | | | | 3,702 | | | Leased - 10/01/13 |

| | | | | | | | | | | |

| Zygo KK | | | | | | | | | | |

| Japan | | | 0 | | | | 1,705 | | | Leased - 08/01/15 |

| Demo Room | | | 0 | | | | 500 | | | Leased - 03/31/15 |

| | | | | | | | | | | |

| Total | | | 194,527 | | | | 423,229 | | | |

(1) We plan to move this operation into the new Tucson location during fiscal 2014. Current lease will terminate in accordance with lease agreements with no penalty.

Item 3. Legal Proceedings

From time to time, we are subject to certain legal proceedings and claims that arise in the normal course of our business. In the opinion of management, we are not party to any litigation that we believe could have a material effect on our financial condition, results of operations or liquidity.

Item 4. Mine Safety Disclosures

N/A.

PART II

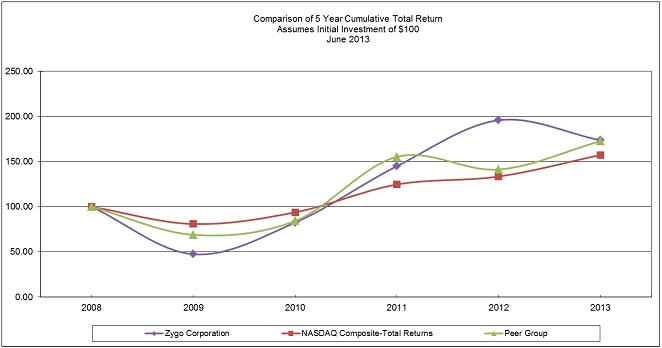

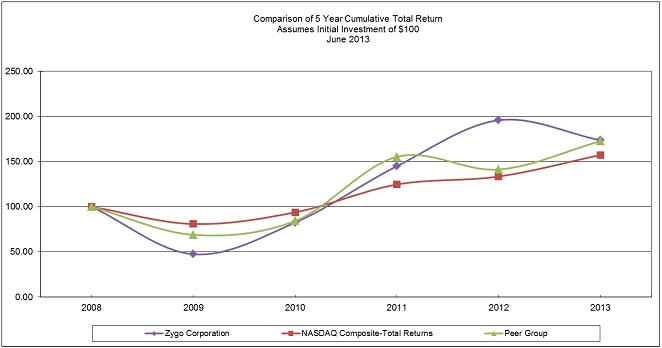

Item 5. Market for the Registrant’s Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities