FINANCIAL HIGHLIGHTS (dollar amounts in thousands, except per share data)

| | | | | | | | | | | |

| | | 2006 | | | 2005 | | | % CHANGE | |

FOR THE YEAR | | | | | | | | | | | |

| | | |

Net sales | | $ | 14,751,270 | | | $ | 12,700,999 | | | 16 | % |

| | | |

Earnings: | | | | | | | | | | | |

| | | |

Earnings before income taxes | | | 2,693,818 | | | | 2,016,368 | | | 34 | % |

| | | |

Provision for income taxes | | | 936,137 | | | | 706,084 | | | 33 | % |

| | | | | | | | | | | |

Net earnings | | | 1,757,681 | | | | 1,310,284 | | | 34 | % |

| | | |

Per share: | | | | | | | | | | | |

| | | |

Basic(1) | | | 5.73 | | | | 4.17 | | | 37 | % |

| | | |

Diluted(1) | | | 5.68 | | | | 4.13 | | | 38 | % |

| | | |

Dividends declared per share(1) | | | 2.15 | | | | 0.93 | | | 131 | % |

| | | |

Percentage of net earnings to net sales | | | 11.9 | % | | | 10.3 | % | | 16 | % |

| | | |

Return on average equity | | | 38.6 | % | | | 33.9 | % | | 14 | % |

| | | |

Capital expenditures | | | 338,404 | | | | 331,466 | | | 2 | % |

| | | |

Depreciation | | | 363,936 | | | | 375,054 | | | -3 | % |

| | | |

Sales per employee | | | 1,273 | | | | 1,159 | | | 10 | % |

| | | |

AT YEAR END | | | | | | | | | | | |

| | | |

Working capital | | $ | 3,225,008 | | | $ | 2,815,854 | | | 15 | % |

| | | |

Property, plant and equipment, net | | | 2,856,415 | | | | 2,855,717 | | | — | |

| | | |

Long-term debt | | | 922,300 | | | | 923,550 | | | — | |

| | | |

Stockholders’ equity | | | 4,825,989 | | | | 4,279,788 | | | 13 | % |

| | | |

Per share(1) | | | 16.04 | | | | 13.80 | | | 16 | % |

| | | |

Shares outstanding(1) | | | 300,949 | | | | 310,220 | | | -3 | % |

| | | |

Employees | | | 11,900 | | | | 11,300 | | | 5 | % |

| (1) | Per share amounts and shares outstanding have been adjusted to reflect the two-for-one stock split effective May 2006. |

FORWARD-LOOKING STATEMENTS Certain statements made in this annual report are forward-looking statements that involve risks and uncertainties. These forward-looking statements reflect the Company’s best judgment based on current information, and although we base these statements on circumstances that we believe to be reasonable when made, there can be no assurance that future events will not affect the accuracy of such forward-looking information. As such, the forward-looking statements are not guarantees of future performance, and actual results may vary materially from the results and expectations discussed in this report. Factors that might cause the Company’s actual results to differ materially from those anticipated in forward-looking statements include, but are not limited to: (1) the sensitivity of the results of our operations to volatility in steel prices and changes in the supply and cost of raw materials, including scrap steel; (2) availability and cost of electricity and natural gas; (3) market demand for steel and steel products, which, in the case of many of our products, is driven by the level of non-residential construction activity in the U.S.; (4) competitive pressure on sales and pricing, including pressure from imports and substitute materials; (5) uncertainties surrounding the global economy, including excess world capacity for steel production and fluctuations in currency conversion rates; (6) U.S. and foreign trade policy affecting steel imports or exports; (7) significant changes in government regulations affecting environmental compliance; (8) the cyclical nature of the steel industry; (9) capital investments and their impact on our performance; and (10) our safety performance.

| | |

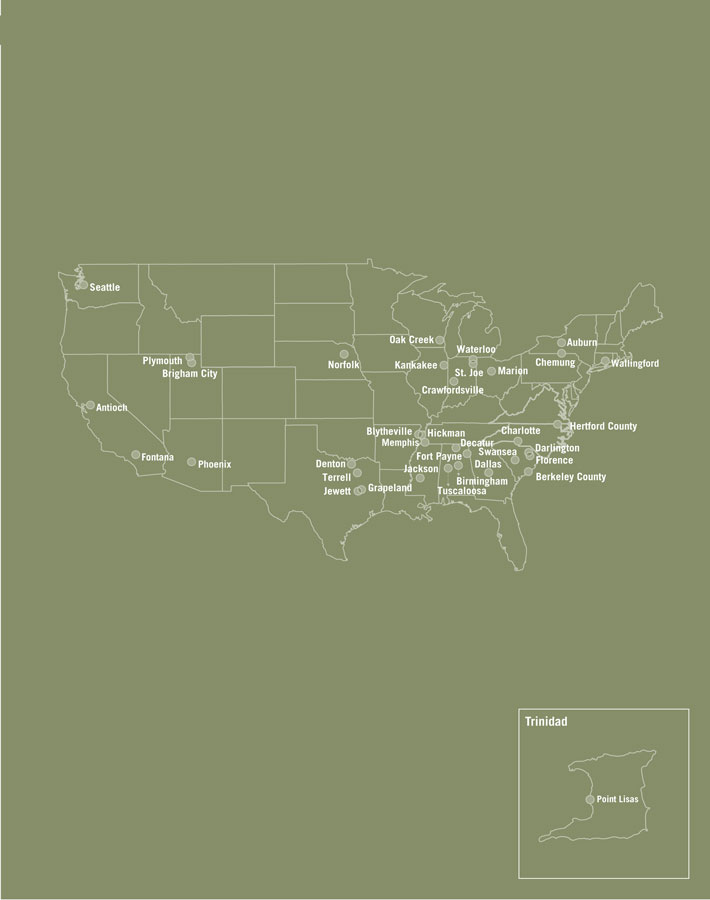

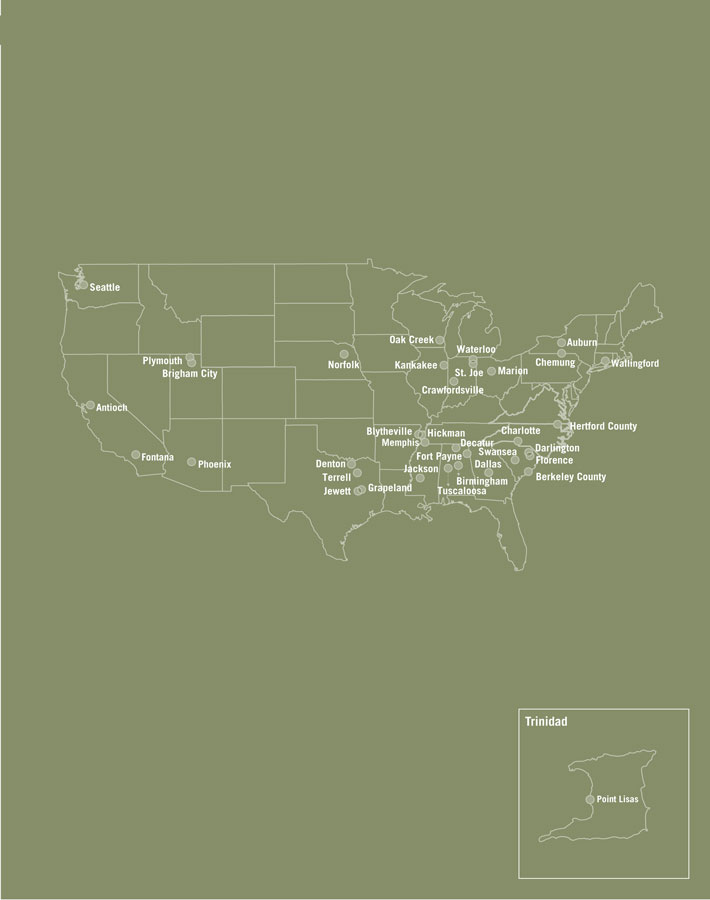

STEEL MILLS SEGMENT | | STEEL PRODUCTS SEGMENT |

BAR MILLS Products: Steel bars, angles and other products for automotive, construction, farm machinery, metal buildings, furniture and recreational equipment. Darlington, South Carolina Norfolk, Nebraska Jewett, Texas Plymouth, Utah Auburn, New York (Nucor Steel Auburn, Inc.) Birmingham, Alabama (Nucor Steel Birmingham, Inc.) Kankakee, Illinois (Nucor Steel Kankakee, Inc.) Jackson, Mississippi (Nucor Steel Jackson, Inc.) Seattle, Washington (Nucor Steel Seattle, Inc.) Marion, Ohio (Nucor Steel Marion, Inc.) Wallingford, Connecticut (Nucor Steel Connecticut, Inc.) Memphis, Tennessee (Nucor Steel Memphis, Inc.) SHEET MILLS Products: Flat-rolled steel for automotive, appliance, pipe and tube, construction and other industries. Crawfordsville, Indiana Hickman, Arkansas Berkeley County, South Carolina Decatur, Alabama (Nucor Steel Decatur, LLC) NUCOR-YAMATO STEEL COMPANY Products: Super-wide flange steel beams, pilings and heavy structural steel products for fabricators, construction companies, manufacturers and steel service centers. Blytheville, Arkansas BEAM MILL Products: Wide flange steel beams, pilings and heavy structural steel products for fabricators, construction companies, manufacturers and steel service centers. Berkeley County, South Carolina PLATE MILLS Products: Steel plate for manufacturers of heavy equipment, rail cars, ships, barges, refinery tanks, pipe and tube, pressure vessels, construction and others. Hertford County, North Carolina Tuscaloosa, Alabama (Nucor Steel Tuscaloosa, Inc.) | | VULCRAFT AND VERCO Products: Steel joists, joist girders and steel deck for non-residential building construction. Florence, South Carolina Norfolk, Nebraska Fort Payne, Alabama Grapeland, Texas St. Joe, Indiana Brigham City, Utah Chemung, New York (Vulcraft of New York, Inc.) Phoenix, Arizona (Verco Decking, Inc.) Fontana, California (Verco Decking, Inc.) Antioch, California (Verco Decking, Inc.) COLD FINISH Products: Cold finished steel bars for shafting and precision machined parts. Norfolk, Nebraska Darlington, South Carolina Brigham City, Utah Oak Creek, Wisconsin (Nucor Cold Finish Wisconsin, Inc.) BUILDING SYSTEMS Products: Metal buildings and metal building components for commercial, industrial and institutional building markets. Waterloo, Indiana Swansea, South Carolina Terrell, Texas Brigham City, Utah (Nucor Building Systems Utah, LLC) FASTENER Products: Steel hexhead cap screws, structural bolts and hex bolts for automotive, machine tools, farm implements, construction and military applications. St. Joe, Indiana NUCON STEEL Products: Load bearing light gauge steel framing systems for the commercial and residential construction markets. Denton, Texas Dallas, Georgia |

| | OTHER |

| | NU-IRON UNLIMITED Products: Direct reduced iron for use as a charge material in our steelmaking operations. Point Lisas, Trinidad |

| | CORPORATE OFFICE |

| | Charlotte, North Carolina |

STEEL MILLS SEGMENT

BAR MILLS, SHEET MILLS, STRUCTURAL MILLS AND PLATE MILLS

Nucor operates scrap-based steel mills in nineteen facilities. these mills utilize modern steelmaking techniques and produce steel at a cost competitive with steel manufactured anywhere in the world.

BAR MILLS

Nucor has eleven bar mills located in South Carolina, Nebraska, Texas, Utah, New York, Alabama, Illinois, Mississippi, Washington, Ohio and Connecticut that produce bars, angles and light structural shapes in carbon and alloy steels. These products have a wide range of usage including automotive, construction, farm equipment, metal buildings, furniture and recreational equipment. Four of the bar mills were constructed by Nucor between 1969 and 1981. Over the years, Nucor has completed extensive capital projects to keep these facilities modernized and globally competitive. Nucor acquired the remaining seven bar mills since 2000, including the purchase of substantially all of the assets of Marion Steel Company (“Marion Steel”) in the second quarter of 2005 and substantially all of the assets of Connecticut Steel Corporation (“Connecticut Steel”) in the second quarter of 2006. Nucor Steel Marion, Inc. has the capacity to produce up to 450,000 tons annually and Nucor Steel Connecticut, Inc. has the capacity to produce up to 300,000 tons annually. With these recent acquisitions, the total capacity of our eleven bar mills is currently approximately 7,960,000 tons per year.

SHEET MILLS

The sheet mills produce flat-rolled steel for automotive, appliance, pipe and tube, construction and other industries. The four sheet mills are located in Indiana, Arkansas, South Carolina and Alabama. Nucor constructed three of the sheet mills between 1989 and 1996. The constructed sheet mills utilize thin slab casters to produce hot rolled sheet. In 2002, Nucor’s wholly owned subsidiary Nucor Steel Decatur, LLC purchased substantially all the assets of Trico Steel Company, LLC (“Trico”). This sheet mill is located in Decatur, Alabama, and has an annual capacity of approximately 2,400,000 tons, expanding our sheet capacity by 30% at the time of the acquisition. In 2004, Nucor Steel Decatur, LLC purchased the adjacent cold rolling mill of Worthington Industries, Inc. (“Worthington”). In 2006 Nucor announced plans to construct its fourth sheet steel galvanizing facility at Nucor Steel Decatur, LLC. Upon completion of the galvanizing facility, all four of our sheet mills will be fully equipped with cold rolling mills and galvanizing lines for further processing of hot rolled sheet. The total capacity of the four sheet mills is approximately 10,800,000 tons per year.

STRUCTURAL MILLS

The structural mills produce wide flange steel beams, pilings and heavy structural steel products for fabricators, construction companies, manufacturers and steel service centers. In 1988, Nucor and Yamato Kogyo, one of Japan’s major producers of wide-flange beams, completed construction of a beam mill located near Blytheville, Arkansas. Nucor owns a 51% interest in Nucor-Yamato Steel Company. During 1999, Nucor started operations at its 1,000,000 tons-per-year steel beam mill in South Carolina. Both mills use a special continuous casting method that produces a beam blank closer in shape to that of the finished beam than traditional methods. Current annual production capacity of our two structural mills is approximately 3,700,000 tons.

PLATE MILLS

Nucor operates two plate mills. Nucor completed construction of its first plate mill, located in North Carolina, in 2000 with the competitive advantages of new, more efficient production technology. This mill produces plate for manufacturers of heavy equipment, rail cars, ships, barges, refinery tanks and others. In 2004, Nucor’s wholly owned subsidiary, Nucor Steel Tuscaloosa, Inc., purchased substantially all the assets of Corus Tuscaloosa. The Tuscaloosa mill has an annual capacity of 1,200,000 tons, and complements our product offering with thinner gauges of coiled and cut-to-length plate used in the pipe and tube, pressure vessel, transportation and construction industries. Current annual production capacity of our two plate mills is approximately 2,800,000 tons.

OPERATIONS

Nucor’s steel mills are among the most modern and efficient mills in the United States. Recycled steel scrap and other metallics are melted in electric arc furnaces and poured into continuous casting systems. Highly sophisticated rolling mills convert the billets, blooms and slabs into rebar, angles, rounds, channels, flats, sheet, beams, plate and other products.

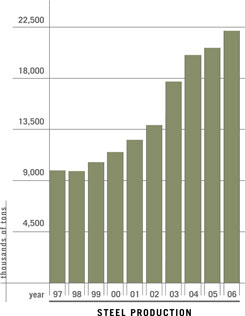

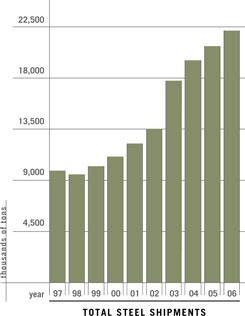

Production in 2006 was a record 22,382,000 tons, a 10% increase from 20,332,000 tons in 2005. Annual production capacity has grown from 120,000 tons in 1970 to a present total of more than 25,000,000 tons.

The operations in the rolling mills are highly automated and require fewer operating employees than older mills. All Nucor steel mills have high productivity, which results in employment costs of approximately 7% of the sales dollar. This is lower than the employment costs of integrated steel companies producing comparable products. Employee turnover in Nucor mills is extremely low. All employees have a significant part of their compensation based on their productivity. Production employees work under group incentives that provide increased earnings for increased production. This additional compensation is paid weekly.

Steel mills are large consumers of electricity and gas. Total energy costs decreased approximately $1 per ton from 2005 to 2006 due to lower natural gas prices. Due to the greater efficiency of Nucor steel mills, these energy costs were less than 10% of the sales dollar in 2006 and 2005. Nucor is partially hedged against exposure to increases in energy costs.

Scrap and scrap substitutes are the most significant element in the total cost of steel production. The average cost of scrap and scrap substitutes used increased 1% to $246 per ton in 2006 from $244 per ton in 2005. A raw material surcharge implemented in 2004 has allowed Nucor to maintain operating margins and to meet our commitments to customers in spite of highly volatile scrap and scrap substitute costs.

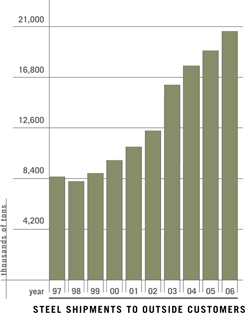

MARKETS AND MARKETING

Approximately 92% of the nineteen steel mills’ production in 2006 was sold to outside customers and the balance was used internally by the Vulcraft, Cold Finish, Building Systems and Fastener divisions. Steel shipments to outside customers increased 9% from 19,020,000 tons in 2005 to a record 20,649,000 tons in 2006.

Our steel mill customers are primarily manufacturers, steel service centers and fabricators. The sheet mills continue to build long-term relationships with contract customers who purchase more value-added products. We enter 2007 with approximately 60% of our sheet mill volume committed to contract customers with terms typically ranging from six to twelve months. These contracts are non-cancelable agreements with a pricing formula that takes into account changes in our raw material costs. The sheet mills will continue to pursue profitable contract business on a long-term basis.

GOVERNMENT AFFAIRS

In 2006, Nucor continued our efforts in governmental affairs on several planes. We have continued the aggressive trade case efforts in which we have engaged over the years with our participation in the current statutory five-year sunset reviews of existing duties for coated sheet and carbon plate products. In late 2006, the International Trade Commission chose to remove the existing duties on many of the countries involved in dumping these products into our country. As a result, more unfairly traded foreign steel may continue to enter our borders with negative effects on our business. We are currently evaluating these decisions for an appeal, and we will continue to fight illegally dumped foreign steel in support of free and fair trade through the legal process.

We have also developed a well-embedded grass roots effort with our state and local legislators to help build support toward many other issues beyond the trade cases. Some of these issues include currency manipulation, climate change, energy and tax policy. Our goal is to move state and local legislators to recognize the importance of domestic manufacturing and the serious threat these issues place against our customer base.

In Washington, we have a strong lobbying effort with the House, Senate, Commerce Department and other Executive Branch agencies. At the federal level, we pursue the same issues of currency manipulation, climate change, energy and tax policy while working with government officials to help design legislation and public policies that recognize the importance of the U.S. manufacturing base. Our end goal in all our governmental affairs work is to help generate changes in our laws to advocate free and fair trade in order to allow domestic manufacturing to thrive and succeed.

NEWER FACILITIES AND EXPANSIONS

As part of our long-term growth strategy, Nucor continues to invest in existing operations, make greenfield investments utilizing advantageous new technologies and pursue acquisitions that are accretive to earnings. Capital expenditures in the steel mill segment totaled $242.5 million, $216.0 million and $195.5 million in 2004, 2005 and 2006, respectively.

Nucor began operations of its 100%-owned Castrip facility in Crawfordsville, Indiana, in May 2002. This facility uses the breakthrough technology of strip casting, to which Nucor holds exclusive rights in the United States and Brazil. Strip casting involves the direct casting of molten steel into final shape and thickness without further hot or cold rolling. This process allows lower investment and operating costs, reduced energy consumption and smaller scale plants than can be economically built with current technology. This process also reduces the overall environmental impact of producing steel by generating significantly lower emissions. In 2006, production and shipments of the Castrip product increased more than 30% over 2005 levels. In 2005, Nucor selected Blytheville, Arkansas, as the second Nucor location for a Castrip operation in the United States. The Blytheville, Arkansas, Castrip facility is expected to begin operating in the second half of 2008. Nucor expects to establish at least one joint venture partner overseas in 2007 to utilize the Castrip technology.

During the third quarter of 2004, Nucor purchased substantially all of the assets of Corus Tuscaloosa for a cash purchase price of approximately $89.4 million. This plate mill had an initial annual capacity of about 800,000 tons and complements the product offering of our Hertford County plate mill with thinner gauges of coiled and cut-to-length plate. With minimal investments in this facility, combined with the benefits of our incentive pay program, we have increased capacity to 1,200,000 tons currently. This acquisition was immediately accretive to earnings and made significant operating contributions in 2004 through 2006.

Also in the third quarter of 2004, Nucor purchased certain cold rolling assets from Worthington, located adjacent to our Decatur, Alabama sheet mill, for a cash purchase price of approximately $80.3 million. The purchased assets include all of the buildings, a pickle line, four-stand tandem mill, temper mill and annealing furnaces. This modern 1,000,000-ton cold mill with 600,000 tons of annealing capacity was constructed in 1998 and, together with our new galvanizing line described below, complements our strategy to serve value-added customers in the Southeast market.

In June 2005, Nucor’s wholly owned subsidiary, Nucor Steel Marion, Inc., purchased substantially all of the assets of Marion Steel for a cash purchase price of approximately $110.7 million. The facility is a bar products mill that manufactures angles, flats, rebar, rounds and signposts. Located in Marion, Ohio, the mill is in close proximity to 60% of the steel consumption in the United States. The facility has already grown its capacity from 400,000 ton to 450,000 tons largely as a result of our incentive based compensation program.

In May 2006, Nucor’s wholly owned subsidiary, Nucor Steel Connecticut, Inc., purchased substantially all of the assets of Connecticut Steel for a cash purchase price of approximately $43.9 million. This facility produces wire rod, rebar, wire mesh and structural mesh products. Located in Wallingford, Connecticut, the bar products mill has an annual capacity of approximately 300,000 tons of wire rod and rebar and approximately 85,000 tons of wire mesh fabrication and structural mesh fabrication.

In June 2006, Nucor announced plans to construct its fourth sheet steel galvanizing facility at Nucor Steel Decatur, LLC, with a capital budget of about $152 million. Annual capacity will be approximately 500,000 tons per year and the facility will galvanize up to 72-inch wide sheet steel. Construction is expected to begin in the second quarter of 2006 with completion and start-up in mid-2008. The addition of this facility will increase Nucor’s total galvanizing annual capacity by one-third to 2,000,000 tons.

In October 2006, Nucor announced plans to construct a “Special Bar Quality Products” (“SBQ”) steel mill in Memphis, Tennessee. The planned site was acquired in 2002 from the bankrupt Birmingham Steel Company, and the project will utilize some of the infrastructure existing at this location. The project is expected to cost approximately $230 million and to have an estimated annual capacity of 850,000 tons. The facility will produce high quality carbon and alloy rounds and round cornered squares from 2.25” to 9”, complementing the product offerings of Nucor’s Nebraska and South Carolina SBQ mills. Construction has begun and start-up is expected in the first quarter of 2008.

RAW MATERIALS STRATEGY

Nucor has established a raw materials strategy to control directly, and indirectly through joint ventures with various partners, the production of 6,000,000 to 7,000,000 tons per year of high quality metallics for consumption at its steel mills. In April 2002, Nucor entered a joint venture with The Rio Tinto Group, Mitsubishi Corporation and Chinese steel maker Shougang Corporation to construct a commercial HIsmelt plant in Kwinana, Western Australia. The HIsmelt process converts iron ore fines and coal fines to liquid metal, eliminating the need for a blast furnace, sinter/pellet plants and coke ovens. Nucor has a 25% interest in the joint venture that owns the HIsmelt commercial plant. Construction was completed and start-up commenced in 2005. This plant has an initial annual capacity of 800,000 metric tons and is expandable to over 1,500,000 metric tons.

In April 2003, Nucor entered a joint venture with CVRD to construct and operate an environmentally friendly pig iron project in northern Brazil. The project, named Ferro Gusa Carajás S.A. (“FGC”), utilizes two conventional mini-blast furnaces to produce about 380,000 metric tons of pig iron per year, using iron ore from CVRD’s Carajás mine in northern Brazil. The charcoal source is exclusively from eucalyptus trees grown in a cultivated forest of about 80,000 acres with the total project encompassing

approximately 175,000 acres in northern Brazil. The cultivated forest removes more carbon dioxide from the atmosphere than the blast furnace emits. Production of pig iron began in the fourth quarter of 2005. Nucor is purchasing all of the production of the plant.

In September 2004, Nucor acquired the assets of an idled DRI plant located in Louisiana and subsequently moved these assets to Trinidad. Construction is complete and heat-up commenced in December 2006. In January 2007, Nucor announced the successful ramp up of Nu-Iron Unlimited to full production capacity of about 2,000,000 tons per year. The Trinidad site benefits from a low cost supply of natural gas and favorable logistics for receipt of Brazilian iron ore and shipment of DRI to the U.S.

STEEL PRODUCTS SEGMENT

VULCRAFT AND VERCO are the nation’s largest producers of open-web steel joists, joist girders and steel deck, which are used for non-residential building construction.

OPERATIONS

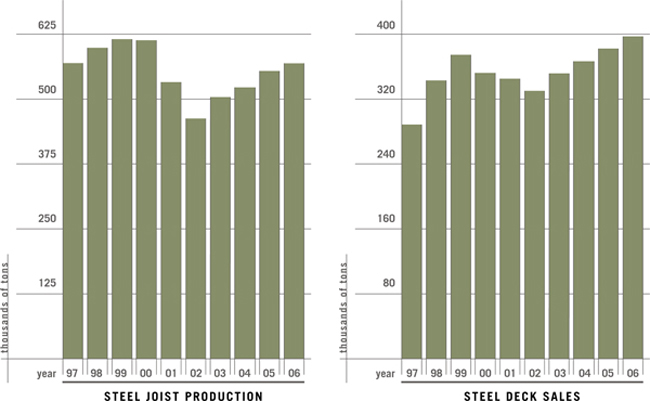

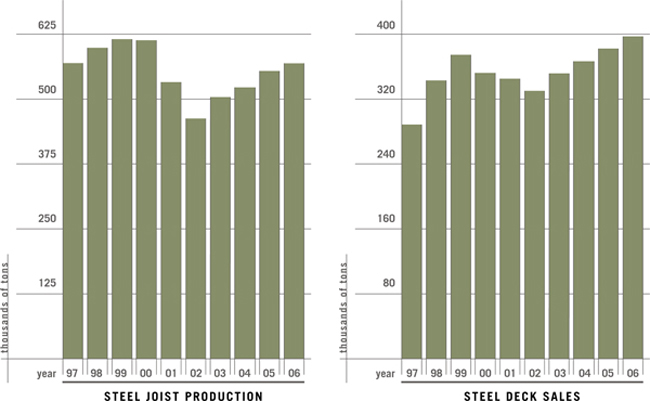

Steel joists and joist girders are produced and marketed nationally through seven Vulcraft facilities located in South Carolina, Nebraska, Alabama, Texas, Indiana, Utah and New York. Current annual production capacity is approximately 715,000 tons. In 2006, Vulcraft produced 570,000 tons of steel joists and joist girders, an increase of 3% from the 554,000 tons produced in 2005.

Material costs, primarily steel, were approximately 53% of the joist sales dollar in 2006 (50% in 2005). Vulcraft obtained 99% of its steel requirements for joists and joist girders from the Nucor bar mills in both 2006 and 2005. Freight costs for joists and joist girders were less than 10% of the sales dollar in 2006 and 2005. Vulcraft maintains an extensive fleet of trucks to ensure and control on-time delivery.

Steel decking is produced and marketed nationally through nine deck plants located in South Carolina, Nebraska, Alabama, Texas, Indiana, New York, Arizona and two in California. Six of these plants were constructed by Nucor adjacent to Vulcraft joist facilities. In November 2006, Nucor’s wholly owned subsidiary, Verco Decking, Inc, purchased substantially all of the assets of Verco Manufacturing Company (“Verco”) for a cash purchase price of approximately $180 million. This acquisition includes three deck plants located in Arizona and California, positioning Nucor to better supply the large western construction market. Current deck annual production capacity is now approximately 530,000 tons. Steel deck sales increased 5% from 380,000 tons in 2005 to a record 398,000 tons in 2006. Coiled sheet steel was approximately 64% of the steel deck sales dollar in 2006 (62% in 2005). In 2006 and 2005, Nucor obtained 99% of its steel requirements for steel deck production from the Nucor sheet mills. For 2006 and 2005, freight costs for deck were less than 10% of the sales dollar.

Production employees of Vulcraft work with a group incentive system that provides increased compensation each week for increased performance.

MARKETS AND MARKETING

Steel joists, joist girders and steel decking are used extensively as part of the roof and floor support systems in manufacturing buildings, retail stores, shopping centers, warehouses, schools, churches, hospitals and, to a lesser extent, in multi-story buildings and apartments. Building support systems using joists, joist girders and steel deck are frequently more economical than other systems.

Steel joists and joist girder sales are obtained by competitive bidding. Vulcraft quotes on a significant percentage of the domestic buildings using steel joists and joist girders as part of the support systems. In 2006, Vulcraft supplied more than 40% of total domestic sales of steel joists. Steel deck is specified in the majority of buildings using steel joists and joist girders. Steel deck is also used as concrete floor support in high rise buildings. In 2006, Vulcraft supplied more than 30% of total domestic sales of steel deck. With the acquisition of Verco in late 2006, Nucor expects to substantially increase deck sales in 2007.

Sales of steel joists, joist girders and steel deck are dependent on the non-residential building construction market.

COLD FINISH AND FASTENER Nucor manufactures a variety of products using steel from Nucor mills.

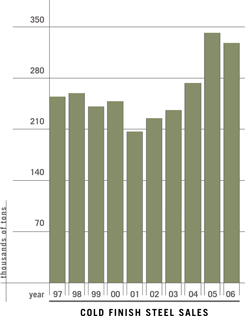

COLD FINISH

Nucor Cold Finish is the largest producer of cold finished bars in the United States and has facilities in Nebraska, South Carolina, Utah and Wisconsin. Three of these facilities were originally constructed by Nucor between 1978 and 1983. In February 2005, Nucor purchased the assets of Fort Howard Steel, Inc.’s (“Fort Howard Steel”) operations in Oak Creek, Wisconsin for a cash purchase price of approximately $44.1 million. This facility has approximately 140,000 tons of annual capacity. The total capacity of the four facilities is approximately 490,000 tons per year. With the successful completion of the acquisition of Harris Steel, the Laurel Steel division of Harris Steel will add to Nucor’s position as the largest producer of cold finish steel in North America.

These facilities produce cold drawn and turned, ground and polished steel bars that are used extensively for shafting and precision machined parts. Nucor Cold Finish produces rounds, hexagons, flats and squares in carbon, alloy and leaded steels. These bars, in turn, are purchased by the automotive, farm machinery, hydraulic, appliance and electric motor industries, as well as by service centers. Nucor Cold Finish bars are used in tens of thousands of products. A few examples include anchor bolts, farm machinery, hydraulic cylinders, and shafting for air conditioner compressors, ceiling fan motors, garage door openers, electric motors and lawn mowers.

All four facilities are among the most modern in the world and use in-line electronic testing to ensure outstanding quality. Nucor Cold Finish obtains most of its steel from the Nucor bar mills. This factor, along with the efficient facilities using the latest technology, results in a highly competitive cost structure.

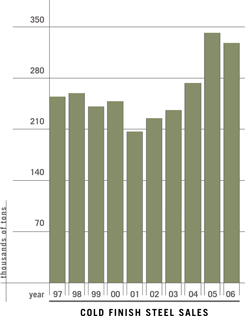

In 2006, sales of cold finished steel products were 327,000 tons, a decrease of 4% from 2005’s record 342,000 tons. The total cold finish market is estimated to be approximately 2,000,000 tons. The Wisconsin facility represents a continuation of our successful value-added strategy and expands our presence in the midwest market. Nucor Cold Finish anticipates opportunities for significant increases in sales and earnings during the next several years.

FASTENER

Nucor Fastener’s state-of-the-art steel bolt-making facility in Indiana produces standard steel hexhead cap screws, hex bolts, structural bolts and custom-engineered fasteners. Fasteners are used in a broad range of markets, including automotive, machine tools, farm implements, construction and military applications.

Annual capacity is more than 75,000 tons. Nucor Fastener’s dedication to quality, on-time delivery and exceptional customer service yields a competitive advantage in a very import-sensitive market. Nucor Fastener obtains much of its steel from the Nucor bar mills.

BUILDING SYSTEMS AND LIGHT GAUGE STEEL FRAMING

Nucor manufactures metal buildings and steel framing systems for commercial, industrial and residential construction markets.

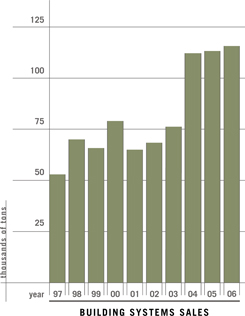

BUILDING SYSTEMS

Nucor Building Systems produces metal building systems and components in Indiana, South Carolina and Texas. The annual capacity is more than 145,000 tons. The size of the buildings that can be produced ranges from less than 500 square feet to more than 1,000,000 square feet. In September 2006, Nucor announced that Brigham City, Utah, had been selected for construction of a new Building Systems facility. The facility is expected to cost approximately $27 million and to add approximately 45,000 tons to Nucor’s annual capacity to produce metal building systems and components.

Complete metal building packages can be customized and combined with other materials such as glass, wood and masonry to produce a cost effective, aesthetically pleasing building designed for customers’ special requirements. The buildings are sold primarily through an independent builder distribution network in order to provide fast-track, customized solutions for building owners.

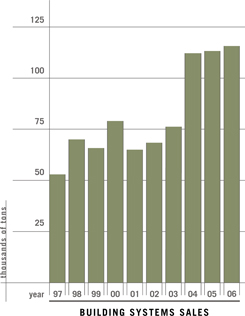

Building systems sales in 2006 were a record 116,000 tons (114,000 tons in 2005). The primary markets are commercial, industrial and institutional buildings, including distribution centers, automobile dealerships, retail centers, schools, warehouses and manufacturing facilities. Nucor Building Systems obtains a significant portion of its steel requirements from the Nucor bar and sheet mills.

LIGHT GAUGE STEEL FRAMING

NUCONSTEEL™ (“Nucon”) specializes in load bearing light gauge steel framing systems for the commercial and residential construction markets with fabrication facilities in Texas and Georgia. Nucon also sells its proprietary products through a growing network of authorized fabricators located throughout the United States.

In 2004, Nucon introduced two new low-cost automated fabrication systems for residential construction: the NUFRAME™ automated wall panel system and the NUTRUSS® automated truss system. Nucon uses these systems in its residential wall panel and truss fabrication facility in Texas and has formed a separate group within Nucon to sell and license the systems to third parties.

In March 2006, Nucor formed a joint venture with Lennar Corporation. NEXFRAME, LP was established to provide comprehensive light gauge steel framing solutions for residential construction markets across the nation. Nucor plans to continue to aggressively broaden Nucon’s opportunities through geographic expansion and the introduction of new products.

| | |

| 20 | | MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS |

OVERVIEW

Nucor is principally a domestic manufacturer of steel and steel products whose customers are located primarily in the United States. Additionally, Nucor is the nation’s largest recycler. Nucor reports its results in two segments, steel mills and steel products.

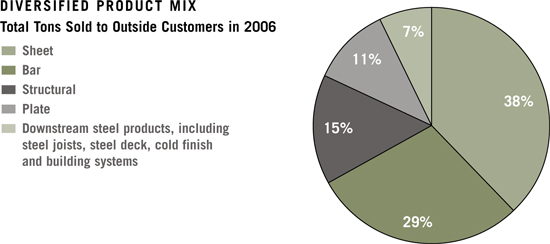

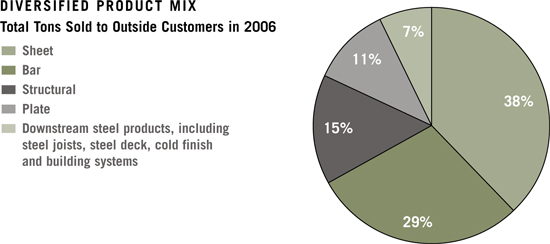

Principal products from the steel mills segment are hot-rolled steel (angles, rounds, flats, channels, sheet, wide-flange beams, pilings, billets, blooms, beam blanks and plate) and cold-rolled steel. Principal products from the steel products segment are steel joists and joist girders, steel deck, cold finished steel, steel fasteners, metal building systems and light gauge steel framing. Hot-rolled steel is manufactured principally from scrap, utilizing electric arc furnaces, continuous casting and automated rolling mills. Cold-rolled steel, cold finished steel, steel joists and joist girders, and steel fasteners are manufactured by further processing of hot-rolled steel. Steel deck is manufactured from cold-rolled steel. In 2006, approximately 92% of the steel mills segment production was sold to non-affiliated customers; the remainder was used internally by the steel products segment.

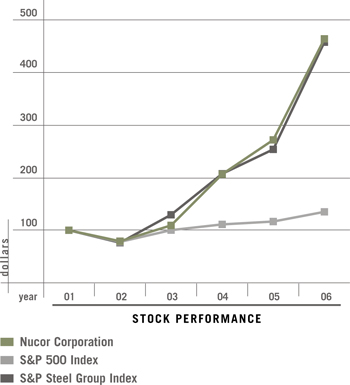

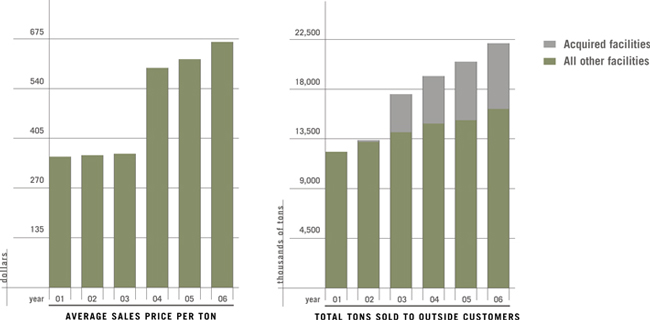

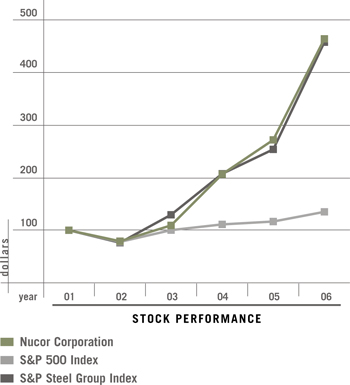

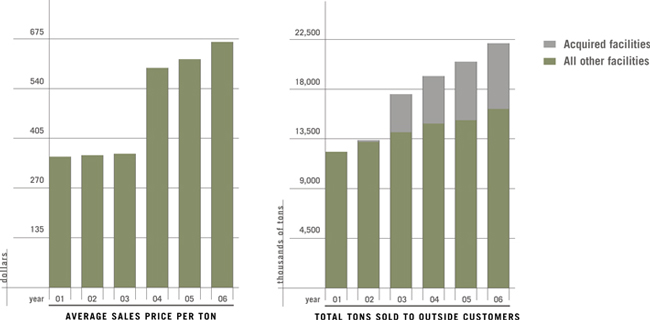

During the last five years, Nucor’s sales have increased over 240% from $4.33 billion in 2001 to $14.75 billion in 2006. Average sales price per ton has increased 88% from $354 in 2001 to $667 in 2006. Total tons sold to external customers have increased 81% from 12,237,000 tons in 2001 to 22,118,000 tons in 2006. This growth has been generated through acquisitions, optimizing existing operations and developing traditional greenfield projects using new technologies. For the third consecutive year, Nucor achieved record sales and net earnings in 2006 due to historically high selling prices, margins and shipments.

In addition to Nucor’s traditional strategy of growing by developing greenfield projects and continually improving existing operations, Nucor’s focus over the past several years has included growing profitably through acquisitions. In the steel mills segment, the capacity of our bar mills has more than doubled over the past five years, increasing from approximately 3,800,000 tons in 2001 to 7,960,000 tons in 2006. This growth was driven by the acquisition of the assets of Birmingham Steel Corporation’s four bar mills in late 2002, the assets of Marion Steel in 2005 and the assets of Connecticut Steel in 2006. Ongoing productivity gains obtained at existing bar mills as well as the acquired mills have supplemented this growth.

The capacity of our sheet mills has increased more than 70% from 6,300,000 tons in 2001 to 10,800,000 tons in 2006 due to the acquisition and start-up in late 2002 of our sheet mill in Decatur, Alabama, as well as by continued productivity advances at our three other sheet mills. The sheet mills are well-positioned to advance our strategic plan for greater participation in higher value-added sheet markets.

In 2001, Nucor’s plate mill in Hertford County, North Carolina, had been operational for less than two years and produced 523,000 tons. With the successful growth of the North Carolina facility and the acquisition of the assets of the Corus Tuscaloosa plate mill in 2004, Nucor’s plate capacity is now approximately 2,800,000 tons allowing us to continue to benefit from healthy plate market conditions.

Nucor has also increased its participation in downstream steel products via acquisitions and joint ventures. The acquisition of Verco Manufacturing Company in late 2006 expanded the reach of Nucor’s steel decking business to the western United States. With the acquisition of Fort Howard Steel’s operations in Oak Creek, Wisconsin in 2005, Nucor became the largest U.S. producer of cold finished bars. Our value-added steel products provide a valuable base load of volume for our steel mills and are less vulnerable to competition from imports. Nucor established several joint ventures in the past few years, forming partnerships to grow in the reinforcing steel construction market and residential light gauge steel framing industry.

Over the past five years, we have strengthened Nucor’s position as North America’s most diversified steel producer. With this product line diversity, Nucor’s short-term performance is not tied to any one market. This diversity has been a significant factor in Nucor’s ability to maintain profitability every year and every quarter since 1966.

COMPARISON OF 2006 TO 2005

NET SALES

Net sales for 2006 increased 16% to $14.75 billion, compared with $12.70 billion in 2005. The average sales price per ton increased 7% from $621 in 2005 to $667 in 2006, while total shipments to outside customers increased 8%. In the steel mills segment, net sales to external customers increased 18% from $11.06 billion in 2005 to $13.03 billion in 2006. Approximately 50% of the sales increase was due to higher sales volume resulting from increased demand for our products, as well as additional production capacity obtained from acquisitions made in 2005 and 2006. The remaining 50% of the increase in sales was due to higher average selling prices. Net sales to external customers in the steel products segment increased 5% from $1.64 billion in 2005 to $1.73 billion in 2006. Approximately 70% of the increase was due to higher average selling prices and approximately 30% of the increase was due to increased volume, reflecting an improved non-residential construction market.

Nucor established annual tonnage records in the steel mills segment for total steel shipments and steel shipments to outside customers in 2006. Total steel shipments, including those to the steel products segment, increased 8% to 22,346,000 tons in 2006, compared with 20,669,000 tons in the previous year. Steel sales to outside customers increased 9% to 20,649,000 tons in 2006, compared with 19,020,000 tons in 2005. In the steel products segment, production and shipment volumes increased over 2005 across most major product lines. Steel joist production for 2006 increased to 570,000 tons, compared with 554,000 tons in the previous year. Steel deck sales increased to a record 398,000 tons in 2006, compared with 380,000 tons in 2005. Cold finished steel sales were 327,000 tons in 2006, compared with 342,000 tons in the previous year.

| | |

COST OF PRODUCTS SOLD The major component of cost of products sold is raw material costs. The volume of raw materials used increased approximately 8% from 2005 to 2006, consisting of an increase of 9% in the steel mills segment and a decrease of 1% in the steel products segment. The average price of raw materials remained unchanged in the steel mills segment and increased 1% in the steel products segment from 2005 to 2006. The average scrap and scrap substitute cost per ton used in our steel mills segment increased 1% from $244 in 2005 to $246 in 2006. Nucor incurred a charge to value inventories using the last-in, first-out (“LIFO”) method of accounting of $5.4 million in 2006, compared with a credit of $151.6 million in 2005 when the costs of scrap and scrap substitutes were decreasing. Another significant component of cost of products sold for the steel mills segment is energy costs, since steel mills are large consumers of electricity and natural gas. Total energy costs decreased approximately $1 per from 2005 to 2006 as natural gas prices decreased approximately 10% and electricity prices increased approximately 2%. Due to the efficiency of Nucor’s steel | |

|

| mills, however, energy costs remained less than 10% of the sales dollar in 2006 and 2005. We expect that our total energy costs will remain high in 2007. Nucor is hedging a portion of its exposure to the variability of future cash flows for forecasted natural gas purchases over various time periods not exceeding four years. In 2006, the settlement of these hedging transactions increased cost of products sold by approximately $6.8 million (reduced cost of products sold by $12.4 million in 2005). In addition to these hedges, Nucor has entered into natural gas purchase contracts that commit Nucor to purchase $144.9 million, $45.3 million and $27.4 million of natural gas in 2007, 2008 and 2009, respectively, and $563.4 million between 2010 and 2028. These natural gas purchase contracts will primarily supply our DRI facility in Trinidad. |

In December 2000, Nucor entered into a consent decree with the United States Environmental Protection Agency (“USEPA”) and certain states in order to resolve alleged environmental violations. Under the terms of this decree, Nucor is conducting testing at some of its facilities, performing corrective action where necessary, and piloting certain pollution control technologies.

Nucor revises estimates for environmental reserves as additional information becomes available and projects are completed. In 2006 Nucor made approximately $3.9 million in cash payments for remedial efforts and increased reserves by approximately $2.9 million ($12.2 million in cash payments and a $9.4 million decrease to reserves in 2005).

GROSS MARGIN

Gross margins increased from 20% in 2005 to 24% in 2006. In addition to the events and trends discussed above, gross margins are affected by pre-operating and start-up costs. Nucor defines pre-operating and start-up costs, all of which are expensed, as the losses attributable to facilities or major projects that are either under construction or in the early stages of operation. Once these facilities or projects have attained a utilization rate that is consistent with our similar operating facilities, they are no longer considered by Nucor to be in start-up. Pre-operating and start-up costs of new facilities increased to $49.1 million in 2006, compared with $14.4 million in 2005. In 2006, these costs primarily related to the refurbishment and start-up of our DRI facility in Trinidad, and to the Hlsmelt project in Australia. In 2005, these costs primarily related to the relocation of the DRI plant and its refurbishment, and to the HIsmelt project.

MARKETING, ADMINISTRATIVE AND OTHER EXPENSES

The major components of marketing, administrative and other expenses are freight and profit sharing costs. Unit freight costs increased 8% from 2005 to 2006 primarily due to higher fuel costs. Profit sharing costs, which are based upon and fluctuate with pre-tax earnings, increased approximately 30% from 2005 to 2006. In 2006, profit sharing costs included $272.6 million for contributions to a Profit Sharing and Retirement Savings Plan for qualified employees, compared with $206.0 million in 2005. In both 2005 and 2006, all employees except for senior officers received a special cash bonus of $2,000 in addition to their regular profit-sharing payments. These extraordinary bonuses were paid to employees for the achievement of record earnings during the year, resulting in additional profit sharing costs of approximately $23.8 million in 2006 and $22.6 million in 2005. Profit sharing costs also fluctuate based on Nucor’s achievement of certain financial performance goals, including comparisons of Nucor’s financial performance to peers in the steel industry and to other high performing companies.

Stock-based compensation expense included in marketing, administrative, and other expenses increased from $6.7 million in 2005 to $17.1 million in 2006. Since stock-based compensation is impacted by changes in Nucor’s stock price, this increase in expense was primarily due to the 64% increase in Nucor’s stock price from 2005 to 2006, compared with an increase of 27% from 2004 to 2005. The additional stock-based compensation expense incurred in 2006 was also due to the granting of restricted stock units to key employees, officers and non-employee directors for the first time in 2006 and the expensing of stock options for the first time in 2006 due to the adoption of Statement of Financial Accounting Standards No. 123(R), “Share-Based Payment.”

INTEREST (INCOME) EXPENSE

Net interest (income) expense is detailed below:

| | | | | | | | |

| | | (in thousands) | |

Year ended December 31, | | 2006 | | | 2005 | |

Interest income | | $ | (77,716 | ) | | $ | (32,370 | ) |

Interest expense | | | 40,351 | | | | 36,571 | |

| | | | | | | | |

Interest (income) expense, net | | $ | (37,365 | ) | | $ | 4,201 | |

| | | | | | | | |

Gross interest income more than doubled due to increases in average cash equivalents and short-term investments and, to a lesser extent, due to increases in average interest rates. Gross interest expense increased approximately 10% primarily due to increased average interest rates.

MINORITY INTERESTS

Minority interests represent the income attributable to the minority partners of Nucor’s joint venture, Nucor-Yamato Steel Company. Income attributable to minority interests almost doubled from $110.7 million in 2005 to $219.2 million in 2006. Cash distributions to minority interests increased from $89.9 million in 2005 to $174.7 million in 2006. Under the partnership agreement, the minimum amount of cash to be distributed each year to the partners of Nucor-Yamato Steel Company is the amount needed by each partner to pay applicable U.S. federal and state income taxes. In some years the amount of cash distributed to minority interests exceeds amounts allocated to minority interests based on mutual agreement of the general partners; however, the cumulative amount of cash distributed to partners is less than the cumulative net earnings of the partnership.

OTHER INCOME

In 2005, Nucor received $9.2 million in settlement of claims against third parties related to environmental matters (none in 2006). Nucor has made claims for reimbursement of additional amounts. No amounts have been recorded for such reimbursements, if any, that may be received.

| | |

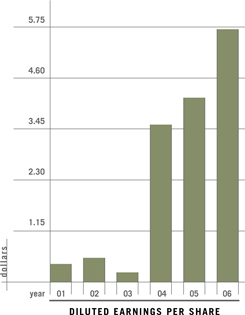

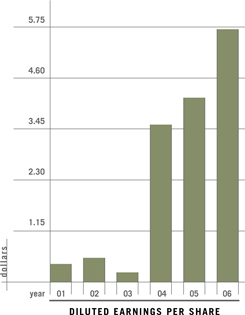

PROVISION FOR IN COME TAXES Nucor had an effective tax rate of 34.75% in 2006 compared with 35.02% in 2005. In 2006, the Internal Revenue Service completed its examination of our 2002 through 2004 tax returns. The 2006 tax rate reflects an approximately 0.26% reduction to the federal statutory tax rate as a result of the reevaluation of our liabilities and contingencies in light of the completion of the examination. In 2006, Nucor recorded refundable state income tax credits of $12.6 million ($10.4 million in 2005). NET EARNINGS AND RETURN ON EQUITY Net earnings and earnings per share for 2006 increased 34% and 38%, respectively, to a record $1.76 billion and $5.68 per diluted share, compared with $1.31 billion and $4.13 per diluted share in 2005. Net earnings as a percentage of net sales were 11.9% in 2006 compared with 10.3% in 2005. The 38% increase in earnings per share also reflects the effect of repurchasing approximately 11.7 million shares of outstanding common stock during 2006. Return on average stockholders’ equity was 38.6% and 33.9% in 2006 and 2005, respectively. | |  |

COMPARISON OF 2005 TO 2004

NET SALES

Net sales increased 12% from $11.38 billion in 2004 to $12.70 billion in 2005. The average sales price per ton increased 4% from $595 in 2004 to $621 in 2005, while total shipments to outside customers increased 7%. In the steel mills segment, net sales to external customers increased 9% from $10.11 billion in 2004 to $11.06 billion in 2005. Approximately 75% of the sales increase was due to higher sales volume resulting from stronger business conditions for bar, plate and structural products, as well as acquisitions made in 2004 and 2005. The remaining 25% of the increase in sales was due to higher average selling prices. Net sales to external customers in the steel products segment were $1.64 billion in 2005 compared with $1.27 billion in 2004, an increase of 29%. Approximately 60% of the increase was due to higher average selling prices and approximately 40% of the increase was due to increased volume, reflecting a stronger non-residential construction market.

In the steel mills segment, total steel shipments, including those to the steel products segment, increased from 19,464,000 tons in 2004 to 20,669,000 tons in 2005, an increase of 6%. Steel sales to outside customers increased 7% to 19,020,000 tons in 2005, compared with 17,787,000 tons in 2004. In the steel products segment, production and shipment volumes increased over the prior year across all major product lines. Steel joist production for 2005 was 554,000 tons, compared with 522,000 tons in the previous year. Steel deck sales were a record 380,000 tons in 2005, compared with 364,000 tons in 2004. Cold finished steel sales were a record 342,000 tons in 2005, compared with 271,000 tons in the previous year, aided by the successful integration of the Fort Howard Steel acquisition.

COST OF PRODUCTS SOLD

The volume of raw materials used increased approximately 5% from 2004 to 2005, consisting of an increase of 4% in the steel mills segment and an increase of 14% in the steel products segment. The average price of raw materials increased approximately 5% from 2004 to 2005. The average price of raw materials in the steel mills segment and the steel products segment increased 3% and 25%, respectively, from 2004 to 2005. The average scrap and scrap substitute cost per ton used in our steel mills segment increased 3% from $238 in 2004 to $244 in 2005.

Nucor incurred a credit to value inventories using the LIFO method of accounting of $151.6 million in 2005, compared with a charge of $375.9 million in 2004.

Total energy costs increased approximately $7 per ton from 2004 to 2005 due to increases of 31% and 19%, respectively, in the prices of natural gas and electricity. Energy costs remained less than 10% of the sales dollar in 2005 and 2004. In 2005, the settlement of natural gas hedging transactions reduced cost of products sold by approximately $12.4 million.

Nucor made approximately $12.2 million in cash payments for remedial efforts and reduced reserves by approximately $9.4 million in 2005 ($0.4 million and $10.0 million, respectively, in 2004). The most significant components of the decreases of reserves in 2005 are related to successful implementation of alternate environmental technologies that achieve full compliance with the agreement between Nucor and the USEPA through minor operational changes. The most significant components of the decreases in 2004 related to an agreement with the USEPA that certain technologies identified in the consent decree are not feasible and a favorable court ruling that implicated additional potentially responsible parties for the cleanup of an off-site waste-recycling facility.

GROSS MARGIN

Gross margins increased slightly from 19% in 2004 to 20% in 2005. In addition to the events and trends discussed above, gross margins improved due to the decrease pre-operating and start-up costs from $28.8 million in 2004 to $14.4 million in 2005. In 2005, these costs primarily related to the relocation and refurbishment of the DRI facility and to the HIsmelt project. In 2004, these costs primarily related to the continuing start-up of the Castrip facility at our sheet mill in Crawfordsville, Indiana. Late in 2004, the Castrip process achieved commercial viability; therefore, the costs associated with this facility were not included in start-up costs in 2005.

MARKETING, ADMINISTRATIVE AND OTHER EXPENSES

Due to the increase in fuel costs, unit freight costs increased 12% from 2004 to 2005. Profit sharing costs, which are based upon and fluctuate with pre-tax earnings, increased approximately 6% from 2004 to 2005. In 2005, profit sharing costs included $206.0 million for contributions to a Profit Sharing and Retirement Savings Plan for qualified employees, compared with $172.3 million in 2004. Profit sharing costs in 2005 and 2004 included an additional $22.6 million and $21.0 million, respectively, in extraordinary bonuses paid to employees for the achievement of record earnings during the year. All employees except for senior officers received a special cash bonus of $2,000 in addition to their regular profit-sharing payments in both 2005 and 2004.

INTEREST (INCOME) EXPENSE

Net interest expense is detailed below:

| | | | | | | | |

| | | (in thousands) | |

Year Ended December 31, | | 2005 | | | 2004 | |

Interest expense | | $ | 36,571 | | | $ | 29,335 | |

Interest income | | | (32,370 | ) | | | (6,983 | ) |

| | | | | | | | |

Interest expense, net | | $ | 4,201 | | | $ | 22,352 | |

| | | | | | | | |

Gross interest expense increased approximately 25% primarily due to increased average interest rates, accompanied by an increase in average long-term debt. Gross interest income increased more than fourfold due to increases in average cash equivalents and short-term investments and, to a lesser extent, due to increases in average interest rates.

MINORITY INTERESTS

Income attributable to minority interests increased from $80.9 million in 2004 to $110.7 million in 2005. Cash distributions to minority interests increased from $84.9 million in 2004 to $89.9 million in 2005.

OTHER INCOME

In 2005, Nucor received $9.2 million in settlement of claims against third parties related to environmental matters. In 2004, Nucor sold equipment resulting in pre-tax gains of $1.6 million.

PROVISION FOR INCOME TAXES

Nucor had an effective tax rate of 35.02% in 2005 compared with 35.22% in 2004. In both 2005 and 2004, Nucor recorded refundable state income tax credits of $10.4 million.

NET EARNINGS AND RETURN ON EQUITY

Net earnings and earnings per share for 2005 increased 17% and 18%, respectively, to a record $1.31 billion and $4.13 per diluted share, compared with $1.12 billion and $3.51 per diluted share in 2004. Net earnings as a percent of net sales were 10.3% in 2005 compared with 9.9% in 2004. The 18% increase in earnings per share also reflects the effect of repurchasing approximately 11.1 million shares of outstanding common stock during 2005. Return on average stockholders’ equity was 33.9% and 38.7% in 2005 and 2004, respectively.

LIQUIDITY AND CAPITAL RESOURCES

Cash flows provided by operating activities provide us with a significant source of liquidity. When needed, we also have external short-term financing sources available including the issuance of commercial paper and borrowings under our bank credit facilities. We also issue long-term debt from time to time. We have earned long-term debt ratings of A+ by Standard and Poor’s and A1 by Moody’s Investors Services, the highest ratings of any metals and mining company in North America. We believe our strong financial position and our industry-high credit rating provide us with flexibility and significant capacity to obtain additional capital on a cost-effective basis.

We anticipate that cash flows from operations and our existing borrowing capacity will be sufficient to fund expected normal operating costs, working capital, dividends and capital expenditures for our existing facilities. Any future significant acquisitions could require additional financing from external sources.

During 2006, cash and cash equivalents decreased 20% to $785.7 million, short-term investments increased 65% to $1.41 billion, and working capital increased 15% to $3.23 billion. Short-term investments consist solely of variable rate demand notes (“VRDN’s”), which are variable rate bonds tied to short-term interest rates, but with stated maturities on the face of the bonds that exceed 90 days. All VRDN’s in which Nucor invests are secured by direct-pay letters of credit issued by high-credit quality financial institutions. This credit enhancement provides a high degree of security and liquidity to the VRDN’s. Nucor is able to receive a cash payment in the amount of its principal invested and interest accrued on the VRDN’s no later than seven days after notifying the financial institution that it has elected to tender the VRDN’s.

| | | | | | |

| | | (in thousands) |

December 31, | | 2006 | | 2005 |

Cash and cash equivalents | | $ | 785,651 | | $ | 980,150 |

Short-term investments | | | 1,410,633 | | | 857,360 |

Working capital | | | 3,225,008 | | | 2,815,854 |

Current ratio | | | 3.2 | | | 3.2 |

The current ratio remained flat at 3.2 at December 31, 2006 when compared to December 31, 2005. Approximately $199.6 million and $144.1 million of the cash and cash equivalents position at December 31, 2006 and December 31, 2005, respectively, was held by our 51%-owned joint venture, Nucor-Yamato Steel Company. We have a simple capital structure with no off-balance sheet arrangements or relationships with unconsolidated special purpose entities. Nucor uses derivative financial instruments from time-to-time primarily to manage the exposure to price risk related to natural gas purchases used in the production process and to manage exposure to changes in interest rates on outstanding debt instruments.

| | |

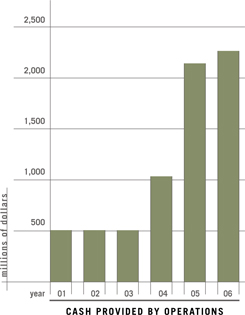

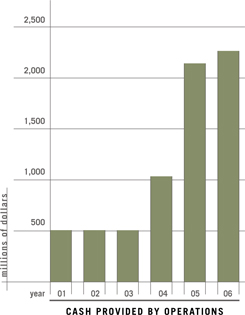

OPERATING ACTIVITIES Nucor generated cash provided by operating activities of a record $2.25 billion in 2006 compared with $2.14 billion in 2005, an increase of 5%. This increase was the result of the 34% increase in net earnings and the 98% increase in minority interests, partially offset by changes in operating assets and liabilities (exclusive of acquisitions) that used cash of $84.0 million in 2006 compared with providing cash of $340.8 million in 2005. Inventories increased in 2006 primarily due to higher quantities to support increased sales levels and higher purchase costs. Inventories decreased in 2005 due to reduced inventory levels accompanied by purchase costs declining from the record highs experienced in the fourth quarter of 2004. INVESTING ACTIVITIES Our business is capital intensive; therefore, cash used in investing activities represents capital expenditures for new facilities, the expansion and upgrading of existing facilities, and the acquisition of the assets of other companies. Additionally, the cash used in investing activities includes investments in joint ventures and purchases of and proceeds from the sale of short-term investments. | |

|

| Cash used in investing activities decreased to $1.15 billion in 2006 compared with $1.38 billion in 2005, primarily due to a reduction in the net purchases of short-term investments ($553.3 million in 2006 compared with $857.4 million in 2005). Nucor invested $338.4 million in new facilities (exclusive of acquisitions) and expansion or upgrading of existing facilities in 2006 compared with $331.5 million in 2005. |

Existing cash and cash equivalents and short-term investments funded the acquisitions of assets of Connecticut Steel and Verco in 2006 and Fort Howard Steel and Marion Steel in 2005. Nucor expects to continue to pursue profitable growth through acquisitions. In January 2007, Nucor commenced a cash tender offer for all of the shares of Harris Steel Group, Inc. for approximately $1.07 billion, which we will fund at closing from existing cash, cash equivalents and short-term investments. We do not expect to incur any additional debt to complete this tender offer. We believe we have the financial ability, however, to borrow significant additional funds to finance future acquisitions and still maintain reasonable leverage.

FINANCING ACTIVITIES

Cash used in financing activities increased to $1.30 billion in 2006 compared with $550.7 million in 2005. In 2006, Nucor increased its base dividend and paid a quarterly supplemental dividend, resulting in dividend payments increasing from $209.8 million in 2005 to $577.8 million in 2006.

During 2006, Nucor repurchased approximately 11.7 million shares of Nucor’s common stock at a cost of approximately $599.4 million under the stock repurchase program. A total of approximately 14.1 million shares remain authorized for repurchase under the current program.

The percentage of long-term debt to total capital (long-term debt plus minority interests plus stockholders’ equity) was 15% and 17% at year-end 2006 and 2005, respectively.

In 2005, Nucor entered into a five-year unsecured revolving credit facility maturing in June 2010 that provides for up to $700.0 million in revolving loans. Up to the equivalent of $600.0 million of the credit facility will be available for foreign currency loans, and up to $450.0 million is available for the issuance of letters of credit. The credit facility may be increased by up to $300.0 million at the election of the Company in accordance with the terms set forth in the credit agreement. No borrowings were outstanding under the credit facility as of December 31, 2006.

MARKET RISK

All of Nucor’s industrial revenue bonds have variable interest rates that are adjusted weekly or annually. These industrial revenue bonds represent 43% of Nucor’s long-term debt outstanding at December 31, 2006. The remaining 57% of Nucor’s long-term debt is at fixed rates. Future changes in interest rates are not expected to significantly impact earnings. From time to time, Nucor makes use of interest rate swaps to manage interest rate risk. As of December 31, 2006, there were no such contracts outstanding. Nucor’s current investment practice is to invest in securities that are highly liquid with short maturities. As a result, we do not expect changes in interest rates to have a significant impact on the value of our investment securities.

Nucor also uses derivative financial instruments from time to time primarily to manage its exposure to price risk related to natural gas purchases used in the production process. Nucor, generally, does not enter into derivative instruments for any purpose other than hedging the cash flows associated with specific volumes of commodities that will be purchased and processed in future periods and hedging the exposures related to changes in the fair value of outstanding fixed rate debt instruments. Nucor recognizes all derivative instruments in the consolidated balance sheets at fair value.

Nucor has ventures in Brazil and Australia that are in the early stages of operations and owns the DRI facility in Trinidad. Accordingly, Nucor is exposed to the effects of currency fluctuations in those countries. As a result of the pending acquisition of Harris Steel, in 2007 Nucor has exposure to Canadian currency fluctuations. Nucor hedged a portion of this exposure in January 2007 in anticipation of the closing of this transaction in the first quarter. Nucor has not hedged any other foreign currency exposures.

CONTRACTUAL OBLIGATIONS AND OTHER COMMERCIAL COMMITMENTS

The following table sets forth our contractual obligations and other commercial commitments as of December 31, 2006 for the periods presented.

| | | | | | | | | | | | | | | |

| | | (in thousands) |

| | | Payments Due By Period |

Contractual Obligations | | Total | | 2007 | | 2008 - 2009 | | 2010 -2011 | | 2012 and thereafter |

Long-term debt | | $ | 922,300 | | $ | — | | $ | 180,400 | | $ | — | | $ | 741,900 |

Estimated interest on long-term debt(1) | | | 482,270 | | | 42,431 | | | 74,279 | | | 63,462 | | | 302,098 |

Operating leases | | | 11,990 | | | 2,289 | | | 1,764 | | | 809 | | | 7,128 |

Raw material purchase commitments(2) | | | 2,574,150 | | | 788,644 | | | 639,420 | | | 599,236 | | | 546,850 |

Utility purchase commitments(2) | | | 1,100,995 | | | 239,393 | | | 197,911 | | | 107,055 | | | 556,636 |

Other unconditional purchase obligations(3) | | | 245,845 | | | 155,010 | | | 90,828 | | | 7 | | | — |

Other long-term obligations(4) | | | 188,759 | | | 77,416 | | | 26,884 | | | 2,447 | | | 82,012 |

| | | | | | | | | | | | | | | |

Total contractual obligations | | $ | 5,526,309 | | $ | 1,305,183 | | $ | 1,211,486 | | $ | 773,016 | | $ | 2,236,624 |

| | | | | | | | | | | | | | | |

| (1) | Interest is estimated using applicable rates at December 31, 2006 for Nucor’s outstanding fixed and variable rate debt. |

| (2) | Nucor enters into contracts for the purchase of scrap and scrap substitutes, iron-ore, electricity, natural gas and other raw materials and related services. These contracts include multi-year commitments and minimum annual purchase requirements and are valued at prices in effect on December 31, 2006, or according to the contract language. These contracts are part of normal operations and are reflected in historical operating cash flow trends. We do not believe such commitments will adversely affect our liquidity position. Approximately $985.7 million of these agreements are with an entity that is the majority investor in one of Nucor’s equity investments. |

| (3) | Purchase obligations include commitments for capital expenditures on operating machinery and equipment. |

| (4) | Other long-term obligations include amounts associated with Nucor’s early retiree medical benefits and management compensation. |

DIVIDENDS

Nucor has increased its cash dividend every year since it began paying dividends in 1973. In 2006, in addition to raising the base dividend by 33%, the board of directors doubled the supplemental dividend based on Nucor’s continued strong performance. Nucor paid dividends of $1.88 per share in 2006 compared with $0.67 per share in 2005. In February 2007, the board of directors announced a 10% increase in the base dividend to $0.11 per share and announced the continuation of the $0.50 per share supplemental dividend, resulting in an annualized dividend rate of $2.44 per share. The supplemental dividend of $0.50 per share represents a portion of a total supplemental dividend estimated to be $2.00 per share to be paid over the next four quarterly dividend payments. The payment of any future supplemental dividends will depend upon many factors, including Nucor’s earnings, cash flows and financial position. Nucor’s dividends paid to stockholders have increased more than nine-fold since 2003: $62 million paid in 2003, $70 million paid in 2004, $210 million paid in 2005, and $578 million paid in 2006.

OUTLOOK

Our objective is to maintain a strong balance sheet while pursuing profitable growth. We expect to expand Nucor’s platform for generating earnings through greenfield construction utilizing advantageous new technologies, expansions at our existing steel mills, future acquisitions and global growth through joint ventures that leverage new technologies.

Capital expenditures are currently projected to be approximately $940 million in 2007, more than two-and-a-half times our capital expenditures in 2006. Nucor continues to invest capital in our core operations to keep them state-of-the-art and globally competitive.

In the steel mills segment, total steel production is anticipated to increase over the next several years from the record 22,382,000 tons produced in 2006. Our current estimated annual capacity is approximately 25,300,000 tons, and additional capacity may be obtained through upgrading existing facilities as well as through acquisitions. Approximately $500 million of the 2007 capital spending is allocated to our greenfield projects, including significant projects in the steel mills segment such as the SBQ steel mill in Memphis, Tennessee; the Castrip facility in Blytheville, Arkansas; and the sheet steel galvanizing facility at our mill in Decatur, Alabama.

Our growth strategy has also expanded our participation in attractive downstream steel products businesses. Our value-added steel products provide a valuable base load of volume for our steel mills and are less vulnerable to competition from imports. We anticipate that the continued improvement in non-residential building will increase sales and the volume guaranteed by Vulcraft and Nucor Building Systems in 2007. With the 2005 purchase of our Wisconsin cold finished bar plant, Nucor became the largest U.S. producer of cold finished bars. Our acquisition of Verco has enhanced our market leadership in the steel decking market. The addition of our fourth metal building systems plant in Brigham City, Utah, gives us a national presence as we execute our strategy to grow profitable market share in this industry.

The acquisition of Harris Steel, which will be Nucor’s largest acquisition to date, is expected to close in the first quarter of 2007, upon acceptance by the shareholders of Harris Steel and satisfactory resolution of regulatory approvals. Harris Steel, which will operate as a subsidiary of Nucor, manufactures and places reinforcing products, and manufactures industrial products principally in the United States and Canada. Harris Steel also participates in steel trading on a worldwide basis, and in the distribution of reinforcing steel and related products to U.S. customers. This acquisition will be a major step in advancing Nucor’s vertical integration strategy. Nucor is the largest producer of rebar in North America. With this acquisition, Nucor will become the third largest rebar fabricator in North America. Under Nucor’s ownership, Harris Steel will be able to accelerate its highly successful growth strategy in rebar fabrication through acquisitions and greenfield facilities. In addition to rebar fabrication, this acquisition will enable us to grow our cold finished bar market leadership position and bring us greater geographic reach into Canada.

We expect that demand in non-residential construction will remain healthy in 2007. Nucor continues to benefit from product line diversification. We have recently announced price increases for many of our products. Excess inventory levels at service centers and OEM’s should continue to decline. We expect steel inventories to be at more normal levels by the end of the first quarter; however, this change will depend on continued strong end-use demand and a decrease in imports from the record levels of 2006.

We recognize that uncertainty in external factors such as raw materials costs, availability and cost of electricity and natural gas, the growth rate of the economy, the level of imports and consolidation in the industry will have a significant impact on our results. In 2007, we will continue working towards our goal of controlling approximately six to seven million tons of our supply of

high-quality scrap substitutes. Our raw materials strategy is driven by Nucor’s ongoing expansion of our steel product portfolio into higher quality grades. We will continue our defense of fair trade and will continue to point out examples of unfair trade policies and practices until they are fixed. We will continue to pursue strategic acquisitions that expand our platform for generating earnings and attractive returns on our stockholders’ capital. While we cannot control these outside forces, Nucor will continue to be at the forefront of anticipating and addressing the issues that this uncertainty in external factors raises for us and other steel producers.

CRITICAL ACCOUNTING POLICIES AND ESTIMATES

Our discussion and analysis of our financial condition and results of operations are based upon our consolidated financial statements, which have been prepared in accordance with accounting principles generally accepted in the United States of America. The preparation of these financial statements requires us to make estimates and assumptions that affect the reported amounts of assets and liabilities, the disclosure of contingent assets and liabilities at year end, and the reported amount of revenues and expenses during the year. On an ongoing basis, we evaluate our estimates, including those related to the valuation allowances for receivables; the carrying value of property, plant and equipment; reserves for environmental obligations; and income taxes. Our estimates are based on historical experience and various other assumptions that we believe to be reasonable under the circumstances, the results of which form the basis for making judgments about the carrying values of assets and liabilities that are not readily apparent from other sources. Accordingly, actual costs could differ materially from these estimates under different assumptions or conditions.

We believe the following critical accounting policies affect our significant judgments and estimates used in the preparation of our consolidated financial statements.

REVENUE RECOGNITION

We recognize revenue when products are shipped, which represents when title and risk of loss have passed to the customer.

ALLOWANCES FOR DOUBTFUL ACCOUNTS

We maintain allowances for doubtful accounts for estimated losses resulting from the inability of our customers to make required payments. If the financial condition of our customers were to deteriorate, resulting in an impairment of their ability to make payments, additional allowances may be required.

INVENTORIES

Inventories are stated at the lower of cost or market. The cost of most inventories is measured on the last in, first out (“LIFO”) method of accounting. The LIFO method allocates the most recent costs to cost of products sold, thereby recognizing into operating results fluctuations in raw material, energy and other capitalizable costs more quickly than other methods. The cost of other inventories is determined on the first-in, first-out (“FIFO”) method.

ASSET IMPAIRMENTS

We evaluate the impairment of our property, plant and equipment on an individual asset basis or by logical groupings of assets. Asset impairments are recognized whenever changes in circumstances indicate that the carrying amounts of those productive assets exceed their projected undiscounted cash flows. When it is determined that an impairment exists, the related assets are written down to estimated fair market value.

GOODWILL AND OTHER INTANGIBLES

Goodwill is the excess of cost over the fair value of net assets of businesses acquired. Goodwill, which is included in other assets, is not amortized but is evaluated annually for impairment or if circumstances indicate a possible impairment may exist. Intangible assets that do not have indefinite lives are amortized over their useful lives and are annually reviewed for impairment.

ENVIRONMENTAL REMEDIATION

We are subject to environmental laws and regulations established by federal, state and local authorities, and make provision for the estimated costs related to compliance. Undiscounted remediation liabilities are accrued based on estimates of known environmental exposures. The accruals are reviewed periodically and, as investigations and remediation proceed, adjustments are made as we believe are necessary. The accruals are not reduced by possible recoveries from insurance carriers or other third parties. Our measurement of environmental liabilities is based on currently available facts, present laws and regulations, and current technology.

INCOME TAXES

We account for income taxes in accordance with Statement of Financial Accounting Standards (“SFAS”) No. 109, “Accounting for Income Taxes.” We estimate our actual current tax expense and assess temporary differences that exist due to differing treatments of items for tax and financial statement purposes. These differences result in the recognition of deferred tax assets and liabilities. The deferred tax assets and liabilities are measured using tax rates expected to apply to taxable income in the years in which those temporary differences are expected to be recovered or settled. The effect on deferred tax assets and liabilities of a change in tax rates is recognized in the period in which the change is enacted. We assess the realizability of deferred tax assets on an ongoing basis by considering whether it is more likely than not that some portion of the deferred tax assets will not be realized. If it is more likely than not, in our judgment, that the deferred tax assets will not be realized, we provide a valuation allowance.

RECENT ACCOUNTING PRONOUNCEMENTS

The Financial Accounting Standards Board (“FASB”) has issued FASB Interpretation No. 48 (“FIN 48”),”Accounting for Uncertainty in Income Taxes, an Interpretation of FASB Statement No. 109,” which clarifies the accounting of uncertainty in income taxes recognized in financial statements in accordance with FASB Statement No. 109, “Accounting of Income Taxes.” FIN 48 prescribes a recognition threshold and measurement attribute for the financial statement recognition and measurement of a tax position taken or expected to be taken in a tax return. The provisions of this Interpretation are effective for Nucor beginning on January 1, 2007. Management does not expect the adoption of FIN 48 to have a material impact on Nucor’s consolidated financial position and results of operations.

The FASB has issued Statement No. 157, “Fair Value Measurements” (“SFAS No. 157”), which defines fair value, establishes a framework for measuring fair value in accordance with generally accepted accounting principles and expands disclosures about fair value measurements. The provisions of SFAS No. 157 are effective for Nucor in 2008. Management is currently evaluating the impact, if any, of this statement.

The FASB has issued FASB Staff Position AUG AIR-1, “Accounting for Planned Major Maintenance Activities,” which is effective for Nucor beginning on January 1, 2007. This position statement eliminates Nucor’s current policy, which is the accrue-in-advance method of accounting for planned major maintenance activities. In accordance with this position statement, Nucor will use the deferral method of accounting for planned major maintenance activities. Although management continues to analyze the impact of this position statement, we do not expect the adoption of this statement to have a material impact on Nucor’s consolidated financial position and results of operations.

| | |

| 34 | | SIX-YEAR FINANCIAL REVIEW |

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | (dollar amounts in thousands, except per share data) | |

| | | 2006 | | | 2005 | | | 2004 | | | 2003 | | | 2002 | | | 2001 | |

FOR THE YEAR | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | |

Net sales | | $ | 14,751,270 | | | $ | 12,700,999 | | | $ | 11,376,828 | | | $ | 6,265,823 | | | $ | 4,801,777 | | | $ | 4,333,707 | |

| | | | | | |

Costs, expenses and other: | | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | |

Cost of products sold | | | 11,283,123 | | | | 10,119,496 | | | | 9,169,172 | | | | 5,996,547 | | | | 4,332,277 | | | | 3,914,278 | |

| | | | | | |

Marketing, administrative and other expenses | | | 592,473 | | | | 459,460 | | | | 374,730 | | | | 165,369 | | | | 175,589 | | | | 150,666 | |

| | | | | | |

Interest (income) expense, net | | | (37,365 | ) | | | 4,201 | | | | 22,352 | | | | 24,627 | | | | 14,286 | | | | 6,525 | |

| | | | | | |

Minority interests | | | 219,221 | | | | 110,674 | | | | 80,894 | | | | 23,950 | | | | 79,472 | | | | 103,069 | |

| | | | | | |

Other income | | | — | | | | (9,200 | ) | | | (1,596 | ) | | | (11,547 | ) | | | (29,900 | ) | | | (20,200 | ) |