Exhibit 99.01

Public Version

UPDATE OF CONSTRUCTION PROGRESS

AND REQUEST FOR UPDATES AND

REVISIONS TO SCHEDULES

Public Service Commission

of South Carolina

BEFORE

THE PUBLIC SERVICE COMMISSION

OF

SOUTH CAROLINA

DOCKET NO. 2009- -E

In Re: Update of Construction Progress and | ) | |

Request for Updates and Revisions to | ) | UPDATE OF CONSTRUCTION |

Schedules Related to the Construction of a | ) | PROGRESS AND REQUEST FOR |

Nuclear Base Load Generation Facility at | ) | UPDATES AND REVISIONS TO |

Jenkinsville, South Carolina | ) | SCHEDULES |

| ) | |

| ) | |

South Carolina Electric & Gas Company (“SCE&G” or the “Company”) hereby petitions the Public Service Commission of South Carolina (the “Commission”) to initiate a proceeding to allow it to provide the Commission with an update of the progress in the licensing and construction of two, 1,117 net megawatt (“MW”) nuclear facilities (“Units”) to be located at the V.C. Summer Nuclear Station site near Jenkinsville, South Carolina. In Order No. 2009-104(A), the Base Load Review Order related to the Units, the Commission directed that SCE&G provide such updates annually. In addition, pursuant to the provisions of the Base Load Review Act, S.C. Code Ann. § 58-33-270(E) (1976 as amended in 2007), SCE&G requests that the Commission issue an order approving updated construction and capital costs schedules for the construction of the Units. These updated schedules were previously filed with the Commission and the South Carolina Office of Regulatory Staff (“ORS”) in SCE&G’s Quarterly Report for the period ended March 31, 2009 (the “March 2009 Quarterly Report”). Pursuant to S.C. Code Ann. § 58-33-270(E), SCE&G seeks to have the updated construction schedule and capital cost schedule adopted as the approved construction schedule and capital cost schedule for the project

1

going forward. As discussed below, and as explained in the March 2009 Quarterly Report, these updated schedules reflect an internal shifting of the sequencing of milestones within the currently approved project schedule and support the Company’s commitment to substantially complete Units 2 & 3 by April 1, 2016 and January 1, 2019, respectively The updated schedules do not change the Company’s commitment to complete the Units for $4,534,747,000 in 2007 dollars net of Allowance for Funds Used During Construction (“AFUDC”).

In accordance with the provisions of the Base Load Review Act, S.C. Code Ann. § 58-33-270(E), and in support of its request, SCE&G would respectfully show to the Commission:

1. SCE&G is a corporation duly organized and existing under the laws of the State of South Carolina, with its principal offices at 1426 Main Street, Columbia, South Carolina, 29201. The Company is engaged in the business of generating, transmitting, delivering, and providing electricity to public and private energy users for compensation.

2. SCE&G owns and operates an integrated electric utility system that serves over 652,000 customers in 24 counties in central and southern South Carolina. SCE&G’s service territory includes the metropolitan areas of Charleston, Columbia, Beaufort, and Aiken and many other smaller cities and towns, and rural areas in South Carolina.

3. The names, titles, addresses and telephone numbers of the persons to whom correspondence or communications relating to this filing should be addressed are as follows:

Catherine D. Taylor

K. Chad Burgess

South Carolina Electric & Gas Company

1426 Main Street, MC 130

Columbia, SC 29201

(803) 217-8141

cdtaylor@scana.com

chad.burgess@scana.com

2

Belton T. Zeigler

Lee E. Dixon

Pope Zeigler, LLC

P.O. Box 11509

Columbia, SC 29211

(803) 354-4949

bzeigler@popezeigler.com ldixon@popezeigler.com

4. On May 30, 2008, SCE&G filed a Combined Application for a Certificate of Environmental Compatibility and Public Convenience and Necessity and for a Base Load Review Order for the Construction and Operation of a Nuclear Facility in Jenkinsville, South Carolina (“Combined Application”) in Docket No. 2008-196-E. As part of the Combined Application, SCE&G provided an anticipated construction schedule setting forth then current projected milestones for construction of the Units (“Exhibit E”) and an anticipated components of capital costs schedule related to the construction of the Units (“Exhibit F”).

5. A hearing on the Combined Application was held before the Commission starting on December 1, 2008 and concluding on December 17, 2008.

6. On March 2, 2009, the Commission issued Order No. 2009-104(A) largely granting the relief requested in the Combined Application and approving, inter alia, Exhibit E and Exhibit F as requested in the Combined Application.

7. The terms of Commission Order No. 2009-104(A) require the Company to “provide the Commission with a yearly status report on its progress and other significant developments.” Order No. 2009-104(A), p. 126. The yearly report for 2009 is being filed as a contested case proceeding to allow it to be combined with the request for modification to the construction schedule and capital cost schedule that apply to the project as permitted under S.C. Code Ann. § 58-33-270(E).

3

8. In compliance with S.C. Code Ann. § 58-33-277(A) and Commission Order No. 2009-104(A), on May 15, 2009, SCE&G timely filed with ORS its March 2009 Quarterly Report. The March 2009 Quarterly Report provides information concerning the status of the construction of the Units and updates the capital cost and construction schedules for the Units as approved in Order No. 2009-104(A). A copy of the March 2009 Quarterly Report is attached as Exhibit 1. The March 2009 Quarterly Report shows that the Units are being constructed in accordance with the construction schedules and cumulative cost forecasts, with contingencies, as approved in Commission Order No. 2009-104(A).

9. As the March 2009 Quarterly Report indicates, as of the end of the first quarter of 2009, the Company and its contractors had completed all required milestones as set forth in Exhibit E as adjusted pursuant to the milestone schedule contingencies approved by the Commission in Order No. 2009-104(A). To allow milestones to be tracked more consistently to the construction schedule, SCE&G has subdivided certain of the milestones as previously approved into several discrete items. The 123 milestones approved in that order are now being tracked as 146 milestones. No milestones have been omitted.

10. Of the 146 milestones being tracked, 28 had been completed as of March 31, 2009, 44 have been accelerated, 41 have been pushed out into the future, and 33 are unchanged.

11. The Company and its contractors are presently on schedule to complete all future milestones as specified or within approved contingencies. Accordingly, the project is in compliance with the approved construction schedules and with the provisions of S.C. Code Ann. § 58-33-275(A)(1).

12. As discussed by SCE&G’s witnesses at the hearing in Docket 2008-196-E, SCE&G requested its contractors for construction of the Units, Westinghouse Electric Company,

4

LLC and Stone & Webster (the “Consortium”), to provide an improved and refined construction schedule for the project by April 1, 2009. This schedule, called the Performance Measurement Baseline Schedule, was received on that date and incorporated equipment procurement and delivery commitments negotiated with vendors and suppliers since May 2008 as well as a more detailed integration of site specific and non-site specific construction activities. The Performance Measurement Baseline Schedule represents a major refinement of the project schedule that was provided in May of 2008 as an attachment to the original engineering, procurement and construction agreement (“EPC Contract”). As stated above, the milestone dates contained in the Performance Measurement Baseline Schedule are fully consistent with the guaranteed Substantial Completion dates for the Units of April 1, 2016 and January 1, 2019 and with the currently approved milestones and milestone contingencies.

13. As permitted by S.C. Code Ann. § 58-33-270(E), the Company requests that the modified milestone schedule, as set forth in the Performance Measurement Baseline Schedule and attached hereto as Exhibit 2, be approved by the Commission for use as the approved construction schedule going forward.

14. In Commission Order No. 2009-104(A), the Commission approved the cumulative project cash flow found on Exhibit F as the approved capital cost schedule for the project. Exhibit F also showed the anticipated capital cost of the plant and associated transmission, by year, broken down into the seven cost categories contained in the EPC Contract as well as owner’s costs, transmission costs, and the forecasted amount of AFUDC to be incurred on capital costs not reflected in revised rates. This schedule also set forth the capital cost contingency associated with the plant costs and transmission costs by year.

5

15. As a result of the modifications to the construction schedule set forth in Exhibit 2, the Company has updated Exhibit F to account for changes in timing and sequence of the construction schedule for the Units, and to reformat the presentation of data to more closely track the terms of Order No. 2009-104(A) related to the administration of the contingency pool. The updated capital costs schedule is attached hereto as Exhibit 3. The updated capital costs schedule does not modify or alter the established cost forecast for the project as approved in Order No. 2009-104(A) of $4,534,747,000 in 2007 dollars net of AFUDC.

16. As will be set forth more fully in prefiled testimony, all modifications of the construction schedule and capital costs schedule are within the approved schedule contingencies in Order No. 2009-104(A).

17. The Company hereby requests that the Commission approve the revised capital costs schedule set forth in Exhibit 3 as a replacement to Exhibit F the currently approved capital cost schedule.

18. For ease of reference, Exhibits 4 and 5 provide information showing the variation between the original Exhibit E and Exhibit F to the Combined Application and Exhibit 2 and Exhibit 3 to this Application, respectively.

19. Pursuant to S.C. Code Ann. § 58-33-270(E) the Company is authorized to petition the Commission for an order modifying any of the schedules related to the construction of a base load generation facility.

20. The only modifications to the operative schedules that SCE&G is proposing in this proceeding are the adoption of the relevant schedules contained in Exhibit 2 and Exhibit 3

6

as the approved construction schedule and schedule of capital costs for the project pursuant to S.C. Code Ann. § 58-33-270(E). SCE&G will continue to monitor and evaluate these schedules. To the extent future revisions or updating of these schedules or other revisions under S.C. Code Ann. § 58-33-270(E) are required, SCE&G will propose such changes in future proceedings.

21. Pursuant to S.C. Code Ann. §§ 58-33-270(E), the Commission “shall grant the relief requested if, after a hearing, the commission finds: (1) as to the changes in the schedules, estimates, findings, or conditions, that the evidence of record justifies a finding that the changes are not the result of imprudence on the part of the utility. . . .” The relief requested herein is not the result of imprudence on the part of the Company.

WHEREFORE, South Carolina Electric & Gas Company respectfully requests that the Commission set the current matter for hearing and thereafter approve the updated construction schedule and capital cost schedule as the operative schedules under S.C. Code Ann. § 58-33-275(A).

[SIGNATURE PAGE FOLLOWS]

7

| Respectfully submitted, |

| |

| |

| /s/ K. Chad Burgess |

| Catherine D. Taylor |

| K. Chad Burgess |

| South Carolina Electric & Gas Company |

| 1426 Main Street, MC130 |

| Columbia, SC 29201 |

| (803) 217-8141 |

| cdtaylor@scana.com |

| chad.burgess@scana.com |

| |

| Belton T. Zeigler |

| Lee E. Dixon |

| Pope Zeigler, LLC |

| P.O. Box 11509 |

| Columbia, SC 29211 |

| (803) 354-4949 |

| bzeigler@popezeigler.com |

| ldixon@popezeigler.com |

| |

| Attorneys for |

| South Carolina Electric & Gas Company |

| |

| |

Date: July 20, 2009 | |

8

LIST OF EXHIBITS

1. Quarterly Report for the quarter ending March 31, 2009

2. UPDATED Exhibit E - - Anticipated Construction Schedule

3. UPDATED Exhibit F – Restated and Updated Construction Expenditures

4. Summary of variations between Exhibit 2 and Approved Exhibit E

5. Summary of variations between Exhibit 3 and Approved Exhibit F

9

V. C. Summer Nuclear Station Units 2 & 3

Quarterly Report to the South Carolina Office of Regulatory Staff

Submitted by South Carolina Electric & Gas Company

Pursuant to Public Service Commission Order No. 2009-104A

Quarter Ending March 31, 2009

I. Introduction and Summary

A. Introduction

This quarterly report is submitted by South Carolina Electric & Gas Company to the Public Service Commission of South Carolina and the South Carolina Office of Regulatory Staff. It is submitted in satisfaction of the requirements of S. C. Code Ann. § 58-33-277 (Supp. 2007) and the terms of Public Service Commission Order No. 2009-104A. The report provides updated information concerning the status of construction of V. C. Summer Nuclear Station Units 2 & 3 (the “Units”) and updates the capital cost and construction schedules for the Units as approved in Order No. 2009-104A. Order No. 2009-104A is the base load review order related to the Units that was issued by the Public Service Commission of South Carolina (the “Commission”) on February 27, 2009.

B. Structure of Report and Appendices

The current reporting period is the quarter ending March 31, 2009. The report is divided into the following sections:

Section I: | | Introduction and Summary; |

| | |

Section II: | | Progress of Construction of the Units; |

| | |

Section III: | | Anticipated Construction Schedules; |

| | |

Section IV: | | Schedules of the Capital Costs Incurred Including Updates to the Information Required by S.C. Code Ann. § 58-33-270(B)(6) (the inflation indices); |

| | |

Section V: | | Updated Schedule of Anticipated Capital Costs; and |

| | |

Section VI: | | Conclusion. |

Appendices I, 2, 4, and 5 to this report contain detailed financial, schedule and other information updating the schedules approved by the Commission in Order No. 2009-104A. For reference purposes, Appendix 3 provides a copy of the original capital cost schedule for the project without adjustments in the form approved in Order No. 2009-104A.

1

A confidential and a public version of this report and its attachments are being provided.

As indicated below, construction of Units 2 & 3 is proceeding in full compliance with the cost and schedule forecasts approved by the Commission, as updated.

C. Construction Schedule and Milestones

As the report indicates, the Company has met all current milestones approved by the Commission in Order No. 2009-104A for the project, as adjusted pursuant to the construction schedule contingencies authorized in that order. As discussed below, the Commission-approved milestones are being tracked as 146 separate items. Of these, 28 have been completed as of March 31, 2009.

As discussed below, the milestones for the project have been adjusted to reflect the Performance Measurement Baseline Schedule. Pursuant to the engineering, procurement, and construction agreement for the Units (the “EPC Contract”), Westinghouse Electric Company, LLC and Stone & Webster (the “Consortium”) provided this schedule to SCE&G on April 1, 2009. The Performance Measurement Baseline Schedule is the integrated engineering, procurement and construction schedule for the project and, as expected, represents a major refinement of the schedule that was provided in May of 2008 as an attachment to the EPC Contract. The milestone dates contained in the Performance Measurement Baseline Schedule are fully consistent with the guaranteed Substantial Completion dates for the Units of April 1, 2016 and January 1, 2019 and with the milestones and milestone contingencies approved in Order No. 2009-104A.

D. Construction Costs and Cost Forecasts

As this report indicates, the Company is on track to complete the Units at the construction cost forecast of $4.5 billion in 2007 dollars, net of Allowance for Funds Used During Construction (“AFUDC”), as approved in Order No. 2009-104A.

In Order No. 2009-104A, the Commission allowed forecasts of AFUDC expense and escalation to vary and required them to be updated with each quarterly report. As stated above, the project remains on track to meet the $4.5 billion construction cost forecast in 2007 dollars. However, as the following chart shows, the forecasted gross construction costs for the project has increased due to increases in AFUDC expense and increases in the escalation expense.

2

Chart A: Reconciliation of Capital Cost ($000)

Forecast Item | | Projected 3/31/09

@ Five-Year

Average Escalation

Rates | | As Approved

Order 2009-

104A | | Change | |

| | | | | | | |

Gross Construction | | $ | 6,875,315 | | $ | 6,313,376 | | $ | 561,939 | |

| | | | | | | |

Less: AFUDC | | $ | 315,739 | | $ | 264,289 | | $ | 51,450 | |

| | | | | | | |

Total Project Cash Flow | | $ | 6,559,576 | | $ | 6,049,087 | | $ | 510,489 | |

| | | | | | | |

Less: Escalation | | $ | 2,024,829 | | $ | 1,514,340 | | $ | 510,489 | |

| | | | | | | |

Capital Cost, 2007 Dollars | | $ | 4,534,747 | | $ | 4,534,747 | | $ | -0- | |

As is discussed in more detail below, this increase in the gross construction cost forecast is principally related to high rates of escalation that are reflected in the historical five-year indices that are used to forecast future escalation and to forecast AFUDC expense. The current five-five year escalation rates capture the height of the inflationary pressure on construction costs and materials during the global commodities crunch of 2002-2008 and have yet to reflect fully the return of inflation rates to more normal levels since mid-2008. For comparison purposes, the following chart shows the gross construction forecast for the project using historical ten-year escalation averages instead of five-year averages. Using the ten-year escalation averages, the gross construction cost forecast would have fallen below the 2008 forecast reflect in Order No. 2009-104A by $153 million.

3

Chart B: Reconciliation of Capital Cost ($000)

Forecast Item | | Projected @

3/31/2009

(Ten-Year

Average Rates) | | As Forecasted

Or Approved In

Order 2009-

104A | | Change | |

| | | | | | | |

Gross Construction | | $ | 6,160,738 | | $ | 6,313,376 | | $ | (152,638 | ) |

| | | | | | | |

Less: AFUDC | | $ | 283,974 | | $ | 264,289 | | $ | 19,685 | |

| | | | | | | |

Total Project Cash Flow | | $ | 5,876,764 | | $ | 6,049,087 | | $ | (172,323 | ) |

| | | | | | | |

Less: Escalation | | $ | 1,342,017 | | $ | 1,514,340 | | $ | (172,323 | ) |

| | | | | | | |

Capital Cost, 2007 Dollars | | $ | 4,534,747 | | $ | 4,534,747 | | $ | 0 | |

The escalation and AFUDC rates and their effects on project costs are discussed more fully below. As discussed there, similar reductions in gross construction cost forecasts would result from recalculating construction cost forecasts using one-year escalation rates.

E. Escalation Rates

Escalation accounts for a $510 million increase in total project cash flows in the current projection. There are two components to this escalation increase. The Performance Measurement Baseline Schedule and related changes in owner’s costs and other items have shifted the schedule of forecasted project cash flow forward. This change in the timing of capital costs has resulted in an increase in overall escalation for the project. Changes in the forecasted timing of capital costs are responsible for $118 million of the additional $510 escalation reported above.

The remaining change in escalation, $392 million, relates to changes in the applicable escalation rates. Under Order No. 2009-104A, escalation for construction costs is computed using historical one-year and five-year escalation rates. As provided in that order, the five-year escalation rate applies to all costs beyond the upcoming twelve months. At this stage of the project, five-year average escalation rates apply to slightly more than 85% of the base construction costs which are subject to indexed escalation. For that reason, the calculation of escalated project costs is particularly sensitive to the five-year escalation rate.

4

As shown on Appendix 5, utility construction costs were at historically high levels during the period 2005-2008, and have since dropped substantially. However, the current five-year averages do not fully reflect the flattening of future escalation rates which has occurred during the last year.

Chart C: Handy-Whitman Escalation Rates

January 2009 Update

| | Escalation Rate | |

HW All Steam Index: | | | |

One year rate | | 4.8 | % |

Five Year Average | | 7.2 | % |

Ten Year Average | | 4.9 | % |

HW All Steam/Nuclear Index: | | | |

One year rate | | 4.8 | % |

Five Year Average | | 7.2 | % |

Ten Year Average | | 4.9 | % |

HW All Transmission Plant Index | | | |

One year rate | | 7.4 | % |

Five Year Average | | 8.6 | % |

Ten Year Average | | 5.5 | % |

The Company does not believe that the current five-year projections reflect current inflation expectations. If the cost projections in this report were made using either one-year escalation rates or the ten-year escalation rates in place of five-year rates, the total project cash flow, net of AFUDC, would be less than the $6.0 billion forecast reflected in Order No. 2009-104A. Using the one-year rates the total project cash flow, net of AFUDC, would be $97 million less than forecasted in Order No. 2009-104A, and using the ten-year rates it would be $172 million less.

5

Chart D: Reconciliation of Capital Cost ($000)

Forecast Item | | As Forecasted

Or Approved In

Order 2009-

104A | | Projected

3/31/09 @ Five-

Year Average

Escalation Rates | | Recomputed

Using One-Year

Average

Escalation Rates | | Recomputed

Using Ten-Year

Average

Escalation Rates | |

| | | | | | | | | |

Capital Cost, 2007 Dollars | | $ | 4,534,747 | | $ | 4,534,747 | | $ | 4,534,747 | | $ | 4,534,747 | |

| | | | | | | | | |

Plus: Escalation | | $ | 1,514,340 | | 2,024,829 | | $ | 1,147,218 | | $ | 1,342,017 | |

| | | | | | | | | |

Total Project Cash Flow | | $ | 6,049,087 | | $ | 6,559,576 | | $ | 5,951,965 | | $ | 5,876,764 | |

| | | | | | | | | |

Change from Total Project Cash Flow as Forecasted in Order 2009-104A | | N/A | | $ | 510,489 | | $ | (97,122 | ) | $ | (172,323 | ) |

F. Increased AFUDC Expense

The projected increase in AFUDC expense for the project is $51 million. Consistent with Order No. 2009-104A, SCE&G computes AFUDC based on the Construction Work in Progress that is outstanding between rate adjustments. The increase in project cash flow due to escalation has resulted in $29 million of the $51 million increase in forecasted AFUDC. In addition, SCE&G’s AFUDC rate is currently 8.08% compared to 5.52% in May of 2008. This rate is forecasted to drop to 5.87% as capital markets recover and SCE&G is able to issue commercial paper to meet its short-term cash needs. However, increases in the AFUDC rates have resulted in $22 million of the $51 million forecasted increase in AFUDC rates.

6

G. Contingency Usage and Availability

As the summary table below indicates, none of the total project contingency of $438,293,000 has been expended to date. One hundred percent of the contingency remains available for use in future periods.

Chart E: Contingency Usage in 2007 Dollars ($000)

Item | | As of

03/31/2009 | | As Approved

Order 2009-104A | | Change | |

| | | | | | | |

Total Project Contingency | | $ | 438,293 | | $ | 438,293 | | $ | 0 | |

| | | | | | | |

Cumulative Contingency to Date (Col. 1: Actual; Col. 2: Approved) | | $ | -0- | | $ | 9,968 | | $ | (9,968 | ) |

| | | | | | | |

Project Contingency Remaining | | $ | 438,293 | | $ | 428,325 | | $ | 9,968 | |

| | | | | | | |

Percent of Project Contingency Remaining | | 100 | % | 97.8 | % | 2.2 | % |

As shown in more detail on Exhibit 4, Chart C, and as discussed below, SCE&G currently forecasts that as of 2018 it will have used a cumulative total of $118 million of the $438 million contingency fund to cover the increased escalation costs associated with project schedule changes.

H. Compliance with the Commission Approved Cumulative Project Cash Flow Target

Order No. 2009-104A established the Cumulative Project Cash Flow, listed on Exhibit F to the Combined Application, as the target for measuring the compliance of the project with the cost-related terms of that order. Order No. 2009-104A provided that this Cumulative Project Cash Flow target would be adjusted with each quarterly report to reflect updated escalation data and any use by the Company of the cost-related contingencies that the Commission approved in Order No. 2009-104A.

Appendix 4, Chart A provides the Cumulative Project Cash Flow target updated for current escalation data as of March 31, 2009 and the current cumulative cash flow schedules for the project. Appendix 4, Chart B compares the approved Cumulative Project Cash Flow target to the current cumulative cash flow schedules for the project,

7

which include actual costs where available and SCE&G’s working forecasts of annual cash flows for future years. As shown on Appendix 4, Chart B, until the year 2015 the projected cash flow in each year of the construction schedule is less than or equal to the Cumulative Project Cash flow approved by the Commission in Order No. 2009-104A. In 2015, for timing reasons, the forecast indicates that the cumulative cash flow will exceed the approved target by $36 million. For similar reasons, the cash flow, on a cumulative basis, before the use of contingency funds, is forecasted to exceed the target by $207 million in 2016, and $147 million in 2017 and $118 million in 2018. However, the forecast also indicates that the Company will apply $36 million in contingency funds in 2015 and $172 million of contingency funds in 2016 to offset the full amount of these overages. SCE&G forecasts that it will have funds sufficient to restore $60 million to the contingency in 2017 and $29 million in 2018. After doing so, the Company forecasts that it will have $320 million in uncommitted contingency funds remaining at the end of construction. Available contingency is not forecasted to drop below $169 million at any time during the period 2014-2018. Accordingly, the analysis presented here shows that the project is in compliance both currently and prospectively with the terms of Order No. 2009-104A.

Furthermore, the timing differences contained in the current forecast are the result of the new construction schedule provided by the Consortium immediately after the close of the reporting period. SCE&G is preparing the necessary documentation to record adjustments to capital cost targets using the capital costs rescheduling contingency provisions approved by the Commission in Order No. 2009-104A. Use of these contingency provisions should eliminate a substantial part of the reported overages. Any rescheduling of these costs will be presented in future filings.

II Progress of Construction of the Units

Construction of the Project is progressing on schedule to meet the Unit 2 & 3 Substantial Completion dates of April 1, 2016 and January 1, 2019 respectively. A summary of the status of the Project is addressed in Section II.A-Section II.H below.

A. Licensing and Permitting Update

1. The Combined Operating License Application (COLA)

The COLA review process continues on schedule for the Nuclear Regulatory Commission (NRC) to issue a Combined Operating License (COL) for the Units no later than July 1, 2011. Issuance of a COL by that date will allow nuclear safety related construction to begin on the Units on a schedule that supports the Substantial Completion dates set forth above. The status of the major COLA review areas is as follows:

8

a) Nuclear Safety Review

1) The Staff of the NRC is proceeding with its Phase 1 review of the Safety Evaluation Report (SER) for the Units. SCE&G, Bechtel Corp (which is SCE&G’s consulting engineer for the COLA), and the Consortium are reviewing a number of Requests for Additional Information (RAIs) from the NRC Staff related to that review. The Company has been working with Bechtel specifically to ensure that Bechtel provides timely and thorough responses to these RAIs as they are issued by the NRC Staff. Bechtel has assured SCE&G that it is devoting the personnel and resources to this matter that are required to provide the required responses in a complete and timely fashion. All RAI activities are on schedule and no issues of concern have been identified based on the RAIs received to date.

2) The NRC Staff conducted a geotechnical/seismic audit at the Site during the week of March 30. This audit was deemed successful and no areas of concern related to geotechnical or seismic issues were identified.

3) The NRC is in the process of completing the SER for the Westinghouse (WEC) Design Control Document (DCD) Revision 17 and has identified several issues relating to engineering items. These issues include concerns related to certain aspects of the design of Category I structures, certain high frequency seismicity issues, and certain issues related to the Shield Building design method. SCE&G has expressed to WEC its absolute expectation that these matters be dealt with in a timely way that does not result in delays in the issuance of a COL for the Units. On April 3, 2009, the NRC issued a letter on the DCD Revision 17 review and approval schedule. The current NRC schedule shows a December 2010 final SER with an August 2011 final rule making. This final rule making is a prerequisite for the COLA approval and does not support the COLA approval date of July 2011 by several months. WEC is working to develop alternatives to assist in accelerating the review schedule or to minimize the impact to the project schedule. SCE&G is closely monitoring the DCD Revision 17 review process because of its potential impact on the schedule for the review and approval of the COLA for the Units. SCE&G has identified the status of the review and approval of DCD 17 as a focus area for on-going monitoring and attention to ensure that WEC does what is required to obtain the necessary approvals on a timely basis.

9

b) Environmental Review

The NRC held public meetings related to its environmental review of the project on the evening of January 27th at Fairfield Central High School in Winnsboro and on the evenings of January 28th and March 28th at McCrorey-Liston Elementary School in Blair. The NRC also conducted a Site audit during the week of March 9 as part of the Phase I scoping for the Environmental Impact Study. The NRC plans to complete the Phase I scoping of the Environmental Impact Study for the Units in June, 2009.

c) Legal Review

Several parties sought to intervene to raise issues before the Atomic Safety Licensing Board (ASLB) in its consideration of the COLA for the Units. As required by ASLB practice, these potential intervenors were required to list specific contentions that they would raise in opposition to the COLA. On February 18, 2009, the ASLB dismissed all contentions by these intervenors as being without merit, and dismissed their petitions for intervention. This action by the ASLB precluded the necessity of the ASLB prehearing that was originally scheduled for February, 2009. The intervenors have appealed the ASLB decision.

2. Other Permits

a) South Carolina Department of Health and Environmental Control (SCDHEC) issued the Storm Water Pollution Prevention Permit (SWPPP) Phase 1 (Notice of Intent), Phase 2A (Railroad Corridor) and Phase 2B (grading in Construction City and the Spoils Area). Work continues on the preparation of the additional SWPPP packages for future stages of construction. SWPPP permitting is proceeding in a timely and satisfactory manner.

b) SCE&G is working with the Army Corps of Engineers (ACOE) to obtain the ACOE 404 (wetlands) permit to allow grading in an area subject to Corps jurisdiction that is located in the area where the Cooling Towers for the Units are planned to be built. The area in question is a small length of intermittent stream bank. The approach that the ACOE is taking to its review and permitting process could delay the issuance of the required permit beyond the date that the permit is required to proceed with the construction schedule. In response, SCE&G and the Consortium are formulating a plan to reconfigure part of the site plan to avoid the need to impact this relatively small area of stream bank. There are no technical impediments to such a plan and the cost of this alternative approach

10

is well within applicable contingencies. This issue is a focus area for future oversight and review to ensure that issues related to ACOE permitting do not result in a delay in construction.

B. Engineering Update

1. Engineering Completion Status

a) The Engineering Completion Status based on the completion percentage for major plant categories is as follows:

1) Standard Plant Design – 72% complete

2) Site Specific Design – 23% complete

3) Total Design (procurement and construction planning)– 67% complete

b) The Engineering Completion Status as reported above reflects only the work necessary to bring the design outputs to a point where they are sufficient to support procurement and construction planning. By the end of 2009, SCE&G and the Consortium will add a new element to the engineering status report to measure the degree to which the design outputs are ready for field construction. This change will reflect an expansion in the scope of the engineering work being measured and will result in the Total Design completion percentage being less than that which is reported here. This change in reporting of design status is expected to be reflected in reporting on the project no later than the Quarterly report for the twelve months ending December 31, 2009. This change will not adversely impact the Engineering schedule or the substantial completion schedule for the Units.

c) In addition, on April 1, 2009, the Consortium provided SCE&G with a Performance Measurement Baseline Schedule (PMB) for the Units, which represents an expanded and refined version of the construction and engineering schedule that was operative through March 31, 2009. This new scheduling information is included in the milestone reports contained in this quarterly report. This expanded and refined schedule information supports the completion of the Units by the Substantial Completion dates, and all milestones are within the parameters of Commission Order No. 2009-104A.

11

2. Standard Plant Design Activities

During the reporting period, the following standard plant design activities were conducted:

a) WEC completed the Final Design Review for the Control Rod Drive Mechanism (CRDM) for the Units. WEC is in the process of performing the CRDM Latch Assembly life test to verify the strength and reliability of the assembly. Four (4) million steps were completed as of the end of March with a goal to complete nine (9) million steps in total. Steps are incremental movements of the control rods using the mechanism.

b) The Squib Valve prototype for the Units is being tested. All tests to date have been successful. These valves are part of the reactor core cooling system and operate to direct coolant to the core in the event of a loss of coolant accident. They are activated by explosive caps to eliminate the need for motors and drives.

c) Drawing packages were completed for:

i. | | The R251 module, which is a composite module for the Demineralizer in the Auxiliary Building; |

ii. | | The CH21-25 modules, which are the floor modules for electrical equipment in the Auxiliary Building; and |

iii. | | The CH31-35 modules, which are the floor modules for Instrument & Control equipment in the Auxiliary Building. |

d) WEC is conducting a three-dimensional model review to confirm the sizes and locations of the seventy-nine (79) penetrations in the CA01 module. The CA01 module is the concrete-filled-in-place structural module for the Steam Generator compartments and the Refueling Canal. This review will support the module fabrication for the project to construct multiple AP1000 units in China. This activity along with other Engineering/Construction activities supporting the China project will benefit the WEC USA projects.

e) A design and construction interface review was performed for the Shield Building Design. The design-construction interface review is a review of the design with fabricators and contractors to ensure practicality of fabrication and construction and to ensure that requirements for fabrication and construction are clearly communicated.

f) A Reactor Coolant loop geometry and manufacturing review was successfully held to critique the manufacturing process for the hot-legs, cold-legs and surge line of the Reactor Coolant loop. The

12

geometry and manufacturing review includes testing to ensure that configuration and materials of the Reactor Coolant loop piping are compatible with the manufacturing processes.

g) WEC plans to issue a Design Control Package (DCP) to the NRC to show an increase in the length of the footprint of the Turbine Building by approximately twelve (12) feet. This increase will allow additional space for Turbine Building equipment. This revision may impact the DCD, COLA and Site Layout but is not expected to raise significant engineering or other issues or to adversely impact the Project schedule. This is a focus area for SCE&G’s oversight of the Consortium’s work in order to ensure that the design and construction of the Turbine Building, equipment and supporting systems remains on schedule.

3. Site Specific Design Activities

a) Shaw Engineering is performing Site Specific Design to support the Site excavation and grading work. Geotechnical evaluations continue, as well as the design work in support of the permit applications. This work is proceeding in an efficient and satisfactory manner.

b) Site Specific Design is in progress for Site Specific Systems, to include the Potable Water System, the Raw Water System, the Yard Fire Water System, the Power System for Construction City and the Switchyard. This work is proceeding in an efficient and satisfactory manner.

C. Procurement/Fabrication Update

1. WEC placed a Purchase Order (PO) for the Turbine/Generator with Toshiba and a PO for the Squib Valves with SPX Copes Vulcan.

2. Mangiarotti, a subcontractor of WEC, issued POs for long lead materials for the Accumulator Tank, the Core Make-Up Tank, the Pressurizer and the Passive Residual Heat Exchanger.

3. NND Engineering representatives from SCE&G visited the Toshiba and Doosan manufacturing facilities in Japan and South Korea during the week of February 9. The visit included kick-off meetings with Doosan for the Reactor Vessel and Steam Generator manufacturing and with Toshiba for the Steam Turbine/Generator manufacturing.

4. Site Specific procurement activities included award of subcontracts to Hinkle for the Railroad Installation; to MC Dean for the Offsite Retail Power System (Construction City); the issuance of a Letter of

13

Inquiry to Hansen Pressure Pipe for the Circulating Water Pipe and Fittings; and the issuance of Request for Quotations (RFQs) for the Switchyard and Mayo Creek Bridge.

5. Shaw Modular Solutions is developing its module manufacturing facility, programs and schedule. Shaw Modular Solutions plans to begin module fabrication at its new manufacturing facility later in 2009.

6. NND is in the process of reviewing the Quality Plans for the Reactor Vessel and Steam Generator for the purpose of adding Owner Witness and Hold Points. The manufacturing of this equipment is scheduled to begin the 2nd quarter of 2009.

14

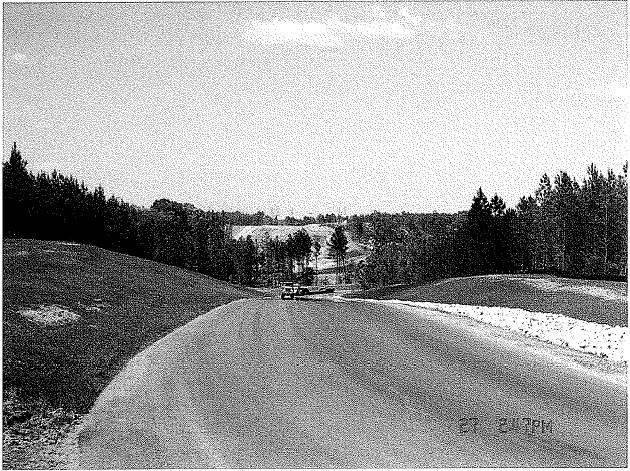

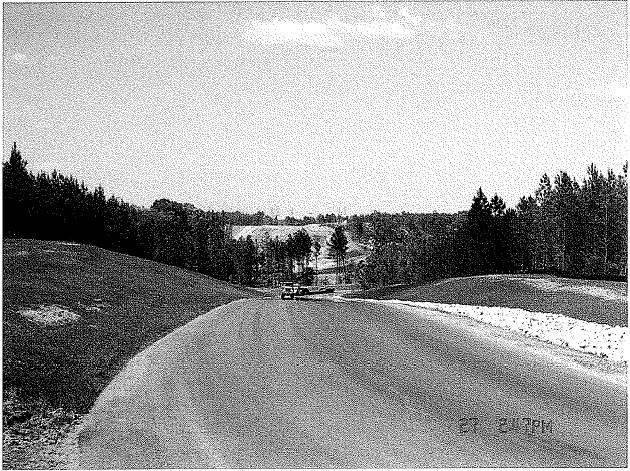

Picture 1 – Construction Access Looking North

D. Construction Update

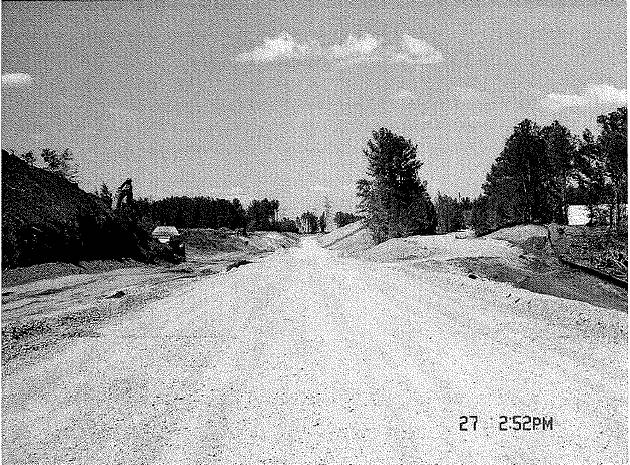

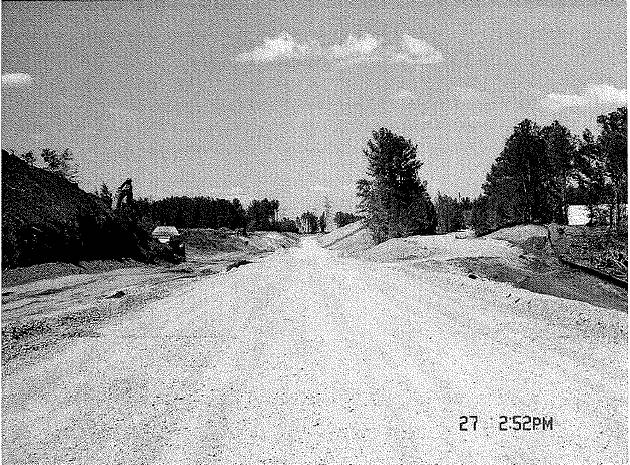

1. The initial Site development work has commenced to include installation of the Construction Access Road (essentially complete), Sediment Basins and other erosion control measures (essentially complete along the Construction Access Road), Laydown Area 1, the Railroad Corridor (essentially ready for railroad ballast and rail installation) and the reconfiguration of the SC Highway 213 and Parr Road intersection (just begun). The Consortium subcontractors Morgan Corporation and Saiia Construction are performing this work.

15

Picture 2 – Construction Access Road and Railroad Corridor

2. Jenkinsville Water Company’s contractor, C.B.G., Inc., started trenching and installation of water piping activities for the Potable Water System supply to Construction City and is approximately 30% complete with this activity.

3. Shaw continues finalization of the technical and commercial reviews to support the Heavy Lift Crane selection and Nuclear Island excavation plan. Close attention is being directed to this activity by the Consortium and SCE&G management to ensure that selection and procurement of the crane and design and construction of its footings do not delay the project’s construction schedule. Because of potential impacts of the crane’s availability on the construction schedule, this is a focus area for continuing oversight of the Consortium’s work.

4. The Consortium finalized and submitted to SCE&G the Performance Measurement Baseline Schedule (PMB) on April 1, 2009 and the payment milestones associated with this schedule on April 15, 2009.

16

Picture 3 – Railroad Spur Corridor – Track 1 Looking North

E. Training update

1. Plans are being made to train the SCE&G Reactor Operator Training Instructors on the WEC Training Development Simulator that will be located at the WEC Training Facility in Pittsburgh.

2. NND is working with WEC to provide a Limited Scope Simulator (LSS) for the on-site training for the Plant Operators. This LSS is needed to support the initial simulator training of the SCE&G Reactor Operators in advance of delivery of the certified simulators scheduled to be delivered in 2013. This is a focus area of SCE&G’s oversight of the Consortium to ensure that the Consortium finalizes the required contractual agreements to support the early delivery of the LSS and associated training activities.

F. Change Control Update

1. NND is working with the Consortium on the processing of Change Order #1 for the training of the SCE&G Reactor Operator Training

17

Instructors referenced in Section II.E.1 above. The cost of this Change Order will be taken out of the Time & Material Work Allowances given in Exhibit H of the EPC Contract.

2. EPC Contract Amendment #1 is being processed to revise the language in several areas of the EPC Contract. These revisions represent updates to the EPC Contract, such as contract language clarifications in the sections relating to Changes in the Work and Taxes, changes made to the Major Equipment Supplier and Contractor exhibits and changes in the milestone payment schedules due to the PMB Schedule received on April 1, 2009.

III. Anticipated Construction Schedules

As of the end of the first quarter of 2009, the Company and its contractors had completed all required milestones as set forth in Exhibit E to the Combined Application as adjusted pursuant to the milestone schedule contingencies approved by the Commission in Order No. 2009-104A. Each of those adjustments is itemized in the Milestone Update section that follows. The Company and its contractors are presently on schedule to complete all future milestones as specified or within approved contingencies. Accordingly, the project is in compliance with the construction schedules approved by the Commission in Order No. 2009-104A and with the provisions of S.C. Code Ann. § 58-33-275(A)(1).

To allow milestones to be tracked more consistently to the construction schedule, SCE&G has subdivided certain of the milestones approved in Order No. 2009-104A into several discrete items. The 123 milestones approved in that order are now being tracked as 146 milestones. No milestones have been omitted, and in each case, where a milestone was divided, the resulting milestones bear a due date no later than the due date of the milestone from which they were derived.

18

A. Construction Schedule Update

The Project Licensing and Permitting, Engineering, Procurement and Construction work remains on schedule to meet the Units 2 & 3 Substantial Completion dates. Rescheduling of the milestones listed in Exhibit E to the Combined Application is addressed in Section III.B herein. The rescheduling of these milestones is within the approved contingencies and has no adverse impact on the Units’ Substantial Completion dates.

B. Performance Measurement Baseline Schedule

On April 1, 2009, the Consortium provided SCE&G with the Performance Measurement Baseline Schedule for the project under the EPC Contract. The Performance Measurement Baseline Schedule is the integrated engineering, procurement and construction schedule for the project and represents a major refinement of the schedule that was provided as an attachment to the EPC Contract in May of 2008.

Of the 146 total milestones, 28 have been completed, 44 have been accelerated, 41 have been pushed out into the future, and 33 are unchanged,.

The Performance Measurement Baseline Schedule is the product of thousands of hours of construction planning and scheduling work by Consortium personnel since the EPC Contract was signed on May 23, 2008. The schedule also reflects a firming up of the vendor and supplier chain for the project and the negotiation of multiple supply agreements and delivery schedules with vendors and fabricators.

Where the Performance Measurement Baseline Schedule has pushed out the due dates for certain milestones, these later deadlines reflect the fact that greater certainty in the schedule allows for more precise scheduling of the dates by which major pieces of equipment will be required to be available on site. The revised deadlines also reflect the fact that a more fully-developed schedule allows more precise scheduling of the dates by which specific on-site construction activities will need to be completed. The project team has added additional certainty and detail to the construction schedule since the EPC Contract was signed on May 23, 2008 and revised milestones are possible for that reason.

Like the schedules contained in the EPC Contract, the new Performance Measurement Baseline Schedule fully supports the Substantial Completion dates for Units 2 and 3 of April 1, 2016 and January 1, 2019, respectively. The updated milestones dates based on the Performance Measurement Baseline Schedule are entirely consistent with the project milestones and contingencies adopted by the Commission in Order No. 2009-104A. The Substantial Completion dates remain as approved in Order No. 2009-104A. As discussed above, the Consortium and SCE&G remain fully committed to completing the Units on the dates promised and the Performance Measurement Baseline Schedule is an important tool for ensuring that this is done.

19

C. Milestone Update

1. Attached as Appendix 1 to this quarterly report are two spreadsheets that list and update each of the specific milestones contained in Exhibit E to the Combined Application and adopted by the Commission as the anticipated construction schedule for the Units pursuant to S.C. Code Ann. § 58-33-270(B)(1). The BLRA Milestone Tracking Sheet (Appendix 1, Chart A) provides the original milestone date and language, the revised milestone date and language, and the impact on the BLRA schedule contingency and Substantial Completion dates for Units 2 and 3. The BLRA Milestone Tracking Summary (Appendix 1, Chart B) highlights the milestones that have been moved from the originally targeted date and gives an explanation for this movement.

2. Exhibit E of the Combined Application contained the original list of milestones as approved by the Commission. It included a total of 123 milestones. As discussed above, several of these milestones have been revised into multiple milestones to reflect the way in which contracts negotiated with equipment suppliers subsequent to the Combined Application submittal were structured and included in the construction schedule for the project. The revised milestone total is 146. As shown on the BLRA Tracking Summary, a number of the milestones have moved out in time primarily to reflect the new schedule contained in the Performance Measurement Baseline Schedule received on April 1, 2009. All resulting milestones adjustments are within the scope of the milestone schedule contingency authorized by the Commission in Order No. 2009-104A. The milestone adjustments do not adversely affect the Substantial Completion dates for Units 2 and 3.

IV. Schedules of the Capital Costs Incurred Including Updates to the Information Required by S.C. Code Ann. § 58-33-270(B)(6) (The Inflation Indices)

The Capital Cost Update section of this report provides an update of the cumulative capital costs incurred and forecasted to be incurred as compared to the cumulative capital cost targets approved by the Commission in Order No. 2009-104A. The approved capital cost targets have been adjusted to reflect the escalation rate changes, and any use by the Company of the cost and timing contingencies that were approved by the Commission in Order No. 2009-104A. The Inflation Adjustments and Indices section of this report provides updated information on inflation indices and the changes in them.

20

A. Capital Costs Update

When adjusted for inflation, the year-end 2009 Cumulative Project Cash Flow as approved in Order No. 2009-104A was $663 million. During calendar year 2009, SCE&G anticipates incurring capital costs for the project amounting to $389 million. This amount reflects actual expenditures to date and forecasted expenditures for the balance of 2009 based on the milestone and construction schedule. This anticipated capital cost of $389 million for 2009 provides for the expenditure of $38 million in contingency funds if necessary, but none of these contingency funds has been expended or committed to be spent to date. As a result, if the actual expenditures track the current forecast, $38 million in contingency funds will be available for use in 2010 or beyond.

The anticipated expenditure of $389 million for the project in 2009 would result in a year-end 2009 cumulative project cash flow, exclusive of AFUDC, of $512 million. This amount is $151 million less than the Cumulative Project Cash Flow approved by the Commission for year-end 2009 as adjusted for inflation. This $151 million reduction in anticipated 2009 project expense represents timing differences and not changes in underlying costs. The Company forecasts that the capital costs in question will be incurred in future periods under the current construction schedule.

Chart A of Appendix 4 shows the Cumulative Project Cash Flow target as approved in Order No. 2009-104A and as updated for escalation and other Commission approved adjustments under the heading “Per Order 2009-104A Adjusted.” As shown there, SCE&G has carried forward into 2009 $10 million in unused contingency funds from 2008 as permitted by the Commission in Order No. 2009-104A. SCE&G has not used the capital cost schedule contingencies to make any adjustments to the approved Cumulative Project Cash Flow as set forth in this filing because the project conforms to approved project cost targets without such adjustments. Nonetheless, SCE&G does not intend to waive or in any way limit its right, as authorized by the Commission, to make appropriate capital cost contingency adjustments associated with current or future changes in cost scheduling. SCE&G may make capital cost contingency adjustments related to recent changes in its scheduling of capital costs in future filings.

Under the heading “Actual Through March, 2009, plus Projected, Appendix 4, Chart A, shows the cumulative cash flow for the project based on actual expenditures to date and the Company’s current forecast of cost and construction schedule” A comparison of the two sets of data is presented at Appendix 4, Chart B. This chart shows that the cumulative capital cost for the project is forecasted to be below the approved Cumulative Project Cash Flow target, as revised, during the years 2009-2014. The forecasted cash flow, on a cumulative basis, is anticipated to exceed the approved target level by $36 million in 2015, and $207 million in 2016, $147 million in 2017, and $118 million in 2018. These overages are calculated before the application of contingency funds and are due to the timing of capital expenditures as currently

21

forecasted, not increases in underlying costs. As shown on Appendix 4, Chart C, SCE&G forecasts using $36 million in contingency funds in 2015 and $172 million of contingency funds in 2016 to offset these overages. SCE&G forecasts that it will have more than adequate contingency funds in these years to absorb the full amount of the overages and will retain substantial contingency funds for other uses. In addition, SCE&G forecasts that it will have budget surpluses sufficient to restore $60 million to the contingency in 2017 and $29 million in 2018. As a result, SCE&G forecasts that it will have $320 million in uncommitted contingency funds at the end of the project.

The information presented in Appendix 4 establishes that the anticipated cumulative project cash flow for the period ending December 31, 2009 is in conformity with the schedule approved by the Commission in Order No. 2009-104A and with the provisions of S.C. Code Ann. § 58-33-275(A)(1). It also establishes that the Company’s best forecasts of future project costs are fully consistent with the Cumulative Project Cash Flows approved by the Commission in Order No. 2009-104A.

The following exhibits support this section:

Appendix 2 updates the original Exhibit F to the Combined Application to show the Company’s actual and forecasted expenditures on the project by plant cost category. In updating its cost projections, the Company has used the Commission-approved inflation indices as updated since Exhibit F to the Combined Application was originally prepared and its current cost and schedule information. In addition, Appendix 2 shows the cumulative Construction Work in Progress for the project and the balance of Construction Work in Progress that is not yet reflected in revised rates.

For comparison purposes, Appendix 3 provides an original version of Exhibit F to the Combined Application. This version of Exhibit F does not include any adjustments for changes in inflation indices or adjustments in capital cost schedules made by the Company.

As discussed above, Appendix 4, Chart A provides the adjusted Cumulative Cash Flow target and the current actual and forecasted cash flow for the project. Appendix 4, Chart B compares the adjusted Cumulative Cash Flow target to the Company’s actual and forecast costs for the project. Appendix 4, Chart C provides detailing concerning the cumulative pool of contingency funds and use of those funds year by year.

22

B. Inflation Indices Update

Appendix 5 shows the changes in the inflation indices approved in Order No. 2009-104A. Included is a ten-year history of the Handy Whitman All Steam Index, South Atlantic Region; the Handy Whitman All Steam and Nuclear Index, South Atlantic Region; Handy Whitman All Transmission Plant Index, South Atlantic Region; and the Chained GDP Index. The changes in these indices and the escalation-related effects of cost rescheduling resulted in an increase in the projected cost of the Units in future dollars from $6,313,376,000 as forecast in Order No. 2009-104A to a forecast of $6,875,316,000 using current inflation data and current AFUDC rates. The $4.5 billion forecast of the cost of the Units in 2007 dollars, net of AFUDC, remains unchanged.

V. Updated Schedule of Anticipated Capital Costs

The updated schedule of anticipated capital costs for Units 2 & 3 is reflected in Appendix 2. Further details as to the changes in these anticipated capital cost components are set forth in Appendix 4.

VI. Conclusion

As indicated above, the project is proceeding in compliance with the cost and schedule forecasts approved by the Commission in Order No. 2009-104A. The scheduled completion dates for Units 2 & 3 remain April 1, 2016 and January 1, 2019, respectively. The Units are on track to be completed within the projected cost of $4.5 billion in 2007 dollars net of AFUDC. The Company maintains an extensive staff of experts that monitors and oversees the work of its contractors and has identified and continues to monitor closely all areas of concerns related to either cost or schedule for the project. The Company will continue to update the Commission and ORS of progress and concerns as the project proceeds.

23

APPENDIX 1

V. C. Summer Nuclear Station Units 2 & 3

Quarterly Report to the South Carolina Office of Regulatory Staff

Submitted by South Carolina Electric & Gas Company

Pursuant to Public Service Commission Order No. 2009-104A

Quarter Ending March 31, 2009

Appendix 1, Chart A lists and updates each of the milestones contained in Exhibit E to the Combined Application (Hearing Exhibit 2, SAB-5) which the Commission adopted as the Approved Construction Schedule for the Units, pursuant to S.C. Code Ann. § 58-33-270(B)(1). Appendix 1, Chart A provides columns with the following information:

1. The original milestone date by year and quarter as approved by the Commission in Order 2009-104A.

2. The description of the milestone as originally provided in Exhibit E to the Combined Application (Hearing Exhibit 2, SAB-5).

3. An updated statement of how the milestone is described in the current project schedule.

4. The revised milestone date by year and quarter where milestones have been adjusted since they were approved in Order No. 2009-104A.

5. Information as to whether any milestone has been shifted outside of the 18/24 Month Contingency approved by the Commission.

6. Information as to whether any current change in this milestone is anticipated to impact the substantial completion date.

7. For completed milestones, the date by which it was completed. For completed milestones, this column entry is shaded.

8. Notes as to individual milestones and milestone adjustments, which include references, where necessary, to additional information concerning certain milestones provided in Appendix 1, Chart B.

Appendix 1, Chart B lists each milestone that has been shifted and gives the number of months by which it is shifted.

24

BLRA Milestone Tracking Summary | Appendix 1, Chart A |

09-1Q | VC Summer Units 2 and 3 |

Original Year | | Original Quarter | | Milestone

(BLRA Exhibit E) | | Updated Milestone

Terminology | | Revised Year/Quarter | | Outside +18/-24 Month

Contingency? | | Sustantial Completion

Date Impact? | | Completion Date | | Notes | |

2008 | | 2 | | 08-2Q-1 Approve Engineering, Procurement and Construction Agreement | | N/A | | N/A | | No | | No | | 5/23/2008 | | | |

| | | | | | | | | | | | | | | | | |

2008 | | 2 | | 08-2Q-2 Issue Purchase Orders to nuclear component fabricators for Units 2 and 3 Containment Vessels, Passive Residual Heat Removal Heat Exchangers, Accumulator Tanks, Core Makeup Tanks, Squib Valves, Steam Generators, Reactor Coolant Pumps, Pressurizer Vessels, Reactor Coolant Loop Hot Leg A Piping, Reactor Vessel Internals, Reactor Vessels, Reactor Integrated Head Packages, Control Rod Drive Mechanisms and Nuclear Island structural CA20 Modules | | Issue P.O.’s to nuclear component fabricators for Units 2 and 3 Containment Vessels | | 08-4Q | | No | | No | | 12/3/2008 | | | |

| | | | | | | | | | | | |

| Contractor Issue PO to Passive Residual Heat Removal Heat Exchanger Fabricator - First Payment - Unit 2 | | 08-3Q | | No | | No | | 8/31/2008 | | | |

| Contractor Issue PO to Accumulator Tank Fabricator - Unit 2 | | 08-3Q | | No | | No | | 7/31/2008 | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | Contractor Issue PO to Core Makeup Tank Fabricator - Units 2 & 3 | | 08-3Q | | No | | No | | 9/30/2008 | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | Contractor Issue PO to Squib Valve Fabricator - Units 2 & 3 | | 09-1Q | | No | | No | | 3/31/2009 | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | Contractor Issue PO to Steam Generator Fabricator - Units 2 & 3 | | 08-2Q | | No | | No | | 6/30/2008 | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | Contractor Issue Long Lead Material PO to Reactor Coolant Pump Fabricator - Units 2 & 3 | | 08-2Q | | No | | No | | 6/30/2008 | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | Contractor Issue PO to Pressurizer Fabricator - Units 2 & 3 | | 08-3Q | | No | | No | | 8/31/2008 | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | Contractor Issue PO to Reactor Coolant Loop Pipe Fabricator - First Payment - Units 2 & 3 | | 08-2Q | | No | | No | | 6/30/2008 | | | |

1

Original Year | | Original Quarter | | Milestone

(BLRA Exhibit E) | | Updated Milestone

Terminology | | Revised Year/Quarter | | Outside +18/-24 Month

Contingency? | | Sustantial Completion

Date Impact? | | Completion Date | | Notes |

| | | | | | Reactor Vessel Internals - Issue Long Lead Material PO to Fabricator - Units 2 and 3 | | 08-4Q | | No | | No | | 11/21/2008 | | |

| | | | | | | | | | | | | | | | |

| | | | | | Contractor Issue Long Lead Material PO to Reactor Vessel Fabricator - Units 2 & 3 | | 08-2Q | | No | | No | | 6/30/2008 | | |

| | | | | | | | | | | | | | | | |

| | | | | | Contractor Issue PO to Integrated Head Package Fabricator - Units 2 & 3 | | 09-3Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

| | | | | | Control Rod Drive Mechanism issue PO for Long Lead Material to Fabricator - Units 2 and 3 - first payment | | 08-2Q | | No | | No | | 6/21/2008 | | |

| | | | | | | | | | | | | | | | |

| | | | | | Issue P.O.’s to nuclear component fabricators for Nuclear Island structural CA20 Modules | | 09-3Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2008 | | 3 | | 08-3Q-1 Start Site Specific and balance of plant detailed design | | N/A | | 08-2Q | | No | | No | | 6/23/2008 | | |

| | | | | | | | | | | | | | | | |

2008 | | 3 | | 08-3Q-2 Issue PO and submit payment to fabricator via Westinghouse for Units 2 and 3 Simulators | | Instrumentation & Control Simulator - Contractor Place Notice to Proceed - Units 2 & 3 | | 08-4Q | | No | | No | | 10/31/2008 | | |

| | | | | | | | | | | | | | | | |

2008 | | 3 | | 08-3Q-3 Issue final PO’s and submit payments to fabricators via Westinghouse for Units 2 and 3 Steam Generators, Reactor Vessel Internals and Reactor Vessels. | | Steam Generator - Issue Final PO to Fabricator for Units 2 and 3 | | 08-2Q | | No | | No | | 6/30/2008 | | |

| | | | | | | | | | | | | | | | |

| | | | | | RVI - Contractor Issue PO for Long Lead Material (Heavy Plate and Heavy Forgings) to Fabricator - Units 2 & 3 | | 10-1Q | | No | | No | | | | |

2

Original Year | | Original Quarter | | Milestone

(BLRA Exhibit E) | | Updated Milestone

Terminology | | Revised Year/Quarter | | Outside +18/-24 Month

Contingency? | | Sustantial Completion

Date Impact? | | Completion Date | | Notes | |

| | | | | | Contractor Issue Final PO to Reactor Vessel Fabricator - Units 2 & 3 | | N/A | | No | | No | | 9/30/2008 | | | |

| | | | | | | | | | | | | | | | | |

2008 | | 3 | | 08-3Q-4 Issue PO and submit payment via Westinghouse to fabricator for Units 2 and 3 Transformers. | | Variable Frequency Drive Fabricator Issue Transformer PO - Units 2 & 3 | | 09-2Q | | No | | No | | | | | |

| | | | | | | | | | | | | | | | | |

2008 | | 4 | | 08-4Q-1 Start clearing, grubbing and grading | | N/A | | 09-1Q | | No | | No | | 1/26/2009 | | | |

| | | | | | | | | | | | | | | | | |

2008 | | 4 | | 08-4Q-2 Issue final Purchase Orders and submit payments to fabricators via Westinghouse for Units 2 and 3 Core Makeup Tanks, Accumulator Tanks, Pressurizers, Reactor Coolant Loop Piping, Intergrated Head Packages, Control Rod Drive Mechanisms and Passive Residual Heat Removal Heat Exchangers | | Core Makeup Tank Fabricator Issue Long Lead Material PO - Units 2 & 3 | | N/A | | No | | No | | 10/31/2008 | | | |

| Acumulator Tank Fabricator Issue Long Lead Material PO - Units 2 & 3 | | N/A | | No | | No | | 10/31/2008 | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | Pressurizer Fabricator Issue Long Lead Material PO - Units 2 & 3 | | N/A | | No | | No | | 10/31/2008 | | | |

| | | | | | | | | | | | | | | | | |

| | | | | | Reactor Coolant Loop Pipe - Contractor Issue PO to Fabricator - Second Payment - Units 2 & 3 | | 09-2Q | | No | | No | | | | | |

3

Original Year | | Original Quarter | | Milestone

(BLRA Exhibit E) | | Updated Milestone

Terminology | | Revised Year/Quarter | | Outside +18/-24 Month

Contingency? | | Sustantial Completion

Date impact? | | Completion Date | | Notes |

| | | | | | Integrated Head Package - Issue PO to Fabricator - Units 2 and 3 - second payment | | 09-3Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

| | | | | | Control Rod Drive Mechanisms -Contractor Issue PO for Long Lead Material to Fabricator - Units 2 & 3 | | 08-2Q | | No | | No | | 6/30/2008 | | |

| | | | | | | | | | | | | | | | |

| | | | | | Contractor Issue PO to Passive Residual Heat Removal Heat Exchanger Fabricator - Second Payment - Units 2 & 3 | | N/A | | No | | No | | 10/31/2008 | | |

| | | | | | | | | | | | | | | | |

2009 | | 1 | | 09-1Q-1 Start Parr Road intersection work. | | N/A | | 09-1Q | | No | | No | | 2/16/2009 | | |

| | | | | | | | | | | | | | | | |

2009 | | 1 | | 09-1Q-2 Issue final Purchase Order and submit payment via Westinghouse to fabricator for Units 2 and 3 Reactor Coolant Pumps | | Reactor Coolant Pump - Issue Final PO to Fabricator - Units 2 and 3 | | 08-2Q | | No | | No | | 6/30/2008 | | |

| | | | | | | | | | | | | | | | |

2009 | | 1 | | 09-1Q-3 Issue Purchase Order for Long Lead Material and submit payment via Westinghouse to fabricator for Units 2 and 3 Integrated Heat Packages | | Integrated Heat Packages Fabricator Issue Long Lead Material PO - Units 2 & 3 | | 09-4Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2009 | | 1 | | 09-1Q-4 Submit partial payment to Westinghouse for Design Finalization | | Design Finalization Payment 3 | | N/A | | No | | No | | 1/31/2009 | | |

| | | | | | | | | | | | | | | | |

2009 | | 2 | | 09-2Q-1 Start site development | | N/A | | 08-2Q | | No | | No | | 6/23/2008 | | |

4

Original Year | | Original Quarter | | Milestone

(BLRA Exhibit E) | | Updated Milestone

Terminology | | Revised Year/Quarter | | Outside +18/-24 Month

Contingency? | | Sustantial Completion

Date Impact? | | Completion Date | | Notes |

2009 | | 2 | | 09-2Q-2 Issue Purchase Orders and submit payments via Westinghouse for Units 2 and 3 Turbine/Generators and Main Transformers | | Contractor Issue PO to Turbine Generator Fabricator - Units 2 & 3 | | 09-1Q | | No | | No | | 2/17/2009 | | |

| | | | | | | | | | | | | | | | |

| | | | | | Contractor Issue PO to Main Transformers Fabricator - Units 2 & 3 | | 09-3Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2009 | | 2 | | 09-2Q-3 Receive Units 2 and 3 Core Makeup Tank material at fabricator | | Core Makeup Tank Fabricator Notice to Contractor Receipt of Long Lead Material - Units 2 & 3 | | 10-4Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2009 | | 2 | | 09-2Q-4 Submit partial payment to Westinghouse for Design Finalization | | Design Finalization Payment 4 | | N/A | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2009 | | 3 | | 09-3Q-1 Issue Purchase Order and submit payment via Westinghouse for Unit 2 Turbine Generator Condenser material | | Turbine Generator Fabricator Issue PO for Condenser Material - Unit 2 | | N/A | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2009 | | 3 | | 09-3Q-2 Submit payments to fabricators via Westinghouse for Units 2 and 3 Reactor Coolant Pumps and Passive Residual Heat Removal Heat Exchangers | | Reactor Coolant Pump Fabricator Issue Long Lead Material Lot 2 -Units 2 & 3 | | 09-2Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

| | | | | | Passive Residual Heat Removal Heat Exchanger Fabricator Receipt of Long Lead Material - Units 2 & 3 | | 10-2Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2009 | | 3 | | 09-3Q-3 Submit partial payment to Westinghouse for Design Finalization | | Design Finalization Payment 5 | | N/A | | No | | No | | | | |

5

Original Year | | Original Quarter | | Milestone

(BLRA Exhibit E) | | Updated Milestone

Terminology | | Revised Year/Quarter | | Outside +18/-24 Month

Contingency? | | Sustantial Completion

Date Impact? | | Completion Date | | Notes |

2009 | | 4 | | 09-4Q-1 Start erection of construction buildings, to include craft facilities for personnel, tools, equipment; first aid facilities; field offices for site management and support personnel; temporary warehouses; and construction hiring office. | | N/A | | 09-3Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2009 | | 4 | | 09-4Q-2 Receive Unit 2 Reactor Vessel flange nozzel shell forging at fabricator | | Reactor Vessel Fabricator Notice to Contractor of Receipt of Flange Nozzle Shell Forging - Unit 2 | | 09-3Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2009 | | 4 | | 09-4Q-3 Submit partial payment to Westinghouse for Design Finalization | | Design Finalization Payment 6 | | N/A | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2009 | | 4 | | 09-4Q-4 Issue Purchase Order and submit payment via Westinghouse to fabricator for Units 2 and 3 Radiation Monitoring Systems | | Instrumentation and Control/Simulator - Contractor Issue PO to Subcontractor for Rad Monitor Sys - Units 2 & 3 | | N/A | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 1 | | 10-1Q-1 Receive Unit 2 Reactor Vessel Internals core shroud material at the fabricator | | Reactor Vessel Internals - Fabricator Start Fit and Welding of Core Shroud Assembly - Unit 2 | | 11-2Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 1 | | 10-1Q-2 Payment to fabricator via Westinghouse for Unit 2 Turbine/Generator Feedwater Heater material | | Turbine Generator Fabricator Issue PO for Moisture Separator Reheater/Feedwater Heater Material - Unit 2 | | 10-2Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 1 | | 10-1Q-3 Receive raw material at fabricator for Unit 2 Reactor Coolant Loop piping | | Reactor Coolant Loop Pipe Fabricator Acceptance of Raw Material - Unit 2 | | 10-2Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 2 | | 1Q-2Q-1 Receive Unit 2 Reactor Vessel Internals upper guide tube Material at the fabricator | | Reactor Vessel internals - Fabricator Start Weld Neutron Shield Spacer Pads to Assembly - Unit 2 | | 11-4Q | | No | | No | | | | |

6

Original Year | | Original Quarter | | Milestone

(BLRA Exhibit E) | | Updated Milestone

Terminology | | Revised Year/Quarter | | Outside +18/-24 Month

Contingency? | | Sustantial Completion

Date Impact? | | Completion Date | | Notes |

| | | | | | | | | | | | | | | | |

2010 | | 2 | | 10-2Q-2 Submit payment to Westinghouse for the Unit 2 Control Rod Drive Mechanisms | | Control Rod Drive Mechanisms -Fabricator to Start Procurement of Long Lead Material - Unit 2 | | 09-2Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 2 | | 10-2Q-3 Perform cladding on Unit 2 Pressurizer bottom head at fabricator | | Contractor Notified that Pressurizer Fabricator Performed Cladding on Bottom Head - Unit 2 | | 10-4Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 3 | | 10-3Q-1 Start excavation and foundation work for the standard plant for Unit 2 | | N/A | | 10-1Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 3 | | 10-3Q-2 Receive Unit 2 Steam Generator tube sheet forging at the fabricator | | Steam Generator Fabricator Notice to Contractor of Receipt of 2nd Steam Generator Tubesheet Forging - Unit 2 | | 10-1Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 3 | | 10-3Q-3 Complete Unit 2 Reactor Vessel outlet nozzle weld to flange at the fabricator | | Reactor Vessel Fabricator Notice to Contractor of Outlet Nozzle Welding to Flange Nozzle Shell Completion - Unit 2 | | 10-1Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 3 | | 10-3Q-4 Start Unit 2 Condenser fabrication at the fabricator | | Turbine Generator Fabricator Notice to Contractor Condenser Fabrication Started - Unit 2 | | 10-2Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 4 | | 10-4Q-1 Complete preparations for receiving the first module on site for Unit 2. | | N/A | | 10-3Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 4 | | 10-4Q-2 Receive Unit 2 Steam Generator transition cone forging at the fabricator | | Steam Generator Fabricator Notice to Contractor of Receipt of 1st Steam Generator Transition Cone Forging - Unit 2 | | 10-2Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2010 | | 4 | | 10-4Q-3 Complete Unit 2 Reactor Coolant Pump casing fabrication | | Reactor Coolant Pump Fabricator Notice to Contractor of Manufacturing of Casing Completion - Unit 2 | | N/A | | No | | No | | | | |

7

Original Year | | Original Quarter | | Milestone

(BLRA Exhibit E) | | Updated Milestone

Terminology | | Revised Year/Quarter | | Outside +18/-24 Month

Contingency? | | Sustantial Completion

Date Impact? | | Completion Date | | Notes |

| | | | | | | | | | | | | | | | |

2010 | | 4 | | 10-4Q-4 Complete machining, heat treatment and Nondestructive examination of Unit 2 Reactor Coolant Loop Hot Leg A piping at the fabricator | | Reactor Coolant Loop Pipe Fabricator Notice to Contractor of Machining, Heat Treating & Non-Destructive Testing Completion - Unit 2 | | N/A | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2011 | | 1 | | 11-1Q-1 Complete Unit hydrotests for Core Makeup Tanks | | Core Makeup Tank Fabricator Notice to Contractor of Satisfactory Completion of Hydrotest - Unit 2 | | 11-2Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2011 | | 1 | | 11-1Q-2 Issue Purchase Order and submit payment via Westinghouse to fabricator for Units 2 and 3 Polar Crane main hoist drums and wire rope. | | Polar Crane Fabricator issue PO for Main Hoist Drum and Wire Rope - Units 2 & 3 | | N/A | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2011 | | 2 | | 11-2Q-1 Receive Unit 3 Control Rod Drive Mechanism latch housing/rod travel housing material at the fabricator | | Control Rod Drive Mechanisms -Fabricator to Start Procurement of Long Lead Material - Unit 3 | | 11-2Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2011 | | 2 | | 11-2Q-2 Complete Unit 2 Condenser shipment preparation at the fabricator | | Turbine Generator Fabricator Notice to Contractor Condenser Ready to Ship - Unit 2 | | 11-4Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2011 | | 3 | | 11-3Q-1 Start placement of mud mat for Unit 2 | | N/A | | N/A | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2011 | | 3 | | 11-3Q-2 Receive Unit 2 Steam Generator tubing at the fabricator | | Steam Generator Fabricator Notice to Contractor of Receipt of 1st Steam Generator Tubing - Unit 2 | | 11-1Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2011 | | 3 | | 11-3Q-3 Complete upper head welding on Unit 2 Pressurizer at the fabricator | | Pressurizer Fabricator Notice to Contractor of Welding of Upper and Intermediate Shells Completion - Unit 2 | | 10-4Q | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2011 | | 3 | | 11-3Q-4 Complete Unit 3 Reactor Vessel closure head cladding at the fabricator | | Reactor Vessel Fabricator Notice to Contractor of Closure Head Cladding Completion - Unit 3 | | 12-1Q | | No | | No | | | | |

8

Original Year | | Original Quarter | | Milestone

(BLRA Exhibit E) | | Updated Milestone

Terminology | | Revised Year/Quarter | | Outside +18/-24 Month

Contingency? | | Sustantial Completion

Date Impact? | | Completion Date | | Notes |

2011 | | 4 | | 11-4Q-1 Begin Unit 2 first nuclear concrete placement | | N/A | | N/A | | No | | No | | | | |

| | | | | | | | | | | | | | | | |

2011 | | 4 | | 11-4Q-2 Complete fabrication of Unit 2 Reactor Coolant Pump stator core at the fabricator | | Reactor Coolant Pump Fabricator Notice to Contractor of Stator Core Completion - Unit 2 | | 11-3Q | | No | | No | | | | |