Exhibit 99.1

BARRICK GOLD CORPORATION

TECHNICAL REPORT ON THE

ZALDÍVAR MINE, REGION II, CHILE

NI 43-101 Report

Qualified Persons:

Luke Evans, P.Eng.

Richard J. Lambert, P.E.

March 16, 2012

ROSCOE POSTLE ASSOCIATES INC.

Report Control Form

| | | | | | | | |

Document Title | | Technical Report on the Zaldívar Mine, Region II, Chile |

| |

Client Name & Address | | Barrick Gold Corporation Brookfield Place, TD Canada Trust Tower Suite 3700, 161 Bay Street, P.O. Box 212 Toronto, Ontario M5J 2S1 |

| | | | |

Document Reference | | Project #1683 | | Status &

Issue No. | | Final

Version | | Rev 0 |

| | |

Issue Date | | March 16, 2012 | | |

| | |

Lead Author | | Luke Evans, P.Eng. Richard J. Lambert, P.E. | | (Signed)

(Signed) |

| | |

Peer Reviewer | | Deborah A. McCombe, P.Geo. | | (Signed) |

| | |

Project Manager Approval | | Luke Evans, P.Eng. | | (Signed) |

| | |

Project Director Approval | | Graham G. Clow, P.Eng. | | (Signed) |

| | |

Report Distribution | | Name | | No. of Copies |

| | |

| | Client | | |

| | |

| | RPA Filing | | 1 (project box) |

|

Roscoe Postle Associates Inc. 55 University Avenue, Suite 501 Toronto, Ontario M5J 2H7 Canada Tel: +1 416 947 0907 Fax: +1 416 947 0395 mining@rpacan.com |

| | |

| | www.rpacan.com |

TABLE OF CONTENTS

| | | | |

| | | PAGE | |

1 SUMMARY | | | 1-1 | |

Executive Summary | | | 1-1 | |

Technical Summary | | | 1-5 | |

2 INTRODUCTION | | | 2-1 | |

3 RELIANCE ON OTHER EXPERTS | | | 3-1 | |

4 PROPERTY DESCRIPTION AND LOCATION | | | 4-1 | |

5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | | | 5-1 | |

6 HISTORY | | | 6-1 | |

Exploration and Ownership History | | | 6-1 | |

Production History | | | 6-1 | |

7 GEOLOGICAL SETTING AND MINERALIZATION | | | 7-1 | |

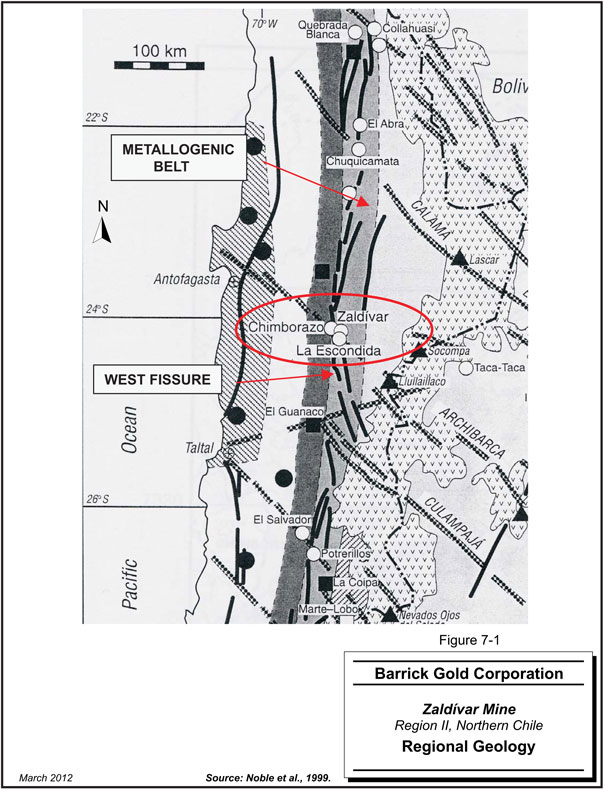

Regional Geology | | | 7-1 | |

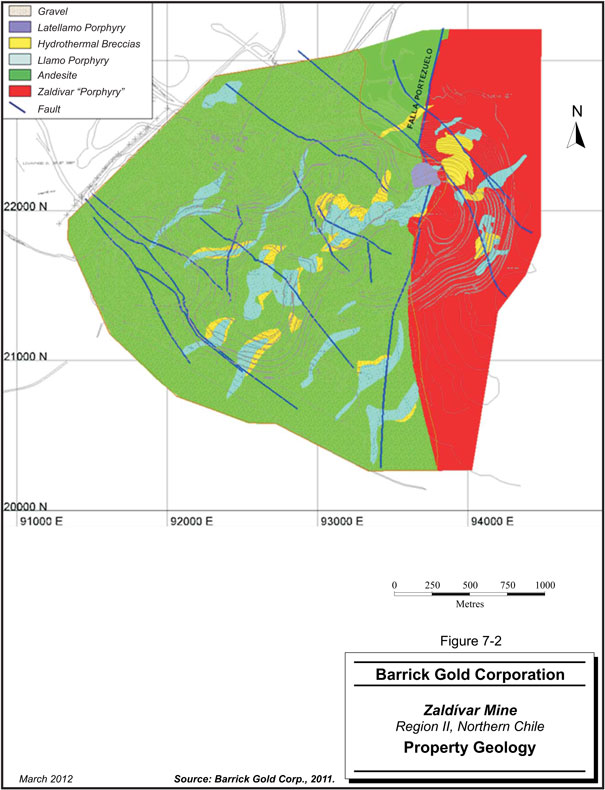

Local and Property Geology | | | 7-3 | |

Alteration | | | 7-5 | |

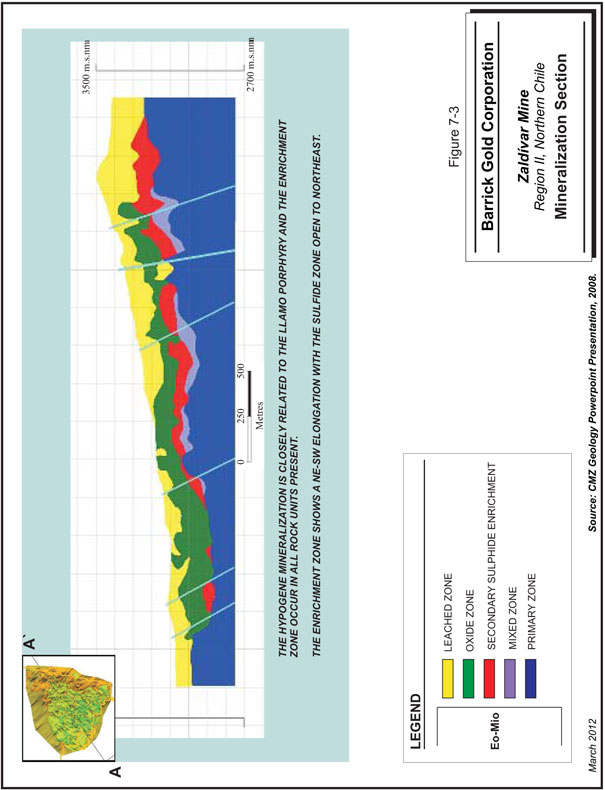

Mineralization | | | 7-6 | |

8 DEPOSIT TYPES | | | 8-1 | |

9 EXPLORATION | | | 9-1 | |

Exploration Potential | | | 9-1 | |

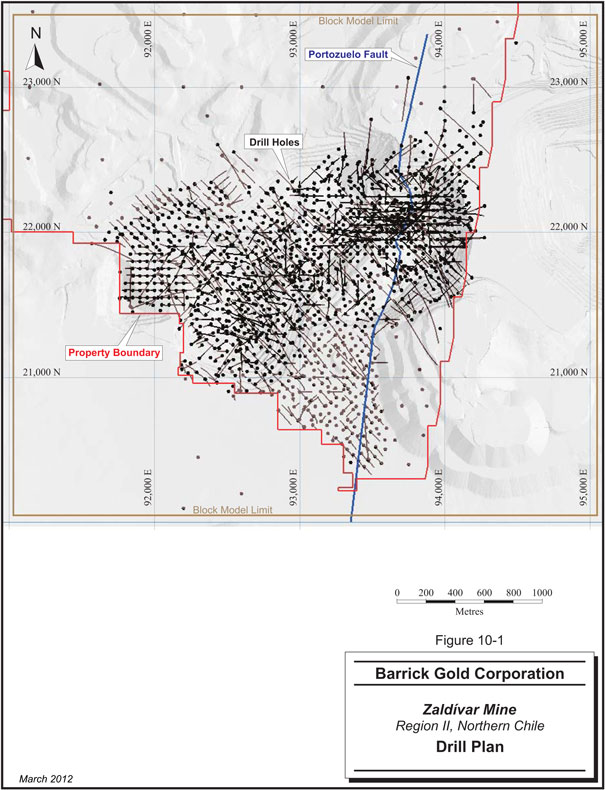

10 DRILLING | | | 10-1 | |

11 SAMPLE PREPARATION, ANALYSES AND SECURITY | | | 11-1 | |

Sampling Method and Approach | | | 11-1 | |

Sample Preparation, Analyses and Security | | | 11-1 | |

12 DATA VERIFICATION | | | 12-1 | |

13 MINERAL PROCESSING AND METALLURGICAL TESTING | | | 13-1 | |

Metallurgical Testing | | | 13-1 | |

14 MINERAL RESOURCE ESTIMATE | | | 14-1 | |

Summary | | | 14-1 | |

Geological Models | | | 14-2 | |

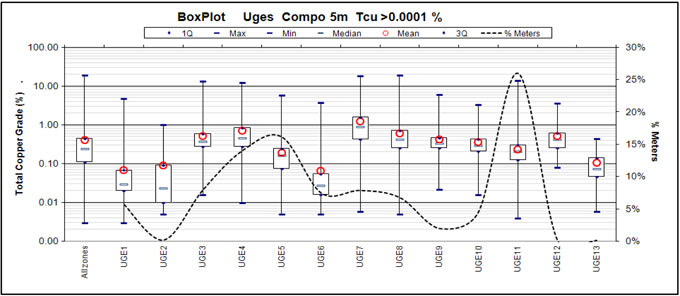

Geological Domains | | | 14-7 | |

Density Data | | | 14-8 | |

Cut-Off Grades | | | 14-8 | |

Capping of High Grade Values | | | 14-8 | |

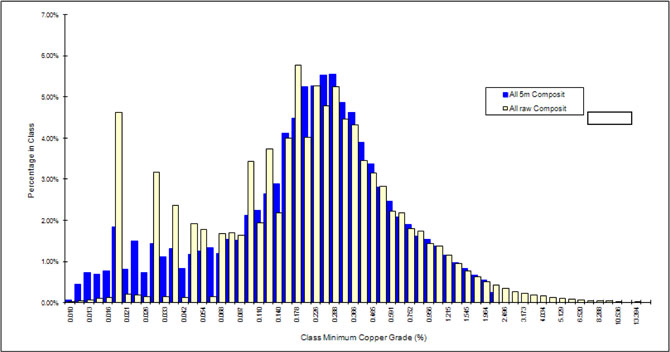

Composites | | | 14-9 | |

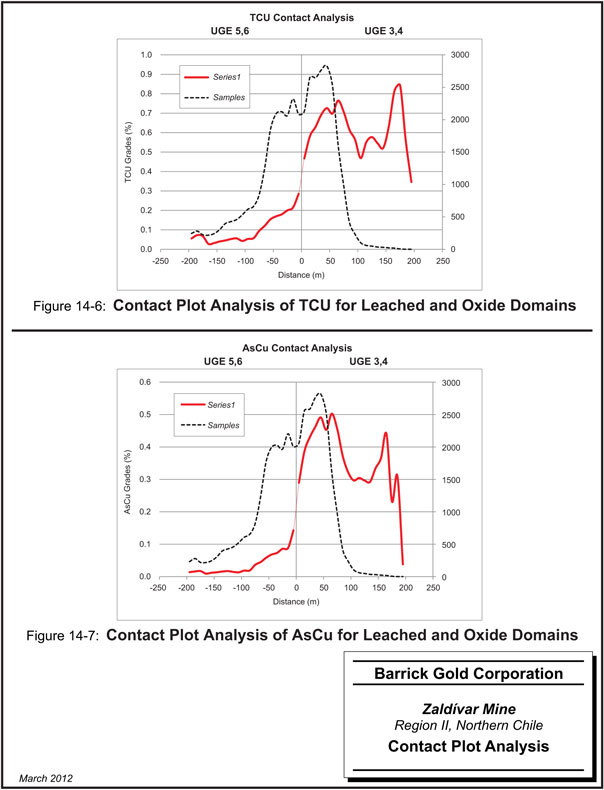

Contact Plot Analysis | | | 14-12 | |

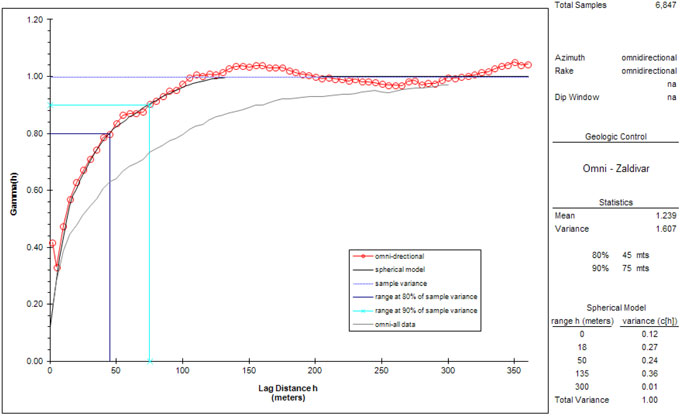

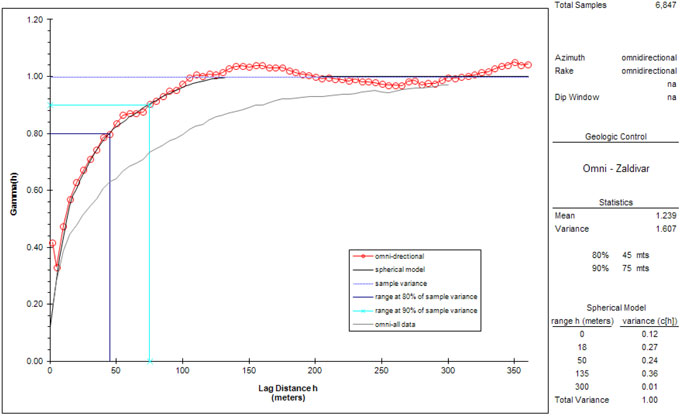

Variography | | | 14-15 | |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page i |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

| | | | |

Resource Estimation Methodology | | | 14-17 | |

Resource Estimate Validation | | | 14-20 | |

Resource Classification | | | 14-21 | |

15 MINERAL RESERVE ESTIMATE | | | 15-1 | |

16 MINING METHODS | | | 16-1 | |

Production Schedule | | | 16-7 | |

Waste Rock | | | 16-8 | |

Mine Equipment | | | 16-8 | |

Mine Infrastucture | | | 16-9 | |

17 RECOVERY METHODS | | | 17-1 | |

Ore Processing | | | 17-1 | |

Dynamic Pad Leach Process | | | 17-2 | |

ROM Leach Pad | | | 17-2 | |

SX/EW Copper Recovery Circuit | | | 17-2 | |

Flotation Concentration Process | | | 17-2 | |

Copper Recovery | | | 17-4 | |

Copper Recovery Algorithms at Zaldívar | | | 17-4 | |

2011 Recovery Model | | | 17-8 | |

18 PROJECT INFRASTRUCTURE | | | 18-1 | |

19 MARKET STUDIES AND CONTRACTS | | | 19-1 | |

Markets | | | 19-1 | |

Contracts | | | 19-1 | |

20 ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | | | 20-1 | |

Environmental Studies | | | 20-1 | |

Project Permitting | | | 20-1 | |

Social or Community Requirements | | | 20-2 | |

Mine Closure Requirements | | | 20-2 | |

21 CAPITAL AND OPERATING COSTS | | | 21-1 | |

Capital Costs | | | 21-1 | |

Operating Costs | | | 21-2 | |

Manpower | | | 21-3 | |

22 ECONOMIC ANALYSIS | | | 22-1 | |

23 ADJACENT PROPERTIES | | | 23-1 | |

24 OTHER RELEVANT DATA AND INFORMATION | | | 24-1 | |

25 INTERPRETATION AND CONCLUSIONS | | | 25-1 | |

26 RECOMMENDATIONS | | | 26-1 | |

27 REFERENCES | | | 27-1 | |

28 DATE AND SIGNATURE PAGE | | | 28-1 | |

29 CERTIFICATE OF QUALIFIED PERSON | | | 29-1 | |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page ii |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

LIST OF TABLES

| | | | |

| | | PAGE | |

Table 1-1 Mineral Resources – December 31, 2011 | | | 1-1 | |

Table 1-2 Mineral Reserves – December 31, 2011 | | | 1-2 | |

Table 4-1 Exploitation Concessions | | | 4-1 | |

Table 6-1 Zaldívar Production – 2007-2011 | | | 6-3 | |

Table 10-1 Drilling Summary | | | 10-2 | |

Table 11-1 QC Insertion Rates | | | 11-2 | |

Table 14-1 Mineral Resources – December 31, 2011 | | | 14-1 | |

Table 14-2 Geological Estimation UGE Codes and Descriptions | | | 14-7 | |

Table 14-3 Tonnage Factors | | | 14-8 | |

Table 14-4 TCU Capping Levels | | | 14-9 | |

Table 14-5 ASCu Capping Levels | | | 14-9 | |

Table 14-6 TCU Composite Statistics By Geological Domain (UGE) | | | 14-11 | |

Table 14-7 %TCu Variogram Parameters | | | 14-15 | |

Table 14-8 %TCu Estimation Search Ellipse Parameters | | | 14-19 | |

Table 15-1 Mineral Reserves – December 31, 2011 | | | 15-1 | |

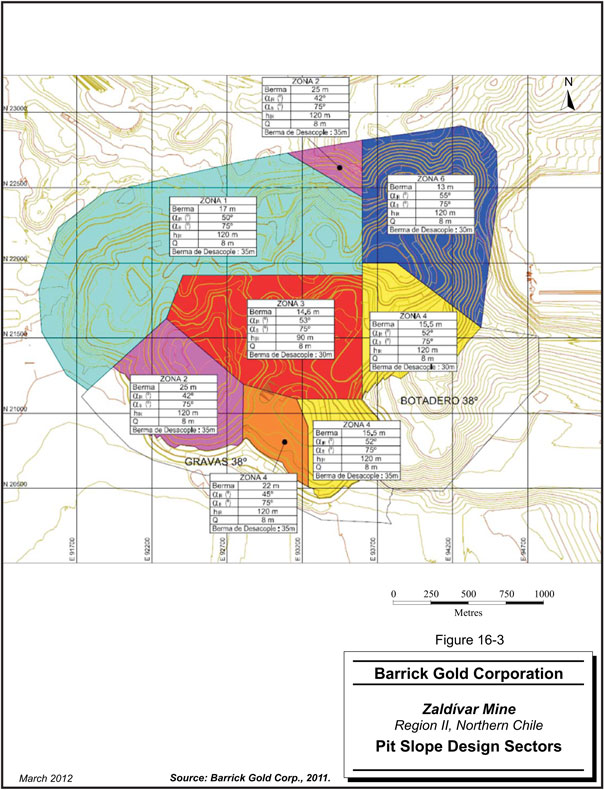

Table 16-1 Mine Design Parameters | | | 16-4 | |

Table 16-2 Mine Production Schedule | | | 16-7 | |

Table 16-3 Mine Equipment Fleet | | | 16-9 | |

Table 17-1 Metallurgical Model Algorithms | | | 17-8 | |

Table 21-1 Capital Costs | | | 21-1 | |

Table 21-2 Mine Operating Costs | | | 21-2 | |

Table 21-3 Unit Process Operating Costs | | | 21-2 | �� |

Table 21-4 G&A Costs | | | 21-3 | |

Table 21-5 Manpower | | | 21-3 | |

LIST OF FIGURES

| | | | |

| | | PAGE | |

Figure 4-1 Location Map | | | 4-3 | |

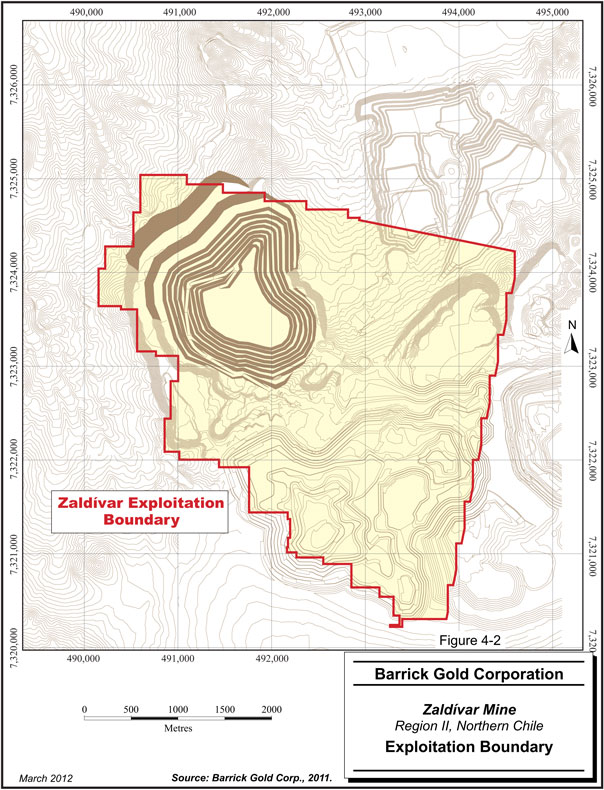

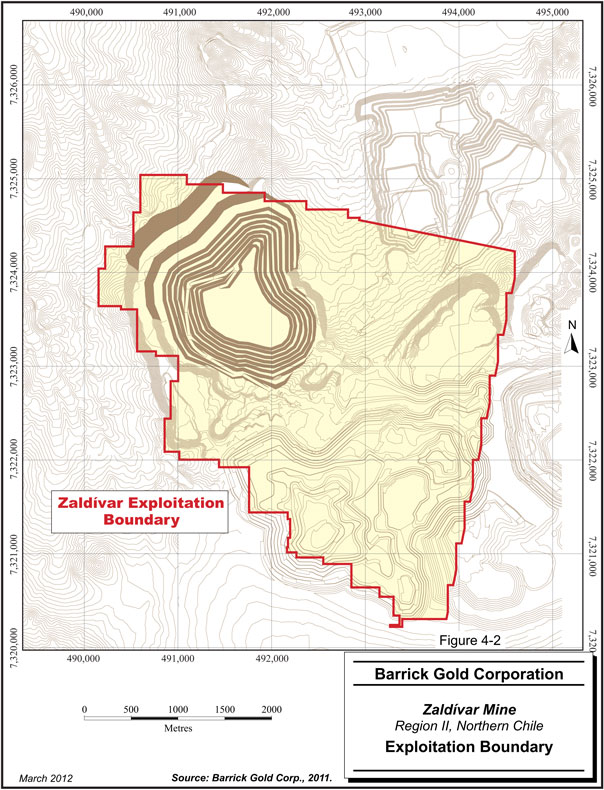

Figure 4-2 Zaldívar Exploitation Boundary | | | 4-4 | |

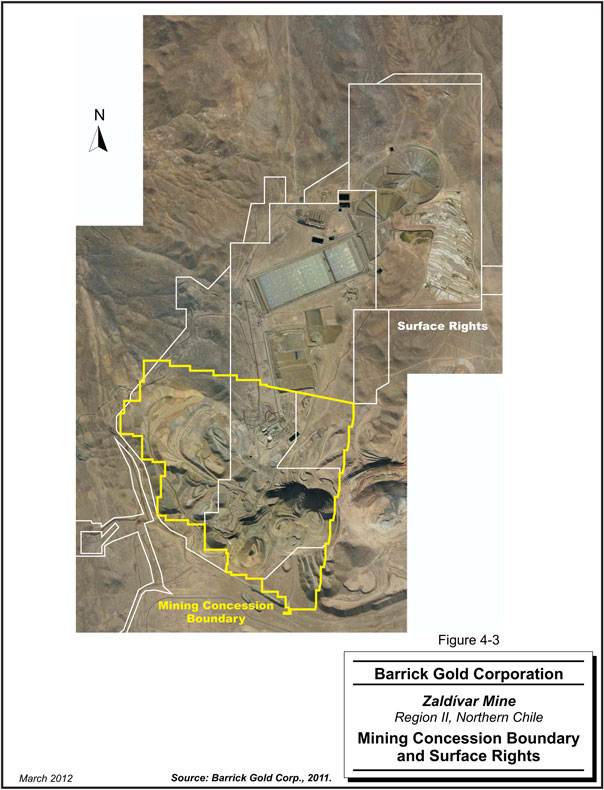

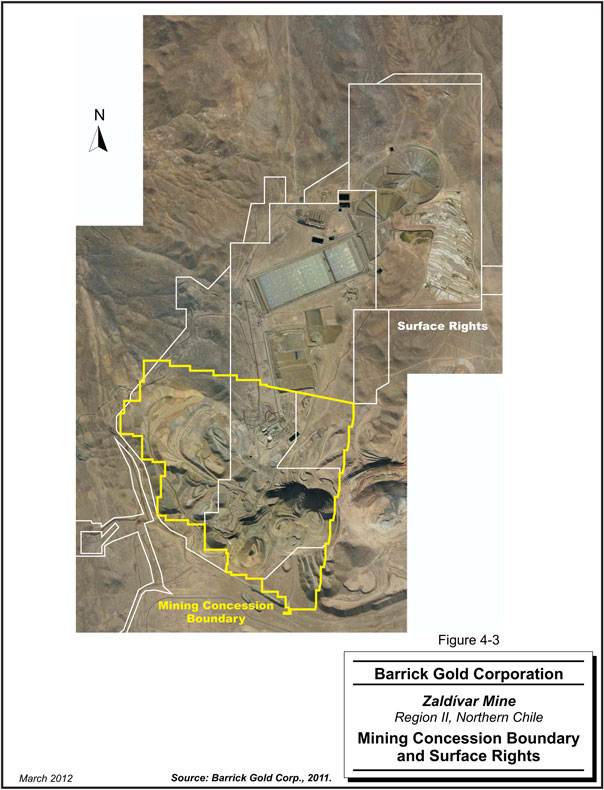

Figure 4-3 Mining Concession Boundary and Surface Rights | | | 4-5 | |

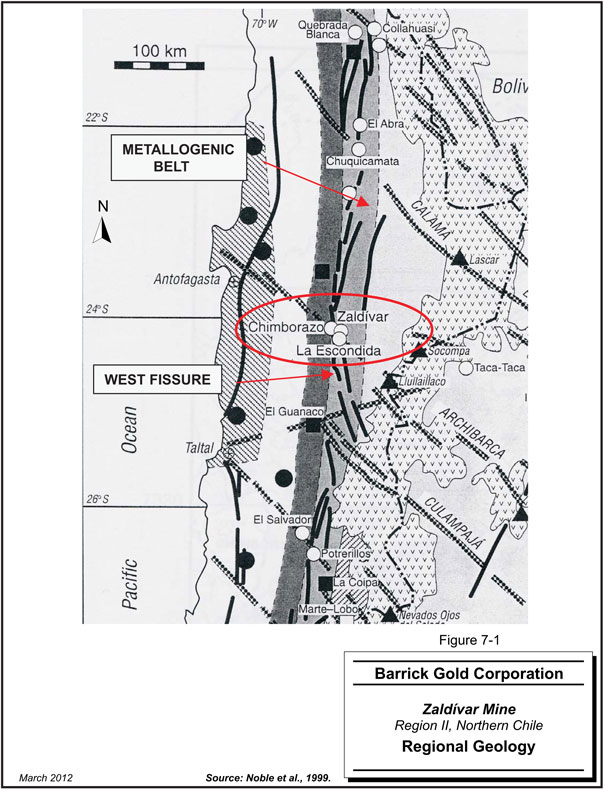

Figure 7-1 Regional Geology | | | 7-2 | |

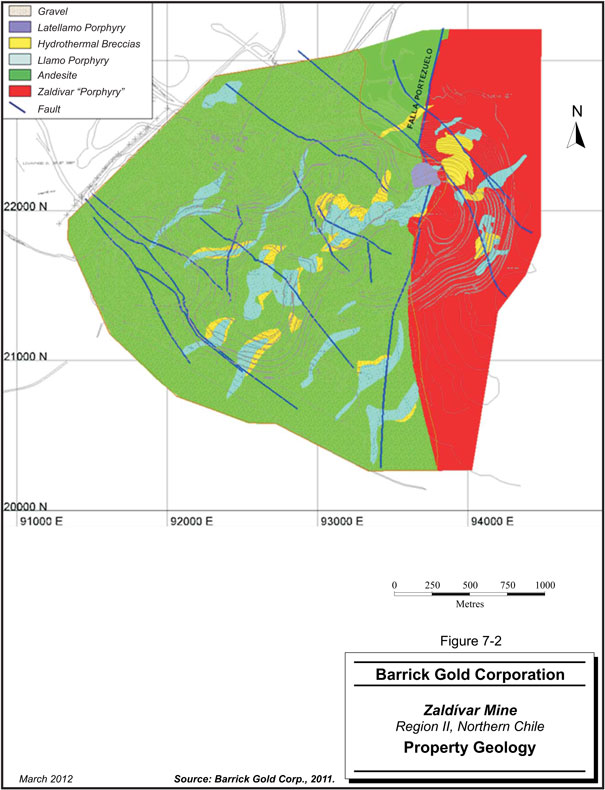

Figure 7-2 Property Geology | | | 7-4 | |

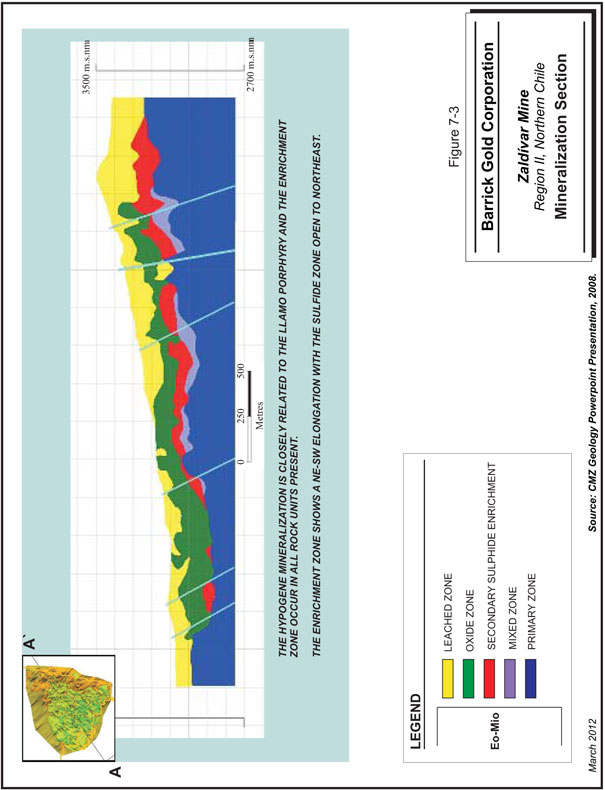

Figure 7-3 Mineralization Section | | | 7-8 | |

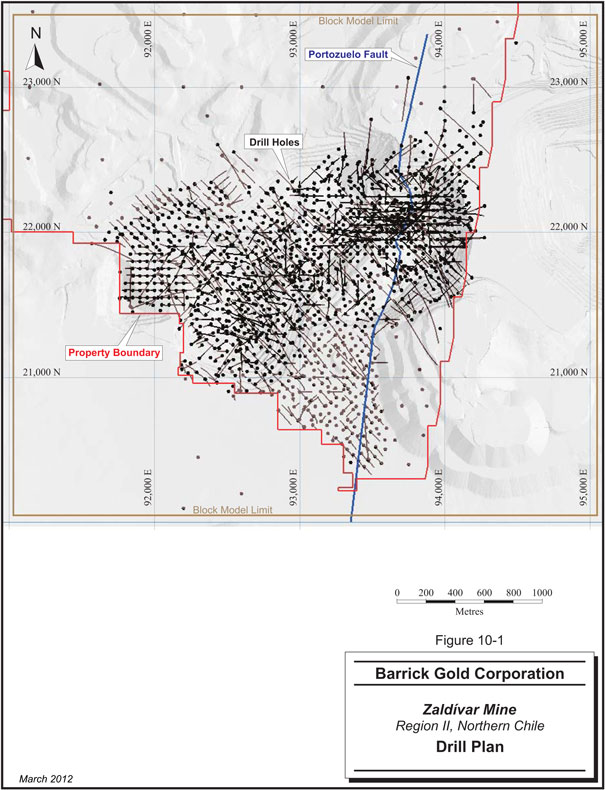

Figure 10-1 Drill Plan | | | 10-4 | |

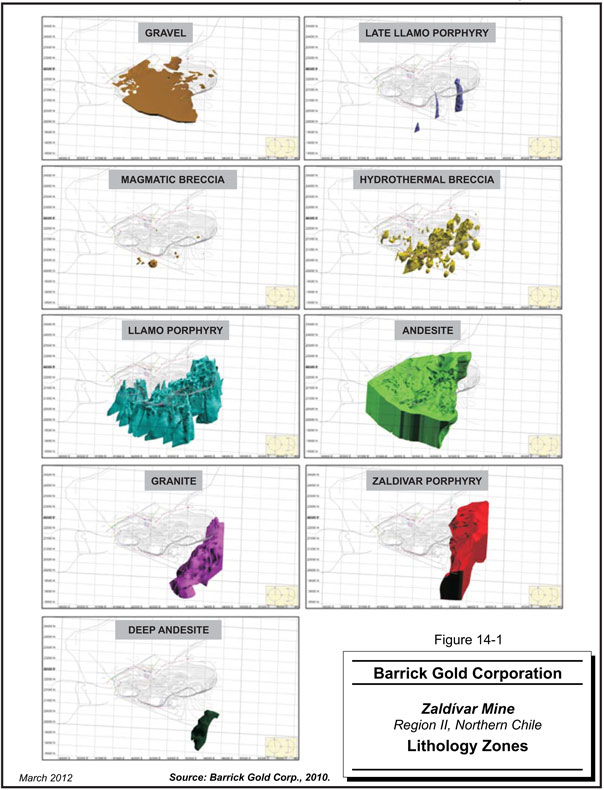

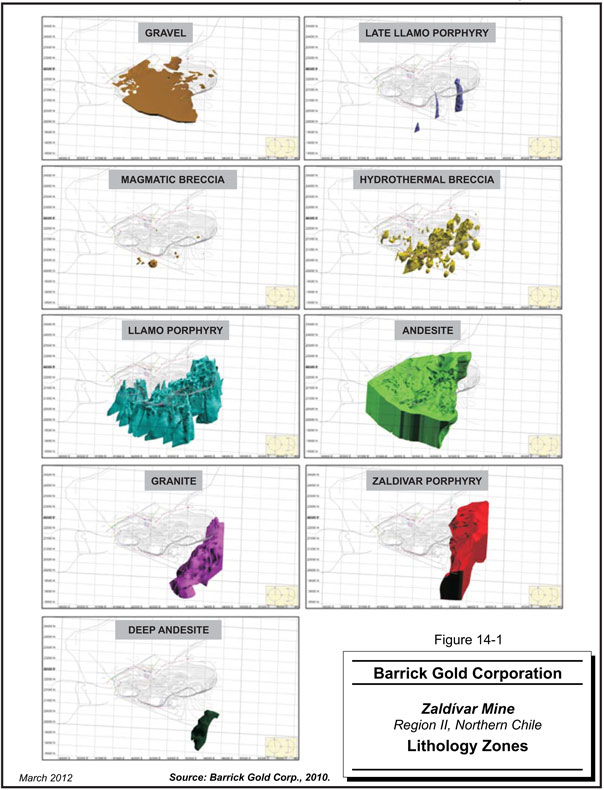

Figure 14-1 Lithology Zones | | | 14-4 | |

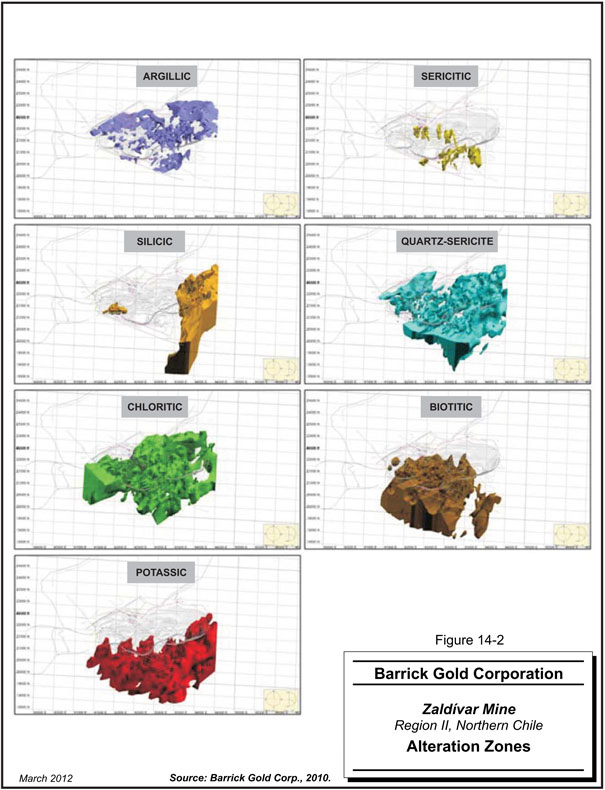

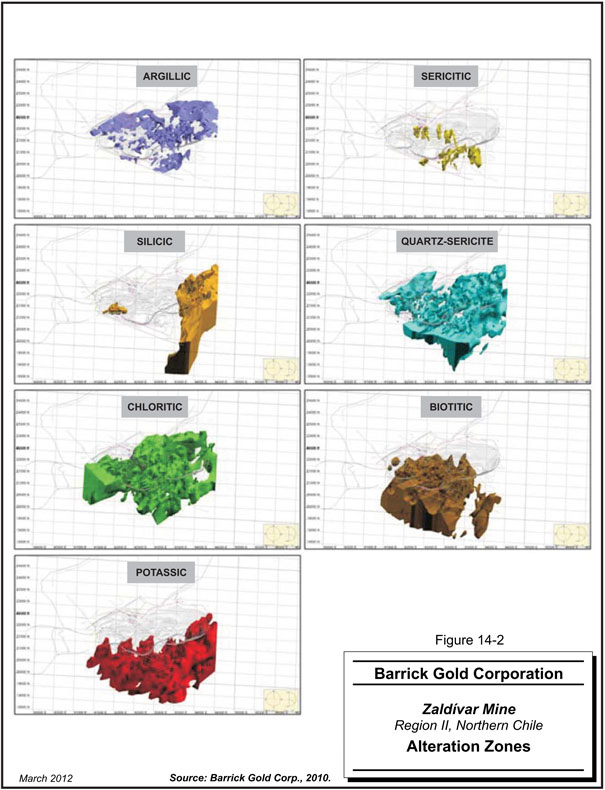

Figure 14-2 Alteration Zones | | | 14-5 | |

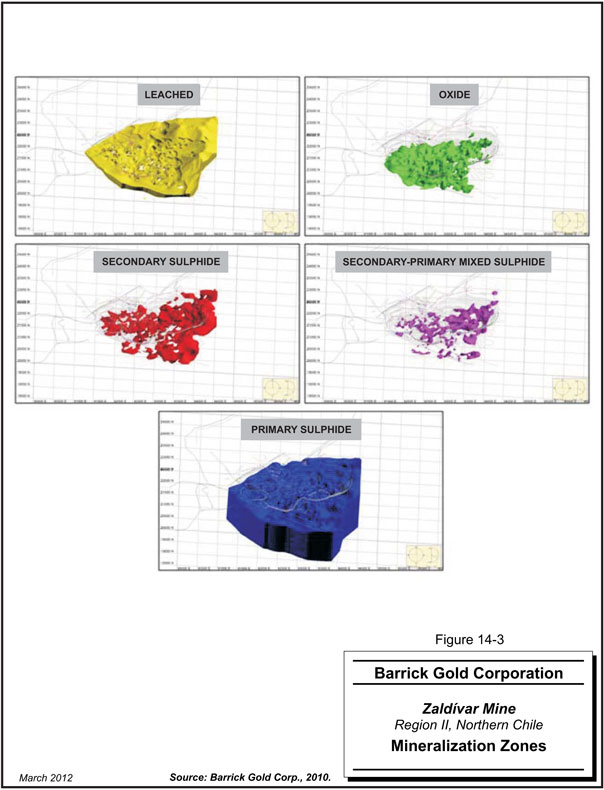

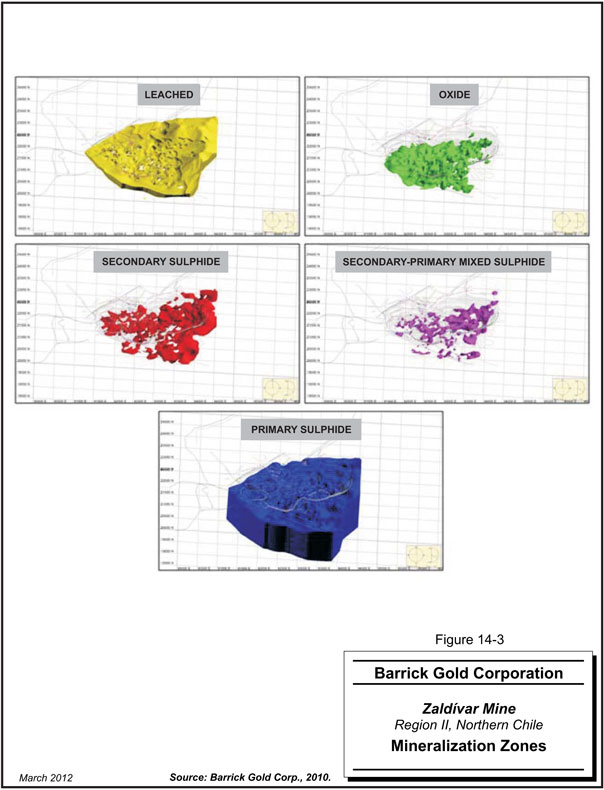

Figure 14-3 Mineralization Zones | | | 14-6 | |

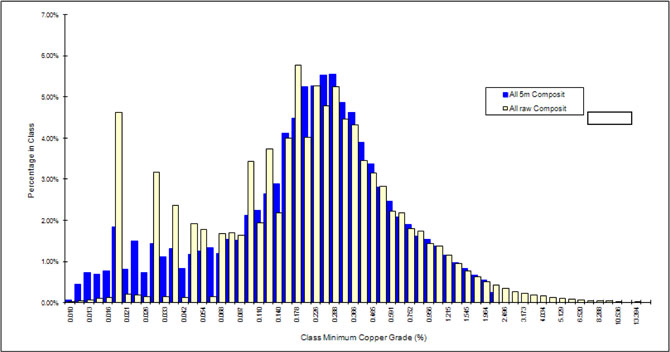

Figure 14-4 Frequency Distribution of TCu Composites Versus Raw Sample Data | | | 14-10 | |

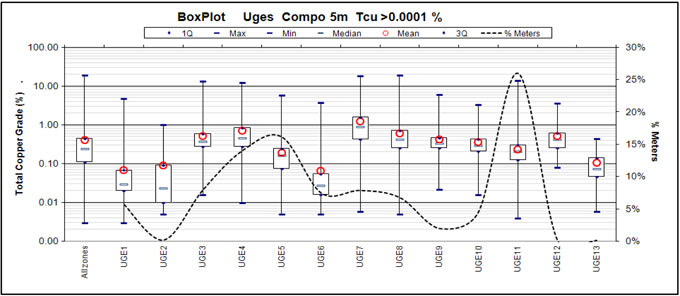

Figure 14-5 Boxplot of TCu Composites for Each UGE | | | 14-11 | |

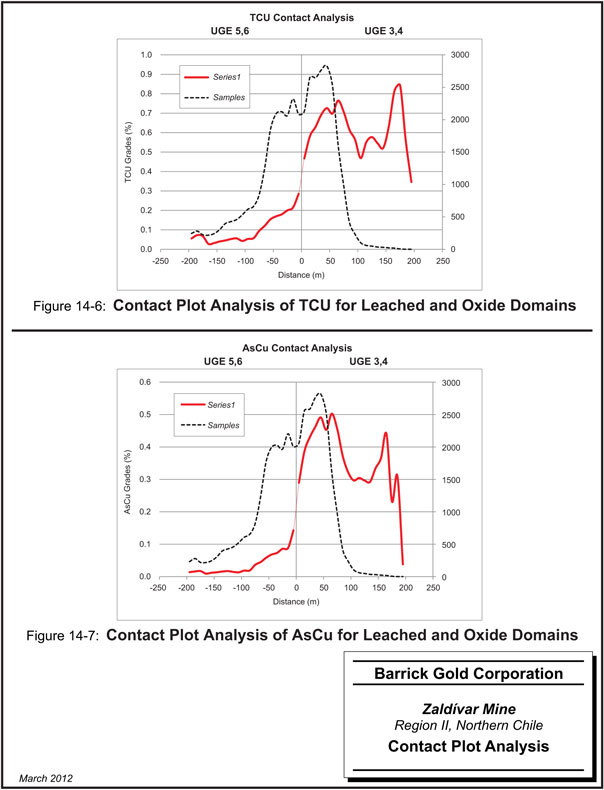

Figure 14-6 Contact Plot Analysis of TCu for Leached and Oxide Domains | | | 14-13 | |

Figure 14-7 Contact Plot Analysis of ASCu for Leached and Oxide Domains | | | 14-13 | |

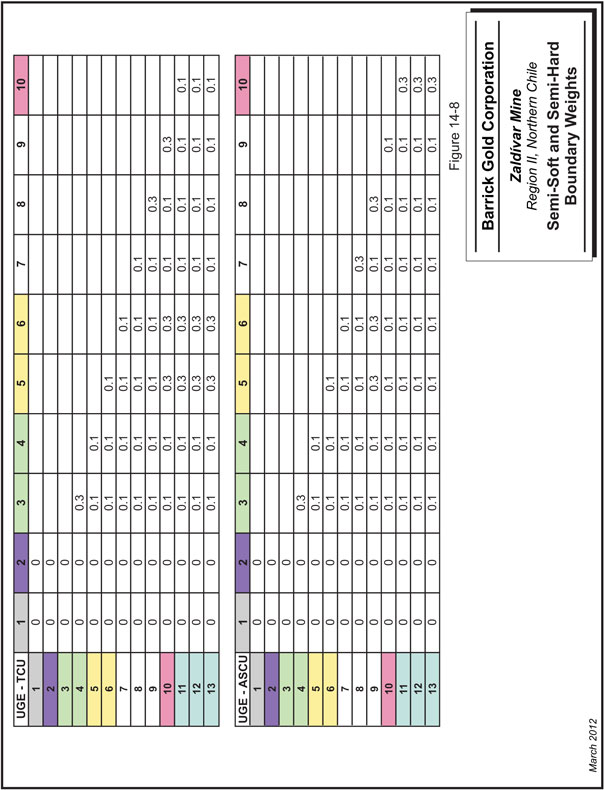

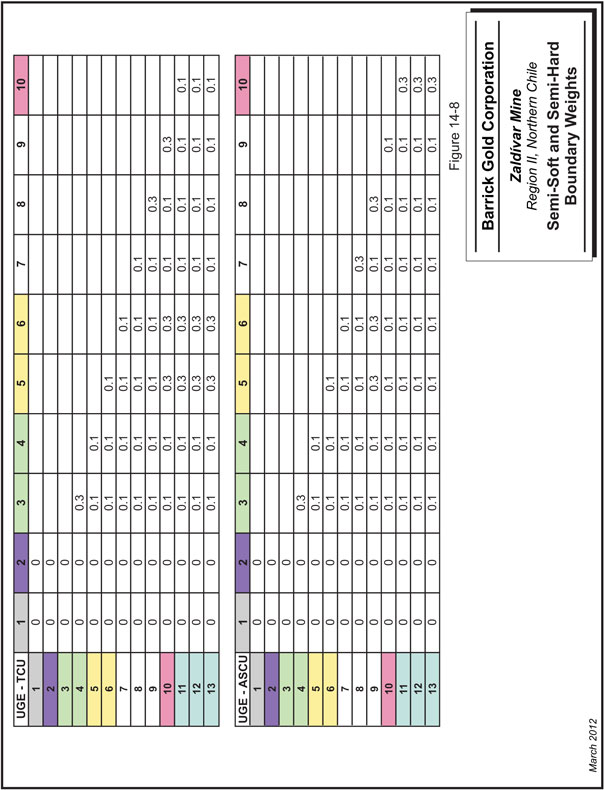

Figure 14-8 Semi-Soft and Semi-Hard Boundary Weights | | | 14-14 | |

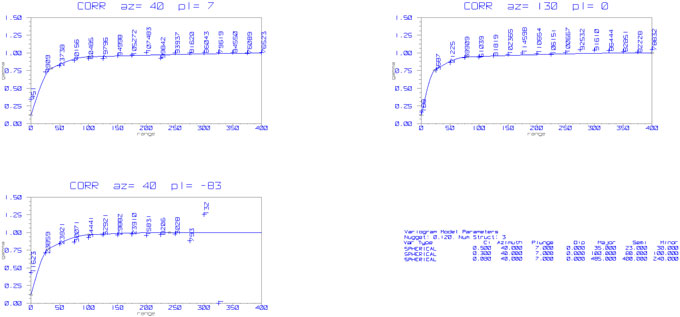

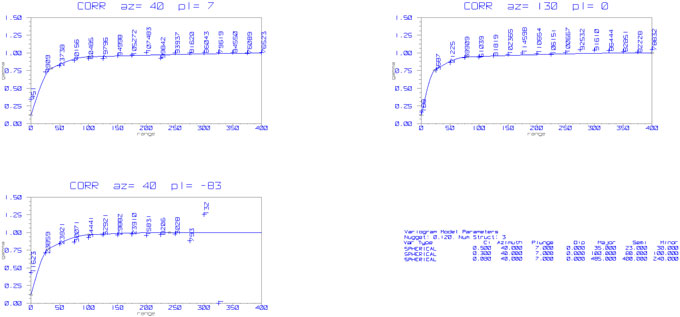

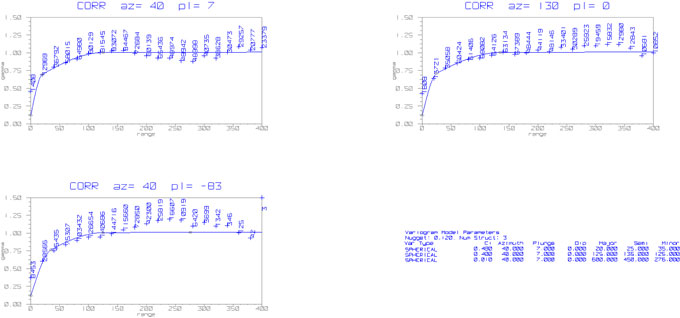

Figure 14-9 TCu Correlogram Models for UGE 3 | | | 14-16 | |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page iii |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

| | | | |

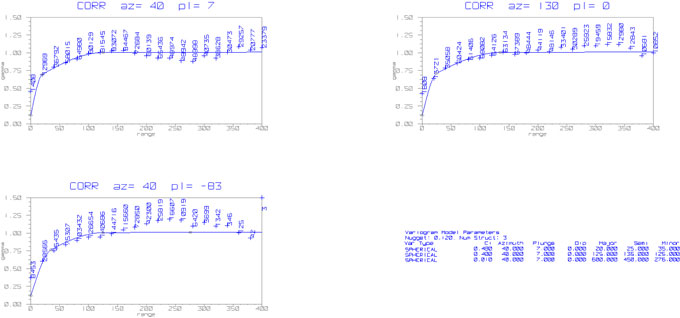

Figure 14-10 TCu Correlogram Models for UGE 7 | | | 14-17 | |

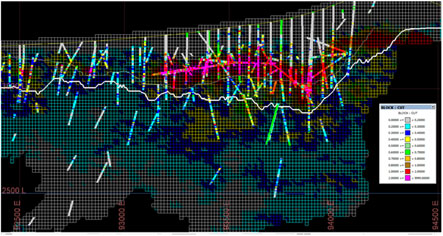

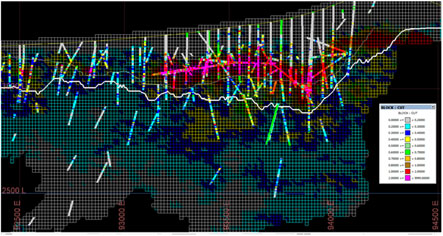

Figure 14-11 TCu Blocks and Assays—Section 22,000N | | | 14-20 | |

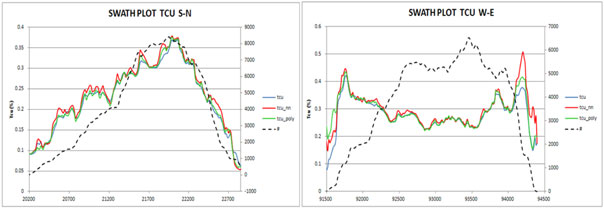

Figure 14-12 Swath Plots | | | 14-21 | |

Figure 14-13 TCu Correlogram for UGE 7 | | | 14-23 | |

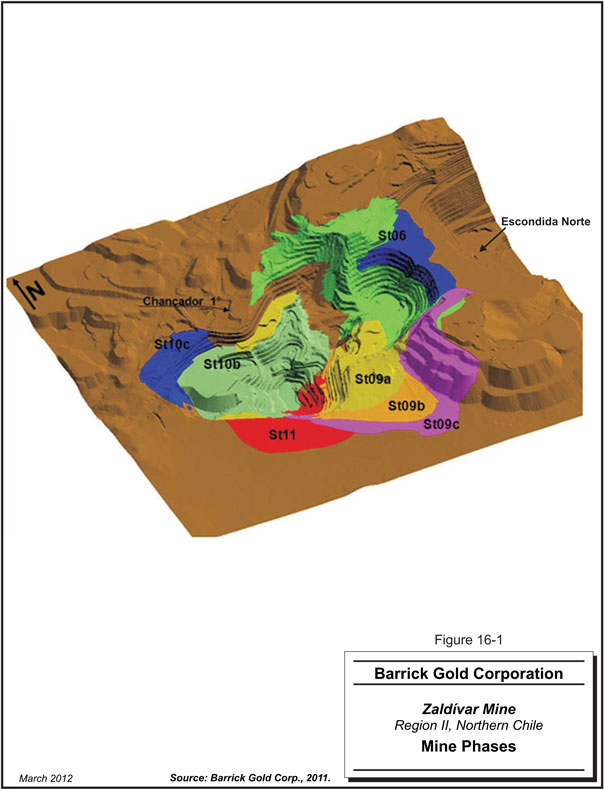

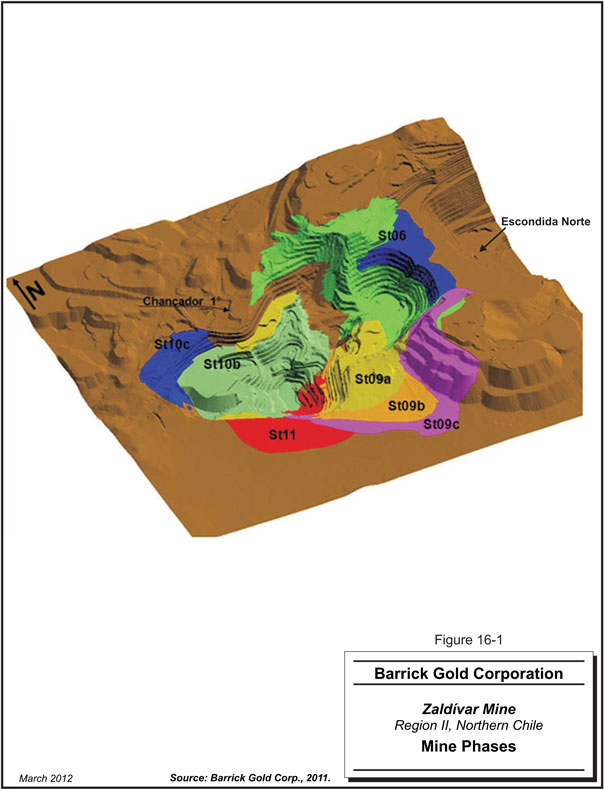

Figure 16-1 Zaldívar Mine Phases | | | 16-2 | |

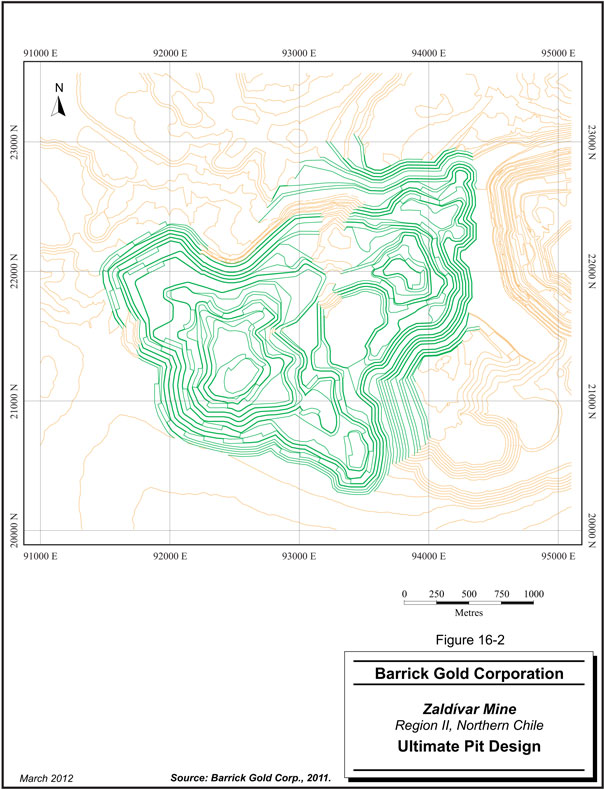

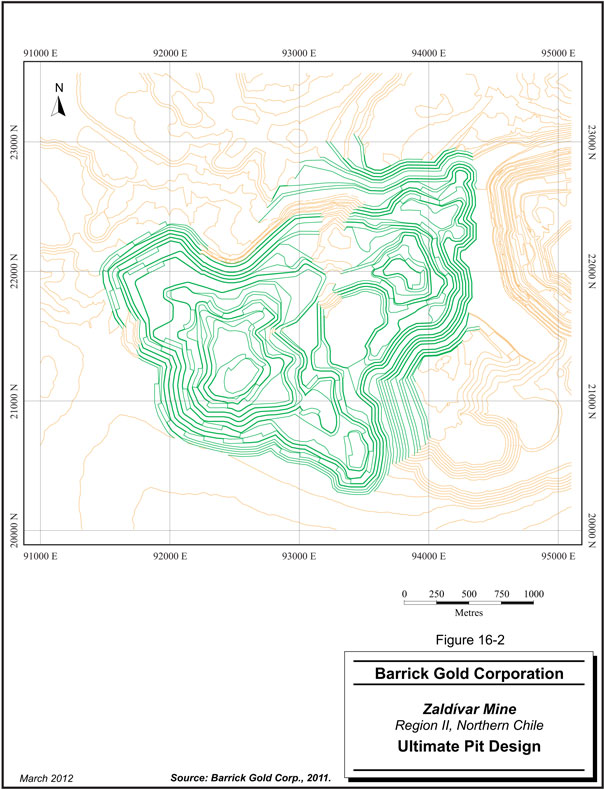

Figure 16-2 Ultimate Pit Design | | | 16-5 | |

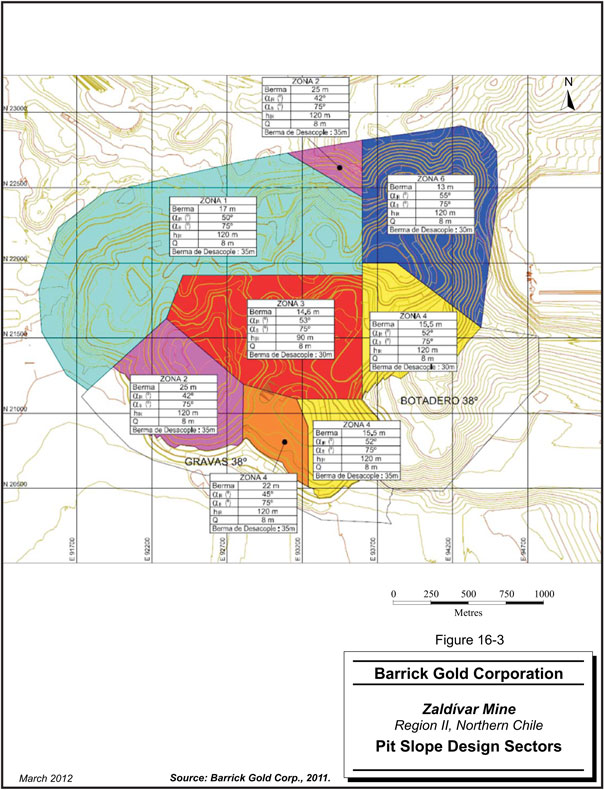

Figure 16-3 Pit Slope Design Sectors | | | 16-6 | |

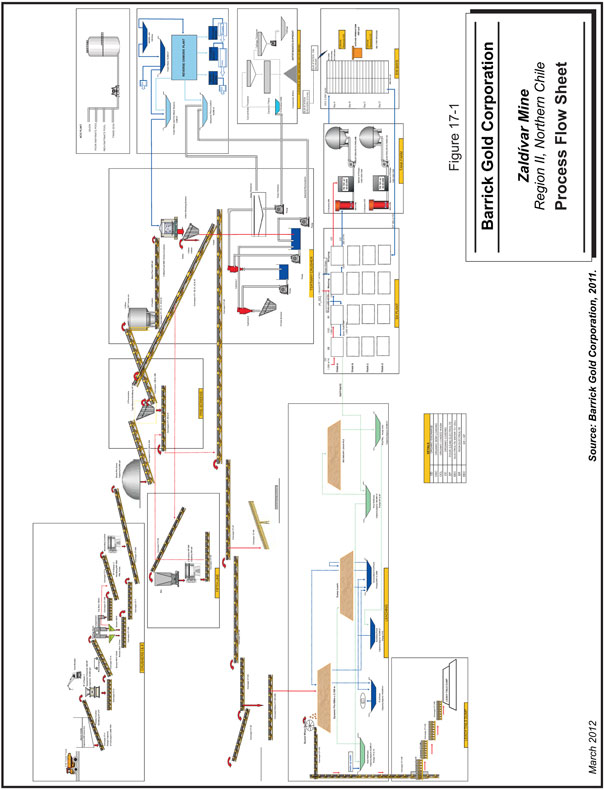

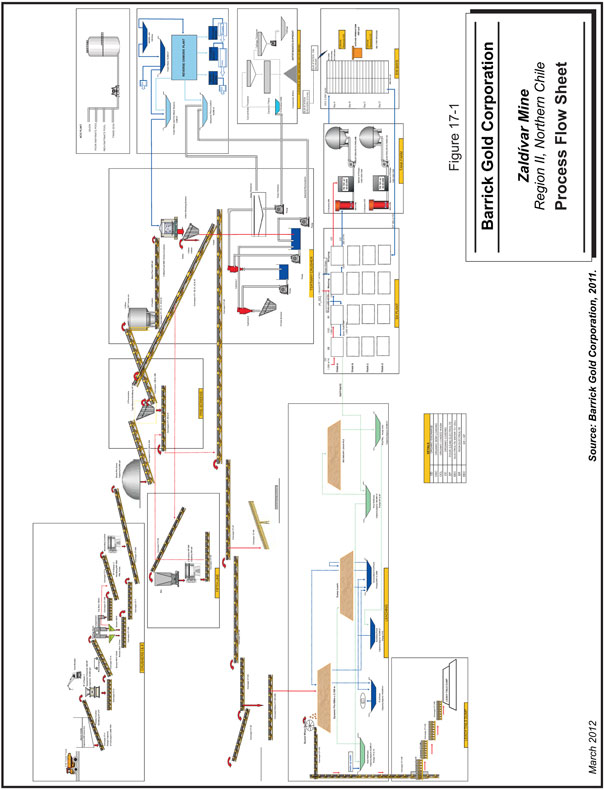

Figure 17-1 Process Flow Sheet | | | 17-3 | |

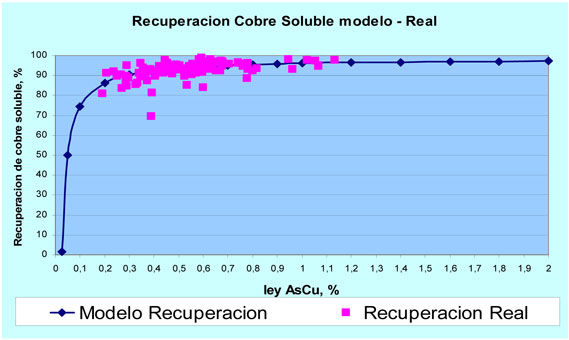

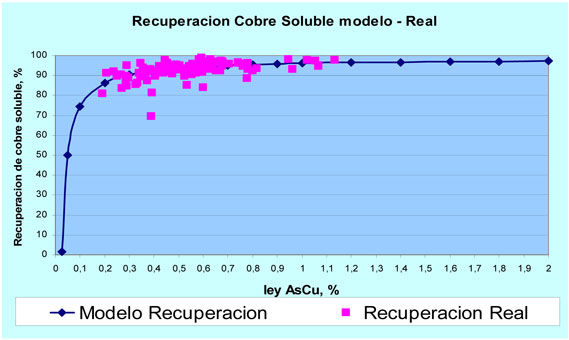

Figure 17-2 ASCu Recovery vs. ASCu Head Grade | | | 17-5 | |

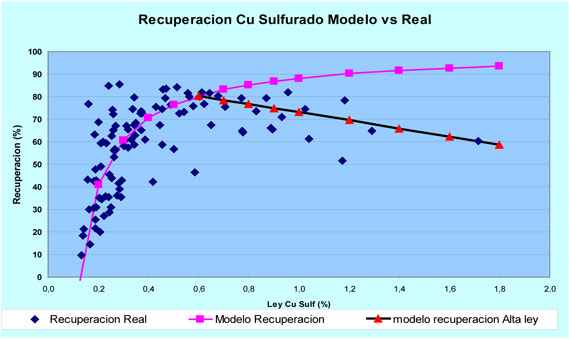

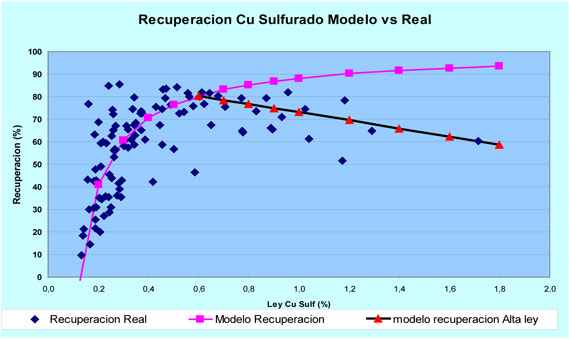

Figure 17-3 SCu Recovery vs. SCu Head Grade | | | 17-6 | |

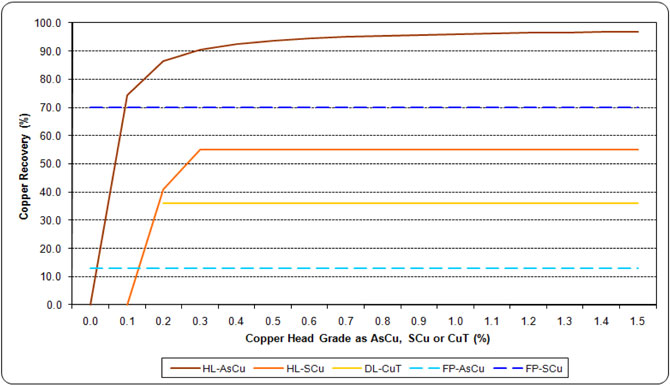

Figure 17-4 Metallurgical Recovery Model Curves | | | 17-9 | |

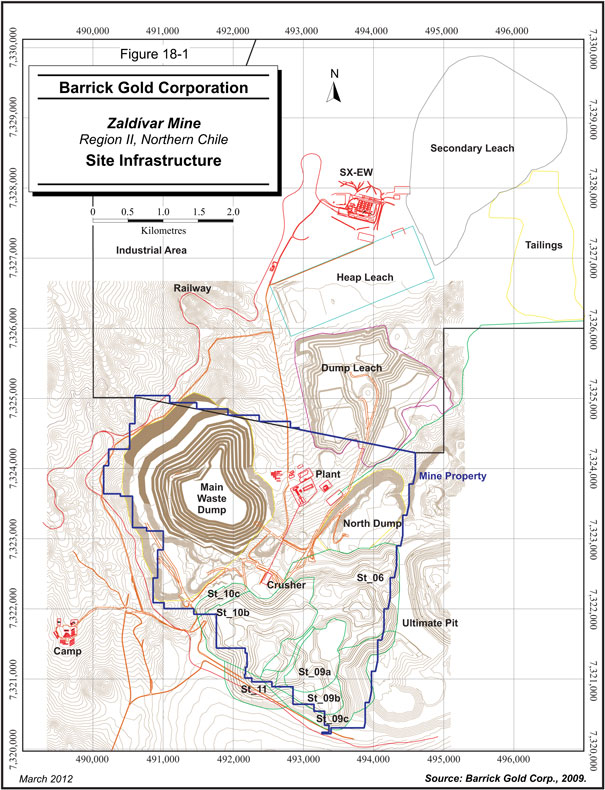

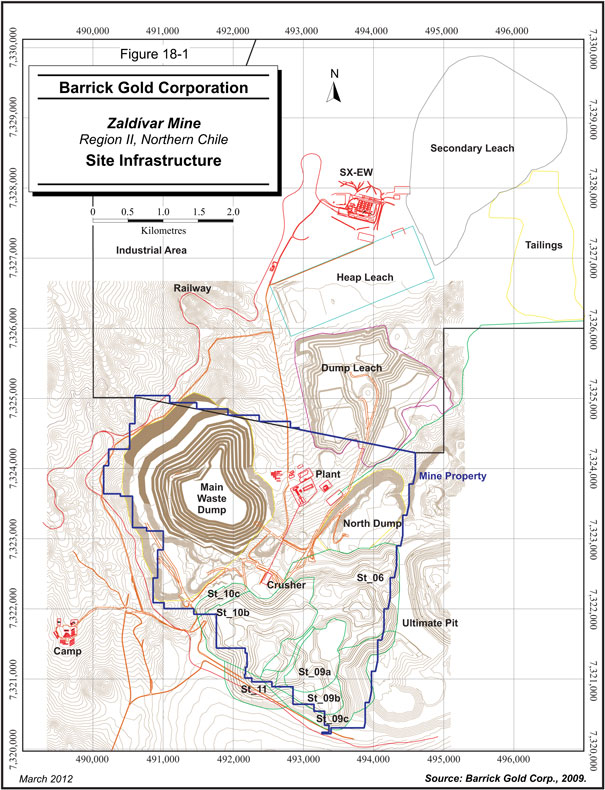

Figure 18-1 Site Infrastructure | | | 18-3 | |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page iv |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

1 SUMMARY

EXECUTIVE SUMMARY

Roscoe Postle Associates Inc. (RPA) was retained by Barrick Gold Corporation (Barrick) to prepare an independent Technical Report on the Zaldívar copper operation (the Project), located in northern Chile. The purpose of this report is to support public disclosure of Mineral Resource and Mineral Reserve estimates at the Project as of December 31, 2011. This Technical Report conforms to National Instrument 43-101 (NI 43-101) Standards of Disclosure for Mineral Projects. RPA visited the Zaldívar Mine on October 24 to 27, 2011.

The Zaldívar Mine is managed and operated by Compañía Minera Zaldívar Ltda. (CMZ), which is 100% owned by Barrick. Zaldívar is a large scale open pit operation utilizing a traditional truck and shovel fleet. Mining is carried out from one open pit at a rate of 83 million tonnes per annum (Mtpa), consisting of 22 Mtpa of crushed ore, 15 Mtpa of dump leach ore, and 46 Mtpa of waste. The ultimate pit will measure approximately 2.8 km east to west, 2.6 km north to south, and have an average depth of approximately 630 m. A total of 578 million tonnes grading 0.52% Cu representing 6.6 billion pounds of contained copper and 3.8 billion pounds of recoverable copper is projected to be produced between 2012 and 2028.

Table 1-1 summarizes open pit Mineral Resources exclusive of Mineral Reserves as of December 31, 2011.

TABLE 1-1 MINERAL RESOURCES – DECEMBER 31, 2011

Barrick Gold Corporation – Zaldívar Mine

| | | | | | | | | | | | |

Category | | Tonnage

(Mt) | | | Grade

(% Cu) | | | Contained

Metal

(Mlb Cu) | |

Measured | | | 71.3 | | | | 0.432 | | | | 679.5 | |

Indicated | | | 53.5 | | | | 0.462 | | | | 545.5 | |

| | | | | | | | | | | | |

Total Measured and Indicated | | | 124.8 | | | | 0.445 | | | | 1,225.0 | |

| | | |

Inferred | | | 37 | | | | 0.54 | | | | 439 | |

Notes:

| 1. | CIM definitions were followed for Mineral Resources. |

| 2. | Mineral Resources are estimated based on a profit model using a copper price of US$3.25 per pound and a CLP/US$ exchange rate of 500. |

| 3. | Mineral Resources are exclusive of Mineral Reserves. |

| 4. | Numbers may not add due to rounding. |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 1-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

Table 1-2 summarizes the Zaldívar end of year 2011 (EOY2011) Mineral Reserve estimate.

TABLE 1-2 MINERAL RESERVES – DECEMBER 31, 2011

Barrick Gold Corporation – Zaldívar Mine

| | | | | | | | | | | | |

Category | | Tonnage

(Mt) | | | Cu (%) | | | Contained Metal

(Mlb Cu). | |

Proven | | | 386.3 | | | | 0.528 | | | | 4,496.5 | |

Probable | | | 191.7 | | | | 0.498 | | | | 2,105.5 | |

| | | | | | | | | | | | |

Proven & Probable | | | 578.0 | | | | 0.518 | | | | 6,602.0 | |

Notes:

| 1. | CIM definitions were followed for Mineral Reserves. |

| 2. | Mineral Reserves are estimated at a variable cut-off grade. |

| 3. | Mineral Reserves are estimated using an average long-term copper price of US$2.75 per pound and a CLP/US$ exchange rate of 500. |

| 4. | Numbers may not add due to rounding. |

CONCLUSIONS

RPA offers the following conclusions:

GEOLOGY AND MINERAL RESOURCE ESTIMATION

| | • | | The EOY2011 Measured and Indicated Mineral Resource is 125 million tonnes at a total copper grade of 0.445% containing 1.225 billion pounds of copper. The Mineral Resources are exclusive of Mineral Reserves. |

| | • | | The EOY2011 Inferred Mineral Resource is 37 million tonnes at a total copper grade of 0.54% containing 439 million pounds of copper. |

| | • | | Mineral Resource estimates have been prepared utilizing acceptable estimation methodologies. The classification of Measured, Indicated, and Inferred Resources, stated in Table 1-1, meet the requirements of NI 43-101 and CIM Definition Standards for Mineral Resources and Mineral Reserves dated November 27, 2010 (CIM definitions). |

| | • | | The methods and procedures utilized by CMZ at the Zaldívar Mine to gather geological, geotechnical, assaying, density, and other information are reasonable and meet generally accepted industry standards. Standard operating protocols are well documented and updated on a regular basis for most of the common tasks. CMZ carries out regular comparisons with blasthole data, previous models, and production reconciliation results to calibrate and improve the resource modelling procedures. |

| | • | | The current drill hole database is reasonable for supporting a resource model for use in Mineral Resource and Mineral Reserve estimation. |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 1-2 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

| | • | | CMZ has conducted the exploration and development sampling and analysis programs using standard practices, providing generally reasonable results. The resulting data can effectively be used for the estimation of Mineral Resources and Mineral Reserves. |

| | • | | Overall, RPA is of the opinion that CMZ has done very high quality work that exceeds industry practice. |

MINING AND MINERAL RESERVES

| | • | | The EOY2011 Proven and Probable Mineral Reserves are 578 million tonnes at a total copper grade of 0.518% containing 6.602 billion pounds of copper. |

| | • | | The Mineral Reserve estimates have been prepared utilizing acceptable estimation methodologies and the classification of Proven and Probable Reserves, stated in Table 1-2, conform to CIM definitions. |

| | • | | The operating data provided by CMZ and the supporting documents were prepared using standard industry practices and provide reasonable results and conclusions. |

| | • | | Standard operating protocols are well documented and updated on a regular basis for most of the common tasks. |

| | • | | Recovery and cost estimates are based upon operating data and engineering to support a Mineral Reserve statement. Economic analysis using these estimates generates a positive cash flow, which supports a statement of Mineral Reserves. |

| | • | | The current Zaldívar Life of Mine (LOM) plan provides reasonable results and, in RPA’s opinion, meets the requirements for statement of Mineral Reserves. In addition to the Mineral Reserves in the LOM plan, there are Mineral Resources and potential sulphide resources that represent opportunities for the future. |

PROCESSING

| | • | | The process includes heap leaching with copper recovery in a solvent extraction/electrowinning (SX/EW) process in the form of copper cathode. |

| | • | | RPA has reviewed the recovery model and finds the development of the recovery formulas and the reconciliation to historic data to be reasonable. The metallurgical testwork, which supports the models, is also reasonable and adequate. |

| | • | | In 2012, a revision will be made to the recovery model. The revised recovery model will account for the current operational parameters and results. |

ENVIRONMENTAL CONSIDERATIONS

| | • | | The Project has approximately 140 active permits. All permits are in good standing and there is an extensive environmental monitoring program to ensure compliance with the requirements of these permits. |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 1-3 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

RECOMMENDATIONS

The Zaldívar LOM plan provides reasonable results and, in RPA’s opinion, meets the requirements for statement of Mineral Reserves. This Technical Report is based on the LOM plan. In addition to the LOM plan, there are additional resources and potential resources that should be given further consideration in the future. Below is a list of recommendations to consider:

MINING

| | • | | The LOM plan is robust and Barrick should proceed to implement the plan as presented. |

| | • | | There is a known primary sulphide resource below the current Proven plus Probable oxide and secondary sulphide reserves. Additional work to drill these resources and develop a Feasibility Study for the primary sulphide should also proceed. |

ENVIRONMENTAL CONSIDERATIONS

| | • | | Evaluation of permit requirements, developing baseline studies, and starting a new Environmental Impact Assessment (EIA) for the sulphide project should proceed in unison with the primary sulphide feasibility study. |

ECONOMIC ANALYSIS

RPA has performed an economic analysis of the Zaldívar Mine using the estimates presented in this report and confirms that the outcome is a positive cash flow that supports the statement of Mineral Reserves.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 1-4 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

TECHNICAL SUMMARY

PROPERTY DESCRIPTION AND LOCATION

Zaldívar is located in the Andean Precordillera in Region II of northern Chile, approximately 1,400 km north of Santiago and 196 km southeast of the city of Antofagasta, a deepwater port with bulk loading and unloading facilities. Zaldívar is connected to Antofagasta by a paved highway as well as the Antofagasta Salta narrow-gauge railway. Antofagasta is served by national airlines, with several flights daily providing a link to Santiago and other major centres. The mine is located at an altitude of 3,200 m.

LAND TENURE

The Zaldívar mineral rights boundary is defined by ten overlapping exploitation concessions that have a combined area of approximately 1,295 ha. The mine is managed and operated by CMZ, which is 100% owned by Barrick through its acquisition of Placer on March 3, 2006. There are no royalties payable. Zaldívar is surrounded by concessions owned by Minera Escondida Limitada (MEL). CMZ has a number of easement or surface rights agreements with MEL. MEL has authorized CMZ to build infrastructure such as heap leach pads, the SX/EW plant, tailings and other facilities within the area covered by the MEL concessions.

EXISTING INFRASTRUCTURE

The Project infrastructure and services have been designed to support an operation of 65,000 tpd of ore to dynamic heap leach processing and a nominal 240,000 tpd of total material mined.

The existing infrastructure includes:

| | • | | Mine camp facilities sufficient for the current Zaldívar workforce of 863 people and the 1,146 contractors and consultants. |

| | • | | A private two-lane paved road, shared by three major mines, Zaldívar, Escondida, and El Peñón, that leads to the Zaldívar camp and offices. |

| | • | | Mine and heap leach facilities and an SX/EW plant located at the mine site. |

| | • | | On-site facilities, including safety/security/first aid/emergency response building, assay laboratory, plant guard house, dining facilities, and offices. |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 1-5 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

| | • | | Related mine services facilities (truckshop, truck wash facility, warehouse, fuel storage and distribution facilities, reagent storage and distribution facilities) and other services facilities to support operations. |

| | • | | Process water supplied from groundwater at Negrillar, 130 km east of Zaldívar. |

| | • | | Rail service that transports sulphuric acid to the mine and copper cathode to the port of Antofagasta. |

| | • | | A dual-circuit, 220 kV, 230 km long transmission line. |

HISTORY

The Zaldívar deposit was discovered in 1979 and exploration drilling was carried out in 1981-1984. In 1989, the mining rights were sold to Sociedad Minera La Cascada Limitada, which in November 1989 transferred them to Outokumpu under a sales contract with Outokumpu Resources (Services) Limited. In December 1992, Outokumpu announced the formation of a 50/50 joint venture with Placer, at which time a joint venture company, CMZ, was formed.

In November 1995, commercial production started. The capital cost of the Project was at approximately $600 million. In December 1999, Placer acquired Outokumpu’s 50% interest in CMZ. In March 2006, Barrick acquired Placer and became owner of the Project.

GEOLOGY AND MINERALIZATION

The Zaldívar porphyry copper deposit is situated on the western margin of the Atacama Plateau in northern Chile. The deposit is part of a large Tertiary porphyry copper system that also includes the Escondida porphyry copper deposit. This porphyry complex occurs within the West Fissure structural system, a major regional feature that has controlled the emplacement of some of the largest porphyry copper deposits in northern Chile. The West Fissure system extends for approximately 1,000 km and separates Paleozoic rocks to the east from Mesozoic and Paleocene rocks to the west.

The Zaldívar deposit occurs at the intersection of three major sets of faults striking north-south, northwest-southeast, and northeast-southwest. This structural setting has controlled the emplacement of the intrusives and hypogene mineralization as well as leaching and secondary enrichment.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 1-6 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

There are three main lithologic units at Zaldívar: the Zaldívar porphyry, the andesite unit, and the Llamo porphyry.

Most of the copper at Zaldívar occurs in a blanket of oxide and secondary sulphide mineralization that overlies deeper primary sulphide mineralization. The oxide mineralization mostly occurs in the andesite unit, whereas the secondary sulphide mineralization generally occurs in the Zaldívar porphyry. The most economically important mineralization types are secondary sulphide (chalcocite) and oxide (brochantite and chrysocolla). CMZ is currently investigating the economic potential of the primary sulphide mineralization, which consists of pyrite, chalcopyrite, bornite, and molybdenite.

EXPLORATION POTENTIAL

Zaldívar is a mature operation with a relatively small mining concession area. The major exploration programs took place prior to the completion of the feasibility study in 1993. A major drilling campaign was completed in 2000 to define the limits of the deposit within the mining concessions. That campaign marked the end of exploration activity targeting oxide mineralization at Zaldívar. More recently, deep drilling campaigns have targeted the underlying sulphide mineralization, Zaldívar Deeps Sulphide Cu-Mo-Au-Ag Project.

CMZ built a new block model for this primary sulphide mineralization as part of the 2010 mid-year update. There appears to be sufficient drill holes and technical studies completed to demonstrate that the mineralization meets the requirement for “reasonable prospects for economic extraction”.

MINERAL RESOURCES

The EOY 2011 open pit Mineral Resources exclusive of Mineral Reserves as stated in Table 1-1 include a Measured and Indicated Mineral Resource of 124.8 million tonnes grading 0.445% Cu containing 1.255 billion pounds of copper and an Inferred Mineral Resource of 37 million tonnes grading 0.54% Cu containing 439 million pounds of copper. The resource model was prepared by Barrick Senior Resource Geologist Cristian Monroy under the supervision of Barrick Superintendent of Resource and Reserve Modelling Benjamin Sanfurgo.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 1-7 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

RPA reviewed the resource assumptions, input parameters, geological interpretation, and block modelling procedures and is of the opinion that the Mineral Resource estimate is appropriate for the style of mineralization and that the resource model is reasonable and acceptable to support the EOY2011 Mineral Resource and Mineral Reserve estimates.

RPA is not aware of any environmental, permitting, legal, title, taxation, socio-economic, marketing, political, or other issues that could materially affect the Mineral Resource and Mineral Reserve estimates.

MINERAL RESERVES

RPA reviewed the reported resources, production schedules, and cash flow analysis to determine if the resources meet the CIM definitions to be classified as reserves. Based on this review, it is RPA’s assessment that the Measured and Indicated Mineral Resource within the final pit design at Zaldívar can be classified as Proven and Probable Mineral Reserves.

The open pit reserves are estimated to be 578 million tonnes at 0.518% Cu, containing 6.602 billion pounds of copper and are classified as Proven and Probable Reserves as presented in Table 1-2.

MINING METHOD

The Zaldívar Mine is a traditional open pit truck/shovel operation. The open pit has seven phases remaining. The ultimate pit will measure approximately 2.8 km east to west, 2.6 km north to south, and have a maximum depth of approximately 630 m. Waste and ore are mined on 15 m benches.

The current mine life is from 2012 to 2028. Mine production is 83 Mtpa over the first eleven years and then decreasing thereafter. This includes a nominal 46 Mtpa of waste and is based only on mining and processing oxide and secondary sulphide ores. Metallurgical investigations are underway to evaluate further leaching of primary sulphide material and/or primary sulphide milling and flotation.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 1-8 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

There are three primary waste rock facilities, a heap leach facility, and a small tailings storage facility that handles tailings from the small flotation plant that processes fines from the primary heap leach crushing plant.

MINERAL PROCESSING

Processing is based on two heap leaching streams, one crushed and one ROM. Separation of the ore types is done by the mine department based on blasthole sample analysis. Primary processing is based on heap leaching a crushed material (80% passing 13 mm) utilizing a dynamic (on-off) heap leach facility. Additionally, marginal ores are processed through dump leaching at a ROM material size on a static pad. Pregnant solution from both leach pads is pumped to the SX/EW plant for metal extraction and production as copper cathodes. From the crushing circuit, 3% of the ore tonnage for the dynamic heap leach processing ends up in fines which are deposited in a sediment pond as a result of the washing system incorporated in the tertiary crushing system. These sediments are periodically processed through a small flotation plant and a copper concentrate is produced for sale.

The dynamic heap leach facility is based on a nominal 65,000 tpd operation (22 Mtpa). The ROM dump leach facility is based on the dynamic heap leach capacity and ore availability in the mine, and will average a nominal 15 Mtpa over the remaining mine life.

ENVIRONMENTAL, PERMITTING AND SOCIAL CONSIDERATIONS

The present operation of the Zaldívar Mine was approved in its original form called the “Zaldívar Project” in 1993 by the Comisión Regional del Medio Ambiente de la II Región de Antofagasta (COREMA). The project had, as its principal installation, an operating open pit mine, primary, secondary and tertiary crushing plants, a concentrating plant for fines, waste dumps, and tailings and a production line for copper cathodes that consists of a dynamic leach facility, ROM leach facility for low grade, and an SX/EW plant.

In 2009, an updated EIA was developed to optimize the mining processes and maintain production levels. The EIA was approved by COREMA in February 2010. On December 9, 2010, CMZ obtained its operational permits from the Servicio Nacional de Geología y Minería (SERNAGEOMIN) and expects to obtain other associated sectoral permits in due course.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 1-9 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

The Zaldívar Mine has approximately 140 active permits. All permits are in good standing. The mine runs an extensive environmental monitoring program to ensure compliance with the requirements of these permits. For the major environmental issues identified, management plans have been developed that include rehabilitation, site decommissioning, and closure.

Zaldívar operates under Barrick’s sustainability policy, which commits the operation to a corporate standard of environmental stewardship. This involves protecting human health, reducing the impact of mining on the ecosystem, and returning the site to a state compatible with a healthy environment. Zaldívar operates in an environmentally responsible manner with limited adverse impacts on the environment. Programs are in place that continuously monitor the process and surrounding areas and employ leak detection wells to detect any potential problems.

Mine closure plans are reviewed and analyzed annually. Current cost estimates for closure are $36.2 million.

CAPITAL AND OPERATING COST ESTIMATES

Remaining capital costs at Zaldívar are all primarily sustaining capital, which includes mine equipment replacement. Total remaining capital costs are a nominal $440 million. Mine prestripping capital of $193 million has been treated as an operating cost for the purposes of this Technical Report. Engineering studies for a primary sulphide flotation and process plant expansion are also included in the sustaining capital.

The Zaldívar Mine has been in production since November 1995. Operating costs are tracked and well understood. Mine operating costs are a nominal $1.47 per tonne of material mined or $3.12 per tonne of ore mined. Process operating costs are $7.35 per tonne ore processed and include the dynamic pad or heap leach and the dump leach, the crushing plant, acid, and all reagents. General and administrative costs (G&A) are $1.25 per tonne ore processed and include all management salaries, camp operating costs, and environmental, health and safety.

Zaldívar Mine site manpower is a nominal 2,000 people. Direct Zaldívar employees are only 863 with 1,146 contractors and consultants as of November 2011.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 1-10 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

2 INTRODUCTION

Roscoe Postle Associates Inc. (RPA) was retained by Barrick Gold Corporation (Barrick) to prepare an independent Technical Report on the Zaldívar copper operation (the Project), located in northern Chile. The purpose of this report is to support public disclosure of Mineral Resource and Mineral Reserve estimates at the Project as of December 31, 2011. This Technical Report conforms to NI 43-101 Standards of Disclosure for Mineral Projects.

Barrick is a Canadian publicly traded mining company with a large portfolio of operating mines and projects across five continents. Zaldívar is located in the Andean Precordillera in Region II of northern Chile, approximately 1,400 km north of Santiago and 196 km southeast of the city of Antofagasta.

The Zaldívar mining operation is managed and operated by Compañía Minera Zaldívar (CMZ), which is 100% owned by Barrick through its acquisition of Placer Dome Inc. (Placer) on March 3, 2006. There are no royalties payable. Zaldívar is surrounded by concessions owned by Minera Escondida Limitada (MEL). MEL has authorized CMZ to build infrastructure such as heap leach pads, the solution extraction/electrowinning (SX/EW) plant, and tailings facilities within the area covered by its mining concessions. MEL has begun mining the high walls that straddle the property boundary and stockpiling CMZ ore for CMZ.

Zaldívar is a large scale operation utilizing a traditional truck and shovel fleet. Mining is carried out from one open pit at a rate of 83 million tonnes per annum (Mtpa), consisting of 22 Mtpa of crushed ore, 15 Mtpa of dump leach ore, and 46 Mtpa of waste. The ultimate pit will measure approximately 2.8 km east to west, 2.6 km north to south, and have an average depth of approximately 630 m. A total of 578 million tonnes grading 0.52% Cu representing 6.6 billion pounds of contained copper and 3.8 billion pounds of recoverable copper is projected to be produced between 2012 and 2028.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 2-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

SOURCES OF INFORMATION

RPA Principal Geological Engineer Luke Evans, M.Sc., P.Eng., and RPA Principal Mining Engineer Richard J. Lambert, MBA., P.E., visited the property from October 24 to 27, 2011.

Discussions were held with the following Barrick personnel:

| | • | | Leonardo González – General Manager of Operations |

| | • | | Eduardo Jofré – Technical Services Superintendent |

| | • | | Roberto Alfaro – Regional Superintendent of Long Range Mine Planning |

| | • | | Guillermo Albornoz – Chief Geotechnical Engineer |

| | • | | Eduardo Riveros – Chief Engineer |

| | • | | Mauricio Rubio – Chief Geologist |

| | • | | Norman Colón – Chief Metallurgist |

| | • | | Ramón Guajardo – Environmental Superintendent |

| | • | | Cristian Monroy – Senior Resource Geologist |

| | • | | Benjamin Sanfurgo – Superintendent of Resource and Reserve Modelling |

| | • | | Romina Ganga – Ore Control Geologist |

| | • | | Carolina Vera – Ore Control Geologist |

| | • | | Victor Diaz- Mine Laboratory Manager |

| | • | | Walter Hevia – Sample Preparation Shift Supervisor |

| | • | | Jorge Vega – Land Manager |

| | • | | Gregorio Olivares – Controller |

| | • | | Carolina Vasquez – Accountant (Capital costs) |

| | • | | Moises Bautista – Accountant (Operating costs) |

The Zaldívar operation has been the subject of resource/reserve technical audits as follows:

| | • | | March 2009, Mineral Reserve and Resource Audit, Scott Wilson Roscoe Postle Associates Inc. (Scott Wilson RPA, a predecessor company to RPA). |

| | • | | February 2007, Reserve Procedure Audit, Scott Wilson RPA. |

| | • | | December 2006, Level 2 Resource and Reserve Audit, Placer Dome Inc. |

| | • | | December 31, 2004, NI 43-101 Technical Report, AMEC Americas Limited (AMEC). |

| | • | | November 2004, Resource and Reserve Audit, Placer Dome Inc. |

Mr. Evans is responsible for the overall preparation of this report. Mr. Evans reviewed the geology, sampling, assaying, and resource estimate work and is responsible for Items 1 to 12 and 14. Mr. Lambert reviewed the metallurgy, mining, reserve estimate,

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 2-2 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

environment, and economics and is responsible for Items 13, and 15 to 26. RPA would like to acknowledge the excellent cooperation in the transmittal of data by Barrick personnel.

The documentation reviewed, and other sources of information, are listed at the end of this report in Section 27 References.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 2-3 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

LIST OF ABBREVIATIONS

Units of measurement used in this report conform to the metric system. All currency in this report is US dollars (US$) unless otherwise noted.

| | |

µ | | micron |

°C | | degree Celsius |

°F | | degree Fahrenheit |

µg | | microgram |

A | | ampere |

a | | annum |

bbl | | barrels |

Btu | | British thermal units |

C$ | | Canadian dollars |

cal | | calorie |

cfm | | cubic feet per minute |

cm | | centimetre |

cm2 | | square centimetre |

d | | day |

dia. | | diameter |

dmt | | dry metric tonne |

dwt | | dead-weight ton |

ft | | foot |

ft/s | | foot per second |

ft2 | | square foot |

ft3 | | cubic foot |

g | | gram |

G | | giga (billion) |

Gal | | Imperial gallon |

g/L | | gram per litre |

g/t | | gram per tonne |

gpm | | Imperial gallons per minute |

gr/ft3 | | grain per cubic foot |

gr/m3 | | grain per cubic metre |

hr | | hour |

ha | | hectare |

hp | | horsepower |

in | | inch |

in2 | | square inch |

J | | joule |

k | | kilo (thousand) |

kcal | | kilocalorie |

kg | | kilogram |

km | | kilometre |

km/h | | kilometre per hour |

| | |

km2 | | square kilometre |

| kPa | | kilopascal |

| kVA | | kilovolt-amperes |

| kW | | kilowatt |

| kWh | | kilowatt-hour |

| L | | litre |

| L/s | | litres per second |

| m | | metre |

| M | | mega (million) |

| m2 | | square metre |

| m3 | | cubic metre |

| min | | minute |

| MASL | | metres above sea level |

| mm | | millimetre |

| mph | | miles per hour |

| MVA | | megavolt-amperes |

| MW | | megawatt |

| MWh | | megawatt-hour |

| m3/h | | cubic metres per hour |

| opt, oz/st | | ounce per short ton |

| oz | | Troy ounce (31.1035g) |

| ppm | | part per million |

| psia | | pound per square inch absolute |

| psig | | pound per square inch gauge |

| RL | | relative elevation |

| s | | second |

| st | | short ton |

| stpa | | short ton per year |

| stpd | | short ton per day |

| t | | metric tonne |

| tpa | | metric tonne per year |

| tpd | | metric tonne per day |

| US$ | | United States dollar |

| USg | | United States gallon |

| USgpm | | US gallon per minute |

| V | | volt |

| W | | watt |

| wmt | | wet metric tonne |

| yd3 | | cubic yard |

| yr | | year |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 2-4 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

3 RELIANCE ON OTHER EXPERTS

This report has been prepared by Roscoe Postle Associates Inc. (RPA) for Barrick Gold Corporation (Barrick). The information, conclusions, opinions, and estimates contained herein are based on:

| | • | | Information available to RPA at the time of preparation of this report, |

| | • | | Assumptions, conditions, and qualifications as set forth in this report, and |

| | • | | Data, reports, and other information supplied by Barrick and other third party sources. |

For the purpose of this report, RPA has relied on ownership information provided by Barrick. RPA has not researched property title or mineral rights for the Zaldívar property and expresses no opinion as to the ownership status of the property.

RPA has relied on Barrick for guidance on applicable taxes, royalties, and other government levies or interests, applicable to revenue or income from Zaldívar.

Except for the purposes legislated under provincial securities laws, any use of this report by any third party is at that party’s sole risk.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 3-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

4 PROPERTY DESCRIPTION AND LOCATION

LOCATION

Zaldívar is located in the Andean Precordillera in Region II of northern Chile, approximately 1,400 km north of Santiago and 196 km southeast of the city of Antofagasta (Figures 4-1 and 4-2). Zaldívar is connected to Antofagasta by a paved highway as well as the Antofagasta Salta narrow-gauge railway. Antofagasta is a deepwater port with bulk loading and unloading facilities. The city is served by national airlines, with several flights daily providing a link to Santiago and other major centres. The mine is located at an altitude of 3,200 m.

LAND TENURE

Under Chilean regulations, the exploitation or mining concessions can be held indefinitely as long as the annual fees are paid to keep the permits in good standing. The exploitation concessions give the right to extract the ore and to sell the final products into the open market.

The Zaldívar mineral rights boundary is defined by combining ten overlapping exploitation concessions that have a total area of approximately 1,295 ha. The individual exploitation concessions are listed in Table 4-1 and the final official property boundary is shown in Figure 4-2.

TABLE 4-1 EXPLOITATION CONCESSIONS

Barrick Gold Corporation – Zaldívar Mine

| | | | | | | | |

Name | | Registration # | | | Area (ha)* | |

Zaldívar 262/509 | | | 02201-1168-7 | | | | 1,240 | |

Ana 1/180 | | | 02201-2489-4 | | | | 180 | |

Antonia 1/191 | | | 02201-2493-2 | | | | 191 | |

Andrea 1/216 | | | 02201-2492-4 | | | | 216 | |

Aurora 1/201 | | | 02201-2491-6 | | | | 201 | |

Amanda 1/220 | | | 02201-2490-8 | | | | 220 | |

Angela 1/127 | | | 02201-2488-6 | | | | 127 | |

Berta 1/76 | | | 02201-2494-0 | | | | 76 | |

Rey 1/133 | | | 02201-2563-7 | | | | 262 | |

Reina 1/115 | | | 02201-2564-5 | | | | 172 | |

| * | Areas have considerable overlap, so total area is 1,295 ha. |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 4-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

The Zaldívar mining operation is managed and operated by Compañía Minera Zaldívar (CMZ), which is 100% owned by Barrick through its acquisition of Placer Dome Inc. (Placer) on March 3, 2006. There are no royalties payable. Zaldívar is surrounded by concessions owned by Minera Escondida Limitada (MEL). CMZ has a number of easement or surface rights agreements with MEL. MEL has authorized CMZ to build infrastructure such as heap leach pads, the SX/EW plant, tailings and other facilities within the area covered by the MEL concessions. The current areas covered by surface rights agreements are shown in Figure 4-3, which also shows the locations of the mine, surface infrastructure, and mining concessions for the Zaldívar operations. MEL has begun mining the high walls that straddle the property boundary.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 4-2 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

4-3

| | |

| | www.rpacan.com |

4-4

| | |

| | www.rpacan.com |

4-5

| | |

| | www.rpacan.com |

5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY

ACCESSIBILITY

Antofagasta is the Capital of Region II and is home to most employees at Zaldívar. Antofagasta has a population of 360,000 people (2009 census). There is daily commercial air service to Antofagasta from Santiago. There is a dirt airstrip at the Zaldívar mine site.

Access to the site is via a paved road from Antofagasta, following Highway 28 for 15 km to the southwest to the intersection with Route 5 (Pan-American Highway). From the intersection with Route 5, there is a private two-lane paved road that is shared by three major mines, Zaldívar, Escondida, and El Peñón, which heads to the east. It is 137 km to the Zaldívar turnoff. From the turnoff, it is seven kilometres to the Zaldívar camp and another eight kilometres to the Zaldívar mine offices. The total distance from Antofagasta is 170 km. Most consumables are transported along this route by truck.

The site is also serviced by rail with Ferrocarril Antofagasta—Bolivia (FCAB) transporting sulphuric acid to the mine and copper cathode to the port of Antofagasta.

CLIMATE

Zaldívar has an arid high desert climate. The mine lies 3,200 m above sea level. Temperatures range from -7°C in July to 22°C in January, with an average temperature of 10°C. Precipitation typically falls in the summer months, with 2 mm to 6 mm per annum. There is little precipitation and water from the area does not reach the sea.

Vegetation is almost absent and is restricted to areas with water accumulation, temporary runoff, or underground phreatic surfaces. Typical vegetation mostly consists of small flowering plants and cacti, such as oxalis hypsophila, cistanthe salsoloides, adesmia atacamensis, and sisymbrium philippianum.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 5-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

LOCAL RESOURCES

The workforce consists of 835 employees. In addition, there are approximately 1,150 contractors. Camp facilities are provided on site for both company personnel and contractor personnel. Personnel generally work on a four day rotation and are transported to and from site by company bus or light vehicles.

INFRASTRUCTURE

WATER

Process water is supplied from groundwater at Negrillar, 130 km east of Zaldívar. The water is drawn from six production wells and pumped to the freshwater pond near the tertiary crushing facility at the plant site. Current use is approximately 220 L/s.

POWER

Zaldívar consumes a nominal 72 MWh to 76 MWh. The power supplier is AES Gener. The power transmission is part of Sistema Interconectado del Norte Grande (SING), the regional electrical grid for Northern Chile. A dual-circuit, 220 kV, 230 km long transmission line was constructed with MEL between the Zaldívar and Escondida Norte plant sites and the SING substation at El Crucero.

PHYSIOGRAPHY

Rugged mountains with incised steep-sided valleys characterize the Zaldívar Project area. Elevations in the region vary from approximately 1,500 m to 3,500 m, and the alpine climate is cold, dry, and windy. Vegetation is sparse. Rock outcrops and colluvial soils predominate in the valley walls with colluvium, alluvium, and moraine till exposed on the valley floors. The overburden is approximately 20 m to 50 m thick in the northern part of the property and up to 100 m thick to the south.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 5-2 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

6 HISTORY

EXPLORATION AND OWNERSHIP HISTORY

The exploration and ownership history is summarized below:

| 1979 | The initial declaration or statement of discovery (manifestación minera) was presented to the First Civil Court of Antofagasta by Mr. Pedro Buttazzoni Alvarez. |

| 1981 | Mr. Buttazzoni, through his company Sociedad Contractual Minera Varillas (SCMV), formed the company Sociedad Legal Minera Zaldívar 262 de Zaldívar. Shareholders in this new company were SCMV (88.33%) and Minera Utah de Chile Inc. and Getty Mining (Chile) Inc. (with a joint interest of 11.67%). |

1981-1984 Exploration drilling was done in the area by Minera Utah de Chile Inc.

| 1989 | As a result of various transactions during the previous eight years, SCMV held 51% and MEL the remaining 49%. In March 1989, the mining rights were sold to Sociedad Minera La Cascada Limitada (SMCL-Pudahuel). A sales contract was executed between SMCL-Pudahuel and Outokumpu Resources (Services) Limited. The mining claims were then transferred to Minera Outokumpu Chile Limitada (Outokumpu) in November. |

| 1992 | Outokumpu announced the formation of a 50/50 joint venture with Placer in December, at which time a joint venture company, CMZ, was formed. |

| 1995 | Commercial production started in November. The capital cost of the project was within budget at approximately $600 million. |

| 1999 | Placer acquired Outokumpu’s 50% interest in CMZ, effective December 13, 1999. |

| 2006 | Barrick acquired Placer on March 3, 2006. |

PRODUCTION HISTORY

Since commencement of commercial operations in 1995, the following significant changes have been made:

| 1996 | The feed system to the secondary crushers was improved in September 1996 by the addition of a feed bin with belt feeders controlling the material flow to each crusher. |

| 1997 | A pre-screening plant was installed in July 1997 to allow -12 mm material (approximately 40% of the heap leach ore) to bypass tertiary crushing. In January 1998 these screens were converted from the original wet design to dry operation. |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 6-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

The installation has not only alleviated problems in the tertiary crusher, but has also proven advantageous to leach performance by bypassing fine material directly to the heap leach pad.

| 1998 | In January 1998 a flotation plant was put into operation to recover copper from the tertiary crusher circuit slimes. |

| 1998 | In May 1998, two-pass leaching was introduced by installing an intermediate PLS pond in the heap leach circuit. This has improved leach recovery by substantially increasing the wash rate and the PLS grade. |

| 1999 | In April 1999 the heap leach operation was converted to an on/off (dynamic) pad. |

| 2000 | In July 2000, a fifth tertiary crusher line was installed, enabling part of the wet flush crusher circulating load to be treated in open circuit by two MP500 crushers. |

| 2001 | In March 2001, the first PLS from dump leaching was introduced to the SX circuit. |

The open pit fleet has been progressively upgraded and expanded as plant feed requirements have increased. The current open pit fleet has the capacity to move approximately 240,000 tpd of material.

The electrowinning plant has been modified to produce 150,000 tonnes (330.7 Mlb) of copper cathode per year, 20% over the original design capacity of 125,000 tonnes.

Table 6-1 shows the production from the Zaldívar Mine since 2007.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 6-2 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

TABLE 6-1 ZALDÍVAR PRODUCTION – 2007-2011

Barrick Gold Corporation – Zaldívar Mine

| | | | | | | | | | | | | | | | | | | | |

Item | | 2007 | | | 2008 | | | 2009 | | | 2010 | | | 2011

(Jan-Oct) | |

Mine to Heap Leach (t) | | | 16,144,945 | | | | 15,141,101 | | | | 15,708,166 | | | | 14,506,756 | | | | 12,782,070 | |

TCu (%) | | | 0.822 | | | | 0.778 | | | | 0.722 | | | | 0.697 | | | | 0.646 | |

ASCu (%) | | | 0.602 | | | | 0.576 | | | | 0.456 | | | | 0.427 | | | | 0.402 | |

Mine to Stockpile (t) | | | 7,839,300 | | | | 9,940,350 | | | | 16,542,135 | | | | 13,087,447 | | | | 4,852,549 | |

TCu (%) | | | 0.563 | | | | 0.538 | | | | 0.520 | | | | 0.534 | | | | 0.634 | |

ASCu (%) | | | 0.325 | | | | 0.335 | | | | 0.256 | | | | 0.260 | | | | 0.354 | |

Mine to Dump Leach (t) | | | 14,037,870 | | | | 19,253,647 | | | | 21,772,868 | | | | 8,413,425 | | | | 9,718,600 | |

TCu (%) | | | 0.348 | | | | 0.364 | | | | 0.404 | | | | 0.386 | | | | 0.349 | |

ASCu (%) | | | 0.177 | | | | 0.183 | | | | 0.165 | | | | 0.173 | | | | 0.176 | |

Waste (t) | | | 32,553,025 | | | | 29,953,500 | | | | 13,183,650 | | | | 21,604,314 | | | | 26150141 | |

Total Mine (t) | | | 70,575,140 | | | | 74,288,598 | | | | 67,206,819 | | | | 57,611,942 | | | | 53,503,360 | |

| | | | | |

Stockpile to Heap Leach (t) | | | 3,169,034 | | | | 4,027,521 | | | | 5,436,157 | | | | 6,560,624 | | | | 4,736,268 | |

TCu (%) | | | 0.782 | | | | 0.827 | | | | 0.724 | | | | 0.740 | | | | 0.595 | |

ASCu (%) | | | 0.536 | | | | 0.511 | | | | 0.466 | | | | 0.469 | | | | 0.364 | |

Stockpile to Dump Leach (t) | | | — | | | | — | | | | — | | | | 11,116,781 | | | | 8,299,575 | |

TCu (%) | | | — | | | | — | | | | — | | | | 0.510 | | | | 0.392 | |

ASCu (%) | | | — | | | | — | | | | — | | | | 0.459 | | | | 0.190 | |

Total Stockpile (t) | | | 3,169,034 | | | | 4,027,521 | | | | 5,436,157 | | | | 17,677,405 | | | | 13,035,843 | |

Total Mine and Stockpile (t) | | | 73,744,174 | | | | 78,316,119 | | | | 72,642,976 | | | | 75,289,347 | | | | 66,539,203 | |

| | | | | |

Total to Heap Leach (t) | | | 19,313,979 | | | | 19,168,622 | | | | 21,144,323 | | | | 21,067,380 | | | | 17,518,337 | |

TCu (%) | | | 0.816 | | | | 0.789 | | | | 0.723 | | | | 0.710 | | | | 0.632 | |

ASCu (%) | | | 0.591 | | | | 0.562 | | | | 0.458 | | | | 0.440 | | | | 0.391 | |

Total to Dump Leach (t) | | | 14,037,870 | | | | 19,253,647 | | | | 21,772,868 | | | | 19,530,206 | | | | 18,018,175 | |

TCu (%) | | | 0.348 | | | | 0.364 | | | | 0.404 | | | | 0.456 | | | | 0.369 | |

ASCu (%) | | | 0.177 | | | | 0.183 | | | | 0.165 | | | | 0.336 | | | | 0.183 | |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 6-3 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

7 GEOLOGICAL SETTING AND MINERALIZATION

REGIONAL GEOLOGY

The Zaldívar porphyry copper deposit is situated on the western margin of the Atacama Plateau in northern Chile. The deposit is part of a large Tertiary porphyry copper system that includes the Escondida porphyry copper deposit. This porphyry complex occurs within the West Fissure structural system, a major regional feature that has controlled the emplacement of some of the largest porphyry copper deposits in northern Chile (Figure 7-1). The West Fissure system extends for approximately 1,000 km and separates Paleozoic rocks to the east from Mesozoic and Paleocene rocks to the west. The Zaldívar porphyry system lies at the intersection of the West Fissure and a series of northwest and northeast striking faults.

Supracrustal rocks in the region range in age from Paleozoic to the Quaternary. Rhyolitic and andesitic flow units of the Upper Paleozoic La Tabla Formation and the Upper Triassic Agua Dulce Formation are exposed in the east. The southwestern portion of the area is overlain by marine sedimentary rocks assigned to the Upper Triassic–Lower Jurassic Profeta Formation and Cretaceous continental units of the Santa Ana Formation. Andesite volcanic and volcaniclastic units occupy the north and central parts of the area. These belong to the Upper Cretaceous–Eocene age Augusta Victoria Formation. Two periods of intrusive activity occurred in the region. Dioritic and monzonitic intrusives were emplaced during the Upper Cretaceous–Eocene age, and dioritic to rhyolitic porphyries occurred during Eocene–Oligocene times. Oligocene–Miocene age unconsolidated gravels, alluvium, and colluvium cover the older rock units.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 7-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

7-2

| | |

| | www.rpacan.com |

LOCAL AND PROPERTY GEOLOGY

The Zaldívar porphyry is located at the intersection of the north-south striking faults of the Domeyko Fault system with the northeast and northwest striking faults. The deposit is generally centred on a northeast striking granodiorite porphyry body that intrudes andesites and rhyolites, and cuts across the north-south striking Portezuelo Fault.

There are three main lithologic units at Zaldívar: the Zaldívar porphyry, the andesite unit, and the Llamo porphyry (Figure 7-2). At approximately 290 million years old (Richards et al., 1999), the Zaldívar porphyry is the oldest unit and occupies most of the area east of the Portezuelo Fault. This rock unit typically consists of grey rhyolitic feldspar-quartz porphyry. Phenocrysts are mainly quartz, K-feldspar, and plagioclase. The quartzo-feldspathic groundmass is variably obliterated by sericite due to prevalent phyllic (quartz–sericite) alteration.

The andesite unit correlates with the August Victoria Formation, which has been dated between 66.6 and 41.2 million years (Marinovic et al., 1995) and it is the dominant lithology west of the Portezuelo Fault. Rocks are greenish grey to dark grey and display a fine-grained porphyritic texture with an aphanitic groundmass. The Llamo porphyry is the most recent intrusive event in the area and is dated at approximately 37.4 million years old (Richards et al., 1999). The porphyry trends roughly northeast-southwest across the deposit, outcropping on either side of the Portezuelo Fault where it intrudes both the andesite unit and the Zaldívar porphyry. It occurs as irregularly shaped dikes to small stock-like bodies 50 m to 200 m wide. This rock unit, a feldspar-biotite-quartz porphyry, is typically light greyish green and fine grained.

Several hydrothermal and tectonic breccias bodies closely associated with major structures, such as the Portezuelo Fault, have been recognized in the mine area. Much of the lower slopes and valley floors in the area are covered with thick Quaternary alluvial/colluvial deposits. These deposits are locally derived and generally consist of dry, loose to dense, well-graded silt, sand, and gravel. Pockets of aeolian silt and fine sand also occur in the area.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 7-3 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

7-4

| | |

| | www.rpacan.com |

The Zaldívar deposit occurs at the intersection of three major sets of faults striking north-south, northwest-southeast, and northeast-southwest. This structural setting has controlled the emplacement of the intrusives and hypogene mineralization as well as leaching and secondary enrichment.

The most prominent structures strike north-south and northwest-southeast and dip moderately to steeply northeast to southwest. Breccia zones one metre to five metres wide are commonly associated with the north-south fault set. These faults mimic the regional structures. The north-south set parallels the West Fissure structural trend, which is approximately 10 km wide and consists of an arrangement of steeply dipping, north-south trending structures. The northwest-southeast set parallels a regionally continuous, secondary structural trend. Both fault sets appear to be pre-intrusive and presumably control the emplacement of subsequent intrusions. It is also at the intersection of these faults that copper mineralization is best developed. A second set of faults strike northeast-southwest with steep dips to the northwest and southeast. This set is weakly to moderately developed, however, it is closely associated with the Zaldívar deposit and may have controlled the emplacement of the Llamo porphyry.

ALTERATION

The alteration developed in the Zaldívar Porphyry correspond to an early potassic alteration event, represented by secondary K-feldspar, which affect the Llamo Porphyry and the Paleozoic rocks below the 3,050 m elevation, and by secondary biotite, which widely affects the andesitic rocks.

This alteration is overprinted by low temperature quartz-sericite hydrothermal alteration with two stages of development. An early wide spread stage of sericite-chlorite alteration followed by the principal stage with more penetrative quartz-sericite-pyrite alteration focused in the mid part of the deposit and with a clear association with the Llamo Porphyry intrusions. Strong sericite alteration is present as discontinuous bodies in the core of the quartz-sericitic alteration zones and typically destroys primary rock textures. Propylitic alteration with chlorite as the main mineral effects the andesitic rocks and the late Llamo Porphyry.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 7-5 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

The final stage of the system is represented by very restricted advanced argillic alteration. Finally, as result of the leaching and oxidation of the rock column of the deposit, the supergene argillic alteration is developed, affecting all the lithological types with variable intensity, but being typically stronger in the andesitic rocks.

MINERALIZATION

The mineralization has an elongated shape trending northeast-southwest. This is the result of the overprinted hypogene and supergene processes, where the latter with its leaching and enrichment process, gave the deposit a characteristic vertical profile with a superior leached zone, an oxide copper zone, and a secondary sulfide zone located between the oxide and the basal primary sulfide zone.

The leached zone is present as a continuous horizon in the upper part of the deposit, with local depths of up to 300 m. The typical mineralogy of this zone includes hydroxides and iron sulfates (hematite-goethite-jarosite) with copper phosphate (turquoise).

The oxide zone extends more or less continuously from the Portezuelo Fault and surrounding areas towards the southwest, covering an area of approximately 2 km by 1.5 km and with an average thickness of approximately 90 m. The oxide zone is incised locally by leached areas related to faults of the northwest-southeast structural system. The mineralogy varies according to lithology and dominant alteration. For example, brochantite-antlerite is found in the rhyolitic rocks and chrysocolla, “black copper”, and copper phosphate are found in the andesitic rocks with chlorite-biotite alteration.

The secondary sulfides cover an area of approximately 2.5 km by 1.5 km, with a variable thickness from a few metres in the southwest extremity up to over 300 m in the northeast extremity. Mineralogy in this area is represented by pyrite, chalcocite, covellite, chalcopyrite and minor sphalerite and molybdenite. Chalcocite is the dominant secondary sulfide mineral (over 80%). Covellite is the main sulfide mineral present in the transition zone to the underlying primary sulfides. Alunite dating indicates an age for the secondary enrichment process of approximately 18 My to 14.7 My (Monroy 2010).

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 7-6 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

The primary sulphide zone follows the Llamo Porphyry trends and over 70% of the mineralization occurs in veinlets. The primary sulfide body has a bornite-rich core with minor chalcopyrite that is located in the Llamo Porphyry and in the late magmatic breccias. The bornite-rich core is enveloped by a chalcopyrite-pyrite zone which in turn is surrounded by a pyritic halo. The primary mineralization age is 37.2 My (Morales 2010).

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 7-7 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

7-8

| | |

| | www.rpacan.com |

8 DEPOSIT TYPES

Zaldívar is a porphyry copper deposit and together with the nearby Escondida and Chimbarazo deposits form part of the Eocene-Oligocene porphyry belt of Northern Chile. They are located at the intersections of the north-south regional faults belonging to the Domeyko Fault System with northwest and northeast fault systems.

The hypogene mineralogy of the deposit begins in the late magmatic stage where early veinlets of biotite and/or magnetite with bornite or minor chalcopyrite were developed. These are followed by “A” veinlets comprising quartz, K-feldspar, anhydrite, bornite, chalcopyrite, and primary chalcocite veinlets. These veinlets occur in strong potassic alteration characterized by biotite and secondary K-feldspar. In the transition from the late magmatic stage to early hydrothermal stage, a third generation of “B” veinlets is developed with quartz and minor K-feldspar and abundant chalcopyrite and/or molybdenite. For the principal hydrothermal event of quartz-sericite alteration two stages are recognized. The “C” veinlets, characterized by quartz with chalcopyrite, molybdenite, or chalcopyrite-pyrite with sericite-chlorite haloes, develop during the early stage. The main stage is represented by “D” veinlets with or without quartz, abundant pyrite, minor chalcopyrite and sphalerite and with quartz- sericite-pyrite alteration haloes.

Later, during the Miocene, the supergene processes associated with the uplift, erosion, oxidation and leaching of the deposit in a desert environment resulted in the leached horizon, immediately underlain by the oxide copper horizon, which is underlain by the secondary sulfide horizon, which all sits on top of the primary sulfide zone.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 8-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

9 EXPLORATION

Zaldívar is a mature operation with a relatively small mining concession area. The major exploration programs took place prior to the completion of the feasibility study in 1993. A major drilling campaign was completed in 2000 to define the limits of the deposit within the mining concessions. More recently, deep drilling campaigns have targeted the underlying sulphide mineralization. CMZ drills approximately 15,000 m of infill reverse circulation drill holes each year.

EXPLORATION POTENTIAL

CMZ has been evaluating the economic potential of the primary copper mineralization for a number of years. RPA first reviewed the Zaldívar Deeps Sulphide Cu-Mo-Au-Ag Project in January 2009 (Scott Wilson RPA, 2009) after Barrick completed an internal scoping study in December 2008 (Croal and Tsafaras, 2008). A new scoping study by Barrick is almost complete.

CMZ built a new block model for this primary sulphide mineralization as part of the 2010 mid-year update. There appears to be sufficient drill holes and technical studies completed to demonstrate that the Zaldívar Deep Sulphide Cu-Mo-Au-Ag Project mineralization meets the requirement for “reasonable prospects for economic extraction”.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 9-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

10 DRILLING

The resource model is based on 1,735 drill holes totalling 460,199 m that were drilled up to April 12, 2011 (Table 10-1). Approximately 60% of the drilling was by reverse circulation (RC) and the balance was diamond drill holes (DDH). Some 57 DDHs totalling 11,470 m were drilled from an underground bulk sample drift, which is now partly visible in the east wall.

Essentially all of the samples have total copper (TCu) grades, approximately 85% of the samples have acid soluble copper (ASCu) grades, and 43% of the samples have cyanide soluble copper (CNCu) grades. Approximately 21% of the samples have molybdenum (Mo), gold (Au), and silver (Ag) grades and these are mostly present in the primary sulphide mineralization.

Most of the resource definition drilling was completed in 1999 and 2000. Most holes were drilled vertically. When inclined, the drilled orientations were generally north-south, east-west, northeast-southwest, or northwest-southeast. Dip angles ranged from -40° to -90°, except for the east-west oriented holes where dip angles ranged from 0° to -90°.

The drill holes were mostly spaced approximately 100 m apart for the feasibility study and are now mostly spaced approximately 50 m apart. The mine plans to drill approximately 15,000 m annually to ensure that three years of production are always supported by approximately 50 m spaced holes.

All drill collars were surveyed by mine survey staff and located relative to the mine grid. Drill holes were downhole surveyed using mostly a Sperry Sun instrument at an average interval of 30 m and more recently gyroscopic downhole surveys have been done by Wellfield Services Ltda. (WS) and Perfochile Ltda. personnel. WS has also scanned holes for detailed structural analyses using a process called “Televisor Acustico de Pozos” and this procedure also generates a second set of downhole survey readings that can be used to confirm the accuracy of the gyroscopic data.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 10-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

TABLE 10-1 DRILLING SUMMARY

Barrick Gold Corporation – Zaldívar Mine

| | | | | | | | | | | | | | | | | | |

| | | | | No. | | | RC | | | DDH | | | Total | |

Description | | Year | | Holes | | | (m) | | | (m) | | | (m) | |

1. Exploration Holes | | | | | | | | | | | | | | | | | | |

Utah | | 1981-1989 | | | 60 | | | | 10,986.0 | | | | 9,090.0 | | | | 20,076.0 | |

Cascada | | 1989 | | | 41 | | | | 15,873.0 | | | | | | | | 15,873.0 | |

Outokumpu | | 1990-1992 | | | 308 | | | | 32,814.0 | | | | 42,479.0 | | | | 75,293.0 | |

Outokumpu /Placer Dome | | 1992 | | | 12 | | | | 952.0 | | | | 1,805.0 | | | | 2,757.000 | |

Placer Dome | | 1992-1993 | | | 80 | | | | 8,910.0 | | | | 5,736.0 | | | | 14,646.0 | |

Total Exploration Holes | | | | | 501 | | | | 69,535.0 | | | | 59,110.0 | | | | 128,645.0 | |

2. Condemnation Holes | | | | | | | | | | | | | | | | | | |

Zaldívar/Escondida | | 1993-1993 | | | 35 | | | | 4,624.0 | | | | | | | | 4,624.0 | |

Zaldívar | | 1995 | | | 5 | | | | 1,556.0 | | | | | | | | 1,556.0 | |

Total Condemnation Holes | | | | | 40 | | | | 6,180.0 | | | | | | | | 6,180 | |

3.-CMZ Holes (Secondary Exploration/Production) | | | | | | | | | | | | | | | | | | |

Minera Zaldívar | | 1994-1998 | | | 243 | | | | 37,777.0 | | | | 4,463.0 | | | | 42,240.0 | |

Geotechnical Drilling | | 1998 | | | 9 | | | | | | | | 2,224.7 | | | | 2,224.7 | |

Zaldívar Total Life Drilling | | 1999 | | | 151 | | | | 21,690.0 | | | | 6,485.7 | | | | 28,175.7 | |

Zaldívar Total Life Drilling | | 2000 | | | 247 | | | | 41,558.0 | | | | 20,045.0 | | | | 61,603.0 | |

Infill Drilling | | 2001 | | | 31 | | | | 2,942.0 | | | | | | | | 2,942.0 | |

Infill Drilling | | 2003 | | | 22 | | | | 2,600.0 | | | | | | | | 2,600.0 | |

Geotechnical Drilling | | 2003 | | | 9 | | | | | | | | 1,920.0 | | | | 1,920.0 | |

Infill Drilling | | 2005 | | | 24 | | | | 4,613.0 | | | | | | | | 4,613.0 | |

Infill Drilling | | 2006 | | | 24 | | | | 5,756.0 | | | | | | | | 5,756.0 | |

Geotechnical Drilling | | 2006 | | | 15 | | | | | | | | 4,595.7 | | | | 4,595.7 | |

Primary Drilling | | 2006 | | | 15 | | | | 3,684.0 | | | | | | | | 3,684.0 | |

Primary Drilling | | 2006 | | | 3 | | | | | | | | 1,401.7 | | | | 1,401.7 | |

Infill Drilling | | 2007 | | | 67 | | | | 15,151.0 | | | | | | | | 15,151.0 | |

Primary Drilling | | 2007 | | | 2 | | | | 600.0 | | | | | | | | 600.0 | |

Primary Drilling | | 2007 | | | 59 | | | | | | | | 42,995.7 | | | | 42,995.7 | |

Geotechnical Drilling | | 2007 | | | 10 | | | | | | | | 2,658.2 | | | | 2,658.2 | |

Geotechnical Drilling | | 2008 | | | 24 | | | | | | | | 14,936.9 | | | | 14,936.9 | |

Hydrogeological | | 2008 | | | 6 | | | | | | | | 3,615.0 | | | | 3,615.0 | |

Hydrogeological | | 2008 | | | 2 | | | | 440.0 | | | | | | | | 440.0 | |

Infill Drilling | | 2008 | | | 70 | | | | 17,172.0 | | | | | | | | 17,172.0 | |

Primary Drilling | | 2008 | | | 41 | | | | | | | | 22,621.4 | | | | 22,621.4 | |

Primary Drilling (Metallurgical) | | 2008 | | | 2 | | | | | | | | 612.9 | | | | 612.9 | |

Hydrogeological | | 2009 | | | 15 | | | | 3,213.0 | | | | | | | | 3,213.0 | |

Infill Drilling | | 2009 | | | 37 | | | | 11,000.0 | | | | | | | | 11,000.0 | |

Infill Drilling | | 2010 | | | 75 | | | | 22,258.0 | | | | | | | | 22,258.0 | |

Hydrogeological | | 2010 | | | 13 | | | | 2,954.0 | | | | | | | | 2,954.0 | |

Infill Drilling | | 2010 | | | 54 | | | | 12,184.0 | | | | | | | | 12,184.0 | |

Infill Drilling | | 2011 | | | 13 | | | | 3,530.0 | | | | | | | | 3,530.0 | |

Total | | | | | 1,283 | | | | 209,122.0 | | | | 128,575.7 | | | | 337,697.7 | |

| | | | | | | | | | | | | | | | | | |

Grand Total (December 2011) | | | | | 1,824 | | | | 284,837.0 | | | | 187,685.7 | | | | 472,522.7 | |

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 10-2 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

The holes have been logged properly and more recently (2007/2008) the mine has started logging directly into hand-held computers using PC Explorer software for the RC holes and GVMapper for the DDHs. The data captured includes lithology, type and degree of alteration, style and mineralogy of oxide and sulphide mineralization, structural observations, and style and frequency of fractures and veins. The blasthole chips are also logged.

A significant amount of core was relogged to update and standardize the lithology, alteration, and mineralization codes in the earlier drill holes. It is RPA’s opinion that the CMZ drilling and logging procedures are of high quality and they exceed standard industry practices. The drill hole locations are shown in Figure 10-1.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 10-3 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

10-4

| | |

| | www.rpacan.com |

11 SAMPLE PREPARATION, ANALYSES AND SECURITY

SAMPLING METHOD AND APPROACH

Core is sampled on one and two metre intervals and RC material is sampled on two metre intervals. Core samples are split, with half being submitted for analyses and the remaining half preserved and stored at a secure facility on site. Holes are commonly sampled in their entirety. The samples are tagged and transported by the geological staff to the respective assay laboratory.

The blasthole samples are taken with a 10 cm diameter by 0.7 m long tube from six locations from the piles around each hole. The blasthole samples are approximately 20 kg to 25 kg. The drills have skirts to help prevent loss of fines during strong winds.

RPA is of the opinion that the core, RC, and blasthole sampling procedures at Zaldívar are reasonable.

SAMPLE PREPARATION, ANALYSES AND SECURITY

In the early phases of drilling (prior to pre-production), outside assay laboratories such as Geoanalitica Ltda. (Geoanalitica), CIMM, and CESMEC were routinely used. Since the commissioning of the mine site assay laboratory in 1994, all drill samples have been prepared on site. CMZ has a large, well-organized, clean, ISO 17025 certified mine laboratory.

In 1996 and 2000, Francis Pitard developed sampling and preparation procedures for RC and blasthole samples. At least 20 kg of material is dried, crushed to 100% passing 10 mesh, passed through a rotary splitter, and approximately 250 g is pulverized to 90% passing 170 mesh. All samples are weighed and the weights are monitored by the geology department. Regular sieve tests are carried out and the CMZ mine lab pulps regularly achieve better than 95% passing 170 mesh.

CMZ has provided Geoanalitica with the CMZ analytical protocols for sequential copper analyses. The samples are analyzed for total copper (TCu), acid soluble copper (ASCu), and cyanide soluble copper (CNCu) at the Geoanalitica laboratory in Coquimbo, Chile. The detection limit is 0.01% for TCu, ASCu, and CNCu.

| | |

| Barrick Gold Corporation – Zaldívar Mine, Project #1683 | | Rev. 0Page 11-1 |

| Technical Report NI 43-101 – March 16, 2012 | |

| | |

| | www.rpacan.com |

The drill core, field duplicates, and reject material is stored for one year at a very well organized and secure location on site. The 250 g pulps are placed in small plastic screw-top containers and stored forever in 45 gal drums.

RPA is of the opinion that the sample preparation, analytical protocols, and security measures are very good and exceed industry standard practice.

QUALITY ASSURANCE AND QUALITY CONTROL

CMZ has very good quality control (QC) and quality assurance (QA) procedures that include the regular insertion of in-house standards, blanks, field duplicates, reject duplicates, and pulp replicates. In addition, pulps are sent to external laboratories on a regular basis.

Geoanalitica is the primary laboratory for the DDH and RC samples and the CMZ laboratory is the primary laboratory for the blasthole samples. The CMZ laboratory is the secondary laboratory for the external DDH and RC pulp replicates and Geoanalitica is the secondary laboratory for the external blasthole pulp replicates. In March 2007, CMZ implemented the Barrick QA/QC procedures and they are well documented in Morales (2009).

The approximate insertion rates for blasthole, RC, and DDH samples are essentially the same and are summarized in Table 11-1.

TABLE 11-1 QC INSERTION RATES

Barrick Gold Corporation – Zaldívar Mine

| | |

Description | | Approximate Insertion Rate |

Standards | | 5% |

Blanks | | 2% |

Pulp Replicates | | 2% |

Reject duplicates | | 2% |

Field Duplicates | | 2% |

Sieve Tests | | 5% |

External pulp replicates (more blanks and standards sent as well) | | 5% |

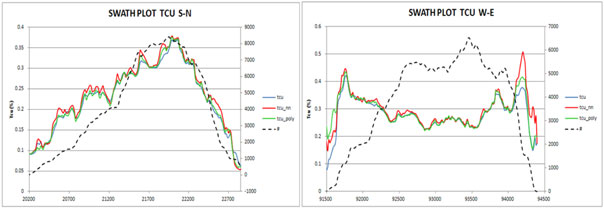

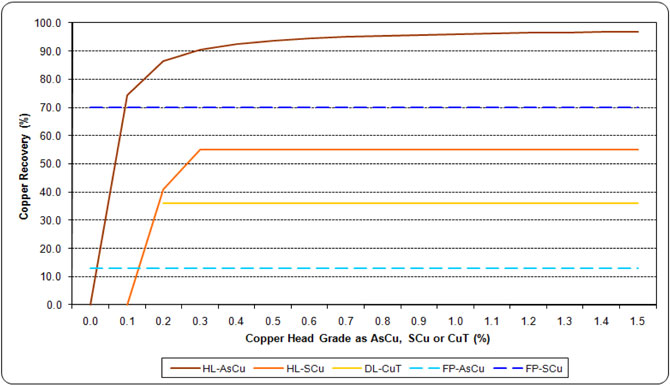

| | |