Exhibit 99.1

BARRICK GOLD CORPORATION

TECHNICAL REPORT ON THE

PORGERA JOINT VENTURE,

ENGA PROVINCE,

PAPUA NEW GUINEA

NI 43-101 Report

Qualified Persons:

David W. Rennie, P.Eng.

Stuart E. Collins, P.E.

Kathleen Ann Altman, Ph.D., P.E.

March 16, 2012

ROSCOE POSTLE ASSOCIATES INC.

Report Control Form

| | | | | | | | |

Document Title | | Technical Report on Porgera Joint Venture, Enga Province, Papua New Guinea |

| |

Client Name & Address | | Brookfield Place, TD Canada Trust Tower Suite 3700, 161 Bay Street, P.O. Box 212 Toronto, Ontario M5J 2S1 |

| | | | |

Document Reference | | Project #1669 | | Status &

Issue No. | | Final

Version | | Rev 0 |

| |

Issue Date | | March 16, 2012 |

| | |

Lead Author | | Dave W. Rennie Stuart E. Collins Kathleen Ann Altman | | (Signed)

(Signed) (Signed) |

| | |

Peer Reviewer | | Graham Clow | | (Signed) |

| | |

Project Manager Approval | | Dave Rennie | | (Signed) |

| | |

Project Director Approval | | Richard Lambert | | (Signed) |

| | |

Report Distribution | | Name | | No. of Copies |

| | |

| | Client | | |

| | |

| | RPA Filing | | 1 (project box) |

|

Roscoe Postle Associates Inc. 55 University Avenue, Suite 501 Toronto, Ontario M5J 2H7 Canada Tel: +1 416 947 0907 Fax: +1 416 947 0395 mining@rpacan.com |

| | |

| | www.rpacan.com |

|

TABLE OF CONTENTS

| | | | |

| | | PAGE | |

| |

1 SUMMARY | | | 1-1 | |

Executive Summary | | | 1-1 | |

Technical Summary | | | 1-8 | |

| |

2 INTRODUCTION | | | 2-1 | |

| |

3 RELIANCE ON OTHER EXPERTS | | | 3-1 | |

| |

4 PROPERTY DESCRIPTION AND LOCATION | | | 4-1 | |

| |

5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | | | 5-1 | |

| |

6 HISTORY | | | 6-1 | |

| |

7 GEOLOGICAL SETTING AND MINERALIZATION | | | 7-1 | |

Regional Geology | | | 7-1 | |

Local Geology | | | 7-4 | |

Property Geology | | | 7-4 | |

Mineralization | | | 7-11 | |

| |

8 DEPOSIT TYPES | | | 8-1 | |

| |

9 EXPLORATION | | | 9-1 | |

| |

Exploration Potential | | | 9-6 | |

| |

10 DRILLING | | | 10-1 | |

| |

11 SAMPLE PREPARATION, ANALYSES AND SECURITY | | | 11-1 | |

| |

12 DATA VERIFICATION | | | 12-1 | |

| |

13 MINERAL PROCESSING AND METALLURGICAL TESTING | | | 13-1 | |

| |

14 MINERAL RESOURCE ESTIMATE | | | 14-1 | |

Summary | | | 14-1 | |

Introduction | | | 14-4 | |

Open Pit Models | | | 14-6 | |

Underground Models | | | 14-27 | |

| |

15 MINERAL RESERVE ESTIMATE | | | 15-1 | |

Summary | | | 15-1 | |

Model Reconciliation | | | 15-8 | |

| |

16 MINING METHODS | | | 16-1 | |

Open Pit Operation Description | | | 16-1 | |

Underground Mine Description | | | 16-17 | |

| |

17 RECOVERY METHODS | | | 17-1 | |

| |

18 PROJECT INFRASTRUCTURE | | | 18-1 | |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page i | |

| | |

| | www.rpacan.com |

|

| | | | |

19 MARKET STUDIES AND CONTRACTS | | | 19-1 | |

Markets | | | 19-1 | |

Contracts | | | 19-1 | |

| |

20 ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | | | 20-1 | |

Introduction | | | 20-1 | |

Environmental Studies | | | 20-2 | |

Project Permitting | | | 20-2 | |

Monitoring | | | 20-4 | |

Social or Community Requirements | | | 20-5 | |

Mine Reclamation and Closure | | | 20-7 | |

| |

21 CAPITAL AND OPERATING COSTS | | | 21-1 | |

Capital Costs | | | 21-1 | |

Operating Costs | | | 21-3 | |

| |

22 ECONOMIC ANALYSIS | | | 22-1 | |

| |

23 ADJACENT PROPERTIES | | | 23-1 | |

| |

24 OTHER RELEVANT DATA AND INFORMATION | | | 24-1 | |

| |

25 INTERPRETATION AND CONCLUSIONS | | | 25-1 | |

| |

26 RECOMMENDATIONS | | | 26-1 | |

| |

27 REFERENCES | | | 27-1 | |

| |

28 DATE AND SIGNATURE PAGE | | | 28-1 | |

| |

29 CERTIFICATE OF QUALIFIED PERSON | | | 29-1 | |

LIST OF TABLES

| | | | | | |

| | | | | PAGE | |

| | |

Table 1-1 | | Mineral Resources (100%) – December 31, 2011 | | | 1-2 | |

| | |

Table 1-2 | | Mineral Reserves (100%) – December 31, 2011 | | | 1-3 | |

| | |

Table 1-3 | | Summary of Open Pit and Underground Sustaining Capital Costs (2011 Mid-Year) | | | 1-21 | |

| | |

Table 1-4 | | Summary of Open Pit Operating Costs (2011 Mid-Year) | | | 1-22 | |

| | |

Table 6-1 | | Porgera JV Historical Ounce Production | | | 6-5 | |

| | |

Table 7-1 | | Mineralization Types at Porgera JV | | | 7-12 | |

| | |

Table 7-2 | | Mineralized Zones at Porgera JV | | | 7-13 | |

| | |

Table 9-1 | | Peruk Significant Drill Intercepts | | | 9-5 | |

| | |

Table 9-2 | | Central Zone Significant Drill Intercepts | | | 9-6 | |

| | |

Table 13-1 | | Lithology Types | | | 13-2 | |

| | |

Table 13-2 | | Gold and Sulphur Recovery Constants by Lithology | | | 13-3 | |

| | |

Table 13-3 | | CIP and ADSS Constants by Lithology | | | 13-5 | |

| | |

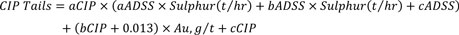

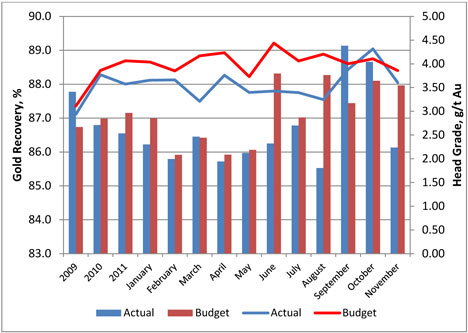

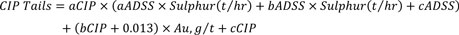

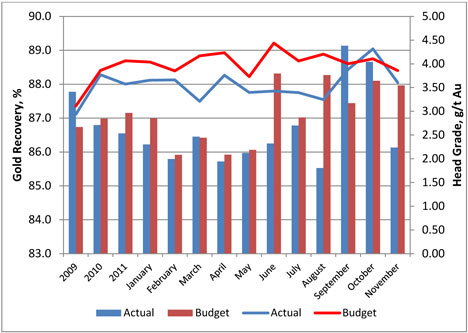

Table 13-4 | | Actual Versus Budgeted Gold Recovery | | | 13-6 | |

| | |

Table 13-5 | | Actual versus Budgeted Gold Recovery | | | 13-6 | |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page ii | |

| | |

| | www.rpacan.com |

|

| | | | | | |

Table 13-6 | | 2011 Mill Budget (2011 through 2039) | | | 13-7 | |

| | |

Table 14-1 | | Mineral Resource Estimate (100%) – December 31, 2011 | | | 14-1 | |

| | |

Table 14-2 | | Change in Mineral Resources | | | 14-3 | |

| | |

Table 14-3 | | Block Model Types | | | 14-5 | |

| | |

Table 14-4 | | Bulk Densities | | | 14-7 | |

| | |

Table 14-5 | | Gold Domains | | | 14-8 | |

| | |

Table 14-6 | | Sulphur Domains | | | 14-9 | |

| | |

Table 14-7 | | Gold Top Cuts | | | 14-11 | |

| | |

Table 14-8 | | Sulphur Top Cuts | | | 14-12 | |

| | |

Table 14-9 | | 2 m Non-Declustered Composite Grades—Gold | | | 14-13 | |

| | |

Table 14-10 | | 2 m Non-Declustered Composite Grades—Sulphur | | | 14-14 | |

| | |

Table 14-11 | | Block Model Geometry | | | 14-17 | |

| | |

Table 14-12 | | Comparison of Mean Composite and Block Grades | | | 14-21 | |

| | |

Table 14-13 | | Comparison of 2011 and 2010 Block Model Results (1.0 g/t Au Cut-Off) | | | 14-23 | |

| | |

Table 14-14 | | Resource Classification by Kriging Variance | | | 14-25 | |

| | |

Table 14-15 | | CNZ Raw Sample Statistics | | | 14-31 | |

| | |

Table 14-16 | | AHD Raw Sample Statistics | | | 14-32 | |

| | |

Table 14-17 | | EZ Raw Sample Statistics | | | 14-33 | |

| | |

Table 14-18 | | PX Raw Sample Statistics | | | 14-33 | |

| | |

Table 14-19 | | OZ Raw Sample Statistics | | | 14-34 | |

| | |

Table 14-20 | | EDX Sample Statistics | | | 14-34 | |

| | |

Table 14-21 | | Top Cuts-underground Models | | | 14-35 | |

| | |

Table 14-22 | | Capped Composite Statistics—Gold | | | 14-36 | |

| | |

Table 14-23 | | Capped Composite Statistics—Sulphur | | | 14-37 | |

| | |

Table 14-24 | | Block Model Geometries | | | 14-41 | |

| | |

Table 14-25 | | Comparison of Mean Composite and Block Gold Grades | | | 14-43 | |

| | |

Table 14-26 | | Comparison of EOY2011 and Previous Block Model Results (1.0 g/t Au Cut-Off) | | | 14-48 | |

| | |

Table 14-27 | | Indicated and Inferred Classification Search Distances | | | 14-49 | |

| | |

Table 15-1 | | Mineral Reserve Estimate (100%) – December 31, 2011 | | | 15-1 | |

| | |

Table 15-2 | | Whittle pit optimization parameters | | | 15-3 | |

| | |

Table 15-3 | | Mine Design Parameters | | | 15-4 | |

| | |

Table 15-4 | | Summary of Development Heading dimensions | | | 15-6 | |

| | |

Table 15-5 | | Summary of Underground Cut-off Grade Inputs | | | 15-8 | |

| | |

Table 15-6 | | Mined Ore Reconciliation Results – December 31, 2011 | | | 15-9 | |

| | |

Table 16-1 | | Summary of Open Pit Equipment Fleet (Estimated 2012) | | | 16-2 | |

| | |

Table 16-2 | | Summary of Open Pit and Underground Equipment Fleet Performance Assumptions | | | 16-3 | |

| | |

| | (Estimated 2012) | | | | |

| | |

Table 16-3 | | Summary of Open Pit Mine Design Parameters | | | 16-4 | |

| | |

Table 16-4 | | Summary of Underground Equipment Fleet (Estimated 2012) | | | 16-23 | |

| | |

Table 16-5 | | Life Of Mine Open and Underground Production Schedule | | | 16-24 | |

| | |

Table 20-1 | | Summary of Major Permits | | | 20-3 | |

| | |

Table 21-1 | | Summary of Open Pit and Underground Sustaining Capital Costs (2011 Mid-Year) | | | 21-2 | |

| | |

Table 21-2 | | Summary of Open Pit Operating Costs (2011 Mid-Year) | | | 21-4 | |

| | |

Table 21-3 | | Porgera 2011 Cost Per Ounce Gold Produced | | | 21-5 | |

| | |

Table 21-4 | | 2011 Cost per Milled Tonne | | | 21-6 | |

| | |

Table 21-5 | | Summary of Manpower as of March 2011 | | | 21-6 | |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page iii | |

| | |

| | www.rpacan.com |

|

LIST OF FIGURES

| | | | | | |

| | |

| | | | | PAGE | |

| | |

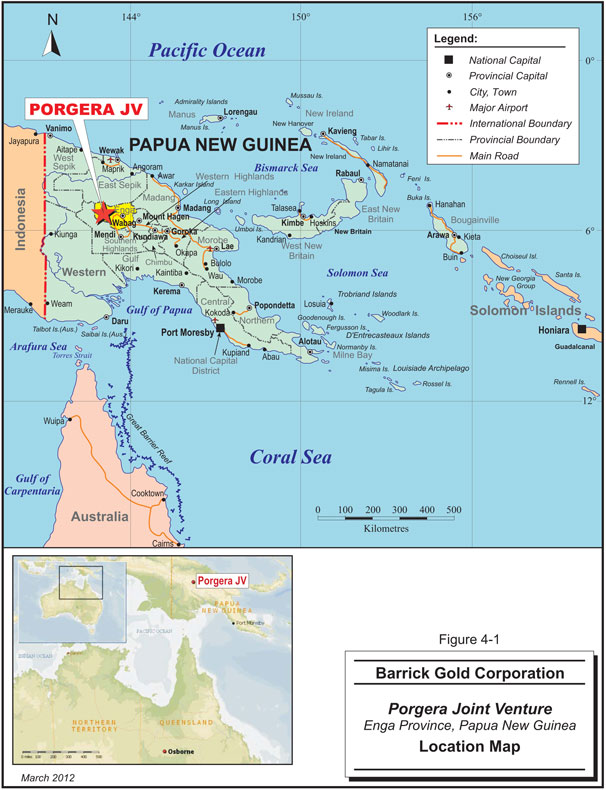

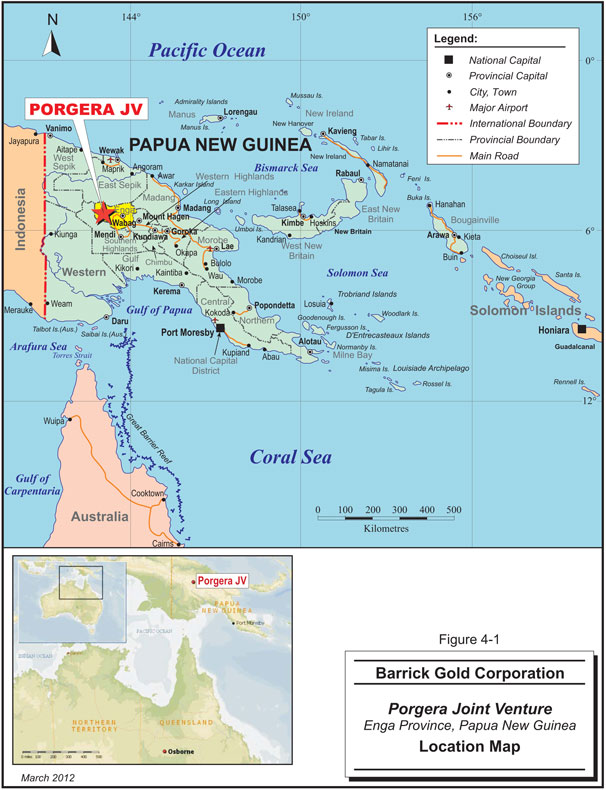

Figure 4-1 | | Porgera JV Location Map | | | 4-4 | |

| | |

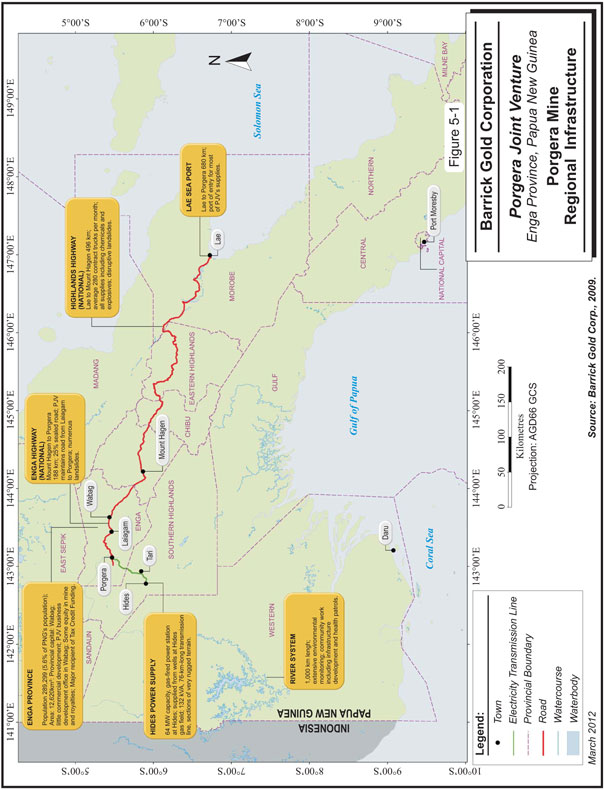

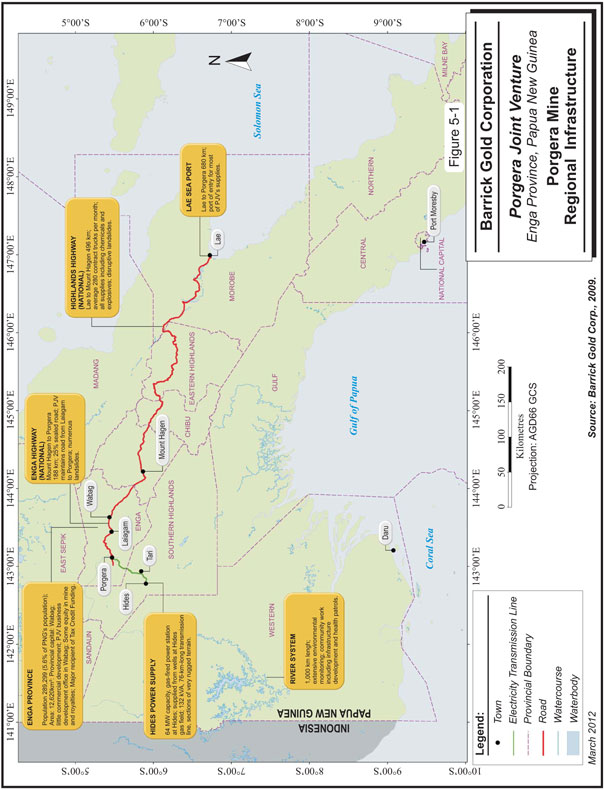

Figure 5-1 | | Porgera Mine Regional Infrastructure | | | 5-3 | |

| | |

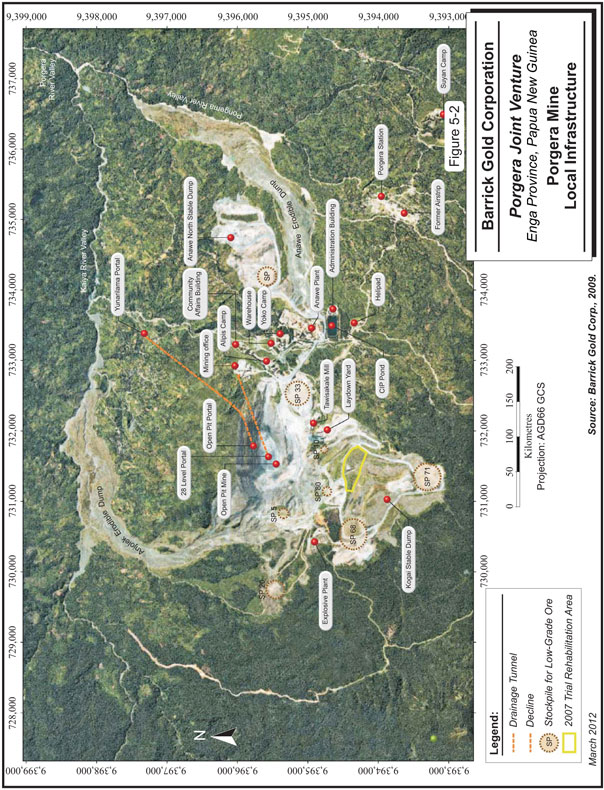

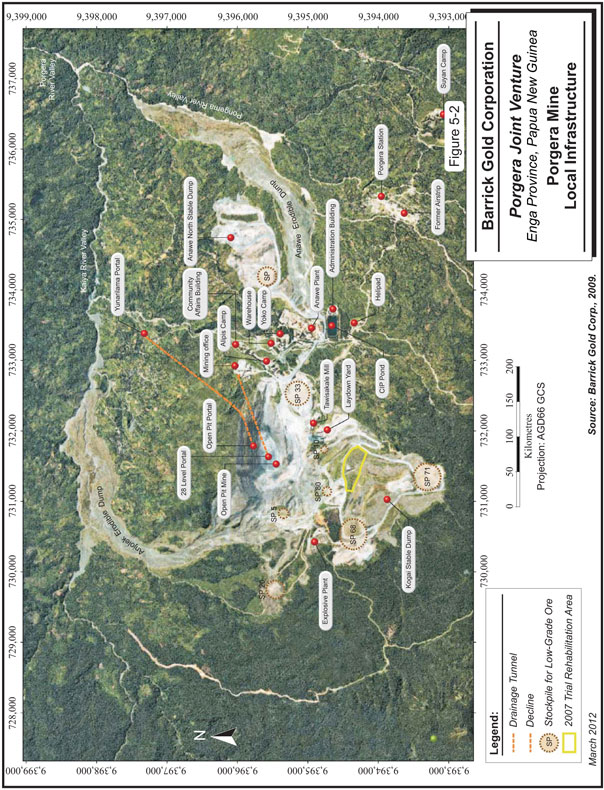

Figure 5-2 | | Porgera Mine Local Infrastructure | | | 5-4 | |

| | |

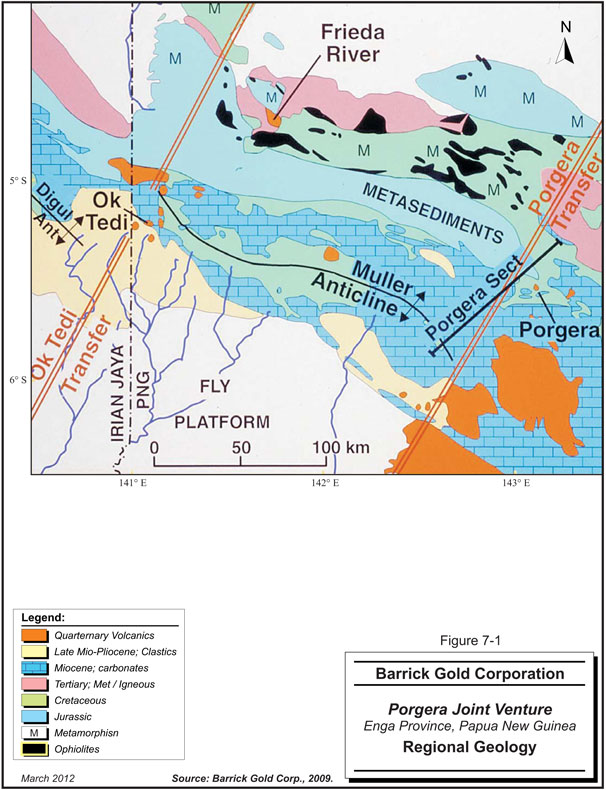

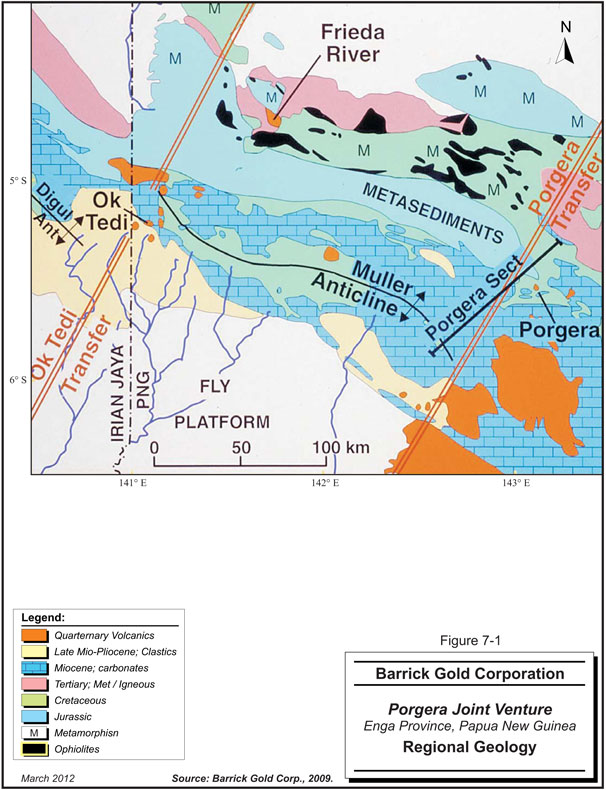

Figure 7-1 | | Regional Geology | | | 7-2 | |

| | |

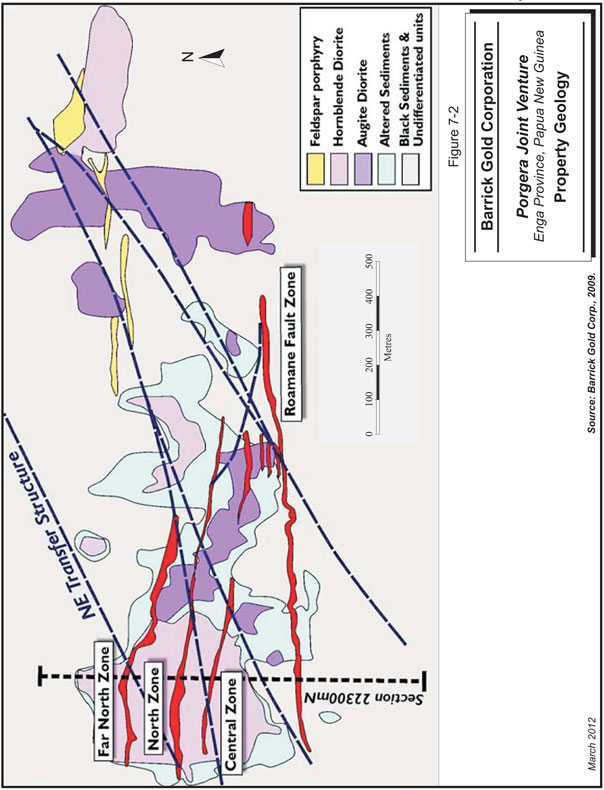

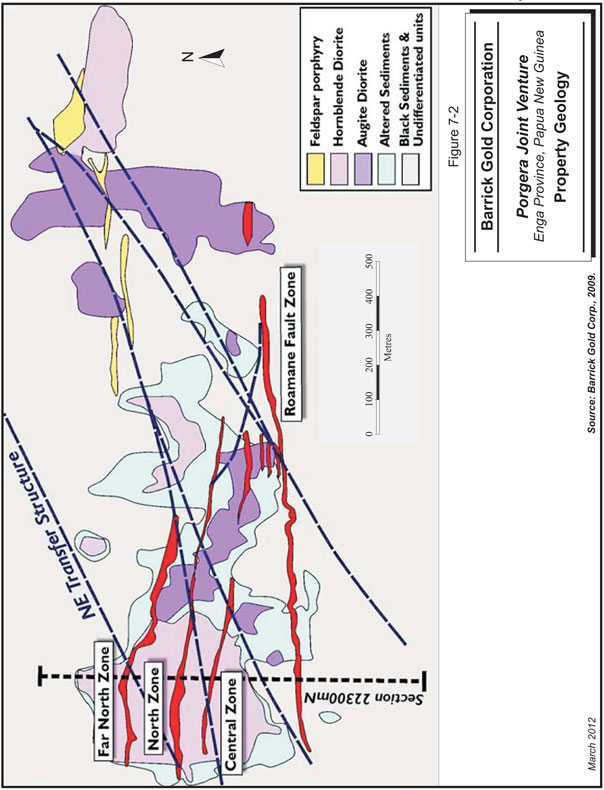

Figure 7-2 | | Property Geology | | | 7-5 | |

| | |

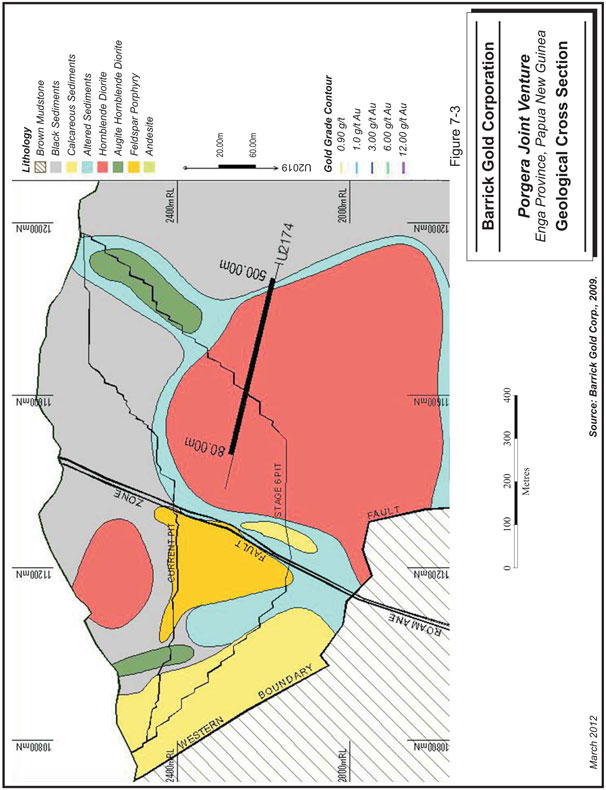

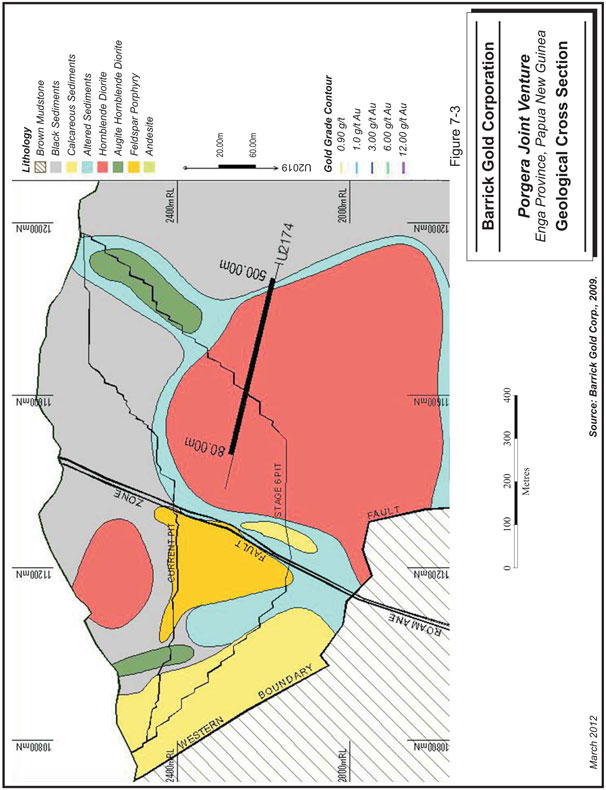

Figure 7-3 | | Geological Cross Section | | | 7-7 | |

| | |

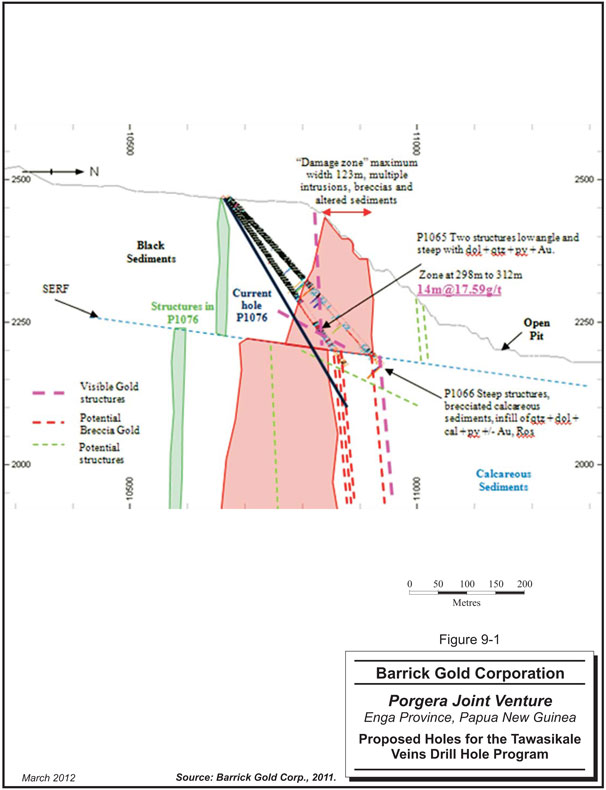

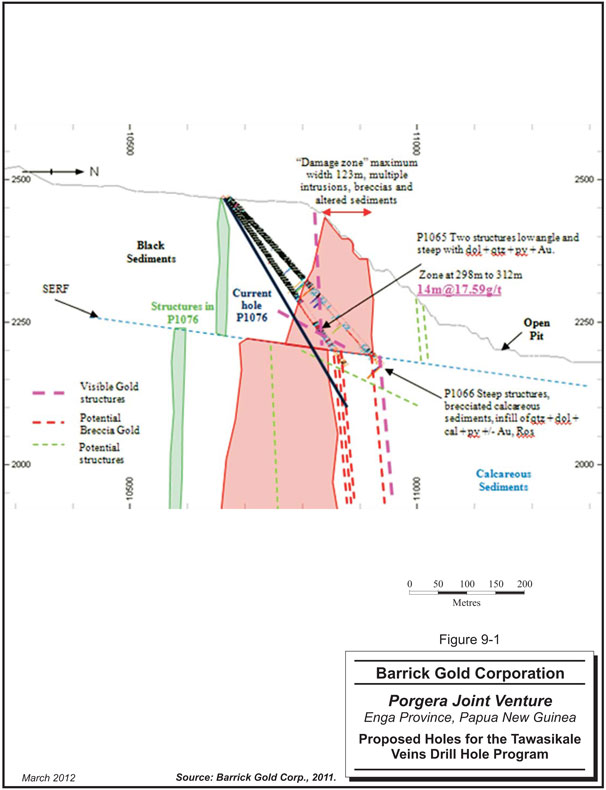

Figure 9-1 | | Proposed Holes for the Tawasikale Veins Drill Hole Program | | | 9-2 | |

| | |

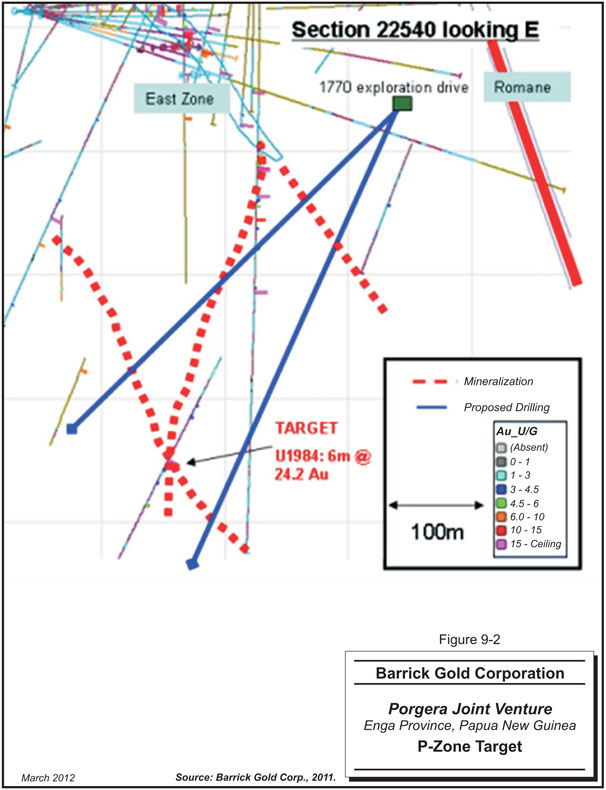

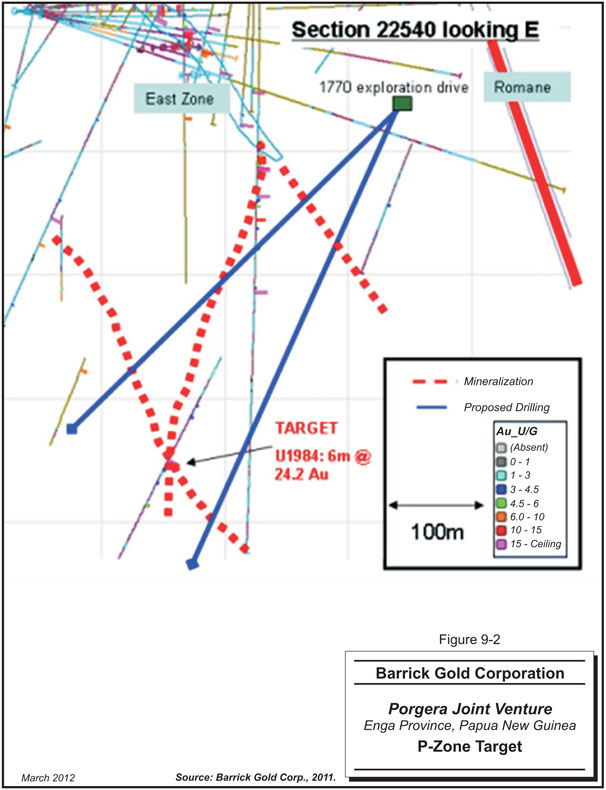

Figure 9-2 | | P-Zone Target | | | 9-4 | |

| | |

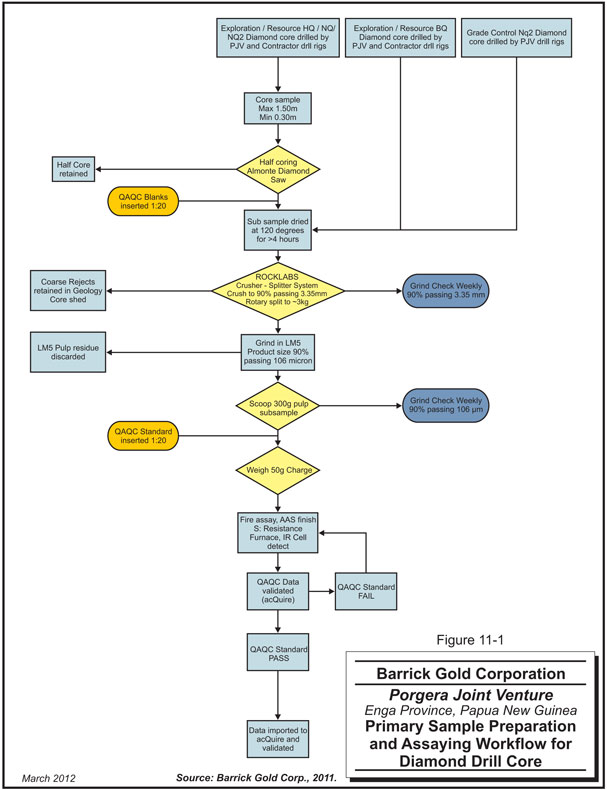

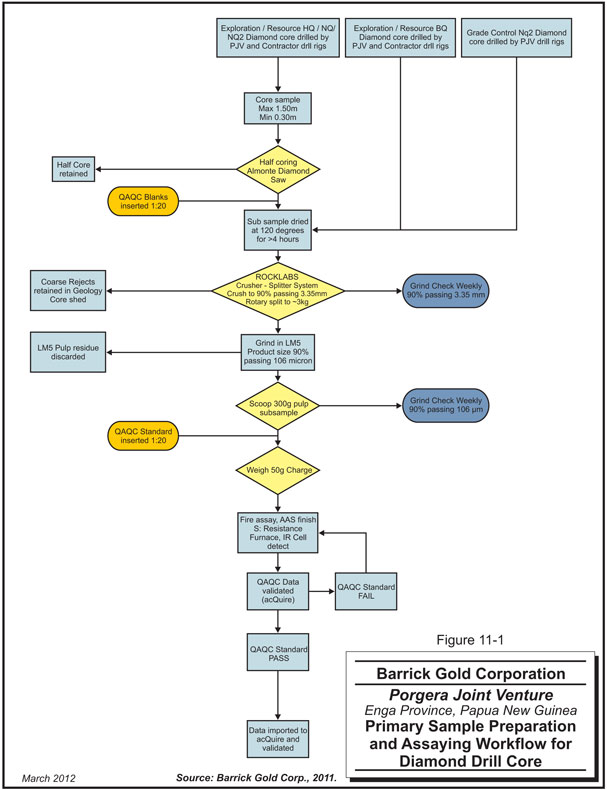

Figure 11-1 | | Primary Sample Preparation and Assaying Workflow for Diamond Drill Core | | | 11-7 | |

| | |

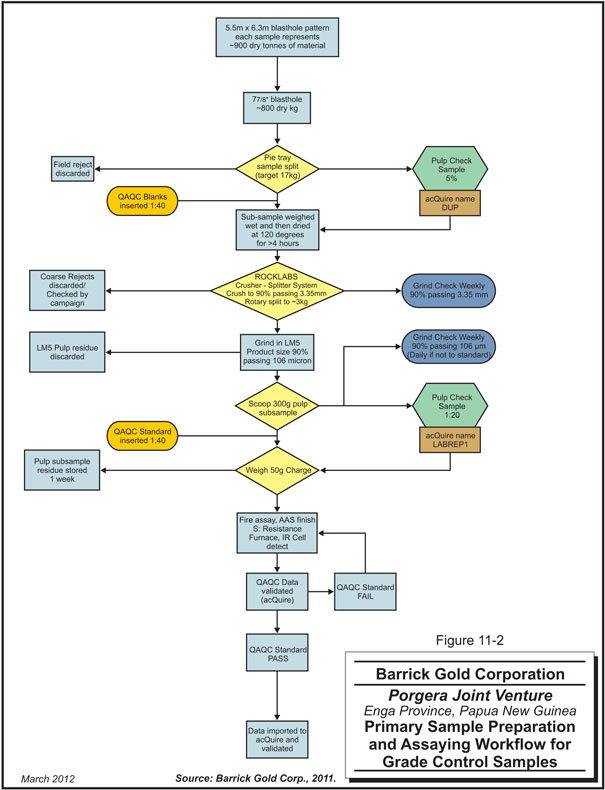

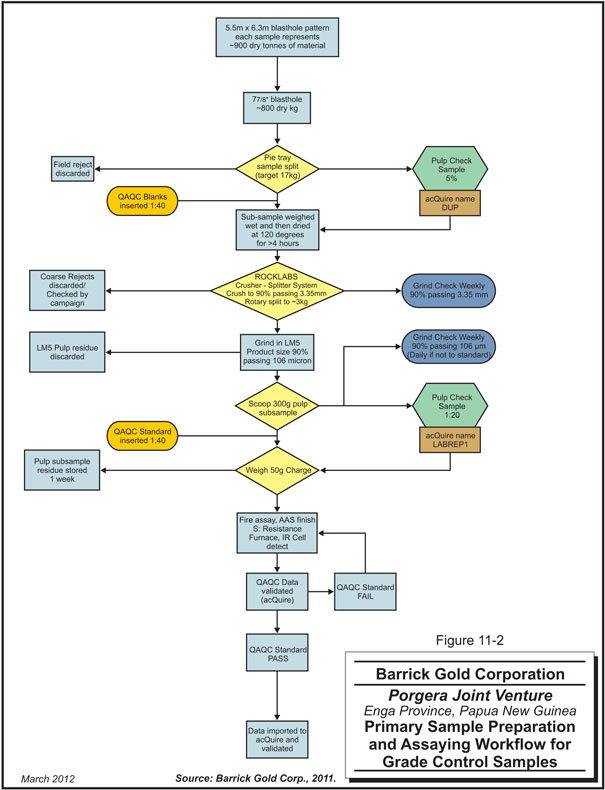

Figure 11-2 | | Primary Sample Preparation and Assaying Workflow for Grade Control Samples | | | 11-8 | |

| | |

Figure 13-1 | | Comparison of Actual Versus Budgeted Gold Recovery | | | 13-5 | |

| | |

Figure 13-2 | | Comparison of Actual Versus Budgeted Ounces Recovered | | | 13-6 | |

| | |

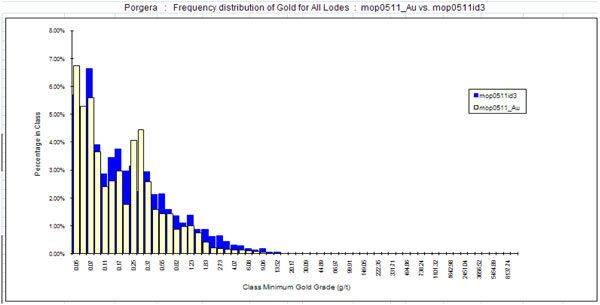

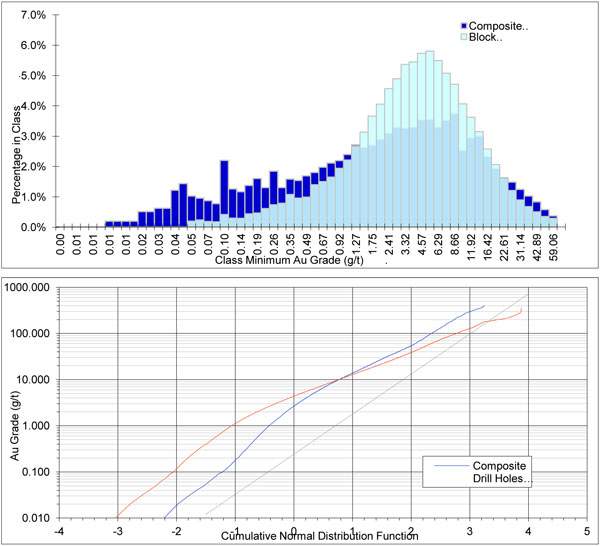

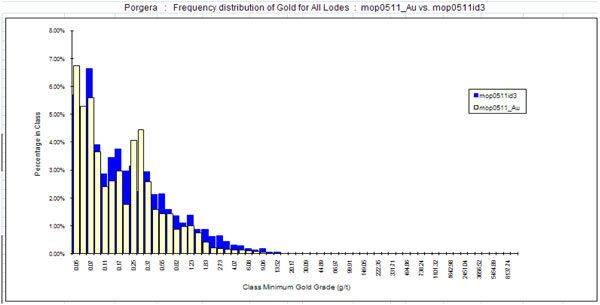

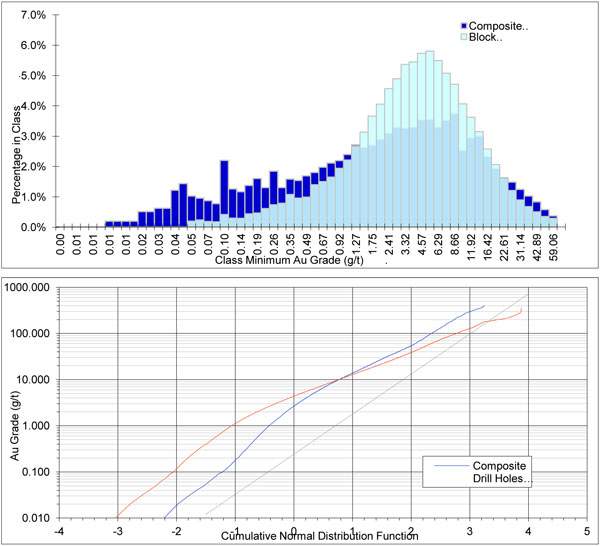

Figure 14-1 | | Example Block and Composite Grade Distributions (All Zones) | | | 14-20 | |

| | |

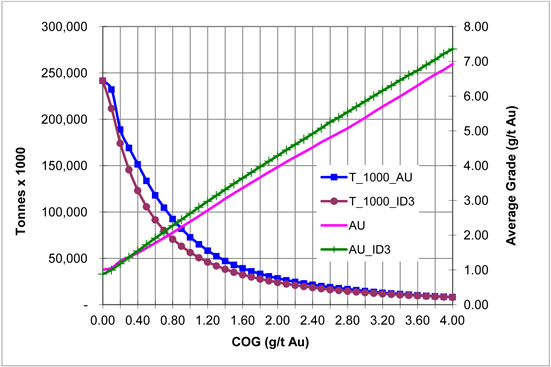

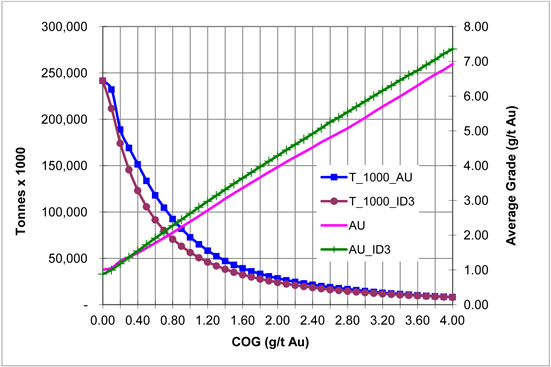

Figure 14-2 | | Tonnage And Grade Curves – ID3 vs Kriging | | | 14-22 | |

| | |

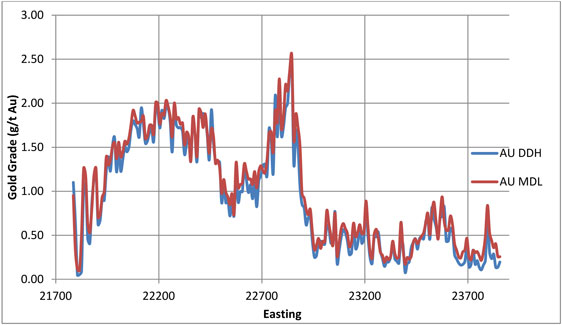

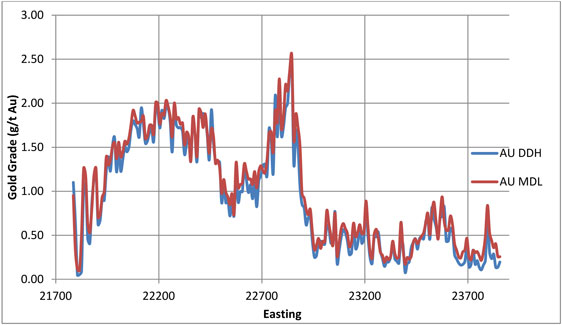

Figure 14-3 | | Drift Diagram (X-Direction) | | | 14-24 | |

| | |

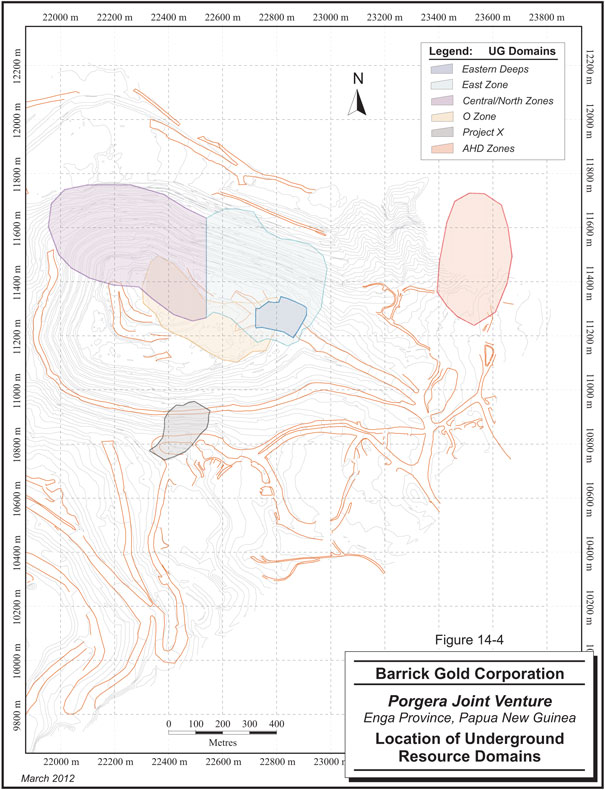

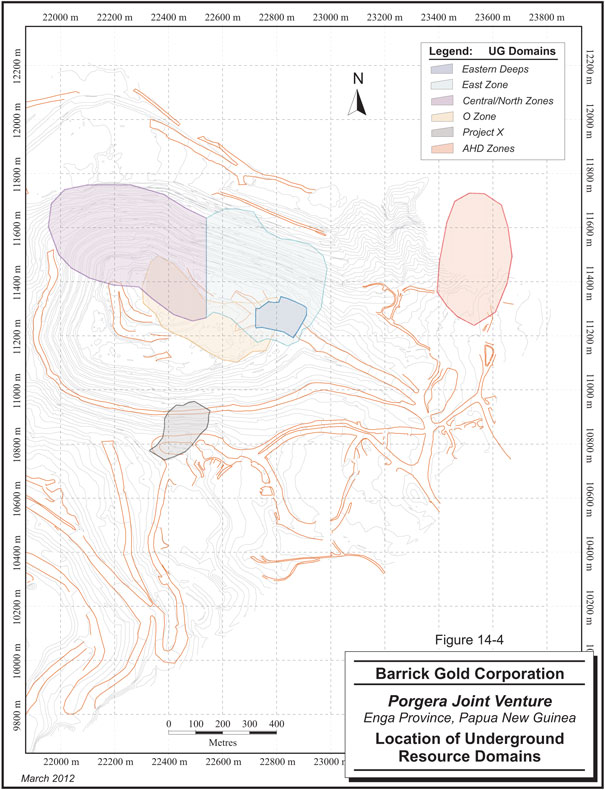

Figure 14-4 | | Location of Underground Resource Domains | | | 14-29 | |

| | |

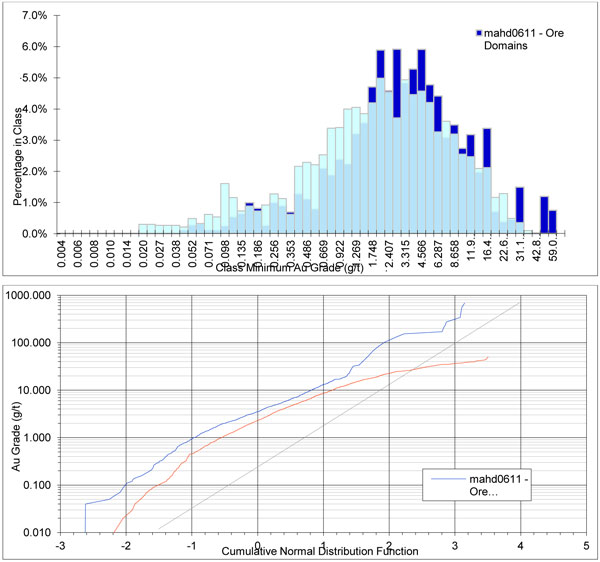

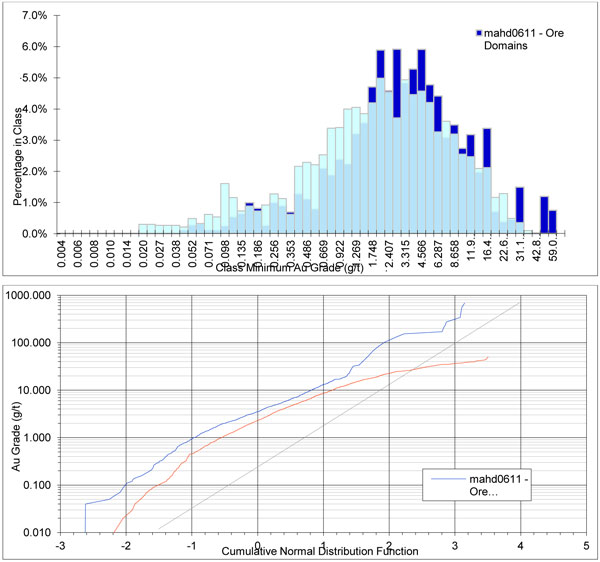

Figure 14-5 | | Example Histogram Comparison of Blocks vs Composites | | | 14-45 | |

| | |

Figure 14-6 | | Example Histogram Comparison of EOY2011 vs Mid-Year 2011 | | | 14-46 | |

| | |

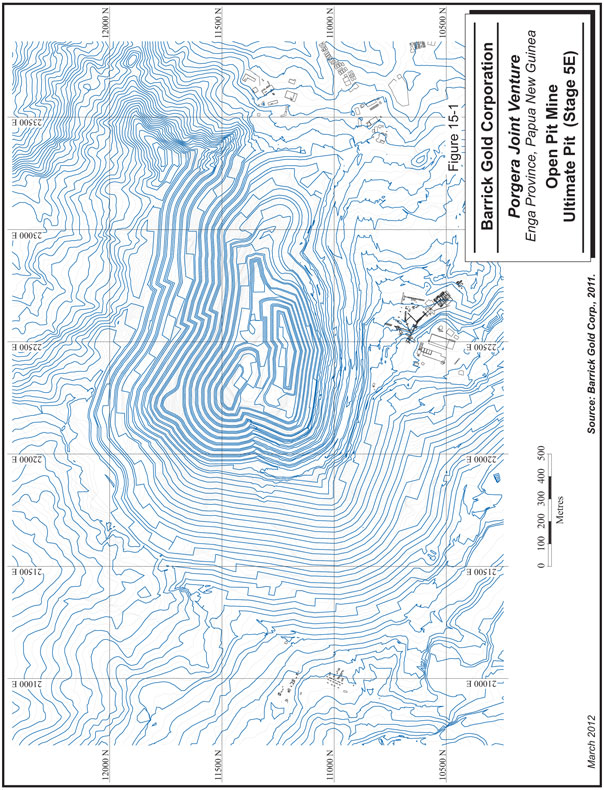

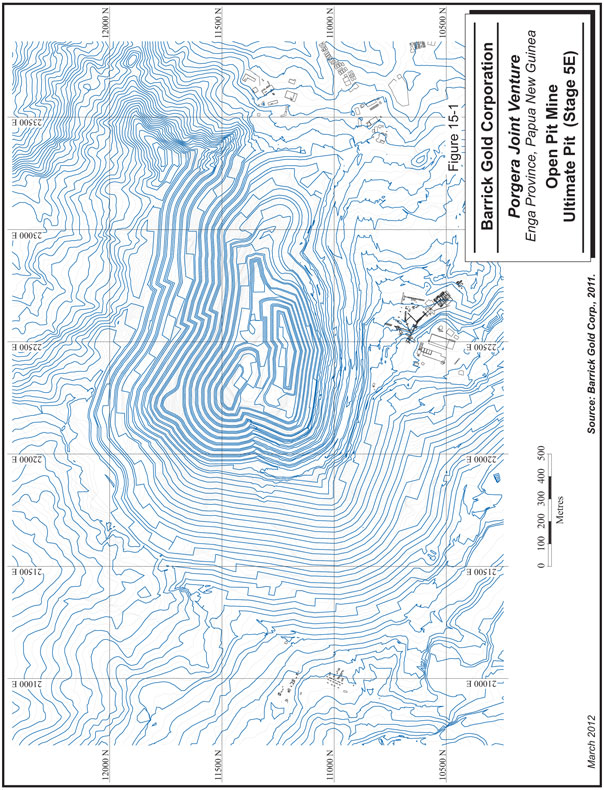

Figure 15-1 | | Open Pit Mine – Ultimate Pit (Stage 5E) | | | 15-5 | |

| | |

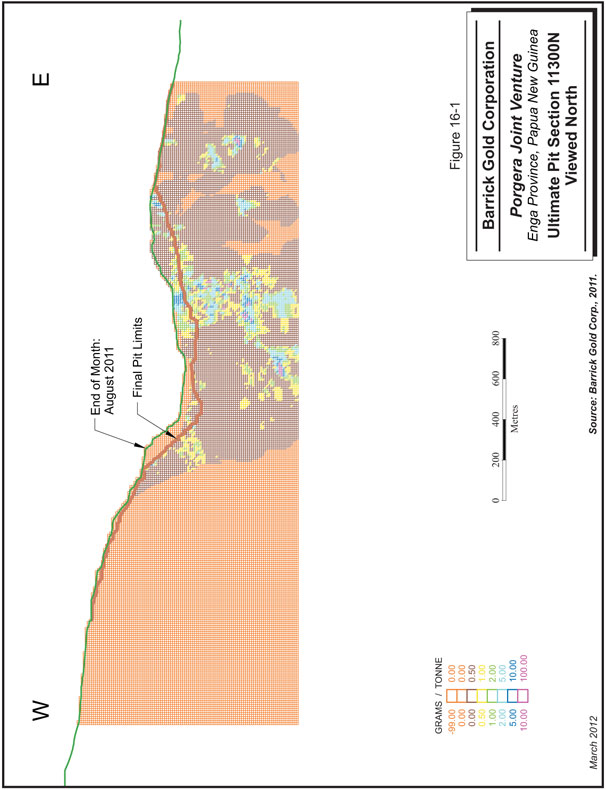

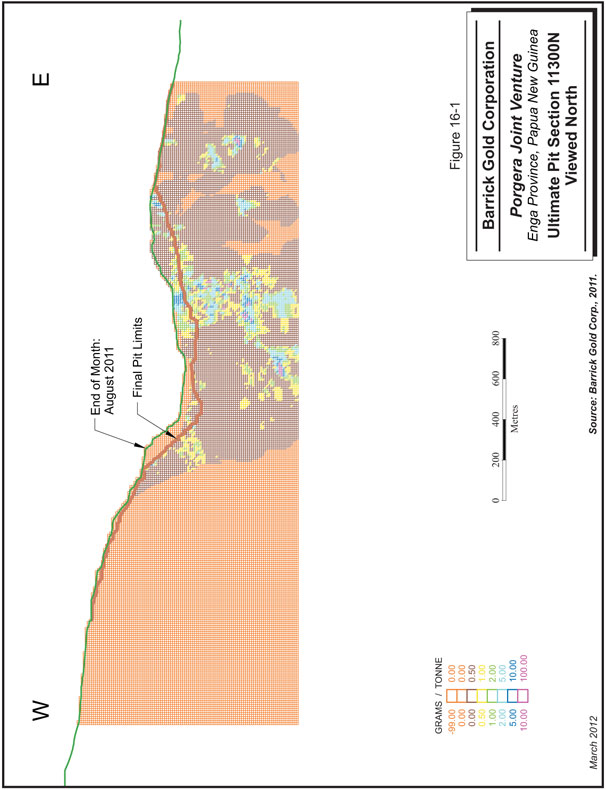

Figure 16-1 | | Ultimate Pit Section 11300N Viewed North | | | 16-5 | |

| | |

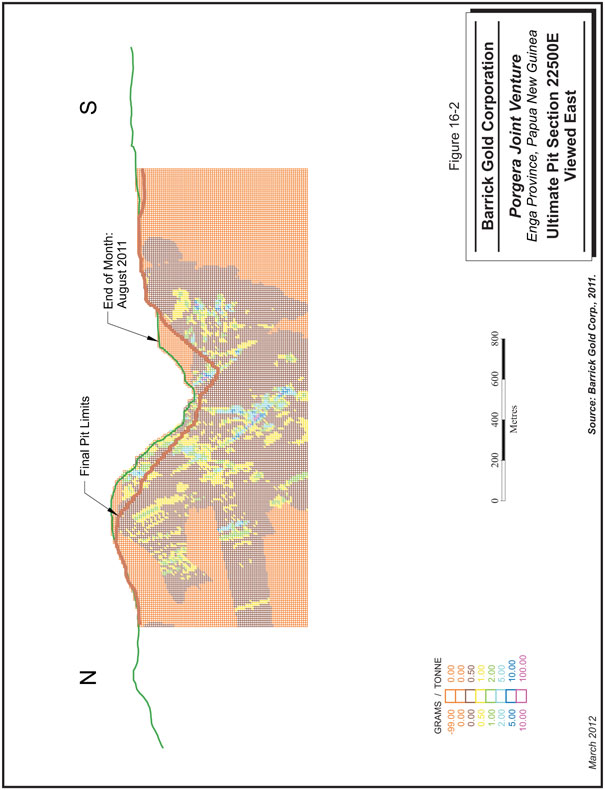

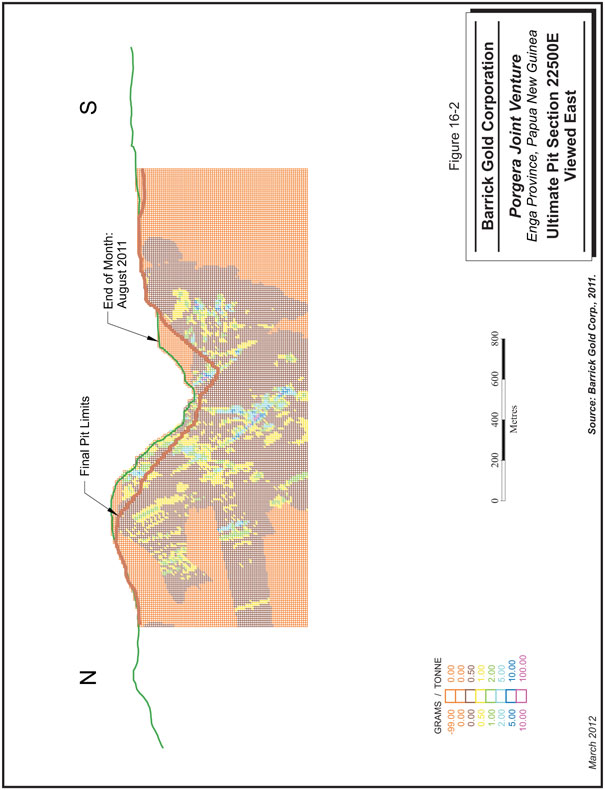

Figure 16-2 | | Ultimate Pit Section 22500E Viewed East | | | 16-6 | |

| | |

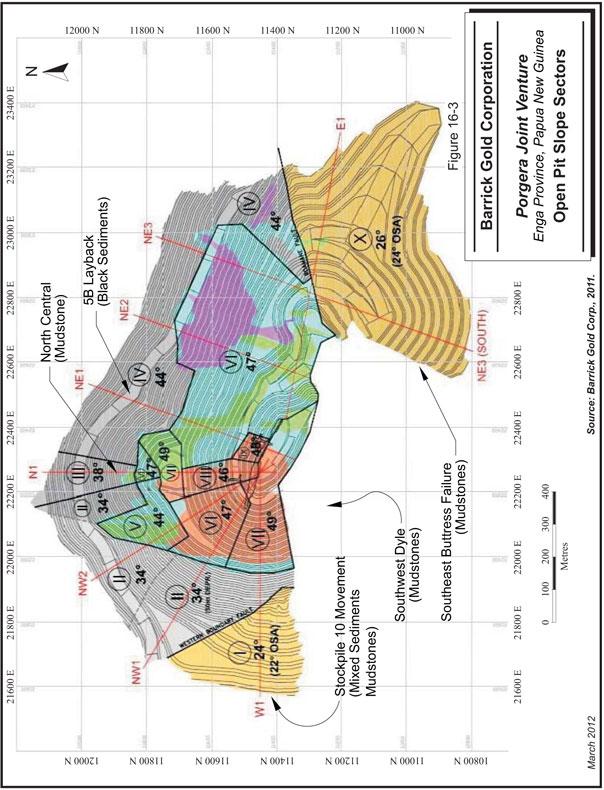

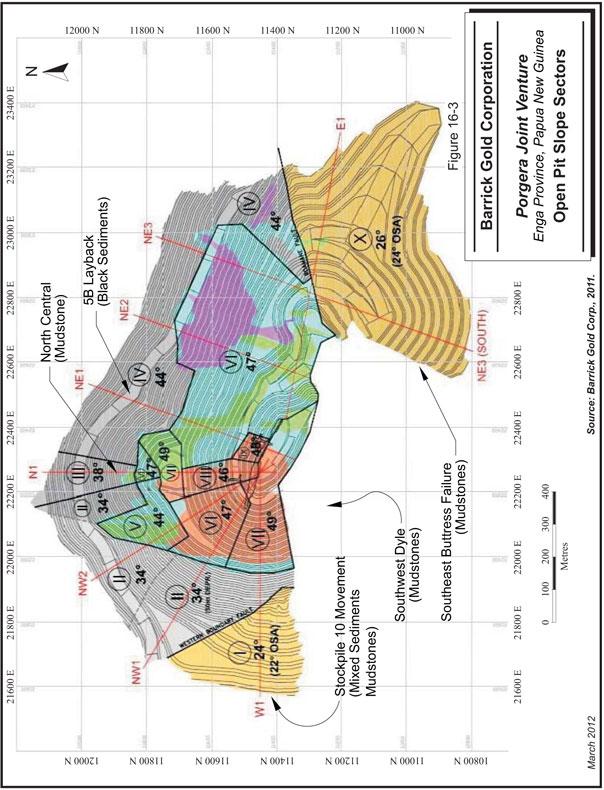

Figure 16-3 | | Open Pit Slope Sectors | | | 16-9 | |

| | |

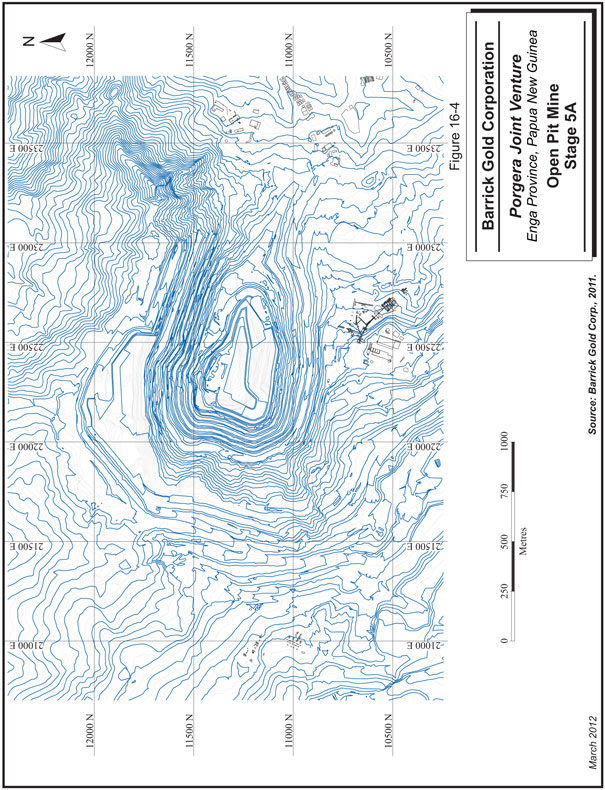

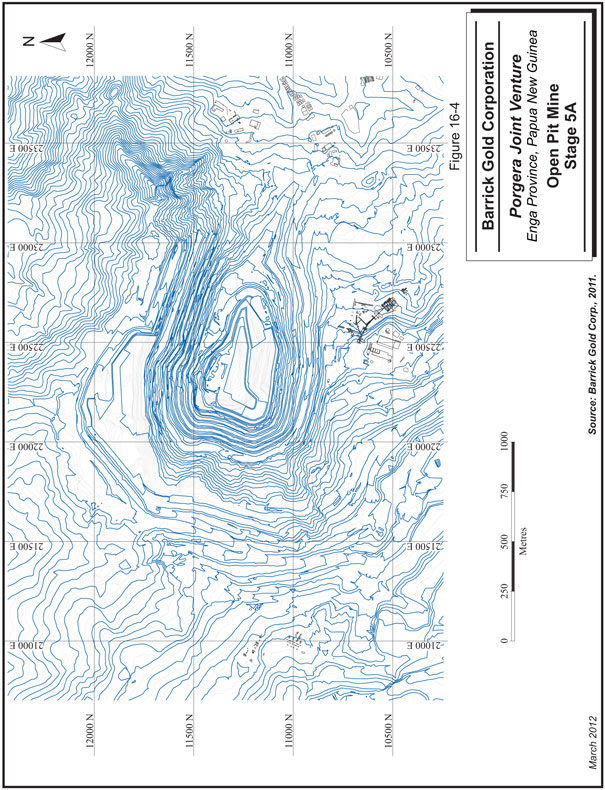

Figure 16-4 | | Open Pit Mine – Stage 5A | | | 16-10 | |

| | |

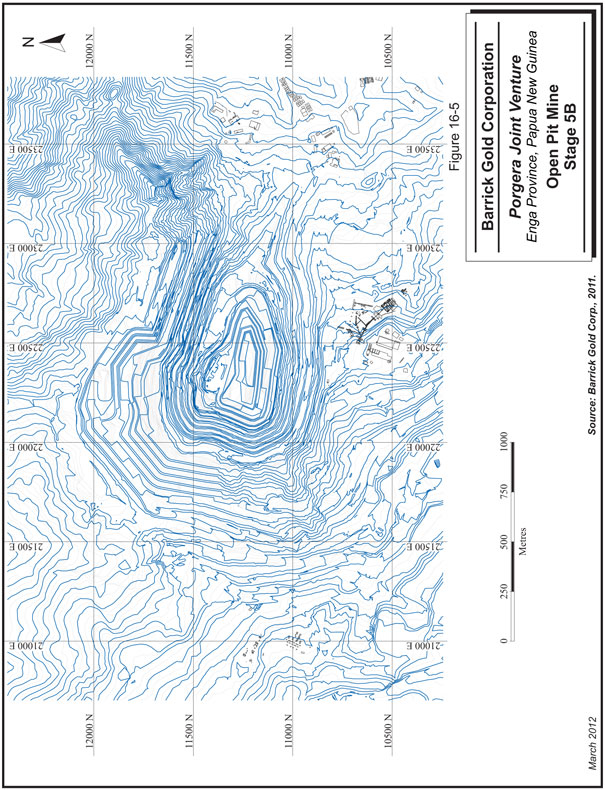

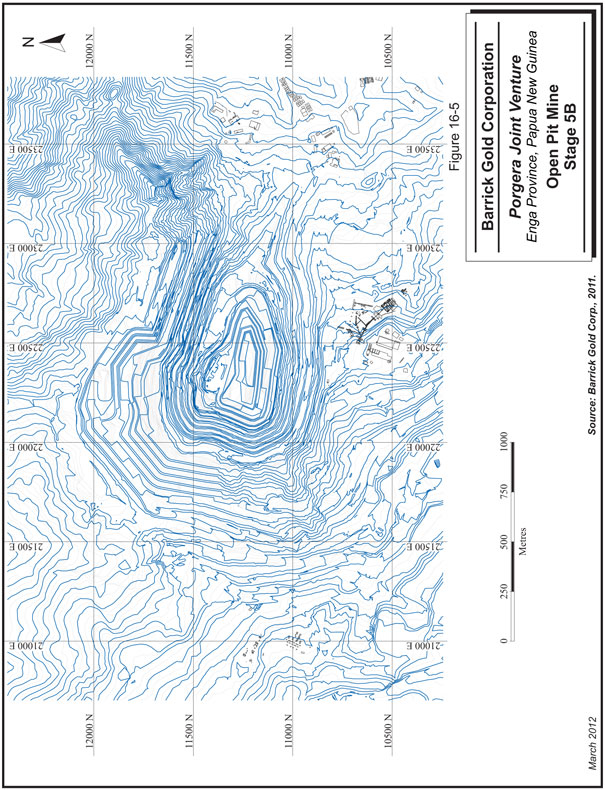

Figure 16-5 | | Open Pit Mine – Stage 5B | | | 16-11 | |

| | |

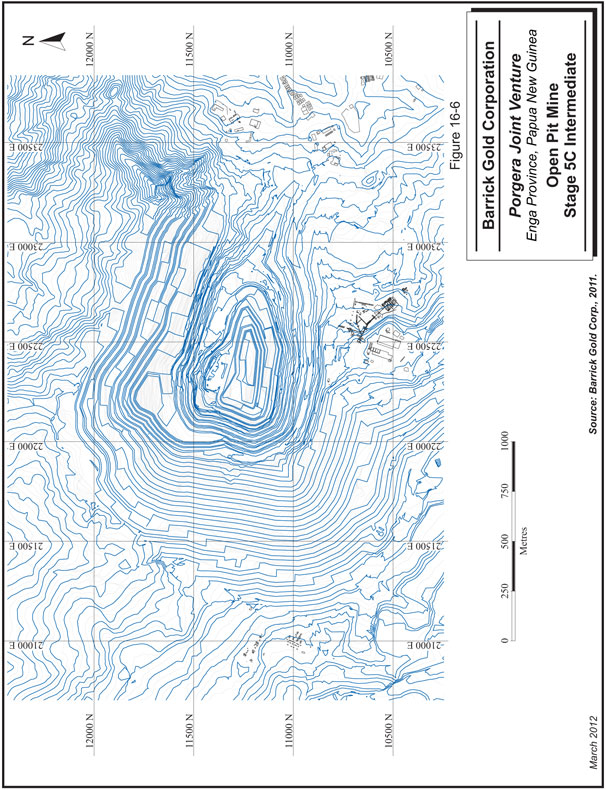

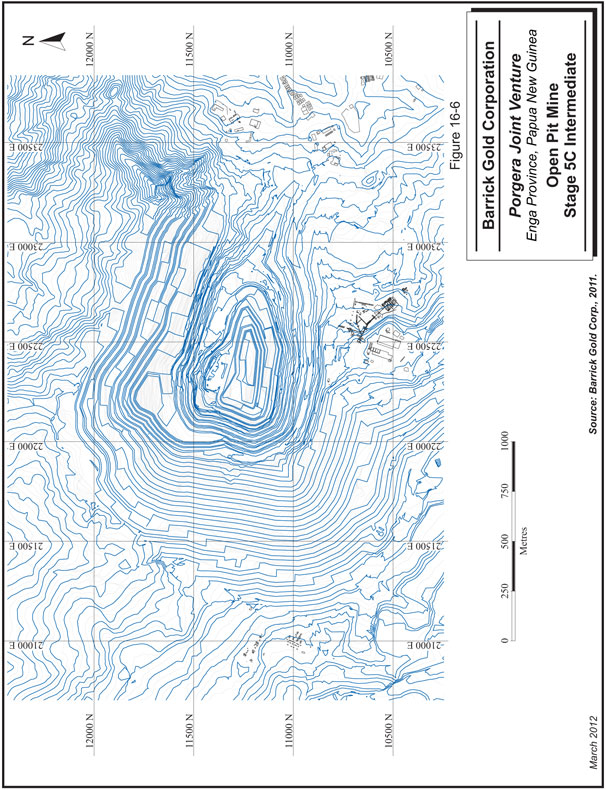

Figure 16-6 | | Open Pit Mine – Stage 5C Intermediate | | | 16-12 | |

| | |

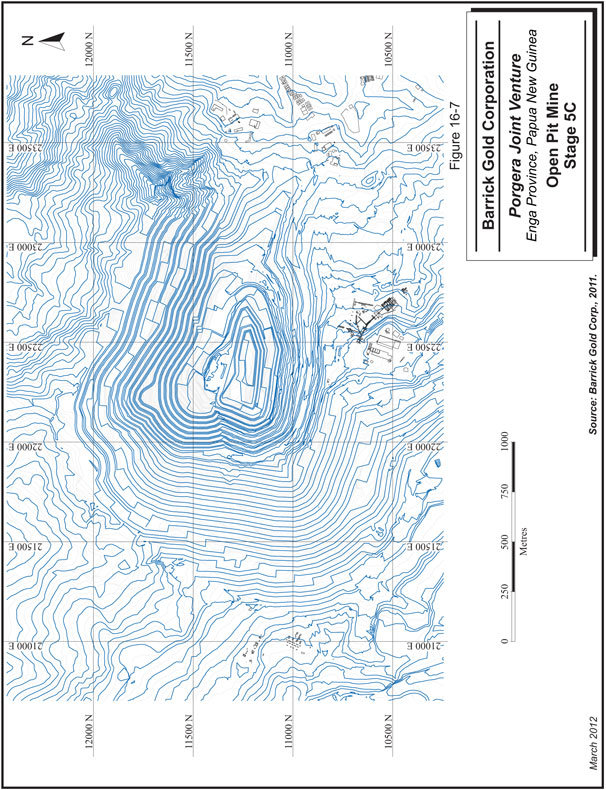

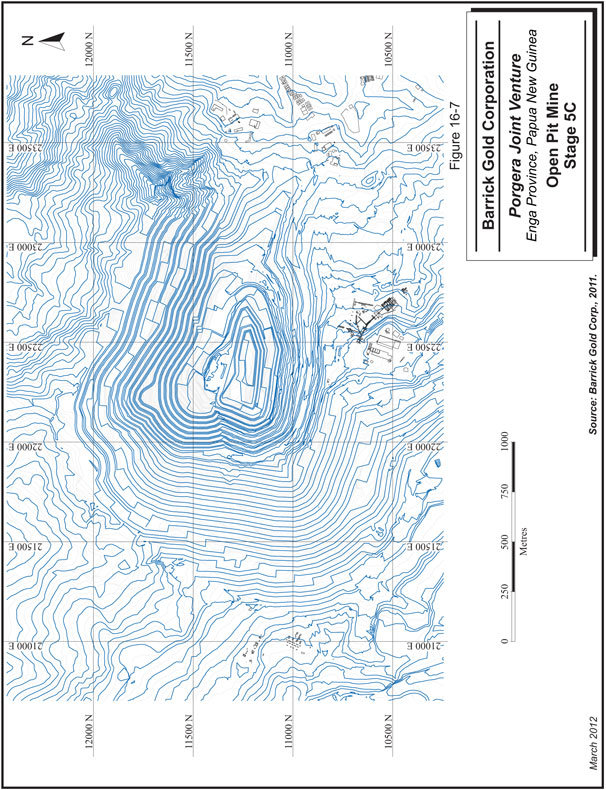

Figure 16-7 | | Open Pit Mine – Stage 5C | | | 16-13 | |

| | |

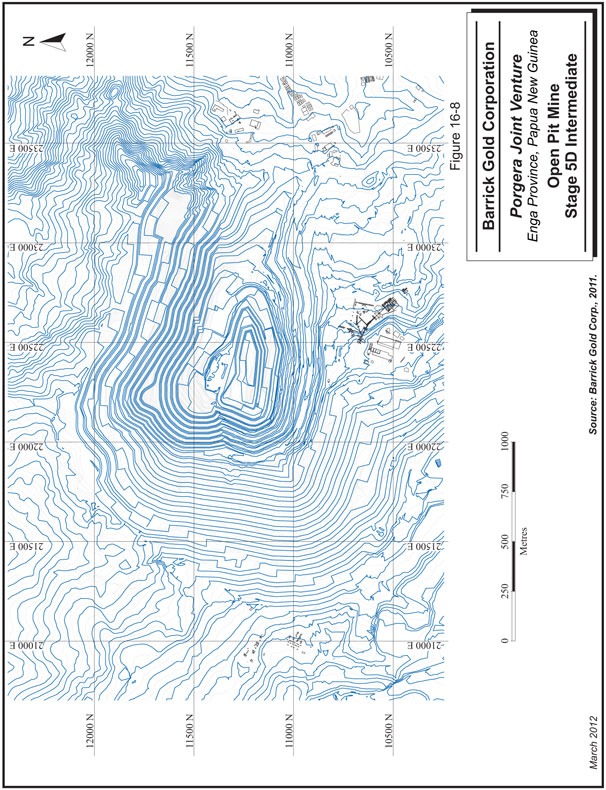

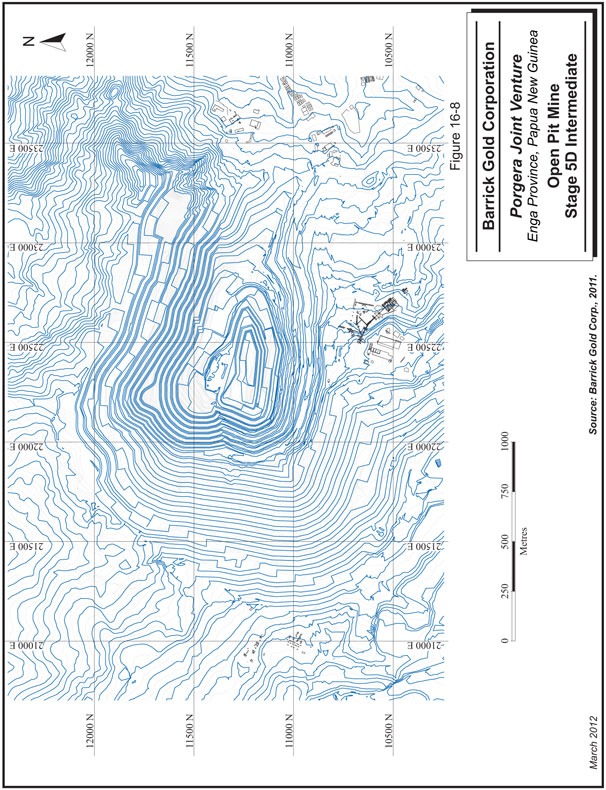

Figure 16-8 | | Open Pit Mine – Stage 5D Intermediate | | | 16-14 | |

| | |

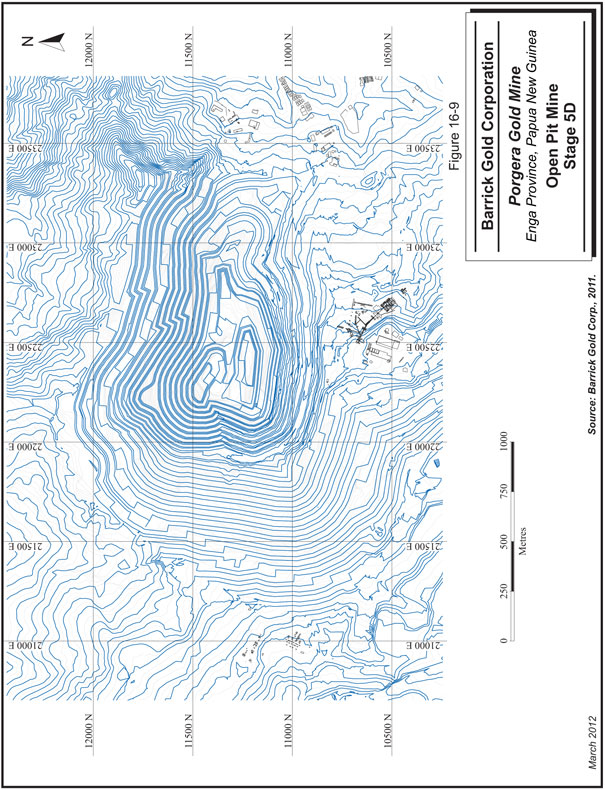

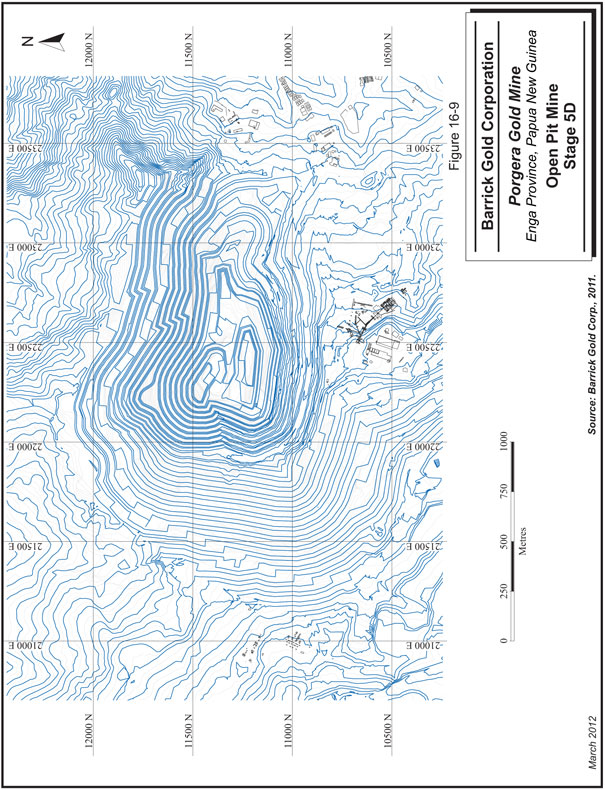

Figure 16-9 | | Open Pit Mine – Stage 5D | | | 16-15 | |

| | |

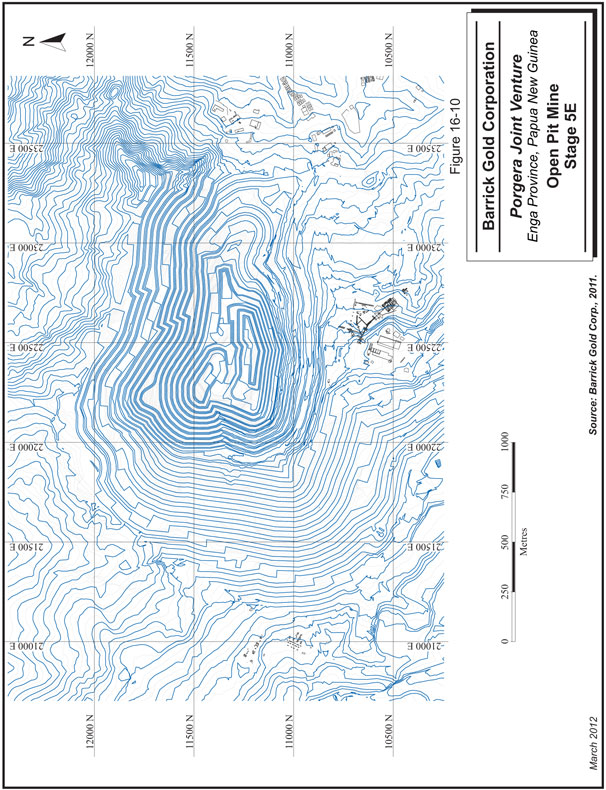

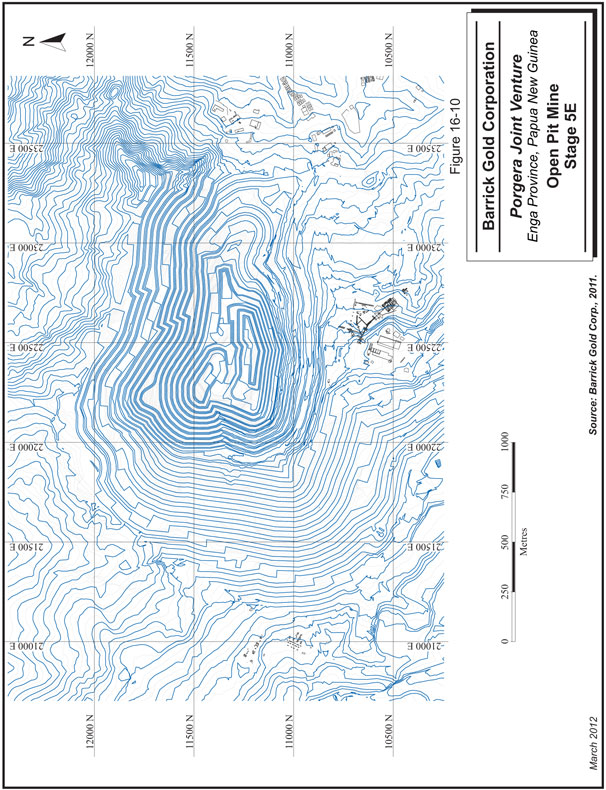

Figure 16-10 | | Open Pit Mine – Stage 5E | | | 16-16 | |

| | |

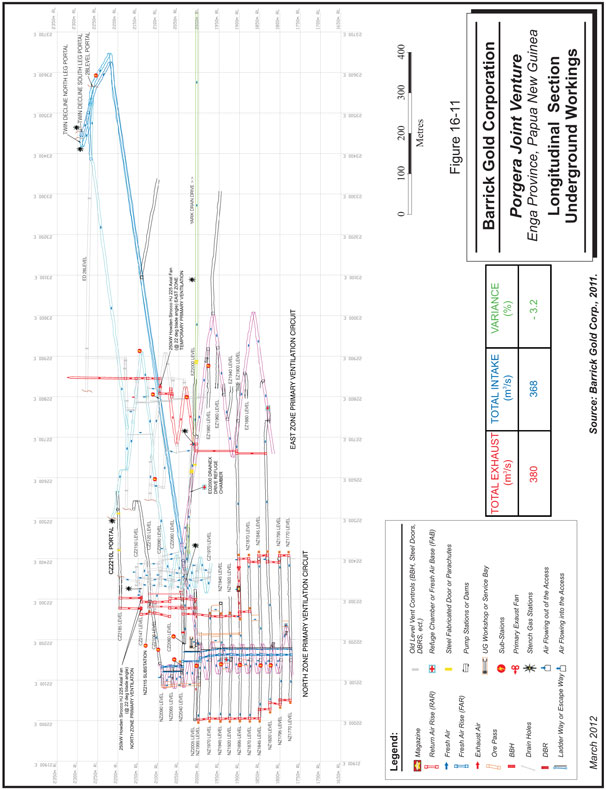

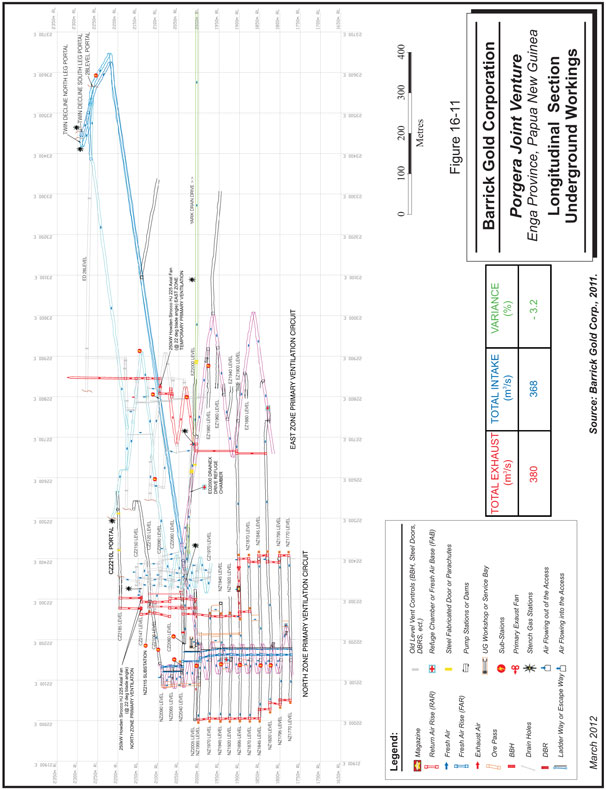

Figure 16-11 | | Longitudinal Section of Underground Workings | | | 16-19 | |

| | |

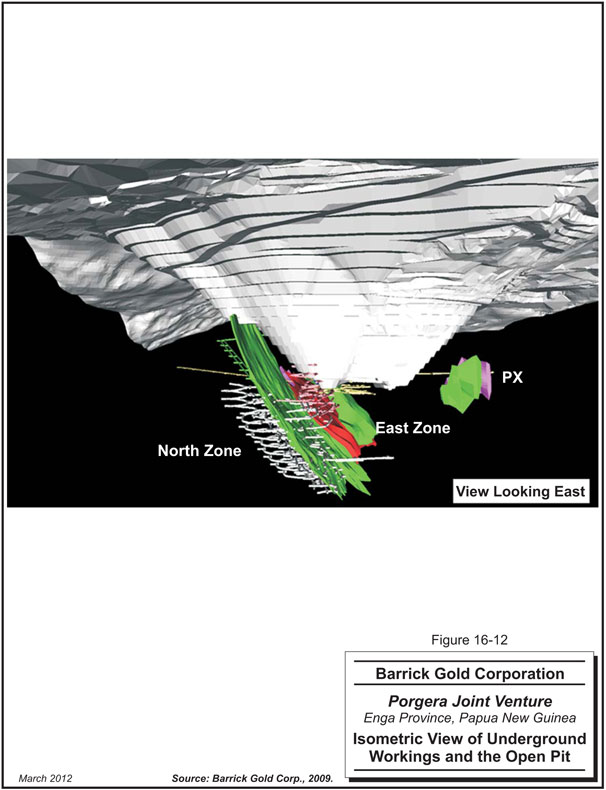

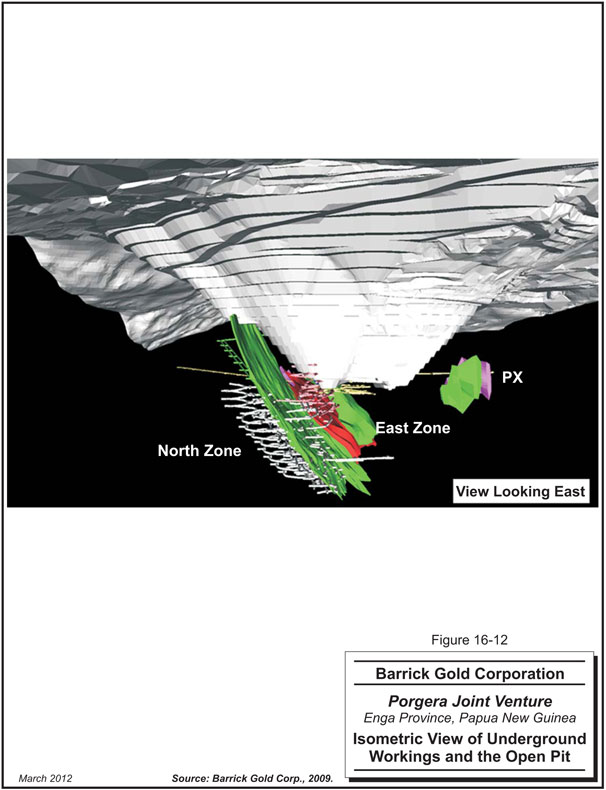

Figure 16-12 | | Isometric View of Underground Workings and the Open Pit | | | 16-20 | |

| | |

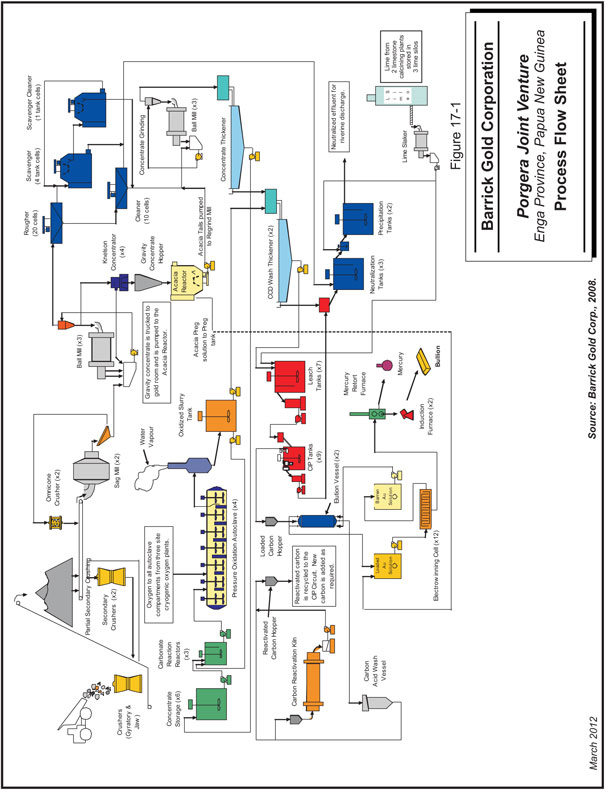

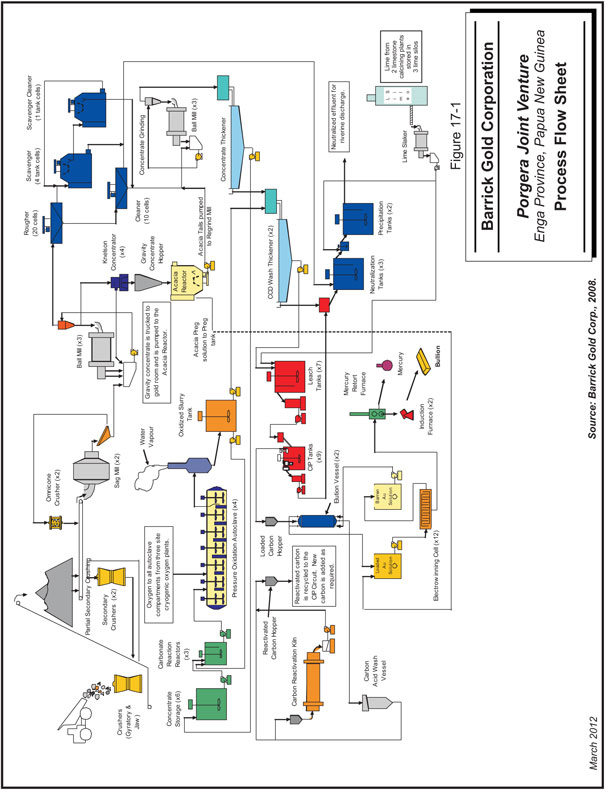

Figure 17-1 | | Process Flow Sheet | | | 17-4 | |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page iv | |

| | |

| | www.rpacan.com |

|

1 SUMMARY

EXECUTIVE SUMMARY

Roscoe Postle Associates Inc. (RPA) was retained by Barrick Gold Corporation (Barrick) to prepare an Independent Technical report on the Porgera Mine (the Project) located in Papua New Guinea (PNG). The purpose of this report is to support public disclosure of Mineral Resource and Mineral Reserve estimates at the Project as of December 31, 2011. This Technical Report conforms to NI 43-101 Standards of Disclosure for Mineral Projects. RPA visited the property from August 28 to September 2, 2011.

The Project is located in Enga Province of the Western Highlands of PNG. The mine is approximately 130 km west-northwest of Mount Hagen, PNG and 600 km northwest of the national capital, Port Moresby, PNG. The property is located at elevations between 2,200 MASL and 2,700 MASL in rugged mountainous terrain, which is largely covered with rain forest.

The Project is owned by Porgera Joint Venture (Porgera JV) whereby Barrick is the operator and has a 95% interest through a wholly owned subsidiary, and Mineral Resources Enga Limited has a 5% interest. The Project is a producing open pit and underground gold mine which has a planned operating rate of approximately 5.2 million tonnes per annum from the open pit and stockpiles and 0.8 million tonnes per annum from the underground. The mine produces gold in doré form from process plants utilizing gravity as well as flotation followed by autoclaves and cyanide leaching. Annual gold production was approximately 526,000 (100% interest) ounces in 2011.

Table 1-1 summarizes the Porgera JV Mineral Resources exclusive of Mineral Reserves as of December 31, 2011; this represents 100% of the Resource estimate and not the 95% attributable to Barrick.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-1 | |

| | |

| | www.rpacan.com |

|

TABLE 1-1 MINERAL RESOURCES (100%) – DECEMBER 31, 2011

Barrick Gold Corporation – Porgera JV

| | | | | | | | |

Category | | Description | | Tonnes

(000) | | Grade

(g/t Au) | | Contained

Gold

(000 oz) |

Measured | | | | | | | | |

| | Open Pit | | 8,190 | | 2.31 | | 609 |

| | Underground | | 463 | | 10.33 | | 154 |

Total Measured | | | | 8,650 | | 2.74 | | 763 |

Indicated | | | | | | | | |

| | Open Pit | | 15,800 | | 1.56 | | 793 |

| | Underground | | 1,630 | | 9.15 | | 480 |

Total Indicated | | | | 17,400 | | 2.27 | | 1,270 |

| | | | | | | | |

Total Measured & Indicated | | | | 26,100 | | 2.41 | | 2,030 |

| | | | | | | | |

Inferred | | | | | | | | |

| | Open Pit | | 13,500 | | 1.77 | | 771 |

| | Underground | | 8,100 | | 8.90 | | 2,320 |

Total Inferred | | | | 21,600 | | 4.45 | | 3,090 |

Notes:

| | 1. | CIM definitions were followed for Mineral Resources. |

| | 2. | Mineral Resources are estimated at a cut-off grade of 1.0 g/t Au for the open pit and 3.0 g/t Au for the underground mine. |

| | 3. | Mineral Resources are estimated using an average gold price of US$1,400 per ounce, and a US$/C$ exchange rate of 1:1. |

| | 4. | A minimum mining width of 5 m was used. |

| | 5. | Bulk density is determined based on lithology |

| | 6. | Measured and Indicated Mineral Resources are exclusive of Mineral Reserves. |

Table 1-2 summarizes the Porgera JV Mineral Reserve estimate as of December 31, 2011; this represents 100% of the Reserves and not the 95% attributable to Barrick. This includes open pit, underground and stockpile reserves.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-2 | |

| | |

| | www.rpacan.com |

|

TABLE 1-2 MINERAL RESERVES (100%) – DECEMBER 31, 2011

Barrick Gold Corporation – Porgera JV

| | | | | | | | | | | | |

Category | | Tonnes

(000) | | | Grade

(g/t Au) | | | Contained

Gold

(000 oz) | |

Open Pit | | | | | | | | | | | | |

Proven | | | 13,944 | | | | 3.00 | | | | 1,343 | |

Probable | | | 31,105 | | | | 2.11 | | | | 2,115 | |

Subtotal | | | 45,049 | | | | 2.39 | | | | 3,458 | |

| | | |

Underground | | | | | | | | | | | | |

Proven | | | 3,500 | | | | 7.17 | | | | 807 | |

Probable | | | 3,624 | | | | 7.56 | | | | 880 | |

Subtotal | | | 7,124 | | | | 7.37 | | | | 1,687 | |

| | | |

Stockpiles | | | | | | | | | | | | |

Proven | | | | | | | | | | | | |

Probable | | | 19,802 | | | | 2.29 | | | | 1,455 | |

Subtotal | | | 19,802 | | | | 2.29 | | | | 1,455 | |

| | | |

Process Inventory | | | — | | | | — | | | | 102 | |

| | | |

Total Proven | | | 17,443 | | | | 3.83 | | | | 2,149 | |

Total Probable | | | 54,532 | | | | 2.60 | | | | 4,552 | |

| | | | | | | | | | | | |

Total Mineral Reserve | | | 71,975 | | | | 2.90 | | | | 6,701 | |

| | | | | | | | | | | | |

Notes:

| | 1. | CIM definitions were followed for Mineral Reserves. |

| | 2. | Open Pit Mineral Reserves are estimated at a breakeven cut-off grades range from 0.95 g/t Au to 1.29 g/t Au (nominal). |

| | 3. | Underground Mineral Reserves are estimated at a cut-off grade of 3.5 g/t Au. |

| | 4. | Open Pit Mineral Reserves are estimated using an average long-term gold price of US$575 per ounce, a US$:C$ exchange rate of 1:1, and a US$:AUS$ exchange rate of 0.9:1. |

| | 5. | A minimum mining open pit width of 25 m was used. |

| | 6. | Bulk densities range from 2.64 t/m3 to 2.79 t/m3, depending on lithology. |

| | 7. | Numbers may not add due to rounding. |

| | 8. | Mineral Reserves do not include Mineral Resources, i.e. Mineral Reserves are exclusive of Mineral Resources. |

Mineral Reserves have been based on only Measured and Indicated Resources. The Mineral Reserves are exclusive of Mineral Resources, i.e. Mineral Reserves are not included in the Mineral Resources.

CONCLUSIONS

Based on the site visit and review, RPA draws the following conclusions:

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-3 | |

| | |

| | www.rpacan.com |

|

GEOLOGY AND MINERAL RESOURCES

| | • | | Sampling methods and protocols are consistent with common industry standards and appropriate for the style of mineralization. |

| | • | | The data capture is conducted in an appropriate fashion, with a reasonable level of safe-guards and validation. |

| | • | | The database is maintained using secure protocols and industry-standard software. |

| | • | | The assaying is done using methods commonly used in the industry and appropriate for the grades, deposit type and style of mineralization. |

| | • | | A minimum level of independent assay quality assurance/quality control (QA/QC) checking is applied. Assay repeatability is observed to be poor for gold, and the use of metallics screen assays is being contemplated. |

| | • | | RPA noted some minor errors in the database. However, in RPA’s opinion the sample database is reasonably free from error and adequate for use in estimation of Mineral Resources and Mineral Reserves. |

| | • | | Mineral Resource estimates are carried out using methods that are, for the most part, conventional and commonly used within the industry, using software that is commercially available. Certain geostatistical and statistical analyses are conducted using in-house software. |

| | • | | There is a good understanding of the geology, mineralogy and deposit model. The geological interpretations of the mineralized zones and the wireframe models derived from those interpretations are reasonable. |

| | • | | Parameters for grade estimation are derived using reasonable and appropriate interpretations of the geology, statistics, and geostatistics. |

| | • | | There are a number of mineralized zones that have been intersected by drill holes but have not yet been fully defined. Most often, these zones are located in the background domains. The block models for these domains are poorly constrained, which results in excessive dilution in some cases, and unrealistic extrapolation of grades in others. These zones require further drilling, interpretation, and wireframe modeling to fully evaluate their potential and bring them into the Mineral Reserves. As an interim solution, Porgera JV mine staff have implemented an estimation strategy which employs search ellipsoids with highly restricted cross-strike radii (the “Statistically Controlled” method). |

| | • | | The implementation of the Statistically Controlled (SC) interpolation method has resulted in the addition of significant volumes of Mineral Resources to the inventory. In RPA’s opinion, this method is acceptable for use in estimation of Inferred Mineral Resources. It will require some time to assess the performance of this estimation method through tracking of the Inferred material through upgrade to Indicated and Measured. |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-4 | |

| | |

| | www.rpacan.com |

|

| | • | | Other recent modifications to the estimation methodology include the application of a two drill hole minimum per block, and a conversion of the classification scheme to one based on distance from samples. These changes are being implemented to bring the process more in line with the guidelines imposed by Barrick’s Tuscon Resource Group. |

| | • | | On a 100% basis, the Measured and Indicated Mineral Resources total 26.1 million tonnes at a grade of 2.41 g/t Au, containing 2.03 million ounces of gold. |

| | • | | On a 100% basis, the Inferred Mineral Resources total 21.6 million tonnes at a grade of 4.45 g/t Au, containing 3.09 million ounces of gold. |

| | • | | Resource classification is reasonable and consistent with the requirements of NI 43-101. |

| | • | | Block model validation techniques are reasonably rigorous and do not indicate that there are any major issues with the grade interpolations. |

| | • | | The mine staff apply an appropriate level of rigour in demonstrating that the Mineral Resources have a reasonable prospect of economic extraction. |

| | • | | The cut-off grades applied are reasonable. |

| | • | | The resource estimate procedures are not very well documented, primarily due to the scheduling of a new set of block models for year end. Reports for some zones (e.g. PX and EDX) in the underground mine are up to six years old and require updates. |

| | • | | There are exploration targets in and around the Porgera JV Mine that could provide additional Mineral Reserves in the future. |

MINING AND MINERAL RESERVES

| | • | | RPA finds the Mineral Reserve estimates to be conservative, reasonable, acceptable, and compliant with NI 43-101. The Mineral Reserves are generated based upon the mine designs applied to the Mineral Resources. The design methodology uses both the cut-off grade estimation and economic assessment to design and validate the mineable reserves. Schedules are generated using industry-accepted methods and programs. |

| | • | | Open pit, underground, stockpile and inventory Proven and Probable Mineral Reserves total, on a 100% basis, 72.0 million tonnes at a grade of 2.90 g/t, containing 6.7 million ounces of gold. |

| | • | | The total closing stockpile at as of December 31, 2010 was 22.0 million tonnes at 2.35 g/t Au and 2.62% S for 1.66 million ounces. The total closing stockpile as of December 31, 2011 was 19.8 million tonnes at 2.29 g/t Au for 1.46 million ounces. |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-5 | |

| | |

| | www.rpacan.com |

|

| | • | | As of December 31, 2011 the mine has produced approximately 17.4 million ounces of gold. Current mine life based on the Mineral Reserves only is approximately eight years. |

| | • | | The location of the Project creates many challenges for the mine planning and mine operations departments. Listed below are some the challenges that Porgera JV faces: |

| | • | | Dewatering of the surface and meteoric (ground) waters is a major challenge, which can impact the open pit slope stability; |

| | • | | Given the impacts of surface and ground waters and lithologies found in the open pit and underground, the ground control conditions can be difficult, which can result in highwall failures; |

| | • | | The Project is in a very remote area of Papua New Guinea that lays in high relief terrain, and experiences yearly precipitation of greater than two metres; |

| | • | | Maintaining the equipment with an experienced staff and sustaining an adequate supply of spare parts is continually being addressed by the Porgera JV management team. |

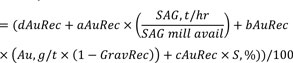

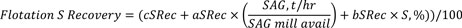

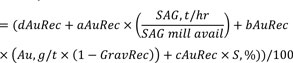

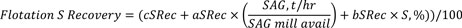

PROCESSING

| | • | | Although the equations used to estimate gold recovery appear to be accurate, they are very complex. RPA observed that communication as to how the estimates are developed was deficient between the process department and the technical services department. As a result the equations are not used in the cut-off-grade calculations or the Resource and Reserve models. |

| | • | | Historical metal recovery has been approximately 86%. |

ENVIRONMENTAL AND COMMUNITY CONSIDERATIONS

| | • | | The practice of segregating potential metal leaching material was initially used in the operation but was subsequently abandoned and was not in use at the time of the RPA site visit. |

| | • | | Illegal mining is one of the principal challenges affecting the operations. |

ECONOMIC ANALYSIS

| | • | | Recovered gold ounces are estimated to be 5.68 million for the period between 2012 and 2025. Mining will be active until 2020, after which time, stockpiles will be reclaimed to provide mill feed. |

| | • | | RPA notes that the economic analysis confirms that the material classified as Mineral Reserves is supported by a positive economic analysis |

| | • | | The Porgera JV has suffered from lack of expenditures to maintain the facilities. |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-6 | |

| | |

| | www.rpacan.com |

|

RECOMMENDATIONS

RPA makes the following recommendations:

GEOLOGY AND MINERAL RESOURCES

| | • | | Porgera JV mine staff are planning to amend the assay QA/QC protocols to include screen metallics analysis in order to try and improve repeatability. RPA concurs with this approach and recommends that it continue. |

| | • | | Exploration work should continue in order to continue to add new Mineral Resources. |

| | • | | The SC method should only be used to estimate Inferred Mineral Resources. |

| | • | | Efforts to simplify the estimation methodologies should continue. However, RPA recommends changes should be implemented gradually and only with complete understanding of the effects of each change. |

| | • | | The present documentation for the resource estimates is fragmented and out-of-date. A single report document should be prepared which describes the methodologies and parameters used in the estimation process. |

MINING AND MINERAL RESERVES

| | • | | RPA recommends that a single resource model be used for both the open pit and underground mine planning. |

| | • | | Another open pit evaluation should be completed at higher gold prices, which should enable the mine to produce a larger open pit beyond the current pit limits. |

| | • | | A concerted effort to eliminate and/or severely reduce surface waters from entering the open pit should be undertaken. |

| | • | | Dilution and ore recovery from the underground stopes needs to be improved. |

| | • | | Longhole drilling accuracy should be reviewed and a quality control program instituted. Modifications to stope drilling and blasting patterns, which would have less impact on the hanging wall should be investigated. |

PROCESSING

| | • | | RPA recommends that the process department and the technical services department work together to simplify the equations used to estimate gold recovery so they can be used in the cut-off grade calculations and in the Resource and Reserve estimates. |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-7 | |

| | |

| | www.rpacan.com |

|

ENVIRONMENTAL AND SOCIAL AND COMMUNITY CONSIDERATIONS

| | • | | RPA recommends that the practice of segregating potential metal leaching (PML) material and impounding it within competent waste that is not PML should be re-instituted unless on-going, detailed waste characterization including assaying, acid-base accounting, and humidity cell tests prove that there is no possibility of PML material causing environmental concerns in the future. |

| | • | | Porgera JV should continue to focus on plans and systems that ensure relocations are handled in a timely manner. |

ECONOMIC ANALYSIS

Under NI 43-101 rules, producing issuers may exclude the information required for Section 22—Economic Analysis, on properties currently in production, unless the technical report includes a material expansion of current production. RPA notes that Barrick is a producing issuer, the Porgera JV mine is currently in production, and an expansion of a material consequence is not being planned. RPA has performed an economic analysis of the Porgera JV mine using the estimates presented in this report and confirms that the outcome is a positive cash flow that supports the statement of Mineral Reserves.

TECHNICAL SUMMARY

PROPERTY DESCRIPTION AND LOCATION

The Porgera JV mine is located in Enga Province of the Western Highlands of PNG, at latitude 5°28’ south and longitude 143°05’ east. The mine is approximately 130 km west-northwest of Mount Hagen, PNG, and 600 km northwest of the national capital, Port Moresby, PNG. The property is located at elevations between 2,200 MASL and 2,700 MASL in rugged mountainous terrain, which is largely covered with rain forest.

LAND TENURE

The Porgera JV is an unincorporated joint venture whereby each party subscribes its portion of operating expenses and in return takes its appropriate portion of the gold production. The operation is managed by Barrick (Niugini) Ltd. (a wholly owned subsidiary of Barrick) on behalf of the joint venturers which are:

| | |

• Barrick (Niugini) Limited | | 95% |

• Mineral Resources Enga Limited | | 5% |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-8 | |

| | |

| | www.rpacan.com |

|

Barrick increased its beneficial interest in the Porgera JV from 75% to 95% in 2007. Mineral Resources Enga Limited’s 5% is divided between the Enga Provincial government (2.5%) and local landowners (2.5%).

There is an area over which the Porgera JV has purchased the land rights from the locals who are the underlying land owners. The Porgera JV has paid compensation for the land and pays an ongoing lease payment but at the completion of operations the land will be returned to the underlying owners.

The Porgera JV operation is subject to a 2% royalty on revenue after the deduction of selling and refining costs.

EXISTING INFRASTRUCTURE

The major assets and facilities associated with the Porgera JV mine are:

| | • | | The open pit mine and associated waste dumps and haul roads. |

| | • | | The underground mine and mine development. |

| | • | | Open pit and underground mining equipment and support equipment. |

| | • | | Six million tonnes per year capacity concentrator with crushers, grinding circuit, flotation circuit, autoclaves, cyanide leaching, cyanide destruction, for the recovery of gold, and paste tailings backfill plant. |

| | • | | Two camps for employees. |

| | • | | A hard surface air strip located approximately 11 km from the mine. |

| | • | | Abundant water from a reservoir containing greater than 7,000,000 m3, located seven kilometres away at the Waile Creek Dam. |

| | • | | Four water treatment plants for potable water and five sewage treatment plants. |

| | • | | Power supplied from the 62 MW gas-fired Hides Power Station via a 73-km transmission line and 13 MW of diesel-powered backup power from a generator located at the mine site. |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-9 | |

| | |

| | www.rpacan.com |

|

HISTORY

Alluvial gold showings were first officially reported in the area in 1938 by PNG Government officers and, in 1948, the first geological investigations traced the source to the Waruwari Hill area.

In 1964 and 1966 Bulolo Gold Dredging Ltd. (Bulolo) conducted mapping, channel sampling, and shallow diamond drilling programs followed, two years later, by Mount Isa Mines (MIM) which also carried out mapping, channel sampling, and diamond drilling. More drilling was done in the area in 1969 by Anaconda Australia Inc. which core drilled six holes at Waruwari and one at Rambari. A small-scale sluicing operation was set up in 1970 by MIM and Ada Explorations Pty. Ltd. to exploit the alluvial gold showings, and two adits were driven at Waruwari and one at Rambari.

In 1979, a three-way joint venture agreement was established between Placer PNG Pty. Ltd. (Place PNG), MIM, and New Guinea Goldfields Ltd. (NG Goldfields). A separate agreement was signed between the joint venture partners and the Independent State of Papua New Guinea (the State) that granted the State the right to acquire, at cost, up to 10% of the project if developed.

A preliminary technical and economic assessment conducted in 1981 based on a planned 15,000 tpd open pit mining operation was deemed uneconomic but later exploration success prompted a reevaluation. Another preliminary economic evaluation, conducted in 1984, returned positive results based on a mining rate of 4,000 tpd and development began in 1985 with the collaring of an exploration adit.

A Feasibility Study in 1989, based on a production rate of 8,000 tpd from combined underground and open pit operations, returned positive results. After regulatory approval was received, full construction began immediately and the State accepted its full 10% entitlement in the project. Through various acquisitions Placer Dome PNG, and later Barrick, was able to establish a 95% beneficial interest in the Porgera JV.

Commercial production was declared in 1990 and the open pit commenced operation in 1992 with a production rate of 8,000 tpd. In 1997, the underground mining operation was placed on care and maintenance but re-started in 2002 after exploration successfully identified additional resources.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-10 | |

| | |

| | www.rpacan.com |

|

The Porgera JV mine has undergone numerous expansions over the life of the mine from the initial Stage 2 expansion in 1991 to the proposed Stage 5 expansions that are now planned. These expansions have resulted in the addition of major components to the processing circuits and pushbacks to the open pit mine. It should be noted again that Barrick increased its beneficial interest in the Porgera JV from 75% to 95% in 2007 following the acquisition of Placer in 2006.

GEOLOGY AND MINERALIZATION

The Porgera deposit is a world-class, largely refractory gold deposit that has already produced over 16.5 million ounces of gold. The high-grade core (Zone VII) is an epithermal-style deposit hosted within thermally metamorphosed sediments of the Cretaceous Chim Formation and the associated Porgera Diorite Intrusive Complex of Miocene age. The deposit is spatially associated with late Tertiary oxidized, hydrous, alkaline (shoshonitic) magmas of the Porgera Igneous Complex (PIC) located approximately 25 km south of the Lagaip fault zone in the northern portion of the Papuan Fold and Thrust Belt. The regional setting for Porgera is thought to be a back-arc region of a continental/island arc collision zone.

The tectonic units of Papua New Guinea result from collision and accretion of the Australian continental plate to the south with the Pacific oceanic plate to the north. The zone of interaction between the two plates forms the Central orogenic zone. The Papuan platform that hosts the Porgera JV mine is separated from the Central orogenic zone by the Lagaip fault zone, located some 25 km north of Porgera JV.

The Porgera intrusive complex is a calc-alkaline series of diorite plugs, stocks and dikes that form predominant relief within a seven kilometre wide basin rimmed to the south and east by limestone cliffs. The stocks and sills of the Porgera intrusive complex range from one metre wide dykes to bodies that are hundreds of metres in width. The stocks and dikes of the Porgera intrusive have experienced variable degrees of alteration.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-11 | |

| | |

| | www.rpacan.com |

|

The Porgera JV mine area geology consists of a complex sequence of high level potassium-rich intrusives and variably altered sedimentary rocks which has characteristics of different deposit types. Despite its alkalic nature, Porgera shares many similarities with porphyry copper deposits. Rapid emplacement at shallow crustal levels distinguishes it from a typical gabbroic intrusion and the nature of the mineralization is more indicative of an epithermal gold deposit.

The primary sediments are pyritic, slightly calcareous, massive, incompetent bituminous shales and mudstones known as “brown mudstones”. These occur on the southwest and northwest margins of Waruwari (located in the southern part of the Porgera intrusive complex). The “black sediments” are the main variant on the “brown mudstones” and are the major host rock. Interpreted to be derived from the “brown mudstone”, the “black sediments” are more competent and less friable.

The major intrusive phases at Porgera are hornblende diorite, feldspar porphyry and hornblende diorite porphyry. These occur as stocks and sills and contacts generally dip steeper than 45°. Each of the intrusive rock types occur as more than one intrusive body, are inhomogeneous in texture and have chilled margins. By volume, hornblende diorite is the most prevalent rock type with two distinct bodies occurring. Feldspar porphyry forms small outcrops to the south of Waruwari and occur as small stocks to the northeast of Waruwari. The second most prevalent rock type by volume, it strikes north-northeast between two hornblende diorite bodies. Andesite and basalt are a fraction of the size of the three main intrusive bodies and occur mostly as dikes with accessory biotite and matrix plagioclase. Field observations have established the relationship between the intrusives. The hornblende diorite was emplaced first and followed by the feldspar porphyry and finally the hornblende diorite porphyry.

The principal structural features in the Porgera intrusive complex are the east trending faults, that control drainage in the area, and the Roamane Fault, which parallels and is subsidiary to the Lagaip Fault. The east trending Roamane Fault dips south at 70º to 80º and defines the northern extent of Waruwari and truncates the Yakatabari and Roamane intrusions. It appears to have moved many times creating a broad zone of deformation that has been invaded by numerous pulses of hydrothermal fluid which altered and mineralized the breccias that were formed by the movement

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-12 | |

| | |

| | www.rpacan.com |

|

Three distinct and highly variable types of breccias have been recognized within the Porgera intrusive complex, namely, sedimentary, tectonic, and hydrothermal. They are important hosts to mineralization and can display strong alteration and open space filling gangue mineralization.

Mineralization occurs within the Porgera intrusive complex and is closely associated with three dominate structural trends, the Roamane Fault, the Hanging Wall Shear Zone and the Footwall Splay Zone. Mineralization occurs around the margins and within the intrusive bodies. The Footwall Diorite (north of the Roamane Fault) and the Eastern Deeps are also mineralized and have contributed significant tonnages at moderate grade.

Gold is suggested to have been transported as a chloride complex in early magmatically derived hypersaline fluids and deposited as disseminate auriferous pyrite during cooling as a result of sulphidation and sericitization reactions with mafic igneous wall rocks.

Precious metal mineralization comprises four types, corresponding to four distinct mineralizing events. From oldest to most recent, these are:

| | • | | Auriferous pyrite, sphalerite and galena; |

| | • | | Coarse euhedral auriferous pyrite; |

| | • | | Fine-grained anhedral auriferous arsenical pyrite; |

| | • | | Gold and electrum associated with roscoelite. |

The fourth mineralization style is typified by very high grades and the presence of roscoelite is a useful visual indicator of these high grade zones. The distribution of mineralization is associated with structural activity and, to a lesser extent, alteration.

Gold mineralization occurs as fracture-fillings and as disseminations in and around faults, breccias and dilatant zones. Gold is usually present as submicroscopic grains within the pyrite, with a relatively minor component occurring as free grains. Important accessory minerals include quartz and roscoelite. Cross cutting relationships indicate the mineralization occurred in several pulses. Evidence suggests that some remobilization of gold may have occurred. Later fluids favoured the deposition of metallic gold suggesting earlier mineralization types may have been affected by later mineralizing events. Gold grade is closely related to fracture intensity and mineralization type.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-13 | |

| | |

| | www.rpacan.com |

|

EXPLORATION

Since RPA’s last Mineral Resource and Reserve audit report in 2009, exploration diamond drilling has taken place in the following areas: Tupegai, Tawasikale Veins, Tawasikale Intrusion, P-Zone, Peruk, Central Zone East, and Alipis.

RPA conducted a cursory review of the exploration work at Porgera JV. The exploration staff are of the opinion that there are significant targets remaining within the mine area as well as underexplored sections of the concessions that warrant further work. In RPA’s opinion, this is a reasonable assessment that exploration work should continue.

MINERAL RESOURCES

The Mineral Resource estimate for Porgera JV is shown in Table 1-1. These represent the in situ Mineral Resource estimate excluding Mineral Reserves. In RPA’s opinion the Mineral Resources are reasonable, acceptable and compliant with NI 43-101.

The estimate was carried out using block models constrained by wireframe models of the geological domains and mined out volumes. Grade interpolations were done using a variety of methods which included Multiple Indicator Kriging (MIK), Ordinary Kriging (OK), and Inverse Distance weighting (ID). Data used in the interpolations comprised diamond drill and face samples. Grades were estimated for gold and sulphur, and the block models contain data for domain codes, bulk density, and classification.

The global Mineral Resources increased substantially in terms both of tonnage and grade from YE2010 to YE2011. The changes to the Mineral Resources were due to the following:

| | • | | increase due to addition of new resources in the O, North and East Zone (underground mine) |

| | • | | increase due to new pit shell with current gold price |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-14 | |

| | |

| | www.rpacan.com |

|

| | • | | increase due to changes to the classification scheme |

| | • | | decrease due to update of cut-off grade |

OPEN PIT

The open pit block model encompasses the entire Porgera JV deposit, including material that will in all probability be mined from underground. The reported Mineral Resources are only those captured within a Lersch-Grossman open pit shell generated using Whittle to demonstrate the economic viability of mining by open pit. This pit shell was created using a gold price of $1,400/oz. Grades for gold and sulphur are interpolated MIK, OK and ID weighting. Kriging variance, which is used in the resource classification, is estimated into the model using OK. The interpolations are constrained by wireframe models of the principal estimation domains, as well as stoped volumes.

The cut-off grade used for the open pit resource estimate was 1.0 g/t Au, which is consistent with Barrick’s Reserve and Reporting Guidelines. This cut-off was derived using a gold price of $1,400/oz.

UNDERGROUND

The Mineral Resource estimates for the underground mine are generated from models created for six separate zones. These are the AHD, Central/North Zone (CNZ), East Zone (EZ), Project X (PX), Eastern Deeps (EDX), and O Zone (OZ). The models are constrained by 3D wireframes constructed using diamond drill and underground chip sampling results.

Grades for gold and sulphur are interpolated into the blocks using OK. The wireframe models are constructed using a nominal cut-off grade of 3 g/t Au and a three-metre minimum mining width. This cut-off was derived using a gold price of $1,400/oz. For some zones, a low-grade halo surrounding the 3 g/t wireframe is also constructed. These halos are based on a nominal 1.5 g/t Au cut-off.

MINERAL RESERVES

The Mineral Reserves for the Porgera JV mine are shown in Table 1-2. These Mineral Reserves are a combination of the open pit and underground operations and the stockpiles and inventory. Overall, RPA finds the Mineral Reserve estimates to be

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-15 | |

| | |

| | www.rpacan.com |

|

reasonable, acceptable, and compliant with NI 43-101. The Mineral Reserves are generated based upon the mine designs applied to the Mineral Resources. The design methodology uses both the cut-off grade estimation and economic assessment to design and validate the mineable reserves.

Block models, along with their associated wireframes, are constructed for both the open pit and underground mines. The open pit models are prepared by Senior Resource Geologists at Porgera JV mine with occasional assistance from external consultants. The models are constructed using Datamine software. Separate models are used for the open pit and underground mines.

Wireframes are also created for the mined volumes by the mine survey personnel. These models comprise stope and development void spaces in the underground mine as well as the volume depleted from the open pit.

Porgera JV maintains a system of both ore and low grade stockpiles, which have been growing since the 1990s.

The Probable Reserves located in 13 different stockpiles are estimated to be 54.5 million tons grading 2.60 g/t Au, containing 4.55 million ounces of gold, as of December 31, 2011. RPA agrees with the ore control rationale for creating the stockpiles, and the accounting methods used to track the stockpile quantities and grades. Consideration should be given to reclassifying these as Proven Reserves.

MINING METHODS

OPEN PIT

Barrick’s Porgera JV open pit is a large scale operation utilizing a traditional truck and shovel fleet. The open pit currently has five remaining phases, with the ultimate pit to measure approximately two kilometers east to west, 1.5 km north to south, and have an average depth of approximately 500 m. The waste rock dumps are located to the southeast and southwest of the open pit.

Ultimate pit limits were determined by generating Whittle® pit shells based on the net cash generated and the pit slopes recommended by Piteau Associates Engineering Ltd.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-16 | |

| | |

| | www.rpacan.com |

|

Haul ramps were designed to be 35 m wide, including the safety berm for double lane traffic accommodating the 175 st class haul trucks, and have a maximum grade of 10%. Mining thickness is 10 m in waste and ore to help minimize dilution.

Barrick optimizes mining by using a multi-phased approach which maximizes stripping rates to keep an ore producing face always available. This multi-phase technique consists of a primary ore layback, a primary stripping layback, and a secondary stripping layback. Historically, this approach was put in place to maintain a consistent mill feed, and keep mine production in the range of 14 to 15 benches per layback per year. There are approximately 135 million tons per year mined.

The single, open pit operation is projected to mine approximately five million tonnes of ore per year at an average strip ratio of four waste tonnes to one ore tonne (4W:1O). The operation uses conventional open pit methods to mine the ore and waste; bench drilling, blasting, and loading with shovels and loaders into off-highway trucks. The primary loading units are supported by motor graders, track-dozers, small excavators, water trucks, and maintenance equipment.

The major risks associated with Porgera JV open pit are the following:

| | • | | Dewatering and slope stability, the Southwest Dyke Failure in particular; |

| | • | | Equipment availabilities; and |

| | • | | Safety and security issues due to artisanal miners who trespass on the Porgera JV mine site. |

UNDERGROUND

Porgera JV started in 1990 as an underground mining operation, which was completed in 1997. Underground mining was restarted in 2002, and it is currently planned to continue as long as the open pit is operating. It is RPA’s opinion that underground mining could continue after the planned completion of the open pit and during the milling of the stockpiles.

The underground mine is expected to produce approximately 1.2 million tonnes of ore per year and the goal is to increase this to 1.4 million tonnes per year. In 2011, the underground mine generated 935,000 tonnes grading 7.29 g/t Au.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-17 | |

| | |

| | www.rpacan.com |

|

There are several underground deposits, but current production is coming from the North zone, and the recently accessed East zone. Underground exploration and development is underway and moving towards the AHD and Project X zones.

The average rock conditions are the key factor in the underground mine design and mining method selection. This has led to two mining methods both of which rely on cemented backfill for support. Where long hole stoping is used, the wall and back exposure is reduced by taking short long hole sections and filling before taking the next section. The underhand drift and fill stoping provides a backfill roof for subsequent lifts in the mining cycle.

Transverse long hole stoping is used where the mineralized zone has a significant width. Footwall drifts are driven parallel to the strike of the ore to provide access for stoping. Mining with transverse stopes requires a primary, secondary, and sometimes tertiary extraction to completely mine out the area. Longitudinal stopes are utilized in areas of the mine with adequate ground conditions to support a stope rib greater than 15 m in height, but do not have mineralized widths greater than 20 m. The stopes are accessed from a footwall drive and then driven parallel to the strike of ore. Each section is mined and filled before the next section is mined. If ground conditions are poor, the long hole stope section length can be reduced.

The underhand drift and fill method is utilized in areas of fair to poor ground conditions regardless of the width of the zone. The underhand drifts are nominally designed as 15 m wide by 15 m high. The minimum width is 15 m. The primary drift is driven with increased ground support to hold the ground open, then backfilled with a high strength cemented rock fill (CRF). Where the ore width exceeds the nominal drift width, subsequent drifts are developed (parallel or at oblique angles to the primary drift) and then backfilled. This process continues until the entire ore shape at a given elevation has been excavated and filled. Successive lifts are taken beneath the primary workings, utilizing the backfill as an engineered back.

MINERAL PROCESSING

The Porgera JV ore processing plant consists of crushing, grinding, flotation, pressure oxidation and leach/carbon-in-leach (CIL) operations. The crushing and grinding plant is

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-18 | |

| | |

| | www.rpacan.com |

|

at Tawisakale, which is physically separated from the concentrator at Anawe. Tawisakale is located immediately adjacent to the open pit and ground ore slurry is delivered by pipeline to the Anawe Concentrator.

ENVIRONMENTAL, PERMITTING AND SOCIAL CONSIDERATIONS

The Porgera JV site is located in an area that poses a number of unique challenges including:

| | • | | Challenging social factors including illegal miners |

For all of these reasons Porgera JV uses two operational practices that are uncommon for large mining operations. They are riverine tailings disposal and erodible dumps for disposal of mudstones. During initial permitting the PNG government and Porgera JV selected riverine tailings disposal as the method that poses the lowest risk to the environment.

Currently, Porgera JV is also developing and implementing an Environmental Management System (EMS) in preparation for certification by ISO 14001 and to meet Barrick corporate environmental standards.

PROJECT PERMITTING

The Porgera JV has approval to work the Porgera deposit within the agreed development plan under the terms of the Porgera Mining Development Contract (MDC) between the Government of PNG and the joint venture partners. The MDC specifies, in addition to other items, the annual rents that must be paid for the Special Mining Lease (SML). The MDC also specifies the classes of compensation that are payable to the landowners for the various land uses. The SML is issued by the Government of PNG. The SML, which expires in 2019, but is renewable, encompasses approximately 2,240 ha, including the mine and Project infrastructure areas. The Government of PNG has also awarded Leases for Mining Purposes (LMPs) for the waste dumps, campsites, and airstrip.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-19 | |

| | |

| | www.rpacan.com |

|

WASTE ROCK STORAGE/DISPOSAL

Waste rock management is permitted under the waste discharge permit. It is generally split into three classifications:

| | • | | Competent waste, comprising Porgera intrusive complex rocks and altered sediment |

| | • | | Semi-competent waste, comprising black and calcareous sediment; |

| | • | | Erodible waste, comprising Chim Formation mudstones (Yakatabari and Western Mudstone) |

Waste is further divided into potential metal leaching (PML) material and non-PML material based on sulphur and zinc grades. PML material is generally competent or semi-competent, and was impounded within the stable dumps during earlier operations. RPA noted that this operating practice was subsequently abandoned and was not in use at the time of the site visit. RPA recommends that this practice should be re-instituted unless on-going, detailed waste characterization including assaying, acid-base accounting, and humidity cell tests prove that there is no possibility of PML material causing environmental concerns in the future.

SOCIAL OR COMMUNITY REQUIREMENTS

Community relations are a significant concern at Porgera JV due to the large influx of people, the local culture and customs, and the impact of the mine on the people of Papua New Guinea. The Porgera Environment Advisory Komiti (PEAK) was formed to provide advice, communication and review services to the mine.

Porgera JV has become a training centre for the mining industry in PNG. Porgera JV is committed to training programs and was developing a $24 million training program at the time of the site visit.

From time to time, civil disturbances and criminal activities such as trespass, illegal mining, sabotage, particularly with respect to power, theft and vandalism have occasionally caused disruptions to the operation and temporarily halted production at Porgera.

Illegal mining is one of the principal challenges affecting the operations at Porgera JV. RPA observed illegal miners in the open pit, at the waste dumps, and at the tailings discharge area. RPA recommends that continued pursuit of measures designed to mitigate the situations should be one of the highest priorities for Porgera JV.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-20 | |

| | |

| | www.rpacan.com |

|

MINE RECLAMATION AND CLOSURE

SRK Consulting established the closure costs using the Barrick Reclamation Cost Estimator (BRCE) methodology and estimated the closure cost as $170 million.

CAPITAL AND OPERATING COST ESTIMATES

The sustaining capital costs for the Porgera JV for the period of 2012 to 2024 has been estimated to be $466 million (Table 1-3).

Operating costs for 2011 are estimated to be $841 per oz Au produced, or $81.78 per tonne milled (Table 1-4).

TABLE 1-3 SUMMARY OF OPEN PIT AND UNDERGROUND SUSTAINING

CAPITAL COSTS (2011 MID-YEAR)

Barrick Gold Corporation – Porgera JV

| | |

Capital Cost Category | | Totals for Years 2012 -2024

(US$ 000) |

Open Pit Mining | | 117,893 |

Underground Mining | | 71,511 |

Processing | | 53,230 |

G&A | | 176,423 |

Other | | 47,730 |

Total | | 466,788 |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-21 | |

| | |

| | www.rpacan.com |

|

TABLE 1-4 SUMMARY OF OPEN PIT OPERATING COSTS

(2011 MID-YEAR)

Barrick Gold Corporation – Porgera JV

| | |

Department Description | | Actual Cost

(US$/tonne –milled) |

Open Pit Total | | 26.78 |

Underground Total | | 8.30 |

Mill Total | | 23.39 |

Maintenance Total | | 6.04 |

Sustainable Development Total | | 0.86 |

Exploration Total | | 0.01 |

Strategic Total | | 0.43 |

Accounting Total | | 0.18 |

Supply Total | | 1.20 |

Business Improvement Total | | 1.04 |

Security Total | | 2.46 |

Personnel Total | | 0.96 |

Occupational Health & Safety Total | | 0.46 |

Community Affairs Total | | 1.50 |

Admin General Services Total | | 5.63 |

Administration & Selling Total | | 1.91 |

Indirect Costs Total | | 0.62 |

Total | | 81.78 |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 1-22 | |

| | |

| | www.rpacan.com |

|

2 INTRODUCTION

Roscoe Postle Associates Inc. (RPA) was retained by Barrick Gold Corporation (Barrick) to prepare an Independent Technical report on the Porgera mine (the Project) located in Papua New Guinea (PNG). The purpose of this report is to support public disclosure of Mineral Resource and Mineral Reserve estimates at the Project as of December 31, 2011. This Technical Report conforms to NI 43-101 Standards of Disclosure for Mineral Projects. RPA visited the property from August 28 to September 2, 2011.

The Project is located in Enga Province of the Western Highlands of PNG, at latitude 5°28’ south and longitude 143°05’ east. The mine is approximately 130 km west-northwest of Mount Hagen, PNG and 600 km northwest of the national capital, Port Moresby, PNG. The property is located at elevations between 2,200 MASL and 2,700 MASL in rugged mountainous terrain, which is largely covered with rain forest.

The Project is a producing open pit and underground gold mine which has a planned operating rate of approximately 5.2 million tonnes per annum (Mtpa) from the open pit and stockpiles and 0.8 Mtpa from the underground. The mine produces gold in doré form from process plants utilizing gravity as well as flotation followed by autoclaves and cyanide leaching. Annual gold production was approximately 526,000 (100% interest) ounces in 2011. The Project is owned by Porgera Joint Venture (Porgera JV) whereby Barrick is the operator and has a 95% interest through a wholly owned subsidiary, and Mineral Resources Enga Limited has a 5% interest.

PERSONNEL

Site visits were carried out from August 28 to September 2, 2011 by the following RPA employees:

| | • | | David Rennie, P. Eng, RPA Principal Geologist |

| | • | | Kathleen Altman, P. E., Ph.D., RPA Principal Metallurgist |

| | • | | Stuart Collins, P. E., RPA Principal Mining Engineer |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 2-1 | |

| | |

| | www.rpacan.com |

|

SOURCES OF INFORMATION

During the visit, the auditors met with the following people:

| | • | | Simon Jackson, General Manager |

| | • | | Ettienne Du Plessis, Technical Services Manager |

| | • | | Bruce Robertson, Resource Geologist |

| | • | | Mike Beatty, Senior Long-term Open Pit Planning |

| | • | | Ridge Nyashanu, Process Manager |

| | • | | John Mark, Senior Metallurgist |

| | • | | Simon, Senior Metallurgist, Crushing & Grinding |

| | • | | Reynold Giwar, Plant Metallurgist, Crushing & Grinding |

| | • | | Charles Ross, Environmental Manager |

| | • | | Steve Mitzelberg, UG Production Foreman |

| | • | | Mark Mousek, UG Engineer |

Mr. Rennie is responsible for the overall preparation of the Report and has contributed to Sections 3 through 12, inclusive, and to Sections 14, 23, 24, and parts of Sections 1, 2, 25 and 26. Dr. Altman is responsible for Sections 13, 17, 18, 19, 20 and contributed to Sections 1, 2, 25, and 26. Mr. Collins is responsible for Sections 15, 16, 19, 21, 22 and contributed to Sections 1, 2, 25, and 26.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 2-2 | |

| | |

| | www.rpacan.com |

|

LIST OF ABBREVIATIONS

Units of measurement used in this report conform to the Imperial system. All currency in this report is US dollars (US$) unless otherwise noted.

| | | | | | |

µm | | micron | | km2 | | square kilometre |

°C | | degree Celsius | | kPa | | kilopascal |

°F | | degree Fahrenheit | | kVA | | kilovolt-amperes |

µg | | microgram | | kW | | kilowatt |

A | | ampere | | kWh | | kilowatt-hour |

a | | annum | | L | | litre |

bbl | | barrels | | L/s | | litres per second |

Btu | | British thermal units | | m | | metre |

C$ | | Canadian dollars | | M | | mega (million) |

cal | | calorie | | m2 | | square metre |

cfm | | cubic feet per minute | | m3 | | cubic metre |

cm | | centimetre | | min | | minute |

cm2 | | square centimetre | | MASL | | metres above sea level |

d | | day | | mm | | millimetre |

dia. | | diameter | | mph | | miles per hour |

dmt | | dry metric tonne | | MVA | | megavolt-amperes |

dwt | | dead-weight ton | | MW | | megawatt |

ft | | foot | | MWh | | megawatt-hour |

ft/s | | foot per second | | m3/h | | cubic metres per hour |

ft2 | | square foot | | opt, oz/st | | ounce per short ton |

ft3 | | cubic foot | | oz | | Troy ounce (31.1035g) |

g | | gram | | ppm | | part per million |

G | | giga (billion) | | psia | | pound per square inch absolute |

Gal | | Imperial gallon | | psig | | pound per square inch gauge |

g/L | | gram per litre | | RL | | relative elevation |

g/t | | gram per tonne | | s | | second |

gpm | | Imperial gallons per minute | | st | | short ton |

gr/ft3 | | grain per cubic foot | | stpa | | short ton per year |

gr/m3 | | grain per cubic metre | | stpd | | short ton per day |

hr | | hour | | t | | metric tonne |

ha | | hectare | | tpa | | metric tonne per year |

hp | | horsepower | | tpd | | metric tonne per day |

in | | inch | | US$ | | United States dollar |

in2 | | square inch | | USg | | United States gallon |

J | | joule | | USgpm | | US gallon per minute |

k | | kilo (thousand) | | V | | volt |

kcal | | kilocalorie | | W | | watt |

kg | | kilogram | | wmt | | wet metric tonne |

km | | kilometre | | yd3 | | cubic yard |

km/h | | kilometre per hour | | yr | | year |

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 2-3 | |

| | |

| | www.rpacan.com |

|

3 RELIANCE ON OTHER EXPERTS

This report has been prepared by Roscoe Postle Associates Inc. (RPA) for Barrick Gold Corp. (Barrick). The information, conclusions, opinions, and estimates contained herein are based on:

| | • | | Information available to RPA at the time of preparation of this report, |

| | • | | Assumptions, conditions, and qualifications as set forth in this report, and |

| | • | | Data, reports, and other information supplied by Barrick and other third party sources. |

For the purpose of this report, RPA has relied on ownership information provided by Barrick. RPA has not researched property title or mineral rights for the Project and expresses no opinion as to the ownership status of the property.

RPA has relied on Barrick for guidance on applicable taxes, royalties, and other government levies or interests, applicable to revenue or income from the Project.

Except for the purposes legislated under provincial securities laws, any use of this report by any third party is at that party’s sole risk.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 3-1 | |

| | |

| | www.rpacan.com |

|

4 PROPERTY DESCRIPTION AND LOCATION

The Porgera Mine property is located in Enga Province of the Western Highlands of PNG, at latitude 5° 28’ south and longitude 143° 05’ east. The mine is approximately 130 km west-northwest of Mount Hagen, PNG and 600 km northwest of the national capital, Port Moresby, PNG. The property is located at elevations between 2,200 MASL and 2,700 MASL in rugged mountainous terrain, which is largely covered with rain forest (Figure 4-1).

LAND TENURE

The Porgera JV is an unincorporated joint venture whereby each party subscribes its portion of operating expenses and in return takes its appropriate portion of the gold production. The operation is managed by Barrick (Niugini) Ltd. (a wholly owned subsidiary of Barrick) on behalf of the joint venture partners which are:

| | • | | Barrick (Niugini) Limited 95% |

| | • | | Mineral Resources Enga Limited 5% |

Barrick increased its beneficial interest in the Porgerga JV from 75% to 95% in 2007. Mineral Resources Enga Limited’s 5% is divided between the Enga Provincial government (2.5%) and local landowners (2.5%).

The Porgera JV has approval to work the Porgera deposit within the agreed development plan under the terms of the Porgera Mining Development Contract (MDC) between the Government of PNG and the joint venture partner. The MDC specifies, inter alia, the annual rents that must be paid for the Special Mining Lease (SML) and the classes of compensation that are payable to the landowners for the various land uses. The SML is issued by the Government of PNG. The SML, which expires in 2019, but which is renewable, encompasses approximately 2,350 ha, including the mine and project infrastructure areas. The Government of PNG has also awarded Leases for Mining Purposes (LMPs) for the waste dumps, campsites, and airstrip.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 4-1 | |

| | |

| | www.rpacan.com |

|

Any future open pit and waste dump expansions that extend the mine life beyond the expiry date of the Special Mining Lease (SML) will require an extension to the SML be approved by the PNG government. It has been postulated that the primary and only significant environmental impact from any potential, future open pit expansion should be the expansion of the existing waste dumps.

While initial overtures to the Government of PNG, related to the extension of the SML, have been received favourably there has been no formal application to extend the SML to include the operations and reclamation, which are now estimated to continue until after mine closure in 2020. Open pit and underground operations are expected to cease in 2020, with the mill continuing to process stockpiles through 2025. Agreements with the local populace concerning the Anawe North Waste Rock Facility (WRF) are deficient with respect to the required duty for this dump in any possible Stage 6 Plan. Negotiations, with the goal of reaching an agreement that is to the satisfaction of all stakeholders, are planned (Bassotti & Woodward, 2010). No Stage 6 expansion plan is being considered at this time. A substantial amount of exploration and development work needs to be completed before any further open pit and waste dump expansion is considered.

Any major change to the Approved Proposal for Development requires State approval under the MDC. The MDC defines a major change as either a material change in:

| | • | | The design, capacity, location or availability of the Works and Facilities including the mine water supply, infrastructure directly associated with the mining or processing of ore and the administration building, and Suyan and Alipis camps. |

| | • | | The design, capacity or availability of facilities located within the Mining Area, or in the mine plan or mine production if the material change would materially reduce the States royalties or revenue or have an adverse impact on the environment (Bassotti & Woodward, 2010). |

There is no expiration date for the MDC, but it is tied to the continuation of the SML. If the mine life is extended, it is required that current environmental permitting arrangements be renewed. Previous submissions regarding pushbacks have met with approval so precedents exist for positive outcomes.

There is an area over which the Porgera JV has purchased the land rights from the locals who are the underlying land owners. The Porgera JV has paid compensation for

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 4-2 | |

| | |

| | www.rpacan.com |

|

the land and pays an ongoing lease payment but, at the completion of operations, the land will be returned to the underlying owners. Land ownership is a major issue for the operation and the extension of the mine area would involve lengthy negotiations with both current and proposed land owners. Land in PNG is owned by individuals and not the State and, as such, “social license” is a very important part of the operation of the Porgera Mine (Bassotti & Woodward, 2010).

The Porgera JV operation is subject to a 2% royalty on revenue after the deduction of selling and refining costs.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 4-3 | |

| | |

| | www.rpacan.com |

|

FIGURE 4-1 PORGERA JV LOCATION MAP

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 4-4 | |

| | |

| | www.rpacan.com |

|

5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY

ACCESSIBILITY

Access to Porgera JV is via the Enga Highway, a road distance of 211 km from Mount Hagen, PNG. There is a 470 km long road connection from Mt Hagen to the port of Lae, PNG. Almost all mine consumables and equipment are transported along this road on highway heavy-goods vehicles.

CLIMATE

The climate at the mine site is temperate year round, with daily temperatures ranging from 10ºC to 25ºC. The average annual rainfall is 3,650 mm spread throughout the year, although there are often drier periods from April through to October. There are high-intensity rainfall events of short duration, but there are no large rainfall events such as cyclones or monsoons. Climate, generally, does not impact on the Project’s operations.

LOCAL RESOURCES

The workforce consists of approximately 2,600 employees In addition, there are approximately 500 contractors. Of the total employee workforce, 94% are PNG citizens (64% local employees and 30% from other parts of PNG).The employees who are not local inhabitants commute to and from the mine by air, either by helicopter from Mt Hagen, PNG, landing directly at the minesite or by a DHC-6 (Twin Otter) light aircraft to the Kairik airstrip, located 11 km from the minesite. A joint venture between Airlines PNG and Heli Niugini operates this service under charter to the Porgera JV. This charter agreement also provides for feeder flights to and from Mt Hagen, PNG utilizing a DHC-8 (Dash 8) aircraft. Destinations are Port Moresby, Lae, Rabaul, Madang, and Wewak in PNG, and Cairns in Australia.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 5-1 | |

| | |

| | www.rpacan.com |

|

LOCAL INFRASTRUCTURE

Local infrastructure and resources to support the mine have grown substantially since the mine started operations. Initially, the local population was estimated to be between 3,000 people and 5,000 people. Currently there are approximately 30,000 to 50,000 people. There is a hospital, schools, and other infrastructure that have improved the quality of life and reduced the mortality rates. The influx of people from outside the area has brought in “outsiders” and intermarriage between the various groups from PNG which has changed the dynamics of the local region. The influx of people provides a virtually unlimited supply of labor to work at the mine. Porgera JV provides a great deal of support in the local communities.

More detailed regional and local infrastructure plans are shown in Figures 5-1 and 5-2.

PHYSIOGRAPHY

The property is located at elevations between 2,200 MASL and 2,700 MASL in rugged mountainous terrain, which is largely covered with rain forest.

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 5-2 | |

| | |

| | www.rpacan.com |

|

FIGURE 5-1 PORGERA MINE REGIONAL INFRASTRUCTURE

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 5-3 | |

| | |

| | www.rpacan.com |

|

FIGURE 5-2 PORGERA MINE LOCAL INFRASTRUCTURE

| | | | |

| |

Barrick Gold Corporation – Porgera Joint Venture, Project #1669 Technical Report NI 43-101 – March 16, 2012 | | | Rev. 0 Page 5-4 | |

| | |

| | www.rpacan.com |

|

6 HISTORY