Exhibit 99.1

BARRICK GOLD CORPORATION

TECHNICAL REPORT ON THE

CORTEZ JOINT VENTURE OPERATIONS,

LANDER AND EUREKA COUNTIES,

STATE OF NEVADA, U.S.A.

NI 43-101 Report

Qualified Persons:

Kathleen Ann Altman, Ph.D., P.E.

R. Dennis Bergen, P.Eng.

Stuart Collins, P.E.

Chester Moore, P.Eng.

Wayne Valliant, P.Geo.

|

March 21, 2016 |

RPA Inc.55 University Ave. Suite 501 | Toronto, ON, Canada M5J 2H7 | T+ 1 (416) 947 0907 www.rpacan.com |

Report Control Form

| | | | | | | | | | | | | | | | | | |

| Document Title | | Technical Report on the Cortez Operations, State of Nevada, U.S.A. |

| | | | |

| Client Name & Address | | Barrick Gold Corporation Brookfield Place, TD Canada Trust Tower Suite 3700, 161 Bay Street, P.O. Box 212 Toronto, Ontario M5J 2S1 |

| | | | | | | | | | | | | | | | | | |

| Document Reference | | Project#2471 | | | | Status &

Issue No. | | | | | | | | FINAL Version | | |

| | | | | | | | | | | | | |

| Issue Date | | March 21, 2016 | | | | | | |

| | | | | | | | | | | | | | | | | | |

| Lead Author | | Wayne Valliant Dennis Bergen Stuart Collins Chester Moore Kathleen A. Altman | | | | (Signed)

(Signed) (Signed) (Signed) (Signed) |

| | | | | | | | | | | | |

| Peer Reviewer | | Deborah McCombe | | | | (Signed) |

| | | | | | | | | | | | |

| Project Manager Approval | | Wayne Valliant | | | | (Signed) |

| | | | | | | | | | | | |

| Project Director Approval | | Graham Clow | | | | (Signed) |

| | | | | | | | | | | | | | | | | | |

| Report Distribution | | Name | | No. of Copies |

| | |

| | Client | | |

| | RPA Filing | | 1 (project box) |

| | | |

| | | | | | Roscoe Postle Associates Inc.

55 University Avenue, Suite 501 Toronto, ON M5J 2H7 Canada Tel: +1 416 947 0907 Fax: +1 416 947 0395 mining@rpacan.com |

FORWARD-LOOKING INFORMATION

This report contains forward-looking statements. All statements, other than statements of historical fact regarding Barrick or Cortez, are forward-looking statements. The words “believe”, “expect”, “anticipate”, “contemplate”, “target”, “plan”, “intend”, “project”, “continue”, “budget”, “estimate”, “potential”, “may”, “will”, “can”, “could” and similar expressions identify forward-looking statements. In particular, this report contains forward-looking statements with respect to cash flow forecasts, projected capital, operating and exploration expenditure, targeted cost reductions, mine life and production rates, potential mineralization and metal or mineral recoveries, and information pertaining to potential improvements to financial and operating performance and mine life at the Cortez mine that may result from the Cortez Underground Expansion Project and certain other Value Realization Initiatives. All forward-looking statements in this report are necessarily based on opinions and estimates made as of the date such statements are made and are subject to important risk factors and uncertainties, many of which cannot be controlled or predicted. Material assumptions regarding forward-looking statements are discussed in this report, where applicable. In addition to such assumptions, the forward-looking statements are inherently subject to significant business, economic and competitive uncertainties and contingencies. Known and unknown factors could cause actual results to differ materially from those projected in the forward-looking statements. Such factors include, but are not limited to: fluctuations in the spot and forward price of commodities (including gold, copper, silver, diesel fuel, natural gas and electricity); the speculative nature of mineral exploration and development; changes in mineral production performance, exploitation and exploration successes; risks associated with the fact that the Cortez Underground Expansion Project and certain other Value Realization Initiatives are still in the early stages of evaluation and additional engineering and other analysis is required to fully assess their impact; diminishing quantities or grades of reserves; increased costs, delays, suspensions, and technical challenges associated with the construction of capital projects; operating or technical difficulties in connection with mining or development activities, including disruptions in the maintenance or provision of required infrastructure and information technology systems; damage to Barrick’s or Cortez’s reputation due to the actual or perceived occurrence of any number of events, including negative publicity with respect to the handling of environmental matters or dealings with community groups, whether true or not; risk of loss due to acts of war, terrorism, sabotage and civil disturbances; uncertainty whether the Cortez Underground Expansion Project or any of the other Value Realization Initiatives will meet Barrick’s capital allocation objectives; the impact of global liquidity and credit availability on the timing of cash flows and the values of assets and liabilities based on projected future cash flows; the impact of inflation; fluctuations in the currency markets; changes in interest rates; changes in national and local government legislation, taxation, controls or regulations and/or changes in the administration of laws, policies and practices, expropriation or nationalization of property and political or economic developments in the United States; failure to comply with environmental and health and safety laws and regulations; timing of receipt of, or failure to comply with, necessary permits and approvals; litigation; contests over title to properties or over access to water, power and other required infrastructure; increased costs and physical risks, including extreme weather events and resource shortages, related to climate change; and availability and increased costs associated with mining inputs and labor. In addition, there are risks and hazards associated with the business of mineral exploration, development and mining, including environmental hazards, industrial accidents, unusual or unexpected formations, pressures, cave-ins, flooding and gold bullion, copper cathode or gold or copper concentrate losses (and the risk of inadequate insurance, or inability to obtain insurance, to cover these risks).

Many of these uncertainties and contingencies can affect Barrick’s actual results and could cause actual results to differ materially from those expressed or implied in any forward-looking statements made by, or on behalf of, Barrick. All of the forward-looking statements made in this report are qualified by these cautionary statements. Barrick and RPA and the Qualified Persons who authored this report undertake no obligation to update publicly or otherwise revise any forward-looking statements whether as a result of new information or future events or otherwise, except as may be required by law.

| | |

| | www.rpacan.com |

TABLE OF CONTENTS

| | | | |

| | | PAGE | |

| |

1 SUMMARY | | | 1-1 | |

Executive Summary | | | 1-1 | |

Technical Summary | | | 1-9 | |

| |

2 INTRODUCTION | | | 2-1 | |

| |

3 RELIANCE ON OTHER EXPERTS | | | 3-1 | |

| |

4 PROPERTY DESCRIPTION AND LOCATION | | | 4-1 | |

Land Tenure | | | 4-1 | |

Royalties | | | 4-2 | |

| |

5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | | | 5-1 | |

Accessibility | | | 5-1 | |

Climate | | | 5-1 | |

Local Resources | | | 5-2 | |

Infrastructure | | | 5-2 | |

Physiography | | | 5-3 | |

| |

6 HISTORY | | | 6-1 | |

| |

7 GEOLOGICAL SETTING AND MINERALIZATION | | | 7-1 | |

Regional Geology | | | 7-1 | |

Local Geology | | | 7-5 | |

Property Geology | | | 7-9 | |

Mineralization | | | 7-12 | |

| |

8 DEPOSIT TYPES | | | 8-1 | |

| |

9 EXPLORATION | | | 9-1 | |

Exploration Potential | | | 9-1 | |

| |

10 DRILLING | | | 10-1 | |

Reverse Circulation Drilling Methods | | | 10-3 | |

Core Drilling Methods | | | 10-3 | |

Conventional and Mud Drilling Methods | | | 10-4 | |

Collar Surveys | | | 10-4 | |

Down Hole Surveys | | | 10-4 | |

Sample Recovery | | | 10-5 | |

Geotechnical and Hydrological Drilling | | | 10-5 | |

Grade Control Drilling | | | 10-6 | |

Mineral Resource Delineation Drilling | | | 10-6 | |

Sampling Method and Approach | | | 10-21 | |

Bulk Density Determination | | | 10-25 | |

Logging, Sampling, and Sample Storage facilities | | | 10-26 | |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page i |

| | |

| | www.rpacan.com |

| | | | |

RPA Comments on Sampling Method and Approach | | | 10-26 | |

Quality Assurance and Quality Control | | | 10-27 | |

Cortez Laboratory | | | 10-31 | |

RPA’s Comments on QA/QC | | | 10-32 | |

| |

11 SAMPLE PREPARATION, ANALYSES AND SECURITY | | | 11-1 | |

Analytical Laboratories | | | 11-1 | |

Sample Preparation | | | 11-2 | |

Analysis | | | 11-3 | |

Sample Security | | | 11-4 | |

RPA’S Comments on Sample Preparation, Analysis, and Security | | | 11-6 | |

| |

12 DATA VERIFICATION | | | 12-1 | |

Databases | | | 12-1 | |

Barrick Reviews | | | 12-1 | |

External Reviews | | | 12-3 | |

RPA Database Review | | | 12-3 | |

RPA Opinion | | | 12-2 | |

| |

13 MINERAL PROCESSING AND METALLURGICAL TESTING | | | 13-1 | |

Introduction | | | 13-1 | |

Metallurgical Testing | | | 13-1 | |

Ore Routing | | | 13-2 | |

Gold Recovery Estimates | | | 13-2 | |

Deep South Zone Metallurgical Testing | | | 13-7 | |

Summary and Conclusions | | | 13-9 | |

| |

14 MINERAL RESOURCE ESTIMATE | | | 14-1 | |

Summary | | | 14-1 | |

Pipeline Complex | | | 14-2 | |

Cortez Hills Complex | | | 14-20 | |

Cortez Pits | | | 14-39 | |

Gold Acres | | | 14-43 | |

| |

15 MINERAL RESERVE ESTIMATE | | | 15-1 | |

Summary | | | 15-1 | |

Open Pit Mineral Reserves | | | 15-6 | |

Underground Mineral Reserves | | | 15-20 | |

Reconciliation | | | 15-26 | |

RPA Opinion | | | 15-36 | |

| |

16 MINING METHODS | | | 16-1 | |

Recent Production History | | | 16-1 | |

Underground Mine | | | 16-15 | |

Cortez Life of Mine Plan | | | 16-41 | |

| |

17 RECOVERY METHODS | | | 17-1 | |

Introduction | | | 17-1 | |

Oxide Ore Milling | | | 17-1 | |

Oxide Ore Heap Leaching | | | 17-3 | |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page ii |

| | |

| | www.rpacan.com |

| | | | |

Refractory Ore Treatment | | | 17-4 | |

| |

18 PROJECT INFRASTRUCTURE | | | 18-1 | |

Roads | | | 18-1 | |

Tailings Storage Facility | | | 18-1 | |

Dumps | | | 18-1 | |

Stockpiles | | | 18-4 | |

Leach Pads | | | 18-4 | |

Power | | | 18-4 | |

| |

19 MARKET STUDIES AND CONTRACTS | | | 19-1 | |

Markets | | | 19-1 | |

Contracts | | | 19-1 | |

| |

20 ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | | | 20-1 | |

Environmental Studies | | | 20-1 | |

Mine Permitting | | | 20-1 | |

Social and Community Requirements | | | 20-9 | |

Mine Closure Requirements | | | 20-15 | |

| |

21 CAPITAL AND OPERATING COSTS | | | 21-1 | |

Capital Cost Estimate | | | 21-1 | |

Operating Costs | | | 21-2 | |

| |

22 ECONOMIC ANALYSIS | | | 22-1 | |

| |

23 ADJACENT PROPERTIES | | | 23-1 | |

| |

24 OTHER RELEVANT DATA AND INFORMATION | | | 24-1 | |

| |

25 INTERPRETATION AND CONCLUSIONS | | | 25-1 | |

| |

26 RECOMMENDATIONS | | | 26-1 | |

| |

27 REFERENCES | | | 27-1 | |

| |

28 DATE AND SIGNATURE PAGE | | | 28-1 | |

| |

29 CERTIFICATE OF QUALIFIED PERSON | | | 29-1 | |

LIST OF TABLES

| | | | | | |

| | | | | PAGE | |

| | |

Table 1-1 | | Mineral Resources – December 31, 2015 | | | 1-3 | |

Table 1-2 | | Mineral Reserves – December 31, 2015 | | | 1-4 | |

Table 1-3 | | Capital Costs | | | 1-18 | |

Table 1-4 | | LOM Operating Costs | | | 1-18 | |

Table 6-1 | | History of Exploration and Mining at Cortez Site | | | 6-2 | |

Table 6-2 | | Annual Production, 1969–2015 | | | 6-6 | |

Table 10-1 | | Drill Hole Types | | | 10-1 | |

Table 10-2 | | RC Sample Reduction | | | 10-22 | |

Table 10-3 | | Blast Hole Sample Reduction | | | 10-25 | |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page iii |

| | |

| | www.rpacan.com |

| | | | | | |

Table 11-1 | | Chain of Custody Summary | | | 11-6 | |

Table 13-1 | | Cortez Oxide Mill Gold Recovery Equations | | | 13-3 | |

Table 13-2 | | Cortez Heap Leach Ultimate Gold Recovery Equations | | | 13-3 | |

Table 13-3 | | Refractory Ore Gold Recovery Equations | | | 13-4 | |

Table 13-4 | | Production Data 2013-2015 | | | 13-5 | |

Table 13-5 | | Heap Leach Gold Production | | | 13-6 | |

Table 13-6 | | Deep South Zone Test Results (Au Recovery) | | | 13-8 | |

Table 13-7 | | Deep South Zone Optimization Samples Analytical Results | | | 13-9 | |

Table 14-1 | | Mineral Resource Summary – December 31, 2015 | | | 14-1 | |

Table 14-2 | | Cortez Mineral Resource Models | | | 14-2 | |

Table 14-3 | | Pipeline Complex Mineral Resource Summary – December 31, 2015 | | | 14-3 | |

Table 14-4 | | Pipeline Complex Mineral Resource Reporting Cut-off Grades | | | 14-4 | |

Table 14-5 | | Pipeline Complex Block Model Parameters | | | 14-6 | |

Table 14-6 | | Search Ellipse Orientations Of Structural Domains – Pipeline Complex | | | 14-8 | |

Table 14-7 | | Summary of Gold Grade Caps – Pipeline Complex | | | 14-9 | |

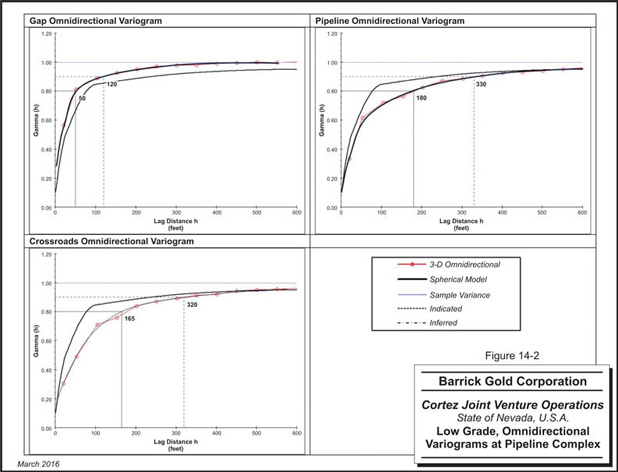

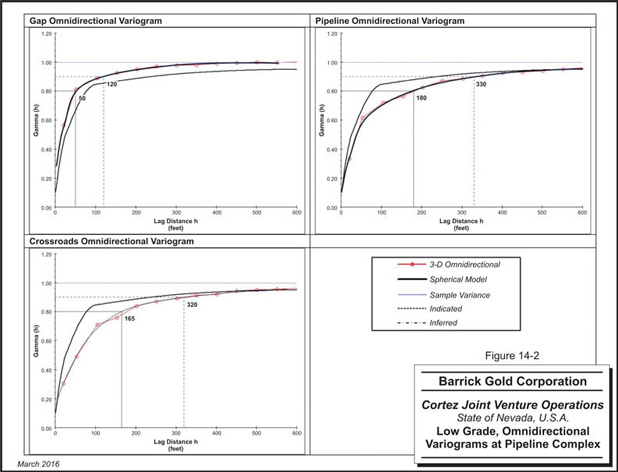

Table 14-8 | | Low Grade Omnidirectional Variogram Models – Pipeline Complex | | | 14-10 | |

Table 14-9 | | Estimation Pass Summary – Pipeline Complex | | | 14-12 | |

Table 14-10 | | Summary of Composite Weights – Pipeline Complex | | | 14-13 | |

Table 14-11 | | Bulk Density – Pipeline Complex | | | 14-14 | |

Table 14-12 | | Comparison of Basic Statistics of Gold Values – Pipeline Complex | | | 14-18 | |

Table 14-13 | | Cortez Hills Complex Mineral Resource Summary – December 31, 2015 | | | 14-20 | |

Table 14-14 | | Cortez Hills Complex Mineral Resource Reporting Cut-off Grades | | | 14-21 | |

Table 14-15 | | Cortez Hills Complex Block Model Parameters | | | 14-23 | |

Table 14-16 | | Cortez Hills Complex CapPing | | | 14-25 | |

Table 14-17 | | Cortez Hills Complex - Bulk Density | | | 14-27 | |

Table 14-18 | | Cortez Hills Complex - Classification Distance Criteria | | | 14-29 | |

Table 14-19 | | Cortez Pits Mineral Resource Summary – December 31, 2015 | | | 14-40 | |

Table 14-20 | | Cortez Pits - Estimation Pass Summary | | | 14-42 | |

Table 14-21 | | Cortez Pits - Bulk Density | | | 14-42 | |

Table 14-22 | | Gold Acres Refractory Mineral Resource Summary – December 31, 2015 | | | 14-44 | |

Table 14-23 | | Gold Acres Indicator Model Estimation Parameters | | | 14-45 | |

Table 14-24 | | Interpolation Passes Inside and Outside the Gold Acres 0.50 Indicator Model | | | 14-46 | |

Table 14-25 | | Gold Acres Bulk Density | | | 14-47 | |

Table 14-26 | | Gold Acres Untransformed Gold Statistics | | | 14-47 | |

Table 15-1 | | Total Mineral Reserves – December 31, 2015 | | | 15-2 | |

Table 15-2 | | Proportion of Reserves by Deposit | | | 15-5 | |

Table 15-3 | | Processing as Percent of Total Tons/Ounces | | | 15-6 | |

Table 15-4 | | Open Pit Leach Cut-Off Grades | | | 15-15 | |

Table 15-5 | | Open Pit Mill Cut-Off Grades | | | 15-16 | |

Table 15-6 | | Open Pit Refractory Cut-Off Grades | | | 15-17 | |

Table 15-7 | | Mill Leach Inter-Process Cut-Off Grade | | | 15-18 | |

Table 15-8 | | Cortez Hills and Pediment Whittle Pit Optimization Parameters | | | 15-19 | |

Table 15-9 | | Pipeline and Crossroads Whittle Pit Optimization Parameters | | | 15-19 | |

Table 15-10 | | Underground Cut-off Grade Calculations | | | 15-23 | |

Table 15-11 | | Cortez Hills Open Pit Reconciliation | | | 15-28 | |

Table 15-12 | | Cortez Hills Open Pit Reconciliation by Process Type | | | 15-29 | |

Table 15-13 | | Pipeline Open Pit Reconciliation | | | 15-31 | |

Table 15-14 | | Pipeline Open Pit Reconciliation By Process Type | | | 15-32 | |

Table 15-15 | | Underground Mineral Reserve Reconciliation | | | 15-33 | |

Table 16-1 | | Mine Operations Summary 2012-2015 | | | 16-1 | |

Table 16-2 | | Cortez Operation – LOM Open Pit Production | | | 16-11 | |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page iv |

| | |

| | www.rpacan.com |

| | | | | | |

Table 16-3 | | Cortez Hills/Pediment – LOM Open Pit Production | | | 16-12 | |

Table 16-4 | | Pipeline/Crossroads – LOM Open Pit Production | | | 16-12 | |

Table 16-5 | | Percentages of Mined Processing Ore Types | | | 16-13 | |

Table 16-6 | | Major Open Pit Equipment | | | 16-14 | |

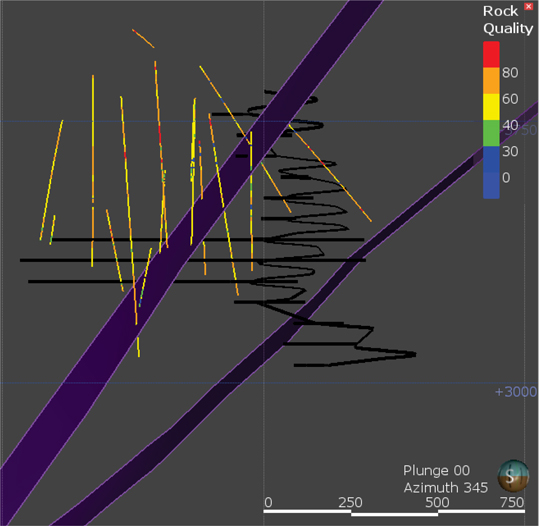

Table 16-7 | | Rock mass characterization for the Deep South Zone | | | 16-22 | |

Table 16-8 | | Summary of Proposed Hydraulic Radii by Geotechnical Domain | | | 16-23 | |

Table 16-9 | | Underground Equipment Fleet | | | 16-36 | |

Table 16-10 | | Key Factors Deep South Zone PFS | | | 16-37 | |

Table 16-11 | | Underground LOM Production | | | 16-40 | |

Table 16-12 | | Underground LOM Ore Types | | | 16-40 | |

Table 16-13 | | Underground Ore Source By Zone | | | 16-41 | |

Table 16-14 | | Cortez Operation – LOM Mining | | | 16-42 | |

Table 16-15 | | LOM Ore Processed - Roaster | | | 16-43 | |

Table 16-16 | | LOM Ore Processed – Pipeline Mill | | | 16-43 | |

Table 16-17 | | LOM Ore Processed – Heap Leach | | | 16-44 | |

Table 16-18 | | LOM Total Ore Processed | | | 16-44 | |

Table 20-1 | | Important Environmental Documents and Plans of Operations for Pipeline and Cortez Hills | | | 20-3 | |

Table 20-2 | | Major Environmental Permits | | | 20-8 | |

Table 20-3 | | Surface Disturbance Authorization | | | 20-16 | |

Table 21-1 | | Capital Costs | | | 21-1 | |

Table 21-2 | | LOM Operating Costs | | | 21-2 | |

Table 21-3 | | Manpower | | | 21-2 | |

LIST OF FIGURES

| | | | | | |

| | | | | PAGE | |

| | |

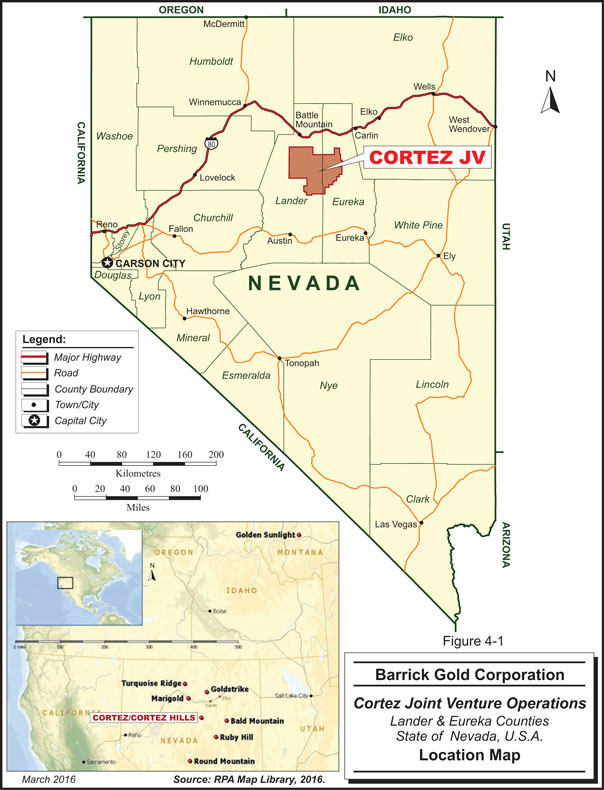

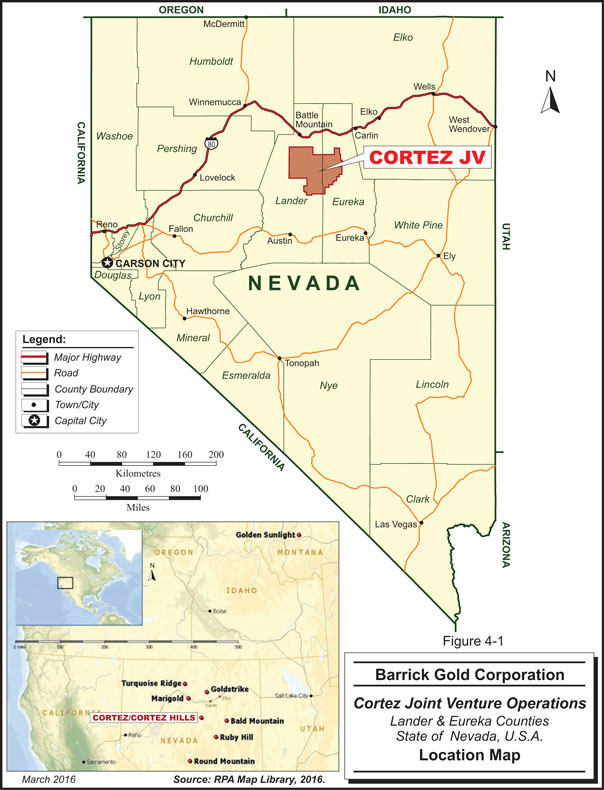

Figure 4-1 | | Location Map | | | 4-3 | |

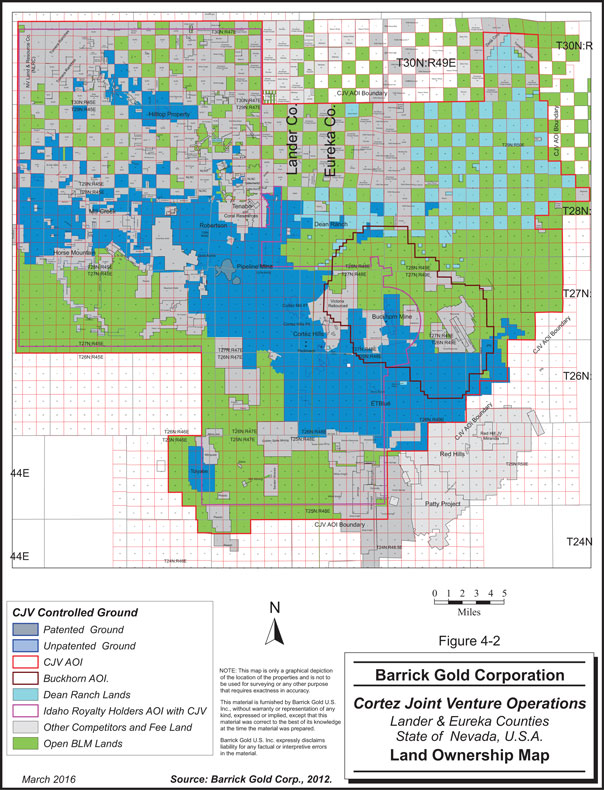

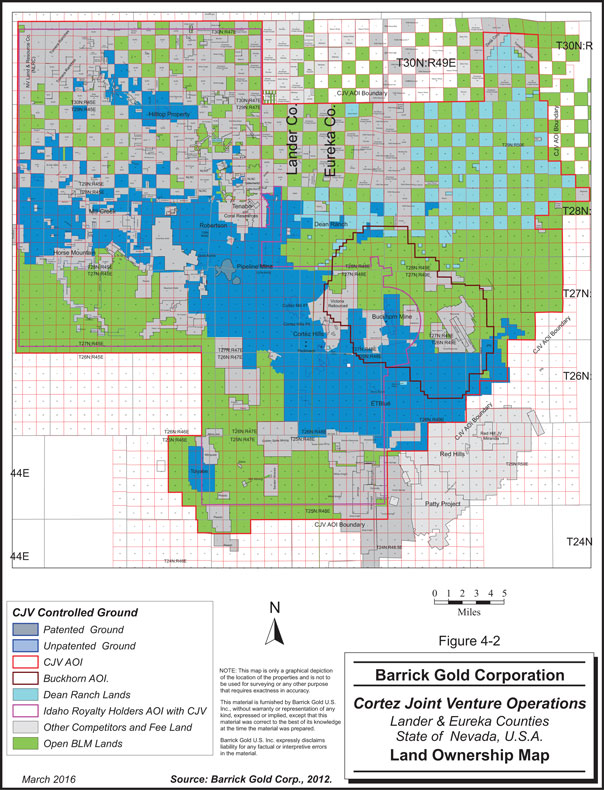

Figure 4-2 | | Land Ownership Map | | | 4-4 | |

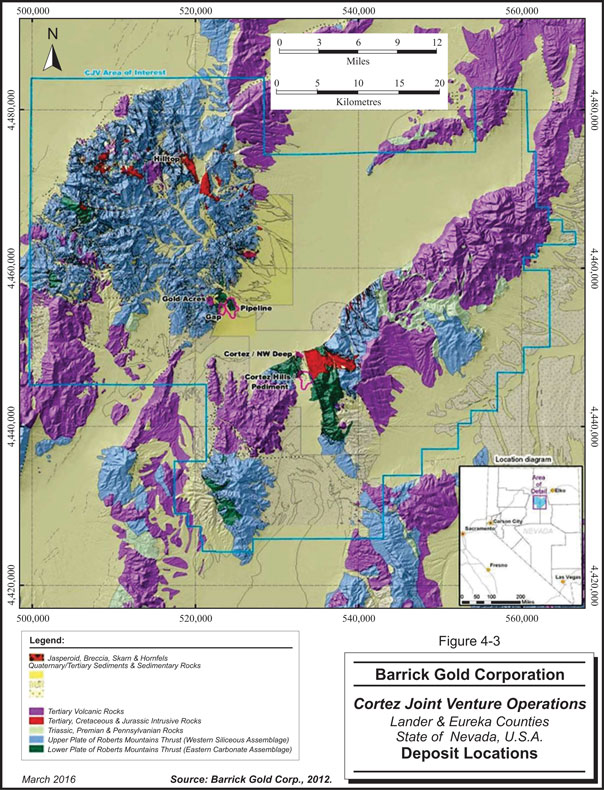

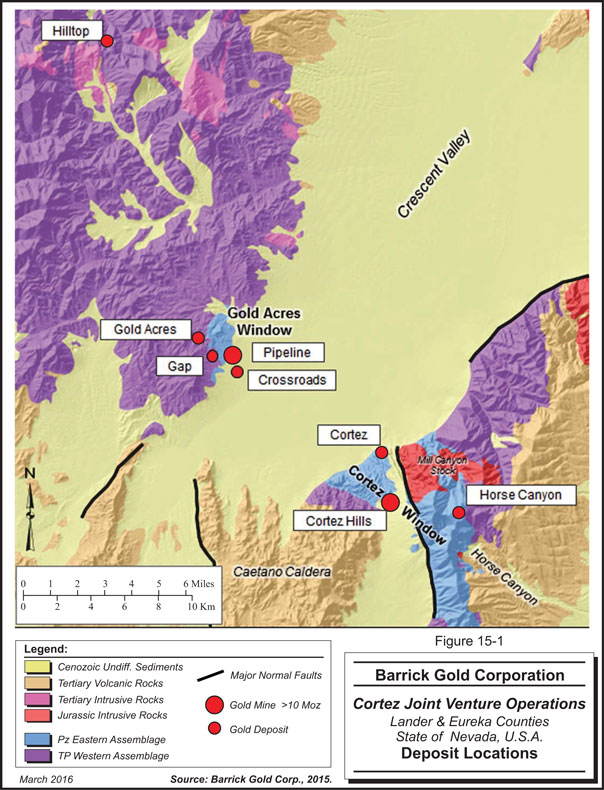

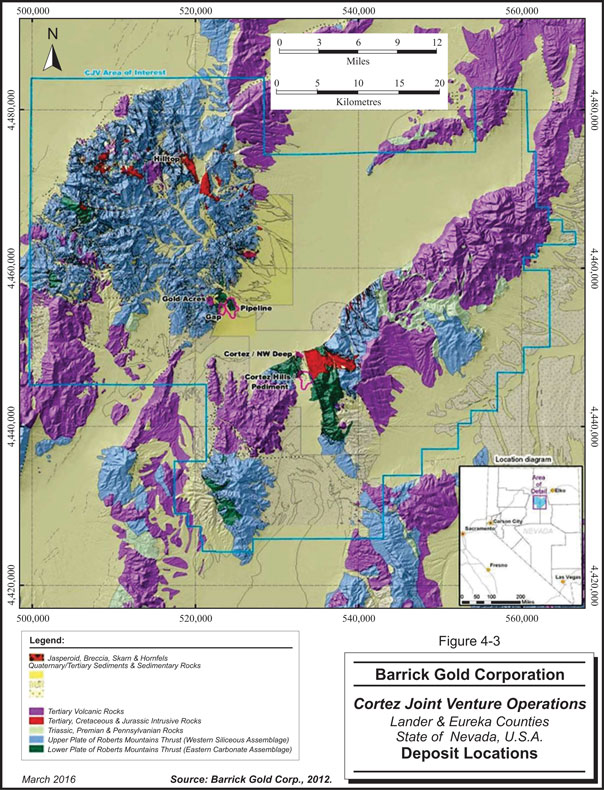

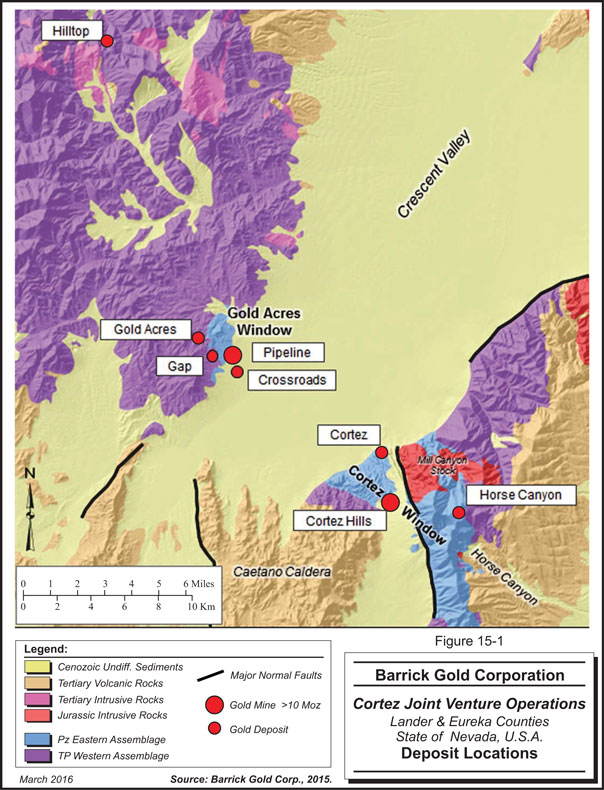

Figure 4-3 | | Deposit Locations | | | 4-5 | |

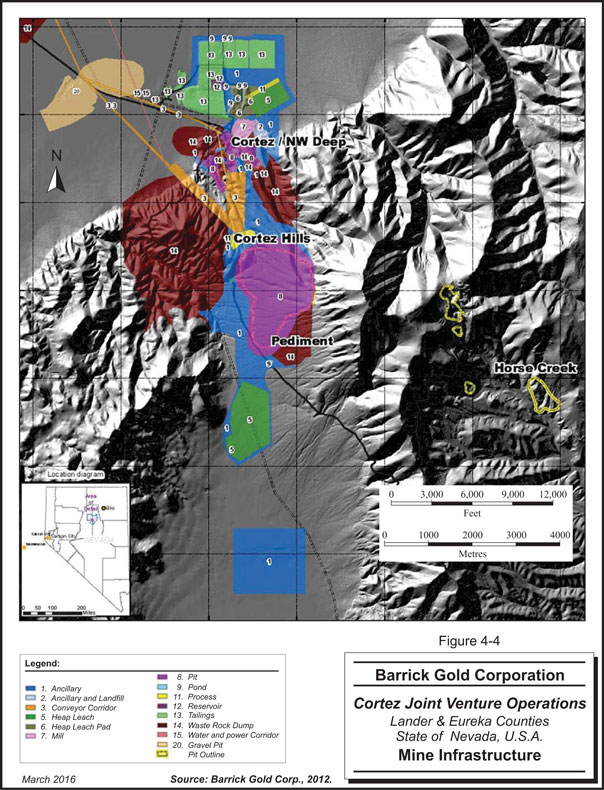

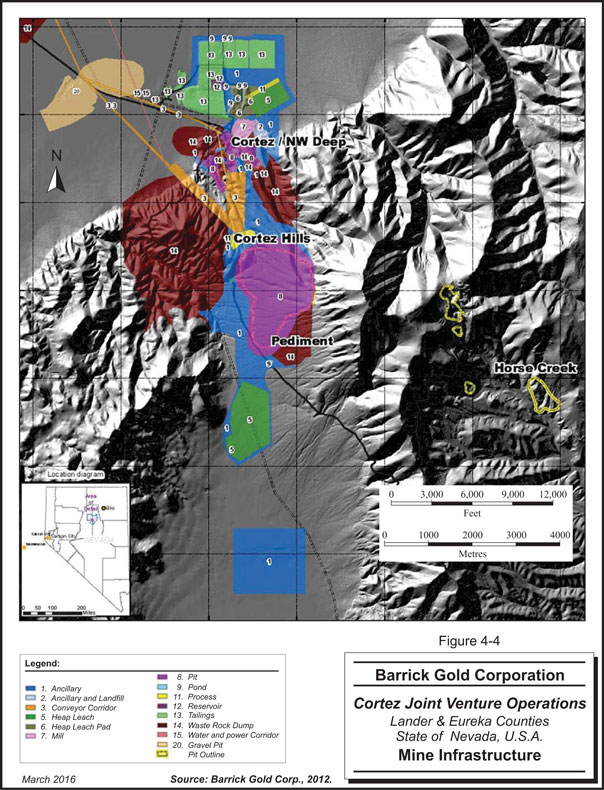

Figure 4-4 | | Cortez Hills Infrastructure | | | 4-6 | |

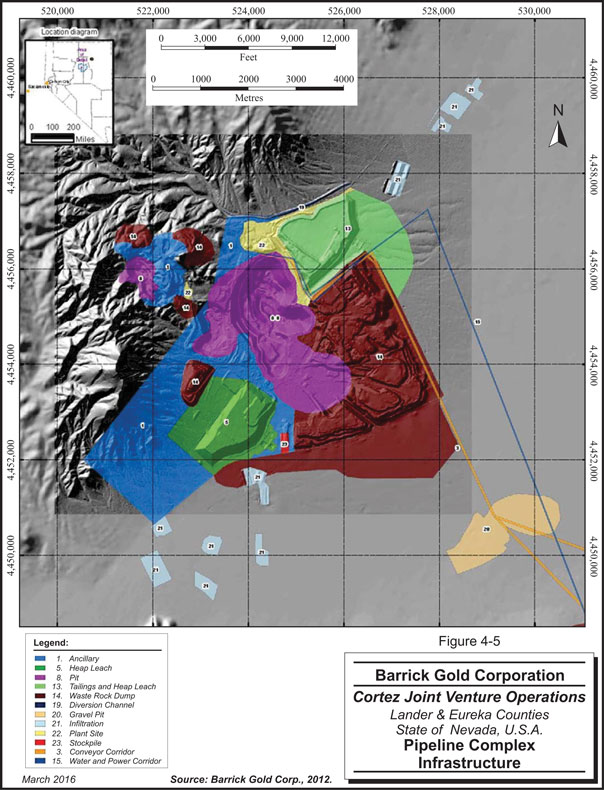

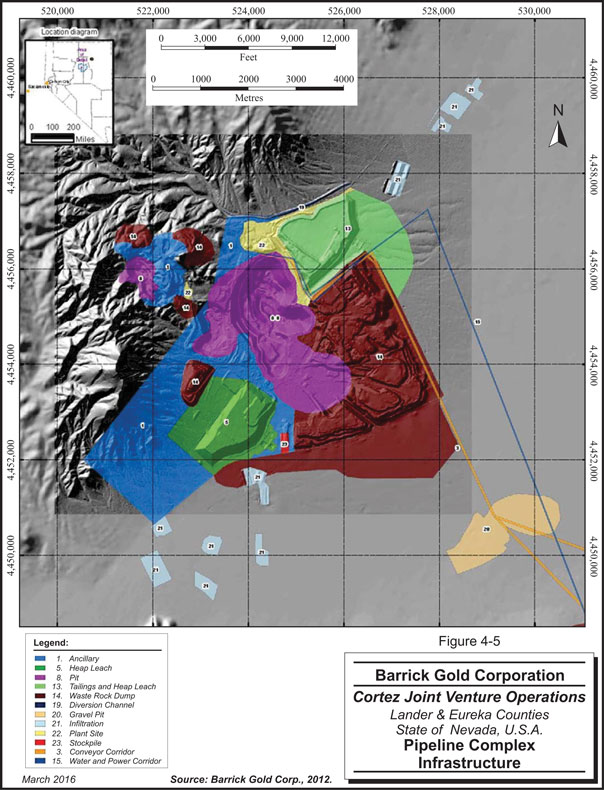

Figure 4-5 | | Pipeline Complex Infrastructure | | | 4-7 | |

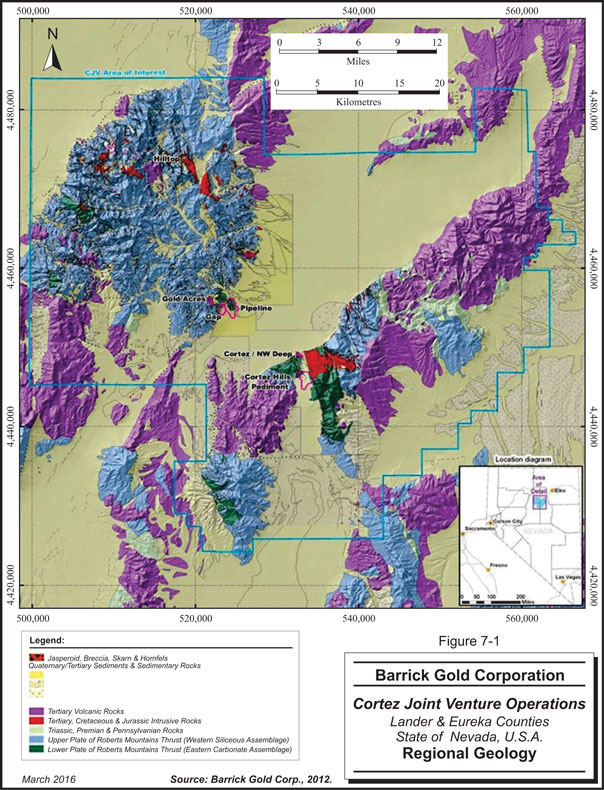

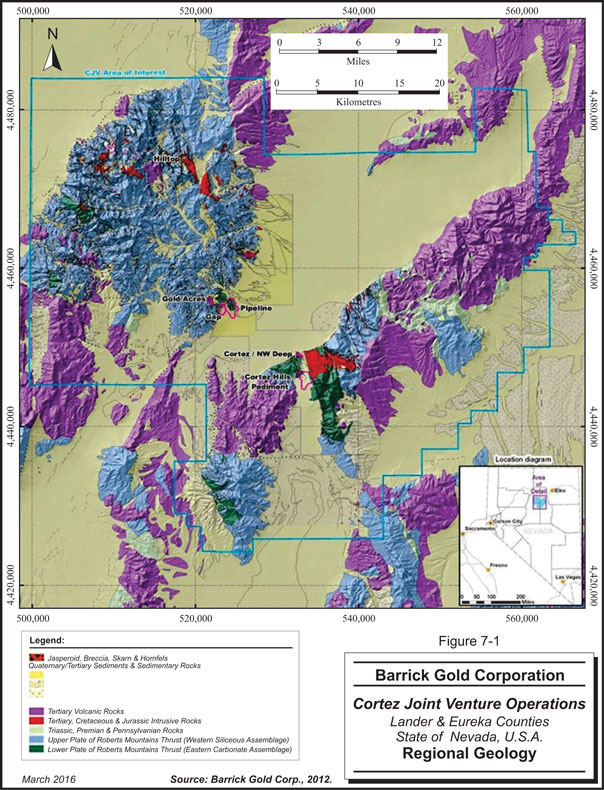

Figure 7-1 | | Regional Geology | | | 7-4 | |

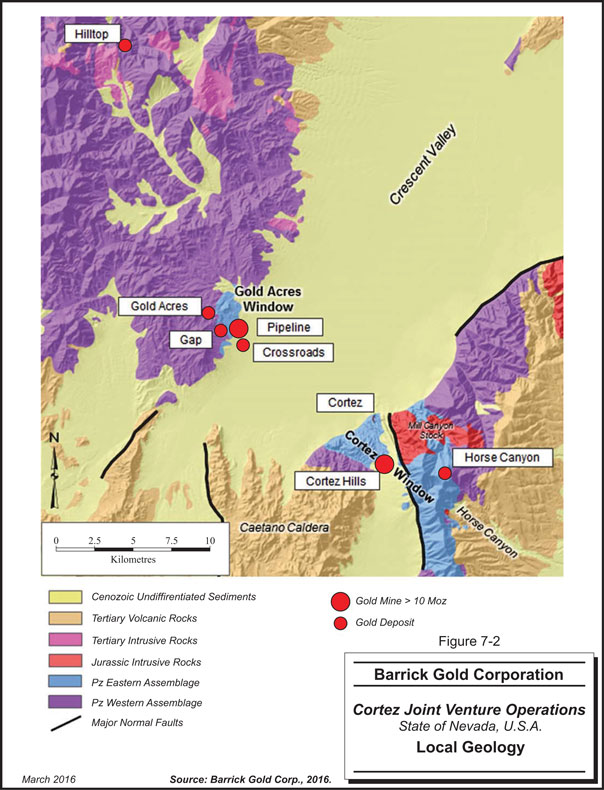

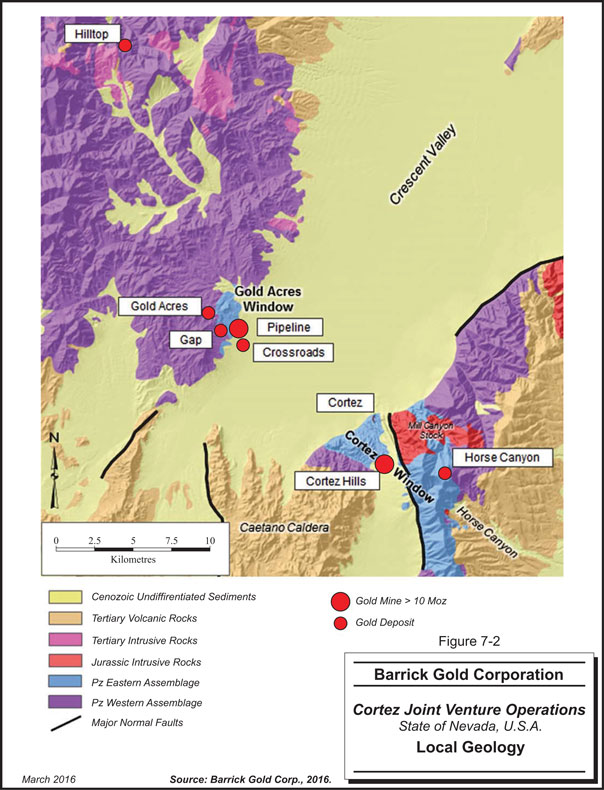

Figure 7-2 | | Local Geology | | | 7-7 | |

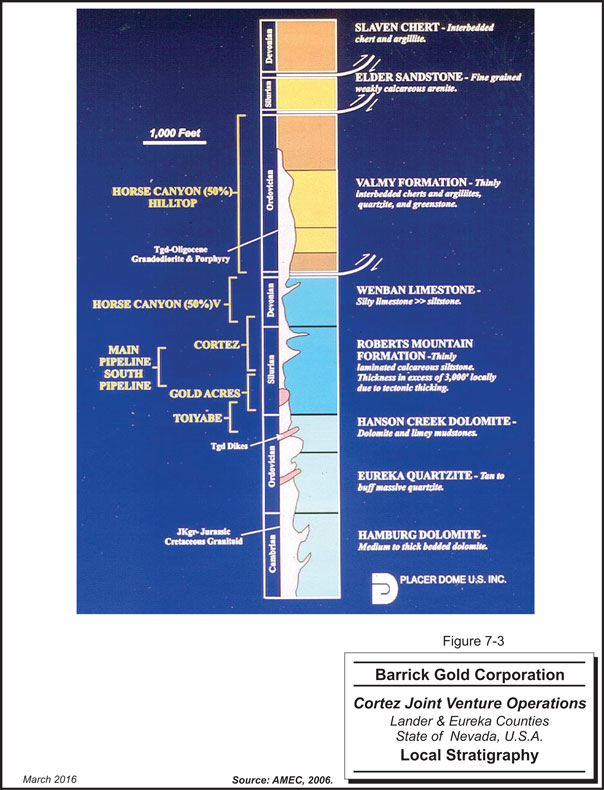

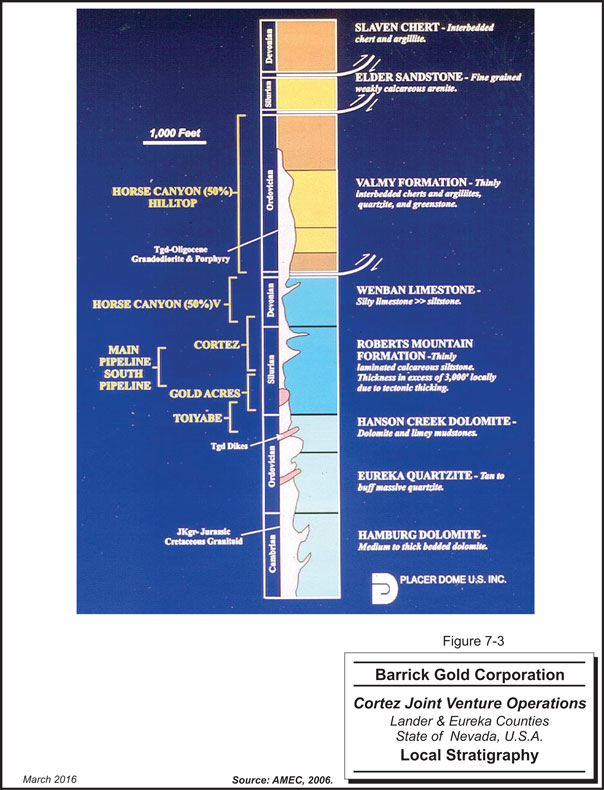

Figure 7-3 | | Local Stratigraphy | | | 7-8 | |

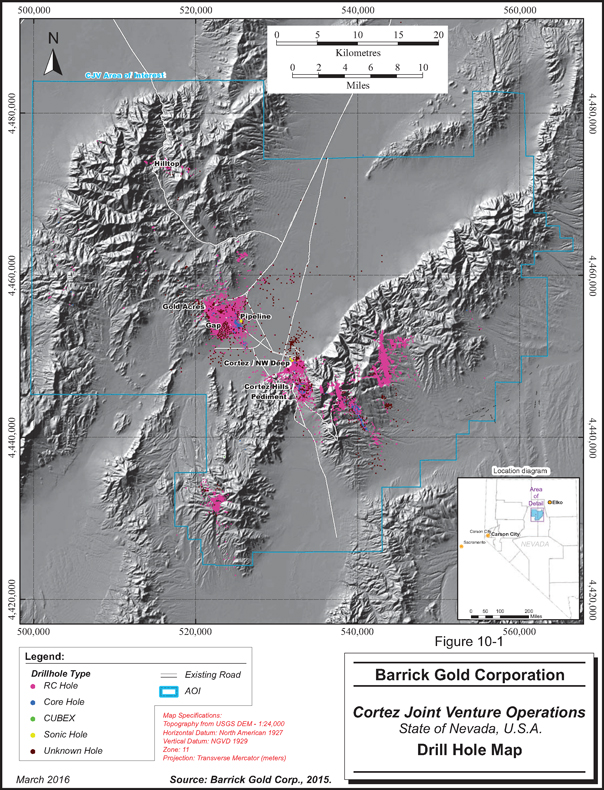

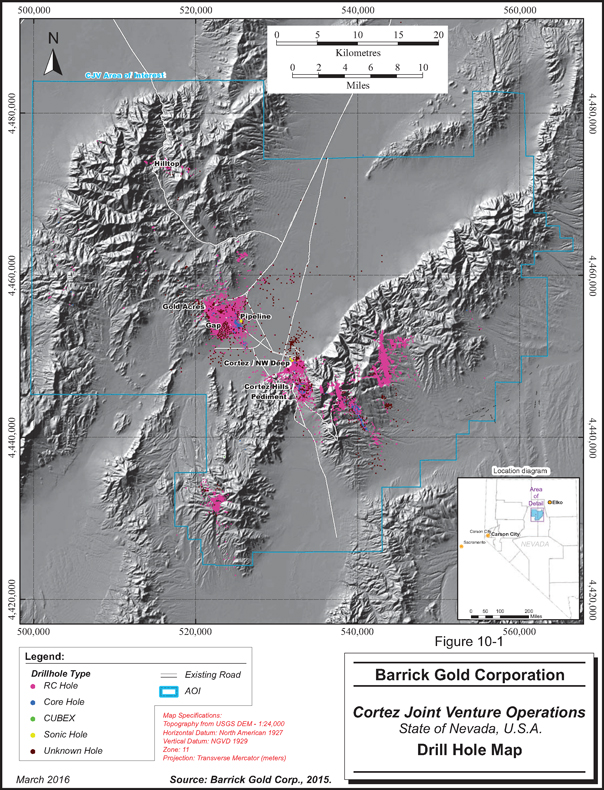

Figure 10-1 | | Drill Hole Map | | | 10-2 | |

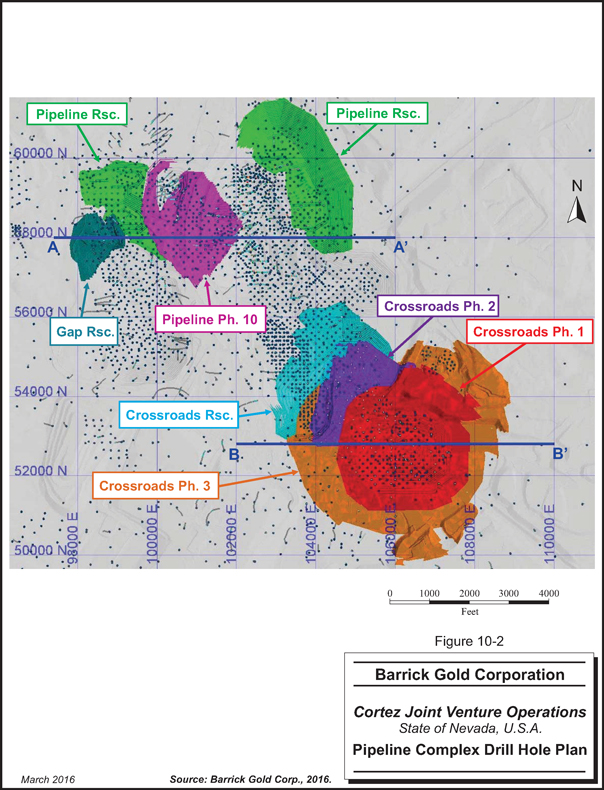

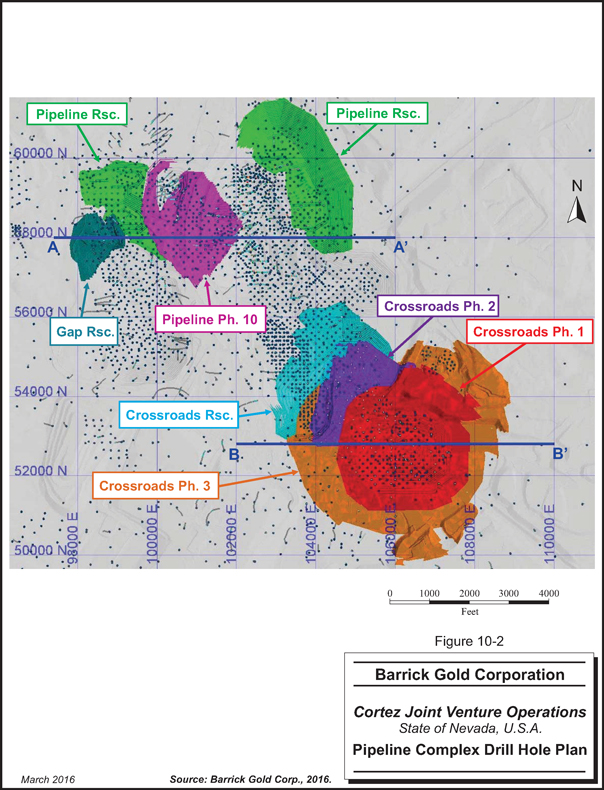

Figure 10-2 | | Pipeline Complex Drill Hole Plan | | | 10-8 | |

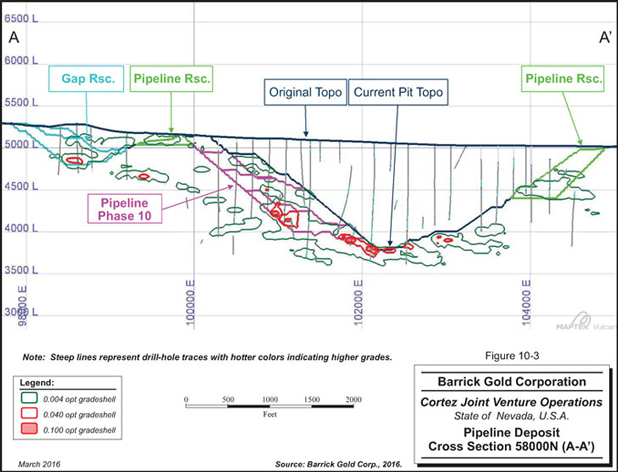

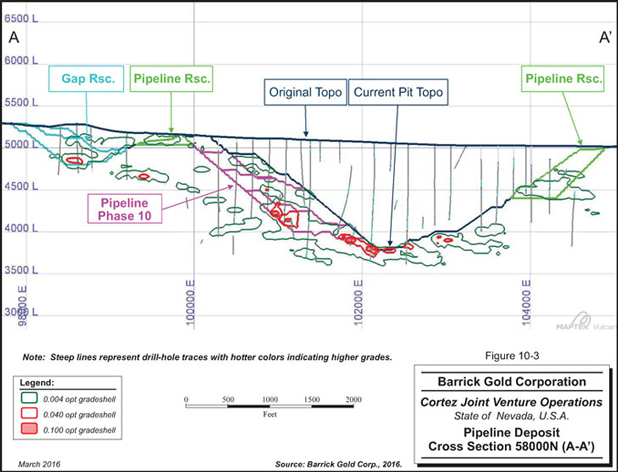

Figure 10-3 | | Pipeline Deposit – Cross Section 58000N (A-A’) | | | 10-9 | |

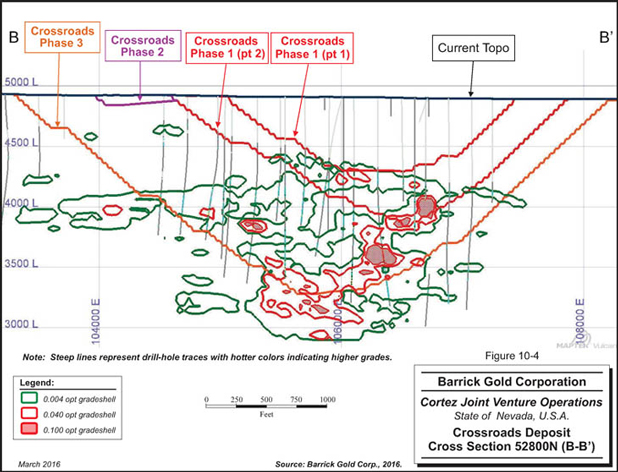

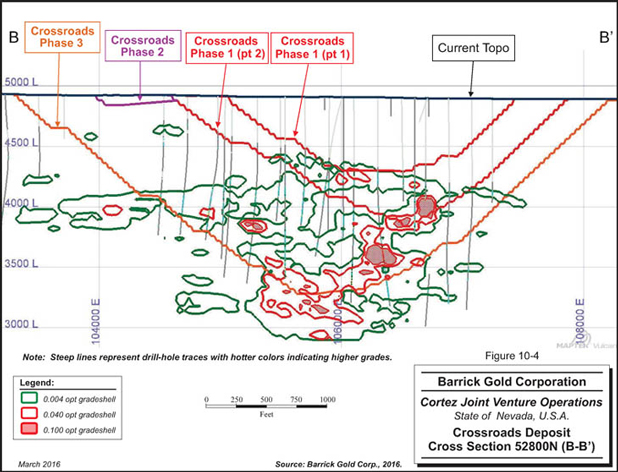

Figure 10-4 | | Crossroads Deposit - Cross Section 52800N (B-B’) | | | 10-10 | |

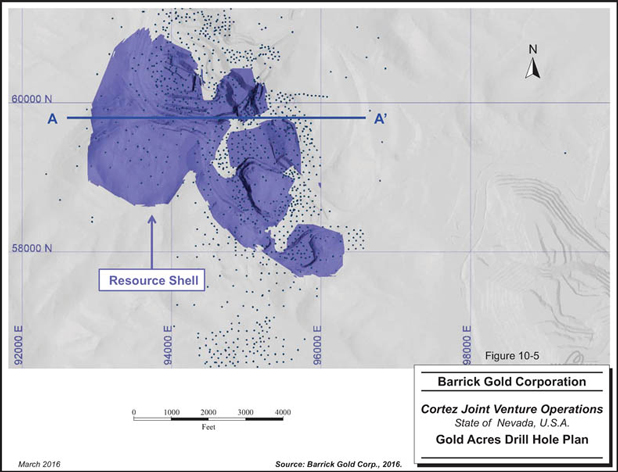

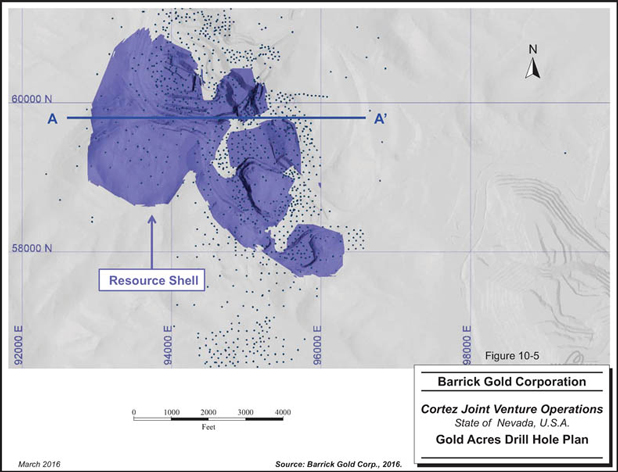

Figure 10-5 | | Gold Acres Drill Hole Plan | | | 10-11 | |

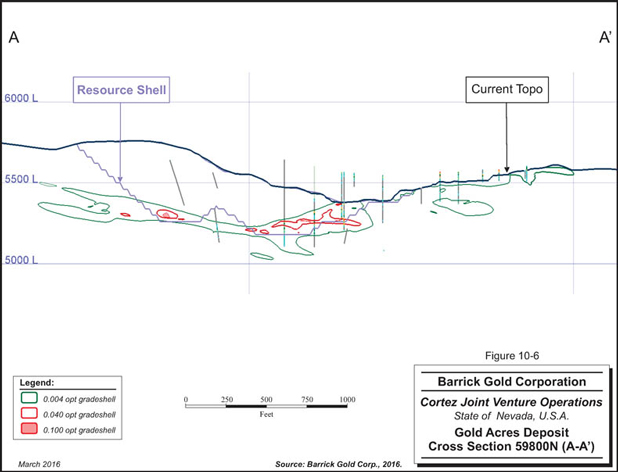

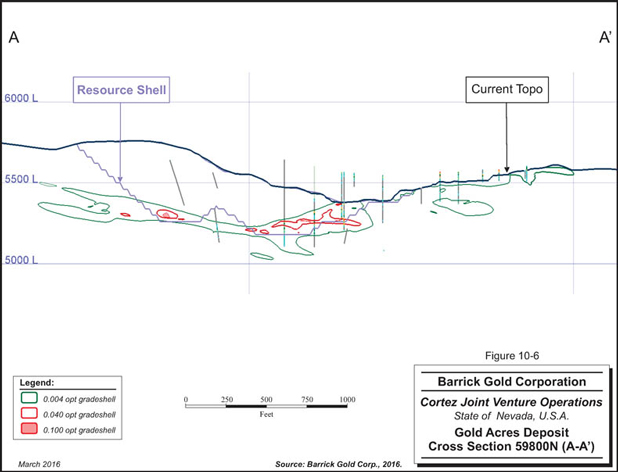

Figure 10-6 | | Gold Acres Deposit - Cross Section 59800N (A-A’) | | | 10-12 | |

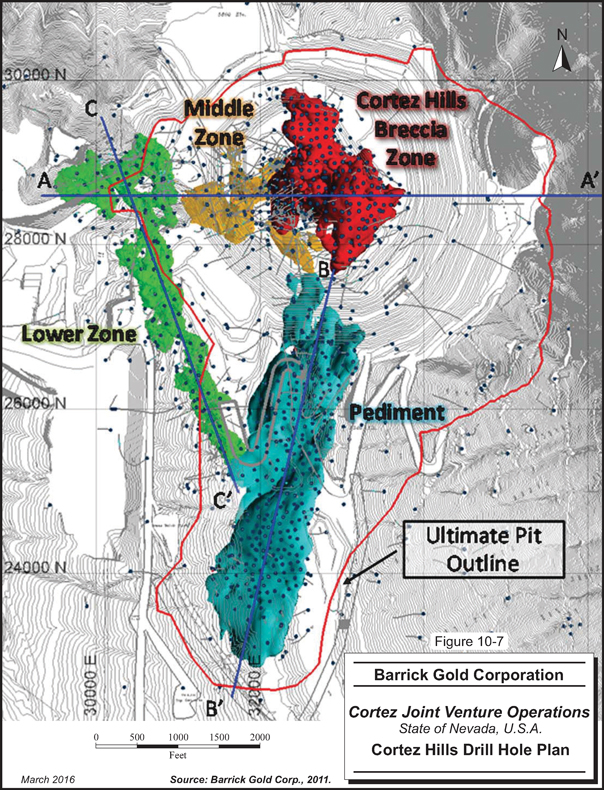

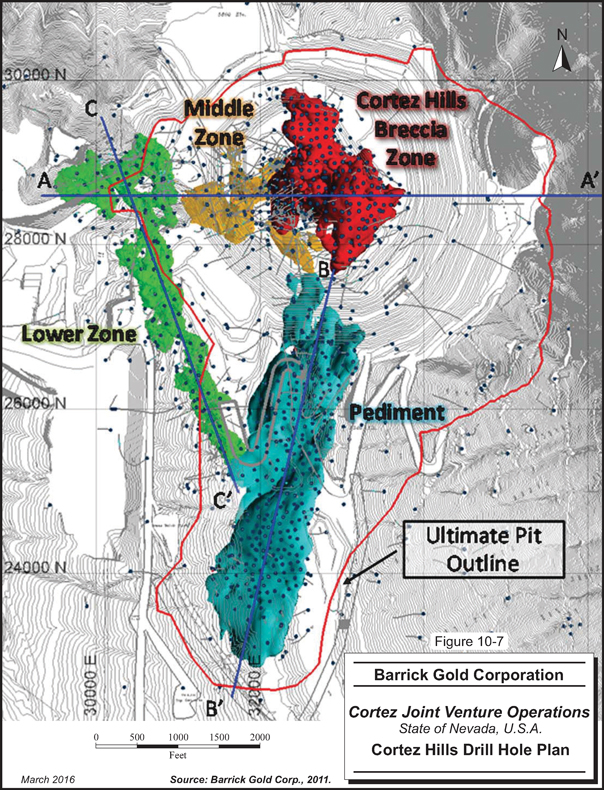

Figure 10-7 | | Cortez Hills Drill Hole Plan | | | 10-14 | |

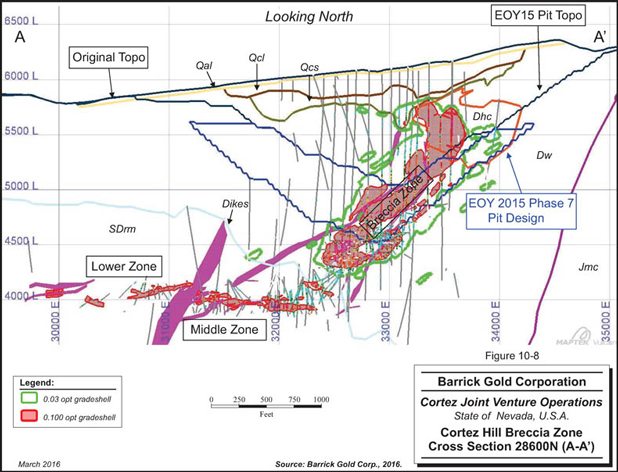

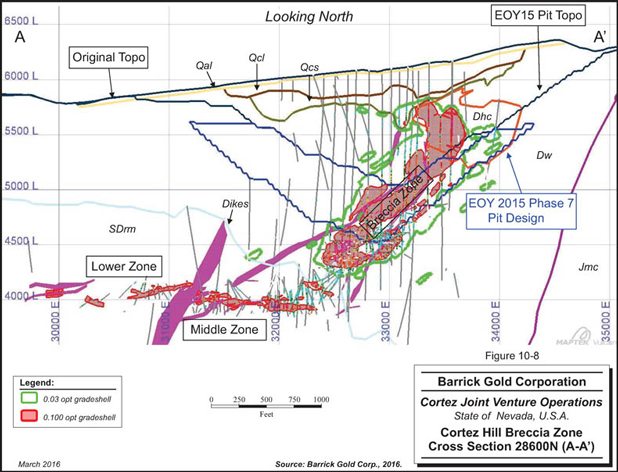

Figure 10-8 | | Cortez Hills – Cross Section 28600N (A-A’) Breccia, Middle and Lower Zones | | | 10-15 | |

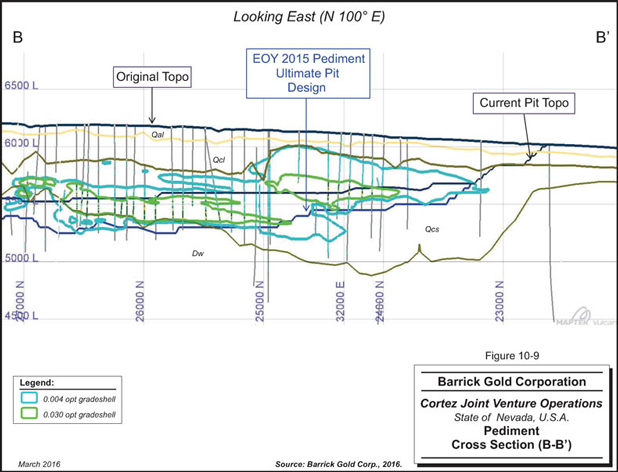

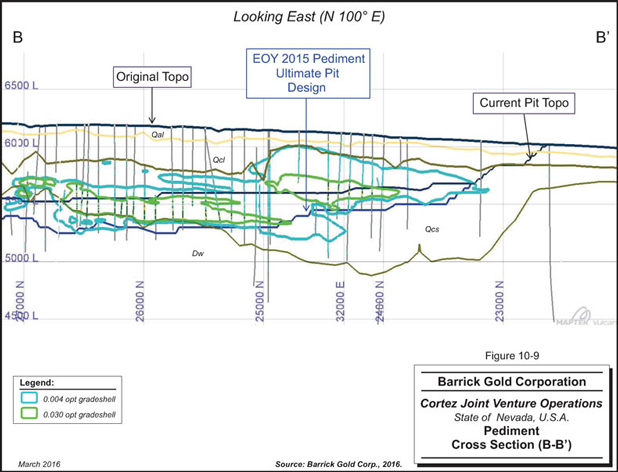

Figure 10-9 | | Pediment - Long-Section B-B’ | | | 10-16 | |

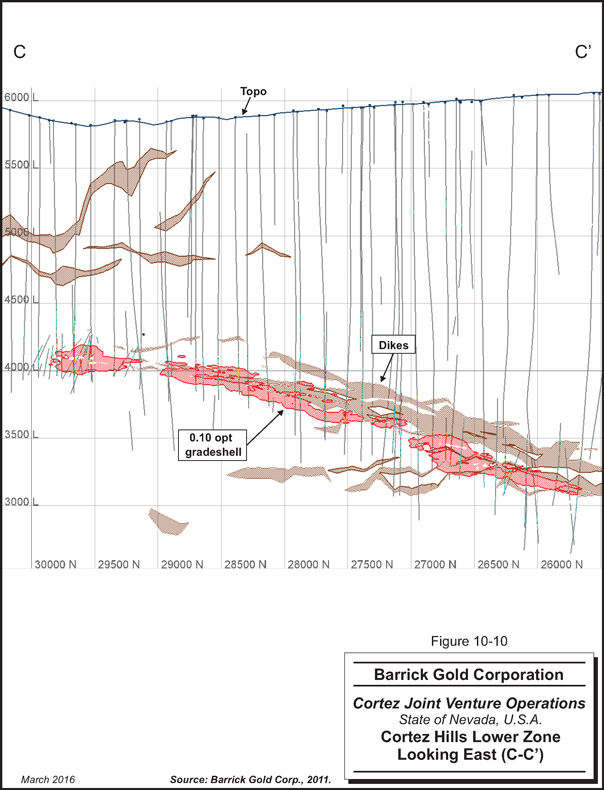

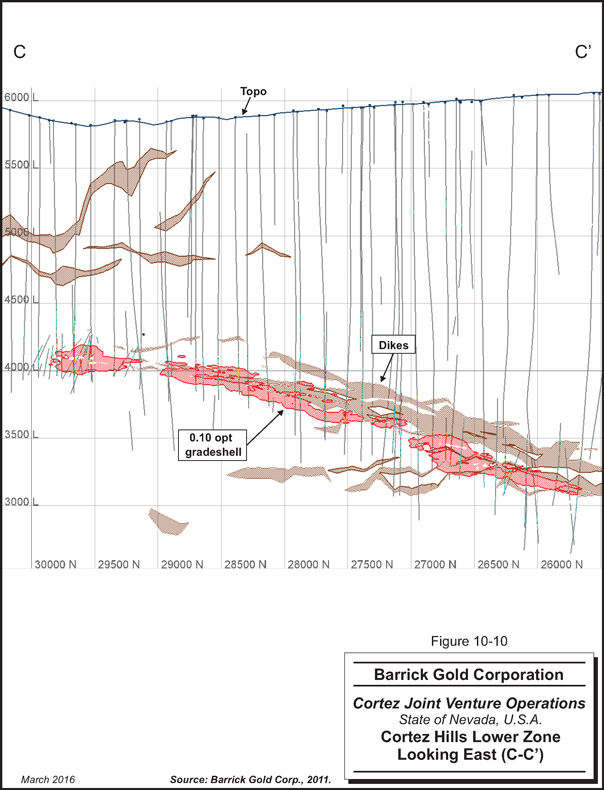

Figure 10-10 | | Lower Zone - Long-Section C-C’ | | | 10-17 | |

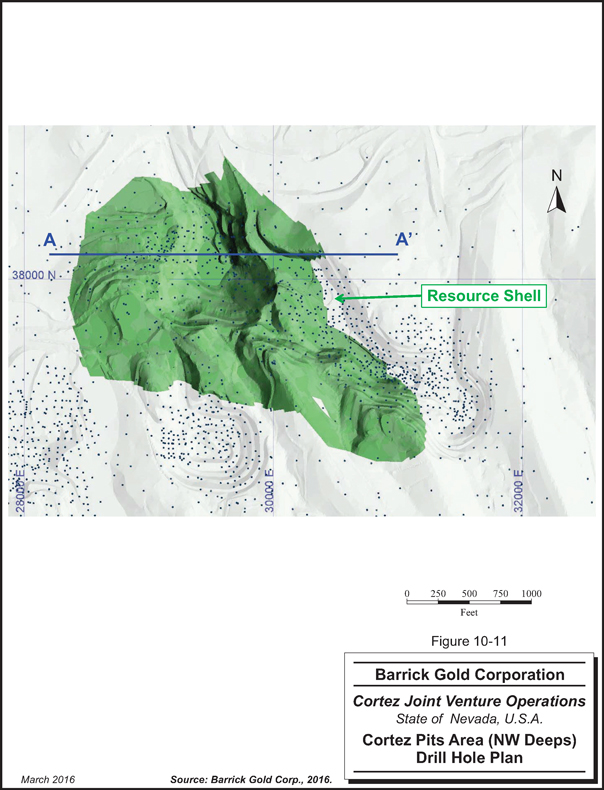

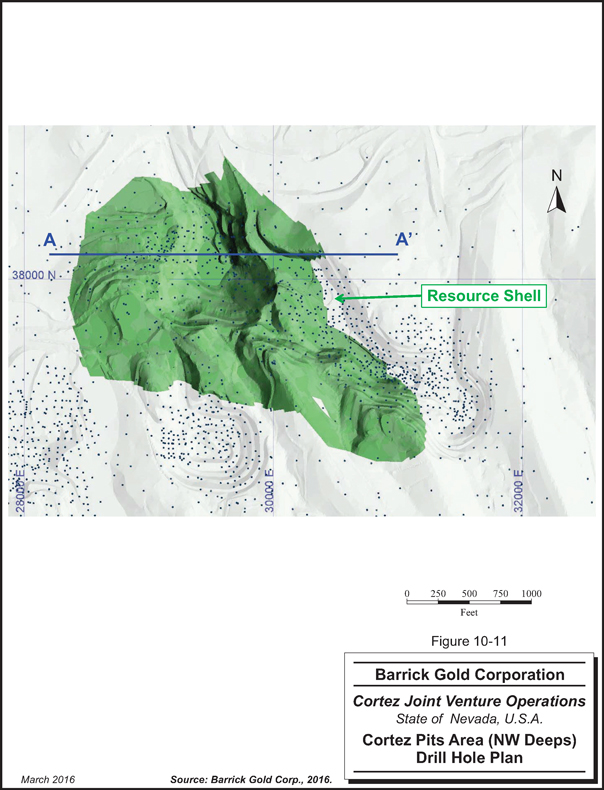

Figure 10-11 | | Cortez Pits Area (NW Deeps) Drill Hole Plan | | | 10-19 | |

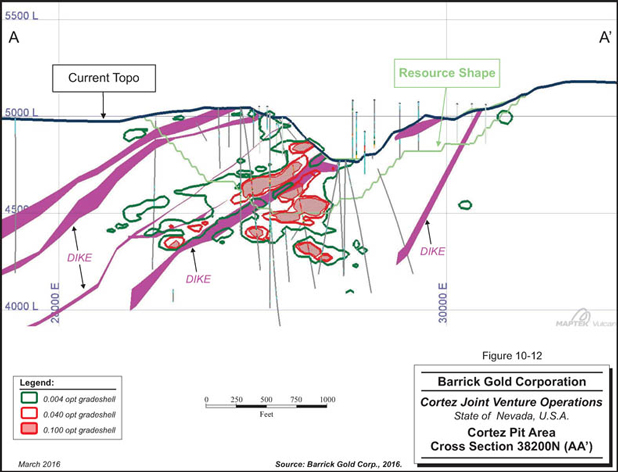

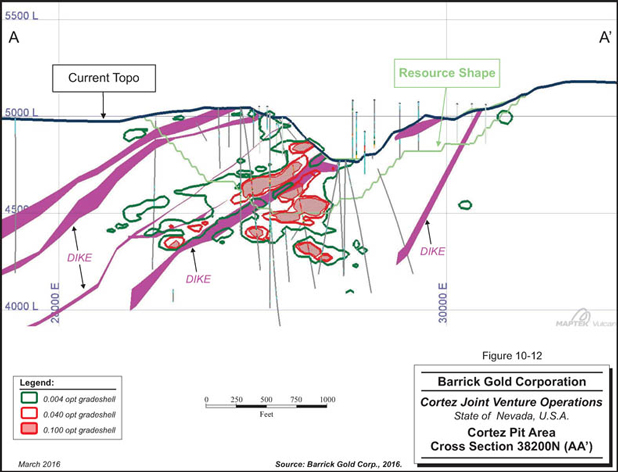

Figure 10-12 | | Cortez Pits Area – Cross Section 38200N | | | 10-20 | |

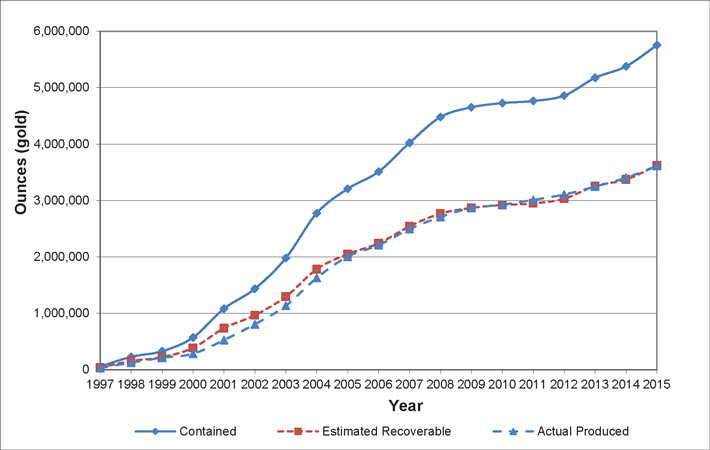

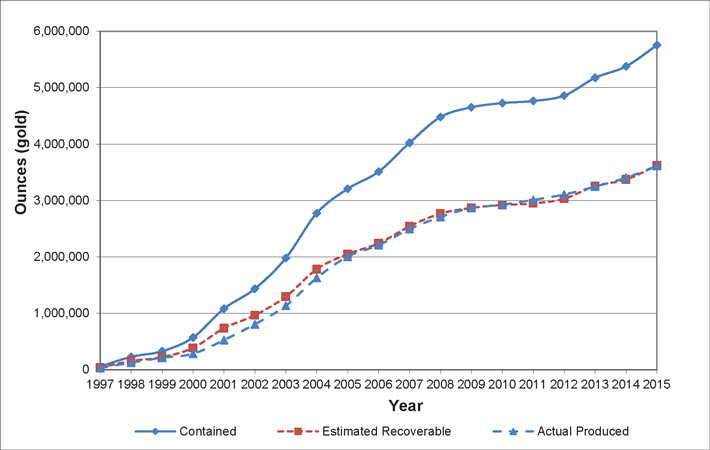

Figure 13-1 | | Historical Heap Leach Data | | | 13-7 | |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page v |

| | |

| | www.rpacan.com |

| | | | | | |

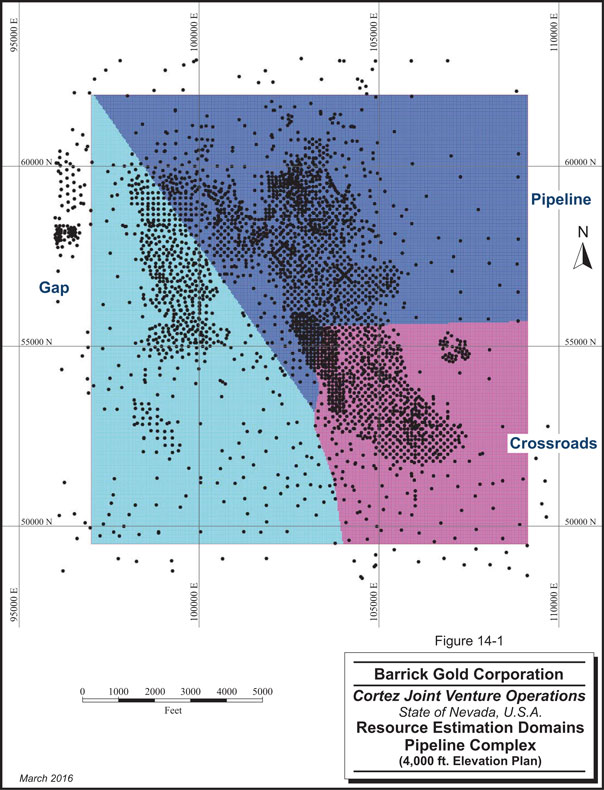

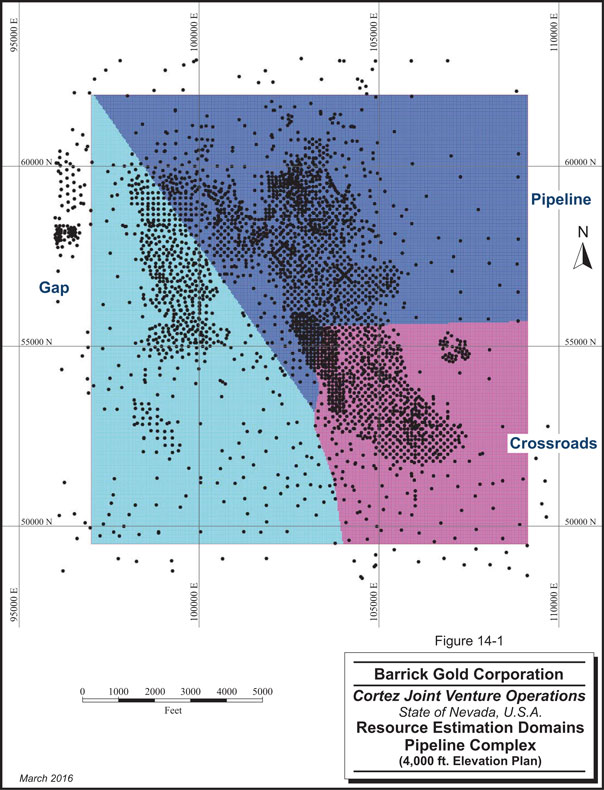

Figure 14-1 | | Resource Estimation Domains Pipeline Complex | | | 14-7 | |

Figure 14-2 | | Low Grade, Omnidirectional Variograms at Pipeline Complex | | | 14-11 | |

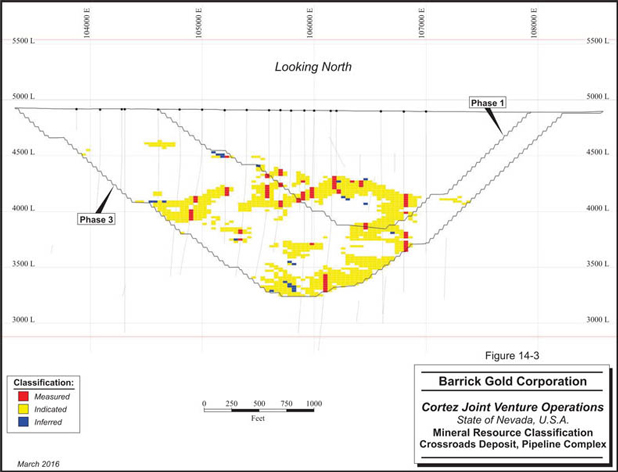

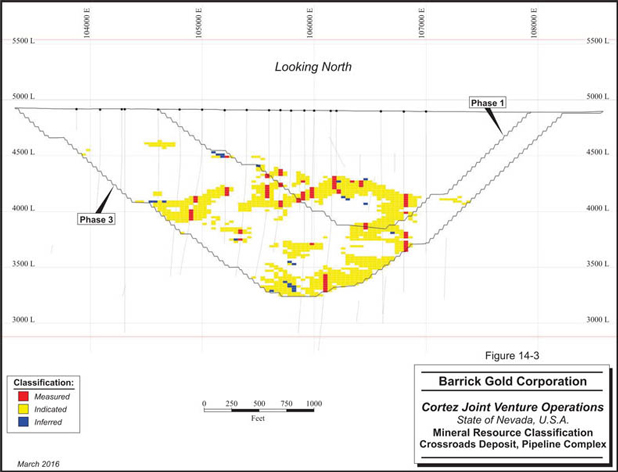

Figure 14-3 | | Mineral Resource Classification, Crossroads Deposit, Pipeline Complex | | | 14-15 | |

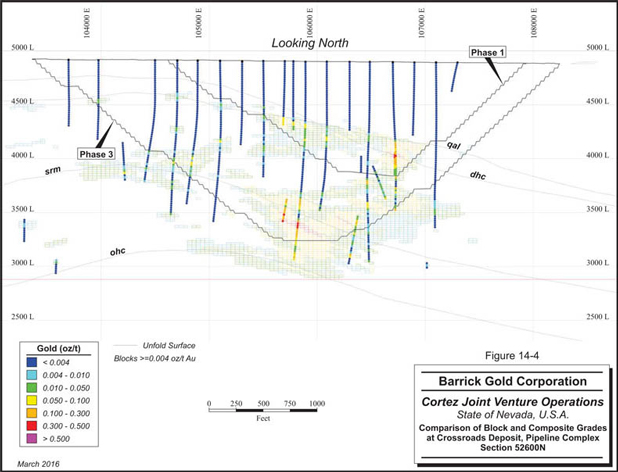

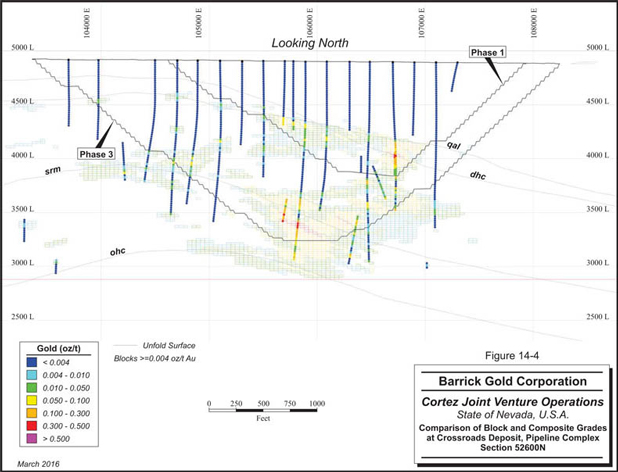

Figure 14-4 | | Section 52600 N: Comparison of Block and Composite Gold Grades at Crossroads Deposit, Pipeline Complex | | | 14-19 | |

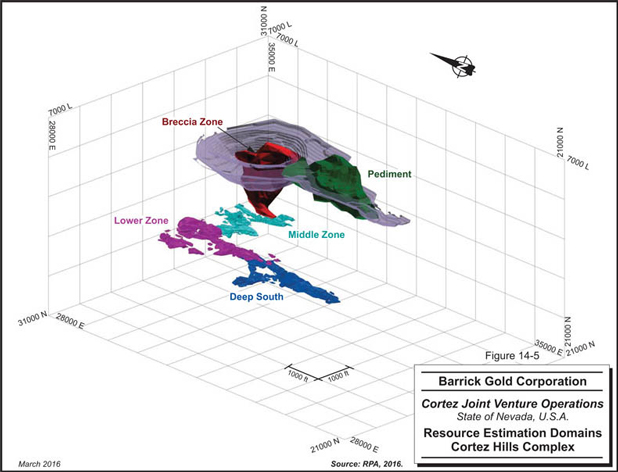

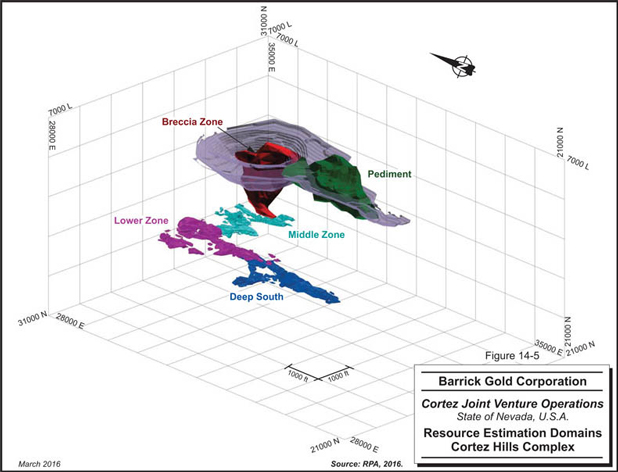

Figure 14-5 | | Resource Estimation Domains Cortez Hills Complex | | | 14-24 | |

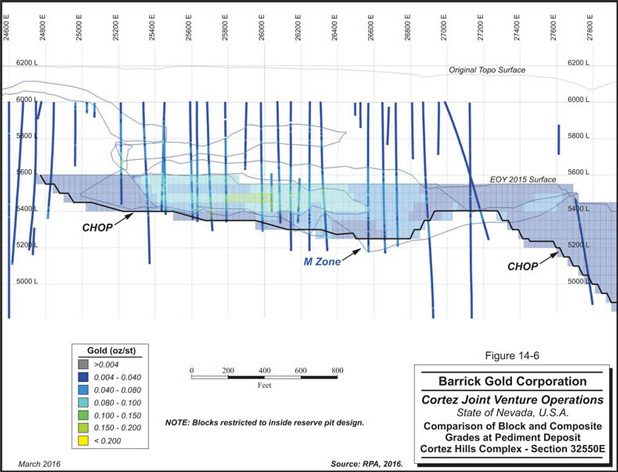

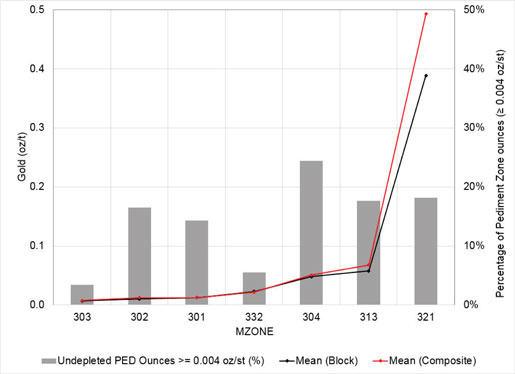

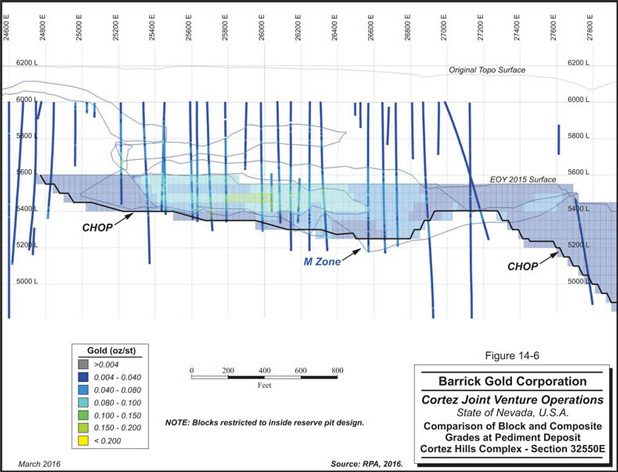

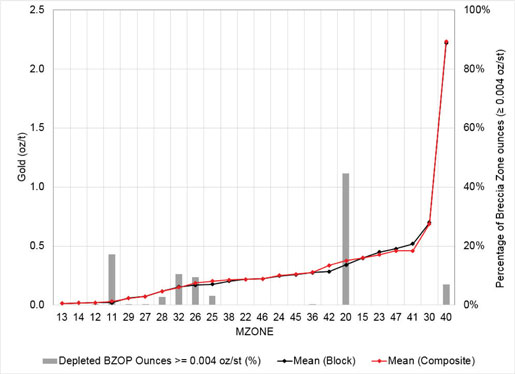

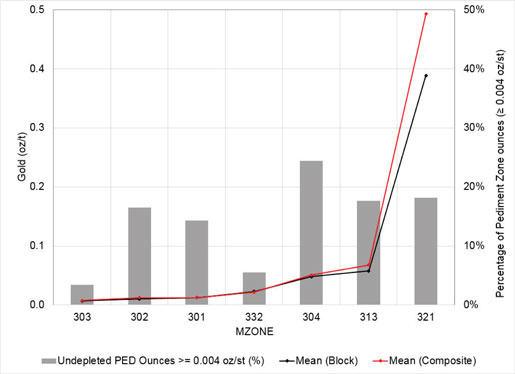

Figure 14-6 | | Comparison of Block and Composite Grades at Pediment Deposit, Cortez Hills Complex | | | 14-32 | |

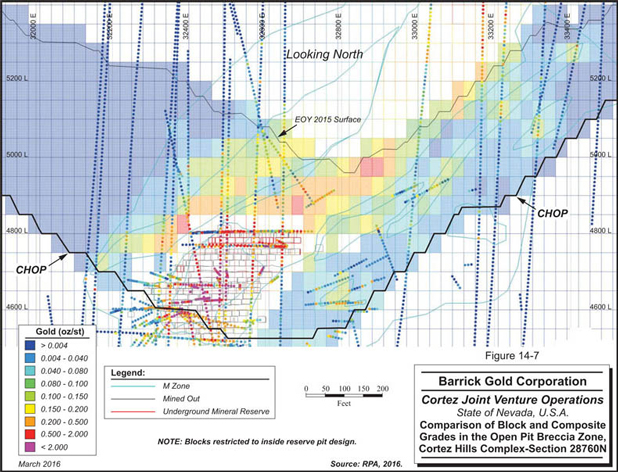

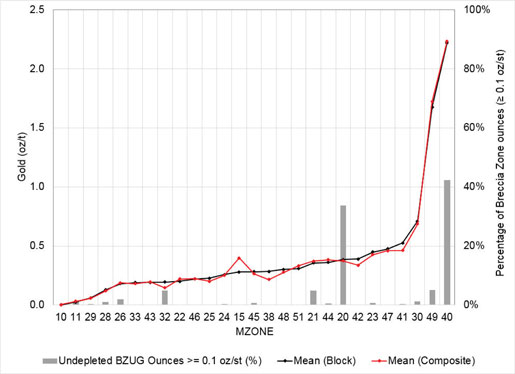

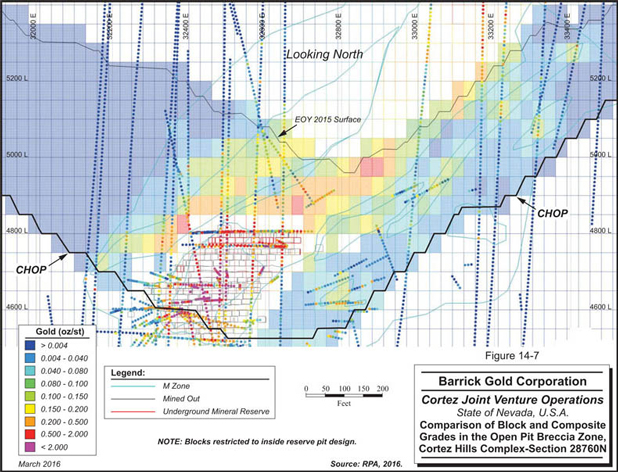

Figure 14-7 | | Comparison of Block and Composite Grades within the Breccia Zone, Open Pit Portion, Cortez Hills Complex | | | 14-33 | |

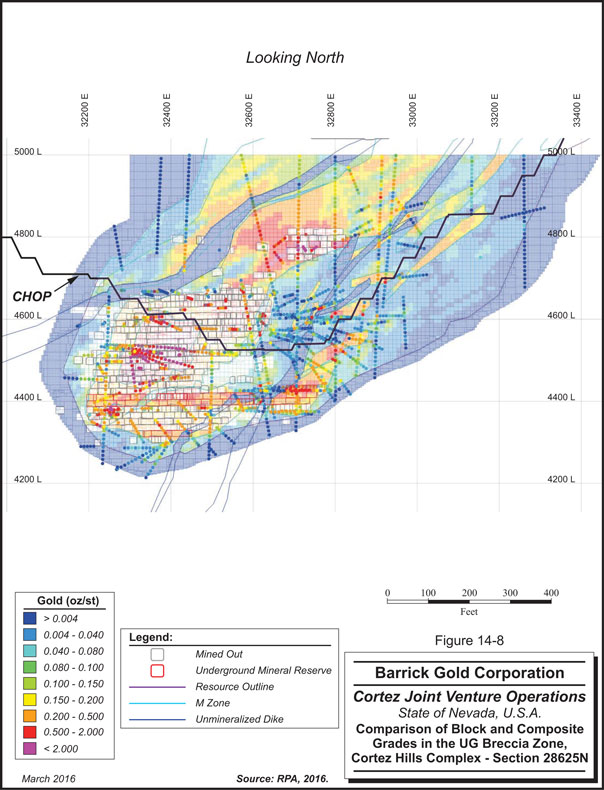

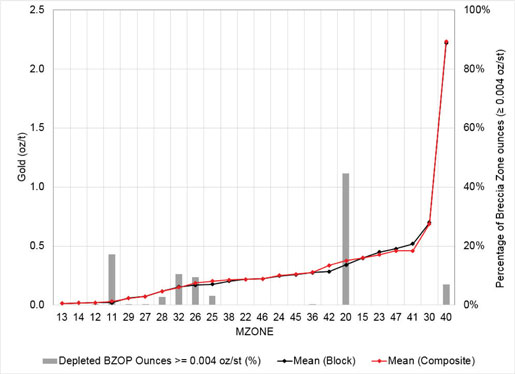

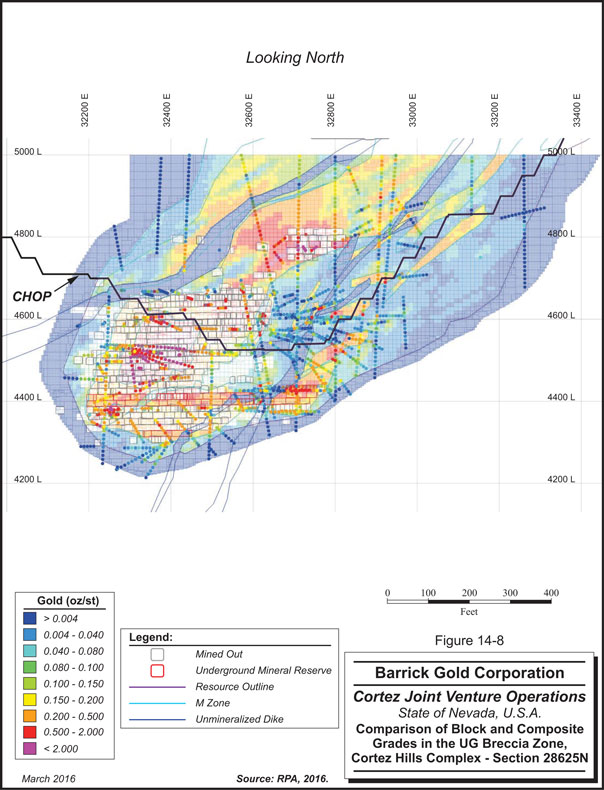

Figure 14-8 | | Comparison of Block and Composite Grades within the Breccia Zone, Underground Portion, Cortez Hills Complex | | | 14-34 | |

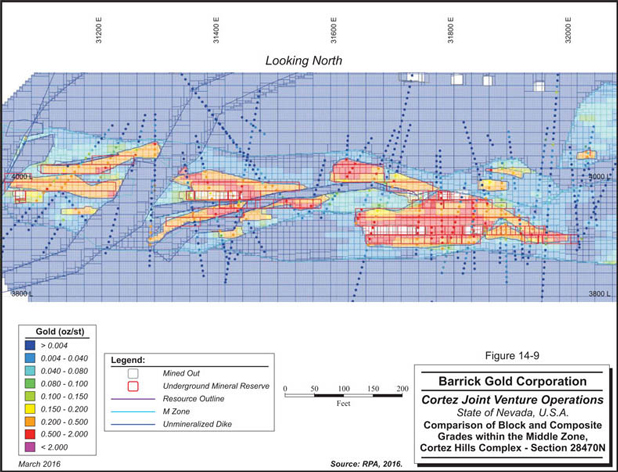

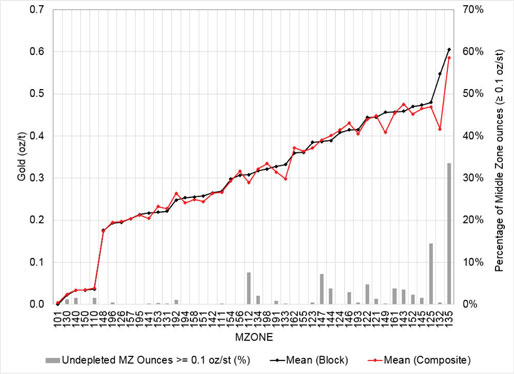

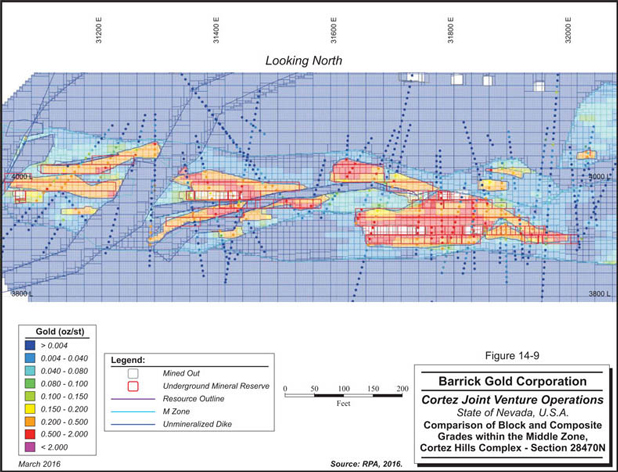

Figure 14-9 | | Comparison of Block and Composite Grades within the Middle Zone, Cortez Hills Complex | | | 14-35 | |

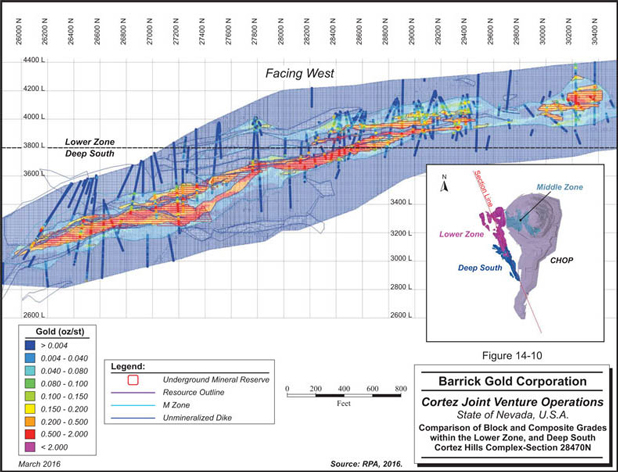

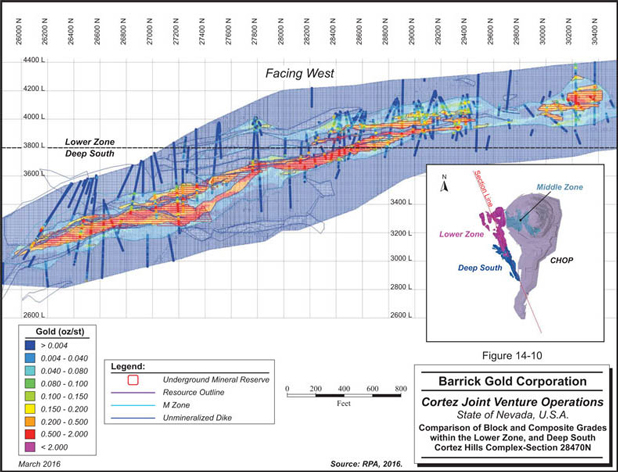

Figure 14-10 | | Comparison of Block and Composite Grades within the Lower Zone, including Deep South, Cortez Hills Complex | | | 14-36 | |

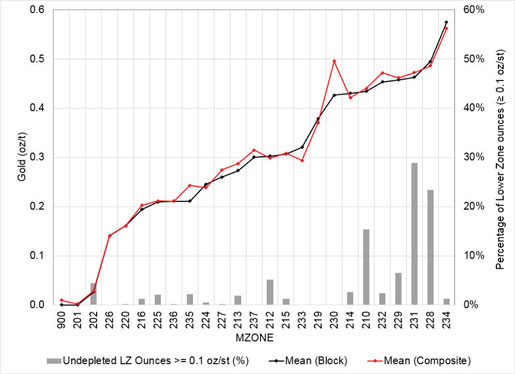

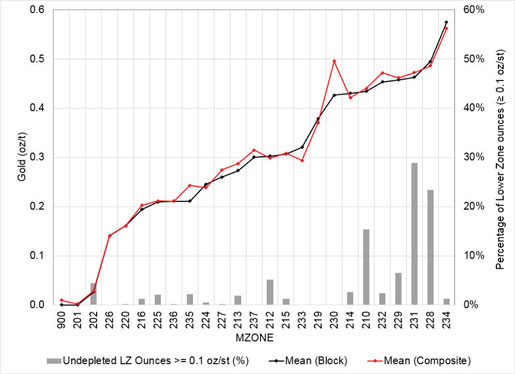

Figure 14-11 | | CHUG Lower Zone Comparison of Block and Composite Mean by Middle Zone one | | | 14-37 | |

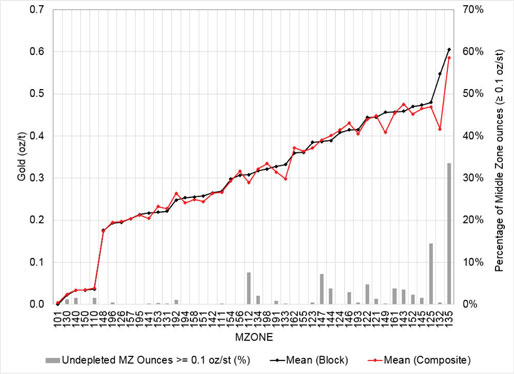

Figure 14-12 | | CHUG Middle Zone Comparison of Block and Composite Mean by Middle Zone one | | | 14-37 | |

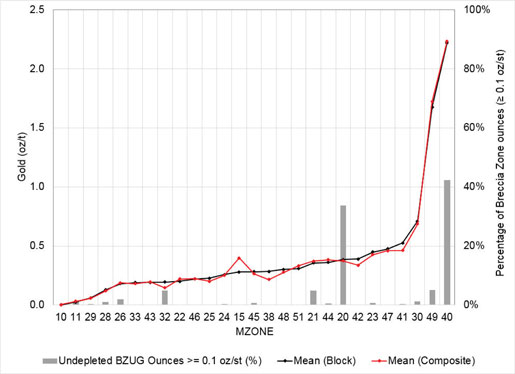

Figure 14-13 | | CHUG Breccia Zone Comparison of Block and Composite Mean by Middle Zone one | | | 14-38 | |

Figure 14-14 | | CHOP Breccia Zone Comparison of Block and Composite Mean by Middle Zone one | | | 14-38 | |

Figure 14-15 | | CHOP Pediment Zone Comparison of Block and Composite Mean by Middle Zone one | | | 14-39 | |

Figure 15-1 | | Deposit Locations | | | 15-4 | |

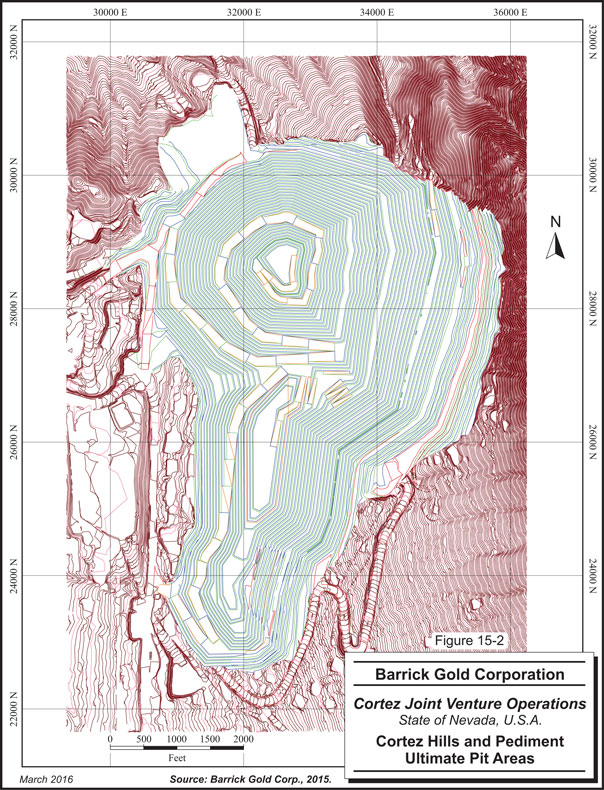

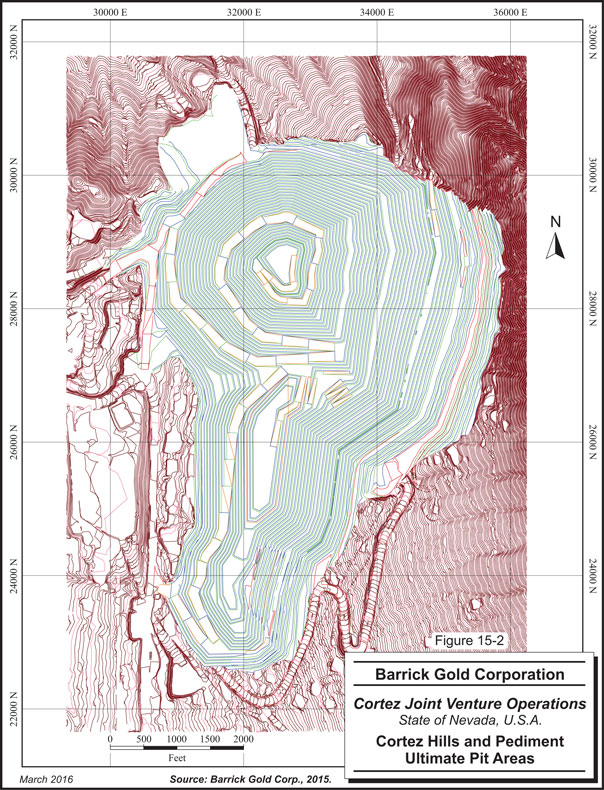

Figure 15-2 | | Cortez Hills and Pediment Ultimate Pit Areas | | | 15-9 | |

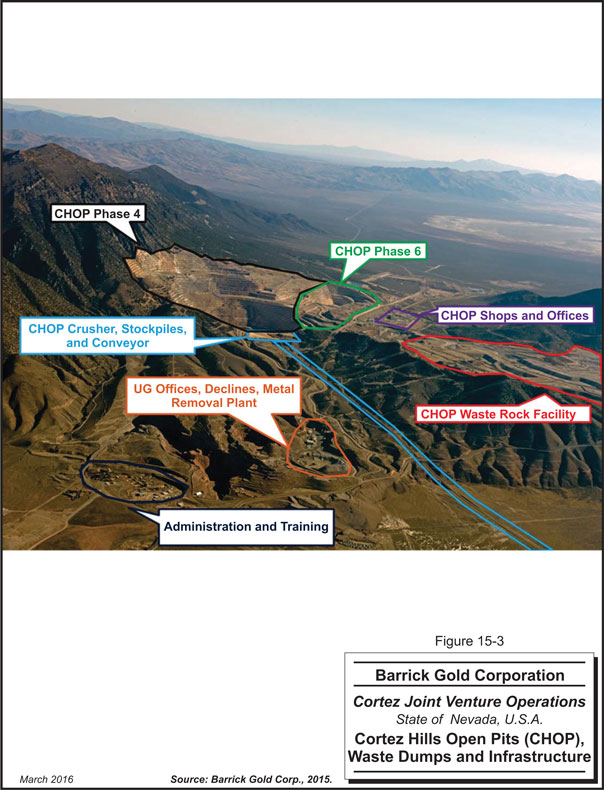

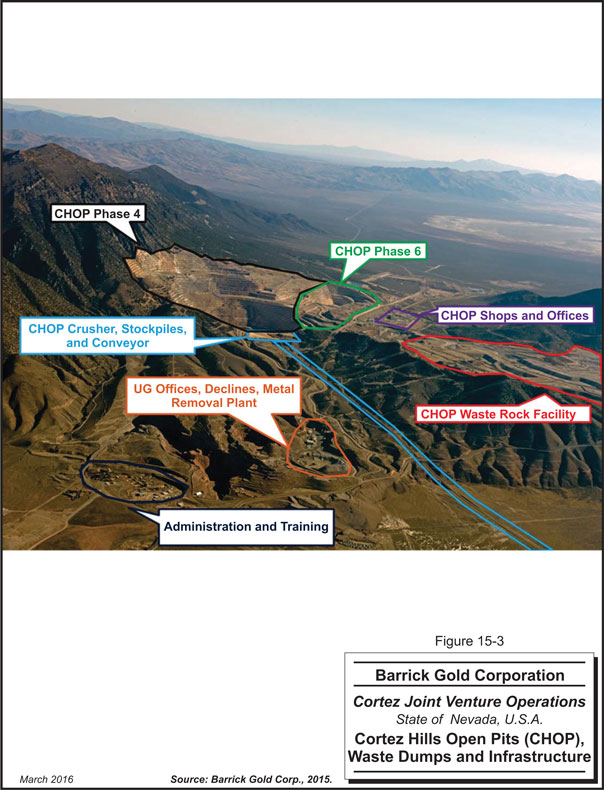

Figure 15-3 | | Cortez Hills Open Pits, Waste Dumps, and Infrastructure | | | 15-10 | |

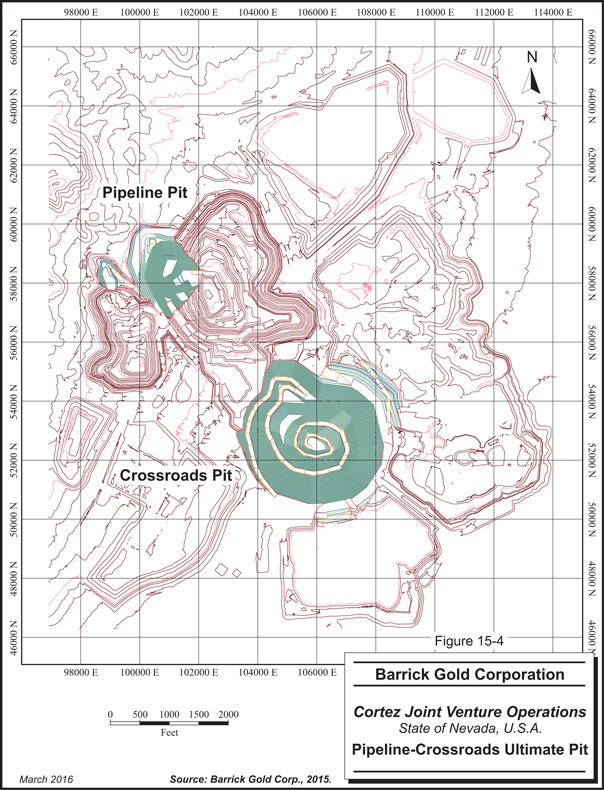

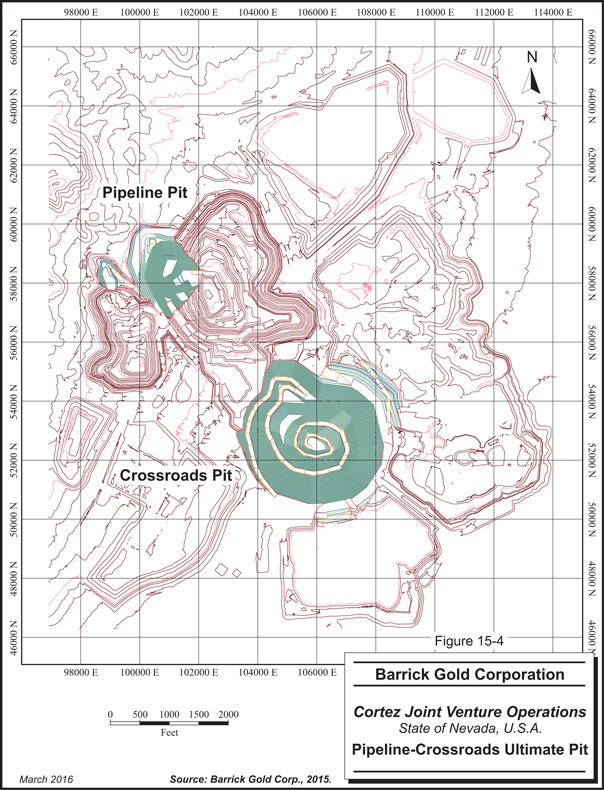

Figure 15-4 | | Pipeline and Crossroads Ultimate Pit Areas | | | 15-12 | |

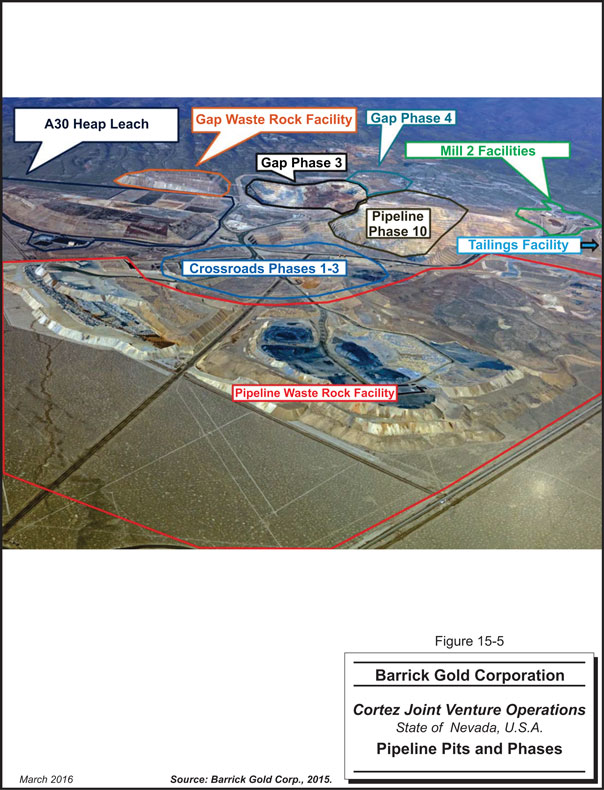

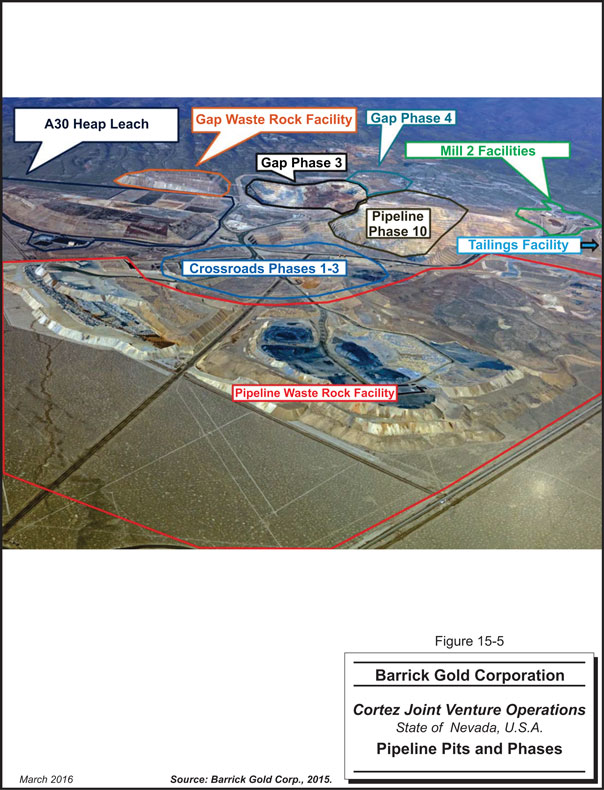

Figure 15-5 | | Pipeline Pits and Phases | | | 15-13 | |

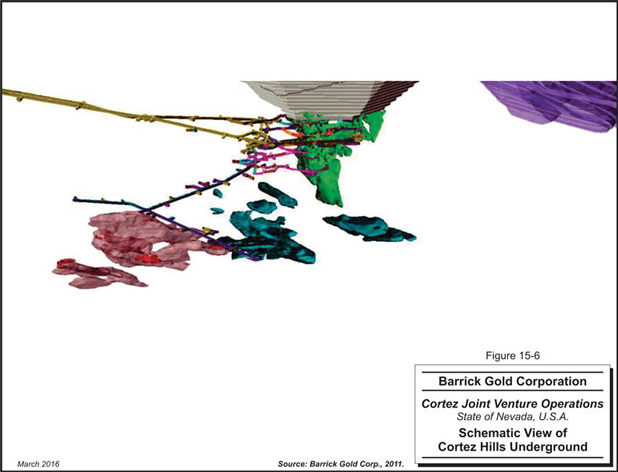

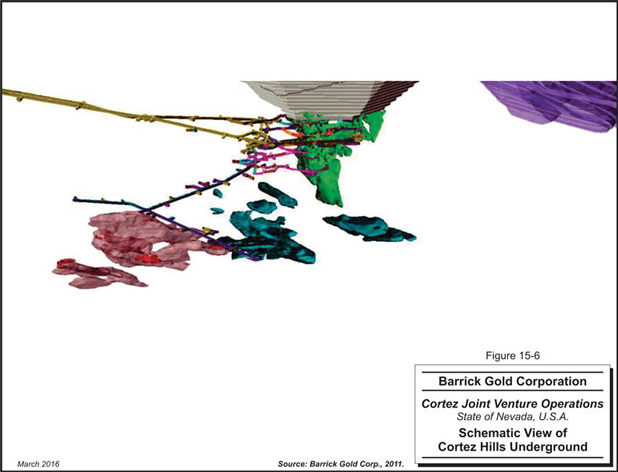

Figure 15-6 | | Schematic View of the Cortez Hills Underground | | | 15-22 | |

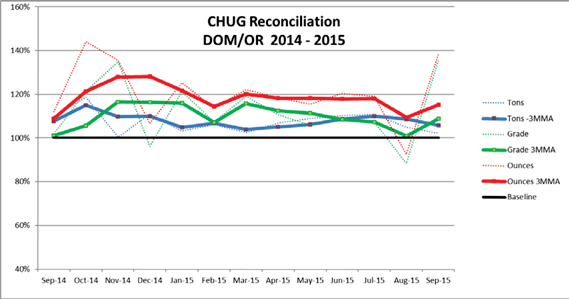

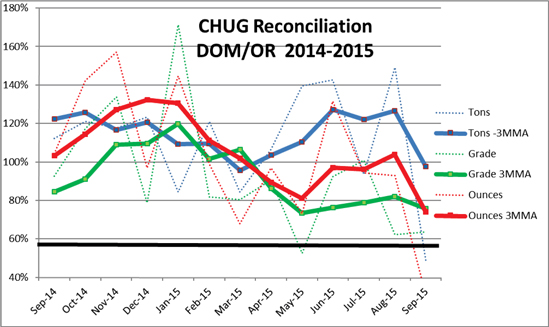

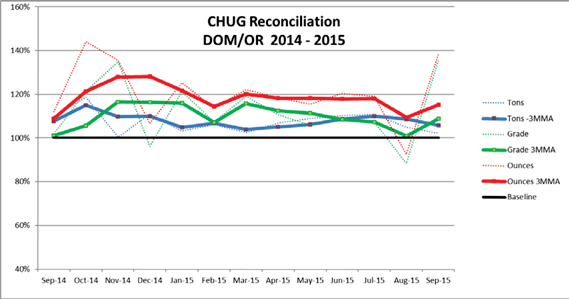

Figure 15-7 | | Total Underground Ore Reconciliation 2014-2015 | | | 15-34 | |

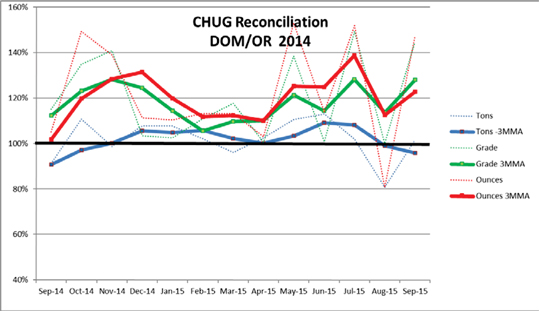

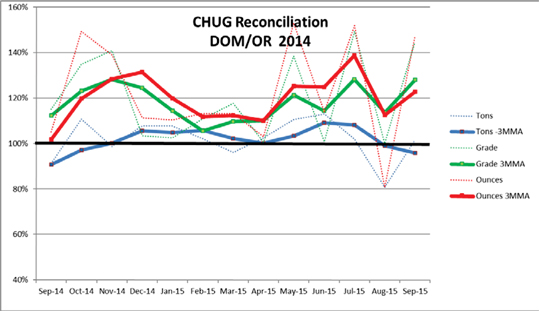

Figure 15-8 | | Underground Oxide Ore Reconciliation 2014-2015 | | | 15-35 | |

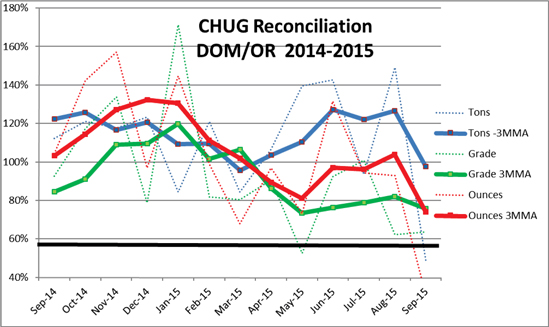

Figure 15-9 | | Underground Roaster Ore Reconciliation 2014-2015 | | | 15-36 | |

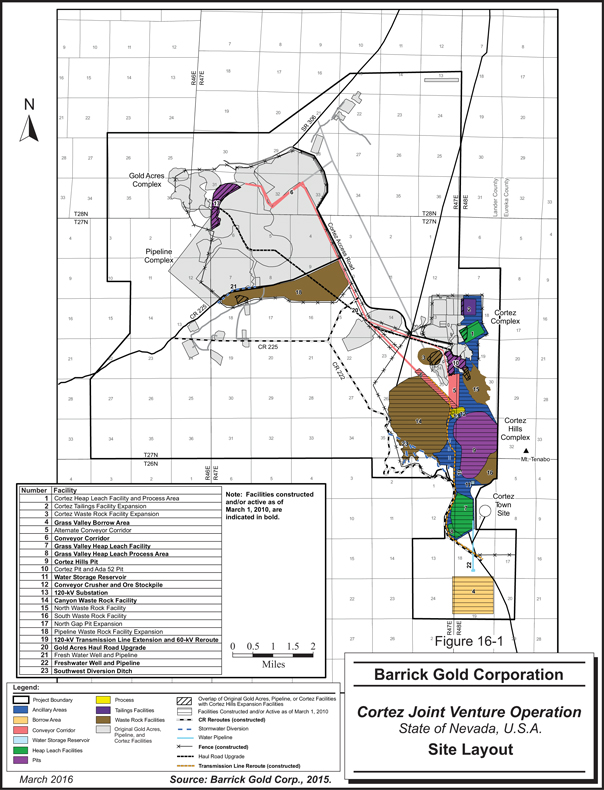

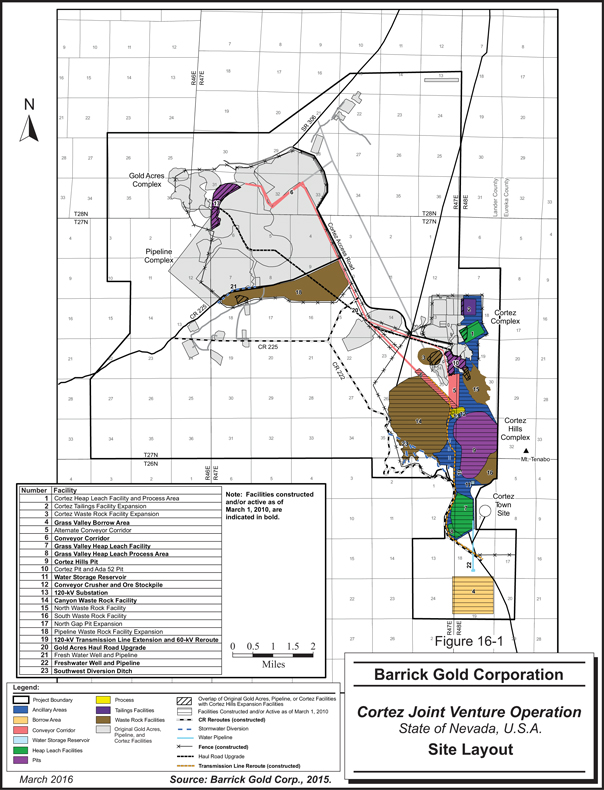

Figure 16-1 | | Site Layout | | | 16-3 | |

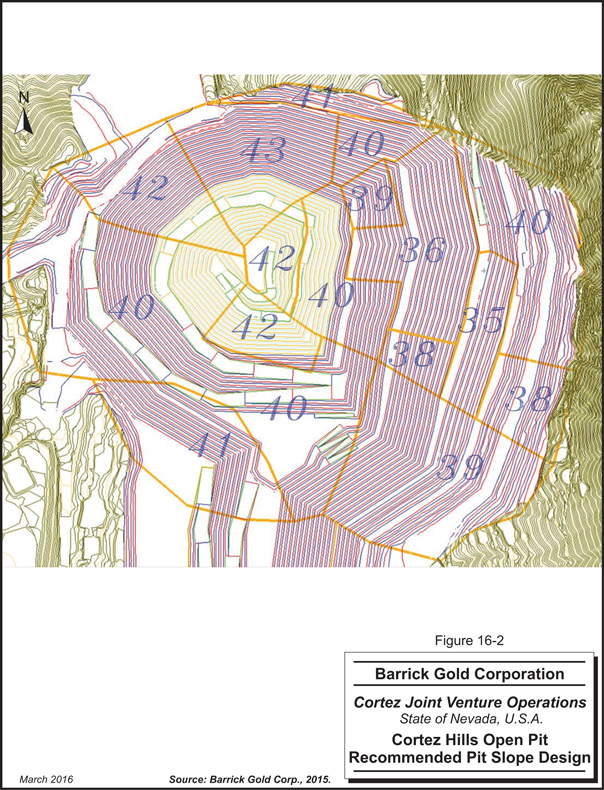

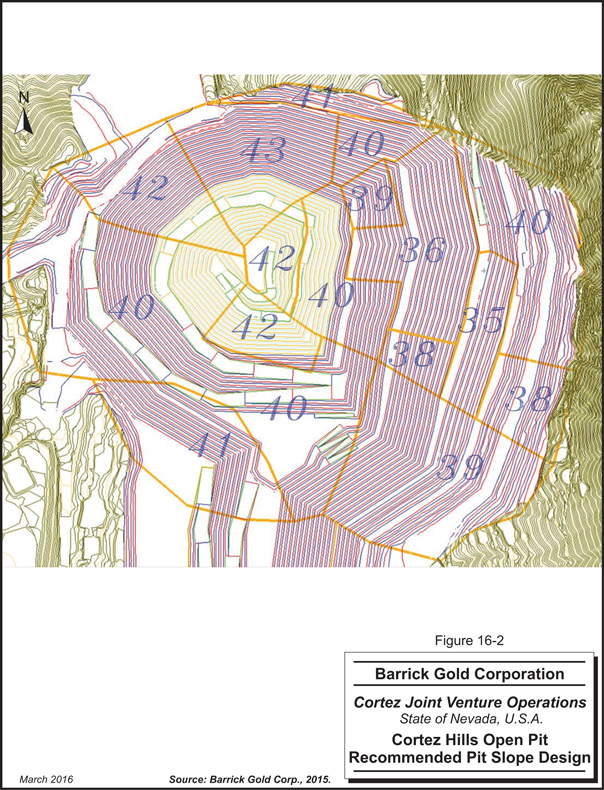

Figure 16-2 | | Cortez Hills Open Pit Recommended Pit Slope Design | | | 16-7 | |

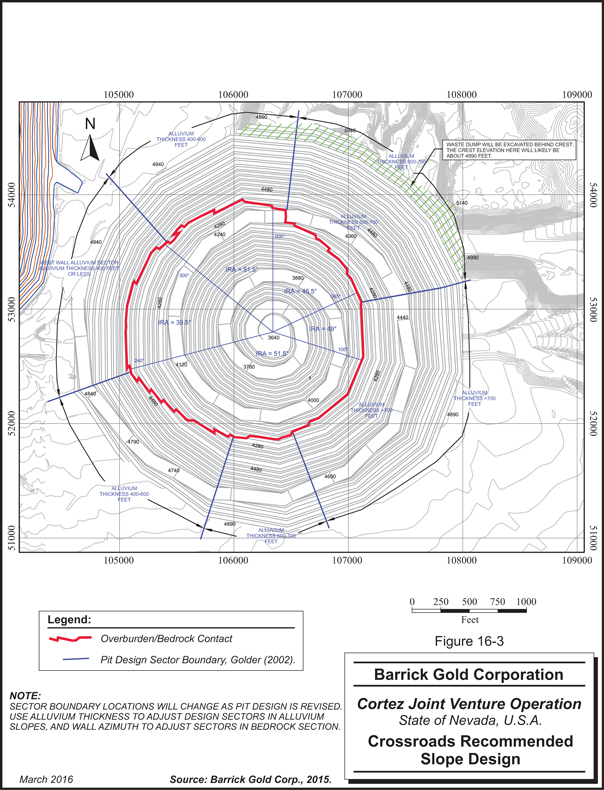

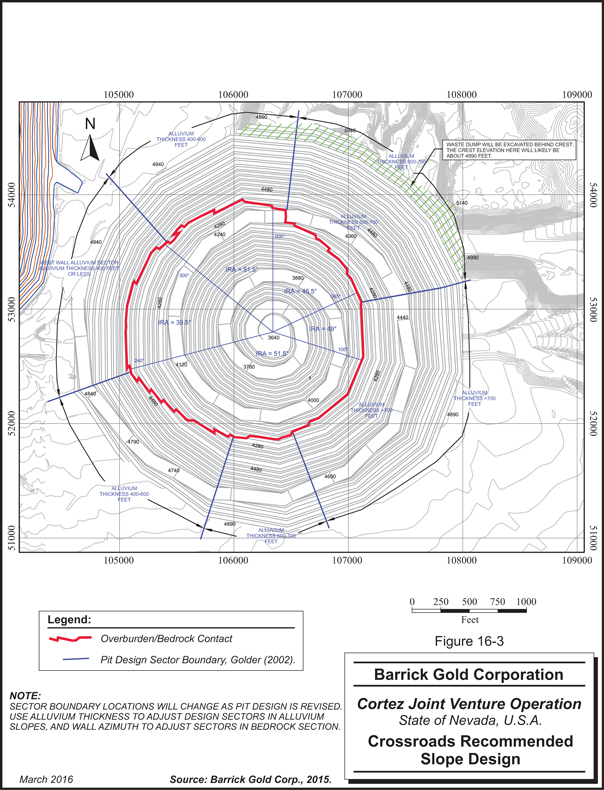

Figure 16-3 | | Crossroads Recommended Slope Design | | | 16-8 | |

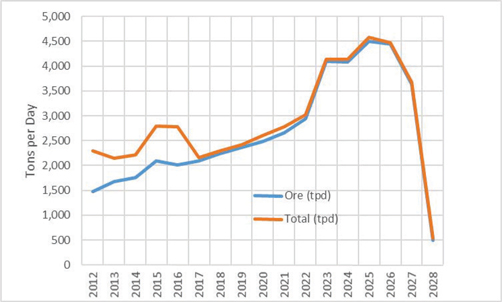

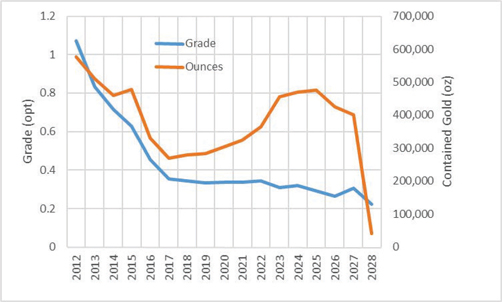

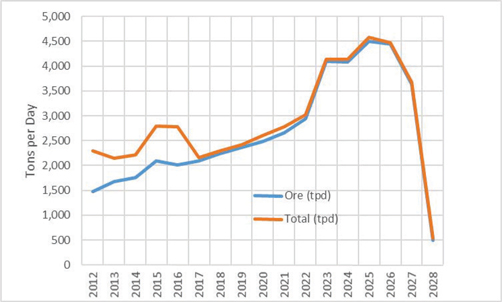

Figure 16-4 | | CHUG LOM Mine Production Rate | | | 16-16 | |

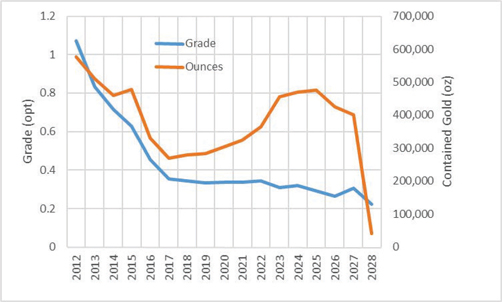

Figure 16-5 | | CHUG LOM Gold Production and Head Grade | | | 16-17 | |

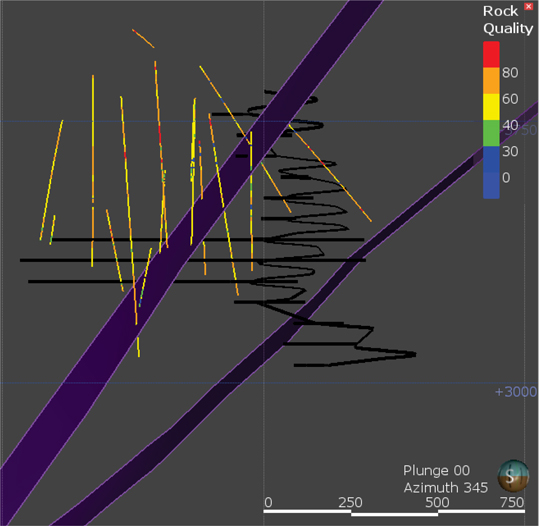

Figure 16-6 | | Geotechnical Domains | | | 16-23 | |

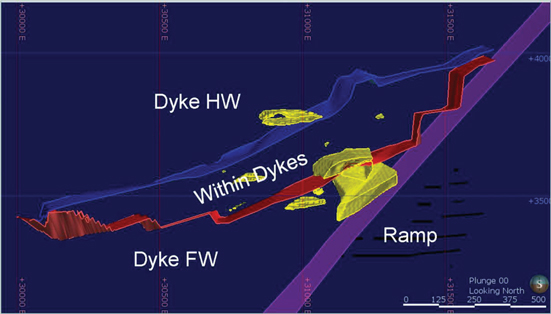

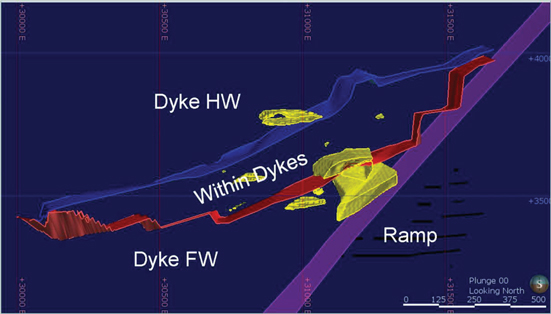

Figure 16-7 | | Main Ramp Layout Relative to Geological Features, Looking North | | | 16-24 | |

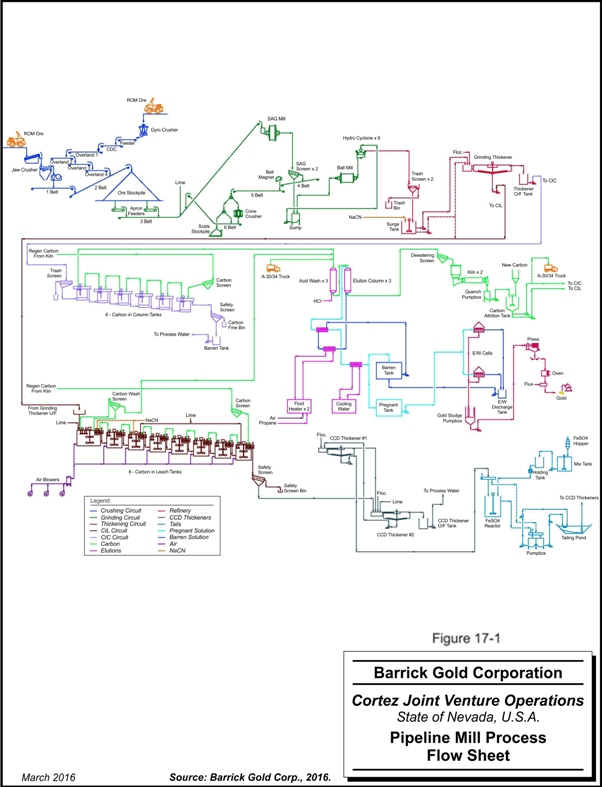

Figure 17-1 | | Pipeline Mill Process Flow Sheet | | | 17-6 | |

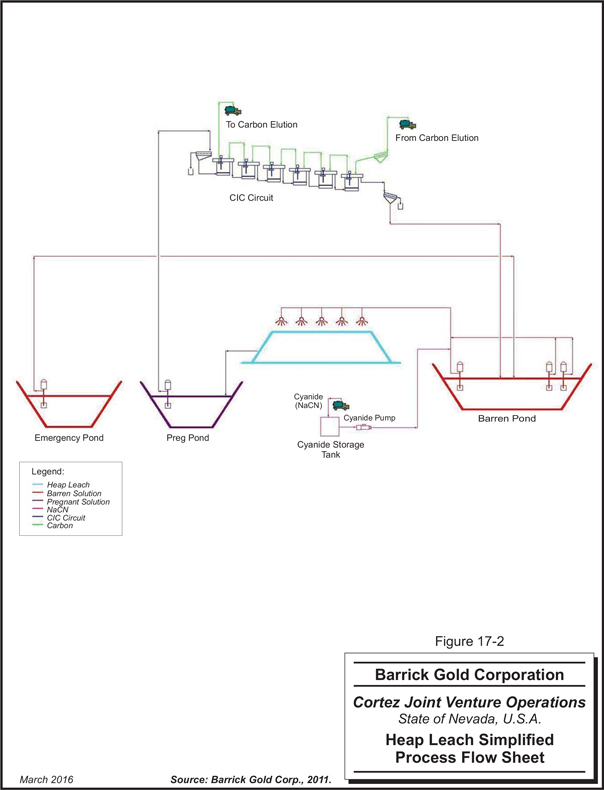

Figure 17-2 | | Simplified Heap Leach Flow Sheet | | | 17-7 | |

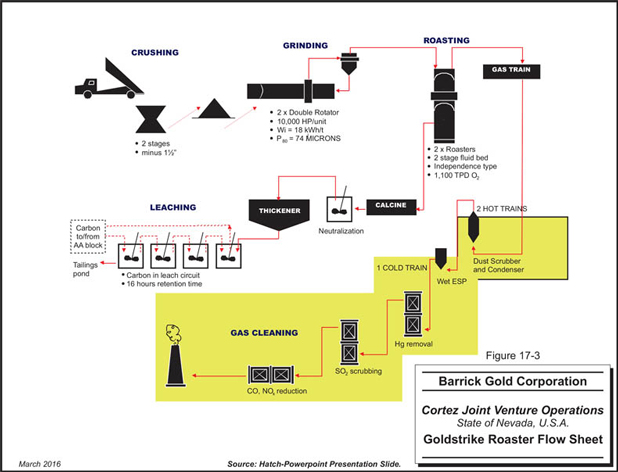

Figure 17-3 | | Goldstrike Roaster Flow Sheet | | | 17-8 | |

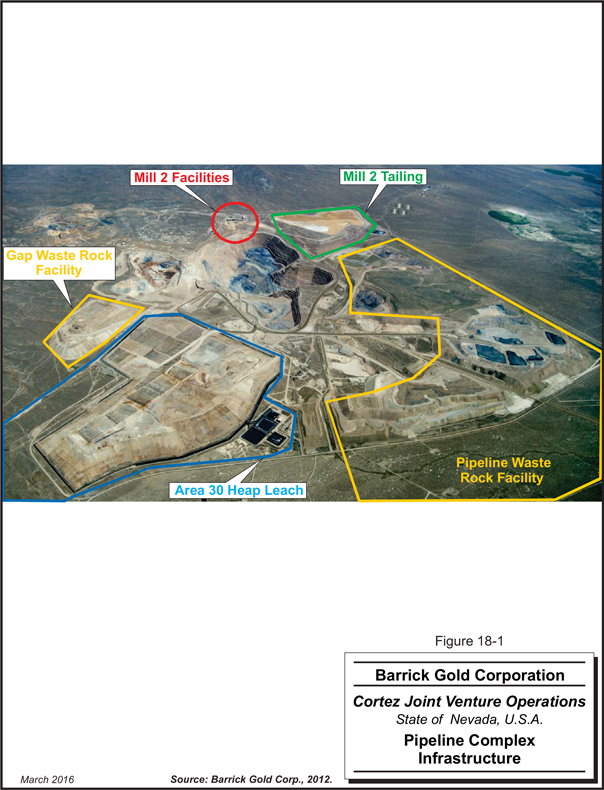

Figure 18-1 | | Pipeline Complex Infrastructure | | | 18-2 | |

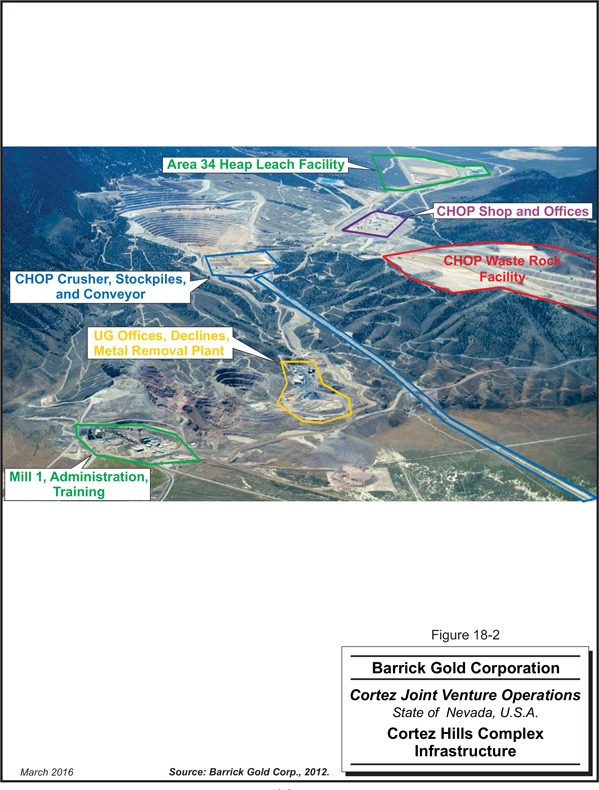

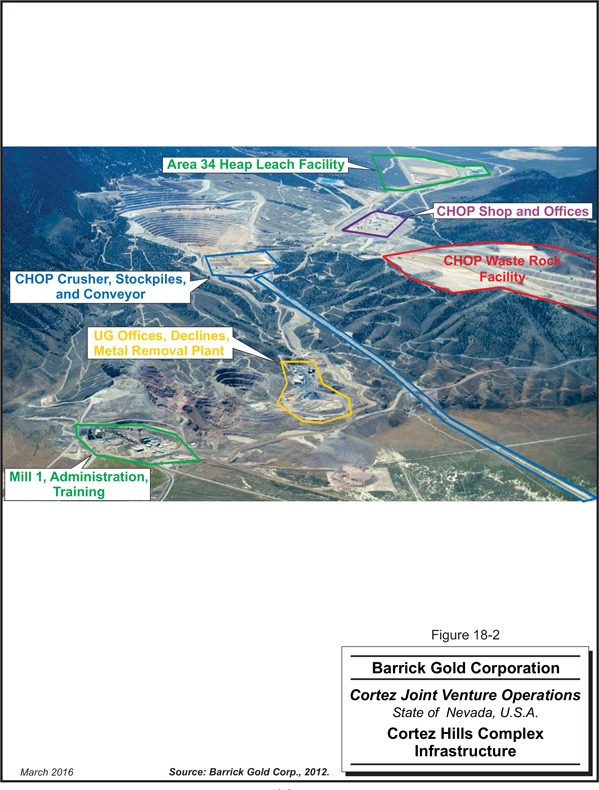

Figure 18-2 | | Cortez Hills Complex Infrastructure | | | 18-3 | |

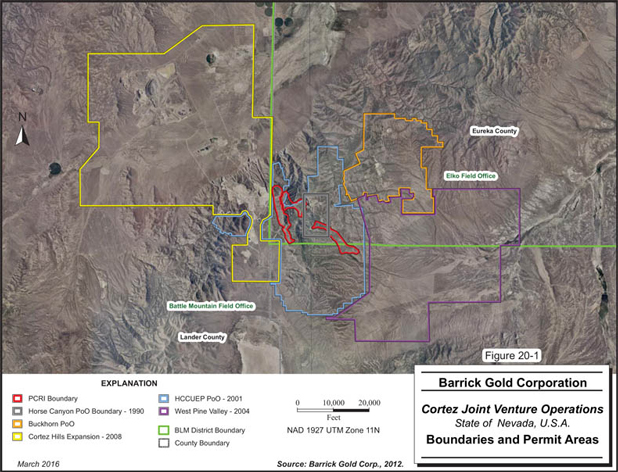

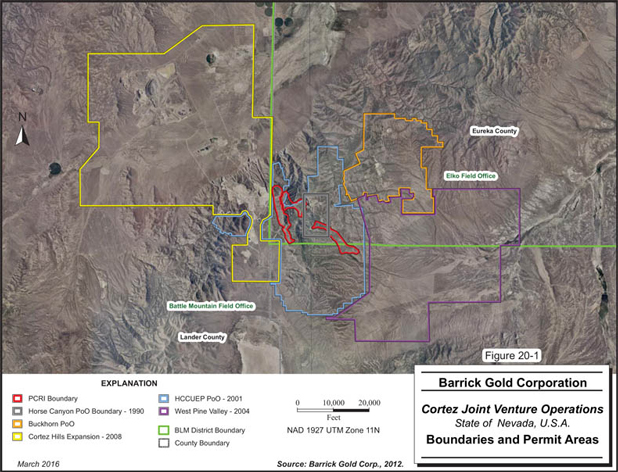

Figure 20-1 | | Boundaries and Permit Areas | | | 20-2 | |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page vi |

| | |

| | www.rpacan.com |

1 SUMMARY

EXECUTIVE SUMMARY

Roscoe Postle Associates Inc. (RPA) was retained by Barrick Gold Corporation (Barrick) to prepare an independent Technical Report on the Cortez Open Pit and Underground Mine Operations (the Cortez Operations or the Mine), in Eureka and Lander Counties, Nevada, USA. The purpose of this report is to support public disclosure of Mineral Resources and Mineral Reserves at Cortez as of December 31, 2015. This Technical Report conforms to NI 43-101 Standards of Disclosure for Mineral Projects. RPA visited the operations between May 5 and 7, 2015.

Barrick is a Canadian publicly traded mining company with a portfolio of operating mines and projects across five continents. The Cortez Operations are located in northeastern Nevada approximately 62 mi west and south of Elko.

The Cortez Mine is a joint venture between two wholly-owned subsidiaries of Barrick, Barrick Cortez Inc. (60%) and Barrick Gold Finance Inc. (40%). The Cortez Operations consist of the Pipeline, Crossroads, Gap, Cortez Hills (CHOP), and Pediment open pits, the Cortez Hills underground (CHUG) mine, a 13,000 ton per day (stpd) carbon-in-leach (CIL) gold plant, heap leach pads and heap leach processing plants, the planned Crossroads open pit, with additional Mineral Resources contained in the Cortez Pits and Gold Acres open pits. The nearby deposit of Hilltop is also part of the Mine but does not have reportable resources at this time.

The open pit is a large scale operation utilizing a conventional truck and shovel fleet and mining approximately 400,000 stpd of ore and waste. Mining operations move between the various pits over the Life of Mine (LOM) plan. The underground mine is a 2,000 stpd mechanized mine. Ore from the mines is treated at an oxide mill at the site, on leach pads, and refractory ore is shipped to Barrick’s Goldstrike operation for processing.

Barrick completed a Pre-feasibility Study (PFS) for underground mining in the Deep South Zone (the Cortez Underground Expansion Project), below currently permitted areas of the CHUG. The PFS indicated that the project has the potential to contribute average underground production of more than 300,000 ounces per year between 2022 and 2026 at average all-in

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-1 |

| | |

| | www.rpacan.com |

sustaining costs of approximately $580 per ounce. More detailed planning, subsequent to the PFS, has resulted in the current LOM beginning underground gold production from the Deep South Zone in 2022 and producing 300,000 ounces per year between 2023 and 2027. Initial capital costs are estimated to be $153 million. The PFS supports conversion of approximately 1.7 million ounces of Measured and Indicated Resources in the Deep South Zone to Proven and Probable Reserves as of December 31, 2015.

The PFS timeline assumes that permitting will take approximately three to four years and Barrick expects to commence this process in the first half of 2016. On this basis, following the receipt of permits, dewatering and development work could begin as early as 2019 or 2020, with initial production from the Deep South Zone commencing in 2022. The expansion of the underground mine is expected to offset the impact of the end of mining in the Cortez Hills open pit, which is scheduled to conclude in 2018.

Table 1-1 summarizes the Cortez Mineral Resources as of December 31, 2015. Table 1-2 summarizes the Cortez Mineral Reserves as of December 31, 2015.

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-2 |

| | |

| | www.rpacan.com |

TABLE 1-1 MINERAL RESOURCES – DECEMBER 31, 2015

Barrick Gold Corporation – Cortez Operations

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | Measured Resources | | | Indicated Resources | | | Measured + Indicated | | | Inferred Resources | |

Mine | | Tons

(000 st) | | | Grade

(oz/st

Au) | | | Contained

Gold

(000 oz) | | | Tons

(000 st) | | | Grade

(oz/st

Au) | | | Contained

Gold

(000 oz) | | | Tons

(000 st) | | | Grade

(oz/st

Au) | | | Contained

Gold

(000 oz) | | | Tons

(000 st) | | | Grade

(oz/st

Au) | | | Contained

Gold

(000 oz) | |

Open Pit | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Pipeline | | | 1,231 | | | | 0.022 | | | | 27 | | | | 14,617 | | | | 0.019 | | | | 275 | | | | 15,848 | | | | 0.019 | | | | 302 | | | | 1,698 | | | | 0.03 | | | | 44 | |

Gap | | | 167 | | | | 0.025 | | | | 4 | | | | 2,402 | | | | 0.019 | | | | 47 | | | | 2,569 | | | | 0.020 | | | | 51 | | | | — | | | | — | | | | — | |

Crossroads | | | 1,530 | | | | 0.014 | | | | 22 | | | | 17,500 | | | | 0.014 | | | | 237 | | | | 19,030 | | | | 0.014 | | | | 259 | | | | 12,220 | | | | 0.01 | | | | 167 | |

Gold Acres | | | 213 | | | | 0.124 | | | | 26 | | | | 3,266 | | | | 0.104 | | | | 340 | | | | 3,479 | | | | 0.105 | | | | 367 | | | | 305 | | | | 0.10 | | | | 32 | |

Cortez Hills | | | — | | | | — | | | | — | | | | — | | | | — | | | | — | | | | — | | | | — | | | | — | | | | 3,440 | | | | 0.04 | | | | 122 | |

Pediment | | | — | | | | — | | | | — | | | | — | | | | — | | | | — | | | | — | | | | — | | | | — | | | | 411 | | | | 0.01 | | | | 3 | |

Cortez Pits | | | 472 | | | | 0.094 | | | | 45 | | | | 3,611 | | | | 0.051 | | | | 183 | | | | 4,083 | | | | 0.056 | | | | 227 | | | | 1,283 | | | | 0.02 | | | | 27 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Sub-Total | | | 3,613 | | | | 0.034 | | | | 124 | | | | 41,395 | | | | 0.026 | | | | 1,082 | | | | 45,009 | | | | 0.027 | | | | 1,206 | | | | 19,359 | | | | 0.02 | | | | 395 | |

| | | | | | | | | | | | |

Underground | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Cortez Hills Breccia | | | 167 | | | | 0.339 | | | | 56 | | | | 335 | | | | 0.329 | | | | 110 | | | | 502 | | | | 0.332 | | | | 167 | | | | 9 | | | | 0.47 | | | | 4 | |

Cortez Hills Middle | | | — | | | | — | | | | — | | | | 1,065 | | | | 0.328 | | | | 350 | | | | 1,065 | | | | 0.328 | | | | 350 | | | | 82 | | | | 0.35 | | | | 28 | |

Cortez Hills Lower | | | — | | | | — | | | | — | | | | 942 | | | | 0.273 | | | | 257 | | | | 942 | | | | 0.273 | | | | 257 | | | | 541 | | | | 0.25 | | | | 133 | |

Cortez Deep South | | | — | | | | — | | | | — | | | | 663 | | | | 0.255 | | | | 169 | | | | 663 | | | | 0.255 | | | | 169 | | | | 710 | | | | 0.42 | | | | 301 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Sub-Total | | | 167 | | | | 0.339 | | | | 56 | | | | 3,005 | | | | 0.295 | | | | 886 | | | | 3,172 | | | | 0.297 | | | | 943 | | | | 1,341 | | | | 0.35 | | | | 466 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Total | | | 3,780 | | | | 0.048 | | | | 181 | | | | 44,400 | | | | 0.044 | | | | 1,969 | | | | 48,180 | | | | 0.045 | | | | 2,149 | | | | 20,700 | | | | 0.04 | | | | 861 | |

Notes:

| 1. | CIM definitions were followed for Mineral Resources. |

| 2. | Mineral Resources are estimated at various cut-off grades depending on material type and processing stream. |

| 3. | Mineral Resources are estimated using an average gold price of US$1,300 per ounce. |

| 4. | A minimum mining width of 10 ft was used. |

| 5. | Mineral Resources are additional to and exclusive of Mineral Reserves. |

| 6. | Numbers may not add due to rounding. |

| | |

Barrick Gold Corporation – Cortez Joint Venture, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-3 |

| | |

| | www.rpacan.com |

TABLE 1-2 MINERAL RESERVES – DECEMBER 31, 2015

Barrick Gold Corporation – Cortez Operations

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | Total Proven | | Total Probable | | | | | Total Proven + Probable | |

Zone | | Tons

(000) | | | Grade

(oz/st) | | | Contained

Gold

(000 oz) | | | | | Tons

(000 st) | | | Grade

(oz/st Au) | | | Contained

Gold

(000 oz) | | | | | Tons

(000 st) | | | Grade

(oz/st Au) | | | Contained

Gold

(000) | |

Open Pit | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Pipeline | | | 1,470 | | | | 0.019 | | | | 28 | | | | | | 15,985 | | | | 0.017 | | | | 266 | | | | | | 17,455 | | | | 0.017 | | | | 294 | |

Crossroads | | | 8,135 | | | | 0.035 | | | | 287 | | | | | | 86,613 | | | | 0.033 | | | | 2,880 | | | | | | 94,749 | | | | 0.033 | | | | 3,167 | |

Cortez Hills | | | 1,564 | | | | 0.127 | | | | 198 | | | | | | 17,145 | | | | 0.116 | | | | 1,984 | | | | | | 18,709 | | | | 0.117 | | | | 2,182 | |

Pediment | | | 762 | | | | 0.032 | | | | 24 | | | | | | 20,506 | | | | 0.027 | | | | 547 | | | | | | 21,268 | | | | 0.027 | | | | 571 | |

Open Pit Subtotals | | | 11,931 | | | | 0.045 | | | | 537 | | | | | | 140,249 | | | | 0.040 | | | | 5,677 | | | | | | 152,181 | | | | 0.041 | | | | 6,214 | |

Underground | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Breccia Zone | | | 120 | | | | 0.514 | | | | 62 | | | | | | 205 | | | | 0.486 | | | | 100 | | | | | | 324 | | | | 0.497 | | | | 161 | |

Middle Zone | | | | | | | | | | | | | | | | | 3.544 | | | | 0.365 | | | | 1,292 | | | | | | 3,544 | | | | 0.365 | | | | 1,292 | |

Lower Zone | | | | | | | | | | | | | | | | | 3.777 | | | | 0.351 | | | | 1,324 | | | | | | 3,777 | | | | 0.351 | | | | 1,324 | |

Deep South | | | | | | | | | | | | | | | | | 5.266 | | | | 0.322 | | | | 1,697 | | | | | | 5,266 | | | | 0.322 | | | | 1,698 | |

Underground Subtotals | | | 120 | | | | 0.514 | | | | 62 | | | | | | 12,792 | | | | 0.345 | | | | 4,414 | | | | | | 12,912 | | | | 0.347 | | | | 4,476 | |

Stockpiles | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Mill Stockpiles | | | 1,510 | | | | 0.096 | | | | 145 | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Leach Stockpiles | | | 57 | | | | 0.014 | | | | 1 | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Refractory Stockpiles | | | 2,248 | | | | 0.130 | | | | 293 | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Stockpile Subtotals | | | 3,814 | | | | 0.115 | | | | 438 | | | | | | | | | | | | | | | | | | | | 3,814 | | | | 0.115 | | | | 438 | |

Total | | | 15,866 | | | | 0.065 | | | | 1,037 | | | | | | 153,042 | | | | 0.066 | | | | 10,092 | | | | | | 168,908 | | | | 0.066 | | | | 11,129 | |

Notes:

| 1. | CIM definitions were followed for Mineral Reserves. |

| 2. | Mineral Reserves are estimated at cut-off grades that range from 0.004 oz/st Au to 0.205 oz/st Au depending on deposit, mining method, and process type. |

| 3. | Mineral Reserves are estimated using an average gold price of US$1,000 per ounce to year 2020 and US$ 1,200 per ounce thereafter. |

| 4. | A minimum mining width of 15 ft was used. |

| 5. | Bulk density varies from 0.052 st/ft3 to 0.091 st/ft3, depending on material type. |

| 6. | Numbers may not add due to rounding. |

| | |

Barrick Gold Corporation – Cortez Joint Venture, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-4 |

| | |

| | www.rpacan.com |

CONCLUSIONS

Based on the site visit and review of the documentation available, RPA offers the following interpretation and conclusions:

GEOLOGY AND MINERAL RESOURCES

| | • | | The Cortez deposits are “Carlin” style porphyry/epithermal deposits hosted by sedimentary rocks. |

| | • | | The sampling, sample preparation, analyses, security, and data verification meet or exceed industry standards and are appropriate for Mineral Resource estimation. |

| | • | | The parameters, assumptions, and methodology used for Mineral Resource estimation are appropriate for the style of mineralization. |

| | • | | Mineral Resources are reported exclusive of Mineral Reserves and are estimated effective December 31, 2015. |

| | • | | Total Mineral Resources at the Cortez Operations are: |

| | • | | Measured - 3.78 million tons, grading 0.048 oz/st Au, containing 181,000 oz Au. |

| | • | | Indicated - 44.40 million tons, grading 0.044 oz/st Au, containing 1,969,000 oz Au. |

| | • | | Inferred - 20.7 million tons, grading 0.04 oz/st Au, containing 861,000 oz Au. |

| | • | | Open Pit Mineral Resources at the Cortez Operations are: |

| | • | | Measured - 3.61 million tons, grading 0.034 oz/st Au, containing 124,000 oz Au. |

| | • | | Indicated - 41.40 million tons, grading 0.026 oz/st Au, containing 1,082,000 oz Au. |

| | • | | Inferred - 19.4 million tons, grading 0.02 oz/st Au, containing 395,000 oz Au. |

| | • | | Underground Mineral Resources at the Cortez Operations are: |

| | • | | Measured - 0.17 million tons, grading 0.339 oz/st Au, containing 56,000 oz Au. |

| | • | | Indicated - 3.01 million tons, grading 0.295 oz/st Au, containing 886,000 oz Au. |

| | • | | Inferred - 1.34 million tons, grading 0.35 oz/st Au, containing 466,000 oz Au. |

MINING AND MINERAL RESERVES

| | • | | The Mineral Reserves are contained within four open pit deposits, four zones in one underground deposit, and surface stockpiles. |

| | • | | The December 31, 2015 Mineral Reserves as stated by Cortez are estimated in a manner consistent with industry practices. |

| | • | | Total Mineral Reserves at the Cortez Operations are: |

| | • | | Proven: 15.9 million tons, grading 0.065 oz/st Au, containing 1.03 million oz Au. |

| | • | | Probable: 153.0 million tons, grading 0.066 oz/st Au, containing 10.09 million oz Au. |

| | • | | Open Pit Mineral Reserves at the Cortez Operations are: |

| | • | | Proven: 11.9 million tons, grading 0.045 oz/st Au, containing 0.54 million oz Au. |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-5 |

| | |

| | www.rpacan.com |

| | • | | Probable: 140.2 million tons, grading 0.040 oz/st Au, containing 5.67 million oz Au. |

| | • | | Underground Mineral Reserves at the Cortez Operations are: |

| | • | | Proven: 0.1 million tons, grading 0.514 oz/st Au, containing 0.06 million oz Au. |

| | • | | Probable: 12.8 million tons, grading 0.345 oz/st Au, containing 4.41 million oz Au. |

| | • | | The open pit mine is a conventional operation that currently has 400 st and 345 st class off-highway haul trucks which are loaded by one 35 yd3 hydraulic shovel and five 48 yd3 to 77 yd3size electric shovels. |

| | • | | The Cortez operation is permitted to dewater up to approximately 36,000 gpm from the underground and open pit mine areas. |

| | • | | Mine production rates are projected to average 157 million tons per year (Mstpa) of total material from 2016 to 2022. Average open pit ore mining rate is approximately 19.1 Mstpa. |

| | • | | CHUG is a mechanized decline access underground mine operating at approximately 2,000 stpd of ore. |

| | • | | The Breccia, Middle, and Lower Zones of the underground mine are mined or planned to be mined using drift and fill mining methods. |

| | • | | The mining methods and equipment are considered to be suitable for the deposits. |

| | • | | In the Deep South Zone, Measured and Indicated Mineral Resources were converted to approximately 1.7 million oz of Proven and Probable Mineral Reserves as of year-end 2015 on the basis of a positive PFS. |

| | • | | The conclusions and recommendations of the Deep South Zone PFS are reasonable and appropriate for the deposit. |

| | • | | The Deep South Zone PFS work included re-evaluation of the geotechnical characteristics and the design for the mining of the Deep South includes long hole stoping which is expected to be more productive and lower cost than the drift and fill mining. |

| | • | | The Deep South Zone has the potential to be a standalone expansion of the CHUG. |

PROCESS

| | • | | RPA is of the opinion that metallurgical test work completed for the Mine has been appropriate to establish optimal processing routes for the different mineralization styles encountered in the deposits and that the gold recovery calculations for all of the processing options are currently appropriate to estimate the amount of gold that will be recovered over the LOM. |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-6 |

| | |

| | www.rpacan.com |

| | • | | The mill and heap leach operations at Cortez are well run, cost effective processing facilities for oxide ore. |

| | • | | There are no appropriate processes for single and double refractory ore at Cortez. Therefore, these ore types are shipped to Goldstrike for processing. Limits to the transportation rates imposed by environmental permits restrict the amount of ore that can be shipped to 1.2 Mstpa. If additional refractory ore is mined, it must be stockpiled. |

| | • | | Total Carbonaceous Material (TCM) processing at Goldstrike is advanced technology that provides additional capacity for processing carbonaceous, preg-robbing ore without displacing material that is processed in the roaster. It also allows processing of ore with elevated concentrations of arsenic. The TCM technology uses calcium thiosulfate (CaTs) to leach the gold after pressure oxidation rather than cyanide and resin-in-pulp to recover the gold from the leach solution. |

ENVIRONMENTAL CONSIDERATIONS

| | • | | One of the risks to the Mine is the receipt of permit approvals from the various government agencies. |

| | • | | Cortez is diligent in managing its permitting and all environmental requirements for the property. |

| | • | | RPA is not aware of any environmental issues that could materially impact Barrick’s ability to extract the Mineral Resources or Mineral Reserves at this time. |

ECONOMIC ANALYSIS

| | • | | RPA has performed an economic analysis of the Cortez Operations using the estimates presented in this report and confirms that the outcome is a positive cash flow that supports the statement of Mineral Reserves. |

RECOMMENDATIONS

Based upon its work, RPA provides the following recommendations.

GEOLOGY AND MINERAL RESOURCES

| | • | | Continue to revise and update the Mineral Resource modelling procedures, with specific consideration to the potential additional mineralization trend in the Crossroads pit and the incorporation of an ordinary kriging run as an additional validation check at Cortez Hills. |

| | • | | Review the classification criteria, with consideration to variogram models based on single mineralization domains at Cortez Hills, and the inclusion of classification wireframe shells, particularly for the Measured component, or the incorporation of classification smoothing scripts. |

MINING AND MINERAL RESERVES

| | • | | Continue ore reconciliation tracking and attempt to identify and report the causes of any large changes on a monthly basis. |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-7 |

| | |

| | www.rpacan.com |

| | • | | Present the reconciliation results showing the percentage differences and not the absolute differences. |

| | • | | Develop a set of orebody characteristics (width, height, grade, rock conditions) considered appropriate for long hole stoping and identify the quantity and location of those portions of the orebody amenable to long hole stoping. |

| | • | | Consider the Lower Zone rock bin capacity to ensure that a smooth ore feed from the mine can be maintained. |

| | • | | Review the small amounts of Inferred material within stope designs with a view to changing the classification of these small areas so that Inferred Mineral Resources are not included in the stope plans. |

| | • | | Modify the LOM and Mineral Reserve estimation process to include: |

| | • | | a reconciliation between the LOM plan and the Mineral Reserve estimate |

| | • | | a tabulation of the Mineral Resources converted by classification including the Inferred Mineral Resources |

| | • | | a review of those Inferred Mineral Resources within the LOM plan to determine whether any can or should be reclassified as Indicated Mineral Resources |

| | • | | the impact on the LOM plan of including the Inferred Mineral Resources within the plan at zero grade |

| | • | | Prepare detailed reconciliations and comparisons for any future conversions to new or different software packages to identify any issues in the process. |

| | • | | Continue the mine dewatering and careful highwall slope monitoring. |

| | • | | Re-evaluate the use of blast movement monitoring to improve grade control. |

| | • | | Develop detailed grade control accounting and stockpile management procedures. |

| | • | | Refine use of cross over grades, and standardize the Mineral Reserve reporting with the LOM production schedule. |

| | • | | Implement ore drive width increases to increase the productivity and/or production rate of the drift and fill mining. |

| | • | | Assess areas of the Lower Zone for the application of long hole stoping methods and implement trials if suitable areas can be identified. |

Continue to advance the planning of the Deep South Zone, which is included in the LOM plan, to optimize the production and development schedules in future years.

| | • | | Continue to evaluate the initiative to process mineralized waste concurrently with material from the underground resource. |

PROCESSING

| | • | | Continue to evaluate new ore types and to optimize the processes to increase recovery and/or to decrease costs. |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-8 |

| | |

| | www.rpacan.com |

| | • | | Continue to work collaboratively with the Goldstrike staff to maintain and improve the metallurgical accounting for treatment of Cortez ore in the roaster and the TCM process. |

ENVIRONMENTAL

| | • | | Continue to expedite environmental permitting as required to support the changes in operations and development of new areas of the Mine. |

COSTS

| | • | | Continue to evaluate and implement opportunities for cost savings and profitability improvements. |

ECONOMIC ANALYSIS

Under NI 43-101 rules, producing issuers may exclude the information required in this section on properties currently in production, unless the technical report includes a material expansion of current production. RPA notes that Barrick is a producing issuer, the Cortez Mine is currently in production, and a material expansion is not being planned. RPA has performed an economic analysis of the Cortez Mine using the estimates presented in this report and confirms that the outcome is a positive cash flow that supports the statement of Mineral Reserves.

TECHNICAL SUMMARY

PROPERTY DESCRIPTION AND LOCATION

The Cortez Operations are located 62 mi southwest of Elko, Nevada, USA, in Eureka and Lander Counties.

All Mineral Reserves and Mineral Resources, in addition to existing and future facilities to be used to exploit the Mine’s deposits, are on public lands administered by the Battle Mountain or Elko Field Offices of the U.S. Department of Interior, Bureau of Land Management (BLM).

At Cortez, Barrick directly controls approximately 216,124 acres of mineral rights with ownership of mining claims and fee lands. There are 10,461 claims consisting of:

| | • | | 9,630 unpatented lode claims |

| | • | | 575 unpatented mill-site claims |

| | • | | 104 patented lode claims |

| | • | | 125 patented mill-site claims |

| | • | | 27 unpatented placer claims and 185 patented mill-site claims |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-9 |

| | |

| | www.rpacan.com |

All lease agreements and claim holdings are current and in good standing.

EXISTING INFRASTRUCTURE

There is extensive infrastructure in place to support the Cortez Operations including:

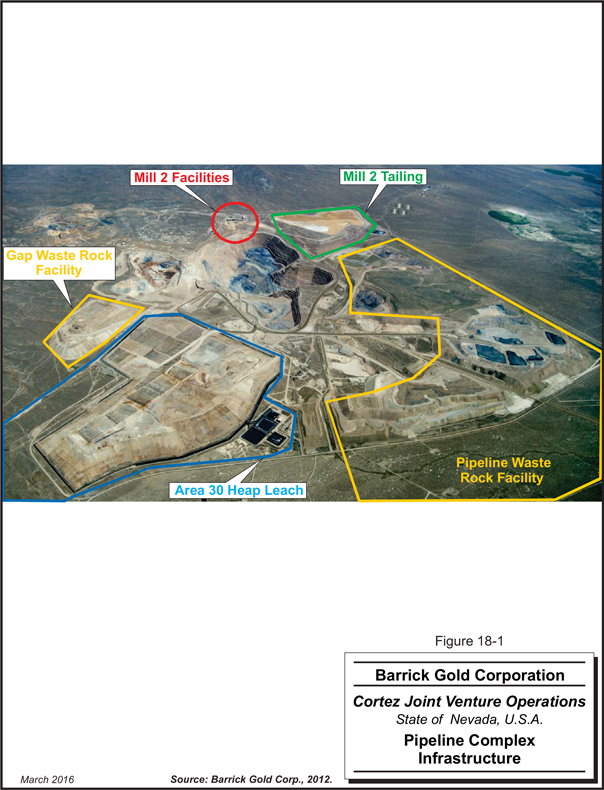

| | • | | The 13,000 stpd No. 2 Mill complete with run-of-mine (ROM) pad and crushing circuit |

| | • | | Pipeline leach pad areas (Area 28 and Area 30) and gold recovery plant |

| | • | | Area 34 leach pad and gold recovery plant for the CHOP and Pediment |

| | • | | A tailings management facility |

| | • | | A gyratory crusher at the CHOP and an 11 mi long conveyor to the No. 2 Mill |

| | • | | Existing open pit mines at CHOP, Cortez, and Pipeline |

| | • | | Pit dewatering wells and pumps for the open pits and the CHUG |

| | • | | Infiltration ponds for the disposal of water |

| | • | | An existing underground mine at CHUG |

| | • | | Batch plant for shotcrete and cemented rock fill preparation |

| | • | | Stockpile areas for an assortment of ore types |

| | • | | Office complexes at the Mill No. 2, Mill No. 1, CHUG, and CHOP |

| | • | | Equipment maintenance shops at CHOP, CHUG, and adjacent to the Mill No. 2 |

| | • | | Exploration offices, core handling and core storage warehouse |

| | • | | System of public and private roads connecting the facilities |

| | • | | Shared business support services from the business unit offices in Elko |

HISTORY

Mining in the Cortez Mining District began with the discovery of silver ore in 1862. Underground silver mining was conducted in the area until the 1930s. Mineralization at Hilltop was also identified during the 1860s. Gold mineralization at Gold Acres was discovered in the late 1920s and mined by a small mining company from 1935 to 1960.

In 1959, American Exploration & Mining Co. (AMEX), a wholly-owned US subsidiary of Placer Development Ltd. (subsequently Placer Dome Inc.), entered into a lease-option agreement on the properties and started extensive exploration. In 1964, AMEX formed the Cortez Joint Venture (CJV).

The CJV initiated open pit mining in the Cortez open pits from 1968 to 1972 and moved to the Gold Acres North and South pits in 1973. Leaching and milling of Gold Acres stockpiles and

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-10 |

| | |

| | www.rpacan.com |

dumps continued until 1983. Mill grade ores were mined from 1987 to 1996 and processed at Cortez Mill No. 1. In 2003, the CJV commenced shipping Gold Acres refractory stockpiles for toll processing at third-party facilities.

The Horse Canyon deposits were discovered in early 1976. Three pits, North, South, and South Extension, were mined in the period from 1984 to 1987. Exploration drilling campaigns at the Horse Creek deposit, originally discovered in the late 1960s, occurred in the mid-1980s and intermittently over the last ten years and are ongoing.

The Pipeline deposit was discovered by CJV geologists in March 1991 during drilling of deep condemnation holes. The Gap deposit was discovered in 1991 adjacent to the planned Stage 9 of the Pipeline pit.

In November 1991, CJV discovered the South Pipeline deposit. Construction of Mill No. 2 and pre-stripping of the first stage of the Pipeline pit began in 1996. Continued drilling resulted in the 1998 discovery of the Crossroads deposit beneath 550 ft of alluvium.

In 1996, CJV geologists began a program that led to the 1998 discovery of the Pediment deposit. The Cortez Hills deposit was discovered in October 2002. In 2004, the Cortez Hills Lower Zone was discovered. In November 2008, the Environmental Impact Statement (EIS) for the Cortez–Pediment development was approved. Production from underground began in late 2008, and the first ore production from CHOP occurred in late December 2009.

Barrick acquired an interest in Cortez through the 2006 acquisition of Placer Dome Inc. In March 2008, Barrick acquired its 100% interest in the Mine, purchasing the former Kennecott 40% interest, from Rio Tinto.

GEOLOGY AND MINERALIZATION

The Cortez gold district is in the eastern Great Basin of the Basin and Range Province. The Paleozoic basement rocks of northeastern Nevada are made up of a western deep-water, eugeoclinal siliclastic assemblage (Upper Plate) and an eastern shallow-water, miogeosynclinal carbonate assemblage (Lower Plate) of sedimentary strata. Cortez lies within the “Battle Mountain-Eureka Trend” (BMT), an alignment of gold mines and occurrences located in a northwest-southeast belt extending from the Marigold Mine some 50 mi northwest

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-11 |

| | |

| | www.rpacan.com |

of Cortez, to Ruby Hill at Eureka 60 mi to the southeast. Paleozoic basement rocks have been folded and faulted, and cut by younger Jurassic and Tertiary aged intrusions.

The Cortez deposits are “Carlin” style sedimentary rock-hosted and porphyry/epithermal deposits. Carlin deposits form as structurally and/or stratigraphically controlled replacement bodies consisting of strata-bound, tabular, disseminated gold mineralization occurring in Silurian-Devonian carbonate rocks. Deposits are localized at contacts between contrasting lithologies, metamorphosed to varying extents. They can also be discordant or breccia-related. The deposits are hydrothermal in origin, are usually structurally controlled and at Cortez are hosted in Lower Plate carbonate strata exposed by two erosional windows through allochthonous Upper Plate siliclastic units; the windows are on either side of Crescent Valley.

Mineralization consists primarily of submicron to micrometre-sized gold particles, very fine sulphide grains, and gold in solid solution in pyrite. Gold is disseminated throughout the host rock matrix in zones of silicified and decarbonatized, argillized, silty calcareous rocks, and associated jasperoids. Gold may occur around limonite pseudomorphs of authigenic pyrite and arsenopyrite. Major ore minerals include native gold, pyrite, arsenopyrite, stibnite, realgar, orpiment, cinnabar, fluorite, barite, and rare thallium minerals. Gangue minerals typically comprise fine-grained quartz, barite, clay minerals, carbonaceous matter, and late-stage calcite veins.

In the Cortez district, the favoured host rocks for gold mineralization are the Devonian Wenban Limestone, followed by the Horse Canyon and Roberts Mountain Formations. Mineralization reflects an interplay between structural and lithological ore controls in which hydrothermal solutions from intrusives moved to favourable porous decalcified limestone.

Mineralized host rocks are predominantly characterized as oxides, along with sulphidic and carbonaceous refractory material. Carbon content in the deposits is highly variable and occurs generally in the Devonian Wenban Limestone and the Roberts Mountain Formation. Supergene alteration extends up to 656 ft depth resulting in oxide ores, which overlie the refractory sulphides. Alteration has liberated gold by the destruction of pyrite and resulted in the formation of oxide and secondary sulphate minerals, which include goethite, hematite, jarosite, scorodite, alunite, and gypsum.

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-12 |

| | |

| | www.rpacan.com |

EXPLORATION STATUS

Modern exploration commenced along the Battle Mountain–Eureka Trend in the 1960s, and has been nearly continuous since that time. Exploration in the Cortez district has been undertaken by Barrick and its predecessor companies such as the CJV and has included mapping, various geochemical and geophysical surveys, pitting, trenching, petrographic, and mineralogy studies, and various types of drilling.

Barrick has advanced stage exploration drilling projects at Cortez. Exploration projects include underground drilling programs at Cortez Hills Lower Zone (Deep South), Horse Canyon Cortez exploration project, and metallurgical testwork at Hilltop.

MINERAL RESOURCES

RPA considers the December 31, 2015 Mineral Resource estimate completed by Barrick to be reasonable, acceptable, and reported in compliance with Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition Standards for Mineral Resources and Mineral Reserves dated May 10, 2014 (CIM definitions) as incorporated by reference into NI 43-101. The Mineral Resources are exclusive of Mineral Reserves and are summarized in Table 1-1.

The Mineral Resources are estimated from three dimensional block models created using Vulcan software. Surfaces and solids representing topography, overburden, geological units, and gold mineralization were incorporated into the resource block models. Resource estimates utilize drill hole, survey, geological, analytical and bulk density information entered, validated and maintained in a centralized acQuire SQL Server database. Industry standard best practices were used to obtain the data; quality assurance and quality control (QA/QC) protocols, as well as data validation procedures, were employed to ensure that the quality and quantity of data used for the resource estimates were appropriate and acceptable.

MINERAL RESERVES

The Mineral Reserves for Cortez as of December 31, 2015 are summarized in Table 1-2. These Mineral Reserves are a combination of the open pit and underground operations and the stockpiles.

RPA considers the Mineral Reserve estimate, completed by Barrick, to be reasonable, acceptable, and reported in accordance with CIM definitions and NI 43-101. The Mineral

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-13 |

| | |

| | www.rpacan.com |

Reserves are generated based upon the mine designs applied to the Measured and Indicated Mineral Resources. The design methodology uses both the cut-off grade estimation and economic assessment to design and validate the Mineral Reserves.

MINING METHOD

The current Cortez site has been operating since 1988. Currently, the active mining areas are the Cortez Hills and Pediment pits, the Pipeline and Crossroads pits, and the Cortez Hills underground.

Open pit mining at Cortez Hills and Pipeline is by conventional open pit methods using hydraulic and electric front shovels and large, off-highway dump haul trucks. The open pit mine life is estimated to be three years for Cortez Hills (2016 through 2018) and eight years for the Pipeline Complex (2016 through 2023). The open pit operations has an estimated current daily material movement capacity of 400,000 stpd.

Underground mining is being carried out in the Breccia, Middle, and Lower zones. The underground mine is operating at a rate of 2,000 stpd with all ore hauled to surface by truck. The mining is all by drift and fill mining method. Management are working on plans to increase the mine production by improving the productivity of the drift and fill mining and implementing long hole stoping in some areas of the Lower Zone. Under the current mine plan, which includes the Deep South Zone project, underground mining at Cortez Hills is scheduled through 2028.

As a result of a positive PFS completed in 2015, approximately 1.7 million ounces of Measured and Indicated Mineral Resources in the Deep South Zone, a down dip extension of the Lower Zone below the 3,800 ft level, were converted to Proven and Probable Mineral Reserves as of year-end 2015. Under the current mine plan, which incorporates the Cortez Underground Expansion Project, the Deep South Zone is proposed to be mined using long hole stoping methods and will use extensions to the planned Lower Zone infrastructure for the movement of rock, men, and materials. Mining of the Deep South Zone requires dewatering below the 3,800 ft level and this requires an amendment to the Plan of Operations (PoO). The permitting process is expected to take three to four years. This permit amendment application is planned to be submitted in 2016. On this basis, following the receipt of permits, dewatering and development work could begin as early as 2019 or 2020, with initial production from the Deep South Zone commencing in 2022. The expansion of the underground mine will help to offset

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-14 |

| | |

| | www.rpacan.com |

the impact of the end of mining in the Cortez Hills open pit, which is expected to conclude in 2018. The majority of the ore in the Deep South Zone is oxide ore which is proposed to be treated in the Pipeline Mill or at heap leach facilities at Cortez after the Pipeline Mill operation ceases in 2023.

Over the past four years, the underground mine production has been steady at approximately 2,000 stpd to 2,200 stpd ore. Over the same period, the grade has decreased from 1.07 oz/st Au to 0.63 oz/st Au.

In 2015, 23.4 Mst of ore was mined and 24.7 Mst was processed at a head grade of 0.50 oz/st Au. Gold production was 999,278 oz.

MINERAL PROCESSING

Ore from Cortez is either processed on site in the oxide processing facilities or transported to Barrick’s Goldstrike operation for refractory ore treatment.

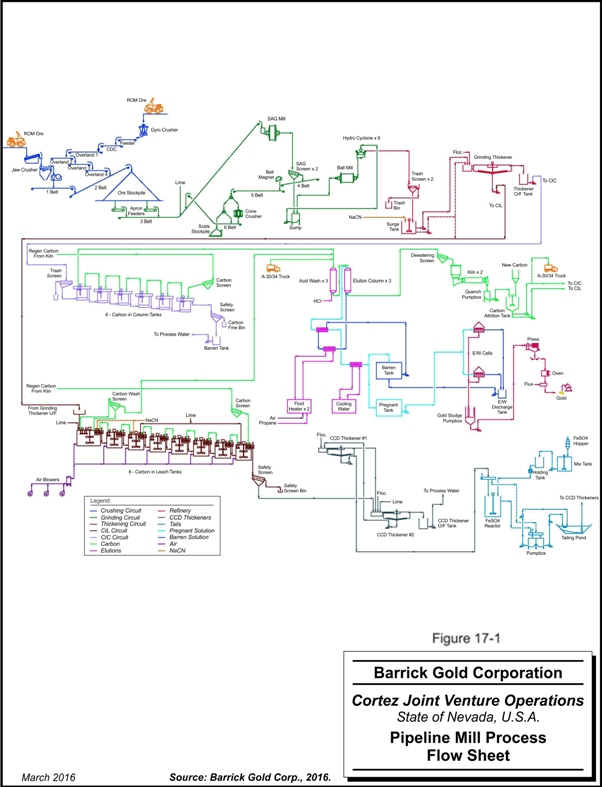

Mill No. 2, or the Pipeline mill, is a nominal 13,000 stpd oxide processing plant with crushing, a semi-autogenous grinding (SAG) mill, a ball mill, grind thickener, a carbon-in-column (CIC) circuit for the grind thickener overflow solution, a CIL circuit, tailings counter-current-decantation (CCD) wash thickener circuit, carbon stripping and reactivation circuits, and a refinery to produce gold doré.

A primary gyratory crusher is located adjacent to the CHOP together with a series of overland conveyors that transport the ore to the coarse ore stockpile at Mill No. 2. There is a primary jaw crusher at Mill No. 2 that is used when processing ore from Pipeline and in the future, Crossroads.

Tailings are stored in a zero-discharge tailings storage facility. A double liner covers the entire tailings area, extending completely under the dam embankment.

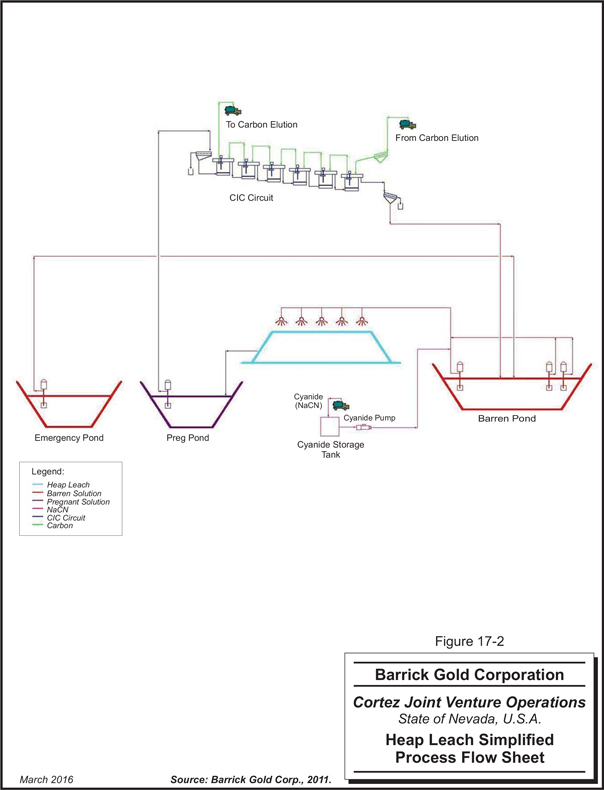

Low-grade oxide material is leached as ROM ore on three prepared double-lined leach pads. Pregnant solution from the leach pads is fed to CIC columns for gold recovery. The loaded carbon from the heap leach operation is transported to the mill for gold recovery.

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-15 |

| | |

| | www.rpacan.com |

Area 28 heap leach circuit has a water balance that is interlinked with the Pipeline mill circuit since it uses the tailings pond under-drain solution as leach solution and excess pad effluent is processed in the mill CIC circuit. Area 28 is at maximum capacity for ore stacking and is no longer an operating leach pad. The Area 30 heap leach circuit is independent of the Pipeline mill. Ore delivery to the pad recommenced in 2013 and is set to continue through 2023. Area 34 heap leach is a third pad that was designed to treat CHOP ore. The first cells were placed under leach during March 2011 and ore deliveries are scheduled to continue through 2018 based on the current LOM plan.

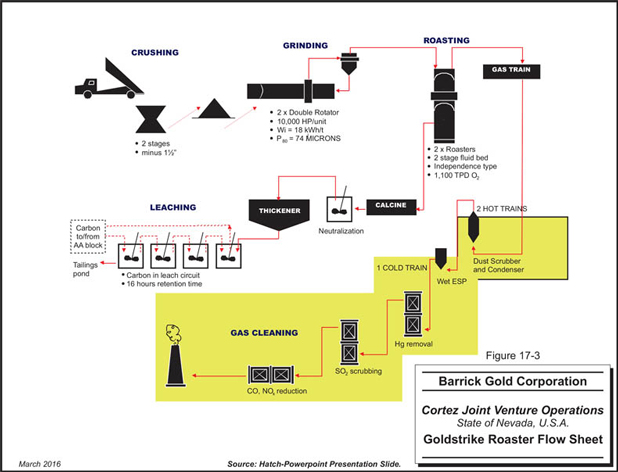

Ores that have a cyanide soluble (shake test) to fire assay gold (AA/FA) ratio of less than 50% are transported to Goldstrike for processing in either the pressure oxidation (POX) circuit or the roaster. Haulage of refractory ore to Goldstrike is currently limited by permit to 1.2 Mstpa. At Goldstrike, two options are currently available for processing refractory ore. It will either be processed in the roaster followed by a CIL circuit or in the TCM process, which includes POX followed by resin-in-leach with CaTs.

MARKET STUDIES

Gold is the principal commodity at Cortez and is freely traded, at prices that are widely known, so that prospects for sale of any production are virtually assured. Prices are usually quoted in US dollars per troy ounce.

ENVIRONMENTAL, PERMITTING, AND SOCIAL CONSIDERATIONS

Cortez and Barrick have environmental groups and management systems to ensure that the necessary permits and licences are obtained and maintained. These groups also carry out the required monitoring and reporting required. Cortez has developed an environmental management system (EMS) to help manage the environmental requirements.

The BLM issued the original EIS and Record of Decision (ROD) in November 2008 and a supplemental EIS and ROD in March 2011. In October 2012, Cortez submitted a second proposed amendment to the existing PoO (APO2). All components of the APO2 application were approved by the BLM on February 24, 2014.

Cortez submitted additional proposed modifications to the PoO in August 2014 and then, following a revision, in October 2014. The proposed modifications include:

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-16 |

| | |

| | www.rpacan.com |

| | • | | Deepen the Gap Pit from 4,400 ft amsl to 4,360 ft amsl |

| | • | | Construct the Range Front Declines and associated infrastructure |

| | • | | Expand the Area 30 heap leach facilities by 240 acres |

| | • | | Modify mining rate between the Cortez Hills and Pipeline |

| | • | | Add a water treatment plant and infrastructure to reduce naturally occurring arsenic concentrations in the dewatering water |

| | • | | Allow off-site ore haulage up to approximately 1.2 Mstpa site wide |

| | • | | Reconfigure the Pipeline, Canyon, and Gap waste rock facilities |

| | • | | Infrastructure additions |

An APO-3 was approved by the BLM and a ROD was completed in 2015.

A number of permits are required to operate the Cortez Mine. Cortez adheres to permitting guidelines from the BLM, the Nevada Revised Statutes (NRS), the Nevada Administrative Code (NAC), and other federal government requirements.

CAPITAL AND OPERATING COST ESTIMATES

The total capital expenditure in the 2016 LOM plan is $2,011 million broken down as shown in Table 1-3.

This total includes capital required to expand underground mining into the Deep South Zone below currently permitted levels. The project has the potential to contribute underground production beginning in 2022 and will average more than 300,000 ounces per year between 2023 and 2027 at average all-in sustaining costs of approximately $580 per ounce. Initial capital costs are estimated to be $153 million and sustaining capital is estimated to be $58 million, for the Deep South Zone project total of $211 million.

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-17 |

| | |

| | www.rpacan.com |

TABLE 1-3 CAPITAL COSTS

Barrick Gold Corporation – Cortez Operations

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Year | | | | | Deferred

Operating | | | Expansion | | | Exploration | | | Fixed

Equipment | | | Mobile

Equipment | | | Regulatory | | | Grand

Total | |

2016 | | US$ | M | | | | 58.6 | | | | 222.1 | | | | 9.8 | | | | 43.5 | | | | 7.4 | | | | 9.1 | | | | 350.5 | |

2017 | | US$ | M | | | | 50.7 | | | | 284.1 | | | | 8.1 | | | | 19.8 | | | | 9.3 | | | | 5.0 | | | | 376.9 | |

2018 | | US$ | M | | | | 145.5 | | | | 169.3 | | | | 11.8 | | | | 22.5 | | | | 12.8 | | | | 37.8 | | | | 399.7 | |

2019 | | US$ | M | | | | 253.8 | | | | 61.5 | | | | 11.0 | | | | 22.5 | | | | 6.1 | | | | 7.4 | | | | 362.2 | |

2020 | | US$ | M | | | | 131.7 | | | | 29.5 | | | | 11.3 | | | | 13.8 | | | | 12.4 | | | | 1.8 | | | | 200.5 | |

2021 | | US$ | M | | | | 19.7 | | | | 21.7 | | | | 6.1 | | | | 13.4 | | | | 7.9 | | | | 1.6 | | | | 70.5 | |

2022 | | US$ | M | | | | 12.9 | | | | 6.8 | | | | 4.0 | | | | 7.5 | | | | 10.7 | | | | 1.6 | | | | 43.6 | |

2023 | | US$ | M | | | | 29.5 | | | | 5.7 | | | | 2.9 | | | | 2.2 | | | | 5.9 | | | | 1.6 | | | | 47.8 | |

2024 | | US$ | M | | | | 46.2 | | | | 7.7 | | | | 2.6 | | | | 0.4 | | | | 8.4 | | | | 1.6 | | | | 67.0 | |

2025 | | US$ | M | | | | 41.4 | | | | 29.4 | | | | 1.8 | | | | 0.4 | | | | 9.8 | | | | 1.7 | | | | 84.5 | |

2026 | | US$ | M | | | | 0.9 | | | | 2.3 | | | | 1.6 | | | | 0.3 | | | | — | | | | 1.6 | | | | 6.7 | |

2027 | | US$ | M | | | | — | | | | — | | | | — | | | | — | | | | — | | | | 0.5 | | | | 0.5 | |

2028 | | US$ | M | | | | — | | | | — | | | | — | | | | — | | | | — | | | | 0.5 | | | | 0.5 | |

Total | | US$ | M | | | | 791 | | | | 840 | | | | 71 | | | | 146 | | | | 91 | | | | 72 | | | | 2,011 | |

The LOM operating costs are shown in Table 1-4.

TABLE 1-4 LOM OPERATING COSTS

Barrick Gold Corporation – Cortez Operations

| | | | | | | | | | | | |

| | | Unit | | | Open Pit | | | Underground | |

Mine $/t mined | | US$ | /st mined | | | | 1.79 | | | | 86.59 | |

| | | |

Mine $/t milled | | US$ | /st milled | | | | 12.60 | | | | 104.82 | |

Process | | US$ | /st milled | | | | 7.43 | | | | 22.87 | |

G&A | | US$ | /st milled | | | | 2.40 | | | | 24.02 | |

Refine freight | | US$ | /st milled | | | | 0.01 | | | | 0.09 | |

Royalty | | US$ | /st milled | | | | 2.21 | | | | 4.90 | |

Total | | US$ | /st milled | | | | 24.66 | | | | 156.70 | |

VALUE REALIZATION INITIATIVES

In addition to the Cortez Underground Expansion, i.e., expanding underground mining into the Deep South Zone, below currently permitted levels, Barrick has recently conducted a technical review of the Cortez Operations with the objective of identifying potential opportunities to increase production capacity. The opportunities that have been identified so far include:

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-18 |

| | |

| | www.rpacan.com |

CORTEZ PITS MINING

The Cortez Pits area is located to the north of the current Cortez Hills underground portal and the area was previously mined between 1969 and 1993. There is a remaining resource below the historic Cortez Pits that is a continuation of the mined-out portion of the Cortez deposit. The current reported Measured plus Indicated Mineral Resources total 4.1 Mt at a grade of 0.056 oz/st Au with 227,000 oz of contained gold. Pending the appropriate level of studies to convert the mineralization to Mineral Reserves, mining would be by open pit methods of the primarily heap leach grade material. A total of 163,000 oz is expected to be recovered using a process recovery of 74.1%.

There is sufficient drilling information associated with this deposit to model the resource in terms of gold grade, however, additional drilling information is required for geotechnical guidance and metallurgical testing. The deposit also allows for resource upgrades at gold prices greater than US$1,400.

HAULAGE CAPACITY INCREASE

The Cortez Hills operation currently ships refractory ores via over-the-highway haul trucks to the Goldstrike operation for processing. Haulage is currently limited by permit to 1.2 Mstpa. An opportunity exists to expand the shipping rate to 2.2 Mstpa during the APO-4 permitting process, allowing increased shipping to begin upon permit receipt in 2020. Permit submittal is currently scheduled for Q1 2016.

Additional technical studies are underway to determine increased haulage parameters including fleet sizing and road base suitability.

Increased shipping rates will allow advancing the current LOM production stream of refractory material.

PRODUCTION CAPACITY INCREASE BY 10%

Cortez Hills operation has identified an opportunity to increase production capacity by an approximately 10% increase of the CIL process plan and heap leach (HL) capacity. This will be achieved as follows:

| | • | | Partial solution recycle is pursued applying pregnant leach solution to new material for the first 30 days of leaching. |

| | • | | CIL process plant throughput is achieved by maximizing SAG and ball mill power draw along with improved secondary grinding circuit control strategies. |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-19 |

| | |

| | www.rpacan.com |

| | • | | Increased capacity will advance production and cash flow streams along with slight reduction in unit costs. Implementation is currently underway (10% complete) as the majority of infrastructure is in place. Capital cost is estimated to be $10 million (conceptual level) for solution distribution. Improvements in throughput are estimated to be 10% to 20% for HL and 5% to 12% for CIL. |

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 1-20 |

| | |

| | www.rpacan.com |

2 INTRODUCTION

Roscoe Postle Associates Inc. (RPA) was retained by Barrick Gold Corporation (Barrick) to prepare an independent Technical Report on the Cortez Open Pit and Underground Mine Operations (the Cortez Operations or the Mine), in Eureka and Lander Counties, Nevada, USA. The purpose of this report is to support the public disclosure of Mineral Resources and Mineral Reserves at Cortez as of December 31, 2015. This Technical Report conforms to NI 43-101 Standards of Disclosure for Mineral Projects.

Barrick is a Canadian publicly traded mining company with a portfolio of operating mines and projects across five continents. The Cortez Operations are located in northeastern Nevada approximately 62 mi west and south of Elko.

The Cortez Mine is a joint venture between two wholly-owned subsidiaries of Barrick, Barrick Cortez Inc. (60%) and Barrick Gold Finance Inc. (40%). The Cortez Hills Project is 100% owned by Barrick Cortez Inc. The Cortez Operations consist of the Pipeline, Crossroads, Gap, Cortez Hills (CHOP), and Pediment open pits, the Cortez Hills underground (CHUG) mine, a 13,000 short ton per day (stpd) carbon-in-leach (CIL) gold plant, heap leach pads and heap leach processing plants, and the planned Crossroads open pit, with additional Mineral Resources contained in the Cortez Pits and Gold Acres open pits. The nearby deposit of Hilltop is also part of the Mine but does not have reportable resources at this time.

The open pit is a large scale operation utilizing a conventional truck and shovel fleet and mining approximately 400,000 stpd of ore and waste. Mining operations move between the various pits over the Life of Mine (LOM) plan. The underground mine is a 2,000 stpd mechanized mine. Ore from the mines is treated at an oxide mill at the site and on leach pads and refractory ore is shipped to Barrick’s Goldstrike operation for processing.

Barrick completed a Pre-feasibility Study (PFS) for underground mining in the Deep South Zone (the Cortez Underground Expansion Project), below currently permitted areas of the CHUG. The PFS indicated that the project has the potential to contribute underground production of more than 300,000 ounces per year between 2022 and 2026 at average all-in sustaining costs of approximately $580 per ounce. More detailed planning, subsequent to the PFS, has resulted in the current LOM beginning underground gold production from the Deep

| | |

Barrick Gold Corporation – Cortez Operations, Project 2471 Technical Report NI 43-101 – March 21, 2016 | | Page 2-1 |

| | |

| | www.rpacan.com |

South Zone in 2022 and producing 300,000 ounces per year between 2023 and 2027. Initial capital costs are estimated to be $153 million. The PFS supports conversion of approximately 1.7 million ounces of Measured and Indicated Resources in the Deep South Zone to Proven and Probable Reserves as of December 31, 2015.

The PFS timeline assumes that permitting will take approximately three to four years and Barrick expects to commence this process in the first half of 2016. On this basis, following the receipt of permits, dewatering and development work could begin as early as 2019 or 2020, with initial production from the Deep South Zone commencing in 2022. The expansion of the underground mine is expected to offset the impact of the end of mining in the Cortez Hills open pit, which is scheduled to conclude in 2018.

SOURCES OF INFORMATION

Site visits were carried out by Wayne Valliant, P.Geo., RPA Principal Geologist, Chester Moore P.Eng., RPA Principal Geologist, Dennis Bergen, P.Eng., RPA Associate Principal Mining Engineer, Stuart Collins, P.E., RPA Principal Mining Engineer, and Kathleen Ann Altman, Ph.D., P.E., RPA Principal Metallurgist, from May 5 to 7, 2015.

Discussions were held with personnel from Barrick and Cortez:

| | • | | Larry Snider, Senior Resource Geologist |

| | • | | Roger Bond, Senior Geologist |

| | • | | Andrew Ostendorf, Resource Geologist |

| | • | | Felipe Salamanca, Open Pit Chief Engineer |

| | • | | Robert Dudley, Accounting Supervisor |

| | • | | Jim MacPherson, Senior Mine Engineer |

| | • | | Dave Pierce, Water Management Superintendent |

| | • | | Lynnette Hutson, Senior Business Analyst |

| | • | | Patrick Jenks, Chief Geotechnical Engineer |

| | • | | Mark D. Miller, Environmental Manager |

| | • | | Nick Atiemo, Environmental Superintendent |

| | • | | Brian D. Taylor, Environmental Specialist III (Public Lands) |

| | • | | Amiee Keys, Environmental Specialist II (Environmental Management System) |

| | • | | Steve Cashin, Process Manager |

| | • | | Jon Kamensky, Superintendent Metallurgical Services & Heap Operations |

| | • | | Jeff Olson, Metallurgist |

| | • | | Emrah Yalcin, Senior Metallurgist |