- GOLD Dashboard

- Financials

- Filings

-

Holdings

- Transcripts

- ETFs

-

Insider

- Institutional

- Shorts

-

6-K Filing

Barrick Gold (GOLD) 6-KCurrent report (foreign)

Filed: 22 Mar 19, 5:24pm

Exhibit 99.1

BARRICK GOLD CORPORATION

TECHNICAL REPORT ON THE

GOLDSTRIKE MINE, EUREKA AND ELKO COUNTIES, STATE OF NEVADA, USA

NI43-101 Report

Qualified Persons:

Jason J. Cox, P.Eng.

Philip A. Geusebroek, P.Geo.

Wayne W. Valliant, P.Geo.

Steve Haggarty, P.Eng.

March 22, 2019

RPA 55 University Ave. Suite 501 I Toronto, ON, Canada M5J 2H7 I T+ 1 (416) 947 0907 | www.rpacan.com | |||

Report Control Form

| Document Title | Technical Report on the Goldstrike Mine, Eureka and Elko Counties, State of Nevada, USA.

| |||

| Client Name & Address | Mr. Rick Sims Senior Director Reserves and Resources Barrick Gold Corporation 10371 N. Oracle Road Suite 201 Tucson, AZ 85737 | |||

Document Reference | Project # 3078 | Status & Issue No. | FINAL Version | 0 |

Issue Date | March 22, 2019 | |||||

Lead Author | Jason J. Cox Wayne W. Valliant Philip A. Geusebroek Steve Haggarty | (Signed) (Signed) (Signed) (Signed) | ||||

Peer Reviewer | Deborah McCombe

|

| (Signed) | |||

Project Manager Approval | Jason J. Cox

| (Signed) | ||||

Project Director Approval | Deborah McCombe

| (Signed) | ||||

Report Distribution | Name | No. of Copies | ||||

Client

RPA Filing

| 1 (project box)

| |||||

Roscoe Postle Associates Inc.

55 University Avenue, Suite 501

Toronto, ON M5J 2H7

Canada

Tel: +1 416 947 0907

Fax: +1 416 947 0395

mining@rpacan.com

| www.rpacan.com |

FORWARD-LOOKING INFORMATION

This report contains forward-looking statements. All statements, other than statements of historical fact regarding Barrick Gold Corporation or the Goldstrike Mine, are forward-looking statements. The words “believe”, “expect”, “anticipate”, “contemplate”, “target”, “plan”, “intend”, “project”, “continue”, “budget”, “estimate”, “potential”, “may”, “will”, “can”, “could” and similar expressions identify forward-looking statements. In particular, this report contains forward-looking statements with respect to cash flow forecasts, projected capital, operating and exploration expenditure, targeted cost reductions, mine life and production rates, potential mineralization and metal or mineral recoveries, the Barrick-Newmont Joint Venture and information pertaining to potential improvements to financial and operating performance and mine life at the Goldstrike Mine. All forward-looking statements in this report are necessarily based on opinions and estimates made as of the date such statements are made and are subject to important risk factors and uncertainties, many of which cannot be controlled or predicted. Material assumptions regarding forward-looking statements are discussed in this report, where applicable. In addition to such assumptions, the forward-looking statements are inherently subject to significant business, economic and competitive uncertainties and contingencies. Known and unknown factors could cause actual results to differ materially from those projected in the forward-looking statements. Such factors include, but are not limited to: fluctuations in the spot and forward price of commodities (including gold, copper, silver, diesel fuel, natural gas and electricity); the speculative nature of mineral exploration and development; changes in mineral production performance, exploitation and exploration successes; and additional engineering and other analysis required to fully assess their impact; diminishing quantities or grades of reserves; increased costs, delays, suspensions, and technical challenges associated with the construction of capital projects; operating or technical difficulties in connection with mining or development activities, including disruptions in the maintenance or provision of required infrastructure and information technology systems; damage to Barrick Gold Corporation’s or the Goldstrike Mine’s reputation due to the actual or perceived occurrence of any number of events, including negative publicity with respect to the handling of environmental matters or dealings with community groups, whether true or not; risk of loss due to acts of war, terrorism, sabotage and civil disturbances; uncertainty whether the Goldstrike Mine will meet Barrick Gold Corporation’s capital allocation objectives; the impact of global liquidity and credit availability on the timing of cash flows and the values of assets and liabilities based on projected future cash flows; the impact of inflation; fluctuations in the currency markets; changes in interest rates; changes in national and local government legislation, taxation, controls or regulations and/or changes in the administration of laws, policies and practices, expropriation or nationalization of property and political or economic developments in the USA; failure to comply with environmental and health and safety laws and regulations; timing of receipt of, or failure to comply with, necessary permits and approvals; litigation; contests over title to properties or over access to water, power and other required infrastructure; increased costs and physical risks including extreme weather events and resource shortages, related to climate change; and availability and increased costs associated with mining inputs and labor. In addition, there are risks and hazards associated with the business of mineral exploration, development and mining, including environmental hazards, industrial accidents, unusual or unexpected formations, pressures,cave-ins, flooding and gold bullion, copper cathode or gold or copper concentrate losses (and the risk of inadequate insurance, or inability to obtain insurance, to cover these risks).

Many of these uncertainties and contingencies can affect Barrick Gold Corporation’s actual results and could cause actual results to differ materially from those expressed or implied in any forward-looking statements made by, or on behalf of, Barrick Gold Corporation. All of the forward-looking statements made in this report are qualified by these cautionary statements. Barrick Gold Corporation and RPA and the Qualified Persons who authored this report undertake no obligation to update publicly or otherwise revise any forward-looking statements whether as a result of new information or future events or otherwise, except as may be required by law.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page i |

| www.rpacan.com |

TABLE OF CONTENTS

| PAGE | ||

1 SUMMARY | 1-1 | |

Executive Summary | 1-1 | |

Economic Analysis | 1-11 | |

Technical Summary | 1-11 | |

2 INTRODUCTION | 2-1 | |

3 RELIANCE ON OTHER EXPERTS | 3-1 | |

4 PROPERTY DESCRIPTION AND LOCATION | 4-1 | |

5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 5-1 | |

6 HISTORY | 6-1 | |

7 GEOLOGICAL SETTING AND MINERALIZATION | 7-1 | |

Regional Geology | 7-1 | |

Property Geology | 7-4 | |

Mineralization | 7-11 | |

8 DEPOSIT TYPES | 8-1 | |

9 EXPLORATION | 9-1 | |

10 DRILLING | 10-1 | |

Open Pit | 10-1 | |

Underground | 10-4 | |

11 SAMPLE PREPARATION, ANALYSES AND SECURITY | 11-1 | |

Goldstrike MineOn-site Assay Laboratory | 11-2 | |

Quality Assurance and Quality Control | 11-7 | |

12 DATA VERIFICATION | 12-1 | |

13 MINERAL PROCESSING AND METALLURGICAL TESTING | 13-1 | |

Mineral Processing | 13-1 | |

Metallurgical Testing | 13-1 | |

Recovery | 13-2 | |

Allocation and Reconciliation | 13-3 | |

Production Statistics | 13-6 | |

14 MINERAL RESOURCE ESTIMATE | 14-1 | |

Summary | 14-1 | |

Open Pit Mineral Resources | 14-5 | |

Underground Mineral Resources | 14-19 | |

Comments and Recommendations | 14-40 | |

15 MINERAL RESERVE ESTIMATE | 15-1 | |

Open Pit | 15-2 | |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page i |

| www.rpacan.com |

Stockpiles | 15-4 | |

Underground | 15-9 | |

16 MINING METHODS | 16-1 | |

Open Pit | 16-1 | |

Underground | 16-7 | |

17 RECOVERY METHODS | 17-1 | |

Mineral Processing | 17-1 | |

Process Description | 17-3 | |

18 PROJECT INFRASTRUCTURE | 18-1 | |

Site | 18-1 | |

Open Pit | 18-3 | |

Underground | 18-4 | |

19 MARKET STUDIES AND CONTRACTS | 19-1 | |

Markets | 19-1 | |

Contracts | 19-1 | |

20 ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | 20-1 | |

Tailings Storage Facilities | 20-1 | |

Project Permitting | 20-2 | |

Surface Disturbance | 20-4 | |

Social or Community Requirements | 20-4 | |

Mine Closure Requirements | 20-4 | |

21 CAPITAL AND OPERATING COSTS | 21-1 | |

Capital Costs | 21-1 | |

Operating Costs | 21-2 | |

22 ECONOMIC ANALYSIS | 22-1 | |

23 ADJACENT PROPERTIES | 23-1 | |

24 OTHER RELEVANT DATA AND INFORMATION | 24-1 | |

25 INTERPRETATION AND CONCLUSIONS | 25-1 | |

26 RECOMMENDATIONS | 26-1 | |

27 REFERENCES | 27-1 | |

28 DATE AND SIGNATURE PAGE | 28-1 | |

29 CERTIFICATE OF QUALIFIED PERSON | 29-1 | |

LIST OF TABLES

| PAGE | ||

Table1-1 Mineral Resources - December 31, 2018 | 1-3 | |

Table1-2 Mineral Resources - December 31, 2018 (Metric Units) | 1-4 | |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page ii |

| www.rpacan.com |

Table1-3 Mineral Reserves - December 31, 2018 | 1-5 | |||

Table1-4 Mineral Reserves - December 31, 2018 (Metric Units) | 1-5 | |||

Table6-1 Past 10 Years Production - Underground Mine | 6-3 | |||

Table6-2 Past 10 Years Production - Open Pit Mine | 6-3 | |||

Table6-3 Historical Production – Plant Facilities | 6-4 | |||

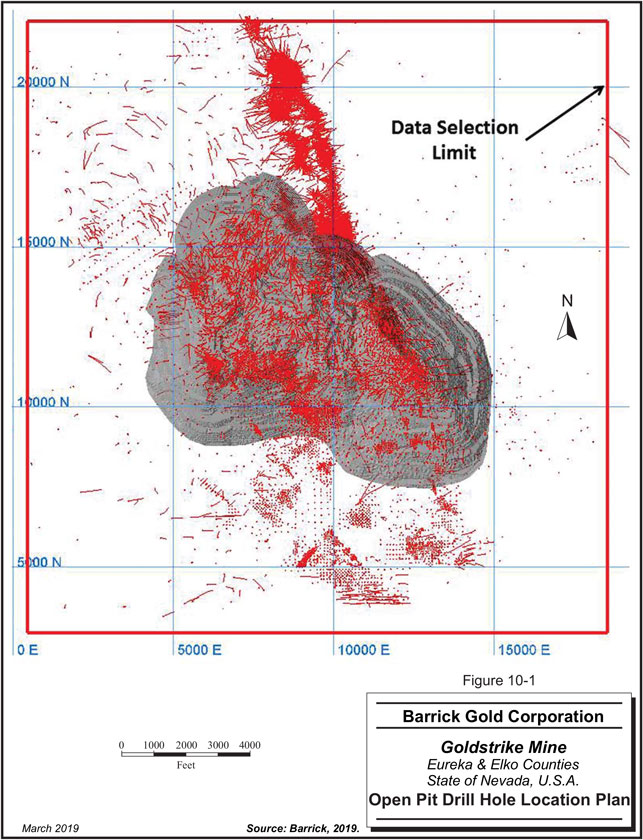

Table10-1 Open Pit Drill Hole Database | 10-2 | |||

Table10-2 Recent Open Pit Drilling | 10-2 | |||

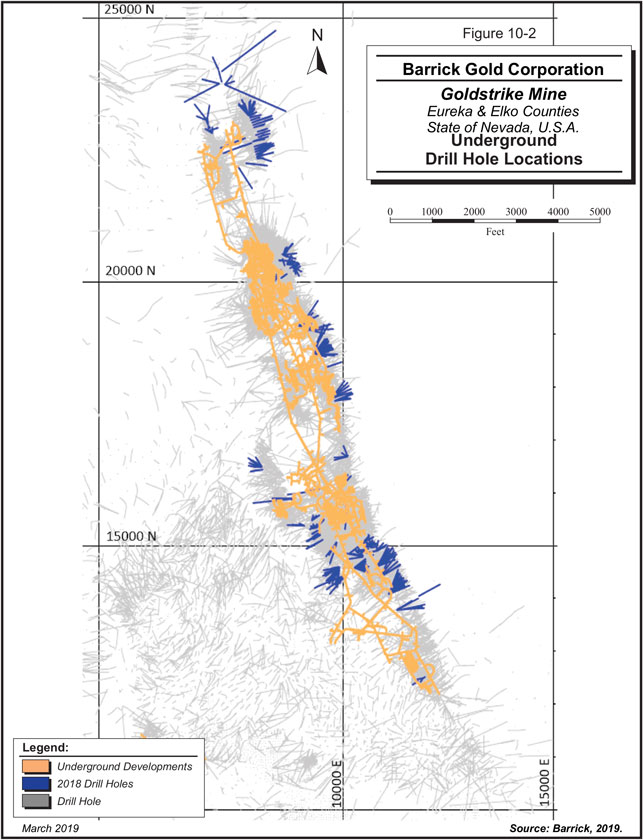

Table10-3 Underground Drill Hole Database | 10-4 | |||

Table10-4 Recent Underground Drilling | 10-4 | |||

Table11-1 QA/QC Samples - Summary 2017-2018 | 11-8 | |||

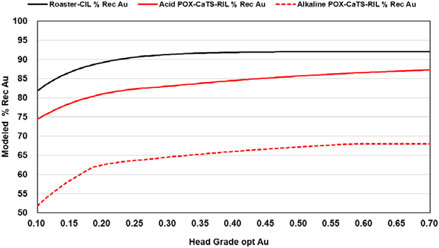

Table13-1 AlkalinePOX-CaTS-RIL Recovery Equations for 2018 | 13-3 | |||

Table13-2 AcidPOX-CaTS-RIL Recovery Equations for 2018 | 13-3 | |||

Table13-3 Roaster-CIL Recovery Equations for 2018 | 13-3 | |||

Table13-4 Summary of Head Grade Adjustments | 13-6 | |||

Table13-5 Autoclave and Roaster Production Statistics 2014-2018 | 13-7 | |||

Table14-1 Mineral Resources - December 31, 2018 | 14-2 | |||

Table14-2 Mineral Resources - December 31, 2018 (Metric Units) | 14-3 | |||

Table14-3 Open Pit Mineral Resources – December 31, 2018 | 14-5 | |||

Table14-4 Open Pit Mineralization Domains | 14-8 | |||

Table14-5 Open Pit Capping of High-Grade Values | 14-9 | |||

Table14-6 Open Pit Sample Statistics | 14-10 | |||

Table14-7 Open Pit Composite Statistics | 14-11 | |||

Table14-8 Open Pit Grade Interpolation Parameters | 14-13 | |||

Table14-9 Open Pit Block Model Definition | 14-15 | |||

Table14-10 Open Pit Composite Weighting | 14-16 | |||

Table14-11 Open Pit Resource Classification | 14-18 | |||

Table14-12 Underground Measured and Indicated Mineral Resources – December 31, 2018 | 14-19 | |||

Table14-13 Underground Densities | 14-22 | |||

Table14-14 Underground Sample Statistics – Capping and HYR | 14-26 | |||

Table14-15 Underground Raw and Capped Sample Statistics | 14-27 | |||

Table14-16 Underground Gold Composite Statistics | 14-28 | |||

Table14-17 Underground Block Model Definitions | 14-31 | |||

Table14-18 Rodeo Zone Interpolation Parameters | 14-32 | |||

Table14-19 Meikle Zone Interpolation Parameters | 14-33 | |||

Table14-20 Low Grade Interpolation Parameters | 14-36 | |||

Table14-21 Underground Classification Criteria | 14-39 | |||

Table15-1 Mineral Reserves - December 31, 2018 | 15-1 | |||

Table15-2 Mineral Reserves - December 31, 2018 (Metric Units) | 15-2 | |||

Table15-3 Betze-Post Open Pit Mineral Reserves - December 31, 2018 | 15-3 | |||

Table15-4 Open PitCut-off Grade Parameters | 15-3 | |||

Table15-5 Open Pit Stockpile Mineral Reserves - December 31, 2018 | 15-5 | |||

Table15-6 Autoclave and Roaster Stockpile Accounting Summary as of December 31, 2018 | 15-9 | |||

Table15-7 Rodeo/Meikle Underground Mineral Reserves – December 31, 2018 | 15-10 | |||

Table15-8 UndergroundCut-off Grade Estimates | 15-12 | |||

Table15-9 Underground Dilution and Extraction by Mining Type EOY2018 | 15-13 | |||

Table15-10 Reconciliation Data for Goldstrike Underground | 15-13 | |||

Table15-11 DOM Compared to Reserve Model | 15-14 | |||

Table15-12 Rodeo Stope Statistics September 2018 | 15-16 | |||

Table15-13 Rodeo Stope Performance | 15-16 | |||

Table16-1 Open Pit Mine Design Parameters | 16-2 |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page iii |

| www.rpacan.com |

Table16-2 Open Pit Mine Equipment Fleet | 16-5 | |||

Table16-3 2019 Open Pit Equipment Productivity | 16-6 | |||

Table16-4 Open Pit Life of Mine Production Summary | 16-6 | |||

Table16-5 Underground 10 Year Production History | 16-7 | |||

Table16-6 Underground Zone Dimensions | 16-9 | |||

Table16-7 Underground Development Compared to Plan | 16-12 | |||

Table16-8 Underground Equipment | 16-13 | |||

Table16-9 Underground Production Schedule – Reserves Only | 16-14 | |||

Table20-1 Goldstrike Mine Permits | 20-3 | |||

Table20-2 Barrick Goldstrike Mine Disturbance Estimate | 20-6 | |||

Table21-1 2019 Life of Mine Capital Cost Estimate | 21-1 | |||

Table21-2 Actual Reported Operating Costs – EOY 2017 and 2018 | 21-2 | |||

Table21-3 LOM Unit Operating Costs (2019-2037) | 21-3 | |||

Table21-4 Projected 2019 Workforce | 21-4 |

LIST OF FIGURES

| PAGE | ||

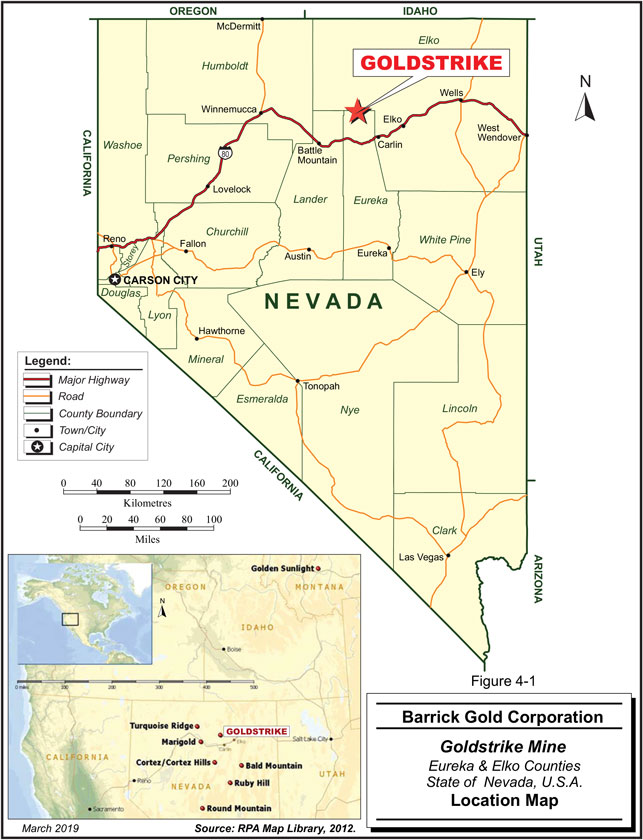

Figure4-1 Location Map | 4-3 | |

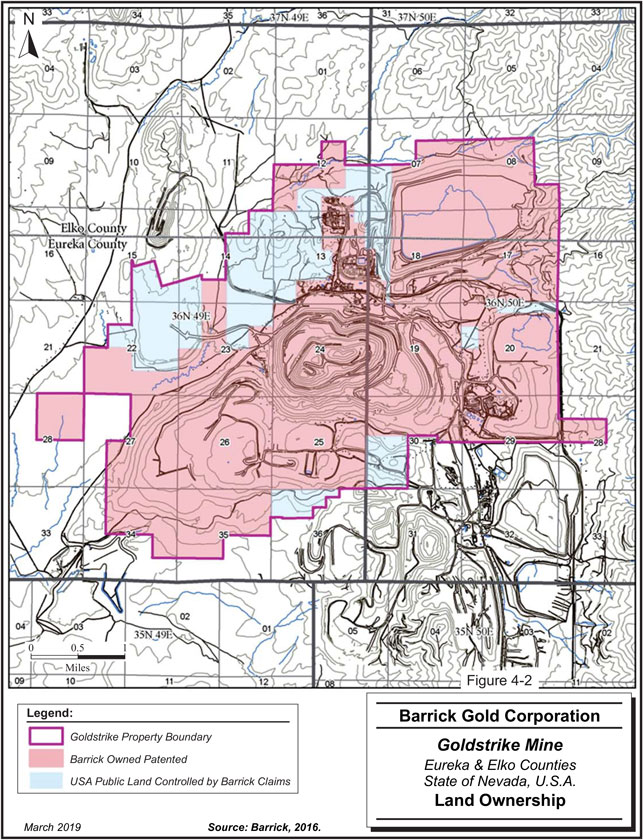

Figure4-2 Land Ownership | 4-4 | |

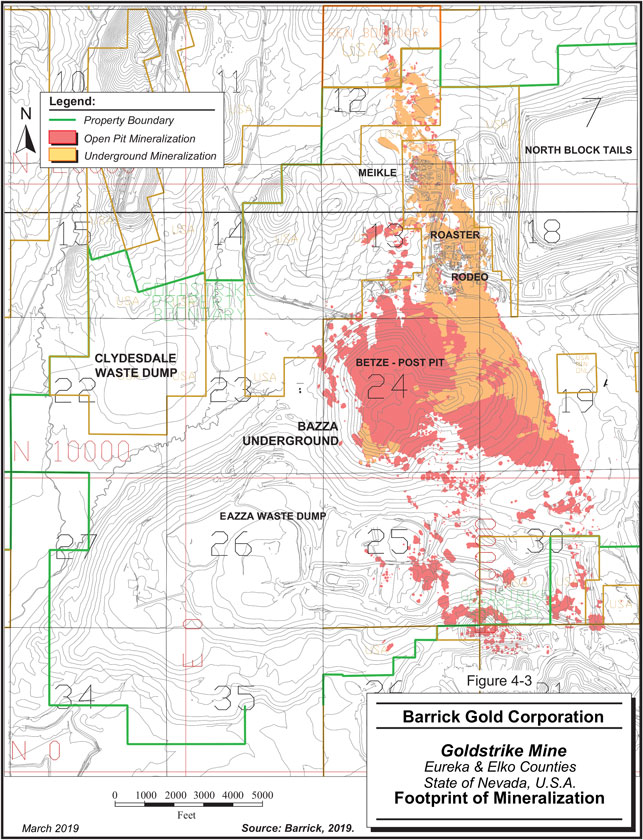

Figure4-3 Footprint of Mineralization | 4-5 | |

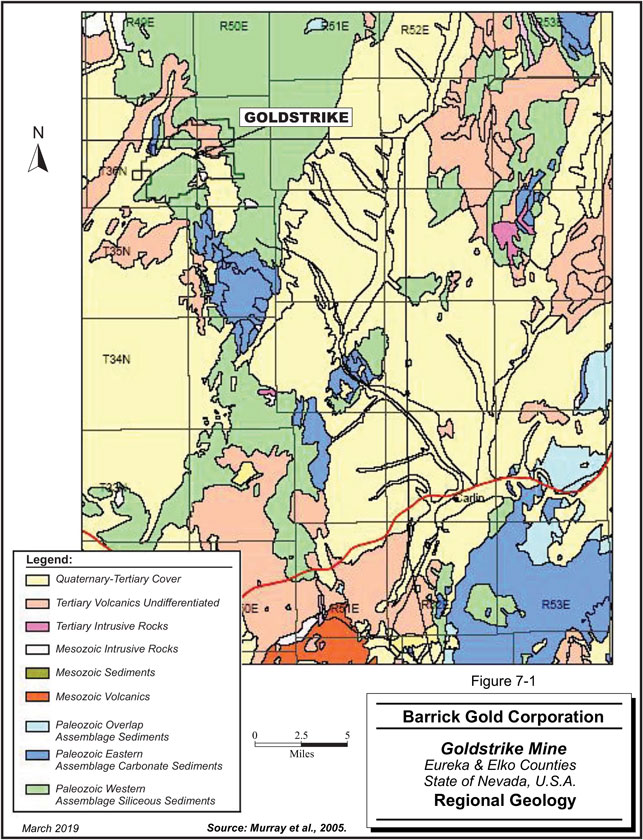

Figure7-1 Regional Geology | 7-3 | |

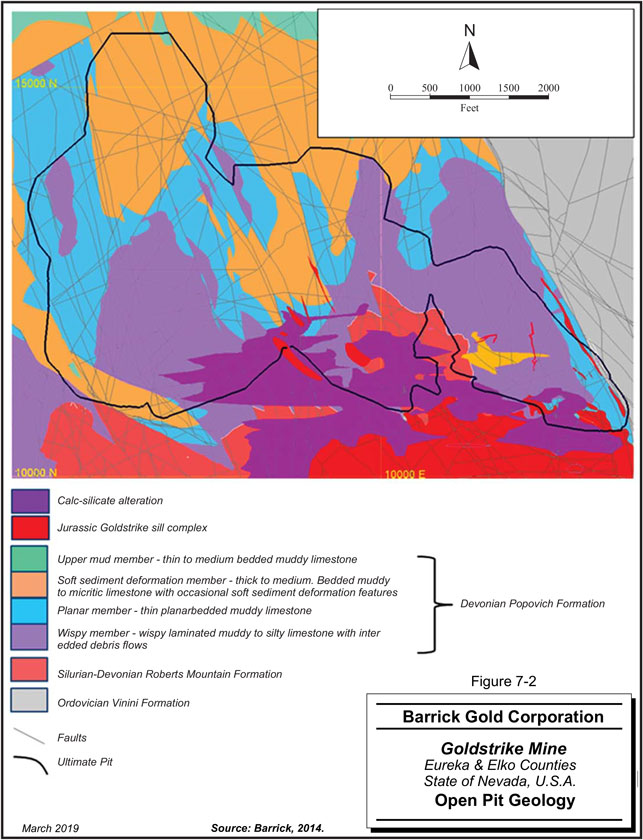

Figure7-2 Open Pit Geology | 7-5 | |

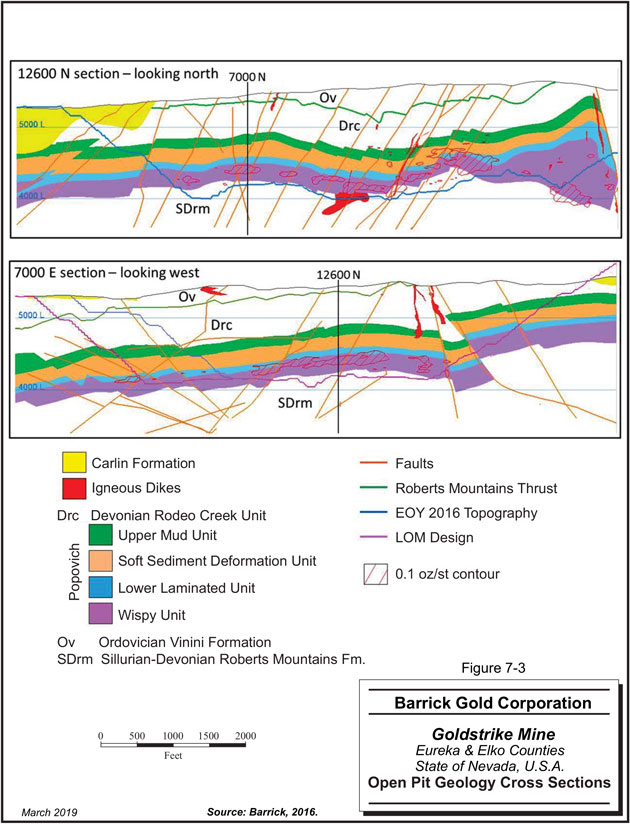

Figure7-3 Open Pit Geology Cross Sections | 7-6 | |

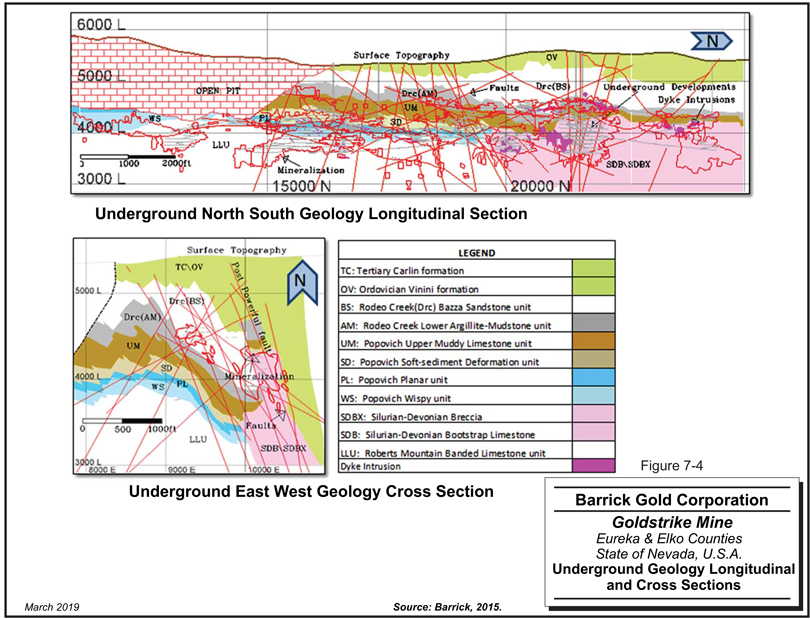

Figure7-4 Underground Geology Long and Cross Sections | 7-10 | |

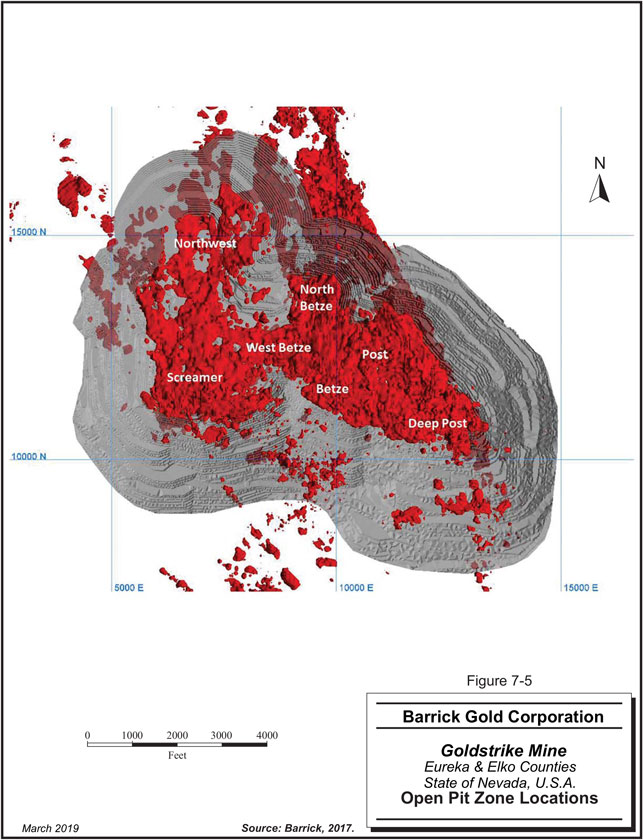

Figure7-5 Open Pit Zone Locations | 7-13 | |

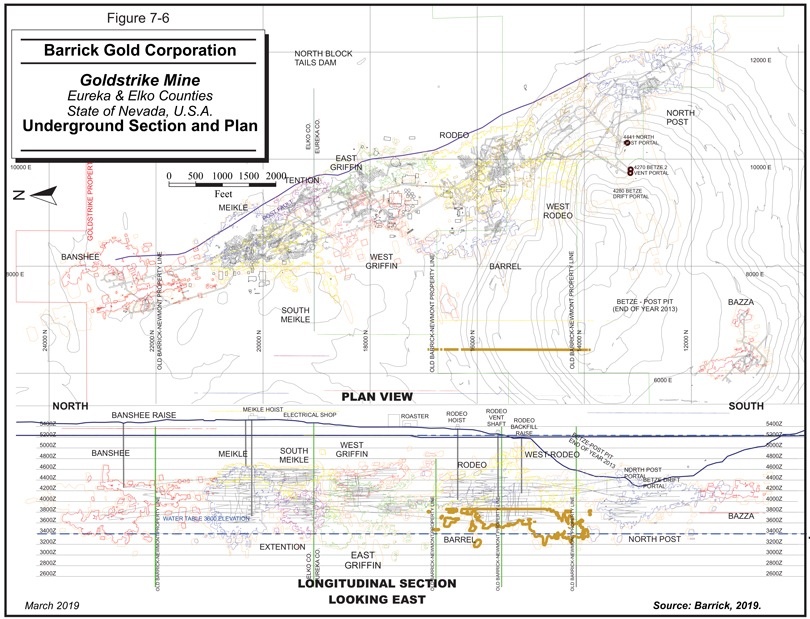

Figure7-6 Underground Longitudinal Section | 7-15 | |

Figure10-1 Open Pit Drill Hole Location Plan | 10-3 | |

Figure10-2 Underground Drill Hole Locations | 10-5 | |

Figure13-1 Gold Recovery | 13-3 | |

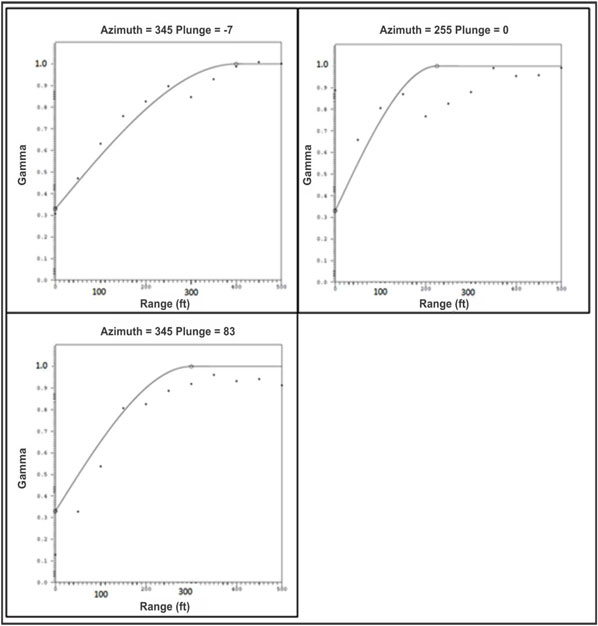

Figure14-1 Open Pit - Correlogram for Latite Domain | 14-12 | |

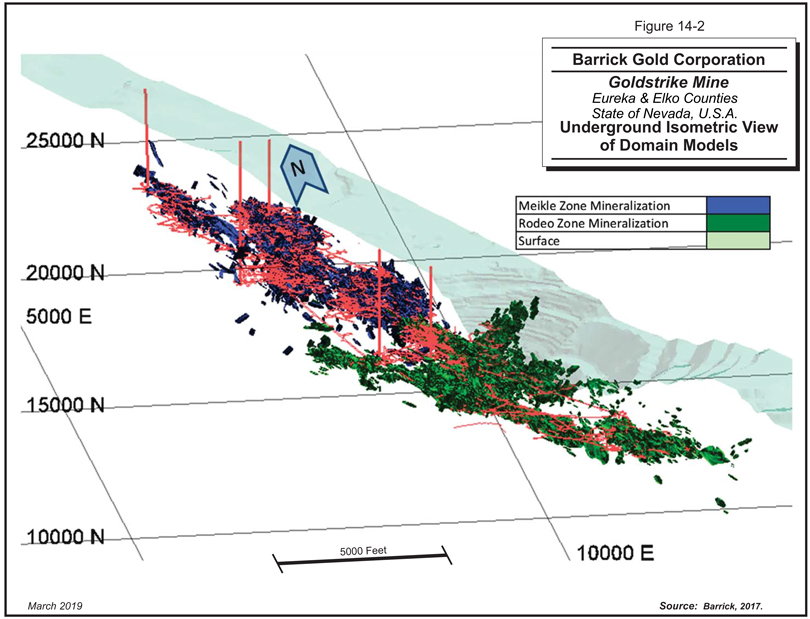

Figure14-2 Underground Isometric View of Domain Models | 14-24 | |

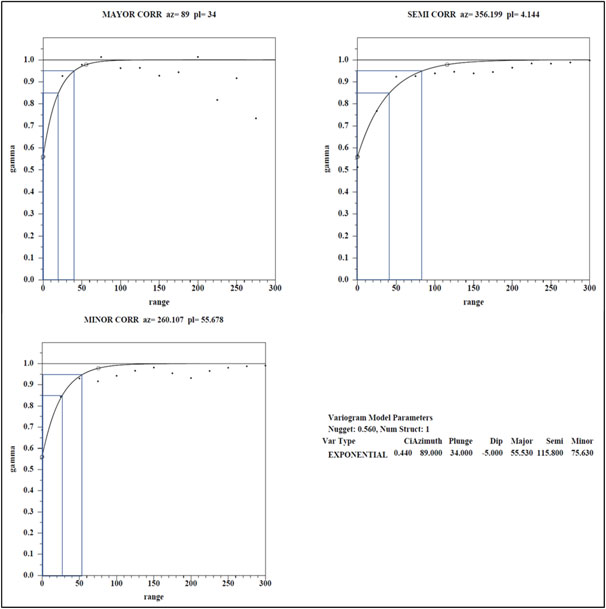

Figure14-3 Underground Correlogram for Banshee–East Dipping Domain | 14-30 | |

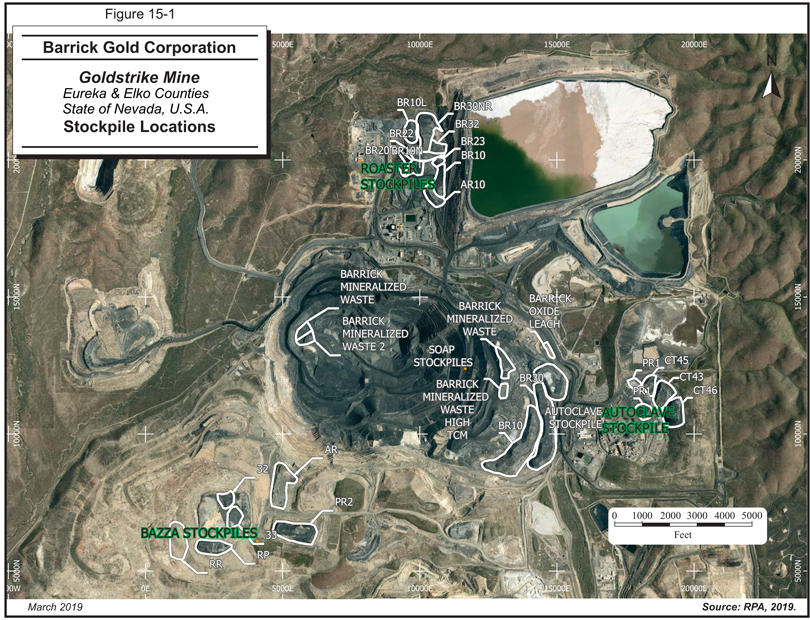

Figure15-1 Stockpile Locations | 15-6 | |

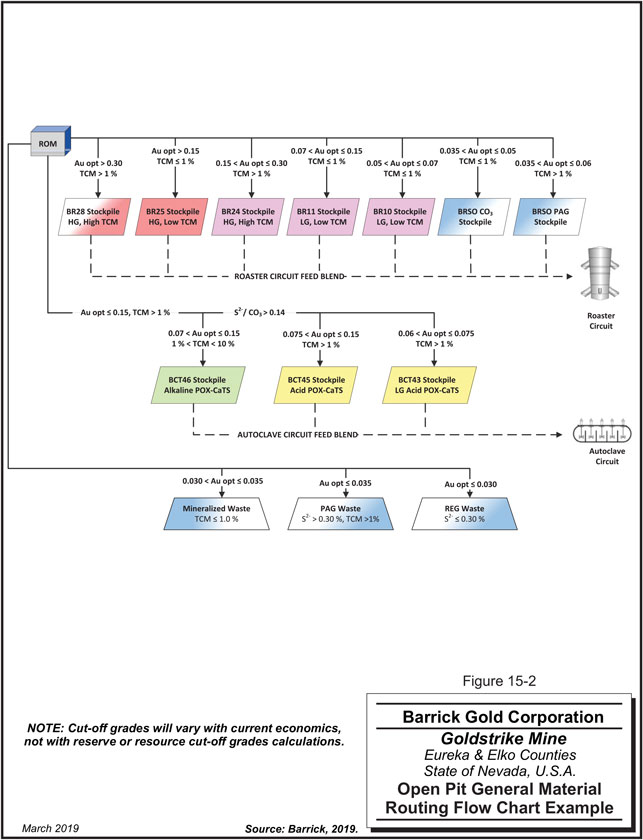

Figure15-2 Goldstrike Mine Open Pit Material Routing Flow Chart | 15-7 | |

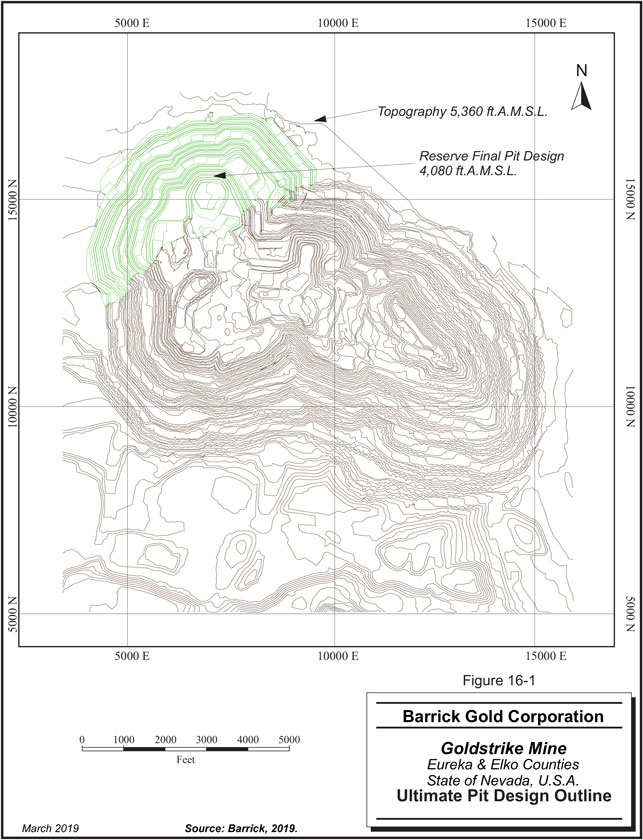

Figure16-1 Ultimate Open Pit Outline | 16-3 | |

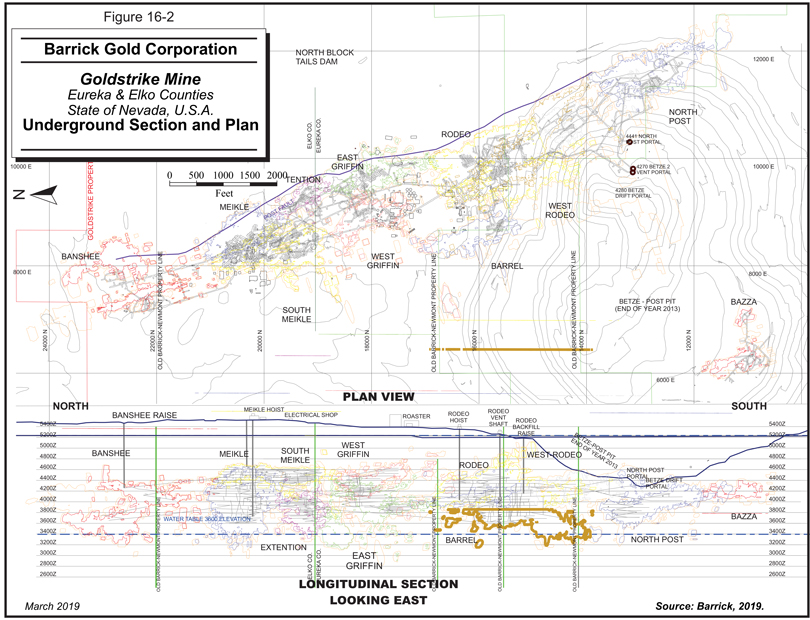

Figure16-2 Underground Section and Plan | 16-8 | |

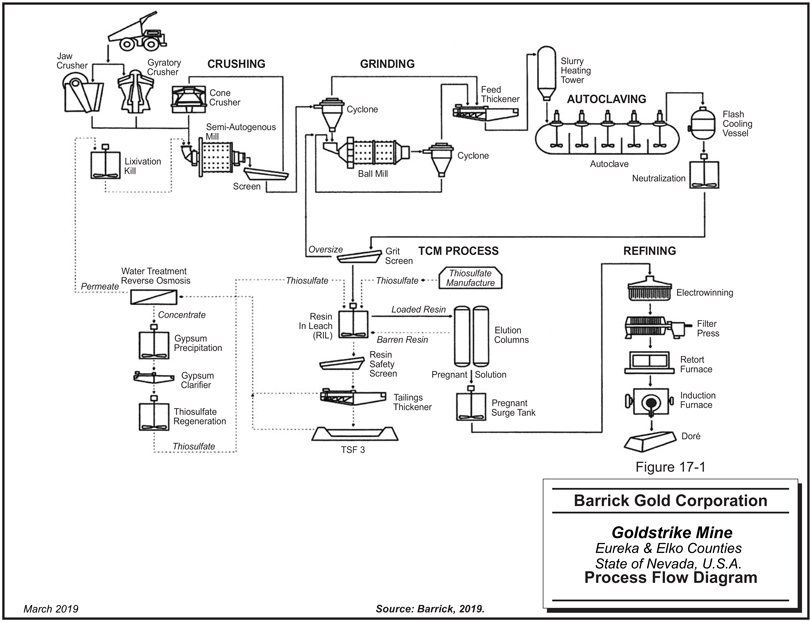

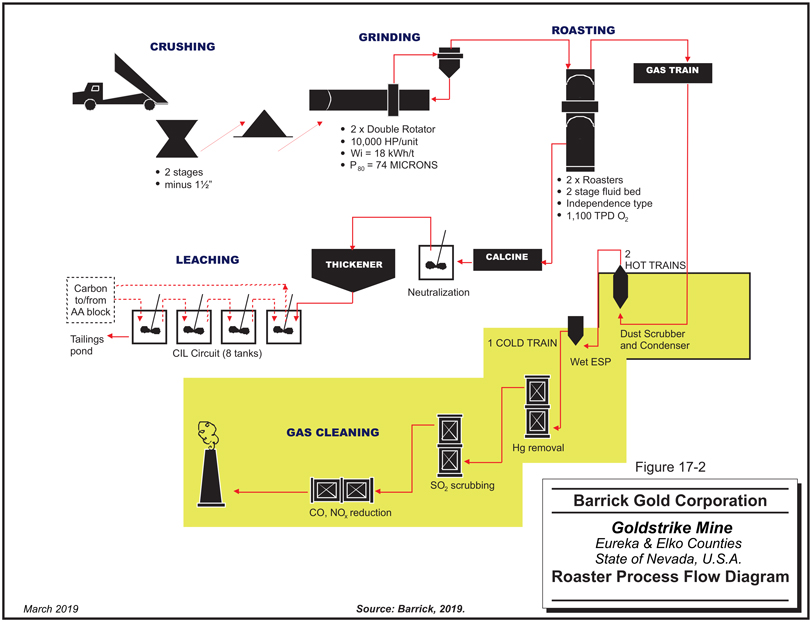

Figure17-1 Process Flow Diagram | 17-2 | |

Figure17-2 Roaster Process Flow Diagram | 17-6 | |

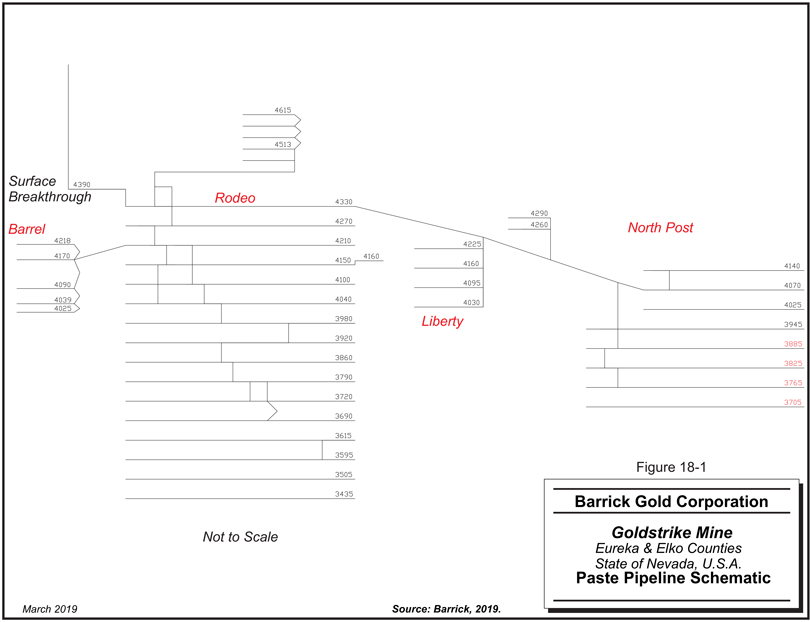

Figure18-1 Paste Fill Schematic | 18-6 | |

Figure18-2 Ventilation Schematic | 18-8 | |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page iv |

| www.rpacan.com |

1 SUMMARY

EXECUTIVE SUMMARY

Roscoe Postle Associates Inc. (RPA) was retained by Barrick Gold Corporation (Barrick) to prepare an independent Technical Report on the Goldstrike Mine (the Mine), in Eureka and Elko Counties, Nevada, USA. The purpose of this report is to support public disclosure of Mineral Resource and Mineral Reserve estimates at the Mine as of December 31, 2018. This Technical Report conforms to NI43-101 Standards of Disclosure for Mineral Projects. The effective date of the Mineral Resource and Mineral Reserve estimates in this Technical Report is December 31, 2018, and information in this Technical Report is current as of that date unless otherwise specified. RPA visited the Mine on December 3 to 5, 2018.

Barrick is a publicly traded Canadian mining company with a large portfolio of operating mines and projects. The Goldstrike Mine property is located within the northern Carlin Trend on the western flank of the Tuscarora Mountains in Eureka and Elko Counties, north central Nevada, USA, approximately 38 mi northwest of Elko and 25 mi north of the town of Carlin.

On March 10, 2019, Barrick and Newmont Mining Corporation entered into an implementation agreement (Implementation Agreement) to create a joint venture combining their respective mining operations, assets, reserves and talent in Nevada (Barrick-Newmont Joint Venture). In connection with the completion of the transactions contemplated by the Implementation Agreement expected later this year, the Mine will be contributed to the Barrick-Newmont Joint Venture. This report documents estimates as of December 31, 2018, for Mineral Resources, Mineral Reserves, production schedules, and cost projections. These estimates do not take into account any changes or benefits that might arise from the commencement of Barrick-Newmont Joint Venture operations.

The Mine consists of both open pit and underground operations. TheBetze-Post open pit is a large-scale operation utilizing a conventional truck and shovel fleet. Current Open Pit Mineral Reserves total 11.9 million tons of ore grading 0.114 oz/st Au. The ultimate pit will measure approximately two miles east to west, 1.5 mi north to south, and have an average depth of approximately 1,300 ft. Open pit mining will continue to 2023, and then go on hiatus until a finaltwo-year pit phase is mined at the end of the underground mine life.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-1 |

| www.rpacan.com |

A large amount of stockpiled open pit ore, which has been accumulating since the late 1980s, is included in Mineral Reserves, totalling 53.1 million tons, grading 0.080 oz/st Au.

The underground mine consists of 11 separate zones stretching over a length of 12,000 ft and a vertical distance from approximately 600 ft to 2,000 ft below surface. Underground mine production is planned from the Rodeo, Meikle, North Post, JV Post, and Banshee mine areas. Underground Mineral Reserves totalling 9.82 million tons at 0.291oz/st Au are projected to sustain the mine operations until 2027.

The open pit resource estimates are based on depleting the 2018mid-year block models, which were built using data available up to May 31, 2018. The Underground Mineral Resource estimates are based on the EOY2018 block models, which were built using data up to November 28, 2018. RPA examined theend-of-year 2018 (EOY2018) Open Pit and Underground Mineral Resource estimates and is of the opinion that they meet or exceed industry standards and are acceptable to support estimation of Mineral Reserves.

Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition Standards for Mineral Resources and Mineral Reserves dated May 10, 2014 (CIM (2014) definitions) were used for the Mineral Resource and Mineral Reserve estimates.

Table1-1 summarizes the total Mineral Resources, exclusive of Mineral Reserves, at the Goldstrike Mine as of December 31, 2018. Measured and Indicated Mineral Resources total 9.0 million tons grading 0.181 oz/st Au, containing 1.63 million ounces of gold. In addition, Inferred Mineral Resources total 2.0 million tons grading 0.237 oz/st Au, containing 474,000 ounces of gold.

In metric units (Table1-2), the Measured and Indicated Mineral Resources total 8.164 million tonnes grading 6.21 g/t Au, containing 1.632 million ounces of gold. In addition, Inferred Mineral Resources total 1.817 million tonnes grading 8.11 g/t Au, containing 474,000 ounces of gold.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-2 |

| www.rpacan.com |

TABLE1-1 MINERAL RESOURCES - DECEMBER 31, 2018

Barrick Gold Corporation - Goldstrike Mine

| Tons | Grade | Contained Gold | |||||||||||||

| Measured | (‘000 st) | (oz/st Au) | (‘000 oz) | ||||||||||||

Open Pit | 1,371 | 0.041 | 56 | ||||||||||||

Underground | 2,567 | 0.280 | 719 | ||||||||||||

Total Measured | 3,938 | 0.197 | 775 | ||||||||||||

Indicated | |||||||||||||||

Open Pit | 1,949 | 0.030 | 59 | ||||||||||||

Underground | 3,113 | 0.256 | 798 | ||||||||||||

Total Indicated | 5,061 | 0.169 | 857 | ||||||||||||

Measured + Indicated | |||||||||||||||

Open Pit | 3,319 | 0.035 | 115 | ||||||||||||

Underground | 5,680 | 0.267 | 1,517 | ||||||||||||

Total Measured + Indicated | 8,999 | 0.181 | 1,632 | ||||||||||||

Inferred | |||||||||||||||

Open Pit | 236 | 0.063 | 15 | ||||||||||||

Underground | 1,767 | 0.260 | 459 | ||||||||||||

Total Inferred | 2,004 | 0.237 | 474 | ||||||||||||

Notes:

| 1. | CIM (2014) definitions were followed for Mineral Resources. |

| 2. | Mineral Resources are estimated using a long-term gold price of US$1,500 per ounce. |

| 3. | Open Pit Mineral Resources are based oncut-off grades of 0.025 oz/st Au for roaster feed, 0.050 oz/st Au for acid autoclave feed, 0.060 oz/st Au for alkaline autoclave feed. |

| 4. | Underground Mineral Resources are reported atcut-off grades between 0.126 oz/st Au and 0.155 oz/st Au. Incremental material at acut-off grade of 0.10 oz/st Au is included if it is part of the mine sequence. |

| 5. | A minimum underground mining width of 15 ft was used. |

| 6. | For open pit, an average tonnage factor fornon-Carlin Formation ore and waste of approximately 13.5 ft3/st was used. For Carlin Formation waste, a tonnage factor of 16.0 ft3/st is used, and for waste dump material, a value of 18.2 ft3/st was used |

| 7. | For underground, bulk density is set by mineralized domain from 12.0 st/ft3 to 13.6 st/ft3. |

| 8. | Mineral Resources are exclusive of Mineral Reserves. |

| 9. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| 10. | Totals may not reconcile due to rounding. |

| 11. | North Post JV (Barrick 70% and Newmont 30%) reported at 70%. |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-3 |

| www.rpacan.com |

TABLE1-2 MINERAL RESOURCES - DECEMBER 31, 2018 (METRIC UNITS)

Barrick Gold Corporation - Goldstrike Mine

| Tonnes | Grade | Contained Gold | |||||||||||||

| Measured | (‘000 t) | (g/t Au) | (‘000 oz) | ||||||||||||

Open Pit | 1,243 | 1.40 | 56 | ||||||||||||

Underground | 2,329 | 9.60 | 719 | ||||||||||||

Total Measured | 3,572 | 6.75 | 775 | ||||||||||||

Indicated | |||||||||||||||

Open Pit | 1,768 | 1.04 | 59 | ||||||||||||

Underground | 2,824 | 8.79 | 798 | ||||||||||||

Total Indicated | 4,592 | 5.80 | 857 | ||||||||||||

Measured + Indicated | |||||||||||||||

Open Pit | 3,011 | 1.20 | 115 | ||||||||||||

Underground | 5,152 | 9.15 | 1,517 | ||||||||||||

Total Measured + Indicated | 8,164 | 6.21 | 1,632 | ||||||||||||

Inferred | |||||||||||||||

Open Pit | 214 | 2.18 | 15 | ||||||||||||

Underground | 1,603 | 8.91 | 459 | ||||||||||||

Total Inferred | 1,817 | 8.11 | 474 | ||||||||||||

Notes:

| 1. | CIM (2014) definitions were followed for Mineral Resources. |

| 2. | Mineral Resources are estimated using a long-term gold price of US$1,500 per ounce. |

| 3. | Open Pit Mineral Resources are based oncut-off grades of 0.86 g/t Au for roaster feed, 1.71 g/t Au for acid autoclave feed, and 2.06 g/t Au for alkaline autoclave feed. |

| 4. | Underground Mineral Resources are reported atcut-off grades between 4.32 g/t Au and 5.31 g/t Au. Incremental material at acut-off grade of 3.43 g/t Au is included if it is part of the mine sequence. |

| 5. | A minimum underground mining width of 4.6 m was used. |

| 6. | For Open Pit, an average density fornon-Carlin Formation ore and waste of approximately 2.37 t/m3 was used. For Carlin Formation waste, a density of 2.0 t/m3 was used, and for waste dump material, a density of 1.76 t/m3 was used |

| 7. | For underground, bulk density is set by mineralized domain from 2.37 t/m3 to 2.66 t/m3. |

| 8. | Mineral Resources are exclusive of Mineral Reserves. |

| 9. | Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| 10. | Totals may not reconcile due to rounding. |

| 11. | North Post JV (Barrick 70% and Newmont 30%) reported at 70%. |

The Mineral Reserves for the Goldstrike Mine as of December 31, 2018 are shown in Table1-3. These Mineral Reserves are a combination of the open pit and underground reserves, stockpiles, and inventory. Proven and Probable Mineral Reserves total 74.840 million tons grading 0.114 oz/st Au and contain 8.525 million ounces of gold.

In metric units (Table1-4), the Proven and Probable Reserves for the Goldstrike Mine total 67.895 million tonnes grading 3.91 g/t Au and contain 8.525 million ounces of gold.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-4 |

| www.rpacan.com |

TABLE1-3 MINERAL RESERVES - DECEMBER 31, 2018

Barrick Gold Corporation - Goldstrike Mine

| Proven Reserves | Probable Reserves | Proven and Probable Reserves | ||||||||||||||||||||||||||||||||||

| Tons | Grade | Contained Gold | Tons | Grade | Contained Gold | Tons | Grade | Contained Gold | ||||||||||||||||||||||||||||

| (000) | (oz/st Au) | (000 oz) | (000) | (oz/st Au) | (000 oz) | (000) | (oz/st Au) | (000 oz) | ||||||||||||||||||||||||||||

Open Pit | 2,305 | 0.130 | 300 | 9,596 | 0.110 | 1,058 | 11,901 | 0.114 | 1,358 | |||||||||||||||||||||||||||

OP Stockpiles | 53,119 | 0.080 | 4,269 | 53,119 | 0.080 | 4,269 | ||||||||||||||||||||||||||||||

Gold in Inventory | 40 | 40 | ||||||||||||||||||||||||||||||||||

Subtotal OP | 55,424 | 0.083 | 4,608 | 9,596 | 0.110 | 1,058 | 65,021 | �� | 0.087 | 5,667 | ||||||||||||||||||||||||||

Underground | 5,712 | 0.330 | 1,888 | 4,051 | 0.236 | 954 | 9,763 | 0.291 | 2,842 | |||||||||||||||||||||||||||

UG Stockpile | 56 | 0.297 | 17 | 56 | 0.297 | 17 | ||||||||||||||||||||||||||||||

Subtotal UG | 5,768 | 0.330 | 1,904 | 4,051 | 0.236 | 954 | 9,819 | 0.291 | 2,859 | |||||||||||||||||||||||||||

TOTAL | 61,192 | 0.106 | 6,513 | 13,647 | 0.147 | 2,012 | 74,840 | 0.114 | 8,525 | |||||||||||||||||||||||||||

Notes:

| 1. | CIM (2014) definitions were followed for Mineral Reserves. |

| 2. | Mineral Reserves are estimated using an average long-term gold price of US$1,200 per ounce. |

| 3. | Stockpiles include Autoclave, Roaster, and Distal. |

| 4. | Cut-off grades vary by processing type, mining method, and location. |

| 5. | Open pit autoclavecut-off grade is 0.060 oz/st Au to 0.070 oz/st Au and the open pit roastercut-off grade is 0.035 oz/st Au. The majority of the ore material in stockpile was generated at highercut-off grades because of lower gold prices. |

| 6. | Undergroundcut-off grades are between 0.158 oz/st Au and 0.194 oz/st Au. |

| 7. | The Mineral Reserve estimate includes inventory. |

| 8. | Totals may not reconcile due to rounding. |

| 9. | North Post JV (Barrick 70% and Newmont 30%) reported at 70%. |

TABLE1-4 MINERAL RESERVES - DECEMBER 31, 2018 (METRIC UNITS)

Barrick Gold Corporation - Goldstrike Mine

| Proven Reserves | Probable Reserves | Proven and Probable Reserves | ||||||||||||||||||||||||||||||||||

| Tonnes | Grade | Contained Gold | Tonnes | Grade | Contained Gold | Tonnes | Grade | Contained Gold | ||||||||||||||||||||||||||||

| (000) | (g/t Au) | (000 oz) | (000) | (g/t Au) | (000 oz) | (000) | (g/t Au) | (000 oz) | ||||||||||||||||||||||||||||

Open Pit | 2,091 | 4.46 | 300 | 8,706 | 3.78 | 1,058 | 10,797 | 3.91 | 1,358 | |||||||||||||||||||||||||||

OP Stockpiles | 48,189 | 2.76 | 4,269 | 48,189 | 2.76 | 4,269 | ||||||||||||||||||||||||||||||

Gold in Inventory | 40 | 40 | ||||||||||||||||||||||||||||||||||

Subtotal OP | 50,281 | 2.85 | 4,609 | 8,706 | 3.78 | 1,058 | 58,987 | 2.99 | 5,667 | |||||||||||||||||||||||||||

Underground | 5,182 | 11.33 | 1,888 | 3,675 | 8.08 | 954 | 8,857 | 9.98 | 2,842 | |||||||||||||||||||||||||||

UG Stockpile | 51 | 10.19 | 17 | �� | 51 | 10.19 | 17 | |||||||||||||||||||||||||||||

Subtotal UG | 5,233 | 11.32 | 1,904 | 3,675 | 8.07 | 954 | 8,908 | 9.98 | 2,858 | |||||||||||||||||||||||||||

TOTAL | 55,514 | 3.65 | 6,513 | 12,381 | 5.05 | 2,012 | 67,895 | 3.91 | 8,525 | |||||||||||||||||||||||||||

Notes:

| 1. | CIM (2014) definitions were followed for Mineral Reserves. |

| 2. | Mineral Reserves are estimated using an average long-term gold price of US$1,200 per ounce. |

| 3. | Stockpiles include Autoclave, Roaster, and Distal. |

| 4. | Cut-off grades vary by processing type, mining method, and location. |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-5 |

| www.rpacan.com |

| 5. | Open pit autoclavecut-off grade is 1.69 g/t Au to 1.98 g/t Au and the open pit roastercut-off grade is 0.99 g/t Au. The majority of the ore material in stockpile was generated at highercut-off grades because of lower gold prices. |

| 6. | Undergroundcut-off grades are between 4.46 g/t Au and 5.47 g/t Au. |

| 7. | The Mineral Reserve estimate includes inventory. |

| 8. | Totals may not reconcile due to rounding. |

| 9. | North Post JV (Barrick 70% and Newmont 30%) reported at 70%. |

RPA is not aware of any environmental, permitting, legal, title, taxation, socio-economic, marketing, political, or other relevant factors which could materially affect the Open Pit or Underground Mineral Resource and Mineral Reserve estimates.

CONCLUSIONS

Based on the site visit and subsequent review, RPA offers the following conclusions.

GEOLOGY AND MINERAL RESOURCE ESTIMATION

General

| ● | Mineral Resource estimates have been prepared utilizing acceptable estimation methodologies. The classification of Measured, Indicated, and Inferred Resources conforms to CIM (2014) definitions. |

| ● | The sampling, sample preparation, and analyses are appropriate for the style of mineralization and Mineral Resource estimation. The current drill hole database is reasonable for supporting the Mineral Resource and Mineral Reserve estimates. |

| ● | Drilling, sampling, and data warehousing are all conducted according to industry best practice. |

| ● | With minor local exceptions, visual inspection of block and composite grades across all of the models shows relatively tight and conservative grade extrapolation which falls in general accord with very closely drilled areas. |

| ● | The EOY2018 open pit and underground resource block models are reasonable for supporting the Mineral Resource and Mineral Reserve estimates. |

| ● | The Mineral Resource modelling steps and results are comprehensively recorded in the master spreadsheets as the workflow is executed. |

| ● | Goldstrike geological personnel have conducted high quality geological and resource modelling work that meets or exceeds industry standard practice. |

| ● | Site geological staff are using the aggregate data mined at the deposits to develop further geological understanding of regional mineralized trends. |

| ● | Mineral Resources are reported exclusive of Mineral Reserves and are estimated effective December 31, 2018 (EOY2018). |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-6 |

| www.rpacan.com |

| ● | Measured and Indicated Mineral Resources total 9.0 million tons grading 0.181 oz/st Au, containing 1.63 million ounces of gold. In addition, Inferred Mineral Resources total 2.0 million tons grading 0.237 oz/st Au, containing 474 thousand ounces of gold. |

| ● | In metric units, the Measured and Indicated Mineral Resources total 8.164 million tonnes grading 6.21 g/t Au, containing 1.632 million ounces of gold. In addition, Inferred Mineral Resources total 1.817 million tonnes grading 8.11 g/t Au, containing 474,000 ounces of gold. |

Open Pit

| ● | Open Pit Measured and Indicated Mineral Resources included in the Mineral Resource total 3.32 million tons grading 0.035 oz/st Au, containing 115,200 ounces of gold. In addition, Inferred Mineral Resources total 236,100 tons grading 0.063 oz/st Au, containing 15,000 ounces of gold. The Open Pit Measured Resources include 0.97 million tons averaging 0.045 oz/st Au from the BMW and BMW2 stockpiles, containing 43,900 ounces of gold. |

| ● | On-going work to update lithology and fault models should improve future open pit resource models. |

Underground

| ● | Barrick staff understands the deposit well, and utilize modern industry standard techniques to control development and record geological information. |

| ● | Underground Measured and Indicated Mineral Resources included in the Mineral Resource total 5.68 million tons grading 0.267 oz/st Au, containing 1.52 million ounces of gold. Underground Inferred Mineral Resources are estimated to be 1.77 million tons grading 0.260 oz/st Au, containing 459,000 ounces of gold. |

MINING AND MINERAL RESERVES

General

| ● | The Mineral Reserve estimates have been prepared utilizing acceptable estimation methodologies and the classification of Proven and Probable Mineral Reserves conforms to CIM (2014) definitions. |

| ● | Mine planning for the Goldstrike Mine follows industry standards. |

| ● | RPA considers the selection of mining methods and the design practices to be appropriate for the deposits. |

| ● | Equipment purchases scheduled for the current Life of Mine (LOM) plan are reasonable. |

| ● | The workforce is well trained and capable of achieving the necessary production targets established by the Engineering Department in a safe manner. |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-7 |

| www.rpacan.com |

| ● | The EOY2018 Proven and Probable Mineral Reserves for the open pit, underground, stockpiles, and inventory total 74.840 million tons grading 0.114 oz/st Au and contain 8.525 million ounces of gold. |

| ● | In metric units, the Proven and Probable Reserves for the Goldstrike Mine total 67.895 million tonnes grading 3.91 g/t Au and contain 8.525 million ounces of gold. |

| ● | The LOM plan is in place and is based upon current operating experience. Recovery and cost estimates are based upon actual operating data and engineering to support a Mineral Reserve statement. Economic analysis using these estimates generates a positive cash flow, which supports a statement of Mineral Reserves. |

Open Pit and Stockpiles

| ● | Open Pit Proven and Probable Mineral Reserves total 11.90 million tons grading 0.114 oz/st Au, containing 1.36 million ounces of gold. |

| ● | Ore control procedures and results for the Goldstrike open pit are well documented. All records have been kept in good condition and are readily accessible. |

| ● | The EOY2018 Proven Mineral Reserves located in 28 different open pit stockpiles are estimated to be 53.1 million tons grading 0.080 oz/st Au, containing 4.27 million ounces of gold. The accounting methods used to track the stockpile tonnages and grades are reasonable. |

| ● | The stockpiles represent approximately 50% of the Mineral Reserve gold ounces and 87% of the Mineral Reserve tons. |

| ● | Reconciliation of open pit estimates to production is difficult to evaluate, because most mined ore goes to stockpiles. Reconciliation to grade control models results in a good match. |

Underground and Stockpiles

| ● | Underground Proven and Probable Mineral Reserves are estimated to be 9.76 million tons grading 0.291 oz/st Au, containing 2.84 million ounces of gold. |

| ● | The reconciliation between production and Mineral Reserves is completed in a comprehensive manner on a monthly basis. Results indicate significant gains over Mineral Reserve estimates, due to mining of material classified as Inferred or unclassified at the time of the estimate. This material is generally upgraded by infill drilling between the time of the estimate and mining. |

| ● | There is potential to extend Mineral Reserves at depth, given further dewatering to depress the water table. |

| ● | The EOY2018 Proven Mineral Reserves located in the underground stockpiles are estimated to be 56,000 tons grading 0.297 oz/st Au, containing 16,734 ounces of gold. The estimation methods used to track the stockpile tonnages and grades are reasonable. |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-8 |

| www.rpacan.com |

| ● | Reconciliation of previous underground estimates to production shows positive results, due to material outside of Mineral Reserves being mined during 2018. |

PROCESSING

| ● | Based on an evaluation of the methodology, data analysis and procedures associated with accounting and reconciliation, RPA is of the opinion that head grade estimation and adjustments, recovery calculations, and gold production accounting are acceptable and aligned with industry practices. |

| ● | While procedures used to estimate gold recovery meet industry standards, they are backwards-looking, based on recent operating performance. A more forward-looking, predictive model may provide better estimates. |

| ● | Planning the process feed is a well-coordinated and complex operation to ensure ore going to the processing operation provides optimum results. The milling operations are well run, safe, and environmentally sound and meet industry standards. |

| ● | The roaster operation was running well during the site visit. |

| ● | The adjustments made to the process production data and mill head grades based on actual gold production conform to industry standards. |

ENVIRONMENTAL CONSIDERATIONS

| ● | Goldstrike has an experienced staff of professionals who are diligent in the maintenance of their permits. |

| ● | Reclamation estimates are realistic, in RPA’s opinion. |

RISKS

RPA has not identified any significant risks and uncertainties that could reasonably be expected to affect the reliability or confidence in the exploration information, the Mineral Resource and Mineral Reserve estimates, or associated projected economic outcomes.

RECOMMENDATIONS

Based on the site visits and review of available data, RPA presents the following recommendations.

GEOLOGY AND MINERAL RESOURCE ESTIMATION

General

| ● | Add a tab to the master spreadsheet for each model which summarizes the information usually included in Technical Reports. |

| ● | Create Mineral Resource workflow documents explaining the workflows encapsulated in the master spreadsheets. |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-9 |

| www.rpacan.com |

Open Pit

| ● | Review/update the composite weighting scheme with more recent reconciliation data. |

| ● | Include the underground and blast hole data in future variography studies. |

| ● | Investigate using the blast hole, drill hole, and mapping data to build high grade wireframes for structurally controlled mineralization. |

Underground

| ● | Use a resource classificationclean-up script or classification wireframes to upgrade a small amount of Inferred Mineral Resource blocks that are scattered within the Indicated Mineral Resource areas. |

| ● | Additional density test work is warranted in some areas. |

MINING AND MINERAL RESERVES

| ● | Use reconciliation results and stope performance analysis to evaluate stope designs to determine where improvements in mine planning would be most advantageous. |

| ● | Review reconciliation of Underground Mineral Reserves to production after first deducting areas mined from outside the Mineral Reserve estimate. |

| ● | Continue to evaluate an extension of the dewatering program to access mineralization at depth. |

| ● | Continue the stockpile sampling program to confirm the grades, especially stockpiles that will be processed within the short term. |

| ● | Continue to sample, test, and review the metallurgical characteristics of the ore stockpiles on a periodic basis to ascertain how they may affect the process and impact recovery and costs. |

| ● | Develop a comprehensive mine planning procedure manual. |

PROCESSING

| ● | Carry out a structured geometallurgical program involving the bench-scale testing of discrete interval geological samples, which will ideally provide a predictive model of expected metallurgical performance for feed blends that differ from recent production. |

| ● | Review roaster feed belt sampling. Improved definition of head grade may serve to improve process feed blending practices and mine to process reconciliation. |

| ● | Real-time analysis of moisture in roaster feed would also be beneficial. The same microwave technology as is currently applied on the Cortez underground mine transfer conveyor could be used at Goldstrike. |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-10 |

| www.rpacan.com |

ECONOMIC ANALYSIS

Under NI43-101, producing issuers may exclude the information required for Section 22 Economic Analysis on properties currently in production, unless the technical report includes a material expansion of current production. Barrick is a producing issuer, the Goldstrike Mine is currently in production, and a material expansion is not being planned. RPA has performed an economic analysis of the Goldstrike Mine using the estimates presented in this report and confirms that the outcome is a positive cash flow that supports the statement of Mineral Reserves.

TECHNICAL SUMMARY

PROPERTY DESCRIPTION, LOCATION, AND LAND TENURE

The Goldstrike Mine property is located within the northern Carlin Trend on the western flank of the Tuscarora Mountains in Eureka and Elko Counties, Nevada, USA, approximately 38 mi northwest of Elko and 25 mi north of the town of Carlin.

The Goldstrike Mine area is composed of approximately 10,372 acres of surface rights of which approximately 1,922 acres are public lands administered by the Bureau of Land Management (BLM) and 8,450 acres are patented, and private lands owned by Barrick Goldstrike Mines, Inc. (Goldstrike), Barrick’s wholly-owned subsidiary. There are approximately 8,736 acres of mineral rights ownership/control made up of 1,962 acres of public lands and 6,774 acres of private land. These rights are owned or controlled through ownership of various forms of patents issued by the USA and by ownership of unpatented mining and mill site claims held subject to the paramount title of the USA.

The Goldstrike Mine property includes a total of 298 unpatented mining and mill-site claims. Unpatented mining claims are maintained on an annual basis, and do not expire as long as the payments are made. All mining leases and subleases are reviewed on a monthly basis and all payments and commitments are paid as required by the specific agreements.

A total disturbance of 9,028 acres is currently authorized for the Mine. The majority (87%) of the total authorized disturbance will occur on private lands owned by Goldstrike. The remainder (13%) of the authorized disturbance will occur on public lands administered by the BLM.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-11 |

| www.rpacan.com |

The Goldstrike property has various royalty holders with a maximum overriding Net Smelter Royalty (NSR) of 4% and Net Profit Interest Royalties (NPI) of between 2.4% and 6% over various parts of the property. Key royalty holders are Franco-Nevada U.S. Corp and Royal Gold, Inc.

INFRASTRUCTURE

The Goldstrike Mine is located in a major mining region and local resources including labour, water, power, and local infrastructure for transportation of supplies are well established. The majority of the workforce lives in the nearby towns of Elko, Spring Creek, Carlin, and Battle Mountain.

The surface rights secured for the Goldstrike Mine are sufficient to provide the necessary space required for all mining and quarrying activities. Enough land area also exists on the property to accommodate all foreseeable processing plants, ore andlow-grade stockpiles, tailings impoundments, and waste disposal areas.

Currently, the major assets and facilities associated with the Goldstrike Mine are:

| ● | Underground and open pit mines with production from several mineralized zones. |

| ● | The physical plant site including the administrative office complex and associated facilities, the open pit and underground mine workings and associated facilities, ore processing plants (autoclave pressure oxidation and roaster circuit) and associated facilities such as the laboratories, ore stockpiles, waste dumps, coarse ore storage, tailings storage, workshops, warehouses. |

| ● | Facilities providing basic infrastructure to the mine, including electric power, water treatment and supply, and sewage treatment. |

| ● | Surface and underground infrastructure including mine ramps, headframes, hoists, ventilation raises, maintenance shops, and mobile equipment fleets. |

The water for processing and mining is delivered from dewatering production wells and is more than adequate for current and planned requirements. Active dewatering operations are required, and a water management group is in place to carry out all dewatering including pumping, distribution, delivery, and disposal.

Barrick has a 115 MW naturalgas-fired power plant, located near Reno, Nevada, that allows the flexibility to provide power to the Mine through a combination of self-generation and market purchases. There is also a 1 MW solar plant at the same site.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-12 |

| www.rpacan.com |

HISTORY

The earliest gold mining activity in the northern part of the Carlin Trend occurred at the Bootstrap and Blue Star mines prior to the discovery of gold at the Goldstrike Mine property. At Bootstrap, just northwest of the Goldstrike Mine, antimony was discovered in 1918, followed by gold in 1946. Gold was produced at Bootstrap during 1957 to 1960. At Blue Star, immediately south of the Goldstrike Mine, gold was identified in 1957 in areas that had been mined for turquoise.

The first discovery of gold in the Goldstrike property was in 1962 by Atlas Minerals. Soil samples and drilling discoveredlow-grade gold mineralization. In 1973 to 1974, the Nevada Syndicate (funded by Lac Minerals) outlined shallow mineralization in the Long Lac and Winston areas. Polar Resources (Polar) in 1975, followed by Pancana Minerals Ltd. (Pancana) from 1976 to 1977, delineated the Number 9 deposit and severallow-grade zones within the Goldstrike intrusion to the east of Nevada Syndicate property. From 1975 to 1977, Polar and Pancana operated a small open pit and heap leach.

In 1978, Western States Minerals Corporation (Western States) entered into a 50/50 joint venture with Pancana, which had consolidated the various claims and leases in the Goldstrike Mine area. The bulk of the production was from oxidized zones, chiefly from the Long Lac, Bazza, and West Bazza deposits, plus some production from deposits within the Goldstrike intrusion. The Post deposit was discovered in 1982. Exploration continued until 1986 when a deep core hole was drilled at Post and the Deep Post deposit was discovered.

American Barrick Resources Corporation acquired the mine and properties from Western States (50%) in December 1986 and subsequently purchased Pancana’s interest (50%) in January 1987 for a total purchase price of $62 million. A deep drilling program outlined the large, high-grade Deep Post deposit, which was subsequently found to continue onto the adjacent property owned by Newmont Gold Company (Newmont). Exploration drilling in 1987 to 1988 led to the discovery of a number of other deposits similar to Deep Post. These included Betze and Screamer, which, together with Deep Post, comprise theBetze-Post deposit. Other discoveries in 1987 and 1988 included Deep Star, Rodeo, Meikle, South Meikle, and Griffin.

Heap leach ore production from theBetze-Post pit continued from the time of purchase to the end of 1998. Oxide mill ore processing started in August 1988 and the autoclave portion of

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-13 |

| www.rpacan.com |

the mill commenced operation in early 1990. The processing of ores by the roaster began in 2000.

The 1999 Asset Exchange with Newmont resulted in the acquisition of the Goldbug (the southern portion of Rodeo), West Rodeo, Barrel, and North Post deposits. These deposits were in the Newmont land corridor separating theBetze-Post and Meikle mines. The Banshee property north of the Meikle was also part of the exchange.

Past production from the Goldstrike Mine from 1987 to the end of 2018 totals over 44 million ounces of gold.

GEOLOGY AND MINERALIZATION

The Goldstrike Mine is located in the eastern Great Basin (Basin and Range Province) within the northern Carlin Trend on the western flank of the Tuscarora Mountains. The Carlin Trend is an alignment of gold mines located in a northwest-southeast belt extending five miles wide and 40 mi long, which accounts for more gold production than any other mining district in the United States. The northern trends account for more than twenty gold mines and deposits.

Carlin deposits comprise stratabound and structurally controlled disseminated hydrothermal gold mineralization hosted by Silurian-Devonian carbonate rocks that have been metamorphosed to varying degrees. The deposits are hydrothermal in origin and are usually structurally controlled. The carbonate host rocks are part of an autochthonous miogeoclinal carbonate sequence exposed as tectonic windows beneath the Roberts Mountains allochthon. The allochthonous rocks are a sequence of lower Paleozoic dominantly siliciclastic eugeoclinal rocks that were displaced eastward along the Roberts Mountains Thrust over younger units during the Upper Paleozoic Antler orogeny.

The western or siliciclastic allochthonous assemblage consists of mudstone, chert, siltstone, and minor limestone and includes imbricate thrust slices of Devonian Slaven, Silurian Elder, and Ordovician Vinini Formations. The eastern autochthonous assemblage of carbonate rocks consists of calcareous mudstone, siltstone and sandstone of the Rodeo Creek Unit, muddy limestone of the Devonian Popovich Formation, silty limestone to massive fossiliferous limestone of the Silurian-Devonian Roberts Mountains Formation, sandy dolomite of the Ordovician Hanson Creek Formation, quartzite of the Ordovician Eureka Quartzite, and limestone, cherty limestone and dolomite of the Ordovician Pogonip Group. Jurassic quartz

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-14 |

| www.rpacan.com |

diorite, as plugs, sills, and dikes, has intruded the Paleozoic sedimentary rocks. Dikes and sills of Jurassic monzonite and lamprophyre, and Tertiary dacite and rhyodacites, are mapped in the area.

Gold mineralization was emplaced approximately 39 Ma ago along favorable stratigraphy and structural features such as faults and folds, and along contacts between sedimentary rocks and the Goldstrike stock. Faulting provided major conduits for mineralizing fluids and may also have produced clay alteration that can act as a mineralizing barrier. Intense fracturing around the contact zone of the Goldstrike stock caused solution collapse and brecciation of the surrounding sedimentary units. Secondary fracture permeability was generated along the crests of anticlines, creating focal points for collapse breccia and dissolution zone formation. Finally, lithology and alteration contacts act as permeability barriers to fluids causing mineralization to pond along them particularly where feeder structures intersect these contacts. Alteration is characterized by decalcification of limestone, silicification of all rock types, and clay development in (argillization) structurally disturbed areas.

The gold mineralization is associated with silicification, argillization, and sulphide mineralization. In refractory sulphide ore, the gold is intimately associated with very fine-grained pyrite and marcasite. In some areas, the pyrite oxidized, freeing the gold and making its extraction relatively easy, as in the historic Post Oxide deposit. Sulphide minerals associated with gold mineralization include arsenopyrite, realgar, orpiment, and stibnite. Gangue minerals include quartz, calcite, and barite. Realgar and orpiment are generally low in abundance; however, these minerals are locally common in stockwork veinlets, fracture fillings, and breccia matrices.

EXPLORATION STATUS

To date, surface geological mapping and prospecting has been completed on the property, with pit mappingon-going. Approximately 28,500 diamond and reverse circulation (RC) holes have been drilled on the property to the end of 2018. Geochemical soil and rock sampling was carried out on the property in early exploration phases. Geophysical surveys include airborne and ground magnetometer; gravity; time domain pole-dipole induced polarization (IP); DC resistivity; controlled source audio magnetotellurics (CSAMT) and magnetotellurics (MT); time domain MT/IP using a distributed assay system; electrical logging of drill holes; and downhole IP. Gold mineralization is not directly detectable by geophysical methods; however, surveys identify subsurface properties that are useful in interpreting lithology, alteration, and structure

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-15 |

| www.rpacan.com |

as guides to gold mineralization. Aerial photographic surveys are performed every other year for open pit survey control.

MINERAL RESOURCES

The Mineral Resource estimate has an effective date of December 31, 2018. The open pit resource estimates were based on depleting the 2018mid-year block models, which were built using data available up to May 31, 2018. The Underground Mineral Resource estimates were based on the EOY2018 block models, which were built using data up to November 28, 2018. RPA examined the EOY2018 Open Pit and Underground Mineral Resource estimates, is of the opinion that they meet or exceed industry standards, and that the Mineral Resource estimates are acceptable to support Mineral Reserve estimation.

The Mineral Resources are reported exclusive of Mineral Reserves. The EOY2018 Measured and Indicated Mineral Resources total 9.0 million tons grading 0.181 oz/st Au and contain 1.63 million ounces of gold. In addition, EOY2018 Inferred Mineral Resources total 2.0 million tons grading 0.237 oz/st Au and contain 474,000 ounces of gold.

Goldstrike has experiencedon-site staff dedicated to maintaining theBetze-Post open pit resource block model and the Meikle and Rodeo underground block models. Different resource estimation procedures and block models are used to estimate the open pit and underground resources at the Goldstrike Mine.

RPA is not aware of any environmental, permitting, legal, title, taxation, socio-economic, marketing, political, or other relevant factors which could materially affect the Open Pit or Underground Mineral Resource estimates.

MINERAL RESERVES

The Mineral Reserves are generated based upon the mine designs applied to the Mineral Resources. The design methodology usescut-off grade estimates, confidence ratings, and economic assessment for validation. The Mineral Reserve estimates have been prepared utilizing acceptable estimation methodologies and the classification of Proven and Probable Reserves conforms to CIM (2014) definitions.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-16 |

| www.rpacan.com |

The EOY2018 Proven and Probable Mineral Reserves for the open pit, underground, stockpiles, and inventory total 74.840 million tons grading 0.114 oz/st Au and contain 8.525 million ounces of gold.

Goldstrike maintains a complex system of ore andlow-grade stockpiles, which have been growing since the late 1980s. There are primarily three major ore stockpile categories: Autoclave, Roaster, and Distal (stockpiles around the property).

The Proven Mineral Reserves located in open pit stockpiles are estimated to be 53.1 million tons grading 0.080 oz/st Au, containing 4.27 million ounces of gold, as of December 31, 2018. RPA agrees with the ore control rationale for creating the stockpiles, and the accounting methods used to track the stockpile quantities and grades. In addition to the open pit stockpiles, a small underground stockpile at the roaster is included in Mineral Reserves.

RPA is not aware of any mining, metallurgical, infrastructure, permitting, and other relevant factors which could materially affect the Mineral Reserve estimates.

MINING METHODS

OPEN PIT

Barrick’sBetze-Post open pit is a large-scale operation utilizing a conventional truck and shovel fleet. With completion of the 3rd NW pushback targeted for March 2019, the open pit currently has two remaining phases, with the ultimate pit to measure approximately two miles east to west, 1.5 mi north to south, and have an average depth of approximately 1,300 ft. The Bazza Waste Dump, located to the southwest of the open pit, has been closed and reclaimed. The mine plan includes continued use of the Clydesdale Dump to the west, and backfilling of the southeast and southwest portion of the open pit. Internal to the pit is the Betze Portal, which connects to the Rodeo underground mine, the North Post Portal, which connects to North Post and Rodeo underground, and the Betze Portal 2, which is used for ventilation.

Ultimate pit limits were determined by generating Whittle pit shells based on the net cash generated, and the pit slopes recommended by Piteau Associates Engineering Ltd. Haul ramps were designed to be 130 ft to 140 ft wide, including a safety berm for double lane traffic accommodating the320-ton class haul trucks, and have a maximum grade of 10%. Mining thickness is 40 ft in waste, and 20 ft in ore to help minimize dilution. In ore, triple benching is

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-17 |

| www.rpacan.com |

utilized creating 60 ft faces between catch benches when needed to steepen the high walls or maximize ore recovery.

Barrick optimizes mining by using a multi-phased approach, which maximizes stripping rates to keep an ore producing face available as much as possible. This multi-phase technique consists of a primary ore layback and a primary stripping layback. Historically, this approach was put in place to maintain a consistent mill feed and keep mine production in the range of 14 to 15 benches per layback per year.

UNDERGROUND

Generallylow-strength rock conditions are the key factor in the underground mine design and mining method selection. This has led to two mining methods, both of which rely on cemented backfill for support. In relatively good to fair ground conditions, where longhole stoping methods are used, the wall and back instability is reduced by mining smaller, long-hole sections and filling before mining the next section. In poor ground, the underhand drift and fill method provides a backfill roof for subsequent lifts in the mining cycle.

Transverse longhole stoping is used where the mineralized zone has a significant width. Footwall drifts are driven parallel to the strike of the ore to provide access for stoping. Mining with transverse stopes requires a primary, secondary, and sometimes tertiary extraction to completely mine out the area. Longitudinal stopes are utilized in areas of the mine where the geometry and ground conditions allow. The stopes are accessed from a footwall drive and then driven parallel to the strike of ore. Each section is mined and filled before the next section is mined.

The underhand drift and fill method is utilized in areas with rock quality ratings of fair to poor, regardless of the width of the zone. The underhand drifts are nominally designed as 15 ft wide by 15 ft high. The minimum ore width is 15 ft (one drift). A primary drift is driven with increased ground support to hold the ground open, then backfilled with a high strength cemented rock fill or paste fill. Where the ore width exceeds the nominal drift width, subsequent drifts are developed (parallel or at oblique angles to the primary drift) and then backfilled. This process continues until the entire ore shape at a given elevation has been excavated and filled. Successive lifts are taken beneath the primary workings, utilizing the backfill as an engineered back.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-18 |

| www.rpacan.com |

MINERAL PROCESSING

The Goldstrike Mine has two separate processing facilities each capable of treating single or double refractory ore including:

| 1. | An autoclave circuit with: |

| ● | Primary crushing |

| ● | Two parallel semi-autogenous grinding (SAG) Mill-Ball Mill grinding circuits with pebble crushing |

| ● | Five parallel autoclaves capable of alkaline or acid pressure oxidation (POX) |

| ● | Two parallel calcium thiosulphate (CaTS) leaching circuits withresin-in-leach (RIL) and electrowinning for gold recovery |

| ● | A refinery producing doré bullion from both autoclave and roaster circuits |

| 2. | A roaster circuit with: |

| ● | Primary and secondary crushing |

| ● | Two parallel dry grinding circuits |

| ● | Two parallel dual stage fluid bed roasters |

| ● | Roasteroff-gas handling and mercury recovery systems |

| ● | A slurry neutralization circuit |

| ● | Acarbon-in-leach (CIL) circuit with carbon stripping, carbon acid wash, carbon regeneration (ADR) and electrowinning for gold recovery |

| ● | Cyanide destruction circuit |

Ore from Goldstrike, Cortez, or external sources for toll processing are dispatched to various blend stockpiles dependent on mineralogical composition including gold, sulphide, arsenic, carbonate and organic carbon content. The routing of ore from stockpiles to the roaster and autoclave circuits is coordinated at Goldstrike by the Strategic Planning department to achieve optimal Au, CO3/S2- and CORGANIC blends to respective processes. Higher grade underground ore from Goldstrike and Cortez is fed to theRoaster-CIL circuit.

METALLURGICAL RECOVERY

Barrick has developed recovery calculations based on evaluation of historical data. They have changed over time as the ore and operations have changed. Based on the evaluation of the head grade adjustments, RPA is of the opinion that the recovery calculations and the equations used to estimate gold recoveries are adequate.

MARKET STUDIES

Gold is the principal commodity at the Goldstrike Mine and is freely traded, at prices that are widely known, so that prospects for sale of any production are virtually assured.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-19 |

| www.rpacan.com |

ENVIRONMENTAL, PERMITTING, AND SOCIAL CONSIDERATIONS

The Goldstrike operations consist of operating open pit and underground mines and process plant facilities. The mines and the corporation have environmental groups and management systems to ensure that the necessary permits and licences are obtained and maintained. These groups also carry out the required monitoring and reporting.

TAILINGS STORAGE FACILITY

Tailings from the roaster operations are deposited in the North Block Tailings Disposal Facility (NBTDF) located immediately to the east of the roaster facility and the Meikle mine. The NBTDF operates as azero-discharge facility under Water Pollution Control Permit NEV091029 with the Nevada Division of Environment Protection (NDEP) and Jurisdictional Dam PermitJ-699 with the Nevada Division of Water Resources (NDWR). The NBTDF is expanded approximately every two years and is currently permitted through a Stage 12 expansion.

Tailings from the TCM Leach operations are deposited in the Tailings Storage Facility 3 (TSF3) located immediately south of the NBTDF. TSF3 operates as azero-discharge facility under Water Pollution Control Permit NEV091029 with the NDEP and Jurisdictional Dam PermitJ-662 with the NDWR. TSF3 is expanded approximately every two years and is currently constructed through Stage 3 and permitted through Stage 6.

An appropriate level of importance and due diligence is being given to the design, integrity, and construction of site tailings facilities. Barrick completes regularly scheduled quarterly andbi-annual reviews of the facilities involving internal subject matter experts, the Engineer of Record (EoR) who is responsible for the design, as well as external third-party subject matter experts.

PROJECT PERMITTING

The BLM issued a Decision on the Amendment to the Plan of Operations for the 2017 Goldstrike Pit Expansion through the Determination of National Environmental Protection Act (NEPA) Adequacy process. The approval of this Amendment ensured the continuance of mining and processing at the Goldstrike Mine.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-20 |

| www.rpacan.com |

COMMUNITY AND SOCIAL ENGAGEMENT

There are no specifically identified social or community requirements at the Goldstrike Mine, however, the Mine is a prominent local business and applies industry best practice social and community engagement standards at its operation.

CAPITAL AND OPERATING COST ESTIMATES

CAPITAL COSTS

Current LOM capital costs are estimated to be $732.9 million. The major capital cost for the open pit will be capitalized waste stripping, which is estimated to be $163.4 million. Sustaining capital is estimated to be $337.0 million, which consists primarily of equipment replacement capital and tailings expansions. Underground mine development is projected to be $197.1 million.

OPERATING COSTS

The total operating cost has been estimated by Goldstrike to be approximately $4.7 billion over the LOM plan (2019-2037). Over the same time period, the average open pit mining operating cost is estimated to be $1.85 per ton mined. Underground mining cost will average $107.11 per ton mined. Processing costs will average $26.56 per ton processed.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 1-21 |

| www.rpacan.com |

2 INTRODUCTION

Roscoe Postle Associates Inc. (RPA) was retained by Barrick Gold Corporation (Barrick) to prepare an independent Technical Report on the Goldstrike Mine (the Mine), in Eureka and Elko Counties, Nevada, USA. The purpose of this report is to support public disclosure of Mineral Resource and Mineral Reserve estimates at the Mine as of December 31, 2018. This Technical Report conforms to NI43-101 Standards of Disclosure for Mineral Projects. The effective date of the Mineral Resource and Mineral Reserve estimates in this Technical Report is December 31, 2018, and information in this Technical Report is current as of that date unless otherwise specified.

Barrick is a publicly traded Canadian mining company with a large portfolio of operating mines and projects. The Goldstrike Mine property is located within the northern Carlin Trend on the western flank of the Tuscarora Mountains in Eureka and Elko Counties, north central Nevada, USA, approximately 38 mi northwest of Elko and 25 mi north of the town of Carlin.

On March 10, 2019, Barrick and Newmont Mining Corporation entered into an implementation agreement (Implementation Agreement) to create a joint venture combining their respective mining operations, assets, reserves and talent in Nevada (Barrick-Newmont Joint Venture). In connection with the completion of the transactions contemplated by the Implementation Agreement expected later this year, the Mine will be contributed to the Barrick-Newmont Joint Venture. This report documents estimates as of December 31, 2018, for Mineral Resources, Mineral Reserves, production schedules, and cost projections. These estimates do not take into account any changes or benefits that might arise from the commencement of Barrick-Newmont Joint Venture operations.

The Mine consists of both open pit and underground operations. TheBetze-Post open pit is a large-scale operation utilizing a conventional truck and shovel fleet. The ultimate pit will measure approximately two miles east to west, 1.5 mi north to south, and have an average depth of approximately 1,300 ft.

The underground mine consists of 11 separate zones stretching over a length of 12,000 ft and a vertical distance from approximately 600 ft to 2,000 ft below surface. Underground mine production is planned from the Rodeo, Meikle, North Post, JV Post, and Banshee mine areas.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 2-1 |

| www.rpacan.com |

A large amount of stockpiled ore, which has been accumulating since the late 1980s, is included in Mineral Reserves.

SOURCES OF INFORMATION

RPA visited the Goldstrike Mine from December 3 to 5, 2018. The RPA team consisted of the following members:

| ● | Jason J. Cox, P.Eng., Project Manager, Principal Mining Engineer |

| ● | Wayne W. Valliant, P.Geo., Principal Geologist |

| ● | Phillip A. Geusebroek, P.Geo., Senior Geologist |

| ● | Steve Haggarty, Managing Director, Haggarty Technical Services |

Discussions were held with personnel from Barrick:

| ● | Ettienne Du Plessis, VP Mineral Exploration, Barrick |

| ● | Rick Sims, Senior Director Reserves and Resources, Barrick |

| ● | Edward Mahoney, Mineral Resources Manager, Goldstrike Operations |

| ● | Janna Linebarger, Chief Resource, Goldstrike Operations |

| ● | Jim Byars, Chief Geologist, Open Pit, Goldstrike Operations |

| ● | Doug Eck, Senior Geologist, Ore Control, Goldstrike |

| ● | Nathan Forsythe, Senior Mine Geologist, Goldstrike |

| ● | Chadwick Spencer, Senior Data Administrator, Goldstrike |

The GoldstrikeBetze-Post and Meikle operations have been the subject of Technical Reports and resource/reserve technical audits as follows:

| ● | April 25, 2017, Technical Report on the Goldstrike Mine, Eureka and Elko Counties, Nevada, USA, Roscoe Postle Associates Inc. |

| ● | March 2012, NI43-101 Technical Report, RPA (RPA, 2012) |

| ● | December 2010, Mineral Reserve & Resource Review, RPA |

| ● | December 2008, Mineral Reserve & Resource Review, Scott Wilson Roscoe Postle Associates Inc. (Scott Wilson RPA, a predecessor company to RPA) |

| ● | June 29, 2008, 2008Mid-year Model Review, Resource Modeling Inc. |

| ● | January 2006, Reserve Procedure Audit, Scott Wilson RPA |

| ● | February 7, 2005, Review of Mineral Reserve Estimation Procedures, Scott Wilson RPA November 2004, Sarbanes Oxley Review, Scott Wilson RPA |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 2-2 |

| www.rpacan.com |

Mr. Cox is responsible for the overall preparation of this report, and reviewed the underground and open pit mine planning and production and is responsible for Sections 15, 16, 18, 19, 21, 22, and 24. Mr. Valliant is responsible for Sections 2 through 11 and 23. Mr. Geusebroek reviewed the resource estimates and is responsible for Sections 12 and 14. Mr. Haggarty reviewed the metallurgical and environmental aspects of the operation and is responsible for Sections 13, 17, 20, and contributed to Section 21. The authors share responsibility for Sections 1, 25, 26, and 27 of this Technical Report. RPA would like to acknowledge the excellent cooperation in the transmittal of data by Barrick and Goldstrike personnel.

This report does not include information on the South Arturo property, located adjacent to the Goldstrike Mine, except where expressly indicated. South Arturo is a joint venture between Premier Gold Mines Limited (40%) and Barrick (60%). The mineralized material from South Arturo is trucked to Goldstrike and toll milled.

The documentation reviewed, and other sources of information, are listed at the end of this report in Section 27 References.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 2-3 |

| www.rpacan.com |

LIST OF ABBREVIATIONS

Units of measurement used in this report conform to the US customary system. All currency in this report is US dollars (US$) unless otherwise noted.

µ | micron | kVA | kilovolt-amperes | |||

µg | microgram | kW | kilowatt | |||

a | annum | kWh | kilowatt-hour | |||

A | ampere | L | litre | |||

bbl | barrels | lb | pound | |||

Btu | British thermal units | L/s | litres per second | |||

°C | degree Celsius | m | metre | |||

C$ | Canadian dollars | M | mega (million); molar | |||

cal | calorie | m2 | square metre | |||

cfm | cubic feet per minute | m3 | cubic metre | |||

cm | centimetre | MASL | metres above sea level | |||

cm2 | square centimetre | m3/h | cubic metres per hour | |||

d | day | mi | mile | |||

dia | diameter | min | minute | |||

dmt | dry metric tonne | µm | micrometre | |||

dwt | dead-weight ton | mm | millimetre | |||

°F | degree Fahrenheit | mph | miles per hour | |||

ft | foot | MVA | megavolt-amperes | |||

ft2 | square foot | MW | megawatt | |||

ft3 | cubic foot | MWh | megawatt-hour | |||

ft/s | foot per second | oz | Troy ounce (31.1035g) | |||

g | gram | oz/st, opt | ounce per short ton | |||

G | giga (billion) | ppb | part per billion | |||

Gal | Imperial gallon | ppm | part per million | |||

g/L | gram per litre | psia | pound per square inch absolute | |||

Gpm | Imperial gallons per minute | psig | pound per square inch gauge | |||

g/t | gram per tonne | RL | relative elevation | |||

gr/ft3 | grain per cubic foot | s | second | |||

gr/m3 | grain per cubic metre | st | short ton | |||

ha | hectare | stpa | short ton per year | |||

hp | horsepower | stpd | short ton per day | |||

hr | hour | t | metric tonne | |||

Hz | hertz | tpa | metric tonne per year | |||

in. | inch | tpd | metric tonne per day | |||

in2 | square inch | US$ | United States dollar | |||

J | joule | USg | United States gallon | |||

k | kilo (thousand) | USgpm | US gallon per minute | |||

kcal | kilocalorie | V | volt | |||

kg | kilogram | W | watt | |||

km | kilometre | wmt | wet metric tonne | |||

km2 | square kilometre | wt% | weight percent | |||

km/h | kilometre per hour | yd3 | cubic yard | |||

kPa | kilopascal | yr | year |

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 2-4 |

| www.rpacan.com |

3 RELIANCE ON OTHER EXPERTS

This report has been prepared by RPA for Barrick. The information, conclusions, opinions, and estimates contained herein are based on:

| ● | Information available to RPA at the time of preparation of this report; and |

| ● | Assumptions, conditions, and qualifications as set forth in this report. |

For the purpose of this report, RPA has relied on ownership information provided by Barrick. The properties and mineral rights are owned or controlled through ownership of various forms of patents issued by the USA and by ownership of unpatented mining and millsite claims held subject to the paramount title of the USA. RPA has not researched property title or mineral rights for the Goldstrike Mine and expresses no opinion as to the ownership status of the property.

RPA has relied on Barrick for guidance on applicable taxes, royalties, and other government levies or interests, applicable to revenue or income from the Goldstrike Mine.

Except for the purposes legislated under provincial securities laws, any use of this report by any third party is at that party’s sole risk.

Barrick Gold Corporation – Goldstrike Mine, Project # 3078 Technical Report NI 43-101 – March 22, 2019 | Page 3-1 |

| www.rpacan.com |

4 PROPERTY DESCRIPTION AND LOCATION

The Goldstrike Mine property is located within the northern Carlin Trend on the western flank of the Tuscarora Mountains in Eureka and Elko Counties, north central Nevada, USA, approximately 38 mi northwest of Elko and 25 mi north-northwest of the town of Carlin. The Goldstrike Mine lies within Township 36 North and Ranges 49 & 50 East MDM. The administration building is located at approximately 40º58.389 N 116º21.149 W NAD 27 (Figure4-1).