Exhibit 99.1

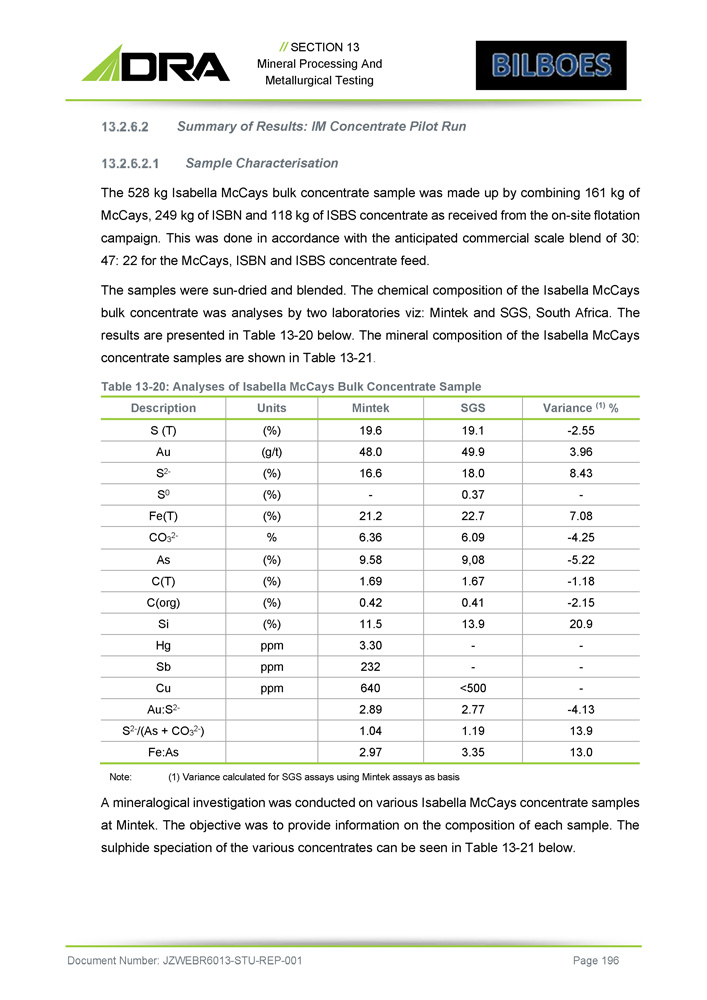

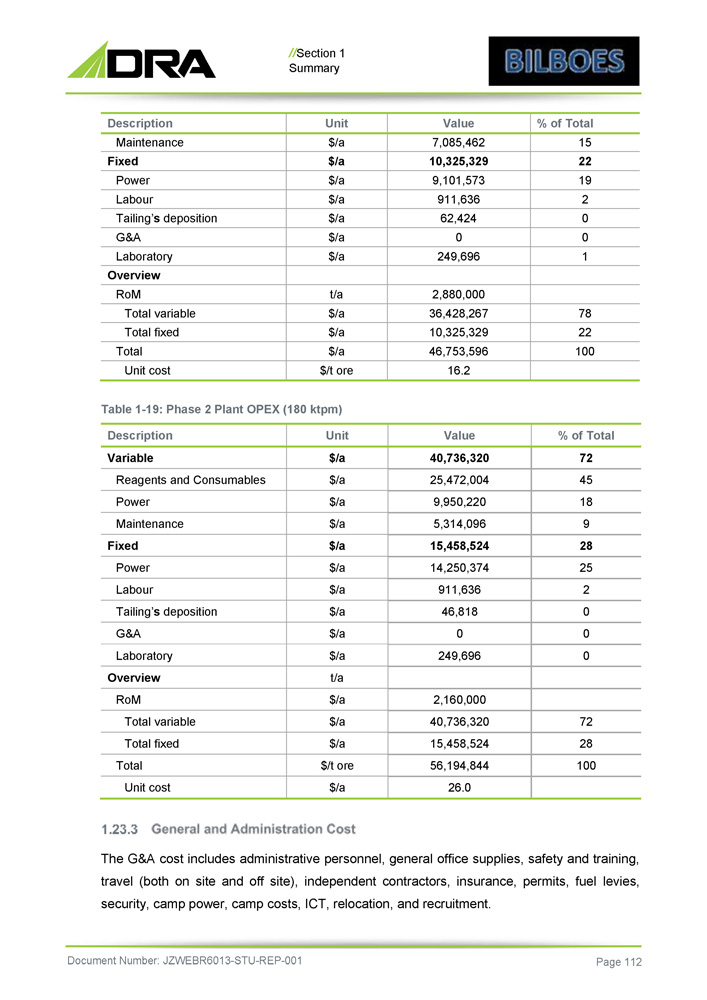

BILBOES GOLD PROJECT FEASIBILITY STUDY NATIONAL INSTRUMENT 43 - 101 TECHNICAL REPORT - PREPARED BY DRA PROJECTS (PTY) LIMITED BILBOES GOLD PROJECT Document Number: JZWEBR6013 - STU - REP - 001

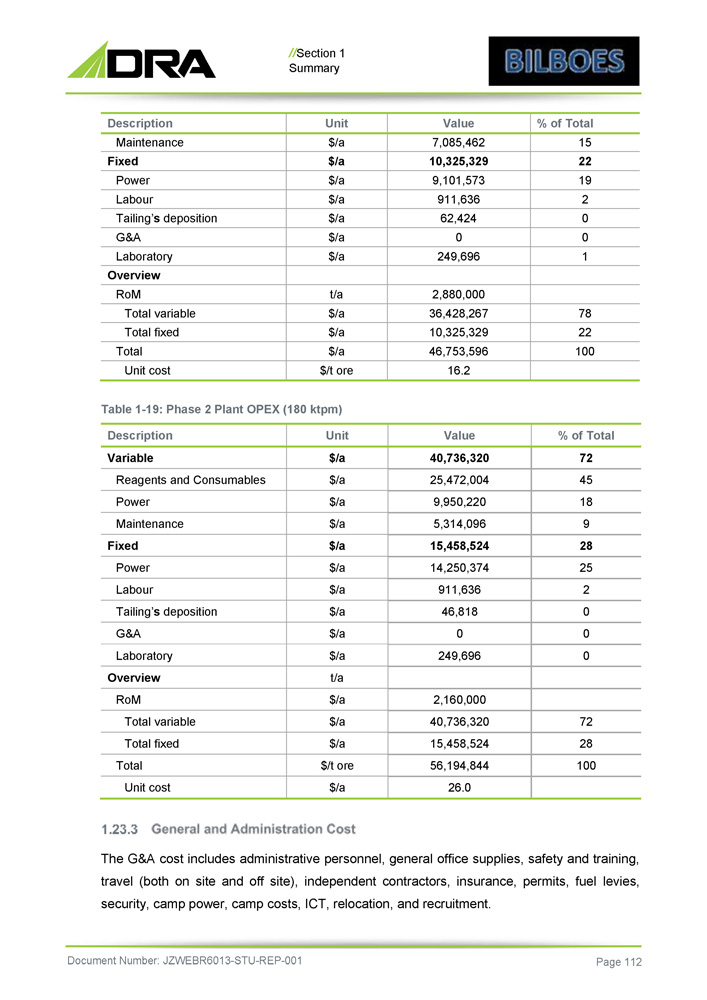

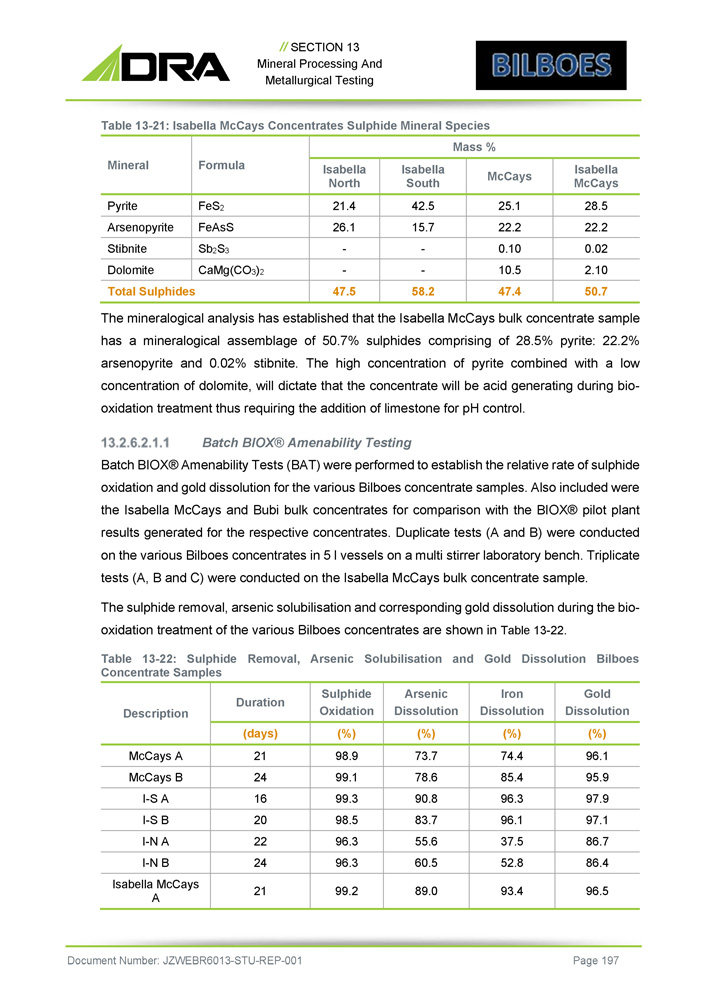

BILBOES GOLD PROJECT FEASIBILITY STUDY SIGNATURES PAGE Document Number: JZWEBR6013 - STU - REP - 001

// Signatures Page Document Number: JZWEBR6013 - STU - REP - 001 - Page 3 QUALIFIED PERSONS Effective Date: 15 December 2021 Qualified Person: Sivanesan (Desmond) Subramani, B.Sc. Hons (Geology), Pr. Sci. Nat Qualified Person: J Mungoshi, NHD (Metallurgy), BSc Eng (Hons) (Metallurgy), MDP (Mining), MBL, Pr. Eng Qualified Person: JW Olivier, B.Eng. (Hons) (Metallurgy), B.Eng. (Hons) (Technology Management) Qualified Person: D Thompson, B - Tech (Mining), Pr. Cert. Eng Qualified Person: J Gemmell BSc, Pr Eng,

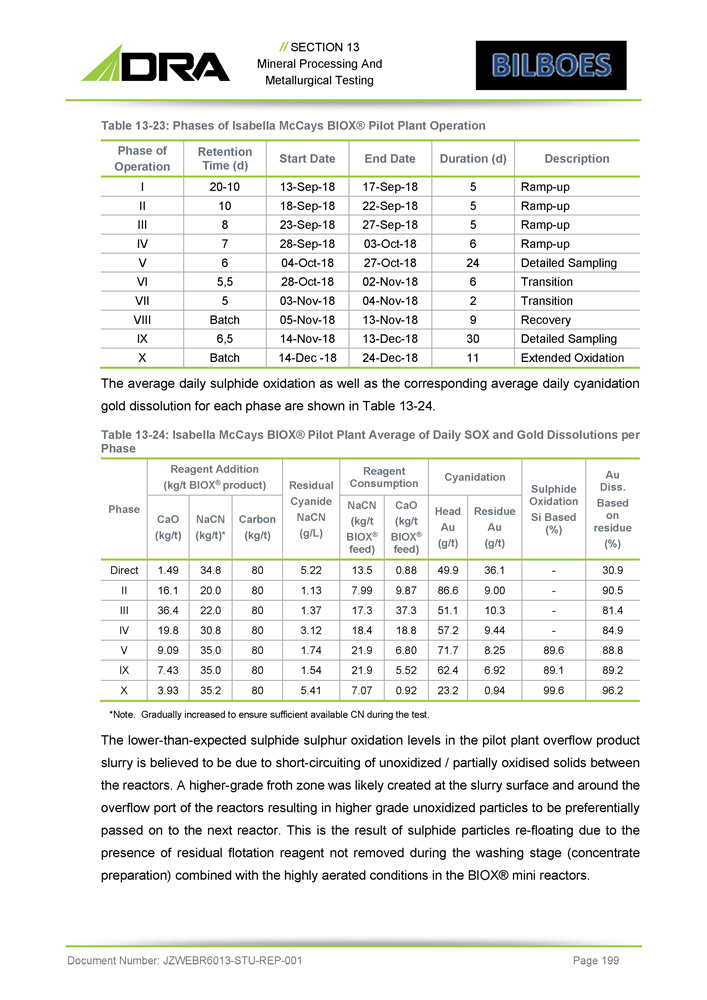

// Signatures Page IMPORTANT NOTICE This notice is an integral component of the Bilboes Gold Project BGP 2021 of the BGP 2021 FS. The BGP 2021 FS has been prepared using the Canadian National Instrument 43 - - The BGP 2021 FS has been prepared for Bilboes Holdings (Private) Limited Bilboes Consultants represented in this document as the Report contributors. The BGP 2021 FS is based on information and data supplied to the Report Contributors by Bilboes and other parties. The quality of information, conclusions, and estimates contained herein are consistent with the level of effort involved in the services of the Report Contributors, based on: Information available at the time of preparation. Data supplied by outside sources; and The assumptions, conditions, and qualifications set forth in this report. Each portion of the report is intended for use by Bilboes subject to the terms and conditions of its contract with the Report Contributors. Except for the purposes legislated under Canadian provincial and territorial securities law, any other use of the report, by any third party, is at that cognising that Bilboes has legal and regulatory obligations, the Report Contributors have consented to the filing of the BGP 2021 FS with Canadian Securities The results of the BGP 2021 FS represent forward - looking information . The forward - looking information includes metal price assumptions, cash flow forecasts, projected capital and operating costs, metal recoveries, mine life and production rates, and other assumptions used in the BGP 2021 FS . Readers are cautioned that actual results may vary from those presented . The factors and assumptions used to develop the forward - looking information, and the risks that could cause the actual results to differ materially are presented in the body of this report under each relevant section . The conclusions and estimates stated in the BGP 2021 FS are to the accuracy stated in the BGP 2021 FS only and rely on assumptions stated in the BGP 2021 FS . The results of further work may indicate that the conclusions, estimates, and assumptions in the BGP 2021 FS need to be revised or reviewed . The Report Contributors have used their experience and industry expertise to produce the estimates and approximations in the BGP 2021 FS . Where the Report Contributors have made those estimates and approximations, they are subject to qualifications and assumptions, and Document Number: JZWEBR6013 - STU - REP - 001 Page 4

// Signatures Page it should also be noted that all estimates and approximations contained in the BGP 2021 FS will be prone to fluctuations with time and changing industry circumstances . The BGP 2021 FS should be construed in light of the methods, procedures, and techniques used to prepare the BGP 2021 FS . Sections, or parts of the BGP 2021 FS should not be read in isolation of or removed from their original context . DATE AND SIGNATURE PAGE Bilboes Gold Project Feasibility Study , National Instrument 43 - 101 Technical Report with an effective date of 15 day of December 2021 was prepared on behalf of Bilboes by Desmond Subramani, Joel Mungoshi, Johan Waldemar Olivier, Dave Thompson, and signed : Date at Gauteng, South Africa on this 15 day of December 2021 Desmond Subramani D Subramani, B.Sc. Hons (Geology), Pr. Sci. Nat. SACNASP Date at Gauteng, South Africa on this 15 day of December 2021 JW Olivier, B.Eng. (Hons) (Metallurgy), B.Eng. (Hons) (Technology Management) Date at Gauteng, South Africa on this 15 day of December 2021 Joel Mungoshi J Mungoshi, NHD (Metallurgy), B.Sc. Eng (Hons) (Metallurgy), MDP (Mining), MBL, Pr. Eng Document Number: JZWEBR6013 - STU - REP - 001 Page 5

// Signatures Page Date at Gauteng, South Africa on this 15 day of December 2021 Dave Thompson D Thompson, B - Tech (Mining), Pr. Cert. Eng, ECSA 201190010 Date at Gauteng, South Africa on this 15 day of December 2021 James Gemmell James Gemmell, BSc, Pr Eng, Document Number: JZWEBR6013 - STU - REP - 001 Page 6

BILBOES GOLD PROJECT FEASIBILITY STUDY NATIONAL INSTRUMENT 43 - 101 TECHNICAL REPORT - PREPARED BY DRA PROJECTS(PTY) LIMITED FOR THE BILBOES GOLD PROJECT FEASIBILITY STUDY Document Number: JZWEBR6013 - STU - REP - 001

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study TABLE OF CONTENTS Document Number: JZWEBR6013 - STU - REP - 001 Page 8 1 SUMMARY 1. Introduction 2. Property Description and Location 3. Accessibility, Climate, Infrastructure and Physiography 4. History 5. Geology and Resource Estimate 1. Geological Setting and Mineralisation 6. Deposit Types 7. Exploration 8. Drilling 9. Sample Preparation, Analysis and Security 10. Data Verification 11. Metallurgical Test Work 1. Preliminary and Flotation Test Work 2. BIOX® 12. Mineral Resource Estimates 13. Open Pit Mineral Reserves 1. Pit Designs 14. Mining Strategy 15. Mine Production Schedules 1. Operating Assumptions 2. Scheduling Results 3. Production Fleets Required 4. Waste Rock Dumps 16. Plant Feed Schedules 17. Tailings Storage Facility 1. Design Standards 2. Design Criteria 18. Infrastructure and Site Layout 19. Environmental and Social 1. Environmental Studies and Potential Impacts 2. Waste, Tailings, Monitoring and Water Management 3. Project Permitting 20. Process Plant 21. Capital Costs 1. Basis of Capital Cost Estimate 35 35 35 37 37 38 38 38 38 39 39 39 40 40 47 49 51 53 56 56 57 57 58 59 61 62 62 63 71 72 72 79 83 89 91 91

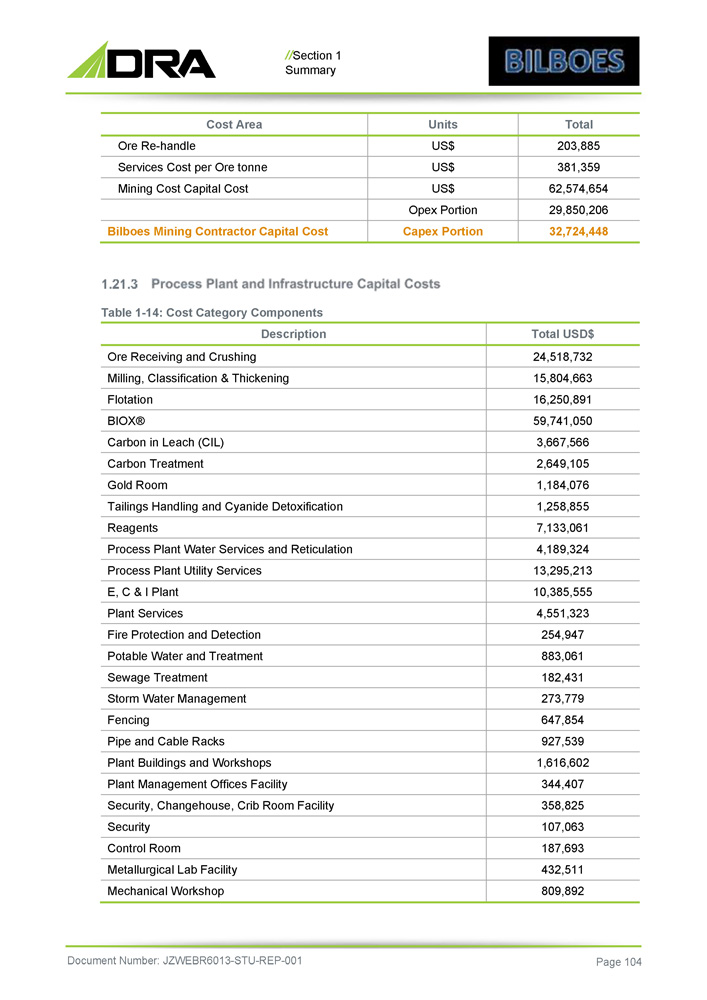

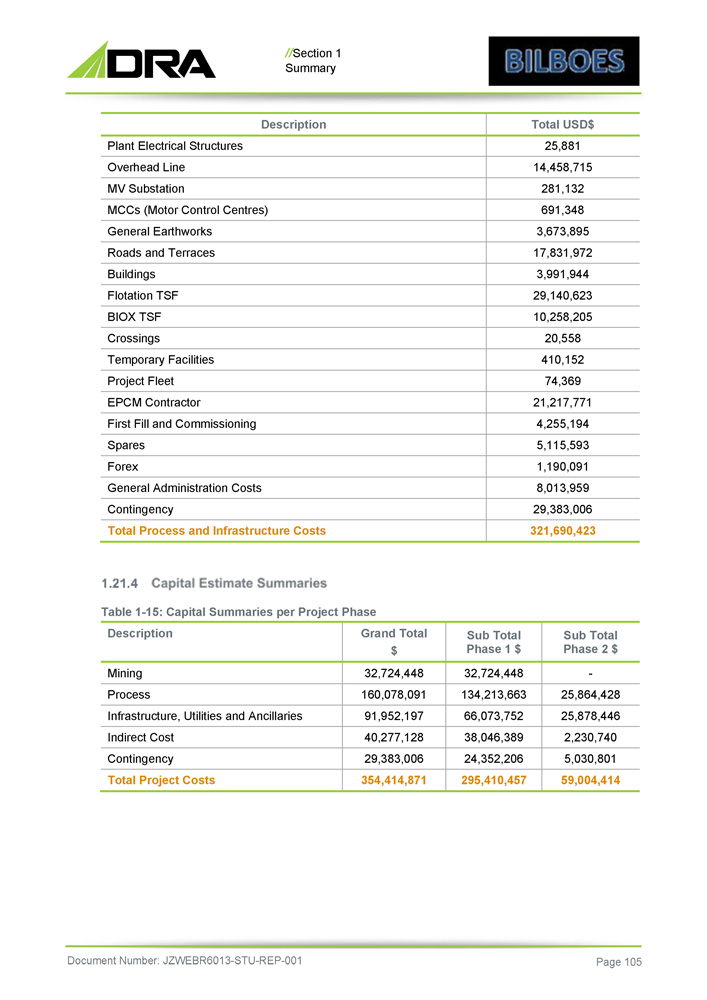

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study 2. Mine Capital Costs 3. Process Plant and Infrastructure Capital Costs 4. Capital Estimate Summaries 5. Cash Flow 6. Stay in Business Operating Cost Estimate 7. Exclusions and Assumptions 8. Risks and Opportunities to Capital Estimate 22. Cash Flow 23. Operating Costs 1. Mining Operating Costs 2. Process Plant Operating Cost 3. General and Administration Cost 4. Bilboes Gold Project Total Operating Costs Summary 24. Economic Outcomes 25. Project Development 26. Recommendations 1. Mining 2. Processing 3. Economic Analysis 4. Project 2 INTRODUCTIONS 1. The Issuer 2. Technical Team 3. Terms of Reference and Purpose 4. Sources of Information 5. Personal Inspections / Site Visits 3 RELIANCE ON OTHER EXPERTS 4 PROPERTY DESCRIPTION AND LOCATION 1. Zimbabwe Overview 1. Country Overview 2. Government Policy and Outlook Regarding the Mining Industry 2. Project Location 3. Property Area 4. Mineral Tenure and Title 5. Royalties 6. Permits 7. Encumbrances and Environmental Liabilities Document Number: JZWEBR6013 - STU - REP - 001 Page 9 103 104 105 106 107 107 108 109 109 110 111 112 113 113 114 114 115 115 115 115 117 117 117 117 118 118 120 122 122 122 123 123 124 124 126 126 127

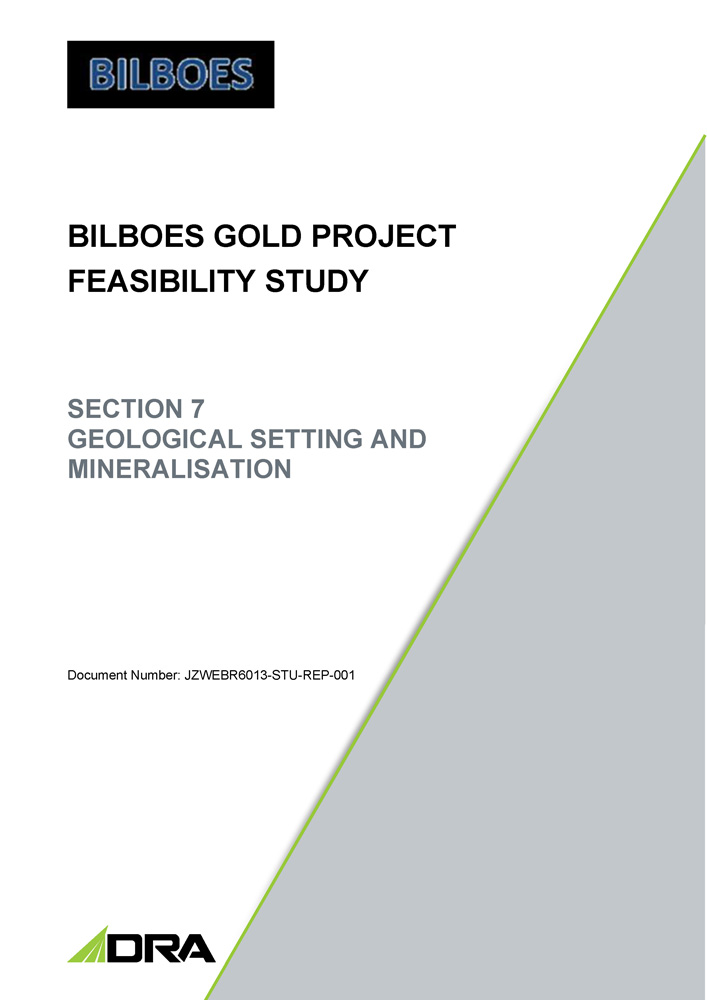

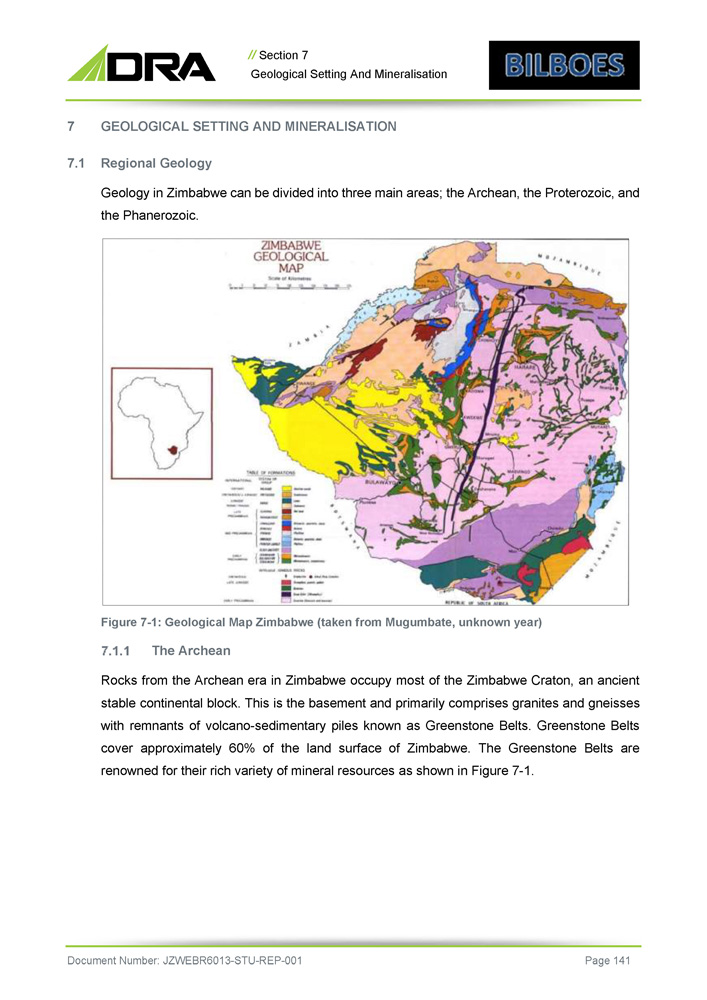

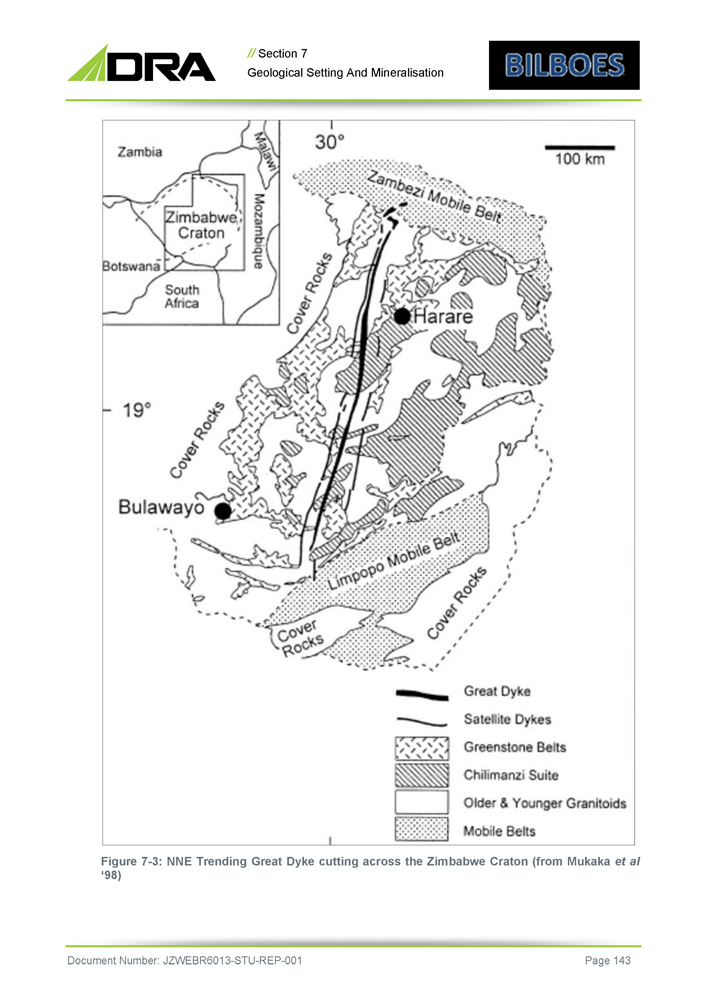

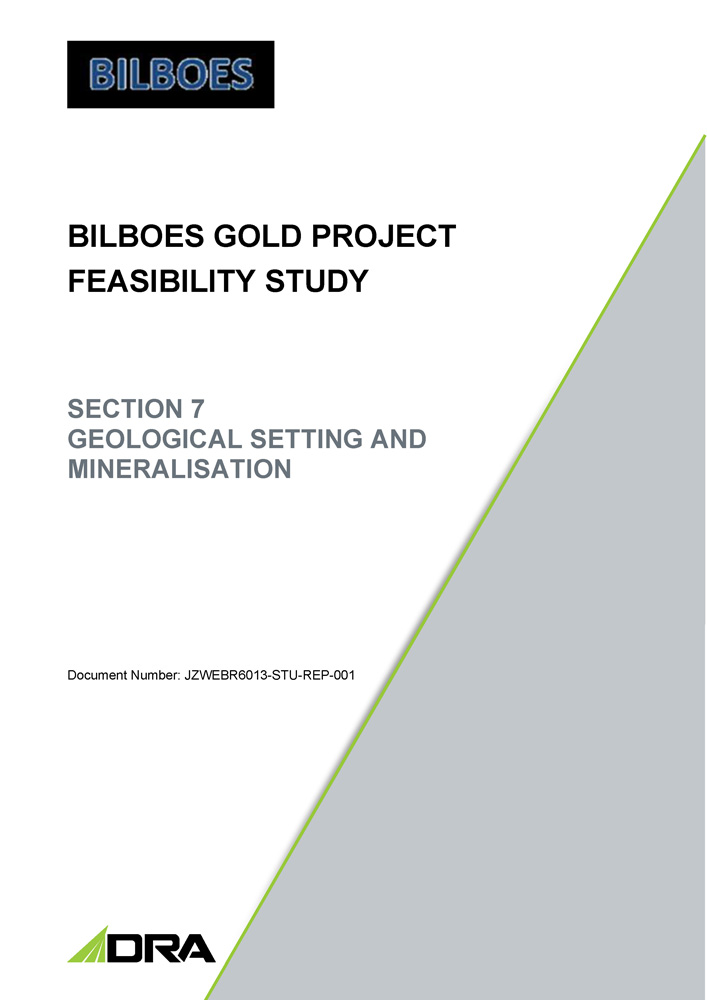

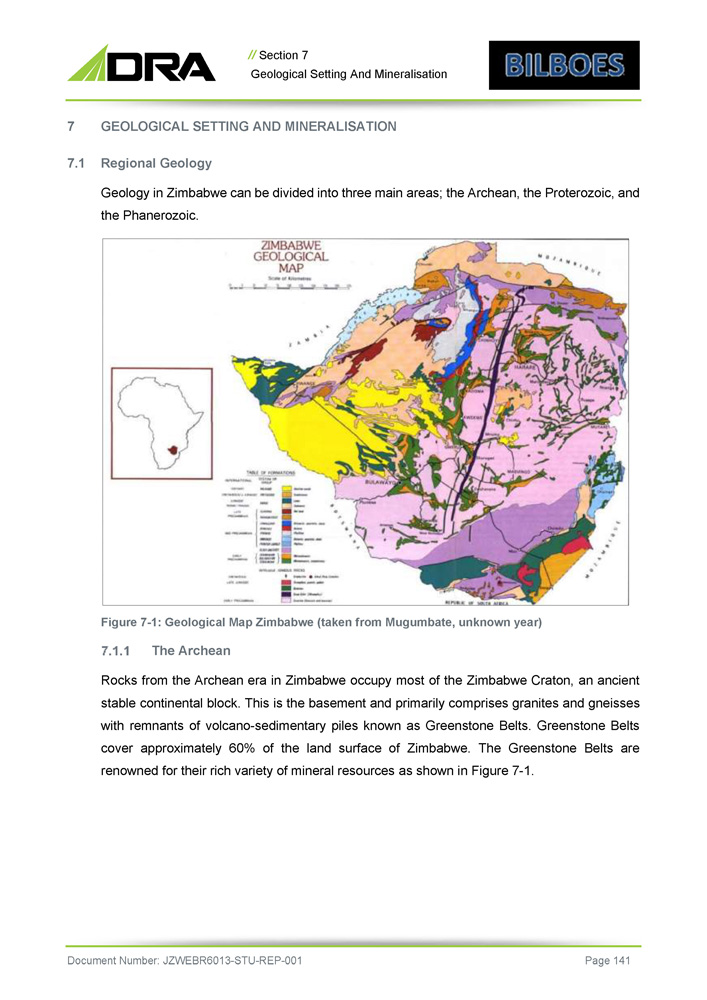

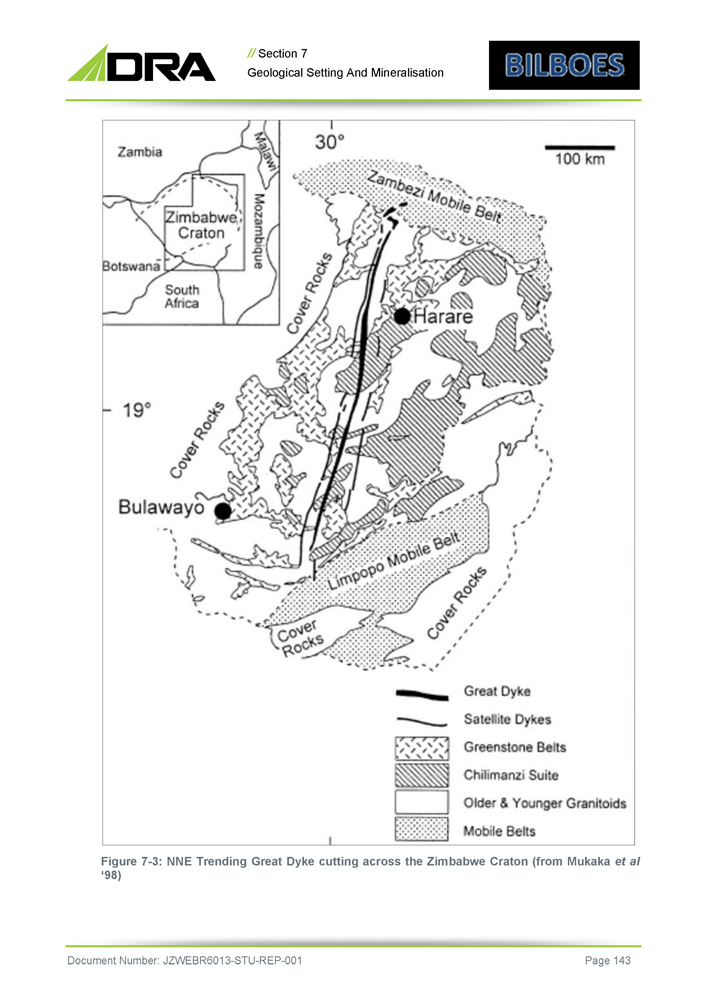

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study 5 Document Number: JZWEBR6013 - STU - REP - 001 Page 10 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES 129 INFRASTRUCTURE AND PHYSIOGRAPHY Access Physiography Climate Local Resources and Infrastructure HISTORY Oxide Mineralisation Isabella Bubi McCays Sulphide Exploration Sulphide Resources Historical Logging and Sampling Procedure 5.1 5.2 5.3 5.4 6 6.1 6.2 6.3 6.4 6.5 6.6 6.6.1 6.6.2 Historical Sulphide Mineral Resource Estimates 6.7 Production 7 GEOLOGICAL SETTING AND MINERALISATION 1. Regional Geology 1. The Archean 2. The Proterozoic 3. The Phanerozoic 7.2 Regional Geology as it Relates to the Bilboes Properties 8 DEPOSIT TYPES 9 EXPLORATIONS 1. Geological Mapping 2. Trenching 3. Ground Geophysical Surveying 4. Prospecting and Sampling 10 DRILLING 11 SAMPLE PREPARATION, ASSAY AND ANALYTICAL SECURITY 1. QA / QC 1. Blank 2. Standards 3. Duplicates 4. Umpire Labs 11.2 Security 12 DATA VERIFICATION 13 METALLURGICAL TEST WORK 129 129 129 129 132 132 132 133 133 133 135 135 136 139 141 141 141 142 144 145 148 150 150 151 151 152 154 156 156 156 158 161 162 163 166 168

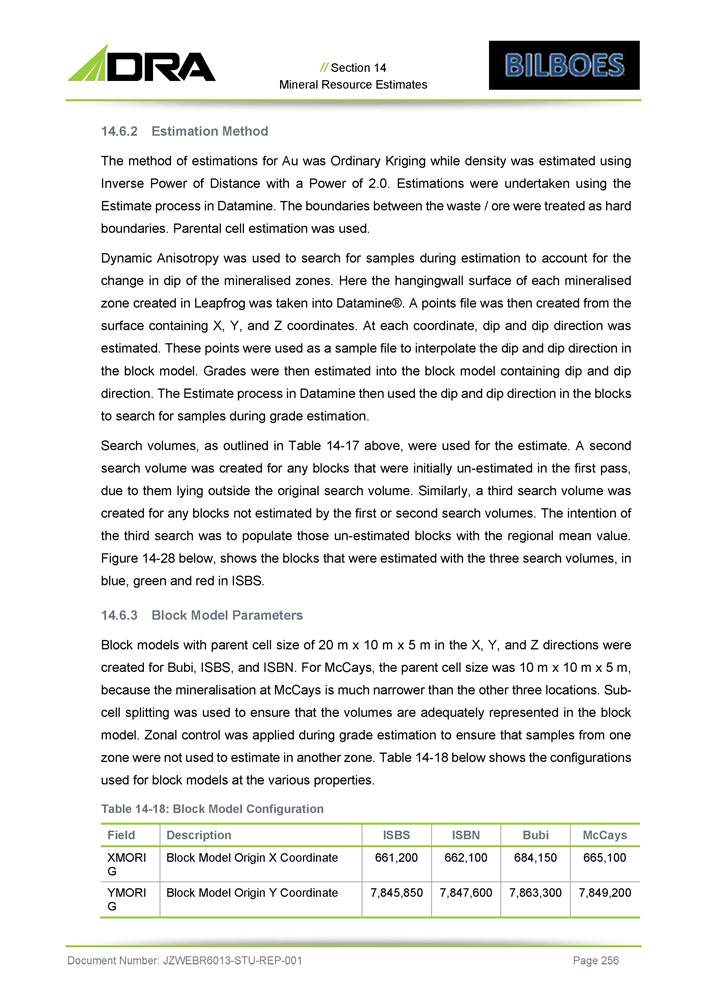

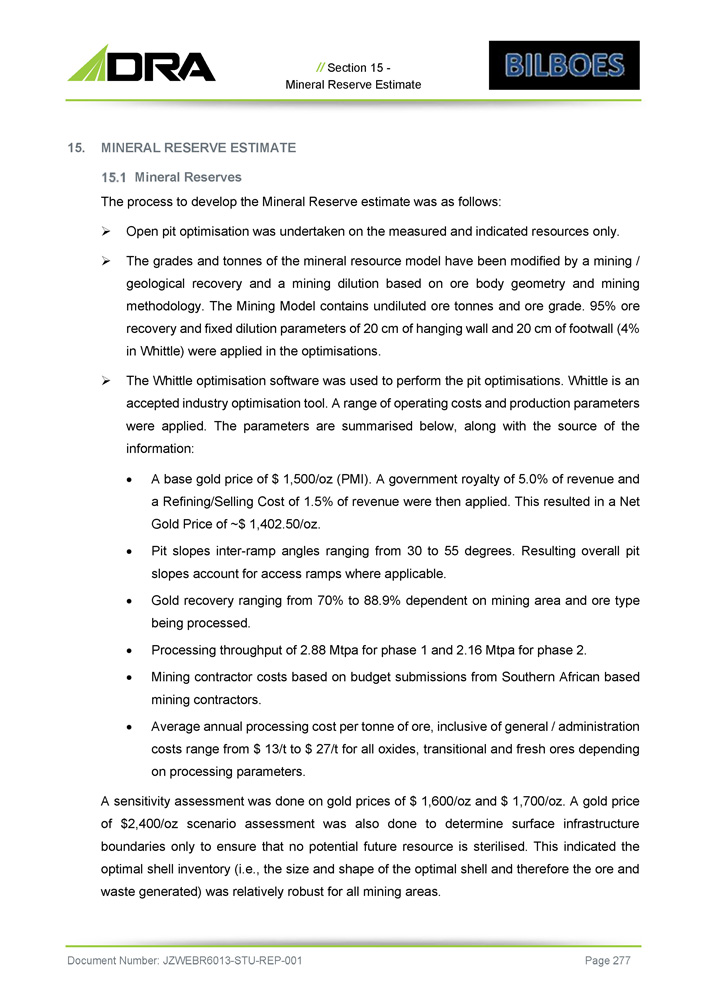

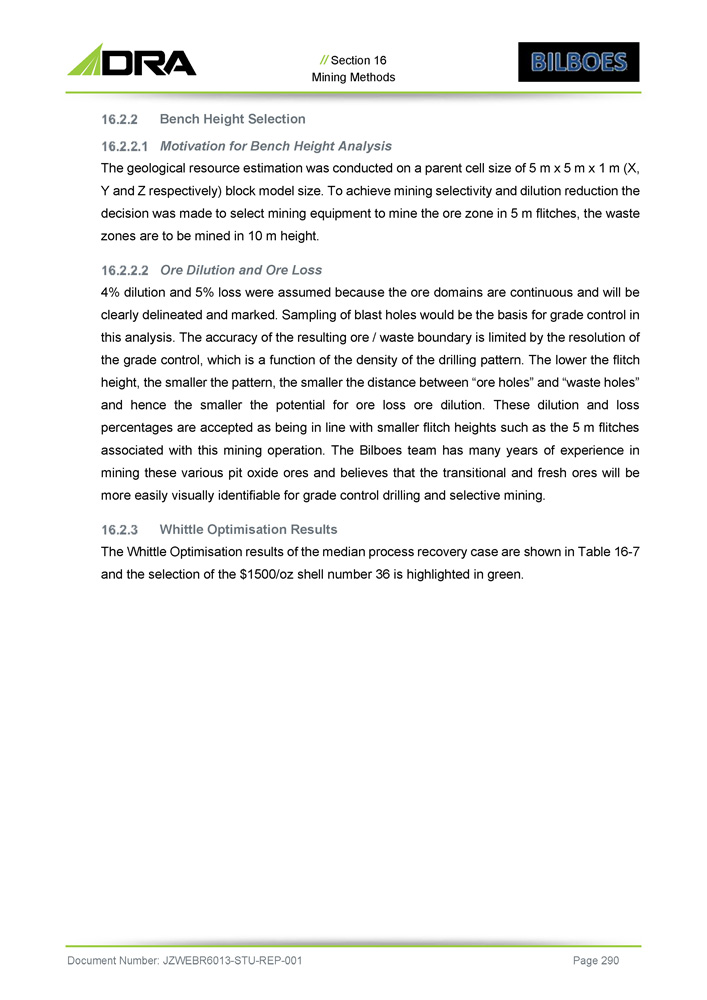

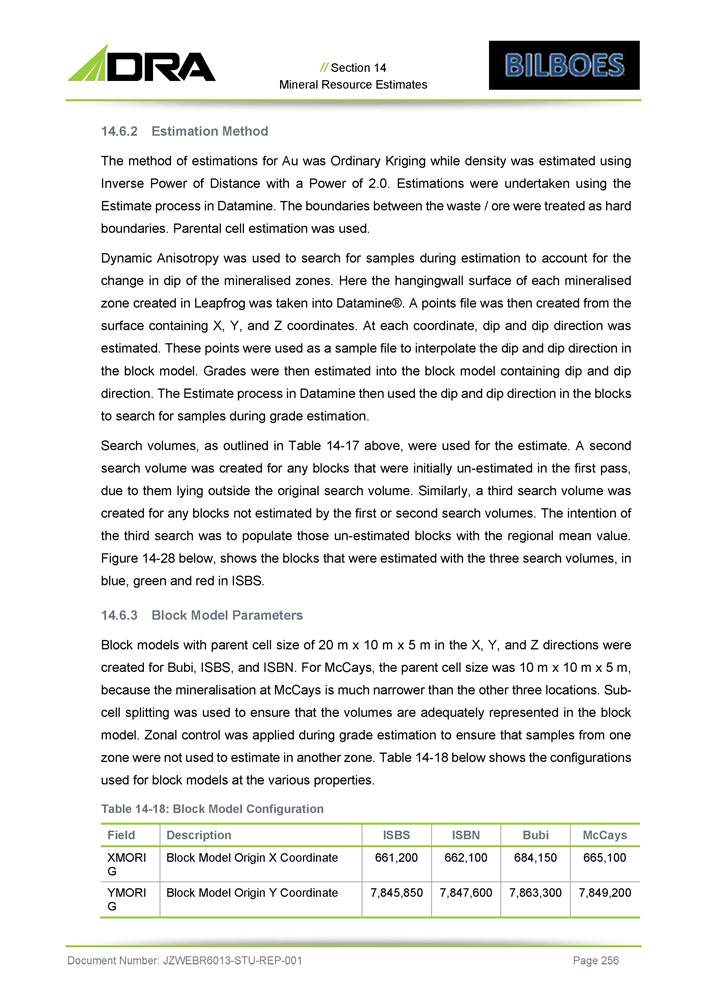

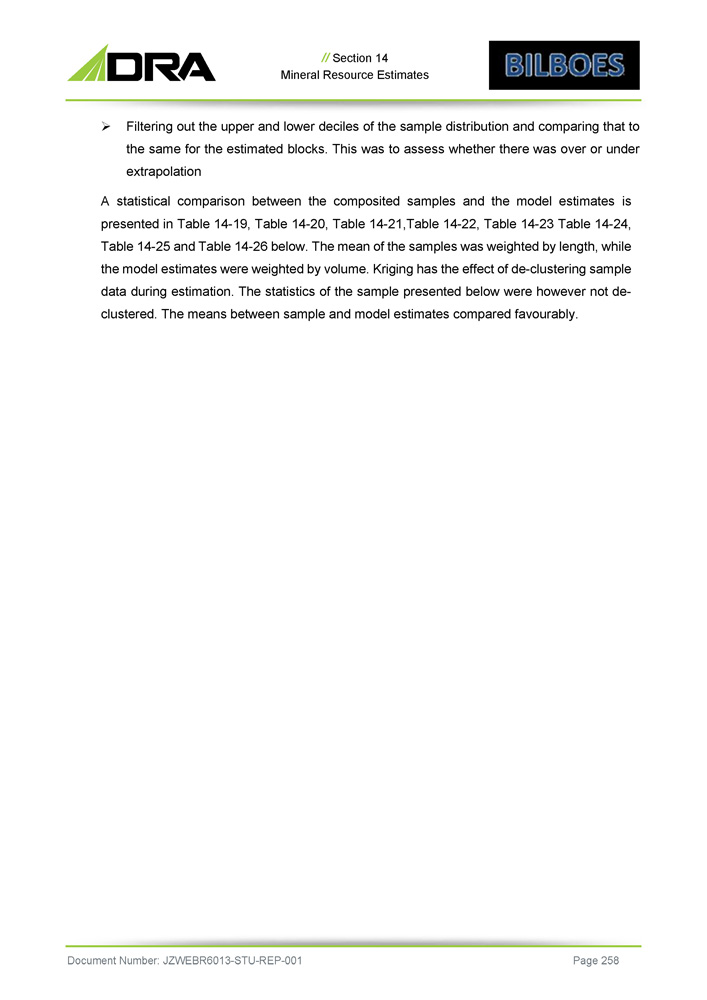

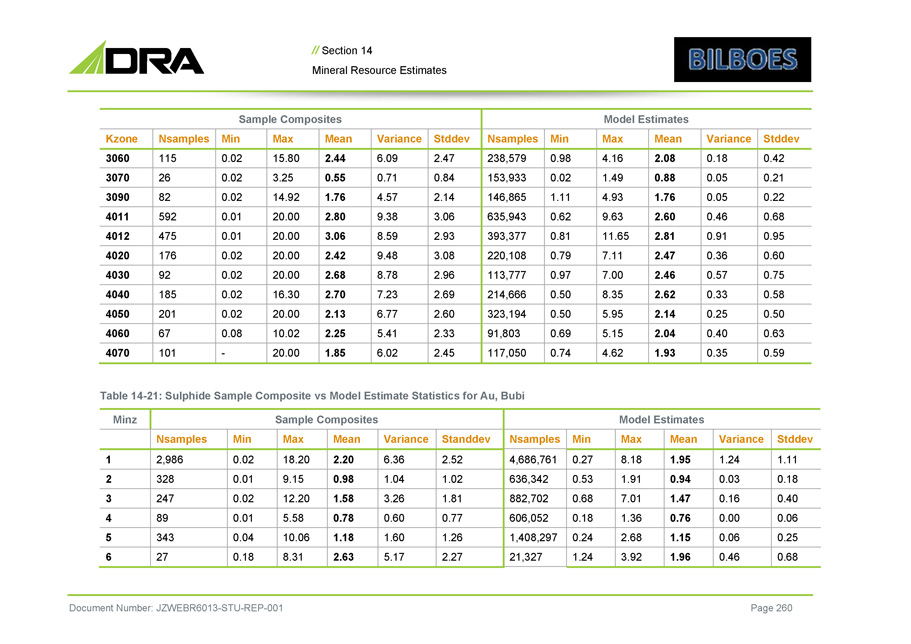

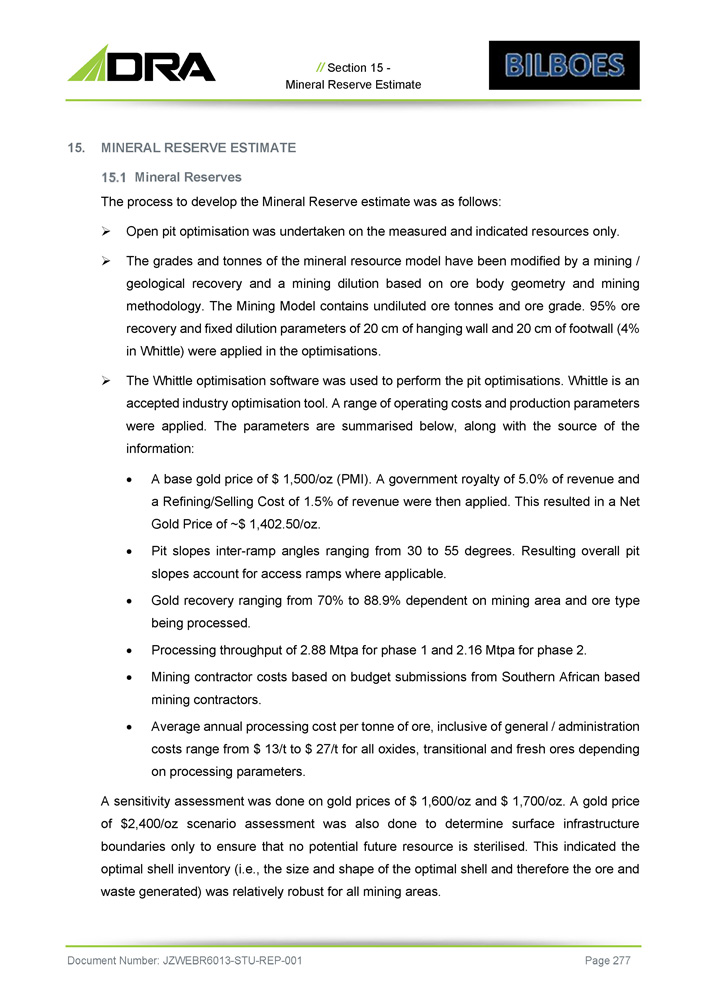

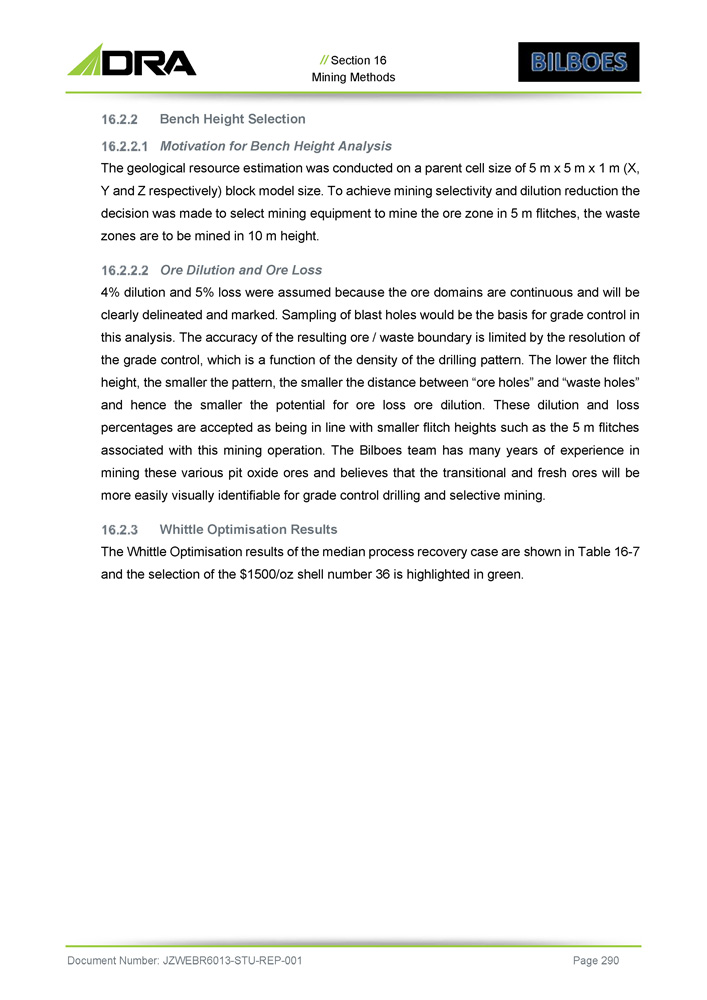

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study 1. Introduction 2. Metallurgical Testwork and Discussion 1. Comminution and Flotation Test Work Campaign 2. Laboratories 3. Consultants 4. Flotation Residence Times 5. Projected Operational Gold Recovery 6. BIOX® Testwork Campaign 14 MINERAL RESOURCE ESTIMATES 1. Geological Database 1. Topography 2. Drill Holes 3. Density 2. Geological Model on which the Grade Estimate is based 1. Geological Interpretation and Ore Zonation 2. Weathering and Oxidation 3. Compositing 1. Composited Statistics 4. Variography 5. Top Capping 6. Grade Estimation 1. Krige Neighbourhood Analysis 2. Estimation Method 3. Block Model Parameters 7. Model Validations 8. Resource Classification 9. Mineral Resource Tabulation 15. MINERAL RESERVE ESTIMATE 1. Mineral Reserves 2. DRA Comments 16 MINING METHODS 1. Introduction 2. Mine Design and Operation 1. Optimisation Parameters 2. Bench Height Selection 3. Whittle Optimisation Results 4. Optimisation Sensitivities 5. General Document Number: JZWEBR6013 - STU - REP - 001 Page 11 168 168 168 168 168 191 191 194 219 219 219 220 224 232 232 241 241 242 247 247 249 249 256 256 257 269 271 277 277 278 281 281 282 282 291 291 293 295

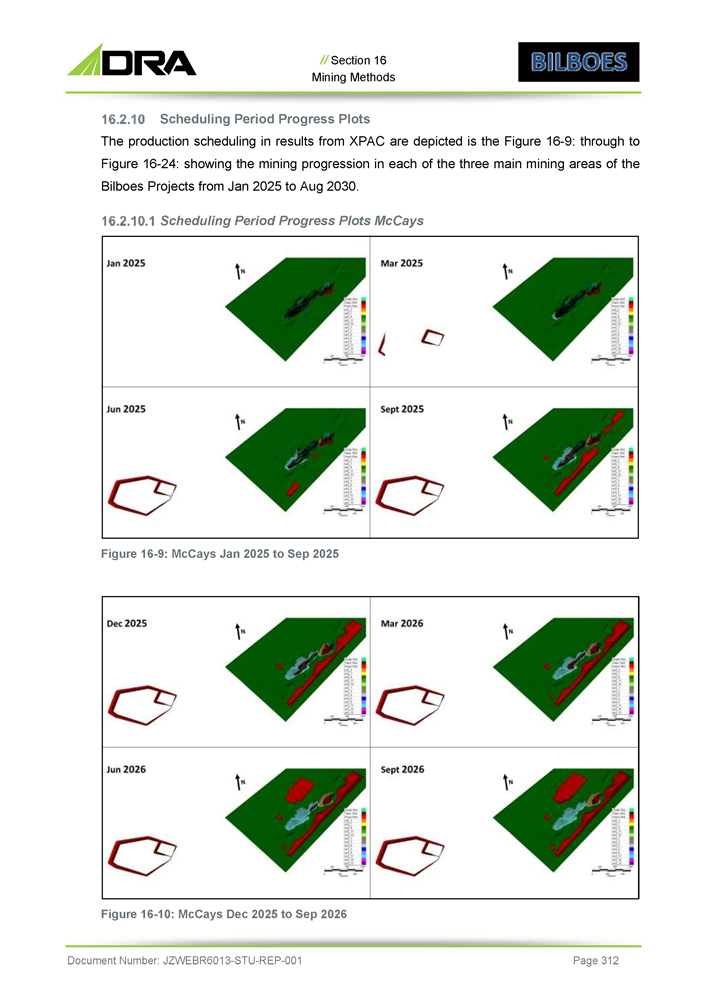

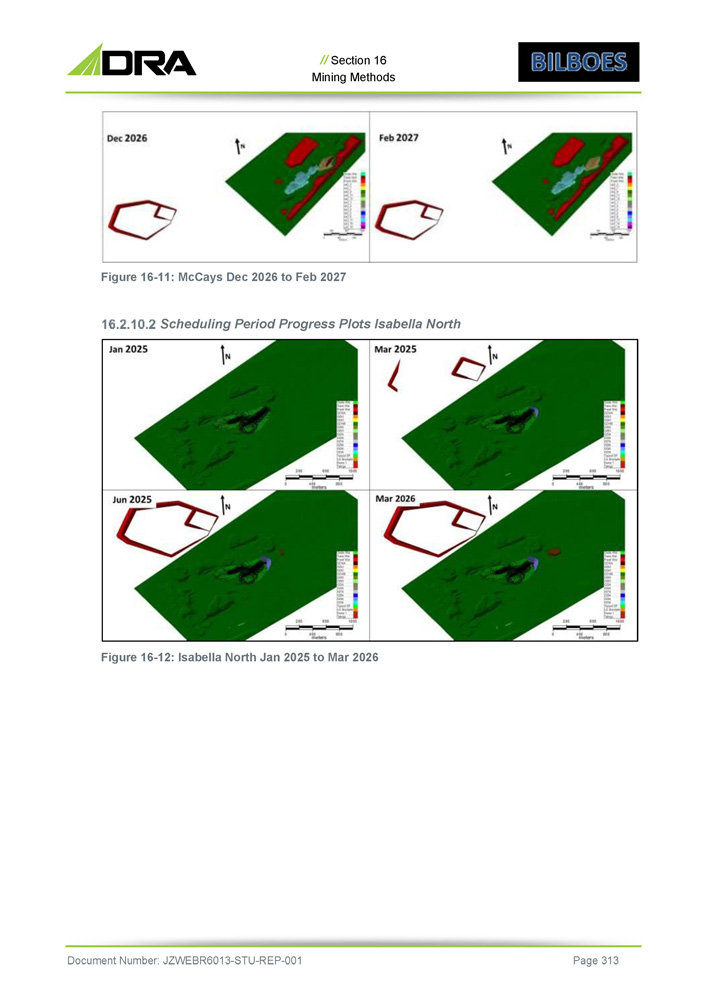

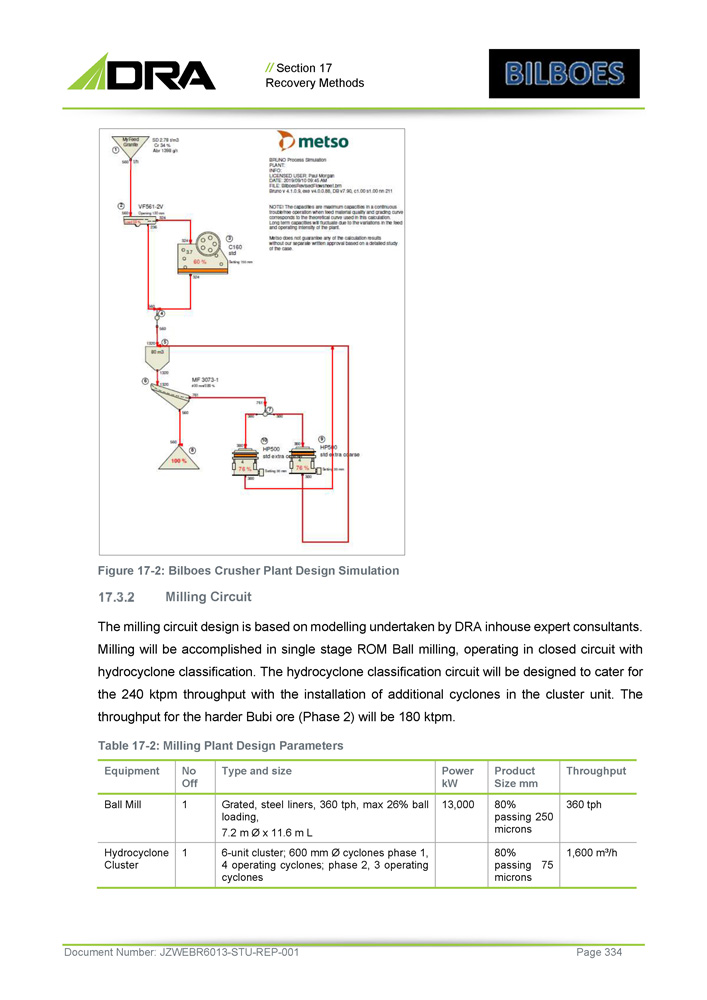

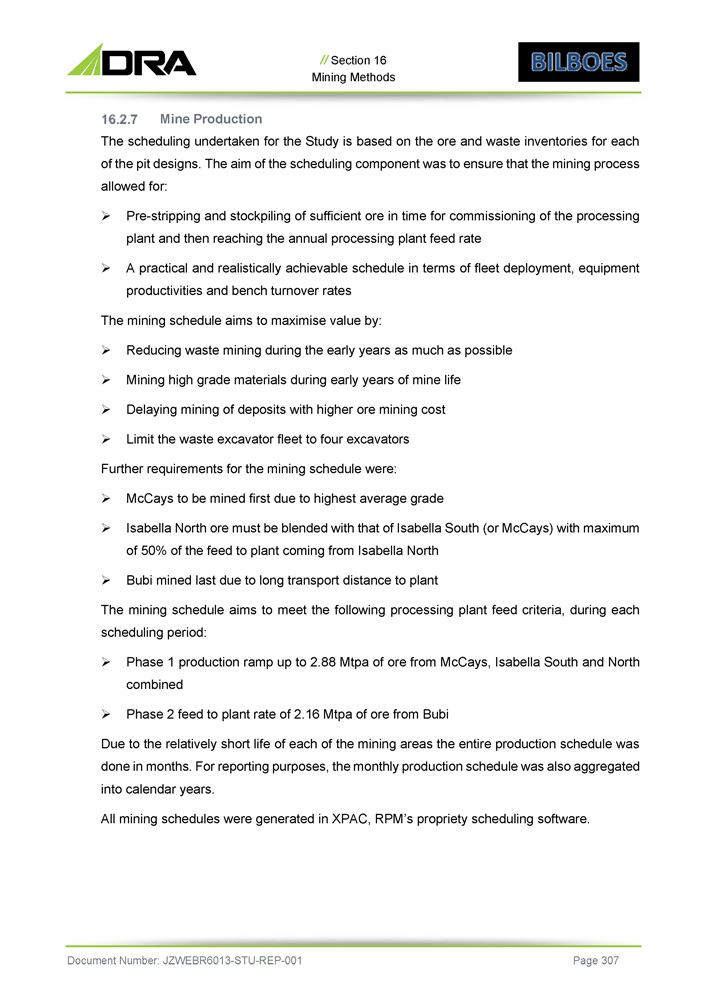

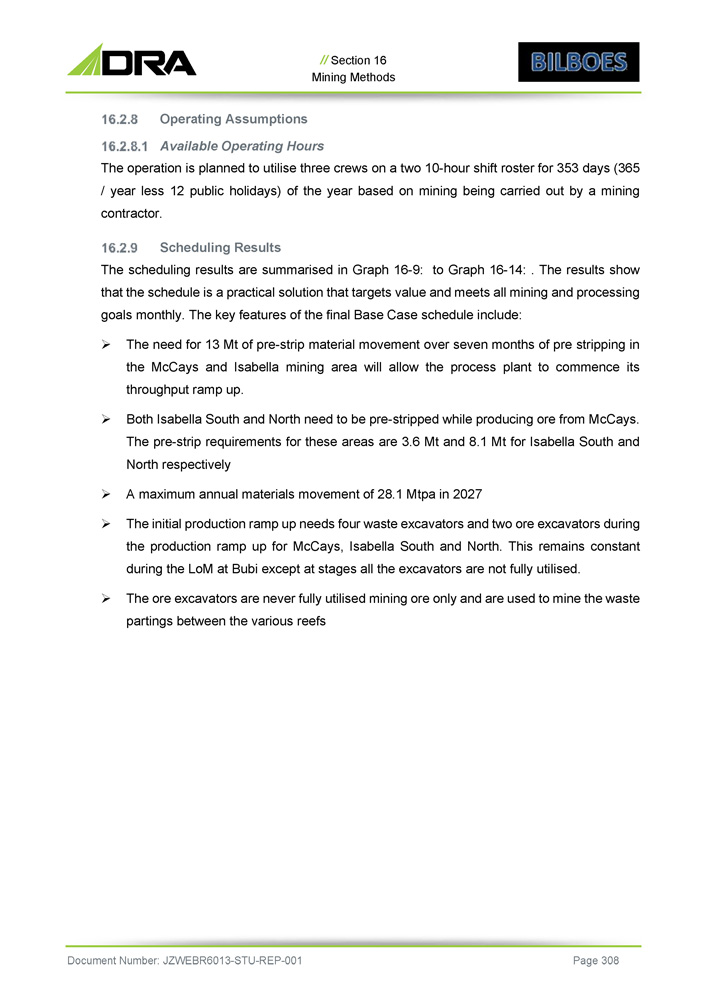

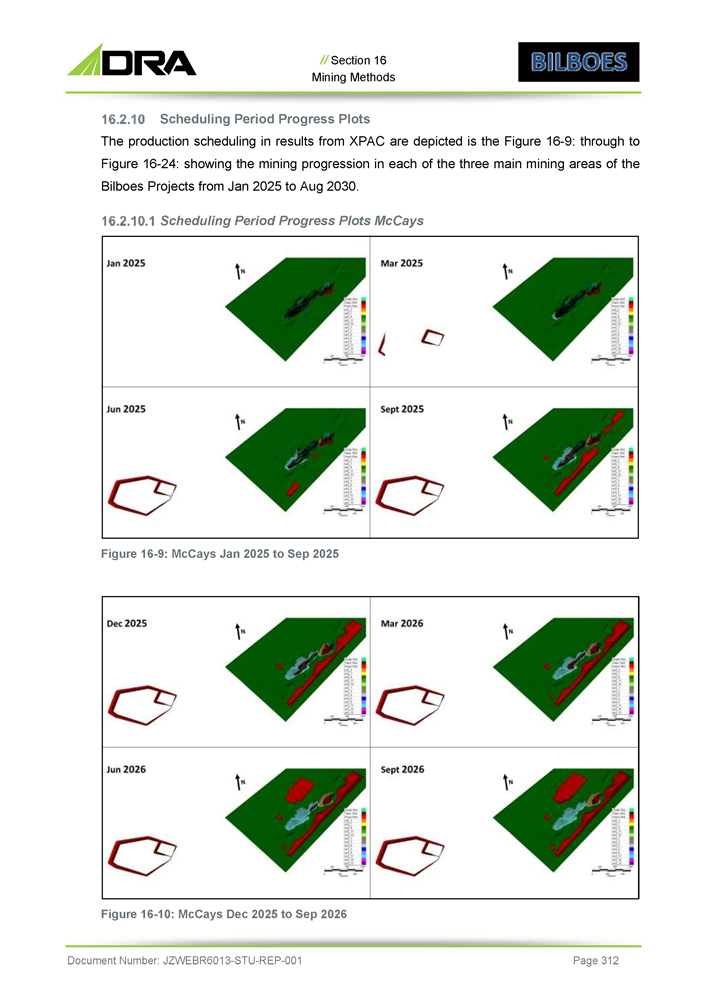

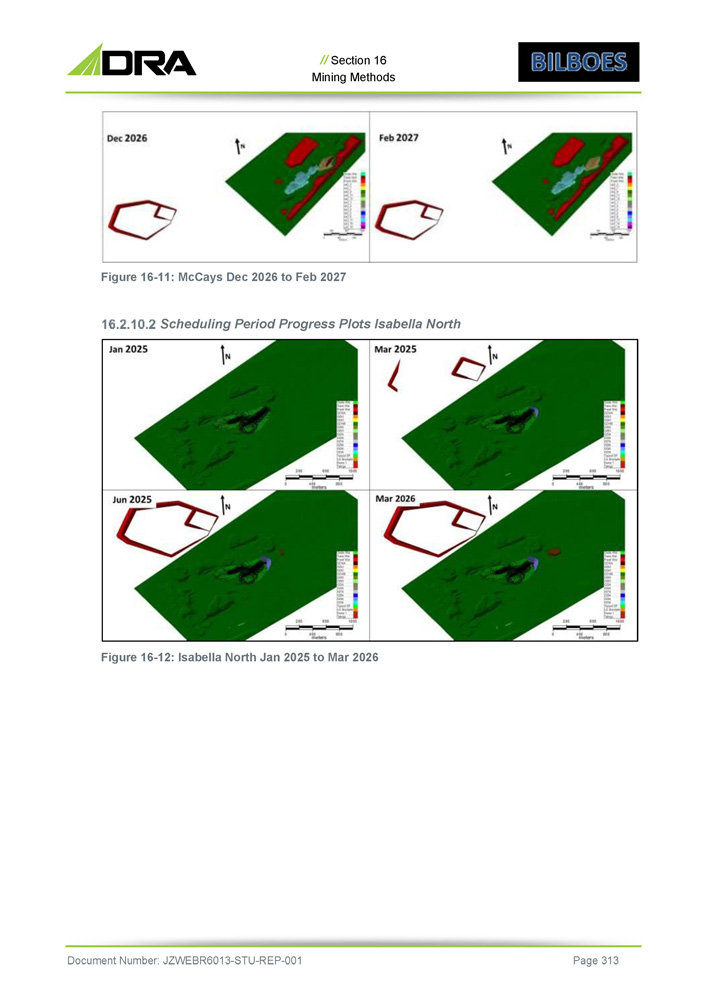

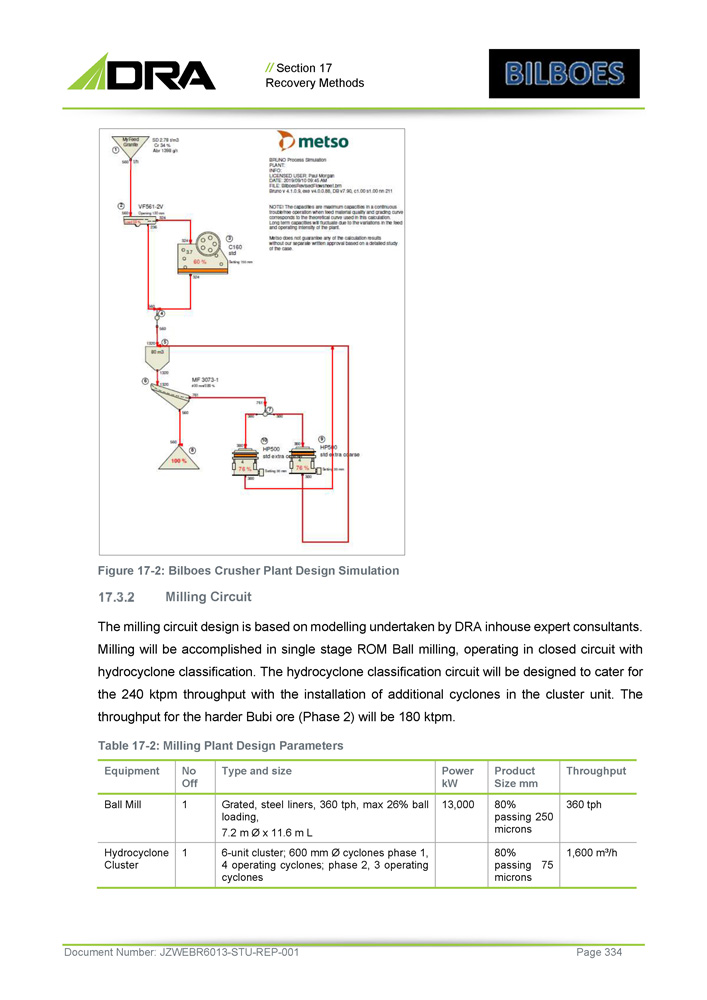

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study 302 16.2.6 Mine Design 308 16.2.7 Mine Production 309 16.2.8 Operating Assumptions 309 16.2.9 Scheduling Results 313 16.2.10 Scheduling Period Progress Plots 322 16.2.11 Fleet Requirements 322 16.2.12 Equipment Size 323 16.2.13 Excavator Productivity 323 16.2.14 Waste Rock Dumps 327 17 RECOVERY METHODS 327 17.1 Process Testwork Results 328 17.2 Process Flow Description 329 17.2.1 Comminution 330 17.2.2 Flotation 330 17.2.3 Biological Oxidation (BIOX®) 332 17.2.4 Carbon in Leach (CIL) 332 17.2.5 Carbon Treatment 333 17.2.6 Electrowinning and Smelting 334 17.2.7 Tailings Handling 334 17.3 Plant Design 334 17.3.1 Crushing Circuit 335 17.3.2 Milling Circuit 337 17.3.3 Biological Oxidation Circuit 338 17.3.4 Carbon in Leach (CIL) Circuit 338 17.3.5 Tailings Detoxification and Handling 339 17.3.6 Carbon Treatment 340 17.4 Water Services 341 17.4.1 Raw Water 341 17.4.2 Process Water 341 17.4.3 Fire Water 342 17.4.4 BIOX® Water 342 17.4.5 Potable Water 342 17.5 Reagent Services 343 17.6 Plant Energy Requirements 343 17.7 Process Control Philosophy Summary 349 18 PROJECT INFRASTURCTURE 346 18.1 Geotechnical Scope 346 18.1.1 Mining – Open Pit Geotechnical Investigation and Design Document Number: JZWEBR6013 - STU - REP - 001 Page 12

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study 18.1.2 Civil – Site Geotechnical Investigation for Process Plat, Tailings Storage 350 Facility and Waste Rock Dumps Sites 2. Tailings Storage Facility 1. Introduction 2. Design Standards 3. Design Criteria 4. Site Geotechnical Investigation 5. Tailings Physical Characterisation 6. Tailings Chemical Characterisation 3. Civil Engineering and Earthworks 1. Infrastructure Capital 2. General Design and Measurement Development Methodology 3. Project Specific Design and Measurement Development Methodology 4. Assumptions 4. Mechanical Engineering 1. Engineering Design Criteria Applied 2. Basis of Mechanical Designs 3. Mechanical Equipment Sourcing and OEM’s 4. Mechanical Issues of Importance 5. Electrical Power Supply and Reticulation (including Communications) 1. Interconnection to National Grid 2. Basis of Design 3. Power Requirements 4. Emergency Power 5. MV Distribution 6. Power Factor Correction 7. Motor Control Centres 8. Earthing and Lighting Protection 9. LV Motors 10. Substation Building and Transformers Enclosures 11. Fire Protection 12. Racking and Steelwork 13. Cables 14. Lighting and Small Power 15. Control and Instrumentation 16. PLC Allowance 17. SCADA Control System 18. Level of Automation Document Number: JZWEBR6013 - STU - REP - 001 Page 13 356 356 356 357 358 360 361 369 369 370 370 378 379 379 379 380 380 381 381 381 382 383 383 383 383 384 384 385 385 385 386 386 387 387 387 387

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study 388 18.5.19 Process Network Communication 388 18.5.20 Solar Plant 389 18.6 General Infrastructure 390 18.7 Water Management Infrastructure 390 18.7.1 Water Balance 411 18.7.2 Ground Water 419 18.8 Sewage Management 420 18.9 Project Execution 420 18.9.1 Project Execution Plan 455 18.9.2 Project Retrospectives 462 18.9.3 High Level Project Master Schedule 462 18.9.4 Project Execution Schedule 464 19 MARKET STUDIES AND CONTRACTS 464 19.1 Category A - Outright Purchase 464 19.2 Category B - Part Payment and Final Payment after a week 466 OR 20 ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL COMMUNITY IMPACT 466 20.1 Environmental Studies and Potential Impacts 466 20.1.1 Summary of Environmental Studies 470 20.1.2 Environmental Issues 473 20.2 Waste, Tailings, Monitoring and Water Management 473 20.2.1 Tailings Management and Disposal 474 20.2.2 Waste Rock Management and Disposal 475 20.2.3 Non - Mineralised Waste Management 475 20.2.4 Site Environmental Monitoring 476 20.2.5 Water Management 477 20.3 Project Permitting 477 20.3.1 Project Permits 477 20.4 Social and Community Related Requirements and Plans 471 20.4.1 Livelihoods Restoration Plan 478 20.4.2 Community Development Plan 478 20.4.3 Labour, Working Condition and Recruitment Policy 479 20.4.4 Skills and Small Business Development 479 20.4.5 Stakeholder Engagement Plan and External Grievance Mechanism 480 20.4.6 Social / Community Issues 481 20.5 Mine Closure 482 20.6 Estimated Environmental Costs for Closure 482 20.7 Schedule for obtaining the Operating License Document Number: JZWEBR6013 - STU - REP - 001 Page 14

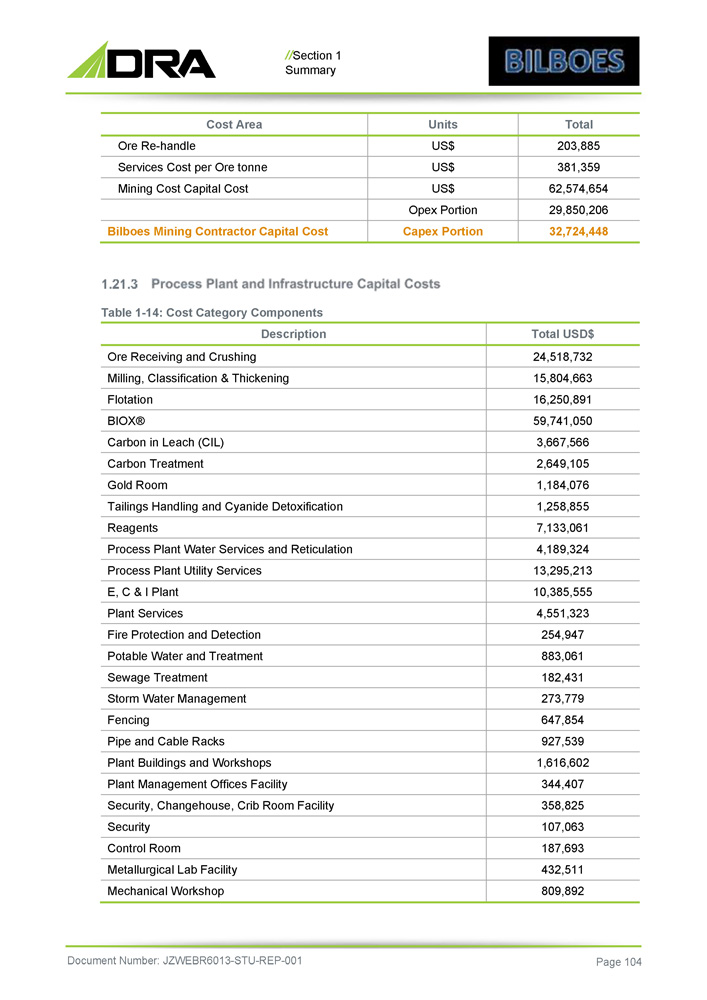

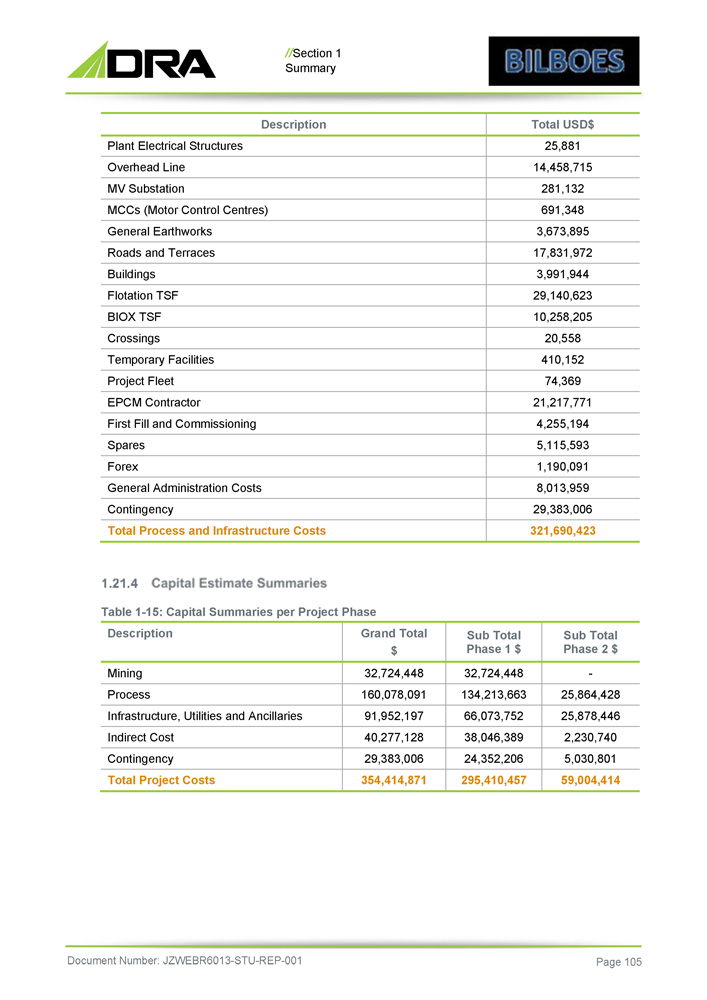

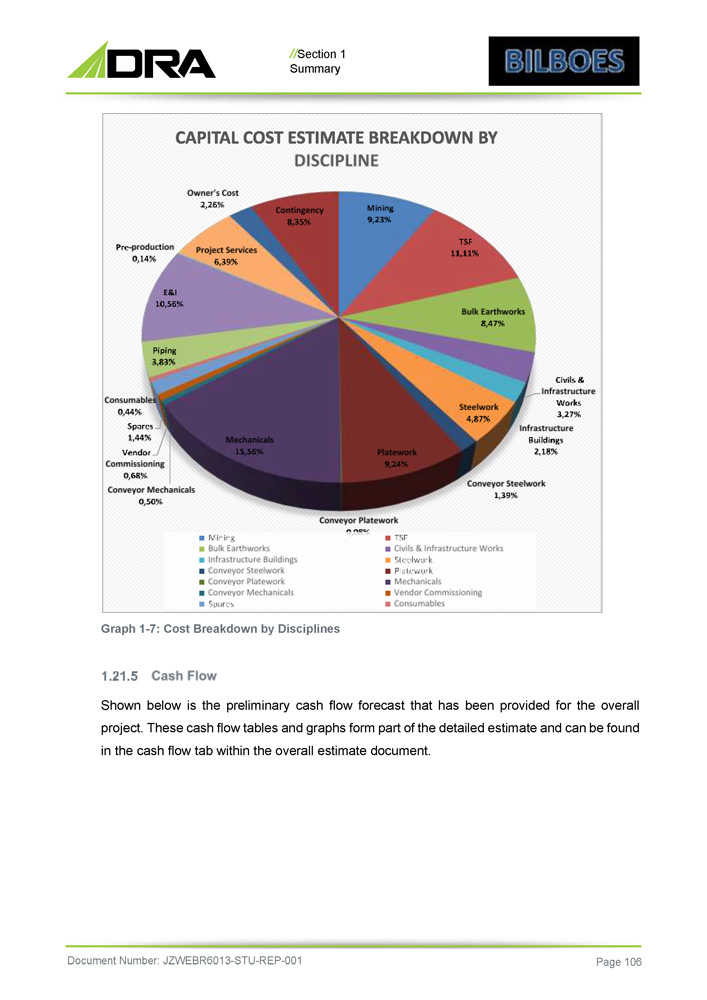

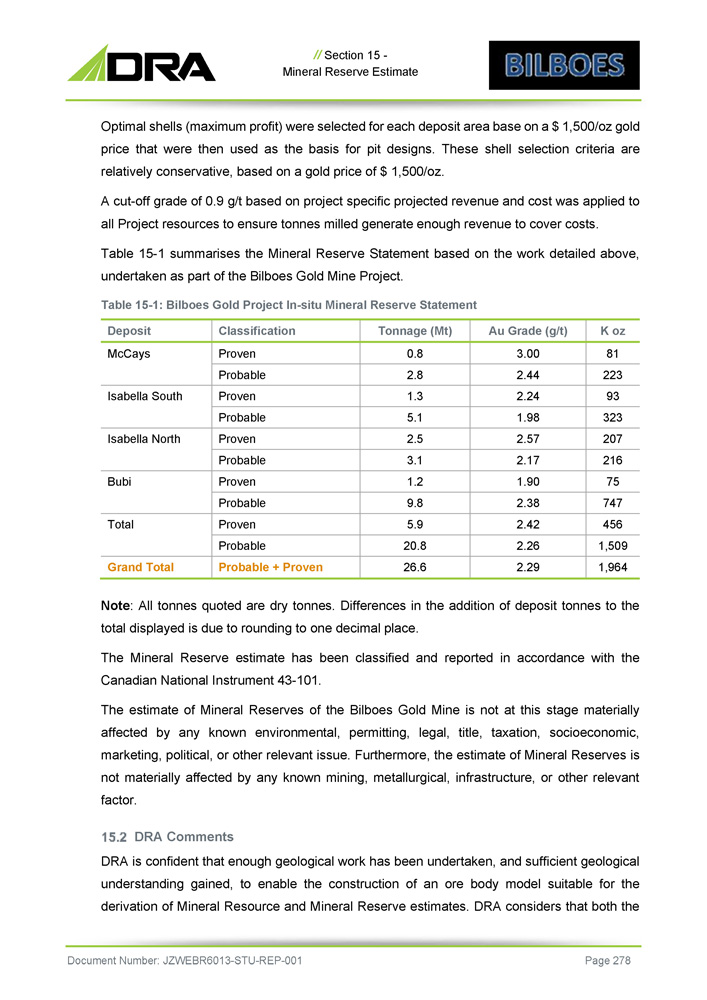

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study 21 CAPITAL AND OPERATING COSTS 1. Capital Cost Estimate 1. Basis of Capital Estimate 2. Estimate Scope 3. Estimate Accuracy 4. Estimate Base Date 5. Estimate Base Currency 6. General Estimate Development Methodology 7. Project Specific Estimate Development Methodology 8. Infrastructure Services 9. Infrastructure Building Works 10. Structural Steelwork Supply and Erection 11. Platework and Lining 12. Mechanical Equipment 13. Conveyors 14. Piping and Valves 15. Electrical, Control and Instrumentation 16. Preliminary and General Costs 17. Transportation 18. EPCM and External Services 19. Spares, First Fill and Consumables 20. Pre - Production Costs 21. Owners Cost 22. Mining Capital Costs 23. Process Plant and Infrastructure Capital Costs 24. Discipline Cost Overview 25. Capital Estimate Summaries 26. Stay in Business Operating Cost Estimate 27. Exclusions and Assumptions 28. Risks and Opportunities to Capital Estimate 29. Escalation 30. Contingencies 31. Project Risk / Management Contingency 32. Cash Flow 2. Operating Cost Estimate 1. Mining Operating Cost 2. Process Plant Operating Cost 3. General Administrative Costs Document Number: JZWEBR6013 - STU - REP - 001 Page 15 485 485 485 485 485 485 485 486 490 493 493 494 494 495 496 496 497 499 500 500 500 501 501 501 502 503 504 507 507 508 509 510 511 512 513 513 519 525

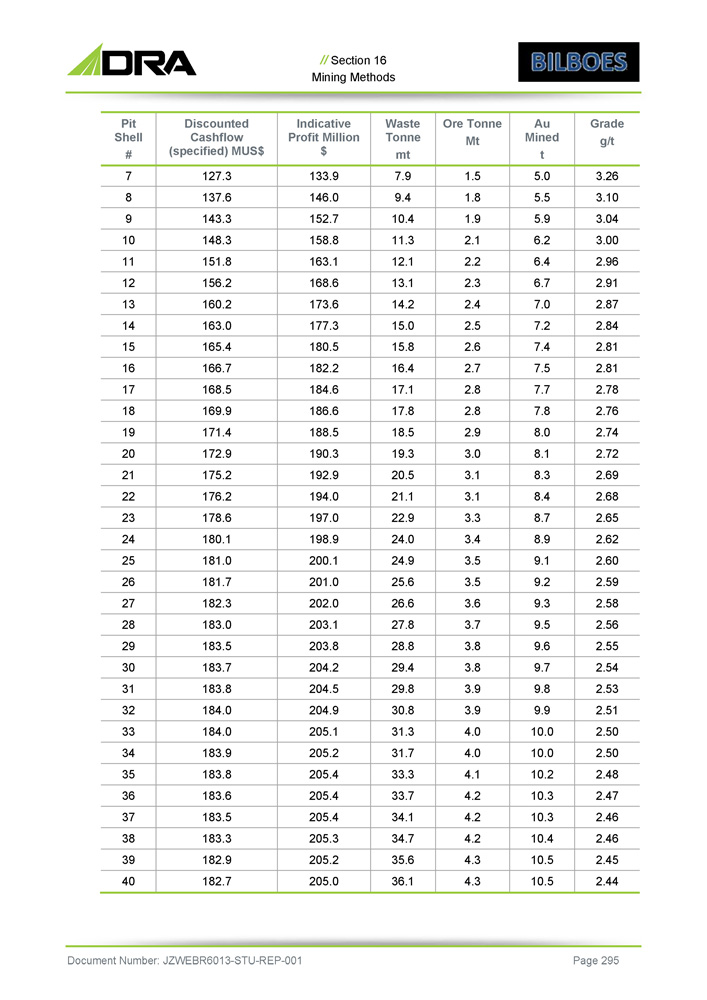

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study 21.2.4 Overall Operating Cost Summary 22. ECONOMIC ANALYSIS 1. Introduction 2. Inputs and Assumptions 1. Process Parameters 2. Revenue Parameters 3. SIB Capital 4. Environmental Rehabilitation and Mine Closure 5. Royalty Tax 6. Income Tax 7. Discounted Cash Flow Parameters 8. Production Profile 9. Initial Capital Costs 10. Operating Costs 11. Working Capital 12. Salvage Value 3. Financial Model Outcomes 4. Sensitivity Analysis 5. Recovery Upside 23 ADJACENT PROPERTIES 24 OTHER RELEVANT DATA AND INFORMATION 1. Royalties, Taxes and Economic Climate in Zimbabwe 1. Royalties 2. Customs Duties 3. Value Added Tax 4. Withholding Taxes 5. Corporate Tax 6. Ring Fencing 7. Employment Levies 8. Electricity Levies 9. Rural Council Levies 10. Other Relevant Points 11. Rebates of Duty 2. Mining Legislation 3. Indigenisation and Economic Empowerment 25 INTERPRETATION AND CONCLUSIONS 1. Risk Assessment Matrix 2. Geology and Resource Estimates Risks Document Number: JZWEBR6013 - STU - REP - 001 Page 16 526 528 528 529 529 529 529 529 530 530 530 530 531 532 532 532 532 534 534 537 540 540 540 541 541 541 541 542 542 542 542 542 544 544 545 547 547 550

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study 3. Mining and Reserves 4. Processing 5. Infrastructure 6. Economic Outcomes 7. Country Risk 1. Political 2. Economic 3. Security 26 RECOMMENDATIONS 1. Mining 2. Processing 3. Economic Analysis 4. Project 27 REFERENCES 1. Geology 2. Legal and Title 3. Geotechnical 1. Open Pit Investigation and Slope Analysis 2. Site Geotechnical Investigation 27.4 Processing Document Number: JZWEBR6013 - STU - REP - 001 Page 17 550 551 551 552 552 552 552 553 555 555 555 556 556 558 558 558 558 558 559 560

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study LIST OF TABLES Table 1 1: Bilboes Claims 37 Table 1 2: Test work Program Outline 40 Table 1 3: Optimum Flotation Conditions 42 Table 1 4: Comparative Pilot Plant Simulated Recoveries 46 Table 1 5: Flotation Residence Times 46 Table 1 6: Summary of the Test Work Feasibility Results 48 Table 1 7: Mineral Resource Tabulation for the Properties using a Base Case Block Cut - Off 50 Grade Table 1 8: Bilboes Gold Project In - situ Mineral Reserve Statement 52 Table 1 9: Tailings Production Profile 63 Table 1 10: Liner System 67 Table 1 11: Process Plant Main Design Criteria 89 Table 1 12: Preliminary and General Percentages 102 Table 1 13: Mining Capital Costs 103 Table 1 14: Cost Category Components 104 Table 1 15: Capital Summaries per Project Phase 105 Table 1 16: Foreign Exchange 108 Table 1 17: Mining Contractor Costs per Area ($/total tonne) 110 Table 1 18: Phase 1 Plant OPEX (240 ktpm, excl G&A) 111 Table 1 19: Phase 2 Plant OPEX (180 ktpm) 112 Table 1 20: LoM Operating Cost Summary 113 Table 1 21: Project Economics Summary 114 Table 4 1: Bilboes Claims 124 Table 6 1: History of Sulphide Project Core Drilling 1994 - 1999 (From Ngilazi & Martin, 2017) 135 Table 6 2: Sulphide Inferred Mineral Resources as of 2009 137 Table 6 3: Sulphide Mineral Resources as of 31 March 2017, 0.0 g/t Au Block Cut - Off Applied 138 Table 6 4: Sulphide Mineral Resources as of 31 March 2017, 0.9 g/t Au Block Cut - Off Applied 138 Table 6 5: Production Data from Bilboes Mines to 31 December 2020 139 Table 13 1: Test work Program Outline 169 Table 13 2 - Preliminary Sample Description and Composition 170 Table 13 3: Chemical Analysis - Variability Samples 172 Table 13 4: Chemical Analysis - Pit Composite Samples 174 Table 13 5: Summary of Comminution Test Results 176 Table 13 6: Summary of Comminution Test Results 178 Table 13 7: Phase 2 Laboratory Flotation Concentrate Qualities 179 Table 13 8: Phase 3 Test work Bulk Sample Composition 180 Table 13 9: Phase 3 Bulk Flotation Concentrate Qualities 181 Document Number: JZWEBR6013 - STU - REP - 001 Page 18

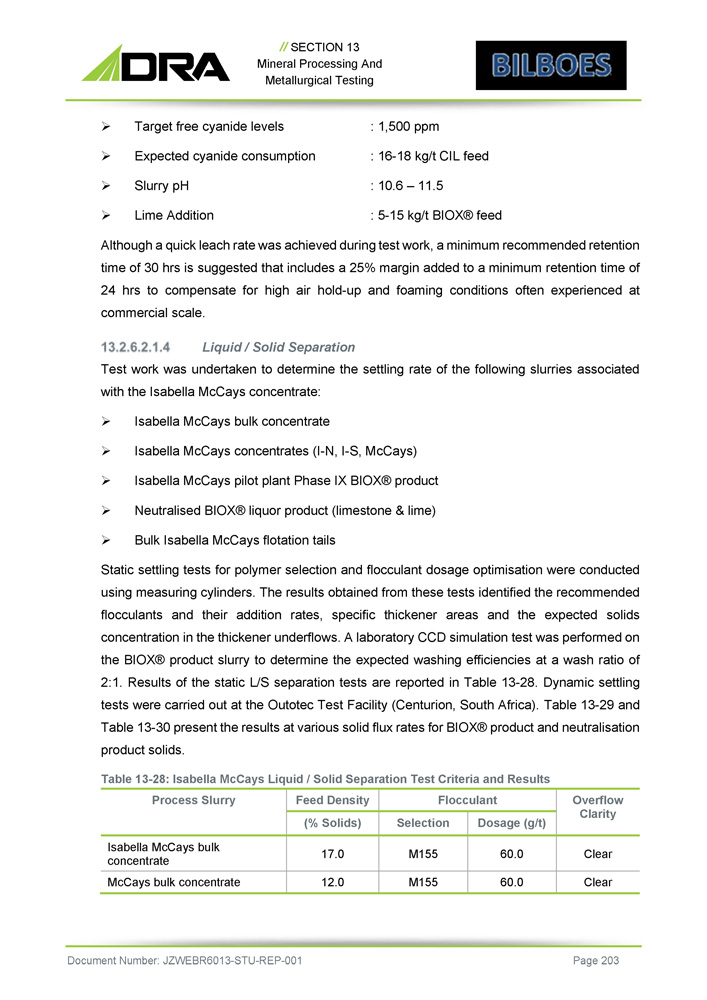

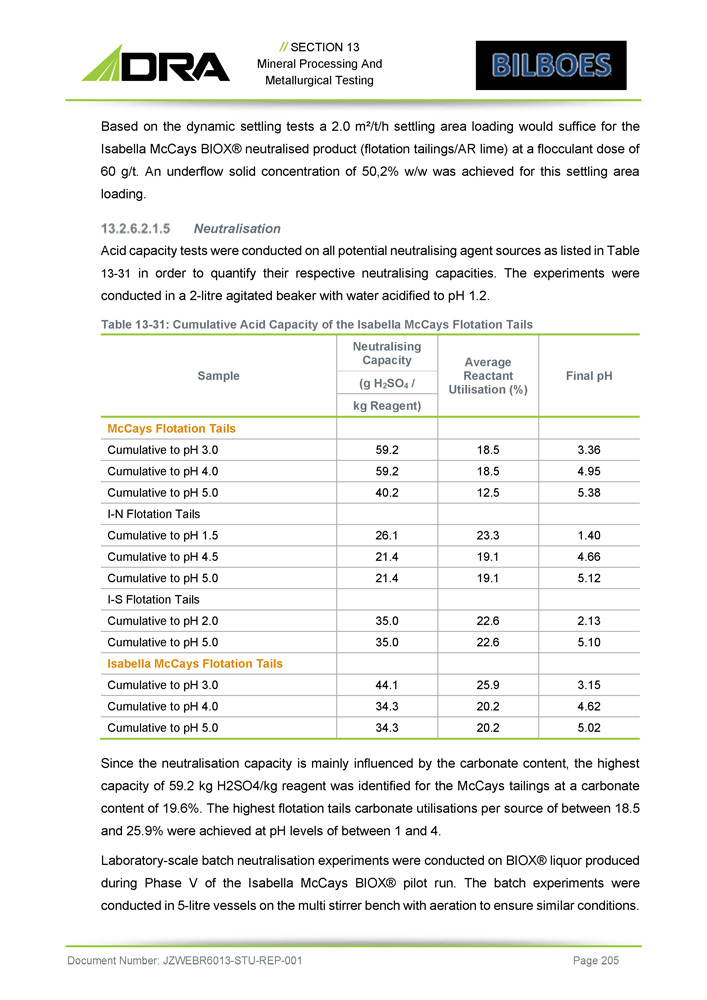

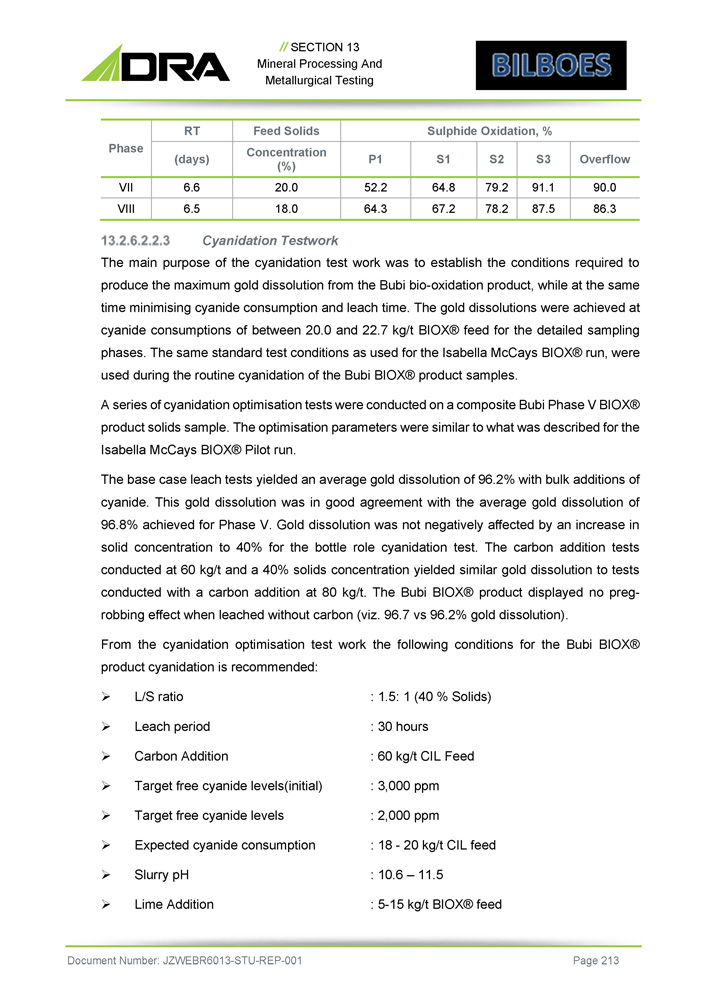

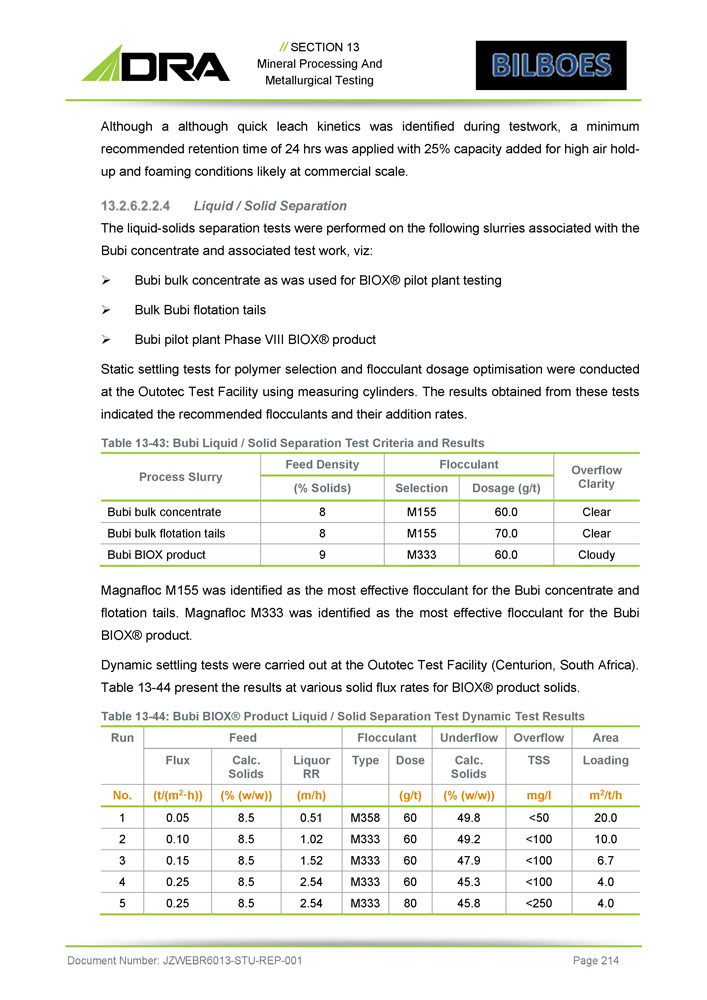

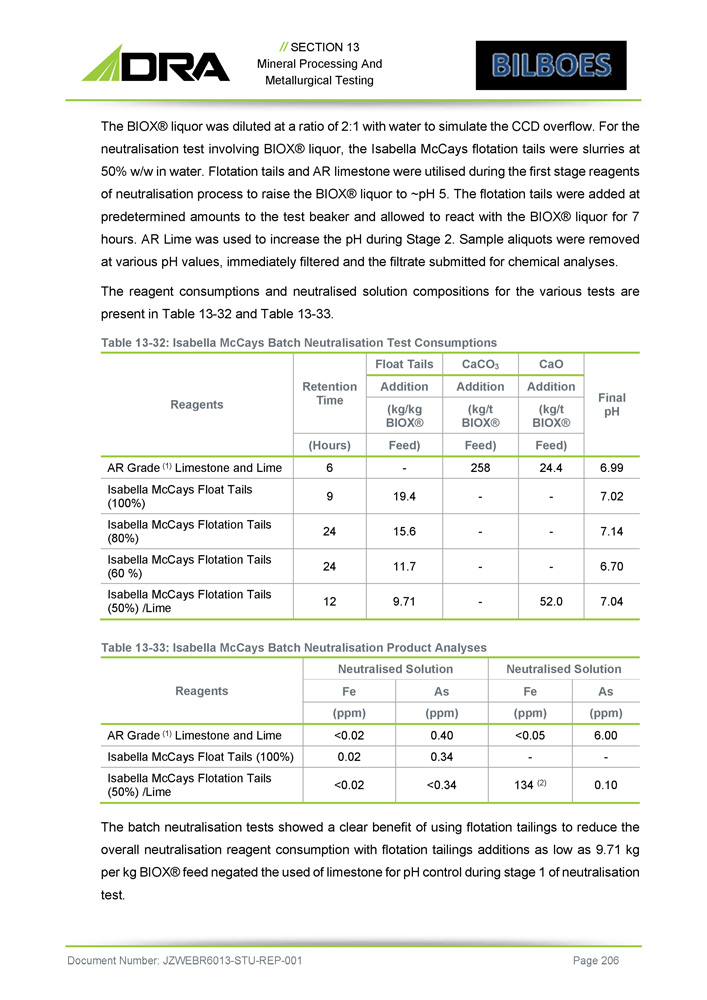

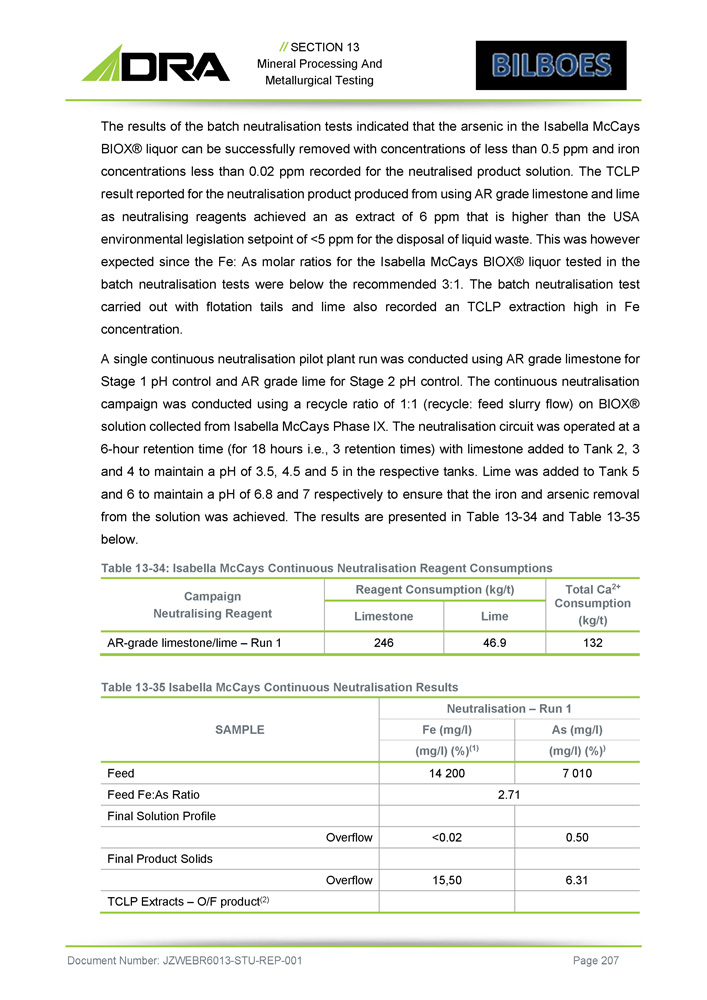

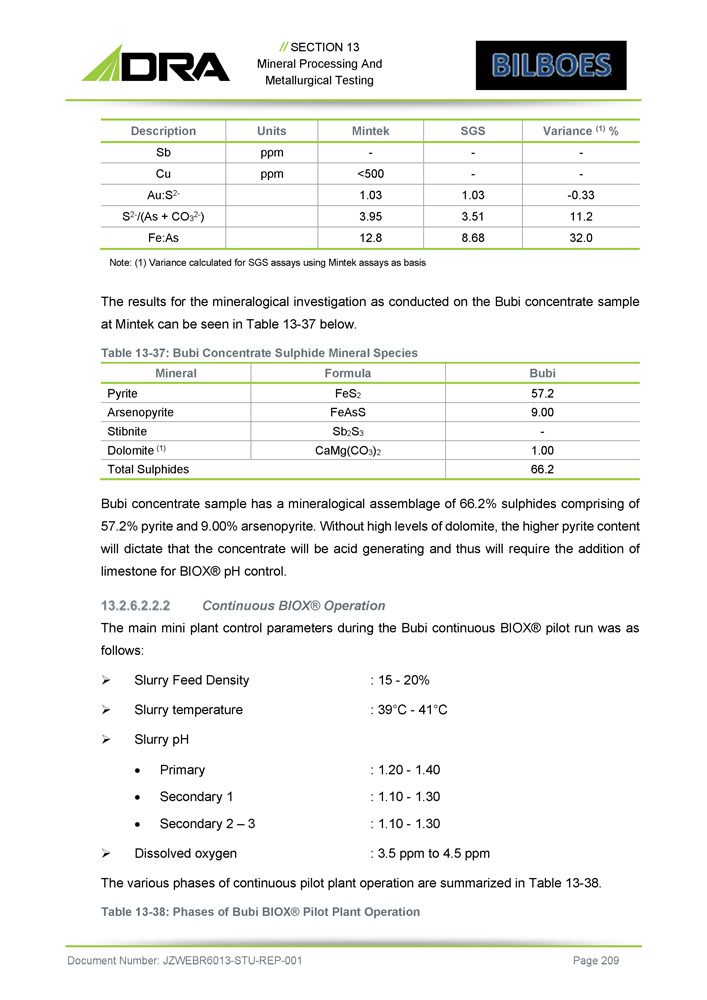

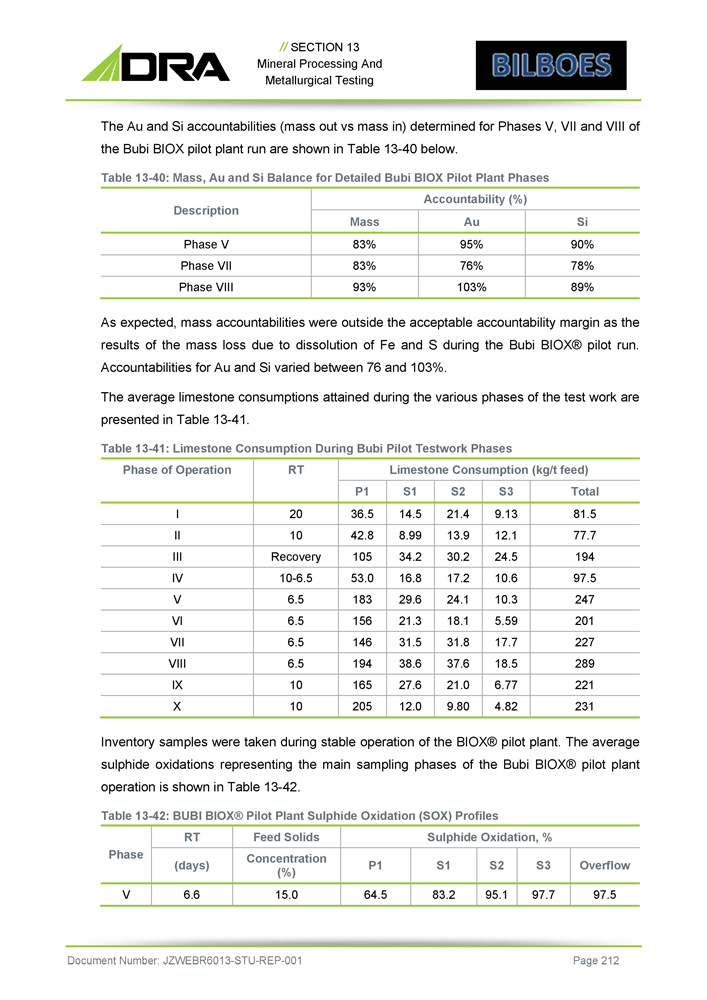

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study Table 13 10: Pilot Plant Campaigns Bulk Samples 182 Table 13 11: Optimum Conditions in Phase 2 Test Work 183 Table 13 12: Summary of Isabella McCays Ores Pilot Plant Results 185 Table 13 13 : Summary of Bubi Ore Pilot Plant Results 185 Table 13 14 : Assays and Chemical Analyses of the Pilot Plant Bulk Concentrates 187 Table 13 15 : Locked Cycle Flotation Test Results 189 Table 13 16: Comparative Grind and Flotation Rate Test Results 189 Table 13 17: Comparative Pilot Plant Simulated Recoveries 191 Table 13 18: Expected Plant Recoveries 191 Table 13 19: Flotation Residence Times 191 Table 13 20: Analyses of Isabella McCays Bulk Concentrate Sample 196 Table 13 21: Isabella McCays Concentrates Sulphide Mineral Species 197 Table 13 22 : Sulphide Removal, Arsenic Solubilisation and Gold Dissolution Bilboes Concentrate 197 Samples Table 13 23: Phases of Isabella McCays BIOX® Pilot Plant Operation 199 Table 13 24 : Isabella McCays BIOX® Pilot Plant Average of Daily SOX and Gold Dissolutions 199 per Phase Table 13 25 : Mass, Au and Si Balance for Detailed Isabella McCays BIOX® Pilot Plant Phases 201 Table 13 26 : Limestone Consumption During Isabella McCays Pilot Testwork Phases 201 Table 13 27 : Isabella McCays BIOX® Pilot Plant Sulphide Oxidation (SOX) Profiles 201 Table 13 28 : Isabella McCays Liquid / Solid Separation Test Criteria and Results 203 Table 13 29 : Isabella McCays BIOX® Product Liquid / Solid Separation Test Dynamic Test 204 Results Table 13 30 : Isabella McCays BIOX® Neutralisation Product and Flotation Tailings Dynamic 204 Settling Test Results Table 13 31 : Cumulative Acid Capacity of the Isabella McCays Flotation Tails 205 Table 13 32 : Isabella McCays Batch Neutralisation Test Consumptions 206 Table 13 33 : Isabella McCays Batch Neutralisation Product Analyses 206 Table 13 34 : Isabella McCays Continuous Neutralisation Reagent Consumptions 207 Table 13 35 Isabella McCays Continuous Neutralisation Results 207 Table 13 36: Analyses of Bubi Concentrate Sample 208 Table 13 37: Bubi Concentrate Sulphide Mineral Species 209 Table 13 38: Phases of Bubi BIOX® Pilot Plant Operation 210 Table 13 39: BUBI BIOX® Pilot Plant Average of Daily Sulphide Oxidation (SOX) and Gold 210 Dissolutions Per Phase Table 13 40: Mass, Au and Si Balance for Detailed Bubi BIOX Pilot Plant Phases Table 13 41: Limestone Consumption During Bubi Pilot Testwork Phases Table 13 42: BUBI BIOX® Pilot Plant Sulphide Oxidation (SOX) Profiles Table 13 43: Bubi Liquid / Solid Separation Test Criteria and Results Table 13 44: Bubi BIOX® Product Liquid / Solid Separation Test Dynamic Test Results Document Number: JZWEBR6013 - STU - REP - 001 Page 19 212 212 212 214 214

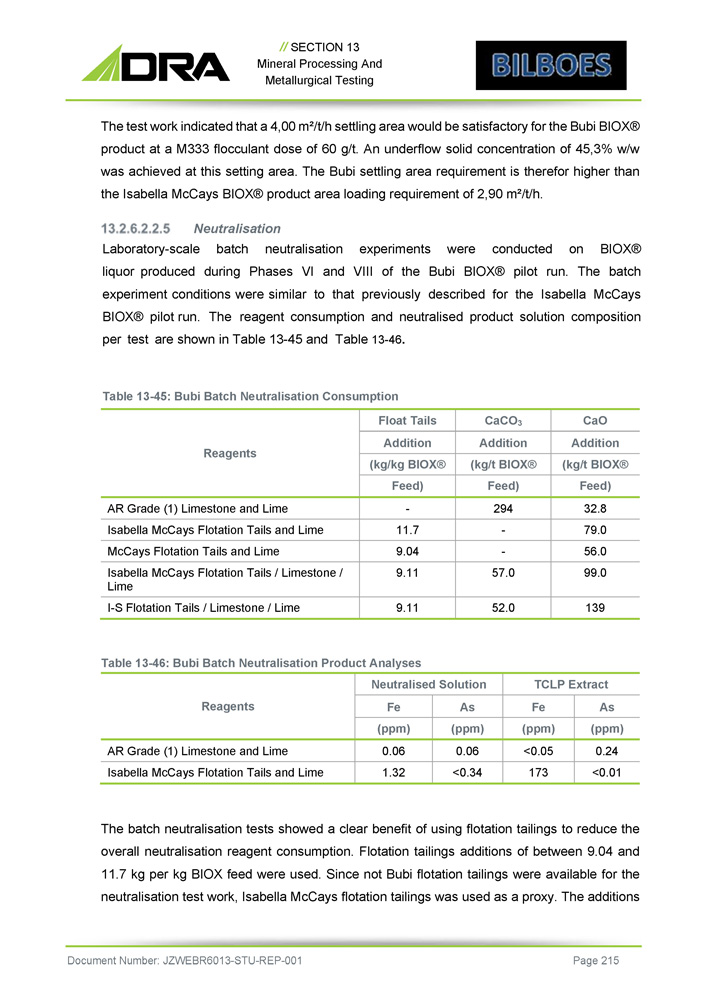

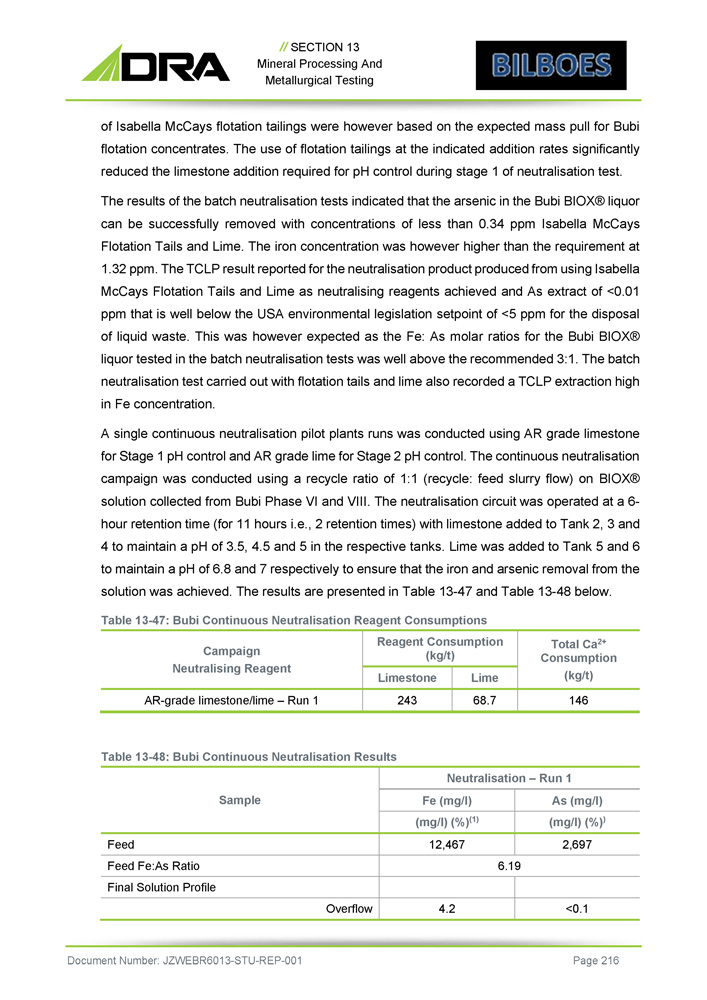

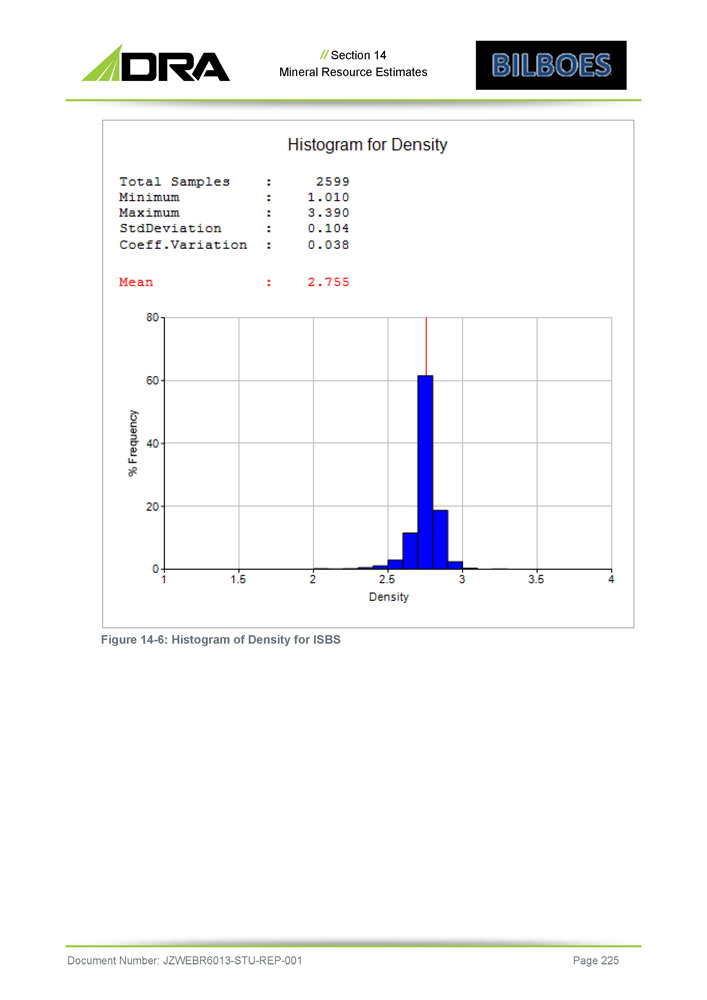

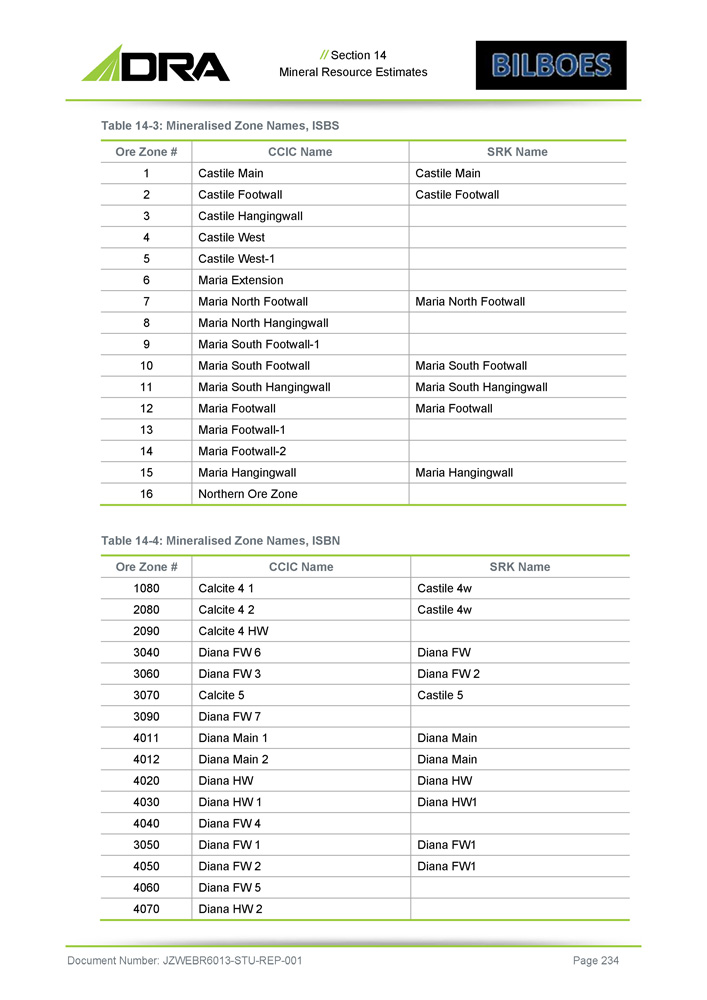

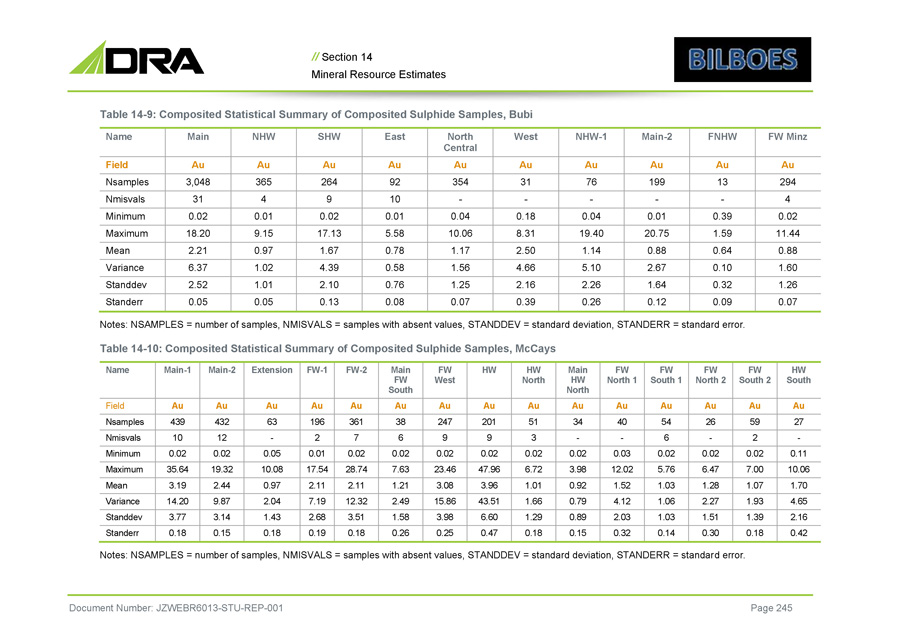

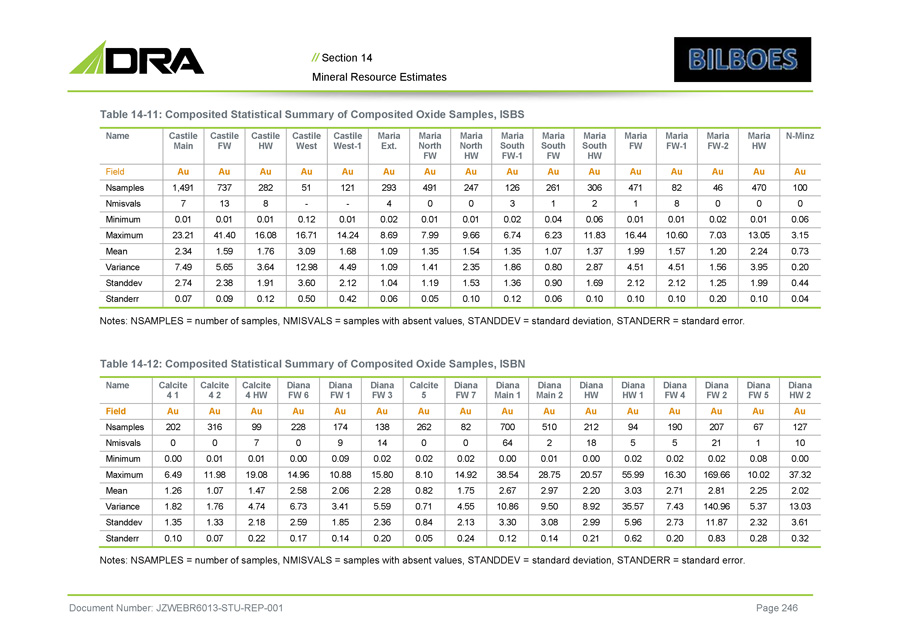

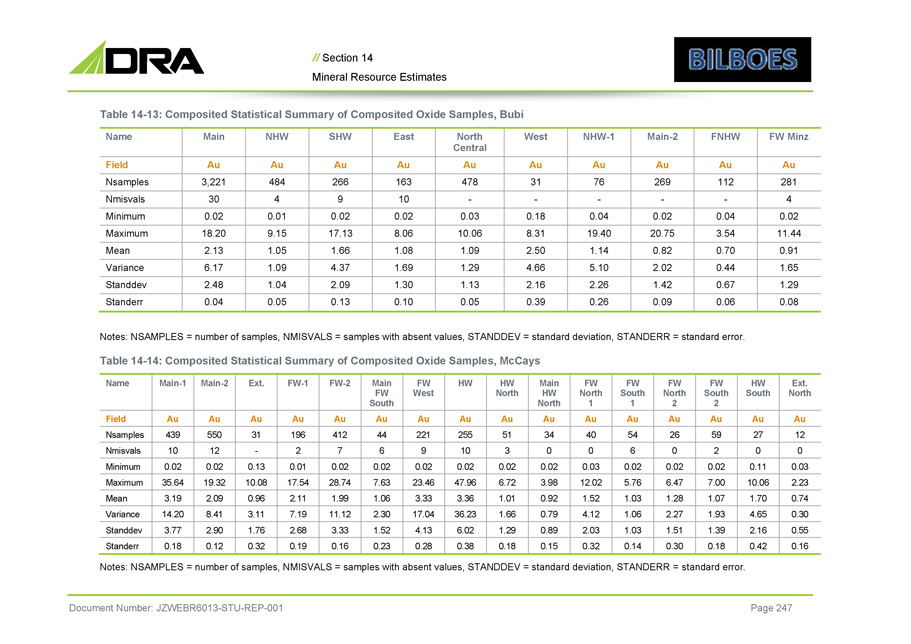

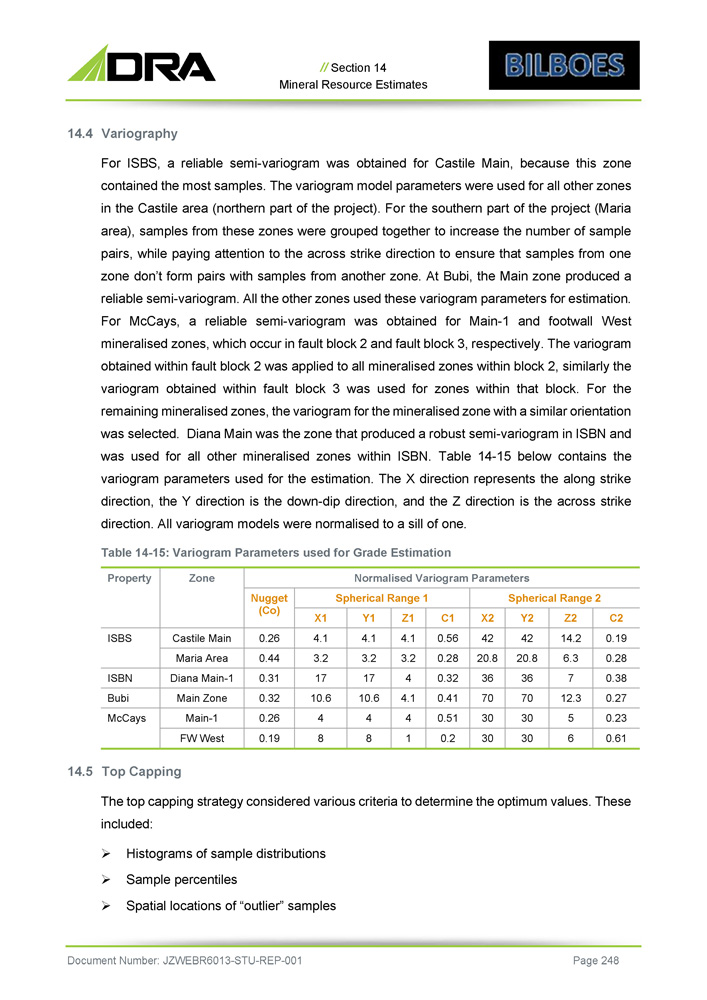

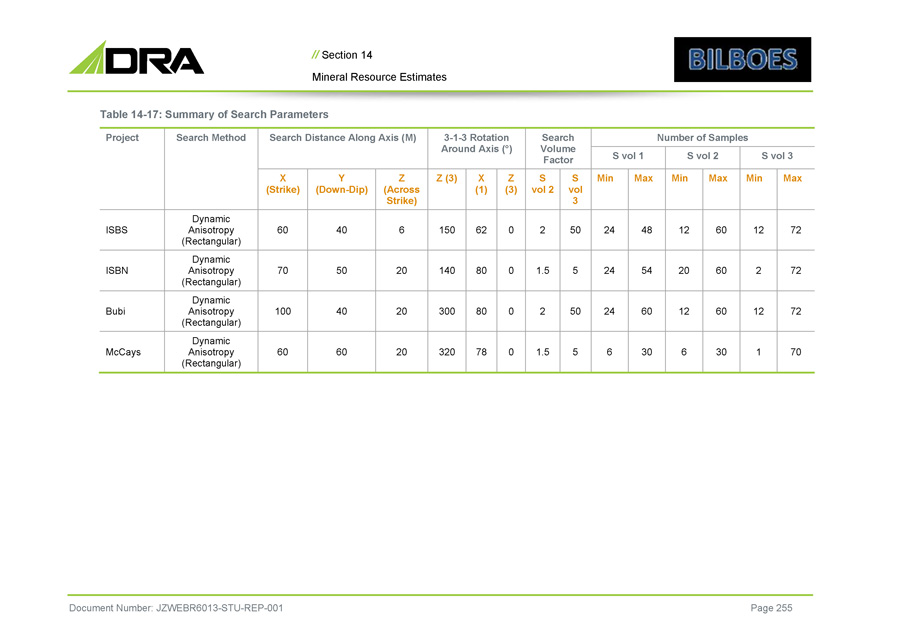

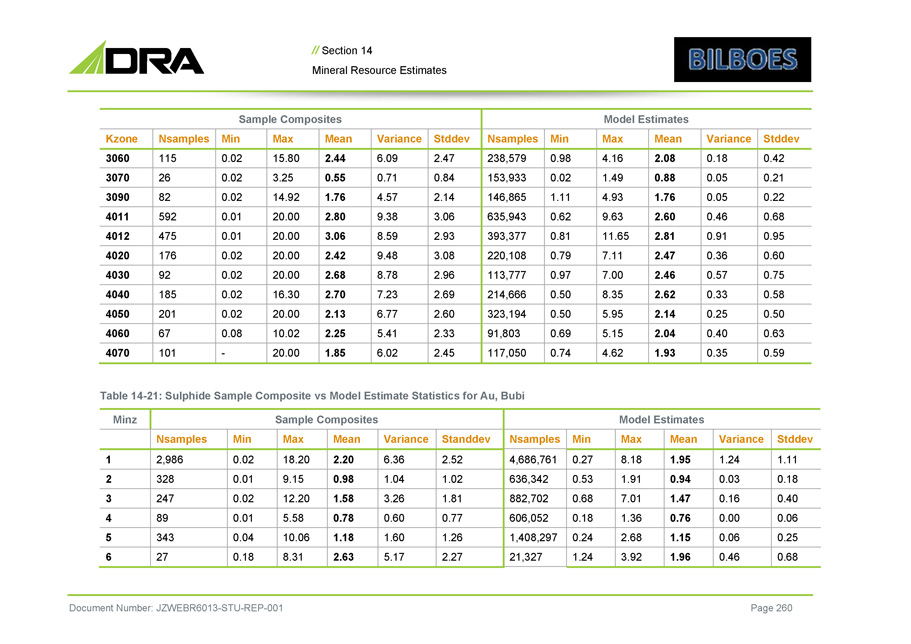

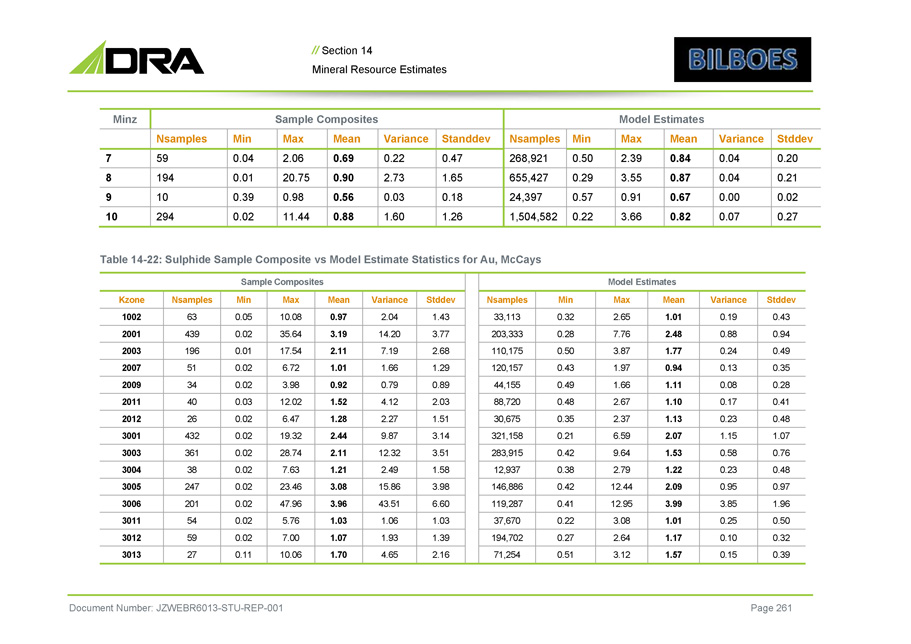

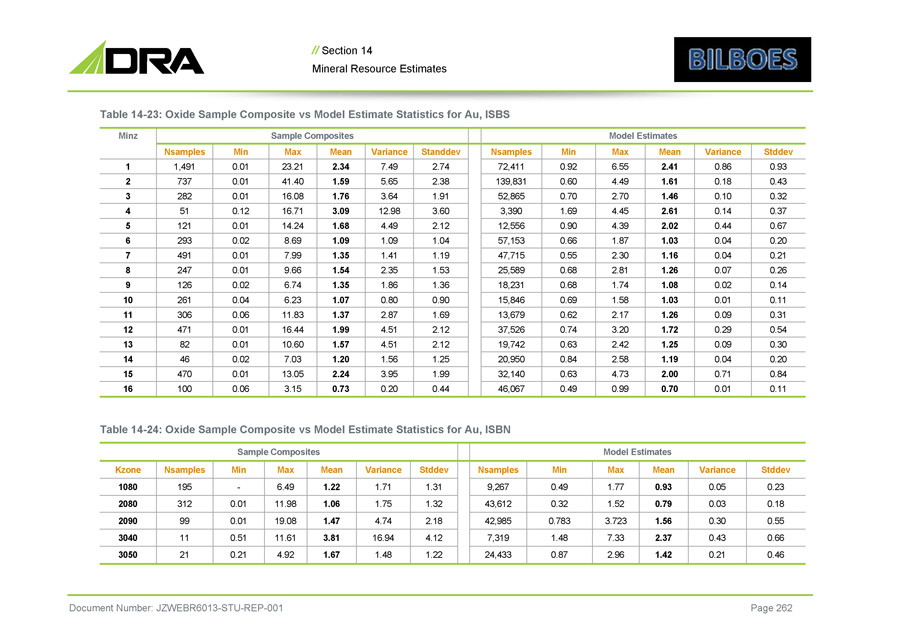

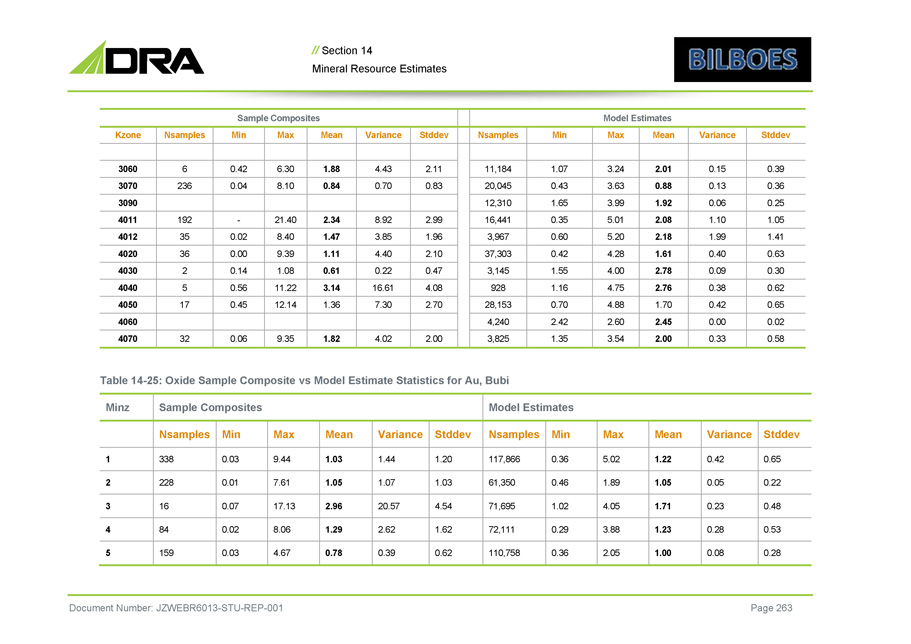

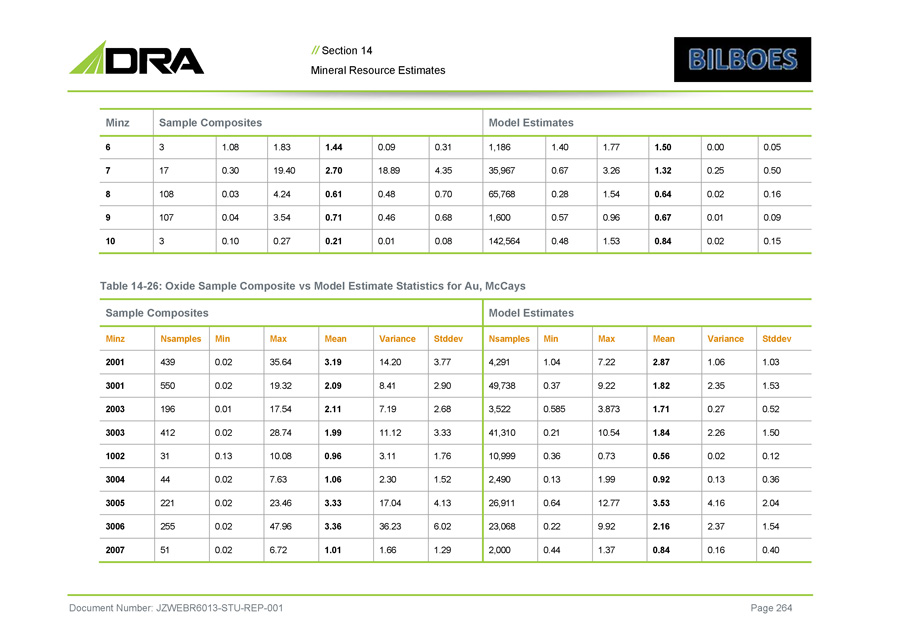

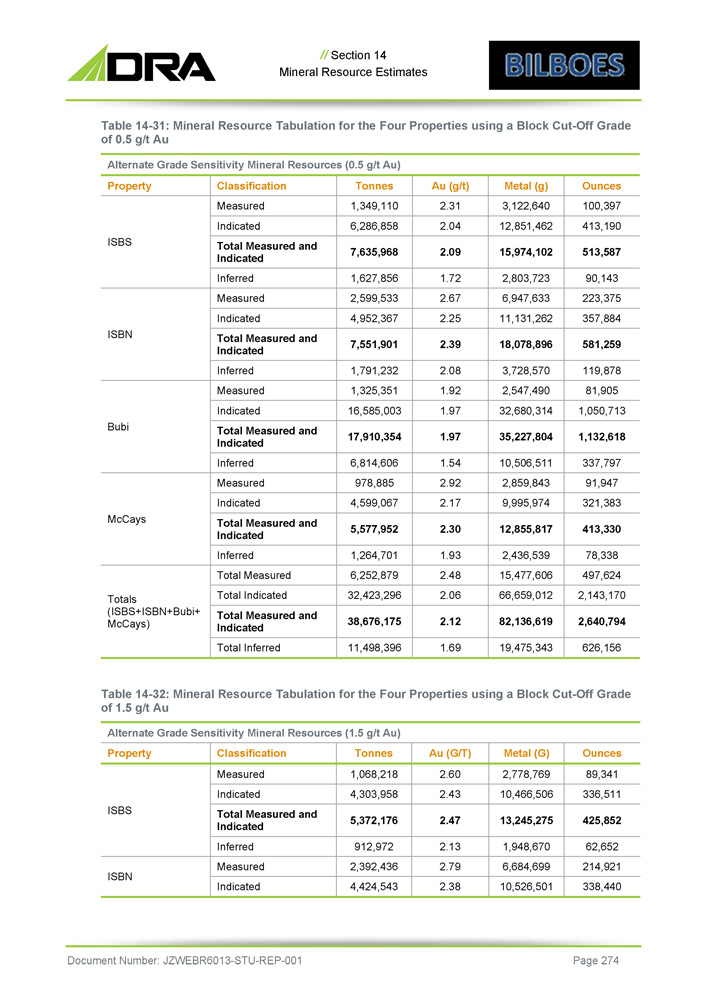

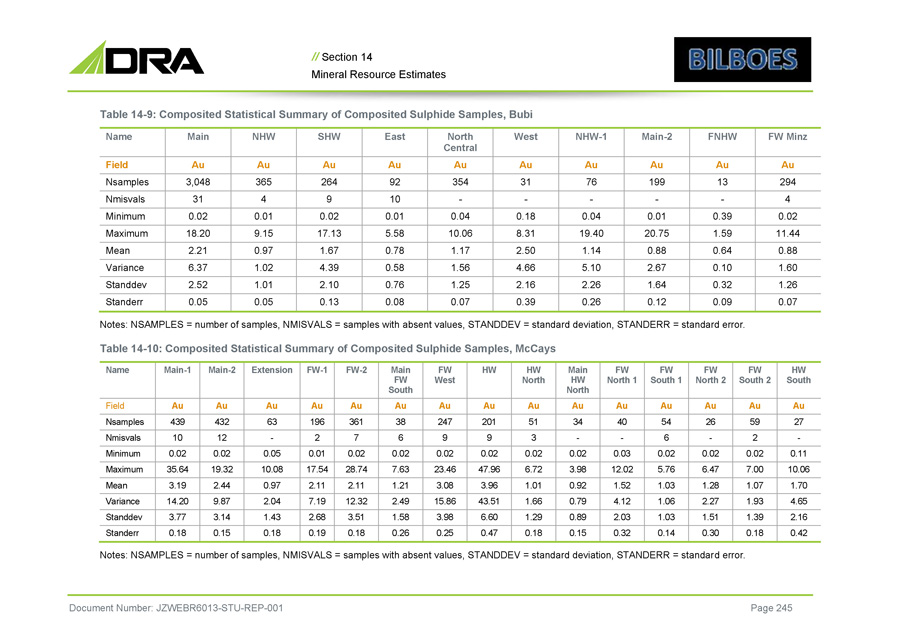

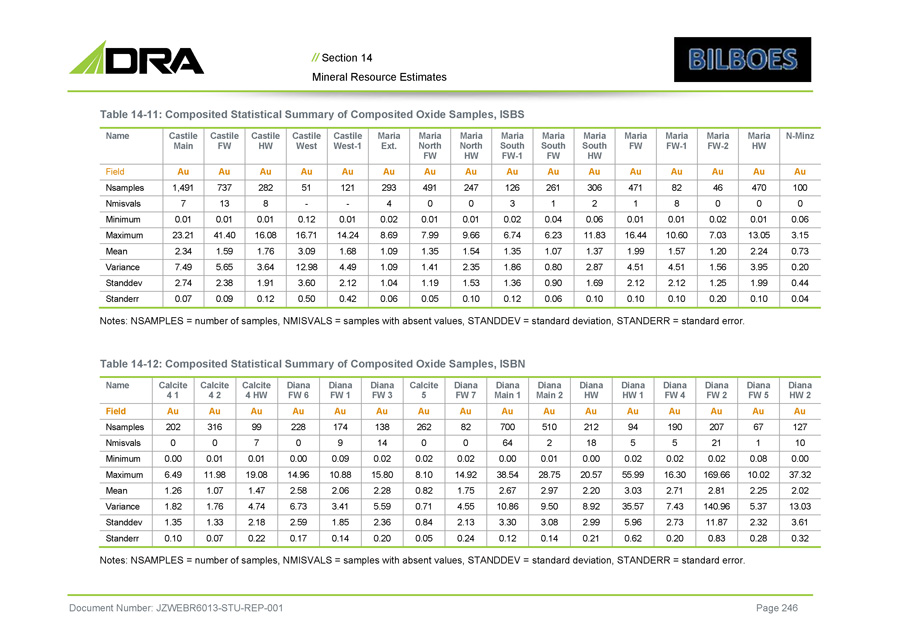

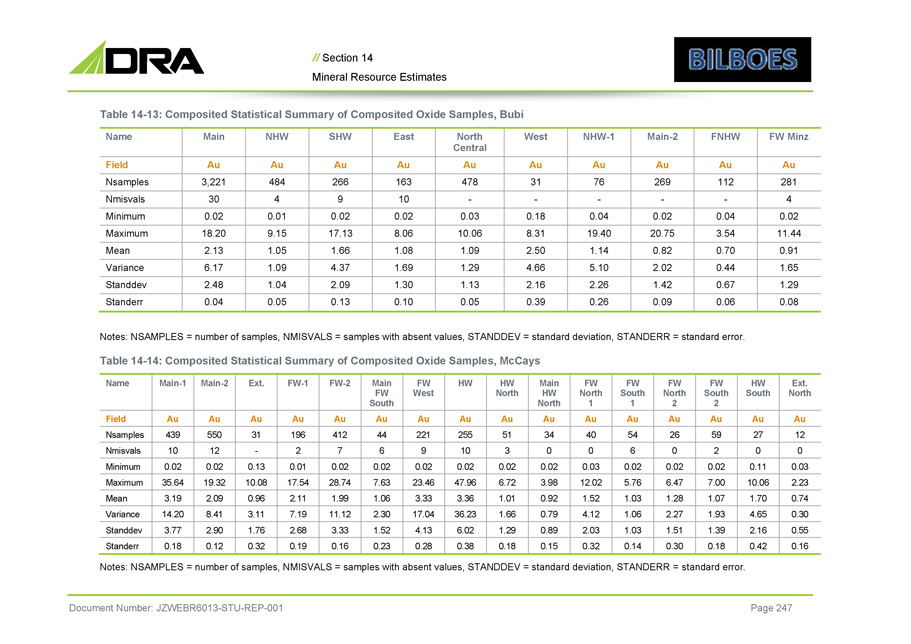

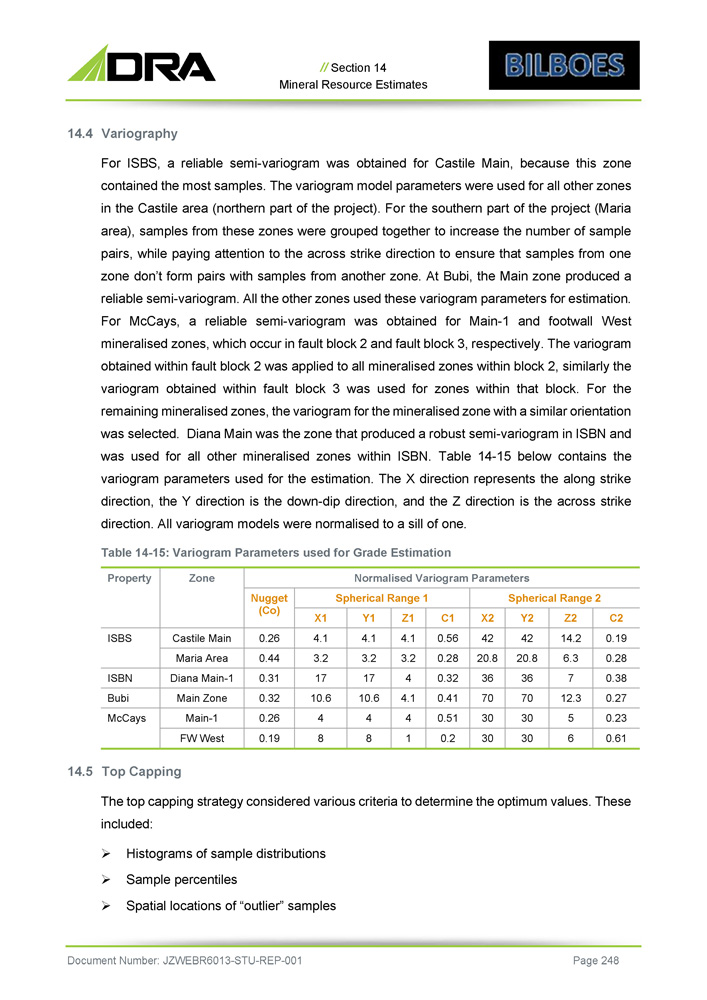

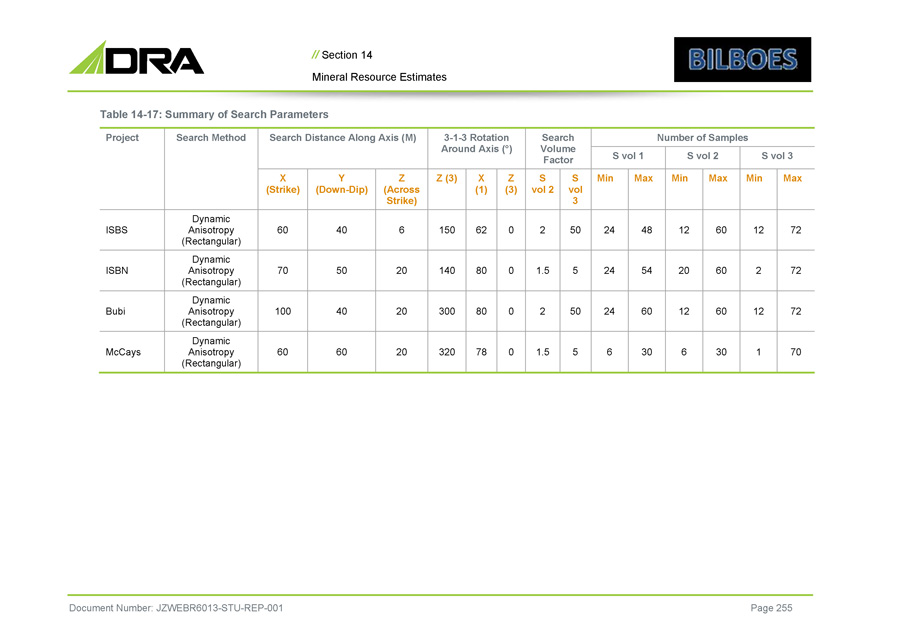

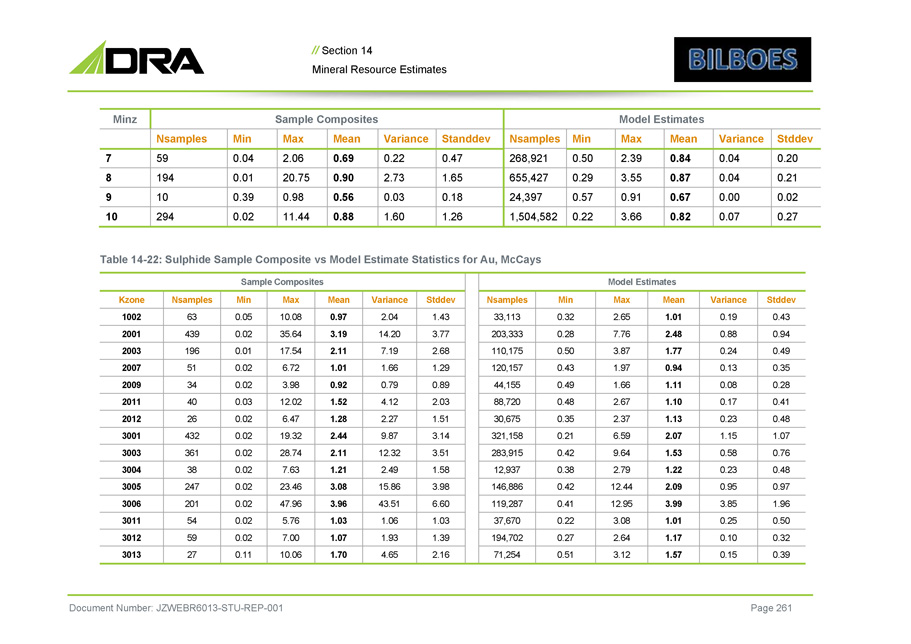

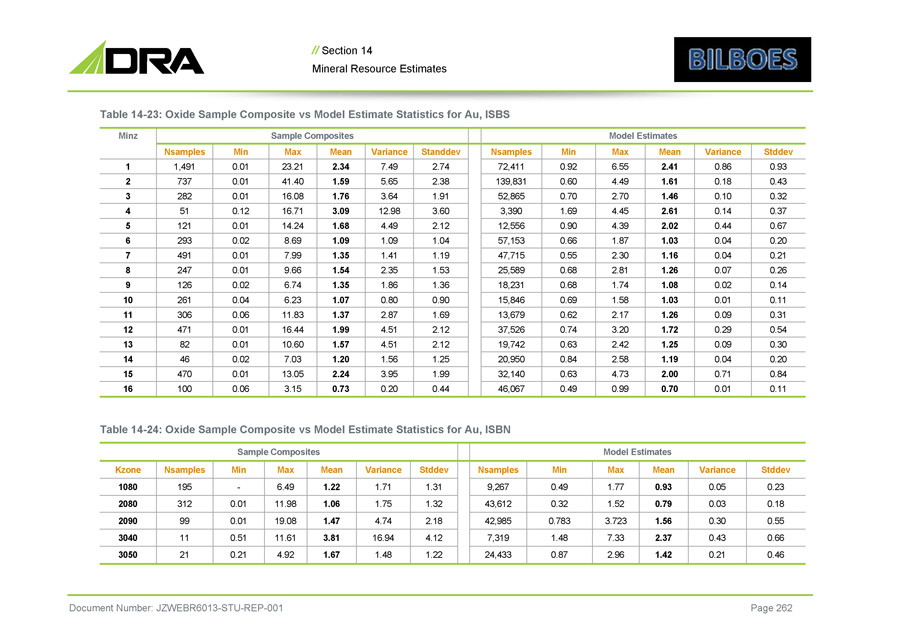

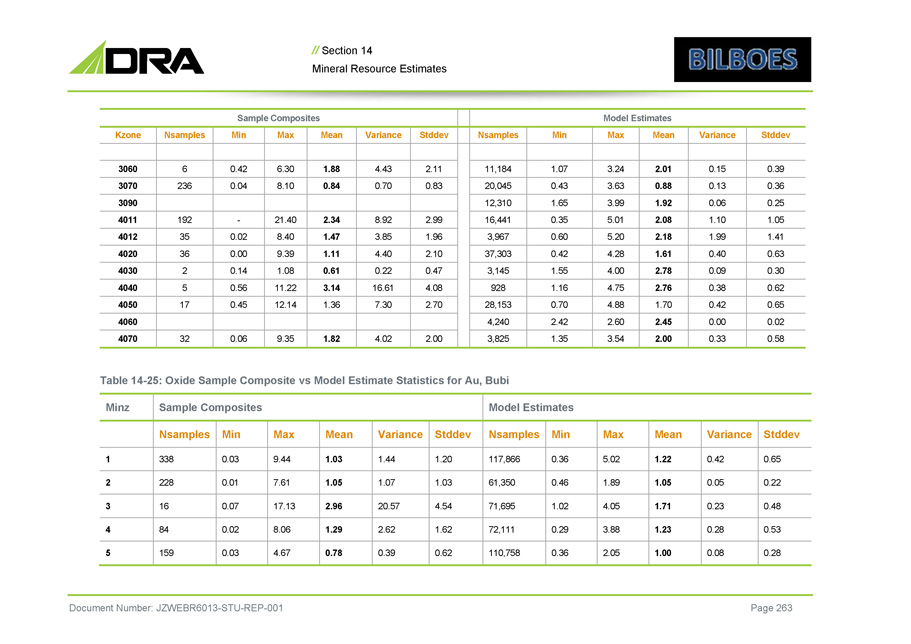

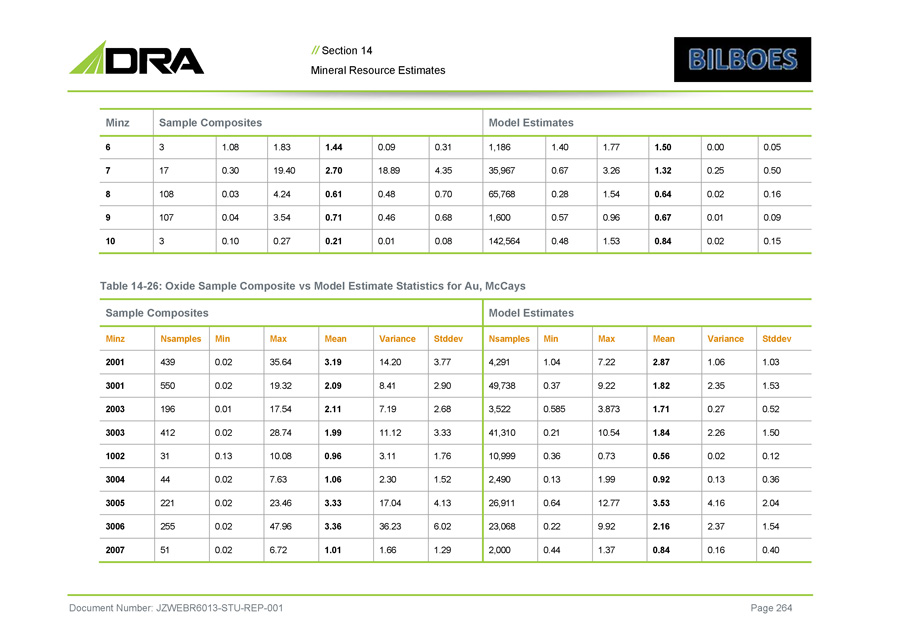

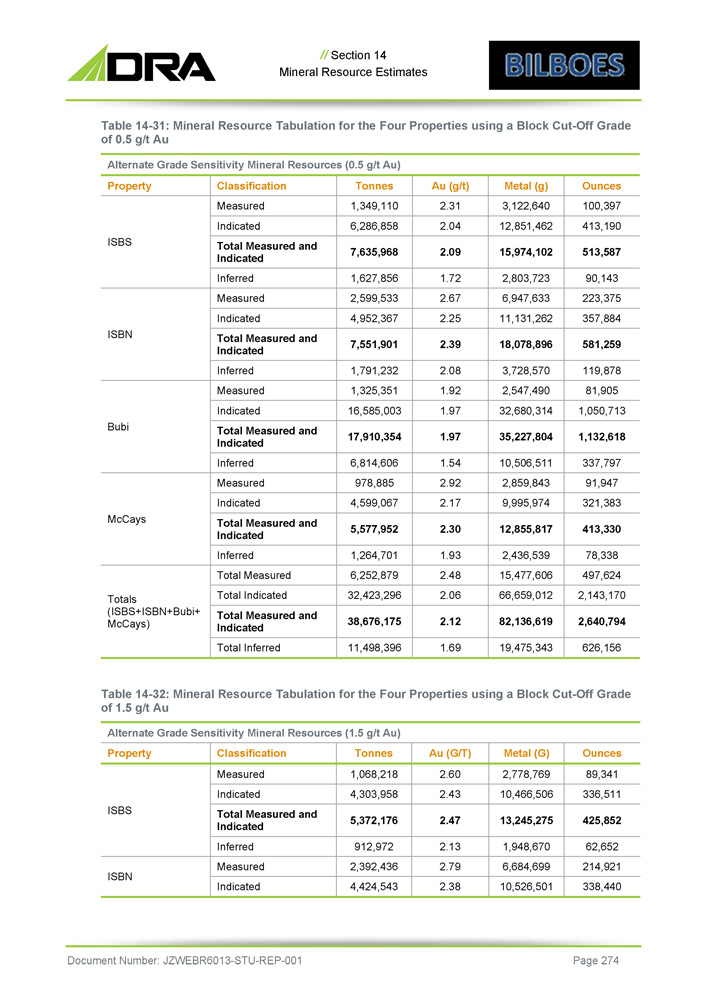

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study Table 13 45: Bubi Batch Neutralisation Consumption 215 Table 13 46: Bubi Batch Neutralisation Product Analyses 215 Table 13 47: Bubi Continuous Neutralisation Reagent Consumptions 216 Table 13 48: Bubi Continuous Neutralisation Results 216 Table 14 1: Summary of Drill Holes 221 Table 14 2: Summary of Density Measurement per Resource Area 224 Table 14 3: Mineralised Zone Names, ISBS 234 Table 14 4: Mineralised Zone Names, ISBN 234 Table 14 5: Mineralised Zone Names, Bubi 235 Table 14 6: Mineralised Zone Names, McCays 235 Table 14 7 : Composited Statistical Summary of Composited Sulphide Samples, ISBS 244 Table 14 8 : Composited Statistical Summary of Composited Sulphide Samples, ISBN 244 Table 14 9 : Composited Statistical Summary of Composited Sulphide Samples, Bubi 245 Table 14 10 : Composited Statistical Summary of Composited Sulphide Samples, McCays 245 Table 14 11 : Composited Statistical Summary of Composited Oxide Samples, ISBS 246 Table 14 12 : Composited Statistical Summary of Composited Oxide Samples, ISBN 246 Table 14 13 : Composited Statistical Summary of Composited Oxide Samples, Bubi 247 Table 14 14 : Composited Statistical Summary of Composited Oxide Samples, McCays 247 Table 14 15 : Variogram Parameters used for Grade Estimation 248 Table 14 16: Top and Bottom Capping Summary 248 Table 14 17: Summary of Search Parameters 255 Table 14 18: Block Model Configuration 256 Table 14 19 : Sulphide Sample Composite vs Model Estimate Statistics for Au, ISBS 259 Table 14 20 : Sulphide Sample Composite vs Model Estimate Statistics for Au, ISBN 259 Table 14 21 : Sulphide Sample Composite vs Model Estimate Statistics for Au, Bubi 260 Table 14 22 : Sulphide Sample Composite vs Model Estimate Statistics for Au, McCays 261 Table 14 23 : Oxide Sample Composite vs Model Estimate Statistics for Au, ISBS 262 Table 14 24 : Oxide Sample Composite vs Model Estimate Statistics for Au, ISBN 262 Table 14 25 : Oxide Sample Composite vs Model Estimate Statistics for Au, Bubi 263 Table 14 26 : Oxide Sample Composite vs Model Estimate Statistics for Au, McCays 264 Table 14 27 : Checklist Criteria for Resource Classification 269 Table 14 28 : Summary of Optimisation Parameters used for the Lerchs - Grossmann Shells 272 Table 14 29 : Mineral Resource Tabulation for the Four Properties using a Base Case Block Cut - 272 Off Grade of 0 . 9 g/t Au Table 14 30 : Mineral Resource Tabulation for the Four Properties using a Block Cut - Off Grade 273 of 0 . 0 g/t Au Table 14 31 : Mineral Resource Tabulation for the Four Properties using a Block Cut - Off Grade 274 of 0 . 5 g/t Au Document Number: JZWEBR6013 - STU - REP - 001 Page 20

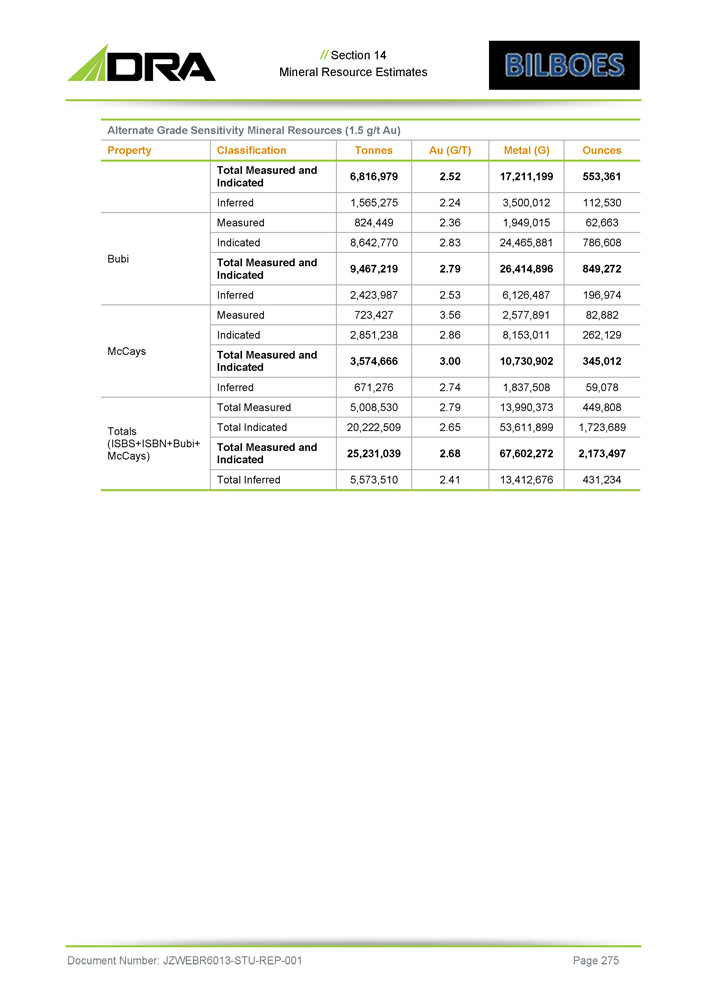

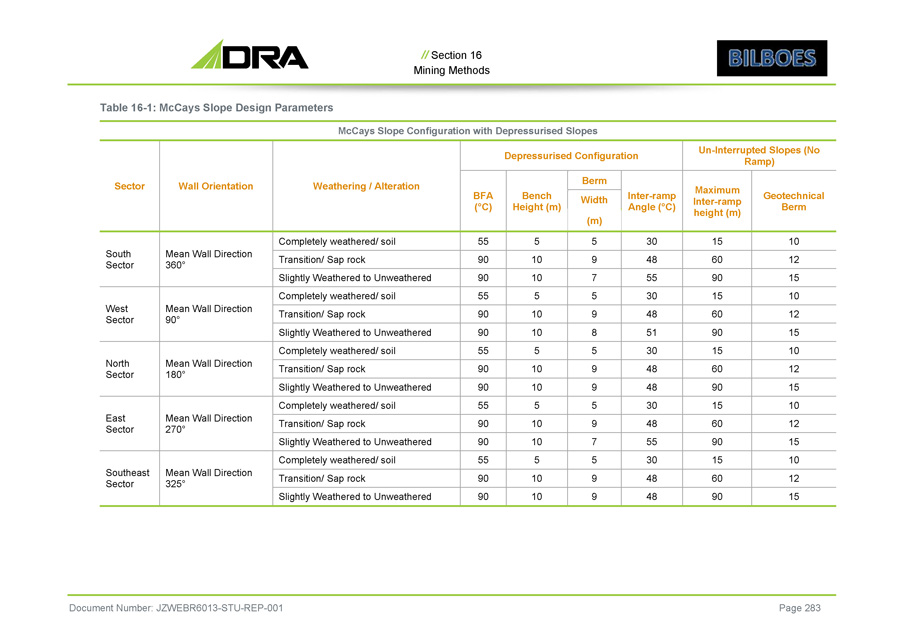

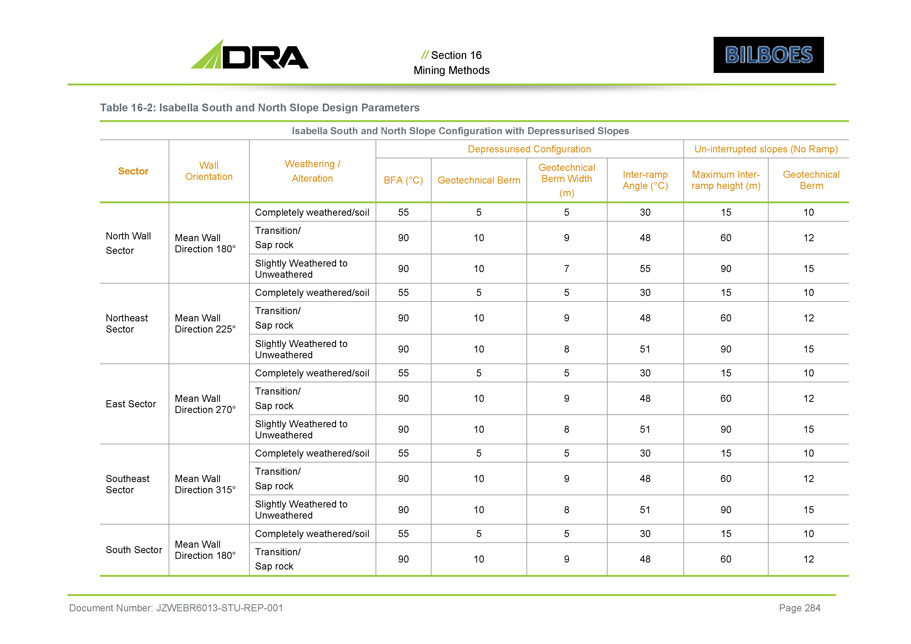

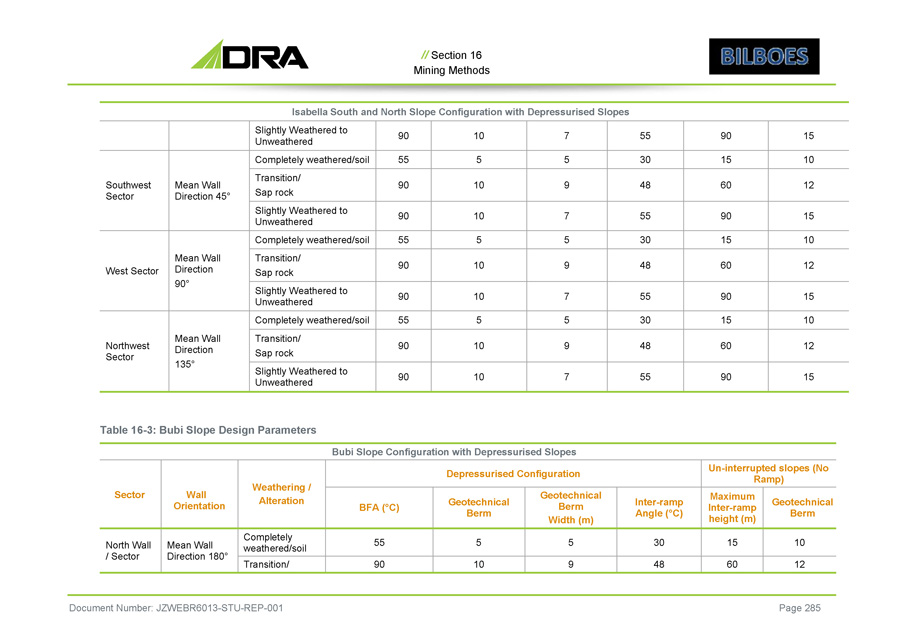

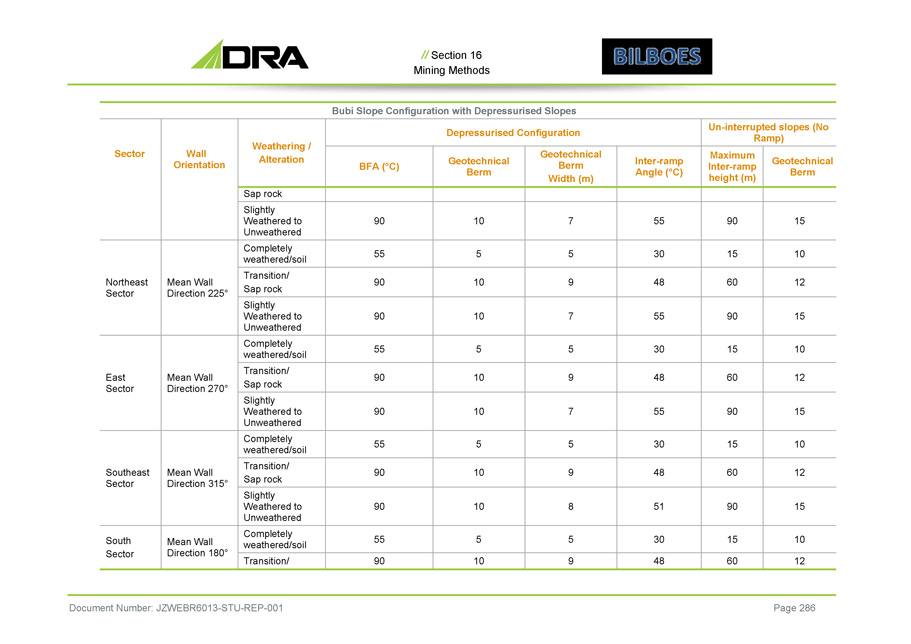

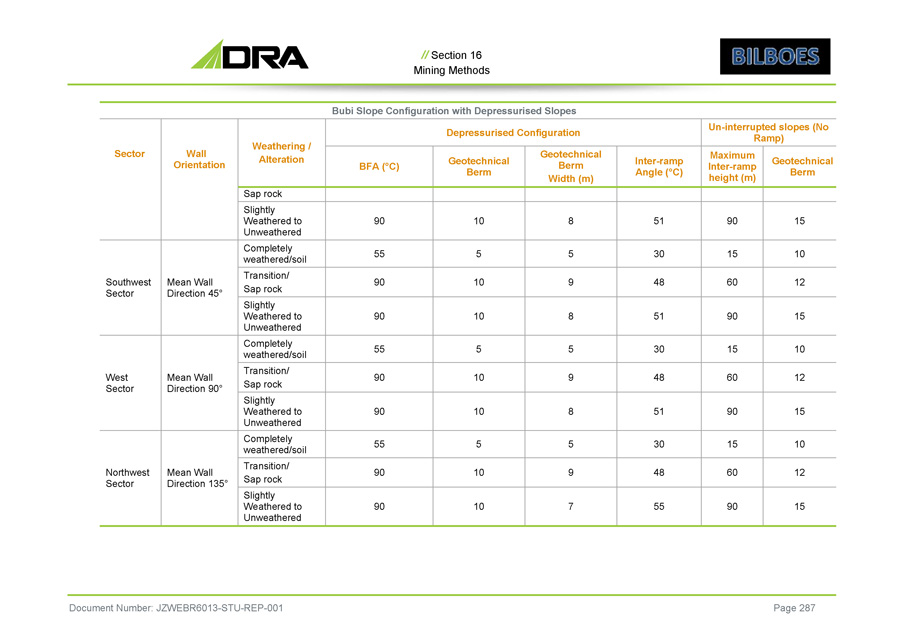

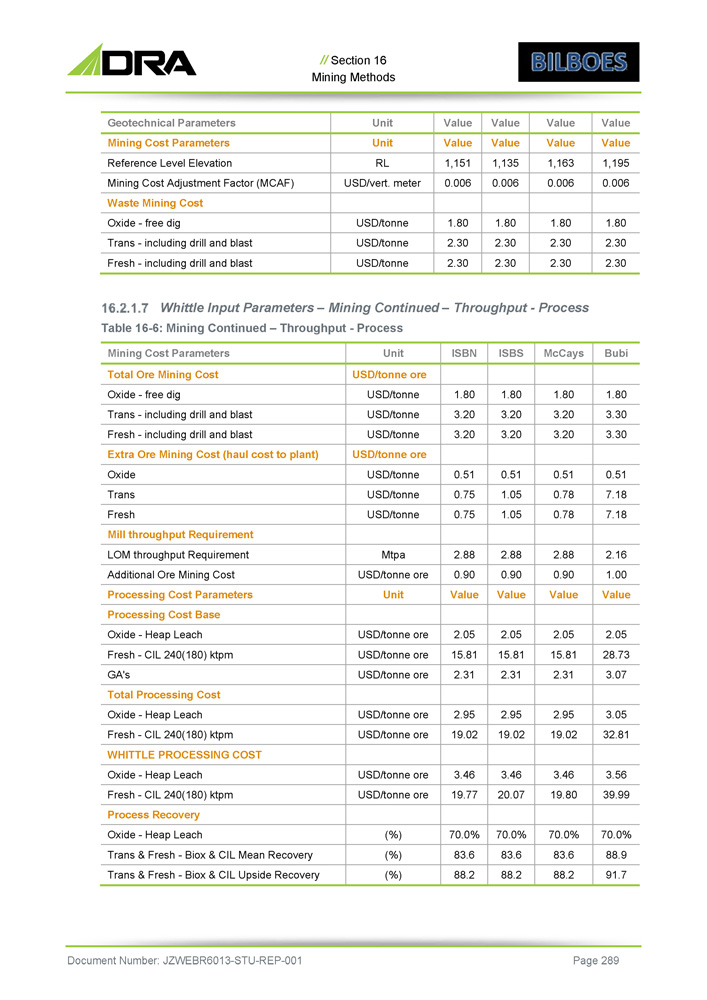

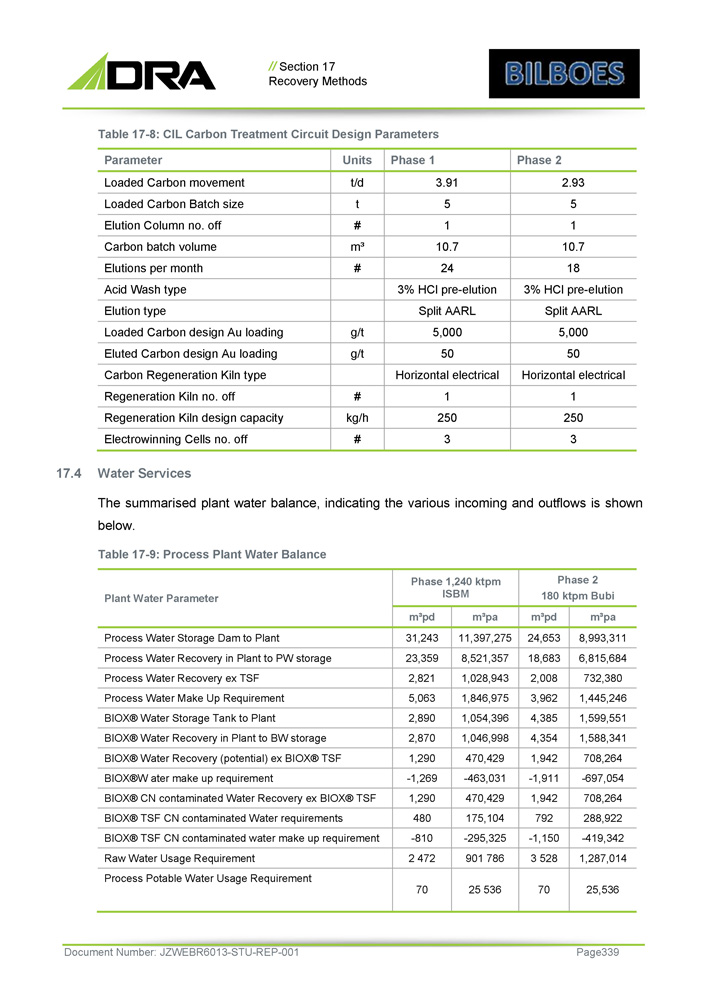

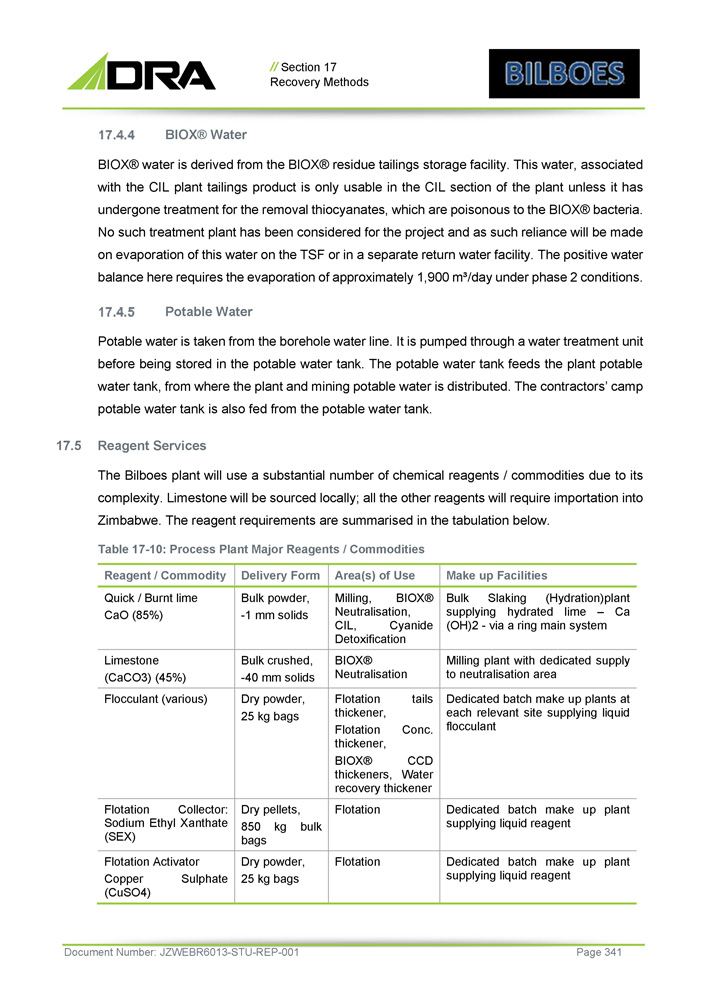

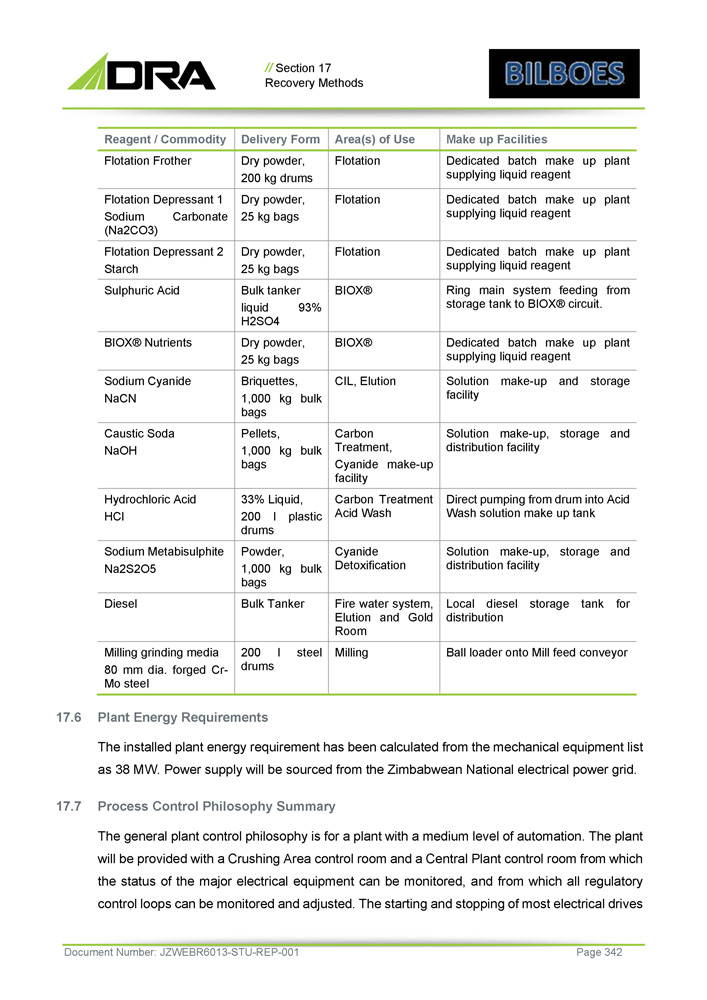

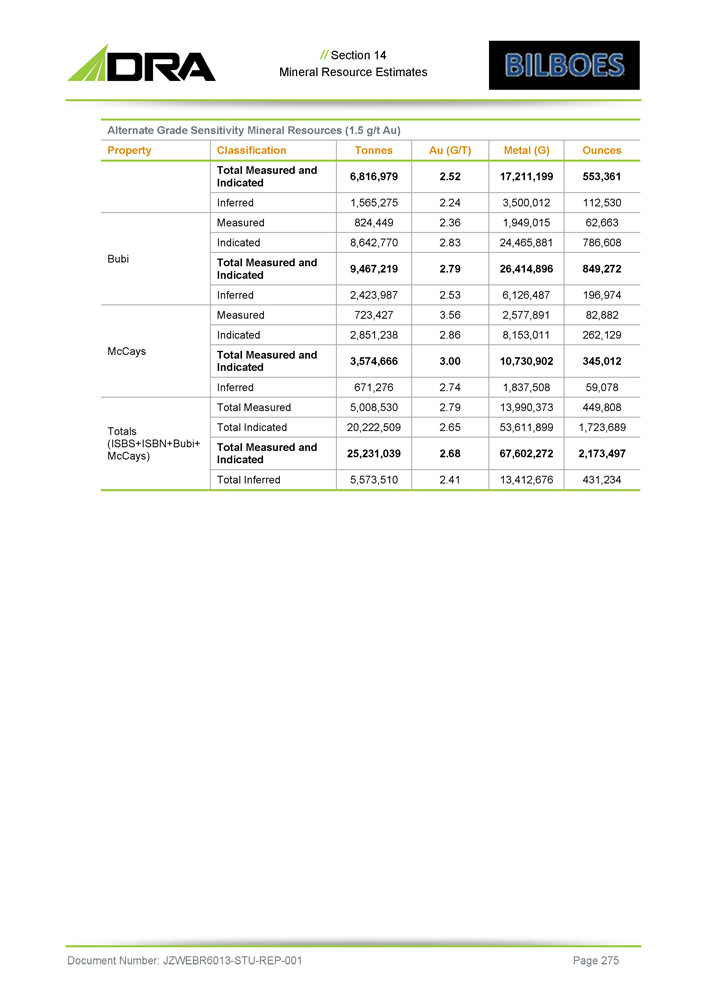

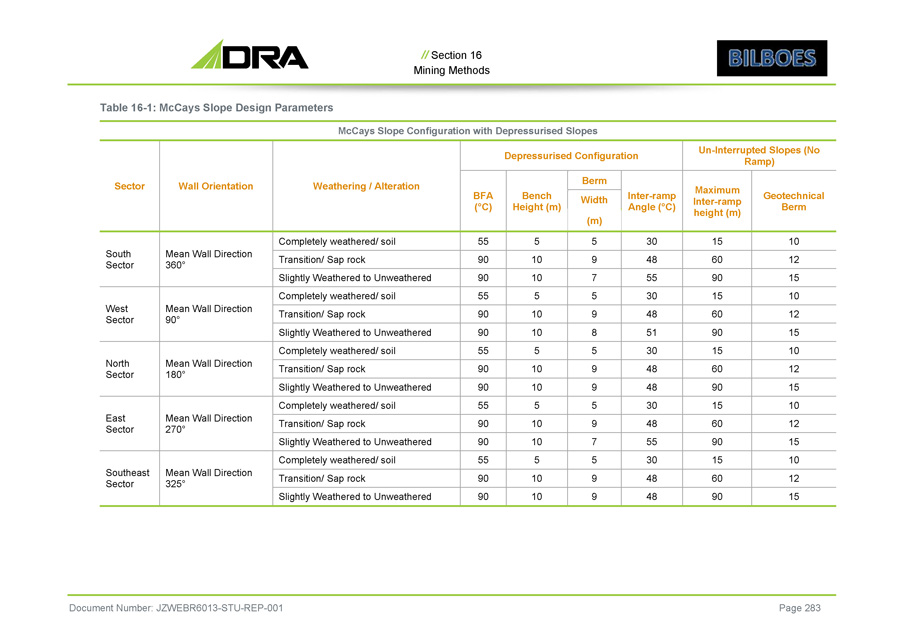

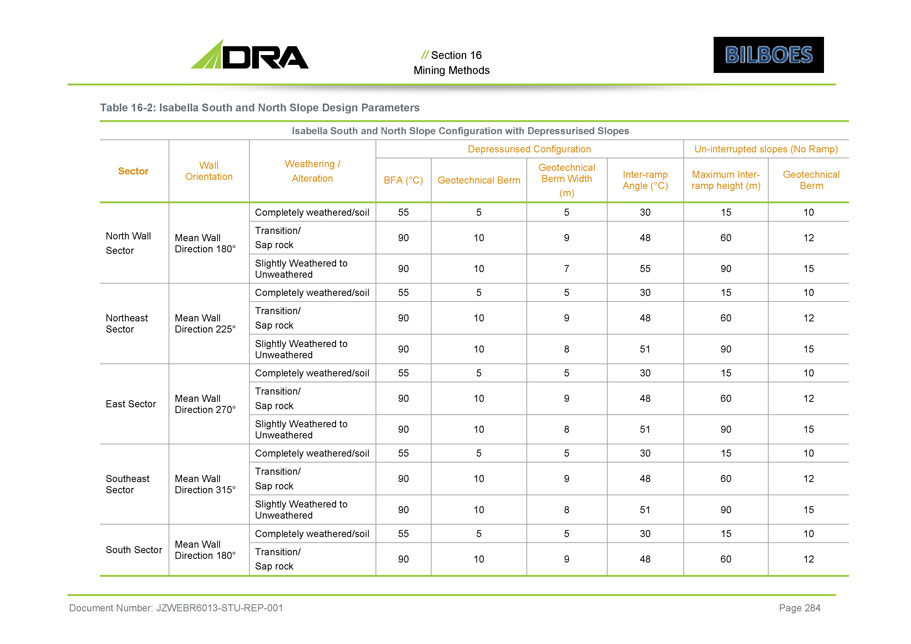

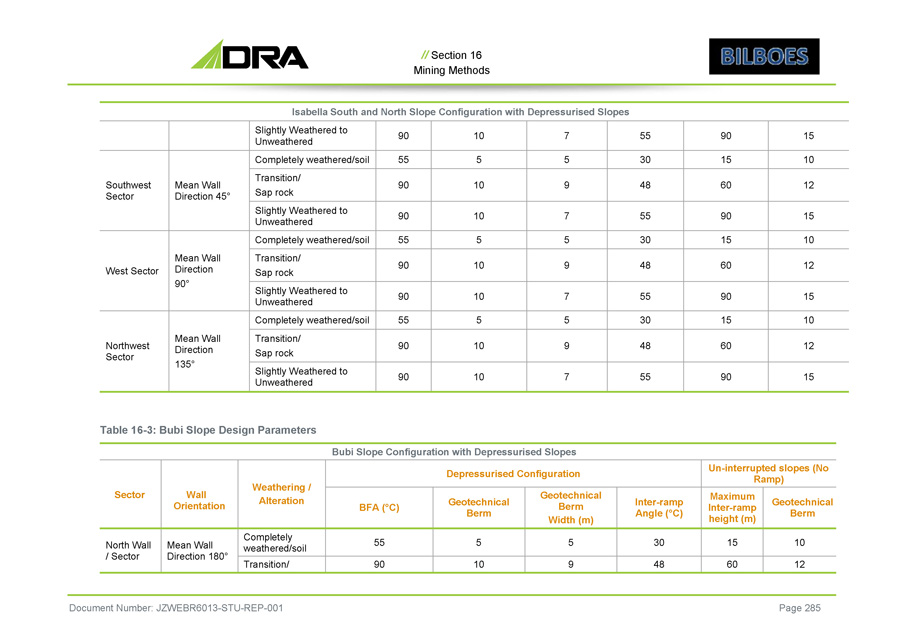

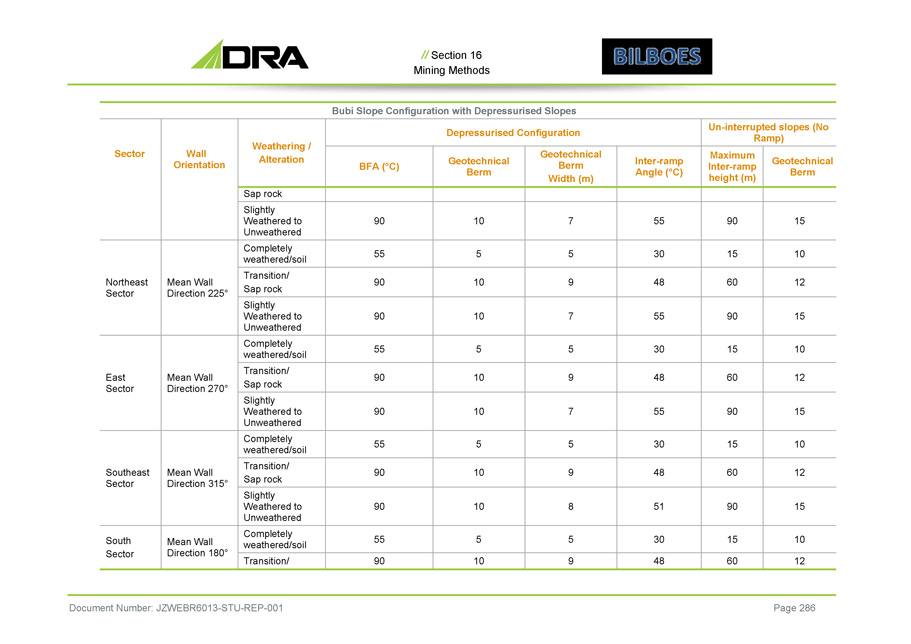

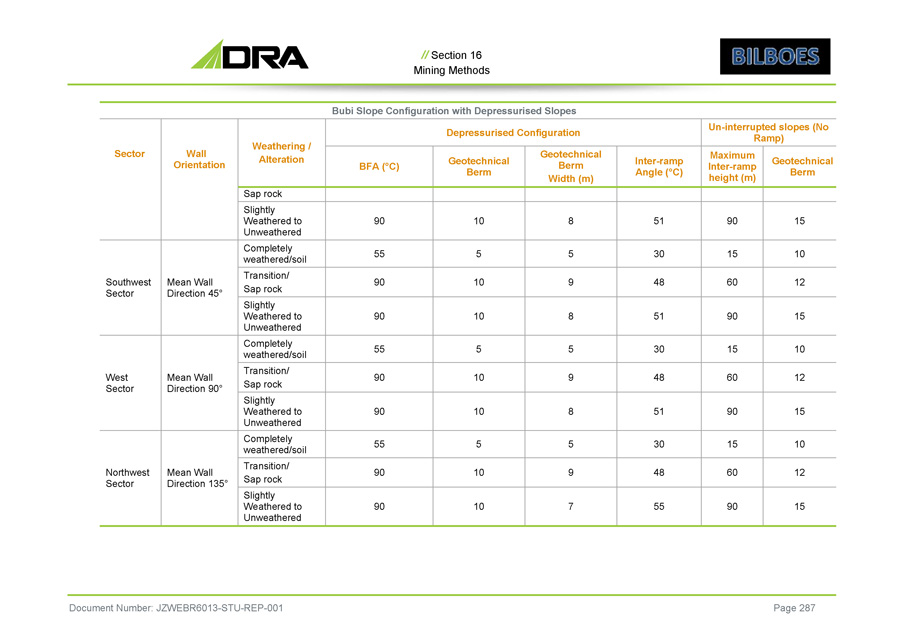

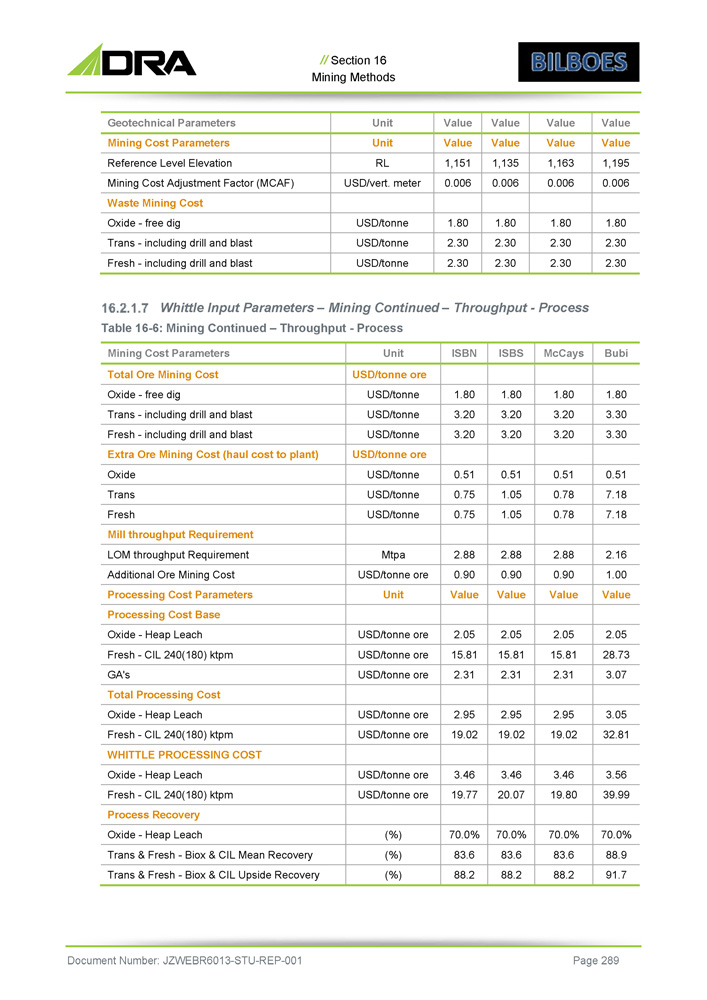

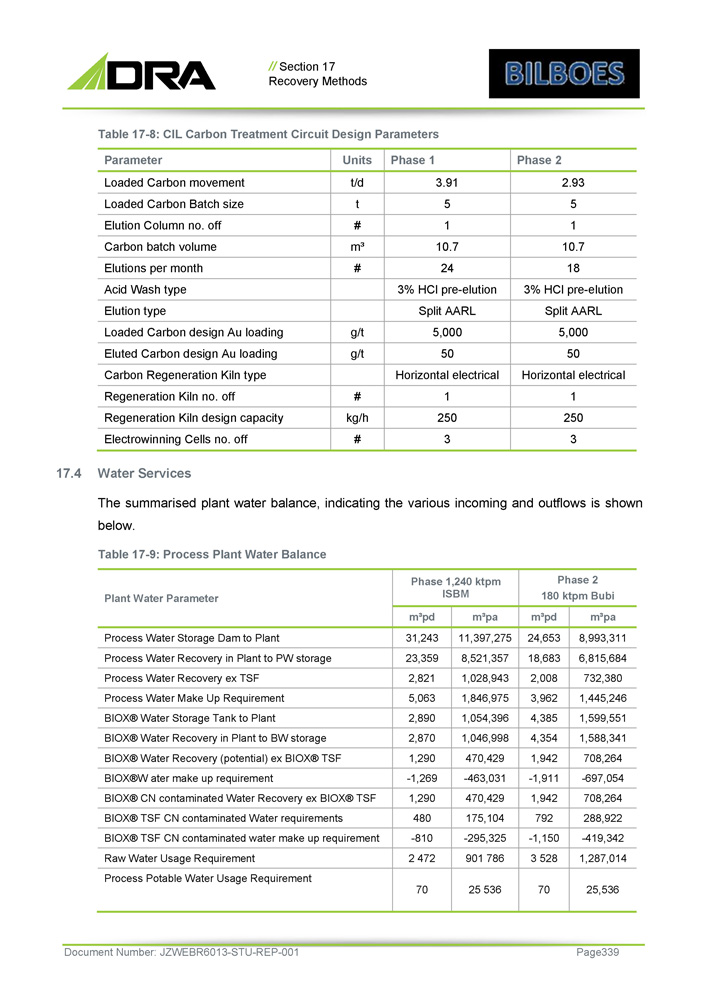

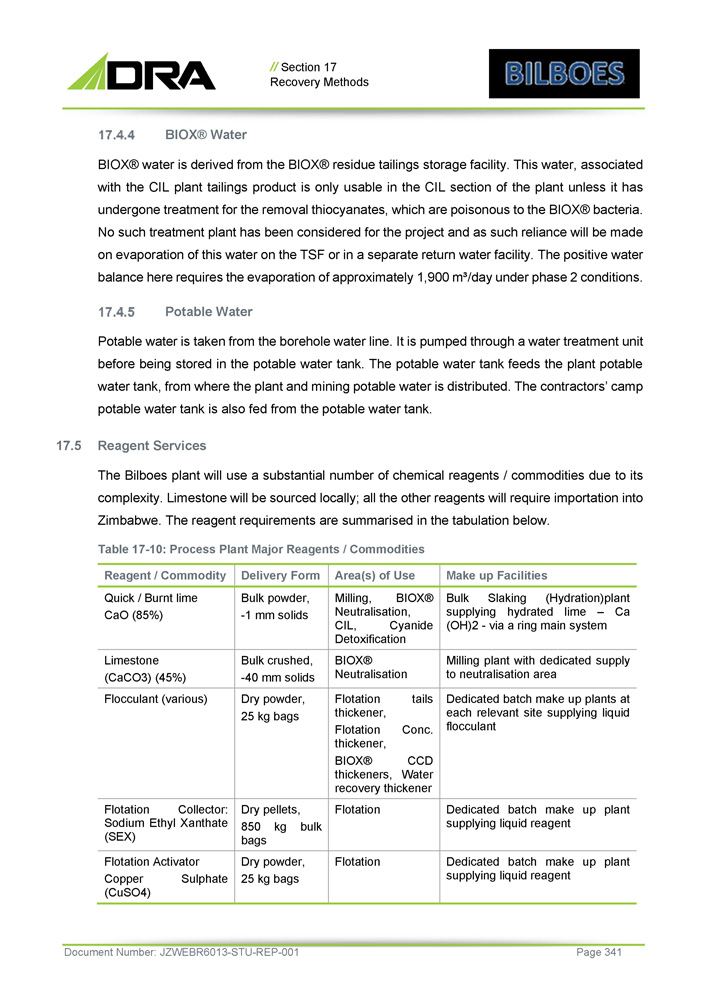

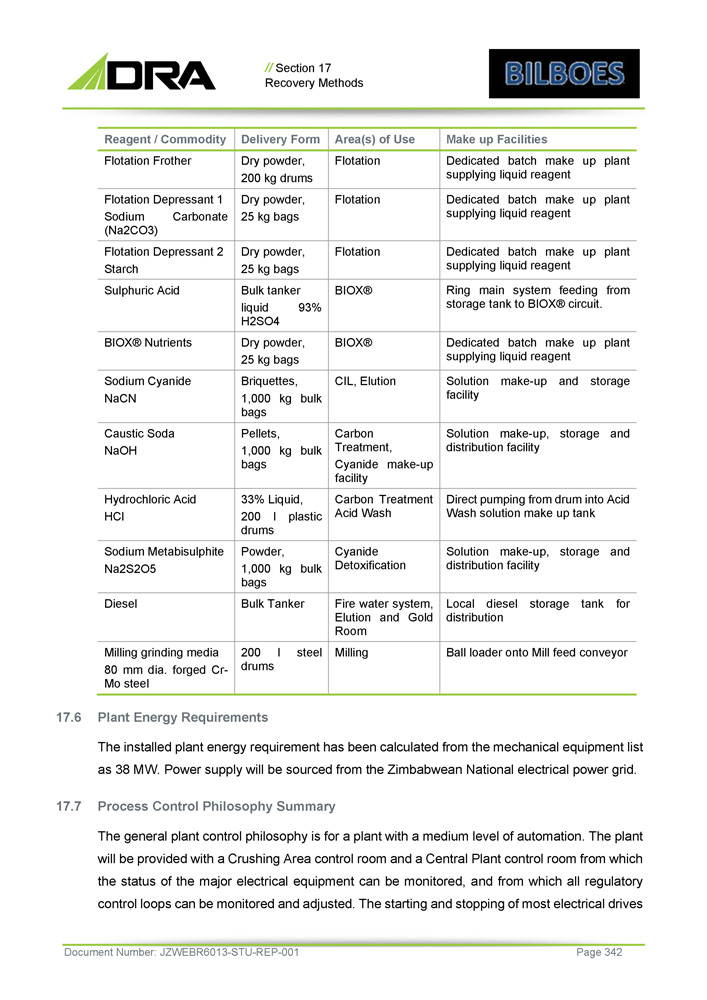

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study Table 14 32: Mineral Resource Tabulation for the Four Properties using a Block Cut - Off Grade 274 of 1.5 g/t Au Table 15 1: Bilboes Gold Project In - situ Mineral Reserve Statement 278 Table 16 1: McCays Slope Design Parameters 283 Table 16 2: Isabella South and North Slope Design Parameters 284 Table 16 3: Bubi Slope Design Parameters 286 Table 16 4: Optimisation Financial Parameters 288 Table 16 5: Geotechnical - Mining 288 Table 16 6: Mining Continued – Throughput - Process 289 Table 16 7: Whittle Optimisation Results 291 Table 16 8: McCays Optimisation Results 294 Table 16 9: Isabella South Optimisation Results 296 Table 16 10: Isabella North Optimisation Results 298 Table 16 11: Bubi Shell Selection 300 Table 16 12: Summary of Selected Shells 301 Table 16 13: Excavator Productivity 322 Table 17 1: Process Plant Design Criteria 327 Table 17 2: Milling Plant Design Parameters 335 Table 17 3: Flotation Plant Design Parameters 336 Table 17 4: BIOX® Circuit Design Parameters 337 Table 17 5: Neutralisation Circuit Design Parameters 338 Table 17 6: CIL Circuit Design Parameters 338 Table 17 7: CIL Tailings Detoxification Circuit Design Parameters 339 Table 17 8: CIL Carbon Treatment Circuit Design Parameters 340 Table 17 9: Process Plant Water Balance 340 Table 17 10: Process Plant Major Reagents / Commodities 342 Table 18 1: Percentage Rock Types at Different Mining Pits 348 Table 18 2: Slope Design 349 Table 18 3: Proposed Soil and Rock Properties for Foundation Modelling on the TSF Site 355 Table 18 4: Proposed Soil and Rock Properties for Foundation Modelling on Process Plant Site 356 Table 18 5: Production Profile 358 Table 18 6: Liner System 363 Table 18 7: Utilization and Diversity Factors 382 Table 18 8: Design Conditions 382 Table 18 9: Substation Loading 382 Table 18 10: Building Infrastructure 389 Table 18 11: Bilboes Tailings Slurry Properties 395 Table 18 12: Water Requirements and Pump - Out Rates during Dry Season for Flotation and 402 BIOX® Compartments Document Number: JZWEBR6013 - STU - REP - 001 Page 21

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study Table 18 13: Water Requirements and Pump - Out Rates during Wet Season for Flotation and 403 BIOX® Compartments Table 18 14: Stormwater Catchments - SCS Curve Numbers and Areas Table 18 15: TSF and Tailings Slurry Characteristics Table 18 16: Bilboes Phases of Tailings Deposition Table 18 17: Flotation Return Water Dam Pool Capacity and Spillages Table 18 18: Hydrogeological units for Isabella McCays and Bubi Table 18 19: Isabella - McCays - Simulation of Contaminant Plume Migration Table 18 20: Bubi - Simulation of Contaminant Plume Migration Table 18 21: Commissioning Sequence Table 18 22: Commissioning Sequence Responsibility Table 18 23: Detail Level of Schedule Table 18 24: Work Breakdown Structure Table 18 25: Schedule Risks Table 21 1: Work Breakdown Structure Table 21 2: Cost Categories Tabs Table 21 3: Mining Contract Budget Price BOQ for LoM Table 21 4: Preliminary and General Percentages Table 21 5: Mining Capital Costs Table 21 6: Cost Category Components Table 21 7: Discipline Price Source Percentage Table 21 8: Capital Summaries Comparison between 2019 and 2021 by Discipline Table 21 9: Capital Summaries Comparison between 2019 and 2021 by WBS Table 21 10: Capital Summaries per Project Phase Table 21 11: Foreign Exchange Table 21 12: Escalation by Discipline Table 21 13: Project Contingency Percentage by Discipline Table 21 14: Bilboes Mining Contractor Adjudication Summary Table 21 15: Bilboes Mining Contractor Adjudication Ranking Table 21 16: Bilboes Explosive Supplier 1 Budget Price Table 21 17: Bilboes Explosive Supplier 2 Budget Price Table 21 18: Mining Contractor Costs per Area ($/total tonne) Table 21 19: Reagents - Unit Consumption Rates and Supply Costs Table 21 20: Labour Compliment – Phase 1 (240 ktpm) Table 21 21: Labour Compliment – Phase 2 (180 ktpm) Table 21 22: Phase 1 Plant OPEX (240 ktpm, excl. G&A) Table 21 23: Phase 2 Plant OPEX (180 ktpm, excl. G&A) Table 21 24: Bilboes Base Case General Administration Costs Document Number: JZWEBR6013 - STU - REP - 001 Page 22 406 406 407 409 412 415 418 448 450 456 460 461 487 488 491 500 501 502 504 504 505 506 509 509 511 513 516 516 517 518 521 522 523 524 525 525

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study Table 21 25: LoM Operating Cost Summary Table 22 1: Discounted Cash Flow Process Inputs Table 22 2: Discounted Cash Flow Revenue Inputs Table 22 3: Initial Capital Cost Summary Table 22 4: LoM Operating Cost Summary Table 22 5: Project Economics Summary Table 23 1: Historic Gold Production from Mines around Isabella McCays and Bubi to 1980 Table 24 1: Capital Gains Tax Table 24 2: Vat Collection Table 25 1: Risks Associated with the Project sorted on Risk Rating Table 25 2: Project Economics Summary Document Number: JZWEBR6013 - STU - REP - 001 Page 23 526 529 529 531 532 532 538 542 543 548 552

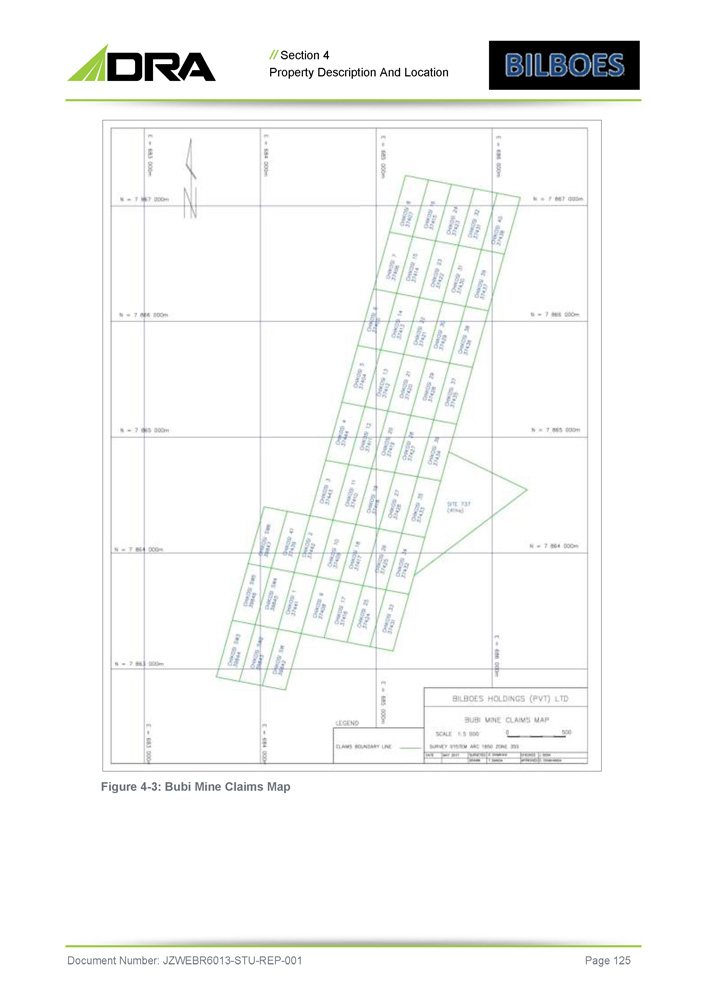

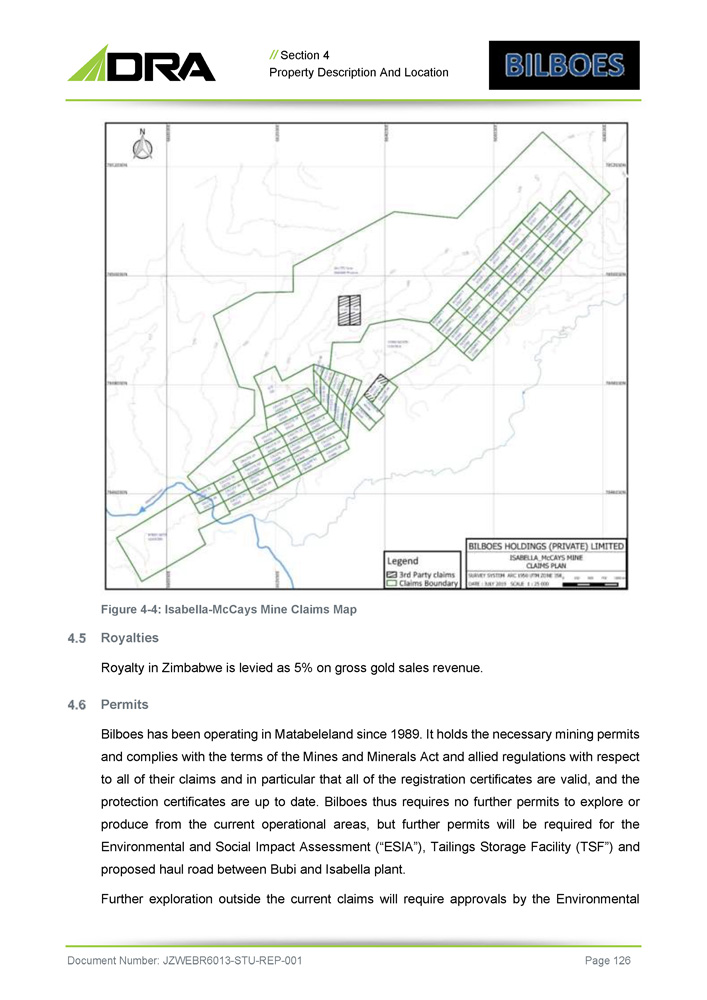

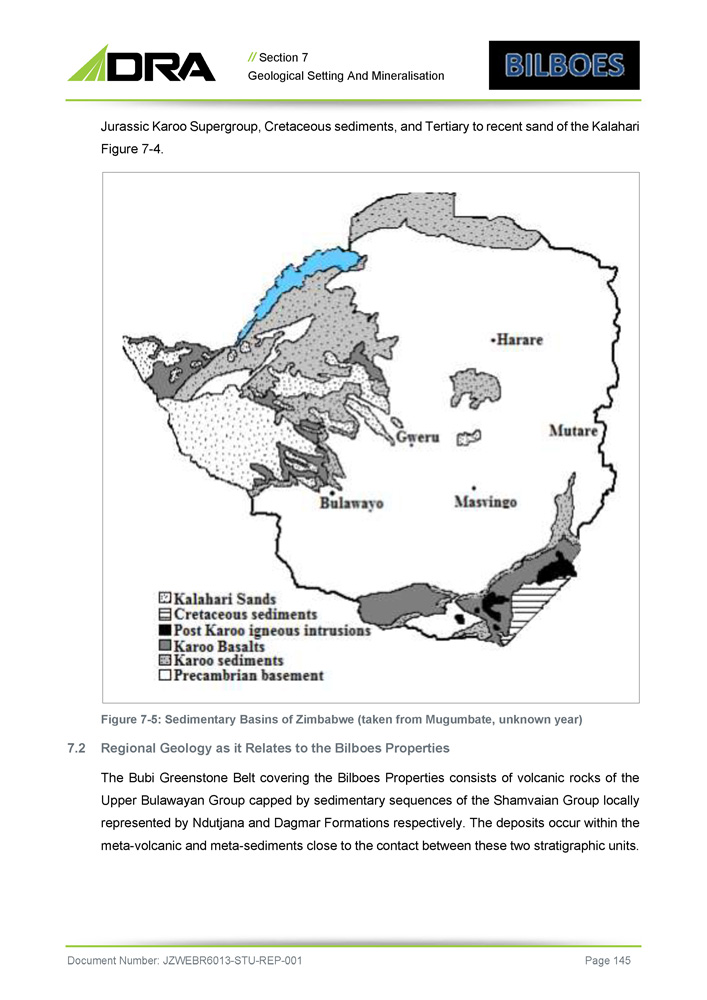

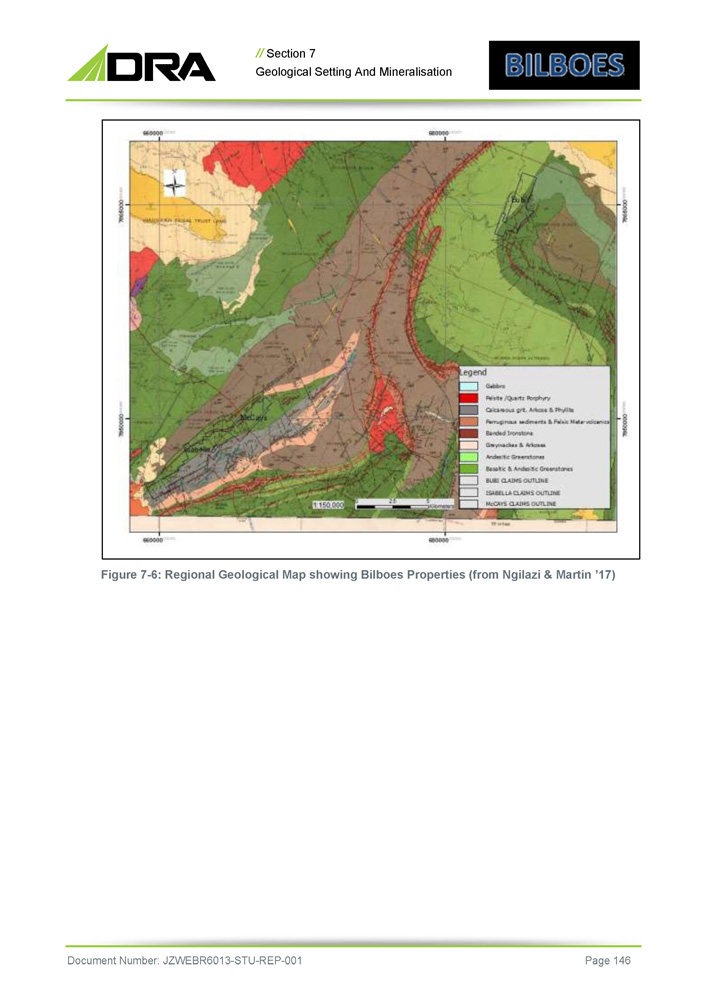

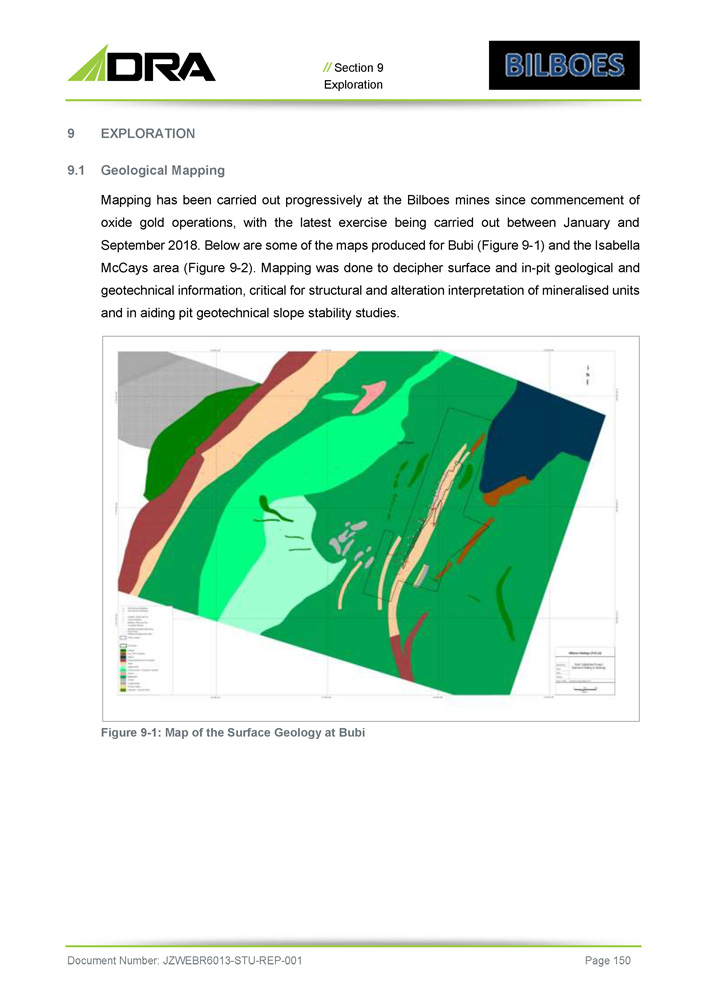

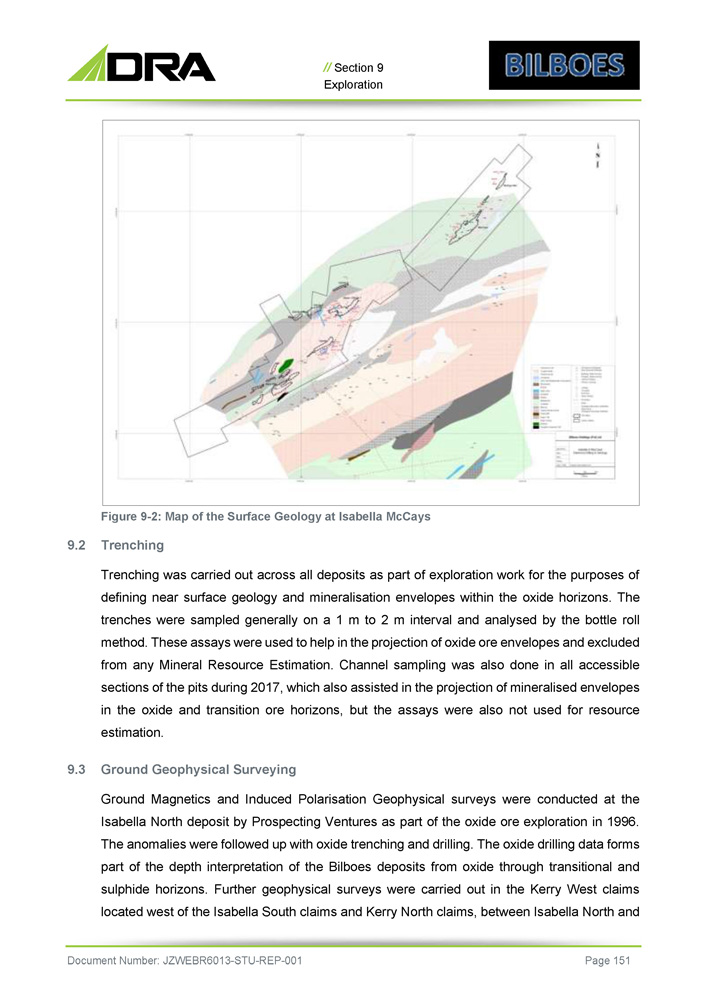

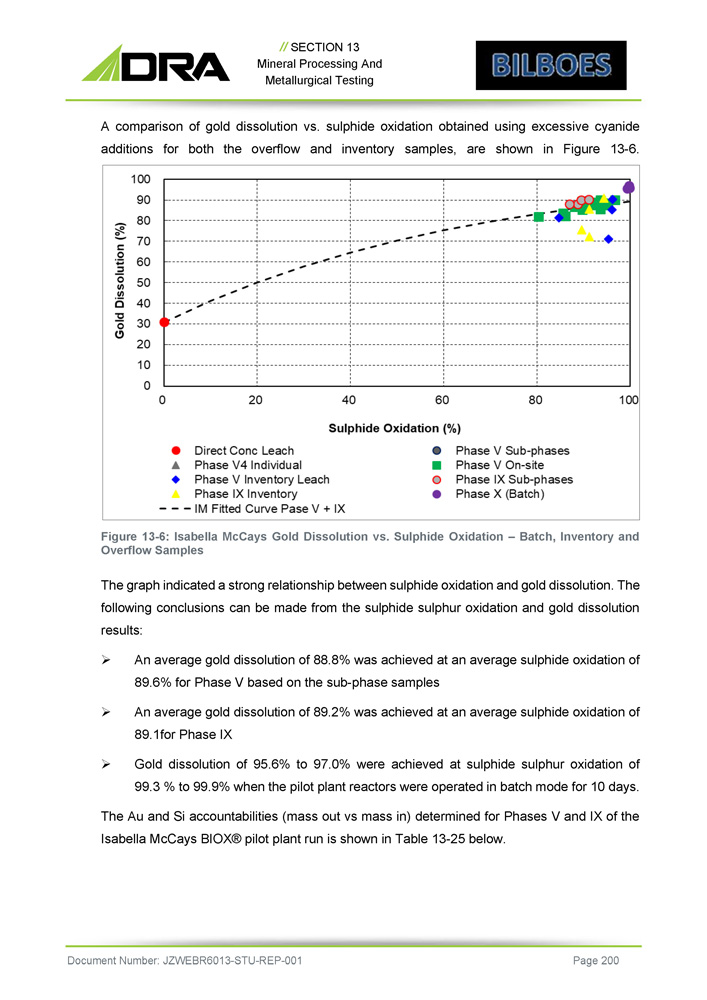

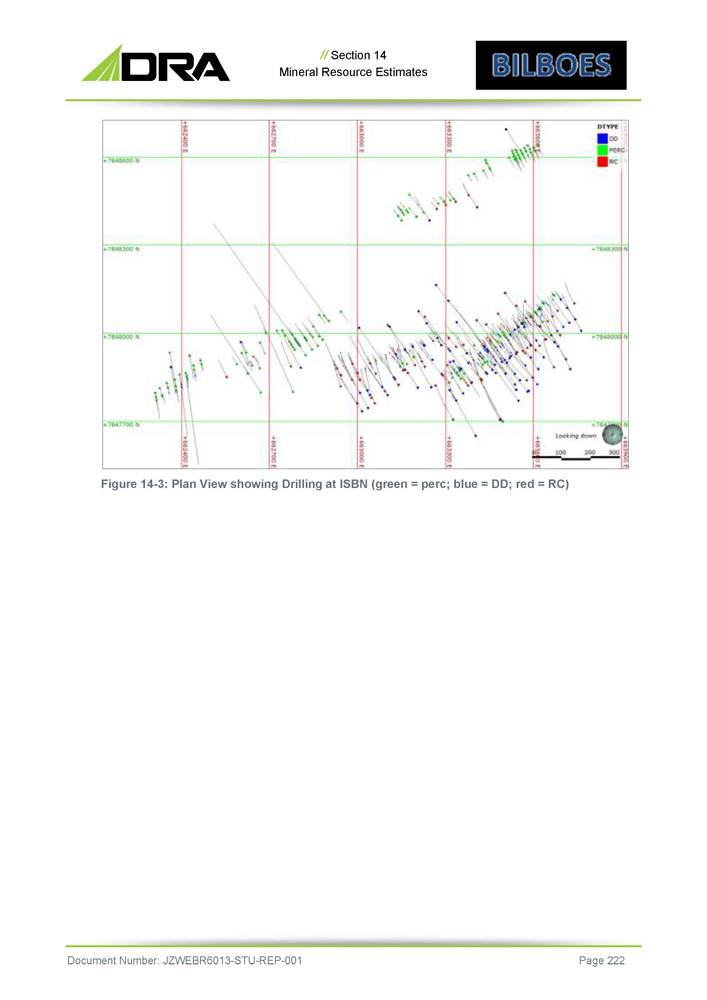

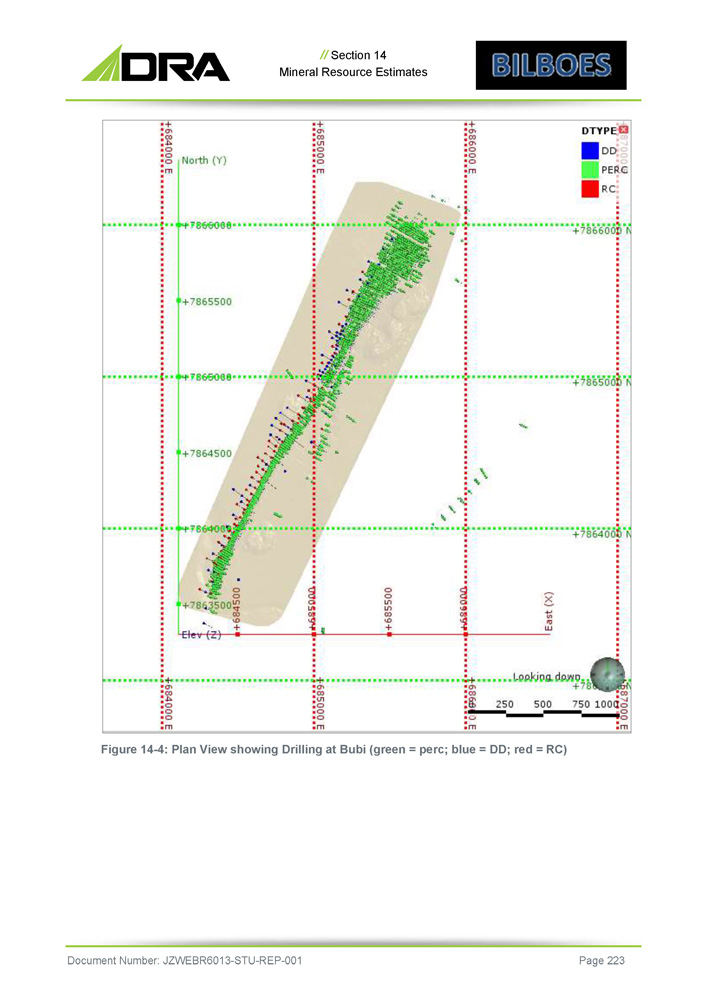

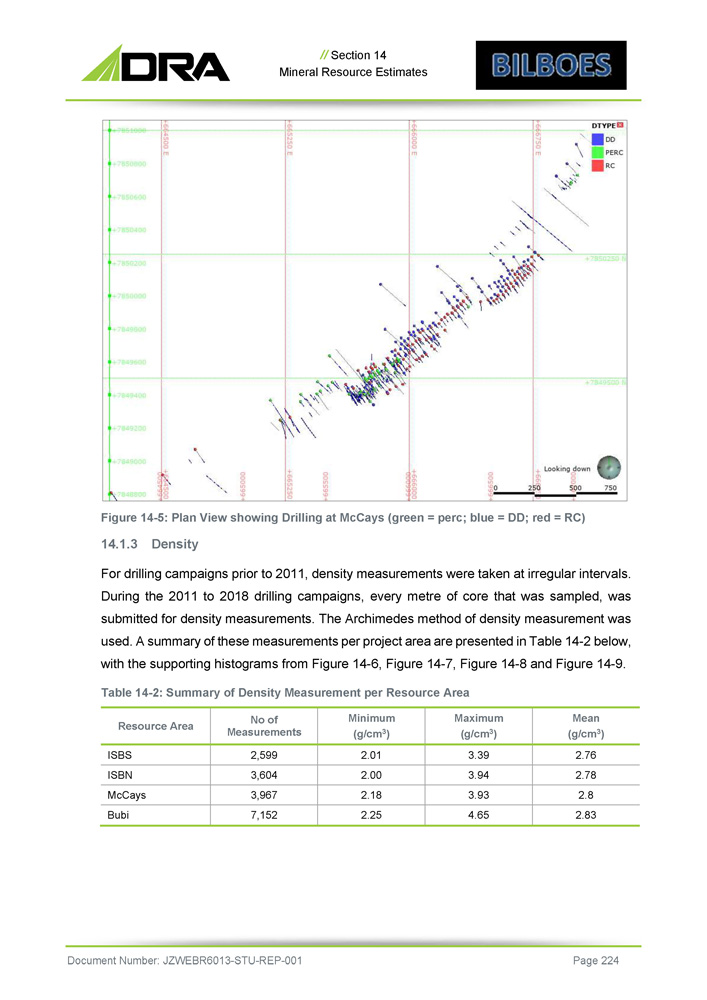

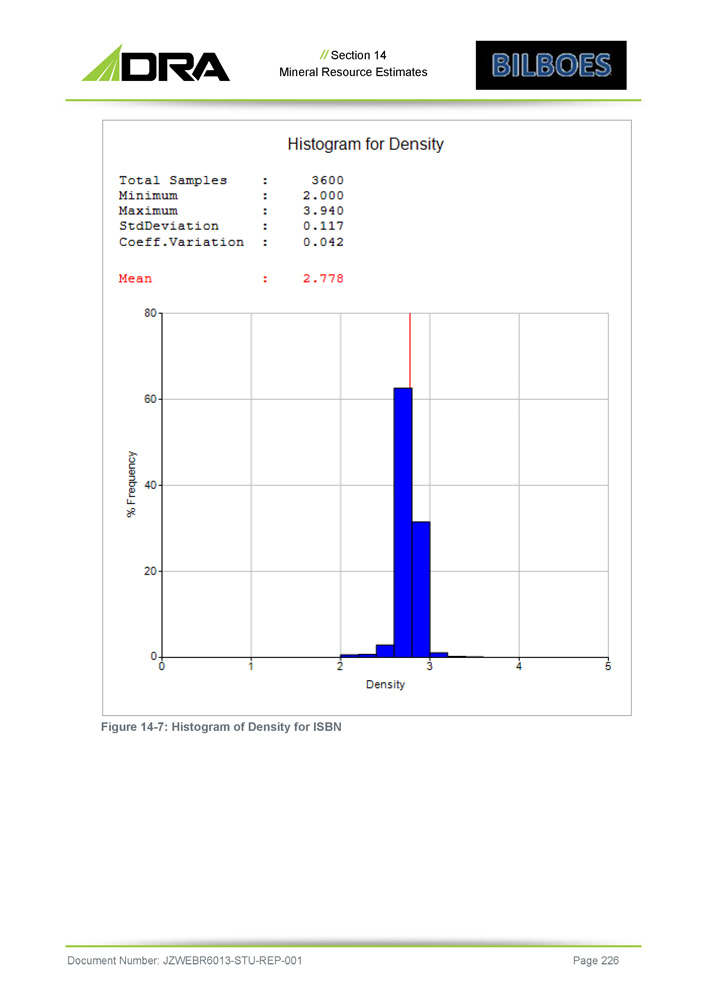

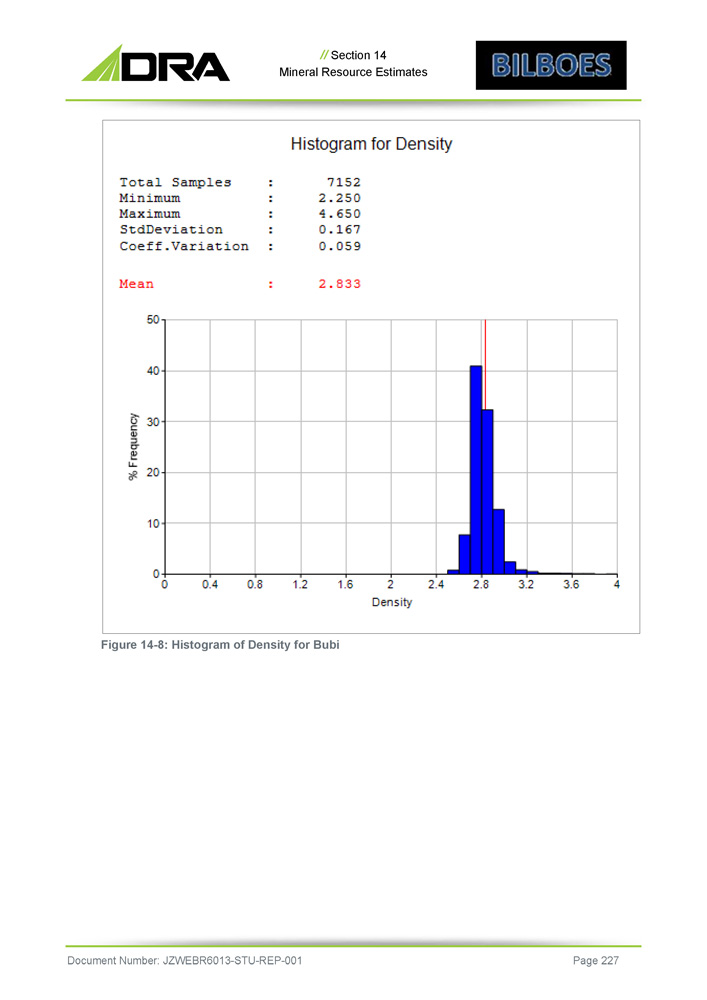

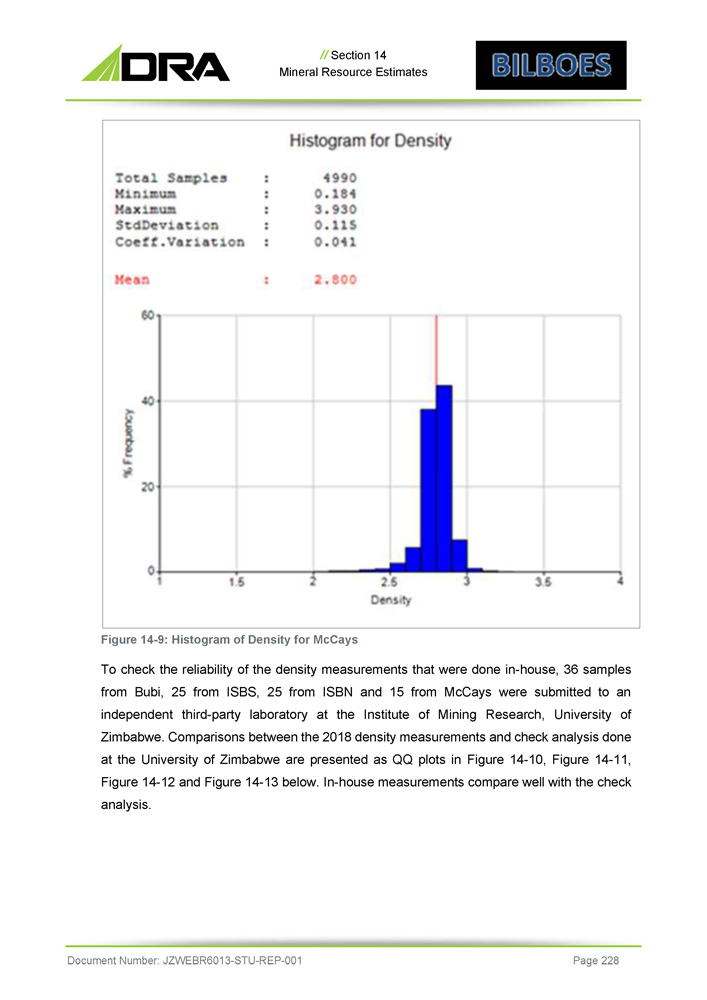

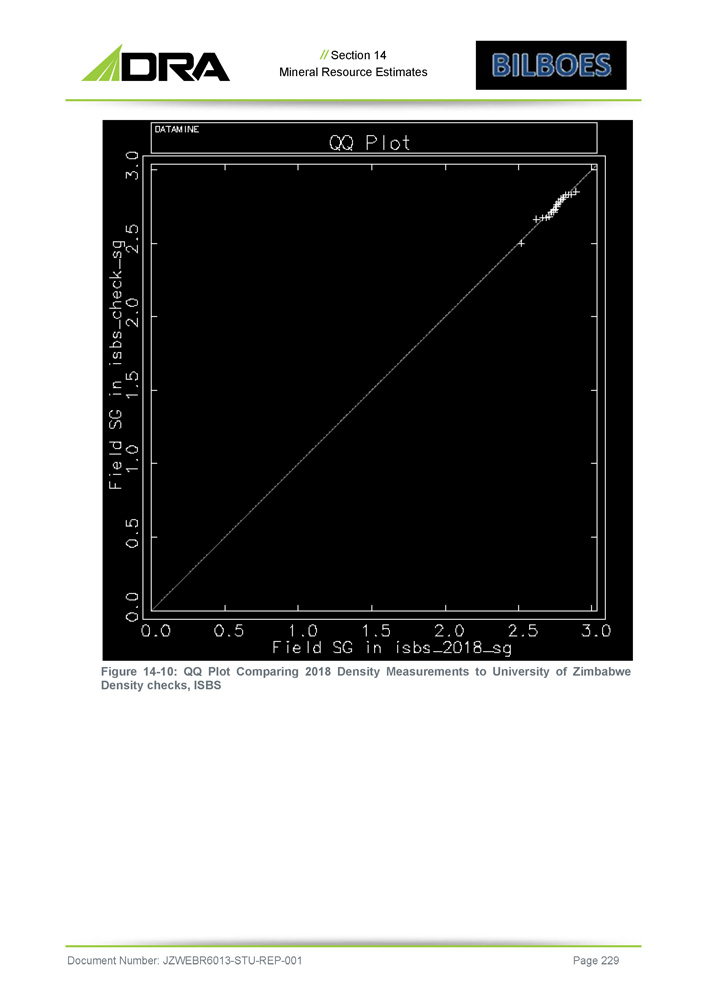

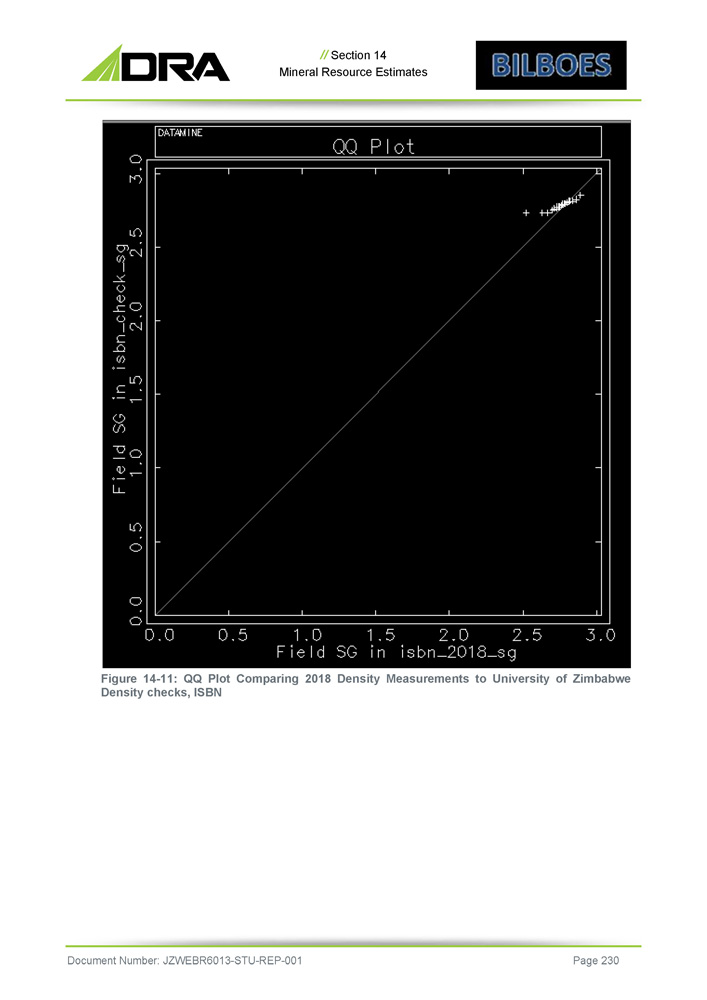

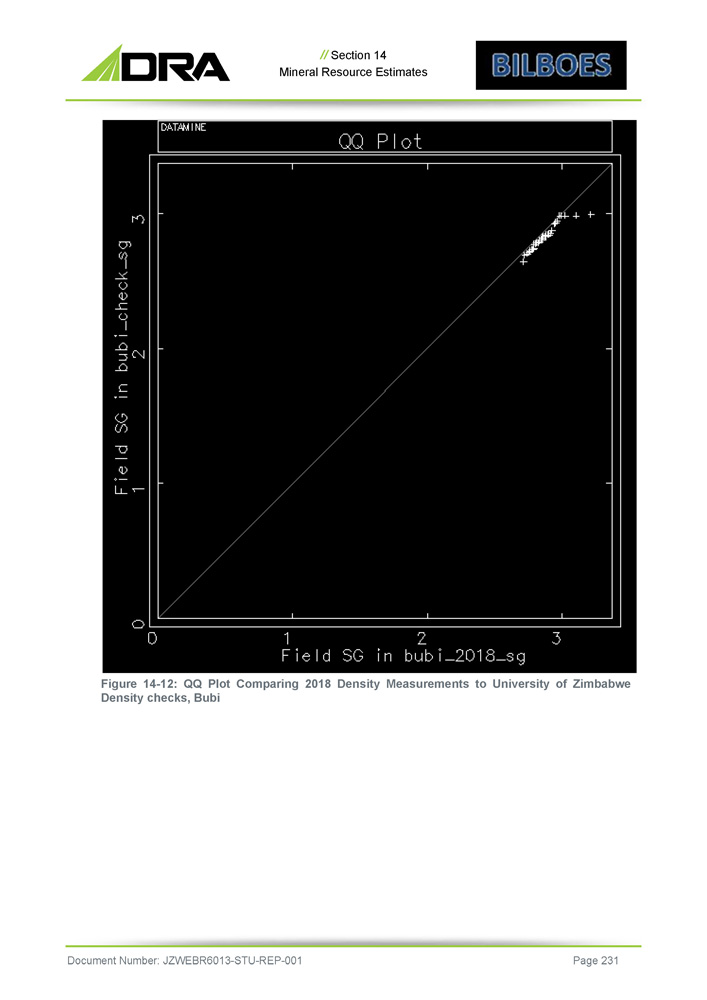

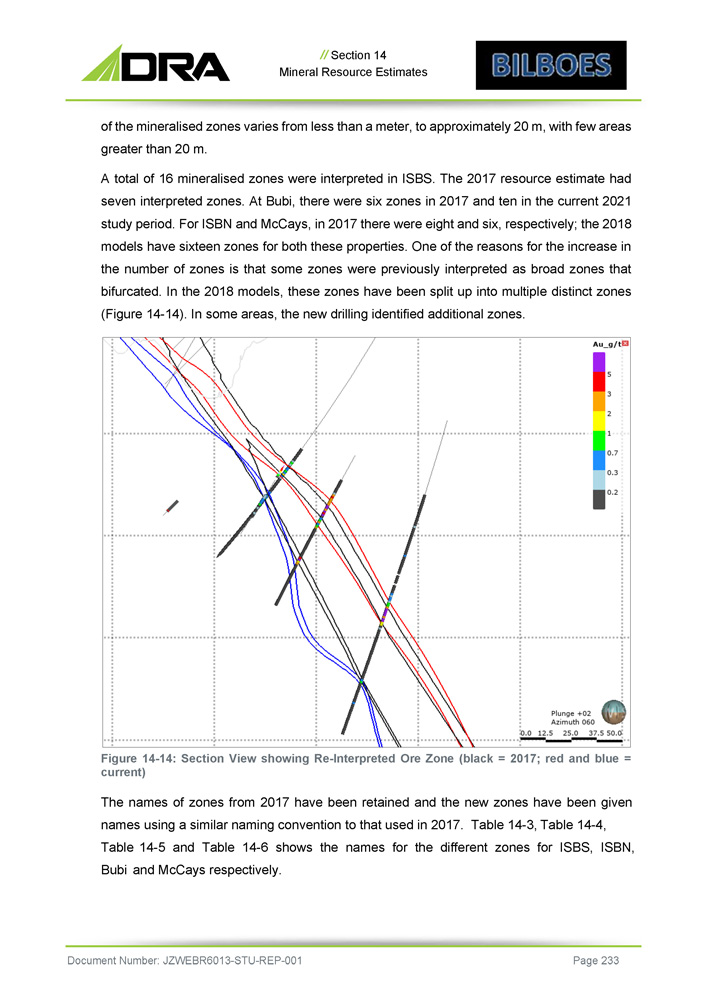

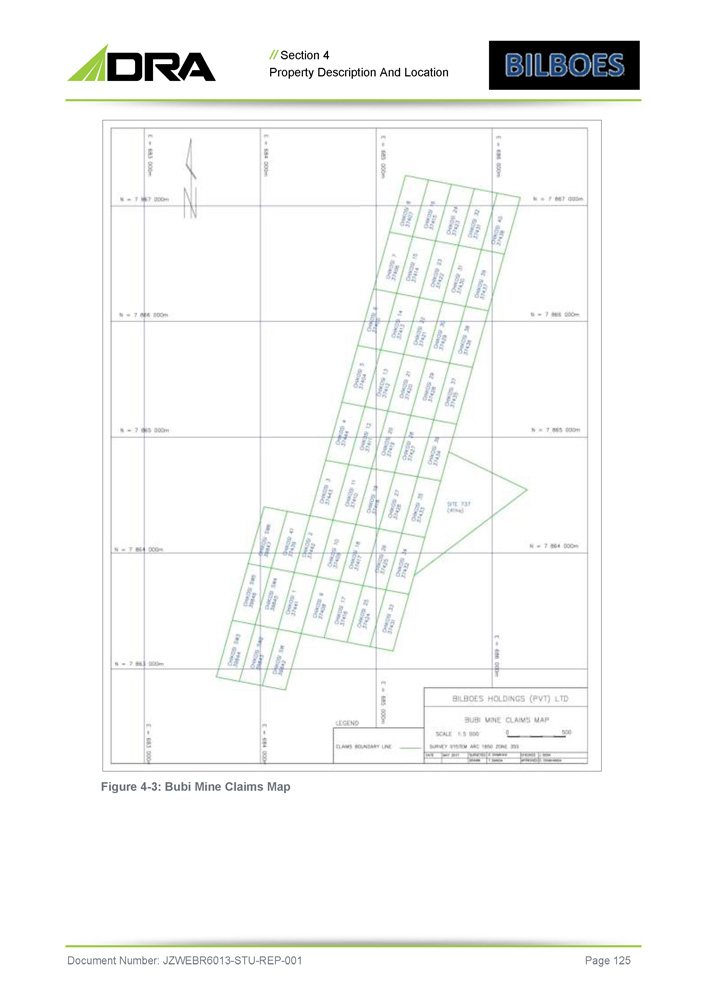

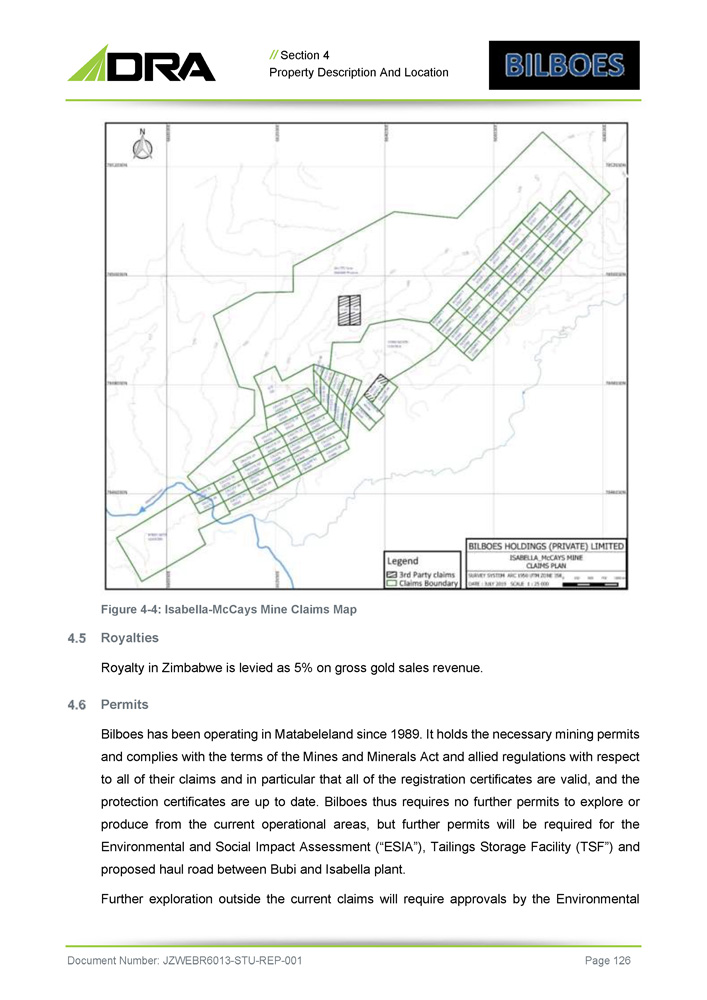

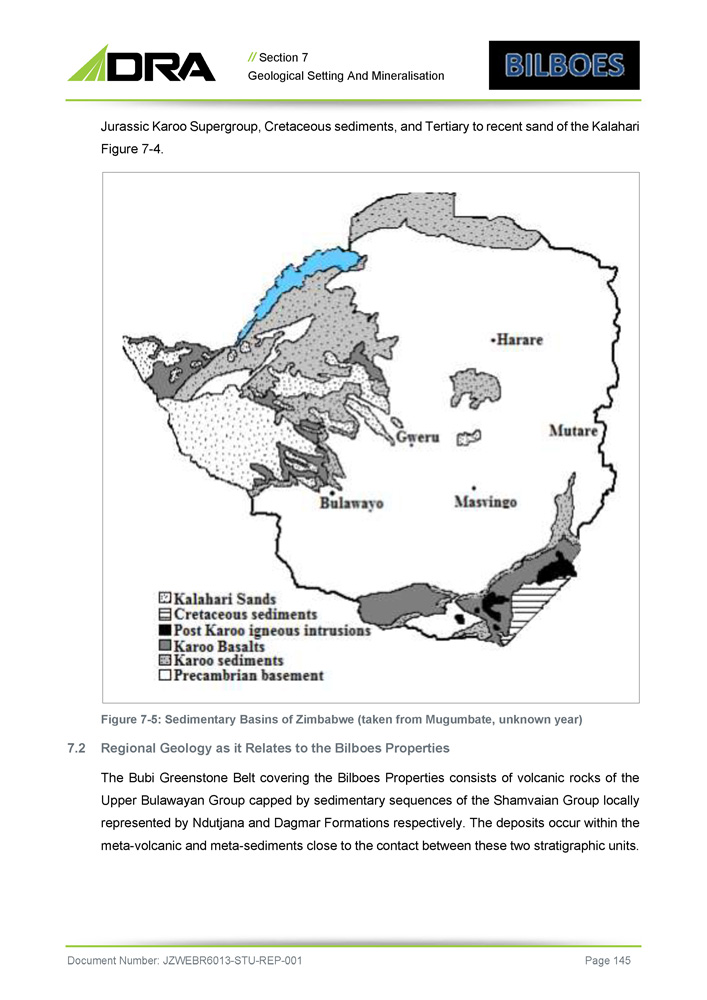

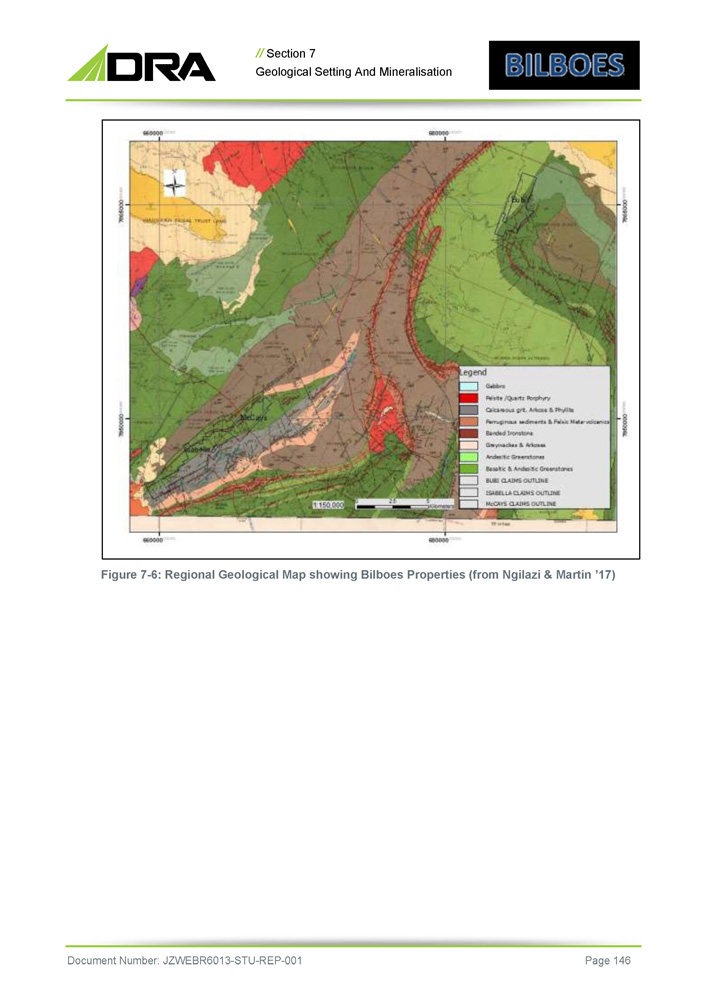

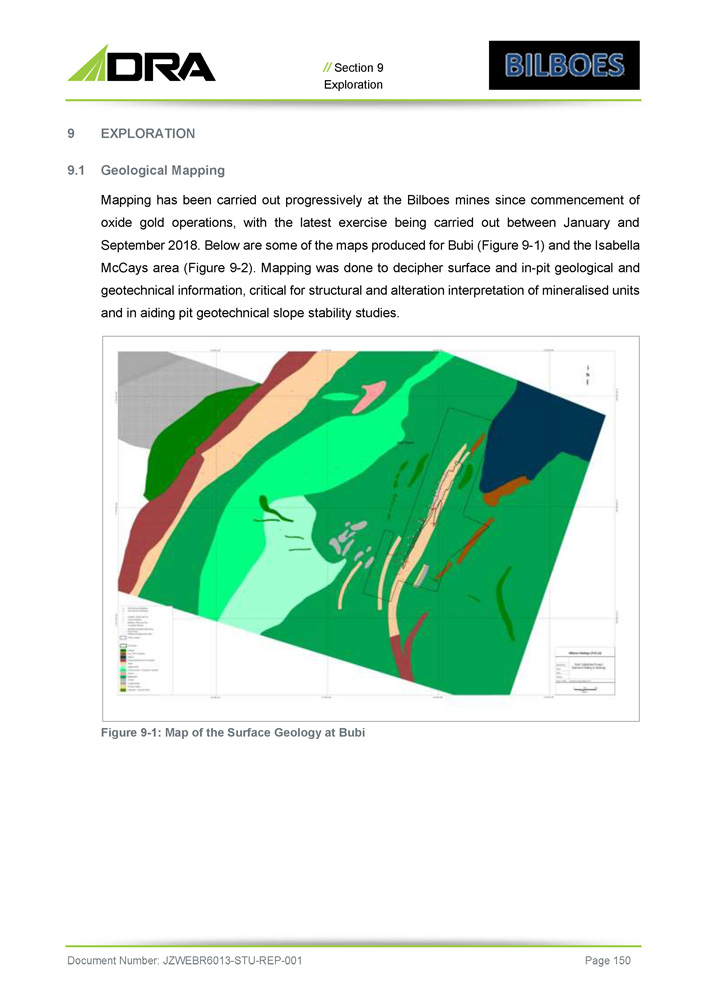

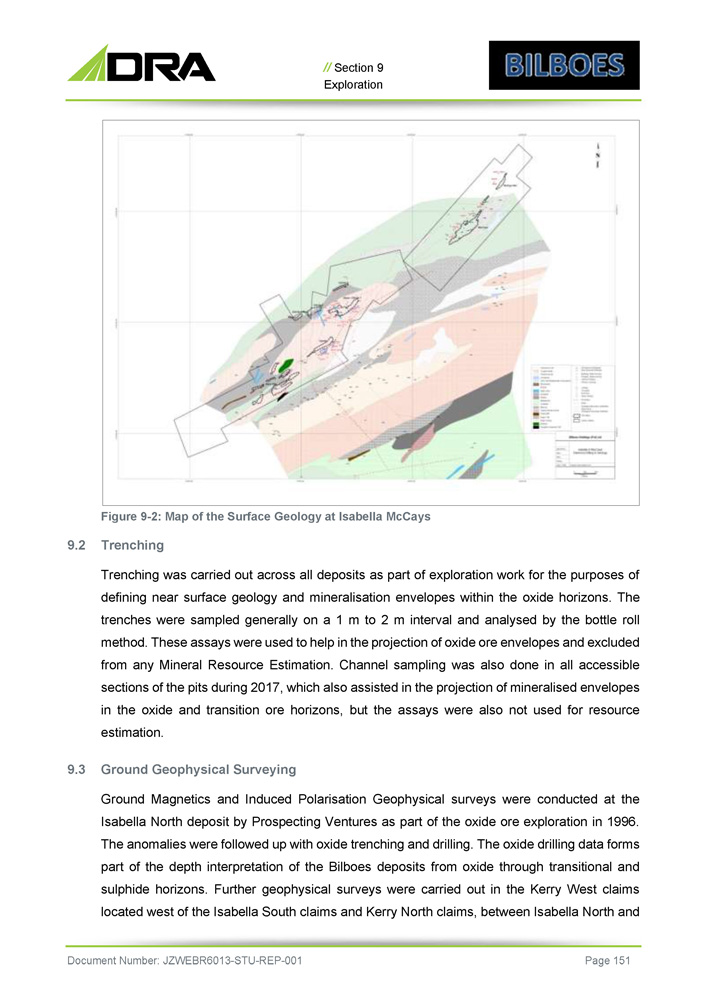

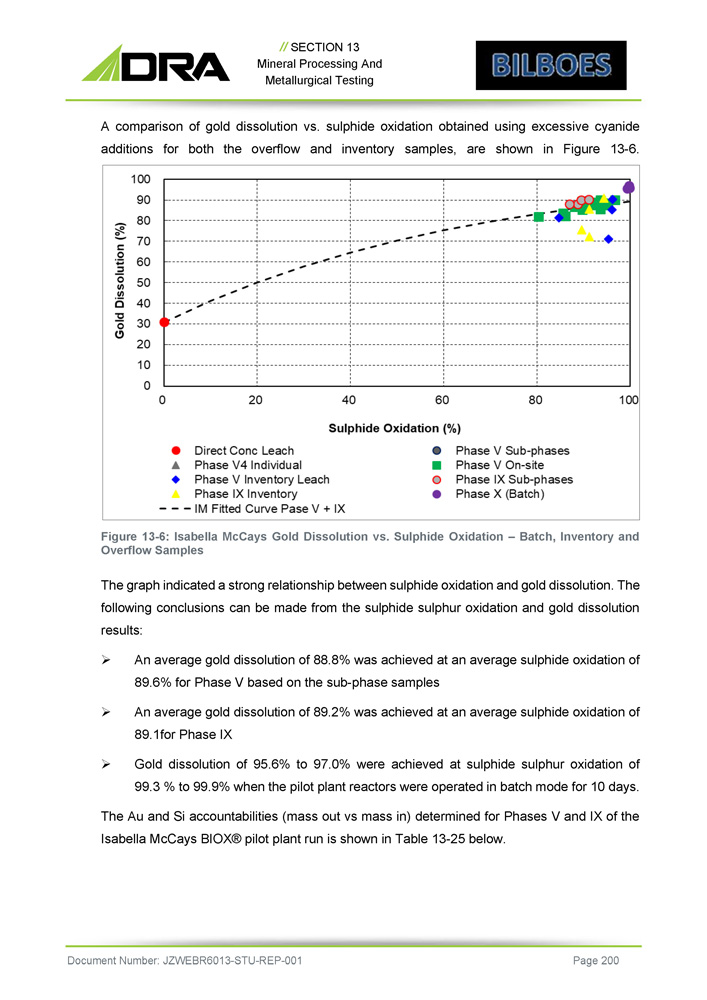

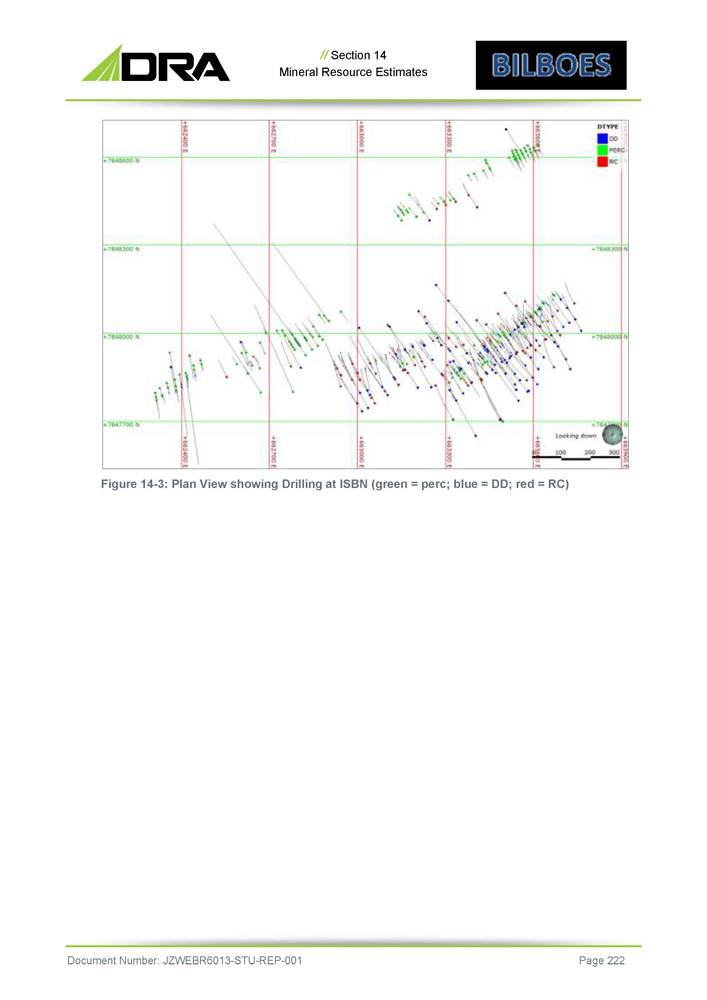

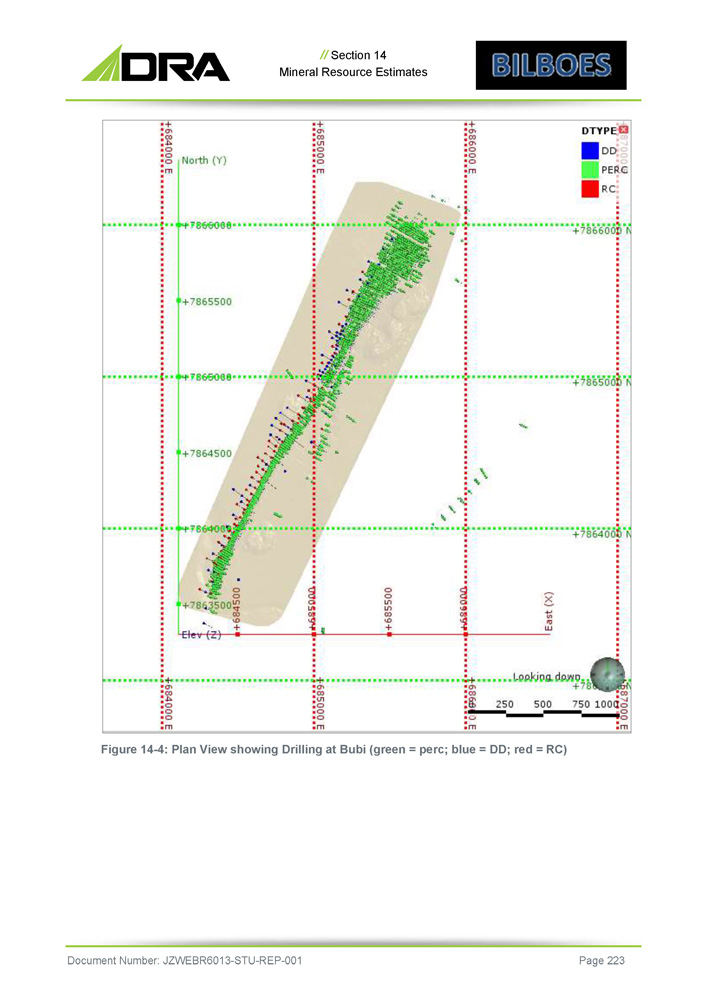

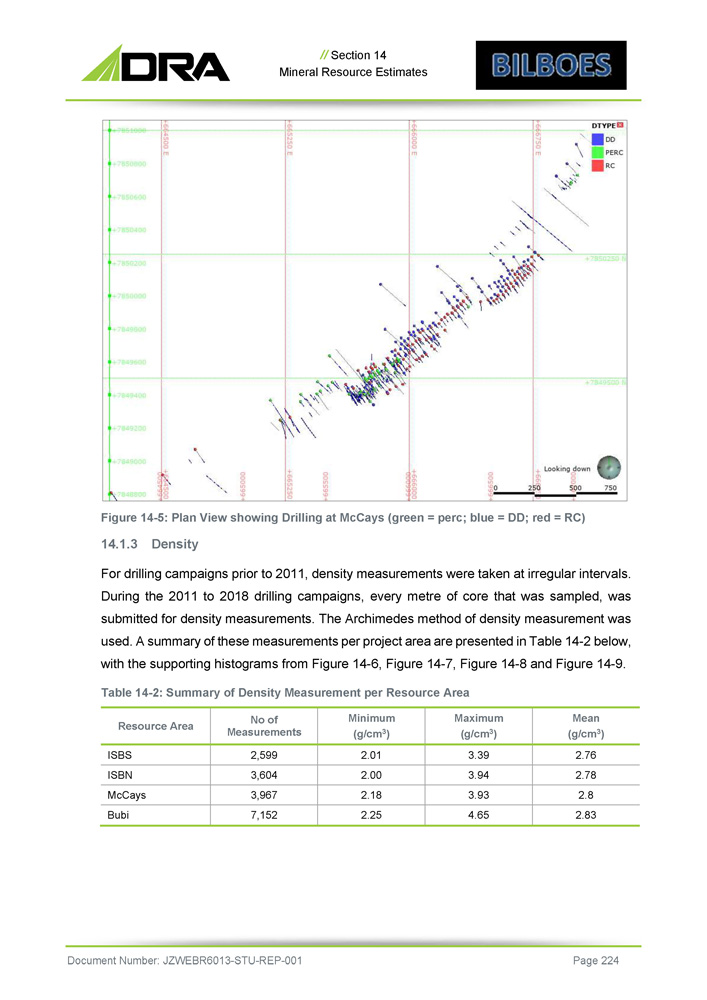

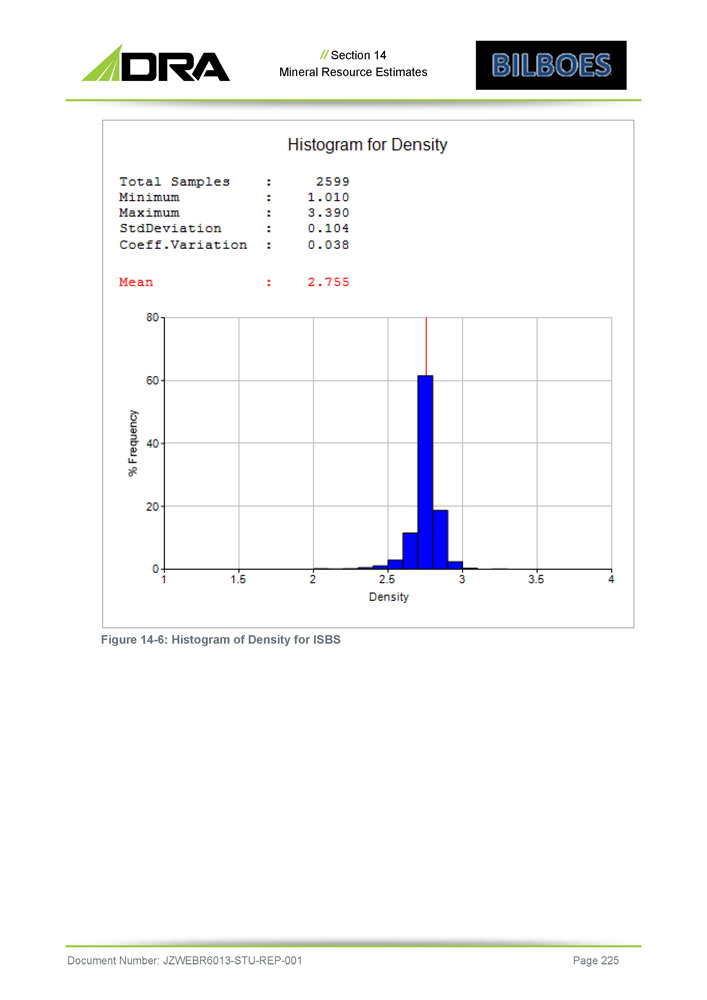

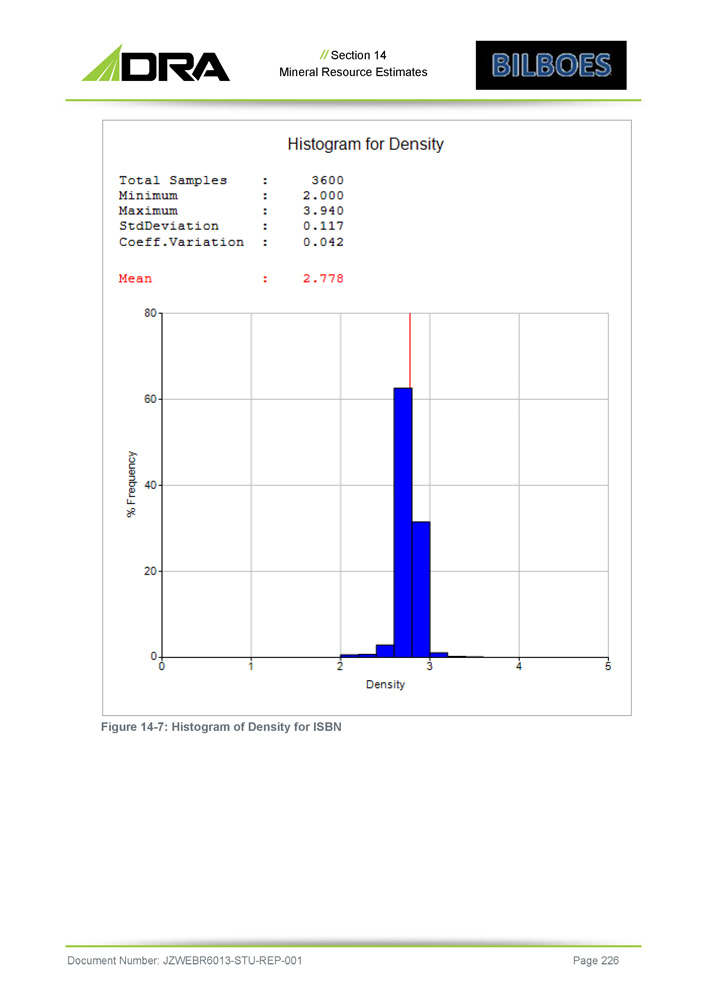

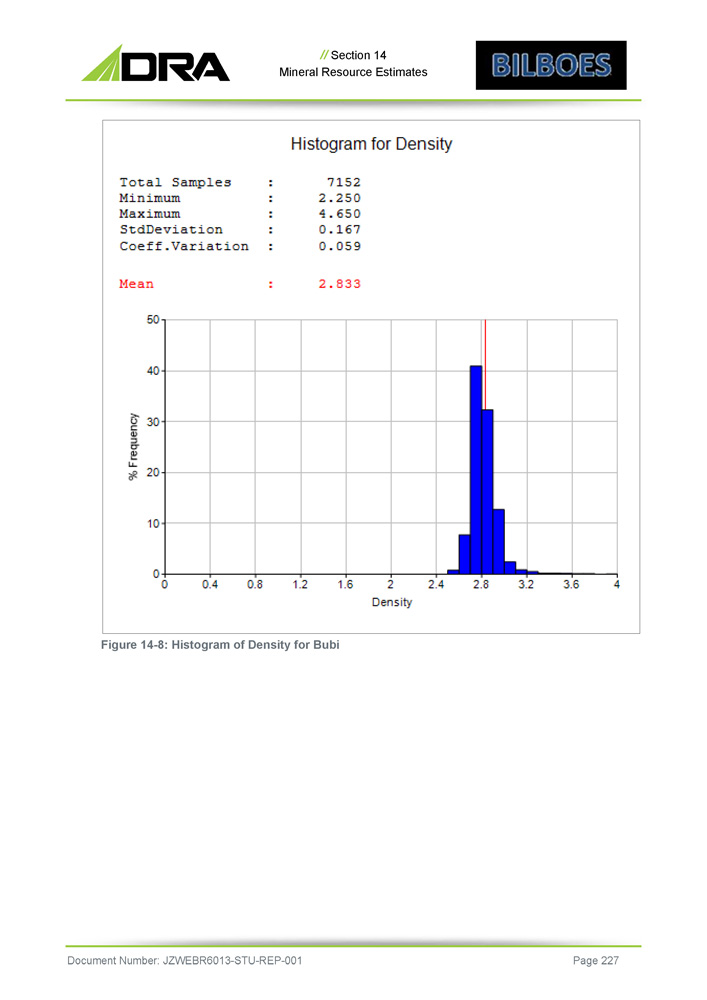

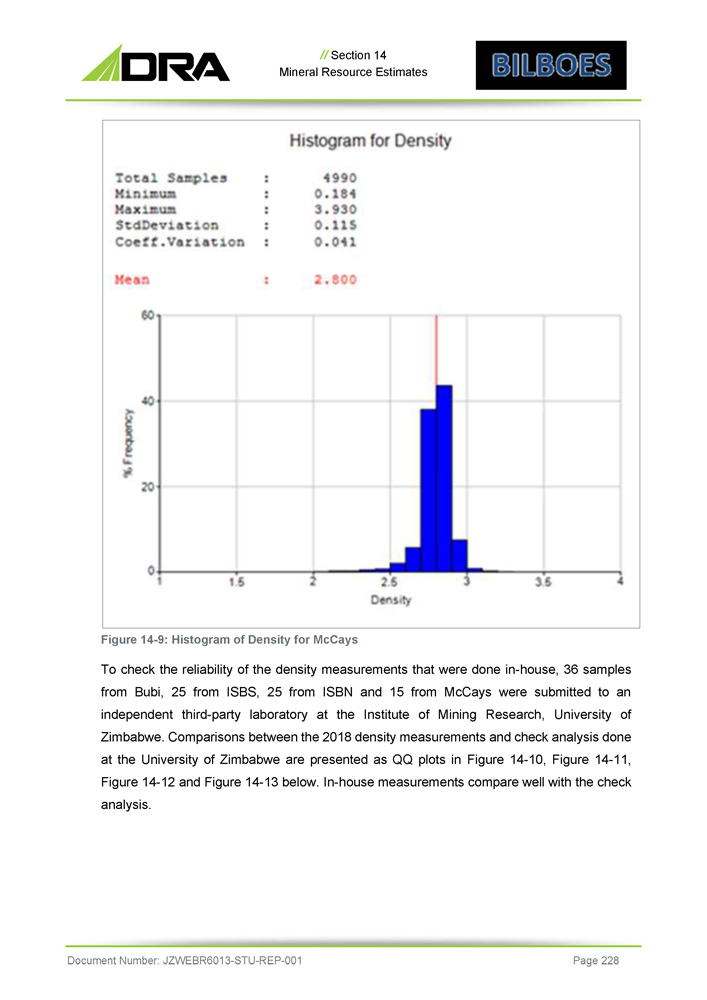

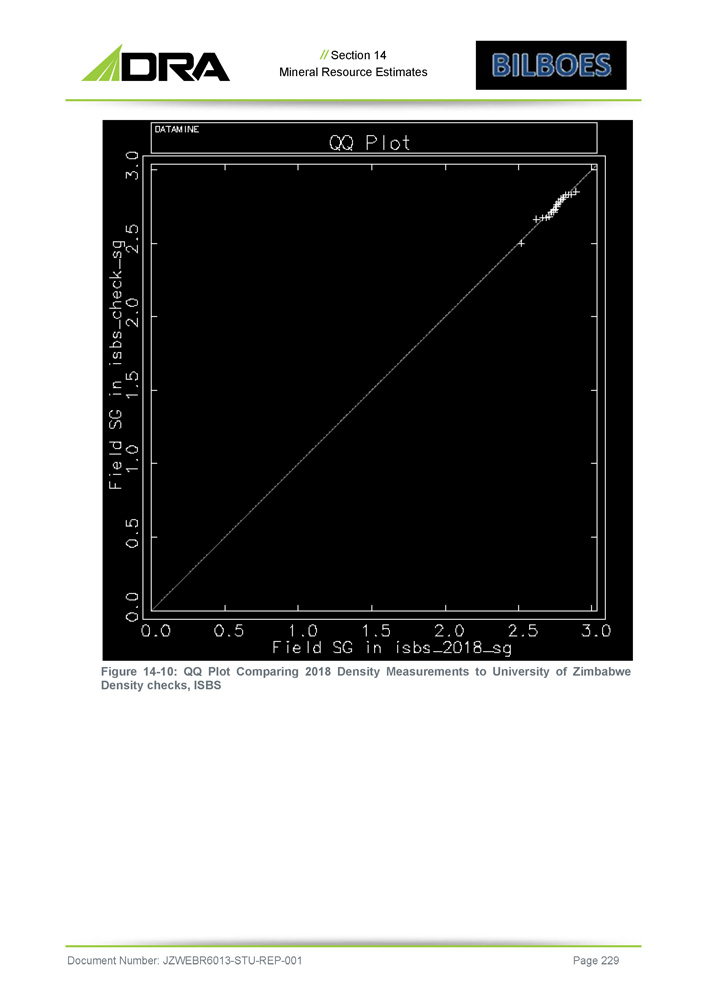

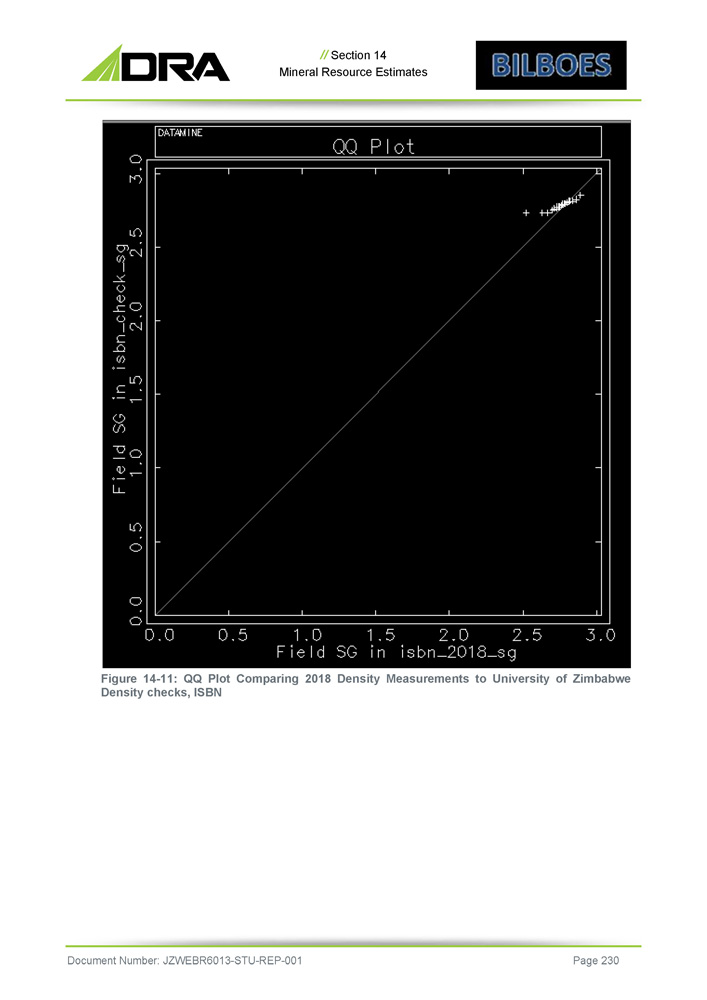

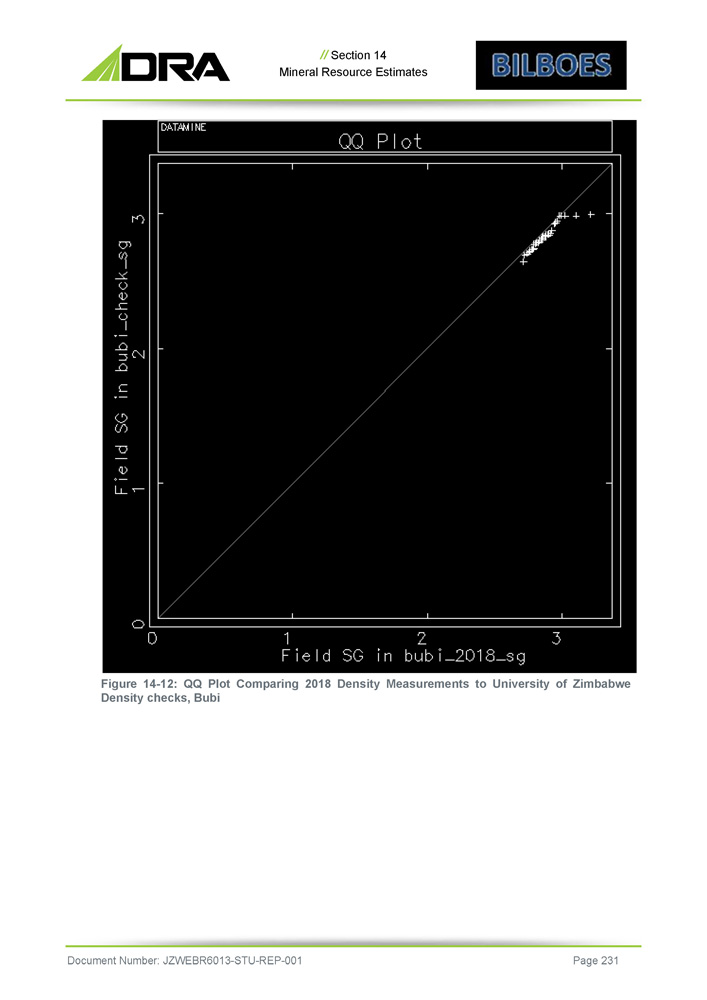

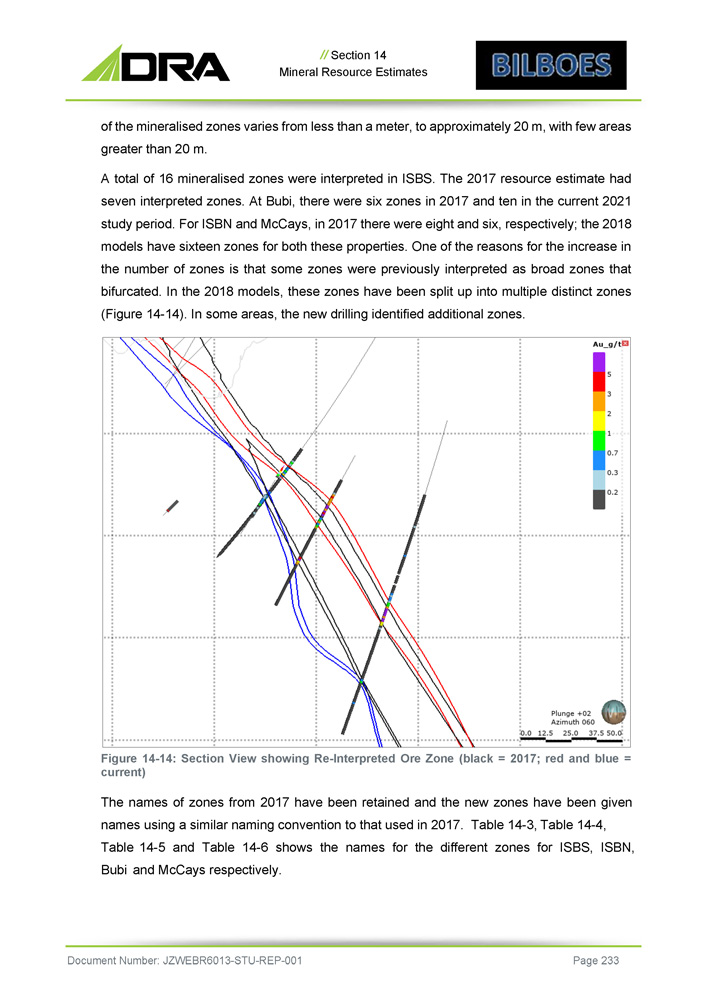

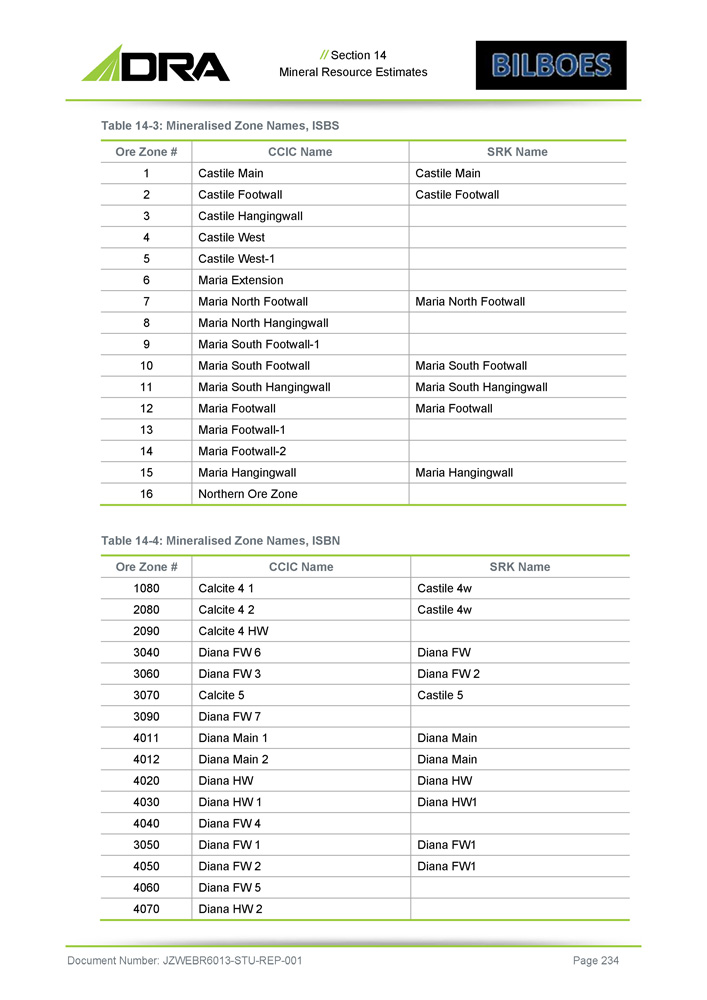

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study LIST OF FIGURES Figure 1 1: Bilboes Corporate Structure (Taken from Ngilazi and Martin, 2017) 35 Figure 1 2: Location Map of Bilboes Properties 36 Figure 1 3: Pilot Plant Campaign Flowsheets 44 Figure 1 4: Block Plan Showing Bilboes Pits and Process Plant Location 53 Figure 1 5: McCays Pits and WRD Designs 54 Figure 1 6: Isabella South Pits and Dumps 54 Figure 1 7: Isabella North Pit Design 55 Figure 1 8: Bubi Pits and Dumps 55 Figure 1 9: Overall Site Plan 72 Figure 1 10: Bilboes Simplified Process Flow Diagram 91 Figure 4 1: Map of the Republic of Zimbabwe 122 Figure 4 2: Regional Location of the Bilboes (Taken from Burger et al, 2017) 123 Figure 4 3: Bubi Mine Claims Map 125 Figure 4 4: Isabella - McCays Mine Claims Map 126 Figure 7 1 : Geological Map Zimbabwe (taken from Mugumbate, unknown year) 141 Figure 7 2 : Greenstone Belts and known Gold Deposits in Zim (from Mugandani ‘ 17 ) 142 Figure 7 3 : NNE Trending Great Dyke cutting across the Zimbabwe Craton (from Mukaka et al ‘ 98 ) 143 Figure 7 4 : Geological Map showing the Zimbabwe Craton and Mobile Belts (taken from Gore et al ‘ 09 ) 143 Figure 7 5 : Sedimentary Basins of Zimbabwe (taken from Mugumbate, unknown year) 145 Figure 7 6 : Regional Geological Map showing Bilboes Properties (from Ngilazi & Martin ’ 17 ) 146 Figure 9 1 : Map of the Surface Geology at Bubi 150 Figure 9 2: Map of the Surface Geology at Isabella McCays 151 Figure 13 1: Summary of Variability Tests Results 181 Figure 13 2: Pilot Plant Campaign Flowsheets 183 Figure 13 3: Variation of Pilot Plant Recoveries with Head grades 192 Figure 13 4: Flotation Circuit Variation 193 Figure 13 5: Statistical Analysis of All Test work Results 194 Figure 13 6: Isabella McCays Gold Dissolution vs. Sulphide Oxidation – Batch, Inventory and Overflow 200 Samples Figure 13 7: Bubi Gold Dissolution vs. Sulphide Oxidation – Inventory a Overflow Samples Figure 14 1: Topography of McCays Figure 14 2: Plan View showing Drilling at ISBS (green = perc; blue = DD; red = RC) Figure 14 3: Plan View showing Drilling at ISBN (green = perc; blue = DD; red = RC) Figure 14 4: Plan View showing Drilling at Bubi (green = perc; blue = DD; red = RC) Figure 14 5: Plan View showing Drilling at McCays (green = perc; blue = DD; red = RC) Figure 14 6: Histogram of Density for ISBS Figure 14 7: Histogram of Density for ISBN Document Number: JZWEBR6013 - STU - REP - 001 Page 24 211 220 221 222 223 224 225 226

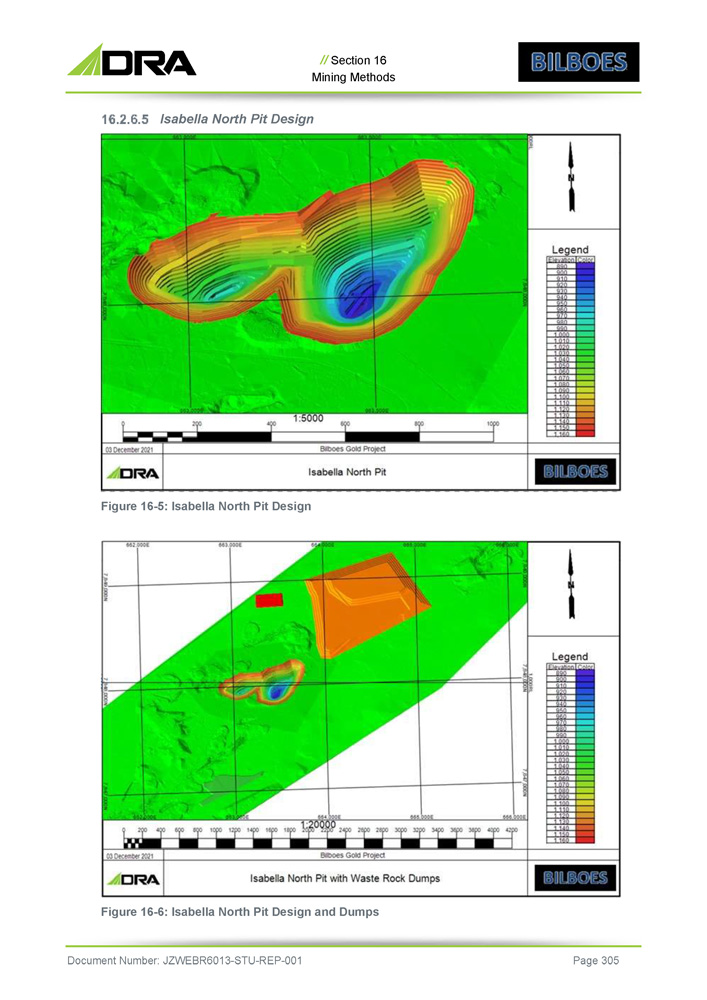

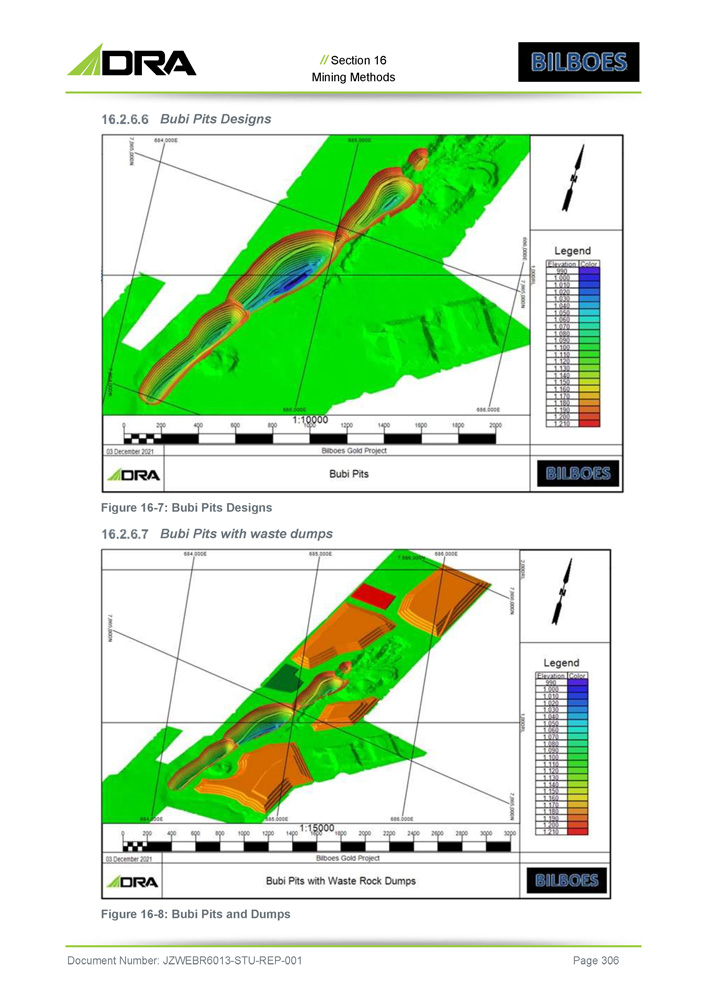

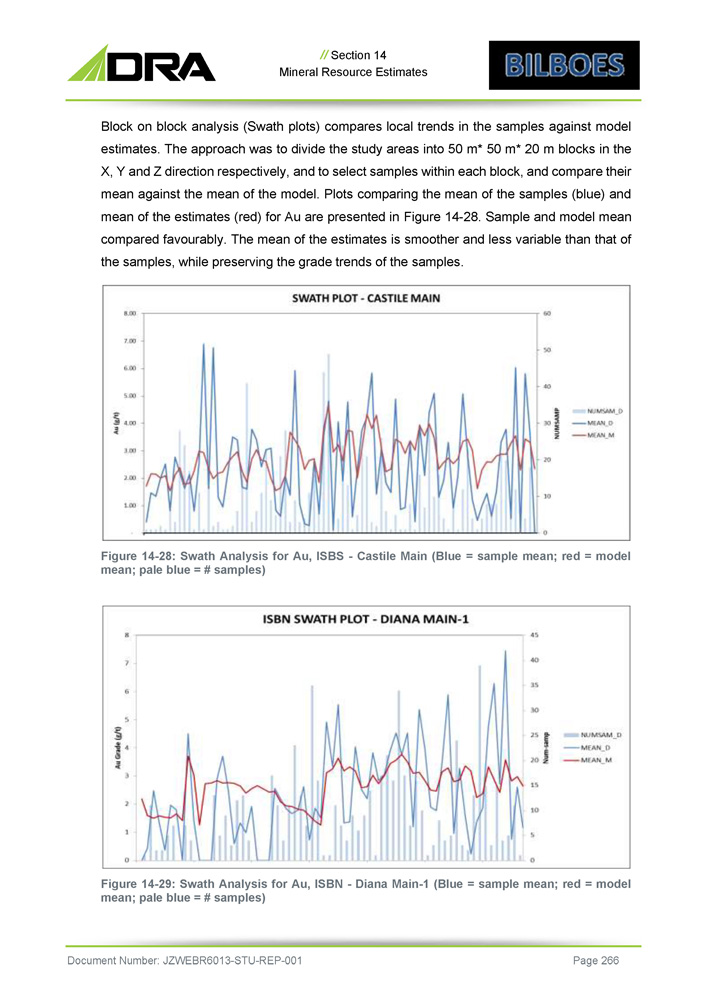

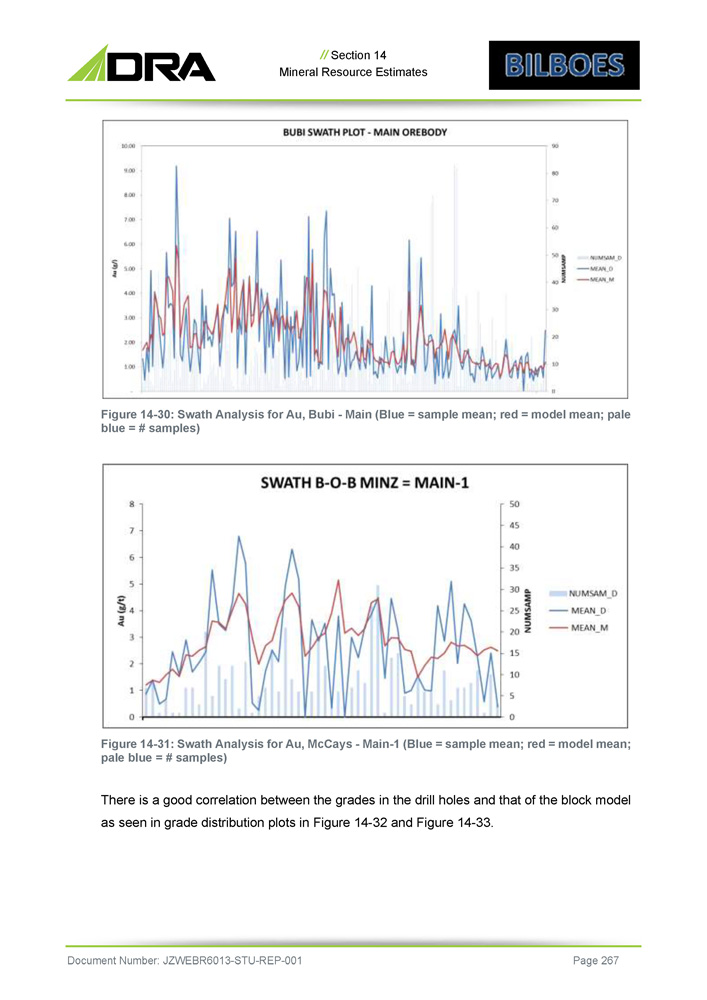

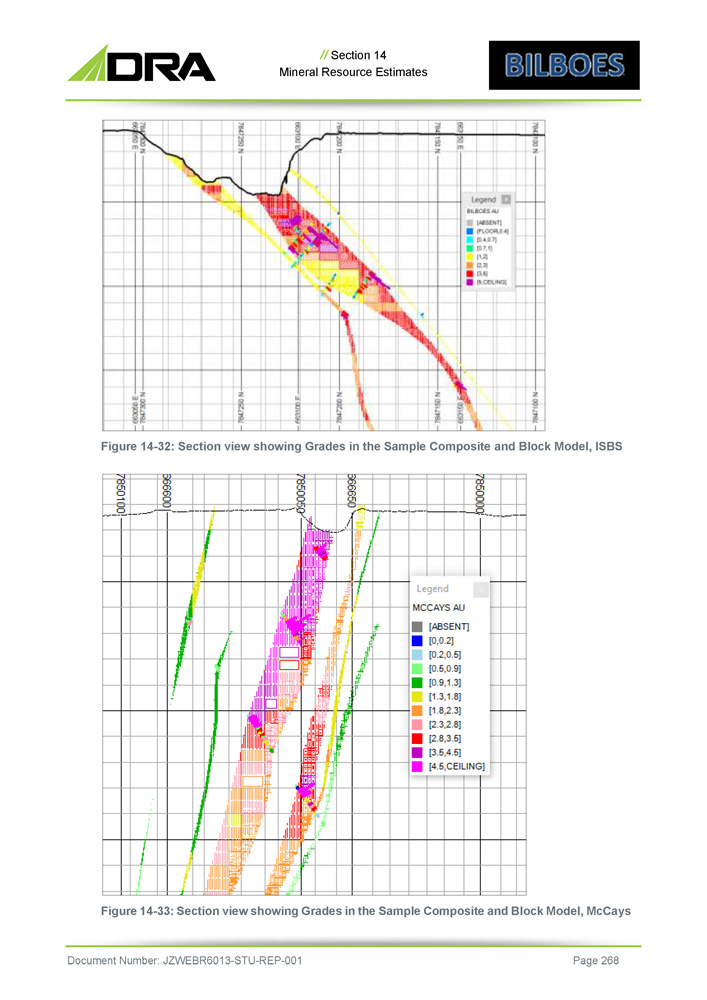

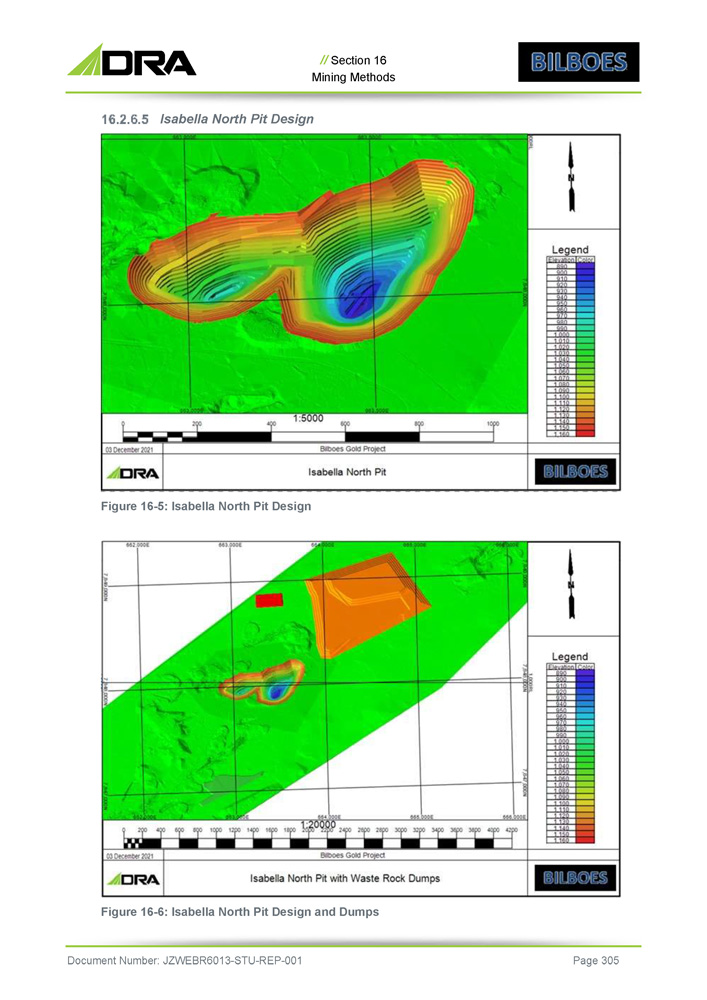

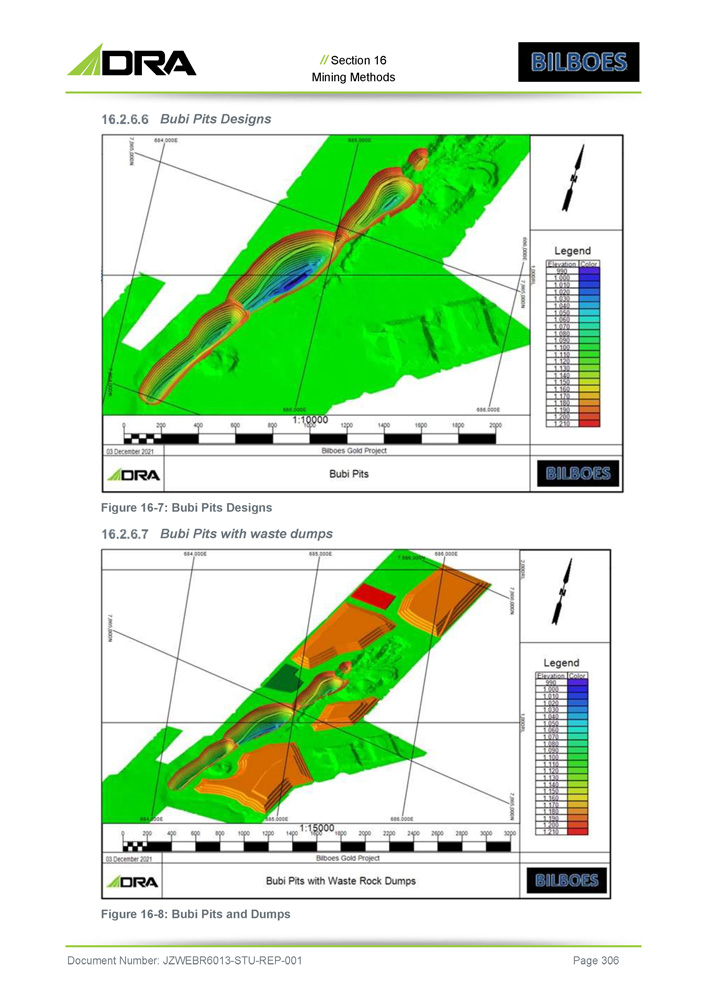

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study Figure 14 8: Histogram of Density for Bubi 227 Figure 14 9: Histogram of Density for McCays 228 Figure 14 10: QQ Plot Comparing 2018 Density Measurements to University of Zimbabwe Density 229 checks, ISBS Figure 14 11: QQ Plot Comparing 2018 Density Measurements to University of Zimbabwe Density 230 checks, ISBN Figure 14 12: QQ Plot Comparing 2018 Density Measurements to University of Zimbabwe Density 231 checks, Bubi Figure 14 13: QQ Plot Comparing 2018 Density Measurements to University of Zimbabwe Density 232 Checks, McCays Figure 14 14: Section View showing Re - Interpreted Ore Zone (black = 2017; red and blue = current) 233 Figure 14 15: ISBS Mineralised Zones 237 Figure 14 16: ISBN Mineralised Zones 238 Figure 14 17: Bubi Mineralised Zones 239 Figure 14 18: McCays Mineralised Zones 240 Figure 14 19 : Section View showing Oxidation Profile at ISBS 241 Figure 14 20 : Histogram of Sample Length Prior (left) and After (right) Compositing for ISBS, Sulphide 242 Figure 14 21 : Plan showing Collars and Location (red dot) where a QKNA was run from, McCays 250 Figure 14 22 : Parent Cell Size Optimisations X Direction, ISBS 251 Figure 14 23: Parent Cell Size Optimisations Y Direction, ISBS 252 Figure 14 24: Parent Cell Size Optimisations Z Direction, ISBS 252 Figure 14 25: Search Distance Optimisations Strike Direction, ISBS 253 Figure 14 26: Search Distance Optimisations Down Dip Direction, ISBS 254 Figure 14 27: Search Distance Optimisations Across Strike Direction, ISBS 254 Figure 14 28: Swath Analysis for Au, ISBS - Castile Main (Blue = sample mean; red = model mean; pale 266 blue = # samples) Figure 14 29: Swath Analysis for Au, ISBN - Diana Main - 1 (Blue = sample mean; red = model mean; 266 pale blue = # samples) Figure 14 30: Swath Analysis for Au, Bubi - Main (Blue = sample mean; red = model mean; pale blue = 267 # samples) Figure 14 31: Swath Analysis for Au, McCays - Main - 1 (Blue = sample mean; red = model mean; pale 267 blue = # samples) Figure 14 32: Section view showing Grades in the Sample Composite and Block Model, ISBS 268 Figure 14 33: Section view showing Grades in the Sample Composite and Block Model, McCays 268 Figure 14 34: Plan showing Mineral Resource Classification, McCays (orange = measured; green = 271 indicated; blue = inferred Figure 16 1: McCays Pits Figure 16 2: McCays Pits and WRD Designs Figure 16 3: Isabella South Pits Figure 16 4: Isabella South Pits and Dumps Figure 16 5: Isabella North Pit Design Document Number: JZWEBR6013 - STU - REP - 001 Page 25 303 303 304 304 305

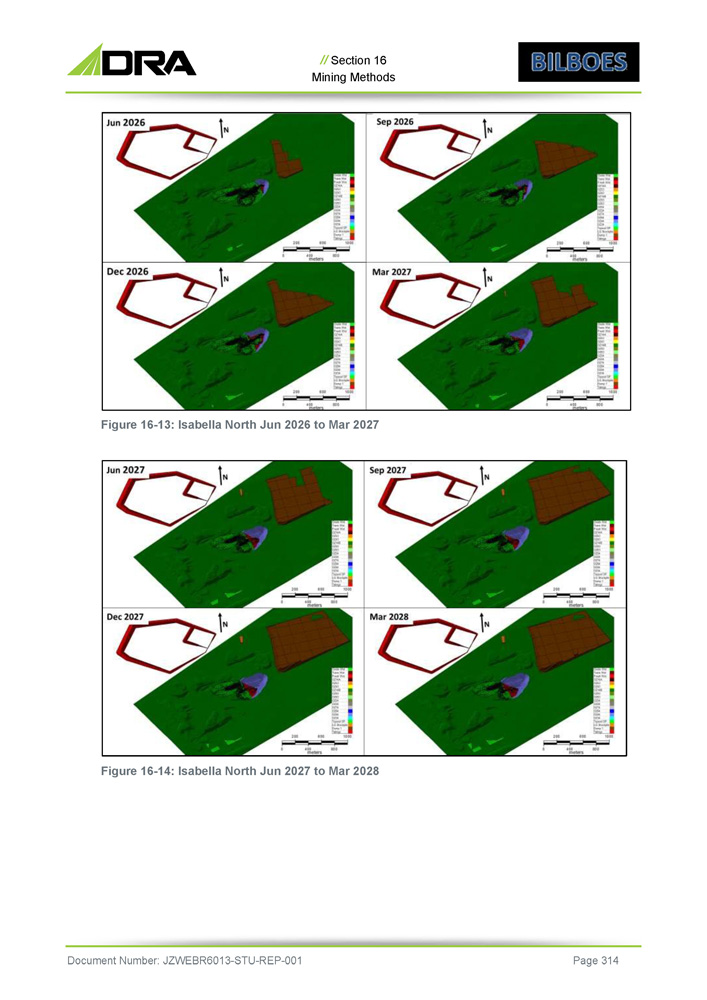

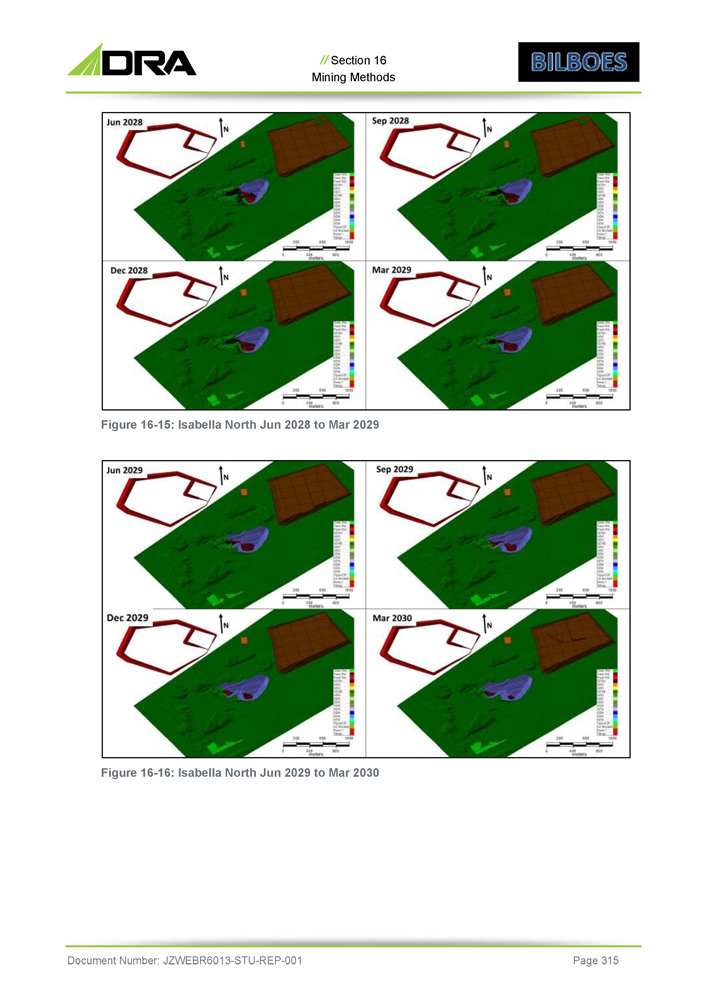

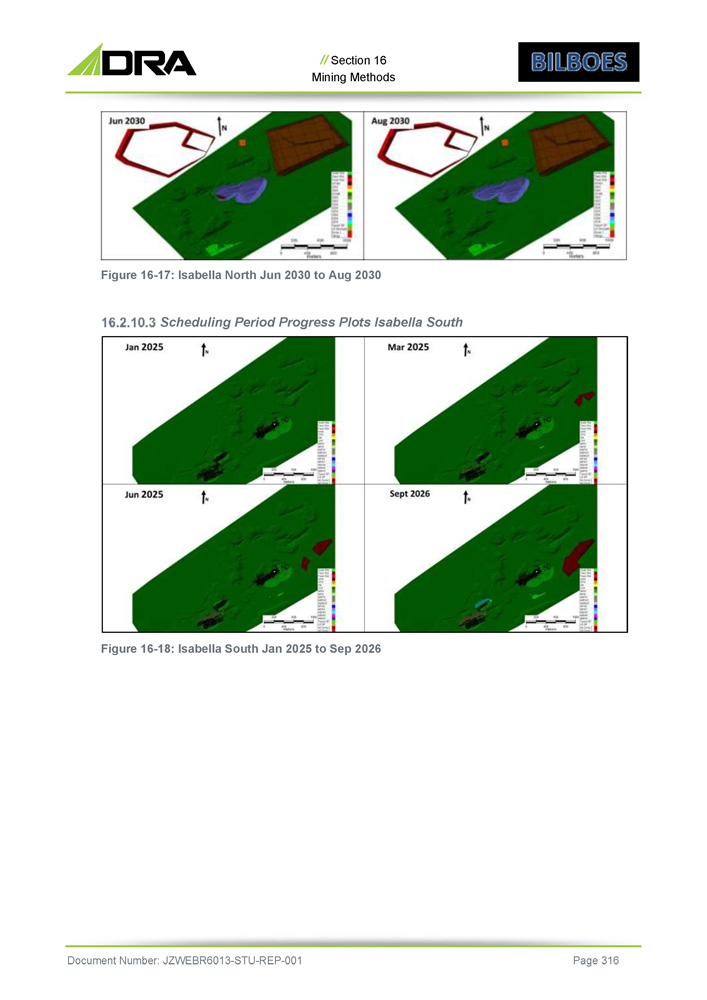

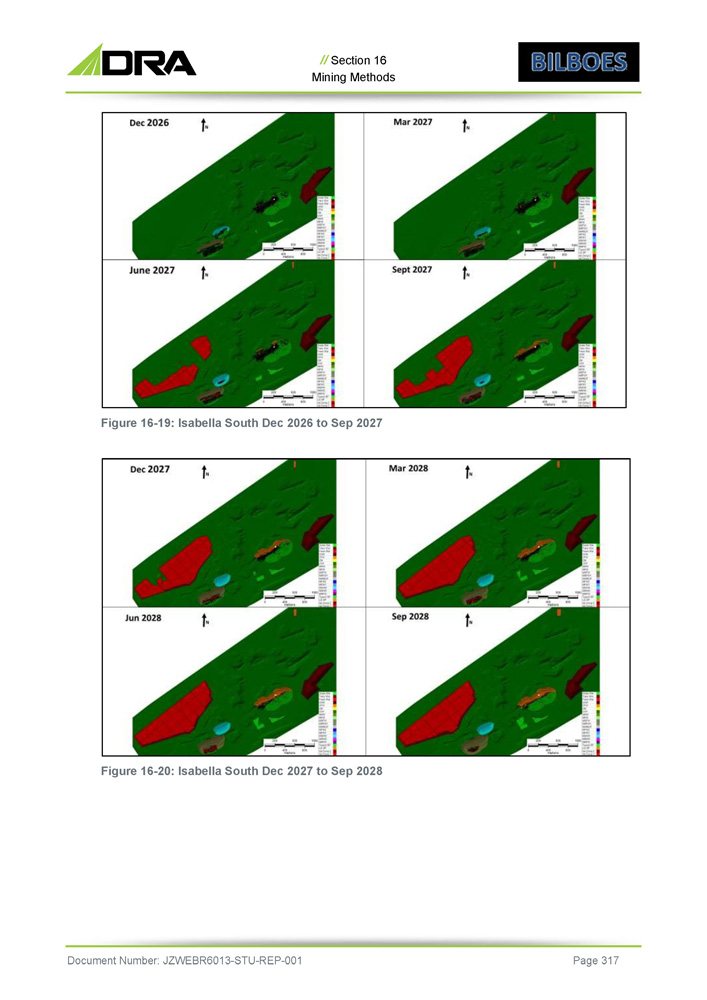

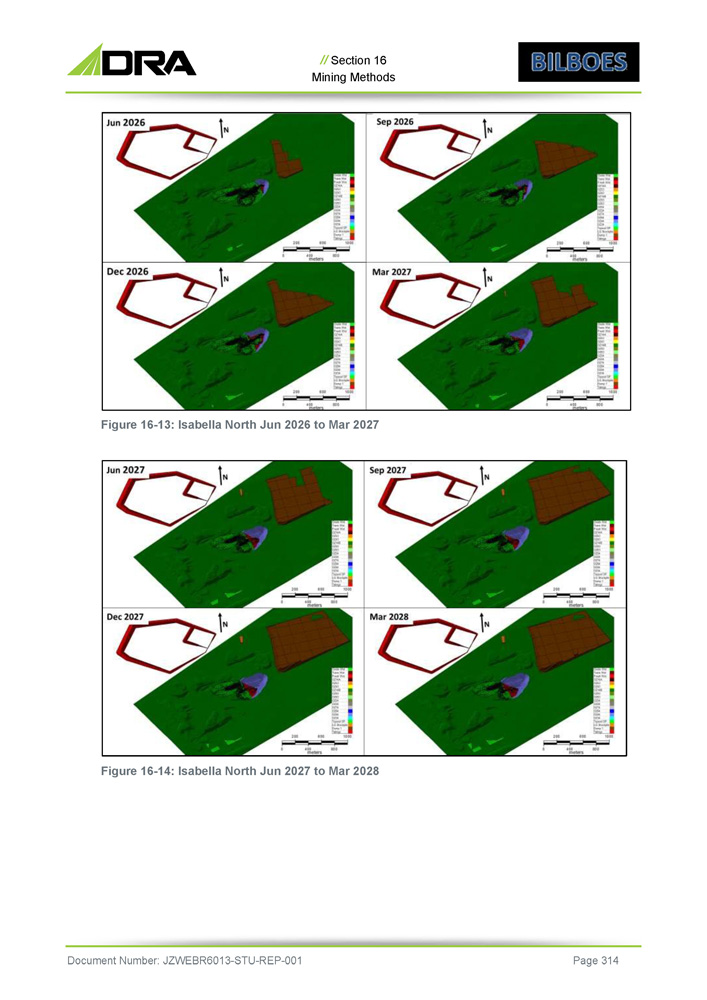

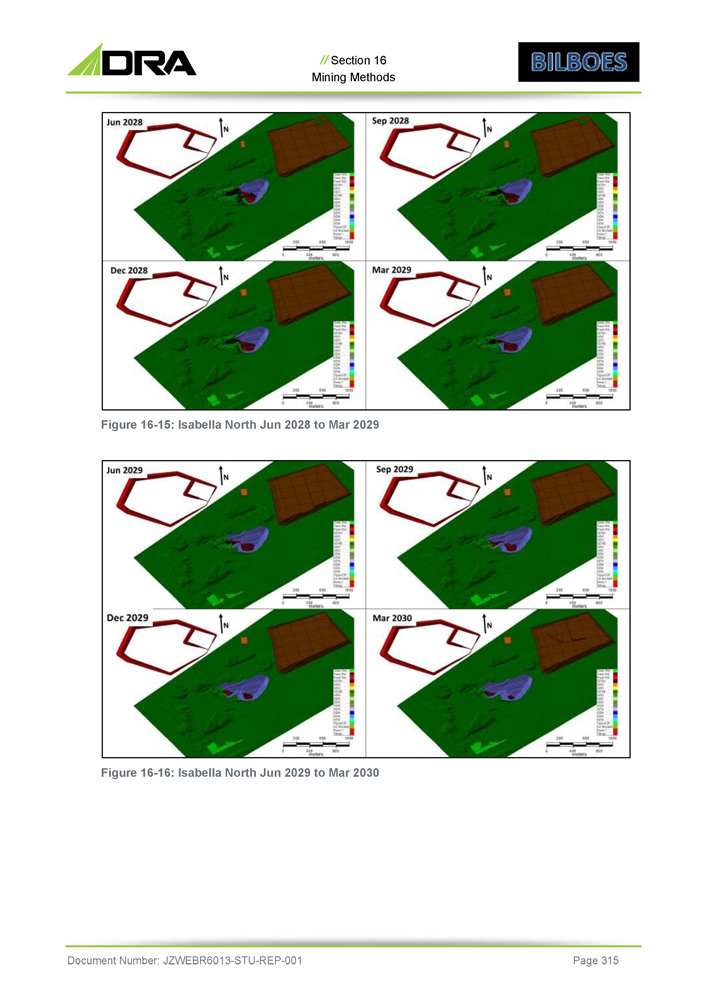

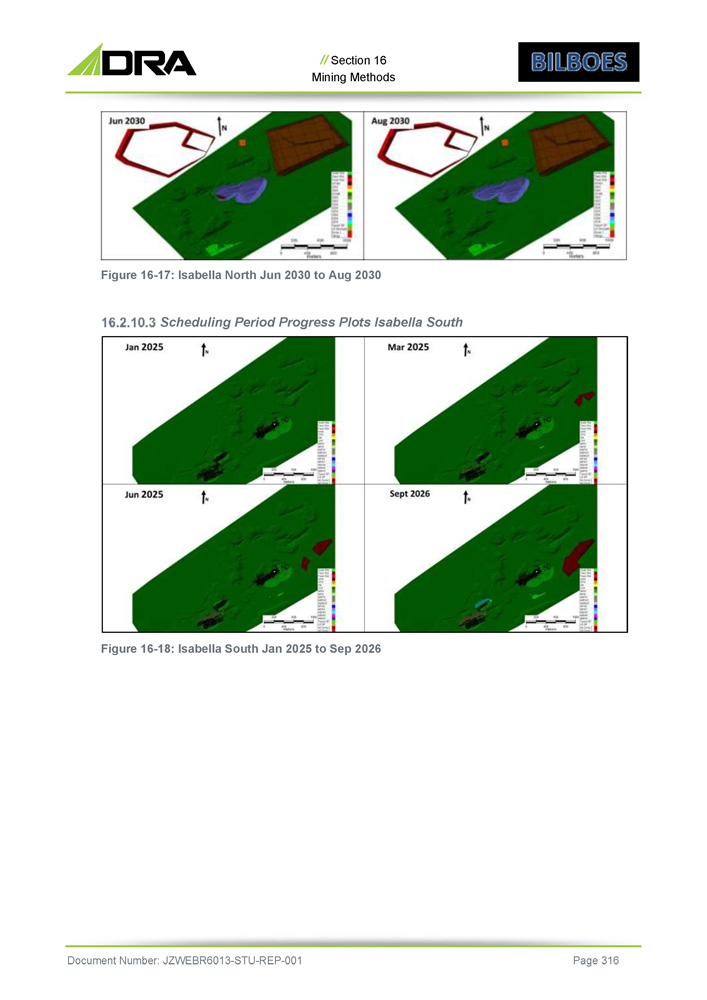

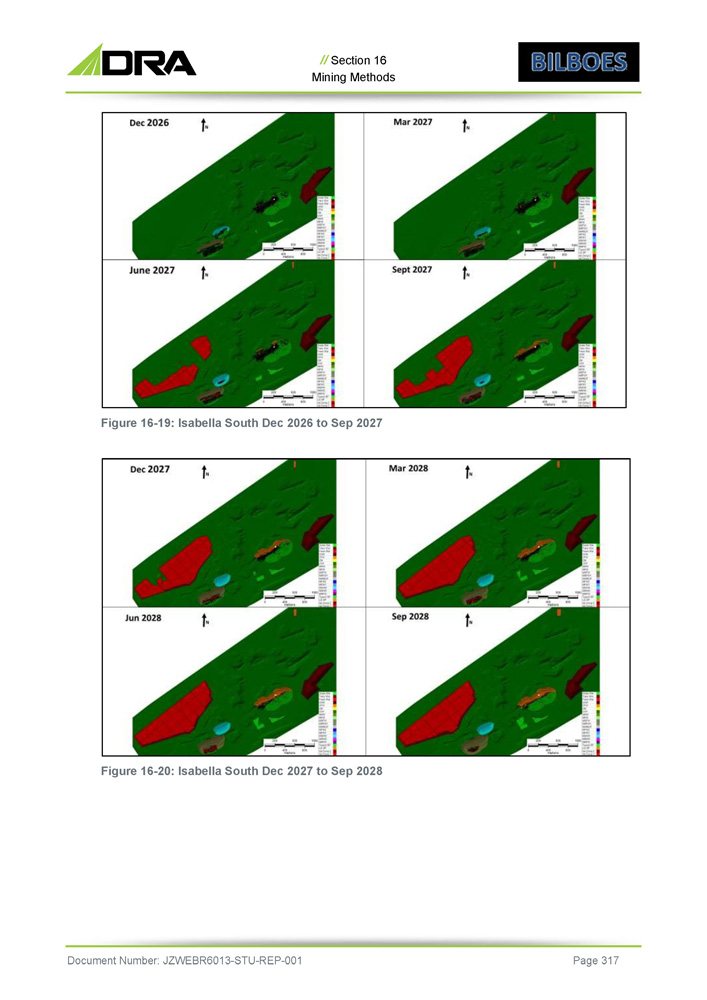

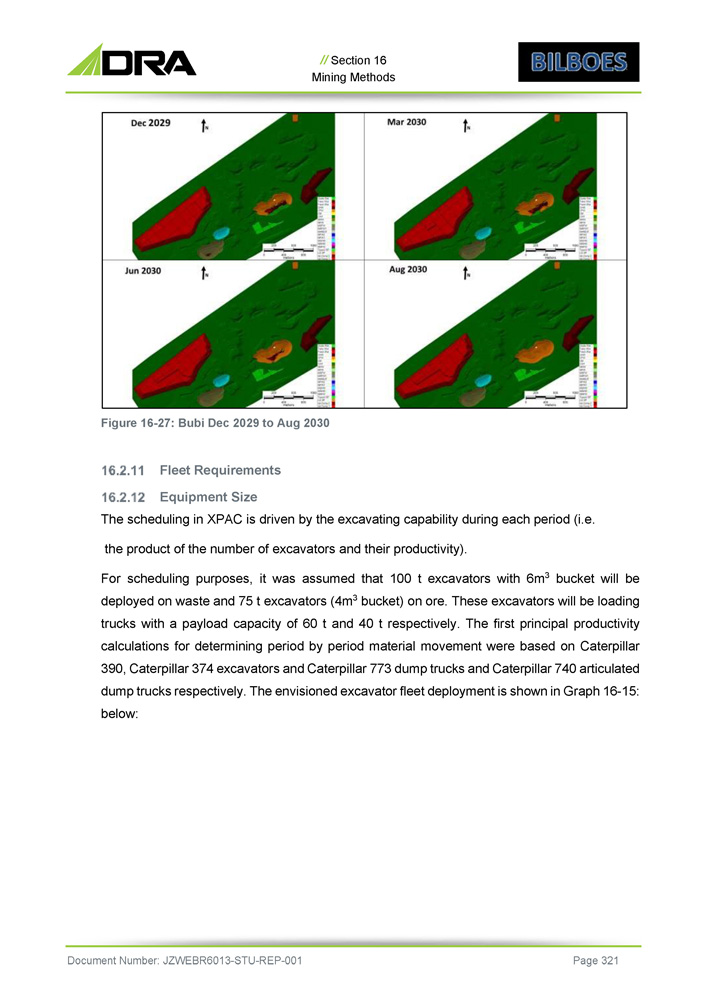

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study Figure 16 6: Isabella North Pit Design and Dumps Figure 16 7: Bubi Pits Designs Figure 16 8: Bubi Pits and Dumps Figure 16 9: McCays January 2025 to September 2025 Figure 16 10: McCays December 2025 to September 2026 Figure 16 11: McCays December 2026 to Feb 2027 Figure 16 12: Isabella North January 2025 to March 2026 Figure 16 13: Isabella North June 2026 to March 2027 Figure 16 14: Isabella North June 2027 to March 2028 Figure 16 15: Isabella North June 2028 to March 2029 Figure 16 16: Isabella North June 2029 to March 2030 Figure 16 17: Isabella North June 2030 to August 2030 Figure 16 18: Isabella South January 2025 to September 2026 Figure 16 19: Isabella South December 2026 to September 2027 Figure 16 20: Isabella South December 2027 to September 2028 Figure 16 21: Isabella South December 2028 to September 2029 Figure 16 22: Isabella South December 2029 to August 2030 Figure 16 23: Bubi June 2028 to December 2029 Figure 16 24: Bubi June 2030 to December 2031 Figure 16 25: Bubi June 2030 to December 2031 Figure 16 26: Bubi June 2030 to December 2031 Figure 16 27: Bubi June 2030 to December 2031 Figure 17 1: Bilboes Simplified Process Flow Diagram Figure 17 2: Bilboes Crusher Plant Design Simulation Figure 17 3: Bilboes Milling Plant Design Simulation Figure 18 1: Bilboes Site Stratigraphy Figure 18 2 : Phase 1 Monthly Wet Season Water Balance Figure 18 3 : Phase 1 Monthly Dry Season Water Balance Figure 18 4 : Phase 1 Monthly Average Water Balance Figure 18 5 : Phase 2 Monthly Wet Season Water Balance Figure 18 6 : Phase 2 Monthly Dry Season Water Balance Figure 18 7 : Phase 2 Monthly Average Water Balance Figure 18 8 : 70 years of Daily Rainfall Generated from the Nkayi Weather Station Record Figure 18 9 : 70 years of Daily Evaporation generated from the Bulawayo Goetz Station Figure 18 10 : Simulated Daily Time Step Water Balance for the 240 ktpm Tailings Deposition Phase Figure 18 11 : Simulated Daily Time Step Water Balance for the 180 ktpm Tailings Deposition Phase Figure 18 12 : Flotation Return Water Dam Pool Capacity and Spillages Figure 18 13 : Isabella - McCays 3 D model Document Number: JZWEBR6013 - STU - REP - 001 Page 26 305 306 306 312 312 313 313 314 314 315 315 316 316 317 317 318 318 319 319 320 320 321 329 335 336 347 397 398 399 400 401 402 405 405 407 408 409 413

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study Figure 18 14: Isabella - McCays Passive Groundwater Inflows Figure 18 15: Isabella - McCays - Predicted Groundwater Level Recovery Figure 18 16: Plume Migration vs. Time for the 3 Defined Scenarios Figure 18 17: Bubi 3D Numerical Model Figure 18 18: Bubi Passive Groundwater Inflows Figure 18 19: Bubi - Predicted Groundwater Level Recovery Figure 18 20: Bubi Contaminant Plume Migration vs. Time Figure 18 21: Sequence of Events Methodology Figure 21 1: Waterfall Chart Comparison between 2019 and 2021 by Discipline Figure 21 2: Waterfall Chart Comparison between 2019 and 2021 by WBS Figure 22 1: Production Profile Figure 22 2: Annual Cash Flow (Pre - Tax) Figure 22 3: Annual Cash Flow (Post - Tax) Figure 22 4: Sensitivity Analysis Summary Figure 22 5: Discount Rate Sensitivity Figure 23 1: Adjacent Properties around Isabella McCays and Bubi Figure 25 1: Risk Assessment Document Number: JZWEBR6013 - STU - REP - 001 Page 27 414 414 415 416 417 418 419 456 505 506 531 533 533 534 534 537 547

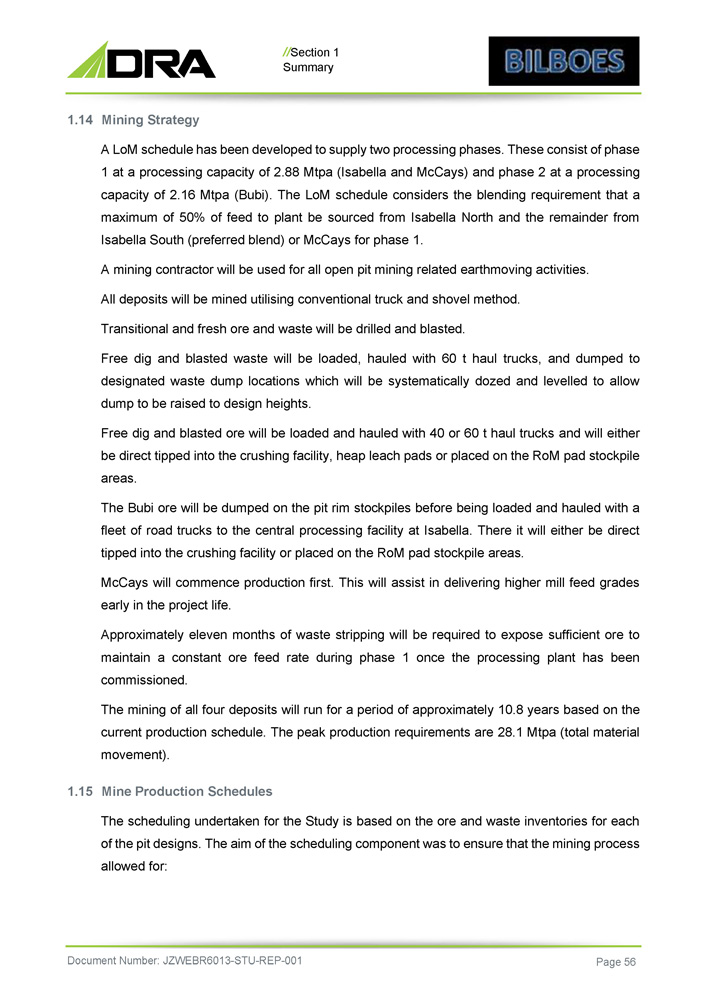

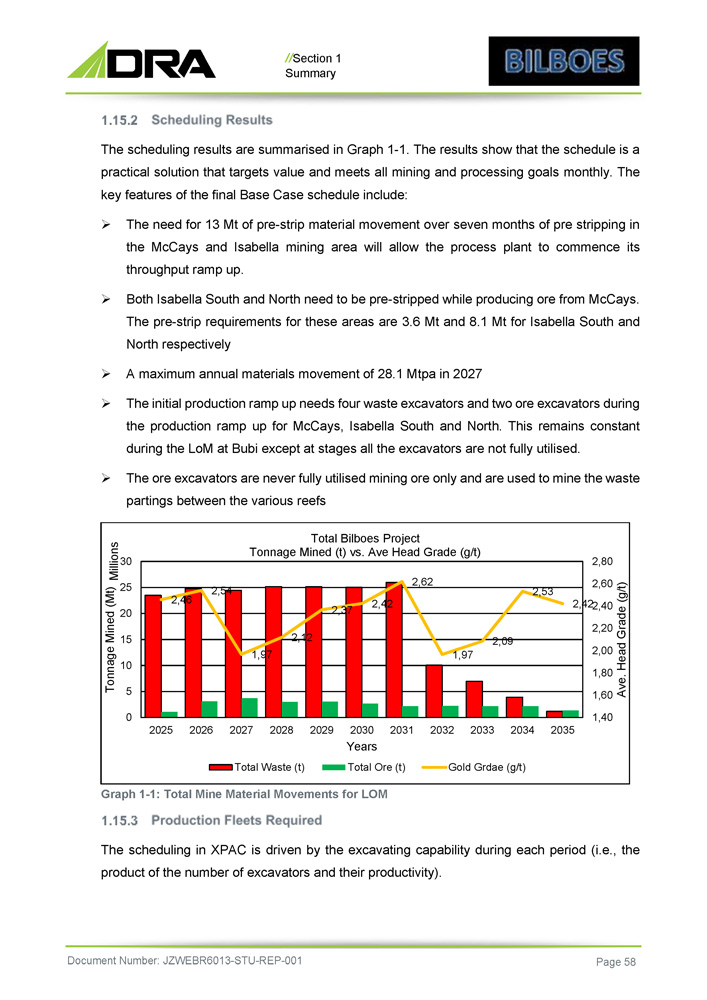

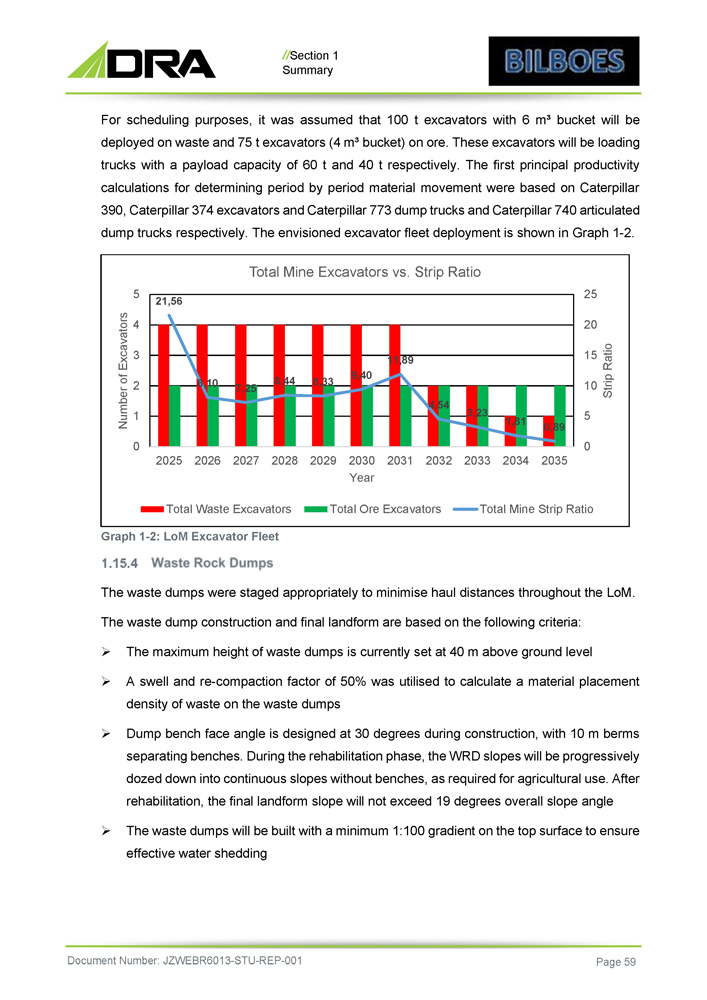

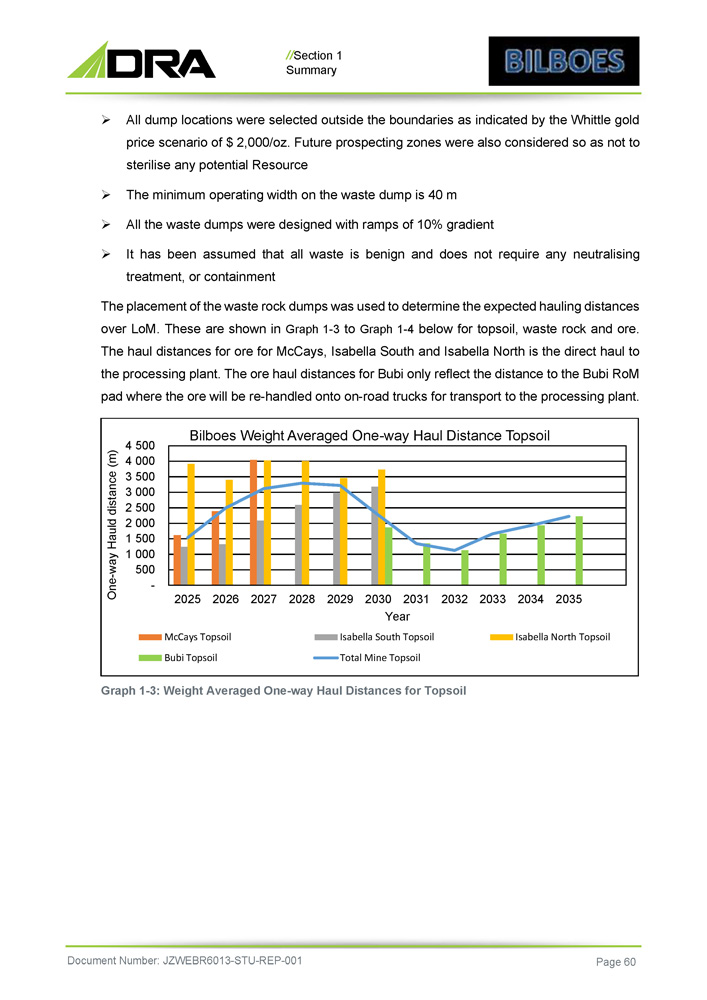

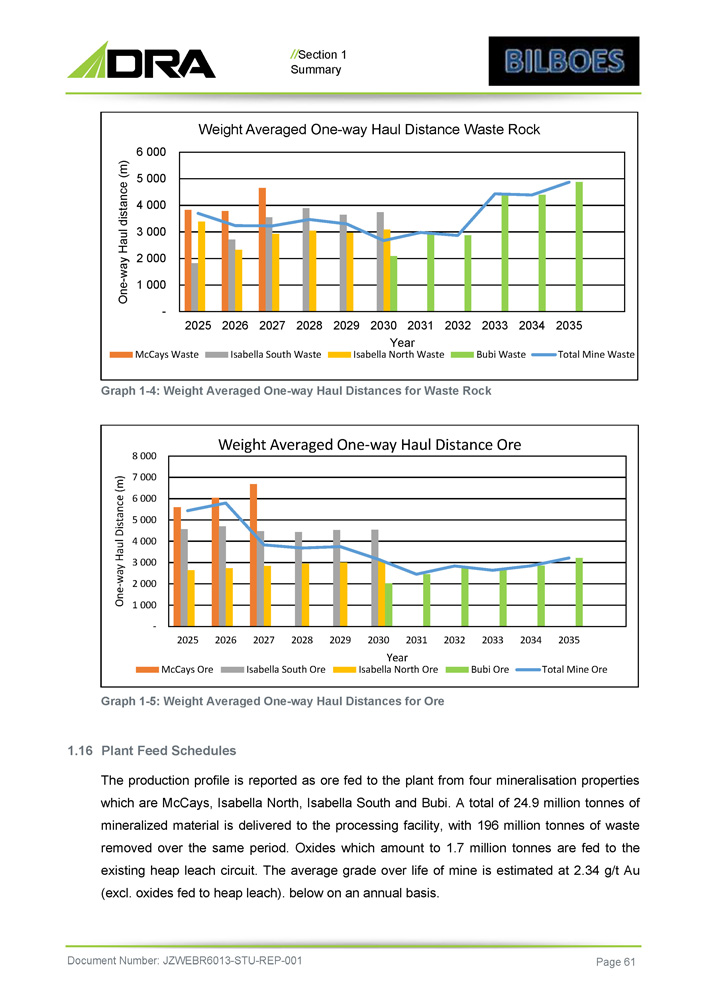

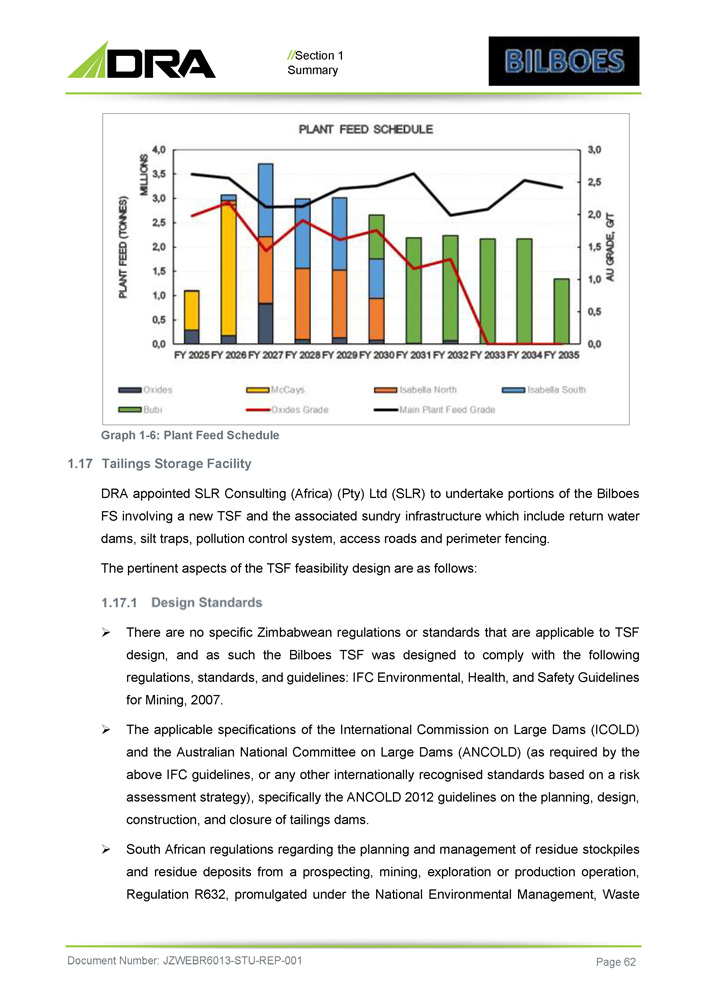

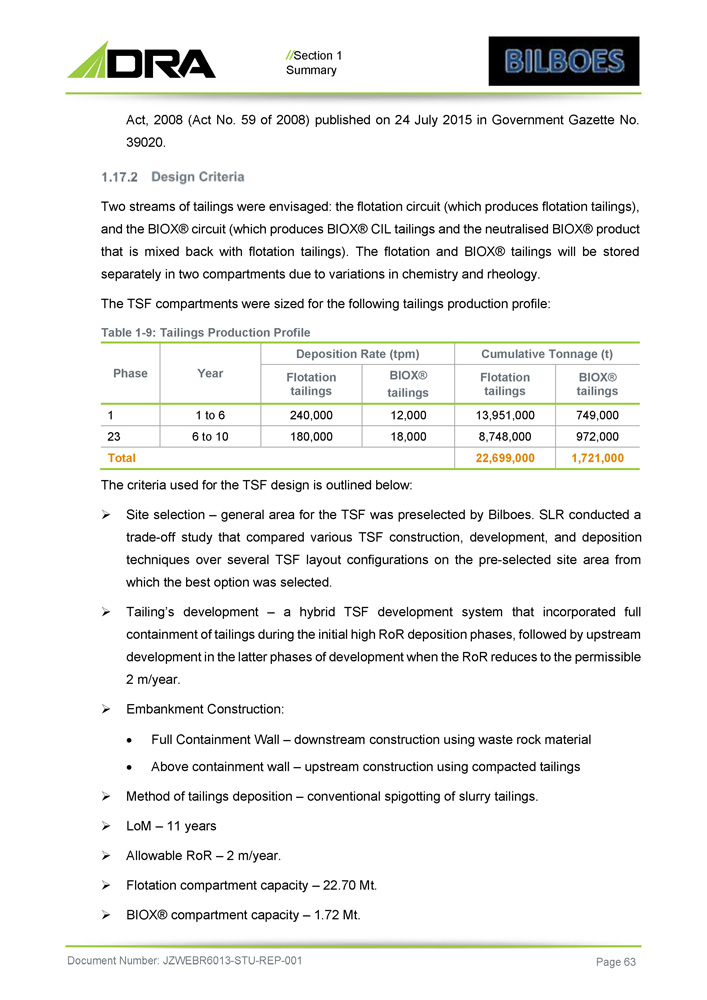

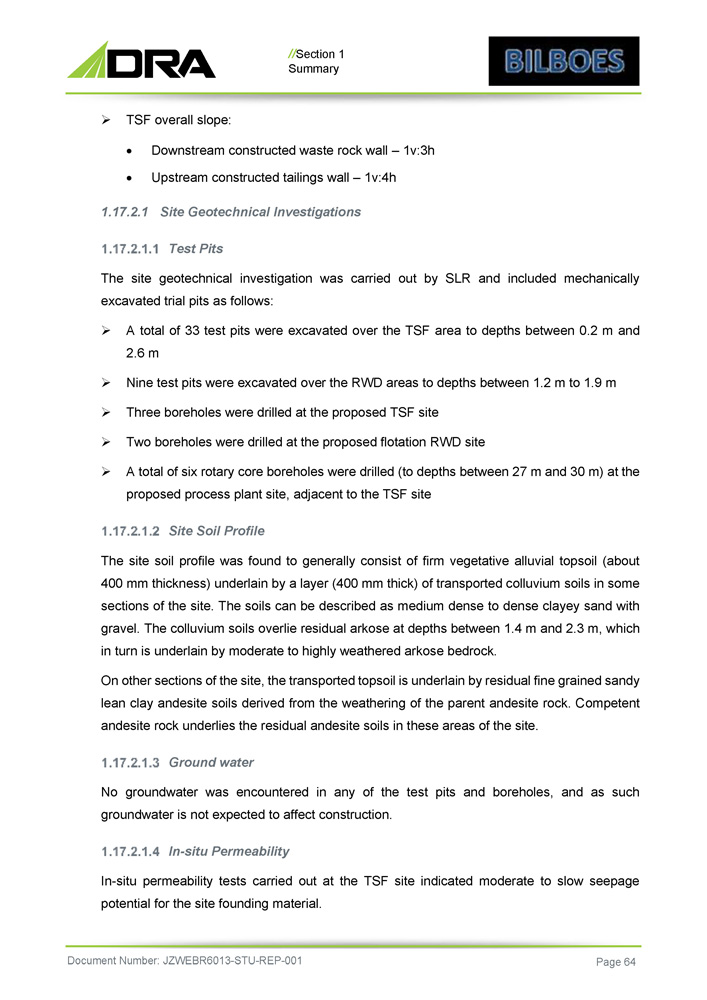

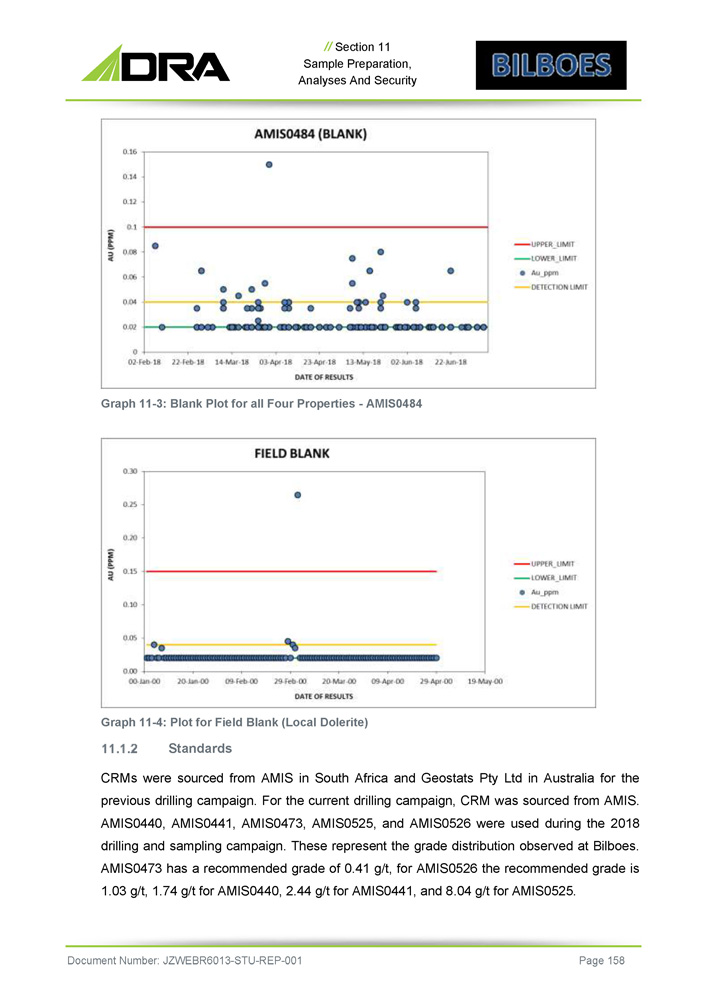

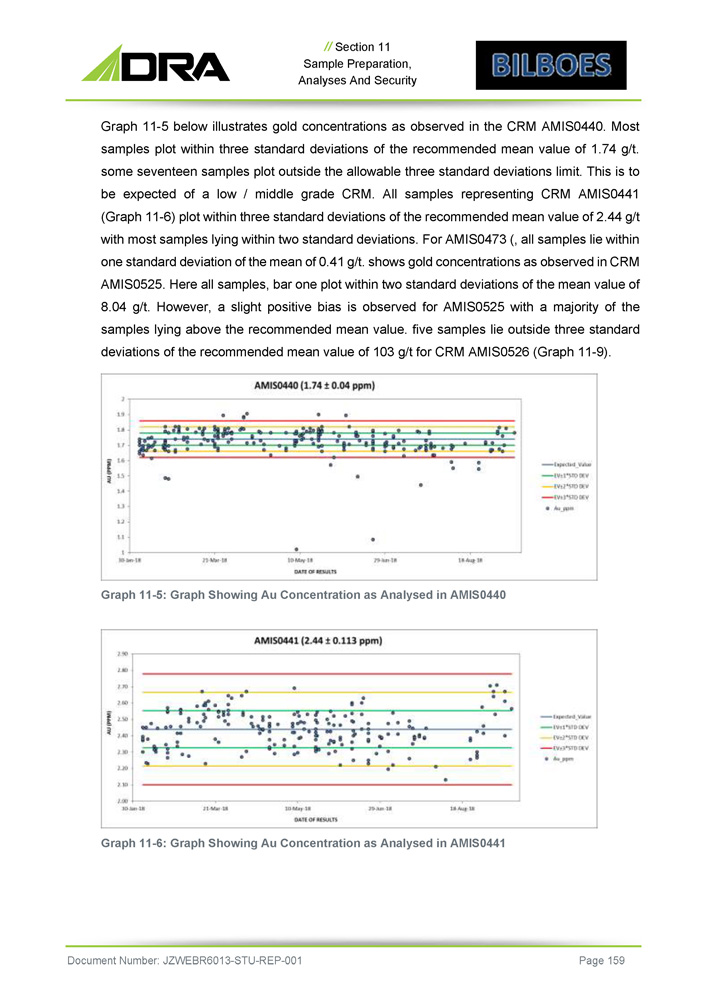

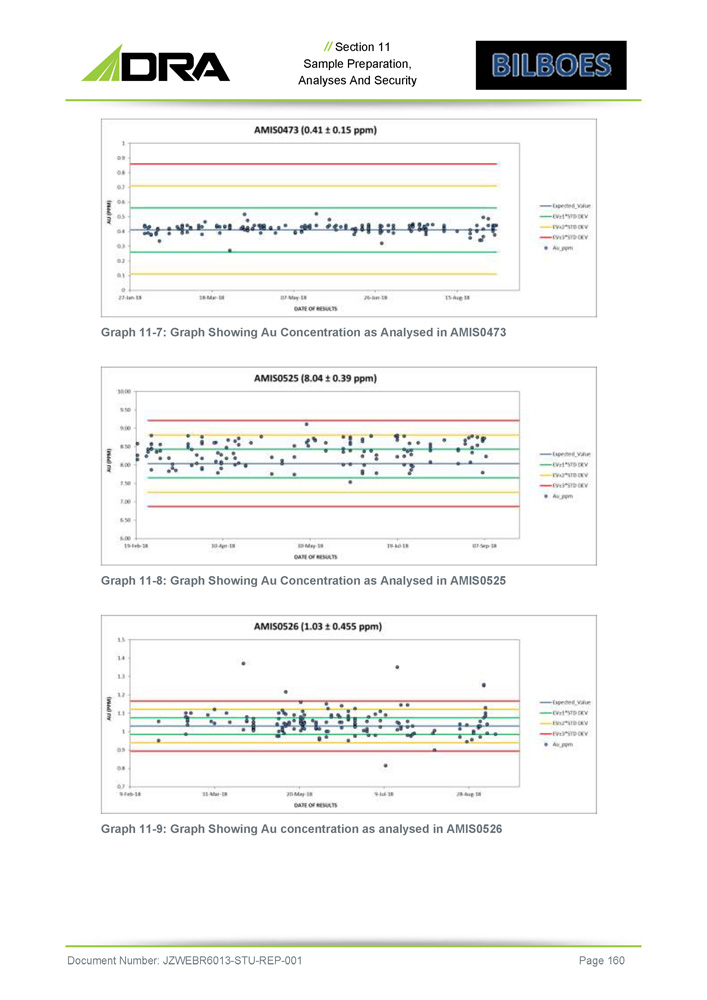

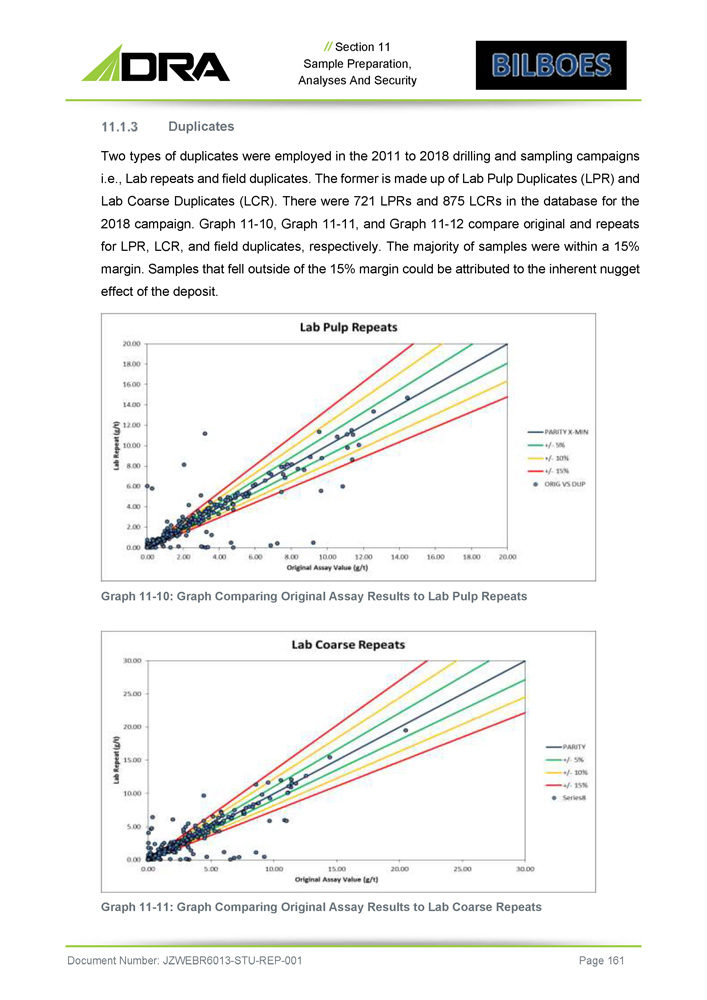

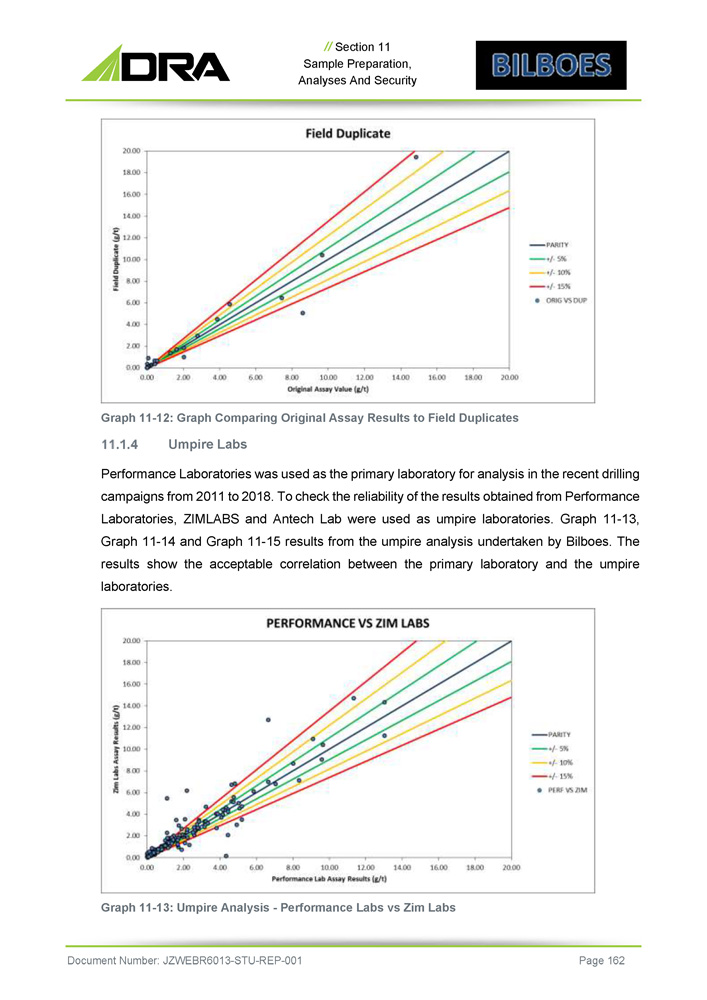

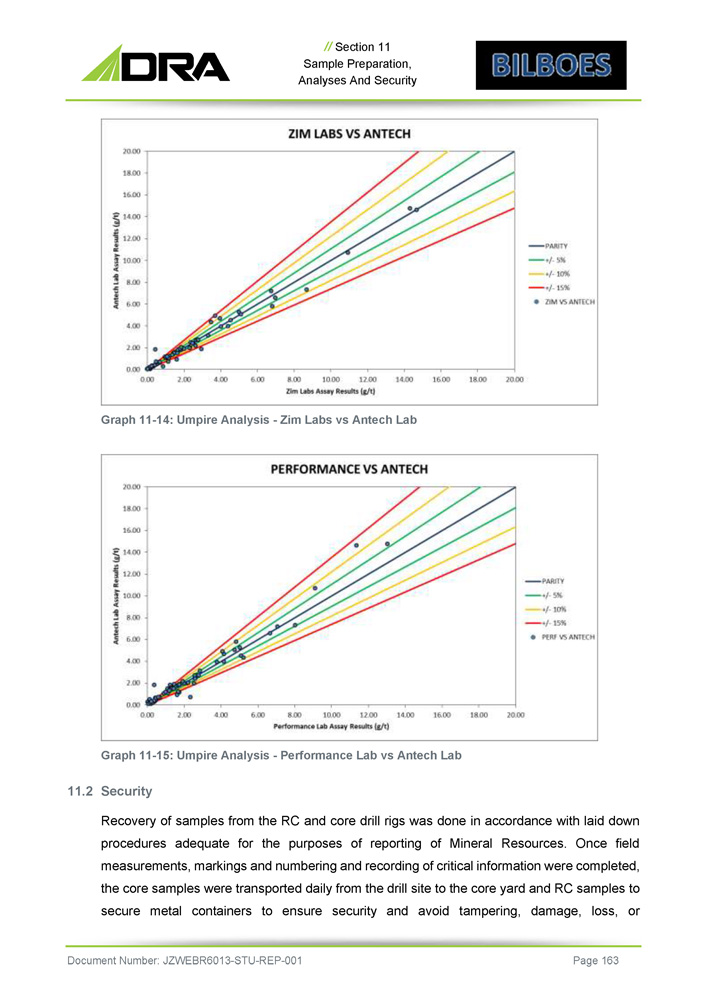

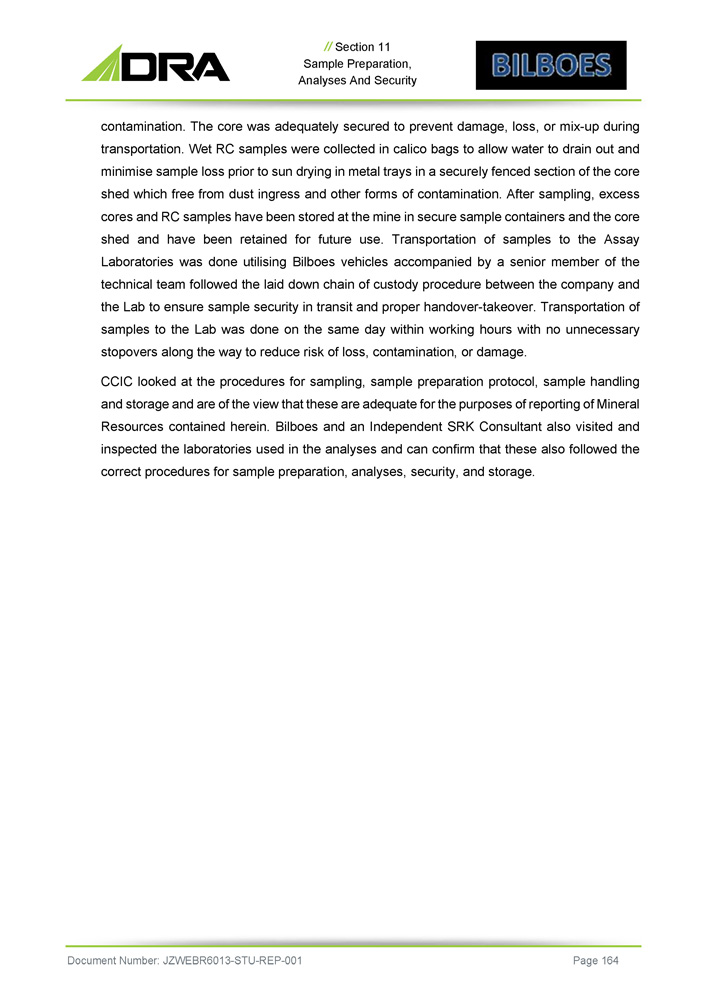

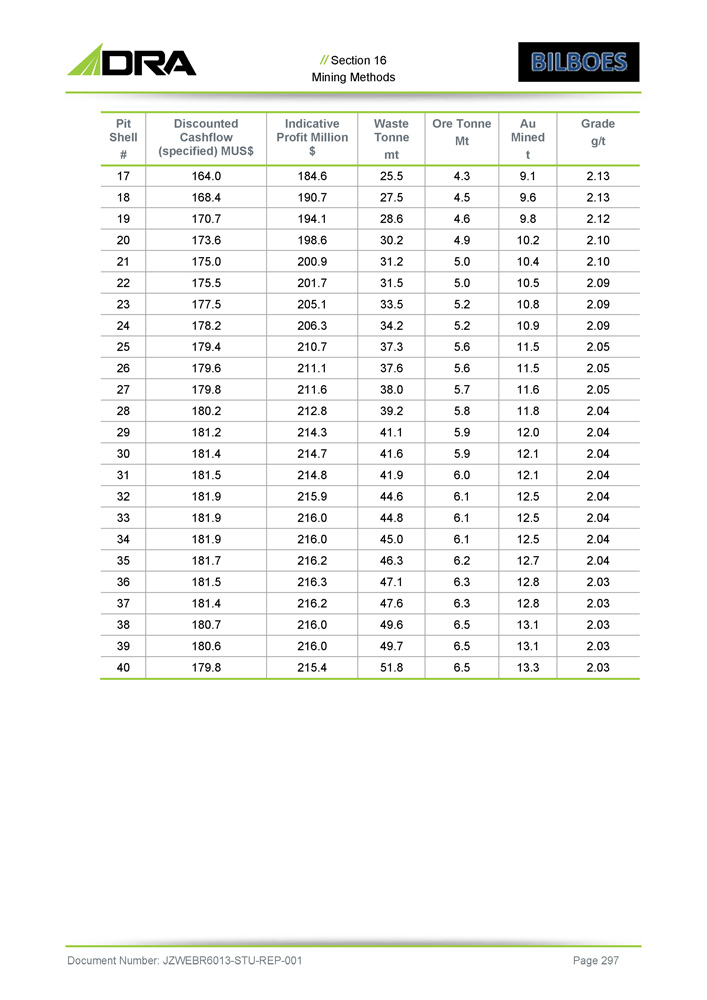

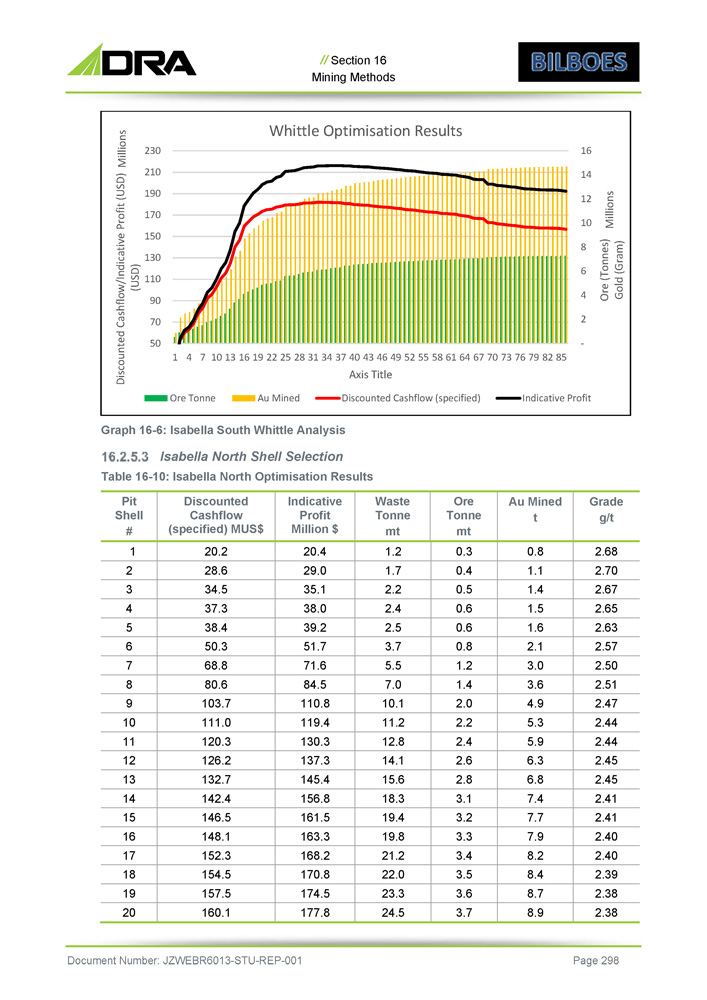

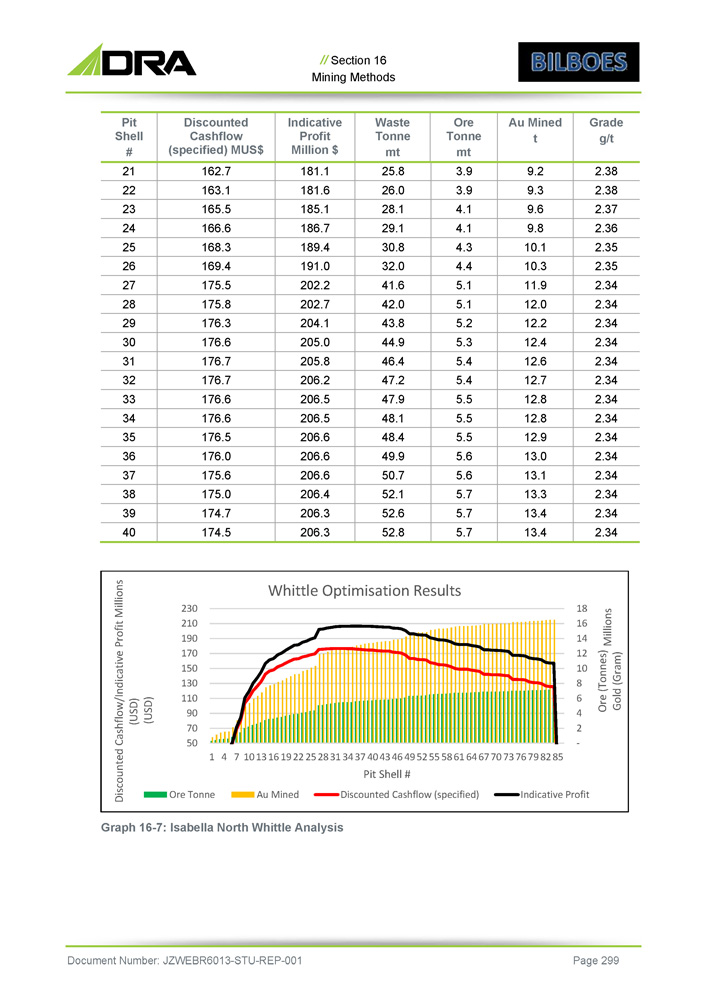

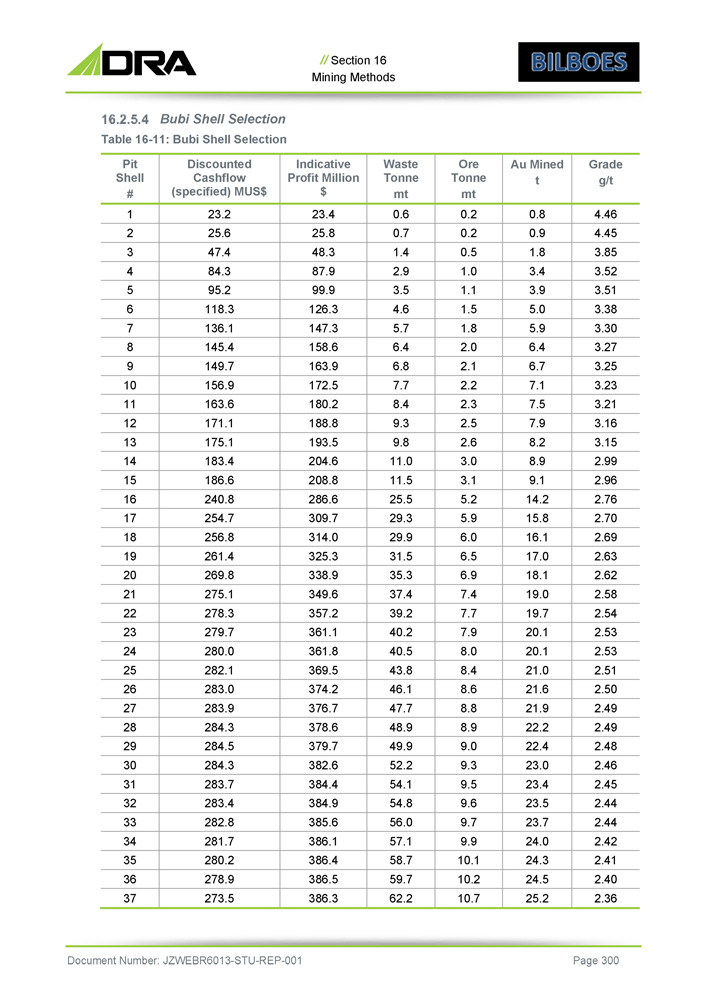

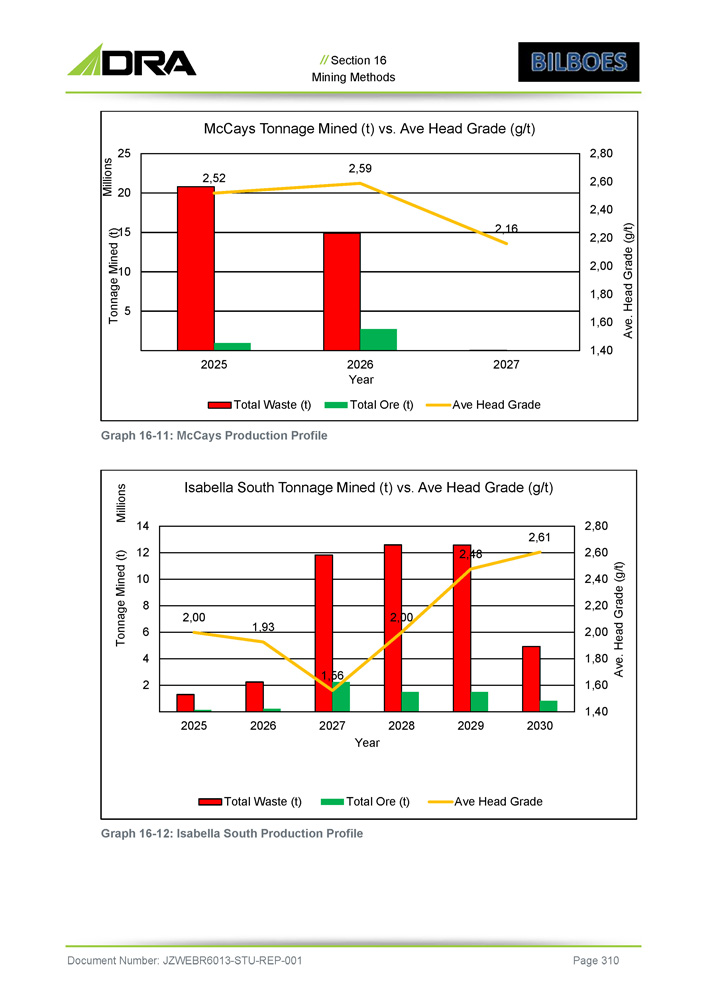

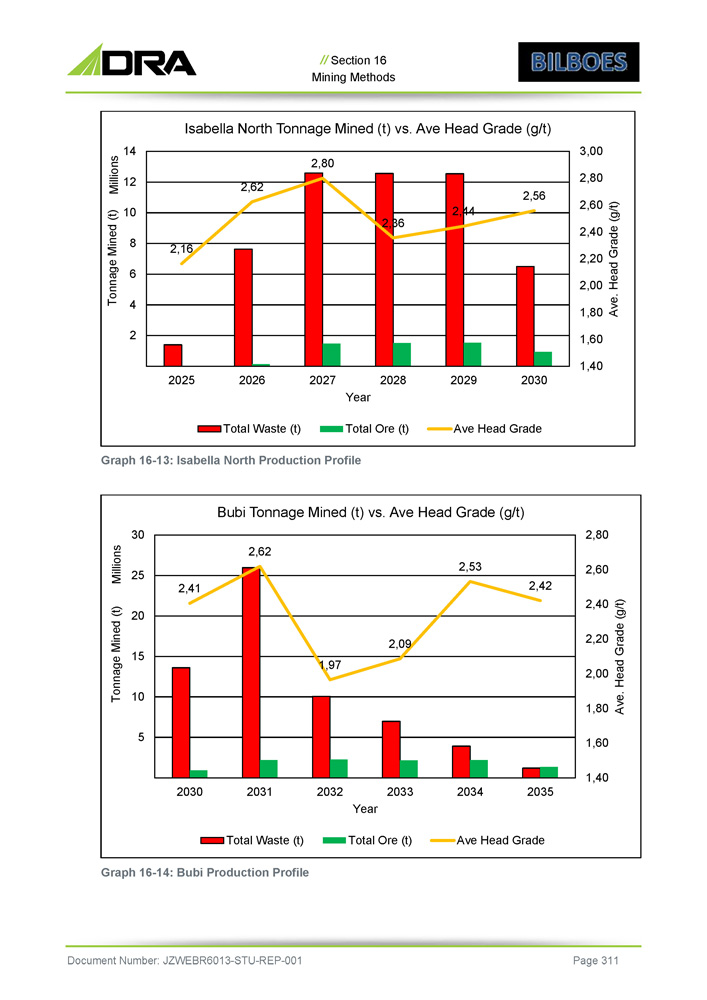

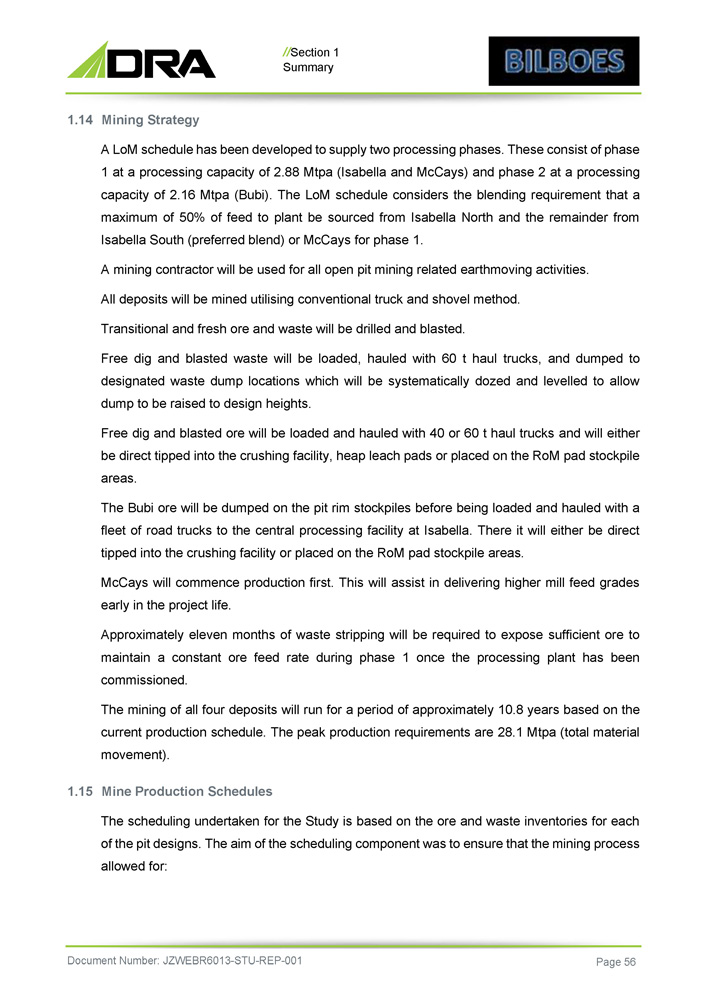

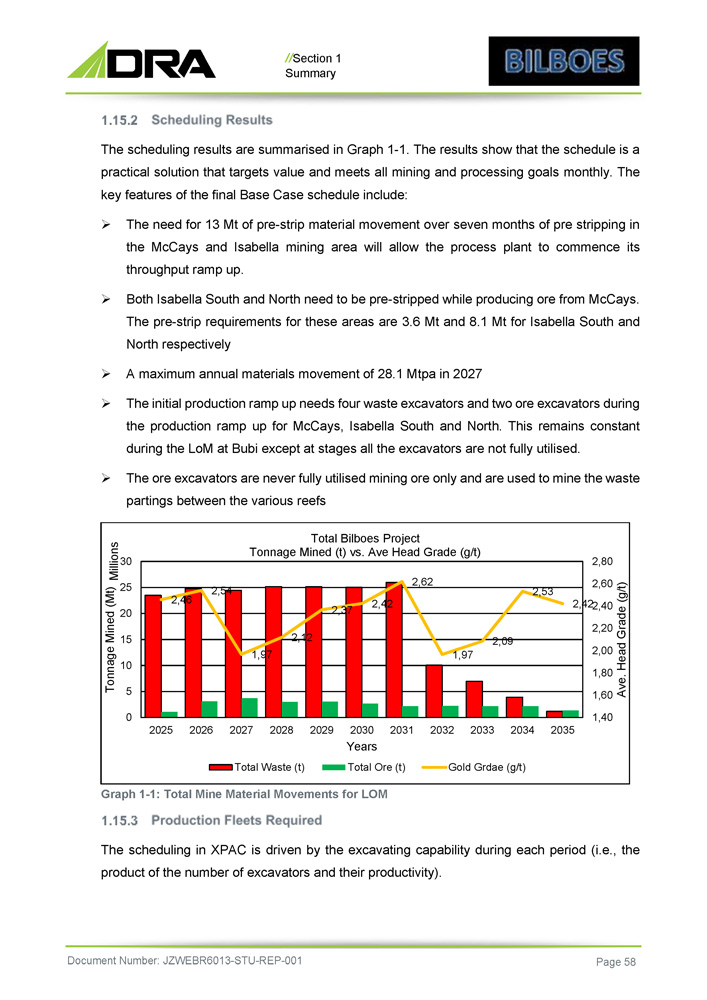

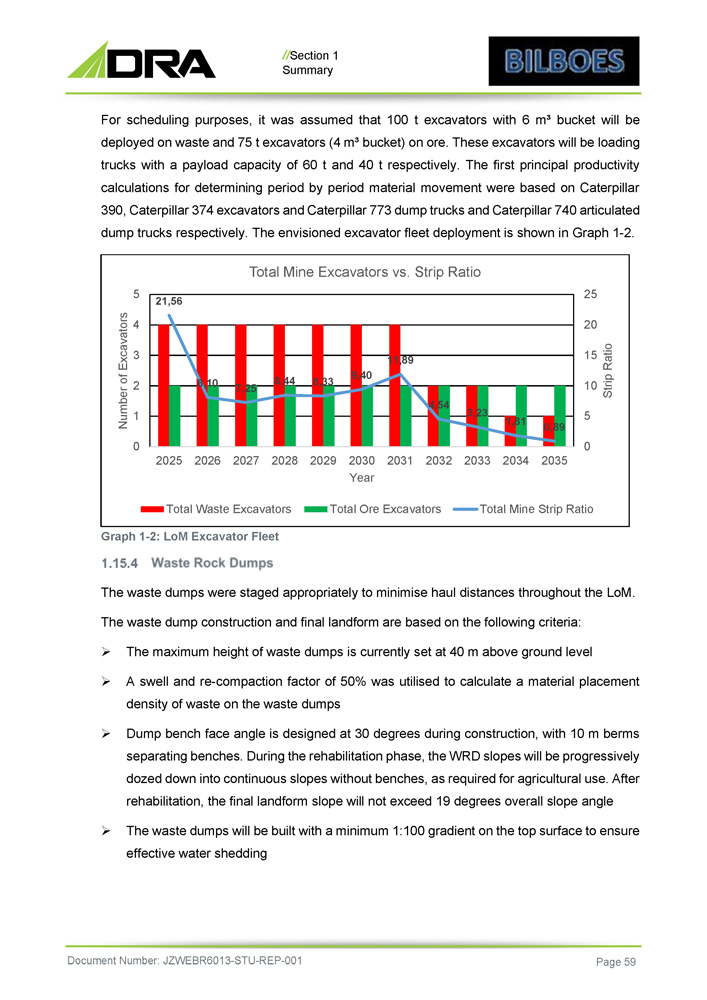

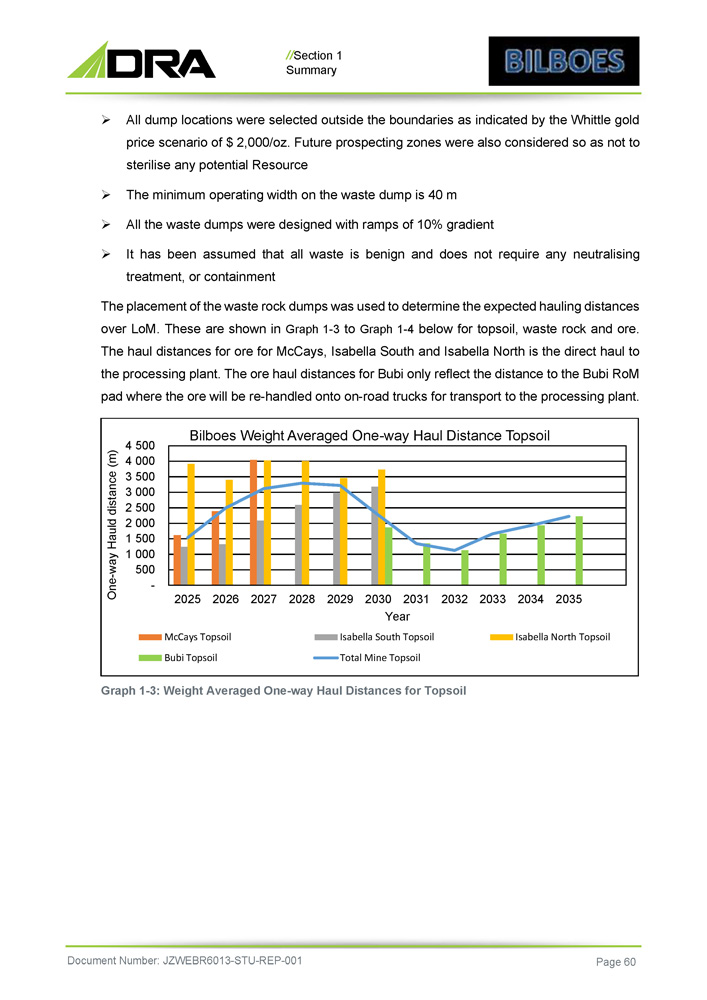

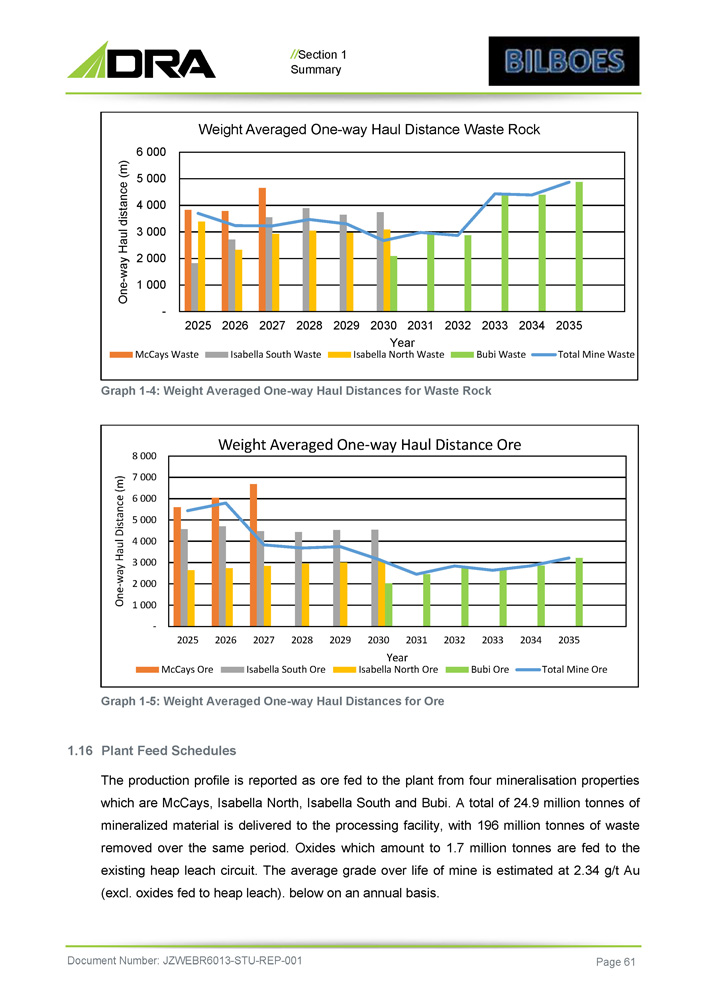

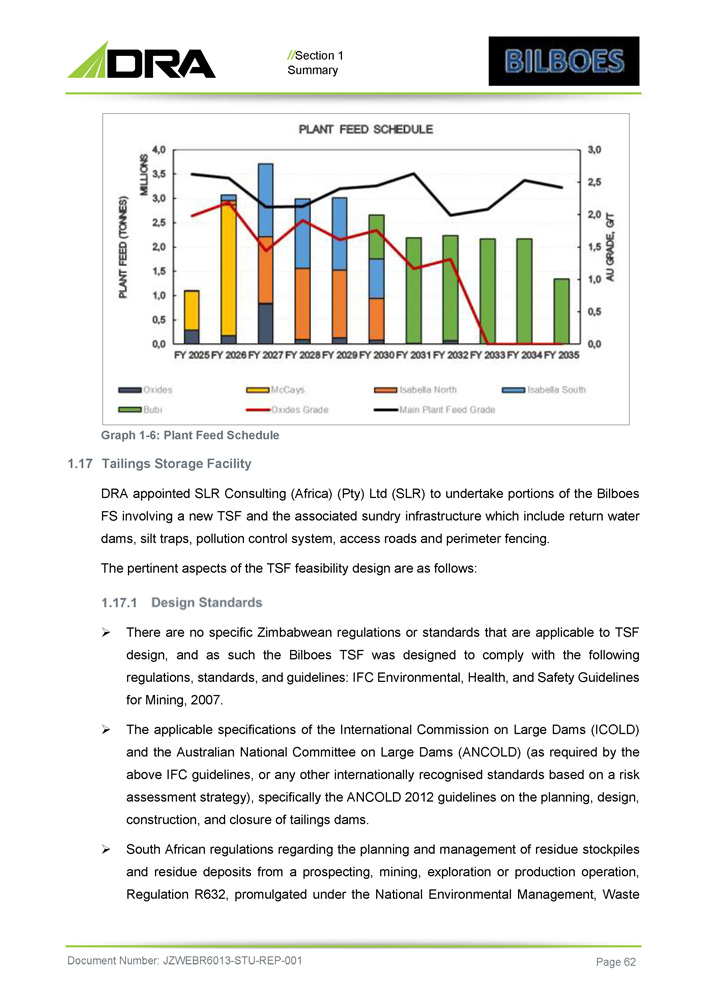

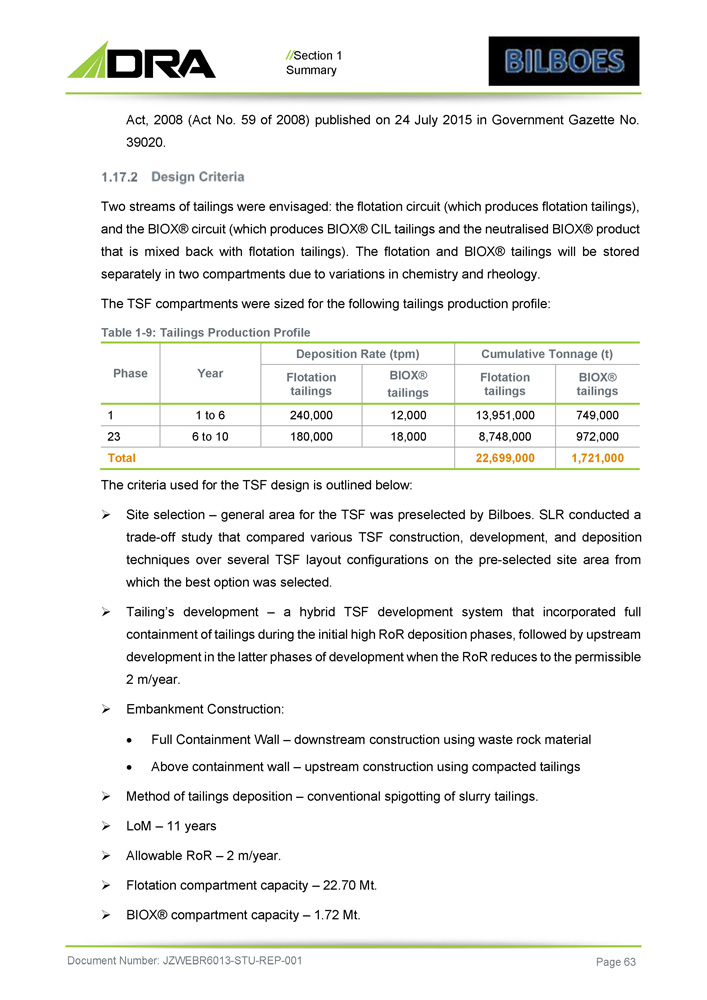

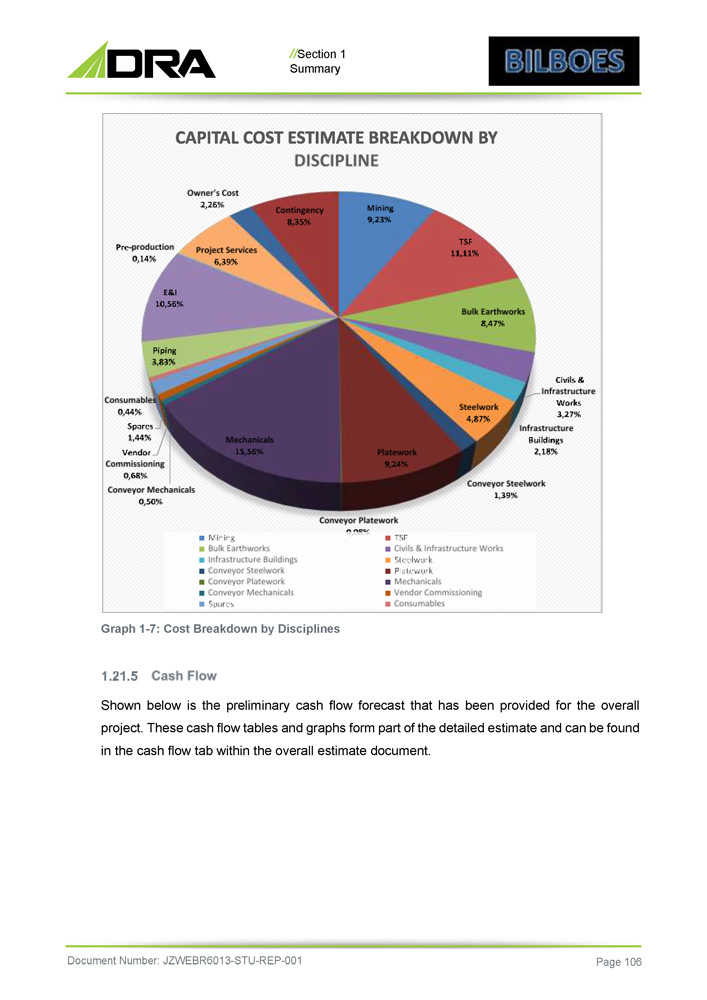

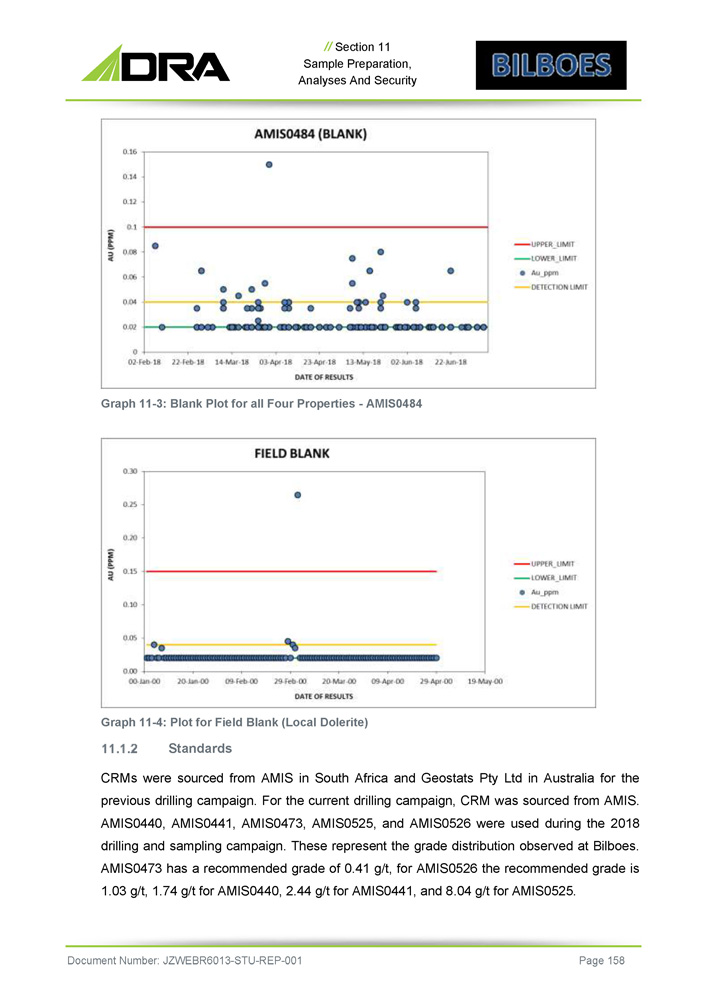

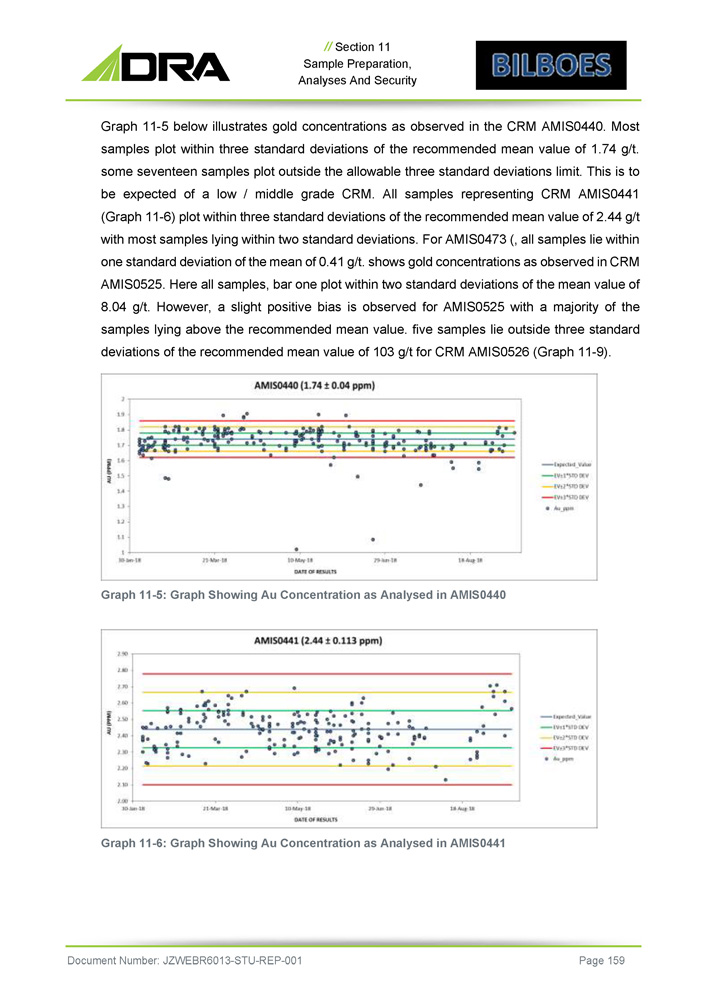

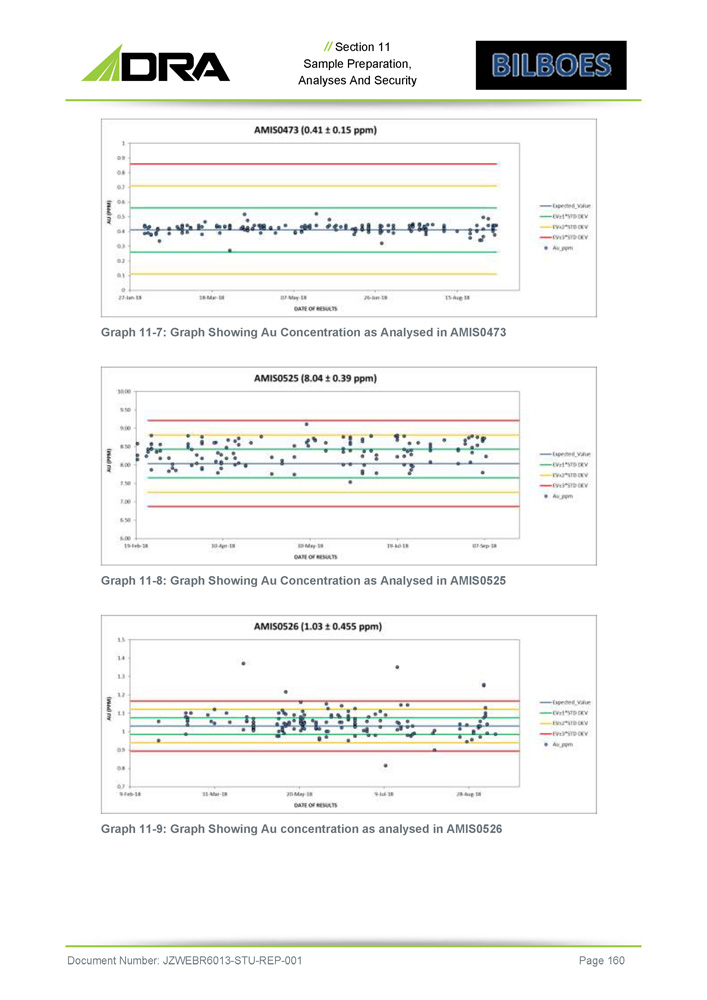

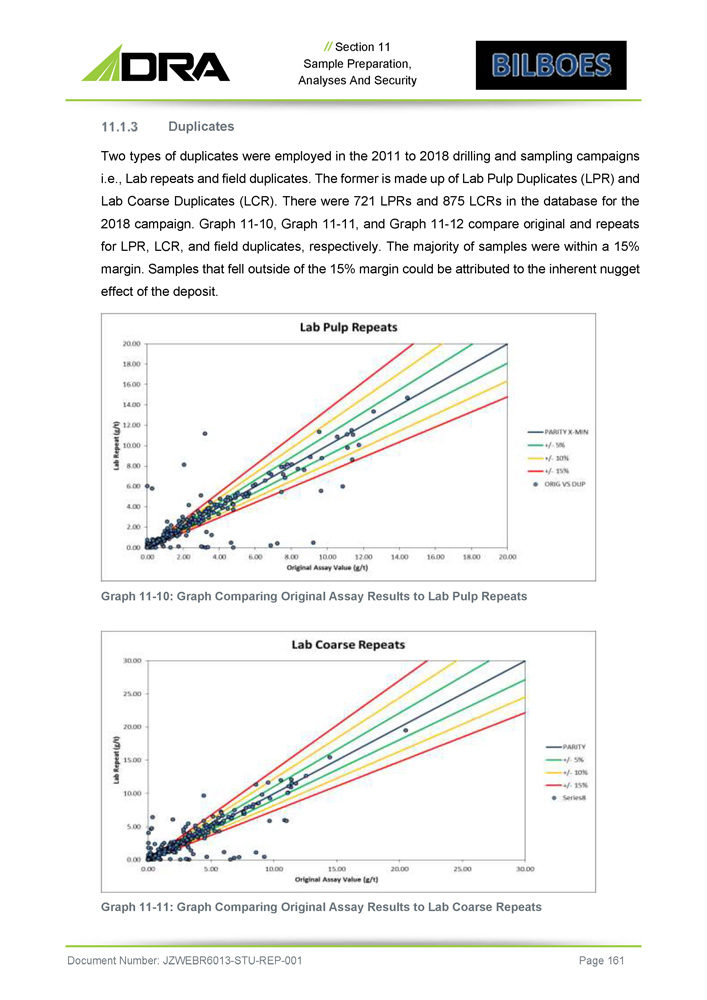

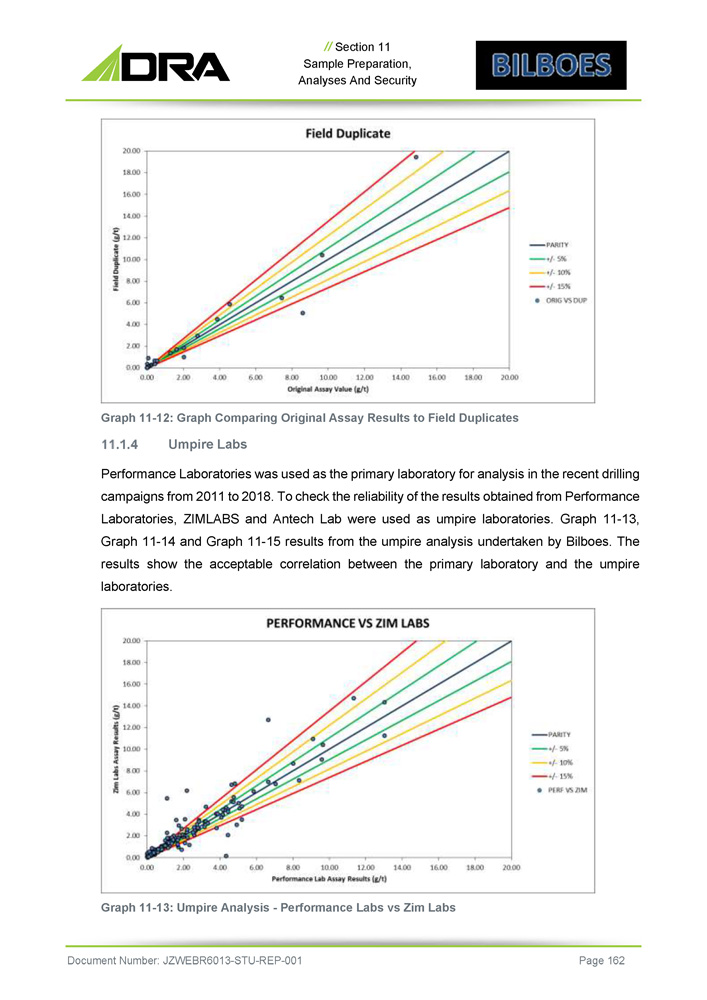

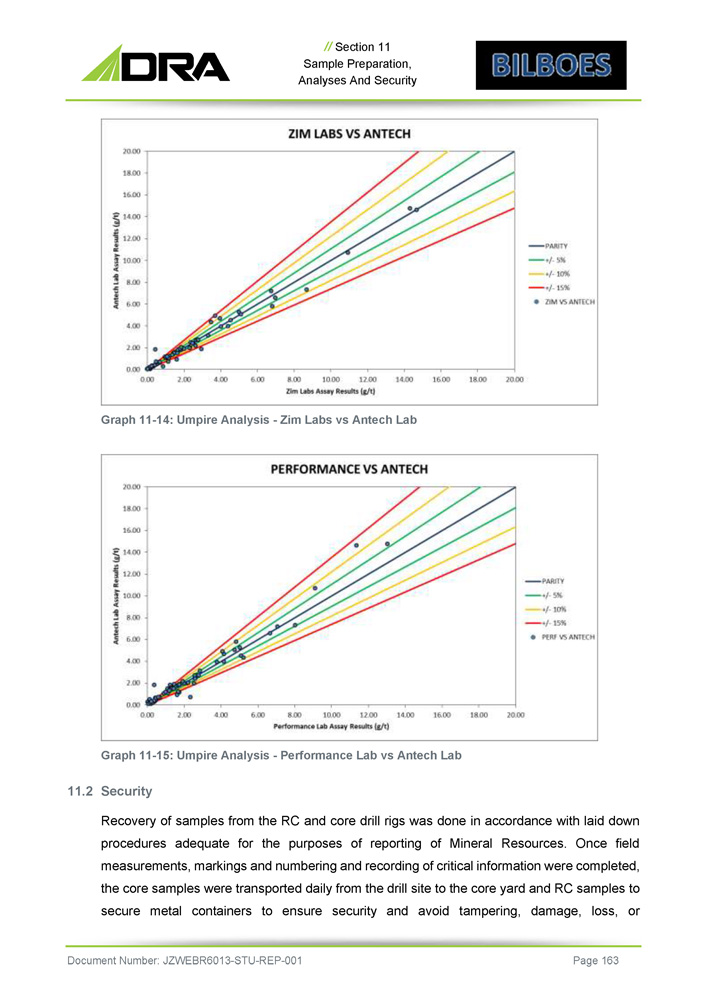

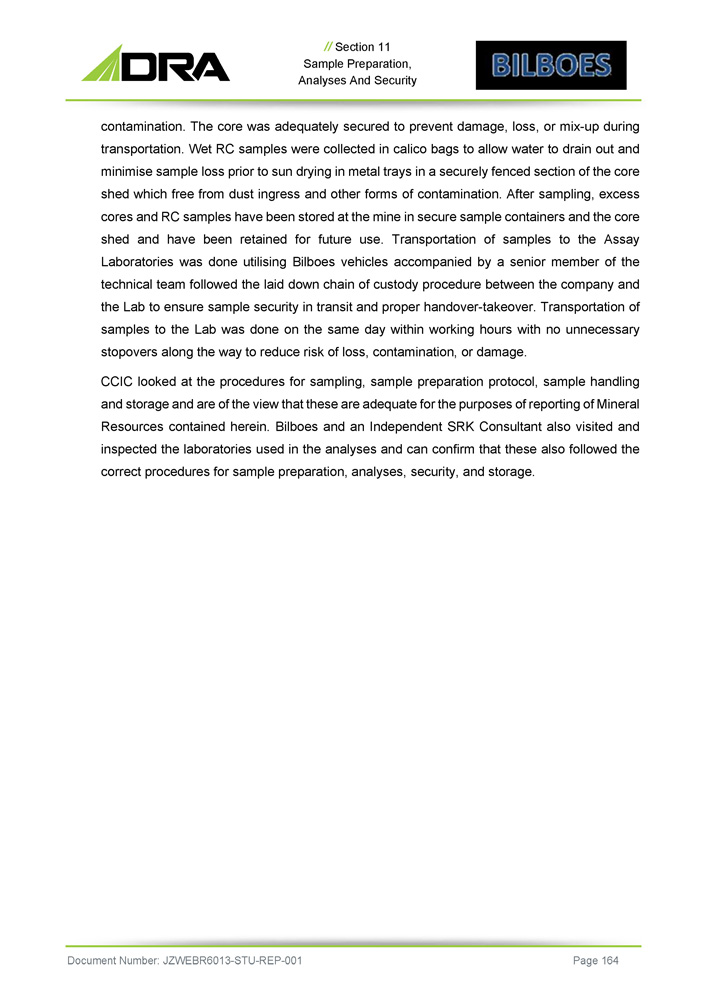

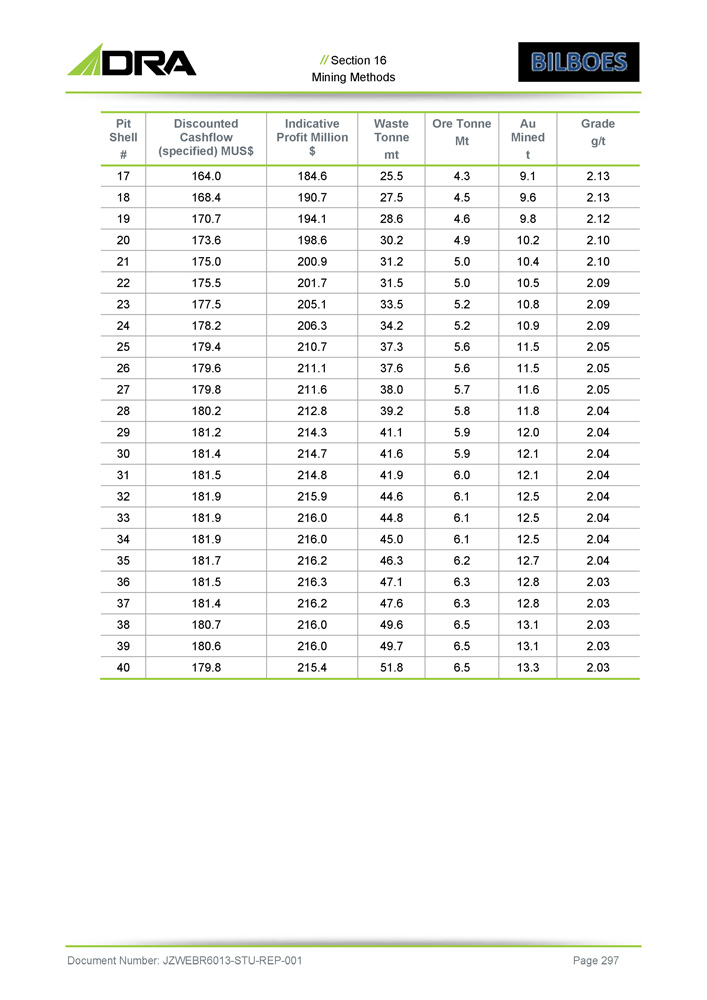

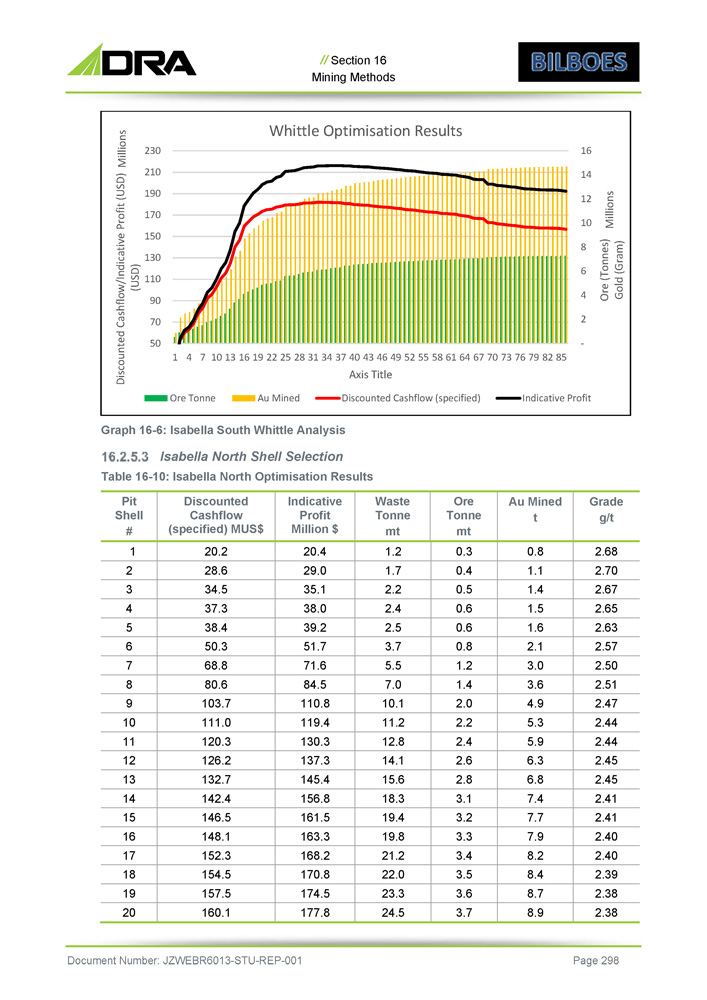

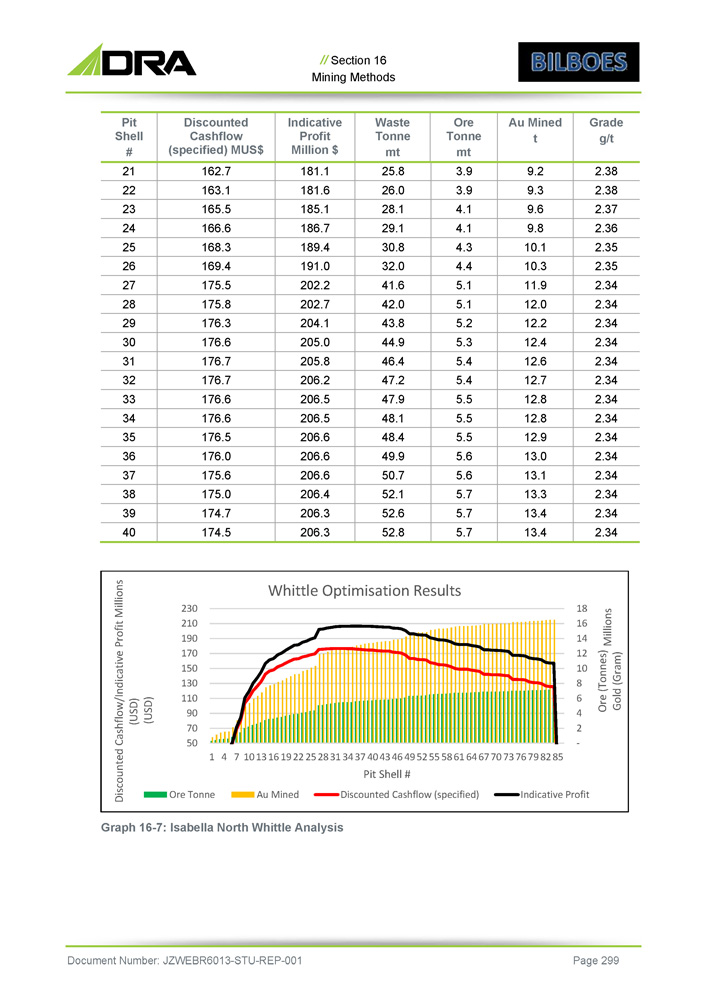

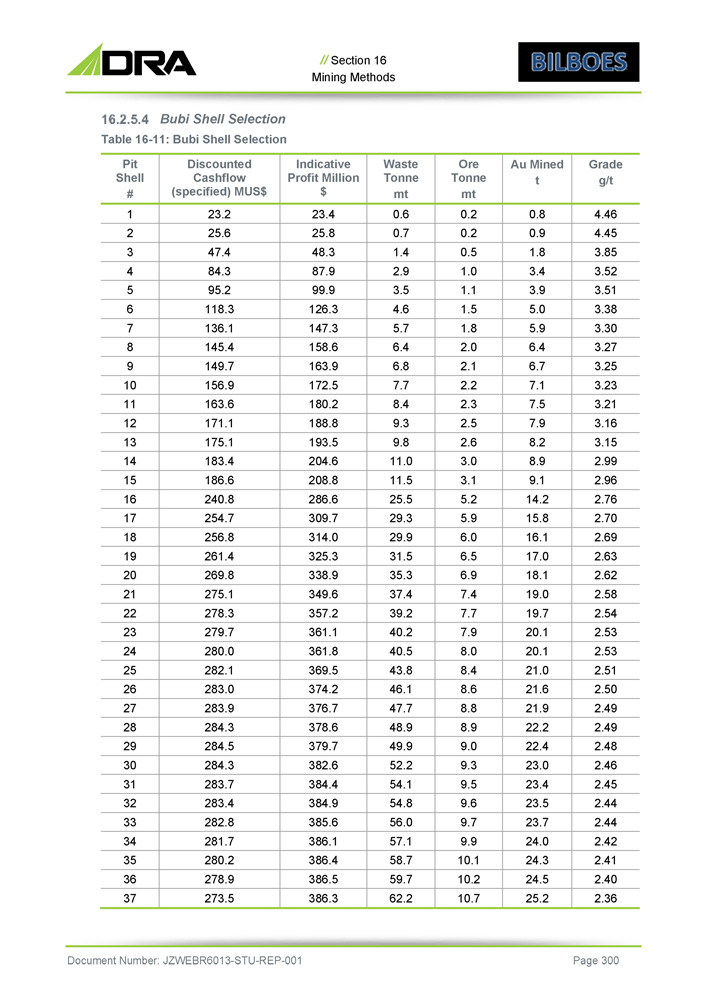

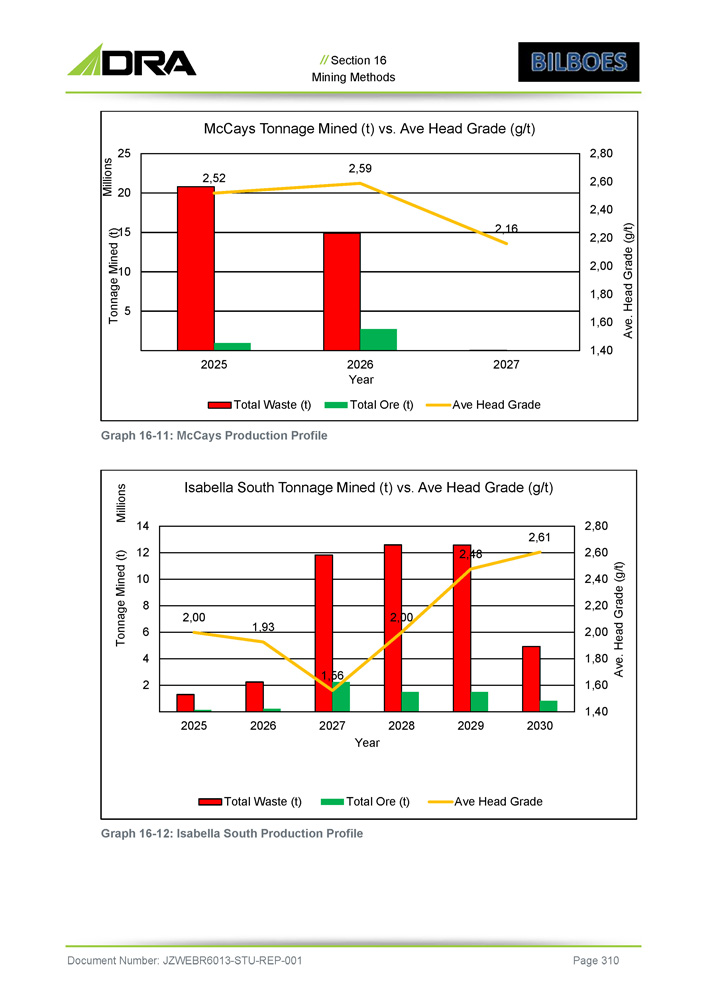

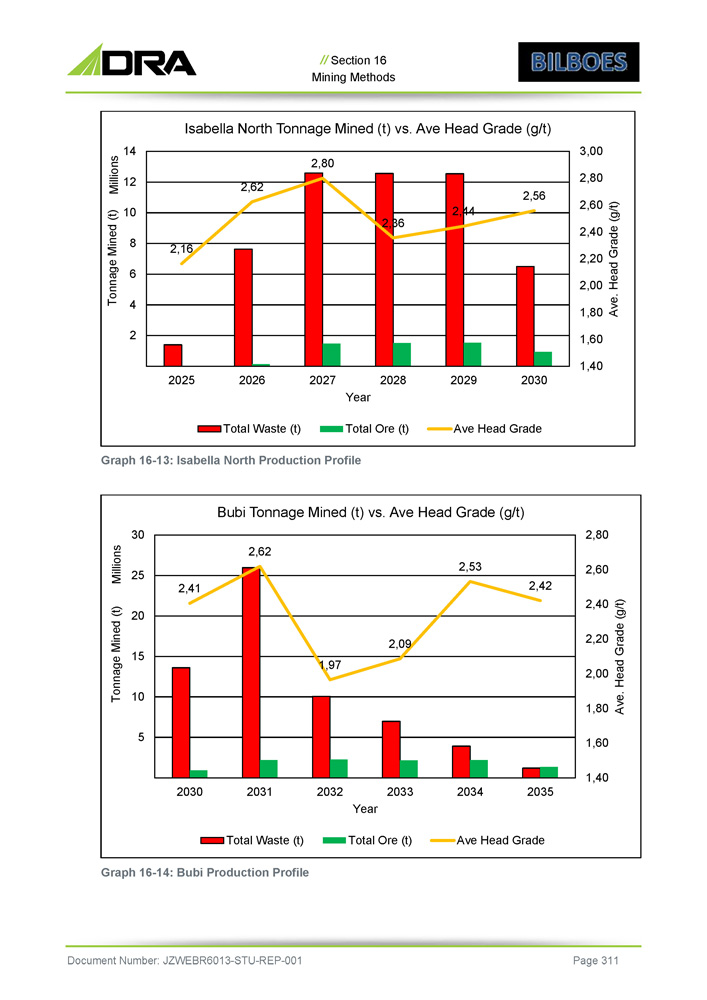

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study LIST OF GRAPHS Graph 1 1: Total Mine Material Movements for LOM Graph 1 2: LoM Excavator Fleet Graph 1 3: Weight Averaged One - way Haul Distances for Topsoil Graph 1 4: Weight Averaged One - way Haul Distances for Waste Rock Graph 1 5: Weight Averaged One - way Haul Distances for Ore Graph 1 6: Plant Feed Schedule Graph 1 7: Cost Breakdown by Disciplines Graph 1 8: Preliminary Cash Flow forecast Graph 1 9: Mining Cost Breakdown per Annum Graph 1 10: Bilboes Total Operating Costs per Annum Graph 11 1: Blank Plot for all Four Properties - AMIS0415 Graph 11 2: Blank Plot for all Four Properties - AMIS0439 Graph 11 3: Blank Plot for all Four Properties - AMIS0484 Graph 11 4: Plot for Field Blank (Local Dolerite) Graph 11 5: Graph Showing Au Concentration as Analysed in AMIS0440 Graph 11 6 : Graph Showing Au Concentration as Analysed in AMIS 0441 Graph 11 7 : Graph Showing Au Concentration as Analysed in AMIS 0473 Graph 11 8 : Graph Showing Au Concentration as Analysed in AMIS 0525 Graph 11 9: Graph Showing Au concentration as analysed in AMIS0526 Graph 11 10: Graph Comparing Original Assay Results to Lab Pulp Repeats Graph 11 11: Graph Comparing Original Assay Results to Lab Coarse Repeats Graph 11 12: Graph Comparing Original Assay Results to Field Duplicates Graph 11 13: Umpire Analysis - Performance Labs vs Zim Labs Graph 11 14: Umpire Analysis - Zim Labs vs Antech Lab Graph 11 15: Umpire Analysis - Performance Lab vs Antech Lab Graph 16 1: Bilboes Discounted Cashflow Graph 16 2: Bilboes Ore Tonnes Graph 16 3: Mining Metal Output Graph 16 4: Mine Life Graph 16 5: McCays Whittle Analysis Graph 16 6: Isabella South Whittle Analysis Graph 16 7: Isabella North Whittle Analysis Graph 16 8: Bubi Whittle Analysis Graph 16 9: Total Mine Material Movements vs. Gold Grade for LOM Graph 16 10: Total Mine Material Movements vs In - situ Gold Ounces for LOM Graph 16 11: McCays Production Profile Graph 16 12: Isabella South Production Profile Document Number: JZWEBR6013 - STU - REP - 001 Page 28 58 59 60 61 61 62 106 107 111 113 157 157 158 158 159 159 160 160 160 161 161 162 162 163 163 292 293 293 294 296 298 299 301 309 309 310 310

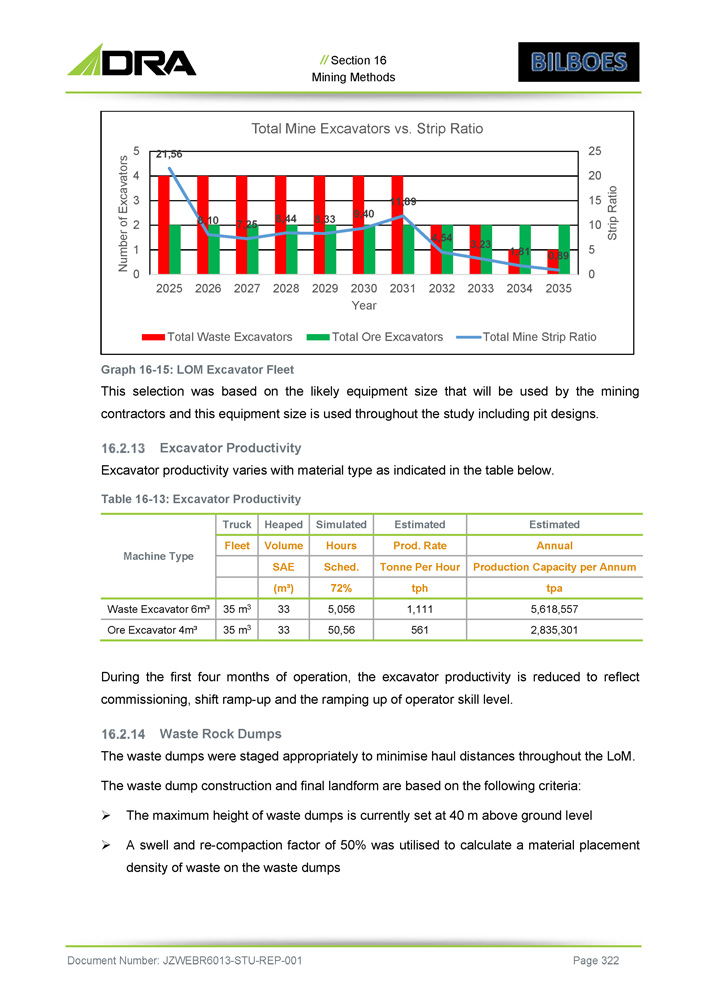

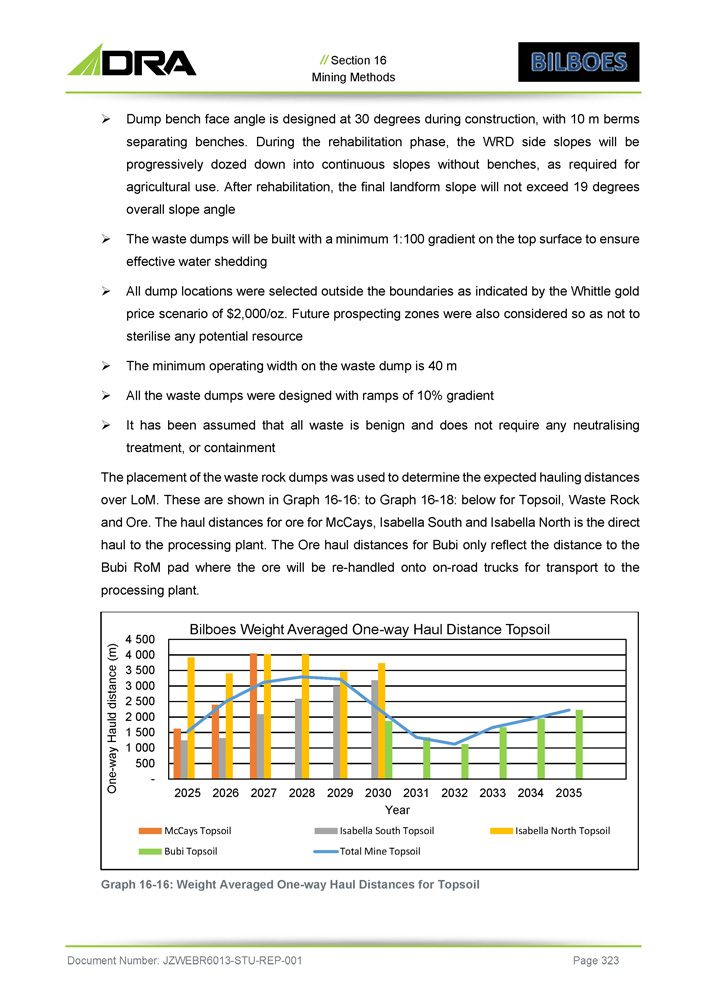

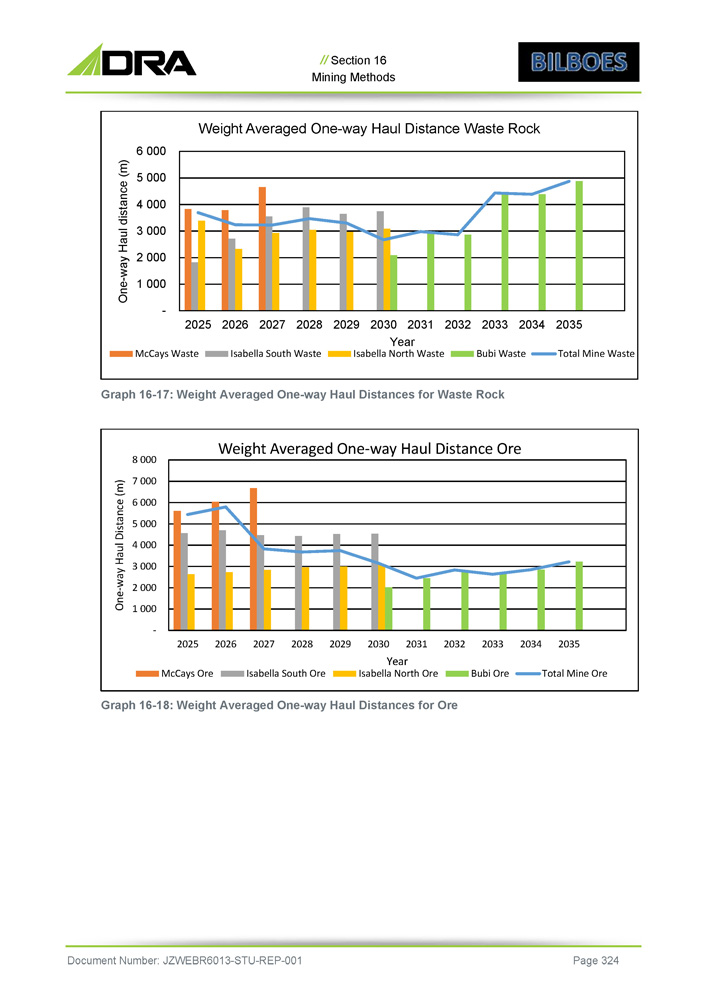

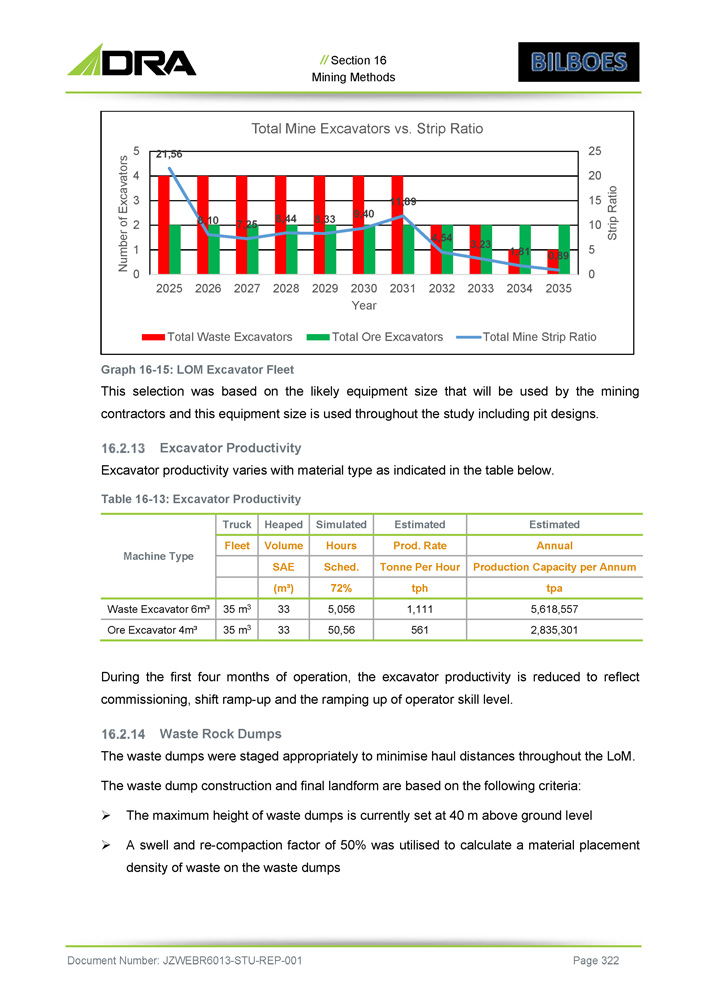

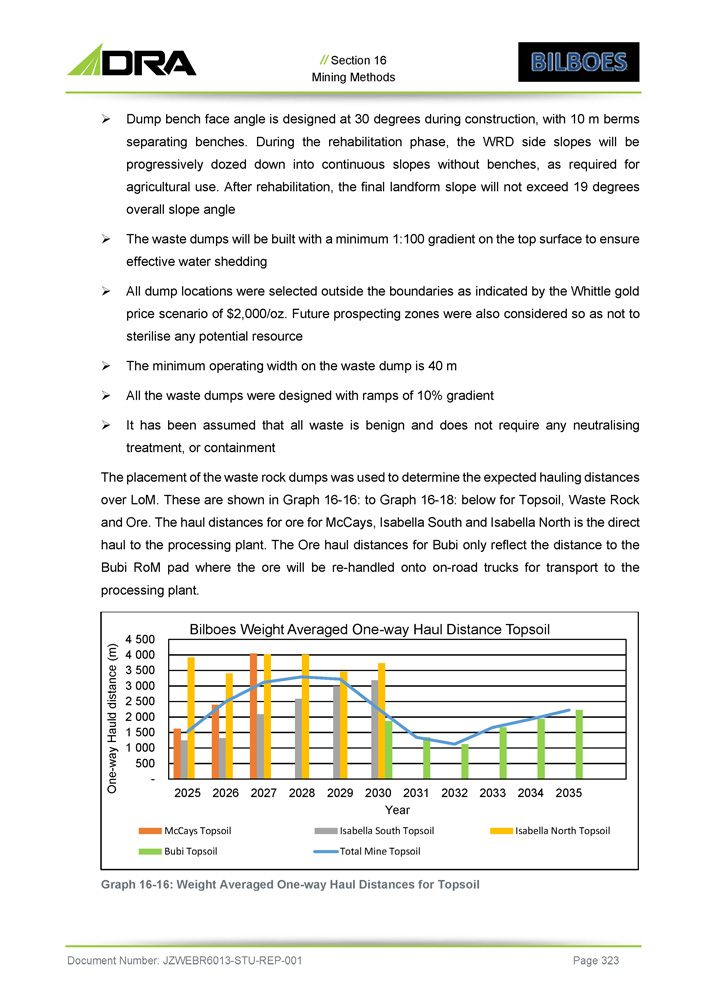

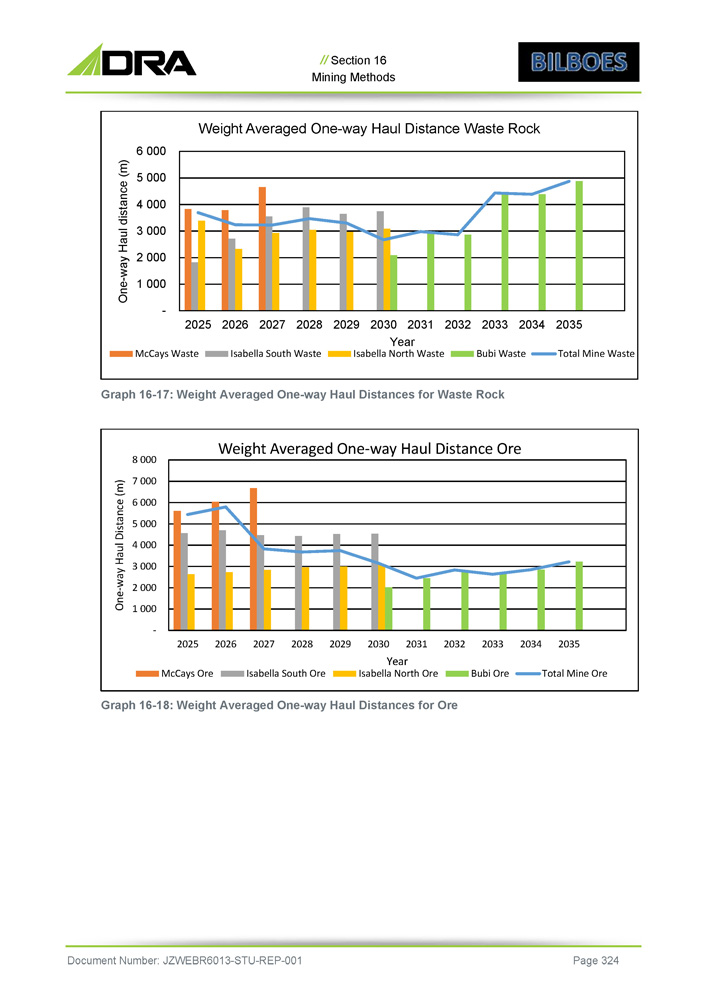

// National Instrument 43 - 101 Technical Report - Prepared By Dra Projects(Pty) Limited For The Bilboes Gold Project Feasibility Study Graph 16 13: Isabella North Production Profile Graph 16 14: Bubi Production Profile Graph 16 15: LOM Excavator Fleet Graph 16 16: Weight Averaged One - way Haul Distances for Topsoil Graph 16 17: Weight Averaged One - way Haul Distances for Waste Rock Graph 16 18: Weight Averaged One - way Haul Distances for Ore Graph 21 1: Cost Breakdown by Disciplines Graph 21 2: Preliminary Cash Flow forecast Graph 21 3: Bilboes Mining Contractor Adjudication Cost per Annum Graph 21 4: Bilboes Mining Contractor Adjudication Mobilisation Cost Graph 21 5: Bilboes Mining Contractor Cumulative Cost Graph 21 6: Bilboes Mining Contractor Adjudication Cost per Ore Tonne Graph 21 7: Bilboes Explosive Supplier Adjudication Cost per Ore Tonne Graph 21 8: Mining Cost Breakdown per Annum Graph 21 9: Mining Unit Cost Breakdown per Total Tonne Graph 21 10: Bilboes Total Operating Costs per Annum Document Number: JZWEBR6013 - STU - REP - 001 Page 29 311 311 322 323 324 324 507 512 514 514 515 516 517 518 519 526

BILBOES GOLD PROJECT FEASIBILITY STUDY SECTION 1 SUMMARY Document Number: JZWEBR6013 - STU - REP - 001

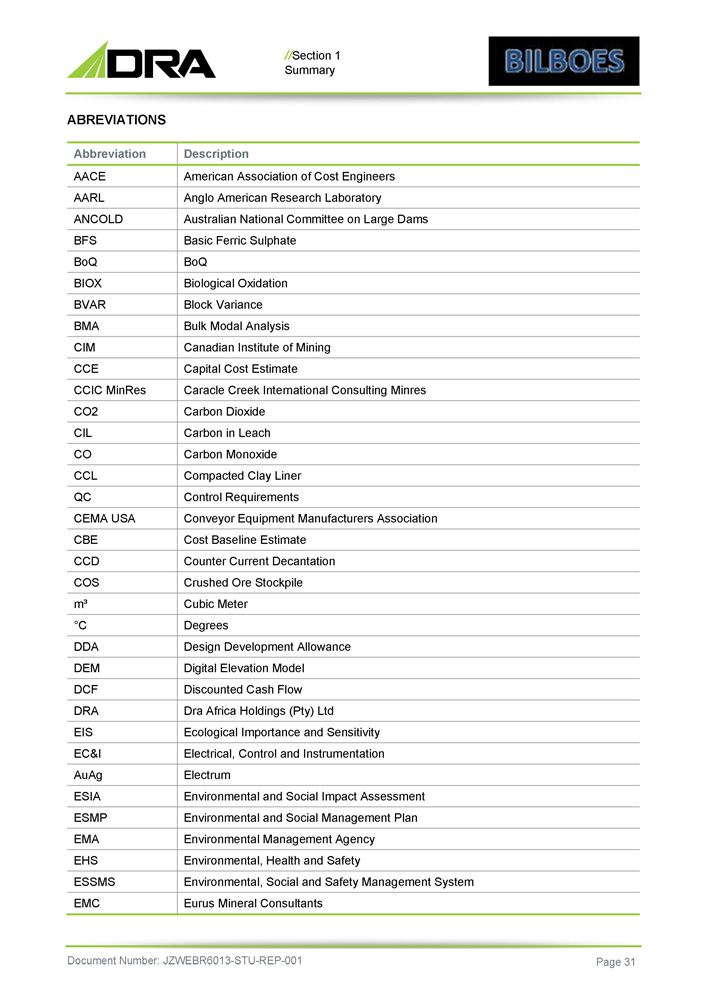

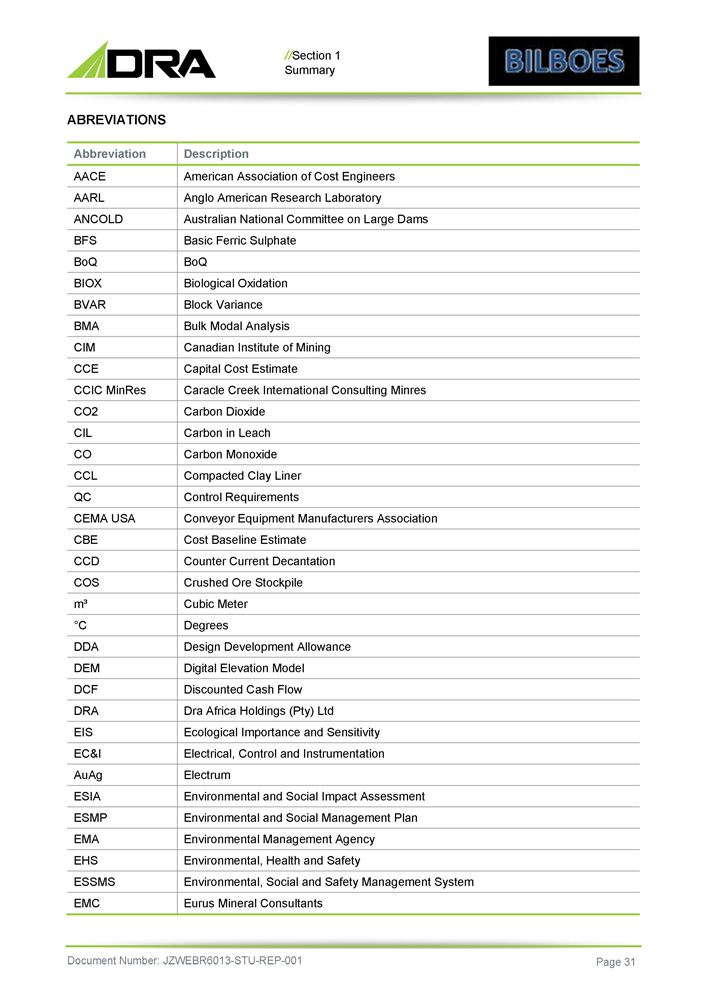

// Section 1 Summary ABREVIATIONS Document Number: JZWEBR6013 - STU - REP - 001 Page 31 Description Abbreviation American Association of Cost Engineers AACE Anglo American Research Laboratory AARL Australian National Committee on Large Dams ANCOLD Basic Ferric Sulphate BFS BoQ BoQ Biological Oxidation BIOX Block Variance BVAR Bulk Modal Analysis BMA Canadian Institute of Mining CIM Capital Cost Estimate CCE Caracle Creek International Consulting Minres CCIC MinRes Carbon Dioxide CO2 Carbon in Leach CIL Carbon Monoxide CO Compacted Clay Liner CCL Control Requirements QC Conveyor Equipment Manufacturers Association CEMA USA Cost Baseline Estimate CBE Counter Current Decantation CCD Crushed Ore Stockpile COS Cubic Meter m³ Degrees ƒ C Design Development Allowance DDA Digital Elevation Model DEM Discounted Cash Flow DCF Dra Africa Holdings (Pty) Ltd DRA Ecological Importance and Sensitivity EIS Electrical, Control and Instrumentation EC&I Electrum AuAg Environmental and Social Impact Assessment ESIA Environmental and Social Management Plan ESMP Environmental Management Agency EMA Environmental, Health and Safety EHS Environmental, Social and Safety Management System ESSMS Eurus Mineral Consultants EMC

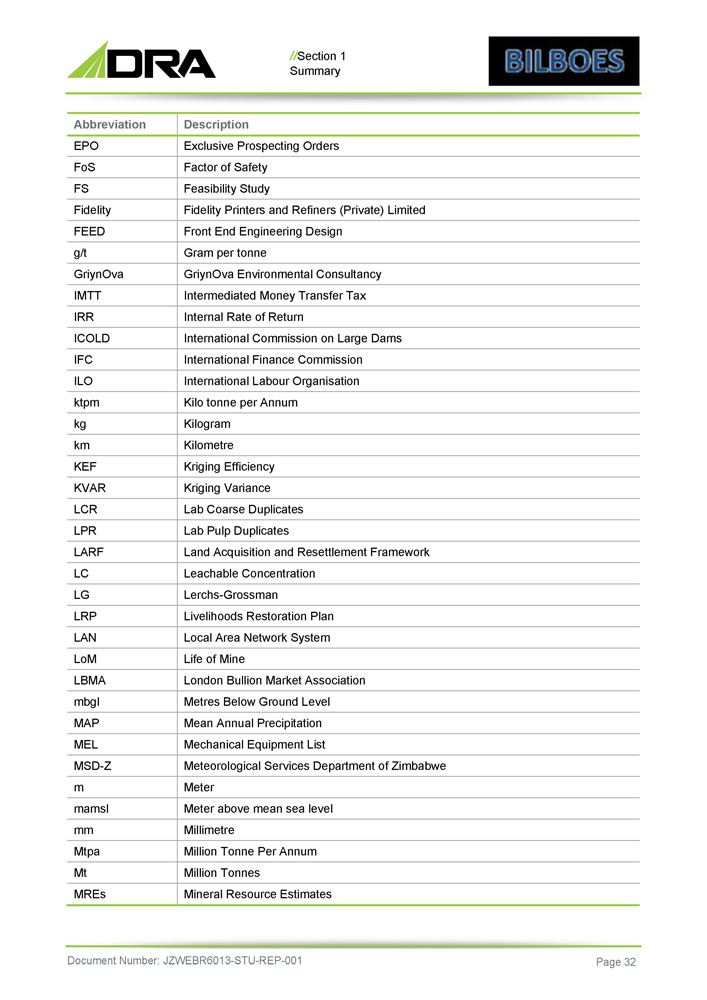

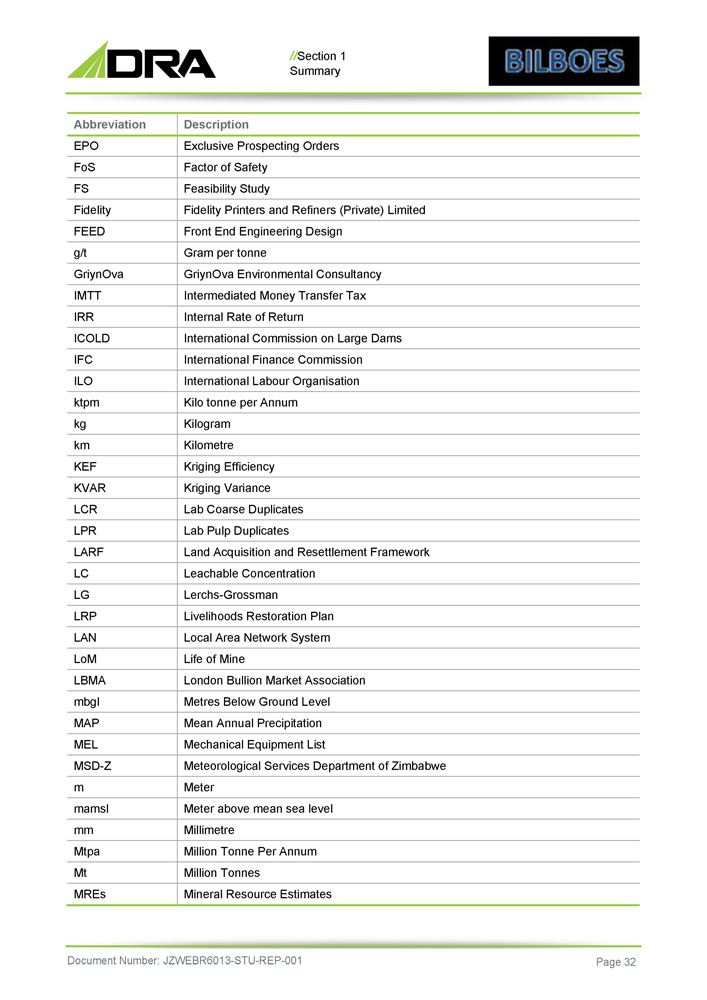

// Section 1 Summary Description Abbreviation Exclusive Prospecting Orders EPO Factor of Safety FoS Feasibility Study FS Fidelity Printers and Refiners (Private) Limited Fidelity Front End Engineering Design FEED Gram per tonne g/t GriynOva Environmental Consultancy GriynOva Intermediated Money Transfer Tax IMTT Internal Rate of Return IRR International Commission on Large Dams ICOLD International Finance Commission IFC International Labour Organisation ILO Kilo tonne per Annum ktpm Kilogram kg Kilometre km Kriging Efficiency KEF Kriging Variance KVAR Lab Coarse Duplicates LCR Lab Pulp Duplicates LPR Land Acquisition and Resettlement Framework LARF Leachable Concentration LC Lerchs - Grossman LG Livelihoods Restoration Plan LRP Local Area Network System LAN Life of Mine LoM London Bullion Market Association LBMA Metres Below Ground Level mbgl Mean Annual Precipitation MAP Mechanical Equipment List MEL Meteorological Services Department of Zimbabwe MSD - Z Meter m Meter above mean sea level mamsl Millimetre mm Million Tonne Per Annum Mtpa Million Tonnes Mt Mineral Resource Estimates MREs Document Number: JZWEBR6013 - STU - REP - 001 Page 32

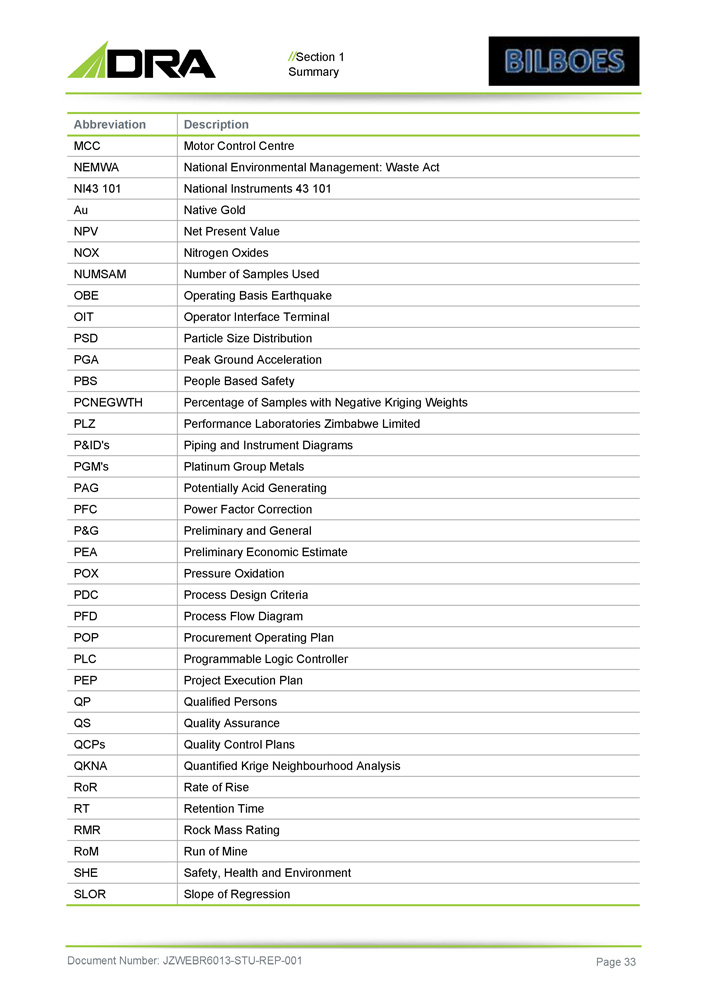

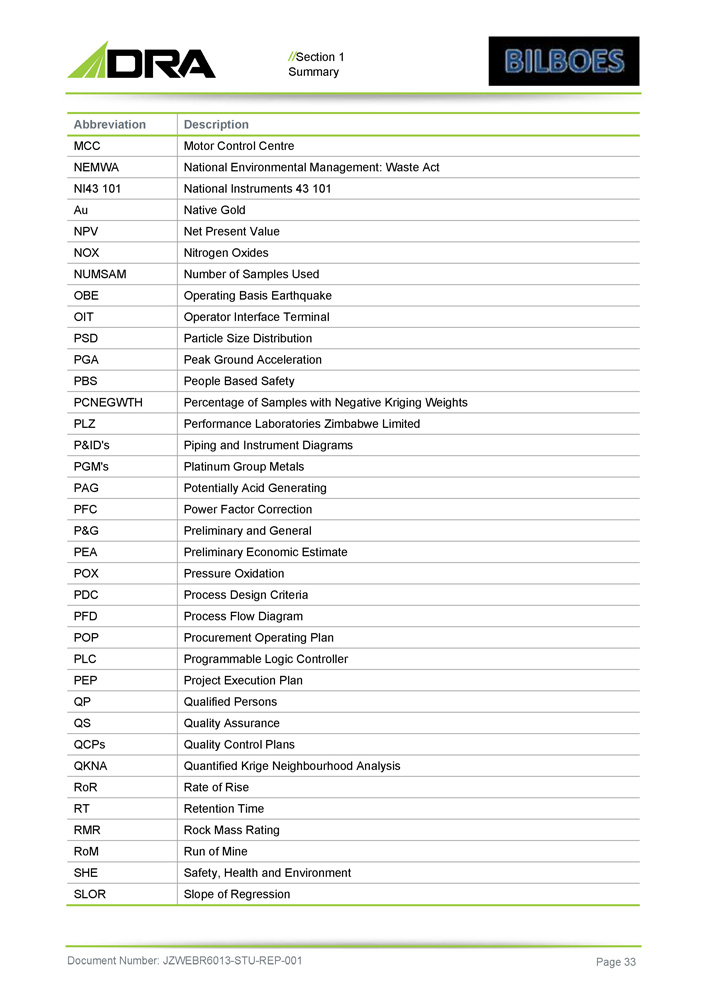

// Section 1 Summary Description Abbreviation Motor Control Centre MCC National Environmental Management: Waste Act NEMWA National Instruments 43 101 NI43 101 Native Gold Au Net Present Value NPV Nitrogen Oxides NOX Number of Samples Used NUMSAM Operating Basis Earthquake OBE Operator Interface Terminal OIT Particle Size Distribution PSD Peak Ground Acceleration PGA People Based Safety PBS Percentage of Samples with Negative Kriging Weights PCNEGWTH Performance Laboratories Zimbabwe Limited PLZ Piping and Instrument Diagrams P&ID's Platinum Group Metals PGM's Potentially Acid Generating PAG Power Factor Correction PFC Preliminary and General P&G Preliminary Economic Estimate PEA Pressure Oxidation POX Process Design Criteria PDC Process Flow Diagram PFD Procurement Operating Plan POP Programmable Logic Controller PLC Project Execution Plan PEP Qualified Persons QP Quality Assurance QS Quality Control Plans QCPs Quantified Krige Neighbourhood Analysis QKNA Rate of Rise RoR Retention Time RT Rock Mass Rating RMR Run of Mine RoM Safety, Health and Environment SHE Slope of Regression SLOR Document Number: JZWEBR6013 - STU - REP - 001 Page 33

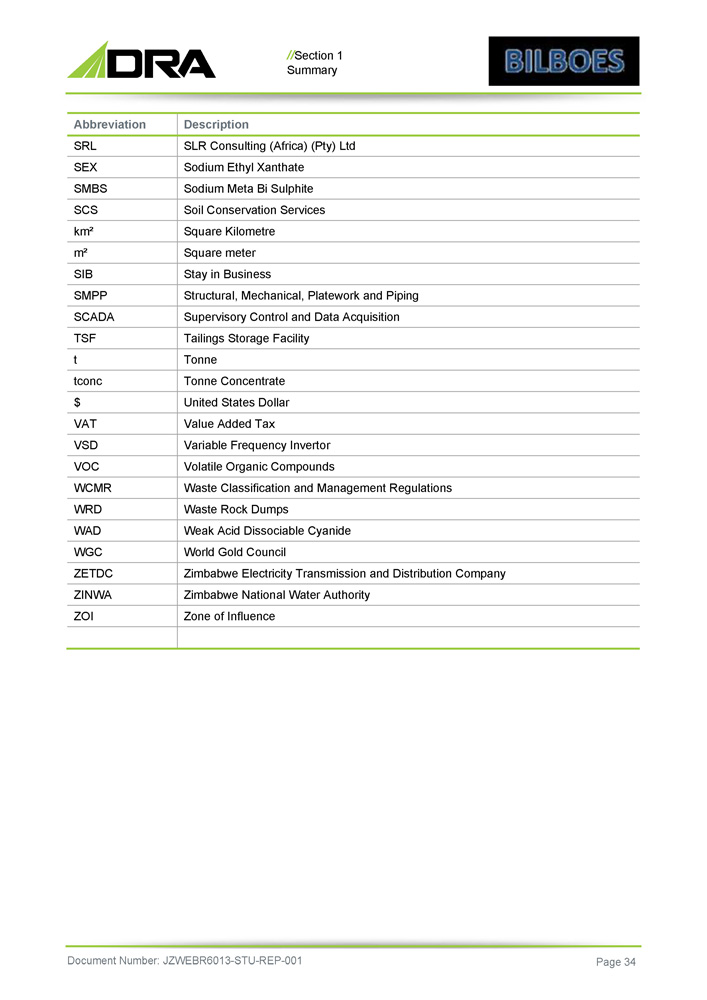

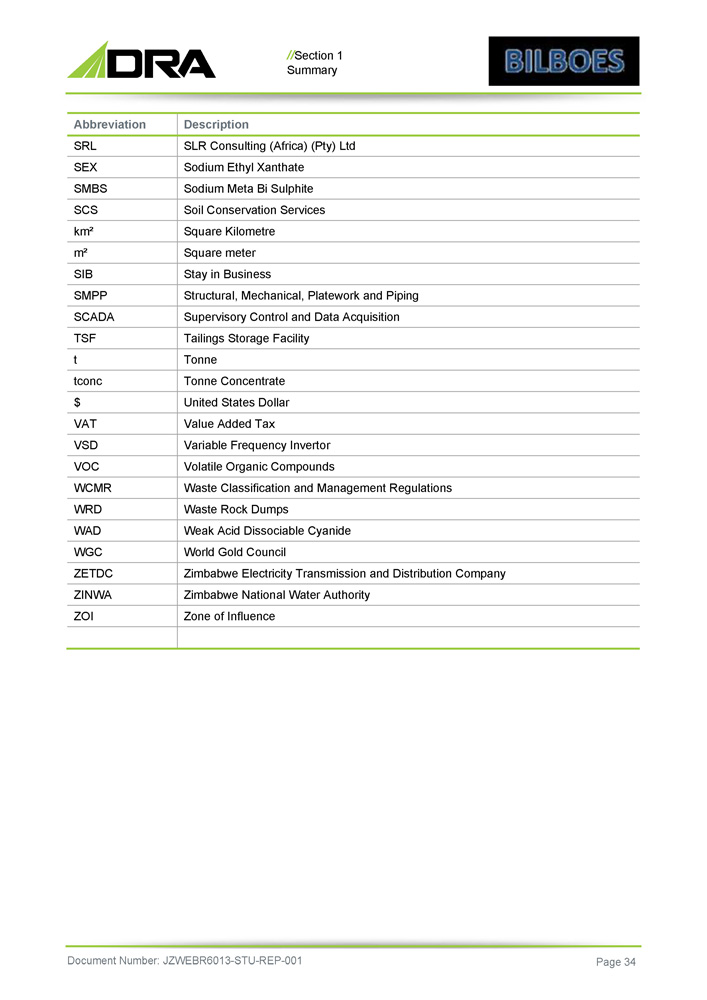

// Section 1 Summary Description Abbreviation SLR Consulting (Africa) (Pty) Ltd SRL Sodium Ethyl Xanthate SEX Sodium Meta Bi Sulphite SMBS Soil Conservation Services SCS Square Kilometre km² Square meter m² Stay in Business SIB Structural, Mechanical, Platework and Piping SMPP Supervisory Control and Data Acquisition SCADA Tailings Storage Facility TSF Tonne t Tonne Concentrate tconc United States Dollar $ Value Added Tax VAT Variable Frequency Invertor VSD Volatile Organic Compounds VOC Waste Classification and Management Regulations WCMR Waste Rock Dumps WRD Weak Acid Dissociable Cyanide WAD World Gold Council WGC Zimbabwe Electricity Transmission and Distribution Company ZETDC Zimbabwe National Water Authority ZINWA Zone of Influence ZOI Document Number: JZWEBR6013 - STU - REP - 001 Page 34

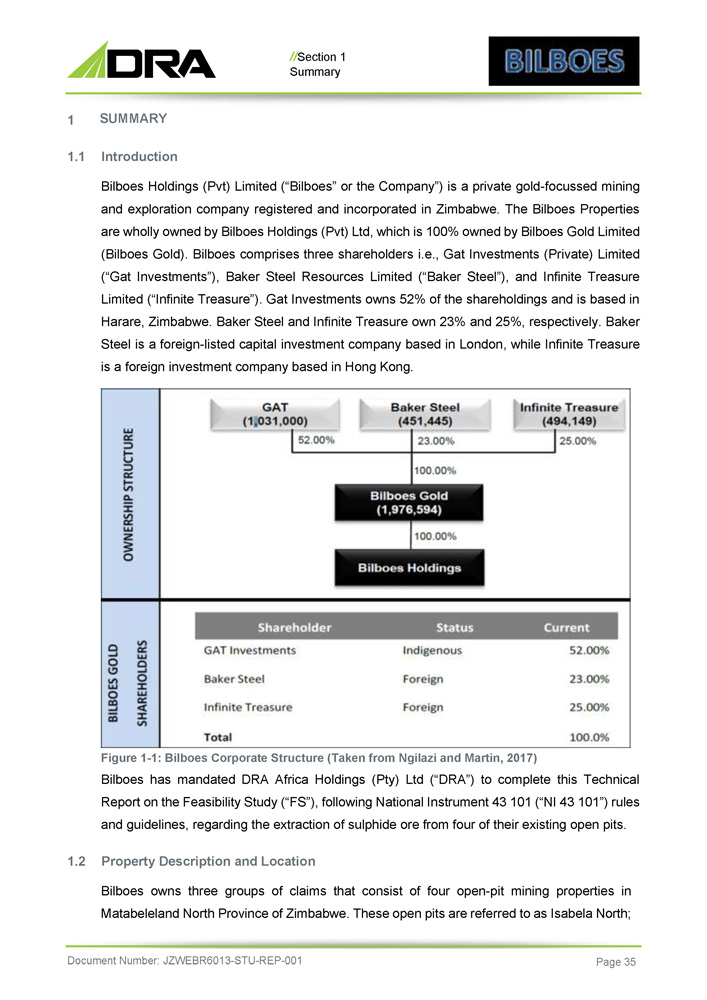

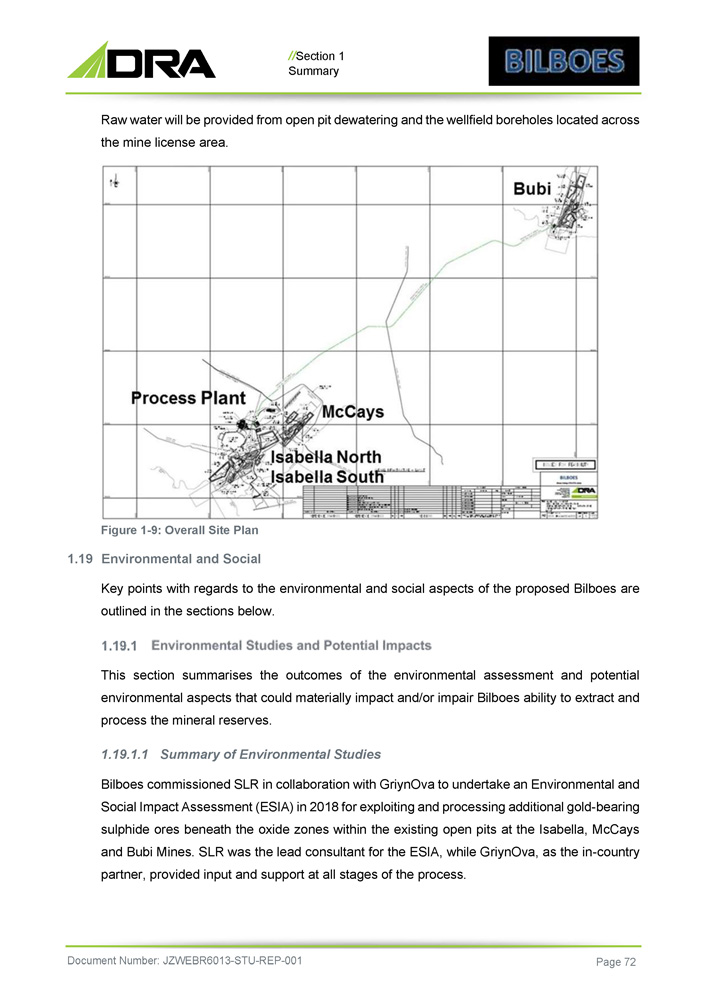

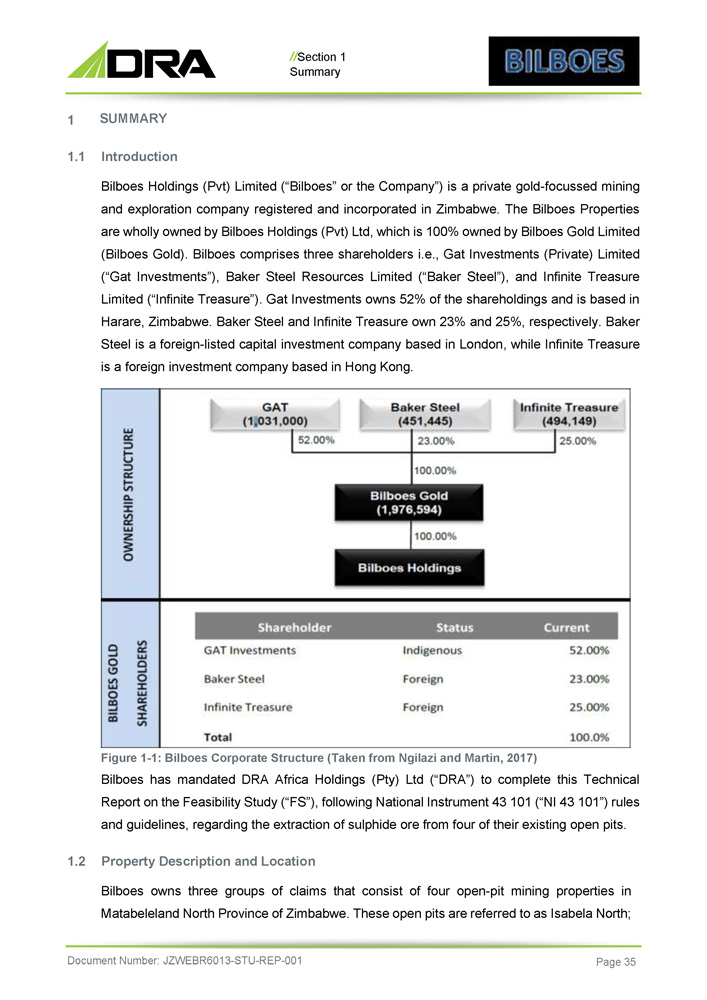

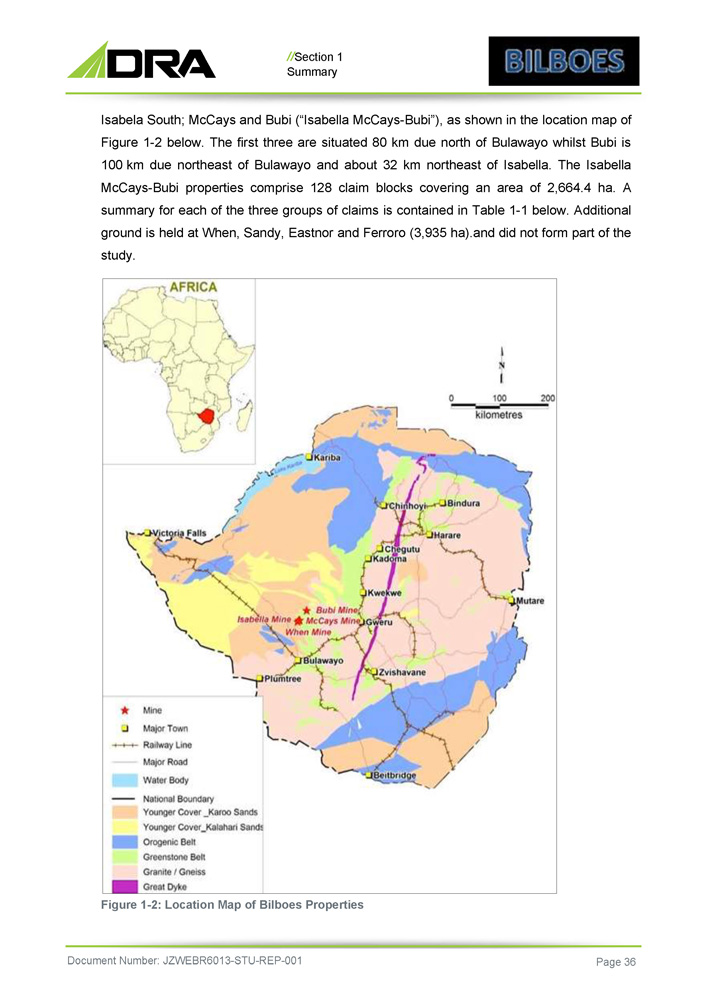

// Section 1 Summary 1 SUMMARY 1 . 1 Introduction Bilboes Holdings (Pvt) Limited (“Bilboes” or the Company”) is a private gold - focussed mining and exploration company registered and incorporated in Zimbabwe . The Bilboes Properties are wholly owned by Bilboes Holdings (Pvt) Ltd, which is 100 % owned by Bilboes Gold Limited (Bilboes Gold) . Bilboes comprises three shareholders i . e . , Gat Investments (Private) Limited (“Gat Investments”), Baker Steel Resources Limited (“Baker Steel”), and Infinite Treasure Limited (“Infinite Treasure”) . Gat Investments owns 52 % of the shareholdings and is based in Harare, Zimbabwe . Baker Steel and Infinite Treasure own 23 % and 25 % , respectively . Baker Steel is a foreign - listed capital investment company based in London, while Infinite Treasure is a foreign investment company based in Hong Kong . Figure 1 - 1 : Bilboes Corporate Structure (Taken from Ngilazi and Martin, 2017 ) Bilboes has mandated DRA Africa Holdings (Pty) Ltd (“DRA”) to complete this Technical Report on the Feasibility Study (“FS”), following National Instrument 43 101 (“NI 43 101 ”) rules and guidelines, regarding the extraction of sulphide ore from four of their existing open pits . 1.2 Property Description and Location Bilboes owns three groups of claims that consist of four open - pit mining properties in Matabeleland North Province of Zimbabwe. These open pits are referred to as Isabela North; Document Number: JZWEBR6013 - STU - REP - 001 Page 35

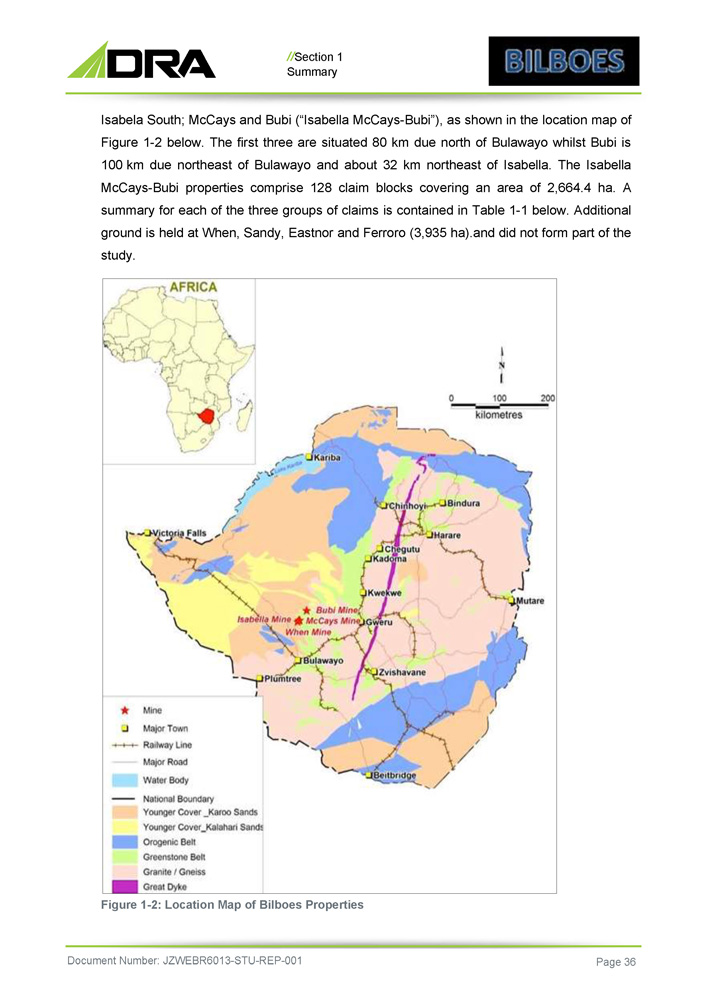

// Section 1 Summary Isabela South ; McCays and Bubi (“Isabella McCays - Bubi”), as shown in the location map of Figure 1 - 2 below . The first three are situated 80 km due north of Bulawayo whilst Bubi is 100 km due northeast of Bulawayo and about 32 km northeast of Isabella . The Isabella McCays - Bubi properties comprise 128 claim blocks covering an area of 2 , 664 . 4 ha . A summary for each of the three groups of claims is contained in Table 1 - 1 below . Additional ground is held at When, Sandy, Eastnor and Ferroro ( 3 , 935 ha) . and did not form part of the study . Figure 1 - 2: Location Map of Bilboes Properties Document Number: JZWEBR6013 - STU - REP - 001 Page 36

// Section 1 . Summary Table 1 - 1: Bilboes Claims Document Number: JZWEBR6013 - STU - REP - 001 Page 37 Coordinate Y1 Coordinate X1 Area (ha) No. of Blocks Province Mining District Group of Claims 7,846,712 662,106 1,864.4 48 Matabeleland North Bulawayo Calcite and Kerry (Isabella Mine) 7,849,975 666,339 330 33 Matabeleland North Bulawayo Ruswayi (McCays Mine) 7,865,515 684,838 470 47 Matabeleland North Bulawayo Chikosi (Bubi Mine) 2,664.4 128 Total 3. Accessibility, Climate, Infrastructure and Physiography Isabella McCays and Bubi are approximately 80 km and 100 km directly north and northeast of Bulawayo, the second largest city of Zimbabwe with an approximate population of 655 , 675 ( 2013 . All the mines are accessed via public roads and although these are of variable quality, they are accessible by all types of vehicles . Isabella is 110 km ( 1 . 5 hours) whilst Bubi is 140 km ( 2 hours) by road from Bulawayo . Bubi can also be accessed by road from Isabella ( 70 km in 1 hour) . Average daily temperatures range from 24 ƒ C in June, to 32 ƒ in October and apart from the occasional heavy downpour in the rainy season, there are no climatic conditions that prevent all year - round exploration and mining . The properties lie between 1 , 150 m and 1 , 200 m above sea level and are covered by red and grey soils of the greenstone rocks in the area . The area is generally flat and covered by woodland interspersed scrubby vegetation . Agricultural activities are mainly small - scale ranching . 4. History Anglo American Corporation of Zimbabwe Ltd (“AMZIM”), a company that formed Bilboes Holdings (Pvt) Ltd and which was later taken over by GAT investments (Pvt) Ltd in 2003 held the Isabella, McCays and Bubi claims . AMZIM acquired the Isabella claims in 1982 . Initial exploration allowed the estimation of a small oxide Resource and an open - pit ; heap - leach mine was commissioned in 1989 . Subsequent exploration extended the Isabella and new discoveries were made at Bubi and McCays, which has yielded 8 , 954 kg of gold ( 287 , 883 oz) to December 2020 . 90 , 048 oz of this being produced since the takeover of the company in 2003 . All mining has been from open pit oxide ore utilising the heap leach extraction processing method .

// Section 1 Summary Exploration for sulphide Mineral Resources began in 1994 / 95 , with a sum of 17 , 650 m of exploratory drilling being completed by 1999 , covering a strike length of 3 , 440 m . A maiden mineral Resource estimate for the sulphide Mineral Resources was completed by SRK in 2009 , containing 4 . 75 Mt of Inferred Mineral Resources grading 3 . 49 g/t . This estimate used a 2 . 0 g/t cut - off for delineation of the mineral Resource estimation domains . 1.5 Geology and Resource Estimate The Bubi Greenstone Belt (Archean) covering the Bilboes Properties consists of volcanic rocks of the Upper Bulawayan Group and capped by sedimentary sequences of the Shamvaian Group, all of which have been metamorphosed into felsic and mafic schists . Gold deposits are concentrated at the interface between these two groups, where major structural breaks and splays provide pathways for hydrothermal vein mineralisation . Gold is associated with sulphides that are commonly found in hydrothermal systems . These include pyrite and arsenopyrite as major components, but copper, lead, zinc, antimony, are also present in some deposits . Common alteration associated with gold mineralisation is silicification, with lesser sericite and chlorite alteration . 6. Deposit Types Mineralisation is hydrothermal and consists of silicified stockworks that host pyrite and arsenopyrite . The stockworks are characterised by a series of subparallel echelon zones . The gold is very finely dispersed within the sulphides and is refractory . All the deposits are oxidised with the sulphide interface occurring between 6 m and 50 m below surface . 7. Exploration Soil sampling, trenching and geological mapping have been progressively carried out since exploration and oxide mining commenced in 1982 . Soil sampling was used to identify areas for trenching and mapping . Trenches were sampled at 1 m to 2 m intervals and analysed using the bottle roll method . These assays were used to guide the interpretation and projection of oxide mineralisation along strike and at depth . The assays from trench sampling were however not used in grade estimation . Ground Magnetics and Induced Polarisation geophysical surveys have been conducted at Isabella, as part of the oxide ore exploration since 1996 . Document Number: JZWEBR6013 - STU - REP - 001 Page 38

// Section 1 Summary 8. Drilling Drilling of the sulphides to provide data for the Resource estimate was done in three phases totalling 93 , 400 m . The first phase by Anglo American Corporation was between 1994 and 1999 and the second phase by Bilboes from 2011 to 2013 . The latest drilling which was from December 2017 to November 2018 . The third campaign focussed on upgrading of the Mineral Resources from the Inferred and Indicated to Indicated and Measured categories, as required for this FS . 9. Sample Preparation, Analysis and Security During the drilling campaigns, all geological logging and sampling was carried out in accordance with Bilboes standard operating procedures which were adopted from AMZIM and enhanced over time to keep up with industry best practices . Independent SANAS accredited laboratories were used in the analyses of samples . Performance Laboratories Zimbabwe Limited (“PLZ”) in Harare was selected as the primary laboratory . ZIMLABS and Antech Laboratories (“Antech”) in Zimbabwe were used for check analyses . Certified Reference Materials (CRMs), blanks, field duplicates, coarse and pulp repeats were used for QA / QC purposes . Excess cores and RC samples have been stored at the mine in sample containers and the core shed and have been retained for future use . The QPs have assessed the standard operating procedures together with the results of the QA / QC program and are of the view that these are adequate for the purposes of reporting the Mineral Resources contained herein . 10. Data Verification Before commencement of the 2017 / 2018 drilling campaign in addition to the Datamine Œ software already in place Bilboes acquired Fusion database software for the capture : storage and management of drill hole information . This software has built in data verification tools to minimise transcription errors . Bilboes standard operating procedure involves a thorough audit by a senior geologist of each drillholes’ geology and sampling logs, from data logging through to capturing into the database and QA / QC checks . Each hardcopy log is audited and signed - off by a senior geologist prior to being used in modelling and estimation . Document Number: JZWEBR6013 - STU - REP - 001 Page 39

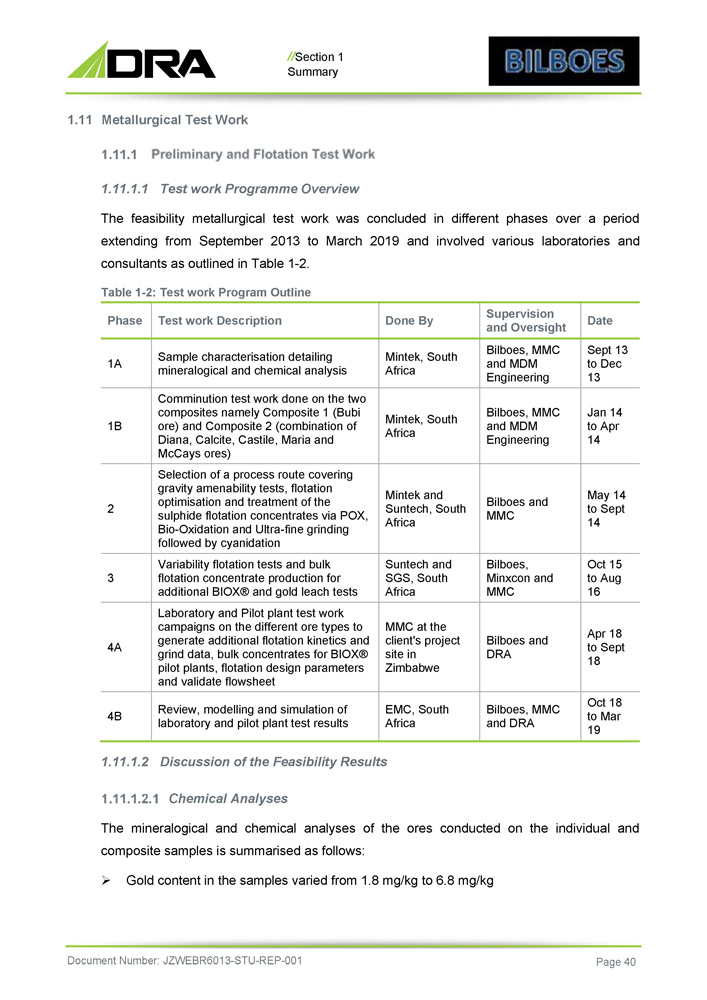

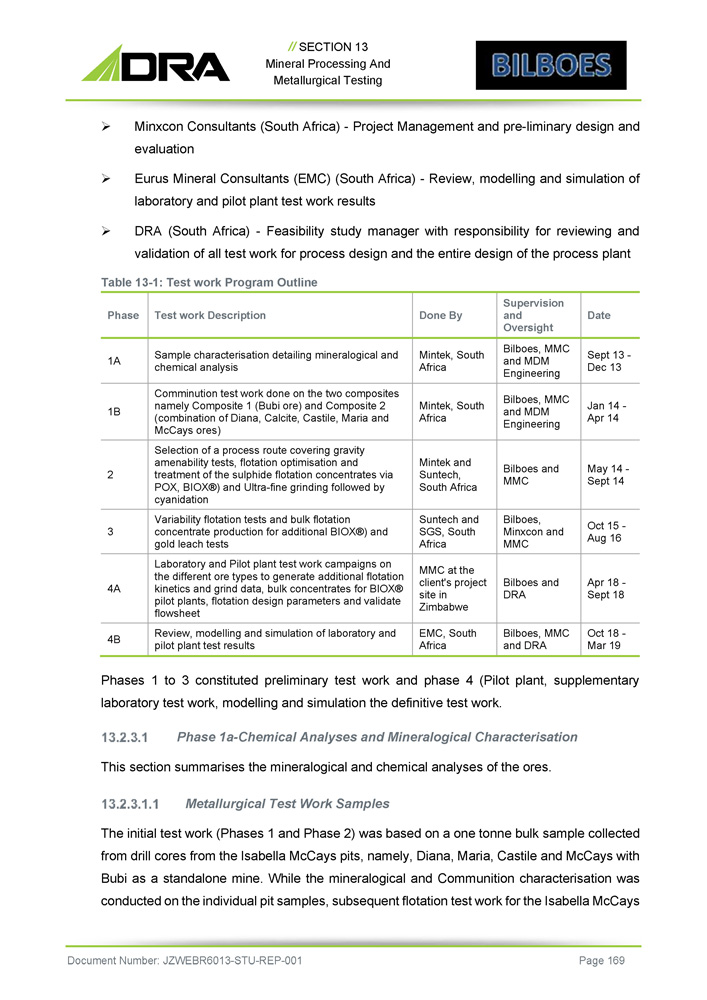

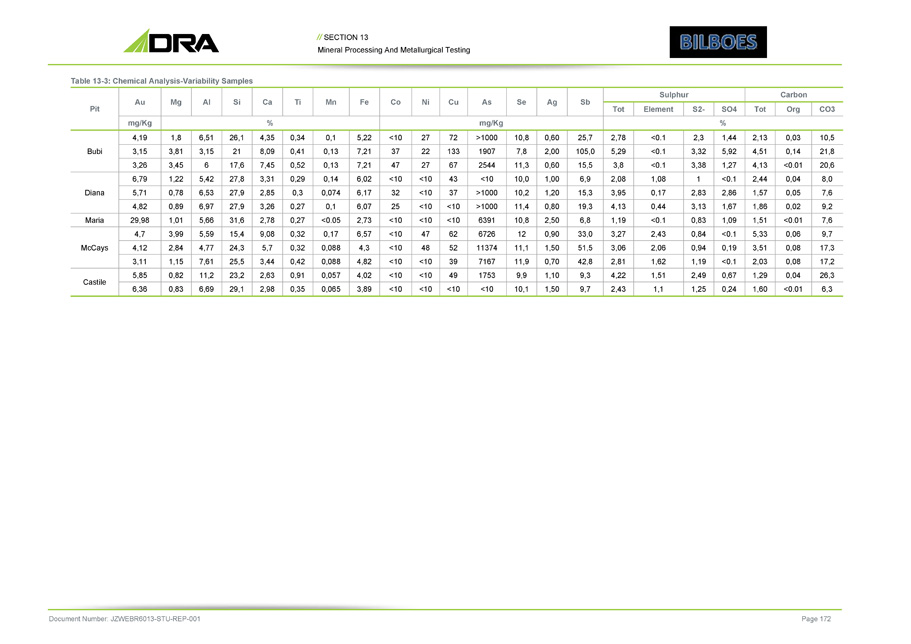

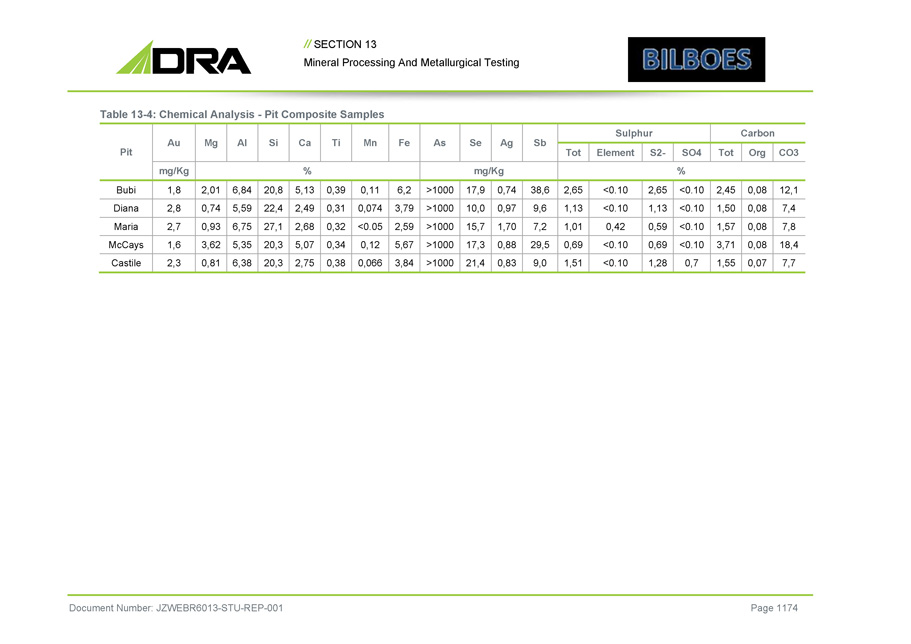

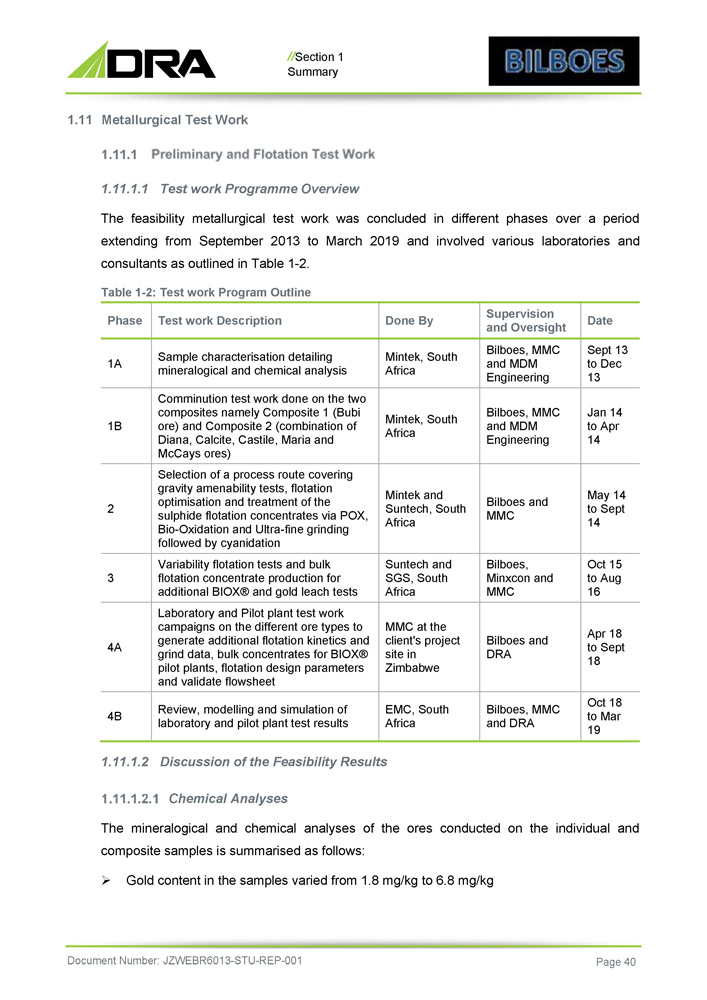

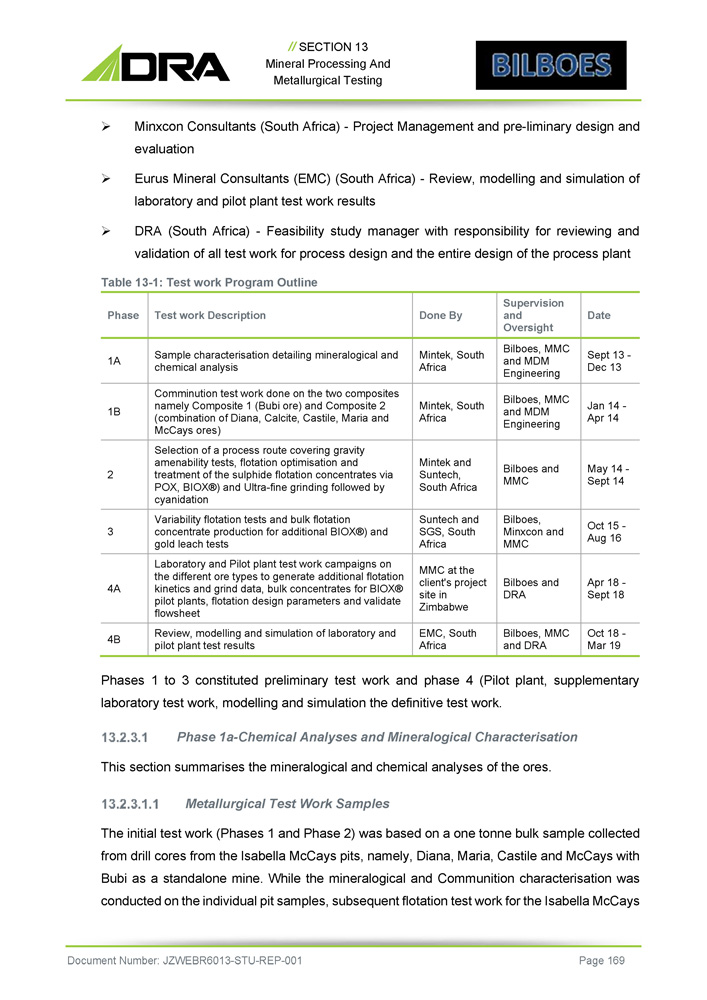

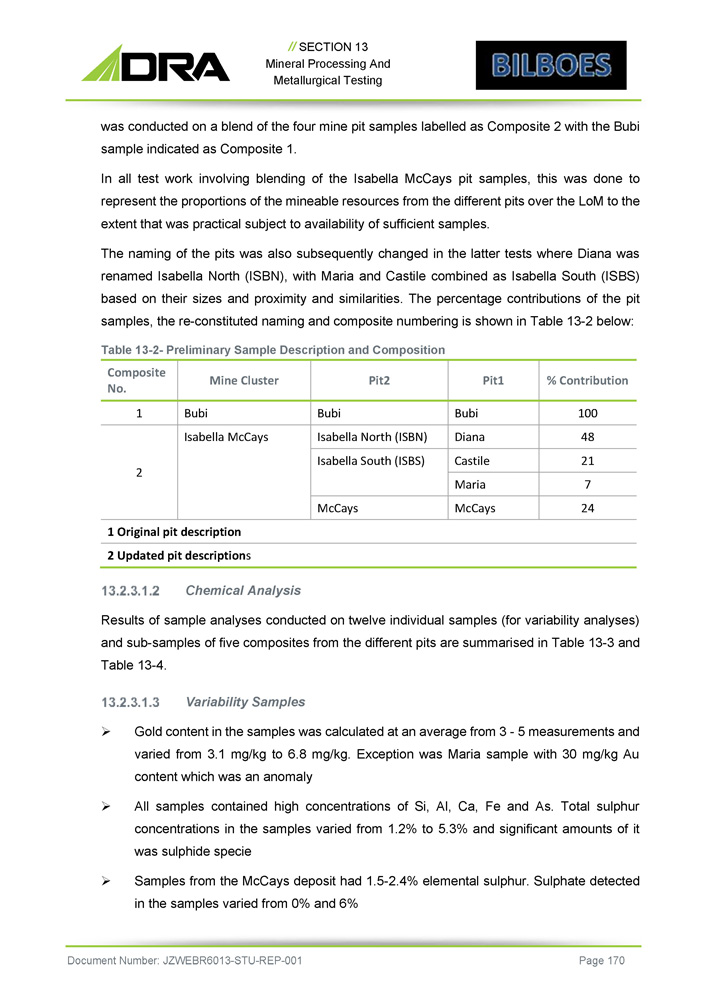

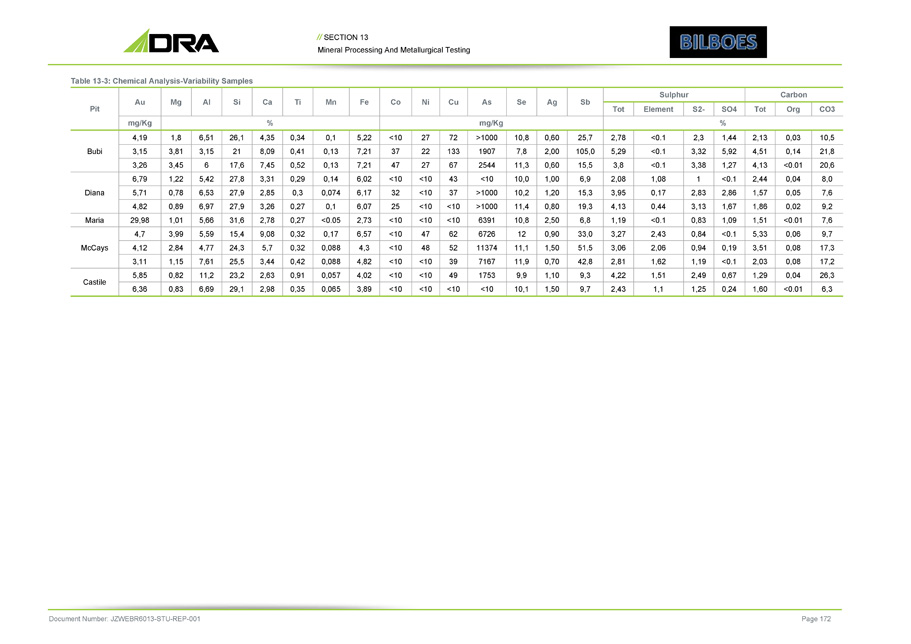

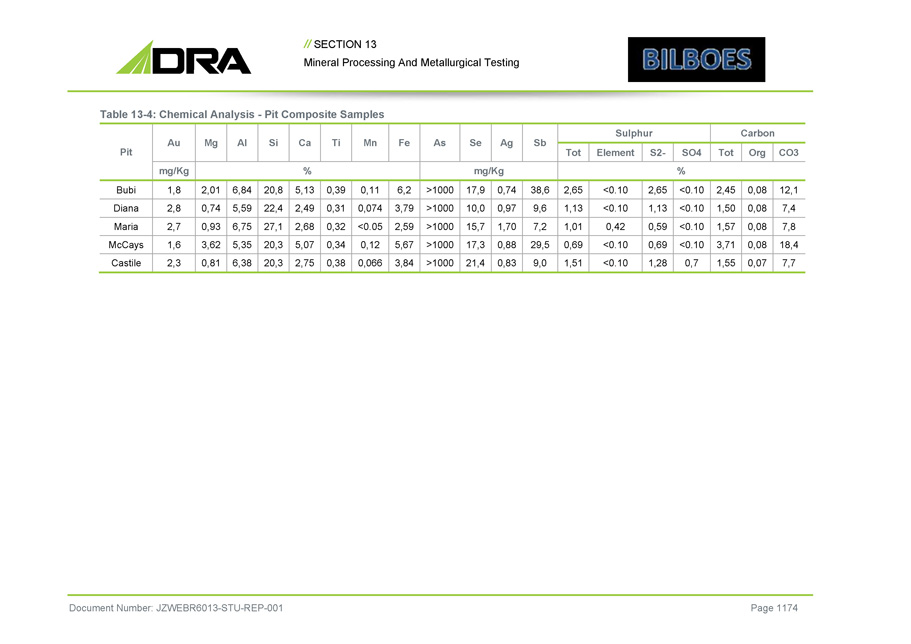

// Section 1 Summary 1.11 Metallurgical Test Work 1 . 11 . 1 . 1 Test work Programme Overview The feasibility metallurgical test work was concluded in different phases over a period extending from September 2013 to March 2019 and involved various laboratories and consultants as outlined in Table 1 - 2 . Table 1 - 2 : Test work Program Outline Date Supervision and Oversight Done By Test work Description Phase Sept 13 to Dec 13 Bilboes, MMC and MDM Engineering Mintek, South Africa Sample characterisation detailing mineralogical and chemical analysis 1A Jan 14 to Apr 14 Bilboes, MMC and MDM Engineering Mintek, South Africa Comminution test work done on the two composites namely Composite 1 (Bubi ore) and Composite 2 (combination of Diana, Calcite, Castile, Maria and McCays ores) 1B May 14 to Sept 14 Bilboes and MMC Mintek and Suntech, South Africa Selection of a process route covering gravity amenability tests, flotation optimisation and treatment of the sulphide flotation concentrates via POX, Bio - Oxidation and Ultra - fine grinding followed by cyanidation 2 Oct 15 to Aug 16 Bilboes, Minxcon and MMC Suntech and SGS, South Africa Variability flotation tests and bulk flotation concentrate production for additional BIOX® and gold leach tests 3 Apr 18 to Sept 18 Bilboes and DRA MMC at the client's project site in Zimbabwe Laboratory and Pilot plant test work campaigns on the different ore types to generate additional flotation kinetics and grind data, bulk concentrates for BIOX® pilot plants, flotation design parameters and validate flowsheet 4A Oct 18 to Mar 19 Bilboes, MMC and DRA EMC, South Africa Review, modelling and simulation of laboratory and pilot plant test results 4B 2. Discussion of the Feasibility Results Chemical Analyses The mineralogical and chemical analyses of the ores conducted on the individual and composite samples is summarised as follows: » Gold content in the samples varied from 1.8 mg/kg to 6.8 mg/kg Document Number: JZWEBR6013 - STU - REP - 001 Page 40

// Section 1 Summary » All samples contained high concentrations of Si, Al, Ca, Fe and As . Total sulphur concentrations in the samples varied from 1 . 2 % to 5 . 3 % and significant amounts of it was sulphide specie » Total carbon in the ores was detected at 1 . 3 - 5 . 3 % and was mainly present as carbonate . Organic carbon was low for all samples tested, indicating low potential for preg - robbing . Carbon (as carbonate) content was high, especially for Bubi and McCays pits (double amount in comparison to other composite samples . Carbonate concentrations of between 7 . 4 % and 18 . 4 % were detected in the samples » The Total sulphur content in the samples was found to be mainly in the sulphide form with the lowest content of 0 . 69 % in the McCays ore and the highest content of 2 . 65 % in the Bubi ore . Concentration of elemental sulphur and sulphate was very low . High As content was detected in all samples which highlighted the importance of investigating as behaviour during the processing steps and to consider possible environmental issues in deciding on process route and economics . The As content in the McCays ore was disproportionately higher than the other pits Mineralogical Characterisation » Diagnostic leach results showed that gold recovery via direct cyanidation was low, varying from 25 % to 50 % and Au locked in sulphides and carbonate minerals varied from 46 % to 72 % » Bulk modal analysis (BMA) showed that Quartz, feldspar, and mica were present in major to intermediate amounts in all the samples, followed by major to minor amounts of carbonates . Sulphide minerals, pyrite and arsenopyrite, were present in minor to trace amounts throughout all samples . All other mineral phases are present in in trace amounts in all samples » The Au bearing minerals identified in this study were electrum (AuAg) and native gold (Au) . Native gold and electrum are variably distributed throughout all samples » Most Au - bearing grains reported to the 0 - 10 μm size class fraction and a smaller quantity in the 10 - 15 μm size class fraction » P yr i te w a s t h e d o m i nan t B MS m i ne r a l prese n t a s m a j o r i ty o f t h e s a m p l e s f o ll o w e d by arsenop yr i te ( f r o m 5 to 5 8 % ) a n d tr ac e amou n ts o f o t he r su l ph i de s (sp ha l e ri t e , pe n t l and i t e, ch a l co p yr i t e , ch a l co s t i bn i t e , u ll m ann i t e , ge rs d o r f ii te an d ga l ena) » The majority of all BMS mineral grains (> 50 mass % ) in all samples reported to the finer, 0 - 21 μm size classes, with lesser amounts reporting to the coarser size classes Document Number: JZWEBR6013 - STU - REP - 001 Page 41

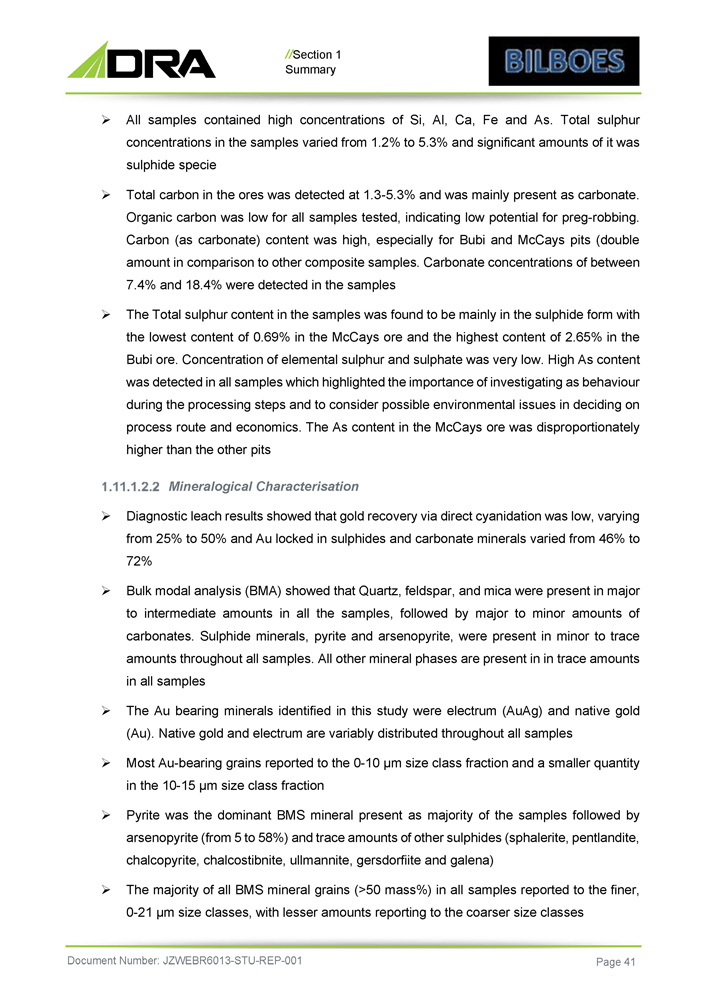

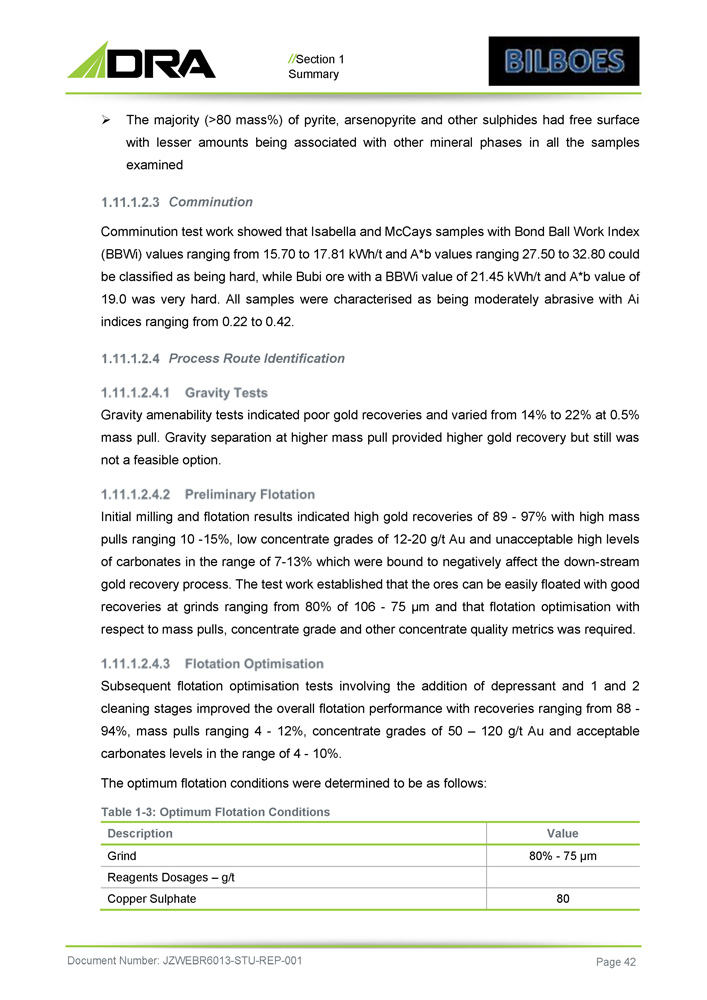

// Section 1 Summary » The majority (> 80 mass % ) of pyrite, arsenopyrite and other sulphides had free surface with lesser amounts being associated with other mineral phases in all the samples examined Comminution Comminution test work showed that Isabella and McCays samples with Bond Ball Work Index (BBWi) values ranging from 15 . 70 to 17 . 81 kWh/t and A*b values ranging 27 . 50 to 32 . 80 could be classified as being hard, while Bubi ore with a BBWi value of 21 . 45 kWh/t and A*b value of 19 . 0 was very hard . All samples were characterised as being moderately abrasive with Ai indices ranging from 0 . 22 to 0 . 42 . Process Route Identification Gravity amenability tests indicated poor gold recoveries and varied from 14 % to 22 % at 0 . 5 % mass pull . Gravity separation at higher mass pull provided higher gold recovery but still was not a feasible option . Initial milling and flotation results indicated high gold recoveries of 89 - 97 % with high mass pulls ranging 10 - 15 % , low concentrate grades of 12 - 20 g/t Au and unacceptable high levels of carbonates in the range of 7 - 13 % which were bound to negatively affect the down - stream gold recovery process . The test work established that the ores can be easily floated with good recoveries at grinds ranging from 80 % of 106 - 75 µm and that flotation optimisation with respect to mass pulls, concentrate grade and other concentrate quality metrics was required . Subsequent flotation optimisation tests involving the addition of depressant and 1 and 2 cleaning stages improved the overall flotation performance with recoveries ranging from 88 - 94 % , mass pulls ranging 4 - 12 % , concentrate grades of 50 – 120 g/t Au and acceptable carbonates levels in the range of 4 - 10 % . The optimum flotation conditions were determined to be as follows : Table 1 - 3 : Optimum Flotation Conditions Document Number: JZWEBR6013 - STU - REP - 001 Page 42 Value Description 80% - 75 µm Grind Reagents Dosages – g/t 80 Copper Sulphate

// Section 1 Summary Value Description 100 Sodium Ethyl Xanthate 200 - 350 Sodium Carbonate 70 - 125 Starch 35 - 60 XP200 Frother » Direct cyanidation of the flotation concentrate resulted in a 27 % gold dissolution . » Ultra - fine grinding ( 80 % - 20 µm) followed by cyanidation and oxygenation resulted in a marginal improvement in gold dissolution from 27 to 30 % . » A single POX test was done on concentrate with the main objective to oxidise 100 % of the sulphide which then resulted in a further 98 % gold dissolution by cyanidation of the POX leach residue . Formation of Basic Ferric Sulphate (BFS) resulting in high lime and cyanide consumption in the downstream processing (cyanidation) was observed . Significant amount of or arsenic was also detected in the POX filtrate . » BIOX® of the concentrate provided 99 % sulphide decomposition with 97 % gold dissolution by cyanidation of the bio - residue . Formation of iron and cyanide complexes was observed . The solid residue after cyanidation was of the bioleach product was stable with respect to arsenic . Based on the above results, historical test work and consideration of environmental impacts and risk minimisation by adopting commercially established and proven processes, the process route identified for additional evaluation was flotation, pre - treatment of the concentrate by Bio - oxidation followed by cyanidation . 3. Variability Testing Variability flotation test work on the ores indicated an average recovery of 89 . 2 % , a recovery range of 83 . 4 - 95 . 9 % and recovery standard deviation of 3 . 4 % for Isabella McCays ore and average recovery of 86 . 6 % , a recovery range of 80 . 5 - 94 . 2 % and recovery standard deviation of 4 . 4 % for Bubi ore . 4. Pilot Plant Test Work Objectives The pilot plant test work was conducted over a period of three months from July 2018 to September 2018 , with the follow up laboratory test work being conducted between September Document Number: JZWEBR6013 - STU - REP - 001 Page 43

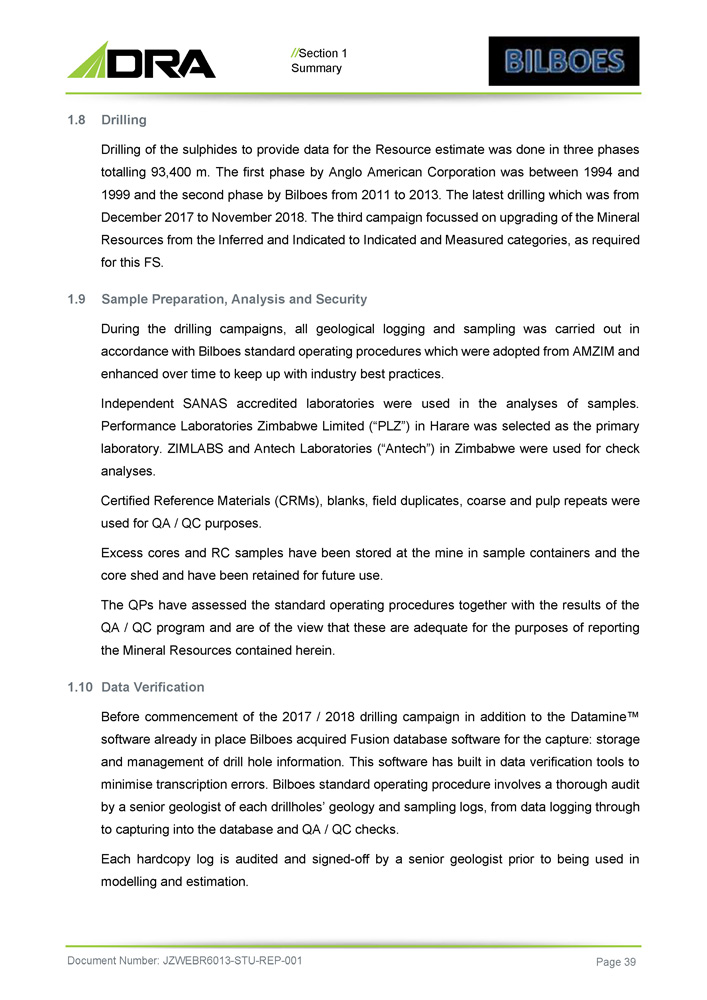

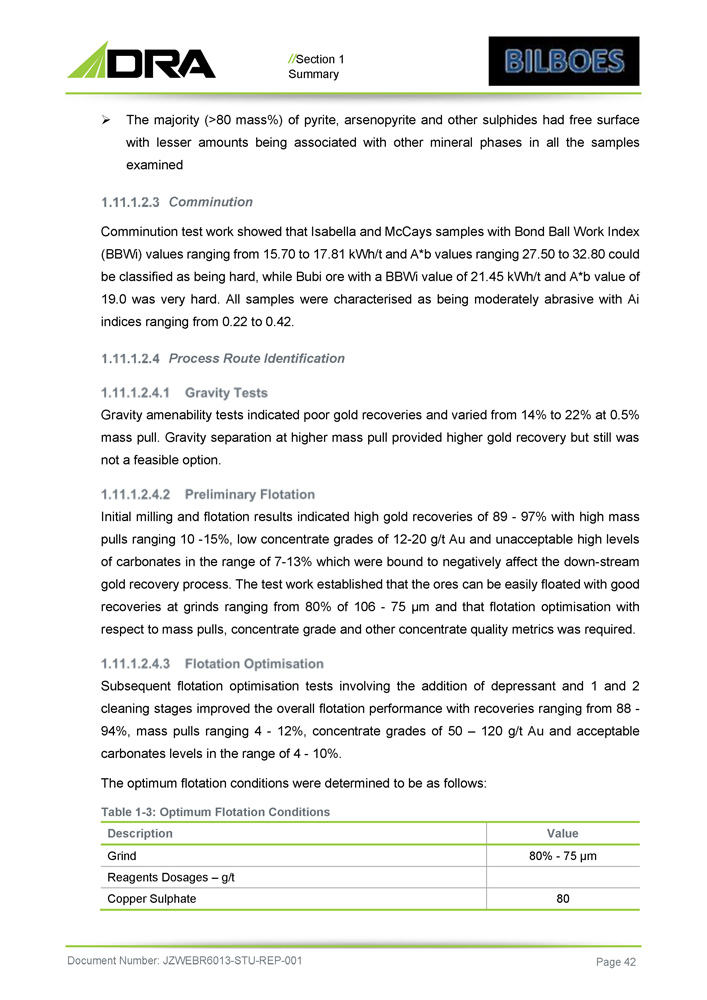

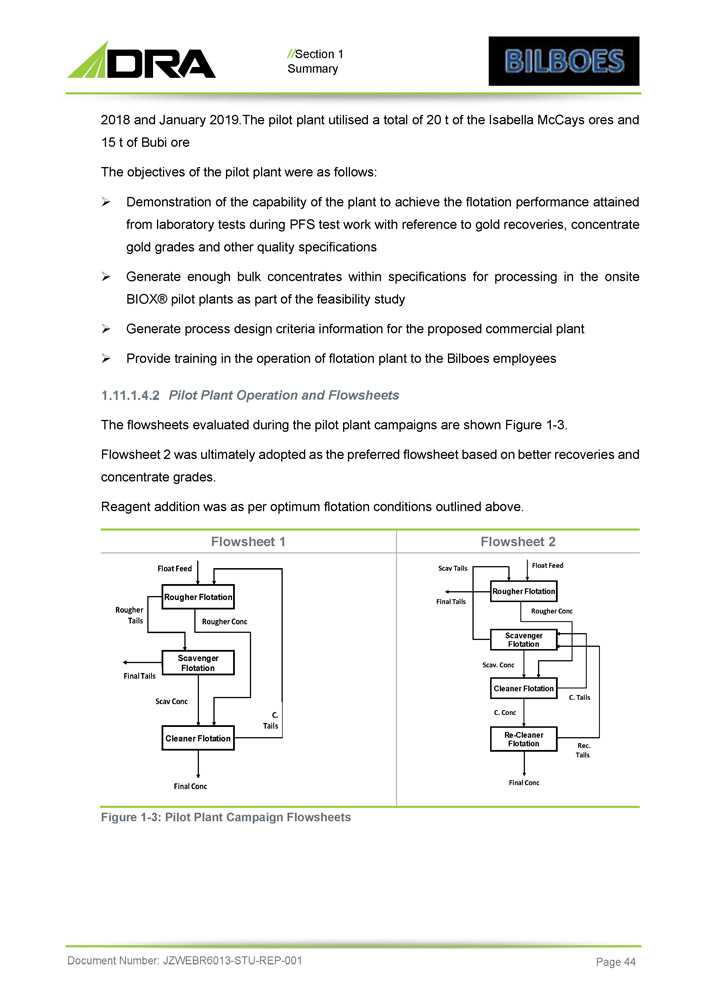

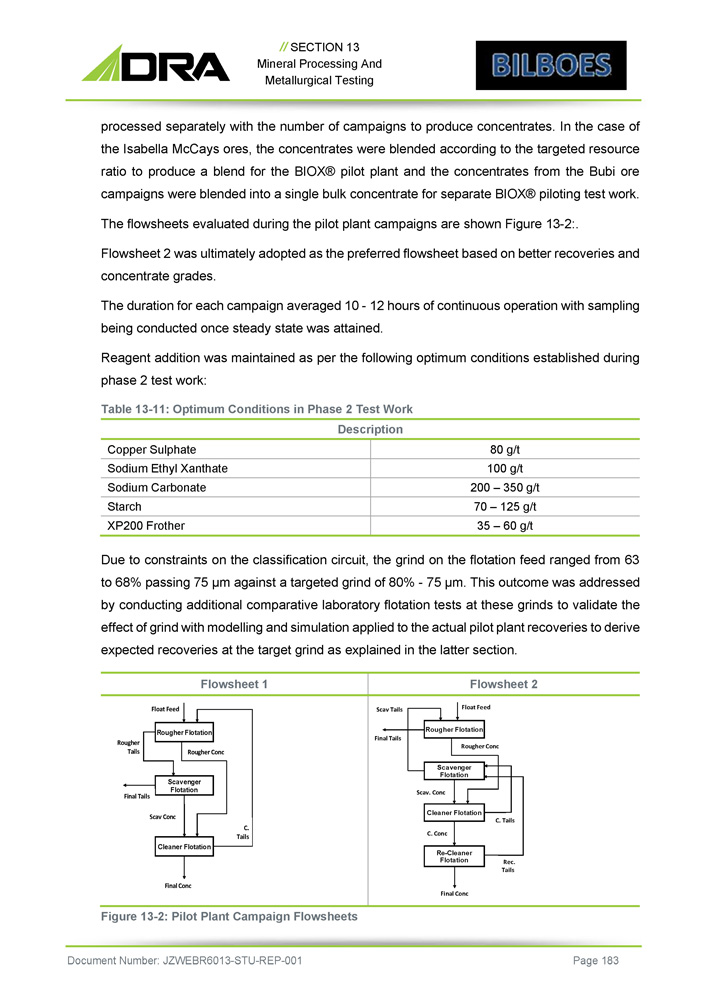

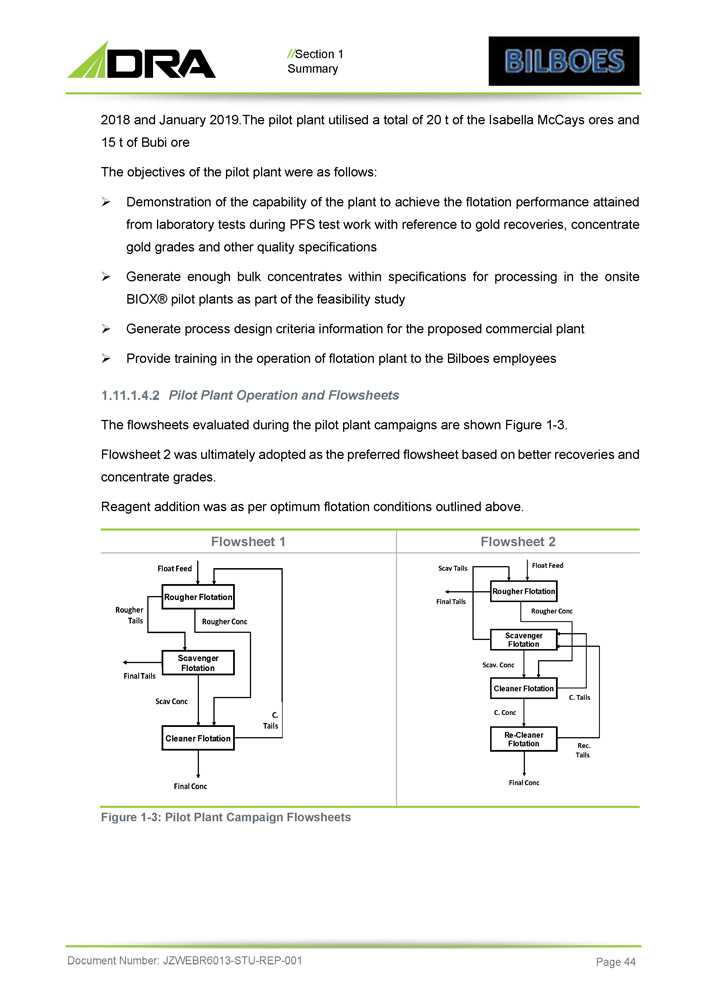

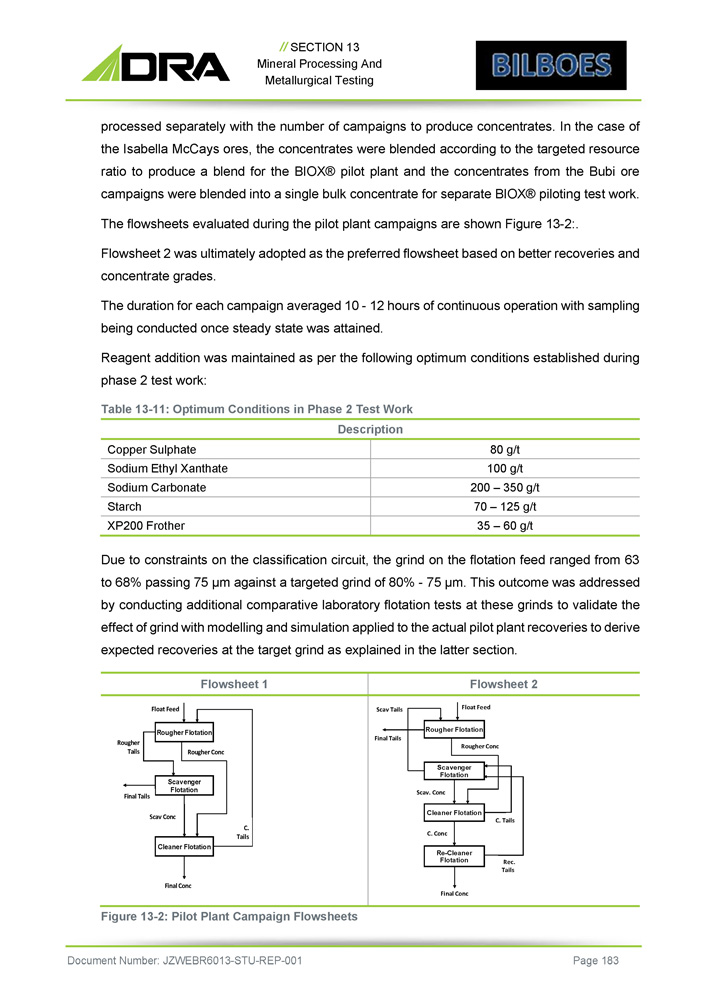

// Section 1 Summary 2018 and January 2019 . The pilot plant utilised a total of 20 t of the Isabella McCays ores and 15 t of Bubi ore The objectives of the pilot plant were as follows : » Demonstration of the capability of the plant to achieve the flotation performance attained from laboratory tests during PFS test work with reference to gold recoveries, concentrate gold grades and other quality specifications » Generate enough bulk concentrates within specifications for processing in the onsite BIOX® pilot plants as part of the feasibility study » Generate process design criteria information for the proposed commercial plant » Provide training in the operation of flotation plant to the Bilboes employees Pilot Plant Operation and Flowsheets The flowsheets evaluated during the pilot plant campaigns are shown Figure 1 - 3 . Flowsheet 2 was ultimately adopted as the preferred flowsheet based on better recoveries and concentrate grades . Reagent addition was as per optimum flotation conditions outlined above . Figure 1 - 3: Pilot Plant Campaign Flowsheets Flowsheet 2 Flowsheet 1 Scav Tails Float Feed Rougher Flotation Final Tails Rougher Conc Scavenger Flotation Scav. Conc Cleaner Flotation C. Tails C. Conc Re - Cleaner Flotation Rec. Tails Final Conc Float Feed Rougher Flotation Rougher Tails Rougher Conc Scavenger Flotation Final Tails Scav Conc C. Tails Cleaner Flotation Final Conc Document Number: JZWEBR6013 - STU - REP - 001 Page 44

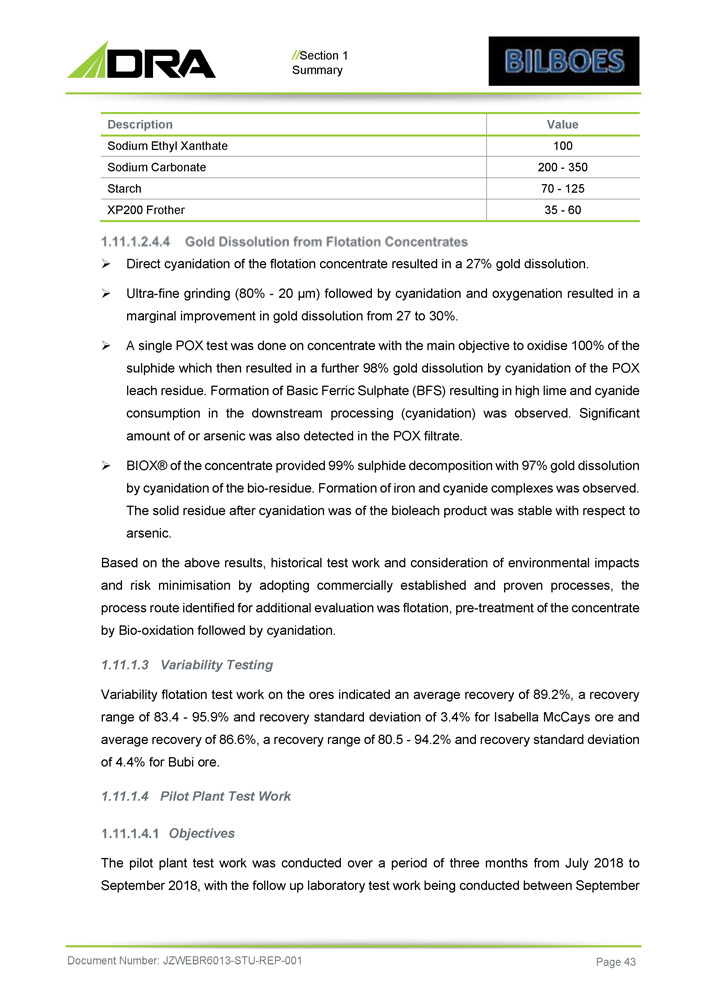

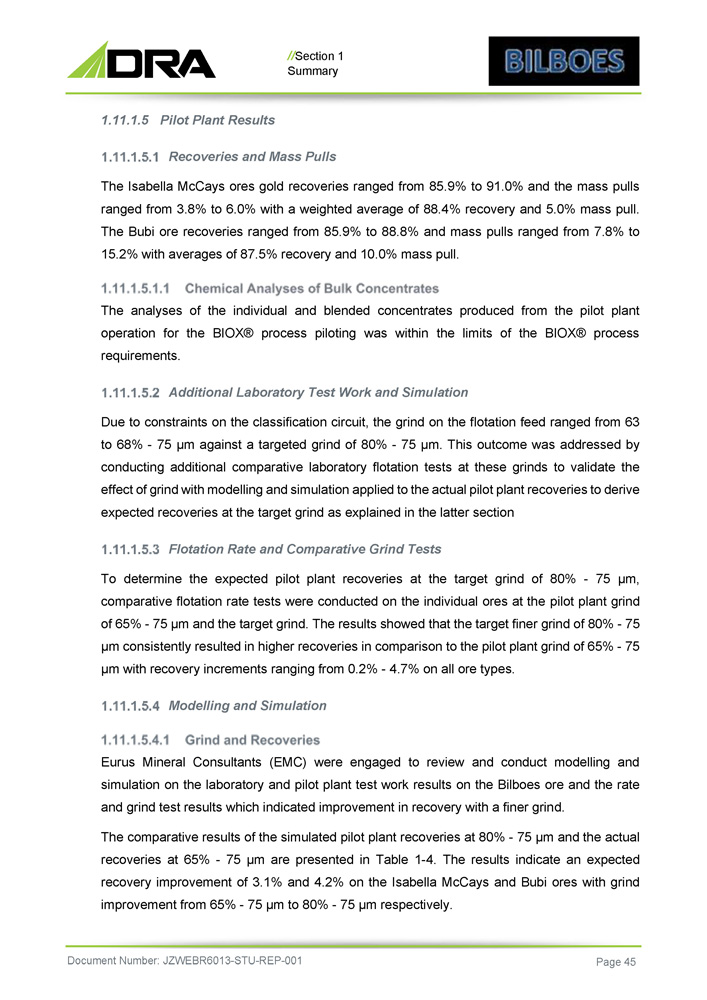

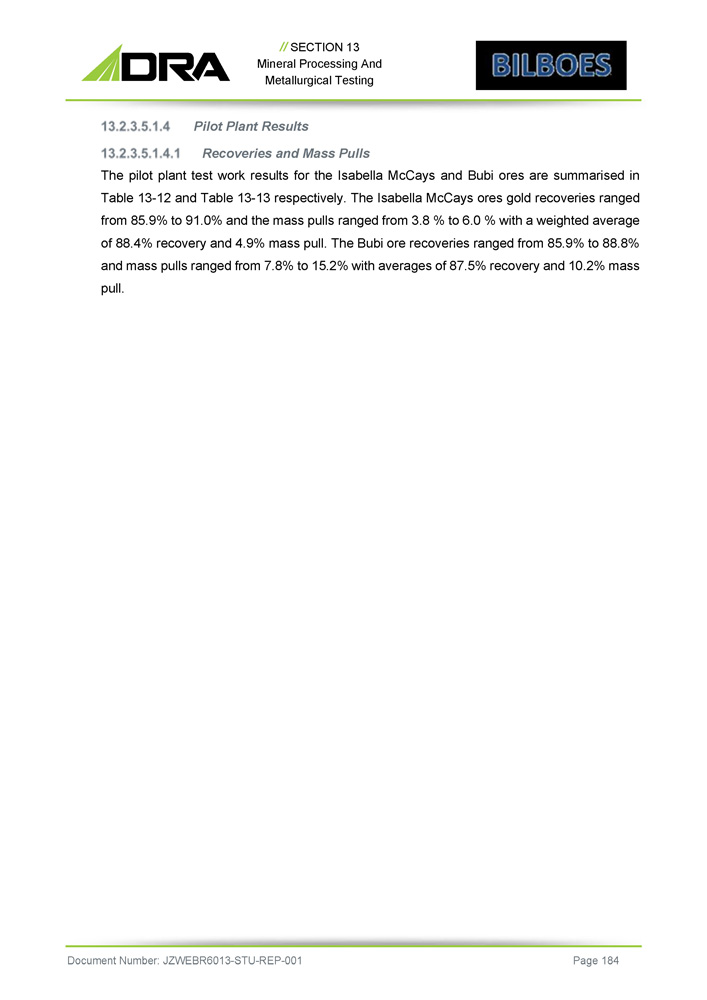

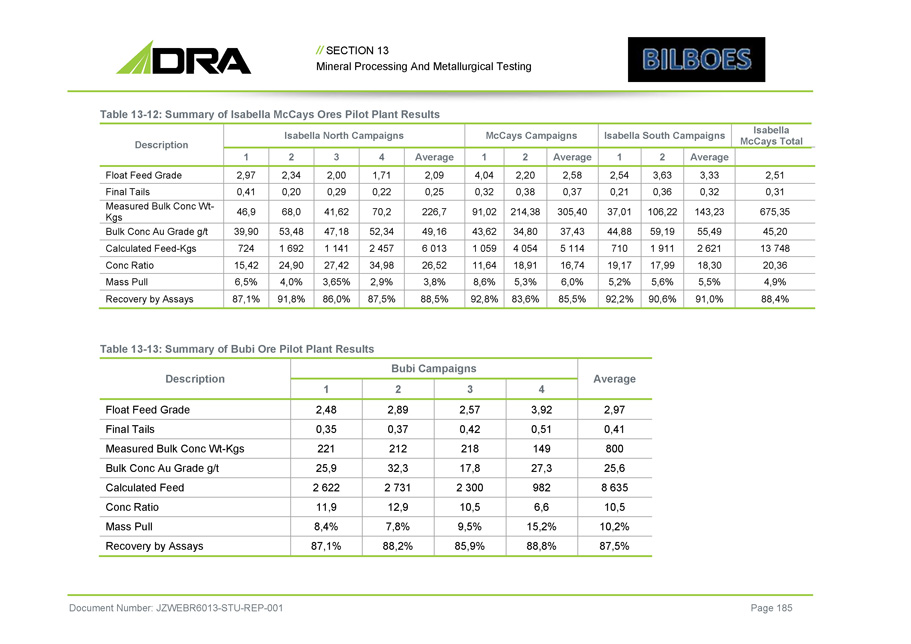

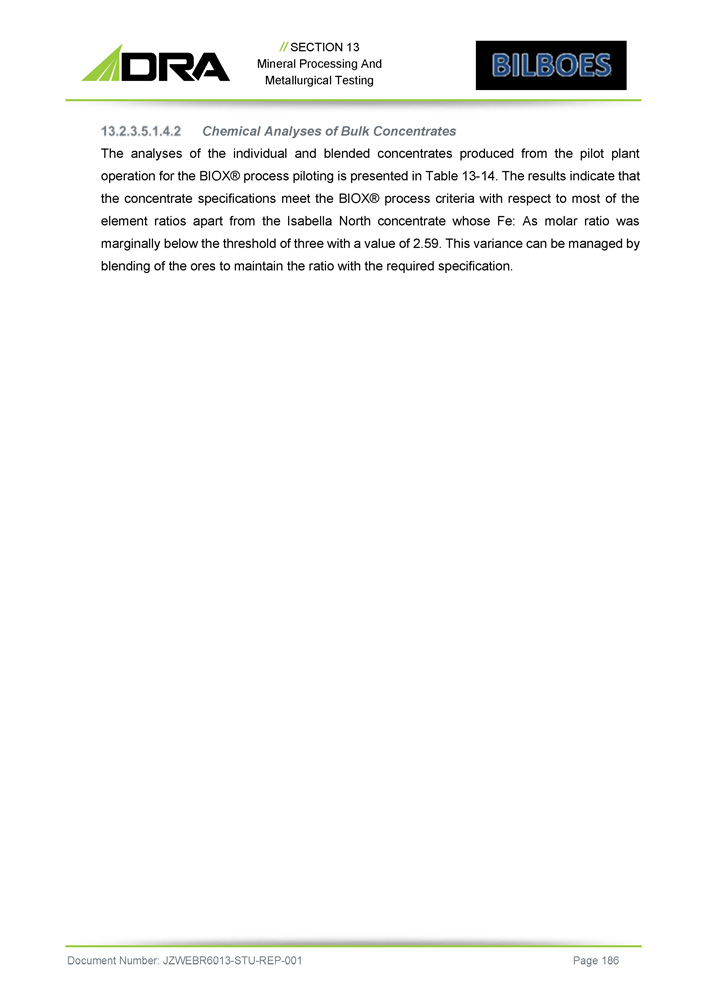

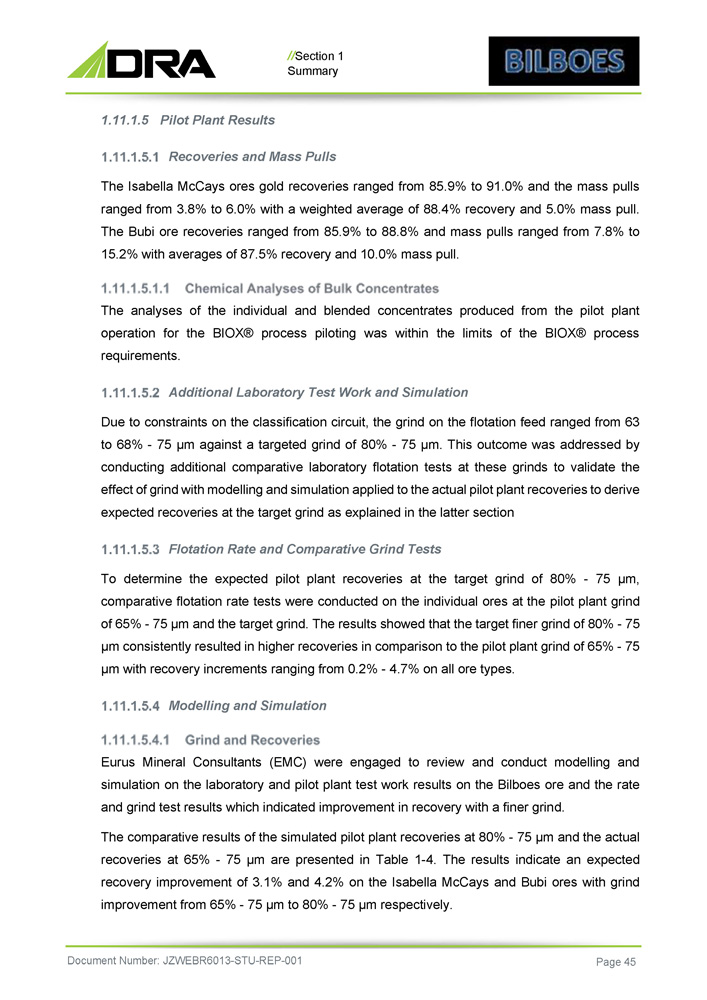

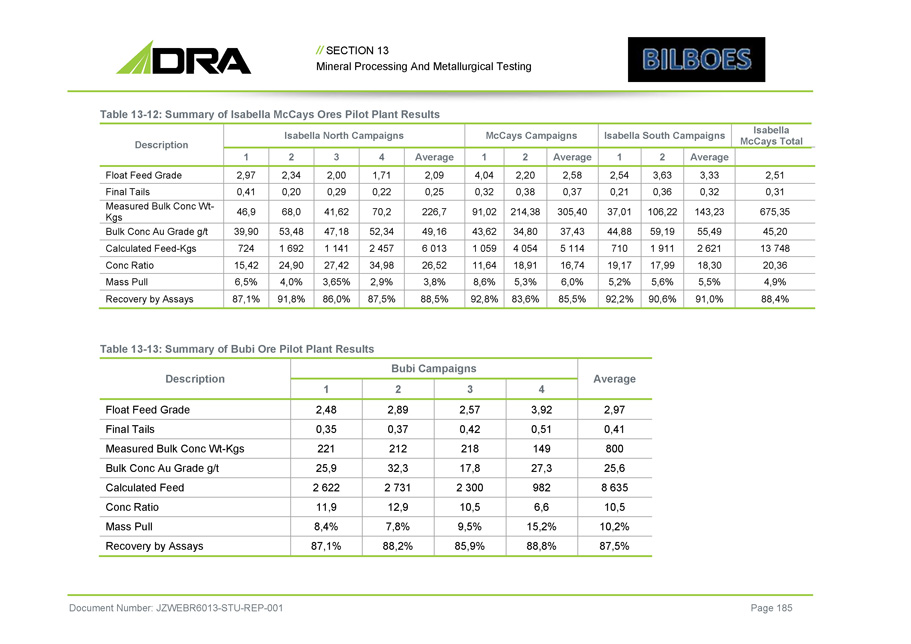

// Section 1 Summary 1.11.1.5 Pilot Plant Results Recoveries and Mass Pulls The Isabella McCays ores gold recoveries ranged from 85 . 9 % to 91 . 0 % and the mass pulls ranged from 3 . 8 % to 6 . 0 % with a weighted average of 88 . 4 % recovery and 5 . 0 % mass pull . The Bubi ore recoveries ranged from 85 . 9 % to 88 . 8 % and mass pulls ranged from 7 . 8 % to 15 . 2 % with averages of 87 . 5 % recovery and 10 . 0 % mass pull . The analyses of the individual and blended concentrates produced from the pilot plant operation for the BIOX® process piloting was within the limits of the BIOX® process requirements . Additional Laboratory Test Work and Simulation Due to constraints on the classification circuit, the grind on the flotation feed ranged from 63 to 68 % - 75 µm against a targeted grind of 80 % - 75 µm . This outcome was addressed by conducting additional comparative laboratory flotation tests at these grinds to validate the effect of grind with modelling and simulation applied to the actual pilot plant recoveries to derive expected recoveries at the target grind as explained in the latter section Flotation Rate and Comparative Grind Tests To determine the expected pilot plant recoveries at the target grind of 80 % - 75 µm, comparative flotation rate tests were conducted on the individual ores at the pilot plant grind of 65 % - 75 µm and the target grind . The results showed that the target finer grind of 80 % - 75 µm consistently resulted in higher recoveries in comparison to the pilot plant grind of 65 % - 75 µm with recovery increments ranging from 0 . 2 % - 4 . 7 % on all ore types . Modelling and Simulation Eurus Mineral Consultants (EMC) were engaged to review and conduct modelling and simulation on the laboratory and pilot plant test work results on the Bilboes ore and the rate and grind test results which indicated improvement in recovery with a finer grind . The comparative results of the simulated pilot plant recoveries at 80 % - 75 µm and the actual recoveries at 65 % - 75 µm are presented in Table 1 - 4 . The results indicate an expected recovery improvement of 3 . 1 % and 4 . 2 % on the Isabella McCays and Bubi ores with grind improvement from 65 % - 75 µm to 80 % - 75 µm respectively . Document Number: JZWEBR6013 - STU - REP - 001 Page 45

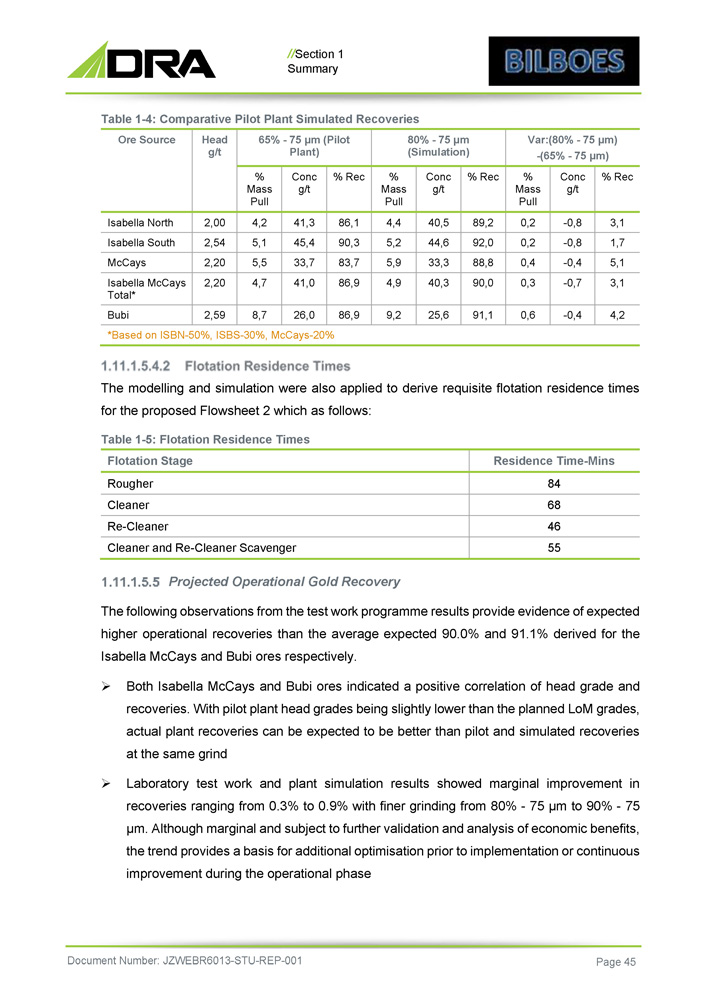

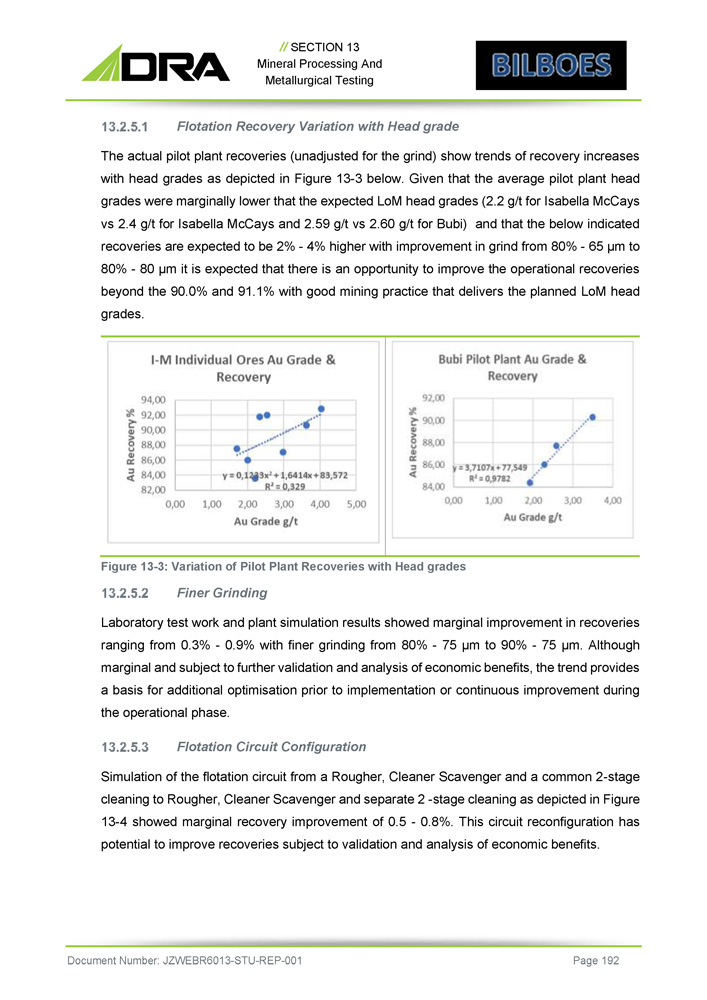

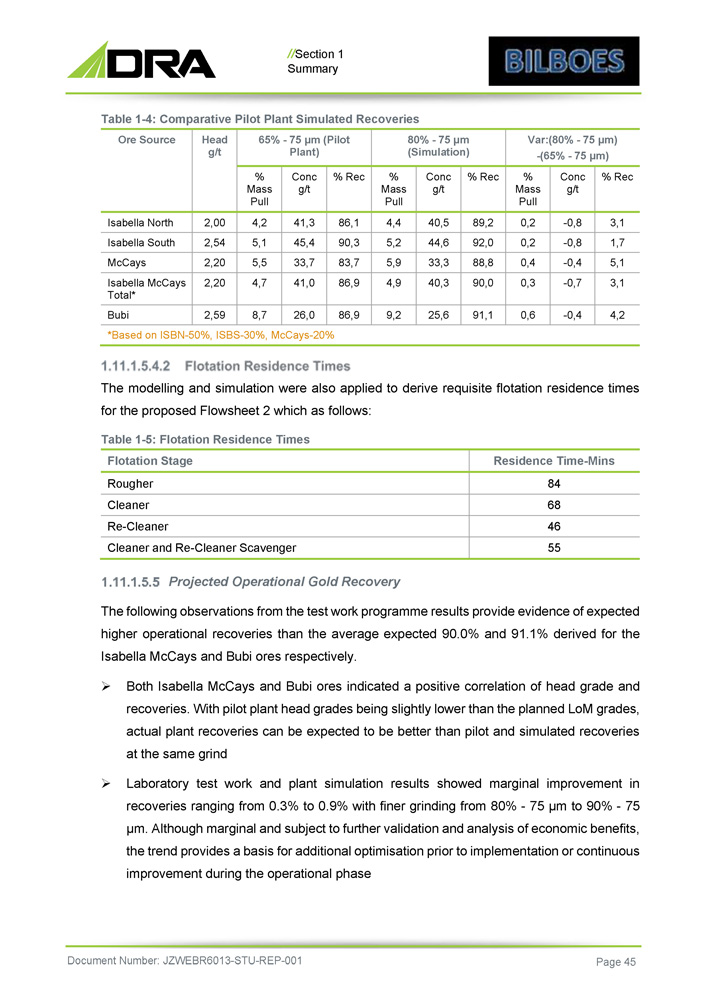

// Section 1 Summary Table 1 - 4: Comparative Pilot Plant Simulated Recoveries Var:(80% - 75 µm) - (65% - 75 µm) 80% - 75 µm (Simulation) 65% - 75 µm (Pilot Plant) Head g/t Ore Source % Rec Conc g/t % Mass Pull % Rec Conc g/t % Mass Pull % Rec Conc g/t % Mass Pull 3,1 - 0,8 0,2 89,2 40,5 4,4 86,1 41,3 4,2 2,00 Isabella North 1,7 - 0,8 0,2 92,0 44,6 5,2 90,3 45,4 5,1 2,54 Isabella South 5,1 - 0,4 0,4 88,8 33,3 5,9 83,7 33,7 5,5 2,20 McCays 3,1 - 0,7 0,3 90,0 40,3 4,9 86,9 41,0 4,7 2,20 Isabella McCays Total* 4,2 - 0,4 0,6 91,1 25,6 9,2 86,9 26,0 8,7 2,59 Bubi *Based on ISBN - 50%, ISBS - 30%, McCays - 20% The modelling and simulation were also applied to derive requisite flotation residence times for the proposed Flowsheet 2 which as follows: Table 1 - 5: Flotation Residence Times Residence Time - Mins Flotation Stage 84 Rougher 68 Cleaner 46 Re - Cleaner 55 Cleaner and Re - Cleaner Scavenger Projected Operational Gold Recovery The following observations from the test work programme results provide evidence of expected higher operational recoveries than the average expected 90 . 0 % and 91 . 1 % derived for the Isabella McCays and Bubi ores respectively . » Both Isabella McCays and Bubi ores indicated a positive correlation of head grade and recoveries . With pilot plant head grades being slightly lower than the planned LoM grades, actual plant recoveries can be expected to be better than pilot and simulated recoveries at the same grind » Laboratory test work and plant simulation results showed marginal improvement in recoveries ranging from 0 . 3 % to 0 . 9 % with finer grinding from 80 % - 75 µm to 90 % - 75 µm . Although marginal and subject to further validation and analysis of economic benefits, the trend provides a basis for additional optimisation prior to implementation or continuous improvement during the operational phase Document Number: JZWEBR6013 - STU - REP - 001 Page 45

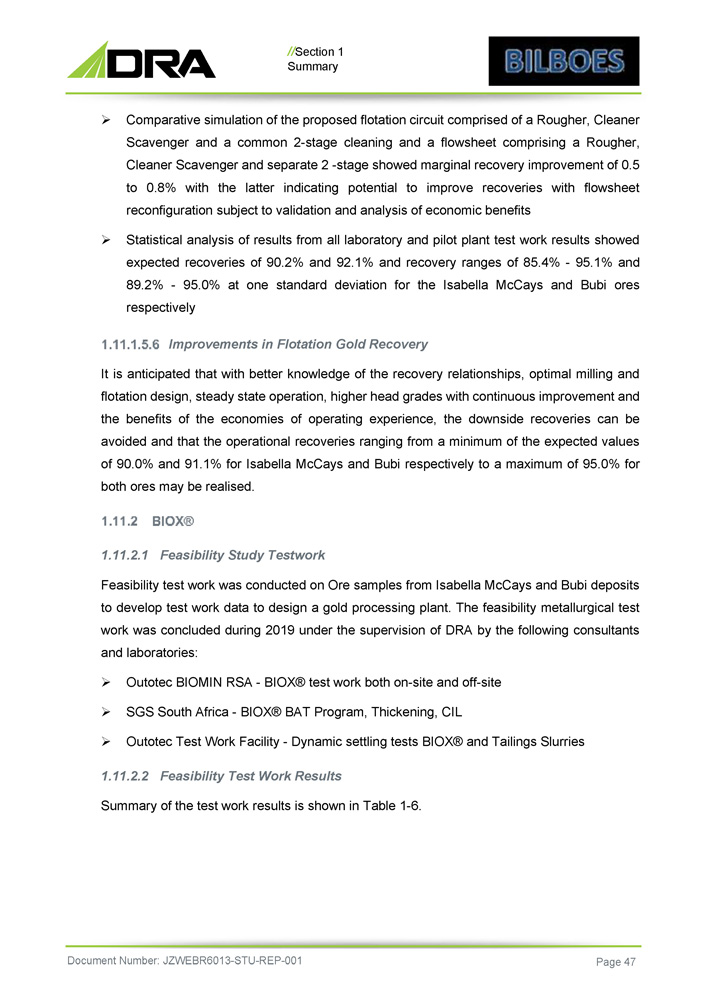

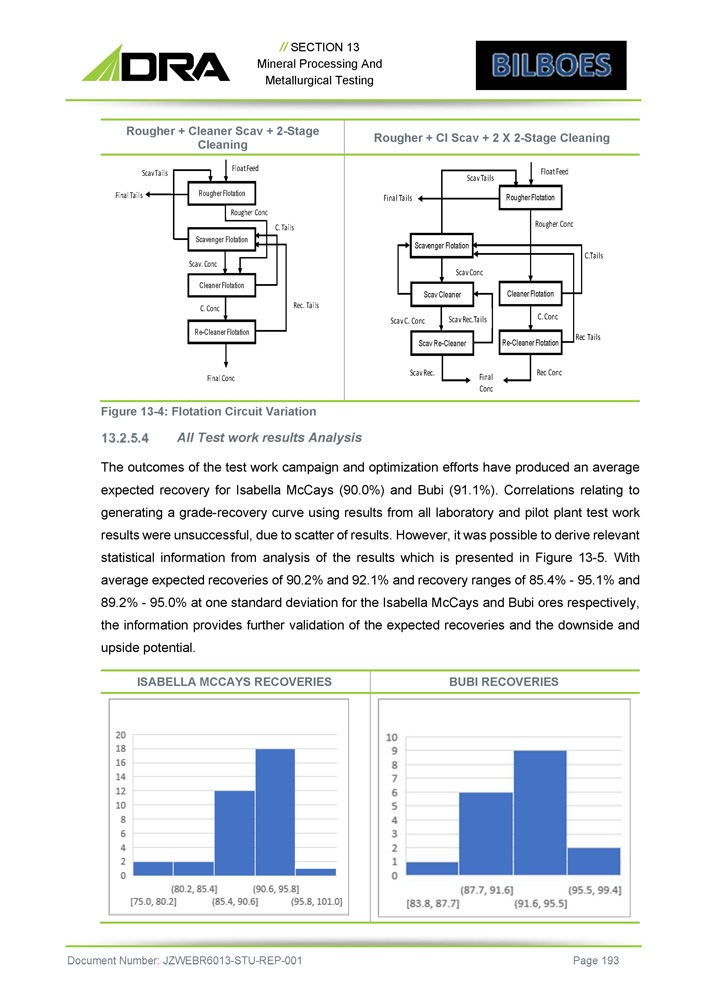

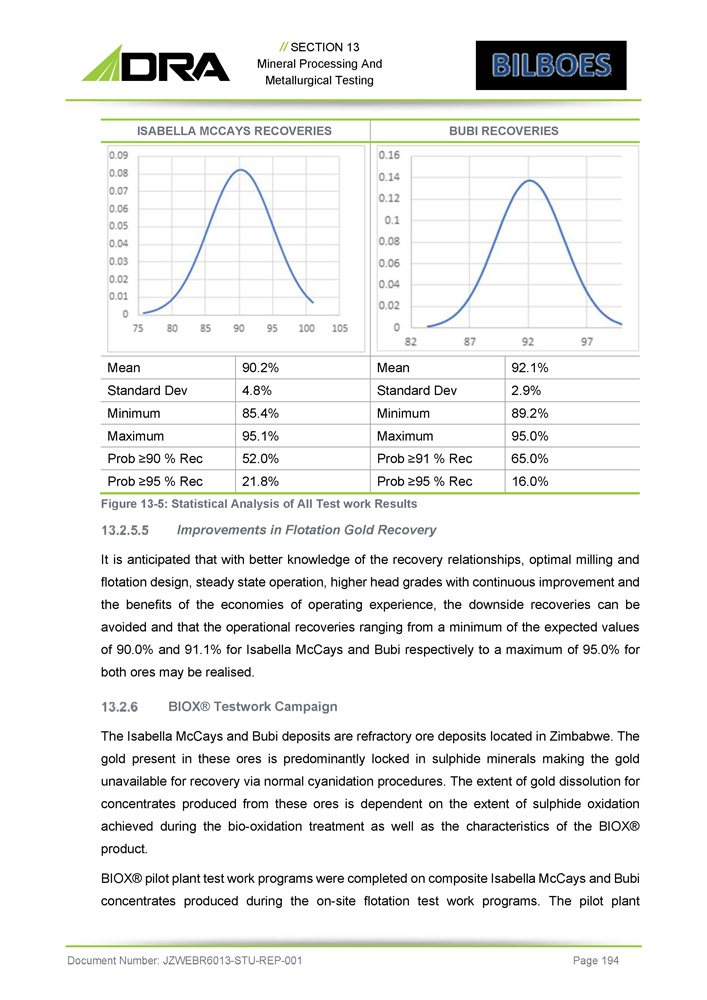

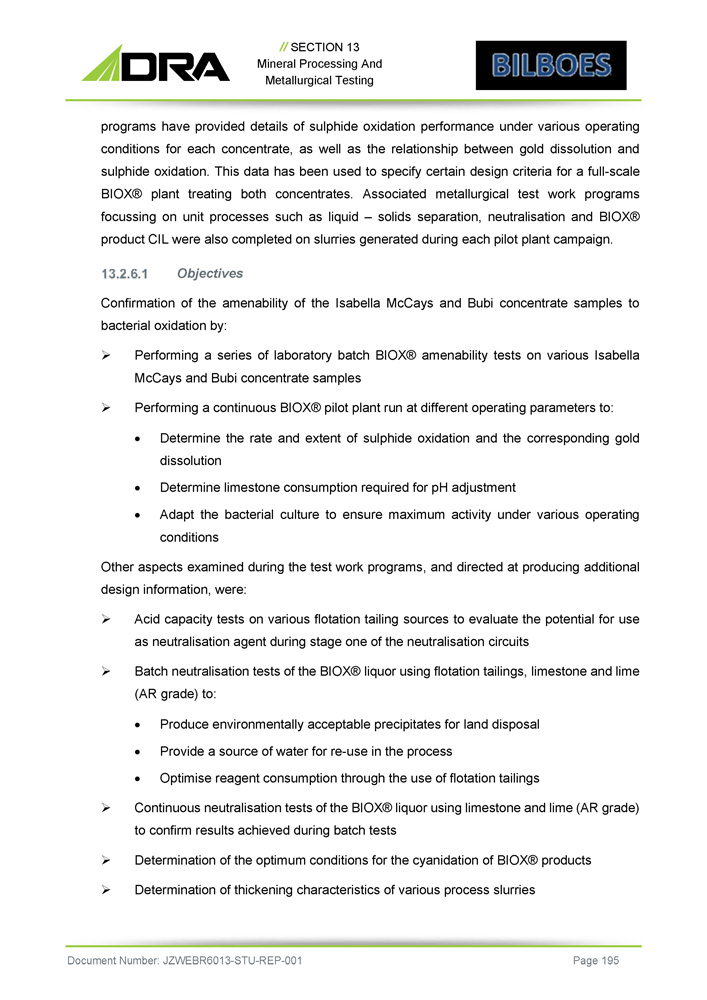

// Section 1 Summary » Comparative simulation of the proposed flotation circuit comprised of a Rougher, Cleaner Scavenger and a common 2 - stage cleaning and a flowsheet comprising a Rougher, Cleaner Scavenger and separate 2 - stage showed marginal recovery improvement of 0 . 5 to 0 . 8 % with the latter indicating potential to improve recoveries with flowsheet reconfiguration subject to validation and analysis of economic benefits » Statistical analysis of results from all laboratory and pilot plant test work results showed expected recoveries of 90 . 2 % and 92 . 1 % and recovery ranges of 85 . 4 % - 95 . 1 % and 89 . 2 % - 95 . 0 % at one standard deviation for the Isabella McCays and Bubi ores respectively Improvements in Flotation Gold Recovery It is anticipated that with better knowledge of the recovery relationships, optimal milling and flotation design, steady state operation, higher head grades with continuous improvement and the benefits of the economies of operating experience, the downside recoveries can be avoided and that the operational recoveries ranging from a minimum of the expected values of 90 . 0 % and 91 . 1 % for Isabella McCays and Bubi respectively to a maximum of 95 . 0 % for both ores may be realised . 1. Feasibility Study Testwork Feasibility test work was conducted on Ore samples from Isabella McCays and Bubi deposits to develop test work data to design a gold processing plant . The feasibility metallurgical test work was concluded during 2019 under the supervision of DRA by the following consultants and laboratories : » Outotec BIOMIN RSA - BIOX® test work both on - site and off - site » SGS South Africa - BIOX® BAT Program, Thickening, CIL » Outotec Test Work Facility - Dynamic settling tests BIOX® and Tailings Slurries 1.11.2.2 Feasibility Test Work Results Summary of the test work results is shown in Table 1 - 6 . Document Number: JZWEBR6013 - STU - REP - 001 Page 47

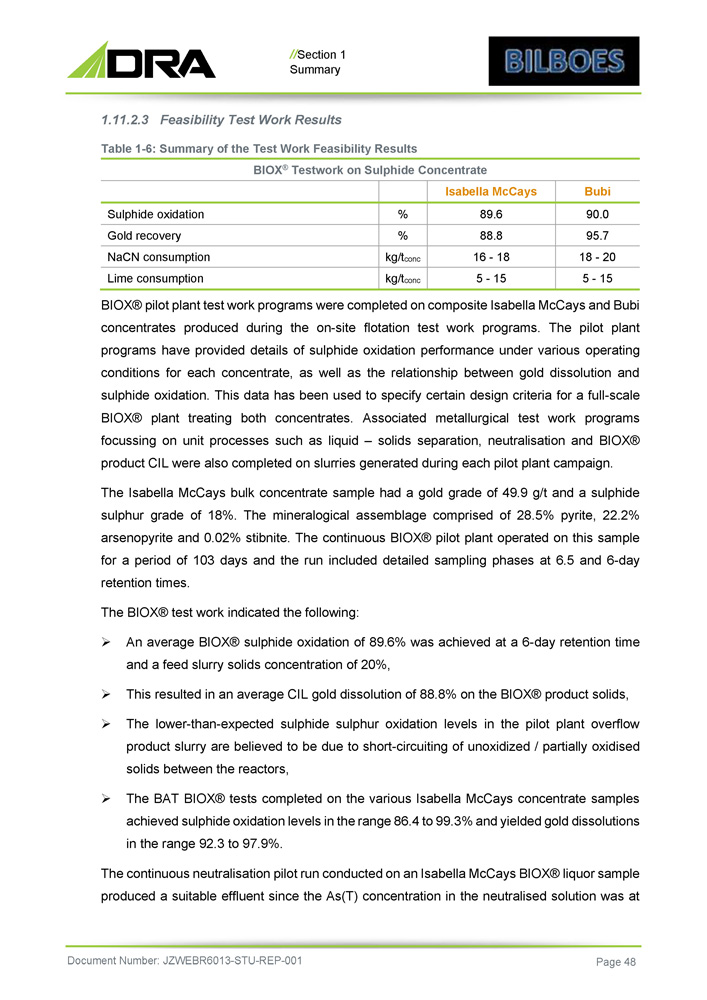

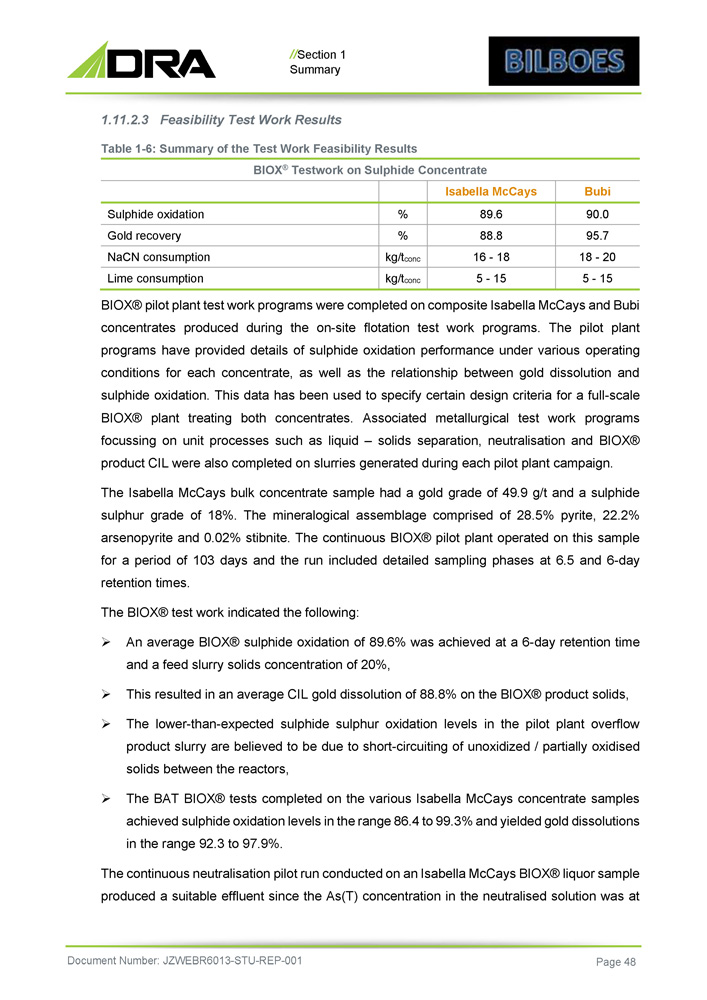

// Section 1 Summary 1.11.2.3 Feasibility Test Work Results Table 1 - 6: Summary of the Test Work Feasibility Results BIOX ® Testwork on Sulphide Concentrate Bubi Isabella McCays 90.0 89.6 % Sulphide oxidation 95.7 88.8 % Gold recovery 18 - 20 16 - 18 kg/t conc NaCN consumption 5 - 15 5 - 15 kg/t conc Lime consumption Document Number: JZWEBR6013 - STU - REP - 001 Page 48 BIOX® pilot plant test work programs were completed on composite Isabella McCays and Bubi concentrates produced during the on - site flotation test work programs . The pilot plant programs have provided details of sulphide oxidation performance under various operating conditions for each concentrate, as well as the relationship between gold dissolution and sulphide oxidation . This data has been used to specify certain design criteria for a full - scale BIOX® plant treating both concentrates . Associated metallurgical test work programs focussing on unit processes such as liquid – solids separation, neutralisation and BIOX® product CIL were also completed on slurries generated during each pilot plant campaign . The Isabella McCays bulk concentrate sample had a gold grade of 49 . 9 g/t and a sulphide sulphur grade of 18 % . The mineralogical assemblage comprised of 28 . 5 % pyrite, 22 . 2 % arsenopyrite and 0 . 02 % stibnite . The continuous BIOX® pilot plant operated on this sample for a period of 103 days and the run included detailed sampling phases at 6 . 5 and 6 - day retention times . The BIOX® test work indicated the following : » An average BIOX® sulphide oxidation of 89 . 6 % was achieved at a 6 - day retention time and a feed slurry solids concentration of 20 % , » This resulted in an average CIL gold dissolution of 88 . 8 % on the BIOX® product solids, » The lower - than - expected sulphide sulphur oxidation levels in the pilot plant overflow product slurry are believed to be due to short - circuiting of unoxidized / partially oxidised solids between the reactors, » The BAT BIOX® tests completed on the various Isabella McCays concentrate samples achieved sulphide oxidation levels in the range 86 . 4 to 99 . 3 % and yielded gold dissolutions in the range 92 . 3 to 97 . 9 % . The continuous neutralisation pilot run conducted on an Isabella McCays BIOX® liquor sample produced a suitable effluent since the As(T) concentration in the neutralised solution was at

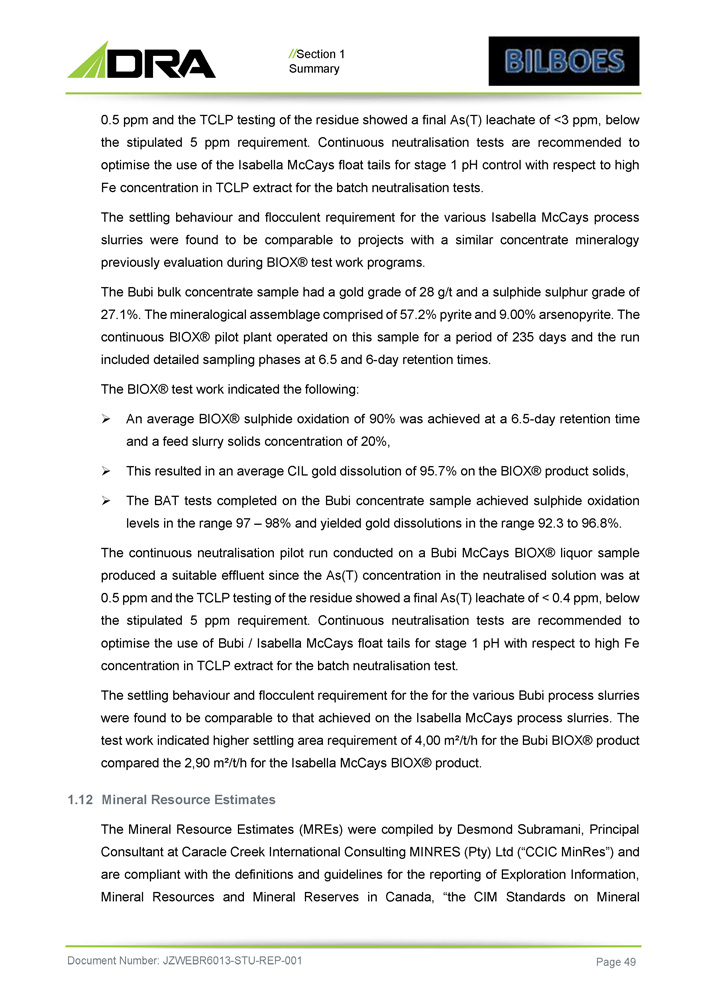

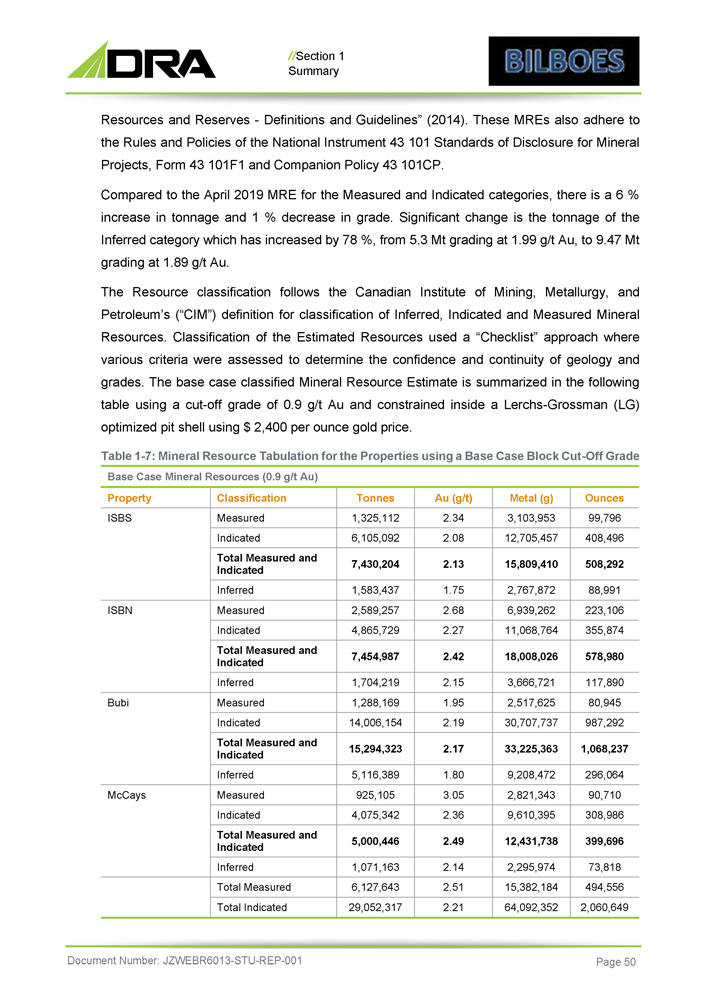

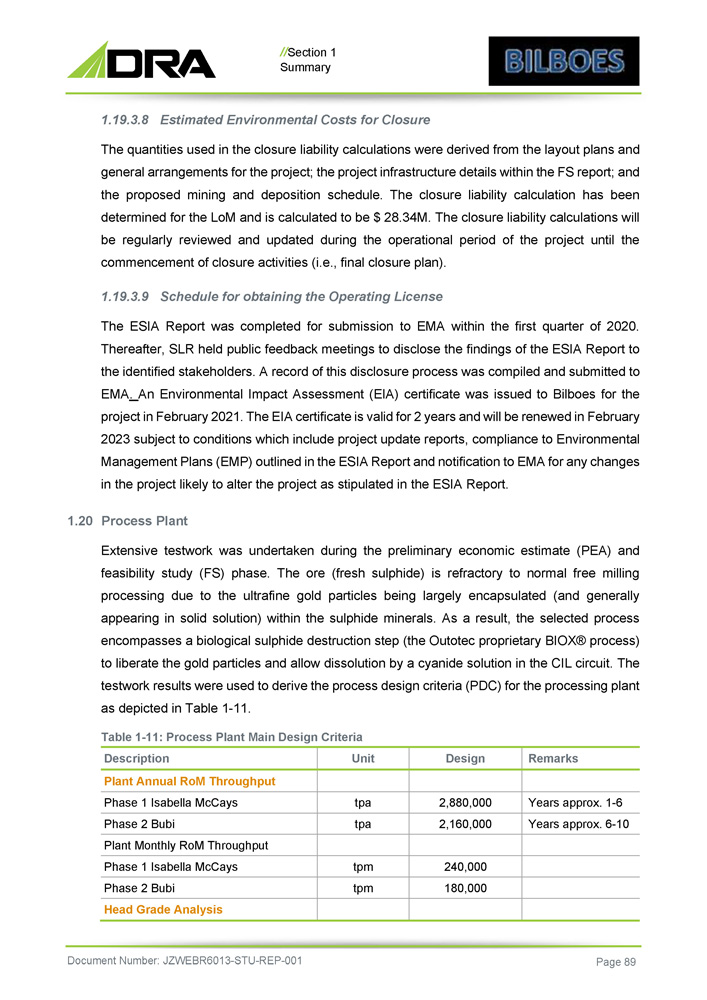

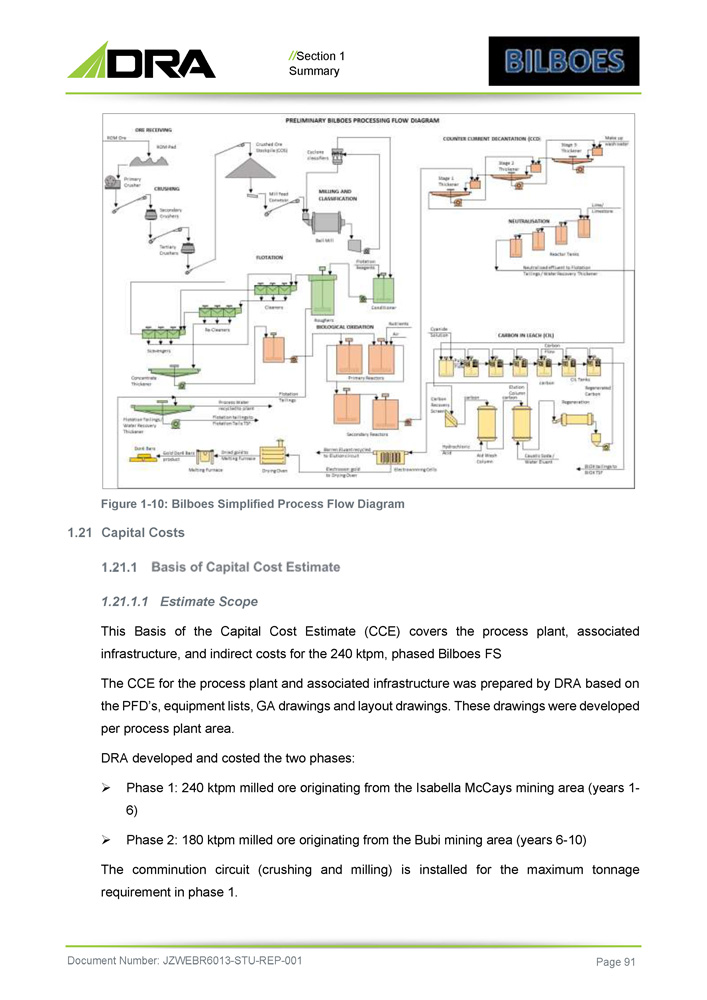

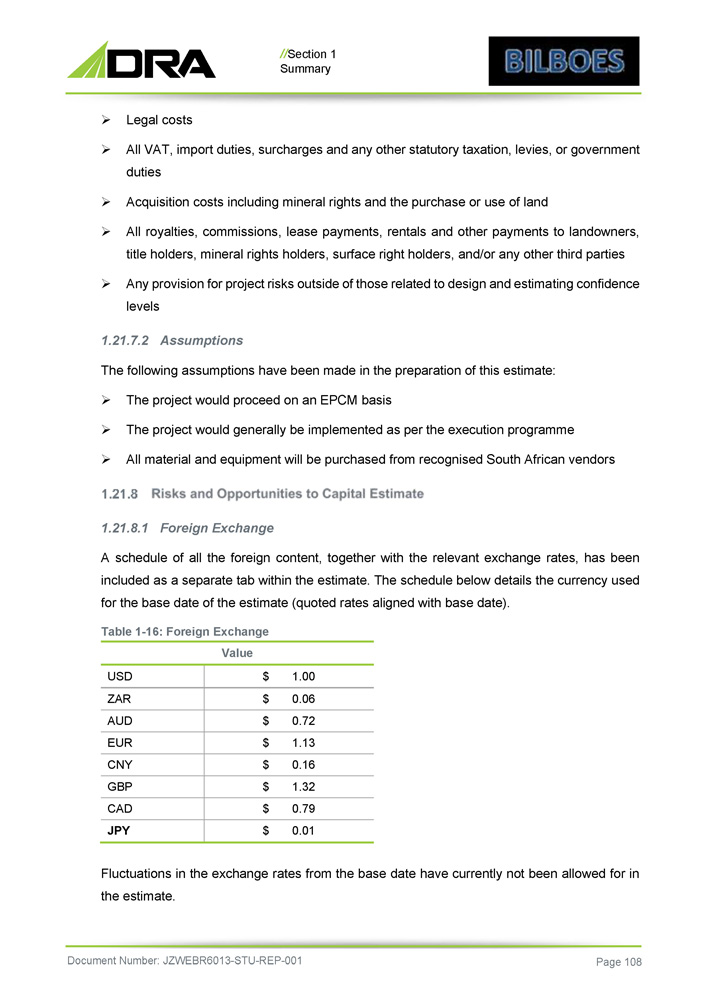

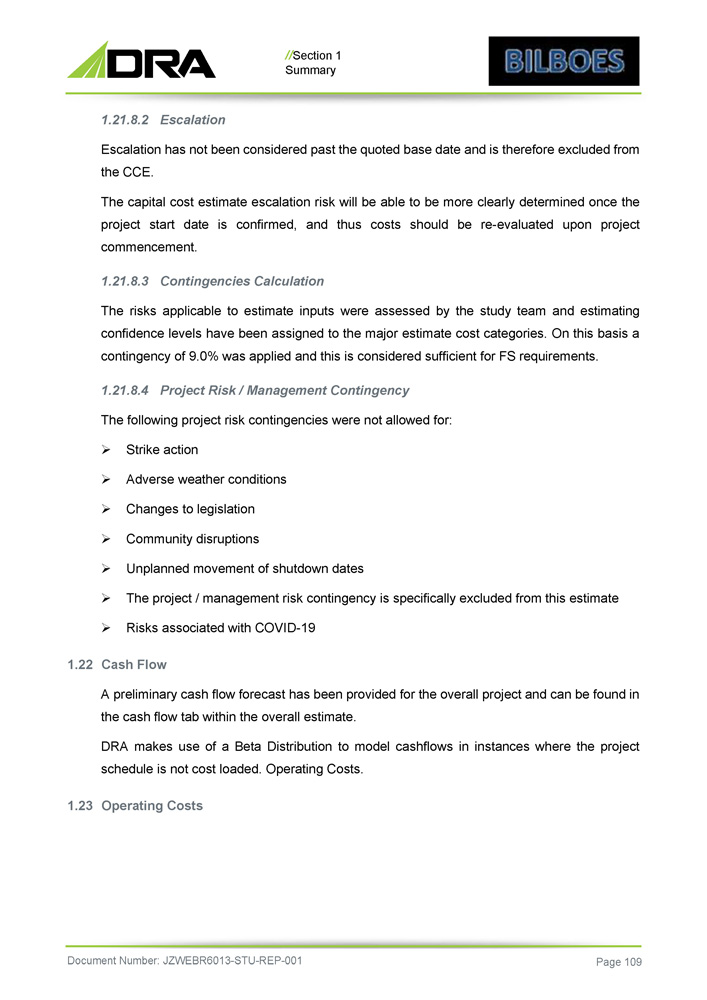

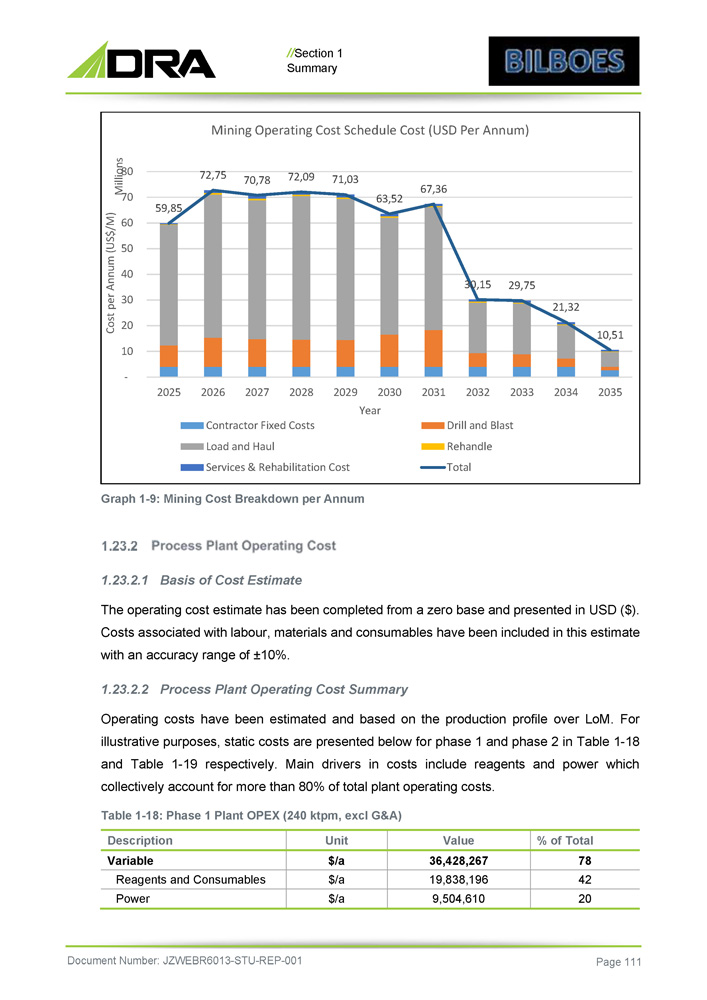

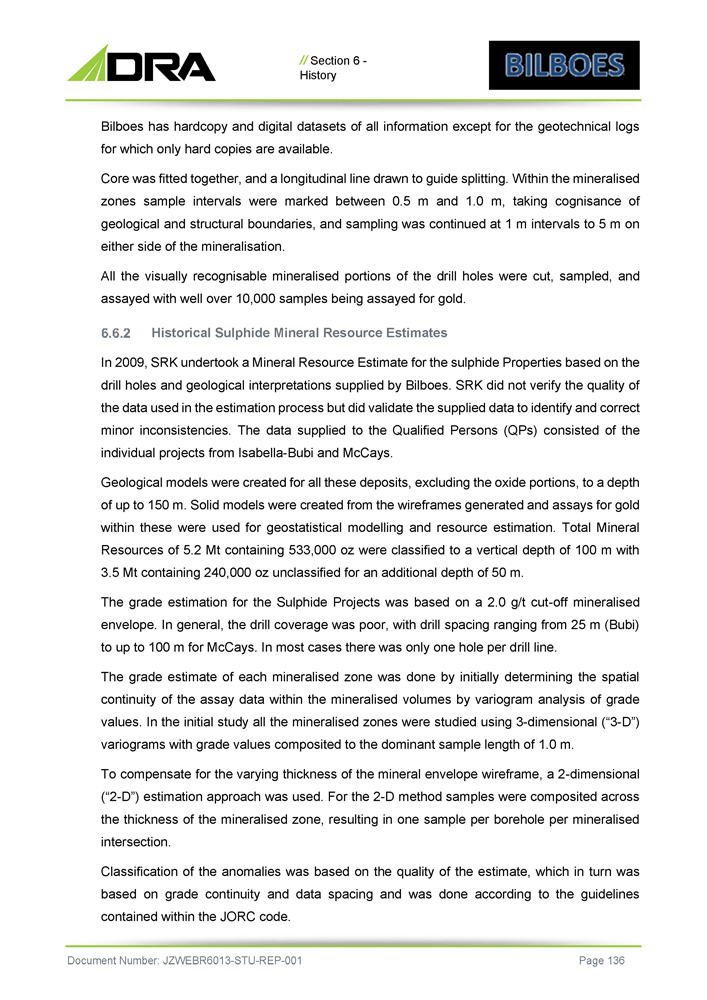

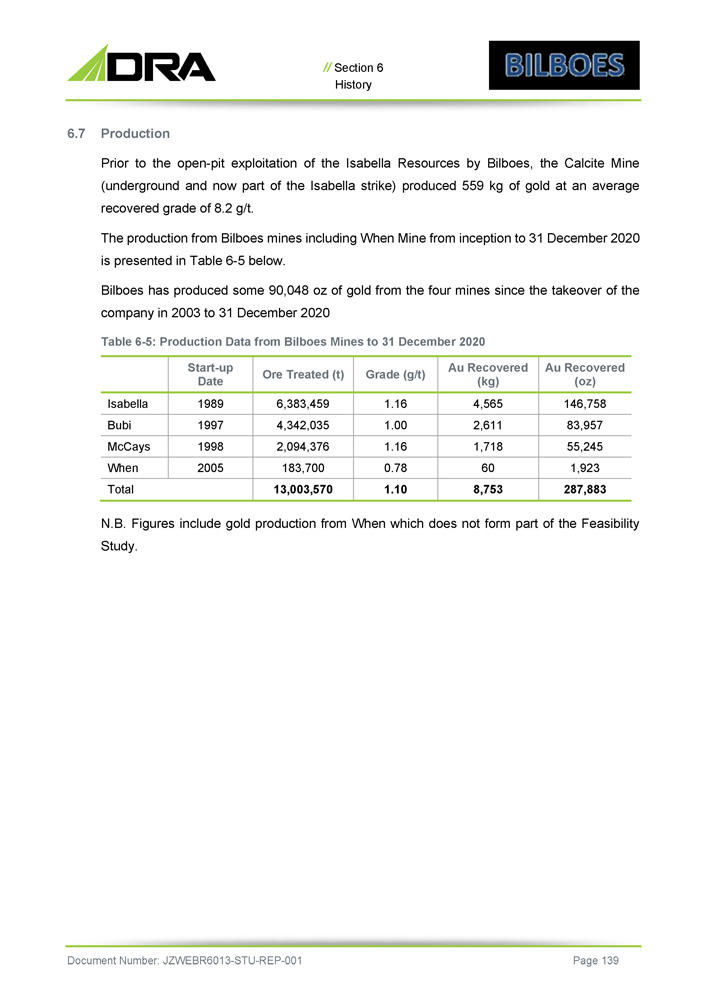

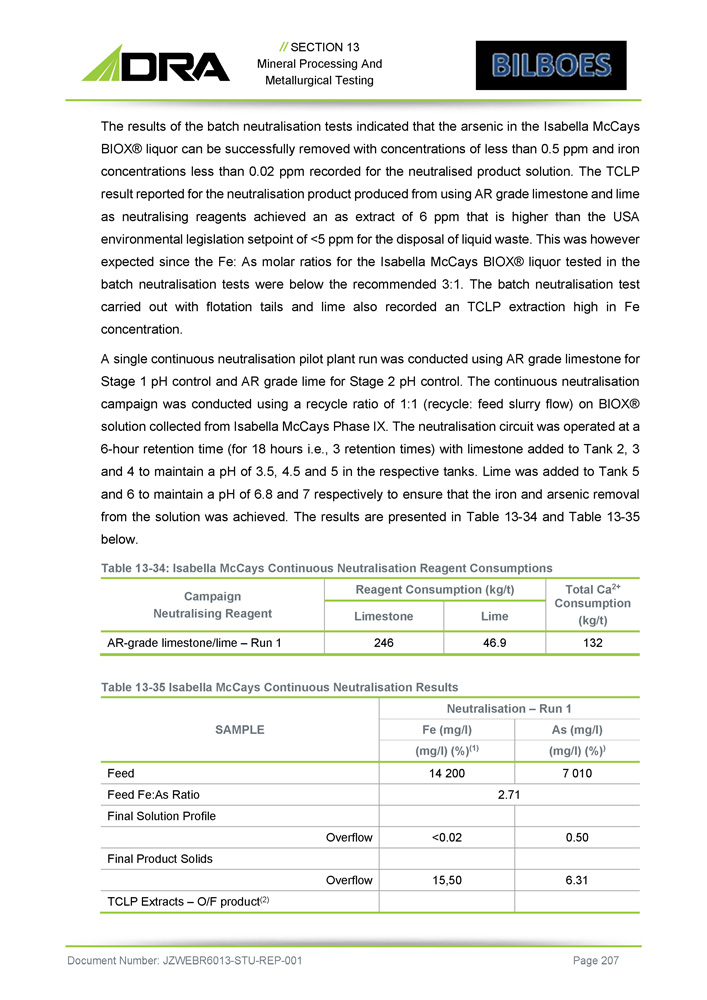

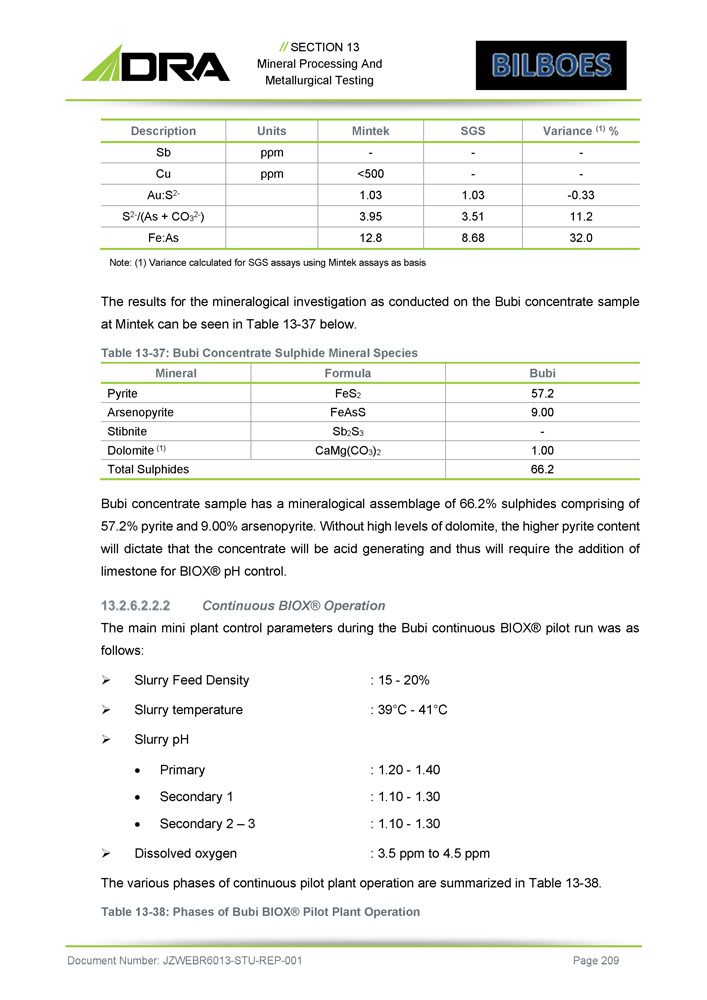

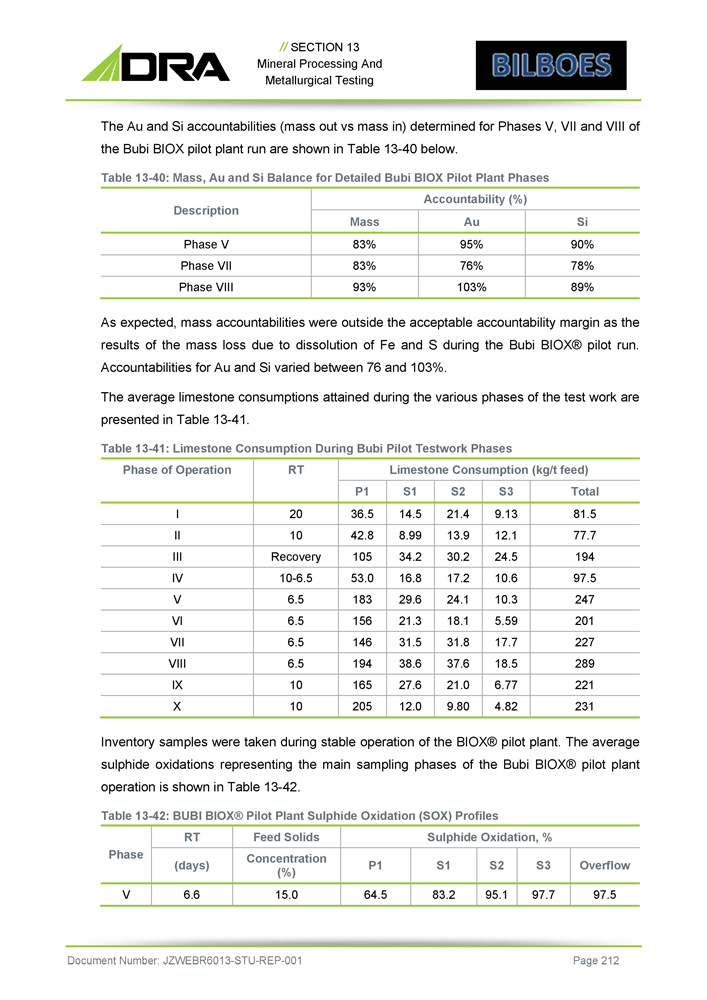

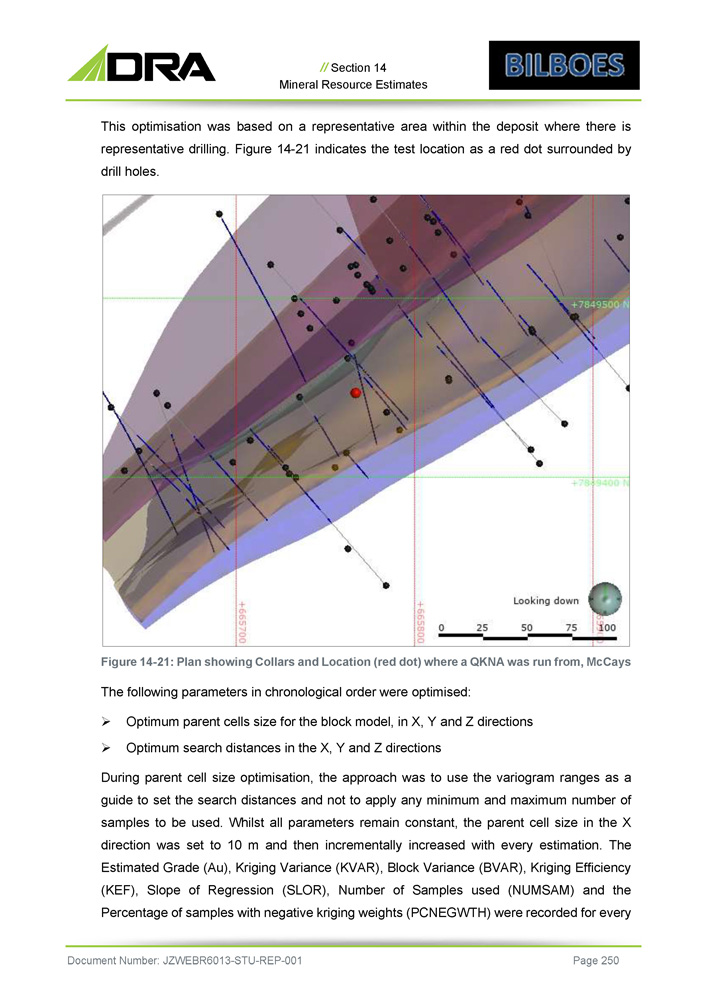

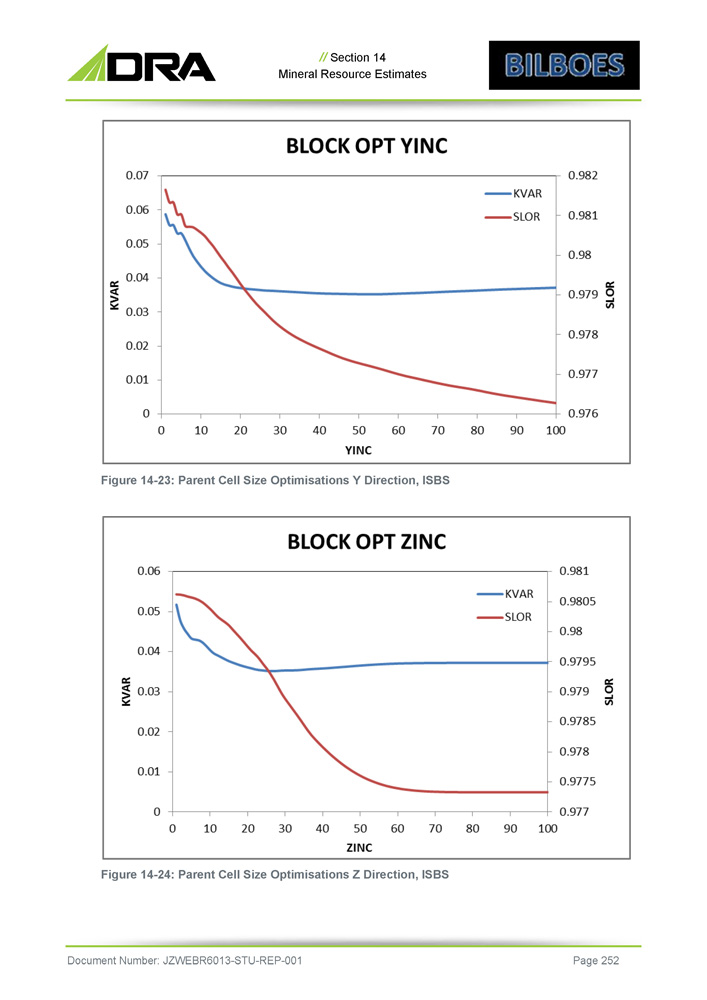

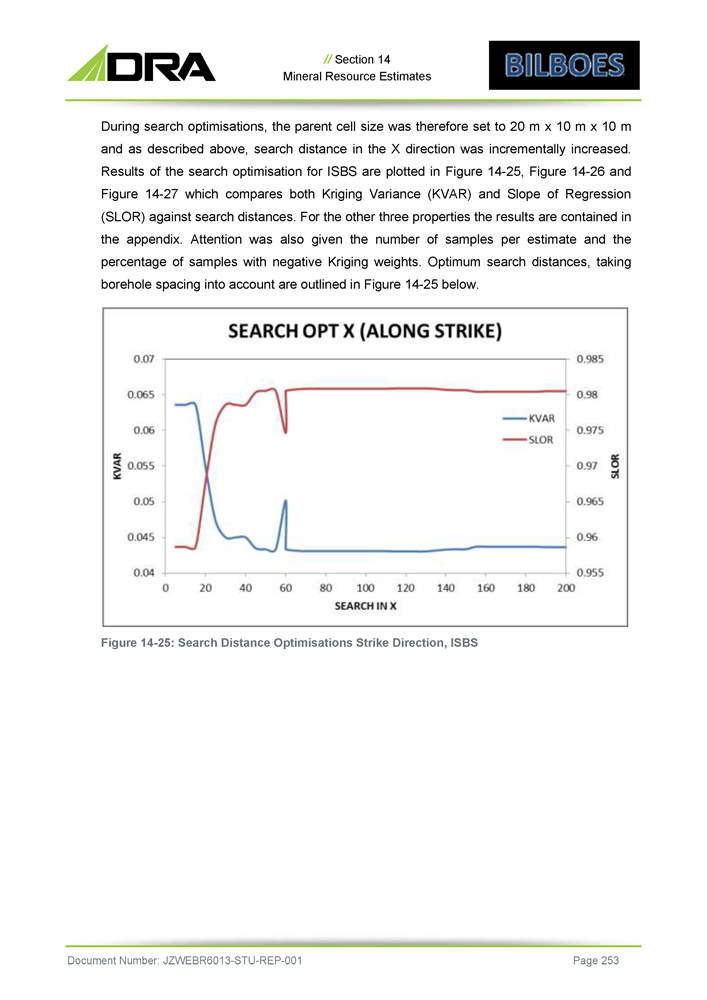

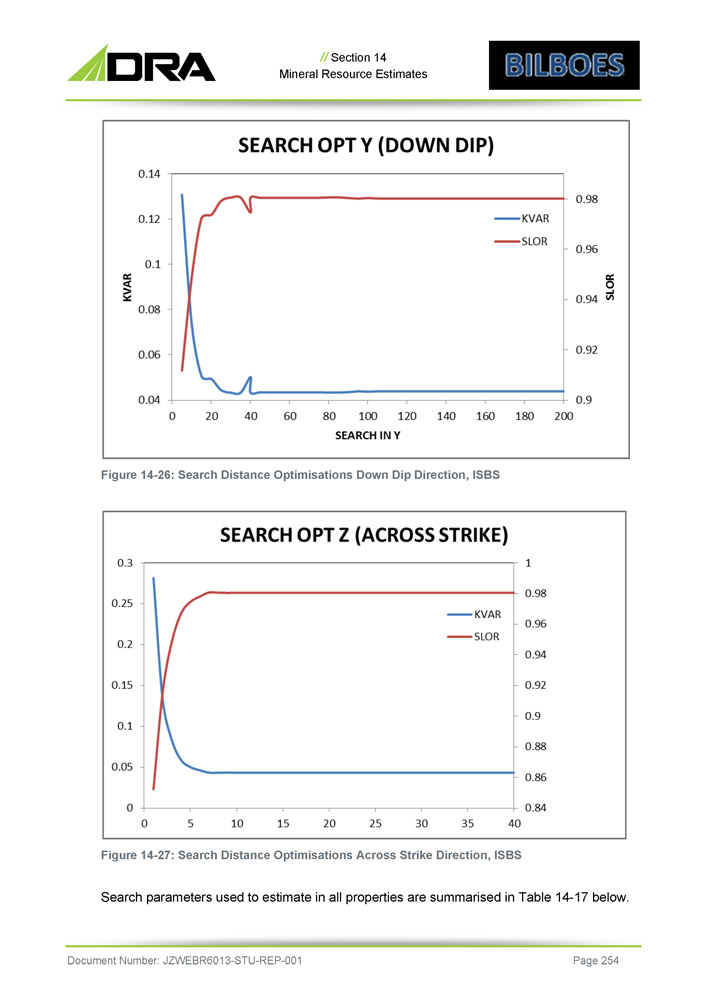

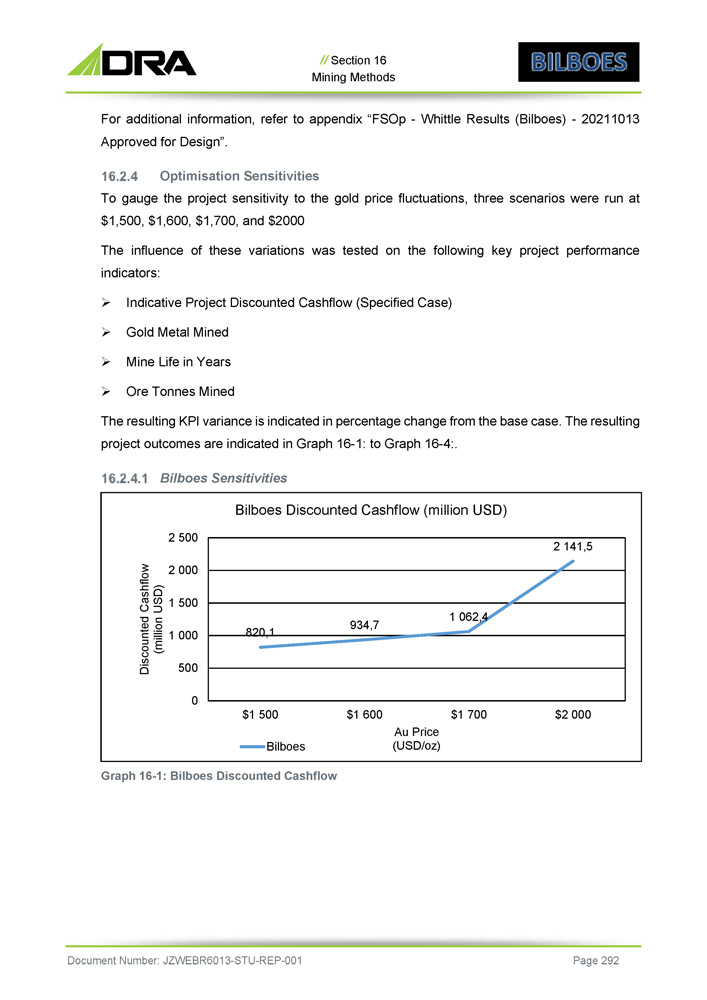

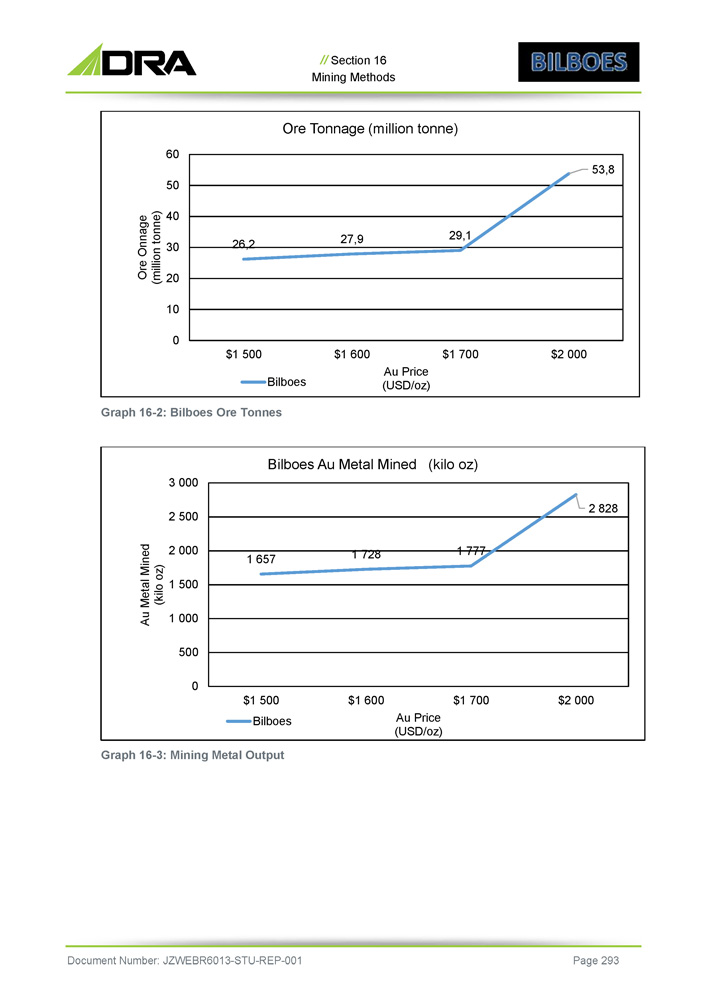

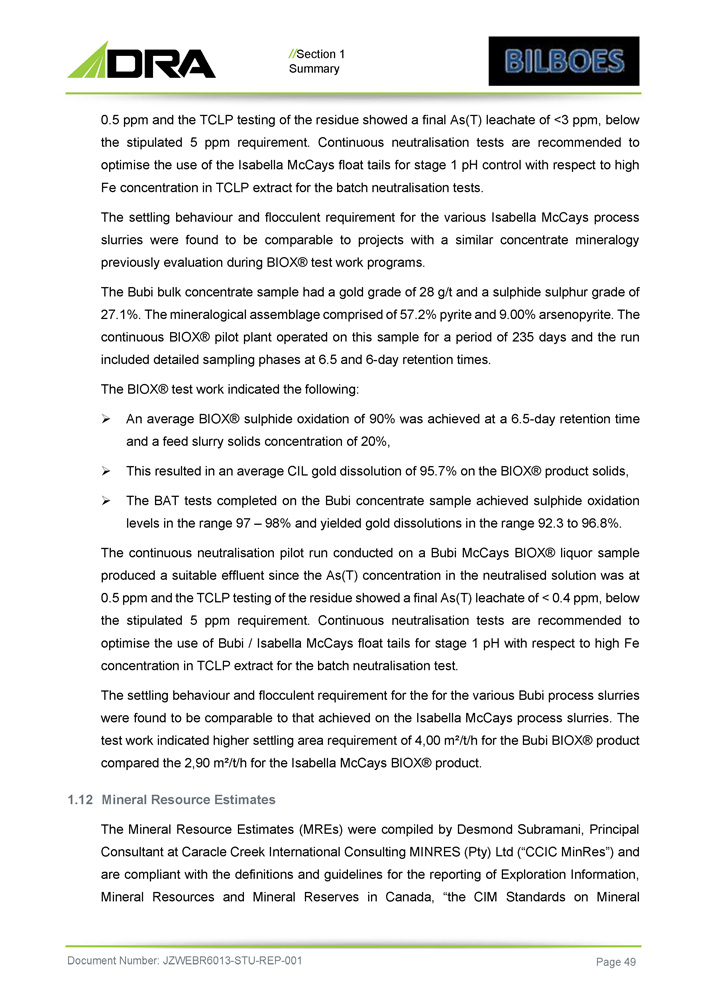

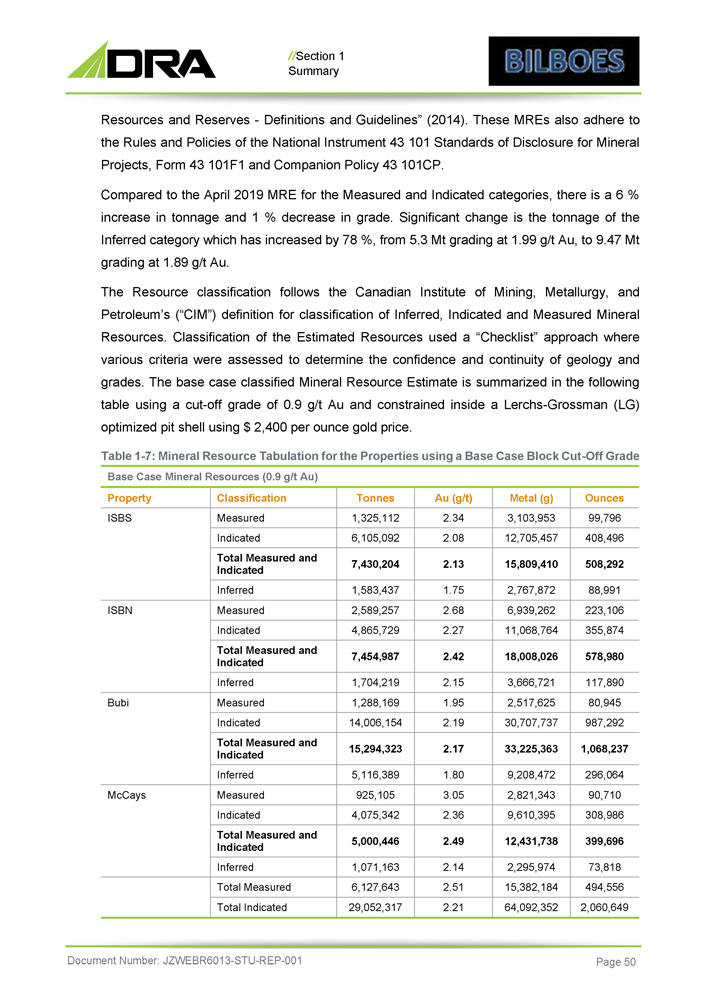

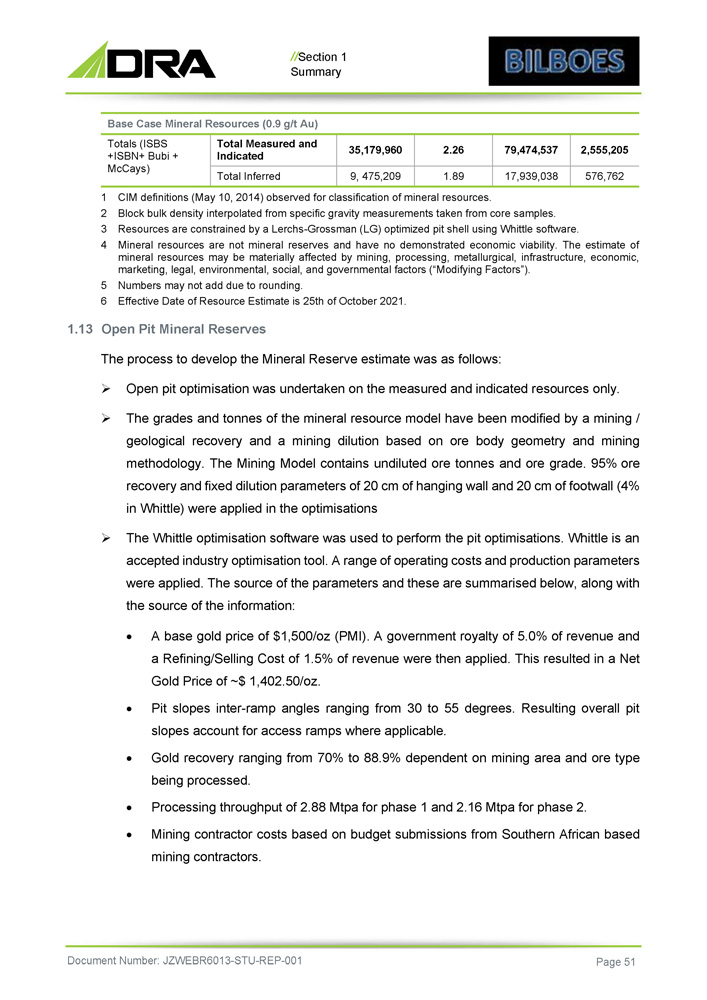

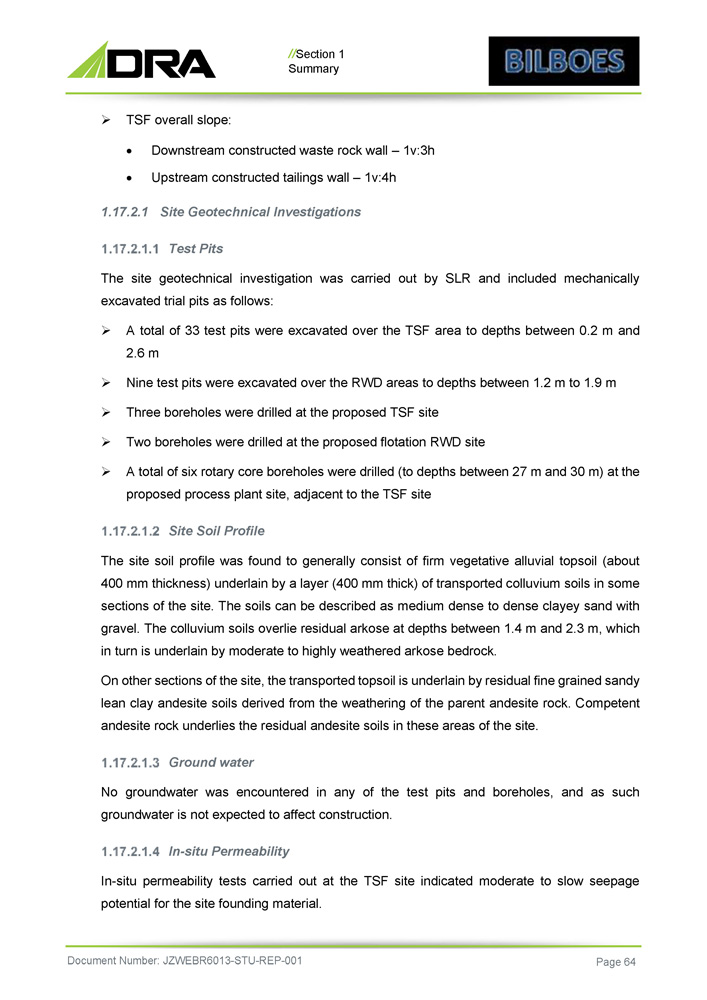

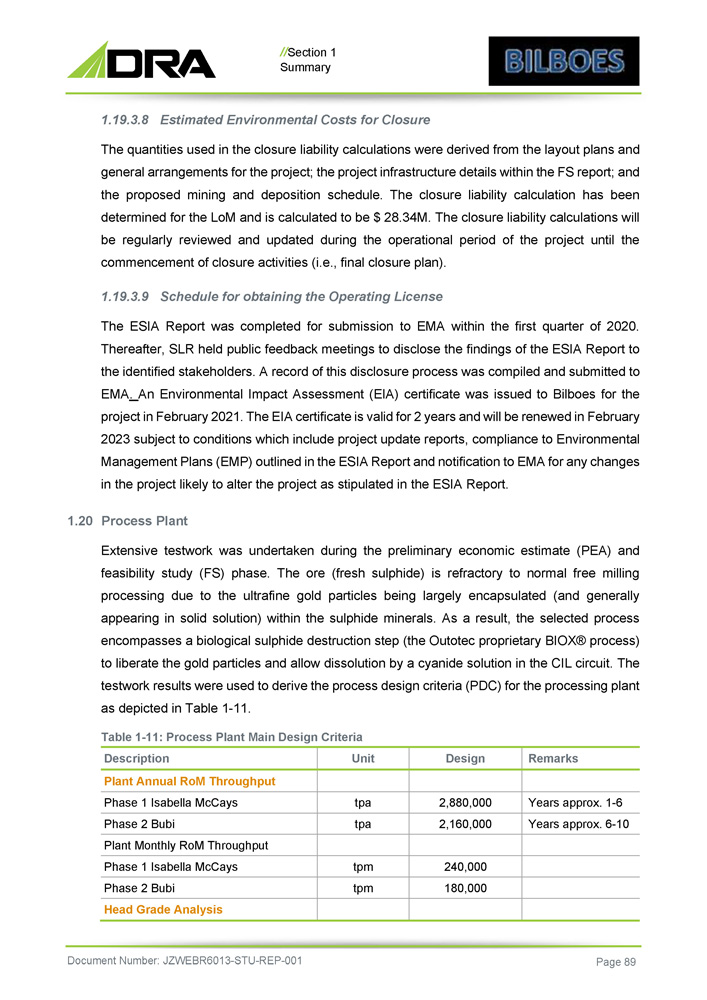

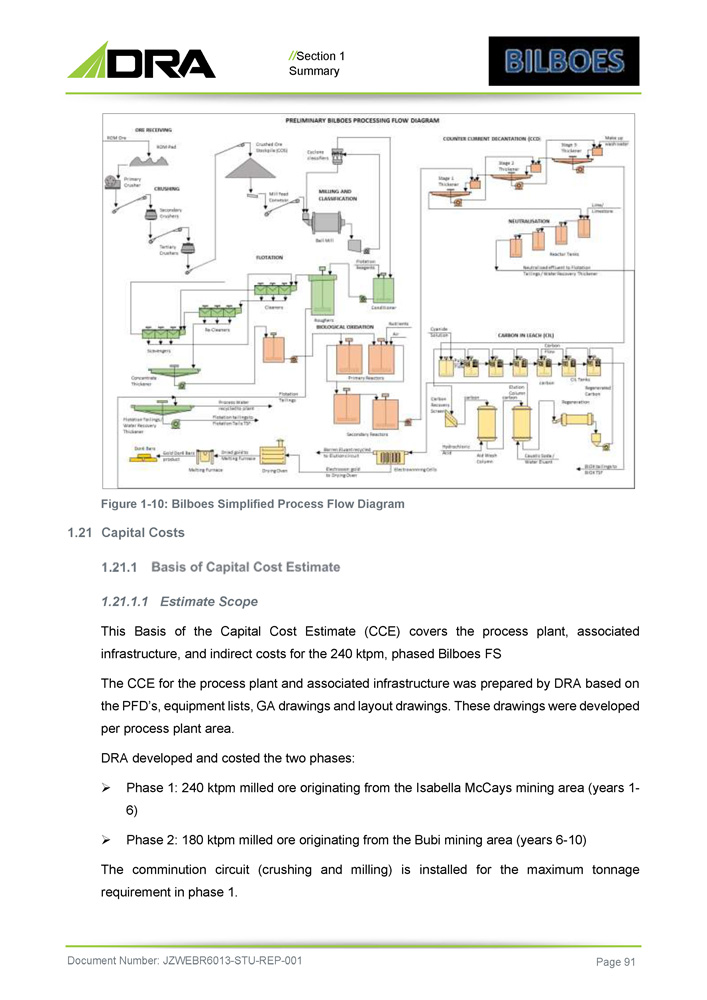

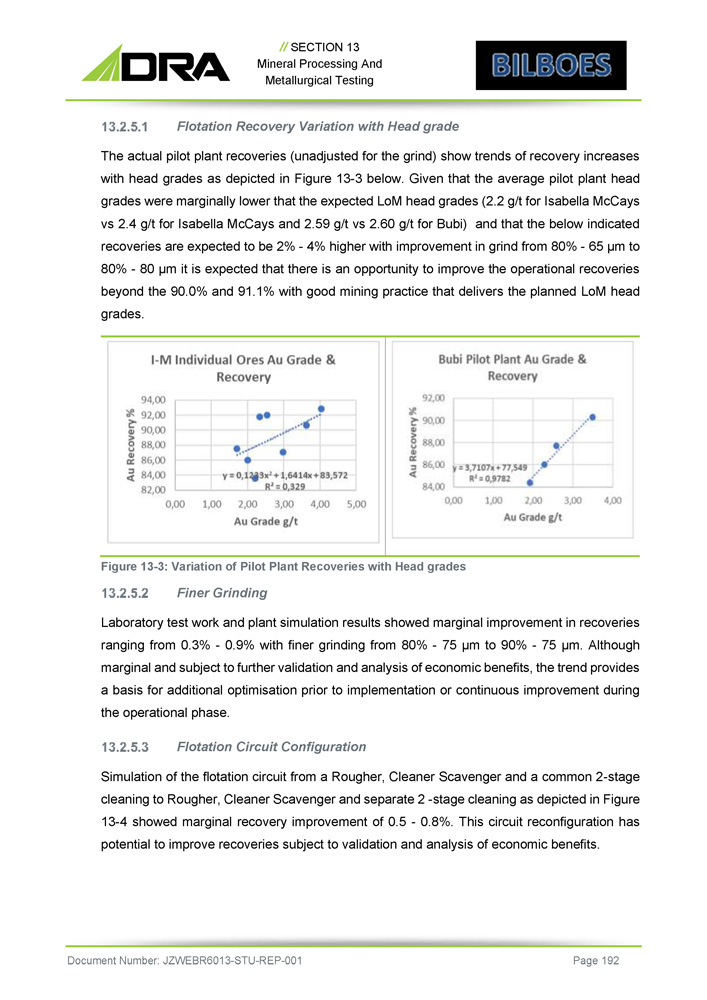

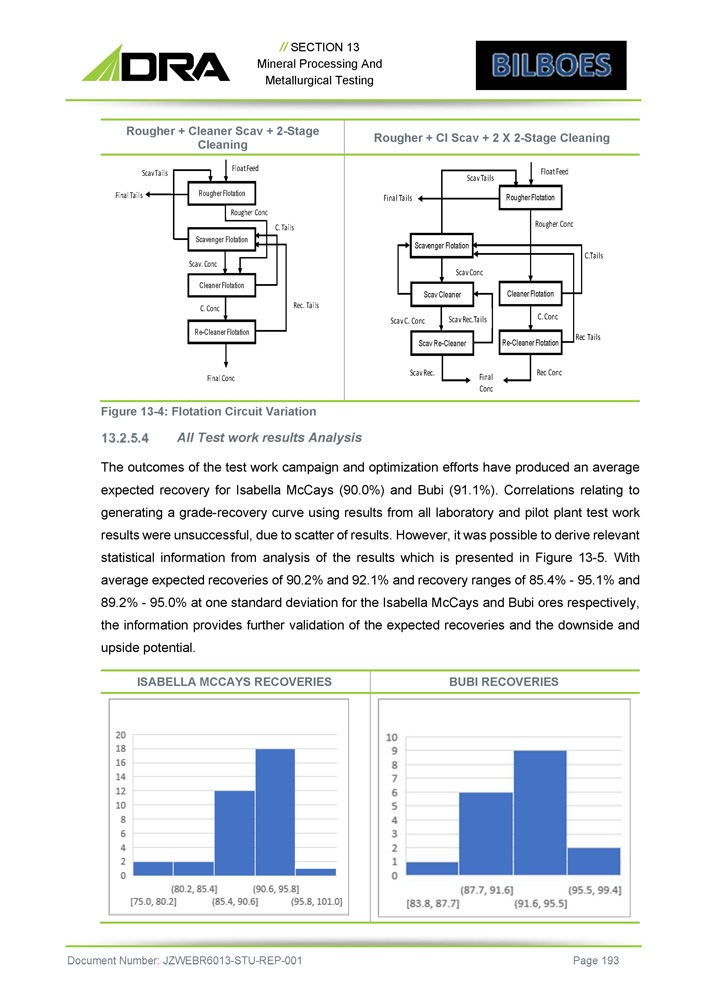

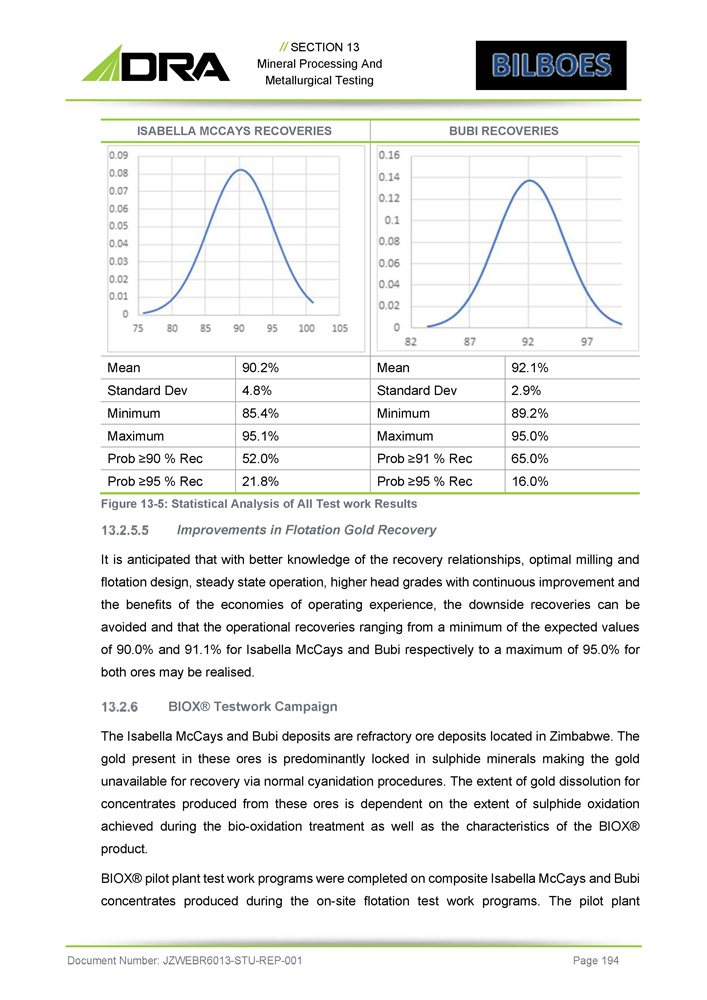

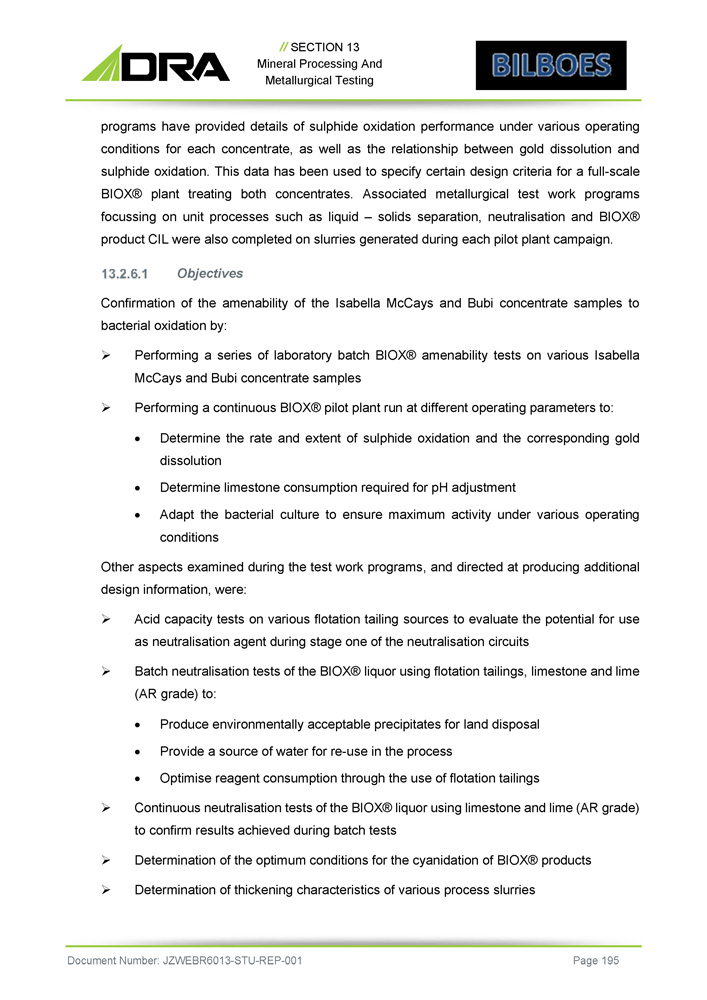

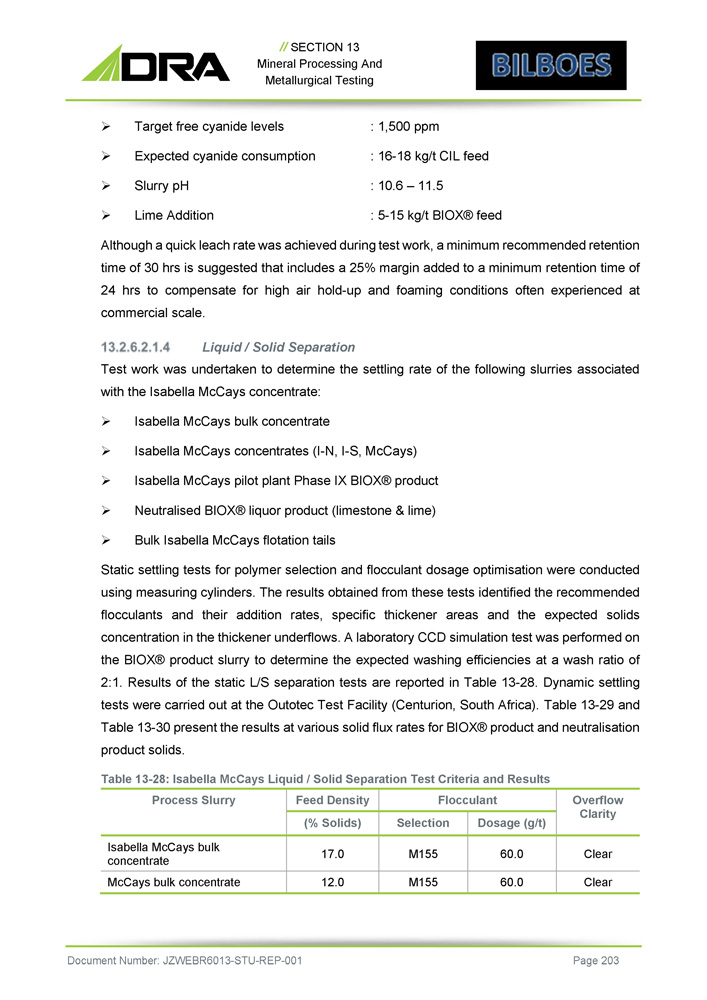

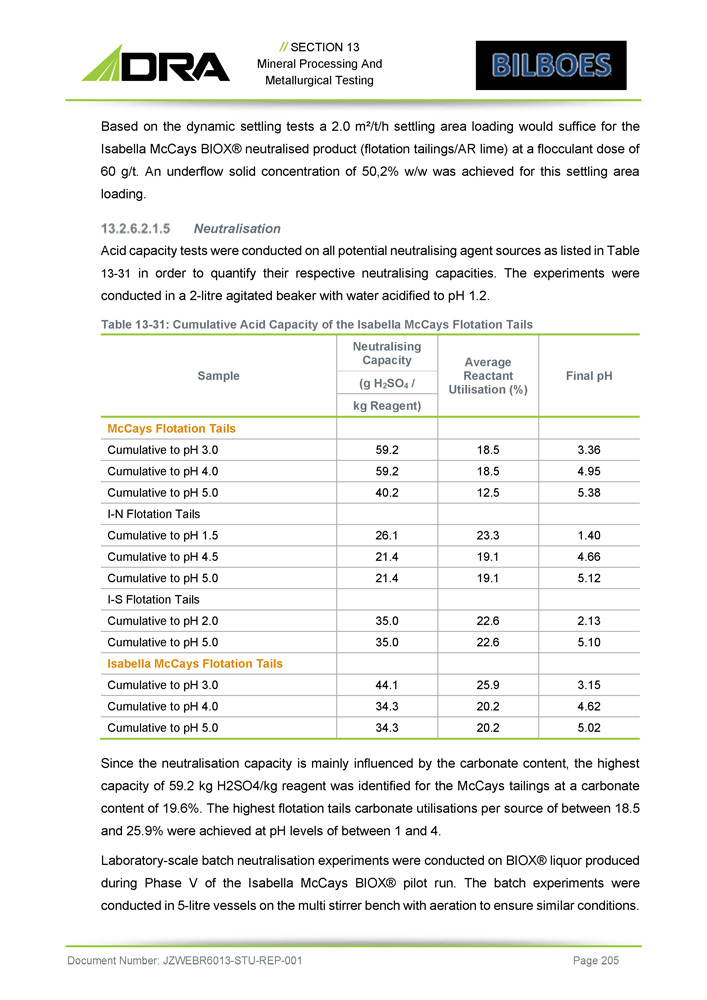

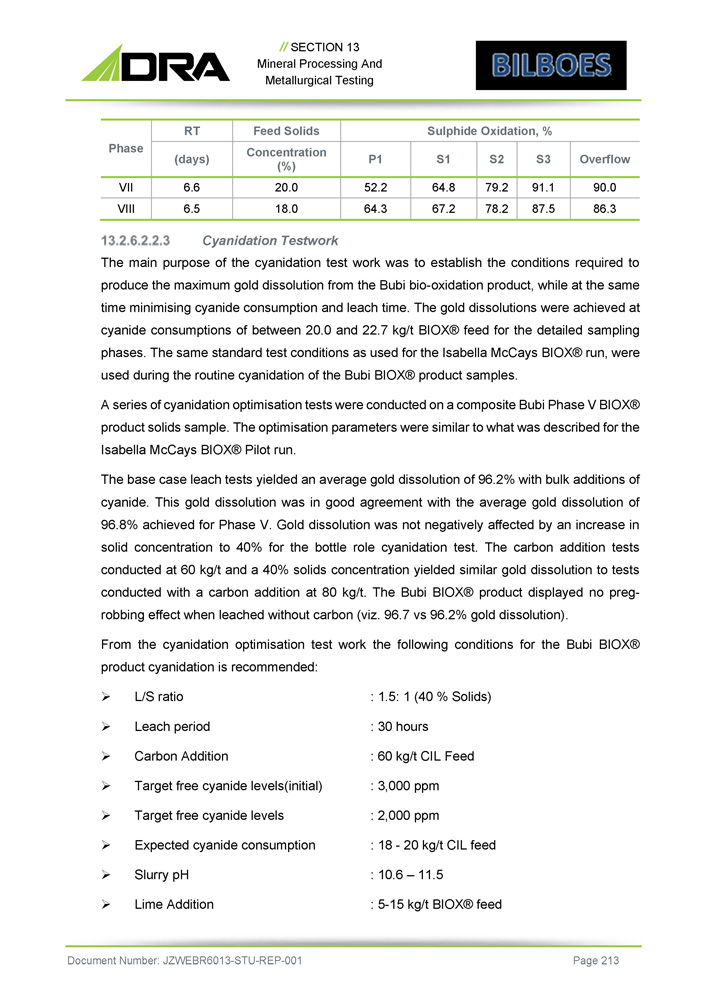

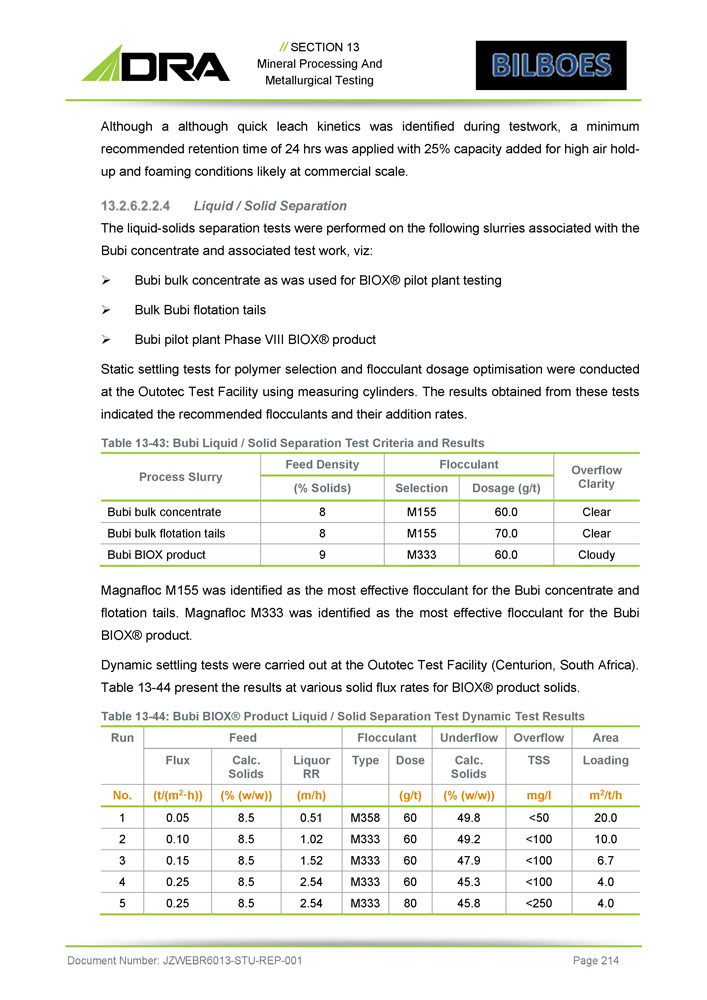

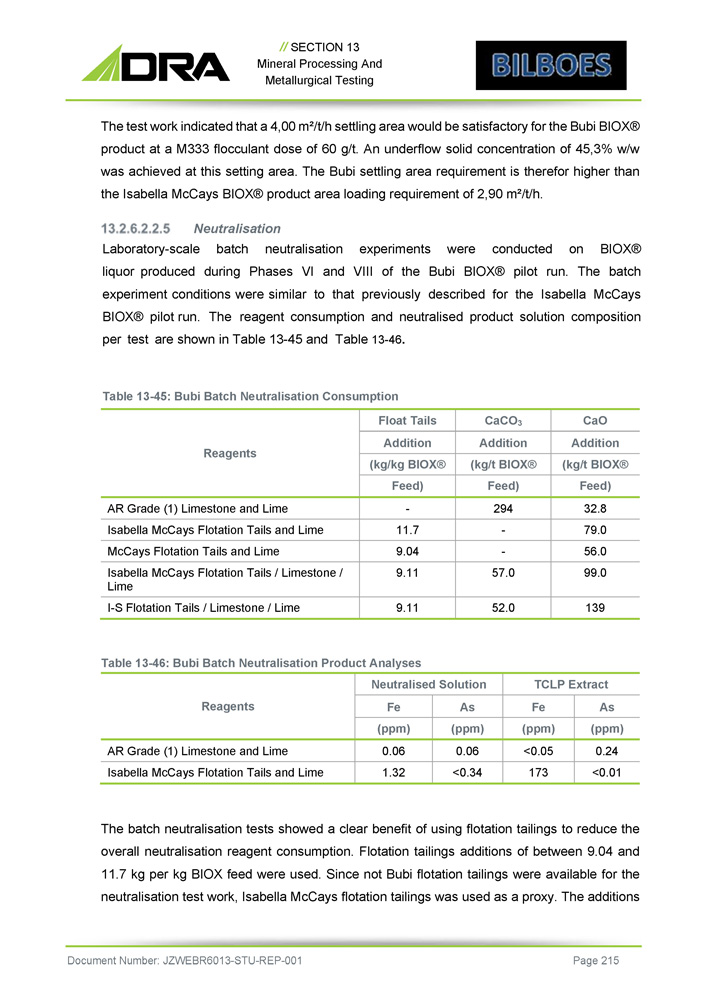

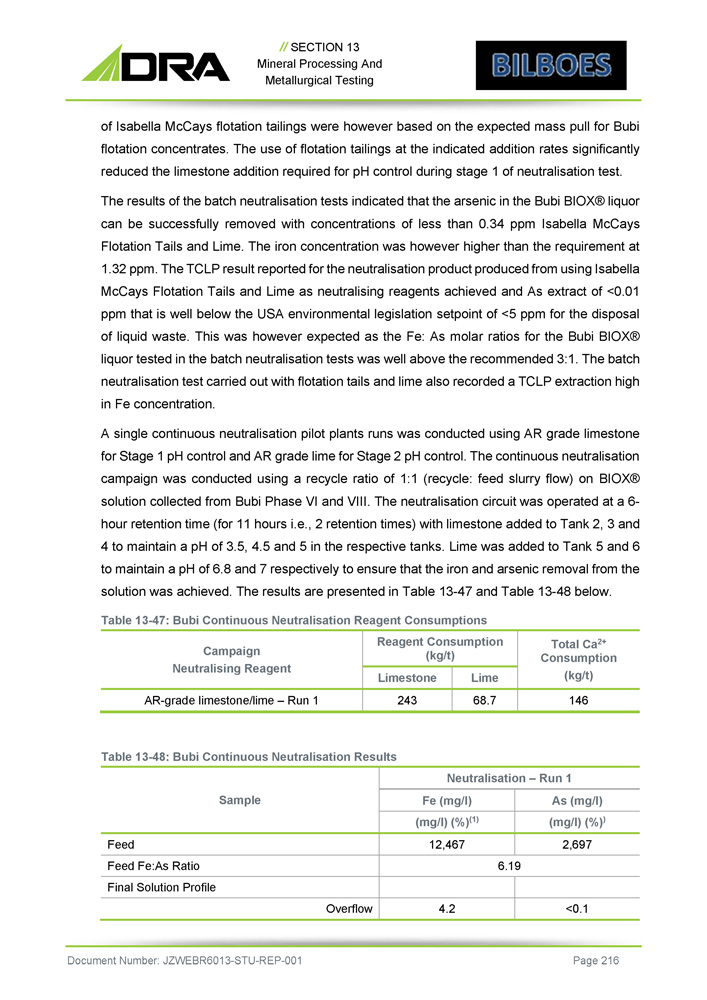

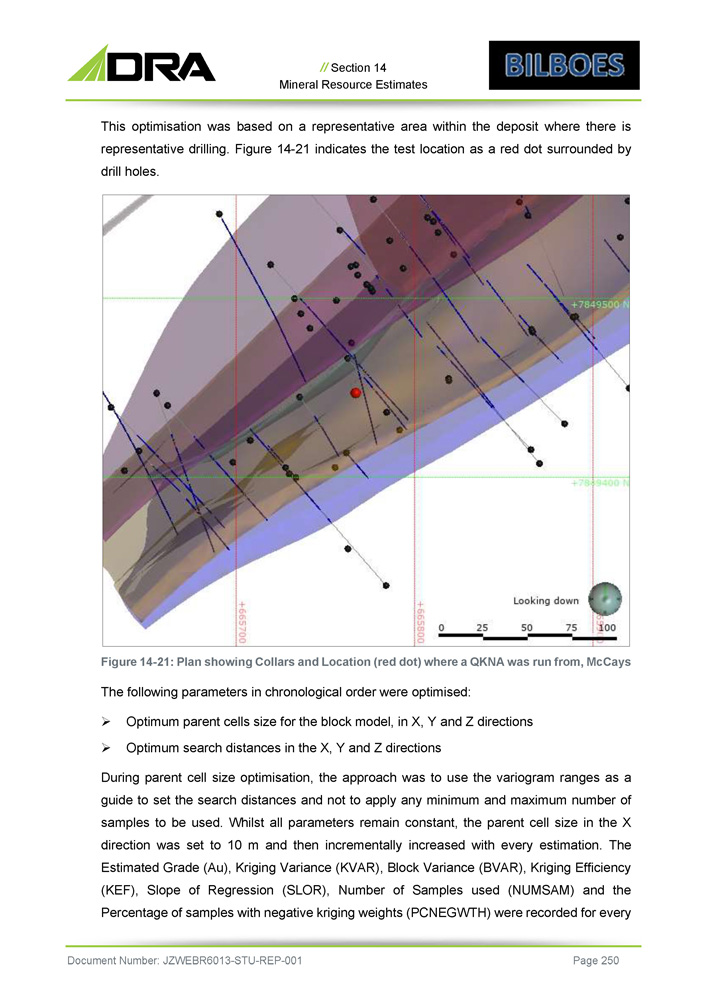

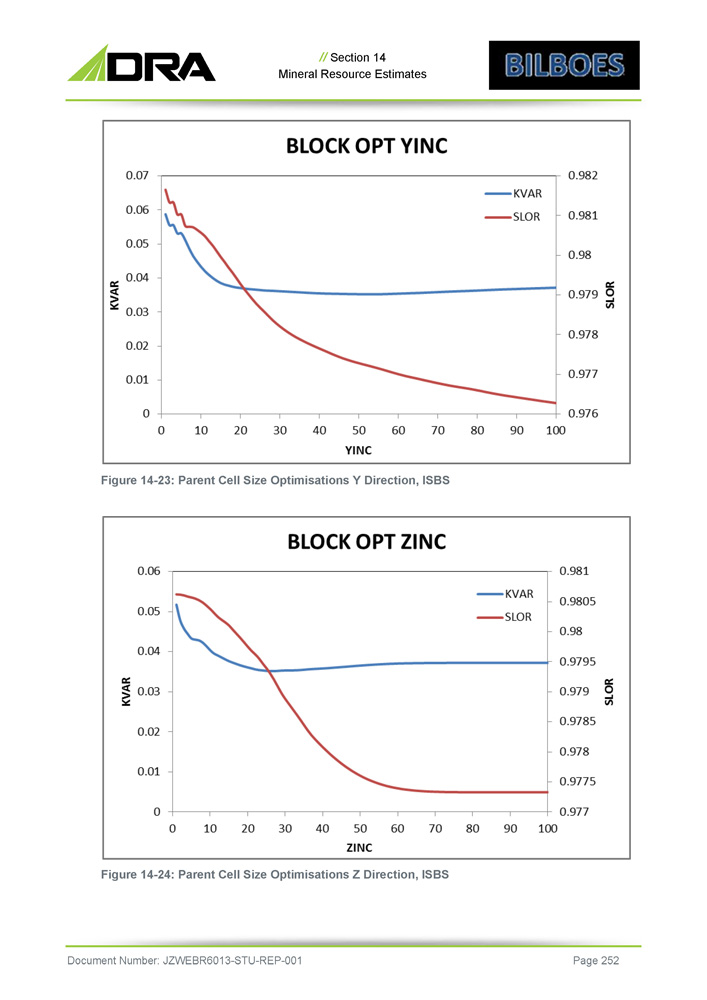

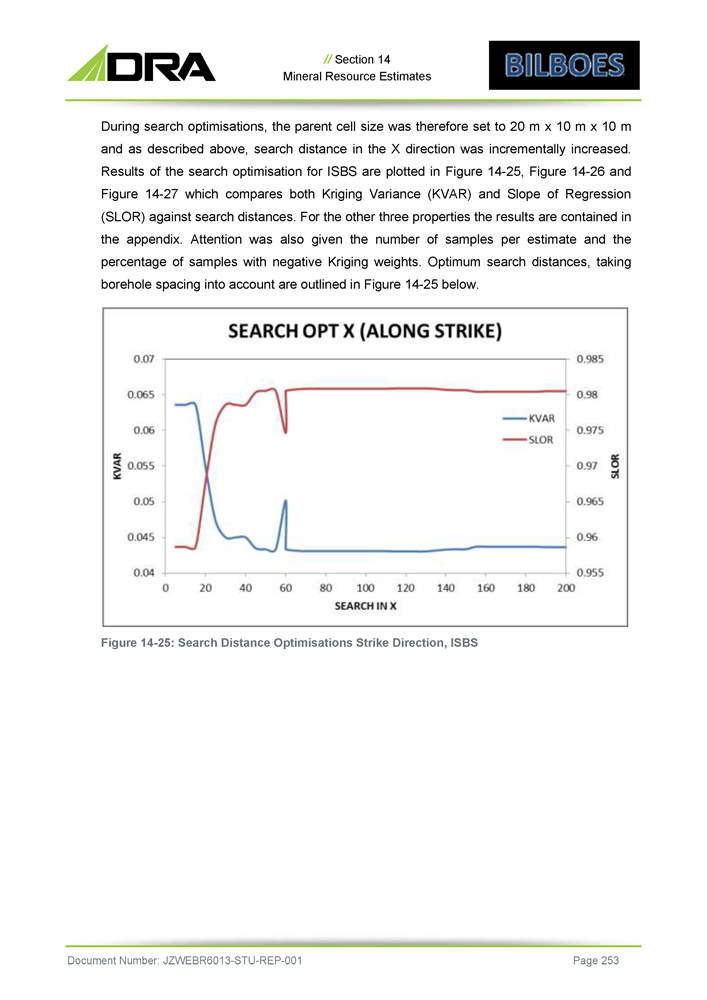

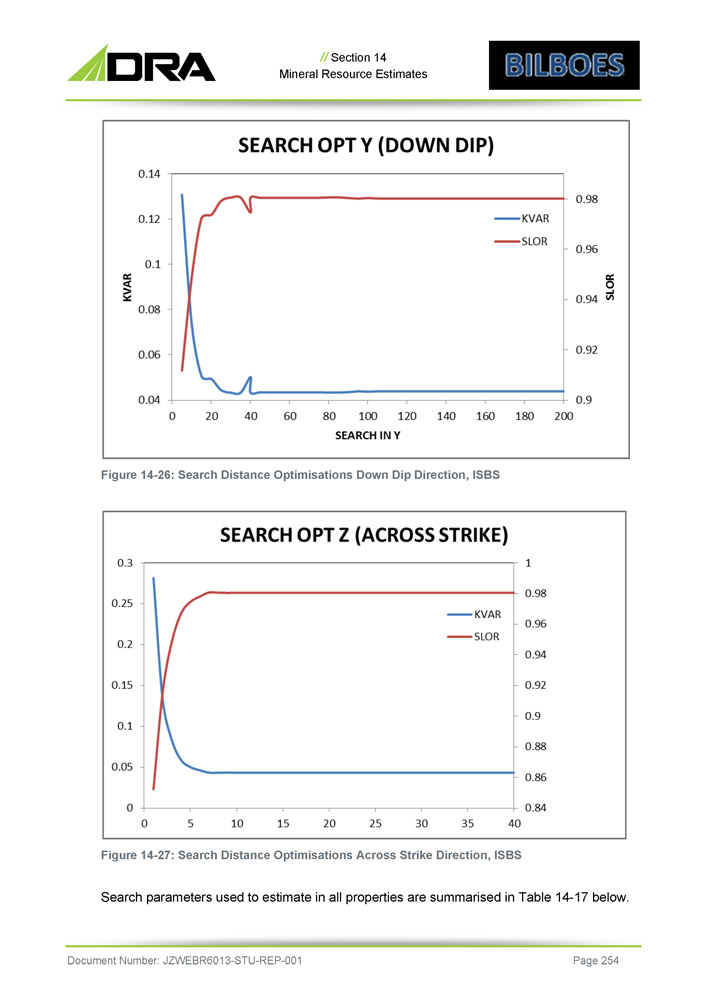

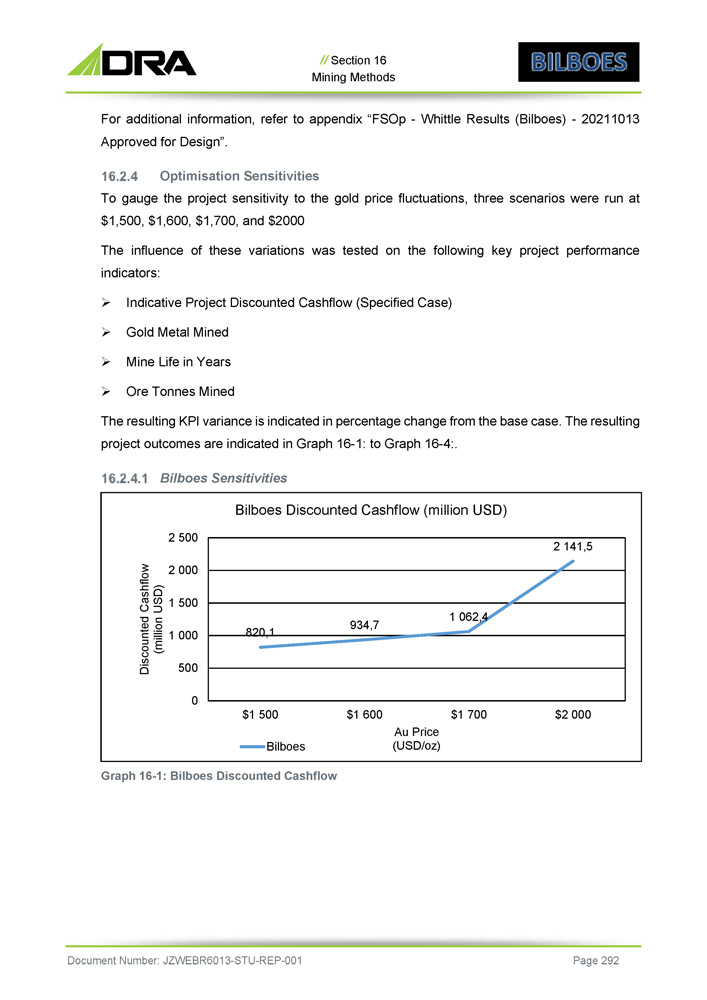

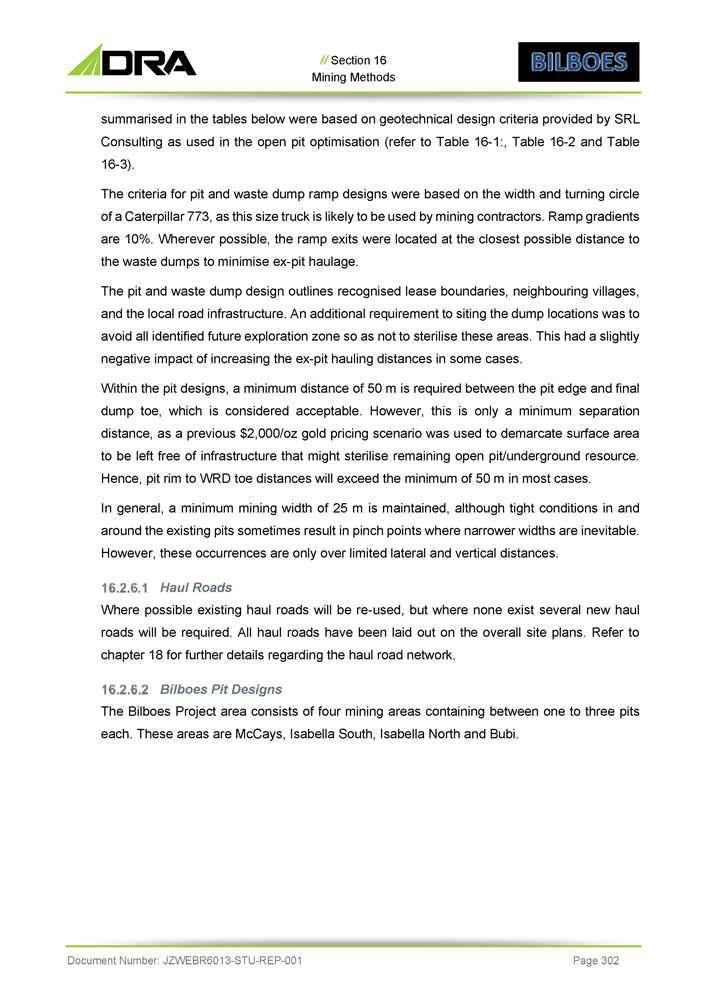

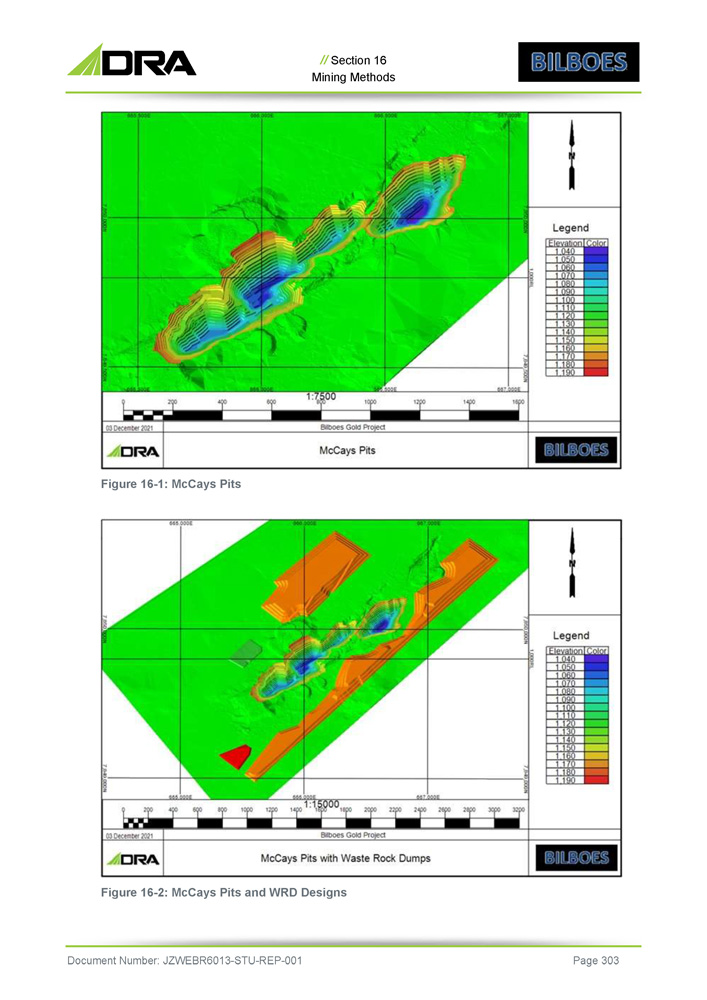

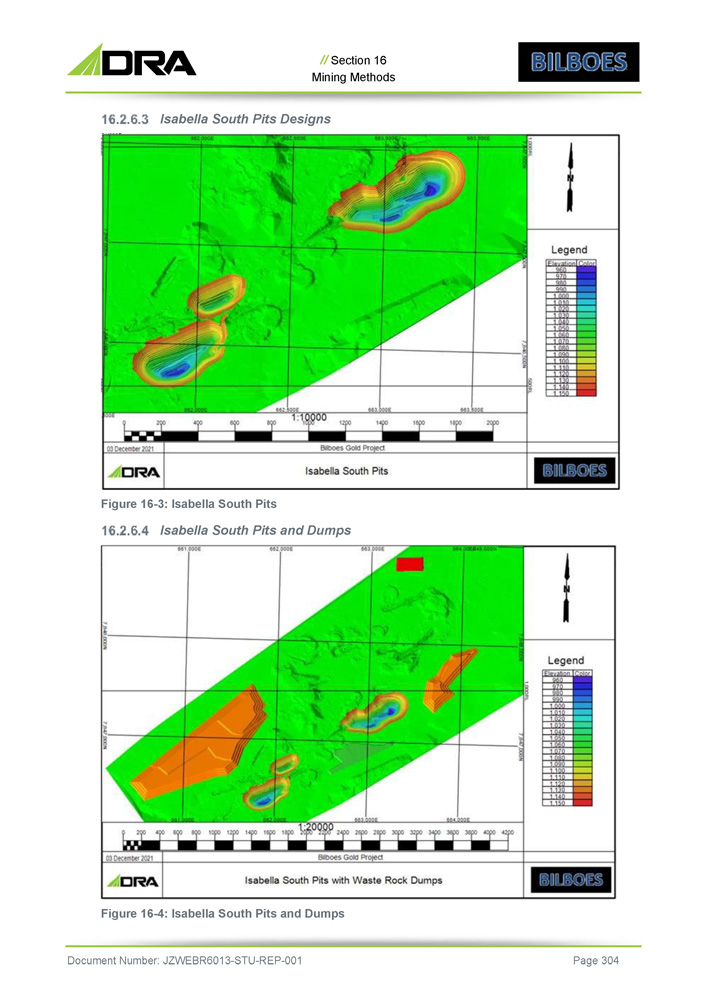

// Section 1 Summary 0 . 5 ppm and the TCLP testing of the residue showed a final As(T) leachate of < 3 ppm, below the stipulated 5 ppm requirement . Continuous neutralisation tests are recommended to optimise the use of the Isabella McCays float tails for stage 1 pH control with respect to high Fe concentration in TCLP extract for the batch neutralisation tests . The settling behaviour and flocculent requirement for the various Isabella McCays process slurries were found to be comparable to projects with a similar concentrate mineralogy previously evaluation during BIOX® test work programs . The Bubi bulk concentrate sample had a gold grade of 28 g/t and a sulphide sulphur grade of 27 . 1 % . The mineralogical assemblage comprised of 57 . 2 % pyrite and 9 . 00 % arsenopyrite . The continuous BIOX® pilot plant operated on this sample for a period of 235 days and the run included detailed sampling phases at 6 . 5 and 6 - day retention times . The BIOX® test work indicated the following : » An average BIOX® sulphide oxidation of 90 % was achieved at a 6 . 5 - day retention time and a feed slurry solids concentration of 20 % , » This resulted in an average CIL gold dissolution of 95 . 7 % on the BIOX® product solids, » The BAT tests completed on the Bubi concentrate sample achieved sulphide oxidation levels in the range 97 – 98 % and yielded gold dissolutions in the range 92 . 3 to 96 . 8 % . The continuous neutralisation pilot run conducted on a Bubi McCays BIOX® liquor sample produced a suitable effluent since the As(T) concentration in the neutralised solution was at 0 . 5 ppm and the TCLP testing of the residue showed a final As(T) leachate of < 0 . 4 ppm, below the stipulated 5 ppm requirement . Continuous neutralisation tests are recommended to optimise the use of Bubi / Isabella McCays float tails for stage 1 pH with respect to high Fe concentration in TCLP extract for the batch neutralisation test . The settling behaviour and flocculent requirement for the for the various Bubi process slurries were found to be comparable to that achieved on the Isabella McCays process slurries . The test work indicated higher settling area requirement of 4 , 00 m²/t/h for the Bubi BIOX® product compared the 2 , 90 m²/t/h for the Isabella McCays BIOX® product . 1 . 12 Mineral Resource Estimates The Mineral Resource Estimates (MREs) were compiled by Desmond Subramani, Principal Consultant at Caracle Creek International Consulting MINRES (Pty) Ltd (“CCIC MinRes”) and are compliant with the definitions and guidelines for the reporting of Exploration Information, Mineral Resources and Mineral Reserves in Canada, “the CIM Standards on Mineral Document Number: JZWEBR6013 - STU - REP - 001 Page 49