Exhibit 99.7

Technical Report on the Selebi Mines,

Central District, Republic of Botswana

Report for NI 43-101

North American Nickel Inc.

Premium Nickel Resources Corporation

Premium Nickel Resources Ltd.

SLR Project No: 233.03374.R0000

Effective Date:

March 01, 2022

Signature Date:

June 16, 2022

Prepared by:

SLR Consulting (Canada) Ltd.

Qualified Persons:

Valerie Wilson, M.Sc., P.Geo.

Brenna J.Y. Scholey, P.Eng.

Sharon Meyer, M.Sc., Pr.Sci.Nat., EAPASA

Technical Report on the Selebi Mines, Central District, Republic of Botswana

SLR Project No: 233.03374.R0000

Prepared by

SLR Consulting (Canada) Ltd.

55 University Ave., Suite 501

Toronto, ON M5J 2H7

for

North American Nickel Inc.

2500 – 666 Burrard St.

Vancouver, BC V6C 2X8

Premium Nickel Resources Corporation

130 Spadina Avenue, Suite 401

Toronto, ON M5V 2L4

Premium Nickel Resources Ltd.

One First Canadian Place

100 King Street West, Suite 3400

Toronto, ON M5X 1A4

Effective Date – March 01, 2022

Signature Date - June 16, 2022

Prepared by: Valerie Wilson, M.Sc., P.Geo. Brenna J.Y. Scholey, P.Eng. Sharon Meyer, M.Sc., Pr.Sci.Nat., EAPASA Peer Reviewed by: Luke Evans, M.Sc., P.Eng. Deborah A. McCombe, P.Geo. | Approved by: Project Manager Sean Horan, P.Geo. Project Director Luke Evans, M.Sc., P.Eng. |

FINAL

| Distribution: | 1 copy – North American Nickel Inc. |

| | 1 copy – Premium Nickel Resources Corporation |

| | 1 copy – Premium Nickel Resources Ltd. |

| | 1 copy – SLR Consulting (Canada) Ltd. |

Contents

| 2.1 | Sources of Information | 2-2 |

| 2.2 | List of Abbreviations | 2-4 |

| 3.0 | Reliance on Other Experts | 3-1 |

| 4.0 | Property Description and Location | 4-1 |

| 4.4 | Royalties and Other Encumbrances | 4-3 |

| 4.5 | Environmental, Social and Permitting Considerations | 4-4 |

| 5.0 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 5-1 |

| 6.2 | Exploration and Development History | 6-2 |

| 6.3 | Historical Resource Estimates | 6-8 |

| 7.0 | Geological Setting and Mineralization | 7-1 |

| 9.1 | Digitization of Existing Information | 9-1 |

| 9.2 | Collar, Downhole, and BHEM Surveys | 9-1 |

| 9.3 | Exploration Potential | 9-3 |

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | i | |

| 10.1 | Early Drilling (1964 to 1994) | 10-1 |

| 10.2 | Recent Drilling (2007 to 2010) | 10-1 |

| 10.3 | Surface Drilling and Core Handling Protocols | 10-4 |

| 10.4 | Underground Drilling and Core Handling Protocols | 10-7 |

| 11.0 | Sample Preparation, Analyses, and Security | 11-1 |

| 11.1 | Sample Preparation, Sample Security and Analysis | 11-1 |

| 11.2 | Quality Assurance and Quality Control | 11-1 |

| 12.0 | Data Verification | 12-1 |

| 12.1 | SLR Site Verification Procedures | 12-1 |

| 12.2 | SLR Audit of the Drill Hole Database | 12-1 |

| 12.3 | SLR Data Verification Conclusions and Recommendations | 12-2 |

| 13.0 | Mineral Processing and Metallurgical Testing | 13-1 |

| 13.1 | 2021 SGS Test Work Program | 13-2 |

| 13.2 | Conclusions and Summary | 13-11 |

| 14.0 | Mineral Resource Estimate | 14-1 |

| 15.0 | Mineral Reserve Estimate | 15-1 |

| 18.0 | Project Infrastructure | 18-1 |

| 19.0 | Market Studies and Contracts | 19-1 |

| 20.0 | Environmental Studies, Permitting, and Social or Community Impact | 20-1 |

| 21.0 | Capital and Operating Costs | 21-1 |

| 22.0 | Economic Analysis | 22-1 |

| 23.0 | Adjacent Properties | 23-1 |

| 24.0 | Other Relevant Data and Information | 24-1 |

| 25.0 | Interpretation and Conclusions | 25-1 |

| 25.1 | Geology and Mineral Resources | 25-1 |

| 25.2 | Mineral Processing | 25-1 |

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | ii | |

| 26.1 | Geology and Mineral Resources | 26-1 |

| 26.2 | Mineral Processing | 26-2 |

| 28.0 | Date and Signature Page | 28-1 |

| 29.0 | Certificate of Qualified Person | 29-1 |

| 29.2 | Brenna J.Y. Scholey | 29-2 |

TABLEs

| Table 1-1: | Proposed Budget – Phase I (18 months) | 1-2 |

| | | |

| Table 2-1: | Summary of QP Responsibilities | 2-3 |

| | | |

| Table 6-1: | Historical Mineral Resources as of September 30, 2016 | 6-8 |

| | | |

| Table 6-2: | Historical Production | 6-10 |

| | | |

| Table 9-1: | Gyro Survey Results | 9-2 |

| | | |

| Table 9-2: | BHEM Surveyed Holes | 9-2 |

| | | |

| Table 10-1: | Summary of Historical Surface and Underground Drilling | 10-1 |

| | | |

| Table 10-2: | Summary of Significant Intercepts at the Project | 10-3 |

| | | |

| Table 11-1: | Historical QA/QC Sample Insertion Rates | 11-2 |

| | | |

| Table 11-2: | Summary of Historical QA/QC Database Entries (Incomplete) | 11-3 |

| | | |

| Table 13-1: | Sample Description and Selection for Selebi North and Selebi | 13-3 |

| | | |

| Table 13-2: | Head Assays of Test Samples | 13-7 |

| | | |

| Table 13-3: | Hardness Characteristics of Test Samples | 13-8 |

| | | |

| Table 13-4: | LCT-1 and LCT-3 Metallurgical Projections | 13-10 |

| | | |

| Table 13-5: | LCT-2 and LCT-3 Metallurgical Projections | 13-10 |

| | | |

| Table 26-1: | Proposed Budget – Phase I (18 months) | 26-1 |

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | iii | |

FIGURES

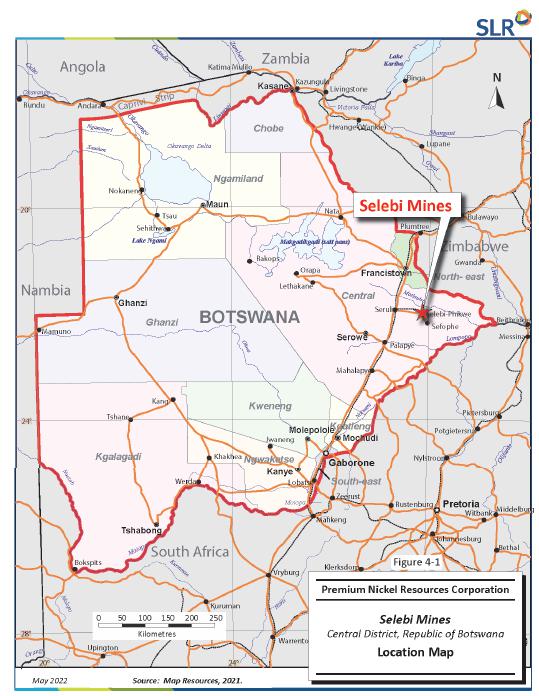

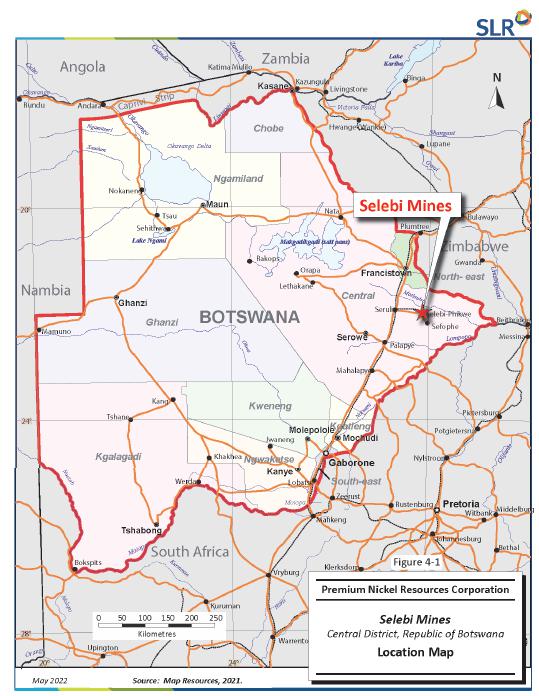

| Figure 4-1: | Location Map | 4-5 |

| | | |

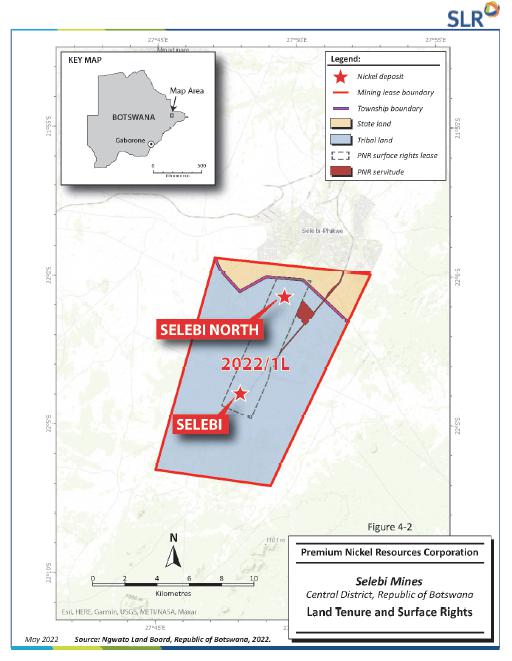

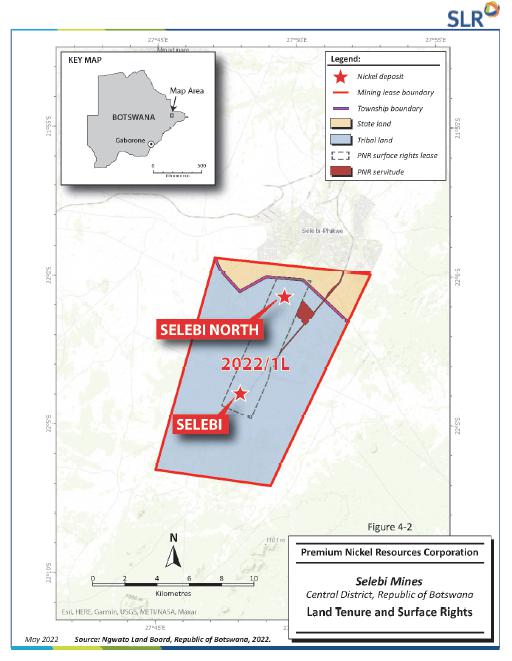

| Figure 4-2: | Land Tenure and Surface Rights Map | 4-6 |

| | | |

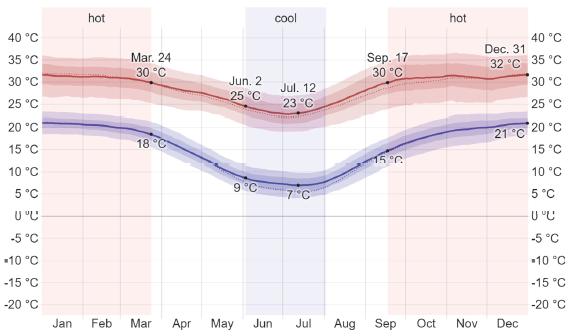

| Figure 5-1: | Average Annual Temperature and Rainfall Profiles | 5-1 |

| | | |

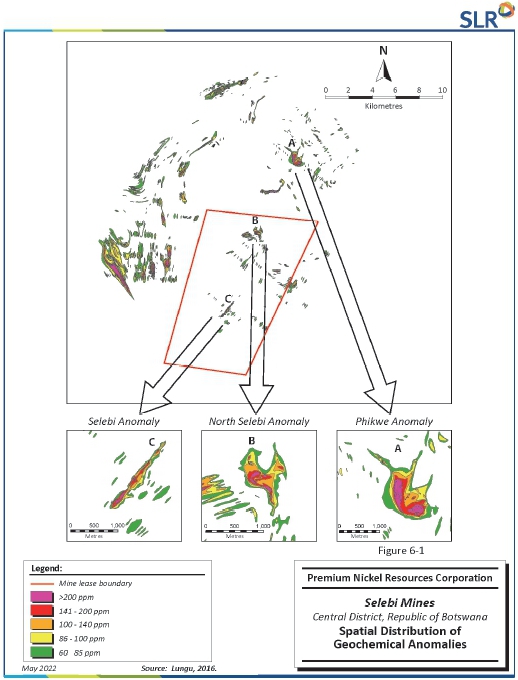

| Figure 6-1: | Spatial Distribution of Geochemical Anomalies | 6-3 |

| | | |

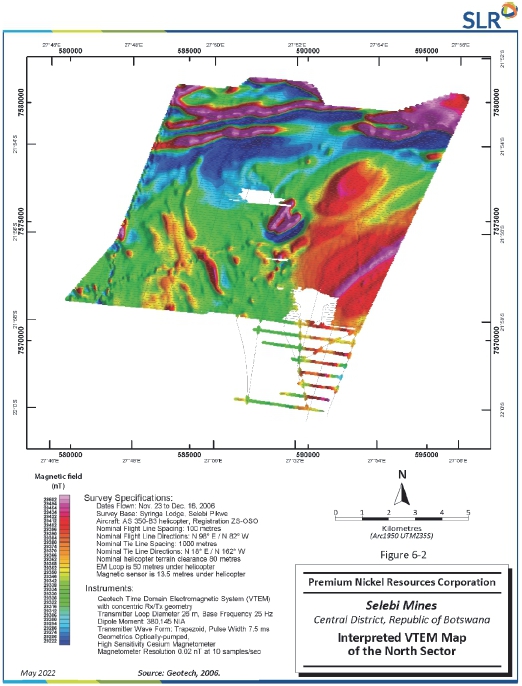

| Figure 6-2: | Interpreted VTEM Map of the North Sector | 6-6 |

| | | |

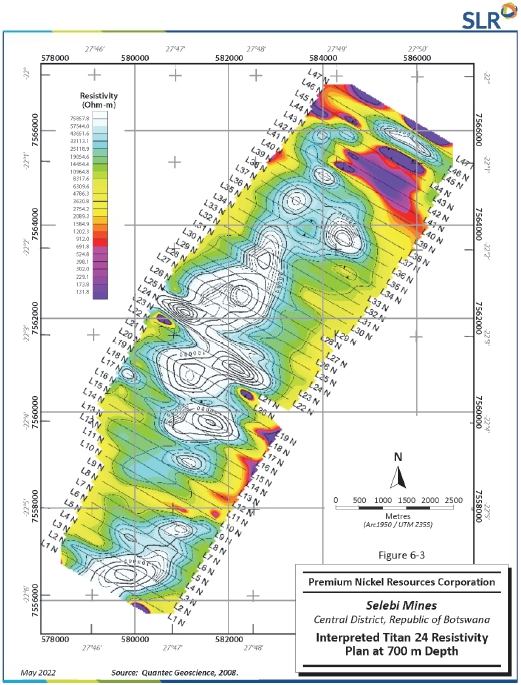

| Figure 6-3: | Interpreted Titan 24 Survey Resistivity at 700 m Depth | 6-7 |

| | | |

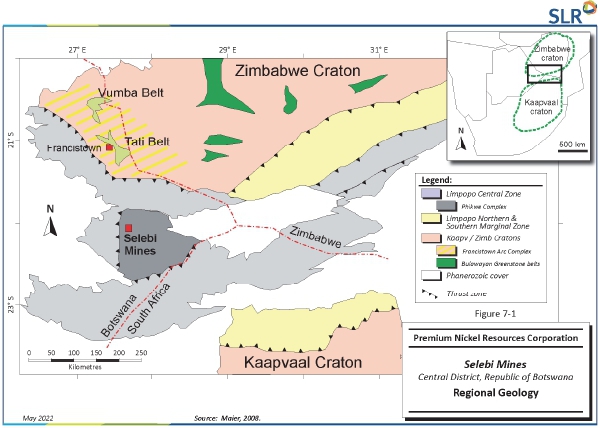

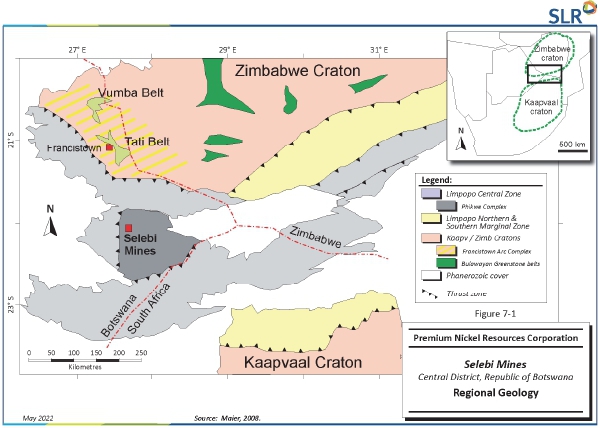

| Figure 7-1: | Regional Geology | 7-2 |

| | | |

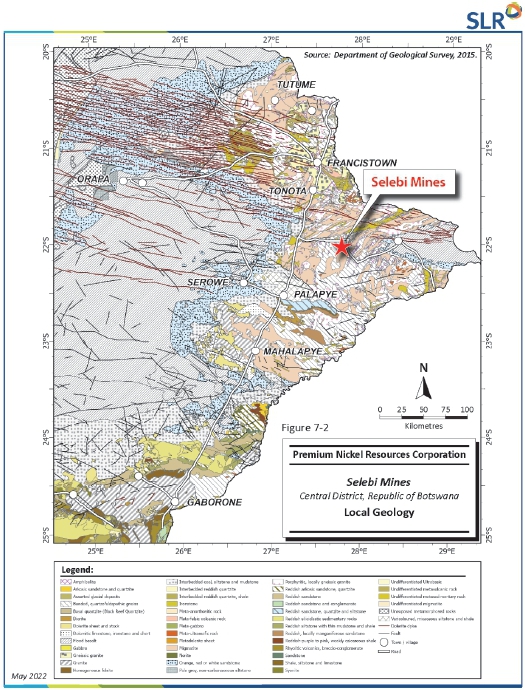

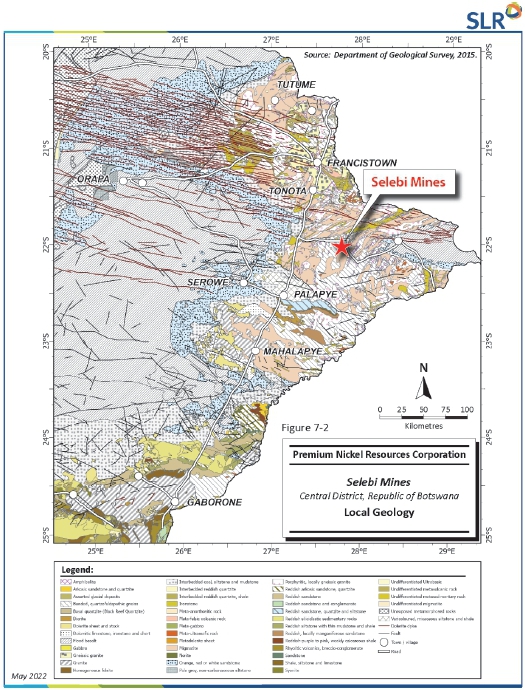

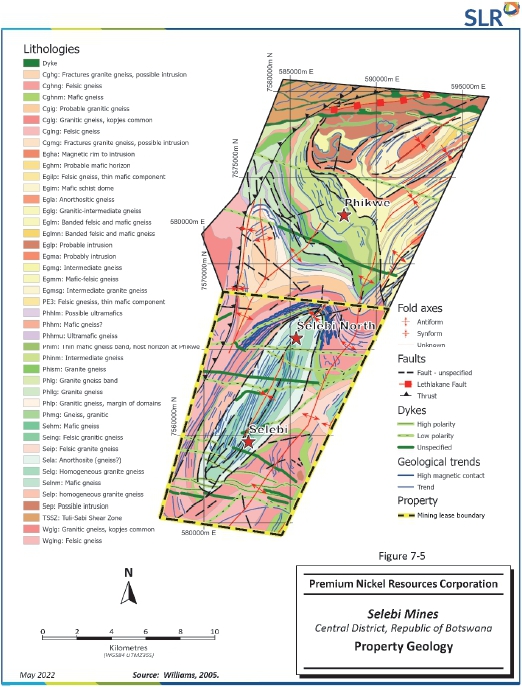

| Figure 7-2: | Local Geology | 7-4 |

| | | |

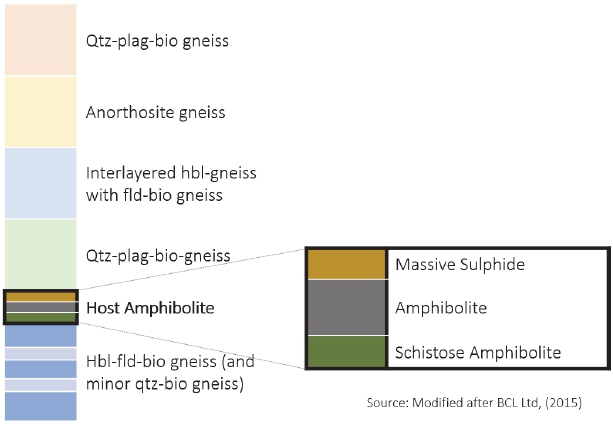

| Figure 7-3: | Generalized Stratigraphic Column | 7-5 |

| | | |

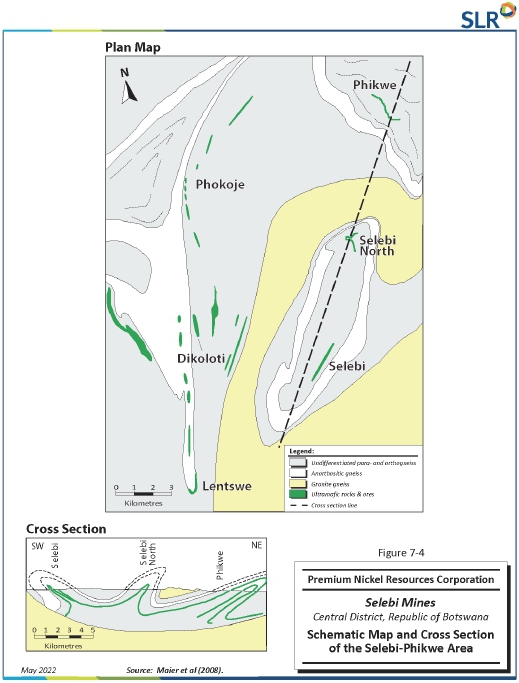

| Figure 7-4: | Schematic Map and Cross Section of the Selebi-Phikwe Area | 7-6 |

| | | |

| Figure 7-5: | Property Geology | 7-7 |

| | | |

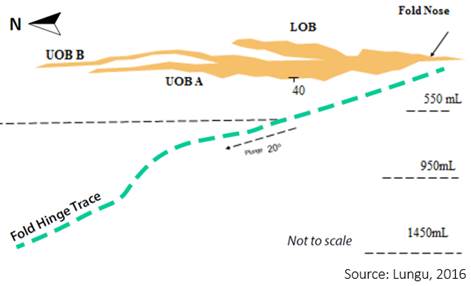

| Figure 7-6: | Longitudinal Sketch of the Selebi Ore Body Showing the Fold Plunge | 7-9 |

| | | |

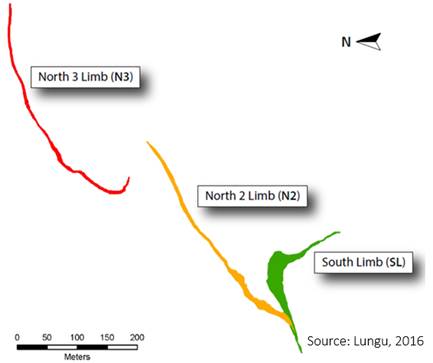

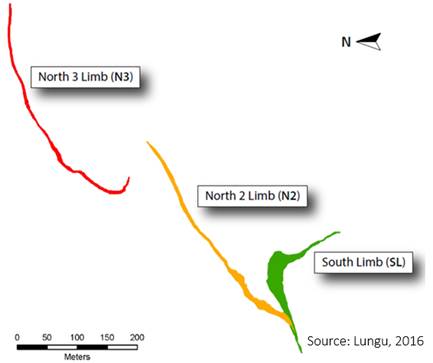

| Figure 7-7: | Relative Positions of Selebi North Ore Bodies (Looking Down) | 7-11 |

| | | |

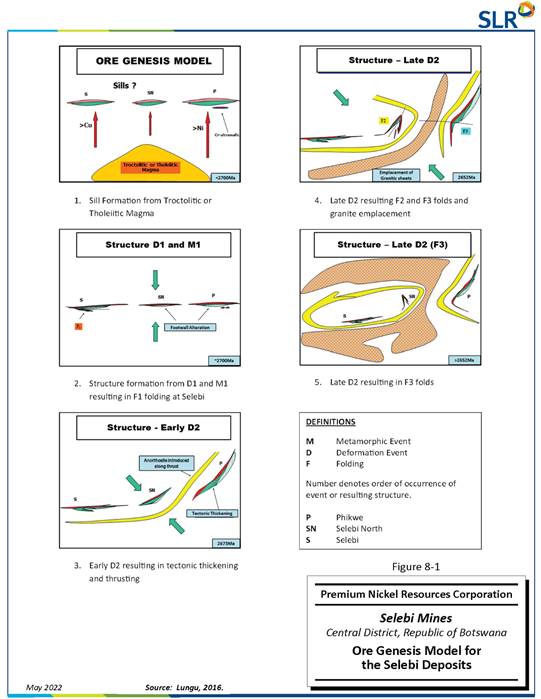

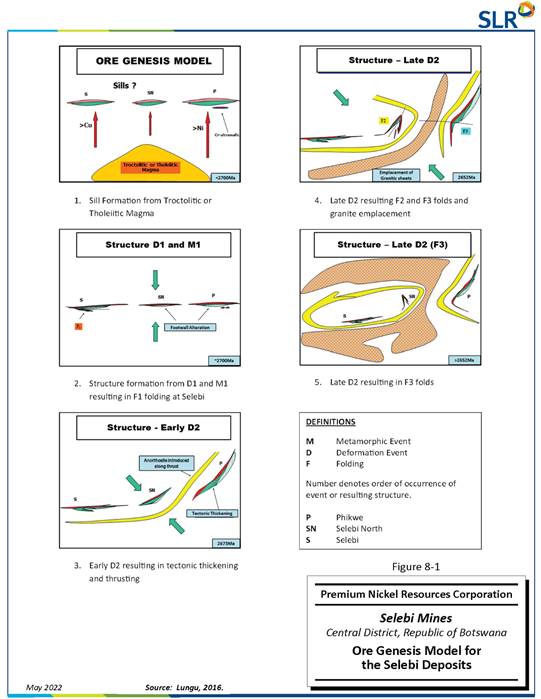

| Figure 8-1: | Ore Genesis Model for the Selebi Deposits | 8-2 |

| | | |

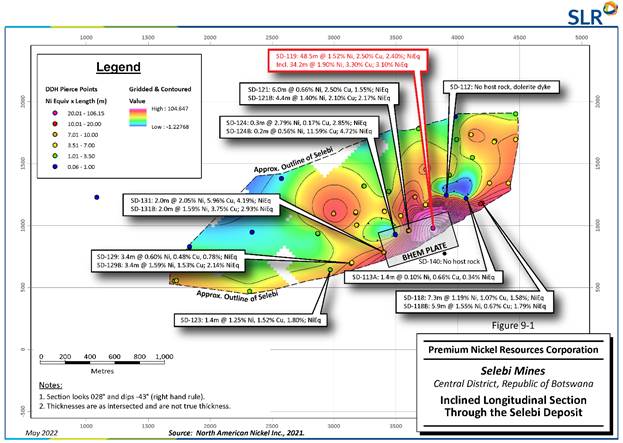

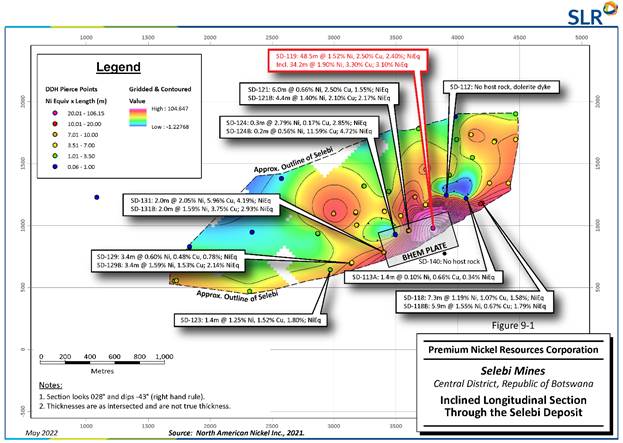

| Figure 9-1: | Inclined Longitudinal Section Through the Selebi Deposit | 9-4 |

| | | |

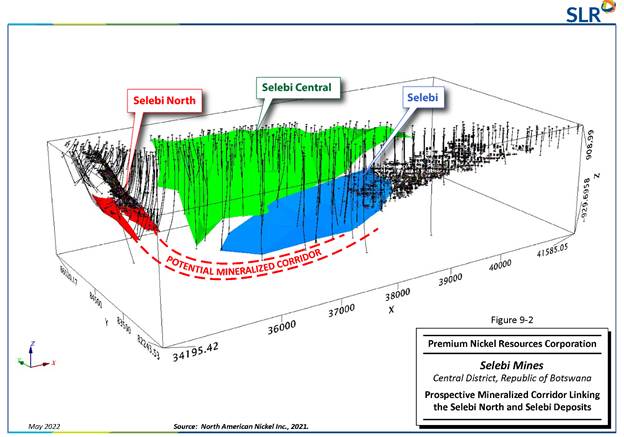

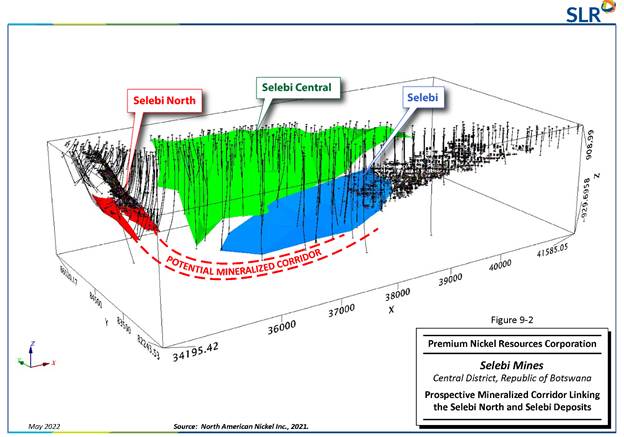

| Figure 9-2: | Prospective Mineralized Corridor Linking the Selebi North and Selebi Deposits | 9-5 |

| | | |

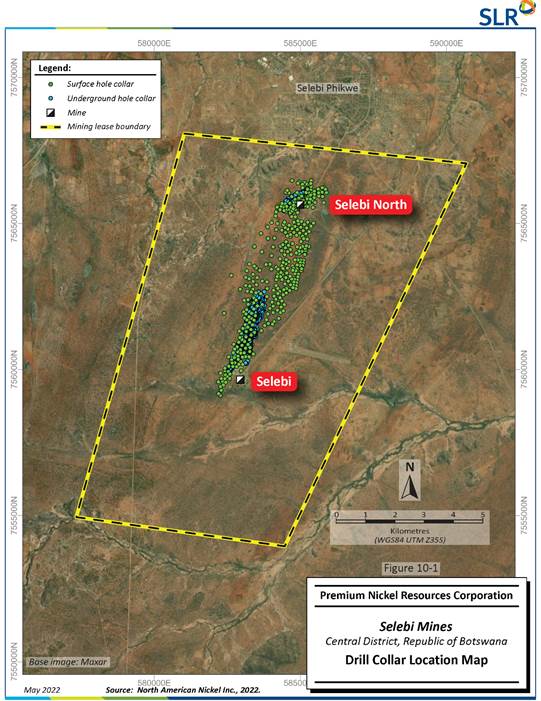

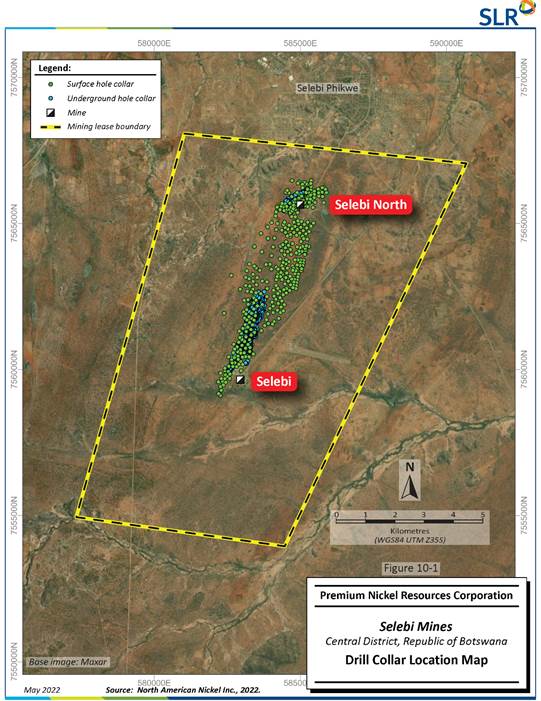

| Figure 10-1: | Drill Hole Collar Location Map | 10-2 |

| | | |

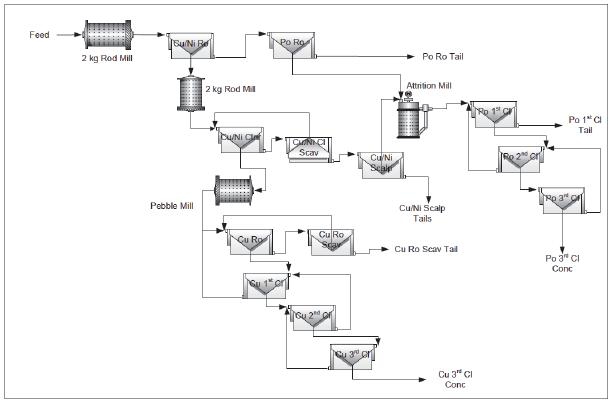

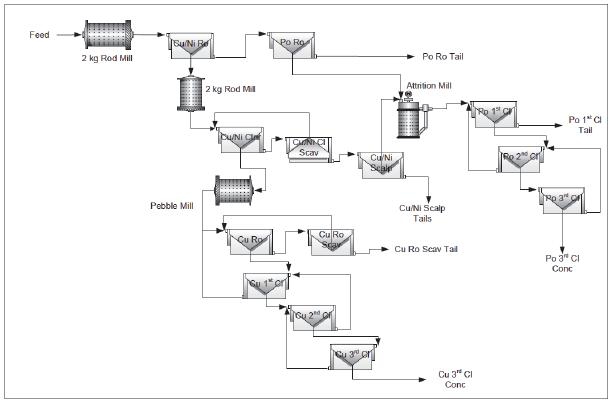

| Figure 13-1: | SGS Flotation Flowsheet for Final Locked Cycle Tests (LCT-2 and LCT-3) | 13-9 |

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | iv | |

SLR Consulting (Canada) Ltd (SLR) was retained by North American Nickel Inc. (NAN) and Premium Nickel Resources Corporation (PNR) (the Project Team) to prepare an independent Technical Report on the Selebi and Selebi North nickel-copper-cobalt (Ni-Cu-Co) Mines (collectively, Selebi Mines or the Project), located in the Central District of the Republic of Botswana. On April 25, 2022, PNR, NAN and 1000178269 Ontario Inc. (Subco) entered into an amalgamation agreement (the Amalgamation Agreement) which provides the terms and conditions upon which PNR will complete a “go-public” transaction by way of a reverse take-over (RTO) of NAN under the policies of the TSX Venture Exchange (TSXV). The purpose of this Technical Report is to document the technical information available on the Project in connection with the RTO as required under the policies of the TSXV. This Technical Report has been addressed to NAN and PNR, as the authors intend that NAN and PNR be entitled to rely on it in connection with the RTO. The authors also intend for this Technical Report to be filed on SEDAR by the resulting issuer of the RTO (the Resulting Issuer or Premium Nickel Resources Ltd.). This Technical Report conforms to the requirements under NI 43-101 Standards of Disclosure for Mineral Projects (NI 43-101). Ms. Sharon Meyer, M.Sc., Pr.Sci.Nat., EAPASA, SLR Associate Environmental Consultant, visited the Project from May 2 to 6, 2021.

NAN is a Vancouver based junior mining company formed in September 1983 and is a reporting issuer in British Columbia, Alberta, Manitoba, and Ontario. NAN is under the jurisdiction of the British Columbia Securities Commission, and its common shares trade on the TSXV. NAN’s exploration activities focus predominately on nickel, with several exploration properties in Greenland and Canada.

The Project was acquired by PNR, a private corporation formed under the laws of the Province of Ontario, on January 31, 2022 through its wholly-owned indirect subsidiary, Premium Nickel Resources Proprietary Limited (PNRB). The Resulting Issuer is expected to change its name to Premium Nickel Resources Ltd. and be listed on the TSXV upon closing of the RTO.

In 2019, NAN became a founding shareholder in PNR and currently holds approximately 10% of the issued and outstanding shares of PNR together with a warrant that entitles NAN to acquire an additional undiluted 15% interest in PNR, for an exercise price of US$10 million (the 15% Warrant). In connection with the RTO, PNR and NAN entered into a waiver and suspension agreement, whereby NAN agreed to suspend its exercise privilege under the 15% Warrant until the later of the 61st calendar day following the date of the Amalgamation Agreement and the date the Amalgamation Agreement is terminated. NAN provides technical and management support to PNR through services and consulting agreements.

PNR submitted an indicative offer to the BCL Limited (BCL) liquidation trustee (the Liquidator) in June 2020 for the purchase of selected assets owned by BCL. On March 24, 2021, PNR signed an exclusivity Memorandum of Understanding (MOU) with the Liquidator that would govern a six month exclusivity period to complete additional due diligence and related purchase agreements on the Botswana Ni-Cu-Co assets formerly operated by BCL.

On September 28, 2021, PNR announced that it had executed the definitive asset purchase agreement (the Selebi Purchase Agreement) with the Liquidator to acquire the Selebi Mines including the related infrastructure and equipment formerly operated by BCL. The acquisition closed on January 31, 2022, transferring the Selebi Mines and new Selebi mining lease to PNR.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 1-1 | |

On April 26, 2022, PNR and NAN announced that they had executed the Amalgamation Agreement which provides the terms and conditions upon which PNR will complete a “go-public” transaction by way of an RTO of NAN under the policies of the TSXV. The Amalgamation Agreement provides for, among other things, a three-cornered amalgamation pursuant to which (i) Subco will amalgamate with PNR under Section 174 of the Business Corporation Act (Ontario) to form one corporation, (ii) the securityholders of PNR will receive securities of the Resulting Issuer in exchange for their securities of PNR at an exchange ratio of 5.27 Resulting Issuer common shares for each outstanding share of PNR (subject to adjustments in accordance with the Amalgamation Agreement), and (iii) the transactions will result in a RTO of NAN in accordance with the policies of the TSXV, all in the manner contemplated by, and pursuant to, the terms and conditions of the Amalgamation Agreement.

BCL operated the combined Selebi-Phikwe project from 1970 until its closure in 2016. Ore was mined from four distinct underground production areas namely Phikwe (1 Shaft, Phikwe Central and Phikwe South), Southeast Extension, Selebi North, and Selebi. PNR’s definitive asset purchase agreement pertains to the Selebi Mines only. In total, 26.6 million tonnes (Mt) grading 0.58% Ni and 1.03% Cu was mined from Selebi (1980 to 2016), and 13.9 Mt grading 0.74% Ni and 0.66% Cu was mined from Selebi North (1990 to 2016).

At the time of liquidation, South African Mineral Resource Committee (SAMREC) compliant Mineral Resources within the Selebi Mines property boundary were reported as in-situ and depleted for mining as of September 30, 2016. These historical Measured and Indicated Mineral Resources used a nickel equivalent (NiEq) cut-off grade of 0.4% and were estimated to total 17.83 Mt at grades of 0.87% Ni and 1.42% Cu containing 155, 000 tonnes (t) Ni and 253,000 t Cu. Historical Inferred Mineral Resources were estimated to total 15.34 Mt at grades of 0.71% Ni and 0.89% Cu containing 109,000 t Ni and 136,000 t Cu. The NiEq cut-off grade was based on a ratio of nickel and copper prices where NiEq = %Ni + (Cu price/Ni price)*%Cu. Nickel and copper prices used were US$8.00/lb Ni and US$3.00/lb Cu, respectively. This estimate is considered to be historical in nature and should not be relied upon, however, it is indicative of the presence of mineralization on the Selebi Mines property. A qualified person has not completed sufficient work to classify the historical estimate as a current Mineral Resource and PNRB is not treating the historical estimates as current Mineral Resources.

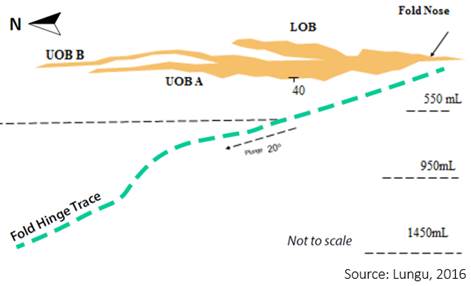

Exploration work completed by the Project Team to date has consisted of the sourcing and digitization of existing historical information, confirming collar and down hole location information of selected historical holes, and completing electromagnetic surveys (borehole electro-magnetic (BHEM)) on selected high priority historical exploration holes. This work has highlighted the potential for establishment of Mineral Resources at depth at the Selebi deposit. Selebi North mineralization is also open at depth, and additional potential to establish Mineral Resources occurs here. Given the basin structure, it is possible that the Selebi North mineralization extends at depth and flattens to the south, while also potentially extending southward.

SLR offers the following conclusions by area:

| 1.1.1.1 | Geology and Mineral Resources |

| · | While there are no current Mineral Resources estimated, there is good potential to establish Mineral Resources at the Selebi and Selebi North deposits, and additional exploration and technical studies are warranted. |

| · | There is good understanding of the geology and the nature of nickel and copper mineralization of the Project. |

| · | The sample collection, preparation, and analytical procedures as designed and implemented by former operator BCL are appropriate for the style of mineralization. |

| · | With further verification in the form of validation of the digital database against original logs and assay certificates, compilation and analysis of quality assurance/quality control (QA/QC) support programs, hole twinning, and down hole survey confirmation, SLR anticipates that the historical information will be suitable for Mineral Resource estimation and a new Mineral Resource estimate can be prepared using updated economic parameters and mining and processing considerations. |

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 1-2 | |

| 1.1.1.2 | Mineral Processing |

| · | A preliminary ‘proof of concept’ metallurgical sampling and testing program over the Project area was completed in 2021 to support the production of market concentrates for both nickel and copper. Though the Project Team’s procedure of sample selection and collection of non-oxidized material is not considered best practice it’s method of hand picking samples was referenced to historical grades during production and is statistically representative of the Selebi mineralization. The test results based on composites prepared from these handpicked samples may not be indicative of the expected metallurgical performance. |

| · | Preliminary comminution testing demonstrated that the samples were very soft at semi-autogenous grinding (SAG) mill grind sizes and progressively harder at finer grind sizes. The samples were also slightly abrasive. |

| · | Preliminary flotation test results demonstrated that while nickel-copper separation is achievable, further representative sampling and testing is required to demonstrate that the target grades of the copper and nickel concentrates can be consistently met. |

SLR offers the following recommendations by area:

| 1.1.2.1 | Geology and Mineral Resources |

| 1. | SLR has reviewed and agrees with PNRB’s proposed exploration budget. Phase I of the recommended work program will include a continuation of the current digitization and verification work, as well as completing 21,000 m of drilling within approximately 40 infill and exploration drill holes to confirm the existing in-situ mineralization and to test the down plunge extension of economic mineralization at Selebi Main and the potential connection of Selebi Main and Selebi North at depth. Infill and exploration drill holes will be surveyed using both a BHEM and a borehole televiewer and their results will be used to support the estimation of Mineral Resources at the Project. Additional budget will be used to support metallurgical studies, to advance existing development at Selebi North to promote accessibility for deep target drilling, and to maintain the existing infrastructure (Table 1-1). |

| o | A Phase II program, contingent upon the results of Phase I would include development of an underground exploration drift at Selebi Main, additional drilling and technical studies, permitting, and advanced metallurgical, engineering, and environmental studies, including the completion of a Preliminary Economic Assessment. |

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 1-3 | |

Table 1-1: Proposed Budget – Phase I (18 months)

Premium Nickel Resources Corporation – Selebi Mines

| March 1. 2022 | |

| Item | | Cost

(US$ 000) | |

Exploration and Infill Drilling Programs (40 holes totalling 21,000 m)1

BHEM and televiewer surveys | | | 5,500 | |

| Additional Historical Data Verification and Digitization | | | 10 | |

| Mineral Resource Estimate | | | 150 | |

| Metallurgical Testing | | | 200 | |

| Care and Maintenance | | | 4,500 | |

| General Site and Administration Costs | | | 4,500 | |

| Subtotal | | | 14,860 | |

| Contingency (5%) | | | 743 | |

| Total | | | 15,603 | |

Notes:

| 1. | Drilling costs are estimated to be US$260/m including salaries, downhole gyro, BHEM and televiewer surveys and associated sample preparation and analysis fees. |

| 1.1.2.2 | Mineral Processing |

| 1. | Complete additional metallurgical testing using samples from drill core that are spatially representative of the deposits to confirm the metallurgical recoveries projected under nickel-copper separation and any process design parameters. |

| 1.2.1 | Property Description and Location |

The Project is located in Botswana approximately 150 km southeast of the city of Francistown, and 410 km northeast of the national capital Gaborone.

The Selebi Mines are readily accessed via paved and gravel roads from the town of Selebi-Phikwe, located just north of the mining licence. With a population of approximately 52,000, the town is accessed via a well-maintained paved road that branches due east from the major A1 highway at the town of Serule, 57 km from the Project.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 1-4 | |

The Project consists of a single mining licence covering an area of 11,504 ha. The mining licence is centred approximately at 22°03’00”S and 27°47’00”E.

Mining licence 2022/1L was granted to PNRB on January 31, 2022 over the Selebi Mines deposits discovered under mining licence 4/72. The original licence which had been granted to BCL on March 7, 1972, covered both Selebi and Phikwe project areas, was amended several times and renewed once, and was set to expire on March 6, 2022. The new mining licence is limited to the Selebi and Selebi North deposits and their surrounding areas and expires January 30, 2032.

| 1.2.3 | Existing Infrastructure |

Project infrastructure includes two mines, currently on care and maintenance, Selebi (#2 Shaft) and Selebi North (#4 Shaft), and associated surface infrastructure.

Exploration in the Project area was initiated in 1959 by Bamangwato Concessions Limited (Bamangwato) and included soil geochemistry, geological mapping, trenching, and diamond drilling over the then combined Selebi-Phikwe area. The Selebi and Phikwe discoveries were made in 1963 and 1967, respectively and a single mining lease was granted to Bamangwato in 1967 covering both areas.

Bamangwato changed its name to BCL in 1977 and operated the combined Selebi-Phikwe project from 1970 until its closure in 2016. Nickel and copper ore was mined from an open pit at Phikwe (1971 to 1980), as well as four distinct underground production areas namely Phikwe (1981 to 2016), Southeast Extension (at Phikwe, 1997 to 2016), Selebi North (1990 to 2016) and Selebi (1980 to 2016). Head grades declined from 2010 to 2015 and in October 2016 BCL was placed into provisional liquidation and all its operations put under care and maintenance.

PNR submitted an indicative offer to the Liquidator in June 2020 for the purchase of select assets owned by BCL. On March 24, 2021, PNR signed an exclusivity MOU with the Liquidator that would govern a six month exclusivity period to complete additional due diligence and related purchase agreements on the Botswana Ni-Cu-Co assets formerly operated by BCL.

The Project was acquired by PNR, a private corporation formed under the laws of the Province of Ontario, on January 31, 2022 through its wholly-owned indirect subsidiary, PNRB.

On September 28, 2021, PNR announced that it had executed the definitive asset purchase agreement (the Selebi Purchase Agreement) with the Liquidator to acquire the Selebi Mines including the related infrastructure and equipment formerly operated by BCL. The acquisition closed on January 31, 2022, transferring the Selebi Mines and new Selebi mining lease to PNR.

On April 26, 2022, PNR and NAN announced that they had executed the Amalgamation Agreement which provides the terms and conditions upon which PNR will complete a “go-public” transaction by way of an RTO of NAN under the policies of the TSXV. The Amalgamation Agreement provides for, among other things, a three-cornered amalgamation pursuant to which (i) Subco will amalgamate with PNR under Section 174 of the Business Corporation Act (Ontario) to form one corporation, (ii) the securityholders of PNR will receive securities of the Resulting Issuer in exchange for their securities of PNR at an exchange ratio of 5.27 Resulting Issuer common shares for each outstanding share of PNR (subject to adjustments in accordance with the Amalgamation Agreement), and (iii) the transactions will result in a RTO of NAN in accordance with the policies of the TSXV, all in the manner contemplated by, and pursuant to, the terms and conditions of the Amalgamation Agreement.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 1-5 | |

The current mining licence is smaller and covers the Selebi Mines and their surrounding areas only. The Selebi Mines were originally covered under mining licence 4/72 which also covered the Phikwe mines and associated infrastructure, including the concentrator and smelter plants used to process ore from both Selebi and Phikwe.

| 1.2.5 | Geology and Mineralization |

The eastern portion of Botswana forms part of the Limpopo Mobile Belt (LMB) which represents a deep crustal section through an orogenic province between the Kaapvaal and Zimbabwe Cratons.

The Project occurs in highly deformed and metamorphosed Archean gneisses near the north margin of the central zone (CZ) of the LMB. The CZ region is characterized by complex structural fold patterns accompanied by regional and cataclastic metamorphism with grades ranging from amphibolite to granulite facies and cataclastic tectonites.

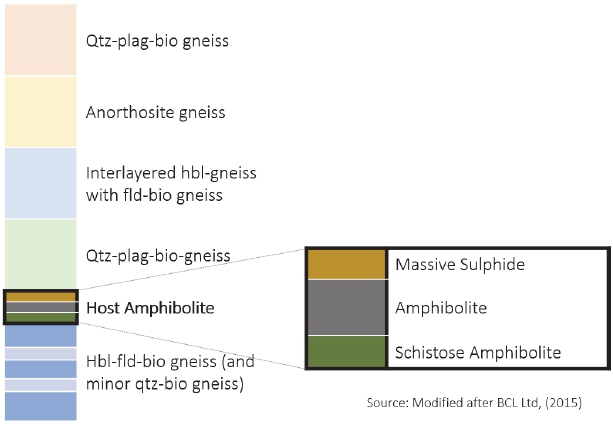

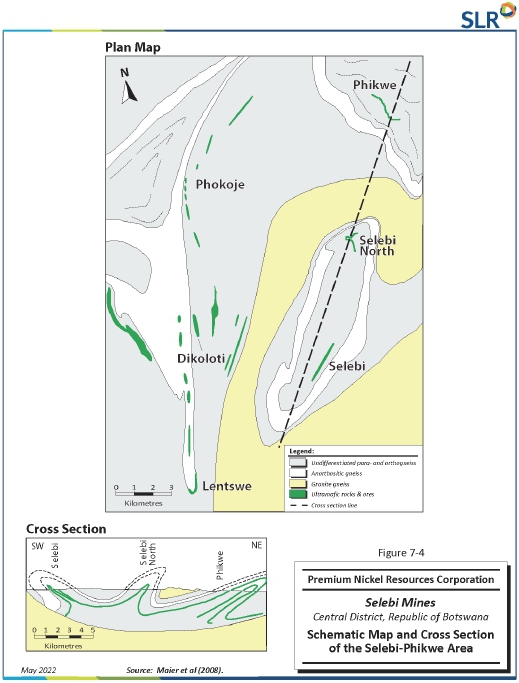

The deposits in the Project area are categorized as ortho-magmatic nickel-copper sulphide-type deposits. They are hosted within amphibolite and understood as a tectono-metamorphically modified tholeiitic magma parents with an immiscible sulphide melt which has undergone all the phases of deformation that have affected the enclosing gneisses. They form part of the Selebi-Phikwe belt of intrusions that also contain the Phikwe, Dikoloti, Lentswe, and Phokoje deposits.

All mineralization horizons pinch and swell, are conformable to the gneissic foliation, and are hosted within or at the hanging wall contact of amphibolite with the gneissic country rocks. Mineralization horizons range in thickness from very thin to over 20 m thick and are commonly one to three metres thick (deposit dependent). Orientation follows country rock foliation, and the zones can dip moderately to steeply, and can extend from 150 m to over 2,000 m.

The principal sulphide minerals are pyrrhotite, chalcopyrite, and pentlandite which occur in massive, semi-massive, and disseminated form. Pyrite occurs as localized overgrowth. Magnetite occurs as rounded inclusions in massive sulphides and as later overgrowths.

Exploration work completed by the Project Team in 2021 consisted of the sourcing and digitization of existing historical information, confirming collar and down hole location information of selected historical holes, and completing electromagnetic surveys (BHEM) on selected high priority historical exploration holes.

This work highlighted an off-hole BHEM anomaly in a 2010 drill hole located down-plunge of the Selebi deposit. The collection of new gyro data confirmed that the off-hole anomaly lies at the downdip edge of the modelled Selebi mineralization which was intersected by a drill hole which reported an estimated true thickness interval of 38.5 m averaging 1.58% Ni and 2.44% Cu, including 21.4 m of 2.34% Ni and 3.39% Cu. This drill hole intersection is located approximately 300 m down plunge of the existing mine workings and approximately 1,200 m below surface and provides support to the potential establishment of Mineral Resources at depth at the Selebi deposit.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 1-6 | |

Selebi North mineralization is also open at depth, and additional potential to establish Mineral Resources occurs here. Given the basin structure, it is possible that the Selebi North mineralization extends at depth and flattens to the south, while also potentially extending southward.

Over the next 18 months, PNRB plans to confirm the existing in-situ mineralization and test the down plunge extension of economic mineralization at Selebi Main, in addition to the potential connection of Selebi Main and Selebi North at depth using a series of infill and extension drill holes surveyed using both a BHEM and borehole televiewer with the objective of using their results to support the estimation of Mineral Resources at the Project.

There is no current Mineral Resource estimate for the Project.

There is no current Mineral Reserve estimate for the Project.

The historical BCL operations consisted of an integrated mining, concentrating, and smelting complex which operated for over 40 years over the Selebi Phikwe project area. The smelter processed Selebi and Phikwe concentrates and toll treated nickel concentrates received from the Nkomati Nickel Mine (a joint venture (JV) between Norilsk Nickel Africa Pty. Ltd. and African Rainbow Minerals) and the Phoenix Mine (Tati Nickel Mining Company, later a subsidiary of BCL). The concentrator plant and smelter were placed on care and maintenance in 2016 and are located adjacent to the Project at the historical Phikwe Mine.

PNR intends to produce separate copper and nickel concentrates for commercial sale (instead of a bulk concentrate) and does not plan to restart the existing concentrator or smelter. In 2021, the Project Team carried out due diligence work that included metallurgical sampling and testing. A preliminary metallurgical study program for separate copper and nickel concentrate production at a conceptual level was completed by SGS Canada Inc. (SGS) in Lakefield, Ontario. The conceptual process flowsheet developed by SGS includes the key unit operations of crushing, grinding, and flotation. Preliminary flotation test results demonstrate that nickel-copper separation is achievable, however, further representative sampling and testing is required to demonstrate that the target grades of the copper and nickel concentrates can be consistently met.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 1-7 | |

SLR Consulting (Canada) Ltd (SLR) was retained by North American Nickel Inc. (NAN) and Premium Nickel Resources Corporation (PNR) (the Project Team) to prepare an independent Technical Report on the Selebi and Selebi North nickel-copper-cobalt (Ni-Cu-Co) Mines (collectively, Selebi Mines or the Project), located in the Central District of the Republic of Botswana. On April 25, 2022, PNR, NAN and 1000178269 Ontario Inc. (Subco) entered into an amalgamation agreement (the Amalgamation Agreement) which provides the terms and conditions upon which PNR will complete a “go-public” transaction by way of a reverse take-over (RTO) of NAN under the policies of the TSX Venture Exchange (TSXV). The purpose of this Technical Report is to document the technical information available on the Project in connection with the RTO as required under the policies of the TSXV. This Technical Report has been addressed to NAN and PNR, as the authors intend that NAN and PNR be entitled to rely on it in connection with the RTO. The authors also intend for this Technical Report to be filed on SEDAR by the resulting issuer of the RTO (the Resulting Issuer or Premium Nickel Resources Ltd.). This Technical Report conforms to the requirements under NI 43-101 Standards of Disclosure for Mineral Projects (NI 43-101).

NAN is a Vancouver based junior mining company formed in September 1983 and is a reporting issuer in British Columbia, Alberta, Manitoba, and Ontario. NAN is under the jurisdiction of the British Columbia Securities Commission, and its common shares trade on the TSXV. NAN’s exploration activities focus predominately on nickel, with several exploration properties in Greenland and Canada.

The Project was acquired by PNR, a private corporation formed under the laws of the Province of Ontario, on January 31, 2022 through its wholly-owned indirect subsidiary, Premium Nickel Resources Proprietary Limited (PNRB). The Resulting Issuer is expected to change its name to Premium Nickel Resources Ltd. and be listed on the TSXV upon closing of the RTO.

In 2019, NAN became a founding shareholder in PNR and currently holds approximately 10% of the issued and outstanding shares of PNR together with a warrant that entitles NAN to acquire an additional undiluted 15% interest in PNR, for an exercise price of US$10 million (the 15% Warrant). In connection with the RTO, PNR and NAN entered into a waiver and suspension agreement, whereby NAN agreed to suspend its exercise privilege under the 15% Warrant until the later of the 61st calendar day following the date of the Amalgamation Agreement and the date the Amalgamation Agreement is terminated. NAN provides technical and management support to PNR through services and consulting agreements.

PNR submitted an indicative offer to the BCL Limited (BCL) liquidation trustee (the Liquidator) in June 2020 for the purchase of selected assets owned by BCL. On March 24, 2021, PNR signed an exclusivity Memorandum of Understanding (MOU) with the Liquidator that would govern a six month exclusivity period to complete additional due diligence and related purchase agreements on the Botswana Ni-Cu-Co assets formerly operated by BCL.

On September 28, 2021, PNR announced that it had executed the definitive asset purchase agreement (the Selebi Purchase Agreement) with the Liquidator to acquire the Selebi Mines including the related infrastructure and equipment formerly operated by BCL. The acquisition closed on January 31, 2022, transferring the Selebi Mines and new Selebi mining lease to PNR.

On April 26, 2022, PNR and NAN announced that they had executed the Amalgamation Agreement which provides the terms and conditions upon which PNR will complete a “go-public” transaction by way of an RTO of NAN under the policies of the TSXV. The Amalgamation Agreement provides for, among other things, a three-cornered amalgamation pursuant to which (i) Subco will amalgamate with PNR under Section 174 of the Business Corporation Act (Ontario) to form one corporation, (ii) the securityholders of PNR will receive securities of the Resulting Issuer in exchange for their securities of PNR at an exchange ratio of 5.27 Resulting Issuer common shares for each outstanding share of PNR (subject to adjustments in accordance with the Amalgamation Agreement), and (iii) the transactions will result in a RTO of NAN in accordance with the policies of the TSXV, all in the manner contemplated by, and pursuant to, the terms and conditions of the Amalgamation Agreement.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 2-1 | |

BCL operated the combined Selebi-Phikwe project from 1970 until its closure in 2016. Ore was mined from four distinct underground production areas namely Phikwe (1 Shaft, Phikwe Central and Phikwe South), Southeast Extension, Selebi North, and Selebi. PNR’s definitive asset purchase agreement pertains to the Selebi Mines only. In total, 26.6 million tonnes (Mt) grading 0.58% Ni and 1.03% Cu was mined from Selebi (1980 to 2016), and 13.9 Mt grading 0.74% Ni and 0.66% Cu was mined from Selebi North (1990 to 2016).

At the time of liquidation, South African Mineral Resource Committee (SAMREC) compliant Mineral Resources within the Selebi Mines property boundary were reported as in-situ and depleted for mining as of September 30, 2016. These historical Measured and Indicated Mineral Resources used a nickel equivalent (NiEq) cut-off grade of 0.4% and were estimated to total 17.83 Mt at grades of 0.87% Ni and 1.42% Cu containing 155, 000 tonnes (t) Ni and 253,000 t Cu. Historical Inferred Mineral Resources were estimated to total 15.34 Mt at grades of 0.71% Ni and 0.89% Cu containing 109,000 t Ni and 136,000 t Cu. The NiEq cut-off grade was based on a ratio of nickel and copper prices where NiEq = %Ni + (Cu price/Ni price)*%Cu. Nickel and copper prices used were US$8.00/lb Ni and US$3.00/lb Cu, respectively. This estimate is considered to be historical in nature and should not be relied upon, however, it is indicative of the presence of mineralization on the Selebi Mines property. A qualified person has not completed sufficient work to classify the historical estimate as a current Mineral Resource and PNRB is not treating the historical estimates as current Mineral Resources.

Exploration work completed by the Project Team to date has consisted of the sourcing and digitization of existing historical information, confirming collar and down hole location information of selected historical holes, and completing electromagnetic surveys (borehole electro-magnetic (BHEM)) on selected high priority historical exploration holes. This work has highlighted the potential for establishment of Mineral Resources at depth at the Selebi deposit. Selebi North mineralization is also open at depth, and additional potential to establish Mineral Resources occurs here. Given the basin structure, it is possible that the Selebi North mineralization extends at depth and flattens to the south, while also potentially extending southward.

| 2.1 | Sources of Information |

A site visit to the Project was conducted by Ms. Sharon Meyer, M.Sc., Pr.Sci.Nat., EAPASA, SLR Associate Environmental Consultant, from May 2 to 6, 2021. During the visit, Ms. Meyer toured the Project both on surface and underground, confirmed the presence of mineralization both in core and in underground openings, confirmed the geology in selected drill holes with respect to the corresponding drill log descriptions, confirmed the location of several drill hole collars, and assessed the environmental condition of the Project.

This Technical Report was prepared by Valerie Wilson, M.Sc., P.Geo., Principal Geologist, Technical Manager, Geology, Brenna J.Y. Scholey, P.Eng., Principal Metallurgist, and Sharon Meyer, M.Sc., Pr.Sci.Nat., EAPASA, SLR Associate Environmental Consultant, all of whom are independent QPs.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 2-2 | |

Table 2-1 presents a summary of the QP responsibilities for this Technical Report.

Table 2-1: Summary of QP Responsibilities

Premium Nickel Resources Corporation – Selebi Mines

| Qualified Person | | Title/Position | | Section |

| Valerie Wilson, M.Sc., P.Geo. | | Technical Manager, Geology | | 1.1, 1.1.1.1, 1.1.2.1, 1.2.1 to 1.2.8, 2.0 to 11.0, 14.0 to 22.0, 25.1, and 26.1 |

| | | | | |

| Brenna J.Y. Scholey, P.Eng. | | Principal Metallurgist | | 1.1.1.2, 1.1.2.2, 1.2.9, 13.0, 25.2, and 26.2 |

| | | | | |

| Sharon Meyer, M.Sc., Pr.Sci.Nat., EAPASA | | Associate Environmental Consultant | | 12.0, 23.0, and 24.0 |

| | | | | |

| All | | - | | 27 |

Discussions were held online and onsite with the following personnel from BCL and the Project Team:

| · | Sharon Taylor, P. Geo., Exploration Manager, NAN/PNR |

| · | Gerry Katchen, P. Geo., Senior Geologist, NAN/PNR |

| · | Modiredi Tumaeletse, Mine Environmental Manager, BCL |

| · | Mpho Mosarwe, Geologist, BCL |

The documentation reviewed, and other sources of information, are listed at the end of this Technical Report in Section 27 References.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 2-3 | |

Units of measurement used in this Technical Report conform to the metric system. All currency in this Technical Report is United States dollars (US$) unless otherwise noted.

| µ | micron | kVA | kilovolt-amperes |

| µg | microgram | kW | kilowatt |

| a | annum | kWh | kilowatt-hour |

| A | ampere | L | litre |

| bbl | barrels | lb | pound |

| Btu | British thermal units | L/s | litres per second |

| °C | degree Celsius | m | metre |

| C$ | Canadian dollars | M | mega (million); molar |

| cal | calorie | m2 | square metre |

| cfm | cubic feet per minute | m3 | cubic metre |

| cm | centimetre | MASL | metres above sea level |

| cm2 | square centimetre | m3/h | cubic metres per hour |

| d | day | mi | mile |

| dia | diameter | min | minute |

| dmt | dry metric tonne | mm | micrometre |

| dwt | dead-weight ton | mm | millimetre |

| °F | degree Fahrenheit | mph | miles per hour |

| ft | foot | MVA | megavolt-amperes |

| ft2 | square foot | MW | megawatt |

| ft3 | cubic foot | MWh | megawatt-hour |

| ft/s | foot per second | oz | Troy ounce (31.1035g) |

| g | gram | oz/st, opt | ounce per short ton |

| G | giga (billion) | ppb | part per billion |

| Gal | Imperial gallon | ppm | part per million |

| g/L | gram per litre | psia | pound per square inch absolute |

| Gpm | Imperial gallons per minute | psig | pound per square inch gauge |

| g/t | gram per tonne | RL | relative elevation |

| gr/ft3 | grain per cubic foot | s | second |

| gr/m3 | grain per cubic metre | st | short ton |

| ha | hectare | stpa | short ton per year |

| hp | horsepower | stpd | short ton per day |

| hr | hour | t | metric tonne |

| Hz | hertz | tpa | metric tonne per year |

| in. | inch | tpd | metric tonne per day |

| in2 | square inch | US$ | United States dollar |

| J | joule | Usg | United States gallon |

| k | kilo (thousand) | Usgpm | US gallon per minute |

| kcal | kilocalorie | V | volt |

| kg | kilogram | W | watt |

| km | kilometre | wmt | wet metric tonne |

| km2 | square kilometre | wt% | weight percent |

| km/h | kilometre per hour | yd3 | cubic yard |

| kPa | kilopascal | yr | year |

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 2-4 | |

| 3.0 | Reliance on Other Experts |

This Technical Report has been prepared by SLR for NAN, PNR and the Resulting Issuer. The information, conclusions, opinions, and estimates contained herein are based on:

| · | Information available to SLR at the time of preparation of this Technical Report. |

| · | Assumptions, conditions, and qualifications as set forth in this Technical Report. |

For this Technical Report, SLR has relied on ownership information provided by PNR. The client has relied on a legal opinion by Bookbinder Business Law (BBL) dated May 2, 2022 entitled “Title Opinion: Premium Nickel Resources Proprietary Limited”, and this opinion is relied on in Section 4 and the Summary of this Technical Report. SLR has not researched property title or mineral rights for the Project and expresses no opinion as to the ownership status of the property.

Except for the purposes legislated under provincial securities laws and for use by the TSXV, any use of this Technical Report by any third party is at that party’s sole risk.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 3-1 | |

| 4.0 | Property Description and Location |

The Project consists of a single mining licence covering an area of 11,504 ha located near the town of Selebi Phikwe, approximately 150 km southeast of the city of Francistown, and 410 km northeast of the national capital Gaborone. The mining licence is centred approximately at 22°03’00” S and 27°47’00” E and is presented in Figure 4-1. This mining licence gives PNRB the right to carry out care and maintenance and conduct exploration work from both surface and underground.

Mining licence 2022/1L was granted to PNRB on January 31, 2022 over the Selebi Mines deposits discovered under mining licence 4/72. The original licence which had been granted to BCL on March 7, 1972, covered both the Selebi and Phikwe project areas, was amended several times and renewed once, and was set to expire on March 6, 2022. The new mining licence is limited to the Selebi and Selebi North deposits and their surrounding areas and expires January 30, 2032.

The terms and conditions for the renewal of the mining licence is framed by the relevant sub-sections of Section 42 of the Mines Act (the Act) and indicate that:

| (4) | The Minister shall grant an application for renewal if satisfied that- |

| (a) | the applicant is not in default; |

| (b) | development of the mining area has proceeded with reasonable diligence; |

| (c) | the proposed programme of mining operations will ensure the most efficient and beneficial use of the mineral resources in the mining area; and |

| (5) | The Minister shall not reject an application on the ground referred to in- |

| (a) | subsection (4)(a), unless the applicant has been given details of the default and has failed to remedy the same within three months of such notification; |

| (b) | subsection (4)(b), unless the applicant has been given reasonable opportunity to make written representations thereon to the Minister; or |

| (c) | subsection (4)(c), unless the applicant has been so notified and has failed to propose amendments to his proposed programme of mining operations satisfactory to the Minister within three months of such notification. |

| (6) | Subject to the provisions of this Act, the period of renewal of a mining licence shall be such period, not exceeding 25 years, as is reasonably required to carry out the mining programme. |

| (7) | On the renewal of a mining licence the Minister shall append thereto the programme of mining operations to be carried out in the period of renewal. |

In order to maintain the mining licence in good order, the holder must make annual payments on its anniversary date in accordance with Section 71 of the Act and monthly royalty payments according to Section 66 of the Act, if appropriate, in each case to the Government of Botswana. The royalties payable are percentages of the gross market value of mineral or mineral products as follows: precious stones (10%), precious metals (5%), and other minerals or mineral products (3%). The term gross market value is defined in the Act as the sale value receivable at the mine gate in an arms-length transaction without discounts, commissions, or deductions for the mineral or mineral product on disposal. No annual payments are required until the mine is in production.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 4-1 | |

In Botswana, mining activities are regulated under the Act, which is administered by the Ministry of Mineral Resources, Green Technology and Energy Security (MMGE). The Act regulates the issuance of exploration and mining licences as well as harmonizing mining activities and environmental impacts. The Act entails:

| · | Introduction of the retention licence which allows exploration companies that have confirmed the discovery of a mineral deposit to retain rights over a period of three years, renewable once for a period of no more than three years. |

| · | Issuing of a prospecting licence for up to 1,000 km2 for an initial period of three years and renewed for two periods of two years each. |

| · | The abolition the Botswanan government’s right to free equity participation. The legislation allows for the Botswanan government to acquire up to 15% in new mining ventures on commercial terms. |

| · | Royalty schedules have been revised, with rates reduced from 5% to 3% for all minerals except precious stones and precious metals, which remain at 10% and 5%, respectively. |

| · | The granting, renewal, and automatic transfer of licences has been made more automatic and predictable. |

| · | Introduction of new mining taxation, which includes: |

| o | A generalized tax regime that applies to all minerals except diamonds, with corporate income tax of 25%. |

| o | Immediate 100% capital write off in the year that the investment is made, with unlimited carry forward of losses. |

| o | Introduction of a variable rate income tax formula. |

The Act further stipulates that the holder of the mineral concession shall:

| · | Conduct operations in a manner that will preserve the natural environment. |

| · | Where unavoidable, promptly treat pollution and contamination of the environment. In the event of an emergency or extraordinary circumstances requiring immediate action, the holder of a mineral concession shall forthwith notify the Director of Mines and shall take all immediate action in accordance with the reasonable directions of the Director of Mines. |

| · | Prepare and submit an Environmental Impact Assessment (EIA) report as part of the mining licence application or renewal. |

| · | Restore the land substantially to the condition in which it was prior to the commencement of operations during and at the end of operations. |

| · | The holder of a mineral concession shall make adequate on-going financial provision for compliance with environmental obligations as stipulated by the Act. |

Any abstraction of water in Botswana is regulated through the Water Act of 1967.

PNRB was granted a mining licence to permit the ongoing care and maintenance activities at the Selebi Mines and to conduct exploration work from both surface and underground.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 4-2 | |

The Project is subject to two land tenure systems namely, State Land within the Township boundary and Tribal Land for the remaining portions. The two land tenures are administered by the Department of Lands and Ngwato Land Board, respectively. PNRB holds a mining lease agreement granting exclusive surface rights over an 1,800 ha portion of the area covered by the mining licence that includes the Selebi Mines. The mining lease agreement is deemed effective January 31, 2022 and is valid for a period of 10 years, equivalent to the duration of mining licence no 2022/1L. If the mining licence is renewed, then the Grant of Lease shall automatically be renewed for the period equivalent to the renewed mining licence, subject to the conditions prevailing during the period of renewal. The rental amount for the first term of the Grant of Lease is Botswana Pula (BWP) 90,020.47 per annum (approximately US$7,700 based on a BWP 1 = US$0.08544 exchange rate) and if renewed, the Land Board and PNRB shall negotiate the appropriate fee for the renewed period. PNRB also holds the surface rights to a 181 ha strip of land for rail and power servitude. The rental amount on the rail and power servitude is BWP 9,052 per annum (approximately US$770 per annum) for the first term of the Grant of Lease, and the Land Board and PNRB shall negotiate the appropriate rental for any renewed period. Figure 4-2 illustrates the disposition of the surface rights.

| 4.4 | Royalties and Other Encumbrances |

PNRB has signed a royalty agreement and contingent compensation agreement with the Liquidator.

A 2% net smelter return (NSR) exists on the sale of concentrates (or any other economic mineral resource material produced and sold) subject to specific rights of purchase by the purchaser and the Government of Botswana:

| · | A reduction to a 1% NSR for a payment of US$20 million on or before the two year anniversary date of the first shipment. |

| · | A general first right of purchase shared between the purchaser and the Government of Botswana. |

There is also a contingent compensation agreement whereby PNRB would pay additional compensation to the Government of Botswana if and when it discovers additional resources over and above the base case scenario of 15.9 Mt:

| · | New resource discovery up until the end of the seven year mine life of the base case resource of 15.9 Mt (minimum grade of 2.5% Ni eq at Decision to Mine) |

| o | 25 Mt < new deposit > 50 Mt US$0.50 per ton |

| o | 50 Mt < new deposit> 75 Mt US$0.20 additional per incremental ton |

| o | 75 Mt < new deposit> 100 Mt US$0.30 additional per incremental ton |

| o | New deposit >100 Mt US$0.40 additional per incremental ton |

| · | The payment of contingent compensation shall be made from operating cash flow of the mine(s) once in operation and subject to adequate liquidity. |

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 4-3 | |

| 4.5 | Environmental, Social and Permitting Considerations |

SLR is not aware of any environmental liabilities on the Selebi Mines property which was assumed by PNRB pursuant to the Selebi Purchase Agreement. PNRB has all required permits to conduct the proposed exploration work on the property. SLR is not aware of any other significant factors and risks that may affect access, title, or the right or ability to perform the proposed work program on the property.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 4-4 | |

Figure 4-1: Location Map

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 4-5 | |

Figure 4-2: Land Tenure and Surface Rights Map

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 4-6 | |

| 5.0 | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

The Selebi Mines are readily accessed via paved and gravel roads from the town of Selebi-Phikwe, located just north of the mining licence. With a population of approximately 52,000, the town is accessed via a well-maintained paved road that branches due east from the major A1 highway at the town of Serule, 57 km from the Project.

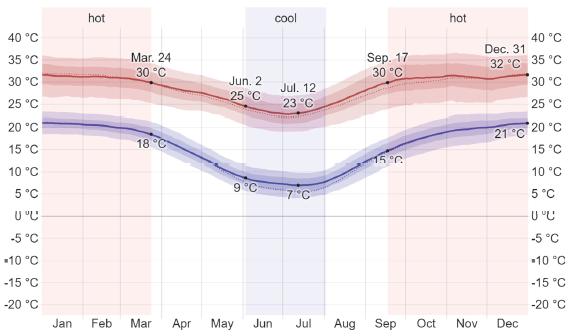

The Project has a semi-arid climate with temperatures that typically vary from 7°C to 37°C. The warm season lasts from September to November with an average daily temperature above 30°C while the colder season lasts from June to the end of July with average lows of 7°C and highs of 24°C. The wetter season lasts 4.5 months, from November to mid March. The wettest month is usually January, with an average of 10 days with at least one millimetre of precipitation (Weatherspark.com, 2022).

No climatic risks exist that would affect the year round exploitation of the resources delineated in future.

Figure 5-1 illustrates the average annual temperature for the Project area.

Source: WeatherSpark.com, 2022.

Notes:

| 1. | The daily average high (red line) and low (blue line) temperature, with 25th to 75th and 10th to 90th percentile bands. The thin dotted lines are the corresponding average perceived temperatures. |

Figure 5-1:Average Annual Temperature and Rainfall Profiles

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 5-1 | |

The town of Selebi Phikwe is serviced by a paved road and a railway line runs from Selebi Phikwe to Serule where it joins the main line from Gaborone to Francistown. The railway line is predominately used for the freighting of materials and goods to and from Selebi Phikwe.

Selebi Phikwe is serviced by a government run airport situated near the Project on the outskirts of town. The day time operated airport is open daily but has no fueling facility onsite and no commercial flights.

Reliable landline telephone communication, using the Botswana Telecommunications Corporation (BTC) network, is available throughout most of the country. BTC, as well as other private cellular network providers, also provide reliable cellphone coverage over most of the country.

Although, Botswana is in a semi-arid terrain, the town of Selebi Phikwe is adequately serviced by the Water Utilities Corporation which supplies treated water to the community as well as the Project. The Letsibogo Dam, located near Mmadinare, approximately 17 km from Selebi Phikwe, is the primary source of water for Selebi Phikwe and surrounding areas. The new Dikgatlhong Dam is approximately 40 km to the north and is also a major source of water, supplying the southern regions including Gaborone.

The source of water for BCL’s mining operation was an underground aquifer at #3 Shaft. PNRB is currently dewatering #2 Shaft and pumping 1.0 Megalitre per day to surface. This volume is sufficient to support mining operations at the Selebi Mines.

All electricity and power supply in Botswana is transmitted and managed by the Botswana Power Corporation (BPC). The Project is supplied through the National Grid, via a 220/66/11KV substation. The 220 KV substation is fed by two 220 KV overhead lines which run 7.6 km from the Phokoje substation.

The purchased infrastructure at the Selebi Mines includes two mines, currently on care and maintenance, Selebi (#2 Shaft) and Selebi North (#4 Shaft), and associated surface infrastructure.

The Selebi Mine has a vertical rock/service shaft down to the 300 m level, and a cable belt conveyor decline from the 300 m level to the 850 level. The shaft is 375 m deep, 6.1 m in diameter, concrete lined and equipped with steel buntons at six metre intervals. The shaft contains five main compartments comprising a 70 person, single deck cage running in balance with a counterweight, two, six tonne bottom discharge skips running in balance, and a ladderway. Stations are at 50 m vertical intervals, commencing on the 100 m level, with a 1,070 mm x 760 mm jaw crusher located on the 300 m level, loading boxes on the 340 m level, and a spillage box located on the 367 m level. The -18° decline currently runs from the 250 m level to the 850 m level providing access to deposits between the 300 m level and 800 m level horizons. A single drum winder at the top of the decline enables transport of personnel and material and is also used for waste rock handling from decline development. Stations are cut at 50 m vertical intervals, with a crusher station on the 850 m level and a cable belt loading facility on the 875 m level. A tertiary sub inclined shaft equipped with twin rails extends from the 850 m level to the 1,050 m level. This shaft provides access to the levels below the 850 m level. A 4.8 m diameter, concrete lined, ventilation shaft is located approximately 1,000 m north of the rock/service shaft.

The Selebi North Mine is serviced by a 3.5 m diameter shaft down to the 745 m level and a twin 7° decline trucking ramp which is currently down to the 900 m level. The shaft is equipped with a Koepe hoist with a two cage/six tonne skip. The cage has a four person capacity. The shaft limitation means that it was primarily used for ore skipping, and that the material and personnel were mainly transported via the ramp.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 5-2 | |

The Selebi Mines are powered by two overhead lines. The first one is from the 11 KV station at the Phikwe processing plant which follows the railway track. The second one is supplied by the BPC at 66 KV. Both power sources go through a booster station to regulate the voltage before supplying the Selebi Mines. The booster station works with two 11 kV transformers.

The topography of the Project area is generally flat and typical of the basement system of Botswana. The Project lies at an altitude between 780 MASL and 980 MASL with a gentle gradient from southwest to northeast. A number of hills, ridges, kopjes, and iselbergs of granitoid rocks are found within the mining licence and surrounding areas with the most prominent hill being Selebi Hill located at the southwest corner of the township boundary.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 5-3 | |

Discussions between the Roan Selection Trust and the Bamangwato tribal chiefs, initiated in 1956, culminated in the signing of an agreement in 1959 that formed Bamangwato Concessions Limited (Bamangwato), allowing for the exploration and exploitation of the nickel and copper deposits in the Project area (Lungu, 2016).

In 1967, the Botswanan government issued to Bamangwato mining lease 13-NQ (State Grant 4/72), covering an area of 27,310.43 ha. This mining lease was granted in regard to copper and nickel ores and associated minerals contained in these mined ores for a renewable period of 25 years.

In 1977, Bamangwato changed its name to BCL. BCL and predecessor Bamangwato operated the combined Selebi-Phikwe Project from 1970 until its closure in 2016. Ore was mined from an open pit at Phikwe, as well as four distinct underground production areas namely Phikwe (1 Shaft, Phikwe Central and Phikwe South), Southeast Extension, Selebi North, and Selebi. In October 2016 BCL was placed into provisional liquidation and all its operations placed on care and maintenance.

PNR submitted an indicative offer to the Liquidator in June 2020 for the purchase of select assets owned by BCL. On March 24, 2021, PNR signed an exclusivity MOU with the Liquidator that would govern a six month exclusivity period to complete additional due diligence and related purchase agreements on the Botswana Ni-Cu-Co assets formerly operated by BCL.

The Project was acquired by PNR, a private corporation formed under the laws of the Province of Ontario, on January 31, 2022 through its wholly-owned indirect subsidiary, PNRB.

On September 28, 2021, PNR announced that it had executed the Selebi Purchase Agreement with the Liquidator to acquire the Selebi Mines including the related infrastructure and equipment formerly operated by BCL. The acquisition closed on January 31, 2022, transferring the Selebi Mines and new Selebi mining lease to PNR.

On April 26, 2022, PNR and NAN announced that they had executed the Amalgamation Agreement which provides the terms and conditions upon which PNR will complete a “go-public” transaction by way of an RTO of NAN under the policies of the TSXV. The Amalgamation Agreement provides for, among other things, a three-cornered amalgamation pursuant to which (i) Subco will amalgamate with PNR under Section 174 of the Business Corporation Act (Ontario) to form one corporation, (ii) the securityholders of PNR will receive securities of the Resulting Issuer in exchange for their securities of PNR at an exchange ratio of 5.27 Resulting Issuer common shares for each outstanding share of PNR (subject to adjustments in accordance with the Amalgamation Agreement), and (iii) the transactions will result in a RTO of NAN in accordance with the policies of the Exchange, all in the manner contemplated by, and pursuant to, the terms and conditions of the Amalgamation Agreement.

The current mining licence is smaller and covers the Selebi Mines and their surrounding areas only. The Selebi Mines were originally covered under mining licence 4/72 which also covered the Phikwe mines and associated infrastructure, including the concentrator and smelter plants used to process ore from both Selebi and Phikwe mines.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 6-1 | |

| 6.2 | Exploration and Development History |

Information in this section describes work completed over the Selebi-Phikwe project and is mostly summarized from Lungu (2016). Information relevant to Phikwe has been retained as it is sometimes difficult to summarize regional exploration work completed concurrently over the Selebi and Phikwe prospects to represent results over Selebi only. Where possible, SLR has noted for which area work is relevant.

| 6.2.1 | Early Exploration (1959 to 1990) |

Exploration in the Project area was initiated in 1959 by Bamangwato.

The anomalous copper and nickel occurrences in the Selebi Phikwe area were all discovered through geochemical soil surveys (Gordon, 1973). This geochemical soil sampling was conducted in stages from reconnaissance to close interval sampling on identified targets. The 1.6 km long nickel-copper geochemical anomaly at Selebi was defined in March/April 1963 and Selebi became a mineral occurrence in May/June 1963. Mineralization outcropped as gossans at the three main target areas of Selebi, Selebi North, and Phikwe. Trenching and mapping were undertaken to determine the lateral extent and geology of the mineralization and associated lithologies. To test for sulphide mineralization at depth, wagon and diamond drilling was conducted on the most favourable targets. Magnetic surveying to define sub-cropping mineralization was also undertaken.

This early stage of exploration is not well documented.

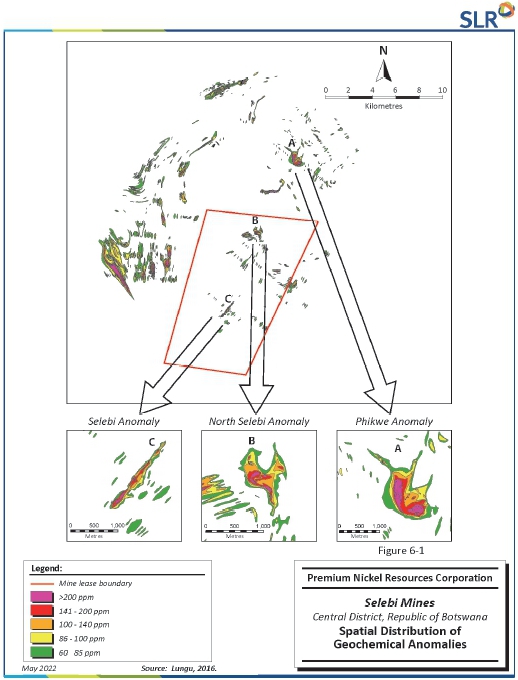

Reconnaissance geochemical traverses were planned from aerial photography. These traverses were planned such that they intersected major fold closures. At the reconnaissance stage, soil samples were collected at 61 m intervals along traverses that had a maximum separation of 16 km (Gordon, 1973). The reconnaissance sampling identified a number of geochemical anomalies. Regular closer spaced follow-up sampling was then conducted with samples collected at 30.4 m intervals on traverses 914 m apart. The distance between traverses was further narrowed down to 304 m in geochemically, geologically, and structurally anomalous areas. The samples were analysed using standard rapid colorimetric methods. The geochemistry was very successful in delineating significant mineralization within the Project area. Figure 6-1 illustrates the spatial distribution of the geochemical anomalies in the vicinity of the Project. Enlarged inserts of the three principal anomalies of Phikwe, Selebi North, and Selebi are also presented.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 6-2 | |

Figure 6-1: Spatial Distribution of Geochemical Anomalies

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 6-3 | |

| 6.2.1.2 | Geological Mapping |

The discovery of the Selebi and Phikwe deposits in 1963 and 1967 respectively, triggered scientific research work undertaken by groups and individuals in the vicinity of Selebi Phikwe, encompassing the Project area. From 1964 to 1975, the Botswana Geological Survey conducted geological mapping and produced geological maps of the rock units and regional structures at a scale of 1:1,000,000 and 1:125,000. This mapping was completed concurrently with scholarly work by Gordon in 1973, Wakefield in 1974, and Gallon in 1986. These scholars were concerned with deciphering the structural occurrence and tectonic sequences of the amphibolites hosting the Selebi and Phikwe deposits.

Drilling was first conducted in 1964 prior to close-spaced geochemical sampling. After completion of eight shallow wagon drill holes, drilling was suspended due to poor results (Gordon, 1973), however, three of the holes indicated possible enrichment with depth. A year later in 1965, drilling resumed and confirmed the improvement of sulphide mineralization grades with depth.

Close spaced geochemical surveys conducted as follow-up produced copper and nickel anomalies at Phikwe and Selebi and drilling was shifted to these areas. Drilling at these targets continued until 1971 with the subsequent opening of the Phikwe open pit. At the end of this drilling 124 holes totalling 34,206 m and 73 holes totalling 19,294 m were completed at Phikwe and Selebi, respectively (Gordon, 1973).

Further surface exploration drilling continued at Selebi between 1980 and 1994 to confirm the down-dip and northerly continuation of the mineralization.

| 6.2.2 | Late Exploration (2004 to 2012) |

Since 2004, several exploration methods have been employed to generate targets for further examination.

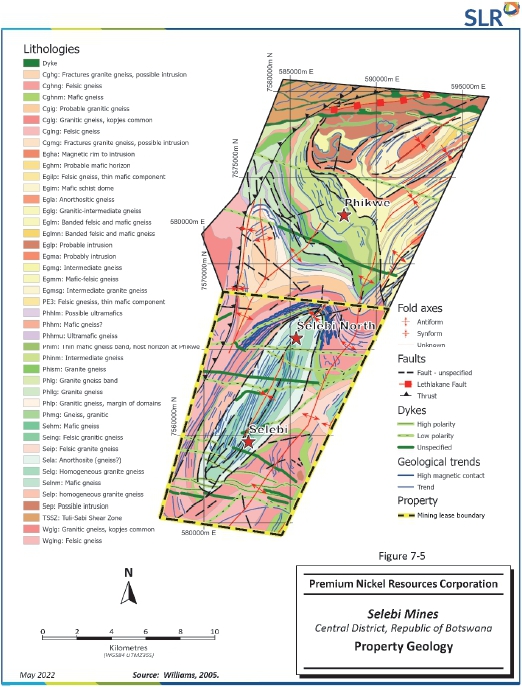

A desktop study employing satellite image interpretation coupled with field mapping was completed by Peter Williams of SRK (Williams, 2005) over the Selebi Phikwe project area. The study generated 23 independent prospects, ten of which were located on the current Project claim area, and Williams recommended specific follow up work including mapping, geochemical surveys, and ground electromagnetic surveys. Follow up work was commissioned and completed by several contractors from 2005 to 2008 and the most prospective areas following this work were drill tested. Surface drilling was also completed to test for down-dip extensions of the existing known deposits (described in Section 10).

| 6.2.2.1 | Ground Electromagnetic Surveying |

In June 2005, Lamontagne Geophysics Limited of Canada was commissioned to complete a UTEM/BHUTEM-3 survey within the Project area, centered on Universal Transverse Mercator (UTM) coordinate location 580500 E / 7558000 N. The survey was carried out to locate conductors in the immediate grid areas with the intention of outlining targets for future work. A total of 21 km of UTEM data was collected using one transmitter loop with the receiver operating in 10 channel mode at a transmitter frequency of 3.251Hz. All lines were surveyed measuring the vertical component. Readings were initially taken at 25 m intervals along 100 m spaced lines, however, the station spacing was later increased to 50 m.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 6-4 | |

| 6.2.2.2 | Airborne Magnetic and VTEM Survey |

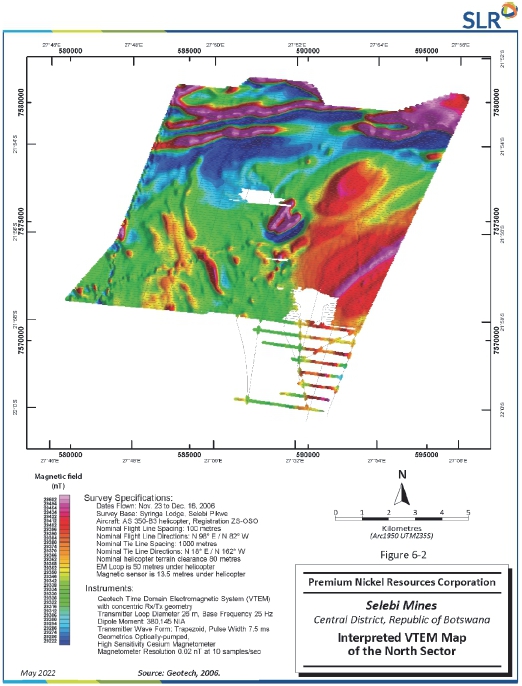

From November to December 2006, Geotech Airborne Limited (Geotech) of South Africa completed a low level, high resolution magnetic and electromagnetic survey over the Project area (Figure 6-2).

The survey was flown in a N98°E direction at nominal traverse line spacing of 100 m for the main grids and 500 m over the additional central block over the town of Selebi Phikwe. Tie lines were flown perpendicular to traverse lines at a nominal tie line spacing of 1,000 m. The helicopter maintained a mean terrain clearance of 95 m which translated into an average height of 45 m above ground for the bird-mounted versatile time domain electromagnetic (VTEM) system and 82.5 m above ground for the magnetic sensor. SLR notes that this is higher than the nominal clearances due to many man-made structures in the area.

Data compilation and processing were carried out by Geotech personnel using Geosoft OASIS Montaj software and programs proprietary to Geotech. Digital databases, grids, and maps were presented to BCL.

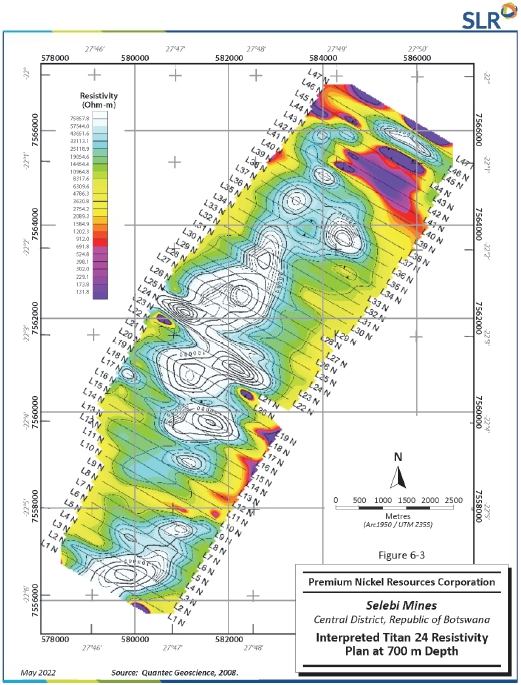

In 2008, Quantec Geosciences Limited of Canada (Quantec) completed a Titan-24 ground survey over the Project area. The system is designed to collected two separate geophysical parameters, direct current induced polarization (DCIP) (resistivity and chargeability) plus magnetotellurics (MT).

This survey was undertaken with the objective of defining conductive and chargeable geophysical features within the Project area. These features are indicative of possible nickel-copper mineralization and hence provide a guide to focused drilling. The survey lines were spaced 250 m apart and were two kilometres to four kilometres long.

The data acquired was modelled and interpreted by Quantec, who identified 208 targets for possible follow-up exploration.

Several two metre deep trenches, 600 m long and spaced 250 m apart, were dug over some of the targets. These were profiled and sampled but did not yield any significant host intersections or grade anomalies.

Figure 6-3 illustrates the plan of resistivity at a depth of 700 m.

| 6.2.2.4 | Borehole Electromagnetic Surveys |

Borehole electromagnetic surveys were completed by AEGIS Instruments (Pty) Limited (AEGIS) between April 2009 and March 2010. These surveys were designed to characterize the size and orientation of conductive mineralization intersected in drill core and search for off-hole conductors that could represent nickel-copper mineralization. A total of 21 drill holes were surveyed in the Selebi Project area utilizing the Geonics PROTEM digital receiver, TEM67 transmitter and MAG43-3D fluxgate probe. Surveys operated at a frequency of 6.25 Hz.

A review of the data completed by the Project Team in 2019 identified high quality off-hole anomalies in drill hole sd140, located down-plunge of the Selebi Mine, and in drill hole sdn137, located near the eastern edge of Selebi North Mine. There is no indication that these targets were drill tested by the previous operator.

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 6-5 | |

Figure 6-2: Interpreted VTEM Map of the North Sector

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 6-6 | |

Figure 6-3: Interpreted Titan 24 Survey Resistivity at 700 m Depth

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 6-7 | |

| 6.2.2.5 | Surface Diamond Drilling |

Diamond drilling was undertaken within the Project area from 2007 to 2012. A two tier approach was adopted targeting on-mine/brownfields and exploration targets. On-mine drilling was undertaken with the objective of defining down dip and strike extensions of existing operations while exploration work targeted areas outside the mining infrastructure to test geochemical, geophysical, and geological targets in order to delineate stand-alone deposits.

A more detailed description of the diamond drilling on the Project can be found in Section 10 of this Technical Report. As at the effective date of this Technical Report, PNRB had not sourced a complete database of regional exploration drilling over the Selebi Mines property.

| 6.3 | Historical Resource Estimates |

At the time of liquidation, Mineral Resources prepared in accordance with SAMREC within the Selebi Mines property boundary were reported as in-situ and depleted for mining as of September 30, 2016 (Lungu, 2017). Table 6-1 replicates the portion of those Mineral Resources relevant for the Project. This estimate is considered to be historical in nature and should not be relied upon. The QP has not completed sufficient work to classify the historical estimate as a current Mineral Resource and PNRB is not treating the historical estimates as current Mineral Resources. With further verification in the form of validation of the digital database against original logs and assay certificates, compilation and analysis of quality assurance/quality control (QA/QC) support programs, hole twinning, and down hole survey confirmation, SLR anticipates that the historical information will be suitable for Mineral Resource estimation and a new Mineral Resource estimate can be prepared using updated economic parameters and mining and processing considerations.

Table 6-1: Historical Mineral Resources as of September 30, 2016

Premium Nickel Resources Corporation – Selebi Mines

| | | Tonnes | | | Grade | | | Contained Metal | |

| Class/Deposit | | (Mt) | | | % Ni | | | % Cu | | | (000 t Ni) | | | (000 t Cu) | |

| | | | | | | | | | | | | | | | |

| | | | | | | | Measured | | | | | | | | | |

| Selebi | | | 0.37 | | | | 1.01 | | | | 2.19 | | | | 3.69 | | | | 8.01 | |

| Selebi North | | | 0.71 | | | | 1.24 | | | | 1.03 | | | | 8.83 | | | | 7.34 | |

| Total Measured | | | 1.08 | | | | 1.16 | | | | 1.42 | | | | 12.53 | | | | 15.34 | |

| | | | | | | | Indicated | | | | | | | | | |

| Selebi | | | 6.82 | | | | 1.05 | | | | 2.29 | | | | 71.65 | | | | 156.27 | |

| Selebi Central | | | 8.79 | | | | 0.64 | | | | 0.78 | | | | 56.28 | | | | 68.59 | |

| Selebi North | | | 1.14 | | | | 1.27 | | | | 1.13 | | | | 14.46 | | | | 12.86 | |

| Total Indicated | | | 16.76 | | | | 0.85 | | | | 1.42 | | | | 142.39 | | | | 237.73 | |

| | | | | | | | Measured and Indicated | | | | | | | | | |

| Selebi | | | 7.19 | | | | 1.05 | | | | 2.28 | | | | 75.35 | | | | 164.28 | |

| Selebi Central | | | 8.79 | | | | 0.64 | | | | 0.78 | | | | 56.28 | | | | 68.59 | |

| Selebi North | | | 1.85 | | | | 1.26 | | | | 1.09 | | | | 23.29 | | | | 20.20 | |

| Total M&I | | | 17.83 | | | | 0.87 | | | | 1.42 | | | | 154.92 | | | | 253.07 | |

| | | | | | | | Inferred | | | | | | | | | |

| Selebi | | | 4.09 | | | | 0.86 | | | | 1.21 | | | | 35.18 | | | | 49.49 | |

| Selebi Central | | | 8.46 | | | | 0.57 | | | | 0.74 | | | | 48.21 | | | | 62.59 | |

| Selebi North | | | 2.79 | | | | 0.93 | | | | 0.87 | | | | 25.97 | | | | 24.30 | |

| Total Inferred | | | 15.34 | | | | 0.71 | | | | 0.89 | | | | 109.36 | | | | 136.38 | |

| Premium Nickel Resources Corporation | Selebi Mines, SLR Project No: 233.03374.R0000 |

| NI 43-101 Technical Report - June 16, 2022 | 6-8 | |

Notes:

| 1. | Mineral Resources are in-situ and depleted for mining as at September 30, 2016. |

| 2. | Mineral Resources are exclusive of pillars left in mined out areas and are corrected for geological losses. |

| 3. | Mineral Resources are inclusive of Mineral Reserves. |

| 4. | Estimated grades and tonnages have been verified both visually and statistically and are considered reasonably representative of the data informing the estimation. |

| 5. | Mineral Resource models were created at a cut-off grade of 0.4% NiEq within a lithology constrained model. |

| 6. | NiEq is calculated using the equation NiEq = %Ni + (Cu price/Ni price)*%Cu. |

| 7. | Nickel and copper prices used are US$8.00/lb Ni and US$3.00/lb Cu, respectively. |

| 8. | Selebi Mineral Resources are exclusive of the Lower Ore Body (LOB) due to uncertainty in interpretation resulting from very low exposure of the zone. |

| 9. | Geological losses are based on estimated losses due to pinch outs, and geotechnical and structural features. |

| 10. | Numbers may not add due to rounding. |