QUALCOMM Incorporated

Conflict Minerals Report

Reporting Period: January 1, 2014 – December 31, 2014

Qualcomm Incorporated is a world leader in 3G, 4G and next-generation wireless technologies. Qualcomm Incorporated includes our licensing business and the vast majority of our patent portfolio. Qualcomm Technologies, Inc., a wholly-owned subsidiary of Qualcomm Incorporated, operates, along with its subsidiaries, substantially all of our products and services businesses, including our semiconductor businesses and substantially all of our engineering, research and development functions. In this document, the words “we,” “our” and “us” refer only to Qualcomm Incorporated, Qualcomm Technologies, Inc. and/or their subsidiaries.

This Conflict Minerals Report (this Report) contains forward-looking statements regarding our business, products and conflict minerals efforts, including steps we intend to take to mitigate the risk that conflict minerals in our products benefit armed groups (identified as a perpetrator of serious human rights abuses) in the Democratic Republic of the Congo (DRC) or an adjoining country (a country that shares an internationally recognized border with the DRC). Words such as “expects,” “intends,” “believes,” “strives” and similar expressions or variations of such words are intended to identify forward-looking statements, but are not the exclusive means of identifying forward-looking statements in this Report. Additionally, statements concerning future matters that are not historical are forward-looking statements.

Although forward-looking statements in this Report reflect our good faith judgment, such statements can only be based on facts and factors currently known by us. Consequently, forward-looking statements are inherently subject to risks and uncertainties, and actual results and outcomes may differ materially from the results and outcomes discussed in or anticipated by the forward-looking statements. Factors that could cause or contribute to such differences in results and outcomes include without limitation: the risk that information reported to us by our suppliers from which we directly procure finished goods, components, materials and/or services for our products (direct suppliers), or industry information used by us, may be inaccurate; the risk that smelters or refiners (processing facilities) may not participate in the Conflict Free Smelter Program (CFSP), which is a voluntary initiative in which independent third parties audit processing facilities' procurement and processing activities and determine if the processing facilities maintain sufficient documentation to reasonably demonstrate conflict-free sourcing; as well as risks discussed under the heading “Risk Factors” in our most recent Quarterly Report on Form 10-Q related to our customer concentrations, our dependence on a limited number of third-party suppliers and our being subject to government regulations and policies. Readers are urged not to place undue reliance on forward-looking statements, which speak only as of the date of this Report. We undertake no obligation to revise or update any forward-looking statements in order to reflect any event or circumstance that may arise after the date of this Report. Throughout this Report, whenever a reference is made to our website, such reference does not incorporate information from the website by reference into this Report unless specifically identified as such.

Background

Pursuant to the Dodd-Frank Wall Street Reform and Consumer Protection Act (Dodd-Frank), the United States Securities and Exchange Commission (SEC) promulgated rules (the Final Rule) requiring certain companies with “conflict minerals” (columbite-tantalite (coltan), cassiterite, gold, wolframite, or their derivatives, which are limited to tantalum, tin and tungsten) that are necessary to the functionality or production of a product manufactured by or for that company to, among other things, disclose annually whether any of those conflict minerals originated in the

DRC or an adjoining country and if so, to submit a report to the SEC that includes a description of the measures it took to exercise due diligence on the conflict minerals’ source and chain of custody.

In anticipation of the Final Rule, the Electronics Industry Citizenship Coalition (EICC) and the Global e-Sustainability Initiative (GeSI) established an initiative that is known as the Conflict-Free Sourcing Initiative (CFSI). The EICC, GeSI and CFSI, which are comprised of numerous industry members, strive to promote the improvement of human welfare and the environment through responsible and proactive supply chain management.

We are a full member of the EICC, have adopted the EICC Code of Conduct and expect all of our direct suppliers to act in accordance with this Code. By employing EICC resources and working collaboratively with our peers, we are working to improve transparency and sustainability in the global electronics supply chain. We hold a leadership position on the Board of the EICC and actively participate in and support the CFSI’s responsible extractives initiatives.

We, along with many other companies, rely on the CFSI’s CFSP to verify processing facilities as not benefiting armed groups in the DRC or an adjoining country (CFSP-compliant). The CFSI also recognizes responsible sourcing practices of processing facilities that have been validated by the London Bullion Market Association (LBMA) and Responsible Jewellery Council (RJC).

Summary

We are a leading developer and supplier of integrated circuits based on CDMA (Code Division Multiple Access), OFDMA (Orthogonal Frequency Division Multiple Access) and other technologies for use in voice and data communications, networking, application processing, multimedia and global positioning system products. We manufacture or contract to manufacture products for which conflict minerals are necessary to the functionality or production of those products and which otherwise constitute products under the Final Rule. We primarily utilize a fabless production and assembly model, which means that we do not own or operate foundries or assemblers responsible for the production and assembly of our products.

In accordance with the Final Rule, we conducted in good faith a reasonable country of origin inquiry (RCOI) that was reasonably designed to determine whether any of the necessary conflict minerals in our products originated in the DRC or an adjoining country, or were from recycled or scrap sources. A description of our RCOI is set forth in this Report.

Based on our RCOI, we have reason to believe that some of the necessary conflict minerals used in our products originated in the DRC or an adjoining country (and may not have been from recycled or scrap sources). Accordingly, we exercised due diligence to determine the source and chain of custody of these conflict minerals. Our due diligence was designed to conform to an internationally recognized due diligence framework, specifically the Organisation for Economic Co-operation and Development (OECD) “Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (OECD Guidance)”, 2nd edition (2013). A description of our due diligence measures is also set forth in this Report.

Following the exercise of our due diligence, we have not identified any instances in which our sourcing of necessary conflict minerals directly or indirectly financed or benefitted armed groups in the DRC or an adjoining country. In addition, our integrated circuit products (described below) are comprised of tantalum sourced from 100% CFSP-compliant processing facilities.

The following descriptions are also provided within this Report:

| |

| • | The facilities used to process the necessary conflict minerals in our products, if known; |

| |

| • | The country of origin of the necessary conflict minerals in our products, if known; |

| |

| • | Our efforts to determine the mine or location of origin of the necessary conflict minerals in our products with the greatest possible specificity; and |

| |

| • | The steps we have taken and the steps that we will take to mitigate the risk that our necessary conflict minerals benefit armed groups in the DRC or an adjoining country, including steps to improve our due diligence. |

Product Description

| |

| I. | Integrated Circuit Products |

Our integrated circuit products are sold to manufacturers that use our products in wireless devices, such as mobile phones, tablets, laptops, data modules, handheld wireless computers and gaming devices, access points and routers, data cards and infrastructure equipment, and in wired devices, particularly broadband gateway equipment, desktop computers and streaming media players. Our Mobile Station Modem (MSMTM) integrated circuits, which include the Mobile Data Modem, Qualcomm Single Chip and Qualcomm® SnapdragonTM processors and LTE modems, perform the core baseband modem functionality in wireless devices providing voice and data communications, as well as multimedia applications and global positioning functions. In addition, our Snapdragon processors provide advanced application and graphics processing capabilities. Because of our experience in designing and developing CDMA- and OFDMA-based products, we design both the baseband integrated circuits and the supporting system as well, including the RF (Radio Frequency), PM (Power Management) and connectivity devices. Our portfolio of RF products includes QFE (Qualcomm Front End) radio front end components.

Our wireless integrated circuit products are also sold to manufacturers that use our products for wireless local area network (WLAN), Bluetooth, frequency modulation (FM) and near field communications as well as technologies that enable location data and services and for implementation of small mobile base stations (known as small cells). Our networking products include Wi-Fi, Powerline and Ethernet integrated circuits and network processors.

Revenues from the sale of integrated circuit products comprised greater than 99% of the total revenues for our products described in this Report during the reporting period.

Our other products include air-to-ground modem cards, display modules, wireless medical devices and wearable devices.

Revenues from the sale of such other products comprised less than 1% of the total revenues for our products described in this Report during the reporting period.

Description of Supply Chain

We utilize a fabless production model, which means that we do not own or operate foundries for the production of silicon wafers from which our integrated circuits are made. Integrated circuits are die cut from silicon wafers that have completed the package assembly and test manufacturing processes. We employ both turnkey and two-stage manufacturing models to purchase our integrated circuits. Turnkey is when our foundry suppliers are responsible for delivering fully assembled and tested integrated circuits. Under the two-stage manufacturing model, we purchase wafers and die from integrated circuit manufacturing foundries and contract with separate third-party suppliers for manufacturing services such as wafer bump, probe, assembly and final test. We rely on our direct suppliers to

perform the manufacturing and assembly, and most of the testing, of our integrated circuits based primarily on our proprietary designs and test programs. Our direct suppliers and, in turn, their suppliers are responsible for the procurement of most of the materials used in the production of our integrated circuits. Certain materials purchased by our direct suppliers may come directly or indirectly from processing facilities that treat ores, concentrates, slags or secondary materials. Because we do not purchase any materials directly from these processing facilities, we must rely on certain information provided by our direct suppliers and the CFSI or other industry organizations in order to prepare this Report.

Our other products are primarily contracted to be manufactured as finished goods with the contract manufacturer responsible for the procurement of the materials and components that comprise these products.

Reasonable Country of Origin Inquiry

In accordance with the Final Rule, we conducted in good faith a reasonable country of origin inquiry (RCOI) that was reasonably designed to determine whether any of the necessary conflict minerals in our products originated in the DRC or an adjoining country or were from recycled or scrap sources.

Our conflict free minerals policy (available at:

https://www.qualcomm.com/#/company/sustainability/products/conflict-free-minerals) communicates the expectation that our direct suppliers obtain materials from environmentally and socially responsible sources, including conflict free sources within the DRC and adjoining countries. To conduct our RCOI and obtain sourcing information from our direct suppliers, we used the CFSI Conflict Minerals Reporting Template (CMRT) to collect information on the necessary conflict minerals in their supply chain. We requested this information from 100% of our direct suppliers that may use necessary conflict minerals in our products to determine whether any of these minerals originated in the DRC or an adjoining country or were from recycled or scrap sources. We received responses from 100% of the direct suppliers of our integrated circuit products and from 97% of the direct suppliers of our other products.

Our RCOI considered the countries of origin information obtained from our direct suppliers and the CFSI (members-only) data for CFSP-compliant processing facilities. Based on this information, we determined that approximately 6% of processing facilities reported by our direct suppliers were confirmed as sourcing conflict minerals from the DRC or an adjoining country. This represents an increase in processing facilities reported in our supply chain that source from the DRC or adjoining countries compared to calendar year 2013. Each of these processing facilities has been validated as CFSP-compliant.

Based on our direct suppliers’ responses to the RCOI, we have reason to believe that some of the necessary conflict minerals used in our products originated in the DRC or an adjoining country, but we have not identified any instances in which our sourcing of necessary conflict minerals directly or indirectly financed or benefitted armed groups in the DRC or an adjoining country.

Design of Due Diligence

Our due diligence measures have been designed to conform, in all material respects, to the framework provided by the OECD Guidance.

Description of Due Diligence Performed

OECD Step 1: Establish Strong Company Management Systems

| |

| • | We continued to publicly communicate our conflict minerals policy. |

| |

| • | We maintained a conflict minerals management team with representation from our finance, government affairs, internal audit, legal, regulatory, quality and supply chain departments which reported on program activities to executive management and the Audit Committee of our Board of Directors on a regular basis. |

| |

| • | We used the CMRT to identify processing facilities in our supply chain as reported by our direct suppliers. |

| |

| • | We communicated our conflict minerals supplier requirements to our integrated circuit direct suppliers. |

| |

| • | We maintained a public email address (conflictminerals@qti.qualcomm.com) available on our website for general inquiries and grievances regarding our conflict minerals program. |

| |

| • | We designed and implemented a comprehensive conflict minerals data management tool that tracks end-to-end communication with direct suppliers, automates the validation of direct supplier data and consolidates CMRT responses for analysis and reporting. |

OECD Step 2: Identify and Assess Risk in the Supply Chain

| |

| • | We used the CMRT to review our direct suppliers’ due diligence activities, such as whether they had a conflict minerals policy, required their own suppliers to source from processing facilities validated by an independent audit firm, and implemented a review process that includes corrective action management. |

| |

| • | We used the CMRT to identify conflict minerals processing facilities if reported in our supply chain by direct suppliers. |

| |

| • | We determined if the processing facilities adhere to responsible sourcing practices by cross-checking with the list of CFSP-compliant processing facilities. |

| |

| • | We obtained countries of origin (when available) for CFSP-compliant processing facilities by relying on information provided by our direct suppliers, the CFSI and other public data sources. |

OECD Step 3: Design and Implement a Strategy to Respond to Risk

| |

| • | We reported information on the source and chain of custody of conflict minerals in our supply chain to our conflict minerals working team and the Audit Committee of our Board of Directors on a regular basis. |

| |

| • | We maintained a conflict minerals risk management plan that sets forth direct supplier-risk management strategies ranging from continued procurement to disengagement. |

| |

| • | We participated in certain CFSP pre-audit site visits to processing facilities in Asia to encourage participation in the CFSP. |

OECD Step 4: Third-Party Audit of Smelter/Refiner’s Due Diligence Practices

| |

| • | Because we do not source directly from processing facilities, we rely on the publicly-available results of the CFSP, LBMA and RJC third-party audits to validate the responsible sourcing practices of processing facilities in our supply chain. |

| |

| • | The CFSI recognizes processing facilities as CFSP-compliant through validations conducted by the LBMA and RJC. |

OECD Step 5: Report Annually on Supply Chain Due Diligence

| |

| • | We file a Form SD and Conflict Minerals Report with the SEC on an annual basis. Our Form SD and Conflict Minerals Report are also available on our website. |

| |

| • | We periodically provide information regarding our conflict minerals program in the Qualcomm Sustainability Report, as well as on our Sustainability website. |

Facilities Used to Process the Necessary Conflict Minerals in Our Products

We rely on the good faith efforts of our direct suppliers to provide us with reasonable representations of the processing facilities used to supply the necessary conflict minerals in our products.

At this time, the processing facilities that we list in Tables 1, 2 and 3 are those that have been determined to be legitimate processing facilities by the CFSI. All processing facilities used in our semiconductor businesses are included in these tables. The direct suppliers of certain of our other products reported other processing facilities as being in our supply chain that are not listed in these tables as the CFSI has not yet determined them to be legitimate. In these tables, we have also indicated the headquarter locations of known processing facilities and whether such facilities have been validated as CFSP-compliant.

Some of our direct supplier responses represented their supply chain at a company-level rather than being product-specific. As such, the list of processing facilities that we have disclosed in this Report may contain more facilities than those that actually process the conflict minerals contained in our products.

Country of Origin of the Necessary Conflict Minerals in Our Products

We requested country of origin information (if known) from each of our direct suppliers, most of which do not source directly from processing facilities, for the purposes of determining the source and chain of custody of the necessary conflict minerals in our supply chain. We also relied on the country of origin information provided by the CFSI (when available) for CFSP-compliant processing facilities.

Based on country of origin information provided by our direct suppliers and the CFSP, we have reason to believe that some of our necessary conflict minerals originated from the DRC and one or more adjoining country, but we have not identified any instances in which our sourcing of necessary conflict minerals directly or indirectly financed or benefitted armed groups in the DRC or an adjoining country.

Our Efforts to Determine the Mine or Location of Origin of the Necessary Conflict Minerals in Our Products

We requested mine or location of origin information of the necessary conflict minerals contained in products from each of our direct suppliers using the CMRT. In some instances our direct suppliers reported name or location of mine (country). However, many of our direct suppliers were unable to obtain reliable mine or location of origin data for their necessary conflict minerals.

Steps We Have Taken to Mitigate the Risk that our Necessary Conflict Minerals Benefit Armed Groups

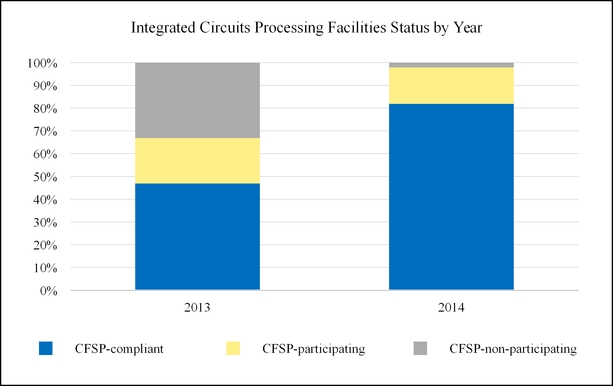

From calendar year 2013 to 2014, we noted CFSP-compliant processing facilities used in our integrated circuits products increased by 38% (Figure 1).

Figure 1. Integrated circuits processing facilities status by year

Figure 1 Notes

CFSP-compliant: Processing facilities reported in our supply chain that were validated as compliant according to the CFSP.

CFSP-participating: Processing facilities reported in our supply chain that have agreed to participate in the CFSP but have not yet completed the program.

CFSP-non-participating: Processing facilities reported in our supply chain that have yet to agree to participate in the CFSP.

From calendar year 2013 to 2014, we noted a 175% increase in our integrated circuit direct suppliers that used 100% CFSP-compliant processing facilities (Figure 2).

Figure 2. Integrated circuits direct suppliers that used 100% CFSP-compliant processing facilities by year

Steps We Will Take to Mitigate the Risk that our Necessary Conflict Minerals Benefit Armed Groups

During calendar year 2015, we intend to advance the effectiveness of our due diligence efforts to mitigate the risk that our necessary conflict minerals benefit armed groups in the DRC or an adjoining country by:

| |

| 1. | Continuing to engage with direct suppliers, processing facilities and the CFSI to encourage non-CFSP validated processing facilities to become validated as CFSP-compliant; |

| |

| 2. | Striving to use only CFSP-compliant direct suppliers for our integrated circuit products; and |

| |

| 3. | Continuing to participate in the following industry coalitions and non-governmental organizations’ efforts to support the responsible sourcing of minerals: EICC, CFSI, International Tin Research Initiative, Public-Private Alliance for Responsible Minerals Trade and the Responsible Sourcing Network multi-stakeholder group. |

Tables of Conflict Minerals Processing Facilities

Table 1. CFSP-compliant processing facilities as of January 31, 2015

Processing facilities and their locations reported in our supply chain that were validated as compliant according to the CFSP.

|

| | |

| Metal | Processing Facility Name | Country |

| Gold | Allgemeine Gold-und Silberscheideanstalt A.G. | GERMANY |

| Gold | AngloGold Ashanti Córrego do Sítio Mineraçäo | BRAZIL |

| Gold | Argor-Heraeus SA | SWITZERLAND |

| Gold | Asahi Pretec Corporation | JAPAN |

| Gold | Aurubis AG | GERMANY |

| Gold | Boliden AB | SWEDEN |

| Gold | CCR Refinery - Glencore Canada Corporation | CANADA |

| Gold | Chimet S.p.A. | ITALY |

| Gold | Dowa | JAPAN |

| Gold | Eco-System Recycling Co., Ltd. | JAPAN |

| Gold | Heimerle + Meule GmbH | GERMANY |

| Gold | Heraeus Ltd. Hong Kong | HONG KONG |

| Gold | Heraeus Precious Metals GmbH & Co. KG | GERMANY |

| Gold | Ishifuku Metal Industry Co., Ltd. | JAPAN |

| Gold | Istanbul Gold Refinery | TURKEY |

| Gold | Japan Mint | JAPAN |

| Gold | Johnson Matthey Inc | UNITED STATES |

| Gold | Johnson Matthey Ltd | CANADA |

| Gold | JX Nippon Mining & Metals Co., Ltd. | JAPAN |

| Gold | Kazzinc Ltd | KAZAKHSTAN |

| Gold | Kennecott Utah Copper LLC | UNITED STATES |

| Gold | Kojima Chemicals Co., Ltd | JAPAN |

| Gold | LS-NIKKO Copper Inc. | KOREA, REPUBLIC OF |

| Gold | Materion | UNITED STATES |

| Gold | Matsuda Sangyo Co., Ltd. | JAPAN |

| Gold | Metalor Technologies (Hong Kong) Ltd | HONG KONG |

| Gold | Metalor Technologies (Singapore) Pte. Ltd. | SINGAPORE |

|

| | |

| Gold | Metalor Technologies SA | SWITZERLAND |

| Gold | Metalor USA Refining Corporation | UNITED STATES |

| Gold | Met-Mex Peñoles, S.A. | MEXICO |

| Gold | Mitsubishi Materials Corporation | JAPAN |

| Gold | Mitsui Mining and Smelting Co., Ltd. | JAPAN |

| Gold | Nadir Metal Rafineri San. Ve Tic. A.Ş. | TURKEY |

| Gold | Nihon Material Co. LTD | JAPAN |

| Gold | Ohio Precious Metals, LLC | UNITED STATES |

| Gold | Ohura Precious Metal Industry Co., Ltd | JAPAN |

| Gold | OJSC Krastvetmet | RUSSIAN FEDERATION |

| Gold | PAMP SA | SWITZERLAND |

| Gold | PX Précinox SA | SWITZERLAND |

| Gold | Rand Refinery (Pty) Ltd | SOUTH AFRICA |

| Gold | Royal Canadian Mint | CANADA |

| Gold | Schöne Edelmetaal B.V. | NETHERLANDS |

| Gold | SEMPSA Joyería Platería SA | SPAIN |

| Gold | Solar Applied Materials Technology Corp. | TAIWAN |

| Gold | Sumitomo Metal Mining Co., Ltd. | JAPAN |

| Gold | Tanaka Kikinzoku Kogyo K.K. | JAPAN |

| Gold | Tokuriki Honten Co., Ltd | JAPAN |

| Gold | Umicore Brasil Ltda | BRAZIL |

| Gold | Umicore Precious Metals Thailand | THAILAND |

| Gold | Umicore SA Business Unit Precious Metals Refining | BELGIUM |

| Gold | United Precious Metal Refining, Inc. | UNITED STATES |

| Gold | Valcambi SA | SWITZERLAND |

| Gold | Western Australian Mint trading as The Perth Mint | AUSTRALIA |

| Tantalum | Changsha South Tantalum Niobium Co., Ltd. | CHINA |

| Tantalum | Conghua Tantalum and Niobium Smeltry | CHINA |

| Tantalum | Duoluoshan | CHINA |

| Tantalum | Exotech Inc. | UNITED STATES |

| Tantalum | F&X Electro-Materials Ltd. | CHINA |

| Tantalum | Global Advanced Metals Aizu | JAPAN |

| Tantalum | Global Advanced Metals Boyertown | UNITED STATES |

| Tantalum | Global Advanced Metals^ | UNITED STATES |

| Tantalum | Guangdong Zhiyuan New Material Co., Ltd. | CHINA |

|

| | |

| Tantalum | H.C. Starck Co., Ltd. | THAILAND |

| Tantalum | H.C. Starck GmbH Goslar | GERMANY |

| Tantalum | H.C. Starck GmbH Laufenburg | GERMANY |

| Tantalum | H.C. Starck Group^ | GERMANY |

| Tantalum | H.C. Starck Hermsdorf GmbH | GERMANY |

| Tantalum | H.C. Starck Inc. | UNITED STATES |

| Tantalum | H.C. Starck Ltd. | JAPAN |

| Tantalum | H.C. Starck Smelting GmbH & Co.KG | GERMANY |

| Tantalum | Hengyang King Xing Lifeng New Materials Co., Ltd. | CHINA |

| Tantalum | Hi-Temp | UNITED STATES |

| Tantalum | JiuJiang JinXin Nonferrous Metals Co., Ltd. | CHINA |

| Tantalum | Jiujiang Tanbre Co., Ltd. | CHINA |

| Tantalum | KEMET Blue Metals | MEXICO |

| Tantalum | KEMET Blue Powder^ | UNITED STATES |

| Tantalum | LSM Brasil S.A. | BRAZIL |

| Tantalum | Metallurgical Products India (Pvt.) Ltd. | INDIA |

| Tantalum | Mineração Taboca S.A. | BRAZIL |

| Tantalum | Mitsui Mining & Smelting | JAPAN |

| Tantalum | Molycorp Silmet A.S. | ESTONIA |

| Tantalum | Ningxia Orient Tantalum Industry Co., Ltd. | CHINA |

| Tantalum | Plansee SE Liezen | AUSTRIA |

| Tantalum | Plansee SE Reutte | AUSTRIA |

| Tantalum | Plansee^ | AUSTRIA |

| Tantalum | QuantumClean | UNITED STATES |

| Tantalum | RFH Tantalum Smeltry Co., Ltd | CHINA |

| Tantalum | Solikamsk Magnesium Works OAO | RUSSIAN FEDERATION |

| Tantalum | Taki Chemical | JAPAN |

| Tantalum | Tantalite Resources# | SOUTH AFRICA |

| Tantalum | Telex | UNITED STATES |

| Tantalum | Ulba | KAZAKHSTAN |

| Tantalum | Zhuzhou Cement Carbide | CHINA |

| Tin | Alpha | UNITED STATES |

| Tin | CV United Smelting | INDONESIA |

| Tin | Gejiu Non-Ferrous Metal Processing Co. Ltd. | CHINA |

| Tin | Magnu's Minerais Metais e Ligas LTDA | BRAZIL |

|

| | |

| Tin | Malaysia Smelting Corporation (MSC) | MALAYSIA |

| Tin | Melt Metais e Ligas S/A | BRAZIL |

| Tin | Mineração Taboca S.A. | BRAZIL |

| Tin | Minsur | PERU |

| Tin | Mitsubishi Materials Corporation | JAPAN |

| Tin | OMSA | BOLIVIA |

| Tin | PT Babel Inti Perkasa | INDONESIA |

| Tin | PT Bangka Putra Karya | INDONESIA |

| Tin | PT Bangka Tin Industry | INDONESIA |

| Tin | PT Bukit Timah | INDONESIA |

| Tin | PT DS Jaya Abadi | INDONESIA |

| Tin | PT REFINED BANGKA TIN | INDONESIA |

| Tin | PT Sariwiguna Binasentosa | INDONESIA |

| Tin | PT Stanindo Inti Perkasa | INDONESIA |

| Tin | PT Tambang Timah | INDONESIA |

| Tin | PT Timah (Persero), Tbk | INDONESIA |

| Tin | Thaisarco | THAILAND |

| Tin | White Solder Metalurgia e Mineração Ltda. | BRAZIL |

| Tin | Yunnan Tin Company, Ltd. | CHINA |

| Tungsten | Ganzhou Huaxing Tungsten Products Co., Ltd. | CHINA |

| Tungsten | Ganzhou Jiangwu Ferrotungsten Co., Ltd. | CHINA |

| Tungsten | Ganzhou Seadragon W & Mo Co., Ltd. | CHINA |

| Tungsten | Global Tungsten & Powders Corp. | UNITED STATES |

| Tungsten | Hunan Chunchang Nonferrous Metals Co., Ltd. | CHINA |

| Tungsten | Japan New Metals Co., Ltd. | JAPAN |

| Tungsten | Malipo Haiyu Tungsten Co., Ltd. | CHINA |

| Tungsten | Xiamen Tungsten (H.C.) Co., Ltd. | CHINA |

| Tungsten | Xiamen Tungsten Co., Ltd. | CHINA |

Table 1 Notes

Processing facilities followed by a pound (#) symbol ceased operation during calendar year 2014.

Processing facilities followed by a caret (^) symbol had previously been identified at a “corporate” or “group” level whereby one entry may have represented multiple individual facilities. With CMRT Revision 3.02, these higher level entities have been eliminated and replaced with entries representing each unique facility.

Table 2. CFSP-participating processing facilities as of January 31, 2015

Processing facilities and their locations reported in our supply chain that have agreed to participate in the CFSP but have not yet completed the program.

|

| | |

| Metal | Processing Facility Name | Country |

| Gold | Aida Chemical Industries Co. Ltd. | JAPAN |

| Gold | Asaka Riken Co Ltd | JAPAN |

| Gold | C. Hafner GmbH + Co. KG | GERMANY |

| Gold | Cendres + Métaux SA | SWITZERLAND |

| Gold | Sabin Metal Corp. | UNITED STATES |

| Gold | Shandong Zhaojin Gold & Silver Refinery Co. Ltd | CHINA |

| Gold | SOE Shyolkovsky Factory of Secondary Precious Metals | RUSSIAN FEDERATION |

| Gold | Yamamoto Precious Metal Co., Ltd. | JAPAN |

| Gold | Yokohama Metal Co Ltd | JAPAN |

| Tantalum | King-Tan Tantalum Industry Ltd | CHINA |

| Tin | China Tin Group Co., Ltd. | CHINA |

| Tin | Cooper Santa | BRAZIL |

| Tin | CV Nurjanah | INDONESIA |

| Tin | CV Serumpun Sebalai | INDONESIA |

| Tin | EM Vinto | BOLIVIA |

| Tin | Fenix Metals | POLAND |

| Tin | Metallo Chimique | BELGIUM |

| Tin | PT Artha Cipta Langgeng | INDONESIA |

| Tin | PT Bangka Kudai Tin | INDONESIA |

| Tin | PT Bangka Timah Utama Sejahtera | INDONESIA |

| Tin | PT Belitung Industri Sejahtera | INDONESIA |

| Tin | PT BilliTin Makmur Lestari | INDONESIA |

| Tin | PT Eunindo Usaha Mandiri | INDONESIA |

| Tin | PT Inti Stania Prima | INDONESIA |

| Tin | PT Karimun Mining | INDONESIA |

| Tin | PT Mitra Stania Prima | INDONESIA |

| Tin | PT Pelat Timah Nusantara Tbk | INDONESIA |

| Tin | PT Prima Timah Utama | INDONESIA |

| Tin | PT Sumber Jaya Indah | INDONESIA |

| Tin | PT Tinindo Inter Nusa | INDONESIA |

| Tin | Rui Da Hung | TAIWAN |

| Tin | Soft Metais, Ltda. | BRAZIL |

|

| | |

| Tin | Yunnan Chengfeng Non-ferrous Metals Co.,Ltd. | CHINA |

| Tungsten | Chongyi Zhangyuan Tungsten Co., Ltd. | CHINA |

| Tungsten | Fujian Jinxin Tungsten Co., Ltd.* | CHINA |

| Tungsten | Ganzhou Non-ferrous Metals Smelting Co., Ltd. | CHINA |

| Tungsten | Guangdong Xianglu Tungsten Industry Co., Ltd. | CHINA |

| Tungsten | Vietnam Youngsun Tungsten Industry Co., Ltd* | VIETNAM |

| Tungsten | Wolfram Bergbau und Hütten AG | AUSTRIA |

| Tungsten | Xinhai Rendan Shaoguan Tungsten Co., Ltd. | CHINA |

Table 2 Notes

Smelters followed by an asterisk (*) symbol are Tungsten Industry - Conflict Minerals Council (TI-CMC) members that have committed to complete a CFSP validation audit within two (2) years of TI-CMC membership issuance.

Table 3. CFSP-non-participating processing facilities as of January 31, 2015

Processing facilities and their locations reported in our supply chain that have not agreed to participate in the CFSP.

|

| | |

| Metal | Processing Facility Name | Country |

| Gold | Almalyk Mining and Metallurgical Complex (AMMC) | UZBEKISTAN |

| Gold | Atasay Kuyumculuk Sanayi Ve Ticaret A.S. | TURKEY |

| Gold | Bangko Sentral ng Pilipinas (Central Bank of the Philippines) | PHILIPPINES |

| Gold | Bauer Walser AG | GERMANY |

| Gold | Caridad | MEXICO |

| Gold | Chugai Mining | JAPAN |

| Gold | Colt Refining | UNITED STATES |

| Gold | Daejin Indus Co. Ltd | KOREA, REPUBLIC OF |

| Gold | DaeryongENC | KOREA, REPUBLIC OF |

| Gold | Daye Non-Ferrous Metals Mining Ltd. | CHINA |

| Gold | Do Sung Corporation | KOREA, REPUBLIC OF |

| Gold | Doduco | GERMANY |

| Gold | FSE Novosibirsk Refinery | RUSSIAN FEDERATION |

| Gold | Gansu Seemine Material Hi-Tech Co Ltd | CHINA |

| Gold | Guangdong Jinding Gold Limited | CHINA |

| Gold | Hunan Chenzhou Mining Group Co., Ltd. | CHINA |

| Gold | Hwasung CJ Co. Ltd | KOREA, REPUBLIC OF |

|

| | |

| Gold | Inner Mongolia Qiankun Gold and Silver Refinery Share Company Limited | CHINA |

| Gold | Jiangxi Copper Company Limited | CHINA |

| Gold | JSC Ekaterinburg Non-Ferrous Metal Processing Plant | RUSSIAN FEDERATION |

| Gold | JSC Uralelectromed | RUSSIAN FEDERATION |

| Gold | Korea Metal Co. Ltd | KOREA, REPUBLIC OF |

| Gold | Kyrgyzaltyn JSC | KYRGYZSTAN |

| Gold | L' azurde Company For Jewelry | SAUDI ARABIA |

| Gold | Lingbao Gold Company Limited | CHINA |

| Gold | Lingbao Jinyuan Tonghui Refinery Co. Ltd. | CHINA |

| Gold | Luoyang Zijin Yinhui Metal Smelt Co Ltd | CHINA |

| Gold | Moscow Special Alloys Processing Plant | RUSSIAN FEDERATION |

| Gold | Navoi Mining and Metallurgical Combinat | UZBEKISTAN |

| Gold | OJSC Kolyma Refinery | RUSSIAN FEDERATION |

| Gold | Prioksky Plant of Non-Ferrous Metals | RUSSIAN FEDERATION |

| Gold | PT Aneka Tambang (Persero) Tbk | INDONESIA |

| Gold | Samwon Metals Corp. | KOREA, REPUBLIC OF |

| Gold | So Accurate Group, Inc. | UNITED STATES |

| Gold | The Great Wall Gold and Silver Refinery of China | CHINA |

| Gold | The Refinery of Shandong Gold Mining Co. Ltd | CHINA |

| Gold | Tongling nonferrous Metals Group Co., Ltd | CHINA |

| Gold | Torecom | KOREA, REPUBLIC OF |

| Gold | Yunnan Copper Industry Co Ltd | CHINA |

| Gold | Zhongyuan Gold Smelter of Zhongjin Gold Corporation | CHINA |

| Gold | Zijin Mining Group Co. Ltd | CHINA |

| Tantalum | Shanghai Jiangxi Metals Co. Ltd | CHINA |

| Tin | CNMC (Guangxi) PGMA Co. Ltd. | CHINA |

| Tin | CV JusTindo | INDONESIA |

| Tin | CV Makmur Jaya | INDONESIA |

| Tin | Estanho de Rondônia S.A. | BRAZIL |

| Tin | Gejiu Kai Meng Industry and Trade LLC | CHINA |

| Tin | Gejiu Zi-Li | CHINA |

| Tin | Huichang Jinshunda Tin Co. Ltd | CHINA |

| Tin | Jiangxi Nanshan | CHINA |

|

| | |

| Tin | Linwu Xianggui Smelter Co | CHINA |

| Tin | Minmetals Ganzhou Tin Co. Ltd.^ | CHINA |

| Tin | Novosibirsk Integrated Tin Works | RUSSIAN FEDERATION |

| Tin | O.M. Manufacturing (Thailand) Co., Ltd. | THAILAND |

| Tin | PT Alam Lestari Kencana | INDONESIA |

| Tin | PT Babel Surya Alam Lestari | INDONESIA |

| Tin | PT Fang Di MulTindo | INDONESIA |

| Tin | PT HP Metals Indonesia | INDONESIA |

| Tin | PT Koba Tin | INDONESIA |

| Tin | PT Yinchendo Mining Industry | INDONESIA |

| Tungsten | A.L.M.T. Corp.* | JAPAN |

| Tungsten | Chenzhou Diamond Tungsten Products Co., Ltd.* | CHINA |

| Tungsten | Dayu Weiliang Tungsten Co., Ltd.* | CHINA |

| Tungsten | H.C. Starck GmbH* | GERMANY |

| Tungsten | H.C. Starck Smelting GmbH & Co.KG* | GERMANY |

| Tungsten | HC Starck GmbH*^ | GERMANY |

| Tungsten | Hunan Chenzhou Mining Group Co* | CHINA |

| Tungsten | Jiangxi Gan Bei Tungsten Co., Ltd.* | CHINA |

| Tungsten | Jiangxi Minmetals Gao'an Non-ferrous Metals Co., Ltd. | CHINA |

| Tungsten | Jiangxi Tonggu Non-ferrous Metallurgical & Chemical Co., Ltd.* | CHINA |

| Tungsten | Jiangxi Xinsheng Tungsten Industry Co., Ltd.* | CHINA |

| Tungsten | Kennametal Fallon* | UNITED STATES |

| Tungsten | Kennametal Huntsville* | UNITED STATES |

| Tungsten | Tejing (Vietnam) Tungsten Co., Ltd.* | VIETNAM |

| Tungsten | Wolfram Company CJSC* | RUSSIAN FEDERATION |

| Tungsten | Zhuzhou Cemented Carbide Group Co Ltd^ | CHINA |

Table 3 Notes

Processing facilities followed by a caret (^) symbol had previously been identified at a “corporate” or “group” level whereby one entry may have represented multiple individual facilities. With CMRT Revision 3.02, these higher level entities have been eliminated and replaced with entries representing each unique facility.

Processing facilities followed by an asterisk (*) symbol are Tungsten Industry - Conflict Minerals Council (TI-CMC) members that have committed to complete a CFSP validation audit within two (2) years of TI-CMC membership issuance.