Let me share a few of the solutions we're working on: ž On-demand under reamers, and hybrid drill bits. ž High-temperature drilling services and the ability to analyze fluids while drilling. ž Large diameter rotary coring, next generation imaging, and high pressure cement bond logs and casing evaluation services. ž High-pressure subsea safety valves and packers. ž Next generation, single-trip, multizone frac systems.

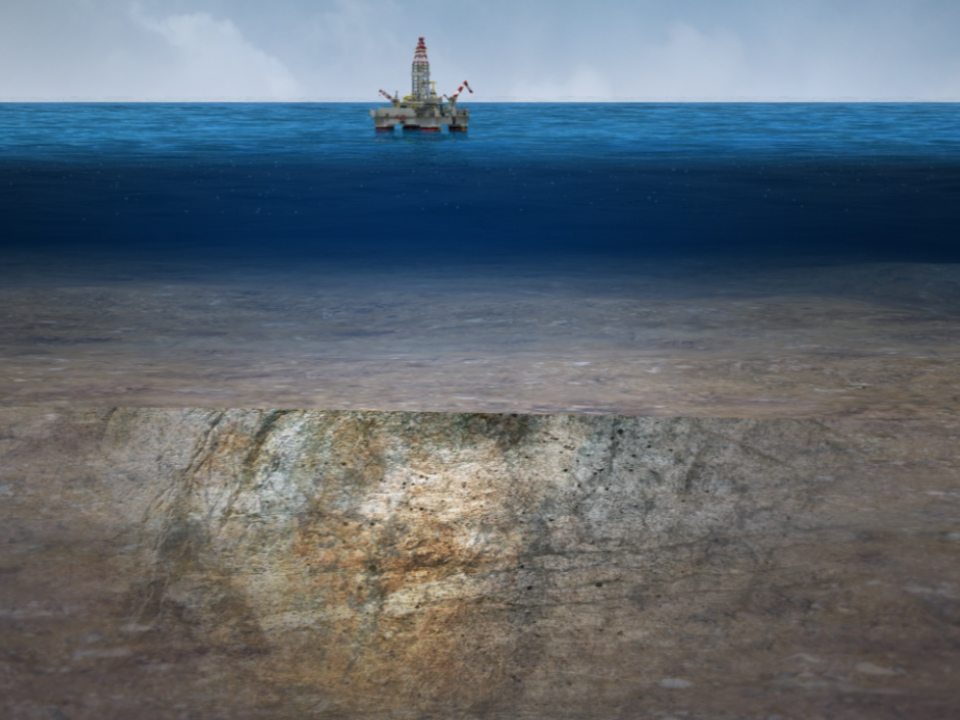

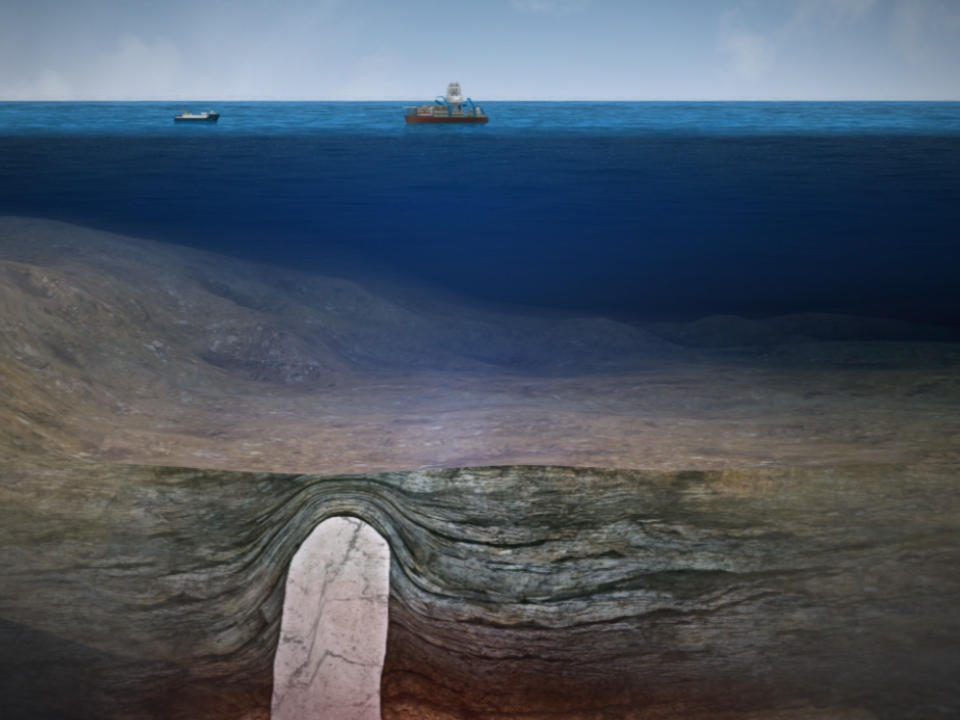

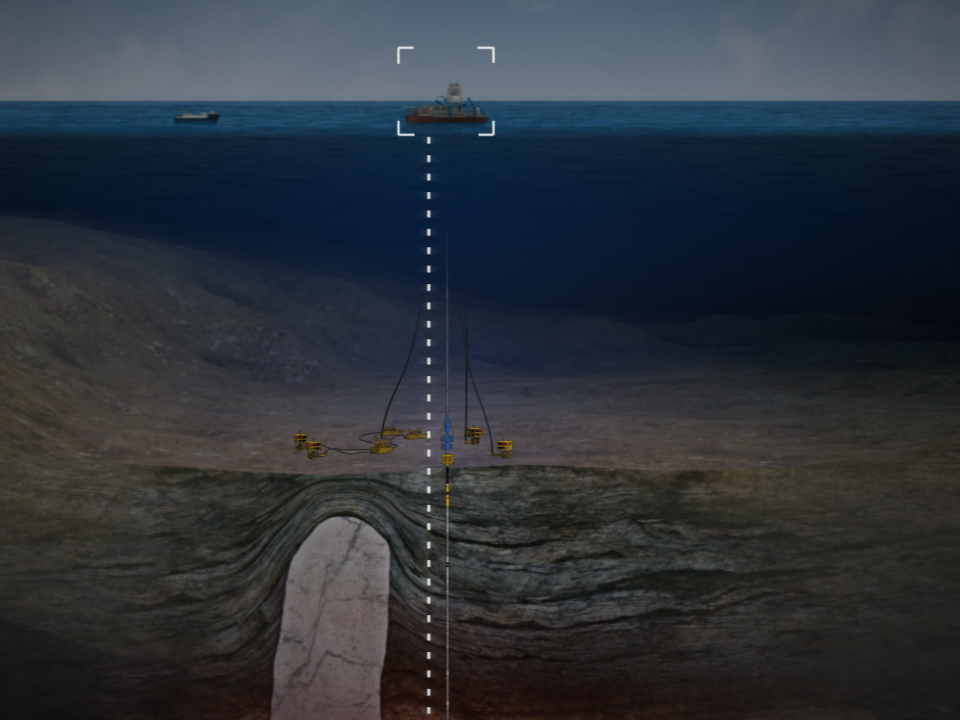

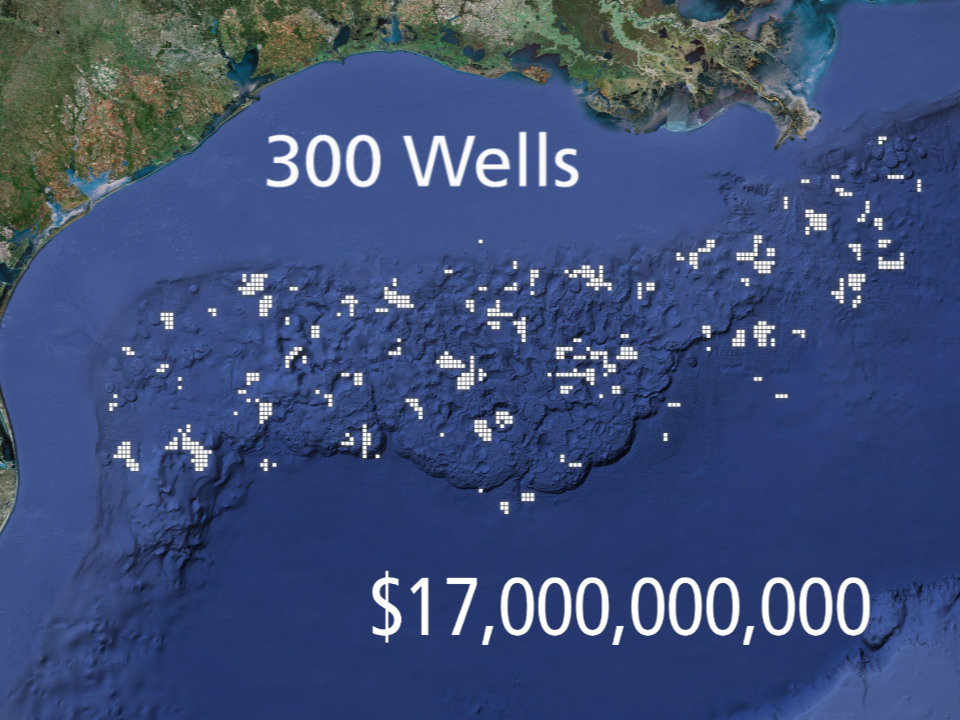

ž And heavy-weight frac fluids. Some of these products and services are meaningful incremental improvements for several of our major drilling and evaluation product lines. But it's the production side where the ultra-deepwater frontier really stands out. Producing in these environments will require a full suite of integrated solutions that simply don't exist today. And the stakes for the winner are huge. In fact, according to one customer, just a 1% improvement in recovery factor on some projects translates into $3.2 billion in NPV. Baker Hughes can make that happen. Because of the high cost of well intervention, some customers are requiring fully redundant, subsea in-well, and boosting systems, with an expected life of 10 years. Just think about the engineering behind that. Today, we've got ESPs that have been operating reliably in deepwater for more than three years, and that's something we're quite proud of. But the next generation will require an ESP that can be counted on to turn on five years after it gets installed. And then operate another five years. Here's another challenge. These wells will require next generation, high-pressure and high-temperature monitoring and control systems, many with fiber optics. The system must come out of the gate fully compatible with the well completion hardware, and it must be able to respond dynamically to downhole conditions over the lifetime of the well.

|