SECURITIES AND EXCHANGE COMMISSION

Washington D.C. 20549

FORM 10-K/A

(Amendment No. 1)

(Mark One)

| x | | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 (FEE REQUIRED) |

For the fiscal year ended December 31, 2001

OR

| ¨ | | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 (NO FEE REQUIRED) |

For the transition period from to

VARCO INTERNATIONAL, INC.

(Exact name of registrant as specified in its charter)

Delaware (State or other jurisdiction of incorporation or organization) | | 001-13309 (Commission File No.) | | 76-0252850 (I.R.S. Employer Identification No.) |

One BriarLake Plaza, 2000 W. Sam Houston Pkwy South, Suite 1700, Houston, TX (Address of principal executive offices) | | 77042 (Zip Code) |

Registrant’s telephone number, including area code: (281) 953-2200

Securities registered pursuant to Section 12(b) of the Act:

Title of each class

| | Name of each exchange on which registered

|

Common stock, $.01 par value Preferred Share Purchase Rights | | New York Stock Exchange New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act:

None

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports) and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

The aggregate market value of the voting stock held by non-affiliates of the registrant as of February 22, 2002, was $1,319,902,784 based on the closing sales price of such stock on such date.

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

The number of shares outstanding of the registrant’s common stock as of February 22, 2002, was 96,049,170.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant’s Proxy Statement for its 2002 Annual Meeting are incorporated by this reference into Part III, as set forth herein.

ITEM 1. BUSINESS

General

Varco International, Inc. (the “Company”) is a leading provider of highly engineered drilling and well-servicing equipment, products and services to the world’s oil and gas industry. The Company is a leading manufacturer and supplier of innovative drilling systems and rig instrumentation; oilfield tubular inspections and internal tubular coating techniques; drill cuttings separation, management and disposal systems and services; and coiled tubing and pressure control equipment for land and offshore drilling and well stimulation operations. The Company also provides in-service pipeline inspections, manufactures high pressure fiberglass tubulars, and sells and rents advanced in-line inspection equipment to makers of oil country tubular goods. The Company has a long tradition of pioneering many drilling and production innovations which have steadily improved the efficiency, safety, cost and environmental impact of petroleum operations.

The Company is engaged in the design, manufacture, sale and rental of drilling and well-remediation equipment, and provides technical services around the world, with operations spanning six continents, 49 countries and every major oilfield market in the world. The Company underwent a significant transformation in May 2000 when Varco International, Inc., a California corporation (“Varco”), merged into Tuboscope Inc. (“Tuboscope”) (the “Merger”). The Merger has been accounted for as a pooling of interests, and unless otherwise indicated, the financial, historical and other information included herein is for the combined company. The Company’s common stock is traded on the New York Stock Exchange under the symbol “VRC.” The Company operates through four business groups: Drilling Equipment Sales, Tubular Services, Drilling Services, and Coiled Tubing & Wireline Products.

The Drilling Equipment Sales group manufactures and sells integrated systems and equipment for rotating and handling pipe on offshore and land drilling rigs; a complete line of conventional drilling rig tools and equipment, including pipe handling tools, hoisting equipment and rotary equipment; pressure control and motion compensation equipment; derricks and rig substructures; and flow devices. Customers include major oil and gas companies, independent producers, national oil companies, oilfield supply stores, and onshore and offshore drilling contractors.

The Tubular Services group provides internal coating products and services, inspection and quality assurance services for oil country tubular goods, including drillpipe, production tubulars and flowlines. Additionally, this group includes the sale and rental of proprietary equipment used to inspect tubular products at steel mills, and the design, manufacture and sale of corrosion-resistant high pressure fiberglass tubular goods. The Tubular Services group also provides technical inspection services and quality assurance services for in-service pipelines used to transport oil and gas. Customers include major oil and gas companies, independent producers, national oil companies, drilling contractors, oilfield supply stores, industrial plant operators and steel mills.

The Drilling Services group sells and rents technical equipment used in, and provides services related to, the separation and management of drill cuttings (solids) from fluids used in the oil and gas drilling processes (Solids Control). The Drilling Services group also includes the sale and rental of data collection and monitoring systems used to manage the drilling process on site (Rig Instrumentation). Customers include major oil and gas companies, independent producers, national oil companies and drilling contractors.

The Coiled Tubing & Wireline Products group designs, manufactures, and sells highly-engineered coiled tubing and related equipment, related pressure control equipment, pressure pumping, wireline and related tools to companies engaged in providing oil and gas well drilling, completion and remediation services. Customers include major oil and gas coiled tubing service companies, as well as major oil companies and independent producers.

1

The following table sets forth the contribution to the Company’s total revenues of its four operating groups:

| | | Years Ended December 31,

|

| | | 2001

| | 2000

| | 1999

|

| | | (in thousands) |

Drilling Equipment Sales | | $ | 395,550 | | $ | 283,360 | | $ | 504,245 |

Tubular Services | | | 352,624 | | | 248,099 | | | 194,929 |

Drilling Services | | | 314,272 | | | 250,229 | | | 202,518 |

Coiled Tubing & Wireline Products | | | 205,363 | | | 84,927 | | | 74,156 |

| | |

|

| |

|

| |

|

|

Total | | $ | 1,267,809 | | $ | 866,615 | | $ | 975,848 |

| | |

|

| |

|

| |

|

|

Influence of Oil and Gas Activity Levels on the Company’s Business

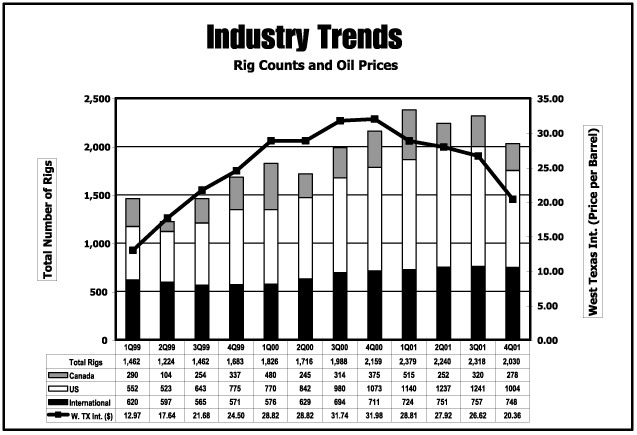

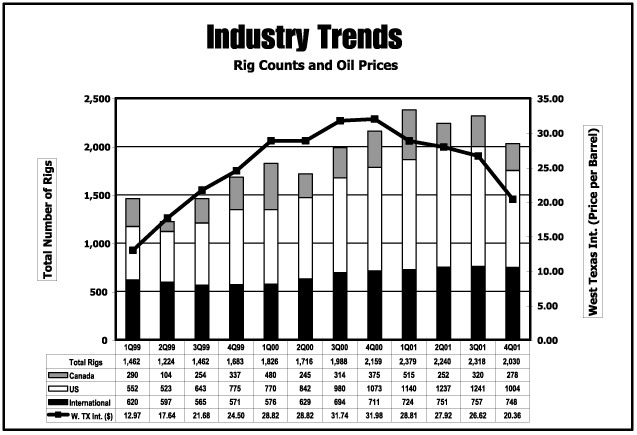

The oil and gas industry in which the Company participates has historically experienced significant volatility. Demand for the Company’s services and products depends primarily upon the general level of activity in the oil and gas industry worldwide, including the number of drilling rigs in operation, the number of oil and gas wells being drilled, the depth and drilling conditions of these wells, the volume of production, the number of well completions and the level of well workover activity. Oil and gas activity is heavily influenced by, among other factors, oil and gas prices worldwide. High levels of drilling and well-remediation activity spur direct demand for the Company’s products and services used to drill and remediate oil and gas wells, particularly in Tubular Services and Drilling Services. Additionally, high levels of oil and gas activity increase cash flows for drilling contractors and well-remediation oilfield service contractors to reinvest in capital equipment which the Company sells through its Drilling Equipment Sales and Coiled Tubing & Wireline Products groups.

Drilling and workover activity can fluctuate significantly in a short period of time, particularly in the United States and Canada. The willingness of oil and gas operators to make capital expenditures to explore for and produce oil and natural gas will continue to be influenced by numerous factors over which the Company has no control, including: the ability of the members of the Organization of Petroleum Exporting Countries to maintain oil price stability through voluntary production limits of oil; the level of oil production by non-OPEC countries; worldwide demand for oil; the supply and demand for natural gas; general economic and political conditions; costs of exploration and production; and the availability of new leases and concessions and governmental regulations regarding, among other things, environmental protection, taxation, price controls and product allocations.

Low petroleum prices adversely affected the Company’s business in the second half of 1998 and throughout 1999 as drilling and well remediation activity declined. The Company’s overall revenues grew in 1998, but declined steadily through 1999 and 2000 as the Company completed orders for Drilling Equipment Sales placed in 1997 and early 1998. Strengthening oil and gas prices in late 1999 and 2000 led to recoveries in the Company’s Tubular Services and Drilling Services groups as drilling and well remediation activity rose during the period. Drilling Equipment Sales and Coiled Tubing & Wireline Products revenues began to rise in late 2000 as drilling contractors and well service companies began to invest in new capital equipment following the higher levels of oilfield activity in 2000. Drilling activity began to decline in mid-2001 due to lower oil and gas prices. The Company’s Drilling Services and Tubular Services revenue began to decline in late 2001, and backlog levels for the Company’s Drilling Equipment Sales and Coiled Tubing Wireline Products divisions also began to decline in late 2001, as a result.

The Drilling Process

Oil and gas wells are usually drilled by a drilling rig using a bit attached to the end of drill stem made up of 30-foot joints of drill pipe. Using the conventional rotary drilling method, the drill stem is turned from the rotary table (the revolving or spinning section of the floor) of the drilling rig by torque applied to the “kelly” (a square or hexagonal section of pipe located at the top of the drill stem) by means of the master bushing and kelly

2

bushing. A kelly bushing is an adapter that connects the kelly to the rotary table, which in turn provides rotating force that rotates the drill pipe. A master bushing is a general purpose adapter that connects the rotary table to a range of types of bushings, including kelly bushings. A master bushing is used when a number of different bushings are required during the drilling process.During the drilling process heavy fluids (“drilling muds”) are pumped down through the drill stem and forced out through the bit. The drilling mud returns to the surface through the hole area surrounding the drill stem, carrying with it the cuttings drilled out by other specialized equipment. The cuttings are removed from the mud by a solids control system which can include shakers, centrifuges and the like and disposed of in an environmentally sound manner. The solids control system permits the mud to be continuously recirculated back into the hole. The drilling mud also serves to contain pressure surges of gas, oil or water (“kicks”) that may intrude into the borehole from the formation. Corrosive fluids may be in the formation or in materials used in the drilling process. Accordingly, it is prudent for operators to protect the expensive drill stem from such corrosive fluids, and to inspect and assess the integrity of the drill pipe from time to time.

As the hole depth increases, the kelly must be removed frequently so that additional 30-foot joints of pipe can be added to the drill stem, which through this process may be assembled into lengths in excess of six miles. When the bit becomes dull, the entire drill stem is pulled out of the hole and disassembled, the disconnected sections of pipe are set aside or “racked,” the old bit is replaced and the drill stem is reassembled and lowered back into the hole (a process called “tripping”). During drilling and tripping operations, tool joints must be screwed together and tightened (“spun in” and “made up”), and loosened and unscrewed (“broken out” and “spun out”). When the hole has reached certain depths, all of the drill pipe is pulled out of the hole and larger diameter pipe known as casing is lowered into the hole and cemented in place in order to protect against collapse and contamination of the hole. The integrity of the casing is typically assessed before it is lowered into the hole.

The raising and lowering of the drill stem while drilling or tripping, and the lowering of casing into the wellbore (the open hole of the well), are accomplished with the rig’s hoisting system. A conventional hoisting system is a block and tackle mechanism, and the drilling rig’s derrick must have sufficient structural integrity to support the entire weight of the drill stem or casing string.

During the drilling process it is possible for formation fluids, such as natural gas, water or oil, to get into the wellbore, creating additional pressure which, if not controlled, could lead to a “blowout” of the well. A blowout is an uncontrolled flow of fluids into the well or to the surface of the well. To prevent blowouts, a series of high-pressure valves known as blowout preventers (“BOPs”) are positioned at the top of the well and, when activated, form pressure tight seals which prevent the escape of fluids. When closed, conventional BOPs prevent normal rig operations and are activated only if drilling mud and normal well control procedures cannot safely contain the pressure. BOPs have been designed to contain pressure of up to 15,000 psi.

After the well has reached its total depth and the final section of casing has been set, the drilling rig is moved off of the well and the well is prepared to begin producing oil or gas in a process known as “well completion.” Well completion usually involves running production tubing concentrically in the casing. Due to the corrosive nature of many produced fluids, this production tubing is often coated, or constructed of corrosion resistant composite materials. From time to time, a producing well may undergo workover procedures to extend its life and increase its production rate. Frequently coiled tubing units or wireline units are used to accomplish certain formation stimulations or well completions. Coiled tubing is a recent advancement in petroleum technology consisting of a continuous length of reeled tubing which can be injected concentrically into the production tubing all the way to the bottom of most wells. It permits many operations to be performed without disassembling the production tubing, and without curtailing the production of the well. Wireline winch units are devices which utilize single-strand or multistrand wires used for well-intervention operations, such as lowering tools and transmitting data.

Drilling Equipment Sales Group

The Company has a long tradition of pioneering innovations such as the top drive and automatic pipe handling systems which improve the efficiency, safety, and cost of drilling operations. The Drilling Equipment

3

Sales group designs, manufactures and sells a wide variety of top drives (discussed below), automated pipe racking systems, motion compensation systems, rig controls, BOPs, handling tools, drawworks (a device used to raise and lower the drill pipe), risers, rotary tables, and other drilling equipment for both the onshore and offshore markets, and is a leader in the development of innovative drilling systems. A riser is a steel conduit used in offshore drilling that runs from the drilling rig on the water’s surface to the seafloor, allowing drill pipe and other tools to be passed through it to the well. Based on its supply of drilling equipment for most of the newly-constructed harsh environment offshore drilling rigs over the past few years, the Company believes it is the worldwide market leader in several of these product categories. During 2001, the Company also emphasized the land rig market and as a result saw a larger portion of its drilling equipment sales business related to onshore drilling rigs. The Drilling Equipment Sales group sells directly to drilling contractors and oil companies. Demand for its products, several of which are described below, is strongly dependent upon capital spending plans by oil and gas companies and drilling contractors.

Top Drives. The Top Drive Drilling System (“TDS”), originally introduced by Varco in 1982, significantly alters the traditional drilling process. Using the TDS, the drill stem is rotated from its top, rather than by the aforementioned rotary table, by means of a large electric motor. This motor is affixed to rails installed in the derrick and traverses from near the top of the derrick to the rig floor as the drill stem penetrates the earth. Therefore, the TDS eliminates the use of the conventional rotary table for drilling. Components of the TDS also are used to connect additional lengths of pipe to the drill stem during drilling operations.

The TDS combines elements of pipe handling tools, as well as hoisting and rotary equipment, in a single system. During drilling operations, elements of the TDS perform functions such as spinning-in and making-up tool joints. It also incorporates a drill pipe elevator, providing the capability to maneuver a stand of pipe into position to be added to the drill string when drilling, or to hold and hoist the entire drill stem. Drilling with a TDS provides several advantages over conventional drilling. It enables drilling with three joints of drill pipe, often reducing by two-thirds the time spent in making connections of drill pipe. In addition, it facilitates “horizontal” and “extended reach” drilling (the practice of drilling wells which deviate substantially from vertical) by providing the ability to rotate the pipe as it is removed from, or replaced into, the hole, thus reducing friction and the incidence of pipe sticking. This can often dramatically reduce drilling “trouble costs”. Trouble costs are costs incurred as a result of unanticipated complications while drilling a well. These costs are often referred to as contingency costs during the planning phase of a well. The TDS also increases the safety of drilling operations.

The TDS has demonstrated substantial economic advantages. Users of the system report reductions in drilling time ranging up to 40%. By facilitating extended reach drilling, the TDS increases the area which can be drilled from a given location, such as a fixed platform or man-made island. Thus, the production from a given reservoir of oil can be increased, and the number of costly fixed platforms required to develop the field can be minimized. The TDS has evolved continuously since its initial introduction. Today, the Company’s top drive product line includes several models, each designed to satisfy specific customer requirements.

Pipe Racking Systems. Pipe racking systems are used to handle drill pipe, casing, tubing and other types of pipe (collectively, “tubulars”) on a drilling rig. Vertical pipe racking systems move drill pipe and casing between the well and a storage (“racking”) area on the rig floor. Horizontal racking systems are used to handle tubulars while stored horizontally (for example, on the pipe deck of an offshore rig) and transport it up to the rig floor and raise it to a vertical position from which it may be passed to a vertical racking system.

Mechanical vertical pipe racking systems greatly reduce the manual effort involved in pipe handling. The Pipe Handling Machine (“PHM”), introduced by Varco in 1985, provides a fully automated mechanism for handling and racking of drill pipe and drill collars during drilling and tripping operations. It incorporates the spinning and torquing functions of the Automated Roughneck with the automatic hoisting and racking of disconnected joints of pipe. These functions are integrated via computer controlled sequencing, and the Pipe Handling Machine is operated by a person in an environmentally secure cabin. The Automated Roughneck is an automated microprocessor-controlled version of the Iron Roughneck, which was originally introduced by Varco

4

in 1976. An Iron Roughneck is an automated device that makes pipe connections on the rig floor and requires less direct involvement of rig floor personnel in potentially dangerous operations.

Vertical pipe racking systems are used predominantly on offshore rigs and are found on almost all floating rigs. Horizontal pipe racking systems were introduced by Varco in 1993. They include the Pipe Deck Machine (“PDM”), which is used to manipulate and move tubulars while stored in a horizontal position; the Pipe Transfer Conveyor (“PTC”), which transports sections of pipe to the rig floor; and a Pickup Laydown System (“PLS”), which raises the pipe to a vertical position for transfer to a vertical racking system. These components may be employed separately, or incorporated together to form a complete horizontal racking system, known as the Pipe Transfer System (“PTS”).

Hoisting systems are used to raise or lower the drill stem while drilling or tripping, and to lower casing into the wellbore. During 1999, Varco introduced its first “Automated Hoisting System” (“AHS”), which uses an AC-powered motor and a braking system that offers precise proportional control. The AHS automates the repetitive hoisting and drilling operations through the user-friendly, touch-screen Electronic Driller interface. The AHS is smaller and lighter than conventional hoisting systems. The Company received its first order for an AHS in 2000 and delivered the first AHS in 2001.

Blow-out Preventers. BOPs are devices used to seal the space (“annulus”) between the drill pipe and the borehole to prevent an uncontrolled flow of formation fluids and gases. The Drilling Equipment Sales group manufactures three types of BOPs under the Shaffer brandname. Ram and annular BOPs are back-up devices and are activated only if other techniques for controlling pressure in the wellbore are inadequate. When closed, these devices prevent normal rig operations. Ram BOPs seal the wellbore by hydraulically closing rams (thick heavy blocks of steel) against each other across the wellbore. Specially designed packers seal around specific sizes of pipe in the wellbore, shear pipe in the wellbore or close off an open hole. Annular BOPs seal the wellbore by hydraulically closing a rubber packing unit around the drill pipe or kelly or by sealing against itself if nothing is in the hole. The rotating BOP allows operators to drill or strip into or out of the well at low pressures without interrupting normal operations.

Varco expanded its BOP line in 1995 with the introduction of a system for achieving Pressure Control While Drilling (PCWD®). This new BOP allows normal drilling operations to proceed while controlling pressures up to 2,000 psi, and will operate as a normal spherical BOP at pressures up to 5,000 psi.

In 1998 Varco introduced the NXT® ram type BOP which eliminates door bolts, providing weight and space savings. Its unique features make subsea operation more efficient through faster ram configuration changes without tripping the BOP stack.

The Company sells conventional BOP control systems under the registered trademark Koomey®. The Koomey control system is hydraulically activated and is used to operate BOPs and associated valves remotely for both land systems and offshore systems. With the recent increase in deep-water drilling depths, traditional hydraulic control systems are inadequate to activate BOPs, which rest on the ocean floor and may be 5,000 feet or more below the surface. In 1997, Varco introduced the IVth Generation MUX, an electronic control system designed specifically for deep-water applications. In 2001, the Company acquired technology from Maris International related to a continuous circulation device the Company hopes to commercialize.

Motion Compensation Systems. The Drilling Equipment Sales group sells motion compensation equipment under the registered trademark Rucker™. Motion compensation equipment stabilizes the bit on the bottom of the hole, increasing drilling effectiveness of floating offshore rigs by compensating for wave and wind action. This group also manufactures tensioners, which provide continuous reliable axial tension to the marine riser pipe (larger diameter pipe which connects floating drilling rigs to the well on the ocean floor) and guide lines on floating drilling rigs, tension leg platforms and jack-up rigs. A jack-up rig is a self-contained combination drilling rig and floating barge, fitted with long support legs that can be raised or lowered independently of each other. An

5

important product extension in 1996 was the Riser Recoil System, which provides a safe disconnect when the floating rig encounters an unanticipated need to leave location.

Pipe Handling Tools. The Company’s pipe handling tools are designed to enhance the safety, efficiency and reliability of pipe handling operations. Many of these tools have provided innovative methods of performing the designated task through mechanization of functions previously performed manually. The Drilling Equipment Sales group manufactures various tools used to grip, hold, raise, and lower pipe, and in the making up and breaking out of drill pipe, workstrings, casing and production tubulars including spinning wrenches, manual tongs, torque wrenches and kelly spinners. The spinning wrench is a tool used to screw together and unscrew joints of drill pipe. Manual tongs are used to make up or break out tool joints, while the torque wrench is a hydraulically powered device which performs this function with enhanced safety and precision. The kelly spinner is a pneumatically or hydraulically powered tool used to connect and disconnect the kelly to and from the drill stem as additional lengths of pipe are added while drilling.

The Drilling Equipment Sales group also manufactures other tools used in various pipe handling functions. Slips are gripping devices which hold pipe or casing in suspension while in the hole, and they may be either manual, spring or hydraulically operated. Other products, which include safety clamps, casing bushings and casing bowls, are used to hold and guide drill pipe or casing while in the hole. Safety clamps prevent tool strings from being dropped down the well accidentally if the devices securing the string lose their grip. A casing bushing is an adapter used in the rotary table when casing is being inserted into the well to ensure that the casing is centered in the hole, which is critical to the well being cemented properly. A casing bowl secures and seals the upper end of the casing.

Rotary Equipment. Rotary equipment products consist of kelly bushings and master bushings. The kelly bushing applies torque to the kelly to rotate the drill stem and fits in the master bushing which is turned by the rotary table on the floor of the rig. The Drilling Equipment Sales group produces kelly bushings and master bushings for most sizes of kellys and makes of rotary tables.

In 1998, Varco introduced the Rotary Support Table for use on rigs with Top Drive Drilling Systems. The Rotary Support Table is used in concert with the TDS to completely eliminate the need for the larger conventional rotary table.

Rig Controls. Drilling consoles, and recently, the V-ICIS™, are typically sold as an integral part of a new rig, or as a major upgrade component for an existing rig. In the United States and Canada, most other drilling instrumentation products are usually rented to the drilling contractor or oil company when necessary, and are therefore not permanently installed on the rig. The Company rents this type of equipment within its Drilling Services group. Internationally, nearly all instrumentation equipment is sold to the rig owner and becomes a permanent part of the drilling rig.

A significant portion of the sales of Drilling Equipment Sales group is in spare and replacement parts. The Company conducts Drilling Equipment manufacturing operations at facilities across North America and Europe, and maintains sales and service offices in most major oilfield markets. The Company expanded its market presence in Norway when it acquired its agent, Scana IOS Desco AS, in December 2000.

Derricks and substructures. The Company began offering design, fabrication and repair services for derricks and substructures through its acquisition of Morinoak International Ltd. in September 2001. Through Morinoak International, the Company operates engineering and fabrication facilities in Great Yarmouth, England and Aberdeen, Scotland. Morinoak’s service offerings include modification of existing drilling rigs to accept top drives and pipe handling equipment. It also refurbishes, repairs and fabricates structural components from both land and offshore rigs.

The products of the Drilling Equipment Sales group are sold in highly competitive markets and its sales and earnings can be affected by competitive actions such as price changes, new product development or improved

6

availability and delivery. The group’s primary competitors are Hydralift AS, a Norwegian company, National-Oilwell, Inc., Cooper Cameron Corporation, Hydril Company, Stewart and Stevenson Service, Inc., DenCon Oil Tools, Weatherford International, Inc., Aker Maritime AS, Tesco Corporation, and Canrig, a division of Nabors Industries.

Tubular Services Group

The Company is a leading provider of a variety of tubular services to oil and gas producers, drilling contractors, well-remediation contractors, pipeline operators, and tubular manufacturers and distributors. The Tubular Services group provides tubular inspection services for drillpipe, casing, production tubing, and line pipe at drilling and workover rig locations, at pipe yards owned by its customers, at steel mills and processing facilities manufacturing tubular goods, and at pipe yard facilities which it owns. This group also provides for the internal coating of tubular goods at coating plants worldwide, including a plant opened in Navasota, Texas in 1998, and through licensees in certain locations. The Company operated 11 tubular coating plants worldwide in 2001, and opened a twelth coating plant in the Far East in early 2002. The Company believes it is the leading provider of oil country tubular goods inspection and internal tubular coating services worldwide. Additionally, the Company designs, manufactures and sells high pressure fiberglass tubulars for use in corrosive applications. The Tubular Services group also provides in-place inspection of oil, gas and product transmission pipelines through its application of instrumented survey tools (“smart pigs”) which it engineers, manufactures and operates.

The Company’s customers rely on tubular inspection services to avoid failure of tubing, casing, flowlines, pipelines and drillpipe. Such tubular failures are expensive and in some cases catastrophic. The Company’s customers rely on internal coatings of tubular goods to prolong the useful lives of tubulars and to increase the volumetric throughput of in-service tubular goods. The Company’s customers sometimes use fiberglass tubulars in lieu of conventional steel tubulars, due to the corrosion-resistant properties of fiberglass. Tubular inspection and coating services, and fiberglass tubulars, are used most frequently in operations in high-temperature, deep, corrosive oil and gas environments. In selecting a provider of tubular inspection and tubular coating services, oil and gas operators consider such factors as reputation, experience, technology of products offered, reliability and price. Following its December 2000 acquisition of the assets of Smith Fiberglass Products and its 2001 acquisition of the assets of Fibercast, the Company believes it is now the largest provider of fiberglass tubulars to oilfield applications worldwide.

Tubular Corrosion Control. The Company develops, manufactures and applies its proprietary tubular coatings, known as Tube-Kote® coatings, to new and used tubulars. Tubular coatings help prevent corrosion of tubulars by providing a tough plastic shield to isolate steel from corrosive oilfield fluids such as CO2, H2S and brine. Delaying or preventing corrosion extends the life of existing tubulars, reduces the frequency of well remediation and reduces expensive interruptions in production for oil and gas producers. In addition, coatings are designed to increase the fluid flow rate through tubulars by decreasing or eliminating paraffin and scale build-up, which can reduce or block oil flow in producing wells. The smooth inner surfaces of coated tubulars often increase the fluid through-put on certain high-rate oil and gas wells.

The Company has a history of introducing new coating products that are custom-engineered to address increasingly corrosive environments encountered in oil and gas drilling and production operations. In 1998, the Company introduced TK®Liner, a fiberglass liner product which offers the strength of steel tubing and the corrosion resistance of fiberglass, and which supplements its traditional plastic coating lines. The Company’s reputation for supplying quality internal coatings is an important factor in its business, since the failure of coatings can lead to expensive production delays and premature tubular failure.

In 1997, the Company acquired Fiber Glass Systems, a leading provider of high pressure fiberglass tubulars used in oilfield applications. Fiber Glass Systems has manufactured fiberglass pipe since 1968 under the name “Star®,” and was the first manufacturer of high-pressure fiberglass pipe to be licensed by the API in 1992. The

7

Company acquired two fiberglass tubing manufacturing facilities in the U.S. and one in China from A.O. Smith in December 2000 and acquired another U.S. fiberglass tubing manufacturing facility from Fibercast in July 2001, which significantly expanded its manufacturing capabilities and product lines. Like coated tubulars, fiberglass pipe is used to guard against corrosive fluids produced in the oilfield and for use in other corrosive industrial applications.

Tubular Inspection. Newly manufactured pipe sometimes contains serious defects that are not detected at the mill. In addition, pipe can be damaged in transit and during handling prior to use at the well site. As a result, exploration and production companies often have new tubulars inspected before they are placed in service to reduce the risk of tubular failures during drilling, completion, or production of oil and gas wells. Used tubulars are inspected by the Company to detect service-induced flaws after the tubulars are removed from operation. Used drill pipe and used tubing inspection programs allow operators to replace defective lengths, thereby prolonging the life of the remaining pipe and saving the customer the cost of unnecessary tubular replacements and expenses related to tubular failures.

The Tubular Services group’s tubular inspection services employ all major non-destructive inspection techniques, including electromagnetic, ultrasonic, magnetic flux leakage and gamma ray. These inspection services are provided both by mobile units which work at the wellhead as used tubing is removed from a well, and at fixed site tubular inspection locations. The group provides an ultrasonic inspection service for detecting potential fatigue cracks in the end area of used drill pipe, the portion of the pipe that traditionally has been the most difficult to inspect. Tubular inspection facilities also offer a wide range of related services, such as API thread inspection, ring and plug gauging, and a complete line of reclamation services necessary to return tubulars to useful service, including tubular cleaning and straightening, hydrostatic testing and re-threading.

In 1998, the Company acquired three tubular services businesses to enhance its competitive positions in Norway, Egypt, and the west coast of the United States. Additionally, these acquisitions provided opportunities to achieve consolidation cost savings. In 1999, the Company completed acquisitions of Geo-Ray Oilfield Inspections Ltd. in Canada, and the tubular services business of AGR Services AS in Floro, Norway. In 2001, it acquired the assets of Servizi Ispettiv, a small tubular services business in Italy, and in early 2002, it acquired the assets of A&A Tubular Inspection in California.

In addition to its new and used tubular inspection and reclamation services, the Company also offers a comprehensive proprietary tubular inventory management system (TDSTM) which permits the real-time tracking of customer’s tubular inventories within the Company’s facilities. The system permits customers to remotely access and monitor tubular inspection and coating progress.

The Company has pioneered many tubular inspection technologies used in the oilfield, and continues to expand its product offering through innovation and acquisition. In 1996, the Company installed its first proprietary high-speed full-body ultrasonic tubular inspection unit (Truscope®). The new service provides 100% ultrasonic coverage of tubulars at a rate of up to 200 feet per minute. In 1997, the Company began offering a proprietary, patented external tubular connection integrity test, the ISO-Gator,TM for use at the rig site. The technology was obtained through the Company’s acquisition of the operating assets of Gator Hawk, Inc. In 1998, the Company introduced a new coiled tubing inspection service with its electromagnetic CT Scope®.

Mill Systems and Sales. The Company engineers and fabricates inspection equipment for steel mills, which it sells and rents. The equipment is operated by steel mills and is used for quality control purposes to detect transverse, longitudinal and three-dimensional defects in the pipe during the high-speed manufacturing process. Each piece of mill inspection equipment is designed to customer specifications and is installed and serviced by the Company. Since 1962, the Company has installed more than 80 units worldwide, in most major steel mills. Equipment is manufactured at the Company’s Houston, Texas and Celle, Germany facilities. Revenue for Mill Systems and Sales fluctuates significantly from year to year due to the timing of negotiating large domestic and export sales contracts, arranging financing and manufacturing equipment.

8

Pipeline Inspection. In-place inspection services for oil and gas pipelines identify anomalies in the pipelines without removing or dismantling the pipelines or stopping the product flow, giving customers a convenient and cost-effective method of identifying potential defects in pipelines. The Tubular Services group inspects pipelines by launching a sophisticated survey instrument into the pipeline. Propelled by the product flow, the instrument uses electromagnetics, ultrasonics, and mechanical measurements received on digital and analog media to monitor the severity and location of internal and external pitting-type corrosion as well as other mechanical anomalies in the pipeline, providing a basis for evaluation and repair by the customer. Once the test is complete, the survey instrument is returned to the Company, refurbished and used for future pipeline inspections.

Management believes the major competitive factors for Pipeline Services are reputation for quality, service, reliability of obtaining a successful survey on the first run, product technology, price, and technical support on survey interpretation. Demand for the Company’s pipeline services is somewhat dependent on commodity prices, which affects funds available for discretionary pipeline inspection and maintenance expenditures by many pipeline operators. This dependence is most pronounced in international markets. Additionally, significant consolidation in the pipeline industry has caused many pipeline operators to defer inspections in recent years as they re-evaluate their pipeline maintenance programs following mergers and acquisitions. Management believes there are growth opportunities for the Company’s Pipeline Services due to the aging of the worldwide pipeline network, and construction of new pipelines. U.S. regulatory inspection requirements and an extensive pipeline infrastructure in Eastern Europe are additional industry factors expected to contribute to the growth of the Company’s Pipeline Services. Catastrophic pipeline failures in the U.S. in recent years have prompted regulators to require more stringent pipeline inspection, which may increase the demand for pipeline inspection services. Additionally, management believes that the Company’s new digital TruRes® inspection technology and other new software and survey products will provide growth opportunities. The TruRes® technology applies advanced digital computer technology and other advancements within the body of the inspection tool to provide greater measurement sampling density and pipe-body coverage. In 2001, the Company acquired certain assets of Geodz, Inc., a software engineering firm, to enhance its pipeline position survey software.

The Tubular Services group’s customers include almost all major oil and gas companies, large and small independent producers, national oil companies, drilling contractors, oilfield supply stores, pipeline operators and steel mills. The Company’s competitors in Tubular Services include, among others, ICO Inc., Ameron International Corp, Pipeline Integrity International Ltd., and ShawCor Ltd. In addition, the Tubular Services group competes with a number of smaller regional competitors in tubular inspection. Certain foreign jurisdictions and government-owned petroleum companies located in some of the countries in which this group operates have adopted policies or regulations which may give local nationals in these countries certain competitive advantages. Within the Company’s corrosion control products, certain substitutes such as non-metallic tubulars, inhibitors, corrosion resistant alloys, cathodic protection systems, and non-metallic liner systems also compete with the Company’s products.

Drilling Services Group

The Company’s Drilling Services group is engaged in the provision of highly-engineered equipment, products and services which separate and manage drill cuttings produced by the drilling process (“Solids Control Services”). Drill cuttings are usually contaminated with petroleum or drilling fluids, and must be disposed of in an environmentally sound manner. Additionally, efficient separation of drill cuttings enhances the drilling effectiveness of the drilling fluids for re-use. The Company believes it’s Brandt® business is the market leader in the provision of solids control services to the oil and gas drilling industry worldwide. The Drilling Services group also rents and sells proprietary drilling rig instrumentation packages which monitor various processes throughout the drilling operation, under the name MD/Totco. The group’s rig instrumentation packages collect and analyze data through both analog and digital media, enabling rig personnel to maintain safe and efficient drilling operations. The Company believes it is the largest provider of drilling rig instrumentation packages worldwide.

Solids Control. The Drilling Services group uses a variety of technologies to separate drill cuttings from drilling fluid, and to further transport, dry and refine drill cuttings for safe disposal. The Company believes the

9

regulatory and industry trends towards minimizing the environmental impact of drilling operations in a number of environmentally sensitive oil and gas producing regions will lead to greater demand for solids control products and closed loop drilling systems. A closed loop drilling system is a solids control system in which the drilling mud is reconditioned and recycled throughout the drilling process on the rig itself. The Company further believes the trend towards more technically complex drilling, including highly deviated directional wells and slim-hole completions, will favorably impact the demand for solid controls technology because of its ability to reduce costly downhole problems. As environmental constraints are increased and as awareness of environmental protection grows, the Company believes that its drill cuttings separation and treating processes will find increased demand.

The Company has a history of introducing new solids control products and services obtained both through its internal development and through acquiring or licensing technologies from others. The Company acquired the Gumbo Chain from Nu-Tec, Inc. in 1997, a product to remove sticky shale or “gumbo,” which is encountered in certain geologic environments, from drilling fluid. In 1998, the Company initiated operations with a proprietary unit which removes hydrocarbons from drill cuttings using heat, a process called “Thermal Desorption”. The processed cuttings are rendered inert and can be disposed of with minimal environmental impact. The Company commenced operation of a second drill cuttings thermal desorption unit in the first quarter of 1999 and expects to commence operations on its third unit in 2002. The Company began offering the VSM 300 shale shaker, a high performance, high priced machine, in 1996. A shale shaker is the primary device on an oil rig for removing drill solids from drilling mud. The VSM 300 was the first shale shaker which offered a balanced elliptical vibratory motion, which improves cuttings conveyance and reduces oil on cuttings. The Company also introduced its new Cobra® shale shaker in 1998. The Cobra® has a small footprint and a lightweight design, and is priced to compete in the more price-sensitive segment of the market. The Company began offering the King Cobra shale shaker in 1999. The King Cobra is approximately one third larger than the Cobra Shaker, and also targets the price sensitive segment of the drilling market. The Company acquired M.S.D. Inc. in 1998 in order to enhance its cuttings slurrification and injection capabilities. In 1999, the Company acquired Manufacturas Rowi, C.A. (Rowica), a Venezuelan solids control company, and the solids control assets of Newpark Resources, Inc. (“Newpark”). In early 2001, the Company acquired certain assets of Angelle Construction, Inc. to enhance its cuttings transport business.

The Drilling Services group manufactures conventional and linear motion shale shakers, high speed and conventional centrifuges, screens, desanders (which remove large drill solids from drilling mud), desilters (which remove small drill solids from drilling mud), degassers (which remove air and gasses from drilling mud) and closed loop drilling fluids systems at its facilities in Conroe, Texas; Houston, Texas; and Aberdeen, Scotland. The group markets solids control equipment under the Brandt® brand name. For the year ended December 31, 2001, approximately 42% of the Drilling Services group’s solids control equipment revenue was generated from the sale of solids control equipment and inventory, and approximately 58% of such revenue was generated from rentals and services.

In 1999, the Company entered into an alliance agreement with Newpark under which the Company, subject to certain conditions, became the exclusive provider of Solids Control Products and Services to Newpark in the United States. The alliance agreement further provides that Newpark, subject to certain conditions, is the exclusive provider of oilfield waste services to the Company in the Gulf Coast market.

Drilling Rig Instrumentation. The Drilling Services group’s rig instrumentation systems provide drilling rig operators real time measurement and monitoring of critical parameters required to improve rig safety and efficiency. Systems are typically comprised of several sensors placed throughout the rig to measure parameters such as weight on bit, hookload, standpipe pressures, mud pump strokes, drilling mud levels, torque, and others, all networked back to a central command station for review, recording and interpretation. Additionally, the rig instrumentation packages typically provide multiple CRT screens around the rig for various rig personnel to perform individual jobs more effectively, and cameras for certain areas to permit remote monitoring. The Company offers proprietary touch-screen displays, interpretive software, and data archival and retrieval

10

capabilities. In 1999, the Company introduced its RigSense™ product, which combines leading hardware and software technologies into an integrated drilling rig package. It recently completed a successful test to permit access of drilling data from offsite locations, which will enable company personnel to monitor drilling operations from an office environment, through a secure link. In 2001, the Company completed the acquisitions of Chimo Equipment Ltd. in Canada; Alberta Instruments Ltd. in Canada; Adair Supply & Rentals, Inc. in Corpus Christi, TX; and Wagner Instrumentation Inc. in Houston, TX; which were all engaged in drilling rig instrumentation business.

The group’s customers for Drilling Services include almost all major oil and gas companies, large and small independent producers, national oil companies, and drilling contractors. Competitors in Drilling Services include Smith International (“SWACO”); Derrick Manufacturing Corp.; Oil Tools Pte. Ltd; National Oilwell Inc.; Petron Industries, Inc.; Epoch, a division of Nabors Industries; Pason Systems, Inc., a Canadian company and a number of regional competitors. The Company’s Drilling Services group operates in highly competitive markets. Management believes that on-site service is becoming an increasingly important competitive element in the Drilling Services market. Management believes that, in addition to on-site services, the principal competitive factors affecting its Drilling Services business are performance, quality, reputation, customer service, product availability, breadth of product line and price.

Coiled Tubing & Wireline Products Group

The Company’s Coiled Tubing & Wireline Products group sells capital equipment and consumables to most of the major oilfield coiled tubing and wireline remediation and drilling service providers. The Company believes it is the world’s leading designer and manufacturer of coiled tubing units, coiled tubing pressure control equipment and wireline pressure control equipment and one of the leading manufacturers of wireline units used in oil and gas well remediation, completion and drilling operations. The Company, through its January 2001 acquisition of Quality Tubing, Inc., also manufactures steel coiled tubing used by well remediation contractors and oil and gas producers. The Company believes it is the second largest producer of coiled tubing worldwide. Demand for the group’s Coiled Tubing & Wireline Products is strongly dependent upon the capital spending plans of coiled tubing and wireline service companies, and the general level of well remediation activity.

Coiled Tubing Products. Coiled tubing consists of flexible steel tubing manufactured in a continuous string and spooled on a reel. It can extend several thousand feet in length and is run in and out of the wellbore at a high rate of speed by a hydraulically operated coiled tubing unit. A coiled tubing unit is typically mounted on a truck or skid (steel frames on which portable equipment is mounted to facilitate handling with cranes or flatbed trucks) and consists of a hydraulically operated tubing reel or drum, an injector head which pushes or pulls the tubing in or out of the wellbore, and various power and control systems. Coiled tubing is typically used with sophisticated pressure control equipment which permits the operator to continue to safely produce the well. The Coiled Tubing and Wireline Products group manufactures and sells both coiled tubing units and the ancillary pressure control equipment used in these operations.

Coiled tubing provides a number of significant functional advantages over the principal alternatives of conventional drillpipe and workover pipe. Coiled tubing allows faster “tripping,” since the coiled tubing can be reeled very quickly on and off a drum and in and out of a wellbore. In addition, the small size of the coiled tubing unit compared to an average workover rig reduces preparation time at the well site. Coiled tubing permits a variety of workover and other operations to be performed without having to pull the existing production tubing from the well and allows ease of operation in horizontal or highly deviated wells. Thus, operations using coiled tubing can be performed much more quickly and, in many instances, at a significantly lower cost. Finally, use of coiled tubing generally allows continuous production of the well, eliminating the need to temporarily stop the flow of hydrocarbons. As a result, the economics of a workover are improved because the well can continue to produce hydrocarbons and thus produce revenues while the well treatments are occurring. Continuous production also reduces the risk of formation damage which can occur when the flow of fluids is stopped or isolated.

11

Currently, most coiled tubing units are used in well remediation and completion applications. The Company believes that advances in the manufacturing process of coiled tubing, tubing fatigue protection and the capability to manufacture larger diameter and increased wall thickness coiled tubing strings have resulted in increased uses and applications for coiled tubing products. For example, well operators are now using coiled tubing in drilling applications such as slim hole reentries of existing wells. The Company engineered and manufactured the first coiled tubing units built specifically for coiled tubing drilling in 1996.

There are certain limitations to the use of coiled tubing. Coiled tubing generally is made of high strength, alloy steel which wears down or fatigues over time as a result of internal pressure, acidic operating environments and normal bending cycles. Thus, operators must carefully monitor the use of the tubing. In addition, coiled tubing will buckle if the weight of the coiled tubing being conveyed in the wall becomes too great or if the tube becomes inhibited by some obstacle or irregularity in the wellbore. Buckling has not proven to be a significant obstacle in most well remediation applications, and the Company believes it will become less of an issue as a result of the availability of stronger and larger diameter coiled tubing.

Generally, the Coiled Tubing & Wireline Products group supplies customers with the equipment and components necessary to use coiled tubing, which the customers typically purchase separately. The group’s coiled tubing product line consists of coiled tubing units, coiled tubing and wireline pressure control equipment, wireline units, pressure pumping equipment, snubbing units (which are units that force tubulars into a well when pressure is contained within the wellbore), nitrogen pumping equipment and cementing, stimulation and blending equipment. The group markets its coiled tubing equipment under the Hydra Rig® brand name primarily to providers of coiled tubing drilling and workover services. The Company’s primary coiled tubing unit production facilities are located at its Hydra Rig facility in Fort Worth, Texas. In addition, the group markets coiled tubing pressure control equipment under the Texas Oil Tools® brand name and manufactures this equipment at its facility in Conroe, Texas. The Company’s 2001 acquisition of Bradon Industries added a significant manufacturing plant in Canada, where it sells equipment now under the brand name Hydra Rig Canada. It also added additional nitrogen-pumping products and technologies through its 2001 acquisition of Albin’s Enterprises in Duncan, Oklahoma. Additionally, the Company began offering its “TEM™” cementing equipment and fabricating nitrogen pumping units in Tulsa, Oklahoma, in December 1997, when it acquired Tulsa Equipment Manufacturing Company.

Wireline Products. Through its 1996 acquisitions of SSR (International) Ltd. and Pressure Control Engineering Ltd., its 1998 acquisition of Hydrolex and Eastern Oil Tools Pte. Ltd, and its 2001 acquisition of Elmar Services, Ltd., the Company believes that it has assembled one of the leading positions in the wireline unit and pressure control manufacturing business, expanded its offering of downhole coiled tubing tools and added manufacturing facilities in Poole and Aberdeen, in the United Kingdom; Perth, Australia; and Singapore.

The Company’s acquisition of Eastern Oil Tools Pte. Ltd. in June, 1998 and Elmar Services Ltd. in August, 2001 also added perforating guns to its offering of products. Additionally, the Company acquired Weston Oilfield Engineering Limited in Norwich, United Kingdom, in December 1998, which strengthened its coiled tubing unit refurbishing, servicing and spare parts business, as well as added new cryogenic nitrogen technologies.

The Company has a history of engineering new technologies and products for its Coiled Tubing & Wireline Products markets. It recently introduced the DSH “Sidedoor” Stripper/Packer, which allows packer and bushing replacement while the operator has coiled tubing in the wellbore, and the CT Slimhole BHA Jetting Tool Assembly, a small diameter jetting tool which can traverse small diameter well completion configurations.

The Company’s customers for Coiled Tubing & Wireline Products include almost all major oil and gas coiled tubing service companies, as well as major oil companies, national oil companies, and small independents. Competitors in Coiled Tubing & Pressure Control Products include Stewart & Stevenson Inc., Precision Tube Technology, Maritime Hydraulics AS, ASEP, National Oilwell Inc. and several smaller competitors.

12

2001 Acquisitions

In 2001, the Company made the following acquisitions and related transactions:

Entity/Assets/Technology

| | Form

| | Product Line

| | Date of Transactions

|

Quality Tubing Inc. | | Stock Purchase | | Coiled Tubing & Wireline Products | | January 2001 |

Angelle Construction Services, Inc. | | Asset Purchase | | Drilling Services | | February 2001 |

Servizi Ispettivi | | Asset Purchase | | Tubular Services | | March 2001 |

Chimo Equipment Ltd. | | Stock Purchase | | Drilling Services | | March 2001 |

Bradon Industries Group | | Stock Purchase | | Coiled Tubing & Wireline Products | | March 2001 |

GeoDZ, Inc. | | Asset Purchase | | Tubular Services | | April 2001 |

Albin’s Enterprise, Inc. | | Stock Purchase | | Coiled Tubing & Wireline Products | | May 2001 |

Alberta Insturment Ltd. | | Stock Purchase | | Drilling Services | | May 2001 |

Maris International

Limited | | Technology License | | Drilling Equipment Sales | | July 2001 |

Fibercast Inc. | | Asset Purchase | | Tubular Services | | July 2001 |

Elmar Services Limited | | Stock Purchase | | Coiled Tubing & Wireline Products | | August 2001 |

Wagner Instrumentation 2000, Inc. | | Stock Purchase | | Drilling Services | | August 2001 |

Morinoak International Limited | | Stock Purchase | | Drilling Equipment Sales | | September 2001 |

Adair Supply & Rentals | | Asset Purchase | | Drilling Services | | October 2001 |

ITM | | Asset Purchase | | Tubular Services | | October 2001 |

Quality Tubing Inc. was acquired for an aggregate cash purchase price of approximately $55,020,000. The remaining fourteen acquisitions were purchased for an aggregate price of $99,044,000, consisting of cash of $90,397,000 and notes and accrued payables of $8,647,000.

Seasonal Nature of the Company’s Business

Historically, the level of the Company’s business has followed seasonal trends to some degree, which are described below.

In past years, the Company’s Tubular Services and Drilling Services businesses in the United States realized lower activity levels during the first quarter of the calendar year due to delays in the approval of drilling budgets and weather restrictions. The Company’s tubular inspection, tubular coating, solids control, and rig instrumentation businesses in Canada typically realized high first quarter activity levels as operators took advantage of the winter freeze to help gain access to remote drilling and production areas, and then declined during the second quarter due to warmer weather conditions which resulted in thawing, softer ground, difficulty accessing drill sites, and road bans that curtailed drilling activity. In past years, Tubular Services activity in both the United States and Canada increased during the third quarter and then peaked in the fourth quarter as operators spent the remaining drilling and/or production capital budgets for the year.

The pipeline inspection portion of Tubular Services has typically experienced reduced activity during the first quarter of the calendar year. The high winter demand for gas and petroleum products in the northern states and the consequent curtailment of pipeline maintenance and inspection programs resulted in less opportunity to perform pipeline inspection during this time. During the second quarter, activity has typically begun to increase

13

and normally has continued at relatively stable levels through the end of the year as operators finished scheduled maintenance programs. Mill systems sales and industrial inspection services have had no particular seasonal trend. The timing of mill equipment sales is not easily predictable and, accordingly, revenue tends to fluctuate from quarter to quarter.

In general, Coiled Tubing & Wireline Products have experienced lower revenue in the fourth quarter due to major customers placing orders, based on their budgeting process, in the fourth quarter for delivery during the next three quarters. This process may change in the future as a major customer has changed to a continuous budgeting process and will place orders throughout the year. There can be no guarantees that this trend will continue or that any other customer will change its ordering process.

In general the Drilling Equipment Sales group has not experienced significant seasonal fluctuation. There can be no guarantee that seasonal effects will not influence future drilling equipment sales.

The Company anticipates that these seasonal trends will continue. However, there can be no guarantee that spending by the Company’s customers will continue or that other customers will remain the same as in prior years.

Marketing & Distribution Network

The Company’s products are marketed through a sales organization and a network of agents and distributors, which spans 49 countries.

The Company’s Drilling Equipment Sales customers include private and government-owned oil companies, drilling contractors, drilling rig manufacturers, rental tool companies, and supply companies, which supply oilfield products to the end users of the Company’s products.

Drilling Equipment, such as the Automated Roughneck, Top Drive Drilling System, pipe racking systems, and pressure control and motion compensation equipment, as well as the Varco integrated control and information systems (“V-ICIS”), represent significant capital expenditures and are usually sold directly to an oil company, drilling contractor or rig builder. Other drilling equipment products may be sold through supply stores or directly to government-owned oil companies or drilling contractors.

The Company’s Tubular Services customers include major and independent oil and gas companies, national oil companies, oilfield equipment and product distributors and manufacturers, drilling and workover contractors, oilfield service companies, pipeline operators, steel mills, and other industrial companies. Certain tubular inspection and tubular coating products and services often are incorporated as a part of a tubular package sold by tubular supply stores to end users. Tubular Services primarily has direct operations in the international marketplace, but operates through agents in certain markets.

The Company’s Drilling Services customers are predominantly major and independent oil and gas companies, national oil companies and drilling contractors. The Drilling Services group operates sales and distribution facilities at strategic locations worldwide to service areas with high drilling activity. The Company’s worldwide Solids Control and Instrumentation sales employees are complemented by service and engineering facilities which provide specialty repair and maintenance services to customers.

The Company’s Coiled Tubing and Wireline Products are primarily sold directly to end users through a worldwide Coiled Tubing and Wireline Products sales organization. The Company also has in place certain exclusive alliances with major oilfield service companies to provide pressure control equipment.

The Company’s foreign operations, which include significant operations in Canada, Europe, the Far East, the Middle East and Latin America, are subject to the risks normally associated with conducting business in foreign countries, including uncertain political and economic environments, which may limit or disrupt markets, restrict the movement of funds or result in the deprivation of contract rights or the taking of property without fair

14

compensation. Government-owned petroleum companies located in some of the countries in which the Company operates have adopted policies (or are subject to governmental policies) giving preference to the purchase of goods and services from companies that are majority-owned by local nationals. As a result of such policies, the Company relies on joint ventures, license arrangements and other business combinations with local nationals in these countries. In addition, political considerations may disrupt the commercial relationship between the Company and such government-owned petroleum companies. Although the Company has not experienced any significant problems in foreign countries arising from nationalistic policies, political instability, economic instability or currency restrictions, there can be no assurance that such a problem will not arise in the future. See Note 12 of the Notes to the Consolidated Financial Statements for information regarding geographic revenue information.

Research and New Product Development and Intellectual Property

The Company believes that it is a leader in the development of new technology and equipment to enhance the safety and productivity of the drilling and the well stimulation process and that its sales and earnings have been dependent, in part, upon the successful introduction of new or improved products. Additionally, the Company believes that its strong market position in its major businesses is enhanced by its leading technologies and reputation for innovation and expertise. Through its internal development programs and certain acquisitions, the Company has assembled an extensive array of technologies protected by a substantial number of trade and service marks, patents, trade secrets, and other proprietary rights.

As of December 31, 2001, the Company held a substantial number of United States patents and had patent applications pending. Expiration dates of such patents range from 2002 to 2019. As of such date, the Company also had foreign patents and patent applications pending relating to inventions covered by the United States patents. Additionally, the Company maintains a substantial number of trade and service marks and maintains a number of trade secrets.

Although the Company believes that this intellectual property has value, competitive products with different designs have been successfully developed and marketed by others. The Company considers the quality and timely delivery of its products, the service it provides to its customers and the technical knowledge and skills of its personnel to be more important than its intellectual property in its ability to compete. While the Company stresses the importance of its research and development programs, the expense and market uncertainties associated with the development and successful introduction of new products are such that there can be no assurance that the Company will realize future revenues from new products.

Engineering and Manufacturing

The manufacturing processes for the Company’s products generally consist of machining, welding and fabrication, heat treating, assembly of manufactured and purchased components and testing. Most equipment is manufactured primarily from alloy steel, and the availability of alloy steel castings, forgings, purchased components and bar stock is critical to the production and timing of shipments. Within the Drilling Equipment Sales group, automated Roughnecks, Top Drive Drilling Systems, and pipe handling systems are manufactured in Orange, California; pressure control and motion compensation equipment, riser pipe and riser tensioners are manufactured at facilities in Houston, Texas; rotating and handling tools are manufactured at the Company’s facilities in Etten-Leur, the Netherlands, and Mexicali, Mexico; and derricks and structural rig components are manufactured in Aberdeen, Scotland and Great Yarmouth, England.

The Company’s Drilling Services group manufactures or assembles the equipment and products which it rents and sells to customers, and which it uses in providing solids control. In addition to producing new solids control and instrumentation equipment and products, Drilling Services also produces spare parts for sale. Drilling Services manufactures screens used in its solids control operations and for sale to others at its New Iberia, Louisiana; Conroe, Texas; Leduc, Alberta; and Couva, Trinidad facilities; manufactures solids control equipment at its facilities in Houston, Conroe, and Aberdeen; and manufactures instrumentation equipment at its Cedar Park, Texas facility.

15

The Tubular Services group manufactures tubular inspection equipment and instrumented pipeline inspection tools at its Houston, Texas facility for resale, and renovates and repairs equipment at its manufacturing facilities in Houston, Texas; Conroe, Texas; Bordon, England; Celle, Germany; Nisku, Alberta and Aberdeen, Scotland. Fiber glass tubulars and fittings are manufactured at its San Antonio, Texas; Big Spring, Texas; Little Rock, Arkansas; Tulsa, Oklahoma and Wichita, Kansas, Harbin, China facilities, while tubular coatings are manufactured in its Houston, Texas facility, or through restricted sale agreements with third party manufacturers.

The Coiled Tubing and Wireline Products group manufactures coiled tubing units, wireline units, pressure pumping equipment, pressure control equipment and perforating guns at its Fort Worth, Texas; Conroe, Texas; Duncan, Oklahoma; Tulsa, Oklahoma; Calgary, Canada; Aberdeen, Scotland; Singapore; Perth, Australia; and Poole, England facilities.

Certain of the Company’s manufacturing facilities and certain of the Company’s products have various certifications, including, ISO 9001, API and ASME.

Raw Materials

The Company believes that materials and components used in its servicing and manufacturing operations and purchased for sales are readily available at competitive prices from numerous sources.

Backlog

Sales of the Company’s products are made on the basis of written purchase orders or contracts and, consistent with industry practice, by e-mail, fax, letter or oral commitment later confirmed by a written order. In accordance with industry practice, orders and commitments generally can be cancelled by customers at any time. However, the Company is generally entitled to cancellation fees for expenses and costs incurred prior to the cancellation of orders. In addition, orders and commitments are sometimes modified before or during manufacture of the products. The Company’s backlog is based upon anticipated revenues from customer orders that the Company believes are firm. The level of backlog at any particular time is not necessarily indicative of the future operating performance of the Company.

Backlog at December 31, 2001, 2000, and 1999 was as follows (in thousands):

| | | December 31,

|

| | | 2001

| | 2000

| | 1999

|

Drilling Equipment Sales | | $ | 251,531 | | $ | 88,055 | | $ | 55,734 |

Coiled Tubing & Wireline Products | | | 55,864 | | | 61,200 | | | 17,946 |

| | |

|

| |

|

| |

|

|

Total | | $ | 307,395 | | $ | 149,255 | | $ | 73,680 |

| | |

|

| |

|

| |

|

|

The Company expects that most of the backlog will be shipped by December 31, 2002.

Environmental Matters

The Company’s manufacturing processes and its inspection, coating and solids control services routinely involve the handling and disposal of chemical substances and waste materials, some of which may be considered to be hazardous wastes. These potential hazardous wastes result primarily from the manufacturing and testing processes and the use of mineral spirits to clean pipe threads during the tubular inspection process and from the coating process, and the handling of and, in normal cases, the disposal of drilling fluids and cuttings on behalf of the drillers and/or producers.

The Company’s operations are subject to numerous local, state and federal laws and regulations, including the regulations promulgated by the Occupational Safety and Health Administration, the United States

16

Environmental Protection Agency (EPA), the Nuclear Regulatory Commission and the United States Department of Transportation. These laws and regulations include the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), the Resource Conservation and Recovery Act (RCRA), the Clean Air Act (CAA), the Clean Water Act (CWA), the Superfund Amendments and Reauthorization Act (SARA) including SARA Title III toxic release reporting, the Safe Drinking Water Act (SDWA) and the Toxic Substance Control Act (TSCA). Management believes that the Company is in substantial compliance with these laws and regulations, and that the compliance and remedial action costs associated with these laws and regulations have not had a material adverse effect on its results of operations, financial condition or competitive position, to date.

The Company cannot predict the effect on it of new laws and regulations with respect to radioactive hazardous wastes caused by naturally occurring radioactive materials or with respect to other environmental matters. Circumstances or developments which are not currently known as well as the future cost of compliance with environmental laws and regulations could be substantial and could have a material adverse effect on the results of operations and financial condition of the Company.

CERCLA imposes liability, without regard to fault or the legality of the original conduct, for the releases of hazardous substances into the environment. Persons subject to CERCLA include the owner and operator of the disposal site or sites where the release occurred and companies that generated, disposed or arranged for the disposal of the hazardous wastes found at the site. Persons who are responsible for releases of hazardous substances under CERCLA may be subject to joint and several liability for the costs of cleaning up the resulting contamination and for damages to natural resources. It is not uncommon for neighboring landowners and other third parties to file claims for personal injury and property damage allegedly caused by the hazardous substances released into the environment.

Certain third-party owned disposal facilities used by the Company or its subsidiaries have been investigated under state and federal Superfund statutes, and the Company is currently named as a potentially responsible party for cleanup at three such sites. Although the Company’s level of involvement varies at each site, in general, the Company is one of numerous parties named and will be obligated to pay an allocated share of the cleanup costs. While it is not feasible to predict the outcome of these matters with certainty, management is of the opinion that their ultimate resolution should not result in material costs to the Company or otherwise materially and adversely affect the Company’s operations or financial position.

Pursuant to an agreement executed as part of the acquisition of the Company in 1988 from Minstar Inc. (“Minstar”), Minstar has agreed, subject to certain limitations concerning the time for submitting claims and the amount of losses to be covered as described below, to indemnify the Company with respect to all losses, liabilities, damages and expenses incurred in connection with, arising out of or resulting from the production, use, generation, emission, storage, treatment, transportation, disposal or other handling or disposition or migration of any kind of any toxic or hazardous wastes at any time prior to the closing of the 1988 acquisition date. Claims for indemnification were required to be made before May 13, 1992. Minstar is obligated to indemnify the Company for the first $1 million of losses incurred by the Company and fifty percent of losses in excess of $2 million. The Company is solely responsible for the second $1 million of losses incurred and fifty percent of losses in excess of $2 million. See “Item 3—Legal Proceedings” for a description of the indemnity to be provided by Minstar with respect to actions, suits, litigation, proceedings or governmental investigations which may also apply to certain environmental matters.

Employees

At December 31, 2001, the Company had a total of 8,651 employees (of which 1,175 were temporary employees). The Company considers its relations with its employees to be excellent and has never suffered a work stoppage or interruption due to a labor dispute.

17

ITEM 2. PROPERTIES

The following is a description of the Company’s major facilities:

Location

| | Description

| | Size (Approximate Square Feet)