ANNUAL INFORMATION FORM

FOR THE YEAR ENDED DECEMBER 31, 2015

AS AT MARCH 30, 2016

TABLE OF CONTENTS

INTRODUCTORY NOTES

Forward-Looking Statements

This Annual Information Form (“AIF”), including the documents incorporated by reference, contain forward-looking statements and forward-looking information (collectively referred to as “forward-looking statements”) which may not be based on historical fact, including without limitation statements regarding our expectations in respect of future financial position, business strategy, future production, reserve potential, exploration drilling, exploitation activities, events or developments that we expect to take place in the future, projected costs and plans and objectives. Often, but not always, forward-looking statements can be identified by the use of the words “believes”, “may”, “plan”, “will”, “estimate”, “scheduled”, “continue”, “anticipates”, “intends”, “expects”, and similar expressions.

Such statements reflect our current views with respect to future events and are subject to risks and uncertainties and are necessarily based upon a number of estimates and assumptions that, while considered reasonable by the Company, are inherently subject to significant business, economic, competitive, political and social uncertainties and contingencies. Many factors could cause the Company’s actual results, performance or achievements to be materially different from any future results, performance, or achievements that may be expressed or implied by such forward-looking statements, including, among others:

| | • | significant declines in the prevailing market price of copper; |

| | | |

| | • | an inability to get the Canadian federal government to reconsider and reverse its decision under theCanadian Environmental Assessment Act, 2012not to authorize the New Prosperity project to proceed; |

| | | |

| | • | the potential for increases in operating and capital costs at existing and future operations |

| | | |

| | • | changes in mineral resource and reserves estimates as estimation of mineral resources is a subjective process, the accuracy of which is a function of the quantity and quality of available data and the assumptions made and judgment used in the engineering and geological interpretation, which may prove to be unreliable, and may be subject to revision based on various factors; |

| | | |

| | • | adverse moves in the US:CDN dollar exchange rate (strengthening of the Canadian dollar) given that copper, the Company’s principal output is priced in US dollars; |

| | | |

| | • | risks associated with large scale construction projects if any of the Company’s advanced stage projects proceed; |

| | | |

| | • | current general global economic and financial conditions; |

| | | |

| | • | changes in and the effect of mining legislation and policies adversely affecting our operations; |

| | | |

| | • | inability to obtain adequate financing on acceptable terms; |

| | | |

| | • | litigation risks and the inherent uncertainty of litigation; |

- 3 -

| | • | uncertainties with respect to the effects of dissident shareholder activities; |

| | | |

| | • | inability to obtain necessary exploration and mining permits and comply with all government requirements including environmental, health and safety laws; and |

| | | |

| | • | inability to attract or retain key personnel. |

Such information is included, among other places, in the AIF under the heading “Risk Factors”.

Should one or more of these risks and uncertainties materialize, or should underlying factors or assumptions prove incorrect, actual results may vary materially from those described in forward-looking statements. Material factors or assumptions involved in developing forward-looking statements include, without limitation, that:

| | • | the price of copper and other metals will not decline significantly or for a protracted period of time; |

| | | |

| | • | the Company will have sufficient working capital and be able to secure additional funding necessary for the development of its projects; and |

| | | |

| | • | the Gibraltar Mine will not experience any significant production disruptions that would materially affect revenues. |

These factors should be considered carefully and readers are cautioned not to place undue reliance on the forward-looking statements. Readers are cautioned that the foregoing list of risk factors is not exhaustive and it is recommended that prospective investors carefully read the more complete discussion of risks and uncertainties facing the Company included under “Risk Factors” in this AIF.

Although the Company believes that the expectations conveyed by the forward-looking statements are reasonable based on the information available to it on the date such statements were made, no assurances can be given as to future results, approvals or achievements. The forward-looking statements contained in this AIF and the documents incorporated by reference herein are expressly qualified by this cautionary statement. The Company disclaims any duty to update any of the forward-looking statements to conform such statements to actual results or to changes in the Company’s expectations except as otherwise required by applicable law.

Documents Incorporated by Reference

Incorporated by reference into this AIF are the audited consolidated financial statements, together with the auditors’ report thereon, and Management’s Discussion and Analysis for Taseko Mines Limited (the “Company” or “Taseko”) for the year ended December 31, 2015. The financial statements are available for review on the SEDAR website located atwww.sedar.com. All financial information in this AIF is prepared in accordance with International Financial Reporting Standards (“IFRS”) as issued by the International Accounting Standards Board using Canadian dollars.

- 4 -

Currency and Metric Equivalents

The Company’s accounts are maintained in Canadian dollars and all dollar amounts herein are expressed in Canadian dollars unless otherwise indicated.

The following factors for converting Imperial measurements into metric equivalents are provided:

| To convert from Imperial | To Metric | Multiply by |

| | | |

| acres | hectares | 0.405 |

| feet | metres | 0.305 |

| miles | kilometres | 1.609 |

| tons (2000 pounds) | tonnes | 0.907 |

| ounces (troy)/ton | grams/tonne | 34.286 |

In this AIF, the following capitalized terms have the defined meanings set forth below:

| NYSE MKT | The NYSE MKT, formerly known as the NYSE Amex, being one of the two stock exchanges (together with the TSX) on which the Common Shares are listed. |

| | |

| ASCu | The weight percentage of copper per unit weight of rock that is acid soluble, including native copper. |

| | |

| Common Shares | The Company’s common shares without par value, being the only class or kind of the Company’s authorized capital. |

| | |

| Company | Taseko Mines Limited, including its subsidiaries, unless the context requires otherwise. |

| | |

| Carbonatite deposit | Carbonatite deposits are igneous rocks largely consisting of the carbonate minerals calcite and dolomite, which contain the niobium mineral pyrochlore, rare earth minerals or copper sulphide minerals. |

| | |

| Concentrator | A type of mineral processing facility that converts raw ore from the mine into a metal concentrate that can then be sold to a smelter for further processing. |

| | |

| Epithermal deposit | A mineral deposit formed at low temperature (50-200°C), usually within one kilometre of the earth’s surface, often as structurally controlled veins. |

| | |

| Flotation | Flotation is a method of mineral separation whereby, after crushing and grinding ore, froth created in a slurry by a variety of reagents causes some finely crushed minerals to float to the surface where they are skimmed off. |

- 5 -

| NSR | Net smelter return, a general proxy for the gross value of metals derived from concentrates delivered to a smelter for refining. |

| | |

| Mineral Deposit | A deposit of mineralization, which may or may not be ore. |

| | |

| Mineral Symbols | Ag – silver; Au – gold; Cu – copper; Pb – lead; Zn – Zinc; Mo – molybdenum; and Nb – niobium. |

| | |

| Porphyry deposit | A type of mineral deposit in which ore minerals are widely disseminated, generally of low grade but large tonnage. |

| | |

Semi-autogenous

grinding (“SAG”) | SAG mills are essentially autogenous mills, but utilize grinding balls to aid in grinding like in a ball mill. A SAG mill is generally used as a primary or first stage grinding solution. |

| | |

Solvent Extraction/

Electrowinning

(“SX/EW”) | Solvent extraction is the technique of transferring a solute from one solution to another; for example when copper oxide is dissolved into solution, copper becomes the solute. Electrowinning is the process in which an electric current flows between a pair of electrodes (anode & cathode) in a solution containing metal ions (electrolyte). Metal is deposited on the cathode in accordance with the metal’s ability to gain or lose electrons. Since ion deposition is selective, the cathode product is generally high grade and requires little further refining. |

| | |

| TSX | The Toronto Stock Exchange, being one of the two stock exchanges (together with the NYSE MKT) on which the Common Shares are listed. |

Resource Category (Classifications) Used in this AIF

The discussion of mineral deposit classifications in this AIF adheres to the resource/reserve definitions and classification criteria developed by the Canadian Institute of Mining and Metallurgy in 2005. Estimated mineral resources fall into two broad categories dependent on whether the economic viability of them has been established and these are namely “resources” (economic viability not established) and ore “reserves” (viable economic production is feasible). Resources are sub-divided into categories depending on the confidence level of the estimate based on level of detail of sampling and geological understanding of the deposit. The categories, from lowest confidence to highest confidence, are inferred resource, indicated resource and measured resource. Reserves are similarly sub-divided by order of confidence into probable (lowest) and proven (highest). These classifications can be more particularly described as follows:

A “Mineral Resource” is a concentration or occurrence of diamonds, natural solid inorganic material, or natural solid fossilized organic material including base and precious metals, coal, and industrial minerals in or on the Earth’s crust in such form and quantity and of such a grade or quality that it has reasonable prospects for economic extraction. The location, quantity, grade, geological characteristics and continuity of a Mineral Resource are known, estimated or interpreted from specific geological evidence and knowledge.

- 6 -

An “Inferred Mineral Resource” is that part of a Mineral Resource for which quantity and grade or quality can be estimated on the basis of geological evidence and limited sampling and reasonably assumed, but not verified, geological and grade continuity. The estimate is based on limited information and sampling gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes.

An “Indicated Mineral Resource” is that part of a Mineral Resource for which quantity, grade or quality, densities, shape and physical characteristics can be estimated with a level of confidence sufficient to allow the appropriate application of technical and economic parameters, to support mine planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes that are spaced closely enough for geological and grade continuity to be reasonably assumed.

A “Measured Mineral Resource” is that part of a Mineral Resource for which quantity, grade or quality, densities, shape, and physical characteristics are so well established that they can be estimated with confidence sufficient to allow the appropriate application of technical and economic parameters, to support production planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration, sampling and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes that are spaced closely enough to confirm both geological and grade continuity.

A “Mineral Reserve” is the economically mineable part of a Measured or Indicated Mineral Resource demonstrated by at least a Preliminary Feasibility Study. This Study must include adequate information on mining, processing, metallurgical, and economic and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified. A Mineral Reserve includes diluting materials and allowances for losses that may occur when the material is mined.

A “Probable Mineral Reserve” is the economically mineable part of an Indicated and, in some circumstances, a Measured Mineral Resource demonstrated by at least a Preliminary Feasibility Study. This Study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified.

A “Proven Mineral Reserve” is the economically mineable part of a Measured Mineral Resource demonstrated by at least a Preliminary Feasibility Study. This Study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction is justified. The U.S. Securities and Exchange Commission require permits in hand or their issuance imminent to classify mineralized material as reserves.

- 7 -

CAUTIONARY NOTE TO UNITED STATES INVESTORS CONCERNING ESTIMATES OF RESERVES AND MEASURED, INDICATED AND INFERRED RESOURCES

The disclosure in this AIF, including the documents incorporated by reference herein, uses terms that comply with reporting standards in Canada and certain estimates are made in accordance with Canadian National Instrument 43-101Standards of Disclosure for Mineral Projects(“NI 43-101”). NI 43-101 is a rule developed by the Canadian Securities Administrators that establishes standards for all public disclosure an issuer makes of scientific and technical information concerning mineral projects. Unless otherwise indicated, all reserve and resource estimates contained in or incorporated by reference in this AIF have been prepared in accordance with NI 43-101. These standards differ significantly from the requirements of the SEC, and reserve and resource information contained herein and incorporated by reference herein may not be comparable to similar information disclosed by U.S. companies.

This AIF includes mineral reserve estimates that have been calculated in accordance with NI 43-101, as required by Canadian securities regulatory authorities. For United States reporting purposes, SEC Industry Guide 7 (under the United States Securities Exchange Act of 1934 (the “Exchange Act”)), as interpreted by Staff of the SEC, applies different standards in order to classify mineralization as a reserve. As a result, the definitions of proven and probable reserves used in NI 43-101 differ from the definitions in the SEC Industry Guide 7. Under SEC standards, mineralization may not be classified as a "reserve" unless the determination has been made that the mineralization could be economically and legally produced or extracted at the time the reserve determination is made. Among other things, all necessary permits would be required to be in-hand or their issuance be imminent in order to classify mineralized material as reserves under the SEC standards. Accordingly, certain mineral reserve estimates contained in this AIF may not qualify as “reserves” under SEC standards, unless expressly stated to so qualify.

In addition, this AIF uses the terms “measured mineral resources”, “indicated mineral resources” and “inferred mineral resources” to comply with the reporting standards in Canada. We advise investors that while those terms are recognized and required by Canadian regulations, the SEC does not recognize them. Investors are cautioned not to assume that any part or all of the mineral deposits in these categories that are not already classified as “reserves” will ever be converted into mineral reserves. These terms have a great amount of uncertainty as to their existence, and great uncertainty as to their economic and legal feasibility.

Further, “inferred resources” have a great amount of uncertainty as to their existence and as to whether they can be mined legally or economically. Therefore, Investors are also cautioned not to assume that all or any part of the inferred resources exist. In accordance with Canadian rules, estimates of “inferred mineral resources” cannot form the basis of feasibility or other economic studies.

It cannot be assumed that all or any part of “measured mineral resources”, “indicated mineral resources”, or “inferred mineral resources” will ever be upgraded to a higher category. Investors are cautioned not to assume that any part of the reported “measured mineral resources”, “indicated mineral resources”, or “inferred mineral resources” in this AIF that are not already classified as “reserves” is economically or legally mineable.

- 8 -

In addition, disclosure of “contained ounces” in respect of resources that do not qualify as reserves is permitted disclosure under Canadian regulations; however, the SEC only permits issuers to report reserves in ounces and requires other mineralized material to be reported as in place tonnage and grade without reference to unit measures.

For the above reasons, information contained in this AIF and the documents incorporated by reference herein containing descriptions of our mineral deposits may not be comparable to similar information made public by U.S. companies subject to the reporting and disclosure requirements under the United States federal securities laws and the rules and regulations thereunder.

CORPORATE STRUCTURE

Taseko Mines Limited was incorporated on April 15, 1966, pursuant to theCompany Act(British Columbia). This corporate legislation was superseded in 2004 by theBritish Columbia Business CorporationsAct which is now the corporate law statute that governs us.Our registered office is located at Suite 1500, 1055 West Georgia Street, Vancouver, British Columbia, V6E 4N7, and our head office is located at Suite 1500, 1040 West Georgia Street, Vancouver, British Columbia, V6E 4H1.

The following is a list of the Company’s principal subsidiaries:

| | Jurisdiction of incorporation | Ownership |

| Gibraltar Mines Ltd.1 | British Columbia | 100% |

| Aley Corporation | British Columbia | 100% |

| Curis Resources Ltd.2 | British Columbia | 100% |

| Curis Holdings (Canada) Ltd.2 | British Columbia | 100% |

| Florence Copper Inc.2 | Nevada | 100% |

1.Taseko owns 100% of Gibraltar Mines Ltd., which owns 75% of the Gibraltar Joint Venture

2.Taseko owns 100% of Curis Resources Ltd., which owns 100% of Curis Holdings (Canada) Ltd., which owns 100% of Florence Copper Inc.

Gibraltar Joint Venture

On March 31, 2010, we established by two contracts an unincorporated joint venture (“JV”) between Gibraltar Mines Ltd., and Cariboo Copper Corp. (“Cariboo”) over the Gibraltar mine, whereby Cariboo acquired a 25% interest in the Gibraltar mine and we retained a 75% interest with Gibraltar Mines Ltd. operating the mine for the two JV participants. Under the related Joint Venture Formation Agreement (“JVFA”), the Company contributed to the Joint Venture substantially all assets and obligations pertaining to the Gibraltar mine, and Cariboo paid the Company US$187 million to obtain its 25% interest in the Joint Venture. Gibraltar Mines Ltd. continues to be the operator of the Gibraltar mine under the Joint Venture Operating Agreement which is filed at www.sedar.com. Cariboo is a Japanese consortium jointly owned by Sojitz Corporation (50%), Dowa Metals & Mining Co., Ltd. (25%) and Furukawa Co., Ltd. (25%).

- 9 -

GENERAL DEVELOPMENT OF TASEKO’s BUSINESS

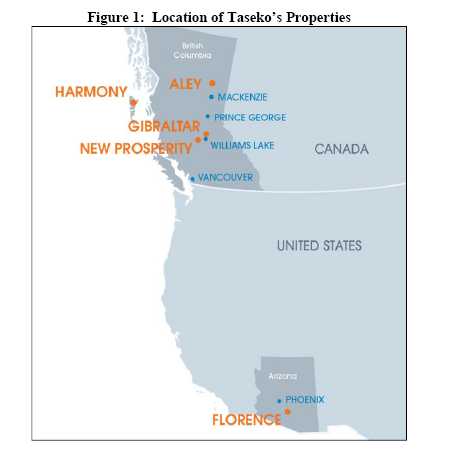

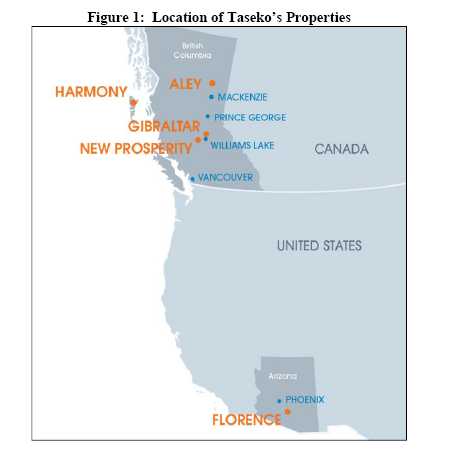

Taseko is a Vancouver, BC headquartered mining company that has been focused on the operation of the Gibraltar copper and molybdenum mine, and on the development of the New Prosperity gold and copper project, the Aley Niobium project, and the Florence Copper project. The first three are located in British Columbia, Canada and the latter is in Arizona. The following is a summary of the development of our business over the last three financial years:

2013

In 2013 Taseko was expanding the Gibraltar mine in a project called Gibraltar Development Plan 3 (“GDP3”). Construction of Gibraltar’s mill expansion related to GDP3 continued through to the spring of 2013, with commissioning being completed in March 2013. The new facility reached design capacity by the end of 2013.

Following public hearings in the summer of 2013, the New Prosperity Panel prepared their report on Taseko’s proposed New Prosperity Project gold and copper project and submitted it to the Federal Minister of the Environment on October 31, 2013.

On November 29, 2013, the Company filed an application for judicial review, seeking to set aside certain findings of the New Prosperity Panel report, with which Taseko disagreed. The Company asked the Federal Court for a declaration that certain findings relating to forecast seepage rates and impacts on water quality be set aside, and that the Panel failed to comply with principles of procedural fairness and the rules of natural justice.

2014

On February 26, 2014, the Minister of the Environment announced her conclusion that the New Prosperity project is likely to cause significant adverse environmental effects. The Minister referred the matter to the Governor in Council who decided that those effects are not justified in the circumstances and accordingly the mine could not proceed.

On March 26, 2014, the Company filed an application for judicial review in Federal Court, seeking to quash (invalidate) the decisions of the Minister and Governor in Council communicated on February 26, 2014. The Company also sought a declaration that certain sections of theCanadian Environmental Assessment Act, 2012, are in whole or in part beyond the powers of the Federal government under theConstitution Act, 1867.

On August 21, 2014, the Company applied to the Federal Court to convert both judicial reviews into a civil action for damages. The motion was heard on October 22, 2014. The motion was subsequently dismissed and both judicial reviews continue.

In September 2014, the Company announced a NI 43-101 compliant reserve estimate for the Aley Niobium project of 84 million tonnes grading 0.50% Nb2O5. The reserve estimate is documented in atechnical report entitled “Technical Report on Mineral Reserves at the Aley Project” dated October 30, 2014, prepared by Scott Jones, P.Eng., Keith Merriam, P.Eng., Greg Yelland, P.Eng., Robert Rotzinger, P.Eng., and Ronald G. Simpson, P.Geo.

- 10 -

On November 20, 2014, the Company acquired a 100% interest in the Florence Copper Project though the acquisition of Curis Resources Ltd. (“Curis”). The aggregate value of the consideration for the acquisition of Curis was approximately $85 million inclusive of debt assumed. The Florence Copper Project is an in-situ copper recovery and solvent extraction/electrowinning project located near the town of Florence in central Arizona, USA.

On December 31, 2014, British Columbia issued a Section 11 Order under the Environmental Assessment Act describing the scope of the Aley Niobium project subject to the environmental assessment, identifying the Aboriginal Groups requiring consultation, and directing Taseko to draft Application Information Requirements for the environmental assessment application.

2015

On January 14, 2015, the British Columbia Minister of Environment granted the Company a five-year extension to the New Prosperity Environmental Assessment Certificate.

In May 5, 2015, the Company completed an updated mine plan for Gibraltar featuring a 50% decrease in strip ratio and a reduced cut-ff grade, achieving an overall reduction in copper production costs with a slightly lower amount of copper procedued. The new mine plan was a result of a detailed, six-month engineering study and forms the basis of an updated NI 43-101 compliant reserve. The reserve estimate is documented in a technical report entitled “Technical Report on Mineral Reserve Update at the Gibraltar Mine” dated June 15, 2015, prepared by Taseko and Gibraltar Mine staff under the supervision of Scott Jones, P.Eng, a Qualified Person under NI 43-101.

Additional Information Early 2016

On February 9, 2016, the Company announced that its Gibraltar mine expects to benefit from a five-year power rate deferral program announced by the government of British Columbia.

On February 11, 2016, the Company filed a civil claim in the B.C. Supreme Court against the Canadian federal government. The claim seeks damages in relation to the February 2014 decision. The lawsuit claims the Government of Canada and its agents failed to meet the legal duties that were owed to Taseko and that in doing so they caused and continue to cause damages, expenses and loss to Taseko.

DESCRIPTION OF BUSINESS

Taseko is a mining company that seeks to acquire, develop, and operate large tonnage mineral deposits which, under conservative metals price assumptions, it believes are potentially capable of supporting a mine for 10 years or longer.

Our principal business activity is operating the Gibraltar copper and molybdenum mine and advancing other projects to a production decision. In recent years, we have expanded the Gibraltar Mine ore concentrator, added a second ore concentrator, increased the mining fleet and made other production improvements at the mine. Our business is focused on increasing production of copper and molybdenum from the Gibraltar mine and on securing environmental permits for the proposed Aley Niobium Project and the New Prosperity gold and copper project (“New Prosperity”). In November 2014, we acquired the Florence Copper Project, a test-stage in-situ copper recovery and SX/EW project located in central Arizona, USA. The Company also owns the Harmony gold project, an exploration stage gold property on BC’s West Coast.

- 11 -

All projects are operated solely by Taseko directly or through subsidiaries and are 100% owned except the Gibraltar Mine which is 75% owned.

The map below highlights the location of the Company’s four properties in British Columbia, Canada and one property in Arizona, USA:

Principal Products and Competitive Conditions

Taseko’s assets include reserves and resources of copper, molybdenum, gold and niobium. Demand for these metals fluctuates in tandem with general global economic conditions.

Taseko’s strategy has been to grow the Company by leveraging off cash flow from the Gibraltar Mine to assemble and develop a pipeline of projects. We continue to believe this will generate the best, long-term returns for shareholders. Our development projects are located in British Columbia and Arizona and represent a diverse range of metals. In light of current market conditions, the Company has taken a prudent approach and minimized spending on development projects in 2015. Total expenditures on projects in 2015 consisted of $5.1 million at the Florence Copper project, $0.9 million on the Aley Project, and $0.9 million on New Prosperity.

- 12 -

At the Gibraltar Mine, average head grade in 2016 is expected to be lower than 2015, with lower grades being mined in the first half of the year and then increasing in the back half of 2016. Copper production for the year is expected to be in the range of 130 to 140 million pounds.

Gibraltar Mine cost control initiatives which were implemented during 2015, including mine plan modifications to reduce waste stripping requirements, workforce reductions and initiatives with vendors to reduce costs of supplies and consumables, are expected to continue to impact operating costs in future years. Mine operating costs continue to benefit from the lower price of diesel, a significant input cost, which has decreased approximately 25% since the beginning of 2015 and is expected to remain at low levels at least through 2016. Overall, Gibraltar has achieved a stable level of operations reflecting the new mine plan and the Company is now focused on further improvements to operating practices to reduce unit costs .

We have no reason to assume that the Canadian dollar will strengthen materially and therefore a weak Canadian dollar will continue to contribute to improved operating margins at Gibraltar as approximately 80% of mine operating costs are paid in Canadian dollars and all of the Company’s revenues denominated in US dollars.

The new, long-term off-take agreement, which the Company signed in the fourth quarter of 2015, will lower treatment and refining costs in 2016. Under the agreement, the Company has committed to sell 600,000 tonnes of Gibraltar copper concentrate (approximately 50% of expected production) through to the end of 2020. The Company has also recently entered into a long-term fixed rate ocean freight contract.

On February 9, 2016, the Company announced that its Gibraltar mine expects to benefit from a five-year electrical power rate deferral program announced by the government of British Columbia. The cost deferral program has the potential to reduce Gibraltar’s annual spending by up to $20 million, or roughly $0.15 per pound of copper production.

A key factor that impacted copper prices in 2015 was the economic slowdown in China. This slowdown has impacted the demand for commodities including the copper produced by Gibraltar. New molybdenum supply combined with a weak steel market continued to put significant downward pressure on molybdenum pricing in 2015. During 2015, molybdenum pricing decreased by 41% to US$5.44 per pound.

Environmental Protection Requirements

Taseko’s mining, exploration and development activities in Canada are subject to various levels of Canadian Federal and British Columbia Provincial laws and regulations relating to the protection of the environment. Similarly, the Florence Copper Project is subject to various levels of US Federal and Arizona State laws and regulations relating to protection of the environment. All of the jurisdictions include requirements for closure and reclamation of mining properties as part of their regulatory framework.

- 13 -

The total liability for reclamation and closure cost obligations as calculated for financial disclosure purposes, at December 31, 2015 was $124.4 million. This amount represents the present value of the estimated future costs of planned and anticipated closure and remediation activities, assuming a pre-tax discount rate ranging between 0.48% and 2.15%, and an inflation rate of 2%.

Environmental and Sustainability Policy

Taseko is committed to continual improvement towards the protection of human health and the stewardship of the environment. Taseko recognizes that responsible environmental management is critical to our success and has committed that it will:

| | • | Consider the environmental impacts of its operations and take appropriate steps to prevent environmental pollution; |

| | | |

| | • | Comply with relevant environmental legislation, regulations and corporate requirements; |

| | | |

| | • | Integrate environmental policies, programs and practices into all activities; |

| | | |

| | • | Ensure that all employees and service providers understand their environmental responsibilities and encourage dialogue on environmental issues; |

| | | |

| | • | Develop, maintain and test emergency preparedness plans to ensure protection of the environment, employees and the public; |

| | | |

| | • | Work with government and the public to develop effective and efficient measures to improve protection of the environment, based on sound science; and |

| | | |

| | • | Maintain an environmental committee to review environmental performance, objectives and targets, and to ensure continued recognition of environmental issues as a high priority. |

Employees

As at December 31, 2015, the Company had the following employees and contractors:

| Location | Full time salaried | Hourly (Unionized) | Contractors |

| Vancouver | 22 | - | 1 |

| Gibraltar | 144 | 500 | 21 |

| Florence, USA | 6 | - | 2 |

| Total | 172 | 500 | 24 |

Occupational Health and Safety Policy

Taseko provides safe and healthy working conditions, and to establish operating practices which safeguard employees and physical assets.

To achieve this goal, the Company commits to:

| | • | Meeting or exceeding all industry standards and legislative requirements; |

- 14 -

| | • | Developing and enforcing safe work rules and procedures; |

| | | |

| | • | Providing employees with the information and training necessary for them to perform their work safely and efficiently; |

| | | |

| | • | Acquiring and maintaining materials, equipment and facilities so as to promote good health and safety; and |

| | | |

| | • | Encouraging employees at all levels to take a leadership role in incident prevention by reporting and/or correcting unsafe situations. |

TSM Initiatives

Taseko is a member of the Mining Association of Canada and the Mining Association of British Columbia. Both of these organizations require members to participate in a program known as Towards Sustainable Mining (“TSM”) which encourages companies to work towards best management practice standards through self-regulation and reporting on key performance areas. These areas include:

| | • | Energy Use and Greenhouse Gas Emissions Management; |

| | | |

| | • | Biological Diversity Conservation Management; |

| | | |

| | • | Aboriginal and Community Outreach; |

| | | |

| | • | Tailings Management; |

| | | |

| | • | Health and Safety; and |

| | | |

| | • | Crisis Management Planning. |

In 2015, Taseko and Gibraltar’s performance and reporting on performance in all of the areas was verified by an external auditor as being at a level of industry best practice. Further details can be found on the Taseko website.

Gibraltar Mine - Technical Information

Current Technical Report

Unless stated otherwise, information of a technical or scientific nature related to the Gibraltar Mine contained in this AIF (including documents incorporated by reference herein) is summarized or extracted from a technical report entitled “Technical Report on the Mineral Reserve Update at the Gibraltar Mine” dated June 15, 2015 (the “Gibraltar Technical Report”), prepared by Scott Jones, P. Eng. filed on Taseko’s profile atwww.sedar.com and updated with production and development results since that time. Mr. Jones is employed by the Company as Vice-President, Engineering and is a “Qualified Person” as defined by Canadian securities regulatory instrument NI 43-101 (Disclosure Standards for Mineral Projects).

- 15 -

Project Description, Location, and Access

The Gibraltar open pit mine and related facilities are located 65 kms north of the town of Williams Lake and are centered at latitude 52o 30’N and longitude 122o 16’W in the Cariboo Mining Division. Williams Lake is approximately 590 kms north of Vancouver, British Columbia.

Access to the Gibraltar mine from Williams Lake is 45 kms via Highway 97 to McLeese Lake, and then 20 kms by paved road to the mine site.

The Gibraltar mine property consists of 241 tenures held as summarized in Table 1 below.

Table 1: Mineral Tenures – Gibraltar Mine

| Tenure Type | Number | Area (ha) |

| Claims | 209 | 17,377 |

| Leases | 32 | 2,275 |

| Total | 241 | 19,652 |

There are 32 mining leases at the Gibraltar mine which are valid until at least October 2033 as long as renewal fees, which are due on an annual basis, are paid. Rights to use the surface accompany each mining lease. There are 209 claims included in the Gibraltar property tenure package. One of these claims is due to expire in September 2016, 22 claims are due to expire in August 2017, 186 claims are due to expire in November 2017 or later. It is intended that all leases and claims will be renewed prior to their renewal fees being due (in the case of the leases) and prior to their expiry in the case of the claims.

There are several land parcels for which surface rights were purchased outright. There is one fee simple lot at the Gibraltar mine (L3728) on which the plant site is located and annual taxes are paid. In addition, the Gibraltar mine holds three other land parcels: DL9170, DL9483, and DL 9497.

There are no royalties, overrides, back-in rights, payments or other agreements to which the project is subject.

There are no significant factors or risks that might affect access or title or ability to perform work on the property.

History

In 1964, Gibraltar acquired a group of claims in the McLeese Lake area from Malabar Mining Co. Ltd. Canadian Exploration Limited (Canex) and Duval Corporation (Duval) had also been exploring on adjacent claims known as the Pollyanna Group. In 1969, Gibraltar, Canex and Duval entered into an agreement providing for the commingling of Gibraltar’s claims with the Pollyanna Group. In 1971, Gibraltar acquired Duval’s remaining interest in the property.

Preliminary development of the Gibraltar mine began in October 1970. The concentrator commenced production in March, 1972 and was fully operational by April 1972. A cathode copper plant with an annual capacity of 10 million pounds of market-ready copper metal began operation in October 1986.

- 16 -

In October 1996, Westmin Resources Limited (“Westmin”) acquired 100% control of Gibraltar and in December 1997, Boliden Limited Westmin (Canada) Limited (“Boliden”) acquired Westmin. In March 1998, Boliden announced that it would cease mining operations at the Gibraltar mine at the end of 1998.

In July 1999, Taseko’s subsidiary, Gibraltar Mines Ltd., purchased the Gibraltar mine assets from Boliden and certain of its affiliates, including all mineral interests, mining and processing equipment and facilities, and assumed responsibility for reclamation obligations.

From 1999 to 2004, Taseko geologists and engineers sought to better define known resources and explored for additional mineralized material. The on-site staff completed on-going reclamation work and maintained the Gibraltar mine for re-start. Operating and environmental permits were kept in good standing. The mine re-opened in October 2004. Copper cathode production at the SX/EW plant recommenced in January 2006.

The Gibraltar mine has been owned and operated as an unincorporated joint venture between Taseko and Cariboo Copper Corp. (“Cariboo”) since March 31, 2010. The Company’s wholly- owned subsidiary, Gibraltar Mines Ltd. and Cariboo hold 75% and 25% beneficial interests in the Joint Venture, respectively.

Gibraltar increased design mill capacity to 55,000 tons per day in 2011. Gibraltar further increased design mill capacity to 85,000 tons per day in 2013 through installation of a complete independent second concentrator and a stand-alone Molybdenum Separation Plant.

Total production since 1972 is 530 million tons of ore producing 2.8 billion pounds of copper in concentrate, 100 million pounds of cathode copper and 32 million pounds of molybdenum.

Geological Setting, Mineralization, and Deposit Types

The Gibraltar deposits are hosted by the upper Triassic Granite Mountain batholith, located within a wedge of Mesozoic and Palaeozoic rocks bounded on the west by the Fraser Fault system and on the east by the Pinchi Fault system. The Granite Mountain Batholith is a composite body consisting of three major phases; Border Phase diorite, Mine Phase tonalite, and Granite Mountain trondjhemite. Contacts between the major phases are gradational over widths ranging from two metres to several hundred metres. The regional deformation was accompanied by localized metasomatic alteration and associated sulphide deposition that led to the concentration of copper mineralization in specific areas of the batholith.

There are currently five defined mineralized zones on the Gibraltar Mine property. They are the Pollyanna, Granite, Gibraltar, Connector, and Extension zones. They occur in a broad zone of shearing and alteration.

Two major ore structure orientations have been recognized; the Sunset and Granite Creek systems. Ore host structures of the Sunset system are mainly shear zones, with minor development of stockworks and associated foliation lamellae whereas oriented stockworks with associated pervasive foliation lamellae predominate in the Granite Creek system.

- 17 -

Pyrite and chalcopyrite are the principal primary sulphide minerals. Small concentrations of other sulphides are present in the Gibraltar ores with molybdenite being a minor but economically important associate of chalcopyrite in the Pollyanna, Granite, and Connector deposits.

Exploration

There has been no material non-drilling exploration conducted on the Gibraltar property since 2000.

A property-scale Induced Polarization (“IP”) geophysical survey was designed and initiated in August 2000. Field activities included 237 kms of line cutting and some 220 kms of IP survey. Several deposit scale anomalies external to current reserves were identified and drill tested in 2003 as described in a report titled “Technical Report on the Gibraltar Mine, British Columbia” by James W. Hendry, P.Eng., and C. Stewart Wallis, P.Geo., dated March 23, 2005, which is filed onwww.sedar.com.

Drilling

From 1999 to 2004, Taseko geologists and engineers sought to better define known resources and explored for additional mineralized material. A core drilling program for pit definition for the Granite Lake and PGE Connector deposits and property exploration at the 98 Oxide Zone was carried out between September and November 2005. A further drilling program carried out in 2006 was designed to define the mineral resources between the existing pits by tying together the extensive mineralization zones, and to test for additional mineralization at depth.

The 2007 program tested a number of targets to define further mineralization, provided definition drilling in the Pollyanna-Granite saddle zone and Granite West areas and included condemnation drilling for the proposed extensions of both the #5 and #6 Dump footprints. The targets for further mineralization were Gibraltar South, Pollyanna North IP anomaly, Granite South and the Gunn Zone.

The 2008 exploration program was conducted on the southern and eastern margins of the Gibraltar pit and northwest of the Gibraltar West pit. The objective was to upgrade identified inferred resources to indicated or measured categories through “in-fill” drilling. Holes drilled in the Gibraltar West pit area were incorporated into the 2008 reserve estimate for the new Gibraltar Extension Pit.

The 2010 program was conducted on the northern and western margins of the Gibraltar pit, and one hole on the southwest margin. The objective was to define the ultimate limit of the Gibraltar pit to the north and west. The 2010 drilling program met the objective of delineating mineralization to the north and west of the Gibraltar pit. A total of 28,129 feet was drilled in 34 drill holes in 2010.

The 2011 program was aimed at identifying mineralization down-dip of the Gibraltar and Granite deposits. A total of 12,229 feet were drilled in 5 holes. A deep zone of anomalous copper ± molybdenum mineralization encountered in drill-hole 2011-003 extends from approximately 2,600 to 3,700 feet and consists of intermittent intercepts grading up to 1.3% TCu and 0.4% Mo.

In 2013, there were two drill programs completed, one in the summer and the other in the fall. Both programs targeted the projected mineralization south of the current Granite pit. A total of 38,068 feet in 31 holes were drilled between the two programs. The objective of both programs was to increase the extent of the mineralization within two of the Granite pit pushbacks.

- 18 -

In early spring of 2014, a resource drill program commenced targeting the Connector pit and the area between Gibraltar East and Granite Pit. At the same time a geotechnical drill program was undertaken. A total of 38 holes between the two programs were drilled with a cumulative length of 37,456 feet. The main goals of the drilling programs were (1) to collect high-quality geological, geotechnical and assay data, (2) to improve the geological understanding of the ore body, and (3) to increase the drill density within and confidence level of the resource model.

In late 2015, one exploration drill hole was drilled to expand the current known mineralization northwest of the Extension deposit. The total depth of the hole was 2,507 feet. A significant interval of copper was encountered at above reserve grade. The mineralization to the west, northwest and at depth is open. More drilling is needed to confirm if the Extension pit can be expanded to include this material.

Sampling, Analysis, and Data Verification

Over 120,000 samples have been taken for total copper analysis from drilling at Gibraltar since 1965. About 95% of these samples were also assayed for molybdenum, 56% for acid soluble copper, 40% for multi-element ICP and 30% for gold. Essentially all rock drilled and recovered is sampled in 10 ft intervals. Unconsolidated overburden material, where it exists, is generally not recovered by core drilling and therefore not usually sampled.

From discovery in 1965 through mine start-up in 1971, and since mine re-start in 2004, assays on exploration drill samples have been performed by reputable, independent third party analytical laboratories. Mine laboratory personnel performed all exploration drill sample analyses from 1979 to 2003.

Well-documented sample preparation, security and analytical procedures used on the Gibraltar drill programs since 1999 have been carried out in an appropriate manner consistent with common industry practice. The results are supported by many years of mine production. A significant amount of due diligence and analytical QAQC for copper and molybdenum has been completed on the samples that were used in the current mineral resource/reserve estimate. The quality of the work performed on the digital database provides confidence that it is of good quality and acceptable for use in geological and resource modeling of the Gibraltar deposits.

Details of sample preparation, assay laboratories, security, and data verification used in the Gibraltar drill hole sampling and analytical programs is documented in the Gibraltar Technical Report.

Mineral Processing and Metallurgical Testing

Sulphide ore from the Gibraltar deposits has been processed on-site since 1972 and run of mine oxide ore has been leached since 1986. The current mineral reserves are contained within zones which have been significantly mined, with the exception of the Extension Zone. Metallurgical testing associated with the Extension Zone returned results consistent with the larger ore body.

- 19 -

The basis for predictions of copper concentrate flotation recovery is plant performance data from both of the existing concentrators based on sulphide and oxide content. Copper recovery averages 88% over the operating period of the reserves.

Closed circuit cleaner locked cycle tests on Gibraltar bulk copper concentrate provide recovery values in the range of 90-93% at a final molybdenum grade greater than 50%. Applying the predicted molybdenum recovery from the locked cycle tests to the average bulk flotation circuit molybdenum recovery supports the molybdenum recovery of 50% used in economic calculations.

The basis of the predictions of copper cathode produced from heap leaching and subsequent solvent extraction is based upon historical leaching recovery curves. These curves take into account the annual recovery declination from the date of material placement.

Mineral Resource and Mineral Reserve Estimates

The Gibraltar mine mineral resources and reserves are based on the published reserves as of December 31, 2014, as documented in the Gibraltar Technical Report and reflects depletion due to mining in 2015.

The reserve estimate uses long-term metal prices of US$2.75/lb for copper and US$11.00/lb for molybdenum and a foreign exchange of C$1=US$0.85.

The proven and probable sulphide reserves as of December 31, 2015, are tabulated in Table 2 below.

Table 2: Gibraltar Mine Sulphide Mineral Reserves at 0.15% Copper Cut-off

Pit |

Category | Tons

(millions) | Cu

(%) | Mo

(%) |

Connector

| Proven

Probable | 153

14 | 0.25

0.22 | 0.010

0.008 |

| Subtotal | 167 | 0.25 | 0.010 |

Gibraltar

| Proven

Probable | 153

111 | 0.25

0.23 | 0.009

0.008 |

| Subtotal | 264 | 0.24 | 0.008 |

Granite

| Proven

Probable | 136

14 | 0.27

0.25 | 0.009

0.007 |

| Subtotal | 150 | 0.27 | 0.009 |

Extension

| Proven

Probable | 50

1 | 0.33

0.26 | 0.002

0.001 |

| Subtotal | 51 | 0.33 | 0.002 |

Pollyanna

| Proven

Probable | 85

5 | 0.25

0.23 | 0.007

0.003 |

| Subtotal | 90 | 0.25 | 0.007 |

| Total | 722 | 0.26 | 0.008 |

There are also oxide reserves as shown in Table 3 below. These oxide reserves are in addition to the sulphide reserves stated in Table 2.

- 20 -

Table 3: Gibraltar Mine – Oxide Mineral Reserves at 0.10% ASCu Cut-off

| Pit | Category | Tons (millions)(1) | ASCu (%) |

Connector

| Proven

Probable | 1

14 | 0.15

0.15 |

| Subtotal | 15 | 0.15 |

Gibraltar

| Proven

Probable | 0

1 | 0.00

0.18 |

| Subtotal | 1 | 0.18 |

Extension

| Proven

Probable | 0

0 | 0.00

0.00 |

| Subtotal | 0 | 0.00 |

Pollyanna

| Proven

Probable | 0

1 | 0.00

0.12 |

| Subtotal | 1 | 0.12 |

| Total | 18 | 0.15 |

(1) Totals may not add due to rounding.

Cautionary Note to Investors concerning estimates of Measured and Indicated Resources

The following section uses the terms “measured” and “indicated resources”. We advise investors that while those terms are recognized and required by Canadian regulations, the U.S. Securities and Exchange Commission does not recognize them.Investors are cautioned not to assume that any part or all mineral deposits in these categories that are not already classified as “reserves” will ever be converted into reserves.

The resource estimate uses long-term metal prices of US$3.50/lb for copper and US$11.00/lb for molybdenum and a foreign exchange rate of C$1=US$0.90.

The mineral reserves stated in Table 2 above are contained within the mineral resources indicated in Table 4 below:

Table 4: Gibraltar Mine Mineral Resources at 0.15% Copper Cut-off

| Category | Tons (millions) | Cu (%) | Mo (%) |

| Measured | 805 | 0.26 | 0.008 |

| Indicated | 261 | 0.24 | 0.007 |

| Total | 1066 | 0.25 | 0.008 |

The mineral resource and reserve estimations were completed by Gibraltar mine staff under the supervision of Scott Jones, P.Eng., Vice-President, Engineering, a Qualified Person under NI 43-101 and the author of the Gibraltar Technical Report. Mr. Jones has verified the methods used to determine grade and tonnage in the geological model, reviewed the long-range mine plan, and directed the updated economic evaluation.

- 21 -

Mining Operations

The Gibraltar mine is a typical open pit operation that utilizes drilling, blasting, cable shovel loading and large-scale truck hauling to excavate rock. The Gibraltar mine is planned for excavation of sulphide mineralized material of sufficient grade that it can be economically mined, crushed, ground and processed to a saleable product by froth flotation.

Rock containing lower grade sulphide mineralization or oxide mineralization is also mined but is not immediately processed. The lower grade sulphide material is stockpiled for later processing in the concentrator. In addition, a portion of the low grade sulphide material and all of the oxide material can be leached with a highly diluted sulphuric acid, which is naturally assisted by bacterial action, and the resultant copper sulphate solution can be processed to cathode copper in the Gibraltar mine’s SX/EW plant.

The strip ratio over the 24 year operating period of the reserve will average 1.9. Strip ratio refers to the ratio of the amount of overburden (or waste material) required to be mined in order to extract a unit of ore. For example, a 3:1 stripping ratio means that mining one tonne of ore will require mining three tonnes of waste rock. While the annual strip ratio generally decreases with time, the strip ratio will vary and be managed over the course of the mine life based on exchange rates, commodity prices, and grade distribution during annual and mid-range mine planning process to optimize the economic performance of the operation.

Processing and Recovery Operations

The processing facilities at the Gibraltar mine consist of two separate bulk sulphide concentrators, a dedicated molybdenum flotation plant, and a series of leach piles which feed a solvent extraction and electrowinning (SX/EW) facility.

Run of mine ore is fed to the two sulphide concentrators in parallel at a combined design rate of 85,000 t/day. These two bulk concentrators, while differing in size, follow the same process path. Ore is fed to primary crushing with the product reporting to a closed circuit SAG/Ball comminution stage. Ground ore is processed through a rougher flotation stage. Tailings from the rougher flotation stage are pumped to a storage facility, while the concentrate is reground and processed through two further cleaner flotation stages. Final bulk concentrate contains both copper and molybdenum values.

The bulk concentrate from both facilities is combined and processed through a single molybdenum flotation plant. The bulk concentrate is floated in a rougher stage which depresses the copper values and selectively recovers molybdenum. The underflow from this plant is the site’s final copper concentrate. This copper concentrate is dewatered and shipped in bulk to market. The rougher concentrate is reground and processed through two further cleaner flotation stages. Molybdenum final concentrate from this plant is dewatered and bagged, and subsequently shipped to market. The molybdenum flotation plant was idled in July 2015 pending a material increase in molybdenum prices.

Oxide ore from the mine is delivered to oxide leach dumps. The SX/EW plant is designed to extract copper from the pregnant leach solutions (“PLS”) collected from the site’s leach dumps. Acidic solution is passed through the leach pile and extracts copper in the form of copper ions in this PLS. This copper laden solution is delivered to the SX/EW plant via collection ditches, ponds and pumping where required. The process takes PLS and selectively extracts the copper ions in solvent extraction mixer-settlers. The copper is transferred from this acid solution to an organic phase and finally to a clean electrolyte. The electrolyte is filtered and heated before being passed through the electrowinning cells where the copper is plated out on stainless steel cathodes. The resultant high quality cathode copper is bundled and sold. The barren solution leaving the plant, raffinate, is pumped back to leach additional copper from the leach piles.

- 22 -

Gibraltar’s copper concentrate has an approximately 28% copper content grade and no significant deleterious elements. Gibraltar copper cathode is nominally 99.9%+ pure copper.

Infrastructure, Permitting and Compliance Activities

The Canadian National (CN) Railway has rail service to facilitate the shipping of copper concentrates to Vancouver Wharves, owned and operated by Kinder Morgan in North Vancouver, British Columbia. The Company owns and operates the concentrate rail load-out facility on the CN rail line at Macalister, 26 kms from the mine site. Electricity is obtained from BC Hydro. Natural gas is provided by Fortis BC. The communities of Williams Lake and Quesnel are sufficiently close to the site to supply goods, services, and personnel to the Gibraltar mine. The Gibraltar mine had over 600 active personnel at the end of December 2015. Make-up fresh water for the mine site is obtained from a set of wells on the Gibraltar mine property. Process facilities operate using reclaimed water from the existing tailings storage facility

Water currently stored in the Gibraltar Pit will be transferred to the completed Granite pit starting in early 2025. This will require the construction of a bulk pit dewatering system.

Relocation of the in-pit crusher feeding concentrator 1 will need to be completed by 2023 prior to starting phase 2 of the Connector Pit.

With the current design parameters and tailings deposition plan, the tailings facility footprint will accommodate tailings storage until at least 2033. It is anticipated that actual tailings deposition performance will enable deposition of all tailings generated in the reserve mine plan within the existing facility footprint.

All material regulatory authorizations and permits are in place to extract the reserves described in this report with the exception of:

| | • | A small extension of lease boundary to include the Extension Pit by 2032. |

| | | |

| | • | Periodic amendments of PE-416 and M-40 for pit wall pushbacks, water discharge, and waste rock and tailings storage. |

Other permit considerations include approvals required for route changes to the access road, hydro transmission line, natural gas line, and water discharge pipeline in order to complete development of the Extension Pit which is scheduled to start in 2032. Approvals will be sought as required.

There have been no material environmental non-compliance incidents since the mine reopened in 2004.

- 23 -

Capital and Operating Costs

As the majority of the mine’s facilities are in place and operating, the only capital requirements are for the relocation of the in-pit crusher/conveyor system and electrical substation, bulk pit dewatering, specific tailings and water discharge related activities, and sustaining capital to maintain the integrity of the mining and processing equipment.

The total anticipated site capital requirements over the next 24 years are summarized in Table 5.

Table 5: Capital Cost Summary

Area | Total Capital (in

millions) |

|

| Bulk Pit Dewatering | $14 |

| Tailings and Water Reclaim/Discharge | $7 |

| Crusher Relocation | $36 |

| Pit Substation Relocation | $3 |

| Road and Gas Line Relocation | $5 |

| General Sustaining | $243 |

| Total | $308 |

Average estimated unit site operating costs over the next 24 years are summarized in Table 6:

Table 6: Site Operating Cost Summary

| Operating Category | Life of Mine Cost |

| Mining cost/ton mined1 | $1.80 |

| Milling cost/ton milled | $3.90 |

| General and Administrative cost/ton milled | $0.90 |

| Total operating cost/ton milled | $10.07 |

1 Mine cost/ton miled is $5.22 at a strip ratio of 1:9:1

The basis for capital and operating cost estimates are documented in the Gibraltar Technical Report.

Exploration, Development, and Production

Gibraltar is pursuing initiatives to improve recovery, concentrator throughput, and mine cost and productivity. Continued improvement in any or all of these areas will have not only positive economic implications but could increase the size of the reserve pits under current commodity assumptions and/or impact the optimum cut-off grade.

Prosperity Project

Current Technical Report

Unless stated otherwise, information of a technical or scientific nature related to the Prosperity project contained in this AIF is summarized or extracted from a technical report entitled “Technical Report on the 344 Million Tonne Increase in Mineral Reserves at the Prosperity Gold – Copper Project” dated December 17, 2009, (the “Prosperity Technical Report”) prepared by Scott Jones, P. Eng. filed on Taseko’s profile on SEDAR atwww.sedar.com. Mr. Jones is employed by the Company as Vice-President, Engineering and is a Qualified Person as defined by NI 43-101 (Disclosure Standards for Mineral Projects). Readers are cautioned that the Prosperity Technical Report is now some six years old and accordingly caution needs to be advised when assessing its conclusions in light of current operating and capital costs, appropriate technologies, metals price outlooks, and like matters.

- 24 -

Project Description, Location, and Access

The Prosperity project is located at latitude 51° 28’ N and longitude 123° 37’ W in the Clinton Mining Division, approximately 125 kms southwest of the City of Williams Lake, British Columbia.

Access from Williams Lake is via Highway 20 to Lee’s Corner, then via an all-weather main logging haulage road to the site, a total road distance of 192 kilometres.

The Prosperity property consists of one mineral lease which is valid until at least June 2035 as long as renewal fees, which are due on an annual basis, are paid. There are 85 mineral claims covering the mineral rights for approximately 190 square kms. Twenty-two claims are in good standing until July 2016, while the remainder are in good standing until at least August 2016. It is intended that all leases and claims will be renewed prior to their renewal fees being due (in the case of the lease) and prior to their expiry in the case of the claims.

The claims are 100% owned by Taseko and are not subject to any royalties or carried interests.

As this is a green-field project, there are no existing environmental liabilities on the property and there has been no development at the site. When additional site work is required, permit applications will be made and approved by responsible regulatory agencies. The Company does not currently hold any surface rights, these would need to be applied for.

History

The Prosperity deposit was originally discovered by prospectors in the early 1930’s. Phelps Dodge Corporation conducted a small exploration program in the early 1960’s and subsequently allowed the claims to lapse.

In 1969, Taseko acquired the property and drilled 18 holes totalling approximately 2,300 metres immediately to the south of the area previously explored, discovering significant tonnage grading 0.25% to 0.30% copper.

From 1970 to 1974, under option agreements with Nittetsu Mining Company and Quintana Minerals Corporation, approximately 5,000 metres of drilling was completed in 29 holes. Bethlehem Copper Corp. (“Bethlehem”) optioned the project in 1979 and by 1981 had completed approximately 14,000 metres of drilling in 73 holes. Following the corporate merger of Bethlehem and Cominco Ltd. (“Cominco”) Cominco acquired the Bethlehem option agreement on the property. From 1982 to 1989 Cominco work programs included geophysical and soil geochemical surveys, an additional 5,300 metres of drilling in 48 holes, and a limited metallurgical test work program. In 1990, Cominco Ltd. reported a drill–indicated mineral resource of 208 million tonnes at an average grade of 0.23% Cu and 0.41 gpt Au to 360 metres below surface.

- 25 -

After a period of disagreement with Cominco regarding compliance with the option agreement, which included legal proceedings, in 1993 Taseko acquired 100% of the project free of any royalties or third party interests through settlement agreements.

Following drilling in 1991 and 1992, Taseko reported mineralized material (unclassified mineral resource) of 976 million tonnes at an average grade of 0.23% Cu and 0.48 gpt Au.

Comprehensive metallurgical tests were completed in 1993 and a pre-feasibility report was completed in 1994.

Following a significant drill program in the latter half of the 1990’s, in 1998 Taseko reported estimated measured and indicated mineral resources of 1.0 billion tonnes at 0.41 gpt Au and 0.24% Cu and an inferred resource of 0.2 billion tonnes grading 0.25 gpt Au and 0.21% Cu at a 0.14% copper cut-off.

Work on the project was deferred from 2000-2005 first due to low metal prices and then later as the Company turned its attention to re-starting the Gibraltar mine. In November 2005, work was reactivated on the project. A pre-feasibility level study was completed in the first quarter of fiscal 2007 followed by a full feasibility study in the fall of that year. In 2008 Taseko worked with a number of consultants to investigate value engineering opportunities, energy efficiency, and operating ease in various areas of the concentrator and support infrastructure. The outcome of this work, in combination with a significantly different outlook for copper and gold prices in 2009 resulted in the current reserve.

In late 2009 and 2010, additional metallurgical testing and geotechnical investigations were undertaken in support of detailed engineering.

In 2010, Taseko worked with various consultants to advance project engineering to the detailed phase and to advance various permit applications.Taseko temporarily suspended work on detailed engineering and permitting in November 2010 following the federal cabinet’s decision on the environmental assessment.

In early 2011 Taseko began design revisions to the project to address the concerns identified during the federal review process.

In early 2012 Taseko completed a geotechnical field investigation to support the design and environmental assessment of the relocated tailings facility proposed as part of a New Prosperity Design.

There has been no production from the property and there is no material infrastructure on the project.

Geological Setting, Mineralization, and Deposit Types

The project is located within the western-most portion of the Intermontane Belt at the boundary between the Intermontane and Coast morphologic belts. The surrounding area is underlain by poorly exposed, Late Paleozoic to Cretaceous litho tectonic assemblages which have been intruded by plutons of Mid-Cretaceous to Early Tertiary age. The main Coast Plutonic Complex is 50 kilometres southwest of the New Prosperity project area.

- 26 -

The Yalakom Fault is the major fault in the region and lies to the southwest of the deposit on the New Prosperity project. Estimates of Eocene dextral strike-slip offsets for the Yalakom Fault have been postulated variously as ranging from 80 to 190 kms, 125 to 175 kms or 115 kms. It may have imparted some related structural controls that are important to the localization of mineralization at the deposit.

The project hosts a large porphyry gold-copper deposit. The deposit is predominantly hosted in Cretaceous andesitic volcaniclastic and volcanic rocks. In the western portion of the deposit, the host rocks have been intruded by the multi-phase, steeply dipping Fish Creek Stock. The stock is surrounded by an east-west trending, south dipping swarm of subparallel quartz-feldspar porphyritic dykes. The stock and dykes comprise the Late Cretaceous Fish Lake Intrusive Complex that is spatially and genetically related to the deposit. Post mineralization porphyritic diorite occurs as narrow dykes that cross-cut all host rocks. The central portion of the deposit is cut by two major faults, striking north-south and dipping steeply to the west.

Pyrite and chalcopyrite are the principal sulphide minerals in the deposit. They are uniformly distributed in disseminations, fracture fillings, veins and veinlets and may be accompanied by bornite and lesser molybdenite and tetrahedrite-tenantite. Native gold occurs as inclusions in and along microfractures with copper-bearing minerals and pyrite.

Exploration

There has been no material non-drilling exploration conducted on the property since the early 1990’s. Exploration programs prior to this time included extensive IP and magnetic geophysical and soil geochemical surveys which contributed to the definition of the mineralization.

Drilling

Until 1991, exploration programs on the property included 176 percussion and diamond drill holes totalling approximately 27,100 metres. This work helped define the project mineralization to a depth of 200 metres, and outlined a gold-copper mineralized zone approximately 850 metres in diameter.

Diamond drilling from 1991 through 1997 totalled approximately 85,000 metres in 267 holes, expanding the deposit to 1400 metres east-west, 600 metres north-south and to 850 metres below surface, increasing the density of drilling in the deposit, and adding to the geotechnical and geochemical characterization of the deposit.

From 1963 to 1997, a total of 155,000 metres had been drilled in 452 holes.

Six core holes totaling 1,762 metres were drilled in 2007 for metallurgical purposes. The purpose of this program was to provide sufficient material representative of the various alteration zones anticipated to be encountered in the first six years of production.

- 27 -

Sampling, Analysis, and Data Verification

Over 65,000 samples have been taken for analysis from drilling since 1969. All of the assays on drill samples have been performed by reputable, independent third party analytical laboratories.

Taseko implemented a quality control quality assurance (QAQC) program consistent with common industry practice after taking over the project in 1991. This program was in addition to the QAQC procedures used internally by the analytical laboratories. The results of this program indicate that analytical results are of high quality and suitable for use in detailed modeling and resource evaluation studies.

Details of sample preparation, assay laboratories, security, and data verification used in the drill hole sampling and analytical programs is documented in the Prosperity Technical Report.

Mineral Processing and Metallurgical Testing

Progressive metallurgical studies over the period 1991 through 1993 included batch and locked cycle flotation tests on composites representing different areas of the deposit to determine achievable copper and gold recoveries and provide detailed concentrate analysis, grind-ability assessments, tailings settling tests, environmental data, and a cursory examination of the removal of deleterious elements from flotation concentrate.

In 1996 a run-in pilot plant was carried out as a precursor to a comprehensive pilot plant; its main objectives to establish basic operating parameters and generate material for initial environmental testing.

In 1997 a pilot plant campaign included batch and locked cycle tests as well as pilot plant runs carried out on composites prepared representing different zones of the deposit. It also included grinding test work, detailed analysis of concentrates, generation of environmental data, tailings settling tests, and concentrate settling and filtration tests.

A test work program was completed in 2008 to investigate the metallurgical performance of Prosperity mineralization at coarser regrinds and alternate regrind flow sheets. This work was conducted on core from the 2007 drilling campaign that represented years 1 through 4 mill feed.

The results support estimated life of mine recoveries of copper and gold recoveries of 87% and 69% respectively using conventional flotation methods.

Estimated average concentrate grades over the mine life are 24% copper, 35 g/t gold and 89 g/t silver. Smelter penalties are anticipated for arsenic, antimony, and mercury.

Additional details with respect to metallurgical test work can be found in the Prosperity Technical Report.

Mineral Resource and Mineral Reserve Estimates

The mineral resources and mineral reserves are as documented in the 2009 Prosperity Technical Report.

- 28 -

The reserve estimate uses long-term metal prices of US$1.65/lb for copper and US$650/oz for gold and a foreign exchange of C$1=US$0.82.

The proven and probable reserves are tabulated in Table 7 below.

Table 7: Prosperity Mineral Reserves at CDN$5.50 NSR/t Pit-Rim Cut-off

| Category | Tonnes

(millions) | Gold

(g/t) | Copper

(%) | Recoverable

Gold Ounces

(millions) | Recoverable

Copper Pounds

(billions) |

Proven

Probable | 481

350 | 0.46

0.35 | 0.26

0.18 | 5.0

2.7 | 2.4

1.2 |

| Total | 831 | 0.41 | 0.23 | 7.7 | 3.6 |

Cautionary Note to Investors concerning estimates of Measured and Indicated Resources

The following section uses the terms “measured” and “indicated resources”. We advise investors that while those terms are recognized and required by Canadian regulations, the U.S. Securities and Exchange Commission does not recognize them.Investors are cautioned not to assume that any part or all mineral deposits in these categories that are not already classified as “reserves” will ever be converted into reserves.

The mineral resources shown in Table 8 include the mineral reserves shown in Table 7. Resource estimates are based on a copper cut-off of 0.14% .

Table 8: Prosperity Mineral Resources at 0.14% Copper Cut-off

| Category | Tonnes (millions) | Gold (g/t) | Copper (%) |

Measured

Indicated | 547.1

463.4 | 0.46

0.34 | 0.27

0.21 |

| Total | 1,010.5 | 0.41 | 0.24 |

Mining Operations

The proposed mine plan utilizes a large-scale conventional open pit mining and milling operation. Following a one and a half year pre-strip period, total material mined from the open pit over years 1 to 31 averages 170,000 tonnes per day at a life-of-mine strip ratio of 1.5:1. A declining net smelter return cutoff is applied to the mill feed, which defers lower grade ore for later processing. The stockpiled ore is processed in the final years of the mine plan.

Processing and Recovery Operations

The processing plant has been designed with a nominal capacity of 70,000 tonnes per day. The plant consists of a single 12 meter diameter SAG mill, two 7.9 -metre diameter ball mills, followed by processing steps that include bulk rougher flotation, regrinding, cleaner flotation, thickening and filtering to produce a copper-gold concentrate. Expected life-of-mine metallurgical recovery is 87% for copper and 69% for gold, with annual production averaging 110 million pounds copper and 234,000 ounces gold over the 33-year mine life.

- 29 -

The copper-gold concentrate will be hauled with highway trucks to an expanded load-out facility at Gibraltar Mines Ltd.’s existing facility near Macalister for rail transport to various points of sale, but primarily through the Port of Vancouver for shipment to smelters/refineries around the world.

Infrastructure, Permitting and Compliance Activities

Power is proposed to be supplied via a new 124 kms long, 230 kV transmission line from Dog Creek on the BC Hydro Grid. The Company does not yet have rights of way or approvals to construct facilities to provide electricity to the site. Ample water is available nearby for a mining operation.

The Canadian National railway services Williams Lake and has rolling stock available to move concentrates by rail to points of sale in North America.

Infrastructure would also include the upgrade of sections of the existing road to the site, construction of a short spur to the mine site, an on-site camp, equipment maintenance shop, administration office, concentrator facility, warehouse, and explosives facilities.

The project would employ up to 460 permanent hourly and staff personnel. In addition, approximately 60 contractor personnel would be employed in areas including catering, concentrate haulage, explosives delivery, and busing.

The City of Williams Lake is sufficiently close and is capable of supplying goods, services, and personnel to a mine.

Between 2009 and 2010, the British Columbia Environmental Assessment Office (“EAO”) led a review of the Project in a coordinated manner with the Canadian Environmental Assessment Agency (“CEAA”).

On January 14, 2010, Taseko received the environmental assessment certificate for the Prosperity Project from the Province of BC.

The Federal process was conducted by a three-person panel, whose findings were in certain respects similar to the conclusions reached in the Provincial Environmental Assessment, although they were not mandated to assess positive economic and social value generated by the project. In July 2010, the panel submitted its final report to the Federal Government.

In November 2010, the Federal Minister of Environment announced that the Prosperity mine project, as proposed, would not be granted federal authorizations to proceed. The Company reviewed and revised its plan and put forth a new design proposal, the New Prosperity project, which included the preservation of Fish Lake by relocating the tailings storage facility and modifying the water management plan. This design addressed the concerns identified during the federal review process, and in February, 2011 the Company submitted a project description for the New Prosperity project to the Federal Government.

- 30 -

In June 2011, Taseko submitted an application to the EAO to amend the Environmental Assessment Certificate in accordance with the New Prosperity project description