UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-K

(Mark One)

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2009

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the transition period from to .

Commission File Number: 0-19582

OLD DOMINION FREIGHT LINE, INC.

(Exact name of registrant as specified in its charter)

| | |

| VIRGINIA | | 56-0751714 |

| (State or other jurisdiction of | | (I.R.S. Employer |

| incorporation or organization) | | Identification No.) |

500 Old Dominion Way

Thomasville, NC 27360

(Address of principal executive offices) (Zip Code)

(336) 889-5000 (Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

| | |

Title of each class | | Name of each exchange on which registered |

| Common Stock ($0.10 par value) | | The NASDAQ Stock Market LLC

(NASDAQ Global Select Market) |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes x No ¨

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yes ¨ No x

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Website, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes ¨ No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one).

| | |

Large accelerated filer x | | Accelerated filer ¨ |

Non-accelerated filer ¨ (Do not check if a smaller reporting company) | | Smaller reporting company ¨ |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes ¨ No x

The aggregate market value of voting stock held by non-affiliates of the registrant as of June 30, 2009 was $935,643,473, based on the closing sales price as reported on the NASDAQ Global Select Market.

As of February 26, 2010, the registrant had 37,284,675 outstanding shares of Common Stock ($0.10 par value).

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Company’s Proxy Statement for the 2010 Annual Meeting of Shareholders are incorporated by reference into Part III of this report.

INDEX

Forward-Looking Information

Forward-looking statements appear in this Annual Report, including but not limited to Item 7, “Management’s Discussion and Analysis of Financial Condition and Results of Operations,” and in other written and oral statements made by or on behalf of us. These forward-looking statements include, but are not limited to, statements relating to our goals, strategies, expectations, competitive environment, regulation, availability of resources, future events and future financial performance. Such forward-looking statements are made pursuant to the safe harbor provisions of the Private Securities Litigation Reform Act of 1995. These forward-looking statements typically can be identified by such words as “anticipate,” “estimate,” “forecast,” “project,” “intend,” “expect,” “believe,” “should,” “could,” “may,” or other similar words or expressions. We caution readers that such forward-looking statements involve risks and uncertainties that could cause actual events or results to differ materially from those expressed or implied herein, including, but not limited to, the risk factors detailed in this Annual Report.

Our forward-looking statements are based on our beliefs and assumptions using information available at the time the statements are made. We caution the reader not to place undue reliance on our forward-looking statements (i) as these statements are neither a prediction nor a guarantee of future events or circumstances and (ii) the assumption, beliefs, expectations and projections about future events may differ materially from actual results. The Company undertakes no obligation to publicly update any forward-looking statement to reflect developments occurring after the statement is made.

PART I

ITEM 1. BUSINESS

Unless the context requires otherwise, references in this report to “Old Dominion,” the “Company,” “we,” “us” and “our” refer to Old Dominion Freight Line, Inc.

Overview

Old Dominion is a leading, less-than-truckload (“LTL”), non-union motor carrier providing regional, inter-regional and national LTL service and value-added logistics services from a single integrated organization. We operate as one business segment and offer our products and services through our four branded product groups: OD-Domestic, OD-Expedited, OD-Global and OD-Technology. We have grown to be the sixth largest LTL motor carrier in the United States, as measured by 2008 revenue, according toTransport Topics. In addition to our LTL services, we offer our customers a broad range of logistics services including ground and air expedited transportation, supply chain consulting, transportation management, truckload brokerage, container delivery and warehousing services. Through marketing and carrier relationships, we also offer door-to-door international freight services to and from all of North America, Central America, South America and the Far East. Our services are complemented by our technological capabilities, which provide the tools to improve the efficiency of our operations while empowering our customers to manage their shipping needs.

We have grown our revenue and customer base through both organic growth and strategic acquisitions. Prior to 1995, we provided regional service within the Southeastern region of the United States as well as inter-regional service connecting the Southeast to select major metropolitan areas. We have since expanded our infrastructure to provide next-day and second-day service within each of our six regions that now cover the entire continental United States, as well as expanded our inter-regional and national service between these regions. To support this geographic expansion, we increased our number of service centers from 53 at December 31, 1995 to 210 at December 31, 2009, including 72 new service centers in the past five years.

We attribute our growth to our focus on meeting our customers’ complete supply chain needs from a single point of contact with a high level of customer service supported by continual investment in our employees,

3

service center network and technology. Our integrated structure allows us to offer our customers consistent and continuous service from origin to destination. We believe our operating structure and proprietary information systems enable us to provide higher customer service levels and better manage our operating costs.

We were organized in 1934 and incorporated in Virginia in 1950. Our principal executive offices are located at 500 Old Dominion Way, Thomasville, North Carolina, 27360. Please refer to the Balance Sheets and Statements of Operations included in Item 8, “Financial Statements and Supplementary Data” of this report for information regarding our total assets, revenue from operations and net income.

Our Industry

Trucking companies provide transportation services to virtually every industry operating in the United States and generally offer higher levels of reliability and faster transit times than other surface transportation options. The trucking industry is comprised principally of two types of motor carriers: LTL and truckload. LTL carriers pick up multiple shipments from multiple customers on a single truck and then route that freight for delivery through service centers where the freight may be transferred to other trucks with similar destinations. In contrast, truckload carriers generally dedicate an entire trailer to one customer from origin to destination.

According to the American Trucking Associations, the trucking industry accounted for 83.1% of total domestic freight revenue in 2008, or $660.3 billion, of which the LTL sector accounted for 7.8%, or $51.8 billion. In contrast to truckload carriers, LTL motor carriers require expansive networks of local pickup and delivery (“P&D”) service centers, as well as larger breakbulk, or hub, facilities. Significant capital is required of LTL motor carriers to create and maintain a network of service centers and a fleet of tractors and trailers. The high fixed costs and capital spending requirements for LTL motor carriers makes it difficult for new start-up or small operators to effectively compete with established companies. In addition, successful LTL motor carriers generally employ, and continuously update, a high level of technology to provide information to customers and to reduce operating costs.

The LTL industry is highly competitive on the basis of service and price and has consolidated significantly since the industry was deregulated in 1980. Based on 2008 revenue, the top 25 LTL motor carriers accounted for approximately 60% of the total LTL market. Consolidation has accelerated in recent years due to an increase in customer demand for single transportation providers offering both national and regional LTL service and complex supply chain services, which smaller regional carriers with lesser financial resources are generally unable to provide. We believe consolidation will continue, particularly in the current economic environment, which appears to have substantially weakened the financial condition of many of our competitors.

Competition

We compete with regional, inter-regional and national LTL carriers and, to a lesser extent, with truckload carriers, small package carriers, airfreight carriers and railroads. Competition is based primarily on service, price and business relationships. We believe that we are able to compete effectively in our markets by providing high-quality and timely service at competitive prices.

At all levels of our organization, we seek to continuously improve customer service by maximizing on-time performance while reducing transit times and minimizing cargo claims. We believe our transit times are generally faster than those of our principal national competitors, in part because of our more efficient service center network, use of team drivers and proprietary technology. In addition, we provide greater geographic coverage than most of our regional competitors. Our diversified mix and scope of regional, inter-regional and national service enables us to provide our customers with a single source to meet their LTL shipping needs, and we believe this provides us with a distinct advantage over our regional, multi-regional and national competition.

4

We also believe our non-union workforce gives us a significant advantage over our unionized LTL competitors. By utilizing flexible scheduling and training our employees to perform multiple tasks, we believe we achieve greater productivity and higher levels of customer service. We believe our focus on communication, continued education, development and motivation strengthens the relationships among our employees.

We compete with several larger transportation service providers, each of which may have more equipment, a broader coverage network and a wider range of services than we have. Our larger competitors may also have greater financial resources and, in general, the ability to reduce prices to gain business, especially during times of reduced growth rates in the economy.

Service Center Operations

At December 31, 2009, we conducted operations through 210 service center locations, of which we own 125 and lease 85. We operate nine major breakbulk facilities in Atlanta, Georgia; Rialto, California; Indianapolis, Indiana; Greensboro, North Carolina; Harrisburg, Pennsylvania; Memphis and Morristown, Tennessee; Dallas, Texas; and Salt Lake City, Utah, while using some smaller service centers for limited breakbulk activity in order to serve our next-day markets. Our service centers are strategically located in six regions of the country to provide the highest quality service and minimize freight rehandling costs.

Each of our service centers is responsible for the pickup and delivery of freight within its service area. Each service center loads outbound freight by destination the day it is picked up. All inbound freight received by the service center in the evening or during the night is scheduled for local delivery the next business day, unless a customer requests a different delivery schedule. Our management reviews the productivity and service performance of each service center on a daily basis to ensure quality service and efficient operations.

While we have established primary responsibility for customer service at the local service center level, our customers may access information and initiate transactions through our centralized customer service department located at our corporate office or several other gateways, such as our website, electronic data interchange (“EDI”), automated voice response systems and automated fax systems. Our systems offer direct access to information such as freight tracking, shipping documents, rate quotes, rate databases and account activity. These centralized systems and our customer service department provide our customers with a single point of contact to access information across all areas of our operations and for each of our service products.

Linehaul Transportation

Linehaul dispatchers are centralized at our corporate office and control the movement of freight among service centers through integrated freight movement systems. We also utilize load-planning software to optimize efficiencies in our linehaul operations. Our senior management continuously monitors freight movements, transit times, load factors and other productivity measurements to ensure that we maintain our highest levels of service and efficiency.

We utilize scheduled routes, and additional linehaul dispatches as necessary, to meet our published service standards. In addition, we lower our cost structure by maintaining flexible workforce rules and by primarily using twin 28-foot trailers in our linehaul operations. The use of twin 28-foot trailers permits us to transport freight directly from its point of origin to destination with minimal unloading and reloading, which also reduces cargo loss and damage expenses. We also utilize long-combination vehicles, such as triple 28-foot trailers and combinations of 48-foot and 28-foot trailers, in states where permitted. Twin trailers and long-combination vehicles permit more freight to be hauled behind a tractor than could otherwise be hauled by one large trailer.

5

Tractors, Trailers and Maintenance

At December 31, 2009, we owned 5,390 tractors. We generally use new tractors in linehaul operations for approximately three to five years and then transfer those tractors to P&D operations for the remainder of their useful lives. In many of our service centers, tractors perform P&D functions during the day and linehaul functions at night to maximize tractor utilization.

At December 31, 2009, we operated a fleet of 21,185 trailers. We primarily purchase new trailers for our operations; however, we occasionally purchase pre-owned equipment that meets our specifications.

At various times, we have also acquired tractors and trailers through our acquisition of business assets from other carriers. The purchase of pre-owned equipment can provide an excellent value, but can increase our fleet’s average age. The table below reflects, as of December 31, 2009, the average age of our tractors, trucks and trailers:

| | | | |

Type of equipment (categorized by primary use) | | Number

of units | | Average

age

(in years) |

Linehaul tractors | | 2,923 | | 2.9 |

P&D tractors | | 2,467 | | 7.7 |

P&D trucks | | 114 | | 3.6 |

Linehaul trailers | | 15,538 | | 7.6 |

P&D trailers | | 5,647 | | 12.4 |

We develop certain specifications for tractors and trailers and then negotiate the production and purchase of this equipment with several manufacturers. These purchases are planned well in advance of anticipated delivery dates in order to accommodate manufacturers’ production schedules. We believe that there is sufficient capacity among suppliers to ensure an uninterrupted supply of equipment to support our operations.

The table below sets forth our capital expenditures for tractors and trailers for the years ended December 31, 2009, 2008 and 2007. Our capital expenditures for tractors and trailers in 2009 were limited to replacing a portion of the equipment scheduled to be retired through the normal replacement cycle. We retained this equipment scheduled for replacement, however, to provide sufficient capacity for us to take advantage of any increase in demand for our services caused by improvements in the economy, potential business failures or consolidation in the LTL industry. As a result of our current capacity, our equipment purchases in 2010 should be significantly reduced.

| | | | | | | | | |

| | | Year ended December 31, |

(In thousands) | | 2009 | | 2008 | | 2007 |

Tractors | | $ | 33,072 | | $ | 27,516 | | $ | 52,807 |

Trailers | | | 32,639 | | | 20,599 | | | 43,793 |

| | | | | | | | | |

Total | | $ | 65,711 | | $ | 48,115 | | $ | 96,600 |

| | | | | | | | | |

At December 31, 2009, we had major maintenance operations at our service centers in Rialto, California; Denver, Colorado; Atlanta, Georgia; Indianapolis, Indiana; Kansas City and Parsons, Kansas; Greensboro, North Carolina; Columbus, Ohio; Harrisburg, Pennsylvania; Morristown and Memphis, Tennessee; Dallas, Texas; and Salt Lake City, Utah. In addition, eighteen other service center locations are equipped to perform routine and preventive maintenance and repairs on our equipment.

We adhere to established maintenance policies and procedures to ensure our fleet is properly maintained. Linehaul tractors are routed to appropriate maintenance facilities at designated mileage or time intervals, depending upon how the equipment was utilized. P&D tractors and trailers are scheduled for maintenance every 90 days.

6

Marketing and Customers

At December 31, 2009, we had a sales staff of 453 employees. We compensate our sales force, in part, based upon on-time service performance, revenue generated and Company and service center profitability, which we believe helps motivate our sales employees to achieve our service, growth and profitability objectives.

We utilize a computerized freight-costing model to determine the price level at which a particular shipment of freight will be profitable. We can modify elements of this freight-costing model to simulate the actual conditions under which the freight will be moved. We also compete for business by participating in bid solicitations. Customers generally solicit bids for relatively large numbers of shipments for a period of one to two years, and typically choose to enter into contractual arrangements with a limited number of motor carriers based upon price and service.

Revenue is generated by customers dispersed primarily throughout the United States and North America. In 2009, our largest customer accounted for approximately 2.9% of our revenue and our largest 5, 10 and 20 customers accounted for approximately 8.9%, 14.0% and 21.0% of our revenue, respectively. For each of the previous three years, at least 90% of our revenue was derived from transporting LTL shipments for our customers and less than 5% of our revenue was generated from international services. We believe the diversity of our customer base helps protect our business from adverse developments in a single geographic region and the reduction or loss of business from a single customer.

Seasonality

Our tonnage levels and revenue mix are subject to seasonal trends common in the motor carrier industry, although other factors, such as the economy, could cause variation in these trends. Operating margins in the first quarter are normally lower due to reduced shipments during the winter months. Harsh winter weather can also adversely impact our performance by reducing demand and increasing operating expenses. Freight volumes typically build to a peak in the third quarter or early fourth quarter, which generally results in improved operating margins for those periods.

In 2009, we experienced harsh winter weather during the first quarter that, as expected, negatively impacted our operating margins. These negative impacts included increased operating costs resulting from inefficiencies in our service center network due to harsh winter weather, as well as a reduction in demand primarily attributable to the ongoing effects of the recessionary economy. Subsequent to the first quarter of 2009, we experienced a seasonal build in freight that was consistent with our normal seasonal trends, though the seasonal build was not as measurable as in prior years. We believe seasonal trends will continue to impact our business; however, we anticipate that our tonnage trends may continue to be inconsistent with historical trends until there is a general improvement in the domestic economy.

Technology

We continually upgrade our technological capabilities, and we provide access to our systems through multiple gateways that offer our customers maximum flexibility and immediate access to information. We employ vehicle safety systems, freight handling systems and logistics technology to reduce costs and transit times. We continue to focus on the development and enhancement of the technology used in our operations in order to improve the efficiency and effectiveness of our services.

Insurance

We carry a significant amount of insurance with third-party insurance carriers and we self-insure a portion of this risk. We are currently self-insured for bodily injury and property damage (“BIPD”) claims up to $2.75 million per occurrence. Cargo loss and damage claims are self-insured up to $100,000 per occurrence. We are

7

exposed to workers’ compensation claims up to $1.0 million per occurrence, through either self-insurance or insurance deductibles. We are insured for group health claims under a graduated aggregating policy, where we are exposed to claims up to $350,000 per occurrence, plus an additional $235,000 for claims exceeding $650,000. Our long-term disability claims are self-insured to a maximum per individual of $3,000 per month.

We believe that our policy of self-insuring a portion of our risk, together with our safety and loss prevention programs, is an effective means of managing insurance costs. We also believe that our current insurance coverage is adequate to cover our liability risks.

Diesel Fuel Availability and Cost

Our industry depends heavily upon the availability of diesel fuel. Although we maintained fuel storage and pumping facilities at 41, or 20%, of our service center locations at December 31, 2009, we may experience shortages at certain locations and may be forced to incur additional expense to ensure adequate supply on a timely basis to prevent a disruption to our service schedules. As a result of higher diesel fuel costs, we implemented a fuel surcharge program in August 1999 that has remained in effect since that time and has become one of many components in the overall price for our transportation services. Our fuel surcharges are generally indexed to the U.S. Department of Energy’s (the “DOE”) published fuel prices that reset each week. Our management believes that our operations and financial condition are susceptible to the same diesel fuel price increases or shortages as those of our competitors. Diesel fuel costs, including fuel taxes, totaled 11.4% and 16.8% of revenue in 2009 and 2008, respectively.

Employees

As of December 31, 2009, we employed 9,608 individuals on a full-time basis, of which none were represented under a collective bargaining agreement. Our full-time employees work in the following roles:

| | |

Category | | Number of

employees |

Drivers | | 5,041 |

Platform | | 1,405 |

Fleet technicians | | 350 |

Sales | | 453 |

Salaried, clerical and other | | 2,359 |

As of December 31, 2009, we employed 2,477 linehaul drivers and 2,564 P&D drivers on a full-time basis. All of our drivers are selected based upon safe driving records and experience. Each of our drivers is required to pass a drug test and have a current U.S. Department of Transportation (“DOT”) physical and a valid commercial driver’s license prior to employment. Once employed, drivers are required to obtain and maintain hazardous materials endorsements to their commercial driver’s licenses. Drivers, as well as all employees, are required to take pre-employment drug and alcohol tests and are randomly selected for periodic additional testing.

To help fulfill driver needs, we offer qualified employees the opportunity to become drivers through the “Old Dominion Driver Training Program.” Since its inception in 1988, 2,598 individuals have graduated from this program. Of the program graduates, we have experienced an annual turnover rate of approximately 8.5%, which is below our company-wide average turnover rate of approximately 10.5% for drivers. We believe our driver training and qualification programs have been important factors in improving our safety record and retaining our qualified drivers. Drivers with safe driving records are rewarded with bonuses of up to $3,000 payable each year. Driver safety bonuses paid during 2009 and 2008 were $2.0 million in each year.

8

Governmental Regulation

We are subject to regulation by the Federal Motor Carrier Safety Administration, the Pipeline and Hazardous Materials Safety Agency and the Surface Transportation Board, which are agencies within the DOT, as well as the regulations of various state agencies. These regulatory authorities have broad powers, generally governing matters such as authority to engage in motor carrier operations, motor carrier registration, driver hours of service, safety and fitness of transportation equipment and drivers, certain mergers, consolidations and acquisitions, and periodic financial reporting. In addition, we are subject to compliance with cargo-security and transportation regulations issued by the Transportation Security Administration within the U.S. Department of Homeland Security.

The trucking industry is subject to regulatory and legislative changes from a variety of other governmental authorities, which address matters such as: (i) increasingly stringent environmental and occupational safety and health regulations; (ii) limits on vehicle weight and size; (iii) ergonomics; and (iv) hours of service. These changes may affect our business or the economics of our industry by requiring changes in operating practices, or by influencing the demand for and increasing the costs of providing our services.

The cost of compliance with current applicable laws and regulations has not materially impacted our results of operations or financial condition. However, future changes to laws or regulations may adversely affect our operations and could result in unforeseen costs to our business.

Environmental Regulation

We are subject to various federal, state and local environmental laws and regulations that focus on, among other things: the emission and discharge of hazardous materials into the environment or their presence on or in our properties and vehicles; fuel storage tanks; transportation of certain materials; and the discharge or retention of storm water. Under specific environmental laws, we could also be held responsible for any costs relating to contamination at our past or present facilities and at third-party waste disposal sites, as well as costs associated with clean-up of accidents involving our vehicles. We do not believe that the cost of future compliance with current environmental laws or regulations will have a material adverse effect on our operations, financial condition, competitive position or capital expenditures for the remainder of fiscal year 2010 or fiscal year 2011. However, future changes to laws or regulations may adversely affect our operations and could result in unforeseen costs to our business.

Available Information

Through our website, http://www.odfl.com, we make available, free of charge, our Annual Report on Form 10-K, Quarterly Reports on Form 10-Q, Current Reports on Form 8-K and any amendments to those reports filed or furnished pursuant to Section 13(a) or 15(d) of the Securities Act of 1934, as soon as practicable after we electronically file the material with or furnish it to the U.S. Securities and Exchange Commission (the “SEC”). The public may read or copy any document we file with the SEC at the SEC’s website,http://www.sec.gov (File No. 0-19582), or at the SEC’s Public Reference Room at 100 F Street, NE, Washington, D.C. 20549. The SEC can be reached at 1-800-SEC-0330 for further information on the operation of the Public Reference Room. Information contained on our website is neither part of nor incorporated by reference in this Form 10-K or any other report we file with or furnish to the SEC.

9

Various factors exist that could cause our actual results to differ materially from those projected in any forward-looking statement. In addition to the factors discussed elsewhere in this report, we believe the following are some of the important risk factors that could materially affect our business, financial condition or results of operations:

We operate in a highly competitive industry, and our business will suffer if we are unable to adequately address potential downward pricing pressures and other factors that may adversely affect our operations and profitability.

Numerous competitive factors could impair our ability to maintain our current profitability. These factors include, but are not limited to, the following:

| | • | | we compete with many other transportation service providers of varying sizes, some of which may have more equipment, a broader coverage network, a wider range of services, greater capital resources or have other competitive advantages; |

| | • | | some of our competitors periodically reduce their prices to gain business, especially during times of reduced growth rates in the economy, which may limit our ability to maintain or increase prices or maintain revenue; |

| | • | | many customers reduce the number of carriers they use by selecting “core carriers” as approved transportation service providers and in some instances we may not be selected; |

| | • | | many customers periodically accept bids from multiple carriers for their shipping needs, and this process may depress prices or result in the loss of some business to competitors; |

| | • | | the trend towards consolidation in the ground transportation industry may create other large carriers with greater financial resources and other competitive advantages relating to their size; |

| | • | | advances in technology require increased investments to remain competitive, and our customers may not be willing to accept higher prices to cover the cost of these investments; and |

| | • | | competition from non-asset-based logistics and freight brokerage companies may adversely affect our customer relationships and pricing policies. |

Since the recessionary environment began, many of our LTL competitors generally reduced their prices to address overcapacity and created a very aggressive pricing environment throughout the industry. Although we remain focused on maintaining our pricing philosophy of charging a fair and reasonable price for the high level of our service offerings, the recessionary environment has had, and could continue to have, a negative impact on our operations and profitability.

If our employees were to unionize, our operating costs would increase and our ability to compete would be impaired.

None of our employees are currently represented by a collective bargaining agreement. However, from time to time there have been efforts to organize our employees at various service centers. We can offer no assurance that our employees will not unionize in the future, particularly if regulatory changes occur that facilitate unionization.

The unionization of our employees could have a material adverse effect on our business, financial condition and results of operations because:

| | • | | some shippers have indicated that they intend to limit their use of unionized trucking companies because of the threat of strikes and other work stoppages; |

| | • | | restrictive work rules could hamper our efforts to improve and sustain operating efficiency; |

10

| | • | | restrictive work rules could impair our service reputation and limit our ability to provide next-day services; |

| | • | | a strike or work stoppage would negatively impact our profitability and could damage customer and employee relationships; and |

| | • | | an election and bargaining process could divert management’s time and attention from our overall objectives and impose significant expenses. |

If we are unable to successfully execute our growth strategy, our business and future results of operations may suffer.

Our growth strategy includes increasing the volume of freight moving through our existing service center network, selectively expanding our geographic footprint and broadening the scope of our service offerings. In connection with our growth strategy, at various times, we have made selective acquisitions, purchased additional equipment, expanded and upgraded service centers and increased our sales and marketing efforts, and we expect to continue to do so. Our growth strategy exposes us to a number of risks, including the following:

| | • | | geographic expansion and acquisitions require start-up costs that could expose us to temporary losses; |

| | • | | growth and geographic expansion is dependent on the availability of real estate. Shortages of suitable real estate may limit our geographic expansion and might cause congestion in our service center network, which could result in increased operating expenses; |

| | • | | growth may strain our management, capital resources, information systems and customer service; |

| | • | | hiring new employees may increase training costs and may result in temporary inefficiencies until those employees become proficient in their jobs; |

| | • | | expanding our service offerings may require us to enter into new markets and encounter new competitive challenges; and |

| | • | | growth through acquisition could require us to temporarily match existing freight rates of the acquiree’s markets, which may be lower than the rates that we would typically charge for our services. |

We cannot assure that we will overcome the risks associated with our growth strategy. If we fail to overcome those risks, we may not realize additional revenue or profits from our efforts, we may incur additional expenses and, therefore, our financial position and results of operations could be materially and adversely affected.

Our customers and suppliers’ business may be impacted by a downturn in the economy and/or a disruption of financial markets.

Adverse economic conditions can negatively affect our customers’ business levels, the amount of transportation services they need and their ability to pay for our services. Customers encountering adverse economic conditions may be unable to obtain additional financing, or financing under acceptable terms, due to disruptions in the capital and credit markets. These customers represent a greater potential for bad debt losses, which may require us to increase our reserve for bad debt. Economic conditions resulting in bankruptcies of one or more of our large customers could have a significant impact on our financial position, results of operations or liquidity in a particular year or quarter.

Our supplier’s business levels also may be negatively affected by adverse economic conditions or financial constraints, which could lead to disruptions in the supply and availability of equipment, parts and services critical to our operations. A significant interruption in our normal supply chain could disrupt our operations, increase our costs and negatively impact our ability to serve our customers.

11

Insurance and claims expenses could significantly reduce our profitability.

We are exposed to claims related to cargo loss and damage, property damage, personal injury, workers’ compensation, long-term disability, group health and dental. We have insurance coverage with third-party insurance carriers, but self-insure a portion of the risk associated with these claims. If the number or severity of claims for which we are self-insured increases, or we are required to accrue or pay additional amounts because the claims prove to be more severe than our original assessment, our operating results would be adversely affected. In addition, insurance companies require us to obtain letters of credit to collateralize our self-insured retention. If these requirements increase, our borrowing capacity could be adversely affected.

We have significant ongoing cash requirements that could limit our growth and affect our profitability if we are unable to obtain sufficient financing.

Our business is highly capital intensive. Our purchases of property and equipment in 2009 and 2008 were $210.9 million and $181.5 million, respectively. We expect our net capital expenditures for 2010 to be approximately $95 million. While we intend to finance expansion and renovation projects with existing cash, cash flow from operations and available borrowings under our existing senior unsecured credit agreement, we may require additional financing to support our continued growth. If we are unable in the future to generate sufficient cash flow from operations or borrow the necessary capital to fund our planned capital expenditures, we will be forced to limit our growth and operate our equipment for longer periods of time, which could have a material adverse effect on our operating results.

In addition, our business has significant operating cash requirements. If our cash requirements are high or our cash flow from operations is low during particular periods, we may need to seek additional financing, which may be costly or difficult to obtain. We have a $225.0 million senior unsecured revolving credit facility that matures on August 10, 2011, which we believe provides us with a sufficient source for borrowing as needed.

Limited supply and increased prices for new equipment may adversely affect our earnings and cash flow.

Investment in new equipment is a significant part of our annual capital expenditures. We may face difficulty in purchasing new equipment due to decreased supply. The price of our equipment may also be adversely affected in the future by regulations on newly manufactured tractors and diesel engines. See the risk factor below entitled: “We are subject to various environmental laws and regulations, and costs of compliance with, liabilities under, or violations of, existing or future environmental laws or regulations could adversely affect our business.”

A decrease in the demand and value of used equipment.

As we purchase new tractors as part of our normal replacement cycle each year, we rely on the used equipment market to dispose of our older equipment. Oversupply in the transportation industry as well as adverse domestic and foreign economic conditions can negatively impact the demand for used tractors and, therefore, reduce the value we can obtain on our used equipment. If we are unable to sell our replacement vehicles at or above salvage value, the resulting losses could have a significant impact on our results of operations.

We may be adversely impacted by fluctuations in the price and availability of diesel fuel.

Diesel fuel is a significant operating expense for our business. We do not hedge against the risk of diesel fuel price increases. An increase in diesel fuel prices or diesel fuel taxes, or any change in federal or state regulations that results in such an increase, could have a material adverse effect on our operating results, unless the increase is offset by increases in freight rates or fuel surcharges charged to our customers. Depending on the base rate and fuel surcharge levels agreed upon by individual shippers, a rapid and significant change in the cost of diesel fuel could also have a material adverse effect on our operating results. We continuously monitor the components of our pricing, including base freight rates and fuel surcharges, and address individual account

12

profitability issues with our customers when necessary. While we have historically been able to adjust our base rate pricing and/or fuel surcharges to offset changes to the cost of diesel fuel, we cannot be certain that we will be able to do so in the future.

We maintained fuel storage and pumping facilities at 41 and 36 of our service center locations at December 31, 2009 and 2008, respectively. However, we may experience shortages in the availability of diesel fuel at certain locations and may be forced to incur additional expense to ensure adequate supply on a timely basis to prevent a disruption to our service schedules. An interruption in the supply of diesel fuel could have a material adverse effect on our operating results.

We are subject to various environmental laws and regulations, and costs of compliance with, liabilities under, or violations of, existing or future environmental laws or regulations could adversely affect our business.

We are subject to various federal, state and local environmental laws and regulations that govern, among other things, the emission and discharge of hazardous materials into the environment, the presence of hazardous materials at our properties or in our vehicles, fuel storage tanks, the transportation of certain materials and the discharge or retention of storm water. Under certain environmental laws, we could also be held responsible for any costs relating to contamination at our past or present facilities and at third-party waste disposal sites, as well as costs associated with the clean-up of accidents involving our vehicles. Environmental laws have become and are expected to continue to be increasingly more stringent over time, and there can be no assurance that our costs of complying with current or future environmental laws or liabilities arising under such laws will not have a material adverse effect on our business, operations or financial condition.

The U.S. Environmental Protection Agency (the “EPA”) has issued regulations that require progressive reductions in exhaust emissions from diesel engines through 2010. Beginning in October 2002, new diesel engines were required to meet these new emission limits. Some of the regulations required reductions in the sulfur content of diesel fuel beginning in June 2006 and the introduction of emissions after-treatment devices on newly-manufactured engines and vehicles beginning with model-year 2007. The final phase of the regulations requires reduced nitrogen and non-methane hydrocarbon emissions beginning with model-year 2010. These regulations have resulted in higher prices for tractors and diesel engines and increased fuel and maintenance costs, and there can be no assurance that continued increases in pricing or costs will not have an adverse effect on our business and operations.

In addition to the EPA regulations on exhaust emissions with which we must comply, there is an increased regulatory focus on climate change and greenhouse gas emissions in the United States. As a result, we may become subject to additional legislation that could adversely impact our business. At this time, we cannot predict the requirements of any future regulations. However, any limitations on the emission of greenhouse gases or other environmental legislation could increase our future capital expenditures and have an adverse impact on our financial condition, results of operations and liquidity.

We operate in a highly regulated industry, and increased costs of compliance with, or liability for violation of, existing or future regulations could have a material adverse effect on our business.

We are regulated by the DOT and by various state agencies. These regulatory authorities have broad powers, generally governing matters such as authority to engage in motor carrier operations, as well as motor carrier registration, driver hours of service, safety and fitness of transportation equipment and drivers, transportation of hazardous materials, certain mergers and acquisitions and periodic financial reporting. In addition, the trucking industry is subject to regulatory and legislative changes from a variety of other governmental authorities, which address matters such as: (i) increasingly stringent environmental, occupational safety and health regulations; (ii) limits on vehicle weight and size; (iii) ergonomics; and (iv) hours of service. In addition, we are subject to compliance with cargo-security and transportation regulations issued by the

13

Transportation Security Administration within the U.S. Department of Homeland Security. Regulatory requirements, and changes in regulatory requirements, may affect our business or the economics of the industry by requiring changes in operating practices or by influencing the demand for and increasing the costs of providing transportation services.

Our results of operations may be affected by seasonal factors and harsh weather conditions.

Our operations are subject to seasonal trends common in the trucking industry. Our operating margins in the first quarter are normally lower due to reduced demand during the winter months. Harsh weather can also adversely affect our performance by reducing demand and reducing our ability to transport freight, which could result in decreased revenue and increased operating expenses.

If we are unable to retain our key employees, our financial condition, results of operations and liquidity could be adversely affected.

Our success will continue to depend upon the experience and leadership of our key employees and executive officers. In that regard, the loss of the services of any of our key personnel could have a material adverse effect on our financial condition, results of operation and liquidity.

Our principal shareholders control a large portion of our outstanding common stock.

Earl E. Congdon, John R. Congdon and members of their respective families beneficially own approximately one-third of the outstanding shares of our common stock. As long as the Congdon family controls a large portion of our voting stock, they may be able to significantly influence the election of the entire Board of Directors and the outcome of all matters involving a shareholder vote. The Congdon family’s interests may differ from the interests of other shareholders.

Our financial results may be adversely impacted by potential future changes in accounting practices.

Future changes in accounting standards or practices, and related legal and regulatory interpretations of those changes, may adversely impact public companies in general, the transportation industry or our operations specifically. New accounting standards or requirements, such as a conversion from U.S. generally accepted accounting principles to International Financial Reporting Standards, could change the way we record revenues, expenses, assets and/or liabilities or could be costly to implement. These types of regulations could have a negative impact on our financial position, liquidity, results of operations and/or access to capital.

Our information technology systems are subject to certain risks that we cannot control.

Our information systems, including our accounting systems, are dependent upon third-party software, global communications providers, telephone systems and other aspects of technology and Internet infrastructure that are susceptible to failure. Although we have implemented redundant systems and network security measures, our information technology remains susceptible to outages, computer viruses, break-ins and similar disruptions that may inhibit our ability to provide services to our customers and the ability of our customers to access our systems. This may result in the loss of customers or a reduction in demand for our services.

| ITEM 1B. | UNRESOLVED STAFF COMMENTS |

None.

14

ITEM 2. PROPERTIES

We own our general office located in Thomasville, North Carolina, consisting of a two-story office building of approximately 160,000 square feet on 30.1 acres of land. At December 31, 2009, we operated 210 service centers, of which 125 were owned and 85 were leased. Our service centers that are owned include most of our larger facilities and account for 77.7% of the total door capacity in our network. We own all of our major breakbulk facilities, which are listed below with the number of doors as of December 31, 2009.

| | |

Service Center | | Doors |

Harrisburg, Pennsylvania | | 305 |

Morristown, Tennessee | | 247 |

Dallas, Texas | | 234 |

Atlanta, Georgia | | 227 |

Indianapolis, Indiana | | 223 |

Greensboro, North Carolina | | 219 |

Memphis, Tennessee | | 169 |

Rialto, California | | 152 |

Salt Lake City, Utah | | 129 |

These facilities are strategically dispersed over the states in which we operate. At December 31, 2009, the terms of our leased properties ranged from month-to-month to a lease that expires in 2023. We believe that as current leases expire, we will be able to renew them or find comparable facilities without incurring any material negative impact on service to our customers or our operating results.

We also own 25 non-operating properties, all of which are held for lease or are planned for future use. Seven of these properties are leased with lease terms that range from month-to-month to a lease that expires in 2012.

We believe that all of our properties are in good repair and are capable of providing the level of service required by current business levels and customer demands. In addition, we believe we have sufficient capacity in our service center network to accommodate a substantial increase in demand for our services.

ITEM 3. LEGAL PROCEEDINGS

We are involved in various legal proceedings and claims that have arisen in the ordinary course of our business that have not been fully adjudicated. Many of these are covered in whole or in part by insurance. Our management does not believe that these actions, when finally concluded and determined, will have a material adverse effect upon our financial position, liquidity or results of operations.

ITEM 4. RESERVED

15

PART II

| ITEM 5. | MARKET FOR THE REGISTRANT’S COMMON EQUITY, RELATED STOCKHOLDER MATTERS AND ISSUER PURCHASES OF EQUITY SECURITIES |

Common Stock and Dividend Information

Our common stock is traded on the NASDAQ Global Select Market under the symbol ODFL. At February 12, 2010, there were approximately 9,925 holders of our common stock, including 151 shareholders of record. We did not pay any dividends on our common stock during fiscal year 2009 or 2008, and we have no current plans to declare or pay any dividends on our common stock during fiscal year 2010. For information concerning restrictions on our ability to make dividend payments, seeLiquidity and Capital Resourcesin Item 7, “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and Note 3 in Item 8, “Financial Statements and Supplementary Data” of this report.

The following table sets forth the high and low sales price of our common stock for the periods indicated, as reported by the NASDAQ Global Select Market:

| | | | | | | | | | | | |

| | | 2009 |

| | | First

Quarter | | Second

Quarter | | Third

Quarter | | Fourth

Quarter |

High | | $ | 29.50 | | $ | 33.81 | | $ | 38.75 | | $ | 34.95 |

Low | | $ | 18.69 | | $ | 22.60 | | $ | 29.63 | | $ | 24.10 |

| |

| | | 2008 |

| | | First

Quarter | | Second

Quarter | | Third

Quarter | | Fourth

Quarter |

High | | $ | 33.62 | | $ | 33.58 | | $ | 40.09 | | $ | 30.60 |

Low | | $ | 20.31 | | $ | 27.00 | | $ | 26.74 | | $ | 18.47 |

16

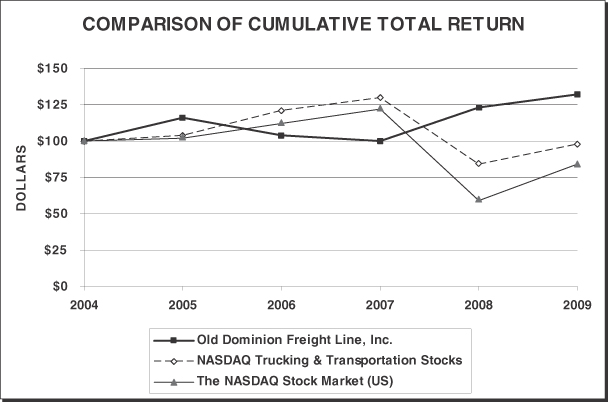

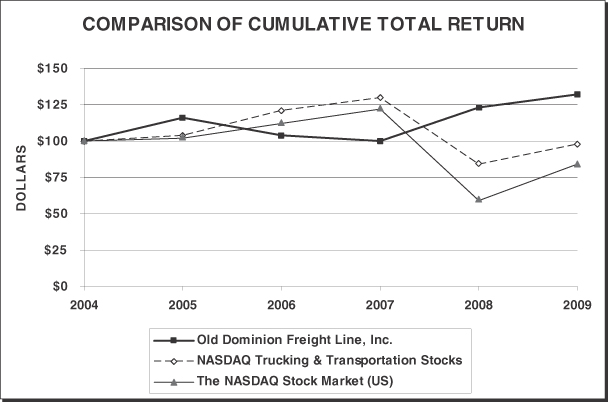

Performance Graph

The following graph compares the total shareholder cumulative returns, assuming the reinvestment of all dividends, of $100 invested on December 31, 2004, in (i) our Common Stock, (ii) the NASDAQ Trucking & Transportation Stocks and (iii) the NASDAQ Stock Market (US) for the five-year period ended December 31, 2009:

Cumulative Total Return

| | | | | | | | | | | | | | | | | | |

| | | 12/31/04 | | 12/31/05 | | 12/31/06 | | 12/31/07 | | 12/31/08 | | 12/31/09 |

Old Dominion Freight Line, Inc | | $ | 100 | | $ | 116 | | $ | 104 | | $ | 100 | | $ | 123 | | $ | 132 |

NASDAQ Trucking and Transportation Stocks. | | $ | 100 | | $ | 104 | | $ | 121 | | $ | 130 | | $ | 84 | | $ | 98 |

The NASDAQ Stock Market (US) | | $ | 100 | | $ | 102 | | $ | 112 | | $ | 122 | | $ | 59 | | $ | 84 |

17

ITEM 6. SELECTED FINANCIAL DATA

| | | | | | | | | | | | | | | | | | | | |

| | | Year Ended December 31, | |

(In thousands, except per share amounts and

operating statistics) | | 2009 | | | 2008 | | | 2007 | | | 2006 | | | 2005 | |

Operating Data: | | | | | | | | | | | | | | | | | | | | |

Revenue from operations | | $ | 1,245,005 | | | $ | 1,537,724 | | | $ | 1,401,542 | | | $ | 1,279,431 | | | $ | 1,061,403 | |

Depreciation and amortization expense | | | 94,784 | | | | 87,083 | | | | 79,863 | | | | 67,634 | | | | 55,897 | |

Total operating expenses | | | 1,174,614 | | | | 1,408,654 | | | | 1,271,605 | | | | 1,148,946 | | | | 963,818 | |

Operating income | | | 70,391 | | | | 129,070 | | | | 129,937 | | | | 130,485 | | | | 97,585 | |

Interest expense, net(1) | | | 12,998 | | | | 13,012 | | | | 12,960 | | | | 10,206 | | | | 6,527 | |

Provision for income taxes | | | 22,294 | | | | 43,989 | | | | 43,963 | | | | 46,774 | | | | 36,388 | |

Income before cumulative effect of accounting change | | | 34,871 | | | | 68,677 | | | | 71,832 | | | | 72,569 | | | | 53,883 | |

Cumulative effect of accounting change, net | | | — | | | | — | | | | — | | | | — | | | | 408 | |

Net income | | | 34,871 | | | | 68,677 | | | | 71,832 | | | | 72,569 | | | | 53,475 | |

Per Share Data: | | | | | | | | | | | | | | | | | | | | |

Diluted earnings per share before cumulative effect of accounting change | | | 0.94 | | | | 1.84 | | | | 1.93 | | | | 1.95 | | | | 1.45 | |

Diluted earnings per share | | | 0.94 | | | | 1.84 | | | | 1.93 | | | | 1.95 | | | | 1.43 | |

Balance Sheet Data: | | | | | | | | | | | | | | | | | | | | |

Cash, cash equivalents and short-term investments | | | 4,171 | | | | 28,965 | | | | 30,703 | | | | 87,724 | | | | 986 | |

Current assets | | | 174,175 | | | | 209,230 | | | | 216,277 | | | | 256,367 | | | | 150,213 | |

Total assets | | | 1,159,278 | | | | 1,074,905 | | | | 981,048 | | | | 892,193 | | | | 641,648 | |

Current liabilities | | | 148,125 | | | | 142,190 | | | | 127,723 | | | | 121,546 | | | | 111,028 | |

Long-term debt (including current maturities) | | | 305,532 | | | | 251,989 | | | | 263,754 | | | | 274,582 | | | | 128,956 | |

Shareholders’ equity | | | 593,000 | | | | 558,129 | | | | 489,452 | | | | 417,620 | | | | 345,051 | |

Operating Statistics: | | | | | | | | | | | | | | | | | | | | |

Operating ratio | | | 94.3 | % | | | 91.6 | % | | | 90.7 | % | | | 89.8 | % | | | 90.8 | % |

Revenue per hundredweight | | $ | 12.70 | | | $ | 13.88 | | | $ | 13.30 | | | $ | 13.16 | | | $ | 12.63 | |

Revenue per intercity mile | | $ | 4.16 | | | $ | 4.60 | | | $ | 4.31 | | | $ | 4.32 | | | $ | 4.12 | |

Intercity miles(in thousands) | | | 299,330 | | | | 334,219 | | | | 325,268 | | | | 296,464 | | | | 257,900 | |

Total tons(in thousands) | | | 4,902 | | | | 5,545 | | | | 5,271 | | | | 4,859 | | | | 4,203 | |

Total shipments(in thousands) | | | 5,750 | | | | 6,691 | | | | 6,765 | | | | 6,428 | | | | 5,751 | |

Average length of haul(2)(miles) | | | 928 | | | | 901 | | | | 926 | | | | 922 | | | | 912 | |

| (1) | For the purpose of this table, interest expense is presented net of interest income. |

| (2) | We refined our average length of haul calculation in 2008 by excluding miles from the Company’s agent carriers, which had the effect of lowering this metric slightly. We were able to recalculate this operating metric for each year and, therefore, we restated this metric for years prior to 2008 presented in this report. |

| ITEM 7. | MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS |

Overview

We are a leading, less-than-truckload (“LTL”), non-union motor carrier providing regional, inter-regional and national LTL service and value-added logistics services from a single integrated organization. We operate as one business segment and offer our products and services through our four branded product groups: OD-Domestic, OD-Expedited, OD-Global and OD-Technology. In addition to our LTL services, we offer our

18

customers a broad range of logistics services including ground and air expedited transportation, supply chain consulting, transportation management, truckload brokerage, container delivery and warehousing services. Through marketing and carrier relationships, we also offer door-to-door international freight services to and from all of North America, Central America, South America and the Far East. More than 90% of our revenue has historically been derived from transporting LTL shipments for our customers, whose demand for our services is generally tied to industrial production and the overall health of the U.S. domestic economy.

In analyzing the components of our revenue, we monitor changes and trends in the following key metrics:

| | • | | Revenue Per Hundredweight – This measurement reflects our pricing policies, which are influenced by competitive market conditions and our growth objectives. Generally, freight is rated by a class system, which is established by the National Motor Freight Traffic Association, Inc. Light, bulky freight typically has a higher class and is priced at higher revenue per hundredweight than dense, heavy freight. Changes in the class, packaging of the freight and length of haul of the shipment can also affect this average. Fuel surcharges, accessorial charges, revenue adjustments and revenue for undelivered freight are included in this measurement. Revenue for undelivered freight is deferred for financial statement purposes in accordance with our revenue recognition policy; however, we believe including this deferred revenue in our revenue per hundredweight measurements results in a better indicator of changes in our yields by matching total billed revenue with the corresponding weight of those shipments. |

| | • | | Weight Per Shipment – Fluctuations in weight per shipment can indicate changes in the class, or mix, of freight we receive from our customers, as well as changes in the number of units included in a shipment. Generally, increases in weight per shipment indicate higher demand for our customers’ products and overall increased economic activity. Beginning in 2008, however, many shippers began consolidating shipments in an effort to reduce the impact of the high cost of diesel fuel on their transportation costs. In doing so, these shippers caused an increase in our weight per shipment by shipping the same volume of goods with fewer shipments. We believe this trend continued in 2009, despite the subsequent overall decline in diesel fuel costs, due to the overall weak demand for shippers’ goods resulting from the recessionary economy. |

| | • | | Average Length of Haul – We consider lengths of haul less than 500 miles to be regional traffic, lengths of haul between 500 miles and 1,000 miles to be inter-regional traffic, and lengths of haul in excess of 1,000 miles to be national traffic. By analyzing this metric, we can determine the success and growth potential of our service products in these markets. |

| | • | | Revenue Per Shipment – This measurement is primarily determined by the three metrics listed above and is used, in conjunction with the number of shipments we receive, to calculate total revenue, excluding adjustments for undelivered freight. |

Our primary revenue focus is to increase shipment and tonnage growth within our existing infrastructure, generally referred to as increasing density, thereby maximizing asset utilization and labor productivity. We measure density over many different functional areas of our operations including revenue per service center, linehaul load factor, P&D stops per hour, P&D shipments per hour, platform pounds handled per hour and platform shipments per hour. In addition to our focus on density, it is critical for us to obtain an appropriate yield on the shipments we handle. We manage our yields by focusing on individual account profitability. We believe yield management and improvements in density are key components in our ability to produce profitable growth.

Our primary cost elements are direct wages and benefits associated with the movement of freight; operating supplies and expenses, which includes fuel and repair parts; and depreciation of our equipment fleet and service center facilities. We gauge our overall success in managing these costs by monitoring our operating ratio, a measure of profitability calculated by dividing total operating expenses by revenue, which also allows industry-wide comparisons with our competition.

19

We continually upgrade our technological capabilities to improve our customer service and lower our operating costs. Our technology provides our customers with visibility of their shipments throughout our network, increases the productivity of our workforce and provides key metrics from which we can monitor our processes.

Results of Operations

The following table sets forth, for the years indicated, expenses and other items as a percentage of revenue from operations:

| | | | | | | | | |

| | | 2009 | | | 2008 | | | 2007 | |

Revenue from operations | | 100.0 | % | | 100.0 | % | | 100.0 | % |

| | | | | | | | | |

Operating expenses: | | | | | | | | | |

Salaries, wages and benefits | | 57.7 | | | 52.3 | | | 53.6 | |

Operating supplies and expenses | | 14.6 | | | 19.9 | | | 17.0 | |

General supplies and expenses | | 2.9 | | | 2.9 | | | 2.9 | |

Operating taxes and licenses | | 4.0 | | | 3.4 | | | 3.6 | |

Insurance and claims | | 1.8 | | | 2.3 | | | 2.4 | |

Communication and utilities | | 1.2 | | | 1.0 | | | 1.1 | |

Depreciation and amortization | | 7.6 | | | 5.7 | | | 5.7 | |

Purchased transportation | | 2.7 | | | 2.8 | | | 3.1 | |

Building and office equipment rents | | 1.1 | | | 0.9 | | | 0.8 | |

Miscellaneous expenses, net | | 0.7 | | | 0.4 | | | 0.5 | |

| | | | | | | | | |

Total operating expenses | | 94.3 | | | 91.6 | | | 90.7 | |

| | | | | | | | | |

Operating income | | 5.7 | | | 8.4 | | | 9.3 | |

Interest expense, net(1) | | 1.1 | | | 0.8 | | | 0.9 | |

Other expense, net | | — | | | 0.2 | | | 0.1 | |

| | | | | | | | | |

Income before income taxes | | 4.6 | | | 7.4 | | | 8.3 | |

Provision for income taxes | | 1.8 | | | 2.9 | | | 3.2 | |

| | | | | | | | | |

Net income | | 2.8 | % | | 4.5 | % | | 5.1 | % |

| | | | | | | | | |

| (1) | For the purpose of this table, interest expense is presented net of interest income. |

2009 Compared to 2008

Key financial and operating metrics for 2009 and 2008 are presented below:

| | | | | | | | | | | | | | | |

| | | 2009 | | | 2008 | | | Change | | | % Change | |

Work days | | | 253 | | | | 254 | | | | (1 | ) | | (0.4 | ) |

Revenue(in thousands) | | $ | 1,245,005 | | | $ | 1,537,724 | | | $ | (292,719 | ) | | (19.0 | ) |

Operating ratio | | | 94.3 | % | | | 91.6 | % | | | 2.7 | % | | 2.9 | |

Net income(in thousands) | | $ | 34,871 | | | $ | 68,677 | | | $ | (33,806 | ) | | (49.2 | ) |

Diluted earnings per share | | $ | 0.94 | | | $ | 1.84 | | | $ | (0.90 | ) | | (48.9 | ) |

Total tons(in thousands) | | | 4,902 | | | | 5,545 | | | | (643 | ) | | (11.6 | ) |

Total shipments(in thousands) | | | 5,750 | | | | 6,691 | | | | (941 | ) | | (14.1 | ) |

Weight per shipment(lbs.) | | | 1,705 | | | | 1,657 | | | | 48 | | | 2.9 | |

Revenue per hundredweight | | $ | 12.70 | | | $ | 13.88 | | | $ | (1.18 | ) | | (8.5 | ) |

Revenue per shipment | | $ | 216.49 | | | $ | 229.99 | | | $ | (13.50 | ) | | (5.9 | ) |

Average length of haul(miles) | | | 928 | | | | 901 | | | | 27 | | | 3.0 | |

20

Our financial results for 2009 reflect our operating strengths as we remained profitable despite a significant decline in tonnage and revenue, which resulted from the negative impacts of a recessionary economy and an increasingly competitive operating environment within the LTL industry. The persistent recessionary economy caused freight demand to weaken throughout 2009. When combined with the overcapacity in the LTL industry, the weakened demand created an aggressive and competitive pricing environment. Confronted with this environment and an 11.6% decline in tonnage, we focused on delivering outstanding service performance, improving the productivity of our employees, managing our variable costs and remaining disciplined with the pricing for our services. Despite the success we had with these measures, we were unable to sufficiently increase our prices or generate enough cost savings to offset our decline in revenue. As a result, our operating ratio increased to 94.3% in 2009 from 91.6% in 2008 and our earnings per diluted share decreased 48.9% to $0.94 for 2009. We believe our strategy mitigated much of the negative impact that we could have experienced as a result of the extremely difficult LTL operating environment, since our operating ratio deteriorated by only 270 basis points despite a 19.0% decline in revenue.

Revenue

The decrease in revenue during 2009 was the result of decreases in tonnage and revenue per hundredweight of 11.6% and 8.5%, respectively. The reduction in tonnage during 2009 resulted from a 14.1% decrease in the number of shipments that was partially offset by a 2.9% increase in weight per shipment. The tonnage decrease was primarily attributable to the impact of the recessionary economy on freight demand, since our research indicates there has been no significant change in our market share. Although certain economic metrics indicate improvement and small amounts of capacity have exited the market, we do not anticipate a change in industry conditions until there is a sustained recovery in the general domestic economy or a significant decrease in industry capacity resulting from potential business failures or consolidation in the LTL industry. Until one or both of these events occur, we could experience additional declines in our tonnage and shipments as well as continued pressure on our yields. However, we believe we have positioned ourselves well, through our commitment to service, to gain additional market share from our existing customers and new customers who seek consistent, claims-free and value-driven service once industry conditions improve.

Revenue per hundredweight decreased 8.5% to $12.70 from $13.88 in 2008. This decrease in our revenue per hundredweight was primarily due to the reduction in fuel surcharge revenue, which resulted from a significant decline in the average price of diesel fuel between the comparable years. Excluding fuel surcharges, revenue per hundredweight remained consistent at $11.49 for 2009 and 2008. We were unable to sufficiently increase our overall pricing during 2009 due to the competitive pricing environment in the LTL industry. During the fourth quarter of 2008 and throughout 2009, pricing emerged as the principal driver of competition as many carriers attempted to either gain market share or minimize tonnage losses through price discounting. Despite the pricing pressure, we remained committed to our pricing philosophy of charging our customers a fair and reasonable price for outstanding service. Our commitment to service is evidenced by an approximate 99% on-time service performance and a historically low cargo claims ratio during 2009. The prolonged impact of overcapacity in the industry and the aggressive competition on prices could continue to impact our ability to increase or even maintain our pricing in future periods, which in turn could have a material adverse impact on our future revenue and net income.

Fuel surcharge revenue decreased to 9.6% of revenue from 17.2% of revenue in 2008. Most of our tariffs and contracts provide for a fuel surcharge, which is recorded as additional revenue, as diesel fuel prices increase above stated levels. These levels are generally indexed to the DOE’s published fuel prices that reset each week. The fuel surcharge is one of many components included in the overall negotiated price for our transportation services with our customers, although it is generally believed to be a measure of the increase in cost of all petroleum products that we use. We continuously monitor the components of our pricing, including base freight rates and fuel surcharges. We also address individual account profitability issues with our customers when necessary as part of our effort to minimize the negative impact on our profitability that would likely result from a rapid and significant change in any of our operating expenses.

21

Operating Costs and Other Expenses

Salaries, wages and benefits increased to 57.7% of revenue in 2009 from 52.3% in 2008. The increase as a percent of revenue is primarily due to the year-over-year decline in fuel surcharge revenue, which has no corresponding decrease in the volume of freight moving through our network. As a result, driver wages increased to 23.1% of revenue from 21.0% in 2008. Platform wages as a percentage of revenue increased to 6.8% from 6.7% in 2008.

While our salaries, wages and benefits increased as a percent of revenue, the $85.9 million overall decrease is attributable to the 11.6% year-over-year reduction in the total number of full-time employees, the decline in the number of hours worked and the overall increased productivity of our employees. Our P&D shipments per hour increased 3.9% and P&D stops per hour increased 3.4%, both reflecting the improved efficiencies and utilization of our experienced drivers. Our linehaul laden load average increased 0.5%. Platform pounds handled per hour increased 9.3%, which allowed our platform wages to remain consistent as a percent of revenue. These productivity improvements partially offset the impact on our operating ratio of the annual wage increase provided to our driver and platform employees in September 2008 as well as the scheduled increases newly hired employees achieved in 2009 as they gained experience.

Employee benefit costs increased to 33.4% of salaries and wages in 2009 from 30.1% in 2008. These increases are primarily attributable to increased costs associated with our group health and dental coverage and workers’ compensation claims experience. Group health and dental costs rose to 12.2% of total salary and wages in 2009 from 10.3% in 2008 due to an increase in the average cost of medical claims per employee, as well as an increase in the number of claims paid for participants who elected coverage under the Consolidated Omnibus Budget Reconciliation Act of 1985 (“COBRA”). Legislation passed in 2009 lengthened the period of coverage for eligible COBRA participants who were involuntarily terminated between September 1, 2008 and February 28, 2010.

Operating supplies and expenses decreased to 14.6% of revenue in 2009 from 19.9% in 2008. This decrease is primarily due to the decline in diesel fuel costs, excluding fuel taxes, which is the largest component of operating supplies and expenses. These costs decreased 50.4% during the year as a result of the combined effect of a 37.3% decrease in our average price per gallon and a 12.8% decrease in gallons consumed. The reduction in fuel consumption is primarily due to the year-over-year decline in overall miles, as well as a 2.2% increase in our miles per gallon. The decreased consumption also lowered our fuel tax expenses and was the principal driver of the $2.5 million reduction in “Operating taxes and licenses.” We do not use diesel fuel hedging instruments and are therefore subject to market price fluctuations.

General supplies and expenses remained consistent as a percent of revenue at 2.9% for both 2009 and 2008. These costs remained consistent as a percent of revenue due to our strict cost control measures put in place to manage our variable costs and the decrease in supplies directly related to lower shipment volumes.

The decrease in insurance and claims expense to 1.8% of revenue from 2.3% in 2008 is attributable to the 32.1% and 39.0% decreases in auto liability and cargo claims expenses, respectively. We self-insure a portion of our auto and cargo claims liabilities and obtain excess insurance coverage for claims above our retention levels. The decrease in our auto liability expenses was primarily due to a $1.9 million favorable adjustment recorded in the fourth quarter that resulted from improved experience in the number of claims during 2009 and a reduction in our estimate for losses in prior years. We believe that our cargo claims expense improved primarily due to the increased training of our employees on claims prevention, which resulted in a historically low cargo claims ratio in 2009 and a 32.8% decrease in total claims paid.

Depreciation and amortization expense increased to 7.6% of revenue in 2009 as compared to 5.7% in 2008. The increase as a percent of revenue reflects the combined impact of the decline in overall revenue in 2009 on these fixed costs and our significant investments in real estate and revenue equipment in 2008 and 2009.

22

Consistent with our long-term growth strategy, we took advantage of real estate opportunities during 2009, which allowed us not only to expand our service center network, but also to relocate certain operations to larger facilities. In addition, we made a strategic decision to purchase new revenue equipment in 2009, while retaining the tractors and trailers scheduled to be replaced. Our decision to increase our equipment capacity placed us in a position to accommodate an increase in demand for our services that could have resulted from business failures or consolidation in the LTL industry that we believed were likely to result from the recessionary economy.

Other expense, net includes the net investment gains or losses on the cash value of our variable life insurance contracts related to our non-qualified deferred compensation plans. The cash value of these contracts was impacted by the improvement in equity markets during 2009, which favorably affected comparisons with 2008.

Our effective tax rate for 2009 and 2008 was 39.0%. Our effective tax rates in 2009 and 2008 were favorably impacted by alternative fuel tax credits for the use of propane in our operations. These fuel tax credits expired on December 31, 2009 and, unless extended by future legislation, will likely increase our effective tax rate in 2010. Our effective tax rate exceeded the federal statutory rate of 35% primarily due to the impact of state taxes and certain non-deductible items.

2008 Compared to 2007

Key financial and operating metrics for 2008 and 2007 are presented below:

| | | | | | | | | | | | | | | |

| | | 2008 | | | 2007 | | | Change | | | % Change | |

Work days | | | 254 | | | | 253 | | | | 1 | | | 0.4 | |

Revenue(in thousands) | | $ | 1,537,724 | | | $ | 1,401,542 | | | $ | 136,182 | | | 9.7 | |

Operating ratio | | | 91.6 | % | | | 90.7 | % | | | 0.9 | % | | 1.0 | |

Net income(in thousands) | | $ | 68,677 | | | $ | 71,832 | | | $ | (3,155 | ) | | (4.4 | ) |

Diluted earnings per share | | $ | 1.84 | | | $ | 1.93 | | | $ | (0.09 | ) | | (4.7 | ) |

Total tons(in thousands) | | | 5,545 | | | | 5,271 | | | | 274 | | | 5.2 | |

Shipments(in thousands) | | | 6,691 | | | | 6,765 | | | | (74 | ) | | (1.1 | ) |

Weight per shipment(lbs.) | | | 1,657 | | | | 1,558 | | | | 99 | | | 6.4 | |

Revenue per hundredweight | | $ | 13.88 | | | $ | 13.30 | | | $ | 0.58 | | | 4.4 | |

Revenue per shipment | | $ | 229.99 | | | $ | 207.24 | | | $ | 22.75 | | | 11.0 | |

Average length of haul(miles) | | | 901 | | | | 926 | | | | (25 | ) | | (2.7 | ) |