Exhibit 99.2

Management’s Discussion & Analysis

Index

This Management’s Discussion and Analysis (“MD&A”) is dated March 13, 2013 and should be read in conjunction with our consolidated financial statements and the accompanying notes for the year ended December 31, 2012. Except where otherwise noted, the financial information presented in this MD&A is prepared in accordance with International Financial Reporting Standards (IFRS) as issued by the International Accounting Standards Board. We use the United States dollar as our reporting currency and, except where otherwise noted, all currency amounts are stated in United States dollars.

At March 13, 2013 we had 94,743,044 common shares issued and outstanding and stock options and tandem share appreciation rights exercisable for 3,618,823 additional common shares.

Additional information relating to Methanex, including our Annual Information Form, is available on our website at www.methanex.com, the Canadian Securities Administrators’ SEDAR website at www.sedar.com and on the United States Securities and Exchange Commission’s EDGAR website at www.sec.gov.

OVERVIEW OF THE BUSINESS

Methanol is a clear liquid commodity chemical that is predominantly produced from natural gas and also, particularly in China, from coal. Approximately two-thirds of all methanol demand is used to produce traditional chemical derivatives, including formaldehyde, acetic acid and a variety of other chemicals that form the basis of a large number of chemical derivatives for which demand is influenced by levels of global economic activity. The remaining one-third of methanol demand comes from energy-related applications. There has been strong demand growth for direct methanol blending into gasoline, as a feedstock in the production of dimethyl ether (DME), which can be blended with liquefied petroleum gas for use in household cooking and heating, and in the production of biodiesel. Methanol is also used to produce methyl tertiary-butyl ether (MTBE), a gasoline component, and olefins. This latter use is emerging as a significant methanol demand driver.

We are the world’s largest supplier of methanol to the major international markets in Asia Pacific, North America, Europe and Latin America. Our total annual production capacity, including Methanex equity interests in jointly owned plants, is currently 9.5 million tonnes and is located in New Zealand, Trinidad, Egypt, Canada and Chile (refer to theProduction Summary section on page 9 for more information). We are currently relocating one of our Chile facilities to Geismar, Louisiana and we expect the relocated facility will be operational by the end of 2014. We have marketing rights for 100% of the production from the jointly owned plants in Trinidad and Egypt and this provides us with an additional 1.2 million tonnes per year of methanol offtake supply when the plants are operating at full capacity. In addition to the methanol produced at our sites, we purchase methanol produced by others under methanol offtake contracts and on the spot market. This gives us flexibility in managing our supply chain while continuing to meet customer needs and support our marketing efforts.

2012 Industry Overview & Outlook

Methanol is a global commodity and our earnings are significantly affected by fluctuations in the price of methanol, which is directly impacted by changes in methanol supply and demand.

Demand for methanol is driven primarily by levels of industrial production, energy prices and the strength of the global economy. Demand for methanol grew by 5% in 2012, leading to global demand of approximately 51 million tonnes, excluding demand from integrated methanol-to-olefins facilities. The increase in demand was driven by both traditional derivatives and energy-related applications in Asia, particularly in China.

Industry supply additions outside of China in 2012 consisted primarily of the restart of our second Motunui facility in New Zealand, which added 0.7 million tonnes to the site’s annual operating capacity, and the restart of a 0.7 million tonne facility in Beaumont, Texas. New production from supply additions inside China was consumed in that country and China continued to be a significant net importer of methanol.

| | | | |

| | Management’s Discussion & Analysis | | Methanex Corporation | Annual Report 2012 5 |

Management’s Discussion & Analysis

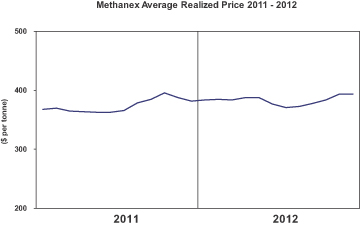

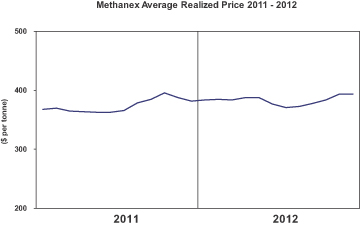

Overall, industry conditions were balanced in 2012 and this led to a relatively stable methanol pricing environment. Our average realized price for 2012 was $382 per tonne compared with $374 per tonne in 2011.

The outlook for methanol demand growth continues to be strong. The wide disparity between the price of crude oil and that of natural gas and coal has resulted in an increased use of methanol in energy-related applications, such as direct methanol blending into gasoline and DME and biodiesel production. Growth of direct methanol blending into gasoline in China has been particularly strong and we believe that future growth in this application is supported by numerous provincial and national fuel-blending standards, such as M15 or M85 (15% methanol and 85% methanol, respectively).

China is also leading the commercialization of methanol’s use as a feedstock to manufacture olefins. The use of methanol to produce olefins, at current energy prices, is proving to be cost competitive relative to the traditional production of olefins from naphtha. There are now five methanol-to-olefins (MTO) plants operating in China, with the capacity to consume approximately seven million tonnes of methanol annually. Three of these projects were not expected to impact the merchant methanol market as they are integrated projects – coal to methanol to olefins. However, over the past two years, these plants have purchased methanol to supplement their own methanol production. The two non-integrated plants (representing over 2 million tonnes of methanol demand annually) are dependent on merchant methanol supply. Several other integrated and non-integrated projects are currently under construction in China and the demand for methanol as a feedstock for producing olefins is anticipated to continue to grow.

While methanol demand in energy-related applications is strongest in China, there are an increasing number of countries around the world that have projects in place or are considering adopting these applications on a wider scale. Direct methanol blending into gasoline is being used in small quantities in the United Kingdom, Netherlands and Iceland, and other countries, including Australia and Israel, are conducting fuel-blending trials. DME is being produced and DME projects are under development in various countries including Japan, Taiwan, Turkey, the United States, Trinidad, India and Indonesia.

We believe demand potential into energy-related applications and olefins production will continue to grow.

We increased our operating capacity in 2012 and anticipate further increases over the next few years. We recently announced our commitment to add a further 0.7 million tonnes of operating capacity to our New Zealand site through the restart of the Waitara Valley facility and a debottlenecking project at the Motunui site. We are relocating one of our idle Chile facilities to Geismar, Louisiana and the plant is expected to commence operations by the end of 2014. We are also considering the relocation of a second facility to the Geismar site and expect to make a decision on this project by mid-2013.

Beyond our own capacity additions, there is a modest level of new capacity expected to come on stream over the next few years outside of China. There is a 0.8 million tonne plant expected to restart in Channelview, Texas in 2013 and a 0.7 million tonne plant expected to start up in Azerbaijan in 2013. We expect that production from new capacity in China will be consumed in that country and that higher-cost production capacity in China will need to operate in order to satisfy demand growth.

Entering 2013, methanol demand has continued to be healthy, supported by a higher energy price environment. With few industry capacity additions expected over the next few years relative to expected demand growth, we believe we are well positioned with several of our own initiatives to increase operating capacity. As production from these initiatives comes on line, we believe our leadership position in the industry will be strengthened and we will have significant upside potential to cash flows and earnings.

The methanol price will ultimately depend on the strength of the global economy, industry operating rates, global energy prices, new supply additions and the strength of global demand. We believe that our financial position and financial flexibility, outstanding global supply network and competitive cost position will provide a sound basis for Methanex to continue to be the leader in the methanol industry.

OUR STRATEGY

Our primary objective is to create value by maintaining and enhancing our leadership in the global production, marketing and delivery of methanol to customers. Our simple, clearly defined strategy – global leadership, low cost and operational excellence – has helped us achieve this objective.

| | | | |

| 6 Methanex Corporation | Annual Report 2012 | | Management’s Discussion & Analysis | | |

Management’s Discussion & Analysis

Global Leadership

Global leadership is a key element of our strategy. We are focused on maintaining and enhancing our position as the major supplier to the global methanol industry, enhancing our ability to cost-effectively deliver methanol supply to customers and supporting both traditional and energy-related global methanol demand growth.

We are the leading supplier of methanol to the major international markets in Asia Pacific, North America, Europe and Latin America. Our 2012 sales volumes of 7.5 million tonnes represented approximately 15% of global methanol demand. Our leadership position has enabled us to play an important role in the industry, which includes publishing Methanex reference prices that are generally used in each major market as the basis of pricing for most customer contracts.

The geographically diverse locations of our production sites allow us to deliver methanol cost-effectively to customers in all major global markets, while investments in global distribution and supply infrastructure, which include a dedicated fleet of ocean-going vessels and terminal capacity within all major international markets, enable us to enhance value to customers by providing reliable and secure supply.

A key component of our global leadership strategy is to strengthen our asset position and we have increased our operating capacity over the last two years. In 2011, we restarted our 0.5 million tonne per year Medicine Hat, Alberta facility and the 1.3 million tonne per year methanol plant in Egypt commenced operations. In 2012, we restarted a second facility in New Zealand and this increased our operating capacity in that country by 0.7 million tonnes. We have several other initiatives in progress in New Zealand that are expected to increase our operating capacity further and allow us to reach the site’s full production capacity of 2.4 million tonnes. Our New Zealand facilities are ideally situated to supply the growing Asia Pacific market.

During 2012, we operated our Chile methanol facilities significantly below site capacity. We expect to idle our Chile operations in March 2013 due to insufficient natural gas feedstock to operate the plant through the southern hemisphere winter (refer to theProduction Summary – Chilesection on page 10 for further information). We are in the process of relocating one of our four Chile facilities to Geismar, Louisiana. The Geismar facility will have an annual production capacity of approximately 1.0 million tonnes and is expected to be operational by the end of 2014. We are also considering other projects to increase the utilization of our Chile assets, including the potential to relocate an additional facility to the Geismar site.

Another key component of our global leadership strategy is our ability to supplement methanol production with methanol purchased from third parties to give us flexibility in our supply chain and continue to meet customer commitments. We purchase through a combination of methanol offtake contracts and spot purchases. We manage the cost of purchased methanol by taking advantage of our global supply chain infrastructure, which allows us to purchase methanol in the most cost-effective region while still maintaining overall security of supply.

The Asia Pacific region continues to lead global methanol demand growth and we have invested in and developed our presence in this important region. We have storage capacity in China, Korea and Japan that allows us to cost-effectively manage supply to customers and we have offices in Hong Kong, Shanghai, Beijing, Seoul and Tokyo to enhance customer service and industry positioning in the region. This enables us to participate in and improve our knowledge of the rapidly evolving and high growth methanol markets in China and other Asian countries. Our expanding presence in Asia has also helped us identify several opportunities to support the development of applications for methanol in the energy sector.

Low Cost

A low cost structure is an important competitive advantage in a commodity industry and is a key element of our strategy. Our approach to major business decisions is guided by a drive to improve our cost structure, expand margins and create value for shareholders. The most significant components of total costs are natural gas for feedstock and distribution costs associated with delivering methanol to customers.

Our ownership interest in production facilities in Trinidad and Egypt represents 2.8 million tonnes per year of competitive-cost production capacity. These facilities are well located to supply global methanol markets and are underpinned by natural gas purchase agreements where the gas price varies with methanol prices. This pricing relationship enables these facilities to be competitive throughout the methanol price cycle.

In January 2013, we entered into a 10-year agreement to purchase all of the natural gas required for the methanol plant we are relocating to Geismar, Louisiana. The agreement is structured so that the natural gas price is linked to the methanol price, which will enable the

| | | | |

| | Management’s Discussion & Analysis | | Methanex Corporation | Annual Report 2012 7 |

Management’s Discussion & Analysis

project to be profitable across a broad range of methanol prices. We also have a 0.5 million tonne facility located in Medicine Hat, Alberta and we believe that the long-term natural gas dynamics in North America will support the long-term operation of this facility.

The cost to distribute methanol from production locations to customers is also a significant component of total operating costs. These include costs for ocean shipping, in-market storage facilities and in-market distribution. We are focused on identifying initiatives to reduce these costs, including optimizing the use of our shipping fleet and taking advantage of prevailing conditions in the shipping market by varying the type and length of term of ocean vessel contracts. We are continuously investigating opportunities to further improve the efficiency and cost-effectiveness of distributing methanol from our production facilities to customers. We also look for opportunities to leverage our global asset position by entering into product exchanges with other methanol producers to reduce distribution costs.

Operational Excellence

We maintain a focus on operational excellence in all aspects of our business. This includes excellence in the manufacturing and supply chain processes, marketing and sales, human resources, corporate governance practices and financial management.

To differentiate ourselves from competitors, we strive to be the best operator in all aspects of our business and to be the preferred supplier to customers. We believe that reliability of supply is critical to the success of our customers’ businesses and our goal is to deliver methanol reliably and cost-effectively. We have a commitment to Responsible Care (a risk-minimization approach developed by the Chemistry Industry Association of Canada) and we use it as the umbrella under which we manage issues related to health, safety, the environment, community involvement, social responsibility, sustainability, security and emergency preparedness at each of our facilities and locations. We believe a commitment to Responsible Care helps us reduce the likelihood of unplanned events and achieve an excellent overall environmental and safety record.

Product stewardship is a vital component of a Responsible Care culture and guides our actions through the complete life cycle of our product. We aim for the highest safety standards to minimize risk to employees, customers and suppliers as well as to the environment and the communities in which we do business. We promote the proper use and safe handling of methanol at all times through a variety of internal and external health, safety and environmental initiatives, and we work with industry colleagues to improve safety standards. We readily share technical and safety expertise with key stakeholders, including customers, end-users, suppliers, logistics providers and industry associations in the methanol and methanol applications marketplace through active participation in local and international industry associations, seminars and conferences, and online education initiatives.

As a natural extension of the Responsible Care ethic, we have a Social Responsibility policy that aligns corporate governance, employee engagement and development, community involvement and social investment strategies with our core values and corporate strategy.

Our strategy of operational excellence also includes the financial management of the Company. We operate in a highly competitive commodity industry. Accordingly, we believe it is important to maintain financial flexibility and we have adopted a prudent approach to financial management. During 2012, we issued a total of $600 million of unsecured notes and a portion of the proceeds was used to repay $200 million of unsecured notes. Also during 2012, we extended the maturity on our undrawn revolving credit facility to 2016 and increased the amount to $400 million. At December 31, 2012, we had a strong balance sheet with a cash balance of $746 million, including $36 million relating to the non-controlling interest in Egypt. We believe we are well positioned to meet our financial commitments and continue investing to grow the Company.

| | | | |

| 8 Methanex Corporation | Annual Report 2012 | | Management’s Discussion & Analysis | | |

Management’s Discussion & Analysis

FINANCIAL HIGHLIGHTS

| | | | | | | | |

| | |

| ($ MILLIONS, EXCEPT AS NOTED) | | 2012 | | | 2011 | |

Production (thousands of tonnes) (attributable to Methanex shareholders) | | | 4,071 | | | | 3,847 | |

Sales volumes (thousands of tonnes): | | | | | | | | |

Methanex-produced methanol (attributable to Methanex shareholders) | | | 4,039 | | | | 3,853 | |

Purchased methanol | | | 2,565 | | | | 2,815 | |

Commission sales1 | | | 855 | | | | 846 | |

Total sales volumes | | | 7,459 | | | | 7,514 | |

Methanex average non-discounted posted price ($ per tonne)2 | | | 443 | | | | 440 | |

Average realized price ($ per tonne)3 | | | 382 | | | | 374 | |

Revenue | | | 2,673 | | | | 2,608 | |

Adjusted EBITDA4 | | | 429 | | | | 427 | |

Adjusted cash flows from operating activities4 | | | 403 | | | | 392 | |

Cash flows from operating activities | | | 458 | | | | 480 | |

Adjusted net income4 | | | 180 | | | | 182 | |

Net income (loss) (attributable to Methanex shareholders) | | | (68 | ) | | | 201 | |

Adjusted net income per common share ($ per share)4 5 | | | 1.90 | | | | 1.93 | |

Basic net income (loss) per common share ($ per share) | | | (0.73 | ) | | | 2.16 | |

Diluted net income (loss) per common share ($ per share) | | | (0.73 | ) | | | 2.06 | |

Common share information (millions of shares): | | | | | | | | |

Weighted average number of common shares | | | 94 | | | | 93 | |

Diluted weighted average number of common shares | | | 94 | | | | 94 | |

Number of common shares outstanding, end of period | | | 94 | | | | 93 | |

| 1 | Commission sales represent volumes marketed on a commission basis related to the 36.9% of the Atlas methanol facility and 40% of the Egypt methanol facility that we do not own. | |

| 2 | Methanex average non-discounted posted price represents the average of our non-discounted posted prices in North America, Europe and Asia Pacific weighted by sales volume. Current and historical pricing information is available at www.methanex.com. | |

| 3 | Average realized price is calculated as revenue, excluding commissions earned and the Egypt non-controlling interest share of revenue, divided by the total sales volumes of Methanex-produced (attributable to Methanex shareholders) and purchased methanol. | |

| 4 | These items are non-GAAP measures that do not have any standardized meaning prescribed by GAAP and therefore are unlikely to be comparable to similar measures presented by other companies. Refer to the Supplemental Non-GAAP Measures section on page 34 for a description of each non-GAAP measure and reconciliations to the most comparable GAAP measures. | |

| 5 | For the year ended December 31, 2012, stock options have been excluded from the calculation of diluted net loss per common share (attributable to Methanex shareholders) as their effect would be anti-dilutive. However, for the calculation of adjusted net income per common share (attributable to Methanex shareholders) stock options have been included in the denominator and the diluted weighted average number of common shares for the year ended December 31, 2012 is 95 million. | |

PRODUCTION SUMMARY

The following table details the annual production capacity and actual production of our facilities in 2012 and 2011:

| | | | | | | | | | | | |

| | | |

| (THOUSANDS OF TONNES) | | ANNUAL

PRODUCTION

CAPACITY1 | | | 2012 | | | 2011 | |

New Zealand2 | | | 2,430 | | | | 1,108 | | | | 830 | |

Atlas (Trinidad) (63.1% interest) | | | 1,125 | | | | 826 | | | | 891 | |

Titan (Trinidad) | | | 875 | | | | 786 | | | | 711 | |

Egypt (60% interest)3 | | | 760 | | | | 557 | | | | 532 | |

Medicine Hat (Canada)3 | | | 470 | | | | 481 | | | | 329 | |

Chile I, III and IV | | | 2,800 | | | | 313 | | | | 554 | |

Geismar, Louisiana (USA)4 | | | 1,000 | | | | – | | | | – | |

| | | | 9,460 | | | | 4,071 | | | | 3,847 | |

| 1 | The annual production capacity of our production facilities may be higher than original nameplate capacity as, over time, these figures have been adjusted to reflect ongoing operating efficiencies at these facilities. Actual production for a facility in any given year may be higher or lower than annual production capacity due to a number of factors, including natural gas composition or the age of the facility’s catalyst. | |

| 2 | The annual production capacity of New Zealand represents the two facilities at Motunui and the currently idle facility at Waitara Valley. The current operating capacity of the Motunui facilities is 1.5 million tonnes due to distillation capacity constraints. We recently announced our commitment to restart the Waitara Valley facility and complete a debottlenecking project at the Motunui site, which we expect will allow our New Zealand operations to operate at their full production capacity of 2.4 million tonnes, depending on natural gas composition. | |

| 3 | The Egypt methanol facility commenced commercial production in March 2011 and the Medicine Hat facility was restarted in April 2011. | |

| 4 | We are relocating the Chile II facility to Geismar, Louisiana. The plant is expected to be operational by the end of 2014. | |

| | | | |

| | Management’s Discussion & Analysis | | Methanex Corporation | Annual Report 2012 9 |

Management’s Discussion & Analysis

New Zealand

In New Zealand, we produced 1.1 million tonnes of methanol in 2012 compared with 0.8 million tonnes in 2011. We have three plants in New Zealand with up to 2.4 million tonnes of annual production capacity. After operating one Motunui facility in 2011, we restarted the second facility in mid-2012 which increased our current operating capacity to 1.5 million tonnes. We recently committed to debottleneck the Motunui facility and restart the Waitara Valley facility and we expect this will allow us to produce at the site’s full production capacity, depending on natural gas composition. Our New Zealand facilities are ideally situated to supply the growing Asia Pacific market.

We have entered into several natural gas purchase agreements with various suppliers to underpin the future operation of our Motunui and Waitara Valley facilities. Each natural gas purchase agreement has base and variable components, where the gas price varies with methanol prices. We are also pursuing natural gas exploration and development opportunities in that country. We have an agreement with Kea Petroleum, an oil and gas exploration and development company, to explore areas of the Taranaki basin, which is close to our plants.

Trinidad

Our equity ownership of methanol facilities in Trinidad represents 2.0 million tonnes of competitive-cost annual capacity. The Titan and Atlas facilities in Trinidad are well located to supply global methanol markets and are underpinned by take-or-pay natural gas purchase agreements that expire in 2014 and 2024, respectively, where the gas price varies with methanol prices. These facilities produced a total of 1.6 million tonnes in each of 2012 and 2011.

The Atlas facility experienced an equipment failure in 2011. During 2012, the plant undertook two outages to repair the equipment failure and overcome a technical issue.

During 2011 and 2012, we experienced some natural gas curtailments to our Trinidad facilities due to a mismatch between upstream commitments to supply The National Gas Company of Trinidad and Tobago Limited (NGC) and downstream demand from NGC’s customers, which becomes apparent when an upstream supplier has a technical issue or planned maintenance that reduces gas delivery. We are engaged with key stakeholders to find a solution to this issue, but in the meantime expect to continue to experience some gas curtailments to the Trinidad site. Refer to theRisk Factors and Risk Management – Trinidad section on page 24 for more information.

Egypt

We have a 60% equity interest in the 1.26 million tonne per year methanol plant in Egypt and have marketing rights for 100% of the production. This facility is well located to supply the European market and is underpinned by a 25-year take-or-pay natural gas purchase agreement where the gas price varies with methanol prices. Production from the Egypt facility in 2012 was lower than capacity due to planned and unplanned maintenance outages and natural gas supply restrictions. Refer to theRisk Factors and Risk Management – Egyptsection on page 25 for more information.

Medicine Hat, Canada

We restarted the Medicine Hat, Alberta facility in 2011 and it operated well in 2012, producing 0.5 million tonnes. We are currently debottlenecking the Medicine Hat facility which we expect will add a further 0.1 million tonnes of annual production capacity by the end of the third quarter of 2013.

Chile

During 2012, we operated our Chile methanol facilities significantly below annual production capacity due to insufficient natural gas feedstock.

In 2007, our natural gas suppliers from Argentina curtailed all gas supply to our plants in Chile. Under the existing circumstances, we do not expect to receive any further natural gas supply from Argentina. As a result of the Argentinean natural gas supply issues, all of the methanol production at our Chile facilities since June 2007 has been produced with natural gas from Chile.

Over the past few years, investments have been made by us and others to accelerate the exploration and development of natural gas in southern Chile. However, the potential for a significant increase in gas production is more challenging than we had originally

| | | | |

| 10 Methanex Corporation | Annual Report 2012 | | Management’s Discussion & Analysis | | |

Management’s Discussion & Analysis

anticipated. As a result of the short-term outlook for gas supply in Chile, we expect to idle our Chile operations in March 2013 due to insufficient natural gas feedstock to keep the plant operating through the southern hemisphere winter. We are continuing to work with Empresa Nacional del Petroleo (ENAP) and others to secure sufficient natural gas to sustain our operations, and while the restart of a Chile plant is possible later in 2013, the restart is dependent on securing a sustainable natural gas position to operate over the medium term.

The future of our Chile operations is primarily dependent on the level of exploration and development in southern Chile and our ability to secure a sustainable natural gas supply to our facilities on economic terms. Refer to theRisk Factors and Risk Management – Chilesection on page 25 for more information.

HOW WE ANALYZE OUR BUSINESS

Our operations consist of a single operating segment – the production and sale of methanol. We review our financial results by analyzing changes in the components of Adjusted EBITDA (refer to theSupplemental Non-GAAP Measures section on page 34 for a description of Adjusted EBITDA and a reconciliation to the most comparable GAAP measure), mark-to-market impact of share-based compensation, Louisiana project relocation expenses and charges, asset impairment charges, depreciation and amortization, finance costs, finance income and other expenses, and income taxes.

In addition to the methanol that we produce at our facilities (“Methanex-produced methanol”), we also purchase and re-sell methanol produced by others (“purchased methanol”) and we sell methanol on a commission basis. We analyze the results of all methanol sales together, excluding commission sales volumes. The key drivers of change in Adjusted EBITDA are average realized price, cash costs and sales volume, which are defined and calculated as follows:

| | |

| PRICE | | The change in Adjusted EBITDA as a result of changes in average realized price is calculated as the difference from period to period in the selling price of methanol multiplied by the current period total methanol sales volume excluding commission sales volume plus the difference from period to period in commission revenue. |

| CASH COSTS | | The change in Adjusted EBITDA as a result of changes in cash costs is calculated as the difference from period to period in cash costs per tonne multiplied by the current period total methanol sales volume excluding commission sales volume in the current period. The cash costs per tonne is the weighted average of the cash cost per tonne of Methanex-produced methanol and the cash cost per tonne of purchased methanol. The cash cost per tonne of Methanex-produced methanol includes absorbed fixed cash costs per tonne and variable cash costs per tonne. The cash cost per tonne of purchased methanol consists principally of the cost of methanol itself. In addition, the change in Adjusted EBITDA as a result of changes in cash costs includes the changes from period to period in unabsorbed fixed production costs, consolidated selling, general and administrative expenses and fixed storage and handling costs. |

| VOLUME | | The change in Adjusted EBITDA as a result of changes in sales volume is calculated as the difference from period to period in total methanol sales volume, excluding commission sales volumes, multiplied by the margin per tonne for the prior period. The margin per tonne for the prior period is the weighted average margin per tonne of Methanex-produced methanol and margin per tonne of purchased methanol. The margin per tonne for Methanex-produced methanol is calculated as the selling price per tonne of methanol less absorbed fixed cash costs per tonne and variable cash costs per tonne. The margin per tonne for purchased methanol is calculated as the selling price per tonne of methanol less the cost of purchased methanol per tonne. |

We own 63.1% of the Atlas methanol facility and market the remaining 36.9% of its production through a commission offtake agreement. We account for this investment using proportionate consolidation, which results in 63.1% of its results being included in revenues and expenses with the remaining 36.9% portion included as commission income.

We own 60% of the 1.26 million tonne per year Egypt methanol facility and market the remaining 40% of its production through a commission offtake agreement. We account for this investment using consolidation accounting, which results in 100% of the revenues and expenses being included in our financial statements with the other investors’ interest in the methanol facility being presented as “non-controlling interests”. For the purposes of analyzing our business, Adjusted EBITDA and Adjusted cash flows from operating activities exclude the amounts associated with the other investors’ 40% non-controlling interest, which are included in commission income on a consistent basis with how we present the Atlas facility.

| | | | |

| | Management’s Discussion & Analysis | | Methanex Corporation | Annual Report 2012 11 |

Management’s Discussion & Analysis

FINANCIAL RESULTS

For the year ended December 31, 2012, we reported Adjusted EBITDA of $429 million and Adjusted net income of $180 million ($1.90 per share on a diluted basis), compared with Adjusted EBITDA of $427 million and Adjusted net income of $182 million ($1.93 per share on a diluted basis) for the year ended December 31, 2011.

In addition, we recorded a non-cash before-tax asset impairment charge of $297 million ($193 million after-tax) related to the carrying value of our Chile assets and a before-tax $65 million charge to earnings related to Louisiana project relocation expenses and charges ($41 million after-tax). Including these items, we reported a net loss attributable to Methanex shareholders for the year ended December 31, 2012 of $68 million ($0.73 loss per share on a diluted basis), compared with net income attributable to Methanex shareholders for the year ended December 31, 2011 of $201 million ($2.06 income per share on a diluted basis).

We calculate Adjusted EBITDA and Adjusted net income by excluding amounts associated with the 40% non-controlling interest in Egypt that we do not own, the mark-to-market impact of share-based compensation as a result of changes in our share price and items that are considered by management to be non-operational, including asset impairment charges and Louisiana project relocation expenses and charges. Refer to theSupplemental Non-GAAP Measures section on page 34 for further discussion on how we calculate these measures.

A reconciliation from net income (loss) attributable to Methanex shareholders to Adjusted net income and the calculation of Adjusted diluted net income per common share is as follows:

| | | | | | | | |

| | |

| ($ MILLIONS EXCEPT NUMBER OF SHARES AND PER SHARE AMOUNTS) | | 2012 | | | 2011 | |

Net income (loss) attributable to Methanex shareholders | | $ | (68 | ) | | $ | 201 | |

Mark-to-market impact of share-based compensation, net of tax | | | 14 | | | | (19 | ) |

Louisiana project relocation expenses and charges, net of tax | | | | | | | | |

Cash expense | | | 23 | | | | – | |

Non-cash charge | | | 18 | | | | – | |

Asset impairment charge, net of tax | | | 193 | | | | – | |

Adjusted net income1 | | $ | 180 | | | $ | 182 | |

Diluted weighted average shares outstanding (millions) | | | 94 | | | | 94 | |

Adjusted diluted net income per common share1 2 | | $ | 1.90 | | | $ | 1.93 | |

| 1 | These items are non-GAAP measures that do not have any standardized meaning prescribed by GAAP and therefore are unlikely to be comparable to similar measures presented by other companies. Refer to the Supplemental Non-GAAP Measures section on page 34 for a description of the non-GAAP measures and a reconciliation to the most comparable GAAP measures. | |

| 2 | For the year ended December 31, 2012, stock options have been excluded from the calculation of diluted net loss per common share (attributable to Methanex shareholders) as their effect would be anti-dilutive. However, for the calculation of adjusted diluted net income per common share (attributable to Methanex shareholders) stock options have been included in the denominator and the diluted weighted average number of common shares for the year ended December 31, 2012 is 95 million. | |

We review our financial results by analyzing changes in the components of Adjusted EBITDA, mark-to-market impact of share-based compensation, Louisiana project relocation expenses and charges, asset impairment charges, depreciation and amortization, finance costs, finance income and other expenses, and income taxes.

| | | | |

| 12 Methanex Corporation | Annual Report 2012 | | Management’s Discussion & Analysis | | |

Management’s Discussion & Analysis

A summary of our consolidated statements of income for 2012 and 2011 is as follows:

| | | | | | | | |

| | |

| ($ MILLIONS) | | 2012 | | | 2011 | |

Consolidated statements of income: | | | | | | | | |

Revenue | | $ | 2,673 | | | $ | 2,608 | |

Cost of sales and operating expenses, excluding mark-to-market impact of share-based compensation | | | (2,171 | ) | | | (2,128 | ) |

| | | 502 | | | | 480 | |

Comprised of: | | | | | | | | |

Adjusted EBITDA (attributable to Methanex shareholders)1 | | | 429 | | | | 427 | |

Amounts attributable to non-controlling interests | | | 73 | | | | 53 | |

| | | 502 | | | | 480 | |

Mark-to-market impact of share-based compensation | | | (16 | ) | | | 21 | |

Louisiana project relocation expenses and charges | | | (65 | ) | | | – | |

Asset impairment charge | | | (297 | ) | | | – | |

Depreciation and amortization | | | (172 | ) | | | (157 | ) |

Operating income (loss)1 | | | (48 | ) | | | 344 | |

Finance costs | | | (71 | ) | | | (62 | ) |

Finance income and other expenses | | | 1 | | | | 2 | |

Income tax recovery (expense) | | | 84 | | | | (56 | ) |

Net income (loss) | | $ | (34 | ) | | $ | 228 | |

Net income (loss) attributable to Methanex shareholders | | $ | (68 | ) | | $ | 201 | |

| 1 | These items are non-GAAP measures that do not have any standardized meaning prescribed by GAAP and therefore are unlikely to be comparable to similar measures presented by other companies. Refer to the Supplemental Non-GAAP Measures section on page 34 for a description of the non-GAAP measures and a reconciliation to the most comparable GAAP measures. | |

Revenue

There are many factors that impact our global and regional revenue levels. The methanol business is a global commodity industry affected by supply and demand fundamentals. Due to the diversity of the end products in which methanol is used, demand for methanol largely depends upon levels of industrial production, energy prices and changes in general economic conditions, which can vary across the major international methanol markets. Methanol prices have been relatively stable over the past two years and our revenue for 2012 was $2.7 billion compared with 2011 revenue of $2.6 billion.

| | | | |

| | Management’s Discussion & Analysis | | Methanex Corporation | Annual Report 2012 13 |

Management’s Discussion & Analysis

Global methanol demand grew approximately 5% in 2012, to approximately 51 million tonnes, excluding methanol demand from integrated methanol-to-olefins facilities. Increases in demand were driven by both traditional derivatives and energy-related applications in Asia, particularly in China.

Industry supply additions outside of China in 2012 consisted primarily of the restart of our second Motunui facility in New Zealand, which added 0.7 million tonnes to the site’s operating capacity on an annualized basis, and the restart of a 0.7 million tonne facility in Beaumont, Texas. New production from supply additions inside China was consumed in that country and China continued to be a significant net importer of methanol.

Overall, industry conditions were balanced in 2012 and this led to a relatively stable methanol pricing environment. Our average realized price for 2012 was $382 per tonne compared with $374 per tonne in 2011.

The methanol industry is highly competitive and prices are affected by supply and demand fundamentals. We publish regional non-discounted reference prices for each major methanol market and these posted prices are reviewed and revised monthly or quarterly based on industry fundamentals and market conditions. Most of our customer contracts use published Methanex reference prices as a basis for pricing, and we offer discounts to customers based on various factors. Our average non-discounted published reference price for 2012 was $443 per tonne compared with $440 per tonne in 2011.

Distribution of Revenue

The geographic distribution of revenue by customer location for 2012 was similar to 2011. Details are as follows:

| | | | | | | | | | | | | | | | |

| | |

| ($ MILLIONS, EXCEPT WHERE NOTED) | | 2012 | | | 2011 | |

Canada | | $ | 180 | | | | 7 | % | | $ | 176 | | | | 7 | % |

United States | | | 563 | | | | 21 | % | | | 632 | | | | 24 | % |

Europe | | | 772 | | | | 29 | % | | | 679 | | | | 26 | % |

China | | | 409 | | | | 15 | % | | | 431 | | | | 17 | % |

Korea | | | 286 | | | | 11 | % | | | 267 | | | | 10 | % |

Other Asia | | | 188 | | | | 7 | % | | | 155 | | | | 6 | % |

Latin America | | | 275 | | | | 10 | % | | | 268 | | | | 10 | % |

| | | $ | 2,673 | | | | 100 | % | | $ | 2,608 | | | | 100 | % |

Adjusted EBITDA (Attributable to Methanex Shareholders)

2012 Adjusted EBITDA was $429 million compared with $427 million in 2011. The key drivers of changes in our Adjusted EBITDA are average realized price, sales volume and cash costs as described below (refer to theHow We Analyze Our Business section on page 11 for more information).

| | | | |

| |

| ($ MILLIONS) | | 2012 VS. 2011 | |

Average realized price | | $ | 57 | |

Sales volume | | | (5 | ) |

Total cash costs | | | (50 | ) |

Increase in Adjusted EBITDA | | $ | 2 | |

Average Realized Price

Our average realized price for the year ended December 31, 2012 was $382 per tonne compared with $374 per tonne for 2011, and this increased Adjusted EBITDA by $57 million (refer to theRevenue section on page 13 for more information).

Sales Volumes

Methanol sales volumes, excluding commission sales volumes, for the year ended December 31, 2012 were 64,000 tonnes lower than in 2011, and this decreased Adjusted EBITDA by $5 million. Including commission sales volumes from the Atlas and Egypt facilities, our total methanol sales volumes were 7.5 million tonnes in both 2012 and 2011.

| | | | |

| 14 Methanex Corporation | Annual Report 2012 | | Management’s Discussion & Analysis | | |

Management’s Discussion & Analysis

Total Cash Costs

The primary drivers of changes in our total cash costs are changes in the cost of methanol we produce at our facilities (Methanex-produced methanol) and changes in the cost of methanol we purchase from others (purchased methanol). All of our production facilities except Medicine Hat are underpinned by natural gas purchase agreements with pricing terms that include base and variable price components. We supplement our production with methanol produced by others through methanol offtake contracts and purchases on the spot market to meet customer needs and support our marketing efforts within the major global markets.

We have adopted the first-in, first-out method of accounting for inventories and it generally takes between 30 and 60 days to sell the methanol we produce or purchase. Accordingly, the changes in Adjusted EBITDA as a result of changes in Methanex-produced and purchased methanol costs primarily depend on changes in methanol pricing and the timing of inventory flows.

The changes in our total cash costs for 2012 compared with 2011 were due to the following:

| | | | |

| |

| ($ MILLIONS) | | 2012 VS. 2011 | |

Methanex-produced methanol costs | | $ | (34 | ) |

Purchased methanol costs | | | (22 | ) |

Proportion of Methanex-produced methanol sales | | | 36 | |

Other, net | | | (30 | ) |

Increase in total cash costs | | $ | (50 | ) |

Methanex-Produced Methanol Costs

Natural gas is the primary feedstock at our methanol facilities and is the most significant component of Methanex-produced methanol costs. We purchase natural gas for the New Zealand, Trinidad, Egypt and Chile methanol facilities under natural gas purchase agreements where the unique terms of each contract include a base price and a variable price component linked to the price of methanol to reduce our commodity price risk exposure. The variable price component of each gas contract is adjusted by a formula related to methanol prices above a certain level. We believe these pricing relationships enable each facility to be competitive throughout the methanol price cycle. Methanex-produced methanol costs were higher in 2012 compared with 2011 by $34 million, primarily due to the impact of higher realized methanol prices on our natural gas costs and a change in the mix of production sold from inventory. For additional information regarding our natural gas supply agreements refer to theSummary of Contractual Obligations and Commercial Commitments section on page 21.

Purchased Methanol Costs

A key element of our corporate strategy is global leadership, and as such we have built a leading market position in each of the major global markets where methanol is sold. We supplement our production with purchased methanol through methanol offtake contracts and on the spot market to meet customer needs and support our marketing efforts within the major global markets. In structuring purchase agreements, we look for opportunities that provide synergies with our existing supply chain that allow us to purchase methanol in the lowest-cost region. The cost of purchased methanol consists principally of the cost of the methanol itself, which is directly related to the price of methanol at the time of purchase. As a result of higher methanol prices in 2012, and the timing of purchases, the cost of purchased methanol per tonne increased and this decreased Adjusted EBITDA by $22 million compared with 2011.

Proportion of Methanex-Produced Methanol Sales

The cost of purchased methanol is directly linked to the selling price for methanol at the time of purchase and the cost of purchased methanol is generally higher than the cost of Methanex-produced methanol. Accordingly, an increase in the proportion of Methanex-produced methanol sales results in a decrease in our overall cost structure for a given period. The proportion of Methanex-produced methanol sales for the year ended 2012 was higher compared with 2011 and this increased Adjusted EBITDA by $36 million. We increased our sales volumes of methanol produced at the New Zealand, Egypt and Medicine Hat facilities and this more than offset the decrease in sales volumes from the Chile facility.

| | | | |

| | Management’s Discussion & Analysis | | Methanex Corporation | Annual Report 2012 15 |

Management’s Discussion & Analysis

Other, Net

Our investment in global distribution and supply infrastructure includes a dedicated fleet of ocean-going vessels. We utilize these vessels to enhance value to customers by providing reliable and secure supply and to optimize supply chain costs overall. For the year ended December 31, 2012 compared with 2011, ocean freight and other logistics costs were higher by $10 million, primarily as a result of a one-time charge to earnings to terminate a time charter vessel lease contract. In addition to changes in fuel prices, logistics costs can vary from period to period depending on the levels of production from each of our production facilities and the resulting impact on our supply chain.

We experienced an equipment failure at our Atlas facility in July 2011. Our operations are covered by business interruption insurance and we finalized our claim related to this event in 2012. We recorded a $17 million recovery in 2011 related to this event with the remaining $11 million recorded in 2012.

In October 2012, we completed a restructuring of our Chile operations which reduced the size of our workforce and resulted in a $5 million charge to earnings in 2012. The remaining change in other cash costs is primarily due to the timing of recognizing fixed manufacturing costs in earnings. We allocate fixed manufacturing costs to inventory based on the normal operating capacity of our manufacturing facilities. During 2012, primarily due to our Chile and Egypt facilities operating below capacity for certain periods, a portion of fixed manufacturing costs were charged directly to earnings rather than to inventory and this decreased Adjusted EBITDA in 2012.

Mark-to-Market Impact of Share-Based Compensation

We grant share-based awards as an element of compensation. Share-based awards granted include stock options, share appreciation rights, tandem share appreciation rights, deferred share units, restricted share units and performance share units. For all the share-based awards, share-based compensation is recognized over the related vesting period for the proportion of the service that has been rendered at each reporting date. Share-based compensation includes an amount related to the grant-date value and a mark-to-market impact as a result of subsequent changes in the Company’s share price. The grant-date value amount is included in Adjusted EBITDA and Adjusted net income. The mark-to-market impact of share-based compensation as a result of changes in our share price is excluded from Adjusted EBITDA and Adjusted net income and analyzed separately.

| | | | | | | | |

| | |

| ($ MILLIONS, EXCEPT AS NOTED) | | 2012 | | | 2011 | |

Methanex Corporation share price1 | | $ | 31.87 | | | $ | 22.82 | |

Grant-date fair value expense included in Adjusted EBITDA | | | 20 | | | | 16 | |

Mark-to-market impact due to change in share price | | | 16 | | | | (21 | ) |

Total share-based compensation expense (recovery) | | $ | 36 | | | $ | (5 | ) |

| 1 | US dollar share price of Methanex Corporation as quoted on NASDAQ Global Market on the last trading day of the respective period. | |

For stock options, the cost is measured based on an estimate of the fair value at the date of grant using the Black-Scholes option pricing model, and this grant-date fair value is recognized as compensation expense over the related vesting period with no subsequent re-measurement in fair value. Accordingly, share-based compensation expense associated with stock options will not vary significantly from period to period.

Share appreciation rights (SARs) and tandem share appreciation rights (TSARs) are units that grant the holder the right to receive a cash payment upon exercise for the difference between the market price of the Company’s common shares and the exercise price, which is determined at the date of grant. The fair values of SARs and TSARs are re-measured each quarter using the Black-Scholes option pricing model, which considers the market value of the Company’s common shares on the last trading day of each quarter.

Deferred, restricted and performance share units are grants of notional common shares that are redeemable for cash based on the market value of the Company’s common shares and are non-dilutive to shareholders. Performance share units have an additional feature where the ultimate number of units that vest will be determined by the Company’s total shareholder return in relation to a predetermined target over the period to vesting. The number of units that will ultimately vest will be in the range of 50% to 120% of the original grant. For deferred, restricted and performance share units, the value is initially measured at the grant date and subsequently re-measured based on the market value of the Company’s common shares on the last trading day of each quarter.

| | | | |

| 16 Methanex Corporation | Annual Report 2012 | | Management’s Discussion & Analysis | | |

Management’s Discussion & Analysis

Louisiana Project Relocation Expenses and Charges

In July 2012, we reached a final investment decision to proceed with the project to relocate an idle Chile facility to Geismar, Louisiana. The project will add approximately one million tonnes of operating capacity and is expected to be operational by the end of 2014. Under IFRS, certain costs associated with relocating an asset are not eligible for capitalization and are required to be charged directly to earnings. During 2012, we charged $39 million ($23 million after-tax) of Louisiana project relocation expenses directly to earnings. In addition, a non-cash charge of $26 million ($18 million after-tax) was recorded to earnings in 2012 related to the carrying value of the Chile facility that is being relocated to Louisiana.

Asset Impairment Charge

As a result of the continuing challenges related to securing a sustainable natural gas supply in Chile, we recorded a non-cash before-tax asset impairment charge of $297 million ($193 million after-tax) to write down the carrying value of our Chile assets at December 31, 2012 to $245 million. The remaining $245 million carrying value excludes the first Chile facility that is being relocated to Geismar, Louisiana but includes the second facility that management is also considering for relocation to Geismar. Refer to theCritical Accounting Estimates – Recoverability of Asset Carrying Values section on page 33 for more information.

Depreciation and Amortization

Depreciation and amortization was $172 million for the year ended December 31, 2012 compared with $157 million for the same period in 2011. The increase in depreciation and amortization in 2012 compared with 2011 is primarily a result of depreciation associated with the Egypt (100% basis) and Medicine Hat methanol facilities, which commenced operations in the first and second quarters of 2011, respectively, and depreciation associated with the second Motunui facility in New Zealand, which commenced operations in the third quarter of 2012.

Finance Costs

| | | | | | | | |

| | |

| ($ MILLIONS) | | 2012 | | | 2011 | |

Finance costs before capitalized interest | | $ | 73 | | | $ | 70 | |

Less capitalized interest | | | (2 | ) | | | (8 | ) |

Finance costs | | $ | 71 | | | $ | 62 | |

Finance costs before capitalized interest primarily relate to interest expense on the unsecured notes and limited recourse debt facilities. Capitalized interest in 2012 relates to interest costs capitalized for the Louisiana project while capitalized interest in 2011 relates to the Egypt project.

Finance Income and Other Expenses

Finance income and other expenses were $1 million and $2 million, respectively, for the years ended December 31, 2012 and 2011.

Income Taxes

A summary of our income taxes for 2012 compared with 2011 is as follows:

| | | | | | | | | | | | |

| |

| | | YEAR ENDED DEC 31, 2012 | |

| ($ MILLIONS, EXCEPT WHERE NOTED) | | AMOUNTS EXCLUDING LOUISIANA PROJECT

RELOCATION EXPENSESAND CHARGES

AND ASSET IMPAIRMENT CHARGE | | | LOUISIANA PROJECT RELOCATION

EXPENSES AND CHARGES AND ASSET

IMPAIRMENT CHARGE | | | TOTAL | |

Income (loss) before income tax expense | | $ | 244 | | | $ | (362 | ) | | $ | (118 | ) |

Income tax recovery (expense) | | | (44 | ) | | | 128 | | | | 84 | |

Net income (loss) | | $ | 200 | | | $ | (234 | ) | | $ | (34 | ) |

Effective tax rate | | | 18 | % | | | 35 | % | | | 71 | % |

| | | | |

| | Management’s Discussion & Analysis | | Methanex Corporation | Annual Report 2012 17 |

Management’s Discussion & Analysis

| | | | | | | | | | | | |

| |

| | | YEAR ENDED DEC 31, 2011 | |

| ($ MILLIONS, EXCEPT WHERE NOTED) | | AMOUNTS EXCLUDING LOUISIANA PROJECT

RELOCATION EXPENSESAND CHARGES

AND ASSET IMPAIRMENT CHARGE | | | LOUISIANA PROJECT RELOCATION

EXPENSES AND CHARGES AND ASSET

IMPAIRMENT CHARGE | | | TOTAL | |

Income before income tax expense | | $ | 284 | | | $ | – | | | $ | 284 | |

Income tax expense | | | (56 | ) | | | – | | | | (56 | ) |

Net income | | $ | 228 | | | $ | – | | | $ | 228 | |

Effective tax rate | | | 20 | % | | | – | | | | 20 | % |

For the year ended December 31, 2012, the effective tax rate excluding income taxes related to Louisiana project relocation expenses and charges and the asset impairment charge was 18% compared with 20% for the year ended December 31, 2011.

We earn the majority of our pre-tax earnings in New Zealand, Trinidad, Egypt, Canada and Chile. In Trinidad and Chile, the statutory tax rate is 35%, and in Egypt, the statutory tax rate is 25%. Our Atlas facility in Trinidad has partial relief from corporation income tax until 2014. We have significant loss carryforwards in Canada and New Zealand that have not been recognized for accounting purposes. During 2012, we earned a higher proportion of our consolidated income from methanol produced in jurisdictions with low effective tax rates and this contributed to a lower effective tax rate compared with 2011.

In Chile, the tax rate consists of a first-tier tax that is payable when income is earned and a second-tier tax that is due when earnings are distributed from Chile. The second category tax is initially recorded as future income tax expense and is subsequently reclassified to current income tax expense when earnings are distributed. Accordingly, the ratio of Chile’s current income tax expense to total income tax expense is dependent on the level of cash distributed from Chile.

For additional information regarding income taxes, refer to note 17 of our 2012 consolidated financial statements.

LIQUIDITY AND CAPITAL RESOURCES

A summary of our consolidated statements of cash flows is as follows:

| | | | | | | | |

| | |

| ($ MILLIONS) | | 2012 | | | 2011 | |

Cash flows from operating activities: | | | | | | | | |

Cash flows from operating activities before changes in non-cash working capital1 | | $ | 436 | | | $ | 444 | |

Changes in non-cash working capital | | | 22 | | | | 36 | |

| | | 458 | | | | 480 | |

Cash flows from financing activities: | | | | | | | | |

Dividend payments | | | (68 | ) | | | (62 | ) |

Interest paid, including interest rate swap settlements | | | (65 | ) | | | (60 | ) |

Net proceeds on issue of long-term debt | | | 590 | | | | 3 | |

Repayment of long-term debt and limited recourse debt | | | (251 | ) | | | (50 | ) |

Other | | | (41 | ) | | | (11 | ) |

| | | 165 | | | | (180 | ) |

Cash flows from investing activities: | | | | | | | | |

Property, plant and equipment | | | (134 | ) | | | (126 | ) |

Louisiana project expenditures | | | (74 | ) | | | (1 | ) |

Oil and gas properties | | | (33 | ) | | | (30 | ) |

GeoPark repayments | | | 10 | | | | 7 | |

Changes in non-cash working capital relating to investing activities | | | 3 | | | | 7 | |

| | | | (228 | ) | | | (143 | ) |

Increase in cash and cash equivalents | | | 395 | | | | 157 | |

Cash and cash equivalents, end of year | | $ | 746 | | | $ | 351 | |

| 1 | These items are non-GAAP measures that do not have any standardized meaning prescribed by GAAP and therefore are unlikely to be comparable to similar measures presented by other companies. Refer to the Supplemental Non-GAAP Measures section on page 34 for a description of the non-GAAP measures and a reconciliation to the most comparable GAAP measures. | |

| | | | |

| 18 Methanex Corporation | Annual Report 2012 | | Management’s Discussion & Analysis | | |

Management’s Discussion & Analysis

Cash Flow Highlights

Cash Flows from Operating Activities

Cash flows from operating activities for the year ended December 31, 2012 were $458 million compared with $480 million for 2011. The decrease in cash flows from operating activities is primarily due to lower net income (loss), after excluding depreciation and amortization, Louisiana project relocation non-cash charges, asset impairment charges and finance costs, and changes in non-cash working capital. The following table provides a summary of these items for 2012 and 2011:

| | | | | | | | |

| | |

| ($ MILLIONS) | | 2012 | | | 2011 | |

Net income (loss) | | $ | (34 | ) | | $ | 228 | |

Add (deduct) non-cash items: | | | | | | | | |

Depreciation and amortization | | | 172 | | | | 157 | |

Louisiana project relocation non-cash charges, net of tax | | | 18 | | | | – | |

Asset impairment charge, net of tax | | | 193 | | | | – | |

Finance costs | | | 71 | | | | 62 | |

Other | | | 16 | | | | (3 | ) |

Cash flows from operating activities before changes in non-cash working capital1 | | | 436 | | | | 444 | |

Changes in non-cash working capital: | | | | | | | | |

Trade and other receivables | | | (45 | ) | | | (59 | ) |

Inventories | | | 27 | | | | (44 | ) |

Prepaid expenses | | | (4 | ) | | | 2 | |

Accounts payable and accrued liabilities, including long-term payables | | | 44 | | | | 137 | |

| | | | 22 | | | | 36 | |

Cash flows from operating activities | | $ | 458 | | | $ | 480 | |

Adjusted cash flows from operating activities (attributable to Methanex shareholders)1 | | $ | 403 | | | $ | 392 | |

| 1 | These items are non-GAAP measures that do not have any standardized meaning prescribed by GAAP and therefore are unlikely to be comparable to similar measures presented by other companies. Refer to the Supplemental Non-GAAP Measures section on page 34 for a description of the non-GAAP measures and a reconciliation to the most comparable GAAP measures. | |

For a discussion of the changes in net income (loss), depreciation and amortization, Louisiana project relocation expenses and charges, asset impairment charges and finance costs, refer to the analysis of our financial results on page 12.

Changes in non-cash working capital increased cash flows from operating activities by $22 million for the year ended December 31, 2012 compared with $36 million for the year ended December 31, 2011. Trade and other receivables increased in 2012 and this decreased cash flows from operating activities by $45 million, primarily due to the impact on customer receivables of a higher average realized methanol price. Inventories decreased primarily due to a lower volume of purchased methanol in ending inventory and this increased cash flows from operating activities by $27 million. Accounts payable and accrued liabilities, including long-term payables increased cash flows from operating activities by $44 million, primarily due to the impact of higher methanol prices on natural gas supply payables.

Adjusted cash flows from operating activities were $403 million for 2012 compared with $392 million for 2011 (refer to theSupplemental Non-GAAP Measures section on page 34 for a reconciliation of cash flows from operating activities to adjusted cash flows from operating activities).

Cash Flows from Financing Activities

During 2012, we increased our regular quarterly dividend by 9% to $0.185 per share, beginning with the dividend payable on June 30, 2012. Total dividend payments in 2012 were $68 million compared with $62 million in 2011.

Also during 2012, we issued two separate tranches of unsecured notes bearing interest rates of 5.25% (effective yield of 5.3%) and 3.25% (effective yield of 3.4%), respectively. The $250 million and $350 million of unsecured notes are due on March 1, 2022 and December 15, 2019, respectively.

During 2012, we repaid $200 million of unsecured notes bearing an interest rate of 8.75% and $51 million of other limited recourse debt. The other limited recourse debt consisted of $34 million of Egypt limited recourse debt facilities, $15 million of Atlas limited recourse debt facilities and $2 million of other limited recourse debt compared with total repayments in 2011 of $50 million. We have entered into interest rate swap contracts to swap the LIBOR-based interest payments on the Egypt limited recourse debt facilities for an average aggregated fixed rate of 4.8% plus a spread on approximately 75% of the Egypt limited recourse debt facilities for the period to March 31,

| | | | |

| | Management’s Discussion & Analysis | | Methanex Corporation | Annual Report 2012 19 |

Management’s Discussion & Analysis

2015 (refer to theFinancial Instruments section on page 23 for more information). The cash settlements associated with these interest rate swap contracts during 2012 and 2011 were included in interest paid of $65 million.

Cash Flows from Investing Activities

During 2012, we reached a final investment decision to proceed with the project to relocate an idle Chile facility to Geismar, Louisiana with an estimated project cost of approximately $550 million. During 2012, we incurred $113 million of expenditures in relation to the project, of which $74 million was capitalized to property, plant and equipment with the remaining amount charged to earnings.

Also during 2012, we incurred a total of $68 million to increase our production capability in New Zealand. We restarted a second Motunui facility in mid-2012 and recently announced our commitment to further increase capacity with the debottleneck of the Motunui site and the restart of the Waitara Valley facility. We also incurred $66 million of costs associated with turnarounds, catalyst and maintenance activities at our other facilities.

We incurred a total of $33 million in 2012 related to our share of oil and gas expenditures in southern Chile. In addition to other exploration blocks in which we are participating, we have an agreement with ENAP to invest in natural gas exploration and development in the Dorado Riquelme exploration block in southern Chile. Under the arrangement, we fund a 50% participation in the block and receive 100% of the natural gas produced in the block.

We also have agreements with GeoPark Chile Limited (GeoPark) under which we have provided $57 million in financing to support and accelerate GeoPark’s natural gas exploration and development activities in southern Chile. During 2012, GeoPark repaid approximately $10 million, bringing cumulative repayments for this financing to $50 million as at December 31, 2012. We have no further obligations to provide funding to GeoPark.

Liquidity and Capitalization

Our objectives in managing liquidity and capital are to provide financial capacity and flexibility to meet our strategic objectives, to provide an adequate return to shareholders commensurate with the level of risk and to return excess cash through a combination of dividends and share repurchases.

The following table provides information on our liquidity and capitalization position as at December 31, 2012 and December 31, 2011:

| | | | | | | | |

| | |

| ($ MILLIONS, EXCEPT WHERE NOTED) | | 2012 | | | 2011 | |

Liquidity: | | | | | | | | |

Cash and cash equivalents | | $ | 746 | | | $ | 351 | |

Undrawn credit facilities | | | 400 | | | | 200 | |

Total liquidity | | | 1,146 | | | | 551 | |

Capitalization: | | | | | | | | |

Unsecured notes | | | 739 | | | | 349 | |

Limited recourse debt facilities, including current portion | | | 506 | | | | 554 | |

Total debt | | | 1,245 | | | | 903 | |

Non-controlling interest | | | 188 | | | | 197 | |

Shareholders’ equity | | | 1,290 | | | | 1,405 | |

Total capitalization | | $ | 2,723 | | | $ | 2,505 | |

Total debt to capitalization1 | | | 46 | % | | | 36 | % |

Net debt to capitalization2 | | | 25 | % | | | 26 | % |

| 1 | Defined as total debt (including 100% of Egypt limited recourse debt facilities) divided by total capitalization. | |

| 2 | Defined as total debt (including 100% of Egypt limited recourse debt facilities) less cash and cash equivalents divided by total capitalization less cash and cash equivalents. | |

We manage our liquidity and capital structure and make adjustments to it in light of changes to economic conditions, the underlying risks inherent in our operations and the capital requirements to maintain and grow our business. The strategies we employ include the issue or repayment of general corporate debt, the issue of project debt, the issue of equity, the payment of dividends and the repurchase of shares.

We are not subject to any statutory capital requirements and have no commitments to sell or otherwise issue common shares except pursuant to outstanding employee stock options.

| | | | |

| 20 Methanex Corporation | Annual Report 2012 | | Management’s Discussion & Analysis | | |

Management’s Discussion & Analysis

We operate in a highly competitive commodity industry and believe that it is appropriate to maintain a conservative balance sheet and retain financial flexibility. At December 31, 2012, we had a strong balance sheet with a cash balance of $746 million, including $36 million relating to the non-controlling interest in Egypt, and a $400 million undrawn credit facility. We invest our cash only in highly rated instruments that have maturities of three months or less to ensure preservation of capital and appropriate liquidity.

At December 31, 2012, our long-term debt obligations included $750 million in unsecured notes ($150 million that matures in 2015, $350 million that matures in 2019 and $250 million that matures in 2022), $450 million related to the Egypt limited recourse debt facilities (100% basis), $50 million related to the Atlas limited recourse debt facilities and $17 million of other limited recourse debt.

We have covenant and default provisions on our long-term debt obligations and we also have certain covenants that could restrict access to the credit facility. The Egypt limited recourse debt facilities contain a covenant to complete by March 31, 2013 certain land title registrations and related mortgages that require action by Egyptian government entities and which we do not expect to complete by March 31, 2013. The Company is seeking a waiver from the lenders. We do not believe the finalization of these items is material to the security provided to the lenders.

At December 31, 2012, management believes the Company was in compliance with all of the covenants and default provisions related to its long-term debt obligations.

Our planned capital maintenance expenditure program directed towards maintenance, turnarounds and catalyst changes for existing operations is currently estimated to total approximately $160 million to the end of 2013, including major refurbishments at some of our plants. In July 2012, we reached a final investment decision to proceed with the project to relocate an idle Chile facility to Geismar, Louisiana with estimated project costs of approximately $550 million. The plant is expected to be operational by the end of 2014 and during 2012 we spent $113 million on the project. We are in the process of debottlenecking the Medicine Hat, Canada and Motunui, New Zealand facilities and restarting the Waitara Valley facility. These projects will result in additional capital expenditures of approximately $100 million by the end of 2013. We believe that we have the financial capacity to fund these growth initiatives with cash on hand, cash generated from operations and the undrawn bank facility.

We believe we are well positioned to meet our financial commitments, invest to grow the Company and continue to deliver on our commitment to return excess cash to shareholders.

Summary of Contractual Obligations and Commercial Commitments

A summary of the estimated amount and estimated timing of cash flows related to our contractual obligations and commercial commitments as at December 31, 2012 is as follows:

| | | | | | | | | | | | | | | | | | | | | | |

| ($ MILLIONS) | | 2013 | | | 2014-2015 | | | 2016-2017 | | | AFTER 2017 | | | | | TOTAL | |

Long-term debt repayments | | $ | 53 | | | $ | 262 | | | $ | 101 | | | $ | 852 | | | | | $ | 1,268 | |

Long-term debt interest obligations | | | 60 | | | | 99 | | | | 66 | | | | 102 | | | | | | 327 | |

Repayments of other long-term liabilities | | | 30 | | | | 110 | | | | 19 | | | | 88 | | | | | | 247 | |

Natural gas and other | | | 263 | | | | 366 | | | | 266 | | | | 1,020 | | | | | | 1,915 | |

Operating lease commitments | | | 124 | | | | 170 | | | | 134 | | | | 281 | | | | | | 709 | |

| | | $ | 530 | | | $ | 1,007 | | | $ | 586 | | | $ | 2,343 | | | | | $ | 4,466 | |

Long-Term Debt Repayments and Interest Obligations

We have $150 million of unsecured notes that mature in 2015, $350 million of unsecured notes that mature in 2019 and $250 million of unsecured notes that mature in 2022. The remaining debt repayments represent the total expected principal repayments relating to the Egypt project debt, our proportionate share of expected principal repayments related to the Atlas limited recourse debt facilities and other limited recourse debt. Interest obligations related to variable interest rate long-term debt were estimated using current interest rates in effect at December 31, 2012. For additional information, refer to note 9 of our 2012 consolidated financial statements.

Repayments of Other Long-Term Liabilities

Repayments of other long-term liabilities represent contractual payment dates or, if the timing is not known, we have estimated the timing of repayment based on management’s expectations.

| | | | |

| | Management’s Discussion & Analysis | | Methanex Corporation | Annual Report 2012 21 |

Management’s Discussion & Analysis

Natural Gas and Other

We have commitments under take-or-pay contracts to purchase natural gas and to pay for transportation capacity related to this natural gas. We also have take-or-pay contracts to purchase oxygen and other feedstock requirements in Trinidad. Take-or-pay means that we are obliged to pay for the supplies regardless of whether we take delivery. Such commitments are common in the methanol industry. These contracts generally provide a quantity that is subject to take-or-pay terms that is lower than the maximum quantity that we are entitled to purchase. The amounts disclosed in the table represent only the minimum take-or-pay quantity.

The natural gas supply contracts for our facilities in New Zealand, Trinidad and Egypt are take-or-pay contracts denominated in United States dollars and include base and variable price components to reduce our commodity price risk exposure. The variable price component of each natural gas contract is adjusted by a formula related to methanol prices above a certain level. We believe this pricing relationship enables these facilities to be competitive at all points in the methanol price cycle and provides gas suppliers with attractive returns. The amounts disclosed in the table for these contracts represent only the base price component.

We have a program in place to purchase natural gas on the Alberta gas market to support the Medicine Hat facility and we believe that the long-term natural gas dynamics in North America will support the long-term operation of this facility. In the above table, we have included natural gas commitments at the contractual volumes and prices.

We also have arrangements with ENAP and GeoPark to accelerate natural gas exploration and development in southern Chile. Under the arrangements, we contribute capital to fund the exploration and development and have contracts to purchase any natural gas discovered. As we cannot determine the amount of natural gas that will be purchased under these agreements in the future, no amounts have been included in the above table.

The above table does not include costs for planned capital maintenance or expansion expenditures or any obligations with original maturities of less than one year.

We have supply contracts that expire between 2017 and 2025 with Argentinean suppliers for natural gas sourced from Argentina for a significant portion of the capacity of our facilities in Chile. We have excluded these potential purchase obligations from the table above. Since June 2007, our natural gas suppliers from Argentina have curtailed all gas supply to our plants in Chile. Under the current circumstances, we do not expect to receive any further natural gas supply from Argentina.

We also have contracts with ENAP to supply natural gas to produce approximately 0.8 million tonnes of methanol at our facilities in Chile. Over the last few years, deliveries from ENAP have been declining and ENAP has delivered significantly less than the full amount of natural gas that it was obligated to deliver under these contracts. We have excluded the potential purchase obligations from the table above.

We have marketing rights for 100% of the production from our jointly owned Atlas and Egypt plants which results in purchase commitments of an additional 1.2 million tonnes per year of methanol offtake supply when these plants operate at capacity. At December 31, 2012, we also have methanol purchase commitments with other suppliers under contracts for approximately 0.5 million tonnes for 2013 and 2.6 million tonnes thereafter. The pricing under these purchase commitments is referenced to pricing at the time of purchase or sale, and accordingly, no amounts have been included in the above table.