Exhibit 99.10

ENVIRONMENTAL SITE ASSESSMENT PHASE I

ARCOTRONICS BAUELEMENTE GmbH

Rudolf-Diesel-Strasse, 21

LANDSBERG AM LECH (GERMANY)

JULY 2007

ECOMAG for BLUE SKYE

ECOMAG Srl | |

Direzione Generale | Sede Legale |

Centro Direzione Colleoni | Viale Vittorio Veneto, 4 |

Palazzo Casslopea 3 | 20124 Milano - Italy |

20041 Agrate Brianza MI - Italy | Capitale Sociale € 10.400.00 i.v. |

Tel. +39 039 6423.1 | R.E.A Milano 1591447 |

Fax +39 039 6892060 | C.F. / Reg. Imprese / P. IVA 12811050157 |

info@ecomag-aa.it | |

Agrate Brianza, | July 2007 |

Project n° | 874 |

| Messrs

BLUE SKYE S.A.R.L.

26, Rue Philippe II

L-2340 LUSSEMBURGO |

For the Attention of: Mr Gianluca D’avanzo

OBJECT: Environmental site assessment phase 1 of the ARCOTRONICS industrial site located in Landsberg am Lech (Germany)

Dear Sirs,

In compliance with Your request, Ecomag, environmental, security and work health company of American Appraisal group, carried out an environmental site assessment phase I.

INDEX

1 EXECUTIVE SUMMARY | 3 |

2 ENVIRONMENTAL ANALYSIS | 4 |

3 DESCRIPTION | 14 |

4 DOCUMENTS | 18 |

5 OBJECTIVES AND LIMITING CONDITIONS | 19 |

6 GENERAL SERVICE CONDITIONS | 20 |

7 CLOSING REMARKS | 23 |

874 – Ecomag for Blue Skye-

July 2007 – Final Report

1

Project Data

Proj. N.: | 874 | |

| | |

Prj Manager: | Chiara Faggioni | |

| | |

Site Visit Technicians: | Claudia Soravia | Ecomag’s party |

| | |

Site Visit Date: | 10th July 2007 | |

| | |

| Dieter Graf | |

Reference persons: | Christian Seelos

Dietmar Zeidler | Arcotronics’s party |

| Inga Mayer | |

Building data

Country: | Germany | |

| | |

Land: | Bayer | |

| | |

City: | Landsberg am Lech - 86899 | |

| | |

Address: | Rudolf-Diesel-Strasse, 21 | |

| | |

Main Use: | Capacitors production | |

| | |

Building typology: | Entire building | Bdg. N. | 1 |

| | | |

Gross Area (SLP): | 7,500 | sqm | |

| | | |

Owner: | Arcotronics Spa | |

2

1 EXECUTIVE SUMMARY

In the next table all costs necessary to achieve the compliance judgement have been identified and subdivided in relation with the following different activities:

· Documents tracing;

· Technical check / In depth analysis;

· Physical adjustment / Management activity.

For each activity, identified costs have been classified as “sure” and/or “potential”:

· Sure costs: related to activities considered to be necessarily carried out. In this case costs have been subdivided into short, medium or long term, according to the urgency of the quoted activity;

· Potential costs: related to activities which could be necessary on the basis of the results coming from the quoted “sure” activity.

3

ENVIRONMENTAL SITE ASSESSMENT PHASE I

EXECUTIVE SUMMARY

COUNTRY | GERMANY | |

TOWN | LANDSBERG AM LECH | |

ADDRESS | Rudolf-Diesel-Strasse, 21 | |

[GRAPHIC] | | ADJUSTMENTS | | SURE COSTS | | POTENTIAL COSTS | |

| | Adjustment typology | | Description | | Short Term

1st year | | Medium Term

2nd-5th year | | Long Term

6th-10th anno | | min | | MAX | |

ENVIRONMENTAL ASSESSMENT PHASE I | | | | | | | | | | | | | | | |

ASBESTOS | | Physical adjustment / Management activity | | [Illegible] | | | | Є 2.000 | | | | | | | |

| | Physical adjustment / Management activity | | [Illegible] | | | | | | | | Є15.000 | | Є20.000 | |

| | | | | | SURE COSTS | | POTENTIAL COSTS | |

| | | | TOTAL AMOUNT | | Short Term

1st year | | Medium Term

2nd-5th year | | Long Term

6th-10th anno | | min | | MAX | |

| | | | | | Є — | | Є 2.000 | | Є — | | Є 15.000 | | Є 20.000 | |

2 ENVIRONMENTAL ANALYSIS

· WATER: COMPLIANT

Water supply

Water supply for sanitary fixtures is granted through drawing from the city supply system. About 1,000 mc are consumed yearly, according to data given by Arcotronics.

Since 2005, groundwater has been drawing in order to guarantee the conditioning of the production halls and of the offices and within a closed cycle to permit the warmth recycling from the three compressors installed to produce compressed air. Groundwater is used within closed systems and can not get in contact with dangerous substances; after use, it is given back to the ground water table through 4 drainage wells, located in the courtyard.

The application for the groundwater drawing was submitted in 2004; the permit was issued to the plot owner (company Assner) on August 2005 by the local authority Landratsamt Landsberg am Lech, in compliance with the German rule WHG (Wasserhaushaltsgesetz) and the regional rule BayWG (Bayer. Wassergesetz); groundwater use is permitted for “thermal scopes” (conditioning of production halls and offices, compressors cooling). The document is valid until December 31st 2025.

In accordance with the permit:

· project plans are available, regularly stamped for approval by the local authority Landratsamt Landsberg am Lech. The company Assner should have submitted a document attesting the well and the related systems were realized exactly as authorized, but this document is not available on the site.

· a booklet is regularly filled in, recording temperatures of the given back water (monthly – the permitted maximal temperature increase is consisting of 4 K) and drawn and given back water volumes (yearly – max. 240,000 cm/year)

Well

|

|

4

Wastewaters

No water is used by the production cycle, therefore no industrial wastewater is produced within the site.

Wastewaters are similar to domestics ones and are discharged within the public sewer system; they are consisting of toilets and of the canteen discharges (about 1,000 m3/year). By the canteen, chilled food is only reheated, so that oily and greases containing wastewaters are not produced. By the compressors house, an oil separator is installed, in compliance with the city regulation about wastewater “Abwassersatzung”.

Rainwater (roof and courtyard) is not collected to the sewer system, but discharged on soil through proper drainage wells.

The plan pertinent to the wastewater sewer net was analysed during the site inspection: drainage wells are quoted, as well as the connection point to the city sewer system, consisting of a single point placed in Robert-Bosch-Strasse.

According to the city regulation about wastewater “Abwassersatzung”, the authorization to discharge wastewaters and rainwater was granted with the approval of the site sewer net project.

Adjustments

None

· AIR EMISSIONS: COMPLIANT

Heating system

During the summer season, hot water for sanitary purposes and to heat the subject property is obtained through warmth recycling from the three air compressors.

During winter, a boiler is used to heat halls and offices and to produce hot water for sanitary purposes. The boiler is fed with oil and has a rated output of 650KW, it was installed in 2006. An agreement is available with the company Pelzl Heizungsbau, in order to warrant the boiler cleaning and the combustion efficiency and fumes tests, in compliance with regulations about boilers maintenance (“Wartungsrichtlinien des Brenner- bzw des Kesselherstellers”).

Boiler

|

|

5

Other air emissions

By the plant used to produce the electric contacts on the capacitors, a dust suction system is installed in order to recycle tin and zinc. The suction system is supplied with proper filters and, according to their informative form, they guarantee a maximal dust emission of 0.5 mg/Nm3. Treated air is then recycled to the plant, in order to reduce energy consumptions. According to German regulations, this kind of plants doesn’t need any authorization.

Dust suction system

|

|

Adjustments

None

· SOIL AND SUBSOIL: COMPLIANT

According to the well stratigraphy, the first 24 meters from the ground level are consisting of sand and pebbles; at lower depths, silt and then marls layers are present. The superficial groundwater table has a depth of about 12 – 13 meters from the ground level. According to available information, the subject property is not located within a “protection area for groundwater (Wasserschutzgebiet)” and is not located within a “flooding area (Ueberschwemmungsgebiet)”.

The whole courtyard, used as parking area and waste containers storage is characterized by waterproof floor (asphalt). Only few decorative green areas are present in front of the building, by the main entrance.

Past contamination

The whole area has a mixed use, characterized by the contemporary presence of commercial and industrial activities and residential buildings; on account of the buildings characteristics, the area was mainly developed in sixties – seventies and subsequent years; before, it was consisting of free fields. According to data received during the site inspection, the subject property was constructed in 1976 by the company Assner. The site has always been used by Arcotronics and before constructing it was raw land. No data about soil and subsoil quality are available, no

6

soil survey through boreholes and lab analyses have never carried out. A certificate from the register of potentially contaminated areas (“Altlastkataster”) is not available. According to available data, no contaminated sites are quoted in proximity of the subject property.

Underground storage tank

An underground storage tank is present, containing oil for the heating system. The tank has a volume of 50m3 and was installed in 1975. It is consisting of steel and is characterized by double walls; its construction observes the prescriptions established by the German norm DIN 6608-2. Last test was carried out by BAP Bayerische Anlageprueforganisation on December 9th 2003; only a defect by the optical alarm (control light) was found and, according from information received during the site visit, it was solved. Next test is scheduled in 2008.

Other potential soil contamination sources

Raw materials are mainly consisting of metals (tin, zinc) and metallized films.

Dangerous substances used within the site are mainly consisting of solvents, such as Methylethylketone, ethanol and diluents. Small quantities of inks are used to stamp the capacitors.

Raw materials and wastes are stored in proper spaces both in closed rooms and outside.

According to our site inspection, they are generally well managed: liquid substances are stored on safety basins and, when outside, under proper coverings.

Moreover, the site has got an environmental management system according to ISO 14001 since 2002 and in the last 5 years no accident has been recorded.

Tins on the proper safety basin

|

|

Tins on the proper safety basin

|

|

7

On account of the described elements, we hold that an in-depth soil survey through boreholes and lab analysis is not necessary at present.

Adjustments

None

· WASTES: COMPLIANT

According to our site visit, wastes are well managed.

Liquid substances are stored on proper safety basins and are mainly placed within a small garage to the south - west side of the subject property or under proper coverings, to avoid the rain washing away.

All recyclable substances (paper and cardboards, plastic, mixed packages, wood, bio wastes) are correctly stored and addresses to recycle, according to available documents.

Wastes bins (subdivided for wastes typology)

|

|

Wastes containers

|

|

8

Following special and dangerous substances are produced:

Waste code | | Waste typology |

070208 | | Other reactions and distilled residuals |

080409 | | Bonding agents and waterproofing rests, which contain solvents |

120111 | | Mud, containing dangerous substances |

110105 | | Acid pickle |

130208 | | Other equipments oils and lubricants |

130502 | | Sludge from the oil separator |

140102

140603 | | Other solvents and solvent mixtures |

150202 | | Filters and cloths contaminated by oils |

160507 | | Used inorganic chemical substances |

160601 | | Lead batteries |

200121 | | Neon lamps |

200301 | | Mixed rest wastes |

For each waste typology, documents are available about the final receiver, the transporters and their authorizations to carry on the activity.

According to the described elements, the situation appears to be compliant.

Adjustments

None

· ASBESTOS CONTAINING MATERIALS: NOT DEFINABLE

Only the following few materials, all characterized by strong bound fibres, have been identified which could contain asbestos:

· Roofing of the compressors house, located to the south-west side of the subject property; plates are about 20 sqm, installed at about 3,5 m height; they are in fair conditions and are not visible from the inside of the compressors house.

|

|

9

· One fibres-cement chimneypot, visible for about 30 cm on the roof

|

|

· About 50 sqm on the whole of old vynil flooring, installed in three offices at the ground floor (year of installation not known)

|

|

· N. 5 old fire protection doors, which have been installed at the end of seventies and which could contain asbestos panels; their external metal coverings are integral and panels, if present, are not visible.

|

|

· Gaskets of flanges by the old air extraction system, located in the toilets (identified about 5 flanges)

|

|

10

Even if the described materials should effectively contain asbestos, according to German regulations about asbestos containing materials (“Asbestrichtlinie”), the urgency class III (necessity of long term surveys, in order to verify materials conditions) is given to materials characterized by strong bound fibres, to fire protection doors and to gaskets. Moreover, the identified materials are not easily accessible, with exception of the vinyl floorings, which however are installed within offices and are subject only to the normal deterioration due to trampling.

Adjustments

No action is necessary in the short term: conditions of the described materials have to be monitored.

Under the hypothesis that described materials contain asbestos, we suggest planning their future removal and disposal, when their conditions should be deteriorated.

· MAN MADE VITREOUS FIBRES: COMPLIANT

Following materials contain man made vitreous fibres, which could be dangerous (breathable), according to German regulation TRGS 905:

· Insulation of the older heating pipelines: the system was renovated in 2006, the largest part of pipelines has be replaced, including the ones installed within the heating room, by the productions hall some older lines are still remaining; they are characterized by plastic coverings in good conditions, no breaks are identifiable.

|

|

· insulation between the metal plates by external walls: according to information received during the site visit, the inner insulation of external walls consists of vitreous fibres. Fibres could be present within inside walls

· insulating mattresses above the false ceiling metal staves; fibres are not visible in any point.

|

|

11

On account of the current regulations, fibres installed during 2006 (insulation of the renovated heating pipelines and of the boiler) are considered to be not dangerous for health.

Adjustments

German regulations do not provide for any actions on man made vitreous fibres; fibres installed before 2000 are considered to be of the “old” dangerous type and have to be handled accordingly.

All maintenance activities have to be limited to necessary actions and employees in charge for maintenance have to be adequately formed and informed.

In case of renovation of the building systems (extraordinary maintenance including removal of insulations), it will be necessary to follow the technical rules TRGS 521 and the law GefStoffV.

· PBC/PCT CONTAINING EQUIPMENTS: COMPLIANT

Not present.

A transformers room is dedicated to the subject property but belonging to the energy supplier company and it was not accessible during the site visit. The pavement around the transformers room is however consisting of asphalt (waterproof).

According to the information given during the site inspection, no PCB containing oil has ever been used within the production cycle. No diathermic oil is used at present.

Adjustments

None

· OZONE DEPLETING SUBSTANCES: COMPLIANT

Conditioning is obtained through groundwater.

Only a split unit is installed by the electronic data archive, using coolant R407c.

A second split unit was used to refresh the manager office but it is no more in use; it was not possible to identify the used coolant, but according to the macroscopic characteristics of the split unit and to the probable installation period, it probably makes use of gas R22.

Adjustments

We suggest to verify the coolant used in the second split unit.

We point out that the use of the gas R22 is currently permitted until 2015. It is not possible to evaluate today the cost of the gas disposal and replace in 8 years.

12

· NOISE EMISSIONS: COMPLIANT

All activities and processes take place within the building, with exception of charge and discharge. This last activity is carried out during the day and we believe it does not increase significantly the traffic in the area, which is characterized by the presence of a lot of commercial and industrial activities.

Building systems (heating systems, compressors) are installed within closed rooms, with exception of the suction system (courtyard), the split units and a refreshing fan (roof), which don’t cause significant noise emissions.

No complaints by neighbours are known.

Adjustments

None

13

3 DESCRIPTION

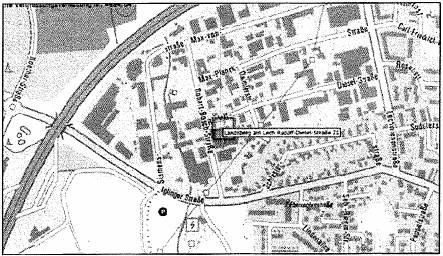

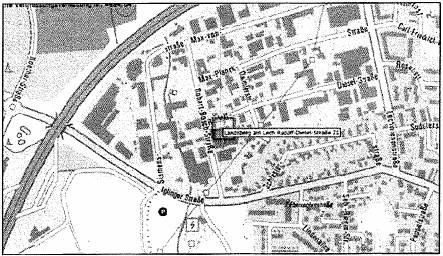

3.1 Zoning

The site is located within a mixed area (grey), characterized by the presence of both industrial and commercial activities and residential buildings.

The site is placed in the northern portion of the city of Landsberg Am Lech; the way out from the motorway E54 is very close.

The pure residential area and the historical centre of the city of Landsberg develop around the river Lech, to the south of the site.

The neighbourhood is characterized by cultivated fields and green areas.

Zoning:

14

3.2 Site description

The site has an extension of about 7,500 sqm; the covered portions extend on about 3,500 sqm.

Free areas are principally used as parking and present an asphalt pavement; few green areas are present by the main entrance, to the north of the site.

The building has a flat roof and is realized partially in concrete masonry and partially with double metal plates.

The building is subdivided between offices and production halls. Offices are located to the northern side, on two aboveground floors; the canteen is placed on the same side. Some offices, technical and services rooms are located on the opposite side, to the south; above them, on the first floor, there are some storage areas and the space for the new air compressor and heat exchangers.

Offices have fitted carpet or a vinyl flooring pavements, fast everywhere there is a false ceiling composed by metal staves. Heating is granted by radiators, while conditioning is granted by fans installed on the ceiling (recently installed, in 2005-06). Production halls are characterized by double height and have an industrial pavement (cement covered by a special resin); heating and refreshing are granted by proper air treatment units.

The compressors house, the small garage used as storage and the tests laboratory are located to the east of the main building; the transformers room, belonging to the electricity supplier company, is placed to the south of the main building.

Heating is produced by the oil boiler in the winter season and by recycling of the warmth produced by the air compressors in the summer seasons. Refreshing is granted by the groundwater.

The building is connected to the city water supply system and to the electricity supplier company.

Roof

|

|

15

Parking area

|

|

Outside view

|

|

Outside view

|

|

16

3.3 Site history

According to data received during the site inspection, the subject property was constructed in 1976 by the company Assner, current owner. The site has always been used by Arcotronics and before constructing it was raw land.

The site has been subject to different renovation activities during years, last one took place in 2005 — 06, with the replacement of the heating boiler and the introduction of the refreshing system thanks to the ground water.

Since 2002, the company has been certified in relation to the environmental management system ISO 14001.

17

4 DOCUMENTS

All the analysed documents have been listed in the next table.

18

ENVIRONMENTAL DOCUMENTS

| TOWN | | Landsberg am Lech | D1STR. | Germany | | |

| ADRESS | | Rudolf-Dieter-Strasse, 21 | | |

ENVIRONMENTAL

Date | | Type of document | | Object | | Attachment | | Notes |

| | | | | | | | |

08/02/2005 | | Permit | | Permit to use the groundwater for thermal scopes | | — | | The permit is valid until December 31st 2025 |

| | | | | | | | |

“- | | Drawing material | | Well stratigrafy | | — | | |

| | | | | | | | |

12/31/2006 | | Tables | | Oil and groundwater consuptions | | — | | |

| | | | | | | | |

“- | | Product informative form | | Product informative form about filters (suction system) | | — | | Dust emissions: 0.25 mg/Nm3 |

| | | | | | | | |

01/01/2007 | | Agreement | | Maintenance agreement with the company PELZL Heizungsbau pertinent to the boiler | | — | | Valid for one year, renewable |

| | | | | | | | |

12/19/2003 | | Test report | | Report about the seal test carried out on the underground storage tank | | — | | |

| | | | | | | | |

06/26/2007 | | Tables | | Wastes management | | — | | |

| | | | | | | | |

07/10/2007 | | Tables | | Process description - articles: W73PW368013JS. R463r415040m1m | | — | | |

| | | | | | | | |

“- | | Plan | | General site plan | | — | | |

5 OBJECTIVES AND LIMITING CONDITIONS

5.1 Objectives of the analysis

Phase I Environmental Due Diligence: inspections and document analyses are carried out in order to verify that present and past activities comply with regulation and also in order to assess their possible environmental impact or contamination, without the execution of sampling, laboratory analysis, or technical tests.

During the inspection, analyses of the following were carried out:

· Sources of water supply;

· Water collection and draining system;

· Atmospheric emissions and the management thereof;

· Storage and management of special and hazardous waste materials;

· Potential sources of contamination of the soil and subsoil;

· Materials potentially containing asbestos (ACM) and the management thereof;

· Materials containing artificial vitreous fibers;

· Systems and equipment that may contain PCB/PCT synthetic oil;

· Materials hazardous to the ozone layer;

· Presence of noise emissions

5.2 Limits of the analysis

ECOMAG has chosen adequate levels and methods of analysis in order to determine the state of the property subject to inspection, with particular attention being paid to environmental liabilities.

All activities deemed appropriate and necessary for the specific circumstances of the analysis have been carried out.

The analysis is based on observing the site, analysing documents available on site or in the data room, and on information obtained from the competent authorities.

During the course of the analysis, any documents obtained that were different from those provided by the Client were not examined.

During the course of the environmental analysis, samples or analyses of materials, soil, and water were not carried out.

Therefore the possibility of additional liabilities that cannot be verified through a visual inspection or through a document analysis should not be excluded.

In cases where the documentation is not considered to be consistent with the dimensions of the property, with the activities carried out, and with the documentation required, in-depth studies aimed at keeping the property in compliance with the applicable regulations are recommended in the Conclusions.

Estimates were not obtained in order to determine the total costs of the works recommended and the costs applied are average values that have been estimated based on our experience with the type of work required.

It is the opinion of ECOMAG that the present or potential liabilities are those outlined in this report and in the relative attachments. However, it is not possible to completely exclude the presence of additional non-compliant situations in certain areas, in addition to those presented.

19

6 GENERAL SERVICE CONDITIONS

6.1 Agreement

The Contract governing this engagement, including these General Service Conditions, represents the entire agreement between ECOMAG and the Client. It supersedes any prior oral or written agreement and may not be altered except by the mutual agreements of all parties thereto.

6.2 Non transferability of Contract and Credit

None of the Parties can transfer the contract to Third Parties, either in whole or in part, without prior written agreement of the other Party, as provided for by art. 1406 c.c, except in the case of conveyance of the firm.

The Client may not delegate Third Parties to make the whole payment of the compensation in favour of ECOMAG, without the written agreement of ECOMAG.

The results of the analysis may be used exclusively by the Client. Only the signed Client may rely on the results of the analysis carried out by ECOMAG.

6.3 Communication

Both parties have the right to communicate information by means of electronic media including e-mail and faxes unless such communication forms are expressly prohibited in the Contract. The Client is expected to communicate and to give information to the Client Service Team assigned by ECOMAG to this engagement. The Client shall not assume nor enlist the Client Service Team assigned by ECOMAG to any work contemplated by the Contract to have knowledge of information provided to others not part of the team.

6.4 Contingent Fees

ECOMAG’s compensation is not contingent in any way upon its opinion or conclusions or upon any subsequent event directly related to those opinions or conclusions.

The Client shall pay ECOMAG’s invoices in accordance with their stated terms.

6.5 Confidentiality

ECOMAG is obligated to maintain the confidentiality of the Client’s confidential information with the same degree of care that ECOMAG uses to keep its own materials confidential and shall not disclose it to anyone or use it for any purpose whatsoever other than the Client’s engagement except in the event that ECOMAG is legally compelled to disclose such information. Should this situation arise, ECOMAG shall provide the Client with prompt written notice so that the Client may seek a protective remedy, if available.

ECOMAG is obligated to comply with the regulations included in the new code with regards to the protection of personal information (Legislative Decree n. 196 dated 30 June 2003).

ECOMAG shall have the right to provide access to work files as required to comply with any quality or compliance audits administered by any necessary accreditation or standards organization with which its employees are associated. Any such access shall continue to be subject to the same confidence by both ECOMAG and the applicable organization.

Information shall not be treated as confidential if:

i) It is now or later becomes available to the public;

ii) At the time of disclosure to ECOMAG, the information was already in its possession;

iii) The information was obtained from a Third Party under no obligation of confidentiality to the Client.

ECOMAG shall have the right to include the Client’s name in its client list.

Possession of this report or any copy thereof does not carry with it the right of publication. No portion of this report shall be disseminated to Third Parties through prospectus, advertising, public relations, news, or any other means of communication without the written consent and approval of ECOMAG.

20

6.6 Force Majeure

Neither the Client nor ECOMAG shall be liable for delays or for failures to perform according to the terms of the Contract due to circumstances that are beyond their individual control.

6.7 Governing Law, Jurisdiction and Venue

This Contract shall be governed exclusively by the Italian Law.

Any disputes regarding these agreements will be handled exclusively by the Italian Judge and will fall within the territorial jurisdiction of the Court of Milan.

6.8 Indemnification

The Client shall indemnify and compensate ECOMAG for any and all losses, claims, actions, damages, expenses, or liabilities, including reasonable attorney fees, to which ECOMAG may become subjected in connection with this engagement, except for those judicially determined to have resulted from the negligence or intentional misconduct of ECOMAG.

ECOMAG shall indemnify and compensate the Client for any and all losses, claims, or expenses for bodily injury or property damage, in proportion to that which is caused by ECOMAG personnel or representatives during the performance of the engagement, except to the extent of the Client’s negligence.

ECOMAG’s liability to the Client shall in no event exceed the fees it receives as a result of the engagement, except to the extent determined to have resulted from the negligence or intentional misconduct of ECOMAG.

While on the Client’s premises, the personnel assigned by ECOMAG to any work contemplated by the Contract shall comply with all posted safety instructions or safety procedures requested by the Client.

6.9 Independent Contractors

ECOMAG and the Client shall operate as independent contractors with respect to each other. ECOMAG reserves the right to use subcontractors in executing the engagement. ECOMAG is an equal opportunity employer.

6.10 Matters Legal in Nature

ECOMAG has not carried out any investigation regarding the title of or any liabilities against the property appraised, nor has any examination been executed regarding cadastral, zoning, building, system, environmental, or safety characteristics though the analysis of documentation other than that supplied by the Client. ECOMAG has not obtained information and/or documents from public bodies, technical offices, or document archives, unless otherwise specified in the contract. Unless otherwise stated in the contract, ECOMAG has assumed that the owner’s claim is valid, the property rights are exercisable and transferable, and that there are no encumbrances that cannot be cleared through normal processes.

6.11 Reliance on Information Provided by the Client

ECOMAG is entitled to rely without independent verification on the accuracy and completeness of all of the information provided by the Client or its advisors upon which ECOMAG will base its conclusions, or which is simply cited in the report.

Although obtained from sources believed to be reliable, ECOMAG does not make any guarantee nor assume any responsibility regarding the truth or accuracy of any data, opinions, or estimates provided by others, unless the verification of such information is expressly stated.

6.12 Retention

Unless stipulated to the contrary in this proposal or in a subsequent written agreement, ECOMAG retains all files, documents, work papers, and other results, acquired during the course of the engagement as its property. Such materials will be retained for a maximum period of 5 years.

21

6.13 Standard of Performance

ECOMAG shall carry out the engagement in accordance with applicable professional standards. However, professional services usually involve judgements made in uncertain environments and based on an analysis of data that may be unverified or subject to change over time.

6.14 Limits of the Engagement

ECOMAG is only obligated to observe the conditions and speculations of the Contract regarding services specifically identified in the Contract itself and in any subsequent written agreements related to the adjustment of such services. Therefore this engagement is not applicable to any services that are not correlated, nor does it include the responsibility to update any work carried out once it has been completed.

Furthermore, ECOMAG reserves the right to refuse the provision of any additional services in any situation where it is deemed that such services may create a real or perceived conflict of interest, or in any situation where such activity may be illegal or in violation of applicable regulations or professional standards.

Should you find the parameters outlined above acceptable, we request that you send us a copy of the enclosed letter of acceptance dutifully filled out in its entirety and signed in accordance with art. 1341 and 1342 c.c.

22

7 CLOSING REMARKS

The present work was managed by Claudia Soravia under the check of Chiara Faggioni and performed by ECOMAG staff:

· Mr Ermanno Pievani

· Mrs Chiara Faggioni

· Mrs Claudia Soravia

· Mr Paolo Foi

· Mr Michelangelo Longo

ECOMAG has carried out the present engagement as an environmental consultant, and is certain that the information contained in this report is in live with the expectations of any future beneficiaries.

For any clarifications or additional information, we ask that you please feel free to contact ECOMAG at your convenience.

Best Regards,

Agrate Brianza

ECOMAG – Environmental Management

| /s/ Ermanno Pievani | | | | | /s/ Chiara Faggioni | | |

| Ermanno Pievani | | | | | Chiara Faggioni | | |

| Technical Manager | | | | | Engagement Manager | | |

23