Investor & Analyst Day Presentation November 18, 2013 A Premier Supplier of Aircraft Structure NYSE MKT: CVU

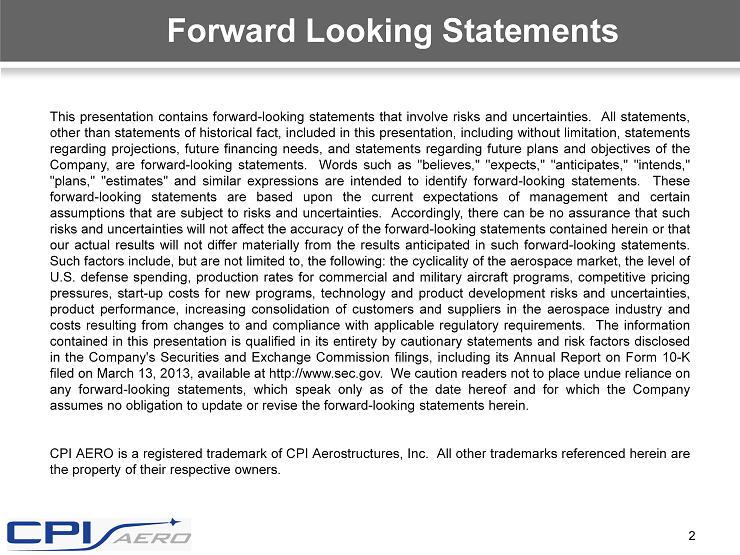

Forward Looking Statements 2 This presentation contains forward - looking statements that involve risks and uncertainties . All statements, other than statements of historical fact, included in this presentation, including without limitation, statements regarding projections, future financing needs, and statements regarding future plans and objectives of the Company, are forward - looking statements . Words such as "believes," "expects," "anticipates," "intends," "plans," "estimates" and similar expressions are intended to identify forward - looking statements . These forward - looking statements are based upon the current expectations of management and certain assumptions that are subject to risks and uncertainties . Accordingly, there can be no assurance that such risks and uncertainties will not affect the accuracy of the forward - looking statements contained herein or that our actual results will not differ materially from the results anticipated in such forward - looking statements . Such factors include, but are not limited to, the following : the cyclicality of the aerospace market, the level of U . S . defense spending, production rates for commercial and military aircraft programs, competitive pricing pressures, start - up costs for new programs, technology and product development risks and uncertainties, product performance, increasing consolidation of customers and suppliers in the aerospace industry and costs resulting from changes to and compliance with applicable regulatory requirements . The information contained in this presentation is qualified in its entirety by cautionary statements and risk factors disclosed in the Company's Securities and Exchange Commission filings, including its Annual Report on Form 10 - K filed on March 13 , 2013 , available at http : //www . sec . gov . We caution readers not to place undue reliance on any forward - looking statements, which speak only as of the date hereof and for which the Company assumes no obligation to update or revise the forward - looking statements herein . CPI AERO is a registered trademark of CPI Aerostructures, Inc . All other trademarks referenced herein are the property of their respective owners .

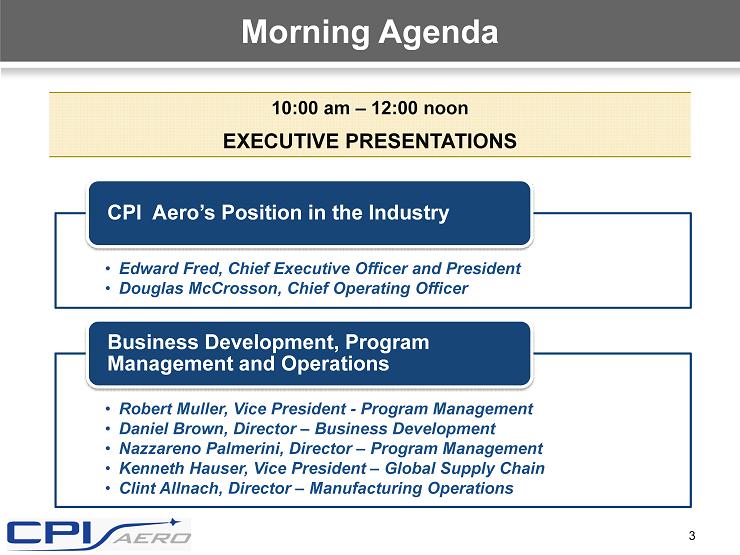

Morning Agenda 10:00 am – 12:00 noon EXECUTIVE PRESENTATIONS 3 • Edward Fred, Chief Executive Officer and President • Douglas McCrosson, Chief Operating Officer CPI Aero’s Position in the Industry • Robert Muller, Vice President - Program Management • Daniel Brown, Director – Business Development • Nazzareno Palmerini, Director – Program Management • Kenneth Hauser, Vice President – Global Supply Chain • Clint Allnach, Director – Manufacturing Operations Business Development, Program Management and Operations

Welcome Remarks Eric Rosenfeld Chairman of Board of Directors Eric S . Rosenfeld has been the non - executive chairman of our BoD since January 2005 and a director and chairman of our strategic planning committee since April 2003 . Mr . Rosenfeld has been the President and CEO of Crescendo Partners, L . P . , a New York based investment firm, since its formation in November 1998 . Prior to forming Crescendo Partners, he held the position of Managing Director at CIBC Oppenheimer and its predecessor company Oppenheimer & Co . , Inc . for 14 years . Mr . Rosenfeld currently serves as a director for several companies, including Cott Corporation (Lead Independent Director), the world’s largest retailer - brand soft drink company, Absolute Software Corporation, a leader in firmware - embedded endpoint security and management for computers and ultraportable devices, Primoris Services Corporation, a specialty construction company and SAExploration Holdings, Inc . Mr . Rosenfeld has also served as a director for numerous companies, including Arpeggio Acquisition Corp . and Rhapsody Acquisition Corp . , both blank check corporations that later merged with Hill International and Primoris Services Corp . respectively, Sierra Systems Group Inc . , an information technology, management consulting and systems integration firm, Emergis Inc . , an electronic commerce company and Geac Computer Corp . Limited, a provider of business - critical software applications and systems . He has also been a board member at Hill International, a construction management firm, Matrikon Inc . , a company that provides industrial intelligence solutions, and DALSA Corp . , a digital imaging and semiconductor firm . Mr . Rosenfeld provides our board of directors with expertise in finance and financial markets and with experience derived from his service on the boards of other public and private companies . 4

CPI Aero’s Position in the Industry Speakers Douglas McCrosson Chief Operating Officer Edward Fred Chief Executive Officer & President 5

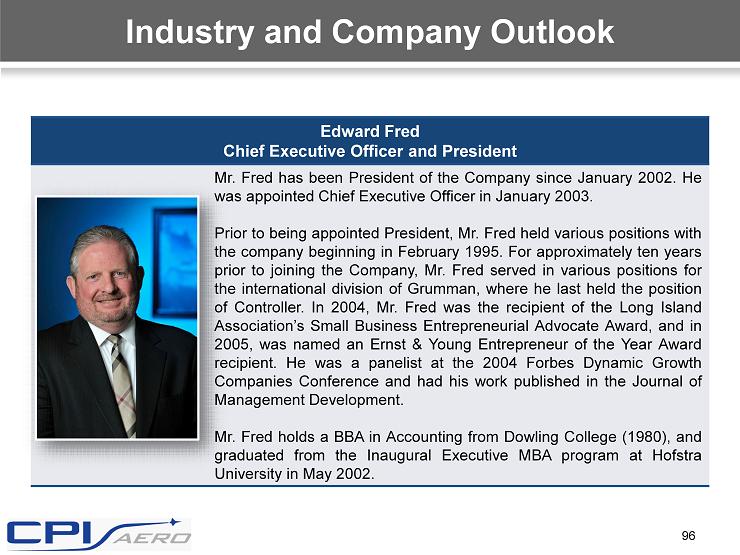

Edward Fred Chief Executive Officer and President Mr . Fred has been President of the Company since January 2002 . He was appointed Chief Executive Officer in January 2003 . Prior to being appointed President, Mr . Fred held various positions with the company beginning in February 1995 . For approximately ten years prior to joining the Company, Mr . Fred served in various positions for the international division of Grumman, where he last held the position of Controller . In 2004 , Mr . Fred was the recipient of the Long Island Association’s Small Business Entrepreneurial Advocate Award, and in 2005 , was named an Ernst & Young Entrepreneur of the Year Award recipient . He was a panelist at the 2004 Forbes Dynamic Growth Companies Conference and had his work published in the Journal of Management Development . Mr . Fred holds a BBA in Accounting from Dowling College ( 1980 ), and graduated from the Inaugural Executive MBA program at Hofstra University in May 2002 . 6 CPI Aero’s Position in the Industry

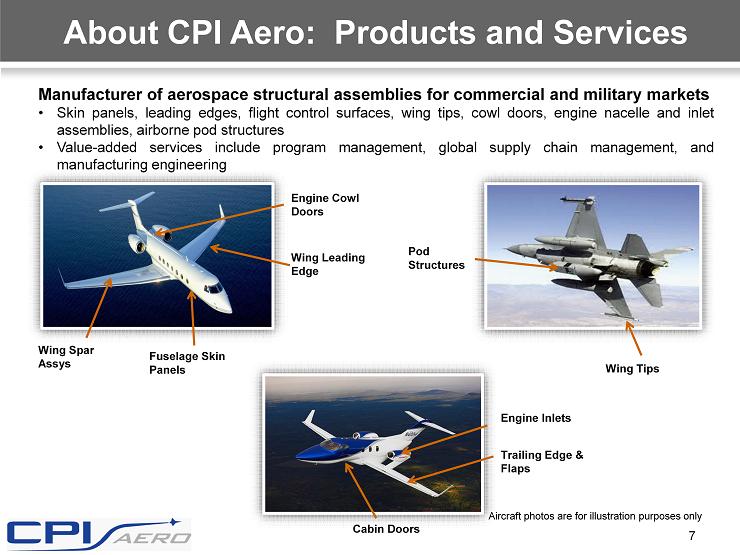

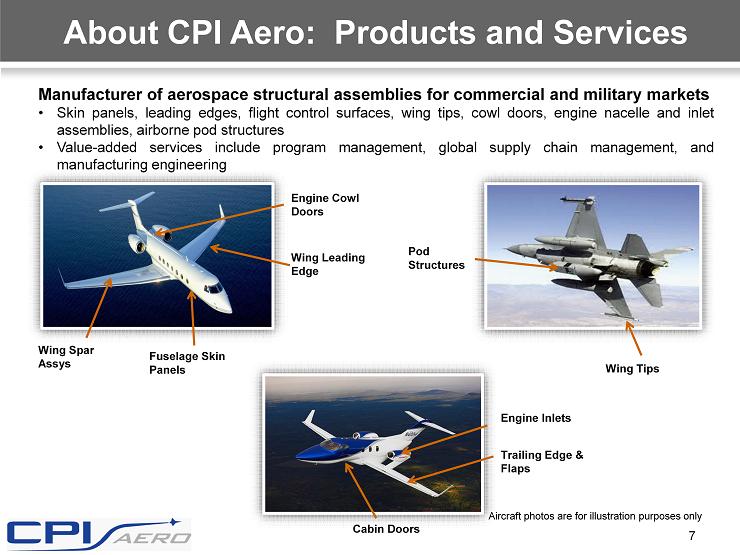

About CPI Aero: Products and Services Manufacturer of aerospace structural assemblies for commercial and military markets • Skin panels, leading edges, flight control surfaces, wing tips, cowl doors, engine nacelle and inlet assemblies, airborne pod structures • Value - added services include program management, global supply chain management, and manufacturing engineering 7 Fuselage Skin Panels Wing Spar Assys Pod Structures Wing Tips Engine Inlets Trailing Edge & Flaps Engine Cowl Doors Cabin Doors Wing Leading Edge Aircraft photos are for illustration purposes only

CPI Aero’s 171,000 Sq. Ft. Facility 8

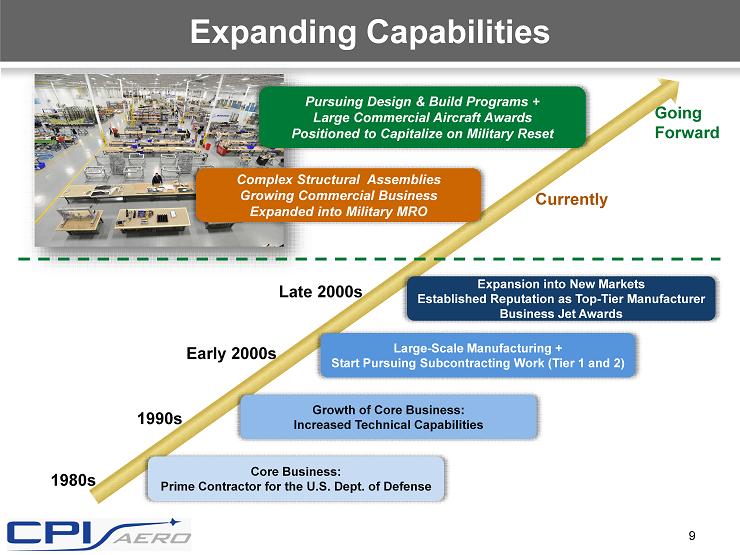

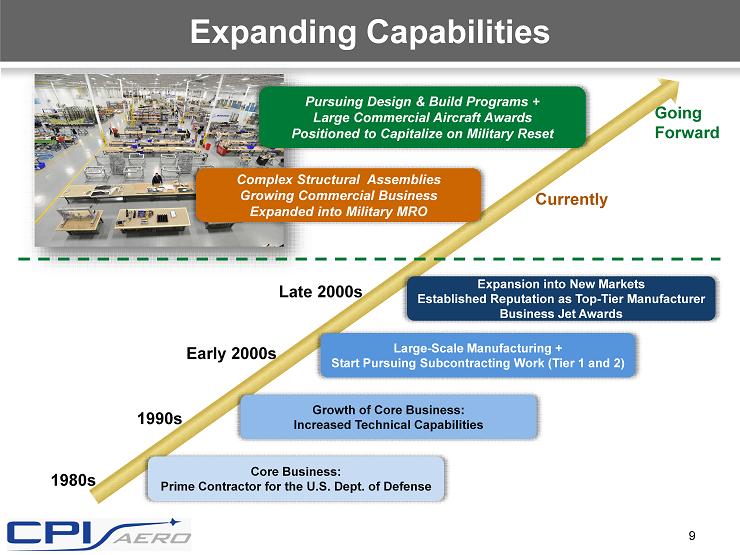

Expanding Capabilities 1980s 1990s Early 2000s Late 2000s Currently Going Forward Core Business: Prime Contractor for the U.S. Dept. of Defense Growth of Core Business: Increased Technical Capabilities Large - Scale Manufacturing + Start Pursuing Subcontracting Work (Tier 1 and 2) Expansion into New Markets Established Reputation as Top - Tier Manufacturer Business Jet Awards Complex Structural Assemblies Growing Commercial Business Expanded into Military MRO Pursuing Design & Build Programs + Large Commercial Aircraft Awards Positioned to Capitalize on Military Reset 9

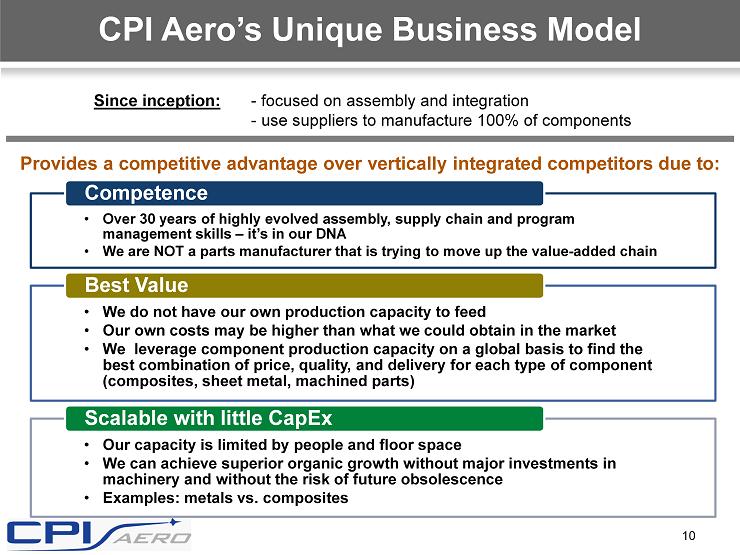

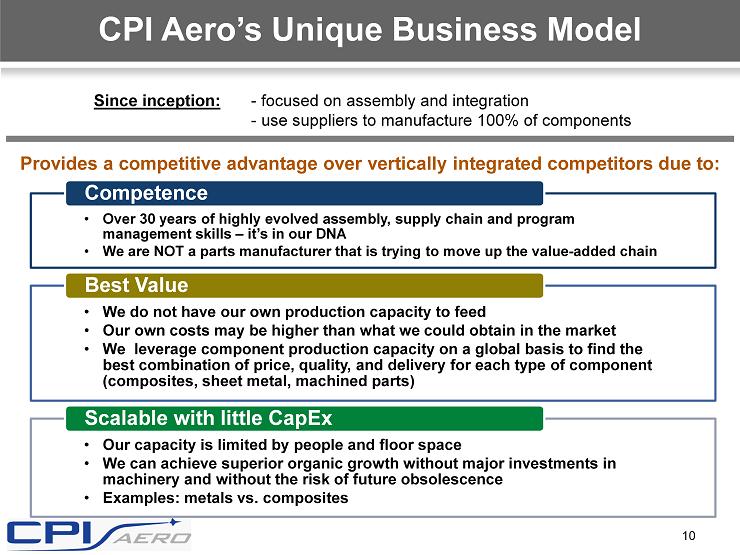

CPI Aero’s Unique Business Model Since inception: - focused on assembly and integration - use suppliers to manufacture 100% of components Provides a competitive advantage over vertically integrated competitors due to: • Over 30 years of highly evolved assembly, supply chain and program management skills – it’s in our DNA • We are NOT a parts manufacturer that is trying to move up the value - added chain Competence • We do not have our own production capacity to feed • Our own costs may be higher than what we could obtain in the market • We leverage component production capacity on a global basis to find the best combination of price, quality, and delivery for each type of component (composites, sheet metal, machined parts) Best Value • Our capacity is limited by people and floor space • We can achieve superior organic growth without major investments in machinery and without the risk of future obsolescence • Examples: metals vs. composites Scalable with little CapEx 10

Douglas McCrosson Chief Operating Officer Mr . McCrosson joined CPI Aero in May 2003 as Director of Business Development . He was promoted to : Vice President of Business Development in January 2006 ; Vice President of Operations in January 2007 ; Senior Vice President of Operations (heading CPI Aero’s Business Development, Engineering, Procurement and Manufacturing organizations) in January 2008 ; and once again to Chief Operating Officer in January 2010 . Prior to joining CPI Aero, Mr . McCrosson was Corporate Secretary and Vice President of Frisby Technologies, Inc . and earlier, he was employed by Frisby Aerospace, Inc . in various engineering and marketing positions . He started his career as a mechanical engineer at Grumman Corporation . Mr . McCrosson holds a Bachelor of Science degree in mechanical engineering from the State University of New York at Buffalo and a Master of Science degree in Management from Polytechnic University . 11 CPI Aero’s Position in the Industry

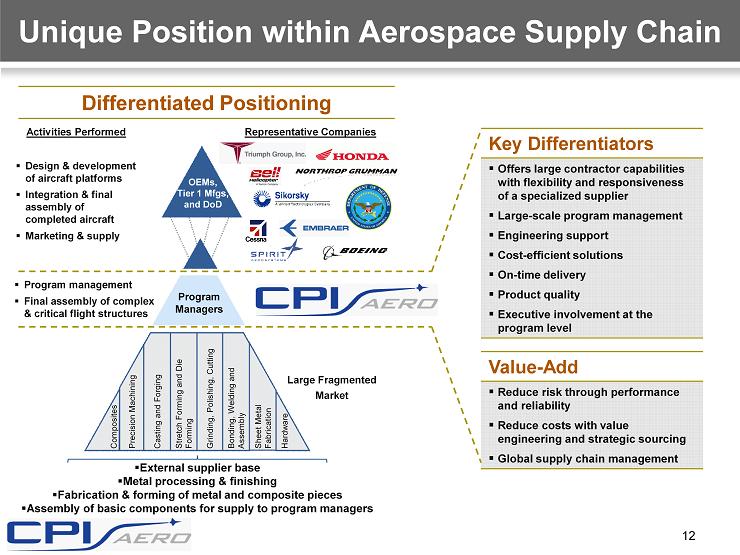

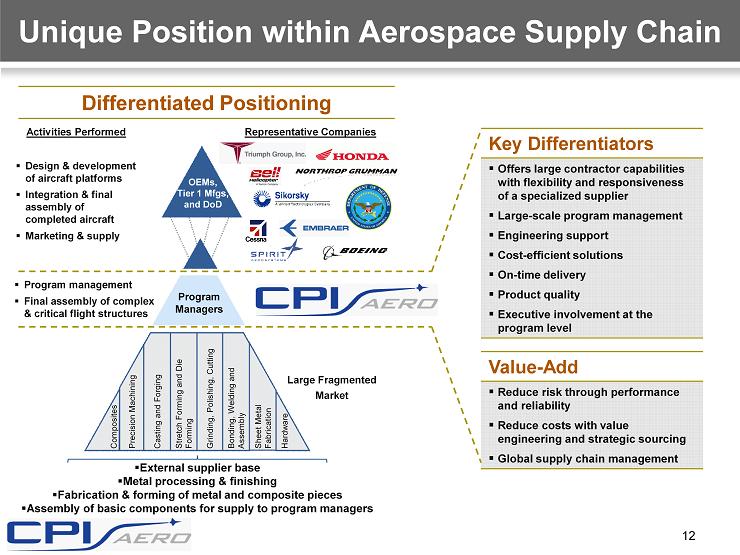

Unique Position within Aerospace Supply Chain Activities Performed Representative Companies ▪ Design & development of aircraft platforms ▪ Integration & final assembly of completed aircraft ▪ Marketing & supply ▪ Program management ▪ Final assembly of complex & critical flight structures ▪ External supplier base ▪ Metal processing & finishing ▪ Fabrication & forming of metal and composite pieces ▪ Assembly of basic components for supply to program managers Composites Precision Machining Casting and Forging Stretch Forming and Die Forming Grinding, Polishing, Cutting Bonding, Welding and Assembly Sheet Metal Fabrication Hardware Large Fragmented Market Program Managers OEMs, Tier 1 Mfgs, and DoD Key Differentiators ▪ Offers large contractor capabilities with flexibility and responsiveness of a specialized supplier ▪ Large - scale program management ▪ Engineering support ▪ Cost - efficient solutions ▪ On - time delivery ▪ Product quality ▪ Executive involvement at the program level Value - Add ▪ Reduce risk through performance and reliability ▪ Reduce costs with value engineering and strategic sourcing ▪ Global supply chain management Differentiated Positioning 12

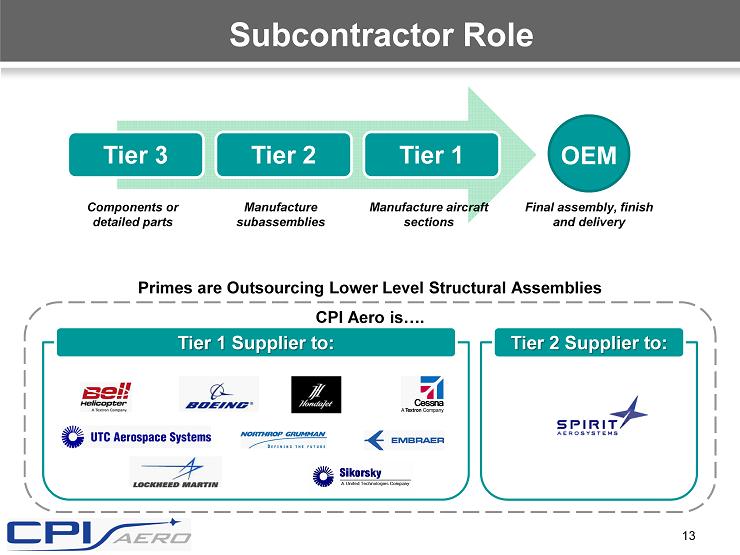

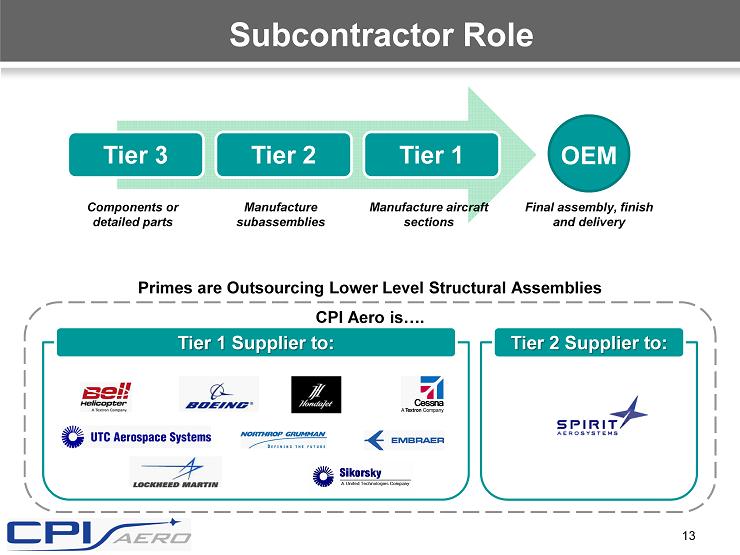

Subcontractor Role Primes are Outsourcing Lower Level Structural Assemblies CPI Aero is…. 13 Tier 3 Tier 1 Tier 2 OEM Components or detailed parts Manufacture subassemblies Manufacture aircraft sections Final assembly, finish and delivery Tier 1 Supplier to: Tier 2 Supplier to:

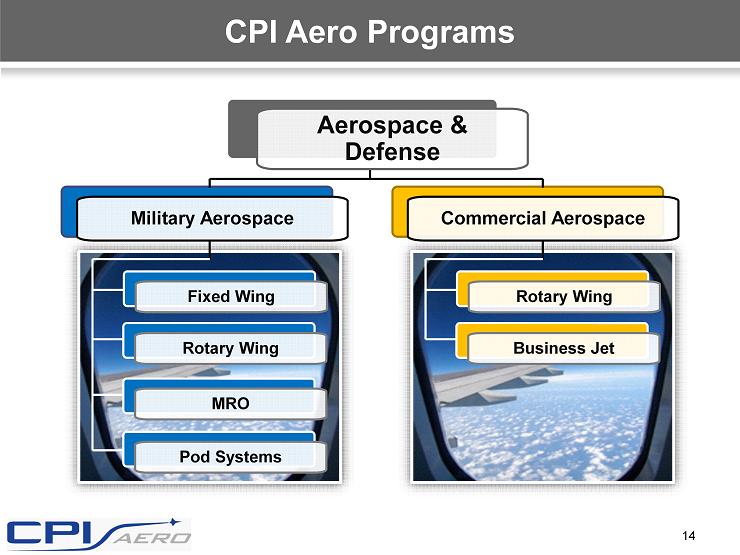

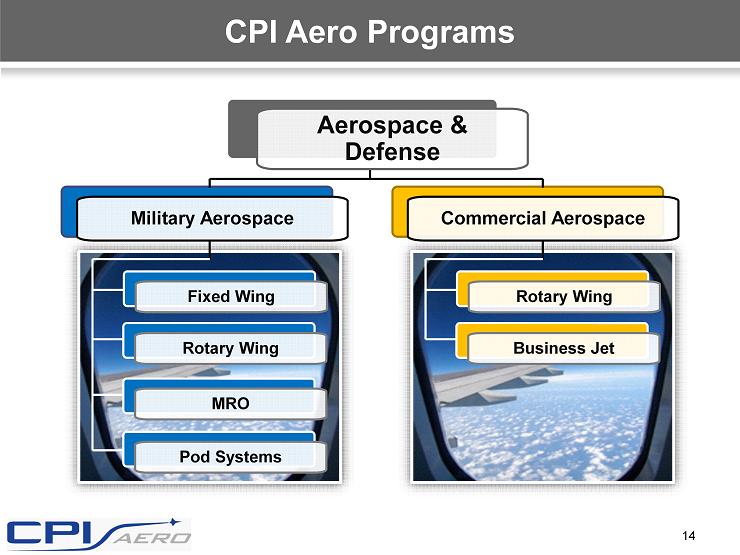

CPI Aero Programs Aerospace & Defense Military Aerospace Commercial Aerospace Fixed Wing Rotary Wing MRO Pod Systems Rotary Wing Business Jet 14

CPI Aero Programs End Markets Military Aerospace Commercial Aerospace In - Production Aircraft Spares/OOP Service Life Extension MRO Off - shore Energy Exploration & Support Search & Rescue 15 Intelligence, Surveillance & Reconnaissance (ISR) VIP Transport Corporate Travel Foreign Military Sales

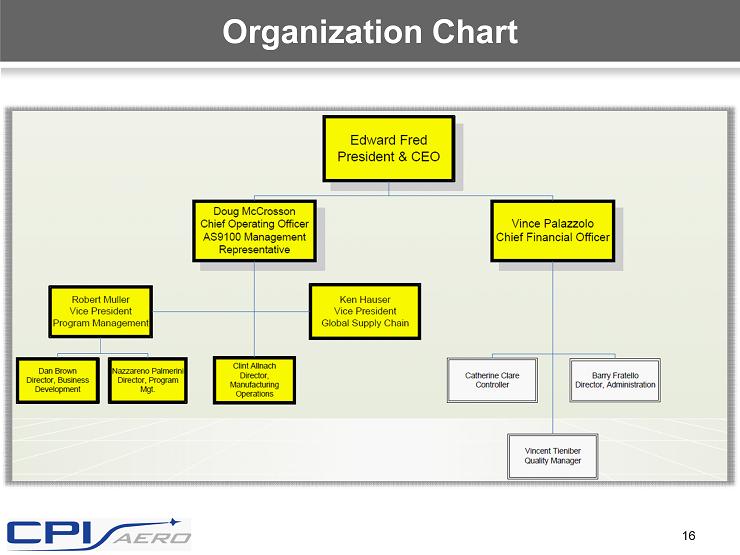

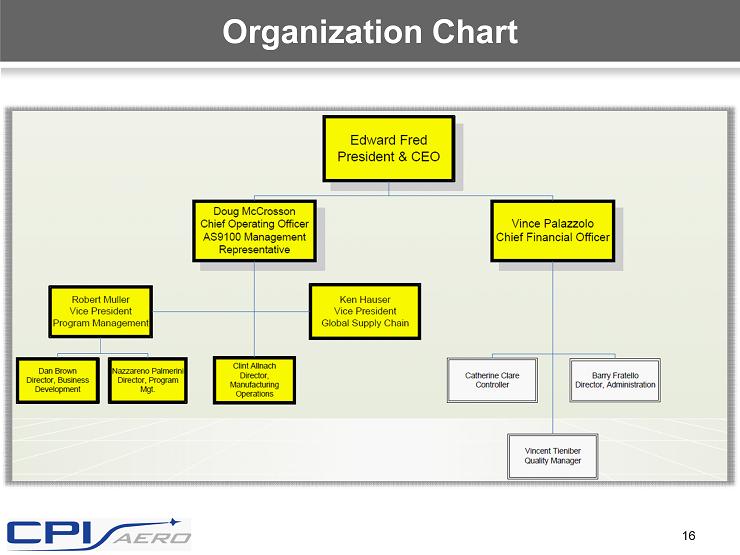

Organization Chart 16

Presentations by… Business Development, Program Management & Operations 17 Clint Allnach Director, Manufacturing Operations Nazzareno Palmerini Director, Program Management Daniel Brown Director, Business Development Robert Muller VP, Program Management Kenneth Hauser VP, Global Supply Chain

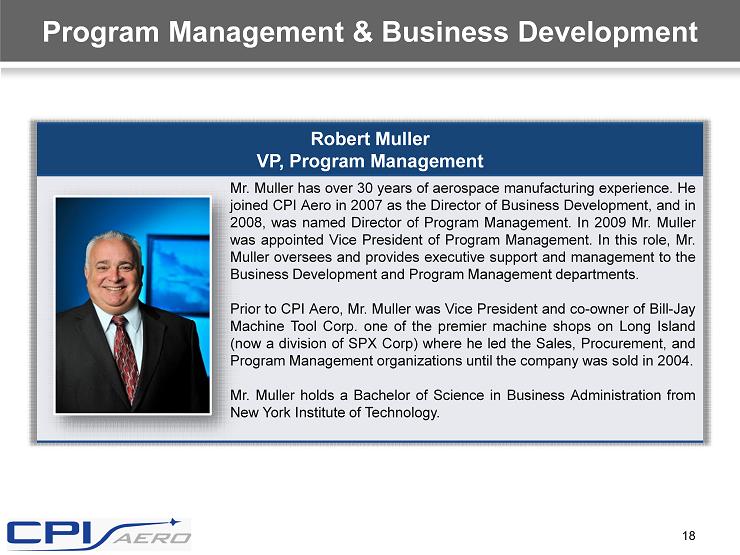

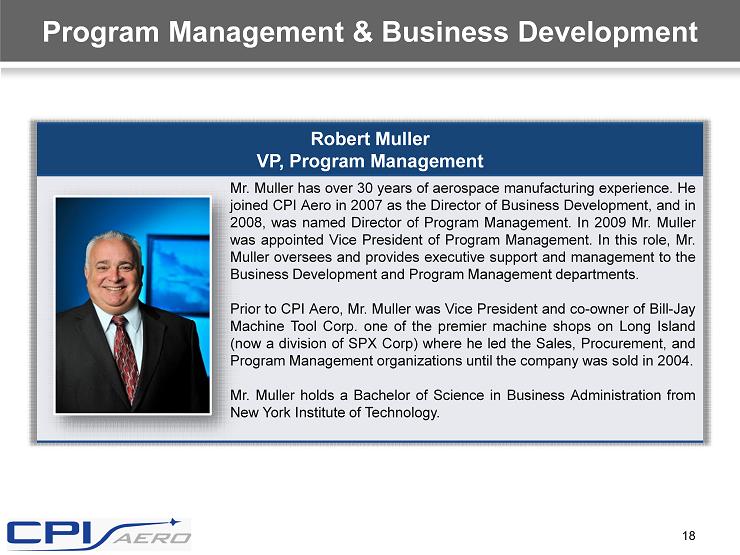

Robert Muller VP, Program Management Mr . Muller has over 30 years of aerospace manufacturing experience . He joined CPI Aero in 2007 as the Director of Business Development, and in 2008 , was named Director of Program Management . In 2009 Mr . Muller was appointed Vice President of Program Management . In this role, Mr . Muller oversees and provides executive support and management to the Business Development and Program Management departments . Prior to CPI Aero, Mr . Muller was Vice President and co - owner of Bill - Jay Machine Tool Corp . one of the premier machine shops on Long Island (now a division of SPX Corp) where he led the Sales, Procurement, and Program Management organizations until the company was sold in 2004 . Mr . Muller holds a Bachelor of Science in Business Administration from New York Institute of Technology . Program Management & Business Development 18

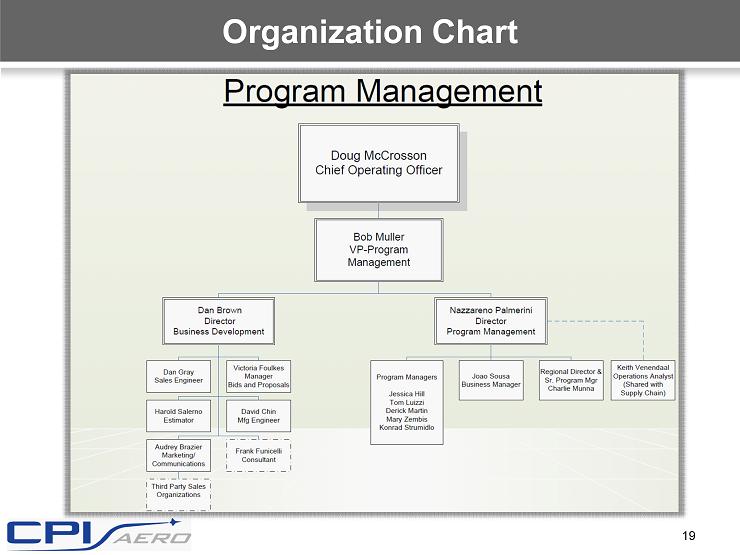

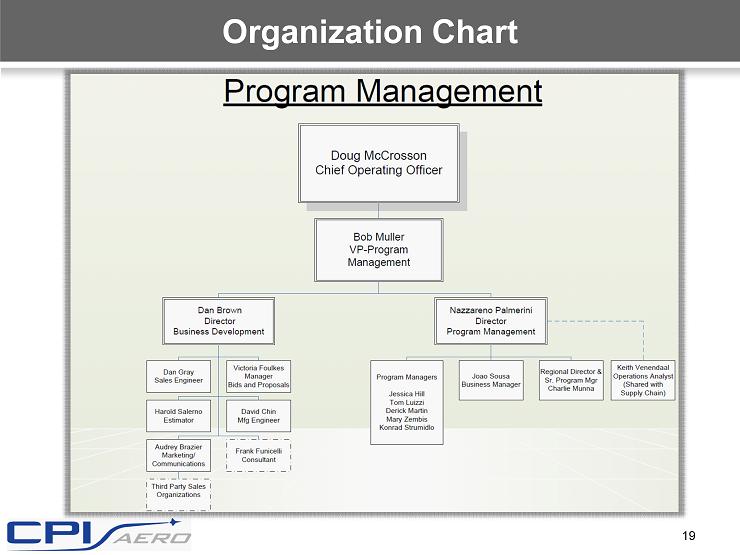

Organization Chart 19

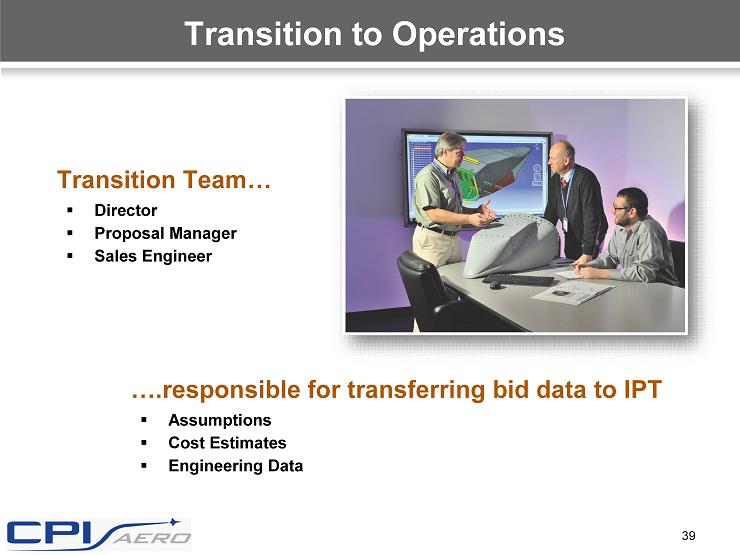

Business Development and Program Management Overview Business Development • Focus on : • Developing new customers • Developing new product/service offerings Program Management • Focus on : • Maintaining a high level of customer satisfaction • Expanding business base with current customers Transitioning Opportunities into Programs • Transition Team • Director, Proposal Manager, Sales Engineer • Responsible for transferring bid data to IPT • Assumptions • Cost Estimates • Supply Chain/Sourcing Strategy • Engineering Data 20

Daniel Brown Director, Business Development Mr . Brown joined CPI Aero in 2010 as Manager of Business Development . In 2013 , he was appointed Director of Business Development . Mr . Brown has had a successful career in business development, serving in various management roles for several companies in the United Kingdom, such as Cobham Group, BMT Reliability Consultants, Qualmark Corporation, and Dalkia Utilities Services . Additionally, Mr . Brown served as a Captain in the British Army where he provided engineering support to the Army . Mr . Brown holds a Bachelor of Engineering from Leeds University . Business Development Overview 21

Business Development Organization Chart 22

Business Development 23 I Business Development Organization/Resources II III IV Market Overview and Strategy Business Development Process Transition of Won Programs to Operations

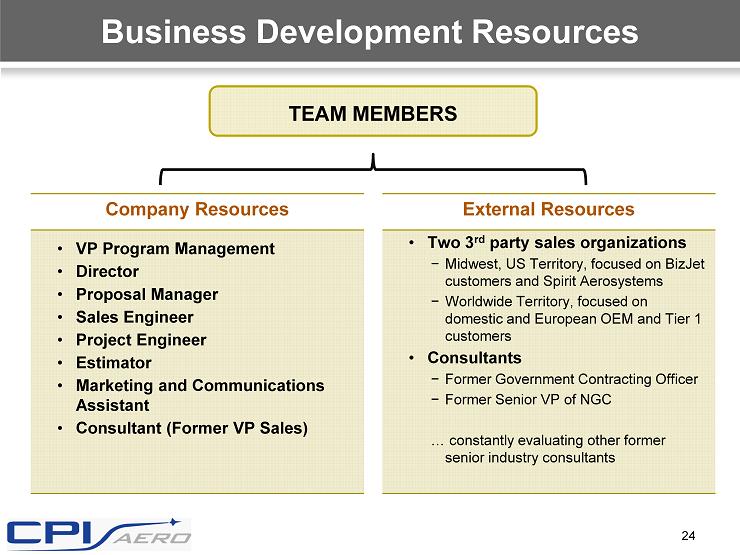

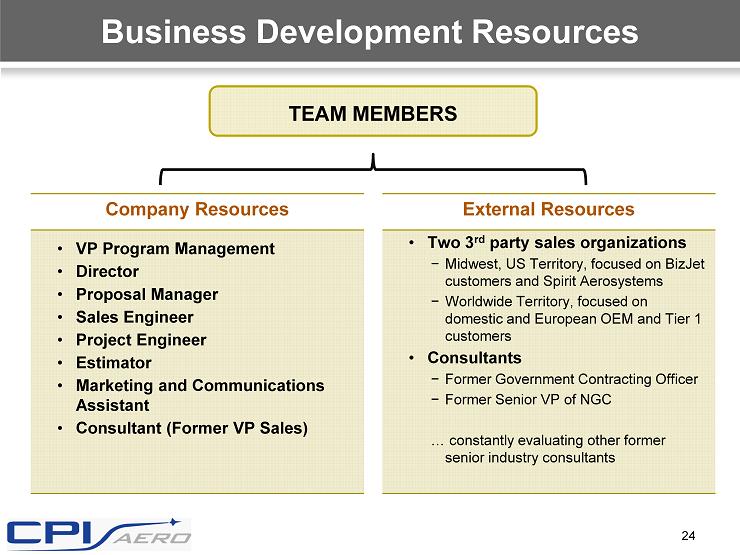

Company Resources External Resources Business Development Resources • VP Program Management • Director • Proposal Manager • Sales Engineer • Project Engineer • Estimator • Marketing and Communications Assistant • Consultant (Former VP Sales) 24 • Two 3 rd party sales organizations − Midwest, US Territory, focused on BizJet customers and Spirit Aerosystems − Worldwide Territory, focused on domestic and European OEM and Tier 1 customers • Consultants − Former Government Contracting Officer − Former Senior VP of NGC … constantly evaluating other former senior industry consultants TEAM MEMBERS

Business Development Strategy 25 Focus on: Marketing Strategy: • Developing new opportunities with new customers • Developing new product / service offerings • Military – Tier 1 • Military – Prime • Commercial: Tier 1 or Tier 2

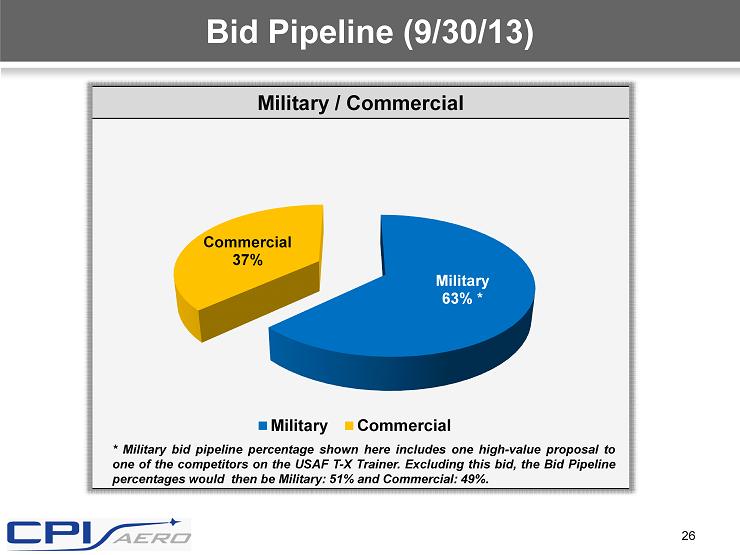

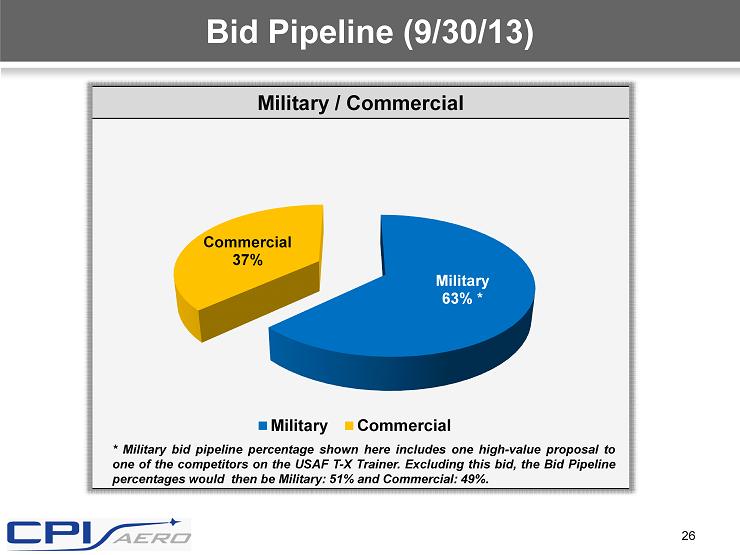

Bid Pipeline (9/30/13) 26 Military / Commercial Military 63 % * Commercial 37% Military Commercial * Military bid pipeline percentage shown here includes one high - value proposal to one of the competitors on the USAF T - X Trainer . Excluding this bid, the Bid Pipeline percentages would then be Military : 51 % and Commercial : 49 % .

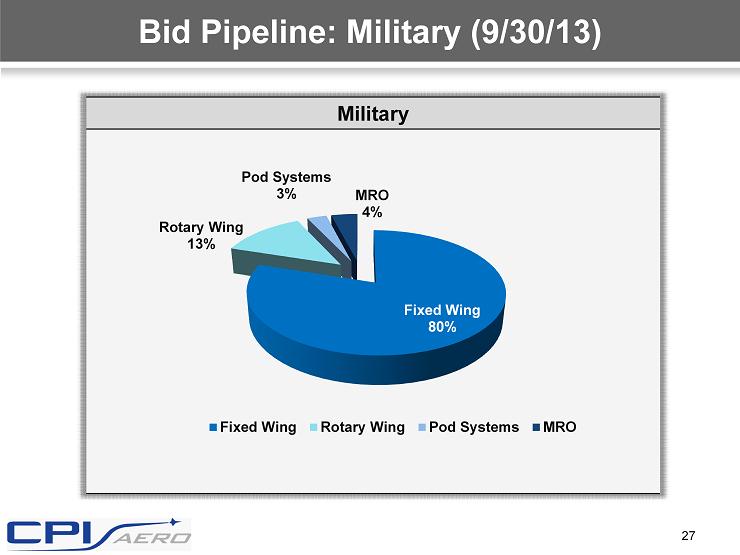

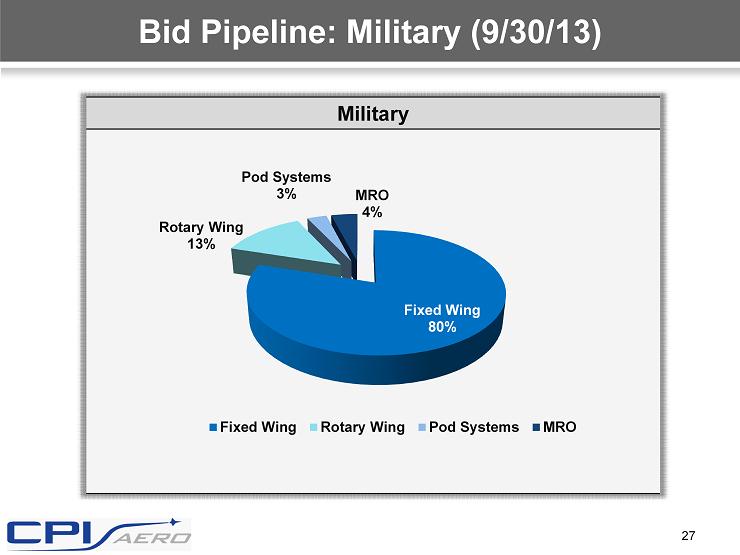

Military Bid Pipeline: Military (9/30/13) 27 Fixed Wing 80% Rotary Wing 13% Pod Systems 3 % MRO 4 % Fixed Wing Rotary Wing Pod Systems MRO

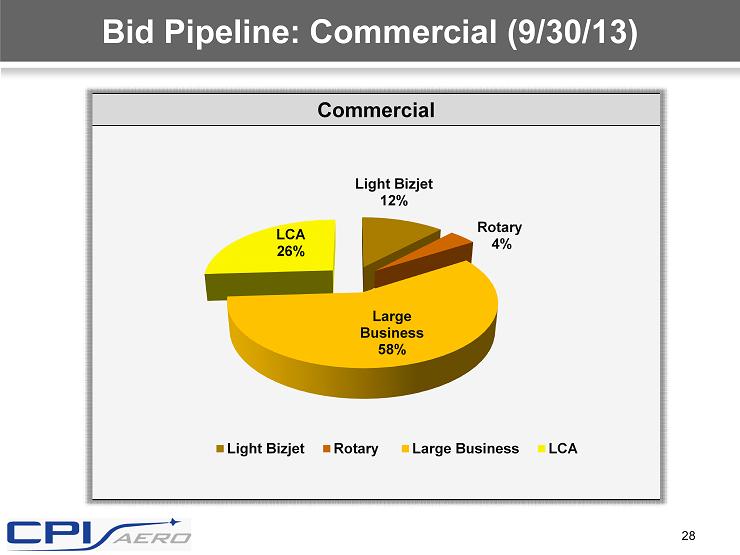

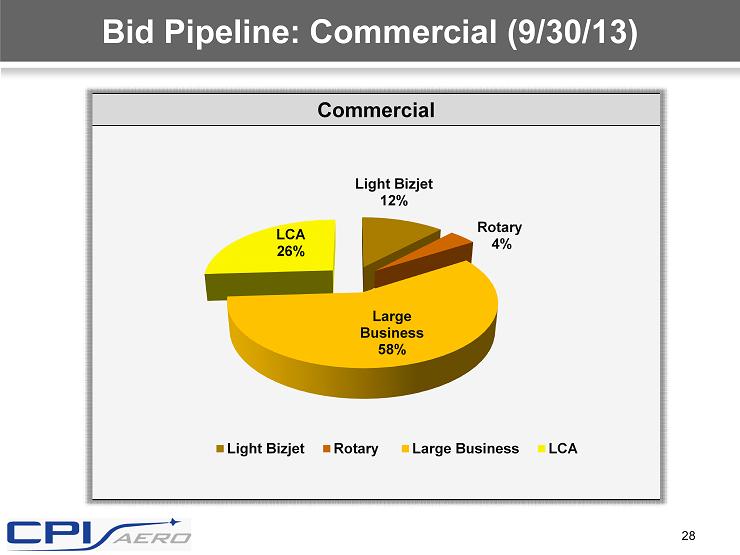

Commercial Bid Pipeline: Commercial (9/30/13) 28 Light Bizjet 12% Rotary 4% Large Business 58% LCA 26 % Light Bizjet Rotary Large Business LCA

Marketing Overview (1 - 3 year outlook) What are the Target Areas for CPI Aero for development & growth? 29 European Tier 1s Design and build opportunities within existing customer base US Defense MRO & aftermarket support Higher level of integration for existing programs Based on our previous contracts, our growth areas are:

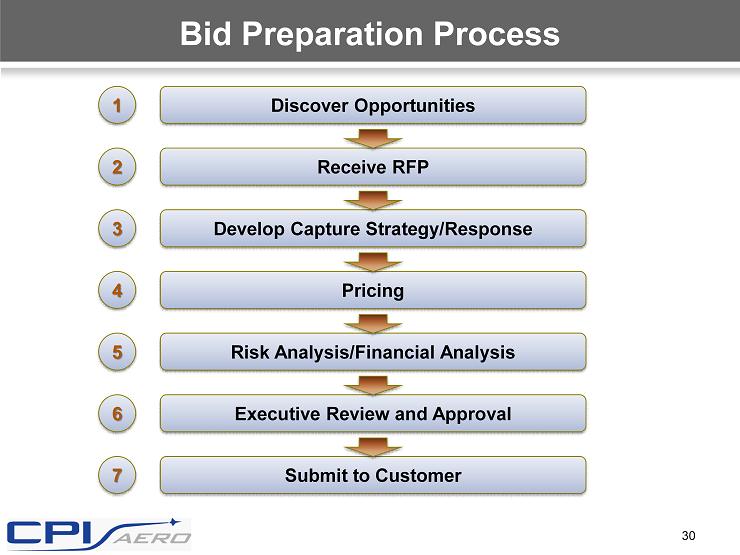

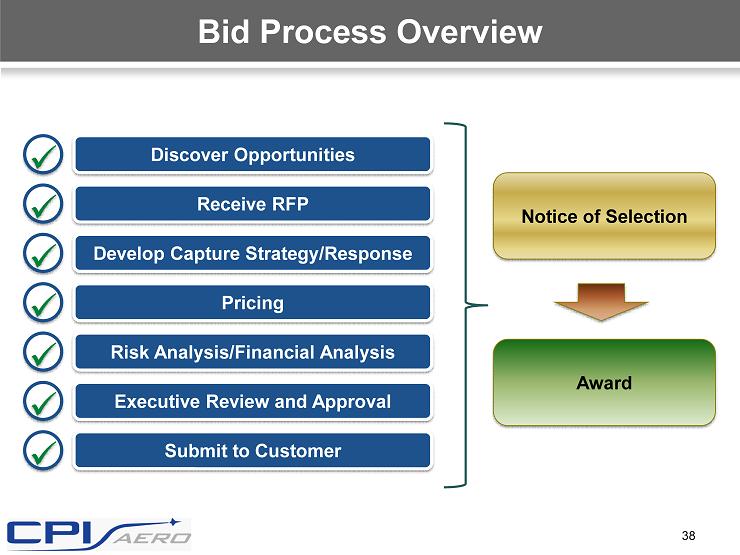

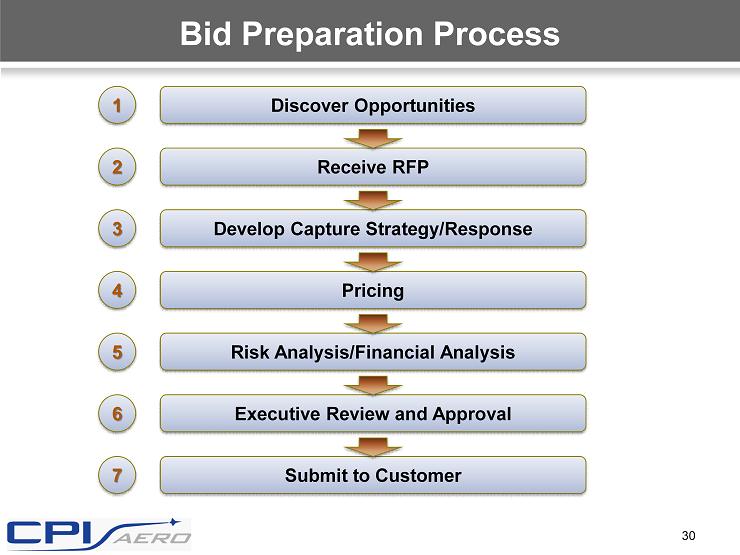

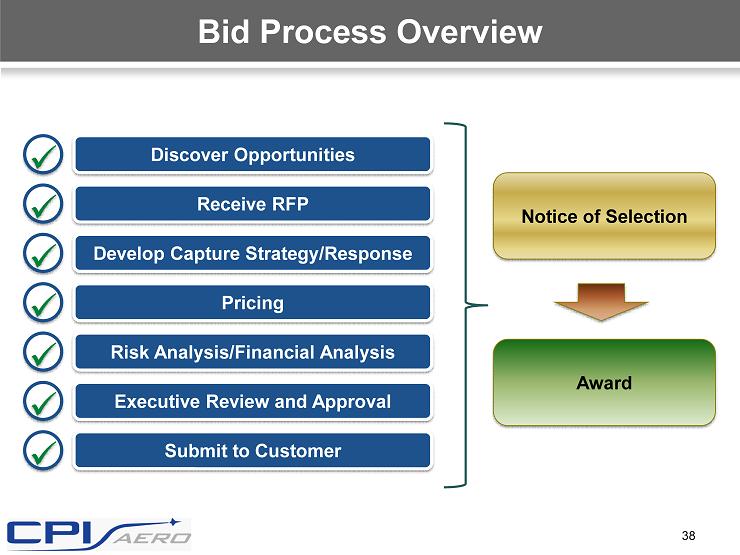

Bid Preparation Process 30 Submit to Customer Executive Review and Approval Risk Analysis/Financial Analysis Pricing Develop Capture Strategy/Response Receive RFP Discover Opportunities 1 2 3 4 5 6 7

Bid Preparation Customer Engagement • Market intelligence • Sales representatives Government Opportunities • Fed Biz Ops website • Attend government - sponsored Industry Days OEM Opportunities • Existing customers via internal Program Managers • New customers via contacts and meetings with Business Development OEM Opportunities Government Opportunities Customer Engagement Discover Opportunities 1 31

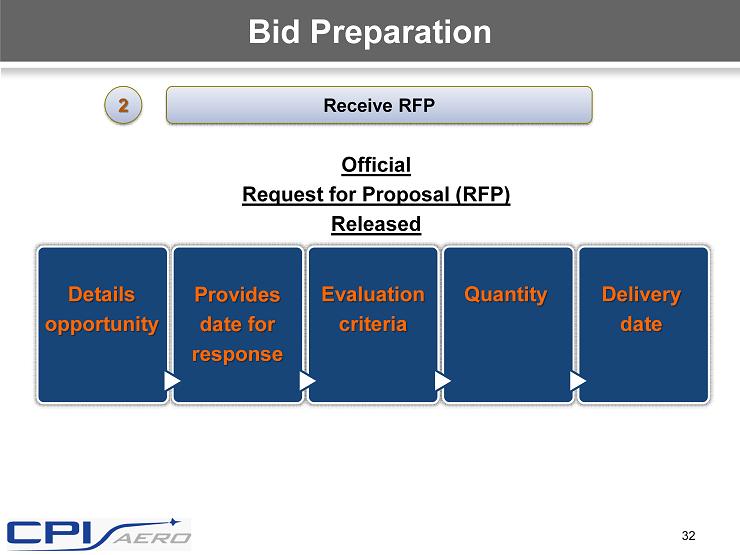

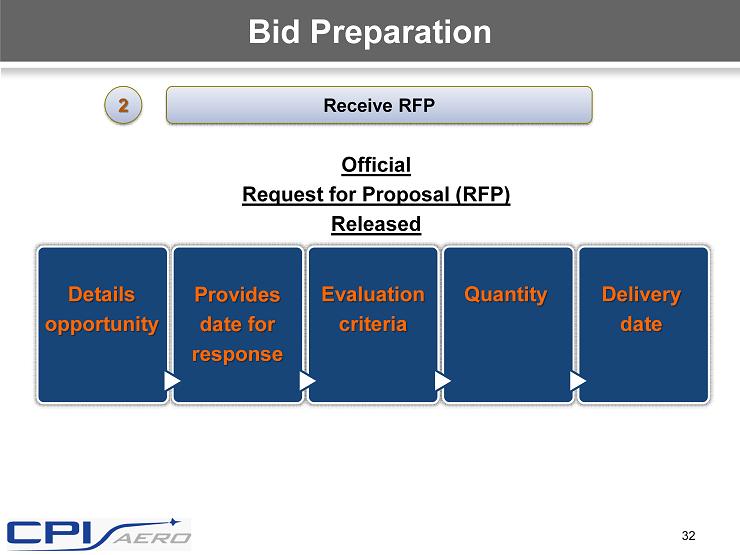

Bid Preparation Official Request for Proposal (RFP) Released Details opportunity Provides date for response Evaluation criteria Quantity Delivery date Receive RFP 2 32

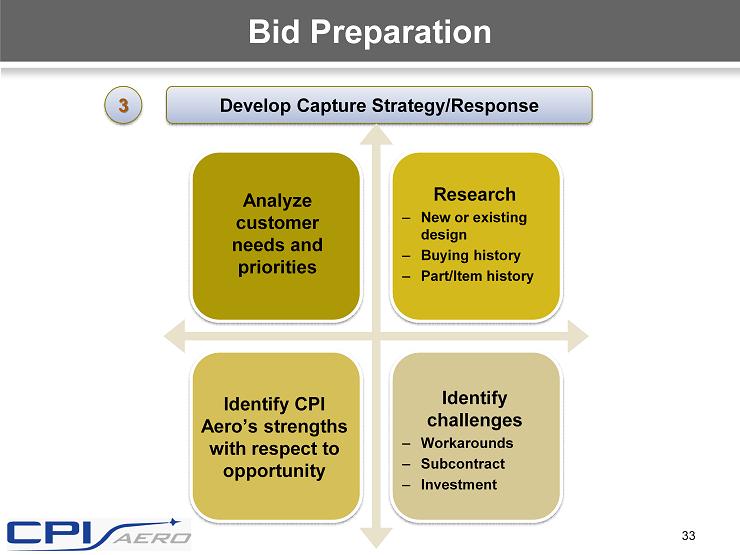

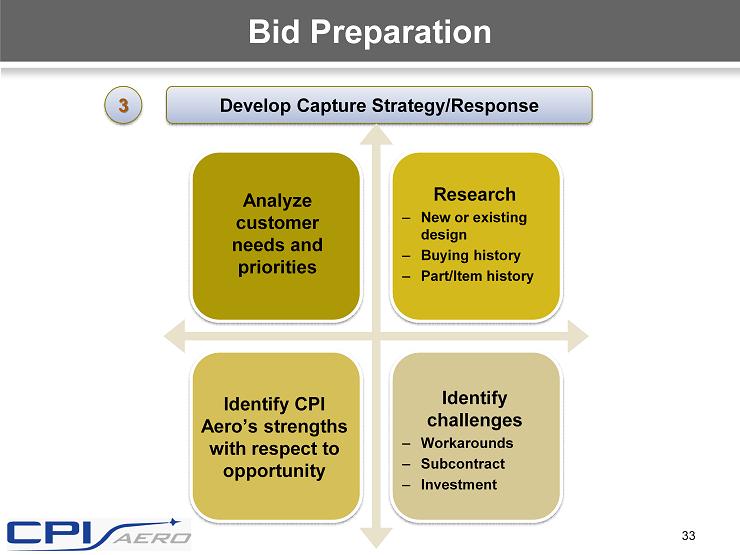

Bid Preparation Develop Capture Strategy/Response 3 Analyze customer needs and priorities Research – New or existing design – Buying history – Part/Item history Identify CPI Aero’s strengths with respect to opportunity Identify challenges – Workarounds – Subcontract – Investment 33

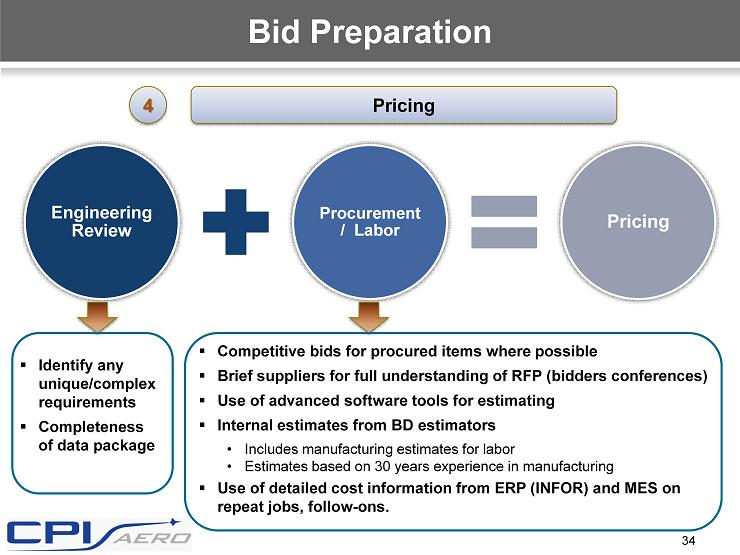

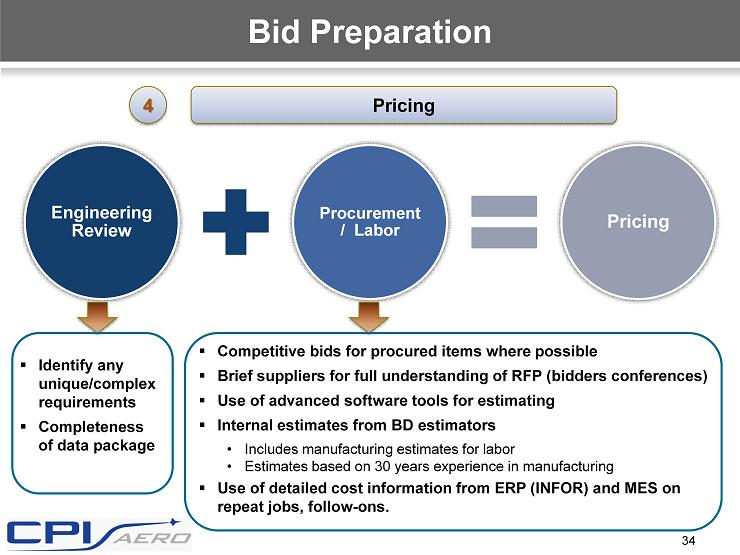

Engineering Review Procurement / Labor Pricing Bid Preparation ▪ Identify any unique/complex requirements ▪ Completeness of data package Pricing 4 ▪ Competitive bids for procured items where possible ▪ Brief suppliers for full understanding of RFP (bidders conferences) ▪ Use of advanced software tools for estimating ▪ Internal estimates from BD estimators • Includes manufacturing estimates for labor • Estimates based on 30 years experience in manufacturing ▪ Use of detailed cost information from ERP (INFOR) and MES on repeat jobs, follow - ons . 34

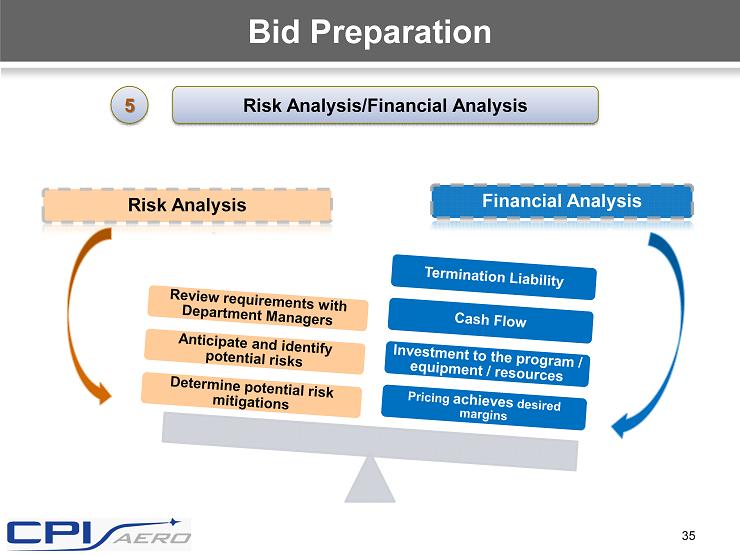

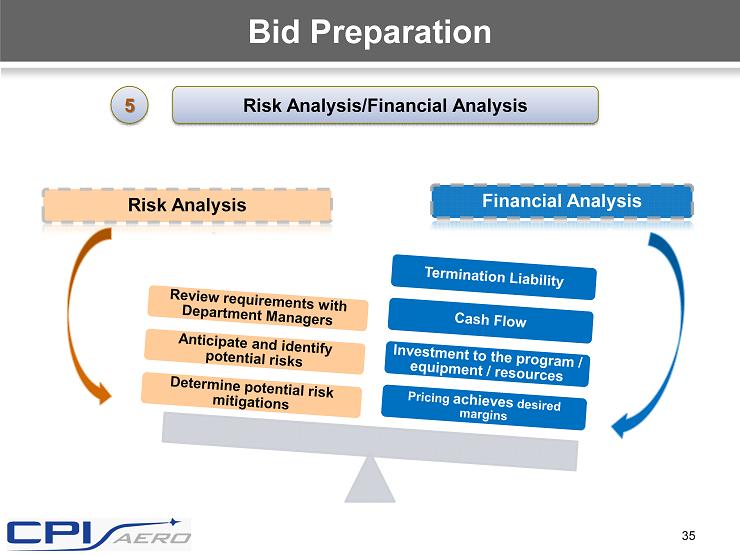

Bid Preparation Risk Analysis/Financial Analysis 5 Risk Analysis Financial Analysis 35

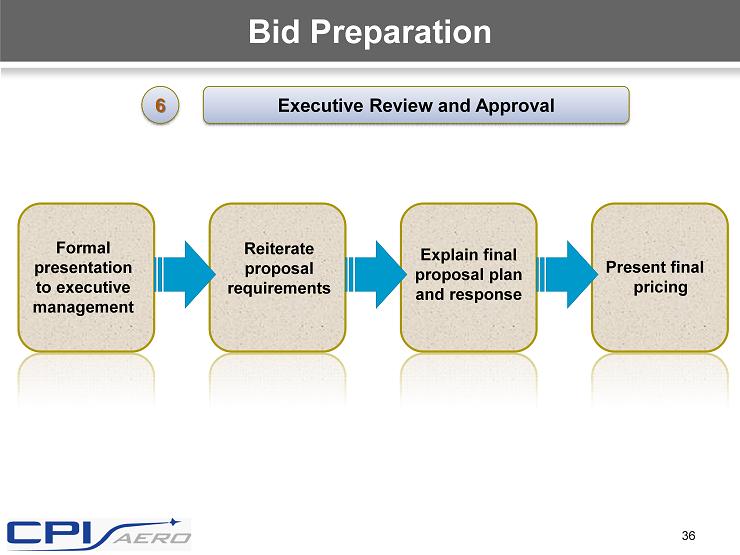

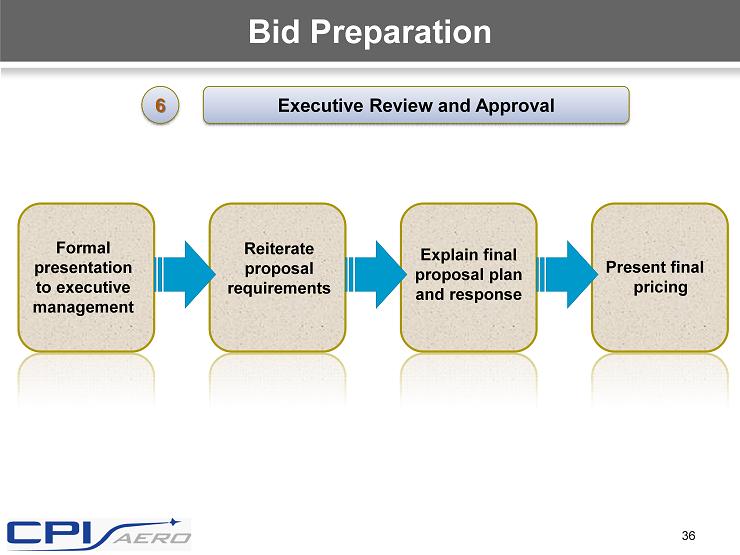

Bid Preparation Executive Review and Approval 6 Formal presentation to executive management Reiterate proposal requirements Explain final proposal plan and response Present final pricing 36

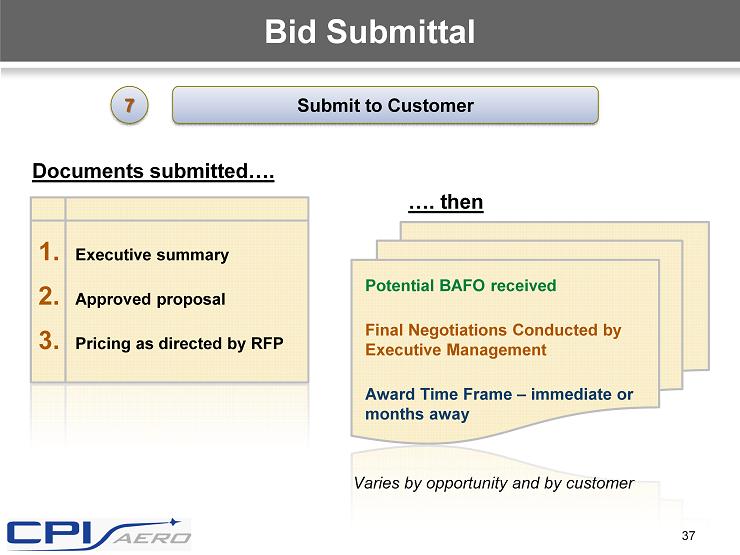

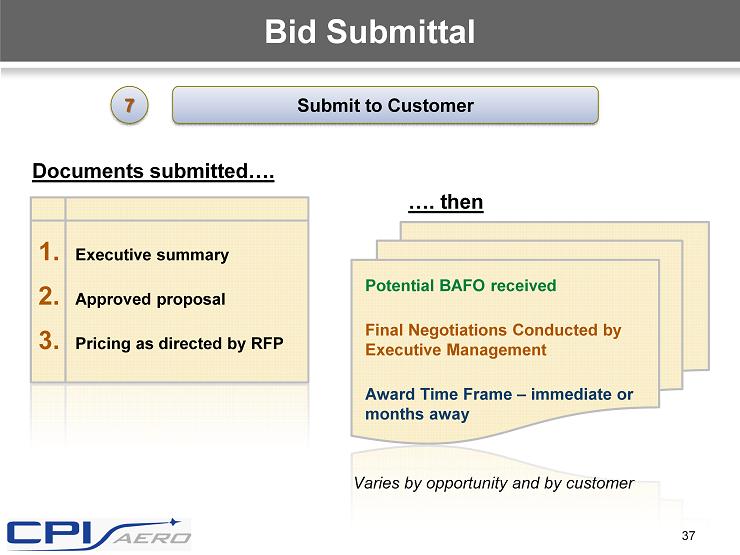

Bid Submittal 1. Executive summary 2. Approved proposal 3. Pricing as directed by RFP Submit to Customer 7 Potential BAFO received Final Negotiations Conducted by Executive Management Award Time Frame – immediate or months away Documents submitted…. …. then Varies by opportunity and by customer 37

Submit to Customer Executive Review and Approval Risk Analysis/Financial Analysis Pricing Develop Capture Strategy/Response Receive RFP Discover Opportunities x Notice of Selection Award Bid Process Overview x x x x x x 38

Transition to Operations Transition Team… ▪ Director ▪ Proposal Manager ▪ Sales Engineer 39 ….responsible for transferring bid data to IPT ▪ Assumptions ▪ Cost Estimates ▪ Engineering Data

Nazzareno Palmerini Director, Program Management Mr . Palmerini was hired in 2013 as Director of Program Management . Prior to joining CPI Aero, Mr . Palmerini spent 30 successful years at GKN Aerospace, where he held various sales, marketing and program management positions, including Director of Business Development and Program Management and Director of Sales and Marketing . Mr . Palmerini holds a Bachelor of Science in Finance from Long Island University . Program Management Overview 40

Program Management Organization Chart 41

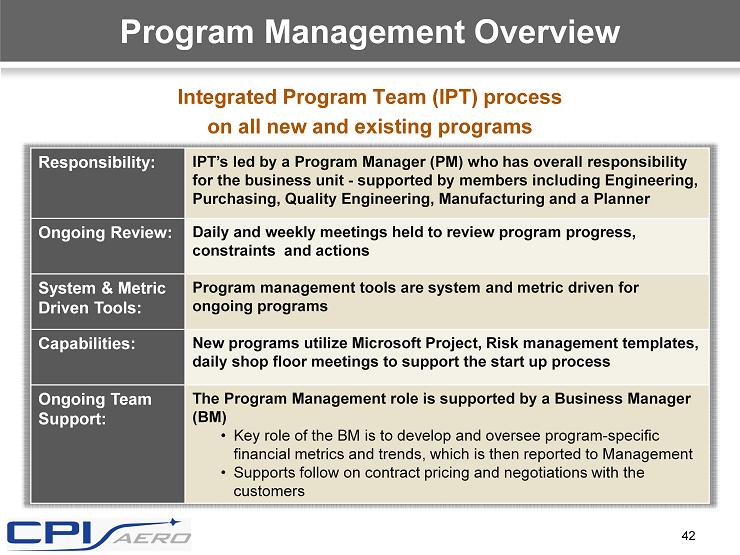

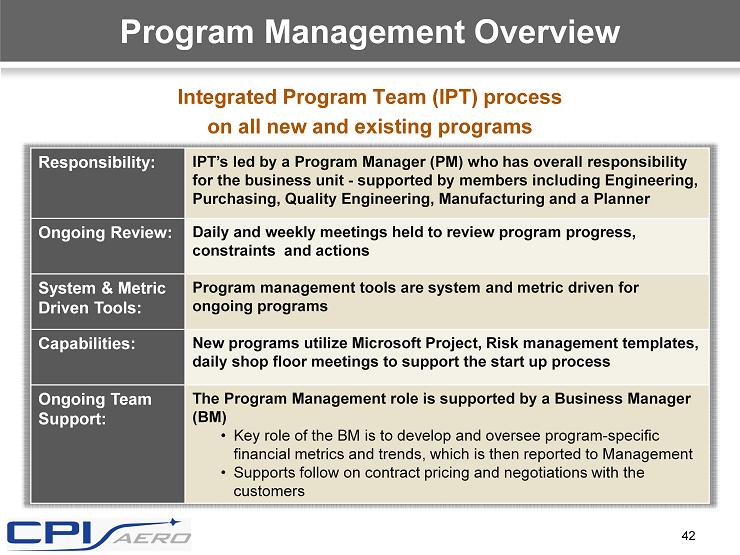

Program Management Overview 42 Integrated Program Team (IPT) process on all new and existing programs Responsibility: IPT’s led by a Program Manager (PM) who has overall responsibility for the business unit - supported by members including Engineering, Purchasing, Quality Engineering, Manufacturing and a Planner Ongoing Review: Daily and weekly meetings held to review program progress, constraints and actions System & Metric Driven Tools: Program management tools are system and metric driven for ongoing programs Capabilities: New programs utilize Microsoft Project, Risk management templates, daily shop floor meetings to support the start up process Ongoing Team Support: The Program Management role is supported by a Business Manager (BM) • Key role of the BM is to develop and oversee program - specific financial metrics and trends, which is then reported to Management • Supports follow on contract pricing and negotiations with the customers

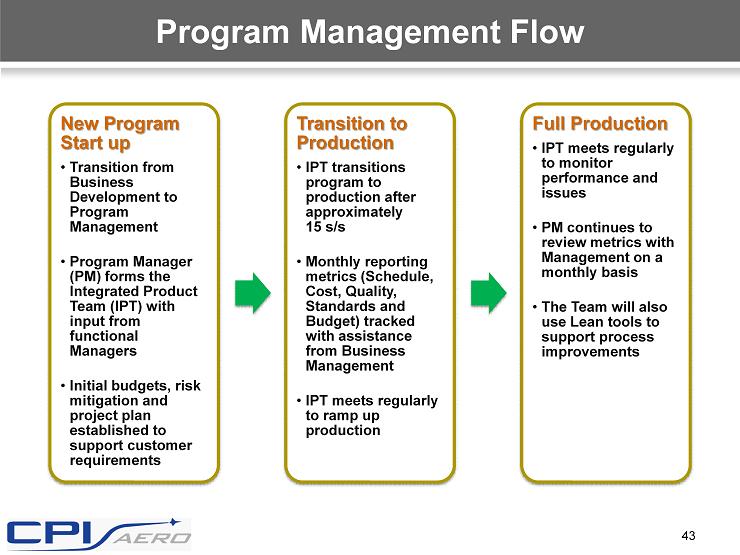

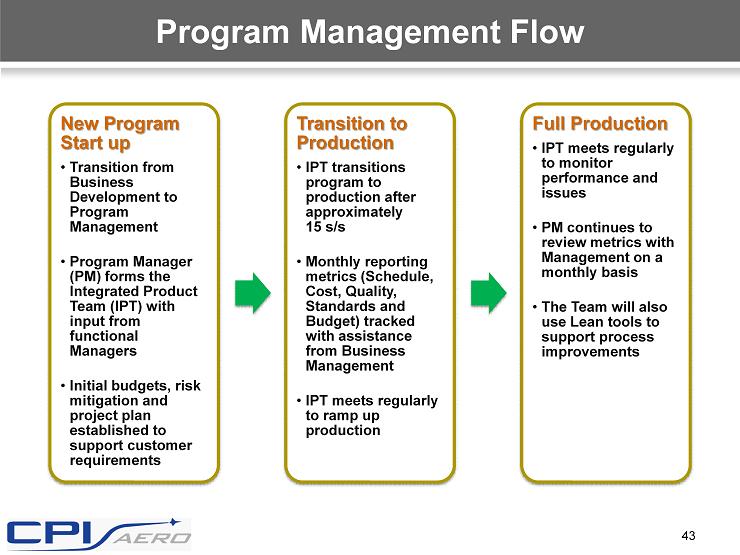

New Program Start up • Transition from Business Development to Program Management • Program Manager (PM) forms the Integrated Product Team (IPT) with input from functional Managers • Initial budgets, risk mitigation and project plan established to support customer requirements Transition to Production • IPT transitions program to production after approximately 15 s/s • Monthly reporting metrics (Schedule, Cost, Quality, Standards and Budget) tracked with assistance from Business Management • IPT meets regularly to ramp up production Full Production • IPT meets regularly to monitor performance and issues • PM continues to review metrics with Management on a monthly basis • The Team will also use Lean tools to support process improvements Program Management Flow 43

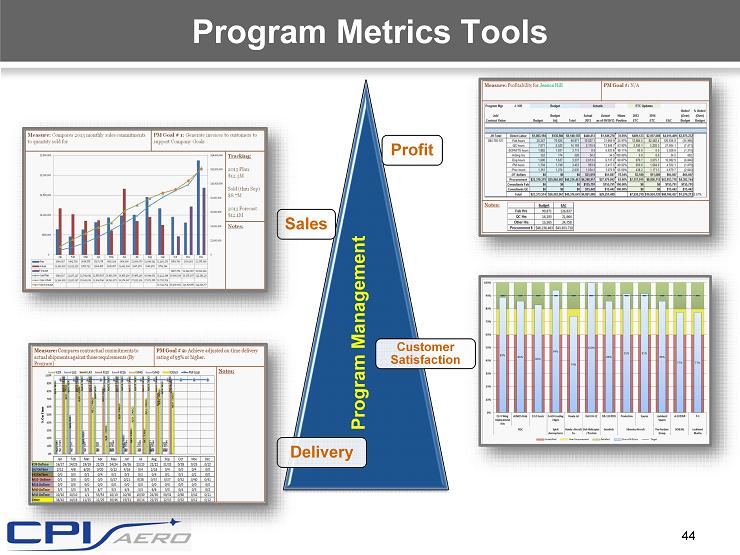

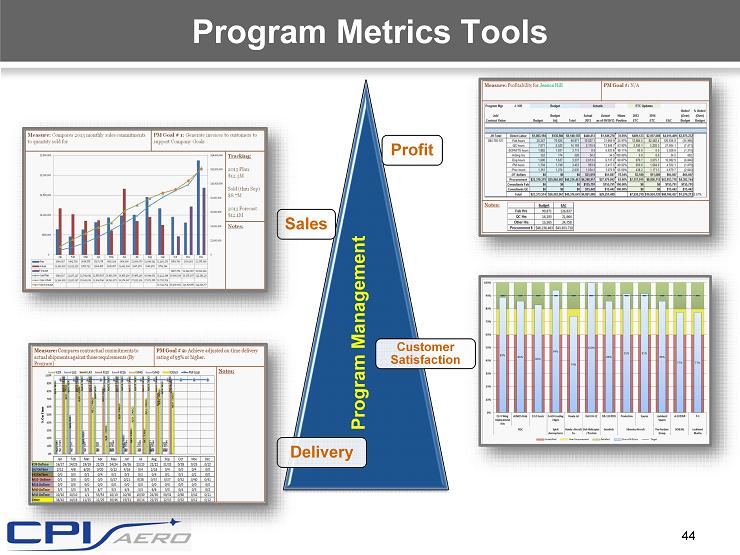

Profit Customer Satisfaction Sales Delivery Program Management Program Metrics Tools 44

Programs (as of 10/31/13): Military Aerospace A - 10 Thunderbolt Wing $92M contract Leading edges, wing tips, trailing edges, main landing gear pods Firm requirements for 117 ship sets $48.1M orders E - 2D Advanced Hawkeye & C - 2A Greyhound $195M program Structural kits for the wing $51.2M in purchase orders UH - 60 BLACK HAWK helicopter $84.3M contracts HIRSS module and Gunner Doors assemblies Outboard stabilator assemblies $5.3M MRO order Manufacture fuel panels Military aircraft $10.7M contract Large structural assemblies Authority to design modifications to the structure AH - 1Z ZULU Helicopter $34M potential Various assemblies $6.9M in orders 45

Current Military Program: Boeing A - 10 46 46 Program Info: • CPI assembles the entire forward section of the wing, along with wingtips, ailerons and trailing edges. CPI has delivered 53 wings to date. Production rate is at 4 wings per month. Wingtips Forward leading edges Main landing gear pods Landing gear doors Ailerons Wing to fuselage fillets Trailing edge panels 3D RENDERING OF CPI ASSEMBLIES SUPPLIED TO BOEING/AIR FORCE (Consists of 23% of the entire wing – estimate)

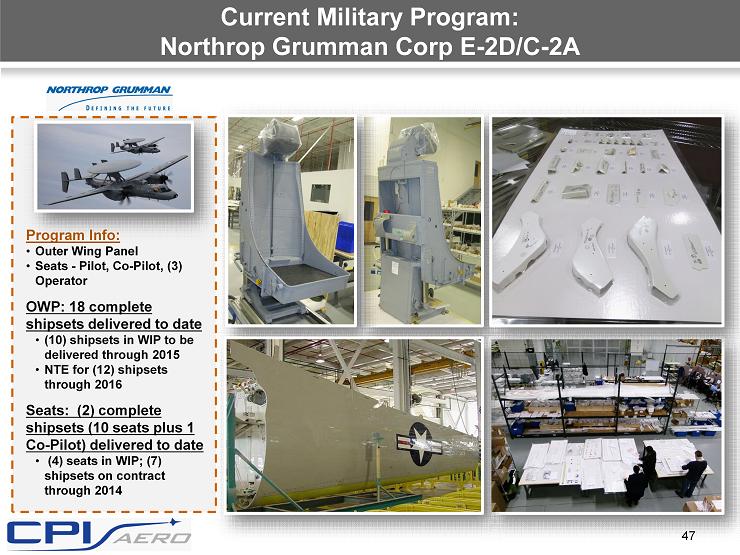

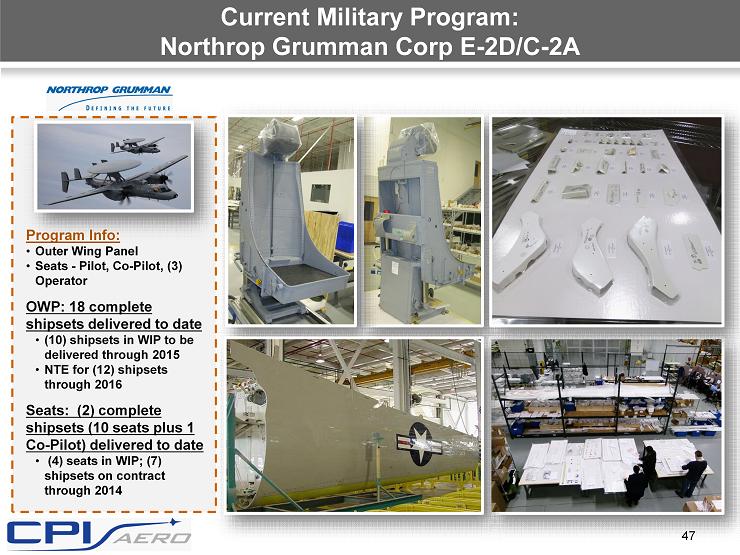

Current Military Program: Northrop Grumman Corp E - 2D/C - 2A 47 Program Info: • Outer Wing Panel • Seats - Pilot, Co - Pilot, (3) Operator OWP: 18 complete shipsets delivered to date • (10) shipsets in WIP to be delivered through 2015 • NTE for (12) shipsets through 2016 Seats: (2) complete shipsets (10 seats plus 1 Co - Pilot) delivered to date • (4) seats in WIP; (7) shipsets on contract through 2014

Current Military Program: Sikorsky UH - 60 48 HIRSS module Attaches to the rear of the engines Program Info: • HIRSS module • Gunner doors • Outboard Stabilator • Fuel panels Fuel Panel Located inside the Fuel Cell by forward engine Gunner Doors Located for Machine Gunner Double Doors on both sides of aircraft Outboard Stabilator LTA for Overhaul and Repair of Outboard Stabilators for Seahawk

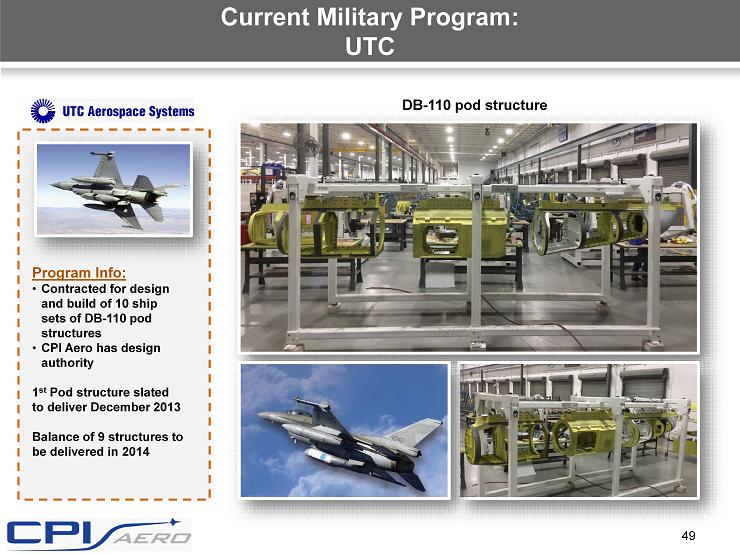

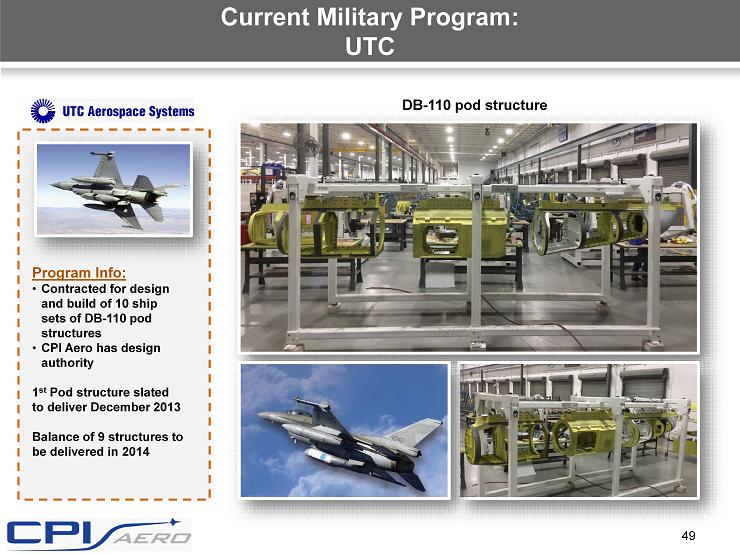

Current Military Program: UTC 49 Program Info: • Contracted for design and build of 10 ship sets of DB - 110 pod structures • CPI Aero has design authority 1 st Pod structure slated to deliver December 2013 Balance of 9 structures to be delivered in 2014 DB - 110 pod structure

Current Military Program: Bell AH - 1Z Support and Cowl Assemblies Program Info: • Panel assembly • A filler • A set of inlets • Support assemblies To date, we have delivered all 2013 requirements to include 11 ship sets of the supports assemblies and all scheduled panels assemblies and fillers - all on time or ahead of schedule. Cowl assemblies – Delivered 8 ship sets of 11 due this year 50 Panel Filler

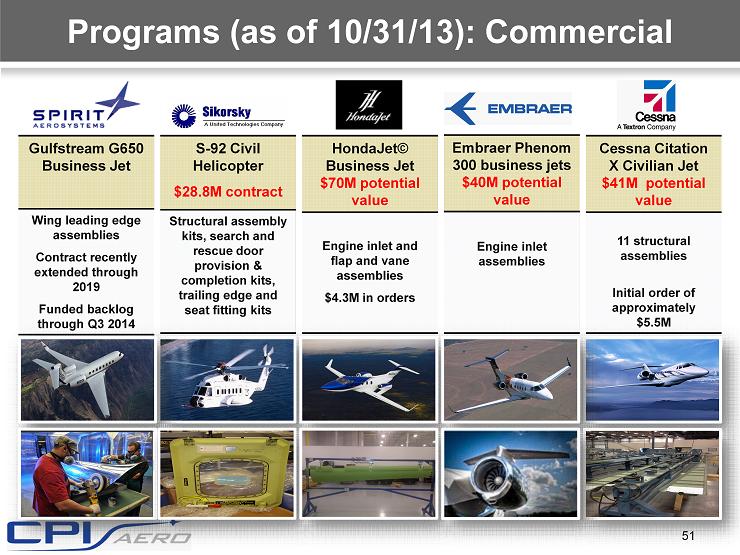

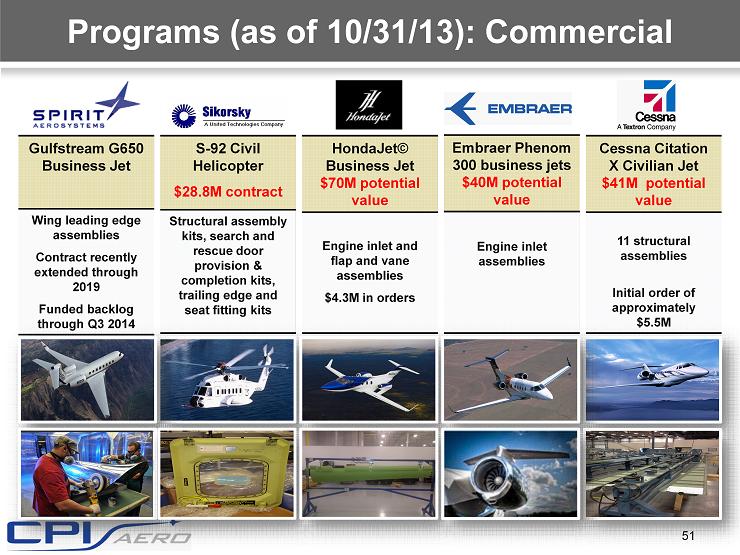

Programs (as of 10/31/13): Commercial Gulfstream G650 Business Jet Wing leading edge assemblies Contract recently extended through 2019 Funded backlog through Q3 2014 S - 92 Civil Helicopter $28.8M contract Structural assembly kits, search and rescue door provision & completion kits, trailing edge and seat fitting kits HondaJet © Business Jet $70M potential value Engine inlet and flap and vane assemblies $4.3M in orders Embraer Phenom 300 business jets $40M potential value Engine inlet assemblies Cessna Citation X Civilian Jet $41M potential value 11 structural assemblies Initial order of approximately $5.5M 51

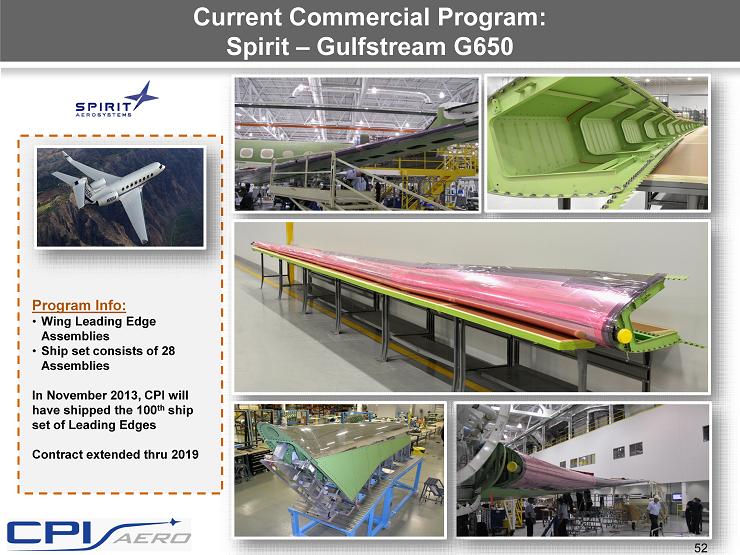

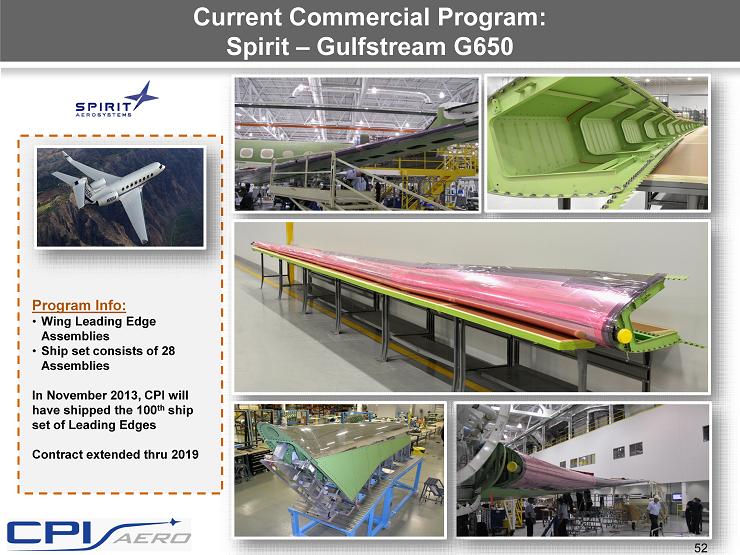

Current Commercial Program: Spirit – Gulfstream G650 Program Info: • Wing Leading Edge Assemblies • Ship set consists of 28 Assemblies In November 2013, CPI will have shipped the 100 th ship set of Leading Edges Contract extended thru 2019 52

Current Commercial Program: Sikorsky S - 92 53 Bond Kits Emergency Exit Door ½ Door Assembly Multiple Kits Including Cover, Provision, Installation Kits Program Info: • Bond Kits • Emergency Exit Door • Half - Door Assembly • Multiple Kits

Current Commercial Program: HondaJet 54 Program Info: • Flaps/Vanes & Engine Inlet Delivered F4 test flight P11 production units in WIP Flaps/Vanes Engine Inlet

Current Commercial Program: Embraer Phenom 300 55 Program Info: • Engine inlet assemblies for Phenom 300 • Ship set consists of one left hand and one right hand unit Delivered through ship set 5. Aggressive ramp up schedule requires rate tooling. In June 2014, the program will be delivering 7 ship sets a month, producing one inlet every 1.5 days. Engine Inlet

Current Commercial Program: Cessna Citation X 56 Program Info : • Delivered 7 First Article parts • Working the last 4 First Article parts (which are the largest) to be due in January, 2014 Will be in production of all parts in 2014 Approx. 12 ship sets

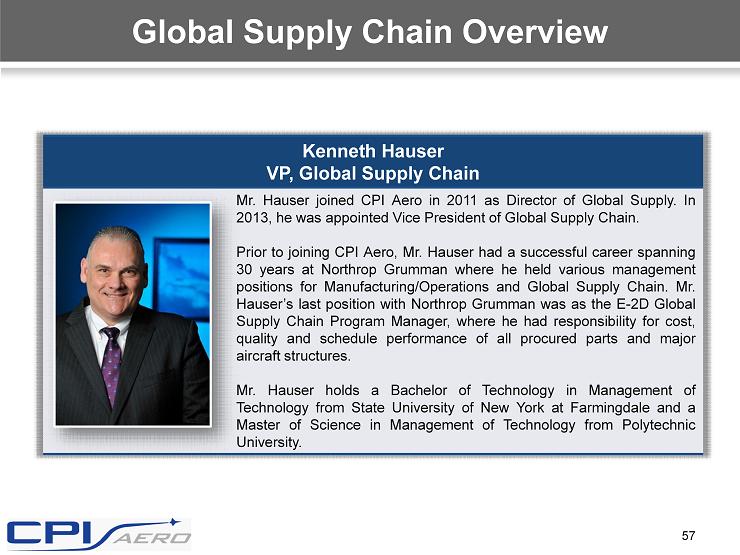

Kenneth Hauser VP, Global Supply Chain Mr . Hauser joined CPI Aero in 2011 as Director of Global Supply . In 2013 , he was appointed Vice President of Global Supply Chain . Prior to joining CPI Aero, Mr . Hauser had a successful career spanning 30 years at Northrop Grumman where he held various management positions for Manufacturing/Operations and Global Supply Chain . Mr . Hauser’s last position with Northrop Grumman was as the E - 2 D Global Supply Chain Program Manager, where he had responsibility for cost, quality and schedule performance of all procured parts and major aircraft structures . Mr . Hauser holds a Bachelor of Technology in Management of Technology from State University of New York at Farmingdale and a Master of Science in Management of Technology from Polytechnic University . Global Supply Chain Overview 57

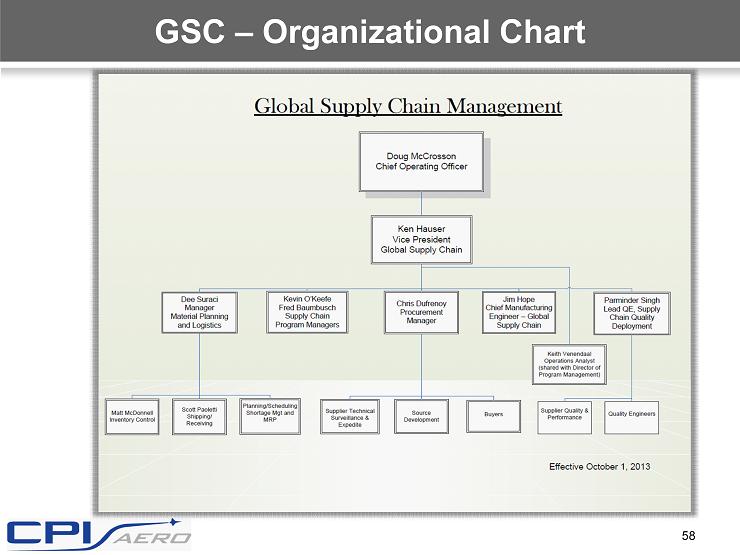

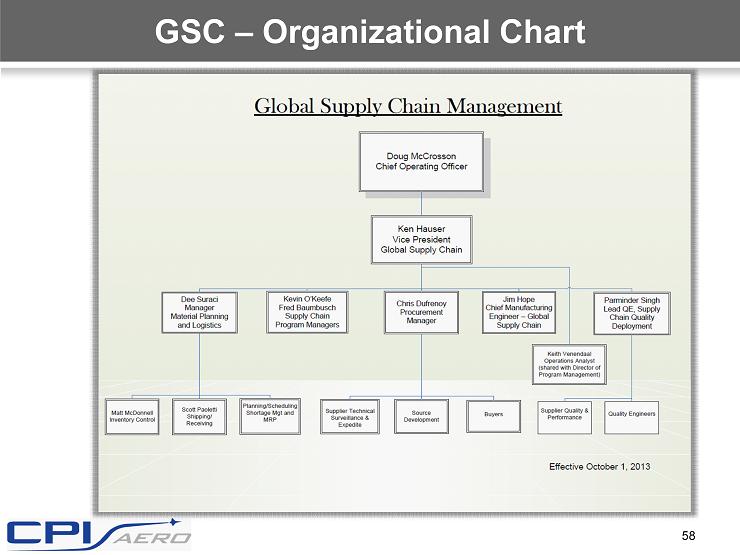

58 GSC – Organizational Chart

Introduction - GSC Implemented integrated Global Supply Chain organization early in 2013 • Separate SCM functions had existed prior, but reported through several different organizations 59 Performance being optimized - significant improvement over 2012 • Robust processes and tools • Performance Measurement Focused on performance and affordability x x x

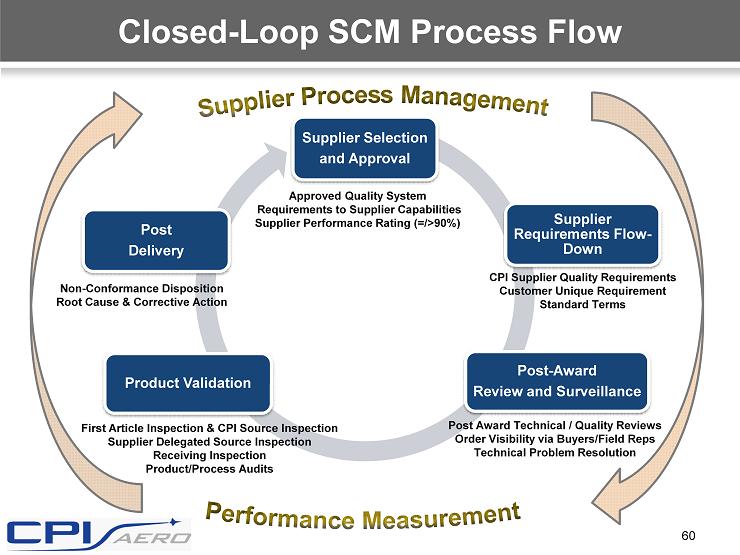

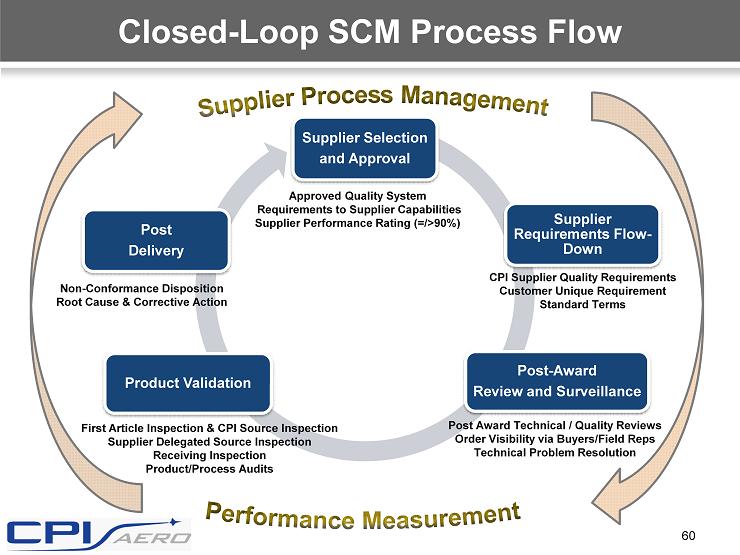

Closed - Loop SCM Process Flow Supplier Selection and Approval Supplier Requirements Flow - Down Post - Award Review and Surveillance Product Validation Post Delivery 60 Approved Quality System Requirements to Supplier Capabilities Supplier Performance Rating (=/>90%) Non - Conformance Disposition Root Cause & Corrective Action CPI Supplier Quality Requirements Customer Unique Requirement Standard Terms First Article Inspection & CPI Source Inspection Supplier Delegated Source Inspection Receiving Inspection Product/Process Audits Post Award Technical / Quality Reviews Order Visibility via Buyers/Field Reps Technical Problem Resolution

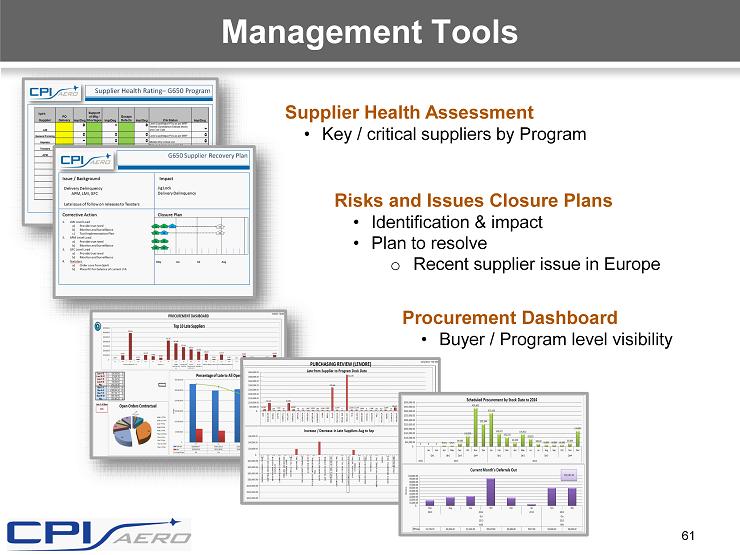

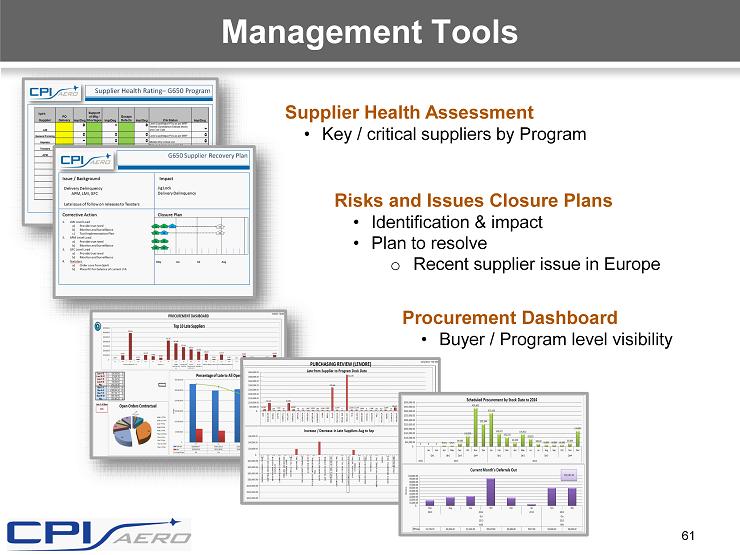

Management Tools 61 Supplier Health Assessment • Key / critical suppliers by Program Procurement Dashboard • Buyer / Program level visibility Risks and Issues Closure Plans • Identification & impact • Plan to resolve o Recent supplier issue in Europe

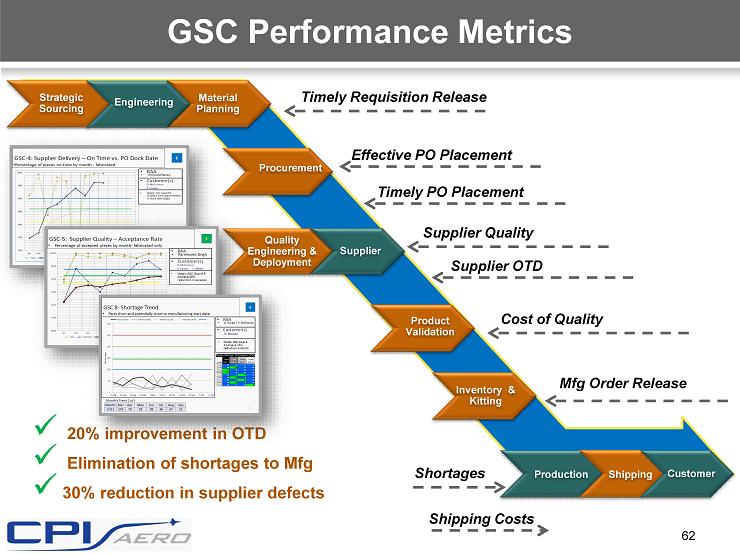

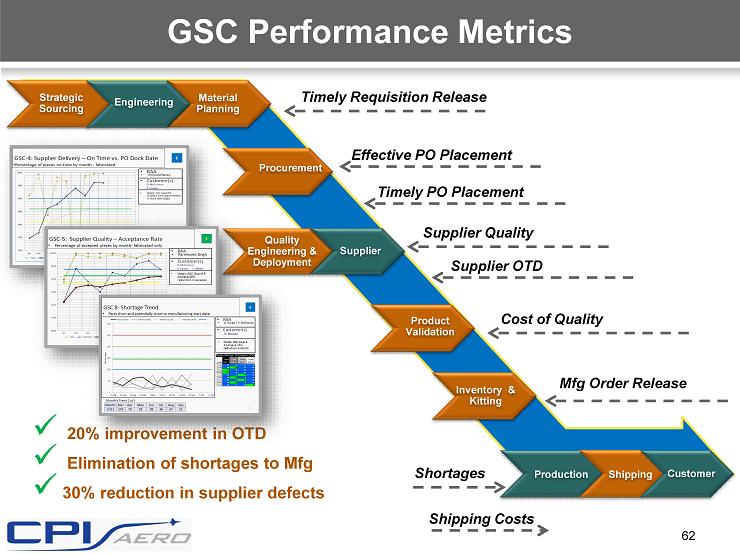

GSC Performance Metrics 62 Strategic Sourcing Procurement Product Validation Inventory & Kitting Production Customer Supplier Material Planning Timely Re quisition Release Quality Engineering & Deployment Shipping Effective PO Placement Timely PO Placement Supplier OTD Supplier Quality Cost of Quality Mfg Order Release Shortages Shipping Costs x 20 % improvement in OTD x Elimination of shortages to Mfg x 30 % reduction in supplier defects Engineering

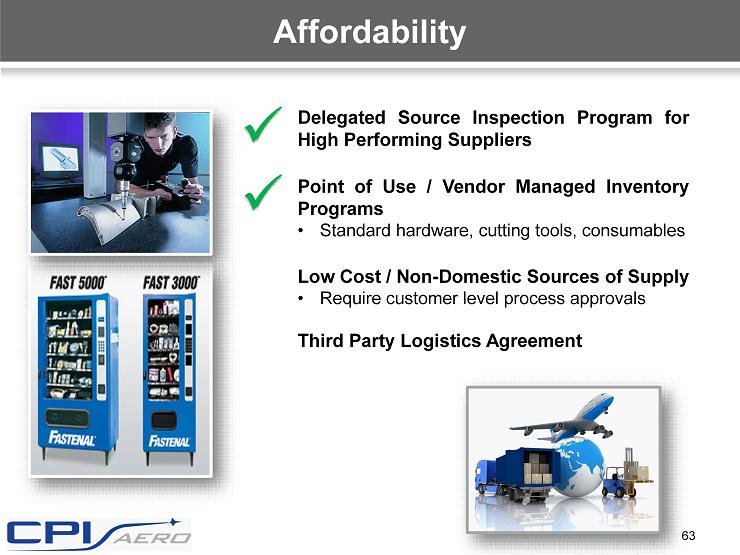

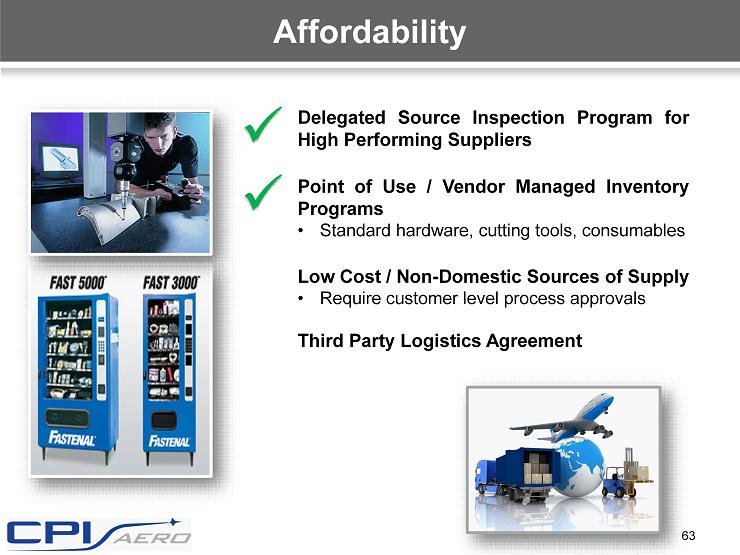

Delegated Source Inspection Program for High Performing Suppliers Point of Use / Vendor Managed Inventory Programs • Standard hardware, cutting tools, consumables Low Cost / Non - Domestic Sources of Supply • Require customer level process approvals Third Party Logistics Agreement Affordability 63 x x

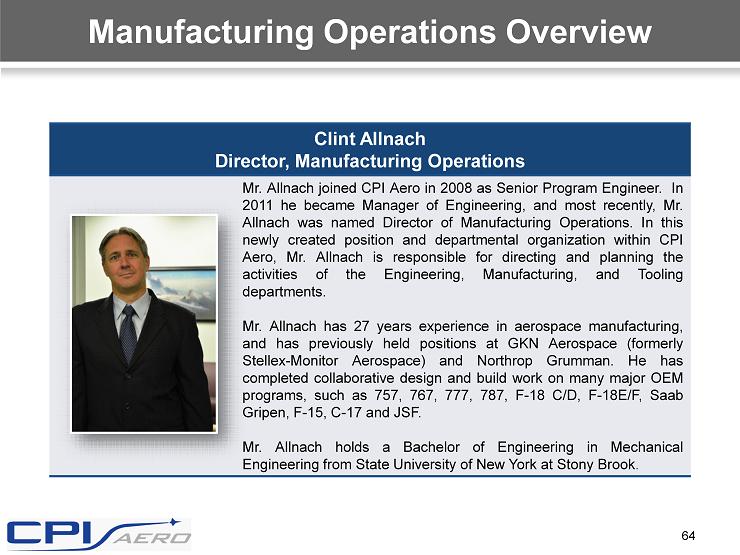

Clint Allnach Director, Manufacturing Operations Mr . Allnach joined CPI Aero in 2008 as Senior Program Engineer . In 2011 he became Manager of Engineering, and most recently, Mr . Allnach was named Director of Manufacturing Operations . In this newly created position and departmental organization within CPI Aero, Mr . Allnach is responsible for directing and planning the activities of the Engineering, Manufacturing, and Tooling departments . Mr . Allnach has 27 years experience in aerospace manufacturing, and has previously held positions at GKN Aerospace (formerly Stellex - Monitor Aerospace) and Northrop Grumman . He has completed collaborative design and build work on many major OEM programs, such as 757 , 767 , 777 , 787 , F - 18 C/D, F - 18 E/F, Saab Gripen , F - 15 , C - 17 and JSF . Mr . Allnach holds a Bachelor of Engineering in Mechanical Engineering from State University of New York at Stony Brook . Manufacturing Operations Overview 64

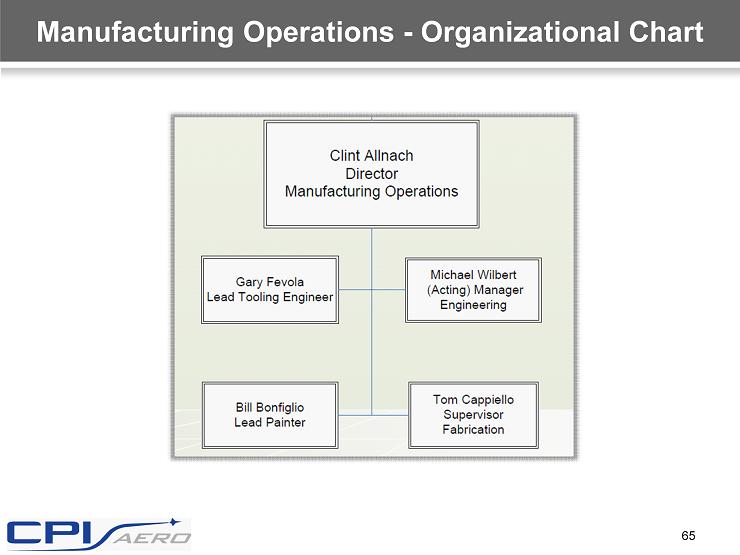

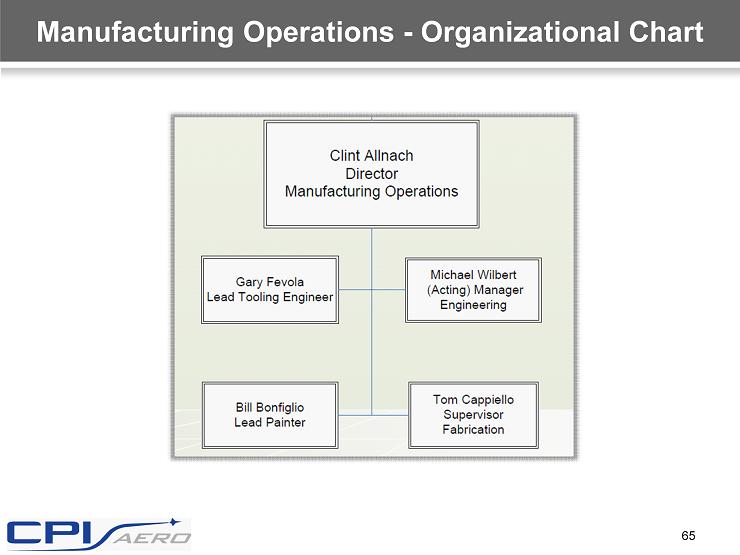

Manufacturing Operations - Organizational Chart 65

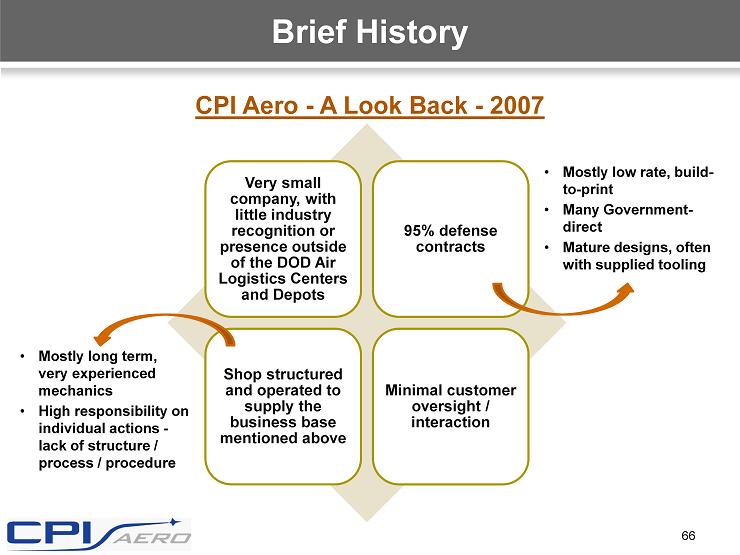

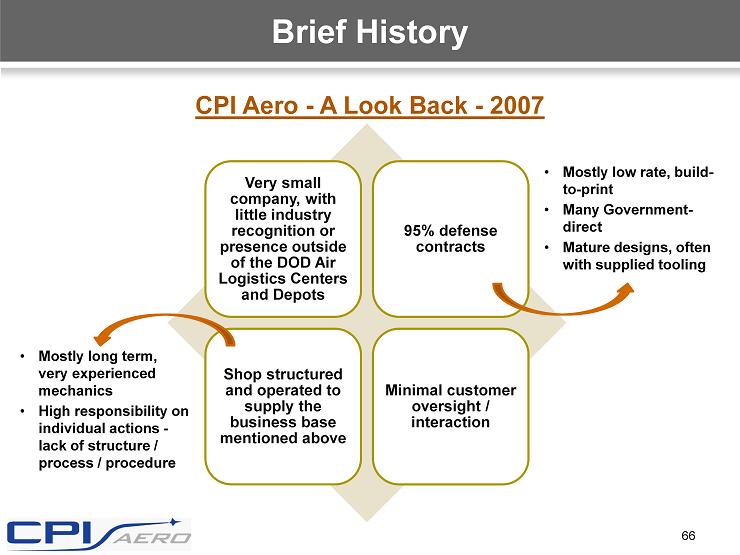

Brief History 66 CPI Aero - A Look Back - 2007 Very small company, with little industry recognition or presence outside of the DOD Air Logistics Centers and Depots 95% defense contracts Shop structured and operated to supply the business base mentioned above Minimal customer oversight / interaction • Mostly low rate, build - to - print • Many Government - direct • Mature designs, often with supplied tooling • Mostly long term, very experienced mechanics • High responsibility on individual actions - lack of structure / process / procedure

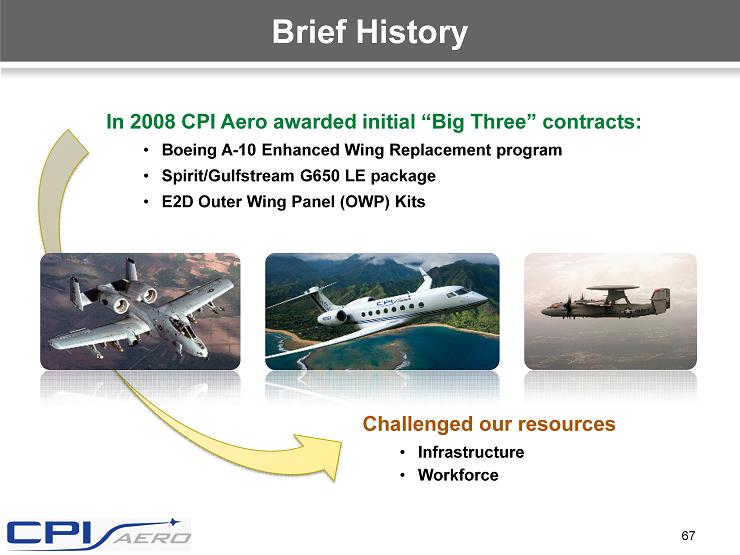

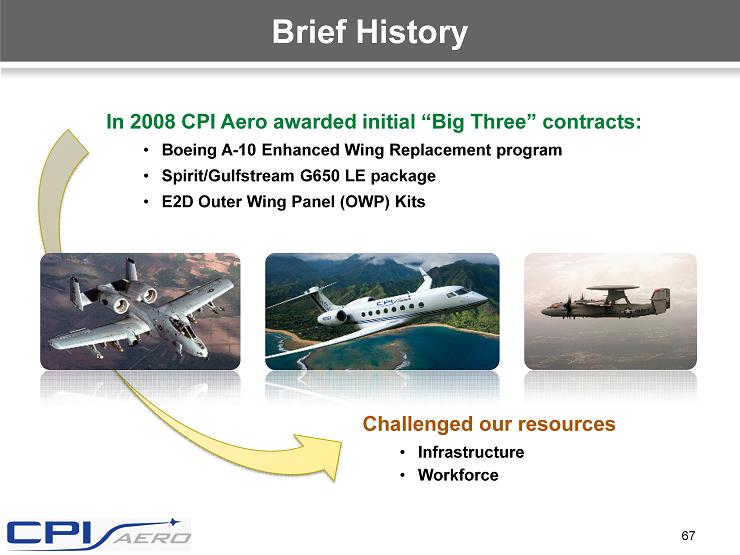

In 2008 CPI Aero awarded initial “Big Three” contracts: • Boeing A - 10 Enhanced Wing Replacement program • Spirit/Gulfstream G650 LE package • E2D Outer Wing Panel (OWP) Kits Brief History 67 Challenged our resources • Infrastructure • Workforce

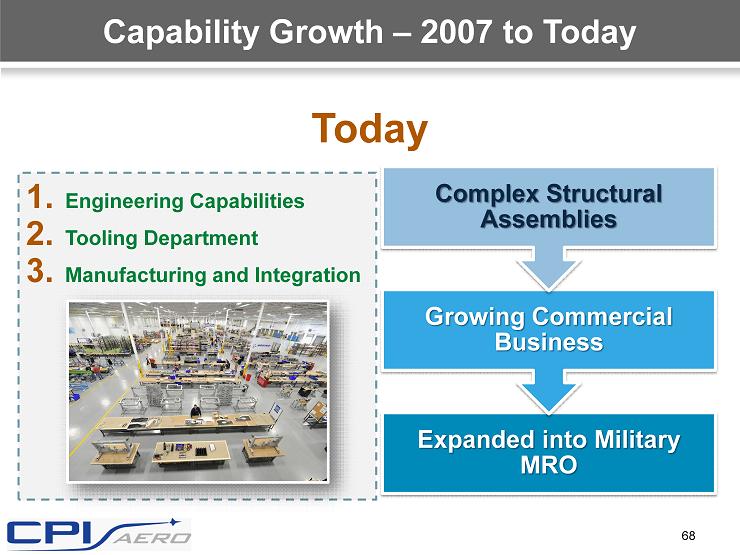

68 Expanded into Military MRO Growing Commercial Business Complex Structural Assemblies Capability Growth – 2007 to Today Today 1. Engineering Capabilities 2. Tooling Department 3. Manufacturing and Integration

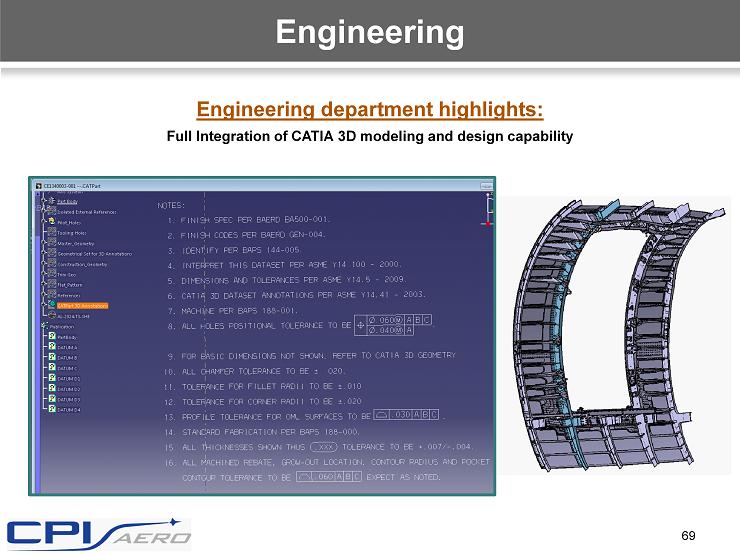

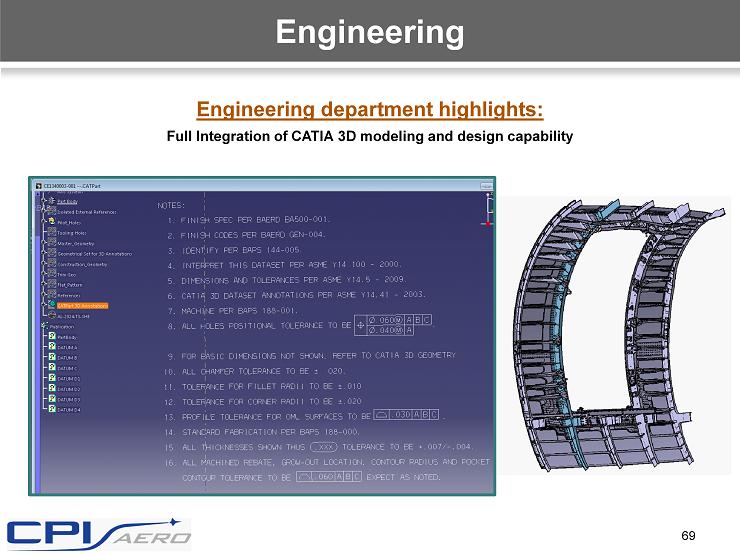

Engineering department highlights: Full Integration of CATIA 3D modeling and design capability Engineering 69

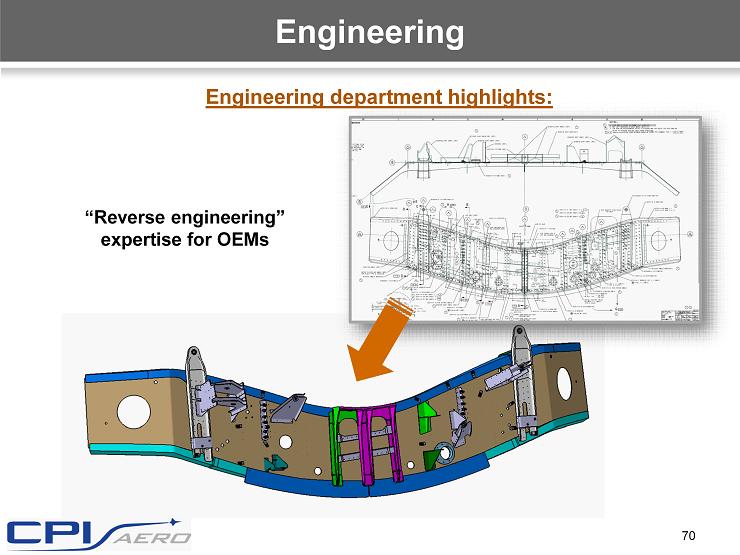

Engineering 70 Engineering department highlights: “Reverse engineering” expertise for OEMs

Engineering department highlights: Engineering 71 2 Refined procedures and processes to provide robust ERP - driven configuration management Focus on large integration programs and new design start ups 3 1 Tool Design capability

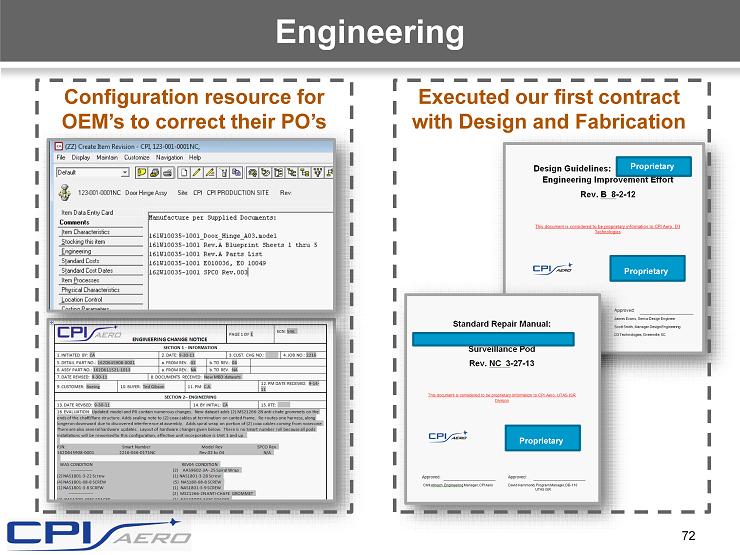

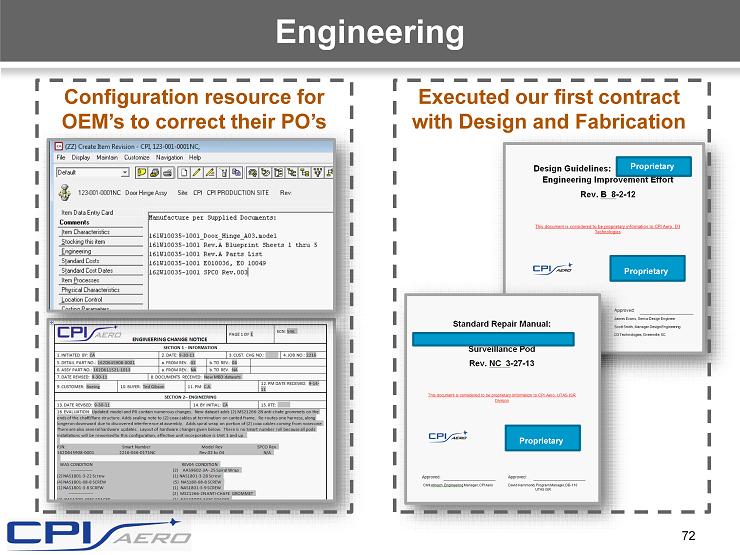

Configuration resource for OEM’s to correct their PO’s Proprietary Proprietary Proprietary Engineering 72 Executed our first contract with Design and Fabrication

Mix of seasoned, experienced engineers and recent hires Our Engineers 73 Comprehensive skill set and capabilities Rapid growth in personnel and contract programs results in intensive on - the - job training for new engineers Diverse educational backgrounds • Industrial Engineering • Applied Physics • Aircraft Design

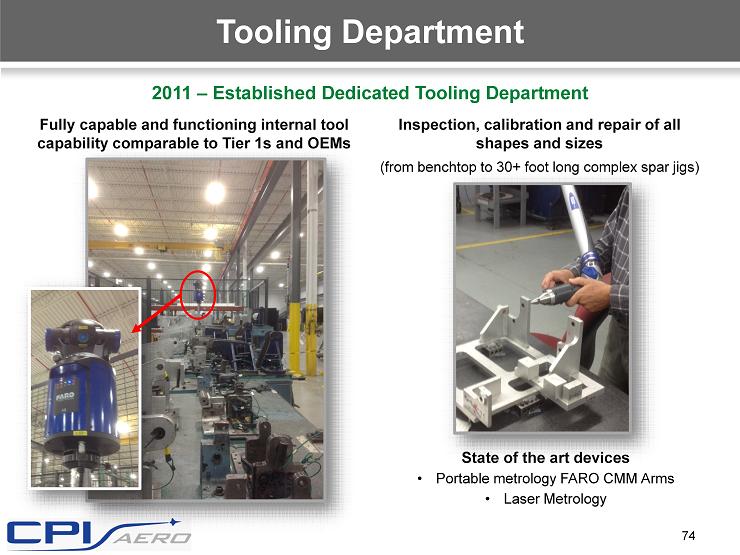

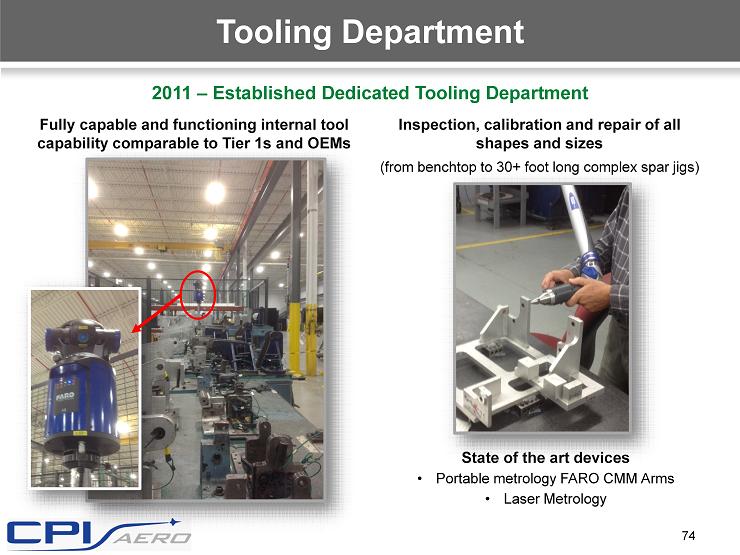

Fully capable and functioning internal tool capability comparable to Tier 1s and OEMs Tooling Department 74 2011 – Established Dedicated Tooling Department State of the art devices • Portable metrology FARO CMM Arms • Laser Metrology Inspection, calibration and repair of all shapes and sizes (from benchtop to 30+ foot long complex spar jigs)

Adding precision machine capability to allow for in - house tool maintenance, small tool fabrication and even some high precision production support Tooling Department 75 • Dedicated tool control database • Tracking of all internal tooling to support periodic inspection and maintenance • Point of use tool service • Rapid response on tooling related issues

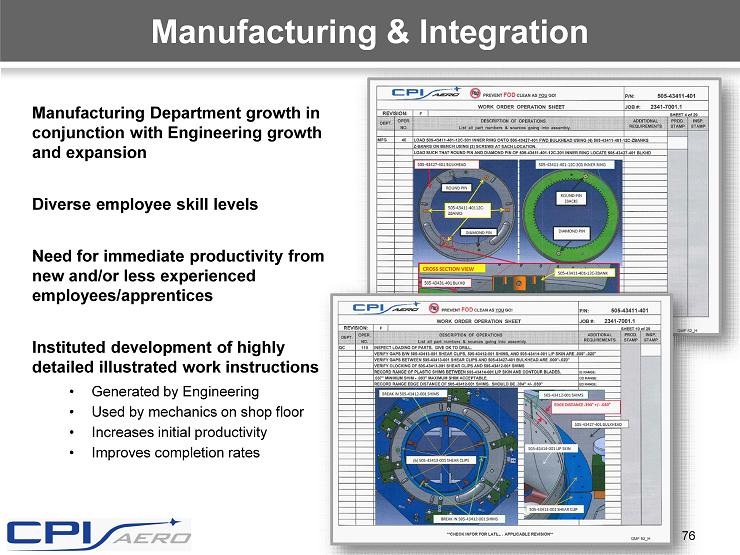

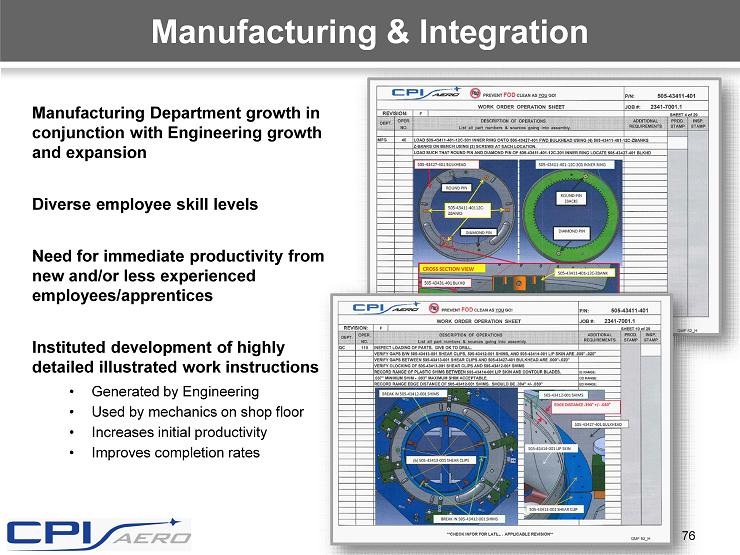

Manufacturing Department growth in conjunction with Engineering growth and expansion Diverse employee skill levels Need for immediate productivity from new and/or less experienced employees/apprentices Instituted development of highly detailed illustrated work instructions • Generated by Engineering • Used by mechanics on shop floor • Increases initial productivity • Improves completion rates Manufacturing & Integration 76

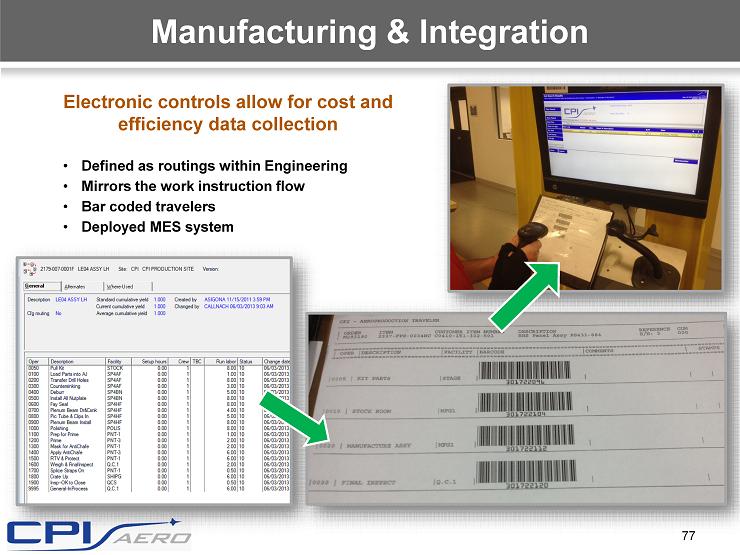

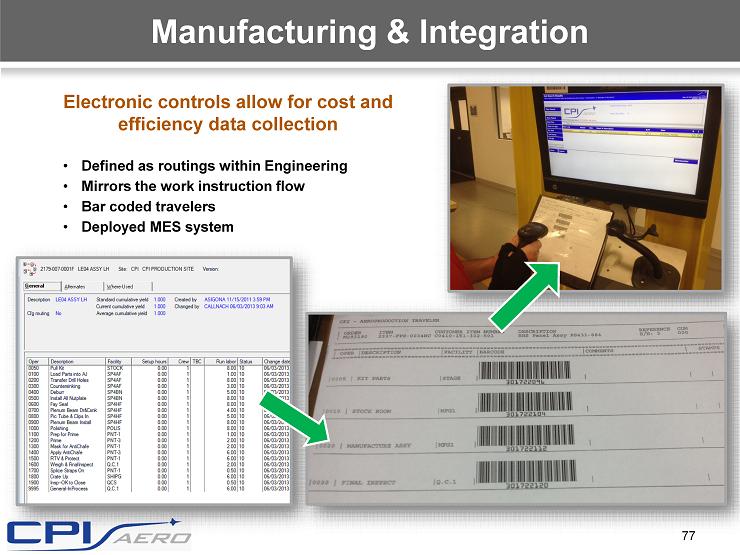

Electronic controls allow for cost and efficiency data collection • Defined as routings within Engineering • Mirrors the work instruction flow • Bar coded travelers • Deployed MES system Manufacturing & Integration 77

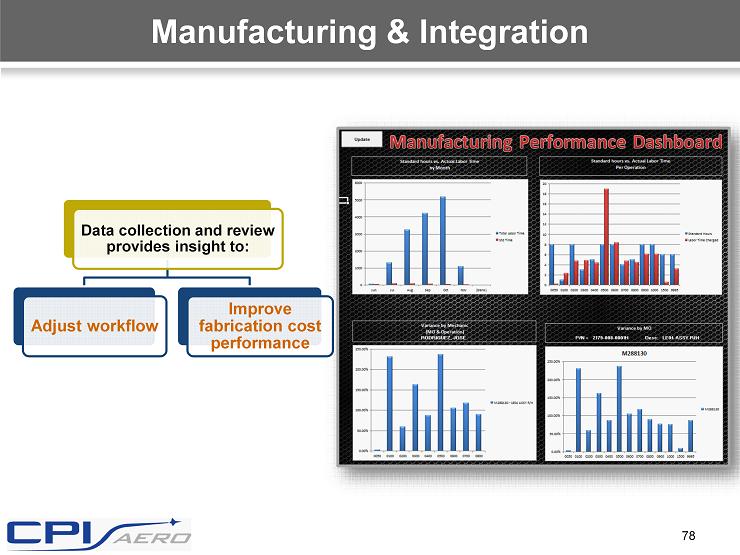

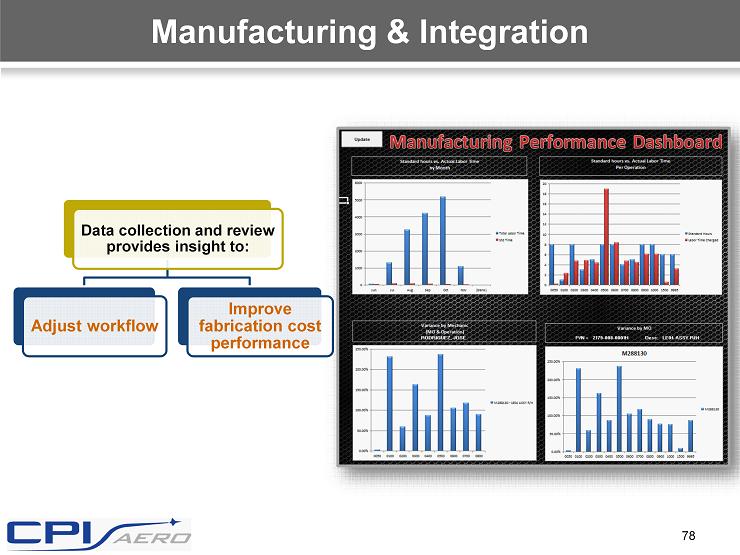

Manufacturing & Integration 78 Data collection and review provides insight to: Adjust workflow Improve fabrication cost performance

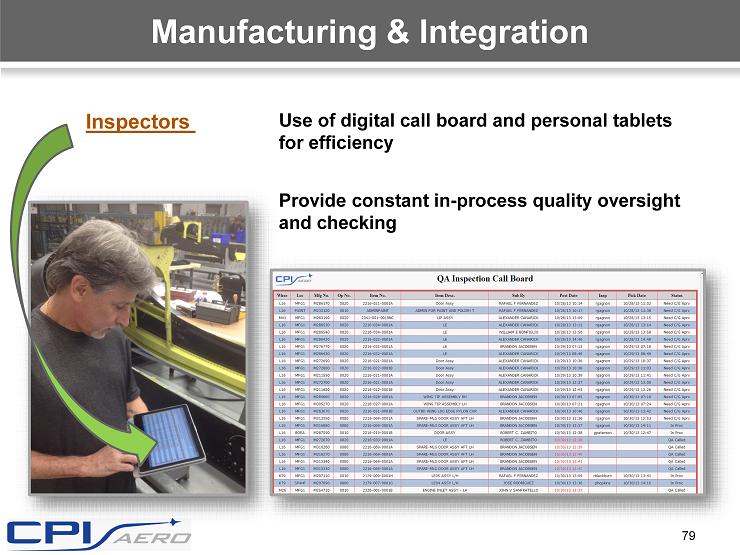

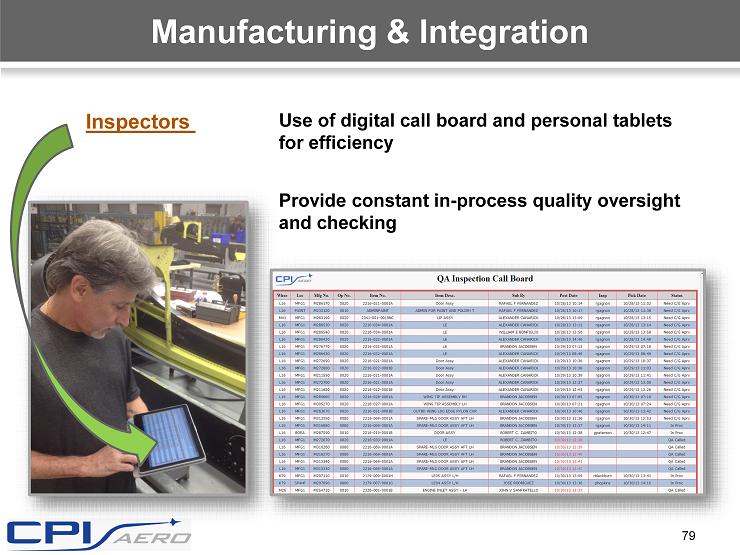

Use of digital call board and personal tablets for efficiency Manufacturing & Integration 79 Inspectors Provide constant in - process quality oversight and checking

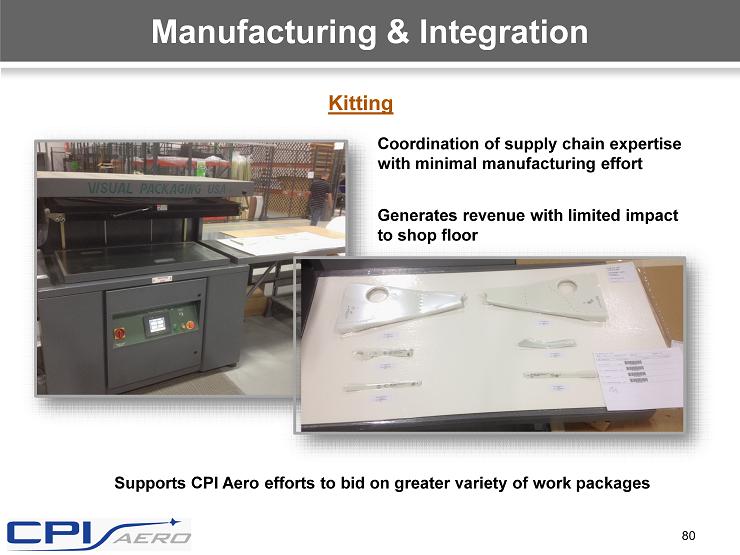

Kitting Supports CPI Aero efforts to bid on greater variety of work packages Manufacturing & Integration 80 Coordination of supply chain expertise with minimal manufacturing effort Generates revenue with limited impact to shop floor

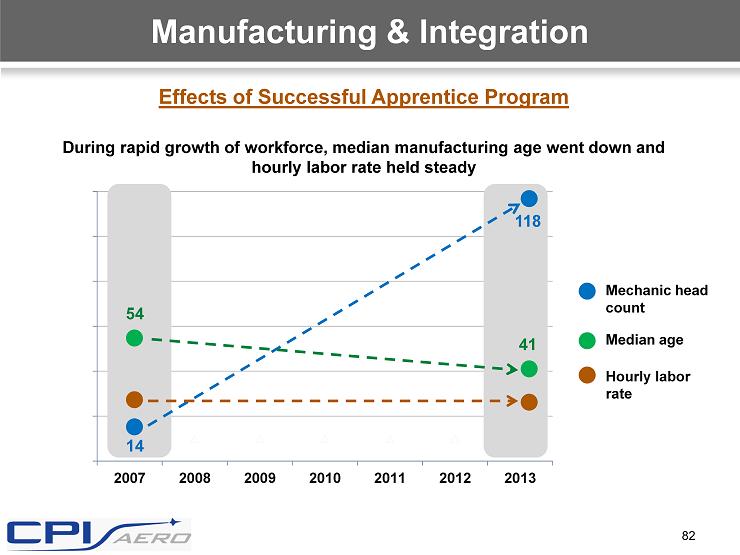

• Defined training syllabus • Rapid rate to a point of meaningful production contribution (average 8 - 10 weeks) • Mentoring program • 95% graduation rate Manufacturing & Integration 81 Apprentice Program Provides steady stream of manpower to cover attrition and support continued steady growth

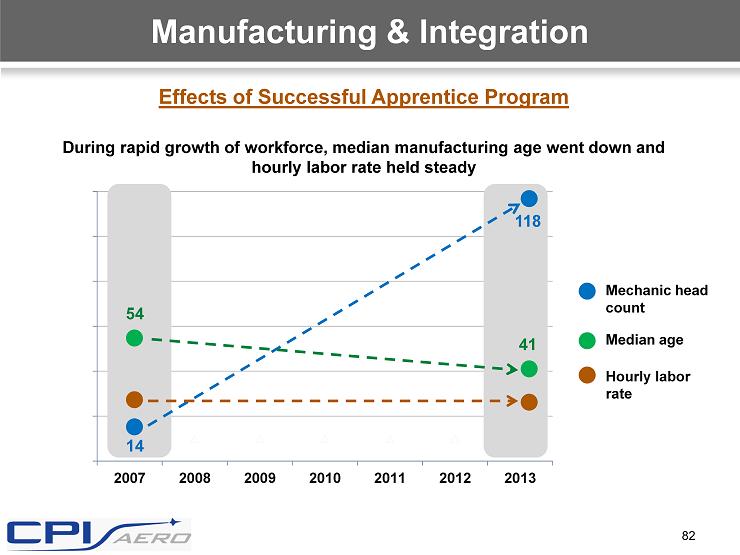

0 20 40 60 80 100 120 2007 2008 2009 2010 2011 2012 2013 Effects of Successful Apprentice Program During rapid growth of workforce, median manufacturing age went down and hourly labor rate held steady Manufacturing & Integration Mechanic head count Median age Hourly labor rate 54 41 14 118 82

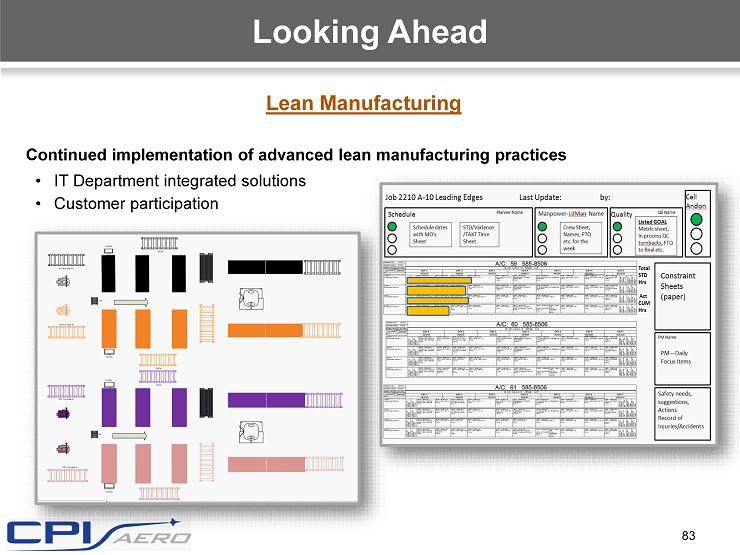

Lean Manufacturing Continued implementation of advanced lean manufacturing practices • IT Department integrated solutions • Customer participation Looking Ahead 83

Automation Technologies Stepped approach ▪ Assimilate ▪ Optimize ▪ Evaluate ▪ Increase scope Looking Ahead 84

Lunch and Facility Tour 12:00 noon – 1:45 pm Meet our program managers, engineers, technicians and mechanics See our assemblies: skin panels, leading edges, flight control surfaces, wing tips, cowl doors and engine inlets 85

Meet our Program Managers and Engineers Mike Wilbert Derick Martin Rob Isoldi Dan Gray Jessica Hill Tour of our 171,000 Sq. Ft. Facility Anthony Sigona Mary Zembis 86 Konrad Strumidlo Charles Munna Tom Luizzi

Afternoon Agenda 1:45 pm – 3:30 pm EXECUTIVE PRESENTATIONS 87 • Vincent Palazzolo, Chief Financial Officer Financial Highlights and Analysis • Edward Fred, Chief Executive Officer and President Industry Outlook and Closing Remarks

Vincent Palazzolo Chief Financial Officer Mr . Palazzolo has been Chief Financial Officer of the Company since May 2004 . From 1988 to 2003 , Mr . Palazzolo was employed by Goldstein Golub Kessler LLP (“GGK”), where he was Audit Partner from 1999 to 2003 . In that role, he managed all aspects of the firm’s audit practice, including SEC reporting and compliance . Mr . Palazzolo also has extensive experience working with manufacturing and distribution companies, as well as corporate finance and mergers and acquisitions . GGK was retained by CPI Aero from 1994 through May 2004 , and during this time, Mr . Palazzolo was an integral member of the CPI audit team . Mr . Palazzolo holds a Bachelor of Business Administration in Accounting from Hofstra University, is a Certified Public Accountant, and a member of AICPA and NYSSCPA . In 2011 , Mr . Palazzolo was named the Long Island Chief Financial Officer of the Year by Long Island Business News . In 2013 , Mr . Palazzolo was named the IMA’s Financial Executive of the Year . Financial Highlights and Analysis 88

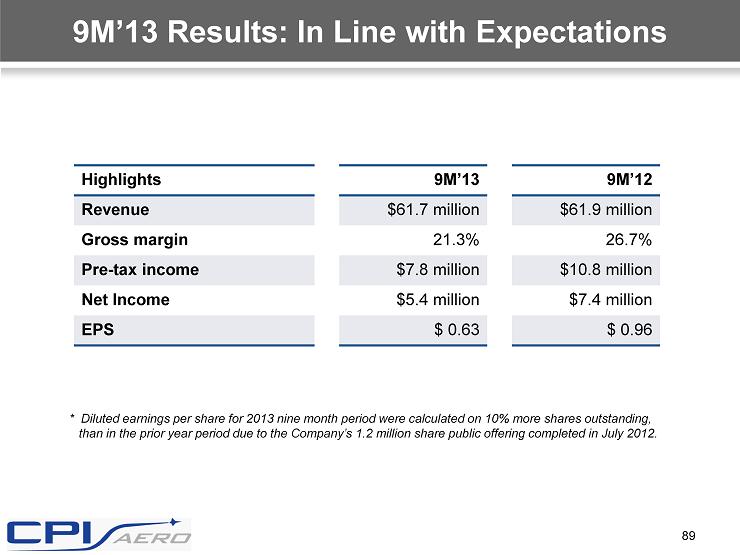

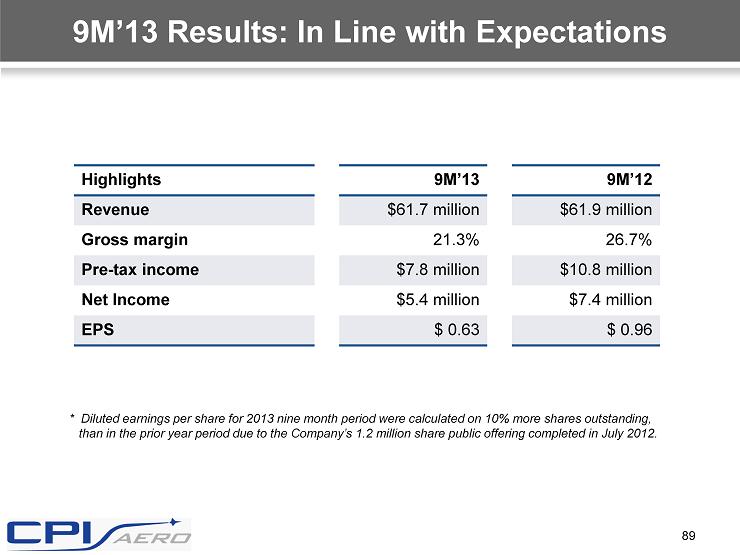

9M ’13 Results: In Line with Expectations 89 Highlights Revenue Gross margin Pre - tax income Net Income EPS 9M’13 $61.7 million 21.3% $7.8 million $5.4 million $ 0.63 9M’12 $61.9 million 26.7% $10.8 million $7.4 million $ 0.96 * Diluted earnings per share for 2013 nine month period were calculated on 10% more shares outstanding, than in the prior year period due to the Company’s 1.2 million share public offering completed in July 2012.

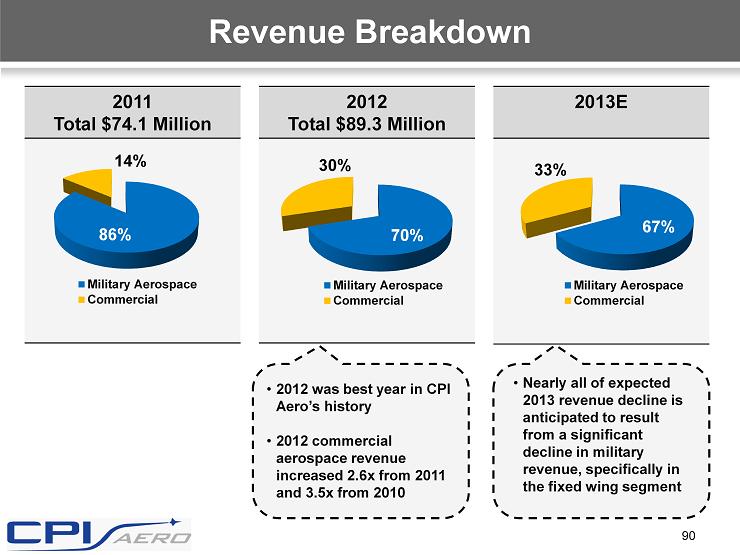

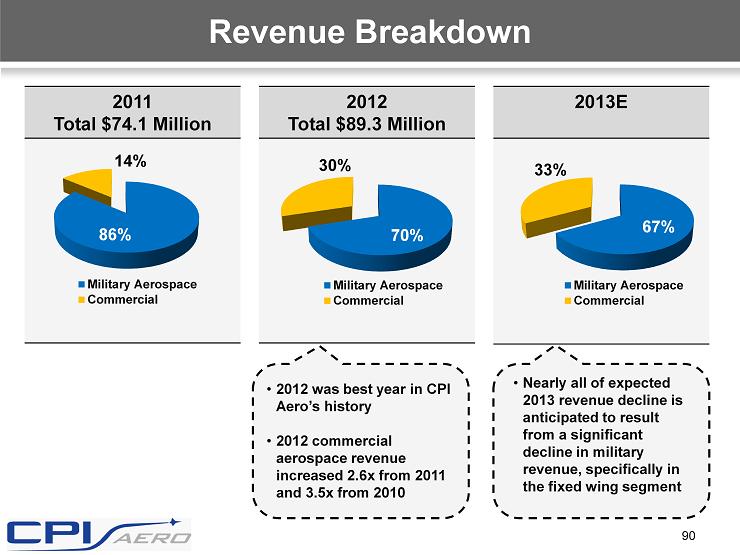

2012 Total $89.3 Million 70% 30% Military Aerospace Commercial 2011 Total $74.1 Million 86% 14% Military Aerospace Commercial 2013E Revenue Breakdown 90 • 2012 was best year in CPI Aero’s history • 2012 commercial aerospace revenue increased 2.6x from 2011 and 3.5x from 2010 67% 33% Military Aerospace Commercial • Nearly all of expected 2013 revenue decline is anticipated to result from a significant decline in military revenue, specifically in the fixed wing segment

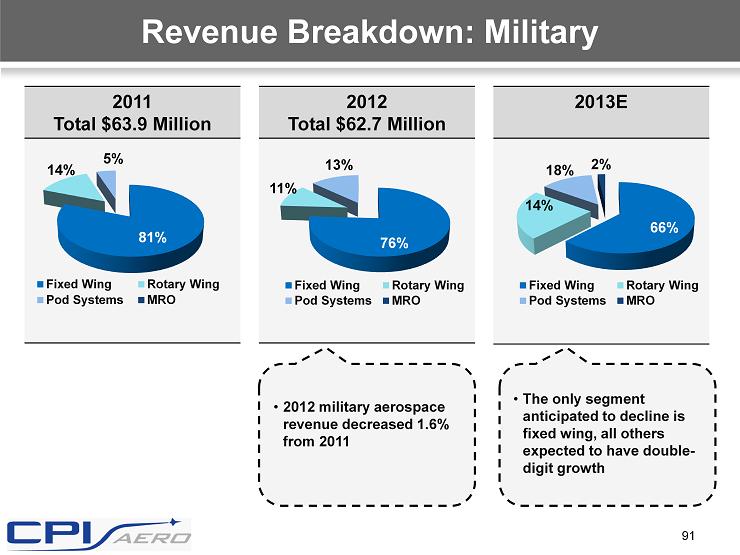

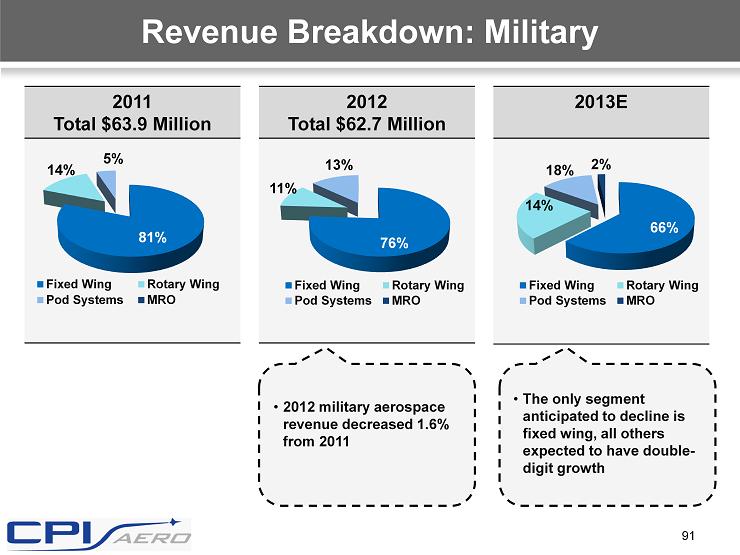

2012 Total $62.7 Million 76% 11% 13% Fixed Wing Rotary Wing Pod Systems MRO 2011 Total $63.9 Million 81% 14% 5% Fixed Wing Rotary Wing Pod Systems MRO • 2012 military aerospace revenue decreased 1.6% from 2011 2013E Revenue Breakdown: Military 91 • The only segment anticipated to decline is fixed wing, all others expected to have double - digit growth 66% 14 % 18% 2% Fixed Wing Rotary Wing Pod Systems MRO

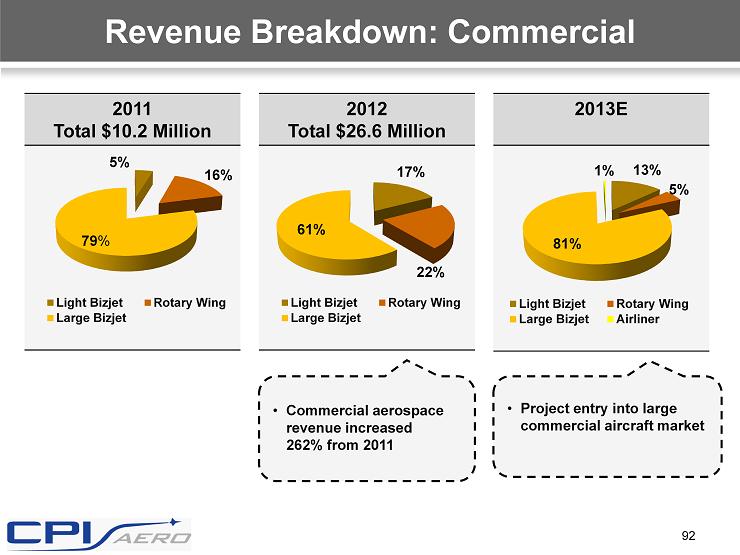

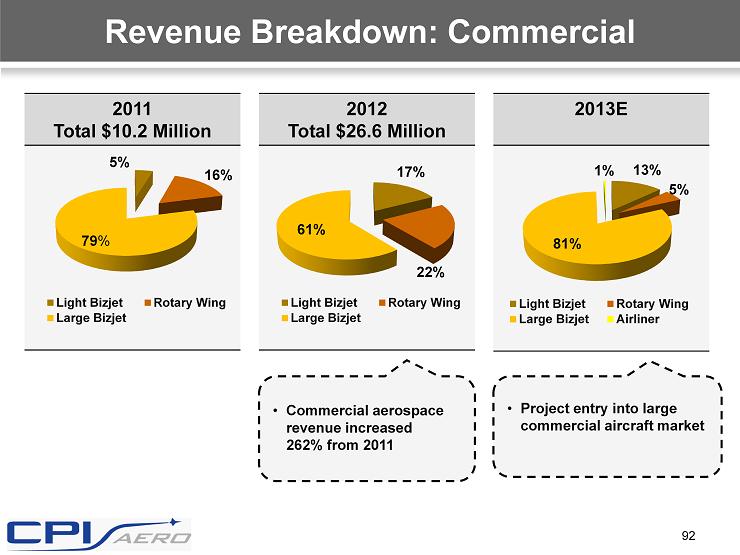

2012 Total $26.6 Million 17% 22% 61% Light Bizjet Rotary Wing Large Bizjet 2011 Total $10.2 Million 5% 16% Light Bizjet Rotary Wing Large Bizjet 79 % 2013E Revenue Breakdown: Commercial 92 • Project entry into large commercial aircraft market 13% 5% 81% 1% Light Bizjet Rotary Wing Large Bizjet Airliner • Commercial aerospace revenue increased 262% from 2011

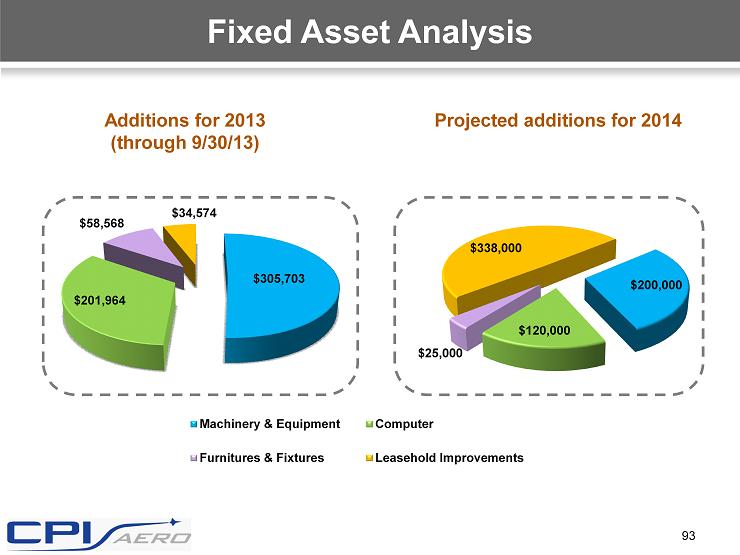

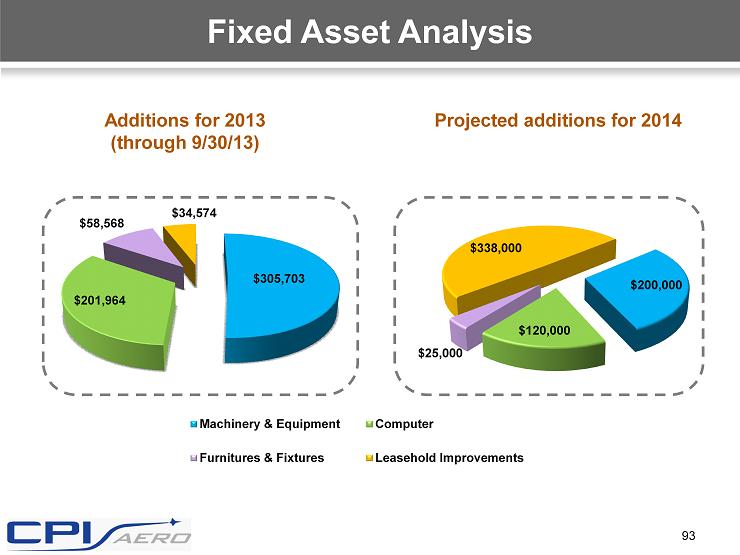

$305,703 $201,964 $58,568 $34,574 Machinery & Equipment Computer Furnitures & Fixtures Leasehold Improvements $200,000 $120,000 $25,000 $338,000 Fixed Asset Analysis Additions for 2013 (through 9/30/13) Projected additions for 2014 93

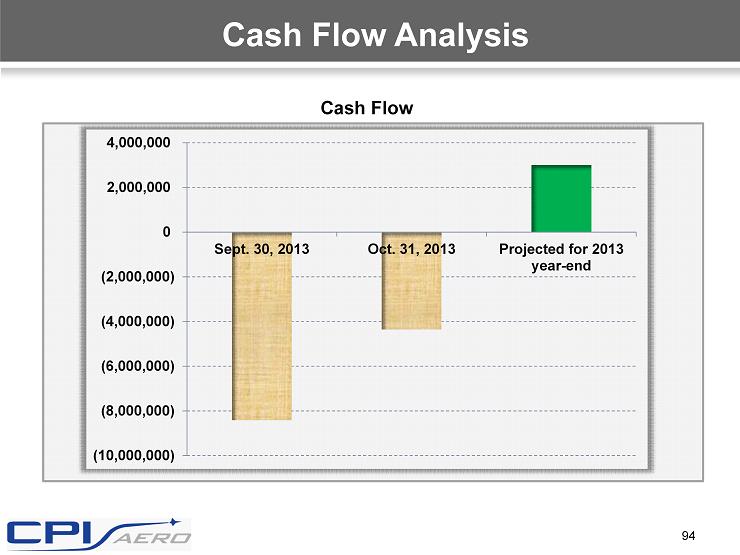

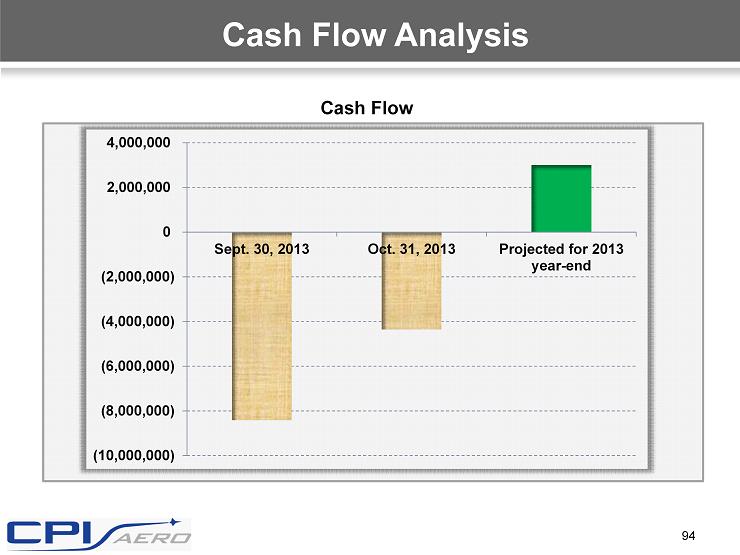

Cash Flow Analysis (10,000,000) (8,000,000) (6,000,000) (4,000,000) (2,000,000) 0 2,000,000 4,000,000 Sept. 30, 2013 Oct. 31, 2013 Projected for 2013 year-end 94 Cash Flow

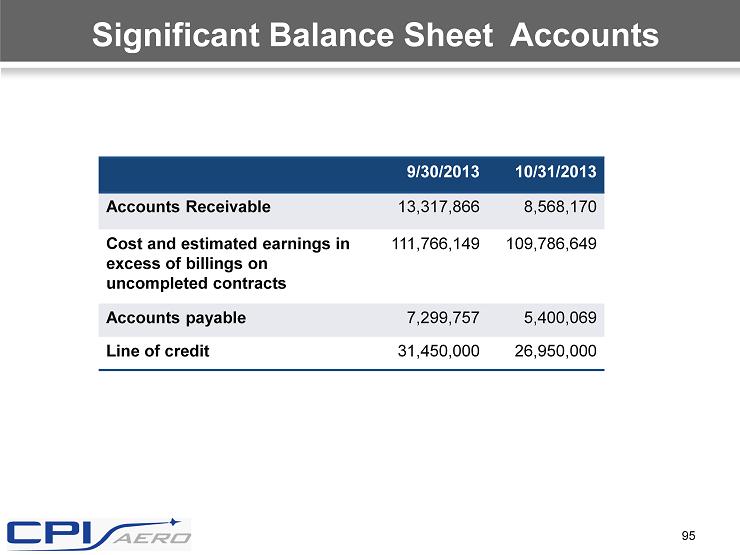

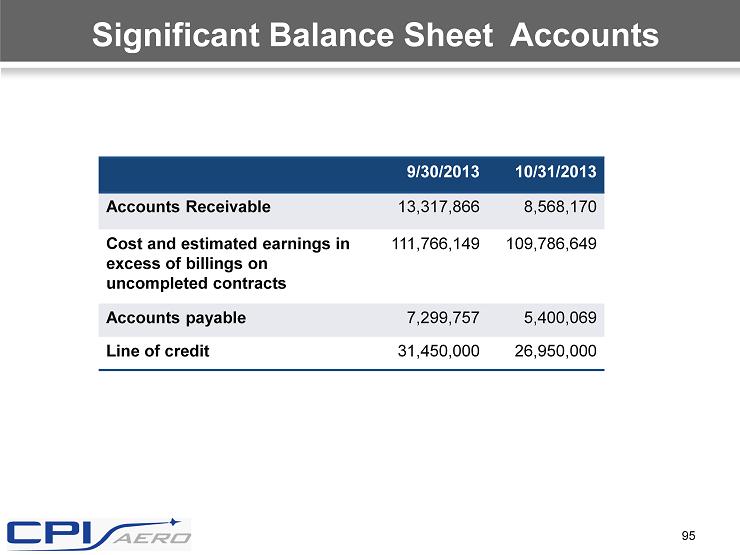

Significant Balance Sheet Accounts 9/30/2013 10/31/2013 Accounts Receivable 13,317,866 8,568,170 Cost and estimated earnings in excess of billings on uncompleted contracts 111,766,149 109,786,649 Accounts payable 7,299,757 5,400,069 Line of credit 31,450,000 26,950,000 95

Edward Fred Chief Executive Officer and President Mr . Fred has been President of the Company since January 2002 . He was appointed Chief Executive Officer in January 2003 . Prior to being appointed President, Mr . Fred held various positions with the company beginning in February 1995 . For approximately ten years prior to joining the Company, Mr . Fred served in various positions for the international division of Grumman, where he last held the position of Controller . In 2004 , Mr . Fred was the recipient of the Long Island Association’s Small Business Entrepreneurial Advocate Award, and in 2005 , was named an Ernst & Young Entrepreneur of the Year Award recipient . He was a panelist at the 2004 Forbes Dynamic Growth Companies Conference and had his work published in the Journal of Management Development . Mr . Fred holds a BBA in Accounting from Dowling College ( 1980 ), and graduated from the Inaugural Executive MBA program at Hofstra University in May 2002 . Industry and Company Outlook 96

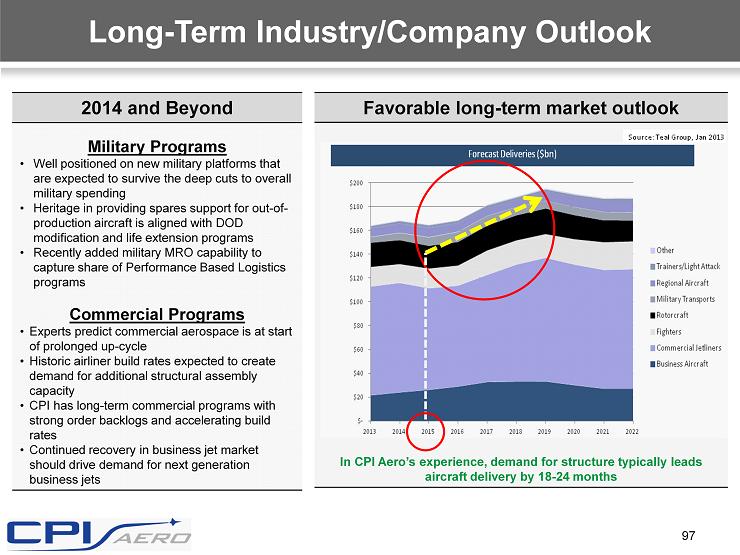

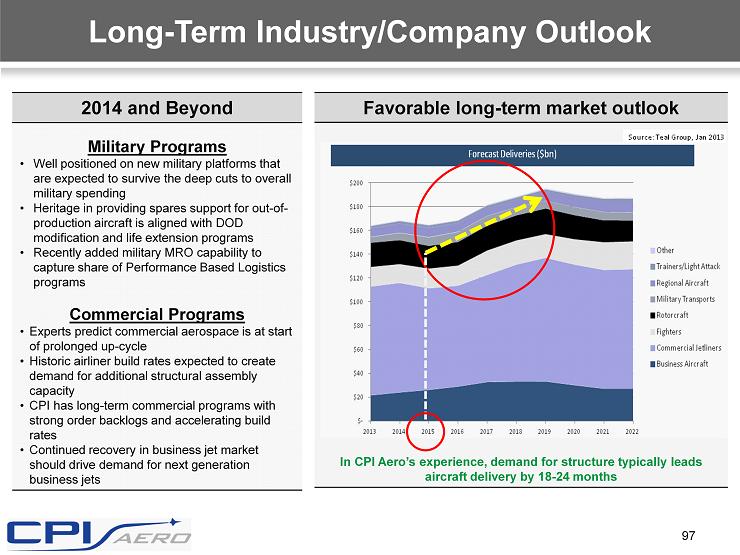

Favorable long - term market outlook Long - Term Industry/Company Outlook 2014 and Beyond Military Programs • Well positioned on new military platforms that are expected to survive the deep cuts to overall military spending • Heritage in providing spares support for out - of - production aircraft is aligned with DOD modification and life extension programs • Recently added military MRO capability to capture share of Performance Based Logistics programs Commercial Programs • Experts predict commercial aerospace is at start of prolonged up - cycle • Historic airliner build rates expected to create demand for additional structural assembly capacity • CPI has long - term commercial programs with strong order backlogs and accelerating build rates • Continued recovery in business jet market should drive demand for next generation business jets 97 In CPI Aero’s experience, demand for structure typically leads aircraft delivery by 18 - 24 months

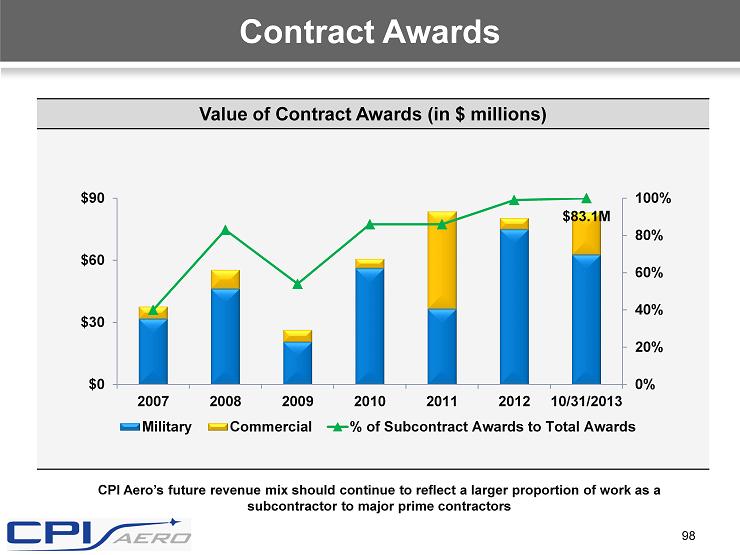

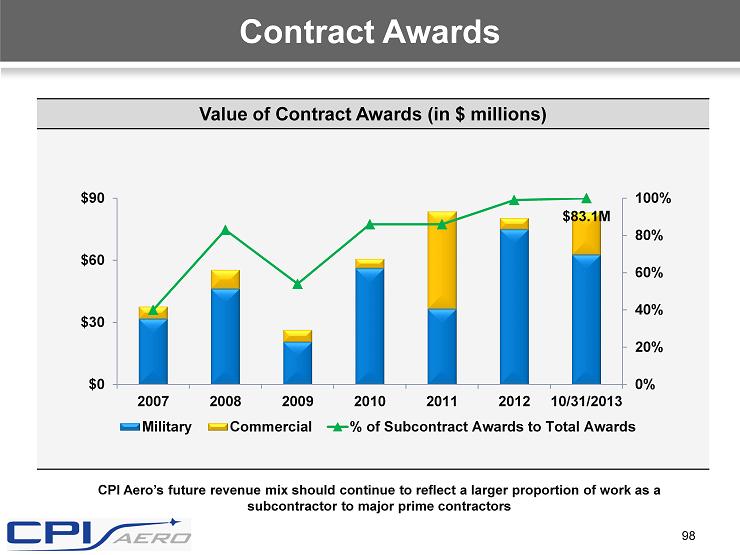

Contract Awards 98 Value of Contract Awards (in $ millions) CPI Aero’s future revenue mix should continue to reflect a larger proportion of work as a subcontractor to major prime contractors 0% 20% 40% 60% 80% 100% $0 $30 $60 $90 2007 2008 2009 2010 2011 2012 10/31/2013 Military Commercial % of Subcontract Awards to Total Awards $83.1M

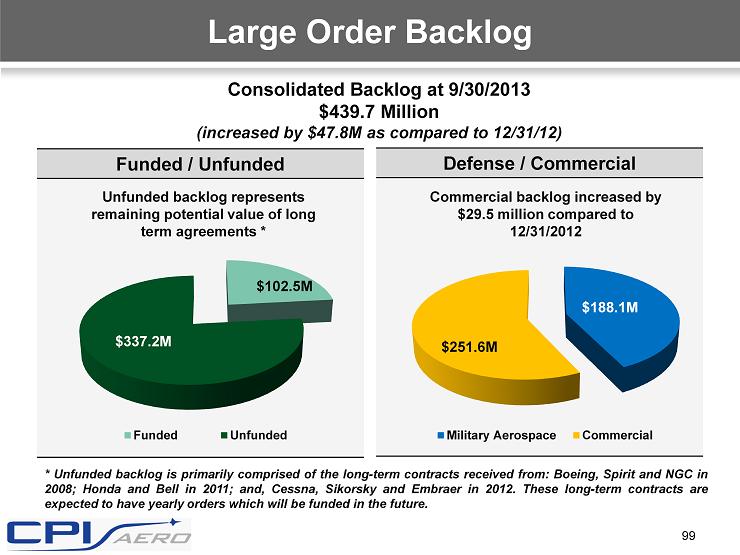

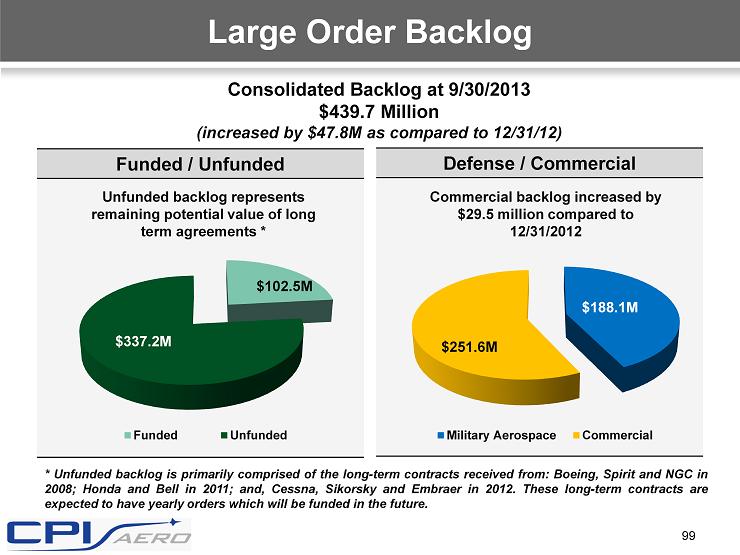

Large Order Backlog Funded / Unfunded $102.5M $ 337.2M Funded Unfunded Unfunded backlog represents remaining potential value of long term agreements * Defense / Commercial Consolidated Backlog at 9/30/2013 $439.7 Million (increased by $47.8M as compared to 12/31/12) $188.1M $251.6M Military Aerospace Commercial Commercial backlog i ncreased by $29.5 million compared to 12/31/2012 99 * Unfunded backlog is primarily comprised of the long - term contracts received from : Boeing, Spirit and NGC in 2008 ; Honda and Bell in 2011 ; and, Cessna, Sikorsky and Embraer in 2012 . These long - term contracts are expected to have yearly orders which will be funded in the future .

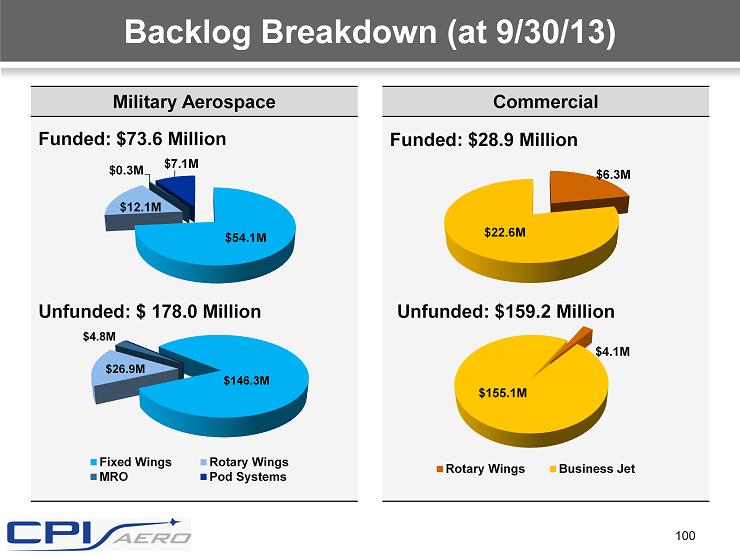

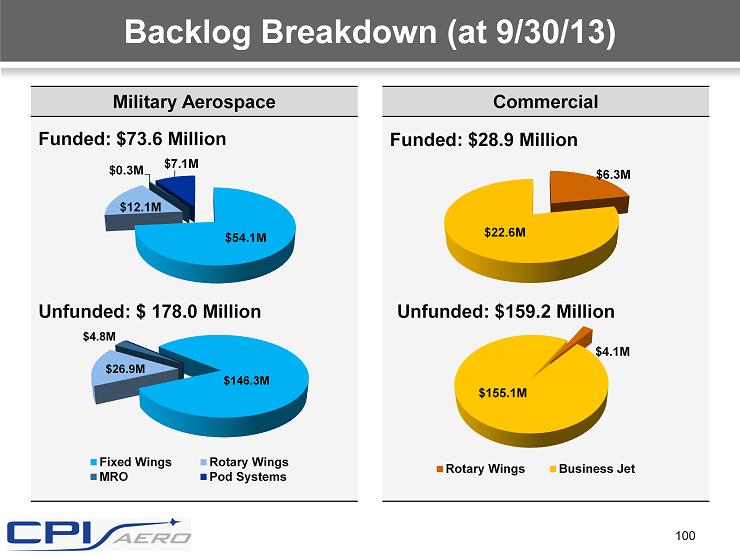

Backlog Breakdown (at 9/30/13) Military Aerospace Commercial Funded: $73.6 Million Unfunded: $ 178.0 Million Funded: $28.9 Million Unfunded: $159.2 Million $54.1M $12.1M $ 0.3M $7.1M $ 146.3M $26.9M $4.8M Fixed Wings Rotary Wings MRO Pod Systems $6.3M $22.6M $4.1M $ 155.1M Rotary Wings Business Jet 100

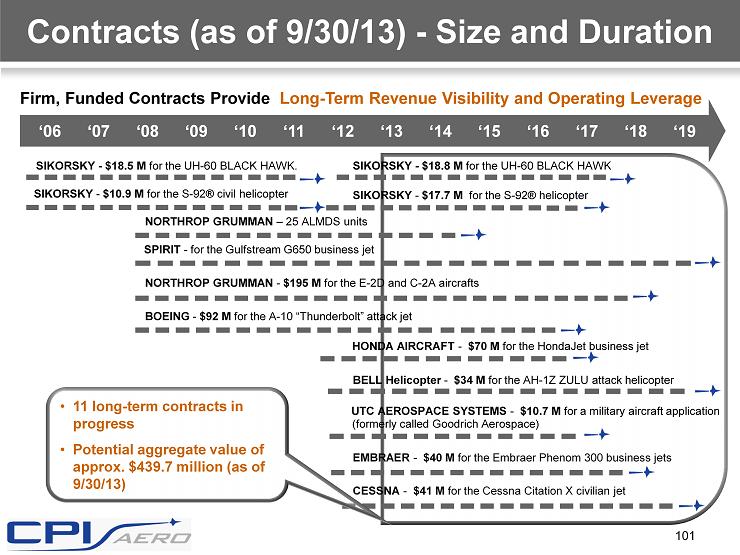

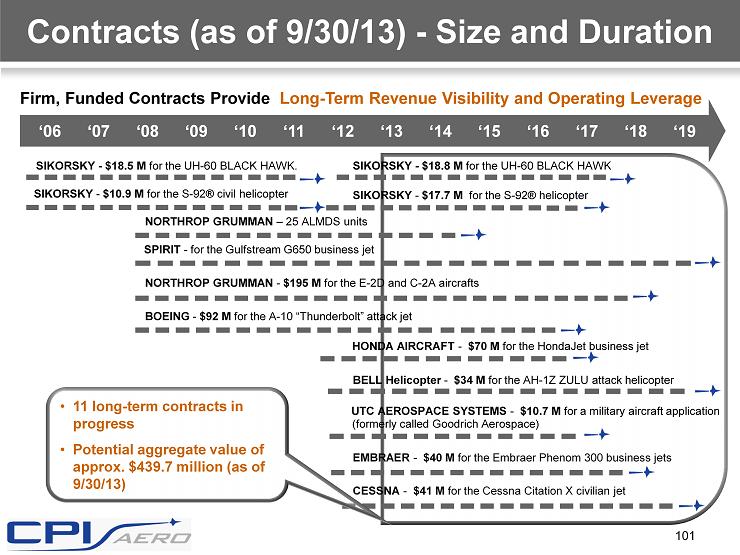

Contracts (as of 9/30/13) - Size and Duration Firm, Funded Contracts Provide Long - Term Revenue Visibility and Operating Leverage ‘06 ‘07 ‘08 ‘09 ‘10 ‘11 ‘12 ‘13 ‘14 ‘15 ‘16 ‘17 ‘18 ‘19 NORTHROP GRUMMAN – 25 ALMDS units NORTHROP GRUMMAN - $195 M for the E - 2D and C - 2A aircrafts SPIRIT - for the Gulfstream G650 business jet BOEING - $92 M for the A - 10 “Thunderbolt” attack jet SIKORSKY - $18.5 M for the UH - 60 BLACK HAWK. SIKORSKY - $10.9 M for the S - 92® civil helicopter SIKORSKY - $17.7 M for the S - 92® helicopter HONDA AIRCRAFT - $70 M for the HondaJet business jet BELL Helicopter - $34 M for the AH - 1Z ZULU attack helicopter UTC AEROSPACE SYSTEMS - $10.7 M for a military aircraft application EMBRAER - $40 M for the Embraer Phenom 300 business jets SIKORSKY - $ 18.8 M for the UH - 60 BLACK HAWK CESSNA - $41 M for the Cessna Citation X civilian jet • 11 long - term contracts in progress • Potential aggregate value of approx. $439.7 million (as of 9/30/13) (formerly called Goodrich Aerospace) 101

Pursue Subcontracts on Large Commercial Aircraft Expand Relationship with Existing Customers (new program opportunities) Additional Growth Opportunities Embraer Boeing Airbus Pursue Subcontracts on Future Defense Programs 102 Future Light Helicopter New USAF Trainer New Presidential Helicopter

103 Setting Record Straight on 787 Commercial Aircraft Opportunity • Opportunity was not awarded to a competitor • Work was kept in house by large international manufacturer - They did not receive anticipated new contract that would have required open floor space • Potential new customer neither visited CPI nor deemed us incapable of performing this work • This opportunity is no longer reflected on our Bid Pipeline - We are still in contact with this manufacturer for future commercial off - load programs 2014 to be a Year of Growth • Projections are firming up • 2014 performance expected to be better than 2013 and possibly 2012 as well • Uncertainty on 2014 federal budgets remains Looking to Further Expand Board of Directors • Searching for an aerospace leader with expertise in our target markets Aviation Week “Company to Watch” – November 2013 Before We Start the Q&A Session…

104 What Have You Learned About CPI Aero Today? Facility: A “real” aerospace company Processes: CPI Aero does it like all the major aerospace companies, just on a smaller scale Programs: The ones we have, and how we get new ones Business Model: Explains no vertical integration The People: Senior Management Directors Program Managers and Engineers Mechanics and Apprentices

Participants Management Board Members Program Managers Investors Analysts Q&A Session Thank You 105

Contact us CPI Aerostructures Vincent Palazzolo, CFO (631) 586 - 5200 www.cpiaero.com Investor Relations Counsel The Equity Group Inc. Lena Cati (212) 836 - 9611 lcati@equityny.com www.theequitygroup.com 106