Barclays CEO Energy-Power Conference September 8, 2020 Patterson-UTI Energy, Inc.

Forward-Looking Statements This material and any oral statements made in connection with this material include "forward-looking statements" within the meaning of the Securities Act of 1933 and the Securities Exchange Act of 1934. Statements made which provide the Company’s or management’s intentions, beliefs, expectations or predictions for the future are forward-looking statements and are inherently uncertain. The opinions, forecasts, projections or other statements other than statements of historical fact, including, without limitation, plans and objectives of management of the Company are forward-looking statements. It is important to note that actual results could differ materially from those discussed in such forward-looking statements. Important factors that could cause actual results to differ materially include the risk factors and other cautionary statements contained from time to time in the Company’s SEC filings, which may be obtained by contacting the Company or the SEC. These filings are also available through the Company’s web site at http://www.patenergy.com or through the SEC’s Electronic Data Gathering and Analysis Retrieval System (EDGAR) at http://www.sec.gov. We undertake no obligation to publicly update or revise any forward-looking statement. Statements made in this presentation include non-U.S. GAAP financial measures. The required reconciliation to U.S. GAAP financial measures are included on our website and/or at the end of this presentation.

Patterson-UTI Energy Contract Drilling Patterson-UTI Drilling is a leading provider of super-spec drilling rigs with a large footprint across U.S. drilling markets. Pressure Pumping Universal is a full-service pressure pumping company and a leading provider of hydraulic fracturing services, primarily in Texas and Appalachia. Directional Drilling MS Directional offers a comprehensive suite of directional drilling services including directional drilling, downhole performance motors, and measurement while drilling ("MWD"). Superior QC provides advanced data analytics software to improve accuracy of horizontal wellbore placement.

Market Outlook U.S. drilling activity appears to have stabilized at historically low levels. Drilling contractors with advanced technologies such as automation and remote operations are expected to benefit once drilling activity improves. U.S. completion activity has improved from lows seen in May 2020. PTEN expects to average approximately five active frac spreads in the third quarter of 2020, an increase from previous guidance. In the near-term, visibility into future drilling and completion activity remains limited. Over the longer-term, higher levels of drilling and completion activity will be needed to support U.S. oil and gas production as global economies continue to open. As the market recovers, PTEN will continue to expand pricing strategies to share in the value delivered to our customers through new technologies and operational excellence.

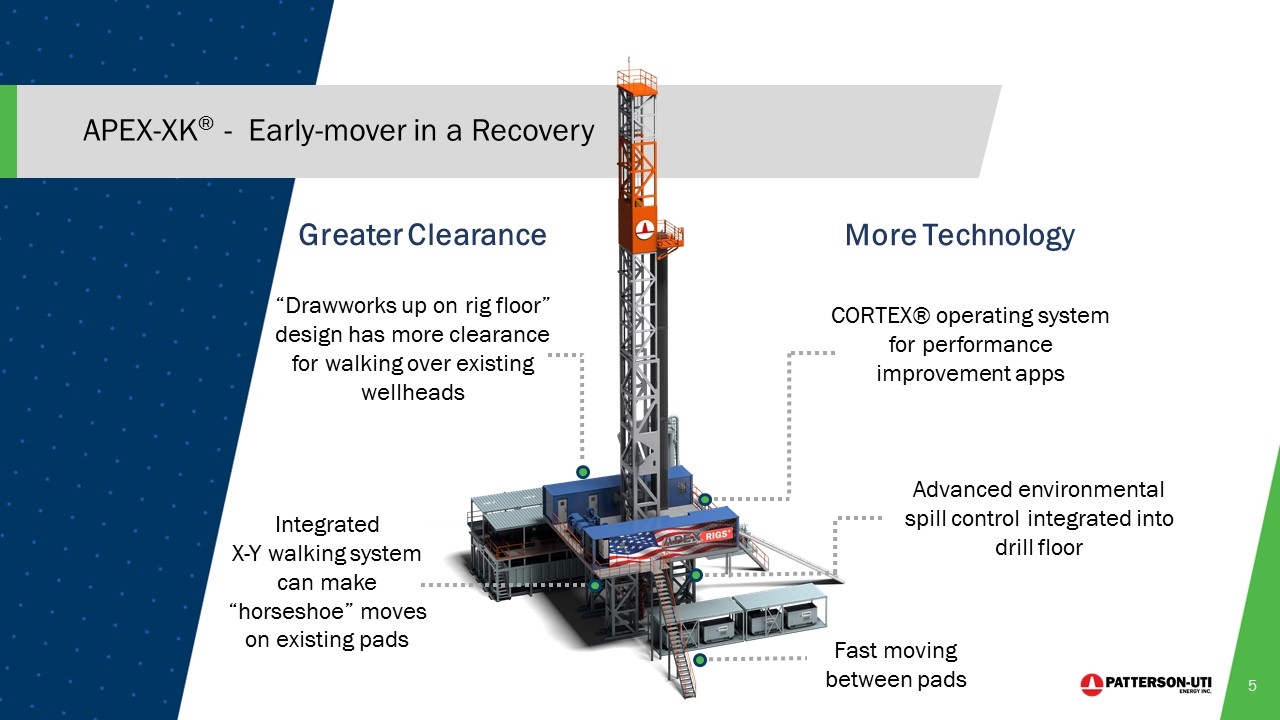

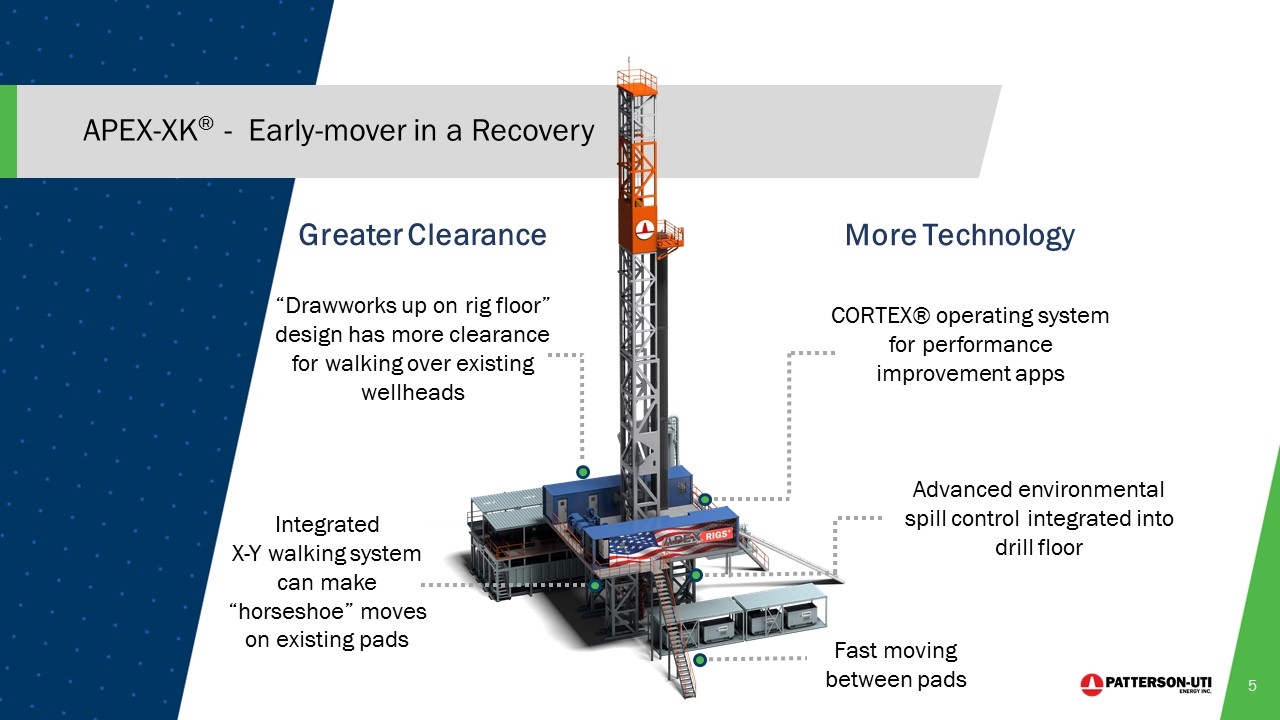

APEX-XK® - Early-mover in a Recovery “Drawworks up on rig floor” design has more clearance for walking over existing wellheads CORTEX® operating system for performance improvement apps Advanced environmental spill control integrated into drill floor Integrated X-Y walking system can make “horseshoe” moves on existing pads Greater Clearance More Technology Fast moving between pads

RIG AUTOMATION

PTEN has the Expertise for Automation and Remote Operations RIG AUTOMATION ® REMOTE OPERATIONS ® ™ ™ DIRECTIONAL DRILLING AUTOMATION ™ ™

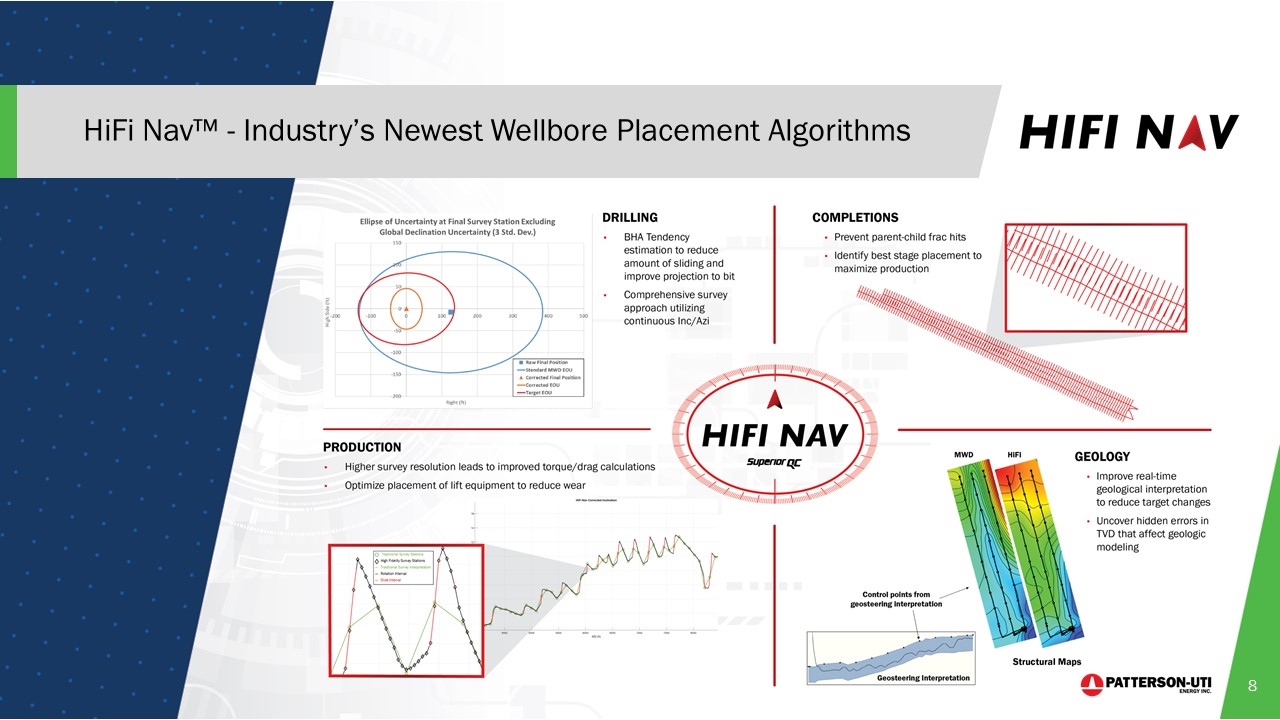

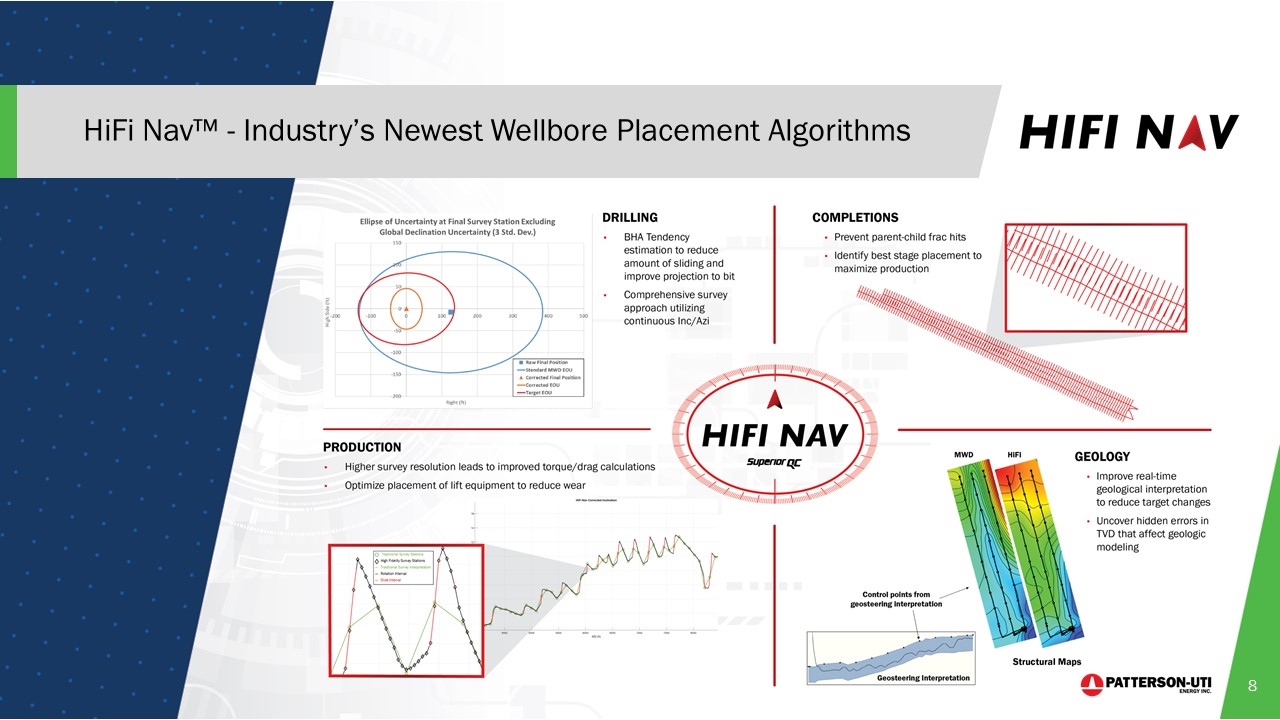

HiFi Nav™ - Industry’s Newest Wellbore Placement Algorithms

Alternative Fuel Leadership

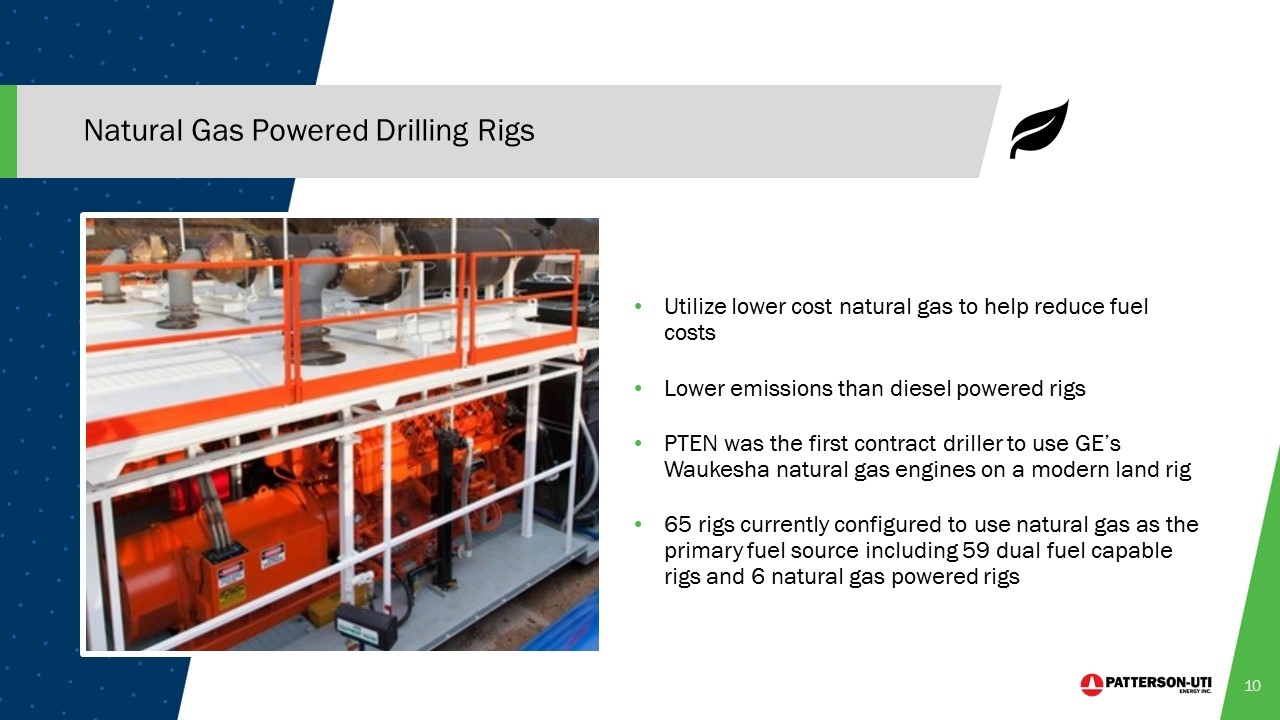

Natural Gas Powered Drilling Rigs Utilize lower cost natural gas to help reduce fuel costs Lower emissions than diesel powered rigs PTEN was the first contract driller to use GE’s Waukesha natural gas engines on a modern land rig 65 rigs currently configured to use natural gas as the primary fuel source including 59 dual fuel capable rigs and 6 natural gas powered rigs

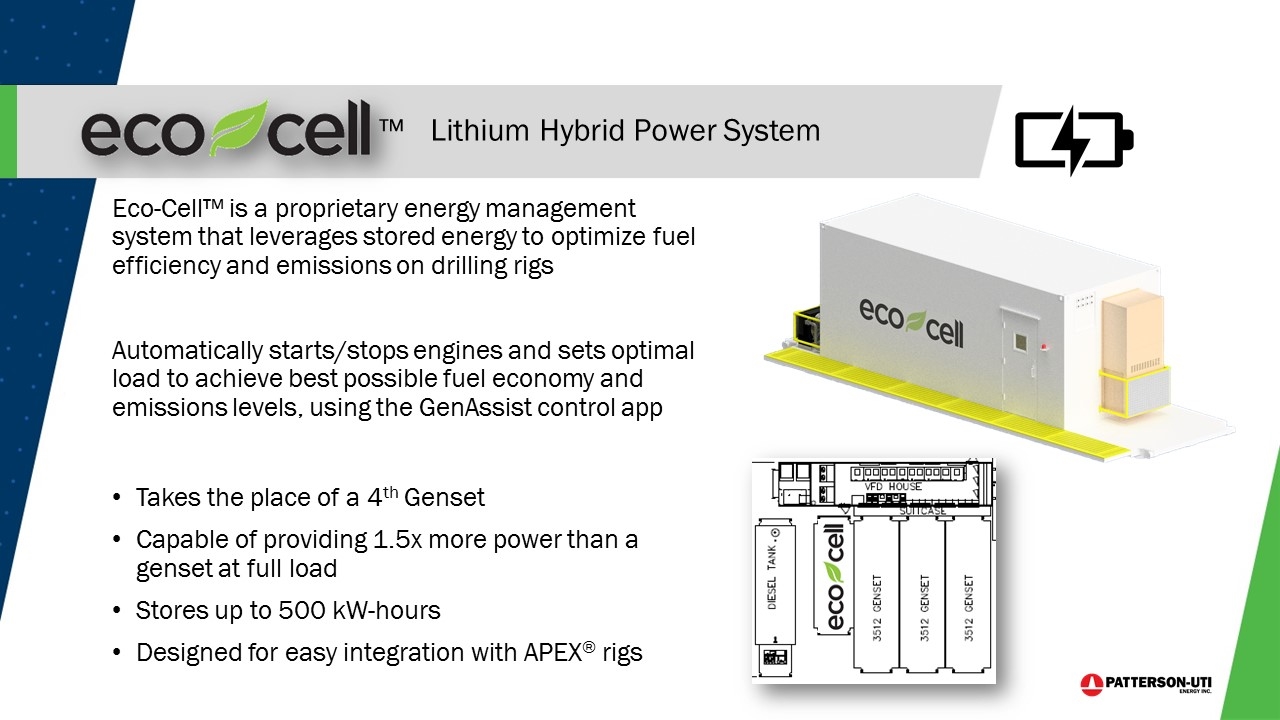

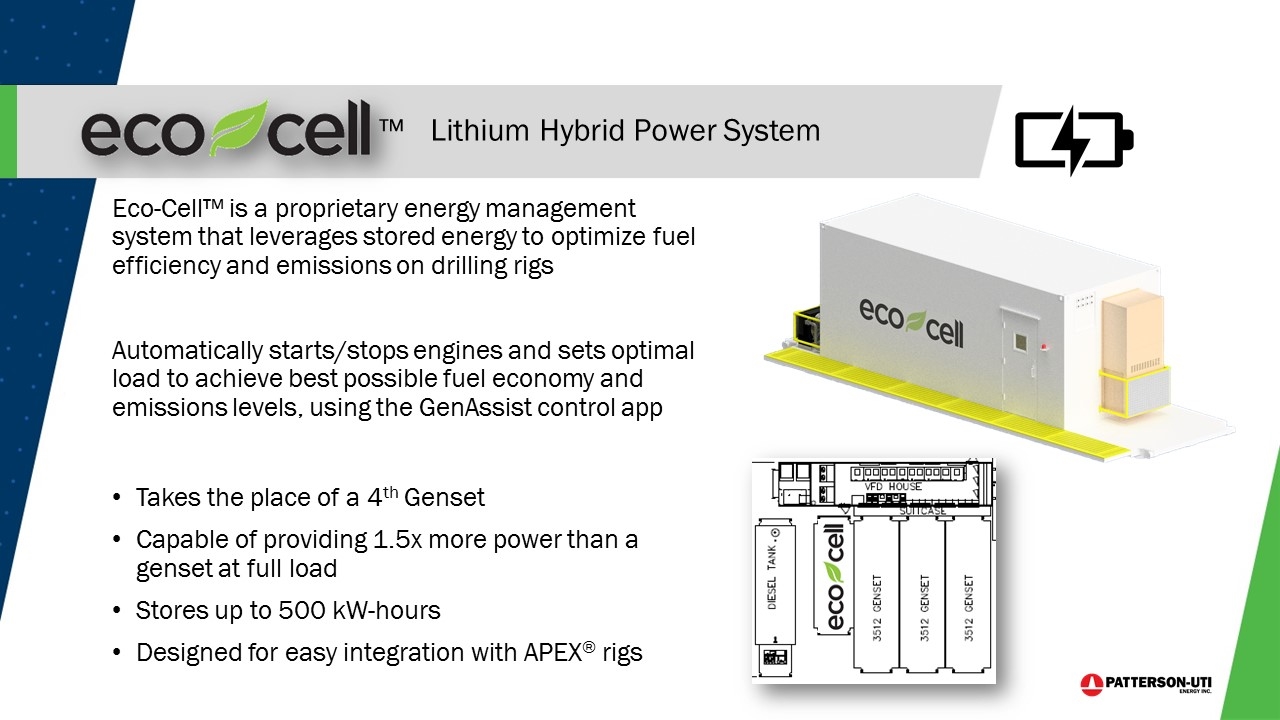

™ Eco-Cell™ is a proprietary energy management system that leverages stored energy to optimize fuel efficiency and emissions on drilling rigs Automatically starts/stops engines and sets optimal load to achieve best possible fuel economy and emissions levels, using the GenAssist control app Takes the place of a 4th Genset Capable of providing 1.5x more power than a genset at full load Stores up to 500 kW-hours Designed for easy integration with APEX® rigs Lithium Hybrid Power System

High Line Electric Utility Power for Drilling Rigs Electrical engineering, control systems and installation services with in-house solutions to connect to high line utility power Unique expertise for drilling rig power requirements Zero drilling rig emissions at the wellsite Recent basins with rigs connected to utility power include Permian and Mid-Con

More flexible fuel source as engines can burn a fuel mix comprised primarily of natural gas PTEN has completed more than 12,400 dual fuel fracturing stages, saving customers approximately 10 million gallons of diesel Reduces operating costs by lowering fuel costs Lowers emissions for environmental sustainability Dual-Fuel Natural Gas Powered Frac Spreads

Appendix

Super-Spec Rigs as the Technology Platform Super-spec rigs will be the platform from which advancements in automation and remote operations are deployed PTEN is well positioned as a leader in the super-spec rig market Advancements in rig technology are expected to be more software driven than hardware driven New business models being applied to advanced technology Performance aspects of contracts are needed to reward contractors for efficiency Contractors should be incentivized to invest in new technology

PTEN’s Proprietary Operating System for APEX® Rigs ®

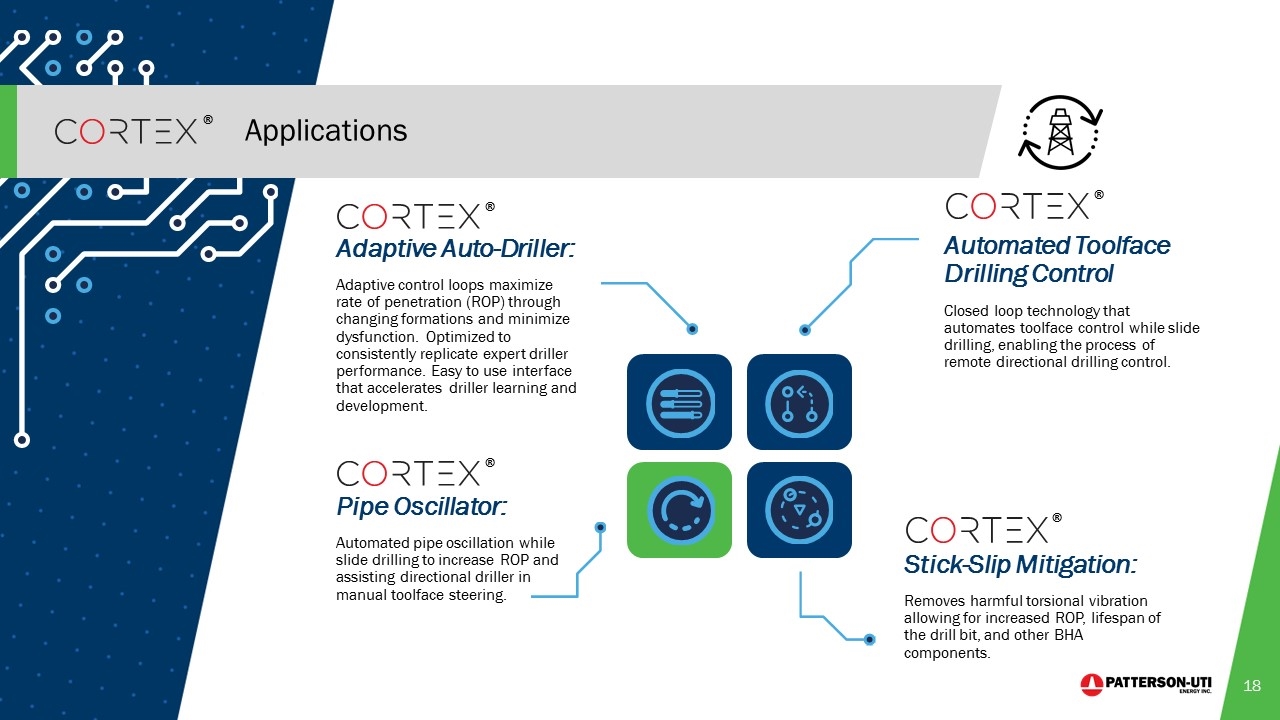

Applications Adaptive Auto-Driller: Adaptive control loops maximize rate of penetration (ROP) through changing formations and minimize dysfunction. Optimized to consistently replicate expert driller performance. Easy to use interface that accelerates driller learning and development. Automated Toolface Drilling Control Closed loop technology that automates toolface control while slide drilling, enabling the process of remote directional drilling control. Stick-Slip Mitigation: Removes harmful torsional vibration allowing for increased ROP, lifespan of the drill bit, and other BHA components. Pipe Oscillator: Automated pipe oscillation while slide drilling to increase ROP and assisting directional driller in manual toolface steering. ® ® ® ® ®

Mpower™ MWD System Robust reliability for today’s drilling conditions The new Mercury™ mud pulse MWD tool from Mpower ™ delivers more information to optimize well placement, improve drilling efficiency and reduce risks New data compression service provides improved telemetry through enhanced data transmission rates Now drill longer laterals with higher MWD signal strength and reduced survey times Maximize MWD measurements Continuous Inclination Continuous Azimuth Live shock & vibration Mercury™ Measurement While Drilling (MWD) Platform

Mpact® Downhole Motor The new Mpact® V+ and VII+ design incorporates next generation bearings and transmission assemblies which produce better reliability and higher overall drilling parameter capabilities >Flow rates >Weight on bit (WOB) >Drilling torque >Differential pressure (increased bit life) Consistently delivering higher ROP, longer motor runs, and less slide drilling in the lateral (typically <5%) Mpact® V+ and VII+ Directional Drilling Mud Motor Design

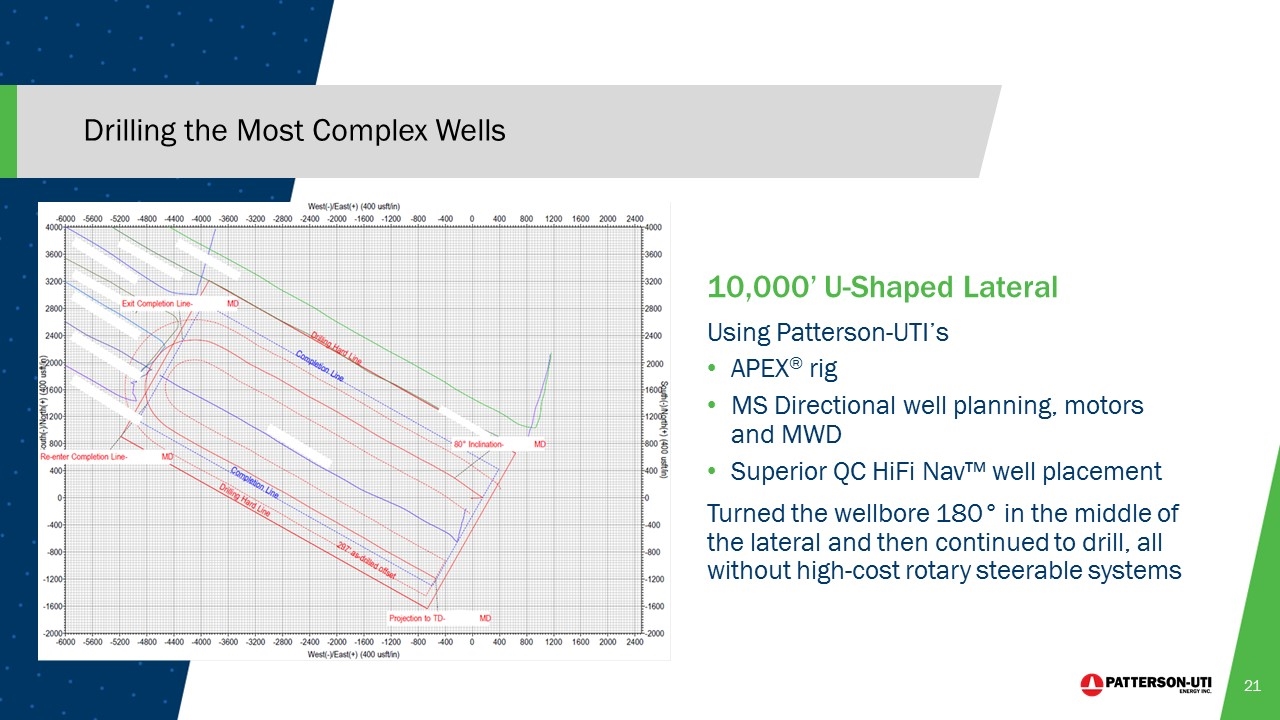

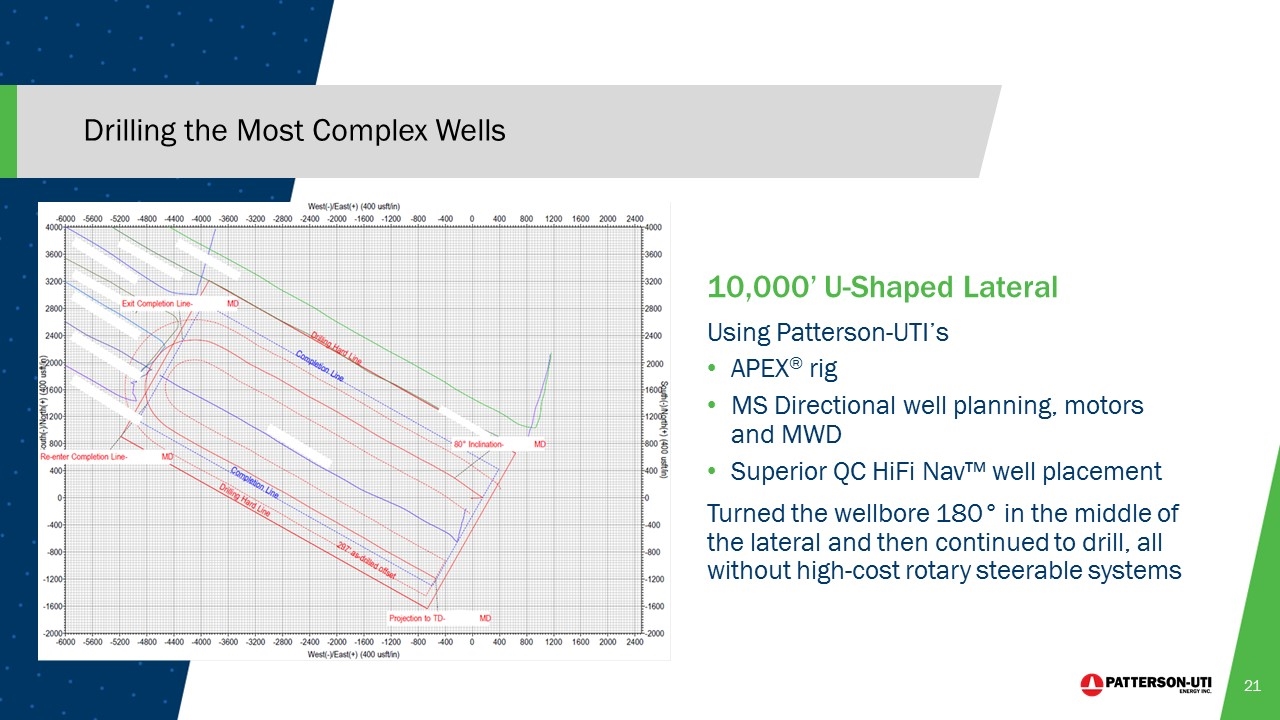

Drilling the Most Complex Wells 10,000’ U-Shaped Lateral Using Patterson-UTI’s APEX® rig MS Directional well planning, motors and MWD Superior QC HiFi Nav™ well placement Turned the wellbore 180° in the middle of the lateral and then continued to drill, all without high-cost rotary steerable systems

DATA ANALYTICS AND REMOTE OPERATIONS

Edge Device Server grade machine installed locally Several communication adapters developed to read/write to control system, EDR, and third party equipment Time series database installed with visualization tools for efficient data management of large data sets Advanced analysis algorithms deployed locally, reducing overall processing required to be completed in the cloud Rig State Stick Slip Detection Auto Driller Dysfunction Procedural Compliance Uses IoT technology to efficiently stream large datasets to remote locations and deploy software updates fleetwide ®

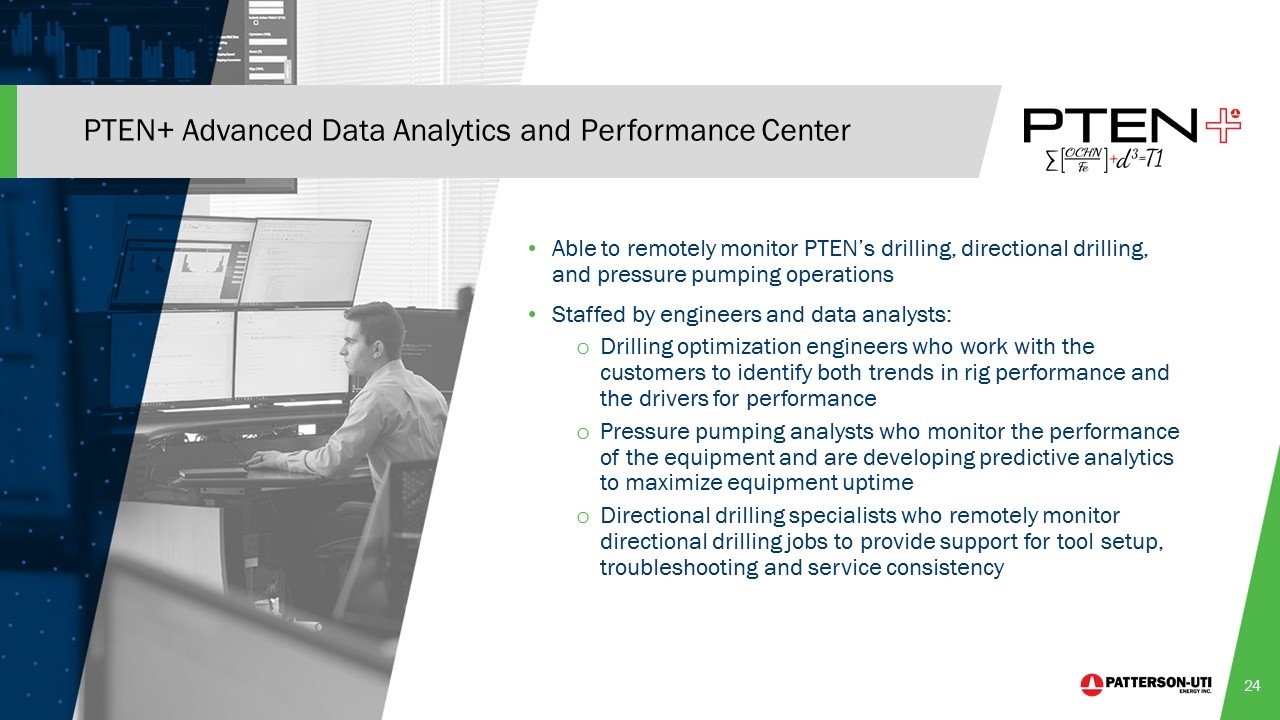

PTEN+ Advanced Data Analytics and Performance Center Able to remotely monitor PTEN’s drilling, directional drilling, and pressure pumping operations Staffed by engineers and data analysts: Drilling optimization engineers who work with the customers to identify both trends in rig performance and the drivers for performance Pressure pumping analysts who monitor the performance of the equipment and are developing predictive analytics to maximize equipment uptime Directional drilling specialists who remotely monitor directional drilling jobs to provide support for tool setup, troubleshooting and service consistency

FINANCIAL FOCUS

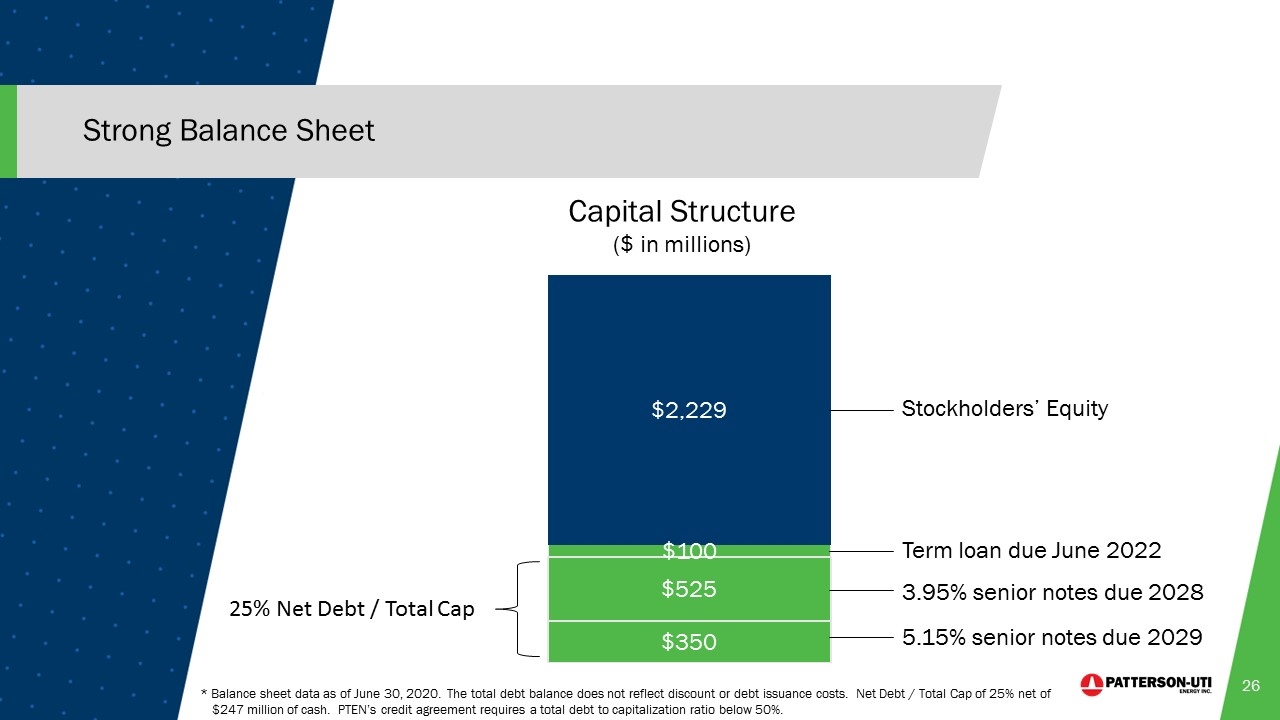

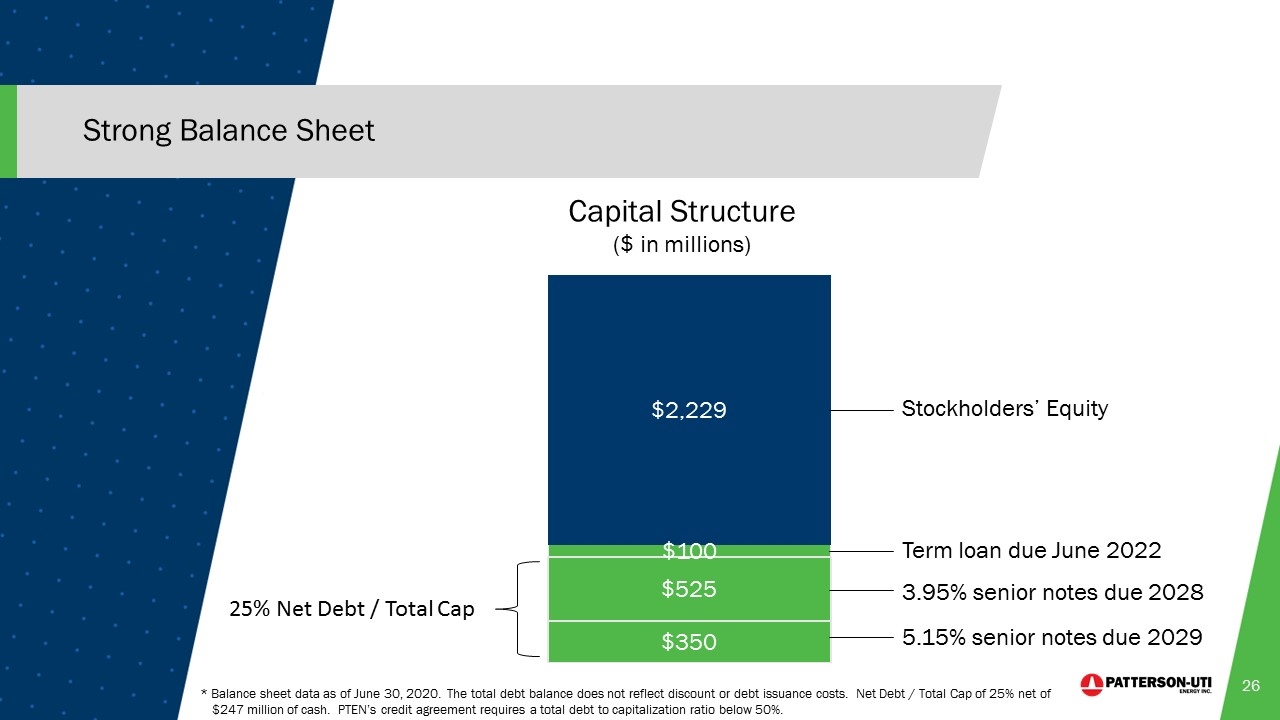

Strong Balance Sheet 5.15% senior notes due 2029 3.95% senior notes due 2028 Stockholders’ Equity Capital Structure ($ in millions) 25% Net Debt / Total Cap * Balance sheet data as of June 30, 2020. The total debt balance does not reflect discount or debt issuance costs. Net Debt / Total Cap of 25% net of $247 million of cash. PTEN’s credit agreement requires a total debt to capitalization ratio below 50%.

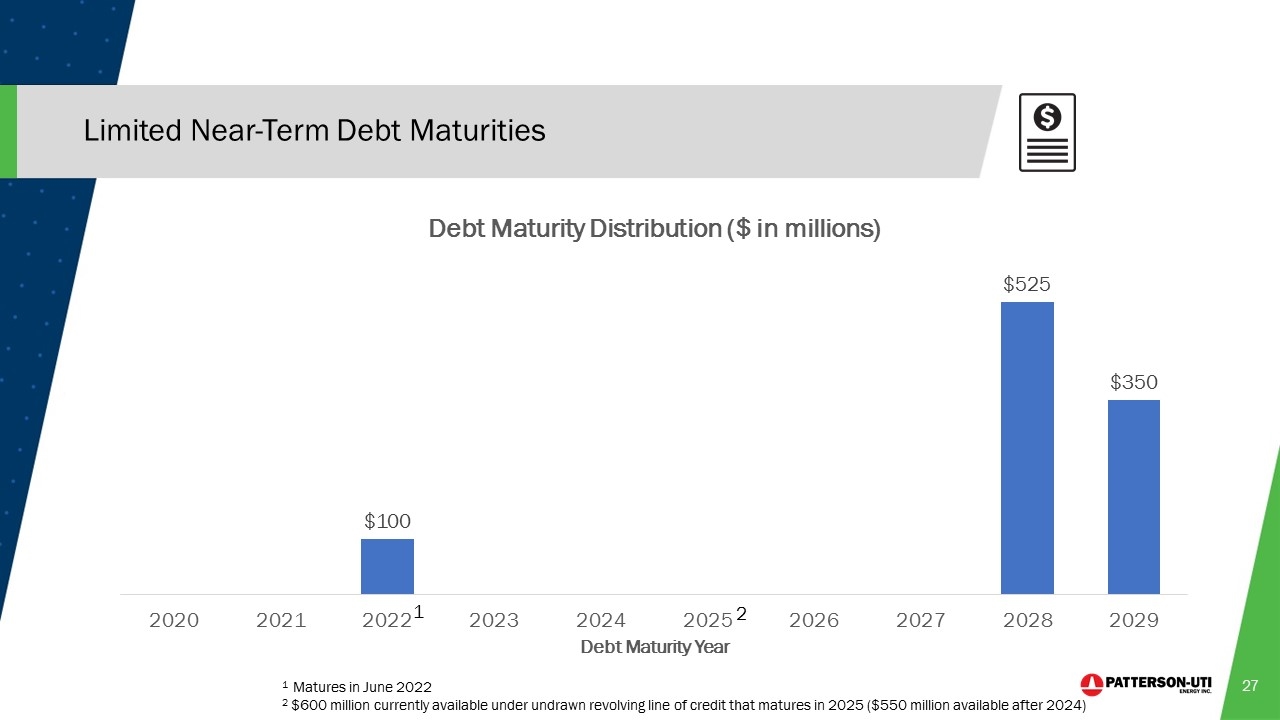

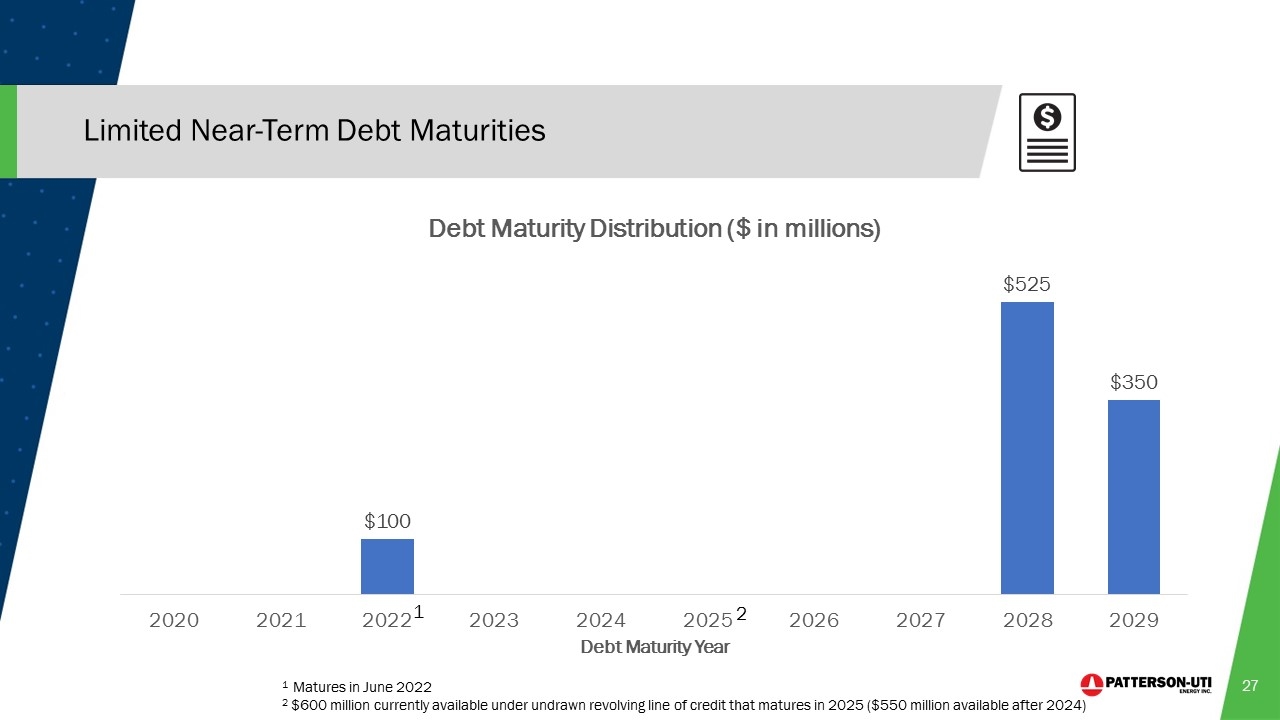

Limited Near-Term Debt Maturities 1 1 Matures in June 2022 2 $600 million currently available under undrawn revolving line of credit that matures in 2025 ($550 million available after 2024) 2

Environmental Sustainability

Patterson-UTI Core Values Safety and Environment We believe that the safety of our employees and the protection of our environment is a cornerstone Operational Excellence We deliver high-quality, value-added services and focus on innovative solutions in all aspects of our work Honesty and Integrity We will act with honesty and integrity in everything we do Respectful Workplace We are committed to providing a working environment that is inclusive, respectful, and supportive Development of our People We are committed to the growth and development of every employee Profitable Business We are committed to delivering superior returns

Environmental Air Quality We utilize natural gas engines, dual-fuel equipment and other technologies that reduce our air emissions Water Quality We strive to conduct our drilling and completion activities in a manner that protects the quality of ground and surface water Land Use We employ spill prevention plans and use additional protective measures in environmentally sensitive areas

Social Our people are our most important asset and our greatest strength Health and Safety Our goal is to provide an incident-free work environment. The safety of our employees and others is our highest priority Diversity and Inclusion We are committed to fostering a work environment where all people feel valued and respected We embrace our diversity of people, thoughts and talents, and combine these strengths to pursue extraordinary results for PTEN, our employees and our stockholders