Exhibit 96.3

TECHNICAL REPORT SUMMARY

FEASIBILITY STUDY

Pampa Orcoma

Sociedad Química y Minera de Chile

Date: April, 2022

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

TECHNICAL REPORT SUMMARY

FEASIBILITY STUDY

Pampa Orcoma

Sociedad Química y Minera de Chile

WSP-SQM0011-TRS-Pampa Orcoma-Rev0

April, 2022

WSP

Av. Las Condes 11.700, Vitacura.

Santiago, Chile

TELÉFONO:

+56 2 2653 8000 wsp.com

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

Statement of Limitations

Sociedad Química y Minera de Chile (SQM) commissioned WSP Ambiental Chile (WSP) to prepare this Technical Report Summary (TRS) on the Orcoma Project in the Tarapacá Region of northern Chile. The disclosure of any information contained in this report is the sole responsibility of the recipient. The content of the TRS has been prepared based on the professional judgment of WSP from the information made available to WSP by SQM at the time of its compilation. Any use made by a third party of this TRS, including any decision made by a third party based on the TRS, is the sole responsibility of the third party. WSP is will not be held responsible for any damages incurred by third parties as a result of decisions taken or actions based on this TRS.

WSP will keep an original copy of this TRS on file for ten years (10 years) from the date of its finalization. This copy, held securely by WSP, will be termed the Master Copy. Any copy of the TRS other than the Master Copy is to be considered a non-controlled copy. WSP cannot vouch for the content or veracity of a non-controlled copy of the TRS. However, if requested to by SQM, or required to by law, WSP will be able to make available a direct copy of the Master Copy for comparison purposes.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

Table of contents

| | 1 | Executive Summary | 1 |

| | 1.1 | Property Summary and Ownership | 1 |

| | 1.2 | Geology and Mineralization | 1 |

| | 1.3 | Status of Exploration | 1 |

| | 1.4 | Mineral Resource Statement | 2 |

| | 1.5 | Mineral Reserve Statement | 3 |

| | 1.6 | Metallurgy and Mineral Processing | 3 |

| | 1.6.1 | Metallurgical Test Work Summary | 3 |

| | 1.6.2 | Processing Summary | 4 |

| | 1.7 | Mine Design, Optimization, and Scheduling | 5 |

| | 1.8 | Capital Costs, Operating Costs, and Financial Analysis | 6 |

| | 1.8.1 | Capital and Operating Costs | 6 |

| | 1.8.2 | Financial Analysis | 6 |

| | 1.9 | Conclusions and Recommendations | 10 |

| | 2 | Introduction | 11 |

| | 2.1 | Terms of Reference and Purpose of the Report | 11 |

| | 2.2 | Source of Data and Information | 11 |

| | 2.3 | Details of Inspection | 16 |

| | 2.4 | Previous Reports on Project | 16 |

| | 3 | Description and Location | 17 |

| | 3.1 | Location | 17 |

| | 3.2 | Area of the property | 18 |

| | 3.3 | Mineral Titles, Claims, Rights, Leases, and Options | 18 |

| | 3.4 | Mineral Rights | 21 |

| | 3.5 | Environmental Impacts and Permitting | 21 |

| | 3.6 | Other Significant Factors and Risks | 22 |

| | 3.7 | Royalties and Agreements | 23 |

| | 4 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 24 |

| | 4.1 | Topography, Elevation and Vegetation | 24 |

| | 4.2 | Accessibility and Transportation to the Property | 24 |

| | 4.3 | Climate and Length of Operating Season | 26 |

| | 4.4 | Infrastructure Availability and Sources | 26 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| | 5 | History | 28 |

| | 6 | Geological Setting, Mineralization, and Deposit | 29 |

| | 6.1 | Geomorphological setting of the Pampa Orcoma Property | 29 |

| | 6.2 | Regional Geology | 31 |

| | 6.3 | Local Geology | 33 |

| | 6.3.1 | Subsurface Units (within the Surface Unit Alluvial and Colluvial Deposits) | 36 |

| | 6.3.2 | Sedimentary Units | 36 |

| | 6.3.3 | Volcanic Rocks | 37 |

| | 6.4 | Deposit Types | 37 |

| | 7 | Exploration | 38 |

| | 7.1 | Surveys and Investigations | 38 |

| | 7.1.1 | Trial Pit Exploration | 38 |

| | 7.1.2 | Borehole Exploration | 38 |

| | 7.1.3 | 400-x-400 m, 200-x-200 m, and 50-x-50 m Grids Drilling Campaign Results | 39 |

| | 7.1.4 | Diamond Drilling (DDH) Campaign Results | 42 |

| | 7.1.5 | 100T Grid Drilling Campaign Results | 43 |

| | 7.2 | Hydrogeology | 43 |

| | 7.3 | Geotechnical Data, Testing, and Analysis | 44 |

| | 8 | Sample Preparation, Analysis and Security | 46 |

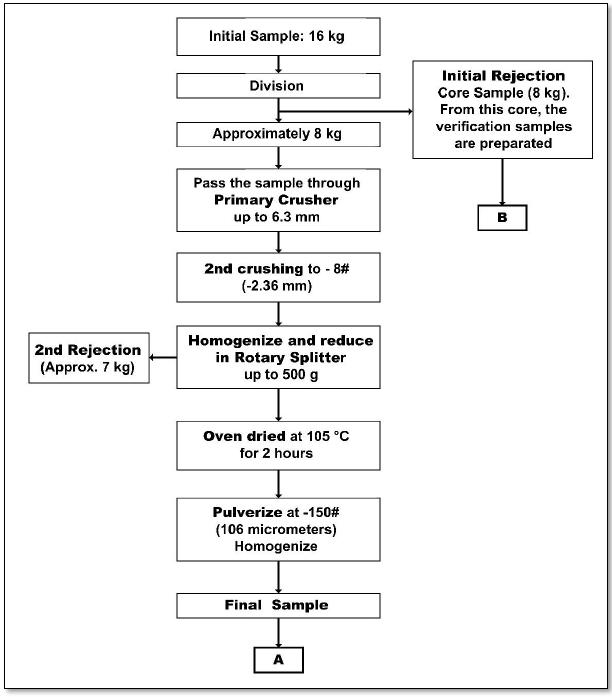

| | 8.1 | Methods, Splitting and Reduction, and Security Measures | 46 |

| | 8.2 | Sample Preparation, Assaying, and Analytical Procedures | 49 |

| | 8.3 | Opinion of Adequacy | 50 |

| | 9 | Data Verification | 51 |

| | 9.1 | Data Verification Procedures | 51 |

| | 9.2 | Data Management | 51 |

| | 9.3 | Technical Procedures | 51 |

| | 9.4 | Quality Control Procedures | 51 |

| | 9.5 | Precision Evaluation | 51 |

| | 9.6 | Accuracy Evaluation | 52 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| | 9.7 | Laboratory Certification | 52 |

| | 9.8 | Quality Control Procedures and Quality Assurance | 52 |

| | 9.8.1 | Quality Control Measures and Results | 52 |

| | 9.8.2 | Quality Assurance Measures | 55 |

| | 9.9 | Qualified Person’s Opinion of Data Adequacy | 55 |

| | 10 | Mineral Processing and Metallurgical Testing | 56 |

| | 10.1 | Metallurgical Testing | 56 |

| | 10.1.1 | Sampling and Sample Preparation | 58 |

| | 10.1.2 | Caliche Chemical and Mineralogical Characterization | 61 |

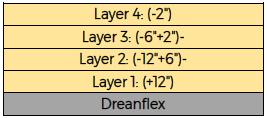

| | 10.1.3 | Caliche Physical Properties | 65 |

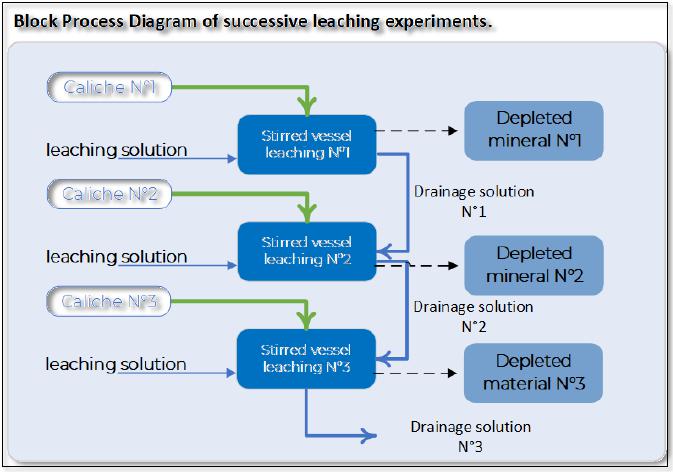

| | 10.1.4 | Agitated Leaching Tests | 68 |

| | 10.1.5 | Leaching in Isocontainers | 72 |

| | 10.1.6 | Column Leach Test using Seawater | 74 |

| | 10.1.7 | Laboratory Control Procedures | 77 |

| | 10.2 | Sample Representativeness | 79 |

| | 10.3 | Analytical and Testing Laboratories | 80 |

| | 10.4 | Test works and Relevant Results | 82 |

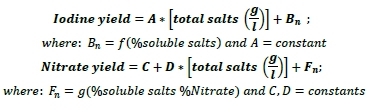

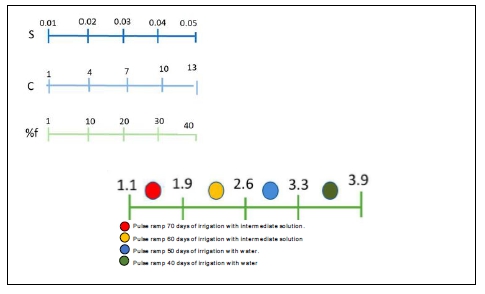

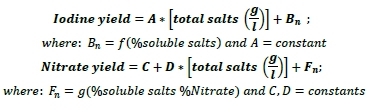

| | 10.4.1 | Metallurgical Recovery Estimation | 82 |

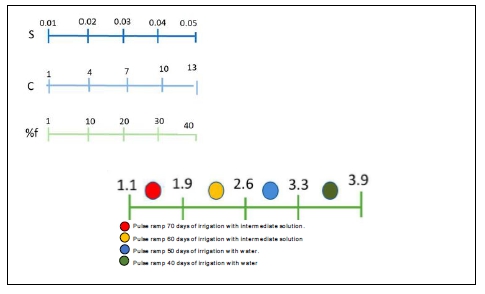

| | 10.4.2 | Irrigation Strategy Selection | 83 |

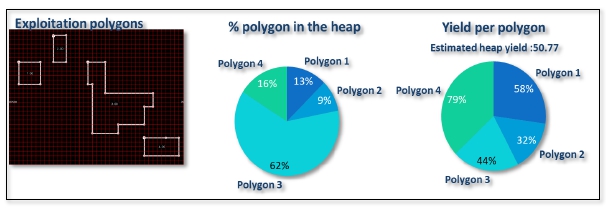

| | 10.4.3 | Industrial Scale Yield Estimation | 85 |

| | 10.5 | Significant Risk Factors | 89 |

| | 10.6 | Qualified Person´s Opinion | 89 |

| | 11 | Mineral Resource Estimate | 91 |

| | 11.1 | Estimation Methods, Parameters, and Assumptions | 91 |

| | 11.2 | Estimation Methodology and Assumptions | 92 |

| | 11.2.1 | Calculation of Drill Hole Average Iodine and Nitrate Grades | 92 |

| | 11.2.2 | Estimation of the Caliche Mineral Resources | 94 |

| | 11.2.3 | Estimation of Mineral Resource Grades | 96 |

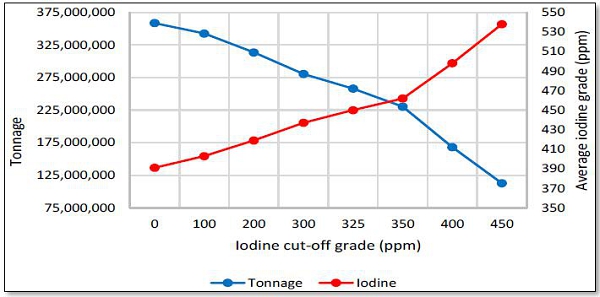

| | 11.3 | Cut-off Grades | 96 |

| | 11.4 | Mineral Resource Classification | 97 |

| | 11.5 | Mineral Resource Estimate | 99 |

| | 11.6 | Qualified Person’s Opinion | 100 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| | 12 | Mineral Reserve Estimate | 101 |

| | 12.1 | Estimation Methods, Parameters, and Assumptions | 101 |

| | 12.2 | Classification Criteria | 102 |

| | 12.3 | Mineral Reserve Estimate | 104 |

| | 12.4 | Qualified Person’s Opinion | 104 |

| | 13 | Mining Methods | 105 |

| | 13.1 | Geotechnical and Hydrological Models, and Other Parameters Relevant to Mine Designs and Plans | 105 |

| | 13.2 | Production Rates, Expected Mine Life, Mining Unit Dimensions, and Mining Dilution and Recovery Factors | 106 |

| | 13.3 | Requirements for Stripping, and Backfilling | 111 |

| | 13.4 | Required Mining Equipment Fleet and Machinery, and Personnel | 113 |

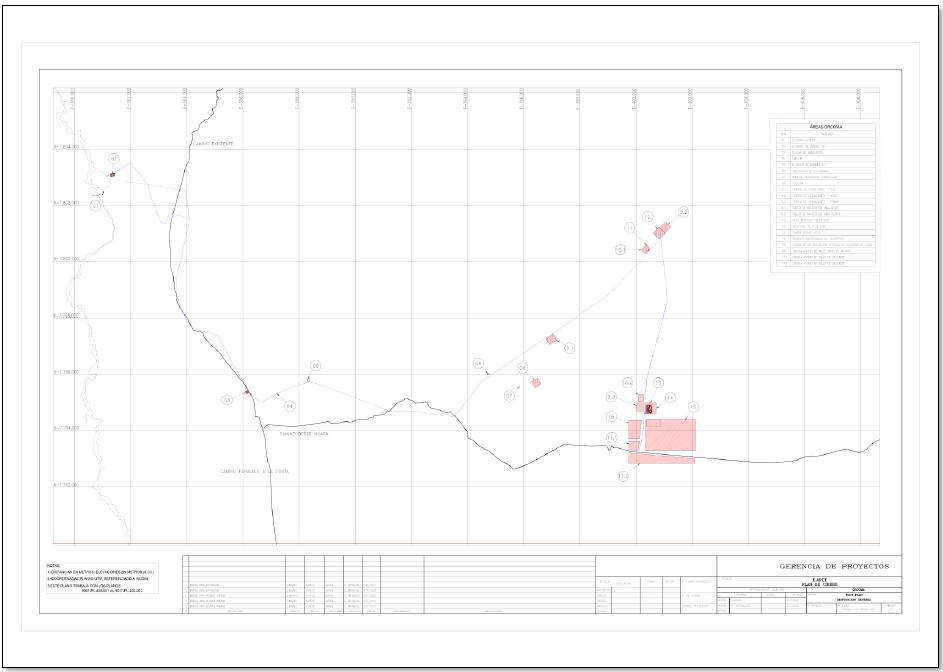

| | 13.5 | Map of the Final Mine Outline | 114 |

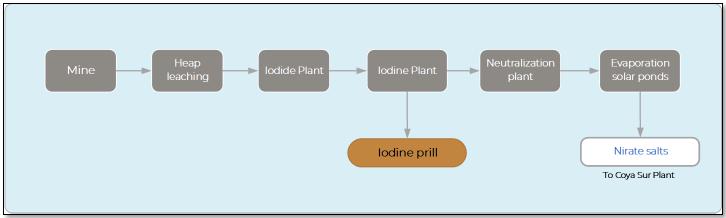

| | 14 | Processing and Recovery Methods | 116 |

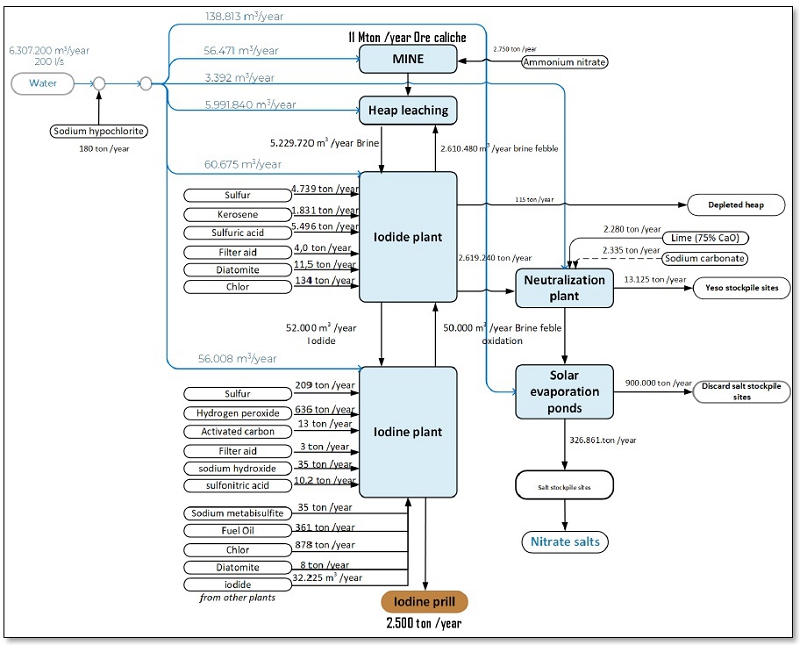

| | 14.1 | Process Description | 120 |

| | 14.1.1 | Mining Zone and Operation Center | 122 |

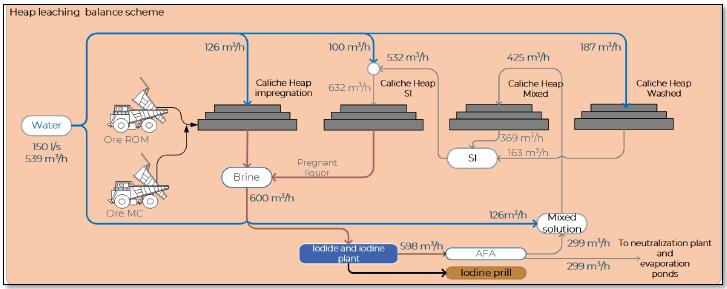

| | 14.1.2 | Heap Leaching | 123 |

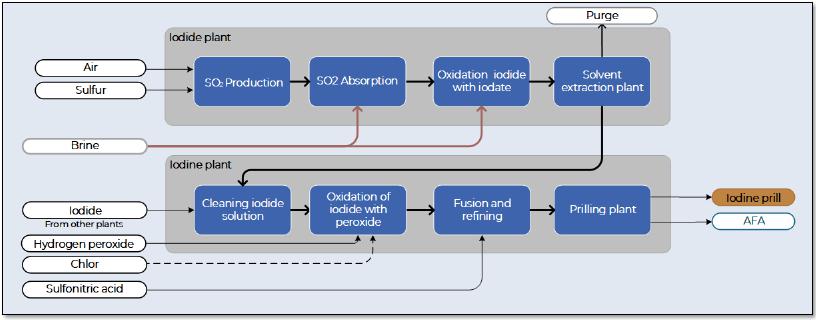

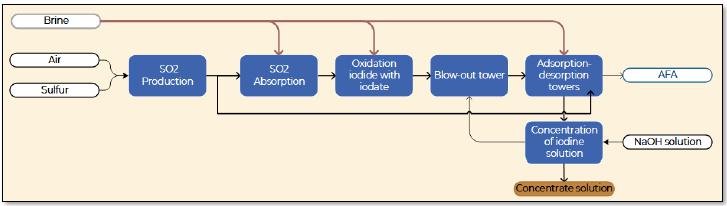

| | 14.1.3 | Iodide-Iodine Production | 124 |

| | 14.1.4 | Neutralization Plant | 129 |

| | 14.1.5 | Solar Evaporation Ponds | 129 |

| | 14.2 | Process Specifications and Efficiencies | 131 |

| | 14.2.1 | Process Criteria | 131 |

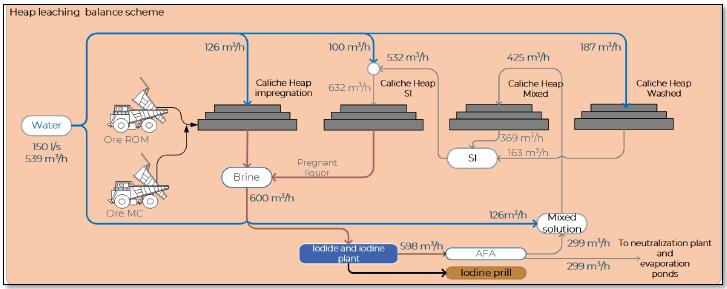

| | 14.2.2 | Heap Leaching Balance | 132 |

| | 14.2.3 | Balance Solutions in Evaporation Ponds | 133 |

| | 14.2.4 | Process Balance Sheet | 133 |

| | 14.2.5 | Production Estimate | 135 |

| | 14.3 | Process requirements | 138 |

| | 14.3.1 | Energy and Fuel Requirements | 138 |

| | 14.3.2 | Water Consumption and Supply | 139 |

| | 14.3.3 | Staff Requirements | 141 |

| | 14.3.4 | Process Plant Consumables | 141 |

| | 14.3.5 | Air Supply | 143 |

| | 14.4 | Qualified Person’s Opinion | 143 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

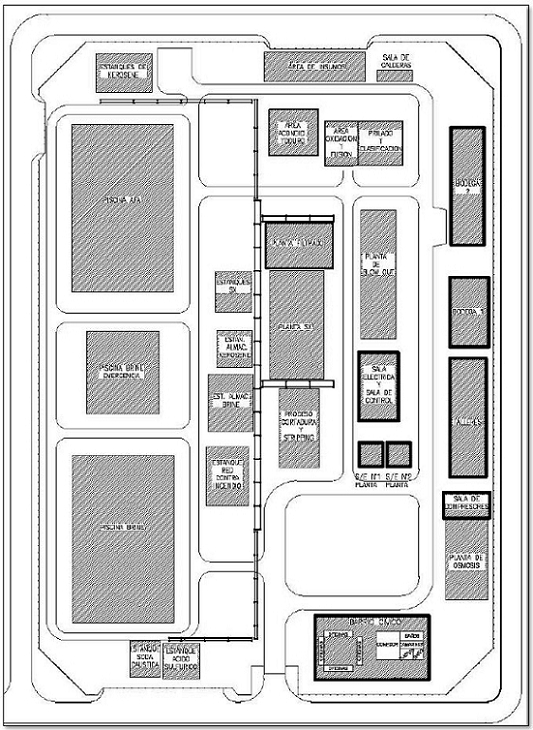

| | 15 | Project Infrastructure | 145 |

| | 15.1 | Access Roads to the Project | 146 |

| | 15.2 | Permanent Works | 147 |

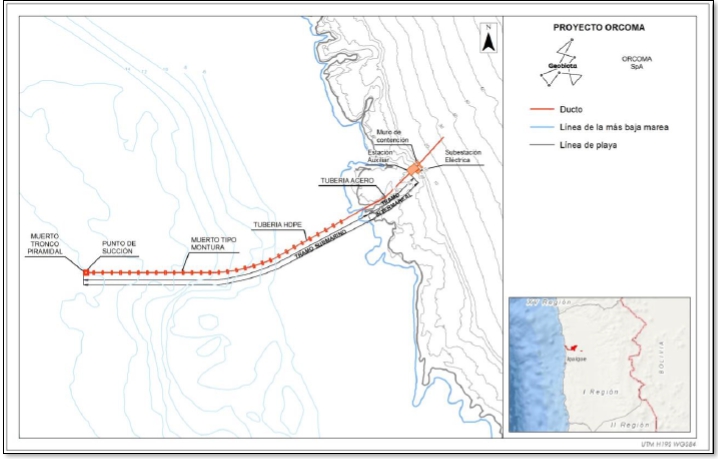

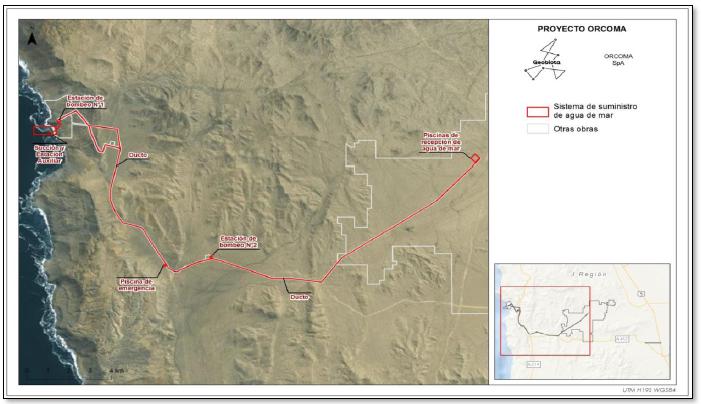

| | 15.2.1 | Seawater Supply System | 147 |

| | 15.2.2 | Power Supply System | 150 |

| | 15.2.3 | Mine Area | 150 |

| | 15.2.4 | Industrial Area | 152 |

| | 16 | Market Studies | 155 |

| | 16.1 | The Company | 155 |

| | 16.2 | Iodine and its Derivatives, Market, Competition, Products, Customers | 156 |

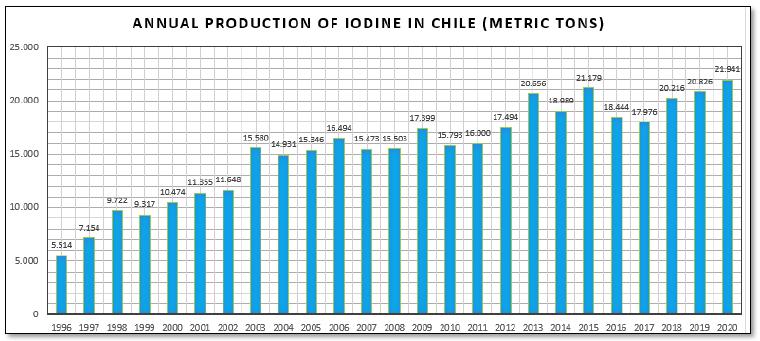

| | 16.2.1 | Iodine Market | 156 |

| | 16.2.2 | Iodine Products | 158 |

| | 16.2.3 | odine Marketing and Customers | 159 |

| | 16.2.4 | Iodine Competition | 160 |

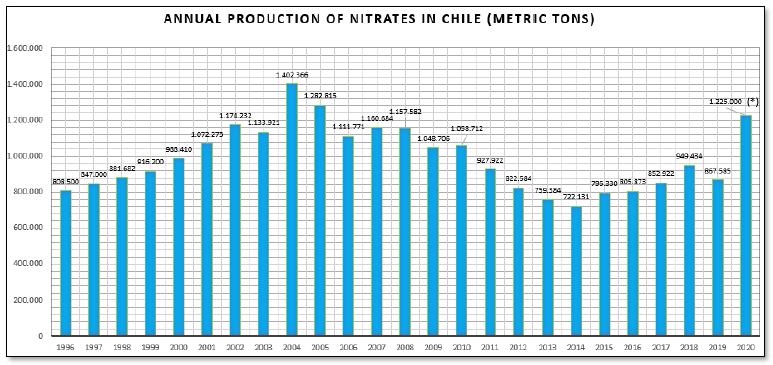

| | 16.3 | Nitrates | 161 |

| | 16.3.1 | Specialty Plant Nutrition, Market, Competition, Products, and Customers | 163 |

| | 16.3.2 | Industrial Chemicals, Market, Competition, Products, and Customers | 168 |

| | 17 | Environmental Studies, Permitting and Social or Community Impact | 173 |

| | 17.1 | Environmental Studies | 173 |

| | 17.1.1 | Baseline Studies | 174 |

| | 17.1.2 | Environmental Impact Assessment | 179 |

| | 17.2 | Operating and Post Closure Requirements and Plans | 182 |

| | 17.2.1 | Waste disposal requirements and plans | 182 |

| | 17.2.2 | Monitoring and Management Plan as Defined in the Environmental Authorization | 183 |

| | 17.2.3 | Requirements and plans for water management during operations and after closure | 188 |

| | 17.3 | Environmental and Sectorial Permits Status | 188 |

| | 17.4 | Social and Community | 190 |

| | 17.4.1 | Plans, Negotiations, or Agreements with Individuals, or Local Groups | 190 |

| | 17.4.2 | Commitments to Local Procurement or Hiring | 191 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| | 17.4.3 | Social Risk Matrix | 191 |

| | 17.5 | Mine Closure | 191 |

| | 17.5.1 | Closure, Remediation, and Reclamation Plans | 192 |

| | 17.5.2 | Closure Cost | 195 |

| | 17.6 | The Qualified Person’s Opinion on the Adequacy of Current Plans to Address any Issues Related to Environmental Compliance, Permitting, and Local Individuals, or Groups | 197 |

| | 18 | Capital and Operating Costs | 198 |

| | 18.1 | Capital Cost Estimates | 198 |

| | 18.2 | Basis for Capital and Operating Cost Estimates | 199 |

| | 19 | Economic Analysis | 201 |

| | 19.1 | Principal Assumptions | 201 |

| | 19.2 | Production and Sales | 201 |

| | 19.3 | Prices and Revenue | 201 |

| | 19.4 | Operating Costs | 205 |

| | 19.5 | Capital Expenditure | 206 |

| | 19.6 | Cashflow Forecast | 207 |

| | 19.7 | Sensitivity Analysis | 209 |

| | 20 | Adjacent Properties | 210 |

| | 21 | Other Relevant Data and Information | 213 |

| | 22 | Interpretation and Conclusions | 214 |

| | 22.1 | Results | 214 |

| | 22.1.1 | Sample Preparation, Analysis, and Security | 214 |

| | 22.1.2 | Data Verification | 214 |

| | 22.1.3 | Mineral Processing and Metallurgical Testing | 214 |

| | 22.1.4 | Mineral Resource Estimate | 215 |

| | 22.1.5 | Mineral Reserve Estimate | 215 |

| | 22.1.6 | Processing and Recovery Methods | 215 |

| | 22.2 | Significant Risks | 216 |

| | 22.2.1 | Sample Preparation, Analysis, and Security | 216 |

| | 22.2.2 | Geology and Mineral Resources | 216 |

| | 22.2.3 | Permitting | 216 |

| | 22.2.4 | Processing and Recovery Methods | 216 |

| | 22.2.5 | Metal Pricing and Market Conditions | 216 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| | 22.2.6 | Mineral Processing and Metallurgical Testing | 217 |

| | 22.2.7 | Environmental Studies, Permitting and Social or Community Impact | 217 |

| | 22.3 | Significant Opportunities | 217 |

| | 22.3.1 | Mineral Resource Statement | 217 |

| | 22.3.2 | Geology and Mineral Resources | 217 |

| | 22.3.3 | Metallurgy and Mineral Processing | 217 |

| | 23 | Recommendations | 218 |

| | 24 | References | 219 |

| | 25 | Reliance on Information Provided by Registrant | 221 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| | TablES | |

| | | |

| | Table 1-1. Mineral Resource Estimate Exclusive of Mineral Reserves (Effective December 31, 2021) | 2 |

| | | |

| | Table 1-2. Mineral Reserve Estimate (Effective December 31, 2021) | 3 |

| | | |

| | Table 1-3. Estimated Net Present Value (NPV) for the Period | 9 |

| | | |

| | Table 2-1. Abbreviations and Acronyms | 12 |

| | | |

| | Table 2-2. Site Visits | 16 |

| | | |

| | Table 3-1. Pampa Orcoma project concessions | 18 |

| | | |

| | Table 3-2. Summary of Current Permits | 21 |

| | | |

| | Table 7-1. Data Available for 400-x-400-m, 200-x-200-m, and 50-x-50-m Drill Hole Grids | 42 |

| | | |

| | Table 7-2. Data Available for 100T Drill Hole Grid | 43 |

| | | |

| | Table 8-1. Analytical Procedures for Salts in SQM's Nitrate-Iodine Lab | 49 |

| | | |

| | Table 9-1. Statistics of Iodine and Nitrate Grades in Original versus Duplicate Samples of the 400-x-400 Drill Hole Grid (n = 212) | 53 |

| | | |

| | Table 9-2. Statistics of Iodine and Nitrate Grades in Original Versus Duplicate Samples of the 400-x-400-m, 200-x-200-m, and 50-x-50-m Drill Hole Grid (n = 511) | 55 |

| | | |

| | Table 10-1. Applied Methods for the Characterization of Caliche or Composite | 61 |

| | | |

| | Table 10-2. Salt Matrix of Pampa Orcoma Sampling Points (piques), taken from 200-x-200-mesh Drillings | 63 |

| | | |

| | Table 10-3. Determination of Physical Properties of Caliche Minerals | 66 |

| | | |

| | Table 10-4. Comparative Results of Physical Tests for Pampa Orcoma and TEA Exploitation Project | 67 |

| | | |

| | Table 10-5. DDH 2020 -Chemical Characterization of Samples Obtained from Successive Leach Test Results | 70 |

| | | |

| | Table 10-6. Conditions for Leaching Experiments in Isocontainers | 72 |

| | | |

| | Table 10-7. Head Grade Samples Loaded to Isocontainers | 73 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| | Table 10-8. Results of isocontainer leaching of samples obtained from trial pits Pampa Orcoma | 73 |

| | | |

| | Table 10-9. Sumo Project 2014 -Result of simulated pile scaling for 6 Pampa Orcoma trial pits | 74 |

| | | |

| | Table 10-10. Conditions for Leaching Experiments with Seawater | 75 |

| | | |

| | Table 10-11. Characteristic Composition of the Caliche used in the Tests | 75 |

| | | |

| | Table 10-12. List of requested analyses for caliche leach brines and iodine prill | 77 |

| | | |

| | Table 10-13. Average Chemical Composition of Pampa Orcoma Brine Feed and Directed Out to the Process | 78 |

| | | |

| | Table 10-14. List of Installations Available for Analysis | 81 |

| | | |

| | Table 10-15. Comparison of the Composition Determined for the 476 Heap Leaching Pile in Operation at Nueva Victoria | 85 |

| | | |

| | Table 10-16. Comparison of Industrial Yield with the Values Predicted by the Model for Nueva Victoria | 88 |

| | | |

| | Table 11-1. Example of Selection of Drill Hole Sections for Average Grade Calculation, in Drill Hole PO-007 | 93 |

| | | |

| | Table 11-2. Mineral Resource Estimate, Exclusive of Mineral Reserves (Effective December 31, 2021) | 99 |

| | | |

| | Table 12-1. Historical Operational Modifying Factors for Iodine and Sodium Nitrate Grades | 101 |

| | | |

| | Table 12-2. Mineral Reserve Statement for Pampa Orcoma (Effective December 31, 2021) | 104 |

| | | |

| | Table 13-1. Mining Plan for Pampa Orcoma project (2024-2040) | 107 |

| | | |

| | Table 13-2. Mining Equipment for mining process – Pampa Orcoma project (20 Mtpy) | 113 |

| | | |

| | Table 13-3. Mine and PAD leaching production for Pampa Orcoma mine – period 2024-2030 | 114 |

| | | |

| | Table 14-1. Description of Water and Brine Reception Ponds by COM | 122 |

| | | |

| | Table 14-2. Solar Evaporation Pond Types | 130 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| | Table 14-3. Process criteria summary. Mine site and caliche heap leaching | 131 |

| | | |

| | Table 14-4. Pampa Orcoma average composition per mining radius | 137 |

| | | |

| | Table 14-5. Pampa Orcoma Process Plant Production Summary | 137 |

| | | |

| | Table 14-6. Projection of energy and fuel requirements to 2024-2028 | 139 |

| | | |

| | Table 14-7. Pampa Orcoma industrial and potable water consumption | 140 |

| | | |

| | Table 14-8. Personnel required by operational activity | 141 |

| | | |

| | Table 14-9. Pampa Orcoma Process Reagents and Consumption rates per year | 142 |

| | | |

| | Table 16-1. Breakdown (%) of Revenues by SQM Production Line for the Years 2020, 2019, and 2018 | 156 |

| | | |

| | Table 16-2. Volumes of and Revenues from Iodine and Iodine Derivatives | 159 |

| | | |

| | Table 16-3. Breakdown of the Revenue | 159 |

| | | |

| | Table 16-4. Volumes of and revenues from specialty plant nutrients | 166 |

| | | |

| | Table 16-5. Breakdown of the sales from Specialty plant nutrition | 167 |

| | | |

| | Table 16-6. Volumes of and Revenues from Industrial Chemicals | 170 |

| | | |

| | Table 16-7. Breakdown of the Sales from Industrial Chemicals | 171 |

| | | |

| | Table 17-1. Pre-construction Activities | 181 |

| | | |

| | Table 17-2. Measures Committed in the RCA 75/2017 | 184 |

| | | |

| | Table 17-3. Committed Follow-up Activities | 186 |

| | | |

| | Table 17-4. Applicable permits related with RCA N° 75/2021 | 189 |

| | | |

| | Table 17-5. Closure Measures of Remaining Facilities ORCOMA Mining Site | 193 |

| | | |

| | Table 17-6. Post-Closure Measures | 193 |

| | | |

| | Table 17-7. ORCOMA Mining Site Remaining Facilities Risk Assessment Summary | 194 |

| | | |

| | Table 17-8. Detail of Closing Cost | 195 |

| | | |

| | Table 17-9. Detail of Post-Closing Cost | 196 |

| | | |

| | Table 17-10. Parameters for Estimation of Pampa Orcoma Guarantees | 196 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| | Table 18-1. Capital Cost for Nitrate and Iodine at the Orcoma Project | 199 |

| | | |

| | Table 18-2. Productions Assumptions for Pampa Orcoma Project | 199 |

| | | |

| | Table 18-3. Estimated Operating costs, per Tonne of Caliche Extracted | 200 |

| | | |

| | Table 18-4. Estimated Costs to Produce Iodine (kg) | 200 |

| | | |

| | Table 18-5. Estimated Costs to Produce Nitrate (per tonne) | 200 |

| | | |

| | Table 19-1. Production of Iodine and Nitrates with and without Orcoma Project | 203 |

| | | |

| | Table 19-2. Sales of Iodine and Nitrates for the Orcoma Project | 204 |

| | | |

| | Table 19-3. Main Costs of Iodine and Nitrates Production | 205 |

| | | |

| | Table 19-4. Estimated Investments | 208 |

| | | |

| | Table 19-5. Estimated Net Present Value (NPV) for the Period | 208 |

| | FigurEs | |

| | | |

| | Figure 1-1 Sensitivity Analysis of the Pampa Orcoma Project | 8 |

| | | |

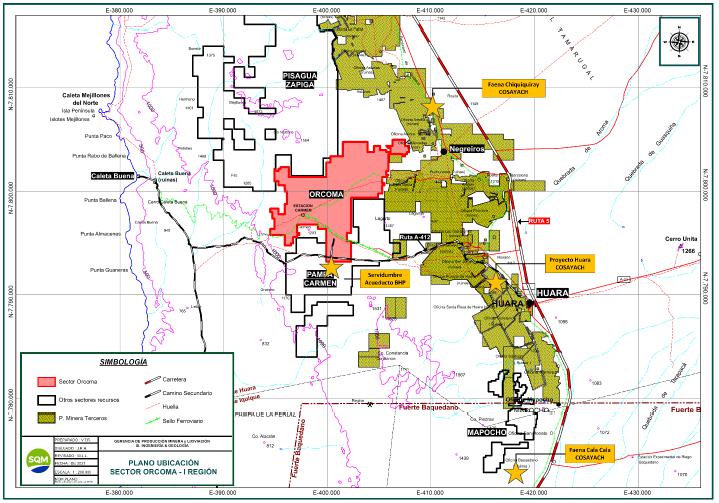

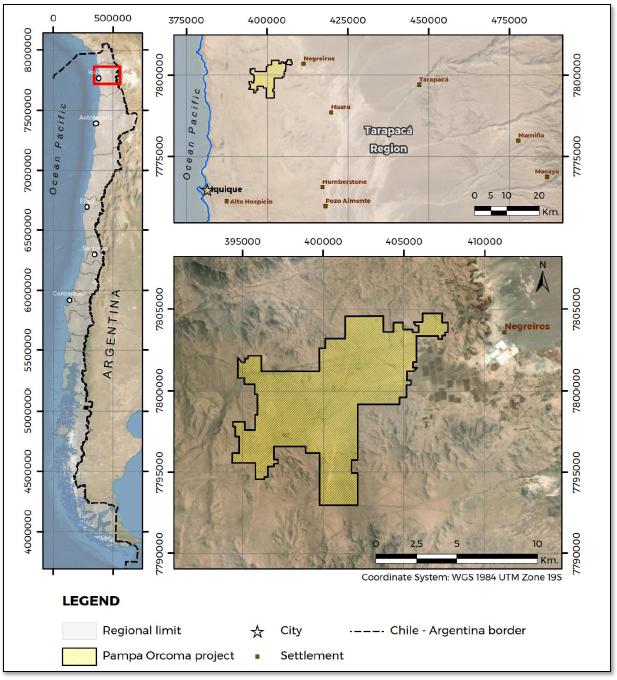

| | Figure 3-1. General Location Map | 17 |

| | | |

| | Figure 3-2. Location of Pampa Orcoma property | 20 |

| | | |

| | Figure 4-1. Slope Parameter Map Sr and Elevation Profile Trace BB" | 25 |

| | | |

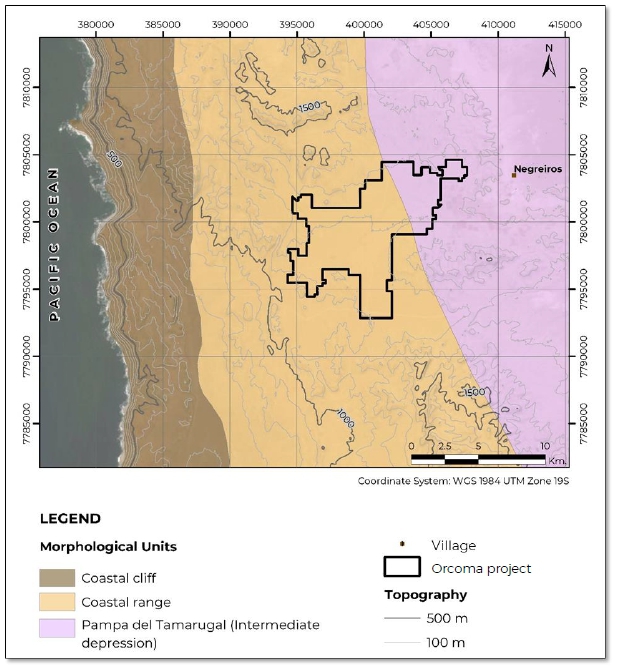

| | Figure 6-1. Geomorphological Map of the Exploration Area | 30 |

| | | |

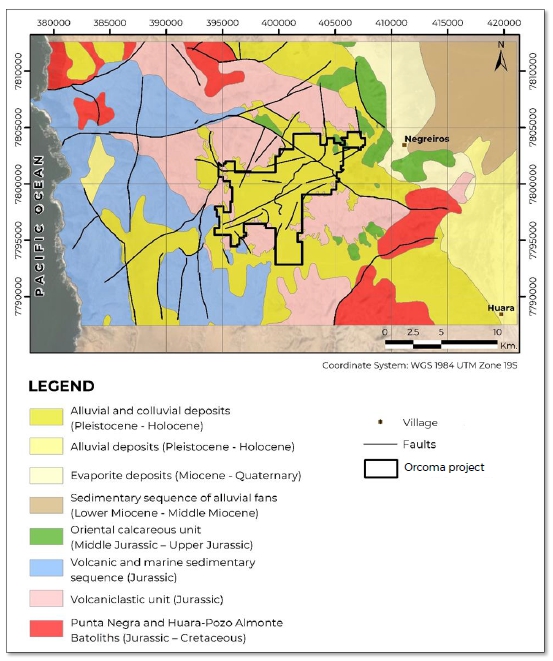

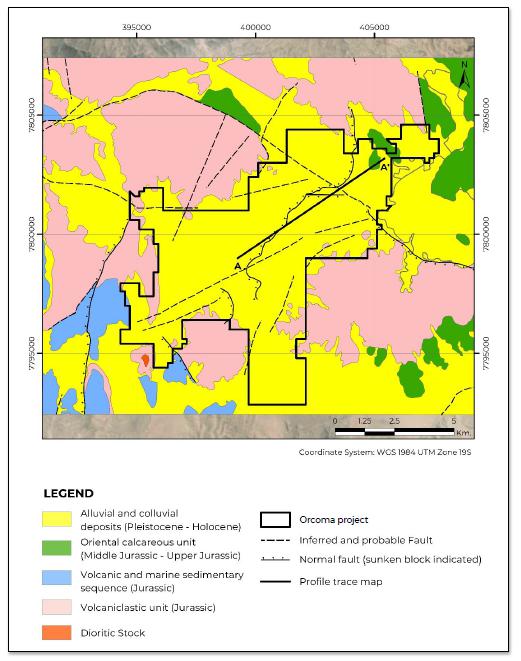

| | Figure 6-2. Regional Geological Map | 32 |

| | | |

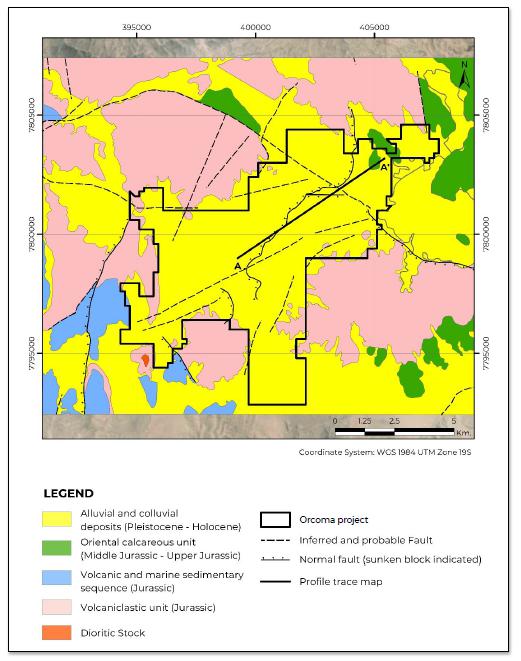

| | Figure 6-3. Local Geology Map | 34 |

| | | |

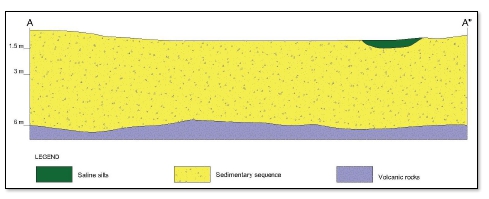

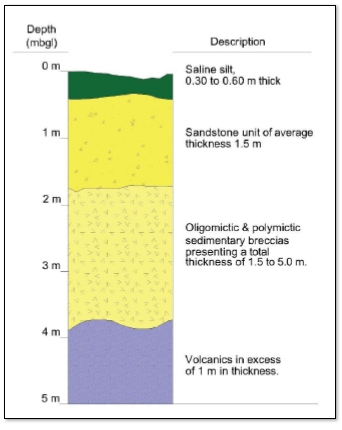

| | Figure 6-4. Stratigraphic Column of Pampa Orcoma | 35 |

| | | |

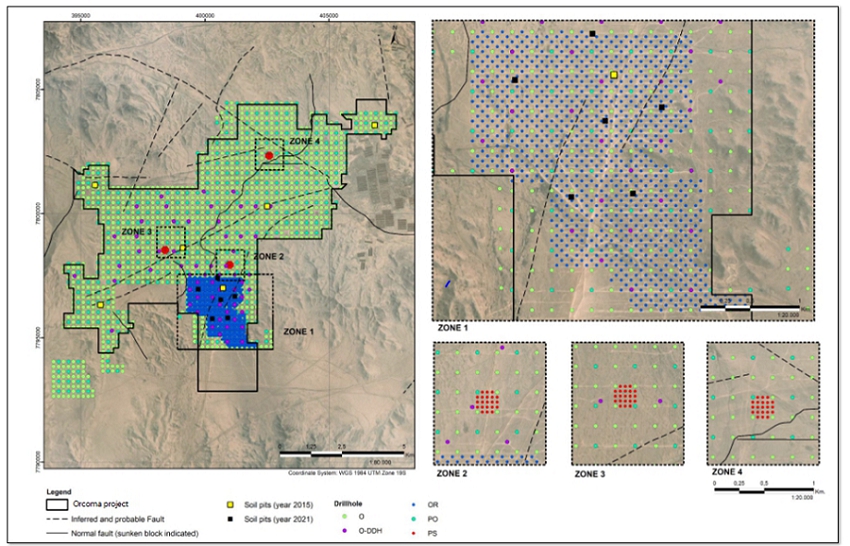

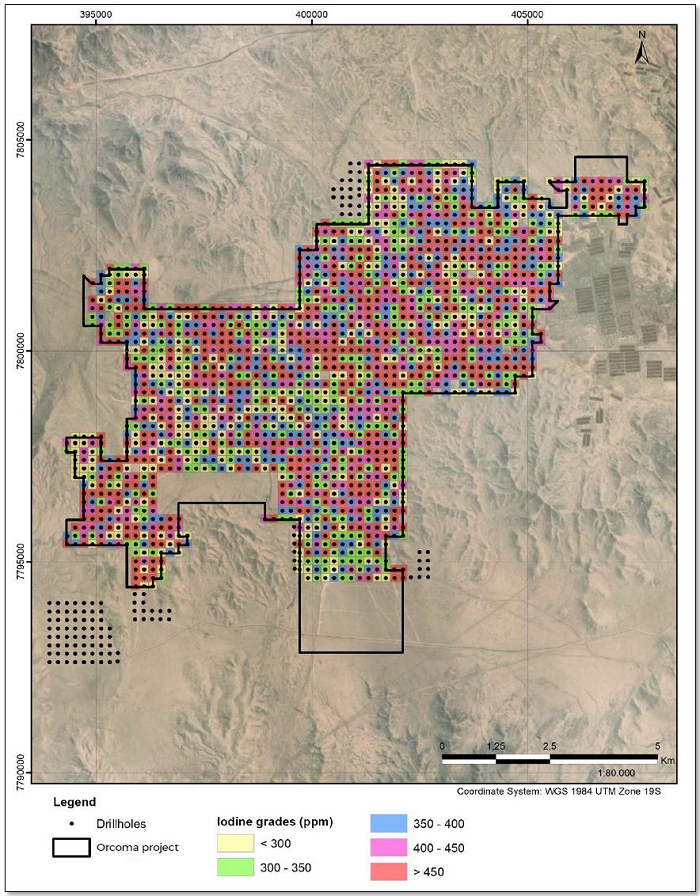

| | Figure 7-1. Distribution of SQM Exploration Drill Holes and Soil Pits | 41 |

| | | |

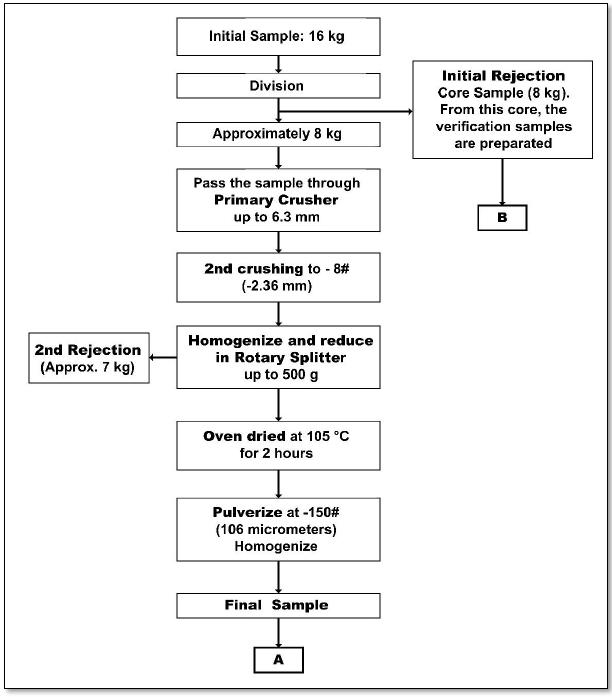

| | Figure 8-1. Process Sequence from the Start of Drilling, Sampling, and Storage | 46 |

| | | |

| | Figure 8-2. Process Sequence from Initial Sample, Reduction, and Final Sample | 48 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

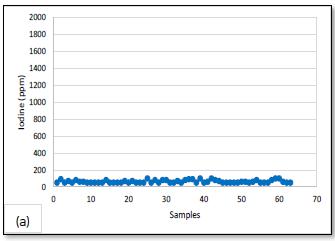

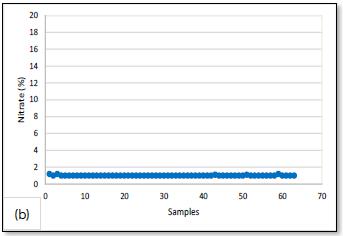

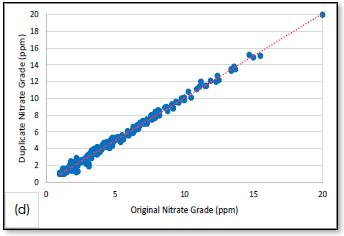

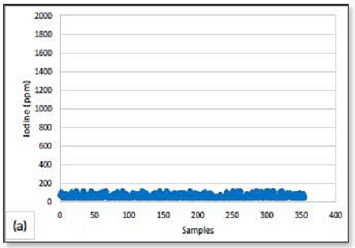

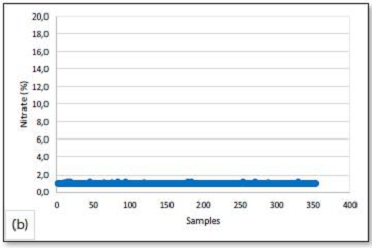

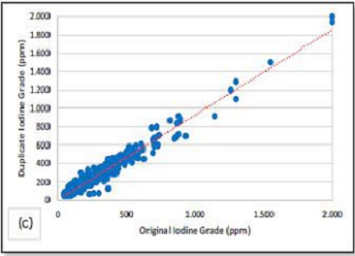

| | Figure 9-1. Results of 400-x-400-m Drill Hole grid Sample Quality Control | 53 |

| | | |

| | Figure 9-2. Results of 400-x-400-m, 200-x-200-m and 50-x-50-m Drill Hole Grid Sample Quality Control | 54 |

| | | |

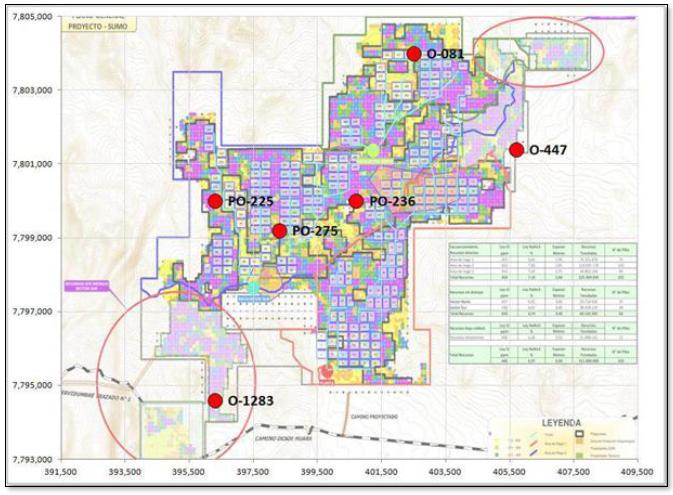

| | Figure 10-1. General Stages of the Sampling Methodology and Development of Metallurgical Tests at Pampa Orcoma | 58 |

| | | |

| | Figure 10-2. Test Pits and Diamond Drilling (DDH) Campaign for Composite Samples from the Orcoma Sector for Metallurgical Testing | 60 |

| | | |

| | Figure 10-3. Samples Obtained from Drill Holes 2014 -Sumo Project | 64 |

| | | |

| | Figure 10-4. Embedding, Compaction, and Sedimentation Tests Performed at the Iris Pilot Plant Laboratory | 67 |

| | | |

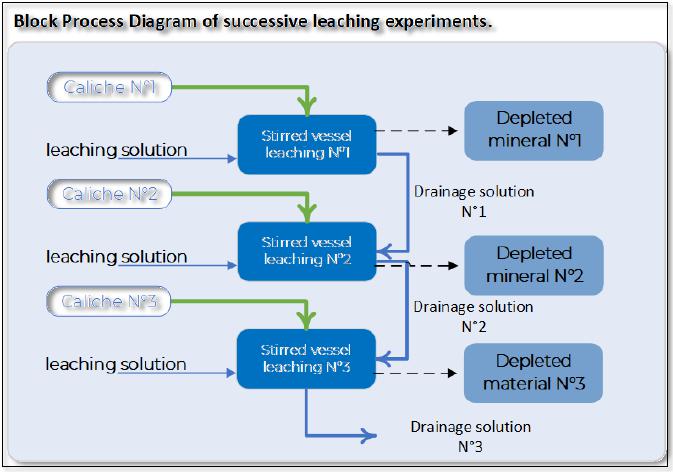

| | Figure 10-5. Successive Leach Test Development Procedure | 69 |

| | | |

| | Figure 10-6. Nitrate and Iodine Yield Obtained by Successive Agitated Leaching Test | 71 |

| | | |

| | Figure 10-7. Loaded isocontainer and Distribution of Material According to Granulometry | 72 |

| | | |

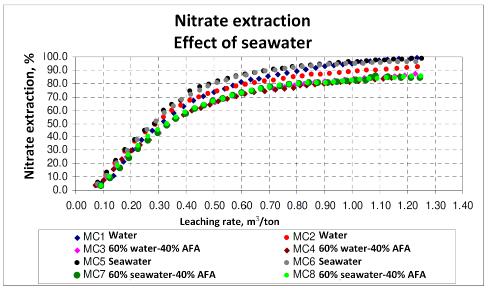

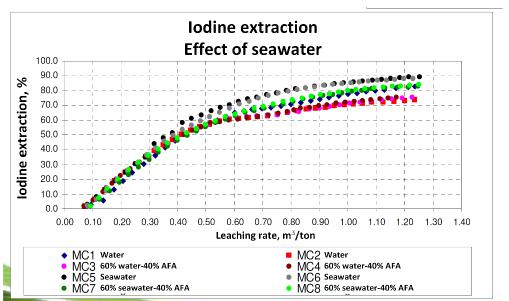

| | Figure 10-8. Results of Nitrate and Iodine Extraction by Seawater Leaching | 76 |

| | | |

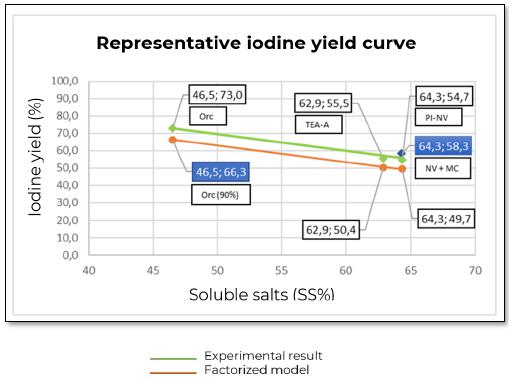

| | Figure 10-9. Iodine Recovery as a Function of Total Sales Content Test Work with Samples from Two Different Resource Sectors to be Exploited by the Company | 83 |

| | | |

| | Figure 10-10. Parameter Scales and Irrigation Strategy in the Impregnation Stage Impregnation | 84 |

| | | |

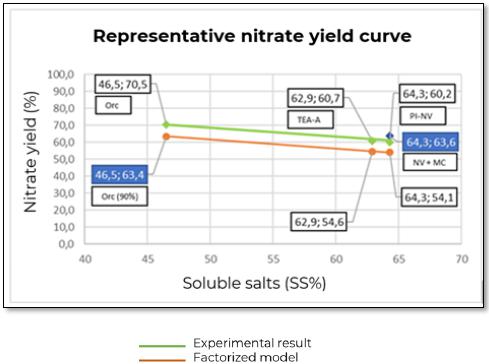

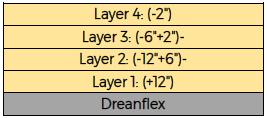

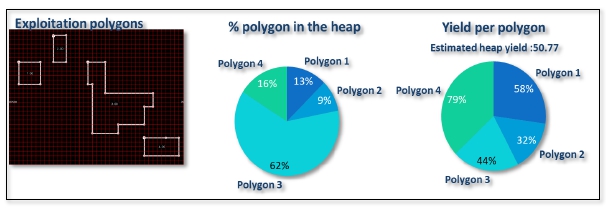

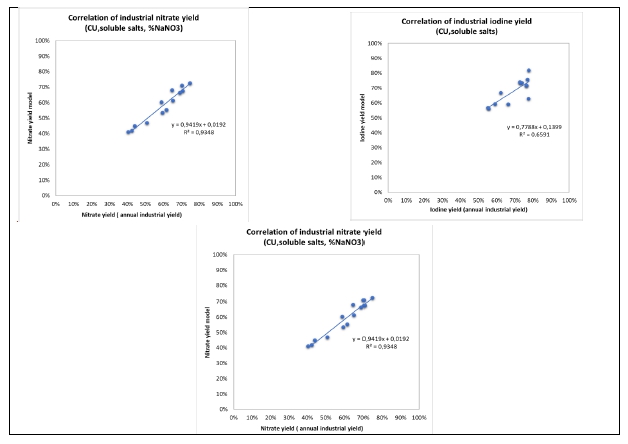

| | Figure 10-11. Heap Yield Characterization and Irrigation Strategy Selection - Pile 476 of Nueva Victoria | 86 |

| | | |

| | Figure 10-12. Nitrate and Iodine Yield Estimation and Industrial Correlation for the Period 2008 to 2020 at Nueva Victoria | 86 |

| | | |

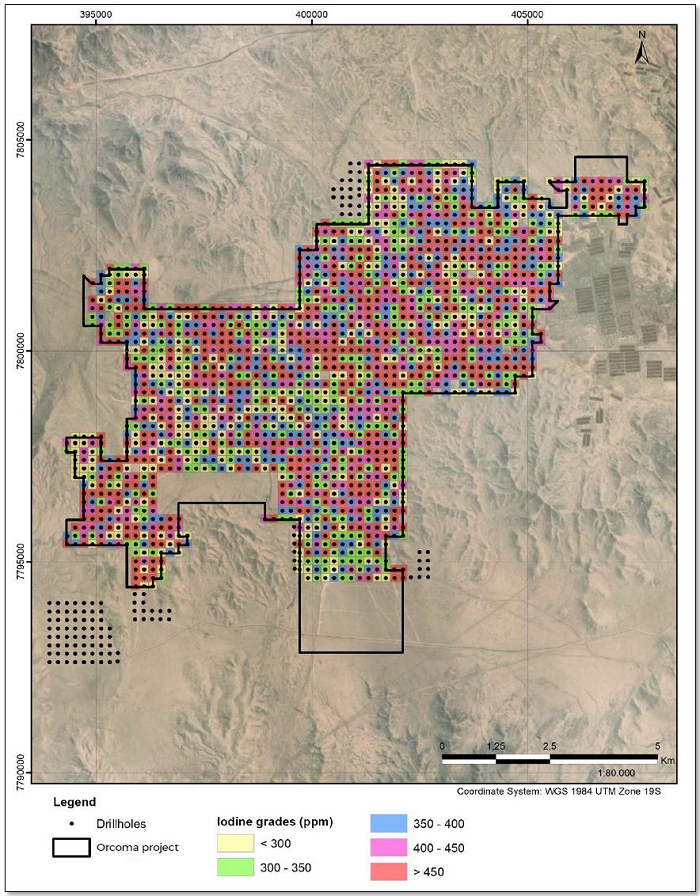

| | Figure 11-1. 200-x-200-m Drill Hole Grid and Polygons of Average Iodine Grades Associated with each Drill Hole | 95 |

| | | |

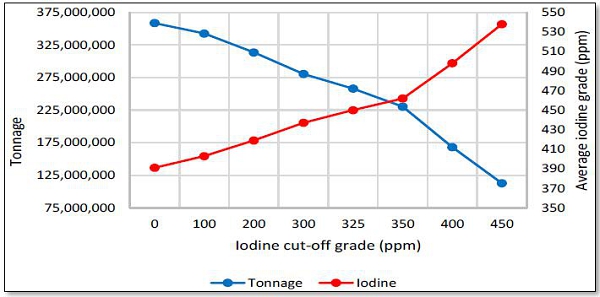

| | Figure 11-2. Tonnage-Grade Curve for Different Values of Iodine Cut-off grades in Pampa Orcoma | 97 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

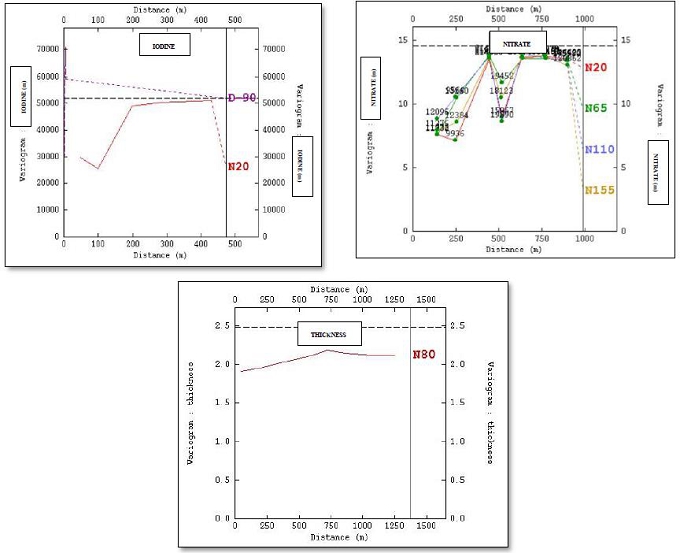

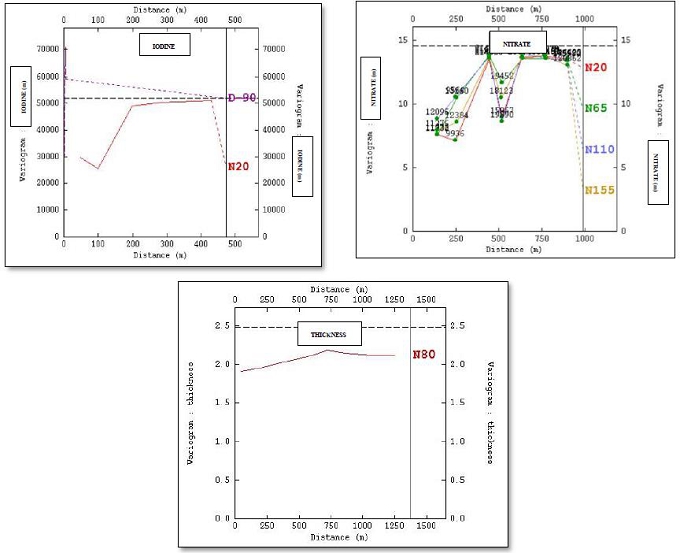

| | Figure 11-3. Experimental Variograms of Iodine and Nitrate for Pampa Orcoma | 98 |

| | | |

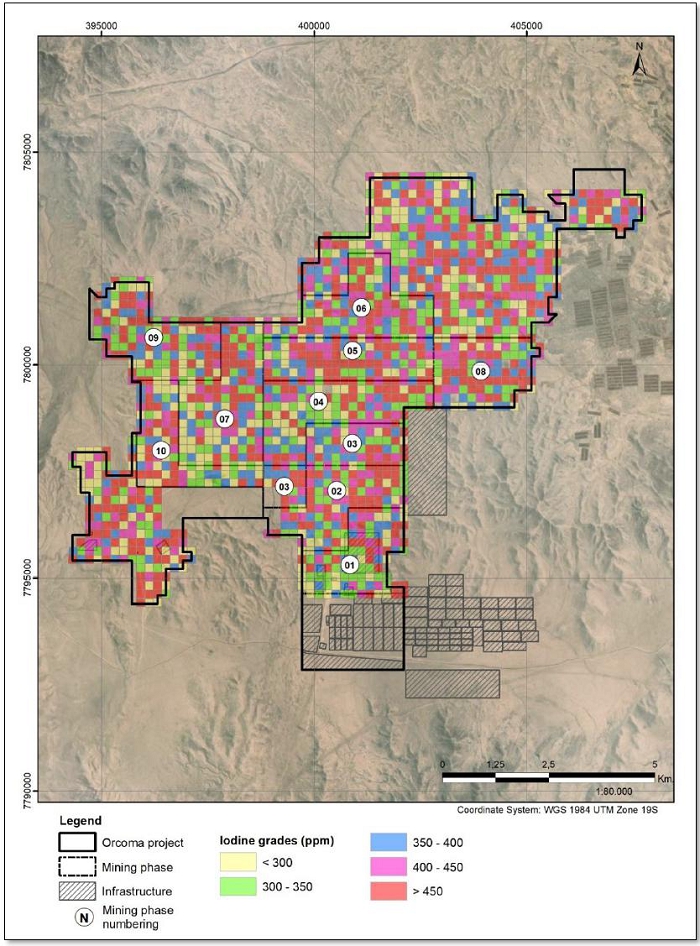

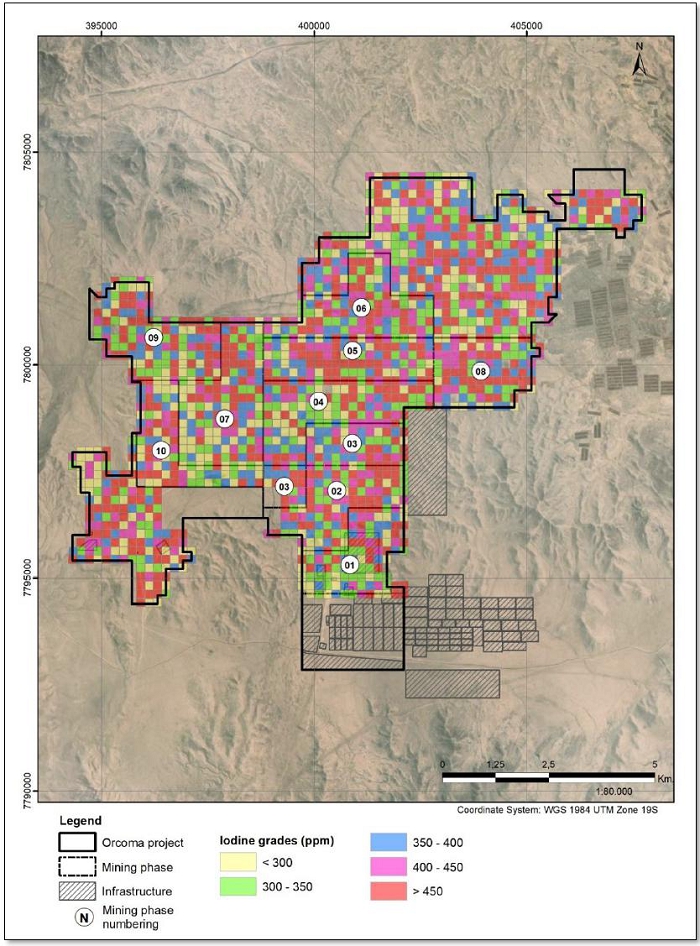

| | Figure 12-1. Mining Phases and Infrastructure in Pampa Orcoma, showing Iodine Grade Polygons from 200-x-200-m Grid Drill Holes | 103 |

| | | |

| | Figure 13-1. Pad Construction and morphology in Caliche Mines | 110 |

| | | |

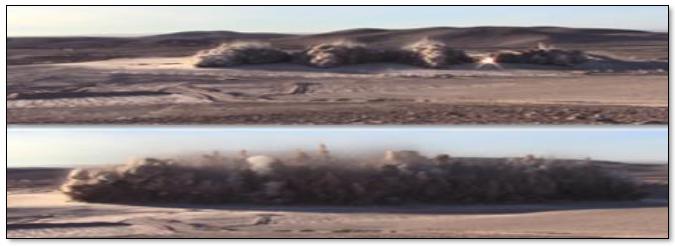

| | Figure 13-2. Picture of a Typical Blast at Caliche Mines | 112 |

| | | |

| | Figure 13-3. Terrain Leveler Surface Excavation Machine (SEM) | 112 |

| | | |

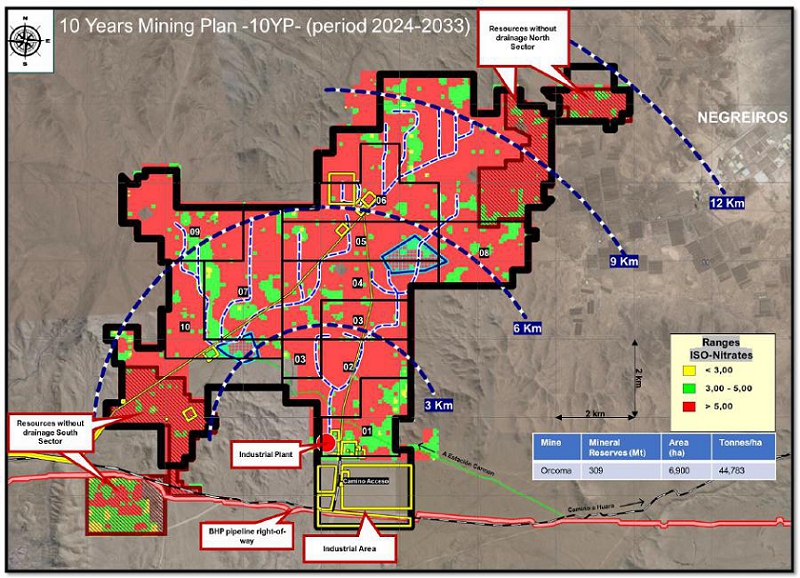

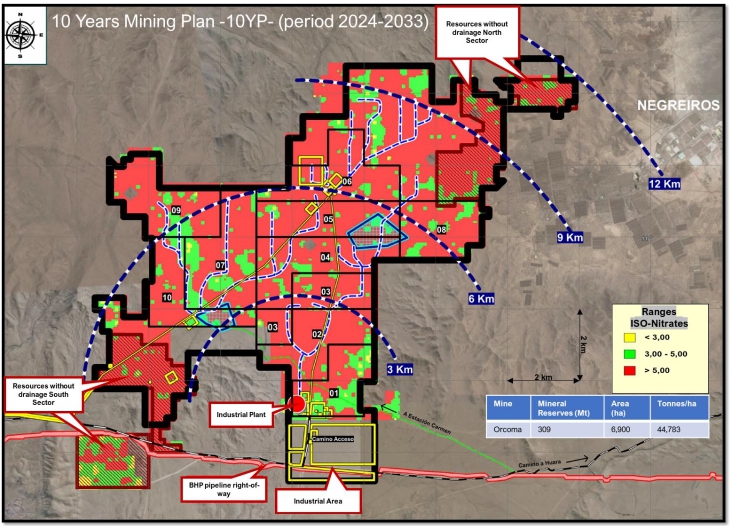

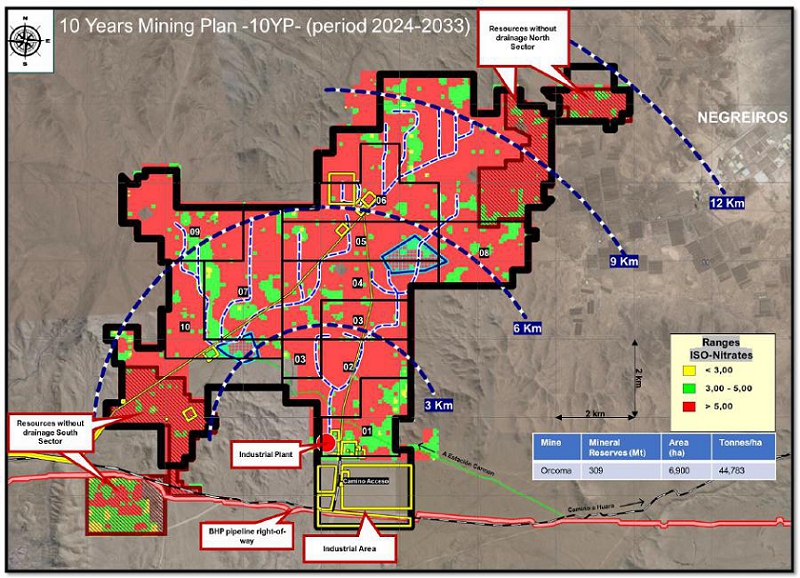

| | Figure 13-4. Ten Year Plan -2024-2033 Pampa Orcoma Mine | 115 |

| | | |

| | Figure 14-1. Simplified Pampa Orcoma Process Flowsheet | 118 |

| | | |

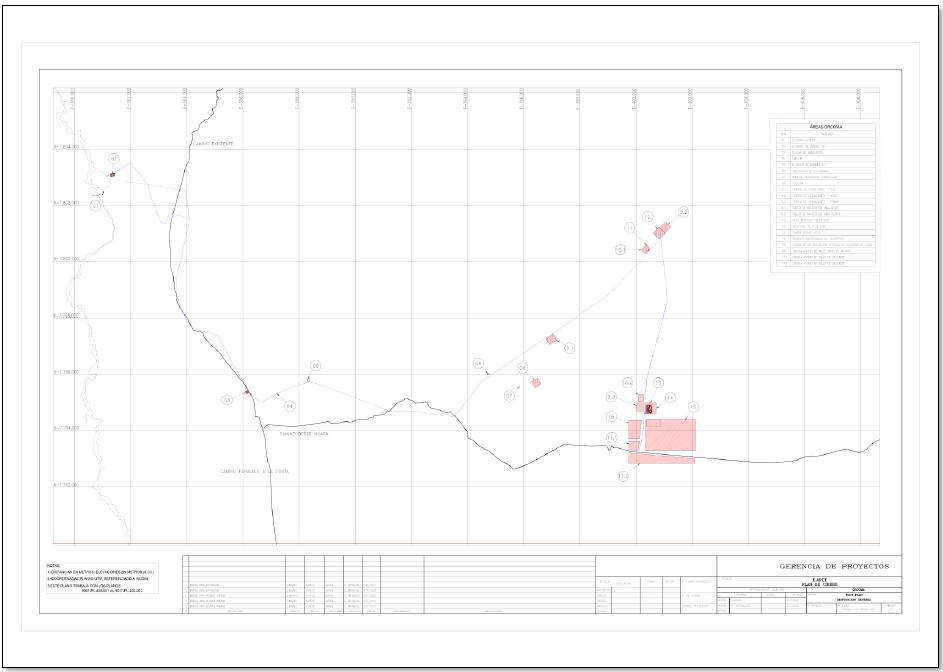

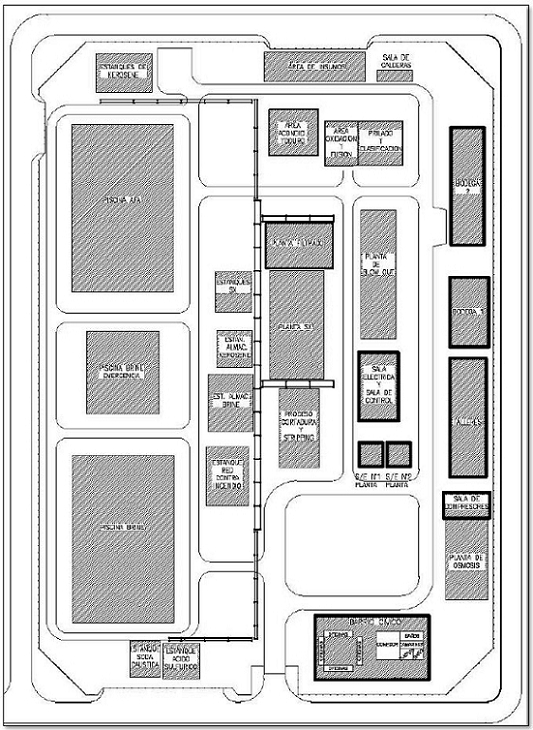

| | Figure 14-2. General Layout of the Facilities of Pampa Orcoma | 119 |

| | | |

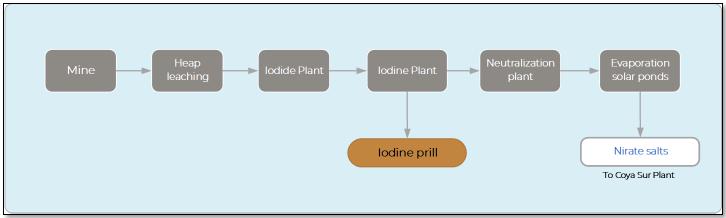

| | Figure 14-3. General Block Process Diagram for Pampa Orcoma | 121 |

| | | |

| | Figure 14-4. Schematic Process Flow of Caliche Leaching | 124 |

| | | |

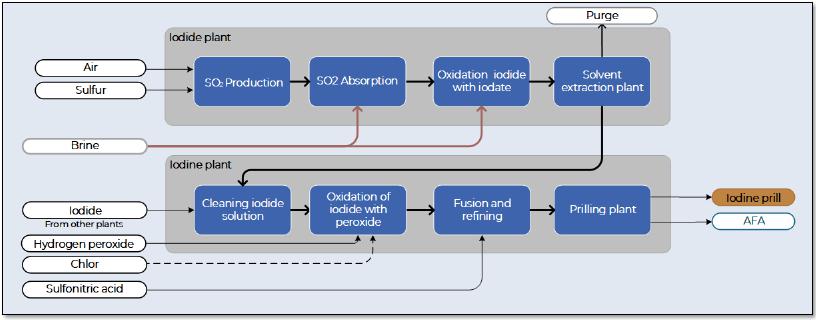

| | Figure 14-5. Block Diagram of Iodide-Iodine Production Process Plants | 125 |

| | | |

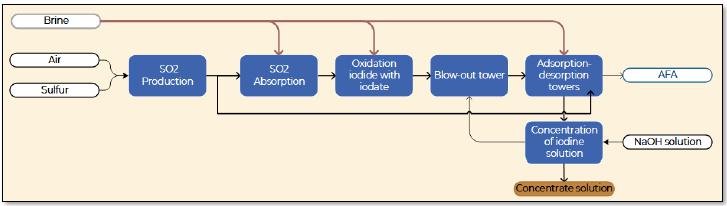

| | Figure 14-6. Process Diagram of Blow-out Production of Iodine Contrate Solution | 128 |

| | | |

| | Figure 14-7. Pampa Orcoma Heap leaching scheme | 132 |

| | | |

| | Figure 14-8. Pampa Orcoma volumetric balance in solar evaporation area | 133 |

| | | |

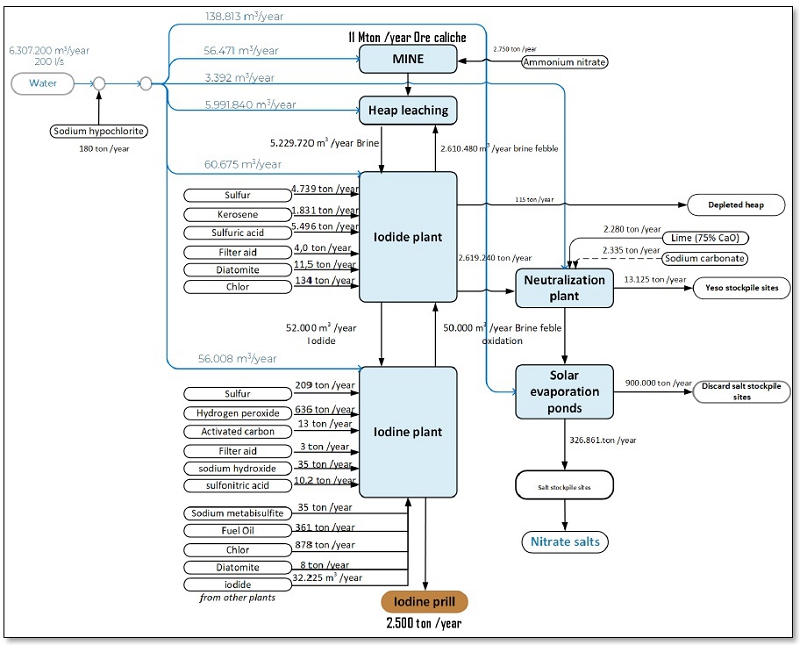

| | Figure 14-9. Mass balance of Pampa Orcoma per year of production | 134 |

| | | |

| | Figure 14-10. 10-year Orcoma. NaNO3 Plan exploitation | 135 |

| | | |

| | Figure 15-1. Project Location | 146 |

| | | |

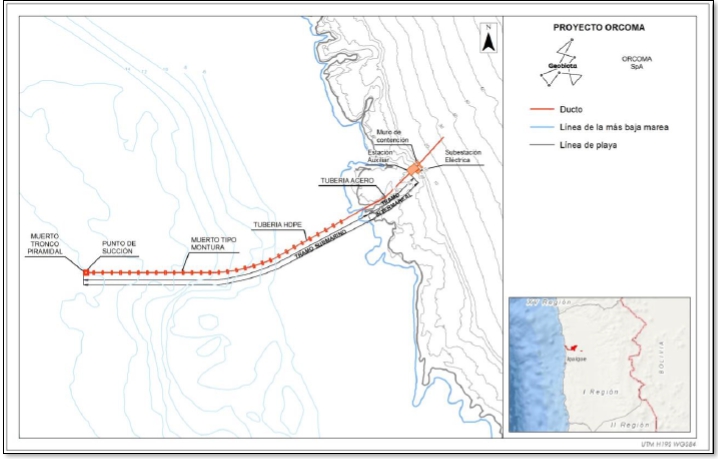

| | Figure 15-2. Seawater Suction System | 148 |

| | | |

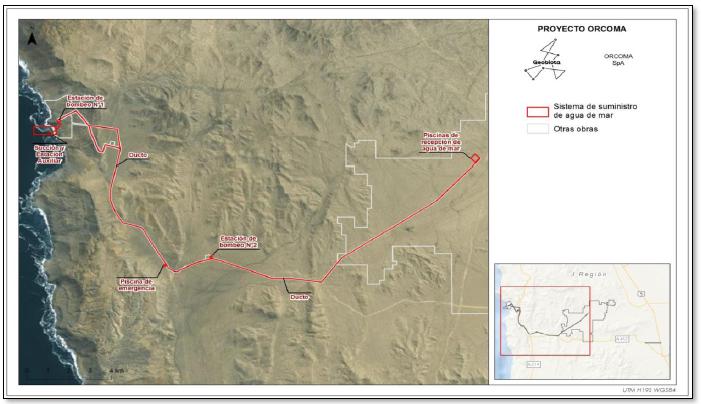

| | Figure 15-3. Seawater Supply System | 149 |

| | | |

| | Figure 15-4. Characteristic Diagram of the Iodine-Iodide Plant | 154 |

| | | |

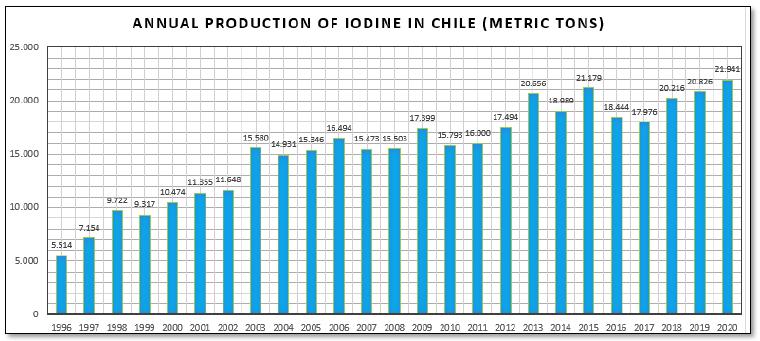

| | Figure 16-1. Iodine and Derivates, Production Evolution 1996-2020 | 158 |

| | | |

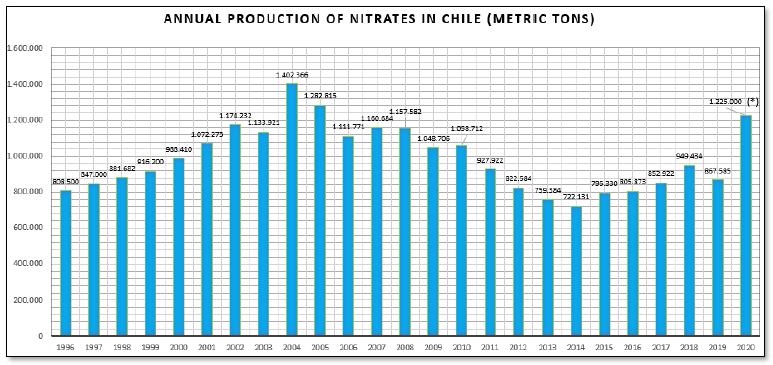

| | Figure 16-2. Annual production of Nitrates in Chile | 163 |

| | | |

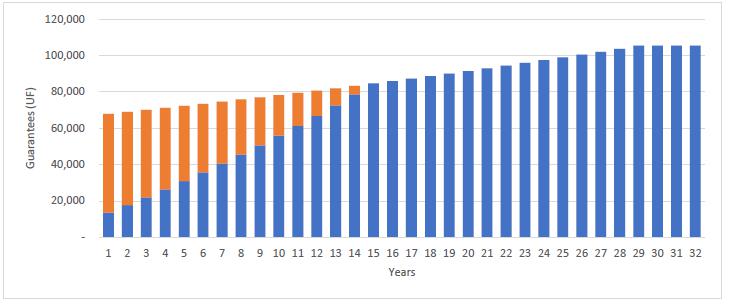

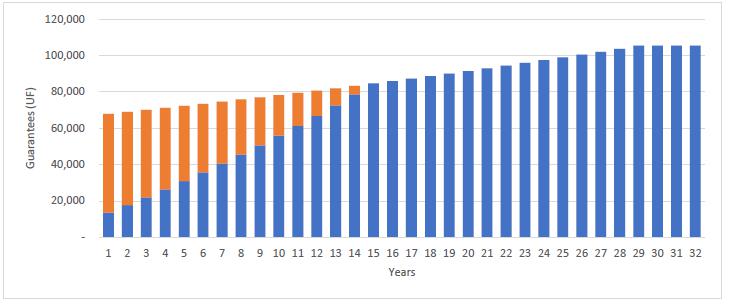

| | Figure 17-1. Disposition of Pampa Orcoma's Financial Guarantees | 197 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| | Figure 19-1. Sensitivity Analysis | 209 |

| | | |

| | Figure 20-1. Pampa Orcoma Adjacent Properties | 211 |

| | | |

| | Figure 20-2. Pampa Orcoma Adjacent Properties | 212 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 |

| 1.1 | Property Summary and Ownership |

Pampa Orcoma, located in northern Chile’s Tarapacá Region, covers a property area of 10,296 ha.

The Pampa Orcoma Project (the Project, or Orcoma Project), which includes the mine area as well as temporary and permanent facilities for the mining operation, involves a surface area of 7,387 ha. In the access sector to the area, there is a "BHP aqueduct easement," and in the surrounding area, there are the populated areas of Huara, Bajo Soga, Colonos Rurales, Pisagua, and also the Pampa del Tamarugal Reserve.

| 1.2 | Geology and Mineralization |

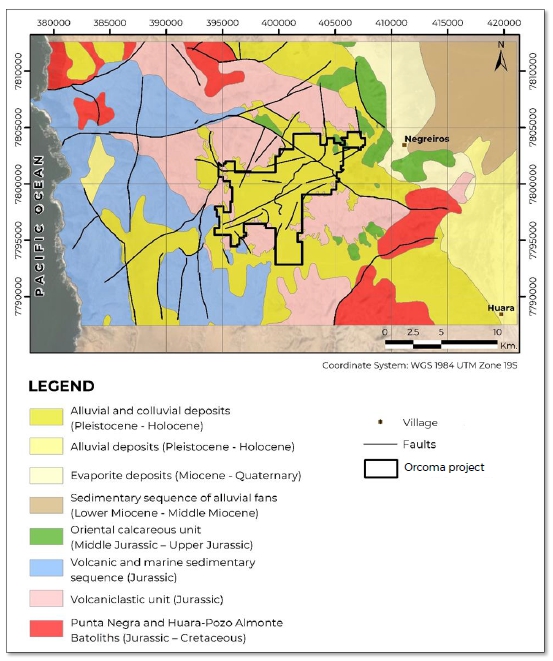

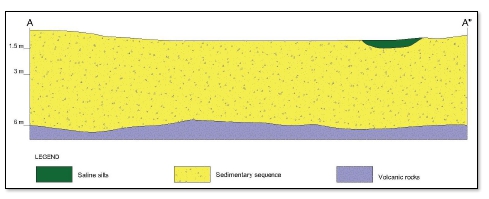

Pliocene to Holocene alluvial and colluvial deposits overlie most of the Pampa Orcoma property’s surface area, overlaying Jurassic volcaniclastic sequences with minor outcrops to the edges of the property, and outcrops of calcareous sedimentary units and evaporite deposits occurring to the northeast of the property.

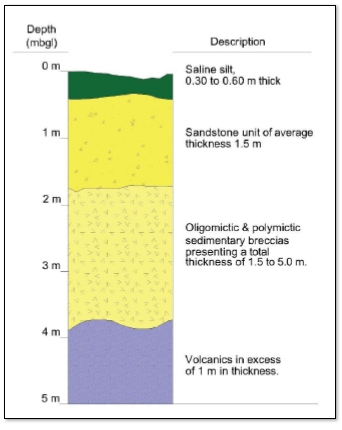

Alluvial deposits host iodine and nitrate bearing caliche deposits, showing lateral continuity with an average thickness of 4 m throughout the property.

The property is located on Jurassic volcaniclastic sequences overlain by alluvial and colluvial sediments of Pliocene to Holocene age. The Jurassic volcaniclastics are exposed at the surface in the vicinity of the property limit and beyond. Calcareous sedimentary units and evaporite deposits occur to the northeast of the property, along the western edge of the Ruta 5 trunk road. Alluvial fans cover the solid geology on the eastern side of Ruta 5 and extend to the settlement of Negreiros to the west of Ruta 5.

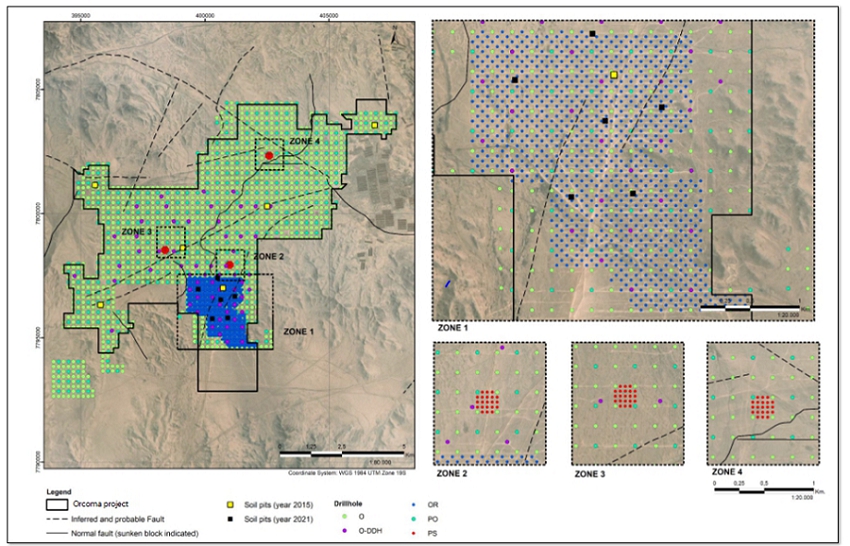

Geologic exploration of Pampa Orcoma includes pit soil and drilling surveys mostly developed in the last seven years. The most recent pit soil survey in 2021, totals 5 out of 86 trenches that have been dug to improving geologic and physical characterization of the caliche deposit. Drilling surveys carried out in 2014 and 2021, total 2,756 drill holes differentiated mainly by grid spacing, with those carried out in 2014 comprising 400-x-400-m and 200-x-200-m RC drilling grids that cover most of the project’s area as the basis for resource estimation, and a 50-x-50-m grid covering three localized areas. Findings from these surveys include iodine and nitrate grades, drill hole characteristics, rock cutting data, geomechanical descriptions, among others.

The 2021 drilling surveys included a diamond drilling campaign, showing core sample descriptions aiming at improving geologic and physical characterization of caliche deposits, and a current RC drilling grid of 100m spacing in an E-W direction and 50m in a NW-SE for recategorization of the 400-x-400-m and 200-x-200-m grids.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 1 |

| 1.4 | Mineral Resource Statement |

This sub-section contains forward-looking information related to Mineral Resource estimates for the Project. The material factors that could cause actual results to differ materially from the conclusions, estimates, designs, forecasts or projections in the forward-looking information include any significant differences from one or more of the material factors or assumptions that were set forth in this sub-section including geological and grade interpretations and controls and assumptions and forecasts associated with establishing the prospects for economic extraction.

Iodine and nitrate Mineral Resources, exclusive of Mineral Reserves, were estimated (Table 1-1.) based on lithologies and iodine and nitrate grades, from a 200-x-200-meter (m) grid of drill holes, considering an iodine cut-off grade of 300 ppm. The Mineral Resource is classified as Indicated, since geologic uncertainty and actual grid spacing do not allow a more precise estimation of the Mineral Resource. The 100 truncated grid (100-x-50-m) drill hole grid currently in process, will likely allow for a future updated Mineral Resource estimates that may result in upgrading a portion of the current Mineral Resources to a Measured level of confidence (SQM(j), 2021). The diamond drilling (DDH) campaign currently in process, will provide, when finished, a comparison of caliche depths and iodine and nitrate grades with respect to the 200-x-200-m grid Mineral Resource estimation.

Table 1-1. Mineral Resource Estimate Exclusive of Mineral Reserves (Effective December 31, 2021)

| Resource Classification | | Resources (Mt) | | | Iodine (ppm) | | | Nitrate (%) | |

| Indicated | | | 18 | | | | 457 | | | | 7.4 | |

Notes:

(1) Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability. There is no certainty that all or any part of the Mineral Resource will be converted into Mineral Reserves upon the application of modifying factors.

(2) Mineral Resources are reported as in-situ and exclusive of Mineral Reserves, where the estimated Mineral Reserve without processing losses during the reported LOM was subtracted from the Mineral Resource inclusive of Mineral Reserves.

(3) Comparisons of values may not add due to rounding of numbers and the differences caused by use of averaging methods.

(4) The units “Mt” and “ppm” refers to million tonnes and parts per million respectively.

(5) The Mineral Resource estimate considers an iodine cut-off grade of 300 ppm, based on accumulated cut-off iodine grades and operational average grades, as well as the cost and medium and long term prices forecast for prilled iodine production (Section 16).

(6) Donald Hulse is the QP responsible for the Mineral Resources.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 2 |

| 1.5 | Mineral Reserve Statement |

This sub-section contains forward-looking information related to Mineral Reserve estimates for the Project. The material factors that could cause actual results to differ materially from the conclusions, estimates, designs, forecasts or projections in the forward-looking information include any significant differences from one or more of the material factors or assumptions that were set forth in this sub-section including Mineral Resource model tonnes and grade, modifying factors including mining and recovery factors, production rate and schedule, mining equipment productivity, commodity market and prices and projected operating and capital costs.

A Probable Mineral Reserve estimate for Pampa Orcoma (Table 1-2) was determined by applying modifying factors to Indicated Mineral Resource estimates. Modifying factors, considering dilution and loss, are considered in the estimation of average iodine and nitrate grades, based on historical operational use in SQM’s various mining facilities. Mineral Reserves are reported as in-situ ore (caliche).

Table 1-2. Mineral Reserve Estimate (Effective December 31, 2021)

| Reserves Classification | | Reserves (Mt) | | | Iodine (ppm) | | | Nitrate (%) | |

| Probable | | | 309 | | | | 413 | | | | 6.9 | |

Notes:

(1) Comparisons of values may not add due to rounding of numbers and the differences caused by use of averaging methods.

(2) The units “Mt” and “ppm” refer to million tonnes and parts per million respectively.

(3) The Mineral Reserve estimate considers an iodine cut-off grade of 300 ppm, based on accumulated cut-off iodine grades and operational average grades, as well as the cost and medium- and long-term prices forecast of generating iodine (Sections 11, 16 and 19).

(4) Modifying factors of historical operational use in various of SQM’s mining facilities, are applied to iodine and nitrate grades, the factors applied to iodine and nitrate grades are 0.9 and 0.85, respectively.

(5) Mineral Resources in the area without an environmental permit are estimated at 18 Mt.

(6) Mineral Reserves are reported as in-situ ore

(7) Donald Hulse is the QP responsible for the Mineral Reserves.

(8) The QP is not aware of any environmental, permitting, legal, title, taxation, socioeconomic, marketing, political or other relevant factors that could materially affect the Mineral Reserve estimate that are not discussed in this TRS.

| 1.6 | Metallurgy and Mineral Processing |

| 1.6.1 | Metallurgical Test Work Summary |

Metallurgical test work performed to date on the project shows that the Orcoma ore outperforms the company's other resources based on its salt composition and leaching tests. SQM's analytical and pilot test laboratories perform the following chemical, mineralogical and metallurgical tests which constitutes the bank of tests carried out on operating projects: 1) Microscopy and chemical composition, 2) Determination of Physical properties: Tail Test, Borra test, Laboratory granulometry, Embedding tests, Permeability, and 3) Leaching tests.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 3 |

For Pampa Orcoma, tests were conducted in 2014 and during 2020. During 2014, through the "Sumo Project (pits or calicatas)", leaching tests were conducted in isocontainers, resulting in an average iodine yield of 67.7% and in the case of nitrate, a yield of 77.6%. The average soluble salt content of Pampa Orcoma in this test is defined as 49.1% on average.

Meanwhile, in 2020 and through the Diamantina Project (DDH), agitated leaching tests were carried out in vessels and successive stages, concluding that the recovery is favorable from a Soluble Salts content about than 50%. In these tests the soluble salts matrix was 53.4% and an iodine content of 65.3% was obtained.

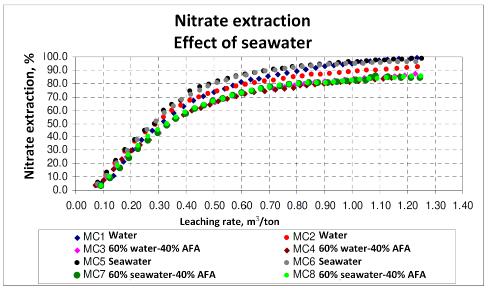

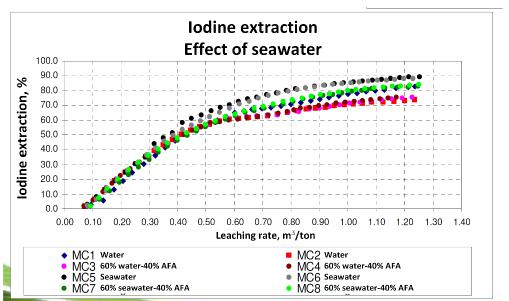

On the other hand, this project contemplates the use of seawater as a leaching solution to replace industrial water. In this way, SQM previously developed a caliche leaching test plan with seawater, to determine the technical feasibility, positive and negative impacts or equivalence on recovery and metallurgical yield. By means of column leaching tests, the feasibility of the process was demonstrated in a pilot plant located at the Iris plant of the Nueva Victoria mine.

The test work developed was adequate to establish appropriate processing routes for the caliche resource and supports the future yield estimates indicated in the planning. Therefore, the deposit is considered favorable for the extraction process.

The Project aims to produce iodide, iodine, and nitrate-rich salts from caliche processing, which will be extracted from deposits rich in this mineral, located in the area known as Pampa Orcoma, commune of Huara. Mining and ore processing at the future Pampa Orcoma mining operation corresponds, in both cases, to conventional methods and stages usually employed by SQM in its other caliche operations.

The production process starts with caliche exploitation (mine) at a rate of up to 11,000,000 tonnes per year (tpy), heap leaching and processing plants to obtain iodine as the main product, and salts rich in sodium nitrate and potassium nitrate as a by-product.

An iodate-rich solution will be obtained through leaching with seawater, or recirculated solutions (a fraction of Brine Feeble [BF] recirculated from the iodide plant), which are then treated in chemical plants to elemental iodine produced for sale as prill. After neutralization, the remaining solution is taken to evaporation areas to obtain sodium nitrate and other salts that will be sent to the Coya Sur Plant, located in the Antofagasta Region.

Pampa Orcoma, through its two iodide plants and one iodine (fusion) plant, is projected to begin operation in 2024 with an annual production of around 2,500 tonnes (t) of iodine and 320 kilotonnes (Kt) per year of nitrate salts, each ones, with an average total recovery of 66% and 63%, respectively.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 4 |

| 1.7 | Mine Design, Optimization, and Scheduling |

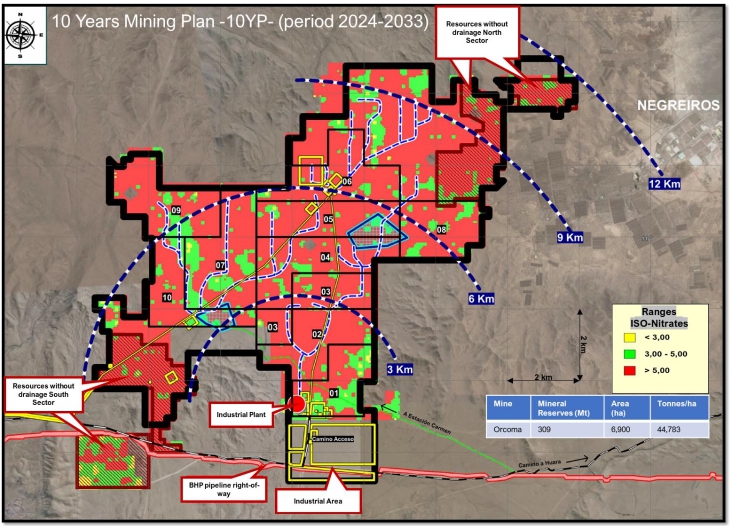

Pampa Orcoma's Mining Plan considers caliche extraction at a first year rate of 7 Million tonnes (Mt) per year (Mtpy) ramping up to a nominal 20 Mtpy. For the period 2024-2040, a total extraction of 309 Mt of caliche with an average grade of 408 parts per million (ppm) iodine and 6.8% nitrates is projected. The area to be mined is 2,395 ha.

Exploitation at the future Pampa Orcoma mine corresponds to SQM's usual method employed in its caliche mining operations, which consists of land preparation (soil and overburden removal), surface extraction of the mineral (caliches), loading, and transport of the mineral (caliche) for leaching heaps to obtain the solutions (fresh brine) enriched in iodine and nitrates.

Mining at Pampa Orcoma is superficial, removing a superficial layer of sterile material (soil + overburden), which is up to 1.50 m thick (sandstones, breccias, and anhydrite crusts). The mineral (caliche) is then extracted, having a thickness of 1.50 m to 6.00 m (average of 3.50 m).

At Pampa Orcoma, between 20% to 30% of the material to be mined is classified as hard to semi-hard, and 70-80% as soft to semi-soft. It also has low clay content and thus favors the use of a continuous miner (CM) and better recovery rates in the leaching heaps (drainage in the heaps is improved).

In the mining processes, SQM considers an efficiency close to 90%, including material losses due to modifying factors and those inherent to the mining process, as well as for the mineral dilution processes. For this mining process performance, the heap leach load expected is a total of 126.2 kt of iodine (21.6 tonnes per day [tpd] of iodine – 7.7 ktpy of iodine-) and 20,966 kt of nitrate salts (3,582 tpd of nitrates -1,286 ktpy of nitrate-). For an average load of 0.85 Mt of caliche in heap leach, there is an average load of 313 t of iodine and 51,908 t of nitrate salts per heap leach for the 2024-2040 period.

In the heap leaching processes, the total seawater demand averages 336 liters per second (L/s) (1,190 cubic meters per hour [m³/h]). Considering the porjected heap leach yields (73.7% for iodine and 76.9% for nitrates), a flow of enriched solutions (Brine flow) of 1,034 m³/h is expected, which means a hydraulic efficiency near of 80%. Average unit consumptions are set at 0.55 cubic meters per tonne (m³/t). For the Mining Plan elaborated by SQM (2024-2040 period), the production of Iodine in piles is planned to be 84 kt (14.3 tpd) and 14,482 Kt of nitrates (2,474 tpd), which implies an average production of 231 t of Iodine and 39,838 t of nitrate salts per pile.

SQM has planned acquisition of the necessary equipment to achieve caliche production, complete the mining and construction of the heap leach, and obtain the enriched liquors that will be sent to the treatment plants to obtain the final products of iodine and nitrate.

Pampa Orcoma's mining operation will be staffed with 155 professionals for mining and heap leaching operations. It is planned that a total of 45 professionals will be employed for heap leach and associated pit maintenance. The unit cost of mining production at Pampa Orcoma is set at 2.13 United States Dollars per tonne (USD/t) of caliche mined, including leach heap drainage construction; and 1.43 USD/t of caliche leached in heap pads, including irrigation, heap pad operations and seawater pipeline.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 5 |

| 1.8 | Capital Costs, Operating Costs, and Financial Analysis |

| 1.8.1 | Capital and Operating Costs |

SQM is the world’s largest producer of potassium nitrate and iodine and one of the world´s largest lithium producers. It also produces specialty plant nutrients, iodine derivatives, lithium derivatives, potassium chloride, potassium sulfate, and certain industrial chemicals (including industrial nitrates and solar salts). The products are sold in approximately 110 countries through SQM worldwide distribution network, with more than 90% of the sales derived from countries outside Chile.

The Orcoma Project contemplates:

| · | Open pit exploitation of mining deposits. |

| · | Enabling support facilities called the Mining Operations Center (COM). |

| · | Construction of an iodide production plant, with a capacity of 2,500 tpy (of equivalent iodine). |

| · | Construction of an iodine plant, to process up to 2,500 tpy. |

| · | Construction of evaporation ponds to produce salts rich in nitrate at a rate of 320,325 tpy. |

| · | Construction of a seawater adduction pipe from the northern sector of Caleta Buena to the mining area, to meet the water needs during the operation phase. |

| · | Connection of the industrial areas of the Project to the Norte Grande Interconnected System (SING), in order to provide sufficient energy for their electrical requirements. |

Orcoma's operating cost comprises the cost to produce the base solution, the cost of iodine production, and the cost of transport the brine nitrate concentrated to the Coya Sur site.

The common variable costs are 3,59 USD per caliche t.

The Iodine variable cost is 16.1 USD per iodine kilogram (kg).

The salt variable cost (including transportation to Coya Sur) is 82.6 USD per nitrate tonne (brine enriched in nitrate).

To obtain the flow of costs, which considers operating and non-operating costs, unit costs have been included for the different production stages, which considers common production cost for iodine and nitrates, such as Mining, Leaching and Seawater.

In addition, the production costs directly associated with the production of iodine in the plant, and the production of nitrates before processing at the Coya Sur site were added.

To the costs indicated above, those related to Depreciation and Others have been added, which include, among other costs, marketing, and exportation.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 6 |

The key valuation assumptions used in the financial model consider a discount rate of 10% and a tax rate of 28% in the period 2024 to 2040.

The estimated production of iodine and nitrates for the period 2024 to 2040 corresponds to the Mining Plan of SQM reviewed by WSP, which implies a total production of 84 kt prilled iodine and 14,482 kt of nitrate concentrate brine. nitrate concentrate brine produced in Nueva Victoria complex will be transported to Coya Sur plant to mix with KCl from Salar de Atacama to produce Potassium Nitrate Fertilizers and Solar Salts.

The economic analysis considers the unit costs for prilled iodine and nitrate concentrate brine production and an unit value for the prilled Iodine selling price and an unit internal price for the nitrate concentrate brine produced in Nueva Victoria complex.

The estimated Net Present Value (NPV) Base Case imply a Net Present Value (NPV) before Financial Cost (FC) & Taxes (kUSD) of $1,012,558; and a NPV after FC and Taxes (kUSD) of $680,060.

For the whole of the iodine and nitrate business, the financial analysis is presented in Table 1-3.

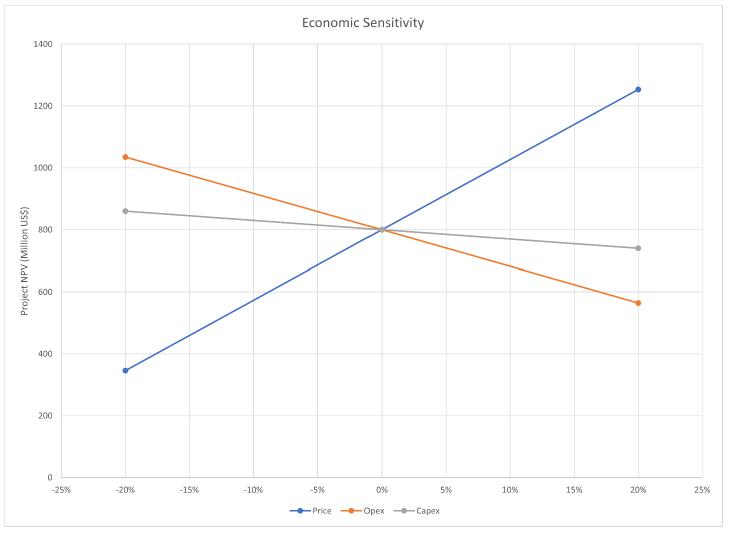

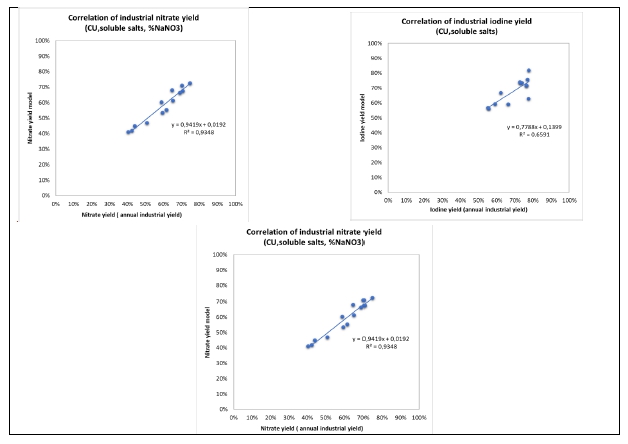

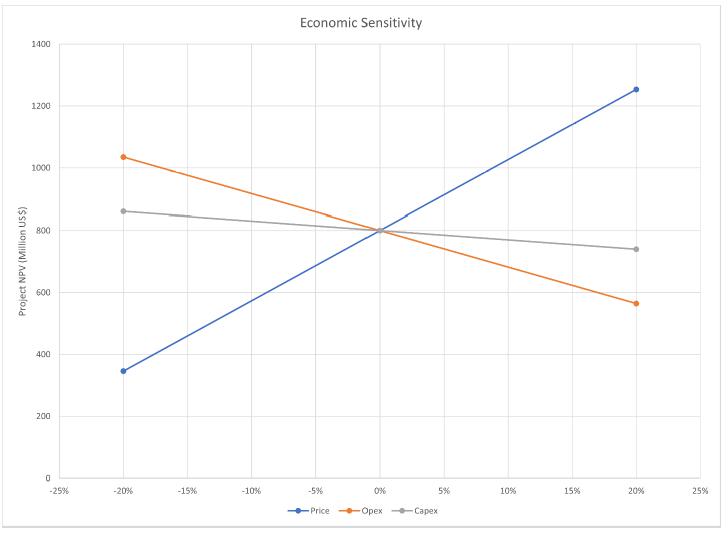

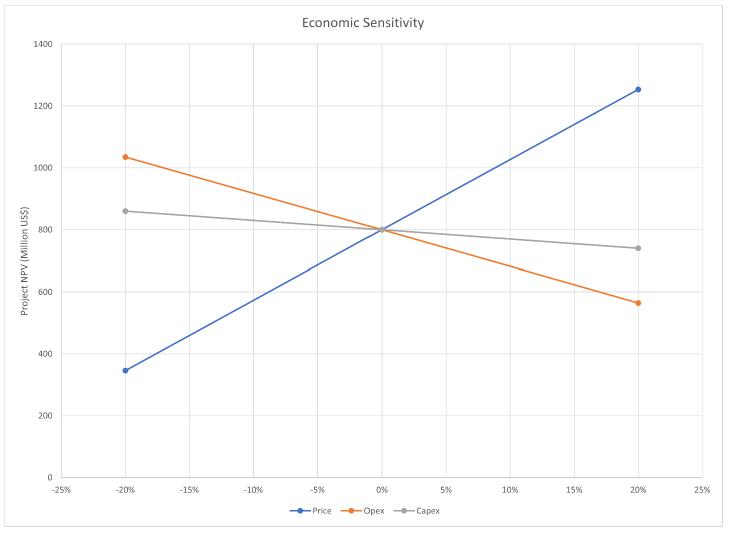

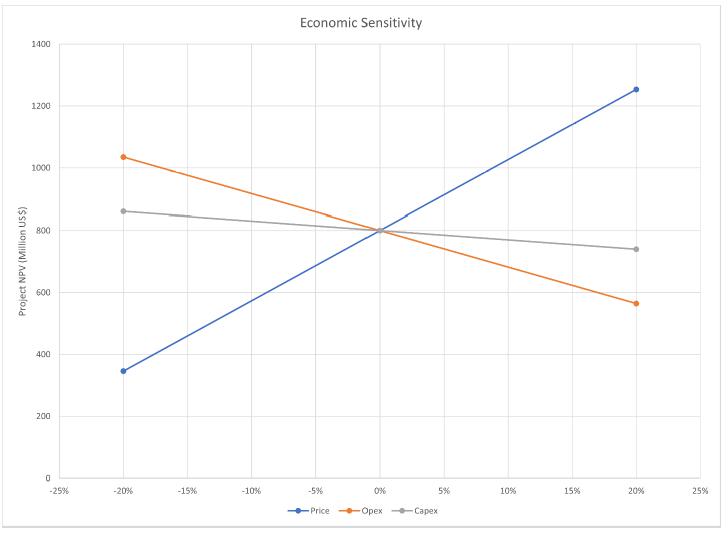

Sensitivity analysis gives visibility to the assumptions that present the key risks to the value of the Project. The analysis also identifies the relative impact of each assumption in terms the net present value (Figure 1-1).

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 7 |

Figure 1-1 Sensitivity Analysis of the Pampa Orcoma Project

As seen in the above figure, the project NPV is more sensitive to product price while being least sensitive to capital and operational costs.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 8 |

Table 1-3. Estimated Net Present Value (NPV) for the Period

| NPV | | | | 2022 | | | 2023 | | | 2024 | | | 2025 | | | 2026 | | | 2027 | | | 2028 | | | 2029 | | | 2030 | | | 2031 | | | 2032 | | | 2033 | | | 2034 | | | 2035 | | | 2036 | | | 2037 | | | 2038 | | | 2039 | | | 2040 | | | TOTAL | |

| REVENUE | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Total Revenues (M US$) | | US$M | | | - | | | | - | | | | 167 | | | | 244 | | | | 297 | | | | 377 | | | | 458 | | | | 453 | | | | 419 | | | | 441 | | | | 468 | | | | 438 | | | | 461 | | | | 461 | | | | 461 | | | | 461 | | | | 461 | | | | 461 | | | | 461 | | | | 6,987 | |

| COSTS | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Common Costs (mining, leaching) | | US$M | | | - | | | | - | | | | 27 | | | | 38 | | | | 48 | | | | 63 | | | | 72 | | | | 72 | | | | 72 | | | | 72 | | | | 72 | | | | 72 | | | | 72 | | | | 72 | | | | 72 | | | | 72 | | | | 72 | | | | 72 | | | | 72 | | | | 1,109 | |

| Iodine Production Costs | | US$M | | | - | | | | - | | | | 30 | | | | 43 | | | | 52 | | | | 68 | | | | 87 | | | | 80 | | | | 77 | | | | 85 | | | | 79 | | | | 77 | | | | 81 | | | | 81 | | | | 81 | | | | 81 | | | | 81 | | | | 81 | | | | 81 | | | | 1,249 | |

| Nitrate Production Costs | | US$M | | | - | | | | - | | | | 28 | | | | 42 | | | | 51 | | | | 64 | | | | 75 | | | | 78 | | | | 71 | | | | 72 | | | | 83 | | | | 76 | | | | 80 | | | | 80 | | | | 80 | | | | 80 | | | | 80 | | | | 80 | | | | 80 | | | | 1,196 | |

| TOTAL OPERATING COST | | US$M | | | - | | | | - | | | | 85 | | | | 123 | | | | 152 | | | | 195 | | | | 234 | | | | 230 | | | | 219 | | | | 229 | | | | 234 | | | | 225 | | | | 233 | | | | 233 | | | | 233 | | | | 233 | | | | 233 | | | | 233 | | | | 233 | | | | 3,554 | |

| EBITDA | | US$M | | | - | | | | - | | | | 81 | | | | 121 | | | | 145 | | | | 182 | | | | 224 | | | | 223 | | | | 200 | | | | 212 | | | | 234 | | | | 213 | | | | 228 | | | | 228 | | | | 228 | | | | 228 | | | | 228 | | | | 228 | | | | 228 | | | | 3,433 | |

| Depreciation | | US$M | | | - | | | | - | | | | 15 | | | | 16 | | | | 16 | | | | 17 | | | | 18 | | | | 18 | | | | 18 | | | | 18 | | | | 19 | | | | 19 | | | | 20 | | | | 20 | | | | 21 | | | | 21 | | | | 21 | | | | 22 | | | | 22 | | | | 321 | |

| Interest Payments | | US$M | | | - | | | | - | | | | 10 | | | | 9 | | | | 7 | | | | 6 | | | | 5 | | | | 4 | | | | 3 | | | | 1 | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | 45 | |

| Pre-Tax Gross Income | | US$M | | | - | | | | - | | | | 57 | | | | 97 | | | | 121 | | | | 158 | | | | 201 | | | | 201 | | | | 179 | | | | 193 | | | | 215 | | | | 194 | | | | 208 | | | | 208 | | | | 208 | | | | 207 | | | | 207 | | | | 206 | | | | 206 | | | | 3,066 | |

| Taxes | | 28% | | | - | | | | - | | | | 16 | | | | 27 | | | | 34 | | | | 44 | | | | 56 | | | | 56 | | | | 50 | | | | 54 | | | | 60 | | | | 54 | | | | 58 | | | | 58 | | | | 58 | | | | 58 | | | | 58 | | | | 58 | | | | 58 | | | | 859 | |

| Operating Income | | US$M | | | - | | | | - | | | | 41 | | | | 70 | | | | 87 | | | | 114 | | | | 145 | | | | 145 | | | | 129 | | | | 139 | | | | 155 | | | | 140 | | | | 150 | | | | 150 | | | | 149 | | | | 149 | | | | 149 | | | | 149 | | | | 148 | | | | 2,208 | |

| Add back depreciation | | US$M | | | - | | | | - | | | | 15 | | | | 16 | | | | 16 | | | | 17 | | | | 18 | | | | 18 | | | | 18 | | | | 18 | | | | 19 | | | | 19 | | | | 20 | | | | 20 | | | | 21 | | | | 21 | | | | 21 | | | | 22 | | | | 22 | | | | 321 | |

| NET INCOME AFTER TAXES | | US$M | | | - | | | | - | | | | 56 | | | | 85 | | | | 103 | | | | 131 | | | | 162 | | | | 163 | | | | 147 | | | | 157 | | | | 174 | | | | 159 | | | | 170 | | | | 170 | | | | 170 | | | | 170 | | | | 170 | | | | 170 | | | | 170 | | | | 2,529 | |

| Total CAPEX | | US$M | | | 150 | | | | 144 | | | | 8 | | | | 8 | | | | 12 | | | | 25 | | | | 9 | | | | 4 | | | | 4 | | | | 4 | | | | 9 | | | | 5 | | | | 10 | | | | 10 | | | | 7 | | | | 8 | | | | 12 | | | | 7 | | | | 5 | | | | 442 | |

| Bank Loan | | US$M | | | 95 | | | | 96 | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | 190 | |

| Loan Amortization | | US$M | | | - | | | | - | | | | 20 | | | | 21 | | | | 22 | | | | 23 | | | | 24 | | | | 25 | | | | 27 | | | | 28 | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | 190 | |

| Working Capital | | US$M | | | - | | | | - | | | | 14 | | | | 7 | | | | 4 | | | | 6 | | | | 7 | | | | -0 | | | | -4 | | | | 2 | | | | 4 | | | | -4 | | | | 2 | | | | - | | | | - | | | | - | | | | - | | | | - | | | | - | | | | 38 | |

| Pre-Tax Cashflow | | US$M | | | -55 | | | | -48 | | | | 30 | | | | 77 | | | | 99 | | | | 122 | | | | 179 | | | | 190 | | | | 170 | | | | 176 | | | | 222 | | | | 211 | | | | 216 | | | | 218 | | | | 221 | | | | 220 | | | | 216 | | | | 221 | | | | 223 | | | | 2,908 | |

| After-Tax Cashflow | | US$M | | | -55 | | | | -48 | | | | 14 | | | | 50 | | | | 66 | | | | 77 | | | | 122 | | | | 133 | | | | 120 | | | | 123 | | | | 161 | | | | 157 | | | | 157 | | | | 160 | | | | 163 | | | | 162 | | | | 158 | | | | 164 | | | | 165 | | | | 2,049 | |

| Pre-Tax NPV | | US$M | | | 1,013 | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| After-Tax NPV | | US$M | | | 680 | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Discount Rate | | US$M | | | 10 | % | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 9 |

| 1.9 | Conclusions and Recommendations |

Mr. Donald Hulse, Qualified Person (QP) for Mineral Reserves, concludes that the work performed in the preparation of this Technical Report Summary (TRS) includes adequate details and information to declare the Mineral Resources and Reserves.

In relation to the resource treatment processes, the conclusion of the responsible QP, Gino Slanzi, is that appropriate work practices and equipment, design methods and processing equipment selection criteria have been used.

In addition, the company has developed new processes that have continuously and systematically optimized operations.

Some recommendations are given in the following areas:

| · | Analyze the mineral distribution and statistical characteristics of drill hole grids currently in process have the potential to upgrade the mineral resource and mineral reserve classification. |

| · | Expand the block model approach for resource estimation to larger drill hole grids to avoid separating the resource model and databases by drill hole spacing. |

| · | Improvements are required for the Quality Assurance/Quality Control (QA/QC) program to align with industry best practice and facilitate more meaningful QC. |

| · | Confirm the accuracy and precision of SQM internal laboratory implementing an external QA/QC check with a representative number of samples as a routine procedure. |

| · | Maintain original and/or digitized records of collar surveys, geological, and geochemical data in a secure database. |

| · | Infilling RC drill hole grids with 100-x-50 -m spacing, which is currently in progress, has the potential to upgrade the Mineral Resource estimates from Indicated to Measured Mineral Resources, and in turn upgrade Mineral Reserves from Probable to Proven. It is recommended to re-estimate Pampa Orcoma’s Mineral Reserves when Mineral Resource have been updated based on the additional drilling |

| · | Estimate caliche density specifically for the Pampa Orcoma project area. This is currently based on operating experience at the Nueva Victoria operation and may improve the accuracy of the mineral resource estimate. |

| · | Construct updated procedures that describe in sufficient detail the activities of capture, administration, and backup of the data. |

| · | Update all the procedures, methodologies, and results in the annual reports. |

| · | Detail the construction development timeline to a feasibility level to best account for the timing of cash flows and risk points to the time and cost. |

All the above recommendations are considered within the declared capital and operating expenditures and do not imply additional costs for their execution.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 10 |

This Technical Report Summary (TRS) was prepared for the Sociedad Química y Minera de Chile (SQM.) The purpose of the TRS is to provide a comprehensive understanding of SQM’s Pampa Orcoma Project in northern Chile based on the requirements of Regulation S-K, Subpart 1300 of the United States Securities Exchange Commission (SEC), which hereafter is referred to as the S-K 1300.

| 2.1 | Terms of Reference and Purpose of the Report |

When the Pampa Orcoma site becomes operational in the year 2024, SQM will produce iodide, iodine and nitrate derived by-products (nitrate-rich salts, sodium nitrate and potassium nitrate), through heap leaching and its process plants. This TRS provides technical information to support the Mineral Resource and Mineral Reserve estimates for SQM's operations at the Pampa Orcoma project.

The date of this TRS Report was March 30, 2022, while the effective date of the Mineral Resource and Mineral Reserve estimates was December 31, 2021. It is the QP’s opinion that there are no known material changes impacting the Mineral Resource and Mineral Reserve estimates between December 31, 2021, and March 30, 2022.

This TRS uses English spelling and Metric units of measure. Nitrate grades are presented in weight percent (wt.%) and iodine grades in parts per million (ppm). Costs are presented in constant US Dollars (USD) as of December 31, 2021.

Except where noted, coordinates in this TRS are presented in Metric units using the World Geodetic System (WGS) 1984 Universal Transverse Mercator (UTM) ZONE 19 South (19S).

The purpose of this TRS is to report Mineral Resources and Mineral Reserves for SQM’s Pampa Orcoma Project.

| 2.2 | Source of Data and Information |

This TRS is based on information provided directly by SQM and public data extracted from published government reports. All information relied upon is cited throughout this TRS and listed in Section 24.

Table 2-1 provides the abbreviations (abbv.) and acronyms used in this TRS.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 11 |

Table 2-1. Abbreviations and Acronyms

| Acronym/Abbv. | Definition |

| ' | minute |

| '' | second |

| % | percent |

| ° | degrees |

| °C | degrees Celsius |

| 100T | 100 truncated grid |

| AA | Atomic absorption |

| AAA | Andes Analytical Assay |

| AFA | Weakly acidic water |

| AFN | Feeble Neutral Water |

| Ajay | Ajay Chemicals Inc. |

| AS | Auxiliary Station |

| ASG | Ajay-SQM Group |

| BF | Brine Feeble |

| BFN | Neutral Brine Feeble |

| BWn | abundant cloudiness |

| CIM | Centro de Investigación Minera y Metalúrgica |

| cm | centimeter |

| CM | continuous miner |

| CU | Water consumption |

| COM | Mining Operations Center |

| CSP | Concentrated solar power |

| CONAF | National Forestry Development Corporation |

| DDH | diamond drill hole |

| DGA | General Directorate of Water |

| DTH | down-the-hole |

| EB 1 | Pumping Station No. 1 |

| EB2 | Pumping Station No. 2 |

| EIA | environmental impact statement |

| EW | east-west |

| FC | financial cost |

| FNW | Feeble neutral water |

| g | gram |

| GU | geological unit |

| g/cc | grams per centimeter |

| g/mL | grams per milliliter |

| g/t | grams per tonne |

| g/L | grams per liter |

| GPS | global positioning system |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 12 |

| h | hour |

| ha | hectare |

| ha/y | hectares per year |

| HDPE | High-density Polyethylene |

| ICH | industrial chemicals |

| ICP | inductively coupled plasma |

| IS | Intermediate solution |

| ISO | International Organization for Standardization |

| kg | kilogram |

| kh | horizontal seismic coefficient |

| kg/m3 | kilogram per cubic meter |

| km | kilometer |

| kv | vertical seismic coefficient |

| kN/m3 | kilonewton per cubic meter |

| km2 | square kilometer |

| kPa | kiloPascal |

| kt | kilotonne |

| ktpd | thousand tonnes per day |

| ktpy | kilotonne per year |

| kUSD | thousand USD |

| kV | kilovolt |

| kVa | kilovolt-amperes |

| L/h-m2 | liters per hour square meter |

| L/m2/d | liters per square meter per day |

| L/s | liters per second |

| LR | Leaching rate |

| LCD/LED | liquid crystal displays/light-emitting diode |

| LCY | Caliche and Iodine Laboratories |

| LdTE | medium voltage electrical transmission line |

| LIMS | Laboratory Information Management System |

| LOM | life-of-mine |

| m | meter |

| M&A | mergers and acquisitions |

| m/km2 | meters per square kilometer |

| m/s | meters per second |

| m2 | square meter |

| m3 | cubic meter |

| m3/d | cubic meter per day |

| m3/h | cubic meter per hour |

| m3/t | cubic meter per tonne |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 13 |

| masl | meters above sea level |

| mbgl | meter below ground level |

| mbsl | meters below sea level |

| mm | millimeter |

| mm/y | millimeters per year |

| Mpa | megapascal |

| Mt | million tonne |

| Mtpy | million tonnes per year |

| MW | megawatt |

| MWh/y | Megawatt hour per year |

| NNE | north-northeast |

| NNW | north-northwest |

| NPV | net present value |

| NS | north-south |

| O3 | ozone |

| ORP | oxidation reduction potential |

| PLS | pregnant leach solution |

| PMA | particle mineral analysis |

| ppbv | parts per billion volume |

| ppm | parts per million |

| PVC | Polyvinyl chloride |

| QA | Quality assurance |

| QA/QC | Quality Assurance/Quality Control |

| QC | Quality control |

| QP | Qualified Person |

| RC | reverse circulation |

| RCA | environmental qualification resolution |

| RMR | Rock Mass Rating |

| ROM | run-of-mine |

| RPM | revolutions per minute |

| RQD | rock quality index |

| SG | Specific gravity |

| SEC | Securities Exchange Commission of the United States |

| SSE | South-southeast |

| SEIA | Environmental Impact Assessment System |

| MMA | Ministry of Environment |

| SMA | Environmental Superintendency |

| SNIFA | National Environmental Qualification Information System (SMA online System) |

| PSA | Environmental Following Plan (Plan de Seguimiento Ambiental) |

| SEM | Terrain Leveler Surface Excavation Machine |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 14 |

| Acronym/Abbv. | Definition |

| SFF | specialty field fertilizer |

| SI | intermediate solution |

| SING | Norte Grande Interconnected System |

| S-K 1300 | of Regulation S-K, Subpart 1300 of the Securities Exchange Commission of the United States |

| SM | salt matrix |

| SPM | sedimentable particulate matter |

| Sr | relief value, or maximum elevation difference in an area of 1 km² |

| SS | soluble salt |

| SX | solvent extraction |

| t | metric tonne |

| TR | Irrigation rate |

| TAS | sewage treatment plant |

| TEA project | Tente en el Aire project |

| tpy | tonnes per year |

| t/m3 | tonnes per cubic meter |

| the Project or Orcoma Project | Pampa Orcoma Project |

| tpd | tonnes per day |

| TRS | Technical Report Summary |

| UF | Development Unit (Unidad de Fomento) is a Chilean financial instrument that is resistant to inflation. Currently valued at 38.7 US$ |

| ug/m3 | microgram per cubic meter |

| USD | United States Dollars |

| USD/kg | United States Dollars per kilogram |

| USD/t | United States Dollars per tonne |

| UTM | Universal Transverse Mercator |

| UV | ultraviolet |

| VEC | Voluntary Environmental Commitments |

| WGS | World Geodetic System |

| WSF | Water soluble fertilizer |

| wt.% | weight percent |

| XRD | X-Ray diffraction |

| XRF | X-ray fluorescence |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 15 |

The details of the site inspections by the QPs are summarized in Table 2-2.

Table 2-2. Site Visits

| QP | | Expertise | | Date of Visit | | Detail of Visit |

| Álvaro Henríquez | | Exploration, Geology | | 6 Dec 2021 | | Drilling grid, extents of the deposit, soil pits |

| Donald Hulse | | Resources and Reserves | | 6 Dec 2021 | | Drilling grid, extents of the deposit, soil pits |

In the visit to Pampa Orcoma, the QPs reviewed the drilling grid, the extents of the deposit, and selected trenches that exposed the thickness and quality of caliche and overburden.

| 2.4 | Previous Reports on Project |

This Report is the first TRS prepared for SQM’s Pampa Orcoma deposit. This TRS is not an update of a previously filed TRS.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 16 |

| 3 | Description and Location |

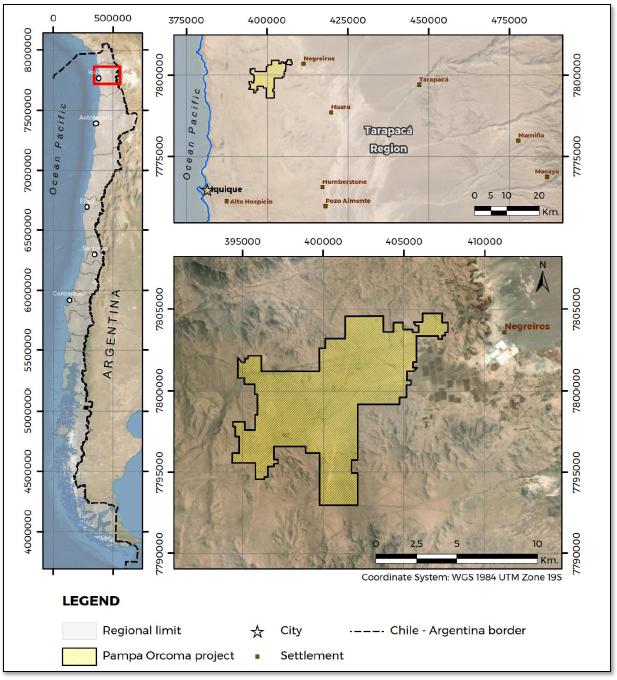

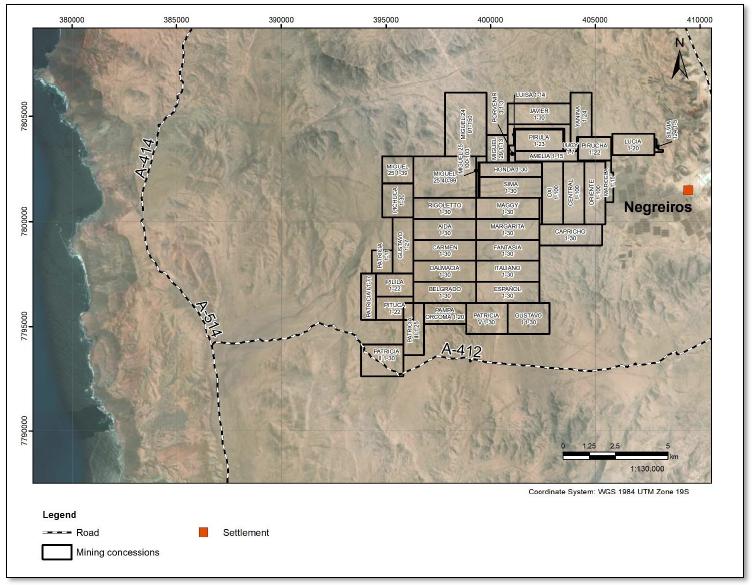

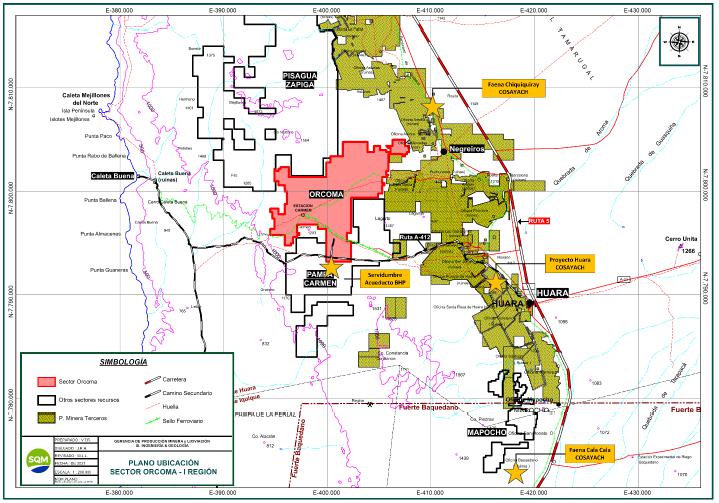

The Pampa Orcoma Project is in the Tarapacá Region of northern Chile. It is situated 99 kilometers (km) to the northeast of the city of Iquique, in the community of Huara (SQM(a), 2019). The property is centered on Latitude 19° 53’ 58’’ S, Longitude 69° 56’ 58’’ W (Figure 3-1).

Figure 3-1. General Location Map

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 17 |

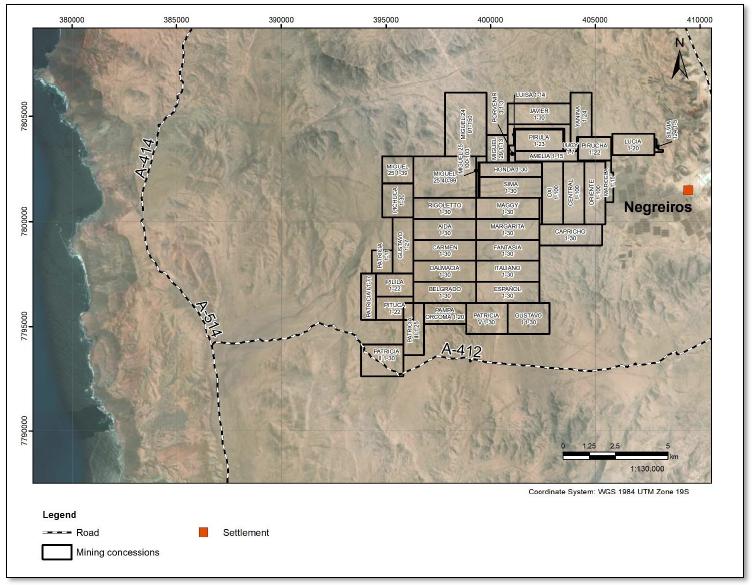

The mining property comprises 43 mining concessions covering a total area of 10,296 ha. The Pampa Orcoma project (the Project, or Orcoma Project) covers 7,387 ha including the mine area of 6,883 ha, as well as temporal and permanent facilities for the mining operation.

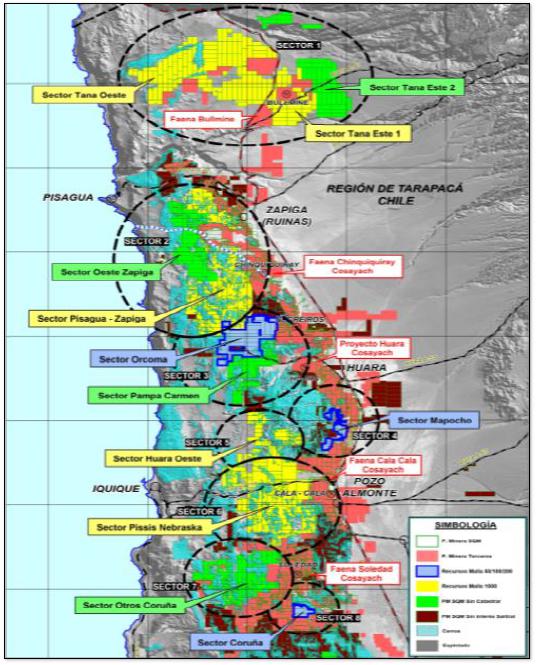

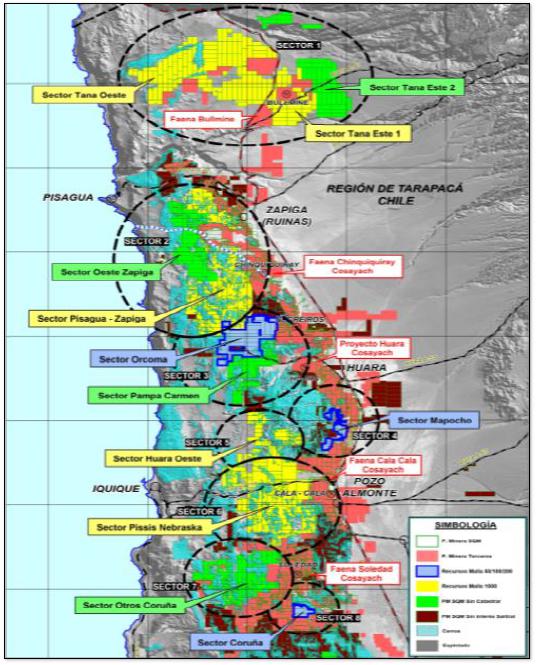

| 3.3 | Mineral Titles, Claims, Rights, Leases, and Options |

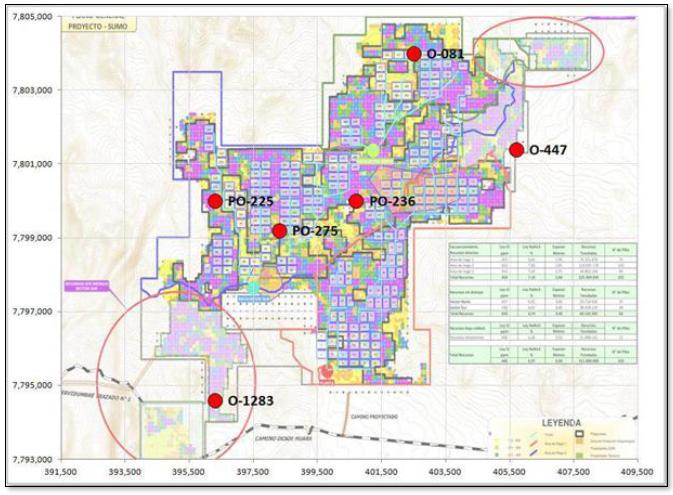

SQM currently has four areas for the generation of Resources and Mineral Reserves located in the I and II Region of Chile, including Pampa Orcoma, covering an area of approximately 291,780 ha with a prospecting grid of less than or equal to 400-x-400 m. Pampa Orcoma covers a mine area of 6,883 ha. Figure 3-2 shows the outline Pampa Orcoma’s mining property and concessions, within which the area considered for resource estimations is contained.

The Pampa Orcoma property comprises 43 mining concessions (Table 3-1) without expiration date, which are maintained through payment of an annual mining patent fee, all of them belong to SQM.

Table 3-1. Pampa Orcoma project concessions

| Rol Nacional | | Nombre Concesión | | Nombre

Titular | | Situación | | Año de

Inscripción |

| 01404-0333-4 | | SILVIA 124 1/5 | | ORCOMA SPA | | CONSTITUIDA | | 2011 |

| 01206-1602-1 | | PORVENIR 3 1/3 | | ORCOMA SPA | | CONSTITUIDA | | 2010 |

| 01206-1215-8 | | MIGUEL 29 1/13 | | ORCOMA SPA | | CONSTITUIDA | | 2003 |

| 01206-1207-7 | | MIGUEL 25 100/103 | | ORCOMA SPA | | CONSTITUIDA | | 2014 |

| 01206-1206-9 | | MIGUEL 25 40/99 | | ORCOMA SPA | | CONSTITUIDA | | 2003 |

| 01206-1205-0 | | MIGUEL 25 1/39 | | ORCOMA SPA | | CONSTITUIDA | | 2003 |

| 01206-1204-2 | | MIGUEL 24 91/150 | | ORCOMA SPA | | CONSTITUIDA | | 2003 |

| 01206-0923-8 | | PAMPA ORCOMA 1/20 | | ORCOMA SPA | | CONSTITUIDA | | 1999 |

| 01206-0816-9 | | LUISA 1/14 | | ORCOMA SPA | | CONSTITUIDA | | 1996 |

| 01206-0815-0 | | JAVIER 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1996 |

| 01206-0814-2 | | YANINA 1/24 | | ORCOMA SPA | | CONSTITUIDA | | 1996 |

| 01206-0812-6 | | LUCY 1/7 | | ORCOMA SPA | | CONSTITUIDA | | 1996 |

| 01206-0477-5 | | PILILA 1/22 | | ORCOMA SPA | | CONSTITUIDA | | 1989 |

| 01206-0476-7 | | PITUCA 1/22 | | ORCOMA SPA | | CONSTITUIDA | | 1989 |

| 01206-0475-9 | | PICHUCA 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1989 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 18 |

| Rol Nacional | | Nombre Concesión | | Nombre Titular | | Situación | | Año de Inscripción |

| 01206-0474-0 | | PIRULA 1/23 | | ORCOMA SPA | | CONSTITUIDA | | 1989 |

| 01206-0473-2 | | PIRUCHA 1/22 | | ORCOMA SPA | | CONSTITUIDA | | 1989 |

| 01206-0459-7 | | HONDA 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0458-9 | | SIMA 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0410-4 | | LUCIA 1/20 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0409-0 | | MARGARITA 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0408-2 | | AMELIA 1/15 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0407-4 | | MAGGI 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0405-8 | | RIGOLETTO 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0404-K | | ITALIANO 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0403-1 | | FANTASIA 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0402-3 | | ESPANOL 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0401-5 | | DALMACIA 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0400-7 | | CARMEN 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0399-K | | CAPRICHO 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0398-1 | | BELGRADO 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0397-3 | | AIDA 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1988 |

| 01206-0348-5 | | MARCELA 1/15 | | ORCOMA SPA | | CONSTITUIDA | | 1987 |

| 01206-0265-9 | | OXI 1/100 | | ORCOMA SPA | | CONSTITUIDA | | 1985 |

| 01206-0264-0 | | ORIENTE 1/100 | | ORCOMA SPA | | CONSTITUIDA | | 1985 |

| 01206-0258-6 | | CENTRAL 1/100 | | ORCOMA SPA | | CONSTITUIDA | | 1985 |

| 01201-1875-7 | | PATRICIA V 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1997 |

| 01201-1873-0 | | PATRICIA III 1/25 | | ORCOMA SPA | | CONSTITUIDA | | 1997 |

| 01201-1872-2 | | PATRICIA II 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1997 |

| 01201-1871-4 | | PATRICIA I 1/77 | | ORCOMA SPA | | CONSTITUIDA | | 1997 |

| 01201-1870-6 | | PATRICIA 1/11 | | ORCOMA SPA | | CONSTITUIDA | | 1997 |

| 01201-1865-K | | GUSTAVO I 1/30 | | ORCOMA SPA | | CONSTITUIDA | | 1997 |

| 01201-1864-1 | | GUSTAVO 1/27 | | ORCOMA SPA | | CONSTITUIDA | | 1998 |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 19 |

Figure 3-2. Location of Pampa Orcoma property

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 20 |

As of the end of 2020, SQM has the right to explore and/or exploit the caliche mineral resources by the Environmental Qualification Resolution (Comisión de Evaluación Región de Tarapacá, 2017) RCA N° 75/2021. The approved area covers more than 1,563,169 ha in the north of Chile, Region I and II. The Company mines annually under 1% of the total area in which it has property rights.

| 3.5 | Environmental Impacts and Permitting |

Environmental permits for mining operations were approved in 2017, as Sectorial Environmental Plans or PAS under the common RCA N° 75/2021. The permit covers water and electricity supply, as well as the infrastructure required for the mining operation. The current PAS are listed in Table 3-2

Table 3-2. Summary of Current Permits

| Permit | Description | Authorization |

| PAS N°119 | Research collection of Marine Life | There is no information |

| PAS N° 132 | Permit for archaeological and anthropological excavations | Ord. N° 2673/2021 (for archeological sites) |

| PAS N° 136 | Permit to establish tailings dump or mineral accumulation | Res. Ex. N° 1985/2021 |

| PAS 137 | Mining Closure Plan | The documents were submitted and currently is under process. |

| PAS N° 138 | Permit for the construction, repair, modification and expansion of any public or private works for the evacuation, treatment or final disposal of wastewater, sewage of any nature | There is no information |

| PAS N° 140 | Permit for the construction, repair, modification and expansion of any garbage and waste treatment plant of any kind or for the installation of any place for the accumulation, selection, industrialization, trade or final disposal of garbage and waste of any kind | There is no information |

| PAS N° 142 | Permit for all hazardous waste storage sites: The project involves the construction of two warehouses in two sectors for the temporary disposal of hazardous waste | There is no information |

| PAS N° 146 | Permit to hunt or capture specimens of animals of protected species for research purposes, for the establishment of breeding centers or hatcheries and for the sustainable use of the resource | There is no information |

| PAS N° 155 | Permit for the construction of certain hydraulic works | The documents were submitted on May 13, 2021, and currently is under process. |

| PAS N° 156 | Permit to make modifications to the riverbed | The documents were submitted on May 10, 2021, and currently is under process. |

| PAS N° 160 | Permit to subdivide and urbanize rural land or for construction outside urban limits | There is no information |

| - | Authorization of the mining exploitation method | Res. Ex. N° 1860/2021 |

| - | Beneficiation Plant Authorization | The documents were submitted and currently is under process. |

It should be noted that the project has not yet been built and construction is expected to begin in 2022. Preconstruction activities are currently underway and sectoral permits are being processed. It is important to mention that to avoid the expiration of the environmental resolution the construction of the project must start before September 2022.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 21 |

SQM has informed of a new environmental impact assessment (EIA) study, currently under execution, that will submit to the Environmental Impact Assessment System (SEIA) in 2023. The new project has as objective to expand Orcoma’s operation with respect to its current environmental authorization. The new project is expected to be authorized by mid-2025.

| 3.6 | Other Significant Factors and Risks |

Certain normal risk factors are associated with the properties, which may affect SQM's business, financial condition, cash flows, or results of operations. There are no other known factors or risks that affect access, title, entitlement, or ability to perform work on the property such that they would have a material impact on the statement of resources.

The factors or risks include, among others, the following:

| · | The risk of obtaining final environmental approvals from the necessary authorities promptly. There are cases where obtaining permits may cause significant delays in the execution and implementation of new projects. |

| · | The risk of obtaining all necessary licenses and permits on acceptable terms, promptly, or in their entirety. Obtaining regulatory approvals, including environmental permits, as well as opposition from political, environmental, and local and/or international ethnic groups, particularly in environmentally sensitive areas or in areas inhabited by indigenous populations, may consequently affect operating projects. |

| · | Risks associated with governmental regulation concerning exploitation. Changes in policies involving natural resource exploitation, taxation, and other industry-related matters may adversely affect the business, financial condition, and results of operations. |

| · | The risk from changes in laws Under current Chilean law, indigenous groups must be notified and consulted before any project is developed on land defined as indigenous. Failure to consult when required by law can result in the revocation or cancellation of regulatory approvals, including environmental permits already granted. |

| · | The risk that activities on adjacent properties will have an impact on the project. |

| · | The risk for the process, as currently defined, will not produce the expected quantity and/or quality required. However, extensive testing has been performed and all process steps are conventional and commonly used in the industry. |

| · | The risk of estimation methods involves numerous uncertainties in reserve quantity and quality, whether expressed in upward or downward changes. A downward shift in reserve estimates and/or quality could affect future production volumes and costs. |

| · | The risk of impurity levels in natural resources increasing over time more than predicted by the model may result in non-compliance with certain governmental or customer product standards. Consequently, the cost of production may increase to comply with the standards. |

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 22 |

| · | Risks associated with rising raw material and energy prices as well as difficulties and disruptions in supply chains, directly impact costs and production capacity. |

| · | Market and competitive risk factors could negatively affect market prices and the company's market share, which in turn could have a material adverse effect on business, financial position, and results of operations. World prices for lithium, fertilizers, and other chemicals vary depending on the relationship between supply and demand at any given time and in recent years, new and existing competitors have increased the supply of iodine, potassium nitrate, and lithium, and this has had an impact on the prices of both products. Additional production increases could harm prices. |

| 3.7 | Royalties and Agreements |

SQM has no obligations to any third party in respect of payments related to licenses, franchises or royalties for its Orcoma Property, as they do not apply to caliche production.

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 23 |

| 4 | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

| 4.1 | Topography, Elevation and Vegetation |

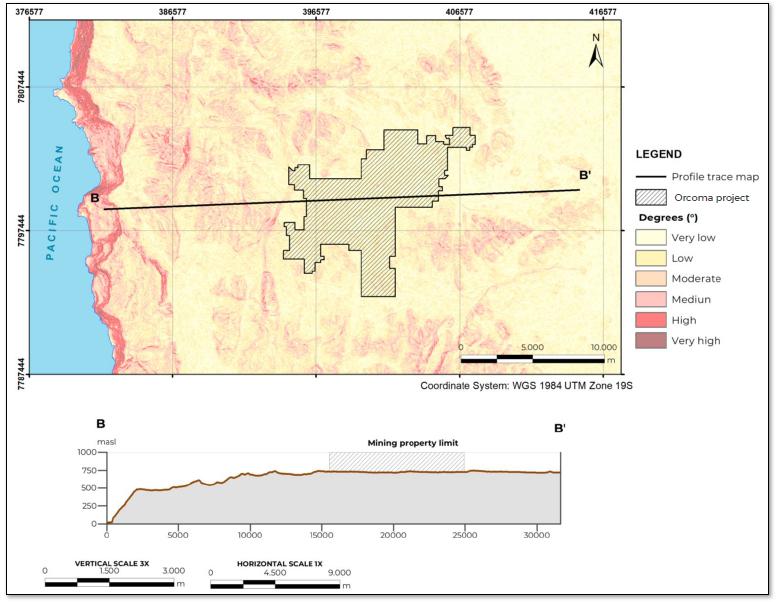

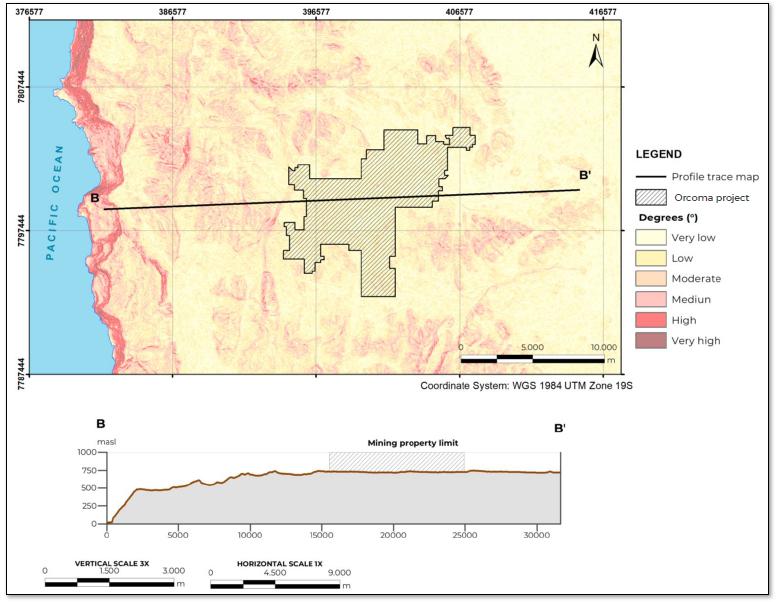

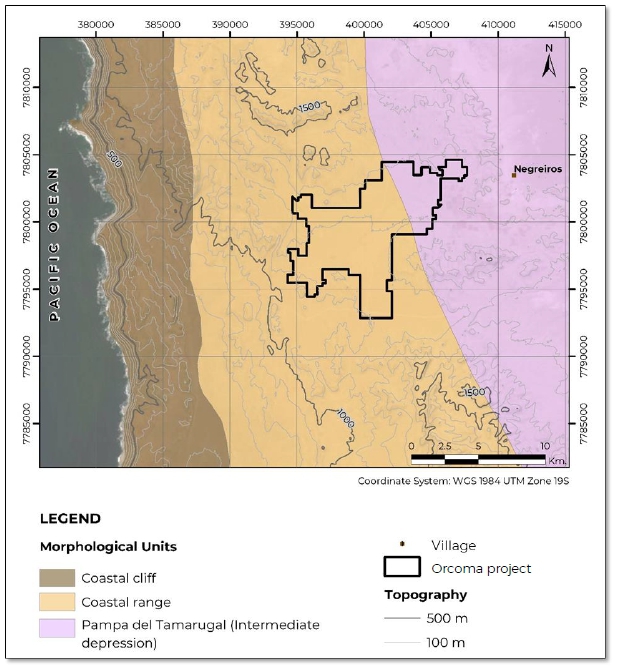

The mining property is located at an elevation of 1,147 masl, within the range of 976 and 1,244 masl (SQM(a), 2019). Specifically, the mining area and industrial area are located mainly in the Cordillera de la Costa (Geobiota, 2015).

Topographic relief on a regional scale contains slopes ranging between 0 to 39°, with the steepest slopes observed close to the coast, due to the coastal scarp. In Pampa Orcoma relief is almost flat (Figure 4-1), the lower slopes imply a low relief factor Sr, close to zero, especially in the Exploration Area.

Regarding vegetation, during the field campaign carried out in July 2015, the absence of vegetation in the project area was indicated. According to studies carried out in 2010, called "Study of Coastal Flora, Tarapacá Region", it is stated that for the project area, the necessary conditions to name the area as an oasis, as well as the presence of vascular plants, have not been documented since 2002 (Pinto, 2010).

| 4.2 | Accessibility and Transportation to the Property |

The Pampa Orcoma Property is situated 40 km north-northeast (NNE) of the coastal city of Iquique, the capital of the Tarapacá Region. There are multiple daily flights between Iquique Airport and Santiago Airport. From Iquique, the Pampa Orcoma Property is reached by road, traveling 46 km east on the paved Ruta 16 (Route 16), then 26.5 km north on the paved Ruta 5 (Route 5) to the town of Huara, from where the access control checkpoint of the property lies 24 km to the northwest and west along local gravel roads (SQM(a), 2019).

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 24 |

Figure 4-1. Slope Parameter Map Sr and Elevation Profile Trace BB"

| WSP-SQM0011-TRS-Pampa Orcoma-Rev1 | Rev1 | Page 25 |

| 4.3 | Climate and Length of Operating Season |

The Tarapacá region is characterized as a mostly arid climate. The temperature tends to decrease as the terrain presents higher elevations, since geomorphologically this region can be divided into three main morphologies to include the Altiplanic zone, the intermediate zone, and the coastal zone. The records of the highest temperatures fall in the field of this last, and they tend to decrease toward the east. In the Cordillera de los Andes sector, the records indicate average temperatures between 11 degrees Celsius (°C) and 13°C, in the intermediate zone the average temperatures oscillate between 15°C and 17°C for the coastal zone. In this last zone, the oceanic influence can be noticed, which generates a non-negligible number of days with high cloudiness and the presence of coastal fog, on the other hand, in the sectors of the Altiplano, the atmosphere is arid with large variation thermal