NI 43-101 Technical Report Preliminary Economic Assessment Florida Canyon Zinc Project Amazonas Department, Peru

Effective Date: July 13, 2017

Report Date:August3, 2017

Report Prepared for

Votorantim Metais Holding S.A. Solitario Zinc Corp.

43 John F. Kennedy Ave., 3rd floor 4251 Kipling Street. Suite 390

Luxembourg, L-1855 Wheat Ridge, Colorado 80033

Report prepared by

SRK Consulting (U.S.), Inc.

1125 SeventeenthStreet, Suite 600

Denver, CO 80202

SRK Project Number:181700.110

Signed by Qualified Persons:

WalterHunt, CPG / SolitarioZinc Corp, COO

J.B. Pennington, MSc, CPG,AIPG / SRK Principal Mining GeologistDaniel H.Sepulveda / SRKAssociate Consultant(Metallurgist)

Joanna Poeck,BEng Mining, SME-RM, MMSAQP / SRKSenior Consultant (Mining Engineer)Jeff Osborn, BEng Mining,MMSAQP / SRK PrincipalConsultant (MiningEngineer)

JamesGilbertson, MCSM,CGeol, FGS / SRK Principal Exploration GeologistJohn Tinucci,PhD, PE / SRK Principal Consultant (GeotechnicalEngineer)

Reviewedby:

Kent Hartley,P.E. (Mining Engineer)

Table of Contents

| 1.2 | PropertyDescriptionand Ownership16 |

| 1.3 | Geology andMineralization 16 |

| 1.4 | Status of Exploration, Development andOperations 17 |

1.4.1 History17

1.4.2Exploration Status 17

1.4.3 DevelopmentandOperations18

| 1.5 | MineralProcessing and MetallurgicalTesting 18 |

| 1.6 | Mineral Resource Estimate19 |

| 1.7 | MineralReserve Estimate21 |

| 1.10 | Project Infrastructure 23 |

| 1.11 | Environmental Studies andPermitting 24 |

| 1.12 | ConclusionsandRecommendations 24 |

1.12.1General 24

1.12.2 Mineral Resource Estimate25

1.12.3MineralProcessing and MetallurgicalTesting 25

1.12.4MineralReserve Estimate26

1.12.5 MiningMethods 26

1.12.6 RecoveryMethods 27

1.12.7Project Infrastructure 27

1.12.8Environmental Studies andPermitting 27

1.12.8Recommendations –Work Programsand Costs 28

| 2.1 | Termsof Reference and Purpose of the Report29 |

| 2.2 | Qualifications of Consultants(SRK) 29 |

| 2.3 | Details of Inspection 30 |

| 2.4 | Sources of Information 30 |

| 3 | Reliance on Other Experts31 |

| 4 | Property Description and Location32 |

4.2.1Nature and Extentof Issuer’sInterest 39

4.2.2 Property and Title inPeru 39

| 4.3 | Royalties, Agreements andEncumbrances 40 |

| 4.4 | Environmental Liabilitiesand Permitting40 |

4.4.1Required Exploration Permitsand Status 40

4.4.2Required Mining Permits40

| 4.5 | Other SignificantFactors andRisks41 |

| 5 | Accessibility, Climate,Local Resources, Infrastructure and Physiography42 |

| 5.1 | Topography, Elevationand Vegetation42 |

| 5.2 | Accessibility and Transportationto the Property42 |

| 5.3 | Climate and Lengthof Operating Season 43 |

| 5.4 | Sufficiencyof Surface Rights43 |

| 5.5 | Infrastructure Availability andSources 43 |

5.5.1 Proximityto PopulationCenter 45

5.5.2Power 45

5.5.3 Water45

5.5.4 Mining Personnel45

5.5.5Potential MineInfrastructureAreas 46

| 6.1 | PriorOwnership and Ownership Changes48 |

| 6.2 | Previous Exploration and DevelopmentResults 48 |

| 6.3 | Historical Mineral Resourceand Reserve Estimates48 |

| 6.4 | HistoricalProduction 49 |

| 7 | Geological Setting and Mineralization50 |

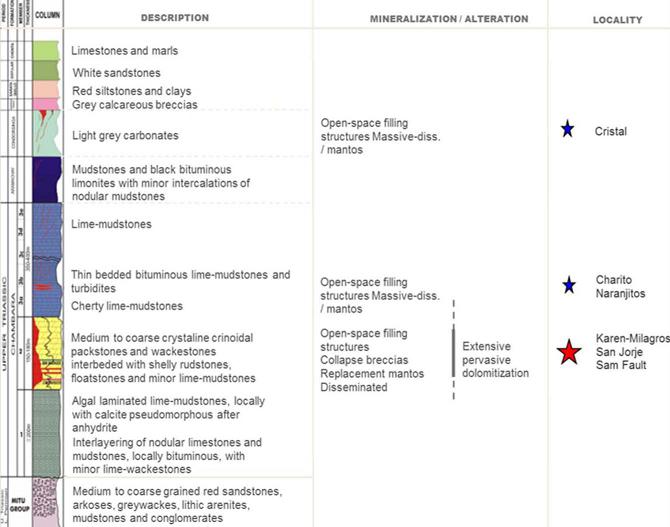

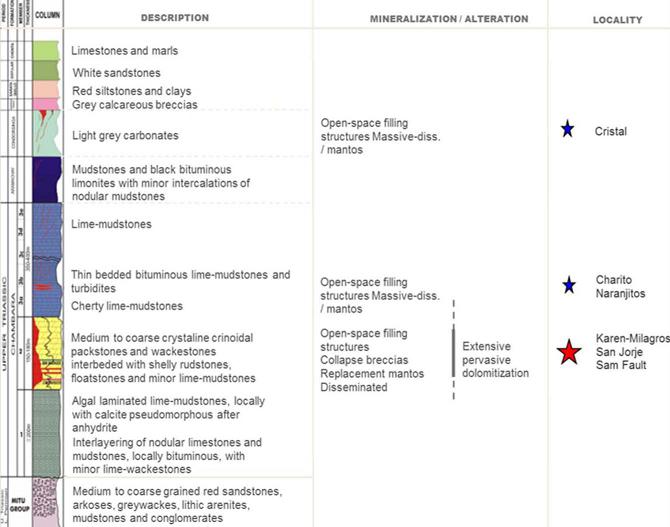

7.2.1 Lithology andStratigraphy 52

7.2.2Structure 53

7.2.3Alteration 54

7.2.4Mineralization 54

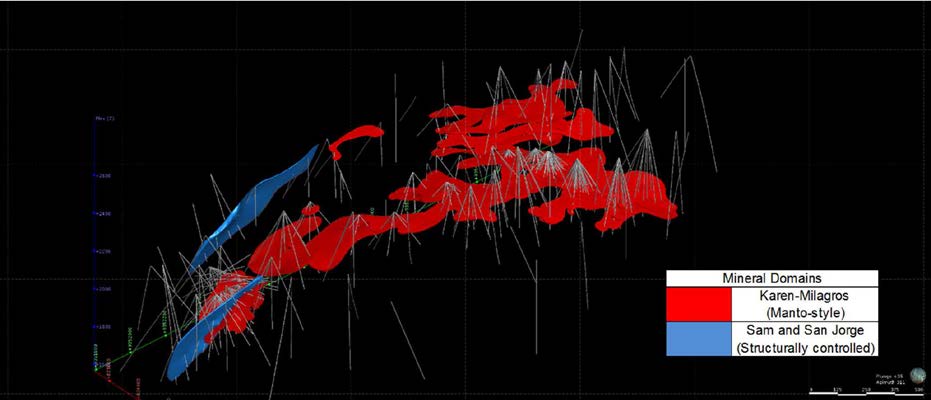

| 7.4 | Significant Mineralized Zones57 |

| 9.1 | Relevant ExplorationWork60 |

| 9.2 | Surveys and Investigations 60 |

| 9.3 | Sampling Methodsand Sample Quality60 |

| 9.4 | Significant Results andInterpretation 60 |

| 10.3 | Interpretation and Relevant Results 68 |

| 11 | Sample Preparation, Analysis and Security70 |

11.1.1Sampling for GeochemicalAnalysis 70

11.1.2Sampling for Density Measurement70

| 11.3 | Sample Preparation forAnalysis 71 |

11.4.1Standards 73

11.4.2 Blanks74

11.4.3Duplicates 74

11.4.4Actions 75

| 11.5 | Opinion on Adequacy75 |

| 12.3 | Opinion onData Adequacy77 |

| 13 | Mineral Processing and MetallurgicalTesting78 |

| 13.1 | Testing and Procedures 78 |

13.2.1 Mineralogy78

13.2.2 Recoveryand Concentrate Grades 79

13.2.3Hardness 82

13.2.4Reagents 83

| 13.3 | RecoveryProjections 83 |

| 13.4 | SignificantFactors andRecommendations 84 |

| 14 | Mineral Resource Estimate85 |

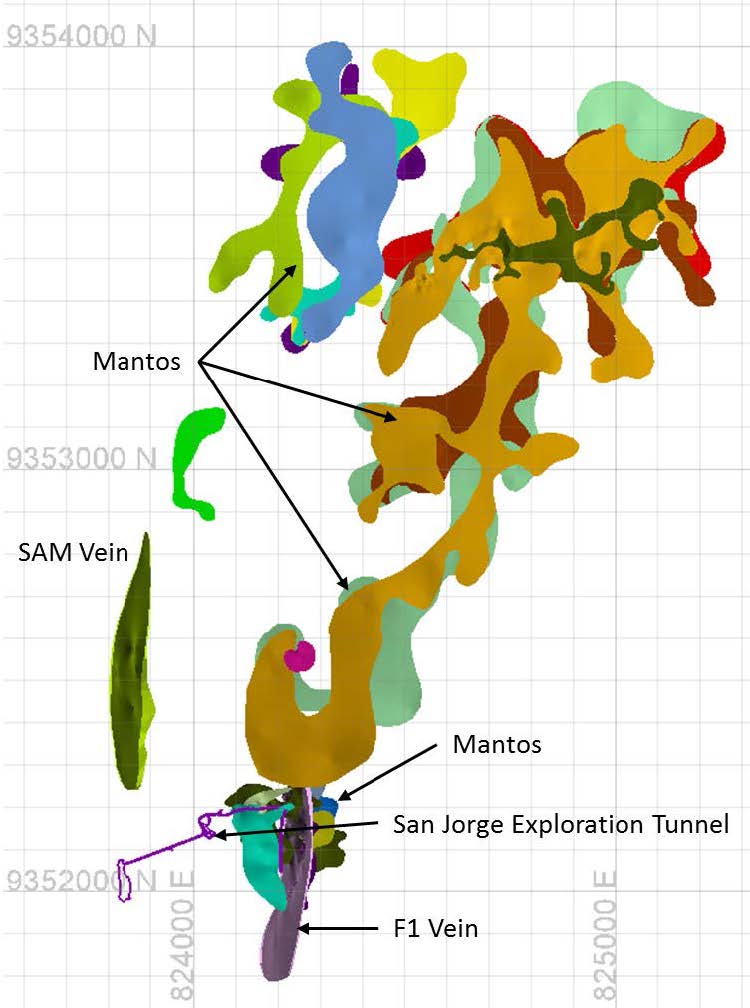

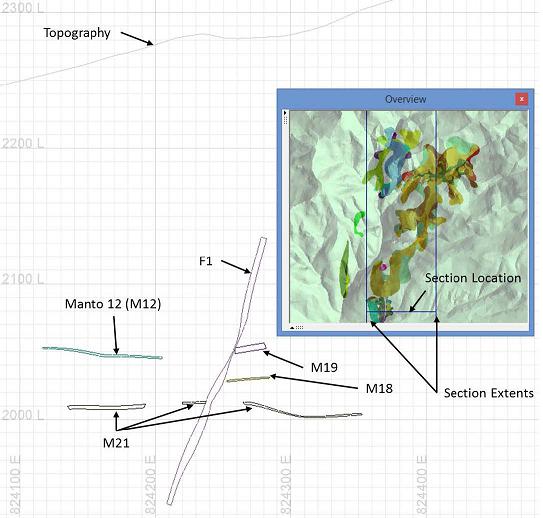

| 14.1 | Geology and Mineral DomainModeling 86 |

14.2.1Database 88

14.2.2 Topography and SampleLocations 89

14.2.3Oxidation Classification in Drillhole Logging 89

| 14.3 | Drilling DataAnalysis 89 |

14.3.1Capping 90

14.3.2Compositing 90

| 14.5 | Variogram Analysis andModeling 92 |

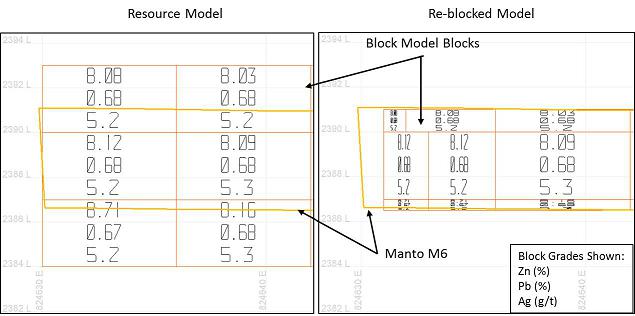

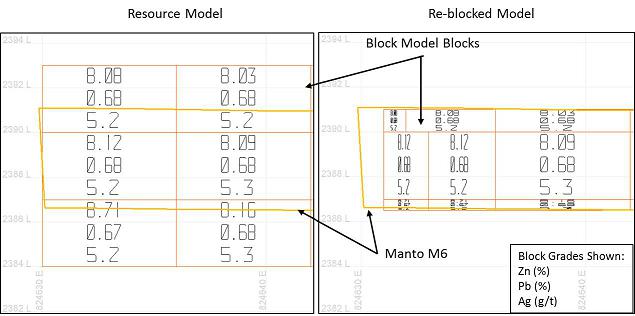

14.6.1Model Specifications 92

14.6.2Model Construction 93

| 14.8 | Zinc, Lead, andSilver Recovery Calculation96 |

| 14.9 | ZincEquivalent Grade Calculation96 |

14.10.1SRK Grade Estimatevs VotorantimGrade Estimate97

14.10.2 Visual Comparison97

14.10.3Comparative Statistics98

| 14.11 | Resource Classification98 |

| 14.12 | Mineral Resource Statement 99 |

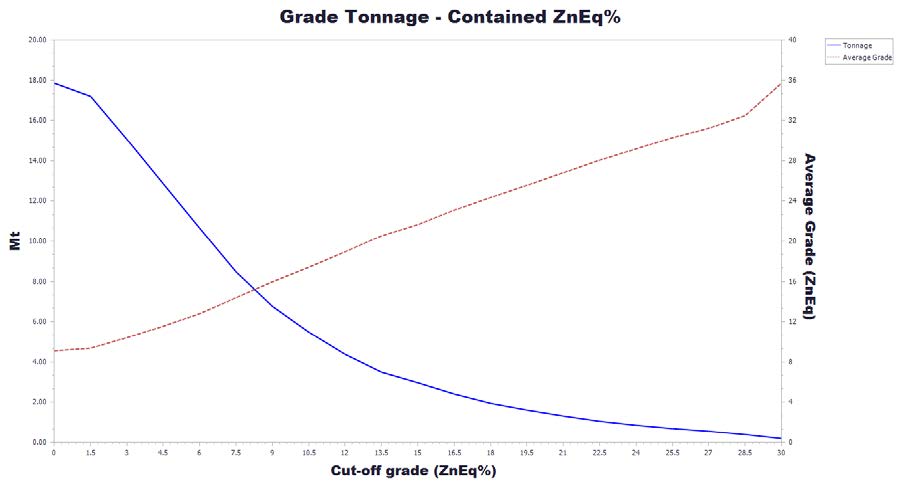

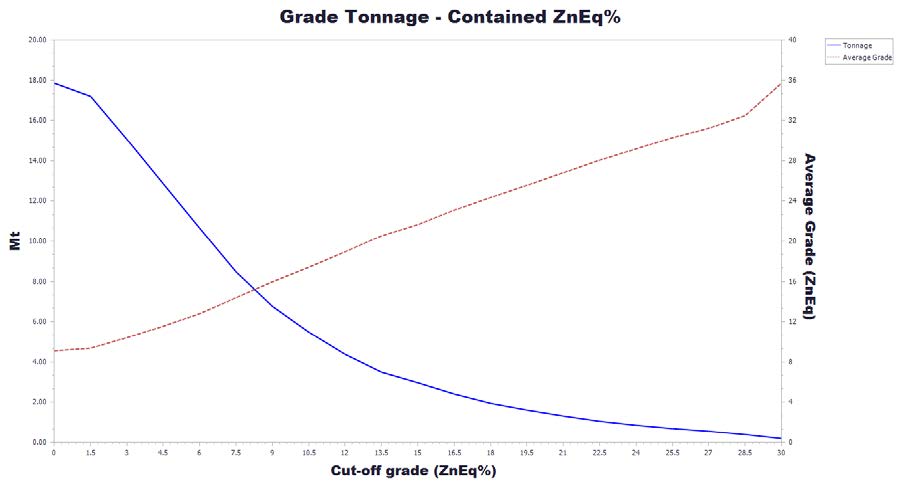

| 14.13 | Mineral ResourceCut-offGrade Determination 99 |

| 14.14 | Mineral Resource Sensitivity100 |

| 15 | Mineral Reserve Estimate101 |

| 16.1 | Proposed MiningMethods 107 |

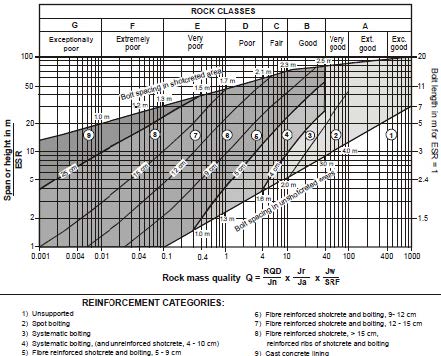

| 16.2 | Geotechnical InputforMine Design108 |

16.2.1Geotechnical Characterization 108

16.2.2StressField and topography110

16.2.3Cut and Fillparameters 110

16.2.4Sub-level Open Stoping Parameters111

16.2.5Crown Pillar 113

16.2.6Sill Pillar Dimensioning113

16.2.7Ground Support 114

16.2.8 Tailings Backfill117

16.3.1Net Smelter Return 118

16.3.2Operating Costs120

16.3.2Stope Optimization 121

16.3.4 Mining Recovery andDilution 122

16.3.5Cut-off Evaluation 123

16.3.6 MiningMethods 124

16.3.7 Mine Plan Resource128

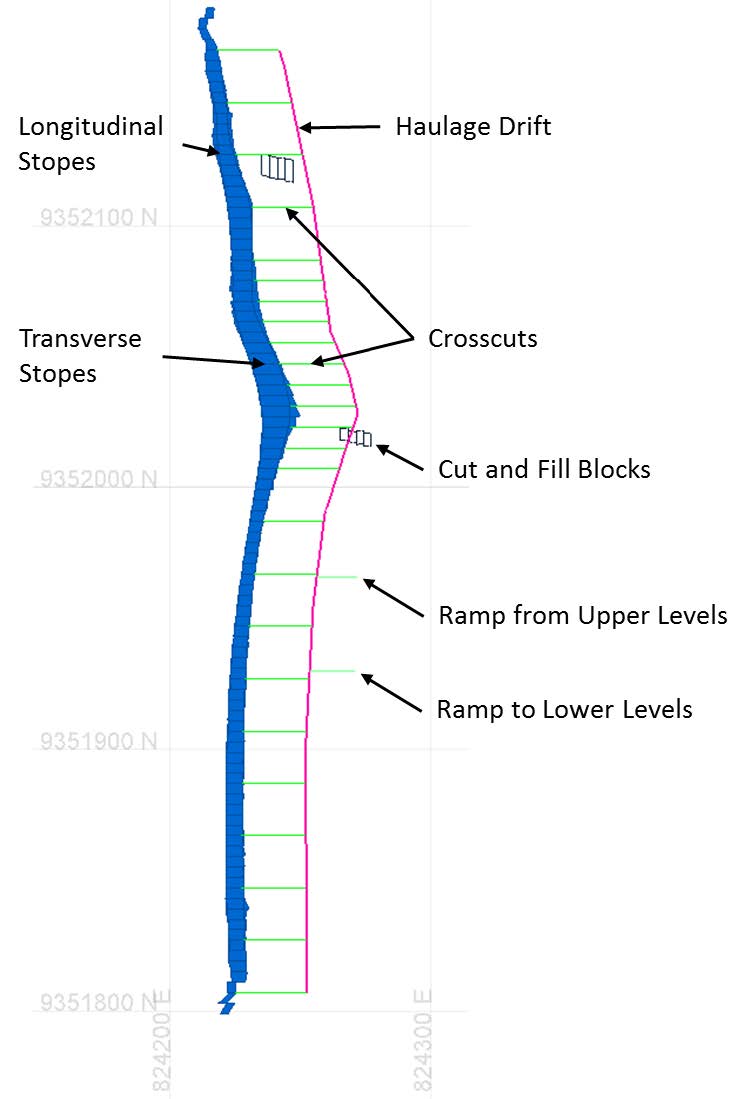

16.3.8 DevelopmentLayout 129

16.3.8 WasteRock Management and Backfilling 136

| 16.4 | Mine Production Schedule136 |

16.2.1Underground MineEquipment 139

16.2.2Electrical 139

16.5.3Ventilation 139

16.2.4 MinePersonnel 141

16.2.5Health and Safety141

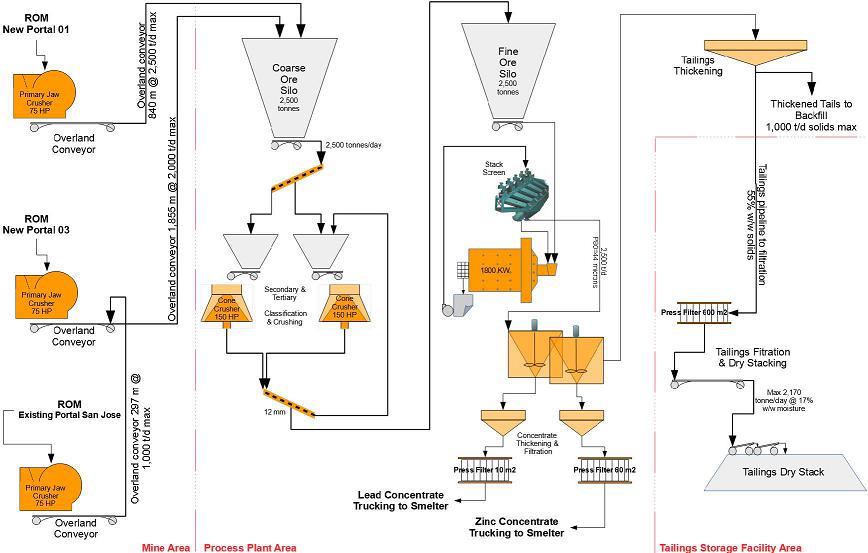

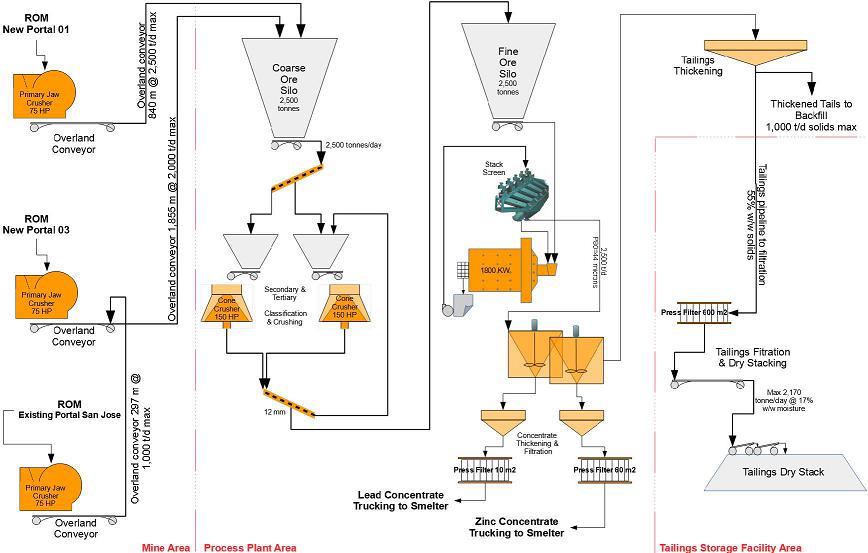

| 17.1 | Processing Projections andMethods 142 |

| 17.2 | Processing Methods andFlowSheet 142 |

| 17.3 | ConsumablesRequirement144 |

| 18 | Project Infrastructure146 |

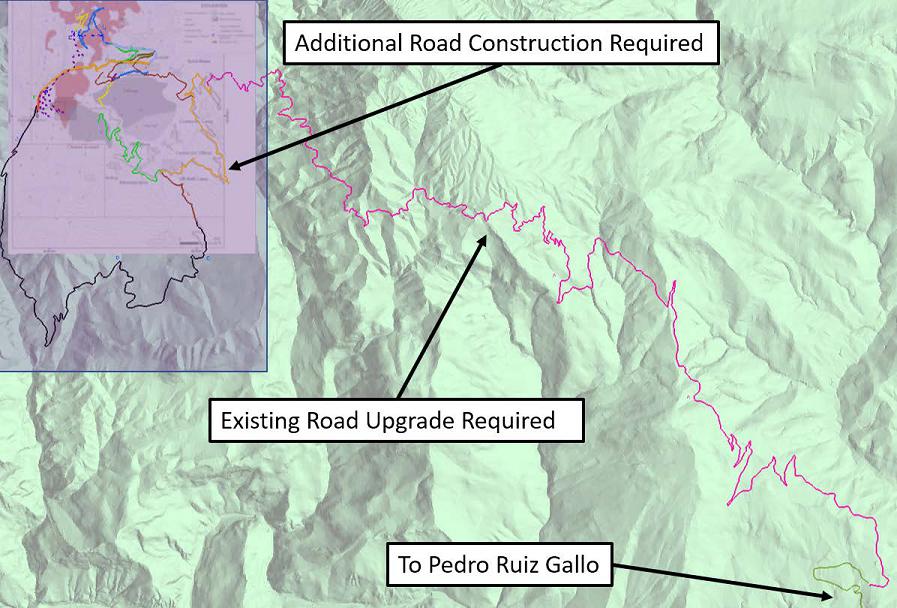

| 18.1 | Infrastructure and Logistics Requirements 146 |

18.1.1 AccessandLocalCommunities 146

18.1.2 SiteWaterManagement 147

18.1.3Project Facilities 148

18.1.4Power Supplyand Distribution 150

| 18.2 | Project Logistics 152 |

| 18.3 | Tailings Management 153 |

| 19 | Market Studies and Contracts155 |

| 19.1 | ContractsandStatus 155 |

| 20 | Environmental Studies, Permitting and Social or Community Impact 156 |

| 20.1 | Required Permitsand Status 156 |

20.1.1Required Exploration Permitsand Status 156

20.1.2Required Mining Permits156

| 20.2 | Environmental Monitoring Results 157 |

| 20.4 | Environmental Issues 159 |

| 20.3.1 | Post Mining Land Use160 |

| 20.3.2 | PortalsandVents 160 |

| 20.3.3 | Buildingsand Infrastructure 160 |

| 20.3.4 | RoadsandMiscellaneous Disturbance 161 |

| 20.3.5 | Tailings Facility161 |

| 20.6 | Post ClosurePlans 161 |

| 20.7 | Reclamation and Closure Cost Estimate162 |

| 20.8 | Post-Performanceor ReclamationsBonds 162 |

| 20.9 | Social and Community162 |

| 21 | Capital and Operating Costs164 |

| 21.1 | CapitalCostEstimates 164 |

21.1.1Basisfor Capital Cost Estimates165

| 21.2 | Operating Cost Estimates168 |

21.2.1BasisforOperating Cost Estimates168

| 22.3 | Taxes,Royalties and OtherInterests 172 |

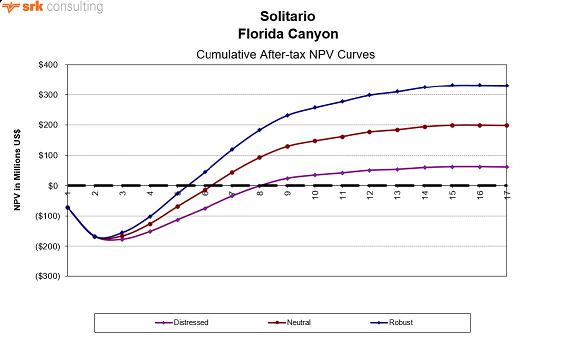

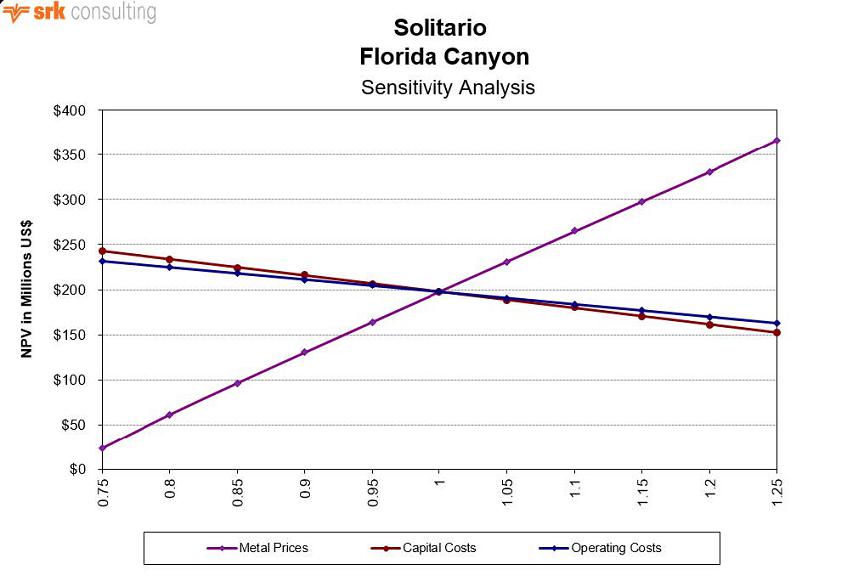

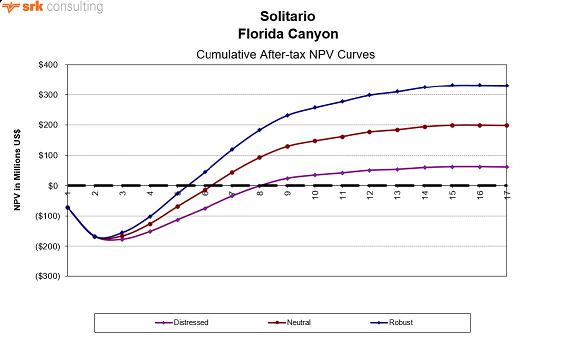

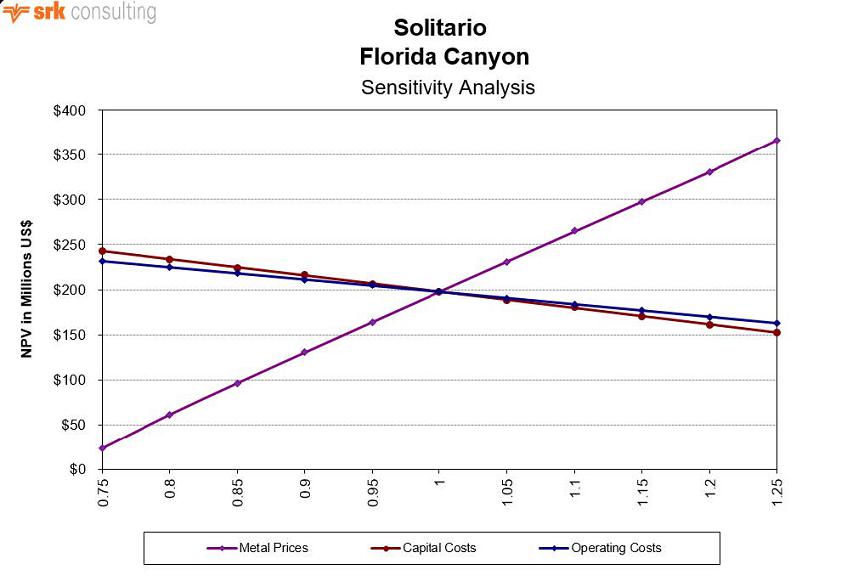

| 22.5 | Base Case SensitivityAnalysis 179 |

| 22.6 | Conservative Metal Price Alternative Analysis 181 |

22.6.1 ImpacttoMinePlanning 182

22.6.2 ImpacttoEconomics183

| 24 | Other Relevant Data and Information190 |

| 25 | Interpretation and Conclusions191 |

| 25.2 | Mineral Resource Estimate191 |

| 25.3 | MineralProcessing and MetallurgicalTesting 192 |

| 25.4 | MineralReserve Estimate193 |

| 25.7 | Project Infrastructure 193 |

| 25.8 | Environmental Studies andPermitting 194 |

| 25.9 | Capitaland Operating Costs194 |

| 26.1 | RecommendedWorkPrograms 196 |

26.1.1 EngineeringStudies (Prefeasibility Level)196

26.1.2 Drilling197

26.1.3 Mining197

| 26.2 | WorkProgram Costs 197 |

| 28.1 | Mineral Resources 201 |

| 28.3 | Definition of Terms202 |

List of Tables

Table1-1: Indicative EconomicResults (US$) 14

Table1-2: CapitalCosts 15

Table1-3: Operating Costs 15

Table1-4: Operating Costs 15

Table1-5: Florida CanyonMetal RecoveriesbyMaterial Type 18

Table1-6: Mineral Resource Statement forthe Florida Canyon Zn-Pb-Ag Deposit, Amazonas Department,Peru, SRK Consulting(U.S.), Inc., July13, 201721

Table1-7: Mine Plan Resource forthe Florida CanyonZn-Pb-Ag Deposit, Amazonas Department,Peru, SRKConsulting (U.S.),Inc.,July21, 201722

Table1-8: Mine Plan ResourceAverageProcess Recovery22

Table1-9: Summaryof Costs forRecommendedWork28

Table4-1: List of Minera Bongará MineralClaims35

Table4-2: List of Minera ChambaraMineralClaims36

Table5-1: Distance and TravelTimeto Florida CanyonProject fromLima, Peru 43

Table6-1: Mineral Resource Statement forthe Florida Canyon Zn-Pb-Ag Deposit, Amazonas Department,Peru, SRK Consulting(U.S.), Inc.,05 June,2014 49

Table 10-1: Downhole Survey DataPoint Spacing68

Table 11-1: Analytical Codesand Methods 71

Table 11-2: Analyzed Elements and MethodDetection Limits 72

Table 11-3: Summaryof SRM Statistics forLead 73

Table 11-4: Summaryof SRM Statistics forZinc 73

Table 11-5: Summaryof Duplicate Samples 74

Table 13-1: Summaryof Florida Canyon Metallurgical Test Work78

Table 13-2: Mineralogyof SulfideComposite79

Table 13-3: Mineralogyof OxideComposite79

Table 13-4: Metallurgical Tests – SelectedResults 81

Table 13-5: Hardness TestResults 82

Table 13-6:Florida CanyonMetal RecoveriesbyMaterialType83

Table 14-1: Statisticsof RawAssays – AllIntervals 89

Table 14-2: Statisticsof RawAssays–Manto IntervalsOnly90

Table 14-3:Item ID’sandDescriptions 91

Table 14-4: Statisticsof AllComposites Inside Mantos 91

Table 14-5:Block Model Specifications 92

Table 14-6:Block Model ItemDescriptions 93

Table 14-7: AdditionalSRK BlockModel ItemDescriptions 93

Table 14-8:Variogram and GradeEstimationParameters 95

Table 14-9:Comparison of Composite and BlockGrades 98

Table 14-10: Mineral Resource Statement for the Florida Canyon Zn-Pb-Ag Deposit,Amazonas Department,Peru, SRK Consulting(U.S.), Inc., July13, 201799

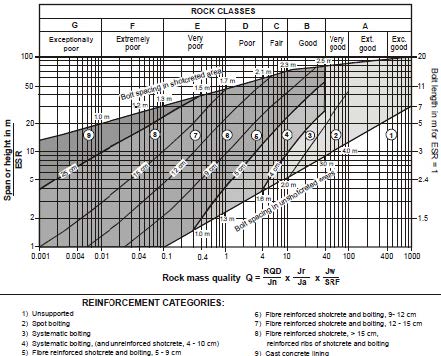

Table 16-1: RockMass Classification Parameters 109

Table 16-2: Stope StabilityGraph Input Parameters 112

Table 16-3:Proposed StopeDimensions 113

Table 16-4: Parameters forthe Barton Method115

Table 16-5: Estimated Support Accordingto theBarton Method 116

Table 16-6: ExpectedProcessing Recoveries 118

Table 16-7: NSR Calculation Parameters forStope Optimization119

Table 16-8: Example NSRCalculation 120

Table 16-9: Operating Costs Used forDetermining Potential Mining Shapes 121

Table 16-10:Stope Optimization Parameters forBase CaseAnalysis 121

Table 16-11:Mine Plan Resource forthe Florida Canyon Zn-Pb-AgDeposit, Amazonas Department,Peru, SRK Consulting (U.S.), Inc., July 21,2017 128

Table 16-12:Mine Plan ResourceAverage Process Recovery128

Table 16-13: DevelopmentDesign Assumptions 130

Table 16-14: DevelopmentQuantities 130

Table 16-15: LoM Backfill and CementQuantitiesby Type136

Table 16-16: Florida Canyon Production Schedule138

Table 16-17:Mine Equipment 139

Table 16-18:Estimated Airflow Requirements –Central/North and Northwest Areas140

Table 16-19:Estimated Airflow Requirements – F1 (SanJorge) 140

Table 16-20:Estimated Airflow Requirements - SAM140

Table 16-21: Hourly and SalariedPersonnel (OnSite) 141

Table 17-1:FloridaCanyon PEA Level Throughputand ConcentrateProduction Projections 142

Table 17-2: Overland Conveying fromUnderground Portals to the Process Plant 143

Table 20-1:Environmental Monitoring During MiningExploration 158

Table 21-1:Florida Canyon Capital Estimate Summary165

Table 21-2:FloridaCanyonUnderground MineEquipment AcquisitionSchedule166

Table 21-3:FloridaCanyon Offsite,Site,Power,WaterandBackfillInfrastructure 167

Table 21-4:Florida CanyonOperatingCosts Summary168

Table 22-1:Florida CanyonPrice Assumptions 170

Table 22-2:Florida CanyonNet Smelter Return Terms170

Table 22-3:Florida Canyon ProductLogistics Cost171

Table 22-4:Florida Canyon MineProduction Assumptions 171

Table 22-5:Florida CanyonMill Production Assumptions172

Table 22-6:Florida Canyon RoyaltyRates 173

Table 22-7:Florida CanyonIndicative EconomicResults(Dry Basis)175

Table 22-8:Florida CanyonLoM AnnualProduction andRevenues 176

Table 22-9:Florida Canyon CashCosts 178

Table 22-10:Alternate MarketForecast Metal Prices 181

Table 22-11: Florida CanyonAlternate CaseIndicativeEconomicResults(Dry Basis)185

Table 22-12: Florida CanyonAlternate Case LoMAnnual Production and Revenues186

Table 22-13: Florida Canyon Cash Costs188

Table 25-1:Florida CanyonOperatingCosts Summary194

Table 26-1: Summaryof Costs forRecommendedWork198

Table 28-1:Definition of Terms202

Table 28-2:Abbreviations 203

List of Figures

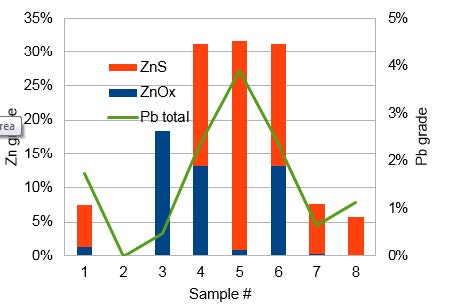

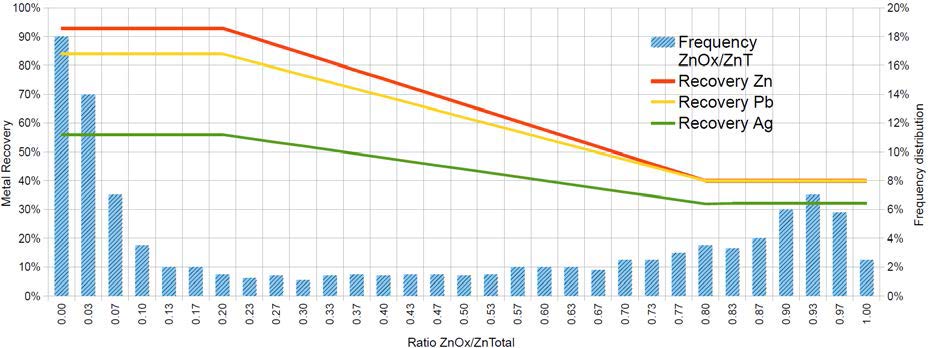

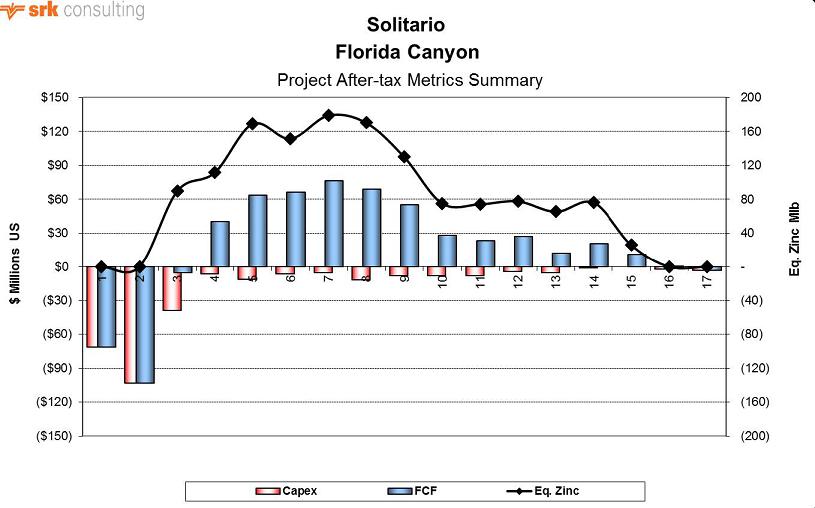

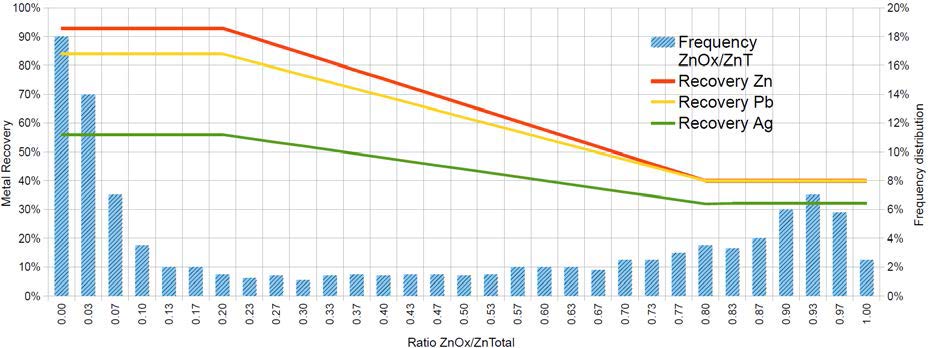

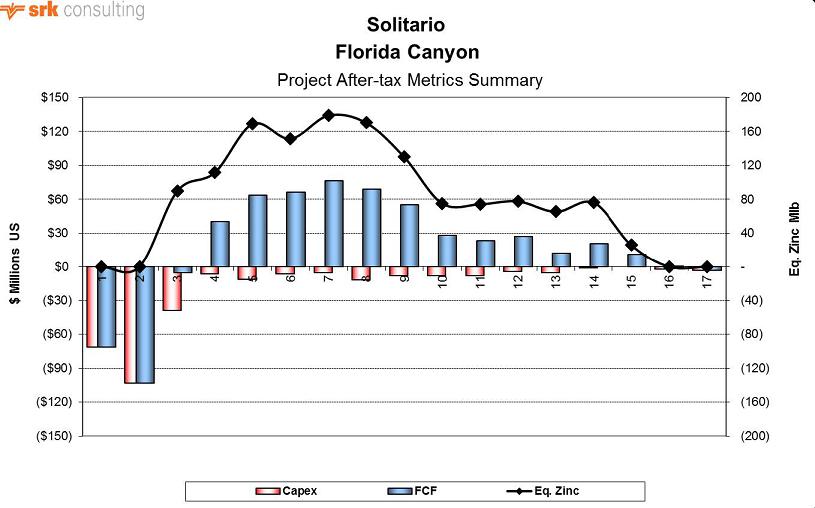

Figure 1-1: Florida CanyonMetal Recoveries RelativetoZnO/ZnT Ratio 19

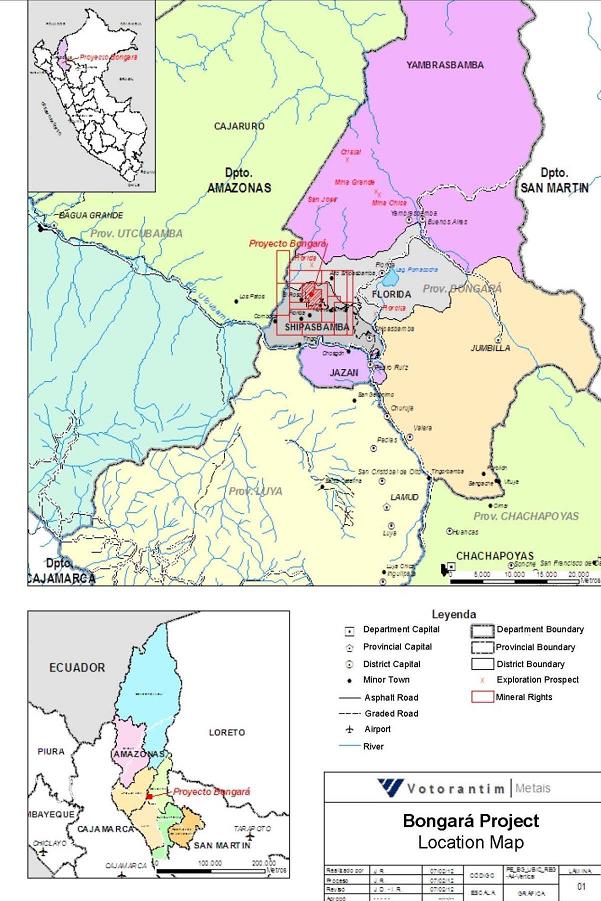

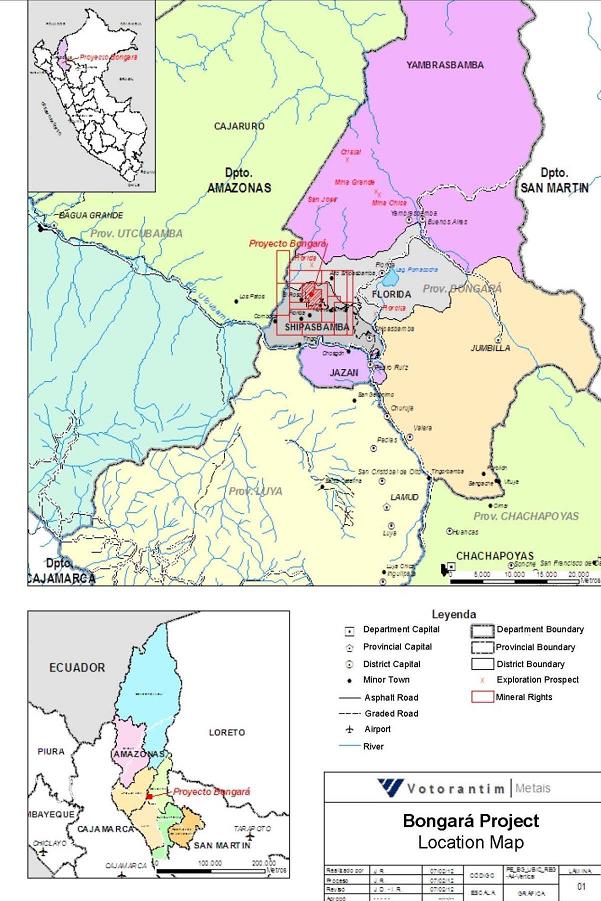

Figure 4-1: Project Location Map33

Figure 4-2: Map of MineralClaims38

Figure 5-1: Photograph of theFlorida CanyonProject Area 42

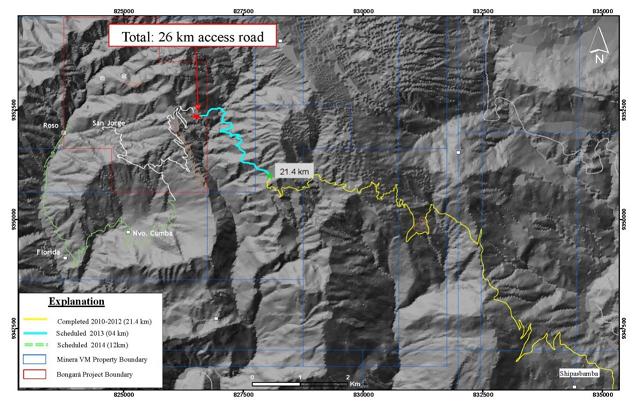

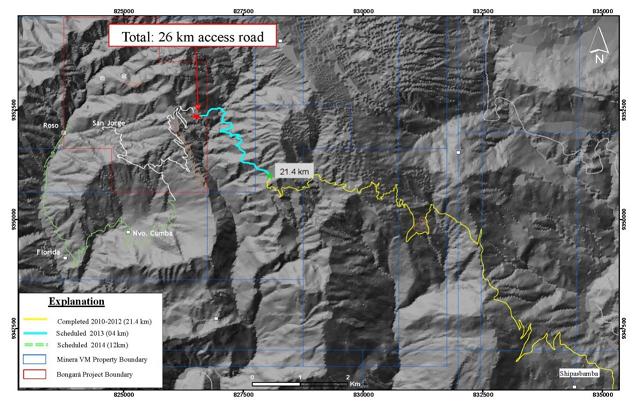

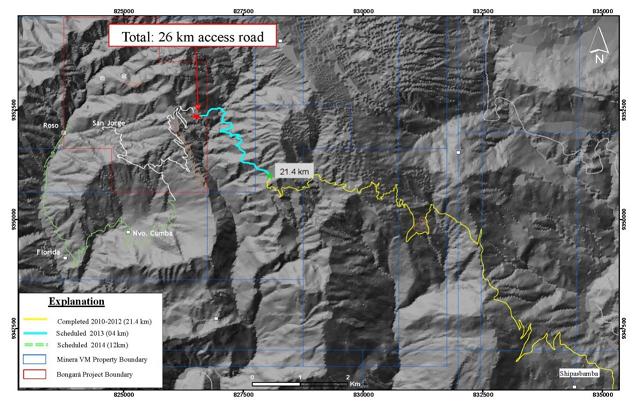

Figure 5-2: ProjectAccessRoad 44

Figure 5-3: Photograph of Drilling Campat Project Site44

Figure 5-4: Potential Mine InfrastructureLocations 47

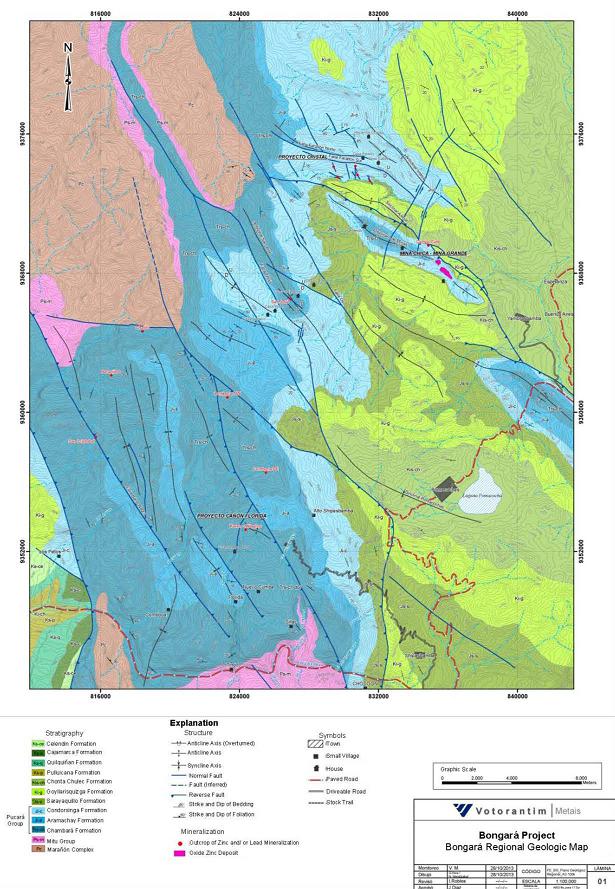

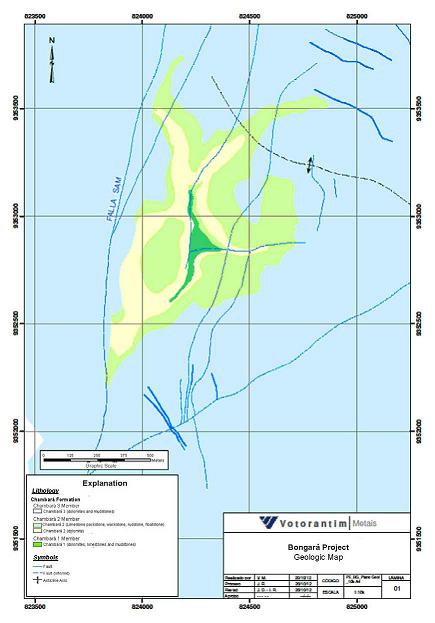

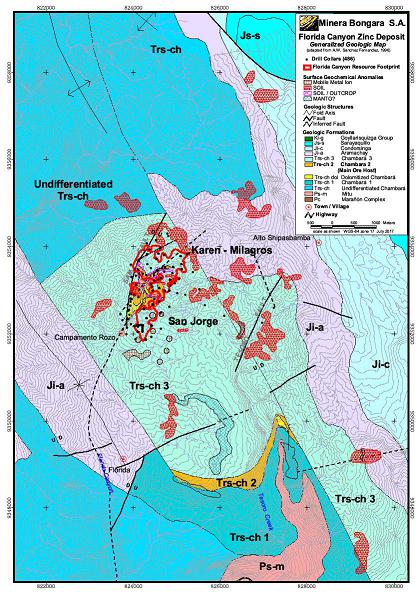

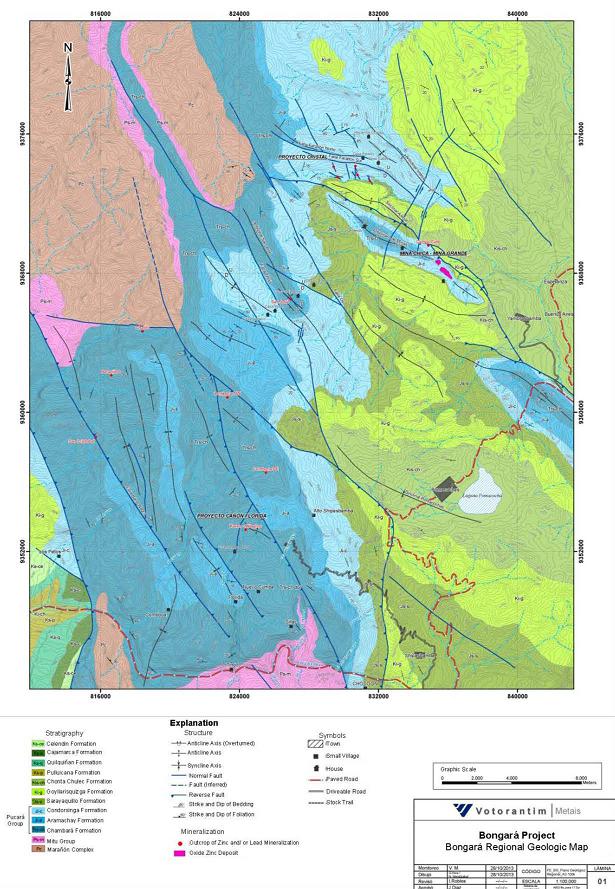

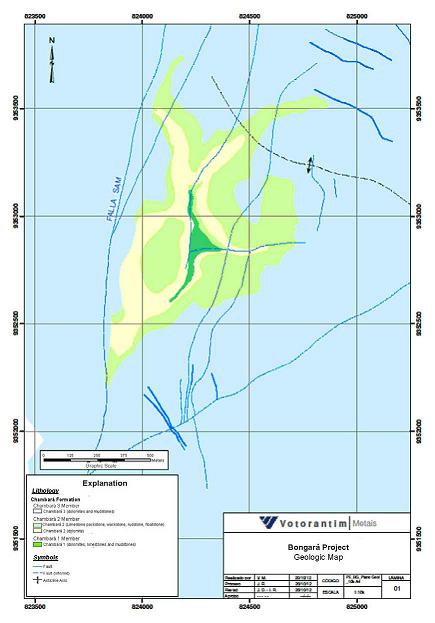

Figure 7-1:Regional Geologic Map51

Figure 7-2: Project AreaStratigraphic Column52

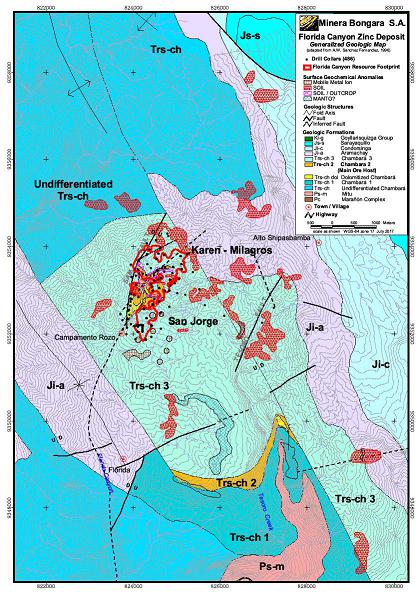

Figure 7-3:Florida CanyonProject Geologic Map56

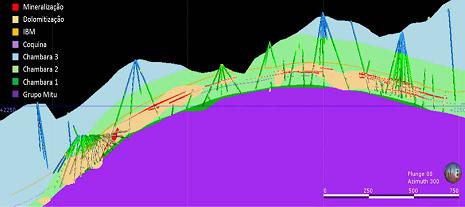

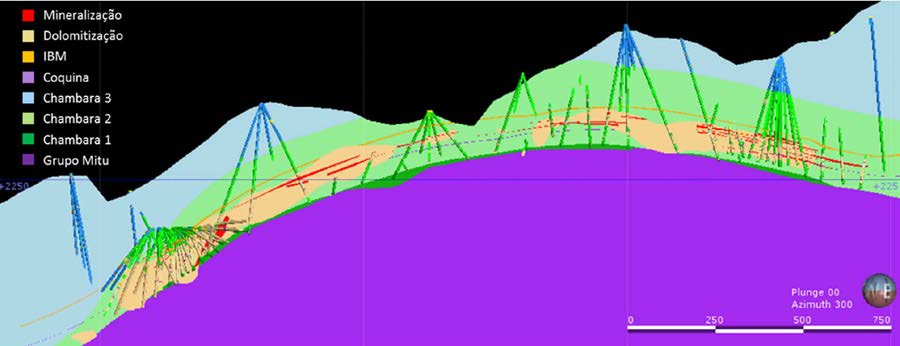

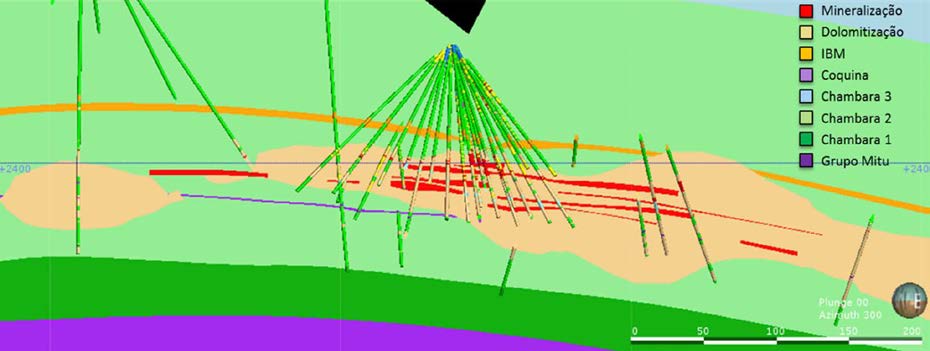

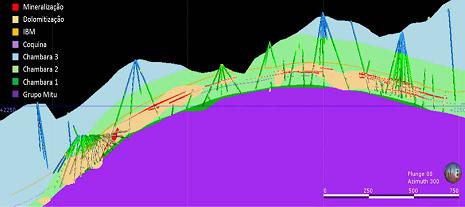

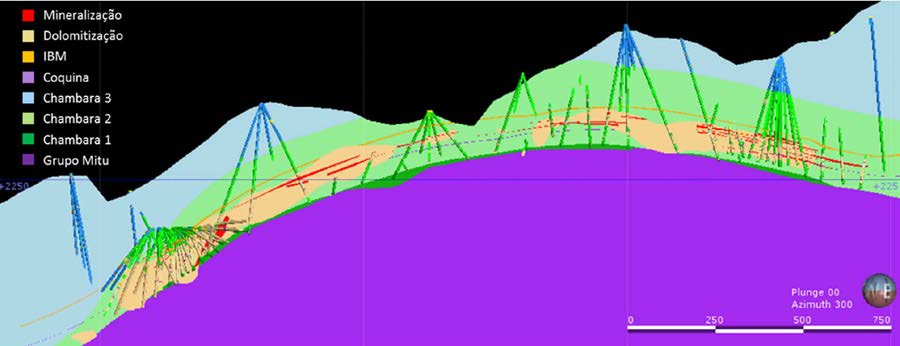

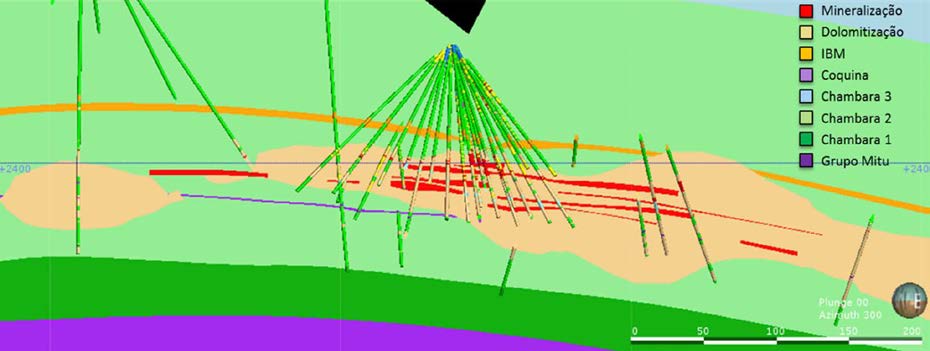

Figure 7-4: CrossSectionofthe ProjectGeologic Model57

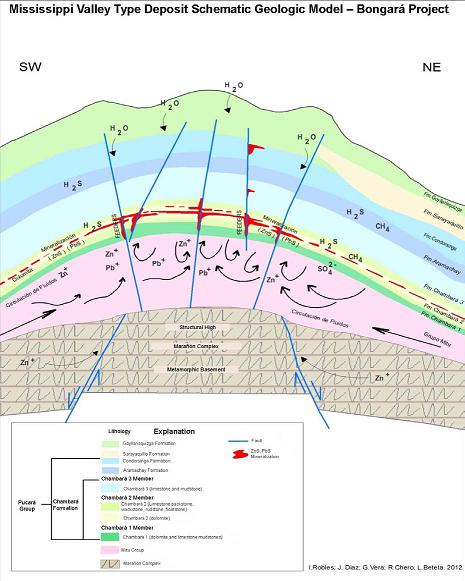

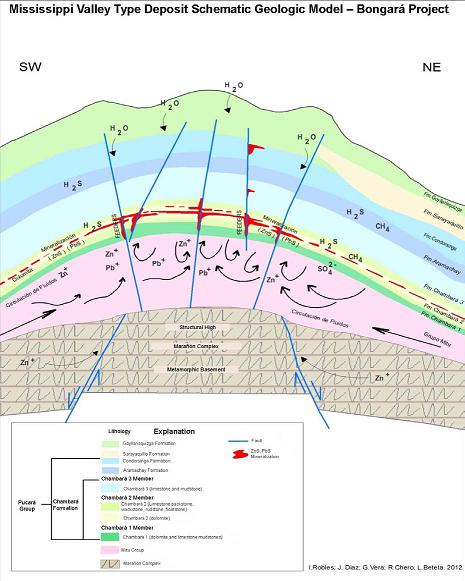

Figure 8-1: MississippiValley-TypeDepositSchematic Model 59

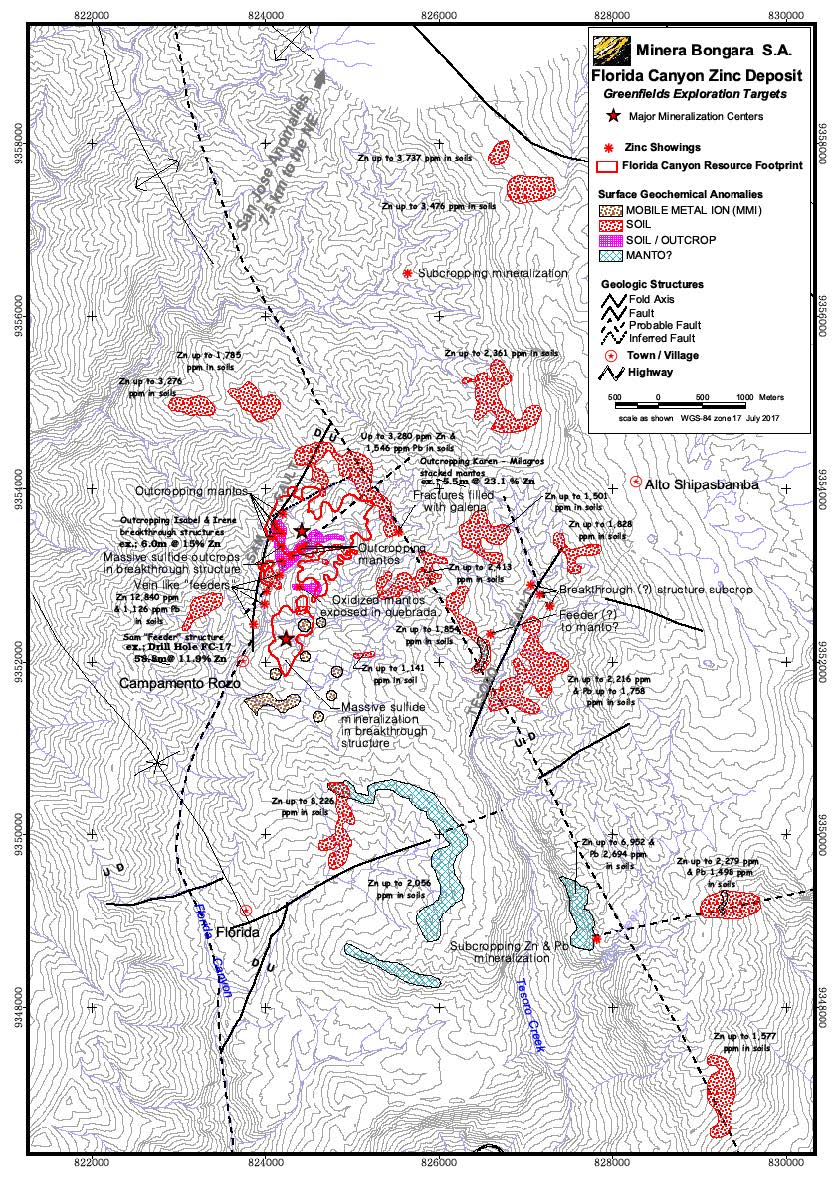

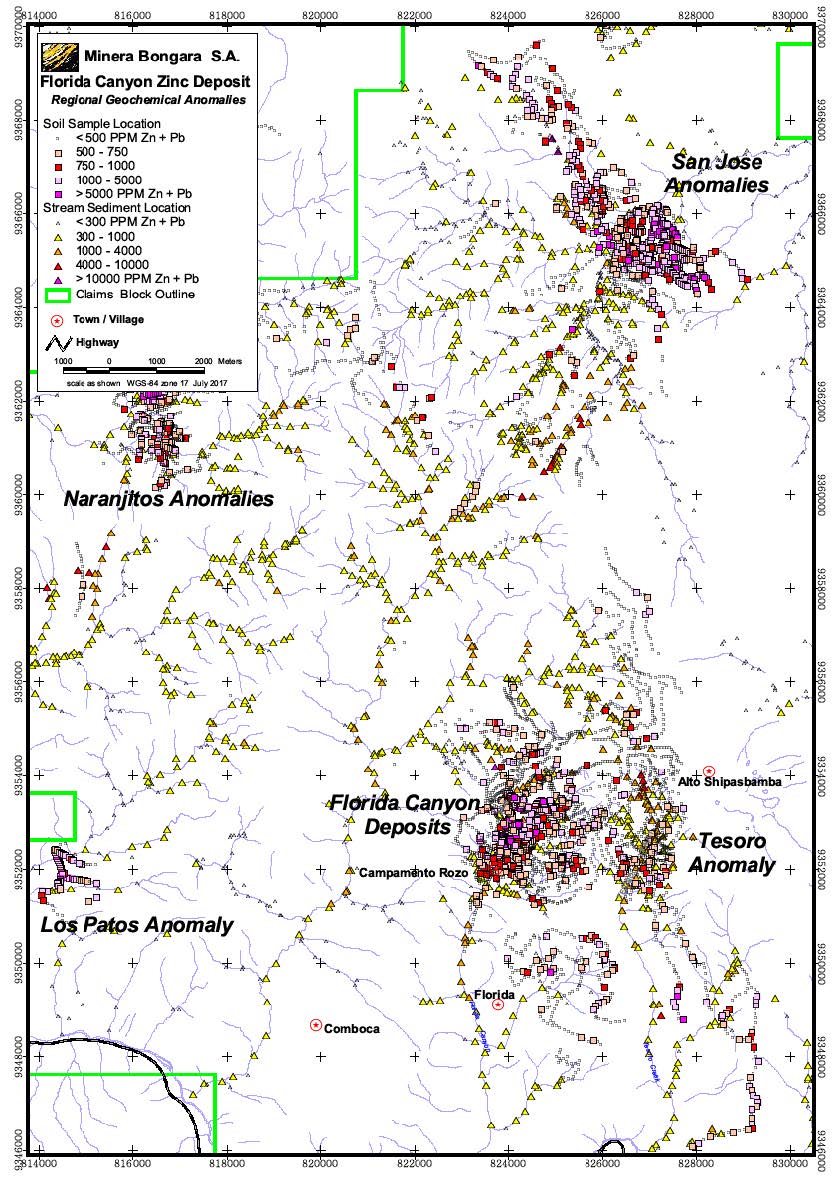

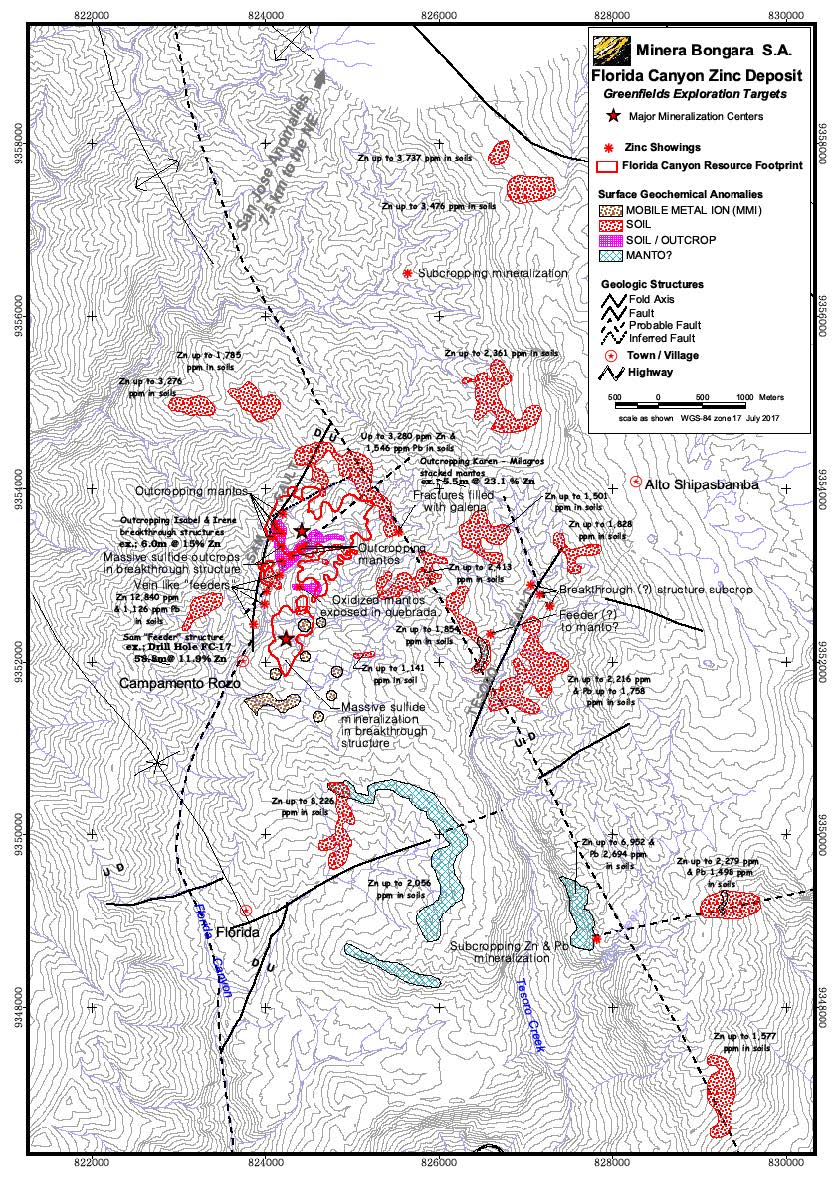

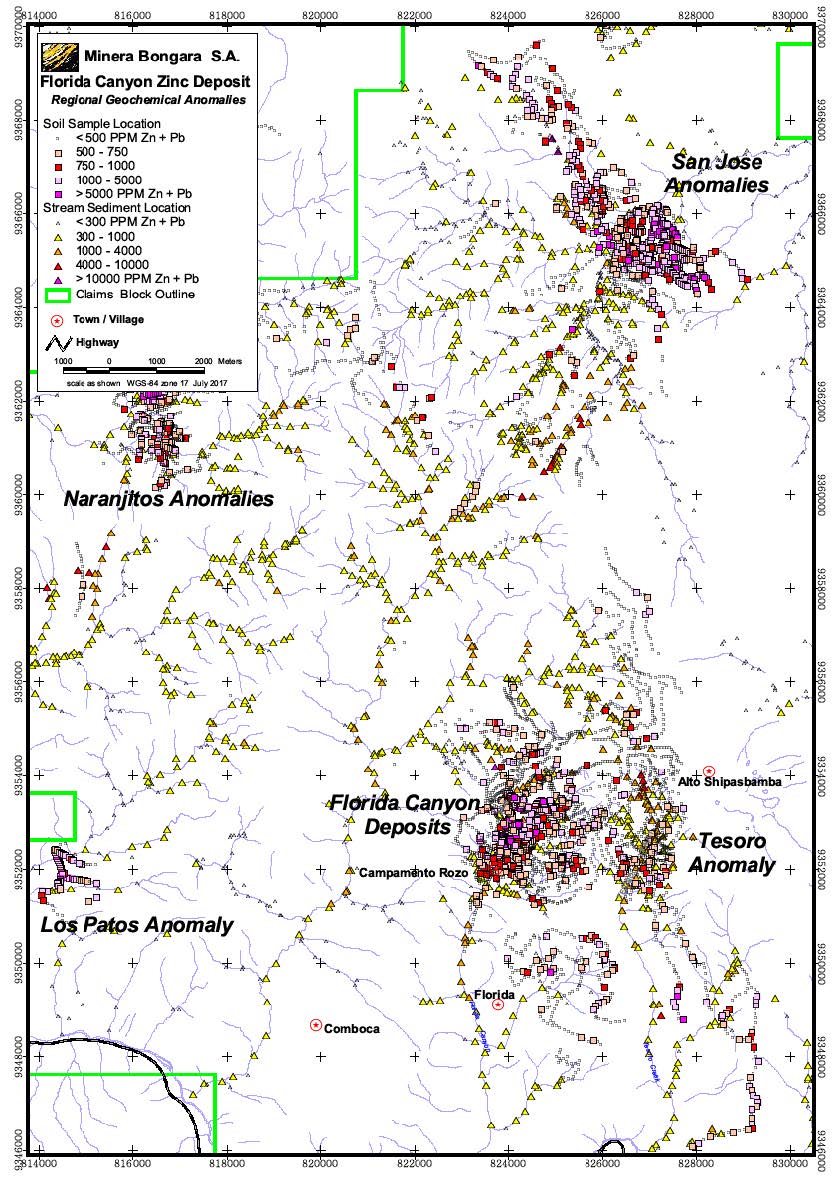

Figure 9-1: Florida CanyonArea Prospect and GeochemistryMap 62

Figure 9-2:Regional GeochemicalResults 64

Figure 9-3: Florida CanyonArea Simplified Geology, Resource and Drillhole Map65

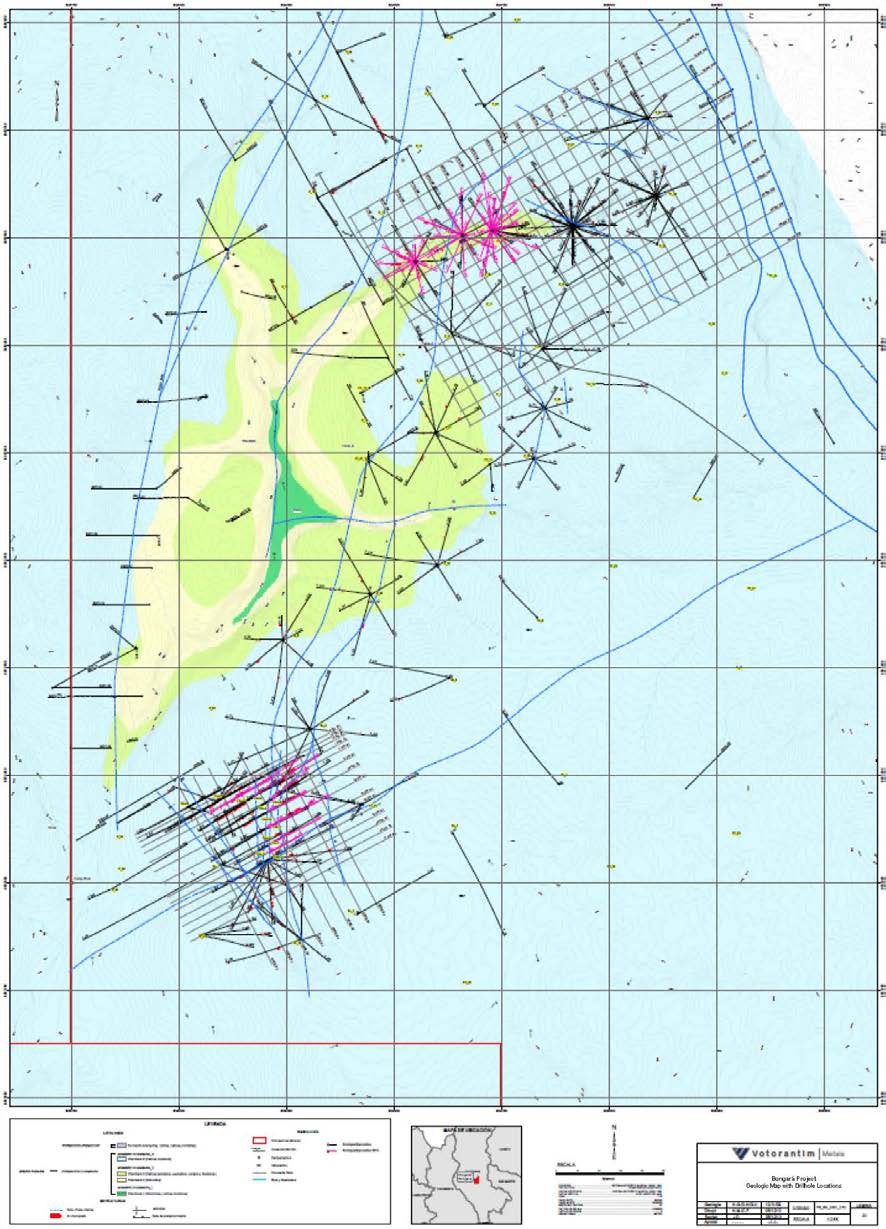

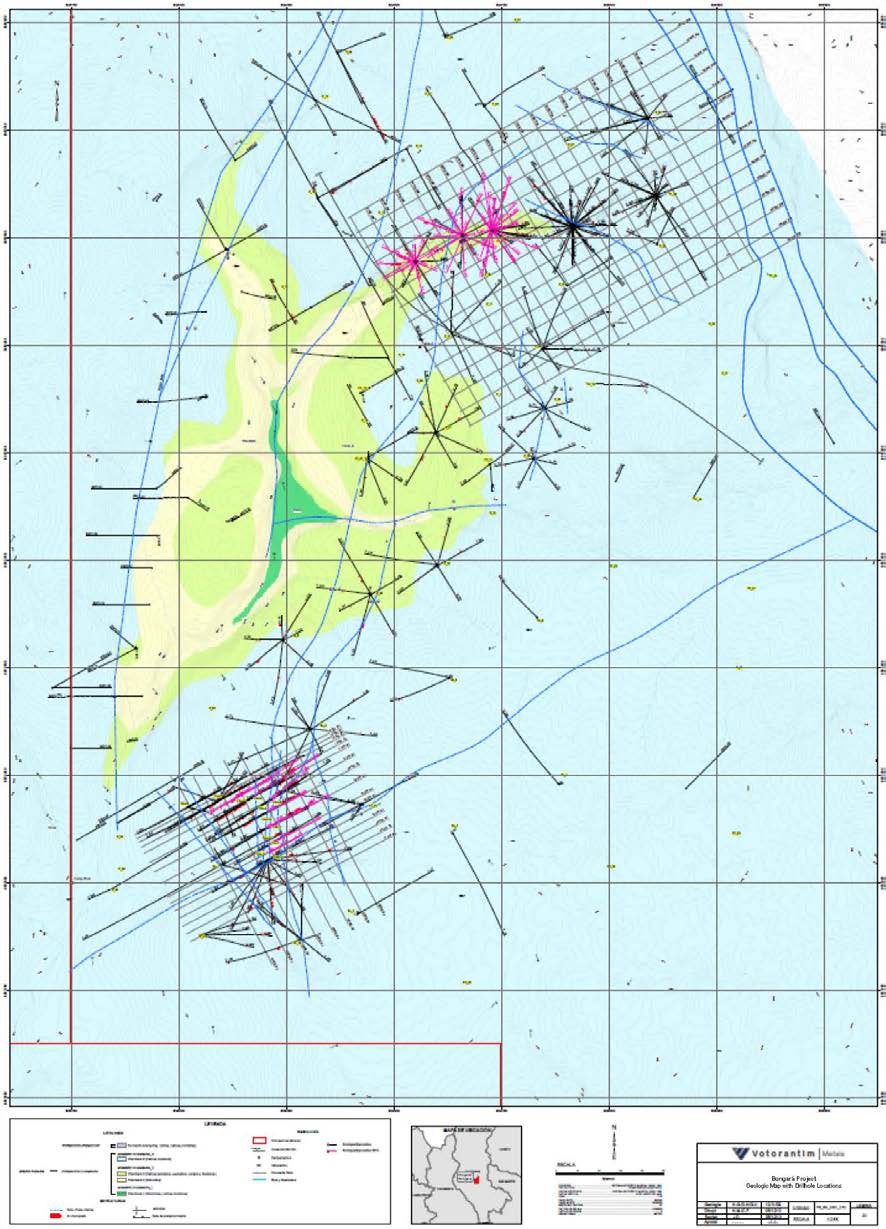

Figure 10-1: ProjectDrilling History66

Figure 10-2:Geologic Mapwith Drillhole Locations 67

Figure 12-1: Photograph of Project Core Lithology Reference Sample Library76

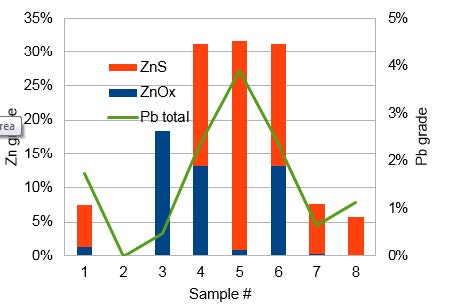

Figure 13-1: MetallurgicalSampleResults –Zinc and Lead HeadGrades 80

Figure 13-2: Florida CanyonMetal RecoveriesRelativeto ZnO/ZnTRatio 83

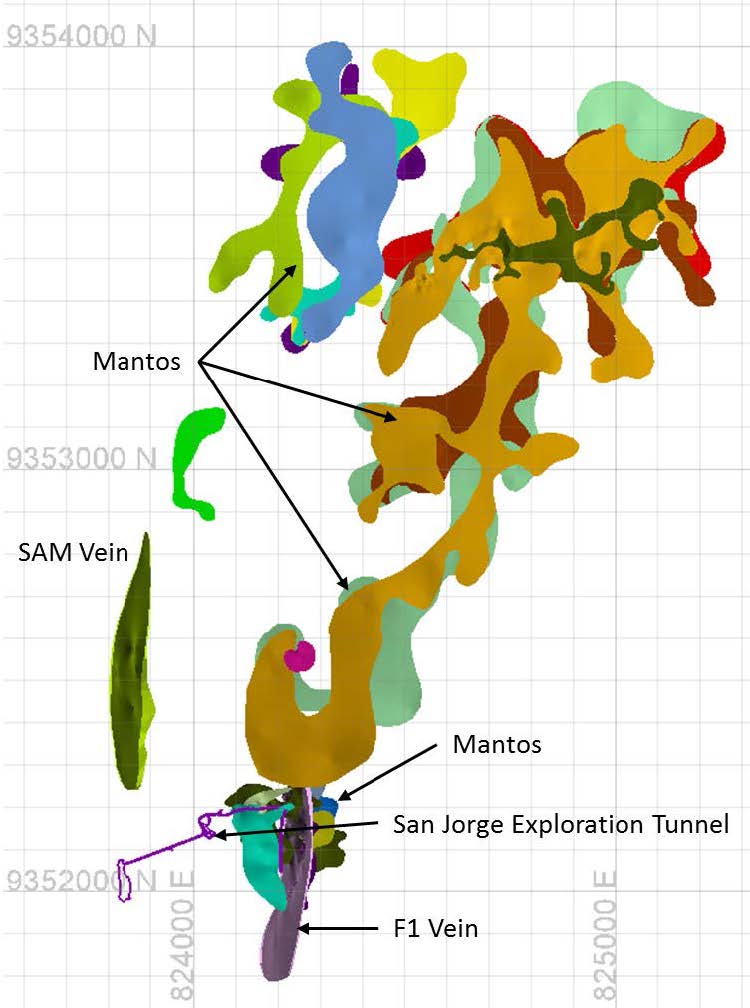

Figure 14-1: North-South LongitudinalSection of GeologicModel87

Figure 14-2: Florida Canyon Geologicaland Structural Map Projectedon Topography87

Figure 14-3: Geological CrossSection of Karen-Milagros Domain88

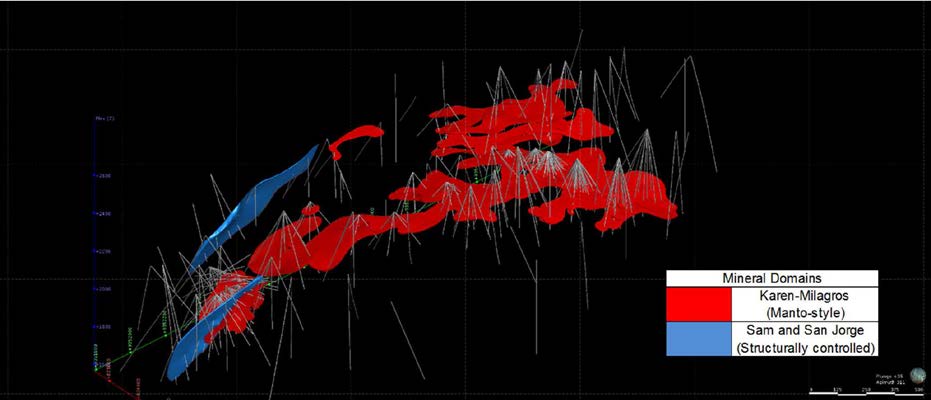

Figure 14-4:Oblique Viewof Mineral Domains88

Figure 14-5: EstimationBLOCKZones 94

Figure 14-6: Grade-Tonnage Curve forContainedZnEq%100

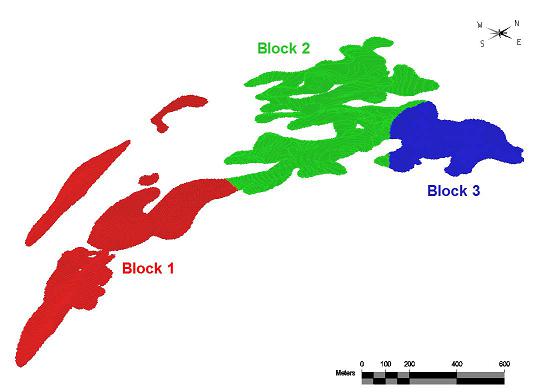

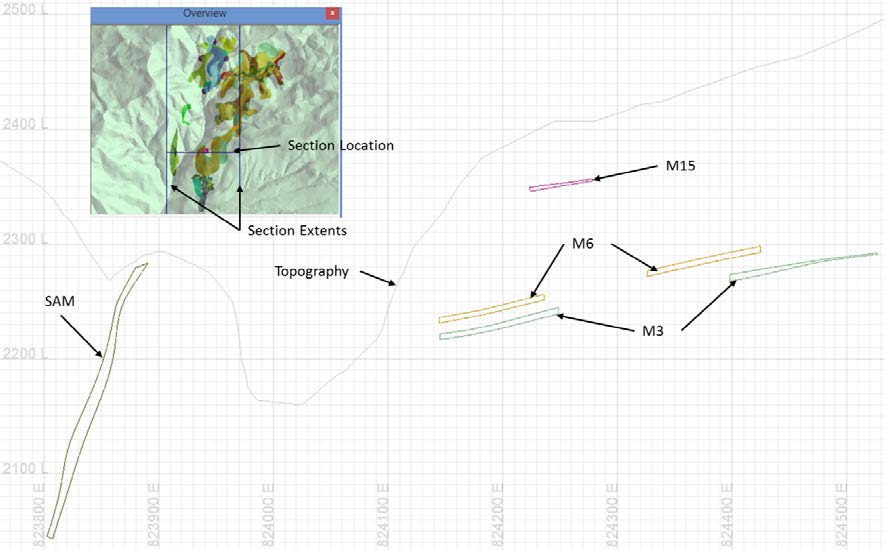

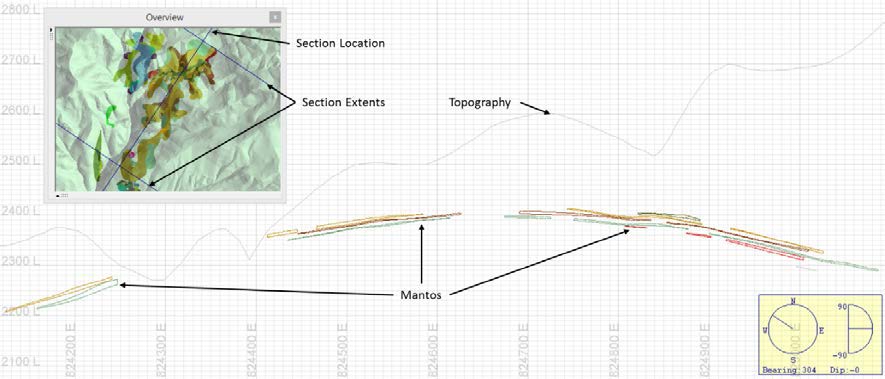

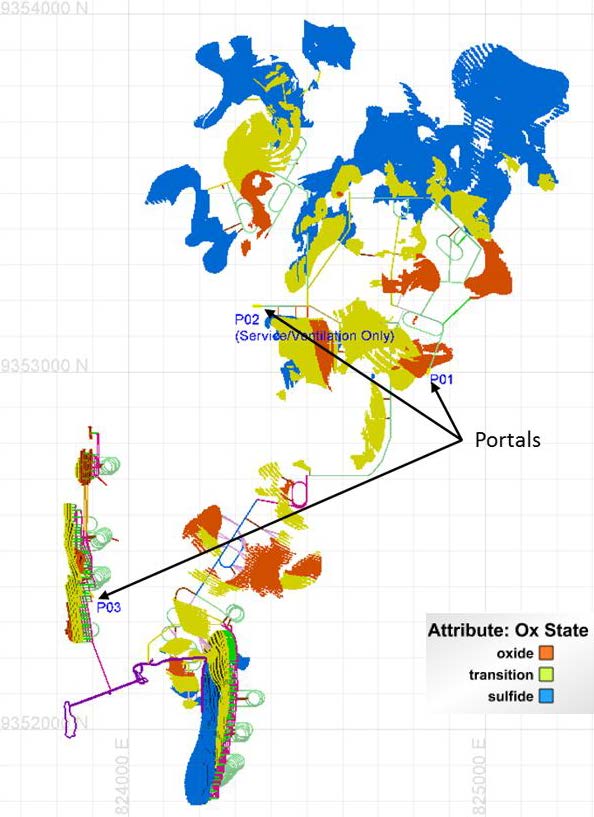

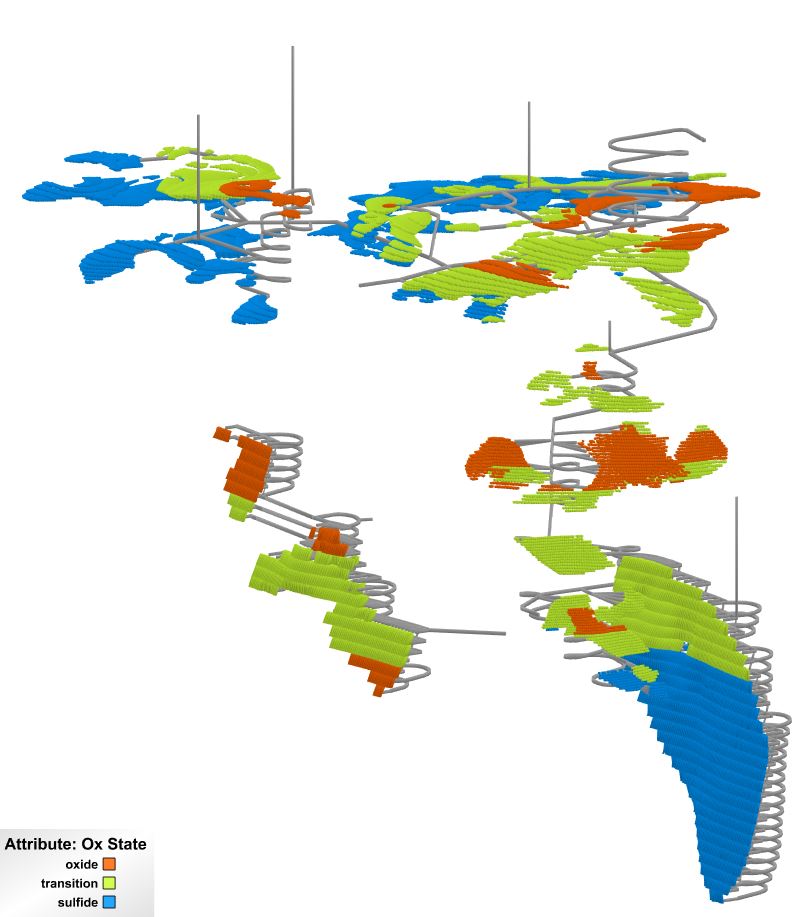

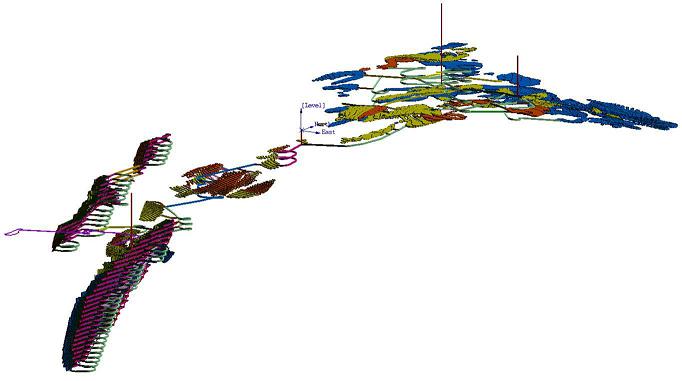

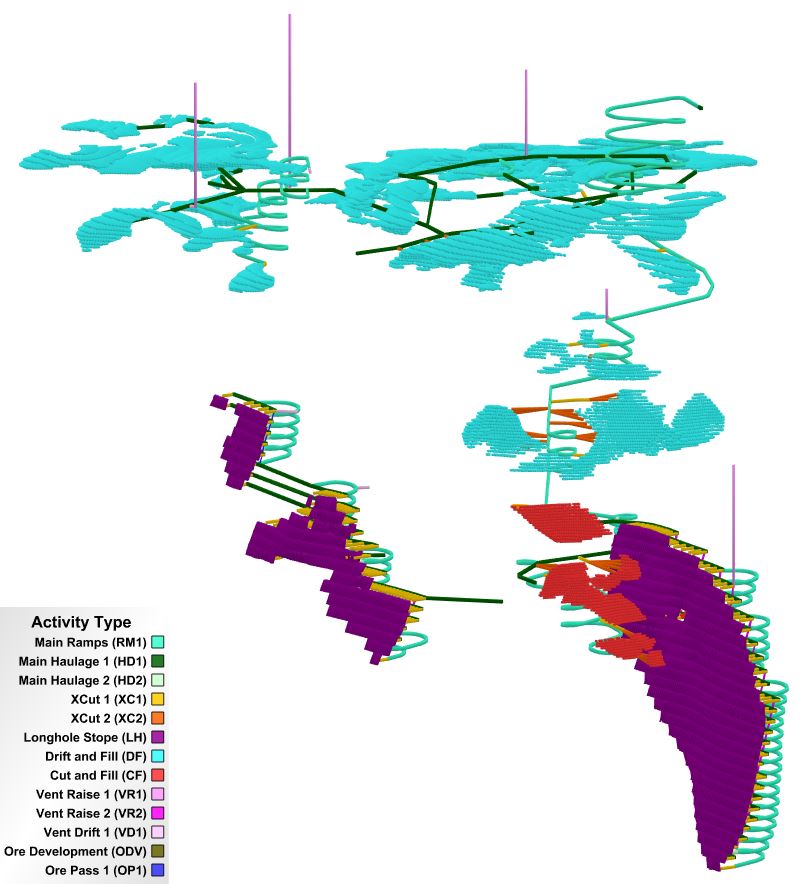

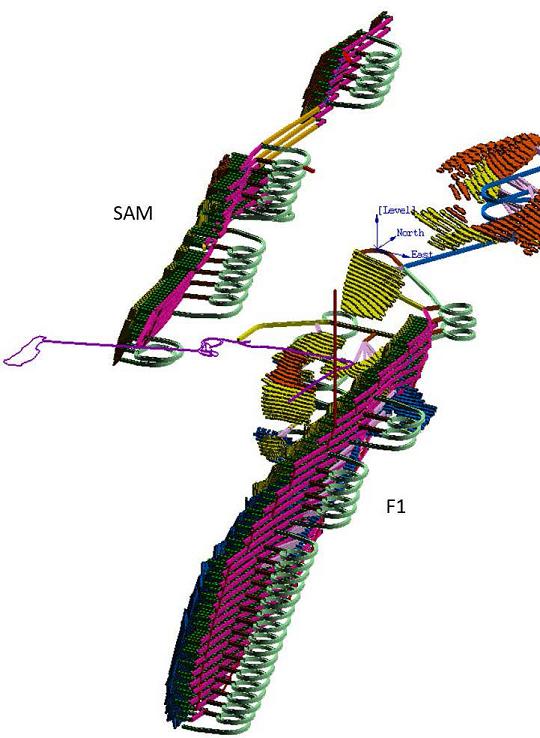

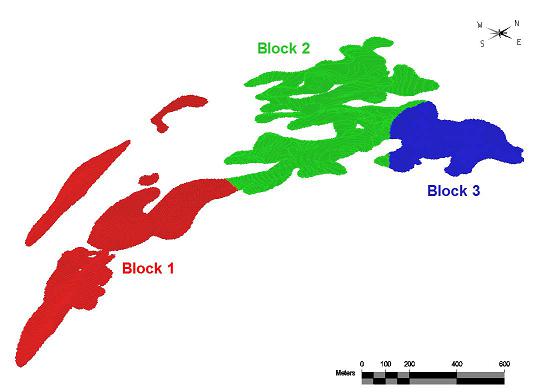

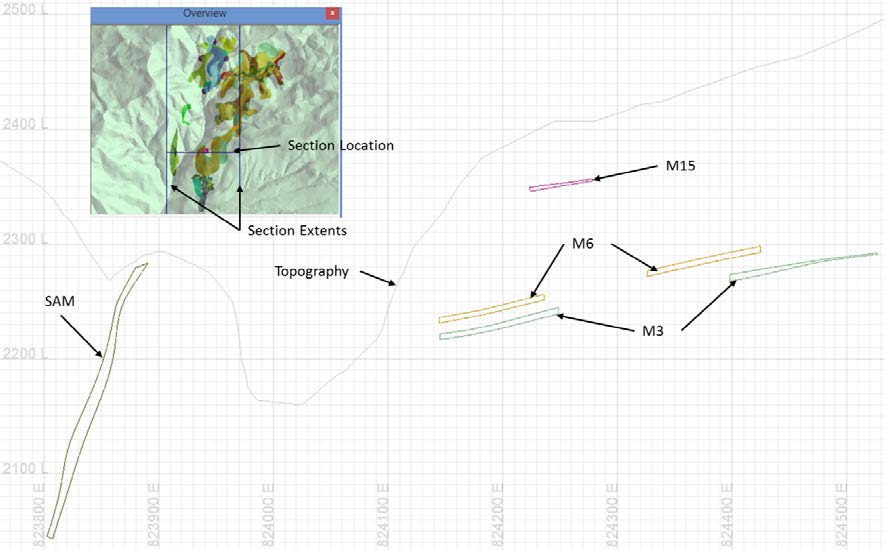

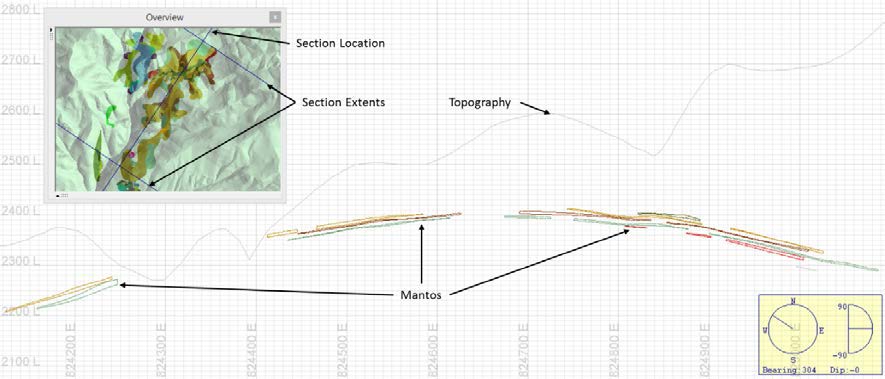

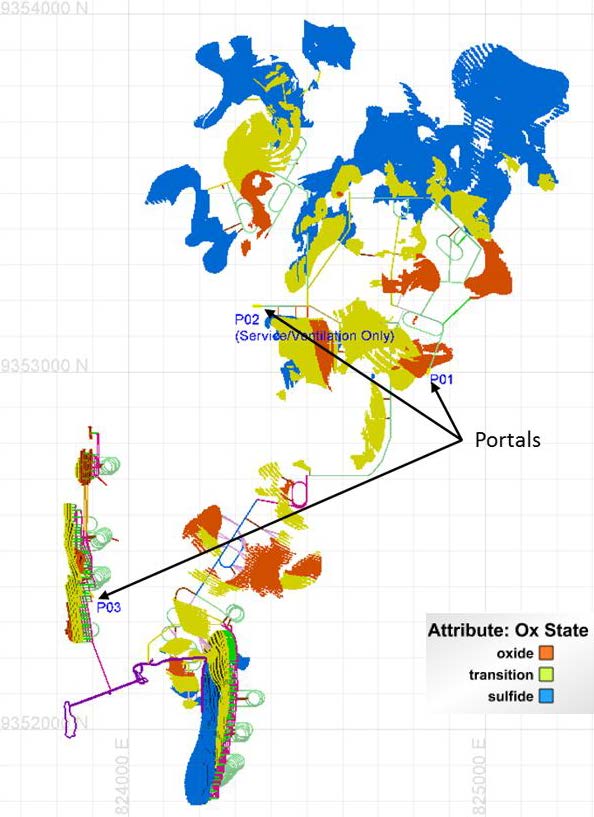

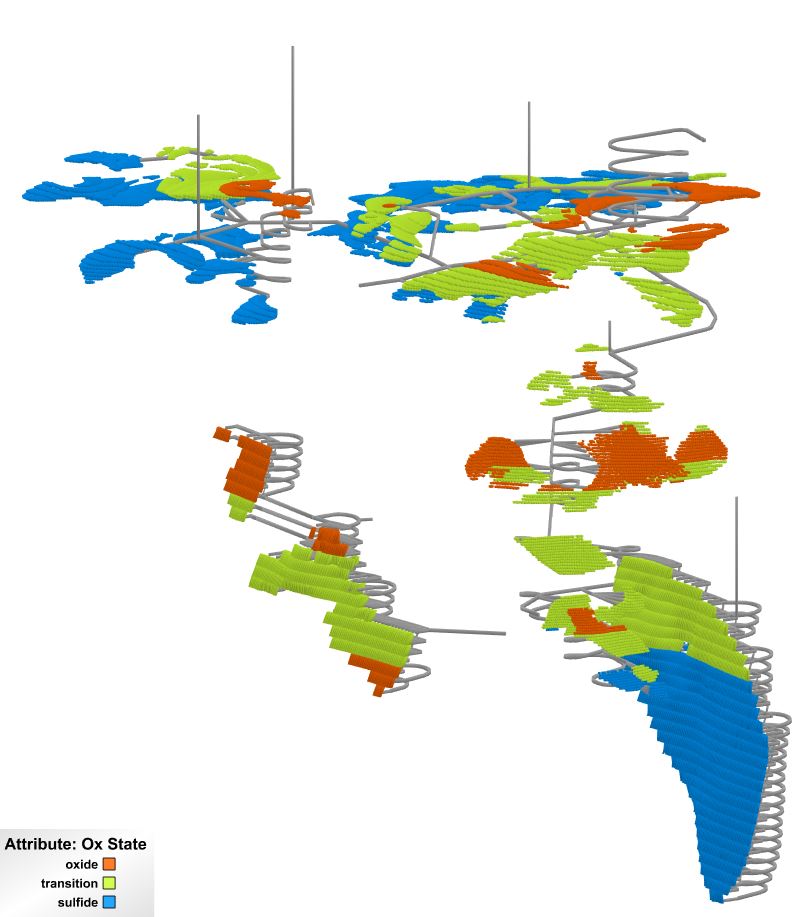

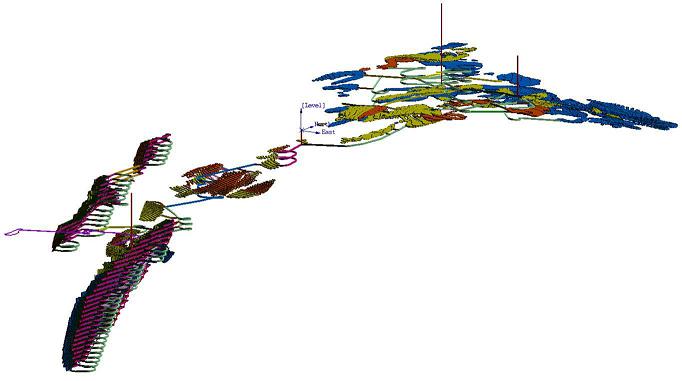

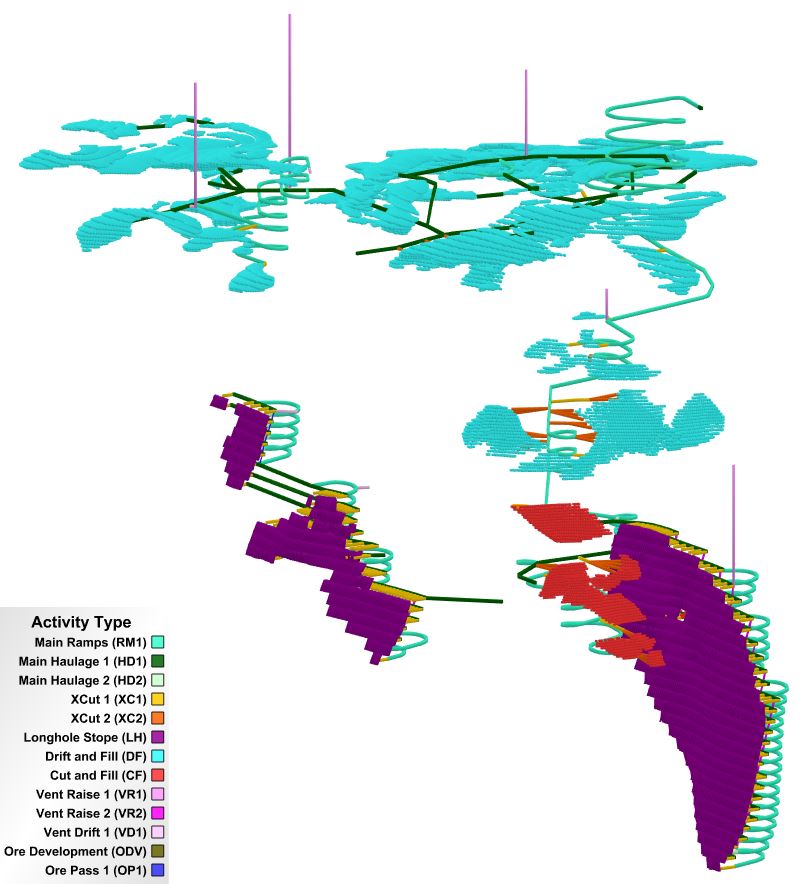

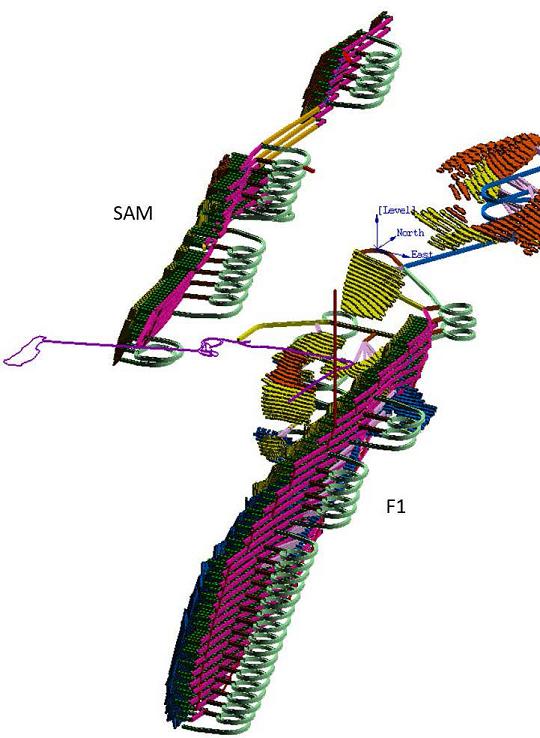

Figure 16-1: Overviewof Florida Canyon MineralizedBodies 104

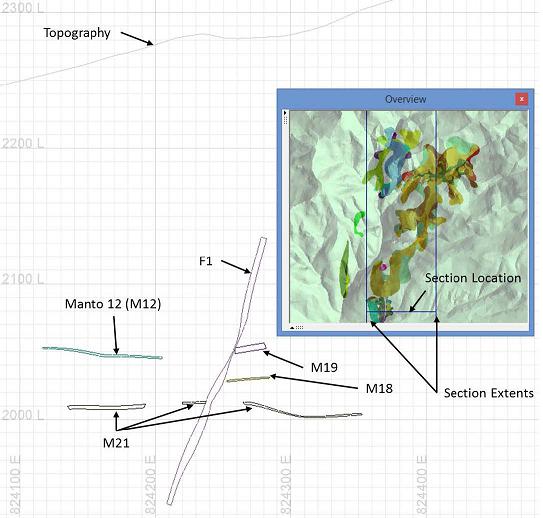

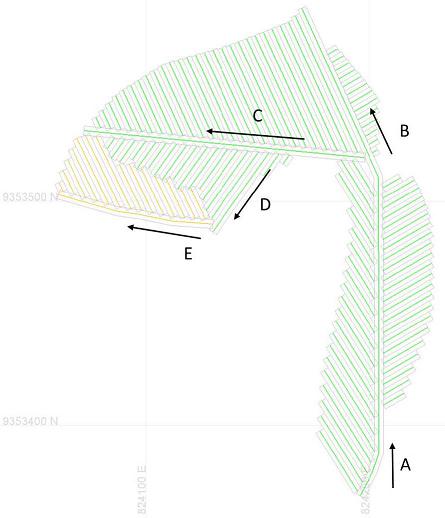

Figure 16-2: Section Viewof the F1Mineralized Bodyand Nearby Mantos(9,352,100N -Looking North)..105Figure 16-3: Section Viewof the SAM Mineralized Body and Nearby Mantos(9,352,530N - LookingNorth)

...........................................................................................................................................................106

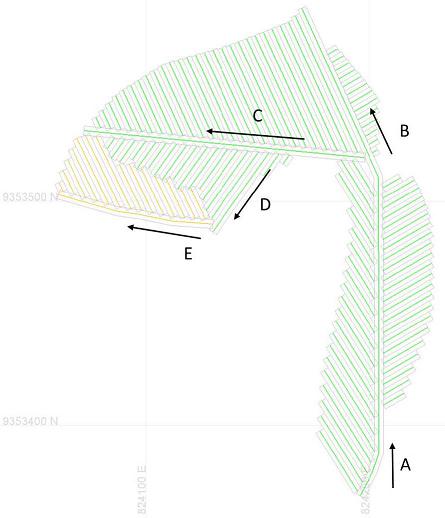

Figure 16-4: Southwestto Northeast Section View Showing theDomeStructure of Mantos (LookingNorthwest)

...........................................................................................................................................................106

Figure 16-5: UCS Strength Testing Summary110

Figure 16-6: EmpiricalStability Graph for StopeGeometriesin Chambara 2112

Figure 16-7: Grimstadand Barton Ground Support Estimate114

Figure 16-8: Section View Showing Resource and Re-blockedModel (9,353,600N-Looking North) 117

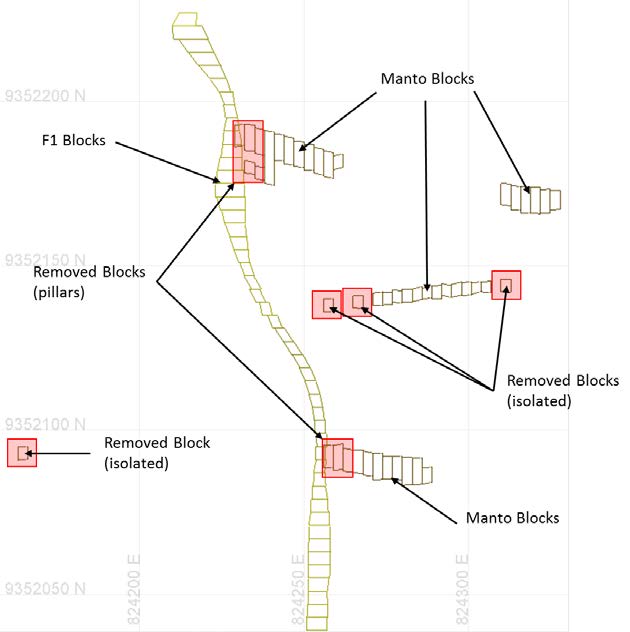

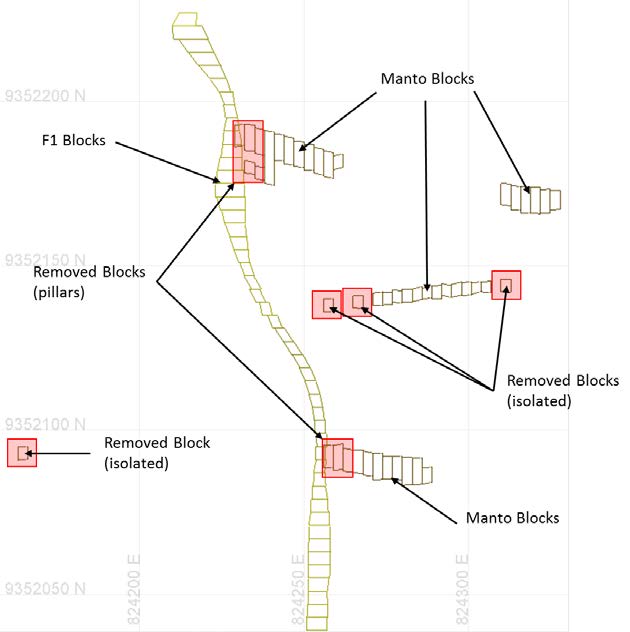

Figure 16-9: Section View Showing BlocksRemovedfromInventory 122

Figure16-10: Plan Viewof F1Area Showing Cut and Filland Longhole Blocks125

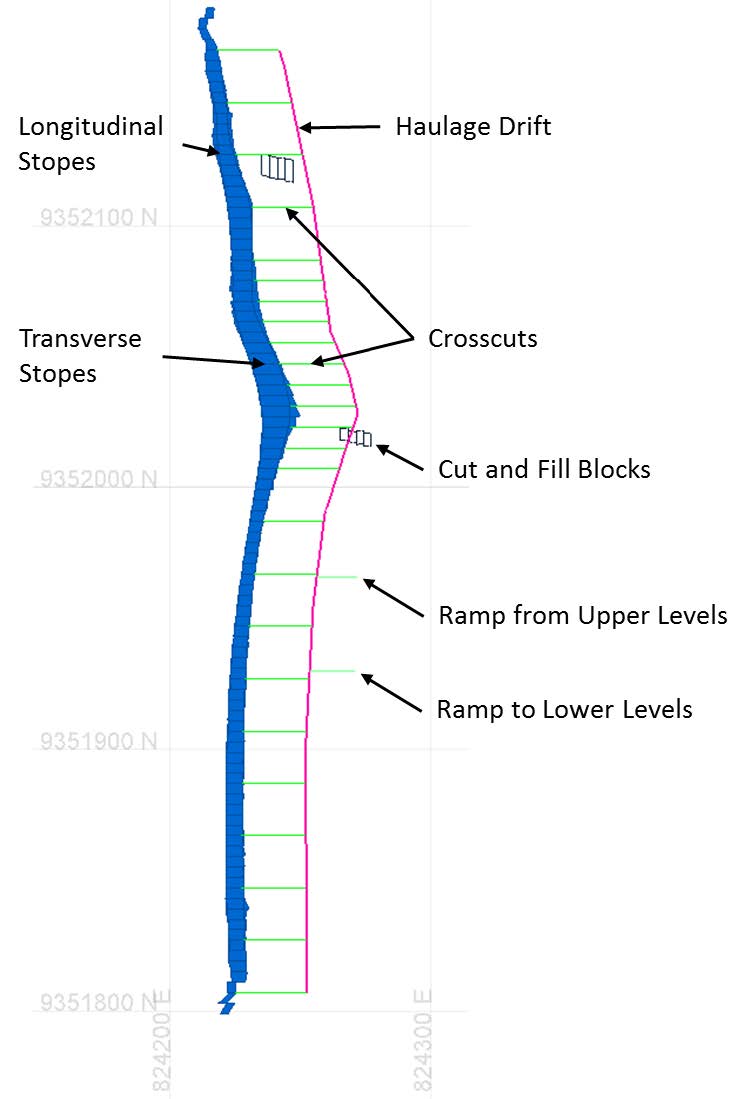

Figure16-11: Section View Showing Typical LongholeLevel Layout(Elevation 1981) 126

Figure 16-12: Example DriftandFill Layout, M10 Manto127

Figure 16-13: Florida Canyon Mining Inventory129

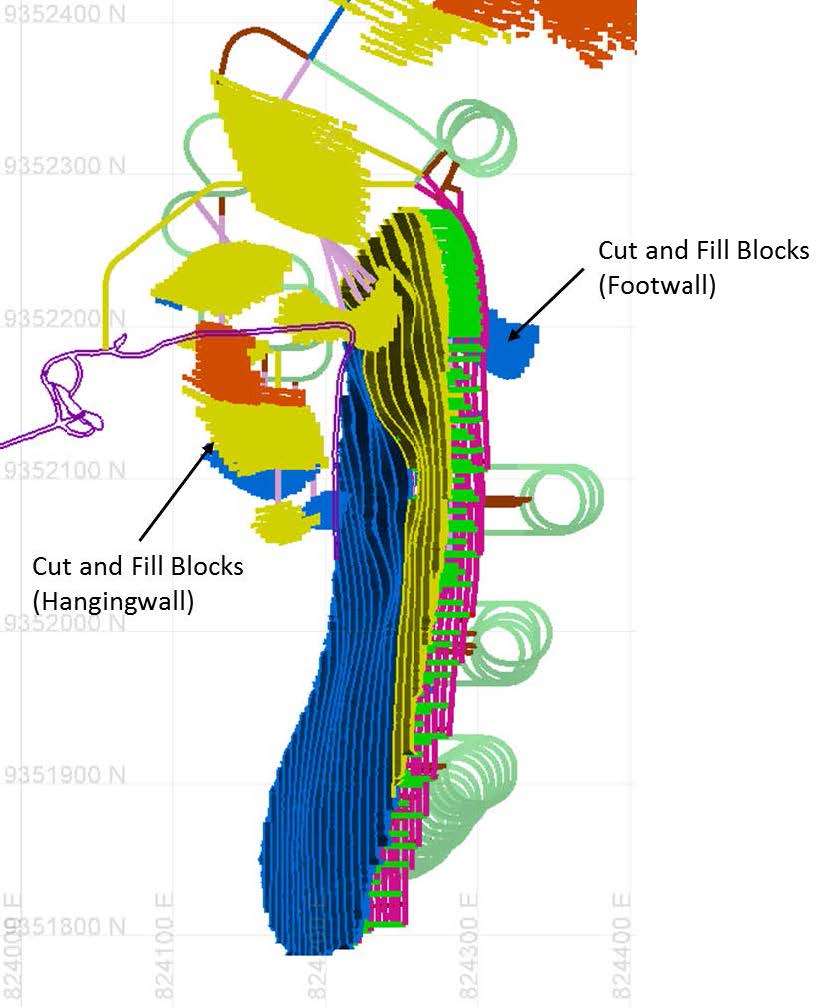

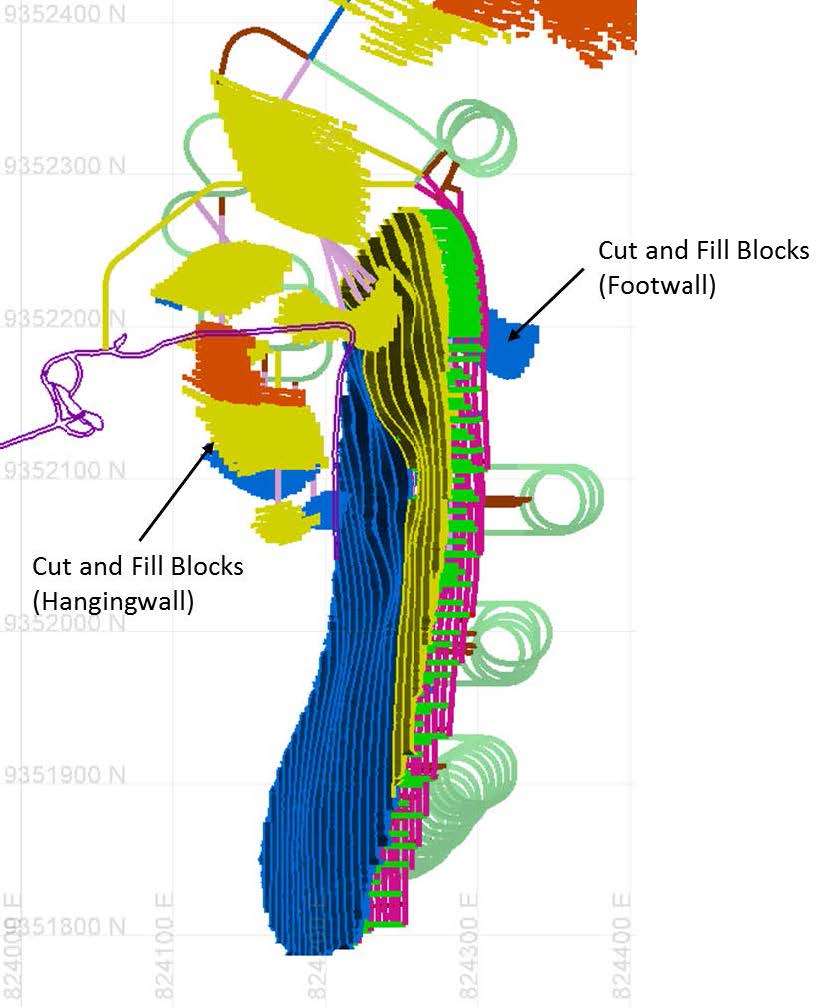

Figure 16-14: Plan Viewof Mining Blocksand DevelopmentLayout 131

Figure 16-15: Rotated Viewof Mining Blocksand Development Layout – AllAreas (Looking Northeast) 132

Figure 16-16: Rotated Viewof Mining Blocksand Development Layout – AllAreas (Looking Northwest) ...133

Figure 16-17: Rotated Viewof Mining Blocksand Development Layout – Drift andFill/Cut and Fill(Looking Northeast) 134

Figure 16-18: Rotated Viewof Mining Blocksand Development Layout – F1 and SAM(Looking Northwest)

...........................................................................................................................................................135

Figure16-19: Rotated Viewof Mining BlocksShowing ProductionSchedule137

Figure 17-1: Florida Canyon PEA Level Process FlowSheet 145

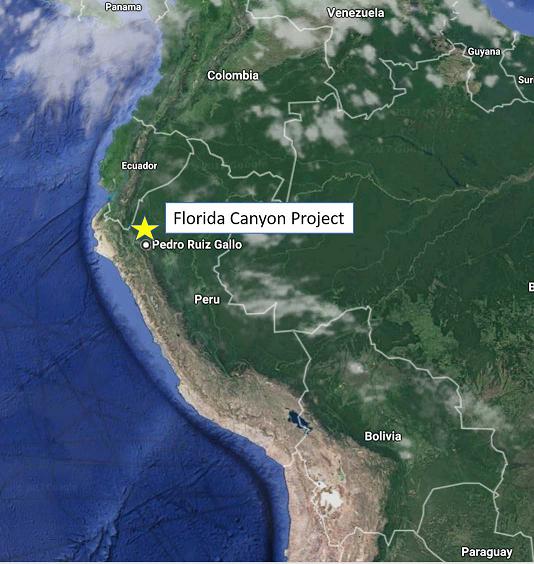

Figure 18-1:Florida Canyon General Location146

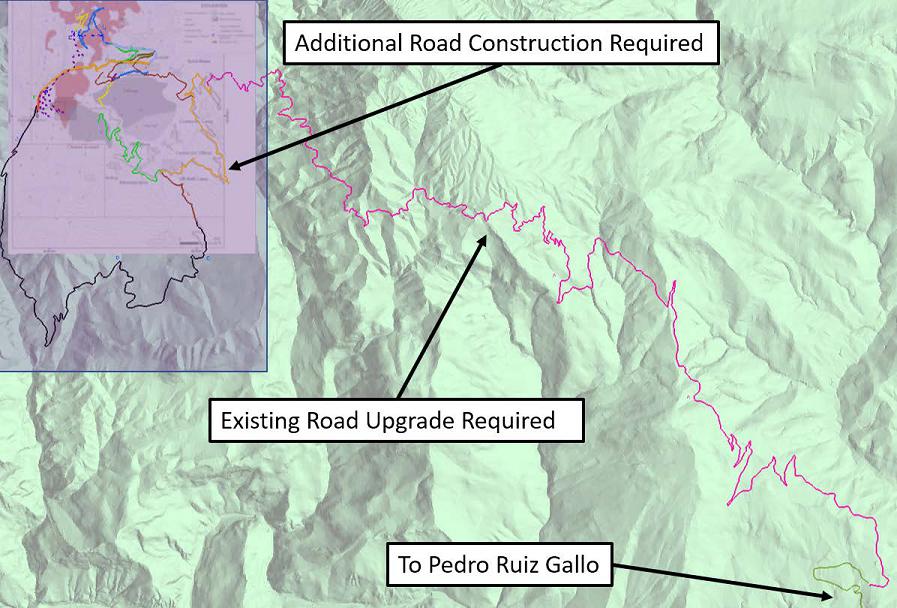

Figure 18-2: Florida CanyonExisting and New RoadConstruction 147

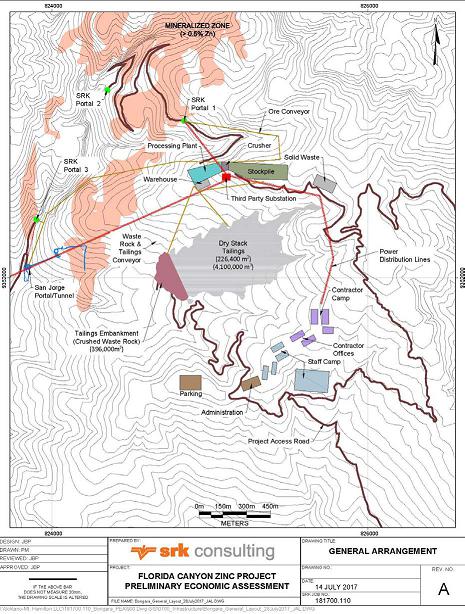

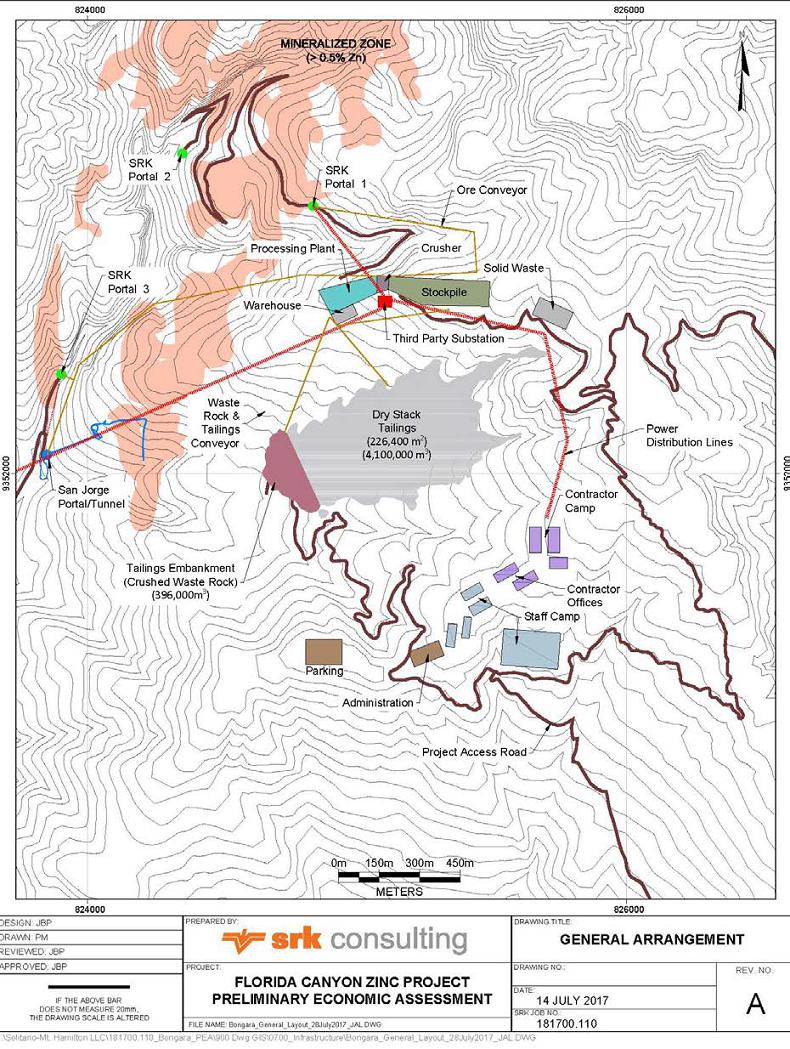

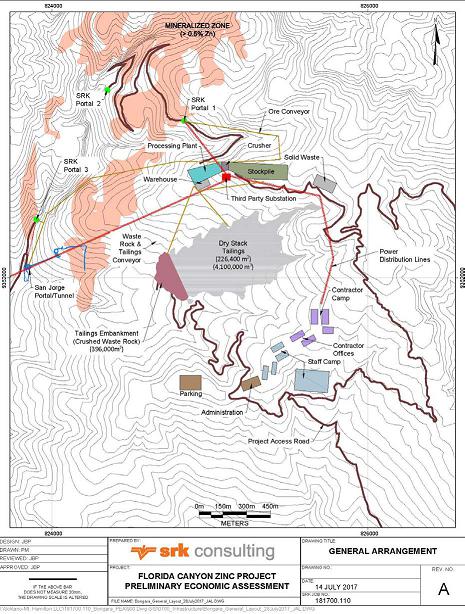

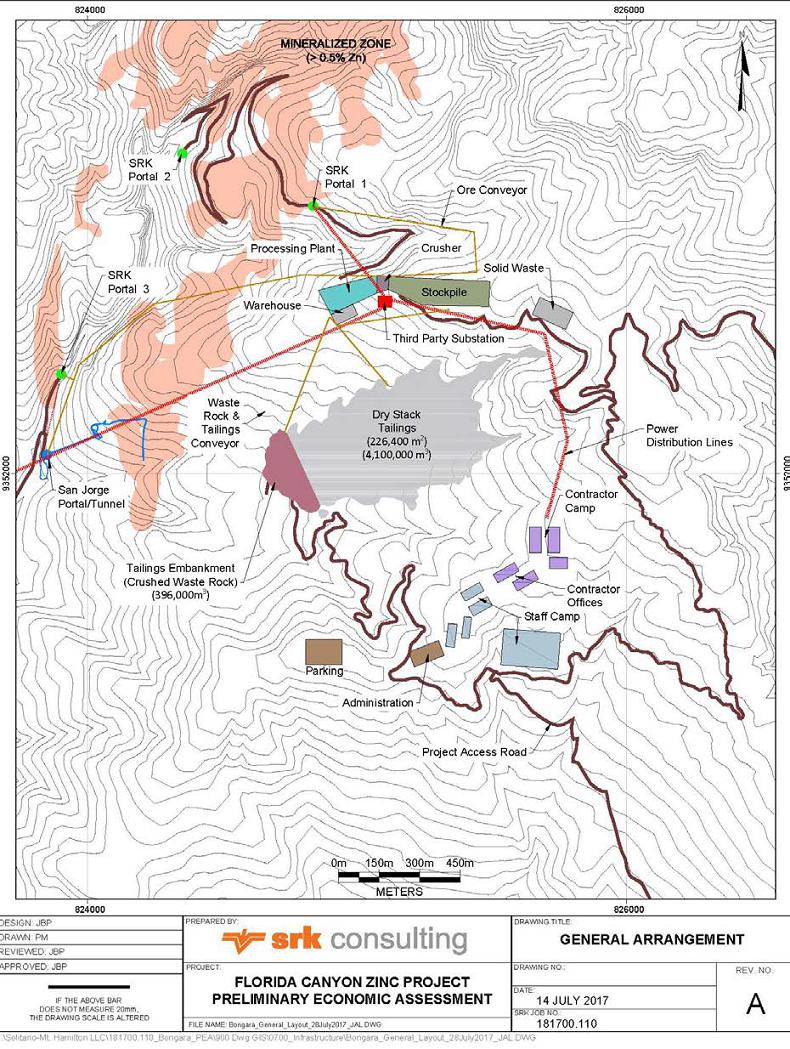

Figure 18-3: Florida CanyonSiteGeneral Arrangement149

Figure 18-4: Florida Canyon Third Power SupplyAlternative 151

Figure 18-5: Typical30 Tonne Concentrate Transport Truck152

Figure 18-6: Port and SmelterLocations 153

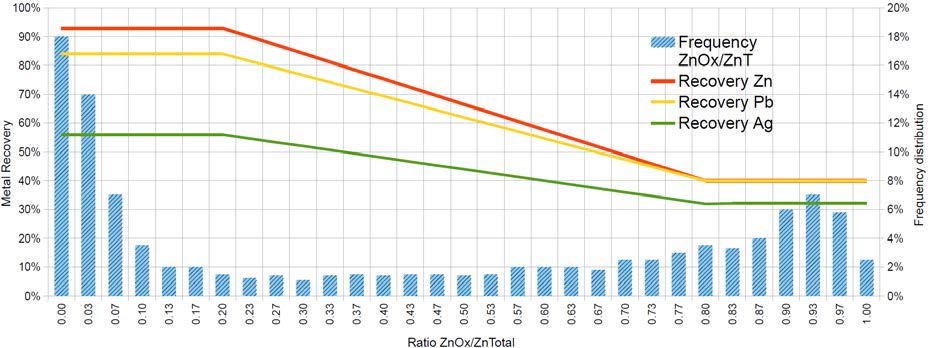

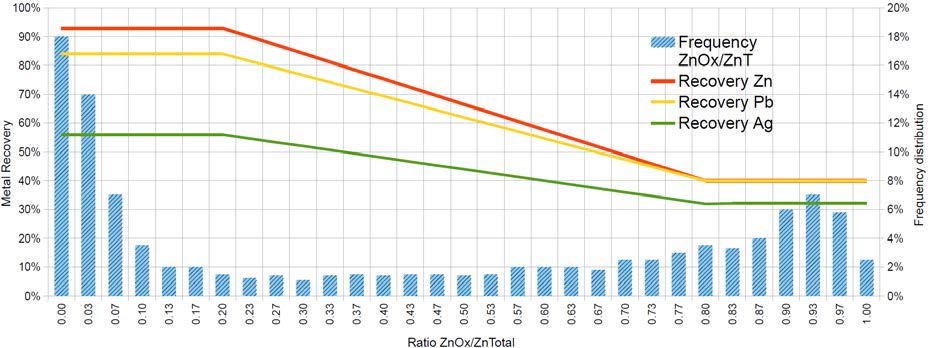

Figure 22-1: Florida Canyon After-Tax Free Cash FlowandEquivalent Metal Production174

Figure 22-2: Metal Participationin Revenue – FloridaCanyon 177

Figure 22-3: Florida CanyonCumulative NPVCurves(aftertax) 179

Figure 22-4: Florida Canyon NPV SensitivitytoHurdle Rate 180

Figure 22-5: Florida Canyon NPVSensitivity (US$000’s)181

Figure 22-6: Mine Plan Resourcecoloredby SensitivityNSR (rotated view, lookingNortheast) 183

Figure 22-7: Florida CanyonAlternate Case After-Tax FCFandEquivalentMetal Production 184

Appendices

Appendix A: Certificates of Qualified Persons

Thisreport was preparedas aNational Instrument43-101 (NI 43-101) TechnicalReport, Preliminary Economic Assessment (TechnicalReport or PEA)by SRK Consulting (U.S.), Inc.(SRK), for Votorantim Metais Holding S.A. (Votorantim)with Solitario ZincCorp. (Solitario), (collectively, owners)on the FloridaCanyon ZincProject locatedin Amazonas Department,Peru (Florida Canyonor Project). TheProject namewas changed in 2017from Bongará, as it was calledpreviously, to FloridaCanyon.

This studyrepresents the advancementof the Project from a2014 Technical Reporton Resources,tothis 2017 PEA.Highlights of this PEA include athirteen-year life-of-mineunderground mineplan, comminution and flotationof zinc andlead concentratesat anominal productionrate of 2,500 millthroughput tonnes perday followedbydry-stack tailings storage. Site infrastructure includesline power to the site, water distribution systems, atownsite and accessroadsforconstruction andre-supplyas wellas forconcentrate transportto the pointof sale.

Akey developmentin thepreparation of this PEAwas the additionof newmetallurgical datathat provided an accurateratio of zinc oxideto zinc sulfide. Theratio allowed block-by-blockrecoverytobe estimated. For each blockin this polymetallic (zinc-lead-silver)deposit a Net SmelterReturn valuewas calculated, making thedefinition of mineablemineralization independent of material type. Thedeposit naturally contains a high percentageof zinc sulfidemineralization; but usingthenew approach, mostof the transitionandsomeof the oxide materialsare alsosuitable for flotationprocessing when they carry sufficient recoverablemetal.

This Technical Reportwasprepared in supportof apress release issuedby the ownerson August2, 2017, inwhich economicresults were reported. Those economicresults are summarized herein.

Technical economicresults forthis PEAare summarized below and inTable 1-1 through Table1-4.

| · | Mill Throughput Rate: 2,500tonnes perday(t/d); |

| · | Recoverable Metal of 1.643 billion poundszinc, 165million pounds (Mlb) lead and 2 millionounces (Moz) silver; |

| · | Average Recovery: 80% forzinc 74% for lead, 52% forsilver; |

| · | Initial Capital Cost: US$214million; |

| · | Lifeof Mine Capital Cost: US$296 million andSustaining Capitalof US$83 million; |

| · | Underlying NSR-Royalty: 1.0%; |

| · | All-in Cost perZinc-Equivalent Payable Pound: US$0.73; |

| · | Average Payable Annual ZincProduction: 131.4 Mlb;Average run-of Mine Zinc Grade:8.34%; |

| · | Average Payable Annual LeadProduction: 13.2Mlb; Average Lead Grade: 0.90%; |

| · | Average Payable AnnualSilver Production: 168 thousand ounces (koz);Average Silver Grade: 11.31 gramsper tonne (g/t); |

| · | After tax NPVat 8%: US$198million; |

| · | After tax Internal Rateof Return (IRR): 24.7%; and |

| · | After tax paybackPeriod: 2.6years. |

Table1-1: Indicative Economic Results(US$)

| Description | Value | Units |

| MarketPrices | | |

| Silver | 16.50 | US$/oz |

| Lead | 1.00 | US$/lb |

| Zinc | $1.20 | US$/lb |

| EstimateofCash Flow (all values in$000s) | | |

| Concentrate Net Return | | $/oz-Ag |

| Silver Sales | $32,957 | $0.02 |

| LeadSales | $156,937 | $0.11 |

| ZincSales | $1,675,977 | $1.20 |

| TotalRevenue | $1,865,871 | $1.34 |

| Treatment, Smelting and Refining Charges | ($337,076) | |

| Freight, Impurities&Third Parties | ($96,935) | ($0.07) |

| Gross Revenue | $1,431,860 | |

| Royalties | ($61,734) | ($0.04) |

| Net Revenue | $1,370,126 | |

| Operating Costs | | |

| Open Pit Mining | $0 | $0.00 |

| Underground Mining | ($228,547) | ($0.16) |

| Process | ($144,063) | ($0.10) |

| G&A | ($39,153) | ($0.03) |

| Ordinary Rights | $0 | $0.00 |

| TotalOperating | ($411,764) | ($0.29) |

| Operating Margin (EBITDA) | $958,362 | |

| Initial Capital | ($213,667) | |

| LoMSustaining Capital | ($82,722) | |

| IncomeTax | ($224,873) | |

| AfterTaxFree Cash Flow | $437,100 | |

| Payback | 2.59 | years |

| After-Tax IRR | 24.7% | |

| NPV @:8% | $197,521 | |

Source: SRK, 2017

Table1-2: Capital Costs

| Description | Initial(US$000’s) | Sustaining (US$000’s) | LoM(US$000’s) |

| Development | 12,293 | 35,741 | 48,033 |

| Vent Raises | 686 | 672 | 1,358 |

| Underground Mining Equipment | 24,625 | 2,474 | 27,099 |

| Surface Crushing&Conveying | 1,430 | 0 | 1,430 |

| OffsiteInfrastructure | 16,227 | 0 | 16,227 |

| Site Facilities | 14,697 | 0 | 14,697 |

| Process Plant | 60,000 | 0 | 60,000 |

| Power Supply | 2,472 | 0 | 2,472 |

| WaterSupply | 250 | 0 | 250 |

| BackFill Infrastructure | 13,200 | 0 | 13,200 |

| CementRockfill Infrastructure | 200 | 0 | 200 |

| Tailings Storage Facility | 12,854 | 11,814 | 24,668 |

| Owner's | 14,595 | 0 | 14,595 |

| Contingencies | 40,138 | 0 | 40,138 |

| Sustaining Capital | 0 | 26,272 | 26,272 |

| Closure | 0 | 4,920 | 4,920 |

| TotalCapital | $213,667 | $81,893 | $295,559 |

Source: SRK, 2017

Table1-3: Operating Costs

| Period | TotalCost (US$/t-Ore) |

| Underground Mining | 20.43 |

| Process | 12.88 |

| G&A | 3.50 |

| Total | $36.81 |

Source: SRK, 2017

Table1-4: Operating Costs

Description | LoM(US$000’s) | LoM(US$/t-Ore) | LoM(US$/lb-Zn) |

| Underground Mining | 228,547 | 20.43 | 0.16 |

| Process | 144,063 | 12.88 | 0.10 |

| G&A | 39,153 | 3.50 | 0.03 |

| TotalOperating | $411,764 | $36.81 | $0.29 |

Source: SRK, 2017

Alternative Economic Case Study

Theowners also requested SRKto evaluate the Project economicsunder a specificalternative metalprice structure. Thisalternative used a pricingof US$1.06/lb, US$0.88/lb, and US$18.19/oz forzinc,lead, andsilver respectively. Thealternative case alsoused a higherdiscount rate of 9%. Allother economicinputs were keptthe sameas the basecase.

Results of thealternative casestudy:

| · | All-in Cost perZinc Pound Recovered: US$0.72; |

| · | After tax NPVat 9%: US$106 million; |

| · | After tax Internal Rateof Return (IRR): 19.1%; and |

| · | After tax paybackPeriod: 3.2years. |

Both the base case andalternative case economicsare detailed in Section22 of this report.

| 1.2 | Property Description and Ownership |

TheFlorida Canyon ZincProject (the Project) is owned and operatedby Minera BongaráS.A., ajoint venture betweenSolitarioand Votorantimin existence since2006. Florida Canyonisan advancedmineral exploration project comprisedof sixteen contiguous mining concessions, covering approximately12,600 hectares (ha). Theconcession titlesare inthe nameof Minera Bongará. Allof these concessions are currently titled.

TheMinera Bongará concessionsare completelyenvelopedby asecond groupof thirty-seven contiguous mining concessions, covering approximately30,700 ha. The concession titlesare in the nameof Minera Chambara,alsoownedby the Owners. Ofthe thirty-sevenconcessions, twelvetitles are pending.

Votorantim, as operatorof the joint venture company Minera Bongará,has entered into a surfacerights agreement with thelocal communityofShipasbambawhich controls the surfacerights of the Project. Thisagreement provides forannual payments andfunding for mutuallyagreed upon socialdevelopment programsin return for theright to performexploration work including road building anddrilling. From time to time,Votorantim alsoenters into surfacerights agreements with individualprivate landowners within the communityto provide access forexploration work.

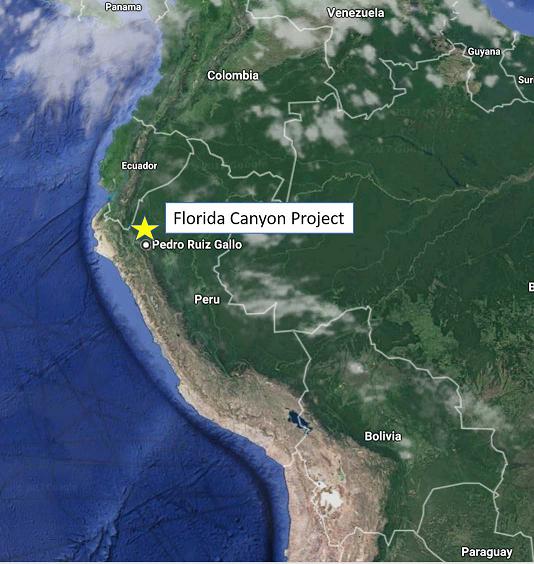

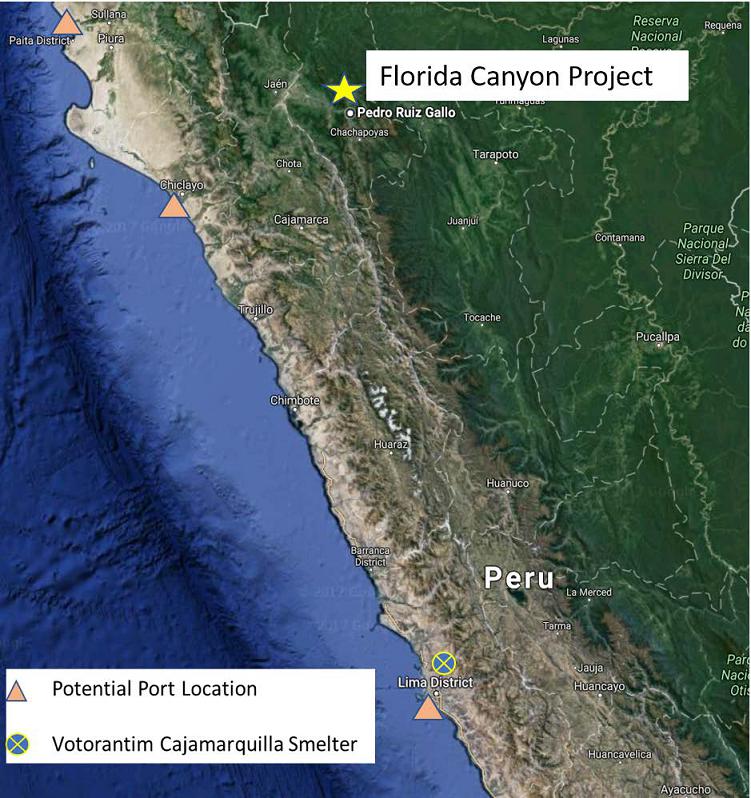

TheProject islocatedin theEastern Cordillera of Peruat the sub-Andean front in theupper AmazonRiver Basin. It is within the boundaryof the Shipasbambacommunity, 680 kilometer (km)north- northeast of Limaand and 245 kmnortheast of Chiclayo, Peru, inthe Districtof Shipasbamba, Bongará Province, Amazonas Department. TheProject areacanbe reachedfrom the coastal cityof Chiclayoby thepaved Carretera Marginal road. The central pointcoordinates of the Project are approximately825,248 East and, 9,352,626 North (UTM Zone 17S,Datum WGS84). Elevation ranges from 1,800 metersabove sea level (masl)to approximately 3,200 masl. The climateis classifiedas high altitudetropical junglein the upper regions of the Amazon basin. Theannual rainfall averageexceeds 1 meter

(m)withupto 2 min the cloud forestat higher elevations.

| 1.3 | Geology andMineralization |

TheProject is located withinan extensive beltof Mesozoic carbonate rocksbelonging to theUpper Triassicto Lower JurassicPucará Group andequivalents. This beltextends through the central andeastern extentof the Peruvian Andes fornearly 1000 kmand which is the host for manypolymetallic and base metalvein and replacement depositsin the Peruvian MineralBelt. Among theseis the San Vicente Mississippi ValleyType (MVT)zinc-lead deposit thathas manysimilarities to the FloridaCanyon deposit and other MVT occurrences in the Projectarea.

Knownzinc,lead andsilver mineralizationin theProjectarea is hostedin dolomitized limestone of the ChambaraFormation subunit 2 in the Pucará Group. The structureat Florida Canyonis dominatedby aN50º-60ºW trendingdomal anticline cutonthe westbytheSam Fault and totheeastby the Tesoro-FloridaFault.Inthe Projectarea, thethreeprospective corridorsfor economicmineralizationstudiedindetailareSanJorge, Karen-Milagros, andSam.In these areas, dolomitization andkarstingis best developed inproximitytofaulting andfracturing associated with each structural zone. Inturn,these structures providedaccess forthe alteringfluidstoflowlaterally into stratigraphic horizons withmorepermeablesedimentarycharacteristics.

The primaryzinc-lead-silver mineralization of the Florida Canyondeposit occursas sphalerite andgalena. Sphalerite is low iron andtogether, zinc andlead sulfideis 70% of the mineablematerial. At shallowdepths, thesesulfide minerals are altered to smithsonite, hemimorphite, and cerussite and collectivelyreferred toas oxides. The mineral suiteis low in pyrite.

| 1.4 | Status ofExploration, DevelopmentandOperations |

1.4.1History

Prior to the discoveryof mineraloccurrencesby Solitarioin 1994, no mineralprospecting had beendone on the Property andnoconcessions had been historicallyrecorded.In 1995and later, Solitario and its joint venture partners stakedthe current mineral concessionsin the Project area.

In 1996, ComincoLtd.formed ajoint venture partnership (JV)with Solitario. This agreementwas terminated in 2000 and Solitarioretained ownership of the property. Between 1997and 1999, Cominco completedgeologic mapping, geophysical surveys, surfacesampling, and82 diamond drillholes.

In 2006, Votorantim andSolitario formed a JV forthe exploration and possibledevelopment of the property. As theoperator of the JVcompany, Votorantimhas carried out surface diamond core drilling,geologic mapping, surfaceoutcrop sampling, underground explorationand drifting andunderground drilling programs.As of August15, 2013, Votorantim had completed404 diamonddrillholes which,when combined with the previous drilling of Cominco,totals 117,260 m.

Therehas not beenany commercial miningin theProject area. The onlyunderground excavationhas been 700 mof underground driftingby Votorantimto provide drill platformsat the San Jorgearea. A subsidiaryof Hochschild MiningPLC tested openpit mining for ashort timeat theMina Grandedeposit off ofProject properties nearthe villageof Yambrasbamba,18 kmnortheast of Florida Canyon,where Solitario had previouslydefined an oxidizedzinc resourcebypitting.

1.4.2Exploration Status

The focusofVotorantim’smostrecent explorationwork at the Project has been resourcedefinition drilling with HQ-diameter coreinthe SanJorge and Karen-Milagros areas. Drilling in theSan Jorge areawas completedunderground froman adit, while drillingin the Karen-Milagros areawas completed from surface.

Future exploration work will focuson infill drilling between the Karen-Milagros, SanJorge andSam areas. Mineralization is opento the northand southand remains largely untestedto the eastof the TesoroFault and westof theSam fault where greater target depthshave lowered the near-termdrilling priority.

1.4.3Development and Operations

Road accessto the Bongaráregion is provided primarilybythe Carretera Marginal paved highwayconnecting theportcityof Chiclayo to Pedro Ruiz (inland).Traveltimeto Pedro Ruiz takeson average 6 hoursby car.It is a regional commercecenter with hotels, restaurants, communication and a populationestimated tobe10,000. The immediate Projectarea is not populated butthere are several smallvillages nearby, whichare supportedby subsistence farming.

Current accessto the Projectisby foot, muleor helicopter. A roadis under construction fromthe communityof Shipasbamba. The Project areahas little existing infrastructure withonly an accessroad under construction and a numberof primitive campsand drill pads. Drilling hasbeen accomplished using helicopter support fromthe village of Shipasbambawhich lies 10 kmto the southeast. AProject coreshed, officeand samplestorage facilityis located in Shipasbamba.

| 1.5 | MineralProcessingand MetallurgicalTesting |

Votorantimretainedametallurgical consultant, SmallvillS.A.C. of Lima, Peru (Smallvill)to perform metallurgical studieson Florida Canyon mineralizationtypes in 2010, 2011and 2014. Allthe metallurgical testing programsaimed to produce commercial quality concentratesfrom apolymetalic lead-zinc mineralization. The tested samples show headsgrades significantly higherwhen comparedto other known mineraldeposits in the region.SRK hasrelied heavilyon these studies for recoveryand cost forecastingto develop cut-offgrades forresource reporting.

The majorityof the resourceis sulfide. TheFlorida Canyon sulfideresource consistsof zinc and lead sulfides in alimestone matrix where zinc is inhigher proportions thanlead. Thereare no deleterious elements present in concentratesin high enough levels totrigger smelter penalties.

The2014 metallurgicaltesting focusedon quantifying recovery inthe transitionaland oxide materialas it relatesto a measurablezinc oxide:zinc total ratio (ZnO/ZnT). Theratio was determined from2,813 samples from423 drillholeswith good spatialrepresentation.Depending ontheir availabilityand applicability, sampleswere takenfrom either coarserejects or pulp samples.Theratio was estimated into the block model foreach metalof interest. SRKdeveloped asliding-scale recovery curve foreach metalusing the ratio.

The recoveryestimates forFlorida Canyon relativeto ZnO/ZnT are illustrated in Figure 1-1. Table 1-5provides the recovery estimatesbymaterial type.

Table1-5: Florida Canyon MetalRecoveriesbyMaterial Type

| Parameter | | MaterialType | |

| | Sulfide | Mixed | Oxide |

| ZnOx/ZnT Ratio | <= 0.2 | 0.2 to 0.8 | >= 0.8 |

| ZnRecovery | 93% | (-0.8833 (ZnOx/ZnT)+1.1067) * 100 | 40% |

| PbRecovery | 84% | (-0.7333 (ZnOx/ZnT)+0.9867) * 100 | 40% |

| Ag Recovery | 56% | (-0.4(ZnOx/ZnT) + 0.64) *100 | 32% |

Source: SRK, 2017

Source: SRK, 2017

Figure 1-1: Florida Canyon MetalRecoveries Relative toZnO/ZnT Ratio

Anticipated concentrategrades used in cut-offgrade calculations are 50% forbothzinc andlead concentrates, the latter containing associated silver.

SRK sees opportunities for moreadvanced test work to optimizethe metallurgicalflow sheet.Previous test work used conventionalprocedures thatwere not specificto Florida Canyon material types.Similarly, finesencountered in previous work were not handledappropriately, resulting in sub-optimalflotation. Sample selectionis akey element and moresite-specific test work is expected to enhanceoverall recoveryprojections at the next levelof study.

| 1.6 | Mineral Resource Estimate |

Since the 2013 resource estimate(SRK, 2013), Millpoconducted aconsiderable amountof resampling and metallurgicaltest work to determinerecoverable sulfideand oxide grades forboth zinc and lead to better understand recoverable metalin the deposit. Thiswork led to a changein thedefinition of oxide, transition, and sulfide domains.In the2013 model, oxide,transition, andsulfide domains were developed basedon corelogging and then individual metallurgicalrecoveries were assignedas to each domain. Following the 2014 metallurgicaltest work, it was determinedthat aquantitative approach utilizing the ratioof estimated oxidezinc gradetoestimated total zinc gradewould provide the bestrepresentation of the recoverable resource.

The2017 resource modelwas builtbyVotorantim andvalidatedby SRK. Developmentof the 2017 resource estimateinvolved two separategrade estimations. First, primary reporting gradeswere estimated using thesamesamples as the 2013resource estimate. Thisestimate assigned the grades from which metalquantities were calculated in the resource. A secondresource estimatewas conducted using the Votorantim 2014 sampleprogram to assign sulfideand oxidegrades for bothzinc andlead. Thesegrades were usedto calculate azinc oxideto total zinc ratio (ZnOx/ZnT),which was then usedto determine if material wasoxide, sulfide,or mixedandto assign a recoverytoeach modeled blockbased on that ratio.

TheMineral Resource estimatewasbased on a 3-D geological modelof majorstructuralfeatures and stratigraphically controlledalteration andmineralization.Atotal of 23 mineral domainswere interpreted from mineralized drill intercepts, comprised mostly of 1 m core samples. The project is in metric units. Zinc, lead and silver were estimated into model blocks using Ordinary Kriging (OK). Oxide, Sulfide and Mixed material types were determined based on the ZnOx/ZnT ratio. Density was determined from a large percentage (55%) of measured values, which were usedtodevelop equations for density assignment based on rock type and kriged metal content of the samples.

Resources were reported to Measured, Indicated andInferred classification compliantwith CIMdefinitions according to NI 43-101 guidance. Blocksclassified as Measuredwere estimatedby Ordinary Krigingusingat least three compositeswithin 25 min the majorand semi-major searchdirections and10 min the minor searchdirection. Blocksclassified as Indicatedwere estimatedby Ordinary Krigingusingat least three compositeswithin 50 min the majorand semi-major searchdirections and20 min the minor searchdirection. Blocksclassified as inferred were estimatedby Ordinary Kriging usingat least two composites within 100 min the majorand semi-major searchdirections and40 min the minor searchdirection. Afourth categorywas flagged inthe model including blocksestimated beyond the limitsabove.

SRK validated theVotorantim model using the followingcriteria:

| · | SRK independent grade estimate comparedto the Votorantim gradeestimate; |

| · | Visualcomparative analysisbetween composite and blockgrades; and |

| · | Statistical comparisonof global averages of the original composite valuesand the model estimates. |

SRK concludes that the modelis adequate if not slightly conservative forthe deposit and is suitable for usein preliminary mineplanning.

TheMineral Resource estimate forthe Florida Canyonzinc-lead-silver deposit is presented in Table1-6.

Table1-6: MineralResource Statement for the FloridaCanyon Zn-Pb-AgDeposit, Amazonas Department, Peru,SRK Consulting (U.S.), Inc., July13, 2017

Zn EqContained

Category | Mass (kt) | ZnGrade | PbGrade | Ag Grade | ZnEqGrade | ZnContained | PbContained | AgContained | Zn Eq Contained |

| (%) | (%) | (g/t) | (%) | (kt) | (klb) | (kt) | (klb) | (kg) | (koz) | (kt) | (klb) |

| Measured | 1,285 | 13.13 | 1.66 | 19.42 | 14.68 | 169 | 372,200 | 21 | 46,900 | 25,000 | 800 | 189 | 415,900 |

| Indicated | 1,970 | 11.59 | 1.45 | 17.91 | 12.95 | 228 | 503,500 | 29 | 63,200 | 35,300 | 1,130 | 255 | 562,700 |

Measured + Indicated | 3,256 | 12.2 | 1.53 | 18.51 | 13.63 | 397 | 875,700 | 50 | 110,100 | 60,300 | 1,930 | 444 | 978,600 |

| Inferred | 8,843 | 10.15 | 1.05 | 13.21 | 11.16 | 898 | 1,978,900 | 93 | 204,900 | 116,900 | 3,760 | 986 | 2,174,80 0 |

Source: SRK, 2017

| · | Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability. Thereisno certainty that all or any part of the Mineral Resourcesestimatedwill be converted into Mineral Reserves. |

| · | Grades reportedinthis table are "contained" and donotincluderecovery. |

| · | Mineral resources are reportedto a2.8% recovered zinc-equivalent (RecZnEq%) cut-off grade. |

| o | Assuming the average recoveries for the resource, this correspondstonon-recovered cut-off grade of 3.6% contained ZnEq%. |

| · | RecZnEq%wascalculated by multiplying each block grade byitsestimated recovery, then applying miningcosts, processing costs, general and administrative (G&A) costs,smeltingcosts, and transportation costs todetermine an equivalent contributionofeachgradeitem tothe Net Smelter Return. |

| o | Mining costs, processing,G&A,smelting, and transportation costs total US$74.70/t. |

| o | Metal price assumptionswere:Zinc (US$/lb 1.20), Lead (US$/lb 1.0) and Silver (US$/oz 17.50), |

| o | Asthe recovery for each elementwasaccounted for inthe RecZnEq%, recoverieswerenot factored into the calculationofthe 2.8% cut-off grade. |

| o | Average metallurgical recoveries for the resource are: Zinc (79%),Lead(72%) and Silver (50%) |

| o | The equivalent grade contribution factors used for calculating RecZnEq%were:(1.0xrecovered Zn%) +(0.807 xrecovered Pb%) +(0.026 xrecovered Agppm). |

| · | The contained ZnEq% grade reported abovewascalculated by dividing the RecZnEq% grade by the calculated zinc recovery. |

| · | Densitywascalculated based on material types and metal grades. The average densityinthe mineralized zonewas |

3.01g/cm3.

| · | Mineral Resources,asreported,areundiluted. |

| · | Mineral Resource tonnage and containedmetalhave been rounded toreflect the precision of the estimate and numbers maynot add due torounding. |

| 1.7 | MineralReserveEstimate |

No MineralReserves were estimated as part of this PEA.

Both longhole open stopingwith backfill and cutand fill miningmethods have been selected forthe mineplanning work. The mining methodselectionwasbased on themineralization shape, orientation, and thedesire to put tailingmaterial underground. Geotechnical assessmentof the orebody shapeand ground conditions confirmedthe mining method selection. Thedesign parametershave beenlaid out usingempirical designmethods based on similar casehistories. Cut and fillopening sizesare 3 m x 3 mand stopes are 3 mwide x16 min height.

AnNSRapproach was usedto calculate thevalue of a block. Twoproducts willbeproduced, lead andzinc concentrates. Thelead concentrate will contain a payable amountsilver.Stopeoptimization within VulcanTMsoftware was usedto determine potentially economically minable material, basedon theNSR value and a cut-offof US$42.93 for cut and fillareas, and a cut-offof US$41.40 for longholeareas.The stope optimizeroutput shapeswerevisuallyinspected andisolated blocks(i.e., small blocks farfrom larger groups of blocks or where additional development is not practical or economicallyfeasible) were removedfromthe mining blockinventory. Theresource modelwas queried against the final stope optimization shapestodeterminetonnes and gradeof material inside the shapes and mining dilution and recovery factorswere applied.

A developmentlayoutwascreatedtoprovide accessto the mining levels andto tie levelsinto ramps. Accessto the undergroundworkings willbevia three mainportals (San Jorge, P01 and P03). Anadditional portal (P02)will be used primarily forventilation, and three additionaldrifts will daylighttofacilitate ventilation.

Thetonnes and gradeof the resource material containedwithin the mining blocks,adjustedby recoveryand dilution, and categorizedby theresource classification is provided in Table 1-7. The mine plan resourceconsists of atotal of 11.2Mt with an averagegrade of 8.34% Zn, 0.90% Pb, and

11.3 g/t Ag and is madeup of Measured, Indicated,andInferred material. Estimated averagedilution, processing recoveries and theZnOx/ZnT ratio is alsoprovided in Table 1-8.

Table1-7: MinePlan Resource for the FloridaCanyon Zn-Pb-Ag Deposit, Amazonas Department, Peru,SRK Consulting (U.S.), Inc., July21, 2017

Category | Mass | ZnGrade | PbGrade | AgGrade | NSR* | ZnEq ** | ZnContained | PbContained | AgContained | ZnEq** Contained |

| | (kt) | (%) | (%) | (g/t) | (US$/t) | (%) | (kt) | (kt) | (kg) | (kt) |

| Measured | 1,293 | 10.64 | 1.33 | 15.60 | 197.12 | 12.38 | 138 | 17 | 20,157 | 160 |

| Indicated | 2,011 | 8.77 | 1.08 | 13.44 | 166.85 | 10.22 | 176 | 22 | 27,026 | 206 |

| M&I | 3,303 | 9.51 | 1.18 | 14.28 | 178.69 | 11.05 | 314 | 39 | 47,182 | 365 |

| Inferred | 7,883 | 7.86 | 0.78 | 10.07 | 135.36 | 9.03 | 619 | 62 | 79,354 | 712 |

| TotalMineDesign | 11,187 | 8.34 | 0.90 | 11.31 | 148.16 | 9.66 | 933 | 101 | 126,536 | 1,081 |

Source: SRK, 2017

*NSRiscalucalted usingvariablerecoveries based on sulfide/oxide ratios (recovery ranging from 32%-93%), a Znprice of US$1.20/lb,a Pbprice of US$1.00/lb, an AgpriceofUS$17.50/oz.Thetransportation chargeis US$70.00/tconc, Zntreatment charge of US$115/t conc, Pbtreatment chargeofUS$100/t conc, Znrefining charge of US$0.115/lb Zn, and Pbrefining charge of US$0.1/lb Pb. These factors were used for mineplanning andvarysomewhat from the final economic model.

** ZnEq estimate isbased on aNSRvalueofUS$19.62 per 1% Zn.TheUS$19.62iscalculated usinga Znprice of US$1.20/lb, a PbpriceofUS$1.00/lb, an Agprice of US$17.50/oz. The ZnEq also includes TC/RC and transportation costs and assumes an average Znrecovery of 78.15% which differs somewhat from that presented inthe economic model. Anexample of the NSR toZnEq calculation is(148.16/19.62)/0.7815.

Table1-8: MinePlan Resource Average Process Recovery

| | Process Recovery | |

| Ag (%) | Pb(%) | Zn(%) | ZnOx/ZnT Ratio | Dilution |

| Mine Plan Resource | 51.7 | 74.3 | 79.8 | 0.26 | 34% |

Source: SRK, 2017

ThePEA is preliminary innature, thatit includesInferred Mineral Resourcesthat are considered toospeculative geologicallytohave the economicconsiderations applied to themthat would enablethem to be categorizedas MineralReserves, and there isno certainty thatthe PEA willbe realized.Mineral Resources thatare not MineralReserves do not havedemonstrated economicviability.

A production schedulewasgenerated using iGanttsoftware. Theschedule targeted a productionrate of 2,500 t/d (912,500 mineralizedtonnes per year).

Given the locationof the deposit, itis anticipatedthree undergroundportals willbe producing mineralized materialat anygiven time.Because of the challenging topography androad conditions,trucking Run-of-Mine (ROM)mineralized materialwould demand a lengthy route fromthe underground portals to the plant’s location. Instead, SRK has designed a setof conventional overland conveyorswith a maximumslope of 20°to simplify theoperation and significantly reduce the costof transferring mineralized material from the mineportals to the processplant. Aportable, primaryjawcrusher is to be installedat eachunderground mineportalto ensure the ROMis adequately sized forthe conveying system.

Florida Canyon mineralizedmaterial willbe processed using a conventional concentrationplant consisting of three stage crushing,grinding using asingle-stage ball millto80% minus44 microns,and differential flotation to produce two final products: azinc concentrate and alead concentrate containing payablesilver. Theconcentrate willbe truck transported to thepoint of sale. Tailingswillbeused as backfillor filtered and conveyedto adry stacktailings storagefacility.

The millwill process 2,500t/d of freshmineralized material, and produce approximately 287 tofzincconcentrate grading 50% Zn,1% Pb, and 0.6g/t Ag and approximately46 tof lead concentrate grading50% Pb, 8.4 g/t Ag, and6%Zn.

Thepower requirements for the projected milling operationis estimated atmaximum3.5 MW.Power formilling operations will be suppliedby a third-partyas line powerat an estimated costof US$0.084/kWh. Thewater requirement for the millat a capacityof 2,500 t/dis estimatedat maximum20 liters per second.Water forprocessing will be acquiredfrom surfacewatersources and as recycled water fromtailings dewatering operations. Reagents andgrinding balls,willbesuppliedby roadfrom Pedro Ruizand stored locally.

Thereare potential synergies forprocessing oxide mineralization at Florida Canyon using expertisethat Votorantim has gained at the Vazante and Morro Agudo mines in Brazil. These other existing operations have demonstrated success recovering hemimorphite, smithsonite, and hydrozincite, which may improve future recovery projections for Florida Canyon.

| 1.10 | Project Infrastructure |

Florida Canyonis agreenfield project with no substantiveexisting infrastructure. Thecommunities in the regionare smalland cannot support theoperation froman infrastructure standpoint so acampwill be required. Theinfrastructure requirements forthe Project will include an upgrade to the existing 26 kmaccess road and the construction of an additional24 kmofsupport roads for accessto mineportals, plant, andother infrastructure.

Sitefacilities will includethe processing plant, mine,crushers and conveyors forore/waste transportation, mine backfill systemsincluding a paste backfill plant and cementedrock fillplant, water supplypiping and tank, a dry stack TSF,400 person camp,septic system,potable water treatment system,site power distribution, health/safetyenvironmental office, mineoffice, minedry, rescue and firstaid building, securitygate house,truck scale, truck wash, laboratory, incinerator system,fuel storage andpumping system.

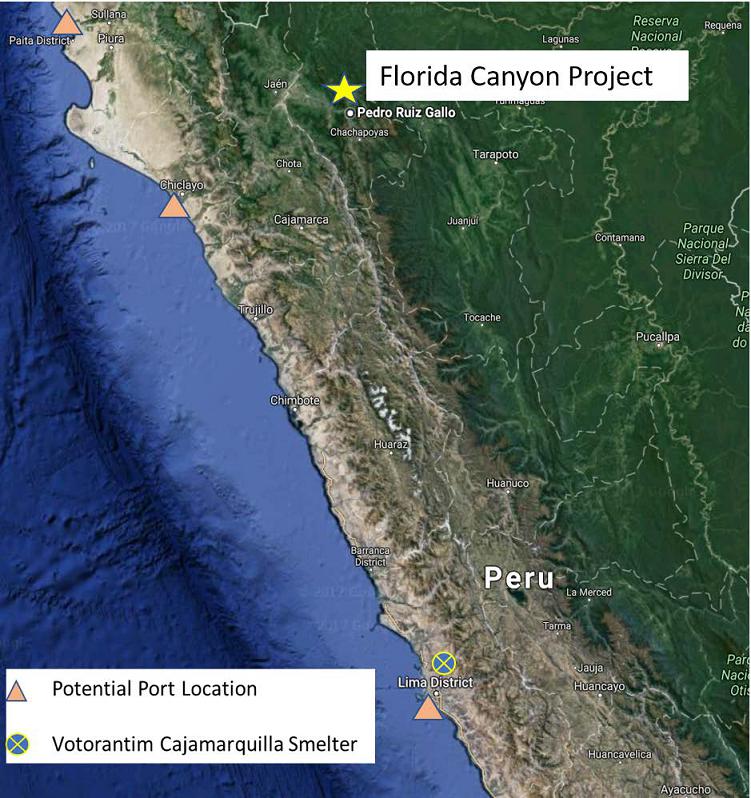

Makeup water forthe processing plant willbesuppliedfrom alocal creek througha piping systemto a storage tankthatwillalso provide fire systemwater.The majorityof thewater requirements willbeprovidedbyrainfalland recycle water from thedry stacktailingsstorage facility (TSF)returnedto theprocessing plantfacility. A third-party will supplylinepower through ahydroelectric power generator,transmissionline, andsubstation ownedbythethirdpartywithcostsrecovered throughan electricitysurcharge over thelifeoftheProject. Zinc concentrate willbe transported by30toverthe road truckstotheVotorantim CajamarquillasmelternearLima. Lead concentratewillbe truckedtothePort of Callao nearLima,and shippedto anoverseaslead smelter.

| 1.11 | EnvironmentalStudiesandPermitting |

Environmental permits for mineralexploration programsare divided into two classes.Class I permits allowconstruction and drilling forup to20 platformswith a maximumdisturbance of 10 ha. A ClassII permitprovides for morethan20 drilllocations or for adisturbance area of greater than 10 ha. Votorantimhas filed applicationsforand received Class II permits forvariousphasesof the Project and has filedand receivedthe requiredassociated permits.

Permitting requirements for mining includean Estudio de Impacto Ambiental (EIA)that describes in detail themining plan andevaluates the impactsof the planon environmental andsocial attributes of the property. Baseline studies includeair quality, surface andgroundwater quality, flora and faunasurveys,archeological surveys and a studyofthe social conditionsoftheimmediate propertyandanarea of interest thatincludes local communities.Public meetings are required inorder that local community members canlearn about and commenton the proposed operation. Manyof the baseline studies required formining have been completed byVotorantim.

| 1.12 | ConclusionsandRecommendations |

1.12.1 General

TheFlorida Canyon Zinc Projectis asignificant greenfields potentially underground mineablehigh- gradezincdeposit containing associated lead andsilver. The Project has a large landposition andstrong technical and financial backingthrough Solitario’searn-inJVpartner Votorantim. Whilethis document represents the first formal economicevaluation of the Project, Votorantim and Comincoreport having previously spentover US$60 millionon drilling,test work and strategic planning fordevelopment (Solitario, 2014). Currentprojections in thezinc metal marketsuggest a near-termreduction inzinc supplyas current majorproducers exhaust reserves.

SRK’s sitevisit to the projecton theground in northern Peru found itto be awell-organized facility,with current QA/QC protocols in place fordrilling dataverification andvalidation. Material handling, corestorage and securitywere allator above industrystandards.

SRK used a numberof methodsto validatethe Votorantim resource block model startingwith a face-to-facemeeting with themodeler and followingonwith athorough auditof the model sourcedata, geologic modeling techniques, gradeand tonnageestimation methodsand classificationprotocols. SRK foundthesetobe in linewith industrystandards, having beenproduced with recognized miningsoftware, defensible data andreasonable assumptions. SRKwas ableto independentlyvalidate the modelresults.

Asignificant component of theSRKinput tothis PEAwas thedevelopmentof the undergroundmineplan.Because Florida Canyonis a polymetalliczinc-lead-silver deposit, each model blockin the mine modelwas evaluatedonan NSR basis,which included an estimateof recovery. Recoverywasdeveloped fromarobust 2014 metallurgicalcampaign thatcharacterizedall expectedmaterialtypes. Arecoveredgradebyblock wasusedtobuildthe undergroundstoping plan,completewithaccess,ventilation and an assessment ofmine recoveryand dilution.

SRK is unaware ofanyenvironmental, permitting, legal,title,taxation or marketing factorsthat couldlimit or affectthe resource stated inthis document. The project will benefitfrom additional infill andexploration drilling, additional process-metallurgicaltest work,detailed engineering studies forinfrastructure andtailings managementand forwardplanning to clearlydefine concentratetransport and smelter costs.

1.12.2Mineral Resource Estimate

Thecurrent exploration model for theProject has beenapplied successfully in drillholeplanning andresource definition. There is low riskto the Project if no additional explorationis completed. However,additional drilling for resourcedefinition has astrong potentialto expand the knownresource extent and upgrade Inferred resourcesto Measured andIndicated. Themostprospective targets include:

| · | Extension drillingsouth of the SanJorge zone and northeastof the Karen-Milagroszones are considered thehighest priorityto increasehigh-grade zinc sulfide mineralization. Both zones are openin the recommended areasof drill testing; |

| · | Infill drillingseveral large un-drill testedareas surroundedbymineralized zones within the mineralized footprint hasthe potentialto significantly increaseresources; |

| · | Extension drillingperipheral to the currentlydefined mineralized footprint; and |

| · | Further developdrill targets over the 20 kmlong northernFlorida Canyonmineralized corridor where large areas of strongzinc in soil and rockchip geochemistry indicate thepotential foradditional mineralized zones. |

At present, thedeposit is open laterallytothe north andsouth as wellas tothe westand easton thedownthrown sidesof the horstthat definesthe limits of explorationtodate. Gapsin the drillpattern within thefootprint of the existingdrilling provide anotheropportunityto increaseresources where drillspacing limits the continuityof stratigraphically controlled mineralization. A constraintoneffective exploration anddelineation drilling in these areas is the accessto drillingstations due to the ruggedterrain. Thecompletion of a roadinto the area will helptoexpedite future drilling anddevelopment programsby providingincreased accessand lowering costs.

The discoveryof the high-angle, high-gradeSan Jorge zone has prompted more emphasison angleddrilling, wheremostof the historic drilling is vertical to near-vertical andis thereforeineffective at locating and definingnear-vertical structures. These“break-through” structures have been mappedon surfacein several locations,but due to logisticalconstraints, have not been adequatelydrill tested fortheir down-dipcontinuity. Similarly, thereappear tobeadditional drill targets at theintersection of the high-angle structures and the flat mantozones, where grades are locally enhanced. Theseconcentrations maybe presentwithin the existing drillingfootprint, but requireadditional drilling to delineate. The highgrade and potential tonnageof suchtargets provideanincentiveto locate andfurther define resourcesof this geometry.

1.12.3Mineral Processing and Metallurgical Testing

Processing of sulfidemineralization (zinc-lead-silver)from the Florida Canyondeposit is straightforwardusing conventionalflotation to a concentrate followedbyoffsitesmelting. Producing a commercial qualityzinc concentrate from mixedmaterial needed to incorporate Dense MediaSeparation methods (DMS)in order to maintainhigh recoveries (80+%). A conventionalflotation approach reached commercial quality(about 50% Zn) at theexpense of lower metal recovery,witha similar outcome forthe lead concentrate. It is SRK’s opinion thatconventional flotation shouldbe ableto achieveenhancedcommercial level results(gradeandrecovery) under improved crushing, grinding,andflotation conditions.

Available information aboutsilver is verylimited. The laboratory developed a relationshipbetween lead's head grade and silvergrade inthe finallead concentrate. Thisrelationship followswhatis typically observed in this typeof deposit, thereforeas this stageof development itis assumedto be valid, but SRK recommends confirmingit in thenext testing phase of the project.

Tooptimize recoveryand grade when attempting to reach separationof thezincand lead minerals into theirrespective commercial quality concentrates, SRK recommendsapproaching the selectionof samples forthe next phaseof metallurgical sampling and testing:

| · | The corelogging needs to incorporate attributes like claypercent,claytype, RQD, oxidecontent, sulfidecontent; |

| · | Assaying of the core should includewhole rockanalysis; and |

| · | Collect samples for metallurgicaltesting representing distinctive zones in the deposit. Grade variability shouldbe secondary criteriawhen selecting samples,but theymustbe reasonably closeto what a potential miningoperation would be able to deliver to the mill. |

1.12.4Mineral Reserve Estimate

Therewere no MineralReserves estimated forthis PEA.

1.12.5Mining Methods

Depending uponthe geometryof the mineralizedzones, SRK selectedlonghole stopingto be used in steeplydipping zones and mechanized drift-and-fill extraction methods in shallowly dipping mantos.Conventional room and pillar miningon a checkerboardpattern couldbe appliedto specificzones of the Florida Canyonproject, particularly in lowergrade areas,and shouldbe consideredin future trade- offstudiesatthe prefeasibilitylevel. Cemented paste backfill will be placed underground to increase mining recovery andto stabilize mined-out areas. Adits will provide accessfrom the surfaceto the mineralized zones currently defined in the mineplan.

Sub-level open stoping parameters forthisstudywere basedon empirical relations from casehistories. As the project advances,additional geotechnical stabilitymodeling using numericalmethods is recommended. Karst topographyis prevalentin the district and karstcaverns were encountered duringthe excavation of the SanJorge Adit. Additional geotechnical and hydrogeological evaluationof this condition is required to ensure safeoperating conditionsin the undergroundmining. A crownpillar of 30 mhas beenused forplanning. This assumption shouldbe reevaluatedin future work. Overall, acost-benefit analysisof ground support, dilution, minerecovery, andventilation shouldbe undertaken at thenext levelof study.

Operating costs,which ultimately define NSR value anddrive stopedesigns, were developed from benchmarks,analogous projects in the region,and commercial cost sources. SRK recommends arevision of these costsfrom firstprinciples as the projectadvances.

SRK notes that thereare likelyopportunities to improve the production schedule.Opportunities includeimproved sequencingof high grade material and,potentially, adecreasein thepre-production timeframe. A more detaileddesign and schedulewith corresponding trade-offstudies, as wellas moredetailed construction timeframeestimates, wouldbe required forthe next phaseof study.

1.12.6Recovery Methods

TheFlorida Canyonpolymetallic zinc-lead-silver deposit canbe processed using a conventionalconcentration plant consistingof three-stage crushing, grinding using ball mill, anddifferential flotation to produce twofinal products: azincconcentrate and a leadconcentrate. Detailedsizingand costingof the processing plant componentswillfollowadditional metallurgicaltesting proposed inthis study. Power supply andwater supplyappear to be fairlywell defined forthe project, though additionalstudies maybe neededto refine theseservices and the costsof these servicesto theproject.

1.12.7Project Infrastructure

TheFlorida Canyondeposit is located in steepterrain in a remote partof northern Peru withmoderate to high rainfall. Thesegeographic and climaticconditions pose challengesto both accessand infrastructure development.

As presentlyunderstood, thekey support servicesof power supplyand water supplyare availableandpart of a district-wideinfrastructure improvement campaign beingimplementedbythe Peruviangovernment and related third-partyproviders. Themostsignificantadvancementin the infrastructure investigation forthe PEAwas identifying the probabilityof hydroelectric power distributionto thesite, as alower costalternative to on-sitepower generation.Water supply for operations appearsto be straight forward, with abundant surfacewater available formineral processing andcampsupport.

Theinfrastructure componentwith the largestfootprint and projected costis thetailings storage facility.As part of this study, SRKhas evaluated this as adrystack facilityin order to achievegeotechnical stability and reducethe area requiringreclamation. Trade-off studies are warranted to optimize moisturecontent, bindingcharacteristics, and placementand compactionmethods during tailings placement.

1.12.8Environmental Studies and Permitting

Additional environmental baseline studiesare required forfurther project development.

Impactto groundwater is expectedtobe minimalas underground surfaceexposures are minorand future exposed sulfidesare not acid generating. Thereare no groundwater wells required forprocessing or potablewater supply. Therewill be littleorno surfacearea disturbance related to waste rock placement.

Tailings are predictedto have lowamounts of iron sulfide andto be geochemicallystable withrespect to acid rockdrainage. Thereis also substantialneutralization capacity inthe carbonatehostrocksto mitigate acid generation. Residuallead andzinc sulfideshave low acid-generating capacity; however, theyare subjectto metal leaching and therefore requirecompaction during placement.

SRK recommendsin future studies to design the tailings surfaceand spillway stormwaterstructure and evaluate options to reduceor eliminate the long-term obligation formonitoring and maintenance.

1.12.8Recommendations– WorkPrograms and Costs

SRK acknowledges,after examination of the Project data set, thatthere havebeen a significant numberof technical studies completedby Votorantim,manyof whichare beyondPEA. Therefore,the work elements listed in Table 1-9represent mostly prefeasibility and feasibility levelengineering and drillingto support those studies.

At the juncturewhere prefeasibility levelengineering hasbeen completed, the Project will likelywarrant further public reporting to an internationalstandard (JORC,or NI43-101). Technicalinformation required to achievethislevelof project developmentare listed in Table 1-9. A cost estimate forthese work elements is included inthe table.

Table1-9: Summary of Costs forRecommended Work

| Work Program | Estimated | Assumptions/Comments |

| Engineering Studies | Cost US$ | |

| Metallugical variability and recovery optimization test work | 500,000 | Commercial Laboratory |

| Prefeasibility Study(PFS)and Trade-off Studies | 600,000 | Votorantimorconsultant engineer |

| SubtotalStudies | $1,100,000 | |

| Drilling | | Salaried newhire orcontractPM |

| Exploration Drilling | 2,100,000 | 20holesto350 m atUS$300/m |

| Resource Conversion Drilling | 2,100,000 | 20holesto350 m atUS$300/m |

| Metallurgical Drilling for Flotation and Comminution | 1,225,000 | 10PQ holesto350 m atUS$350/m |

| Geotechical DrillingforMining | 500,000 | 10holes oriented to 100 m atUS$500/m |

| Geotechnical Drilling for Foundation Stability | 225,000 | 50holesto30 m atUS$150/m |

| Hydrogeological Drilling | 600,000 | 4holesto300 m atUS$500/m |

| Subtotal Drilling | $6,750,000 | |

| Studies+Drilling | 7,600,000 | |

| Contingencyat15% | 1,435,000 | |

| Total | $9,285,000 | |

Source: SRK, 2017

| 2.1 | Terms of Reference and Purpose of the Report |

Thisreport was preparedas aNational Instrument43-101 (NI 43-101) TechnicalReport, Preliminary Economic Assessment(Technical Reportor PEA)by SRKConsulting (U.S.),Inc. (SRK),with Votorantim Metais Holding S.A. (Votorantim) withSolitario ZincCorp. (Solitario), (collectively, owners)on theFlorida Canyon ZincProject located in Amazonas Department,Peru (Florida Canyonor Project). TheProject namewas changed in 2017from Bongará,asit was called previously, to FloridaCanyon. Someof the figures in this report stillreference Bongará. Thereader is advisedtouse Bongará interchangeably with Florida Canyonwhen reviewing thosefigures.

This studyrepresents the advancementof the Project from a2014 Technical Reporton Resources,tothis 2017 PEA.Highlights of this PEA include athirteen-year life-of-mineunderground mineplan, comminution andflotationofzinc and lead concentrateswith at aproduction rateof2,500 t/d followedbydry-stack tailings storage. Siteinfrastructure includes line powerto the site,water distribution systems, atownsite and accessroads forconstruction and re-supplyas well as forzinc concentrate transportto apoint of saleat theCajamarquilla smelter.

The qualityof information,conclusions, andestimates containedherein is consistent with the levelof effortinvolved in SRK’sservices, basedon: i) information availableat thetimeof preparation, ii) datasuppliedby outside sources,and iii) the assumptions, conditions, and qualifications set forthin this report. Thisreport is intended for use by the owners subjectto the termsand conditions of its contract with SRK andrelevant securities legislation. The contract permitsthe owners to file thisreport as aTechnical Report with Canadian securities regulatoryauthorities pursuant toNI43-101, Standards of Disclosure for Mineral Projects.Except forthe purposeslegislated under provincial securities law,anyother uses of this reportby anythird partyis at thatparty’s solerisk. The responsibility forthis disclosure remainswith the issuing companies. The userof this document should ensurethat thisis themostrecent TechnicalReport for the propertyas it is not validif a new Technical Report hasbeen issued.

ThePEA is preliminary innature, thatit includesInferred Mineral Resourcesthat are considered toospeculative geologicallytohave the economicconsiderations applied to themthat would enablethem to be categorizedas MineralReserves, and there isno certainty thatthe PEA willbe realized.Mineral Resources thatare not MineralReserves do not havedemonstrated economicviability.

Thisreport provides Mineral Resources, and a classificationof resources prepared in accordance with the CanadianInstitute of Mining, Metallurgy andPetroleum Standards on Mineral Resourcesand Reserves: Definitions andGuidelines, May 10, 2014 (CIM, 2014).

| 2.2 | Qualifications of Consultants(SRK) |

TheConsultants preparing this technical reportare specialists in the fieldsof geology, exploration, Mineral Resource andMineral Reserve estimation andclassification, underground mining, geotechnical, environmental, permitting, metallurgical testing, mineralprocessing, processing design, capital andoperating cost estimation, and mineral economics.

Thefollowing individuals,by virtueof their education, experience and professionalassociation, are considered QualifiedPersons(QP)as definedintheNI 43-101standard, forthis report,andare members in good standing of appropriate professional institutions.QPcertificates of authors are provided in Appendix A.TheQP’s are responsible for specific sections as follows:

| · | WalterHunt, CPG,an employeeof Solitario, is the QPresponsible forSections 2, 4and partsof 20; |

| · | J.B. Pennington, CPG is the QP responsible for Sections5-10, 12, 14, 23,24 andpart of 1, 20, 25, and26; |

| · | Joanna Poeck,PE, MMSA isthe QPresponsible forSections 15-16and partof 1, 25 and 26; |

| · | Jeff Osborn BEngMining, MMSA is theQPresponsible forSection 18-19, 21-22and partof 1, 25 and 26; |

| · | Daniel Sepulveda, RM-SMEis theQP responsibleforSections 13, 17, the capital andoperating cost forprocessing in Section 21, andpartof1, 25 and 26; and |

| · | JamesGilbertson, CGeol isthe QPresponsible forSection 11, thesite visit, inspection of geological sampling and datacollection practices, and reviewof resource estimationpractices. |

| · | John Tinucci,PhD, PEisthe QP responsible for Section16.2. |

��

JamesGilbertson, C. Geol.,of SRKExploration Services(U.K.), visited the Florida CanyonProject site and core storage facility in Shipasbamba, Peruon May 5to7, 2014. Thistrip included a follow-upvisit to Votorantim’s Lima,PeruofficeonMay9, 2014.Mr.Gilbertsonis a Chartered Geologist in the Geological Societyof London, and a Qualified Personin the disciplineof resource geology, accordingto NI43-101 requirements.

Thesources of information include dataand reports suppliedbySolitario personnel andrepresentatives of Votorantim, as well as documentscited throughout thereport andreferencedinSection 27.

Theeffective date of this reportisJuly13, 2017.

The metricsystem has beenused throughout this report.Tonnes are metricof 1,000 kg,or 2,204.6 lb. All currencyis in U.S. dollars(US$) unlessotherwise stated.

TheConsultants used theirexperience to determineif the information from previous reports was suitable forinclusion in thistechnical report and adjustedinformation that required amending. Thisreport includestechnical information,which requiredsubsequent calculations to derivesubtotals, totals and weighted averages. Suchcalculations inherentlyinvolve adegree of rounding and consequentlyintroduce a marginof error. Wherethese occur, theConsultants do not consider themto be material.

Items suchas mineraltitles and agreementshave not been independently reviewedby SRK and SRKdid not seekan independent legal opinionof theseitems.

| 4 | Property Description and Location |

TheFlorida Canyon ZincProject (the Project, formerly calledBongará) is located in theEastern Cordillera of Peru at the sub-Andean frontin theupper AmazonRiver Basin. It is within the boundaryof the Shipasbamba community, 680 kmnorth-northeast of Limaand and 245 kmnortheast of Chiclayo,Peru, in the Districtof Shipasbamba, Bongará Province,Amazonas Department(Figure 4-1). TheProject area canbe reached from the coastal cityof Chiclayoby thepaved Carretera Marginalroad. Thecentral point coordinates of the Project areapproximately 825,248East and,9,352,626 North(UTM Zone 17S, Datum WGS84). Elevationranges from1,800maslto approximately 3,200 masl. The climateis classified as highaltitude tropical junglein theupper regionsofthe Amazon basin. Theannual rainfall averageexceeds 1 mwith upto 2 min the cloud forestat higher elevations.

Source: Votorantim, 2013b

Figure 4-1: Project LocationMap

Florida Canyonis a mineralexploration projectcomprised of sixteen contiguous miningconcessions covering approximately12,600 ha (Table4-1). Theconcession titles are inthe nameof Minera Bongará andare subjectto the Minera Bongará jointventure agreementbetween Solitario andVotorantim. Allof these concessionsare currentlytitled.

TheMinera Bongará concessionsare completely envelopedby asecond groupof thirty-seven contiguous mining concessions, covering approximately 30,700ha (Table4-2). The concession titlesare in the nameof Minera Chambara. Ofthe thirty-seven concessions, twelvetitles are pending. Claim areas are shownin Figure4-2.

According to Peruvian law,concessionsmaybe heldindefinitely, subject onlyto paymentof annual feesto the government. Atthetimeof this study, concessionpayments were current forMinera Bongará claims, with 2017 feesof US$122,600 (Table4-1). The fees forMinera Chambaratotal US$140,530 and these feesdo not include the additional nine Charlita claimsfiled in January,2017, which are still pending (Table4-2). Minera Chambara, aPeruvian companyalso subjectof aseparate joint venture agreementbetween Votorantimand Solitario,holds mineral concessionssurrounding theMinera Bongará claimsbut which do not containanyof the resources subjectof thiseconomic analysis.

Votorantim, who has servedas operator of the joint venture company MineraBongará, entered into a surfacerights agreementwith the local communityof Shipasbambawhich controls the surfacerights of the Project. This agreementprovides for annual paymentsand funding for mutuallyagreed upon socialdevelopment programsin return for theright to performexploration work including road building anddrilling.

Table4-1: List of MineraBongará Mineral Claims

| Concession Name | Number | Status | Hectares | Claim Date | 2017 Holding Fees (US$) | District |

| BONGARA CINCUENTICINCO | 10233396 | Titled | 1,000 | 8/7/1996 | 23,000.00 | FLORIDA/SHIPASBAMBA |

| BONGARA CINCUENTICUATRO | 10233296 | Titled | 600 | 8/7/1996 | 13,800.00 | FLORIDA/SHIPASBAMBA |

| BONGARA VEINTISIETE | 10783595 | Titled | 300 | 6/26/1995 | 6,900.00 | SHIPASBAMBA |

| DEL PIERO UNO | 10338505 | Titled | 1,000 | 11/2/2005 | 9,000.00 | FLORIDA/SHIPASBAMBA |

| DEL PIER DOS | 10338405 | Titled | 600 | 11/2/2005 | 5,400.00 | FLORIDA/SHIPASBAMBA |

| DEL PIERO TRES | 10338605 | Titled | 700 | 11/2/2005 | 6,300.00 | FLORIDA/SHIPASBAMBA |

| DEL PIERO CUATRO | 10000206 | Titled | 500 | 1/3/2006 | 4,500.00 | FLORIDA/SHIPASBAMBA |

| DEL PIERO CINCO | 10000306 | Titled | 1,000 | 1/3/2006 | 9,000.00 | SHIPASBAMBA |

| DEL PIERO SEIS | 10204507 | Titled | 1,000 | 3/23/2007 | 9,000.00 | CAJARURO/FLORIDA |

| VM42 | 10190507 | Titled | 1,000 | 3/21/2007 | 9,000.00 | CAJARURO/FLORIDA/ SHIPASBAMBA |

| VM74 | 10193707 | Titled | 1,000 | 3/21/2007 | 9,000.00 | SHIPASBAMBA |

| VM75 | 10193807 | Titled | 1,000 | 3/21/2007 | 9,000.00 | SHIPASBAMBA |

| VM94 | 10045708 | Titled | 900 | 1/28/2008 | 2,700.00 | FLORIDA/SHIPASBAMBA |

| VM95 | 10045808 | Titled | 500 | 1/28/2008 | 1,500.00 | FLORIDA |

| VM97 | 10046008 | Titled | 1,000 | 1/28/2008 | 3,000.00 | FLORIDA/SHIPASBAMBA |

| VM98 | 10046108 | Titled | 500 | 1/28/2008 | 1,500.00 | FLORIDA/SHIPASBAMBA |

| Total | | | | | $122,600.00 | |

Source: Solitario, 2017

Table4-2: List of MineraChambara Mineral Claims

| Concession Name | Number | Status | Hectares | Claim Date | 2017 Holding Fees (US$) | District |

| ANGIE KAROLL TRES | 10387906 | Titled | 900 | 1/3/2006 | 8,100.00 | CAJARURO |

| ANGIE KAROLL CUATRO | 10388106 | Titled | 300 | 1/3/2006 | 2,700.00 | CAJARURO |

| BONGARA VEINTIDOSM | 10053315 | Titled | 1000 | 1/5/2015 | 3,000.00 | CAJARURO/ YAMBRASBAMBA |

| BONGARA VEINTITRESM | 10053215 | Titled | 671.9322 | 1/5/2015 | 2,015.80 | YAMBRASBAMBA |

| CAROLINA1 M | 10106114 | TitlePending | 500 | 1/2/2014 | 1,500.00 | YAMBRASBAMBA |

| CAROLINA2 M | 10106014 | Titled | 500 | 1/2/2014 | 1,500.00 | FLORIDA/ YAMBRASBAMBA |

| CHARITO 2007 | 10199807 | Titled | 1000 | 3/23/2007 | 9,000.00 | CAJARURO/ SHIPASBAMBA |

| DEL PIERO SIETE | 10205907 | Titled | 1000 | 3/23/2007 | 9,000.00 | CAJARURO/ YAMBRASBAMBA |

| DEL PIERO OCHO | 10205807 | Titled | 1000 | 3/23/2007 | 9,000.00 | CAJARURO/ YAMBRASBAMBA |

| MINA4 M | 10052215 | Titled | 300 | 1/5/2015 | 900.00 | CAJARURO |

| SANJOSECITO M | 10052015 | TitlePending | 1000 | 1/5/2015 | 3,000.00 | CAJARURO/ YAMBRASBAMBA |

| TIAVIOLETAM | 10113114 | TitlePending | 1000 | 1/2/2014 | 3,000.00 | YAMBRASBAMBA |

| VIOLETA1 M | 10113214 | Titled | 1000 | 1/2/2014 | 3,000.00 | FLORIDA/ YAMBRASBAMBA |

| VM29 | 10189207 | Titled | 1000 | 3/21/2007 | 9,000.00 | CAJARURO |

| VM30 | 10189307 | Titled | 1000 | 3/21/2007 | 9,000.00 | CAJARURO |

| VM33 | 10189707 | Titled | 1000 | 3/21/2007 | 9,000.00 | CAJARURO |

| VM34 | 10189607 | Titled | 1000 | 3/21/2007 | 9,000.00 | CAJARURO |

| VM36 | 10190107 | Titled | 1000 | 3/21/2007 | 9,000.00 | CAJARURO |

| VM37 | 10189907 | Titled | 1000 | 3/21/2007 | 9,000.00 | CAJARURO |

| VM39 | 10190207 | Titled | 1000 | 3/21/2007 | 9,000.00 | CAJARURO/JAMALCA |

| VM40 | 10190407 | Titled | 1000 | 3/21/2007 | 9,000.00 | CAJARURO/JAMALCA/ SHIPASBAMBA |

| VM96 | 10045908 | Titled | 271.4725 | 1/28/2008 | 814.42 | FLORIDA |

| VM99 | 10046208 | Titled | 244.745 | 1/28/2008 | 734.24 | FLORIDA/ SHIPASBAMBA |

| VM100 | 10046308 | Titled | 1000 | 1/28/2008 | 3,000.00 | JAZAN/ SHIPASBAMBA |

| VM101 | 10046408 | Titled | 1000 | 1/28/2008 | 3,000.00 | JAZAN/SANJERONIMO/ SHIPASBAMBA |

| VM102 | 10046508 | Titled | 600 | 1/28/2008 | 1,800.00 | SANJERONIMO/ SHIPASBAMBA |

| VM133 | 10134708 | Titled | 600 | 2/6/2008 | 1,800.00 | JAZAN/ SHIPASBAMBA |

| VM311 | 10099610 | Titled | 555.282 | 2/1/2010 | 1,665.85 | FLORIDA/ YAMBRASBAMBA |

| | | | | | | |

| CHARLITA 5BM | 10049017 | TitlePending | 600 | 1/2/2017 | 0.00 | FLORIDA/ YAMBRASBAMBA |

| CHARLITA 5AM | 10049117 | TitlePending | 800 | 1/2/2017 | 0.00 | FLORIDA/ YAMBRASBAMBA |

| CHARLITA4 M | 10049217 | TitlePending | 1000 | 1/2/2017 | 0.00 | FLORIDA/ YAMBRASBAMBA |

| CHARLITA3 M | 10049317 | TitlePending | 1000 | 1/2/2017 | 0.00 | CAJARURO/FLORIDA/ YAMBRASBAMBA |

| CHARLITA2 M | 10049417 | TitlePending | 1000 | 1/2/2017 | 0.00 | CAJARURO/FLORIDA/ YAMBRASBAMBA |

| Concession Name | Number | Status | Hectares | Claim Date | 2017 Holding Fees (US$) | District |

| CHARLITA 1BM | 10049517 | TitlePending | 900 | 1/2/2017 | 0.00 | CAJARURO/ YAMBRASBAMBA |

| CHARLITA 1AM | 10049617 | TitlePending | 1000 | 1/2/2017 | 0.00 | CAJARURO/ YAMBRASBAMBA |

| BONGARA 60AM | 10049717 | TitlePending | 1000 | 1/2/2017 | 0.00 | YAMBRASBAMBA |

| BONGARA 57M | 10049817 | TitlePending | 1000 | 1/2/2017 | 0.00 | YAMBRASBAMBA |

| Total | | | | | $140,530.30 | |

Source: Solitario, 2017

Source: Solitario2017

Source: Solitario2017

Figure 4-2:Map of MineralClaims

4.2.1Nature and Extent of Issuer’s Interest

Bongará

TheProject is controlledbyMinera BongaráS.A., and is subjectto ajoint ventureagreement between VotorantimandSolitariosince2006. Votorantimistheoperatorofthe Project andisresponsible for keepingthe propertyin good standing.Current ownershipis39%Solitario, 61% Votorantim. Votorantimwill earn a70% interest in Minera Bongaráby continuingto fund all projectexpenditures through a feasibility studywith no paybackby Solitario. Votorantimis requiredtooffer a loan facilityat marketrates forrepayment of Solitario’s portion of construction capital.Solitario repaysthe loanthrough 50%of its project cash flow.

On August15,2006,an Agreement LetterwassignedbetweenSolitario, Minera Bongará andVotorantim Metais. TheLetter defined the commitmentofVotorantimto fund US$1.0 millionin an annual mineralexploration program,which began inlate October 2006.