ANNUAL INFORMATION FORM

FOR THE FISCAL YEAR ENDED DECEMBER 31, 2013

Dated: March 24, 2014

| | ANNUAL INFORMATION FORM - 2013 |

TABLE OF CONTENTS

| | 2 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

PRELIMINARY NOTES

Incorporation of Financial Statements and MD&A

The following documents are incorporated by reference and form part of this annual information form (the “Annual Information Form” or “AIF”) which is prepared in accordance with Form 51-102F2 – Annual Information Form (“Form 51-102F2”). These documents may be accessed using the System for Electronic Document Analysis and Retrieval (“SEDAR”) at www.sedar.com and the Electronic Data Gathering Analysis and Retrieval (“EDGAR”) at http://www.sec.gov/edgar.shtml:

| | Consolidated financial statements for the year ended December 31, 2013, together with the auditors’ report thereon dated March 24, 2014; and Management’s Discussion and Analysis (“MD&A”) for the year ended December 31, 2013 and 2012. |

Currency and Exchange Rates

All dollar amounts in this AIF are expressed in USD, unless otherwise indicated (“USD” denotes United States dollars and “CAD” denotes Canadian dollars). The following table sets forth the value of the CAD expressed in USDs on December 31 of each year and the average, high and low exchange rates during the year indicated based on the noon rate of exchange as reported by the Bank of Canada:

| CADs into USDs | 2013 | 2012 | 2011 |

| Closing | 0.94 | 1.01 | 0.98 |

| Average | 0.97 | 1.00 | 1.01 |

| High | 1.02 | 1.03 | 1.06 |

| Low | 0.93 | 0.96 | 0.94 |

The noon rate of exchange on March 24, 2014, as reported by the Bank of Canada for the conversion of CADs into USDs was CAD$1.00 equals US$0.8915.

For ease of reference, the following factors for converting metric measurements to imperial equivalents are provided:

| To Convert from Metric | To Imperial | Multiply by |

| Hectares | Acres | 2.471 |

| Metres | Feet | 3.281 |

| Kilometres | Miles | 0.621 |

| Tonnes | Tons (2,000 pounds) | 1.102 |

| Grams/tonne | Ounces (troy/ton) | 0.029 |

Forward-Looking Statements

This AIF contains forward-looking statements within the meaning of the United States Private Securities Litigation Reform Act of 1995 and applicable Canadian securities legislation concerning anticipated developments in the Company’s continuing and future operations in Eritrea and in the putative class action lawsuit, the adequacy of the Company’s financial resources and financial projections. Forward-looking statements include, but are not limited to, statements concerning or the assumptions related to estimates of capital and operating costs, the timing, nature and extent of future copper and gold production, expanding exploration licenses, the estimation of mineral reserves and resources,

| | 3 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

methodologies and models used to prepare resource and reserve estimates, the realization of mineral reserve estimates, the conversion of mineral properties to reserves and resources, the potential to expand resources, reserves and mine life, future exploration budgets, plans, targets and work programs, capital expenditures and objectives, anticipated timing of grant of permits, mining and development plans and activities, construction and production targets and timetables, grades, processing rates, life of mine, net cash flows, metal prices, exchange rates, reclamation costs, results of drill programs, dividend plans and policy, litigation matters, integration or expansion of operations, requirements for additional capital, government regulation of mining operations, environmental risks, political risks and uncertainties, unanticipated reclamation expenses, and other events or conditions that may occur in the future. Forward-looking statements are frequently, but not always, identified by words such as “expects,” “anticipates,” “believes,” “intends,” “estimates,” “potential,” “possible,” “budget” and similar expressions, or statements that events, conditions or results “will,” “may,” “could” or “should” occur or be achieved. Information concerning the interpretation of drill results and mineral resource and reserve estimates also may be deemed to be forward-looking statements, as such information constitutes a prediction of what mineralization might be found to be present if and when a project is actually developed, and in the case of mineral reserves, such statements reflect the conclusion based on certain assumptions that the mineral deposit can be economically exploited.

Forward-looking statements are statements about the future and are inherently uncertain, and actual achievements of the Company or other future events or conditions may differ materially from those reflected in the forward-looking statements due to a variety of risks, uncertainties and other factors, including, without limitation, the risks more fully described under the Section titled “Risk Factors”.

Although the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking statements, there may be other factors that cause results not to be as anticipated, estimated or intended. The Company’s forward-looking statements are based on the beliefs, expectations and opinions of management on the date the statements are made and the Company assumes no obligation to update such forward-looking statements in the future, except as required by law. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. For the reasons set forth above, investors should not place undue reliance on forward-looking statements.

Information Concerning Preparation of Reserve and Resource Estimates

The disclosure in this AIF uses mineral resource and mineral reserve classification terms that comply with reporting standards in Canada, and, unless otherwise indicated, all mineral resource and mineral reserve estimates included in this AIF have been prepared in accordance with Canadian National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and the Canadian Institute of Mining, Metallurgy and Petroleum’s Classification System. The SEC’s disclosure standards normally do not permit the inclusion of information concerning “measured mineral resources”, “indicated mineral resources” or “inferred mineral resources” in documents filed with the SEC, unless such information is required to be disclosed by the law of the Company’s jurisdiction of incorporation or of a jurisdiction in which its securities are traded.

The NI 43-101 is a rule developed by the Canadian Securities Administrators that establishes standards for all public disclosure an issuer makes of scientific and technical information concerning mineral projects. These standards differ significantly from the disclosure requirements of the SEC set forth in Industry Guide 7. Consequently, mineral resource and mineral reserve information contained in this AIF is not comparable to similar information that would generally be disclosed by US companies in accordance with the rules of the SEC.

In particular, the SEC’s Industry Guide 7 applies different standards in order to classify mineralization as a reserve. As a result, the definitions of proven and probable reserves used in NI 43-101 differ from the definitions in Industry Guide 7. Under SEC standards, mineralization may not be classified as a “reserve” unless the determination has been made that the mineralization could be economically and legally produced or extracted at the time the reserve determination is made. Accordingly, mineral reserve estimates contained in this AIF may not qualify as “reserves” under SEC standards.

| | 4 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

In addition, this AIF uses the terms “measured mineral resources”, “indicated mineral resources” and “inferred mineral resources” to comply with the reporting standards in Canada. The SEC’s Industry Guide 7 does not recognize mineral resources and US companies are generally not permitted to disclose resources in documents they file with the SEC. Investors are cautioned not to assume that any part or all of the mineral deposits in these categories will ever be converted into SEC defined mineral “reserves.” Further, “inferred mineral resources” have a great amount of uncertainty as to their existence and as to whether they can be mined legally or economically.

Therefore, investors are also cautioned not to assume that all or any part of an inferred mineral resource exists. In accordance with reporting standards in Canada, estimates of “inferred mineral resources” cannot form the basis of feasibility or other economic studies, except in rare cases. In addition, disclosure of “contained ounces” in a mineral resource estimate is permitted disclosure under NI 43-101 provided that the grade or quality and the quantity of each category is stated; however, the SEC normally only permits issuers to report mineralization that does not constitute “reserves” by SEC standards as in place tonnage and grade without reference to unit measures. For the above reasons, information contained in this AIF containing descriptions of mineral resource and mineral reserve estimates is not comparable to similar information made public by US companies subject to the reporting and disclosure requirements of the SEC.

| | 5 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

Glossary and Defined Terms

Unless otherwise defined in this AIF or the context requires otherwise, certain mining terms and capitalized terms used in this AIF shall have the following meanings:

| 2003 Phase I Program: | The drilling program conducted between February and June, 2003. |

| 2012 Technical Report: | The NI 43-101 technical report on the Bisha Mine titled “Bisha Polymetallic Operation, Eritrea Africa” with an effective date of August 31, 2012, prepared by AGP . |

| 2013 Technical Report: | The NI 43-101 technical report on the Bisha Mine titled “Bisha Mine NI 43-101 Technical Report” with an effective date of December 31, 2013. |

| Ag: | Atomic symbol for silver. |

| AGP: | AGP Mining Consultants, Inc. |

| AIF: | This Annual Information Form. |

| alteration: | Refers to process of changing primary rock minerals (such as quartz, feldspar and hornblende) to secondary minerals (quartz, carbonate, and clay minerals) by hydrothermal fluids (hot water). |

| arsenic: | Means in geology, the general term for a grayish-white element having a metallic lustre, vaporizing when heated with atomic symbol As. |

| Assay: | An analysis of the contents of metals in mineralized rocks. |

| Au: | Atomic symbol for gold. |

| Bisha Feasibility Study: | The feasibility study dated November 15, 2006 on the Bisha Property prepared by AMEC Americas Limited titled “Bisha Property, Gash-Barka District, Eritrea”. |

| Bisha Mine: | Refers to both the Bisha Polymetallic Operation inclusive of Bisha Main Pit, Harena Pit, and to the Northwest deposit and the Hambok deposit. |

| Bisha Mining License: | The mining license issued to BMSC in 2008 and valid for 20 years covering an area of 16.5 square kilometres over the Bisha Main and NW Zone deposits. |

| Bisha Property or Bisha: | The Company’s principal property located in Eritrea in Northeast Africa. |

| BMSC: | Bisha Mining Share Company, an Eritrean entity that owns and operates the Bisha Mine and is a 60% owned indirect subsidiary of Nevsun with the 40% balance of the outstanding shares owned by ENAMCO. |

| Board: | Board of directors of Nevsun Resources Ltd. |

| chalcopyrite: | A very common mineral, copper iron sulphide, CuFeS2 , an ore of copper; copper pyrites. |

| CIL: | A carbon-in-leach process where soluble complexes of gold and silver attach (without a chemical reaction) to the surfaces of activated carbon particles. |

| CIM: | Canadian Institute of Mining, Metallurgy and Petroleum. |

| concentrate: | Powdery product of high grade ore which has the majority of the waste removed. |

| Cu: | Atomic symbol for copper. |

| | 6 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

| deposit: | Natural mineralization in the ground in sufficient quantities to warrant further studies. |

| Diamond drill holes (DDH): | Holes drilled by a method whereby rock is drilled with a diamond impregnated, hollow drilling bit which produces a continuous, in-situ record of the rock mass intersected in the form of solid cylinders of rock which are referred to as core. |

| disseminated: | A texture in which minerals occur as scattered particles in the rock. |

| doré: | A semi-pure alloy of gold and silver, usually created at the site of a mine; it is then transported to a refinery for further purification. |

| dyke: | An intrusive tabular body of igneous rock that cuts across the layering or fabric of the host rock. |

| EITI: | Extractive Industries Transparency Initiative. |

| ENAMCO: | Eritrean National Mining Corporation, an Eritrean entity owned by the State of Eritrea. |

| fault: | A fracture in a rock across which there has been displacement. |

| feasibility study: | A feasibility study is a comprehensive technical and economic study of the selected development option for a mineral project that includes appropriately detailed assessments of realistically assumed mining, processing, metallurgical, economic, marketing, legal, environmental, social and governmental considerations together with any other relevant operational factors and detailed financial analysis, that are necessary to demonstrate at the time of reporting that extraction is reasonably justified (economically mineable). The results of the study may reasonably serve as the basis for a final decision by a proponent or financial institution to proceed with, or finance, the development of the project. |

| flotation: | Milling process that uses bubbles to capture valuable mineral particles that float to the surface, thereby separating them from waste which sinks to the bottom. |

| geotechnical work: | Tasks that provide representative data of the geological rock quality in a known volume. |

| gossan: | An iron-bearing weathered product overlying a sulphide deposit. It is formed by the oxidation of sulphides and the leaching-out of the sulphur and most metals, leaving hydrated iron oxides and rarely sulphates. |

| grade: | The amount of valuable mineral in each tonne of ore, expressed as g/t for precious metal and as a percentage by weight for other metals such as copper and zinc. |

| gravity: | A methodology using instrumentation allowing the accurate measuring of the difference between densities of various geological units in-situ. |

| g/t: | Grams per metric tonne. |

| | 7 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

| Harena Mining License: | A conditional license issued to BMSC in 2012 for the Harena deposit and valid for 10 years, covering an area of 7.5 square kilometres located approximately 9 kilometres from the Bisha Mine. |

| HW Copper Zone: | The Bisha Hanging Wall Copper Zone. |

| hydrothermal: | Applied to metamorphic and magmatic emanations high in water content; the processes in which they are concerned; and the rocks or ore deposits, alteration products, and springs produced by them. |

| IFC: | International Finance Corporation. |

| IFC Performance Standards: | IFC Social and Environmental Performance Standards of April, 2006. |

| igneous: | A type of rock that is crystallized from a liquid magma. |

| indicated mineral resource: | That part of a mineral resource for which quantity, grade or quality, densities, shape and physical characteristics can be estimated with a level of confidence sufficient to allow the appropriate application of technical and economic parameters, to support mine planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes that are spaced closely enough for geological and grade continuity to be reasonably assumed. |

| inferred mineral resource: | That part of a mineral resource for which quantity and grade or quality can be estimated on the basis of geological evidence and limited sampling and reasonably assumed, but not verified, geological and grade continuity. The estimate is based on limited information and sampling gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes. |

| in-situ: | Natural material or processes prior to transport. |

| IRC: | Impact Review Committee. |

| ISO: | International Organization for Standardization |

| Lerchs-Grossmann (LG): | A method used to determine the optimal open pit limit within the ground including the mineralized material, founded in 3-dimensional graph theory and relying upon a regular system of blocks which defines the value (profit, loss) and type (ore, waste) of material contained in the blocks. Each block receives a positive or negative value representing the dollar value (profit/loss) that would be expected by excavating and extracting the mineral. The LG method uses the geologic mineral resource block model for its basis and requires wall slope constraints as determined by the geotechnical analysis. The positive and negative block values are derived from metal prices, recoveries, and operating costs. LG pit shells are used as design guidance for mineable pit designs, and to apply the ‘reasonable prospects for economic extraction’ test to mineral resources. |

| lithologic: | Pertaining to lithology. |

| lithology: | The study of rocks, with particular emphasis on their description and classification. |

| | 8 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

| masl: | Metres above sea level. |

| measured mineral resource: | That part of a mineral resource for which quantity, grade or quality, densities, shape, physical characteristics are so well established that they can be estimated with confidence sufficient to allow the appropriate application of technical and economic parameters, to support production planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration, sampling and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes that are spaced closely enough to confirm both geological and grade continuity. |

| mineralization: | An anomalous occurrence of metal or other commodity of value defined by any method of sampling (surface outcrops, drill core, underground channels). |

| mineralogic: | Pertaining to mineralogy. |

| mineralogy: | The study of chemistry, crystal structure, and physical (including optical) properties of minerals. Specific studies within mineralogy include the processes of mineral origin and formation, classification of minerals, their geographical distribution, as well as their utilization. |

| mineral reserve: | The economically mineable part of a measured mineral resource or indicated mineral resource demonstrated by at least a preliminary feasibility study. This study must include adequate information on mining, processing, metallurgical, economic and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified. A mineral reserve includes diluting materials and allowances for losses that may occur when the material is mined. |

| mineral resource: | A concentration or occurrence of diamonds, natural solid inorganic material, or natural solid fossilized organic material including base and precious metals, coal and industrial minerals in or on the earth’s crust in such form and quantity and of such a grade or quality that it has reasonable prospects for economic extraction. The location, quantity, grade, geological characteristics and continuity of a mineral resource are known, estimated or interpreted from specific geological evidence and knowledge. |

| Mining Agreement: | The mining agreement between BMSC and the Government of the State of Eritrea dated December, 2007 covering the future development and operations for the Bisha Property, including all substantive requirements of international financial institutions. |

| Morgoraib River Exploration License: | The exploration license acquired by the Company from Sanu Resources, a subsidiary of NGEx Resources, containing 73.1 square kilometres of area located 16 kilometres southwest of the Bisha Mine. |

| Nevsun or Company: | Nevsun Resources Ltd. and its wholly and partially owned subsidiaries unless the context requires otherwise. |

| NSR: | Net Smelter Return used in mineral resource and reserve calculations is the net value per tonne of ore, inclusive of all recoveries and costs outside the mine gate. It does not include operating costs inside the mine gate. |

| | 9 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

| NW Zone: | The northwest polymetallic massive sulphide deposit located two kilometres from the Bisha processing plant within the Bisha Mining License. |

| Ordinary Kriging (OK): | A statistical method employed when creating a geological block model of interpolation of geological metal assay data using the spatial correlation structure of the data in giving the best linear unbiased prediction of the intermediate interpolation point representing a metal assay value. |

| ore: | Rock, generally containing metallic or non-metallic materials, which can be mined and processed at a profit. |

| PAG: | Potentially acid generating. |

| probable mineral reserve: | The economically mineable part of an indicated mineral resource and, in some circumstances, a measured mineral resource demonstrated by at least a preliminary feasibility study. This study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified. |

| proven mineral reserve: | The economically mineable part of a measured mineral resource demonstrated by at least a preliminary feasibility study. This study must include adequate information on mining, processing, metallurgical, economic, and other relevant factors that demonstrate, at the time of reporting, that economic extraction is justified. |

| pyrite: | An iron sulphide mineral (FeS2), the most common naturally occurring sulphide mineral. |

| Qualified Person (QP): | A qualified person as defined in NI 43-101 as an individual who: |

| | a) | is an engineer or geoscientist with at least five years of experience in mineral exploration, mine development or operation or mineral project assessment, or any combination of these; |

| | b) | has experience relevant to the subject matter of the mineral project and the technical report; and |

| | c) | is a member in good standing of a professional association. |

| RC drilling: | Reverse circulation drilling. |

| reserve: | See “mineral reserve”. |

| resource: | See “mineral resource”. |

| Rights Plan: | Nevsun Resources Ltd.’s shareholder rights plan dated June 8, 2011. |

| Run of mine (ROM): | Material from a mine that has not been crushed or screened. |

| SAG: | Semi-Autogenous grinding. |

| SEC: | United States Securities and Exchange Commission. |

| SEIA: | Social and Environmental Impact Assessment. |

| SEMP: | Social and Environmental Management Plan. |

| sphalerite: | A very common mineral, zinc sulphide, usually containing some iron and a little cadmium, (Zn Fe)S: the principal ore of zinc. |

| | 10 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

| SRM: | Standard reference material. |

| strike: | The direction, or bearing from true north, of a vein or rock formation measured on a horizontal surface. |

| sulphide (sulfide): | A compound of sulphur (sulfur) and some other metallic element. |

| supergene: | A word suggesting an origin literally “from above”. It is used almost exclusively for processes involving water, with or without dissolved material, percolating down from the surface. Typical supergene processes are solution, hydration, oxidation, deposition from solution, reactions of ions in solution with ions in existing minerals (replacement or enrichment). |

| tailings: | Waste minerals extracted from ore through various mineral processes and deposited in an enclosed ground storage area. |

| terrane: | A fragment of crustal material formed on, or broken off from, one techtonic plate and accreted or sutured crust lying on another plate. |

| TMF: | Tailings management facility. |

| trenching: | The mechanical or human excavation of ground material to expose material below surface. |

| TSX: | The Toronto Stock Exchange. |

| UTM: | The Universal Transverse Mercator coordinate system. |

| vein: | Sheet-like body of minerals formed by fracture-filling or replacement of the host rock. |

| VMS: | Volcanic hosted massive sulphides. |

| WGS84: | The World Geodetic System, 1984. |

| Zn: | Atomic symbol for zinc. |

| | 11 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

CORPORATE STRUCTURE

Name and Incorporation

Nevsun Resources Ltd. was incorporated under the laws of the Province of British Columbia under the Companies Act (British Columbia) on July 19, 1965 under the name of “Hogan Mines Ltd.” Since inception, it has undergone four name changes until December 19, 1991 when it adopted the name of “Nevsun Resources Ltd.” It is governed by the Business Corporations Act (British Columbia) and its Articles.

The head office of Nevsun Resources Ltd. is located at 760 - 669 Howe Street, Vancouver, British Columbia, V6C 0B4 and its registered and records office is located at 1000 ‑ 840 Howe Street, Vancouver, British Columbia, V6Z 2M1.

Intercorporate Relationships

The following diagram explains the intercorporate relationships among the Company; the name and place of incorporation of each subsidiary; and the percentage of voting securities legally and beneficially owned:

British Columbia, Canada

| | 12 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

GENERAL DEVELOPMENT OF THE BUSINESS

Three Year History

Nevsun Resources Ltd. is a British Columbia company listed on the TSX and the NYSE MKT LLC and is engaged through its wholly and majority owned direct and indirect subsidiaries in the exploration for, and the development and production of, mineral resource properties. The Company’s principal property is the Bisha Property and its primary asset is the Bisha Mine located in Eritrea in North East Africa. The Company’s major achievements during the past three fiscal years include the commencement of commercial production of copper at Bisha in December, 2013; the transition to copper production and completion of the copper expansion on-time and under budget; the production of approximately 784,000 ounces of gold at Bisha from 2011 through December 31, 2013; the commencement of commercial gold production at Bisha in February, 2011; maintaining an industry leading safety performance record at Bisha; generating substantial cash flows; declaring and paying semi-annual dividends to shareholders in 2013, 2012 and 2011; and enhancing its corporate social responsibility program initiatives to reflect evolving international standards.

The most significant activities impacting the Company during the three year period ended December 31, 2013 are set out below.

2013 Developments

On January 9, 2014, the Company announced that it had produced 92,000 ounces of gold doré plus 20,000 equivalent gold ounces in precious metal concentrate and 48 million pounds of copper from the Bisha Mine in 2013. Copper production resulted from nearly 100,000 tonnes of copper concentrate produced. Over 65,000 tonnes of this concentrate had been shipped in six separate shipments in the fourth quarter of 2013. The new copper flotation plant continued a successful ramp up with a December annualized production rate of 190 million pounds of copper, copper recovery of 84% and copper concentrate grade of 32%.

On December 2, 2013, the Company announced that it reached commercial production of copper with the successful commissioning of its flotation plant. From initial flotation plant commissioning to commercial production, the operation had produced approximately 60,000 tonnes of copper concentrate. In November the plant had achieved over 80% of its targeted metrics of feed grade, recovery rates, and copper produced in concentrate. It further announced that transportation logistics from site to Massawa port were on track and working well and Bisha made three ocean shipments totalling approximately $60 million in value. Pre-commercial production sales proceeds and production costs to-date, including mining, processing and general and administrative costs directly attributable to the copper project, were capitalized against the build cost. The build cost of the copper plant and infrastructure at this time was estimated at $110 million, compared to a budget of $125 million.

On November 18, 2013, the Company announced diamond drill results from an eight hole 2,713 metre in-fill resource definition drilling program completed in 2013 at the Hambok polymetallic massive sulphide deposit, located 16 kilometres southwest from the BMSC processing plant. A new mineral resource estimate for Hambok was expected to be released in early 2014 and would incorporate these results in an updated mineral reserve and resource statement for BMSC which would also include updated mineral reserves and resources for Bisha Main and Harena, and a maiden mineral resource for the NW Zone.

On November 14, 2013 and May 15, 2013, respectively, the Company declared semi-annual cash dividends of $0.07 per common share ($0.14 per common share annually) which were paid to shareholders on January 15, 2014 and July 15, 2013, respectively.

On October 21, 2013, the Company announced further diamond drill results from resource definition drilling at the NW Zone. BMSC completed the resource definition and expansion drilling program totaling 216 holes at the NW Zone in May, 2013 and drilled a further 4 holes in July and August, 2013. A total of 18,892 metres of drilling had been completed at the NW Zone in 2013.

| | 13 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

On October 15, 2013, the Company announced the first shipment of 11,000 tonnes of pre-commercial production copper concentrate from the new Bisha copper plant. Commissioning and ramp up in mill throughput continued with commercial production on track for late 2013 or Q1 2014.

On September 4, 2013, the Company announced previously unreported assay results from drilling completed by the previous owner of the Mogoraib River Exploration License that includes the Hambok mineral deposit. Bisha had started a resource definition drilling program at Hambok with expectation that the results would be included in a mineral resource estimate for Hambok that would be part of an overall resource and reserve estimate in Q1 2014 for the Bisha area deposits.

On July 16, 2013, the Company announced the voting results of the Annual and Special Meeting of Shareholders which was held on May 14, 2013. The nominees listed in the management proxy circular for the Annual Meeting of Shareholders were elected as directors of Nevsun – R. Stuart Angus, Clifford T. Davis, Robert J. Gayton, Gary E. German, Gerard E. Munera. A total of 80.47% of outstanding shares were voted. The Advance Notice Policy of the Company was adopted by a 99.78% majority of the votes cast. The number of directors was set at five, and KPMG LLP was appointed auditor of the Company.

On June 17, 2013, the Company reported that after close of trading on June 21, 2013, Nevsun would be removed from NYSE Arca Gold Miners Index because Nevsun’s revenue was switching to majority copper from majority gold during 2013. Nevsun has been advised that the Van Eck Gold Miners ETF is required to sell its position in Nevsun since the ETF tracks the index. During March, 2013 a similar event occurred when Nevsun was deleted from the Van Eck’s proprietary Market Vectors Junior Gold Miners index, at which time the company experienced very significant trading volumes and was essentially price neutral.

On June 17, 2013, the Company announced revised production guidance of gold production increased to 110,000 ounces and copper production revised to 30 to 50 million pounds. The Company also announced the decision to commission the new flotation plant with pyrite sand ore to produce a precious metals concentrate and thereby postponing copper supergene ore flotation.

On May 23, 2013, the Company announced diamond drill results from resource definition drilling at the NW Zone. In 2013, 15,890 metres of drilling was completed at the NW Zone. This was in addition to 4,325 metres completed in 2011 and 13,520 metres completed in 2012.

On April 18, 2013, the Company announced the release of its 2012 corporate social responsibility report which may be viewed on the Company website: http://www.nevsun.com/responsibility/reporting/. The report was written and released under the Global Reporting Initiative’s G3.1 guidelines and self-declaring Application Level C.

On February 21, 2013, the Company announced its planned exploration program for 2013.

On January 23, 2013, the Company announced its 2013 outlook for planned gold and copper production from the Bisha Mine of 80,000 to 90,000 ounces of gold produced in doré and 60 to 80 million pounds of copper produced in copper concentrate.

On January 11, 2013, the Company in a news release commented on its approach to human rights at the Bisha Mine and its commitment to responsible operations and practices at the Bisha Mine, based on international standards of safety, governance and human rights.

On January 9, 2013, the Company announced it had produced 313,000 ounces of gold in doré from the Bisha Mine in 2012, and the copper plant expansion at the Bisha Mine had progressed on schedule and on budget with concentrate production expected in mid-2013. The Company had maintained top quartile safety performance at Bisha operations and advanced its corporate responsibility initiatives to reflect evolving international standards for the safety and health of its employees, protecting the environment, respecting human rights of its employees and residents of the communities in which it operates, and contributing to the sustainable development of those communities. The Company began personnel expansion to support management in its operations, to oversee its strategy and implementation of the Company’s corporate social responsibility programs, and to drive organic growth and Nevsun’s acquisition and expansion strategy.

| | 14 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

2012 Developments

On May 15, 2012 and November 15, 2012, respectively, the Company declared cash dividends of $0.05 per common share ($0.10 per common share annually) which were paid to shareholders on July 16, 2012 and January 15, 2013, respectively.

On October 10, 2012, the Company announced that it had acquired the Mogoraib River Exploration License and has identified high priority exploration targets. The Hambok historic resource is potential additional feed for the Bisha plant.

On September 7, 2012, the Company filed the 2012 Technical Report. The probable mineral reserves (effective date May 31, 2012) consisted of 26.5 million tonnes. This included 0.9 million tonnes of oxide ores grading 5.79 grams per tonne gold for a total of 167,000 troy ounces of gold, 6.4 million tonnes of supergene ore grading 4.09% copper for a total of 579 million pounds of copper, and 19.2 million tonnes of primary ores grading 1.09% copper and 6.33% zinc for a total of 462 million pounds of copper and 2,680 million pounds of zinc.

On August 8, 2012, the Company announced it had completed its 13,500 metre exploration drill program at the NW Zone which lies 3 kilometres from the Bisha deposit.

On July 9, 2012, the Company announced that it was granted the Harena Mining License. The Harena deposit is a satellite VMS deposit with oxide gold and base metal sulphide ores, similar in configuration to Bisha but smaller and lower in grade.

On June 18, 2012, the Company announced its progress on the construction of the copper plant and that it had purchased all required equipment to allow for a containerized transport and handling solution for its copper concentrate.

On March 19, 2012, the Company announced a share repurchase program of its outstanding common shares under a normal course issuer bid on the TSX. The Company repurchased a total of 1,732,600 common shares during the year ended December 31, 2012.

In March, 2012, a class action lawsuit was commenced against the Company and certain of its executive officers. The action is still pending (see the Section, “Legal Proceeding and Regulatory Actions”).

On February 7, 2012, the Company announced its 2012 outlook for planned gold production from the Bisha Mine of 190,000 to 210,000 ounces of gold and that it was on track with its copper phase of development for the copper phase process plant in advance of commercial production in 2013.

On January 10, 2012, the Company announced that it produced 379,000 ounces of gold doré in its first year of operations at the Bisha Mine.

2011 Developments

November 21, 2011 and May 18, 2011, respectively, the Company declared its first dividends which were paid to shareholders in January, 2012 and July, 2011, respectively.

On November 17, 2011, the Company reported the voting results at its special meeting of shareholders held on November 16, 2011 which shareholders approved setting the number of directors at six with 99.77% shares voting in favour and approved the Rights Plan with 87.23% of shares voting in favour.

On August 23, 2011, the Company announced that it had finalized its arrangements with the State of Eritrea regarding the purchase of 30% of the Bisha mine by the ENAMCO. The agreed price was $253.5 million, which would be settled from the after tax cash flows generated at Bisha.

On June 8, 2011, the Company announced it had adopted a Rights Plan to ensure the fair treatment of shareholders in connection with any take-over bid for the common shares of Nevsun.

| | 15 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

In June, 2011 the Company began civil works in preparation for construction of the second phase copper flotation plant.

On May 11, 2011, the Company announced that it completed development and commissioning of the Bisha Mine on schedule and under budget and concluded the first quarter of 2011 with its first five weeks of commercial operations.

The Company also announced successful completion of another phase of significant exploration and development drill programs at the Bisha Main pit area and adjacent HW Copper Zone adjacent to Bisha.

DESCRIPTION OF THE BUSINESS

The Company’s principal mineral property is the Bisha Property which hosts the Bisha Mine and satellite VMS deposits at Harena, the NW Zone and Hambok. The Mining Agreement governs the development of the Bisha Property and covers an area of 39.0 square kilometres and contains the Bisha Mine and the Bisha Mining License. In addition, the Company owns the Harena Mining License and the Mogoraib River Exploration License. The Company has also made application for additional exploration rights in areas surrounding the Bisha Property.

The Bisha Mine

The Bisha Mine, owned and operated by BMSC, is a gold, copper and zinc deposit that is projected to have a strong economic return over the remaining eleven year mine life. Nevsun is a 60% shareholder in BMSC with the remaining 40% interest held by ENAMCO. BMSC is governed under the terms of a shareholder agreement between Nevsun and ENAMCO.

The top layer of the deposit at Bisha was gold oxide material lying at the surface. The mine began commercial production of gold in February, 2011 that allowed an early payback of gold phase capital and allowed for funding of the copper phase expansion. Mining of the gold oxide phase was completed for the most part at the end of Q2, 2013. The Bisha Mine transitioned from gold production to copper production in late 2013 and commenced commercial production of copper in December, 2013. The development of the zinc flotation circuit required for future zinc production is expected to be online in late H1 2016, and is presently underway. The Bisha Mine has the full support of the Eritrean Government.

Gold, Silver and Copper Sales

The Company recorded revenues of $156 million based on sales of 96,700 ounces of gold and by-product sales of 507,935 ounces of silver in 2013 compared to revenues of $566 million based on sales of 320,500 ounces of gold and by-product sales of 962,000 ounces of silver in 2012. The significant reduction of revenue was anticipated and was impacted as the Company transitioned from gold production to copper production. Copper concentrate sales during 2013 were credited to copper development costs as all such sales related to pre-commercial production activity.

There are numerous purchasers of copper, gold and other metals and the Company is not dependent upon any one purchaser. Gold production from Bisha was in the form of doré bars (gold and silver) which were flown from the Bisha site to the capital city of Asmara, and then flown to refiners in Europe and Canada. With the commencement of copper production in mid-2013, copper production from Bisha is in the form of copper concentrates (including small amounts of gold and silver credits) produced at site and transported in country by truck and trailer to the port of Massawa and in turn loaded into ocean freighters for transport to smelters in Europe and Asia.

Methods of Production

Bisha has an owner-operated mining fleet and for its gold production, used standard CIL processing facilities to initially process the gold oxide cap by traditional cyanide leaching. Following completion of processing the gold oxide cap in mid-2013, the CIL facility was cleaned and decommissioned but remained in place for future use. The Company then began processing supergene copper ores using flotation to recover copper as a sulphide concentrate and will use the same process when primary copper and zinc ores are processed starting in 2016.

| | 16 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

The current mine life is estimated to be 11 years, projected to 2024, followed by six months of final processing of remnant oxide ores and gold doré extraction using the original CIL circuit. The Company also expects to further expand its mineral resources with subsequent conversion into mineral reserves. Opportunities to expand the Bisha Mine life may be found by additional drilling in and around the Bisha Mine including the NW Zone, on the Harena Mining License and on the Mogoraib River Exploration License. Numerous untested geophysical targets remain on these properties and both the Bisha and Harena deposits have not been fully defined by drilling to date. Several new targets will continue to be evaluated on the Mogoraib River Exploration License and in addition to efforts to expand the existing resource at Hambok, high potential targets along the Hambok trend and other new areas will also be tested. These properties have the potential to provide additional near term mineral resources for the Bisha operations. If this potential is achieved, the Company will evaluate through a cost-benefit analysis if there are sufficient economic resources to transport to and process at the Bisha mill.

Skill and Knowledge

BMSC has built a management team of skilled mining, processing, environmental, financial, and administrative personnel reporting to the general manager at the Bisha Mine who is in charge of mine production, process plant facilities, exploration programs, and future operations of the Bisha Mine. The specialized knowledge and skills required in all areas of mining include mining, engineering, geology, metallurgy, environmental permitting, drilling, and exploration program planning. The Bisha Mine is the first modern mining operation in Eritrea. Training and re-training of local staff to attain and maintain the requisite skills in all aspects of mining operations is and has been a priority.

Employees

BMSC directly employs approximately 1,000 Eritreans and 110 expatriates at the Bisha Mine and provides a safe and supportive working environment. Nevsun strives to ensure that its presence has a positive social and economic impact. With spin-off effects, the Bisha Mine has created meaningful employment for thousands of Eritreans. Compensation for Eritreans directly employed by BMSC is well above the average for Eritrea. Employees are provided free food and free accommodations or free local commuting. These employees also receive free training and have opportunities for advancement. Employees also have access to free medical care at the mine’s clinic. The use of conscripted labour at the Bisha site is not allowed, and BMSC has strong practices and procedures to ensure that all individuals at Bisha are working of their own free will and are not conscripts. The procedures include the inspection of national service discharge documentation for all Eritrean workers at Bisha, and Bisha-issued photo identification cards for those employed directly or by subcontractors.

Corporate Social Responsibility

The Company’s objective is to generate sustainable prosperity through its business operations, which means respecting the safety and health of its employees, protecting the environment, respecting the human rights of its employees and the residents of the communities in which it operates, and contributing to the sustainable development of those communities. The Social, Environmental, Health and Safety Committee established by the Board oversees the Company’s efforts in meeting these objectives.

While not a member of the EITI, the Company supports the goals of fiscal transparency and governance and has taken the approach of disclosing payments made to governments in countries in which it operates, whether or not the host government is a member of EITI.

From commencement of commercial gold production in early 2011, Bisha has contributed more than $670 million in cash remittances to the Eritrean government and government-owned entities. In addition, the Bisha Mine contributed tens of millions of dollars to the economy of Eritrea through salaries, wages, benefits, local supply-chain purchases, and community assistance, and the mine did not displace any local communities. Considering that the Bisha Mine is the only modern mine in Eritrea, this direct contribution is a significant benefit to the national economy and the local communities. The resulting impact through the indirect multiplier effect on the economy of Eritrea is difficult to estimate but is believed to be very significant.

| | 17 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

The Company voluntarily releases a corporate social responsibility report annually that adheres to the Global Reporting Initiative (GRI) G4.0 Core requirements. The report addresses a hybrid of general and specific sectorial information about the Bisha Mine and its relevance to annualized corporate social responsibility objectives.

Social Responsibility

The Company recognizes that its activities have the potential to impact the human rights of individuals affected by its business operations. As such, the Company seeks to integrate human rights best practices into its business processes and conducts its business within a framework that promotes worker and community health and safety, environmental protection, community involvement, community benefits and quality of life for employees and their families. The Company is committed to responsible operations and practices at its Bisha Mine, based on national and international standards of safety, governance and human rights and strives to ensure that the Company’s presence has a positive social and economic impact to the national economy and the local communities. Some of the Company’s social responsibility commitments and practices include:

- actively promoting understanding by all employees of the culture, language and history of the communities, regions and countries in which it operates;

- working to protect cultural heritage resources potentially affected by the Company’s activities;

- conducting activities in a manner that respects traditional-use rights, cultures, customs and social values;

- promoting job equity and equal access to employment opportunities for women;

- maintaining formal human resources practices and procedures to ensure that conscripted labour is prohibited at Bisha, including inspection of national service discharge documentation for all Eritrean workers at Bisha;

- building capacity by sharing environmental and social experiences and solutions with local communities and regional and national governments;

- actively consulting with local communities to identify and resolve environmental and social issues;

- procuring materials, goods and services in a manner that enhances local benefits and protects against unethical practices such as child labour and forced labour;

- establishing social responsibility performance criteria; and

- monitoring and reporting performance to senior management through periodic audits.

Health and Safety

The Company recognizes that the safety and security of its employees and the communities in which it operates is an integral part of its business. The Company has maintained top quartile safety performance at Bisha operations now exceeding 15 million hours without a lost time injury. As to safety, the long-term goal is for employees of the Company to operate injury-free, regardless of what role they perform. The Company likewise has advanced its corporate responsibility initiatives to reflect evolving international standards.

To achieve its health and safety objectives, the Company is training employees to work in a safe and responsible manner, carrying out risk assessments for all construction and operational activities, conducting thorough investigations when incidents do occur to understand the underlying causes, ensuring that health and safety performances comply with relevant legislation and regulation, adhering to local laws as well as international standards on law enforcement in securing its operations, particularly those that relate to the use of force, carrying out risk assessments in relation to security issues at each of its project sites, ensuring that security is managed in a way that respects and protects human rights, avoids creating conflict, and addresses security threats in as peaceful a way as possible and assisting the local community in health awareness activities.

| | 18 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

Environment

The Company is committed to achieving high standards of environmental responsibility in its operations and compliance with all applicable regulations and laws.

The Company is committed to devoting its resources to the goal of:

- complying with all host country environmental laws and regulations together with industry best practice standards, or whichever is the more stringent of the two;

- ensuring the necessary resources are provided to support and implement the Company’s environmental policy;

- continual improvement in environmental performance by developing environmental indicators, monitoring and auditing performance, and by implementing corrective actions where needed;

- reporting externally on environmental performance and encouraging dialogue with employees, local communities and other stakeholders to promote environmental awareness;

- applying the principles of best available technology to environment management;

- reducing, re-using and recycling resources and implementing proper waste management practices;

- training, motivating and ensuring that all employees adhere to environmental protection and pollution prevention policies;

- incorporating an emergency preparedness and response system into standard operating practices; and

- monitoring and reporting on performance to senior management through periodic audits.

MINERAL PROPERTIES

The Company’s principal mineral property is the Bisha Property in Eritrea, North-East Africa and its primary operating asset is the Bisha Mine located on the Bisha Property with gold, silver, copper and zinc mineral resources and mineral reserves. Unless otherwise stated, the technical and scientific information included in this AIF concerning Bisha are derived from the 2013 Technical Report prepared by Paul Gribble, C. Eng., FIMMM, Chief Resource Geologist, BMSC; Jay Melnyk, P.Eng. AGP; and Peter Munro, BAppSc., Mineralurgy Pty. Ltd. The authors of the 2013 Technical Report are QPs within the meaning of NI 43-101. The information included herein is also based on the assumptions, qualifications and procedures which are set out in the 2013 Technical Report. For more detailed information and a complete description of assumptions, qualifications and procedures associated with the following information, reference should be made to the full text of the 2013 Technical Report which has been filed and is available for review on SEDAR (www.sedar.com) and EDGAR (http://www.sec.gov/edgar.shtml).

Commercial production of copper concentrates from the supergene ores at Bisha was achieved in December, 2013 after transition from the oxide phase to the supergene phase of development of the Bisha Property. Commercial production of gold doré from the oxide ores at Bisha was achieved in February, 2011 with approximately 784,000 ounces of gold being produced from 2011 through 2013.

Project Description and Location

In October, 2007, the Government of Eritrea evidenced its strong support for the Bisha Mine and for the development of a new and strong mining sector in Eritrea through its purchase of a 30% paid participating interest through ENAMCO. The purchase price and settlement for the 30% interest was determined in 2011. In December, 2007, BMSC concluded the Mining Agreement with the State of Eritrea. Royalties payable to the State of Eritrea include royalties of 5.0% on precious metal sales and 3.5% on base metal sales.

| | 19 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

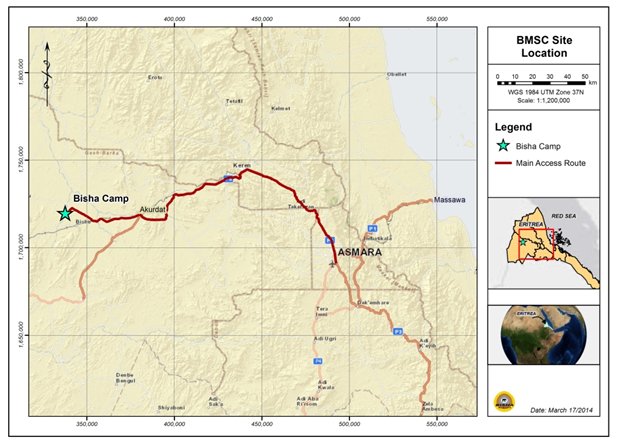

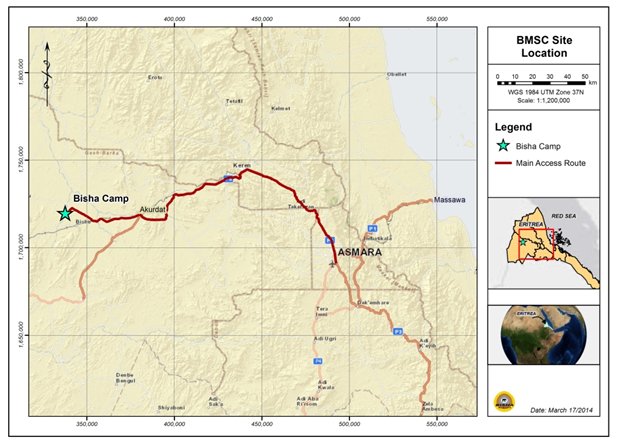

The Bisha Mine is located 150 kilometres west of Asmara, 43 kilometres southwest of the regional town of Akurdat, and 50 kilometres north of Barentu, the regional or zone Administration Centre of the Gash-Barka District, in Eritrea, East Africa. Access to the Bisha Mine is by paved road from Asmara to Akurdat, a distance by road of 181 kilometres and then 52 kilometres from Akurdat via an all-weather unpaved road, which is currently being upgraded with over 13 kilometres now paved. The drive from Asmara to the Bisha camp (also referred to as Bisha Village) takes approximately four hours by a passenger vehicle, over five hours by a passenger bus. Current onsite infrastructure includes: two open pits (Bisha and Harena), process plant (crushers and grinding mills, leach, flotation, thickener and other tanks, filter presses) wet tailings facility and waste rock storage facilities, offices, maintenance and laboratory facilities, fuel storage areas, an on-site power plant, and an airstrip. The Bisha Mine is located at approximate latitude 15°28'N and longitude 37°27'E. The UTM coordinates (WGS84) of the centre of the Bisha Property are 1,711,000 N and 334,500 E (UTM zone 37). The following Figure 1 shows the location of the Bisha Property.

| Figure 1 – Bisha Site Location |

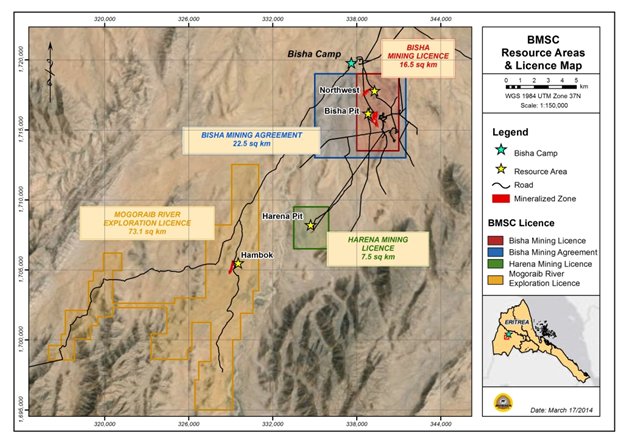

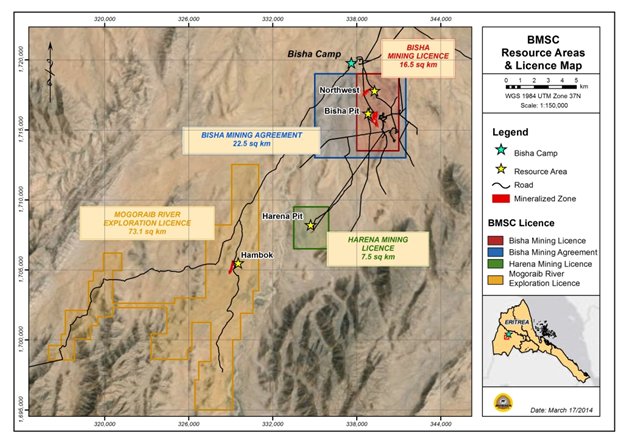

The BMSC properties host the Bisha Main deposit, which is a large precious metal (Au) and base metal rich (Cu, Zn) VMS deposit which is currently in production, as well as the satellite VMS deposit at Harena of which the oxide gold cap was mostly mined in 2013 and it now sits dormant until future mining around 2021. The BMSC properties also include the potential satellite VMS deposits called Northwest and Hambok deposits. The Bisha Mining License and the Harena Mining License are also held by BMSC and all conditions of the Harena Mining License have been met by BMSC and submitted to the Ministry of Mines with approval expected in due course.

| | 20 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

Under the terms of the various mining licenses held by BMSC, BMSC has the exclusive right of land use in the areas comprising these mining licenses. This right is subject to the acquisition and settlement of any third-party land-use rights by payment of compensation and/or relocation at the expense of BMSC. The Company also owns the Mogoraib River Exploration License. The Mogoraib River Exploration License covers the Hambok VMS deposit and during 2013, BMSC was required to reduce the license area by 25% (now 73.1 square kilometres). This license is valid until July 2, 2014 pending further extensions which consist of part of an annual application process. The annual exploration license fee is approximately $32 per square kilometre and $96 per square kilometre for a mining license.

In 2013 the Company made applications for additional exploration rights in the area surrounding the BMSC properties. These applications are currently the subject of discussions with the Ministry of Mines and ENAMCO. The following Figure 2 shows the areas which comprise the Mining Agreement and BMSC’s mining licenses.

| Figure 2 – BMSC Resource Areas and License Map |

Accessibility, Climate, Local Resources, Infrastructure & Physiography

Eritrea is located above the Horn of Africa on the continent’s east coast, between Sudan to the north and west, and Ethiopia and Djibouti to the south. Eritrea has an area of 124,320 square kilometres and a 1,151 kilometre long coastline on the Red Sea, which separates the country from Saudi Arabia and Yemen.

Access to the Bisha Property is by paved road from Asmara to Akurdat, and then from Akurdat via an all-weather unpaved road, which is currently being upgraded. The principal port for importation of heavy equipment and shipment of concentrate is Massawa on the Red Sea coast, which is about 350 kilometres from the Property. The port has sufficient draught and the Company has a rotainer handling system which is flexible and able to be expanded through a modular design to accommodate the handling and loading of both copper and future zinc concentrates. Asmara is the capital city of Eritrea and is serviced currently by regular international flights out of Cairo, and Sanaa.

| | 21 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

The climate is semi-arid, with elevated temperatures year-round. During the hot season in April and May, the average temperature is +42°C, although temperatures may rise to +50°C for short periods. The main rainy season is between June and September, and periodic flooding of the Mogoraib and Barka Rivers can result in flash floods. Total rainfall is sparse, with between 250 millimetres and 300 millimetres. All mining activities are planned on a year-round basis.

The Bisha Property is located on a flat to rolling, desert-like plain along the western foot of the central highlands. The plain is at 560 masl and contains scattered vegetation and few trees. Steep hills and ridges rise above the plain with the Bisha, Wade, and Neve peaks reaching elevations of up to 1,226 masl above the alluvial plain at the southern boundary of the Property.

Abundant seasonal streams cross the area, flow northward from the Property into the Barka River which flow northward into Sudan. The Property is crosscut by the Mogoraib River, a tributary of the Barka River that flows northwards along the western side of the Property. A smaller seasonal tributary, the Ferektatet River, flows north-northwest into the Mogoraib River. The Ferektatet River crosses the Bisha Property and passes immediately west of a zone called the Bisha gossan zone.

The village of Mogoraib (6 kilometres from the Bisha Mine) is the local administration centre for the Dighe Sub-zone within the Gash-Barka District. The village has a small refugee resettlement site, and subsidiary military and commercial interests. The village contains a well-equipped, eight-person health centre with a nursing staff capable of taking care of small medical problems in preparation for referring patients to larger, better-equipped hospitals in Akurdat and Keren. Camp Mogoraib is a military training site located just outside the village boundaries. With the presence of the mine development and exploration project at Bisha, this camp has been re-activated as a security post from its previous care/maintenance basis.

Few basic goods are commercially available in the immediate region near the Bisha Mine, either in Mogoraib or in Akurdat. The main centre for support of exploration and development is the capital city, Asmara.

Electric power for the mine and processing plant site is supplied from a diesel-fuelled power station located adjacent to the process facilities.

Process water is sourced from maximizing the recycling of water within the plant, and additional needs are supplemented from local groundwater sources. Although evaporation rates in this region are very high, a tailings-management facility, supernatant water reclaim pumping-system is installed to reclaim seasonal decant water from this source. In addition, water from the pit is pumped to the process plant, which further reduces dependence on raw water.

Freshwater is supplied to the property from groundwater. Two well farms have been established by BMSC, the first approximately 1 kilometre south of the open pit on the western bank of the non-perennial Ferektatet River (which also serves to dewater the Bisha pit), and the second 5 kilometres to the west, adjacent to the Mogoraib River. Potable water sourced from the well fields is pumped to a potable water plant utilizing chlorination filtration and ultraviolet radiation treatment.

Current site communication is via radio, cellular service, and a satellite communications system.

Under the terms of the Mining Agreement, BMSC has the exclusive right of land use in the area comprising the Bisha Mining License that is granted under the Mining Agreement and in the area comprising the Harena Mining License. This right is subject to the acquisition and settlement of any third-party land-use rights by payment of compensation and/or relocation at the expense of BMSC, in accordance with Eritrean Government Proclamation No. 68/1995, “Proclamation to Promote the Development of Mineral Resources and the Mining Agreement”.

| | 22 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

BMSC holds all the necessary permits to support a mining operation. For the mining operations, grant of the mining lease provides permission to construct and operate the Bisha Mine. A permit had been granted for use of water from the Mogoraib River (currently being used with permission) and for the construction of a water diversion dyke which has been completed.

Mineral Property History

Nevsun has no record of any previous exploration or mining activities on the property or surrounding areas prior to 1998. In June, 1998, Nevsun signed a prospecting license agreement with the State of Eritrea. In 1999, this agreement was converted to an exploration license that covered an area of 49 square kilometres. This license was expanded to an area of 224 square kilometres in 2003.

Geological Setting

Eritrea is divided into several north or northeast trending Proterozoic terranes, which are separated by major crustal sutures. The Nacfa Terrane comprises low-grade metamorphosed calc-alkaline volcanics and sediments, and hosts base metal mineralization in the region surrounding the city of Asmara, and in the Gash-Barka district, including the Bisha polymetallic mineralization.

The VMS deposits at Bisha are hosted by a folded and locally intensely foliated bimodal sequence of volcanic rocks. Felsic volcanics directly host and both underlie and overlie the mineralization at Bisha, Harena and the NW Zone. These felsic volcanics are flow dominated indicating proximity to volcanic vents. Mafic volcanic rocks occur deeper in the footwall to the east of the known mineralized zones. Alteration of the felsic volcanics is often very intense with the primary mineralogy being converted to sericite and chlorite. The Hambok deposit in contrast to the Bisha deposits is entirely hosted in mafic volcanic rocks. These rocks are strongly foliated and highly chloritized.

Exploration

1998 - 1999

Exploration activities consisted of reconnaissance-scale geological mapping, multi-element stream sediment sampling, ground geophysical surveys and limited “orientation” soil sampling, which showed the Bisha gossan zone to be highly anomalous in lead with significant values of copper, zinc and silver. Grab samples of the gossan returned anomalous gold values ranging up to 30.4 g/t Au.

1999 - 2002

Work was suspended between 1999 until late 2002 due to the border war with Ethiopia.

2002

In November, 2002, Nevsun completed a diamond-drilling program of six holes totalling 811 metres at Bisha to test the geophysical and geochemical anomalies at the gossan outcrop area. The drilling was sufficient to confirm the presence of a VMS deposit overlain by a supergene copper-enriched zone and a gold-enriched gossan cap.

2003

Two phases of diamond drilling were completed in 2003 for a total of 18,619 metres in 141 holes. Additional work conducted during this program included mapping, geochemical sampling, trenching, geophysics (airborne and ground), metallurgical test work, petrographic work and bulk density measurements.

2004

Further diamond drilling (163 holes totalling 28,879 metres), RC drilling (33 holes totalling 1,814 metres) and core/RC combination holes (9 holes totalling 592 metres) were completed between January and June. Additional work included geophysical surveys, mapping, geochemical sampling, petrographic work, bulk density measurements, geotechnical work, environmental baseline work, and metallurgical test work.

| | 23 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

2005

Nevsun completed the diamond drilling of 135 holes for 18,053 metres in three zones (86 holes in Bisha Main zone, 22 holes in the NW Zone, 27 holes in the Harena zone). The Bisha Main zone drilling included 20 geotechnical and 8 metallurgical drill holes, drilled to provide further information on the deposit for use in the Bisha Feasibility Study. The mineral resource and mineral reserve contained in this study was updated in a technical report at that time.

2006

Eight diamond drill holes (1,680 metres) were completed. This included one deep drill hole at the Bisha Main zone, three drill holes in the HW Copper Zone and 4 drill holes at the NW Zone.

2007

Additional ground geophysical (gravity) surveys were performed on new target areas at Bisha.

2008

Mechanical trenching/pitting and geological mapping were completed on targets defined by geophysical ground surveys in 2007.

2009

Twenty nine diamond drill holes (3,578 metres) were completed in the Bisha Main zone and at Harena. The Bisha Main zone drilling consisted of 9 geotechnical holes to provide additional information for the pit design and 3 metallurgical holes drilled to collect additional samples for the design of the copper phase of the mill. Harena drilling consisted of 17 infill holes drilled at 50 metre spacings to better define the mineralization. An additional ground gravity survey was also performed on the southwest of the Harena zone.

2010

A total of 34 diamond drill holes (2,448 metres) were drilled to better define the oxide and supergene zone at the Harena deposit. Thirteen diamond drill holes (1,918 metres) were also drilled to test gravity targets in the Harena area. No significant mineralization was intersected. At the Bisha Main zone, an additional 6 metallurgical holes were drilled to collect additional samples for designing the copper phase of the mill.

2011

In 2011, 167 diamond drill holes (33,788 metres) were drilled to infill areas of known mineralization for resource upgrading as well as for metallurgical and geotechnical studies and exploration.

At the Bisha Main zone, 41 holes (15,950 metres) were drilled to infill and upgrade the primary zone portion of the deposit from inferred resource to indicated resource. As well, 3 exploration holes (1,572 metres) were drilled to further define the depth extent of the primary zone in the southern portion of the deposit. For the HW Copper Zone that lies immediately west of the Bisha Main zone, 82 holes (9,421 metres) were drilled to outline and expand this resource. These hanging wall copper exploration drill holes were drilled in 2 phases. The first was to define the mineralized area and the second was to infill with sufficiently tight spacing to allow resource estimation. In addition, 6 holes (695 metres) were drilled for further geotechnical studies and 2 holes (180 metres) for supplementary supergene metallurgical test work.

At Harena, 5 regional exploration holes (859 metres) were drilled to test coincident gravity/EM/soil geochemical anomalies 300 metres along strike to the southwest of the Harena deposit. No significant mineralization was encountered. Four holes (603 metres) were drilled for geotechnical studies, 2 holes (182 metres) were drilled for metallurgical studies.

| | 24 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

In 2011 drilling began to define and provide sufficient drill density for the NW Zone to bring it to a maiden resource estimate. A total of 22 holes (4,325 metres) were drilled as part of this program which continued into 2012.

2012

Diamond drilling programs were undertaken at the Bisha Main, HW Copper Zone, NW Zone and Harena, for a total of 112 holes and 19,432 metres. This was a combination of exploration, extension and infill drilling as well as geotechnical and metallurgical investigative drilling required for mineral resource and mineral reserve estimations.

At Bisha Main, 12 geotechnical holes (3,049 metres) were drilled to provide data for a pit design optimization that included the HW Copper Zone extension to the Bisha Main deposit. Metallurgical drilling for a total of 12 holes (821 metres) was completed across the supergene zone and HW Copper Zone extension to provide supplemental data for the Bisha Main mineral resource estimate update of May 31, 2012. A further 7 diamond cored holes for 410 metres were completed to test for the gold potential above the HW Copper Zone within the phase 5 cutback of the Bisha Main open pit.

The majority of drilling was focussed on the development of the NW Zone. From March to July, 49 diamond cored holes (9,215 metres) completed the initial NW Zone drill program that had commenced in 2011. This drilling was done to a sufficient density in the central portion of the zone to allow for an indicated resource to be calculated to a depth of 200 metres. This drilling also showed potential for additional along strike, near surface and down dip extensions to the deposit. During November and December, 16 additional diamond drill holes (2,776 metres) were completed to test these further extensions with success. A separate gold and base metal enriched horizon to the east of the main body of mineralization was also discovered. Eight geotechnical holes (1,568 metres) and two metallurgical holes (471 metres) were also completed and the geotechnical holes north of the then outlined zone encountered additional mineralization.

At Harena, exploration diamond drilling included a total of 6 holes (1,123 metres) with one of the holes intersecting mineralization peripheral to the Harena open pit.

2013

Diamond drilling consisted of 27,828 metres of exploration and resource development drilling at Bisha Main, the NW Zone and Hambok. Ten geotechnical and metallurgical holes for 1,007 metres were also drilled at Bisha largely for new material for test work on the primary zinc deposit. Six RC holes (1,148 metres) for hydrology and condemnation programs were completed at Bisha and five holes (833 metres) were completed for hydrology at the NW Zone.

At Bisha, 23 holes for 6,223 metres were completed in the immediate Bisha area testing geophysical targets. In addition, 8 holes tested below the northern portion of the Bisha Main deposit.

Drilling concluded at the NW Zone with 18,892 metres of drilling being completed in 93 holes. The NW Zone was sufficiently drilled to allow for a maiden resource estimate to be completed.

At Hambok, eight holes for 2,713 metres were completed to infill areas of the deposit that had large gaps in the geological model. This work allowed for a new open pit constrained mineral resource estimate to be completed.

Mineralization

Mineralization found to date, within the Bisha Property, is typical of precious and base metal-rich VMS deposits.

Eritrea is divided into several north or northeast trending Proterozoic terranes, which are separated by major crustal sutures. The Nacfa Terrane comprises low-grade metamorphosed calc-alkaline volcanics and sediments, and hosts base metal mineralization in the region surrounding the city of Asmara, and in the Gash-Barka district, including the Bisha polymetallic mineralization.

| | 25 | Nevsun Resources Ltd. |

| | ANNUAL INFORMATION FORM - 2013 |

The VMS deposits at Bisha are hosted by a folded and locally intensely foliated bimodal sequence of volcanic rocks. Felsic volcanics directly host and underlie and overlie the mineralization at Bisha, Harena and NW. These felsic volcanics are flow dominated indicating proximity to volcanic vents. Mafic volcanic rocks occur deeper in the footwall to the east of the known mineralized zones. Alteration of the felsic volcanics is often very intense with the primary mineralogy being converted to sericite and chlorite. The Hambok deposit in contrast to the Bisha deposits is entirely hosted in mafic volcanic rocks. These rocks are strongly foliated and highly chloritized.

The mineralized components of the Bisha Main deposit are divided into three major zones, namely the oxide, supergene, and primary zones. The large majority of the oxide component is mined out while a small zone remains in the northeast of the deposit. The massive sulphide bodies of the supergene and primary zones are divided into a southern zone called the main zone and a northern zone, whose dip extent is limited. The southern zone strikes at some 345° and dips steeply to the west, with strike and dip lengths of some 650 metres and 600 metres, respectively. The northern zone strikes at around 0° and dips steeply to the west, with strike and dip lengths of some 500 metres and 100 metres, respectively. In addition, there are massive sulphide pods in the HW Copper Zone of the main massive sulphide units and development of supergene-mineralized material, also in the HW Copper Zone. These last tend to be of lower-grade material. There are also additional zones of low-grade disseminated copper mineralization in the footwall and hanging wall of the massive sulphide bodies. Work since 2012 has shown that the mineralization is fault bounded and controlled and this model has replaced the original folding model.

Deep weathering has affected these primary massive sulphides producing high-grade stratified gossanous zone near surface that are enriched in gold and beneath these, supergene blankets enriched in copper. The gossan zone can vary in composition from highly siliceous and somewhat ferruginous to a massive goethite-hematite-jarosite gossan. The depth of this oxidation zone is on the order of 35 metres. The oxidation of the massive sulphides generated strong acid solutions that have progressively destroyed the sulphides and host rock. Gold remains in the oxide zone and is concentrated, and as the acid solutions percolate downward, they deposit their dissolved copper at the primary sulphide interface to produce a copper-rich supergene zone. A horizon of extremely acid-leached material or “soap” has developed between the oxide and supergene/primary domains and the host rocks.

The Harena deposit has been traced over a strike length of 400 metres and is interpreted to be a northwest-dipping, tabular massive sulphide body. The host rocks to the Harena deposit are intensely chloritized and sericitized hydrothermally-altered felsic volcanic rocks. Surficial weathering processes have produced a surficial oxide/gossan zone with good gold grades underlain by a primary massive sulphide deposit. Supergene mineralization is not well developed. The massive sulphide zone ranges in thickness of between 5 metres and 15 metres and is open at depth.

Mineralization at the NW Zone occurs in a series of massive sulphide lenses hosted within altered felsic volcanic rocks containing abundant copper and zinc-rich stringer sulphide mineralization. Some of the massive sulphides have been exposed to weathering at surface creating oxide zone that are locally enriched in gold. Beneath these areas, some supergene copper mineralization may also be present. Core recovery is often poor in the oxide zone as unconsolidated material is easily washed away and not recovered during the diamond drilling process. Further testing of these areas by reverse circulation drilling will be completed in due course.