Michigan Antrim Shale

and

New Albany Shale of Indiana and Western Kentucky

First Albany Capital

EMERGING RESOURCE PLAYS CONFERENCE

July 19, 2006

Total Quality Management in

Exploration and Production Methods

Disclaimer

In this slide presentation, statements regarding our goals and objectives, our expected

methods of operation and development strategies, our expected and potential production

volumes, the volume of potential reserves, potential drilling locations, the timing of drilling

activities, when wells will begin producing, how many wells will be drilled, potential new

development theatres, the spacing of wells, drilling and operating costs, and other

statements that are not historical facts, contain predictions, estimates and other Forward-

Looking Statements within the meaning of Section 27A of the Securities Act of 1933 and

Section 21E of the Securities Exchange Act of 1934. Although we believe that our

expectations are based on reasonable assumptions, we can give no assurance that our

goals will be achieved. Important factors that could cause our actual results to differ

materially from those included in the Forward-Looking Statements include the timing and

extent of changes in commodity prices for oil and gas, changes in market demand, drilling

and operating risks, the availability of drilling rigs, uncertainties about the estimates of

reserves, the availability of transportation pipelines, changes in laws or government

regulations, unforeseen engineering and mechanical or technological difficulties in drilling

and operating the wells, operating hazards, weather related delays, the loss of existing

credit facilities, availability of capital, and other risks more fully described in our filings with

the Securities and Exchange Commission, including Form 10-KSB filed March 31, 2006. We

may also change our business focus as new opportunities arise. All Forward-Looking

Statements contained in this presentation, including any forecasts and estimates, are based

on management’s outlook only as of the date of this presentation and we undertake no

obligation to update or revise these Forward-Looking Statements, whether as a result of

subsequent developments or otherwise.

Executive Summary

Low-risk, long-term production of unconventional gas

reservoirs in Antrim and New Albany Shales

88 BCF in proven reserves (1/31/06)

7,250 mcfe/day in production (mid-June)

Over 460,000 net acres (3/31/06) with over 3,000

potential drilling locations and over 2 TCF in potential

reserves

Of total acreage, ~20% Antrim and 80% New Albany

2006 Objectives:

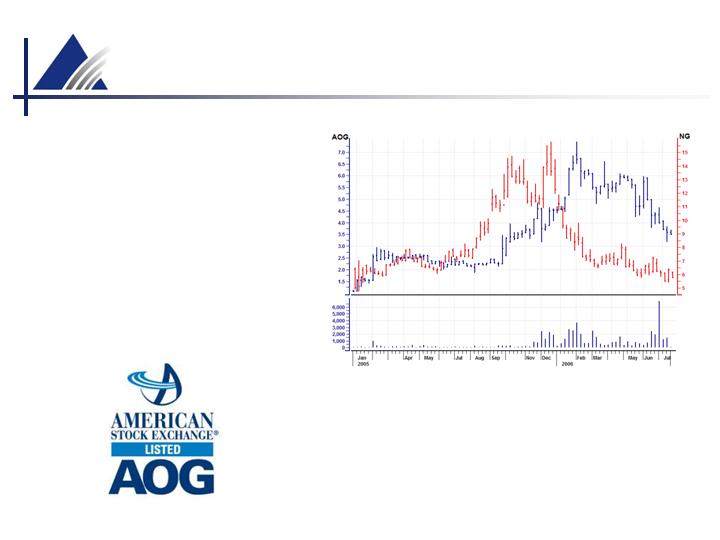

AMEX listing by mid-year

Drill 200 wells (gross)

100 BCF in proven reserves by mid-year

The Company

Active in Antrim and New Albany Shales since 1997

Reverse merger with Cadence Resources, 10/31/05

AMEX listing, 5/24/06; Russell Indexes, 6/30/06

Management team has 18-24 years experience

Engineering/Geology team has 24-32 years experience

Foster an environment that appreciates creative

thinking and innovative use of technology

Dedicated to thoughtful and prudent pursuit of natural

resources while creating long-term value for

shareholders

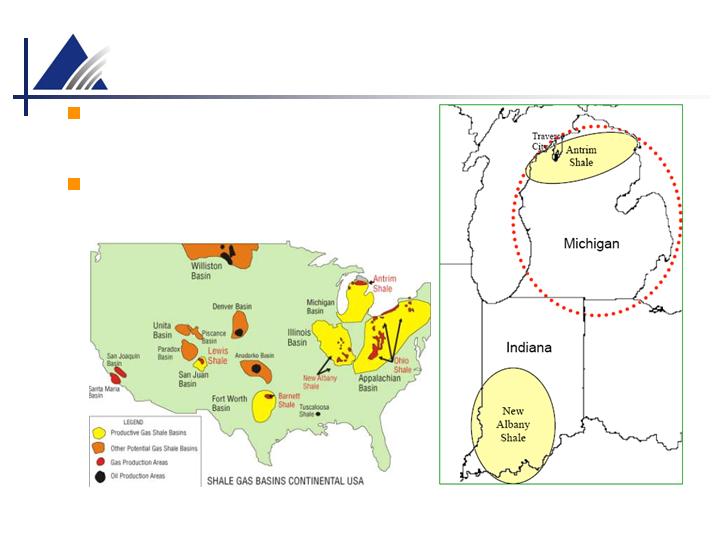

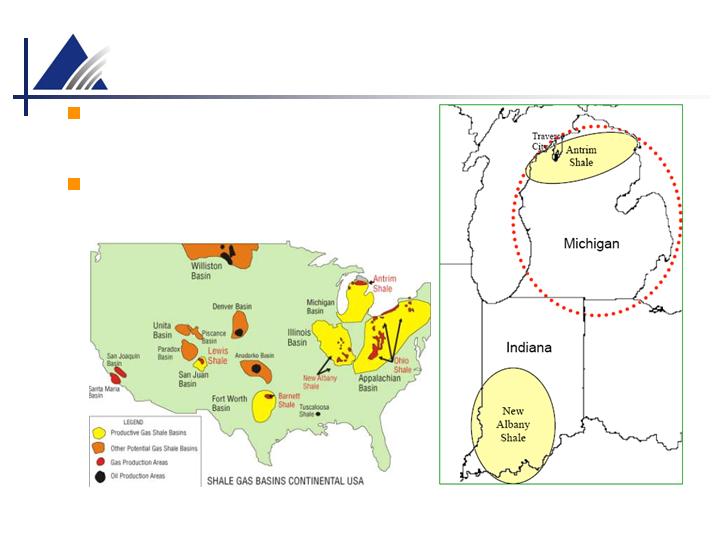

Antrim and New Albany Shale Plays

Relatively shallow blanket

shale formations

High-upside, lower-risk

development potential

Technologies to Cope with Reservoir Risk

The Antrim Shale and New Albany Shale are “blanket”

formations covering significant areas of the Michigan

and Illinois Basins. Dry holes are rare.

Nevertheless, there are inherent reservoir risks.

What tools are being used to detect risky drilling areas?

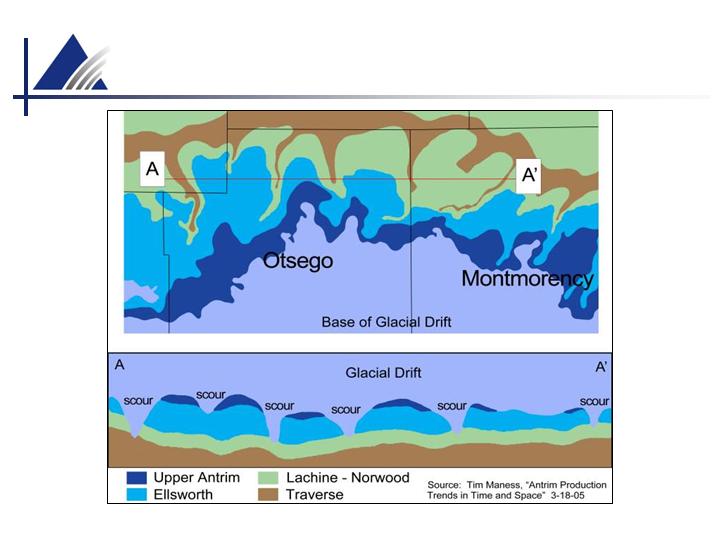

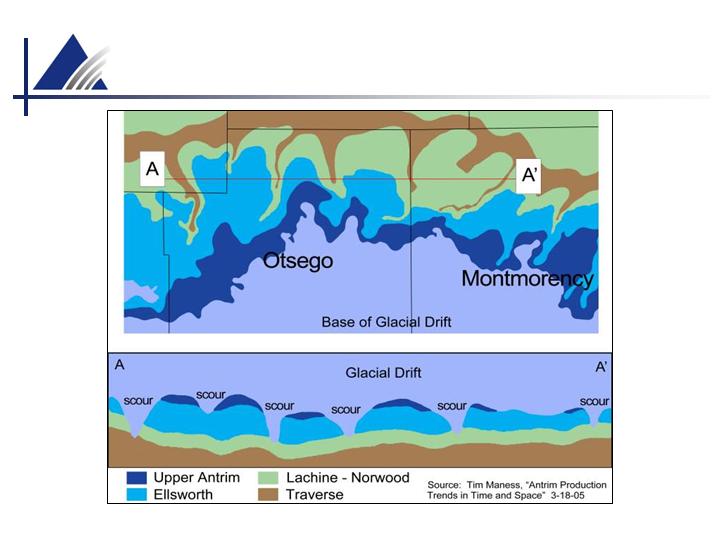

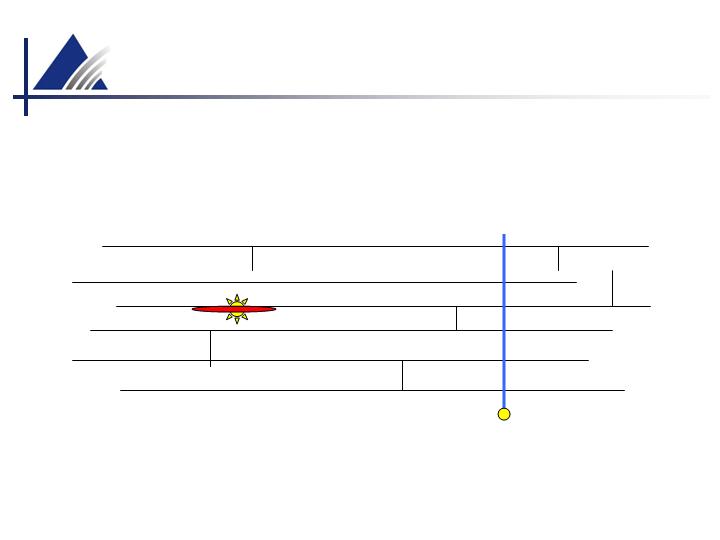

Identification of Antrim Shale Scours

The Antrim Shale is partially or totally absent

in localized areas where ancient rivers and

glaciers have carved through the bedrock

This results in the drilling of dry holes unless

the scours can be identified in advance

Illustration of Antrim Shale Scours

Gravity Survey

Seismic can be used to

identify scours, but gravity

surveys provide an

inexpensive alternative

Identification of Antrim Shale Scours

Gravimeter

Antrim Shale Fracture Stimulations

How has Aurora optimized stimulations

of vertical Antrim Shale wells?

Primary Objectives:

Contact all potential pay

Reduce gel loadings to maximize fracture

conductivity

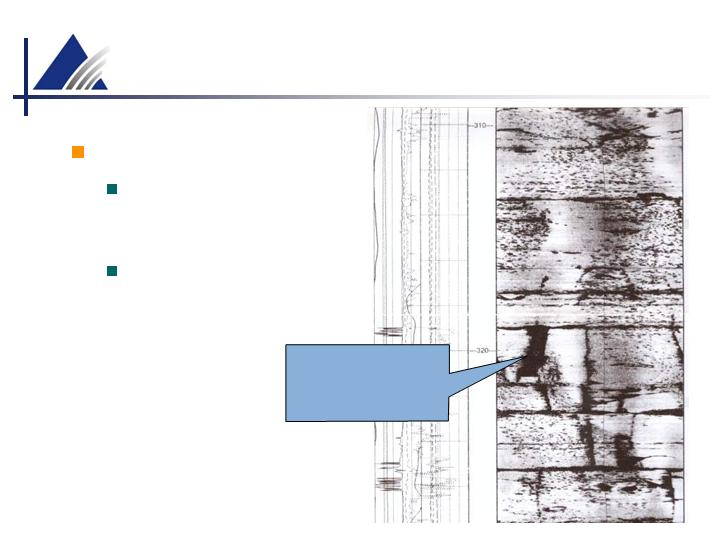

Antrim Shale Fracture Stimulations

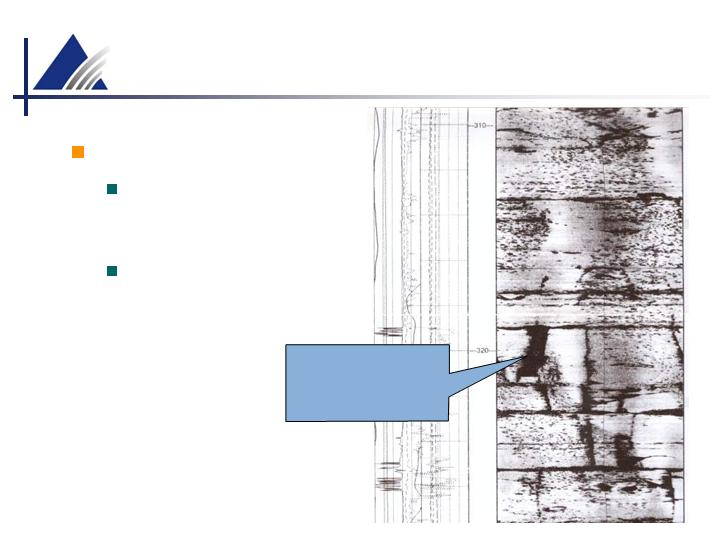

Antrim Shale Well Log

Intervals of natural

fracturing: focus of

completion intervals

Bedding planes:

containment for fracture

stimulations

Black images

indicate fracturing

in the wellbore

Antrim Shale Fracture Stimulations

Aurora Procedure

300+ Perforations

Acid Wash Foot-By-Foot

4-stage Frac

Low Gel Guar-Borate System

Photos and illustrations courtesy of

BJ Services Company, U.S.A.

Operational Efficiencies

How has Aurora optimized the

production infrastructure for Antrim

Shale wells?

Primary Objectives:

Minimize back

pressure to maximize

gas desorption

Minimize

environmental

exposure

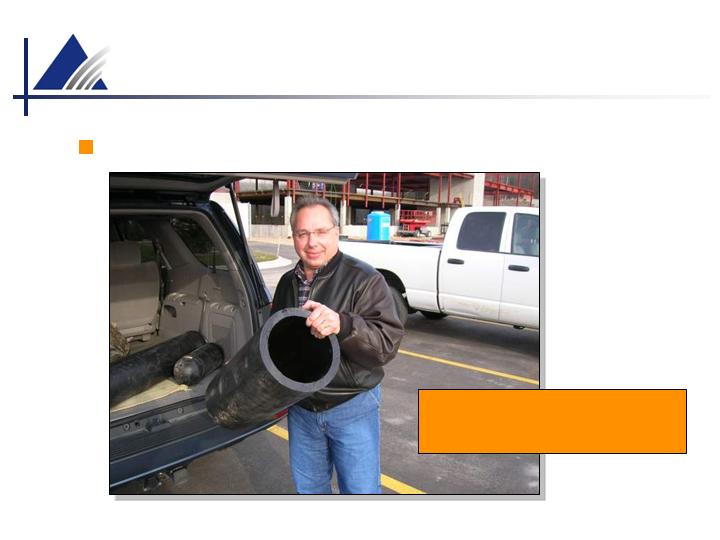

Operational Efficiencies

Low Pressure Gathering Systems

10" Poly Pipe used as flow

lines for gas and water

Use of Large Diameter Poly Pipe

Operational Efficiencies

Low Pressure Gathering Systems

Separate systems for gas and water

Gas and water lines

prior to burial

Operational Efficiencies

Low Pressure Gathering Systems

Flowline Sumps

Some water is entrained in

gas flowing from wells to

facilities

In areas of extreme

elevation changes, water

tends to collect in low spots

Electric water sumps are

installed to transfer water

from gas flowlines to water

flowlines in areas of difficult

access

This enables us to maintain

low wellhead pressures and

reduce frequency of pigging

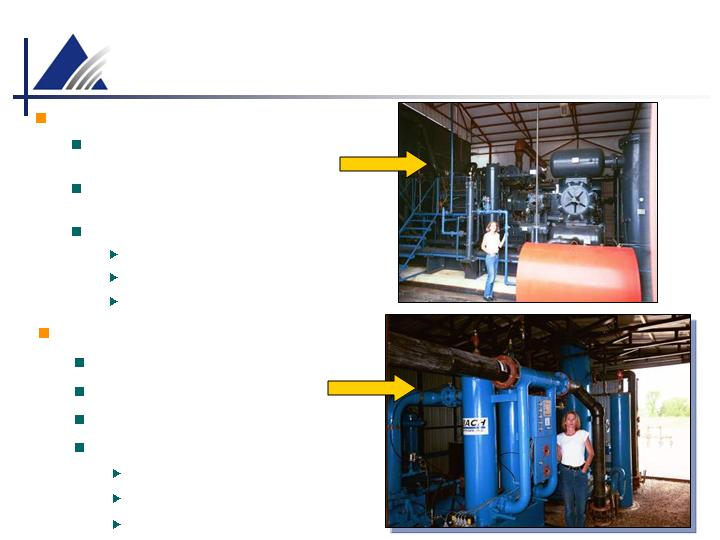

Operational Efficiencies

Low Pressure Production Facilities

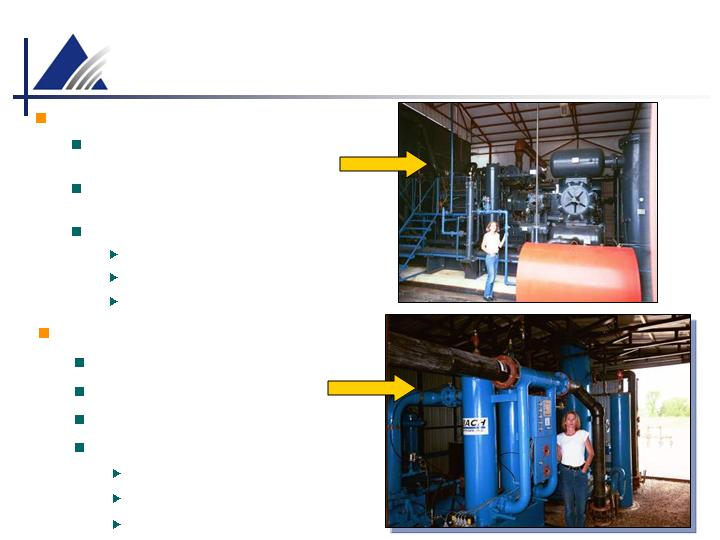

Traditional Reciprocating

Compressor Unit

Aurora’s Skid-Mounted

Compressor and Separator

Modular Screw Compressors

Flexibility in placement

Parallel or series

Single or 2-stage compression

Electric

Lower capital cost

Lower maintenance

Environmentally preferable

Reciprocating Compressors

Large size of units precludes

throughput flexibility

Typically up to 4 stages of

compression

Gas Driven

High capital cost

High maintenance

LOUD!

Operational Efficiencies

Low Pressure Production Facilities

Traditional Gas

Processing Facility

Aurora’s Low Pressure

Gas Processing Facility

BIG

small

Operational Efficiencies

Low Pressure CO2 Processing

Low Pressure Carbon Dioxide

Extraction

CO2 extracted at 100 psi

Less horsepower and fuel

required

Prototype installed in 2003

High Pressure Carbon Dioxide Extraction

Raw methane - CO2 mix compressed as necessary to enter sales line

(typically 1200 psig or greater)

CO2 removed by third party downstream and vented to atmosphere

Operational Efficiencies

Water Disposal

Tank-less Water

Disposal

Lower capital cost

Low profile automated

water handling system

has environmental

advantages

Would you want these

eyesores in your back yard?

Operational Efficiencies

Advantages of Aurora’s Low Pressure System

Significant reduction in capital expenditures

Increased production rates due to reduced

back pressure on wells

Commercial life of wells extended due to

reduced costs

Facility capacities can be optimized over life

of wells

Moving Forward

What innovations are currently

being implemented by Aurora?

Electric Submersible Pumps (ESP’s)

installed on Composite Coiled Tubing

Horizontal Drilling Designed to

Minimize Back Pressure

ESP Installations On Composite Coiled Tubing

Developed by

collaboration of Aurora

with two vendors

Patent pending on

ESP/composite tubing

connection

Composite coiled

tubing unit owned by

Aurora

No rig required -

significant cost savings

6 units currently

installed

Longest installation to

date is 3 months

6 additional units to be

installed over next 30

days

Horizontal Drilling Premise

New Albany Shale

Large vertical fractures

Predominant fracture orientation is E-W

Occurrence of N-S fracturing is limited

Horizontal drilling is the only effective means

to connect fracture planes

Orthogonal Vertical Fractures

Non-uniform Spacing

Characteristics of Natural Fractures

New Albany Shale

Vertical Well with

Fracture Stimulation

Horizontal Well

Drilling & Completion Objectives

New Albany Shale

Avoid plugging of natural fractures while drilling

Complete laterals open hole with no stimulation

Recover gas reserves from all organic members

Optimize drilling geometry and pump

selection/placement for water removal and

reduction of back pressure

Minimize surface footprint and optimize access to

locations

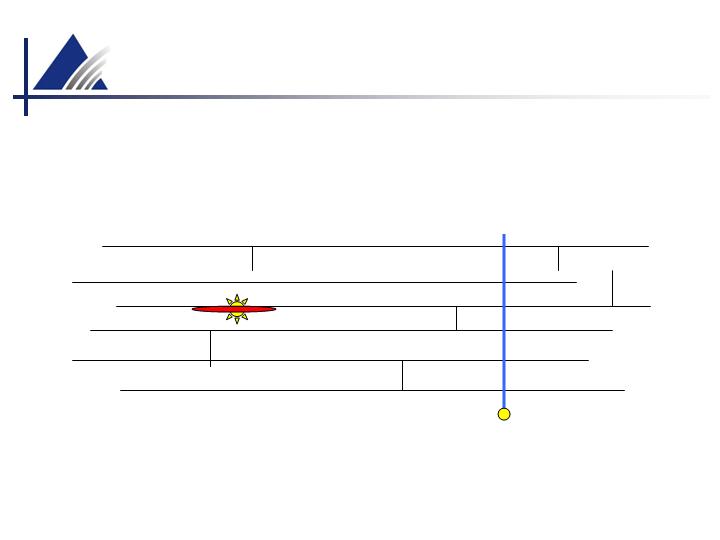

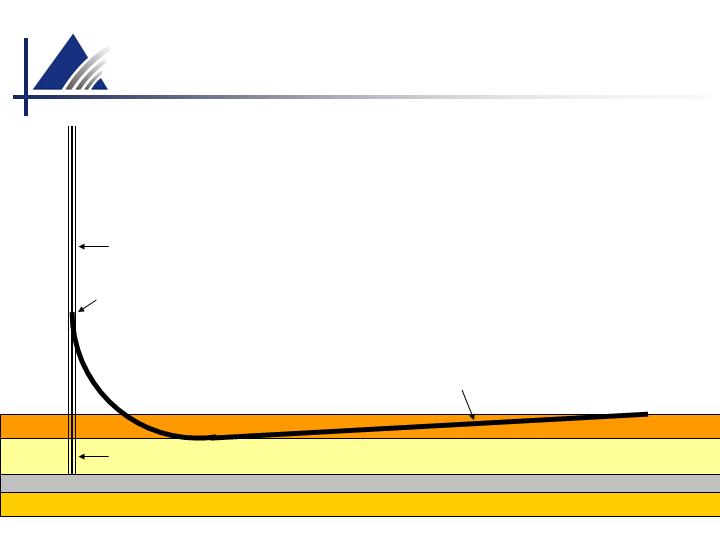

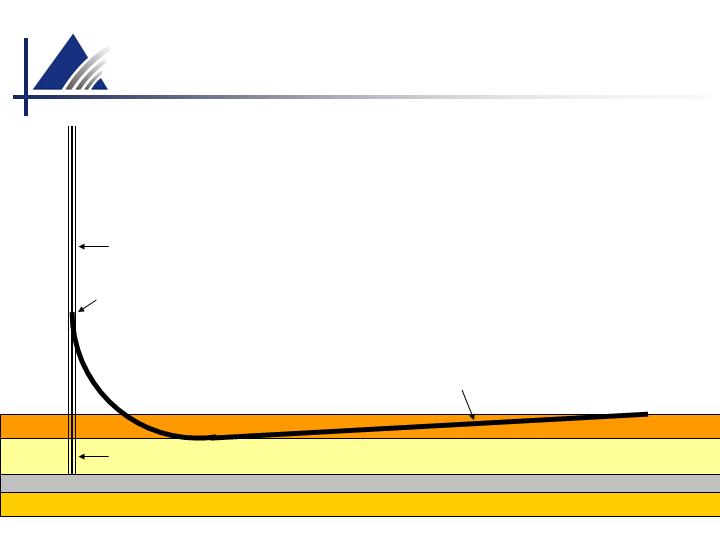

Horizontal Well – Typical Geometry

New Albany Shale

Window Milled in Casing at

KOP (Spill Point)

Cased Sump for

Pump

Open Hole Lateral

Clegg Creek

Camp Run /

Morgan Trail

Selmier

Blocher

Vertical Pilot Hole / Medium Radius / Open Hole

Lateral

- Gravity drainage to heel of lateral

- Fluid must overcome vertical distance to spill point

7” or 5-1/2” Casing Set at TD

Horizontal Well – Preferred Geometry

New Albany Shale

7” or 5-1/2” Casing

Set at KOP in Borden

Shale

Open Hole Lateral

Underreamed

Sump for Pump

Vertical Producer

(Water Production)

Pilot Hole for

Laterals

(Gas Production)

Clegg Creek

Camp Run /

Morgan Trail

Selmier

Blocher

Vertical Producer at Toe of Horizontal Well

- Gravity drainage to sump at toe of lateral

- Gas will travel uphole to pilot hole for laterals

- Water will travel downhole to vertical producer

- Declining lateral trajectory easier to drill

- More conducive to traversing deeper members

7” Casing Set at Top

New Albany Shale

Alternate Lateral

Questions?

Contact:

Jeffrey W. Deneau - Investor Relations

Aurora Oil & Gas Corp.

4110 Copper Ridge Drive, Suite 100

Traverse City, MI 49684

www.auroraogc.com

T: 231-941-0073

E: jdeneau@auroraogc.com

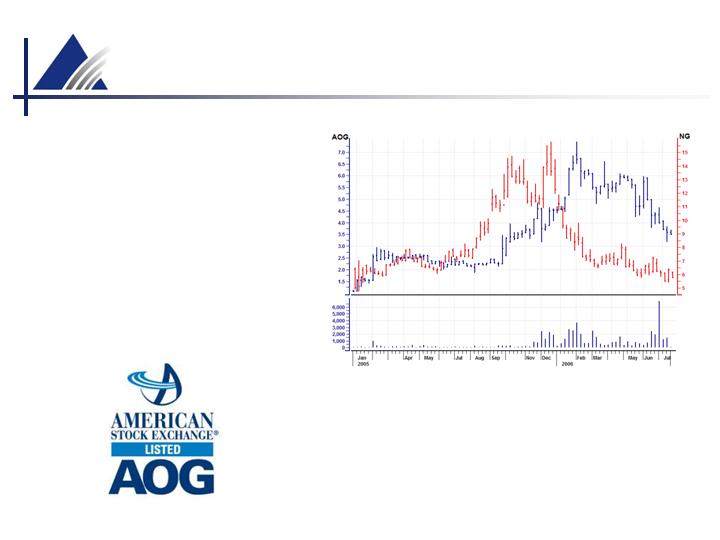

Share Price: $3.60

Shares Outstanding: 81.69M

Market Cap: $294M

*Price-related figures based on close 7/14/06