Exhibit 99.2

Forward Looking Statements

ASML

Public

This document contains statements relating to certain projections and business trends that are forward-looking, including statements with respect to productivity of our tools and systems performance, EUV system performance, expected industry trends, and EUV targets (including availability, productivity and shipments) and roadmaps. You can generally identify these statements by the use of words like “may”, “will”, “could”, “should”, “project”, “believe”, “anticipate”, “expect”, “plan”, “estimate”, “forecast”, “potential”, “intend”, “continue” and variations of these words or comparable words. These statements are not historical facts, but rather are based on current expectations, estimates, assumptions and projections about the business and our future financial results and readers should not place undue reliance on them. Forward-looking statements do not guarantee future performance and involve risks and uncertainties. These risks and uncertainties include, without limitation, the impact of manufacturing efficiencies and capacity constraints, performance of our systems, the continuing success of technology advances and the related pace of new product development and customer acceptance of new products, the number and timing of EUV systems expected to be shipped and recognized in revenue, delays in EUV systems production and development, our ability to enforce patents and protect intellectual property rights, the risk of intellectual property litigation, availability of raw materials and critical manufacturing equipment and other risks indicated in the risk factors included in ASML’s Annual Report on Form 20-F and other filings with the US Securities and Exchange Commission. These forward-looking statements are made only as of the date of this document. We do not undertake to update or revise the forward-looking statements, whether as a result of new information, future events or otherwise.

ASML

NXE 3300

Public

ASML

EUV lithography performance for manufacturing: status and outlook

Alberto Pirati

ASML Netherlands B.V., De Run 6501, 5504 DR Veldhoven, The Netherlands

SPIE 2016

ASML

Public

Slide 3

23 Feb 2016

Special appreciation to:

Matthew Colburn of IBM

Dan Corliss of IBM

Danilo de Simone of IMEC

Tony Yen of TSMC

Britt Turkot of Intel corporation

Chang Moon Lim of SK Hynix

Seong Sue Kim of Samsung Electronics

Andrew Grenville of Inpria

Martin Lowisch of Zeiss

ASML:

Rudy Peeters

Daniel Smith

Roderik van Es

Eric Verhoeven

Jo Finders

Arthur Minnaert

Marrit Hermens

Eelco van Setten

Lisa Mohanty

Jan-Willem van der Horst

Jan van Schoot

Jeannot Driedonkx

Sander Hofman

Niclas Mika

Bill Arnold

Derk Brouns

Joerg Mallmann

Daniel Brown

Christophe Smeets

Kars Troost

Rik Hoefnagels

Gijsbert Rispens

Raymond Maas

Hans Meiling

Judon Stoeldraijer

Herman Boom

Christian Wagner

Sjoerd Lok

Uwe Stamm

Michael Purvis

Alex Schafgans

Igor Fomenkov

Michael Lercel

David Brandt

Geert Fisser

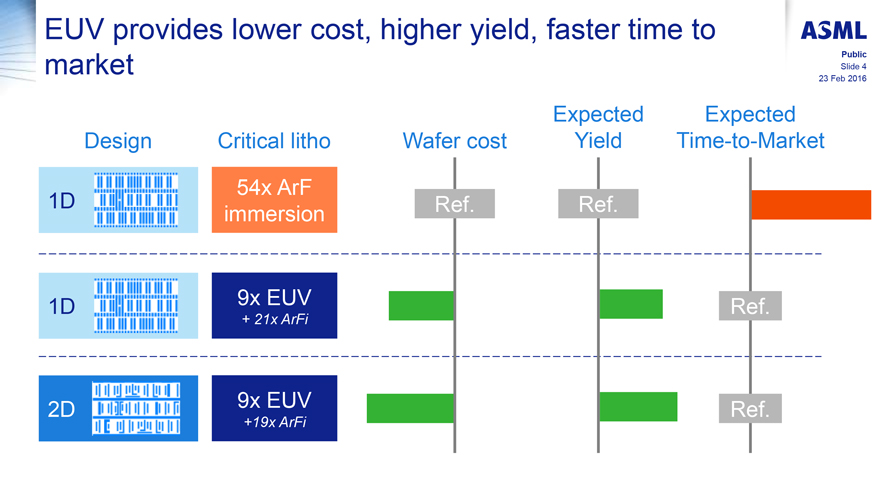

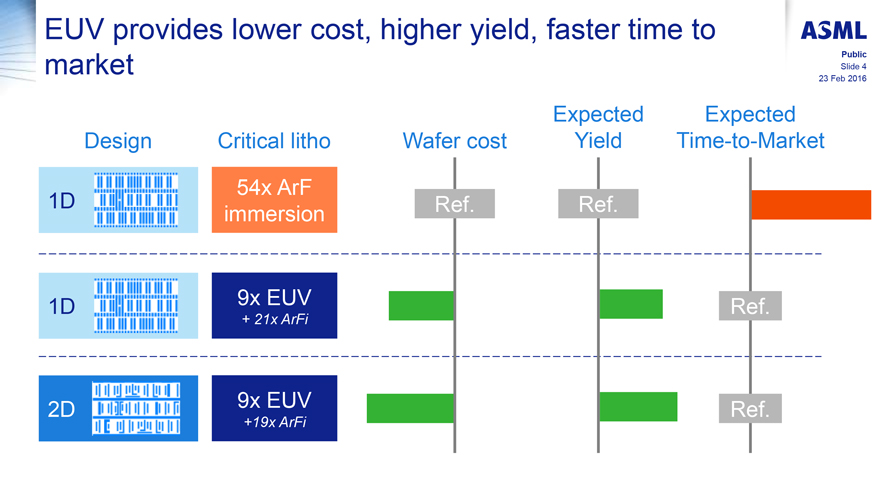

EUV provides lower cost, higher yield, faster time to market

ASML

Public

Slide 4

23 Feb 2016

1D

1D

2D

Design

Critical litho

54x ArF

immersion

9x EUV

+ 21x ArFi

9x EUV

+19x ArFi

Wafer cost

Ref.

Expected

Yield

Ref.

Expected

Time-to-Market

Ref.

Ref.

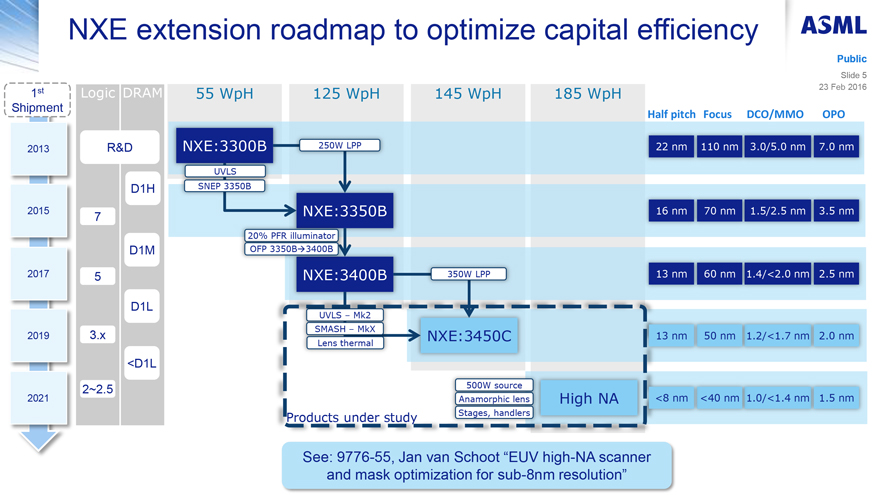

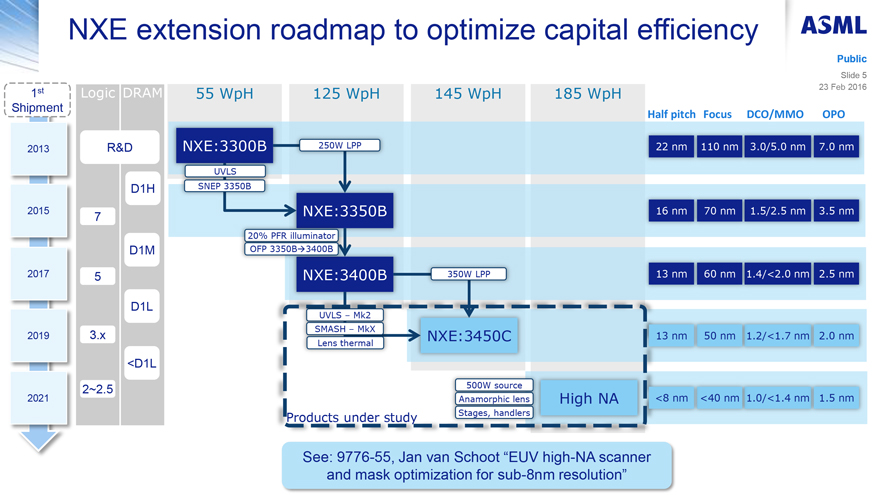

NXE extension roadmap to optimize capital efficiency

ASML

Public

Slide 5

23 Feb 2016

1st

Shipment

2013

20157

20175

2019

2021

Logic DRAM

R&D

D1H

D1M

D1L

3.x

<D1L

2~2.5

55 WpH

NXE:3300B

UVLS

SNEP 3350B

20% PFR illuminator

OFP 3350B 3400B

125 WpH

250W LPP

NXE:3350B

NXE:3400B

UVLS – Mk2

SMASH – MkX

Lens thermal

145 WpH

350W LPP

NXE: 3450C

500W source

Anamorphic lens

Stages, handlers

Products under study

185 WpH

Half pitch Focus

22 nm 16 nm 13 nm 13 nm <8 nm

DCO/MMO OPO

110 nm 3.0/5.0 nm 7.0 nm 70 nm

1.5/2.5 nm 3.5 nm

60 nm

1.4/<2.0 nm

2.5 nm

50 nm

1.2/<1.7 nm

2.0 nm

<40 nm

1.0/<1.4 nm

1.5 nm

See: 9776-55, Jan van Schoot “EUV high-NA scanner and mask optimization for sub-8nm resolution”

Outline

ASML NXE 3300

ASML

Public

Slide 6

23 Feb 2016

Throughput & Wafers per Day (WpD)

Availability

Defectivity, imaging and overlay

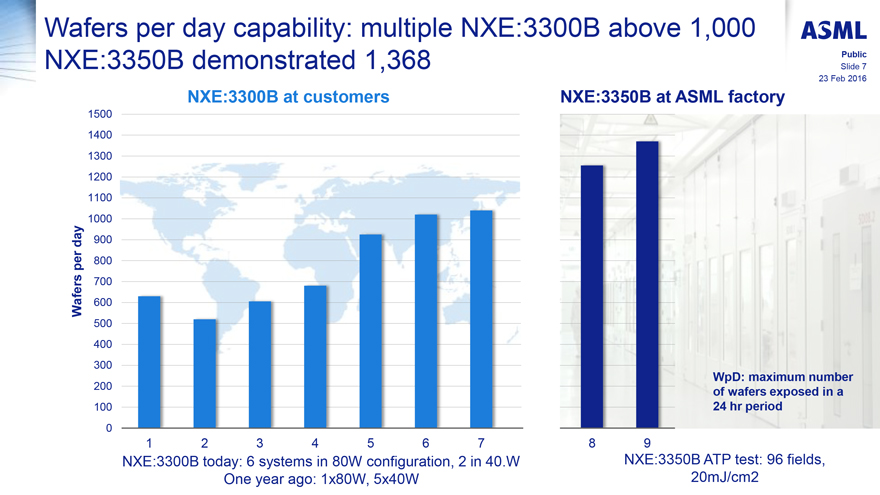

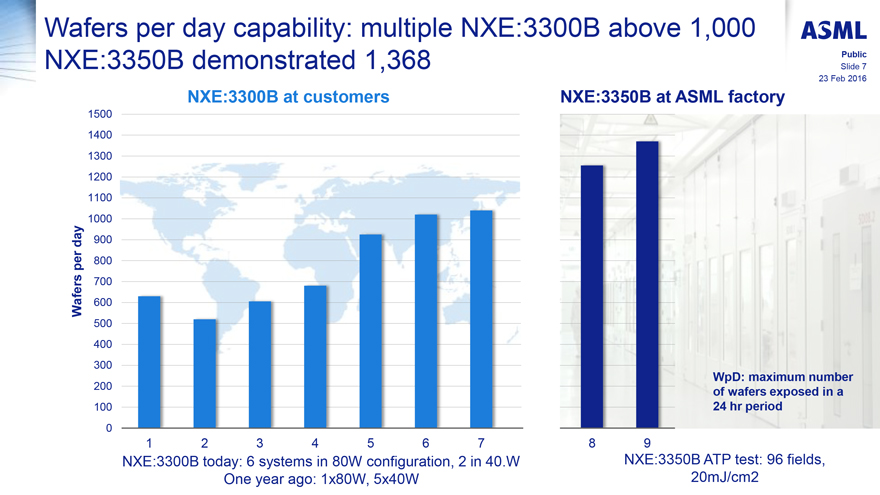

Wafers per day capability: multiple NXE:3300B above 1,000

NXE:3350B demonstrated 1,368

ASML

Public

Slide 7

23 Feb 2016

NXE:3300B at customers

NXE:3350B at ASML factory

1500

1400

1300

1200

1100

1000

day

900

per

800

700

Wafers

600

500

400

300

200

100

0

1

2

3

4

5

6

7

8

9

WpD: maximum number of wafers exposed in a

24 hr period

NXE:3300B today: 6 systems in 80W configuration, 2 in 40.W

One year ago: 1x80W, 5x40W

NXE:3350B ATP test: 96 fields,

20mJ/cm2

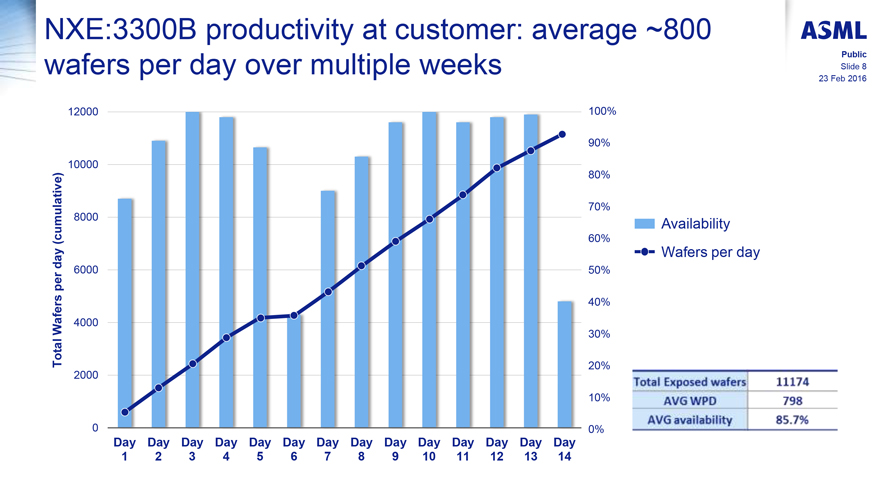

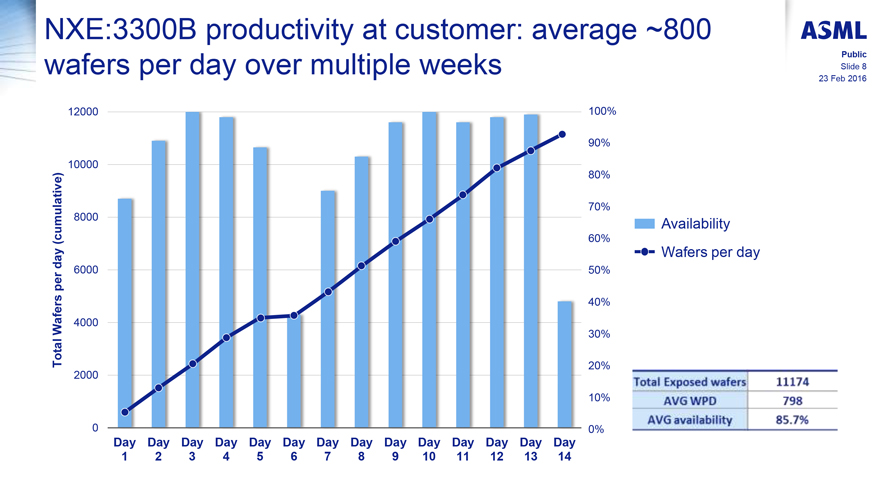

NXE:3300B productivity at customer: average ~800

wafers per day over multiple weeks

ASML

Public

Slide 8

23 Feb 2016

Total Wafers per day (cumulative)

12000

10000

8000

6000

4000

2000

0

100%

90%

80%

70%

60%

50%

40%

Availability

30%

Wafers per day

20%

10%

0%

Total Exposed Wafers

11174

AVG WPD

798

AVG availability

85.7%

Day Day Day Day Day Day Day Day Day Day Day Day Day Day

1 2 3 4 5 6 7 8 9 10 11 12 13 14

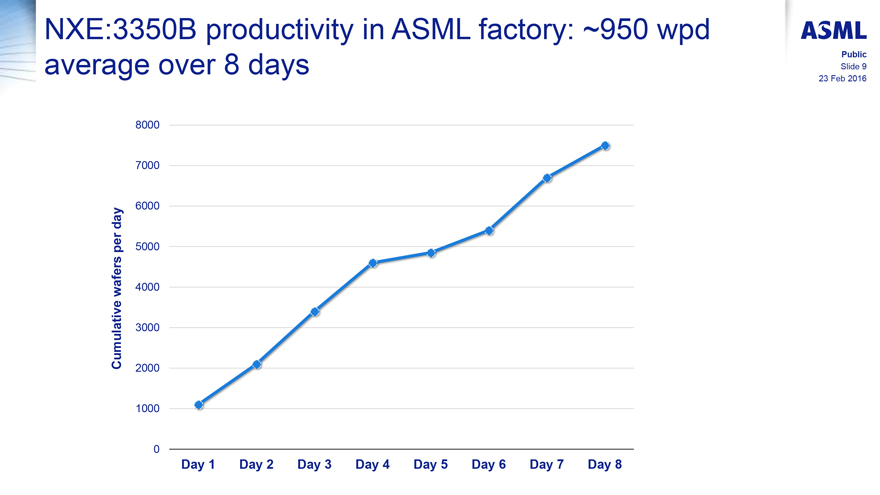

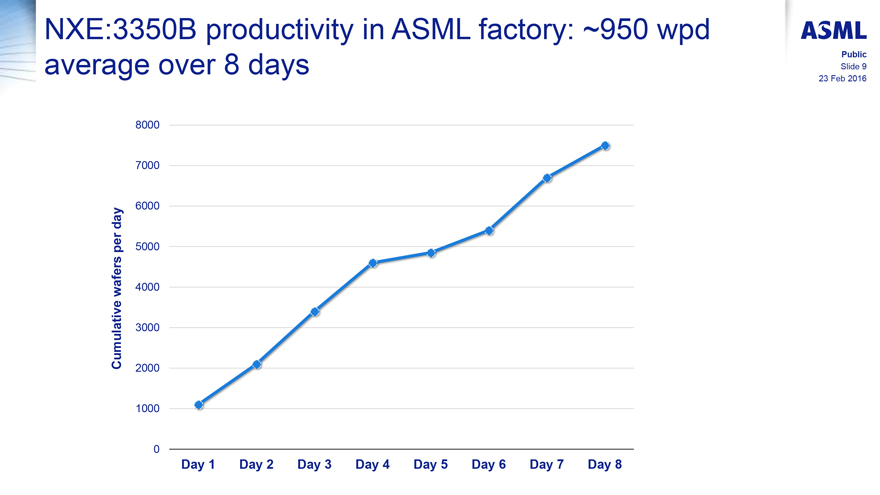

NXE:3350B productivity in ASML factory:

~950 wpd

average over 8 days

ASML

Public

Slide 9

23 Feb 2016

Cumulative wafers per day

8000

7000

6000

5000

4000

3000

2000

1000

0

Day 1

Day 2

Day 3

Day 4

Day 5

Day 6

Day 7

Day 8

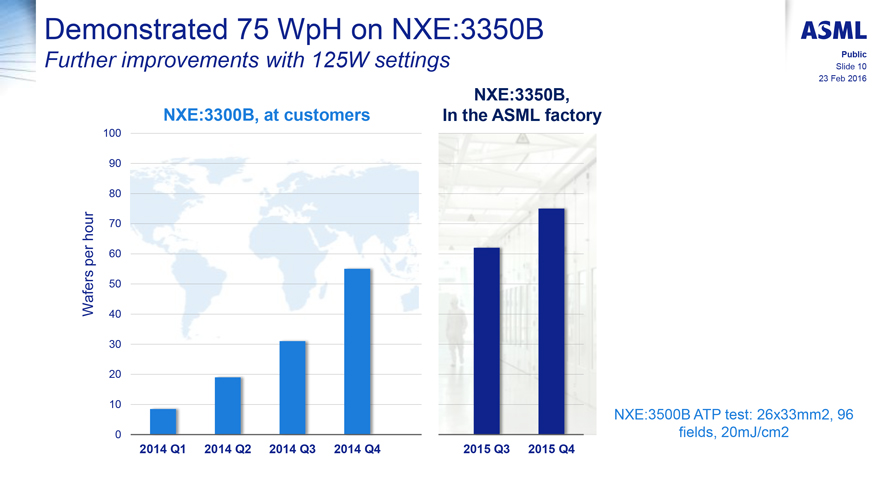

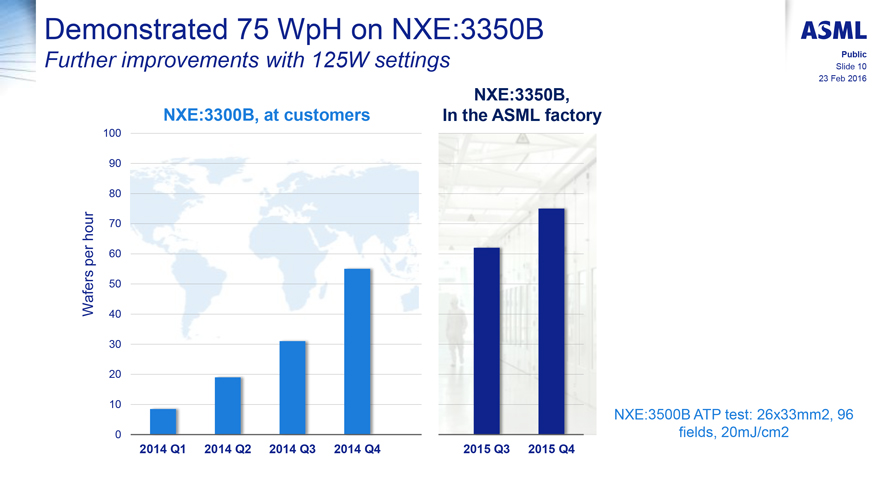

Demonstrated 75 WpH on NXE:3350B

Further improvements with 125W settings

ASML

Public

Slide 10

23 Feb 2016

Wafers per hour

NXE:3300B, at customers

NXE:3350B,

In the ASML factory

100

90

80

70

60

50

40

30

20

10

0

2014 Q1

2014 Q2

2014 Q3

2014 Q4

2015 Q3

2015 Q4

NXE:3500B ATP test: 26x33mm2, 96 fields, 20mJ/cm2

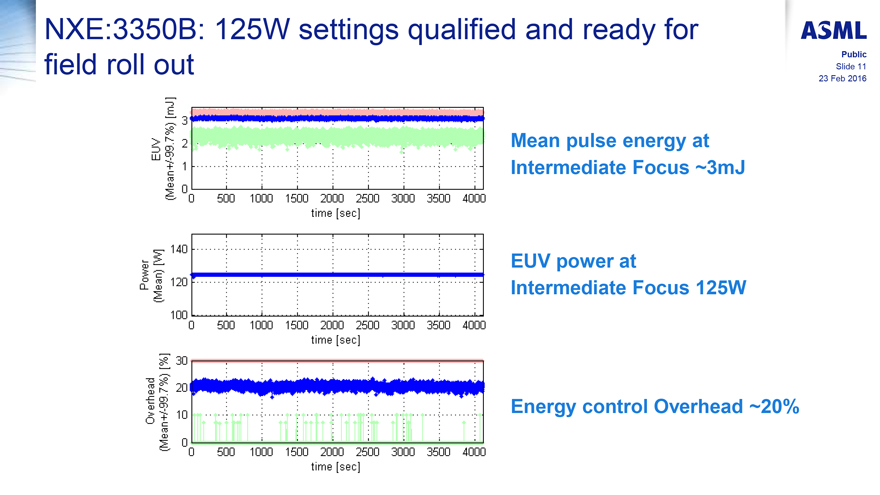

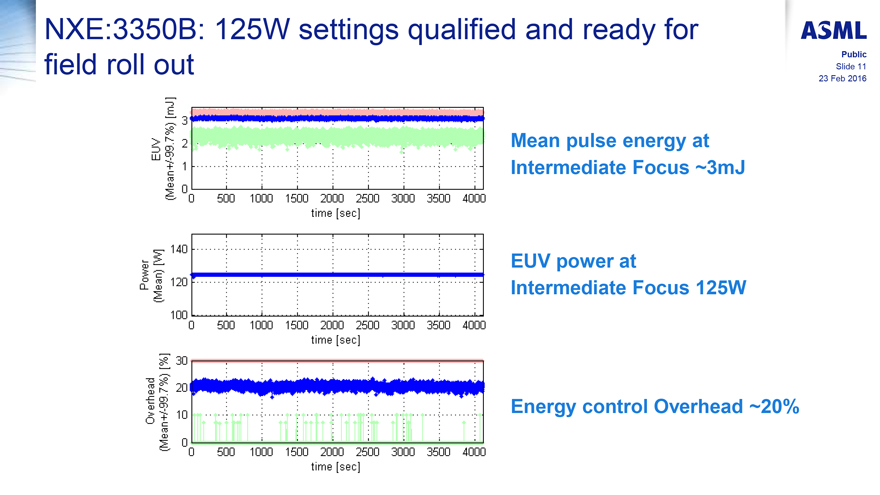

NXE:3350B: 125W settings qualified and ready for field roll out

ASML

Public

Slide 11

23 Feb 2016

Euv

(Mean+/-99.7%) [mJ]

0 1 2 3

0 500 1000 1500 2000 2500 3000 3500 4000

time [sec]

Mean pulse energy at Intermediate Focus ~3mJ

Power (Mean) [W]

140 120 100

0 500 1000 1500 2000 2500 3000 3500 4000

time [sec]

EUV power at Intermediate Focus 125W

Overhead

(Mean+/-99.7%) [%]

0 10 20 30

0 500 1000 1500 2000 2500 3000 3500 4000

time [sec]

Energy control Overhead

~20%

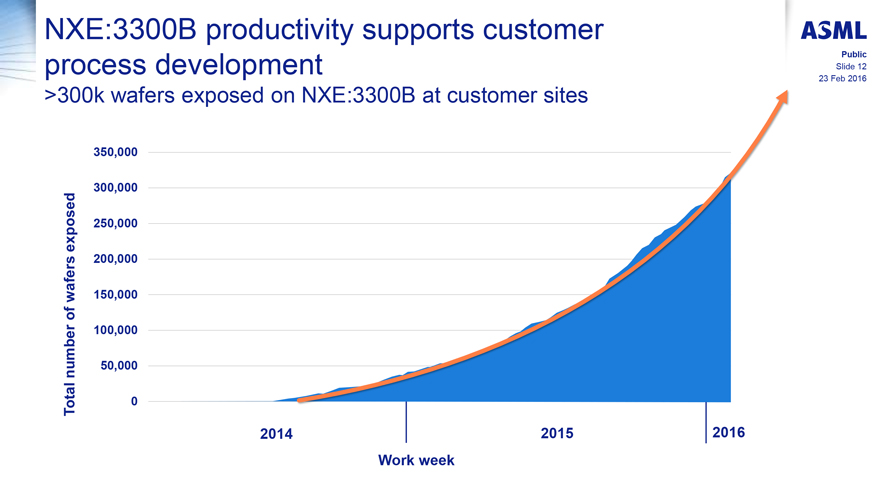

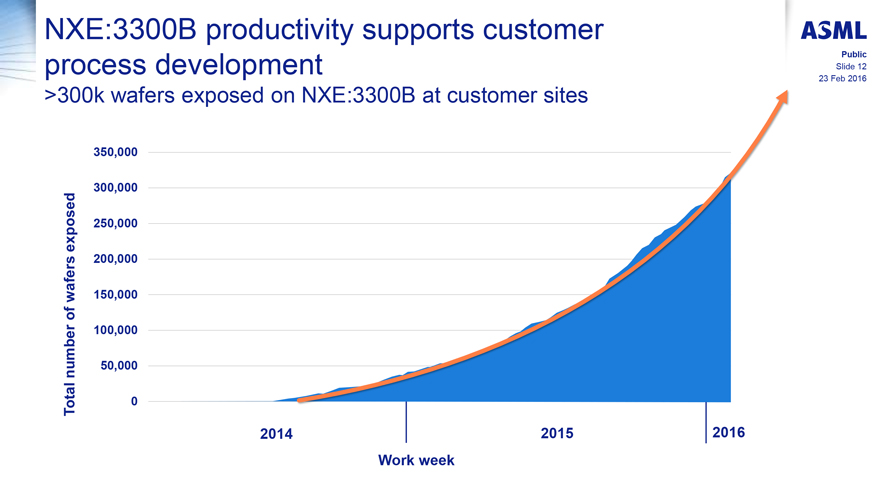

NXE:3300B productivity supports customer process development

>300k wafers exposed on NXE:3300B at customer sites

ASML

Public

Slide 12

23 Feb 2016

Total number of wafers exposed

350,000

300,000

250,000

200,000

150,000

100,000

50,000

0

2014

2015

2016

Work week

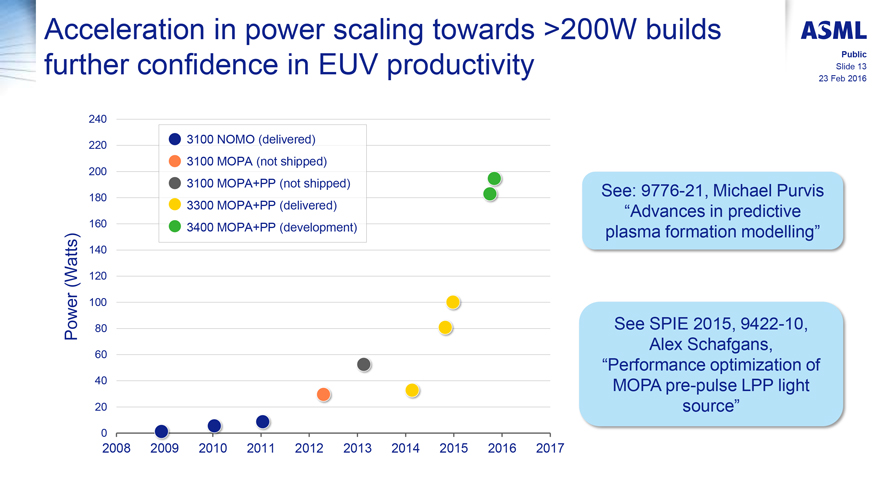

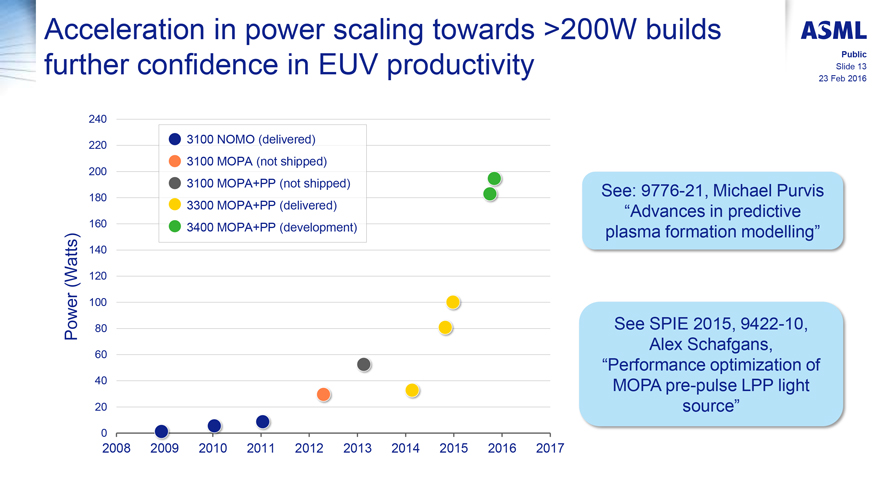

Acceleration in power scaling towards >200W builds further confidence in EUV productivity

ASML

Public

Slide 13

23 Feb 2016

240

220

3100 NOMO (delivered)

200

3100 MOPA (not shipped)

180

3100 MOPA+PP (not shipped)

See: 9776-21, Michael Purvis “Advances in predictive plasma formation modelling”

160

3300 MOPA+PP (delivered)

See SPIE 2015, 9422-10, Alex Schafgans, “Performance optimization of MOPA pre-pulse LPP light source”

140

3400 MOPA+PP (development)

120

100

Power (Watts)

80

60

40

20

0

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

Outline

ASML

Public

Slide 14

23 Feb 2016

Throughput & Wafers per Day (WpD)

Availability

Defectivity, imaging and overlay

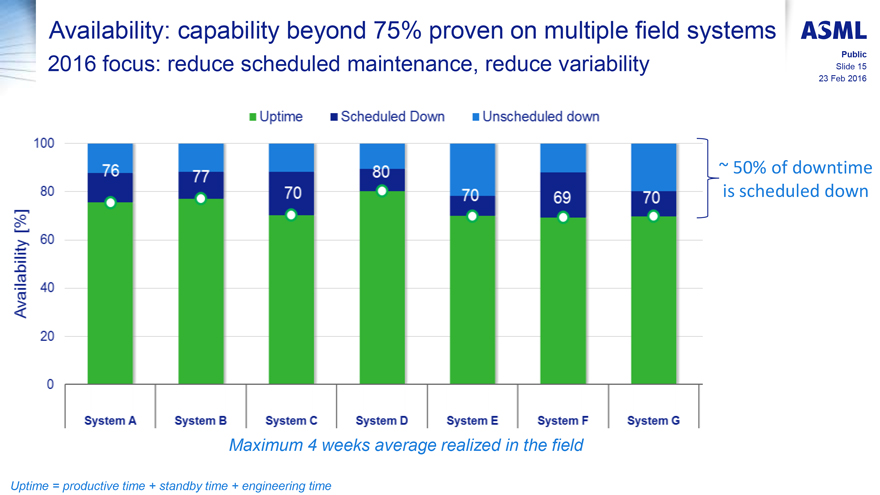

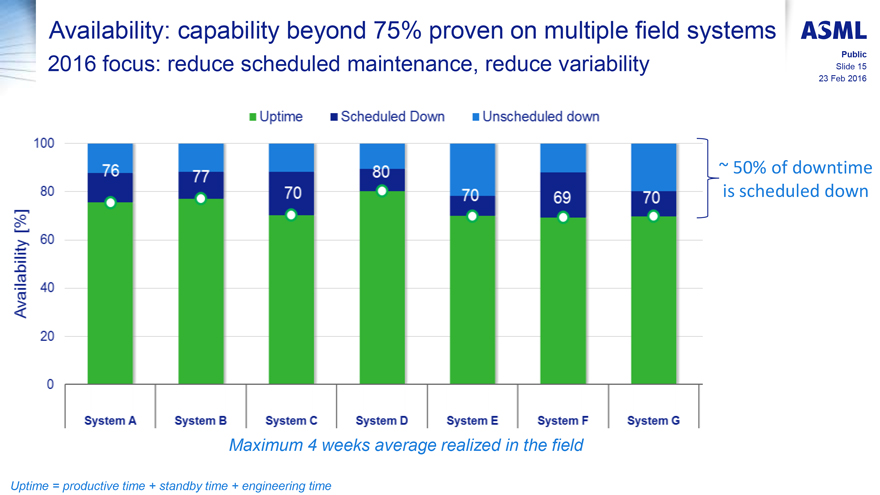

Availability: capability beyond 75% proven on multiple field systems

2016 focus: reduce scheduled maintenance, reduce variability

ASML

Public

Slide 15

23 Feb 2016

Uptime Scheduled Down Unscheduled down

Availability [%]

0 20 40 60 80 100

76 77 70 80 70 69 70

~50% of downtime is scheduled down

System A System B System C System D System E System F System G

Maximum 4 weeks average realized in the field

Uptime = productive time + standby time + engineering time

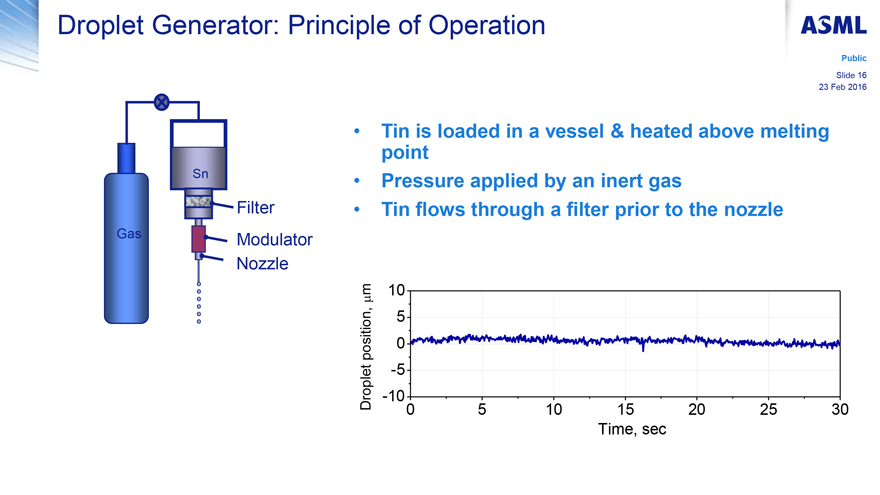

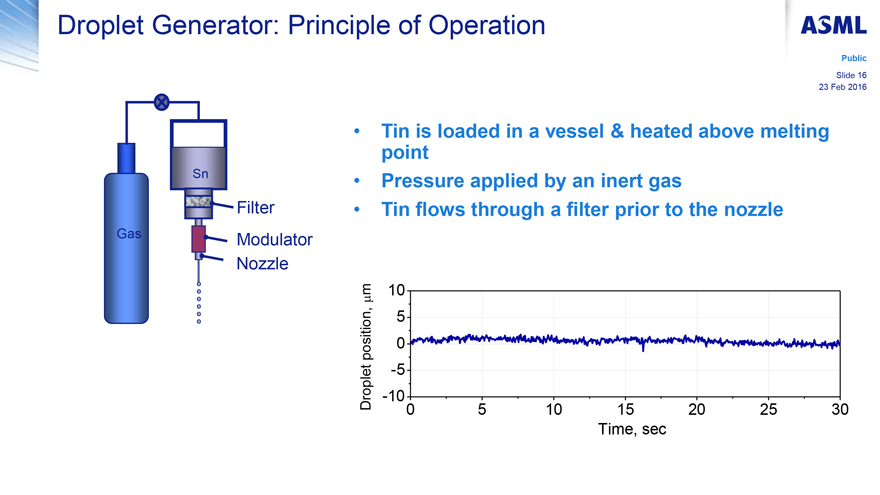

Droplet Generator: Principle of Operation

ASML

Public

Slide 16

23 Feb 2016

Sn

Gas

Filter

Modulator

Nozzle

Tin is loaded in a vessel & heated above melting point

Pressure applied by an inert gas

Tin flows through a filter prior to the nozzle

Droplet

position,

m

10

5

0

-5

-10

0

5

10

15

20

25

30

Time, sec

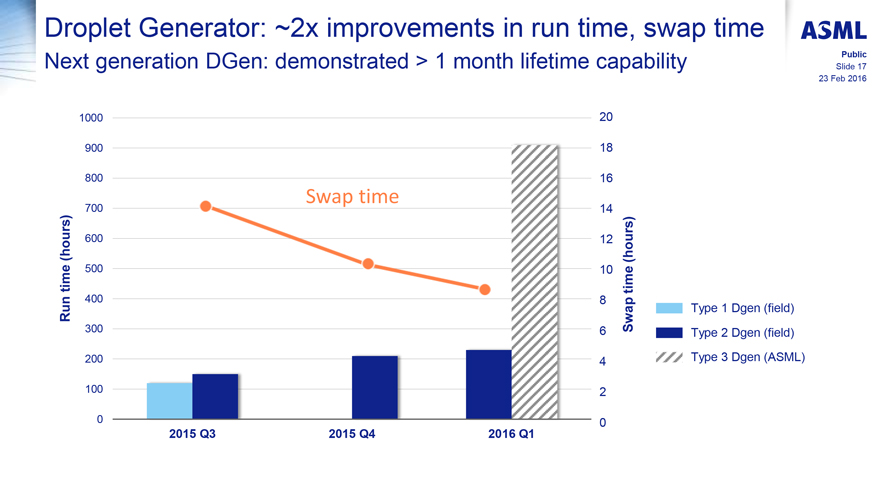

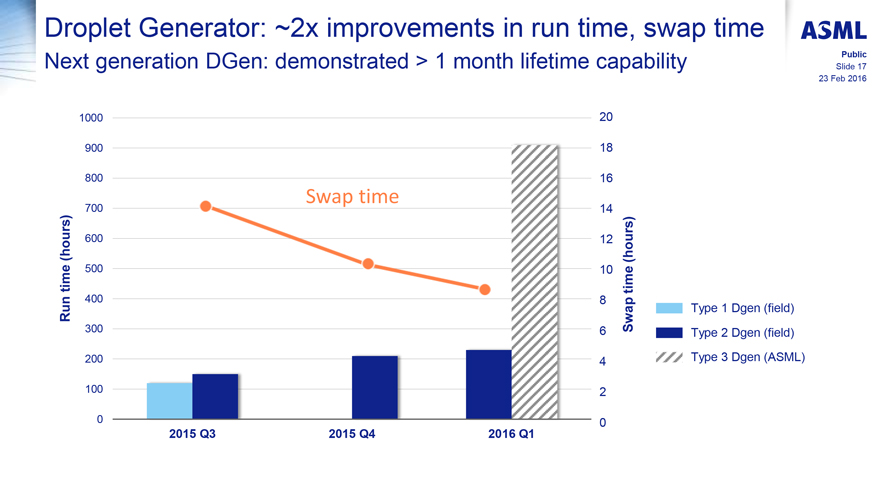

Droplet Generator: ~2x improvements in run time, swap time

Next generation DGen: demonstrated > 1 month lifetime capability

ASML

Public

Slide 17

23 Feb 2016

Run time (hours)

1000

900

800

700

600

500

400

300

200

100

0

Swap time

2015 Q3

2015 Q4

2016 Q1

20

18

16

14

12

10

8

6

4

2

0

Swap time (hours)

Type 1 Dgen (field)

Type 2 Dgen (field)

Type 3 Dgen (ASML)

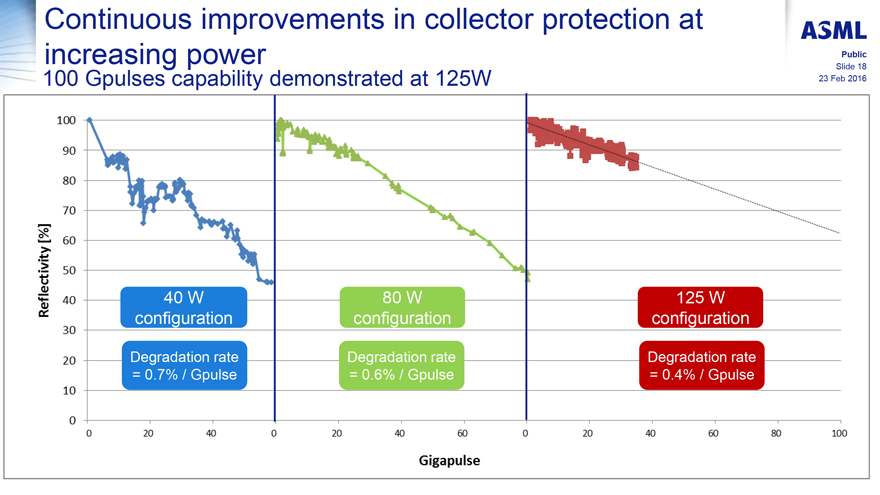

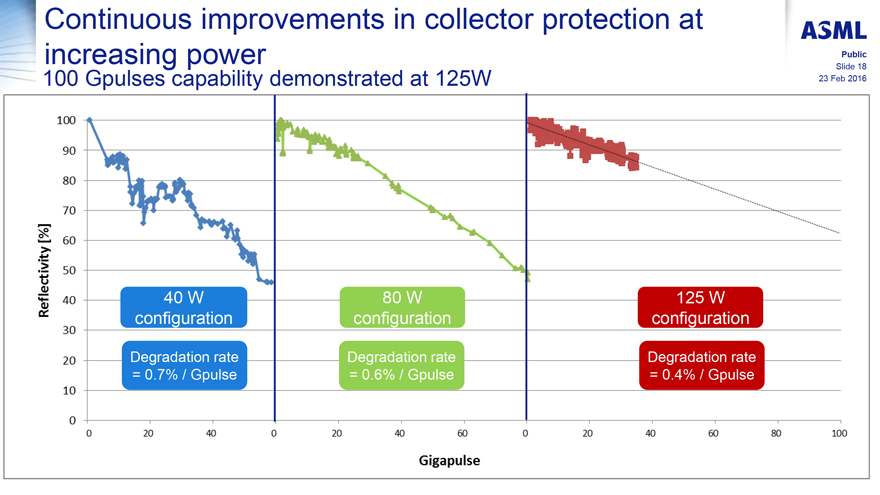

Continuous improvements in collector protection at increasing power

100 Gpulses capability demonstrated at 125W

ASML

Public

Slide 18

23 Feb 2016

Reflectivity [%]

100

90

80

70

60

50

40

30

20

10

0

0

20

40

0

20

40

60

0

20

40

60

80

100

40 W Configuration

Degradation rate = 0.7% / Gpulse

80 W Configuration

Degradation rate = 0.6% / Gpulse

125 W Configuration

Degradation rate = 0.4% / Gpulse

Gigapulse

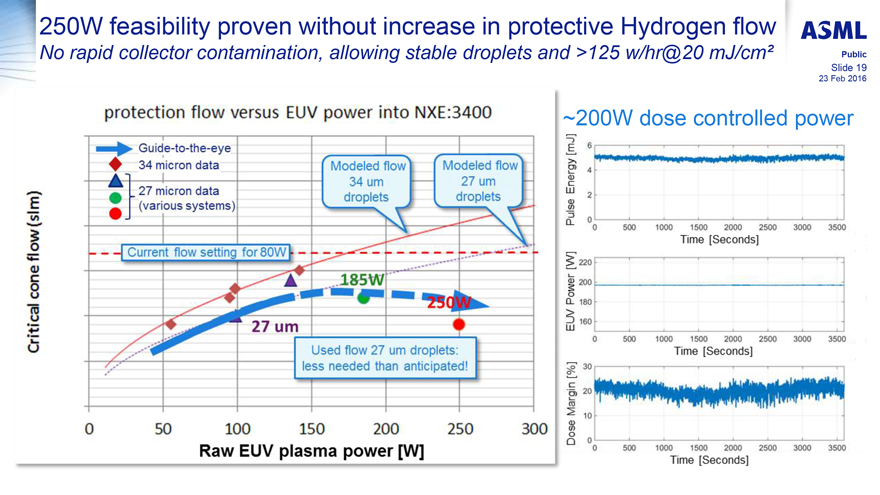

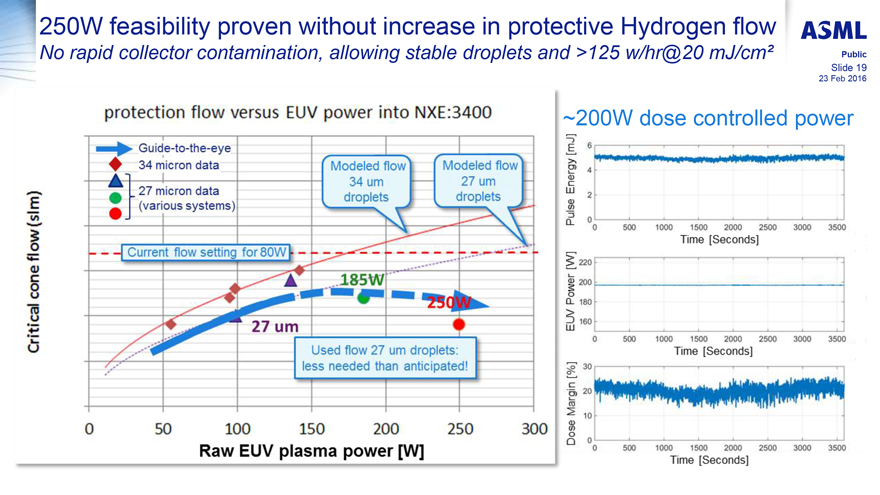

250W feasibility proven without increase in protective Hydrogen flow

No rapid collector contamination, allowing stable droplets and >125 w/hr@20 mJ/cm²

ASML

Public

Slide 19

23 Feb 2016

protection flow versus EUV power into NXE:3400

Critical cone flow (slm)

Guide-to-the-eye

34 micron data

27 micron data

(various systems)

Current flow setting for 80W

27 um 185 W 250 W

Used flow 27 um droplets: less needed than anticipated!

Modeled flow 34 um droplets

Modeled flow 27 um droplets

0

50

100

150

200

250

300

~200W dose controlled power

Pulse Energy [mJ]

6

4

2

0

0

500

1000

1500

2000

2500

3000

3500

Time [Seconds]

EUV Power [W]

220

200

180

160

0

500

1000

1500

2000

2500

3000

3500

Time [Seconds]

Dose Margin [%]

30

20

10

0

0

500

1000

1500

2000

2500

3000

3500

Time [Seconds]

Raw EUV plasma power [W]

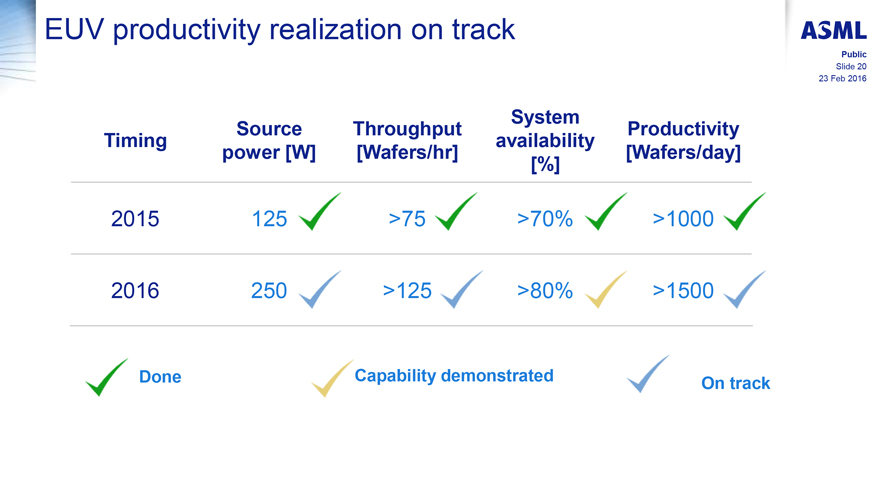

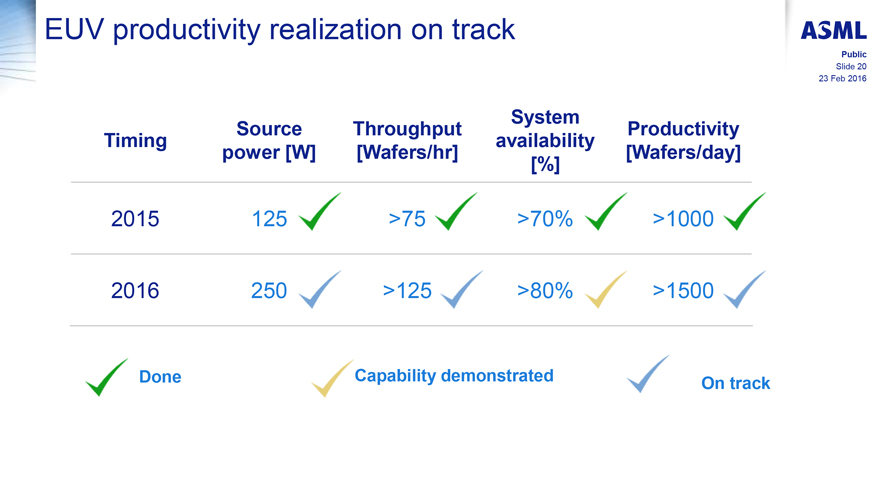

EUV productivity realization on track

ASML

Public

Slide 20

23 Feb 2016

Timing

Source power [W]

Throughput [Wafers/hr]

System availability [%]

Productivity [Wafers/day]

2015

125

>75

>70%

>1000

2016

250

>125

>80%

>1500

Done

Capability demonstrated

On track

Outline

ASML

Public

Slide 21

23 Feb 2016

Throughput & Wafers per Day (WpD)

Availability

Defectivity, imaging and overlay

Front-side reticle defectivity: 10x reduction/year realized

ASML

Public

Slide 22

23 Feb 2016

Added particles > 92nm per reticle pass

100

10

1

0.1

0.01

0.001

0.0001

2010 2011 2012 2013 2014 2015

NXE:3100

NXE:3300B

NXE:3350B

Test

A

B

C

D

E

Cumulative

#

Cycles

228

140

450

222

133

1173

# Added

Particles

0

0

0

1

0

1

PRP

Value

<0.004

<0.007

<0.002

0.0045

<0.007

0.0008

Customer requirement for full production without pellicle

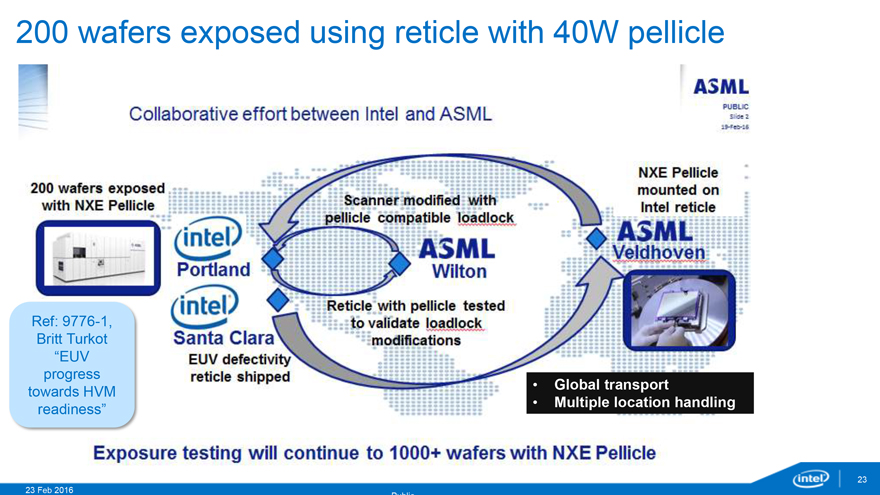

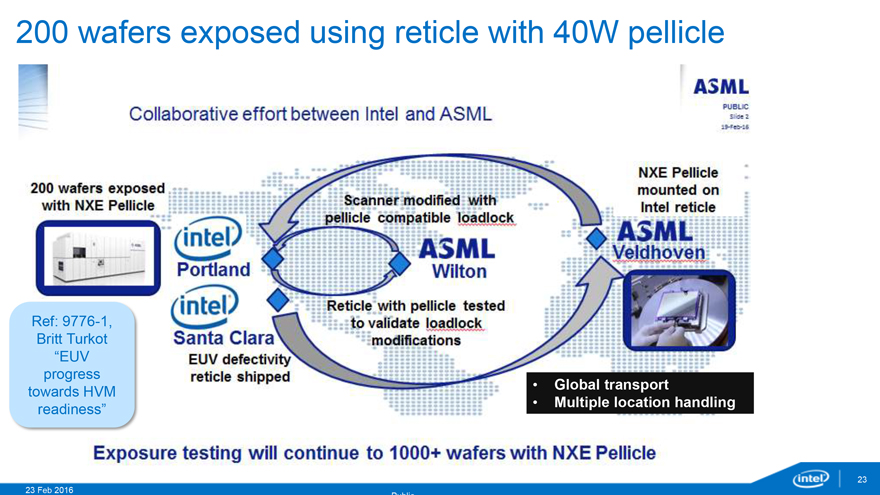

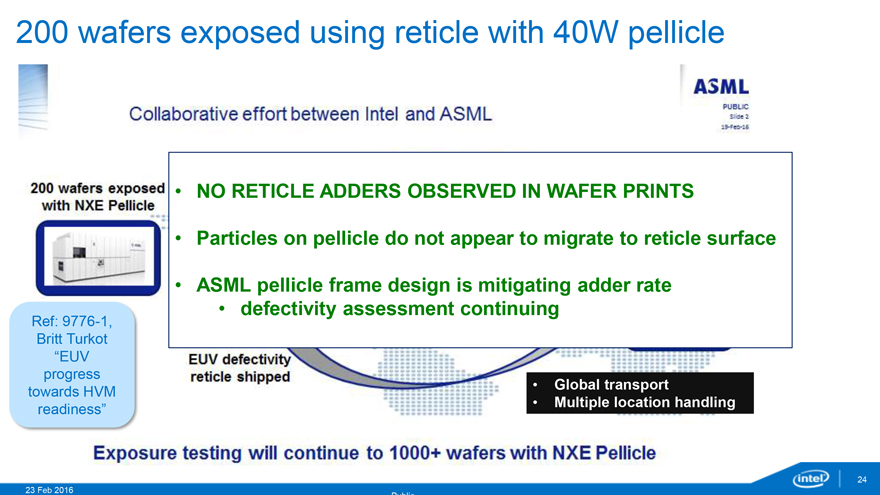

200 wafers exposed using reticle with 40W pellicle

ASML

Public

Slide 2

19 Feb 2016

Collaborative effort between Intel and ASML

200 wafers exposed with NXE Pellicle

Ref: 9776-1,

Britt Turkot

“EUV

progress towards HVM

readiness”

intel Portland

intel Santa Clara

EUV defectivity reticle shipped

Scanner modified with pellicle compatible loadlock

ASML

Wilton

Reticle with pellicle tested to validate loadlock modifications

NXE Pellicle mounted on Intel reticle

ASML

Veldhoven

Global transport

Multiple location handling

Exposure testing will continue to 1000+ wafers with NXE Pellicle

23 Feb 2016

intel

23

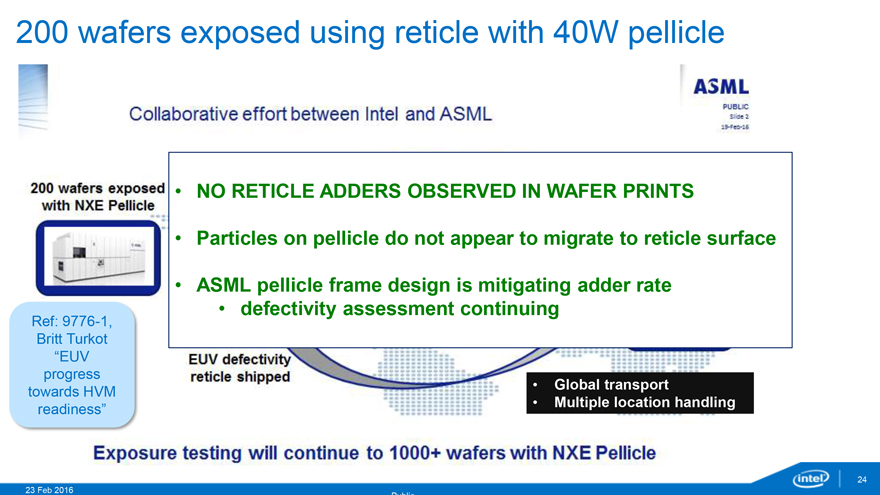

200 wafers exposed using reticle with 40W pellicle

ASML

Public

Slide 24

19 Feb 2016

Collaborative effort between Intel and ASML

200 wafers exposed with NXE Pellicle

Ref: 9776-1,

Britt Turkot

“EUV

progress towards HVM

readiness”

NO RETICLE ADDERS OBSERVED IN WAFER PRINTS

Particles on pellicle do not appear to migrate to reticle surface

ASML pellicle frame design is mitigating adder rate

defectivity assessment continuing

EUV defectivity reticle shipped

Global transport

Multiple location handling

Exposure testing will continue to 1000+ wafers with NXE Pellicle

23 Feb 2016

intel

24

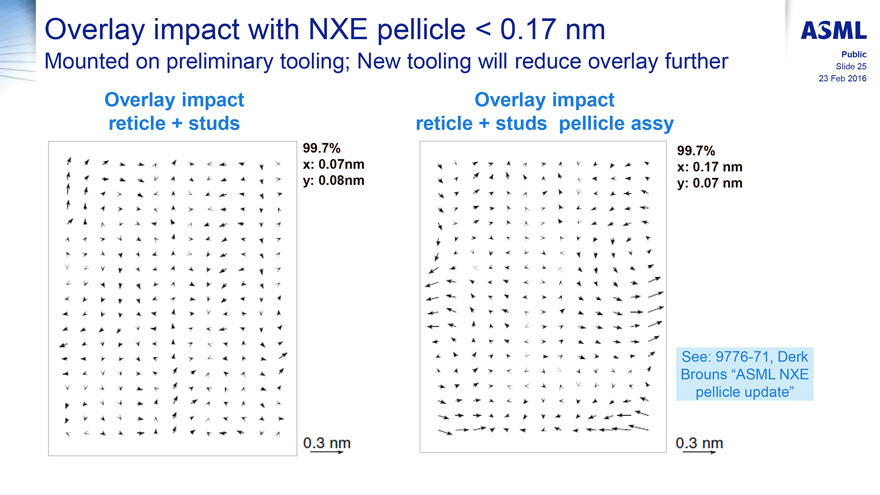

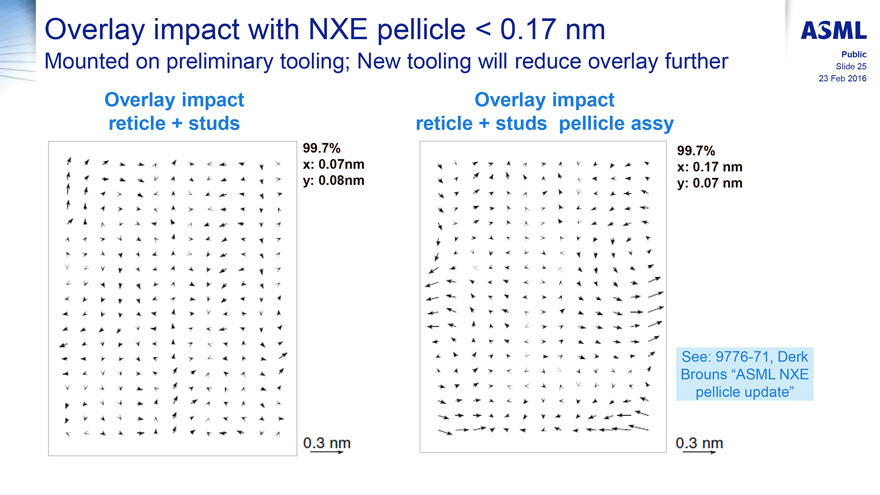

Overlay impact with NXE pellicle < 0.17 nm

Mounted on preliminary tooling; New tooling will reduce overlay further

ASML

Public

Slide 25

23 Feb 2016

Overlay impact reticle + studs

99.7%

x: 0.07nm

y: 0.08nm

0.3 nm

Overlay impact reticle + studs pellicle assy

99.7%

x: 0.17 nm

y: 0.07 nm

See: 9776-71, Derk

Brouns “ASML NXE pellicle update”

0.3nm

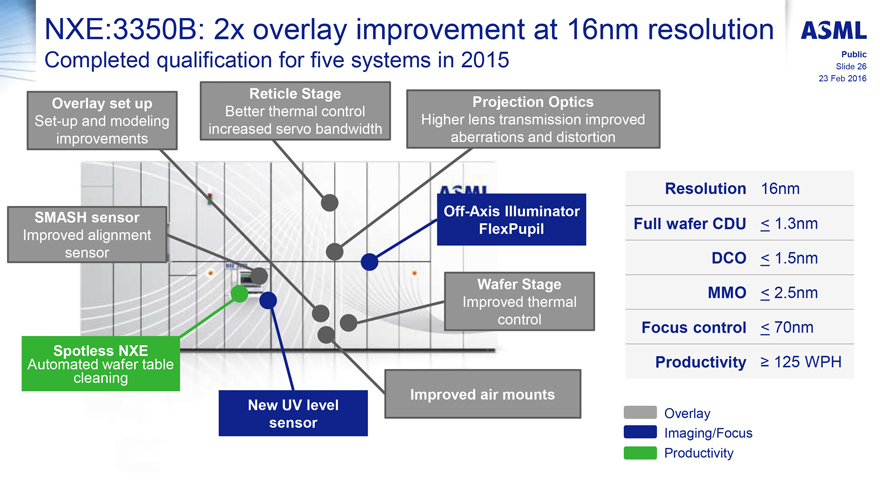

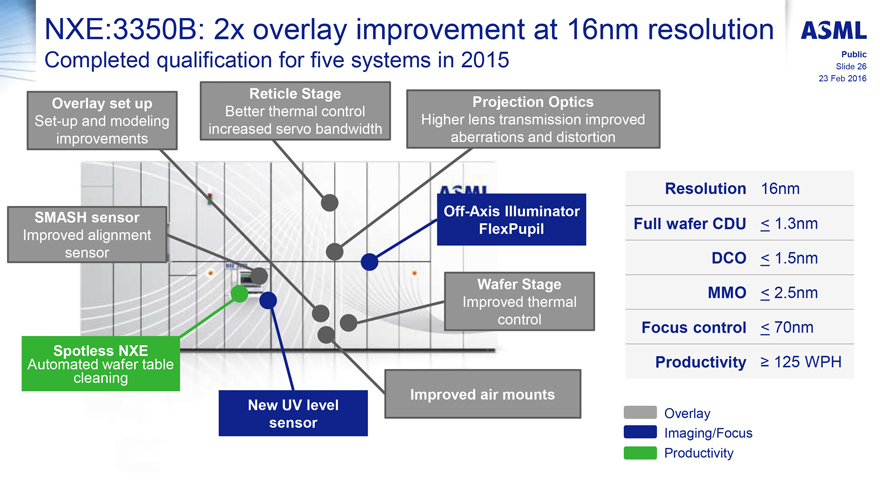

NXE:3350B: 2x overlay improvement at 16nm resolution

Completed qualification for five systems in 2015

ASML

Public

Slide 26

23 Feb 2016

Overlay set up

Set-up and modeling improvements

SMASH sensor

Improved alignment sensor

Spotless NXE

Automated wafer table cleaning

Reticle Stage

Better thermal control increased servo bandwidth

New UV level sensor

Projection Optics

Higher lens transmission improved aberrations and distortion

Off-Axis Illuminator FlexPupil

Wafer Stage

Improved thermal control

Improved air mounts

Resolution 16nm

Full wafer CDU£ 1.3nm

DCO£ 1.5nm

MMO£ 2.5nm

Focus control£ 70nm

Productivity³ 125 WPH

Overlay

Imaging/Focus

Productivity

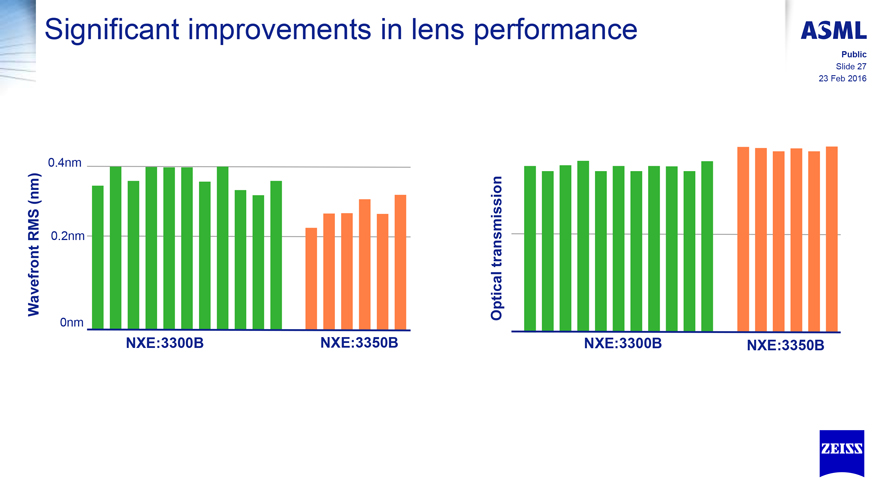

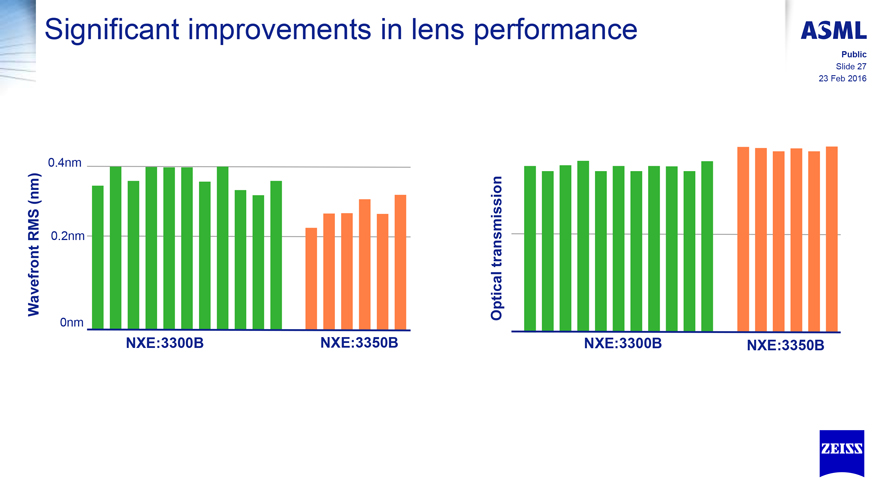

Significant improvements in lens performance

ASML

Public

Slide 27

23 Feb 2016

Wavefront RMS (nm)

0.4nm 0.2nm 0nm

NXE:3300B NXE:3350B

Optical transmission

NXE:3300B NXE:3350B

ZEISS

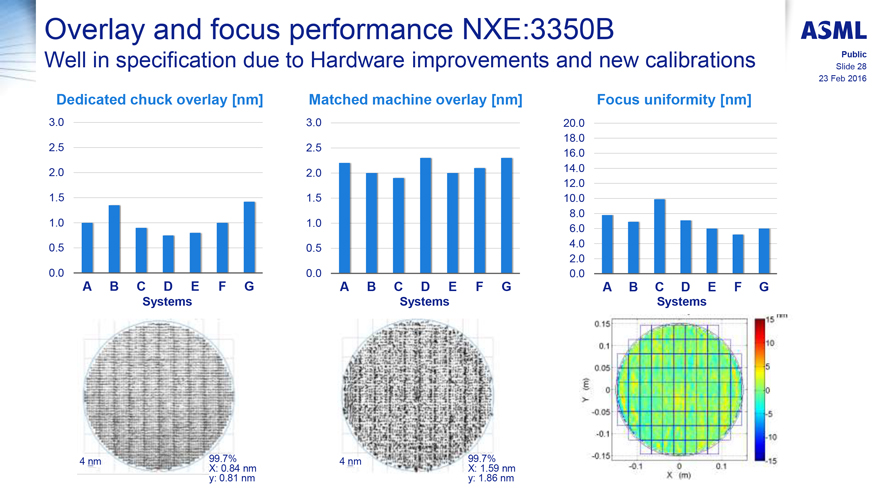

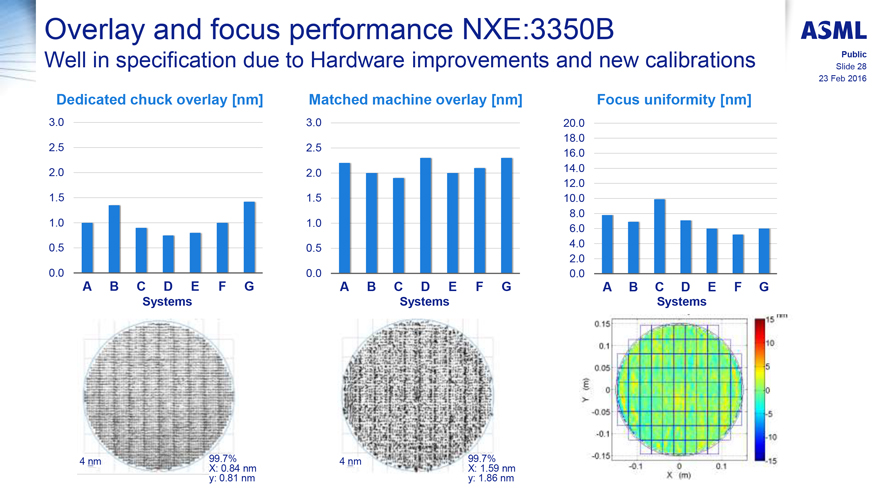

Overlay and focus performance NXE:3350B

Well in specification due to Hardware improvements and new calibrations

Dedicated chuck overlay [nm]

3.0

2.5

2.0

1.5

1.0

0.5

0.0

ABCDEFG

Matched machine overlay [nm]

3.0

2.5

2.0

1.5

1.0

0.5

0.0

ABCDEFG

Focus uniformity [nm]

20.2

18.0

16.0

14.0

12.0

10.0

8.0

6.0

4.0

2.0

0.0

ABCDEFG

Systems

4 nm

99.7%

X:0.84 nm

Y: 0.81 nm

Systems

4 nm

99.7%

X: 1.59 nm

Y: 1.86 nm

System

Y (m)

0.15

01

0.05

0

-0.05

-0.1

-0.15

-0.1

0

0.1

15 nm

10

5

0

-5

-10

-15

X (m)

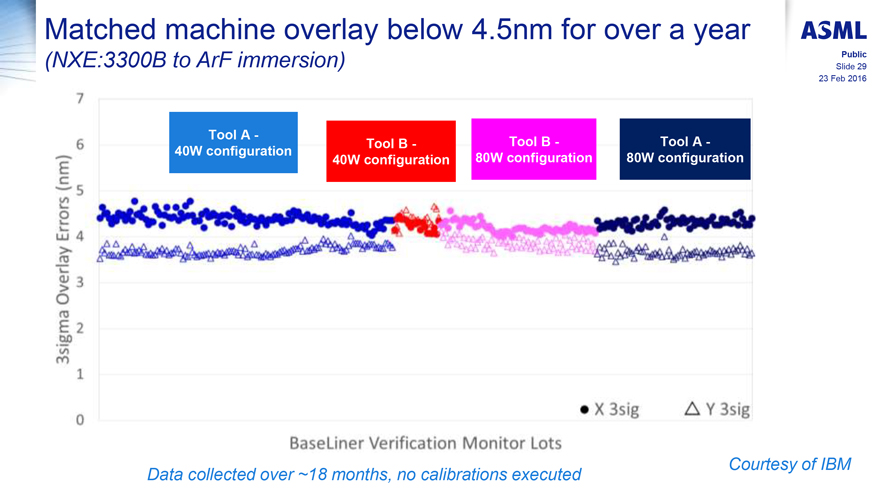

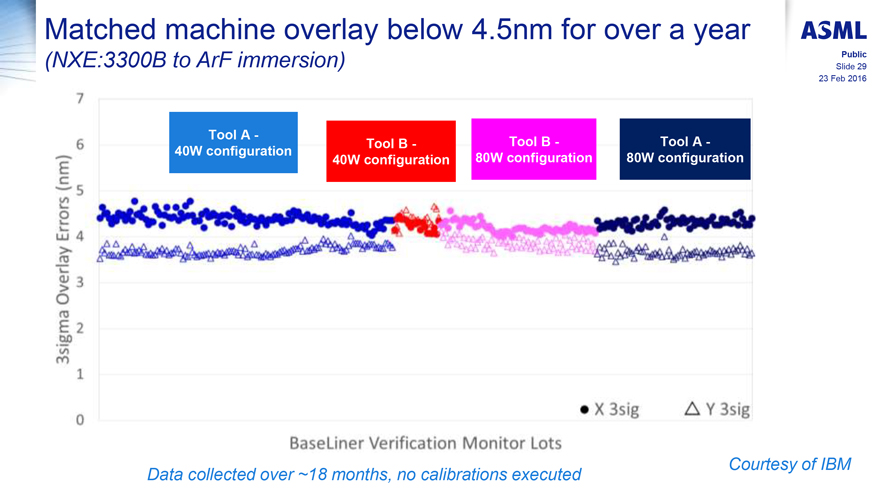

Matched machine overlay below 4.5nm for over a year

(NXE:3300B to ArF immersion)

ASML

Public

Slide 29

23 Feb 2016

3sigma Overlay Errors (nm)

76543210

Tool A - 40W configuration

Tool B - 40W configuration

Tool B - 80W configuration

Tool A - 80W configuration

X 3sig

Y 3sig

BaseLiner Verification Monitor Lots

Courtesy of IBM

Data collected over ~ 18 months, no calibrations executed

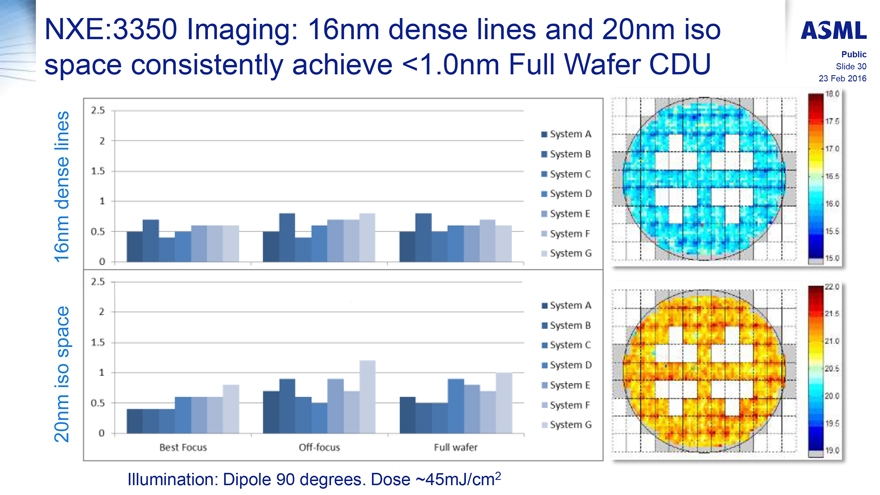

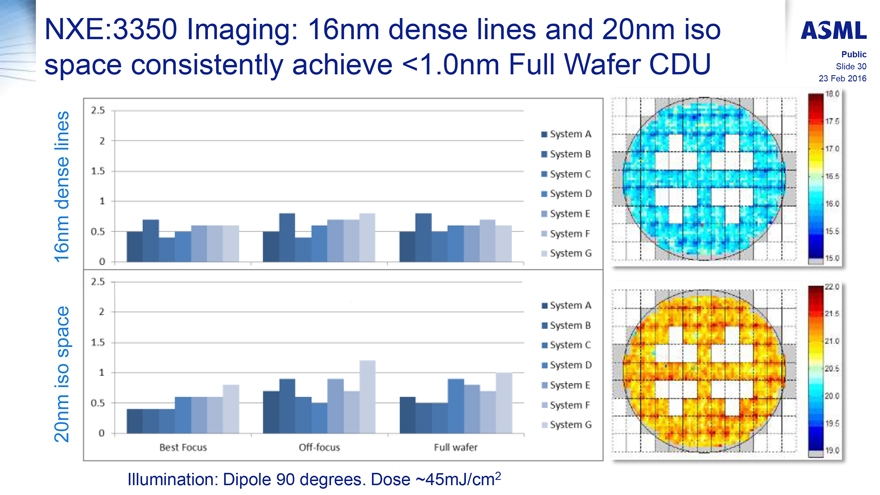

NXE:3350 Imaging: 16nm dense lines and 20nm iso space consistently achieve <1.0nm Full Wafer CDU

ASML

Public

Slide 30

23 Feb 2016

16 nm dense lines

2.5

2 System A

1.5 System B

1 System C

0.5 System D

System E

System F

0 System G

20 nm is so space

2.5 System A

2 System B

1.5 System C

1 System D

0.5 System E

System F

0 System G

Best Focus

Off-focus

Full wafer

18.0

17.5

17.0

16.5

16.0

15.5

15.0

22.0

21.5

21.0

21.5

20.5

20.0

19.5

19.0

Illumination: Dipole 90 degrees. Dose ~45mJ/cm2

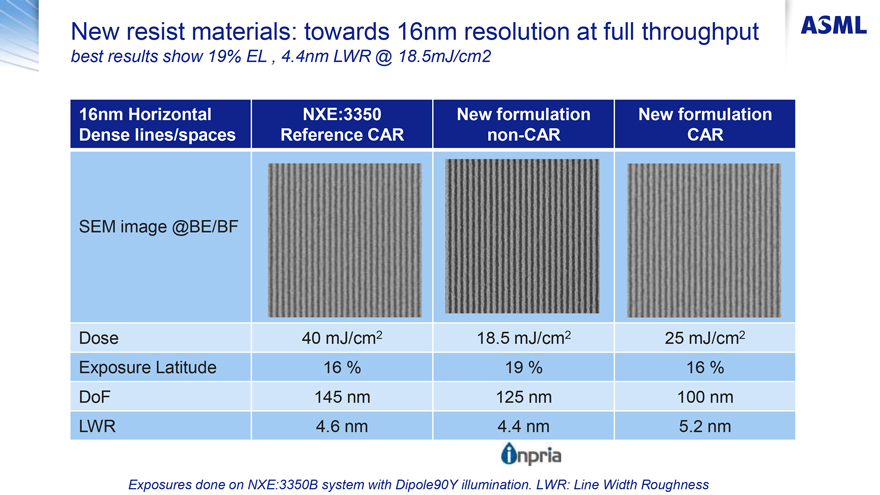

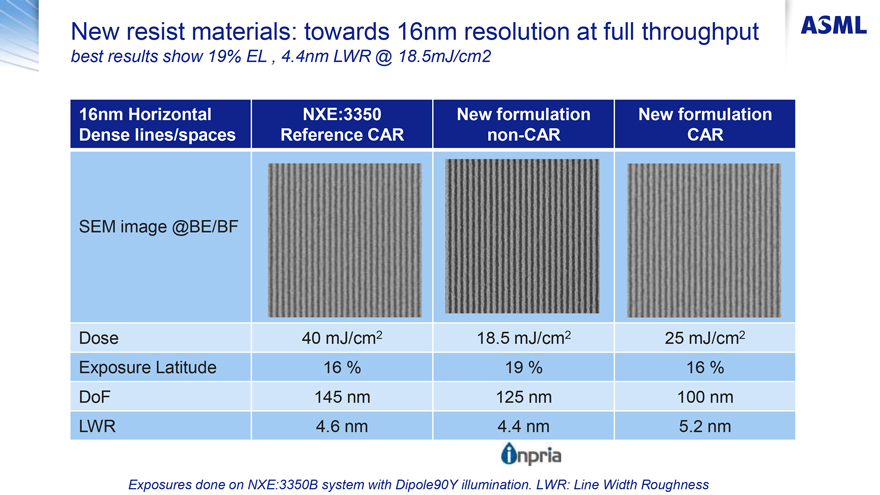

New resist materials: towards 16nm resolution at full throughput

best results show 19% EL, 4.4nm LWR @ 18.5mJ/cm2

ASML

|

| 16nm Horizontal Dense lines/spaces NXE:3350 Reference CAR New formulation non-CAR New formulation CAR |

| SEM image @BE/BF |

| Dose 40 mJ/cm2 18.5 mJ/cm2 25 mJ/cm2 |

| Exposure Latitude 16% 19% 16% |

| DoF 145 nm 125 nm 100 nm |

| LWR 4.6 nm 4.4 nm 5.2 nm |

inpria

Exposures done on NXE:3350B system with Dipole90Y illumination. LWR: Line Width Roughness

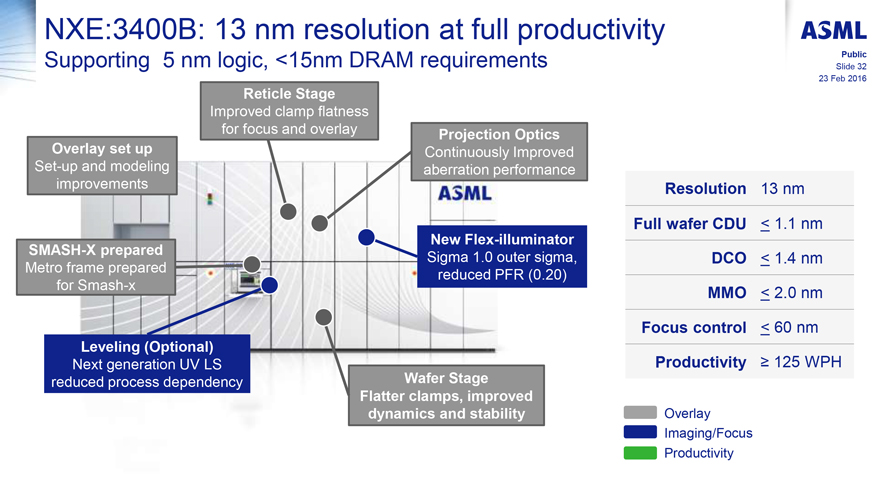

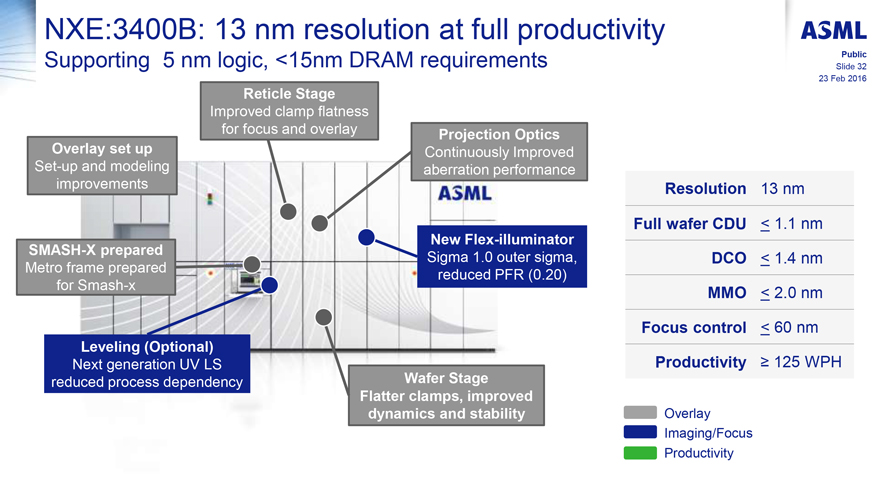

NXE:3400B: 13 nm resolution at full productivity

Supporting 5 nm logic, <15nm DRAM requirements

ASML

Public

Slide 32

23 Feb 2016

Reticle Stage

Improved clamp flatness for focus and overlay

Overlay set up

Set-up and modeling improvements

Projection Optics

Continuously Improved

aberration performance

SMASH-X prepared

Metro frame prepared for Smash-x

New Flex-illuminator

Sigma 1.0 outer sigma, reduced PFR (0.20)

Leveling (Optional)

Next generation UV LS reduced process dependency

Wafer Stage Flatter clamps, improved dynamics and stability

| | |

| Resolution | | 13 nm |

| Full wafer CDU | | £ 1.1 nm |

| DCO | | £ 1.4 nm |

| MMO | | £ 2.0 nm |

| Focus control | | £ 60 nm |

| Productivity | | ³ 125 WPH |

Overlay

Imaging/Focus Productivity

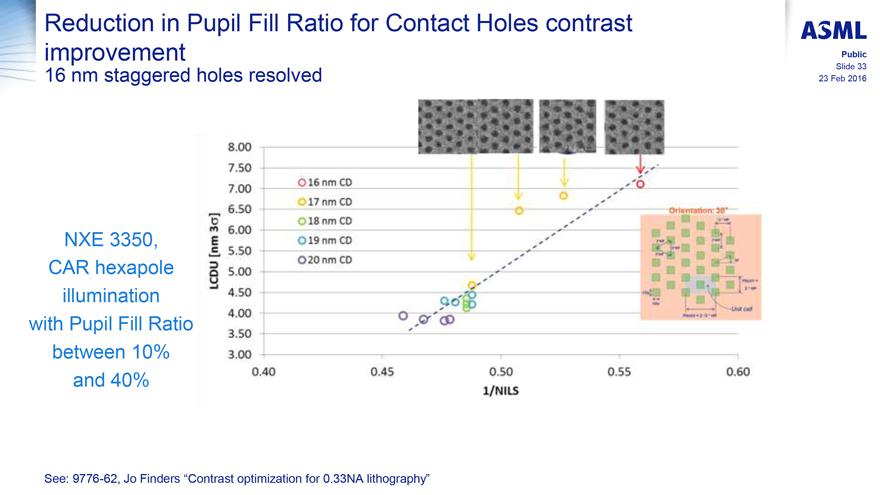

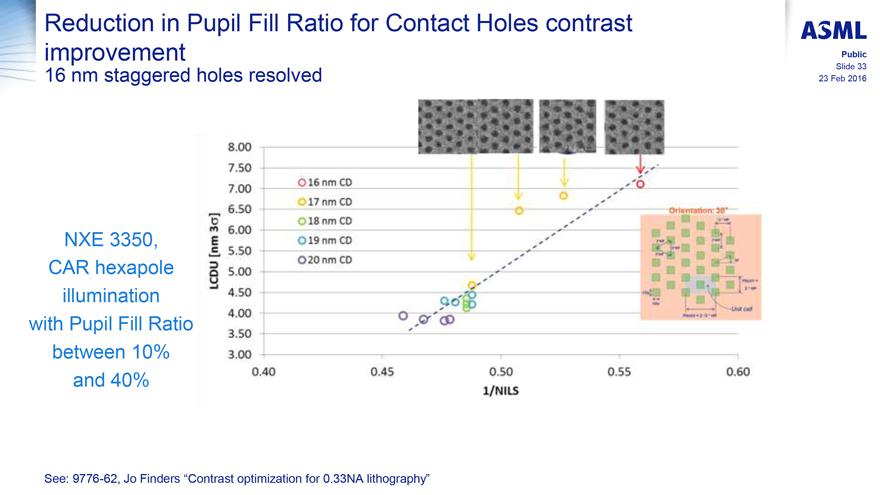

Reduction in Pupil Fill Ratio for Contact Holes contrast improvement

16 nm staggered holes resolved

ASML

Public

Slide 33

23 Feb 2016

NXE 3350,

CAR hexapole

illumination

with Pupil Fill Ratio

between 10%

and 40%

LCDU [nm 3]

8.00

7.50

7.00

6.50

6.00

5.50

5.00

4.50

4.00

3.50

3.00

16 nm CD

17 nm CD

18 nm CD

19 nm CD

20 nm CD

0.40

0.45

0.50

0.55

0.60

1/NILS

See: 9776-62, Jo Finders “Contrast optimization for 0.33NA lithography”

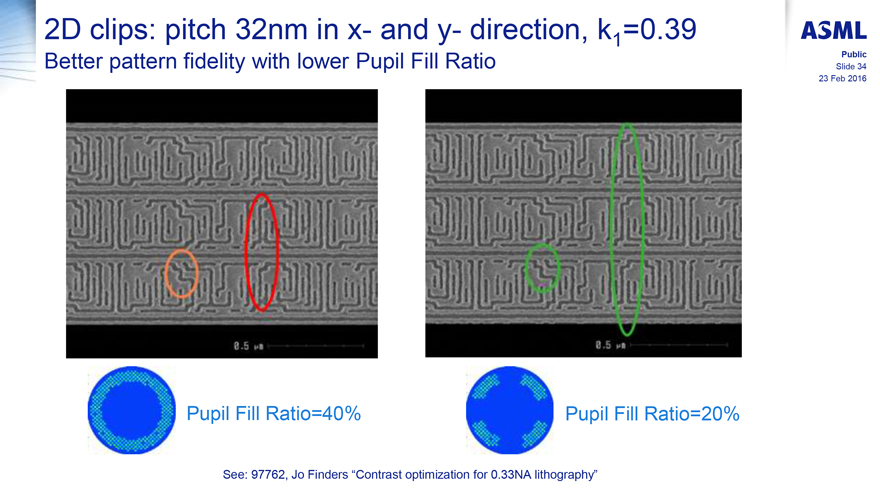

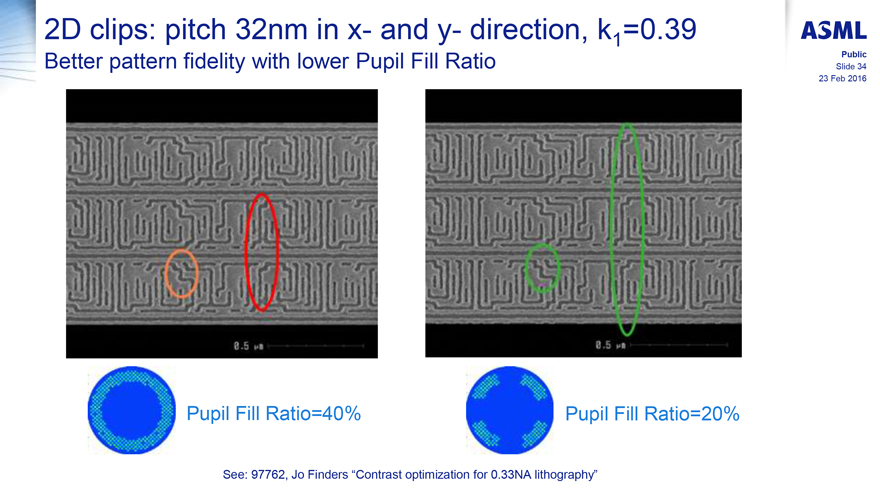

2D clips: pitch 32nm in x- and y- direction, k1=0.39

Better pattern fidelity with lower Pupil Fill Ratio

ASML

Public

Slide 34

23 Feb 2016

0.5

0.5

Pupil Fill Ratio=40%

Pupil Fill Ratio=20%

See: 97762, Jo Finders “Contrast optimization for 0.33NA lithography”

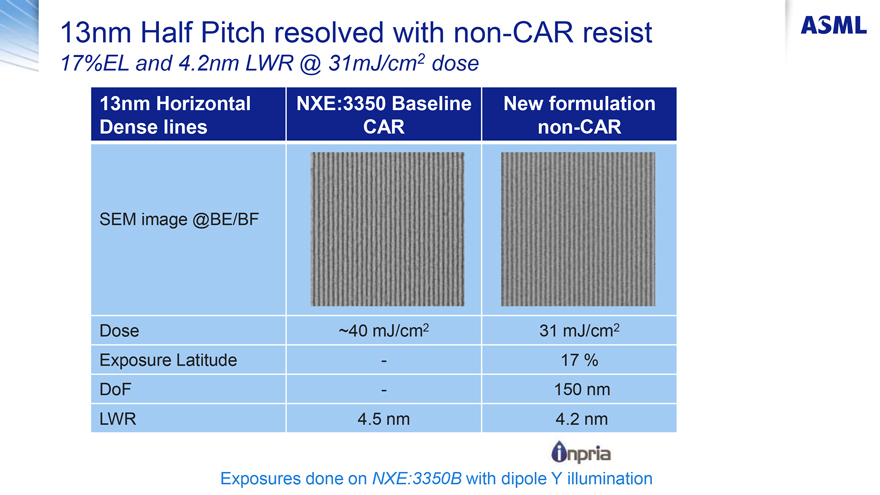

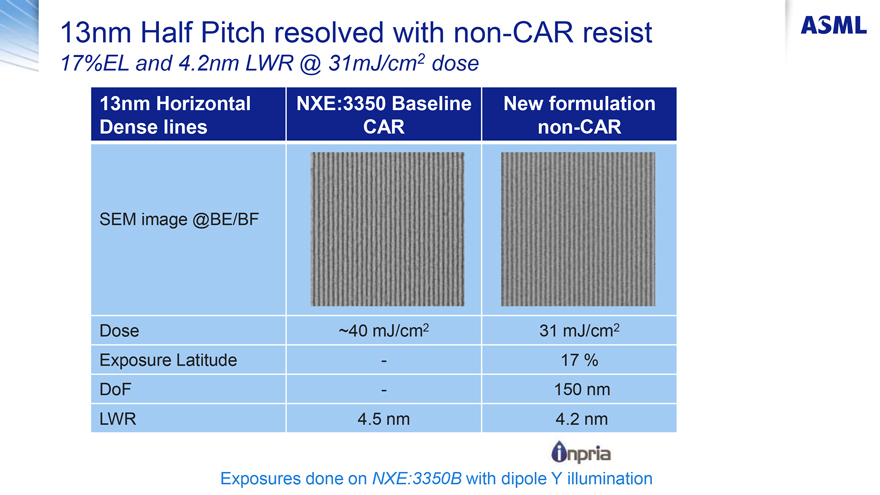

13nm Half Pitch resolved with non-CAR resist

17%EL and 4.2nm LWR @ 31mJ/cm2 dose

ASML

|

| 13nm Horizontal NXE:3350 Baseline New formulation |

| Dense lines CAR non-CAR |

| SEM image @BE/BF |

| Dose ~40 mJ/cm2 31 mJ/cm2 |

| Exposure Latitude - 17% |

| DoF - 150 nm |

| LWR 4.5 nm 4.2 nm |

Inpria

Exposures done on NXE:3350B with dipole Y illumination

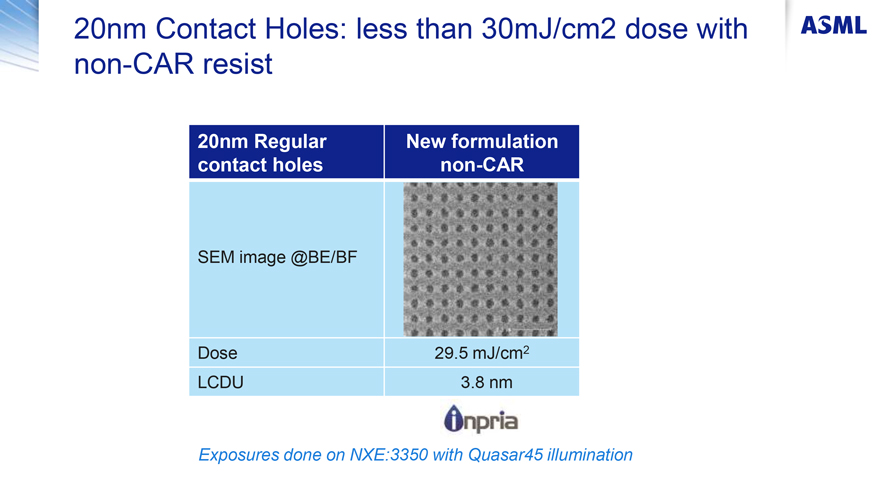

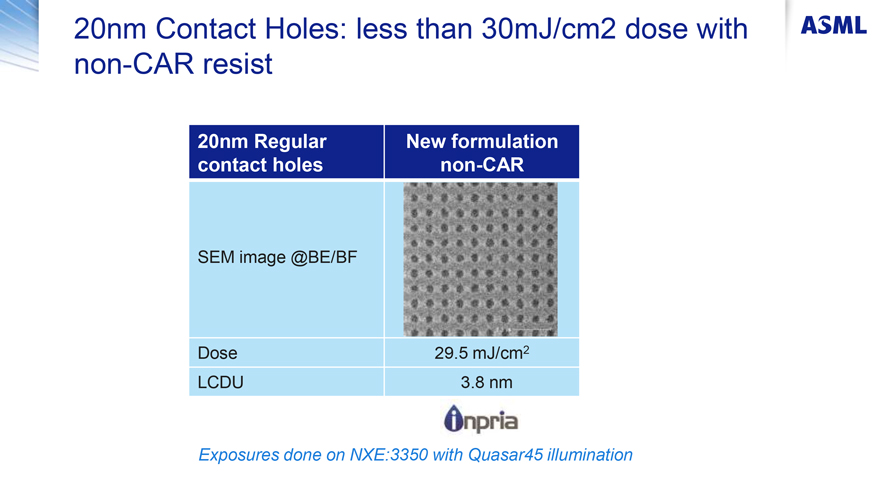

20nm Contact Holes: less than 30mJ/cm2 dose with non-CAR resist

ASML

|

| 20nm Regular New formulation |

| contact holes non-CAR |

| SEM image @BE/BF |

| Dose 29.5 mJ/cm2 |

| LCDU 3.8 nm |

Inpria

Exposures done on NXE:3350 with Quasar45 illumination

Summary: EUV readying for volume manufacturing

ASML

Public

Slide 37

23 Feb 2016

Completed qualification of five NXE:3350B, the 4th generation EUV exposure tool, one system qualified at 75 wph

Multiple systems demonstrated >1,000 wafers per day capability, with one system exceeding 1,350 wpd

80W configuration operational in the field, 125W configuration qualification completed

80% system availability capability demonstrated

Excellent NXE:3350B imaging and overlay performance at> 80W power

Continuous progress in resist formulation promising towards enabling 13nm half pitch at high throughput