UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D. C. 20549

FORM 10-K

☒ ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended December 31, 2018

☐ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from to

Commission File Number 001-07349

Ball Corporation

|

|

|

State of Indiana |

| 35-0160610 |

(State or other jurisdiction of |

| (I.R.S. Employer |

incorporation or organization) |

| Identification No.) |

|

|

|

10 Longs Peak Drive, P.O. Box 5000 |

|

|

Broomfield, Colorado |

| 80021-2510 |

(Address of registrant’s principal executive office) |

| (Zip Code) |

Registrant’s telephone number, including area code: (303) 469-3131

Securities registered pursuant to Section 12(b) of the Act:

|

|

|

Title of each class |

| Name of each exchange on which registered |

Common Stock, without par value |

| New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act: NONE

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. YES ☒ NO ☐

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. YES ☐ NO ☒

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. YES ☒ NO ☐

Indicate by check mark whether the registrant has submitted electronically every Interactive Data File required to be submitted pursuant to Rule 405 of Regulation S-T during the preceding 12 months. YES ☒ NO ☐

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. ☒

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer. See definitions of “large accelerated filer”, “accelerated filer”, “smaller reporting company” and “emerging growth company” in Rule 12b-2 of the Exchange Act.

|

|

|

|

|

|

|

Large accelerated filer ☒ |

| Accelerated filer ☐ |

| Non-accelerated filer ☐ |

| Smaller reporting company ☐ |

Emerging growth company ☐ |

|

|

|

|

|

|

If an emerging growth company, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards provided pursuant to Section 13(a) of the Exchange Act. ☐

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). YES ☐ NO ☒

The aggregate market value of voting stock held by non-affiliates of the registrant was $12.3 billion based upon the closing market price and common shares outstanding as of June 30, 2018.

Number of shares and rights outstanding as of the latest practicable date.

|

|

|

Class |

| Outstanding at February 20, 2019 |

|

|

|

Common Stock, without par value |

| 334,338,125 shares |

|

|

|

DOCUMENTS INCORPORATED BY REFERENCE

1.Proxy statement to be filed with the Commission within 120 days after December 31, 2018, to the extent indicated in Part III.

Ball Corporation

ANNUAL REPORT ON FORM 10-K

For the year ended December 31, 2018

Ball Corporation and its consolidated subsidiaries (collectively, Ball, the company, we or our) is one of the world’s leading suppliers of metal packaging to the beverage, personal care and household products industries. The company was organized in 1880 and incorporated in the state of Indiana, United States of America (U.S.), in 1922. Our packaging products are produced for a variety of end uses and are manufactured in facilities around the world. We also provide aerospace and other technologies and services to governmental and commercial customers within our aerospace segment. In 2018, our total consolidated net sales were $12 billion. Our packaging businesses were responsible for 90 percent of our net sales, with the remaining 10 percent contributed by our aerospace business.

Our largest product line is aluminum beverage containers. We also produce aerosol containers, extruded aluminum aerosol containers and aluminum slugs.

We sell our packaging products mainly to large multinational beverage, personal care and household products companies with which we have developed long-term relationships. This is evidenced by our high customer retention and large number of long-term supply contracts. While we have a diversified customer base, we sell a significant portion of our packaging products to major companies and brands, as well as to numerous regional customers. Our significant customers include: The Coca-Cola Company and its affiliated bottlers, Anheuser-Busch InBev n.v./s.a., Molson Coors Brewing Company and Unilever N.V.

Our aerospace business is a leader in the design, development and manufacture of innovative aerospace systems for civil, commercial and national cyber security aerospace markets. It produces spacecraft, instruments and sensors, radio frequency systems and components, data exploitation solutions and a variety of advanced aerospace technologies and products that enable deep space missions.

We are headquartered in Broomfield, Colorado, and our stock is listed for trading on the New York Stock Exchange under the ticker symbol BLL.

Our Strategy

Our overall business strategy is defined by our Drive for 10 vision, which at its highest level, is a mindset around perfection, with a greater sense of urgency around our future success. Launched in 2011, our Drive for 10 vision encompasses five strategic levers that are key to growing our businesses and achieving long-term success. These five levers are:

· | Maximizing value in our existing businesses |

· | Expanding into new products and capabilities |

· | Aligning ourselves with the right customers and markets |

· | Broadening our geographic reach and |

· | Leveraging our know-how and technological expertise to provide a competitive advantage |

We also maintain a clear and disciplined financial strategy focused on improving shareholder returns through:

· | Seeking to deliver comparable diluted earnings per share growth of 10 percent to 15 percent per annum over the long-term |

· | Maximizing free cash flow generation |

· | Increasing Economic Value Added (EVA®) dollars |

1

The cash generated by our businesses is used primarily: (1) to finance the company’s operations, (2) to fund strategic capital investments, (3) to service the company’s debt and (4) to return value to our shareholders via stock buy-backs and dividend payments. From time to time, we have evaluated and expect to continue to evaluate possible transactions that we believe will benefit the company and our shareholders, which may include strategic acquisitions, divestitures of parts of our company or joint ventures. At any time we may be engaged in discussions or negotiations with respect to possible transactions or may have entered into non-binding letters of intent. There can be no assurance if or when we will enter into any such transactions or the terms of such transactions. The compensation of many of our employees is tied directly to the company’s performance through our EVA®-based incentive programs.

Sustainability

Sustainability is a key part of our business strategy at Ball. By enhancing the unique sustainability credentials of our products along their life cycles, we position our metal containers as the most sustainable packaging choice and help our customers grow their businesses. Aluminum is an infinitely recyclable material. It also has the highest scrap value of all commonly used packaging substrates. These qualities make cans an increasingly attractive option for sustainability-conscious consumers and brands who acknowledge that metal packaging is a true enabler of a circular economy in terms of economic value, recyclability, real recycling and the avoidance of down cycling. In 2017, Resource Recycling Systems recognized aluminum beverage cans as the most recycled beverage package in the world, with a global weighted average recycling rate for aluminum of 69 percent. This finding solidifies the aluminum can as the leader in real recycling, where the package is collected and then transformed into an item of equal value (product to product or material to material recycling). In comparison, only 43 percent of PET and 46 percent of glass bottles were collected for recycling, although not necessarily recycled.

In some of Ball’s markets such as Brazil, China and several European countries, recycling rates for aluminum beverage cans are at or above 90 percent. The most recently available recycling rates for aluminum beverage cans are 97 percent in Brazil in 2017, 74 percent in Europe in 2015, and 49 percent in the U.S. in 2016.

We focus our sustainability efforts on product stewardship, operational excellence, talent management and community engagement. In our global operations, we work on continuous improvement of employee safety, energy and water efficiency, waste generation and air emissions.

Because metal recycling saves resources and uses significantly less energy than primary metal production, the biggest opportunity to further enhance the positive environmental attributes of metal packaging is to increase recycling rates. In markets where recycling rates are below where we believe they should be, we help establish and financially support packaging collection and recycling initiatives. These initiatives typically focus on collaborating with public and private partners to create effective collection and recycling systems, including education of consumers about the sustainability benefits of metal packaging.

Our Reportable Segments

Ball Corporation reports its financial performance in four reportable segments: (1) beverage packaging, North and Central America; (2) beverage packaging, South America; (3) beverage packaging, Europe and (4) aerospace. Ball also has investments in the U.S., Guatemala, Panama, South Korea and Vietnam that are accounted for using the equity method of accounting and, accordingly, those results are not included in segment sales or earnings. Financial information related to each of our segments is included in Note 3 to the consolidated financial statements within Item 8 of this Annual Report on Form 10-K (annual report).

On July 31, 2018, Ball sold its U.S. steel food and steel aerosol packaging business and formed a joint venture, Ball Metalpack. See Note 4 to the consolidated financial statements within Item 8 of this annual report for further information. As a result of the sale, the remaining global aluminum aerosol and Argentine steel aerosol businesses of the legacy food and aerosol packaging segment are now a non-reportable segment that manufactures and sells aerosol containers, extruded aluminum aerosol containers and aluminum slugs (aerosol packaging). For comparative periods, the entire former food and aerosol packaging segment is now presented within other.

2

Beverage Packaging, North and Central America, Segment

Beverage packaging, North and Central America is Ball’s largest segment, accounting for 40 percent of consolidated net sales in 2018. Metal beverage containers are primarily sold under multi-year supply contracts to fillers of carbonated soft drinks, beer, energy drinks and other beverages.

Metal beverage containers and ends are produced at 17 manufacturing facilities in the U.S., one in Canada and two in Mexico. The beverage packaging, North and Central America, segment also includes interests in three joint ventures that are accounted for using the equity method.

The North American beverage container manufacturing industry is relatively mature. Where growth or contractions are projected in certain markets or for certain products, Ball undertakes selected capacity increases or decreases primarily in its existing facilities to meet market demand. A meaningful portion of the industry-wide reduction in demand for standard 12-ounce aluminum cans for the carbonated soft drink market is being offset with growing demand for specialty container volumes from new and existing customers and consumer demand. During 2016, we began production at our newly constructed beverage can and end manufacturing facility in Monterrey, Mexico. In order to serve growing customer demand for specialty cans in the southwestern U.S., the company constructed a four line beverage packaging facility in Goodyear, Arizona, which began production in the second quarter of 2018.

According to publicly available information and company estimates, the North American beverage container industry represents approximately 112 billion units. Five companies manufacture substantially all of the metal beverage containers in the U.S., Canada and Mexico. Ball produced approximately 46 billion recyclable aluminum beverage containers in North America in 2018, which represented approximately 44 percent of the aggregate production in these countries. Historically, sales volumes of metal beverage containers in North America tend to be highest during the period from April through September. All of the beverage containers produced by Ball in the U.S., Canada and Mexico are made of aluminum. In North and Central America, five suppliers provide the majority of our aluminum can and end sheet requirements.

Beverage containers are sold based on price, quality, service, innovation and sustainability in a highly competitive market, which is relatively capital intensive and characterized by facilities that run more or less continuously in order to operate profitably. In addition, the metal beverage container competes aggressively with other packaging materials which include meaningful industry positions by the glass bottle in the packaged beer industry and the polyethylene terephthalate (PET) bottle in the carbonated soft drink and water industries.

We believe we have limited our exposure to changes in the cost of aluminum ingot as a result of the inclusion of provisions in most metal beverage container sales contracts to pass through aluminum price changes, as well as through the use of derivative instruments.

Our beverage can manufacturing facility in Reidsville, North Carolina, ceased production at the end of June 2017, the Birmingham, Alabama, facility ceased production during the second quarter of 2018 and the Chatsworth, California, and Longview, Texas, facilities ceased production during the third quarter of 2018. These facilities produced beverage cans in a variety of sizes and their customers are now supplied by the company’s other U.S. facilities.

Beverage Packaging, South America, Segment

The beverage packaging, South America, segment accounted for 15 percent of Ball’s consolidated net sales in 2018. Our operations consist of 12 facilities, 10 in Brazil and one each in Argentina and Chile. For the countries where we operate, the South American beverage container market is approximately 31 billion containers, and we are the largest producer in this region with an estimated 53 percent of South American shipments in 2018. Four companies currently manufacture substantially all of the metal beverage containers in Brazil.

The company’s South American beverage facilities produced approximately 16 billion aluminum beverage containers in 2018. Historically, sales volumes of beverage containers in South America tend to be highest during the period from September through December. In South America, two suppliers provide virtually all our aluminum sheet requirements with certain requirements also being imported from Asia.

3

In order to support contracted volumes for aluminum beverage packaging across Paraguay, Argentina, Chile and Bolivia, the company is constructing a one-line beverage can and end manufacturing facility in Paraguay and will add capacity to its Buenos Aires, Argentina, and Santiago, Chile, facilities. The Paraguay facility is expected to begin production in the second half of 2019. The company ceased operations at its Cuiabá, Brazil, beverage packaging facility in July 2018 and has relocated equipment from the Cuiabá facility to other existing facilities in South America.

We believe we have limited our exposure to changes in the cost of aluminum ingot as a result of the inclusion of provisions in most metal beverage container sales contracts to pass through aluminum ingot price changes, as well as through the use of derivative instruments.

Beverage Packaging, Europe, Segment

The beverage packaging, Europe, segment accounted for 23 percent of Ball’s consolidated net sales in 2018. Our European operations consist of 20 facilities throughout Europe. The European beverage container market is approximately 67 billion containers, including Russia and excluding Turkey, and we are the largest producer with an estimated 43 percent of European shipments. The European market is highly regional in terms of sales growth rates and packaging mix. Four companies manufacture substantially all of the metal beverage containers in Europe. Our European beverage facilities produced 30 billion beverage containers in 2018, the vast majority of which were produced from aluminum.

Historically, sales volumes of metal beverage containers in Europe tend to be highest during the period from May through August with a smaller increase in demand leading up to the winter holiday season in the U.K. offset by much lower demand in Russia. Much like other parts of the world, the metal beverage container competes aggressively with other packaging materials used by the European beer and carbonated soft drink industries. The glass bottle is heavily utilized in the packaged beer industry, while the PET container is utilized in the carbonated soft drink, beer, juice and water industries.

European raw material supply contracts generally have longer term agreements. In Europe, five aluminum suppliers and one steel supplier provide almost all of our requirements. Aluminum is traded primarily in U.S. dollars, while the functional currencies of our European operations are various other currencies. The company minimizes its exchange rate risk using derivative and supply contracts in local currencies. Purchase and sales contracts generally include fixed-price, floating or pass-through aluminum ingot component pricing arrangements.

In order to support growth for beverage cans in the Iberian Peninsula, the company constructed a two-line, aluminum beverage can manufacturing facility near Madrid, Spain, with a majority of the facility’s capacity secured under a long-term customer contract. The facility is fully operational and produces multiple can sizes utilizing both lines. In the third quarter of 2017, our beverage packaging container and end production facilities in Recklinghausen, Germany, ceased production, and the capacity was transitioned to existing European Ball facilities. In December 2018, we closed a one-line beverage packaging facility located in San Martino, Italy.

Aerospace Segment

Ball’s aerospace segment, which accounted for 10 percent of consolidated net sales in 2018, includes national defense hardware, antenna and video tactical solutions, civil and operational space hardware and systems engineering services. The segment develops spacecraft, sensors and instruments, radio frequency systems and other advanced technologies for the civil, commercial and national security aerospace markets. The majority of the aerospace business involves work under contracts, generally from one to five years in duration, as a prime contractor or subcontractor for the U.S. Department of Defense (DoD), the National Aeronautics and Space Administration (NASA) and other U.S. government agencies. The company competes against both large and small prime contractors and subcontractors for these contracts. Contracts funded by the various agencies of the federal government represented 99 percent of segment sales in 2018.

Intense competition and long operating cycles are key characteristics of both the company’s business and the aerospace and defense industry. It is common in the aerospace and defense industry for work on major programs to be shared among a number of companies. A company competing to be a prime contractor may, upon ultimate award of the contract to a competitor, become a subcontractor for the ultimate prime contracting company. It is not unusual to compete for a contract award with a peer company and, simultaneously, perform as a supplier to or a customer of that same competitor on other contracts, or vice versa.

4

Geopolitical events and shifting executive and legislative branch priorities have resulted in an increase in opportunities over the past decade in areas matching our aerospace segment’s core capabilities in space hardware. The businesses include hardware and services sold primarily to U.S. customers, with emphasis on space science and exploration, environmental and earth sciences, and defense and intelligence applications. Major activities frequently involve the design, manufacture and testing of satellites, remote sensors and ground station control hardware and software, as well as related services such as launch vehicle integration and satellite operations.

Other hardware activities include target identification, warning and attitude control systems and components; cryogenic systems for reactant storage, and associated sensor cooling devices; star trackers, which are general-purpose stellar attitude sensors; and fast-steering mirrors. Additionally, the aerospace segment provides diversified technical services and products to government agencies, prime contractors and commercial organizations for a broad range of information warfare, electronic warfare, avionics, intelligence, training and space system needs.

Contracted backlog in the aerospace segment was $2.2 billion and $1.75 billion at December 31, 2018 and 2017, respectively, and consisted of the aggregate contract value of firm orders, excluding amounts previously recognized as revenue. The 2018 contracted backlog includes $1.1 billion expected to be recognized in revenues during 2019, with the remainder expected to be recognized in revenues in the years thereafter. Unfunded amounts included in backlog for certain firm government orders, which are subject to annual funding, were $1.4 billion and $1.3 billion at December 31, 2018 and 2017, respectively. Year-over-year comparisons of backlog are not necessarily indicative of the trend of future operations due to the nature of varying delivery and milestone schedules on contracts, funding of programs and the uncertainty of timing of future contract awards. Uncertainties in the federal government budgeting process could delay the funding, or even result in cancellation of certain programs currently in our reported backlog.

Other

Other consists of non-reportable segments located in Africa, Middle East and Asia (beverage packaging, AMEA) and Asia Pacific (beverage packaging, Asia Pacific) that manufacture and sell metal beverage containers; a non-reportable segment that manufactures and sells aerosol containers, extruded aluminum aerosol containers and aluminum slugs (aerosol packaging); undistributed corporate expenses; intercompany eliminations and other business activities.

Beverage Packaging, AMEA

Our metal beverage container operations in the AMEA region consist of five aluminum container and end manufacturing facilities–two in India and one each in Egypt, Saudi Arabia and Turkey. The beverage container market in these regions produced 27 billion cans in 2018, and we are one of six major producers in this region with 15 percent of shipments. Our manufacturing facility in Saudi Arabia, Rexam United Arab Can Manufacturing Limited, is a joint venture 51 percent owned by Ball and consolidated in our results. Additionally, Ball has an ownership interest in an equity method joint venture in South Korea.

The company opened a metal beverage container facility in Sri City, India, near Chennai, which began production in the second quarter of 2017.

Beverage Packaging, Asia Pacific

The metal beverage container market in the People’s Republic of China (PRC) is 44 billion containers, of which Ball’s operations represented an estimated 12 percent in 2018. Our percentage of the industry makes us one of the largest manufacturers of metal beverage containers in the PRC. We, along with five other manufacturers, account for approximately 75 percent of the production. Our operations include the manufacture of aluminum containers and ends in four facilities in the PRC and one aluminum container facility in Myanmar. Our aluminum can and end sheet requirements are provided by several suppliers.

Ball has ownership interests in beverage packaging manufacturing operations in Vietnam and Thailand.

On December 13, 2018, we announced an agreement to sell our beverage packaging facilities in China for upfront consideration of approximately $225 million plus potential additional consideration related to the future relocation of an existing facility in China. The transaction is subject to customary regulatory approvals and is expected to close during the second half of 2019.

5

Aerosol Packaging

Our aerosol packaging operations manufacture and sell extruded aluminum aerosol containers, steel aerosol containers and aluminum slugs, which represented less than 5 percent of Ball’s consolidated net sales in 2018. There are 10 manufacturing facilities that manufacture these products – four in Europe, two in Argentina, one each in the U.S., Canada, Mexico and India. The aerosol packaging market in these countries produced approximately 5 billion aluminum aerosol units in 2018 and we are one of the major producers in this combined area with shipments of 1.1 billion aluminum aerosol packaging containers, representing approximately 20 percent of total shipments in these markets. Our aluminum and steel aerosol sheet requirements are provided by several suppliers.

Patents

In the opinion of the company’s management, none of our active patents or groups of patents is material to the successful operation of our business as a whole. We manage our intellectual property portfolio to obtain the durations necessary to achieve our business objectives.

Research and Development

Research and development (R&D) efforts in our packaging segments are primarily directed toward packaging innovation, specifically the development of new features, sizes, shapes and types of containers, as well as new uses for existing containers. Other R&D efforts in these segments seek to improve manufacturing efficiencies and the overall sustainability of our products. Our packaging R&D activities are primarily conducted in a technical center located in Westminster, Colorado.

In our aerospace business, we continue to focus our R&D activities on the design, development and manufacture of innovative aerospace products and systems. This includes the production of spacecraft, instruments and sensors, radio frequency and system components, data exploitation solutions and a variety of advanced aerospace technologies and products that enable deep space missions. Our aerospace R&D activities are conducted at various locations in the U.S.

Additional information regarding company R&D activity is contained in Note 1 to the consolidated financial statements within Item 8 of this annual report, as well as in Item 2, “Properties.”

Employee Relations

At the end of 2018, the company and its subsidiaries employed approximately 17,500 employees, including approximately 7,300 employees in the U.S. Details of collective bargaining agreements are included within Item 1A, Risk Factors, of this annual report.

Where to Find More Information

Ball Corporation is subject to the reporting and other information requirements of the Securities Exchange Act of 1934, as amended (Exchange Act). Reports and other information filed with the Securities and Exchange Commission (SEC) pursuant to the Exchange Act may be inspected and copied at the public reference facility maintained by the SEC in Washington, D.C. The SEC maintains a website at www.sec.gov containing our reports, proxy materials and other items. The company also maintains a website at www.ball.com/investors on which it provides a link to access Ball’s SEC reports free of charge, under the link “Financials.”

The company has established written Ball Corporation Corporate Governance Guidelines; a Ball Corporation Executive Officers and Board of Directors Business Ethics Statement; a Business Ethics Code of Conduct; and charters for its Audit Committee, Nominating/Corporate Governance Committee, Human Resources Committee and Finance Committee. These documents are on the company’s website at www.ball.com/investors, under the link “Corporate Governance.” A copy may also be obtained upon request from the company’s corporate secretary. The company’s sustainability report and updates on Ball’s progress are available at www.ball.com/sustainability.

6

The company intends to post on its website the nature of any amendments to the company’s codes of ethics that apply to executive officers and directors, including the chief executive officer, chief financial officer and controller, and the nature of any waiver or implied waiver from any code of ethics granted by the company to any executive officer or director. These postings will appear on the company’s website at www.ball.com/investors, under the link “Corporate Governance.”

Any of the following risks could materially and adversely affect our business, financial condition or results of operations.

We may not realize all of the anticipated benefits of the acquisition of Rexam, or those benefits may take longer to realize than expected. We may also encounter significant unexpected difficulties in integrating the two businesses.

Our ability to realize the anticipated benefits of the acquisition of Rexam will depend, to a large extent, on our ability to integrate our beverage packaging business with Rexam’s business. Combining two independent businesses is a complex, costly and time-consuming process. As a result, we are required to devote significant management attention and resources to integrating the business practices and operations of the company and the Rexam business we acquired. The integration process may disrupt the combined business and, if implemented ineffectively, could preclude the realization of the full benefits of the acquisition that are currently expected. Our failure to meet the challenges involved in integrating the two businesses and to realize the anticipated benefits of the acquisition could cause an interruption of, or a loss of momentum in, the activities of the company and could adversely affect the company’s results of operations. In addition, the overall integration of the businesses may result in material unanticipated problems, expenses, liabilities, competitive responses, loss of customer relationships and diversion of management’s attention. The possible difficulties of combining the operations of the companies also include, among others:

· | difficulties in achieving anticipated cost savings, synergies, business opportunities and growth prospects from combining our business with that of Rexam; |

· | difficulties in integrating operations, business practices and systems; |

· | difficulties in assimilating and retaining employees; |

· | difficulties in managing the expanded operations of a significantly larger and more complex combined company; |

· | challenges in retaining existing customers and suppliers; |

· | challenges in obtaining new customers and suppliers; |

· | potential unknown liabilities and unforeseen increased expenses associated with the acquisition; and |

· | challenges in retaining and attracting key personnel. |

Many of these factors are or will be outside of our control and any one of them could result in increased costs, decreases in the amount of expected revenues and diversion of management’s time and energy, which could materially impact the business, financial condition and results of operations of the company. In addition, even if the operations of the businesses of the company and Rexam are integrated successfully, we may not realize the full benefits of the acquisition, including the synergies, cost savings or sales or growth opportunities that we expect, or the full benefits may not be achieved within the anticipated time frame, or at all. Additional unanticipated costs may be incurred in the integration of the businesses of the company and Rexam. All of these factors could adversely affect the earnings of the company, decrease or delay the expected accretive effect of the acquisition, or negatively impact the price of the company’s common stock. As a result, we cannot assure that the combination of the company’s and Rexam’s beverage packaging businesses will result in the realization of the full benefits anticipated from the acquisition.

In connection with satisfying requirements under the antitrust laws of the U.S., the European Union and Brazil, and obtaining associated approvals and clearances, we were required to effect significant divestitures. As a result of the required divestitures, we may not realize all or a significant portion of the anticipated benefits of the Rexam acquisition, including anticipated synergies, and the company may otherwise suffer other negative consequences that may materially and adversely affect the company’s business, financial condition and results of operations and, to the extent that the current price of the company’s common stock reflects an assumption that the anticipated benefits of the acquisition will be realized, the price per share for the company’s common stock could be negatively impacted.

7

We have a significant level of debt that could have important consequences for our business and any investment in our securities.

The company had $6.7 billion of interest-bearing debt at December 31, 2018. Such indebtedness could have significant consequences for our business and any investment in our securities, including:

· | increasing our vulnerability to adverse economic, industry or competitive developments; |

· | requiring more of our cash flows from operations to be dedicated to the payment of principal and interest on our indebtedness, limiting our cash flow available to fund our operations, capital expenditures and future business opportunities or returning additional cash to our shareholders; |

· | restricting us from making additional acquisitions; |

· | limiting our ability to obtain additional financing for working capital, capital expenditures, product development, debt service requirements, acquisitions and general corporate or other purposes; and |

· | limiting our flexibility in planning for, or reacting to, changes in our business or market conditions and placing us at a competitive disadvantage compared to our competitors who may be less leveraged and who, therefore, may be able to take advantage of opportunities that our leverage prevents us from exploiting. |

Our business, operating results and financial condition are subject to particular risks in certain regions of the world.

We may experience an operating loss in one or more regions of the world for one or more periods, which could have a material adverse effect on our business, operating results or financial condition. Moreover, overcapacity, which often leads to lower prices, exists in certain regions in which we operate and may persist even if demand grows. Our ability to manage such operational fluctuations and to maintain adequate long-term strategies in the face of such developments will be critical to our continued growth and profitability.

The loss of a key customer, or a reduction in its requirements, could have a significant negative impact on our sales.

We sell a majority of our packaging products to a relatively limited number of major beverage, personal care and household product companies, some of which operate in multiple geographical markets we serve.

Although the majority of our customer contracts are long-term, these contracts, unless they are renewed, expire in accordance with their respective terms and are terminable under certain circumstances, such as our failure to meet quality, volume or market pricing requirements. Because we depend on a relatively limited number of major customers, our business, financial condition or results of operations could be adversely affected by the loss of any of these customers, a reduction in the purchasing levels of these customers, a strike or work stoppage by a significant number of these customers’ employees or an adverse change in the terms of the supply agreements with these customers.

The primary customers for our aerospace segment are U.S. government agencies or their prime contractors. Our contracts with these customers are subject to several risks, including funding cuts and delays, technical uncertainties, budget changes, government shutdowns, competitive activity and changes in scope.

We face competitive risks from many sources that may negatively impact our profitability.

Competition within the packaging and aerospace industries is intense. Increases in productivity, combined with existing or potential surplus capacity in the industry, have maintained competitive pricing pressures. The principal methods of competition in the general packaging industry are price, innovation, sustainability, service and quality. In the aerospace industry, they are technical capability, cost and schedule. Some of our competitors may have greater financial, technical and marketing resources, and some may currently have excess capacity. Our current or potential competitors may offer products at a lower price or products that are deemed superior to ours. The global economic environment has resulted in reductions in demand for our products in some instances, which, in turn, could increase these competitive pressures.

8

We are subject to competition from alternative products, which could result in lower profits and reduced cash flows.

Our metal packaging products are subject to significant competition from substitute products, particularly plastic carbonated soft drink bottles made from PET, single serve beer bottles and other beverage containers made of glass, cardboard or other materials. Competition from plastic carbonated soft drink bottles is particularly intense in the U.S., Europe and the PRC. Certain of our aerospace products are also subject to competition from alternative products and solutions. There can be no assurance that our products will successfully compete against alternative products, which could result in a reduction in our profits or cash flow.

Our packaging businesses have a narrow product range, and our business would suffer if usage of our products decreased or if decreases occur in the demand for the beverages and other goods filled in our products.

The majority of our consolidated net sales were from the sale of beverage containers, and we expect to derive a significant portion of our future revenues and cash flows from the sale of beverage containers. Our business would suffer if the use of beverage containers decreased. Accordingly, broad acceptance by consumers of aluminum containers for a wide variety of beverages is critical to our future success. If demand for glass and PET bottles increases relative to metal containers, or the demand for aluminum containers does not develop as expected, our business, financial condition or results of operations could be materially adversely affected.

Changes in laws and governmental regulations may adversely affect our business and operations.

We and our customers and suppliers are subject to various federal, state, provincial and local laws and regulations, which have been increasing in number and complexity. Each of our, and their, facilities is subject to federal, state, provincial and local licensing and regulation by health, environmental, workplace safety and other agencies in multiple jurisdictions. Requirements of worldwide governmental authorities with respect to manufacturing, manufacturing facility locations within the jurisdiction, product content and safety, climate change, workplace safety and health, environmental, expropriation of assets and other standards could adversely affect our ability to manufacture or sell our products, and the ability of our customers and suppliers to manufacture and sell their products. In addition, we face risks arising from compliance with and enforcement of numerous and complex federal, state, provincial and local laws and regulations.

Enacted regulatory developments regarding the reporting and use of “conflict minerals” mined from the Democratic Republic of the Congo and adjoining countries could affect the sourcing, availability and price of minerals used in the manufacture of certain of our products. As a result, there may only be a limited pool of suppliers who provide conflict-free materials, and we cannot give assurance that we will be able to obtain such products in sufficient quantities or at competitive prices. Also, because our supply chains are complex, we may face reputational challenges with our customers and other stakeholders if we are unable to sufficiently verify the origins of all materials used in the products that we sell. The compliance and reporting aspects of these regulations may result in incremental costs to the company. While deposit systems and other container-related legislation have been adopted in some jurisdictions, similar legislation has been defeated in public referenda and legislative bodies in many others. We anticipate that continuing efforts will be made to consider and adopt such legislation in the future. The packages we produce are widely used and perform well in U.S. states, Canadian provinces and European countries that have deposit systems, as well as in other countries worldwide.

Significant environmental, employment-related and other legislation and regulatory requirements exist and are also evolving. The compliance costs associated with current and proposed laws and potential regulations could be substantial, and any failure or alleged failure to comply with these laws or regulations could lead to litigation or governmental action, all of which could adversely affect our financial condition or results of operations.

9

Our business, financial condition and results of operations are subject to risks resulting from broader geographic operations.

We derived more than 50 percent of our consolidated net sales from outside of the U.S. for the year ended December 31, 2018. The sizeable scope of operations outside of the U.S. may lead to more volatile financial results and make it more difficult for us to manage our business. Reasons for this include, but are not limited to, the following:

· | political and economic instability; |

· | governments’ restrictive trade policies; |

· | the imposition or rescission of duties, taxes or government royalties; |

· | exchange rate risks; |

· | difficulties in enforcement of contractual obligations and intellectual property rights; and |

· | the geographic, language and cultural differences between personnel in different areas of the world. |

We are exposed to exchange rate fluctuations.

The financial results of the company are exposed to currency exchange rate fluctuations and an increased proportion of assets, liabilities and earnings denominated in non-U.S. dollar currencies. The company presents its financial statements in U.S. dollars and has a significant proportion of its net assets, debt and income in non-U.S. dollar currencies, primarily the euro, as well as the Russian ruble and other emerging market currencies. The company’s financial results and capital ratios are therefore sensitive to movements in foreign exchange rates.

We manage our exposure to currency fluctuations, particularly our exposure to fluctuations in the euro to U.S. dollar exchange rate to attempt to mitigate the effect of cash flow and earnings volatility associated with exchange rate changes. We primarily use forward contracts and options to manage our currency exposures and, as a result, we experience gains and losses on these derivative positions offset, in part, by the impact of currency fluctuations on existing assets and liabilities.

If we fail to retain key management and personnel, we may be unable to implement our key objectives.

We believe our future success depends, in part, on our experienced management team. Unforeseen losses of key members of our management team without appropriate succession and/or compensation planning could make it difficult for us to manage our business and meet our objectives.

Decreases in our ability to develop or apply new technology and know-how may affect our competitiveness.

Our success depends partially on our ability to improve production processes and services. We must also introduce new products and services to meet changing customer needs. If we are unable to implement better production processes or to develop new products through research and development or licensing of new technology, we may not be able to remain competitive with other manufacturers. As a result, our business, financial condition or results of operations could be adversely affected.

Adverse weather and climate changes may result in lower sales.

We manufacture packaging products primarily for beverages. Unseasonably cool weather can reduce demand for certain beverages packaged in our containers. Climate change could have various effects on the demand for our products and the costs of inputs to our production in different regions around the world.

10

We are vulnerable to fluctuations in the supply and price of raw materials.

We purchase aluminum, steel and other raw materials and packaging supplies from several sources. While all such materials are available from independent suppliers, raw materials are subject to fluctuations in price and availability attributable to a number of factors, including general economic conditions, commodity price fluctuations (particularly aluminum on the London Metal Exchange), the demand by other industries for the same raw materials and the availability of complementary and substitute materials. Although we enter into commodities purchase agreements from time to time and sometimes use derivative instruments to seek to manage our risk, we cannot ensure that our current suppliers of raw materials will be able to supply us with sufficient quantities at reasonable prices. Economic, operational and financial factors, as well as governmental action, could impact our suppliers, thereby causing supply shortages. Increases in raw material costs, including potential increases due to tariffs, sanctions, or other trade actions, could have a material adverse effect on our business, financial condition or results of operations. In the Americas, Europe and Asia, some contracts do not allow us to pass along increased raw material costs and we generally use derivative agreements to seek to manage this risk. Our hedging procedures may be insufficient and our results could be materially impacted if costs of materials increase. Due to the fixed-price contracts and derivative activities, while increasing raw material costs may not impact our near-term profitability, increased prices could decrease our sales volume over time.

Prolonged work stoppages at facilities with union employees could jeopardize our financial position.

As of December 31, 2018, 14 percent of our North American packaging facility employees and 56 percent of our European employees were covered by collective bargaining agreements. These collective bargaining agreements have staggered expirations during the next several years. Although we consider our employee relations to be generally good, a prolonged work stoppage or strike at any facility with union employees could have a material adverse effect on our business, financial condition or results of operations. In addition, we cannot ensure that upon the expiration of existing collective bargaining agreements, new agreements will be reached without union action or that any such new agreements will be on terms satisfactory to us.

Our aerospace segment is subject to certain risks specific to that business.

In our aerospace business, U.S. government contracts are subject to reduction or modification in the event of changes in requirements, and the government may also terminate contracts at its convenience pursuant to standard termination provisions. In such instances, Ball may be entitled to reimbursement for allowable costs and profits on authorized work that has been performed through the date of termination.

In addition, budgetary constraints and government shutdowns may result in further reductions to projected spending levels by the U.S. government. In particular, government expenditures are subject to the potential for automatic reductions, generally referred to as “sequestration.” Sequestration may occur in any given year, resulting in significant additional reductions to spending by various U.S government defense and aerospace agencies on both existing and new contracts, as well as the disruption of ongoing programs. Even if sequestration does not occur, we expect that budgetary constraints and ongoing concerns regarding the U.S. national debt will continue to place downward pressure on agency spending levels. Due to these and other factors, overall spending on various programs could decline, which could result in significant reductions to revenue, cash flows, net earnings and backlog primarily in our aerospace segment.

We use estimates in accounting for many of our programs in our aerospace business, and changes in our estimates could adversely affect our future financial results.

We account for sales and profits on a portion of long-term contracts in our aerospace business in accordance with the percentage-of-completion method of accounting, using the cost-to-cost method to account for updates in estimates. The percentage-of-completion method of accounting involves the use of various estimating techniques to project revenues and costs at completion and various assumptions and projections relative to the outcome of future events, including the quantity and timing of product deliveries, future labor performance and rates, and material and overhead costs. These assumptions involve various levels of expected performance improvements. Under the cost-to-cost method, the impact of updates in our estimates related to units shipped to date or progress made to date is recognized immediately.

Because of the significance of the judgments and estimates described above, it is likely that we could record materially different amounts if we used different assumptions or if the underlying circumstances or estimates were to change.

11

Our backlog includes both cost-type and fixed-price contracts. Cost-type contracts generally have lower profit margins than fixed-price contracts. Our earnings and margins may vary depending on the types of government contracts undertaken, the nature of the work performed under those contracts, the costs incurred in performing the work, the achievement of other performance objectives and their impact on our ability to receive fees. The fixed-price contracts could subject us to losses if we have cost overruns or if increases in our costs exceed the applicable escalation rate.

As a U.S. government contractor, we could be adversely affected by changes in regulations or any negative findings from a U.S. government audit or investigation.

Our aerospace business operates in a highly regulated environment and is routinely audited and reviewed by the U.S. government and its agencies, such as the Defense Contract Audit Agency (DCAA) and Defense Contract Management Agency (DCMA). These agencies review performance under our contracts, our cost structure and our compliance with applicable laws, regulations and standards, as well as the adequacy of, and our compliance with, our internal control systems and policies. Business systems that are subject to review under the DoD Federal Acquisition Regulation Supplement (DFARS) are purchasing, estimating, material management and accounting, as well as property and earned value management. Any costs ultimately found to be unallowable or improperly allocated to a specific contract will not be reimbursed or must be refunded if already reimbursed. If an audit uncovers improper or illegal activities, we may be subject to civil and criminal penalties, sanctions or suspension or debarment from doing business with the U.S. government. Whether or not illegal activities are alleged, the U.S. government also has the ability to decrease or withhold certain payments when it deems systems subject to its review to be inadequate. If such actions were to result in suspension or debarment, this could have a material adverse effect on our business.

Our business is subject to substantial environmental remediation and compliance costs.

Our operations are subject to federal, state, provincial and local laws and regulations in multiple jurisdictions relating to environmental hazards, such as emissions to air, discharges to water, the handling and disposal of hazardous and solid wastes and the clean-up of hazardous substances. We have been designated, along with numerous other companies, as a potentially responsible party for the clean-up of several hazardous waste sites. Based on available information, we do not believe that any costs incurred in connection with such sites will have a material adverse effect on our financial condition, results of operations, capital expenditures or competitive position. There is increased focus on the regulation of greenhouse gas emissions and other environmental issues worldwide.

Our business faces the potential of increased regulation on some of the raw materials utilized in our packaging operations.

Our operations are subject to federal, state, provincial and local laws and regulations in multiple jurisdictions relating to some of the raw materials, such as epoxy-based coatings utilized in our container making process. Epoxy-based coatings may contain Bisphenol-A (BPA). Scientific evidence evaluated by regulatory agencies in the U.S., Canada, Europe, Japan, Australia and New Zealand has consistently shown these coatings to be safe for food contact at current levels, and these regulatory agencies have stated that human exposure to BPA from epoxy-based container coatings is well below safe exposure limits set by government bodies worldwide. A significant change in these regulatory agency statements, adverse information concerning BPA, or rulings made within certain federal, state, provincial and local jurisdictions could have a material adverse effect on our business, financial condition or results of operations. Ball recognizes that significant interest exists in non-epoxy based coatings, and we have been proactively working with coatings suppliers and our customers to transition to alternative coatings.

12

Net earnings and net assets could be materially affected by an impairment of goodwill.

We have a significant amount of goodwill recorded on the consolidated balance sheet as of December 31, 2018. We are required at least annually to test the recoverability of goodwill. The recoverability test of goodwill is based on the current fair value of our identified reporting units. Fair value measurement requires assumptions and estimates of many critical factors, including revenue and market growth, operating cash flows and discount rates. If general market conditions deteriorate in portions of our business, we could experience a significant decline in the fair value of reporting units. This decline could lead to an impairment of all or a significant portion of the goodwill balance, which could materially affect our U.S. GAAP net earnings and net assets.

We continue to see the industry supply of beverage packaging exceed demand in China, resulting in significant pricing pressure and negative impacts on the profitability of our beverage packaging, Asia Pacific, reporting unit. The worsening business climate in Saudi Arabia has resulted in negative impacts to the profitability of our beverage packaging, AMEA, reporting unit. If it becomes an expectation that these situations will continue for an extended period of time, it may result in a noncash impairment of some or all of the goodwill associated with these reporting units, totaling $78 million and $100 million, respectively, at December 31, 2018. The company’s annual goodwill impairment test completed in the fourth quarter of 2018 indicated the estimated fair value of the beverage packaging, Asia Pacific, and beverage packaging, AMEA, reporting units exceeded their carrying amounts, including goodwill, by 11 percent and 15 percent, respectively. The goodwill associated with the beverage packaging, Asia Pacific, reporting unit predominantly relates to the China beverage packaging facilities. On December 13, 2018, we announced an agreement to sell our beverage packaging facilities in China. The transaction is expected to close during the second half of 2019.

If the investments in Ball’s pension plans, or in the multi-employer pension plans in which Ball participates, do not perform as expected, we may have to contribute additional amounts to the plans, which would otherwise be available for other general corporate purposes.

Ball maintains defined benefit pension plans covering substantially all of its North American employees and a significant portion of United Kingdom employees, which are funded based on certain actuarial assumptions. The plans’ assets consist primarily of common stocks, fixed-income securities and, in the U.S., alternative investments. Market declines, longevity increases or legislative changes, such as the Pension Protection Act in the U.S., could result in a prospective decrease in our available cash flow and net earnings over time, and the recognition of an increase in our pension obligations could result in a reduction to our shareholders’ equity. Additional risks exist related to the company’s participation in multi-employer pension plans. Assets contributed to a multi-employer pension plan by one employer may be used to provide benefits to employees of other participating employers. If a participating employer in a multi-employer pension plan stops contributing to the plan, the unfunded obligations of the plan may be borne by the remaining participants. This could result in increases to our contributions to the plans as well as pension expense.

Restricted access to capital markets could adversely affect our short-term liquidity and prevent us from fulfilling our obligations under the notes issued pursuant to our bond indentures.

A reduction in global market liquidity could:

· | restrict our ability to fund working capital, capital expenditures, research and development expenditures and other business activities; |

· | increase our vulnerability to general adverse economic and industry conditions, including the credit risks stemming from the economic environment; |

· | limit our flexibility in planning for, or reacting to, changes in our businesses and the industries in which we operate; |

· | restrict us from making strategic acquisitions or exploiting business opportunities; and |

· | limit, along with the financial and other restrictive covenants in our debt, among other things, our ability to borrow additional funds, dispose of assets, pay cash dividends or refinance debt maturities. |

As market interest rates increase, our variable-rate debt will create higher debt service requirements, which adversely affects our cash flow. While we sometimes enter into agreements limiting our exposure, any such agreements may not offer complete protection from this risk.

13

The global credit, financial and economic environment could have a negative impact on our results of operations, financial position or cash flows.

The overall credit, financial and economic environment could have significant negative effects on our operations, including:

· | the creditworthiness of customers, suppliers and counterparties could deteriorate resulting in a financial loss or a disruption in our supply of raw materials; |

· | volatile market performance could affect the fair value of our pension assets, potentially requiring us to make significant additional contributions to our defined benefit pension plans to maintain prescribed funding levels; |

· | a significant weakening of our financial position or operating results could result in noncompliance with our debt covenants; and |

· | reduced cash flow from our operations could adversely affect our ability to execute our long-term strategy to increase liquidity, reduce debt, repurchase our stock and invest in our businesses. |

Changes in U.S. generally accepted accounting principles (U.S. GAAP) and SEC rules and regulations could materially impact our reported results.

U.S. GAAP and SEC accounting and reporting changes are common and have become more frequent and significant over the past several years. These changes could have significant effects on our reported results when compared to prior periods and other companies and may even require us to retrospectively adjust prior periods. Additionally, material changes to the presentation of transactions in the consolidated financial statements could impact key ratios that analysts and credit rating agencies use to rate Ball and ultimately impact our ability to access the credit markets in an efficient manner.

Earnings and cash flows can be impacted by changes in tax laws.

As a U.S.-based multinational business, the company is subject to income tax in the U.S. and numerous jurisdictions outside the U.S. The relevant tax rules and regulations are complex, often changing and, in some cases, are interdependent. If these or other tax rules and regulations should change, the company’s earnings and cash flows could be impacted.

In particular, the U.S. Tax Cuts and Jobs Act (the Act), which was signed into law on December 22, 2017, may continue to result in fluctuations in the company’s net earnings and cash flows. The Act introduced major changes to U.S. income tax law that require significant judgment to interpret the impact of the provisions of the Act on the company’s financial results.

Due to the timing of its enactment and the complexity associated with the provisions of the Act, the company made reasonable estimates of its effects where possible and recorded provisional estimates in its financial statements for the year ended December 31, 2017. The company has updated these provisional estimates as needed and its financial statements now reflect the final impact of these items based on currently available guidance, including proposed regulations. Given the various uncertainties and ambiguities that still remain with respect to the application of the Act, the Internal Revenue Service and the U.S. Treasury Department may issue subsequent guidance on the provisions of the Act, including final regulations, that differs from our current interpretations. The impact of any adjustments required as a result of such subsequent guidance could materially affect the company’s financial results.

The company’s worldwide provision for income taxes is determined, in part, through the use of significant estimates and judgments. Numerous transactions arise in the ordinary course of business where the ultimate tax determination is uncertain. The company undergoes tax examinations by various worldwide tax authorities on a regular basis. While the company believes its estimates of its tax obligations are reasonable, the final outcome after the conclusion of any tax examinations and any litigation could be materially different from what has been reflected in the company’s historical financial statements.

14

Increased information technology (IT) security threats and more sophisticated and targeted computer crime could pose a risk to our systems, networks, products, solutions and services.

The company’s IT systems, or any third party’s system on which the company relies, could fail on their own accord or may be vulnerable to a variety of interruptions or shutdowns, including interruptions or shutdowns due to natural disasters, power outages or telecommunications failures, terrorist attacks or failures during the process of upgrading or replacing software or hardware. Increased global IT security threats and more sophisticated and targeted computer crime also pose a risk to the security of our systems and networks and the confidentiality, availability and integrity of our data. As a provider of products and services to government and commercial customers, our aerospace business in particular may be the target of cyber-attacks, including attempts to gain unauthorized access to classified or sensitive information and networks. The company has a number of shared service centers where many of the company’s IT systems are concentrated and any disruption at such a location could impact the company’s business within the operating zones served by the impacted service center.

While we attempt to mitigate all of these risks by employing a number of measures, including employee training, comprehensive monitoring of our networks and systems, and maintenance of backup and protective systems, our systems, networks, products, solutions and services remain potentially vulnerable to advanced persistent threats or other IT disruptions. Depending on their nature and scope, such threats could potentially lead to the compromise of confidential information, improper use of our systems and networks, manipulation and destruction of data, defective products, harm to individuals or property, contractual or regulatory actions and fines, penalties and potential liabilities, production downtimes and operational disruptions, which in turn could adversely affect our reputation, competitiveness and results of operations. Data privacy and protection laws are evolving and present increasing compliance challenges, which may increase our costs, affect our competitiveness and could expose us to substantial fines or other penalties. In addition, a security breach that involves classified or other sensitive government information could subject us to civil or criminal penalties and could result in the loss of our secure facility clearance and other accreditation, loss of our government contracts, loss of access to classified information or debarment as a government contractor.

A material weakness in our internal control over financial reporting could, if not remediated, result in material misstatements in our financial statements.

Management is responsible for establishing and maintaining adequate internal control over financial reporting, as defined in Rule 13a-15(f) under the Securities Exchange Act. A material weakness is defined as a deficiency, or combination of deficiencies, in internal control over financial reporting, such that there is a reasonable possibility that a material misstatement of annual or interim financial statements will not be prevented or detected on a timely basis. If a material weakness is identified, management could conclude that internal control over financial reporting is not effective based on criteria set forth by the Committee of Sponsoring Organization of the Treadway Commission in “Internal Control—An Integrated Framework (2013).” If a material weakness is identified, a remediation plan would be designed to address the material weakness. If remedial measures are insufficient to address the material weakness, or if additional material weaknesses in internal control are discovered or occur in the future, our consolidated financial statements may contain material misstatements and we could be required to restate our financial results. As of December 31, 2018, the company had no material weaknesses.

Significant developments stemming from the U.K.’s referendum on membership in the EU could have a material adverse effect on us.

In June 2016, the U.K. held a referendum and voted in favor of leaving the European Union (EU). This referendum has created political and economic uncertainty, particularly in the U.K. and the EU, and this uncertainty may last for years, particularly as the U.K. and the EU continue to negotiate the terms of withdrawal from the EU. Our business in the U.K., the EU and worldwide could be affected by uncertainty prior to and after the upcoming March 29, 2019, withdrawal date by the impact of the U.K.’s referendum and anticipated withdrawal from the EU. There are many ways in which our business could be affected, only some of which we can identify at the present time, such as supply chain constraints, increased material costs due to rising tariffs, effects on employee mobility and increased costs of doing business in the U.K. These effects could be more severe if the U.K. and the EU fail to reach an agreement prior to the withdrawal date.

15

The referendum, and the likely withdrawal of the U.K. from the EU it triggers, has caused and, along with events that could occur in the future as a consequence of the U.K.’s withdrawal, including the possible breakup of the U.K. or the EU, may continue to cause significant volatility in global financial markets, including in global currency and debt markets. A failure by the U.K. and the EU to reach an agreement prior to the U.K.’s departure from the EU, scheduled for March 29, 2019, may increase this volatility. This volatility could cause a slowdown in economic activity in the U.K., Europe or globally, which could adversely affect our operating results and growth prospects. In addition, our business could be negatively affected by new trade agreements between the U.K. and other countries, including the U.S., and by the possible imposition of trade or other regulatory barriers in the U.K. These possible negative impacts, and others resulting from the U.K.’s actual or threatened withdrawal from the EU, may adversely affect our operating results and growth prospects.

Item 1B. Unresolved Staff Comments

There were no matters required to be reported under this item.

The company’s properties described below are well maintained, and management considers them to be adequate and utilized for their intended purposes.

Ball’s corporate headquarters and the aerospace segment management offices are located in Broomfield, Colorado, U.S. The operations of the aerospace segment occupy a variety of company-owned and leased facilities in Colorado, U.S., which together aggregate 1.8 million square feet of office, laboratory, research and development, engineering and test and manufacturing space. Other aerospace operations carry on business in smaller company owned and leased facilities in other U.S. locations outside of Colorado.

The offices of the company’s various beverage packaging, North and Central America, operations are located in Westminster, Colorado, U.S.; the offices for the beverage packaging, Europe, operations are located in Luton, U.K.; the offices for the beverage packaging, AMEA, operations are located in Dubai, United Arab Emirates; the offices for the beverage packaging, Asia Pacific, operations are located in Hong Kong; and the beverage packaging, South America, offices are located in Rio de Janeiro, Brazil. The company’s research and development facilities are primarily located in Westminster, Colorado, U.S. The company has shared service centers located in Queretaro, Mexico; Belgrade, Serbia; and São José dos Campos, Brazil.

Information regarding the approximate size of the manufacturing locations for significant packaging operations, which are owned or leased by the company, is set forth below. Facilities in the process of being constructed, or that have ceased production, have been excluded from the list. Where certain locations include multiple facilities, the total approximate size for the location is noted. In addition to the facilities listed, the company leases other warehousing space.

16

|

|

|

|

| Approximate |

|

| Floor Space in |

Plant Location |

| Square Feet |

|

|

|

Beverage packaging, North and Central America: |

|

|

Conroe, Texas |

| 315,000 |

Fairfield, California |

| 337,000 |

Findlay, Ohio |

| 733,000 |

Fort Atkinson, Wisconsin |

| 250,000 |

Fort Worth, Texas |

| 322,000 |

Golden, Colorado |

| 509,000 |

Goodyear, Arizona |

| 495,000 |

Kapolei, Hawaii |

| 131,000 |

Kent, Washington |

| 127,000 |

Monterrey, Mexico |

| 440,000 |

Monticello, Indiana |

| 356,000 |

Phoenix, Arizona |

| 106,000 |

Queretaro, Mexico |

| 253,000 |

Rome, Georgia |

| 386,000 |

Saint Paul, Minnesota |

| 165,000 |

Saratoga Springs, New York |

| 290,000 |

Tampa, Florida |

| 276,000 |

Wallkill, New York |

| 312,000 |

Whitby, Ontario, Canada |

| 205,000 |

Williamsburg, Virginia |

| 400,000 |

|

|

|

Beverage packaging, South America: |

|

|

Aguas Claras, Brazil |

| 292,000 |

Brasilia, Brazil |

| 267,000 |

Buenos Aires, Argentina |

| 272,000 |

Extrema, Brazil |

| 375,000 |

Jacarei, Sao Paulo, Brazil |

| 476,000 |

Manaus, Brazil |

| 303,000 |

Pouso Alegre, Brazil |

| 430,000 |

Recife, Brazil |

| 455,000 |

Santa Cruz, Brazil |

| 311,000 |

Santiago, Chile |

| 275,000 |

Simoes Filho, Brazil |

| 96,000 |

Tres Rios, Rio de Janeiro, Brazil |

| 428,000 |

|

|

|

Beverage packaging, Europe: |

|

|

Argayash, Russia |

| 256,000 |

Belgrade, Serbia |

| 342,000 |

Bierne, France |

| 274,000 |

Cabanillas del Campo, Spain |

| 145,000 |

Ejpovice, Czech Republic |

| 185,000 |

Fosie, Sweden |

| 669,000 |

Fredericia, Denmark |

| 329,000 |

Gelsenkirchen, Germany |

| 378,000 |

La Selva, Spain |

| 278,000 |

Lublin, Poland |

| 280,000 |

Ludesch, Austria |

| 337,000 |

Mantsala, Finland |

| 230,000 |

Milton Keynes, United Kingdom |

| 148,000 |

Mont, France |

| 45,000 |

Naro Fominsk, Russia |

| 544,000 |

Nogara, Italy |

| 122,000 |

Vsevolozhsk, Russia |

| 316,000 |

Wakefield, United Kingdom |

| 269,000 |

Waterford, Ireland |

| 129,000 |

Widnau, Switzerland |

| 321,000 |

|

|

|

|

|

|

|

|

|

17

|

| Approximate |

|

| Floor Space in |

Plant Location |

| Square Feet |

Beverage packaging, AMEA: |

|

|

Cairo, Egypt |

| 201,000 |

Dammam, Saudi Arabia |

| 416,000 |

Manisa, Turkey |

| 173,000 |

Mumbai, India |

| 175,000 |

Sri City, India |

| 215,000 |

|

|

|

Beverage packaging, Asia Pacific: |

|

|

Beijing, PRC |

| 303,000 |

Hubei (Wuhan), PRC |

| 416,000 |

Qingdao, PRC |

| 326,000 |

Sanshui (Foshan), PRC |

| 672,000 |

Yangon, Myanmar |

| 432,000 |

|

|

|

Aerosol packaging: |

|

|

Ahmedabad, India |

| 58,000 |

Beaurepaire, France |

| 89,000 |

Bellegarde, France |

| 124,000 |

Buenos Aires, Argentina |

| 34,000 |

Devizes, United Kingdom |

| 110,000 |

San Luis, Argentina |

| 51,000 |

San Luis Potosí, Mexico |

| 158,000 |

Sherbrooke, Quebec, Canada |

| 100,000 |

Velim, Czech Republic |

| 252,000 |

Verona, Virginia |

| 72,000 |

|

|

|

Details of the company’s legal proceedings are included in Note 23 to the consolidated financial statements within Item 8 of this annual report.

Item 4. Mine Safety Disclosures

Not applicable.

18

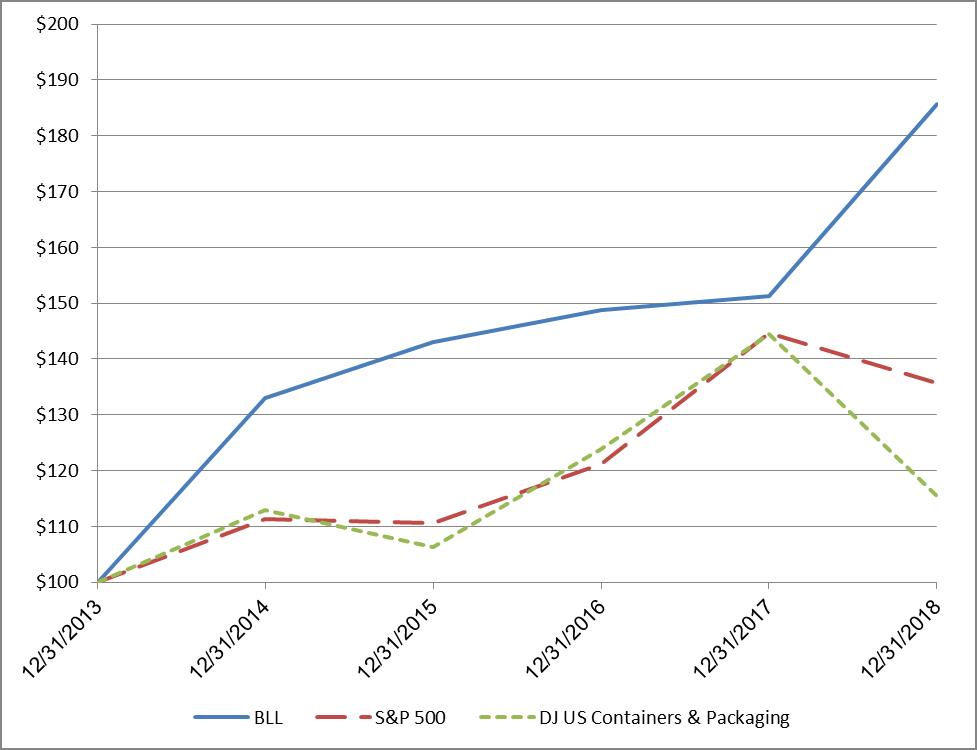

Item 5. Market for the Registrant’s Common Stock and Related Stockholder Matters

Ball Corporation common stock (BLL) is listed for trading on the New York Stock Exchange. There were 6,048 common shareholders of record on February 20, 2019.

Common Stock Repurchases

The following table summarizes the company’s repurchases of its common stock during the quarter ended December 31, 2018.

|

|

|

|

|

|

|

|

|

|

Purchases of Securities | |||||||||

($ in millions) |

| Total Number of Shares Purchased (a) |

| Average |

| Total Number of |

| Maximum Number of | |

|

|

|

|

|

|

|

|

|

|

October 1 to October 31, 2018 |

| 1,820,293 |

| $ | 44.84 |

| 1,820,293 |

| 13,458,171 |

November 1 to November 31, 2018 |

| 2,286,260 |

|

| 49.06 |

| 2,286,260 |

| 11,171,911 |

December 1 to December 31, 2018 |

| 1,923,374 |

|

| 46.81 |

| 1,923,374 |

| 9,248,537 |

Total |

| 6,029,927 |

|

| 47.07 |

| 6,029,927 |

|

|

(a)Includes any open market purchases (on a trade-date basis), share repurchase agreements and/or shares retained by the company to settle employee withholding tax liabilities.