EXHIBIT 99.2

AGRIUM INC.

2011

MANAGEMENT’S DISCUSSION & ANALYSIS OF

OPERATIONS AND FINANCIAL CONDITION

February 23, 2012

Inside the MD&A

Management’s Discussion and Analysis

This Management’s Discussion and Analysis (“MD&A”) of operations and financial condition focuses on Agrium’s long-term vision, strategy and growth opportunities as well as its historical performance for the two years ended December 31, 2011. The Board of Directors carries out its responsibility for review of this disclosure principally through its audit committee, comprised exclusively of independent directors. The audit committee reviews, and prior to publication, approves, pursuant to the authority delegated to it by the Board of Directors, this disclosure. The reader should consider the cautionary notes regarding forward-looking statements (page 76) and the Consolidated Financial Statements and related notes (pages 82 to 133).

Throughout this MD&A (unless otherwise specified), “Agrium”, “the Company”, “we”, “our”, “us” and similar expressions refer collectively to Agrium Inc. and its subsidiaries, any partnerships involving Agrium Inc. or any of its subsidiaries, and our significant equity investments and joint ventures.

The Company’s consolidated quarterly and annual financial information and its Annual Information Form (“AIF”) are available at SEDAR (www.sedar.com). The Company’s reports are also filed with the United States (“U.S.”) Securities and Exchange Commission on EDGAR (www.sec.gov).

All dollar amounts refer to U.S. dollars except where otherwise stated. 2011 and 2010 financial information presented and discussed in this MD&A is prepared in accordance with International Financial Reporting Standards (“IFRS”) as issued by the International Accounting Standards Board (“IASB”). All financial information prior to 2010 is prepared in accordance with previous Canadian generally accepted accounting principles (“CGAAP”) in place prior to the adoption of IFRS. For more information about our conversion to IFRS, please see note 30 of the Notes to the Consolidated Financial Statements.

FORWARD-LOOKING STATEMENTS

Certain statements and other information included in this MD&A constitute “forward-looking information” within the meaning of applicable Canadian securities legislation or “forward-looking statements” within the meaning of applicable U.S. securities legislation (collectively herein referred to as “forward-looking statements”), including the “safe harbour” provisions of provincial securities legislation and the U.S. Private Securities Litigation Reform Act of 1995, Section 21E of the U.S. Securities Exchange Act of 1934, as amended, and Section 27A of the U.S. Securities Act of 1933, as amended. Forward-looking statements are typically identified by the words “believe”, “expect”, “anticipate”, “project”, “intend”, “estimate”, “outlook”, “focus”, “potential”, “will”, “should”, “would”, “could” and other similar expressions. These forward-looking statements include, but are not limited to, references to: disclosures made under the heading “Crop Input Situation and 2012 Outlook”; our 2012 key corporate goals, including expansion and growth of our business and operations; estimates, forecasts and statements as to management’s expectations with respect to, among other things, business, growth, demand and financial prospects, financial multiples and accretion estimates, future trends, plans, objectives and expectations; key drivers for our business and industry trends; future capital expenditures and capital resources; future cash requirements and long-term obligations; anticipated tax rates; business strategies and plans for implementing them; future crop input sales and prices; availability of raw materials; risk mitigation activities; environmental and civil liabilities; and our future results and plans, including any expected synergies and benefits received from, and our integration plans relating to, our recent, proposed and future acquisitions and dispositions.

These forward-looking statements are based on certain assumptions and analyses made by us in light of our experience and perception of historical trends, current conditions and expected future developments as well as other factors we believe are appropriate in the circumstances. In addition, readers are cautioned not to place undue reliance on the forward-looking statements which involve known and unknown material risks and uncertainties that may cause our actual results, performance or achievements to be materially different from any future results, performance or achievements expressed or implied by such forward-looking statements. Please refer to the discussion under the heading “Key Assumptions and Risks in Respect of Forward-Looking Statements” with respect to the material assumptions and risks associated with the forward-looking statements. All of the forward-looking statements contained in this MD&A are qualified by the cautionary statements contained herein and by stated or inherent assumptions and apply only as of the date of this MD&A. Except as required by law, Agrium disclaims any intention or obligation to update or revise any forward-looking statements as a result of new information or future events.

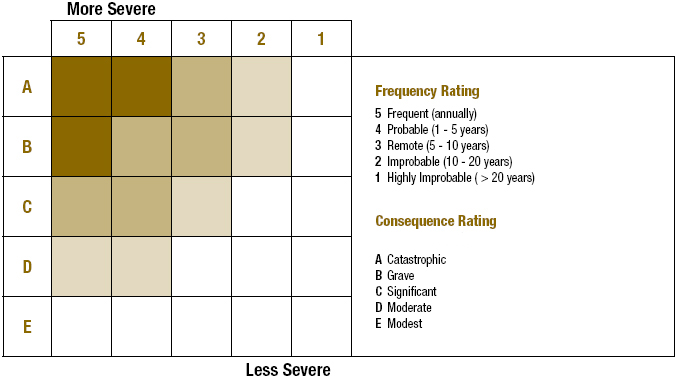

Additional risks and uncertainties that may affect all forward-looking information included in this MD&A include, but are not limited to, the following:

| ¨ | General economic, market, business and weather conditions, including global agricultural supply/demand factors and crop price levels; global and regional supply/demand factors impacting the crop input application season and the price of crop nutrients and raw materials/feedstock; global economic and market conditions affecting availability of credit and access to capital markets; build-up of inventories in distribution channels; changes to foreign exchange rates; tightening of the labor market; and availability of labor supply; |

| ¨ | Changes in government policies and legislation and regulation, or the interpretation, administration and enforcement thereof, in the jurisdictions in which we operate, regarding agriculture and crop input prices, safety, production processes, environment, greenhouse gas and others; |

AGRIUM2011 ANNUAL REPORT 9

| ¨ | Actions by competitors and others that include changes to industry capacity, utilization rates and product pricing; performance by customers, suppliers and counterparties to financial instruments; potential for expansion plans to be delayed; and restrictions on our ability to transport or deliver production to markets, including potential changes to anti-trust laws, or interpretations thereof, that could negatively impact our international marketing operations through Canpotex Limited (“Canpotex”) the offshore marketing agency for potash produced in the Province of Saskatchewan, wholly-owned by us and the two other major potash producers in Canada; |

| ¨ | Changes in margins and/or levels of supplier rebates for major crop inputs such as crop protection products, nutrients and seed, as well as crop input prices declining below cost of inventory between the time of purchase and sales; |

| ¨ | General operating risks associated with investment in foreign jurisdictions; the level and effectiveness of future capital expenditures; reliability of performance of existing capital assets; and fluctuations in foreign exchange and tax rates in the jurisdictions in which we operate; |

| ¨ | Future operating rates, production costs and sustaining capital of our facilities; unexpected costs from present and discontinued mining operations and/or labor disruptions; changes to timing, construction cost and performance of other parties; and political risks associated with our interest in the Egyptian Misr Fertilizers Production Company S.A.E. (“MOPCO”), Argentine Profertil nitrogen facilities, and other facilities; |

| ¨ | Changes in development plans for our potash expansion project, nitrogen de-bottlenecking and other major capital expansion projects, including the potential for capital construction costs to be higher than expected or construction progress to be delayed, due to factors such as availability of equipment and labor, the performance of other parties, risks associated with technology or inflationary pressure; |

| ¨ | Environmental, health, safety and security risks typical of those found throughout the agriculture, mining and chemical manufacturing sectors and the fertilizer supply chain, including risk of injury to employees and contractors, possible environmental contamination, risks associated with the transportation, storage and use of chemicals and the security of our facilities and personnel; |

| ¨ | Integration risks that might cause anticipated synergies from our recent (including those described in this MD&A) and future acquisitions to be less than expected, including: the acquired business’ actual results being different than those upon which we based our expectations; and industry factors which may affect us and the acquired business in general and thereby impact the demand for our products and services; and |

| ¨ | Strategic risks including our ability to effectively implement our business strategy and our risk mitigation strategies, including hedging and insurance; our ability to close pending and proposed acquisitions and dispositions as anticipated and to integrate and achieve synergies from any assets we may acquire within the time or performance expected of those assets; and the introduction of technologies in the agricultural industry that may be disruptive to our business. |

The above items and their possible impact are discussed more fully in the relevant parts of this MD&A, including the sections headed “Key Business Sensitivities” and “Enterprise Risk Management” and in our Annual Information Form.

Non-IFRS Financial Measures

Some financial measures referenced in this MD&A are not recognized under IFRS, including net earnings (loss) from continuing operations before finance costs, income taxes, depreciation, amortization and asset impairment (“EBITDA”). Net debt includes short-term and long-term debt, net of cash and cash equivalents. Net debt is not a recognized measure under IFRS and our method of calculation may not be comparable to other companies. Please refer to the discussion of non-IFRS measures on page 42 when referring to these measures.

10 CULTIVATING PERFORMANCE.DELIVERING VALUE.

Executive Summary //

Cultivating Performance, Delivering Value

2011 IN REVIEW

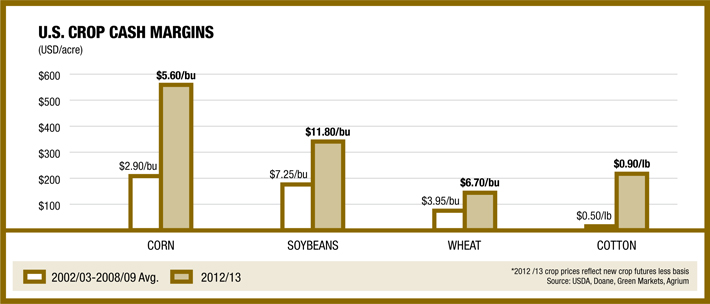

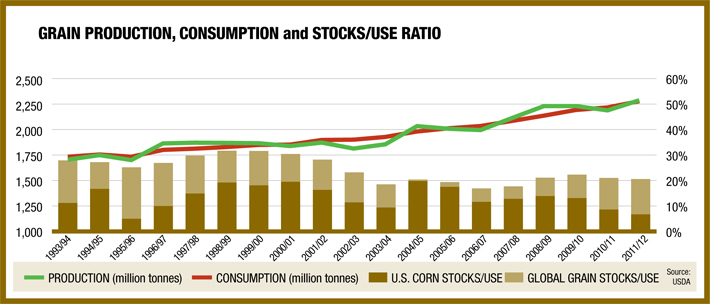

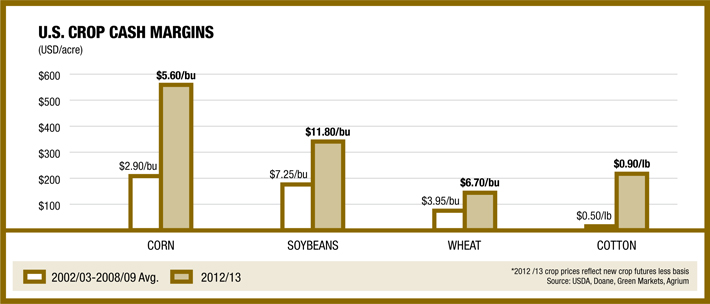

2011 was a record year for Agrium. We reported the highest consolidated net earnings (“net earnings”) in our 17-year history, with record earnings from both our Wholesale and Retail business units. Net earnings in 2011 were almost double those achieved in 2010, and surpassed the previous record set in 2008. These outstanding results were achieved in part due to strong demand for all crop inputs, as strong global crop prices and record grower cash margins provided an economic incentive for farmers to optimize planted acreage and yields. Agrium is one of the world’s largest publicly traded wholesale producers and distributors of crop nutrients and the leading global agricultural retailer and provider of controlled-release nutrients. We believe that our unique position across the agricultural value chain, combined with our focus on cultivating strong performance in all that we do and our expectation of the persistent strength in agricultural fundamentals, will allow us to continue delivering value to all of our stakeholders.

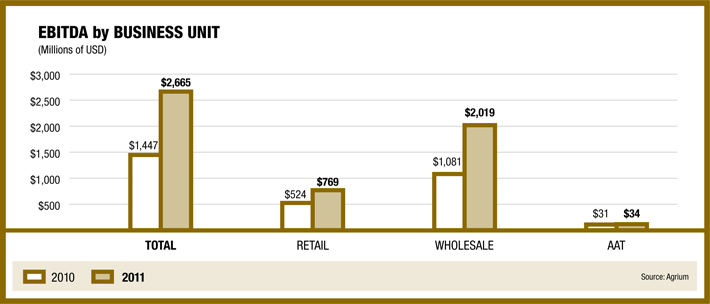

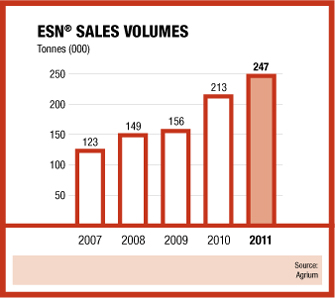

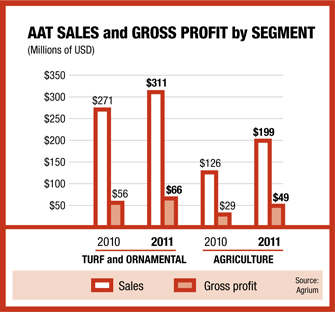

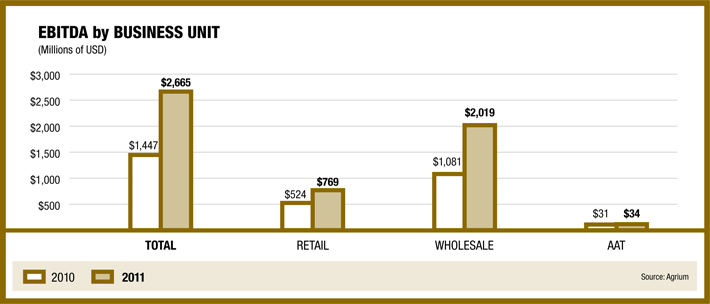

2011 // Consolidated and Business Unit Financial Performance

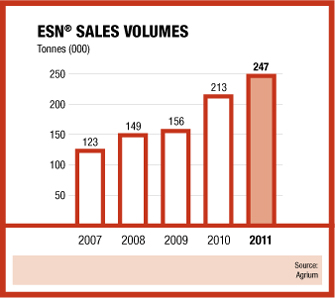

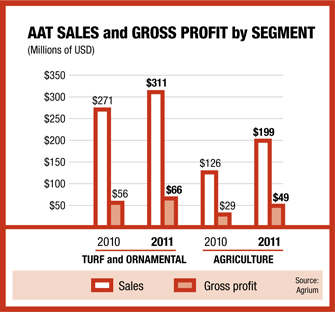

In 2011, Agrium’s net earnings from continuing operations were $1.5-billion, significantly higher than the $730-million in 2010 and higher than the previous record of $1.3-billion in 2008, and were supported by strong industry fundamentals. Our 2011 EBITDA also rose to a record $2.7-billion in 2011, from $1.4-billion in 2010. OurRetail business unit achieved record EBITDA of $769-million in 2011, compared to $524-million in 2010, as a result of stronger demand for crop inputs related to higher crop prices, as well as the inclusion of a full year of results from various acquisitions, including the Landmark Rural Holdings Limited (“Landmark”) business in Australia. OurWholesale business unit also achieved record EBITDA of $2.0-billion in 2011 compared to $1.1-billion in 2010, due to higher margins across all our major nutrient products as a result of higher global nutrient pricing and our competitive cost structure. Agrium’sAdvanced Technologies (“AAT”) business unitproduced EBITDA of $34-million in 2011, compared to $31-million in 2010 due to stronger grower demand and pricing for Environmentally Smart Nitrogen - ESN® (“ESN”) and the inclusion of earnings from recent acquisitions.

AGRIUM2011 ANNUAL REPORT 11

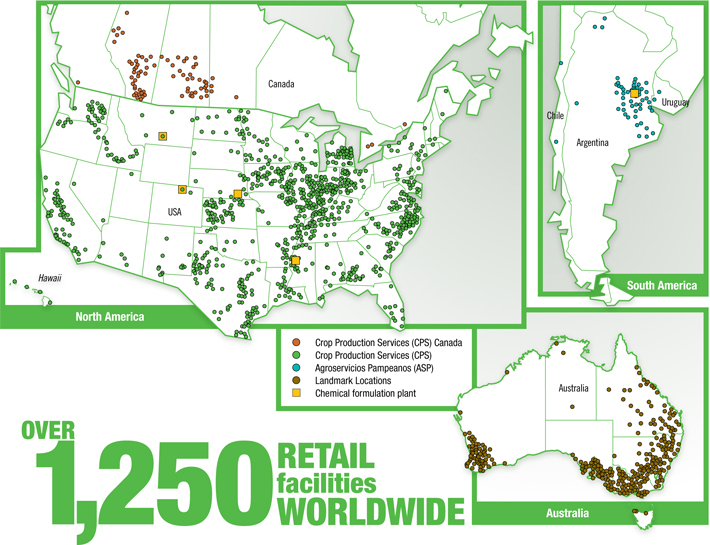

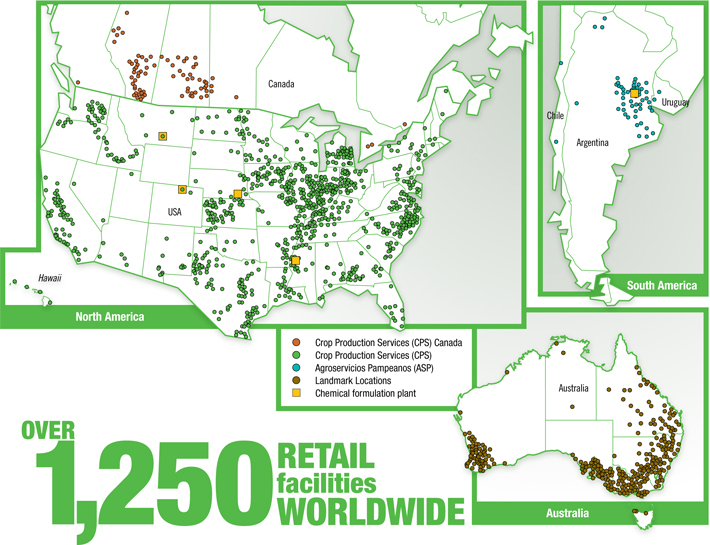

Our Retail Business Unit

Agrium’s Retail business unit offers innovative crop input products and services to our grower customers across North America, South America and Australia. Our proven ability to supply customers with leading products and services, including high quality seed, crop nutrition, crop protection and related services, has enabled the business to grow significantly in both size and profitability. Our Retail business unit demonstrated significant growth in 2011, with sales increasing by 48 percent to reach a record $10.3-billion and EBITDA increasing by 47 percent to reach a record $769-million.

RETAIL // Strategy

Our proven business model and focus on growth has made us the largest agricultural retailer in the United States, as well as one of the largest in Australia and Argentina. We have also established a growing presence in Western Canada, Uruguay and Chile. Retail works with growers to implement best management practices based on a thorough understanding of local soils, climate conditions and crop requirements. We provide innovative technologies, products and experience, backed by a commitment to sound environmental practices. Retail also offers application services for the products we sell, using the latest equipment and standards to meet growers’ needs. Agrium’s business activities support our farm customers in meeting the demands of a growing global population for healthy foods and a sustainable future.

A core component of our Retail strategy is the focus we place on performance management, building upon our strong grower relationships and the strength of our brands – including our proprietary Loveland Products, Inc. (“Loveland”) crop protection products and Dyna-Gro seed. We provide a complete offering of products and agronomic services in order to achieve greater market penetration and stronger customer loyalty. Additionally, we strive to build strong relationships with leading growers in each of our markets, allowing us to grow along with our customers. As the world’s largest publically traded crop input retailer, we leverage the scale of our retail chain to minimize costs, to grow sales of our proprietary products and to adopt appropriate technologies to more effectively serve our customers. Our proven record of value-added growth is expected to continue to stem from improvements to the base business, particularly through a focus on expanding our seed market share and proprietary crop protection products, as well as through acquisitions. Through it all, we are committed to protecting the environment and the health and safety of our employees, customers and the communities in which we operate.

12 CULTIVATING PERFORMANCE.DELIVERING VALUE.

RETAIL // Key Developments

In December 2010, Agrium acquired Landmark, the leading agricultural retailer in Australia through its acquisition of AWB Limited (“AWB”). Landmark is comprised of more than 250 retail facilities serving the major agricultural regions of the country. Landmark’s sales were $2.2-billion in 2011, and as a result, this acquisition will influence comparability of our year-over-year results, as only one month of Landmark’s results are included in our 2010 results.

In 2011, we continued to make numerous smaller retail acquisitions across the U.S. and Canada, representing an additional 32 retail locations and nearly $210-million in annual sales. One of the larger acquisitions in 2011 was International Mineral Technologies (“Tetra Micronutrients”), a specialty producer, marketer and distributor of custom liquid plant nutrition and dry micronutrients located in Fairbury, Nebraska. Agrium Retail will benefit from the ability to continue marketing Tetra Micronutrients liquid products through our Loveland branded product line, while also capturing the associated manufacturing margin. Additionally, AAT will operate and market product from Tetra Micronutrients’ dry granulation facility.

AGRIUM2011 ANNUAL REPORT 13

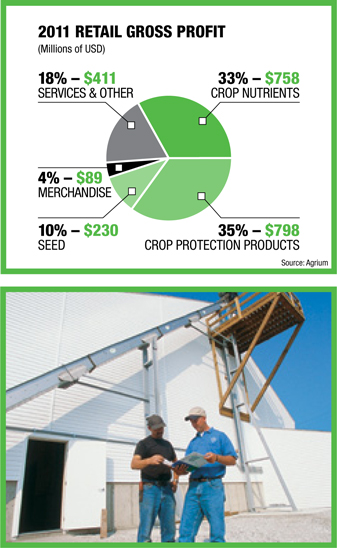

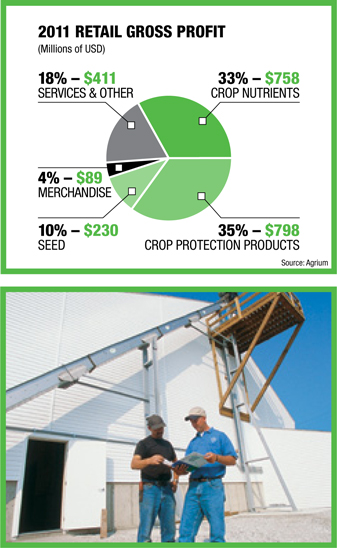

RETAIL // Financial Results

Retail delivered record 2011 results in terms of sales, gross profit and earnings from continuing operations before finance costs and income taxes (“EBIT”). Retail sales reached $10.3-billion in 2011, compared to $7.0-billion in 2010. Gross profit rose to $2.3-billion, from $1.6-billion in 2010. EBIT was $600-million, compared to $409-million in 2010 and EBITDA was $769-million, up from $524-million the year before.

The strength in the 2011 financial results was driven by a combination of strong global crop prices and high planted acreage in key regions, which supported both demand and prices for crop input products. The addition of the Landmark business in 2010 and numerous other smaller 2011 acquisitions were also important contributing factors. Landmark accounted for about $2.2-billion in sales and $419-million in gross profit in 2011. Depreciation and amortization expense increased to $169-million in 2011, compared to $115-million in 2010, primarily due to full-year inclusion of the acquisition of Landmark and other recent retail acquisitions. Record sales were partly offset by a corresponding increase in the cost of product sold, which was $8.0-billion in 2011, compared to $5.4-billion in 2010.

RETAIL // Expenses

Retail selling expense rose to $1.6-billion in 2011, compared to $1.1-billion in 2010. Higher selling expenses were due to the increased scale of the business through acquisitions, the increase in fuel costs and performance-based incentives in our legacy retail operations. The addition of the Landmark business accounted for approximately 70 percent of the increase in selling expenses in 2011. Retail selling expense tends to vary directly with sales activity. We also measure EBIT and EBITDA as a percent of sales, in addition to gross margins. In 2011, EBIT amounted to 6 percent of sales, while EBITDA was 7 percent. Total 2011 selling expense as a percentage of sales was 15.5 percent, slightly lower than the 15.7 percent recorded in 2010.

Retail Performance

| | | | | | | | |

Years ended December 31, (millions of U.S. dollars, except as noted) | | 2011 | | | 2010 | |

Sales | | | 10,316 | | | | 6,969 | |

Cost of product sold | | | 8,030 | | | | 5,418 | |

Gross profit | | | 2,286 | | | | 1,551 | |

Selling | | | 1,595 | | | | 1,094 | |

General and administrative | | | 120 | | | | 61 | |

Earnings from associates | | | (1 | ) | | | — | |

Other income | | | (28 | ) | | | (13 | ) |

EBIT | | | 600 | | | | 409 | |

EBITDA | | | 769 | | | | 524 | |

EBITDA as a percent of sales(%) | | | 7 | | | | 8 | |

Crop nutrients: Products and services

Retail supplies the crop nutrients that are essential to growing healthy plants, including dry and liquid nitrogen, phosphate, potash, sulfur and micronutrients. These are typically bulk blended at Agrium Retail branches to match local conditions and grower requirements for each field and crop. Our Retail agronomists use the 4R Nutrient Stewardship system to help determine the right nutrient source, in the right amounts, applied at the right time and in the right place. The 4R Nutrient Stewardship provides a framework to achieve cropping system goals, like increasing production, increasing grower profitability and improving environmental protection. The four ‘rights’ are interdependent and all are necessary for sustainable plant nutrition management. Our Retail branches understand the complexity of growing crops. They work closely with growers to understand their goals and then deliver the products, the agronomic advice and the product application services that help achieve them. Agrium Retail also delivers additional value to growers through its application business which is provided on a fee-for-service basis.

Agrium Retail operations acquire crop nutrient products from a wide variety of suppliers at market prices, including purchases from Agrium Wholesale. Crop nutrients accounted for 44 percent of Retail sales in 2011.

14 CULTIVATING PERFORMANCE.DELIVERING VALUE.

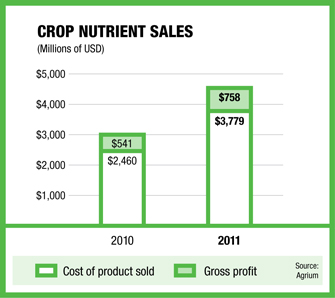

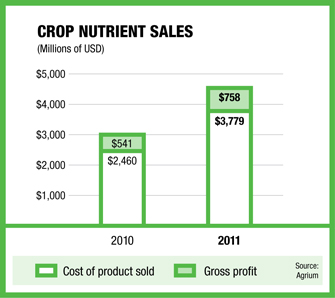

Crop nutrients: Financial results

Crop nutrients sales were $4.5-billion in 2011, compared to $3.0-billion in 2010. The increase was due to the full-year impact of the Landmark retail network in Australia, high crop nutrient prices and strong demand due to higher seeded acreage and excellent cash margins for our grower customers. Cost of product sold rose for the same reasons in 2011 to $3.8-billion, compared to $2.5-billion in 2010. Total gross profit for the year was $758-million, compared to $541-million in 2010. The significant increase was due to strong nutrient margins and higher sales volumes in 2011. Margins on crop nutrient sales decreased slightly in 2011 to 16.7 percent, compared to 18.0 percent in 2010, due to lower margins on the recently acquired Landmark business. The Landmark nutrient margins are lower than in North America as Landmark nutrients are sold primarily on a fee-for-service basis rather than blending nutrients at the farm center to the specific needs of each grower’s field.

Crop protection products: Products and services

Agrium Retail’s crop protection business markets a broad spectrum of herbicide, fungicide, adjuvant and insecticide products that help growers minimize yield losses and protect crop quality from weeds, disease and insects. Our Retail business serves as both a retailer of crop protection products and a wholesaler to other retail operators. We buy brand-name and generic products from recognized suppliers and we market more than 250 proprietary, Loveland branded products across more than 30 countries. We are the largest distributor of crop protection products in the U.S. and we own and operate four blending and formulation facilities in Greeley, Colorado; Billings, Montana; Greenville, Mississippi; and Casilda, Argentina.

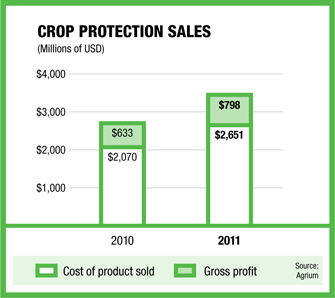

Crop protection products: Financial results

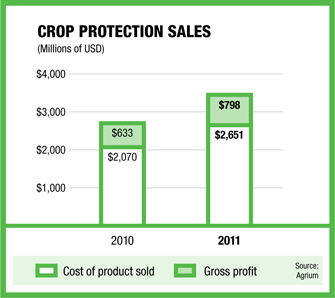

Crop protection sales increased to $3.4-billion in 2011, compared to $2.7-billion in 2010. The cost of crop protection products also increased to $2.7-billion in 2011, compared to $2.1-billion in 2010. Gross profit for this product category reached $798-million in 2011, compared to $633-million in 2010. The notable increase in sales, costs and margins was primarily due to the addition of the Landmark business. Over 29 percent of the increase in sales was due to stronger demand for crop protection products in our legacy retail operations, which more than offset the impact of continued depressed glyphosate prices globally. In North America, our proprietary Loveland products accounted for approximately 16 percent of our total crop protection product sales and contributed margins significantly higher than other crop protection products.

Seed: Products and services

Agrium Retail’s network is an important source of seed product and information for growers in the over $15-billion U.S. seed market. We offer our own Dyna-Gro branded seed and also procure seed from top global suppliers. Our Dyna-Gro seed specialists source key genetics from major seed suppliers and match seed characteristics to local soil and growing conditions for best results in each area. Increases in seed market share, combined with continued technological advancements in seed genetics and our focus on delivering high quality seed products to our customers, all provide significant potential for continued strong growth.

AGRIUM2011 ANNUAL REPORT 15

Seed: Financial results

Seed sales reached $1.1-billion in 2011, an increase of 24 percent compared to the $877-million reported in 2010. This significant increase in seed sales was due to a combination of factors: the continued growth of our private label branded Dyna-Gro seed sales; expanded acreage, particularly for corn and cotton crops in the U.S. this year; and the impact of recent acquisitions, including the Landmark business in Australia. Gross profit from seed was $230-million, compared to $171-million in 2010. In 2011, Agrium’s proprietary Dyna-Gro branded seed sales rose by 19 percent over the previous year and accounted for 19 percent of our total seed sales in 2011.

Merchandise: Products and services

The merchandise product category includes wool, fencing, feed supplements, animal health products and other products, such as irrigation equipment. The size of the merchandise category has become large enough to be reported separately as this is a much larger component of the Landmark business than for Agrium’s legacy retail operations.

Merchandise: Financial results

Merchandise sales totaled $629-million for 2011, compared to $158-million in 2010. Gross profit reached $89-million, compared to $14-million in 2010. Virtually all of the year-over-year increase in sales and gross profit was due to the inclusion of Landmark’s significant merchandise business into Agrium Retail.

Services and Other: Products and services

Agrium delivers value to growers and earns customer loyalty through services such as product application, soil and leaf testing and crop scouting. We maintain a large fleet of application equipment in order to ensure timely applications at optimal rates, helping customers to maximize yields while saving time and resources. Landmark services also include agency fees associated with providing customers with livestock and wool marketing and various financial and real estate services.

Crop Production Services offers customers a variety of specialty services in the Western U.S. to help ensure effective crop input applications aimed to optimize yields and minimize input losses on the region’s high-value crops. This includes operation of our Precision Ag Lab laboratory services and a wireless network of weather stations in the region. The stations supply field-specific weather data and soil moisture information to proprietary software that predicts disease and infestation.

Services and Other: Financial results

Sales for this product grouping were $616-million in 2011, compared to $230-million in 2010. This was largely due to the inclusion of the Landmark livestock, wool and agency businesses, and to strong demand for application services in North America as a result of high crop prices. Gross profit reached $411-million in 2011, compared to $192-million the previous year.

Segment Performance

| | | | | | | | |

Years ended December 31, (millions of U.S. dollars, except as noted) | | 2011 | | | 2010 | |

Crop nutrients | | | | | | | | |

Sales | | | 4,537 | | | | 3,001 | |

Cost of product sold | | | 3,779 | | | | 2,460 | |

Gross profit | | | 758 | | | | 541 | |

Gross profit (%) | | | 16.7 | | | | 18.0 | |

Crop protection products | | | | | | | | |

Sales | | | 3,449 | | | | 2,703 | |

Cost of product sold | | | 2,651 | | | | 2,070 | |

Gross profit | | | 798 | | | | 633 | |

Gross profit (%) | | | 23.1 | | | | 23.4 | |

Seed | | | | | | | | |

Sales | | | 1,085 | | | | 877 | |

Cost of product sold | | | 855 | | | | 706 | |

Gross profit | | | 230 | | | | 171 | |

Gross profit (%) | | | 21.2 | | | | 19.5 | |

Merchandise | | | | | | | | |

Sales | | | 629 | | | | 158 | |

Cost of product sold | | | 540 | | | | 144 | |

Gross profit | | | 89 | | | | 14 | |

Gross profit (%) | | | 14.1 | | | | 8.9 | |

Services and other | | | | | | | | |

Sales | | | 616 | | | | 230 | |

Cost of product sold | | | 205 | | | | 38 | |

Gross profit | | | 411 | | | | 192 | |

Gross profit (%) | | | 66.7 | | | | 83.5 | |

Total sales | | | 10,316 | | | | 6,969 | |

Total cost of product sold | | | 8,030 | | | | 5,418 | |

Total gross profit | | | 2,286 | | | | 1,551 | |

Total gross profit (%) | | | 22.2 | | | | 22.3 | |

16 CULTIVATING PERFORMANCE.DELIVERING VALUE.

RETAIL // Quarterly Results

Our Retail business is seasonal in nature and strongly influenced by the North American second-quarter planting season. The second quarter is also important to Agroservicios Pampeanos in South America, as this is the main application season ahead of fall planting of winter wheat. The acquisition of Landmark in Australia is expected to contribute to first quarter sales, but it too has a significant second-quarter performance profile due to input applications ahead of the planting season for winter wheat.

Retail Quarterly Results

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | 2011 | | | 2010 | |

| (millions of U.S. dollars, except as noted) | | Q4 | | | Q3 | | | Q2 | | | Q1 | | | Q4 | | | Q3 | | | Q2 | | | Q1 | |

Sales – domestic | | | 1,253 | | | | 1,400 | | | | 3,790 | | | | 1,247 | | | | 1,082 | | | | 1,138 | | | | 3,281 | | | | 1,033 | |

Sales – international | | | 582 | | | | 611 | | | | 858 | | | | 575 | | | | 243 | | | | 106 | | | | 59 | | | | 27 | |

Total sales | | | 1,835 | | | | 2,011 | | | | 4,648 | | | | 1,822 | | | | 1,325 | | | | 1,244 | | | | 3,340 | | | | 1,060 | |

Cost of product sold | | | 1,383 | | | | 1,513 | | | | 3,652 | | | | 1,482 | | | | 974 | | | | 925 | | | | 2,621 | | | | 898 | |

Gross profit | | | 452 | | | | 498 | | | | 996 | | | | 340 | | | | 351 | | | | 319 | | | | 719 | | | | 162 | |

Gross profit (%) | | | 25 | | | | 25 | | | | 21 | | | | 19 | | | | 26 | | | | 26 | | | | 22 | | | | 15 | |

Gross profit by product | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Crop nutrients | | | 142 | | | | 124 | | | | 377 | | | | 115 | | | | 140 | | | | 86 | | | | 252 | | | | 63 | |

Crop protection products | | | 145 | | | | 226 | | | | 325 | | | | 102 | | | | 118 | | | | 172 | | | | 274 | | | | 69 | |

Seed | | | 33 | | | | 30 | | | | 132 | | | | 35 | | | | 26 | | | | 24 | | | | 106 | | | | 15 | |

Merchandise | | | 26 | | | | 19 | | | | 27 | | | | 17 | | | | 8 | | | | 2 | | | | 3 | | | | 1 | |

Services and other | | | 106 | | | | 99 | | | | 135 | | | | 71 | | | | 59 | | | | 35 | | | | 84 | | | | 14 | |

EBIT | | | 37 | | | | 92 | | | | 486 | | | | (15 | ) | | | 46 | | | | 70 | | | | 361 | | | | (68 | ) |

EBITDA | | | 80 | | | | 135 | | | | 529 | | | | 25 | | | | 79 | | | | 98 | | | | 388 | | | | (41 | ) |

| * | Table includes Landmark results from December 4, 2010 onward. |

AGRIUM2011 ANNUAL REPORT 17

Our Wholesale Business Unit

18 CULTIVATING PERFORMANCE.DELIVERING VALUE.

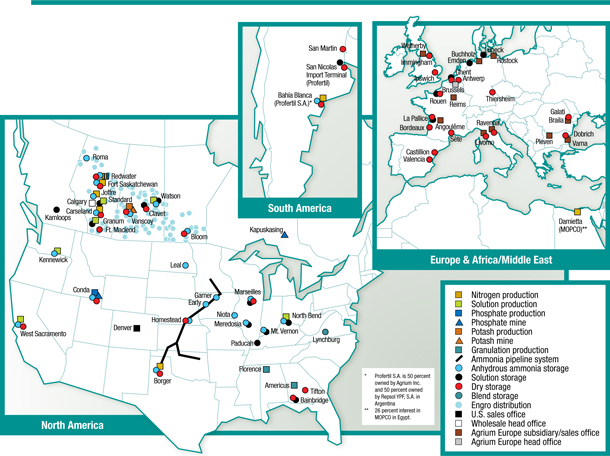

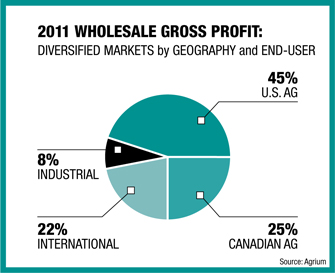

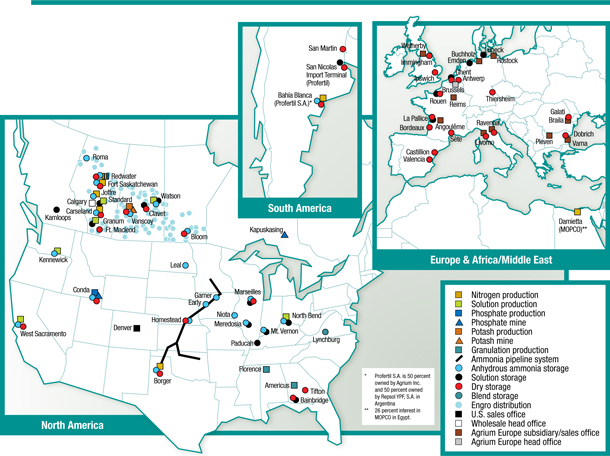

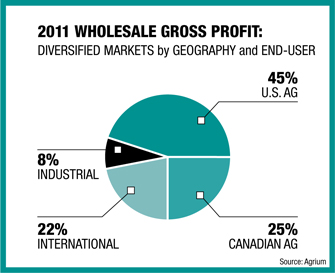

Agrium’s Wholesale business unit is a major global producer, marketer and distributor of all major fertilizer products, with over nine million tonnes of annual crop nutrient production capacity. We have a broad portfolio of assets that produce a diverse mix of crop nutrient products servicing a wide cross section of customers and geographies. The primary end consumer for our products is the agriculture market - in particular, growers of grains, oilseeds and other crops who strive to optimize crop yields and quality. In 2011, our Wholesale business unit capitalized on strong agricultural fundamentals by delivering a record performance, achieving sales of $5.6-billion and $2.0-billion of EBITDA, both of which were the highest in our company history.

2011 Wholesale Capacity, Production and Sales

| | | | | | | | | | | | |

| (thousands of product tonnes) | | Capacity | | | Production | | | Sales (d) | |

Nitrogen Volumes | | | | | | | | | | | | |

North America | | | | | | | | | | | | |

Canada | | | 3,515 | | | | 2,825 | | | | 1,569 | |

U.S. | | | 1,273 | | | | 1,101 | | | | 1,981 | |

International(a) | | | 635 | | | | 561 | | | | 509 | |

Total Nitrogen | | | 5,423 | | | | 4,487 | | | | 4,059 | |

Potash Volumes | | | | | | | | | | | | |

North America | | | | | | | | | | | | |

Canada | | | 2,050 | | | | 1,737 | | | | 131 | |

U.S. | | | | | | | | | | | 715 | |

International | | | | | | | | | | | 919 | |

Total Potash | | | 2,050 | | | | 1,737 | | | | 1,765 | |

Phosphate Volumes | | | | | | | | | | | | |

North America | | | | | | | | | | | | |

Canada | | | 660 | (b) | | | 645 | | | | 584 | |

U.S. | | | 510 | (b) | | | 497 | | | | 543 | |

Total Phosphate | | | 1,170 | (b) | | | 1,142 | | | | 1,127 | |

Other Volumes | | | | | | | | | | | | |

North America | | | | | | | | | | | | |

Canada | | | 355 | | | | 358 | | | | 257 | |

U.S. | | | 294 | | | | 196 | | | | 334 | |

International | | | | | | | | | | | 47 | |

Total Other | | | 649 | | | | 554 | | | | 638 | |

Total Produced Product | | | 9,292 | | | | 7,920 | | | | 7,589 | |

Purchase for Resale Volumes(c) | | | | | | | | | | | | |

North America | | | | | | | | | | | | |

U.S. | | | | | | | | | | | 764 | |

International | | | | | | | | | | | 2,481 | |

Total Purchase for Resale | | | | | | | | | | | 3,245 | |

Total Wholesale | | | 9,292 | | | | 7,920 | | | | 10,834 | |

| (a) | Represents our 50 percent joint-venture interest in the capacity of Profertil S.A. (“Profertil”). |

| (b) | Superphosphoric Acid (“SPA”) and Merchant Grade Phosphoric Acid (“MGA”) are reported in cargo weight. |

| (c) | Purchase for resale includes sales of all the major crop nutrient products. |

| (d) | Sales represent country of sales destination, not country of production. |

AGRIUM2011 ANNUAL REPORT 19

WHOLESALE // Strategy

Our Wholesale strategy focuses on leveraging our strong competitive position within key global crop nutrient markets in order to deliver value for our stakeholders. In addition to employing a rigorous focus on continually improving our core businesses, we actively seek out opportunities to strengthen our industry position through value-enhancing acquisitions and investments. All of our activities are driven by a culture that prides itself on providing products that help to feed the world’s growing population, while constantly striving to protect the environment and the health, safety and security of our employees and contractors. Additionally, we are committed to establishing and maintaining effective relationships with our partners, suppliers and customers, while actively supporting the communities in which we operate.

WHOLESALE // Key Developments

In December 2011, Agrium’s Board of Directors approved the brownfield expansion of our potash facility, located in Vanscoy, Saskatchewan. The project is expected to result in an additional one million tonnes of annual production capacity, increasing our total nameplate capacity to nearly three million tonnes per year. Construction activity has already begun and the project is expected to be completed in the second half of 2014. The capital cost associated with this project is expected to be approximately $1.5-billion or about $1,500 per tonne of additional capacity.(a)

We commenced a brownfield debottlenecking project in the second half of 2011 at our Profertil nitrogen facility in Argentina, in which we have a 50 percent joint-venture interest. The facility has a total capacity of 1.2 million tonnes of urea and 70,000 net tonnes of merchant ammonia. The project is expected to be completed by 2014 and will increase the facility’s total annual production capacity by approximately 123,000 tonnes of urea and 10,000 net tonnes of merchant ammonia. Additionally, it is anticipated that per tonne production costs will be reduced following completion of the debottlenecking project as a result of more efficient gas utilization. Agrium is also constructing a terminal on the Parana River, near the city of Rosario, Argentina. This terminal will include a dedicated berth and two 100,000 tonne dry storage buildings that will move product into a key agricultural region of Argentina. Completion of this project is expected by the end of 2012. The potential for additional expansion opportunities is also being evaluated within our existing North American nitrogen facilities. Engineering scoping studies were initiated in late 2011 and we will be undertaking a detailed evaluation of our findings and establishing a definitive plan for potential future investment.

The Egyptian Nitrogen Products Company S.A.E. (“ENPC”), a wholly-owned subsidiary of MOPCO, in which Agrium owns a 26 percent stake, continued to move forward through most of 2011 with its project to add two new trains to the existing single train at the Egyptian nitrogen facility. The expansion project is expected to triple the facility’s current production capacity, increasing total annual production at the site to 1.95 million tonnes of urea and 150,000 net tonnes of merchant ammonia. Civil unrest within the country resulted in the suspension of construction of the expansion and operations in the fourth quarter of 2011. However, we are optimistic the facility will be allowed to re-open and construction of the expansion restarted in 2012 given its strong environmental performance, as recently reconfirmed by a government appointed independent Egyptian scientific review panel, as well as the positive contribution it can provide the Egyptian economy.

Agrium signed an agreement with OCP S.A. (“OCP”) of Morocco in September 2011 for the long-term supply of phosphate rock to our Canadian Redwater phosphate facility. This new supply of phosphate rock from OCP will replace the phosphate rock currently supplied from our mine at Kapuskasing, Ontario. The move to utilizing rock from OCP is expected to take place in the second half of 2013, at which time economic rock reserves at Kapuskasing will be depleted. The agreement covers rock supply for a period up to 2020, with prices based on a formula that tracks finished product pricing and key published input costs. We will commence construction of an import terminal on the West Coast of Canada in 2012, which will facilitate the handling and delivery of the imported phosphate rock to our facility in Redwater, Alberta. The agreement will enable Agrium to continue benefiting from our competitive sulfur and ammonia cost positions and in-market delivered pricing advantage in Western Canada.

| (a) | Certain scientific and technical information regarding Vanscoy Potash Operations is based on the technical report titled “National Instrument 43-101 Technical Report on Vanscoy Potash Operations” dated February 15, 2012 and with an effective date of December 31, 2011 (the “Technical Report”) prepared by A. Dave Mackintosh, P. Geo of ADM Consulting Limited and Erika D. Stoner of the Company, both of whom are Qualified Persons as defined in National Instrument 43-101 – Standards of Disclosure for Mineral Projects. The Technical Report has been filed with the securities regulatory authorities in each of the provinces of Canada. Portions of the following information are based on assumptions, qualifications and procedures that are not fully described herein. References should be made to the full text of the Technical Report which is available for review on SEDAR located at www.sedar.com. |

20 CULTIVATING PERFORMANCE.DELIVERING VALUE.

Agrium acquired three phosphate leases in the vicinity of Vernal, Utah in 2011. These leases are in the very early stages of evaluation as a potential economically viable source of phosphate rock in the long term.

We concluded the purchase of a 100 percent equity position in Cerealtoscana S.p.A. (“Cerealtoscana”), a fertilizer distribution company in Italy, and Agroport, its subsidiary in Romania, in May of 2011. These entities have been subsequently renamed as Agrium Italia S.p.A. and Agrium-Agroport Romania S.A., respectively. This acquisition represented the addition of 90,000 tonnes of storage to Agrium Europe S.A.’s (“Agrium Europe”) existing fertilizer distribution business and enables us to continue strengthening our presence within growing markets in Europe, while also leveraging the value of our marketing off-take agreement of urea from the MOPCO Egyptian nitrogen facility.

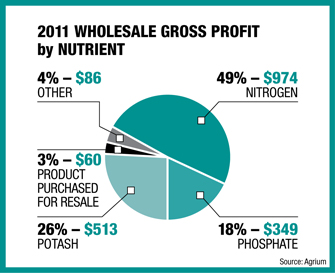

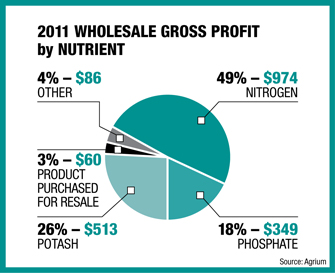

WHOLESALE // Financial Results

Sales from Wholesale operations reached a record $5.6-billion in 2011, compared to $4.0-billion in 2010. Gross profit increased to a record $2.0-billion in 2011, compared to $1.0-billion in 2010. Wholesale EBIT was also a record $1.8-billion in 2011, compared to $889-million in 2010. The record results achieved this year were attributable to robust demand and sales, as well as strong prices and margins for crop nutrients due to the strength in agricultural fundamentals.

WHOLESALE // Expenses

Wholesale expenses were $136-million in 2011, compared with $120-million in 2010. The variance was due primarily to recent acquisitions along with marginal increases across different expense categories.

Wholesale Performance

| | | | | | | | |

Years ended December 31, (millions of U.S. dollars, except as noted) | | 2011 | | | 2010 | |

Nitrogen | | | | | | | | |

Sales | | | 2,051 | | | | 1,458 | |

Gross profit | | | 974 | | | | 452 | |

Potash | | | | | | | | |

Sales | | | 809 | | | | 675 | |

Gross profit | | | 513 | | | | 371 | |

Phosphate | | | | | | | | |

Sales | | | 893 | | | | 596 | |

Gross profit | | | 349 | | | | 106 | |

Other | | | | | | | | |

Sales | | | 257 | | | | 216 | |

Gross profit | | | 86 | | | | 32 | |

Product purchased for resale | | | | | | | | |

Sales | | | 1,566 | | | | 1,039 | |

Gross profit | | | 60 | | | | 48 | |

Total sales | | | 5,576 | | | | 3,984 | |

Total gross profit | | | 1,982 | | | | 1,009 | |

Selling | | | 42 | | | | 35 | |

General and administrative | | | 47 | | | | 34 | |

Earnings from associates | | | (19 | ) | | | (22 | ) |

Other expenses | | | 66 | | | | 73 | |

EBIT | | | 1,846 | | | | 889 | |

EBITDA | | | 2,019 | | | | 1,081 | |

EBITDA as a percent of sales(%) | | | 36 | | | | 27 | |

AGRIUM2011 ANNUAL REPORT 21

Nitrogen[ N ] Products

Nitrogen plays a fundamental role in improving crop growth, yield and protein levels, making it the most important nutrient in global crop nutrient production, trade and consumption. It is also the one crop nutrient that is most likely to show the most immediate adverse impact on a crop’s yield if application rates are reduced. In 2011, Nitrogen represented over 60 percent of the total volume of crop nutrients used globally and approximately half of our 2011 wholesale sales and gross profit on manufactured product.

The building block for virtually all nitrogen products is ammonia, which can be applied directly as a fertilizer or upgraded to urea, urea ammonium nitrate (“UAN”) solutions or ammonium nitrate.

Agrium owns and operates five major nitrogen production facilities in North America and has a 50 percent joint-venture interest in a nitrogen facility in South America, along with five facilities in North America that upgrade ammonia to other nitrogen products, such as UAN and nitric acid. These facilities have a combined annual nitrogen production capacity of approximately 5.4 million tonnes. We also have a 26 percent equity position in an Egyptian nitrogen facility. Collectively, these global production assets place Agrium among the world’s top three publicly traded nitrogen producers.

The competitive position and diversity of our nitrogen production facilities in terms of geography, customer reach and product offering are among our key competitive strengths. Our Alberta production facilities in particular are ideally positioned to benefit from low gas costs relative to other parts of North America, and North America is itself well positioned relative to most other regions of the world due to the development of non-conventional (shale) natural gas. Furthermore, nitrogen prices in North America are generally higher the further from a major port or the Mississippi river system, which includes our core markets of Western Canada, the Northern U.S. Plains and the Pacific Northwest. Our Argentine nitrogen facility also benefits from competitive pricing for natural gas, in addition to a similar in-market advantaged position within Argentina’s large and growing domestic end-market. Furthermore, our equity interest in the Egyptian nitrogen facility provides an advantageous competitive position, with direct access to key markets in Europe and the Americas.

On an annual basis, approximately 75 percent of our nitrogen sales are to agricultural markets, with the remaining 25 percent sold to industrial customers. Domestic demand from agricultural customers is highly seasonal in nature, while industrial demand is more evenly distributed throughout the year. Much of the industrial ammonia that Agrium sells is priced on a gas index-plus margin basis, thereby contributing to stability in sales and earnings throughout the year. As a result, our average sales price for ammonia in a given quarter will be influenced by the relative weighting of industrial sales versus those made to agricultural markets and the differential between industrial and agricultural sales prices. The influence of industrial ammonia tends to be larger in the first and third quarters, which are generally slower quarters for agricultural sales.

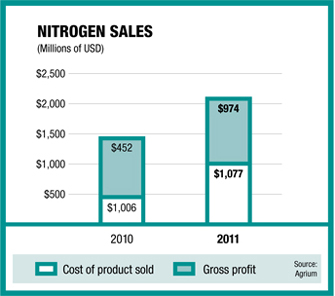

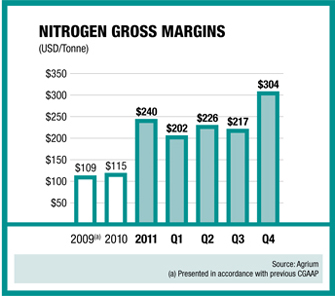

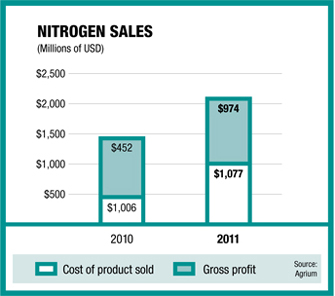

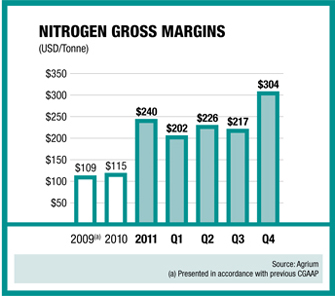

Nitrogen // Financial Results

Nitrogen gross profit

Nitrogen gross profit reached a record of $974-million in 2011, compared to $452-million in 2010. This significant increase was primarily due to higher realized prices for nitrogen products. Our average margins on a per tonne basis were $240 per tonne in 2011, compared to $115 per tonne in 2010.

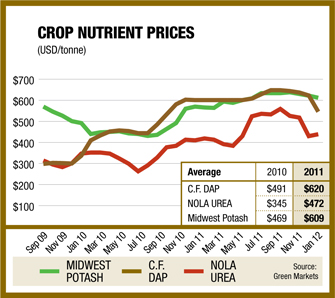

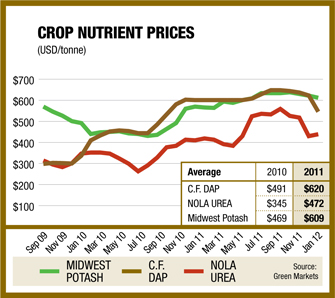

Nitrogen prices

Agrium’s average realized nitrogen price was $506 per tonne in 2011, compared with $372 per tonne in 2010. Benchmark U.S. Gulf (NOLA) urea prices were $472 per tonne in 2011, a 36 percent increase over 2010. NOLA urea prices started the year at approximately $420 per tonne, rising to $570 per tonne in September 2011, and ending the year at approximately $400 per tonne.

22 CULTIVATING PERFORMANCE.DELIVERING VALUE.

Nitrogen Performance

| | | | | | | | |

Years ended December 31, (millions of U.S. dollars, except as noted) | | 2011 | | | 2010 | |

Nitrogen Domestic | | | | | | | | |

Sales | | | 1,797 | | | | 1,289 | |

Cost of product sold | | | 970 | | | | 911 | |

Gross profit | | | 827 | | | | 378 | |

Tonnes sold (‘000) | | | | | | | | |

Ammonia | | | 1,152 | | | | 1,125 | |

Urea | | | 1,376 | | | | 1,401 | |

Other | | | 1,022 | | | | 952 | |

Total domestic tonnes sold (‘000) | | | 3,550 | | | | 3,478 | |

Selling price per tonne | | | | | | | | |

Ammonia | | | 586 | | | | 432 | |

Urea | | | 544 | | | | 389 | |

Other | | | 367 | | | | 267 | |

Selling price per tonne | | | 506 | | | | 371 | |

Margin per tonne | | | 233 | | | | 108 | |

Nitrogen International | | | | | | | | |

Sales | | | 254 | | | | 169 | |

Cost of product sold | | | 107 | | | | 95 | |

Gross profit | | | 147 | | | | 74 | |

Tonnes sold (‘000) | | | 509 | | | | 440 | |

Selling price per tonne | | | 500 | | | | 386 | |

Margin per tonne | | | 290 | | | | 166 | |

Total Nitrogen | | | | | | | | |

Sales | | | 2,051 | | | | 1,458 | |

Cost of product sold | | | 1,077 | | | | 1,006 | |

Gross profit | | | 974 | | | | 452 | |

Tonnes sold (‘000) | | | 4,059 | | | | 3,918 | |

Selling price per tonne | | | 506 | | | | 372 | |

Cost of product sold per tonne | | | 266 | | | | 257 | |

Margin per tonne | | | 240 | | | | 115 | |

Nitrogen product and gas cost

Nitrogen cost of product sold was $1.1-billion in 2011, compared to $1.0-billion in 2010. On a per tonne basis, cost of product sold in 2011 averaged $266 per tonne, compared with $257 per tonne in 2010. The increase in per tonne cost of product sold was primarily due to higher costs associated with planned turnarounds and unscheduled outages in 2011, as compared to 2010. Production asset depreciation and amortization expense is included in cost of product sold in the amount of $20 per tonne in 2011, compared to $20 per tonne in 2010.

Gas volumes purchased in 2011 were 112 billion cubic feet, up from 104 billion cubic feet in 2010. Agrium’s overall gas cost for 2011 was $4.03 per MMBtu ($3.83 per MMBtu excluding the impact of natural gas derivatives), compared to $4.47 per MMBtu in 2010 ($4.08 per MMBtu excluding the impact of natural gas derivatives). Realized and unrealized hedging gains and losses on gas derivatives are reported below gross profit and are therefore not included in cost of product sold. The average U.S. benchmark price of natural gas on the New York Mercantile Exchange (NYMEX) was $4.07 per MMBtu in 2011, compared with $4.42 per MMBtu in 2010. In 2011, the average Alberta (AECO) basis differential was a $0.33 per MMBtu discount to NYMEX, compared to a discount of $0.43 per MMBtu in 2010.

In Argentina, our Profertil S.A. (“Profertil”) nitrogen facility has three competitively-priced gas contracts, which cover approximately 80 percent of its gas requirements. All three contracts extend to 2017, while additional gas requirements are fulfilled through a mix of spot purchases and short-term (one- and two-year) contracts. Pan American Energy is our largest gas supplier, followed by Petrobras S.A. and Repsol YPF, S.A. The Argentine government has at times limited industrial gas deliveries in order to meet residential demand during the peak winter season.

Natural Gas Prices: North American Indices and Agrium Prices

| | | | | | | | |

| (U.S. dollars per MMBtu) | | 2011 | | | 2010 | |

NYMEX | | | 4.07 | | | | 4.42 | |

AECO | | | 3.74 | | | | 3.99 | |

Basis | | | 0.33 | | | | 0.43 | |

Wholesale | | | | | | | | |

Overall gas cost excluding realized hedging losses | | | 3.83 | | | | 4.08 | |

Realized hedging impact | | | 0.20 | | | | 0.39 | |

Overall gas cost(a) | | | 4.03 | | | | 4.47 | |

| (a) | Weighted average gas price of all gas purchases, including our 50 percent share of the Profertil facility. |

Nitrogen sales volumes and operating rates

Wholesale nitrogen sales volumes for 2011 were 4.1 million tonnes, compared to 3.9 million tonnes in 2010. The nitrogen product category is primarily made up of urea, ammonia, UAN and industrial grade ammonium nitrate. Urea is the most important nitrogen product globally, and accounts for over 40 percent of Agrium’s nitrogen capacity and 2011 production.

Natural Gas Use (BCF)

| | | | | | | | | | | | | | | | | | | | |

| | | Western

Canada | | | U.S.

(Borger, TX) | | | International

(Profertil) | | | Potash

and Other | | | Total | |

2011 | | | 75 | | | | 19 | | | | 15 | | | | 3 | | | | 112 | |

2010 | | | 71 | | | | 18 | | | | 12 | | | | 3 | | | | 104 | |

AGRIUM2011 ANNUAL REPORT 23

Potash[ K ] Products

Agrium is North America’s third largest producer of potash, a nutrient that regulates plant growth processes and helps protect crops from drought and disease. Potash deposits are highly concentrated within only a few regions of the world. The world’s largest known potash deposits are in Saskatchewan, Canada, whose mines accounted for about 46 percent of 2011 global potash reserves. Additionally, Canada accounted for approximately 40 percent of global potash trade in 2011. Agrium produces muriate of potash (“MOP” or “potash”) at our facility in Vanscoy, Saskatchewan.

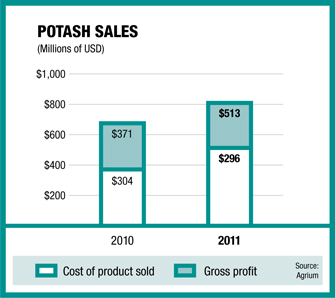

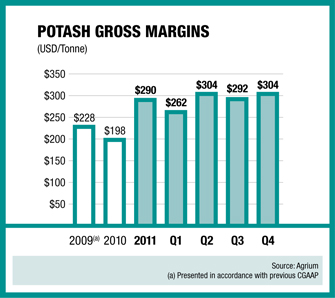

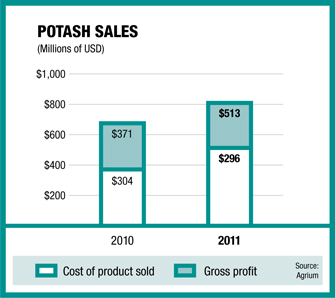

Potash // Financial Results

Potash gross profit

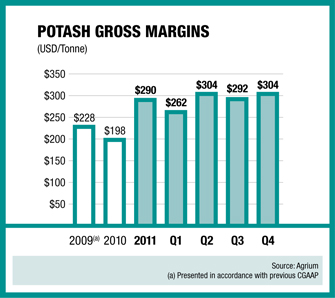

Our potash gross profit was $513-million in 2011, compared to $371-million in 2010. The significant increase in gross profit was due to substantially higher realized sales prices and margins in North America and internationally. On a per tonne basis, potash margins averaged $290 per tonne in 2011, compared with $198 per tonne in 2010.

Potash Performance

| | | | | | | | |

Years ended December 31, (millions of U.S. dollars, except as noted) | | 2011 | | | 2010 | |

Potash Domestic | | | | | | | | |

Sales | | | 471 | | | | 470 | |

Cost of product sold | | | 176 | | | | 215 | |

Gross profit | | | 295 | | | | 255 | |

Tonnes sold (‘000) | | | 846 | | | | 1,119 | |

Selling price per tonne | | | 556 | | | | 420 | |

Margin per tonne | | | 348 | | | | 228 | |

Potash International | | | | | | | | |

Sales | | | 338 | | | | 205 | |

Cost of product sold | | | 120 | | | | 89 | |

Gross profit | | | 218 | | | | 116 | |

Tonnes sold (‘000) | | | 919 | | | | 749 | |

Selling price per tonne | | | 368 | | | | 273 | |

Margin per tonne | | | 238 | | | | 153 | |

Total Potash | | | | | | | | |

Sales | | | 809 | | | | 675 | |

Cost of product sold | | | 296 | | | | 304 | |

Gross profit | | | 513 | | | | 371 | |

Tonnes sold (‘000) | | | 1,765 | | | | 1,868 | |

Selling price per tonne | | | 458 | | | | 361 | |

Cost of product sold per tonne | | | 168 | | | | 163 | |

Margin per tonne | | | 290 | | | | 198 | |

Potash prices

Agrium’s average potash selling price was $458 per tonne in 2011, compared to $361 per tonne in 2010. Our international sales are marketed through Canpotex and these prices are referenced at the mine site. Our average international sales price was $368 per tonne in 2011, a 35 percent increase over 2010. Our realized North American sales price increased by 32 percent to $556 per tonne in 2011. Benchmark potash prices in North America and globally were supported by a rebound in global demand and resulted in high operating rates and a tightening inventory situation through most of 2011. Potash prices in the U.S. Corn Belt started 2011 at roughly $570 per tonne, rose to $630 per tonne by July 2011 and declined to approximately $610 per tonne by the end of 2011.

24 CULTIVATING PERFORMANCE.DELIVERING VALUE.

Potash product cost

Potash cost of product sold in 2011 was $296-million, compared to $304-million in 2010. On a per tonne basis, the average cost of product sold was $168 per tonne, compared to $163 per tonne in 2010. The increase in per tonne costs relative to 2010 was primarily attributable to a decrease in production volumes. Production asset depreciation and amortization expense is included in cost of product sold in the amount of $22 per tonne in 2011, compared to $19 per tonne in 2010.

Potash sales volumes and operating rates

Potash sales volumes were 1.8 million tonnes in 2011, compared to 1.9 million tonnes in 2010. The year-over-year decrease in sales volumes was due primarily to lower beginning inventories and lower production due to a variety of short-term mining related issues experienced at our Vanscoy mine during the second half of 2011. We sold 48 percent of our potash sales into the domestic market in 2011, which was down significantly from the 60 percent sold to domestic customers in 2010. The decrease in domestic sales in 2011 was due to the large increase in demand from international buyers in 2011. Potash sales to international markets represented 52 percent of sales volumes in 2011, up from the 40 percent sold to these markets in 2010. Our international sales are marketed through Canpotex, the offshore marketing agency for potash produced in the province of Saskatchewan, which is wholly-owned by the three major potash producers in Canada. Our share of Canpotex total sales in 2011 was 9 percent.

Our current annual production capacity of 2.05 million tonnes requires 5.9 million tonnes of feed at a grade of 24.6 percent K2O and a milling recovery of 85 percent. Our 2012 Technical Report(a) gives an expected mine life of 46 years when considering Proven and Probable Mineral Reserves and Measured and Indicated Mineral Resources, with an additional 15 years estimated to be contained in Inferred Mineral Resources at our higher forecasted post-expansion rate, which is based on the updated estimate of 65.8 million tonnes of Proven Mineral Reserves (24.5% K2O), 15.2 million tonnes of Probable Mineral Reserves (22.7% K2O), 168.2 million tonnes of Measured Mineral Resources (22.7% K2O) and 113.0 million tonnes of Indicated Mineral Resources (24.9% K2O). Changes to the primary mine life estimate are as a result of the reclassification of Mineral Resources from Inferred to Measured and Indicated due to the drilling campaign executed over the South Block and KP 313 in 2010 and 2011. Mineral resources that are not mineral reserves do not have demonstrated economic viability.

| (a) | Certain scientific and technical information regarding Vanscoy Potash Operations is based on the technical report titled “National Instrument 43-101 Technical Report on Vanscoy Potash Operations” dated February 15, 2012 and with an effective date of December 31, 2011 (the “Technical Report”) prepared by A. Dave Mackintosh, P. Geo of ADM Consulting Limited and Erika D. Stoner of the Company, both of whom are Qualified Persons as defined in National Instrument 43-101 –Standards of Disclosure for Mineral Projects. The Technical Report has been filed with the securities regulatory authorities in each of the provinces of Canada. Portions of the following information are based on assumptions, qualifications and procedures that are not fully described herein. References should be made to the full text of the Technical Report which is available for review on SEDAR located at www.sedar.com. |

AGRIUM2011 ANNUAL REPORT 25

Phosphate[ P ] Products

Agrium is North America’s fifth largest producer of phosphate. Phosphate is a key nutrient that stimulates root development and flowering, while encouraging early crop development. Collectively, Agrium’s two phosphate facilities have the capacity to produce approximately 1.2 million tonnes of phosphate fertilizer products annually.

At our facility in Conda, Idaho, we produce mono-ammonium phosphate (“MAP”) and superphosphoric acid (“SPA”) products, which we sell primarily in the Northwestern U.S. Our Redwater, Alberta facility is the only phosphate facility in Canada and produces MAP primarily for distribution in Western Canada.

Three primary raw materials are required to produce granular ammonium phosphates: phosphate rock, sulfur and ammonia. Each of our two facilities has a dedicated phosphate rock mine; Redwater obtains phosphate rock from our mine in Kapuskasing, Ontario, while our Rasmussen Ridge rock mine supplies our Conda facility, having moved from our Dry Valley mine in 2011. Economic rock reserves at Kapuskasing will be depleted by the second half of 2013. By this time, phosphate rock for our Redwater facility is expected to be sourced primarily from Morocco as part of our long-term agreement with OCP. This agreement covers rock supply for a period up to 2020, with prices based on a formula that accounts for the finished phosphate prices and input prices. This structure provides downside protection to Agrium during periods of low phosphate prices and affords OCP an opportunity to benefit from the upside associated with periods of strong phosphate prices. If the agreement had been in place in 2011, our average phosphate margins would have been lower than in 2011 as our rock costs would have been higher. However, our total average phosphate margins would have still been highly competitive compared to other publicly traded North American phosphate producers due to our other competitive advantages. Our Redwater facility produces ammonia on-site and sources sulfur locally. Given the significant availability of sulfur in the region due to the presence of oil and gas producers, we obtain sulfur at highly favorable prices relative to global prices. Our Conda facility also sources sulfur and sulfuric acid locally, while obtaining the majority of its ammonia from Agrium’s Alberta nitrogen plants. Our competitive cost position on sulfur and ammonia is a major benefit to Agrium’s phosphate business. Agrium’s competitive advantage for phosphate products is also a result of our transportation cost advantage relative to the major phosphate producers based in Florida, given that our facilities are located in close proximity to our key end-markets in Western Canada and the Western U.S.

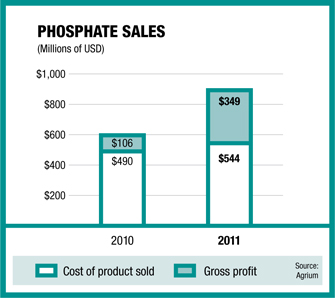

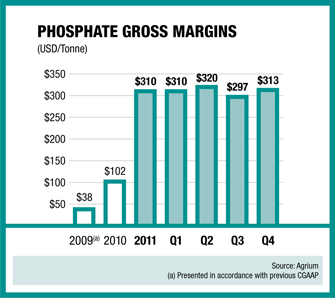

Phosphate // Financial Results

Phosphate gross profit

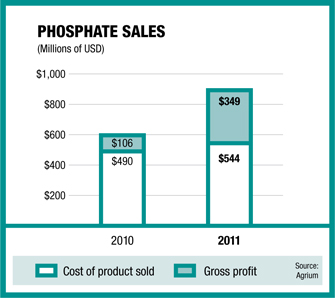

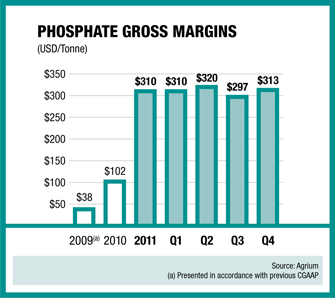

Phosphate gross profit was $349-million in 2011, compared to $106-million in 2010. The substantial increase was due to increased sales volumes and higher per tonne margins for our phosphate products, which was driven by stronger realized sales prices. On a per tonne basis, phosphate margins were $310 per tonne in 2011, compared to $102 per tonne in 2010.

Phosphate Performance

| | | | | | | | |

Years ended December 31, (millions of U.S. dollars, except as noted) | | 2011 | | | 2010 | |

Phosphate | | | | | | | | |

Sales | | | 893 | | | | 596 | |

Cost of product sold | | | 544 | | | | 490 | |

Gross profit | | | 349 | | | | 106 | |

Tonnes sold (‘000) | | | 1,127 | | | | 1,041 | |

Selling price per tonne | | | 792 | | | | 573 | |

Cost of product sold per tonne | | | 482 | | | | 471 | |

Margin per tonne | | | 310 | | | | 102 | |

26 CULTIVATING PERFORMANCE.DELIVERING VALUE.

Phosphate prices

Benchmark phosphate prices continued to increase during 2011, driven by robust global demand, tight supply availability and substantial increases in global prices of phosphate rock, sulfur and ammonia. Central Florida di-ammonium phosphate (“DAP”) prices averaged $621 per tonne in 2011, compared with $492 per tonne in 2010. Benchmark Central Florida prices started the year at approximately $606 per tonne, peaked at $645 per tonne in August and ended the year at about $530 per tonne. Agrium’s realized phosphate prices represent a blend of phosphate products, with over 80 percent of our sales being MAP, and the remainder made up of higher valued SPA and merchant grade phosphoric acid. Our average realized phosphate sales price was $792 per tonne in 2011, compared to $573 per tonne in 2010. Our realized prices for MAP are higher than in the Southern U.S. or Corn Belt, given that Western Canada is a net importer of phosphate products from the Southeastern U.S.

Phosphate product cost

Phosphate cost of product sold was $544-million in 2011, compared to $490-million in 2010. The increase was attributable primarily to higher sales volumes in 2011 relative to 2010 and increases in sulfur costs. On a per tonne basis, cost of product sold was $482 per tonne in 2011, compared with $471 per tonne in 2010. Production asset depreciation and amortization expense is included in cost of product sold in the amount of $41 per tonne in 2011, compared to $65 per tonne in 2010.

Sales volumes and operating rates

Phosphate sales volumes were 1.1 million tonnes in 2011, compared with 1.0 million tonnes in 2010. Higher operating rates achieved in 2011 were due to increased efficiencies at our Conda and Redwater facilities.

Other Wholesale Products

Our Other Wholesale products group is mainly comprised of ammonium sulfate products produced in Western Canada and our Rainbow® Plant Food (“Rainbow”) business, which produces nitrogen, phosphate and potash (“NPK”) products in the Southeastern United States. Ammonium sulfate fertilizer contains both nitrogen and sulfur, resulting in one of the most effective ways of supplying sulfur to soils in an immediately available form.

The Rainbow product line offers homogeneous distributions of NPK products, with a specific combination of nutrients contained within each granule. In contrast to the more common practice of blending different nutrient granules at a farm center, this alternative offers the advantages of reduced product segregation and a more unified distribution of nutrients. Rainbow products are produced at our facilities in Americus, Georgia, and Florence, Alabama and are often used on high-value crops such as cotton, peanuts, vegetables, tobacco, as well as some limited use on row crops.

Other Wholesale // Financial Results

Other Wholesale gross profit was $86-million in 2011, compared with $32-million in 2010. The increase was due primarily to an improvement in realized sales prices and margins for both ammonium sulfate and our Rainbow product line.

Other Performance

| | | | | | | | |

Years ended December 31, (millions of U.S. dollars, except as noted) | | 2011 | | | 2010 | |

Other | | | | | | | | |

Sales | | | 257 | | | | 216 | |

Cost of product sold | | | 171 | | | | 184 | |

Gross profit | | | 86 | | | | 32 | |

Tonnes sold (‘000) | | | | | | | | |

Ammonium sulfate | | | 358 | | | | 347 | |

Other | | | 280 | | | | 344 | |

Total other tonnes sold (‘000) | | | 638 | | | | 691 | |

Selling price per tonne | | | | | | | | |

Ammonium sulfate | | | 366 | | | | 256 | |

Cost of product sold per tonne | | | | | | | | |

Ammonium sulfate | | | 195 | | | | 180 | |

Margin per tonne | | | | | | | | |

Ammonium sulfate | | | 171 | | | | 76 | |

Product Purchased for Resale

In addition to selling our manufactured products, Agrium’s Wholesale unit purchases crop nutrient products from other suppliers for resale to our customers residing primarily in the Americas and Western Europe. This business enables us to leverage the value of our extensive distribution and marketing network beyond what is possible through the sale of our manufactured product alone.

Sales of product purchased for resale were $1.6-billion in 2011, compared with $1.0-billion in 2010. Total sales volumes for this business were 3.2 million tonnes in 2011, compared with 3.0 million

AGRIUM2011 ANNUAL REPORT 27

tonnes in 2010. The increase in volumes was due to the recent acquisition of Cerealtoscana and its subsidiary Agroport in Europe and strong nutrient demand in the Americas, offsetting the impact of cautious buying by distributors in the second half of 2011 due to the economic uncertainty. The breakdown of sales volumes by geographic region were: 0.8 million tonnes in North America; 2.2 million tonnes in Europe and 0.2 million tonnes in South America.

Gross profit from our purchase for resale business was $60-million in 2011, compared with $48-million in 2010. Our average selling price was $483 per tonne in 2011, compared with $346 per tonne in 2010. Our average per tonne margins were $18 per tonne in 2011, slightly higher than the $16 per tonne achieved in 2010.

Distribution and Storage

Agrium Wholesale has developed an extensive transportation, storage and warehousing system to optimize deliverability of product to our agricultural customers in the highly seasonal peak demand periods. In total, our global distribution and storage capacity amounts to over 2.7 million tonnes. We also have over 4,000 railcars under long-term lease and use barges, pipelines, and ocean vessels to move our product. Agrium acquired the remaining 30 percent of Common Market Fertilizers S.A. (“CMF”) and subsequently renamed Agrium Europe in 2010, significantly strengthening our position in Europe, where Agrium Europe owns and leases over 390,000 tonnes of dry and liquid storage at both port and inland sites, including 90,000 tonnes of incremental storage capacity provided through the acquisition of Cerealtoscana and its subsidiary, Agroport. We also plan to move a portion of urea volumes from the expanded Egyptian nitrogen facility into Europe, following completion of the expansion project.

Egyptian Nitrogen Facility: MOPCO

Our equity interest in MOPCO, whose subsidiary, ENPC, owns a nitrogen facility in Damietta, Egypt, contributed $19-million in equity earnings in 2011, compared to $17-million in 2010. The existing annual capacity is 675,000 tonnes of urea and 80,000 net tonnes of merchant ammonia. The project to triple production capacity to 1.95 million tonnes of urea and 150,000 net tonnes of merchant ammonia and operation of the existing facility was temporarily suspended in the fourth quarter due to civil unrest. Agrium will have a 26 percent equity interest in the expanded plant. Agrium also has an associated off-take agreement to market all of the additional export volume resulting from the expansion.

WHOLESALE // Quarterly Results

Given that the agricultural sector is the primary market for our Wholesale business unit, results tend to fluctuate with the seasons of crop production. The second quarter, which coincides with the spring application season in North America, is typically Wholesale’s most important quarter from a sales volume and EBIT perspective. The fourth quarter is also important in terms of sales volume and EBIT, as it encompasses the fall fertilizer application season in the northern hemisphere and the spring application season in Argentina. The first quarter is generally the weakest, as application and sales volumes are light in the winter months. In 2011, the spring season in North America was impacted by extremely wet weather conditions which reduced the window for plantings and applications across much of the Eastern Corn Belt and Western Canada and fall applications were impacted by the severe drought in the Southern U.S. Plains.

28 CULTIVATING PERFORMANCE.DELIVERING VALUE.

Wholesale Quarterly Results

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | 2011 | | | 2010 | |

| (millions of U.S. dollars, except as noted) | | Q4 | | | Q3 | | | Q2 | | | Q1 | | | Q4 | | | Q3 | | | Q2 | | | Q1 | |

Sales – external | | | 1,226 | | | | 1,023 | | | | 1,438 | | | | 1,072 | | | | 1,006 | | | | 744 | | | | 970 | | | | 740 | |

Sales – inter-segment | | | 228 | | | | 153 | | | | 275 | | | | 161 | | | | 154 | | | | 121 | | | | 141 | | | | 108 | |

Total sales | | | 1,454 | | | | 1,176 | | | | 1,713 | | | | 1,233 | | | | 1,160 | | | | 865 | | | | 1,111 | | | | 848 | |

Cost of product sold | | | 898 | | | | 779 | | | | 1,093 | | | | 824 | | | | 820 | | | | 688 | | | | 837 | | | | 630 | |

Gross profit | | | 556 | | | | 397 | | | | 620 | | | | 409 | | | | 340 | | | | 177 | | | | 274 | | | | 218 | |

Gross profit (%) | | | 38 | | | | 34 | | | | 36 | | | | 33 | | | | 29 | | | | 20 | | | | 25 | | | | 26 | |

Nitrogen | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Sales | | | 595 | | | | 405 | | | | 717 | | | | 334 | | | | 397 | | | | 319 | | | | 481 | | | | 261 | |

Cost of product sold | | | 273 | | | | 228 | | | | 393 | | | | 183 | | | | 237 | | | | 237 | | | | 343 | | | | 189 | |

Gross profit | | | 322 | | | | 177 | | | | 324 | | | | 151 | | | | 160 | | | | 82 | | | | 138 | | | | 72 | |

Tonnes sold (‘000) | | | 1,060 | | | | 817 | | | | 1,433 | | | | 749 | | | | 980 | | | | 950 | | | | 1,256 | | | | 732 | |

Selling price (per tonne) | | | 562 | | | | 497 | | | | 500 | | | | 446 | | | | 406 | | | | 336 | | | | 382 | | | | 358 | |

Margin (per tonne) | | | 304 | | | | 217 | | | | 226 | | | | 202 | | | | 163 | | | | 84 | | | | 109 | | | | 98 | |

Potash | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Sales | | | 188 | | | | 167 | | | | 259 | | | | 195 | | | | 158 | | | | 131 | | | | 195 | | | | 191 | |

Cost of product sold | | | 67 | | | | 65 | | | | 94 | | | | 70 | | | | 62 | | | | 71 | | | | 86 | | | | 85 | |

Gross profit | | | 121 | | | | 102 | | | | 165 | | | | 125 | | | | 96 | | | | 60 | | | | 109 | | | | 106 | |

Tonnes sold (‘000) | | | 398 | | | | 347 | | | | 543 | | | | 477 | | | | 417 | | | | 388 | | | | 529 | | | | 534 | |

Selling price (per tonne) | | | 473 | | | | 480 | | | | 477 | | | | 409 | | | | 378 | | | | 340 | | | | 366 | | | | 358 | |

Margin (per tonne) | | | 304 | | | | 292 | | | | 304 | | | | 262 | | | | 228 | | | | 154 | | | | 205 | | | | 199 | |

Phosphate | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Sales | | | 232 | | | | 217 | | | | 206 | | | | 238 | | | | 165 | | | | 170 | | | | 134 | | | | 127 | |

Cost of product sold | | | 143 | | | | 135 | | | | 123 | | | | 143 | | | | 111 | | | | 145 | | | | 125 | | | | 109 | |

Gross profit | | | 89 | | | | 82 | | | | 83 | | | | 95 | | | | 54 | | | | 25 | | | | 9 | | | | 18 | |

Tonnes sold (‘000) | | | 285 | | | | 277 | | | | 259 | | | | 306 | | | | 246 | | | | 302 | | | | 243 | | | | 250 | |

Selling price (per tonne) | | | 813 | | | | 784 | | | | 795 | | | | 778 | | | | 672 | | | | 563 | | | | 553 | | | | 506 | |

Margin (per tonne) | | | 313 | | | | 297 | | | | 320 | | | | 310 | | | | 218 | | | | 82 | | | | 39 | | | | 72 | |

Other | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Sales | | | 68 | | | | 52 | | | | 82 | | | | 55 | | | | 52 | | | | 38 | | | | 73 | | | | 53 | |

Cost of product sold | | | 45 | | | | 37 | | | | 56 | | | | 33 | | | | 45 | | | | 37 | | | | 59 | | | | 43 | |

Gross profit | | | 23 | | | | 15 | | | | 26 | | | | 22 | | | | 7 | | | | 1 | | | | 14 | | | | 10 | |

Tonnes sold (‘000) | | | 162 | | | | 132 | | | | 188 | | | | 156 | | | | 162 | | | | 132 | | | | 223 | | | | 174 | |

Product purchased for resale | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Sales | | | 371 | | | | 335 | | | | 449 | | | | 411 | | | | 388 | | | | 207 | | | | 228 | | | | 216 | |

Cost of product sold | | | 370 | | | | 314 | | | | 427 | | | | 395 | | | | 365 | | | | 198 | | | | 224 | | | | 204 | |

Gross profit | | | 1 | | | | 21 | | | | 22 | | | | 16 | | | | 23 | | | | 9 | | | | 4 | | | | 12 | |

Tonnes sold (‘000) | | | 721 | | | | 599 | | | | 1,014 | | | | 911 | | | | 944 | | | | 620 | | | | 759 | | | | 677 | |

Selling price (per tonne) | | | 514 | | | | 559 | | | | 443 | | | | 451 | | | | 410 | | | | 335 | | | | 301 | | | | 319 | |

Margin (per tonne) | | | 1 | | | | 35 | | | | 22 | | | | 18 | | | | 25 | | | | 14 | | | | 5 | | | | 18 | |

EBIT | | | 507 | | | | 393 | | | | 569 | | | | 377 | | | | 315 | | | | 151 | | | | 276 | | | | 147 | |

EBITDA | | | 552 | | | | 438 | | | | 617 | | | | 412 | | | | 354 | | | | 206 | | | | 339 | | | | 182 | |

AGRIUM2011 ANNUAL REPORT 29

Our Advanced Technologies Business Unit

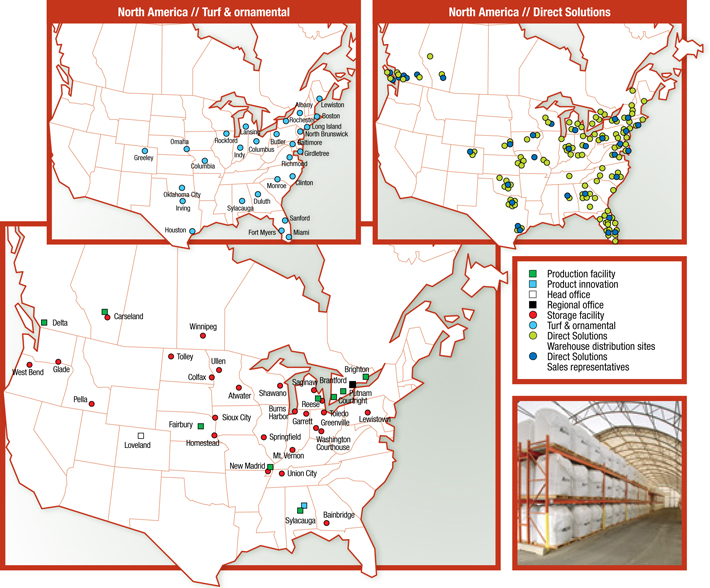

Agrium’s Advanced Technologies business unit is a global leader in the development and sales of Enhanced Efficiency Fertilizer (“EEF”) products, utilizing slow and controlled-release fertilizers to provide both economic and environmental benefits. We add value for our customers by offering the latest technologies through an extensive line of innovative products to a broad range of target markets, including: agriculture, specialty agriculture, professional turf, horticulture and consumer lawn and garden.

ADVANCED TECHNOLOGIES // Strategy and Key Developments

To achieve our aggressive growth target for the AAT business unit in the coming years, we will focus on five core objectives:1) growing end-user demand in key markets;2) expanding ESN capacity;3) capitalizing on international opportunities;4) targeting complimentary acquisitions; and5) developing new technologies and product offerings.

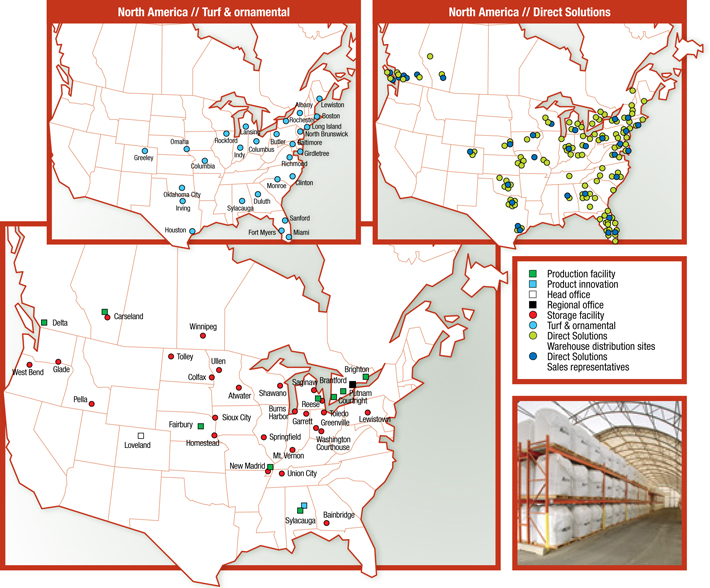

Over the past five years, AAT has grown steadily through a combination of acquisitions, business expansions and capacity additions. AAT made strides in laying the foundation for future growth and development with the establishment of our Direct Solutions sales division in 2010, a direct-to-market sales force with over 100 industry professional field representatives across North America, and the completion of a new ESN facility in New Madrid, Missouri in the spring of 2010. Additionally, Agrium’s Board of Directors approved a 136,000 tonne expansion of this facility in December 2011, which is expected to bring AAT’s total ESN production capacity to 464,000 tonnes upon project completion in the second half of 2012. Over the past year, we also expanded our business in North America with the acquisitions of Evergro Canada (“Evergro”) and Tetra Micronutrients.

In July 2011, AAT announced the acquisition of Evergro, a leading manufacturer and distributor of horticultural and professional turf products in Western Canada. In addition to providing AAT with seven distribution and blending facilities throughout British Columbia and Alberta in Canada, Evergro is expected to also add value to our growing Direct Solutions business through its expertise in providing innovative controlled-release fertilizers, as well as turf, pest control and soil amendment products to North American specialty markets. The geographic location of these operations is expected to provide AAT with an expanded platform to grow our international business in the Pacific Rim. The acquisition of Tetra Micronutrients, a specialty producer, marketer and distributor of custom liquid plant nutrition and dry micronutrients, was completed in July 2011 and represents a strong addition to Agrium’s AAT and Retail businesses. AAT will operate and market product from Tetra Micronutrients’ dry

30 CULTIVATING PERFORMANCE.DELIVERING VALUE.

granulation facility, while Loveland will assume operation of its liquid facility and market production directly to Agrium Retail’s customers. AAT also expects to benefit from the liquid plant nutrition business by marketing products to third party customers.

ADVANCED TECHNOLOGIES // Products and Services

AAT has established itself as a world leader in producing a broad spectrum of slow and controlled-release fertilizers, including polymer-coated, sulfur-coated and reacted products in a variety of sizes and compositions, which are custom designed to meet the specific needs of our target markets. We also demonstrate our commitment to protecting and preserving the environment through specially engineered product offerings with advanced-generation coatings and other technology to prevent nutrient loss to the environment. Our EEF products allow end-users to optimize quality and yield, while reducing the frequency of required application.

AGRIUM2011 ANNUAL REPORT 31