EXHIBIT 99.2

AGRIUM INC.

2016

MANAGEMENT’S DISCUSSION & ANALYSIS OF

OPERATIONS AND FINANCIAL CONDITION

Management’s Discussion and Analysis

Table of Contents

6 | ANNUAL REPORT 2016AGRIUM

February 22, 2017

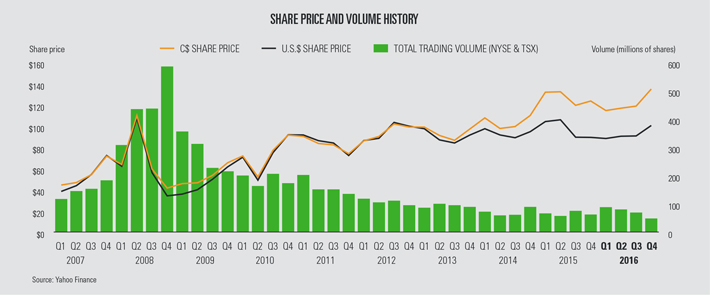

This Management’s Discussion and Analysis (MD&A) of operations and financial condition focuses on Agrium’s long-term vision, strategy and growth opportunities as well as its historical performance for the years ended December 31, 2016 and 2015. The Board of Directors of Agrium (the “Board”) carried out its responsibility for review of this disclosure and, prior to publication, approved this disclosure.

Throughout this MD&A, unless otherwise specified, “Agrium”, “the Company”, “we”, “our”, “us” and similar expressions refer collectively to Agrium Inc. and its subsidiaries, any partnerships involving Agrium Inc. or any of its subsidiaries, its significant equity investments and Agrium Inc.’s share of its joint ventures.

Additional information relating to the Company, including its consolidated quarterly and annual financial information and its Annual Information Form (AIF) for the year ended December 31, 2016, is available under Agrium’s corporate profile on SEDAR (www.sedar.com). The Company’s reports are also filed with the U.S. Securities and Exchange Commission on EDGAR (www.sec.gov).

All dollar amounts refer to U.S. dollars, except where otherwise stated. 2016, 2015 and 2014 financial information presented and discussed in this MD&A is prepared in accordance with International Financial Reporting Standards (IFRS) as issued by the International Accounting Standards Board (IASB).

Certain financial measures in this MD&A, listed in the table below, are not prescribed by and do not have any standardized meaning under IFRS. Our method of calculation of thenon-IFRS financial measures may not be directly comparable to that of other companies. We consider thesenon-IFRS financial measures to provide useful information to both management and investors in measuring our financial performance and financial condition. Thesenon-IFRS financial measures should not be considered as a substitute for, or superior to, measures of financial performance prepared in accordance with IFRS. Refer to the“Non-IFRS Financial Measures” section for further details, including a reconciliation of thenon-IFRS financial measures to their most directly comparable measures calculated in accordance with IFRS.

|

Non-IFRS financial measures |

| Cash operating coverage ratio |

| Cash cost of product manufactured (COPM) |

| Comparable store sales and normalized comparable store sales |

| Earnings Before Interest, Tax, Depreciation and Amortization (EBITDA), EBITDA to sales, cash selling and general and administrative costs |

| Free cash flow, dividends paid as a percent of free cash flow |

| Wholesale measures including share of joint ventures: sales, cost of product sold, gross profit |

FORWARD-LOOKING

STATEMENTS

Certain statements and other information included in this MD&A constitute “forward-looking information” and/or “financial outlook” within the meaning of applicable Canadian securities legislation or “forward-looking statements” within the meaning of applicable U.S. securities legislation (collectively herein referred to as “forward-looking statements”), including the “safe harbour” provisions of provincial securities legislation and the U.S. Private Securities Litigation Reform Act of 1995, Section 21E of the U.S. Securities Exchange Act of 1934, as amended, and Section 27A of the U.S. Securities Act of 1933, as amended. Forward-looking statements are typically identified by the words “believe”, “expect”, “anticipate”, “project”, “intend”, “estimate”, “outlook”, “focus”, “potential”, “will”, “should”, “would”, “could” and other similar expressions.

Forward-looking statements in this MD&A are intended to provide Agrium securityholders and potential investors with information regarding Agrium, including management’s assessment of future financial and operational plans and outlook, and may not be appropriate for other purposes. These forward-looking statements are subject to a number of assumptions, risks and uncertainties, many of which are beyond our control and which could cause actual results to differ materially from such forward-looking statements. As such, readers should not place undue reliance on these forward-looking statements. Refer to the “Key Assumptions and Risks in Respect of Forward-looking Statements” section for further details.

AGRIUM ANNUAL REPORT 2016 | 7

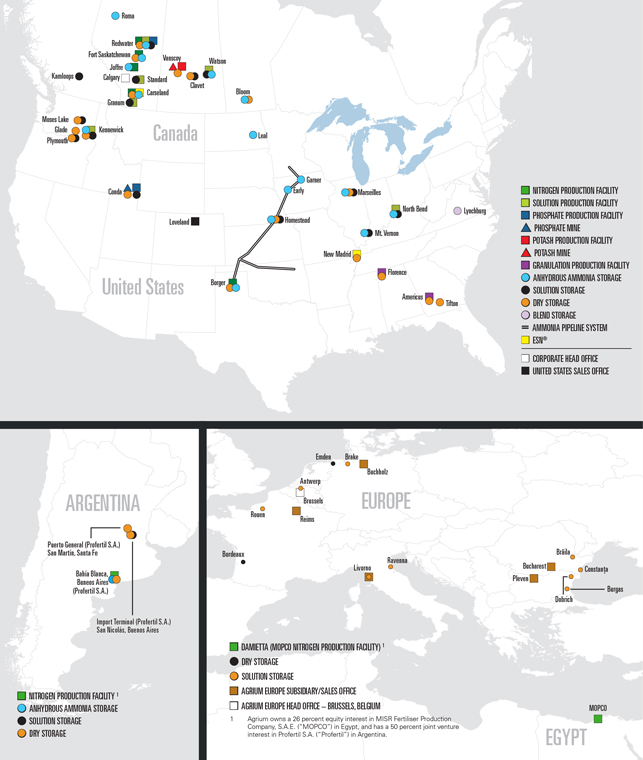

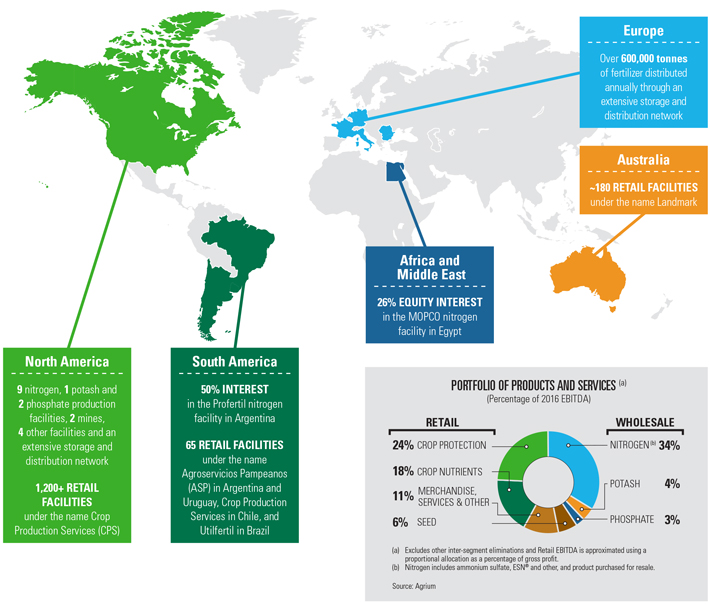

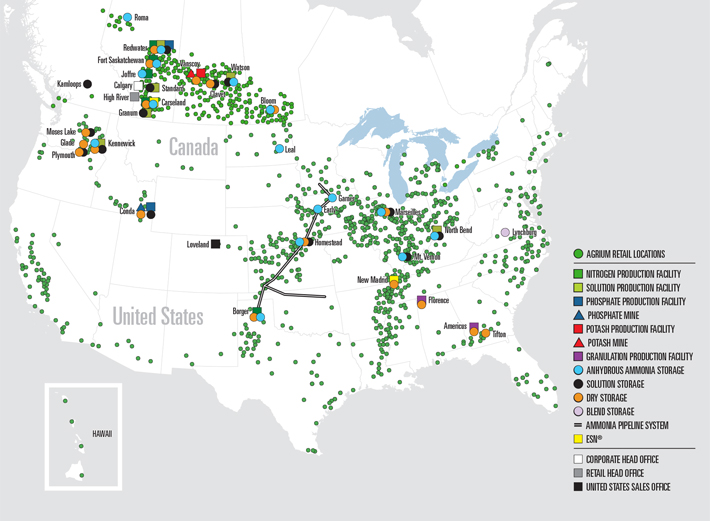

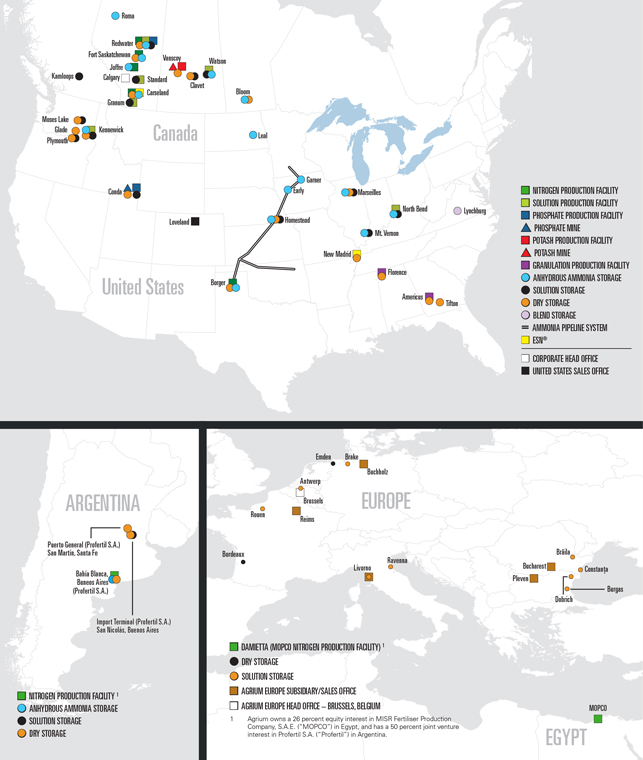

Agrium’s Strategic Footprint

Agrium has significant competitive advantages across our global footprint of operations. We are focused on supplying the important crop inputs, services and solutions farmers require to meet the ever-growing global demand for crops and food, and we are committed to doing so safely and sustainably. Our Retail operations provide us with stability, diversity and long-term earnings growth potential, and our strategically positioned Wholesale operations withlow-cost nitrogen and potash operations allow us to reach markets across North America and around the world.

8 | ANNUAL REPORT 2016AGRIUM

THE MARKET FOR OUR PRODUCTS AND SERVICES

| | | | |

| Annual Fertilizer | | Annual Growth | | Total Crop Land in |

| Demand in | | in Global N, P & K | | U.S., Canada, Australia |

| North America | | Product Demand | | and Argentina |

| 50 million | | 8 million | | 700 million |

| TONNES | | TONNES | | ACRES |

| Source: AAPFCO, TFI, Agrium | | Source: CRU, Fertecon, IFA, Agrium | | Source: U.N. Food and Agriculture |

| | | | Organization, FAOSTAT, Agrium |

Merger With PotashCorp will Create World-Class Integrated Global Supplier of Crop Inputs

The new combined company will be the largest crop nutrient company in the world and the third largest natural resource company in Canada. Combined, the new company will have a diverse and complementary portfolio of high quality potash, nitrogen and phosphate production assets. These assets will be complemented by Agrium’s leading global retail distribution network. The optimization of these combined portfolios is expected to generate$500-million of annual operating synergies.

AGRIUM ANNUAL REPORT 2016 | 9

REVIEW OF 2016 – EXECUTING ON OUR OPERATIONAL EXCELLENCE INITIATIVES

Consolidated and business unit financial performance

| | | | | | | | | | | | |

(millions of U.S. dollars, except as noted) | | 2016 | | | 2015 | | | % Change | |

Sales | | | 13,665 | | | | 14,795 | | | | (8 | ) |

Gross profit | | | 3,395 | | | | 3,888 | | | | (13 | ) |

Selling and general and administrative expenses | | | 2,156 | | | | 2,189 | | | | (2 | ) |

EBIT(a) | | | 1,098 | | | | 1,616 | | | | (34 | ) |

EBITDA | | | 1,630 | | | | 2,096 | | | | (24 | ) |

Retail EBITDA | | | 1,091 | | | | 1,033 | | | | 6 | |

Wholesale EBITDA | | | 751 | | | | 1,284 | | | | (44 | ) |

Diluted earnings per share | | | 4.29 | | | | 6.98 | | | | (39 | ) |

| (a) | Earnings before finance costs and income taxes (EBIT) |

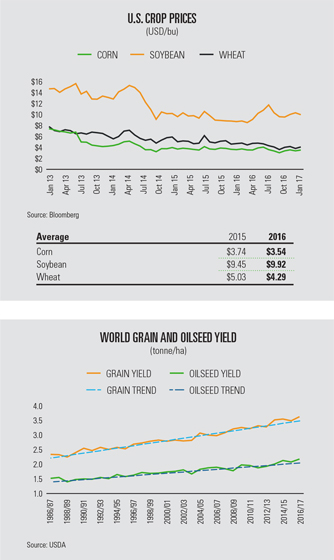

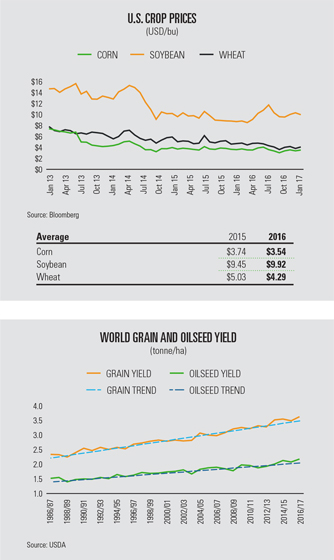

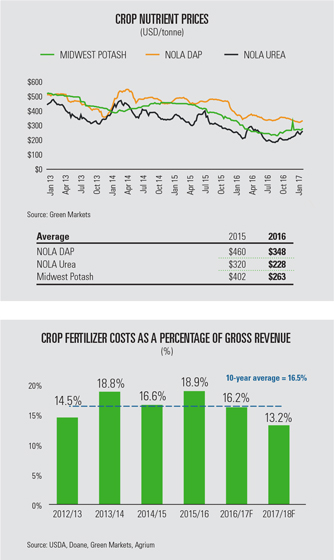

| ● | | During 2016, Agrium remained focused on our Operational Excellence initiatives and on controlling our controllables. While earnings were impacted by weak crop prices and lower global nutrient benchmarks, Agrium drove further cost efficiencies across the organization, improved our operational performance and organically grew key product lines, which supported improvement in several key performance metrics. |

| ● | | OurRetail businessunit grew its EBITDA in 2016, despite facing pressure in the U.S. due to weak crop prices pressuring grower cash margins and their crop input decisions. However, this was offset by an improvement in our International and Canadian Retail earnings, organic growth, increased sales of our higher-margin proprietary products, and cost savings as a result of our Operational Excellence initiatives across the business unit. In the face of a challenging macro-economic environment, Retail EBITDA increased 6 percent or$58-million year-over-year, while cash selling and general administrative expenses excluding acquisitions made in 2016 decreased by over$70-million compared to 2015. This marks the second consecutive year that our Retail business unit has successfully implemented cost savings initiatives and decreased selling and general administrative costs. While there was competitive pressure on most crop inputs this year, sales of our crop protection products and seeds increased by$178-million compared to the prior year. This was supported by sales of our proprietary products which increased 7 percent over 2015. As a result of these factors, our EBITDA to sales ratio improved by one percentage point to 9 percent in 2016. |

| ● | | OurWholesale businessunit’s EBITDA decreased due to overall fertilizer market weakness and low realized nutrient pricing during the year. Total potash sales volumes increased as we continued to ramp up production post-expansion at Vanscoy, while nitrogen and phosphate sales volumes remained relatively constant. We made significant progress toward our Operational Excellence initiatives, realizing overall fixed cost efficiencies of$66-million, together with increased ammonia and phosphoric acid utilization rates, which supported lower cash cost of product manufactured per tonne across all our major products versus 2015. Wholesale also reported higher earnings from our international joint venture and equity interests compared to the prior year. This was due to an improved political landscape and support for the agricultural sector in Argentina and new production trains coming online in Egypt. |

PROPOSED MERGER WITH POTASHCORP

Agrium and Potash Corporation of Saskatchewan Inc. (“PotashCorp”) entered into an agreement dated September 11, 2016 (the “Arrangement Agreement”), under which the companies will combine in a merger of equals into a newly incorporated parent entity (“New Parent”) to be formed to manage and hold the combined businesses of both Agrium and PotashCorp. The Arrangement Agreement will be implemented by a proposed plan of arrangement (the “Arrangement”). Under the Arrangement, Agrium shareholders will receive 2.23 New Parent shares for each Agrium share held and PotashCorp shareholders will receive 0.40 of a New Parent share for each PotashCorp share held. Following the completion of the Arrangement Agreement, Agrium and PotashCorp will become wholly owned subsidiaries of New Parent and New Parent will continue the operations of Agrium and PotashCorp on a combined basis.

At meetings of their respective shareholders held on November 3, 2016, shareholders of both Agrium and PotashCorp approved the Arrangement with over 98 percent of the Agrium shares and voting options voted at the meeting voting in favor of the Arrangement. More than 108 million, or over 78 percent, of Agrium’s outstanding shares and voting options were voted at the meeting. On November 8, 2016, the Ontario Superior Court of Justice issued a final order approving the Arrangement and Agrium and PotashCorp are working through the regulatory process as planned. Agrium continues to expect the transaction to closemid-2017, subject to the satisfaction of customary closing conditions, including receipt of regulatory approvals. See 2016 AIF “Item 5 – Description of the Business – 5.2 Risk Factors – Risks Related to the Arrangement”. Additional information and the full text of the Arrangement Agreement and the Arrangement are included in Agrium and PotashCorp’s joint proxy circular filed on SEDAR on October 6, 2016.

10 | ANNUAL REPORT 2016AGRIUM

Retail Overview and 2016 Results

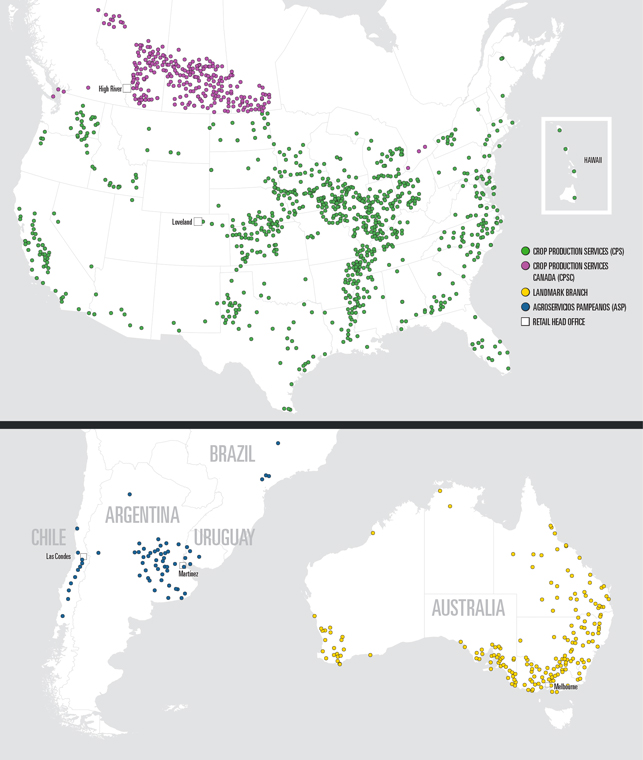

Agrium’s Retail business is the world’s largest retail distributor of agricultural crop inputs, providing growers with fertilizer, crop protection products, seed, services and solutions. We operate approximately 1,500 retail facilities across the U.S., Canada, Australia and key areas of South America, providing custom-built portfolios of products, services and advice to growers. This combination of products and services helps our farm-customers achieve their yield goals and maximize their return on investments in an environmentally sustainable manner. Instrumental to our mutual success is the strong partnership and trust that we have built with customers by delivering value to them year after year.

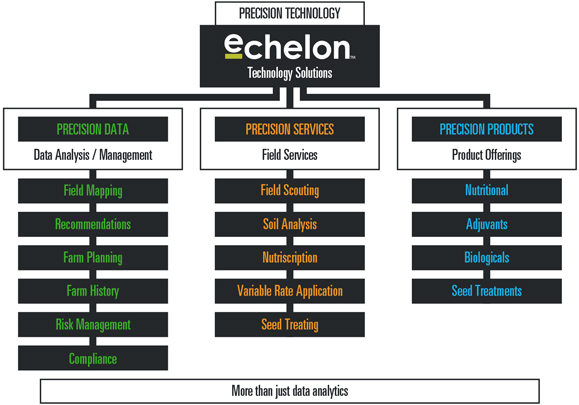

Our more than 3,300 agronomists and field experts work directly with growers, helping them maximize the productivity of their farms by implementing the best management practices based on a thorough understanding of soils, climate conditions, crop requirements and our portfolio of products. Our Retail distribution and services business provides growers with leading crop input products, such as the newest seed, crop protection products, technologies and extensive agronomic experience, all backed by a commitment to sound environmental practices. Supporting this expertise is our own ECHELON® precision agriculture platform, which provides diagnostic analysis and recommendations to further enhance crop yields, optimize use of crop inputs and create additional value for the grower.

We also manufacture and sell innovative proprietary crop protection products and nutritionals under the Loveland Products® brand, seed products under the brand namesDyna-Gro® and Proven®, and animal health products under the Dalgety® brand. These leading crop input and animal health products provide farmers and ranchers with several competitive options to profitably produce and protect their investments while providing higher margins for Agrium Retail.

Our products and services can vary somewhat depending on the region or country. For example, in Australia, we provide livestock marketing and auction services, and we facilitate an extensive offering of insurance products and financial services. In Western Canada, we market crop storage bins, provide fuel sales and services, and offer financial services to our customers. Starting in the middle of 2016, we initiated new financial services across North America through our new Agrium Financial Services™ (AFS) business, and we acquired a 28.5 percent equity ownership position in Agrifund, LLC and Ag Resource Holdings, LLC (collectively, Ag Resource Management or ARM), which provides specialized higher interest rate lending in the U.S., backed by growers’ collateral.

AGRIUM ANNUAL REPORT 2016 | 11

PRODUCTS AND SERVICES

Crop Nutrients

Crop nutrients are essential to growing healthy plants, and Retail provides growers with all their required dry and liquid macronutrient products, which include nitrogen, potash, phosphates and sulfur, as well as proprietary micronutrient products. Retail acquires crop nutrient products from a wide variety of suppliers at market prices, including Agrium’s Wholesale business unit. Retail’s North American segment purchases approximately 32 percent of its annual nutrient requirements from Wholesale, although for certain regions and products, Wholesale supplies the majority of Retail’s nutrient requirements. These crop nutrient products are typically blended at the local Retail branch, or applied in the field using variable-rate application equipment. Retail delivers additional value to growers through its nutrient application services, provided on afee-for-service basis.

Retail has an extensive portfolio of proprietary liquid micronutrients that support optimal soil fertility and yield enhancement opportunities. These are essential plant nutrient elements such as boron and zinc, required for plant and soil health. Micronutrients represent a strong organic growth platform for us as more growers implement this crop input through thepre-planting and growth stages of plant development. We have backward integrated into production and technology through our investment in a formulation facility in Fairbury, Nebraska, equity positions or ownership in CH Biotech R&D Co. Ltd. and Advanced Microbial Solutions, LLC, and a strategic alliance with Actagro; to remain at the forefront of innovation and provide differentiated technology and product offerings to our grower customers.

Our Retail branches work closely with growers to understand their nutrient goals and customize our delivery of products, agronomic advice and product application services to help achieve those goals. Retail’s agronomists use the 4R Nutrient Stewardship System, often utilizing our ECHELON® precision agriculture platform, to help determine the right nutrient source and apply it at the right time, at the right rate and in the right place. Using ECHELON®’s highly sophisticated tools, our agronomists help growers identify the differences in yield potential within a field and adjust crop inputs accordingly, thereby increasing their productivity and crop input use efficiency while reducing environmental impacts.

Nutrient application windows can be limited, and the timing can vary significantly depending on weather conditions. As a result, growers need a reliable and efficient distribution system for crop nutrients and other crop inputs. Retail’s global distribution network has efficiently moved, on average, approximately ten million tonnes of crop nutrients to our grower customers annually. Our network of branches, terminals and distribution centers allow us to have product readily availablein-market when the growers need it, while carefully managing our working capital levels.

Crop Protection Products

Retail’s crop protection products, along with our advisory services, provide growers with an integrated plant protection program that draws on our extensive agronomic expertise and a broad spectrum of third-party supplier and proprietary products. These products are designed to maintain crop quality and manage plant diseases, weeds and other pests that can damage crops and lower yields. We are the largest independent distributor of crop protection products in North America, and our product offering is supported by sound technical advice and product application services. We are a retailer of crop protection products directly to growers, and we have a smaller wholesale business that provides crop protection products to other retail operators.

As part of our crop protection offering, we sell proprietary products that incorporate the latest in chemistry and adjuvant technology under the Loveland Products® brand. We own and operate numerous blending and formulation facilities, including major production facilities in Greeley, Colorado; Billings, Montana; Greenville, Mississippi; Casilda, Argentina; Buenos Aires, Argentina; and two formulation facilities in Western Australia and Victoria, Australia. We also have an investment in a formulation plant in Winnipeg, Manitoba. Retail also owns significant interests in several agricultural biotechnology companies through our Loveland business. These investments allow us to be at the forefront of the latest developments in crop protection for our customers, and to benefit from sales of these higher margin products without incurring the associated upfront research and development capital investment.

Agrium’s Retail locations also provide seed treatment products and related services, which involve applying crop protection products specifically designed to promote healthy seed germination and early stage plant growth directly to the seed prior to planting.

12 | ANNUAL REPORT 2016AGRIUM

RETAIL GLOBAL OPERATIONS – NORTH AMERICA, SOUTH AMERICA AND AUSTRALIA

AGRIUM ANNUAL REPORT 2016 | 13

Seed

Our Retail operations provide the seed and seed-related information and analysis our customers require. We sell a wide array of seed brands from top global suppliers as well as our proprietary seed product lines under the brand namesDyna-Gro® and Proven®. OurDyna-Gro® seed specialists license leading seed traits from major suppliers, match seed characteristics to local soil and growing conditions, and research and test these choices to ensure the best results for each grower’s area. We strive to continue to grow our seed sales and market share over the medium term.

We also have significant investments in canola and rice plant breeding programs to supply industry-leading seed products for these crops. Our canola program has laboratories in Saskatoon, Saskatchewan, and Horsham, Australia, as well as vast germplasm bank and research farms in Saskatchewan with seed marketed under the brand name Proven®. We expect to sell our proprietary rice seed products commercially starting in 2017. In total, these proprietary product lines represented 22 percent of our total seed sales in 2016 and add growth opportunity and significant margin value to our overall seed sales.

Merchandise

The merchandise product category includes fencing, feed supplements, livestock-related animal health products, storage and irrigation equipment, and other products. It also includes the fuel and equipment businesses in Canada. Merchandise is a much larger component of our Australian and Canadian operations than our U.S. and South American Retail operations.

Services and Other

Agrium delivers value to growers and earns customer loyalty through services, such as product application, soil and leaf testing, crop scouting and precision agriculture services under our ECHELON® platform. We maintain a large fleet of application equipment and other rolling stock to ensure timely and optimal applications of both nutrients and crop protection products in a safe and effective manner for our grower customers. Our Australian operations also offer livestock marketing, as well as various insurance and real estate services.

In 2016, Agrium introduced an innovative financial services program to our grower customers. Known as Agrium Financial Services™ (AFS), it is a new lending program to provide credit for crop input purchases to our Retail customers in North America. We also made a 28.5 percent investment in ARM, which provides specialized lending backed by growers’ collateral such as crop insurance, liens on crops and Farm Services Agency (FSA) payments. The combination of these two lending platforms will provide complementary credit options for not only our existing growers but new customers, and it will help them to purchase their required crop inputs in a timely manner. This gives Agrium another avenue to strengthen and expand our customer base, increase revenue from existing customers, drive additional crop input sales and decrease our overall credit risk profile.

14 | ANNUAL REPORT 2016AGRIUM

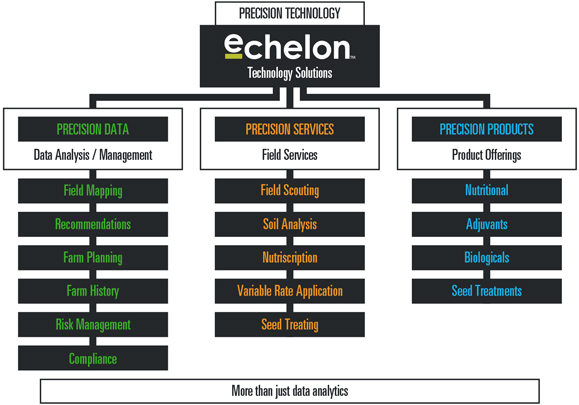

Precision Agriculture: Yield-enhancing Technology and Solutions for Growers

Most cropland is not uniform in terms of soil type, nutrient level or pest pressure. The variance in soil or field conditions results in variability in yields or yield potential within a field. Precision agriculture is the practice of using the latest technology, including global positioning systems and geospatial data processing analytics, to allow growers to address this variability in a field’s yield potential and crop input needs. This technology allows growers to better match crop inputs and other farming practices to specific conditions, which helps optimize yields and returns. To obtain the greatest value from precision agriculture technology, service providers help growers analyze large amounts of information including yield maps, detailed field analyses, and soil and foliar nutrient analyses to create specific crop input recommendations that can be precisely applied at variable rates across a field. This typically includes variable-rate application of crop inputs as well as monitoring of crop, soil and yield conditions. This technology also helps growers with recordkeeping, planning and soil mapping. Targeted measurement and placement of crop inputs help maximize uptake by the plants and minimizes waste, thereby delivering significant environmental benefits. With continual improvements in research and development, including analytical capabilities, accuracy, connectivity, equipment design and data synthesis, the focus on and benefits from precision agriculture products and services are expected to continue to improve.

Agrium has been offering precision agriculture services to grower customers around the globe for more than a decade. Currently, we provide this multi-crop service offering to over 70,000 growers, have mapped more than 36 million acres across our retail footprint, and maintained over 4.8 million acres of actionable soil fertility data based on regular sampling and soil testing results. ECHELON® is our branded precision agriculture technology platform, which offers services such as soil nutrient testing, tissue sampling, yield data mapping, recordkeeping, soil fertility management, variable-rate fertilizer application and variable-rate seeding recommendations along with agronomic advice and proprietary product considerations. ECHELON® is also integrated with our Enterprise Resource Planning sales system, which provides efficiencies for our Retail operations.

With our custom-built ECHELON® platform, our goal is to provide our grower customers with the highest fidelity data-driven advice to optimize their crop production. This allows our crop consultants to better analyze and illustrate the effectiveness of new products and practices as well as our proprietary products in an unbiased environment. ECHELON® generates value for Retail primarily through direct charge services (such as soil sampling), product bundling opportunities and objective recommendations for specific products, including our extensive propriety product offering. This combination of expert agronomic advice, with the latest technological tools strengthens our relationships with existing customers and increases opportunities to bring in new growers.

AGRIUM ANNUAL REPORT 2016 | 15

RETAIL >> KEY DEVELOPMENTS IN 2016

Operational Excellence

Agrium’s Retail business continued to drive improvement in its operations as part of our Company’s commitment to Operational Excellence. As a result, we were able to demonstrate improvements across the majority of our key metrics in 2016, despite some continued challenges in agricultural markets this year. These enhancements included focusing on improving product, service and solution offerings to our approximately half-million farm customers globally, growing our propriety product sales, optimizing our extensive distribution network, managing working capital and reducing costs – measures that we expect will continue to drive improvement in our key metrics and financial measures going forward.

| ● | | Retail was able to improve upon many key metrics in 2016 despite weakness in the agricultural markets throughout much of the year. Focusing on continued proprietary product growth and prudent inventory management allowed us to increase our gross profit margin by two percentage points in 2016, while EBITDA grew 6 percent, excluding incremental earnings from acquisitions made in 2016. |

| ● | | Normalized comparable store sales (normalized for changes in commodity nutrient prices and foreign exchange rates) increased by 2 percent in 2016 as a result of higher sales in our International segment and the U.S., partly offset by lower sales in Canada. Our International Retail segment made further improvements in earnings in 2016 with Australian operations reaching a record$122-million in EBITDA compared to$94-million in 2015, and South America increasing EBITDA by 77 percent to$44-million. The continuing year-over-year improvement in the International segment reflects ongoing emphasis on cost control, increased proprietary product sales and improved agricultural conditions. |

| ● | | Excluding acquisitions made in 2016, Retail reduced cash selling and general and administrative expenses by approximately$70-million, which improved our cash operating coverage ratio by one percentage point compared to 2015. |

| ● | | We took action this year to further optimize our distribution network and reduce operational costs, closing over 65 retail locations during the year. These efforts tie to our “hub and spoke” strategy, where we are able to serve local customers more efficiently with a centralized regional service and distribution structure. |

| ● | | Our continued focus on working capital resulted in our averagenon-cash working capital to sales ratio to improve by one percentage point to 17 percent. At the end of the year,non-cash working capital was 25 percent lower than the prior year. |

| ● | | In 2016, we undertook several initiatives to reduce costs within our Loveland Products operations, which will result in annual savings of over$20-million and will further enhance our proprietary product margins. |

| ● | | All these Operational Excellence initiatives helped to improve EBITDA to sales by approximately one full percentage point to reach 9.2 percent. |

| ● | | Despite a significant additional focus on perpetuating a safety culture throughout the business, Retail experienced three fatalities during 2016. We continue to review our procedures and make every effort to meet our commitment to zero incidents in the future. |

Retail metrics

| | | | | | | | | | | | |

| | | 2016 | | | 2015 | | | 2014 | |

Averagenon-cash working capital to sales (%) | | | 17 | | | | 18 | | | | 17 | |

Cash operating coverage ratio (%) | | | 61 | | | | 62 | | | | 61 | |

EBITDA (millions of U.S. dollars) | | | 1,091 | | | | 1,033 | | | | 1,119 | |

EBITDA to sales (%) | | | 9 | | | | 8 | | | | 9 | |

Normalized comparable store sales(a)(%) | | | 2 | | | | (3 | ) | | | (1 | ) |

| (a) | In 2016, we revised our definition of normalized comparable store sales, which previously normalized for fertilizer prices, to now also include the impact of foreign exchange. We have restated our 2015 and 2014 comparative information. |

Focused Growth

| ● | | In line with our strategy of continuing to grow through accretive retail acquisitions, Agrium purchased 76 locations with over$500-million in expected annual sales and anticipated EBITDA of approximately$35-million and$45-million in 2017 and 2018, respectively. Similar types of acquisitions have historically achieved meaningful synergies by leveraging our scale and size in terms of buying power and procurement agreements, introducing proprietary products with higher margins, and delivering other operational and back-office synergies. Opportunities for valuable Retail acquisitions remain strong in the U.S. and are expected to continue to be a key focus for the Company in 2017 and beyond. |

| ● | | Retail is pursuing potential greenfield location builds in seven U.S. states in 2017 and currently has several locations under design and construction. These new builds remain an attractive investment option and Agrium will continue to review other locations for market growth and network synergies. |

| ● | | Agrium also unveiled a new financial services and risk management solutions program for existing and new grower customers inmid-2016. Seeing an opportunity to provide credit to financially strained growers and allowing them to continue with their normal annual crop input purchases, we created two lending options: standard client loans under AFS and specialized lending at higher interest rates through ARM. AFS is a formalized crop inputs loan program for existing customers that is expected to strengthen our existing grower base and sales. Agrium acquired a 28.5 percent share in ARM, and at December 31, 2016 the organization had over 450 loan originations clients and 20 locations in the southern U.S. With close proximity to numerous Retail operations, we expect to be able to |

16 | ANNUAL REPORT 2016AGRIUM

| | provide services across the entire Corn Belt through ARM in 2017. This business is also expected to generate customer referrals from ARM and additional crop input sales in Retail. The higher rate loans are protected by growers’ collateral, such as crop insurance and liens on crops. |

| ● | | In 2016, Agrium committed to invest as a limited partner in Finistere Ventures Fund II (“Finistere”), a leading agricultural technology fund, focused on identifying and investing in world-class technologies throughearly-to-growth stage companies, specifically in the areas of plant nutrition, biologicals, seed technology, digital agriculture and novel farm systems. This forms a part of our increasing focus on innovation and technology, to continuously enhance our total-acre solutions for our grower customers. |

Proprietary products – percent of total Retail sales by product

| | | | | | | | |

(in percentages) | | 2016 | | | 2015 | |

Crop nutrients | | | 8 | | | | 7 | |

Crop protection products | | | 24 | | | | 22 | |

Seed | | | 22 | | | | 23 | |

Total | | | 15 | | | | 14 | |

| | | | | | | | |

| ● | | In 2016, our proprietary product sales continued to grow on an absolute basis and on a percentage of total sales basis. The continued growth in proprietary products also supported our overall gross profit margins. Total proprietary sales increased by 7 percent relative to 2015, and proprietary crop protection sales grew by 12 percent, while proprietary seed sales remained flat from 2015. We will continue to highlight the importance and value of these products to our customers to reach more global acres and drive further organic growth across this platform. |

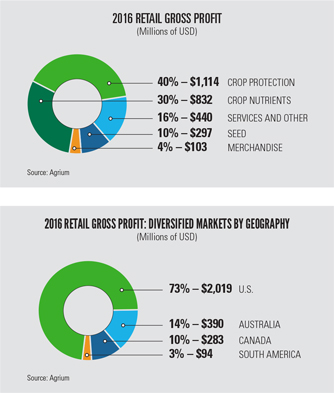

RETAIL >> FINANCIAL RESULTS

Retail performance

| | | | | | | | |

(millions of U.S. dollars, except as noted) | | 2016 | | | 2015 | |

Sales | | | 11,766 | | | | 12,199 | |

Cost of product sold | | | 8,980 | | | | 9,471 | |

| | | | | | | | |

Gross profit | | | 2,786 | | | | 2,728 | |

| | | | | | | | |

Expenses | | | | | | | | |

Selling | | | 1,899 | | | | 1,902 | |

General and administrative | | | 102 | | | | 112 | |

Earnings from associates and joint ventures | | | (6 | ) | | | (5 | ) |

Other income | | | (26 | ) | | | (60 | ) |

| | | | | | | | |

EBIT | | | 817 | | | | 779 | |

| | | | | | | | |

EBITDA | | | 1,091 | | | | 1,033 | |

EBITDA to sales(%) | | | 9 | | | | 8 | |

Selling expense to sales(%) | | | 16 | | | | 16 | |

Cash operating coverage ratio(%) | | | 61 | | | | 62 | |

Comparable store sales(%) | | | (5 | ) | | | (7 | ) |

Normalized comparable store sales(%) | | | 2 | | | | (3 | ) |

Averagenon-cash working capital to sales(%) | | | 17 | | | | 18 | |

Non-cash working capital | | | 1,528 | | | | 2,044 | |

| | | | | | | | |

| ● | | As a result of significantly lower crop nutrient prices in 2016, Retail total sales were down year-over-year. The reduction in sales was offset by lower cost of product sold, leading to slightly higher gross profit in 2016. The improvement in gross profit and EBITDA were supported by cost reduction initiatives and a higher-margin product mix in 2016. |

| ● | | North American Retail earnings were up slightly from 2015 levels. However, good growing conditions, lower crop prices and a lack of pest pressure during the summer growing period in the U.S. adversely impacted demand for crop protection products in the third quarter of 2016. Canadian operations were also impacted by an early winter, reducing nutrient applications in that region in the second half of the year. |

| ● | | International Retail segment reported a further improvement in EBITDA in 2016, partly due to good growing conditions in Australia and South America and an improved political environment in Argentina. Australia reported a record annual EBITDA in 2016. |

| ● | | Excluding earnings from acquisitions made in 2016, Retail reported EBITDA growth of 6 percent over 2015. EBITDA to sales also increased by one percentage point, supported by cost saving measures and higher-margin proprietary product growth. |

AGRIUM ANNUAL REPORT 2016 | 17

RETAIL >> EXPENSES

| ● | | Retail selling expenses in 2016 and selling expenses as a percentage of sales both stayed relatively consistent with 2015 levels. Retail also reduced general and administrative costs by$10-million. Cash selling and general and administrative expenses were approximately$70-million lower than 2015 after adjusting for acquisitions made during 2016. The reduction in costs was largely a result of Operational Excellence initiatives on cost control, including optimization of our distribution network. |

| ● | | Our cash operating coverage ratio improved by one percentage point this year as a result of the reduction in total selling and general and administrative costs and higher gross profit in 2016. |

| ● | | Depreciation and amortization increased to$274-million in 2016 from$254-million in 2015 due to ongoing sustaining capital expenditures at existing facilities as well as additional property, equipment and intangibles associated with acquisitions made in recent years. |

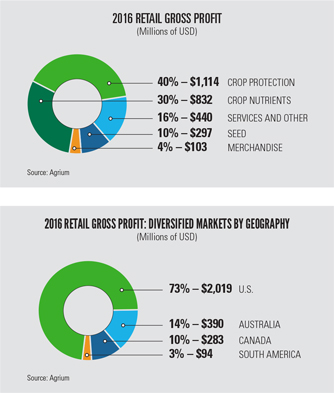

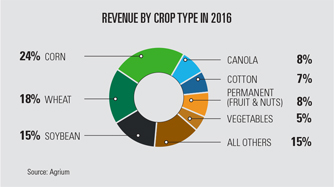

RETAIL >> PRODUCT LINE PERFORMANCE

Product line performance

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | Sales | | | Gross profit | | | Gross profit (%) | |

(millions of U.S. dollars, except as noted) | | 2016 | | | 2015 | | | 2016 | | | 2015 | | | 2016 | | | 2015 | |

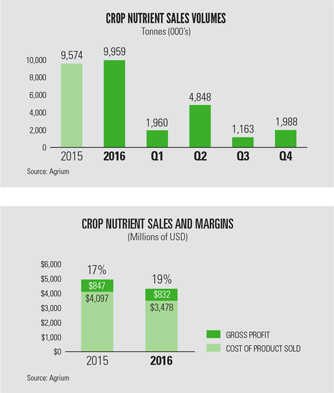

Crop nutrients | | | 4,310 | | | | 4,944 | | | | 832 | | | | 847 | | | | 19 | | | | 17 | |

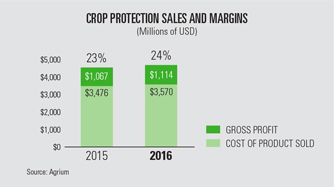

Crop protection products | | | 4,684 | | | | 4,543 | | | | 1,114 | | | | 1,067 | | | | 24 | | | | 23 | |

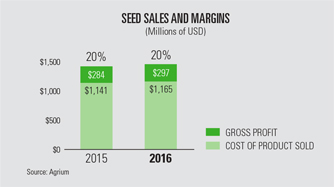

Seed | | | 1,462 | | | | 1,425 | | | | 297 | | | | 284 | | | | 20 | | | | 20 | |

Merchandise | | | 621 | | | | 638 | | | | 103 | | | | 99 | | | | 17 | | | | 16 | |

Services and other | | | 689 | | | | 649 | | | | 440 | | | | 431 | | | | 64 | | | | 66 | |

| | | | | | | | | | | | | | | | | | | | | | | | |

Total | | | 11,766 | | | | 12,199 | | | | 2,786 | | | | 2,728 | | | | 24 | | | | 22 | |

| | | | | | | | | | | | | | | | | | | | | | | | |

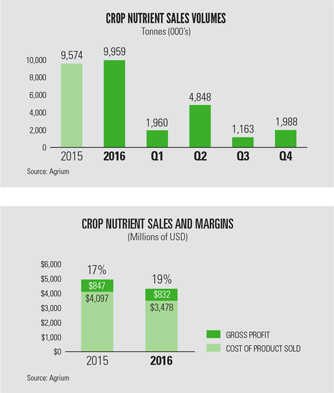

Crop Nutrients: Financial Results

| ● | | Our crop nutrient sales decreased in 2016 due to significantly lower global nutrient prices compared to 2015. Total nutrient sales volumes were higher this year at 9.9 million tonnes compared to 9.6 million tonnes in 2015. The increase in volumes was due to stronger sales in our International segment and higher tonnes in the U.S. resulting from acquisitions made during the year. In Canada, a significant acreage shift towards pulse crops (which require no nitrogen) and adverse weather conditions reduced ammonia sales volumes during the fall application season. |

| ● | | Gross profit decreased in 2016 as the increase in sales volumes was not sufficient to offset the impact of significantly lower fertilizer benchmark prices on gross profit per tonne. Our realized sales price per tonne declined by $83 in 2016; however, we were able to maintain gross profit per tonne, which dropped by only $5 per tonne. |

| ● | | Sales of our proprietary crop nutrient products were slightly higher than 2015 levels and increased as a percentage of total crop nutrient sales by one percentage point to 8 percent. This product line helped support Agrium’s overall crop nutrient margins again in 2016, and we remain focused on growing volumes of this high value-added product line. |

18 | ANNUAL REPORT 2016AGRIUM

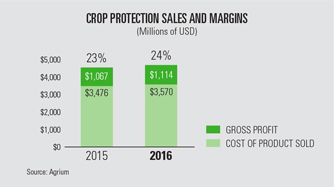

Crop Protection Products: Financial Results

| ● | | Our crop protection product line reported a record gross profit and gross profit as a percentage of sales in 2016. This was due to both stronger proprietary product sales again this year and higher International sales, despite weakness in U.S. demand for fungicides and insecticides this summer due to a combination of low pest pressure and low grain prices. |

| ● | | Favorable growing conditions and an improved political environment in Argentina heightened demand for crop protection products in our International and Canadian Retail operations in 2016. |

| ● | | Our proprietary crop protection products accounted for 24 percent of our total crop protection product sales, compared to approximately 22 percent in 2015. Sales growth for our proprietary crop protection products rose 12 percent over last year and continued to represent the largest portion of our total proprietary product offering, primarily under the Loveland Products®brand. |

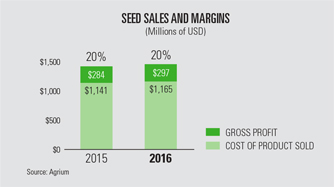

Seed: Financial Results

| ● | | Seed sales increased 3 percent in 2016, driven primarily by higher total acres planted in the U.S. and stronger sales in our International segment. Results were also supported by a shift in the U.S. in 2016 to more corn and cotton acres, which have higher margins than other row crops. Strong volumes of our proprietary seed sales and increased sales of treated seeds also supported seed margins. As a result, seed gross profit increased by$13-million in 2016. Gross profit as a percentage of sales was flat compared to 2015. |

| ● | | In 2016, Agrium’s proprietary seed sales were flat compared to 2015 levels. Sales of proprietary seeds as a percentage of total seed sales decreased slightly to 22 percent in 2016 from 23 percent in 2015. In the U.S., ourDyna-Gro®brand increased sales by 4 percent, in line with an increase in overall U.S. corn acreage in 2016. Total sales for this product group were impacted partially by a decline in our Proven®proprietary canola seed this year as a result of the significant shift by Canadian growers out of canola and cereals and into pulse crops. |

Merchandise: Financial Results

| ● | | Merchandise sales decreased by 3 percent in 2016 due primarily to lower fuel prices in our Canadian fuel business. |

| ● | | Merchandise gross profit increased by$4-million or 4 percent in 2016, while gross profit as a percentage of sales increased by one percentage point in 2016. The higher margins this year reflect a higher proportion of sales in our higher-marginag-equipment business compared to our lower-margin fuel business. |

AGRIUM ANNUAL REPORT 2016 | 19

Services and Other: Financial Results

| ● | | Sales of services and other were up 6 percent in 2016 – a result of stronger demand for application and other services in the U.S. during the fall application season and in our International Retail segment, where the stronger demand was related to increased livestock marketing in Australia. |

| ● | | Gross profit was up$9-million this year, while gross profit as a percentage of sales decreased by 2 percent to 64 percent in 2016. |

| ● | | Financial results for our newly formed financial services segment were not material in 2016, although we anticipate these to increase over time. |

Regional performance

| | | | | | | | | | | | | | | | |

| | | 2016 | | | 2015 | |

(millions of U.S. dollars, except as noted) | | North America | | | International | | | North America | | | International | |

Sales | | | 9,608 | | | | 2,158 | | | | 10,124 | | | | 2,075 | |

Cost of product sold | | | 7,306 | | | | 1,674 | | | | 7,826 | | | | 1,645 | |

| | | | | | | | | | | | | | | | |

Gross profit | | | 2,302 | | | | 484 | | | | 2,298 | | | | 430 | |

Gross profit (%) | | | 24 | | | | 22 | | | | 23 | | | | 21 | |

| | | | | | | | | | | | | | | | |

Expenses | | | | | | | | | | | | | | | | |

Selling | | | 1,555 | | | | 344 | | | | 1,571 | | | | 331 | |

General and administrative | | | 72 | | | | 30 | | | | 79 | | | | 33 | |

Earnings from associates and joint ventures | | | (4 | ) | | | (2 | ) | | | (3 | ) | | | (2 | ) |

Other expense (income) | | | 3 | | | | (29 | ) | | | (35 | ) | | | (25 | ) |

| | | | | | | | | | | | | | | | |

EBIT | | | 676 | | | | 141 | | | | 686 | | | | 93 | |

EBITDA | | | 925 | | | | 166 | | | | 915 | | | | 118 | |

| | | | | | | | | | | | | | | | |

| ● | | On a regional basis, we demonstrated improvement in EBITDA across all our key countries and regions. Lower global fertilizer prices led to a decline in North America Retail sales in 2016. However, EBITDA increased due to Operational Excellence initiatives, including proprietary product growth and acquisitions made in 2016. Canada experienced a weather-delayed harvest in the second half of 2016, which negatively impacted ammonia application and services. |

| ● | | International Retail demonstrated improvement in earnings across all product lines as a result of favorable growing conditions, Operational Excellence results and increased proprietary product sales in both Australia and South America as well as an improved political environment in Argentina. Australia achieved record EBITDA of$122-million in 2016. |

20 | ANNUAL REPORT 2016AGRIUM

RETAIL >> QUARTERLY RESULTS

| ● | | Our Retail business is seasonal. The most important quarter is the second quarter, which includes the spring application and planting season in North America and the early fall application season that precedes the winter wheat seeding season in Australia. |

| ● | | The U.S. experienced an early spring in 2016, which pulled some nutrient volumes and applications into the first quarter. Western Canada’s first half nutrient volumes were lower than the previous year due to higher pulse crop acreage. |

| ● | | The third and fourth quarters of 2016 saw a normal fall nutrient application for the U.S. but weak demand for crop protection products, particularly fungicides, in the third quarter due to lower-than-normal pest pressure and lower crop prices. Western Canada experienced wet weather during the 2016 harvest season and an early winter, impacting nutrient applications that we expect will be largely made up for in the spring of 2017. |

Retail quarterly results

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | 2016 | | | 2015 | |

(millions of U.S. dollars, except as noted) | | Q4 | | | Q3 | | | Q2 | | | Q1 | | | Q4 | | | Q3 | | | Q2 | | | Q1 | |

Sales – North America | | | 1,344 | | | | 1,406 | | | | 5,049 | | | | 1,809 | | | | 1,340 | | | | 1,587 | | | | 5,421 | | | | 1,776 | |

Sales – International | | | 484 | | | | 451 | | | | 742 | | | | 481 | | | | 425 | | | | 424 | | | | 739 | | | | 487 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Total sales | | | 1,828 | | | | 1,857 | | | | 5,791 | | | | 2,290 | | | | 1,765 | | | | 2,011 | | | | 6,160 | | | | 2,263 | |

Cost of product sold | | | 1,205 | | | | 1,375 | | | | 4,512 | | | | 1,888 | | | | 1,166 | | | | 1,517 | | | | 4,896 | | | | 1,892 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Gross profit | | | 623 | | | | 482 | | | | 1,279 | | | | 402 | | | | 599 | | | | 494 | | | | 1,264 | | | | 371 | |

Gross profit (%) | | | 34 | | | | 26 | | | | 22 | | | | 18 | | | | 34 | | | | 25 | | | | 21 | | | | 16 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Gross profit by product | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Crop nutrients | | | 147 | | | | 118 | | | | 433 | | | | 134 | | | | 154 | | | | 113 | | | | 454 | | | | 126 | |

Crop protection products | | | 296 | | | | 226 | | | | 471 | | | | 121 | | | | 268 | | | | 234 | | | | 457 | | | | 108 | |

Seed | | | 43 | | | | 22 | | | | 181 | | | | 51 | | | | 54 | | | | 26 | | | | 164 | | | | 40 | |

Merchandise | | | 27 | | | | 29 | | | | 28 | | | | 19 | | | | 27 | | | | 25 | | | | 27 | | | | 20 | |

Services and other | | | 110 | | | | 87 | | | | 166 | | | | 77 | | | | 96 | | | | 96 | | | | 162 | | | | 77 | |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

EBIT | | | 134 | | | | 30 | | | | 676 | | | | (23 | ) | | | 133 | | | | 64 | | | | 647 | | | | (65 | ) |

EBITDA | | | 202 | | | | 101 | | | | 744 | | | | 44 | | | | 199 | | | | 129 | | | | 713 | | | | (8 | ) |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

Total Retail | | 2016 | | | 2015 | |

(in percentages) | | Dec 31 | | | Sept 30 | | | June 30 | | | March 31 | | | Dec 31 | | | Sept 30 | | | June 30 | | | March 31 | |

Averagenon-cash working capital to sales(a) | | | 17 | | | | 18 | | | | 18 | | | | 18 | | | | 18 | | | | 18 | | | | 18 | | | | 18 | |

Cash operating coverage ratio(a) | | | 61 | | | | 61 | | | | 60 | | | | 61 | | | | 62 | | | | 63 | | | | 64 | | | | 62 | |

EBITDA to sales(a) | | | 9 | | | | 9 | | | | 9 | | | | 9 | | | | 8 | | | | 8 | | | | 8 | | | | 8 | |

Comparable store sales(b) | | | (5 | ) | | | | | | | (5 | ) | | | | | | | (7 | ) | | | | | | | (4 | ) | | | | |

Normalized comparable store sales(b) | | | 2 | | | | | | | | 2 | | | | | | | | (3 | ) | | | | | | | (1 | ) | | | | |

Retail – North America(a) | | 2016 | | | 2015 | |

(in percentages) | | Dec 31 | | | Sept 30 | | | June 30 | | | March 31 | | | Dec 31 | | | Sept 30 | | | June 30 | | | March 31 | |

EBITDA to sales | | | 10 | | | | 10 | | | | 10 | | | | 9 | | | | 9 | | | | 9 | | | | 9 | | | | 9 | |

| (a) | These measures are based on rolling four quarters ended. |

| (b) | These measures are based on six months ended for June 30 results and 12 months ended for December 31 results. |

AGRIUM ANNUAL REPORT 2016 | 21

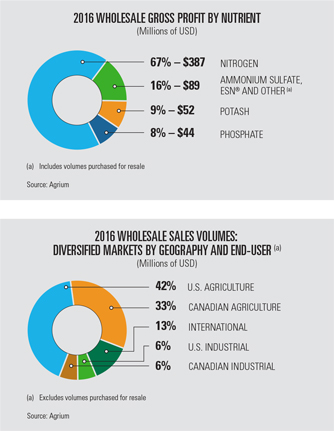

Wholesale Overview and 2016 Results

Agrium’s Wholesale business unit produces and markets all three major crop nutrients, which are essential for farmers to optimize crop yields and quality. With a combined global production capacity of approximately 11 million product tonnes and significant competitive advantages across our product lines, we are one of the largest manufacturers of fertilizer in the world. We strive to produce, distribute and use these products as efficiently, safely and sustainably as possible for the benefit of our customers and other stakeholders and to make a significant contribution to improving the security of the world’s food supply. Wholesale completed construction of a610,000-tonne urea plant at our Borger, Texas, facility in late 2016 and continues to ramp up production at our potash mine following the expansion project completed in 2015.

Our Wholesale operations include nine nitrogen, one potash and two phosphate production facilities and four other facilities across North America. We also have significant equity interests in nitrogen facilities in Argentina and Egypt. In total, our nitrogen capacity is almost six million product tonnes, our potash capacity is three million tonnes and our phosphate capacity is over one million tonnes. We also have over one million tonnes of capacity for upgrading and production of other nutrients such as Environmentally Smart Nitrogen (ESN®) and ammonium sulfate. One key Wholesale advantage is that the majority of our production and distribution capability is located close to ourend-markets, allowing us to benefit from lower freight costs and, hence, higher margins.

Additional benefits stem from Agrium’s position as the largest agricultural retail distribution business in North America, allowing us to realize meaningful logistical and utilization synergies. Our nitrogen facilities have access to some of the lowest cost natural gas globally due to their locations in Alberta, Canada and the U.S. Our potash reserves in Saskatchewan, Canada, represent some of the highest quality and lowest cost reserves in the world. For our phosphate products, we benefit from anin-market transportation advantage and a competitive cost position in sulfur and ammonia, which is partly offset by slightly higher rock costs.

22 | ANNUAL REPORT 2016AGRIUM

PRODUCTS AND SERVICES

Growers use the following three critical crop nutrients to help restore soil nutrient balance and enhance crop yields and quality.

| | | | | | | | | | |

| |  | |  |

| NITROGEN | | POTASH | | PHOSPHATE |

|

| Role of nutrient |

| | |

| Improves crop growth, yield and protein levels | | Regulates plant growth processes and helps protect crops from drought and disease | | Stimulates root development and flowering and encourages early crop development |

|

| Our products |

| | |

| Ammonia, urea, urea ammonium nitrate (UAN) solutions, ammonium nitrate | | Muriate of potash (MOP or “potash”) | | Monoammonium phosphate (MAP), superphosphoric acid (SPA) products |

|

| Our advantages |

| | | | | |

| ● | | Overall low North American natural gas prices and a further Western Canadian AECO gas advantage relative to NYMEX | | ● | | World-scale, high-quality andlow-cost advantage | | ● | | Competitive cost position for sulfur and ammonia |

● | | Facilities located near keyend-markets in the Americas and Europe | | ● | | High historical operating rate due to integration with Retail and a balanced geographic sales mix | | ● | | In-market freight advantage |

| | | | | ● | | Integrated Conda rock supply |

● | | Retail distribution network in Western Canada and Northern Plains allowing product to be placed in higher netback markets | | ● | | Capacity expansion drives lower cost of manufacturing | | ● | | Retail distribution network in Western Canada and Northern Plains allowing product to be placed in higher netback markets |

| | | ● | | Partner in a major international marketing and logistics company (Canpotex) | | | |

| | | | | | | | |

| | |

| |  | |  |

AGRIUM ANNUAL REPORT 2016 | 23

Nitrogen [N] Products

Nitrogen – the most important crop nutrient in terms of global use and trade – represents approximately 60 percent of the total volume of crop nutrients used globally. It is also the crop nutrient for which reduced application rates within a growing season are most likely to immediately and adversely impact yield for most crops. For Agrium, nitrogen is the most important nutrient in terms of capacity, production and sales. It represents close to 60 percent of our nutrient capacity. Natural gas is the primary input for producing ammonia – the base for virtually all nitrogen products. Ammonia can be applied directly as a fertilizer or upgraded to products such as urea, UAN solutions and ammonium nitrate.

Agrium owns and operates five major nitrogen production facilities in North America and has a 50 percent joint venture interest in Profertil S.A. (“Profertil”), which owns a South American nitrogen facility. We also own four facilities in North America that upgrade ammonia to other nitrogen products such as UAN and nitric acid. These facilities have a combined annual nitrogen production capacity of approximately 5.2 million tonnes. Agrium also has a 26 percent equity ownership position in Misr Fertilizers Production Company S.A.E. (“MOPCO”), which has a total annual production capacity of approximately two million tonnes of urea (of which over 500,000 tonnes are attributable to Agrium through our equity position). This puts our global nitrogen capacity at approximately 5.7 million tonnes, placing Agrium among the world’s top five publicly traded nitrogen producers.

Our extensive North American nitrogen facilities benefit from the development of long-term,low-cost,non-conventional (shale) natural gas, which has positioned North America – and Alberta in particular – among the lowest-cost gas and nitrogen producing regions in the world. Most of our facilities are located in Alberta, which has historically enjoyed a significant natural gas price discount relative to NYMEX. Furthermore, Agrium’s numerous production facilities and ability to leverage our extensive North American Retail distribution operations to optimize operating rates and margins by placing greater tonnes through these distribution channels are key competitive advantages. Much of our nitrogen and phosphate product volumes are supplied to our core markets in Western Canada and the U.S. Pacific Northwest, where we obtain more attractive netbacks due to logistical efficiencies. Profertil’s nitrogen facility benefits from similarin-market advantages related to its position in Argentina’s large domestic fertilizer market. The MOPCO Egyptian facility benefits from its proximity to tidewater for international exports.

In 2016, approximately 77 percent of our North American nitrogen sales were directed to agricultural markets, with the remaining 23 percent sold to industrial customers. Agricultural customer demand is seasonal, while industrial demand is more evenly distributed throughout the year. As a result, our average sales price for ammonia in a given quarter will be influenced by the relative weighting of sales to industrial customers compared to sales to the generally higher-return agricultural markets. A high proportion of our industrial ammonia sales are priced on a gas index-plus margin basis, thereby contributing to stability in sales and earnings throughout the year. Industrial ammonia sales volumes were approximately 476,000 tonnes in 2016, compared to 513,000 tonnes in 2015. The startup of the new urea facility at Borger is expected to further expand our urea industrial sales in 2017, as up to 100,000 tonnes of the new urea production can be converted to liquid diesel exhaust fluid (DEF) and sold into the diesel emission fuel-grade urea market. DEF is used to reduce smog-related nitrogen oxide emissions in diesel vehicles.

Potash [K] Products

Global potash deposits are highly concentrated in only a few specific regions of the globe. The world’s largest known potash deposits are located in Saskatchewan, Canada; and accounted for approximately 35 percent of the global potash trade in 2016. Agrium produces potash at our facility in Vanscoy, Saskatchewan, and exports international sales through our interest in Canpotex – an industry association owned by the three major Canadian potash producers and tasked with marketing potash sold outside of Canada and the U.S. Our share of Canpotex total sales was 10.3 percent in 2016 and averaged 7.3 percent in 2015. The increase resulted from the completion of Agrium’s one million tonne capacity expansion and the Canpotex proving run in 2015.

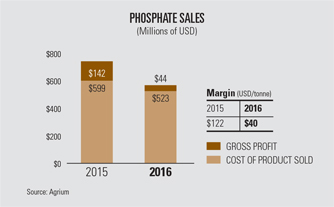

Phosphate [P] Products

Together, Agrium’s two phosphate facilities have the capacity to produce approximately 1.2 million tonnes of phosphate-based fertilizer products annually. At our facility in Conda, Idaho, we produce MAP, SPA and merchant grade phosphoric acid (MGA) products, which are sold primarily in the Northwestern U.S. Our Redwater, Alberta, facility – the only phosphate production site in Canada – produces MAP primarily for distribution in Western Canada.

Three primary raw materials are required to produce granular ammonium phosphates: phosphate rock, sulfur and ammonia. Our Conda, Idaho, facility obtains rock from our associated mines in the region. Recently, a new open pit phosphate mine in the Rasmussen Valley area near our Conda operations has been approved by the U.S. government’s Bureau of Land Management. There were no further updates to the Rasmussen Valley reserve estimate, therefore the final 2014 estimate of 10.1 million tonnes remains in place. Our Redwater, Alberta, facility sources rock primarily from a supply agreement with OCP S.A. (“OCP”). This agreement covers rock supply through 2018, with purchase prices based on a formula derived from the global price of finished phosphate products. The agreement enables Agrium to continue to benefit from our Redwater phosphate facility’s competitive local sulfur and integrated ammonia cost positions as well as ourin-market logistical advantage in Western Canada.

Our Conda facility has major advantages from sourcing sulfur and sulfuric acid domestically while obtaining the majority of its ammonia from our Alberta nitrogen facilities at production cost plus freight expenses. An additional competitive strength is our transportation cost advantage for local customers in Western Canada and the Western U.S. relative to the major phosphate producers based in Florida.

24 | ANNUAL REPORT 2016AGRIUM

WHOLESALE GLOBAL OPERATIONS — NORTH AMERICA, ARGENTINA, EUROPE AND EGYPT

AGRIUM ANNUAL REPORT 2016 | 25

Ammonium sulfate, Environmentally Smart Nitrogen (ESN®) and Other Wholesale products

Our Other Wholesale products primarily comprise ammonium sulfate products produced in Western Canada, ESN® and product purchased for resale. Ammonium sulfate fertilizer contains both nitrogen and sulfur, resulting in one of the most effective methods of supplying sulfur to soils in an immediately available form. Agrium produces ammonium sulfate at our Redwater facility, where we have competitive advantages fromin-market selling price premiums and logistical advantages as well as lower-priced sulfur, which is a byproduct from the oil and gas industry. ESN® is a leading controlled-release nitrogen fertilizer product providing growers with significant economic and environmental benefits. This patented coated-fertilizer product allows for more efficient delivery of the nitrogen to the plant while it grows based on soil moisture and temperature characteristics. By delivering nitrogen when the plant needs it most, this advanced product can significantly reduce the risk of nitrogen loss to the air and water. Agrium operates two facilities that upgrade urea to ESN® – one in Western Canada and one in the Southern U.S.

Our Rainbow® Plant Food (“Rainbow”) operations manufacture compound nitrogen, phosphate and potash (NPK) products in the Southeastern U.S. The Rainbow product line offers homogeneous distribution of NPK products, with a specific combination of nutrients and additional micronutrients contained in each granule.

In addition to selling our manufactured products, our Wholesale business unit purchases crop nutrient products from other suppliers for resale to customers primarily in Europe. This product purchased for resale business enables us to leverage our distribution and marketing network beyond what is possible through the sale of our manufactured products alone.

26 | ANNUAL REPORT 2016AGRIUM

Wholesale Distribution and Storage

Wholesale has an extensive transportation, storage and warehousing network to optimize deliverability of product to our agricultural customers in the highly seasonal peak demand periods. In total, our global distribution and storage capacity amounts to approximately 2.2 million tonnes. This is in addition to the extensive distribution and warehousing available through our Retail business and, in some cases, warehousing facilities shared between the business units. We have more than 5,200 railcars under long-term operating leases. We also use barges, pipelines and ocean vessels to transport our products. Agrium Europe owns and leases approximately 215,000 tonnes of dry and liquid storage capacity at both port and inland sites.

2016 Wholesale capacity, production and sales

| | | | | | | | | | | | |

(thousands of metric product tonnes) | | Capacity (a) | | | Production (a)(b) | | | Sales (c) | |

Nitrogen volumes | | | | | | | | | | | | |

North America | | | | | | | | | | | | |

Canada | | | 3,459 | | | | 2,879 | | | | 1,862 | |

U.S. | | | 1,090 | | | | 772 | | | | 1,740 | |

| | | | | | | | | | | | |

Total nitrogen | | | 4,549 | | | | 3,651 | | | | 3,602 | |

| | | | | | | | | | | | |

Potash volumes(f) | | | | | | | | | | | | |

North America | | | | | | | | | | | | |

Canada | | | 3,024 | | | | 2,171 | | | | 164 | |

U.S. | | | | | | | | | | | 1,023 | |

International | | | | | | | | | | | 1,052 | |

| | | | | | | | | | | | |

Total potash | | | 3,024 | | | | 2,171 | | | | 2,239 | |

| | | | | | | | | | | | |

Phosphate volumes | | | | | | | | | | | | |

North America | | | | | | | | | | | | |

Canada | | | 660 | | | | 637 | | | | 606 | |

U.S. | | | 510 | | | | 520 | | | | 502 | |

| | | | | | | | | | | | |

Total phosphate | | | 1,170 | | | | 1,157 | | | | 1,106 | |

| | | | | | | | | | | | |

Ammonium sulfate, ESN® and other volumes | | | | | | | | | | | | |

North America | | | | | | | | | | | | |

Canada | | | 546 | | | | 533 | | | | 521 | |

U.S. | | | 559 | | | | 411 | | | | 514 | |

| | | | | | | | | | | | |

Total ammonium sulfate, ESN® and other | | | 1,105 | | | | 944 | | | | 1,035 | |

| | | | | | | | | | | | |

Total produced product | | | 9,848 | | | | 7,923 | | | | 7,982 | |

| | | | | | | | | | | | |

Product purchased for resale volumes(d) | | | | | | | | | | | | |

North America | | | | | | | | | | | | |

U.S. | | | | | | | | | | | 121 | |

International | | | | | | | | | | | 624 | |

| | | | | | | | | | | | |

Total product purchased for resale | | | | | | | | | | | 745 | |

| | | | | | | | | | | | |

Total Wholesale | | | 9,848 | | | | 7,923 | | | | 8,727 | |

| | | | | | | | | | | | |

Wholesale equity accounted joint ventures: | | | | | | | | | | | | |

International nitrogen(e) | | | 687 | | | | 587 | | | | 669 | |

| | | | | | | | | | | | |

| (a) | SPA and MGA are reported at 100 percent nutrient basis. |

| (b) | Production, net of transfers, except where noted. |

| (c) | Sales represent country of sales destination, not country of production. |

| (d) | Product purchased for resale includes sales of all the major crop nutrient products. |

| (e) | Primarily represents our 50 percent joint venture interest in the capacity of Profertil, which is accounted for using the equity method. |

| (f) | Potash is reported at gross (40 tonnes of product was consumed at Rainbow facilities). |

AGRIUM ANNUAL REPORT 2016 | 27

WHOLESALE >> KEY DEVELOPMENTS

| ● | | In 2016, Wholesale successfully executed on its Operational Excellence objectives including completion of its major growth projects. We successfully completed construction of our Borger urea facility as planned and continued theramp-up of production at our recently expanded Vanscoy potash facility. We also made great strides in reducing fixed costs across the business unit while continuing to improve the reliability, operating rates, and safety and environmental measures of our facilities. |

Operational Excellence

| ● | | In 2016, Wholesale achieved a total of$66-million in cost savings – largely the result of a fixed cost review that commenced inmid-2016. This involved a systematic review of all costs at each facility and the baseline requirements of the business. This evaluation is ongoing and was expanded to cover manpower costs in late 2016. |

| ● | | Continuing to optimize our capacity utilization rate at our production facilities was another major focus in 2016. We achieved 95 percent capacity utilization for ammonia production and 96 percent for phosphoric acid in 2016 – a one to two percentage point improvement over 2015 levels for both product categories. However, for potash and, to a lesser extent, ammonia, we were below our 2016 target levels. |

| ● | | Wholesale implemented further environmental, health and safety processes through our Commitment to Zero program in 2016; however, we regretfully experienced two fatalities at our production operations. We are committed to achieving an incident-free workplace and have taken numerous further steps and process reviews to create and perpetuate a much stronger culture of safety. |

Focused Growth

| ● | | The Vanscoy potash expansion project was completed in 2014, with the facility expected to reach full operating production potential in 2017. Our focus in 2016 was the continuedramp-up of production at the facility, with target production for 2016 of approximately 80 percent of nameplate capacity, or approximately 2.4 million tonnes. Our actual production was 2.2 million tonnes in 2016, with production impacted by a turnaround to address certain post-expansion deficiencies. We expect to further ramp up capacity utilization rates at the facility in 2017. |

| ● | | Cash cost of product manufactured per tonne continued to decrease at the Vanscoy facility as we ramped up additional production and benefited from the weakening Canadian dollar. We expect to see further reductions in the cash cost of product manufactured per tonne as the facility moves closer to full production levels. |

| ● | | The construction of the610,000-tonne urea plant at our Borger facility was successfully completed at the end of 2016. Commissioning of the plant has started, with production expected in the first quarter of 2017. The construction was completed on time and on budget, as per the revised project scope announced inmid-2015. |

28 | ANNUAL REPORT 2016AGRIUM

WHOLESALE >> FINANCIAL RESULTS

Wholesale performance

| | | | | | | | |

(millions of U.S. dollars) | | 2016 | | | 2015 | |

Sales | | | 2,706 | | | | 3,602 | |

Cost of product sold | | | 2,134 | | | | 2,421 | |

| | | | | | | | |

Gross profit | | | 572 | | | | 1,181 | |

| | | | | | | | |

Expenses | | | | | | | | |

Selling | | | 32 | | | | 36 | |

General and administrative | | | 30 | | | | 39 | |

(Earnings) loss from associates and joint ventures | | | (61 | ) | | | 10 | |

Other expenses | | | 62 | | | | 23 | |

| | | | | | | | |

EBIT | | | 509 | | | | 1,073 | |

| | | | | | | | |

EBITDA | | | 751 | | | | 1,284 | |

| | | | | | | | |

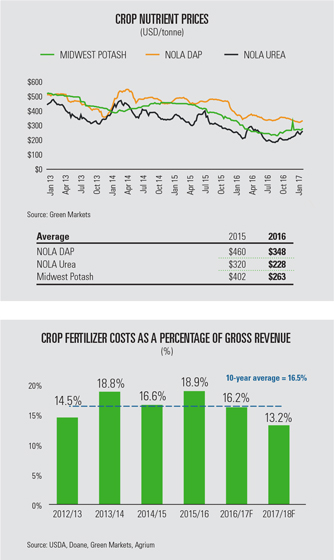

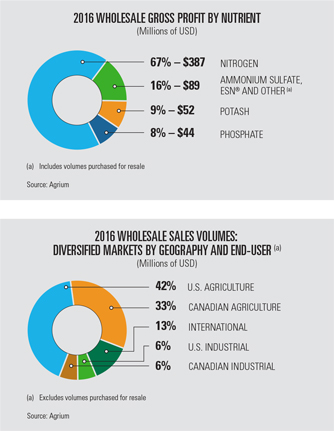

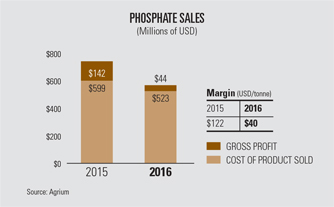

Wholesale gross profit in 2016 was lower than the previous year due to the significant decline in global nutrient prices this year. The resulting decline in sales was partly offset by a reduction in our cost of production across all nutrients and higher potash sales volumes this year.

| ● | | Cost of product sold was lower compared to 2015 due to lower natural gas and other input costs, improved operating rates and efficiencies at our nitrogen and phosphate facilities, and the further weakening of the Canadian dollar. |

| ● | | Total Wholesale expenses in 2016 were lower than in 2015, with selling and general and administrative costs benefiting from the fixed cost review we conducted in 2016. We realized higher earnings from associates and joint ventures in 2016, which pertain to our interests in the nitrogen facilities in Egypt and Argentina and are accounted for in expenses. Our 26 percent interest in MOPCO reported$35-million, net of tax, in equity earnings in 2016 compared to a$5-million equity loss in 2015. The improvement in earnings was primarily a result of the Egyptian pound devaluation in the fourth quarter of 2016, and partly due to higher production from the expanded facilities. Our 50 percent interest in Profertil reported a$26-million equity gain in 2016 compared to a$5-million equity loss in 2015 due to improved economic conditions in Argentina and$21-million reversal of a gas tariff provision. |

| ● | | Other expenses were higher in 2016, due to the benefit of the recognized gains of$55-million in 2015 that resulted from the sale of our West Sacramento andnon-core Purchase for Resale terminals. |

AGRIUM ANNUAL REPORT 2016 | 29

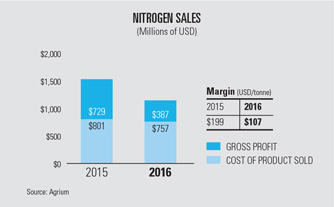

NITROGEN >> FINANCIAL RESULTS

Nitrogen performance

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | 2016 | | | 2015 | |

(millions of U.S. dollars, except as noted) | | Consolidated | | | Equity

accounted

joint ventures | | | Total (a) | | | Consolidated | | | Equity

accounted

joint ventures | | | Total (a) | |

Sales | | | 1,144 | | | | 196 | | | | 1,340 | | | | 1,530 | | | | 194 | | | | 1,724 | |

Cost of product sold | | | 757 | | | | 164 | | | | 921 | | | | 801 | | | | 178 | | | | 979 | |

| | | | | | | | | | | | | | | | | | | | | | | | |

Gross profit | | | 387 | | | | 32 | | | | 419 | | | | 729 | | | | 16 | | | | 745 | |

| | | | | | | | | | | | | | | | | | | | | | | | |

| (a) | Wholesale measures including share of joint ventures. |

Nitrogen performance

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| | | 2016 | | | 2015 | |

| | | Ammonia | | | Urea | | | Other | | | Total | | | Ammonia | | | Urea | | | Other | | | Total | |

Tonnes sold (‘000) | | | 1,165 | | | | 1,620 | | | | 817 | | | | 3,602 | | | | 1,209 | | | | 1,583 | | | | 864 | | | | 3,656 | |

Selling price per tonne (U.S. dollars) | | | 402 | | | | 294 | | | | 244 | | | | 318 | | | | 530 | | | | 395 | | | | 305 | | | | 418 | |

Cost of product sold per tonne (U.S. dollars) | | | | | | | | | | | | | | | 211 | | | | | | | | | | | | | | | | 219 | |

Margin per tonne (U.S. dollars) | | | | | | | | | | | | | | | 107 | | | | | | | | | | | | | | | | 199 | |

Tonnes produced(a) (‘000) | | | 2,720 | | | | 1,895 | | | | | | | | | | | | 2,653 | | | | 1,780 | | | | | | | | | |

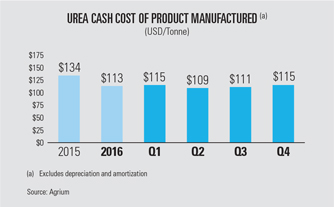

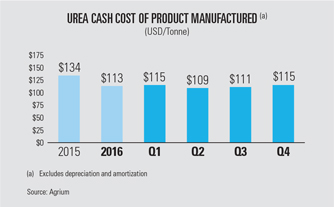

Cash COPM per tonne (U.S. dollars) | | | 130 | | | | 113 | | | | | | | | | | | | 145 | | | | 134 | | | | | | | | | |

Capacity utilization(b) (%) (2016 Target: 98%) | | | 95 | | | | | | | | | | | | | | | | 94 | | | | | | | | | | | | | |

| (a) | Gross production, before transfers. |

| (b) | Excludes results from Joffre nitrogen facility. As of January 1, 2016, ammonia capacity has been adjusted for normal outages and planned maintenance, with prior period comparative figures restated. |

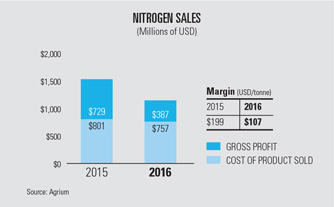

Nitrogen gross profit

| ● | | Nitrogen gross profit decreased by 47 percent in 2016 due to significantly lower realized selling prices, which were only partially offset by lower cost of product sold. |

Nitrogen sales volumes and operating rates

| ● | | Our nitrogen product category primarily consists of urea, ammonia, UAN and industrial-grade ammonium nitrate. Urea is the highest volume nitrogen product sold globally and accounted for 45 percent of Agrium’s nitrogen sales in 2016. |

| ● | | Agrium improved its nitrogen operating rates in 2016, with ammonia capacity utilization of 95 percent in 2016 compared to 94 percent in 2015. The improvement reflects our continued focus on reliability of the plants and steps we have taken to increase operational performance. However, the 2016 rate was still below our target of 98 percent capacity utilization. |

Nitrogen prices

| ● | | The 24 percent decrease in average realized nitrogen selling price per tonne reflects lower benchmark nitrogen prices throughout 2016. Benchmark prices for international urea and North American ammonia and UAN solutions were down between 25 and 40 percent in 2016 compared to 2015. |

Nitrogen product and gas cost

| ● | | The decrease in cost of product sold was due to lower average natural gas costs in 2016 as well as our focus on cost reduction and the further weakening of the Canadian dollar during the year. Our average natural gas costs declined by 15 percent in 2016 compared to 2015. |

| ● | | Production asset depreciation and amortization expense of $22 per tonne in 2016 (compared to $19 per tonne in 2015) is included in cost of product sold. |

30 | ANNUAL REPORT 2016AGRIUM

| ● | | In February 2017 we entered into additional natural gas hedge positions for the next three years under our existing long-term hedge program. As a result, we have hedged approximately 67 percent of our expected North American natural gas needs for 2017 at an average cost of approximately $2.50 per MMBtu. This includes our industrial business, which accounts for approximately 20 percent of our total nitrogen sales and, because it is largely on a cost-plus contract, is not at risk of gas price fluctuations. |

| ● | | For 2018 and 2019 we have hedged approximately 36 percent and 25 percent, respectively, of expected natural gas requirements at approximately $2.60 per MMBtu and $2.00 per MMBtu (excluding the industrial business). |

Natural gas prices: North American indices and North American Agrium prices

| | | | | | | | |

(U.S. dollars per MMBtu) | | 2016 | | | 2015 | |

NYMEX | | | 2.44 | | | | 2.67 | |

AECO | | | 1.57 | | | | 2.18 | |

| | | | | | | | |

Basis | | | 0.87 | | | | 0.49 | |

| | | | | | | | |

Wholesale | | | | | | | | |

Overall gas cost excluding realized derivative impact | | | 1.87 | | | | 2.36 | |

Realized derivative impact | | | 0.29 | | | | 0.18 | |

Overall gas cost(a) | | | 2.16 | | | | 2.54 | |

| | | | | | | | |

| (a) | Weighted average gas price of all gas purchases, excluding our 50 percent share of the Profertil facility. |

Natural Gas Use

| | | | | | | | | | | | | | | | | | | | |

| | | | | | U.S. | | | International | | | | | | | |

(Billion Cubic Feet (“BCF”)) | | Western Canada | | | (Borger, Texas) | | | (Profertil) | | | Potash and other | | | Total | |

2016 | | | 89 | | | | 16 | | | | 15 | | | | 2 | | | | 122 | |

2015 | | | 84 | | | | 19 | | | | 14 | | | | 1 | | | | 118 | |

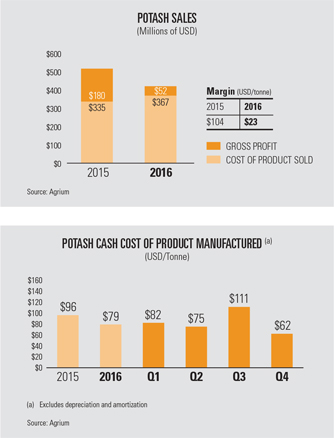

POTASH >> FINANCIAL RESULTS

Potash performance

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | 2016 | | | 2015 | |

| | | North | | | | | | | | | North | | | | | | | |

(millions of U.S. dollars, except as noted) | | America | | | International | | | Total | | | America | | | International | | | Total | |

Sales | | | 257 | | | | 162 | | | | 419 | | | | 374 | | | | 141 | | | | 515 | |

Cost of product sold | | | | | | | | | | | 367 | | | | | | | | | | | | 335 | |

| | | | | | | | | | | | | | | | | | | | | | | | |

Gross profit | | | | | | | | | | | 52 | | | | | | | | | | | | 180 | |

| | | | | | | | | | | | | | | | | | | | | | | | |

Tonnes sold (‘000) | | | 1,187 | | | | 1,052 | | | | 2,239 | | | | 1,133 | | | | 601 | | | | 1,734 | |

Selling price per tonne | | | 217 | | | | 154 | | | | 187 | | | | 330 | | | | 235 | | | | 297 | |

Cost of product sold per tonne | | | | | | | | | | | 164 | | | | | | | | | | | | 193 | |

Margin per tonne | | | | | | | | | | | 23 | | | | | | | | | | | | 104 | |

Tonnes produced (‘000) | | | | | | | | | | | 2,171 | | | | | | | | | | | | 1,967 | |

Cash COPM per tonne | | | | | | | | | | | 79 | | | | | | | | | | | | 96 | |

Capacity utilization (2016 Target: 100%) | | | | | | | | | | | 88 | | | | | | | | | | | | 94 | |

| | | | | | | | | | | | | | | | | | | | | | | | |

AGRIUM ANNUAL REPORT 2016 | 31

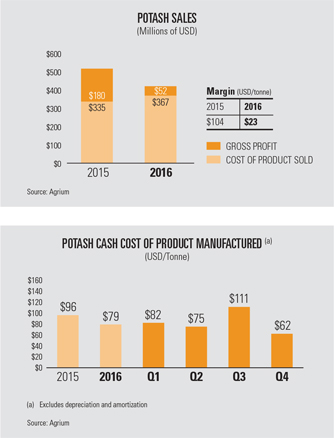

Potash gross profit

| ● | | A considerable weakening in global potash benchmark prices in 2016 led to the decrease in potash gross profit though this was more than offset by lower production costs and higher production and sales volumes in 2016. |

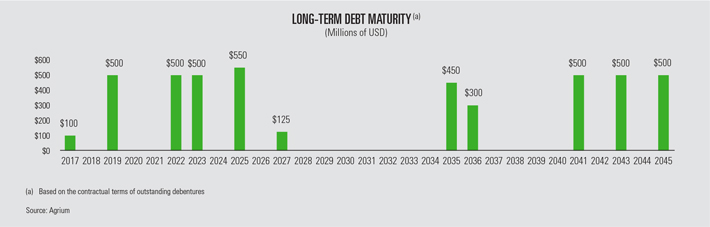

Potash sales volumes and operating rates