Exhibit 99.1

PETAQUILLAMINERALSLTD.

A TECHNICALREPORT ON THEBOTIJAABAJOPROJECT

A SATELLITEDEPOSIT OF THE

MOLEJÓNMINE

DONOSODISTRICT, COLONPROVINCE

REPUBLIC OFPANAMÁ

80° 37 27 114 W LONGITUDE

8° 49 23 339 N LATITUTDE

(975,321N, 541,326E UTM)

PREPAREDFOR:

PETAQUILLAMINERALSLTD.

410-475 WESTGEORGIASTREET

VANCOUVER, BRITISHCOLUMBIA, CANADAV6B 4M9

24 SEPTEMBER2012

PREPAREDBY:

ROBERTCAMERON, PH.D., MMSA 01357QP

RICHARDS. KUNTER, PH.D

MICHAELD. MARTIN, B.Sc.

BALTAZARSOLANO-RICO, B.S., MSC.,

BEHREDOLBEAR& COMPANY(USA), INC.

999 Eighteenth Street, Suite 1500

Denver, Colorado 80202

(303) 620-0020

A Member of the Behre Dolbear Group Inc.

© 2012, Behre Dolbear Group Inc. All Rights Reserved.

www.dolbear.com

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

TABLE OFCONTENTS

| | | | |

| 1.0 | SUMMARY | | 1 |

| | 1.1 | GENERAL | 1 |

| | 1.2 | ENVIRONMENTAL | 1 |

| | 1.3 | GEOLOGY | 2 |

| | 1.4 | ABBREVIATIONS | 2 |

| | 1.5 | UNITS OF MEASUREMENT AND CURRENCY | 3 |

| | 1.6 | EXPLORATION | 3 |

| | 1.7 | DRILLING | 3 |

| | 1.8 | SAMPLING PROCEDURES | 3 |

| | 1.9 | MINERAL RESOURCES | 4 |

| | 1.10 | ORE RESERVES | 5 |

| | 1.11 | MINING AND PROCESSING OPERATIONS | 5 |

| | 1.12 | PROCESS-RELATED STUDY RECOMMENDATIONS | 6 |

| | 1.13 | MINERAL RESOURCE AND RESERVE RECOMMENDATIONS | 6 |

| | 1.14 | CONCLUSIONS | 6 |

| 2.0 | INTRODUCTION | 7 |

| | 2.1 | GENERAL INFORMATION | 7 |

| | 2.2 | TERMS OF REFERENCE | 7 |

| | 2.3 | MAIN SOURCES OF INFORMATION | 7 |

| | | 2.3.1 | Main Sources of Information by the Authors | 7 |

| | | 2.3.2 | Main Sources of Information by Area | 8 |

| | | | 2.3.2.1 Geology | 8 |

| | | | 2.3.2.2 Drilling | 8 |

| | | | 2.3.2.3 Data Handling – QA/QC | 8 |

| | | | 2.3.2.4 Environmental | 8 |

| | | | 2.3.2.5 Operations | 9 |

| 3.0 | RELIANCE ON OTHER EXPERTS | 10 |

| | 3.1 | NI 43-101 REPORT PARTICIPANTS | 10 |

| | 3.2 | DISCLAIMER | 11 |

| 4.0 | PROPERTY DESCRIPTION AND LOCATION | 12 |

| | 4.1 | MINERAL PROPERTY DESCRIPTION | 12 |

| | | 4.1.1 | Mineral Property Location | 14 |

| | | 4.1.2 | Mineral Concessions and Obligations | 17 |

| 5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, AND PHYSIOGRAPHY | 21 |

| | 5.1 | ACCESSIBILITY | 21 |

| | 5.2 | PHYSIOGRAPHY | 22 |

| | 5.3 | VEGETATION AND LAND USE | 22 |

| | 5.4 | CLIMATE | 23 |

| | 5.5 | LOCAL RESOURCES | 24 |

| | 5.6 | INFRASTRUCTURE | 24 |

| 6.0 | HISTORY | | 27 |

| | 6.1 | HISTORICAL RESOURCE AND RESERVE ESTIMATES | 31 |

| | | 6.1.1 | H. A. Simons 1998 Report/Adrian Resources | 31 |

| | | 6.1.2 | AAT Mining Services Estimate of Resources | 31 |

| | |

| Project 12-208 (NI 43-101) | i | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

TABLE OFCONTENTS

(CONTINUED)

| | | | | |

| 7.0 | GEOLOGICAL SETTING AND MINERALIZATION | 32 |

| | 7.1 | REGIONAL GEOLOGY | 32 |

| | 7.2 | LOCAL GEOLOGY | 34 |

| | 7.3 | STRUCTURAL GEOLOGY | 36 |

| | 7.4 | STRUCTURAL CONTROL OF MINERALIZATION | 37 |

| | 7.5 | LITHOLOGY AND ALTERATION | 38 |

| | 7.6 | MINERALIZATION | 40 |

| | | 7.6.1 | Mineralization Zones | 40 |

| | | 7.6.2 | Weathered Zone – Saprolite | 40 |

| | | 7.6.3 | Weathered Zone – Oxide-transition Zone | 40 |

| | | 7.6.4 | Primary Sulfides Zone | 40 |

| | | 7.6.5 | Mineralogy | 41 |

| | | 7.6.6 | Mineral Deposits | 42 |

| | | | 7.6.6.1 | Botija Abajo Mineral Deposit | 42 |

| | | | 7.6.6.2 | Botija Abajo West Mineral Deposit | 45 |

| | | | 7.6.6.3 | Geological Considerations in the Metallurgical Treatment of the Ore | 47 |

| 8.0 | DEPOSIT TYPES | | 48 |

| 9.0 | EXPLORATION | | 52 |

| | 9.1 | ADRIAN RESOURCES EXPLORATION ACTIVITIES AND RESULTS | 52 |

| | 9.2 | PETAQUILLA MINERALS EXPLORATION ACTIVITIES AND RESULTS | 52 |

| | | 9.2.1 | Trenching Programs | 52 |

| | 9.3 | PML DRILLING CAMPAIGNS AND RESULTS | 53 |

| 10.0 | DRILLING | | | 55 |

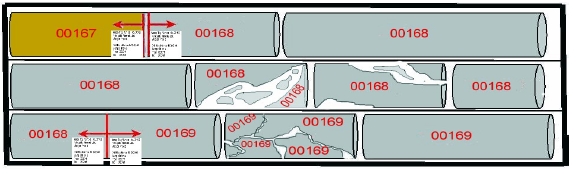

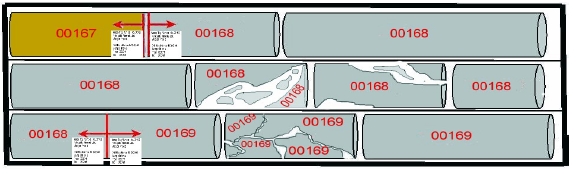

| | 10.1 | DRILLING SUPERVISION, SAMPLING, AND RECOVERY | 61 |

| | 10.2 | CORE RECOVERY VERIFICATION | 61 |

| | 10.3 | DRILL HOLE SURVEYING | 62 |

| | 10.4 | CONCLUSIONS | 63 |

| 11.0 | SAMPLE PREPARATION, ANALYSIS, AND SECURITY | 64 |

| | 11.1 | PML SAMPLING PROTOCOL | 64 |

| | 11.2 | PML SAMPLE PREPARATION PROCEDURES | 64 |

| | 11.3 | QUALITY CONTROL (QC), ASSAY PROCEDURES, AND SECURITY | 65 |

| | 11.4 | ALS CHEMEX LABORATORIES ASSAY AND QUALITY ASSURANCE (QA) PROCEDURES | 65 |

| 12.0 | DATA VERIFICATION | 67 |

| | 12.1 | AAT MINING SERVICES QA/QC (2006-2007) | 67 |

| | 12.2 | QA/QC PROCESS | 67 |

| | 12.3 | AUTHORS VERIFICATION OF PML DATA | 69 |

| | 12.4 | VERIFICATION OF PML DATA HANDLING | 69 |

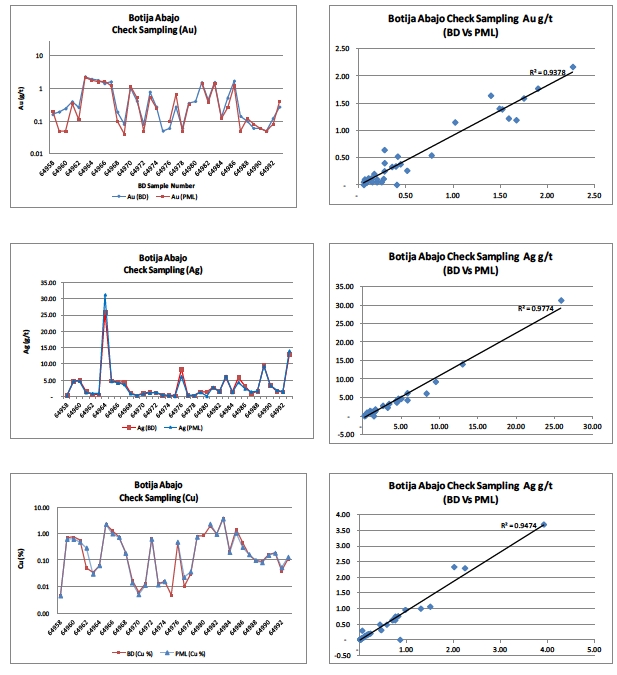

| | 12.5 | CHECK SAMPLING | 70 |

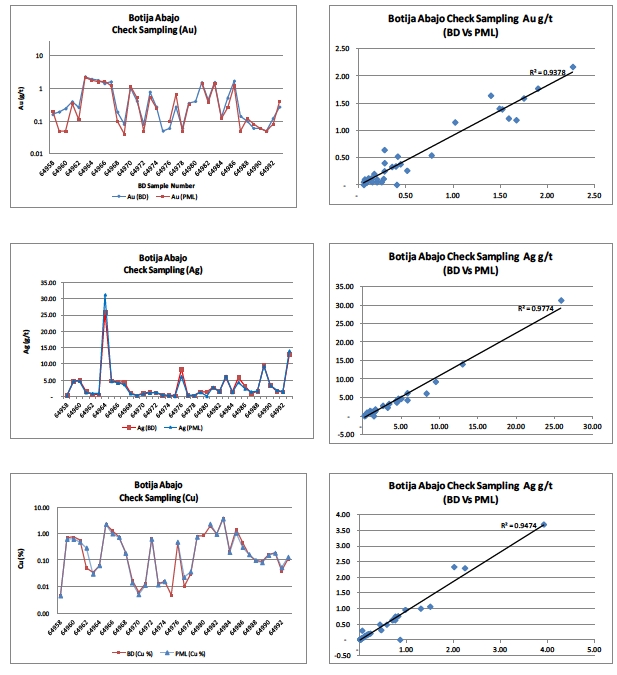

| | | 12.5.1 | Drill Hole Core Sampling Verification | 70 |

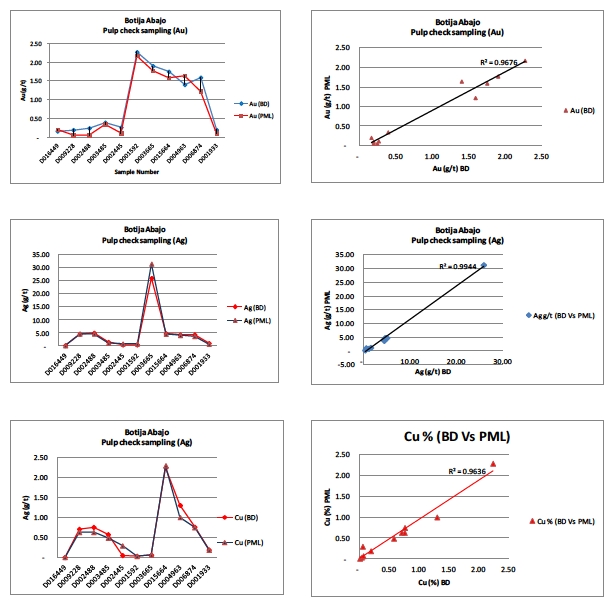

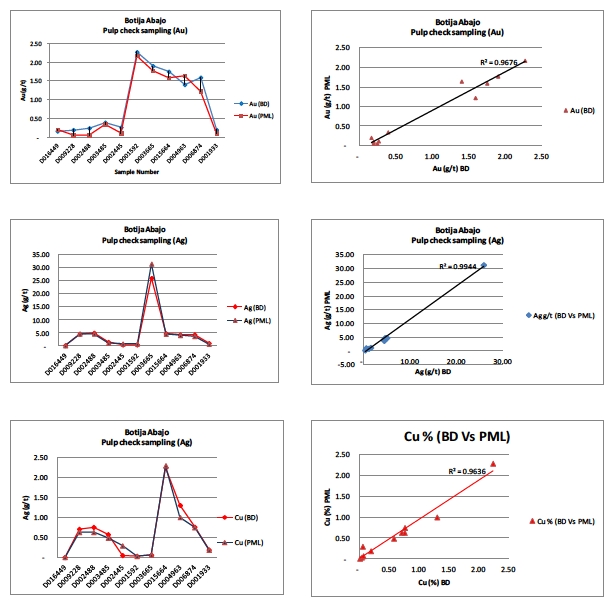

| | | 12.2.1 | Verification of Pulps in ALS Chemex Labs | 74 |

| | 12.6 | ASSAY VERIFICATION CONCLUSIONS | 77 |

| | |

| Project 12-208 (NI 43-101) | ii | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

TABLE OFCONTENTS

(CONTINUED)

| | | | |

| 13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 78 |

| | 13.1 | INTRODUCTION | 78 |

| | | 13.1.1 | Metallurgical Testing Discussion and Results | 79 |

| | | 13.1.2 | Mineral Processing | 82 |

| | 13.2 | METALLURGICAL TEST WORK | 83 |

| | | 13.2.1 | Sample Preparation | 84 |

| | | | 13.2.1.1Total Copper and Total Gold Analysis | 84 |

| | | 13.2.2 | Comments on Results | 84 |

| | 13.3 | CONCLUSION AND SUMMARY | 84 |

| | 13.4 | CAPITAL COST ESTIMATE | 84 |

| | 13.5 | OPERATING COST ESTIMATE | 85 |

| | | 13.5.1 | Botija Abajo Operating Costs | 86 |

| 14.0 | MINERAL RESOURCE ESTIMATE | 87 |

| | 14.1 | INTRODUCTION | 87 |

| | 14.2 | RESOURCE MODEL ESTIMATION | 87 |

| | | 14.2.1 | Estimation Procedures | 87 |

| | | 14.2.2 | Electronic Database | 88 |

| | | 14.2.3 | Statistics and Grade Capping | 88 |

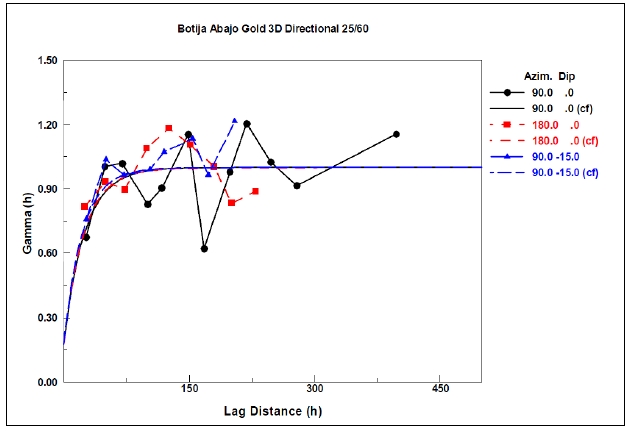

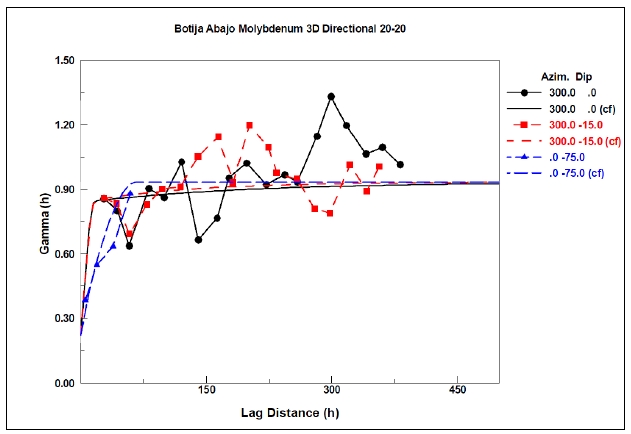

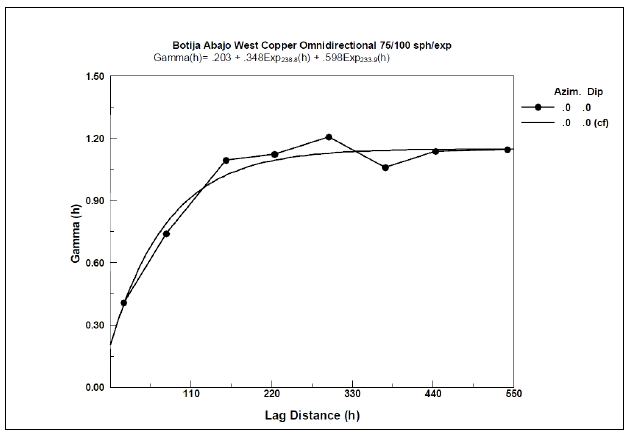

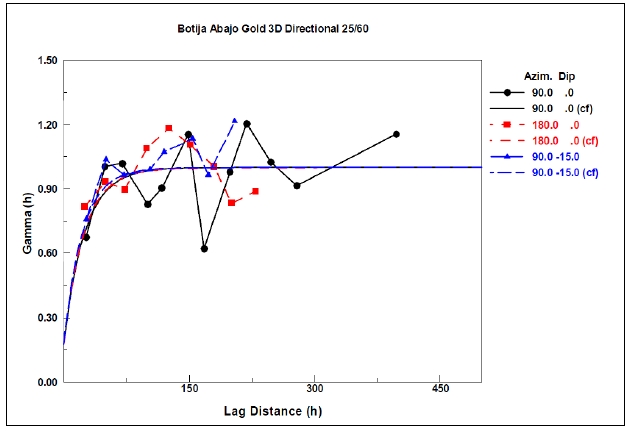

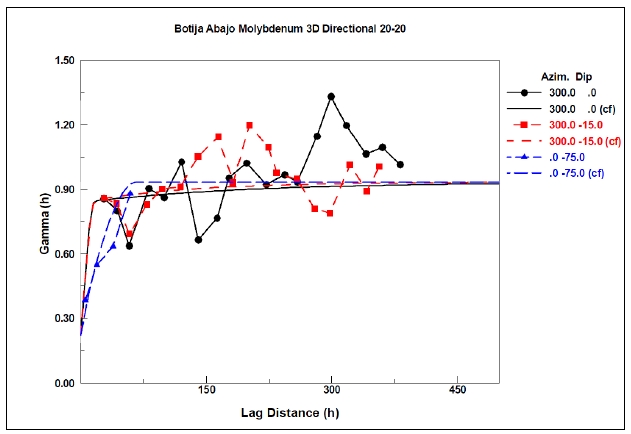

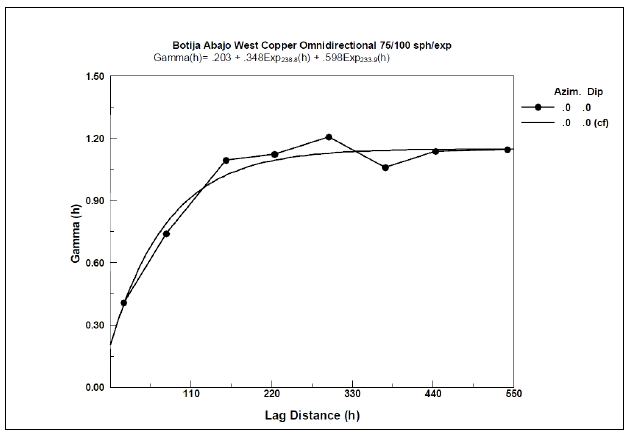

| | | 14.2.4 | Variography | 89 |

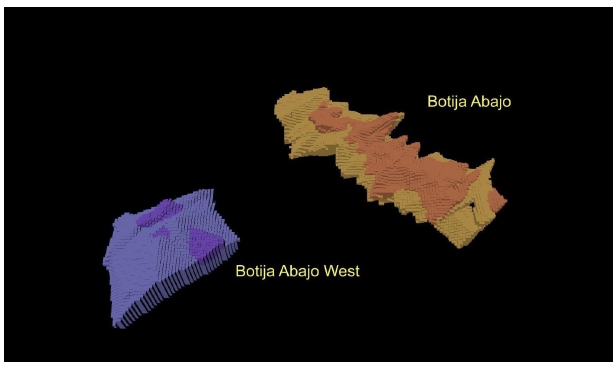

| | | 14.2.5 | Mineralized Envelopes | 92 |

| | | 14.2.6 | Bulk Density | 92 |

| | | 14.2.7 | Grade Estimation | 92 |

| | | 14.2.8 | Block Model Validation | 93 |

| | 14.3 | RESOURCE CATEGORIZATION | 93 |

| | 14.4 | RESOURCE CONCLUSIONS AND RECOMMENDATIONS | 95 |

| 15.0 | MINERAL RESERVE ESTIMATE | 96 |

| | 15.1 | INTRODUCTION | 96 |

| | | 15.1.1 | Summary of Reserve Estimation Procedures | 96 |

| | 15.2 | ECONOMIC BLOCK MODEL | 96 |

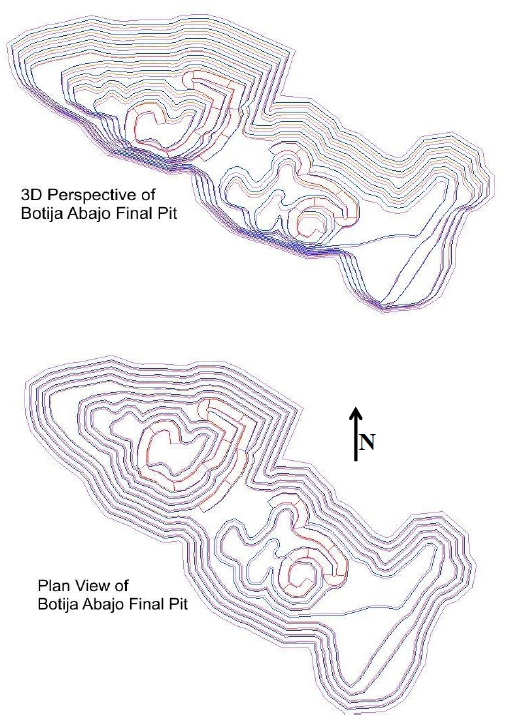

| | 15.3 | PIT DESIGN | 97 |

| | 15.4 | PRODUCTION SCHEDULE | 100 |

| | 15.5 | RESERVE DEFINITIONS | 102 |

| | 15.6 | RISKS TO RESERVES | 103 |

| | 15.7 | RESERVES CONCLUSIONS AND RECOMMENDATIONS | 104 |

| 16.0 | MINING METHODS | 105 |

| | 16.1 | MINING OPERATIONS | 105 |

| | 16.2 | MINE PLANNING AND DESIGN | 105 |

| | 16.3 | FINAL PIT DESIGN | 106 |

| 17.0 | RECOVERY METHODS | 108 |

| | 17.1 | PRIMARY AND SECONDARY CRUSHING | 108 |

| | 17.2 | GRINDING | 108 |

| | 17.3 | HYDROCYCLONES | 108 |

| | 17.4 | FLOTATION CIRCUIT | 109 |

| | 17.5 | THROUGHPUT AND AVAILABILITY | 109 |

| | 17.6 | HEAD GRADE CONTROL | 109 |

| | |

| Project 12-208 (NI 43-101) | iii | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

TABLE OFCONTENTS

(CONTINUED)

| | | | |

| 18.0 | PROJECT INFRASTRUCTURE | 110 |

| | 18.1 | MINE INFRASTRUCTURE AND SUPPORT FACILITIES | 110 |

| 19.0 | MARKET STUDIES AND CONTRACTS | 113 |

| | 19.1 | MARKETS | 113 |

| 20.0 | ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | 114 |

| | 20.1 | CURRENT ENVIRONMENTAL PERMITTING STATUS AND ISSUES | 114 |

| | 20.2 | CURRENT ENVIRONMENTAL AND ISSUES | 117 |

| 21.0 | CAPITAL AND OPERATING COSTS | 118 |

| | 21.1 | OPERATING COSTS | 118 |

| | | 21.1.1 | Mining | 118 |

| | | 21.1.2 | Milling | 118 |

| | | 21.1.3 | Heap Leaching | 118 |

| | | 21.1.4 | General and Administration (G&A) | 118 |

| | | 21.1.5 | Smelting, Refining, and Freight Costs for the Gold/Copper Concentrates | 118 |

| | | 21.16 | Operating Cost Summary | 119 |

| | 21.2 | CAPITAL COSTS | 119 |

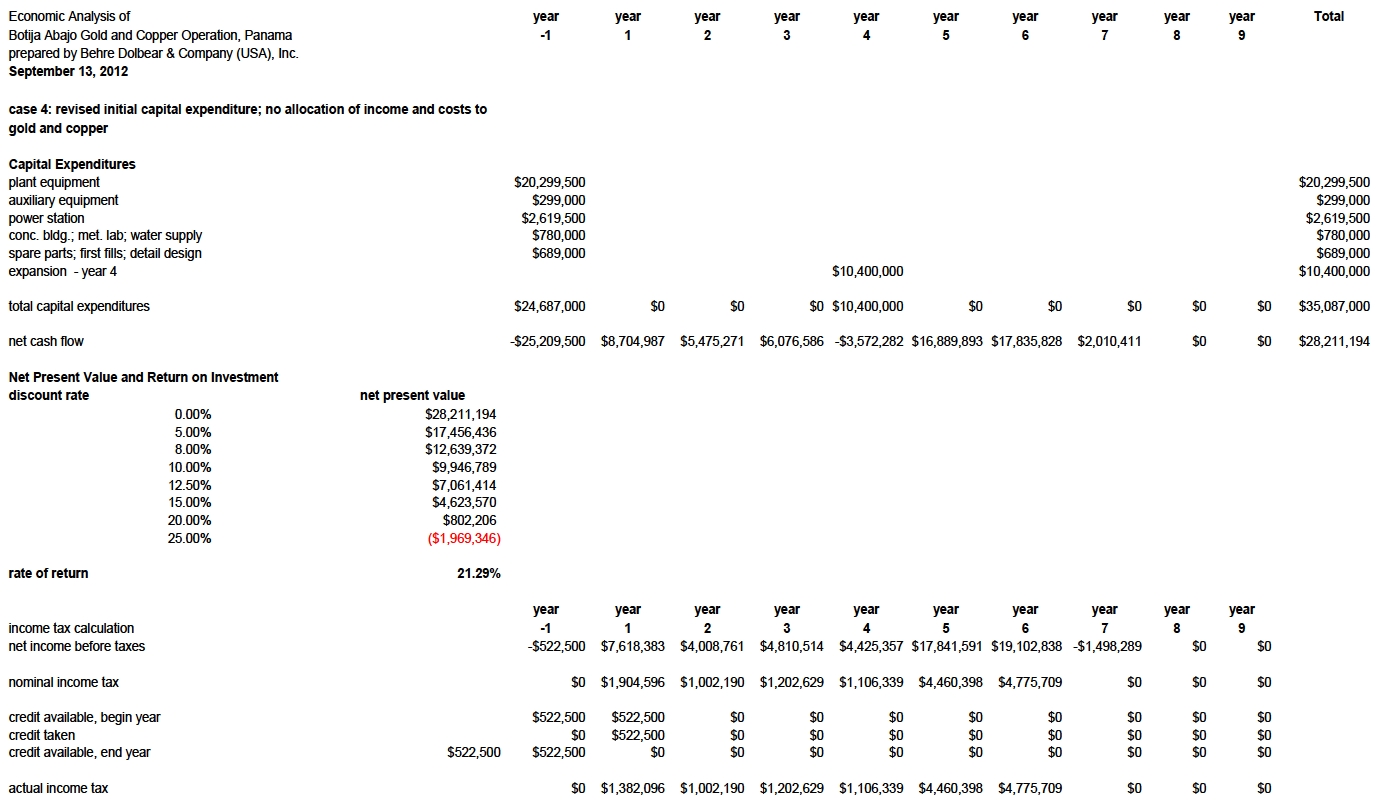

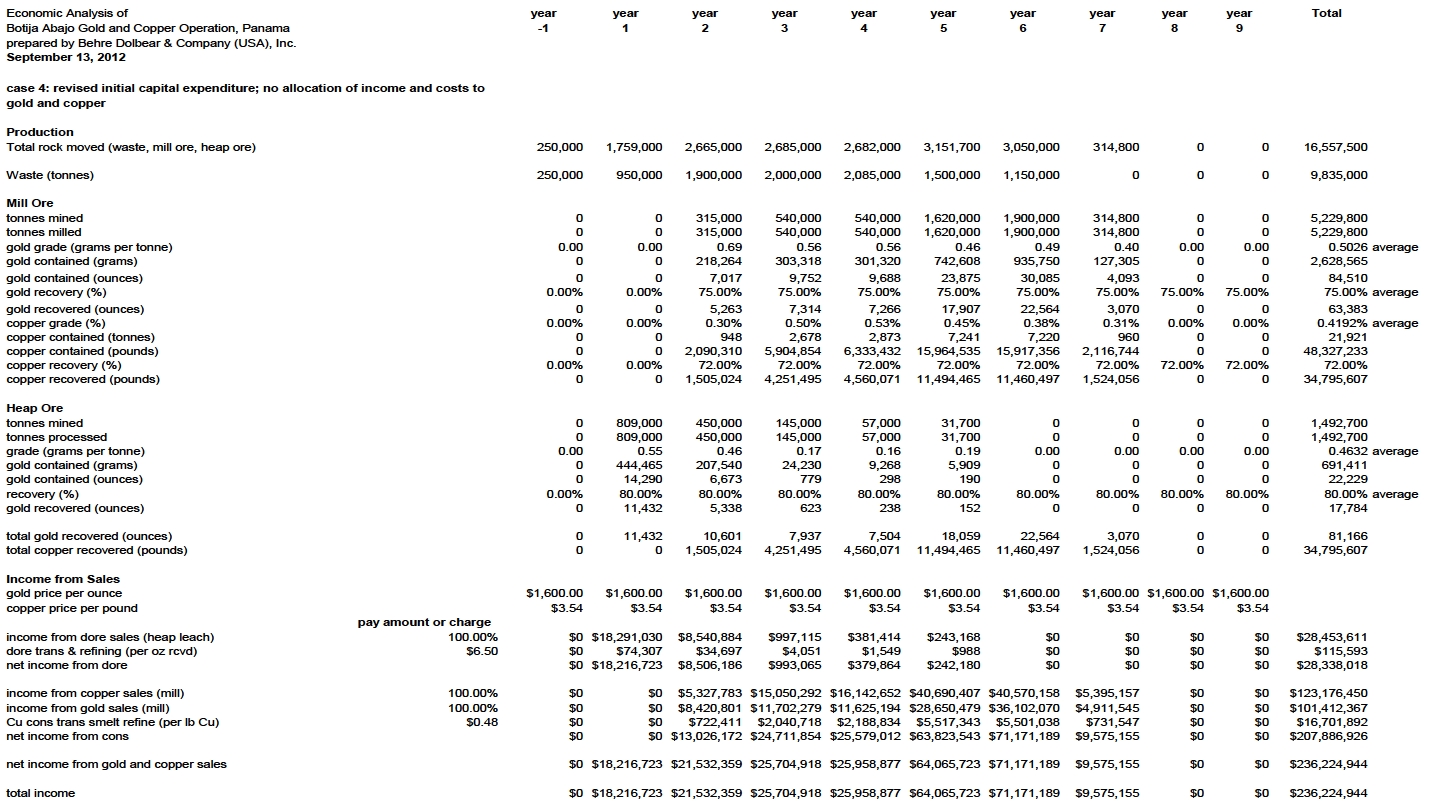

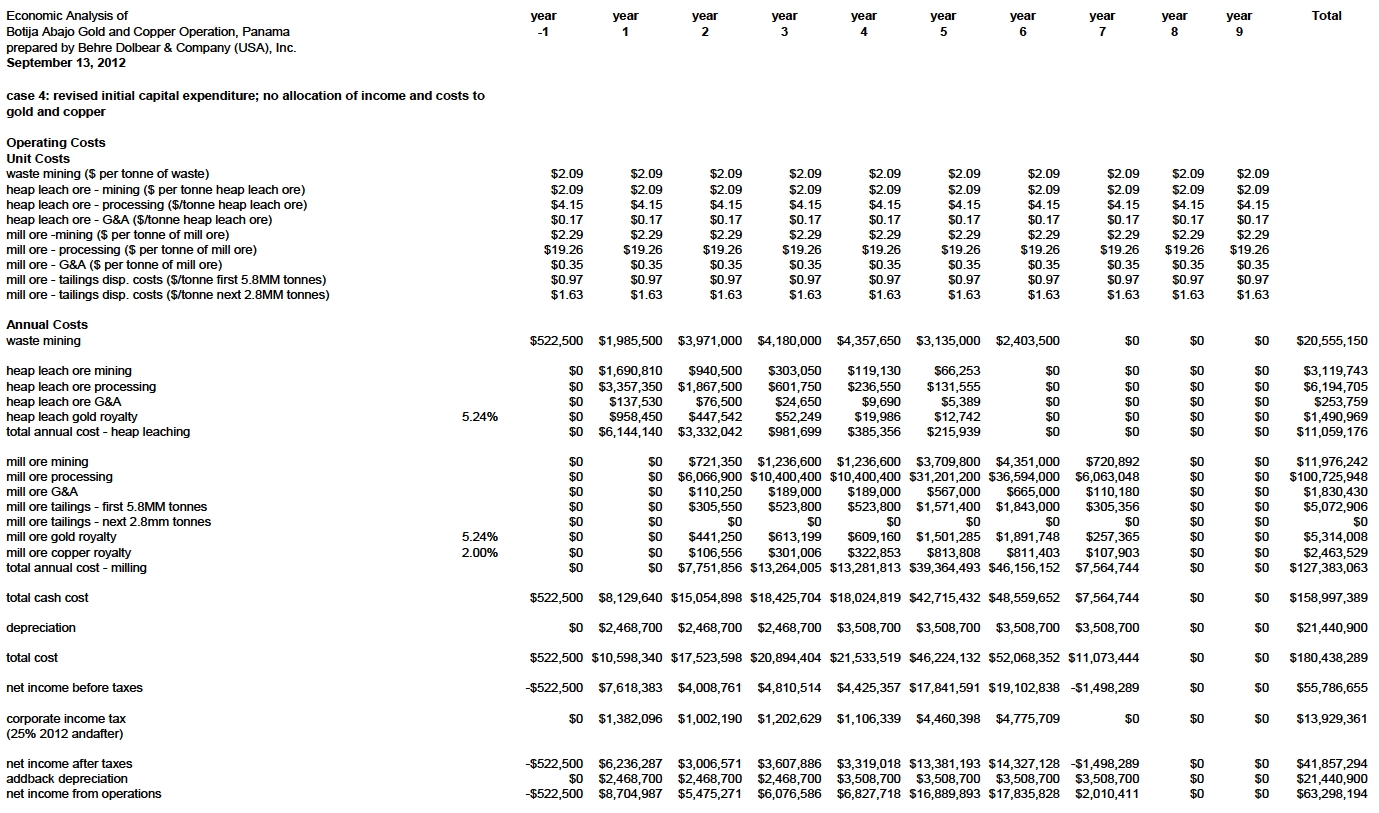

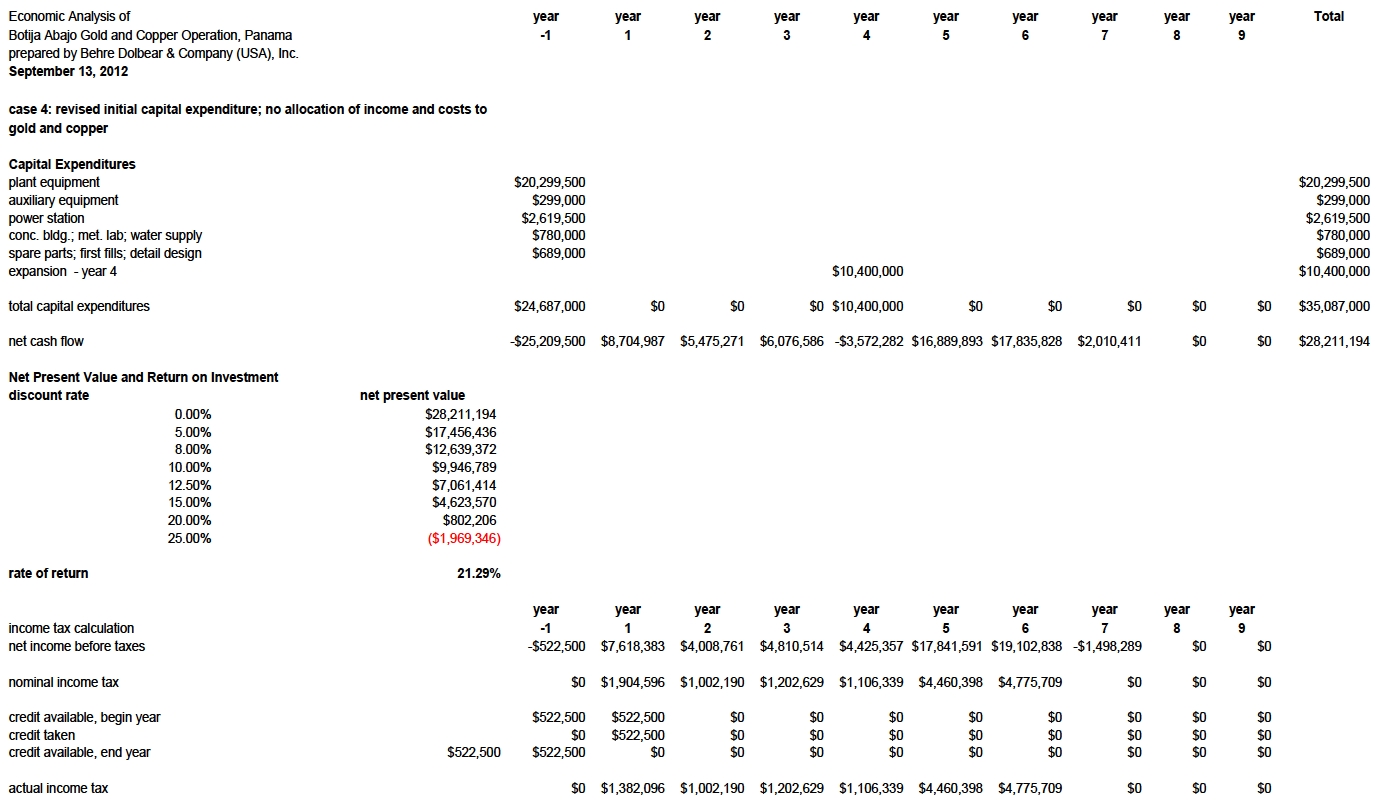

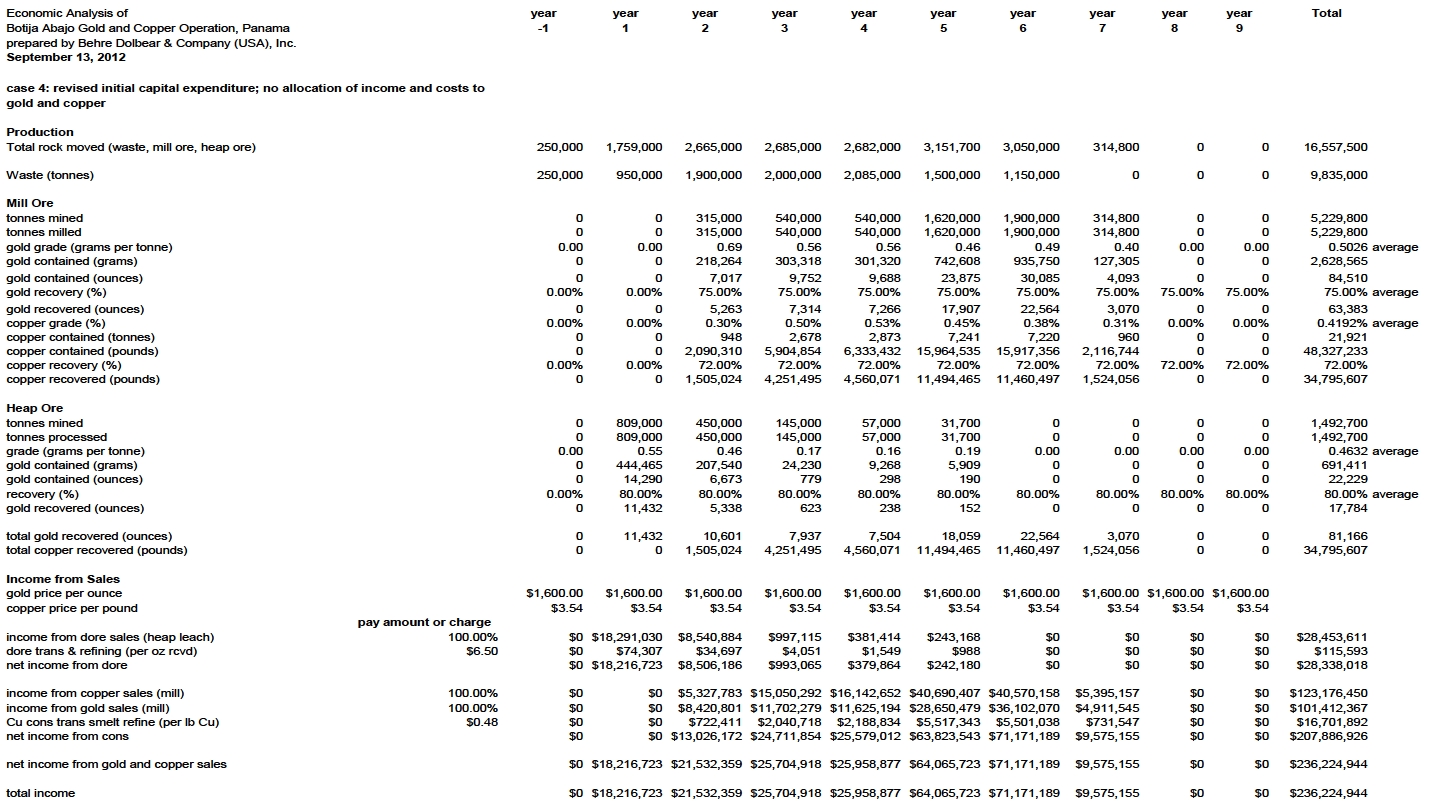

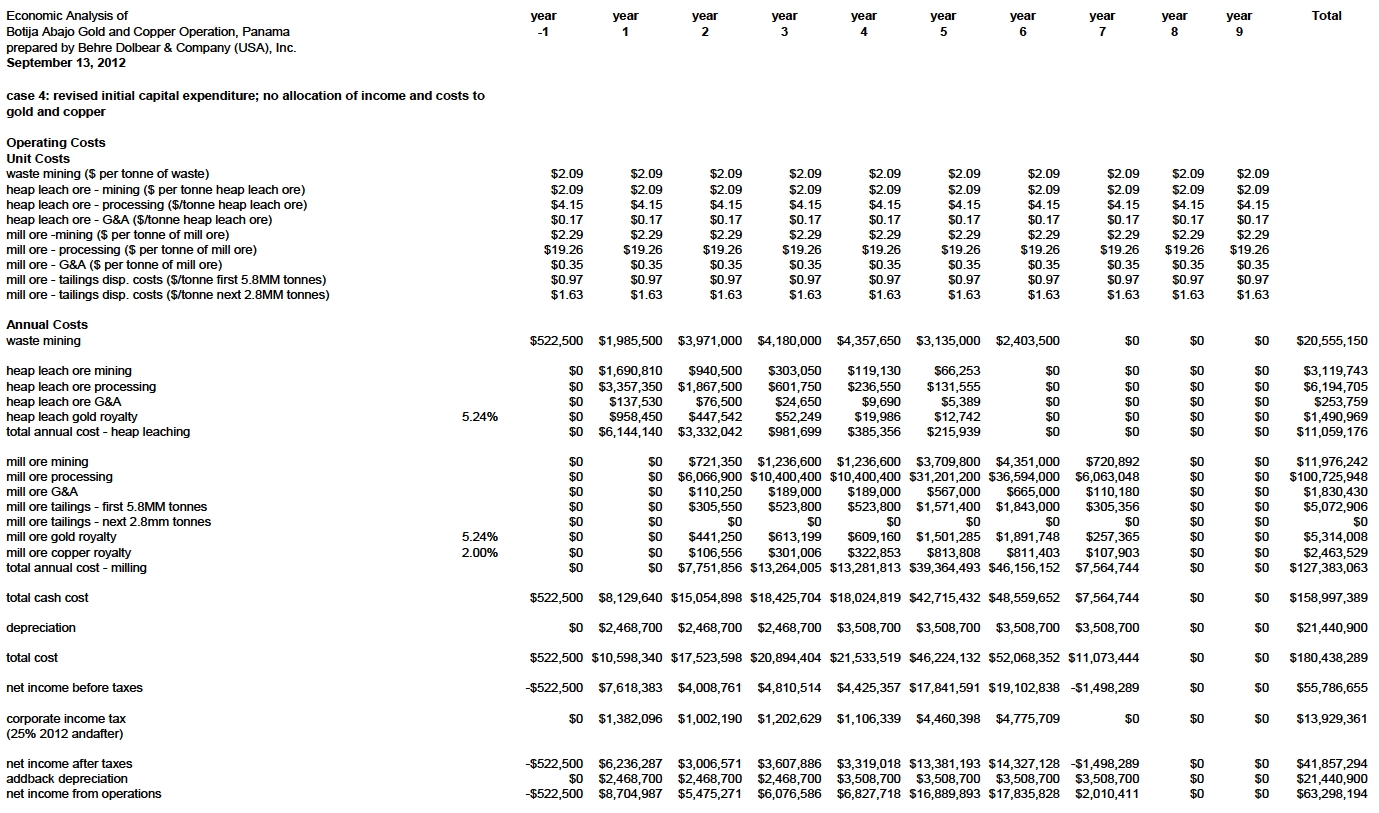

| 22.0 | ECONOMIC ANALYSIS | 121 |

| | 22.1 | MINE LIFE | 121 |

| | 22.2 | CASH FLOW SPREADSHEET MODEL | 122 |

| 23.0 | ADJACENT PROPERTIES | 123 |

| | 23.1 | MINA DE COBRE PANAMÁ PROJECT | 123 |

| | 23.2 | PML CONCESSIONS | 123 |

| | 23.3 | BOCA DE HIQUI | 123 |

| 24.0 | OTHER RELEVANT DATA AND INFORMATION | 124 |

| 25.0 | INTERPRETATION AND CONCLUSIONS | 125 |

| | 25.1 | INTERPRETATION | 125 |

| 26.0 | RECOMMENDATIONS | 127 |

| | 26.1 | MINERAL RESOURCE AND RESERVE RECOMMENDATIONS | 127 |

| | 26.2 | EXPLORATION PROJECT RECOMMENDATIONS | 127 |

| 27.0 | REFERENCES | 128 |

| APPENDIX 1.0 | CONCESSIONS | A1-1 |

| APPENDIX 2.0 | ALS MINERALS CERTIFICATES | A2-1 |

| APPENDIX 3.0 | QA/QC SAMPLE LOGGING AND SAMPLE PREPARATION (PROTOCOL) | A3-1 |

| APPENDIX 4.0 | BOTIJA ABAJO CASH FLOW SPREADSHEET | A4-1 |

| | |

| Project 12-208 (NI 43-101) | iv | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

LIST OFTABLES

| | |

| Table 1.1 | Measured and Indicated Mineral Resources within the Final Pit Design | 4 |

| Table 1.2 | Proven and Probable Mineral Reserves within the Final Pit Design | 5 |

| Table 3.1 | Metallic Mineral Concessions | 10 |

| Table 4.1 | Molejón Mine Area Titled Mining Concessions (Ley Petaquilla) | 13 |

| Table 4.2 | Mineral Production Taxes and Royalties under the Petaquilla Law | 19 |

| Table 4.3 | Surface Taxes under the Petaquilla Law | 20 |

| Table 6.1 | Summary of Exploration History and Ownership | 28 |

| Table 7.1 | Mineral Specimens Identified at Botija Abajo | 41 |

| Table 7.2 | Mineral Composition of Weathered Zone at Botija Abajo | 42 |

| Table 9.1 | PML Botija Abajo and Botija Abajo West 2006–2008 Core Drilling Summary | 53 |

| Table 10.1 | PML Botija Abajo and Botija Abajo West 2006-2008 Core Drilling | 56 |

| Table 10.2 | Core Recovery Verification – Botija Abajo Project | 62 |

| Table 12.1 | Standard Samples Used at Molejón | 68 |

| Table 12.2 | Behre Dolbear Core Check Sample Location | 71 |

| Table 12.3 | Core Sample Verification – Behre Dolbear PML Assay Comparison | 72 |

| Table 12.4 | Behre Dolbear-PML Drill Core Sampling Correlation | 74 |

| Table 12.5 | Pulp Sampling Verification | 75 |

| Table 12.6 | Behre Dolbear-MLN Laboratory Pulp Assay Correlation | 77 |

| Table 13.1 | Botija Abajo Project – Drill Hole Samples for Composite Metallurgical Testing | 79 |

| Table 13.2 | Botija Abajo Capex | 85 |

| Table 14.1 | Composite Statistics | 89 |

| Table 14.2 | Variography and Search Ellipsoid Parameters | 91 |

| Table 14.3 | Measured and Indicated Mineral Resources within the Final Pit Design | 95 |

| Table 15.1 | Economic Parameters Used for Pit Optimization | 97 |

| Table 15.2 | Pit Design Parameters | 97 |

| Table 15.3 | Botija Abajo and Botija Abajo West – LOM Production Schedule | 101 |

| Table 15.4 | Proven and Probable Mineral Reserves within the Final Pit Design | 103 |

| Table 15.5 | Proven and Probable Mineral Reserves by Processing Stream | 103 |

| Table 16.1 | Economic Parameters Used for Pit Optimization | 105 |

| Table 16.2 | Pit Design Parameters | 106 |

| Table 21.1 | Smelting, Refining, and Freight Charges per Pound of Saleable Copper | 119 |

| Table 21.2 | Botija Abajo Operating Costs | 119 |

| Table 21.3 | Botija Abajo Capex | 120 |

| | |

| Project 12-208 (NI 43-101) | v | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

LIST OFFIGURES

| | |

| Figure 4.1. | Petaquilla Concessions and Botija Abajo location and access map ( 2009) | 14 |

| Figure 4.2. | Botija Abajo Location map (2009) | 15 |

| Figure 4.3. | Mineral concessions granted by Law Number 9 (Ley Petaquilla) (1997) | 17 |

| Figure 5.1. | Molejón Mine-Botija Abajo Project access map (2007) | 21 |

| Figure 5.2. | Botija Abajo physiography | 22 |

| Figure 5.3. | Botija Abajo vegetation | 23 |

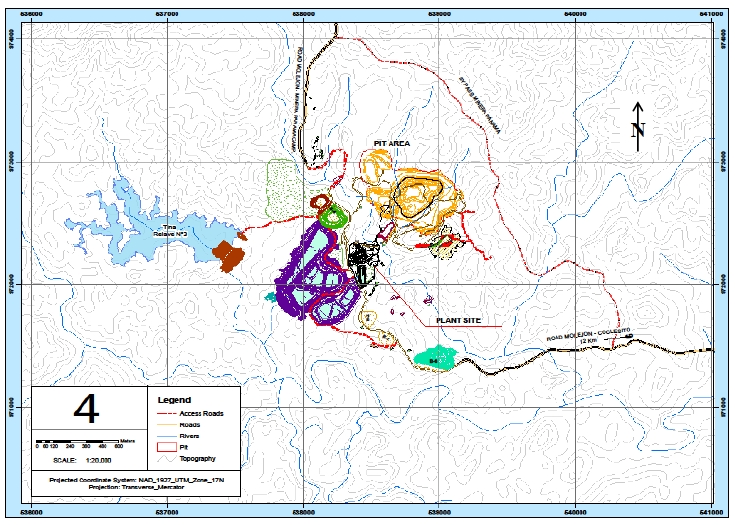

| Figure 5.4. | Molejón-Botija Abajo area infrastructure map (2012) | 25 |

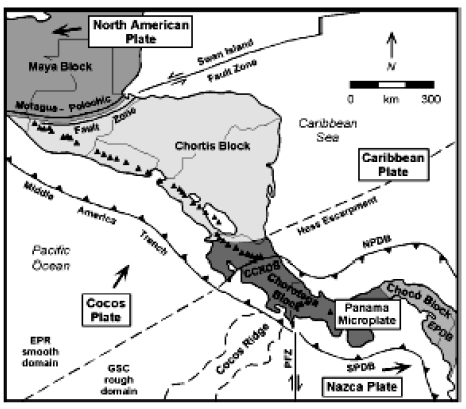

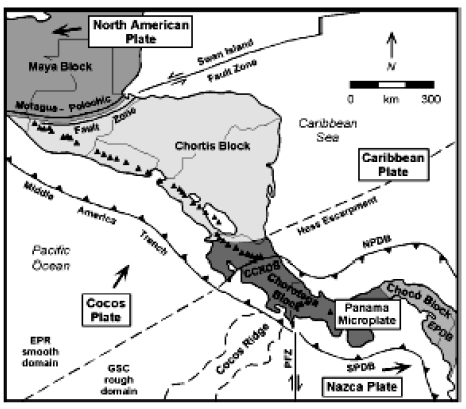

| Figure 7.1. | Tectonic map of Central America | 32 |

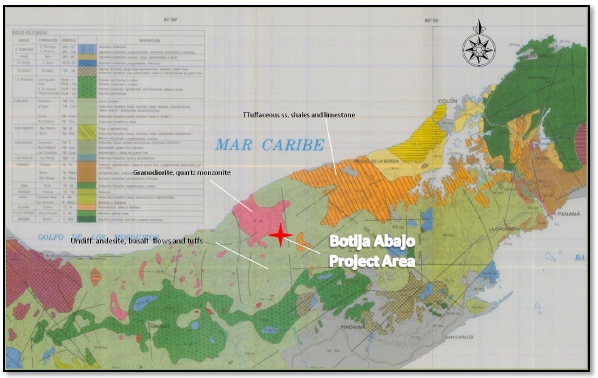

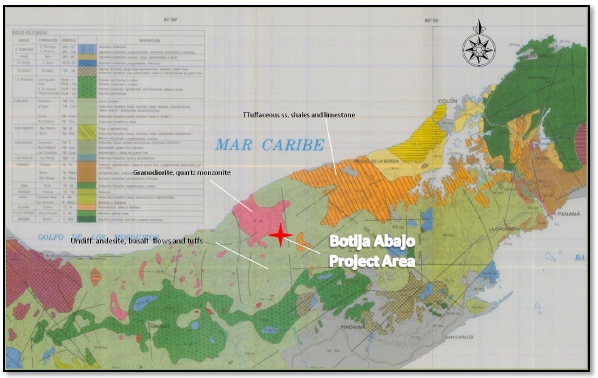

| Figure 7.2. | Regional geology and location map | 33 |

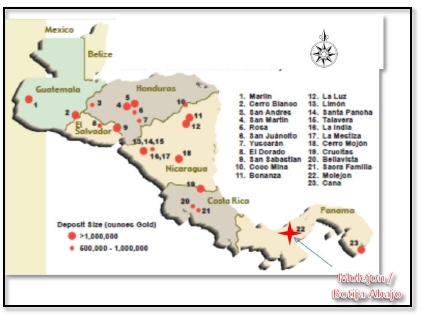

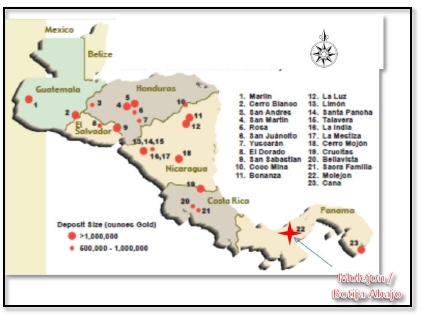

| Figure 7.3. | Epithermal deposits in Central America | 34 |

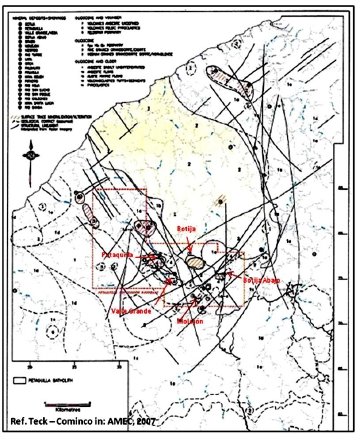

| Figure 7.4. | Regional geological map and structural interpretation | 35 |

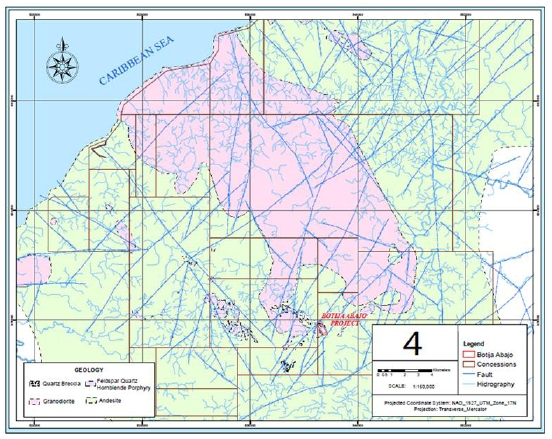

| Figure 7.5. | District geology and structural lineaments | 36 |

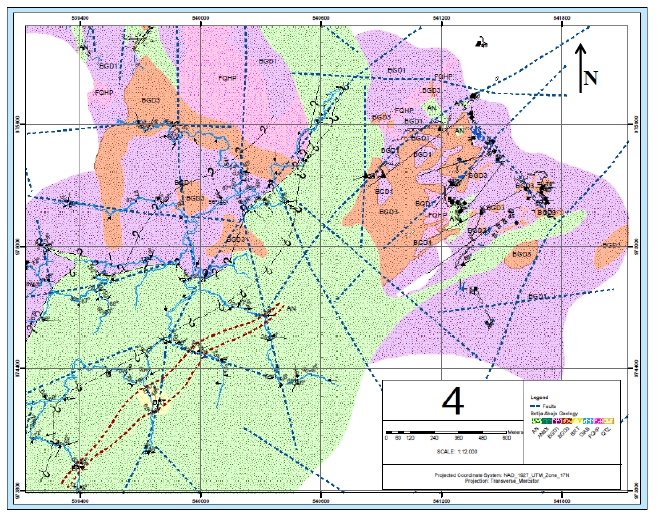

| Figure 7.6. | Botija Abajo – district geology and structural lineaments | 39 |

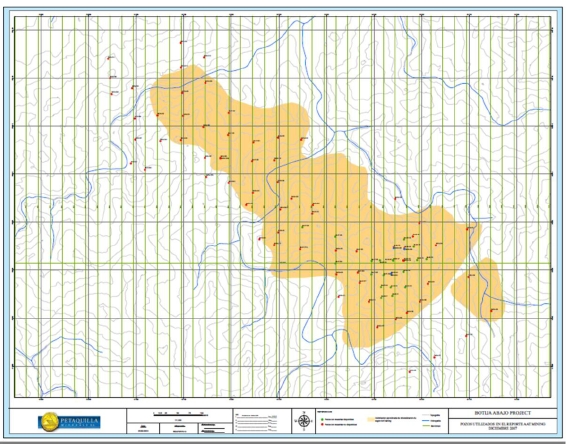

| Figure 7.7. | Botija Abajo interpretation of gold mineralization boundaries | 43 |

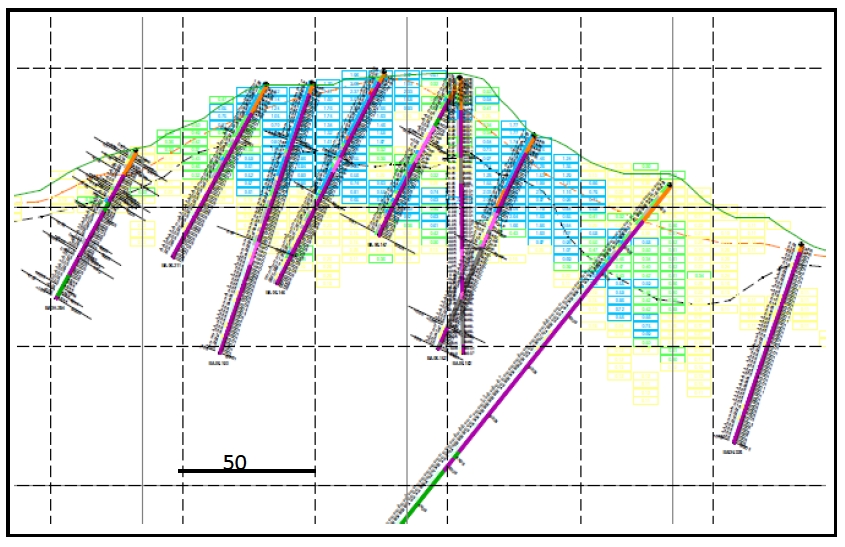

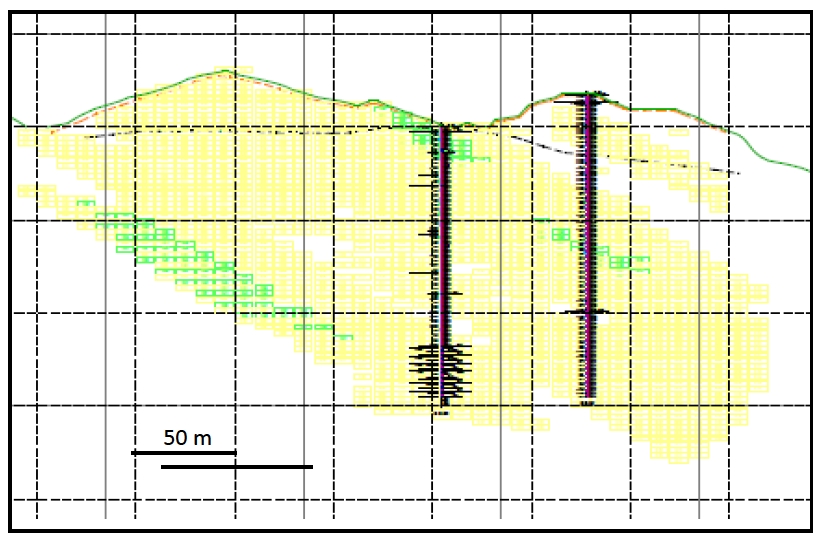

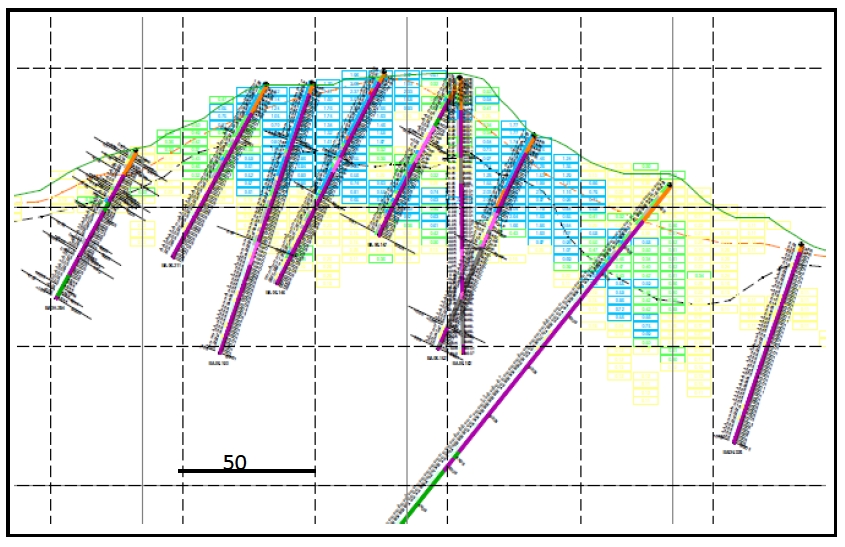

| Figure 7.8. | Botija Abajo – cross Section 0E looking west | 44 |

| Figure 7.9. | Botija Abajo West – cross Section 1050W looking west | 46 |

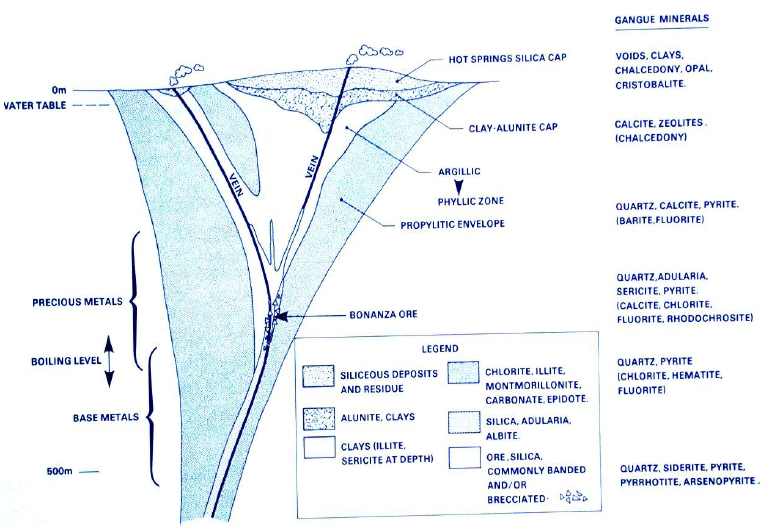

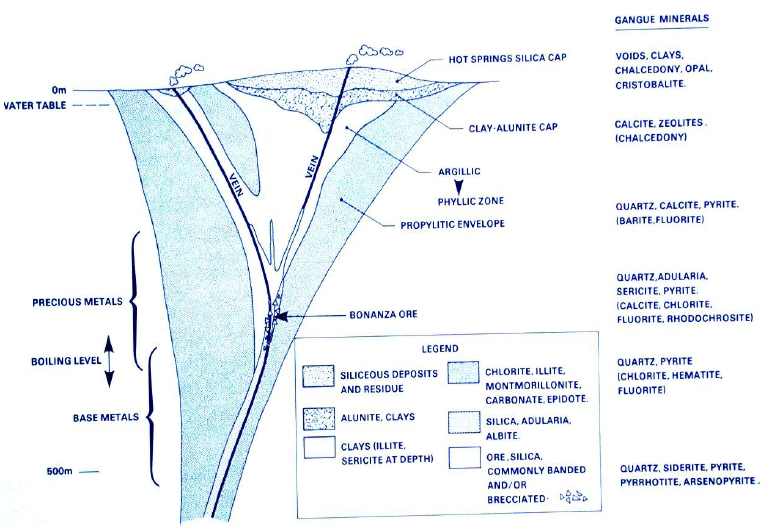

| Figure 8.1. | Conceptual model for styles of magmatic arc epithermal gold-silver and porphyry gold-copper mineralization | 49 |

| Figure 8.2. | Idealized section of a Bonanza Epithermal deposit | 51 |

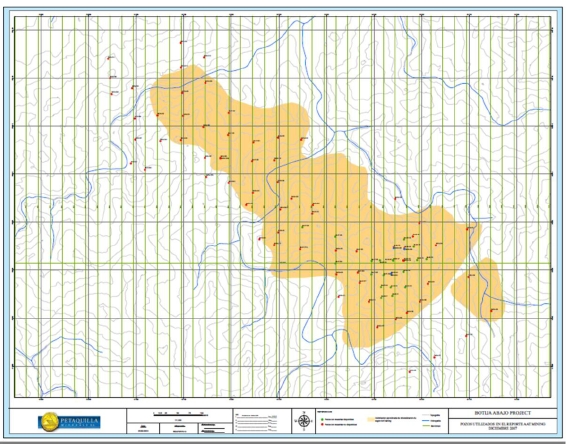

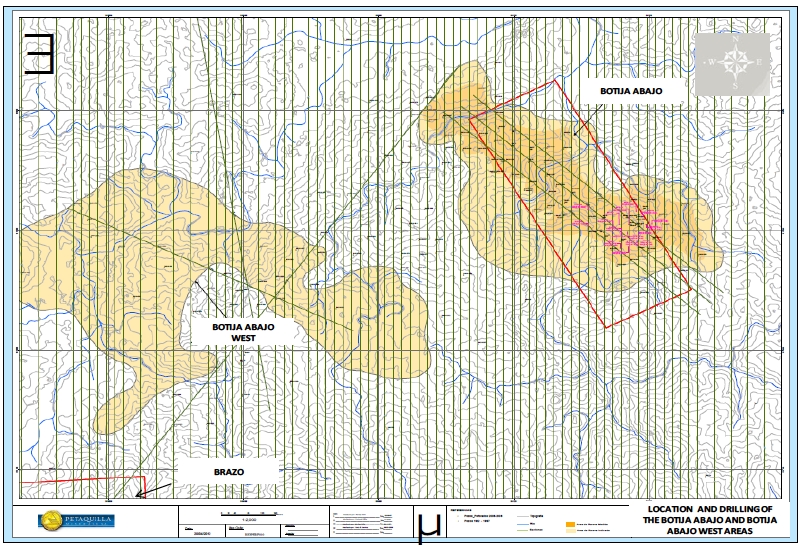

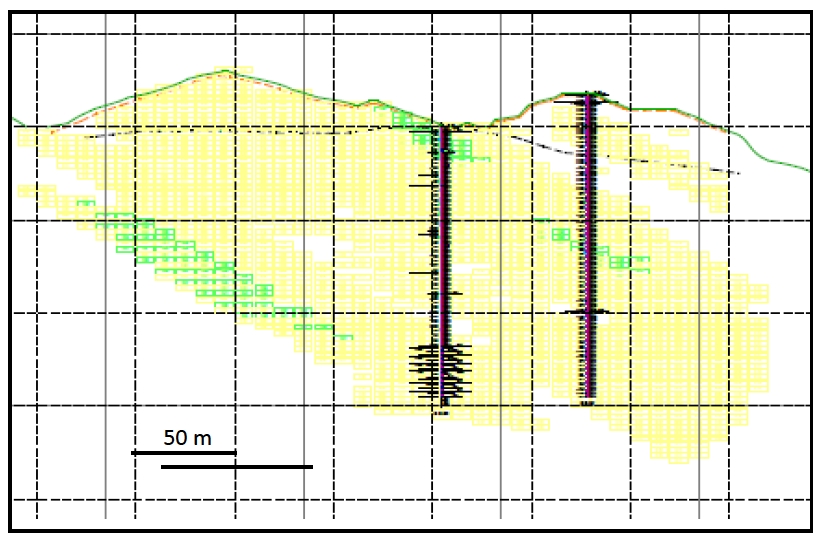

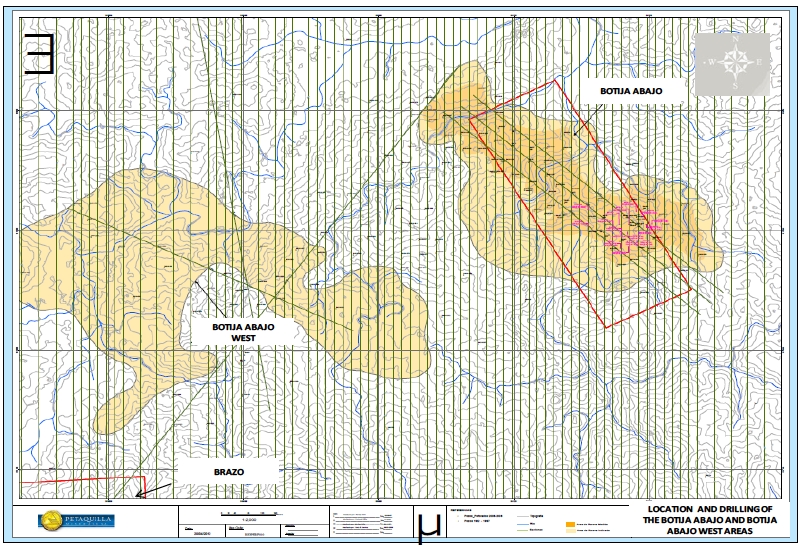

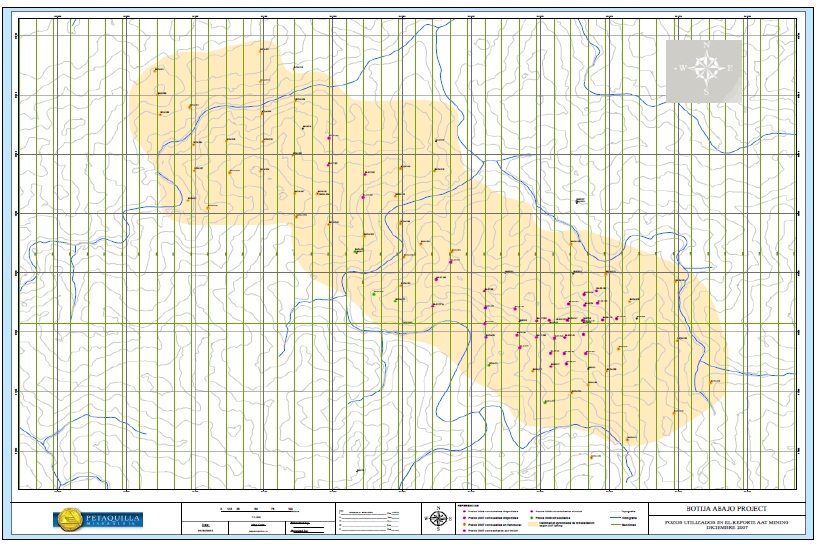

| Figure 9.1. | Location and drill sites of the Botija Abajo and Botija Abajo West areas (2008) | 54 |

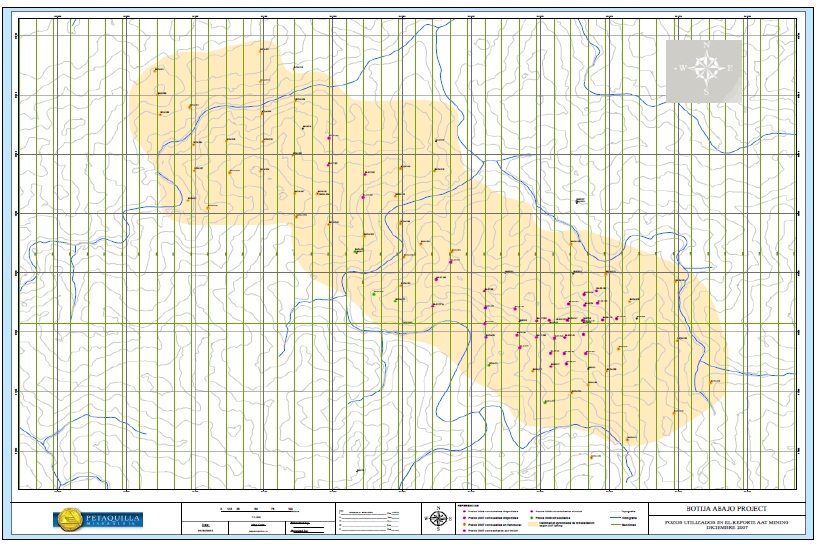

| Figure 10.1. | Botija Abajo Project drill hole location map (2008) | 60 |

| Figure 12.1. | Digital flow diagram of the QA/QC process at Molejón and followed at Botija Abajo | 67 |

| Figure 12.2. | Drill core check assay correlations: Au, Ag, Cu | 73 |

| Figure 12.3. | Behre Dolbear-PML pulp check assay correlations: Au, Ag, Cu | 76 |

| Figure 13.1. | Metal recoveries versus P80(µ m) | 81 |

| Figure 14.1 | Gold variogram at Botija Abajo | 89 |

| Figure 14.2 | Copper variogram at Botija Abajo | 90 |

| Figure 14.3 | Copper variogram at Botija Abajo West | 91 |

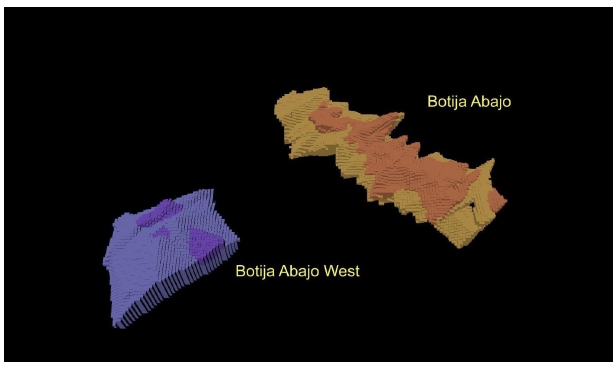

| Figure 14.4. | 3D solids for Botija Abajo and Botija Abajo West | 92 |

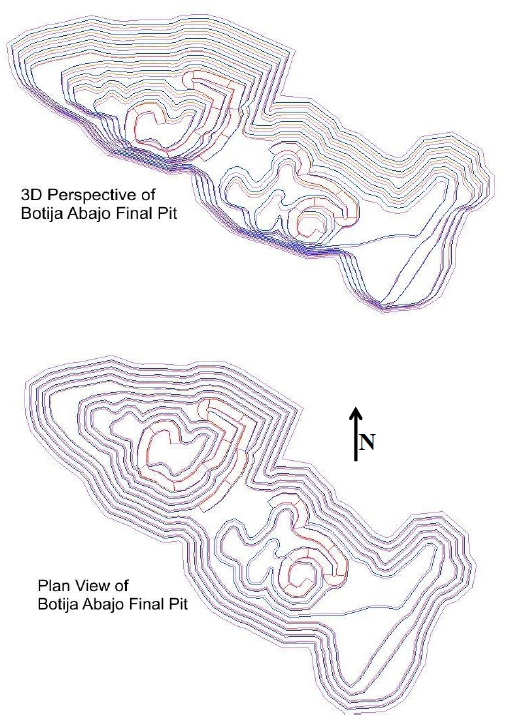

| Figure 15.1 | Botija Abajo final pit design (2012) | 98 |

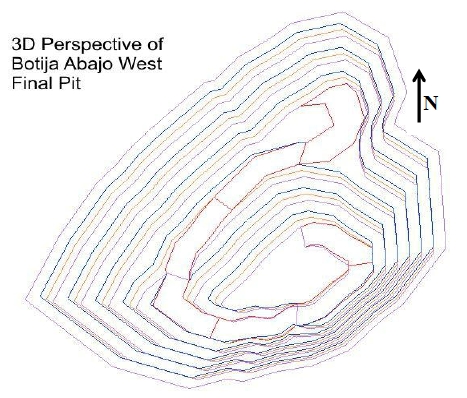

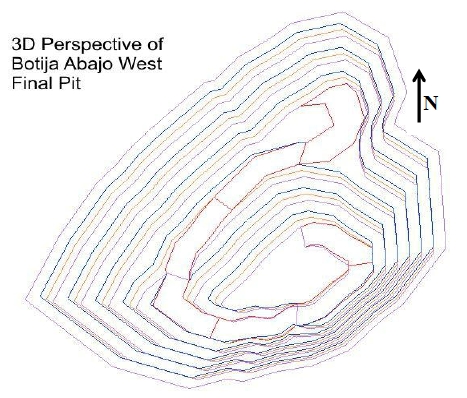

| Figure 15.2 | Botija Abajo West final pit design (2012) | 99 |

| Figure 16.1. | Botija Abajo final pit design (2012) | 107 |

| Figure 16.2. | Botija Abajo West final pit design (2012) | 107 |

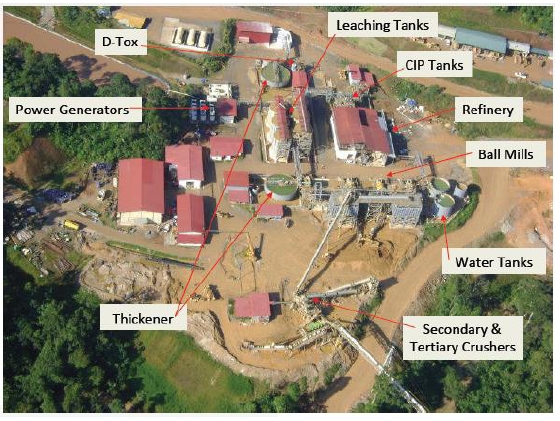

| Figure 18.1. | Local project infrastructure | 111 |

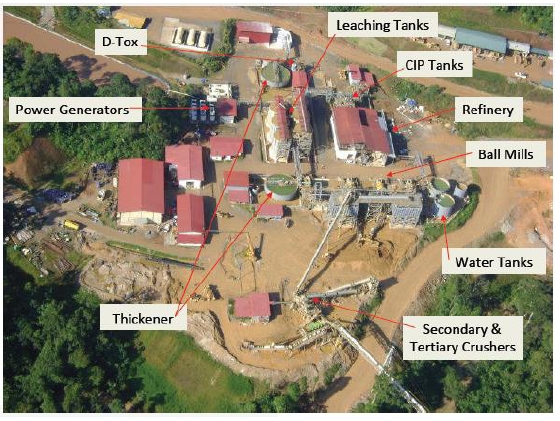

| Figure 18.2. | Molejón gold plant aerial view | 112 |

| | |

| Project 12-208 (NI 43-101) | vi | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

1.0 SUMMARY

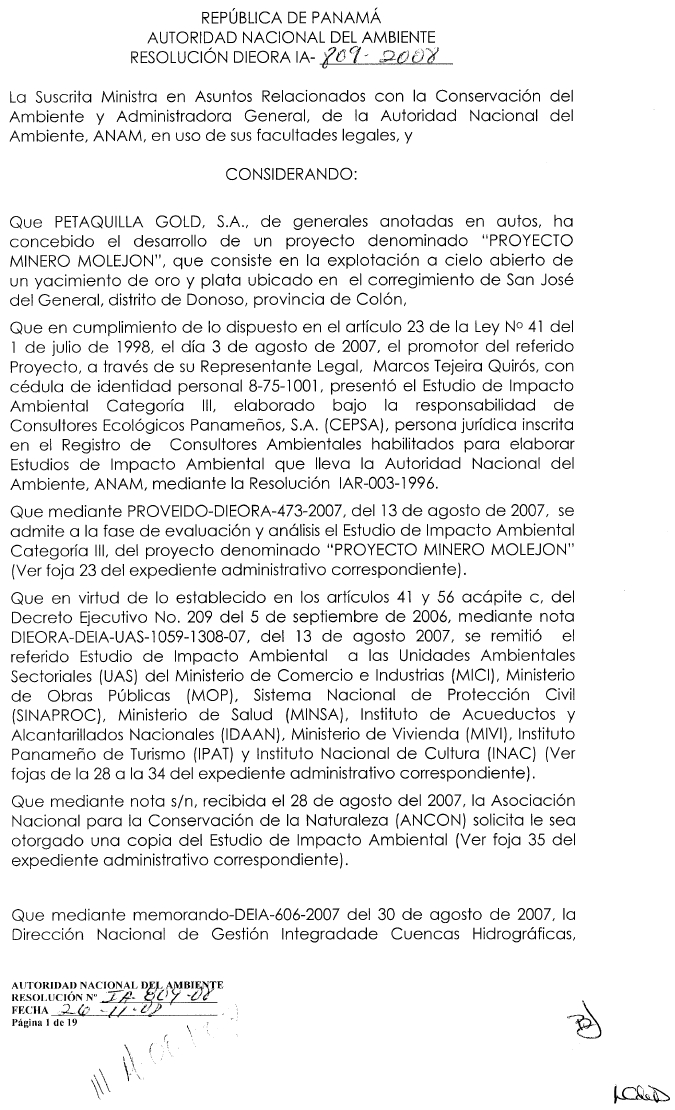

The Botija Abajo gold and copper deposit is a satellite deposit of the Molejón gold deposit and operation, and is located within the same block of Claims granted by the Petaquilla Law; therefore, all rights, permits, and environmental liabilities are contained within those of the Molejón deposit, currently in operation.

Southwest of the Petaquilla batholith, that hosts such deposits as the Petaquilla, Botija and Valle Grande copper deposits, are a series of intrusives that follow a northeast structural trend from the Molejón gold deposit. Three mineralized areas have been identified in the El Real trend known as the Brazo, Botija Abajo West, and Botija Abajo deposits. While the Molejón gold deposit lies on the same northeast lineament as the El Real Trend as these three deposits, a genetic connection to the Brazo, Botija Abajo, and Botija Abajo West has not yet been established.

Originally drilled in the mid-1990s after soil sampling, these El Real deposits are currently being evaluated by a combination of in-fill drilling, delineation drilling, and surface mapping.

Botija Abajo is located in the Donoso District, Colon Province, Republic of Panamá. The site is roughly 130 kilometers (km) west of Panamá City, Panamá and approximately centered at 80º 37 27 114 W Longitude and 8º 49 23 339 N Latitude (975,321N, 541,326E UTM).

The property is accessed through the Molejón Gold Mine property, via a well-maintained gravel road passing through La Pintada, a town of 5,000 people and Coclecito, which is the closest settlement to the project area, approximately 4 km to the southeast of the center of the project area, and thence via an approximately 5 km dirt access road to the Botija Abajo pits.

Since commercial production commenced at the Molejón Mineon (January 8, 2010), gold has been produced at a rate of approximately 6,000 ounces per month.

The National Authority of the Environment (ANAM) on November 26, 2008, issued Resolution DIEORA IA-809-2008, approving the EIS Type III of reference (Appendix 1.0). In accordance with Contract Law Number 9 of February 26, 1997 (a copy is available in the PML files), the Ministry of Commerce and Industry of the Government of Panamá issued a letter to the Company dated November 18, 2009, authorizing Petaquilla Minerals Ltd (PML)’s subsidiary, Petaquilla Gold, S.A., to initiate commercial production at its Molejón gold mine. This authorization includes 13 conditions and 27 recommendations. PML has reportedly responded with action on all these conditions and recommendations. This resolution also covers the satellite operations of Botija Abajo.

Section 20.0 provides a detailed account of all environmental issues, permits and potential risks relating mainly to the Molejón operation but also applicable to satellite deposits (Botija Abajo) and future operations.

| | |

| Project 12-208 (NI 43-101) | 1 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

The Botija Abajo gold deposit is within a thick, undifferentiated sequence of andesites, andesitic basalts, and tuffs intruded by a quartz-feldspar porphyry and other feldspar porphyries. On a district-wide scale, several major structures are evident, a northeast-southwest fracture trend that seems to control the main Molejón quartz breccia connecting with the Brazo, Botija Abajo West, and Botija Abajo zones and a north-northwest/south-southeast structural feature that seems to connect the Faldalito, Vega, and Molejón areas.

In general terms, Botija Abajo is an epitermal structure apparently superposed to a porphyry copper-type body. The epithermal structure is related to a “stockwork” of vuggy quartz that seems to be controlled by the “Real Corridor” structural trend. Gold-copper mineralization in the Botija Abajo area is associated to three distinct zones: Weathered - including saprolite, oxide-transition, and primary sulfide.

| |

| A | annum (year) |

| % | percent |

| ° | degree |

| °C | degree Celsius |

| cm | centimeters |

| dwt | deadweight tonnes |

| g | grams |

| g/cm3 | grams per cubic centimeter |

| g/m3 | grams per cubic meter |

| g/t | grams per metric tonne |

| h | hour(s) |

| ha | hectares (10,000 square meters) |

| HP | horsepower |

| kg | kilograms |

| klm3 | thousands of loose cubic meters |

| km | kilometers |

| km2 | square kilometers |

| KN | kilo Newtons |

| k oz | thousand ounces |

| kW | kilowatts |

| LOM | life-of-mine |

| m | millions |

| m | meter |

| m3 | cubic meters |

| masl | meters above sea level |

| mm | millimeters |

| million m3 | million cubic meters |

| million N/m2 | million Newtons per square meter |

| Mt | million tonnes |

| Mt/yr | million tonnes per year |

| MW | megawatts |

| ppm | parts per million |

| st | short tons |

| | |

| Project 12-208 (NI 43-101) | 2 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

| |

| t | tonnes (metric) |

| t/h | tonnes per hour |

| t/a | tonnes per year |

| tpd | tonnes (metric) per day |

| CDN$M | million Canadian Dollars |

| US$M | million US Dollars |

| CDN$/t | Canadian Dollars per tonne |

| US$/t | US Dollars per tonne |

| US$/st | US Dollars per short ton |

| wt % | weight percent |

| |

| 1.5 | UNITS OF MEASUREMENT AND CURRENCY |

The metric system is used throughout this report and the currency used is the United States dollar (US$), unless specifically stated otherwise.

Exploration in the subject property area dates back to the UNDP campaign of 1968, and later activities by Minnova and Geotec and Adrian Resources, later to become Petaquilla Minerals Ltd. (PML). Mapping and sampling of quartz vein and quartz breccias outcrops in the Molejón area resulted in the discovery of a significant deposit of epithermal gold, silver mineralization hosted predominantly within quartz breccia, and altered feldspar-quartz porphyry intrusive. It also resulted in the identification or investigation of several other targets (Botija Abajo, Brazo, Faldalito, Cuatro Crestas, and Lata, Orca).

A total of 9,608.3 meters of trenching was undertaken in 2006 followed by more than 19,000 meters of core drilling in 2006 and 2007 (161 holes).

Core of the Adrian 1994 campaigns was lost during the period that the project was idle, and most of the 2006-2008 drilling campaigns by PML was stored in the then PML’s Petaquilla facilities based at the Botija and Petaquilla camps and the core boxes remained in the local shacks, unavailable now for review or re-sampling. Core handling, sampling and security followed protocols established by PML. A review of core recovery by the authors found that the overall core recovery obtained was 81% with 80% in oxidized material and 87% in the primary, fresh rock.

It is the authors’ opinion that drilling procedures and control during the PML 2006-2008 campaigns followed Industry Standards and are reliable for the purpose of Resource and Reserve estimates.

In order to verify the reliability and compliance with Canadian National Instrument (NI) 43-101 standards of the early drilling campaigns at Molejón, PML hired AAT Mining Services to ensure that PML drilling, trenching, and survey activities were conducted to standards suitable for NI 43-101 reporting. AAT concluded that the 1990s drilling program was adequately validated by a drill hole twining campaign in 2006 and that 2007 drill core samples were analyzed to Industry Standards with minimal variance of protocols or analytical results. A Quality Assurance/Quality Control (QA/QC) protocol was established by PML at Molejón with the insertion of standard, blank, and duplicate samples with the objective of

| | |

| Project 12-208 (NI 43-101) | 3 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

providing credibility to the database. During the site visit, the authors had the opportunity to review all the process from drilling being done at the Palmilla property northwest of Molejón and held discussions with several of PML geologists. It was found that the procedures as established in the protocol were being followed.

It is the authors’ opinion that sampling procedures and control during the PML 2006 and 2007 campaigns followed Industry Standards and provided reliable samples and assay results for the purpose of Resource and Reserve estimates following NI 43-101 standards.

AAT Mining Services (AAT) completed a geologic model and a NI 43-101 compliant resource estimate in December 2007. The authors were provided with the digital geological database and a geologic block model that was developed by AAT for their work.

The authors reviewed the mineralization block model developed by AAT and found that the estimates conformed to CIM guidelines for mineral resource and was appropriate and sufficient for a pre-feasibility level economic pit design and mineral reserve estimate. The mineralization block model however covers more than just the Botija Abajo and Botija Abajo West area. However, the in-situ resource summary presented in this report is limited to the mineralization at these two deposits. The author delineated the appropriate extent of the potential mineral resource by using floating cone with delineated projected project economics for these areas. Only that portion of the resource block model contained within an optimized pit shell was utilized for reporting the in-situ Mineral Resource.

The author estimates that the Botija Abajo and Botija Abajo West areas contain resources of approximately 4.5 Mt of Measured and 1.8 Mt of Indicated Mineral Resources averaging 0.54 grams of gold per tonne and approximately 1.7 Mt of Measured and 3.0 Mt of Indicated copper Mineral Resources averaging 0.49% copper per tonne, as shown in Table 1.1. As Inferred Mineral Resources within a final pit design have no economic value and cannot be considered part of a Mineral Reserve under the CIM reporting guidelines, any Inferred Resource contained within the pit was treated as waste and was not considered or reported as part of the Mineral Resource.

The resources as shown in Table 1.1 are an in-situ mineral resource. The Mineral Resources stated in Table 1.1 are inclusive of the Mineral Reserves discussed in this report.

| | | | | | |

TABLE 1.1

MEASURED AND INDICATED MINERAL RESOURCES WITHIN THE FINAL PIT DESIGN

(AS OF SEPTEMBER 1, 2012) |

| | Au | Cu |

| | Kt | Contained | Kt | Contained |

| | g/t | oz | % | Klbs |

| Measured | 4,454 | 0.572 | 81,906 | 1,705 | 0.487 | 18,295 |

| Indicated | 1,846 | 0.474 | 28,136 | 2,981 | 0.486 | 31,929 |

| | | | | | | |

| Total | 6,300 | 0.543 | 110,042 | 4,687 | 0.486 | 50,225 |

| Slight numerical differences may exist in table values due to rounding | | | |

| | |

| Project 12-208 (NI 43-101) | 4 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

To estimate the potential mineral reserves at the Botija Abajo property, the author used the resource block model summarized above. This work involved creating an economic block model from the model, using the floating cone pit optimization algorithm to develop an economic pit shell, designing a final pit, and producing a mine production schedule to determine the economically extractable portion of the original block model.

The author estimates that the Botija Abajo and Botija Abajo West areas have Mineral Reserves that were estimated from a pre-feasibility level pit design work which includes allowances for 3% mining losses and 10% dilution.

It is estimated that there are approximately 6.7 Mt of gold reserves averaging 0.49 grams of gold per tonne and 5.0 Mt of copper reserves averaging 0.44% copper per tonne, so containing approximately 106,000 ounces of gold and 48.7 million pounds of copper. The reserves were estimated based on a $1,600 per troy ounce selling price for gold and a $3.54 per pound selling price for copper. The Proven and Probable Mineral Reserves, at the Botija Abajo and Botija Abajo West areas, are summarized in Table 1.2.

| | | | | | | | | | |

TABLE 1.2

PROVEN AND PROBABLE MINERAL RESERVES WITHIN THE FINAL PIT DESIGN

(AS OF SEPTEMBER 1, 2012) |

| | Au | Cu |

| | Kt | Contained | Recovered | Kt | Contained | Recovered |

| | g/t | oz | g/t | oz | % | Klbs | % | Klbs |

| Proven | 4,753 | 0.55 | 79,448 | 0.438 | 60,524 | 1,820 | 0.44 | 17,747 | 0.32 | 12,640 |

| Probable | 1,970 | 0.25 | 27,291 | 0.201 | 20,642 | 3,181 | 0.44 | 30,971 | 0.32 | 22,156 |

| | | | | | | | | | | |

| Total | 6,723 | 0.49 | 106,739 | 0.376 | 81,166 | 5,001 | 0.44 | 48,718 | 0.32 | 34,796 |

Numerical differences may exist in table values due to rounding

Reserves include 3% Mining Losses and 10% Dilution | | | | | | |

Based on the metallurgical test work and design, Petaquilla is expected to recover and produce approximately 81,000 ounces of gold and 34.8 million pounds of copper from these reserves. The Mineral Resources are inclusive of the Mineral Reserves and there are no estimated Measured and Indicated Mineral Resources in addition to the above stated Reserves at the present time.

The author affirms that the reserve estimate and summary presented is in accordance with NI 43-101 technical standards.

| |

| 1.11 | MINING AND PROCESSING OPERATIONS |

Mining, using open pit methodology, will be undertaken by the same mining contractor who is currently mining at the adjacent Molejón mine. Minimum stripping is necessary as the gold only section of the ore body surface outcrops.

The upper, gold only orebody section, that approximates 1.5 million tonnes (Mt) and has a copper grade of less than 0.05% copper will be trucked to one of the existing Molejón crushers, and then heap leached in new heaps alongside existing Molejón heap leach pads. The resulting pregnant solution will be piped to

| | |

| Project 12-208 (NI 43-101) | 5 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

the Molejón gold mill and treated separately in a new ADR plant. The underlying gold/copper zone of some 5.23 Mt will be trucked to the Molejón mill and treated through its own dedicated circuit comprised of crushing, grinding, and flotation to produce concentrates containing gold and copper. Under this scenario, the heap leach operation would have a life of approximately 15 months and the milling operation a life of approximately 6 years. The LOM (including the subsequent copper production) stripping ratio is 1.46 to 1 (waste to ore). Based on Molejón test work on similar type ore, heap leach recoveries are forecast to be 80%. Metallurgical data obtained from new flotation test work indicates gold and copper recoveries of 75% and 72%, respectively.

| |

| 1.12 | PROCESS-RELATED STUDY RECOMMENDATIONS |

Care will be needed to ensure that any oxidation of the sulfides in the fresh material will not provide any acid solutions at the end of the heap leach. The preponderance of highly alkaline oxide leached material should be sufficient to ensure that there is more than sufficient chemical capacity to neutralize any acid generated by subsequent oxidation of the low-grade sulfuric material. It is recommended that this issue be given further study to confirm this conclusion during the heap leach planning phase.

| |

| 1.13 | MINERAL RESOURCE AND RESERVE RECOMMENDATIONS |

The authors recommend that, for the subsequent feasibility level review, the resource and reserve model is further refined using specific data obtained from the Botija Abajon and Botija Abajo West properties.

The authors have made use of abundant information provided by PML, previous owners and operators, consultants, PML internal files, public information, and Behre Dolbear’s files and reports on Molejón. This information covered concession, environmental, geology, exploration, drilling, core and data handling, sampling preparation and assaying procedures, QA/QC protocols, historic resource estimates, current resource and reserve estimates, and mine planning.

The authors have no reason to believe that the information used in the preparation of the report is invalid or contains misrepresentations.

The authors, by virtue of their review and estimate of the project resources and reserves, affirm that the resource and reserve estimates are in accordance with CIMM Definition Standards. The authors have no reason to infer that the information used in the preparation of the report is invalid or contains misrepresentations. The technical program recommended herein is based on the project technical data that has been judged appropriate.

| | |

| Project 12-208 (NI 43-101) | 6 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

2.0 INTRODUCTION

Petaquilla Minerals Ltd. (PML) PML commissioned Behre Dolbear to undertake the preparation of the NI 43-101 Technical Report. Behre Dolbear then assigned the authors of this report to undertake this commission.

This report was prepared to demonstrate the economic viability of the gold only mineralization for which production PML is the beneficiary and the gold/copper mineralization in the Botija Abajo main and west deposits using pre-feasibility study analysis levels of estimated capital and operating costs, metallurgical recoveries, pit design, mine planning and scheduling, and financial analysis

| |

| 2.3 | MAIN SOURCES OF INFORMATION |

| |

| 2.3.1 | Main Sources of Information by the Authors |

Information provided in this report comes from different sources that are listed in Section 27.0. However, a short list of documents that constitute the principal source of information follows.

AAT Mining Services, 2007, Data Usability Assessment. Petaquilla, Botija & Valle Grande Copper Deposits. Colon Province, Panamá. Prepared for Petaquilla Copper Ltd., February 2007.

AAT Mining Services, 2007, Data Usability Assessment. Resource Estimate of the Molejón Gold Deposit through September 2007. Colon Province, Panamá. Prepared for: Petaquilla Gold Ltd. October 2007. Prepared by Sean C. Muller, P.G., AAT Mining Services, Centennial, Colorado.

AAT Mining Services,2007, Technical Report on the Gold and Copper Resources Contained at the Botija Abajo and Brazos Deposits, Colon Province, Panama July 2007, AAT Mining Services, Centennial, CO, USA

AAT Mining Services, 2007, Copper and Gold Resources along the El Real Corridor, Colon Province, Panama Prepared for Petaquilla Minerals, Ltd. AAT Mining Services Centennial, CO, USA. December 2007

AMEC Americas Ltd., 2007, Petaquilla Project Panamá, NI 43-101 Report, Prepared for Teck Cominco Ltd., Inmet Mining Corporation and Petaquilla Minerals, Ltd. Effective Date November 30, 2007.

Behre Dolbear & Company, Inc., 2012, Mine Design and Mine Plan.

Behre Dolbear & Company (USA), Inc., Molejón Project NI 43-101 Technical Report, May 2012.

| | |

| Project 12-208 (NI 43-101) | 7 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

Fluor Daniel Wright, Ltd., 1997, Adrian Resources Ltd., Petaquilla Project, Scoping Study and Valuation, February 1997.

Petaquilla Minerals, Ltd., 2007-2009, Molejón Deposit Databases. Drill Hole and Map Compilation.

Petaquilla Minerals, Ltd., 2006-200u, Botija Abajo and Botija Abajo West Deposit Databases. Drill Hole and Map Compilation.

Teck Corporation – Simons Mining Group, 1998, Petaquilla Project Feasibility Study, January 1998.

| |

| 2.3.2 | Main Sources of Information by Area |

Abundant geological information is available in a number of reports, including the 1997 Fluor Daniel, 1998 Simons, 2007 AMEC, and 2007 AAT reports. Most of this information is based on the original work carried out by UNDP (1969), PMRD (1969-1980), Inmet and Adrian (1990-1995), and Teck (1994-1997) and by PML between 1996 and 2012.

The 2007-2009 PML Data Base of drill surveying, sampling, assaying, core logging, geotechnical information etc., is the main and most complete source of information as regards the different exploration campaigns carried out at Molejón, Botija Abajo, and Botija Abajo West through 2009, with summary tables and a short description of activities for each of the drilling campaigns.

| |

| 2.3.2.3 | Data Handling–QA/QC |

Petaquilla Gold Ltd. commissioned Sean Muller of AAT Mining Services to make a thorough review and a Resource Estimate through September 2007 at Molejón and through December 2007 at Botija Abajo and Botija Abajo West, including the evaluation of data collected during the drilling campaigns, and to verify that the data would be suitable for NI 43-101 resource and reserve estimates and mine planning.

The AAT reports conclude that the 2006-2007 drill core samples were analyzed to Industry Standards with minimal variance of protocols or analytical results and where variance in 2007 data were obvious; these variances were investigated and resolved in all instances. The variances were usually due to transcription errors.

In order to comply with all requirements for the environmental approval process for the proposed mine, Petaquilla Gold, S.A, submitted an Environmental Impact Study Category III, for the implementation of the Molejón Mining Project adding other measures mandated by the ANAM. The ANAM on November 26, 2008, issued Resolution DIEORA IA-809-2008, approving the EIS of reference. In accordance with Contract Law Number 9 of February 26, 1997, the Ministry of Commerce and Industry of the Government of Panamá issued a letter to the Company dated November 18, 2009,

| | |

| Project 12-208 (NI 43-101) | 8 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

authorizing Petaquilla’s subsidiary, Petaquilla Gold, S.A., to initiate commercial production at its Molejón gold mine.

Behre Dolbear has performed a series of studies for PML, including the Petaquilla Copper report, precious metal and aggregate resources, mine design and mine plan for high-grade, low-grade, and aggregate resources, and reserve/resource estimates at Molejón (BDCI, MO 2011).

Between 2010 and 2012, several site visits to the Botija Abajo property and the adjacent Molejón mine have been made by the Behre Dolbear professionals in the areas of geology, mining, and metallurgical process.

| | |

| Project 12-208 (NI 43-101) | 9 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

3.0 RELIANCE ON OTHER EXPERTS

Technical data were supplied by Petaquilla Minerals and its agents and drawn from other public and technical information sources. The authors reviewed and appraised these data and information sources and believe that the information used in the preparation of this report and in its conclusions and recommendations is valid and appropriate considering the status of the project and the purpose for which the report has been prepared.

| |

| 3.1 | NI 43-101 REPORT PARTICIPANTS |

The authors conducted an independent technical review of Petaquilla Mineral’s Molejón gold project in the Province of Cocle, Panamá. Several site visits were made to the property during the period 2007 through 2010 and during 2011 by Behre Dolbear’s Qualified Persons, as defined in NI 43-101. These Qualified Persons are:

Michael D. Martin, Project Manager, (Mine Design – Mine Planning)

Baltazar Solano-Rico (Geology, Environmental, Coordination)

Richard S. Kunter (Heap Leach Analysis)

The following authors also participated in the development of the present document but did not make a site visit.

The authors reviewed technical data, reports, and studies as well as information provided by Petaquilla Minerals, inspected the subject mineral concessions, and reviewed the technical data derived at the properties by Petaquilla Minerals and others during their tenure of the concessions. The author’s review was conducted on a reasonableness basis and it has been noted herein where such provided information engendered questions. Except for the instances in which we have noted questions, the authors have relied upon the information provided as being accurate and suitable for use in this report.

Information provided by Petaquilla indicates that the rights to the mining concessions have been established by the enactment of the “Ley Petaquilla,” a contract with the Government of Panamá that guarantees land tenure and the right to develop and exploit of the mineral deposits.

The authors obtained public information from the “Dirección Nacional de Recursos Minerales” (DNRM) indicating that the concession is included in the list of Concessions of Metallic Minerals and granted by Contract No. 9 of February 26, 1997 or “Ley Petaquilla” (Table 3.1).

TABLE3.1

METALLICMINERALCONCESSIONS

(DNRM, NOVEMBER30, 2008)

|

| | | | | |

| No | EXP. | EMPRESA | MINERAL | CORREGI

MIENTOS | DISTRITOS | PROVINCIAS | ZONAS | HAS | STATUS |

| 17 | Contrato Ley | MINERA

PETAQUILLA, S.A. | cobre, oro y

otros | San Jose del

General y

Cocle del Norte | Donoso | Colon | 4 | 13,600 | Contrato No 9 del 26/02/97

Gaceta 23,235 de 28 feb. 97 |

| | |

| Project 12-208 (NI 43-101) | 10 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

Copies of the official documentation are in the files of PML.

The authors did not conduct a due diligence review of legal, land tenure, or concessions information, and we are not qualified to express a legal opinion with respect to the property titles and the status of current ownership and possible encumbrances.

| | |

| Project 12-208 (NI 43-101) | 11 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

4.0 PROPERTY DESCRIPTION AND LOCATION

| |

| 4.1 | MINERAL PROPERTY DESCRIPTION |

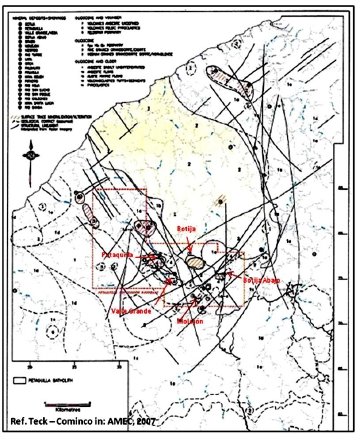

The subject area of this report is located within the so-called El Real northeast-trending structural lineament where the Molejón, Brazo, Botija Abajo West, and Botija Abajo mineral deposits have been located.

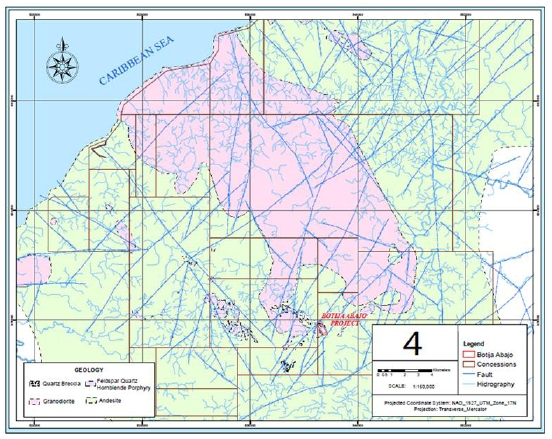

The Botija Abajo deposit is fully contained within the Petaquilla Zone 4 Concession, of 1,800 hectares, part of the Petaquilla block of claimsgranted to of Minera Petaquilla, S.A. (MPSA) by enactment of theFebruary 26, 1997 Law Number 9 or “Ley Petaquilla.”This area is located at80° 37 27 114 Wlongitudeand 8° 49 23 339 N Latitude.

On October 12, 2004, the Company changed its name from Adrian Resources Ltd. to PML to correspond with the Company’s Petaquilla project in Panamá. On June 1, 2005, the Company entered into the Molejón Gold Project Agreement with Teck, Inmet, and MPSA. Under the agreement, PML has the exclusive right to develop any gold deposits in the remainder of the MPSA concessions, provided that such right does not impair or impede MPSA’s interest or ability to exploit copper deposits on the concession remainder. A deposit is a gold deposit if more than 50% of its net present value, as a developed mine, would derive from its gold or other precious metals content.

The original concession area contains several known mineral deposits, including the Petaquilla, Botija, Valle Grande, and Molejón deposits. Copper interests (Petaquilla, Botija, and Valle Grande) were passed to Petaquilla Copper and eventually to Minera Panamá (Inmet) and gold interests, including the Molejón gold deposit and other satellite deposits, such as Botija Abajo, were retained by Petaquilla Gold, S.A. (part of PML). Property history details are included in Section 6.0 and Mineral Concessions information in Table 4.1 and Figure 4.1. Molejón is the only operating mine in the region. It was developed by PML and has a current operating rate in the order of 3,000 tonnes per day (tpd), including an opencast mine operation and a cyanide gold-processing plant. Commercial production began on January 8, 2010.

| | |

| Project 12-208 (NI 43-101) | 12 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

| | | | | |

TABLE 4.1

MOLEJÓN MINE AREA TITLED MINING CONCESSIONS (LEY PETAQUILLA) |

| | Concession Name | Date Granted | Expiration Date | Hectares | Concessionaire |

| 1 | Petaquilla Zona 1 | February 26, 1997 | February 25, 2017 | 4,000 | Minera Petaquilla, S.A. |

| 2 | Petaquilla Zona 2 | February 26, 1997 | February 25, 2017 | 6,600 | Minera Petaquilla, S.A. |

| 3 | Petaquilla Zona 3 | February 26, 1997 | February 25, 2017 | 1,200 | Minera Petaquilla, S.A. |

| 4 | Petaquilla Zona 4 | February 26, 1997 | February 25, 2017 | 1,800 | Minera Petaquilla, S.A. |

| | | | | | |

| | Subtotal | | | 13,600 | |

| | |

| Project 12-208 (NI 43-101) | 13 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

| |

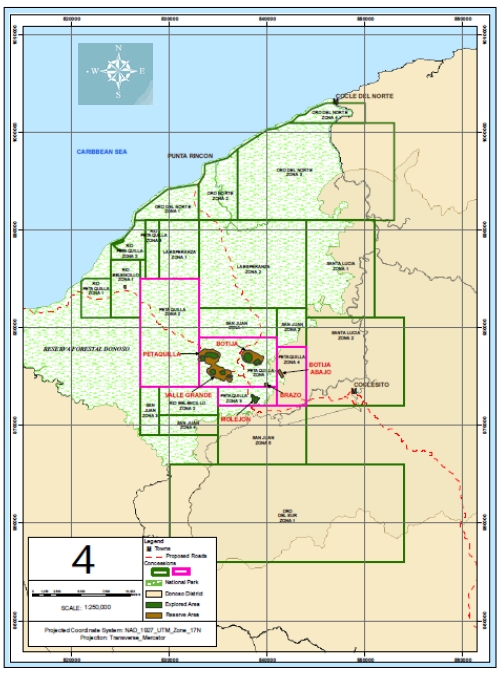

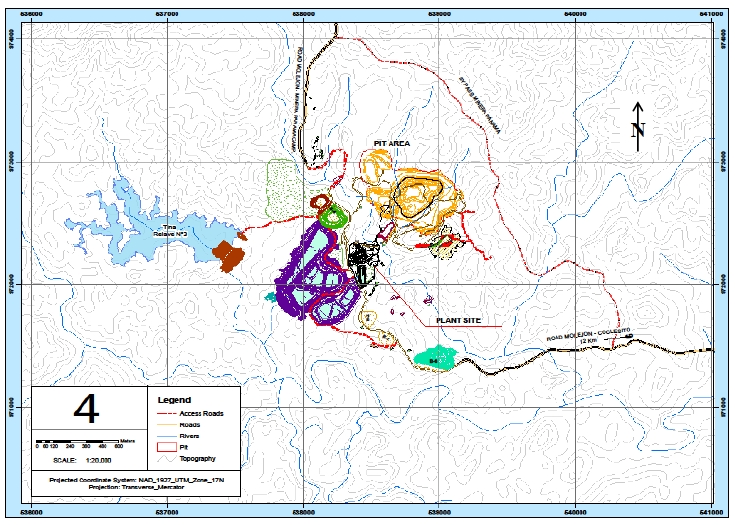

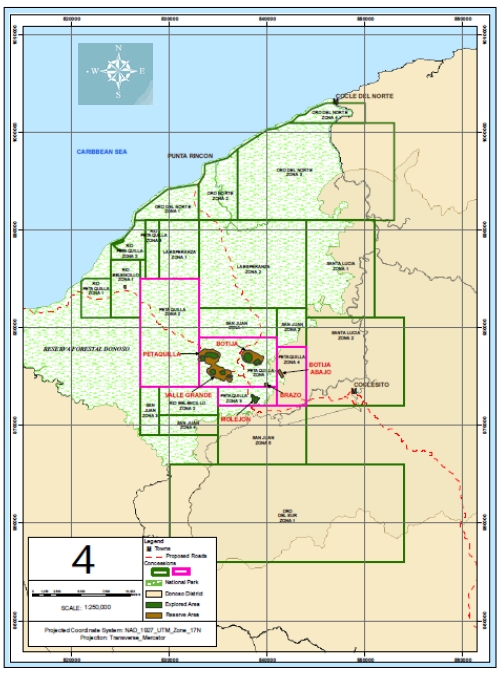

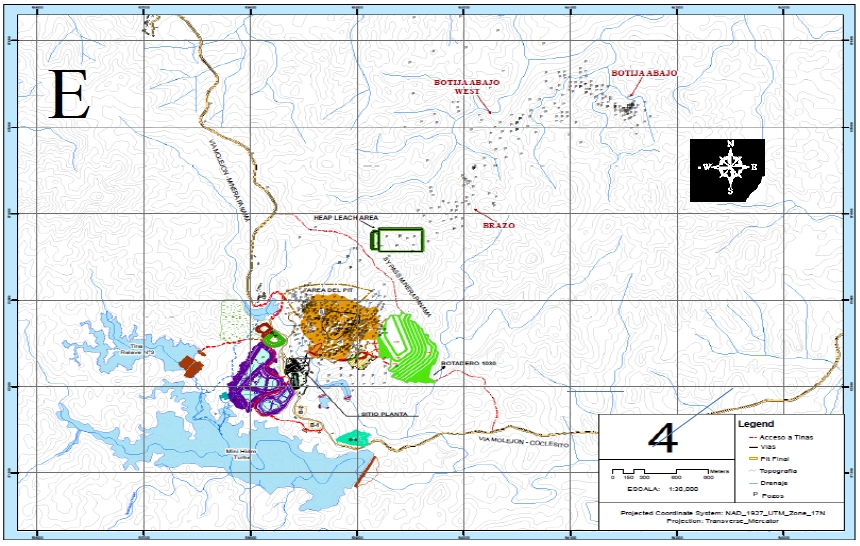

| Figure 4.1. | Petaquilla Concessions and Botija Abajo location and access map ( 2009) |

| |

| 4.1.1 | Mineral Property Location |

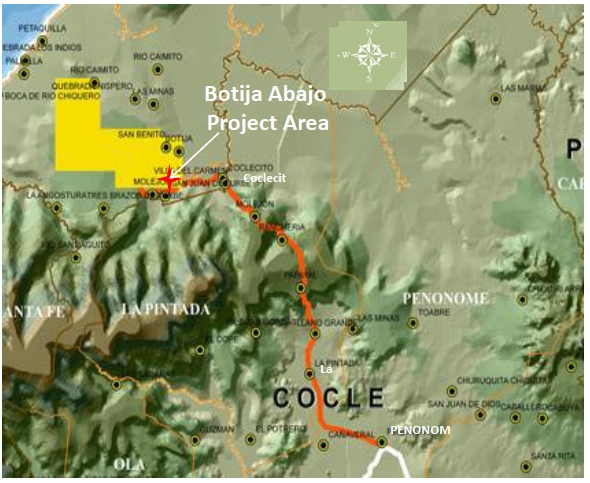

The Botija Abajo gold exploration property is located in the Donoso District, Colon Province, Republic of Panamá in the Petaquilla Concession. The site is roughly 130 km west of Panamá City (Figure 4.2).

| | |

| Project 12-208 (NI 43-101) | 14 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

| |

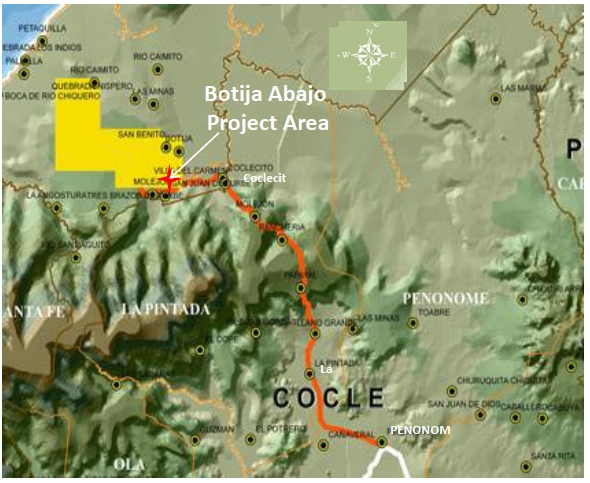

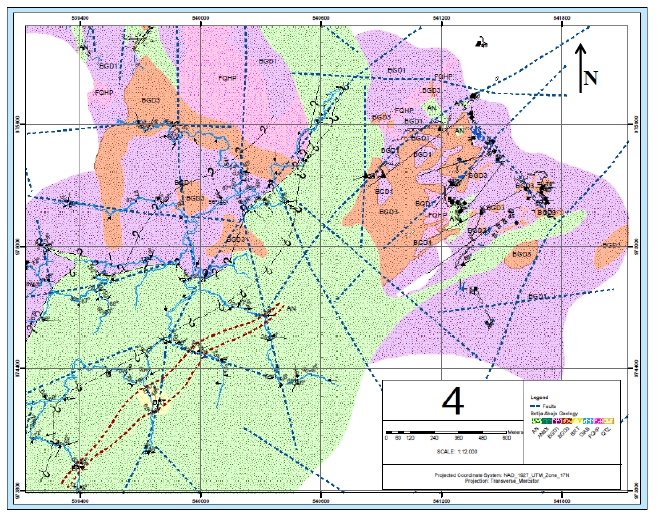

| Figure 4.2. | Botija Abajo Location map (2009) |

| | |

| Project 12-208 (NI 43-101) | 15 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

The Petaquilla Zone 4 Concession, of 1,800 hectares, is part of the Petaquilla Block of claims originally in the hands of Minera Petaquilla, S.A. (MPSA), 100%-owned by Adrian Resources (later Petaquilla Minerals Ltd., PML), Teck Corp., and Inmet Mining Corp. Minera Petaquilla, S.A., by enactment of the February 26, 1997 Law Number 9 or “Ley Petaquilla” as commonly known, and as published in the Official Gazette February 28, 1997. MPSA was granted four mining concession comprising 13,600 hectares (ha) divided in 4 different contiguous concessions in the Jurisdictions of Northern Coclé and San José del General in the Donoso District, Province of Colon.

Table 4.1 shows the characteristics of titled mining concessions as granted by theLey Petaquilla, for a period of 20 years (due February 25, 2017), that can be renewed twice for a total of 60 years, as long as a formal request is submitted 120 days before expiry.

PML is at various stages of the process of applying for and being granted rights in respect of additional claims in the San Juan, Río Belencillo, Esperanza, Rio Petaquilla, and Oro Norte areas, located in the surroundings of Botija Abajo. Figure 4.3 shows the location of these claims (in green).

| | |

| Project 12-208 (NI 43-101) | 16 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

| |

| Figure 4.3. | Mineral concessions granted by Law Number 9 (Ley Petaquilla) (1997) |

| |

| 4.1.2 | Mineral Concessions and Obligations |

Minera Petaquilla, S.A. is a Panamanian Company established in 1997 to acquire the rights of the mineral concession in the subject area. This concession was granted by the Government of Panamá through a Contract Law named “Ley Petaquilla, Contrato N° 9 del 26/02/97” published in the National Gazette 23,235 – February 28, 1997 and approved by the National Assembly. A copy of the same can be

| | |

| Project 12-208 (NI 43-101) | 17 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

found in the files of PML and at http://docs.panama.justia.com/federales/leyes/9-de-1997-feb-28-1997.pdf (Figure 4.3).

The Botija Abajo deposit is fully contained within the Petaquilla Zone 4 Concession, of 1,800 hectares, part of the Petaquilla Block of claims that is bound by PML’s San Juan Zona 2 to the North, Santa Lucía Zona 2 to the East, San Juan Zone 5 to the South, and MP’s Petaquilla Zone 3 and Petaquilla Zone 1 to the West. Other deposits with gold mineralization identified in the area include the Botija Abajo and Brazo mineralized zones (Figure 4.3).

Ley Petaquilla

This Law gives the land tenure, property rights, and a special tax regime for the development and operation of the project. Some of the most important rights and conditions established by this Law are:

The mineral concession is granted for a period of 20 years with two renewal periods of 20 years each for a total of 60 years.

Construction of the mine should start within three years of submission of a feasibility study to the state with allowance to delays, if copper prices are below a certain limit.

An environmental bond must be provided before starting production.

The Company will be granted rights of way for the construction of access roads to the Caribbean Sea.

Taxes on interest will not be retained to international lenders nor retained to foreign stockholders in profit sharing revenues.

The owners will be exonerated of paying the income tax (except for royalties on mineral production) until construction financing has been completed.

The Company will be able to carry forward incurred losses for up to five years.

Taxes will not be paid on retained earnings.

There will be a government income tax credit upon all expenditures made to construct the required infrastructure although no depreciation on these will be allowed.

Most goods and supplies required by the project will be exempt of import duties.

There will be a government income tax credit upon all tax payments of more than US$100,000 to any municipality in any year.

A ruling for tax payment stability was designed to protect the Company from any increase in taxes and/or new taxes, but it will be able to take advantage of any tax reduction.

Future changes in the legislation will be applied to the owners except when these are contrary, inconsistent, or incompatible with the “Ley Petaquilla.”

The Company will pay to the state, subject to some deductions established in Clause 10 of the Petaquilla Law Number 9, the following mining taxes per hectare (ha) of those zones included as Project Areas, according to Clause 4th of the Petaquilla Law and annual royalties on extracted minerals according to Table 4.2.

| | |

| Project 12-208 (NI 43-101) | 18 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

| | | | | |

TABLE 4.2

MINERAL PRODUCTION TAXES AND ROYALTIES UNDER THE PETAQUILLA LAW |

| Type of Mineral | First Five

Years

(B) | From 6thto

10thYear

(B) | 11thYear

Onward

(B) | Royalty

(%) |

| I | Industrial Minerals Construction

Materials Excluded | 0.75 | 1.25 | 2.00 | 2 |

| II | Metallic Minerals Precious Metals

Excluded | 1.00 | 2.00 | 3.00 | 2 |

| III | Precious Metals (Alluvial) | 1.00 | 2.00 | 3.00 | 4 |

| IV | Precious Metals Alluvial excluded | 1.00 | 2.50 | 3.50 | 2 |

| V | Fuel Minerals, Hydrocarbons

Excluded | 0.50 | 1.00 | 1.00 | 2 |

| VI | Reserve Minerals | 1.50 | 3.00 | 4.00 | 2 |

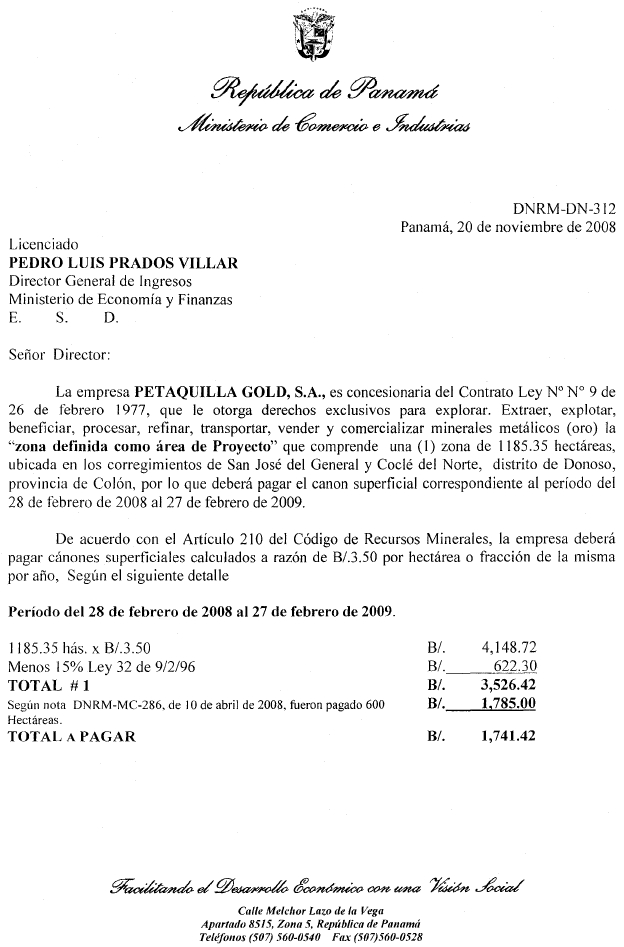

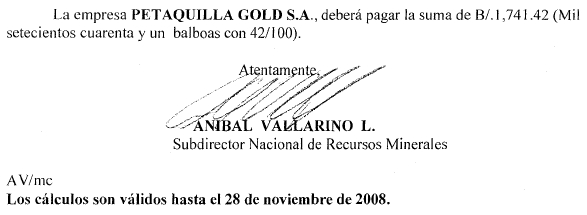

Taxes are calculated by the Ministry of Economy and requested from the company (in this case, Petaquilla Gold, S.A.). As an example of tax calculations for 2008 were:

| | | | |

| February 2008 to February 2009 Period | |

| 1,185.35 ha at $3.50 per ha | B. | $4,184.72 | |

| Less 15% according to Law 32 of 9/02/06 | B. | $622.30 | |

| Total | B. | $3,526.42 | |

(Reference:Ministerio de Comercio e Industria, 2008, Comunicación DNRM-DN-312. Cánones Superficiales, Appendix 3.0)

In relation to the contract law under which the Petaquilla concession was granted by the Government of the Republic of Panamá, Minera Petaquilla, S.A. through Petaquilla Minerals, S.A. delivered a multiphase Mine Development Plan to the Government of Panamá that was approved in September and November of 2005.

The first phase in the plan was the development of the Molejón Gold Deposit by Minera Petaquilla commencing in 2006. The development of the Petaquilla copper deposit is included in subsequent phases of the plan, and will be the responsibility of Minera Petaquilla, S.A., the joint venture company previously owned by Petaquilla Minerals, Teck, and Inmet (before September 19, 2008) and currently 100%-controlled by Inmet.

Under PanamanianLey Petaquillaor Law Number 9, 1997, the concession rights to the Mina de Cobre Panamá (then Petaquilla) property were granted to Minera Petaquilla, S.A. (now Minera Panamá, S.A.). This project-specific law gave Minera Petaquilla rights over the gold, copper, and other mineral deposits for the purposes of exploring, extracting, processing, transporting, and marketing of all base or precious minerals located in the 13,600 ha Concession Area. The Molejón Gold Project Agreement, executed 1 June 2005 by and between Teck Cominco Limited, PML, Inmet Mining Corporation, and Minera Petaquilla, S.A. (now Minera Panamá, S.A.),assigns to PML the surface and mineral rights over 1,186 ha located within the Concession Area (Molejón Concession)to permit PML to independently develop the Molejón gold deposit as the first phase of a multiphase development of the Concession Area. PML was also given the right to explore and mine gold deposits in the larger Concession Area, while Minera

| | |

| Project 12-208 (NI 43-101) | 19 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

Petaquilla retains the right to develop any copper deposits on the Molejón Concession (PML Communication, L. de Carrizo, 19-04-11).

The map of Figure 4.3 (UTM NAD 27 coordinates) shows the boundaries of the concession and surface rights (in red) as granted by Petaquilla Law Number 9. Topographic control was based on surveyed targets that were identified on the 1978 1:60,000 scale photograph. Absolute accuracy to the UTM NAD 27 coordinate system was reported to be ±12 meters and relative accuracy is ±3 meters on clear ground (AMEC, 2007). This map also shows the location of the three main subject deposits, namely Botija Abajo within the Petaquilla Zona 4 concession, Botija Abajo West and Brazo (Petaquilla Zona 1) and also the Molejón operation within the Petaquilla Zona 1 concessions.

We were informed that PML is at various stages of the process of applying for and being granted rights in respect of claims in excess of 850 km2in the area.

According to Ley Petaquilla, land tenure, property rights, and a special tax regime for the development and operation of the project were granted.The Company will pay to the state, subject to some deductions established in Clause 10 of the Petaquilla Law Number 9, the following annual surface taxes (Table 4.3).

| |

| | |

TABLE 4.3

SURFACE TAXES UNDER THE PETAQUILLA LAW |

| Years | US$ per Hectare |

| 1stand 2nd | $0.50 |

| 3rdand 4th | $1.00 |

| 5thand Onwards | $1.50 |

Outside of the concessions granted by the Petaquilla Law, in order to purchase or rent any private land property, PML is subject to the regular procedures for acquisition between particulars, including a purchase-sale contract, transfer of property rights, and registration on the National Public Registry as established by corresponding Laws and Regulations. Private property purchases information is in the files of PML.

It is important to note, as described above, that according to the Molejón Gold Project Agreement dated June 1, 2005 between Teck, Inmet, MPSA, and PML, PML retained the rights to those targets and mineral deposits with predominant gold mineralization, such as Molejón and Botija Abajo within the Petaquilla block of concessions granted by the Petaquilla Law, shown in Table 4.1 and a copy of which is available from PML.

It can be considered that the Brazo, Botija Abajo West, and Botija Abajo are satellite deposits of the Molejón gold deposit and operation, and are located, as previously established, within the same block of Claims granted by the Petaquilla Law; therefore, all rights, permits, and environmental liabilities are contained within those of the Molejón deposit, currently in operation.

Section 20.0 provides a detailed account of all environmental issues, permitting and potential risks related mainly to the Molejón operation but also applicable to satellite deposits and future operations.

| | |

| Project 12-208 (NI 43-101) | 20 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

5.0 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, AND PHYSIOGRAPHY

The Botija Abajo mineral deposit is located in the Donoso District, Colon Province. It is 130 km west of Panamá City and 45 km northwest of the city of Penonomé, a service center of some 105,000 inhabitants on the Pan American Highway. Access to the general Molejón area, from Panamá City, is west along the Pan-American Highway to km 149.7 at Penonomé (a service center of some 105,000 inhabitants on the Pan American Highway), then 13 km, by paved road, to La Pintada (5000 inhabitants), and 41 km by a well-maintained gravel road, that was constructed in 2006 to the Molejón mine, process plant, camps, and offices. The road passes through La Pintada, a town of 5,000 people and Coclecito (approximately 700 inhabitants), which is the closest settlement to the project area, approximately 7.35 km to the east-southeast of the center of the Botija Abajo (Figure 5.1).

| |

| Figure 5.1. | Molejón Mine-Botija Abajo Project access map (2007) |

From Molejón, currently there is no access to the general Botija Abajo area, 4 km to the northeast and access is made along creeks and jungle trails walking, or by helicopter to several pads that have been kept and originally serviced drilling stations of the different exploration campaigns.

| | |

| Project 12-208 (NI 43-101) | 21 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

Currently, Minera Panamá, S.A. is in the process of realigning the road through the Molejón property, around the mine workings for use during the initial construction phase of the copper project, until a permanent Eastern Access Road is ready for use. This road will be roughly 12.6 km long, starting approximately 5.2 km west of the town of Coclecito. A bridge has been installed across Río Botija to allow the road to continue north. During late 2010 and early 2011, Minera Panamá constructed two concrete bridges across the Molejón and San Juan de Turbe rivers facilitating access to the properties.

Although access to the area is difficult due to the heavy rains in the region, permanent running rivers, heavy forests, and deep clayey soil, the preliminary activities for the construction of the Petaquilla Copper mine and operations at Molejón, with the construction of bridge/culverts and gravel cover have resulted in a serviceable road that allows the continuous access to the Molejón mine.

Physiography of the area is juvenile in nature with strong, locally rugged and steep slope topography and deepy incised creeks. The area is located on the southern slope of the easternmost extension of the Central American Volcanic Belt, within the Northern Lowlands of Panamá, below 150 meters above sea level (masl).

Topographic relief shows elongated ridges running northwest and northeast. Locally the Botija Abajo hills are characterized by an elongated northwest-southeast-trending ridge dissected by two northeast-trending creeks, which join another structurally-controlled stream that limits the ridge to the north. Elevations vary between 80 masl at the northwestern end of the mineralized ridge to about 150 masl at the southeastern corner. Topography is moderately rugged, although heavily covered with jungle and deeply incised streams (Figure 5.2). Morphology shows a marked structural grid controlled by major geological features and defined by a major series of northwest-southeast and northeast-southwest creeks dissected in the rocks flowing generally to the north.

| |

| Figure 5.2. | Botija Abajo physiography |

| |

| 5.3 | VEGETATION AND LAND USE |

Vegetation is classified as lowland tropical rain forest. The project is located within one of the few remaining intact tracts of primary rainforest near the Mesoamerican Biological corridor in a relatively

| | |

| Project 12-208 (NI 43-101) | 22 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

pristine environment. Most of the concession area is covered with evergreen forest, either primary or secondary, with very little human-induced change. Land uses are limited to predominant cattle grazing, subsistence agriculture, and other rural activities, very localized to small areas in the southern section of the Petaquilla Concession area in the vicinity of Coclecito and a number of small farms along the access road. Local substantial deforestation is only observed occurring along major drainages near small population centers. There is no commercial timber extraction in the Coclé Province; however, local substantial deforestation is observed occurring along major drainages near small communities (Figure 5.3).

| |

| Figure 5.3. | Botija Abajo vegetation |

The general climate in the northern region of Panamá is tropical monsoon, characterized by high humidity and rainfall with a rainy season from April to November and maximum rainfall registered during October and November. According to the Köppen classification (IGNTG, 1988), the climate is wet tropical, with rainfall fluctuating between 3,000 millimeters per annum (mm/a) and 5,000 mm/a, with an average of approximately 4,700 mm/a. In the tropics, there is not much seasonal variation in temperature; average temperatures range between 25°C and 30°C. The median temperature during the coolest month is above 18°C. Seasonal differences are mostly manifested in rainfall variations.

Locally, the Molejón-Botija Abajo area falls within the rainfall shadow of the Continental Divide, and the climate is characteristic of tropical rainforests. Precipitation is high throughout the year, with a total precipitation of approximately 3 meters per annum. The heaviest precipitation is evenly distributed from May to December. January, February, and March are typically the driest months (Simons, 1998). However, data collected at a weather station at the Colina camp for the period July 1995 to June 1996 indicated rainfall of 5.4 meters with much of the heaviest rainfall in the “dry” season in an especially wet period throughout Panamá.

The Molejón property has an equatorial climate with high precipitation and high humidity. Temperatures reach 25°C to 30°C year round. Humidity is rarely below 85% in the project area. The 100-year, 24-hour storm precipitation has been calculated at 337 mm and the 24-hour probable maximum precipitation was estimated at 1,008 mm at the nearby Petaquilla Copper Project.

| | |

| Project 12-208 (NI 43-101) | 23 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

The extreme rainfall in the project area has a profound impact on the mining activities, due to limited access, extreme working conditions, lack of outcrops and hard rock, development of thick saprolite cover, etc. Major impacts are in the pit area of the mine and in the excess of clay delivered to the crushing section of the Molejón plant. Clay is expected to be a problem at Botija Abajo in the first meters of overburden and laterite/saprolite cover, but less of a problem, as the proposed pit deepens into levels with hard rock.

Logistics, exploration development, and mining activities have to be planned according to weather and flying conditions, etc.; however, these activities can be carried out year-round with temporary limitations due to more than usual heavy rains and stream run-offs. It is expected that a road to access the Botija Abajo area from Molejón will be built and carpeted with crushed stone as well as maintained for continuous operation.

Local resources, other than the gold deposit at Molejón, include abundant running water, rock aggregate for road base, minor timber, and limited manpower, restricted to Coclecito and other small settlements. Agriculture and grazing activities do not occur in the area. Mining-related operators and skilled personnel are imported from elsewhere in Panamá and from abroad. Coclecito is the largest and closest settlement to Molejón, approximately 12 km to the east.

Approximately 6,000 people reside within a 20 km radius of the proposed mine, mainly in small communities varying in size from 100 to 600 people. Most of these communities have no infrastructure, only rudimentary health facilities, and basic schooling. Average income ranges from $300 to $400 per month per family, with many families dependent on subsistence agriculture or activities, such as artisanal mining. Water resources for human use are abundant, although drinking water quality is poor, with high levels of fecal coliform in many drinking water sources (Petaquilla Minerals S.A., 2010, www.minerapanama.com).

Considering that Botija Abajo is a satellite deposit to Molejón, it is planned to haul the ore to the process plant; therefore, activities will be reduced to stripping, development, and mining operations. After more than five years of operations at Molejón, a number of local mine and equipment operators have been formed and it is planned that the Molejón staff and operators will carry out operations at Botija Abajo.

Currently, most operators and staff are lodged at any of the Molejón camps and it is planned that the Botija Abajo operators will stay there too and be transported to the mine daily on a shift basis.

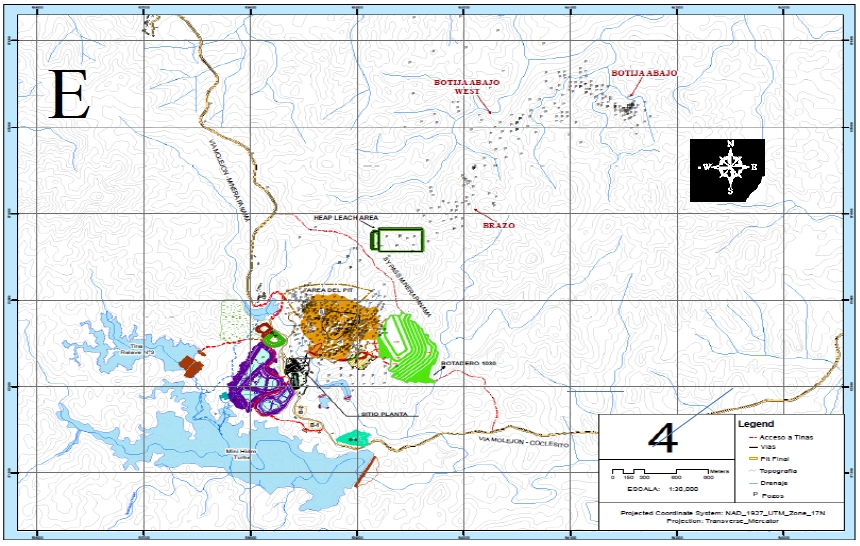

It has been mentioned that operations at Botija Abajo will rely on existing infrastructure at Molejón (Figure 5.4) and only mine-related infrastructure and facilities will be created on site. Basically, there is no local infrastructure at Botija Abajo other than several helicopter pads distributed in the exploration area that were extensively used during the exploration days to fly most core boxes and supplies from Molejón to drill pads and back. Some of these helicopter pads are maintained for current and future use. Transportation of local operators and personnel is partially covered by Company vehicles that serve the neighboring settlements and provide daily service. No public transportation is available between Coclecito, the largest town in the area, and Penonomé.

| | |

| Project 12-208 (NI 43-101) | 24 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

| |

| Figure 5.4. | Molejón - Botija Abajo area infrastructure map (2012) |

| | |

| Project 12-208 (NI 43-101) | 25 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

Some of the infrastructure that will have to be created at Botija Abajo are the access roads from Molejón and site roads to the pits, waste dumps; local power needs will be covered with portable diesel generators. Most other infrastructure needs will make use of the Molejón facilities, including crushing, milling, and eventual flotation and heap leaching and tailings disposal facilities as well as other requirements, such as a heavy equipment shop, magazine, camps, office buildings, etc. A more detailed account of existing infrastructure at Molejón is included in Section 18.0 of this report.

| | |

| Project 12-208 (NI 43-101) | 26 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

6.0 HISTORY

In recent times, the establishment of the United Nations Development Program (UNDP), in 1965, resulted in the funding of mineral exploration activities throughout Latin America, including Panamá, in collaboration with local governments. Systematic exploration in the project region covered an original area of 810 square kilometer (km2) where copper mineralization related to the late Tertiary intermediate intrusives was identified, in 1967, by A. Metti, UNDP geologist. Copper-gold-molybdenum-porphyry mineralization was first discovered in the Petaquilla River region during a regional geological and geochemical survey by a UNDP team in 1968.

After the first discovery of copper mineralization, the promising zones were enlarged by geochemical and geological surveying with the location of three main ore bearing prospects, Botija, Petaquilla, and Rio del Medio, as well as five minor mineralized zones that were outlined by July 1969 (Ferencic, 1970), the primary focus was on porphyry copper mineralization. Further exploration by several companies outlined three large deposits and a host of smaller ones, as well as epithermal gold mineralization including the Molejón, Botija Abajo, and other smaller targets. Table 6.1 summarizes the exploration history and ownership of the Petaquilla Concession and provides information about the amount of exploration carried out by each of the different companies involved in the project through the years until the discovery of the Molejón and Botija Abajo deposits and development of the first.

| | |

| Project 12-208 (NI 43-101) | 27 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

| | |

TABLE 6.1

SUMMARY OF EXPLORATION HISTORY AND OWNERSHIP |

| Year | Party | Exploration and Property History Description |

| 1968 – 1969 | United Nations

Development

Program (UNDP) | Regional geological and geochemical survey of central Panamá by the UNDP, widespread silicification and copper mineralization discovered in the area of the Petaquilla and Botija deposits. Stream sediment sampling field magnetometry and preliminary drilling resulted in the discovery of the Petaquilla, Botija, Vega, and Medio deposits. |

| 1969 – 1976 | Panamá Mineral

Resources

Development

Company

(PMRD) | Panamanian government tendered Petaquilla Concession exploration rights to international bidding; concession awarded in 1971 to Panamá Mineral Resources Development Company (PMRD), a consortium of seven Japanese copper companies. Approximately 14,000 meters of drilling at Petaquilla, Botija, Medio, and Vega, totaling approximately 14,000 meters, preliminary Resource and Reserve calculations based on prefeasibility report completed. Feasibility work updated; unsuccessful negotiations with the Panamanian government over terms of production, property abandoned in 1980 for 10 years. |

| 1990 – 1992 | Minnova | Property acquired by Minnova (now Inmet) 80% and Georecursos International S.A. 20%. Exploration activity included regional lithogeochemical sampling. |

| 1991 – 1992 | Minnova-Geotec | Minnova and Geotec, in 1991, completed regional geochemical rock sampling covering the southeastern two-thirds of the original Petaquilla concession. Their work identified anomalous gold (>100 ppb) and arsenic (>12 ppm) values at Molejón area. |

| 1992 – 1993 | Adrian Resources

Ltd. (Adrian) | Adrian Resources (now Petaquilla Minerals Ltd.) was granted an option to earn 40% of Minnova’s interest through cash payments, work commitment, and production of a feasibility study. Adrian subsequently acquired Georecurso’s interest, bringing its total interest to 52%, andstarted formalexploration at Molejón in 1993with preliminary geological mapping and silt and rock sampling.Mapping of quartz vein and quartz brecciasoutcrops returned anomalous gold values between 1.0 and 8.0 g/t gold. |

| 1992 – 1995 | Adrian | Adrian carried out grid-based soil sampling and magnetic surveying, geologic mapping of selected areas, and starting February 1994, drilling of approximately 394 diamond drill holes in Petaquilla, Botija, and other exploration targets. Activity included investigation of the Valle Grande deposit anddiscovery of epithermal gold mineralization at Molejón, as well as identification orinvestigationof several other targets (Botija Abajo,Botija Abajo WestBrazo, Faldalito, Cuatro Crestas, Lata, Orca). |

| | |

| Project 12-208 (NI 43-101) | 28 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

| | |

TABLE 6.1

SUMMARY OF EXPLORATION HISTORY AND OWNERSHIP |

| Year | Party | Exploration and Property History Description |

| 1994 – 1995 | Adrian | Auger drilling was done at 25 meter intervals along lines spaced 50 meters apart in a 1,200 meter by 1,200-meter area. Prospect drilling and magnetic surveys were followed by a second phase of drilling in June 1994. This phase of drilling comprised 4,155.3 meters of drilling in 24 holes and led to the discovery of significant epithermal gold and silver mineralization hosted predominantly within quartz breccia and altered feldspar-quartz porphyry intrusive. Adrian Resources Ltd. completed a further drilling program at Molejón in 1995 comprised of 10,504.4 meters in 94 drill holes. |

| 1997 | Minera Petaquilla | Minera Petaquilla S.A. (Minera Petaquilla) was formed by Adrian Resources, Inmet, and Teck Corp.The Petaquilla Concession was granted by the Government of Panamáto Minera Petaquilla, S.A. through a Contract Law named “Ley Petaquilla, Contrato N° 9 del 26/02/97” covering a total of 13,600 ha. In May 1997, Lakefield (Report No. 4667) conducted metallurgical test work on Molejón samples. This test work included preliminary flotation tests on six Molejón composite samples. |

| 2004 | PML | On October 12, 2004, the Company changed its name from Adrian Resources Ltd. to PML to correspond with the Company’s Petaquilla project in Panamá. In December 2004, the Company resumed exploration within Minera Petaquilla project in Panamá. |

| 2005 | PML, Minera

Petaquilla | On June 1, 2005, the Company, Teck, Inmet, and MPSA entered into the Molejón Gold Project Agreement. As described above,the Company may obtain 100% ofgold deposits within the concession remainder. PML created two companies, Petaquilla Gold Ltd. and Petaquilla Copper. Ltd., handle exploration, development, and operations of gold interests (Molejón, Botija Abajo) and copper deposits, respectively. Minera Petaquilla undertook a large trenching program comprised of 5,000 meters in 113 trenches during the summer of 2005. The trenches were often no more than 2.0 meters deep mostly on weathered material to fresh rock. Minera Petaquilla developed the mine plan (2005) that has been approved by the government. |

| 2006 | PML | In 2006, PML excavated in the generalMolejón area12,294 meters of new trenches and drilled 220 core holes on a 14,005 meter Phase II drill program, including 11,398 meters devoted to infill drilling to confirm resource estimates, 980 meters of condemnation drilling to establish the location of the plant site, and 1,627 meters devoted to exploration drilling. |

| 2006 – 2007 | PML | As of 2007, 10,142.4 metres ofcore drillingwerecompleted on the Botija Abajodeposit: 18 core holes for 2,326.6 metres between 1993 and 1995 by Adrian Resources and 86 holes for 7815.8 metres between 2006 and 2007 by PML. |

| | |

| Project 12-208 (NI 43-101) | 29 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

| | |

TABLE 6.1

SUMMARY OF EXPLORATION HISTORY AND OWNERSHIP |

| Year | Party | Exploration and Property History Description |

| 2007 – 2009 | PML | Inmet buys Petaquilla Copper and makes agreements with Teck creating Cobre Panamá, which is the owner of Minera Panamá, S.A. Currently, there are two companies under the Law Number 9, Petaquilla Gold, S.A. with a concessioned area of 1,186 ha and Minera Panamá, S.A. with the rest of the concession, 12,414 ha. Phase II drilling at Molejón continued into 2007 to enable mine planning. The mine was developed and the processing plant was built. |

| 2008 | | Environmental authorities (ANAM) on November 26, 2008, issuedResolution DIEORA IA-809-2008, approving the Environmental Impact Study Category III, submitted by Petaquilla Gold,S.A., for the implementation of the Molejón Mining Projectand other measures mandated by the ANAM. |

| 2009 | | In accordance with Contract Law Number 9 of February 26, 1997, the Ministry of Commerce and Industry of the Government of Panamá issued a letter to the Company dated November 18, 2009, authorizing Petaquilla’s subsidiary, Petaquilla Gold, S.A., to initiate commercial production at its Molejón gold mine located in the District of Donoso, Province of Colon, Republic of Panamá. |

| 2010 | PML | Commercial production started on January 8, 2010, when an average of 70% of design capacity was maintained continuously for a period of 30 days with metallurgical recoveries near forecast levels. Ore throughput at the process three-ball mills/carbon-in-pulp processing facility was 1,500 tpd with the operating rate planned at 2,200 tpd for the first year of production. Plans at the time were to increase production to 5,000 tpd with the addition of a SAG mill as the supply of mill feed permits. |

| | |

| Project 12-208 (NI 43-101) | 30 | BEHRE DOLBEAR |

|

| Botija Abajo Project – Molejón Mine |

| September 2012 |

It is observed that Table 6.1 provides information regarding most exploration targets found within the concessions granted by theLey Petaquilla, mainly copper (Petaquilla, Botija, Valle Grande, and others); but also includes exploration activities at the Molejón, Brazo, Botija Abajo West, and Botija Abajo Au or gold-copper mineralization. Only the last two are the subject of this report. Most of this information is derived of a summary compilation published in the Molejón NI 43-101 Technical Report (2012) by Behre Dolbear & Company, Inc.

| |

| 6.1 | HISTORICAL RESOURCE AND RESERVE ESTIMATES |

Northeast of the Molejón deposit is a series of intrusives that follow a northeast structural trend known as El Real Corridor. Three additional mineralized areas have been identified along this trend and are known as the Brazo, Botija Abajo West, and Botija Abajo deposits (AAT, December 2007).

| |

| 6.1.1 | H. A. Simons 1998 Report/Adrian Resources |

In the feasibility study prepared by H.A. Simons, Ltd., it is referenced, a claim by Adrian Resources, that 30 million tonnes of 0.45% copper and 0.51 grams of gold per tonne had been discovered by drilling at Botija Abajo.

| |

| 6.1.2 | AAT Mining Services Estimate of Resources |