QuickLinks -- Click here to rapidly navigate through this document

FALCONBRIDGE LIMITED

2002 ANNUAL INFORMATION FORM

April 30, 2003

TABLE OF CONTENTS

| | Page

|

|---|

| TECHNICAL GLOSSARY | | 2 |

| KEY ASSUMPTIONS FOR MINERAL RESERVE AND RESOURCE ESTIMATION | | 4 |

| CURRENCY | | 4 |

| METRIC/IMPERIAL CONVERSION TABLE | | 4 |

| FALCONBRIDGE LIMITED | | 5 |

| Overview | | 5 |

| Corporate Strategy and Business Developments | | 5 |

| Organizational Chart | | 7 |

| BUSINESS OF FALCONBRIDGE | | 8 |

| Integrated Nickel Operations | | 8 |

| | Sudbury Operations | | 8 |

| | | Sudbury Mines/Mill | | 9 |

| | | Sudbury Smelter | | 10 |

| | Raglan | | 11 |

| | Nikkelverk | | 12 |

| | FIL | | 12 |

| Kidd Creek Operations | | 13 |

| | | Kidd Mining Division | | 13 |

| | | Kidd Metallurgical Division | | 14 |

| Falcondo | | 16 |

| Collahuasi | | 17 |

| Lomas Bayas | | 18 |

| Corporate | | 20 |

| | Exploration | | 20 |

| | Koniambo Project, New Caledonia | | 22 |

| | Montcalm Project, Canada | | 22 |

| | Business Development | | 22 |

| | Technology | | 22 |

| | Employees | | 23 |

| PRINCIPAL PRODUCTS | | 24 |

| Nickel | | 24 |

| Copper | | 26 |

| Zinc | | 27 |

| Cobalt | | 29 |

| Other Metals and Products | | 29 |

| Sales Volumes, Average Prices and Revenue | | 30 |

| ENVIRONMENT, SAFETY AND HEALTH | | 32 |

| Environment | | 32 |

| Safety and Health | | 34 |

| TRENDS, RISKS AND UNCERTAINTIES | | 35 |

| SELECTED CONSOLIDATED FINANCIAL INFORMATION | | 39 |

| DIVIDEND POLICY | | 39 |

| MANAGEMENT'S DISCUSSION AND ANALYSIS | | 39 |

| RECONCILIATION OF NON-GAAP FINANCIAL MEASURES | | 39 |

| MARKET FOR SECURITIES OF THE CORPORATION | | 41 |

| DIRECTORS AND EXECUTIVE OFFICERS | | 41 |

| ADDITIONAL INFORMATION | | 44 |

1

TECHNICAL GLOSSARY

bankable feasibility study: means a comprehensive study of a deposit in which all geological, engineering, operating, economic and other relevant factors are considered in sufficient detail that it could reasonably serve as a basis for a financial decision by a financial institution to finance the development of the deposit for mineral production.

by-product credits: all revenues received from by-products.

capacity: the design number of units which can be produced in a given time period based on operations with a normal number of shifts and maintenance interruptions.

CIS: the Commonwealth of Independent States.

Comex: The New York Commodity Exchange.

concentrate: a product containing valuable minerals from which most of the waste material in the ore has been separated.

copper cathode: flat plate of pure (approximately 99.9%) copper that is the product of electrolytic copper refining or the solvent extraction/electrowinning process.

Defence Logistics Agency: a United States of America Department of Defence, defence agency. One of the responsibilities of the Defence Logistics Agency is the Defence National Stockpile.

Eastern Bloc: Albania, Bulgaria, the CIS, Cuba, the Czech Republic, Hungary, Mongolia, North Korea, the People's Republic of China, Poland, Romania and Slovakia.

Falcondo: Falconbridge Dominicana, C. por A. The Corporation owns 85.26% of the outstanding shares of Falcondo.

ferronickel: an alloy containing nickel and iron (approximately 38% nickel and 62% iron in the case of ferronickel produced by Falcondo). The volumes produced and prices realized by Falconbridge set forth in this annual information form are expressed in terms of nickel contained in ferronickel.

LME: the London Metal Exchange.

matte: a mixture of metal sulphides enriched with nickel, copper, cobalt, silver, gold and platinum group metals.

mill: a plant where ore is ground and undergoes physical or chemical treatment to extract and produce a concentrate of the valuable minerals.

mineral reserve:(1) the economically mineable part of a measured or indicated mineral resource demonstrated by at least a preliminary feasibility study. This study must include adequate information on mining, processing, metallurgical, economic and other relevant factors that demonstrate, at the time of reporting, that economic extraction can be justified. A mineral reserve includes diluting materials and allowances for losses that may occur when the material is mined. Mineral reserves are categorized as follows:

- •

- A"proven mineral reserve" is the economically mineable part of a measured mineral resource demonstrated by at least a preliminary feasibility study. This study must include adequate information on mining, processing, metallurgical, economic and other relevant factors that demonstrate, at the time of reporting, that economic extraction is justified.

- •

- A"probable mineral reserve" is the economically mineable part of an indicated, and in some circumstances a measured mineral resource demonstrated by at least a preliminary feasibility study. This study must include adequate information on mining, processing, metallurgical, economic and other relevant factors that demonstrate, at the time of reporting, that economic extraction is justified.

mineral resource:(1) a concentration or occurrence of natural, solid, inorganic or fossilized organic material in or on the Earth's crust in such form and quantity and of such grade or quality that it has reasonable prospects for economic extraction. The location, quantity, grade, geological characteristics and continuity of a mineral

2

resource are known, estimated or interpreted from specific geological evidence and knowledge. Mineral resources are categorized as follows:

- •

- A"measured mineral resource" is that part of a mineral resource for which quantity, grade or quality, densities, shape and physical characteristics are so well established that they can be estimated with confidence sufficient to allow the appropriate application of technical and economic parameters, to support production planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration, sampling and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes that are spaced closely enough to confirm both geological and grade continuity.

- •

- An"indicated mineral resource" is that part of a mineral resource for which quantity, grade or quality, densities, shape and physical characteristics can be estimated with a level of confidence sufficient to allow the appropriate application of technical and economic parameters, to support mine planning and evaluation of the economic viability of the deposit. The estimate is based on detailed and reliable exploration and testing information gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes that are spaced closely enough for geological and grade continuity to be reasonably assumed.

- •

- An"inferred mineral resource" is that part of a mineral resource for which quantity, grade or quality can be estimated on the basis of geological evidence and limited sampling and reasonably assumed, but not verified, geological and grade continuity. The estimate is based on limited information and sampling gathered through appropriate techniques from locations such as outcrops, trenches, pits, workings and drill holes.

National Instrument 43-101: National Instrument 43-101, Standards of Disclosure for Mineral Exploration and Development of Mining Properties published by the Canadian Securities Administrators.

off-warrant nickel stocks: nickel stocks not held in LME registered warehouses.

ounce: troy ounce.

platinum group metals: platinum, palladium, rhodium and related metals present in some nickel/copper ores.

preliminary feasibility study: a comprehensive study of the viability of a mineral project that has advanced to a stage where a mining method, in the case of underground mining, or a pit configuration, in the case of an open pit, has been established, and where an effective method of mineral processing has been determined, includes a financial analysis based on reasonable assumptions of technical, engineering, operating, economic factors and the evaluation of other relevant factors which are sufficient for a "qualified person", (as defined in National Instrument 43-101), acting reasonably, to determine if all or part of the mineral resource may be classified as a mineral reserve.

primary nickel: the nickel contained in products of smelters and refineries which are in a form ready for use by consumers.

refinery: a plant where concentrates or matte are processed into one or more refined metals.

smelter: a plant where concentrates are processed into an upgraded product.

tonne: 1,000 kilograms.

Western World: all countries other than those in the Eastern Bloc.

Note:

- (1)

- The definitions of mineral reserve, proven mineral reserve, probable mineral reserve, mineral resource, measured mineral resource, indicated mineral resource and inferred mineral resource are from the definitions adopted by the Canadian Institute of Mining, Metallurgy and Petroleum on August 20, 2000 (the "CIM Standards"). The disclosure contained in this annual information form with respect to mineral reserves and mineral resources has been compiled in accordance with CIM Standards under the direction of and verified by Chester M. Moore, the Corporation's Director, Mineral Reserve Estimation and Reporting. Mr. Moore is a member of the Ontario Association of Professional Geoscientists of Ontario, with 30 years of experience as a geologist and is a "qualified person" as defined in National Instrument 43-101. The mineral reserve and mineral resource estimates have been prepared using classical and/or

3

geostatistical methods plus economic and mining parameters appropriate to each deposit. Falconbridge is not aware of any environmental, permitting, legal, taxation, political, marketing or other relevant issue that would materially affect the estimates of the mineral reserves. The mineral resources which are not reserves have reasonable prospects for economic extraction but have not yet had complete formal evaluation, and do not have demonstrated economic viability.

KEY ASSUMPTIONS FOR MINERAL RESERVE AND RESOURCE ESTIMATION

Bulk Density: The factor used to convert volume into tonnage. This factor is a function of the mineralogy and physical characteristics of a deposit. Formulae are developed using regression analyses on a suitably large number of individual determinations.

Cut-Off Grade: The grade that ensures that the revenue from the metal content of the lowest grade parcel included in a deposit will be at least equal to the anticipated prime operating costs of producing this revenue. These costs include mining, milling, smelting, refining, selling and all transportation and administration costs. The cut-off grade will vary greatly from property to property due to a range of factors, including deposit size and shape, metal content and prime cost structure.

Exchange Rate (U.S. $ to Cdn $): 1.50

Long Term Metal Prices (U.S. $ per pound): Nickel $3.25, Copper $0.90, Zinc $0.50

Minimum Mining Width: The smallest horizontal thickness used in an estimation based on the selected mining method and the minimum opening size required by mining equipment used. The grade across this minimum width must equal or exceed the cut-off grade.

Mining Dilution:(1) All external material with grades lower than the cut-off grade that must be removed with the ore. The amount of this diluting material can vary considerably and depends upon mining method and the location, attitude, size, shape and wall rocks of the ore zone.

Mining Recovery:(1) The proportion of the ore that is extracted after accounting for mining losses. The mining recovery can vary widely both within a single mine and from property to property due to a range of factors including deposit geometry and mining method.

Note:

- (1)

- Used for mineral reserve estimation only.

CURRENCY

All references in this annual information form to "dollars" or "$" are to Canadian dollars, unless otherwise indicated.

METRIC/IMPERIAL CONVERSION TABLE

The imperial equivalents of the metric units of measurement used in this annual information form are as follows:

Metric Unit

| | Imperial Equivalent

|

|---|

| gram | | 0.03215 troy ounces |

| hectare | | 2.4711 acres |

| kilogram | | 2.2046223 pounds |

| kilometre | | 0.62139 miles |

| metre | | 3.2808 feet |

| tonne | | 1.1023 short tons |

4

FALCONBRIDGE LIMITED

Overview

Falconbridge Limited (the "Corporation") is the continuing corporation resulting from the amalgamation under theBusiness Corporations Act (Ontario) on June 22, 1994 of several companies including a company also named Falconbridge Limited. Predecessors of the Corporation have carried on business under the Falconbridge Limited name since 1928. The registered and principal office of the Corporation is at BCE Place, Suite 200, 181 Bay Street, Toronto, Ontario, M5J 2T3.

At December 31, 2002, Noranda Inc. ("Noranda") owned, directly and indirectly, approximately 59.5% and public shareholders owned approximately 40.5% of the outstanding common shares of the Corporation.

The Corporation's articles of amalgamation were amended on March 5, 1997 to provide for the issuance of cumulative preferred shares series 1, 2 and 3. On March 7, 1997 the Corporation completed the issue of 8,000,000 units, each unit consisting of one cumulative preferred share series 1 and one cumulative preferred share series 2 purchase warrant. The holder of a unit was entitled, on each of September 1, 1998, December 1, 1998 and March 1, 1999, to acquire one cumulative preferred share series 2 upon the exercise of the warrant and the payment of $15.00 and the concurrent conversion of the cumulative preferred share series 1 into a cumulative preferred share series 2. At December 31, 2002, there were 89,835 cumulative preferred shares, series 1, and 7,910,165 cumulative preferred shares, series 2, issued and outstanding. In 2004, the cumulative preferred shares series 2 will be convertible into cumulative preferred shares series 3.

The Corporation and its subsidiaries (collectively, "Falconbridge") are engaged in the exploration, development, mining, processing and marketing of metals and minerals. Falconbridge is also engaged in the custom feed business through the processing and recycling of third-party materials. Falconbridge has mining and mineral processing facilities in Canada (Sudbury Operations, Raglan, Kidd Creek Operations), Norway (Nikkelverk), the Dominican Republic (Falcondo) and Chile (Collahuasi and Lomas Bayas).

In April 2002, the Corporation and Noranda agreed to combine certain of their respective management functions. As a result there are a number of officers of the Corporation who are also officers of Noranda and a number of the functions of each company that are managed jointly.

Falconbridge's principal products are nickel, ferronickel, copper, zinc and cobalt. Other products include silver, gold, platinum group metals, cadmium, indium and sulphuric acid. Falconbridge markets and sells nickel and cobalt and certain other products through marketing and sales offices in Canada, the United States, Belgium and Japan. In 2002, approximately 42% of Falconbridge's revenues were from sales of nickel and ferronickel, 41% from sales of copper, 8% from sales of zinc, 3% from sales of cobalt and 6% from sales of other products.

The Corporation believes that Falconbridge is the third-largest producer of refined nickel in the world. Approximately 32% of Falconbridge's combined nickel and ferronickel sales are used in the manufacture of stainless steel. Approximately 58% of Falconbridge's 2002 combined nickel and ferronickel sales by volume were to customers in Europe, 18% to customers in the United States and the balance to customers in Japan, Canada, Mexico, Latin America, Southeast Asia and Korea.

Corporate Strategy and Business Developments

Falconbridge's strategy remains focused on the exploration, development and production of nickel and copper metals.

Mine Development, Capacity Expansion and Exploration

At the Sudbury Mines/Mill and Kidd Mining Division, Falconbridge's focus during the past three years has been on the development of higher grade mines and initiatives to reduce operating costs. The Fraser and Strathcona mine rationalization program was completed during this period. The second phase of the development of the Kidd Mining Division's No. 3 mine was completed in 2002. The development of the Kidd Mining Division's Mine D was approved during this period.

During the last three years, the capacity of the smelter at the Kidd Metallurgical Division was expanded from 148,000 to 150,000 tonnes of blister copper per year, the copper refinery capacity was expanded from

5

145,000 to 147,000 tonnes of copper cathode per year and the zinc plant capacity from 146,000 to 147,000 tonnes of zinc per year. Raglan increased its annual rate of milled tonnage from 800,000 to 1 million tonnes of ore and completed an optimization plan to increase mill capacity from 2,400 to 3,000 tonnes of ore throughput per day. During this period, Collahuasi completed a preliminary feasibility study regarding the transfer of mining activity from the Ujina to the Rosario orebody and a bankable feasibility study to increase concentrator throughput. In 2002, the decision to proceed with the expansion of the concentrator was made and construction at the site began in November 2002.

Exploration on Falconbridge's land holdings has continued over the past three years. At the Sudbury Operations exploration programs conducted in 2001 and 2002 have resulted in the discovery of a new mineral resource at Nickel Rim South. Falconbridge's business development group continued to search for new opportunities for growth in nickel, platinum group metals and advanced copper projects during this period.

In 2002, Falconbridge completed a three-year program to improve the performance of the tailings management system at the Kidd Metallurgical Division. In 2001, construction of Pond E was completed at a cost of $5.25 million and Pond E was commissioned in February 2002. The settling pond is expected to increase capacity for settling metals and suspended solids during extreme weather events. In the past, extreme weather events have led to some exceedances over the allowable discharge of metals and suspended solids.

Also during 2002, Raglan commissioned a project to recycle 100% of the mill effluent water. Recycling will ensure compliance with provincial regulations, including effluent toxicity which has been a seasonal problem. The management of water originating from mine pit operations is currently the subject of a study to improve practices that will simplify operations affected by extreme seasonal variations. This is expected to lead to improved performance and lower operating costs for current and future mine developments.

Since January 1, 2000, Falconbridge's capital and project expenditures have totaled $955.7 million, including $352.4 million at the Kidd Creek Operations, $134.6 million at Collahuasi, $130.9 million at Raglan, $108.9 million at the Sudbury Operations, $96.6 million on the Koniambo project, $73.8 million at Falcondo, $32.8 million at Nikkelverk, $18.9 million at Lomas Bayas, and $6.8 million at other locations.

During the same period, Falconbridge spent $119.0 million on exploration and $57.8 million on research and development.

In 2001, Falconbridge completed the acquisition of Lomas Bayas for a cash payment of $100.7 million. See "Business of Falconbridge — Lomas Bayas".

In the last three years, Falconbridge's consolidated long-term debt increased by $447.5 million. Long-term debt increased primarily as a result of the issue of $558.4 million principal amount of debentures by the Corporation, the acquisition of Lomas Bayas and its outstanding debt of $161.8 million, the net repayment of $179.6 million of indebtedness outstanding under the Corporation's bank credit facilities and commercial paper program, the repayment of $213.8 million and $23.9 million in bank loans by Collahuasi and Lomas Bayas respectively. The balance of the increase is primarily due to changes over the last three years in the Canadian/U.S. exchange rate.

The United States Department of Justice has convened a grand jury to investigate possible criminal antitrust violations by Falconbridge, Noranda and other sulphuric acid producers in the United States. To the Corporation's knowledge, no decision has been made by the Department of Justice as to whether it will bring charges or close the investigation. In addition, several federal and state class action suits have been filed in the United States alleging antitrust violations in connection with the sale of sulphuric acid in the United States by Noranda, Falconbridge and NorFalco LLC (a joint venture owned 65% by Noranda and 35% by Falconbridge that markets, transports and distributes sulphuric acid in North America). The complaints allege that Noranda, Falconbridge and NorFalco LLC conspired with certain alleged co-conspirators to fix the price of sulphuric acid in the United States. In each action, the plaintiffs claim prices for sulphuric acid were artificially inflated and therefore the plaintiffs paid more than they otherwise would have paid for sulphuric acid in the absence of the

6

alleged price fixing conspiracy. Each complaint seeks unspecified treble damages, attorney fees and costs. Falconbridge denies engaging in any such conspiracy and has asserted that its actions relating to the sale of sulphuric acid during the period in question were lawful. Falconbridge intends to vigorously defend these actions.

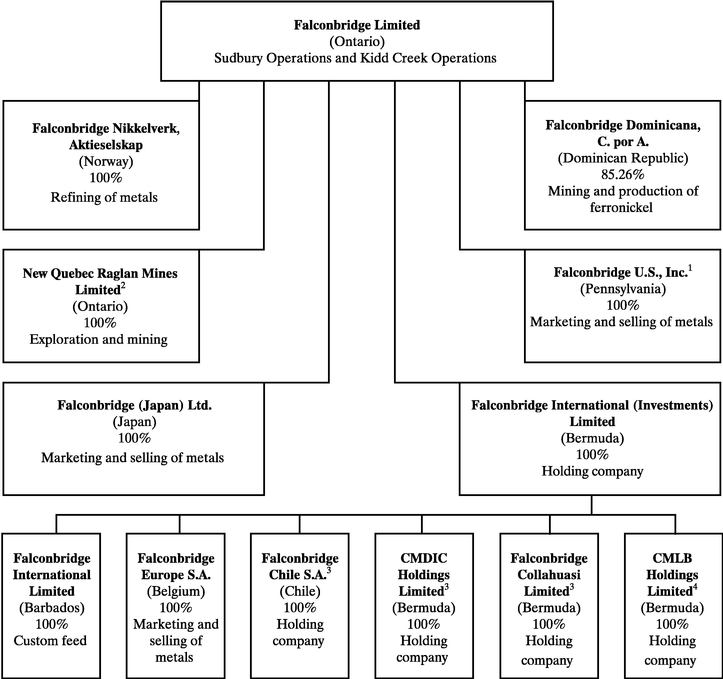

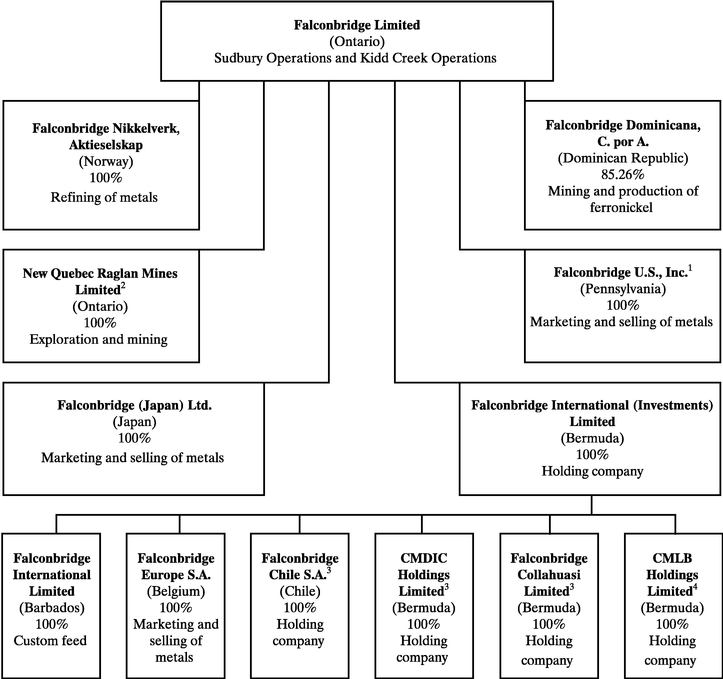

Organizational Chart

The principal direct and indirect subsidiaries of the Corporation and the jurisdictions in which they were incorporated or organized are set out below:

Notes:

- (1)

- The Corporation owns 100% of the shares of Natresco Incorporated which, in turn, owns 100% of the shares of Falconbridge U.S., Inc.

- (2)

- New Quebec Raglan Mines Limited owns 100% of the common shares of Société minière Raglan du Québec ltée, which owns the Raglan mine.

- (3)

- Falconbridge Chile S.A., CMDIC Holdings Limited and Falconbridge Collahuasi Limited own 21.77%, 17.88% and 4.35%, respectively, and 44%, collectively, of the shares of Compañia Minera Doña Inés de Collahuasi S.C.M. ("Collahuasi"), which owns 100% of Collahuasi.

- (4)

- CMLB Holdings Limited owns 100% of the shares of Compañia Minera Falconbridge Lomas Bayas ("Lomas Bayas"), which owns 100% of Lomas Bayas.

7

BUSINESS OF FALCONBRIDGE

Falconbridge operates in one industry – the exploration, development, mining, processing and marketing of mineral products. These activities are conducted through six segments – the Integrated Nickel Operations, Kidd Creek Operations, Falcondo, Collahuasi, Lomas Bayas and Corporate. All are 100% owned except for Falcondo and Collahuasi which are 85.26% and 44% owned, respectively.

- •

- Integrated Nickel Operations ("INO")

- •

- Sudbury Operations — mines, mills and smelts its own nickel/copper ores and smelts Raglan concentrates and custom feed from other sources.

- •

- Société minière Raglan du Québec ltée ("Raglan") — mines and mills its own nickel/copper ores.

- •

- Falconbridge Nikkelverk, Aktieselskap ("Nikkelverk") — refines matte produced by the Sudbury Operations and custom feed from other sources.

- •

- Falconbridge International Limited ("FIL") — manages and develops the INO's custom feed business outside Canada.

- •

- Falconbridge U.S., Inc. — markets and sells nickel, cobalt and other products throughout the United States, Canada, Mexico and Latin America.

- •

- Falconbridge Europe S.A. — markets and sells nickel, cobalt and other products throughout Europe, India and Africa, and silver, gold and platinum group metals throughout the world. Falconbridge Europe S.A. also sells all the copper cathode produced at the Nikkelverk refinery.

- •

- Falconbridge (Japan) Ltd. — markets and sells nickel, cobalt and other products throughout Japan and Asia.

- •

- Kidd Creek Operations

- •

- Kidd Mining Division — mines its own copper/zinc ores.

- •

- Kidd Metallurgical Division — mills, smelts and refines copper/zinc ores from the Kidd Mining Division and processes Sudbury Operations' copper concentrate; smelts and refines custom feed from other sources including some Collahuasi feed.

- •

- Falconbridge Dominicana, C. por A. ("Falcondo") — mines, mills, smelts and refines its own nickel laterite ores.

- •

- Compañia Minera Doña Inés de Collahuasi S.C.M. ("Collahuasi") — mines and mills its own copper sulphide ores into concentrate; mines and leaches its own copper oxide ores to produce copper cathode.

- •

- Compañia Minera Falconbridge Lomas Bayas ("Lomas Bayas") — mines and processes its own copper oxide ores to produce copper cathode.

- •

- Corporate

- •

- Exploration — conducts exploration worldwide.

- •

- Business Development — searches worldwide for attractive investment opportunities to support Falconbridge's growth strategy.

- •

- Marketing and Sales — provides marketing and sales support to all INO sales offices and markets.

- •

- Technology — conducts research, development and engineering.

Integrated Nickel Operations

Sudbury Operations

The Sudbury Operations consist of the Sudbury Mines/Mill and Sudbury Smelter.

8

Sudbury Mines/Mill

Properties and Mines

The Corporation has been mining nickel/copper ores in the Sudbury area of northern Ontario since 1929. The Sudbury Mines/Mill principal nickel/copper producing properties in the Sudbury area are located in the Townships of Falconbridge, Levack, Garson, Dowling, Blezard and Denison. The properties comprise 2,670 hectares owned by the Corporation and 14 hectares held under two licences of occupation of mining rights from the Province of Ontario. The licences of occupation are held in perpetuity.

Sudbury Mines/Mill operates four underground nickel/copper mines in the Sudbury area: the Craig, Fraser, Lindsley and Lockerby mines. In 2002, the Craig mine provided 43% of Sudbury Mines/Mill's ore production.

Total mine production for 2002 was 3.7% higher than planned while nickel grades were approximately the same as planned.

In July 2002, the Ontario Ministry of Labour laid charges against the Corporation under the Occupational Health and Safety Act with respect to the underground fatality of an employee that occurred in July 2001 at the Fraser mine at Sudbury Mines/Mill. A trial of the action is expected to be scheduled for later in 2003.

The Sudbury Mines/Mill's mineral reserves and mineral resources as at December 31, 2001 and December 31, 2002 were as follows:

| |

| |

| |

| | Changes in 2002 (tonnes)

| |

| |

| |

|

|---|

| | December 31, 2001

| | December 31, 2002

|

|---|

Category

| | Tonnes milled

| | Revisions/

discoveries

|

|---|

| | Tonnes

| | Nickel

| | Copper

| | Tonnes

| | Nickel

| | Copper

|

|---|

| | (000's)

| | %

| | %

| | (000's)

| | (000's)

| | (000's)

| | %

| | %

|

|---|

| Mineral Reserves(1) | | | | | | | | | | | | | | | | |

| Proven | | 9,906 | | 1.51 | | 1.28 | | (2,076 | ) | 84 | | 7,914 | | 1.45 | | 1.36 |

| Probable | | 7,113 | | 1.30 | | 1.32 | | (76 | ) | 2,175 | | 9,212 | | 1.22 | | 1.21 |

| | |

| |

| |

| |

| |

| |

| |

| |

|

| Total | | 17,019 | | 1.42 | | 1.30 | | (2,152 | ) | 2,259 | | 17,126 | | 1.33 | | 1.28 |

| | |

| |

| |

| |

| |

| |

| |

| |

|

Mineral Resources (in addition to Mineral Reserves) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Measured | | 164 | | 1.63 | | 0.90 | | (10 | ) | (69 | ) | 85 | | 2.38 | | 1.27 |

| Indicated | | 16,131 | | 2.47 | | 1.16 | | — | | 617 | | 16,748 | | 2.38 | | 1.10 |

| | |

| |

| |

| |

| |

| |

| |

| |

|

| Total | | 16,295 | | 2.46 | | 1.16 | | (10 | ) | 548 | | 16,833 | | 2.38 | | 1.10 |

| | |

| |

| |

| |

| |

| |

| |

| |

|

| Inferred | | 15,300 | | 1.80 | | 2.04 | | — | | 6,800 | | 22,100 | | 1.8 | | 2.4 |

Note:

- (1)

- Mineral reserves remained constant in 2002 because the annual production was replaced with increases in reserves at Craig, Lindsley and Fraser mines.

At planned operating rates, the mineral reserves at Sudbury Mines/Mill are equal to approximately eight years of production.

The ore from the Sudbury Mines/Mill's mines is crushed and ground and the nickel/copper-bearing sulphide minerals contained in the ore are separated from waste materials at the Sudbury Mines/Mill's Strathcona mill to produce nickel/copper concentrate and copper concentrate. The Strathcona mill has a capacity of approximately 10,000 tonnes of ore per day.

9

The copper concentrate from the Strathcona mill is delivered to the Kidd Metallurgical Division's mineral processing facilities for smelting and refining. See "Kidd Creek Operations — Kidd Metallurgical Division". The nickel/copper concentrate from the Strathcona mill is delivered to Sudbury Smelter for smelting.

The annual production of the Sudbury Mines/Mill for the two years ended December 31, 2002 was as follows:

| |

| | 2002

| | 2001

|

|---|

| |

| | (tonnes)

|

|---|

| Ore milled from all sources | | 2,295,000 | | 1,946,000 |

| Mine output in concentrate | | — nickel | | 27,800 | | 25,200 |

| | | — copper | | 31,100 | | 22,900 |

| | | — cobalt | | 690 | | 630 |

The mineral processing facilities operated by Sudbury Smelter include a smelter and a sulphuric acid plant. The smelter processes concentrates and other feed material containing nickel, copper, cobalt, silver, gold and platinum group metals. In 2002, the smelter treated all of the nickel/copper concentrates from the Sudbury Mines/Mill and all the concentrate from Raglan, as well as a variety of metal bearing, secondary, recyclable and intermediate feedstocks from third parties and smaller amounts of concentrates from third parties.

Sudbury Smelter produces a matte containing nickel, copper and cobalt, as well as silver, gold and platinum group metals. The Sudbury Smelter has the capacity to produce approximately 130,000 tonnes of matte per year. The roaster gas from the smelter operation is treated in an adjacent plant to produce sulphuric acid thereby reducing sulphur dioxide emissions to the natural environment. The sulphuric acid plant has the capacity to produce approximately 300,000 tonnes of sulphuric acid per year. The Sudbury Smelter's output of sulphuric acid is purchased for resale by a subsidiary of Noranda (which is partly owned by Falconbridge) that markets, transports and distributes sulphuric acid in North America.

The matte produced by the Sudbury Smelter is shipped by rail to Quebec City and by sea to the Nikkelverk refinery for further processing. See "Business of Falconbridge — Integrated Nickel Operations — Nikkelverk".

The annual production of the Sudbury Smelter for the two years ended December 31, 2002 was as follows:

| |

| | 2002

| | 2001

|

|---|

| |

| | (tonnes)

|

|---|

| Smelter output of nickel | | | | |

| | Sudbury mines | | 28,300 | | 24,600 |

| | Raglan | | 25,200 | | 26,900 |

| | Custom feed | | 4,400 | | 3,400 |

| | |

| |

| |

|

| | Total | | 57,900 | | 54,900 |

| | |

| |

| |

|

| Smelter output of copper | | | | |

| | Sudbury mines | | 11,200 | | 8,900 |

| | Raglan | | 6,600 | | 7,200 |

| | Custom feed | | 2,700 | | 1,800 |

| | |

| |

| |

|

| | Total | | 20,500 | | 17,900 |

| | |

| |

| |

|

| Smelter output of cobalt | | | | |

| | Sudbury mines | | 690 | | 590 |

| | Raglan | | 370 | | 420 |

| | Custom feed | | 900 | | 780 |

| | |

| |

| |

|

| | Total | | 1,960 | | 1,790 |

| | |

| |

| |

|

| Copper concentrate | | — nickel | | 90 | | 60 |

| | | — copper | | 21,700 | | 14,000 |

Sulphuric acid |

|

246,800 |

|

224,600 |

10

Raglan

The Raglan property is located 105 kilometres south of the northern tip of the Ungava (Nunavik) Peninsula in the Province of Quebec, approximately 1,800 kilometres north of Montreal. The property comprises 1,226 map-designated claims covering 48,655 hectares and six 20-year mining leases covering 441 hectares. The first of the leases expires in June 2016. All are renewable for three 10-year terms, provided that mining has taken place for at least two of the preceding ten years. The property is owned by Société minière Raglan du Québec ltée, an indirect wholly-owned subsidiary of the Corporation.

Falconbridge has explored the Raglan property since the 1960s. Development of the Raglan mine site at Katinniq began in 1996 following receipt of environmental approvals and the conclusion of agreements with Makivik Corporation (the representative of the local Inuit population) and the Province of Quebec regarding infrastructure funding. The Raglan facilities include underground mine development and open pits, a concentrator, a power plant, accommodation and administration buildings, fresh water supply and fuel storage tanks. The facilities are linked by all-weather roads to an airstrip at Donaldson and to concentrate storage and shiploading facilities at Deception Bay, 100 kilometres from Katinniq. Raglan concentrate is transported by ship to unloading, storage and rail load-out facilities in Quebec City.

Commercial production at Raglan began in 1998. Raglan's annual production capacity is 1,000,000 tonnes per year of ore milled.

Raglan's mineral reserves and mineral resources as at December 31, 2001 and December 31, 2002 were as follows:

| |

| |

| |

| | Changes in 2002 (tonnes)

| |

| |

| |

|

|---|

| | December 31, 2001

| | December 31, 2002

|

|---|

Category

| |

| | Revisions/

discoveries

|

|---|

| | Tonnes

| | Nickel

| | Copper

| | Production

| | Tonnes

| | Nickel

| | Copper

|

|---|

| | (000's)

| | %

| | %

| | (000's)

| | (000's)

| | (000's)

| | %

| | %

|

|---|

Mineral Reserves(1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Proven | | 7,136 | | 3.05 | | 0.81 | | (869 | ) | 424 | | 6,691 | | 3.04 | | 0.81 |

| Probable | | 12,404 | | 2.76 | | 0.78 | | — | | (986 | ) | 11,418 | | 2.78 | | 0.78 |

| | |

| |

| |

| |

| |

| |

| |

| |

|

| Total | | 19,540 | | 2.87 | | 0.79 | | (869 | ) | (562 | ) | 18,109 | | 2.88 | | 0.79 |

| | |

| |

| |

| |

| |

| |

| |

| |

|

Mineral Resources (in addition to Mineral Reserves) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Measured | | — | | — | | — | | — | | 289 | | 289 | | 1.62 | | 0.41 |

| Indicated | | 3,066 | | 1.93 | | 0.70 | | — | | (479 | ) | 2,587 | | 1.98 | | 0.76 |

| | |

| |

| |

| |

| |

| |

| |

| |

|

| Total | | 3,066 | | 1.93 | | 0.70 | | — | | (190 | ) | 2,876 | | 1.95 | | 0.72 |

| | |

| |

| |

| |

| |

| |

| |

| |

|

| Inferred | | 2,600 | | 2.60 | | 0.89 | | — | | 800 | | 3,400 | | 2.7 | | 0.87 |

Note:

- (1)

- Annual production and negative reserve adjustments resulted in a decrease of 1.4 million tonnes of mineral reserves.

At planned operating rates, the mineral reserves at Raglan are equal to approximately 18 years of production.

The ore from the Raglan mine is crushed, ground and treated at the Raglan mill in Katinniq to produce nickel/copper concentrate. The current capacity of the mill is 3,000 tonnes of ore throughput per day.

11

Raglan concentrate is trucked to Deception Bay for marine shipment to Quebec City and then transported by rail to the Sudbury Smelter for treatment. There were six shipments from Deception Bay during 2002. No shipping occurs from mid-March to early-June.

Raglan's annual production for the two years ended December 31, 2002, was as follows:

| |

| | 2002

| | 2001

|

|---|

| |

| | (tonnes)

|

|---|

| Ore milled | | 868,000 | | 961,000 |

| Mine output in concentrate | | — nickel | | 24,600 | | 24,600 |

| | | — copper | | 6,500 | | 6,900 |

| | | — cobalt | | 390 | | 320 |

Nikkelverk

Nikkelverk owns and operates a refinery and sulphuric acid plant at Kristiansand, Norway. The refinery processes the matte produced by the Sudbury Smelter as well as custom feed from other sources. The Corporation believes that the Nikkelverk refinery is among the lowest cost nickel refineries in the western world.

The Nikkelverk refinery uses a chlorine leach and electrowinning process developed by Falconbridge to separate and recover component metals. The process is cost-efficient in the treatment of complex raw materials and achieves high productivity and recoveries. This efficiency allows greater flexibility in the sourcing and treatment of custom feed. The refinery has an annual capacity of approximately 85,000 tonnes of nickel, 38,000 tonnes of copper and 4,500 tonnes of cobalt. Expansion of the refinery to 100,000 tonnes of nickel, 60,000 tonnes of copper and 5,000 tonnes of cobalt per year or higher is possible when market conditions warrant. The sulphuric acid plant has a capacity of approximately 100,000 tonnes of sulphuric acid per year.

The Nikkelverk refinery also treats the silver, gold and platinum group metals contained in the matte produced by Sudbury Smelter and the custom feed from other sources. Mattes from Sudbury Smelter and from BCL Limited ("BCL") in Botswana were the main sources of nickel/copper feed materials for the Nikkelverk refinery in 2002. See "FIL — Custom Feed".

The production of platinum group metals grew in importance during 2002 as production volumes expanded. The Nikkelverk refinery produced approximately 355,000 ounces of platinum group metals in 2002 compared with approximately 234,000 ounces in 2001.

The Nikkelverk refinery's annual production for the two years ended December 31, 2002 was as follows:

| | 2002

| | 2001

|

|---|

| | (tonnes)

|

|---|

| Nickel | | 68,500 | | 68,200 |

| Copper | | 30,600 | | 26,700 |

| Cobalt | | 4,000 | | 3,300 |

| Sulphuric acid | | 89,900 | | 86,400 |

The Nikkelverk refinery operated at low levels during the third quarter of 2002 due to a shortage of feed from the feed suppliers and was shut down for three weeks in July/August, 2002.

FIL

FIL, through its offices in Bridgetown, Barbados and Brussels, Belgium is responsible for managing the INO's custom feed business outside Canada. Custom feed, or third-party primary smelter production (matte) and secondary raw materials, provides a significant source of feed to the Sudbury Smelter and the Nikkelverk refinery. The availability of and profit margins associated with the secondary raw materials processed at the Sudbury Smelter and the Nikkelverk refinery are largely a function of metal grade and the level and relationship of nickel, copper, cobalt, silver, gold and platinum group metals prices.

12

The custom feed processed at the Sudbury Smelter consists largely of nickel/copper/cobalt secondary raw materials. Most secondary raw materials are sourced on a spot basis or under contracts of one to three years' duration. In 2002, Sudbury Smelter's output from secondary raw materials included 4,400 tonnes of nickel, 2,700 tonnes of copper and 900 tonnes of cobalt.

In 1985, FIL entered into a long-term agreement with BCL to treat complex nickel/copper matte from BCL's smelter in Botswana. The BCL matte represented approximately 49% of the nickel and copper-bearing custom feeds processed at the Nikkelverk refinery in 2002. Under the agreement, which was extended in 1998 to at least the end of 2010, BCL has agreed to deliver approximately 13,000 to 16,000 tonnes of nickel in matte per year to the Nikkelverk refinery.

In 2002, custom feed represented approximately 25% of the nickel, 42% of the copper and 76% of the cobalt output at the Nikkelverk refinery.

Kidd Creek Operations

The Kidd Creek Operations consist of the Kidd Mining Division and the Kidd Metallurgical Division.

Kidd Mining Division

Properties and Mines

The Corporation has been mining the Kidd Creek copper/zinc deposits in Timmins, Ontario since 1966. The Kidd Mining Division's principal copper/zinc properties in the Timmins area are located in Kidd Township, Porcupine Mining Division, Ontario. The properties owned by the Corporation comprise 14 patented half lots covering 896 hectares of freehold mining land.

The Kidd Creek deposits are mined through two separate shafts, accessing mining areas known as the No. 1, 2 and 3 mines, which access progressively deeper levels. In 2002, the No. 1 mine accounted for 40%, the No. 2 mine accounted for 10% and the No. 3 mine accounted for 50% of the Kidd Mining Division's mine ore production.

Ore production has been decreasing as mining has progressed to deeper levels of the orebody. The Corporation anticipates that the Kidd Mining Division's annual ore production will increase slightly from approximately 2.2 million tonnes in 2002 to approximately 2.4 million tonnes in 2003, 2004 and 2005.

In 2000, the Corporation approved the development of Mine D, the depth extension of the Kidd Creek orebody beyond the limits of the No. 3 mine at 6,800 feet (2,070 metres) to a depth of 10,200 feet (3,100 metres). Production from Mine D is scheduled to begin in 2004 and production is expected to reach 550,000 tonnes in 2005.

In 2002, the Kidd Mining Division substantially completed the development of the second phase of its No. 3 mine. Production, which began late in 2001, contributed 490,000 tonnes in 2002 and is expected to contribute 600,000 tonnes of ore annually when full production levels are reached in 2004.

The Kidd Creek orebody is intersected by a number of major faults and other discontinuities. Mining and the resulting stress redistribution cause periodic ground adjustment along these faults resulting in seismic activity. The Corporation has taken steps to minimize the impact of seismic activity on its Kidd Creek mining operations. These steps include the use of seismic monitoring equipment and the development and use of safe and cost-effective mining systems and procedures. On occasion, a seismic event will occur which has the potential to cause personal injury, equipment damage or production interruption. Such events have been infrequent.

13

The Kidd Mining Division's annual production for the two years ended December 31, 2002 was as follows:

| |

| | 2002

| | 2001

|

|---|

| |

| | (tonnes unless otherwise noted)

|

|---|

| Ore hoisted | | 2,230,000 | | 1,977,000 |

| Mine output in concentrate | | — copper | | 45,400 | | 42,300 |

| | | | | — zinc | | 104,100 | | 81,700 |

| | | | — silver (ounces) | | 3,671,000 | | 2,865,000 |

In November 2002, the Corporation plead guilty and was fined $225,000 for a charge under the Occupational Health and Safety Act (Ontario) in connection with a September 2000 accident at the Kidd mine site where an employee, who was part of a four-person underground crew, was fatally injured during the removal and re-installation of a section of pressurized air pipes.

The Kidd Mining Division's mineral reserves and mineral resources as at December 31, 2001 and December 31, 2002 were as follows:

| |

| |

| |

| |

| | Changes in 2002 (tonnes)

| |

| |

| |

| |

|

|---|

| | December 31, 2001

| | December 31, 2002

|

|---|

Category

| | Tonnes milled

| | Revisions/

discoveries

|

|---|

| | Tonnes

| | Copper

| | Zinc

| | Silver

| | Tonnes

| | Copper

| | Zinc

| | Silver

|

|---|

| | (000's)

| | %

| | %

| | (grams/

tonne)

| | (000's)

| | (000's)

| | (000's)

| | %

| | %

| | (grams/

tonne)

|

|---|

Mineral Reserves(1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Proven | | 14,697 | | 2.17 | | 5.85 | | 77 | | (2,202 | ) | 914 | | 13,409 | | 2.01 | | 5.77 | | 76 |

| Probable | | 10,285 | | 2.25 | | 6.98 | | 54 | | — | | — | | 10,285 | | 2.25 | | 6.98 | | 54 |

| | |

| |

| |

| |

| |

| |

| |

| |

| |

| |

|

| Total | | 24,982 | | 2.20 | | 6.32 | | 68 | | (2,202 | ) | 914 | | 23,694 | | 2.11 | | 6.30 | | 66 |

| | |

| |

| |

| |

| |

| |

| |

| |

| |

| |

|

Mineral Resources (in addition to Mineral Reserves) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Indicated | | 348 | | 2.06 | | 6.69 | | 30 | | — | | (248 | ) | 100 | | 2.96 | | 6.79 | | 50 |

| Inferred | | 14,150 | | 3.35 | | 4.90 | | 91 | | — | | (50 | ) | 14,100 | | 3.4 | | 4.9 | | 91 |

Note:

- (1)

- Mineral reserves decreased by 1.3 million tonnes after production of 2.2 million tonnes. Approximately 900,000 tonnes of reserves were added in 2002 by the complete re-estimation of the stopes in No. 3 mine.

At planned operating rates, the mineral reserves at Kidd Mining Division are equal to approximately 10 years of production. The proposed development of Mine D is expected to extend the life of the Kidd Mining Division beyond 10 years.

Kidd Metallurgical Division

Milling, Smelting and Refining

The ore from the Kidd Mining Division is transported by a company-owned railway to the Kidd Metallurgical Division's mineral processing facilities located 27 kilometres southeast of the minesite. These facilities include a concentrator, a copper smelter and refinery, a zinc plant, a cadmium plant, a dust treatment plant (which recovers indium, copper and zinc) and two sulphuric acid plants. The Kidd Metallurgical Division also operates, on a cost plus basis, a liquid sulphur dioxide plant in a joint venture with Chemtrade Ltd.

14

The concentrator produces copper and zinc concentrates and treats all ores from the Kidd Mining Division in two of four available grinding/flotation circuits. The remaining two circuits are available to process custom ore.

The copper concentrate produced at Kidd, together with that shipped from the Sudbury Strathcona mill and other copper custom feeds, are fed into the smelter, which has the capacity to produce 150,000 tonnes of blister copper per year. Custom feeds originating outside of the Corporation's Ontario operations comprised approximately 50% of copper smelter feed in 2002 and are expected to be at a similar level in 2003.

The blister copper produced at the smelter is either treated in the refinery, which currently has the capacity to produce 147,000 tonnes of copper cathode per year, or sold to outside refineries, including Noranda. In addition to copper, the refinery produces substantial amounts of silver containing anode slimes that are further toll refined by outside refineries, including Noranda's CCR refinery for precious metal recovery.

The zinc plant has the capacity to produce 147,000 tonnes of zinc per year. This capacity is sufficient to process the Kidd Metallurgical Division's zinc concentrates and custom feed from other sources. Custom feed comprised approximately 30% of the total zinc plant feed in 2002 and is expected to comprise approximately 40% in 2003.

The Corporation has an agreement with Noranda, whereby Noranda acts as the sales agent for all products, other than sulphuric acid, anode slimes and indium, produced by the Kidd Metallurgical Division. Under this agreement, which may be terminated on 12 months' notice, an annual marketing fee is paid. In addition, all of the sulphuric acid produced by Kidd Metallurgical Division is purchased for resale by a subsidiary of Noranda (which is partly owned by Falconbridge).

In June 2002, the Corporation plead guilty to four charges laid under the Environmental Protection Act (Ontario) and agreed to a fine of $16,000. The charges relate to effluent discharge limits for zinc, copper and suspended solids that were exceeded in 1999. A total of 12 other charges were withdrawn.

The Kidd Metallurgical Division purchases a variety of primary and secondary copper and zinc-bearing materials on both a long and short-term basis. Suppliers of these materials include the Noranda group of companies.

The Corporation has an agreement for the supply of zinc concentrate from Billiton Metals Canada Inc.'s Selbaie mine/mill facility in northern Quebec and sources additional zinc concentrates from other suppliers. The Kidd Metallurgical Division also has agreements to process copper concentrate shipped from Collahuasi, and sources additional concentrates from Minera Escondida Limitada, Minera Alumbrera Limitada and others. These shipments, together with concentrates produced from the Kidd Mining Division's ores, should enable the zinc and copper plants to operate at capacity.

Both copper and zinc operations of the Kidd Metallurgical Division evaluate the economics of custom feeds on an ongoing basis to ensure financial viability as part of the process to determine, confirm or modify annual operating plans. In addition, copper and zinc concentrates are sometimes sold when overall economics are favorable.

The Kidd Metallurgical Division's production for the two years ended December 31, 2002 was as follows:

| | 2002

| | 2001

|

|---|

| | (tonnes)

|

|---|

| Zinc refinery output | | 145,300 | | 140,100 |

| Copper cathode — refinery output | | 146,500 | | 127,800 |

| Blister copper | | 144,100 | | 132,100 |

| Sulphuric acid | | 584,200 | | 514,300 |

Production records were established for refined zinc production, blister copper and copper cathode production in 2002 and the smelter also achieved its best ever on-line time. The copper smelter conducted a

15

shortened 7-day maintenance shutdown in September 2002 and deferred some repairs to a 3-week maintenance shutdown planned for the second quarter of 2003. Zinc operations undertook a 12-day maintenance outage in 2002.

In April 2003, the Corporation announced that the zinc refinery operations will shut down for 13 weeks during the summer as a result of persistently low treatment charges combined with recent changes in currency exchange rates and higher costs relative to Falconbridge's concentrate purchase and metal sales positions. This represents an extension to the shutdown of eight weeks previously announced in February 2003. The Corporation will continue to re-evaluate market forecasts and the profitability of the Kidd Metallurgical Division's zinc business.

Falcondo

The Corporation owns 85.26% of the outstanding shares of Falcondo. Of the balance, the Government of the Dominican Republic owns approximately 10%, Redstone Resources Inc. owns approximately 4.1% and various individuals own the remainder. Falcondo holds a mining concession and owns mining and mineral processing facilities for the production of ferronickel located near the town of Bonao, approximately 80 kilometres northwest of Santo Domingo, Dominican Republic.

Falcondo has been mining and processing nickel laterite ore in the Dominican Republic since 1971. Falcondo's mining concession covers approximately 24,100 hectares. Falcondo owns 4,831 hectares, 4,771 of which are inside the mining concession and include the mining areas and the mineral processing facilities, and 60 of which are outside the mining concession and include the townsite at Bonao. The term of the mining concession is for an unlimited period.

Mining at Falcondo is carried out from the surface using bulldozers, loaders and trucks. Falcondo's total mine production for the year ended December 31, 2002, as obtained through a metallurgical balance calculation, was 3,040,600 tonnes of ore at an average nickel grade of 1.23%.

Falcondo's mineral reserves and mineral resources as at December 31, 2001 and December 31, 2002 were as follows:

| | December 31, 2001

| | Changes in 2002 (tonnes)

| | December 31, 2002

|

|---|

Category

| |

| | Revisions/

discoveries

|

|---|

| | Tonnes

| | Nickel

| | Production

| | Tonnes

| | Nickel

|

|---|

| | (000's)

| | %

| | (000's)

| | (000's)

| | (000's)

| | %

|

|---|

Mineral Reserves(1) |

|

|

|

|

|

|

|

|

|

|

|

|

| Proven | | 48,982 | | 1.18 | | (3,041 | ) | 6,543 | | 52,484 | | 1.19 |

| Probable | | 11,716 | | 0.96 | | — | | (80 | ) | 11,636 | | 0.96 |

| | |

| |

| |

| |

| |

| |

|

| Total | | 60,698 | | 1.14 | | (3,041 | ) | 6,463 | | 64,120 | | 1.15 |

| | |

| |

| |

| |

| |

| |

|

Mineral Resources (in addition to Mineral Reserves) |

|

|

|

|

|

|

|

|

|

|

|

|

| Indicated | | 13,840 | | 1.53 | | — | | — | | 13,840 | | 1.53 |

| Inferred | | 6,400 | | 1.41 | | — | | — | | 6,400 | | 1.41 |

Note:

- (1)

- The mineral reserves showed a net increase of 3.4 million tonnes after production of 3.0 million tonnes in 2002. The increase is mainly due to mining gains of 4.5 million tonnes plus the discovery of 1.5 million tonnes primarily at the Caribe and Guardarraya deposits.

At planned operating rates, mineral reserves at Falcondo are equal to approximately 15 years of production.

16

Milling, Smelting, Refining and Marketing

The ore mined at Falcondo is milled, smelted and refined at Falcondo's mineral processing facilities which have a capacity of approximately 29,000 tonnes of nickel contained in ferronickel per year. The facilities include a metallurgical treatment plant, a crude oil processor and a 200 megawatt thermal power plant. In 2002, Falcondo sold 62,138 megawatts of excess power produced at the power plant through the national electricity grid. Falcondo has dock facilities and a crude oil tank farm at the port of Haina (near Santo Domingo) and a 70-kilometre crude oil pipeline from the port to its mineral processing facilities. Falcondo's production of nickel in ferronickel for the two years ended December 31, 2002 and 2001 was 23,303 tonnes and 21,662 tonnes, respectively.

As a result of declining ferronickel prices and the high price of crude oil Falcondo was shutdown from October 2001 to January 2002. General maintenance work on the plant facilities was carried out during the shutdown.

In December 2002, production at Falcondo was restricted because of required maintenance at the power plant and a shortage of oil caused by the Venezuelan national strike. Falcondo secured new oil supplies and the restriction in production was limited to a few days in January 2003 after which full production resumed.

Marketing and sales of ferronickel produced at Falcondo are conducted through Falconbridge U.S., Inc., Falconbridge Europe S.A. and Falconbridge (Japan) Ltd.

Collahuasi

Falconbridge and Anglo American Plc each own a 44% interest in Collahuasi. A Japanese consortium of Mitsui and Co., Nippon Mining and Metals Co. and Mitsui Mining and Smelting Co. holds the remaining 12% interest.

Capital expenditures of U.S.$l,792 million were required to bring the Collahuasi operation into commercial production. Total capital requirements incurred at Collahuasi, including working capital, were approximately U.S.$1,870 million. These expenditures were financed through a combination of third party debt and equity and subordinated loans from Collahuasi's shareholders.

The Collahuasi property covers 380 exploitation concessions over 110,710 hectares and 85 exploration concessions over 41,800 hectares. The property is located in northern Chile, about 180 kilometres southeast of the port of Iquique. The Collahuasi operation sites are serviced by an airstrip and roads linking them to Calama and Iquique.

The Collahuasi property contains two separate porphyry copper deposits known as Ujina and Rosario, each with important secondary enrichment zones, and the exotic copper deposit Huinquintipa located downstream from the Rosario deposit. In addition to the porphyry copper deposits, which have not been delineated at depth, the property contains high grade copper/silver vein systems at the adjacent deposit of La Grande.

The Collahuasi facilities include a 60,000 tonne per day concentrator at Ujina, a copper oxide leaching plant, an oxide solvent extraction/electrowinning plant, a concentrate pipeline, dewatering plant and port at Punta Patache, 65 kilometres south of Iquique, and other project infrastructure. Production will average 350,000 tonnes per year of copper in concentrate and 50,000 tonnes per year of copper cathode during the initial 10 years of mine life. The mine site is serviced under a 20-year power supply contract with Empresa Nacional de Electricidad S.A., a Chilean electric utility company, which has constructed a 150 megawatt coal-fired generating station at Punta Patache and 180 kilometres of high voltage transmission lines to the Ujina site.

The Collahuasi property is located in a high altitude desert area, or Altiplano, 4,300 metres above sea level. Collahuasi holds licences which permit it to extract and use the 850 litres of water per second required for production from two nearby subterranean reservoirs at Coposa and Michincha.

17

Mining, Milling and Processing

Commercial production at the Collahuasi operation began in 1999.

During 2002, 130.2 million tonnes of raw material was mined, 25.2 million tonnes of ore was milled at the concentrator and 5.4 million tonnes of ore was processed at the copper oxide leaching plant. Falconbridge's share of the copper produced by Collahuasi during 2002 was 26,700 tonnes of cathode copper and 158,300 tonnes of copper in concentrate. A new SAG mill pebble crushing plant was successfully commissioned in 2001. This facility significantly mitigates the effect of hard ore on concentrator throughput rates.

In 2001, a bankable feasibility study relating to the transfer in 2004 of mining activities from the Ujina orebody to the Rosario orebody and the expansion of the concentrator milling capacity to 110,000 tonnes per day was completed. The transition to Rosario includes the construction of an overland conveyor to transport sulphide ore to the concentrator. A final decision on the expansion of the concentrator was made and detailed engineering commenced in May 2002. Construction activities at the site began in November 2002. Prestripping at the Rosario pit began in July 2002. The Rosario infrastructure facilities, including offices, maintenance workshop and dewatering pumps, were completed by year end. Total capital expenditures associated with the transition and the concentrator expansion project were estimated to be U.S.$654 million, with Falconbridge's 44% share of this cost totalling U.S. $288 million.

Collahuasi's mineral reserves and mineral resources as at December 31, 2001 and December 31, 2002 were as follows:

| |

| |

| | Changes in 2002 (tonnes)

| |

| |

|

|---|

| | December 31, 2001

| | December 31, 2002

|

|---|

Category

| |

| | Revisions/

discoveries

|

|---|

| | Tonnes

| | Copper

| | Production

| | Tonnes

| | Copper

|

|---|

| | (000's)

| | %

| | (000's)

| | (000's)

| | (000's)

| | %

|

|---|

Mineral Reserves |

|

|

|

|

|

|

|

|

|

|

|

|

| Proven | | 321,508 | | 1.05 | | (22,097 | ) | 10,843 | | 310,254 | | 1.02 |

| Probable | | 1,546,150 | | 0.90 | | (8,593 | ) | (9,063 | ) | 1,528,494 | | 0.90 |

| | |

| |

| |

| |

| |

| |

|

| Tota1(2) | | 1,867,658 | | 0.93 | | (30,690 | ) | 1,780 | | 1,838,748 | | 0.92 |

| | |

| |

| |

| |

| |

| |

|

Mineral Resources (in addition to Mineral Reserves) |

|

|

|

|

|

|

|

|

|

|

|

|

| Measured | | 203,215 | | 0.70 | | — | | (155,010 | ) | 48,205 | | 0.57 |

| Indicated | | 275,853 | | 0.57 | | — | | 153,913 | | 429,766 | | 0.63 |

| | |

| |

| |

| |

| |

| |

|

| Total | | 479,068 | | 0.63 | | — | | (1,097 | ) | 477,971 | | 0.63 |

| | |

| |

| |

| |

| |

| |

|

| Inferred | | 1,840,000 | | 0.72 | | — | | — | | 1,840,000 | | 0.72 |

Notes:

- (1)

- The mineral reserves and resources at Collahuasi are estimated and classified to industry standards following the Australasian Institute of Mining and Metallurgy's Joint Ore Reserve Committee code. These estimates have been restated to conform to the definitions adopted by the Canadian Institute of Mining, Metallurgy and Petroleum on August 20, 2000.

- (2)

- The decrease in mineral reserves in 2002 is due to annual mine production offset slightly by mining gains.

At planned operating rates, mineral reserves at Collahuasi are equal to approximately 44 years of production.

Lomas Bayas

In 2001, Falconbridge acquired 100% of the Lomas Bayas copper mine and adjacent Fortuna de Cobre copper deposit from Boliden Limited for a cash payment of $100.7 million. Falconbridge will also pay

18

U.S.$15 million if it exercises its right to retain the Fortuna de Cobre deposit before the fifth anniversary of closing.

Property and Mines

The Lomas Bayas mine comprises seven exploitation concessions covering approximately 2,022 hectares. The Fortuna de Cobre deposit comprises 11 exploitation concessions covering approximately 1,217 hectares. Falconbridge also holds 20 exploitation concessions and six exploitation concession applications covering approximately 4,933 hectares between the Lomas Bayas mine and the Fortuna de Cobre deposit, as well as 53 exploration concessions covering an area around the Fortuna de Cobre deposit.

The Lomas Bayas mine is located in the Second Region of Chile, approximately 110 kilometres northeast of the port city of Antofagasta. The mine is situated at an altitude of 1,500 metres in the Atacama desert. The Fortuna de Cobre deposit is situated 3 kilometres to the south of the Lomas Bayas mine.

Lomas Bayas currently operates one open pit mine. Heap leach grade ore is crushed and then placed on leach pads by a series of portable conveyors and a stacking system. Lower grade ore that does not economically justify the cost of crushing and additional handling is placed directly on separate leach pads by mine haulage trucks. Solutions containing sulphuric acid are then applied to leach the ores and copper recovery occurs by a solvent extraction-electrowinning process. The copper cathode is transported by truck and rail to the port at Antofagasta and shipped to customers overseas. Lomas Bayas is serviced by the electrical grid of northern Chile under long-term contracts with a local electricity supplier.

In 2002, Lomas Bayas mined 26.7 million tonnes of ore from which 59,300 tonnes of copper cathode were produced.

Lomas Bayas' mineral reserves and mineral resources as at December 31, 2001 and December 31, 2002 were as follows:

| |

| |

| | Changes in 2002(1) (tonnes)

| |

| |

|

|---|

| | December 31, 2001

| | December 31, 2002

|

|---|

Category

| |

| | Revisions/

discoveries

|

|---|

| | Tonnes

| | Copper

| | Production

| | Tonnes

| | Copper

|

|---|

| | (000's)

| | %

| | (000's)

| | (000's)

| | (000's)

| | %

|

|---|

| Mineral Reserves | | | | | | | | | | | | |

| Proven | | 90,904 | | 0.37 | | (8,556 | ) | (4,434 | ) | 77,914 | | 0.37 |

| Probable | | 354,659 | | 0.30 | | (14,986 | ) | (20,238 | ) | 319,435 | | 0.31 |

| | |

| |

| |

| |

| |

| |

|

| Total | | 445,563 | | 0.32 | | (23,542 | ) | (24,672 | ) | 397,349 | | 0.32 |

| | |

| |

| |

| |

| |

| |

|

Mineral Resources (in addition to Mineral Reserves) |

|

|

|

|

|

|

|

|

|

|

|

|

| Measured | | 11,741 | | 0.28 | | — | | 2,013 | | 13,754 | | 0.27 |

| Indicated | | 140,247 | | 0.28 | | — | | 17,360 | | 157,607 | | 0.27 |

| | |

| |

| |

| |

| |

| |

|

| Total | | 151,988 | | 0.28 | | — | | 19,373 | | 171,361 | | 0.27 |

| | |

| |

| |

| |

| |

| |

|

| Inferred | | 73,500 | | 0.26 | | (3,160 | ) | 3,060 | | 73,400 | | 0.28 |

Note:

- (1)

- The mineral reserves decreased by 48.2 million tonnes due to mine production of 26.7 million tonnes and the revision of the long-term price of copper from U.S.$0.95 to U.S.$0.90. Much of the material deleted from the mineral reserves was added to the mineral resources which increased by 19.4 million tonnes.

At planned operating rates, mineral reserves at Lomas Bayas are equal to approximately 14 years of production.

19

Corporate

Exploration

The Falconbridge and Noranda exploration groups have been combined. The integrated team conducts worldwide exploration on behalf of Noranda and Falconbridge with the focus of exploration for Falconbridge consisting of nickel and platinum group metals.

The Falconbridge exploration group is organized around four activities:

- •

- exploration support for existing operations;

- •

- project and business development support;

- •

- worldwide "greenfield" exploration and project generation; and

- •

- technical support, technology and mineral reserve/resource evaluation and reporting.

The mandate of the exploration group for Falconbridge is to:

- •

- add mineral reserves at the existing operations;

- •

- add new low cost nickel and platinum group metal mineral reserves through exploration or acquisitions to enable Falconbridge to pursue profitable growth;

- •

- ensure that technological advances in exploration methodology are used to improve efficiency; and

- •

- conduct safe and environmentally responsible exploration.

Exploration in support of existing operations in Canada is conducted from offices in Sudbury and at the Kidd Creek mine site and from a field office at the Raglan site. Greenfield exploration in North America is carried out from offices in Laval, Quebec. International greenfield exploration is conducted from the Corporation's Toronto office and from offices in Brisbane, Australia, Belo Horizonte, Brazil and Pretoria, South Africa and from a field office in Abidjan, Côte d'Ivoire. Administration, accounting, legal and technical support is provided from the Toronto corporate office.

At December 31, 2002, Falconbridge had a permanent exploration staff of 67, including 54 geologists and geophysicists.

Falconbridge's exploration expenditures for the two years ended December 31, 2002 and its planned exploration expenditures for 2003 are as follows:

| | 2003

| | 2002

| | 2001

|

|---|

| | (Planned)

| |

| |

|

|---|

| | ($ millions)

|

|---|

| Support of core operations in Canada | | 19 | | 19 | | 22 |

| Exploration projects in Canada | | 4 | | 5 | | 5 |

| Collahuasi | | — | | — | | 1 |

| Exploration projects outside Canada | | 6 | | 10 | | 12 |

| | |

| |

| |

|

| | Total | | 29 | | 34 | | 40 |

| | |

| |

| |

|

The Sudbury area is one of the world's largest sources of nickel and contains significant copper, cobalt, silver, gold and platinum group metals. In addition to its operating mines, the Corporation has large property holdings covering favourable geology of the Sudbury Igneous Complex.

Exploration programs conducted in 2001 and 2002 have resulted in the discovery of a new mineral resource at Nickel Rim South located 2.7 kilometres north of the airport at a depth of approximately 1600 metres. Surface drilling to-date has defined an inferred resource consisting of 6.3 million tonnes of 1.7% nickel, 3.4% copper, 2.2 grams per tonne platinum, 2.5 grams per tonne palladium and 1.5 grams per tonne gold. A decision whether or not to proceed with an underground exploration program will be made in 2003.

20

The Corporation spent $11.9 million in 2002 on exploration in support of the Sudbury Operations and plans to spend $12.5 million in 2003. In addition, diamond drilling and other exploration was carried out on certain of the Corporation's properties by option and joint venture partners, who also have exploration programs planned for 2003.

A reduced exploration program in 2002 resulted in the discovery of approximately 250,000 tonnes of mineral reserves in two individual lenses at Zone 2 and Katinniq. When added to the mining gains and losses, these discoveries replaced part of the annual production of 869,000 tonnes. In combination with production and other reserve write-downs the overall mineral reserves decreased by 1.4 million tonnes in 2002.

The Corporation spent $2.6 million in 2002 on exploration in support of the Raglan operation and plans to spend $4.4 million in 2003.

Exploration in the Timmins region in support of the Kidd Creek Operations focuses primarily on two areas: within the immediate area of the mine and in a 150 square kilometre area in the townships located north of Kidd mine. In addition, the Corporation conducts copper-zinc exploration joint ventures with other companies and focuses on areas within 200 kilometres of the Kidd Metallurgical Division's facilities.

The Corporation spent $2.7 million on its Timmins region exploration program in 2002 and plans to spend approximately $1.0 million in 2003. Regional exploration programs are supplemented by additional funds supplied through joint venture initiatives with other companies.

Falconbridge is the operator of a joint venture with La Société pour le Développement Minier de la Côte d'Ivoire, the state mining company of the Côte d'Ivoire, encompassing four significant nickel/cobalt bearing laterite deposits (Sipilou North, Foungouesso, Moyango and Viala) and three other occurrences (Sipilou South, Yamatoulo and Touoba). The Corporation has an 85% interest in the project.

Exploration work has identified an indicated resource of 123.9 million tonnes of 1.57% nickel and 0.10% cobalt plus an inferred resource of 134.2 million tonnes of 1.39% nickel and 0.12% cobalt. Hydrometallurgical exploitation of the resources is potentially viable provided several key requirements can be satisfied, such as the development of a rail link to the coast.

Following a coup d'état in December 1999, there has been a period of political turmoil in the Côte d'Ivoire that has included several changes in the composition of the Cabinet, including three changes in the position of Minister of Mines and Energy. A civil war is presently being waged and the future political situation in the country continues to be uncertain.

Greenfield exploration activity for nickel sulphide and platinum group metals ("PGMs") extends worldwide. The preferred exploration target is a high-grade deposit with significant by-product credits. Joint venturing to spread risk and cost and to increase the level of focused activity is a continuing strategy. Falconbridge and Impala Platinum Holdings Limited have formed a strategic alliance to jointly explore for PGMs. Under the terms of this five-year agreement, Falconbridge will conduct grassroots exploration for new high quality PGM projects worldwide.

Exploration efficiency continues to be improved by cost sharing arrangements with Noranda with respect to several offices. In addition to the exploration programs at the Corporation's current operations, exploration projects are in progress in Canada, Africa, Australia, and Brazil.

21

Koniambo Project, New Caledonia

In 1998, Falconbridge entered into a joint venture agreement with Société Minière du Sud Pacifique S.A. and its controlling shareholder, Société de Financement et d'Investissement de la Province Nord, for the evaluation and development of a 60,000 tonne per year nickel in ferronickel mining and smelting complex. The project is based on the Koniambo deposit located in the Northern Province of New Caledonia near the provincial capital of Kone. Falconbridge has a right to earn a 49% interest in the project.

A work program leading to the production of a bankable feasibility study began in the fourth quarter of 1998. The prefeasibility study was completed by the second half of 2002 and is currently under review. Further geological drilling has been undertaken in order to delineate a minimum of 10 years of measured resources and 15 years of indicated resources at a 2.0% nickel cut-off grade. This drilling was completed in February 2003 and analysis of the new data is expected to be completed in May 2003. An environmental impact assessment is also expected to be issued by the end of the second quarter of 2003.

U.S.$20.3 million was spent on the program in 2002, bringing the total expenditure to date to U.S.$87.5 million. It is expected that work on the bankable feasibility study will begin in the second half of 2003 and be completed by mid-2004. Total project cost through to the completion of the bankable feasibility study is expected to be U.S.$123 million.

Montcalm Project, Canada

A feasibility study for the Montcalm nickel-copper property located near Timmins, Ontario is now underway and is tentatively scheduled for completion during the second quarter of 2003. The study is based on an indicated mineral resource of 7.0 million tonnes grading 1.36% nickel and 0.67% copper and an inferred mineral resource of 0.7 million tonnes grading 1.7% nickel and 0.70% copper. Montcalm has the potential to produce 5 million tonnes at a rate of 750,000 tonnes annually. The ore would be milled and concentrated at the Kidd Metallurgical Division, and could contribute up to 8,000 tonnes annually to nickel output from the Sudbury smelter.

Business Development

The Falconbridge and Noranda business development groups have been combined. The group assesses new business opportunities worldwide on behalf of Falconbridge and Noranda with the focus for Falconbridge on nickel, platinum group metals and advanced copper projects.

Technology

Falconbridge participates in a number of exploration research projects designed to decrease the cost of mineral exploration. Projects cover the areas of geophysics, geology, geochemistry and remote sensing. The primary research thrust is to improve the radius of detection surrounding a drill hole, and this is being accomplished by financial support for the development of the Lamontagne Geophysics UTEM IV high powered transmitter. The development of this instrument was completed in 2002 and field trials were carried out at exploration projects in the Sudbury area. Final testing and optimization of the instrument prior to full production usage will be done early in 2003.

Investigations into improving the detection of massive sulphide nickel deposits from the surface have continued with the development of innovative electromagnetic techniques. These techniques have led to improved discrimination of targets in support of the Raglan operation. In addition, work on improved computer modelling and 3-D visualization of geophysical and geological models continues.

Remote sensing investigations continue to be focused on the use of hyperspectral imaging for direct nickel exploration and satellite multispectral imaging for regional geological compilations. A large scale airborne hyperspectral survey was flown over projects in the Canadian Arctic during the 2002 summer field season.