Exhibit 96.1

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

DATE AND SIGNATURE PAGE

This report is effective as of the 29th day of October 2021.

| “Original signed on file” | | October 13, 2023 |

| BBA USA Inc. | | Date |

| | | |

| | | |

| | | |

| | | |

| “Original signed on file” | | October 13, 2023 |

| NewFields Mining & Design & Technical Services, LLC | | Date |

| | | |

| | | |

| | | |

| | | |

| “Original signed on file” | | October 13, 2023 |

| JDS Energy & Mining Inc. | | Date |

| | | |

| | | |

| | | |

| | | |

| “Original signed on file” | | October 13, 2023 |

| Resource Development Associates Inc. | | Date |

| OCTOBER 2023 | | BBA Document No.: 3661013-000000-40-ERA-0001-R00 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

TABLE OF CONTENTS

| 1.1.1 | 2023 TRS Amendments | 1-2 |

| 1.3 | Key Project Outcomes | 1-3 |

| 1.4 | Property Description, Location and Access | 1-4 |

| 1.8 | Mineral Processing and Metallurgical Testing | 1-8 |

| 1.9 | Mineral Resource Estimate | 1-9 |

| 1.10 | Mineral Reserve Estimate | 1-11 |

| 1.13 | Local Resources and Project Infrastructure | 1-17 |

| 1.13.1 | Local Resources | 1-17 |

| 1.13.2 | Project Infrastructure | 1-18 |

| 1.14 | Environmental and Permitting | 1-20 |

| 1.15 | Socioeconomic Conditions | 1-21 |

| 1.16 | Capital Cost and Operating Cost Estimates | 1-22 |

| 1.16.2 | Operating Costs | 1-23 |

| 1.17 | Project Economics | 1-24 |

| 1.19 | Interpretations and Conclusions | 1-28 |

| 2.1.1 | 2023 TRS Amendments | 2-1 |

| 2.2 | Basis of the Technical Report Summary | 2-1 |

| 2.4 | Report Responsibility | 2-2 |

| 2.5 | Personal Inspection of the Livengood Property | 2-3 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| 2.6 | Effective Dates and Declaration | 2-3 |

| 2.7 | Sources of Information | 2-4 |

| 2.8 | Currency, Units of Measure, and Calculations | 2-6 |

| 3. | Property Description and Location | 3-1 |

| 3.1 | Property Description | 3-1 |

| 3.1.1 | 100% Owned Patented Mining Claims | 3-1 |

| 3.1.2 | 100% Owned State of Alaska Mining Claims | 3-1 |

| 3.1.3 | 100% Owned Federal Unpatented Placer Mining Claims | 3-1 |

| 3.1.4 | 100% Owned by Livengood Placers, Inc. | 3-2 |

| 3.1.6 | Patented Mining Claims (Undivided Interests Less Than 100%) | 3-4 |

| 3.1.7 | Other Land Obligations | 3-5 |

| 3.1.9 | Environmental Liabilities | 3-6 |

| 4. | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 4-1 |

| 4.3 | Local Resources and Infrastructure | 4-1 |

| 6. | Geological Setting and Mineralization and Deposit | 6-1 |

| 6.1 | Geological Setting and Mineralization | 6-1 |

| 6.1.2 | Mineralization and Alteration | 6-4 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| 6.1.3 | Massive Stibnite Veins | 6-5 |

| 6.1.4 | Antimony Mineralization Halo | 6-7 |

| 7.1 | Exploration History | 7-1 |

| 7.2.1 | Reverse Circulation vs Core Drilling | 7-3 |

| 7.2.2 | Resource Verification Drilling | 7-7 |

| 8. | Sample Preparation, Assaying and Security | 8-1 |

| 8.1 | Sample Collection, Procedures and Security | 8-1 |

| 8.3 | QA/QC Procedures and Results | 8-2 |

| 8.4 | Data Collection, Entry and Maintenance | 8-2 |

| 10. | Mineral Processing and Metallurgical Testing | 10-1 |

| 10.2 | FS – Sample Selection and Preparation | 10-2 |

| 10.3 | FS – Mineralogy and Gold Deportment Study | 10-5 |

| 10.4 | Comminution Testing | 10-6 |

| 10.4.1 | FS – Comminution Testing | 10-6 |

| 10.4.2 | 2017 PFS – Comminution Testing | 10-8 |

| 10.4.3 | Testwork Summary for Crushing and Grinding Circuit Design | 10-9 |

| 10.4.4 | Project Throughput Estimation | 10-12 |

| 10.4.5 | Comminution Circuit Simulations and Design Summary | 10-16 |

| 10.5 | Metallurgical Testwork | 10-20 |

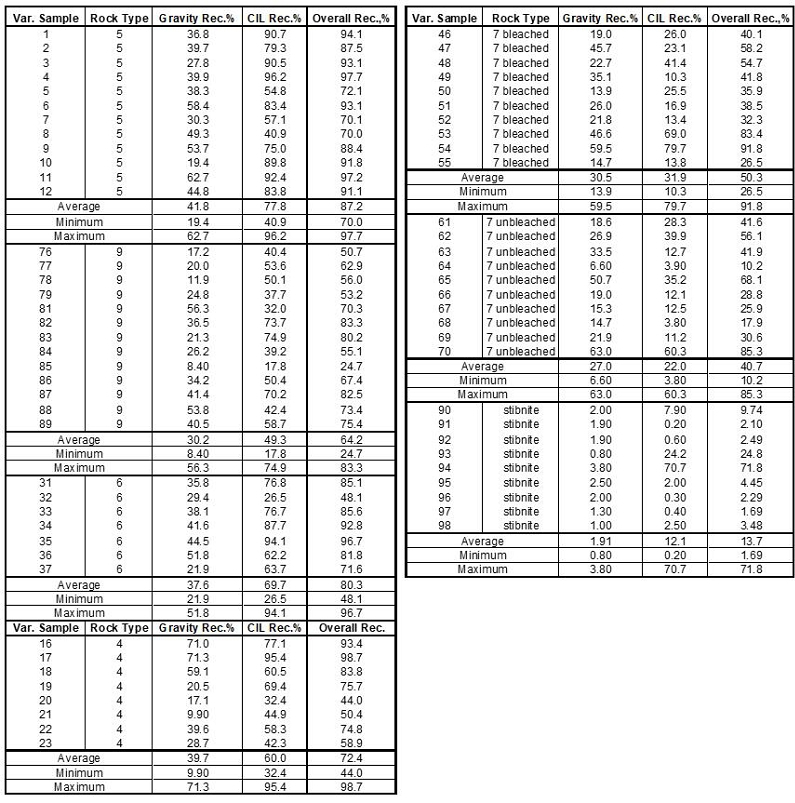

| 10.5.1 | 2013 FS – Metallurgical Testwork | 10-20 |

| 10.5.2 | 2013 FS – Optimization Test Program | 10-20 |

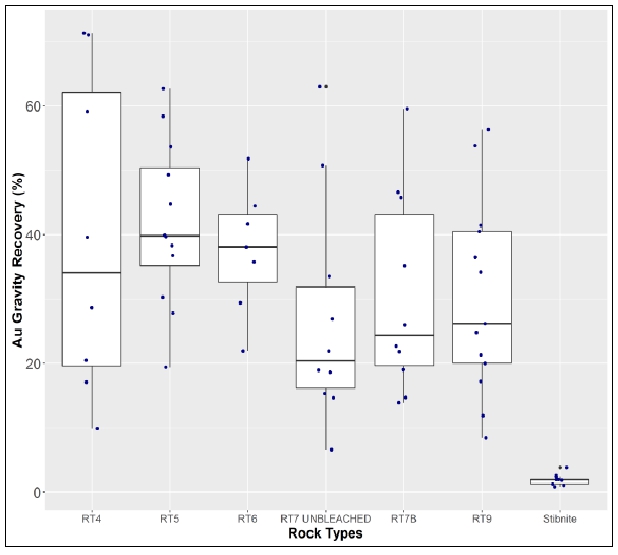

| 10.5.3 | 2013 FS – Variability Test Program | 10-29 |

| 10.5.4 | 2013 FS – Solid / Liquid Separation Testwork | 10-33 |

| 10.5.5 | 2013 FS – Cyanide Detoxification Tests | 10-33 |

| 10.5.6 | 2017 PFS – Metallurgical Testwork | 10-34 |

| 10.5.7 | 2017 PFS – Continuous Testwork | 10-35 |

| 10.5.8 | 2017 PFS – Phase 7 - Assay Procedures and Water Source Testing | 10-35 |

| 10.5.9 | 2017 PFS – Phase 8 - Grind, Recovery, Gravity, Flotation Testing | 10-35 |

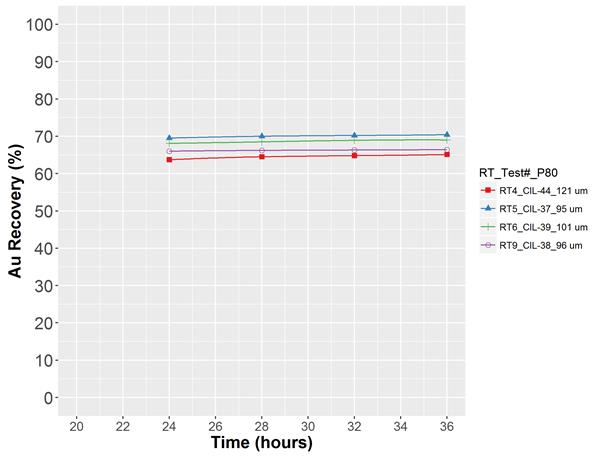

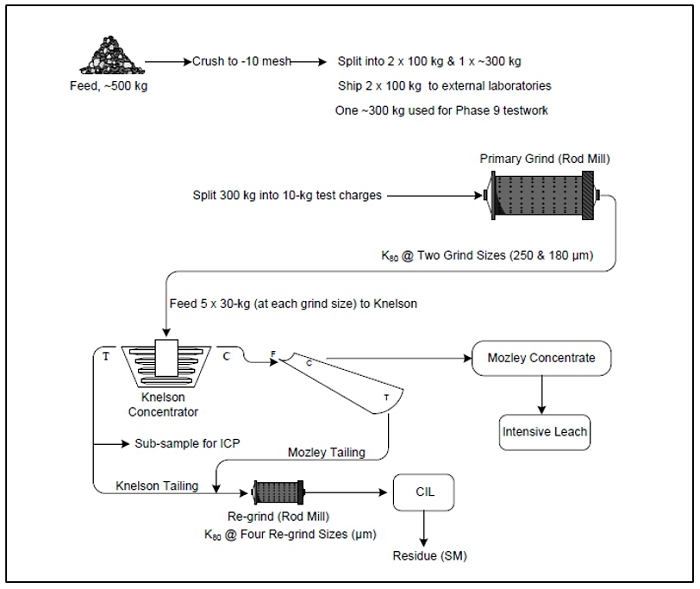

| 10.5.10 | 2017 PFS – Phase 9 - SGS and FLS-Curtin University Test Program | 10-37 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| 10.5.11 | 2017 PFS – Phase 10 - Stirred Tank Reactor (STR) Leach Tests | 10-50 |

| 10.5.12 | 2021 PFS – Metallurgical Testwork | 10-53 |

| 10.5.13 | 2021 PFS – Phase 9a - Cyanide Leach Testing | 10-53 |

| 10.5.14 | 2021 PFS – Phase 9b - Gravity, Grind, Leaching, STR and Flotation Testing | 10-61 |

| 10.5.15 | 2021 PFS – Phase 11 | 10-76 |

| 10.5.16 | 2021 PFS – Phase 12 | 10-86 |

| 10.5.17 | 2021 PFS – Phase 13 | 10-102 |

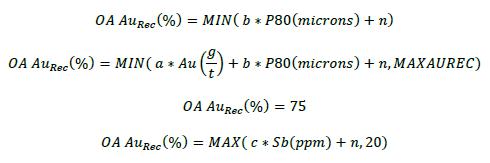

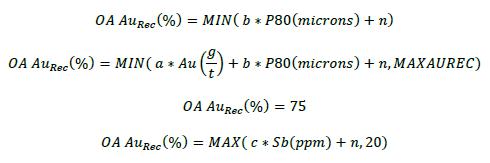

| 10.6 | Recovery Equations | 10-105 |

| 10.6.1 | 2017 PFS Recovery Equations – Grind Sizes of 90 µm and 180 µm | 10-105 |

| 10.6.2 | 2021 PFS Recovery Equations – Grind Size of 50-250 µm | 10-108 |

| 10.7 | Flowsheet Development | 10-112 |

| 10.7.1 | 2017 PFS Comparative Studies | 10-112 |

| 10.7.2 | 2021 PFS Comparative Study | 10-118 |

| 10.7.3 | Flowsheet Development Summary | 10-120 |

| 10.8 | Opportunities for Further Investigation | 10-121 |

| 11. | Mineral Resource Estimates | 11-1 |

| 11.1 | Mineral Resource Estimation Methodology | 11-1 |

| 11.4 | Grade Capping – Handling of Outliers | 11-5 |

| 11.7 | Contact Profile Analysis | 11-8 |

| 11.10 | Grade Estimation | 11-16 |

| 11.11 | Model Validation | 11-18 |

| 11.12 | Resource Classification | 11-21 |

| 11.13 | Qualified Person Opinion – Further Work | 11-23 |

| 11.14 | Mineral Resource Summary | 11-24 |

| 11.15 | Grade Sensitivity Analysis | 11-26 |

| 11.16 | Sensitivity of Mineralization to Gold Price | 11-28 |

| 12. | Mineral Reserve Estimates | 12-1 |

| 12.2 | General Parameters Used to Estimate the Mineral Reserves | 12-3 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| 12.2.1 | Topographical Data | 12-3 |

| 12.2.2 | Mineral Resource Block Model | 12-3 |

| 12.2.4 | Moisture Content | 12-6 |

| 12.3 | Modifying Factors That Affect the Mineral Reserves | 12-6 |

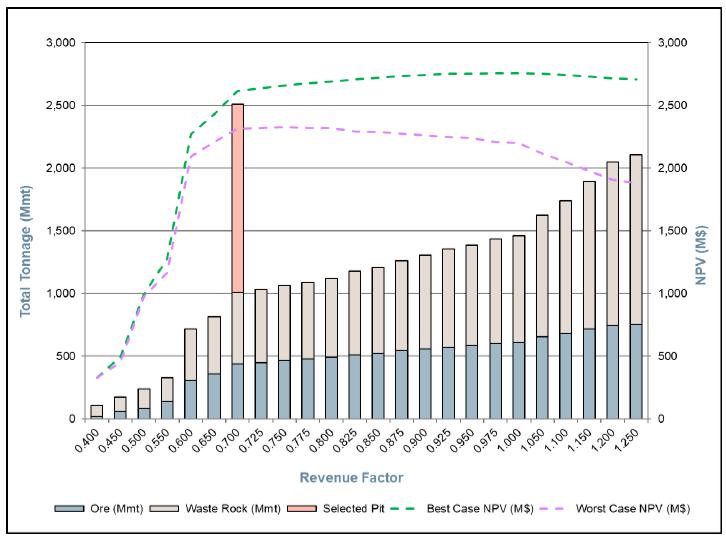

| 12.3.2 | Open Pit Optimization | 12-7 |

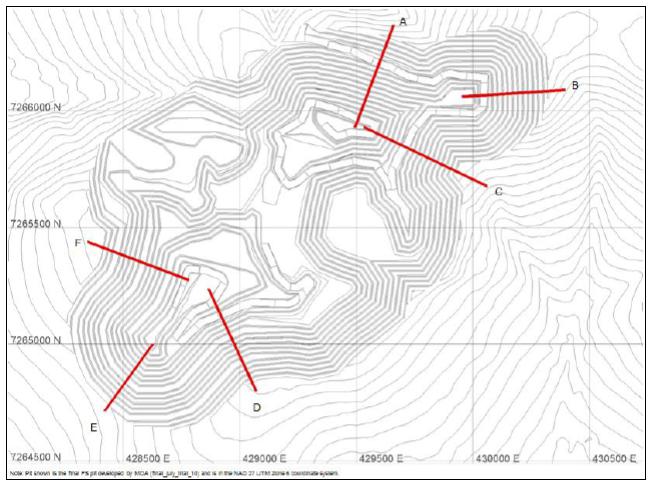

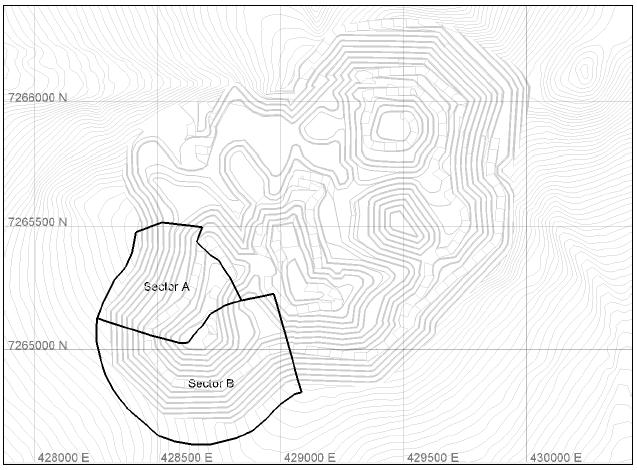

| 12.3.3 | Open Pit Design | 12-14 |

| 13.1.1 | Geotechnical Pit Slope Parameters | 13-1 |

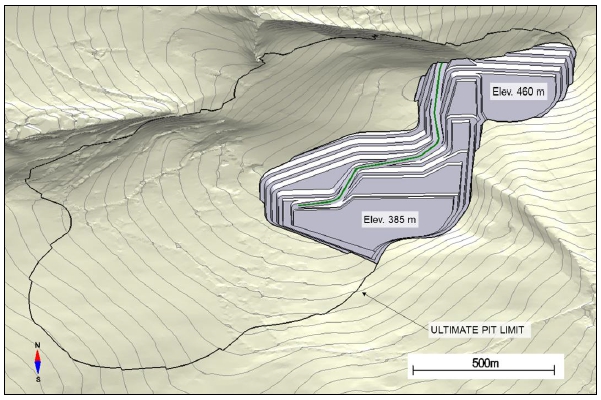

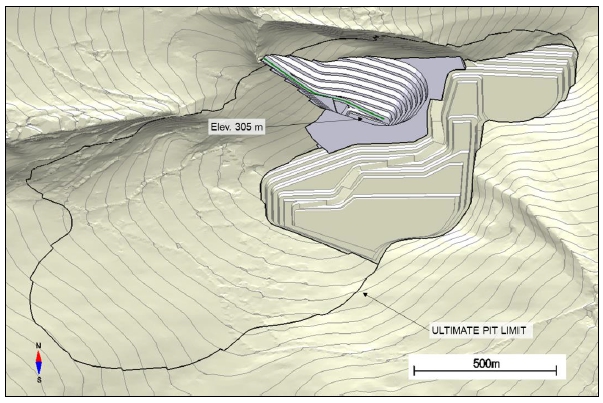

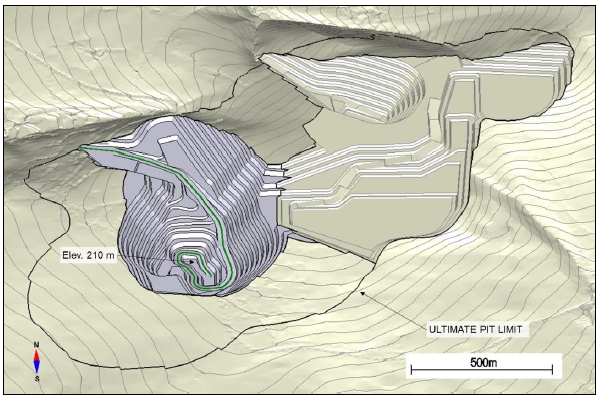

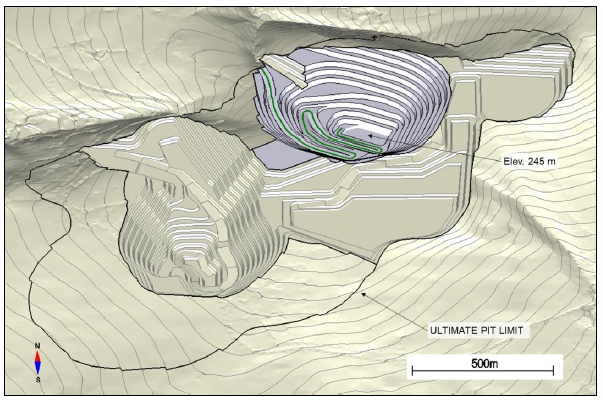

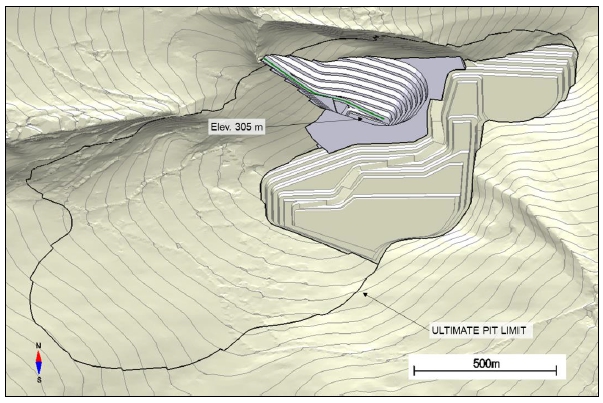

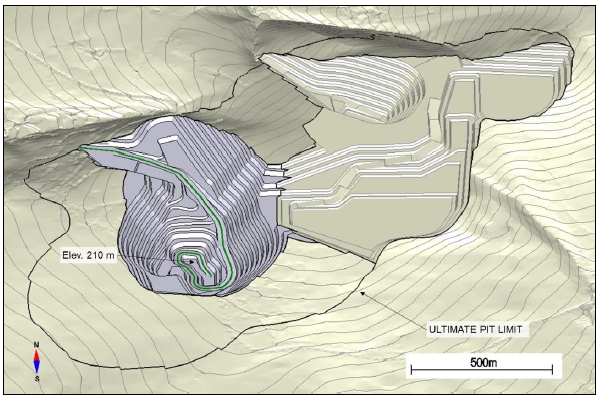

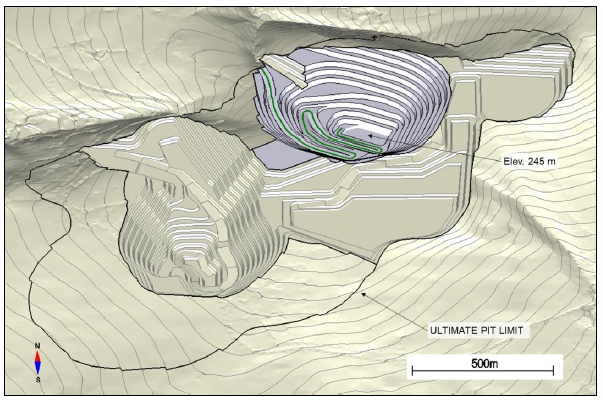

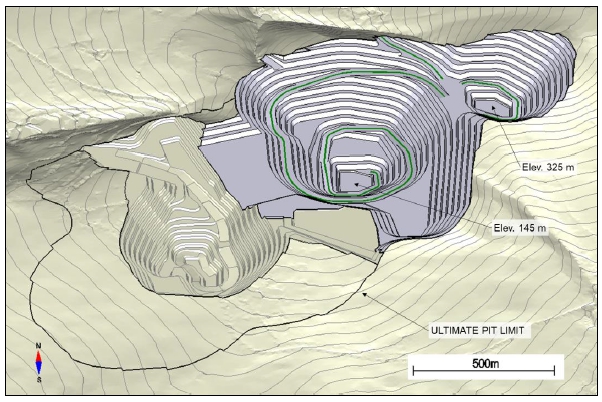

| 13.2.2 | Phase Design Results | 13-2 |

| 13.3 | Waste Rock Storage Facility and Stockpile Designs | 13-7 |

| 13.3.1 | Growth Media Stockpiles | 13-7 |

| 13.3.2 | Overburden Stockpile | 13-7 |

| 13.3.3 | Waste Rock Storage Facility | 13-7 |

| 13.3.4 | Low Grade Ore Stockpile | 13-8 |

| 13.3.5 | Emergency Ore Stockpile | 13-8 |

| 13.3.6 | Acid Rock Drainage | 13-9 |

| 13.4 | Mine Production Plan | 13-9 |

| 13.5 | Mine Equipment Fleet | 13-18 |

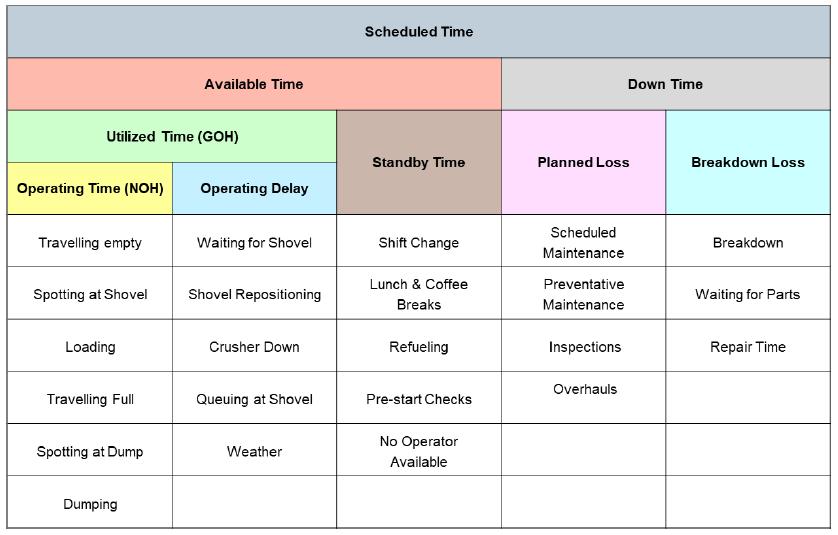

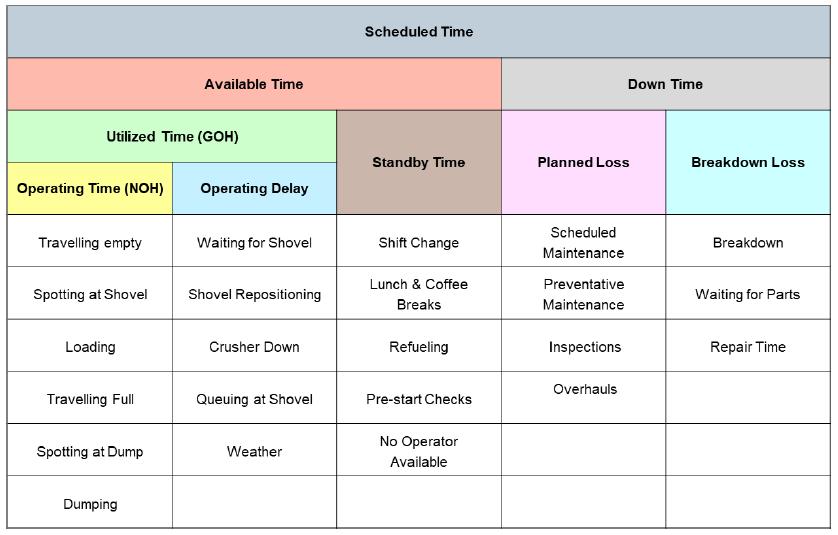

| 13.5.1 | Operating Schedule | 13-19 |

| 13.5.2 | Equipment Utilization Model | 13-19 |

| 13.5.3 | Drilling and Blasting | 13-21 |

| 13.5.6 | Auxiliary Equipment | 13-23 |

| 13.5.7 | Mine Dispatch System | 13-24 |

| 13.5.8 | Mine Dewatering | 13-24 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

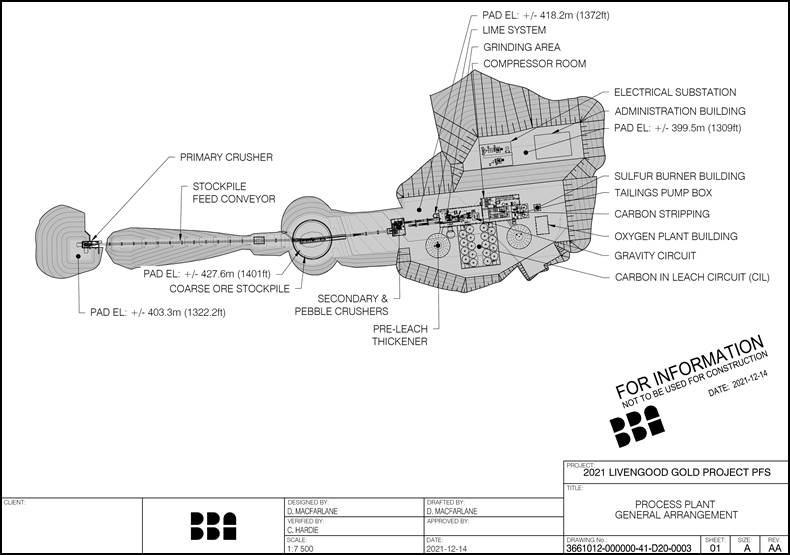

| 14.2 | Process Plant Production Schedule | 14-1 |

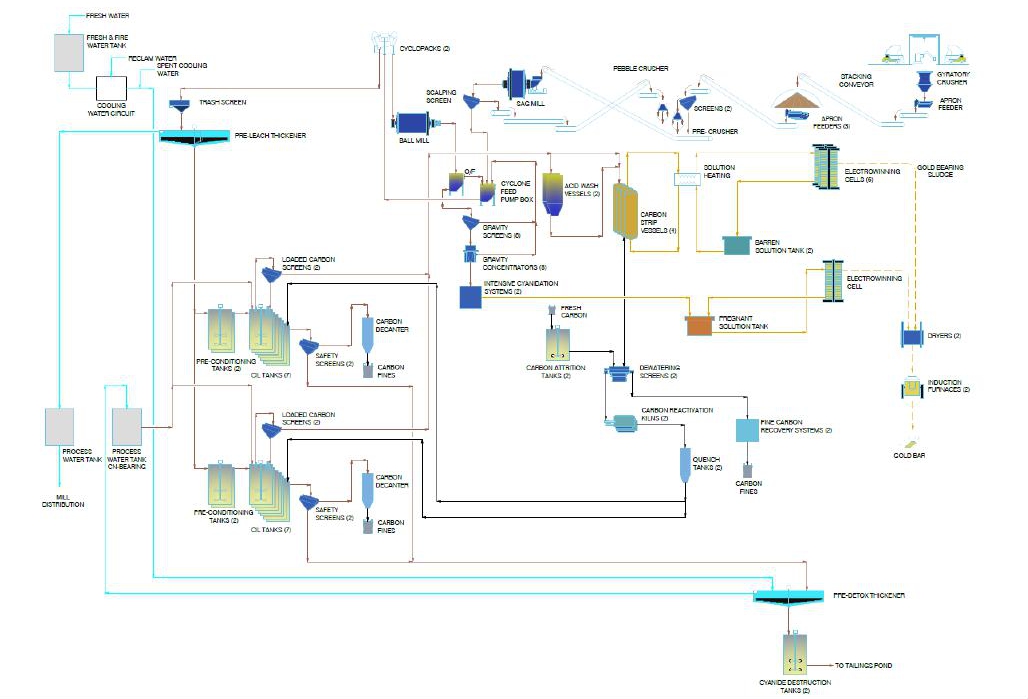

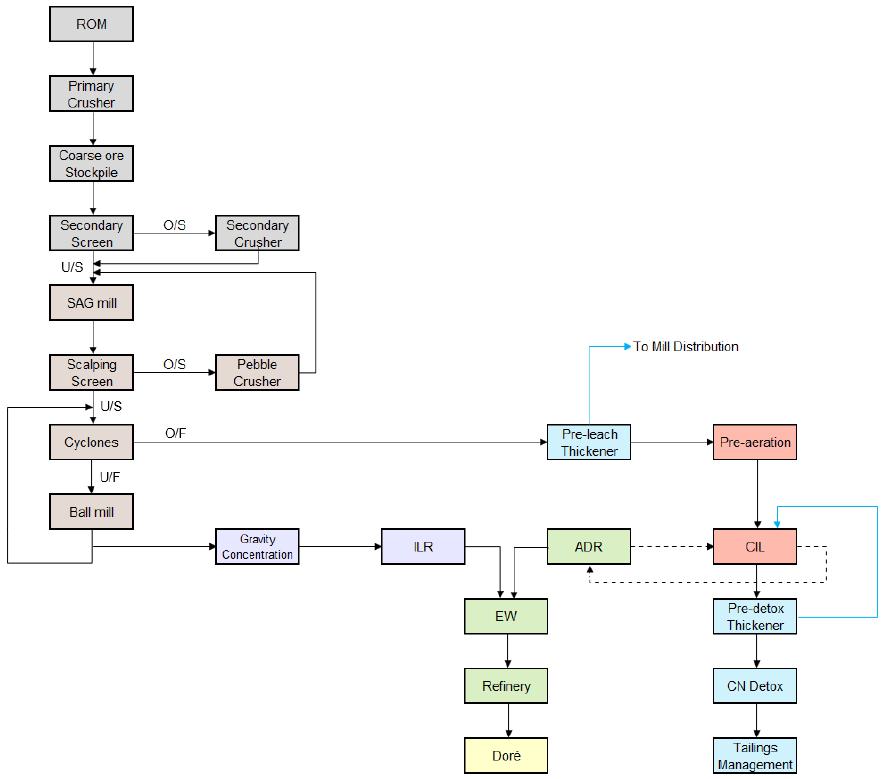

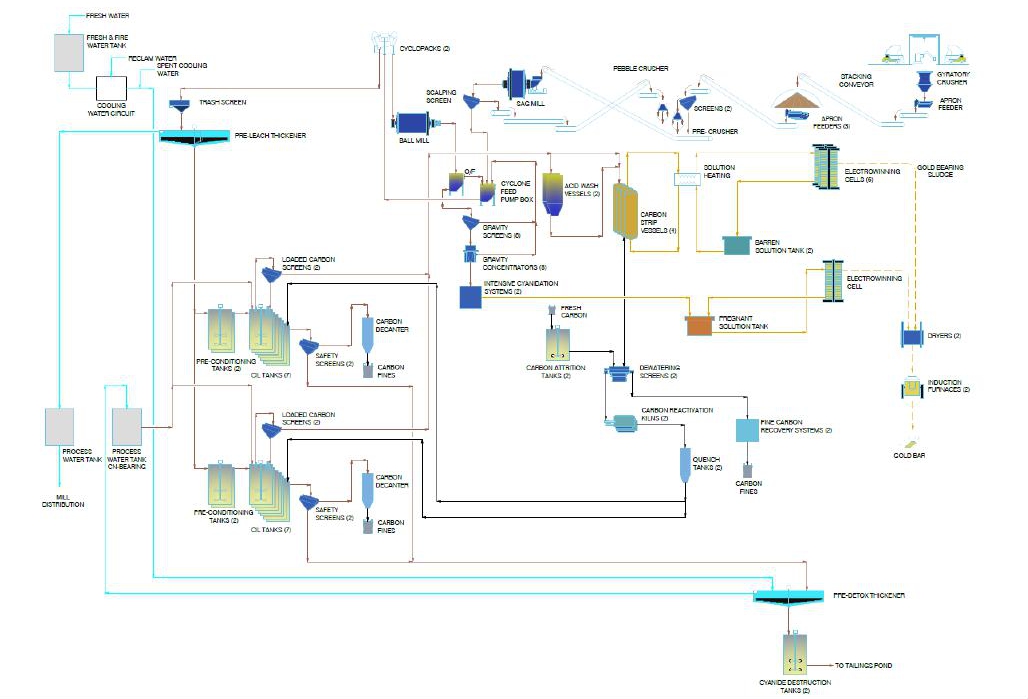

| 14.3 | Conceptual Process Flow Diagram | 14-1 |

| 14.4 | Plant Operating Design Parameters | 14-2 |

| 14.5 | Process Plant Facilities Description | 14-5 |

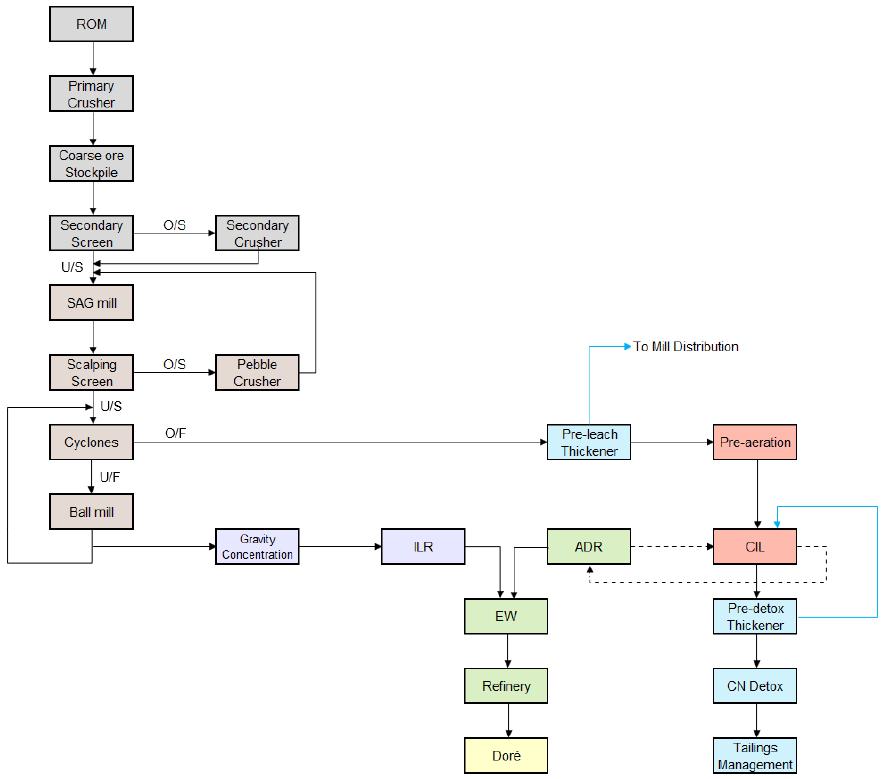

| 14.5.1 | Primary Crushing | 14-7 |

| 14.5.2 | Crushed Ore Stockpile | 14-7 |

| 14.5.3 | Secondary Crushing (Pre-Crushing) | 14-7 |

| 14.5.4 | Grinding and Pebble Crushing | 14-7 |

| 14.5.5 | Gravity and Intensive Leaching | 14-8 |

| 14.5.6 | Carbon in Leach | 14-8 |

| 14.5.7 | Adsorption, Desorption and Recovery (ADR) | 14-9 |

| 14.5.8 | Pre-Detox Thickening and Cyanide Detoxification | 14-9 |

| 14.7 | Ancillary Facilities | 14-12 |

| 14.8 | Process Plant Controls | 14-12 |

| 14.10 | Energy Requirements | 14-13 |

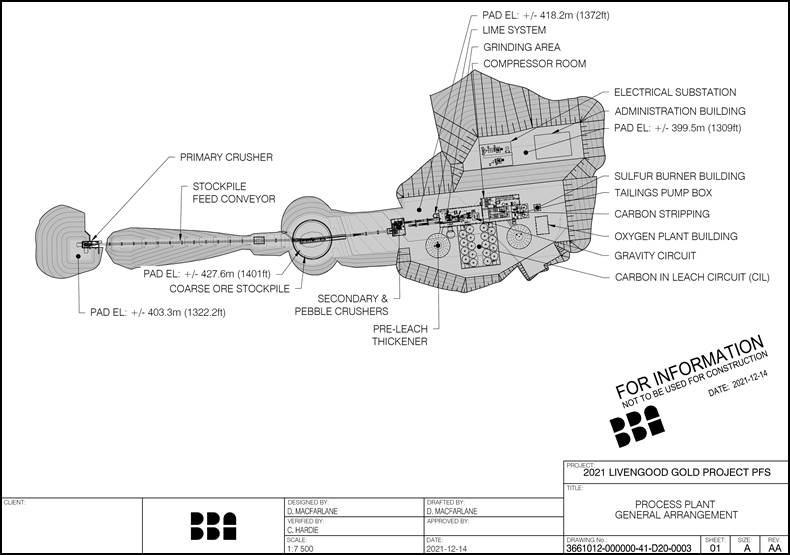

| 14.11 | Process Plant Arrangement | 14-13 |

| 14.12 | Process Plant Personnel | 14-15 |

| 15. | Project Infrastructure | 15-1 |

| 15.2 | General Site Arrangement | 15-2 |

| 15.4.1 | O’Connor Creek Substation | 15-3 |

| 15.4.2 | GVEA Transmission System Upgrades | 15-4 |

| 15.4.3 | 230 kV Transmission Line | 15-4 |

| 15.5 | Site Electrical Distribution | 15-5 |

| 15.5.1 | Emergency Power | 15-5 |

| 15.7.1 | Light Vehicle Roads | 15-6 |

| 15.7.2 | Mine Haul Roads | 15-6 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| 15.8 | Explosives Storage Facilities | 15-6 |

| 15.10 | Administration and Mine Services Facility | 15-7 |

| 15.10.1 | Lube Storage and Distribution | 15-7 |

| 15.10.2 | Warehouse and Storage | 15-7 |

| 15.10.3 | Mechanical Workshop | 15-8 |

| 15.10.4 | Administration Offices | 15-8 |

| 15.11 | Other Structures | 15-8 |

| 15.12 | Communications / Information Technology (IT) | 15-9 |

| 15.13 | Fire Protection | 15-10 |

| 15.15 | Construction Camp | 15-10 |

| 15.16 | Personnel Transportation | 15-10 |

| 15.17 | Fairbanks Infrastructure | 15-10 |

| 15.17.1 | Integrated Remote Operation Centre (IROC) | 15-11 |

| 15.18 | Waste Rock Storage Facility (WRSF) and Stockpiles | 15-11 |

| 15.18.1 | Growth Media Stockpiles | 15-11 |

| 15.18.2 | Overburden Stockpile | 15-11 |

| 15.18.3 | Waste Rock Storage Facility (WRSF) | 15-12 |

| 15.18.4 | Low Grade Ore Stockpile | 15-12 |

| 15.18.5 | Emergency Ore Stockpile | 15-12 |

| 15.19 | TMF and Water Management | 15-13 |

| 15.19.1 | Tailings Management Facility | 15-13 |

| 15.19.2 | Water Management | 15-14 |

| 16. | Market Studies and Contracts | 16-1 |

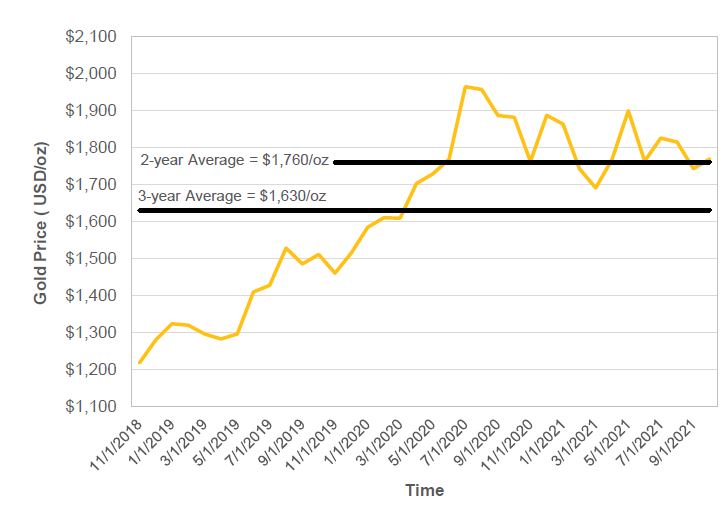

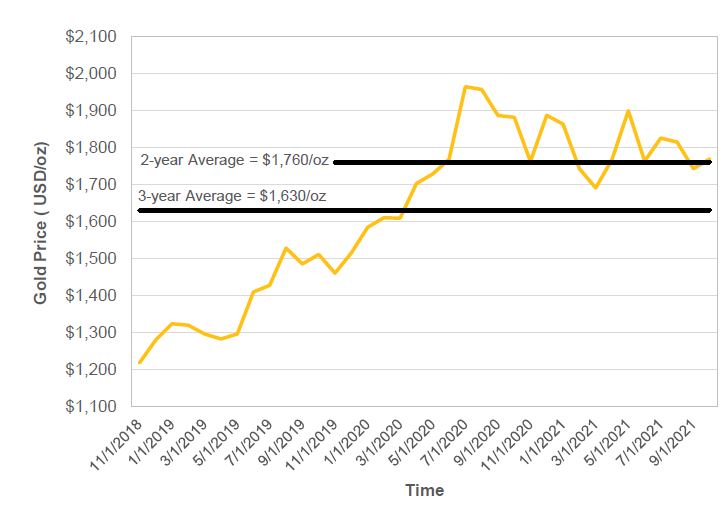

| 16.3 | Gold Price Projections | 16-1 |

| 17. | Environmental Studies, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups | 17-1 |

| 17.1.1 | Historical Project Activities and Permitting | 17-1 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| 17.1.2 | Baseline Studies | 17-1 |

| 17.1.3 | Environmental Management Strategies | 17-5 |

| 17.2.1 | Closure Activities | 17-6 |

| 17.2.2 | Post Closure Activities | 17-7 |

| 17.3.1 | Project Permitting Requirements | 17-7 |

| 17.3.2 | Status of Permit Applications | 17-9 |

| 17.4 | Requirements for Performance or Reclamation Bonds | 17-10 |

| 17.5 | Mine Closure Requirements and Costs | 17-10 |

| 17.6 | Socioeconomic Conditions | 17-10 |

| 17.6.1 | Regional Economy | 17-11 |

| 17.6.2 | Recreational and Subsistence Resources | 17-11 |

| 17.6.3 | Socioeconomic and Project Consequences | 17-11 |

| 17.6.4 | Support Services | 17-12 |

| 17.6.5 | Employment and Training | 17-12 |

| 17.7 | Adequacy of Current Plans | 17-12 |

| 18. | Capital and Operating Costs | 18-1 |

| 18.1 | Capital Cost Summary and Basis | 18-1 |

| 18.2 | Initial Capital Costs | 18-3 |

| 18.2.2 | Mine Development | 18-4 |

| 18.2.3 | Mining Equipment | 18-4 |

| 18.2.6 | Infrastructure Facilities | 18-6 |

| 18.2.7 | Indirect and Owner’s Costs | 18-7 |

| 18.3 | Sustaining Capital Costs | 18-9 |

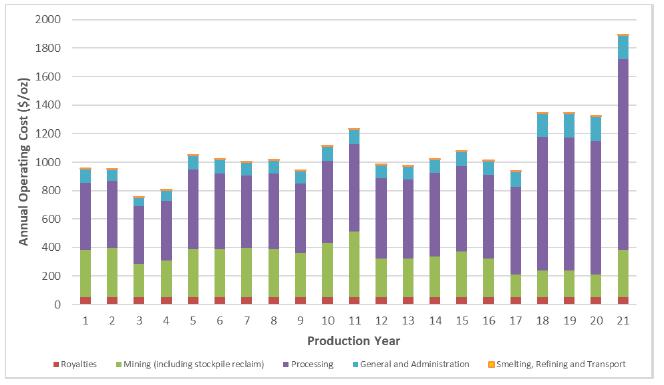

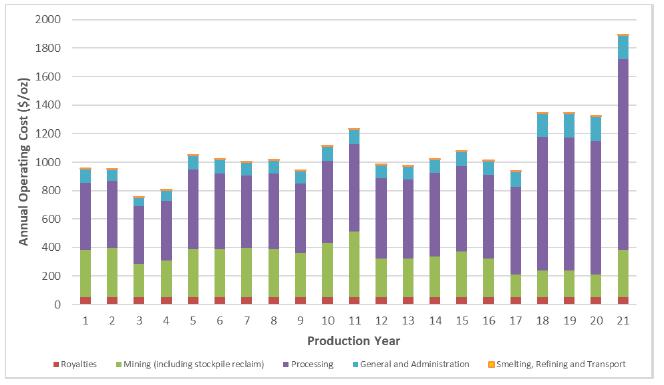

| 18.4 | Operating Cost Summary and Basis | 18-10 |

| 18.4.1 | Electricity, Diesel and LNG | 18-12 |

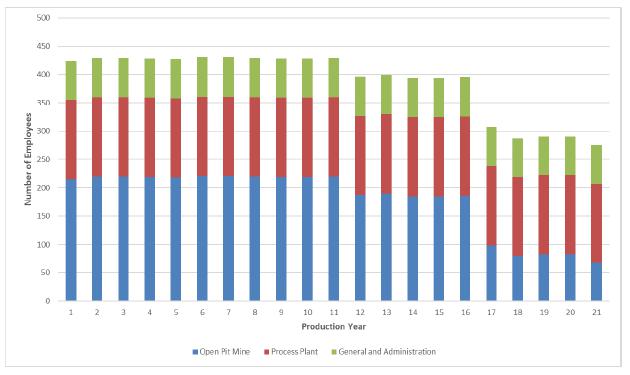

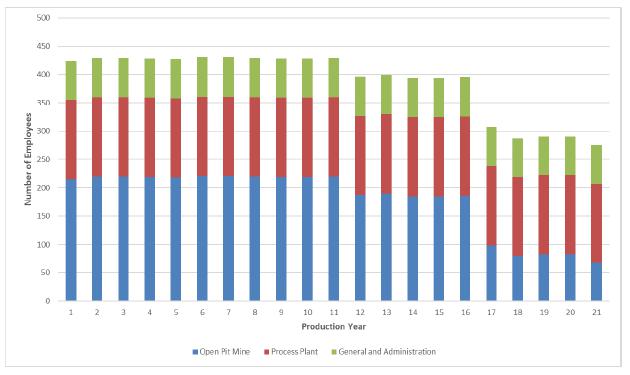

| 18.4.2 | Project Personnel | 18-12 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| 18.4.5 | General and Administration (G&A) | 18-18 |

| 18.6 | Transportation and Refining | 18-20 |

| 19.2 | Assumptions and Basis | 19-1 |

| 19.4 | Third Party Smelting, Refining and Transportation | 19-3 |

| 19.9 | Operating, All-in Sustaining, and All-in Costs | 19-6 |

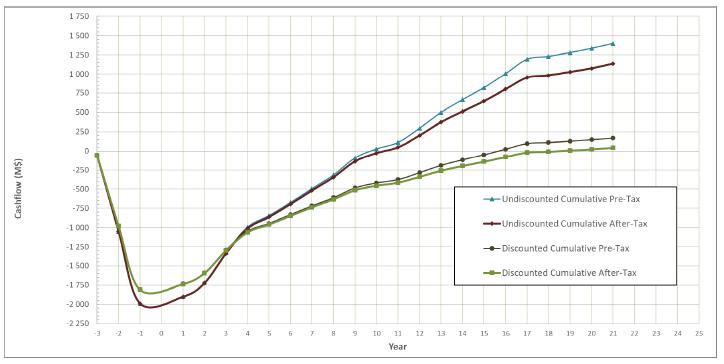

| 19.10 | Financial Analysis | 19-6 |

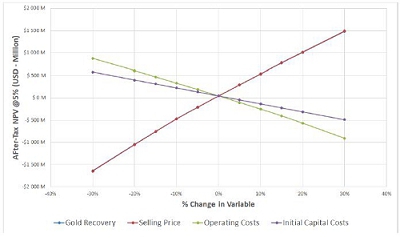

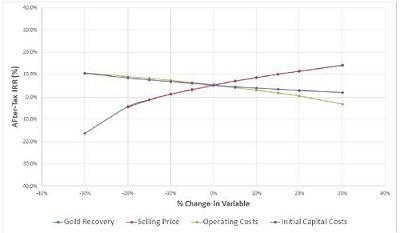

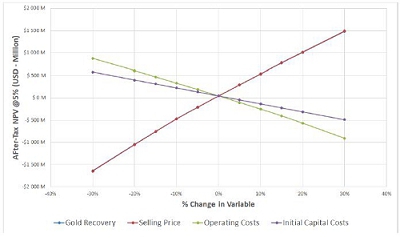

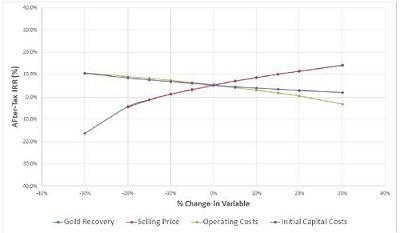

| 19.11 | Sensitivity Analysis | 19-9 |

| 20. | Adjacent Properties | 20-1 |

| 20.1 | Producing Properties | 20-1 |

| 20.2 | Exploration Projects | 20-1 |

| 21. | Other Relevant Data and Information | 21-1 |

| 21.1 | Execution Plan and Schedule | 21-1 |

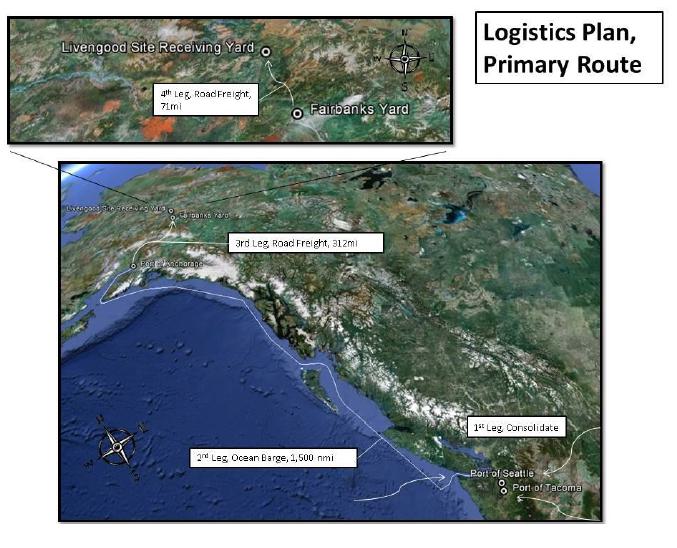

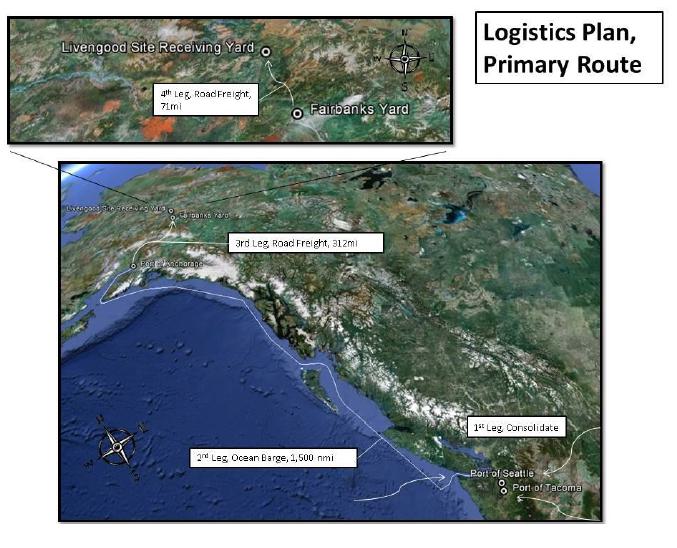

| 21.2 | Logistics and Transportation | 21-4 |

| 21.2.2 | Freight Options Considered | 21-4 |

| 21.2.3 | Recommended Base Routes | 21-5 |

| 22. | Interpretation and Conclusions | 22-1 |

| 22.4 | Indicative Economics | 22-3 |

| 22.5 | Project Risks and Opportunities | 22-3 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| 23.2 | Sampling Program to Obtain Fresh Core | 23-2 |

| 23.3 | Metallurgical Testwork | 23-2 |

| 23.4 | Feasibility Study | 23-2 |

| 24.2 | Geology and Resources | 24-1 |

| 24.4 | Mineral Processing and Metallurgy | 24-3 |

| 24.6 | TMF and Water Management | 24-6 |

| 25. | Reliance on Information Provided by Registrant | 25-1 |

APPENDICES

Appendix A: Properties and Claims

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

LIST OF TABLES

| Table 1-1: PFS contributors | 1-2 |

| Table 1-2: Average gold recovery (Gravity+CIL) estimated for each rock type | 1-9 |

| Table 1-3: Constraining parameters used for the Livengood Gold Project | 1-10 |

| Table 1-4: Livengood Gold Project mineral resource estimate (exclusive of mineral reserves) | 1-10 |

| Table 1-5: Livengood Gold Project mineral resource estimate (inclusive of mineral reserves) | 1-11 |

| Table 1-6: Livengood Gold Project Mineral Reserves, October 22, 2021 – BBA USA Inc. | 1-12 |

| Table 1-7: Environmental baseline studies (2008-2021) | 1-20 |

| Table 1-8: Initial capital and sustaining capital costs by major area | 1-23 |

| Table 1-9: Total operating cost breakdown (LOM average) | 1-24 |

| Table 1-10: Financial model inputs | 1-25 |

| Table 1-11: Summary of pre-feasibility study results | 1-25 |

| Table 1-12: Key project activities (preliminary) | 1-28 |

| Table 2-1: Primary PFS contributors | 2-2 |

| Table 2-2: Chapter/Section responsibility by Consulting Firm | 2-3 |

| Table 7-1: Comparison of modeled gold grades between core and RC drilling by stratigraphic unit | 7-4 |

| Table 7-2: Calculated resources for Area 50 by drill sample type | 7-6 |

| Table 7-3: Calculated resources for the Core Cross, Sunshine Cross and Area 50 | 7-7 |

| Table 10-1: Livengood gold ore sample selection weights (kg) used in the FS test programs | 10-2 |

| Table 10-2: Definition of Livengood rock types (FS) | 10-3 |

| Table 10-3: Comminution data (FS) | 10-6 |

| Table 10-4: Average JK drop weight parameters by rock type (FS) | 10-7 |

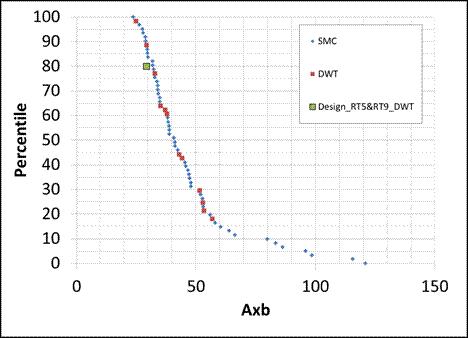

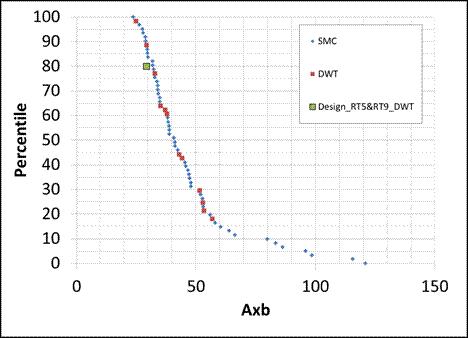

| Table 10-5: SMC testwork statistical analysis (2017 PFS) | 10-9 |

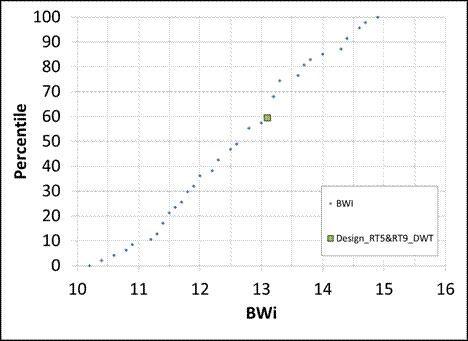

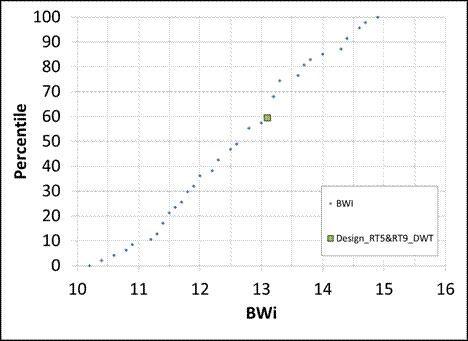

| Table 10-6: Comminution test statistical analysis by rock type | 10-9 |

| Table 10-7: Comminution test statistics using all 2013 FS and 2017 PFS testwork data | 10-10 |

| Table 10-8: Grinding circuit design values | 10-10 |

| Table 10-9: SAG and ball mill design criteria for simulations | 10-13 |

| Table 10-10: Throughput estimations for each scenario in metric tons per day (mt/d) | 10-14 |

| Table 10-11: Specific energy calculations for each scenario at design (80th percentile) A×b | 10-15 |

| Table 10-12: Comminution simulations summary | 10-18 |

| Table 10-13: Optimization composites used for testwork | 10-20 |

| Table 10-14: Comparison of gravity test results | 10-21 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| Table 10-15: Gold recovery resulting from the combination of gravity, flotation and CIL (FS) | 10-25 |

| Table 10-16: Gold recovery resulting from whole ore leaching (FS) | 10-28 |

| Table 10-17: Overall gold recovery of optimization samples for both process options (FS) | 10-28 |

| Table 10-18: Variability sample gold recovery (FS) | 10-30 |

| Table 10-19: Gold head assay | 10-38 |

| Table 10-20: Composite naming and weights for Phase 9 (2017 PFS) test program. | 10-38 |

| Table 10-21: ICP Analysis of the CIL feed from the continuous testwork for each rock type | 10-40 |

| Table 10-22: Comparison of cyanide addition in Phase 9 versus Continuous | 10-40 |

| Table 10-23: Intensive leach results | 10-45 |

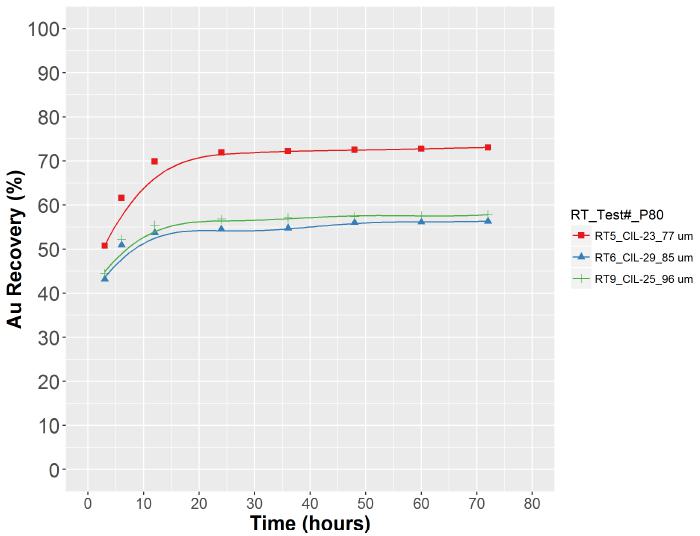

| Table 10-24: Kinetic results from Phase 9 | 10-48 |

| Table 10-25: Phase 10 results (2017 PFS) | 10-51 |

| Table 10-26: Reproducibility of cyanidation tests on the Livengood Gold Project | 10-52 |

| Table 10-27: Test conditions (2021 PFS – Phase 9a) | 10-55 |

| Table 10-28: Test results for all Rock Types (2021 PFS – Phase 9a) | 10-55 |

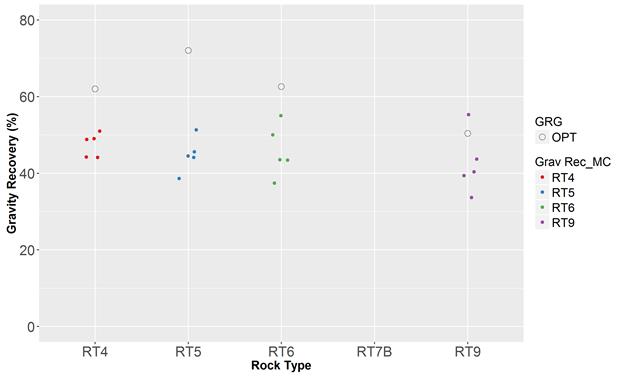

| Table 10-29: Average gold gravity recovery results for each rock type | 10-63 |

| Table 10-30: Phase 9 and Phase 9b recovery results comparison | 10-63 |

| Table 10-31: Result summary of the second pass gravity test at 180 µm | 10-67 |

| Table 10-32: Result summary of the second pass gravity test at 135 µm | 10-67 |

| Table 10-33: Result summary of the second pass gravity test at 90 µm | 10-68 |

| Table 10-34: Flotation testwork results | 10-69 |

| Table 10-35: Overall recovery comparison | 10-69 |

| Table 10-36: Composition of blend composites | 10-70 |

| Table 10-37: Effect of ore blend on CIL recovery, leach residue, flotation recovery and mass pull | 10-70 |

| Table 10-38: STR leach matrix conditions | 10-73 |

| Table 10-39: Average STR testwork results | 10-74 |

| Table 10-40: Knelson concentrate intensive leach results | 10-75 |

| Table 10-41: Knelson tailings CIL results | 10-76 |

| Table 10-42: Composites characteristics | 10-77 |

| Table 10-43: Gravity separation results | 10-79 |

| Table 10-44: 10 kg Bulk results from Phase 11 | 10-86 |

| Table 10-45: Composites characteristics | 10-87 |

| Table 10-46: Gravity separation results | 10-88 |

| Table 10-47: Average CIL testwork results | 10-95 |

| Table 10-48: Flotation testwork results | 10-96 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| Table 10-49: Flotation concentrate leach results | 10-97 |

| Table 10-50: Overall recovery comparison when using POX | 10-98 |

| Table 10-51: Enhanced gravity followed by POX/CIL results | 10-98 |

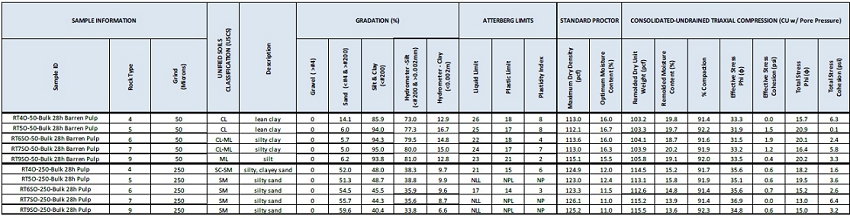

| Table 10-52: Index and Strength testing results (all samples) | 10-100 |

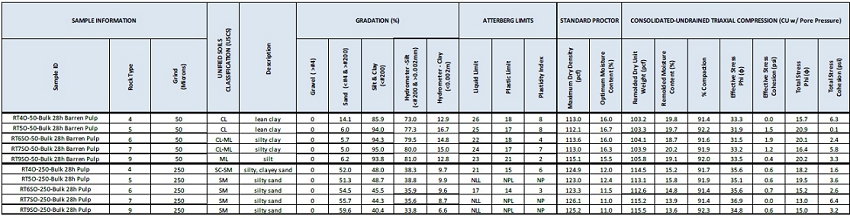

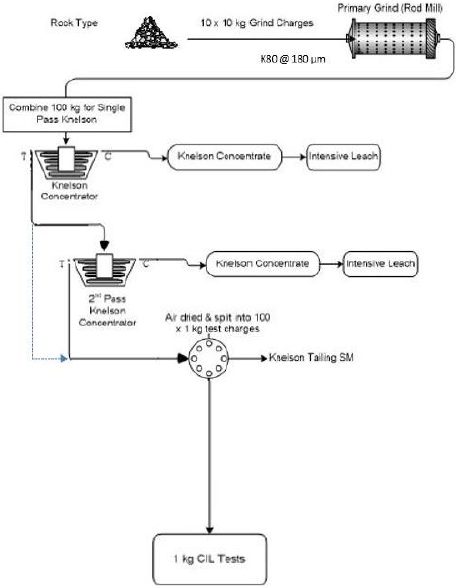

| Table 10-53: Permeability testing (select samples) | 10-101 |

| Table 10-54: Massive Stibnite shell recovery estimation | 10-104 |

| Table 10-55: Average gold recovery estimated for each rock type | 10-105 |

| Table 10-56: Average gold recovery estimated for each rock type (2021 PFS) | 10-111 |

| Table 10-57: Summary of recovery results from different testwork programs | 10-114 |

| Table 10-58: Simulated gold recoveries for the WOL vs Flotation trade-off | 10-115 |

| Table 10-59: Annual operating cost comparison | 10-117 |

| Table 11-1: Historical drilling and sampling | 11-2 |

| Table 11-2: THM resource drilling and sampling | 11-3 |

| Table 11-3: Density determinations | 11-3 |

| Table 11-4: Au assay statistics for Livengood | 11-4 |

| Table 11-5: Capping statistics | 11-5 |

| Table 11-6: Model extents | 11-12 |

| Table 11-7: ID3 Estimation Parameters | 11-16 |

| Table 11-8: Livengood deposit massive stibnite grade estimates | 11-17 |

| Table 11-9: Comparison of ID3 to NN estimates to evaluate for biases in the 2021 MRE | 11-18 |

| Table 11-10: Sources and Degree of Uncertainty | 11-22 |

| Table 11-11: Pit constraining parameters used for the Livengood Gold Project | 11-24 |

| Table 11-12: Livengood Gold Project mineral resource estimate (exclusive of mineral reserves) | 11-25 |

| Table 11-13: Livengood Gold Project mineral resource estimate (inclusive of mineral reserves) | 11-26 |

| Table 11-14: Sensitivity of block model to cut-off grade | 11-27 |

| Table 11-15: Sensitivity of mineralization inventory contained in pit shells | 11-28 |

| Table 12-1: Livengood Project mineral reserves (October 22, 2021- BBA USA Inc.) | 12-2 |

| Table 12-2: Lowest grades processed | 12-3 |

| Table 12-3: Block model specifications | 12-4 |

| Table 12-4: Block model item list | 12-4 |

| Table 12-5: Rock type numbering | 12-5 |

| Table 12-6: Bulk dry densities | 12-6 |

| Table 12-7: Processing throughput capacities by rock type | 12-8 |

| Table 12-8: Fixed costs by area | 12-8 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| Table 12-9: Pit optimization cost inputs ($/mt) | 12-9 |

| Table 12-10: Revenue parameters | 12-9 |

| Table 12-11: Mill recoveries (OSX = 1) | 12-10 |

| Table 12-12: Mill recoveries (OSX = 2) | 12-10 |

| Table 12-13: Mill recoveries (OSX = 3) | 12-10 |

| Table 12-14: Average mill recoveries by rock type (%) (1) | 12-11 |

| Table 12-15: Pit optimization results | 12-13 |

| Table 12-16: Distributions of RMR (Bienawski, 1989) per engineering unit | 12-16 |

| Table 12-17: Distributions of UCS per engineering unit | 12-16 |

| Table 12-18: Overall slope stability analysis results for the ultimate pit | 12-18 |

| Table 12-19: Pit slope design recommendations for ultimate pit | 12-18 |

| Table 12-20: Pit wall configuration | 12-20 |

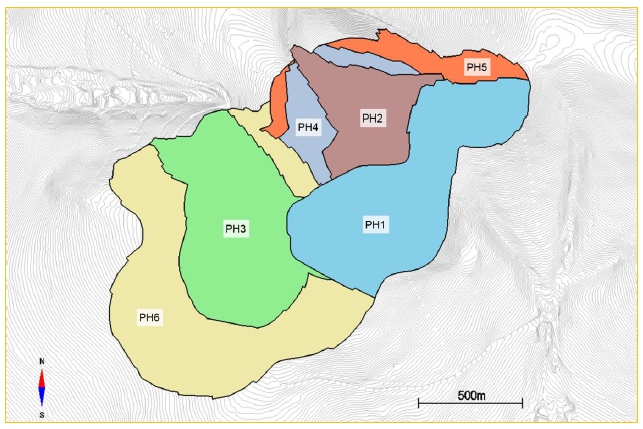

| Table 13-1: Mineral reserves by phase | 13-2 |

| Table 13-2: WRSF slope configuration | 13-8 |

| Table 13-3: Mine production schedule | 13-11 |

| Table 13-4: Mill feed by rock type | 13-12 |

| Table 13-5: Mine equipment fleet | 13-18 |

| Table 13-6: Mine equipment KPIs | 13-20 |

| Table 13-7: Fixed drilling time per hole | 13-21 |

| Table 13-8: Blast patterns (ore) | 13-22 |

| Table 13-9: Blast patterns (waste) | 13-22 |

| Table 13-10: Mine workforce | 13-25 |

| Table 14-1: General process design criteria | 14-3 |

| Table 14-2: Reagents and area of use | 14-10 |

| Table 14-3: Grinding media and area of use | 14-11 |

| Table 14-4: Process plant power demand by area | 14-13 |

| Table 14-5: Process plant salaried manpower | 14-15 |

| Table 14-6: Process plant hourly manpower | 14-16 |

| Table 15-1: Estimated total project power demand | 15-3 |

| Table 16-1: Refining and pricing assumptions | 16-2 |

| Table 17-1: Environmental baseline studies (2008-2016) | 17-1 |

| Table 17-2: Summary of environmental baseline studies | 17-2 |

| Table 17-3: Project permit requirements | 17-7 |

| Table 18-1: Capital cost estimate contributors | 18-1 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| Table 18-2: Initial capital and sustaining capital costs by major area | 18-2 |

| Table 18-3: Open pit mine initial capital costs | 18-3 |

| Table 18-4: Mining equipment initial capital costs | 18-4 |

| Table 18-5: Power supply capital costs by major area | 18-5 |

| Table 18-6: Process plant capital costs by major area | 18-5 |

| Table 18-7: Infrastructure capital costs by area | 18-7 |

| Table 18-8: Indirect and Owner’s costs by area | 18-8 |

| Table 18-9: Contingency by major area | 18-9 |

| Table 18-10: Sustaining capital costs by major area | 18-9 |

| Table 18-11: Operating cost estimate contributors | 18-10 |

| Table 18-12: Total operating cost breakdown (LOM average) | 18-11 |

| Table 18-13: Project peak personnel (Year 6) | 18-13 |

| Table 18-14: Average annual and life of mine operating costs – by activity | 18-14 |

| Table 18-15: Average annual and life of mine operating costs – by consumable | 18-14 |

| Table 18-16: Average annual and life of mine operating costs – process plant | 18-16 |

| Table 18-17: Average LOM media wear and consumption rates | 18-16 |

| Table 18-18: Average annual and life of mine operating costs – general and administration | 18-19 |

| Table 18-19: G&A employee list | 18-20 |

| Table 19-1: Financial model criteria | 19-2 |

| Table 19-2: Operating, All-in Sustaining, and All-in costs (pre-tax) | 19-6 |

| Table 19-3: Financial analysis summary (pre-tax and after-tax) | 19-7 |

| Table 19-4: Simplified cash flow table | 19-8 |

| Table 19-5: Project sensitivity analysis – after-tax IRR and NPV | 19-10 |

| Table 21-1: Key project activities (preliminary) | 21-1 |

| Table 21-2: Preferred base route legs and distances | 21-5 |

| Table 22-1: Project risks (preliminary risk assessment) | 22-4 |

| Table 22-2: Project opportunities (preliminary opportunity assessment) | 22-7 |

| Table 23-1: Cost estimate for feasibility study recommendations | 23-1 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

LIST OF FIGURES

| Figure 1-1: Project location map | 1-5 |

| Figure 1-2: Map illustrating the company’s Livengood Gold Project land holdings | 1-6 |

| Figure 1-3: Simplified process flow diagram | 1-16 |

| Figure 1-4: Gold production schedule (oz/year) | 1-17 |

| Figure 1-5: After-tax sensitivity analysis for project net present value (NPV @ 5% discount rate) | 1-27 |

| Figure 1-6: After-tax sensitivity analysis for project internal rate of return (IRR %) | 1-27 |

| Figure 3-1: Map illustrating the company’s Livengood Gold Project land holdings | 3-3 |

| Figure 3-2: Project location map | 3-7 |

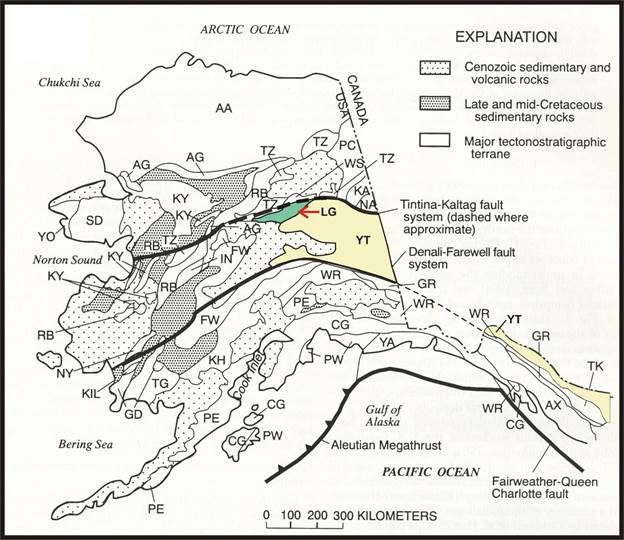

| Figure 6-1: Terrane map of Alaska showing Livengood Terrane (LG: red arrow) | 6-2 |

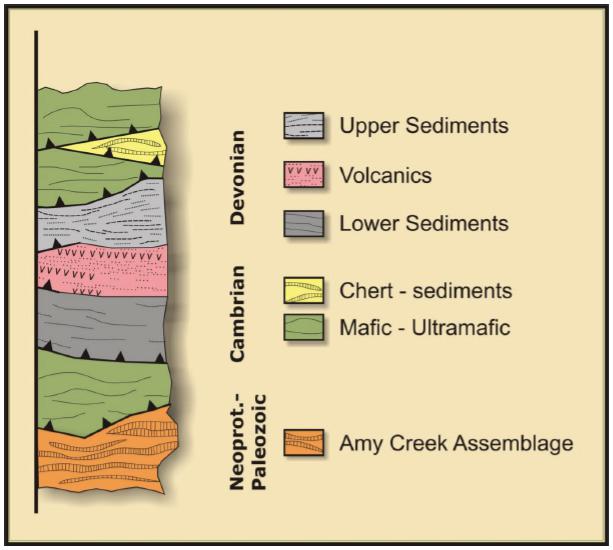

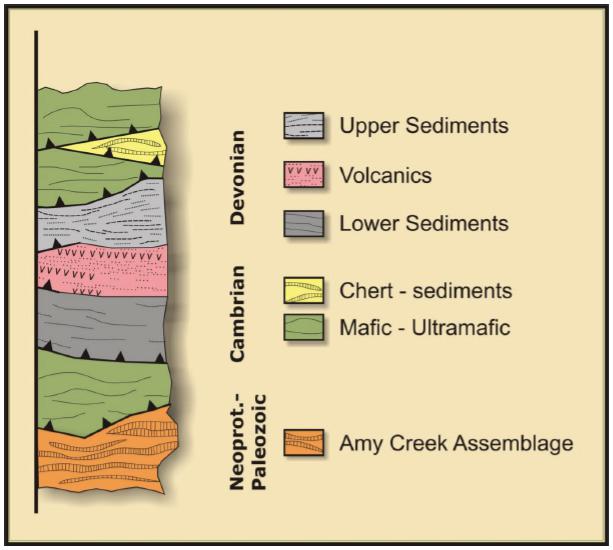

| Figure 6-2: Diagrammatic thrust/stratigraphic column in the Livengood area | 6-3 |

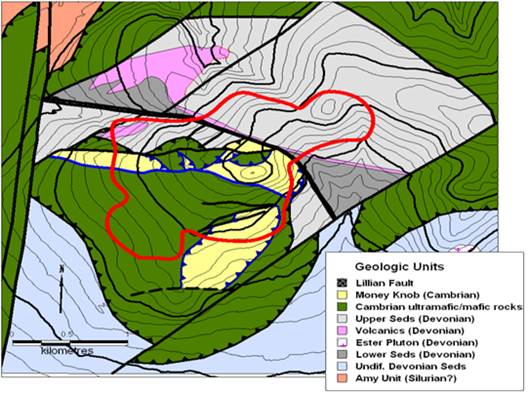

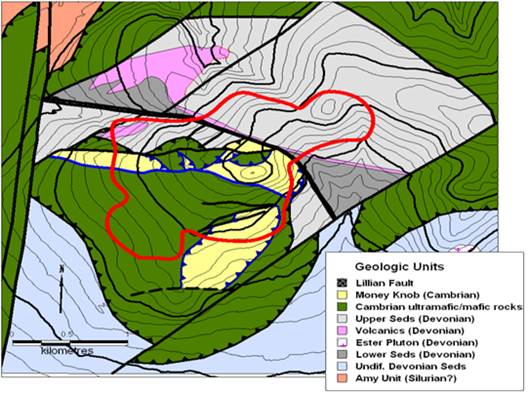

| Figure 6-3: Generalized geologic map of the Money Knob area based on geologic work by THM | 6-4 |

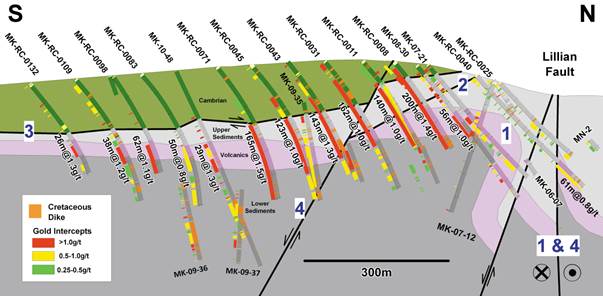

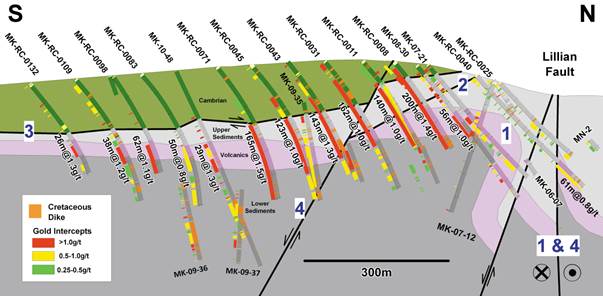

| Figure 6-4: Cross section through the deposit | 6-5 |

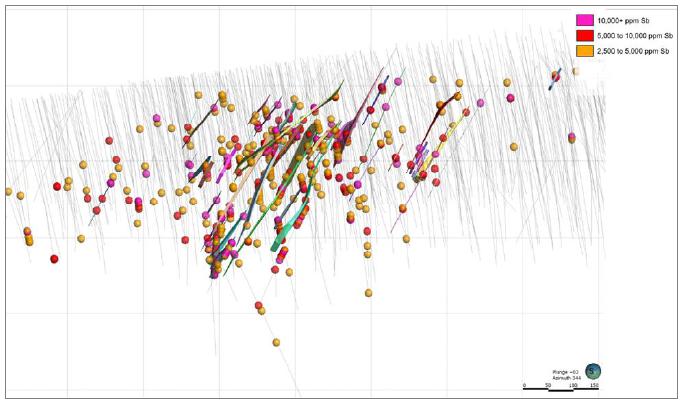

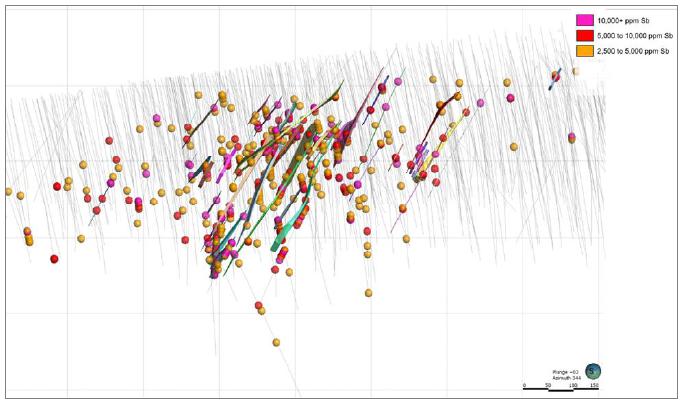

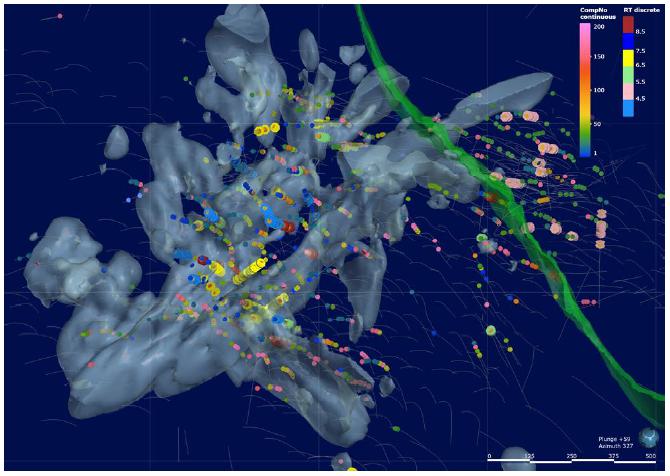

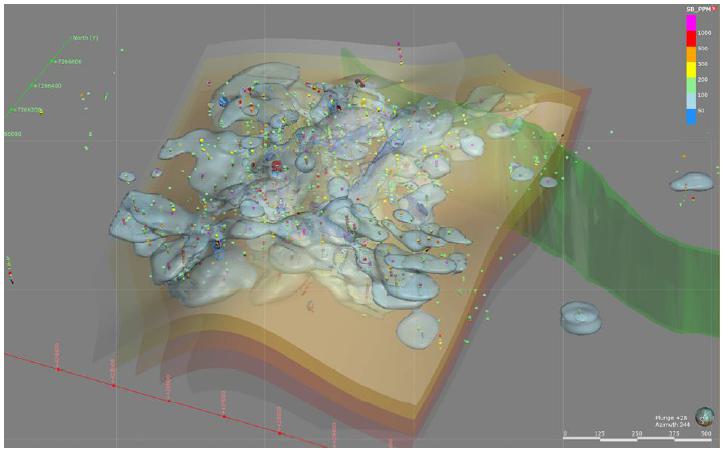

| Figure 6-5: Caption 3D view of MSV and >2,500 ppm Sb assays | 6-6 |

| Figure 6-6: Caption 3D view of MSV and >2,500 ppm Sb assays | 6-6 |

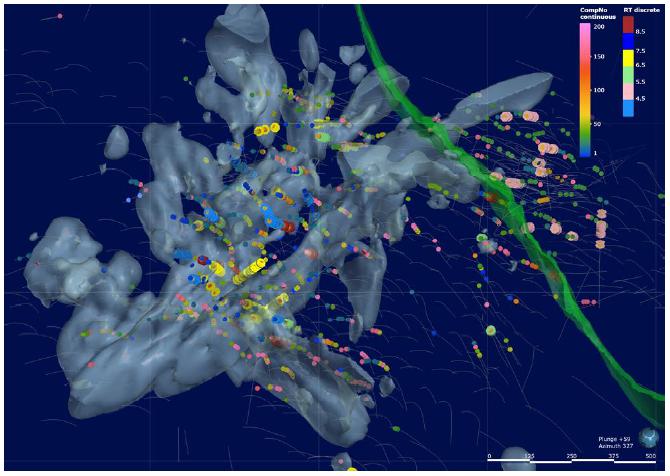

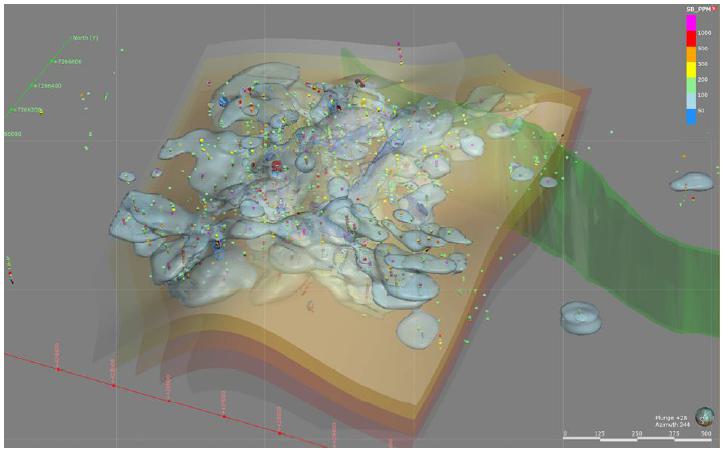

| Figure 6-7: 3D view of the Sb_100ppm grade shell generated from preferential linear alignments | 6-7 |

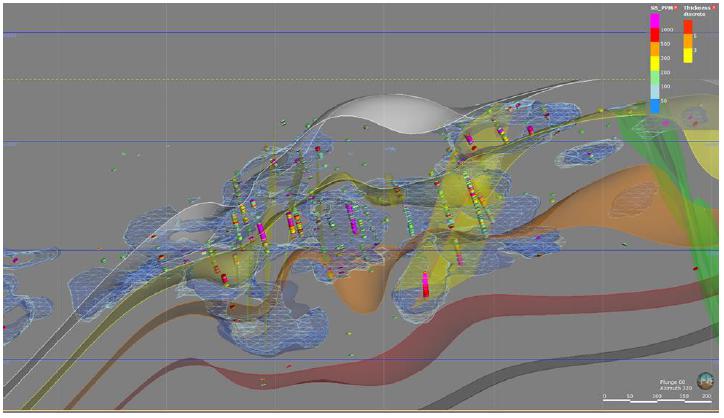

| Figure 6-8: 3D view of the Sb_100 ppm grade shell | 6-8 |

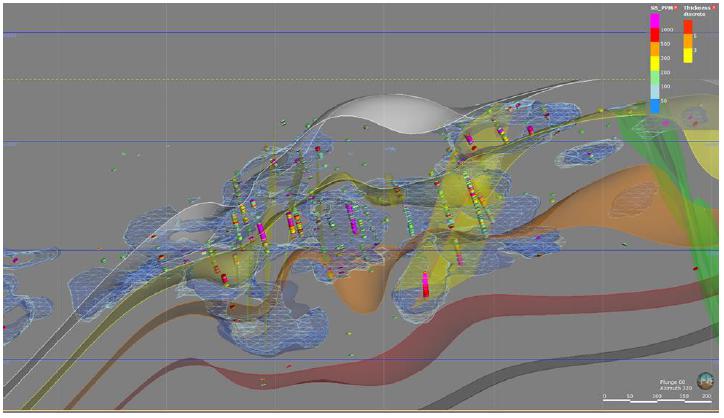

| Figure 6-9: Cross section view of the Sb_100 ppm grade shell (meshed solid) | 6-9 |

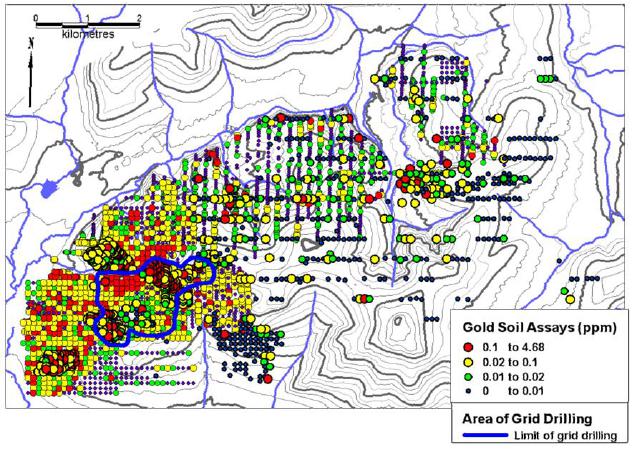

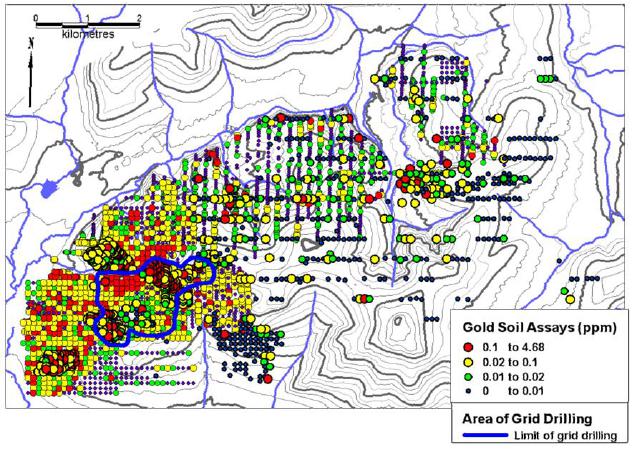

| Figure 7-1: Plot of gold values in soil samples | 7-1 |

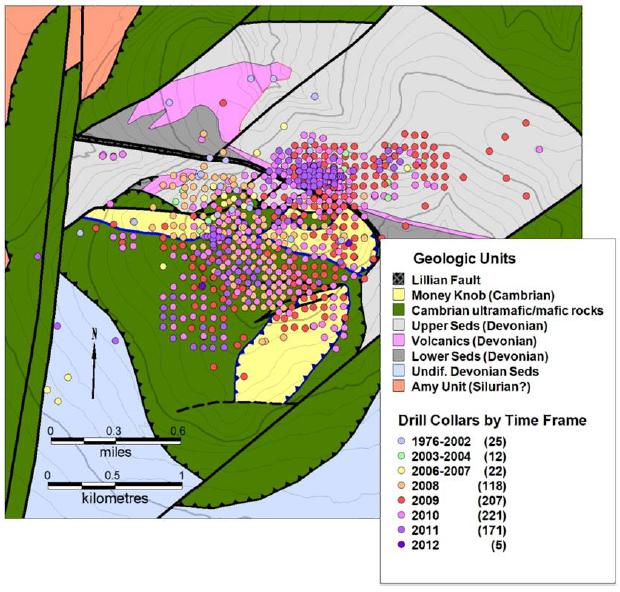

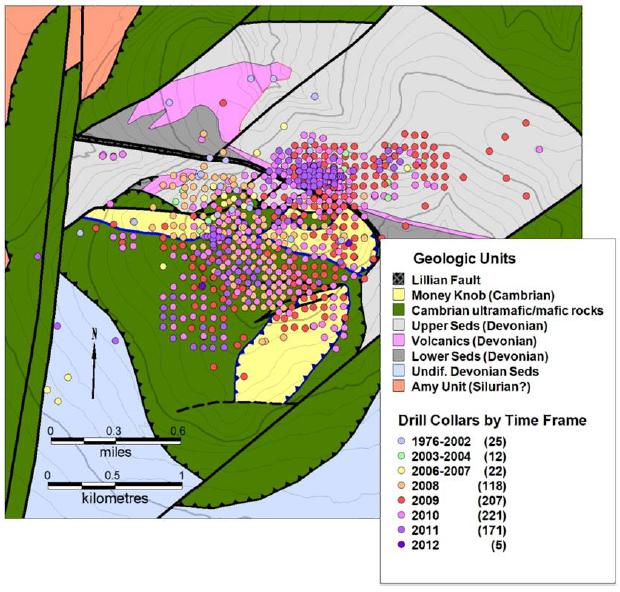

| Figure 7-2: Distribution of resource / delineation drill holes in Money Knob area over time | 7-2 |

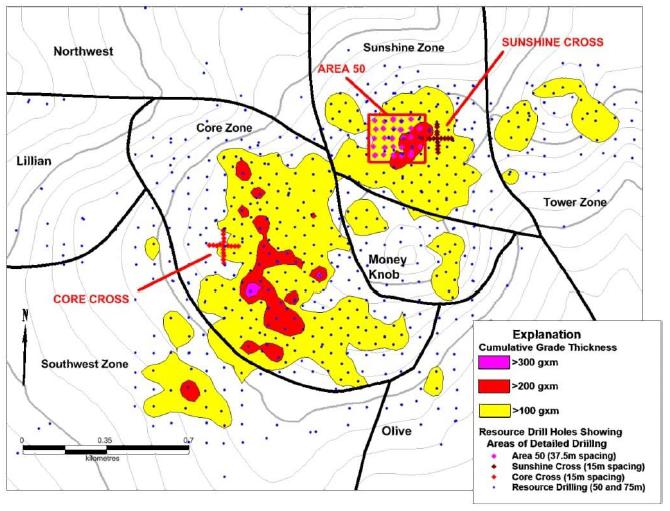

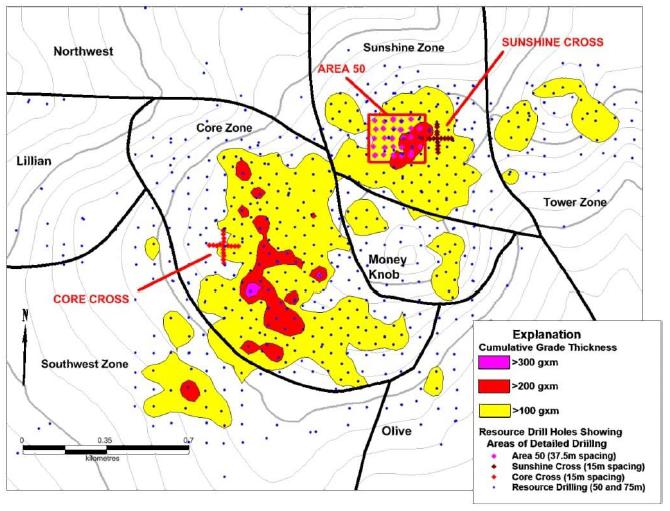

| Figure 7-3: Map showing location of areas of detailed drilling | 7-5 |

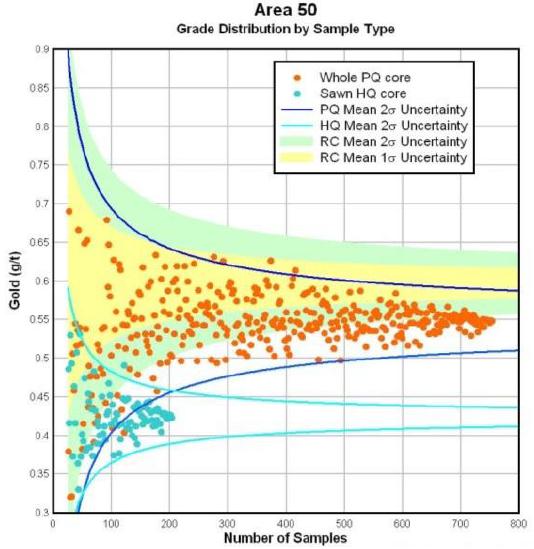

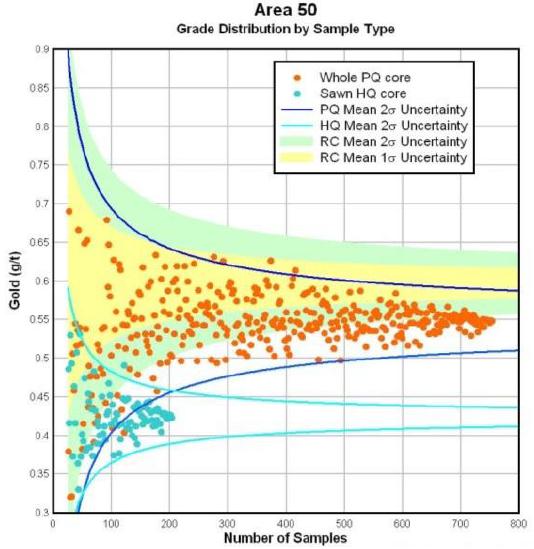

| Figure 7-4: Models for RC, Whole PQ, and Sawn HQ from Area 50 | 7-6 |

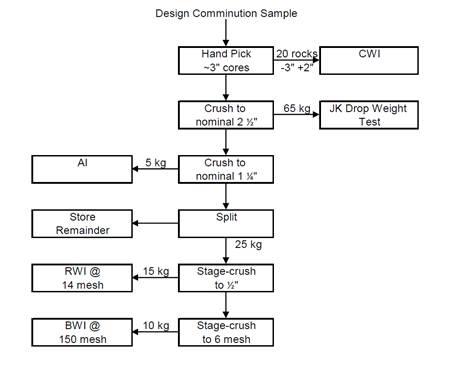

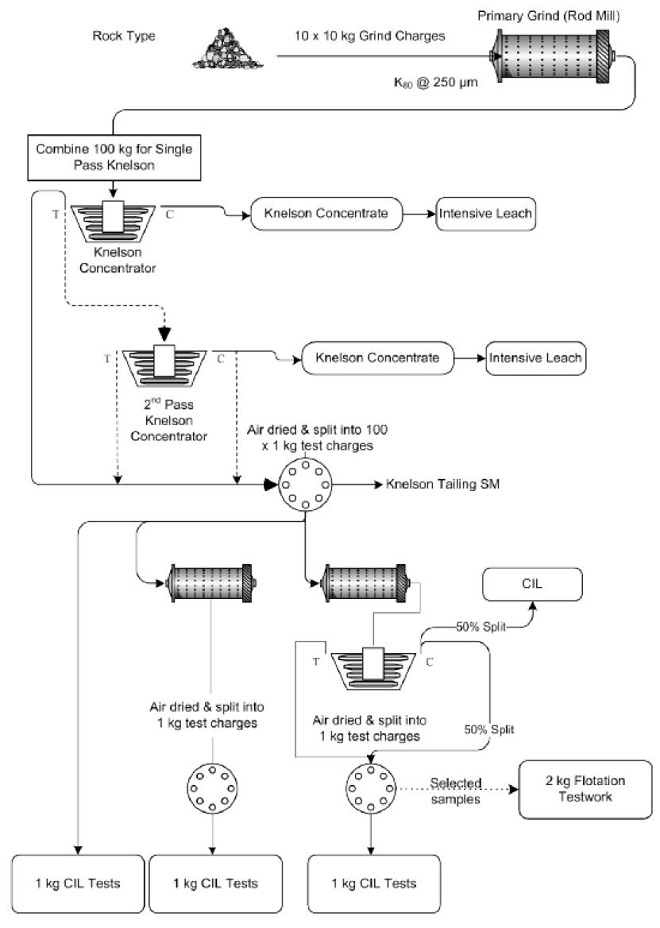

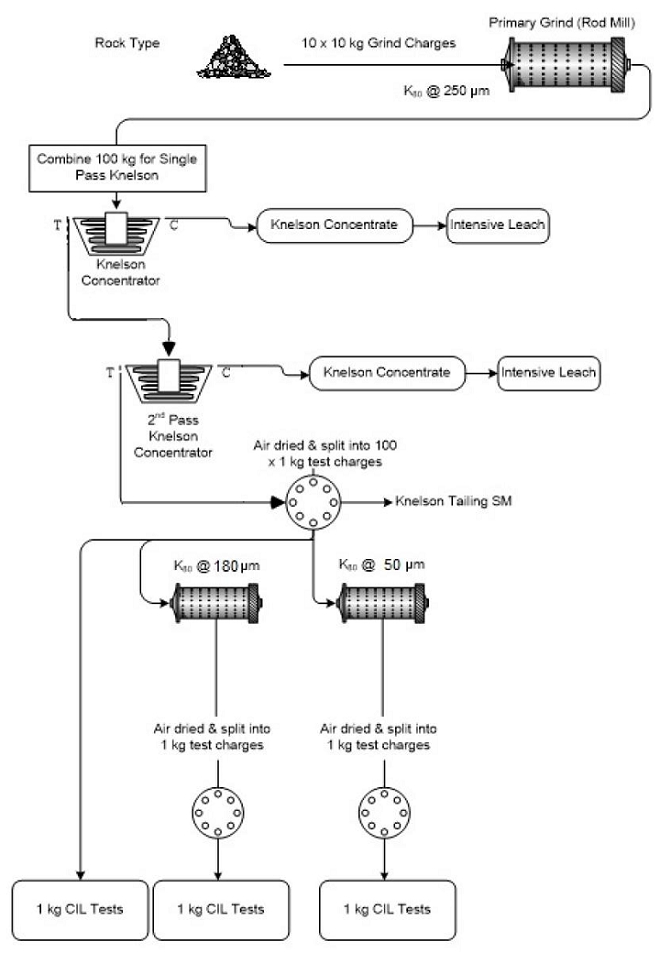

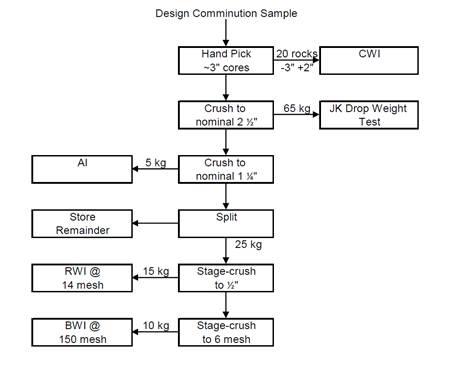

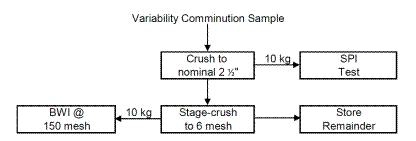

| Figure 10-1: FS Design comminution sample preparation flowsheet (SGS report) | 10-4 |

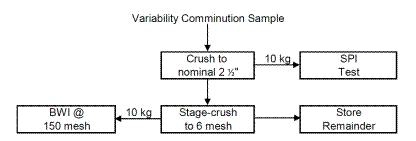

| Figure 10-2: FS Variability comminution sample preparation flowsheet | 10-4 |

| Figure 10-3: Cumulative A × b (DWT + SMC) results for the Livengood Gold Project | 10-11 |

| Figure 10-4: Cumulative BWi results for the Livengood Gold Project | 10-11 |

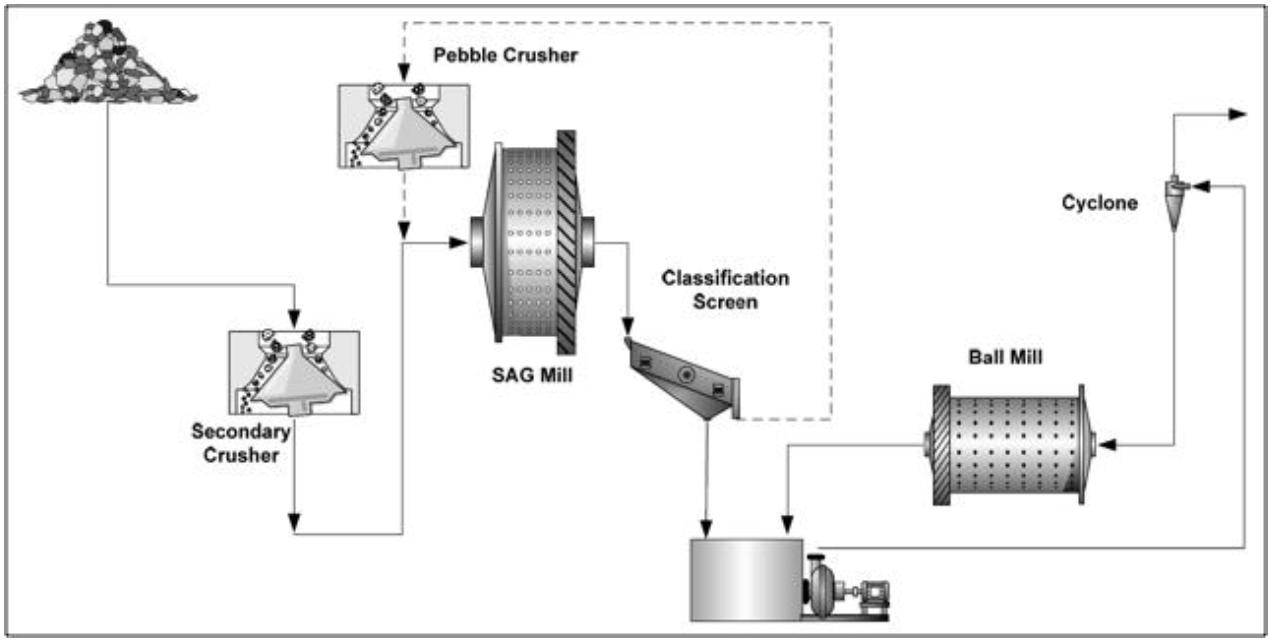

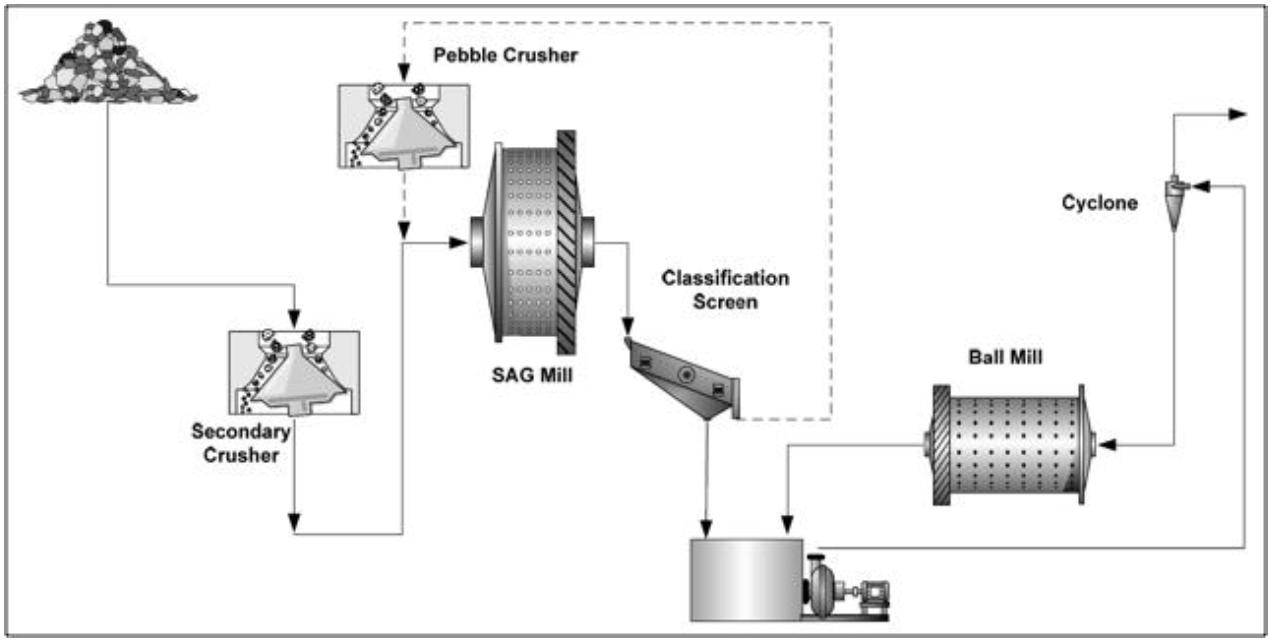

| Figure 10-5: SABC with pre-crushing (secondary crusher) circuit configuration | 10-12 |

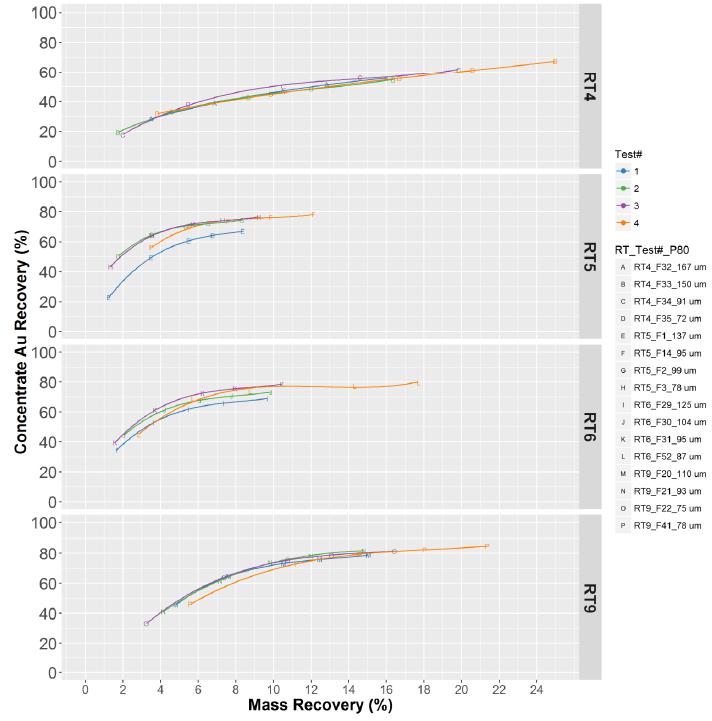

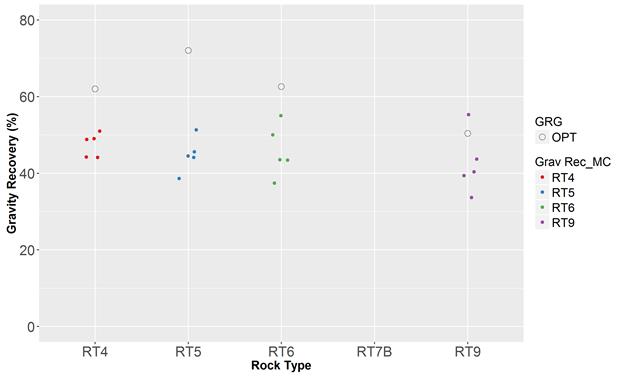

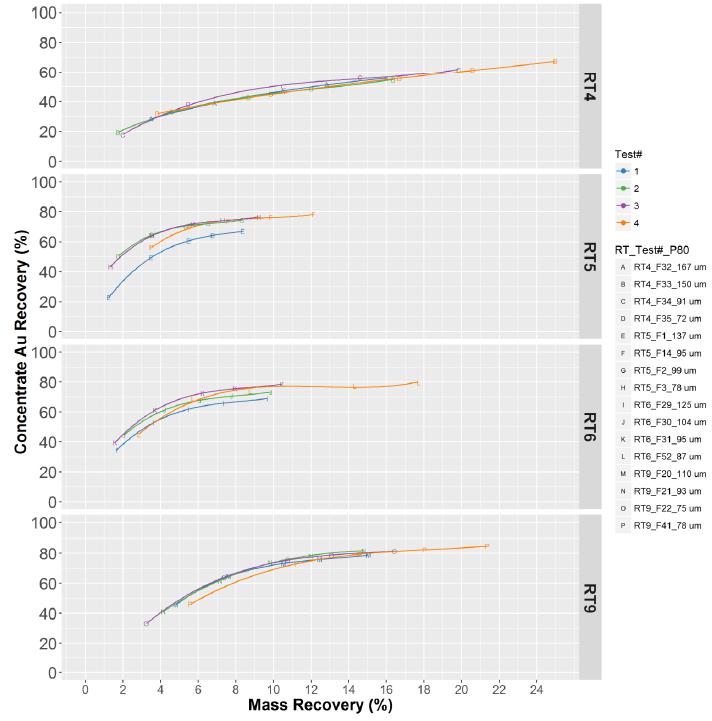

| Figure 10-6: Gold gravity concentration grind-recovery relationships | 10-21 |

| Figure 10-7: Effect of primary grind on gold rougher flotation test Kinetics | 10-23 |

| Figure 10-8: Flotation concentrates CIL test gold leach kinetics for different rock types (FS) | 10-24 |

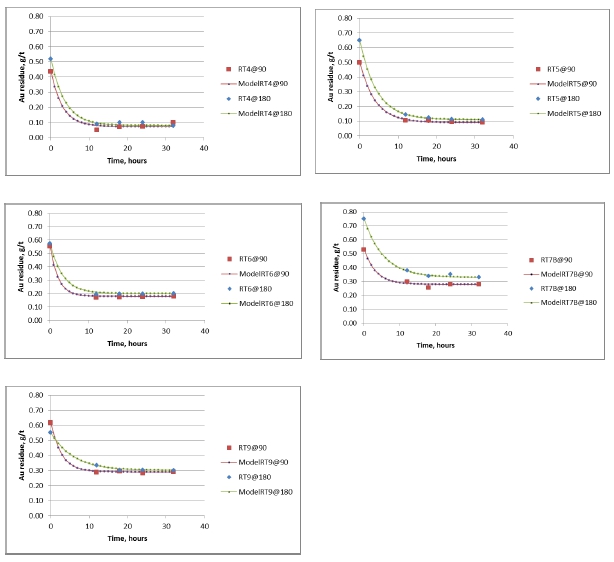

| Figure 10-9: Effect of grind on gold extraction kinetics for RT4, RT5, RT6 and RT9 (FS) | 10-26 |

| Figure 10-10: Mozley gravity tailings CIL test kinetics for different rock types (FS) | 10-27 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| Figure 10-11: Gold gravity recovery box plots (FS) | 10-31 |

| Figure 10-12: Gold in Residues from CIL testwork vs P80 for each rock type (FS) | 10-32 |

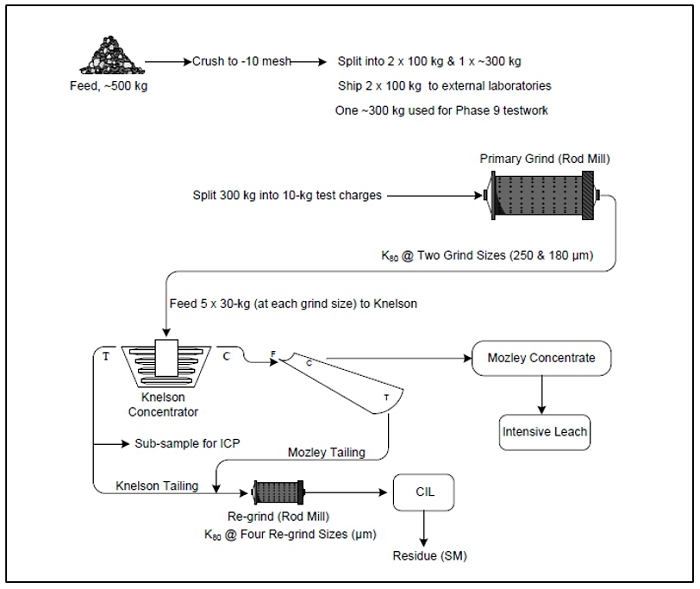

| Figure 10-13: 2017 PFS (Phase 9) testwork outline | 10-39 |

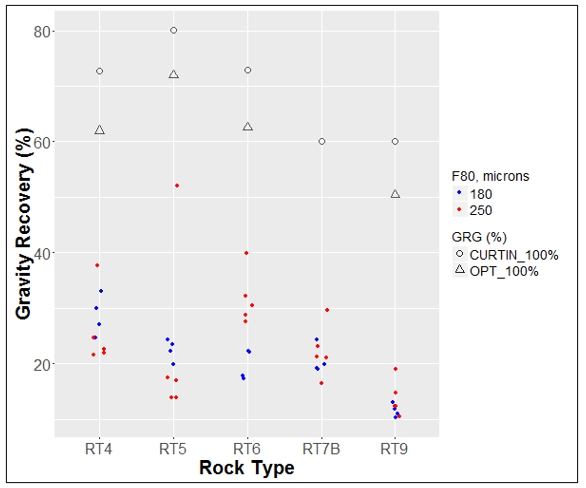

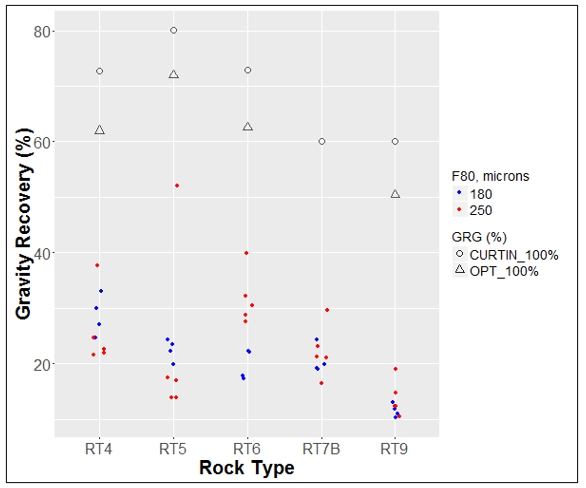

| Figure 10-14: 2017 PFS (Phase 9) gravity recovery for all tock types | 10-41 |

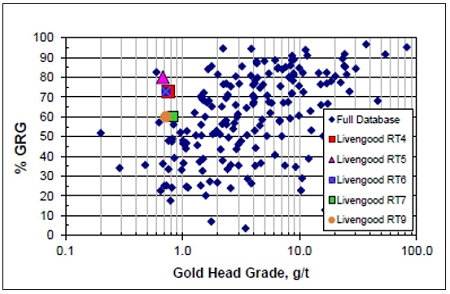

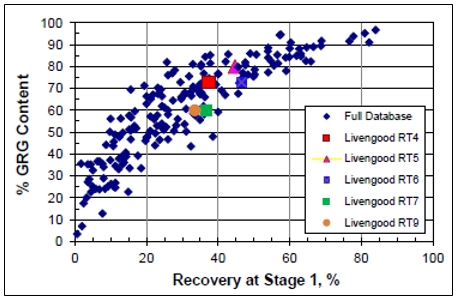

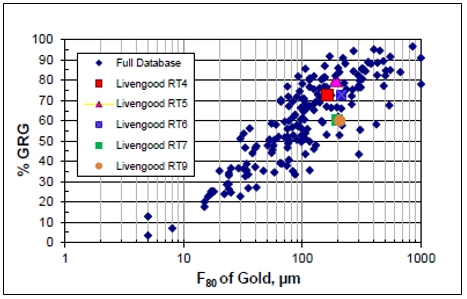

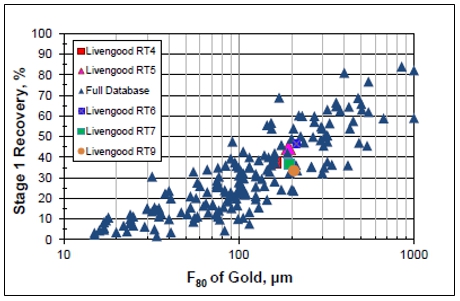

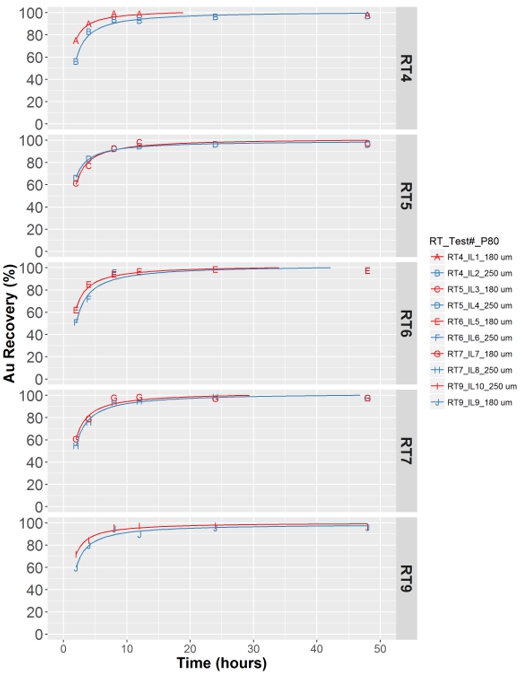

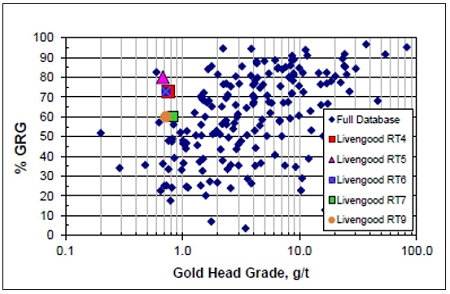

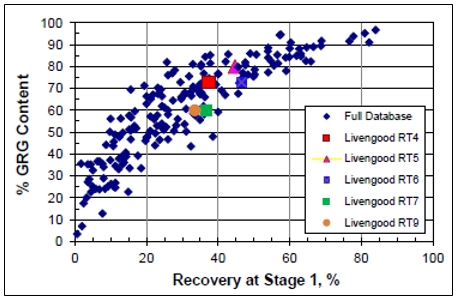

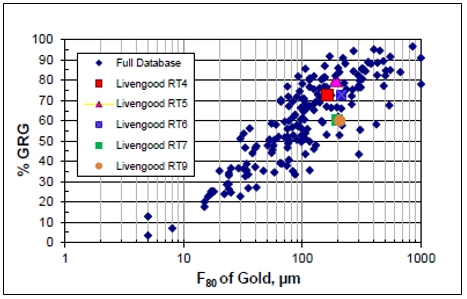

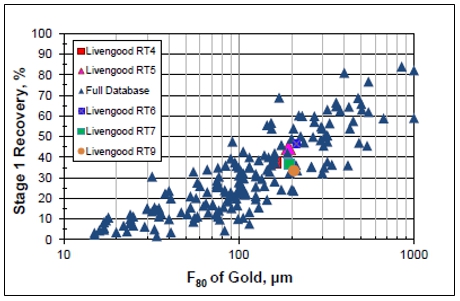

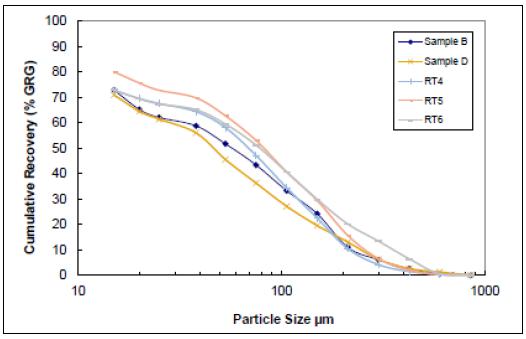

| Figure 10-15: Livengood GRG results vs FLS/Curtin database (source Curtin report) | 10-42 |

| Figure 10-16: Livengood GRG results vs FLS/Curtin database (source Curtin report) | 10-43 |

| Figure 10-17: Livengood GRG results vs FLS/Curtin database (source Curtin report) | 10-43 |

| Figure 10-18: Livengood GRG results vs FLS/Curtin database (source Curtin report) | 10-44 |

| Figure 10-19: Livengood GRG results vs FLS/Curtin database (source Curtin report) | 10-44 |

| Figure 10-20: Intensive leach of Mozley concentrate | 10-46 |

| Figure 10-21: 2017 PFS (Phase 9) - Leach kinetics analyses according to rock type | 10-49 |

| Figure 10-22: 2021 PFS (Phase 9a) testwork outline | 10-54 |

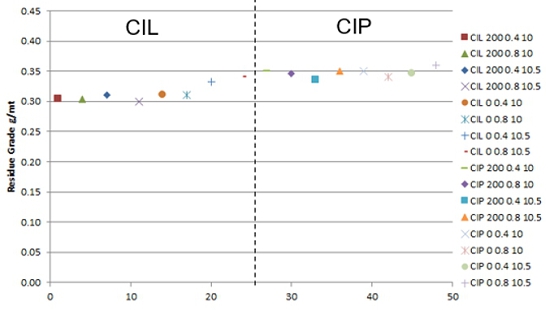

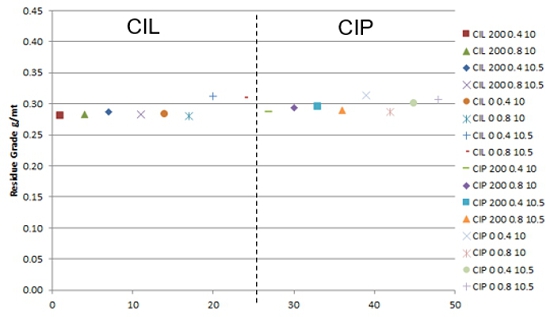

| Figure 10-23: RT4 Average CIL and CIP residue grades at a P80 of 112 µm | 10-56 |

| Figure 10-24: RT5 Average CIL and CIP residue grades at a P80 of 111 µm | 10-57 |

| Figure 10-25: RT6 Average CIL and CIP residue grades at a P80 of 99 µm | 10-57 |

| Figure 10-26: RT7 Average CIL and CIP residue grades at a P80 of 120 µm | 10-58 |

| Figure 10-27: RT9 Average CIL and CIP residue grades at a P80 of 113 µm | 10-58 |

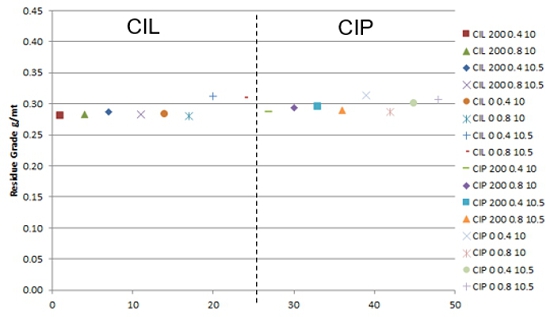

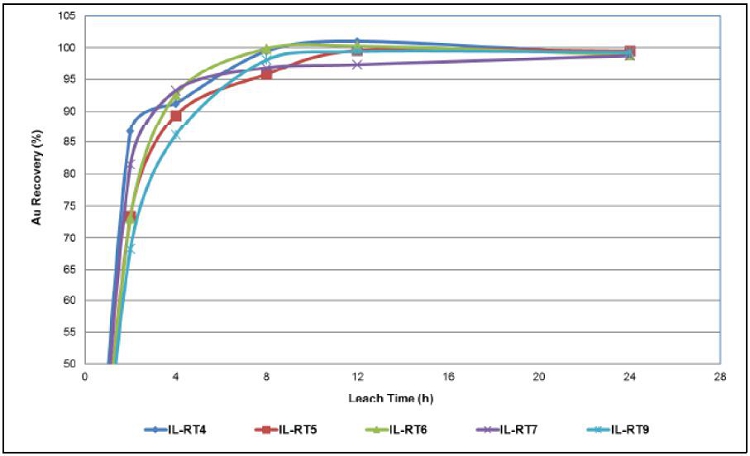

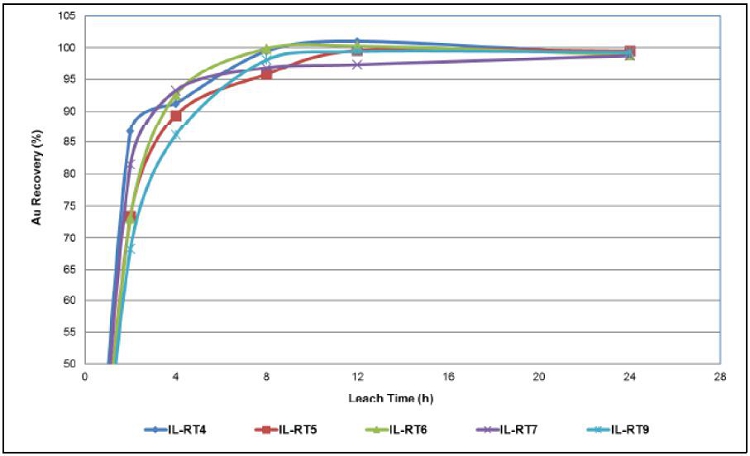

| Figure 10-28: Leach kinetics results for RT4, RT5, RT6, RT7 and RT9 | 10-59 |

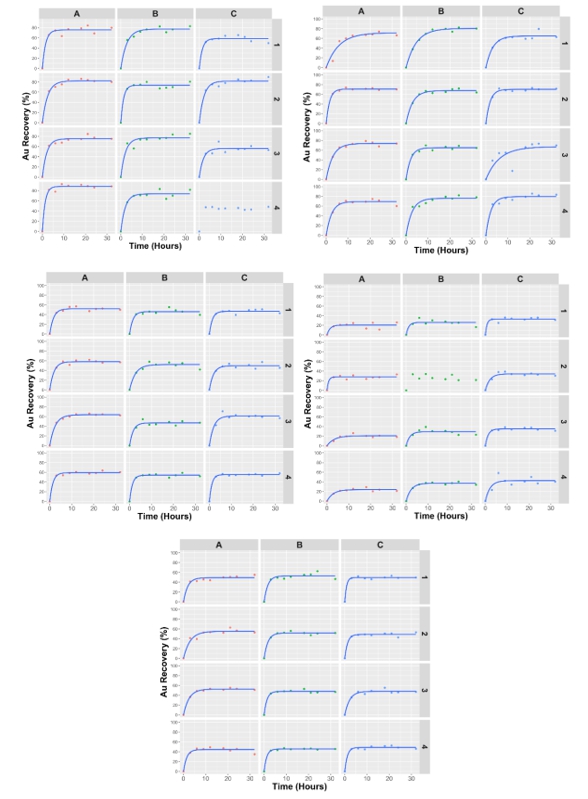

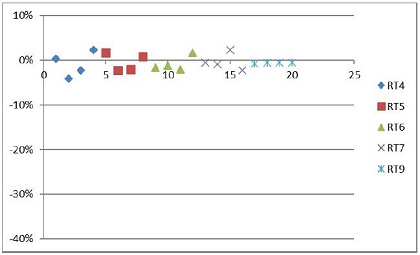

| Figure 10-29: % Au gain preg-robbing level | 10-60 |

| Figure 10-30: 2021 PFS (Phase 9b) testwork outline | 10-62 |

| Figure 10-31: Leach kinetics of the Knelson concentrate | 10-64 |

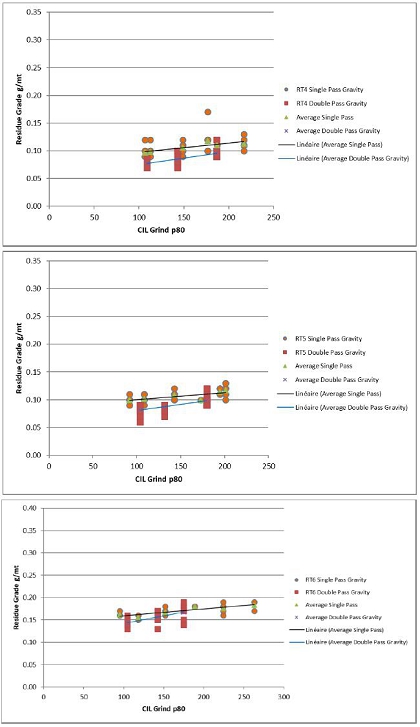

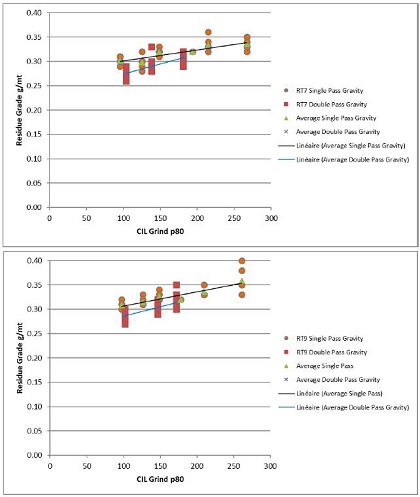

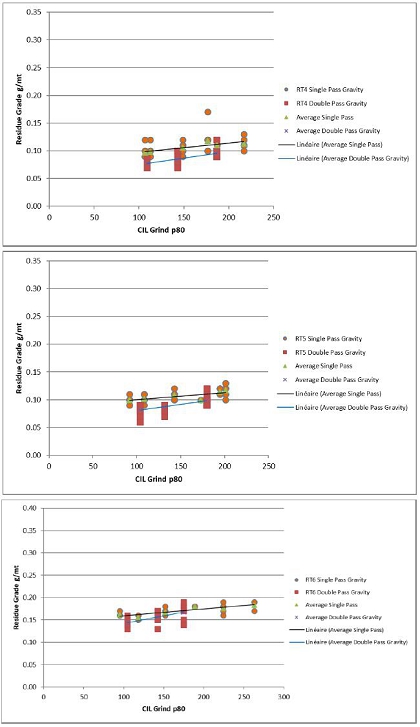

| Figure 10-32: CIL residue grade according to grind size | 10-66 |

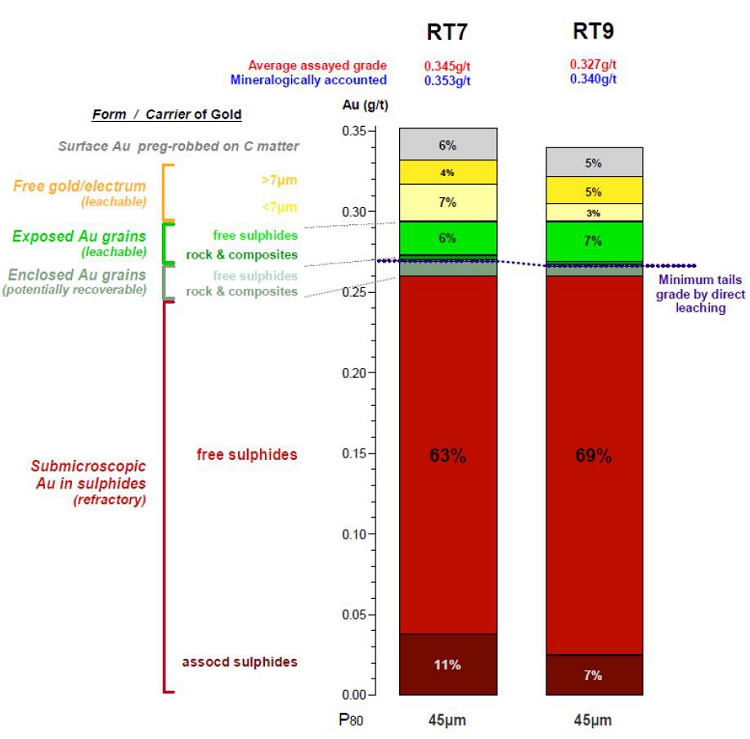

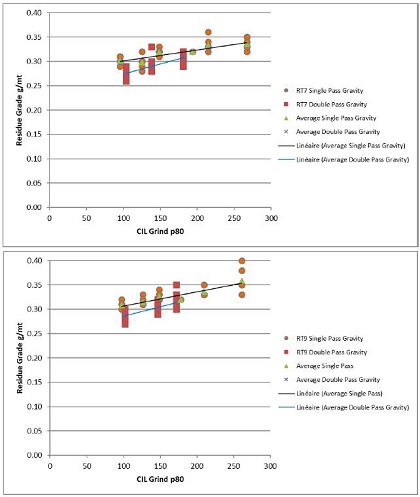

| Figure 10-33: Deportment of gold by leach form and carrier | 10-71 |

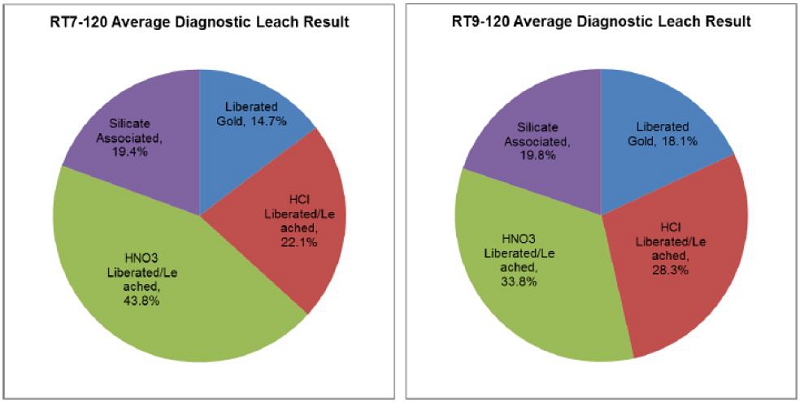

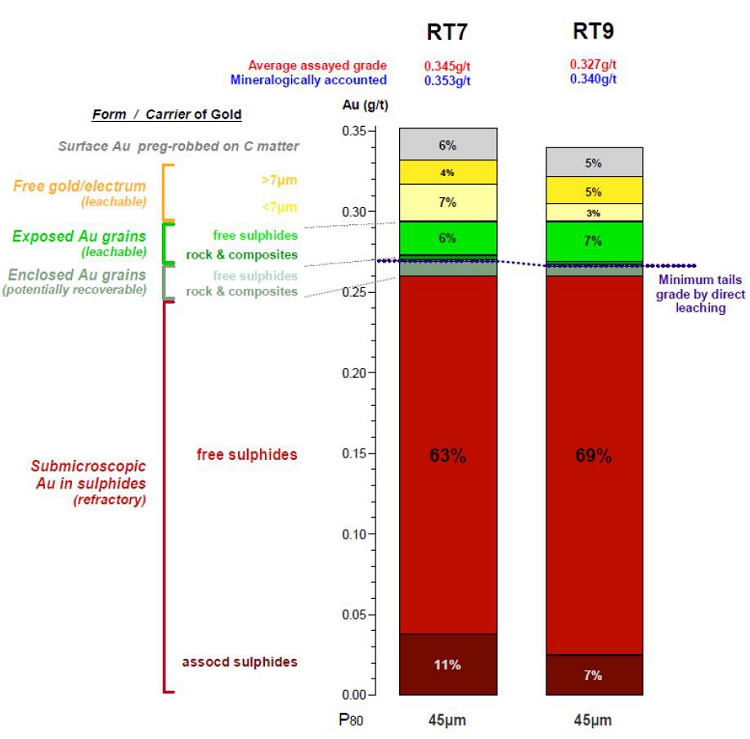

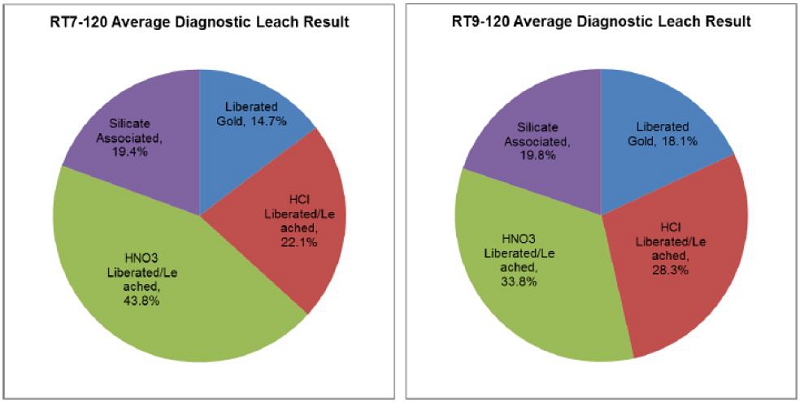

| Figure 10-34: Diagnostic leach result distribution | 10-72 |

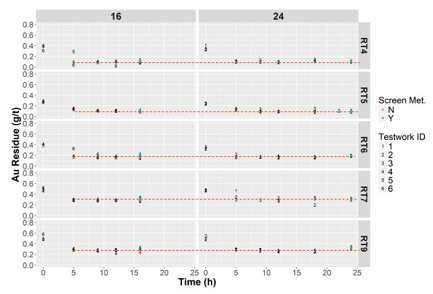

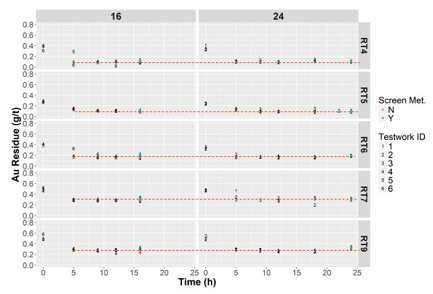

| Figure 10-35: Leach kinetics 16 vs 24 hours | 10-75 |

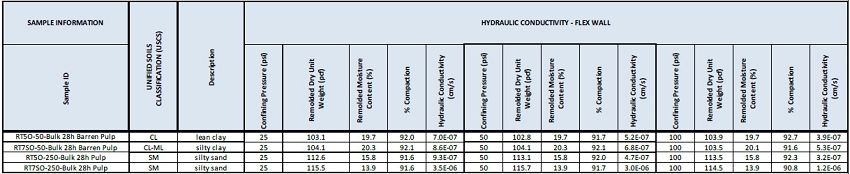

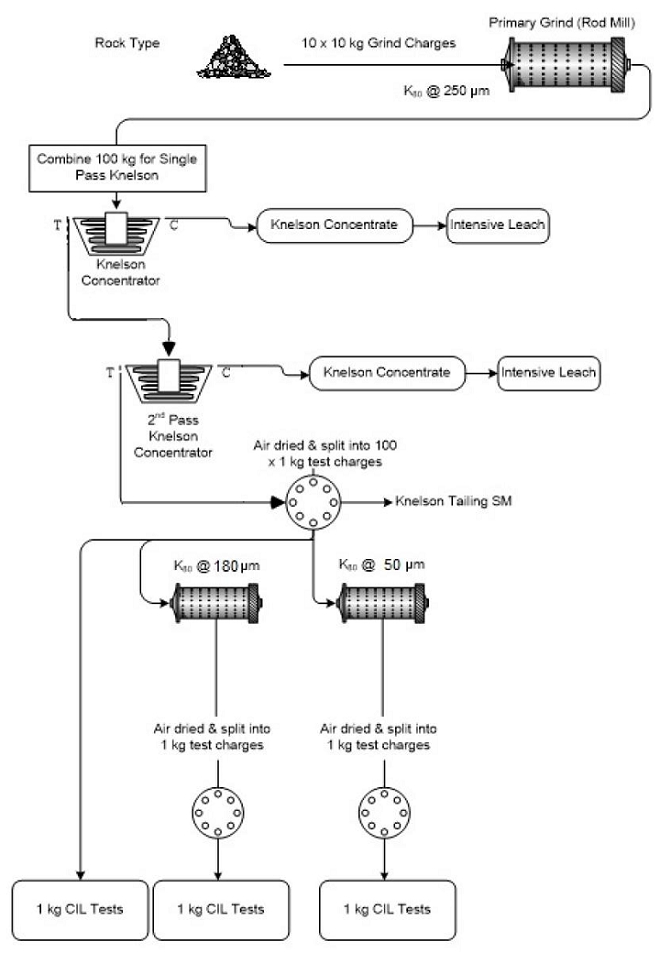

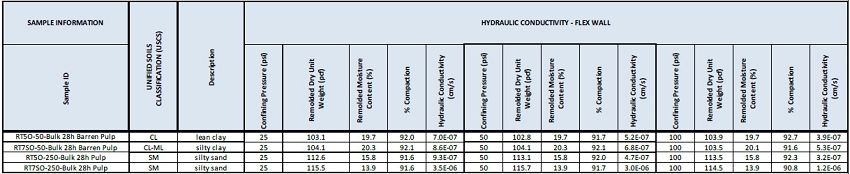

| Figure 10-36: 2021 PFS (Phase 11) testwork outline | 10-78 |

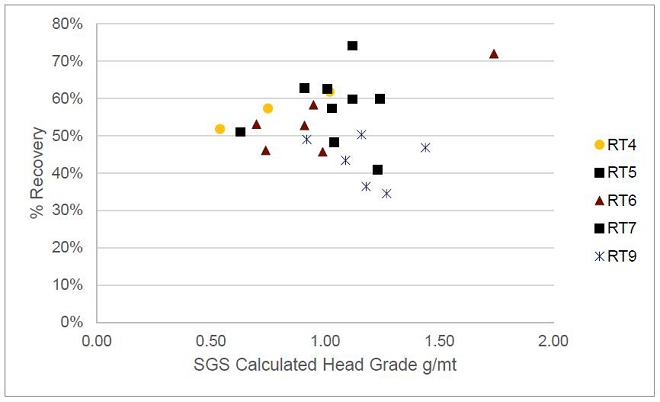

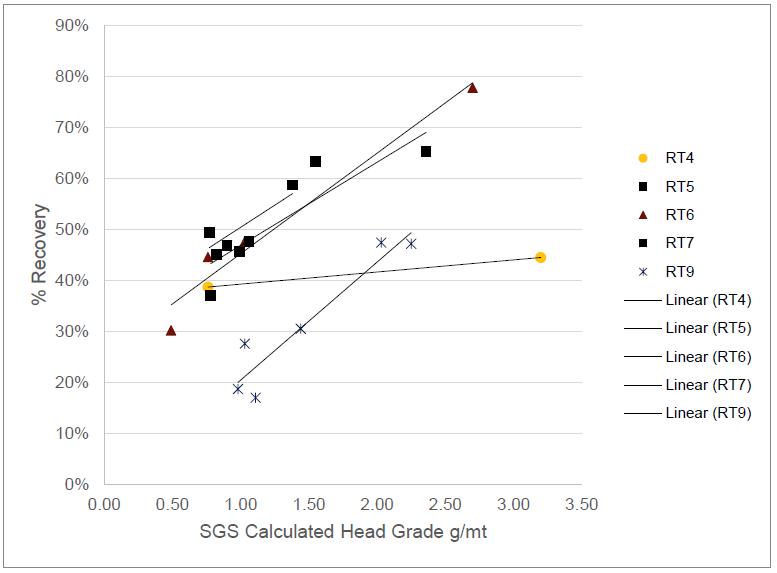

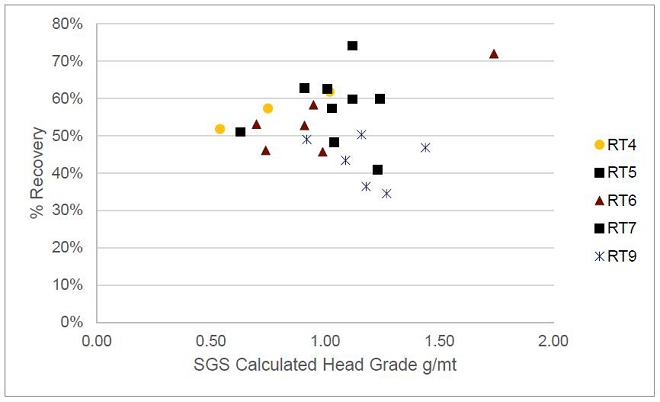

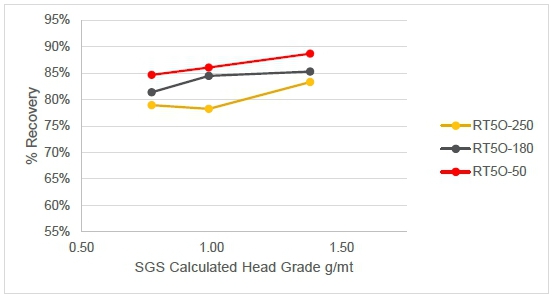

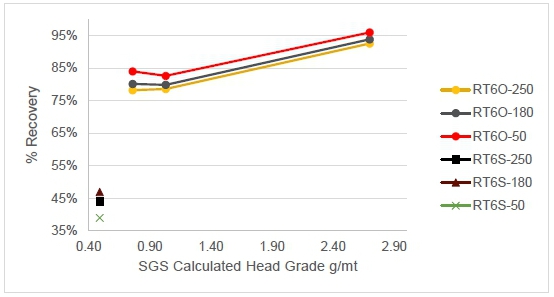

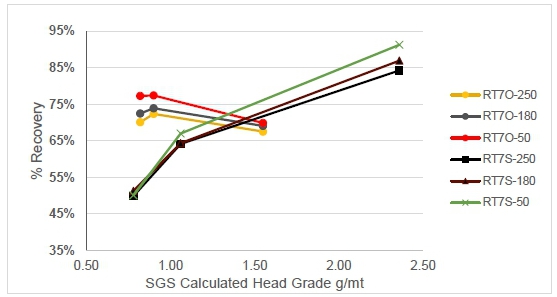

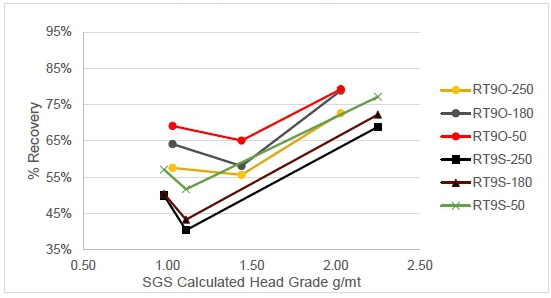

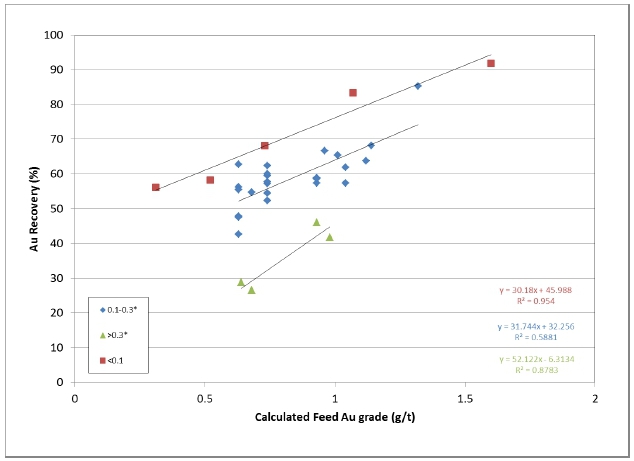

| Figure 10-37: Gravity recovery vs calculated head by rock type | 10-80 |

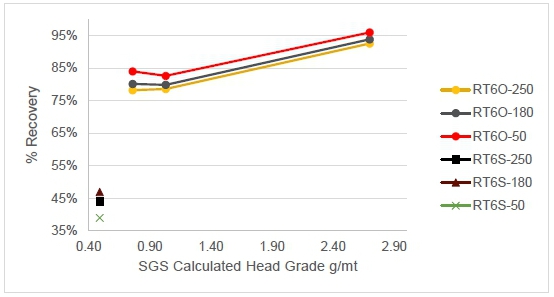

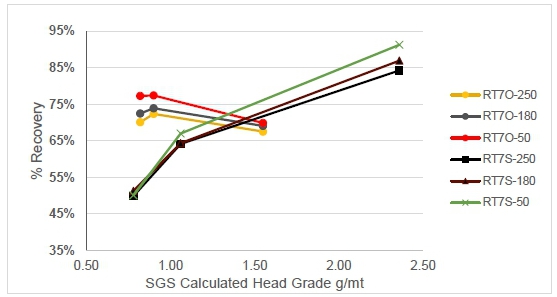

| Figure 10-38: Overall gold recovery according to location inside or outside the 100 ppm Sb shell | 10-83 |

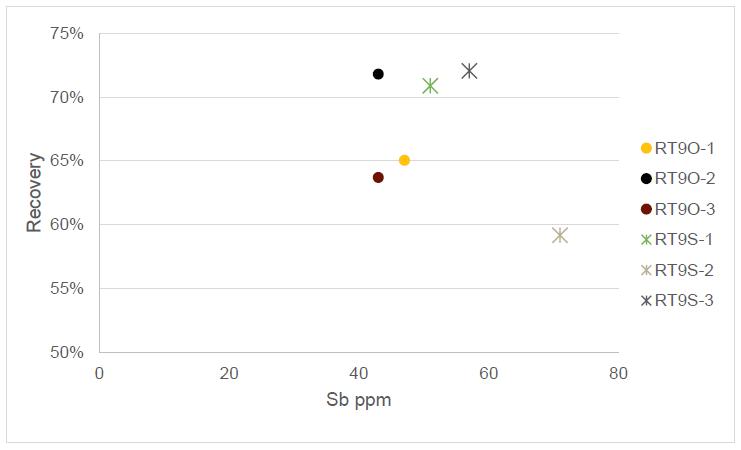

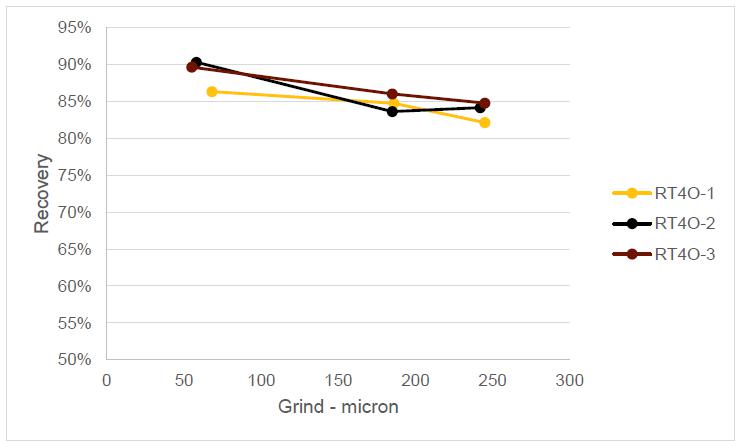

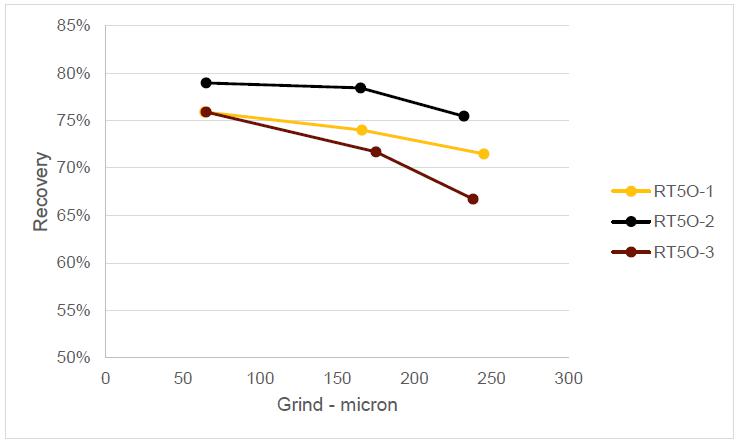

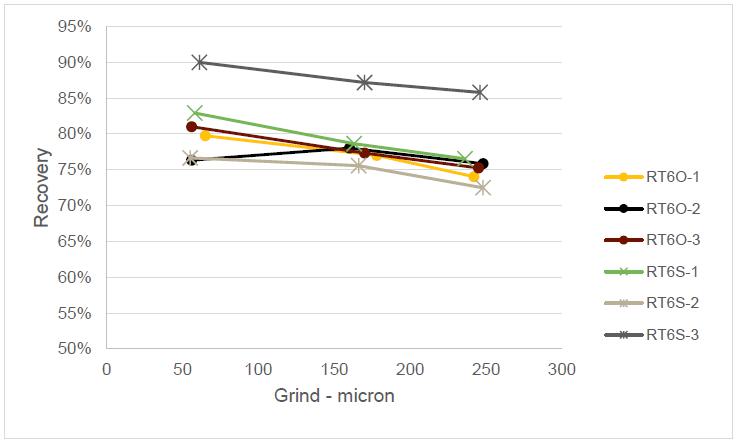

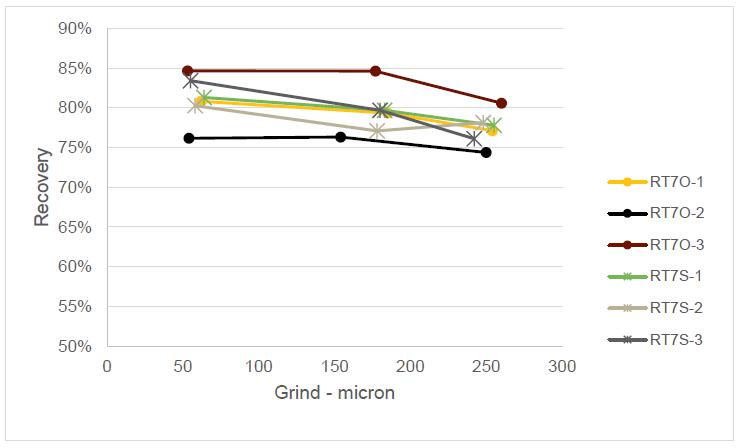

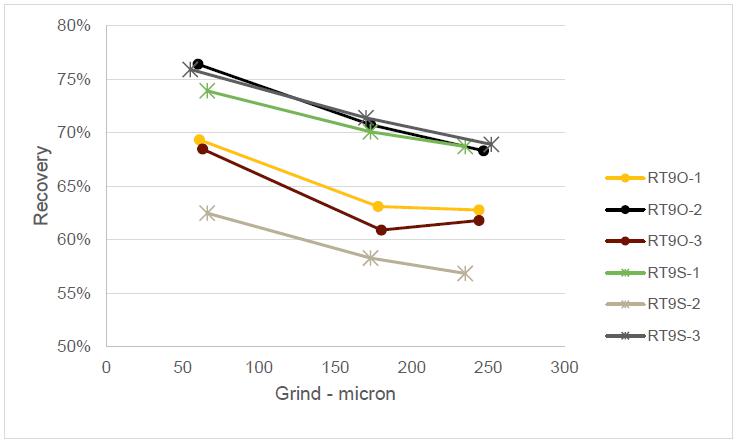

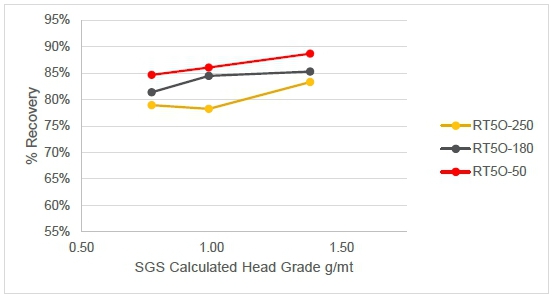

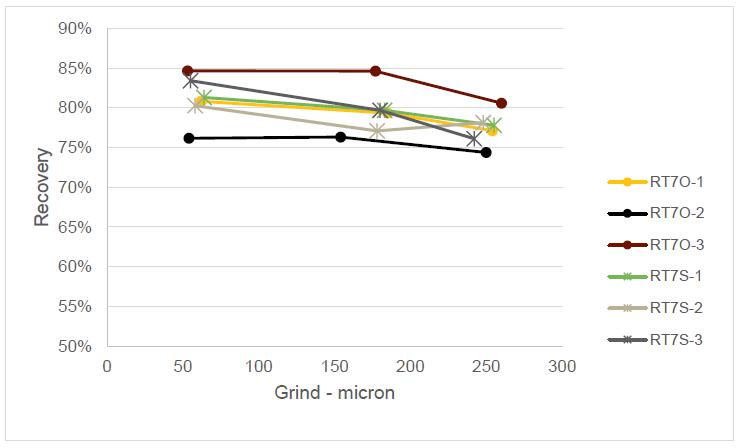

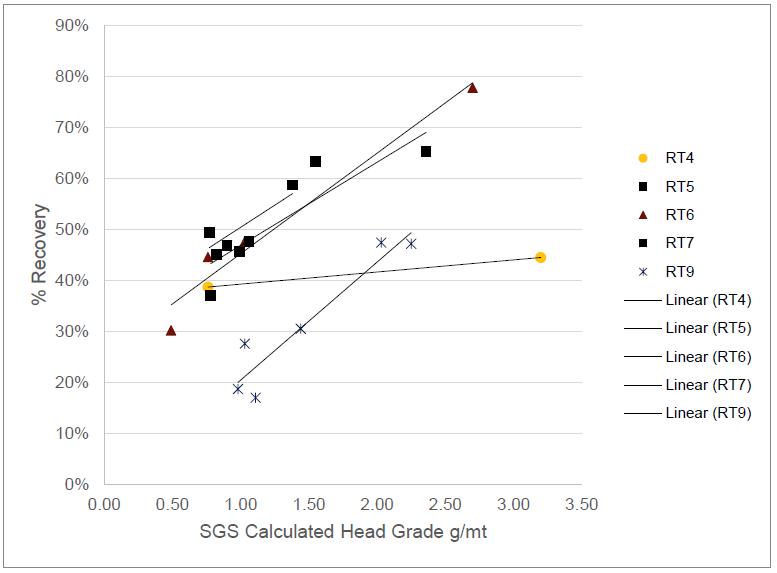

| Figure 10-39: Overall gold recovery according to grind size | 10-85 |

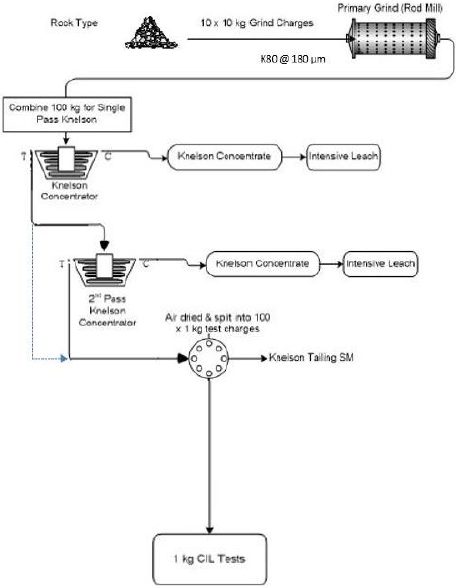

| Figure 10-40: Gravity recovery vs calculated head by rock type | 10-89 |

| Figure 10-41: Overall gold recovery according to location inside or outside the 100 ppm Sb shell | 10-92 |

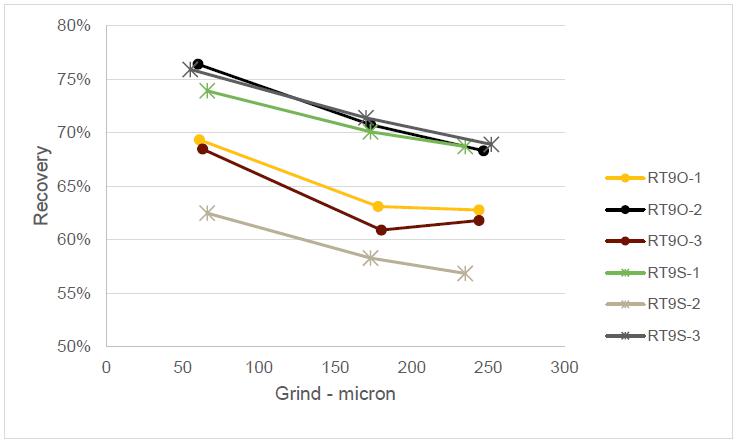

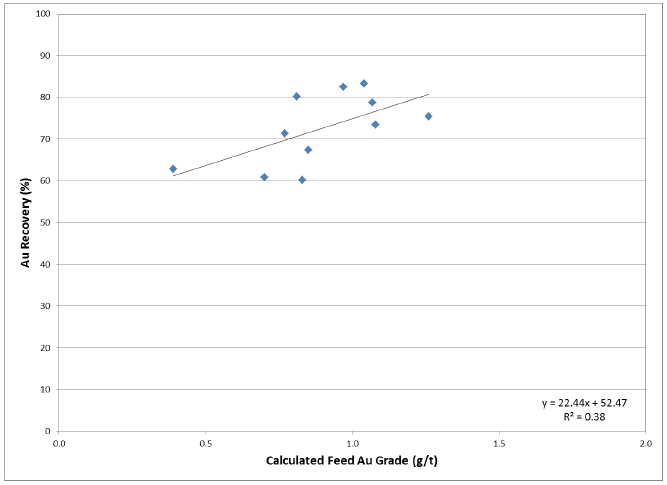

| Figure 10-42: Overall gold recovery according to calculated head grade | 10-94 |

| Figure 10-43: 2021 PFS (Phase 13) testwork outline | 10-103 |

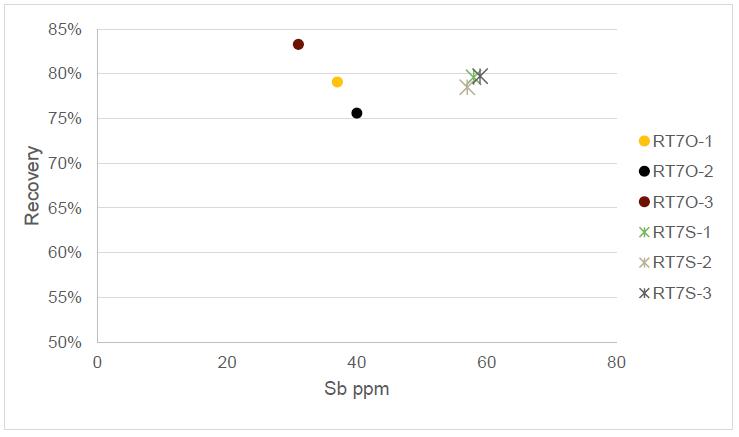

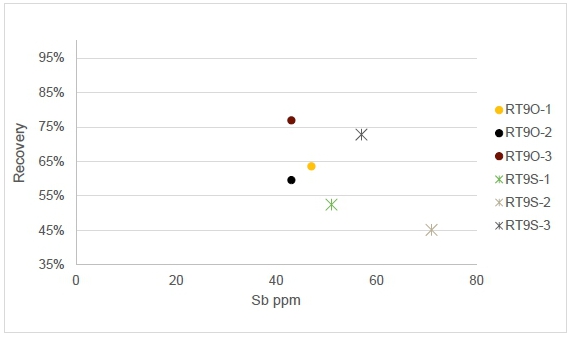

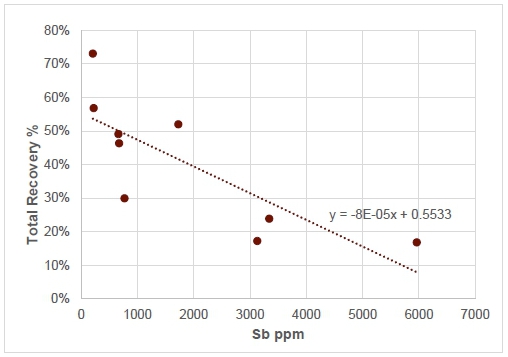

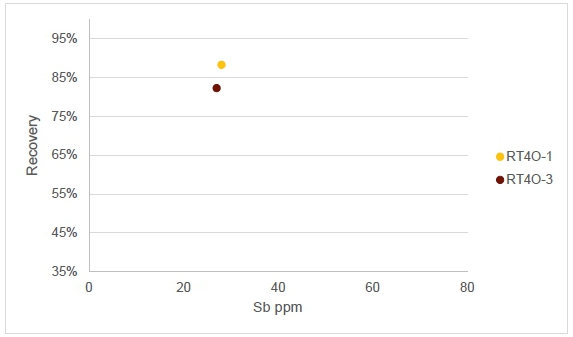

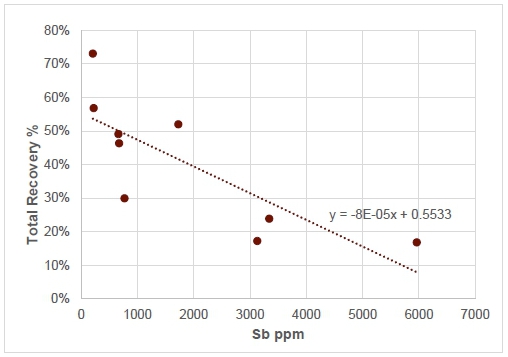

| Figure 10-44: Overall recovery related to the antimony concentration | 10-104 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

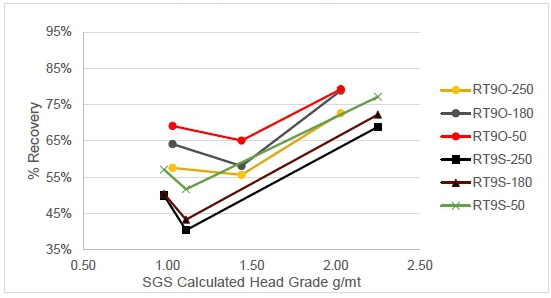

| Figure 10-45: 2017 PFS (Phase 9) - RT7 gold recovery vs head grade | 10-106 |

| Figure 10-46: 2017 PFS (Phase 9) - RT9 gold recovery vs head grade | 10-107 |

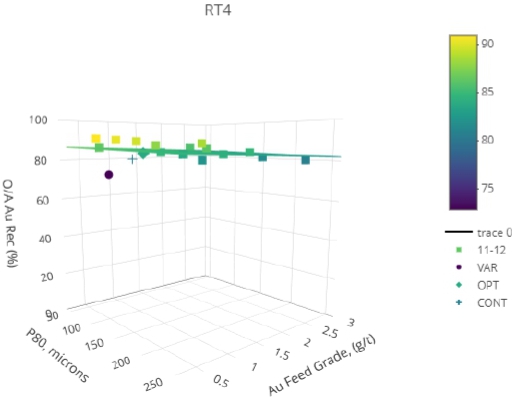

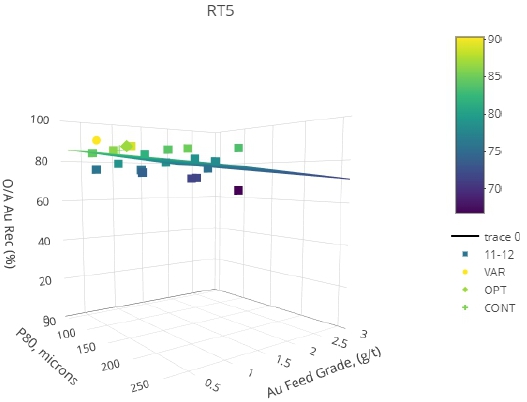

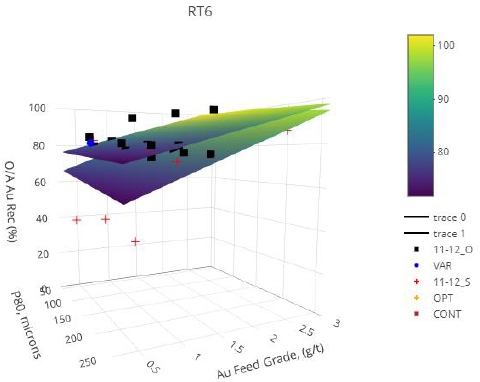

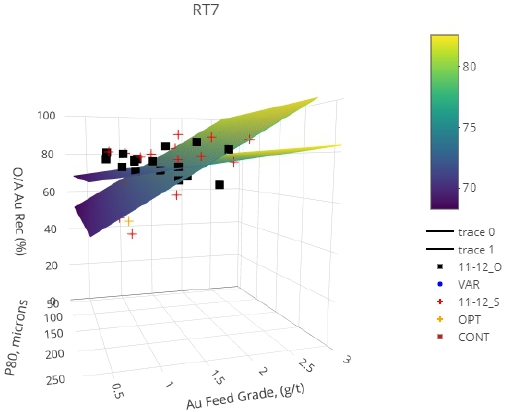

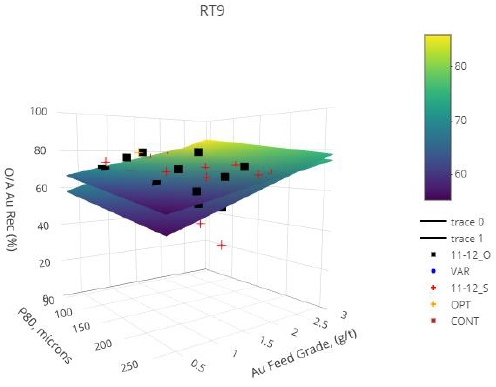

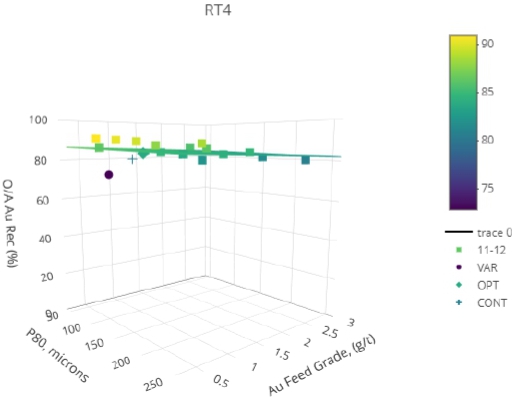

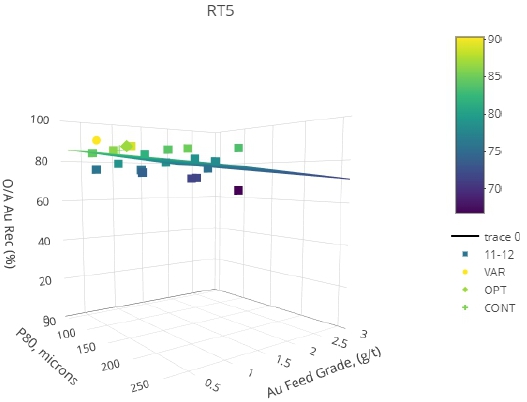

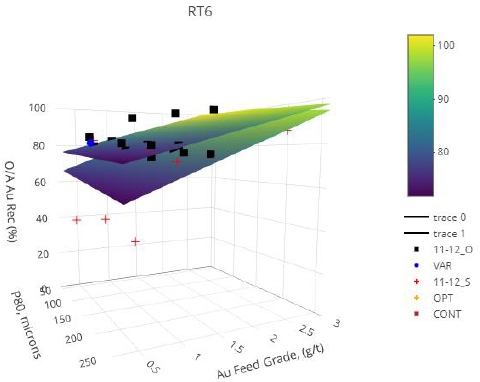

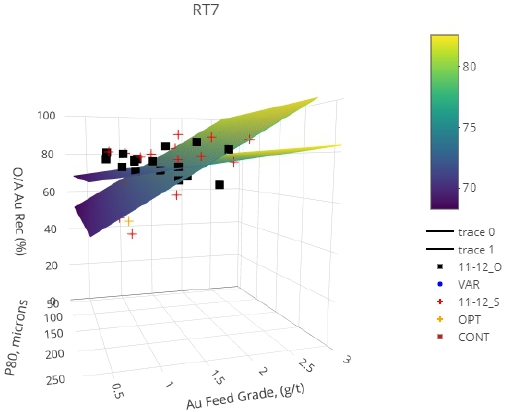

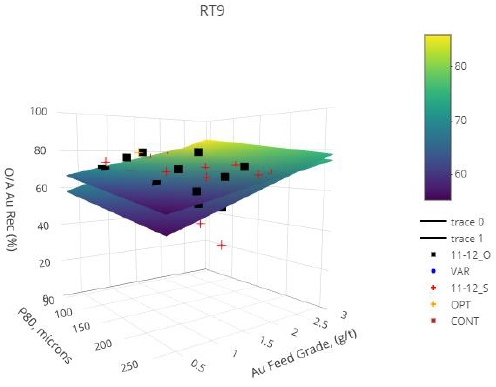

| Figure 10-47: 3D representation of the overall Au recovery versus Au grade and P80 (2021 PFS) | 10-111 |

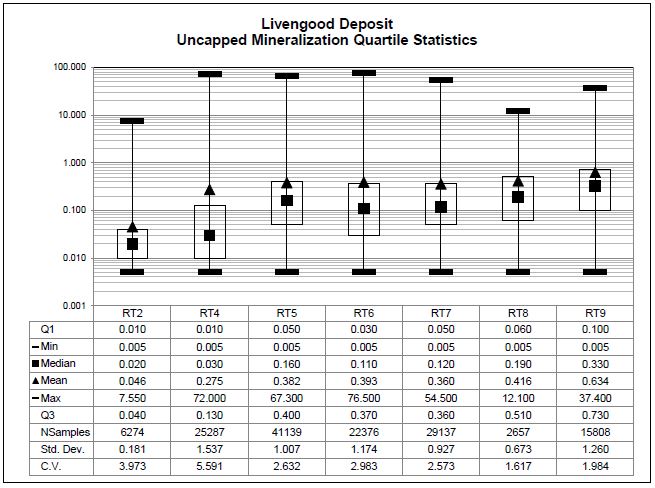

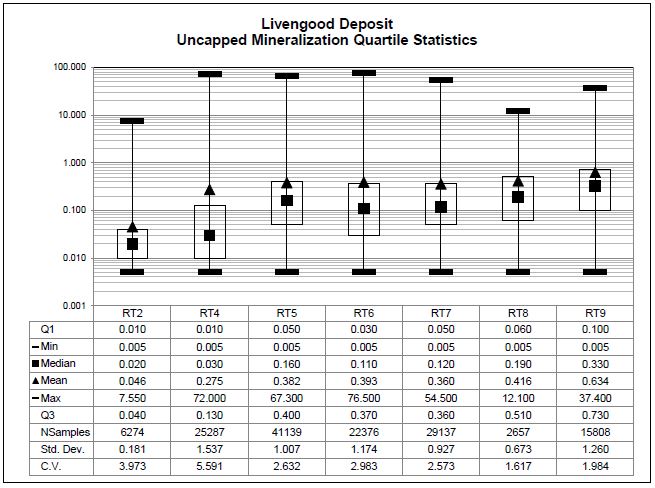

| Figure 11-1: Uncapped gold grade distribution by stratigraphic unit | 11-4 |

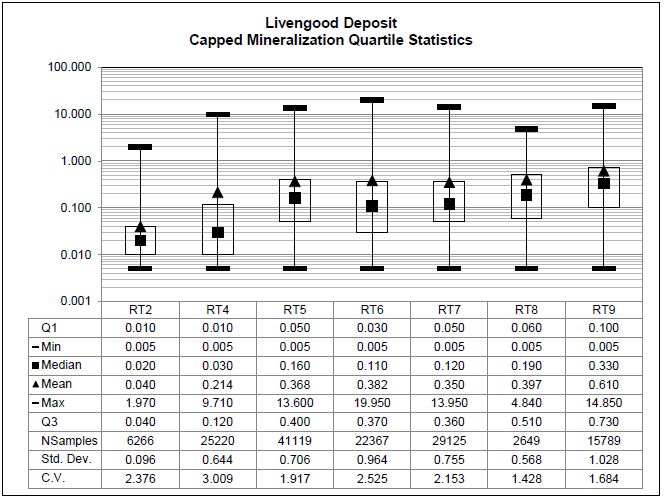

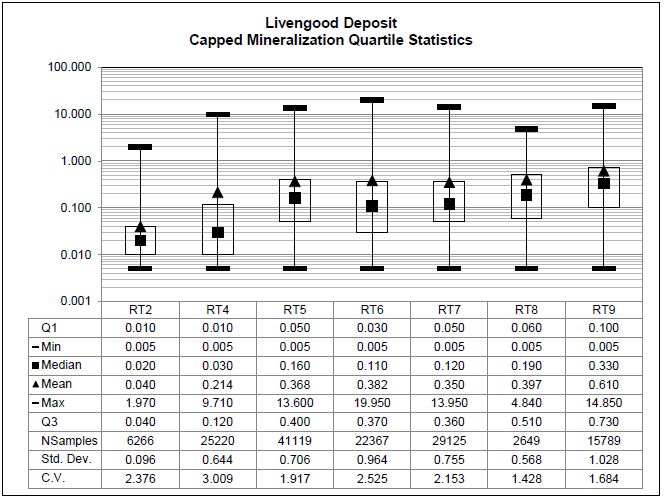

| Figure 11-2: Capped quartile statistics | 11-6 |

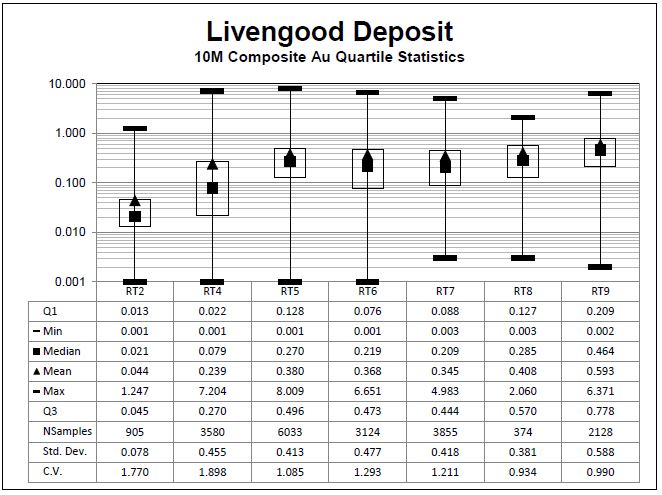

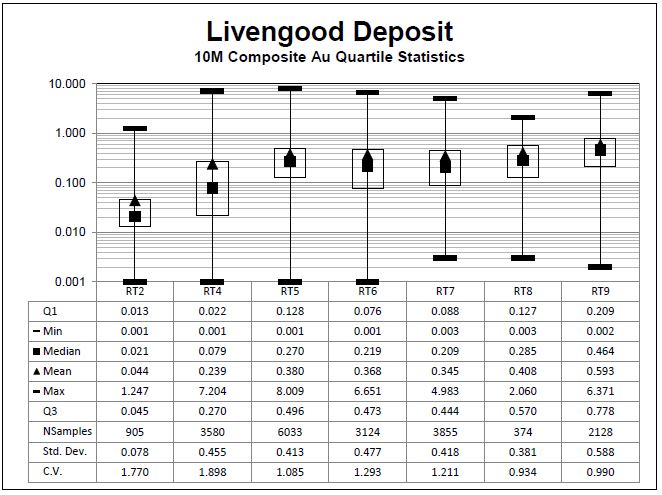

| Figure 11-3: Capped composite statistics | 11-7 |

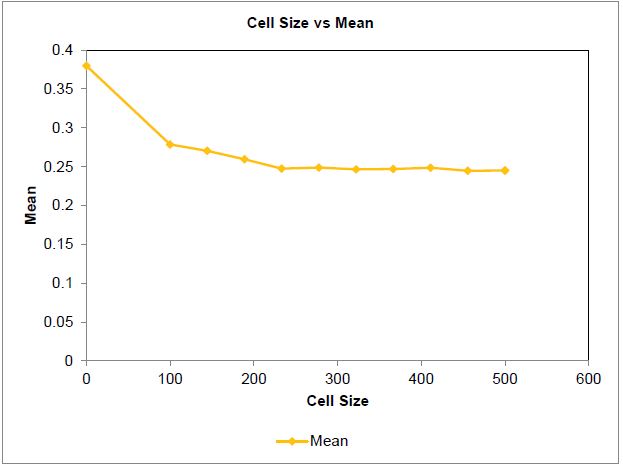

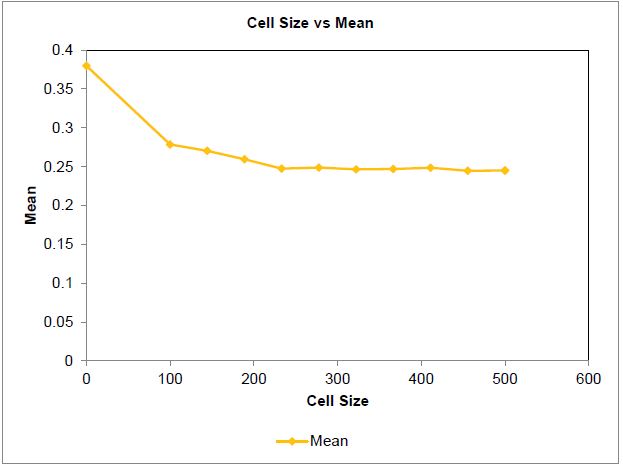

| Figure 11-4: Cell declustering chart demonstrates sample clustering is not a factor for the deposit | 11-8 |

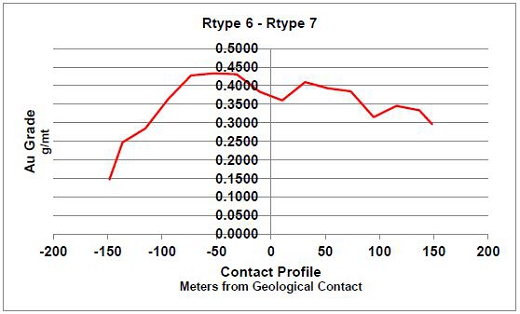

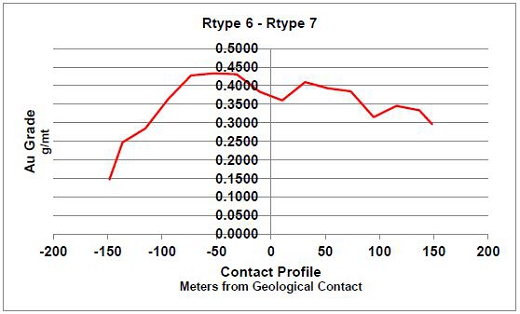

| Figure 11-5: Contact profile of RT6 and RT7. Grades converge at the contact. Soft boundary | 11-9 |

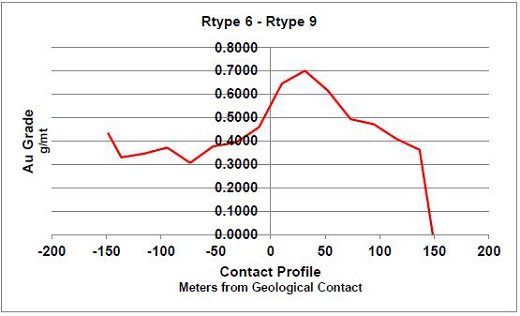

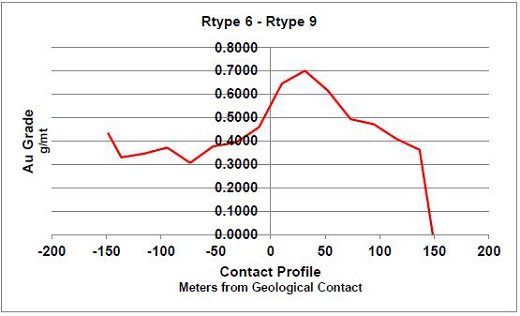

| Figure 11-6: RT6 and RT9. Grades converge at contact. Soft boundary | 11-9 |

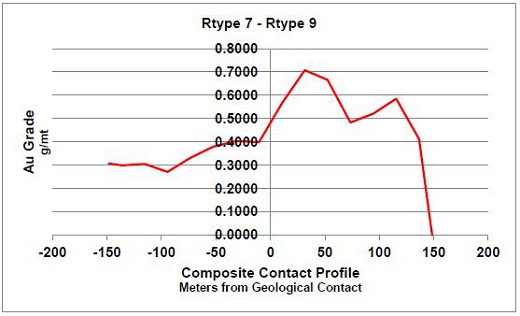

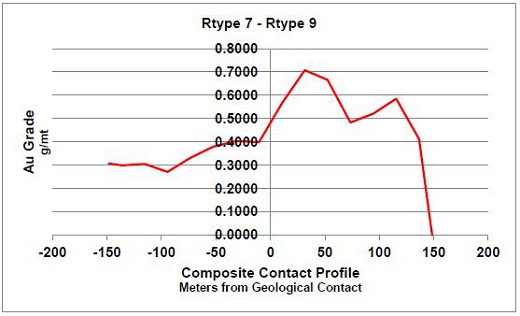

| Figure 11-7: RT7 and RT9 Grades converge at the contact. Soft boundary | 11-10 |

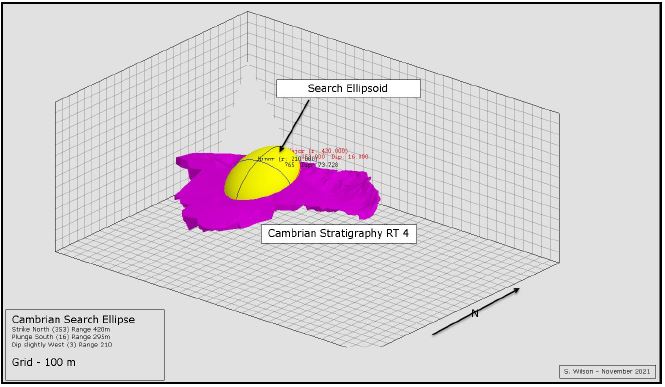

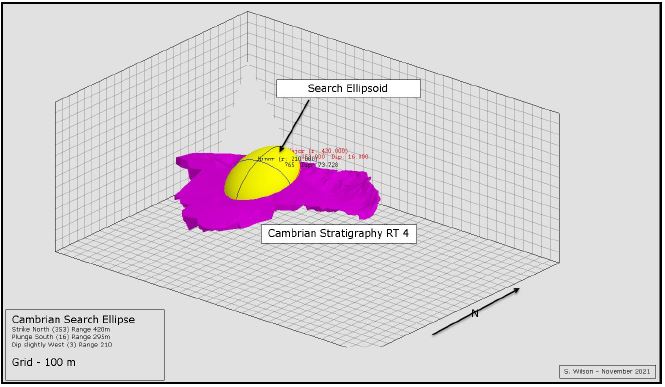

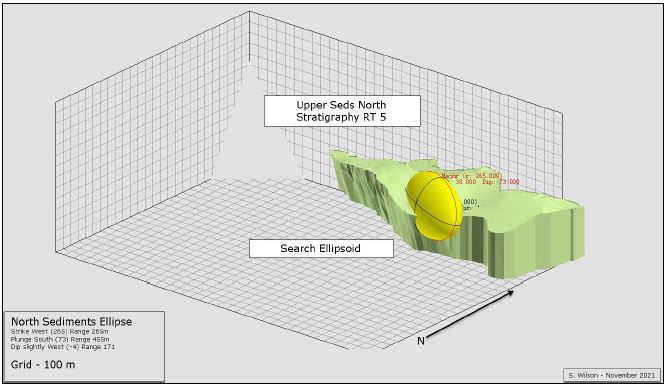

| Figure 11-8: Cambrian stratigraphy search ellipse | 11-11 |

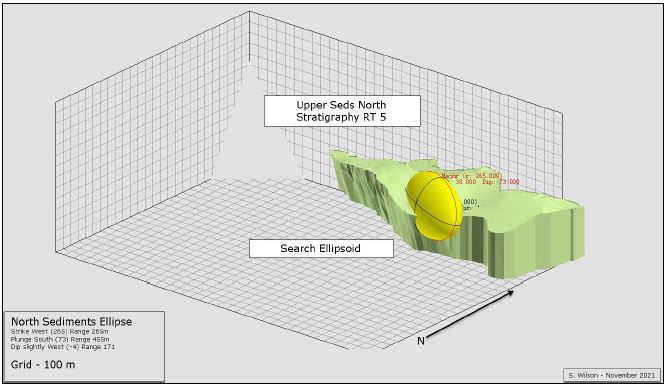

| Figure 11-9: Upper Sediments North search ellipse | 11-11 |

| Figure 11-10: Type 679 search ellipse | 11-12 |

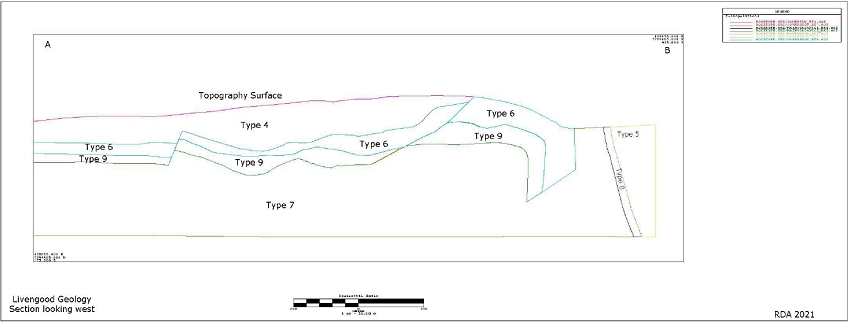

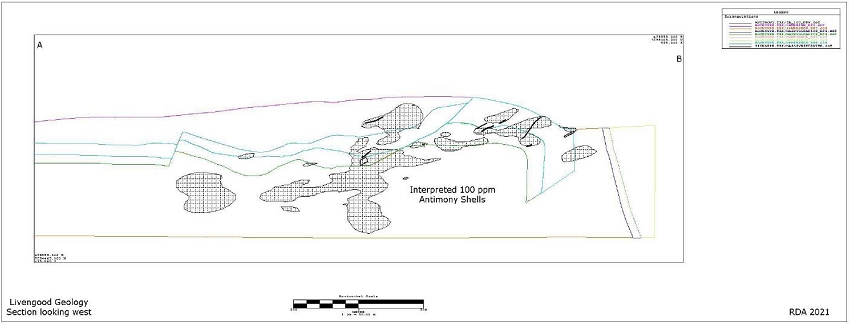

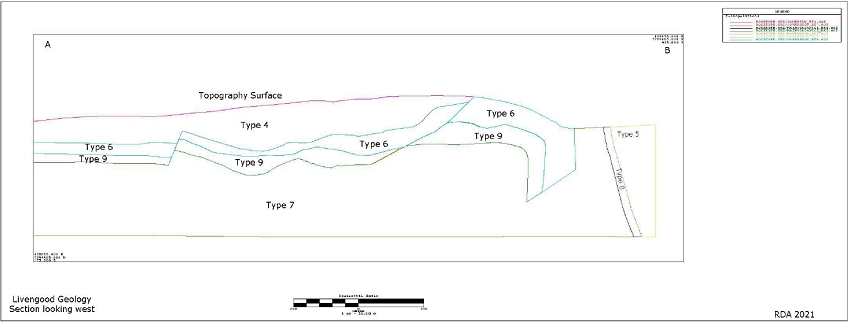

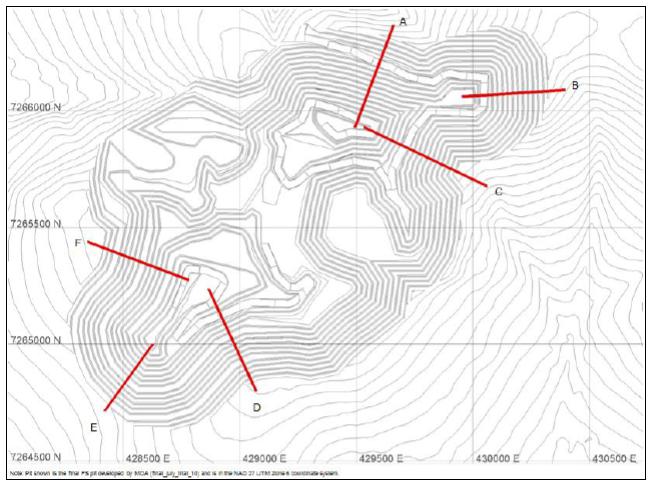

| Figure 11-11: Section A-B looking west. Geologic models used to flag the Livengood block model | 11-13 |

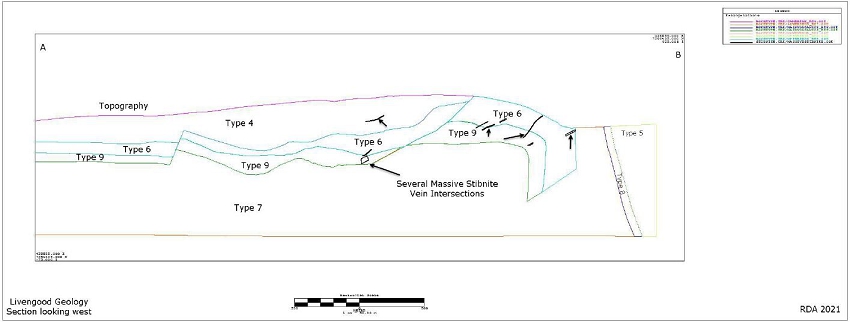

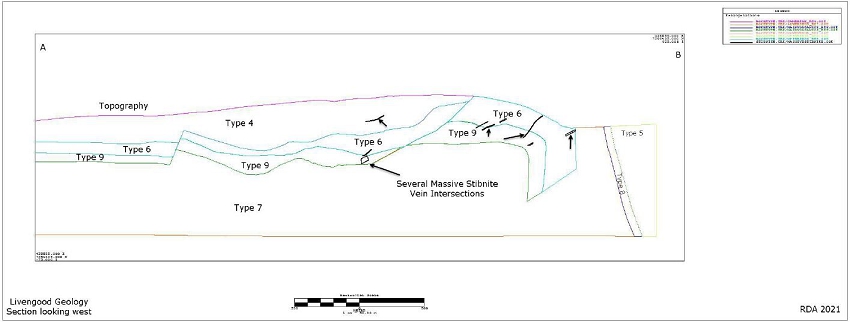

| Figure 11-12: Intersection of massive stibnite veins on cross section A-B | 11-14 |

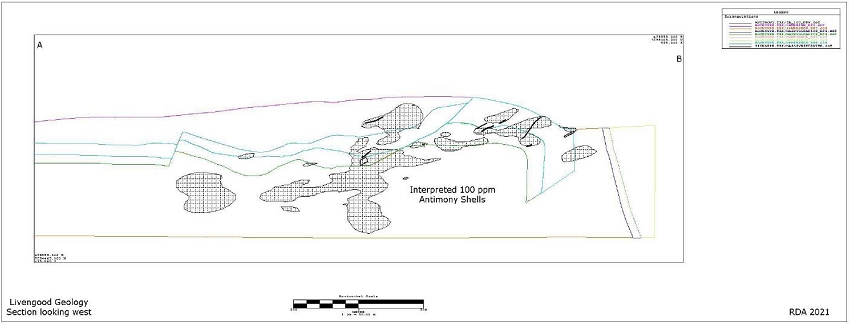

| Figure 11-13: Cross section A-B showing the 100 ppm antimony halo for Livengood | 11-15 |

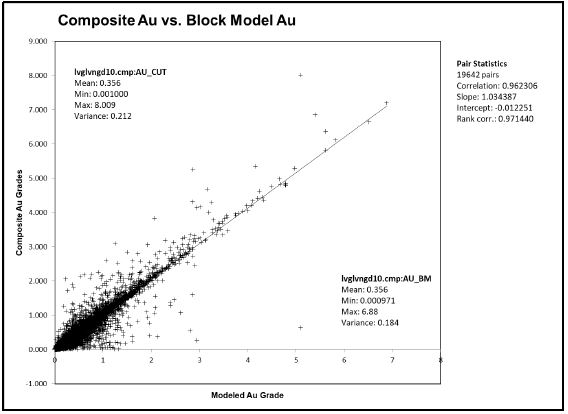

| Figure 11-14: Visual comparison of composite database with estimated Au grades for Section A-B | 11-19 |

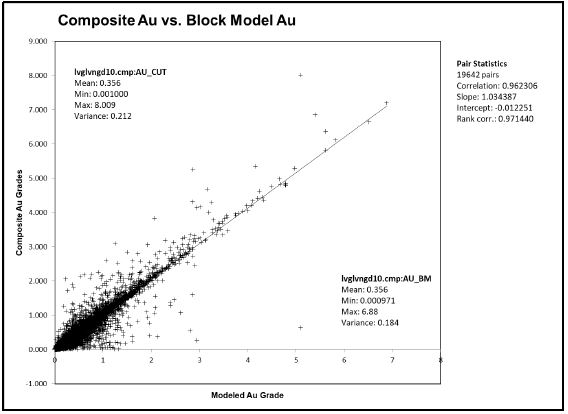

| Figure 11-15: Scattergram comparing global estimated Au grade to composite database Au values | 11-20 |

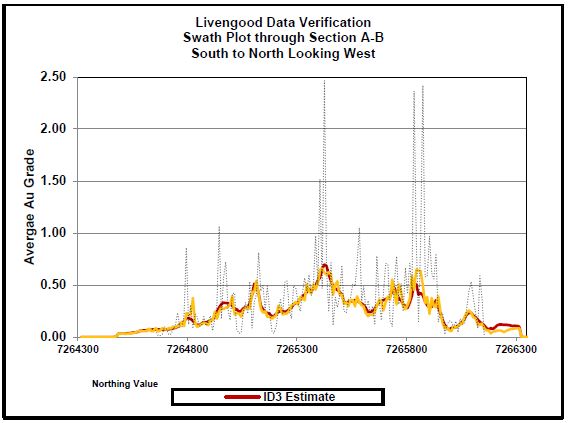

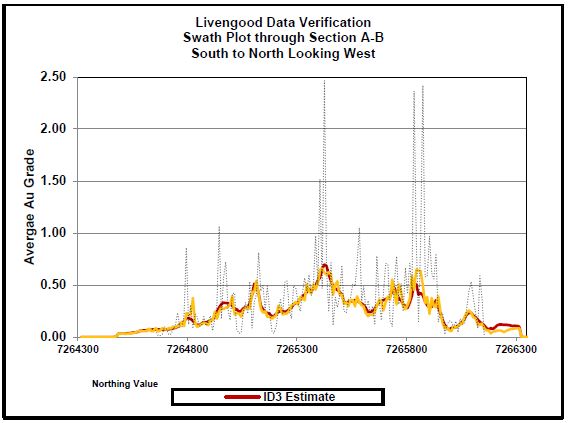

| Figure 11-16: Swath plot through Section A-B | 11-21 |

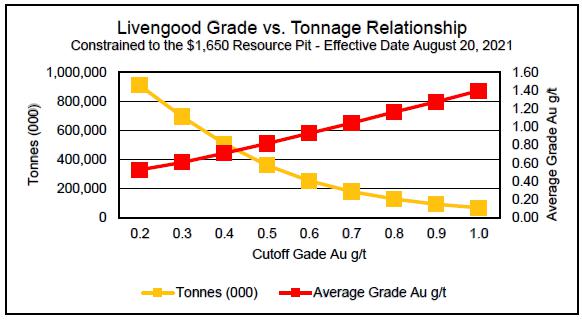

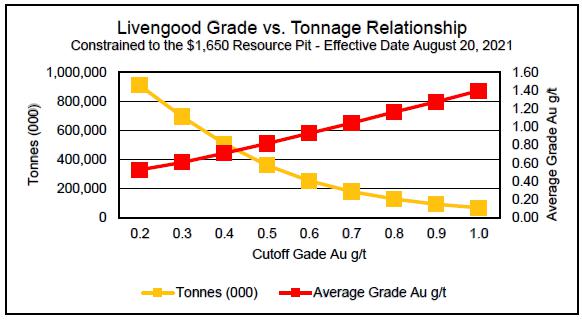

| Figure 11-17: Livengood grade vs tonnage relationship | 11-28 |

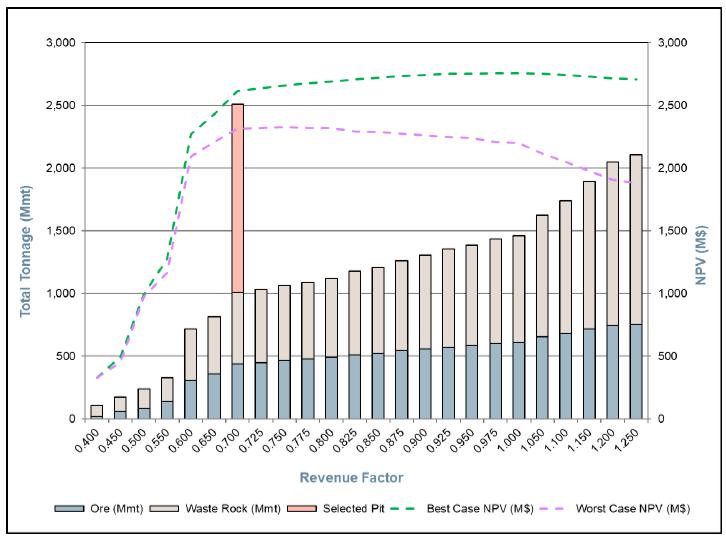

| Figure 12-1: Pit optimization results | 12-12 |

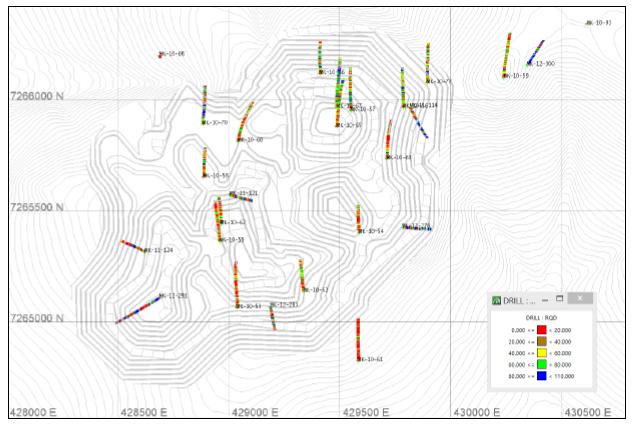

| Figure 12-2: Location of geotechnical drill holes | 12-15 |

| Figure 12-3: Critical slope stability sections for the (2013) ultimate pit | 12-17 |

| Figure 12-4: Pit Slope Design Sectors for the Ultimate Pit | 12-19 |

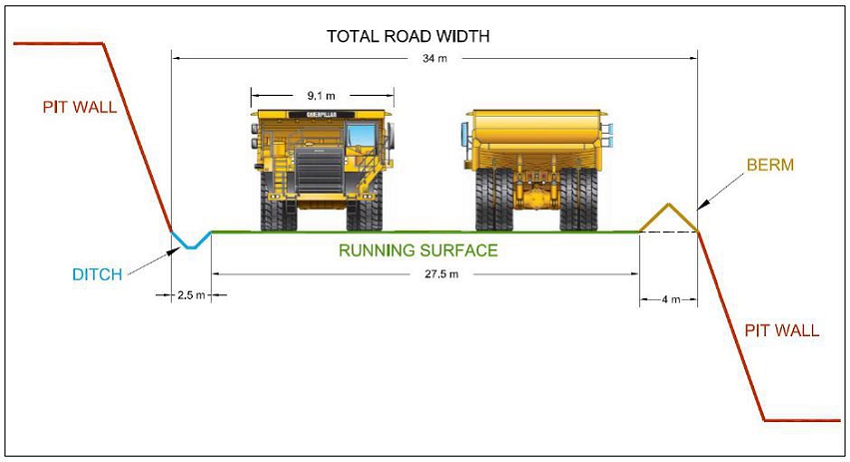

| Figure 12-5: Haul road configuration | 12-21 |

| Figure 12-6: Final bench access | 12-22 |

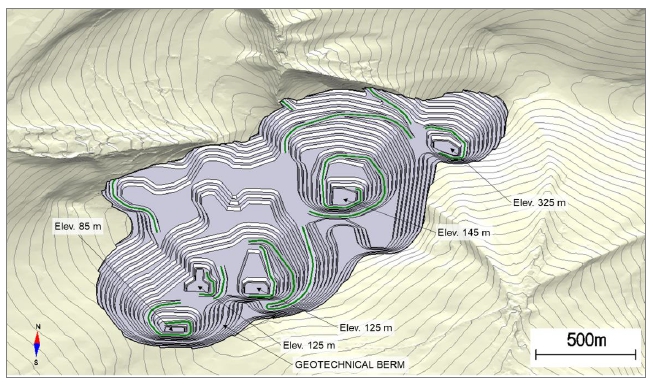

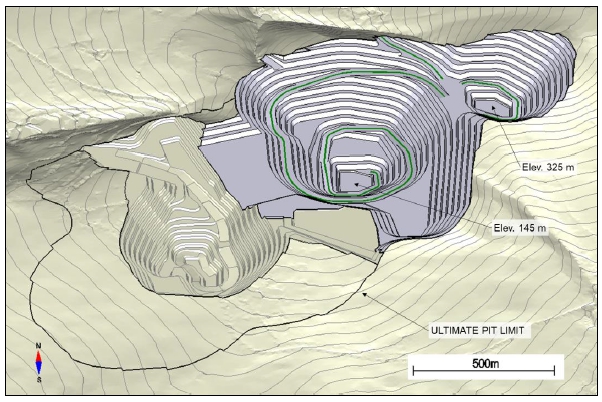

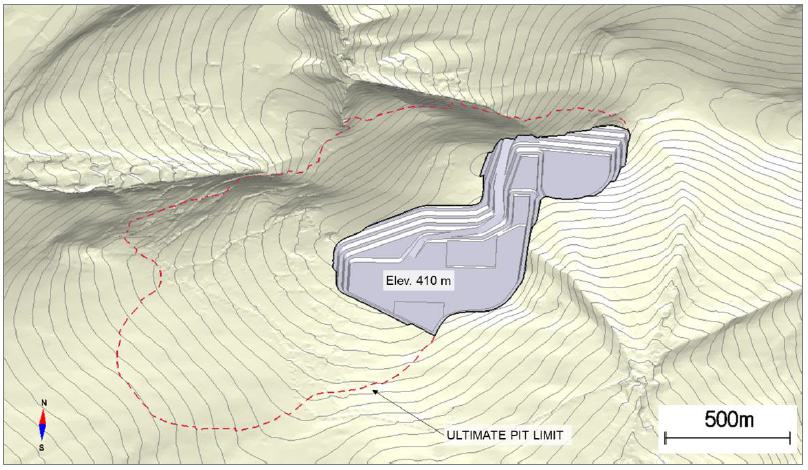

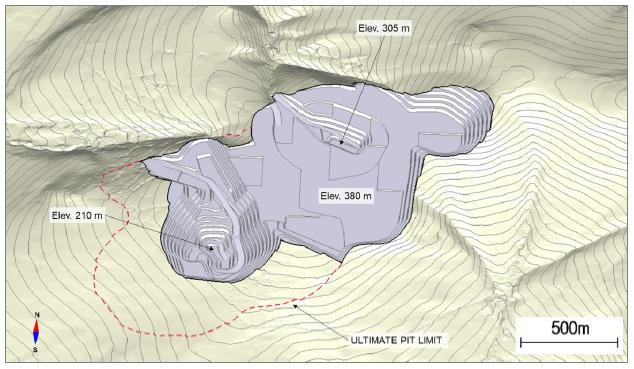

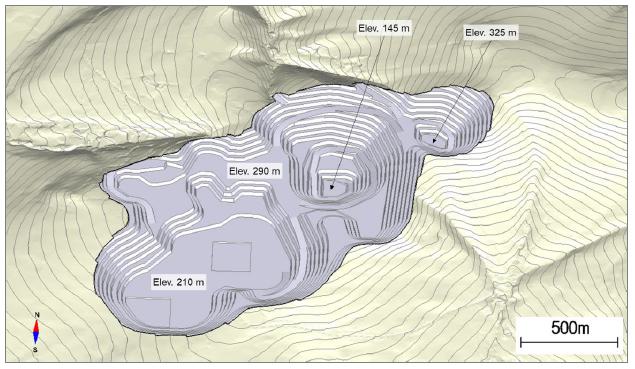

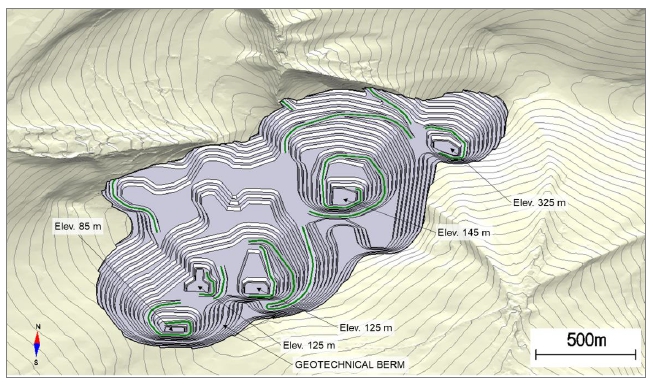

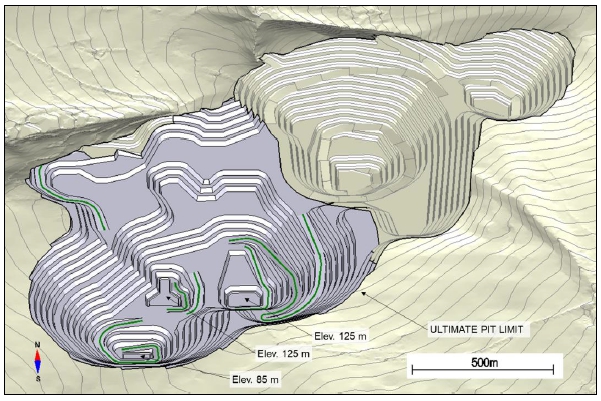

| Figure 12-7: Open pit design | 12-23 |

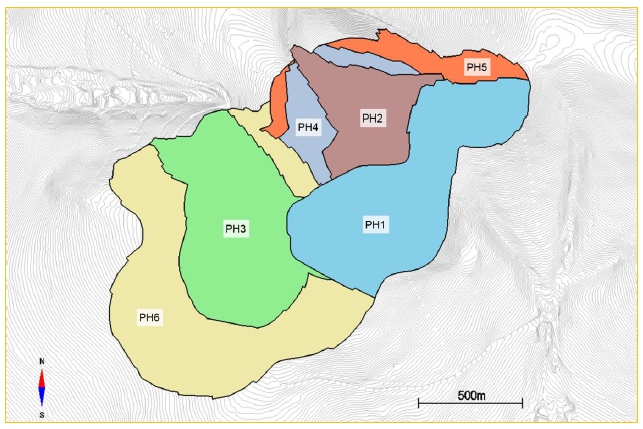

| Figure 13-1: Phase designs | 13-3 |

| Figure 13-2: Phase 1 design | 13-4 |

| Figure 13-3: Phase 2 design | 13-4 |

| Figure 13-4: Phase 3 design | 13-5 |

| Figure 13-5: Phase 4 design | 13-5 |

| Figure 13-6: Phase 5 design | 13-6 |

| Figure 13-7: Phase 6 design | 13-6 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

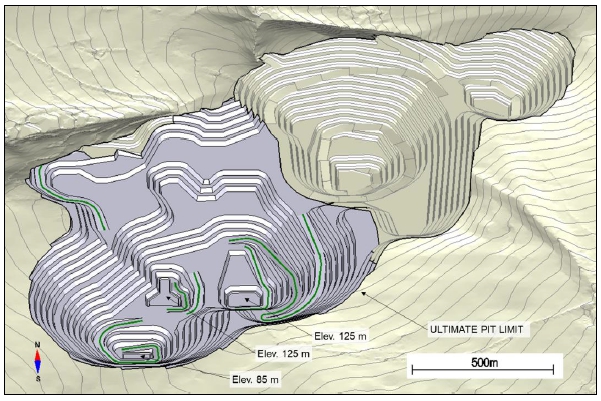

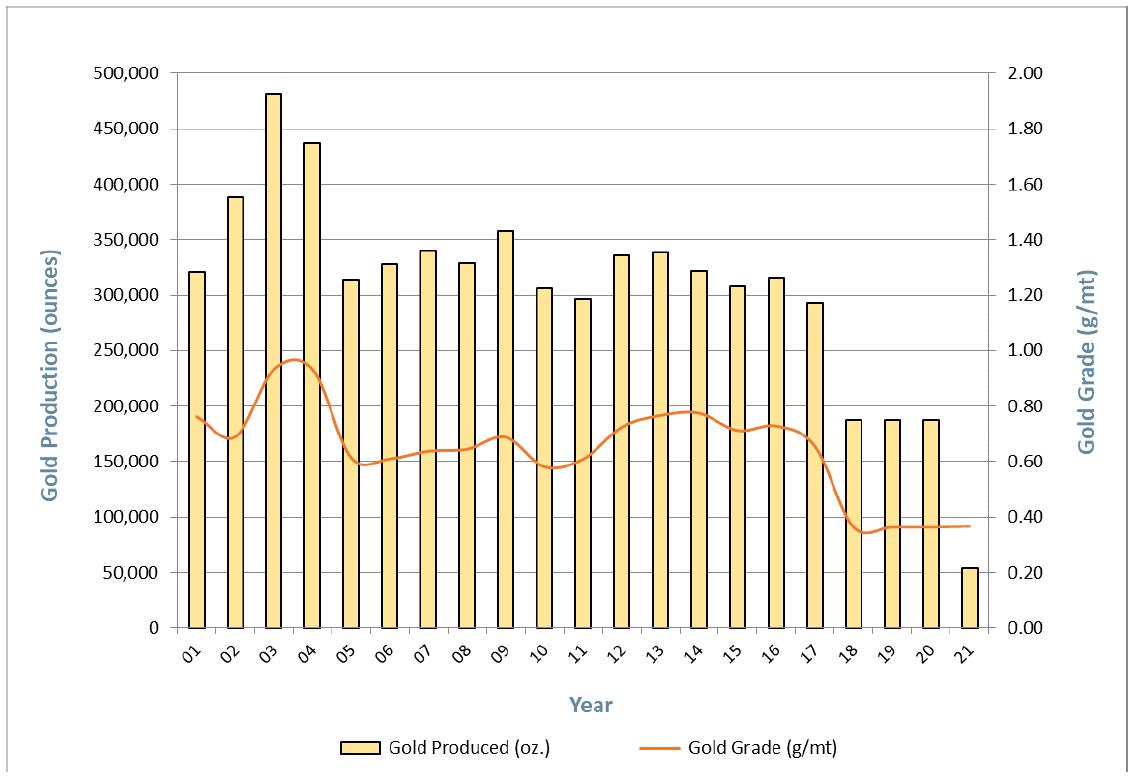

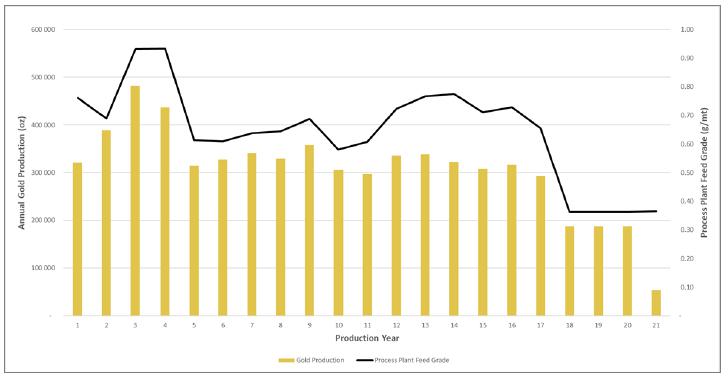

| Figure 13-8: Gold production | 13-13 |

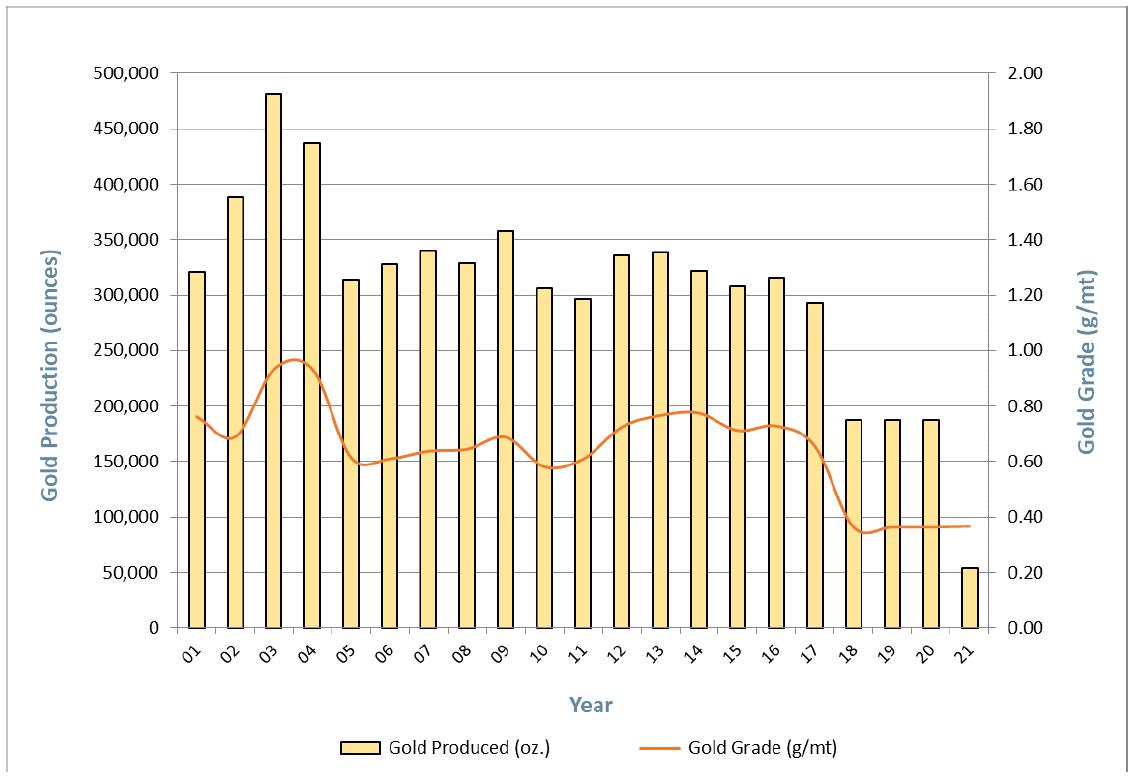

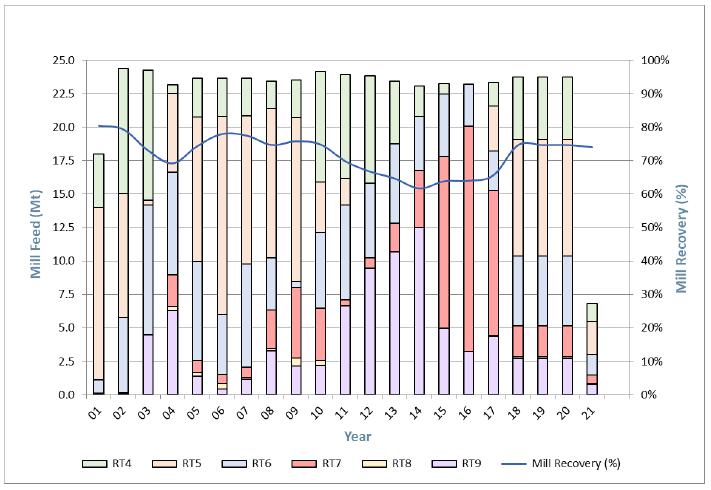

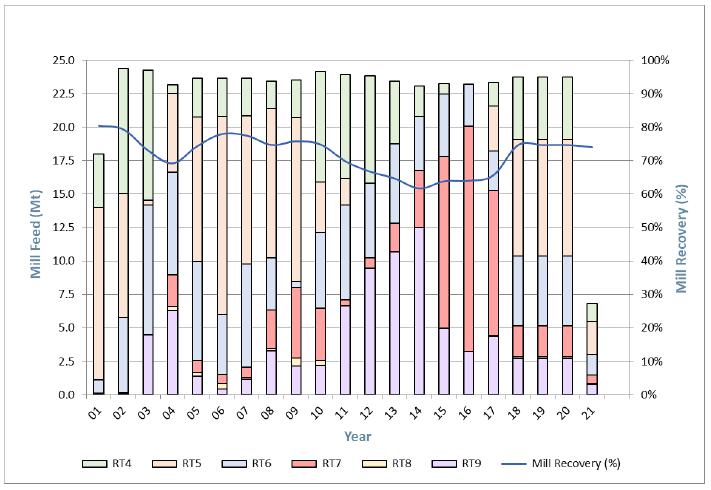

| Figure 13-9: Mill feed | 13-13 |

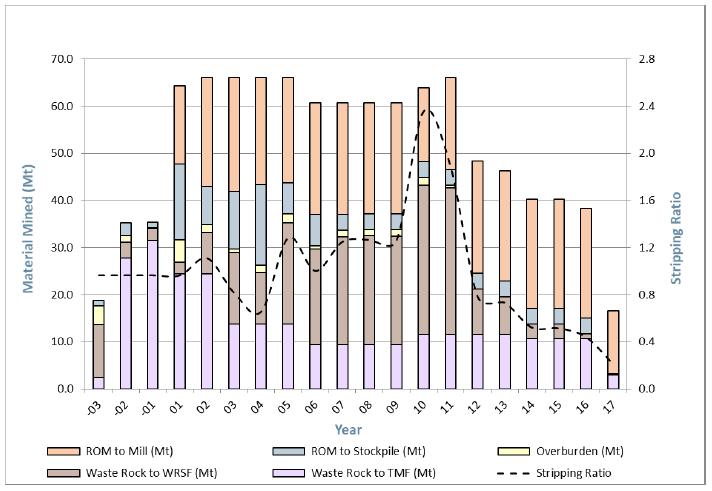

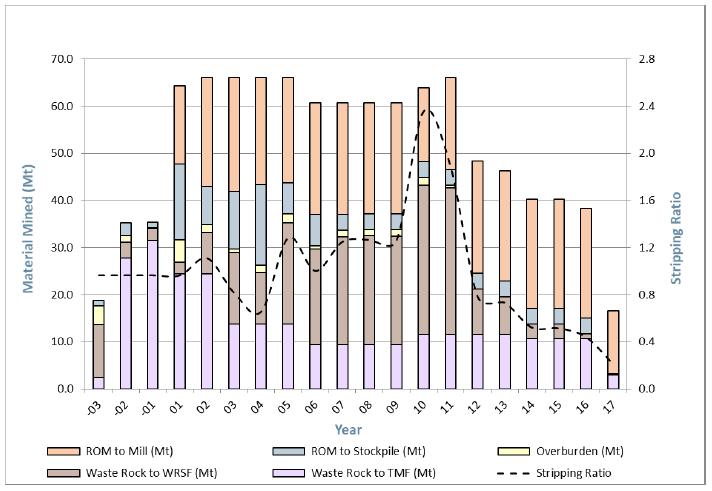

| Figure 13-10: Material mined (ROM) | 13-14 |

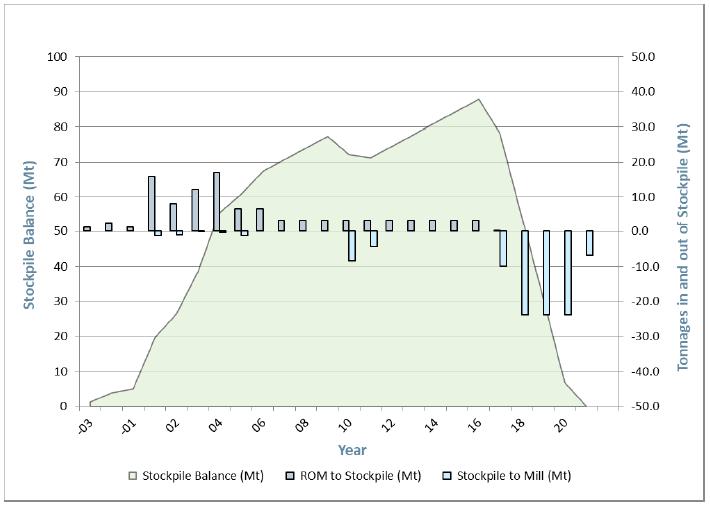

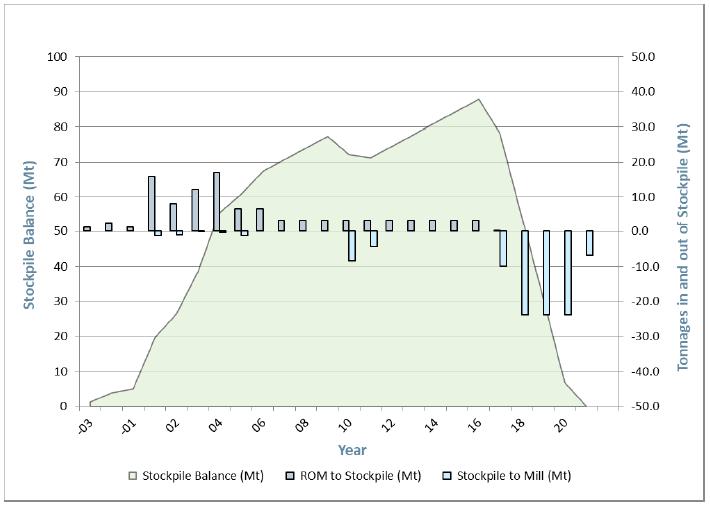

| Figure 13-11: Low grade ore stockpile balance | 13-14 |

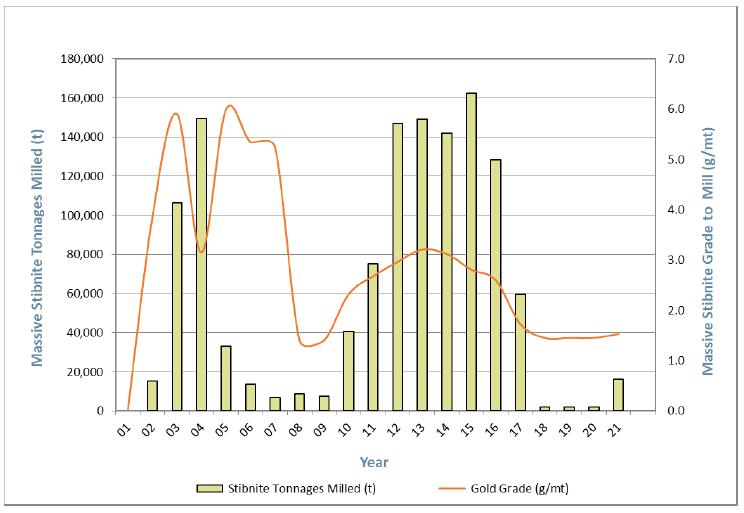

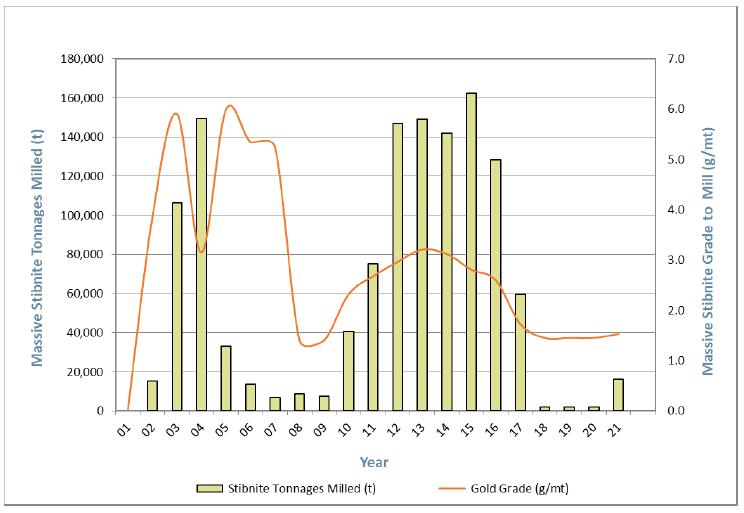

| Figure 13-12: Massive stibnite tonnages milled | 13-15 |

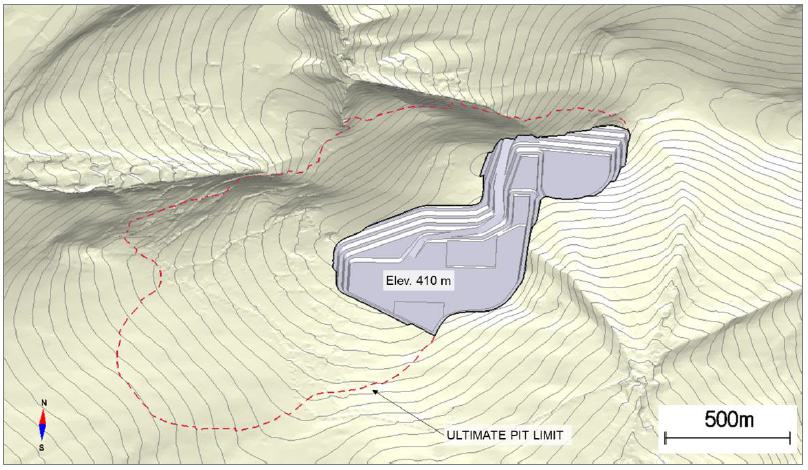

| Figure 13-13: End of preproduction | 13-16 |

| Figure 13-14: End of Year 05 | 13-16 |

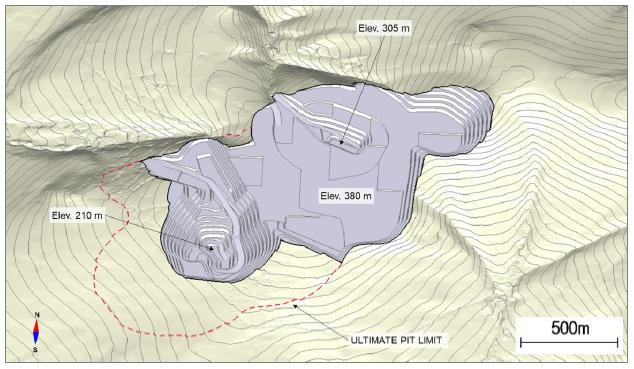

| Figure 13-15: End of Year 10 | 13-17 |

| Figure 13-16: End of Year 15 | 13-17 |

| Figure 13-17: Equipment utilization model | 13-19 |

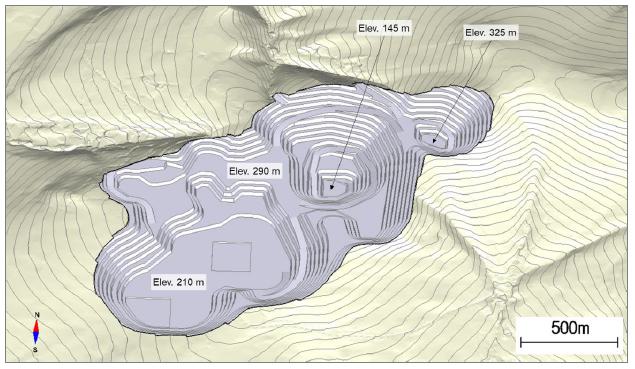

| Figure 14-1: Conceptual process block flow diagram | 14-2 |

| Figure 14-2: Conceptual process flowsheet | 14-6 |

| Figure 14-3: Process plant general arrangement | 14-14 |

| Figure 15-1: Livengood property – conceptual infrastructure arrangement drawing | 15-1 |

| Figure 16-1: Gold spot price on a monthly basis since November 2018 | 16-2 |

| Figure 18-1: Annual operating cash costs ($/oz) | 18-11 |

| Figure 18-2: Operations Personnel | 18-12 |

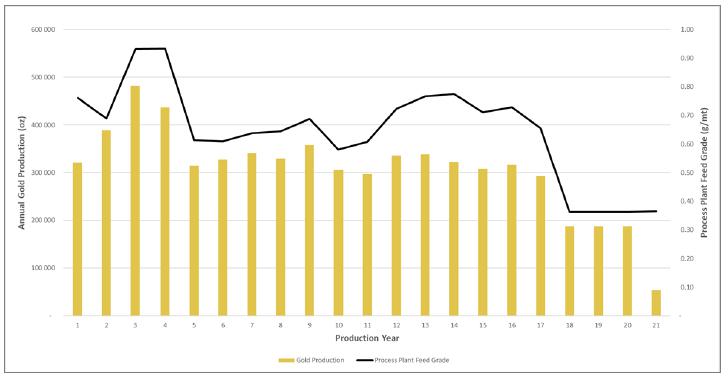

| Figure 19-1: Annual gold production schedule | 19-5 |

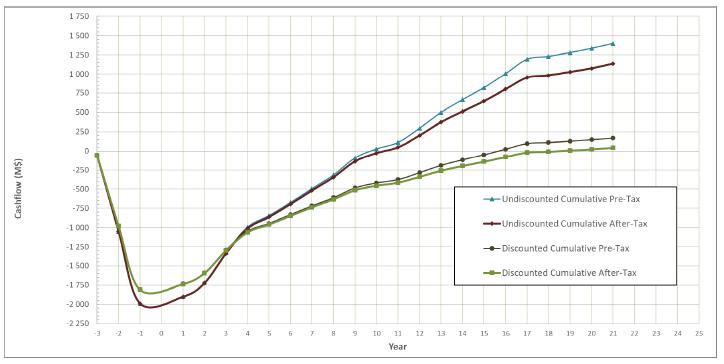

| Figure 19-2: Life-of-mine cash flow projection (pre-tax and after-tax, discount rate: 5%) | 19-9 |

| Figure 19-3: After-tax sensitivity analysis for project net present value (NPV @ 5% discount rate) | 19-10 |

| Figure 19-4: After-tax sensitivity analysis for project internal rate of return (IRR %) | 19-10 |

| Figure 21-1: Summary project execution schedule | 21-3 |

| Figure 21-2: Primary route, Livengood logistics plan (Google Earth) | 21-6 |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| LIST OF ABBREVIATIONS |

| Abbreviation | Description |

| AARL | Anglo American Research Laboratories |

| ADR | Adsorption, desorption and reactivation |

| Ag | Silver |

| AGA | AngloGold Ashanti |

| Ai | Abrasion index |

| AISC | all-in sustaining costs |

| AMHT | Alaska Mental Health Trust |

| amsl | above mean sea level |

| ANFO | Ammonium Nitrate Fuel Oil |

| APDES | Alaska Pollution Discharge Elimination System |

| APR | Annual Percentage Rate |

| ARD | Acid Rock Drainage |

| Au | Gold |

| B | Billion |

| BBA | BBA Inc. |

| BWi | Bond Work index |

| C | Carbon |

| CaO | Calcium oxide (quicklime) |

| CCTV | closed-circuit television |

| CEQ | Council of Environmental Quality |

| CIL | Carbon in leach |

| CIM | Canadian Institute of Mining |

| CIP | Carbon in pulp |

| CN | Cyanide |

| CND | Cyanide detoxification |

| CNT | Cyanide (total) |

| CNWAD | Cyanide (weak acid dissociable) |

| CSS | Contact Support Services |

| Cu | Copper |

| CuSO4 | Copper sulphate |

| CWi | Crusher Work index |

| DEF | Diesel exhaust fluid |

| DOT | Department of Transportation |

| DTH | down-the-hole |

| DWT | JK Drop Weight Test |

| EC | Engineer’s compliance |

| EIS | Environmental Impact Study |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| LIST OF ABBREVIATIONS |

| Abbreviation | Description |

| EO | Enterprise Optimization |

| EPA | United States Environmental Protection Agency |

| EPCM | Engineering, Procurement, Construction Management |

| EPS | Electric Power Systems, Inc. |

| et al. | and others |

| FNSB | Fairbanks North Star Borough |

| FOB | Freight on board |

| FS | Feasibility Study |

| G&A | General and Administration |

| GCL | Geosynthetic clay liner |

| GOH | Gross operating hours |

| GRG | Gravity recoverable gold |

| GVEA | Golden Valley Electrical Association |

| HCI | Hydrochloric acid |

| Hg | mercury |

| ICP | Inductively coupled plasma |

| ID2 | Inverse Distance square |

| ID3 | Inverse Distance cube |

| IDW | Inverse Distance Weighting |

| ILR | Intensive Leach Reactor |

| IROC | Integrated remote operating center |

| IRR | Internal Rate of Return |

| IT | Information Technology |

| ITH | International Tower Hill Mines, Ltd. |

| JDS | JDS Energy and Mining Inc. |

| K | Thousand |

| KPI(s) | Key performance indictors |

| LLC | Limited Liability Company |

| LLDPE | Linear low density polyethylene |

| LNG | Liquefied natural gas |

| LOM | Life of mine |

| LPI | Livengood Placers, Inc. |

| M | Million |

| MACRS | Modified Accelerated Cost Recovery System |

| ML | Metal leaching |

| MMBTU | Metric Million British thermal units |

| MPSO | MinePlan Schedule Optimizer |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| LIST OF ABBREVIATIONS |

| Abbreviation | Description |

| MS | Mineral survey |

| MSV | massive stibnite veins |

| MWMP | Meteoric Water Mobility Potential |

| Na2S2O5 | Sodium Metabisulfite |

| NaCN | Sodium cyanide |

| NAD | North American Datum (Topographical Surveying) |

| NaOH | Sodium hydroxide |

| NEPA | National Environmental Policy Act |

| NewFields | NewFields Mining Design & Technical Services, LLC |

| NHPA | National Historic Preservation Act |

| NN | Nearest neighbor |

| no. | Number |

| NOH | Net operating hours |

| NPI | Net Profits Interest |

| NPV | Net Present Value |

| NSR | Net Smelter Return |

| O2 | Oxygen |

| OCS | O’Connor Creek Substation |

| OK | Ordinary Kriging |

| PAG | Potentially Acid Generating |

| PbNO3 | Lead nitrate |

| PEP | Project execution plan |

| PFS | Pre-feasibility Study |

| PLT(s) | Point load test(s) |

| POF | Probability of failure |

| QA/QC | Quality Assurance/Quality Control |

| QP(s) | Qualified Person(s) |

| QSV | Quartz-stibnite-vein |

| RC | Reverse Circulation |

| RCM | Reliability-Centred Maintenance |

| RCRA | Resource Conservation and Recovery Act |

| RDA | Resource Development Associates Inc. |

| RMR | Rock Mass Rating |

| ROM | Run of mine |

| ROW | Right of way |

| RT | Rock type |

| RWi | Rod Work index |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| LIST OF ABBREVIATIONS |

| Abbreviation | Description |

| S | Sulfur |

| SABC | Comminution circuit consisting of a SAG mill, ball mill and pebble crusher |

| SAG | Semi-Autogenous Grinding |

| Sb | Antimony |

| sg | Specific gravity |

| SHPO | State Historic Preservation Office |

| SMC | SAG Mill Comminution |

| SO2 | Sulfur dioxide |

| SPCC | Spill Prevention, Control and Countermeasure Plan |

| SPI | SAG Power Index |

| SRIL | SR International Logistics |

| SRK | SRK Consulting (Canada and US) Inc. |

| SVC | Static VAR Compensator |

| SWPPP | Storm Water Pollution Protection Plan |

| TAPS | Trans-Alaska Pipeline |

| TBC | To be confirmed |

| THM | Tower Hill Mines, Inc. |

| TMF | Tailings management facility |

| TRS | Technical Report Summary |

| TSF | Tailing storage facility |

| UCS | Uniaxial Compressive Strength |

| US | United States |

| USD | United States dollars |

| USGS | United States Geological Survey |

| UTM | Universal Transverse Mercator Coordinate System |

| VPSA | Vacuum pressure swing adsorption |

| WOL | Whole ore leach |

| WRSF | Waste rock storage facility |

| XRF | X-ray Fluorescence |

| YT | Yukon-Tanana |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| LIST OF ABBREVIATIONS – UNITS OF MEASUREMENT |

| Unit | Description |

| $ or USD | United States dollar |

| $/mt | Dollars per metric ton |

| $/t | Dollars per ton |

| % | Percent |

| a | Annum (year) |

| A | Ampere |

| ˚C | Degrees Celsius |

| ˚F | Degrees Fahrenheit |

| µm | micron |

| cm | centimeter |

| cm3 | cubic centimeter |

| d | day (24 hours) |

| deg or o | angular degree |

| F80 | 80% passing - Feed |

| ft | feet (12 inches) |

| ft2 | square feet |

| g | gram |

| g/g | grams per gram |

| g/L | gram per Liter |

| g/mt | grams per metric ton |

| gal | gallon |

| gpm | (US) gallons per minute |

| h | hour (60 minutes) |

| ha | hectare |

| hp | horsepower |

| Hz | Hertz |

| in | inch |

| k | kips (1,000 pounds) |

| kg | kilogram |

| kg/m2 | kilograms per square meter |

| kg/mt | kilograms per metric ton |

| km | kilometer |

| km/h | kilometers per hour |

| kW | kilowatt |

| kWh/mt | kilowatt hour per metric ton |

| kWh/t | kilowatt hour per ton |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| LIST OF ABBREVIATIONS – UNITS OF MEASUREMENT |

| Unit | Description |

| L | liter |

| L/m | liters per minute |

| lb | pound |

| lb/ft | pounds per foot |

| lb/t | pounds per ton |

| m | meter |

| m2 | square meter |

| m3 | cubic meter |

| m3 | cubic meter |

| m3/h | cubic meters per hour |

| mesh | US Mesh |

| mi | mile |

| mil | one thousandth of an inch |

| min | minute (60 seconds) |

| mm | millimeter |

| mm | millimeter |

| Mmt | Million metric ton |

| mph | miles per hour |

| mt | metric ton (1,000 kg) |

| Mt | Million ton |

| mt/d | metric ton per day |

| mt/h | metric ton per hour |

| MW | Megawatt |

| oz | Troy ounce |

| oz/y | Troy ounces per year |

| P100 | 100% passing - Product |

| P80 | 80% passing - Product |

| ppm | parts per million |

| t | ton (2,000 lbs) |

| t/d | (short) ton per day |

| t/h | (short) ton per hour |

| V | Volt |

| wt% | weight percent |

| y | year (365 days) |

| yd | yard (36 inches) |

| yd3 | cubic yard |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

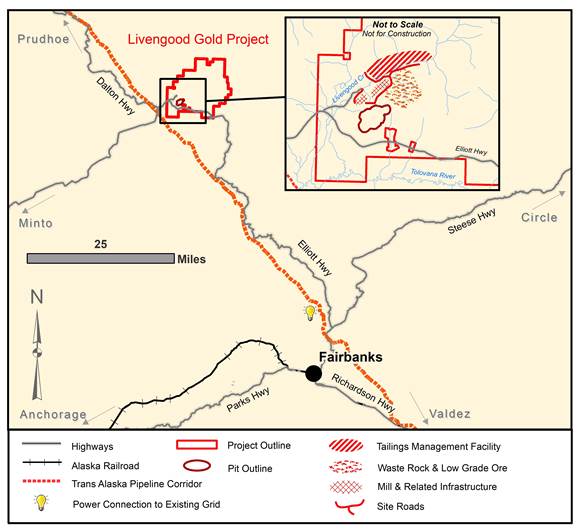

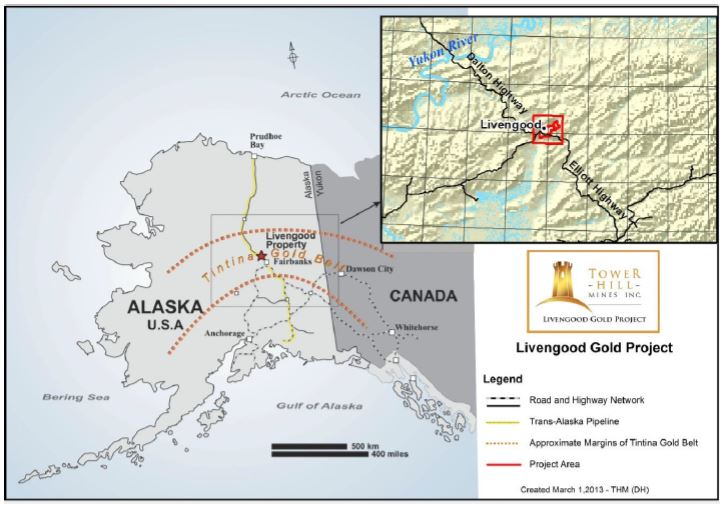

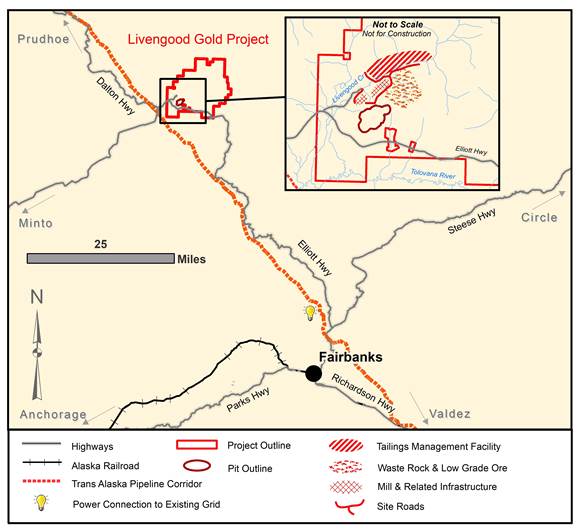

The Livengood Gold Project (herein also referred to as “the Project”) is a gold exploration project located 70 mi (113 km) northwest of Fairbanks, Alaska, USA. The Project is in an active mining district that has been mined for gold since 1914.

This amended Technical Report Summary (the “TRS”) was prepared and compiled by BBA USA Inc. at the request of International Tower Hill Mines Ltd. (ITH) through its wholly owned subsidiary Tower Hill Mines, Inc. (THM). The purpose of the TRS is to summarize the results of the Pre-feasibility Study (PFS) for the Livengood gold deposit on the THM property. This TRS, as amended, has been prepared in accordance with §§229.1300 through 229.1305 (subpart 229.1300 of Regulation S-K). The TRS supports the ITH November 4, 2021 news release “International Tower Hill Mines Announces Pre-Feasibility Study Results on 13.6 Million Ounce Gold Resource” announcing the results of the study. This TRS also supports the mineral resource, mineral reserve and property disclosures in ITH’s Annual Report on Form 10-K for the fiscal years ended December 31, 2021 and December 31, 2022, in addition to the November 4, 2021 release.

The PFS and this TRS are based on an updated resource estimate, effective as of August 20, 2021, and has an optimized Project configuration of 65,000 t/d. The Project configuration in this TRS remains a conventional, owner-operated surface mine that will utilize large-scale mining equipment in a blast/load/haul operation. Mill feed would be processed in a 65,000 t/d (59,000 mt/d) comminution circuit consisting of primary and secondary crushing, wet grinding in a single semi-autogenous (SAG) mill and single ball mill, followed by a gravity gold circuit and a conventional carbon in leach (CIL) circuit. As a result of the changes to the Project as summarized in this TRS, including differences in the mineral resource estimation methodology and changes to the economic parameters applied to the geologic block model (gold price, recovery, CAPEX, and OPEX), all of which resulted in a change in the mineral resources, the Project as evaluated in the 2017 PFS is no longer considered current and the 2017 PFS should therefore not be relied upon by investors.

This TRS assumes that the Livengood Gold Project will be constructed using imperial units. Therefore, to the maximum extent practicable, all design work and equipment descriptions were completed and reported in imperial units, with metric units shown in parentheses. Every effort has been made to clearly display the appropriate units being used throughout this TRS. However, it is important to note that both the Livengood Gold Project drill hole database and the block model were originally created in metric units and have been consistently maintained in metric units. Therefore, some tables and figures in this TRS may be presented in metric units only to minimize the risk of data unit conversion errors.

For financial modeling, ore tonnage is reported in short tons (t), with all costs reported in $/t.

Certain other testwork, such as comminution results and unconfined compressive strength tests, are reported in metric units.

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

All monetary units are in United States dollars ($), unless otherwise specified. Costs are based on third quarter (Q3) 2021 dollars.

On October 13, 2023, this TRS was amended by adding a stratigraphic column to Section 6.1.1 and an opinion of the QPs to Sections 10.8, 12.3, and 17.7 as prescribed by Item 601(b)(96) of Regulation S-K.

The independent PFS was prepared through the collaboration of a number of industry-recognized consulting firms “Contributors”, including BBA USA Inc. (“BBA”, Montreal, Quebec, Canada), NewFields Mining Design & Technical Services, LLC (“NewFields”, Lone Tree, Colorado, USA), JDS Energy and Mining Inc. (“JDS”, Denver, Colorado, USA), and Resource Development Associates Inc. (“RDA”, Highlands Ranch, Colorado, USA). Qualified Persons as defined in S-K 1300 guidelines from these firms provided resource estimates, design parameters and cost estimates for mine operations, process facilities, major equipment selection, waste and tailings storage, reclamation, permitting, operating and capital expenditures. A summary of contributors to the PFS is included in Table 1-1.

Table 1-1: PFS contributors

| Consulting Firm | General Overview of Responsibilities |

| BBA USA Inc. | § Mineral reserve estimation § Mine engineering § Mine CAPEX and OPEX § Mineral processing and metallurgical testing § Process engineering and process plant OPEX § Process plant and infrastructure CAPEX § G&A OPEX § Environmental Studies and Permitting § Financial model § Overall PFS TRS integration |

| NewFields Mining Design & Technical Services, LLC | § Geotechnical engineering § Waste rock and water management § Tailings Management Facility (TMF) engineering and CAPEX |

| JDS Energy and Mining Inc. | § Mine pit wall slope stability |

| Resource Development Associates Inc. | § Geology § Drilling § Resource estimation. |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

The reader is advised that the results of the PFS summarized in this TRS are intended to provide an initial, high-level review of the proposed optimized project configuration and revised design options. The PFS mine plan, execution plan and economic model include numerous assumptions. There is no guarantee that the Project economics described herein will be achieved.

The key outcomes of this PFS are the following:

| § | The Livengood Gold Project Mineral Resource (exclusive of reserves) is estimated at 234.5 M Measured metric tons at an average grade of 0.53 g/mt (3.99 Moz) and 40.01 M Indicated metric tons at an average grade of 0.49 g/mt (0.63 Moz), for a total (Measured and Indicated) of 274.5 M metric tons at an average grade of 0.52 g/mt (4.62 Moz). Inferred Mineral resources total 16.0 M metric tons at an average grade of 0.40 g/mt (0.21 Moz). |

| § | The Livengood Gold Project Mineral Resource (inclusive of reserves) is estimated at 646.0 M Measured metric tons at an average grade of 0.60 g/mt (12.48 Moz) and 58.5 M Indicated metric tons at an average grade of 0.61 g/mt (1.14 Moz), for a total (Measured and Indicated) of 704.5 M metric tons at an average grade of 0.60 g/mt. Inferred Mineral resources total 16.0 M metric tons at an average grade of 0.40 g/mt (0.21 Moz). |

| § | Defined and estimated Proven Mineral Reserves of 411.5 M metric tons at an average grade of 0.64 g/mt (8.5 Moz contained) and Probable Mineral Reserves of 18.5 M metric tons at an average grade of 0.86 g/mt (0.5 Moz contained), for a total of 430.1 M metric tons at an average grade of 0.65 g/mt (9.0 Moz contained). To access these mineral reserves, 496.1 M metric tons of overburden and waste rock must be mined, resulting in a strip ratio of 1.15:1 |

| § | The mine plan developed for the PFS provides sufficient ore to support an annual production rate of approximately 317,000 oz/y over an estimated 20.3-year mine life, producing a total of approximately 6.4 Moz of gold. |

| § | The material mined from the open pit peaks at 66 Mt (60 Mmt) per year and averages 57 Mt (52 Mmt). A total of 105 Mt (95 Mmt) of ore is sent to the low-grade ore stockpile over the life of the mine, with an average gold grade of 0.38 g/mt. The maximum size of the low-grade ore stockpile is 88 Mt (88 Mmt). |

| § | The peak mine fleet requirements have been estimated at 18 x 320 t haul trucks, 2 x 40 yd3 hydraulic shovels, 2 x 40 yd3 wheel loaders and 5-production drills. |

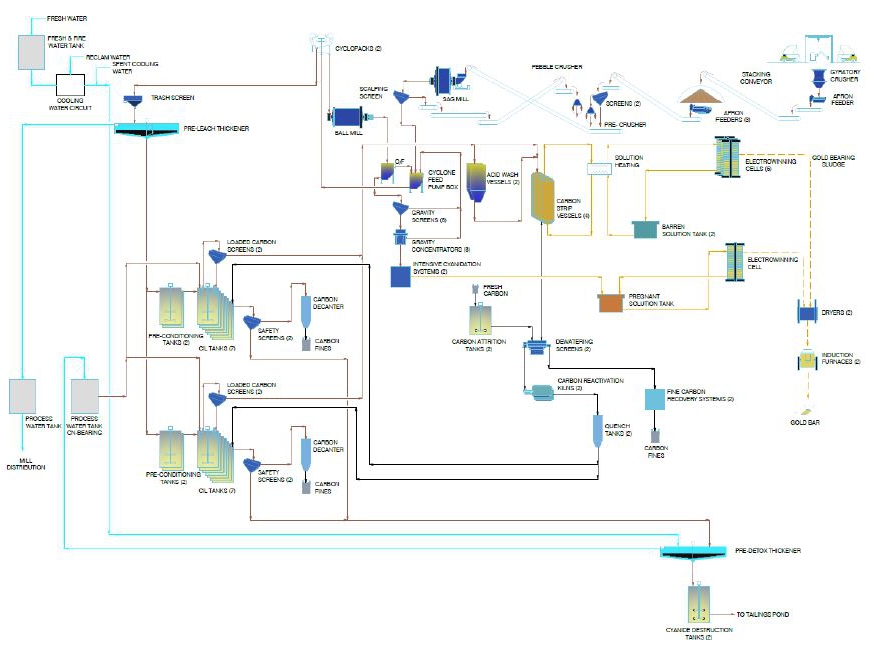

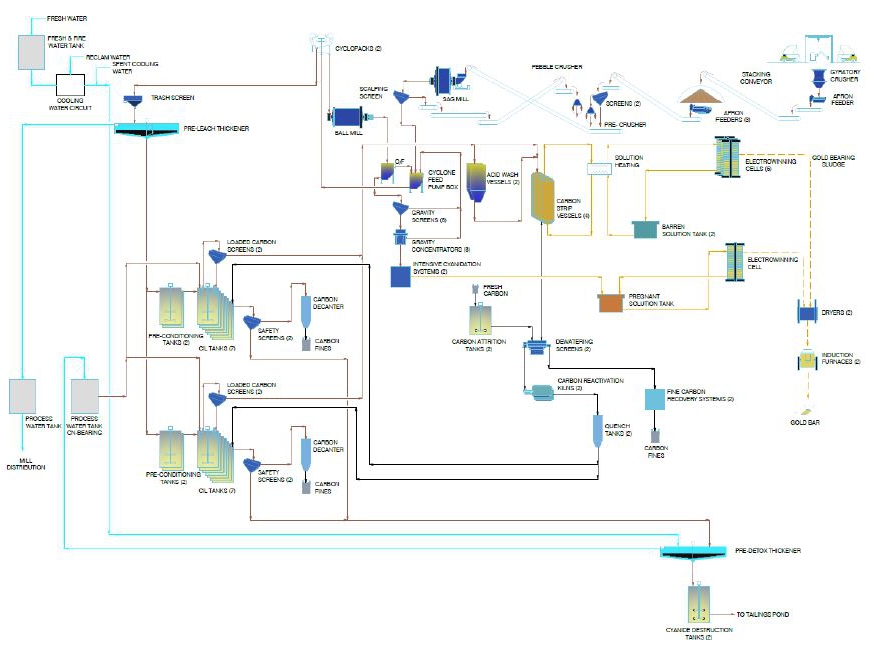

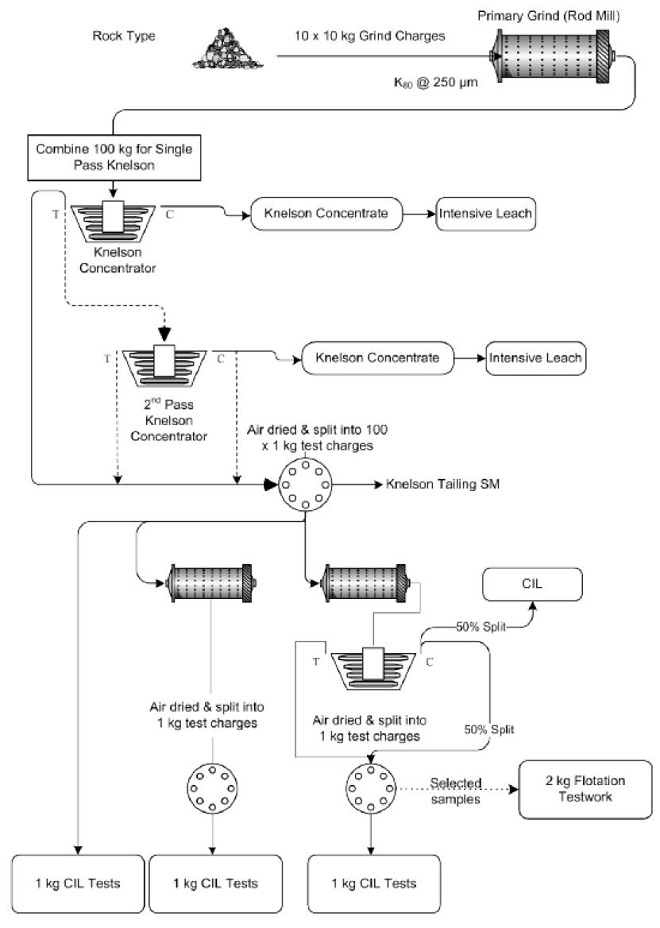

| § | Metallurgical testwork has confirmed the preferred flowsheet consisting of primary crushing, secondary crushing, and a comminution circuit (SABC configuration) producing a final grind size of 250 µm (P80), with gravity recovery followed by whole ore leaching of the gravity tailings. LOM gold recovery is estimated to be 71.4% based on the rock types tested and mine plan. |

| § | The initial capital cost (-20% / +25% accuracy) of the open pit mine, 65,000 t/d (59,000 mt/d) process plant and general site infrastructure is estimated at $1.93B, including a contingency of $220M. |

| § | LOM project sustaining capital costs total $658M, excluding reclamation costs of $317M. |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

| § | The mining cost is estimated at $2.05/t mined, process plant operating cost is estimated at an average of $7.72/t ore processed, and general and administrative costs of $1.35/t ore processed. |

| § | All-in sustaining cost of production of 1,171 $/oz over LOM, including sustaining capital and before reclamation expenses, royalties, mining, and income taxes. |

| § | Base case ($1,680/oz) positive Project NPV of $45M at a 5% discount rate and an IRR of 5.3% after mining and income taxes. Payback period is 10.4 years. |

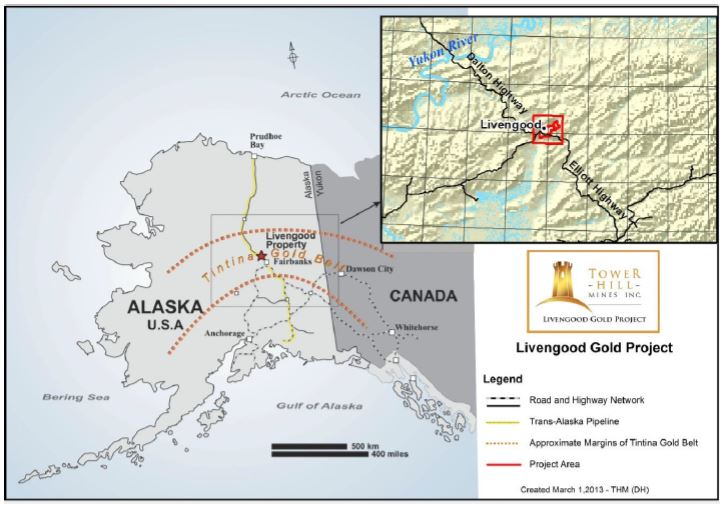

| 1.4 | Property Description, Location and Access |

The Livengood property is located approximately 70 mi (113 km) by road (47 mi (75 km) by air) northwest of Fairbanks, Alaska in the Tolovana Mining District within the Tintina Gold Belt. The deposit area is centered near Money Knob, a local topographic high point. This feature and the adjoining ridge lines are the probable lode gold source for the Livengood placer deposits that lie in the adjacent valleys. These placer deposits have been actively mined since 1914 and have produced more than 500,000 oz of gold.

The property lies in numerous sections of Fairbanks Meridian Township 8N and Ranges 4W and 5W. Money Knob, the principal geographic feature within the known deposit, is located at 65 ̊30’16’’N, 148 ̊31’33’’W.

The property straddles Highway 2 (also known as the Elliott Highway), a paved, all-weather highway linking the North Slope oil fields to Fairbanks, and adjoins the Trans-Alaska Pipeline (TAPS) corridor, which transports crude oil from the North Slope south and contains the fiber optic communications cable that may be used at the Project site (see Figure 1-1). Locally, a number of unpaved roads lead from the Elliott Highway into and across the deposit. A 3,000 ft (914 m) runway is located 3.73 mi (6 km) to the southwest of the Project and is suitable for light aircraft.

The site is approximately 40 mi (64 km) south of the Arctic Circle. The climate in this part of Alaska is continental with temperate and mild conditions in summer with average lows and highs in the range of 44°F to 72°F (7°C to 22°C). Winter is cold with average lows and highs for December through March in the range of -17°F to 23°F (-27°C to -5°C). The lowest temperatures are about – 40°F (-40°C). Annual precipitation is approximately 15.7 in (400 mm) water equivalent. Winter snow pack depth is approximately 26 in (66 cm).

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

Figure 1-1: Project location map

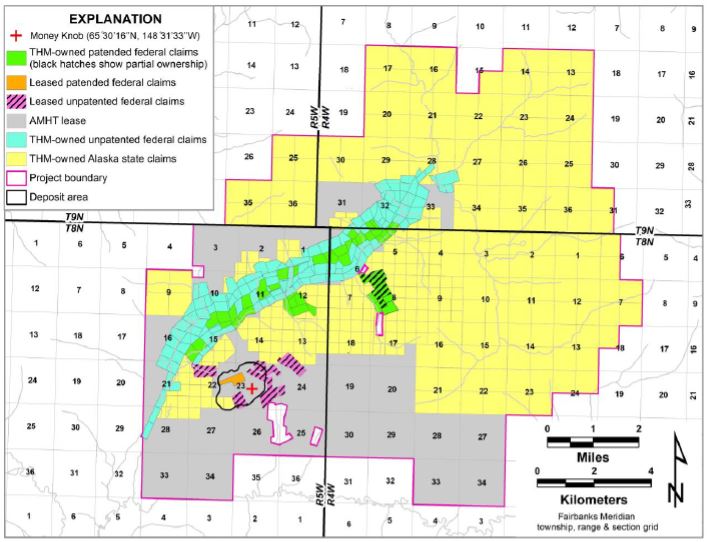

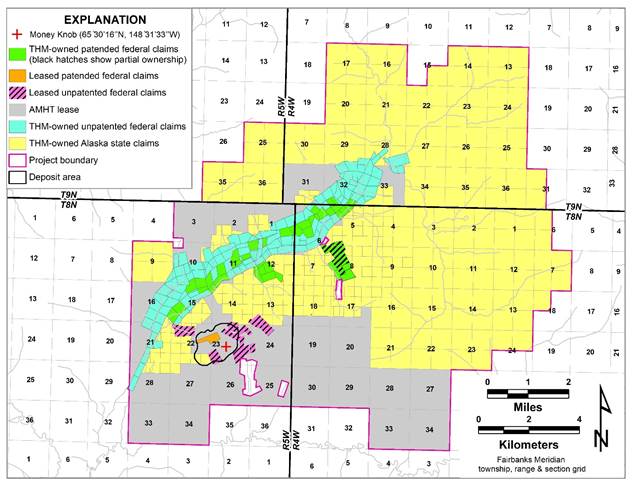

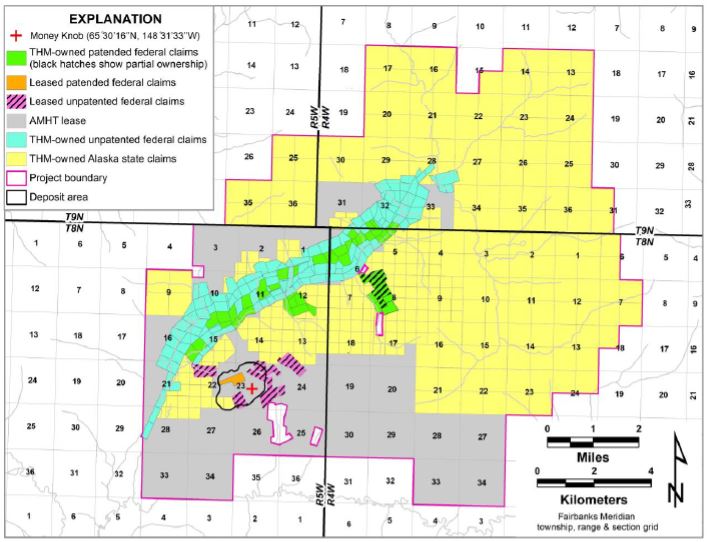

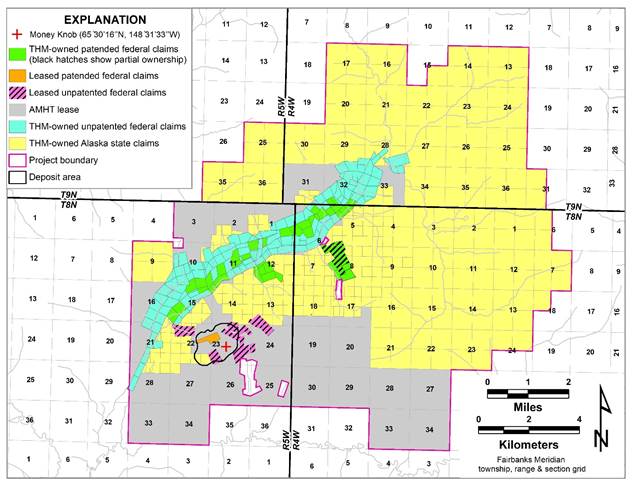

The Livengood Gold Project property covers approximately 48,300 acres (19,546 hectares), all of which is controlled by ITH through its wholly-owned subsidiaries, THM and Livengood Placers, Inc. (LPI). The Livengood Gold Project is comprised of multiple land parcels: 100% owned patented mining claims, 100% owned State of Alaska mining claims, and 100% owned federal unpatented placer claims, land leased from the Alaska Mental Health Trust (AMHT), land leased from holders of state and federal patented and unpatented lode and placer mining claims, and undivided interests in patented mining claims. The property and claims controlled through ownership, leases or agreements are shown in Figure 1-2.

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

Figure 1-2: Map illustrating the company’s Livengood Gold Project land holdings

(As at September 30, 2021, by tenure type, referenced to the Fairbanks Meridian Township, range and section grid.)

Gold was first discovered in the gravels of Livengood Creek in 1914 (Brooks, 1916) and led to the founding of the Town of Livengood. Subsequently, more than 500,000 oz of placer gold has been produced. From 1914 through the 1970s, the primary focus of prospecting activity was placer deposits. Historically, prospectors considered Money Knob and the associated ridgeline the source of the placer gold. Prospecting, primarily in the 1950s and in the form of dozer trenches, was carried out for lode type mineralization in the vicinity of Money Knob. However, no significant lode production has occurred to date.

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

Since the 1970s, the property has been prospected and explored by several companies. Geochemical surveys by Cambior Inc. in 2000 and AngloGold Ashanti (U.S.A.) Exploration Inc. (AGA) in 2003 and 2004, outlined a 1.0 × 0.5 mi2 (1.6 × 0.8 km2) area with anomalous gold in soil. Scattered anomalous samples continue along strike for an additional 1.2 mi (2 km) to the northeast and 1 mi (1.6 km) to the southwest. Eight reverse circulation (RC) holes were drilled by AGA in 2003 and a further four diamond core holes were drilled in 2004 to evaluate this anomaly. Favorable results from these holes revealed wide intervals of gold mineralization (BAF-7: 455 ft (138.7 m) @ 1.07 g/mt Au; MK-04-03: 181.4 ft (55.3 m) @ 0.51 g/mt Au) along with lesser intervals over a broad area. In 2006, AGA sold the Livengood Gold Project to ITH. In the same year, THM drilled a 4,026 ft (1,227 m), seven-hole core program. The success of that program led to the drilling of an additional 14,432 ft (4,400 m) in 15 diamond core holes in 2007 to test surface anomalies, expand the area of previously intersected mineralization, and advance geologic and structural understanding of the deposit. Subsequent programs have continued to expand the resource, leading to consideration of development of the deposit. Concomitant programs have included geotechnical, engineering, and metallurgical work, along with the collection of environmental baseline data. As of the end of 2014, completed exploration and delineation drilling totals 574,599 ft (175,138 m) in 621 RC holes and 140.854 ft (42,932 m) in 151 core drill holes.

Beginning in 2009, technical studies were performed to generate preliminary surface mine designs, to generate metallurgical data for process definition, and to develop pre-conceptual information on the location and capacities of potential tailings management, overburden management, water reservoir and mill process facilities. A pre-feasibility study was begun in 2011, but was not completed, as advancing technical studies indicated major changes to the flowsheet and project configuration warranted a shift to the feasibility study, which was completed in August 2013.

From 2013 through 2016, additional metallurgical testwork was performed, along with various techno-economic trade-off studies, to form the basis for the project configuration that was presented in the 2017 PFS.

The 2017 PFS work indicated that the project economics are sensitive to recovery, grind size, reagent consumption and test conditions. Further testwork was executed from 2017 through 2021, along with an Enterprise Optimization (EO) study (the “Whittle and BBA Study’’) to confirm the project configuration as well as the process conditions that are presented in this PFS.

Gold mineralization is associated with disseminated arsenopyrite and pyrite in volcanic, sedimentary, and intrusive rocks, and in quartz veins cutting the more competent lithologies, primarily volcanic rocks, sandstones, and to a lesser degree, ultramafic rocks. Three principal stages of alteration are currently recognized. In order from oldest to youngest, these are characterized by biotite, albite, and sericite. Carbonate was introduced with and subsequent to these stages. Arsenopyrite and pyrite were introduced primarily during the albite and sericite stages. Gold correlates strongly with arsenic and occurs primarily within and on the margins of arsenopyrite and pyrite.

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

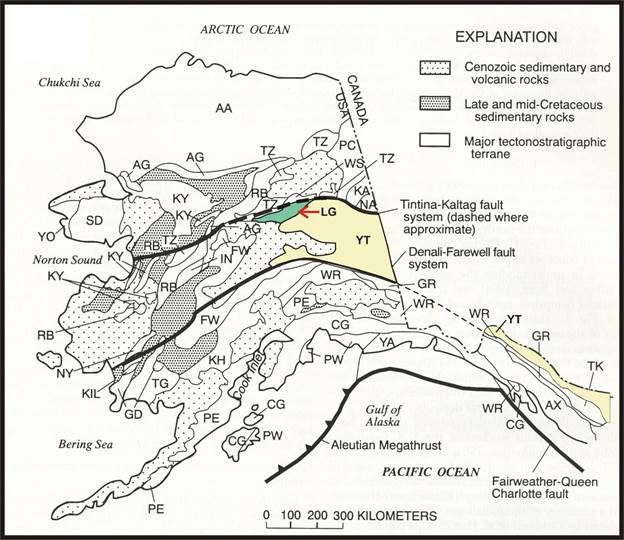

Mineralization is interpreted to be intrusion-related, consistent with other gold deposits of the Tintina Gold Belt and has a similar arsenic-antimony (As-Sb) geochemical association. Mineralization is controlled partly by stratigraphic units, but thrust-fold architecture is apparently key to providing pathways for magma (dikes and sills) and hydrothermal fluid.

| 1.8 | Mineral Processing and Metallurgical Testing |

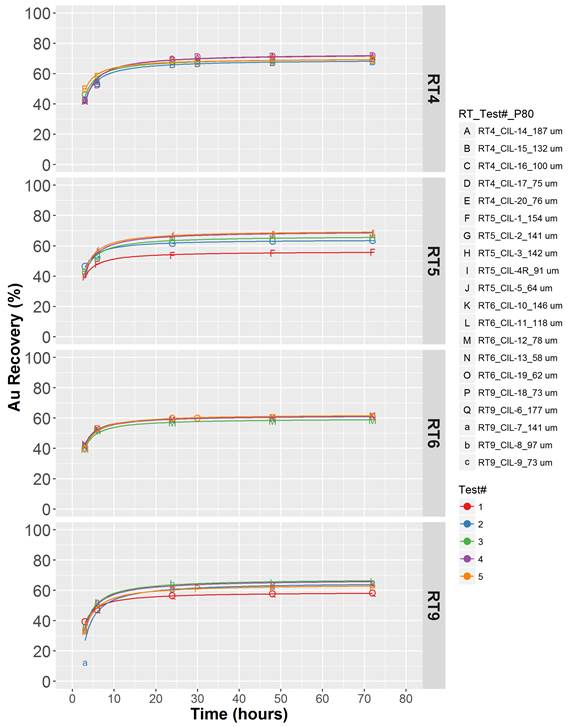

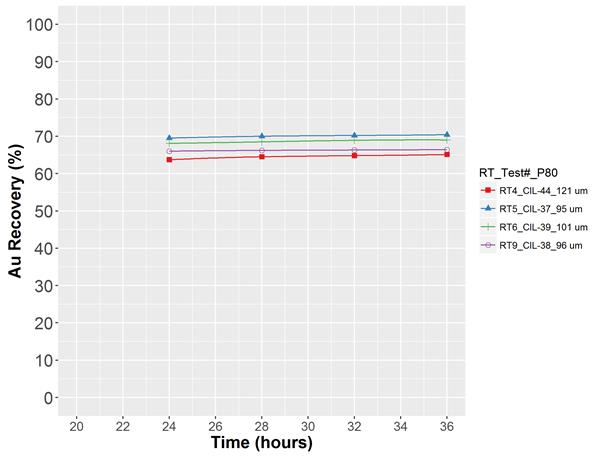

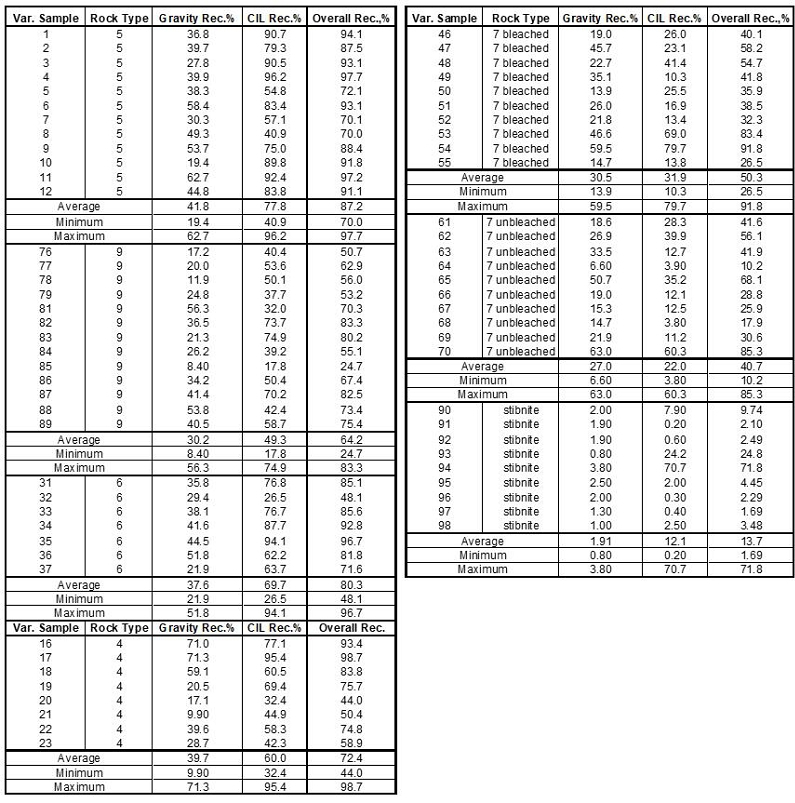

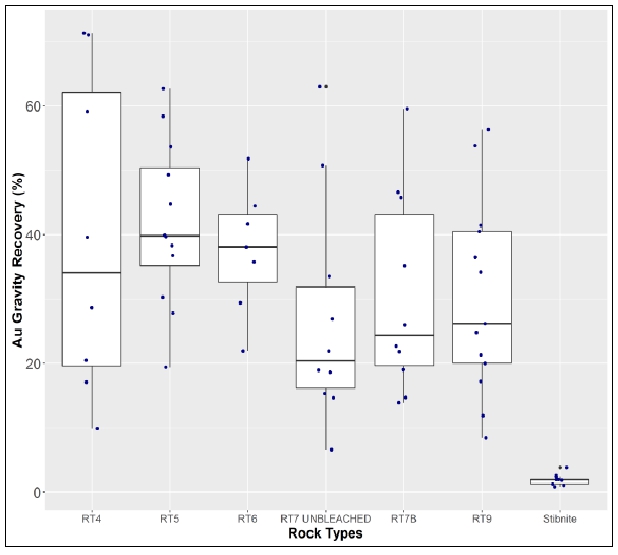

Several phases of testwork, along with an enterprise optimization study (the “Whittle and BBA Study’’), have been completed since the 2017 PFS was issued.

A new round of simulations was completed at different grind sizes to determine the maximum achievable throughput using the recommended 2017 PFS configuration, which is a single line SABC circuit with pre-crushing, generating data that was used in the Whittle and BBA Study. The result of the work was a maximum throughput of 65,000 t/d (59,000 mt/d), operating to a target grind size of 250 µm (P80). The design relies upon an optimized drill & blast strategy to achieve the rated throughput with a SAG mill (D × L) 36 ft × 20 ft with 15 MW of installed power and a ball mill (26 ft × 40.5 ft) with 15 MW of installed power. The SAG mill is operated in closed circuit with a pebble crusher and the ball mill is operated in closed circuit with hydrocyclones.

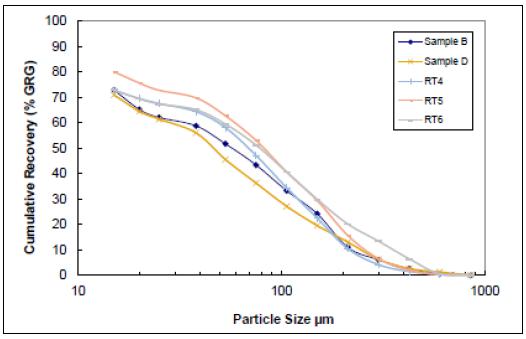

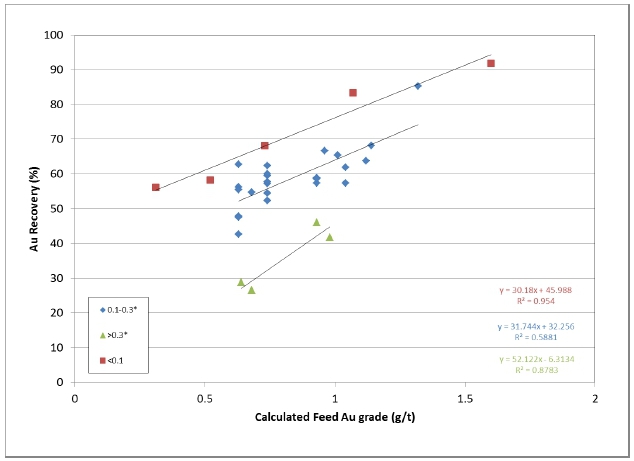

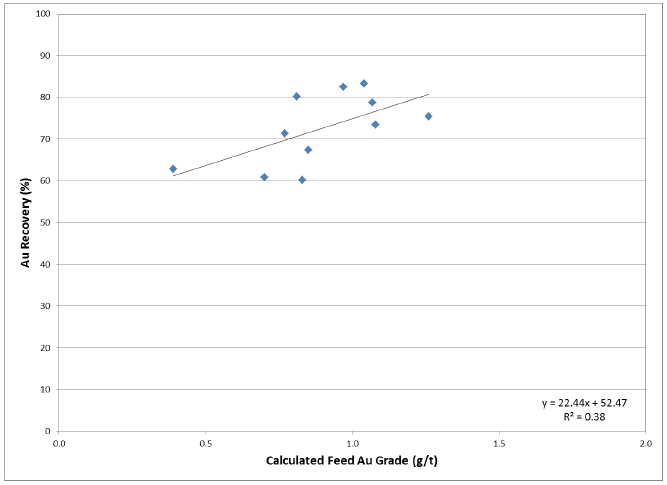

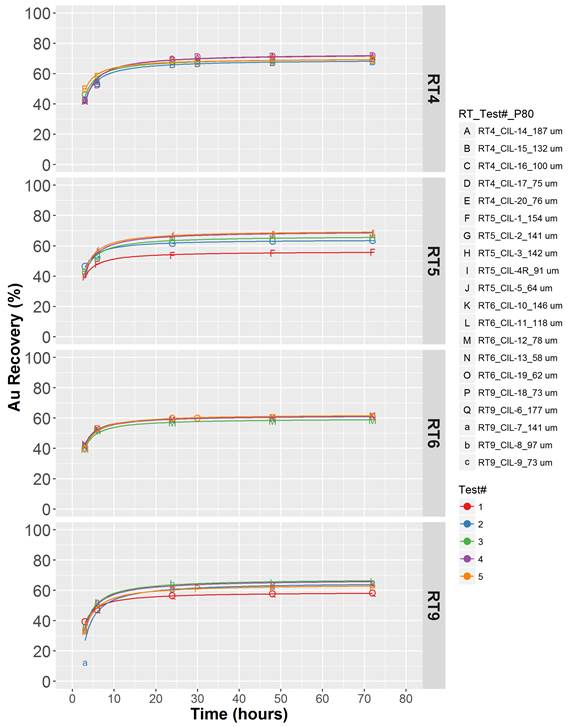

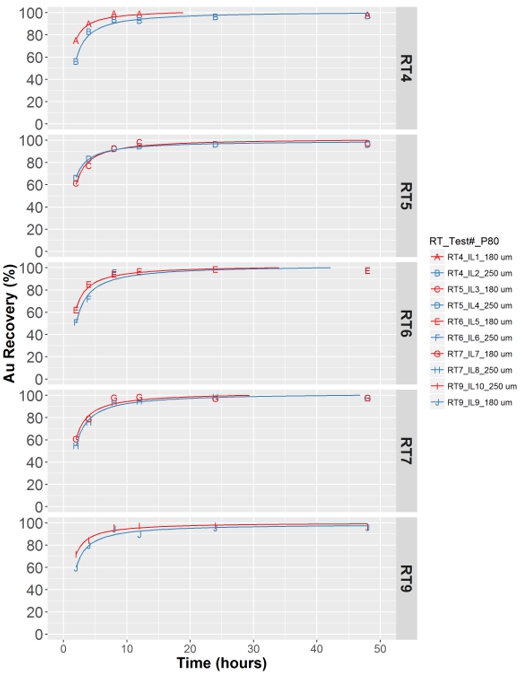

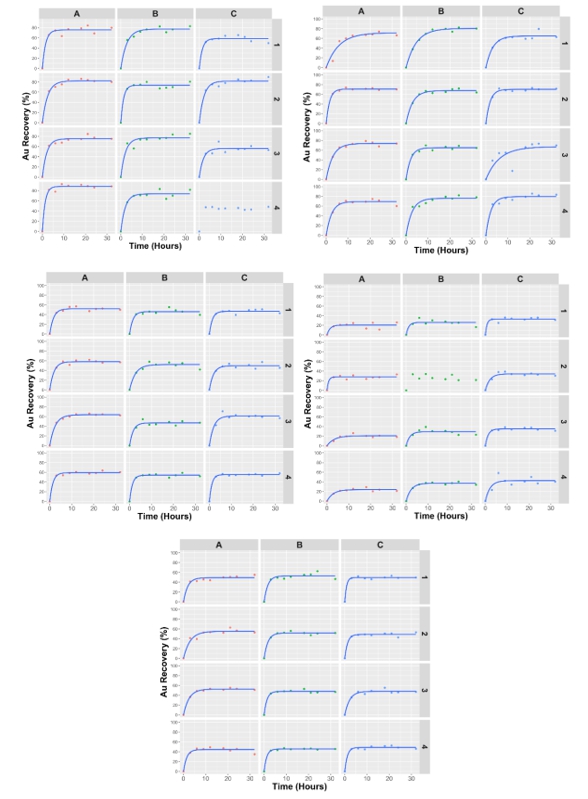

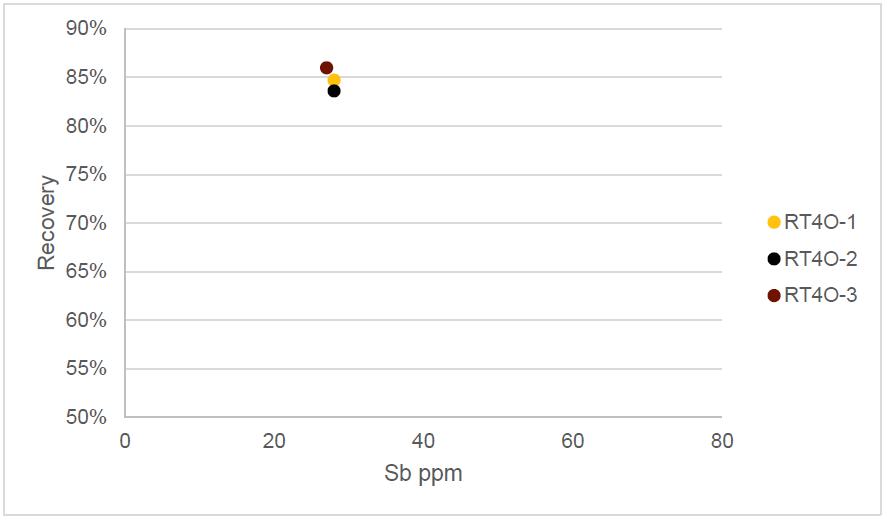

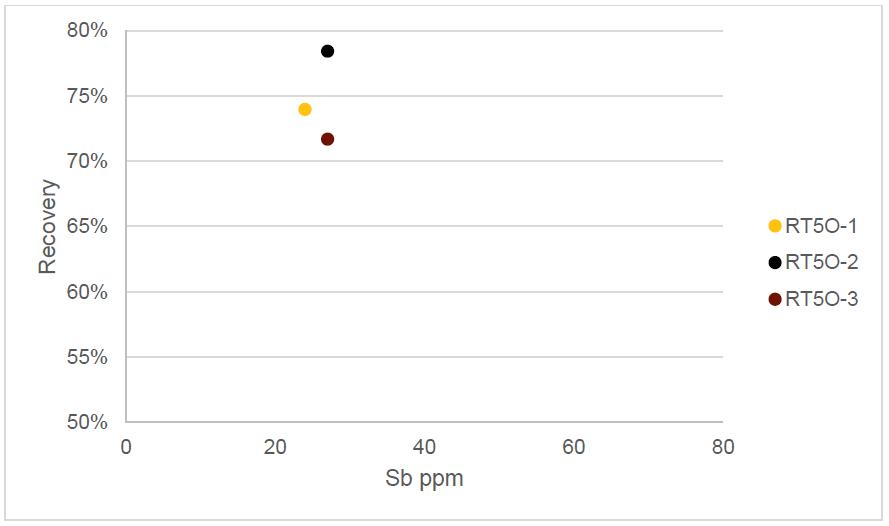

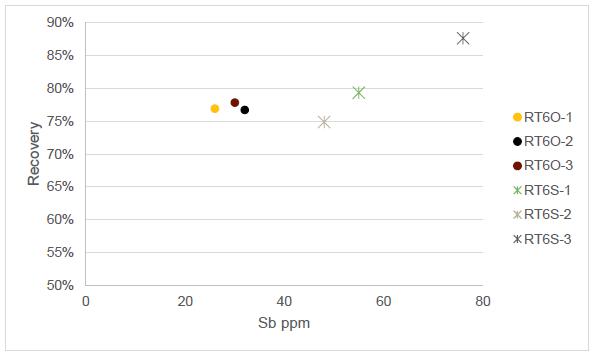

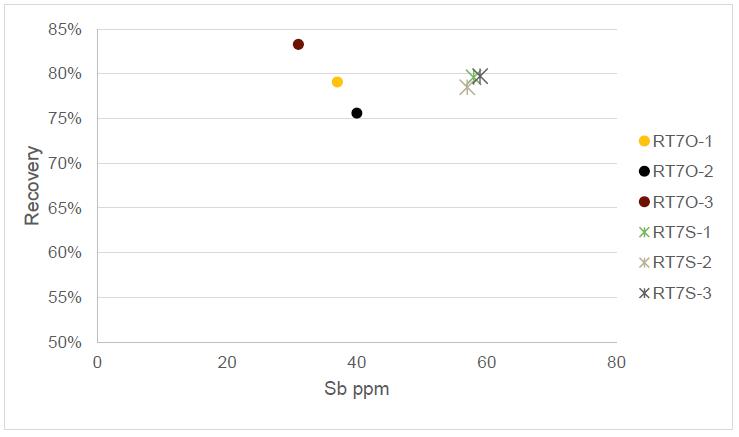

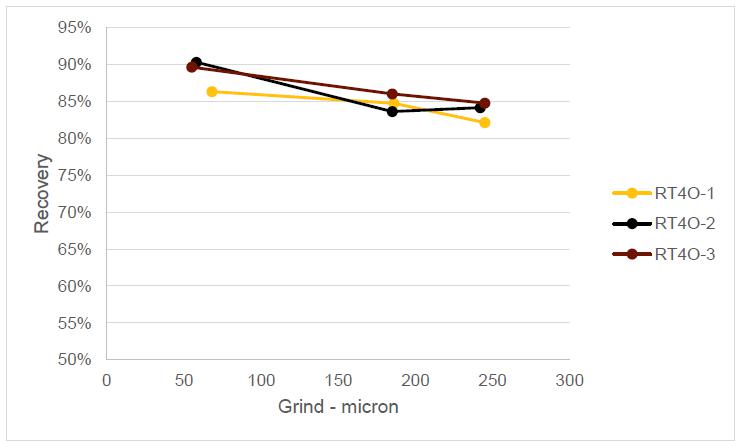

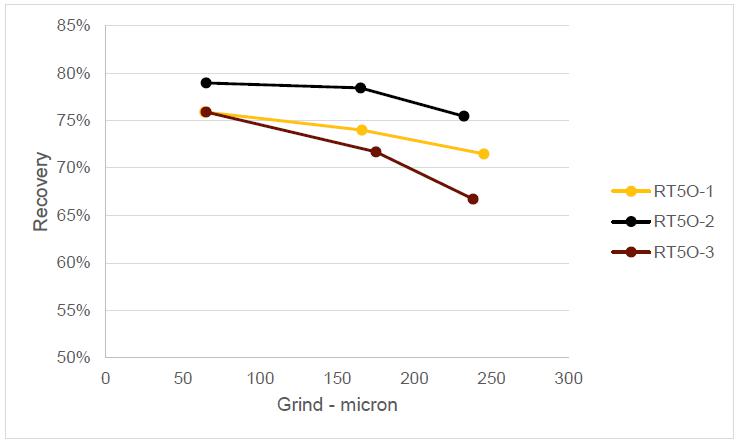

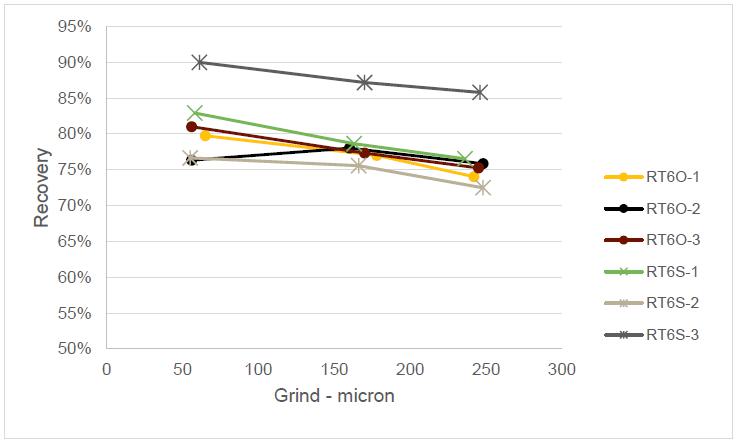

The back end of the plant, all that follows comminution, was optimized as a result of this PFS work, which included a detailed analysis of previous work, completed by BBA, as well as the completion of five new rounds of testwork, completed since the issue of the 2017 PFS. The various test programs (Phases 9a, 9b, 11-13) were conducted to expand on knowledge developed through the course of the FS optimization, FS variability and 2017 PFS test programs. In the process of completing the five rounds of this PFS testwork, several key conclusions were drawn:

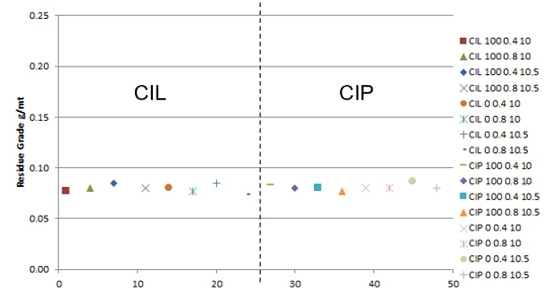

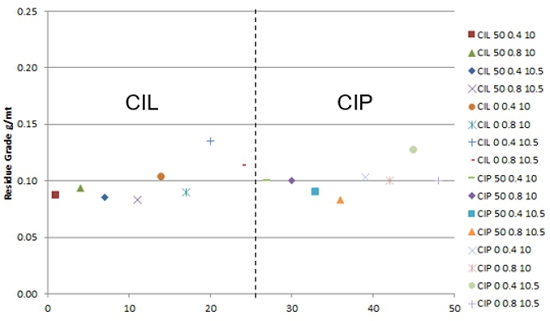

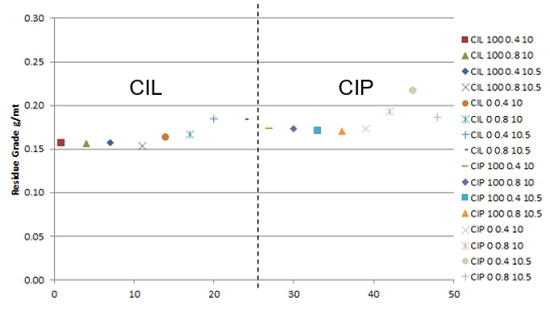

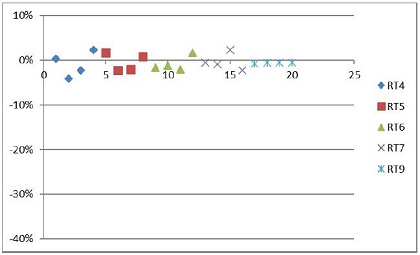

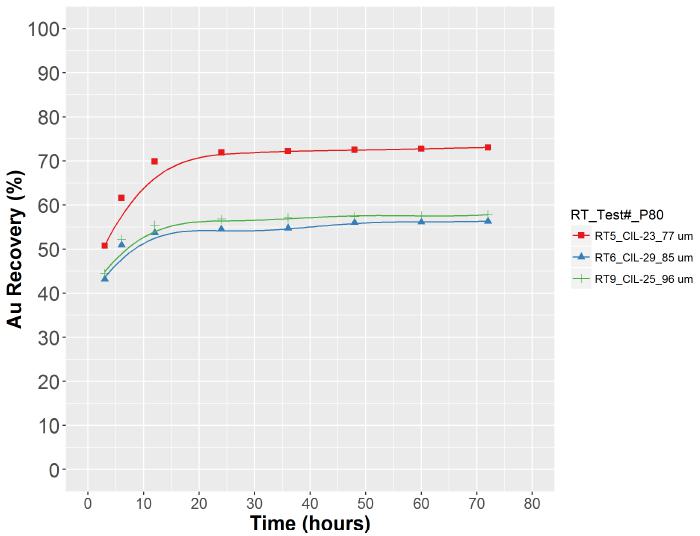

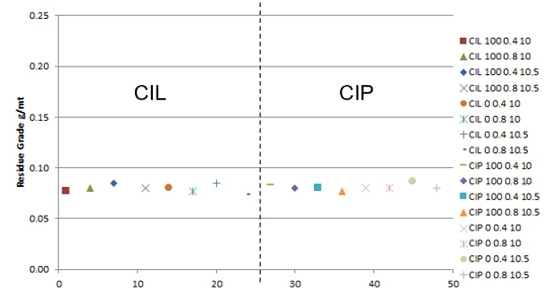

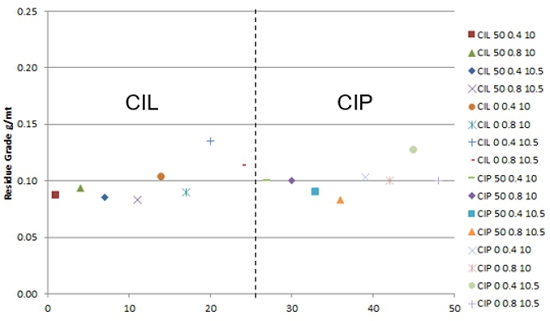

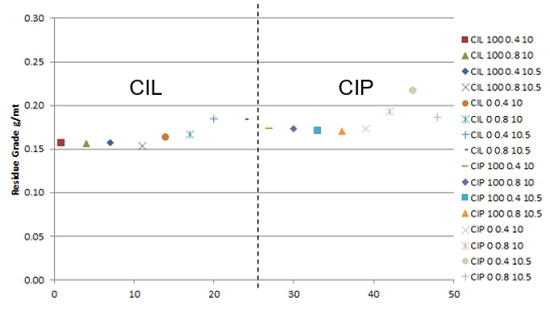

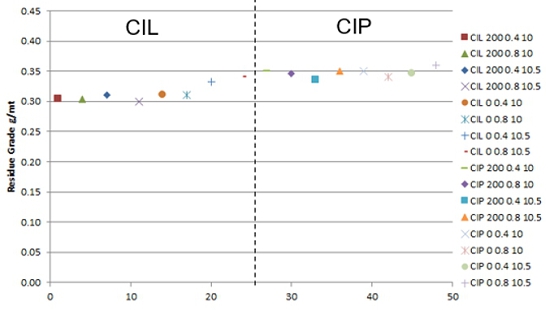

| § | Carbon in leach (CIL) methodology was retained over the carbon in pulp (CIP) of whole gravity tails (WOL). This decision was based on the 2017 PFS comparative study and on testwork results from this PFS, showing that better recoveries were obtained on RT6 and RT7 with CIL, while the other rock types appeared insensitive to CIL vs CIP. |

| § | There are no significant adverse recovery issues introduced by mixing the chemical and physical properties of the ore types. |

| § | Increasing the target particle size from a P80 of 180 to 250 µm resulted in a decrease in gold recovery of between 1% and 7%, depending upon rock type and head grades. The benefit of the coarser grind, which outweighs the recovery loss, is the higher throughput that facilitates a higher daily gold production. |

| § | The effectiveness of gravity recovery was further confirmed because of this PFS testwork, using samples generated from both drill core and RC rig drill chips. |

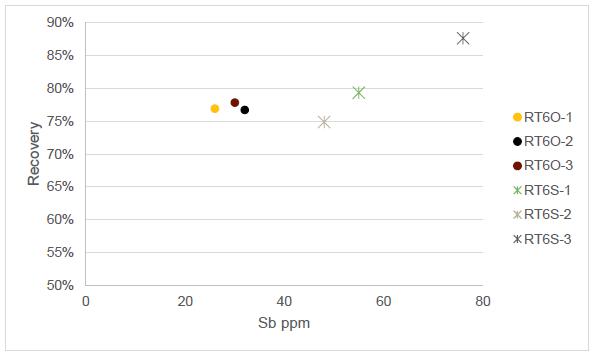

| § | Depending upon rock type, gold recovery is slightly related to location, either inside or outside the 100 ppm antimony shell. |

| § | The overall gold recovery does not appear to be highly sensitive to either lead nitrate (0-200 ppm) or cyanide (0.4-0.8 kg/t) concentration. |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

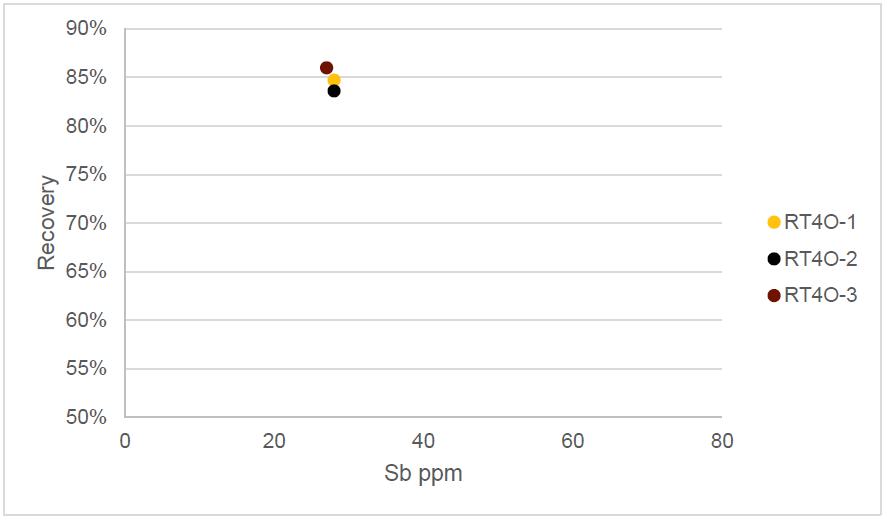

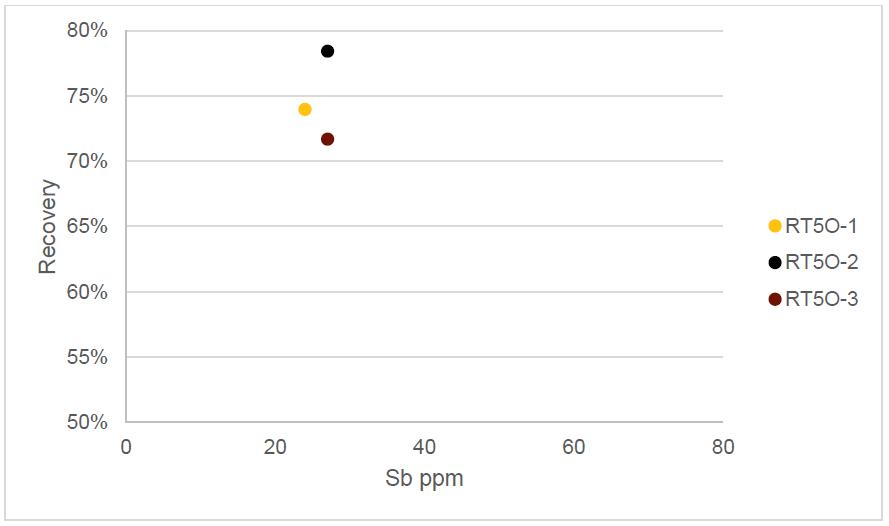

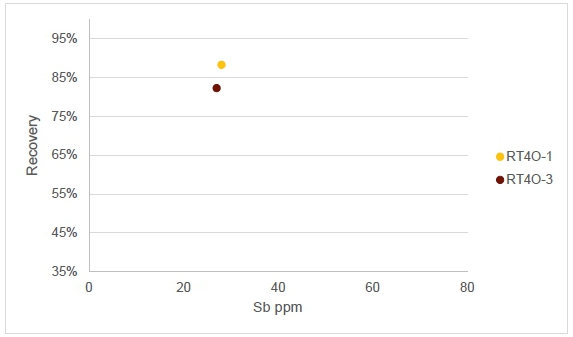

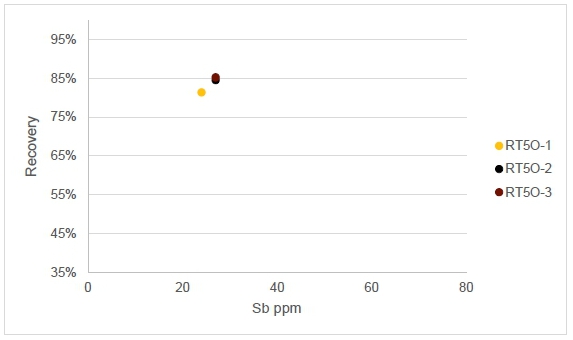

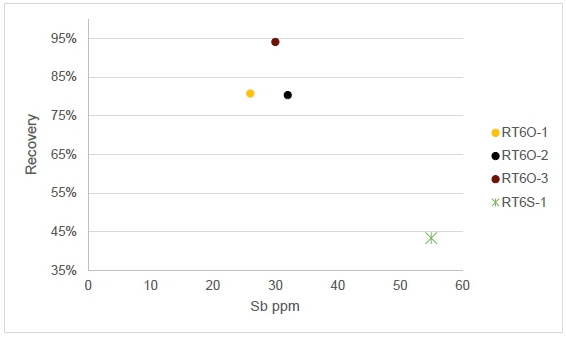

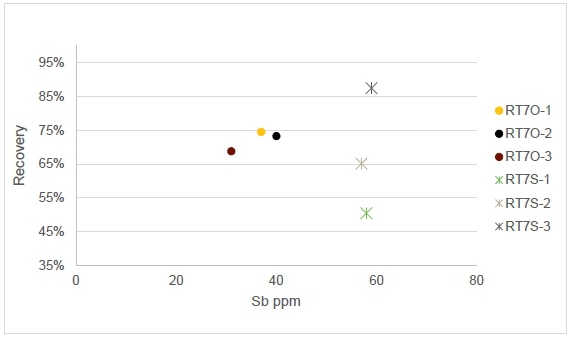

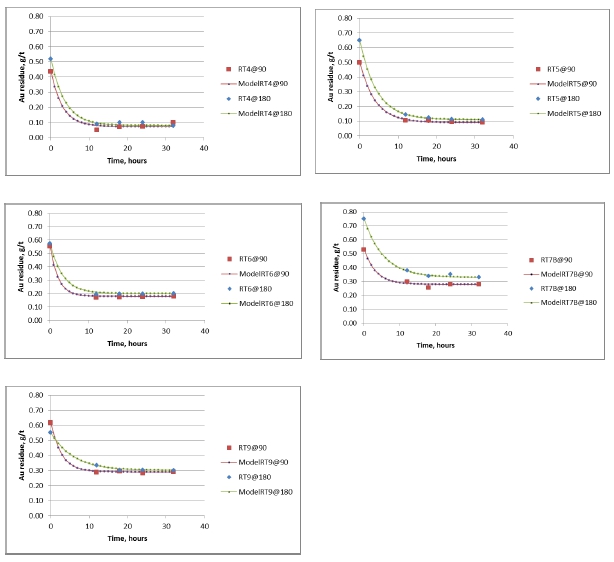

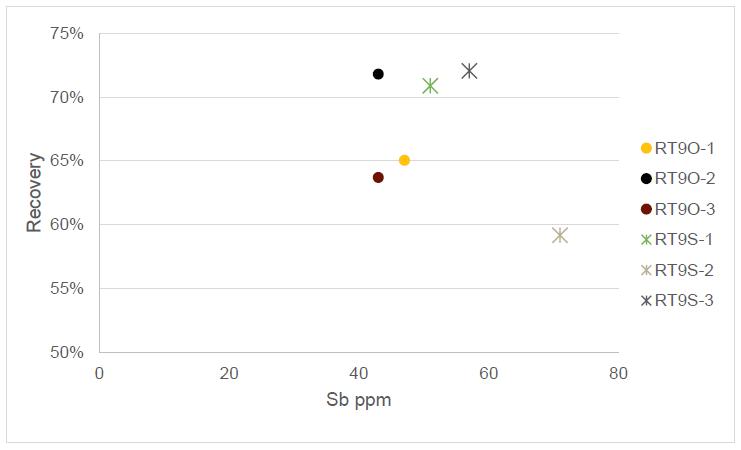

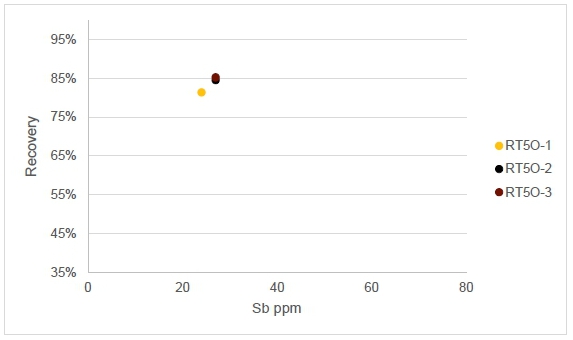

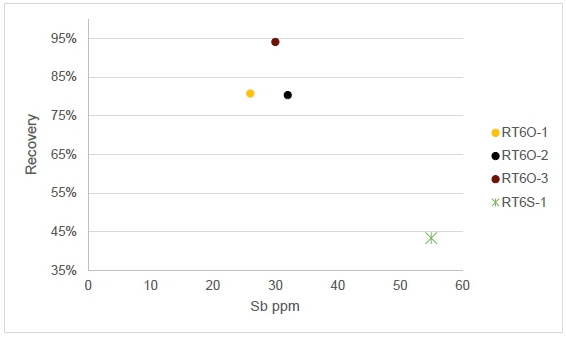

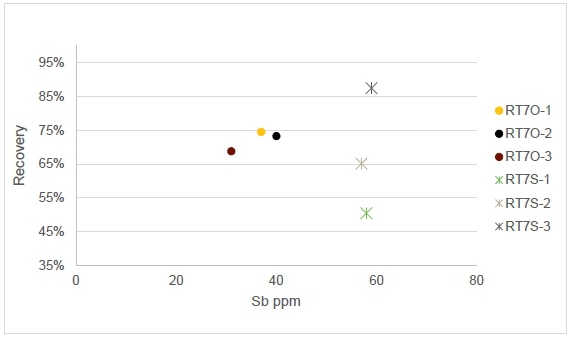

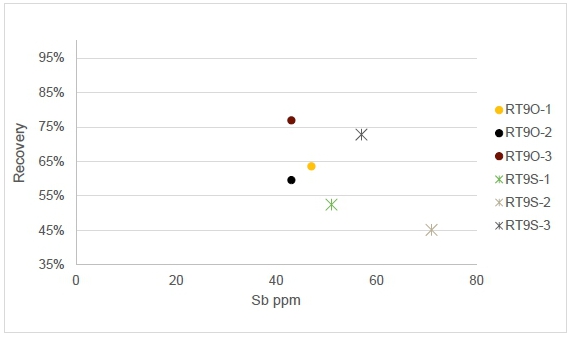

After the 2017 PFS, a focused effort was made to better understand the gold recovery implications of antimony concentration in the orebody. The data collected during Phases 11, 12 and 13 were used to develop linear recovery equations for each of the five rock types, both inside and outside the 100 ppm antimony shell, and as a function of antimony concentration, grind size and gold grade. A linear equation was developed for the composites having an antimony grade above 200 ppm, regardless of whether they were in or out of the 100 ppm antimony shell. Gold recoveries (Gravity+CIL) were established for each of the Livengood ore rock types at a grind size of 250 µm (P80) and are presented in Table 1-2.

Table 1-2: Average gold recovery (Gravity+CIL) estimated for each rock type

| Rock Type | Au Recovery (%) |

| RT4 | 83.3 |

| RT5 | 79.8 |

| RT6 | 73.5 |

| RT7 | 66.4 |

| RT9 | 57.1 |

The Whittle and BBA Study reviewed various technologies and project configurations with the objective of recommending an optimum configuration for this PFS. This study determined that the gravity/CIL plant at a grind size of 250 µm (P80) with conventional tailings provided the highest NPV.

| 1.9 | Mineral Resource Estimate |

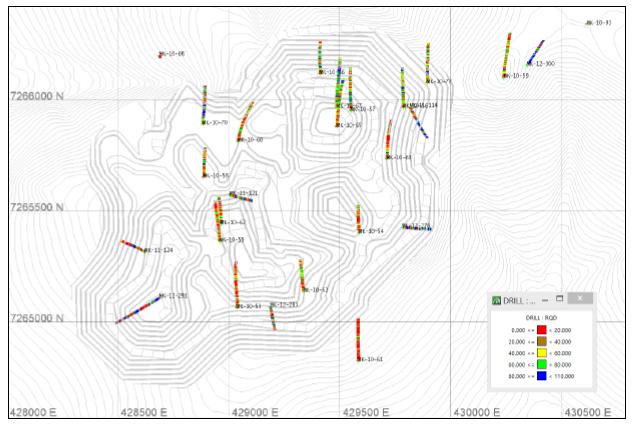

The Livengood mineral resource (Effective date August 20, 2021) was estimated using Inverse Distance Weighting (IDW) interpolation techniques. A database comprising 776 drill holes containing 125,450 assays was the basis of the estimate. Assays were composited to nominal 10-meter lengths, yielding 20,806 individual samples that were used for the estimation of mineralization.

Three sources of volumetric determination were used for the resource model. One was a three-dimensional (3D) stratigraphic model used to assign rock type codes to the block model. The second was an implicit model that interpolated a 100-ppm antimony halo or “shell” for the mineral deposit, with blocks flagged as either inside or outside this halo. The third was 54 individually interpreted massive stibnite veins that were used to determine the volume percentage and grade of veins within each model block that is intersected by the veins. Gold contained within each block was estimated using Inverse Distance cubed (ID3) parameters.

Mineral resources must demonstrate reasonable prospects for eventual economic extraction. The deposit gold is amenable for open pit extraction. To determine the quantities of material meeting the “reasonable prospects” test by an open pit, the author used the Lerchs-Grossman © economic algorithm to determine economic pit limits.

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

Economic parameters used in the analysis are based on the average gold price ($1,650/oz) at effective date of August 20, 2021. Pit optimization parameters are shown in Table 1-3. Gold recoveries are tonnage-weighted and include the recovery from massive stibnite of 22%.

Table 1-3: Constraining parameters used for the Livengood Gold Project

| Parameter | Unit | Rock

type 4 | Rock

type 5 | Rock

type 6 | Rock

type 7 | Rock

Type 8 | Rock

Type 9 |

| Mining Cost | $/total mt | 1.76 | 1.74 | 1.74 | 1.68 | 1.76 | 1.76 |

| Gold Cut-off | g/mt | 0.21 | 0.20 | 0.25 | 0.25 | 0.33 | 0.33 |

| Processing Cost | $/process mt | 9.27 | 9.15 | 9.17 | 9.50 | 9.71 | 9.71 |

| Gold Recovery | % | 84 | 80 | 71 | 67 | 55 | 56 |

| Administrative Cost | $/process mt | 1.55 | 1.55 | 1.55 | 1.55 | 1.55 | 1.55 |

| Royalty | % | 3 | 3 | 3 | 3 | 3 | 3 |

| Gold Selling Price | $/oz | 1,650 | 1,650 | 1,650 | 1,650 | 1,650 | 1,650 |

| Overall Slope Angle | Degrees | 45 | 45 | 45 | 45 | 45 | 45 |

The mineral resource estimate for the Livengood Gold project is shown in Table 1-4 (Exclusive of Reserves) and Table 1-5 (Inclusive of Reserves).

Table 1-4: Livengood Gold Project mineral resource estimate (exclusive of mineral reserves)

(2021 MRE), August 20, 2021 – Resource Development Associates Inc.

| Classification | Ore

Metric tons (Mmt) | Au Grade

(g/mt) | Contained Au

(Koz) |

| Measured | 234.50 | 0.53 | 3,990.49 |

| Indicated | 40.01 | 0.49 | 629.61 |

| Total Measured and Indicated (M & I) | 274.51 | 0.52 | 4,620.10 |

| Inferred | 15.98 | 0.40 | 206.98 |

| 1. | The effective date of the estimate is August 20, 2021. |

| 2. | Mineral resources for the Project are enumerated as per §229.1302(d)(1)(iii)(A) (Item 1302(d)(1)(iii)(A) of Regulation S-K). |

| 3. | Mineral resources are not mineral reserves and do not meet the threshold for reserve modifying factors, such as economic viability, that would allow for conversion to mineral reserves. There is no certainty that any part of the mineral resources estimated will be converted into mineral reserves. |

| 4. | Open pit resources stated as contained within a potentially economically mineable open pit; pit optimization was based on an assumed price for gold of US$1,650/oz., variable mining and recoveries, general and administrative costs of US$1.55/t and a pit slope angle of 45 degrees. |

| 5. | Numbers in the table have been rounded to reflect the accuracy of the estimate and may not sum due to rounding. |

| 6. | Mineral resources are reported exclusive of mineral reserves. The reserves disclosed in the TRS represent measured mineral resources and indicated mineral resources that were evaluated with modifying factors related to open pit mining. |

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

Table 1-5: Livengood Gold Project mineral resource estimate (inclusive of mineral reserves)

(2021 MRE), August 20, 2021 – Resource Development Associates Inc.

| Classification | Ore

Metric tons (Mmt) | Au Grade

(g/mt) | Contained Au

(Koz) |

| Measured | 646.00 | 0.60 | 12,482.49 |

| Indicated | 58.51 | 0.61 | 1,141.61 |

| Total Measured and Indicated (M & I) | 704.51 | 0.60 | 13,624.10 |

| Inferred | 15.98 | 0.40 | 206.98 |

| 1. | The effective date of the estimate is August 20, 2021. |

| 2. | Mineral resources for the Project are enumerated as per §229.1302(d)(1)(iii)(A) (Item 1302(d)(1)(iii)(A) of Regulation S-K). |

| 3. | Mineral resources are not mineral reserves and do not meet the threshold for reserve modifying factors, such as economic viability, that would allow for conversion to mineral reserves. There is no certainty that any part of the mineral resources estimated will be converted into mineral reserves. |

| 4. | Open pit resources stated as contained within a potentially economically mineable open pit; pit optimization was based on an assumed price for gold of US$1,650/oz., variable mining and recoveries, general and administrative costs of US$1.55/t and a pit slope angle of 45 degrees. |

| 5. | Numbers in the table have been rounded to reflect the accuracy of the estimate and may not sum due to rounding. |

| 6. | Mineral resources are reported inclusive of mineral reserves. The reserves disclosed in the TRS represent measured mineral resources and indicated mineral resources that were evaluated with modifying factors related to open pit mining. |

| 1.10 | Mineral Reserve Estimate |

Mineral reserves have been estimated for the Project by BBA USA Inc., using a gold price of $1,680/oz. The mine design and mineral reserve estimate have been completed to a level appropriate for a PFS. The mineral reserve estimate stated herein is consistent with the S-K 1300 requirements and is suitable for public reporting. As such, the mineral reserves are based on Measured and Indicated Mineral Resources, and do not include any Inferred Mineral Resources.

Development of the mine production plan included pit optimization, pit and phase designs, mine scheduling and the application of modifying factors to the Measured and Indicated Mineral Resources. The Qualified Person is not aware of any legal, political, or other risks that could materially affect the development of the mineral reserve.

Table 1-6 presents the mineral reserves for the Project, which include 411.5 Mmt of Proven Mineral Reserves at an average gold grade of 0.64 g/mt, and 18.5 Mmt of Probable Mineral Reserves at an average gold grade of 0.86 g/mt for a total of 430.1 Mmt of Proven and Probable Mineral Reserves at an average gold grade of 0.65 g/mt. To access these mineral reserves, 496.1 Mmt of overburden and waste rock must be mined, resulting in a strip ratio of 1.15:1.

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

Table 1-6: Livengood Gold Project Mineral Reserves, October 22, 2021 – BBA USA Inc.

| Classification | Ore

Metric tons (Mmt) | Au Grade

(g/mt) | Contained Au

Koz |

| Proven | 411.5 | 0.64 | 8,492 |

| Probable | 18.5 | 0.86 | 512 |

| Proven and Probable Totals | 430.1 | 0.65 | 9,004 |

| 1. | The effective date of the estimate is October 22, 2021. |

| 2. | Mineral reserves are estimated using a gold price of US$1,680 per ounce, and consider a 3% royalty, 1.80/oz for smelting, refining, and transportation costs, and a gold payable of 99.9%. |

| 3. | Metallurgical recovery curves were developed for each rock type, with the Mineral Reserves having the following tonnage weighted averages: 83.3% for RT4, 79.8% for RT5, 73.5% for RT6, 66.4% for RT7, 58.7% for RT8 and 57.1% for RT9, including 22% for massive stibnite mineralization. |

| 4. | As a result of the complex metallurgical recovery equations, it is difficult to determine specific cut-off grades. The following presents the lowest gold grades for each rock type that are processed in the life of mine plan: 0.26 g/t for RT4, 0.28 g/t for RT5, 0.31 g/t for RT6, 0.31 g/t for RT7, 0.42 g/t for RT8 and 0.42 g/t for RT9. |

| 5. | The strip ratio for the open pit is 1.15 to 1. |

| 6. | The mineral reserves are inclusive of mining dilution and ore loss. |

| 7. | The reference point for the mineral reserves is the primary crusher. |

| 8. | Totals may not add due to rounding. |

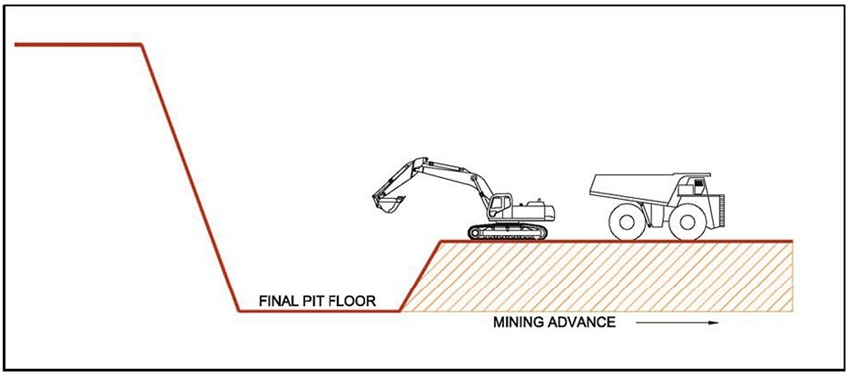

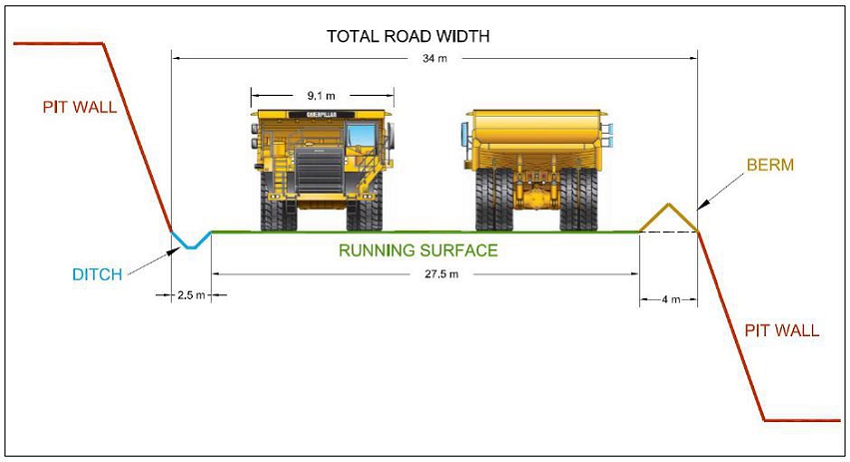

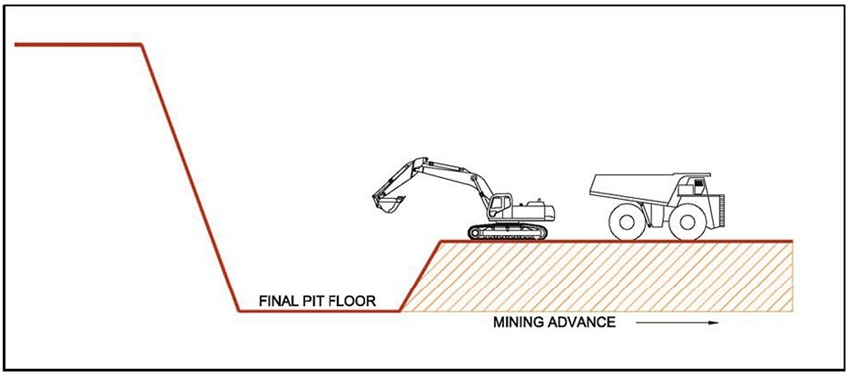

The Livengood deposit will be mined using conventional open pit mining methods consisting of drilling, blasting, loading, and hauling with large-scale mining equipment. Vegetation, topsoil, and overburden will be stripped and stockpiled for future reclamation use. The ore and waste rock will be drilled and blasted with 32.8 ft (10 m) high benches and loaded into haul trucks with a fleet of diesel-powered hydraulic excavators and front-end wheel loaders.

The processing flowsheet consists of primary crushing, secondary crushing, and a comminution circuit (SABC configuration) producing a final grind size of 250 μm (P80), with gravity recovery followed by whole ore leaching (CIL) of the gravity tailings. The mill has been designed with a nominal throughput of 65,000 t/d (59,000 mt/d). Tailings will be stored in a conventional slurry tailings facility.

Material mined from the open pit that is not directly hauled to the primary crusher will be placed in several storage facilities across the Livengood site. These facilities include growth media stockpiles, an overburden stockpile, a waste rock storage facility (WRSF), and a low-grade ore stockpile. Waste rock will also be used as construction material both during preproduction and to raise the height of the TMF dike as the mine life progresses.

| International Tower Hill Mines Ltd. S-K 1300 – Technical Report Summary Livengood Gold Project Pre-feasibility Study |  |

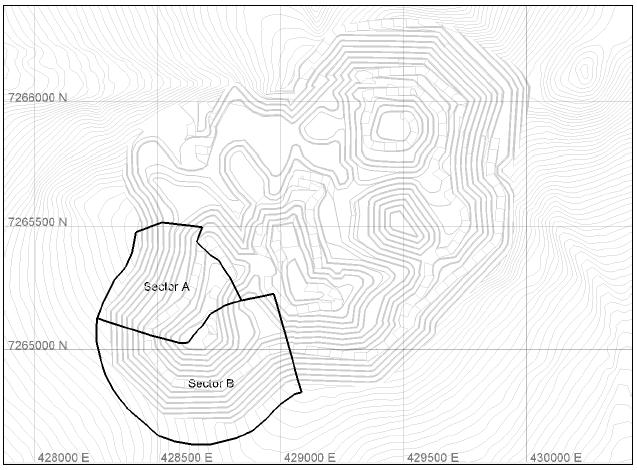

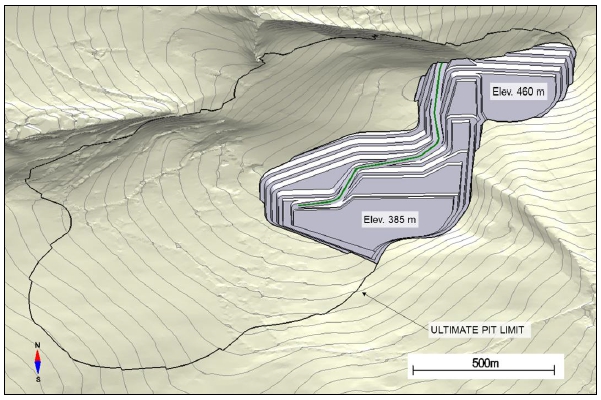

To maximize the NPV of the Project, a total of six mining phases (pushbacks) have been designed and incorporated into the mining sequence to bring higher grade material forward and to defer waste rock stripping. The mining phases include a starter pit that will be mined during the three years of preproduction, during which a total of 89 Mt (81 Mmt) of waste rock has been estimated to be required for the construction of certain infrastructure such as the TMF starter dike, mine haul roads, site access roads, and platforms for the processing facilities and other buildings. Ore mined during preproduction will be stockpiled and processed after mill start-up.

A mine production plan has been prepared using the MinePlan Schedule Optimizer (MPSO) tool in the Hexagon MinePlan 3D software. Provided with economic input parameters and operational constraints such as phase sequencing, maximum bench sink rates, and mining and milling capacities, the software determines the optimal mining sequence and low-grade ore stockpiling strategy, which maximizes the NPV of the mine production plan. The mine plan has been prepared quarterly for the first two years of production and annually thereafter.

The mine production plan resulted in a 20.3-year mine life plus 3 years of preproduction development. A contractor will operate the pit during the first year of preproduction to develop the first benches in the Phase 1 starter pit and construct the network of mine haul roads. By the second year, the owner’s fleet of equipment will be on-site and assembled and will take over from the contractor.