UNITED STATES SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 20-F

| ¨ | REGISTRATION STATEMENT PURSUANT TO SECTION 12(b) OR (g) OF THE SECURITIES EXCHANGE ACT OF 1934 |

| | OR |

| | |

| þ | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 FOR THE FISCAL YEAR ENDED DECEMBER 31, 2015 |

| | OR |

| | |

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

| | OR |

| | |

| ¨ | SHELL COMPANY REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

| | |

| | Date of event requiring this shell company report |

| | |

| | FOR THE TRANSITION PERIOD FROM TO JANUARY 1, 2015 TO DECEMBER 31, 2015 |

COMMISSION FILE NUMBER 000-49751

Catalyst Paper Corporation

(Exact name of Registrant as specified in its charter)

N/A

(Translation of Registrant’s name into English)

British Columbia, Canada

(Jurisdiction of incorporation or organization)

2nd Floor, 3600 Lysander Lane

Richmond

British Columbia, Canada V7B 1C3

(Address of principal executive offices)

James Isaac, 604-247-4738,james.isaac@catalystpaper.com,

2nd Floor, 3600 Lysander Lane, Richmond, BC V7B 1C3

(Name, Telephone, E-mail and/or Facsimile number and Address of Company Contact Person)

Securities registered or to be registered pursuant to Section 12(b) of the Act:

None.

Securities registered or to be registered pursuant to Section 12(g) of the Act:

Common Shares.

Securities for which there is a reporting obligation pursuant to Section 15(d) of the Act:

None.

The number of outstanding shares of each of the issuer’s classes of capital or common stock as of

December 31, 2015 was:

14,527,571

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes¨ Nox

If this report is an annual or transition report, indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934. Yes¨ Nox

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yesx No¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes¨ No¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer. See definition of “accelerated filer and large accelerated filer” in Rule 12b-2 of the Exchange Act. (Check one):

| Large accelerated filer ¨ | Accelerated filer ¨ | Non-accelerated filer x |

Indicate by check mark which basis of accounting the registrant has used to prepare the financial statements included in this filing:

| U.S. GAAP x | International Financial Reporting Standards as issued | Other ¨ |

| | by the International Accounting Standards Board ¨ | |

If this is an annual report, indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes¨ Nox

(APPLICABLE ONLY TO ISSUERS INVOLVED IN BANKRUPTCY PROCEEDINGS DURING THE PAST FIVE YEARS)

Indicate by check mark whether the registrant has filed all documents and reports required to be filed by Sections 12, 13 or 15(d) of the Securities Exchange Act of 1934 subsequent to the distribution of securities under a plan confirmed by a court. Yesx No¨

TABLE OF CONTENTS

PART I

Unless otherwise specified, “Catalyst”, the “Company”, the “Corporation”, “we”, “us”, “our” and similar terms refer to Catalyst Paper Corporation and its subsidiaries and affiliates. Unless otherwise indicated, all dollar amounts are expressed in Canadian dollars, references to “$” and “dollars” are to Canadian dollars and references to “U.S.$” and “U.S. dollars” are to United States dollars. As used in this annual report references to “tonnes” means metric tonnes, which is equivalent to 1,000 kilograms or 2,204 pounds (1.1023 tons) and the term “ton”, or the symbol “ST”, refers to a short ton, an imperial unit of measurement equal to 0.9072 metric tonnes.

| ITEM 1 | IDENTITY OF DIRECTORS, SENIOR MANAGEMENT, ADVISERS AND AUDITORS |

| A. | Directors and Senior Management |

Information not required for an annual report.

Information not required for an annual report.

Information not required for an annual report.

| ITEM 2 | OFFER STATISTICS AND EXPECTED TIMETABLE |

Information not required for an annual report.

Cautionary Statement with Regard to Forward-Looking Statements

This annual report contains forward-looking statements within the meaning of the U.S. Private Securities Litigation Reform Act of 1995 and forward-looking information within the meaning of Canadian securities laws (collectively, “forward-looking statements”) including, without limitation, forward-looking statements concerning our strategy, plans, future operating performance, contingent liabilities and outlook. These statements relate to, among other things, analyses and other information that are based on forecasts of future results, estimates of amounts not yet determinable and assumptions of management.

Generally, forward-looking statements can be identified by the use of words or phrases such as “expects,” “anticipates,” “plans,” “projects,” “estimates,” “assumes,” “intends,” “strategy,” “goals,” “objectives,” “potential,” or variations thereof, or stating that certain actions, events or results “may,” “could,” “would,” “might” or “will” be taken, occur or be achieved, or the negative of any of these terms or similar expressions. These forward-looking statements are subject to a variety of known and unknown risks, uncertainties and other factors that could cause actual events or results to differ from those expressed or implied, including, without limitation, the following risks and uncertainties discussed in this annual report and in Management’s Discussion and Analysis for the financial year-ended December 31, 2015, which may be found on SEDAR atwww.sedar.com and EDGAR atwww.sec.gov:

Various market, environmental, financial and human resource risks related to the recent acquisition of the Biron and Rumford paper mills in the United States;

Supply interruptions which may occur due to reliance by the Biron paper mill on the Wisconsin Rapids pulp and paper mill and the Lake States Wood Supply Group;

Uncertainty related to our ability to successfully integrate the recently acquired Biron and Rumford paper mills into our operations;

| · | Our inability to generate sufficient cash to service all our indebtedness; |

| · | Risks related to our level of indebtedness which may limit our financial and operating activities; |

| · | The limited trading market for our common shares; |

| · | Fluctuations in the demand and market price for our products; |

| · | The impact that media trends may have on demand for our products; |

| · | Fluctuations in foreign exchange rates; |

| · | The effects of competition from domestic and foreign producers; |

| · | Risks related to the international sale of our products; |

| · | Fluctuations in the cost and supply of wood fibre; |

| · | Dependence on the supply of certain raw materials; |

| · | The effect of future losses on our liquidity and ongoing operations; |

| · | Uncertainty relating to labour relations; |

| · | Dependence on third party transportation providers; |

| · | The impact on our operations of aboriginal land claims in Canada; |

| · | The impact of increases in energy costs on our business; |

| · | Costs which may be necessary for us to incur in order to comply with environmental laws and regulations; |

| · | The impact on our business of equipment failures and the need to increase capital and maintenance expenditures; |

| · | Failure of certain customers to pay us promptly and in full under the credit terms that we extend to them; |

| · | The retention of certain qualified management personnel; |

| · | Limitations and exclusions contained in our insurance policies; |

| · | Risks related to natural disasters in regions where our mills are located; |

| · | The impact of our benefit pensions plans and other post-retirement benefit plans on our financial condition; and |

| · | The impact of a change in legal control. |

This list is not exhaustive of the factors that may affect any of our forward-looking statements. Our forward-looking statements are based on what management considers to be reasonable assumptions, beliefs, expectations and opinions based on information currently available to management. We cannot assure you that actual events, performance or results will be consistent with these forward-looking statements, and management’s assumptions may prove to be incorrect.

Assumptions have been made with respect to our forward-looking statements, including those identified below, which could prove to be significantly incorrect:

| · | Our ability to develop, manufacture and sell new products and services that meet the needs of our customers and gain commercial acceptance; |

| · | Our ability to continue to sell our products and services in the expected quantities at the expected prices and expected times; |

| · | Our ability to successfully obtain cost savings from our cost reduction initiatives; |

| · | Our ability to successfully integrate the recently acquired Biron and Rumford mills into our operations; |

| · | Our ability to implement business strategies and pursue opportunities; |

| · | Expected cost of goods sold; |

| · | Expected component supply costs and constraints; and |

| · | Expected foreign exchange and tax rates. |

You are cautioned that the foregoing list is not exhaustive of all factors and assumptions which may have been used. Our forward-looking statements reflect current expectations regarding future events and operating performance and speak only as of the date hereof and we do not assume any obligation to update forward-looking statements if circumstances or management’s beliefs, expectations or opinions should change other than as required by applicable law. For the reasons set forth above, you should not place undue reliance on forward-looking statements.

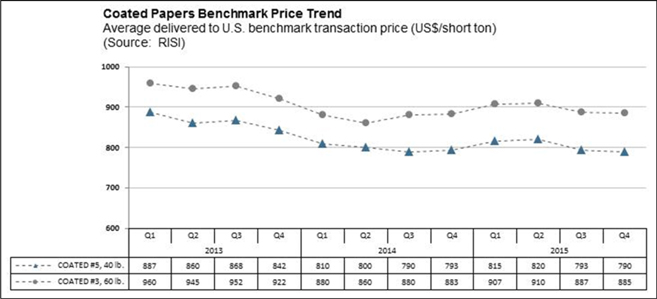

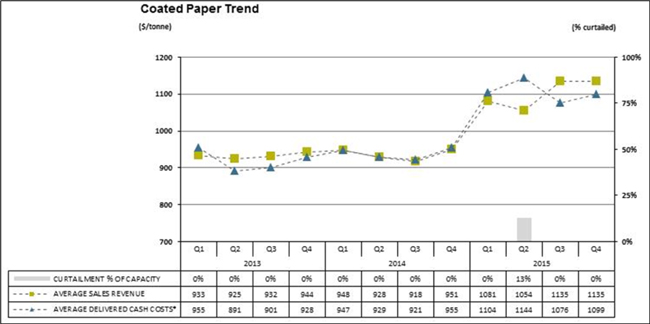

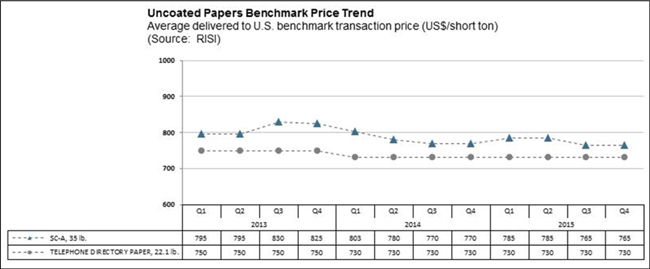

Market and Industry Data and Forecast

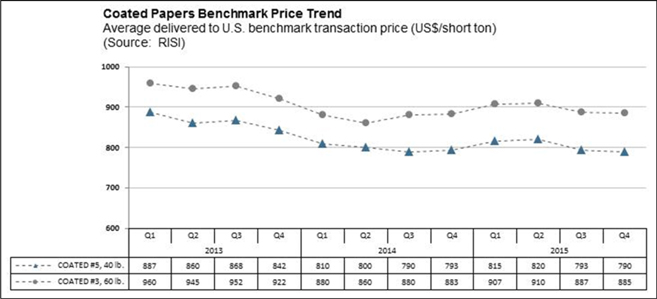

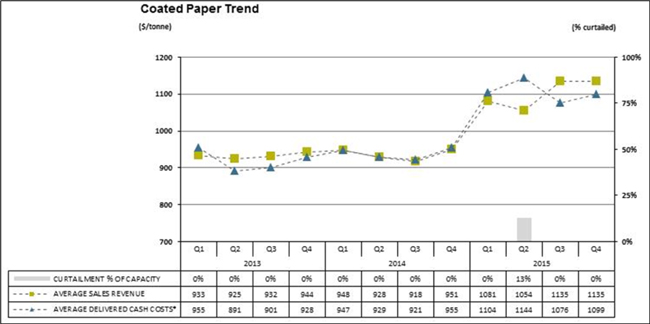

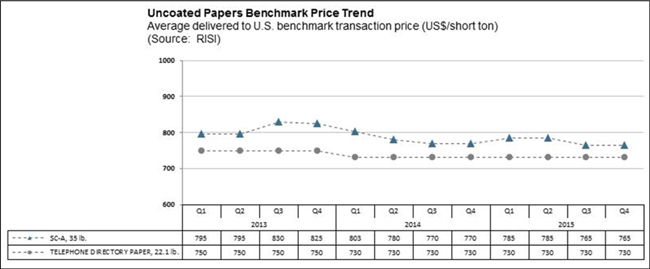

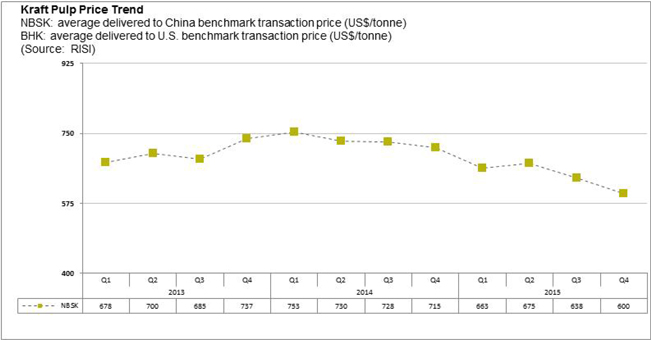

This annual report on Form 20-F includes market share and industry data and other statistical information and forecasts that we have obtained from independent industry publications, government publications, market research reports and other published independent sources. Some data is also based on our good faith estimates, which is derived from our internal surveys, as well as independent sources. RISI, Inc., an independent paper and forest products industry research firm (“RISI”), is the source of a considerable amount of the third party industry data and forecasts contained herein. Industry publications, surveys and forecasts generally state that the information contained therein has been obtained from sources believed to be reliable. However, we cannot and do not provide any assurance as to the accuracy or completeness of included information and do not guarantee the accuracy or completeness of such information.

Forecasts are particularly likely to be inaccurate, especially over long periods of time. Although we believe these sources to be reliable, we have not independently verified any of the data nor have we ascertained the underlying economic assumptions relied upon therein.

Presentation of Financial Information

We prepare our consolidated financial statements in accordance with U.S. generally accepted accounting principles (U.S. GAAP).

In accordance with U.S. GAAP, an enterprise value was established for the Company as of September 30, 2012, the end of the quarter following the effective date of our plan of arrangement under theCompanies’ Creditors Arrangement Act(“CCAA”), under fresh start accounting. This enterprise value was determined with the assistance of an independent financial advisor. References to Successor or Successor company refer to the Company on or after September 30, 2012, and references to Predecessor or Predecessor company refer to the Company prior to September 30, 2012.

| A. | Selected Financial Data |

The following table sets forth consolidated historical financial and operating data for Catalyst Paper Corporation for the periods indicated. The financial statement data as of December 31, 2015, December 31, 2014, December 31, 2013, December 31, 2012, September 30, 2012 and December 31, 2011, for the years ended December 31, 2015, 2014 and 2013, the three months ended December 31, 2013 and nine months ended September 30, 2013, and the year ended December 31, 2011 is derived from our audited consolidated financial statements in our annual report. This information should be read in conjunction with Operating and Financial Review and Prospects, which is included inthe annual report. The financial information has been derived from consolidated financial statements that have been prepared in accordance with U.S. GAAP. All information provided below is in millions of Canadian dollars, except information related to volume, information per share, and revenue per tonne.

CONSOLIDATED STATEMENTS OF EARNINGS (LOSS) DATA

(In millions of Canadian dollars)

| | | Successor | | | Predecessor | |

| | | Year

ended December 31, | | | Three months

ended

December 31, | | | Nine months

ended

September 30, | | | Year

ended

December 31, | |

| | | 2015 | | | 2014 | | | 2013 | | | 2012 | | | 2012 | | | 2011 | |

| Sales | | $ | 1,991.1 | | | $ | 1,109.3 | | | $ | 1,051.4 | | | $ | 260.5 | | | $ | 797.7 | | | $ | 1,079.7 | |

| Operating expenses | | | | | | | | | | | | | | | | | | | | | | | | |

| Cost of sales, excluding depreciation and amortization | | | 1,882.4 | | | | 1,028.2 | | | | 970.9 | | | | 245.6 | | | | 718.0 | | | | 970.7 | |

| Depreciation and amortization | | | 61.4 | | | | 44.6 | | | | 47.0 | | | | 12.9 | | | | 23.4 | | | | 105.5 | |

| Selling, general and administrative | | | 58.2 | | | | 33.0 | | | | 33.2 | | | | 7.7 | | | | 26.2 | | | | 40.3 | |

| Restructuring and change-of-control | | | 1.8 | | | | 0.5 | | | | 1.2 | | | | – | | | | 5.3 | | | | 5.9 | |

| Impairment and other closure costs | | | – | | | | 16.5 | | | | 86.9 | | | | – | | | | – | | | | 661.8 | |

| | | | 2,003.8 | | | | 1,122.8 | | | | 1,139.2 | | | | 266.2 | | | | 772.9 | | | | 1,784.2 | |

| Operating earnings (loss) | | | (12.7 | ) | | | (13.5 | ) | | | (87.8 | ) | | | (5.7 | ) | | | 24.8 | | | | (704.5 | ) |

| Interest expense, net | | | (49.4 | ) | | | (35.5 | ) | | | (37.4 | ) | | | (11.6 | ) | | | (60.3 | ) | | | (73.2 | ) |

| Foreign exchange gain (loss) on long-term debt | | | (57.7 | ) | | | (24.1 | ) | | | (18.8 | ) | | | (3.2 | ) | | | 24.0 | | | | (9.7 | ) |

| Other income (expense), net | | | 43.0 | | | | 1.2 | | | | 14.9 | | | | 0.1 | | | | (2.6 | ) | | | (2.1 | ) |

| Loss before reorganization items and income taxes | | | (76.8 | ) | | | (71.9 | ) | | | (129.1 | ) | | | (20.4 | ) | | | (14.1 | ) | | | (789.5 | ) |

| Reorganization items, net | | | – | | | | – | | | | (1.2 | ) | | | (3.2 | ) | | | 666.9 | | | | – | |

| Income (loss) before income taxes | | | (76.8 | ) | | | (71.9 | ) | | | (130.3 | ) | | | (23.6 | ) | | | 652.8 | | | | (789.5 | ) |

| Income tax expense (recovery) | | | (27.4 | ) | | | 0.4 | | | | 0.1 | | | | 0.2 | | | | (1.1 | ) | | | (8.4 | ) |

| Earnings (loss) from continuing operations | | | (49.4 | ) | | | (72.3 | ) | | | (130.4 | ) | | | (23.8 | ) | | | 653.9 | | | | (781.1 | ) |

| Gain (loss) from discontinued operations net of tax | | | – | | | | – | | | | 3.1 | | | | (12.9 | ) | | | (3.6 | ) | | | (195.5 | ) |

| Net earnings (loss) | | | (49.4 | ) | | | (72.3 | ) | | | (127.3 | ) | | | (36.7 | ) | | | 650.3 | | | | (976.6 | ) |

| Net (earnings) loss attributable to non-controlling interest | | | – | | | | – | | | | (0.3 | ) | | | 1.5 | | | | (31.9 | ) | | | 2.6 | |

| Net earnings (loss) attributable to the Company | | $ | (49.4 | ) | | $ | (72.3 | ) | | $ | (127.6 | ) | | $ | (35.2 | ) | | $ | 618.4 | | | $ | (974.0 | ) |

CONSOLIDATED BALANCE SHEET DATA

(In millions of Canadian dollars)

| | | Successor | | | Predecessor | |

| | | As at

December 31, | | | As at

September 30, | | | As at

December 31, | |

| | | 2015 | | | 2014 | | | 2013 | | | 2012 | | | 2012 | | | 2011 | |

| Working Capital1 | | $ | 210.6 | | | $ | 144.6 | | | $ | 153.6 | | | $ | 151.4 | | | $ | 203.7 | | | $ | 152.4 | |

| Property, plant and equipment | | | 456.9 | | | | 379.3 | | | | 412.2 | | | | 611.6 | | | | 614.1 | | | | 386.3 | |

| Total Assets | | | 919.1 | | | | 668.7 | | | | 700.1 | | | | 978.8 | | | | 1040.1 | | | | 737.6 | |

| Current portion of long-term debt | | | 3.2 | | | | 3.0 | | | | 2.0 | | | | 6.6 | | | | 6.7 | | | | 466.8 | |

| Total debt1 | | | 497.8 | | | | 329.1 | | | | 303.8 | | | | 428.6 | | | | 465.6 | | | | 842.3 | |

| Shareholders’ equity (deficiency) | | | (116.7 | ) | | | (95.6 | ) | | | 12.9 | | | | 116.3 | | | | 144.9 | | | | (593.6 | ) |

CONSOLIDATED STATEMENTS OF CASH FLOWS DATA

(In millions of Canadian dollars)

| | | Successor | | | Predecessor | |

| | | Year

ended December 31, | | | Three months

ended

December 31, | | | Nine months

ended

September 30, | | | Year

ended

December 31, | |

| | | 2015 | | | 2014 | | | 2013 | | | 2012 | | | 2012 | | | 2011 | |

| Cash flows provided (used) by operating activities | | $ | (6.6 | ) | | $ | 21.3 | | | $ | (7.5 | ) | | $ | 52.1 | | | $ | (44.0 | ) | | $ | (71.5 | ) |

| Cash flows provided (used) by investing activities | | | (103.4 | ) | | | (19.2 | ) | | | 31.4 | | | | (6.2 | ) | | | (3.4 | ) | | | (17.7 | ) |

| Cash flows provided (used) by financing activities | | $ | 107.4 | | | $ | (3.3 | ) | | $ | (30.3 | ) | | $ | (40.0 | ) | | $ | 34.9 | | | $ | 18.9 | |

OTHER FINANCIAL DATA

(In millions of Canadian dollars, except per tonne)

| | | Successor | | | Predecessor | |

| | | Year

ended December 31, | | | Three months

ended

December 31, | | | Nine months

ended

September 30, | | | Year ended

December 31, | |

| | | 2015 | | | 2014 | | | 2013 | | | 2012 | | | 2012 | | | 2011 | |

| Adjusted EBITDA 2 | | $ | 48.7 | | | $ | 47.6 | | | $ | 46.1 | | | $ | 7.2 | | | $ | 48.2 | | | $ | 62.8 | |

| Adjusted EBITDA margin 3 | | | 2.4 | % | | | 4.3 | % | | | 4.4 | % | | | 2.8 | % | | | 6.0 | % | | | 5.8 | % |

| Weighted average common shares outstanding (in millions) | | | 14.5 | | | | 14.5 | | | | 14.5 | | | | 14.4 | | | | 381.9 | | | | 381.9 | |

| Basic and diluted earnings (loss) per share (in dollars) | | | | | | | | | | | | | | | | | | | | | | | | |

| - Continuing operations | | $ | (3.41 | ) | | $ | (4.99 | ) | | $ | (9.01 | ) | | $ | (1.55 | ) | | $ | 1.63 | | | $ | (2.04 | ) |

| - Discontinued operations | | | – | | | | – | | | | 0.21 | | | | (0.89 | ) | | | (0.01 | ) | | | (0.51 | ) |

| Common shares outstanding at end of period (in millions) | | | 14.5 | | | | 14.5 | | | | 14.5 | | | | 14.5 | | | | 14.4 | | | | 381.9 | |

| Sales (000 tonnes) | | | | | | | | | | | | | | | | | | | | | | | | |

| Coated paper | | | 937 | | | | 194 | | | | 189 | | | | 51 | | | | 145 | | | | 179 | |

| Uncoated paper | | | 426 | | | | 508 | | | | 573 | | | | 156 | | | | 460 | | | | 659 | |

| Newsprint | | | 346 | | | | 347 | | | | 283 | | | | 66 | | | | 198 | | | | 205 | |

| Pulp | | | 345 | | | | 340 | | | | 328 | | | | 74 | | | | 251 | | | | 308 | |

| Average Sales Revenue per tonne | | | | | | | | | | | | | | | | | | | | | | | | |

| Coated paper | | | 1,103 | | | | 936 | | | | 934 | | | | 930 | | | | 909 | | | | 939 | |

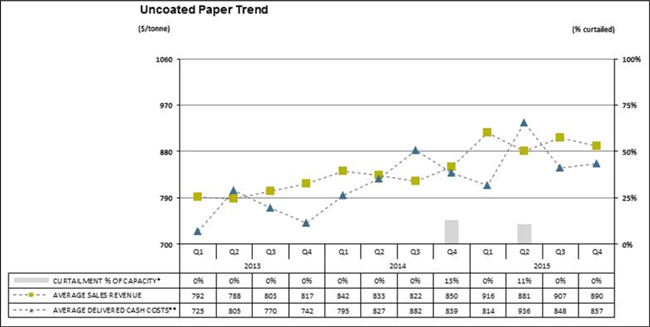

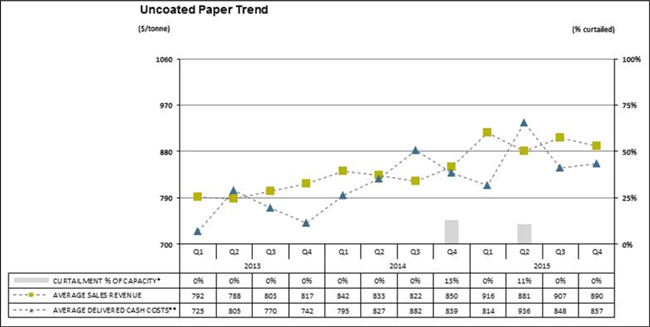

| Uncoated paper | | | 898 | | | | 837 | | | | 800 | | | | 795 | | | | 808 | | | | 793 | |

| Newsprint | | | 681 | | | | 685 | | | | 679 | | | | 666 | | | | 678 | | | | 689 | |

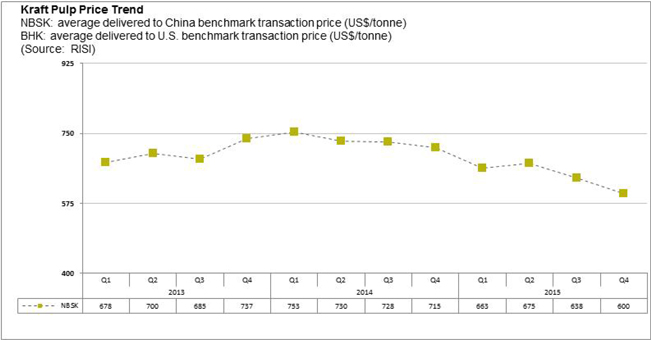

| Pulp | | | 807 | | | | 779 | | | | 683 | | | | 604 | | | | 637 | | | | 804 | |

| Production (000 tonnes) | | | | | | | | | | | | | | | | | | | | | | | | |

| Coated paper | | | 943 | | | | 197 | | | | 191 | | | | 49 | | | | 147 | | | | 180 | |

| Uncoated paper | | | 418 | | | | 511 | | | | 580 | | | | 144 | | | | 465 | | | | 662 | |

| Newsprint | | | 343 | | | | 352 | | | | 289 | | | | 65 | | | | 200 | | | | 208 | |

| Pulp | | | 345 | | | | 344 | | | | 323 | | | | 75 | | | | 243 | | | | 315 | |

Notes to Selected Consolidated Financial Information

| 1 | Current portion of long term debt is included in total debt and excluded from working capital. |

| 2 | Adjusted EBITDA is a non-GAAP measure. Adjusted EBITDA does not have a standardized meaning. Adjusted EBITDA as set forth above represents net earnings (loss) before net interest expense, income taxes, depreciation and amortization and impairment, foreign exchange gain (loss) on long-term debt, loss on repayment of long-term debt, other income (expense), and non-controlling interests. We focus on adjusted EBITDA as we believe this measure enables comparison of our results between periods without regard to debt service, income taxes and capital expenditure requirements. Adjusted EBITDA is also useful in analyzing our ability to comply with our debt covenants. As such, we believe it would be useful for investors and other users to be aware of this measure so they can better assess our operating performance. Adjusted EBITDA should not be considered by an investor as an alternative to net income, an indicator of our financial performance or an alternative to cash flows as a measure of liquidity. As there are no generally accepted methods for calculating adjusted EBITDA, this measure as calculated by us might not be comparable to similarly titled measures reported by other companies. |

| 3 | Adjusted EBITDA margin is defined as adjusted EBITDA as a percentage of sales. |

We have provided below a reconciliation of adjusted EBITDA to net earnings (loss) attributable to the Company, which we believe is the most directly comparable U.S. GAAP measure.

| (In millions of dollars) | | 2011 | | | 2012 | | | 2013 | | | 2014 | | | 2015 | |

| Net earnings (loss) attributable to the Company | | $ | (974.0 | ) | | $ | 583.2 | | | $ | (127.6 | ) | | $ | (72.3 | ) | | $ | (49.4 | ) |

| Net earnings (loss) attributable to non-controlling interest | | | (2.6 | ) | | | 30.4 | | | | 0.3 | | | | – | | | | – | |

| Net earnings (loss) | | | (976.6 | ) | | | 613.6 | | | | (127.3 | ) | | | (72.3 | ) | | | (49.4 | ) |

| Depreciation and amortization | | | 105.5 | | | | 36.3 | | | | 47.0 | | | | 44.6 | | | | 61.4 | |

| Impairment | | | 661.8 | | | | – | | | | 86.9 | | | | 16.5 | | | | – | |

| Foreign exchange (gain) loss on long-term debt | | | 9.7 | | | | (20.8 | ) | | | 18.8 | | | | 24.1 | | | | 57.7 | |

| Bargain purchase gain | | | – | | | | – | | | | – | | | | – | | | | (43.9 | ) |

| Loss on Powell River fire | | | 2.4 | | | | – | | | | – | | | | – | | | | – | |

| Other (income) expense, net | | | (0.3 | ) | | | 2.5 | | | | (14.9 | ) | | | (1.2 | ) | | | 0.9 | |

| Interest expense, net | | | 73.2 | | | | 71.9 | | | | 37.4 | | | | 35.5 | | | | 49.4 | |

| Income tax expense (recovery) | | | (8.4 | ) | | | (0.9 | ) | | | 0.1 | | | | 0.4 | | | | (27.4 | ) |

| Reorganization items, net | | | – | | | | (663.7 | ) | | | 1.2 | | | | – | | | | – | |

| (Earnings) loss from discontinued operations, net of tax | | | 195.5 | | | | 16.5 | | | | (3.1 | ) | | | – | | | | – | |

| Adjusted EBITDA 1 | | $ | 62.8 | | | $ | 55.4 | | | $ | 46.1 | | | $ | 47.6 | | | $ | 48.7 | |

| 1 | Adjusted EBITDA is a non-GAAP measure. Adjusted EBITDA does not have a standardized meaning. Adjusted EBITDA as set forth above represents net earnings (loss) before net interest expense, income taxes, depreciation and amortization and impairment, foreign exchange gain (loss) on long-term debt, loss on repayment of long-term debt, other income (expense), and non-controlling interests. We focus on adjusted EBITDA as we believe this measure enables comparison of our results between periods without regard to debt service, income taxes and capital expenditure requirements. Adjusted EBITDA is also useful in analyzing our ability to comply with our debt covenants. As such, we believe it would be useful for investors and other users to be aware of this measure so they can better assess our operating performance. Adjusted EBITDA should not be considered by an investor as an alternative to net income, an indicator of our financial performance or an alternative to cash flows as a measure of liquidity. As there are no generally accepted methods for calculating adjusted EBITDA, this measure as calculated by us might not be comparable to similarly titled measures reported by other companies. |

Exchange Rate Data

Bank of Canada

The following table sets forth certain exchange rates based upon the noon rate as quoted by the Bank of Canada. Such rates are set forth as, for the period indicated, U.S. dollars per Canadian $1.00. On March 3, 2016, the noon rate was 0.7459 U.S. dollars per Canadian $1.00.

| | | 2010 | | | 2011 | | | 2012 | | | 2013 | | | 2014 | | | 2015 | |

| | | | | | | | | | | | | | | | | | | |

| Low | | | 0.9278 | | | | 0.9430 | | | | 0.9599 | | | | 0.9348 | | | | 0.8589 | | | | 0.7148 | |

| High | | | 1.0054 | | | | 1.0583 | | | | 1.0299 | | | | 1.0164 | | | | 0.9422 | | | | 0.7485 | |

| Period-end | | | 1.0054 | | | | 0.9833 | | | | 1.0051 | | | | 0.9402 | | | | 0.8620 | | | | 0.7225 | |

| Average rate 1 | | | 0.9710 | | | | 1.0110 | | | | 1.0004 | | | | 0.9710 | | | | 0.9054 | | | | 0.7820 | |

| | | 2015 | | | 2016 | |

| | | September | | | October | | | November | | | December | | | January | | | February | |

| Low | | | 0.7455 | | | | 0.7552 | | | | 0.7485 | | | | 0.7148 | | | | 0.6854 | | | | 0.7123 | |

| High | | | 0.7606 | | | | 0.7750 | | | | 0.7637 | | | | 0.7485 | | | | 0.7159 | | | | 0.7395 | |

| Period-end | | | 0.7466 | | | | 0.7644 | | | | 0.7500 | | | | 0.7225 | | | | 0.7102 | | | | 0.7395 | |

| Average rate 1 | | | 0.7538 | | | | 0.7650 | | | | 0.7530 | | | | 0.7297 | | | | 0.7031 | | | | 0.7248 | |

| 1 | The average rate is derived by taking the average of the noon rate for each business day during the relevant period. |

| B. | Capitalization and Indebtedness |

Information not required for an annual report.

| C. | Reasons for the Offer and Use of Proceeds |

Information not required for an annual report.

We face risks and uncertainties which fall into the general business areas of markets, international commodity prices, currency exchange rates, environmental issues, fibre supply, government regulation and policy and, for Canadian companies, trade barriers and potential impacts of Aboriginal rights, including unresolved Aboriginal land claims in British Columbia.

In order to address our business risks and effectively manage them, we have developed a process for managing risk and the interrelationship risks have with our strategic plan. We provide regular updates to the Audit Committee, work with corporate and operational management to identify, measure, and prioritize the critical risks facing the Company and manage these risks by ensuring that they are adequately addressed through mitigating procedures where appropriate. The objectives of the risk-management function include developing a common framework for understanding what constitutes principal business risks, ensuring that risk management activities are aligned with business strategies, and providing an effective mechanism for governance in the area of risk management.

The recent acquisition of two U.S. paper mills exposes the Company to market, environmental, financial and human resource risks

The completion of the acquisition of the Biron paper mill located in Wisconsin and the Rumford paper and pulp mill located in Maine, USA has significantly increased Catalyst Paper’s operations, specialty paper market share, environmental footprint and supply requirements and significantly increases our operations in the United States. The acquisition exposes us to various risks, some of which are general in nature and some of which are unique to the operations of these mills, the regions they are located in, and the markets they sell their product to.

Key risks include but are not limited to:

| · | ongoing decline in coated paper markets due to general weakness in North American and international demand and due to market share lost to lower cost product alternatives, |

| · | erosion of future profitability due to general inflation and regional price pressure on fibre and energy, |

| · | the introduction of onerous environmental laws and regulations that may impose restrictions on our operations and processes, |

| · | potential environmental and labour claims that may arise from circumstances not currently identified, including but not limited to instances of site contamination and labour grievances, |

| · | unexpected delays in production and major maintenance events may negatively impact operations, customer service and costs, |

| · | breakdowns, obsolescence and impairment of long-lived assets, parts and supplies may negatively impact operations, customer service and costs, |

| · | potential labour unrest may negatively impact operations, customer service and costs, |

| · | delays and unexpected costs associated with post-acquisition activities including transition, integration and system separation may negatively impact liquidity, free cash flow and future profitability, |

| · | unexpected issues with the assignment of supply agreements or credit terms with vendors may negatively impact operations, customer service and costs, |

| · | actual results falling short of earnings projections and synergies identified by management may negatively impact to liquidity, free cash flow and future profitability, and |

| · | management not having the capacity to complete an orderly transition and integration of the U.S. mills while simultaneously operating the Canadian mills. |

Reliance by the Biron paper mill on the Wisconsin Rapids pulp and paper mill and the Lake States Wood Supply Group may result in supply interruption

The newly acquired Biron paper mill is a semi-integrated mill that is connected by way of three subterranean tunnels to Verso Corporation’s Wisconsin Rapids pulp and paper mill. Biron currently relies on the Wisconsin Rapids mill for the supply of softwood kraft pulp which is required to produce Biron’s coated mechanical paper products. Biron also relies on the Wisconsin Rapids mill for waste transfer and treatment services, including the landfilling of flyash generated by Biron’s power boilers and the treatment of process water by the Water Quality Center which is owned and operated by the Wisconsin Rapids mill. Wood is currently being purchased for the Biron mill by the Lake States Wood Supply Group which buys wood for a number of other regional mills that are owned and operated by Verso Corporation. An extended interruption in the supply of softwood kraft pulp or waste treatment services by the Wisconsin Rapids mill, or an interruption in wood supply by the Lake States Wood Supply Group, could have adverse consequences to our operations, customer service and costs. We have entered into agreements with Verso Corporation related to the supply of these goods and services that contain provisions and remedies that are intended to mitigate material losses due to extended supply interruptions. The recent Chapter 11 bankruptcy filings of both Verso Corporation and its affiliate, NewPage Corporation, could potentially have an adverse impact on such arrangements, however, other viable market options would be available to us.

We may not be able to successfully integrate the recently acquired U.S. paper mills into our operations

Any acquisition is accompanied by risks. For example, there may be significant change in commodity prices after we have committed to complete the transaction; we may have difficulty integrating and assimilating the operations and personnel of any acquired companies, realizing anticipated synergies and maximizing the final and strategic position of the combined enterprise, and maintaining uniform standards, policies and controls across the organization; and the acquired business or assets may have unknown liabilities which may be significant. The success of our acquisition will depend upon our ability to effectively manage the integration and operations of properties or assets we acquired and to realize anticipated benefits. The process of managing acquired businesses may involve unforeseen difficulties and may require a disproportionate amount of management resources, which may divert management’s focus and resources from other strategic opportunities and from operational matters during this process. There can be no assurance that we will be able to successfully manage the integration and operations of the businesses or assets we acquire.

There is a risk that our systems, procedures and controls will not be adequate to support the expansion of our operations resulting from the acquisition of the Biron paper mill located in Wisconsin and the Rumford paper and pulp mill located in Maine, USA. Our future operating results could be affected by the ability of our officers and key employees to manage the changing business conditions and to integrate the Biron paper mill and the Rumford paper and pulp mill operations into our own. No assurance can be given that the acquisition of the Biron paper mill and the Rumford paper and pulp mill will result in the anticipated benefits expected from the acquisition. In addition, there may be liabilities, such as environmental liabilities, that we have failed to discover or have underestimated in connection with the acquisition. There may also be capital expenditure requirements that we have failed to discover or underestimated in connection with the acquisition, which amounts may be material. Any such liabilities or capital expenditure requirements could have a material adverse effect on our business, financial condition or future prospects.

We may not be able to generate sufficient cash to service all of our indebtedness and may be forced to take other actions to satisfy our obligations under our indebtedness, which may not be successful

Our ability to service our debt obligations or to refinance our debt obligations depends on our financial condition and operating performance, which are subject to prevailing economic and competitive conditions and certain financial, business, legislative, regulatory and other factors beyond our control. We may not be able to maintain the required level of cash flows from operating activities sufficient to permit us to fund our day-to-day operations or to pay the principal, premium, if any, and interest on our indebtedness.

If our cash flows and capital resources are insufficient to fund our debt service obligations, we could face substantial liquidity problems and could be forced to reduce or delay capital expenditures or to sell assets or operations, seek additional capital or restructure or refinance our indebtedness. We may not be able to affect any such alternative measures, if necessary, on commercially reasonable terms or at all and, even if successful, such alternative actions may not allow us to meet our scheduled debt service obligations. The credit agreements that govern the ABL Facility and a US $20.0 million loan that matures on July 31, 2017 (“Term Loan”) and the indentures that govern our PIK Toggle Senior Secured Notes due 2017 (“2017 Notes”), including the PIK Toggle Senior Secured Notes due 2017 with a principal amount of US $25.0 million (“Offered Notes”) restrict our ability to dispose of assets and use the proceeds from any such dispositions and may also restrict our ability to raise debt or equity capital to be used to repay other indebtedness when it becomes due. We may not be able to consummate those dispositions or obtain proceeds in an amount sufficient to meet debt service obligations when due. Our inability to generate sufficient cash flows to satisfy our debt obligations, or to refinance our indebtedness on commercially reasonable terms or at all, would materially and adversely affect our financial position and results of operations and our ability to satisfy our obligations under the 2017 Notes (including the Offered Notes), the Term Loan and the ABL Facility.

If we cannot service our debt obligations, we will be in default and as a result, holders of the 2017 Notes could declare all outstanding principal and interest to be due and payable, the lenders under the ABL Facility and Term Loan could terminate their commitments to loan money, our secured lenders could foreclose against the assets securing such borrowings and we could be forced into bankruptcy or liquidation.

Our degree of leverage may limit our financial and operating activities

Our historical capital requirements have been considerable and our future capital requirements could vary significantly and may be affected by general economic conditions, wood fibre supply, currency exchange rates, industry trends, performance, interest rates and many other factors that are not within our control. Subject to the limits contained in the credit agreements that governs the ABL Facility and Term Loan and the indentures that govern the 2017 Notes (including the Offered Notes), we may be able to incur additional debt from time to time to finance working capital, capital expenditures, investments or acquisitions, or for other purposes. If we do so, the risks related to our high level of debt could intensify. Our substantial level of indebtedness has had in the past, and could have in the future, important consequences, including the following:

| · | making it more difficult for us to satisfy our obligations with respect to our debt, |

| · | limiting our ability to obtain additional financing to fund future working capital, capital expenditures, product developments, acquisitions or other general corporate requirements, |

| · | requiring a substantial portion of our cash flows to be dedicated to debt service payments instead of other purposes, thereby reducing the amount of cash flows available for working capital, capital expenditures and other general corporate purposes, |

| · | increasing our vulnerability to general adverse economic and industry conditions, |

| · | exposing us to the risk of increased interest rates as certain of our borrowings including our borrowings under the ABL Facility are at variable rates of interest, |

| · | limiting our flexibility in planning for and reacting to changes in our industry, |

| · | placing us at a disadvantage compared to other, less leveraged competitors, and |

| · | increasing our cost of borrowing. |

There is a limited trading market for the Company’s common shares

Although our common shares are listed on the Toronto Stock Exchange (“TSX”), certain holders of common shares may also be creditors of the Company and there is no certainty of a viable trading market for the common shares. The potential lack of liquidity for the common shares may make it more difficult for us to raise additional capital, if necessary, and it may affect the price volatility of the common shares. There can also be no assurance that a holder will be able to sell its common shares at a particular time or that the prices such holder receives when it sells will be favorable. Future trading prices of the common shares will depend on many factors, including our operating performance and financial condition.

Certain holders of common shares may also be creditors of the Company and may seek to dispose of such securities to obtain liquidity. Such sales could cause the trading prices for these securities to be depressed. Further, the possibility that the holders of common shares may determine to sell all or a large portion of their shares in a short period of time may adversely affect the market price of the common shares.

Our business is of a cyclical nature and demand for our products may fluctuate significantly

The markets for pulp and paper products are highly cyclical and are characterized by periods of excess product supply due to many factors, including additions to industry capacity, increased industry production, structural changes in the industry, periods of weak demand due to weak general economic activity or other causes, and reduced inventory levels maintained by customers.

Demand for forest products generally correlates to global economic conditions. Demand for pulp and paper products in particular is driven primarily by levels of advertising. In periods of economic weakness, reduced spending by consumers and businesses results in decreased demand for forest products, causing lower product prices and possible manufacturing downtime. The North American newsprint and directory paper market is mature with demand for newsprint declining significantly in the last five years.

We believe these declines in newsprint and directory paper demand will continue long term, although we have the ability to partially mitigate the impact by switching production from newsprint and directory paper to other paper grades. Demand for our products is traditionally weaker in the first half of the year.

As at December 31, 2015, one of the paper machines at our Crofton mill continues to be indefinitely curtailed. On December 15, 2014, we indefinitely curtailed Paper Machine No. 9 at Powell River due to a lack of orders and a declining market for the paper manufactured on No. 9. On September 1, 2015, we indefinitely curtailed Paper Machine No. 12 at Rumford due to a lack of orders and a declining market for the coated paper manufactured on No. 12. Should demand for our products weaken, additional indefinite or periodic production curtailments may be required, which could have an adverse impact on our financial condition and ability to generate sufficient cash flows to satisfy our operational needs and debt service requirements.

We operate in a commodity market where prices may fluctuate significantly

The pulp and paper industry is a commodity market in which producers compete primarily on the basis of price. Prices for our products have fluctuated significantly in the past and may fluctuate significantly in the future, principally as a result of market conditions of supply and demand, as well as changes in exchange rates. Our earnings are sensitive to price changes for our principal products, with the effect of price changes on newsprint and mechanical specialty printing paper grades being the greatest. Market prices for our products typically are not directly affected by input costs or other costs of sales and, consequently, we have limited ability to pass through increases in operating costs to our customers without an increase in market prices. Even though our costs may increase, our customers may not accept price increases for our products or the prices for our products may decline. As our financial performance is principally dependent on the prices we receive for our products, prolonged periods of low prices, customer refusal to accept announced price increases, or significant cost increases that cannot be passed on in product prices may be materially adverse to us.

Media trends may lead to continued declines in demand for our products

Trends in advertising, Internet use and electronic data transmission and storage have had and continue to have adverse effects on traditional print media. As our newsprint, telephone directory and retail customers increase their use of other forms of media and advertising, demand for our newsprint, uncoated mechanical and coated mechanical papers may continue to decline on a long-term basis.

We are subject to exchange rate fluctuations

Nearly all of our sales are based upon prices set in U.S. dollars, while a substantial portion of our costs and expenses are incurred in Canadian dollars and our results of operations and financial condition are reported in Canadian dollars. The acquisition on January 7, 2015 of the U.S. paper mills will continue to further increase the Company’s U.S. dollar exposure on sales and costs. Increases in the value of the Canadian dollar relative to the U.S. dollar reduce the amount of revenue in Canadian dollar terms from sales made in U.S. dollars, and would reduce cash flow available to fund operations and debt service obligations.

Since we have debt denominated in U.S. dollars including our 2017 Notes (including the Offered Notes), our reported earnings could fluctuate materially as a result of exchange rates given that changes in the value of the Canadian dollar against the U.S. dollar during a given financial reporting period result in a foreign currency gain or loss on the translation of U.S. dollar cash and debt into Canadian currency.

We manage a part of our currency exposure through the use of currency options and forward contracts to hedge anticipated future sales denominated in foreign currencies and U.S. dollar denominated debt. However, no assurance can be made that we will engage in any hedging transactions or, if we decide to engage in any such transactions, that we will be successful in eliminating or mitigating currency exchange risks.

We face significant global competition

We compete with American, European and Asian producers in highly competitive global markets. Some of our competitors are larger and can accordingly achieve greater economies of scale, some have greater financial resources and some operate mills in locations that have lower energy, furnish or labour costs or have less stringent environmental and governmental regulations than the locations where we operate.

Our ability to compete is also affected by the quality of our products and customer service and our ability to maintain high plant efficiencies and operating rates and to control our manufacturing costs. If we were unable to compete effectively, there may be a materially adverse impact on our business.

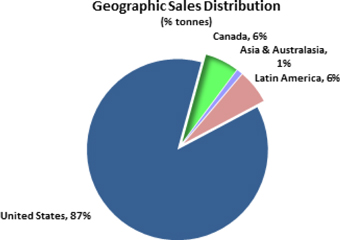

We face risks related to our international sales

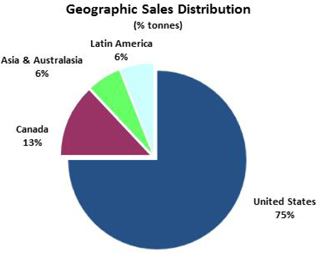

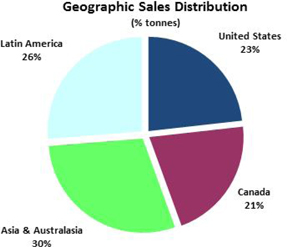

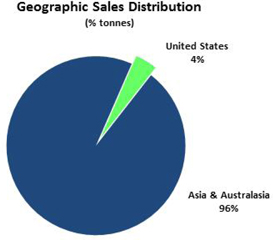

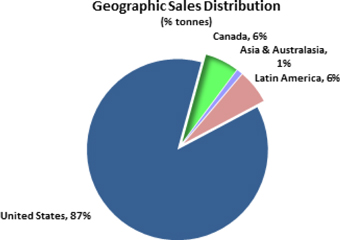

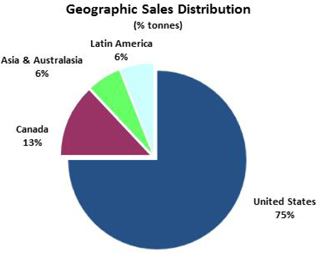

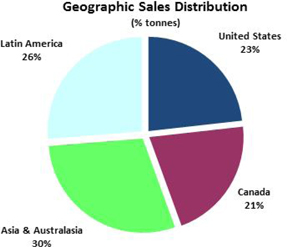

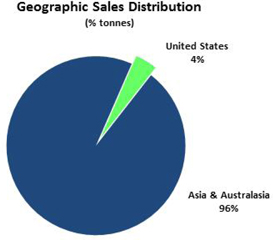

A significant portion of our sales are outside of Canada and the United States. For the year of 2015, 84% of our pulp sales and 16% of our paper sales were international. These international sales result in additional risks including restrictive government actions (including trade quotas, tariffs and other trade barriers and currency restrictions), local labour laws and regulations, the need to comply with multiple and potentially conflicting laws and regulations, unfavourable national or regional business conditions or political or economic instability in some of these jurisdictions, higher transportation costs and difficulty in obtaining distribution and sales support.

We export a significant quantity of a super calendered paper (“SC paper”) from Canada to the United States. On December 10, 2015, the U.S. Department of Commerce (“DOC”) issued its Final Order to impose countervailing duties on Canadian imports of SC paper from Catalyst Paper and three other Canadian SC paper producers. Catalyst was assigned an “all-others” countervailing duty rate of 18.85%, the weighted average rate of the two companies for whom individual investigations were conducted. The imposition of countervailing duties may negatively impact the profitability of SC paper exports into the United States and our ability to compete against U.S. producers of SC paper. On December 15, 2015, the Company filed a request for the DOC to initiate an expedited review pursuant to which the DOC would examine the countervailing duty order on SC Paper specifically with respect to Catalyst. On February 8, 2016, the DOC published its notice initiating the requested expedited review.

We are exposed to fluctuations in the cost and supply of wood fibre

We have no significant timber holdings and are dependent on third parties for the supply of wood fibre required for our paper manufacturing operations.

For our B.C. operations, approximately 70% of our fibre is provided by five suppliers. Our fibre supply could be reduced as a result of events beyond our control, including industrial disputes, natural disasters and material curtailments and shutdown of operations by suppliers for market or other reasons. Market-related curtailments or shutdowns can be influenced by both seasonal and cyclical factors, such as raw material availability, finished goods inventory levels, interest rates and demand for lumber. Weakness in the U.S. housing market could lead to production curtailment for B.C. lumber producers and result in a reduction in residual fibre supply available to us. We source a significant quantity of our fibre from the interior of B.C. The current mountain pine beetle infestation in the B.C. interior is expected to reduce the long-term fibre supply in the B.C. interior and could have a significant impact on the availability, quality and cost of fibre.

As it relates to the newly acquired U.S. paper mills, fibre suppliers in the region are significantly less concentrated than our B.C. operations, with the top five suppliers for each respective mill providing 47% of fibre at the Rumford mill and 18% of fibre at the Biron mill. For the Biron mill, which currently relies on the Lake States Wood Supply Group for its wood supply, wood supply interruption is a potential risk in 2016 along with the other regional mills owned by Verso Corporation, if the region experiences a challenging late winter or longer winter break-up period given the very low inventories at the Biron mill and.

For our B.C. operations, approximately 70% of our fibre is sourced under long-term fibre agreements with third parties with pricing based on market prices or on prices determined under market-based formulas. For our newly acquired U.S. operations, approximately 98% is sourced directly from third parties with the remaining 2% sourced from short term stumpage purchases.

Given that the market price for fibre varies due to external factors, there is a risk that we will not continue to have access to wood fibre at previous levels or pricing.

Aboriginal groups have claimed aboriginal title over substantial portions of B.C.’s timberlands, including areas where the forest tenures held by our suppliers are located. Although the renewal of forest tenures held by our suppliers may be adversely affected by claims of aboriginal title, the specific impact cannot be estimated at this time.

We are dependent on the supply of certain raw materials

In addition to wood fibre, we are dependent on the supply of certain chemicals and raw materials used in our manufacturing processes. Any material disruption in the supply of these chemicals or raw materials could affect our ability to meet customer demand in a timely manner and harm our reputation, and any material increase in the cost of these chemicals or other raw materials could negatively affect our business and the results of our operations.

We have incurred losses in recent periods and may incur losses in the future that may affect liquidity and ongoing operations

As of December 31, 2015, we had recorded net losses in 11 of the last 12 quarters. These losses were driven by reduced prices, weak market demand, production curtailments, general inflationary pressure and increased input costs and, until recently, a strong Canadian dollar. Should we be unable to return to sustained profitability, cash generated through operations may be insufficient to meet operating cash requirements, requiring increased reliance on the ABL Facility to fund operating costs. If sufficient funding is not available under the ABL Facility, then additional funding sources may be required and there is no assurance that we will be able to access additional funding sources on favourable terms or at all to meet our cash requirements. The failure to obtain such funding could adversely affect our operations and our ability to maintain compliance with covenants under the ABL Facility, the 2017 Notes, and the Term Loan. While the acquisition on January 7, 2015 of the U.S. paper mills will provide additional sources of income, the operation of these newly acquired mills and the related transition and integration activities may place additional pressure on future liquidity.

Labour disruptions could have a negative impact on our business

Labour disruptions could occur and have a negative impact on our business. In Canada, our labour agreements with Unifor and Public and Private Works of Canada (“PPWC”) for our manufacturing facilities expire on April 30, 2017 and the labour agreement with Unifor for our distribution facility expires on March 31, 2019. In the United States, our labour agreements with the unions located in our Biron, Wisconsin manufacturing facilities expire on March 31, 2018 while the agreements with the unions in our Rumford, Maine facility expire on June 30, 2018.

We are dependent on third party transportation providers

We are dependent on third party service providers for the transportation of our raw materials and products by rail, truck, barge or ship. Material disruptions in the operations of our transportation service providers due to weather, seasonal impacts, labour disruptions or other factors could negatively affect our ability to meet customer demand in a timely manner and result in increased costs and a material adverse impact on our business, the results of our operations and reputation.

Claims of aboriginal title and rights in Canada may affect our operations

The ability to operate our mills in Canada may be affected by claims of aboriginal rights and title by aboriginal groups. The governments of Canada and B.C. have established a formal process to negotiate settlements with aboriginal groups throughout B.C. in order to resolve these land claims. It is the policy of the governments that ownership of lands held in fee simple by third parties (such as us) will not be affected by treaty negotiations. The Powell River mill site has been included in areas to which an aboriginal group has asserted aboriginal title both through treaty negotiations with government and by commencing an action in 2005 in the Supreme Court of B.C. While we and other industrial companies have been named as parties in the court proceeding along with the governments of Canada and B.C., counsel for the aboriginal group has advised us that the plaintiffs are currently negotiating with these two governments and have no intention of proceeding with the action at this time. Based on the history of similar proceedings, we expect that it would be many years before a final court decision could be rendered if the proceeding were pursued.

Recent Supreme Court of Canada decisions have confirmed that the governments of Canada and B.C. are obligated to consult with and, in certain circumstances, accommodate aboriginal groups whenever there is a reasonable prospect decision, such as a decision to issue or amend a regulatory permit, which may affect aboriginal groups’ rights or title. This duty of consultation and accommodation may affect our ability to obtain or amend necessary regulatory permits on a timely basis and may influence the conditions set out in such permits.

On January 22, 2016, a Notice of Civil Claim was filed jointly by the Halalt, Sunvault Energy Inc., and Aboriginal Power Corp., alleging that Catalyst disclosed certain confidential information pertaining to a proposed anaerobic digester facility in breach of a confidentiality agreement. The claim brought against Catalyst by the Halalt and its partner, Sunvault, relates to a long-term joint venture biomass project at the Crofton mill that the Halalt proposed to Catalyst. Aboriginal Power Corp. is an affiliated entity of both Sunvault and the Halalt. Catalyst was concurrently evaluating a distinctly different proposal by another party.

Ultimately, Catalyst decided not to proceed with either joint-venture proposal.

After informing the Halalt of our decision, they filed a claim against Catalyst for breach of contract in connection with the long-term joint venture biomass project proposed by the Halalt and Sunvault seeking, among other things, approximately $100 million in damages. Also on January 22, 2016, a Notice of Civil Claim was filed by the Halalt First Nation and its members alleging Catalyst has illegally trespassed on, and caused damages to, the Halalt’s asserted territories and fisheries resources through the operation of Catalyst’s Crofton Mill since 1957. The Halalt is seeking, among other things, an interim and permanent injunction restraining Catalyst from conducting its operations at the Crofton Mill that interfere with the Halalt’s claimed riparian, water and land rights and are also seeking approximately $2 billion in damages. Catalyst denies the allegations in both claims and intends to vigorously defend itself.

Increases in energy costs could have a negative impact on our business

Our operations consume a significant amount of electricity, natural gas and fuel oil. Increases in prices for these commodities can increase manufacturing costs and have an adverse impact on our business and results of our operations.

In British Columbia, although our electricity supply agreements are provincially regulated and pricing has historically been stable, B.C. Hydro and Power Authority (“B.C. Hydro”) in recent years has sought, and to some extent achieved, rate increases above historical levels. In the past three years, rate increases totaled 27% which added $30 million to our costs annually. In November 2013, the British Columbia government announced a proposed 10 year electricity plan commencing in April, 2014. Based on our 2013 electricity consumption levels, this plan could result in an increase in our electricity costs from 2013 levels totaling 27% over the first four years of the plan which results in increases in electricity costs of approximately $13 million in the first year of the plan, approximately $24 million in the second year of the plan and approximately $33 million per year in each of the next two years of the plan. If the plan is implemented in its present form, rate increases at these levels will have an impact on our earnings. We have mitigated some of the impact of rate increases in the past through reductions in usage at the highest incremental power rate and intend to further mitigate rate increases by implementing energy conservation projects and increasing our capacity to self-generate electricity. Although we are working with government and BC Hydro to identify and explore options and solutions to mitigate the effect of these increases, there can be no assurance that we will be able to eliminate or mitigate our exposure to the effect of all the rate increases.

Electricity costs in our U.S. operations are mitigated by the larger proportion of self-generation capacity. The Biron, Wisconsin mill is supplied by a regulated utility and the rates are projected to be relatively stable for this year. The mill in Rumford, Maine operates in a deregulated jurisdiction and has the capacity to generate all of its electrical needs with self-generation and effectively hedges power costs with the fuel costs for self-generation.

The U.S. operations both consume significant volumes of coal; this pricing is set in annual contracts.

Our Canadian and U.S. mills consume oil and natural gas which are purchased on spot markets and for which pricing fluctuates significantly due to various external factors. We manage our exposure to the price volatility for these fuels by using lower priced alternatives where feasible and in some circumstances through the use of financial instruments and physical supply agreements under a hedging program. There is, however, no assurance that we will be successful in eliminating or mitigating exposure to price volatility for these fuels.

We are subject to significant environmental regulation

We are subject to extensive environmental laws and regulations that impose stringent requirements on our operations, including, among other things, air emissions, liquid effluent discharges, water regulation, the storage, handling and disposal of hazardous materials and wastes, remediation of contaminated sites and landfill operation and closure obligations. It may be necessary for us to incur substantial costs to comply with such environmental laws and regulations.

Some of our operations are subject to stringent permitting requirements and from time to time we face opposition to construction or expansion of proposed facilities. We may discover currently unknown environmental liabilities in relation to our past or present operations or at our current or former facilities, or we may be faced with difficulty in obtaining project approvals in the future. These occurrences may (i) require site or other remediation costs to maintain compliance or correct violations of environmental laws and regulations, (ii) result in denial of required permits, (iii) result in government or private claims for damage to person, property or the environment, or (iv) result in civil or criminal fines and penalties or other sanctions.

On March 12, 2015, charges were laid against us by Environment and Climate Change Canada following two separate incidents that took place at the Company’s Powell River operations in September 2012. Both unrelated incidents were caused by unforeseen power failures which led to releases of cooling water and effluent, generally consisting of untreated waste water containing organic matter such as pulverized wood fibres. On December 8, 2015, Catalyst Paper and the Federal Crown made a joint recommendation to the Court pursuant to which Catalyst pleaded guilty to three counts, two related to deposits that occurred in 2012 and one in relation to a failure to take legally required samples when there was a potential deposit in 2014. In addition, the recommendation required us to pay a $15,000 fine, and a further payment of $185,000 to the Environmental Damages Fund. The Court accepted the recommendation and directed that funds be allocated by the Environmental Damages Fund for salmon habitat restoration, protection or enhancement in British Columbia. As a result of pleading guilty to the foregoing charges, under new environmental legislation expected to come into force in the first half of 2016, Catalyst would be subject to stiffer fines for subsequent such incidents and other offences.

Our Canadian operations may be affected by the regulation of greenhouse gases: The Federal government has proposed combustion appliance based standards which could come into effect in 2020 and all Canadian mills currently meet those standards with ease. British Columbia announced its goal of reducing the provincial release of greenhouse gases (“GHG”) by 33% by 2020, based on 2007 levels, with interim reduction targets of 6% by 2012 and 18% by 2016. B.C. has not issued regulations for this GHG reduction program at this time. It is too early to determine the impact on the Company under such a program.

Our U.S. operations are subject to various stringent air regulations including the U.S. Environmental Protection Agency (“EPA”). Maximum Achievable Control Technology (MACT) standards. One boiler at Biron and two at Rumford are impacted by the standard and may require capital infusion of approximately $6 million in total by end of 2016 to meet their respective deadlines of January 31, 2017. Federal authorities could revise the standard before it comes into force and the Company continues to consider all approaches to reaching compliance including fuel switching, emissions controls, and energy reduction initiatives.

Equipment failures and the need to increase capital and maintenance expenditures could have a negative impact on our business

Our business is capital intensive. Our annual capital expenditure requirements vary due to differing requirements for current maintenance, expansion, business capital and environmental compliance and future projects. We regularly carry out maintenance on our manufacturing equipment but key components may still require repair or replacement. The costs associated with such maintenance and capital expenditures or our inability to source the necessary funds to enable us to maintain or upgrade our facilities as required could have an adverse effect on our business and operations.

In addition, we may from time to time temporarily suspend operations at one or more facilities to perform necessary maintenance or carry out capital projects. These temporary suspensions could affect the ability to meet customer demand in a timely manner and adversely affect our business.

We may be subject to litigation which could result in unexpected costs and expenditure of time and resources

We may from time to time be subject to claims and litigation proceedings generally associated with commercial and employment law issues. Given that these claims are subject to many uncertainties and the inability to predict with any certainty their outcomes and financial impacts, there is no guarantee that actions that may be brought against us in the future will be resolved in our favour or covered by our insurance. Any losses from settlements or adverse judgments arising out of these claims could be materially adverse to our operations and business.

The Snowflake mill sources water from groundwater wells in the vicinity of the Little Colorado River for its process requirements. The Little Colorado River Adjudication, filed in 1978, is pending in the Superior Court of Arizona, Apache County. The purpose of this adjudication is to determine the nature, extent and relative priority, if applicable, of the water rights of all claimants to the Little Colorado River system and sources. There are more than 3,500 participants. Catalyst sold its interest in the Snowflake mill in January, 2013, and therefore, the new owner will become a party to the adjudication as a result of its acquisition of the mill. Native American tribes and the United States government contend that the Snowflake mill’s withdrawal and use of groundwater impermissibly interferes with water rights to the Little Colorado River. We dispute this contention. However, an adverse determination could result in claims for damages that may be materially adverse to us.

In addition, securities class-action litigation often has been brought against public companies following periods of volatility in the market price of their securities. It is possible that we could be the target of similar litigation in future. Securities litigation could result in substantial costs and damages and divert management’s attention and resources.

We extend trade credit to our customers and they may not pay us promptly or in full

We extend trade credit to many purchasers of our products and rely on their creditworthiness. Some of these customers operate in highly competitive, mature, cyclical or low-margin businesses and some are highly leveraged financially or are experiencing negative cash flows which may result in them needing to refinance, restructure or file for bankruptcy protection or bankruptcy. We will typically have a greater number of such customers during economic downturns. The failure of such customers to pay us promptly and in full under the credit terms we extend to them could have a material adverse impact on our operating cash flows.

We are dependent upon certain of our management personnel

The success of our operations is influenced to a significant degree by our ability to attract and retain senior management with relevant industry experience. Successful implementation of our business strategy is dependent on our ability to attract and retain our executive officers and management team. The unexpected loss of services of any key management personnel or the inability to recruit and retain qualified personnel in the future could have an adverse effect on our business and financial results.

Consumer boycotts or increases in costs due to chain-of-custody programs may adversely affectdemand for our products

Some of our customers are sensitive to issues associated with harvesting of old growth forests and require us to supply products that are not produced from these forests. A growing number of customers want to purchase products that originate from sustainable managed forests as validated by certification programs. We have implemented our chain-of-custody systems to verify that selected paper products contain 100% certified wood fibre, but we may be required to implement additional or more stringent chain-of-custody certification programs with increased costs to meet our customers’ demands. Demand for our products may be adversely affected if we do not implement such programs or if we become subject to organized boycotts or similar actions by environmental or other groups.

Our insurance has limitations and exclusions

We maintain insurance coverage that we believe would ordinarily be maintained by an operator of facilities similar to our own. The insurance policies are subject to limits and exclusions. Damage to or destruction of our facilities could accordingly exceed the limits of our policies or be subject to policy exclusions.

Our Canadian mills are located in seismically active areas

Our three operating mills in Canada are situated adjacent to the ocean on the south coast of B.C. This is a seismically active area and these mills and the surrounding transportation infrastructure are accordingly susceptible to risk of damage or destruction caused by earthquakes and tsunamis. Our insurance may not cover the total losses associated with damage or destruction caused by an earthquake or tsunami, and this insurance is subject to limits and deductibles in respect of such damage that may limit the amount recoverable.

Our mills in the United States are partially located on flood plains

Our two U.S. based mills are situated adjacent to rivers. These rivers occasionally experience rising water levels and as such are susceptible to risk of damage or destruction caused by floods. Our insurance may not cover the total losses associated with damage or destruction caused by floods and this insurance is subject to limits and deductibles in respect of such damage that may limit the amount recoverable. Both mills have comprehensive flood response plans that are tested annually and early warning systems that alert the mills to rising water levels.

Post-retirement plan obligations may affect our financial condition

We maintain defined benefit pension plans and other post-retirement benefit plans for certain retired employees. As at December 31, 2015, the underfunded liability associated with the defined benefit pension plans was $108.5 million and the underfunded liability associated with the other post-retirement benefit plans was $172.9 million. Funding requirements for these plans are dependent on various factors, including interest rates, asset returns, regulatory requirements for funding purposes, and changes to plan benefits. In 2016, we are required to contribute $6.5 million towards the underfunded liability of the defined benefit pension plans. Although we expect to continue to make contributions to fund post-retirement plan obligations and to meet legal funding obligations for the defined benefit pension plan, no assurance can be made that the underfunded liability under these plans will not be materially adverse to us in the future.

A change in our legal control could be materially adverse

As at February 29, 2016, we have outstanding debt of US$260.5 million of 2017 Notes (including the Offered Notes) and $16.5million of Term Loans. If a Change of Control (as such term is defined in the indentures governing these notes) occurs, we are required to make an offer to purchase all outstanding 2017 Notes (including the Offered Notes) at a price equal to 101% of their principal amount, plus accrued and unpaid interest to the date of payment, in accordance with the procedures set out in the indentures. The credit agreement for the Term Loan entered into on March 20, 2014 contains a provision whereby the loan will be deemed to be in default in the case of a change in legal control. On the occurrence of an event of default the Term Loan becomes due and payable in whole together with any accrued interest. We may not have sufficient financial resources to fund any such repurchase.

| ITEM 4 | INFORMATION ON THE CORPORATION |

| A. | History and Development of the Corporation |

Incorporation

We were formed on September 1, 2001 by the amalgamation under theCanada Business Corporations Act of Norske Skog Canada Limited and Pacifica Papers Inc. On October 3, 2005, we changed our name to Catalyst Paper Corporation.

Catalyst’s principal predecessor was British Columbia Forest Products Limited, which was a company formed by the amalgamation under the laws of the Province of British Columbia on December 30, 1971 of its predecessor company, incorporated by certificate of incorporation, with memorandum and articles, under the laws of the Province of British Columbia on January 31, 1946, and 24 of its wholly owned subsidiaries. On September 2, 1988, British Columbia Forest Products Limited changed its name to Fletcher Challenge Canada Limited. Prior to July 2000, 50.76% of Fletcher Challenge Canada Limited was owned by Fletcher Challenge Limited of New Zealand (“Fletcher Challenge New Zealand”). On July 28, 2000, Norske Skogindustrier ASA completed a transaction with Fletcher Challenge New Zealand whereby all of the business and assets of Fletcher Challenge New Zealand’s worldwide paper division were acquired by Norske Skogindustrier ASA. As part of this transaction, Norske Skogindustrier ASA acquired Fletcher Challenge New Zealand’s 50.76% interest in Fletcher Challenge Canada Limited. On December 15, 2000, Fletcher Challenge Canada Limited changed its name to Norske Skog Canada Limited.

As a result of the amalgamation with Pacifica Papers Inc. and subsequent equity issues, Norske Skogindustrier ASA’s interest in Catalyst decreased to 29.4%. In February 2006, Norske Skogindustrier ASA sold its remaining 29.4% interest in Catalyst by way of a secondary offering.

Pacifica Papers Inc.’s predecessor was Pacifica Papers Limited Partnership. On June 8, 1998, Pacifica Papers Limited Partnership, through its indirect wholly owned subsidiary, Pacifica Papers Acquisition Company Ltd., acquired all the shares of MB Paper Limited from MacMillan Bloedel Limited. On March 12, 1999, the unitholders of Pacifica Papers Limited Partnership approved a reorganization, pursuant to which Pacifica Papers Limited Partnership changed its corporate form from a partnership to a corporation. As part of this reorganization, 28,750,000 common shares of Pacifica Papers Inc. were distributed to all the unitholders of Pacifica Paper Limited Partnership in exchange for their partnership units on a one for one basis.

14,400,000 new common shares were issued from the treasury of the Corporation to certain secured creditors of the Corporation on September 13, 2012 and 127,571 new common shares were further issued from treasury on December 19, 2012 to certain unsecured creditors of the Corporation in accordance with the Corporation’s plan of arrangement under theCompanies’ Creditors Arrangement Act. Under the terms of that plan of arrangement, all former securities of the Corporation issued and outstanding on September 13, 2012 were deemed automatically cancelled. See “Proceedings Under the Companies’ Creditors Arrangement Act – Implementation of Plan”.

On January 7, 2015, Catalyst Paper completed the acquisition of the Biron paper mill located in Wisconsin and the Rumford pulp and paper mill located in Maine, USA from NewPage Corporation, NewPage Wisconsin System Inc., and Rumford Paper Company (“Sellers”). On closing of the acquisition, Catalyst, through its subsidiary, acquired from the Sellers certain properties and assets used to operate the two mills. Catalyst and its subsidiaries also entered into various ancillary agreements with the Sellers providing for, among other things, the purchase and sale of certain raw materials to and from the mills, transition of certain customer orders and accounts, licenses or transfer of certain intellectual property rights, treatment and disposal of waste and wastewater and certain transitional services.

Our head and registered office is located at 2nd Floor, 3600 Lysander Lane, Richmond, British Columbia, V7B 1C3 and our telephone number is 604-247-4400.

2015 HISTORY

2016 Subsequent Developments

Executive Changes

On March 10, 2016, the Corporation announced that Sean Curran was appointed Senior Vice President, Sales and Marketing, effective April 18, 2016. His predecessor, Jim Bayles, retired on March 31, 2016.

Fatality at Crofton Mill

On January 27, 2016, a mill employee was fatally injured at the Crofton mill as a result of an industrial vehicle roll-over. The mill activated its Emergency Response Plan, and the RCMP and WorkSafe BC were promptly contracted to launch an investigation of the incident. WorkSafe BC is leading the investigation into the circumstances surrounding the incident to determine cause. The RCMP and Coroner’s Office are also investigating and the Corporation is fully supporting the investigations.

Two Lawsuits Filed by Halalt First Nation