UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 10-Q

(Mark One)

| x | QUARTERLY REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the Quarterly Period Ended March 31, 2008

or

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the Transition Period From to

Commission File Number 001-32331

Foundation Coal Holdings, Inc.

(Exact Name of Registrant as Specified in Its Charter)

| | |

| Delaware | | 42-1638663 |

(State or Other Jurisdiction of Incorporation or Organization) | | (I.R.S. Employer Identification No.) |

| | |

999 Corporate Boulevard, Suite 300 Linthicum Heights, Maryland | | 21090 |

| (Address of Principal Executive Offices) | | (Zip Code) |

Registrant’s telephone number, including area code (410) 689-7500

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See definition of “accelerated filer”, “large accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

Large accelerated filer x Accelerated filer ¨ Non-accelerated filer ¨ Smaller reporting company ¨

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes ¨ No x

There were 45,364,473 shares of common stock outstanding on April 30, 2008.

TABLE OF CONTENTS

2

PART I – FINANCIAL INFORMATION

Unless the context otherwise indicates, as used in this Form 10-Q the terms “we,” “our,” “us” and similar terms refer to Foundation Coal Holdings, Inc. and its consolidated subsidiaries.

| ITEM 1. | FINANCIAL STATEMENTS. |

Foundation Coal Holdings, Inc. and Subsidiaries

Consolidated Balance Sheets

(Dollars in thousands, except per share data)

| | | | | | | | |

| | | March 31,

2008 | | | December 31,

2007 | |

| | | (Unaudited) | | | | |

| ASSETS | | | | | | | | |

Current assets: | | | | | | | | |

Cash and cash equivalents | | $ | 23,131 | | | $ | 50,071 | |

Trade accounts receivable | | | 125,678 | | | | 100,931 | |

Inventories, net | | | 44,217 | | | | 44,122 | |

Deferred income taxes, net | | | 11,358 | | | | 11,358 | |

Prepaid expenses | | | 23,083 | | | | 30,534 | |

Other current assets | | | 5,747 | | | | 6,678 | |

| | | | | | | | |

Total current assets | | | 233,214 | | | | 243,694 | |

Owned surface lands | | | 39,198 | | | | 36,807 | |

Plant, equipment and mine development costs, net | | | 659,080 | | | | 664,429 | |

Owned and leased mineral rights, net | | | 944,469 | | | | 928,439 | |

Coal supply agreements, net | | | 18,756 | | | | 20,644 | |

Other noncurrent assets | | | 23,824 | | | | 14,151 | |

| | | | | | | | |

Total assets | | $ | 1,918,541 | | | $ | 1,908,164 | |

| | | | | | | | |

| LIABILITIES | | | | | | | | |

Current liabilities: | | | | | | | | |

Trade accounts payable | | $ | 47,838 | | | $ | 43,206 | |

Accrued expenses and other current liabilities | | | 146,055 | | | | 160,991 | |

| | | | | | | | |

Total current liabilities | | | 193,893 | | | | 204,197 | |

Long-term debt | | | 599,785 | | | | 599,785 | |

Deferred income taxes | | | 1,108 | | | | 3,161 | |

Coal supply agreements, net | | | 7,653 | | | | 9,417 | |

Postretirement benefits | | | 511,004 | | | | 505,787 | |

Other noncurrent liabilities | | | 256,829 | | | | 249,480 | |

| | | | | | | | |

Total liabilities | | | 1,570,272 | | | | 1,571,827 | |

| | | | | | | | |

Commitments and contingencies (Note 17) | | | | | | | | |

| STOCKHOLDERS’ EQUITY | | | | | | | | |

Common stock, $0.01 par value; 100.0 million shares authorized, 46.6 million shares issued and 45.2 million shares outstanding at March 31, 2008; 46.4 million shares issued and 45.0 million shares outstanding at December 31, 2007 | | | 466 | | | | 464 | |

Additional paid-in capital | | | 302,667 | | | | 293,920 | |

Retained earnings | | | 90,717 | | | | 86,800 | |

Accumulated other comprehensive income | | | 3,593 | | | | 2,403 | |

Treasury stock, at cost: 1.4 million shares at March 31, 2008; 1.4 million shares at December 31, 2007 | | | (49,174 | ) | | | (47,250 | ) |

| | | | | | | | |

Total stockholders’ equity | | | 348,269 | | | | 336,337 | |

| | | | | | | | |

Total liabilities and stockholders’ equity | | $ | 1,918,541 | | | $ | 1,908,164 | |

| | | | | | | | |

The accompanying notes are an integral part of these consolidated financial statements.

3

Foundation Coal Holdings, Inc. and Subsidiaries

Consolidated Statements of Operations and Comprehensive Income

(Unaudited, dollars in thousands, except per share data)

| | | | | | | | |

| | | Three Months Ended

March 31, | |

| | | 2008 | | | 2007 | |

Revenues: | | | | | | | | |

Coal sales | | $ | 406,946 | | | $ | 386,232 | |

Other revenue | | | 5,358 | | | | 8,690 | |

| | | | | | | | |

Total revenues | | | 412,304 | | | | 394,922 | |

Costs and expenses: | | | | | | | | |

Cost of coal sales (excludes depreciation, depletion and amortization) | | | 315,473 | | | | 284,242 | |

Selling, general and administrative expenses (excludes depreciation, depletion and amortization) | | | 19,791 | | | | 13,827 | |

Accretion on asset retirement obligations | | | 2,557 | | | | 2,372 | |

Depreciation, depletion and amortization | | | 53,265 | | | | 51,084 | |

Amortization of coal supply agreements | | | 125 | | | | (1,130 | ) |

Employee and contract termination costs and other | | | - | | | | 2,252 | |

| | | | | | | | |

Income from operations | | | 21,093 | | | | 42,275 | |

Other income (expense): | | | | | | | | |

Interest expense | | | (12,914 | ) | | | (13,020 | ) |

Interest income | | | 443 | | | | 632 | |

| | | | | | | | |

Income before income tax expense and equity in losses of affiliate | | | 8,622 | | | | 29,887 | |

Income tax expense | | | (2,267 | ) | | | (5,333 | ) |

Equity in losses of affiliate | | | (185 | ) | | | - | |

| | | | | | | | |

Net income | | | 6,170 | | | | 24,554 | |

Other comprehensive income: | | | | | | | | |

Adjustments to unrecognized gains and losses and amortization of employee benefit plan costs, net of tax expense of $20 in 2008 and $42 in 2007 | | | 613 | | | | 62 | |

Unrealized gain on natural gas swaps, net of tax expense of $365 in 2008 | | | 577 | | | | - | |

Reclassification of unrealized gain on interest rate swap into interest expense | | | - | | | | (370 | ) |

| | | | | | | | |

Comprehensive income | | $ | 7,360 | | | $ | 24,246 | |

| | | | | | | | |

Basic earnings per common share | | $ | 0.14 | | | $ | 0.54 | |

Diluted earnings per common share | | $ | 0.13 | | | $ | 0.53 | |

Weighted-average shares-basic | | | 45,009,728 | | | | 45,121,903 | |

Weighted-average shares-diluted | | | 46,259,336 | | | | 46,387,018 | |

Dividends declared per share | | $ | 0.05 | | | $ | 0.05 | |

The accompanying notes are an integral part of these consolidated financial statements.

4

Foundation Coal Holdings, Inc. and Subsidiaries

Consolidated Statements of Cash Flows

(Unaudited, dollars in thousands)

| | | | | | | | |

| | | Three Months Ended

March 31, | |

| | | 2008 | | | 2007 | |

Operating activities: | | | | | | | | |

Net income | | $ | 6,170 | | | $ | 24,554 | |

Adjustments to reconcile net income to net cash provided by operating activities: | | | | | | | | |

Accretion on asset retirement obligations | | | 2,557 | | | | 2,372 | |

Depreciation, depletion and amortization | | | 53,390 | | | | 49,954 | |

Amortization of deferred financing costs | | | 454 | | | | 457 | |

Gain on sale of assets | | | (84 | ) | | | (343 | ) |

Non-cash stock compensation | | | 6,134 | | | | 1,663 | |

Excess tax benefit from stock-based awards | | | (1,664 | ) | | | (354 | ) |

Deferred income taxes | | | (2,398 | ) | | | (7,394 | ) |

Asset retirement obligations | | | (322 | ) | | | (108 | ) |

Equity in losses of affiliate | | | 185 | | | | - | |

Other | | | 643 | | | | 119 | |

Changes in operating assets and liabilities: | | | | | | | | |

Trade accounts receivable | | | (24,747 | ) | | | (3,809 | ) |

Inventories, net | | | (145 | ) | | | (12,829 | ) |

Prepaid expenses and other current assets | | | 8,815 | | | | 4,466 | |

Other noncurrent assets | | | (43 | ) | | | 224 | |

Trade accounts payable | | | 4,632 | | | | (17,614 | ) |

Accrued expenses and other current liabilities | | | (8,067 | ) | | | (742 | ) |

Noncurrent liabilities | | | 10,018 | | | | 11,162 | |

| | | | | | | | |

Net cash provided by operating activities | | | 55,528 | | | | 51,778 | |

| | | | | | | | |

Investing activities: | | | | | | | | |

Purchases of property, plant and equipment | | | (35,252 | ) | | | (48,059 | ) |

Lease by application bonus bid deposit | | | (36,108 | ) | | | - | |

Purchases of equity-method investments | | | (9,799 | ) | | | - | |

Proceeds from disposition of property, plant and equipment | | | 254 | | | | 349 | |

| | | | | | | | |

Net cash used in investing activities | | | (80,905 | ) | | | (47,710 | ) |

| | | | | | | | |

Financing activities: | | | | | | | | |

Payment of cash dividends | | | (2,253 | ) | | | (2,255 | ) |

Proceeds from issuance of common stock | | | 950 | | | | 315 | |

Excess tax benefit from stock-based awards | | | 1,664 | | | | 354 | |

Common stock repurchases | | | (1,924 | ) | | | (13,267 | ) |

| | | | | | | | |

Net cash used in financing activities | | | (1,563 | ) | | | (14,853 | ) |

| | | | | | | | |

Net decrease in cash and cash equivalents | | | (26,940 | ) | | | (10,785 | ) |

Cash and cash equivalents at beginning of period | | | 50,071 | | | | 33,720 | |

| | | | | | | | |

Cash and cash equivalents at end of period | | $ | 23,131 | | | $ | 22,935 | |

| | | | | | | | |

Supplemental cash flow information: | | | | | | | | |

Cash paid for interest | | $ | 16,422 | | | $ | 17,196 | |

Cash paid for income taxes, net of refunds | | $ | (282 | ) | | $ | (495 | ) |

The accompanying notes are an integral part of these consolidated financial statements.

5

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements

(Unaudited, dollars in thousands)

| (1) | Basis of Presentation of Consolidated Financial Statements |

The accompanying interim consolidated financial statements of Foundation Coal Holdings, Inc. and Subsidiaries (the “Company”) are unaudited and prepared in accordance with the rules and regulations of the United States Securities and Exchange Commission for Form 10-Q. Such rules and regulations allow the omission of certain information and footnote disclosures normally included in financial statements prepared in accordance with accounting principles generally accepted in the United States of America as long as the statements are not misleading. In the opinion of management, these interim consolidated financial statements reflect all normal and recurring adjustments necessary for a fair presentation of the results for the periods presented. These interim consolidated financial statements should be read in conjunction with the consolidated financial statements of the Company included in its Annual Report on Form 10-K for the twelve months ended December 31, 2007, filed February 29, 2008.

The Company’s consolidated financial statements have been prepared in accordance with accounting principles generally accepted in the United States of America. The preparation of the Company’s consolidated financial statements requires management to make estimates and assumptions that affect the reported amounts of assets and liabilities at the date of the consolidated financial statements and the reported amounts of revenues and expenses during the reporting period. The more significant areas requiring the use of management estimates and assumptions relate to coal reserves that are the basis for future cash flow estimates and units-of-production depreciation, depletion and amortization calculations; environmental and reclamation obligations; asset impairments; postemployment, postretirement and other employee benefit liabilities; valuation allowances for deferred income taxes; income tax provision calculations; reserves for contingencies and litigation; and the fair value and accounting treatment of certain financial instruments. Management bases its estimates on historical experience and on various other assumptions that are believed to be reasonable under the circumstances. Accordingly, actual results may differ from these estimates. In addition, different assumptions or conditions could reasonably be expected to yield different results. The operating results for the three months ended March 31, 2008 may not necessarily be indicative of the results to be expected in any quarter or for the twelve months ended December 31, 2008.

| (2) | Recent Accounting Pronouncements |

In March 2008, the Financial Accounting Standards Board (the “FASB”) issued Statement of Financial Accounting Standards (“SFAS”) No. 161,Disclosures about Derivative Instruments and Hedging Activities (“SFAS No. 161”). This standard amends and expands the disclosure requirements of SFAS No. 133,Accounting for Derivative Financial Instruments and Hedging Activities (“SFAS No. 133”) and establishes, among other things, the disclosure requirements for derivative instruments and for hedging activities. SFAS No. 161 is effective for fiscal years beginning after November 15, 2008. The Company expects to adopt SFAS No. 161 on January 1, 2009 and does not believe it will have a material impact on its consolidated financial statements.

In December 2007, the FASB issued SFAS No. 160,Noncontrolling Interests in Consolidated Financial Statements (“SFAS No. 160”). This standard outlines the accounting and reporting for an ownership interest in a subsidiary held by parties other than the parent. SFAS No. 160 is effective for fiscal years beginning after December 15, 2008. The Company expects to adopt SFAS No. 160 on January 1, 2009 and does not believe it will have a material impact on its consolidated financial statements.

In December 2007, the FASB issued SFAS No. 141(R),Business Combinations (“SFAS No. 141(R)”). This standard amends SFAS No. 141,Business Combinations and revises established principles and requirements for identifiable assets and goodwill acquired, liabilities assumed, and non-controlling interest in the acquiree. This statement also establishes disclosure requirements which will enable users to evaluate the nature and financial effects of the business combination. SFAS No.141(R) is effective for acquisitions for which the acquisition date is on or after the beginning of the first annual reporting period beginning on or after December 15, 2008. The Company expects to apply the provisions of SFAS No. 141(R) to acquisitions made on or after January 1, 2009.

6

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements (Continued)

(Unaudited, dollars in thousands)

In February 2007, the FASB issued SFAS No. 159,The Fair Value Option for Financial Assets and Liabilities Including an amendment of FASB Statement No. 115 (“SFAS No. 159”). SFAS No. 159 permits entities to choose to measure many financial instruments and certain other items at fair value that are not currently required to be measured at fair value. SFAS No. 159 also establishes presentation and disclosure requirements designed to facilitate comparisons between entities that choose different measurement attributes for similar types of assets and liabilities. SFAS No. 159 is effective as of the beginning of an entity’s first fiscal year that begins after November 15, 2007. The Company did not elect the fair value option under SFAS No. 159 for any of its financial assets or liabilities that are not required to be presented at fair value under generally accepted accounting principles and therefore the adoption of SFAS No. 159 had no impact on the Company’s consolidated financial statements.

In September 2006, the FASB issued SFAS No. 157,Fair Value Measurements (“SFAS No. 157”) which defines fair value, establishes a framework for measuring fair value in generally accepted accounting principles and expands disclosures about fair value measurements. SFAS No. 157 clarifies how to measure fair value as permitted under other accounting pronouncements but does not require any new fair value measurements. SFAS No. 157 was originally effective for financial statements issued for fiscal years beginning after November 15, 2007, and interim periods within those fiscal years. On February 12, 2008, the FASB issued Final FASB Staff Position (“FSP”) No. Financial Accounting Standard (“FAS”) 157-2,Effective Date of FASB Statement No. 157 (“FSP No. 157-2”). FSP No. 157-2 was effective upon issuance and delayed the effective date of SFAS No. 157 for nonfinancial assets and nonfinancial liabilities, except for items that are recognized or disclosed at fair value in the financial statements on a recurring basis or at least once a year, to fiscal years beginning after November 15, 2008. The provisions of FSP No. 157-2 are effective for the Company’s fiscal year beginning January 1, 2009.

The Company adopted the provisions of SFAS No. 157 on January 1, 2008. SFAS No. 157 establishes a fair value hierarchy that prioritizes the inputs to valuation techniques used to measure fair value. Inputs are either observable or unobservable and refer broadly to the assumptions that are used in pricing assets or liabilities. Observable inputs are reflective of market data and unobservable inputs reflect the entity’s own assumptions about pricing assets or liabilities. As defined below, the fair value hierarchy gives the highest priority to unadjusted quoted prices in active markets for identical assets or liabilities (Level 1) and the lowest priority to unobservable inputs (Level 3). The three levels of the fair value hierarchy under SFAS 157 are further described as follows:

| | |

Level 1 | | Unadjusted quoted prices in active markets that are accessible at the measurement date for identical, unrestricted assets or liabilities; |

| |

Level 2 | | Quoted prices for identical or similar assets or liabilities in markets that are not active, or inputs that are observable, either directly or indirectly, for substantially the full term of the asset or liability, or by market-corroborated inputs; |

| |

Level 3 | | Unobservable inputs for the assets or liability in which the fair value measurement is supported by little or no market activity but reflects the best information available to the reporting entity and may include the entity’s own data. |

These levels are not necessarily an indication of the risk or liquidity associated with the financial assets or liabilities disclosed. The following table sets forth the Company’s financial assets and liabilities measured at fair value by level within the fair value hierarchy at March 31, 2008. As required by SFAS No. 157, assets and liabilities are classified in their entirety based on the lowest level of input that is significant to the fair value measurement.

| | | | | | | | |

| | | Level 1 | | Level 2 | | Level 3 |

Cash equivalents | | $ | 26,000 | | | - | | - |

Sulfur dioxide emission allowances | | | - | | $ | 1,082 | | - |

Derivative instruments | | | - | | $ | 916 | | - |

The Company’s cash equivalents represent investments in short-term commercial paper, consisting of short-term debt obligations of the issuer bank earning money market rates of return, which are used by the Company primarily for the overnight investment of excess cash and are classified within Level 1 of the fair value hierarchy. The instruments are valued based on unadjusted market prices in active markets for investment grade commercial paper held on a short-term basis.

7

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements (Continued)

(Unaudited, dollars in thousands)

The Company’s sulfur dioxide emission allowances (“emission allowances”) are reported at fair value and are valued based on quoted prices in markets where there are fewer transactions as they are less actively traded due to the limited market for emission allowances. As such, the emission allowances are classified within Level 2 of the fair value hierarchy.

The Company’s derivative instruments are reported at fair value which are derived using valuation models commonly used for derivatives. Where possible, the Company verifies the values produced by such models to market prices. Valuation models require a variety of inputs, including contractual terms, market fixed prices, inputs from forward price yield curves, notional quantities, measures of volatility and correlations of such inputs. The Company’s derivatives trade in liquid markets, and as such, model inputs can generally be verified and do not involve significant management judgment. Such instruments are typically classified within Level 2 of the fair value hierarchy.

Inventories consisted of the following:

| | | | | | | | |

| | | March 31,

2008 | | | December 31,

2007 | |

Saleable coal | | $ | 17,220 | | | $ | 16,317 | |

Raw coal | | | 1,972 | | | | 2,497 | |

Materials and supplies | | | 33,022 | | | | 31,930 | |

| | | | | | | | |

| | | 52,214 | | | | 50,744 | |

Less materials and supplies reserve for obsolescence | | | (7,997 | ) | | | (6,622 | ) |

| | | | | | | | |

| | $ | 44,217 | | | $ | 44,122 | |

| | | | | | | | |

Saleable coal represents coal stockpiles ready for shipment to a customer. Raw coal represents coal that requires further processing prior to shipment.

Prepaid expenses consisted of the following:

| | | | | | |

| | | March 31,

2008 | | December 31,

2007 |

Prepaid royalties | | $ | 1,127 | | $ | 1,358 |

Prepaid longwall move expenses | | | 7,980 | | | 9,636 |

Prepaid SO2 emission allowances | | | 1,082 | | | 1,711 |

Prepaid taxes | | | 4,296 | | | 5,803 |

Prepaid insurance | | | 6,008 | | | 10,030 |

Other | | | 2,590 | | | 1,996 |

| | | | | | |

| | $ | 23,083 | | $ | 30,534 |

| | | | | | |

8

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements (Continued)

(Unaudited, dollars in thousands)

| (5) | Plant, Equipment, Mine Development Costs and Owned and Leased Mineral Rights |

Plant, equipment, mine development costs and owned and leased mineral rights consisted of the following:

| | | | | | | | |

| | | March 31,

2008 | | | December 31,

2007 | |

Owned surface lands and mineral rights | | | | | | | | |

Owned surface lands | | $ | 39,198 | | | $ | 36,807 | |

| | | | | | | | |

Owned and leased mineral rights | | $ | 1,291,326 | | | $ | 1,255,218 | |

Less accumulated depletion | | | (346,857 | ) | | | (326,779 | ) |

| | | | | | | | |

| | $ | 944,469 | | | $ | 928,439 | |

| | | | | | | | |

Plant, equipment and mine development costs | | | | | | | | |

Plant, equipment and asset retirement costs | | $ | 942,584 | | | $ | 921,446 | |

Mine development costs | | | 51,531 | | | | 48,693 | |

Internal use software | | | 35,890 | | | | 35,838 | |

Coalbed methane equipment and development costs | | | 13,317 | | | | 11,684 | |

| | | | | | | | |

| | | 1,043,322 | | | | 1,017,661 | |

| | | | | | | | |

Less accumulated depreciation and amortization: | | | | | | | | |

Plant, equipment and asset retirement costs | | | (362,363 | ) | | | (332,492 | ) |

Mine development costs | | | (8,158 | ) | | | (7,144 | ) |

Internal use software | | | (10,847 | ) | | | (11,347 | ) |

Coalbed methane equipment and development costs | | | (2,874 | ) | | | (2,249 | ) |

| | | | | | | | |

| | | (384,242 | ) | | | (353,232 | ) |

| | | | | | | | |

| | $ | 659,080 | | | $ | 664,429 | |

| | | | | | | | |

On February 20, 2008, the Company was the successful bidder on a new federal coal lease adjacent to the western boundary of the Eagle Butte mine located north of Gillette, Wyoming. The Company’s lease bonus bid was $180,540, payable in five equal annual installments of $36,108. The Company made the first payment of $36,108 as a deposit on the lease during the three months ended March 31, 2008. The lease became fully executed in April with an effective date of May 1, 2008. The payment was capitalized as a component ofOwned and leased mineral rights, netin the Consolidated Balance Sheets. The cost of owned and leased mineral rights are depleted using the units-of-production method over proven and probable reserves directly benefiting from the capital expenditure. This Federal coal lease contains an estimated 255 million tons of minable coal reserves.

| (6) | Other Noncurrent Assets |

Other noncurrent assets consisted of the following:

| | | | | | |

| | | March 31,

2008 | | December 31,

2007 |

Receivables from asset dispositions | | $ | 943 | | $ | 943 |

Unamortized deferred financing costs, net | | | 9,568 | | | 10,022 |

Advance mining royalties | | | 1,637 | | | 1,615 |

Equity-method investments | | | 9,614 | | | - |

Other | | | 2,062 | | | 1,571 |

| | | | | | |

| | $ | 23,824 | | $ | 14,151 |

| | | | | | |

During the three months ended March 31, 2008, the Company acquired a 49% interest in the common stock of Target Drilling Inc. (“Target”), a privately-held contract drilling company for $9,246. The Company has the ability to exercise significant influence over, but not control the operating activities of Target and accordingly uses the equity method of accounting in accordance with Accounting Principles Board Opinion No. 18,The Equity Method of Accounting for

9

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements (Continued)

(Unaudited, dollars in thousands)

Investments in Common Stock (“APB 18”). The Company records its proportionate share of earnings or losses of Target in its Consolidated Statements of Operations and Comprehensive Income under the captionEquity in earnings (losses) of affiliate. The Company adjusts the carrying amount of its investment in Target for its share of earnings or losses of Target accordingly. The difference, if any, between the cost of the investment and the Company’s underlying equity in the net assets of Target will be accounted for as if Target was a consolidated subsidiary. The Company is currently undergoing a fair value analysis on Target to determine any allocations that may be necessary in accounting for its investment in accordance with APB 18.

| (7) | Accrued Expenses and Other Current Liabilities |

Accrued expenses and other current liabilities consisted of the following:

| | | | | | |

| | | March 31,

2008 | | December 31,

2007 |

Wages and employee benefits | | $ | 30,201 | | $ | 37,503 |

Employee termination costs | | | 129 | | | 214 |

Postretirement benefits other than pension | | | 23,304 | | | 23,304 |

Interest | | | 3,604 | | | 9,011 |

Royalties | | | 7,020 | | | 5,492 |

Taxes, other than income taxes | | | 36,506 | | | 38,107 |

Asset retirement obligations | | | 4,386 | | | 4,649 |

Workers’ compensation | | | 10,450 | | | 10,450 |

Accrued capital expenditures | | | 6,725 | | | 11,641 |

Other | | | 23,730 | | | 20,620 |

| | | | | | |

| | $ | 146,055 | | $ | 160,991 |

| | | | | | |

| (8) | Other Noncurrent Liabilities |

Other noncurrent liabilities consisted of the following:

| | | | | | |

| | | March 31,

2008 | | December 31,

2007 |

Postemployment benefits | | $ | 5,120 | | $ | 5,090 |

Pension benefits | | | 29,994 | | | 28,564 |

Workers’ compensation | | | 23,462 | | | 24,268 |

Black lung reserves | | | 12,944 | | | 12,377 |

Contract settlement accrual | | | 8,498 | | | 10,272 |

Asset retirement obligations | | | 151,912 | | | 149,414 |

Deferred production tax | | | 16,284 | | | 11,002 |

Deferred credits and other | | | 8,615 | | | 8,493 |

| | | | | | |

| | $ | 256,829 | | $ | 249,480 |

| | | | | | |

10

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements (Continued)

(Unaudited, dollars in thousands)

| (9) | Accumulated Other Comprehensive Income |

Accumulated other comprehensive income consisted of the following:

| | | | | | | |

| | | March 31,

2008 | | December 31,

2007 | |

Defined benefit pension, postretirement and other | | | | | | | |

Company sponsored plans | | $ | 3,042 | | $ | 2,429 | |

Unrealized gain (loss) on natural gas swaps | | | 551 | | | (26 | ) |

| | | | | | | |

Total | | $ | 3,593 | | $ | 2,403 | |

| | | | | | | |

| (10) | Pension, Other Postretirement Benefit Plans and Pneumoconiosis |

Components of Net Periodic Pension Costs

The components of net periodic benefit costs are as follows:

| | | | | | | | |

| | | Three Months Ended

March 31, | |

| | | 2008 | | | 2007 | |

Service cost | | $ | 1,575 | | | $ | 1,531 | |

Interest cost | | | 3,118 | | | | 2,954 | |

Expected return on plan assets | | | (3,333 | ) | | | (2,928 | ) |

Amortization of: | | | | | | | | |

Prior service cost | | | (3 | ) | | | (2 | ) |

Actuarial losses | | | 38 | | | | 62 | |

| | | | | | | | |

Net expense | | $ | 1,395 | | | $ | 1,617 | |

| | | | | | | | |

Components of Net Periodic Other Postretirement Benefit Plans Costs

The components of net periodic benefit costs are as follows:

| | | | | | |

| | | Three Months Ended

March 31, |

| | | 2008 | | 2007 |

Service cost | | $ | 1,925 | | $ | 2,256 |

Interest cost | | | 8,525 | | | 8,140 |

| | | | | | |

Net expense | | $ | 10,450 | | $ | 10,396 |

| | | | | | |

The Company’s postretirement medical and life insurance plans are unfunded.

11

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements (Continued)

(Unaudited, dollars in thousands)

Components of Pneumoconiosis Costs

The components of net periodic benefit costs are as follows:

| | | | | | | | |

| | | Three Months Ended

March 31, | |

| | | 2008 | | | 2007 | |

Service cost | | $ | 168 | | | $ | 182 | |

Interest cost | | | 353 | | | | 334 | |

Expected return on plan assets | | | (107 | ) | | | (131 | ) |

Amortization of actuarial losses | | | 14 | | | | 44 | |

Other | | | 125 | | | | - | |

| | | | | | | | |

Net expense | | $ | 553 | | | $ | 429 | |

| | | | | | | | |

| (11) | Stock-Based Compensation |

On July 30, 2004, the Company’s Board of Directors adopted the Foundation Coal Holdings, Inc. 2004 Stock Incentive Plan (the “Plan”), which is designed to assist the Company in recruiting and retaining key employees, directors and consultants. The Plan, which was amended and restated December 14, 2006, permits the Company to grant its key employees, directors and consultants nonqualified stock options (“options”), stock appreciation rights, restricted stock or other stock-based awards. The shares under the Plan may be issued at an exercise price of no less than 100% of the fair market value of the Company’s common stock on the date of grant. The Plan is currently authorized for the issuance of awards for up to 5,978,483 shares of common stock. At March 31, 2008, 2,091,314 shares of common stock were available for grant under the Plan.

The Company has three types of stock-based awards: restricted stock units, restricted stock and options. Total compensation expense related to the stock-based awards recognized inSelling, general and administrative expenses for the three months ended March 31, 2008 was $6,134, consisting of $3,375, $144 and $2,615 for restricted stock units, restricted stock and options, respectively. Compensation expense related to stock-based awards recognized inSelling, general and administrative expenses for the three months ended March 31, 2007 was $1,663, consisting of $1,131, $98 and $434 for restricted stock units, restricted stock and options, respectively. During the three months ended March 31, 2008, the Company modified the vesting conditions for certain of its outstanding stock-based awards. As a result, the Company remeasured the affected stock-based awards in accordance with SFAS No. 123 (revised 2004),Share-Based Payment (“SFAS No. 123(R)”) and recognized additional compensation expense of approximately $2,544 inSelling, general and administrative expenses for the three months ended March 31, 2008.

The Company’s objectives for holding or issuing derivative instruments are to mitigate its exposure to variability in the prices of certain operating supplies and to interest rate risk. The Company’s strategy for minimizing exposure to variability is to enter into pay-fixed, receive-variable financial swaps.

On September 30, 2004, the Company entered into pay-fixed, receive-variable interest rate swap agreements on a notional amount of $85,000. The term of these swaps was for three years. Under these swaps, the Company received a variable rate of three month US dollar LIBOR and paid a fixed rate of 3.26%. Settlement of interest payments occurred quarterly. The Company was required to enter into these swaps in order to maintain at least 50% of its outstanding debt at a fixed rate as required by the original facility. These swap agreements essentially converted $85,000 of the Company’s variable rate borrowings under the original facility to fixed rate borrowings beginning September 30, 2004. The Company designated these interest rate swaps at inception as cash flow hedges of the variable interest payments due on $85,000 of its variable rate debt through September 2007 under SFAS No. 133. In connection with the closing of the Senior Secured Credit Facility on July 7, 2006, the Company terminated the interest rate swaps. On the date the Company made the decision to terminate the interest rate swaps, the interest rate swaps no longer qualified for cash flow hedge accounting treatment and accordingly, any change in the market value of the interest rate swaps affected net income. On July 11, 2006, the Company monetized the $2,371 derivative asset included inOther noncurrent assets in the Consolidated Balance Sheets at June 30, 2006 and recognized a $112 mark-to-market loss on the swaps inOther income (expense). The $1,841 unrealized gain from the change in the market value of the interest rate swaps recorded inAccumulated other comprehensive income (loss)was being amortized into income on a prorated basis over the remaining term of the original interest rate swap agreement through

12

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements (Continued)

(Unaudited, dollars in thousands)

September 28, 2007, in accordance with SFAS No. 133 and related amendments. At December 31, 2007 and 2006, the unamortized unrealized gain on the swaps was $0 and $1,114, respectively. During the three months ended March 31, 2008 and 2007, the Company amortized $0 and $370, respectively, which was recorded as an offset againstInterest expense.

| (13) | Asset Retirement Obligations |

The Company’s mining activities are subject to various federal and state laws and regulations governing the protection of the environment. These laws and regulations are continually changing and are generally becoming more restrictive. The Company conducts its operations to protect the public health and environment and believes its operations are in material compliance with all applicable laws and regulations. The Company has made, and expects to make in the future, expenditures to comply with such laws and regulations, but cannot predict the exact amount of such future expenditures. Estimated future reclamation costs are based principally on legal and regulatory requirements.

The following table is a reconciliation of the Company’s asset retirement obligation liability from December 31, 2007 through March 31, 2008:

| | | | |

Asset retirement obligation, December 31, 2007 | | $ | 154,063 | |

Accretion expense | | | 2,557 | |

Payments | | | (322 | ) |

| | | | |

Asset retirement obligation, March 31, 2008 | | $ | 156,298 | |

| | | | |

The current portions of the asset retirement obligation liabilities of $4,386 and $4,649 at March 31, 2008 and December 31, 2007, respectively, are included inAccrued expenses and other current liabilities. See Note 7. The noncurrent portions of the Company’s asset retirement obligation liabilities of $151,912 and $149,414 at March 31, 2008 and December 31, 2007, respectively, are included inOther noncurrent liabilities. See Note 8. There were no assets that were legally restricted for purposes of settling asset retirement obligations at March 31, 2008 or December 31, 2007. At March 31, 2008, regulatory obligations for asset retirements are secured by surety bonds in the amount of $268,106. These surety bonds are partially collateralized by letters of credit issued by the Company.

| (14) | Stockholders’ Equity, Earnings Per Share and Common Share Repurchases |

Stockholders’ Equity

During the three months ended March 31, 2008, the Company declared and paid cash dividends of $2,253.

During the three months ended March 31 2008, 142,624 options were exercised.

Earnings Per Share

The following table provides a reconciliation of weighted-average shares outstanding used in the basic and diluted earnings per share computations for the periods presented:

| | | | |

| | | Three Months Ended

March 31, |

| | | 2008 | | 2007 |

Weighted average shares outstanding-basic | | 45,009,728 | | 45,121,903 |

Dilutive impact of stock options | | 1,010,061 | | 1,205,452 |

Dilutive impact of restricted stock and restricted stock units | | 239,547 | | 59,663 |

| | | | |

Weighted average shares outstanding-diluted | | 46,259,336 | | 46,387,018 |

| | | | |

Common Share Repurchases

In July 2006, the Board of Directors authorized a stock repurchase program (the “Repurchase Program”), authorizing the Company to repurchase shares of its common stock. The Company may repurchase its common stock from time to time,

13

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements (Continued)

(Unaudited, dollars in thousands)

as determined by authorized officers of the Company, up to an aggregate amount of $100,000. During the three months ended March 31, 2008, the Company did not purchase any shares under the Repurchase Program. At March 31, 2008, $52,849 of funds remained under the Repurchase Program. During the three months ended March 31, 2008, the Company issued 103,518 shares of common stock to employees upon vesting of restricted stock units. The Company withheld 36,546 shares of common stock to satisfy the employees’ minimum statutory tax withholding upon vesting.

The Company produces primarily steam coal from surface and deep mines for sale to utility and industrial customers, which is distributed by rail, barge and/or truck. The Company operates only in the United States with operating mines in three of the major coal basins. The Company has four reportable business segments: Northern Appalachia, consisting of two underground mines in southwestern Pennsylvania; Central Appalachia, consisting of seven underground mines and two surface mines in southern West Virginia; the Powder River Basin, consisting of two surface mines in Wyoming and the Company’s Other segment. Other includes an idled underground mine in Illinois; expenses associated with closed mines; Dry Systems Technologies; purchased coal activities, which are for physical delivery; coalbed methane operations; selling, general and administrative expenses not charged out to the Powder River Basin, Northern Appalachia or Central Appalachia mines and the elimination of intercompany transactions. The Company evaluates the performance of its segments based on income (loss) from operations.

Segment results for the three months ended March 31, 2008 are as follows:

| | | | | | | | | | | | | | | | | | | | |

| | | Powder River

Basin | | Northern

Appalachia | | | Central

Appalachia | | | Other | | | Consolidated | | |

Total revenues | | $ | 128,137 | | $ | 176,155 | | | $ | 102,690 | | | $ | 5,322 | | | $ | 412,304 | | |

Income (loss) from operations | | | 12,755 | | | 34,140 | | | | (2,701 | ) | | | (23,101 | ) | | | 21,093 | | |

Depreciation, depletion and amortization | | | 11,756 | | | 22,132 | | | | 17,131 | | | | 2,246 | | | | 53,265 | | |

Amortization of coal supply agreements | | | 1,139 | | | (76 | ) | | | (1,067 | ) | | | 129 | | | | 125 | | |

Capital expenditures | | | 2,844 | | | 28,616 | | | | 3,414 | | | | 378 | | | | 35,252 | | |

Federal coal lease bonus bid deposit | | | 36,108 | | | - | | | | - | | | | - | | | | 36,108 | | |

Total assets at March 31, 2008 | | $ | 523,315 | | $ | 881,144 | | | $ | 416,116 | | | $ | 97,966 | | | $ | 1,918,541 | | |

Segment results for the three months ended March 31, 2007 are as follows:

| | | | | | | | | | | | | | | | | | | | |

| | | Powder River

Basin | | Northern

Appalachia | | Central

Appalachia | | | Other | | | Consolidated | | | |

Total revenues | | $ | 115,741 | | $ | 148,139 | | $ | 116,673 | | | $ | 14,369 | | | $ | 394,922 | | | |

Income (loss) from operations | | | 20,830 | | | 40,110 | | | 3,125 | | | | (21,790 | ) | | | 42,275 | | | |

Depreciation, depletion and amortization | | | 10,627 | | | 21,824 | | | 17,019 | | | | 1,614 | | | | 51,084 | | | |

Amortization of coal supply agreements | | | 872 | | | 546 | | | (2,359 | ) | | | (189 | ) | | | (1,130 | ) | | |

Capital expenditures | | | 2,591 | | | 17,276 | | | 15,198 | | | | 12,994 | | | | 48,059 | | | |

Total assets at December 31, 2007 | | $ | 490,343 | | $ | 862,972 | | $ | 427,040 | | | $ | 127,809 | | | $ | 1,908,164 | | | |

14

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements (Continued)

(Unaudited, dollars in thousands)

Other revenue consisted of the following:

| | | | | | |

| | | Three Months Ended

March 31, |

| | | 2008 | | 2007 |

Royalty income | | $ | 1,325 | | $ | 793 |

Synfuel fees | | | - | | | 1,279 |

Coalbed methane | | | 1,748 | | | 728 |

Transloading and plant processing fees | | | 397 | | | 184 |

Gain on disposition of assets | | | 84 | | | 343 |

Combined Benefit Fund refund | | | - | | | 1,325 |

Natural gas | | | 156 | | | 196 |

Dry Systems Technologies equipment and filter sales | | | 1,648 | | | 1,011 |

Other | | | - | | | 2,831 |

| | | | | | |

Total other revenue | | $ | 5,358 | | $ | 8,690 |

| | | | | | |

| (17) | Commitments and Contingencies |

General

The Company follows SFAS No. 5,Accounting for Contingencies, in determining its accruals and disclosures with respect to loss contingencies. Accordingly, estimated losses from loss contingencies and legal expenses associated with the contingency are accrued by a charge to income when information available indicates that it is probable that an asset had been impaired or a liability had been incurred and the amount of the loss can be reasonably estimated. If a loss contingency is not probable or reasonably estimable, disclosure of the loss contingency is made in the consolidated financial statements when it is at least reasonably possible that a loss will be incurred and the loss is material. Additionally, see Note 13 regarding Asset Retirement Obligations.

Commitments

On February 20, 2008, the Company was determined to be the successful bidder on a federal coal lease by the Bureau of Land Management (“BLM”), a unit of the United States Department of the Interior. The bid was accepted as submitted in the amount of $180,540 for an approximate 1,428 acre tract of federal land. The lease became fully executed in April with an effective date of May 1, 2008. This lease is subject to the deferred bonus payment provisions of the Code of Federal Regulations and as such, the Company remits the bonus payments in five equal installments, the first of which was submitted with the bid as a deposit on the lease in February 2008. The remaining four annual installments of $36,108 are due on the annual anniversary dates of the lease as required by the deferral provisions.

Guarantees

Neweagle Industries, Inc., Neweagle Coal Sales Corp., Laurel Creek Co., Inc. and Rockspring Development, Inc. (“Sellers”) are indirect wholly owned subsidiaries of the Company. The Sellers sell coal to Birchwood Power Partners, L.P. (“Birchwood”) under a Coal Supply Agreement dated July 22, 1993 (“Birchwood Contract”). Laurel Creek Co., Inc. and Rockspring Development, Inc. were parties to the Birchwood Contract since its inception, at which time those entities were not affiliated with Neweagle Industries, Inc., Neweagle Coal Sales Corp. or the Company. Effective January 31, 1994, the Birchwood Contract was assigned to Neweagle Industries, Inc. and Neweagle Coal Sales Corp. by AgipCoal Holding USA, Inc. and AgipCoal Sales USA, Inc., which at the time were affiliates of Arch Coal, Inc. Despite this assignment, Arch Coal, Inc. (“Arch”) and its affiliates have separate contractual obligations to provide coal to Birchwood if Sellers fail to perform. Pursuant to an Agreement & Release dated September 30, 1997, the Company agreed to defend, indemnify and hold harmless Arch and its subsidiaries from and against any claims arising out of any failure of Sellers to perform under the Birchwood Contract. By acknowledgement dated February 16, 2005, the Company and Arch acknowledged the continuing validity and effect of said Agreement & Release.

15

Foundation Coal Holdings, Inc. and Subsidiaries

Notes to Consolidated Financial Statements (Continued)

(Unaudited, dollars in thousands)

In the normal course of business, the Company is a party to guarantees and financial instruments with off-balance sheet risk, such as bank letters of credit, performance or surety bonds and other guarantees and indemnities related to the obligations of affiliated entities, which are not reflected in the accompanying Consolidated Balance Sheets. Management does not expect any material losses to result from these guarantees and other off-balance sheet instruments.

Contingencies

Extensive regulation of the impacts of mining on the environment and of maintaining workplace safety, and related litigation, has had or may have a significant effect on the Company’s costs of production and results of operations. Further regulations, legislation or litigation in these areas may also cause the Company’s sales or profitability to decline by increasing costs or by hindering the Company’s ability to continue mining at existing operations or to permit new operations.

Legal Proceedings

The Company is involved in various claims and other legal actions arising in the ordinary course of business. In the opinion of management, the ultimate disposition of these matters will not have a material adverse effect on the Company’s consolidated financial position, consolidated results of operations or consolidated cash flows.

Letters of Credit

At March 31, 2008, the Company had $172,623 of letters of credit outstanding under its revolving credit facility.

| (18) | Employee and Contract Termination Costs and Other |

Employee Termination Costs

In April 2007, Wabash Mine Holding Company (“Wabash”) announced the idling of the mine in southern Illinois. The mining operation had become economically unviable at that time as a result of a combination of factors, including aging infrastructure, softening market conditions and the prospect of a new higher cost labor contract with the UMWA. The Wabash mine remains idled and the effects of the idling had been negotiated with the UMWA.

During the three months ended March 31, 2007, as a result of the Wabash mine idling, the Company recognized employee termination costs for salaried employees resulting from ongoing benefit obligations of $2,252 in accordance with the provisions of SFAS No. 112,Employers’ Accounting for Postemployment Benefits. These costs are recorded asEmployee and contract termination costs and other in the Consolidated Statements of Operations and Comprehensive Income for the three months ended March 31, 2007. The Wabash mine is included in the Company’sOther segment. See Note 15.

As of March 31, 2008 and December 31, 2007, the Company’s liabilities for employee termination costs were $129 and $214, respectively, and are included inAccrued Expenses and Other Current Liabilities. See Note 7.

For the three months ended March 31, 2008, income taxes were provided at an effective rate of 26% and for the three months ended March 31, 2007, income taxes were provided at an effective rate of 18%. The effective rate in the three months ended March 31, 2008 is comprised of two elements: (1) a 14% effective rate based on forecasted annual results for 2008; and (2) a discrete tax expense of $1,129 recorded in the first quarter of 2008. Without the discrete expense, the forecasted effective rate of 14% for 2008 decreased from the 2007 effective rate of 18% due primarily to the expected benefit obtained from excess depletion deductions which are projected to be greater in 2008 than in 2007.

16

| ITEM 2. | MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS. |

Special Note Regarding Forward-Looking Statements

This Form 10-Q contains forward-looking statements that are not statements of historical fact and may involve a number of risks and uncertainties. These statements relate to analyses and other information that are based on forecasts of future results and estimates of amounts not yet determinable. These statements may also relate to our future prospects, developments and business strategies.

We have used the words “anticipate,” “believe,” “could,” “estimate,” “expect,” “intend,” “may,” “plan,” “predict,” “project” and similar terms and phrases, including references to assumptions, in this Form 10-Q to identify forward-looking statements. These forward-looking statements are made based on expectations and beliefs concerning future events affecting us and are subject to uncertainties and factors relating to our operations and business environment, all of which are difficult to predict and many of which are beyond our control, that could cause our actual results to differ materially from those matters expressed in or implied by these forward-looking statements. The following factors are among those that may cause actual results to differ materially from our forward-looking statements:

| | • | | market demand for coal, electricity and steel; |

| | • | | future economic or capital market conditions; |

| | • | | weather conditions or catastrophic weather-related damage; |

| | • | | our ability to produce coal at existing and planned future operations; |

| | • | | the consummation of financing, acquisition or disposition transactions and the effect thereof on our business; |

| | • | | our plans and objectives for future operations and expansion or consolidation; |

| | • | | our relationships with, and other conditions affecting, our customers; |

| | • | | timing of reductions or increases in customer coal inventories; |

| | • | | long-term coal supply arrangements; |

| | • | | environmental laws, including those directly affecting our coal mining and production, and those affecting our customers’ coal usage; |

| | • | | railroad, barge, trucking and other transportation performance and costs; |

| | • | | our assumptions concerning economically recoverable coal reserve estimates; |

| | • | | employee workforce factors; |

| | • | | regulatory and court decisions; |

| | • | | future legislation and changes in regulations or governmental policies or changes in interpretations thereof; |

| | • | | changes in postretirement benefit and pension obligations; |

| | • | | our liquidity, results of operations and financial condition; |

| | • | | disruptions in delivery or changes in pricing from third party vendors of goods and services which are necessary for our operations, such as fuel, steel products, explosives and tires. |

You should keep in mind that any forward-looking statement made by us in this Form 10-Q or elsewhere speaks only as of the date on which we make it. New risks and uncertainties come up from time to time, and it is impossible for us to predict these events or how they may affect us. We have no duty to, and do not intend to, update or revise the forward-looking statements in this Form 10-Q after the date of this Form 10-Q, except as may be required by law. In light of these risks and uncertainties, you should keep in mind that any forward-looking statement made in this Form 10-Q or elsewhere might not occur.

17

Overview

We are the fourth largest coal producer in the United States, operating eight mining complexes that consist of thirteen individual coal mines. Our mining operations are located in southwest Pennsylvania, southern West Virginia and the southern Powder River Basin region of Wyoming. Four of our operations are surface mines, two of our operations are underground mines using highly efficient longwall mining technology and the remaining seven operations are underground mines that utilize continuous miners. In addition to mining coal, we also purchase coal from other producers and utilize it with our own production in coal brokering and trading activities.

For the three months ended March 31, 2008, we sold 18.5 million tons of coal, including 17.9 million tons that were produced and processed at our operations. For the comparable period in 2007, we sold 18.8 million tons of coal, including 18.4 million tons that were produced and processed at our operations. As of December 31, 2007, we had approximately 1.6 billion tons of proven and probable coal reserves. On February 20, 2008, we were the successful bidder on a new federal coal lease adjacent to the western boundary of the Eagle Butte mine located north of Gillette, Wyoming. The lease became fully executed in April with an effective date of May 1, 2008. This federal coal lease contains an estimated 255 million tons of minable coal reserves. In addition to mining coal, we are also involved in marketing coal produced by others to supplement our own production and, through blending, provide our customers with a wide array of coal qualities beyond those available from our own production. We purchased and resold approximately 0.6 million and 0.4 million tons of coal in the three months ended March 31, 2008 and 2007, respectively.

We are primarily a supplier of steam coal to U.S. utilities for use in generating electricity. We also sell steam coal to industrial plants. Steam coal sales accounted for approximately 98% and 97% of our coal sales volume for the three month periods ended March 31, 2008 and 2007, respectively, representing approximately 92% and 90% of our coal sales revenue in the three month periods ended March 31, 2008 and 2007, respectively. We sell metallurgical coal to steel producers where it is used to make coke for steel production. Metallurgical coal accounted for approximately 2% and 3% of our coal sales volume for the three month periods ended March 31, 2008 and 2007, respectively, representing approximately 8% and 10% of our coal sales revenue in the three month periods ended March 31, 2008 and 2007, respectively.

While the majority of our revenues are derived from the sale of coal, we also realize revenues from coal production royalties, override royalty payments from a coal supply agreement now fulfilled by another producer, fees to transload coal through our Rivereagle facility on the Big Sandy River and revenues from the sale of coalbed methane, Dry Systems Technologies equipment and filters and natural gas.

Results of Operations

Three Months Ended March 31, 2008 Compared to Three Months Ended March 31, 2007

Coal sales realization per ton sold represents the average revenue realized on each ton of coal sold. It is calculated by dividing coal sales revenues by tons sold.

Revenues

| | | | | | | | | | | | | |

| | | Three Months Ended

March 31, | | Increase (Decrease) | |

| | | 2008 | | 2007 | | Amount | | | Percent | |

| | | (Unaudited, in thousands, except per ton data) | |

Coal sales | | $ | 406,946 | | $ | 386,232 | | $ | 20,714 | | | 5 | % |

Other revenue | | | 5,358 | | | 8,690 | | | (3,332 | ) | | (38 | )% |

| | | | | | | | | | | | | |

Total revenues | | $ | 412,304 | | $ | 394,922 | | $ | 17,382 | | | 4 | % |

| | | | | | | | | | | | | |

Tons sold | | | 18,451 | | | 18,804 | | | (353 | ) | | (2 | )% |

Coal sales realization per ton sold | | $ | 22.06 | | $ | 20.54 | | $ | 1.52 | | | 7 | % |

18

Coal sales revenues for the three months ended March 31, 2008 increased by $20.7 million, or 5% compared to coal sales revenues for the three months ended March 31, 2007. Our consolidated average coal sales realization per ton increased 7% period-over-period, while tons sold decreased by 2% period-over-period. The consolidated weighted-average coal sales realization per ton for the three months ended March 31, 2008 reflected increased prices per ton sold in all three of our operating segments consisting of an 11% increase in Central Appalachia and the Powder River Basin, respectively, and a 6% increase in Northern Appalachia.

Coal sales revenues in Northern Appalachia for the three months ended March 31, 2008 increased by $28.8 million, or 20% compared to coal sales revenues for the three months ended March 31, 2007 due primarily to a combination of higher coal sales volumes from higher tons shipped and higher average sales realization per ton. Coal sales realization per ton in Northern Appalachia increased 6% period-over-period due to increased pricing per ton sold. Coal sales volumes in Northern Appalachia increased by 0.5 million tons, or 13% period-over-period as a result of increased shipments from both mines, which included the purchase of approximately 0.3 million tons of coal to fulfill existing contracts so that coal produced by the Emerald mine could be sold at prices more indicative of the current market prices. Despite a scheduled longwall move during the last week of the quarter, tons sold at the Cumberland mine increased 9% in the three months ended March 31, 2008 compared to the prior year period. Tons sold at the Emerald mine increased 18% in the three months ended March 31, 2008 compared to the prior year period primarily due to sales of purchased coal mentioned previously. Production at Emerald decreased 12% period-over-period due to a decrease in tons mined by the longwall mining units. Lower tons mined resulted from production delays that were caused by hard cutting conditions due to sandstone intrusions, equipment failures, weather-related power outages and reduced mining rates to maintain compliance with ventilation plans. This lower production was partially offset by the introduction of a second longwall operating in a new district at Emerald in late February 2008.

Coal sales revenues in Central Appalachia for the three months ended March 31, 2008 decreased $11.7 million, or 10% compared to coal sales revenues for the three months ended March 31, 2007 primarily as a result of lower coal sales volumes, partially offset by higher coal sales realization per ton. Coal sales realization per ton increased 11% period-over-period as a result of increased pricing per ton sold. Coal sales volumes declined by 0.4 million tons, or 19% in the three months ended March 31, 2008 compared to the prior year period. Coal sales volumes in Central Appalachia decreased at all mining operations except for the Rockspring mine. Coal sales volumes were negatively impacted by the absence of coal purchased and resold due to the expiration of the synfuel tax credit in December 2007.

Coal sales revenues in the Powder River Basin for the three months ended March 31, 2008 increased $11.9 million, or 10% compared to coal sales revenues for the three months ended March 31, 2007 as a result of higher coal sales realization per ton. Coal sales realization per ton sold increased 11% due to increased pricing per ton sold. Coal sales volumes in the Powder River Basin remained flat period-over-period. An 8% period-over-period increase in both production and shipments at the Belle Ayr mine were offset by lower period-over-period production and shipments at the Eagle Butte mine.

Coal sales revenues in the Illinois Basin for the three months ended March 31, 2008 were $0 compared to coal sales revenues of $10.9 million for the three months ended March 31, 2007 due to the April 4, 2007 idling of the Wabash mine in southern Illinois.

19

Revenues from purchased coal activities by our trading group increased $2.7 million in the three months ended March 31, 2008 compared to the prior year period. Coal is purchased for physical delivery to customers.

Other revenues for the three months ended March 31, 2008 decreased by $3.3 million (38%) compared to the three months ended March 31, 2007. The decrease was due to: (a) the absence of synfuel revenues due to the expiration of the synfuel tax credit in December, 2007 ($1.3 million); (b) decreased gains on sales of assets ($0.3 million); (c) the absence of a refund from the Combined Benefit Fund received in the first quarter of 2007 ($1.3 million); (d) lower other miscellaneous revenues ($2.7 million); partially offset by (e) increased royalty fees ($0.5 million); (f) increased transloading and plant processing fees ($0.2 million); (g) increased coalbed methane revenues ($1.0 million); and (h) higher revenues from the sale of equipment and filters by Dry Systems Technologies ($0.6 million).

Costs and Expenses

| | | | | | | | | | | | | | |

| | | Three Months Ended

March 31, | | | Increase (Decrease) | |

| | | 2008 | | 2007 | | | Amount | | | Percent | |

| | | (Unaudited, in thousands) | |

Cost of coal sales (excludes depreciation, depletion and amortization) | | $ | 315,473 | | $ | 284,242 | | | $ | 31,231 | | | 11 | % |

Selling, general and administrative expenses (excludes depreciation, depletion and amortization) | | | 19,791 | | | 13,827 | | | | 5,964 | | | 43 | % |

Accretion on asset retirement obligations | | | 2,557 | | | 2,372 | | | | 185 | | | 8 | % |

Depreciation, depletion and amortization | | | 53,265 | | | 51,084 | | | | 2,181 | | | 4 | % |

Amortization of coal supply agreements | | | 125 | | | (1,130 | ) | | | 1,255 | | | 111 | % |

Employee and contract termination costs and other | | | - | | | 2,252 | | | | (2,252 | ) | | (100 | )% |

| | | | | | | | | | | | | | |

Total costs and expenses | | $ | 391,211 | | $ | 352,647 | | | $ | 38,564 | | | 11 | % |

| | | | | | | | | | | | | | |

Cost of coal sales.Cost of coal sales increased $31.2 million for the three months ended March 31, 2008 compared to the three months ended March 31, 2007, primarily due to: (a) increases in labor and benefit costs as a result of both compensation increases and hiring of additional personnel ($5.6 million); (b) increases in royalties due to mining a higher proportion of coal subject to federal royalty ($6.8 million); (c) higher repair and maintenance and operating supply costs ($4.4 million); (d) increases in outside services ($1.7 million); (e) an increase in inventory charges to expense related to an overall higher ratio of tons sold vs. tons produced in the three months ended March 31, 2008 compared to the prior year period ($12.4 million); (f) increased longwall move expenses ($1.4 million); (g) increased purchased coal costs as a result of higher purchased coal volumes ($1.6 million) and (h) increased miscellaneous other expenses ($0.3 million); partially offset by (i) decreased transportation and loading costs ($3.0 million). Cost of coal sales per ton was $17.10 for the three months ended March 31, 2008 compared to $15.12 per ton for the three months ended March 31, 2007.

Selling, general and administrative expenses. Selling, general and administrative expenses for the three months ended March 31, 2008 increased $6.0 million compared to the three months ended March 31, 2007. Period-over-period increases were due to: (a) higher expenses incurred for employee compensation and benefit related expenses ($5.2 million) which includes approximately $2.5 million in additional stock-based compensation related to modifying the vesting conditions for certain stock-based awards; (b) higher miscellaneous overhead expenses including legal and insurance expenses ($1.0 million); partially offset by (c) lower consulting fees ($0.2 million).

20

Accretion on asset retirement obligations.Accretion on asset retirement obligations is a result of accounting for asset retirement obligations under Statement of Financial Accounting Standards (“SFAS”) No. 143,Accounting for Asset Retirement Obligations (“SFAS No. 143”). Accretion represents the increase in the asset retirement liability to reflect the change in the liability for the passage of time because the initial liability is recorded at present value. Higher accretion expense in 2008 was due to increased asset retirement obligation estimates for the comparable periods.

Depreciation, depletion and amortization. Depreciation, depletion and amortization includes depreciation of plant and equipment, cost depletion of amounts assigned to owned and leased mineral rights and amortization of mine development costs, internal use software and leasehold improvements. Depreciation, depletion and amortization expense increased $2.2 million for the three months ended March 31, 2008 compared to the three months ended March 31, 2007, primarily due to higher depreciation and amortization partially offset by decreased cost depletion. Depreciation and amortization increased by $3.8 million in the three months ended March 31, 2008 compared to the prior year period mainly due to depreciation associated with capital additions to plant and equipment during the twelve months ended March 31, 2008, including depreciation of the Company’s enterprise resource planning (“ERP”) software and implementation costs for which depreciation began in April 2007. Also contributing to higher depreciation expense in the three months ended March 31, 2008 was the completion of an overland conveyor belt that was placed into service in the third quarter of 2007 at the Powder River Basin. Cost depletion decreased by $1.6 million due to decreased production period-over-period.

Coal supply agreement amortization. Application of purchase accounting in 2004 resulted in the recognition of a significant liability for below market priced coal supply agreements as well as a significant asset for above market priced coal supply agreements, both in relation to market prices at the date of acquisition of mining assets by the Company in 2004. Coal supply agreement amortization increased $1.3 million for the three months ended March 31, 2008 compared to the three months ended March 31, 2007 primarily due to a decrease in the amortization expense credit from below market liability contracts of $2.3 million combined with a $1.0 million decrease in amortization expense from above market contracts. Amortization of the liability for below market priced coal supply agreements during the three months ended March 31, 2008 was $1.7 million of credit to expense compared to $4.0 million of credit to expense in the comparable period of the prior year. Amortization of the asset for above market priced coal supply agreements during the three months ended March 31, 2008 was $1.9 million of expense compared to $2.9 million of expense in the comparable period of the prior year. As shipments on coal supply agreements valued in purchase accounting are completed, the period-over-period impact of the amortization on both the asset and liability balances will continue to diminish until approximately 2010 when shipments associated with these coal supply agreements are estimated to be complete.

Employee and contract termination costs and other. On April 4, 2007, Wabash announced the idling of the mine in southern Illinois. The mine had become economically unviable at that time as a result of a combination of factors, including aged infrastructure, softening market conditions and the prospect of a new higher cost labor contract with the UMWA. The Company recognized employee termination costs for salaried employees resulting from ongoing benefit obligations of $2.3 million in accordance with the provisions of SFAS No. 112,Employers’ Accounting for Postemployment Benefits. These costs are recorded asEmployee and contract termination costs and other in the Consolidated Statements of Operations and Comprehensive Income for the three months ended March 31, 2007. As of March 31, 2008 and December 31, 2007, the Company’s liabilities for employee termination costs were $0.1 million and $0.2 million, respectively, and are included inAccrued Expenses and Other Current Liabilities.

21

Segment Analysis

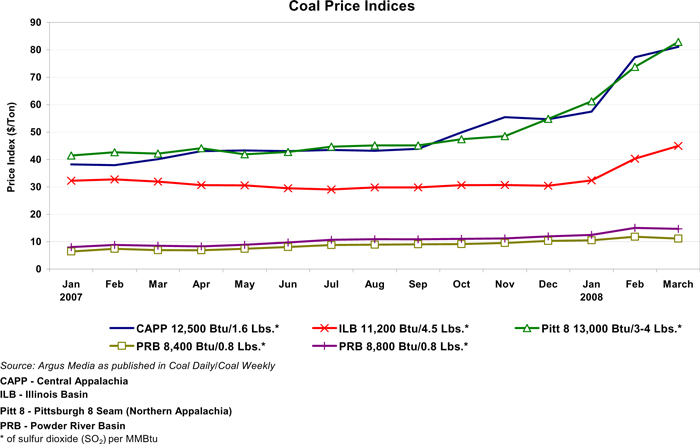

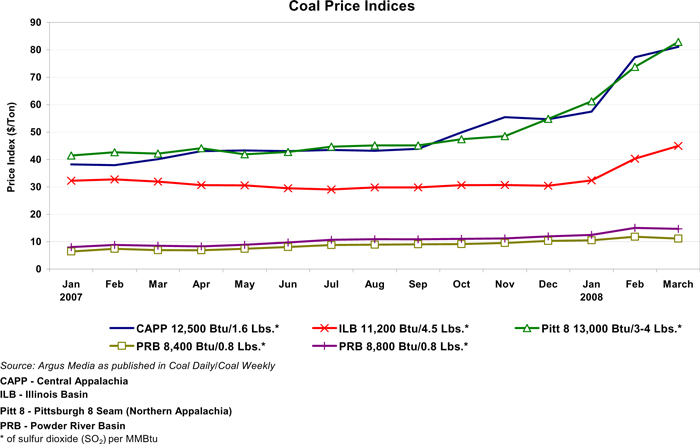

Utilizing data published by Argus Media, the following graph sets forth representative steam coal prices in various U.S. markets. The prices are not necessarily representative of the coal prices actually obtained by the Company. Changes in coal prices have an impact over time on the Company’s average sales realization per ton and, ultimately, its consolidated financial results.

22

| | | | | | | | | | | | | | |

| | | Three Months Ended

March 31, | | Increase (Decrease) | |

| | | 2008 | | | 2007 | | Tons/$ | | | Percent | |

| | | (Unaudited, in thousands, except sales realization per ton) | |

Powder River Basin | | | | | | | | | | | | | | |

Tons sold | | | 12,603 | | | | 12,637 | | | (34 | ) | | — | |

Average sales realization per ton | | $ | 10.10 | | | $ | 9.13 | | $ | 0.97 | | | 11 | % |

Total revenues | | $ | 128,137 | | | $ | 115,741 | | $ | 12,396 | | | 11 | % |

Income from operations | | $ | 12,755 | | | $ | 20,830 | | $ | (8,075 | ) | | (39 | )% |

Northern Appalachia | | | | | | | | | | | | | | |

Tons sold | | | 4,072 | | | | 3,600 | | | 472 | | | 13 | % |

Average sales realization per ton | | $ | 42.97 | | | $ | 40.61 | | $ | 2.36 | | | 6 | % |

Total revenues | | $ | 176,155 | | | $ | 148,139 | | $ | 28,016 | | | 19 | % |

Income from operations | | $ | 34,140 | | | $ | 40,110 | | $ | (5,970 | ) | | (15 | )% |

Central Appalachia | | | | | | | | | | | | | | |

Tons sold | | | 1,750 | | | | 2,161 | | | (411 | ) | | (19 | )% |

Average sales realization per ton | | $ | 58.04 | | | $ | 52.41 | | $ | 5.63 | | | 11 | % |

Total revenues | | $ | 102,690 | | | $ | 116,673 | | $ | (13,983 | ) | | (12 | )% |

(Loss) income from operations | | $ | (2,701 | ) | | $ | 3,125 | | $ | (5,826 | ) | | (186 | )% |

Powder River Basin—Income from operations decreased $8.1 million period-over-period due to increased production costs of $20.5 million partially offset by increased revenues of $12.4 million. As explained in the revenue section above, the increased revenues resulted from an 11% increase in average coal sales realization per ton. Assuming acceptable market conditions exist, we expect future increases in tons sold at the Belle Ayr mine primarily due to the expansion of its annual capacity. Production costs increased $20.5 million for the three months ended March 31, 2008 compared to the three months ended March 31, 2007, reflecting higher period-over-period cost of sales of $18.8 million, an increase in depreciation, depletion and amortization costs of $1.4 million and an increase in other miscellaneous expenses of $0.3 million.

The $18.8 million increase in cost of sales referred to above resulted from an increase in cash costs ($18.7 million) and increased miscellaneous other expenses ($0.1 million). The $18.7 million period-over-period increase in cash costs were primarily in the following areas: (a) supply and service costs primarily consisting of operating supply costs, explosives, diesel fuel and outside services ($8.4 million); (b) labor and employee benefits ($1.9 million); (c) increased royalty costs mainly due to mining a higher amount of coal that is subject to federal royalties ($7.2 million); and (d) miscellaneous expenses ($1.2 million). Cost of coal sales per ton increased 24% period-over-period.

Higher total depreciation, depletion and amortization costs of $1.4 million related primarily to a period-over-period $0.3 million increase in amortization of coal supply agreements due to a decrease in the credit to amortization expense from below market liability contracts, as shipments on a number of these below market liability coal supply agreements valued in purchase accounting were completed and higher depreciation of $1.1 million as a result of higher capital expenditures during the prior twelve months and increased depreciation related to the completion of an overland conveyor belt that was placed into service during the three months ended September 30, 2007.

Northern Appalachia—Income from operations decreased by $6.0 million period-over-period due to increased production costs of $34.2 million partially offset by increased revenues of $28.0 million and decreased other miscellaneous costs of $0.2 million. As explained in the revenue section above, the increase in revenues resulted from a 13% period-over-period increase in tons sold and a 6% increase in average sales realization per ton. Coal sales volumes increased as a result of increased shipments from both mines, which included the purchase of approximately 0.3 million tons of coal to fulfill existing contracts so that coal produced by the Emerald mine could be sold at prices more indicative of the current market prices. Despite a scheduled longwall move during the last week of the quarter, tons sold at the Cumberland mine increased 9% in the three months ended March 31, 2008 compared to the prior year period. Tons sold at the Emerald mine increased 18% in the three months ended March 31, 2008 compared to the prior year period primarily due to sales of purchased coal mentioned previously. Production at Emerald decreased 12% period-over-period due to a decrease in tons mined by the longwall mining units. Lower tons mined resulted from production delays that were caused by hard cutting conditions due to sandstone intrusions, equipment failures, weather-related power outages and reduced mining rates to maintain compliance with ventilation plans. This lower production was offset partially by the late February 2008 introduction of a second longwall operating in a new district at Emerald.

23

Total production costs increased $34.2 million for the three months ended March 31, 2008 compared to the three months ended March 31, 2007, reflecting higher period-over-period cost of sales of $34.3 million and higher miscellaneous other costs of $0.2 million, partially offset by lower depreciation, depletion and amortization costs of $0.3 million.

The $34.3 million period-over-period increase in cost of sales referred to above was the result of increased cash costs ($9.7 million), increased purchased coal expense ($14.9 million), increased inventory charges to expense related to a higher ratio of tons sold vs. tons produced in the three months ended March 31, 2008 compared to the prior year period ($9.5 million) and increased miscellaneous other costs ($0.2 million). The $9.7 million increase in cash costs were primarily incurred in the following areas: (a) higher labor and employee benefit costs, due to a higher number of employees and period-over-period wage and benefit increases, due primarily to the UMWA wage agreement signed in the second quarter of 2007 ($8.1 million); (b) higher supply and service costs primarily consisting of operating supply costs from increased usage of roof bolts, miner bits and water handling requirements, repairs and maintenance costs due to the timing of rebuilding longwall and other mining equipment and outside services ($1.7 million); (c) higher longwall move expenses ($1.4 million); (d) increased miscellaneous expenses ($0.1 million); partially offset by (e) lower transportation and loading costs ($1.6 million). Cost of coal sales per ton increased by 25% period-over-period.