UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, DC 20549

FORM 10-K/A

(Amendment No. 1)

| x | ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2006

OR

| ¨ | TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

Commission file number: 001-32679

International Coal Group, Inc.

(Exact name of Registrant as specified in its charter)

| | |

| Delaware | | 20-2641185 |

(State or other jurisdiction of incorporation or organization) | | (I.R.S. Employer Identification No.) |

300 Corporate Centre Drive

Scott Depot, WV 25560

(Address of principal executive offices—zip code)

(304) 760-2400

Registrant’s telephone number, including area code

| | |

| Securities registered pursuant to Section 12(b) of the Act: | | Name on each exchange on which registered: |

| |

Common Stock, par value $0.01 per share | | The New York Stock Exchange |

Securities registered pursuant to Section 12(g) of the Act:

None.

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes ¨ No x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Exchange Act. Yes ¨ No x

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K/A or any amendment to this Form 10-K/A. Yes x No ¨

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, or a non-accelerated filer. See definition of “accelerated filer and large accelerated filer” in Rule 12b-2 of the Exchange Act. (Check one).

| | | | |

Large accelerated filer x | | Accelerated filer ¨ | | Non-accelerated filer ¨ |

Indicate by check mark whether the registrant is a shell company (as defined in the Exchange Act Rule 12b-2). Yes ¨ No x

Aggregate market value of common stock held by non-affiliates of the registrant as of December 31, 2006, the last business day of the registrant’s most recently completed fiscal year, at a closing price of $5.45 per share as reported by the New York Stock Exchange, was $695,347,869. Shares of common stock beneficially held by each executive officer and director and their respective spouses have been excluded since such persons may be deemed to be affiliates. This determination of affiliate status is not necessarily a conclusive determination for other purposes.

Number of shares of common stock outstanding as of February 22, 2007 was 152,904,788.

DOCUMENTS INCORPORATED BY REFERENCE

Part III incorporates certain information by reference from the registrant’s definitive proxy statement for the 2007 annual meeting of stockholders, which proxy statement will be filed on or about April 20, 2007.

EXPLANATORY NOTE

We are filing this Form 10-K/A Amendment No. 1 (this Amendment) to correct information that was included in our original Annual Report on Form 10-K for the year ended December 31, 2006 (2006 Form 10-K) as described below. For the convenience of the reader, this Amendment sets forth the entire 2006 Form 10-K. However, this Amendment amends and restates only Items 6, 7 and 8 of Part II of the 2006 Form 10-K. The other Items are not being amended. Except as described in this Explanatory Note, this Amendment does not modify or update the disclosures in our 2006 Form 10-K. Therefore, this Amendment does not reflect any other events that occurred after the original March 1, 2007 filing date of the 2006 Form 10-K. Forward-looking statements in this Amendment have also not been updated from the 2006 Form 10-K that we filed on March 1, 2007. For updated information, please see the reports that we have filed with the SEC for subsequent periods. In addition, in connection with the filing of this Amendment and pursuant to Rules 12b-15 and 13a-14 under the Exchange Act, we are including with this Amendment currently dated certifications.

In preparing our consolidated financial statements for the year ended December 31, 2006, we incorrectly reported the effect of our adoption of Statement of Financial Accounting Standards No. 158,Employers’ Accounting for Defined Benefit Pension and Other Postretirement Plans—an amendment of FASB Statements No. 87, 88, 106 and 132(R), by including the transition adjustment of $(4.3) million, net of tax of $2.6 million, as a component of comprehensive loss. Also within the transition adjustment, we incorrectly recorded deferred taxes of $0.4 million associated with actuarial gains related to the subsidy provided for by the Medicare Prescription Drug, Improvement, and Modernization Act of 2003. The amount originally reported as comprehensive loss for the year ended December 31, 2006 was $(13.6) million; the restated amount after the correction of the error is $(9.3) million. The amounts originally reported as deferred income taxes and the transition adjustment were $143.1 million and $(4.3) million, respectively; the restated amounts after the correction of the error were $142.6 million and $(3.8) million, respectively.

Additionally, we incorrectly presented our consolidating financial statement schedules contained in the supplementary guarantor information in Note 22 within the consolidated financial statements included in Item 8 by using the cost method of accounting for our investments in subsidiaries rather than the equity method. The presentation of the supplementary guarantor information has been restated to reflect the accounting for all investments in subsidiaries using the equity method of accounting. Net income (loss) of the subsidiaries is therefore reflected in the parent’s investment accounts. The net loss of the parent as originally reported was $(0.7) million and $(16.7) million for the years ended December 31, 2006 and 2005, respectively, and $(2.6) million for the period May 13, 2004 to December 31, 2004. The restated net income (loss) of the parent after the correction was $(9.3) million and $31.8 million for the years ended December 31, 2006 and 2005, respectively, and $4.2 million for the period May 13, 2004 to December 31, 2004. The balance sheets of the parent as originally reported were restated to reflect the parent’s investment in its subsidiaries of $958.4 million and $700.4 million at December 31, 2006 and 2005, respectively, with a corresponding increase in stockholders’ equity. The statements of cash flows of the parent as originally reported were restated to reflect investments by the parent in its subsidiaries of $172.8 million and $193.4 million for the years ended December 31, 2006 and 2005, respectively, and $147.6 million for the period May 13, 2004 to December 31, 2004. Eliminations were added to the consolidating financial statement schedules to adjust for the parent’s investments in subsidiaries and intercompany balances and transactions. The changes in presentation did not affect our consolidated financial position, consolidated results of operations or consolidated cash flows.

INDEX TO ANNUAL REPORT

ON FORM 10-K/A

Table of Contents

| * | The information required by Items 10, 11, 12, 13 and 14, to the extent not included in this document, is incorporated herein by reference to the information included under the captions “Election of Directors”, “Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters,” “Certain Relationships and Related Party Transactions,” “Audit Matters,” and “ Executive Officers” in the registrant’s definitive proxy statement which is expected to be filed on or about April 20, 2007. |

i

SPECIAL NOTE REGARDING FORWARD-LOOKING STATEMENTS

This Annual Report on Form 10-K/A contains forward-looking statements that are not statements of historical fact and may involve a number of risks and uncertainties. We have used the words “anticipate,” “believe,” “could,” “estimate,” “expect,” “intend,” “may,” “plan,” “predict,” “project” and similar terms and phrases, including references to assumptions, in this report to identify forward-looking statements. These forward-looking statements are made based on expectations and beliefs concerning future events affecting us and are subject to uncertainties and factors relating to our operations and business environment, all of which are difficult to predict and many of which are beyond our control, that could cause our actual results to differ materially from those matters expressed in or implied by these forward-looking statements. The following factors are among those that may cause actual results to differ materially from our forward-looking statements:

| | • | | market demand for coal, electricity and steel; |

| | • | | availability of qualified workers; |

| | • | | future economic or capital market conditions; |

| | • | | weather conditions or catastrophic weather-related damage; |

| | • | | our production capabilities; |

| | • | | the ongoing integration of the former Anker and CoalQuest entities into our business; |

| | • | | the consummation of financing, acquisition or disposition transactions and the effect thereof on our business; |

| | • | | our plans and objectives for future operations and expansion or consolidation; |

| | • | | our relationships with, and other conditions affecting, our customers; |

| | • | | the availability and costs of key supplies or commodities such as diesel fuel, steel, explosives and tires; |

| | • | | prices of fuels which compete with or impact coal usage, such as oil and natural gas; |

| | • | | timing of reductions or increases in customer coal inventories; |

| | • | | long-term coal supply arrangements; |

| | • | | unexpected maintenance and equipment failure; |

| | • | | environmental, safety and other laws and regulations, including those directly affecting our coal mining and production, and those affecting our customers’ coal usage; |

| | • | | railroad, barge, trucking and other transportation availability, performance and costs; |

| | • | | employee benefits costs and labor relations issues; |

| | • | | replacement of our reserves; |

| | • | | our assumptions concerning economically recoverable coal reserve estimates; |

| | • | | availability and costs of credit, surety bonds and letters of credit; |

| | • | | title defects or loss of leasehold interests in our properties which could result in unanticipated costs or inability to mine these properties; |

| | • | | future legislation and changes in regulations or governmental policies or changes in interpretations thereof, including with respect to safety enhancements; |

| | • | | the impairment of the value of our goodwill; |

ii

| | • | | the ongoing effects of the Sago mine explosion; |

| | • | | our liquidity, results of operations and financial condition; |

| | • | | the adequacy and sufficiency of our internal controls; and |

| | • | | legal and administrative proceedings, settlements, investigations and claims. |

You should keep in mind that any forward-looking statement made by us in this Annual Report on Form 10-K/A speaks only as of the date on which we make it. New risks and uncertainties arise from time to time, and it is impossible for us to predict these events or how they may affect us. We have no duty to, and do not intend to, update or revise the forward-looking statements in this report after the date of this report, except as may be required by law. In light of these risks and uncertainties, you should keep in mind that any forward-looking statement made in this report might not occur.

iii

PART I

Introduction

This report is both our 2006 annual report to stockholders and our 2006 Annual Report on Form 10-K/A required under the federal securities laws.

In this annual report, the term “Horizon” refers to Horizon NR, LLC (the entity holding the operating subsidiaries of Horizon Natural Resources Company) and its consolidated subsidiaries, the term “Anker” refers to Anker Coal Group, Inc. and its consolidated subsidiaries, and the term “CoalQuest” refers to CoalQuest Development, LLC. References to the “Anker and CoalQuest acquisitions” refer to our acquisition, respectively, of each of Anker and CoalQuest, which occurred on November 18, 2005. Unless otherwise noted, all of our actual production and financial information includes the results of Anker and CoalQuest since November 19, 2005. On November 18, 2005, we and our subsidiaries also underwent a corporate reorganization in which we became the parent holding company and ICG, Inc., the prior parent holding company, became our subsidiary. Unless the context otherwise indicates, as used in this annual report, the terms “ICG,” “we,” “our,” “us” and similar terms refer to International Coal Group, Inc. and its consolidated subsidiaries, after giving effect to the corporate reorganization and the Anker and CoalQuest acquisitions.

For purposes of all financial disclosures contained in this report, Horizon (together with its predecessor AEI Resources Holding, Inc. and its consolidated subsidiaries) is the predecessor to ICG.

The term “coal reserves” as used in this report means proven and probable reserves that are the part of a mineral deposit that can be economically and legally extracted or produced at the time of the reserve determination and the term “non-reserve coal deposits” in this report means a coal bearing body that has been sufficiently sampled and analyzed to assume continuity between sample points but do not qualify as a commercially viable coal reserve as prescribed by SEC rules until a final comprehensive SEC prescribed evaluation is performed.

Because certain terms used in the coal industry may be unfamiliar to many investors, we have provided a “Glossary of Selected Terms” at the end of Item 1.

Overview

We are a leading producer of coal in Northern and Central Appalachia with a broad range of mid to high Btu, low to medium sulfur steam and metallurgical coal. Our Appalachian mining complexes, which include ten of our mining complexes, are located in West Virginia, Kentucky and Maryland. We also have a complementary mining complex of mid to high sulfur steam coal strategically located in the Illinois Basin. We market our coal to a diverse customer base of largely investment grade electric utilities, as well as domestic and international industrial customers. The high quality of our coal and the availability of multiple transportation options, including rail, truck and barge, throughout the Appalachian region enable us to participate in both the domestic and international coal markets. Appalachian coal markets exhibited price volatility in 2006 due to a supply-demand imbalance that continues into 2007.

ICG, Inc. was formed by WL Ross & Co. LLC (“WLR”), and other investors in May 2004 to acquire and operate competitive coal mining facilities. As of September 30, 2004, ICG, Inc. acquired certain key assets of Horizon through a bankruptcy auction. These assets are high quality reserves strategically located in Appalachia and the Illinois Basin, are union free, have limited reclamation liabilities and are substantially free of other legacy liabilities. Due to its initial capitalization, ICG, Inc. was able to complete the acquisition without incurring a significant level of indebtedness. Consistent with the WLR investor group’s strategy to consolidate attractive coal assets, we completed the corporate reorganization and acquired Anker and CoalQuest in November 2005, which further diversified our reserves.

1

As of December 31, 2006, based on an independent evaluation performed as of January 1, 2005 and management’s estimates, we owned or controlled approximately 317 million tons of metallurgical quality coal reserves and approximately 746 million tons of steam coal reserves. Further, we own or control approximately 566 million tons of non-reserve coal deposits.

Steam coal is primarily consumed by large electric utilities and industrial customers as fuel for electricity generation. Demand for low sulfur steam coal has grown significantly since the introduction of certain controls associated with the Clean Air Act and the decline in coal production in the eastern half of the United States. Metallurgical coal is primarily used to produce coke, a key raw material used in the steel making process. Generally, metallurgical coal sells at a premium to steam coal because of its higher quality and its importance and value in the steel making process.

For the year ended December 31, 2006, we sold 19.4 million tons of coal, of which 19.2 million tons were steam coal and 0.2 million tons were metallurgical coal. Our steam coal sales volume in 2006 consisted of mid to high quality, high Btu (greater than 12,000 Btu/lb.), low to medium sulfur (1.5% or less) coal, which typically sells at a premium to lower quality, lower Btu, higher sulfur steam coal. Our three largest customers for the year ended December 31, 2006 were Georgia Power Company, Duke Power and Carolina Power & Light Company and we derived approximately 56% of our coal revenues from sales to our five largest customers. Revenues from sales to Georgia Power Company, Duke Power and Carolina Power & Light Company each accounted for more than 10% of coal revenues in 2006.

We have three reportable business segments, which are based on the coal regions in which we operate: (i) Central Appalachian, comprised of both surface and underground mines, (ii) Northern Appalachian, comprised of both surface and underground mines, and (iii) Illinois Basin, representing one underground mine. Financial information concerning industry segments, as defined by accounting principles generally accepted in the United States of America, as of and for the years ended December 31, 2006 and 2005 and for the period May 13, 2004 (inception) to December 31, 2004 is included in Note 21 to our consolidated financial statements, and for the period January 1, 2004 to September 30, 2004 is included in Note 11 to the combined financial statements of Horizon, each included at the end of this report.

History

The Horizon Acquisition

On February 28, 2002, Horizon (at that time operating as AEI Resources Holdings, Inc.) filed a voluntary petition for Chapter 11 and its plan of reorganization became effective on May 8, 2002. However, Horizon’s profit margins and cash flows were negatively impacted in fiscal year 2002 by, among other things, the falling price of coal and continued increases in certain operating expenses. Due to capital and permit constraints, Horizon had to mine in areas which produced coal at greatly reduced profit margins thus severely reducing cash flow.

As a result of its continuing financial and operational difficulties, Horizon filed a second voluntary petition for relief under Chapter 11 on November 13, 2002. Horizon obtained a debtor-in-possession financing facility of up to $350.0 million and was effective in rationalizing its operations, selling non-core assets, paying down outstanding borrowings and generating substantial operating profit. With stabilized operations and a significantly improved coal market, Horizon filed a joint plan of reorganization and a joint plan of liquidation under Chapter 11.

ICG, Inc. was formed by WLR and other investors in May 2004. The Horizon assets were sold through a bankruptcy auction on August 17, 2004. Presented as a combined $290.0 million cash bid with A.T. Massey, ICG, Inc. agreed to pay $285.0 million in cash plus the assumption of up to $5.0 million of liabilities to be paid to contract counterparties to cure the pre-sale defaults under the leases and contracts assumed and assigned to ICG, Inc. to acquire the assets. ICG, Inc. also contributed a credit bid of second lien Horizon bonds, and A.T. Massey agreed to pay $5.0 million in cash to acquire a separate group of assets associated with two Horizon

2

subsidiaries. The credit bid included the cancellation of $482.0 million of certain Horizon bonds in return for which those Horizon bondholders received the right to participate in a rights offering to purchase ICG common stock. Shares issued in connection with the rights offering are included in our outstanding stock.

In addition, Lexington Coal Company, LLC, a newly formed entity, was organized by the founding ICG, Inc. stockholders to assume certain reclamation liabilities and assets not otherwise being purchased by A.T. Massey or ICG, Inc. In order to provide support to Lexington Coal Company in consideration for assuming these liabilities, we agreed, among other things, to pay a 0.75% additional payment on the gross sales receipts for coal mined and sold from the assets we acquired from Horizon until the completion by Lexington Coal Company of all reclamation liabilities acquired from Horizon. Other than the initial limited commonality of ownership of ICG and Lexington Coal Company, there is no relationship between the entities.

The bankruptcy court confirmed the sale on September 16, 2004 as part of the completion of the Horizon bankruptcy proceedings. At closing, we increased the purchase price by $6.25 million, primarily to satisfy increased administrative expenses, and the sale was completed as of September 30, 2004.

The acquisition was financed through equity investments and borrowings under our senior secured credit facility, which we entered into at the closing of the Horizon acquisition.

The Anker and CoalQuest Acquisitions

On March 31, 2005, ICG, Inc. entered into a business combination agreement with us, Anker and ICG Merger Sub, Inc., our indirect wholly owned subsidiary, and Anker Merger Sub, Inc., our indirect wholly owned subsidiary. Under the terms of the business combination agreement, on November 18, 2005, ICG Merger Sub merged with and into ICG, Inc. and Anker Merger Sub merged with and into Anker, with each of ICG, Inc. and Anker surviving their respective mergers as our wholly owned subsidiaries and we became the new parent holding company. The stockholders of Anker, collectively, received 14,840,909 shares of our common stock.

On March 31, 2005, ICG, Inc. also entered into a business combination agreement with us, CoalQuest and CoalQuest Merger Sub LLC, our indirect wholly owned subsidiary, and the members of CoalQuest. Under the terms of the business combination agreement, on November 18, 2005, the members of CoalQuest contributed their interests in CoalQuest to us in exchange for shares of our common stock. As a result of this contribution, CoalQuest became our wholly owned subsidiary. The members of CoalQuest, collectively, received 9,250,000 shares of our common stock.

Our Reorganization and Public Offering

On November 18, 2005, International Coal Group, Inc. also completed a corporate reorganization. Prior to this reorganization, the top-tier parent holding company was ICG, Inc. Upon completion of this reorganization, International Coal Group, Inc. became the new top-tier parent holding company. In the corporate reorganization, the stockholders of ICG, Inc. received one share of International Coal Group, Inc. common stock for each share of ICG, Inc. common stock. On November 21, 2005, International Coal Group, Inc. common stock commenced trading on the New York Stock Exchange.

On December 12, 2005, we completed a public offering of 21 million shares of common stock. Net proceeds from the public offering were approximately $210.5 million. We used the proceeds to repay $188.7 million of our term loan debt and $21.2 million of borrowings under our revolving credit facility.

The Coal Industry

A major contributor to the world energy supply, coal represents over 25% of the world’s primary energy consumption according to the World Coal Institute. The primary use for coal is to fuel electric power generation. In 2006, coal-fired plants generated approximately 50% of the electricity produced in the United States, according to the Energy Information Administration (“EIA”), a statistical agency of the U.S. Department of Energy.

3

Coal Markets

Coal produced in the United States is used primarily by utilities to generate electricity, by steel companies to produce coke for use in blast furnaces and by a variety of industrial users to heat and power foundries, cement plants, paper mills, chemical plants and other manufacturing and processing facilities. Significant quantities of coal are also exported from both east and west coast terminals. Coal used as fuel to generate electricity is commonly referred to as “steam coal.”

Coal has long been favored as an electricity generating fuel by regulated utilities because of its basic economic advantage. The largest cost component in electricity generation is fuel. According to the National Mining Association, coal is by far the cheapest source of power fuel per million Btu, averaging less than one-third the price of both petroleum and natural gas.

The other major market for coal is the steel industry. The type of coal used in steel making is referred to as metallurgical coal and is distinguished by special quality characteristics that include high carbon content, favorable coking characteristics and various other chemical attributes. Metallurgical coal is also generally higher in heat content (as measured in Btus), and therefore is also desirable to utilities as fuel for electricity generation. Consequently, metallurgical coal producers have the ongoing opportunity to select the market that provides maximum revenue and margins. The premium price offered by steel makers for the metallurgical quality attributes is typically higher than the price offered by utility coal buyers that value only the heat content.

Coal Mining Methods

We produce coal using two mining methods: underground room-and-pillar mining using continuous mining equipment, and surface mining, which are explained as follows:

Underground mining

Underground mines in the United States are typically operated using one of two different techniques: room-and-pillar mining or longwall mining. In 2006, approximately 34% of our produced and processed coal volume came from underground mining operations generally using the room-and-pillar method with continuous mining equipment.

Room-and-Pillar Mining

In room-and-pillar mining, rooms are cut into the coalbed leaving a series of pillars, or columns of coal, to help support the mine roof and control the flow of air. Continuous mining equipment is used to cut the coal from the mining face. Generally, openings are driven 20 feet wide and the pillars are generally rectangular in shape measuring 35-50 feet wide by 35-80 feet long. As mining advances, a grid-like pattern of entries and pillars is formed. Shuttle cars are used to transport coal to the conveyor belt for transport to the surface. When mining advances to the end of a panel, retreat mining may begin. In retreat mining, as much coal as is feasible is mined from the pillars that were created in advancing the panel, allowing the roof to cave. When retreat mining is completed to the mouth of the panel, the mined panel is abandoned. The room-and-pillar method is often used to mine smaller coal blocks or thinner seams. It is also employed whenever subsidence is prohibited. Seam recovery ranges from 35% to 70%, with higher seam recovery rates applicable where retreat mining is combined with room-and-pillar mining.

Longwall Mining

The other underground mining method commonly used in the United States is the longwall mining method. We do not currently have any longwall mining operations, but we expect to use this mining method in the development of our Hillman property in West Virginia. In longwall mining, a rotating drum is trammed mechanically across the face of coal and a hydraulic system supports the roof of the mine while it advances through the coal. Chain conveyors then move the loosened coal to an underground mine conveyor system for delivery to the surface.

4

Surface mining

Surface mining is used when coal is found close to the surface. In 2006, approximately 66% of our produced and processed coal volume came from surface mines. This method involves the removal of overburden (earth and rock covering the coal) with heavy earth moving equipment and explosives, loading out the coal, replacing the overburden and topsoil after the coal has been excavated and reestablishing vegetation and plant life and frequently making other improvements that have local community and environmental benefit. Overburden is typically removed at our mines using large, rubber-tired diesel loaders. Seam recovery for surface mining is typically between 80% and 90%. Productivity depends on equipment, geological composition and mining ratios.

We use the following three types of surface mining methods.

Truck-and-Shovel/Loader Mining

Truck-and-shovel/loader mining is a surface mining method that uses large shovels or loaders to remove overburden which is used to backfill pits after coal removal. Shovels or loaders load coal into haul trucks for transportation to a preparation plant or unit train loadout facility. Seam recovery using the truck-and-shovel/loader mining method is typically 85% or more.

Dragline Mining

Dragline mining is a surface mining method that uses large capacity draglines to remove overburden to expose the coal seams. Shovels or loaders load coal in haul trucks for transportation to a preparation plant or unit train loadout facility. Seam recovery using the dragline method is typically 85% or more and productivity levels are similar to those for truck-and-shovel/loader mining.

Highwall Mining

Highwall mining is a surface mining method generally utilized in conjunction with truck-and-shovel/ loader surface mining. At the highwall exposed by the truck-and-shovel/loader operation a modified continuous miner with an attached beltline system cuts horizontal passages from the highwall into a seam. These passages can penetrate to a depth of up to 1,600 feet. This method typically can recover up to 65% of the reserve block penetrated.

Coal preparation and blending

Depending on coal quality and customer requirements, raw coal may in some cases be shipped directly from the mine to the customer. Generally, raw coal from surface mines can be shipped in this manner. However, the quality of most underground raw coal does not allow it to be shipped directly to the customer without processing in a preparation plant. Preparation plants separate impurities from coal. This processing upgrades the quality and heating value of the coal by removing or reducing sulfur and ash-producing materials, but entails additional expense and results in some loss of coal. Coals of various sulfur and ash contents can be mixed or “blended” at a preparation plant or loading facility to meet the specific combustion and environmental needs of customers. Coal blending helps increase profitability by reducing the cost of meeting the quality requirements of specific customer contracts, thereby optimizing contract revenue.

Coal Characteristics

In general, coal of all geological composition is characterized by end use as either steam coal or metallurgical coal. Heat value and sulfur content are the most important variables in the profitable marketing and transportation of steam coal, while ash, sulfur and various coking characteristics are important variables in the profitable marketing and transportation of metallurgical coal. We mine, process, market and transport bituminous steam and metallurgical coal, characteristics of which are described below.

5

Heat Value

The heat value of coal is commonly measured in Btus per pound of coal. A Btu is the amount of heat needed to raise one pound of water one degree Fahrenheit. Coal found in the Eastern and Midwestern regions of the United States tends to have a heat content ranging from 10,000 to 14,000 Btus per pound, as received. As received Btus per pound includes the weight of moisture in the coal on an as sold basis. Most coal found in the Western United States ranges from 8,000 to 10,000 Btus per pound, as received.

Bituminous Coal

Bituminous coal is a relatively soft black coal with a heat content that ranges from 10,000 to 14,000 Btus per pound. This coal is located primarily in Appalachia, Arizona, Colorado, the Midwest and Utah, and is the type most commonly used for electricity generation in the United States. Bituminous coal is also used for industrial steam purposes by utility and industrial customers, and as metallurgical coal in steel production.

Sulfur Content

Sulfur content can vary from seam to seam and sometimes within each seam. When coal is burned, it produces sulfur dioxide, the amount of which varies depending on the chemical composition and the concentration of sulfur in the coal. Compliance coal is coal which, when burned, emits 1.2 pounds or less of sulfur dioxide per million Btus and complies with the requirements of the Clean Air Act Acid Rain program. Low sulfur coal is coal which, when burned, emits approximately 1.6 pounds or less of sulfur dioxide per million Btus. Mid-sulfur coal is characterized as coal which, when burned, emits greater than 1.6 pounds of sulfur dioxide per million Btus but less than 2.5 pounds of sulfur dioxide per million Btus. High sulfur coal is generally characterized as coal which, when burned, emits greater than 2.5 pounds per million Btus.

High sulfur coal can be burned in electric utility plants equipped with sulfur-reduction technology, such as scrubbers, which can reduce sulfur dioxide emissions by up to 99%. Plants without scrubbers can burn high sulfur coal by blending it with lower sulfur coal or by purchasing emission allowances on the open market. Each emission allowance permits the user to emit a ton of sulfur dioxide. By 2000, 90,000 megawatts of electric generation capacity utilized scrubbing technologies. According to the EIA, by 2025, an additional 27,000 megawatts of electric generation capacity will have installed scrubbers. Additional scrubbing will provide new market opportunities for our medium to high sulfur coal. All new coal-fired electric utility generation plants built in the United States will use clean coal-burning technology.

Other Characteristics

Ash is the inorganic residue remaining after the combustion of coal. As with sulfur content, ash content varies from coal seam to coal seam. Ash content is an important characteristic of coal because it increases transportation costs and electric generating plants must handle and dispose of ash following combustion.

Moisture content of coal varies by the type of coal, the region where it is mined and the location of coal within a seam. In general, high moisture content decreases the heat value per pound of coal, thereby increasing the delivered cost per Btu. Moisture content in coal, as sold, can range from approximately 5% to 30% of the coal’s weight.

Operations

As of December 31, 2006, we operated a total of 13 surface and 12 underground coal mines located in Kentucky, Maryland, West Virginia and Illinois. Approximately 66% of our production has come from surface mines, and the remaining production has come from our underground mines. These mining facilities include eight preparation plants, each of which receive, blend, process and ship coal that is produced from one or more of

6

our 25 active mines. Our underground mines generally consist of one or more single or dual continuous miner sections which are made up of the continuous miner, shuttle cars, roof bolters and various ancillary equipment. Our surface mines are a combination of mountain top removal, highwall contour and cross ridge operations using truck/loader equipment fleets along with large production tractors. A dragline is employed as the prime earthmover at one of our surface mines. Most of our preparation plants are modern heavy media plants that generally have both coarse and fine coal cleaning circuits. We currently own most of the equipment utilized in our mining operations. We employ preventive maintenance and rebuild programs to ensure that our equipment is modern and well maintained. The mobile equipment utilized at our mining operations is replaced on an on-going basis with new, more efficient units based on equipment age and mechanical condition. Each year we endeavor to replace the oldest units, thereby maintaining productivity while minimizing capital expenditures. The following table provides summary information regarding our principal active operations as of December 31, 2006.

| | | | | | | | | | | | | | | | | | |

| | | | | | | | Number and Type of Mines | | | | | | | |

Mining Complexes(1) | | Location | | Preparation Plant(s) | | | Under-

ground | | Surface | | Total | | Mining Method(2) | | Transportation | | Tons

Produced in

2006 | |

| | | | | | | | | | | | | | | | | | (in thousands) | |

ICG Eastern, LLC | | Cowen, WV | | 1 | | | 0 | | 1 | | 1 | | MTR, DL, TSL | | Rail | | 3,048.8 | |

ICG Hazard, LLC | | Hazard, KY | | 0 | | | 0 | | 5 | | 5 | | HW, MTR, TSL | | Rail, Truck | | 3,709.9 | |

Flint Ridge | | Hazard, KY | | 1 | | | 2 | | 1 | | 3 | | CTR, TSL, R&P, HW | | Rail, Truck | | 1,718.3 | |

ICG Knott County, LLC | | Kite, KY | | 2 | | | 5 | | 0 | | 5 | | R&P | | Rail | | 1,515.2 | |

ICG East Kentucky, LLC | | Pike Co., KY | | 0 | | | 0 | | 1 | | 1 | | MTR, TSL | | Rail | | 1,255.5 | |

Vindex Energy Corporation(7) | | Garrett Co., MD | | 1 | | | 0 | | 3 | | 3 | | CRM, CTR | | Truck, Rail(3) | | 1,062.9 | |

Patriot Mining Company | | Monongalia Co., WV | | 0 | | | 0 | | 2 | | 2 | | CTR, TSL | | Barge, Rail, Truck | | 888.3 | |

Wolf Run Mining Buckhannon Division | | Upshur Co., WV | | 1 | | | 2 | | 0 | | 2 | | R&P | | Rail, Truck | | 820.7 | |

Wolf Run Mining Philippi Development Division | | Barbour Co., WV | | 1 | (4) | | 1 | | 0 | | 1 | | R&P | | Rail | | 58.4 | |

Sycamore Group | | Harrison Co., WV | | 0 | | | 1 | | 0 | | 1 | | R&P | | Truck | | 347.2 | (5)(6) |

ICG Illinois, LLC | | Williamsville, IL | | 1 | | | 1 | | 0 | | 1 | | R&P | | Truck | | 2,084.2 | |

| (1) | Does not include two inactive mining complexes: ICG Beckley and Juliana. |

| (2) | CRM = Cross Ridge Mining; CTR = Contour Mining; R&P = Room-and-pillar; LW = Longwall; MTR = Mountain Top Removal; DL = Dragline; HW = Highwall; TSL = Truck and Shovel/Loader. |

| (3) | Utilizing third-party loadout. |

| (4) | Currently utilizing one circuit. |

| (5) | Mine permitted but undeveloped. |

| (6) | Represents Wolf Run Mining Company’s (f/k/a Anker West Virginia Mining Company, Inc.) 50% share in The Sycamore Group LLC. |

| (7) | Includes Vindex Division of Wolf Run Mining Company (formerly referred to as the “Mt. Storm Division”). |

7

The following table provides the last three years annual production for each of our mining complexes and the average prices received for our coal.

| | | | | | | | | | | | | | | | | | |

| | | 2006 | | 2005 | | 2004 |

Mining Complexes(1) | | Tons

Produced | | | Sales

Realizations(2) | | Tons

Produced | | | Sales

Realizations(2) | | Tons

Produced | | | Sales

Realizations(2) |

ICG Eastern, LLC | | 3,048,800 | | | $ | 43.92 | | 2,766,365 | | | $ | 42.75 | | 2,712,067 | | | $ | 34.12 |

ICG Hazard, LLC | | 3,709,924 | | | $ | 50.05 | | 3,432,153 | | | $ | 44.49 | | 3,978,038 | | | $ | 32.69 |

Flint Ridge(3) | | 1,718,300 | | | $ | 50.81 | | 906,207 | | | $ | 46.17 | | — | | | $ | — |

ICG Knott County, LLC | | 1,515,187 | | | $ | 51.01 | | 1,277,438 | | | $ | 46.74 | | 1,386,554 | | | $ | 39.44 |

ICG East Kentucky, LLC | | 1,255,522 | | | $ | 53.28 | | 1,441,236 | | | $ | 52.15 | | 1,576,345 | | | $ | 40.36 |

Vindex Energy Corporation(4)* | | 1,062,925 | | | $ | 36.62 | | 649,623 | | | $ | 45.00 | | 170,745 | | | $ | 40.70 |

Patriot Mining Company* | | 888,265 | (5) | | $ | 23.52 | | 700,762 | | | $ | 24.26 | | 423,448 | (5) | | $ | 20.46 |

Wolf Run Mining Buckhannon Division* | | 820,688 | | | $ | 42.46 | | 801,435 | | | $ | 37.05 | | 1,213,851 | | | $ | 34.18 |

Wolf Run Mining Philippi Development Division* | | 58,403 | | | $ | 41.25 | | 122,343 | | | $ | 51.62 | | 255,439 | | | $ | 45.36 |

Sycamore Group* | | 347,241 | | | $ | 29.13 | | 452,349 | | | $ | 27.48 | | 259,270 | | | $ | 24.89 |

ICG Illinois, LLC | | 2,084,193 | | | $ | 24.68 | | 2,325,370 | | | $ | 23.23 | | 2,117,567 | | | $ | 22.44 |

| | | | | | | | | | | | | | | | | | |

| | 16,509,448 | | | | | | 14,875,281 | | | | | | 14,093,324 | | | | |

| | | | | | | | | | | | | | | | | | |

| * | Operated by Anker during 2004 and through November 18, 2005 and by us since November 19, 2005. |

| (1) | Does not include two inactive mining complexes: ICG Beckley and Juliana. |

| (2) | Excludes freight and handling revenue. |

| (3) | Flint Ridge began production in 2005. |

| (4) | Includes Vindex Division of Wolf Run Mining Company (formerly referred to as the “Mt. Storm Division”). |

| (5) | Does not include Patriot’s waste fuel. |

8

Northern and Central Appalachia Mining Operations

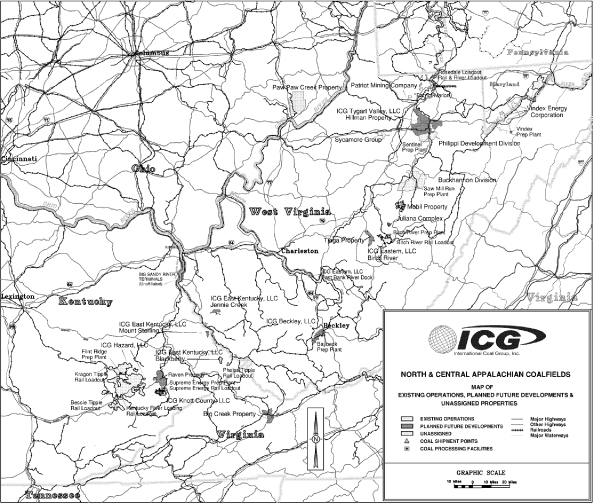

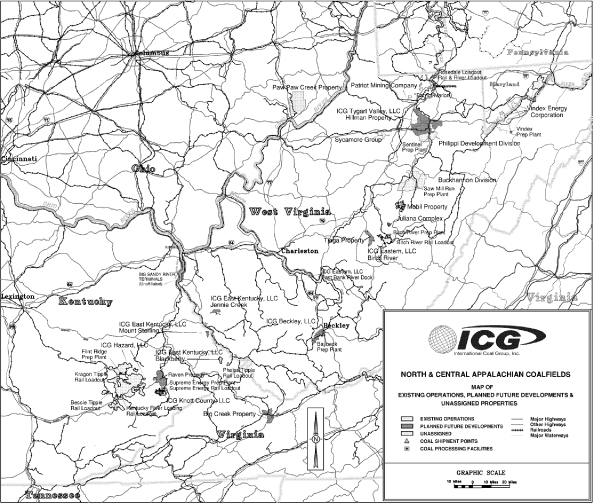

Below is a map showing the location and access to our coal operations in Northern and Central Appalachia:

Our Northern and Central Appalachian mining facilities and reserves are strategically located across West Virginia, Kentucky, Maryland and Virginia and are used to produce and ship coal to its customers located primarily in the eastern half of the United States. All of our Northern and Central Appalachian mining operations are union free.

Our mines in Central Appalachia produced 11.2 million tons of coal in 2006 and our mines in Northern Appalachia produced 3.2 million tons of coal in 2006. The coal produced in 2006 from our Northern and Central Appalachian mining operations was, on average, 12,050 Btu/lb., 1.4% sulfur and 13.6% ash by content. Shipments bound for electric utilities accounted for approximately 95% of the coal shipped by these mines in 2006 compared to 90% of shipments in 2005. Within each mining complex, mines have been developed at strategic locations in proximity to our preparation plants and rail shipping facilities. The mines located in Central Appalachia ship the majority of their coal by the Norfolk Southern and CSX rail lines, although production may also be delivered by truck or barge, depending on the customer.

As of December 31, 2006, these mines had 1,718 employees.

9

ICG Eastern, LLC

ICG Eastern, LLC operates the Birch River surface mine, located 60 miles east of Charleston, near Cowen in Webster County, West Virginia. Birch River started operations in 1990 under Shell Mining Company, was purchased by Zeigler Coal Holding Company, or “Zeigler,” in 1992, and was subsequently acquired by AEI Resources, Inc. from Zeigler in 1998.

Birch River is extracting coal from five distinct coalbeds: (i) Freeport; (ii) Upper Kittanning; (iii) Middle Kittanning; (iv) Upper Clarion; and (v) Lower Clarion. We estimate that Birch River controls 11.5 million tons of coal reserves. Additional potential reserves have been identified in the immediate vicinity of the Birch River mine and exploration activities are currently being conducted in order to add those to the reserve base.

Approximately 81% of the coal reserves are leased, while approximately 19% are owned in fee. Most of the leased reserves are held by four lessors. The leases are retained by annual minimum payments and by tonnage-based royalty payments. All leases can be renewed until all mineable and merchantable coal has been exhausted.

Overburden is removed by a dragline, shovel, front-end loaders, end dumps and bulldozers. Approximately one-third of the total coal sales are run-of-mine, while the other two-thirds are washed at Birch River’s preparation plant. Coal is transported by conveyor belt from the preparation plant to Birch River’s rail loadout, which is served by CSX with origination by the A&O Railroad, a short-line operator.

ICG Hazard, LLC

ICG Hazard, LLC is comprised of two mining complexes: (i) ICG Hazard and (ii) Flint Ridge which together currently operate six surface mines, two underground mines, a unit train loadout (Kentucky River Loading), a preparation plant (Flint Ridge Plant) and other support facilities in eastern Kentucky, near Hazard. The coal reserves and operations were acquired in late-1997 and 1998 by AEI Resources.

ICG Hazard’s five surface mines include: (i) East Mac & Nellie; (ii) Vicco; (iii) Rowdy Gap; (iv) Tip Top; and (v) Thunder Ridge. The coal from these mines is being extracted from the Hazard 11, Hazard 10, Hazard 9, Hazard 8, Hazard 7 and Hazard 5A seams. Nearly all of the coal is marketed run-of-mine. Overburden is removed by front-end loaders, end dumps, bulldozers and blast casting. Coal is transported by on-highway trucks from the mines to the Kentucky River Loading rail loadout, which is served by CSX. Some coal is direct shipped to the customer by truck from the mine pits.

We estimate that ICG Hazard controls 38.8 million tons of coal reserves, plus 1.9 million tons of coal that is classified as non-reserve coal deposits. Most of the property has been adequately explored, but additional core drilling will be conducted within specified locations to better define the reserves.

Approximately 99.6% of ICG Hazard’s reserves are leased. Most of the leased reserves are held by six lessors. In several cases, ICG Hazard has multiple leases with each lessor. The leases are retained by annual minimum payments and by tonnage-based royalty payments. Most leases can be renewed until all mineable and merchantable coal has been exhausted.

Flint Ridge is currently operating two underground mines, one surface mine and one preparation plant. The Flint Ridge underground operations are room-and-pillar mining utilizing continuous miners and shuttle cars. The Flint Ridge surface/highwall mine utilizes front-end loaders, end dumps and bulldozers for the overburden removal. Once the contour is established and the coal is removed, the highwall miner will then complete the coal extraction from the exposed highwall. Coal from the underground mines and the highwall miner is trucked to the preparation plant, processed and hauled to the Kentucky River Loading rail loadout by on-highway trucks or directly to the customer. Coal from the contour mining operation is hauled directly to the Kentucky River Loading rail loadout.

10

We estimate that Flint Ridge controls 30.6 million tons of coal reserves, plus 2.8 million tons of non-reserve coal deposits. Approximately 99.2% of Flint Ridge’s reserves are leased, while 0.8% are owned in fee. The leases are retained by annual minimum payments and by tonnage-based royalty payments. Most leases can be renewed until all mineable and merchantable coal has been exhausted.

An existing preparation plant structure was extensively upgraded in early 2005. Since July 2005, it has been processing coal from ICG Hazard and Flint Ridge mining complexes.

ICG Knott County, LLC

ICG Knott County, LLC operates five underground mines, the Supreme Energy and Raven preparation plants and rail loadouts and other facilities necessary to support the mining operations in eastern Kentucky, near Kite. ICG Knott County was acquired by AEI Resources from Zeigler in 1998 with reserves acquired through a lease from Penn Virginia.

ICG Knott County is producing coal from the Hazard 4, Elkhorn 2 and Elkhorn 3 coalbeds. Three mines are operating in the Hazard 4 coalbed: Calvary, Clean Energy and Elk Hollow. The Raven and Classic mines are operating in the Elkhorn 2 and Elkhorn 3 coalbeds, respectively. We estimate these properties contain 16.0 million tons of coal reserves. Most of the property has been extensively explored, but additional core drilling will be conducted within specified locations to better define the reserves.

Approximately 26% of ICG Knott County’s reserves are owned in fee, while approximately 74% are leased. The leases are retained by annual minimum payments and by tonnage-based royalty payments. The leases can be renewed until all mineable and merchantable coal has been exhausted.

ICG Knott County’s five underground mines are room-and-pillar operations, utilizing continuous miners and shuttle cars. Nearly all of the run-of-mine coal is processed at the Supreme Energy and Raven preparation plants; some of the Hazard 4 run-of-mine coal is blended with the washed coal. ICG Knott County began operations at the Raven preparation plant during 2006 in conjunction with Loadout, LLC, an affiliate of Penn Virginia Resources Partners, L.P.

Nearly all of ICG Knott County’s coal is transported by rail. The loadouts are served by CSX.

ICG East Kentucky, LLC

ICG East Kentucky, LLC is a surface mining operation located in Pike County, Kentucky, near Phelps. ICG East Kentucky currently operates the Blackberry surface mine and the Phelps Loadout. ICG East Kentucky was acquired by AEI Resources in the second quarter of 1999.

Blackberry is an area surface mine that produces coal from four separate coalbeds: (i) Taylor; (ii) Fireclay; (iii) Lower Fireclay; and (iv) Hamlin. All of the coal is sold run-of-mine.

We estimate that the Blackberry mine controls 0.8 million tons of coal reserves; no additional exploration is required. Overburden at the Blackberry mine is removed by front-end loaders, end dumps, bulldozers and blast casting. Coal from the pits is transported by truck to the Phelps Loadout.

After Blackberry is depleted, ICG East Kentucky intends to begin mining the Mount Sterling property, which contains an additional 5.0 million tons of coal reserves. Mount Sterling is located in Martin and Pike Counties, Kentucky near the Tug Fork River. Although Mount Sterling is expected to be mined by ICG East Kentucky, the property is held by ICG Natural Resources, LLC. The leases are retained by annual minimum payments and by tonnage-based royalty payments. Most leases can be renewed until all mineable and merchantable coal has been exhausted.

11

Vindex Energy Corporation

Vindex Energy Corporation operates three surface mines, the Carlos mine, the Douglas mine and the Jackson Mountain mine, all located in the Potomac Basin in Garrett County, Maryland. The Stony River underground mine was idled in the first quarter of 2006 and has now been reclaimed. In the first quarter of 2006, we commenced operations at the Carlos mine and idled the Island mine in the third quarter of 2006. The reserves at Vindex are leased from multiple landowners under leases that expire at varying times and are renewable on a year-by-year basis with annual holding costs. Vindex Energy is a cross-ridge mining operation extracting coal from the Upper Freeport, Bakerstown, Middle Kittanning, Upper Kittanning, Pittsburgh and Redstone seams. All surface mines operated by Vindex Energy are truck-and-shovel/loader mining operations utilizing dozers, hydraulic excavators, loaders and trucks. Operations are conducted with relatively new equipment and exploration and development is conducted on a continual basis ahead of mining.

Coal is processed at our preparation plant located near Mount Storm, West Virginia, where the product is shipped to the customer by either truck or rail using a recently acquired rail loading facility.

Patriot Mining Company

Patriot Mining Company consists of two active surface mines: Crown No. 4 and New Hill East both located near Morgantown in Monongalia County, West Virginia. The majority of the coal and surface is leased under renewable contracts with small annual minimum holding costs. Patriot’s mines are extracting coal from the Waynesburg seam using contour mining methods with dozers, loaders and trucks. As mining progresses, reserves are being acquired and permitted for future operations. The coal is shipped to the customer by either rail, truck or barge using our barge loading facility.

Buckhannon Division

Wolf Run Mining Company’s Buckhannon Division currently consists of two active underground mines: the Sago mine and the Imperial mine, both located in Upshur County, West Virginia, near the town of Buckhannon. Both mines extract coal from the Middle Kittanning seam. Nearly all of the reserves in the Buckhannon Division are owned by us. The Sago mine, which was originally opened in 1999 as a contract mine, closed in 2002 and then reopened as a captive operation in the first quarter of 2004. The Sago mine neared full production in the fourth quarter of 2005. On January 2, 2006, an explosion occurred at the Sago mine resulting in the death of twelve miners and the critical injury of a thirteenth miner. As a result of the explosion, the Sago mine ceased active production during state and federal investigations into the cause of the explosion. The Sago mine resumed coal production on March 15, 2006.

The Imperial mine began producing in the second quarter of 2006 as a replacement for the Spruce No. 1 mine.

All of the coal extracted from the Sago mine and the Imperial mine is processed through the nearby Sawmill Run preparation plant where coal is then primarily shipped by CSX rail with origination by the A&O Railroad, as short-line operator, although some coal is trucked to local industrial customers. The reserves at the Buckhannon Division have characteristics that make it marketable to both steam and export metallurgical coal customers.

The Sycamore No. 2 mine, is located in Harrison County, West Virginia, approximately ten miles west of Clarksburg. The Sycamore No. 2 mine began producing coal from the Pittsburgh seam by room-and-pillar mining method with continuous miners and shuttle cars in the fourth quarter of 2005. The reserve is primarily leased from one major landowner with an annual minimum holding cost and an automatic renewal based on an annual minimum production of 250,000 tons. Unexpected adverse mining conditions forced the idling of the Sycamore No. 2 mine during the third quarter of 2006. It is expected that the Sycamore No. 2 mine will resume production during the third quarter of 2007.

The coal produced from the Sycamore No. 2 mine is expected to be sold on a raw basis and shipped to Allegheny Power Service Corporation’s Harrison Power Station by truck.

12

Philippi Development Division

Wolf Run Mining Company’s Philippi Development Division operates the Sentinel mine in Barbour County, West Virginia near the town of Philippi. The mine was acquired by Anker in 1990 and has been operating ever since. Historically, coal was extracted from the Lower Kittanning seam; however, the mine was idled in the second quarter of 2006 to extend the slope and shafts to the underlying Clarion seam where development mining is currently being conducted using the room-and-pillar mining method. Initial production began in the Clarion seam in November 2006. The current operations are expected to be supplemented with a second continuous miner section in the first quarter of 2007.

Coal is fed directly from the mine to our preparation plant and loadout facility served by the CSX railroad with origination by the A&O Railroad, as short-line operator. The product can be shipped to steam or metallurgical markets.

Sycamore Group

Sycamore Group consists of The Sycamore Group LLC and the Harrison Division. The Sycamore Group LLC is a joint venture between ICG and Emily Gibson Coal Company. The joint venture, through an independent contract miner, operates one underground mine, the Sycamore No. 1 mine (a/k/a the Fairfax No. 3 mine), in Harrison County, West Virginia, approximately ten miles west of Clarksburg, where coal is extracted from the Pittsburgh seam by room-and-pillar mining method with continuous miners and shuttle cars for coal extraction.

The majority of the coal is leased with an annual minimum holding cost. It is anticipated that this reserve will be depleted and the mine closed during the first quarter of 2007. All of The Sycamore Group LLC production is sold on a raw basis and shipped to Allegheny Power Service Corporation’s Harrison Power Station by truck.

New Appalachian Mine Developments

Hillman Property

The Hillman property, located in Northern Appalachia, includes approximately 186.0 million tons of deep coal reserves of both steam and metallurgical quality coal in the Lower Kittanning seam covering approximately 65,000 acres located predominantly in Taylor County, West Virginia, near Grafton. The reserve extends into parts of Barbour, Marion and Harrison Counties as well. ICG owns the Hillman coal reserve in addition to nearly 4,000 acres of surface property to accommodate the development of two projected mining operations. In addition to the Lower Kittanning reserves, we also own significant non-reserve coal deposits in the Kittanning, Freeport, Clarion and Mercer seams on the Hillman property.

The Hillman reserves are expected to support development of two longwall mining operations. Design and permitting of the first, the Tygart No. 1 mine, is nearing completion. To be situated in the reserve block east of the Tygart Valley Lake, this underground mine and preparation plant will be operated by ICG Tygart Valley, LLC. Developmental production from this complex is projected to begin in 2009.

Upshur Property

The Upshur Property, located in Northern Appalachia, contains approximately 93.0 million tons of non-reserve coal deposits owned or controlled by us in the Middle and Lower Kittanning seams. The non-reserve coal deposits are surface mineable at a ratio of slightly greater than 2 to 1. The low product heat content limits the distance over which the fuel can be transported and sold; however, the low mining cost makes Upshur an attractive location for an on-site power plant. Some preliminary research, including air quality monitoring, has been completed in association with the potential future construction of a circulating fluidized bed power plant at Upshur.

13

Big Creek Property

Our Big Creek reserve, located in Central Appalachia, covers 10,000 acres of leased coal lands located north of the town of Richlands in Tazewell County, Virginia. Total recoverable reserves are 27.5 million tons in the Jawbone, Greasy Creek and War Creek seams. The Big Creek reserve is all leased from Southern Regional Industrial Realty. The War Creek mine, which is permitted as a room-and-pillar mining operation, will be developed in the future as market conditions warrant. We receive an overriding royalty on coalbed methane production from this property.

Beckley Property

The Beckley Pocahontas mine (formerly referred to as the Bay Hill reserve), located in Central Appalachia, accesses a 29 million-ton deep reserve of high quality low-volatile metallurgical coal in the Pocahontas No. 3 seam in Raleigh County west of Beckley, West Virginia. The southwest portion of the reserve underlies part of the recently closed BayBeck mine in the Beckley seam. Most of the 16,800 acre Beckley reserve is leased from three land companies: Western Pocahontas Properties, Crab Orchard Coal Company and Beaver Coal Company. Initial underground mine development is in progress via a completed shaft and commercial production is expected to commence in the second half of 2007 following completion of the slope portal and a second shaft. Construction of a new coal preparation plant is underway with completion scheduled for the fourth quarter of 2007. We plan to market the coal produced from the Beckley reserve to domestic steel producers and for export.

Juliana Complex

Mining on the Juliana property, located in Central Appalachia, in Webster County, West Virginia, began in 1979 and was stopped in December 1999. Contour and mountain top removal surface mining methods were utilized to produce coal from the Kittanning and Upper Freeport seams. In addition, a substantial amount of deep-mined coal was produced from the Middle Kittanning seam. A 500 TPH preparation facility with 100,000 tons of raw and clean coal storage and a unit-train loadout was used to process and load coal on the CSX railroad.

Currently at Juliana, there are two Kittanning deep mine permits and one surface mine permit in place. Permitted deep and surface non-reserve coal deposits are 1.2 million tons and 1.9 million tons, respectively. The ratio for the surface reserve is 17.3 to 1 bank cubic yard per clean ton.

Jennie Creek Property

The Jennie Creek reserve, located in Mingo County, West Virginia, is a 44.9 million ton reserve of surface and deep mineable steam coal. This property contains 14.7 million tons of surface mineable, low sulfur coal reserves. A deep reserve in the high Btu, mid-sulfur Alma seam constitutes the largest block of coal at 30.2 million tons. Permitting is now in progress for a surface mine on this Central Appalachian property. Development of the entire Jennie Creek reserve is subject to the resolution of certain disputes with lessors arising out of the Horizon bankruptcy proceedings. These disputes are the subject of pending motions in the bankruptcy court. However, the resolution of such motions has been held in abeyance while such lessors and the Company engage in negotiation of a final binding settlement agreement pursuant to the terms of non-binding letters of understanding. Additionally, on September 22, 2006, the Company entered into a final settlement with one lessor that confirmed the validity of a lease of 10.3 million tons of surface mineable coal and 8.8 million tons of deep mineable coal. The coal will be produced by contouring, highwall mining and area mining.

14

Illinois Basin Mining Operations

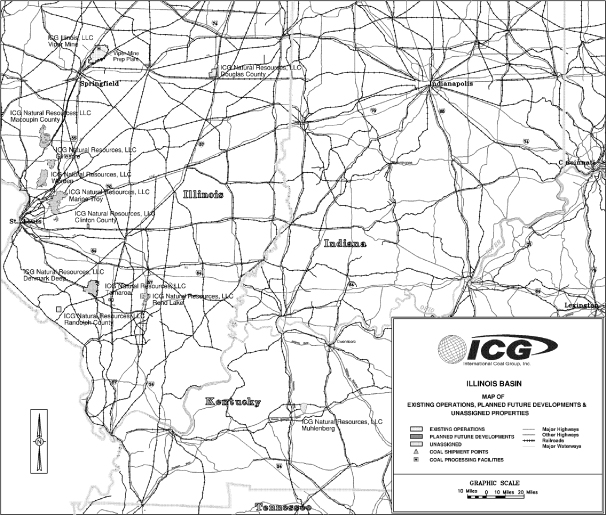

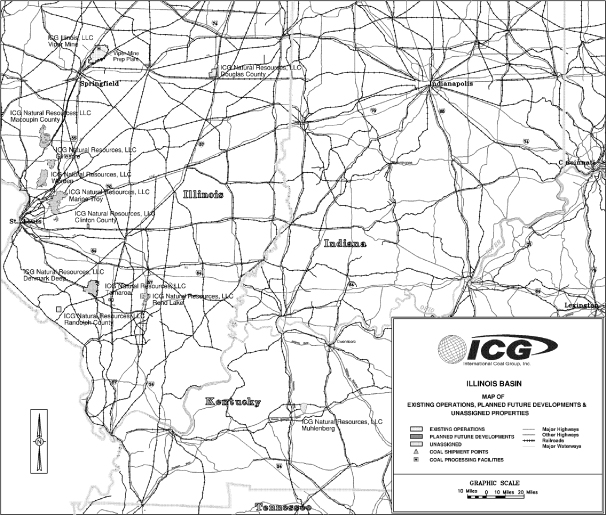

Below is a map showing the location and access to our coal operations in the Illinois Basin:

ICG Illinois, LLC operates one large underground coal mine, the Viper mine, in central Illinois. Viper commenced mining operations in 1982 as a union free operation for Shell Oil Company. Viper was acquired by Ziegler in 1992 and subsequently acquired by AEI Resources in 1998.

The Viper mine is mining the Illinois No. 5 Seam, also referred to as the Springfield Seam. We estimate that Viper controls approximately 25.2 million tons of coal reserves, plus an additional 38.5 million tons of non-reserve coal deposits.

Approximately 61% of the coal reserves are leased, while 39% is owned in fee. The leases are retained by annual minimum payments and by tonnage-based royalty payments. The leases can be renewed until all mineable and merchantable coal has been exhausted.

The Viper mine is a room-and-pillar operation, utilizing continuous miners and shuttle cars. Management believes that ICG Illinois is one of the lowest cost and highest productivity mines in the Illinois Basin. All of the raw coal is processed at Viper’s preparation plant. The clean coal is transported to utility and industrial customers

15

located in North Central Illinois by on-highway trucks operated by independent trucking companies. A major rail line is located a short distance from the plant, giving Viper the option of constructing a rail loadout. Shipments to electric utilities account for approximately 58% of coal sales.

On April 8, 2006, we suffered a fire at the Viper mine that idled the mine and forced replacement of its high angle conveyor belt. Repairs were completed and production resumed on May 8, 2006. Force Majeure notices were issued to affected customers, but coal continued to be shipped from existing inventory through May 2, 2006. No one was injured in the incident.

The underground equipment, infrastructure and preparation plant are well maintained. The majority of underground equipment will be replaced or rebuilt depending on the age and mechanical condition of the equipment.

Other Operations

Coal sales

In addition to the coal we mine, from time to time we also opportunistically secure coal purchase agreements with other coal producers to take advantage of differences in market prices.

ICG ADDCAR Systems, LLC

In our highwall mining business, we have six systems available for operations or lease using our patented ADDCAR highwall mining system and intend to build additional ADDCAR systems as required. ADDCAR(TM) is the registered trademark of ICG. The ADDCAR highwall mining system is an innovative and efficient mining system often deployed at reserves that cannot be economically mined by other methods.

In a typical ADDCAR highwall mining system, there is a launch vehicle, continuous miner, conveyor cars, a stacker conveyor, electric generator, water tanker for cooling and dust suppression and a wheel loader with forklift attachment.

A five person crew operates the entire ADDCAR highwall mining system with control of the continuous miner being performed remotely by one person from the climate-controlled cab located at the rear of the launch vehicle. Our system utilizes a navigational package to provide horizontal guidance, which helps to control rib width and thus roof stability. In addition, the system provides vertical guidance for control out of seam dilutions. The ADDCAR highwall mining system is equipped with high-quality video monitors to provide the operator with visual displays of the mining process from inside each entry being mined.

The mining cycle begins by aligning the ADDCAR highwall mining system onto the desired heading and starting the entry. As the remotely controlled continuous miner penetrates the coal seam, ADDCAR conveyor cars are added behind it, forming a continuous cascading conveyor train. This continues until the entry is at the planned full depths of up to 1,200 to 1,500 feet. After retraction, the launch vehicle is moved to the next entry, leaving a support pillar of coal between entries. This process recovers as much as 65% of the reserves while keeping all personnel outside the coal seam in a safe working environment. A wide range of seam heights can be mined with high production in seams as low as 3.5 feet and as high as 15 feet in a single pass. If the seam height is greater than 15 feet, then multi lifts can be mined to create an unlimited entry height. The navigational features on the ADDCAR highwall mining system allow for multi-lift mining while ensuring that the designed pillar width is maintained.

During the mining cycle, in addition to the tractive effort provided by the crawler drive of the continuous miner, the ADDCAR highwall mining system bolsters the cutting capability of the machine through an additional pumping force provided by hydraulic cylinders which transmit thrust to the back of the miner through blocks mounted on the side of the conveyor cars. This additional energy allows the continuous miner to achieve maximum cutting and loading rates as it moves forward into the seam.

16

ICG ADDCAR has recently developed a new narrow bench ADDCAR highwall mining system that adapts highwall mining technology to mining on narrower mine benches. Initial production of a narrow bench highwall mining system is underway.

We currently have the exclusive North American distribution rights for the ADDCAR highwall mining system.

Coalbed methane

CoalQuest has entered into a joint operating agreement pursuant to which it produces coalbed methane, which is pipeline quality gas that resides in coal seams, from its properties in Barbour, Harrison and Taylor counties in West Virginia. Drilling at the first production well site for coalbed methane, in Barbour County, began in November 2005 and was completed with initial marketable production of coalbed methane in June 2006. Production increased significantly during the fourth quarter of 2006. In the eastern United States, conventional natural gas fields are typically located in various sedimentary formations at depths ranging from 2,000 to 15,000 feet. Exploration companies often put capital at risk by searching for gas in commercially exploitable quantities at these depths. By contrast, the coal seams from which we recover coalbed methane are typically less than 1,000 feet deep and are usually better defined than deeper formations. We believe that this contributes to lower exploration costs than those incurred by producers that operate in deeper, less defined formations. We believe this project is part of the first application of proprietary horizontal drilling technology for coalbed methane in northern West Virginia coalfields. We have not filed reserve estimates with any federal agency.

Customers and Coal Contracts

Customers

Our primary customers are investment grade electric utility companies primarily in the eastern half of the United States. The majority of our customers purchase coal for terms of one year or longer, but we also supply coal on a spot basis for some of our customers. Our three largest customers for the year ended December 31, 2006 were Georgia Power Company, Duke Power and Carolina Power & Light Company and we derived approximately 56% of our coal revenues from sales to our five largest customers. Revenues from sales to Georgia Power Company, Duke Power and Carolina Power & Light Company each accounted for more than 10% of coal revenues in 2006.

Long-term coal supply agreements

As is customary in the coal industry, we enter into long-term supply contracts (exceeding one year in duration) with many of our customers when market conditions are appropriate. These contracts allow customers to secure a supply for their future needs and provide us with greater predictability of sales volume and sales price. For the year ended December 31, 2006, approximately 77% of our revenues were derived from long-term supply contracts. We sell the remainder of our coal through short-term contracts and on the spot market. We have also entered into certain brokered transactions to purchase certain amounts of coal to meet our sales commitments. These purchase coal contracts expire between 2007 and 2010 are expected to provide us a minimum of approximately 3.1 million tons of coal through the remaining lives of the contracts.

As a result of the Horizon bankruptcy process, we were able to renegotiate certain contracts at significantly higher prices that reflected the current pricing environment and not purchase unfavorable contracts. However, we do have certain contracts which are set below current market rates because Anker entered into these contracts before the rise in the coal prices in 2005. As the net costs associated with producing coal have increased due to higher energy, transportation and steel prices, the price adjustment mechanisms within several of our long-term contracts do not reflect current market prices. This has resulted in certain counterparties to these contracts benefiting from below-market prices for our coal.

17

The terms of our coal supply agreements result from competitive bidding and extensive negotiations with customers. Consequently, the terms of these contracts vary significantly by customer, including price adjustment features, price reopener terms, coal quality requirements, quantity adjustment mechanisms, permitted sources of supply, future regulatory changes, extension options, force majeure provisions and termination and assignment provisions.

Some of our long-term contracts provide for a pre-determined adjustment to the stipulated base price at times specified in the agreement or at other periodic intervals to account for changes due to inflation or deflation.

In addition, most of our contracts contain provisions to adjust the base price due to new statutes, ordinances or regulations that impact our costs related to performance of the agreement. Also, some of our contracts contain provisions that allow for the recovery of costs impacted by modifications or changes in the interpretations or application of any applicable government statutes.

Price reopener provisions are present in many of our long-term contracts. These price reopener provisions may automatically set a new price based on prevailing market price or, in some instances, require the parties to agree on a new price, sometimes within a specified range of prices. In a limited number of agreements, failure of the parties to agree on a price under a price reopener provision can lead to termination of the contract. Under some of our contracts, we have the right to match lower prices offered to our customers by other suppliers.

Quality and volumes for the coal are stipulated in coal supply agreements and, in some instances, buyers have the option to vary annual or monthly volumes. Most of our coal supply agreements contain provisions requiring us to deliver coal within certain ranges for specific coal characteristics such as heat content, sulfur, ash, hardness and ash fusion temperature. Failure to meet these specifications can result in economic penalties, suspension or cancellation of shipments or termination of the contracts.

Transportation/Logistics

We ship coal to our customers by rail, truck or barge. We typically pay the transportation costs for our coal to be delivered to the barge or rail loadout facility, where the coal is then loaded for final delivery. Once the coal is loaded in the barge or railcar, our customer is typically responsible for the freight costs to the ultimate destination. Transportation costs vary greatly based on the customer’s proximity to the mine and our proximity to the loadout facilities. We use a variety of independent companies for our transportation needs and typically enter into multiple agreements with trucking companies throughout the year.

In 2006, approximately 96% of our coal (both produced and purchased) from our Central Appalachian operations was delivered to our customers by rail on either the Norfolk Southern or CSX rail lines, with the remaining 4% delivered by truck. For our Illinois Basin operations, all of our coal was delivered by truck to customers, generally within an 80 mile radius of our Illinois mine.

We believe we enjoy good relationships with rail carriers and barge companies due, in part, to our modern coal-loading facilities and the experience of our transportation and distribution employees.

Suppliers

In 2006, we spent more than $283 million to procure goods and services in support of our business activities, excluding capital expenditures. Principal commodities include maintenance and repair parts and services, fuel, roof control and support items, explosives, tires, conveyance structure, ventilation supplies and lubricants. Our outside suppliers perform a significant portion of our equipment rebuilds and repairs both on and off-site, as well as construction and reclamation activities.

Each of our regional mining operations has developed its own supplier base consistent with local needs. We have a centralized sourcing group for major supplier contract negotiation and administration, for the negotiation

18

and purchase of major capital goods and to support the business units. The supplier base has been relatively stable for many years, but there has been some consolidation. We are not dependent on any one supplier in any region. We promote competition between suppliers and seek to develop relationships with those suppliers whose focus is on lowering our costs. We seek suppliers who identify and concentrate on implementing continuous improvement opportunities within their area of expertise.

Competition

The coal industry is intensely competitive. Our main competitors are Massey Energy Company, Arch Coal, Consol Energy, Alpha Natural Resources, Foundation Coal Holdings and various other smaller, independent producers. The most important factors on which we compete are coal price at the mine, coal quality and characteristics, transportation costs and the reliability of supply. Demand for coal and the prices that we are able to obtain for our coal are closely linked to coal consumption patterns of the domestic electric generation industry, which accounted for approximately 92% of domestic coal consumption in 2005. These coal consumption patterns are influenced by factors beyond our control, including the demand for electricity which is significantly dependent upon economic activity and summer and winter temperatures in the United States, government regulation, technological developments and the location, availability, quality and price of competing sources of coal, alternative fuels such as natural gas, oil and nuclear and alternative energy sources, such as hydroelectric power.

Employees

As of December 31, 2006, we had 2,222 employees of which 22% were salaried and 78% were hourly. We believe our relationship with our employees is good. Our entire workforce is union free.

Reclamation

Reclamation expenses are a significant part of any coal mining operation. Prior to commencing mining operations, a company is required to apply for numerous permits in the state where the mining is to occur. Before a state will approve and issue these permits, it typically requires the mine operator to present a reclamation plan which meets regulatory criteria and to secure a surety bond to guarantee performance of reclamation in an amount determined under state law. These bonding companies, in turn, require that we backstop the surety bonds with cash and/or letters of credit. While bonds are issued against reclamation liability for a particular permit at a particular site, collateral posted in support of the bond is not allocated to a specific bond, but instead is part of a collateral pool supporting all bonds issued by that particular insurer. Bonds are released in phases as reclamation is completed in a particular area.

Environmental, Safety and Other Regulatory Matters