UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

Amendment No. 1 to

FORM 10-K

x ANNUAL REPORT UNDER SECTION 13 OR 15 (D) OF THE SECURITIES EXCHANGE ACT OF 1934

FOR THE FISCAL YEAR ENDED DECEMBER 31, 2012

o TRANSITION REPORT PURSUANT TO SECTION 13 OF 15 (D) OF THE SECURITIES EXCHANGE ACT OF 1934

FOR THE TRANSITION PERIOD FROM TO

COMMISSION FILE NUMBER:

KEYUAN PETROCHEMICALS, INC.

(formerly Silver Pearl Enterprises, Inc.)

(Exact name of registrant as specified in its charter)

| Nevada | 45-0538522 | |

| (State or other jurisdiction of incorporation) | (I.R.S. Employer Identification or Organization No.) |

Qingshi Industrial Park

Ningbo Economic & Technological Development Zone

Ningbo, Zhejiang Province

P.R. China 315803

(86) 574-8623-2955

(Address and telephone number of principal executive offices and principal place of business)

Securities registered under Section 12 (b) of the Exchange Act: NONE

Securities registered under Section 12 (g) of the Exchange Act:

COMMON STOCK WITH $.001 PAR VALUE

(Title of Class)

Indicate by check mark if the Registrant is a well known seasoned issuer as defined in Rule 405 of the securities Act. Yes o No x

Indicate by check mark if Registrant is not required to file reports pursuant to Section 13 or Section 15 (d) of the Act. Yes o No x

Indicate by check mark whether the Registrant (1) has filed all reports required to be filed by Section 13 or 15 (d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes x No o

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of Registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the Registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer,” and “smaller reporting company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer o | Accelerated Filer o |

Non-accelerated filer o | Smaller reporting company x |

Indicate by check mark whether the Registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act). Yes o No x

The aggregate market value of the 9,871,301 shares of voting and non-voting common equity stock held by non-affiliates of the registrant was approximately $ 13,918,534.41 as of June 29, 2012, the last business day of the registrant’s most recently completed second fiscal quarter, based on the last sale price of the registrant’s common stock on such date of $1.41 per share*, as reported on the OTCBB.

As of August 29, 2013, the Registrant has 57,646,160 shares of common stock outstanding.

Explanatory Note

We are filing this Amendment No. 1 to our annual report on Form 10-K (“Amended Report”) pursuant to a SEC comment letter dated July 3, 2013 to amend certain disclosures in the Form 10-K filed with the SEC on June 6, 2013 (“Original Report”). Pursuant to the SEC comments, changes and revisions have been made to the following items: Item 1. Business; Item 1A. Risk Factors; Item 3. Legal Proceedings; Item 7. Management’s Discussion and Analysis of Financial Conditions and Results of Operations; Item 10. Directors, Executive Officers and Corporate Governance; Item 11. Executive Compensation; and Item 13. Certain Relationships and Related Transactions and Director Independence (collectively, “Revised Items”). The Revised Items are filed herewith in this Amended Report in their entirety.

This Amended Report may not reflect events occurring after the filing of the Original Report, nor does it modify or update those disclosures in the items not described in the above paragraph of this Explanatory Note. Accordingly, this Amended Report should be read in conjunction with the Original Report and our other reports filed with the SEC subsequent to the filing of our Original Report, including any amendments to those filings.

In addition, pursuant to Rule 12b-15 under the Securities Exchange Act of 1934, as a result of this Amended Report, the certifications pursuant to Section 302 and Section 906 of the Sarbanes-Oxley Act of 2002, filed and furnished, respectively, as exhibits to the Original Report have been re-executed and re-filed as of the date of this Amended Report and are included as exhibits hereto.

KEYUAN PETROCHEMICALS,, INC

TABLE OF CONTENTS

Annual Report on Form 10-K/A for the Year Ended December 31, 2012

| PART I | Page | |

| Item 1 | 1 | |

| Item 1A | 24 | |

| Item 3 | 41 | |

| PART II | ||

| Item 7 | 42 | |

| PART III | ||

| Item 10 | 51 | |

| Item 11 | 55 | |

| Item 13 | 57 | |

| PART IV | ||

| Item 15 | 62 | |

| 64 |

INTRODUCTORY NOTE

Except as otherwise indicated by the context, references in this Annual Report on Form 10-K (this “Form 10-K”) to the “Company,” “Keyuan” “we,” “us” or “our” are references to the combined business of Keyuan Petrochemicals, Inc. and its consolidated subsidiaries. References to “Sinotech Group” are references to our wholly-owned subsidiary, Sinotech Group Limited, previously known as Keyuan International Group Limited”; references to “Keyuan HK” are references to our wholly-owned subsidiary, Keyuan Group Limited; references to “Ningbo Keyuan” are references to our wholly-owned subsidiary, Ningbo Keyuan Plastics Co., Ltd.; references to “Ningbo Keyuan Petrochemicals” are to our wholly-owned subsidiary, Ningbo Keyuan Petrochemicals Co., Ltd; references to “Keyuan Synthetic Rubbers” are references to our wholly-owned subsidiary, Ningbo Keyuan Synthetic Rubbers Co., Ltd.; references to ”Guangxi Keyuan” are references to our wholly-owned subsidiary, Guangxi Keyuan New Materials Co., Ltd. References to “China” or “PRC” are references to the People’s Republic of China. References to “RMB” are to Renminbi, the legal currency of China, and all references to “$” and dollar are to the U.S. dollar, the legal currency of the United States.

Special Note Regarding Forward-Looking Statements

This report contains forward-looking statements and information that are based on the beliefs of our management as well as assumptions made by and information currently available to us. Such statements should not be unduly relied upon. When used in this report, forward-looking statements include, but are not limited to, the words “anticipate,” “believe,” “estimate,” “expect,” “intend,” “plan” and similar expressions, as well as statements regarding new and existing products, technologies and opportunities, statements regarding market and industry segment growth and demand and acceptance of new and existing products, any projections of sales, earnings, revenue, margins or other financial items, any statements of the plans, strategies and objectives of management for future operations, any statements regarding future economic conditions or performance, uncertainties related to conducting business in China, any statements of belief or intention, and any statements or assumptions underlying any of the foregoing. These statements reflect our current view concerning future events and are subject to risks, uncertainties and assumptions. There are important factors that could cause actual results to vary materially from those described in this report as anticipated, estimated or expected, including, but not limited to: competition in the industry in which we operate and the impact of such competition on pricing, revenues and margins, volatility in the securities market due to the general economic downturn; Securities and Exchange Commission (the “SEC”) regulations which affect trading in the securities of “penny stocks,” and other risks and uncertainties. Except as required by law, we assume no obligation to update any forward-looking statements publicly, or to update the reasons actual results could differ materially from those anticipated in any forward- looking statements, even if new information becomes available in the future. Depending on the market for our stock and other conditional tests, a specific safe harbor under the Private Securities Litigation Reform Act of 1995 may be available. Notwithstanding the above, Section 27A of the Securities Act of 1933, as amended (the “Securities Act”) and Section 21E of the Securities Exchange Act of 1934, as amended (the “Exchange Act”) expressly state that the safe harbor for forward-looking statements does not apply to companies that issue penny stock. Because we may from time to time be considered to be an issuer of penny stock, the safe harbor for forward-looking statements may not apply to us at certain times.

PART I

GENERAL OVERVIEW

(a) Nature of business

We, through our PRC operating subsidiaries, Ningbo Keyuan Plastics Co., Ltd. (“Ningbo Keyuan”), Ningbo Keyuan Petrochemicals Co., Ltd (“Ningbo Keyuan Petrochemicals”), Keyuan Synthetic Rubbers Co., Ltd (“Keyuan Synthetic Rubbers”) and Guangxi Keyuan Co., Ltd (“Guangxi Keyuan”) , are engaged in the manufacture and sale of petrochemical products in the PRC. Our operations include (i) a production facility with an annual petrochemical production capacity of 720,000 metric tons (MT) of a variety of petrochemical products, (ii) facilities for the storage and loading of raw materials and finished goods and (iii) a manufacturing technology that can support our manufacturing process with relatively low raw material costs and high utilization and yields, all of which are led by a management team consisting of petrochemical experts with proven track records from some of China’s largest state-owned enterprises in the petrochemical industry.

Due to China’s growing demand for refined petrochemical products, we expanded our annual production capacity from 550,000 MT to 720,000 MT in April 2011. We also completed the construction of a Styrene-Butadience-Styrene (the “SBS”) production facility with an annual production capacity of 70,000 MT in September 2011 and began initial trial production in October and November 2011. One SBS production line began commercial production in December 2011 and the second line began commercial production in August, 2012.

In January 2012, we signed a cooperation agreement with Fangchenggang City to build a new petrochemicals production facility, Guangxi Keyuan New Materials Industrial Park, in Guangxi Province (the "Guangxi Project"). Once the facility is fully operational, it is expected to have annual production capacity of 400,000 metric tons of Acrylonitrile Butadiene Styrene (the "ABS") and related products. As the date of this filing, we have been focused on the complex pre-construction government approval work and on research to improve the efficiency of the production of Guangxi Project since the signing of the agreement.

(b) Organization

Keyuan Petrochemicals, Inc. (“Company” or “the Company”, formerly known as “Silver Pearl Enterprises, Inc.”, together with its subsidiaries, herein referred to as “we” “us” and “our”) was incorporated in the State of Texas on May 4, 2004.

On April 22, 2010, the Company entered into a share exchange agreement (the “Exchange Agreement”) with Keyuan International Group Limited (“Keyuan International”), a privately held investment holding company organized on June 11, 2009 under the laws of the British Virgin Islands, Delight Reward Limited (“Delight Reward”), the sole stockholder of Keyuan International and Denise D. Smith (“Smith”), the Company’s former principal stockholder. Pursuant to the terms of the Exchange Agreement, Delight Reward transferred to the Company all of its shares of Keyuan International in exchange for 47,658 shares of the Company’s Series M convertible preferred stock (the “Share Exchange”). On an “as converted” basis, the Series M convertible preferred stock represented approximately 95% of the Company’s outstanding common stock right after the Share Exchange. The Series M convertible preferred stock voted with the common stock on an “as converted basis” and was converted into 47,658,000 shares of the Company’s common stock on December 28, 2010.

1

As a result of the Share Exchange, Keyuan International became a wholly-owned subsidiary of the Company and Delight Reward became the controlling stockholder of the Company. The Share Exchange was accounted for as a reverse acquisition and recapitalization whereby Keyuan International is deemed to be the accounting acquirer (and the legal acquire). The common stock of the Company continues post the Share Exchange, while the retained deficit of the Company was eliminated as the historical operations are deemed to be those of Keyuan International.

On May 12, 2010, the Company formed a corporation under the laws of the State of Nevada called Keyuan Petrochemicals, Inc. and on the same day, acquired 100% of the entity’s stock for cash. As such, the entity became the Company’s wholly-owned subsidiary (the “Merger Subsidiary”).

Effective as of May 17, 2010, the Merger Subsidiary was merged with and into the Company. As a result of the merger, the Company’s name was changed to “Keyuan Petrochemicals, Inc.”. Prior to the merger, the Merger Subsidiary had no liabilities and nominal assets and, as a result of the merger, the separate existence of the merger subsidiary ceased. The Company is the surviving corporation in the merger and, except for the name change, there was no change in the Company’s directors, officers, capital structure or business.

On August 8, 2010, Keyuan Group Limited (“Keyuan HK”) established a wholly owned subsidiary in the People’s Republic of China (“PRC”), Ningbo Keyuan Petrochemicals, which is engaged in the sale of petrochemical products in the PRC.

On April 4, 2012, Guangxi Keyuan was incorporated by Ningbo Keyuan (75% ownership) and Keyuan HK (25% ownership) in Guangxi province, PRC, as a Sino-Foreign joint venture subsidiary, for the purpose of developing the Guangxi Project.

On June 15, 2012, Ningbo Keyuan Synthetic Rubbers was established as a wholly-owned PRC subsidiary of Ningbo Keyuan to engage in the sales and marketing of various petrochemical products, specifically synthetic rubbers .

On October 15, 2012, Keyuan International Group Limited changed its name to Sinotech Group Limited.

(c) History of Keyuan International before the Share Exchange

Immediately prior to the date of the Share Exchange, the Company was a shell company with no operations and a nominal amount of cash, and Keyuan International, through Keyuan Group Limited (“Keyuan HK”) and its indirect subsidiary, Ningbo Keyuan, was engaged in the manufacturing and sale of petrochemical products.

Keyuan HK was established in Hong Kong in 2009, and is a holding company with no significant assets or operations. On April 26, 2007, Ningbo Keyuan was established as a wholly foreign owned enterprise in Ningbo, PRC by Hong Kong Keyuan PEC Investment Holdings Limited (“Hong Kong Keyuan”, 51%), Hong Kong Development Enterprise Co., Limited (“Hong Kong Development”, 26%) and Wayes International Trading Limited (“Wayes International”, 23%). Hong Kong Keyuan was controlled by Mr. Chunfeng Tao, Hong Kong Development was controlled by Mr. Jicun Wang and Wayes International was controlled by Mr. Peijun Chen. Ningbo Keyuan had an original registered capital of USD $12,000,000. The Ningbo Foreign Trade & Economic Cooperation Bureau approved Ningbo Keyuan’s increase in its registered capital from USD$12,000,000 to USD$20,400,000 on February 27, 2009. The registered capital of Ningbo Keyuan was then increased from USD $20,400,000 to USD$50,400,000 and a new Certificate of Approval was issued by the Ningbo Foreign Trade & Economic Cooperation Bureau on March 22, 2010.

2

On April 1, 2008 Ningbo Litong Petrochemical (“Ningbo Litong”) acquired 12.75% of the shares of Ningbo Keyuan from Hong Kong Keyuan on behalf of Mr. Chunfeng Tao. On November 25, 2008 Ningbo Kewei Investments Co., Limited (“Ningbo Kewei”), a company controlled by Mr. Tao acquired 12.75% of Ningbo Keyuan from Ningbo Litong. On June 24, 2009, Ningbo Kewei acquired 15.75% of Ningbo Keyuan from Hong Kong Keyuan through a capital increase. On July 17, 2009, Hong Kong Keyuan acquired 28.5% shares from Ningbo Kewei. Through these transactions Mr. Tao’s 51% ownership of Ningbo Keyuan remained unchanged.

In 2009, Apex Smart Limited, Best Castle Investments Limited, Chance Brilliant Holdings Limited, Delight Reward Limited and Keyuan International Group Limited were established in the British Virgin Island (BVI) and Keyuan HK was established in Hong Kong. Delight Reward Limited holds 100% of the equity interests of Keyuan International Group Limited which holds 100% of the equity interests of Keyuan HK. Delight Reward Limited is owned by:

| ● | Apex Smart Limited (45.6132%), which was 100% held by Stewart Shiang Lor, subsequently by Mr. Brian Pak-Lun Mok and subsequently by Mr. Chunfeng Tao. |

| ● | Best Castle Investments Limited (23.2523%), which was 100% held by Mr. O. Wing Po and subsequently by Mr. Jicun Wang. |

| ● | Chance Brilliant Holdings Limited (20.5694%), which was 100% held by Mr. Lo Kan Kwan and subsequently by Mr. Peijun Chen. |

| ● | Harvest Point Limited (5.3896%), which was 100% held by Mr. Brian Pak-Lun Mok and subsequently by Ms. Muxia Duan. |

| ● | Strategic Synergy Limited (5.1755%), which was 100% held by Mr. Brian Pak-Lun Mok and subsequently Mr. Mok transferred one third of the ownership to Mr. Xin Yue |

On November 16, 2009 Keyuan HK acquired 100% of Ningbo Keyuan from Hong Kong Keyuan, HongKong Development and Wayes International. Mr. Brian Pak-Lun Mok, Mr. O. Wing Po and Mr. Lo Kan Kwan also agreed to support Mr. Chunfeng Tao, Mr. Jicun Wang and Mr. Peijun Chen respectively to retain their controls in Delight Reward Limited and its subsidiaries. The reorganization is considered as restructuring under common control and Mr. Chunfeng Tao, Mr. Jicun Wang and Mr. Peijun Chen remained as the controlling parties.

On April 2, 2010, Mr. Brian Pak-Lun Mok, Mr. O. Wing Po, and Mr. Lo Kan Kwan, who indirectly held 100% of the equity interest in Delight Reward Limited, entered into certain share transfer agreements with Mr. Chunfeng Tao, Mr. Jicun Wang, Mr. Peijun Chen and Mr. Xin Yue, pursuant to which each of these persons agreed to transfer all of its interests in Apex Smart Limited, Best Castle Investments Limited and Chance Brilliant Holdings Limited, Harvest Point Limited and Strategic Synergy Limited (collectively the “BVI Holding Companies”), to Mr. Chunfeng Tao, Mr. Jicun Wang, Mr. Peijun Chen and Mr. Xin Yue respectively, subject to achievement of certain performance targets of Ningbo Keyuan. The performance targets are the Company achieving: at least $39 million of gross revenue for the three months commencing from July 2010 to September 2010; at least $40 million of gross revenue for the three months commencing from October 2010 to December 2010; and, at least $41 million of gross revenue for the three months commencing from January 2011 to March 2011.

Pursuant to the share transfer agreements, (i) Mr. Brian Pak-Lun Mok granted Mr.Chunfeng Tao an option to acquire 100% of the equity of Apex Smart Limited in three installments provided that certain performance targets are met; (ii) Mr. O. Wing Po granted Mr. Jicun Wang an option to acquire 100% of the Best Castle Investments Limited in three installments provided that certain performance targets are met; (iii) Mr. Lo Kan Kwan granted Mr. Peijun Chen an option to acquire 100% of the equity of Chance Brilliant Holdings Limited in three installments provided that certain performance targets are met; (iv) Mr. Brian Pak-Lun Mok granted Mr. Xin Yue an option to acquire 100% of the equity of Harvest Point Limited in three installments provided that certain performance targets are met; and (v) Mr. Brian Pak-Lun Mok granted Mr. Xin Yue an option to acquire 100% of the equity of Strategic Synergy Limited in three installments provided the performance targets are met (the share transfer agreements are herein referred as “Slow Walk Agreement(s)” or “Slow Walk”. Options are herein sometimes referred as “Slow Walk Option(s)”).

3

(d) Current Shareholding Structure of the Company

On November 4, 2010, the Company exercised its conversion rights under the terms of the Series A Preferred Stock to convert all of outstanding shares of its Series A 6% Cumulative Convertible Preferred Stock into a total of 6,132,032 shares of Common Stock, $0.001 par value per share. As a result, following the conversion, all 6,132,032 shares of Series A Preferred Stock that had been outstanding were cancelled and were automatically converted, without any delivery of conversion notice required on the part of the holders of Series A preferred stock.

On November 15, 2010, one-third of the Slow Walk Options were exercised after the first performance target was met.

On December 28, 2010, the Company exercised its mandatory conversion rights under the terms of the Series M preferred stock to convert all of outstanding shares of its Series M preferred stock into a total of 47,658,000 shares of Common Stock, $0.001 par value per share, all of which are held by Delight Reward Limited.

On April 29, 2011, Harvest Point Limited transferred 1,028 shares of Delight Reward Limited’s stock to Strategic Synergy Limited, changing their ownership of Delight Reward Limited’s stock to 3.334% and 7.232% respectively. On the same day, Mr. Brian Pak-Lun Mok and Mr. Xin Yue transferred 33,333 shares and 16,667 shares of Harvest Point Limited, respectively, to Ms. Muxia Duan thus transferred 100% ownership of Harvest Point Limited to Ms. Muxia Duan.

After the second and third performance targets were met, Mr. Peijun Chen and Mr. Jicun Wang exercised their remaining two-thirds of the Slow Walk Options on February 15, 2012. Mr. Chunfeng Tao exercised his remaining two-thirds of the Slow Walk Options on November 15, 2012.

On April 8, 2012, Strategic Synergy Limited transferred 105 shares of Delight Reward shares to Happyvale Limited. On October 23, 2012, Delight Reward repurchased 105 shares of Delight Reward shares from Happyvale Limited in a consideration of 100,000 shares of common stock of the Company.

On March 25, 2013, Best Castle Investments Limited transferred 11,626 shares of Delight Reward Limited to Apex Smart Limited, increasing Apex Smart Limited’s ownership of Delight Reward Limited from 45.6132% to 68.864%.

4

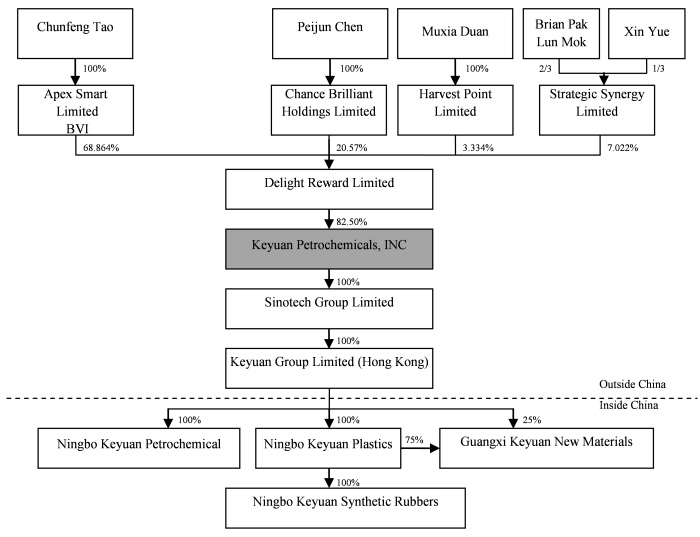

As a result, the shareholding structure following the restructuring is as follows:

(e) Independent Investigation and Nasdaq Delisting Decision

During the process of preparing the Company’s Annual Report on Form 10-K for the year ending December 31, 2010, on or about March 24, 2011, KPMG, the Company’s former independent auditor, raised certain issues primarily relating to unexplained issues regarding certain cash transactions and recorded sales and requested that the Audit Committee conduct an independent investigation. Based on the issues raised by KPMG, on March 31, 2011, our Audit Committee elected to commence an independent investigation of the issues raised and engaged the services of independent counsel, Pillsbury Winthrop Shaw Pittman LLP (“Pillsbury”), which in turn engaged Deloitte Financial Advisory Services LLP (“Deloitte”), as independent forensic accountants, and King & Wood, as Audit Committee counsel in the People’s Republic of China (Pillsbury, Deloitte and King & Wood are collectively referred herein as “Investigation Team”).

On September 28, 2011, the Investigation Team completed the investigation. On October 3, 2011, the Company provided the Nasdaq Hearings Panel with a copy of the final investigation report along with a comprehensive list of remedial actions the Company has taken and is committed to taking to remediate the accounting and internal control issues. On October 5, 2011, the Company was notified that the Nasdaq Hearings Panel exercised its discretionary authority pursuant to NASDAQ Listing Rule 5101 to delist the Company’s securities from the Nasdaq Stock Market. As a result, the Company’s shares resumed trading in the pink sheets under the ticker symbol KEYP.PK beginning October 7, 2011. The Company’s common stock is currently traded on the Over-the-Counter Bulletin Board under the symbol KEYP.

5

(f) SEC Settlement

The Company has reached a settlement in a case filed by the Securities and Exchange Commission (“SEC”) on February 28, 2013 in the United States District Count for the District of Columbia against the Company, alleging the Company violated Sections 17(a)(2) and 17(a)(3) of the Securities Act of 1933, Sections 13(a), 13(b)(2)(A) and 13(b)(2)(B) of the Securities Exchange Act of 1934, and Rules 12b-20 and 13a-13 thereunder. Under the terms agreed to by the Company and the SEC, the Company, without admitting or denying the allegation of the complaint, will pay a civil penalty of $1million and will be permanently enjoined from violating certain securities law. The settlement remains subject to approval by the United District Court for the District of Columbia, which must approve its terms and enter the final judgment. As the date of this filing, the United District Court for the District of Columbia has not approved the settlement yet.

(g) FINANCINGS

April – May 2010 Private Placement

Following the Share Exchange, we entered into a securities purchase agreement with 122 accredited investors for the issuance and sale of 748,704 Units at a purchase price of $35 per unit, for aggregate gross proceeds of approximately $26,204,640 consisting of, in the aggregate, (a) 6,738,336 shares of Series A convertible preferred stock, par value $0.001 per share convertible into the same number of shares of Common Stock, (b) 748,704 shares of Common Stock, (c) three-year Series A Warrants to purchase up to 748,704 shares of Common Stock, at an exercise price of $4.50 per, and (d) three-year Series B Warrants to purchase up to 748,704 shares of Common Stock, at an exercise price of $5.25 per share (the “April-May 2010 Private Placement”).

In connection with the April-May 2010 Private Placement, we also entered into a registration rights agreement with the investors, in which we agreed to file a registration statement with the SEC to register for resale of the Common Stock, the Common Stock issuable upon conversion of the Series A Preferred Stock, the Series A Warrant Shares and the Series B Warrant Shares issued in the financing, within 30 calendar days of April 22, 2010 and to have such registration statement declared effective within 150 calendar days of April 22, 2010 or within 180 calendar days of April 22, 2010 in the event of a full review of the registration statement by the SEC. If we can not comply with the foregoing obligations under the registration rights agreement, we will be required to pay liquidated damages in cash to each investor, at the rate of 1% of the applicable subscription amount for each 30 day period in which we are not in compliance; provided, that such liquidated damages will be capped at 10% of the subscription amount of each investor and will not apply to any registrable securities that may be sold pursuant to Rule 144 under the Securities Act if all of the conditions in Rule 144(i)(2) are satisfied at the time of the proposed sale, or are subject to an SEC comment with respect to Rule 415 promulgated under the Securities Act.

Accordingly, we filed a registration statement on Form S-1 in connection with the April-May 2010 private placement transaction. Amendment No. 4 to such Form S-1 which we filed on October 15, 2010 was declared effective on October 19, 2010. However, because of the delinquency of the Company’s annual report on Form 10-K for fiscal year ended December 31, 2010 and interim reports on Form 10-Q for three months ended March 31, 2011 and June 30, 2011 respectively, as of April 10, 2012, the Amendment No. 4 to such Form S-1 is no longer effective. As a result, we began to accrue penalties pursuant to the terms of the registration rights agreement from April, 2011 to November 1, 2011, the period that the registerable securities were not able to be sold pursuant to Rule 144 under the Securities Act.

Pursuant to the terms of the securities purchase agreement and the terms of the Certificate of Designation of Series A preferred stock, we exercised our conversion rights to convert all of the outstanding Series A preferred stock into a total of 6,132,032 shares of Common Stock. As a result of the conversation, since November 4, 2010, we have no longer incurred the Series A dividends, payable quarterly, at the rate of 6% per annum for each outstanding share.

September 2010 Private Placement

On September 28, 2010, we closed an offering for $20,250,000 consisting of a total of 540,001 units at a purchase price of $37.50 per unit, each unit consisting of, (a) ten (10) shares of Series B convertible preferred stock of the Company, (b) one and a half (1.5) three year Series C warrants to purchase one and a half (1.5) shares of Common Stock, at an exercise price of $4.50 per share, and (c) one and a half (1.5) three year Series D warrants to purchase one and a half (1.5 ) shares of Common Stock, at an exercise price of $5.25 per share (the “ September 2010 Private Placement”) in reliance upon the exemption from securities registration afforded by Regulation S as promulgated under the Securities Act of 1933.

6

In connection with the September 2010 Private Placement, we also entered into a Registration Rights Agreement with the investors, in which we agreed to file a registration statement with the Commission to register for resale the Common Stock issuable upon conversion of the Series B Preferred Stock, the Series C Warrant Shares and the Series D Warrant Shares, within 30 calendar days of October 19, 2010 and to have the registration statement declared effective within 150 calendar days of October 19, 2010 or within 180 calendar days of October 19, 2010 in the event of a full review of the registration statement by the Commission. If we do not comply with the foregoing obligations under the registration rights agreement, we will be required to pay cash liquidated damages to each Series B Investor, at the rate of 1% of the applicable subscription amount for each 30 day period in which the Company is not in compliance; provided, that such liquidated damages will be capped at 10% of the subscription amount of each investor and will not apply to any registrable securities that may be sold pursuant to Rule 144 under the Securities Act if all of the conditions in Rule 144(i)(2) are satisfied at the time of the proposed sale, or are subject to an SEC comment with respect to Rule 415 promulgated under the Securities Act.

Accordingly, we filed a registration statement on Form S-1 in connection with the September 2010 private placement transaction. Amendment No. 2 to such Form S-1 which we filed on January 14, 2011 was declared effective on January 19, 2011. However, because of the delinquency of the Company’s annual report on Form 10-K for fiscal year ended December 31, 2010 and interim reports on Form 10-Q for three months ended March 31, 2011 and June 30, 2011 respective, as of April 10, 2012, Amendment No. 2 to such Form S-1 is no longer effective. As a result, we began to accrue penalties pursuant to; the terms of the registration rights agreement from April 2011to November 2011, the period that the registerable securities were not able to be sold pursuant to Rule 144 under the Securities Act.

(h) Mandatory Conversion of Series A Preferred Stock and Series M Preferred Stock

On November 4, 2010, we exercised our mandatory conversion rights under the terms of the Series A Preferred Stock to convert all of outstanding shares of its Series A 6% Cumulative Convertible Preferred Stock into a total of 6,132,032 shares of Common Stock. As a result, following the conversion, all 6,132,032 shares of Series A Preferred Stock that had been outstanding were cancelled and automatically converted, without any delivery of conversion notice required on the part of the holders of Series A Preferred Stock. Dividends on the Series A Preferred Stock accrued through November 3, 2010 and amounted to approximately $143,000 and were paid to the holders of Series A Preferred Stock on the regularly scheduled payment date of January 31, 2011.

As a result of foregoing, as of November 4, 2010, we longer incurred the Series A Dividend that was payable quarterly, at the rate of 6% per annum for each outstanding share, payable in cash or common stock dividends, as applicable.

On December 28, 2010, we exercised our mandatory conversion rights under the terms of the Series M preferred stock to convert all of the outstanding shares of the Series M preferred stock into a total of 47,658,000 shares of Common Stock, $0.001 par value per share. As a result, following the conversion, all 47,658 shares of Series M preferred stock that had been outstanding were cancelled and were automatically converted, without any delivery of conversion notice required on the part of the holders of Series M Preferred Stock.

(i) Stock Repurchase Program

On September 17, 2012, our Board of Directors authorized the repurchase of $2 million of the Company’s stock for up to $1.50 per share. On December 31, 2012, the Company engaged TriPoint Global Equities LLC (“TriPoint Global”) as its agent to design and execute the stock repurchase program, that complies with the requirements of Rule 10b5-1(c)(1) and Rule 10b-18 under the Securities Exchange Act of 1934, as amended (the “Exchange Act”). As of March 31, 2013, the Company has purchased 117,554 shares of common stock through the stock repurchase program. On April 17, 2013, in connection with the delay in filing our Annual Report on Form 10-K for the year ended December 31, 2012, we decided to temporarily suspend the stock repurchase program until we file all periodic reports required under Section 13 or 15(d) of the Securities Exchange Act of 1934.

| Period | Total Number of Shares Purchased | Average Price Paid per Share | Total Number of Shares Purchased as Part of Publicly Announced Plans or Programs | Approximate Dollar Value of Shares that May Yet Be Purchased Under the Plans or Programs | ||||||||||||

| December 1 - December 31, 2012 | 0 | $ | 0.00 | 0 | $ | 2,000,000 | ||||||||||

| January 1 - January 31, 2013 | 11,200 | $ | 0.73 | 11,200 | $ | 1,991,861 | ||||||||||

| February 1 - February 28, 2013 | 15,850 | $ | 0.77 | 15,850 | $ | 1,979,668 | ||||||||||

| March 1 - March 31, 2013 | 90,504 | $ | 1.25 | 90,504 | $ | 1,866,488 | ||||||||||

| Total | 117,554 | $ | 1.14 | 117,554 | $ | 1,866,488 | ||||||||||

7

OUR PRODUCTS

We manufacture and supply a variety of petrochemical products, including BenzeneToluene-Xylene Aromatics (BTX Aromatics), propylene, styrene, liquid petroleum gas (LPG), Methyl Tertiary Butyl Ether (MTBE), Styrene butadiene styrene (SBS), and other petrochemicals, each of which is described below:

| ● | BTX Aromatics: consists of benzene, toluene, xylene and other chemical components used for further processing into plastics, gasoline and solvent materials widely used in paint, ink, construction coating and pesticide; |

| ● | Propylene: a chemical intermediate which is one of the building blocks for an array of chemical and plastic products that are commonly used to produce polypropylene, acrylonitrile, oxo alcohols, propylene oxide, cumene, isopropyl alcohol, acrylic acid and other chemicals for paints, household detergents, automotive brake fluids, indoor/outdoor carpeting, textile, insulating materials, auto parts and electrical appliances; |

| ● | Styrene: a precursor to polystyrene and several copolymers widely used for packaging materials, construction materials, electronic parts, home appliances, household goods, home furnishings, toys, sporting goods and other products; |

| ● | LPG: a mixture of hydrocarbon gases used as fuel in heating appliances and vehicles. A replacement for chlorofluorocarbons as an aerosol propellant and a refrigerant which reduces damage to the ozone layer; and |

| ● | MTBE & Other Chemicals: MTBE, oil slurry, sulphur and others which are used for a variety of applications including fuel components, refrigeration systems, fertilizers, insecticides and fungicides. |

| ● | Styrene butadiene styrene (SBS): a thermoplastic elastomer with features similar to rubber, widely used in the manufacture of resin, shoes, tape, tubes and asphalt. |

Production Capacity and Expansion

Our annual designed manufacturing capacity was 550,000 metric tons of a variety of petrochemical products at the end of 2010. We upgraded the catalytic pyrolysis processing equipment used in production facilities to expand the capacity from 550,000 MT to 720,000 MT. This capacity expansion project started in March 2011 and was completed in April 2011.

In September 2011, we completed building a new facility designed for producing Styrene-Butadience-Styrene (the “SBS”), one of the Styreneic Block Copolymers. SBS is a product with higher product margin with significant applications in the footwear, adhesive, polymer modification and modified asphalt industries. The SBS facility was built on part of the 1.2 million square feet of land for which we obtained the right of use in August 2010. The construction started in September, 2010 and was completed as scheduled in September 2011. One SBS production line began commercial production in December 2011 and the second line began commercial production in August, 2012. The designed capacity of the SBS facility allows for production of up to 70,000 metric tons per year. The SBS facility achieved a 41% utilization rate in 2012, as the first full year of production, and generated approximately $71.1 million in sales and $7.7 million in profit. We expect to generate net profit margins of 10% from our production of SBS once the facility reaches normal production levels, which means the actual production volume reach more than 80% of the design capacity. However, market conditions, the volatility of feedstock and SBS product prices can significantly impact the estimated profitability and we cannot guaranty that our SBS production will reach more than 80% of the design capacity in the near future.

8

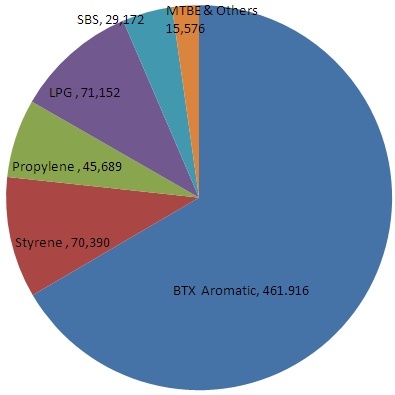

The following chart depicts our production capacity in 2012:

Breakdown of 2012 Capability of 693,895 (MT)

Other than the utilization rate for SBS facility discussed above, the utilization rates for our other facilities are as follows:

| ● | styrene production: 88%; |

| ● | propylene: 78%; |

| ● | LPG: 85%; |

| ● | BTX Aromatic: 105%; and |

| ● | MTBE & others: 50% |

Most of our facilities have been operating since 2009, so the current utilization rates for each product (except for the newly developed SBS) has been optimized to achieve stable output, less raw material cost and less equipment maintenance. We also made slight adjustments to the utilization rate for the BTX Aromatic facility to reduce the output to achieve more stable production conditions. We have been working on existing equipment upgrades to achieve increased stabilized production. However, in order to develop our business to meet increasing customer demands, optimizing the utilization rates for our current facilities is not adequate to achieve our goals. More specifically, the increasing market demand in tire and auto parts has resulted in increasing market demand for styrene, ABS and SSBR; and higher requirements related to environmental protection imposed by the PRC government has lead to higher demand for transformer oil and catalytic cracking oil. Based on these market trends, rather than focusing on optimizing our current utilization rates for our different facilities, we have been focusing on the following improvements to our infrastructure to expand our manufacturing capacity:

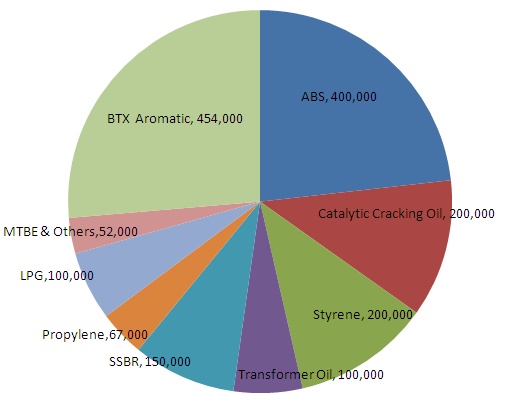

| a) | an ABS production facility in Guangxi Province, which will have an annual production capacity of 400,000 MT of ABS. The Company began pre-construction activities in February 2012, and the first phase is expected to be completed by the fourth quarter of 2014; |

| b) | an oil catalytic cracking processing facility as an extension of our catalytic pyrolysis processing equipment, as well as the feed way of the main raw materials to produce synthetic rubber. This facility can reduce production costs and the market risk in the purchase of raw materials, and improve the stability and efficiency of project production to 200,000 MT of heavy oil per year; |

| c) | increased the annual production capacity of our ethylbenzene-styrene facility from 80,000 MT to 200,000 MT, among which 120,000 MT can be used for producing synthetic and 80,000 MT can be sold to downstream petrochemical companies. One of the main raw materials, ethylene can be acquired from the oil catalytic cracking facility. This facility can be considered the bridge between original products and high-value added products and will complete the integration of internal resources; |

9

d) | a transformer oil facility using hydrogen from the ethylene-styrene facility to complete a double hydrogenation process on original products (BTX Aromatic) for refining transformer oil, and producing high value transformer oil with a design capability of 100,000 MT per year; and |

| e) | an SSBR (Solution Polymerized Styrene Butadiene Rubber) production facility with a design capability of 150,000 MT per year, that will use its own production process technology in synthetic rubber, combining styrene and butadiene, to produce SSBR. This product can be used as raw materials for tires, instead of imported hexakis (methoxymethy) melamine (“HMMM”). |

We registered our catalytic oil processing facility and transformer oil plant with the Ningbo local government in February 2013, and expect it to be completed and operational in late 2013, at which time, we will be able to produce medical use and edible products such as tubes and chewing gum.

The total estimated cost of processing equipment for product refinement and the SSBR production facility is approximately $149.3 million, including $49.8 million for processing equipment and $99.5 million for the SSBR production facility. We are currently going through the governmental approval and design phase of the ABS production facility and estimating the related costs. Upon full completion of our expansion, our total production capacity will reach 2,443,000 MT per year including, but not limited to, our current petrochemical production of 720,000 MT, styrene of 200,000 MT, catalytic cracking oil of 200,000 MT, ABS of 400,000 MT, SSBR of 150,000 MT and transformer oil of 100,000 MT. The following chart depicts the breakdown of our planned production capacity of 2,443,000 MT.

Capacity Breakdown after expansion projects (2,443,000 MT)

We are currently evaluating the timeline for our expansion projects. Our current estimate is as follows:

| Expansion Project | Expected Completion Date | |

Oil Catalytic Processing Facility | End of Q4, 2013 | |

| Ethylene-Styrene Facility | End of Q4, 2014 | |

| Transformer Oil Facility | End of Q4, 2014 | |

| SSBR production facility | End of Q4, 2015 | |

| ABS Production Facility | End of Q4, 2014 |

10

Petrochemical Manufacturing Process

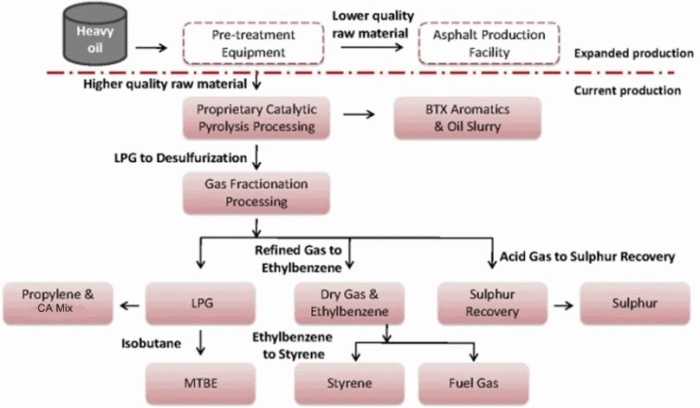

The following chart illustrates our petrochemical manufacturing process:

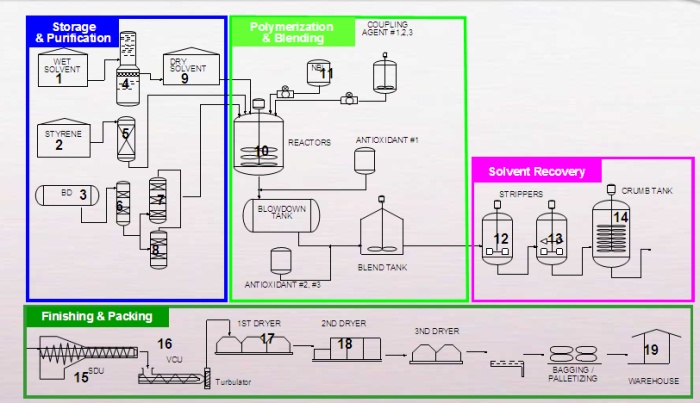

The following chart illustrates the manufacturing process of SBS:

11

Petrochemical Market in China

China has the world’s second largest petrochemical market after the U.S. in terms of production and consumption. China’s petrochemical output value grew from RMB 1,240 billion in 2000 to RMB 11,000 billion in 2011 representing a Compound Annual Growth Rate (CAGR) of 21.95%. China Petrol and Chemical Industry Association (CPCIA) expect that the total profits in the petrochemical industry will increase 12.5% in 2012. (Source: http://www.cu-market.com.cn/hgjj/2013-1-7/15504023.html)

Based on a report from China’s petroleum and chemical industry federation, production for the petroleum and chemical industry will remain stable, based on an assumed total output for 2013 of RMB14.25 trillion, and profits of RMB870 billion . (source: http://www.askci.com/news/201301/21/219524756358.shtml)

China’s increasing domestic demand for petrochemical products has exceeded the domestic supply in the past several years:

| ● | China’s benzene supply grew from 2.13 million MT in 2002 to 6.626 million MT in 2011 representing a CAGR of 13.5%. China’s benzene demand increased from 2.08 million MT in 2002 to 5.609 million MT in 2011, representing a CAGR of 11.65%. (data source http://chem.oilchem.net/chemical/2_3_3662667.html ) |

| ● | China’s toluene supply grew from 697,000 MT in 2002 to 2.55 million MT in 2011, representing a CAGR of 15.5%. China’s toluene demand increased from 1.56 million MT in 2002 to 2.30 million MT in 2010, representing a CAGR of 5%. (data source: http://info.pcrm.hc360.com/2012/02/020858176690.shtml ) |

| ● | China’s xylene supply grew from 820,000 MT in 2002 to 6.5 million MT in 2010, representing a CAGR of 30%. China’s xylene demand increased from 1.1 million MT in 2002 to 7.5 million MT in 2009 representing a CAGR of 32%. (data source: www.stats.gov.cn ) (www.chem99.com) |

| ● | China’s propylene supply has grown from 3.78 million MT in 2000 to 15.93 million MT in 2012, representing a CAGR of 14.16%. China’s propylene demand has risen from 4.39 million MT in 2000 to 18.60 million MT in 2010, representing a CAGR of 16%. (data source: http://www.oilchem.net/chemical/5_3_37153.html) |

| ● | China’s styrene supply has grown from 0.89 million MT in 2002 to 3.806 million MT in 2010, representing a CAGR of 20%. China’s Styrene demand has increased from 2.69 million MT in 2002 to 7.3 million MT in 2010, representing a CAGR of 13%. (data http://chem.chem365.net/Web/jckxx_news/30869.htm, http://static.sse.com.cn/cs/zhs/scfw/gg/ssgs/2010-04-29/600481_20100429_3.pdf ) |

12

| ● | China’s LPG supply has grown from 12.56 million MT in 2003 to 21.811 million MT in 2011 representing a CAGR of 7.14%. China’s LPG demand has increased from 18.77 million MT in 2003 to 23.64 million MT in 2010, representing a CAGR of 3%. (data source: http://www.oilchem.net:88/coalchem/2_1_2991360.html,) |

As a result, China has imported petrochemical products to meet the domestic demand, which is expected to continue for a number of years (source: Publication by Business Monitor International Ltd.: China Petrochemicals Report, Includes 5 Year Forecast to 2014; Q2 2010):

| ● | China imported 1.862 million MT of benzene between 2003 and 2011. (data source: http://chem.oilchem.net/chemical/5_3_54578.html) |

| ● | China imported 863,000 MT of toluene in 2002 and 659,630 MT in 2011 (data source: http://chem.oilchem.net/chemical/5_3_53435.html) |

| ● | China imported 271,000 MT of xylene in 2002 and 477,183 MT in 2012 (data source: http://chem.oilchem.net/chemical/5_3_54074.html) |

| ● | China’s imports of propylene increased from 210,000 MT in 2004 to 2.15 million MT in 2012 (data source: http://chem.oilchem.net/chemical/5_3_54205.html)) |

| ● | China’s imports of styrene increased from 1.79 million MT in 2002 to 3.607 million MT in 2011 (data source: http://chem.oilchem.net/chemical/5_3_53475.html) |

| ● | China imported butadiene 344,826MT in 2012, increased 88% compared to butadiene imported in 2011,. (data source: http://finance.oilchem.net/bulk/108_8697.html,) |

Asphalt Market in China and Pretreatment & Asphalt Process

In addition to its use as raw materials for emulsified, diluted and modified asphalt-based products, asphalt is widely used for highways, roads and airport pavements. At the end of 2011, the length of China’s highways has reached 85,000 km (52,816 miles) in the aggregate (http://www.ptbtv.com/news.asp?ID=78058), which made China rank the second in the world in terms of the length of its highway system. According to the PRC government plan, the length of China's highways will reach 100,000 km (62,137 miles) by 2020 (http://www.cngaosu.com/a/2010/1109/71783.html). In November 2008, the PRC Ministry of Communication issued a RMB 5 trillion investment plan and according to this plan, the average annual investment for construction of highways in the next five years will be RMB 980 billion, among which 60% will be used for construction of expressways, 20% for provincial highways and 20% for highways in the countryside.

To ensure the high-quality condition of roads and highways, the PRC government requires regular pavement maintenance every five years. In the past five years, the domestic demand for asphalt in China has exceeded supply with total imports of approximately 5.6 million MT in 2010.

13

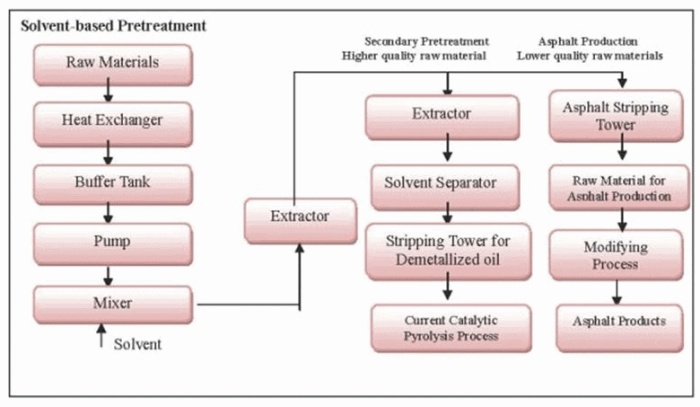

The following chart depicts the pretreatment and asphalt process:

Environmental Protection and Safety Measures

We are committed to environmental protection, facility safety and quality control throughout the design, maintenance and growth of our operation facilities and manufacturing process.

Environmental Protection

We have taken various measures to meet national standards and ensure our environmental compliance. For example, we recycle the water for cooling in our production process and large amounts of water can be saved through recycling. Sulfureted hydrogen generated in production is sent to the facility for sulfur recovery. The waste water and waste gas is treated by our sewage water treatment station and emission control facility to meet the national standards before discharge. The industrial residue and garbage is sent to qualified companies for safe treatment.

Safety Measures

Our safety control measures include:

| 1. | Distribution control system; |

| 2. | Emergency shutdown mechanism; |

| 3. | Automatic interlocking system; |

| 4. | Detection & alarm system for flammable and toxic gas; |

| 5. | Fire detection & automatic sprinkler system; and |

| 6. | Real-time system and process monitoring system |

14

Quality Control

With our commitment to quality control, our petrochemical products have met all applicable national standards for petrochemical products set by the General Administration of Quality Supervision, Inspection and Quarantine of the PRC. For instance, the purity of our Styrene product exceeded the national standard of 99.7%, and the purity and our Propylene product exceeded the national standard of 99.5%.

Our Competitive Strengths

As an independent petrochemical manufacturer and supplier, our competitive strengths include:

Technology Advantage

We have proprietary manufacturing technologies that allow for better use of raw materials, higher yield rate and enhanced operational efficiency.

Specifically, we possess the technology to use heavy oil, instead of naphtha, which is a commonly used feedstock in the petrochemical production industry. Heavy oil is approximately 15% cheaper per ton and more readily available than naphtha, which provides us with competitive advantage in the selection of raw materials. In addition, we use proprietary catalytic pyrolysis with higher reaction temperatures, which results in a 15% higher Olefin yield rate than that of conventional fluidized catalytic cracking processes. Finally, we use enhanced technologies in our production process that allow for lower capital investment and higher operations efficiency.

Our yield rate in 2010 for our entire production line indicated a yield rate of 87.6% for finished products. The yield rate in 2011 for our entire line was 87.2% for finished products. The yield rate in 2012 for our entire line was 87.3% for finished products. Yield rate represents the percentage of finished product produced from input of raw material and net input of unfinished products and is calculated by dividing the sum of crude oil and net unfinished input into the individual net production of finished products. A yield rate of 87.3% means, for instance, 100 tons of heavy oil can generate approximately 87.3 tons of finished products.

In addition, we use enhanced technologies in our production process that allow for lower capital investment and higher operations efficiency. Our proprietary catalytic pyrolysis process uses a set of dual risers for one precipitator and one regenerator, while the commonly used fluidized catalytic cracking process uses one riser for one precipitator and one regenerator respectively. The dual riser, one precipitator and one regenerator are integrated into one complete process, which provides for ease of operation, higher operation efficiency and higher reaction temperature. It was estimated that the technology generates a 15% higher olefin yield rate than that of the fluidized catalytic cracking process, which allows us to produce more higher-margin olefin products such as styrene and propylene

Furthermore, a catalytic pyrolysis process with high temperatures can produce more olefin hydrocarbon based products compared with other equipment using low temperatures for the same product. In other words, our cost is reduced while producing the same amount of the product.

Our management considers our manufacturing technologies and manufacturing design critical to our business, and has taken steps to protect these technologies. In January 2011, we received the approval for our patent application for MEP technology (Multiple Ethylene Propylene) from the National Intellectual Property Bureau in China, #ZL-2010-2-0191523.6. In addition to patent protection, we also entered into confidentiality and license agreements with certain employees, customers and others to protect the confidentiality of our technologies.

In 2013, we received the patent notices for three devices used in the production process for Acrylonitrile: Fluidization Reaction System of Acrylonitrile (#ZL-2012-2-0381020.4), Cooler of Acrylonitrile Gas (#ZL-2012-2-0382047.5), and Absorption Tower of Acrylonitrile (#ZL-2012-2-0381066.6), respectively. These techniques were developed together with East China University Of Science and Technology (ECUST), and can be used for improving the output capacity and recovery rates, and for decreasing discharge waste to improve production efficiency.

15

On January 10, 2012, we started an application for a patent called “the synthetic method for transparent segmented copolymer”, which has been accepted and posted on the China patent data website in July 2012. Assuming there is no objection for this patent application during 2013, we will automatically obtain the patent in the end of 2013. Obtaining this patent will not only expand our SBS products range and increase the “K resin” content in the styrene, which will further improve our product portfolio to avoid market risk; but also benefit us for applying for High Tech Company. For more details about this patent application, please ref to the following website:

http://dbpub.cnki.net/Grid2008/Dbpub/Detail.aspx?DBName=SCPD2012&FileName=CN102558466A&QueryID=4&CurRec=1

Elite Workforce

Our management team, composed of seasoned petrochemical experts with proven track records from China’s largest state-owned enterprises, provides us with specialized operating management and technical administration. In addition, we have allied with many industry-renowned technology experts and advisors assisting us to achieve consistent technological improvement.

Ideal Location

Our operation and storage facilities are at the ocean-front and in close proximity to suppliers and customers which provides us with an advantage of lower logistics cost and readily available access to raw materials and target customers. In addition, being located in Qingshi Chemical Park in Ningbo provides us with access to skilled labor and industry resources.

Sales and Pricing

Sales

In selling our products, most of our customers pay cash in advance. For core customers with excellent credit history, we may make an exception by conducting credit sales, which is part of our strategy to maintain customer relationship.

In order to meet customers’ demand, we have improved our manufacturing technologies and streamlined our conversion process to achieve an approximately 30 days’ raw material-to-sales cycle.

In order to facilitate our future growth, Ningbo Keyuan Petrochemicals was incorporated in Ningbo, China with a registered capital of $3 million as a wholly-owned subsidiary of Keyuan HK on August 27, 2010. Ningbo Keyuan Petrochemicals is responsible for the sales and marketing, raw materials sourcing and market analysis for the Company. Dr. Jingtao Ma was appointed as the General Manager of the new entity. Dr. Ma was the head of the former sales and marketing division of Ningbo Keyuan. This new entity will also serve as the “market thermometer” that can better monitor market conditions and obtain first hand market data through buying and selling activities. Management believes that the consolidation of the sales and marketing and raw material procurement function under one business unit will help efficiently manage the future expansion of the Company.

Pricing

Our raw material price fluctuations are primarily attributable to international oil prices and market effects of supply and demand. We set our selling prices based upon benchmark prices published by national petrochemical companies, and/or through individually negotiated prices with customers. Specifically, BTX aromatic prices are influenced by benchmark prices set by National Development and Reform Commission, or NDRC.

16

Energy required for production of our products consists of water, electricity and steam, the costs of which are attributed to cost of sales rather than operating expense. The supply prices of these energy sources in China have historically been very stable as a result of PRC government policy. Accordingly, the potential impact of changing energy costs to our production is minimal. Following are the costs for water, electricity and stream for the years ended December 31, 2012 and 2011 (amounts in thousands):

For the Years Ended December 31, | ||||||||

2012 (Unaudited) | 2011 (Unaudited) | |||||||

| Water | $ | 1,337 | $ | 904 | ||||

| Electricity | $ | 11,276 | $ | 7,486 | ||||

| Steam | $ | 1,497 | $ | 4,433 | ||||

Total energy cost was approximately $14,110 for the fiscal year ended December 31, 2012, which constitutes approximately 1. 9% of sales. Total energy cost was approximately $12,823 in the fiscal year ended December 31, 2011, which constitutes approximately 2% of sales.

Customers

Customers for Petrochemicals Products

Our main customer base is downstream petrochemicals manufacturers and distributors (trading companies) located in and near the Yangtze River Delta and Pearl River Delta. 14% of our sales are direct sales to petrochemical companies that use our products as raw materials for their own products such as polystyrene, isoprene, dicyclopentadiene, acrylic acid, oil fuel products and other chemical products. 86% of our sales are through the trading companies, i.e., distributors who sell our products to petrochemicals derivative companies and manufacturers. We engage distributors as customers mainly because: (1) distributors customarily pay the entire purchase price prior to shipment, while end-users often request credit payment terms; and (2) it decreases our overhead by allowing for a more streamlined sales force as distributors do not require regular client visits, entertaining or a highly specialized sales team to maintain the relationships.

In order to estimate the total orders for a year, we conduct surveys with our major customers to obtain their preliminary orders for the next one or two years and update the information annually. We enter into purchase contracts with customers on an order-to-order basis. In each contract, price is determined based on market price and the quantity is specified based on (1) the customer demand for a particular order and (2) our capability to satisfy that particular order. Our five largest customers accounted for 36% and 44 % of the sales for the years ended December 31, 2012 and 2011, respectively. We anticipate that our overall customer composition and the concentration of our top customers will change as we expand our business and modify our product portfolio to include new products and higher-margin products; however, we can give no assurance that this will be the case.

Customers for SBS Products

The sales for SBS commenced at the end of 2011. 60% of our SBS customers are trading agents and the rest of our customers are end-user factories. Most of our SBS customers are located in the Yangtze River delta, South China and Northern cities in China such as Hebei and Shangdong. The end-user factories purchase our SBS as raw materials for their various products, such as shoe sole material, adhesive, waterproof rolling material, asphalt and plastic modifier.

We currently have 15% of the Chinese market for SBS. We engage agents as our main customers primarily because: (1) trading agents pay 30% in advance when placing their order and pay the rest before shipment, and (2) it decreases our overhead by allowing for a more streamlined sales force as trading agents do not require regular client visits, entertaining or a highly specialized sales team to maintain the relationships.

To maintain and develop our relationship with SBS customers, we set up a customer relationship department to closely monitor and timely respond to customers’ requests and feedback, as well as a technical team in charge of improving product quality and adjusting product chemical features to meet different requirements from customers. We also have monthly meetings with our major customers to obtain their preliminary orders. Because the price of SBS fluctuates monthly, and we do not have a warehouse distribution system, the price of SBS usually includes the shipment cost and profit. Our five largest customers accounted for 23% of the sales of SBS for the year ended December 31, 2012. We anticipate that our overall customer composition and the concentration of our top customers will change as we expand our business and modify our product portfolio to include new products and higher-margin products; however, we can give no assurance that this will be the case.

Intellectual Property

We have a pending trademark application for the Ningbo Keyuan company logo with the State Administration for Industry and Commerce, Trademark Office. On January 25, 2011 we received approval for a patent related to the Company's proprietary production process, called MEP (Multiple Ethylene Propylene). MEP is an exclusive and leading technology used in Keyuan's existing production process. Through the ingenuity of our CEO, Mr. Tao, we have developed this proprietary production process that improves the manufacturing efficiency and flexibility for a wide range of petrochemicals. The utility model patent received, #ZL-2010-2-0191523.6, applies to a processing technology used in the production of ethylene and propylene. This technology allows us to use lower grade feedstock (such as heavy oil) instead of a higher grade feedstock commonly used in other existing petrochemical production processes. It also allow us to improve the yield and utilization rate of its production line, resulting in a 15% cost savings.

17

In 2013, we received the patent notices for three devices used in the production process for Acrylonitrile: Fluidization Reaction System of Acrylonitrile (#ZL-2012-2-0381020.4), Cooler of Acrylonitrile Gas (#ZL-2012-2-0382047.5), and Absorption Tower of Acrylonitrile (#ZL-2012-2-0381066.6), respectively. These techniques were developed together with ECUST, and can be used for improving the output capacity and recovery rates, and for decreasing discharge waste to improve production efficiency.

On January 10, 2012, we started an application for a patent called “the synthesis for transparent block copolymer”, which has been accepted and posted on the China patent data website in July 2012. Assuming there is no objection to this patent application during 2013, we will automatically obtain the patent at the end of 2013. Obtaining this patent will not only expand our SBS products range and increase the “K resin” content in styrene, which will further improve our product portfolio; but it will also benefit us in our application for status as a High Tech Company. For more details about this patent application, please refer to the following website:

http://dbpub.cnki.net/Grid2008/Dbpub/Detail.aspx?DBName=SCPD2012&FileName=CN102558466A&QueryID=4&CurRec=1

Going Concern and Management’s Plans

Our audited financial statements for the years ended December 31, 2012 and 2011 have been prepared assuming we will continue as a going concern. We reported a net loss of approximately $5.85 million in 2012 and cash flows used in operations of approximately $7.1 million for the year ended December 31, 2012. At December 31, 2012, we had a working capital deficit of approximately $159 million. The Report of the Independent Registered Public Accounting Firm on our consolidated financial statements as of and for the year ended December 31, 2012 includes a going concern explanatory paragraph which means that the accounting firm has express substantial doubt about the Company’s ability to continue as a going concern.

We continue to finance its operations primarily through short-term bank borrowings. Short-term bank borrowings and bills payable amounted to approximately $397.8 million at December 31, 2012, and have increased to approximately $414 million at May 28, 2013. Management expects that short-term bank financing will continue to be available through at least the end of 2013.

We continue to benefit from favorable PRC tax policies related to consumption tax, approximately $51.3 million of which was refundable at December 31, 2012. Management believes that this amount will be refunded by June 30, 2013 and that additional consumption tax deposits of approximately $84.1 million through May 28, 2013 will be refunded more promptly in the second half of 2013.

We are expanding our production line to include Styrene-Ethylene-Butylene-Styrene (“SEBS”). Management expects production and sale of SEBS to commence in the second half of 2013, and that SEBS will yield a higher gross margin than some of the Company’s current products.

We are also exploring sources of additional financing, including short-term financing from vendors and other parties. In addition, the Company is closely monitoring its cash balances, cash needs and expense levels.

The ability of the Company to continue as a going concern is dependent upon management’s ability to implement its strategic plan, obtain additional capital and generate net income and positive cash flows from operations. There can be no assurance that these plans will be sufficient or that additional financing will be available in amounts or terms acceptable to the Company, if at all.

Government Regulation

In addition to U.S. securities laws, banking laws and laws applicable to all companies, such as The Foreign Corrupt Practices Act, as a China-based entity, we are subject to various Chinese regulations. This section sets forth a summary of the most significant China regulations or requirements that may affect our business activities operated in China or our shareholders’ right to receive dividends and other distributions of profits from the PRC subsidiary.

Foreign Investment in PRC Operating Companies

The Foreign Investment Industrial Catalogue jointly issued by China's Ministry of Commerce (MOFCOM) and NDRC in 2007 classified various industries/businesses into three different categories: (i) encouraged for foreign investment; (ii) restricted to foreign investment; and (iii) prohibited from foreign investment. For any industry/business not covered by any of these three categories, they will be deemed industries/businesses permitted for foreign investment. Except for those expressly provided with restrictions, encouraged and permitted industries/businesses are usually 100% open to foreign investment and ownership. With regard to those industries/businesses restricted to foreign investment, there is always a limitation on foreign investment and ownership. Foreign investment is prohibited in prohibited industries/business. The PRC subsidiary’s business does not fall under the industry categories that are restricted to, or prohibited from foreign investment and is not subject to limitation on foreign investment and ownership.

Regulation of Foreign Currency Exchange

Foreign currency exchange in the PRC is governed by a series of regulations, including the Foreign Currency Administrative Rules (1996), as amended, and the Administrative Regulations Regarding Settlement, Sale and Payment of Foreign Exchange (1996), as amended. Under these regulations, the Renminbi is freely convertible for trade and service-related foreign exchange transactions, but not for direct investment, loans or investments in securities outside the PRC without the prior approval of State Administration of Foreign Exchange (SAFE). Pursuant to the Administrative Regulations Regarding Settlement, Sale and Payment of Foreign Exchange (1996), foreign investment enterprises, or FIEs may purchase foreign exchange without the approval of SAFE for trade and service-related foreign exchange transactions by providing commercial documents evidencing these transactions. They may also retain foreign exchange, subject to a cap approved by SAFE, to satisfy foreign exchange liabilities or to pay dividends. However, the relevant Chinese government authorities may limit or eliminate the ability of FIEs to purchase and retain foreign currencies in the future. In addition, foreign exchange transactions for direct investment, loan and investment in securities outside the PRC are still subject to limitations and require approvals from SAFE.

18

Regulation of FIEs’ Dividend Distribution

The principal laws and regulations in the PRC governing distribution of dividends by FIEs include:

| (i) | The Sino-foreign Equity Joint Venture Law (1979), as amended, and the Regulations for the Implementation of the Sino-foreign Equity Joint Venture Law (1983), as amended; |

| (ii) | The Sino-foreign Cooperative Enterprise Law (1988), as amended, and the Detailed Rules for the Implementation of the Sino-foreign Cooperative Enterprise Law (1995), as amended; |

| (iii) | The Foreign Investment Enterprise Law (1986), as amended, and the Regulations of Implementation of the Foreign Investment Enterprise Law (1990), as amended. |

Under these regulations, FIEs in the PRC may pay dividends only out of their accumulated profits, if any, determined in accordance with Chinese accounting standards and regulations. In addition, the wholly-owned foreign enterprises in the PRC are required to set aside at least 10% of their respective accumulated profits each year, if any, to fund certain reserve funds unless such reserve funds have reached 50% of their respective registered capital. These reserves are not distributable as cash dividends.

Regulation of a Foreign Currency’s Conversion into RMB and Investment by FIEs

On August 29, 2008, SAFE issued a Notice of the General Affairs Department of the State Administration of Foreign Exchange on the Relevant Operating Issues concerning the Improvement of the Administration of Payment and Settlement of Foreign Currency Capital of Foreign-Invested Enterprises or Notice 142, to further regulate the foreign exchange of FIEs. According to Notice 142, FIEs shall obtain a verification report from a local accounting firm before converting its registered capital in foreign currency into Renminbi, and the converted Renminbi shall be used for the business within its permitted business scope. Notice 142 explicitly prohibits FIEs from using RMB converted from foreign capital to make equity investments in the PRC, unless the domestic equity investment is within the approved business scope of the FIE and has been approved by SAFE in advance. In addition, SAFE strengthened its oversight over the flow and use of Renminbi funds converted from the foreign currency-dominated capital of a FIE. The use of such Renminbi may not be changed without approval from SAFE, and may not be used to repay Renminbi loans if the proceeds of such loans have not yet been used. Violations of Notice 142 may result in severe penalties, including substantial fines as set forth in the SAFE rules.

Regulation of Foreign Exchange in Certain Onshore and Offshore Transactions

In October 2005, SAFE issued the Notice on Issues Relating to the Administration of Foreign Exchange in Fund-raising and Return Investment Activities of Domestic Residents Conducted via Offshore Special Purpose Companies, or SAFE Notice 75, which became effective as of November 1, 2005. SAFE has also issued implemented rules to SAFE Notice 75. SAFE Notice 75 and its implementation rules require PRC residents (including both corporate entities and natural persons) to register with SAFE or its competent local branch in connection with their direct or indirect shareholding in any company outside of China referred to as an “offshore special purpose company” established for the purpose of raising fund from overseas to acquire assets of, or equity interests in, PRC companies. Under SAFE Notice 75, a “special purpose vehicle”, or SPV, refers to an offshore entity established or controlled, directly or indirectly, by PRC residents for the purpose of seeking offshore equity financing using assets or interests owned by such PRC residents in onshore companies. In addition, any PRC resident that is the shareholder of an offshore special purpose company is required to amend his or her SAFE registration with the SAFE or its competent local branch, with respect to that offshore special purpose company in connection with any of its increase or decrease of capital, transfer of shares, merger, division, equity investment or creation of any security interest over any assets located in China. The SAFE regulations require retroactive approval and registration of direct or indirect investments previously made by PRC residents in offshore special purpose companies. PRC subsidiaries of an offshore special purpose company are required to coordinate and supervise the filing of SAFE registrations by the offshore holding company’s shareholders who are PRC residents in a timely manner. In the event that a PRC resident shareholder with a direct or indirect investment in an offshore parent company fails to obtain the required SAFE approval and make the required registration, the PRC subsidiaries of such offshore parent company may be prohibited from making distributions of profit to the offshore parent and from paying the offshore parent proceeds from any reduction in capital, share transfer or liquidation in respect of the PRC subsidiaries. Further, failure to comply with the various SAFE approval and registration requirements described above, as currently drafted, could result in liability under PRC law for foreign exchange evasion.

19

There still remain uncertainties as to how certain procedures and requirements under the aforesaid SAFE regulations will be enforced, and it remains unclear how these existing regulations, and any future legislation concerning offshore or cross-border transactions, will be interpreted, amended and implemented by the relevant government authorities. Although we have requested PRC residents who, to our knowledge, hold direct or indirect interests in our Company to make the necessary applications, filings and amendments as required under the SAFE Notice 75 and other related rules, our PRC resident beneficial holders have not completed such approvals and registrations required by the SAFE regulations. We will attempt to comply, and attempt to ensure that all of our shareholders subject to these rules comply with the relevant requirements. We cannot, however, assure the compliance of all of our China-resident shareholders. Any current or future failure to comply with the relevant requirements could subject us to fines or sanctions imposed by the Chinese government, including restrictions on certain of our subsidiaries’ ability to pay dividends or hinder our investment in those subsidiaries or affect our ownership structure, which could adversely affect our business and prospects.

Regulations on Employee Stock Option Plans