|

|

|

UNITED STATES | ||

SECURITIES AND EXCHANGE COMMISSION | ||

Washington, D.C. 20549 | ||

|

| |

|

|

|

Form 10-K | ||

|

|

|

|

|

|

| þ ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES |

|

For the fiscal year ended December 31, 2012

Commission file number: 001-33966

|

|

|

|

MAKO SURGICAL CORP. |

(Exact Name of Registrant as Specified in Its Charter) |

|

|

Delaware | 20-1901148 |

(State or Other Jurisdiction of Incorporation or Organization) | (I.R.S. Employer Identification No.) |

|

|

2555 Davie Road, Fort Lauderdale, FL | 33317 |

(Address of Principal Executive Offices) | (Zip Code) |

|

(954) 927-2044 |

(Registrant’s telephone number, including area code) |

Securities registered pursuant to Section 12(b) of the Act:

|

|

Title of Class | Name of Exchange on Which Registered |

|

|

Common stock, $0.001 par value per share | The NASDAQ Global Select Market |

Securities registered pursuant to Section 12(g) of the Act: None

|

|

|

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yeso Noþ

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act. Yeso Noþ

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 (the “Exchange Act”) during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yesþ Noo

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yesþ Noo

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K.þ

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See definition of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. (Check one):

|

|

|

|

þ Large accelerated filer | o Accelerated filer | o Non-accelerated filer | o Smaller reporting company |

| (Do not check if a smaller reporting company)o | ||

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act) Yes o No þ

The aggregate market value of the common stock held by non-affiliates of the registrant as of June 30, 2012 was approximately $820,591,868 (based on a closing price of $25.61 per share on The NASDAQ Global Market as of such date).

As of February 21, 2013, the registrant had outstanding 47,216,722 shares of common stock.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the Company’s definitive proxy statement for the 2013 annual meeting of stockholders will be incorporated by reference into Part III of this Annual Report on Form 10-K when filed with the Securities and Exchange Commission.

MAKO Surgical Corp.

We have received or applied for trademark registration of and/or claim trademark rights, including in the following marks that appear in this report: “MAKOplasty®,” “RIO®,” “RESTORIS®,” “Tactile Guidance System” and “TGS,” as well as in the MAKO Surgical Corp. “MAKO” logo, whether standing alone or in connection with the words “MAKO Surgical Corp.” All other trademarks, trade names and service marks appearing in this report are the property of their respective owners. Unless the context requires otherwise, the terms “registrant,” “company,” “we,” “us” and “our” refer to MAKO Surgical Corp.

2

This report contains forward-looking statements within the meaning of the U.S. federal securities laws. Statements that are not historical facts, including statements about our beliefs and expectations, are forward-looking statements. Forward-looking statements include statements generally preceded by, followed by or that include the words “may,” “will,” “could,” “would,” “should,” “expect,” “intend,” “plan,” “aim,” “anticipate,” “believe,” “estimate,” “predict,” “project,” “potential,” “continue,” “ongoing,” or the negative of these terms or other similar expressions. These statements include, but are not limited to, statements related to:

|

|

|

| • | the nature, timing and number of planned new product introductions; |

|

|

|

| • | market acceptance of MAKOplasty, including our RIO® Robotic Arm Interactive Orthopedic system, or RIO, joint specific applications for the knee and hip, and our RESTORIS family of implant systems; |

|

|

|

| • | the effect of anticipated changes in the size, health and activities of population on the demand for our products; |

|

|

|

| • | assumptions and estimates regarding the size and growth of certain market segments; |

|

|

|

| • | our ability and intent to expand into international markets; |

|

|

|

| • | the timing and anticipated outcome of clinical studies; |

|

|

|

| • | assumptions concerning anticipated product developments and emerging technologies; |

|

|

|

| • | the future availability from third parties, including single source suppliers, of development services and implants for and components of our RIO; |

|

|

|

| • | the viability of maintaining our licensed intellectual property or our ability to obtain additional licenses necessary to our growth; |

|

|

|

| • | the anticipated adequacy of our capital resources to meet the needs of our business; |

|

|

|

| • | our continued investment in new products and technologies; |

|

|

|

| • | the ultimate marketability of newly launched products and products currently being developed; |

|

|

|

| • | the ability to implement new technologies successfully; |

|

|

|

| • | our ability to sustain, and our goals for, sales and earnings growth, including projections regarding RIO system installations and post-installation system utilization; |

|

|

|

| • | our success in achieving timely approval or clearance of products with domestic and foreign regulatory entities; |

|

|

|

| • | our compliance with domestic and foreign regulatory requirements, including Medical Device Reporting requirements and other required reporting to the United States Food and Drug Administration; |

|

|

|

| • | the stability of certain domestic and foreign economic markets; |

|

|

|

| • | the impact of anticipated changes in the U.S. healthcare industry and the medical device industry and our ability to react to and capitalize on those changes; |

|

|

|

| • | future declarations of cash dividends; and |

|

|

|

| • | the impact of any managerial changes. |

Forward-looking statements reflect our current expectations and are not guarantees of performance. These statements are based on management’s beliefs and assumptions, which in turn are based on currently available information. Important assumptions relating to these forward-looking statements include, among others, assumptions regarding demand for our products, expected pricing levels, raw material costs, the timing and cost of planned capital expenditures, competitive conditions and general regulatory and economic conditions. You are cautioned that reliance on any forward-looking statement involves risks and uncertainties. Although we believe

3

that the assumptions on which the forward-looking statements contained herein are based are reasonable, any of those assumptions could prove to be inaccurate given the inherent uncertainties as to the occurrence or nonoccurrence of future events. There can be no assurance that the forward-looking statements contained in this report will prove to be accurate. The inclusion of a forward-looking statement in this report should not be regarded as a representation by us that our objectives will be achieved.

Forward-looking statements also involve risks and uncertainties, which could cause actual results to differ materially from those contained in any forward-looking statement. Many of these factors are beyond our ability to control or predict and could, among other things, cause actual results to differ, perhaps materially, from those contained in forward-looking statements made in this report. Such factors, among others, may have a material adverse effect on our business, financial condition and results of operations and may include, but are not limited to, factors discussed under Item 1A, “Risk Factors,” and the following:

|

|

|

| • | the potentially significant impact of a continued economic downturn or delayed economic recovery on the ability of our customers to secure adequate funding, including access to credit, for the purchase of our products or cause our customers to delay a purchasing decision; |

|

|

|

| • | changes in general economic conditions and credit conditions; |

|

|

|

| • | changes in the availability of capital and financing sources for our company and our customers; |

|

|

|

| • | unanticipated changes in the timing of the sales cycle for our products or the vetting process undertaken by prospective customers; |

|

|

|

| • | changes in competitive conditions and prices in our markets; |

|

|

|

| • | changes in the relationship between supply of and demand for our products; |

|

|

|

| • | fluctuations in costs and availability of raw materials and labor; |

|

|

|

| • | changes in other significant operating expenses; |

|

|

|

| • | unanticipated issues relating to intended product launches; |

|

|

|

| • | decreases in sales of our principal product lines; |

|

|

|

| • | slowdowns, delays, or inefficiencies in our product research and development efforts; |

|

|

|

| • | decreases in utilization of our principal product line or in procedure volume; |

|

|

|

| • | increases in expenditures related to increased or changing governmental regulation or taxation of our business, both nationally and internationally; |

|

|

|

| • | the impact of the United States healthcare reform legislation enacted in March 2010 on hospital spending, reimbursement, and the taxing of medical device companies; |

|

|

|

| • | unanticipated changes in reimbursement to our customers for our products; |

|

|

|

| • | unanticipated issues in complying with domestic or foreign regulatory requirements related to MAKO’s current products, including initiating and communicating product actions or product recalls and meeting Medical Device reporting requirements and other requirements of the United States Food and Drug Administration, or securing regulatory clearance or approvals for new products or upgrades or changes to our current products; |

|

|

|

| • | developments adversely affecting our potential sales activities outside the United States; |

|

|

|

| • | increases in cost containment efforts by group purchasing organizations; |

|

|

|

| • | loss of key management and other personnel or inability to attract such management and other personnel; |

|

|

|

| • | increases in costs of retaining a direct sales force and building a distributor network; |

|

|

|

| • | unanticipated issues related to, or unanticipated changes in or difficulties associated with, the recruitment of agents and distributors of our products; |

4

|

|

|

| • | any unanticipated impact arising out of the securities class action or any other litigation, inquiry, or investigation brought against us; and |

|

|

|

| • | unanticipated intellectual property expenditures required to develop, market, protect, and defend our products. |

We caution you not to place undue reliance on these forward-looking statements, as they speak only as of the date they were made. We do not undertake any obligation to release any revisions to these forward-looking statements publicly to reflect events or circumstances after the date of this report or to reflect the occurrence of unanticipated events.

5

|

|

BUSINESS |

Overview

We are an emerging medical device company that markets our advanced robotic arm solution, joint specific applications for the knee and hip, and orthopedic implants for orthopedic procedures. We offer MAKOplasty, an innovative, restorative surgical solution that enables orthopedic surgeons to consistently, reproducibly and precisely treat patient specific, osteoarthritic disease.

MAKOplasty is performed using our proprietary RIO® Robotic Arm Interactive Orthopedic system, or RIO. The RIO is a technology platform that utilizes tactile guided robotic arm technology and patient specific planning and visualization to offer consistently reproducible precision to surgeons. The RIO is currently used to treat early to mid-stage osteoarthritic knee disease and osteoarthritic hip disease. We believe that the RIO has the potential to serve as a platform for applications for other orthopedic procedures beyond partial knee and hip and that MAKOplasty has the potential to empower physicians to address the needs of the large and growing, yet underserved, population of patients with joint disease who desire a restoration of quality of life and reduction of pain, but for whom current surgical treatments are not appropriate or desirable.

We currently offer MAKOplasty Partial Knee Arthroplasty, or MAKOplasty PKA, and MAKOplasty Total Hip Arthroplasty, or MAKOplasty THA. Unlike conventional total knee replacement surgery, which requires extraction and replacement of the entire joint, MAKOplasty PKA enables resurfacing of one or two specific diseased compartments of the joint, preserving significantly more soft tissue and healthy bone of the knee. We believe localized resurfacing can be optimized using the RIO to achieve optimal implant placement and alignment for smaller, more easily inserted implant components. The RIO is used to prepare the knee joint for the insertion and alignment of our proprietary RESTORIS® MCK unicompartmental and bicompartmental knee implant systems through a small incision in a minimally invasive, bone preserving and tissue sparing procedure. Our RESTORIS family of knee implants is designed to enable minimally invasive restoration of one or two of the diseased compartments of the knee joint.

We believe that the tissue sparing and bone conserving techniques enabled with MAKOplasty PKA can offer substantial advantages to patients, surgeons and healthcare providers. Because of the minimally invasive nature of the procedure, smaller incisions are possible, which lead to less tissue damage and faster recoveries, thereby reducing the overall costs of rehabilitation, medication and hospitalization. In addition, because more of the patient’s natural anatomy is preserved and less trauma is inflicted on the knee, we believe that patients who undergo MAKOplasty PKA have the potential to experience better functionality and more natural knee motion, thereby achieving an improved post-operative quality of life. Our RESTORIS family of knee implants for use in single and bicompartmental knee resurfacing procedures provides the ability to address a broad range of the patient population suffering from early to mid-stage knee osteoarthritis. Finally, because our RIO system is easy to use, we believe that our MAKOplasty PKA solution makes knee resurfacing procedures accessible to orthopedic surgeons with varied levels of training and skills and has the potential to lead to greater adoption of knee resurfacing solutions for early to mid-stage osteoarthritis of the knee.

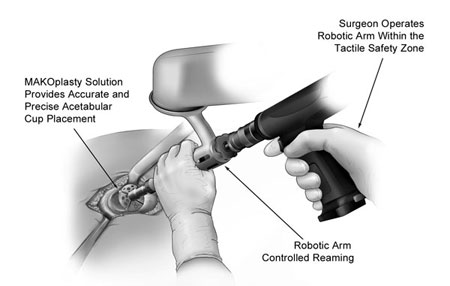

We also offer MAKOplasty THA, a surgical solution that enables orthopedic surgeons to perform total hip arthroplasty with the same potential for consistently reproducible precision, accuracy, and dexterity as MAKOplasty PKA. In the same way that the cutting system of the RIO allows for the precise resection of bone in the knee joint, we believe that surgeons will use the RIO for MAKOplasty THA to accurately plan and prepare the patient’s acetabulum, or hip socket, for the implantation of a replacement cup, and accurately plan and prepare the placement of the femoral stem. During the insertion of the cup implant, the RIO can assist the surgeon in accurately positioning the cup implant at the orientation to the femoral stem implant that was planned by the surgeon on a preoperative computed tomography, or CT, scan. Additionally, the robotic-arm assisted reaming and cup impaction assure accurate placement of the cup at the planned center of rotation and maximize cup

6

fixation. We believe that MAKOplasty THA will allow surgeons to seat these implants according to a plan that is optimized for each patient and at a level of accuracy that we believe is extremely difficult to accomplish manually, resulting in placement of the implants in the optimal position to reduce the chance of dislocation and reduce surface wear.

A total of 45 new RIO systems were sold worldwide in 2012, bringing the total number of worldwide commercial MAKOplasty sites to 156 and domestic commercial MAKOplasty sites to 151, each as of December 31, 2012. A total of 10,204 MAKOplasty procedures were performed in 2012 and, as of December 31, 2012, approximately 23,000 MAKOplasty procedures had been performed since commercial introduction in June 2006.

As of February 21, 2013, we have sixty-nine scientific studies, either recently completed or in progress, which are aimed at measuring the clinical and economic value of MAKOplasty as follows: twelve studies are focused on quantifying the accuracy of MAKOplasty procedures; twelve studies are focused on assessing basic clinical and radiographic outcomes; eight studies are focused evaluating the functional and kinematic outcomes of patients; nine studies are focused on supporting implant design and product development; eighteen studies are focused on codifying surgical technique, ergonomic robotic use, and surgical indications; and ten studies are focused on quantifying the economic impact of less invasive and more accurate arthroplasty.

As of February 21, 2013, we have an intellectual property portfolio of more than 300 U.S. and foreign, owned and licensed, patents and patent applications relating to the areas of computer assisted surgery, robotics, haptics and implants.

We generate revenue from unit sales of our RIO system, sales of our implants and disposable products and sales of maintenance services.

Industry Background

The Growing Osteoarthritis Problem

Osteoarthritis is a common medical condition that leads to the degeneration of joints from aging and repetitive stresses, resulting in a loss of the flexibility, elasticity and shock-absorbing properties of the joints. As osteoarthritis disease progresses, the cartilage and other soft tissues protecting the surfaces of key joints in the body, including knees, hips and shoulders, deteriorate, resulting in substantial and chronic joint pain, numbness and loss of motor function. This pain can be overwhelming for patients and can have significant physical, psychological, quality of life and financial implications. According to estimates by the National Institutes of Health, or NIH, 27 million people in the U.S., age 25 and older, suffer from osteoarthritis.

Compelling demographic trends, such as the growing, aging and more active population and rising obesity rates, are expected to be key drivers in the continued growth of osteoarthritis occurrence. The NIH projects that by 2030, approximately sixty-seven million people in the U.S. will be 65 years or older and will be at high risk of developing osteoarthritis. According toNational Health and Nutrition Examination Study, it is estimated that of the U.S. population over the age of 20, approximately 33% was overweight and 42% was obese or seriously obese in 2009-2010. According toThe Orthopaedic Industry Annual Report for the year ended December 31, 2011, 22% of the U.S. overweight population and 31% of the U.S. obese population will be diagnosed with some form of osteoarthritis compared to only 16% of the U.S. normal and underweight population.

For the most severe cases of osteoarthritis, in which patients suffer from extreme pain, reconstructive joint surgery may be required. Reconstructive joint surgery involves the removal of the bone area surrounding the affected joint and the insertion of one or more artificial implants as a replacement for the affected bone. According toThe Orthopaedic Industry Annual Report, global sales of joint replacement products in 2011, including knees, hips, elbows, wrists, digits and shoulders, exceeded $13.8 billion, slightly more than 50% of which were attributed to sales in the United States.The Orthopaedic Industry Annual Report also reported that of the over $13.8 billion of global sales of joint replacement products in 2011, $12.78 billion was attributed to

7

knee and hip products. According toMillennium Research Group’s 2012 Report, the U.S. large joint reconstructive implant market (composed of hip and knee implant systems) will grow to approximately $7.2 billion by 2016.

Introduction of Minimally Invasive Surgery

Over the past thirty years, one of the most significant medical trends has been the development of minimally invasive methods of performing surgical procedures. Compared to traditional, open surgical techniques, minimally invasive techniques that employ image guided surgical systems offer potentially superior benefits for patients, surgeons and hospitals. For patients, these techniques result in reduced procedure-related pain and less scarring at the incision site, leading to faster recovery times and shorter post-operative hospital stays, as well as better aesthetic outcomes. For the surgeon, these techniques can reduce procedure-related complications and have the potential to reduce risks associated with more invasive procedures. For the hospital, these procedures can result in reduced hospital stays from faster recovery times and lower rates of complications.

Despite the many benefits of minimally invasive techniques, however, these techniques also present several notable limitations due to the restricted surgical space, including:

|

|

|

| • | restricted vision at the anatomical site; |

|

|

|

| • | cumbersome handling of surgical instruments; |

|

|

|

| • | difficult hand-eye coordination; and |

|

|

|

| • | limited tactile feedback. |

Minimally invasive approaches have seen substantial adoption in various surgical fields where procedures can be performed within existing anatomical cavities of the human body. However, because of the limitations of minimally invasive techniques, they have been less successful for complex surgical procedures requiring cutting and replacement of large anatomical parts that nevertheless require precision and control.

Introduction of Robotics into Other Surgical Fields

We believe that the application of robotic technologies in minimally invasive surgical procedures represents the next generation in the evolution of the surgical technique. These technologies are being developed to provide surgeons with a more precise, repeatable and controlled ability to perform complex procedures by offering increased visual acuity and greatly improved tactile feedback. These characteristics empower surgeons to better control their surgical technique and limit the margin of error.

With the assistance of robotic technologies, an increasing number of surgeons have been able to perform procedures previously limited to a small subset of highly skilled surgeons. In addition, robotic technologies have allowed these procedures to be performed in a more minimally invasive manner, requiring only small incisions, which can result in reduced procedure related trauma, fewer infections and post-procedure complications and reduced recovery and hospitalization periods.

Robotic technologies have been successfully applied in a variety of diverse medical fields including urology, gynecology, cardiothoracic surgery, general surgery, radiosurgery and catheter based interventional cardiology and radiology. The success of robotic technologies in these applications has led to the growing adoption and commercialization of these technologies throughout the medical world.

The Use of Robotics in Orthopedic Surgical Procedures

Despite the success of robotic technologies in other medical fields, prior to the introduction of

8

MAKOplasty only limited applications had been commercialized in the field of orthopedics, although, as further described in the “Competition” section below, we are aware of certain orthopedic robotic development by other companies. Some orthopedic companies have introduced instruments that incorporate additional information like position, force, or mechanical alignment and are marketed as “smart instruments,” but these instruments still require large incisions, trauma to the soft tissue and removal of large portions of the bone to perform the surgical procedure. Orthopedic companies have also introduced computer assisted surgical, or CAS, systems that are designed for use in open procedures. However, while these systems do provide a less invasive means of viewing the anatomical site, their benefits are marginal because, unlike with robotics, they do not improve a surgeon’s ability to execute a consistently reproducible and precise surgical action through a relatively small incision.

Introduction of Patient Specific Instrumentation and Implants

A recent trend in orthopedics is the use of patient specific instrumentation and implants in total and partial knee arthroplasty. The patient specific instrumentation and implants are developed by orthopedic implant manufacturers using digitized information obtained from a preoperative CT scan or magnetic resonance imaging, or MRI, of the affected knee joint. During surgery, the surgeon is able to seat the patient specific cutting instrumentation in position for cutting more quickly than with traditional surgical instrumentation. The surgeon then implants either a traditional, off the shelf knee implant or a patient specific knee implant.

We believe patient specific instrumentation and implants present several limitations, including the following:

|

|

|

| • | The patient specific instrumentation does not accommodate intra-operative adjustments of implant position and orientation and does not incorporate intra-operative information such as soft tissue balancing in the implant plan. |

|

|

|

| • | The fit of the patient specific instrumentation on the bone is subject to potential misalignment and subsequent inaccuracies in bone cuts and final implant position. |

|

|

|

| • | The patient specific instrumentation introduces an additional recurring disposable expense to the procedure. |

|

|

|

| • | Most patient specific instrumentation is developed using a preoperative MRI in order to fit the instrumentation to the cartilage surface, which may add additional expense to the procedure in comparison to MAKOplasty. |

Three different studies presented at the 2012 American Association of Hip and Knee Surgeons (Patient Specific Instrumentation Does Not Shorten Surgical Time: A Prospective Randomized Trial,RCT Multicenter Comparison of Primary TKA using Patient Specific versus Conventional Instrumentation, and Patient Specific Instrumentation versus Large Console Computer Assisted Navigation in Total Knee Arthroplasty) showed no significant advantages for patient specific instrumentation over conventional instrumentation or navigation. In particular, these studies found that patient specific instrumentation is unable to reproduce the same degree of alignment accuracy as traditional surgical navigation and exhibited longer surgical times to deliver similar, not superior, alignment to traditional instrumentation.

We believe that the limitations of currently available surgical options for osteoarthritic disease have created a sizeable market for treatment of a large and growing population of patients with osteoarthritic disease. We believe that robotic technologies are the key to enabling surgeons to perform the kind of consistently reproducible and precise surgery that results in restoration of function and improved post-operative outcomes for such patients.

9

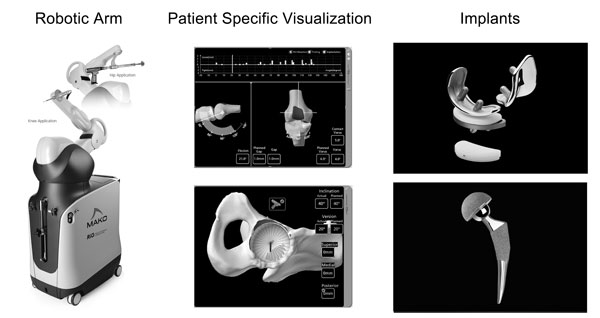

The MAKO Solution

We have designed our MAKOplasty solution to provide the consistently reproducible precision, accuracy and dexterity necessary for a surgeon to successfully plan and perform orthopedic arthroplasty procedures. Our MAKOplasty solution is composed of two critical components: the RIO system, which consists of the proprietary tactile robotic arm and our patient specific visualization system that provides both pre-operative and intra-operative guidance to the surgeon, and our RESTORIS family of implant systems that are designed for optimized restoration of the diseased compartments of the joint. By integrating robotic arm and patient specific visualization technologies with the touch and feel of the surgeon’s skilled hand, MAKOplasty is designed to enable a level of surgical precision and accuracy that is beyond the scope of the typical surgeon’s manual capabilities, which we believe will result in broad adoption of our technologies by orthopedic surgeons and better outcomes for patients. We believe MAKOplasty offers the following key benefits to patients, surgeons and hospitals:

|

|

|

| • | Consistently Reproducible Precision. We believe that MAKOplasty reduces the variability of procedure outcomes and increases efficacy through the consistently reproducible precision provided by our computer assisted and tactile robotic arm technology. We believe that the precision of our cutting process and placement and alignment of implants according to a preoperative plan leads to significantly improved and reliable results, compared to conventional, manually executed orthopedic procedures. The surgeon retains control of the actual movements of the robotic arm within a pre-established volume of space, the tactile “safety zone,” which is tracked and bounded by the RIO system. We believe that the tactile “safety zone” enables improved placement and alignment of the implant, while the visualization guides the surgeon through each step of the procedure. We believe that this consistently reproducible precision enables physicians to be trained in the use of MAKOplasty in a relatively short period of time and also will increase the number of physicians who are willing and able to perform MAKOplasty procedures. |

|

|

|

| • | Ease of Use. We believe that our RIO system leverages and complements the surgical skills and techniques already familiar to the surgeon, while providing substantial incremental control and precision that has not previously been possible. The customized, patient specific visualization system guides the surgeon through each step of the surgical procedure, while the tactile “safety zone” ensures that the surgeon does not apply the bone cutting instrument beyond the intended area. We believe that the RIO’s ease of use makes MAKOplasty procedures accessible to orthopedic surgeons with a broad range of training and skills and has the potential to lead to greater adoption of MAKOplasty procedures. We also believe that the ease of use provided by the RIO may enable physicians to shorten operating room time and potentially allows for treatment of a greater number of patients. |

|

|

|

| • | Improved Restorative Post-Operative Outcomes. Due to the reproducible and precise nature of the MAKOplasty procedure, we believe that patients who undergo MAKOplasty are likely to experience less tissue loss, less visible scarring and a faster recovery, thereby reducing the cost of rehabilitation, physical therapy, medication and hospitalization. In addition, because of the improved placement and alignment of the implants, patients who undergo MAKOplasty have the potential to experience better mobility, comfort, range of motion and more natural joint movements to achieve an improved post-operative quality of life. |

|

|

|

| • | Reduced Costs for Patients, Hospitals, and Third-Party Payors. The consistently reproducible precision of MAKOplasty has the potential to aid hospitals, third-party payors and patients in reducing costs by shortening hospital stays and recovery periods and reducing the amount of rehabilitation and medication. |

|

|

|

| • | Patient Optimized Implant Systems.Because all implants used in MAKOplasty procedures are sized and planned for based on patient-specific anatomical indications, utilizing a preoperative CT scan of the patient’s anatomy, the potential for favorable clinical outcomes is enhanced. We believe that our proprietary knee resurfacing implants allow surgeons to customize a knee resurfacing solution for individual patients facing early to mid-stage osteoarthritis in one or two compartments of the knee joint. Our RESTORIS MCK implant system, which has represented the significant majority of our |

10

|

|

|

|

| MAKOplasty procedure volume, provides for this same choice for medial or lateral unicompartmental disease and allows for the resurfacing of the patellofemoral compartment as well, either independently or in combination with the medial compartment in a bicompartmental MAKOplasty PKA. Similar to our commercialization strategy with knee implant systems, we initially utilized and sold commercially available implant systems for use in performing MAKOplasty THA and, in the fourth quarter of 2012, we commercially released our proprietary hip implant system, the MAKO RESTORIS PST Cup and Tapered Stem implant. |

The comprehensive nature of the MAKOplasty solution also provides hospitals with the implants and disposable products necessary to perform the MAKOplasty procedures. We believe that our complete solution represents a substantial improvement over currently available approaches.

The figure below illustrates the MAKOplasty solution.

Our Strategy

Our goal is to continue to drive sales of the RIO system and generate recurring revenue through sales of implants, disposable products and service contracts by establishing MAKOplasty as the preferred surgical procedure for patients with osteoarthritic disease. We believe that we can achieve this objective by working with hospitals and surgeons to demonstrate potential key benefits of MAKOplasty, such as consistently reproducible surgical precision, improved post-operative outcomes and reduced healthcare costs. Our strategy includes the following key elements:

|

|

|

| • | Focus on key physicians and thought leaders to encourage adoption of our MAKOplasty solution. We plan to continue to focus our marketing efforts on key orthopedic surgeons who are actively involved in the development and use of innovative orthopedic approaches. We also plan to continue to focus our marketing efforts on the hospitals with which these key surgeons are affiliated and engage them to promote the benefits of MAKOplasty. Our strategy is to convince hospitals that through early adoption of MAKOplasty and acquisition of our RIO system, they can improve their clinical outcomes and, as a result, reinforce their reputations as leading institutions for the treatment of osteoarthritic disease. |

|

|

|

| • | Drive volume sales of our RESTORIS family ofimplant systems and disposable products for installed RIO systems. We intend to increase the number of orthopedic surgeons who use our RIO system and work with the hospitals and their surgeons to promote patient education about the benefits of MAKOplasty. Our goal is to increase utilization per RIO system to drive higher volume sales of our RESTORIS family of implant systems and disposable products. |

|

|

|

| • | Expand the market for multicompartmental knee resurfacing. We plan to expand the market for multicompartmental knee resurfacing procedures by encouraging use of the MAKOplasty PKA procedure for patients who, given only conventional surgical alternatives, would have opted for total knee replacement surgery or no surgery at all. Our current application of MAKOplasty PKA is for unicompartmental and bicompartmental knee resurfacing procedures using the RESTORIS family of knee implant systems, allowing us the potential of accommodating varied patient profiles and surgeon preferences. We believe that the potential benefits of our MAKOplasty PKA solution and the combination of these product offerings will facilitate our efforts to expand and capture the market for multicompartmental knee resurfacing. |

|

|

|

| • | Deliver consistently reproducible precision to additional orthopedic procedures, including total hip arthroplasty.We believe that the introduction of MAKOplasty THA will increase the overall value proposition for MAKOplasty by enabling surgeons to use the RIO system to perform total hip arthroplasty with the same consistently reproducible precision, accuracy, and dexterity as MAKOplasty |

11

|

|

|

|

| PKA, resulting in the placement of the hip implants in the best position to reduce the chance of dislocation and reduce surface wear. We believe this expansion of our product offerings will facilitate our efforts to increase the number of commercial MAKOplasty sites, the number of orthopedic surgeons who use our RIO system, and the utilization at our existing MAKOplasty sites. |

|

|

|

| • | Demonstrate the clinical and financial value proposition of MAKOplasty. We intend to continue to collaborate with leading surgeons and hospitals through such programs as our MAKOplasty Center of Excellence to build clinical and financial data that support the benefits of MAKOplasty. The MAKOplasty Center of Excellence is a program developed in conjunction with participating hospitals to educate surgeons and patients regarding the benefits of MAKOplasty. As part of the collaborative program, participating hospitals agree to maintain and provide us with certain clinical and financial data that we use to support the business and clinical case for the MAKOplasty solution. Our goal is to obtain clinical data further supporting the value of MAKOplasty procedures, as well as the accuracy of such implant placements and resulting longevity of the implants, while demonstrating to hospitals the top and bottom line financial benefits of our MAKOplasty solution. Furthermore, if we are able to commercialize additional applications for our RIO system, we believe that we would be able to further enhance the financial value proposition of MAKOplasty to hospitals. |

The Knee

Market for Osteoarthritis of the Knee

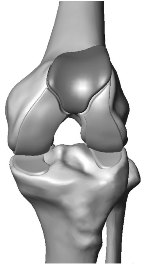

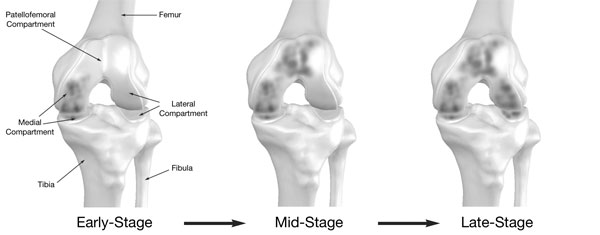

The knee joint consists of the medial, patellofemoral and lateral compartments. As depicted below by the shaded diseased areas of the knee joint, osteoarthritis of the knee usually begins with the deterioration of the soft tissue and cartilage in the medial (inner) compartment and progresses to either or both the patellofemoral (sub-kneecap) and lateral (outer) compartments. The progression of osteoarthritis of the knee, as illustrated in the figure below, can take many years, and even in the early stages, it can result in substantial pain for the patient and a reduction in the quality of life.

According to the Centers for Disease Control, there are currently more than fifteen million people in the U.S. with osteoarthritis of the knee. The growth of osteoarthritis of the knee among the U.S. population is expected to accelerate as the increasingly active population ages and obesity rates increase. TheOrthopaedic Industry Annual Report reports that being overweight significantly increases the risk of developing knee osteoarthritis and that obese women had nearly four times the risk of suffering from osteoarthritis of the knee as non-obese women, and obese men had nearly five times the risk of suffering from osteoarthritis of the knee as non-obese men. As a result of this substantial clinical need, the market for orthopedic knee procedures in the U.S. has experienced tremendous growth over the past decade and is expected to continue to experience growth. According to data compiled byMillennium Research Group, the U.S. knee implant market was approximately $4.1 billion in 2012 and is anticipated to grow to over $4.3 billion in 2016. In addition to the substantial costs of the procedure itself, total knee replacement and resurfacing procedures represent significant incremental costs to the healthcare system. These include costs associated with rehabilitation, medication, hospitalization and, over the long-term, costs incurred as a result of replacements or revisions that may be required due to wear and tear or improper placement.

Current Orthopedic Knee Arthroplasty Approaches

Arthroplasty options for treating osteoarthritis of the knee have historically been limited to either total knee replacement surgery or knee resurfacing procedures.

Total Knee Replacement. Currently, most patients who choose to surgically address osteoarthritis of the knee elect to undergo total knee replacement surgery.Millennium Research Group has estimated that 586,400

12

primary total knee replacement procedures were performed in 2012 in the United States, which represents a 2.2% increase from the estimated 573,900 such procedures performed in 2011 in the United States. Standard total knee replacement is a highly invasive surgical procedure in which a patient’s diseased knee joint is removed and replaced with a manufactured replacement knee joint comprised of several components that attempt to mimic the normal function of the knee joint. The procedure requires a large incision ranging from four to twelve inches to accommodate the complex scaffold of cutting blocks and jigs required to execute the blunt, planar cuts involved in total knee replacement surgery and to prepare the knee for insertion of the large implants. Soft tissue damage is significant in this procedure as the entire knee joint is fully exposed and much of the bone and tissue surrounding it are removed. The bone cuts are also extensive, presenting a large surface area for bone bleeding. The implants are typically manufactured out of metal, ceramic or polymers and have an approximate useful life of between fifteen and twenty years before they usually are revised or replaced.

The figures below illustrate a conventional total knee replacement surgery and implant:

|

|

|

|

Total Knee Replacement Surgery | Total Knee Implant |

Despite its long history as an established and effective orthopedic procedure, standard total knee replacement surgery is not an ideal option for many patients suffering from early to mid-stage, unicompartmental or multicompartmental degeneration of the knee. Some of the principal limitations of standard total knee replacement surgeries include:

|

|

|

| • | highly invasive nature of the surgical procedure, which requires a large incision ranging from four to twelve inches to prepare and implant the large implants; |

|

|

|

| • | significant damage to the bone and tissue surrounding the joint, including the typical removal of anterior cruciate ligament and the frequent removal of the posterior cruciate ligament; |

|

|

|

| • | substantial bone bleeding; |

|

|

|

| • | required removal of all three compartments of the knee, regardless of which compartments are actually diseased; |

|

|

|

| • | extended and often painful recovery time and rehabilitation; |

|

|

|

| • | reduced mobility and range of motion; and |

|

|

|

| • | likely implant replacement or revision in approximately 15 to 20 years when the implant reaches the end of its useful life. |

For these and other reasons, many people who are eligible for total knee replacement surgery elect not to undergo or postpone the procedure, choosing instead to suffer significant pain and limited mobility.

Partial Knee Resurfacing. Partial knee resurfacing is a less invasive arthroplasty procedure in which only the arthritic region of the knee is removed and a small implant is inserted to resurface the diseased compartment of the knee. Partial knee resurfacing procedures are ideal for patients with early to mid-stage osteoarthritis and are aimed at sparing the healthy bone, cartilage and other soft tissues typically removed in a conventional total knee replacement procedure. These procedures have traditionally been performed manually, requiring a level of training, expertise and precision that significantly exceeds what is required for standard total knee replacement surgery.Millennium Research Group has estimated that 56,800 unicompartmental knee resurfacing procedures were performed in 2012 in the United States, which represents a 1.6% increase from the estimated 55,900 such procedures performed in 2011 in the United States.

13

Partial knee resurfacing are potentially more desirable procedures than total knee replacement surgery for patients suffering from early to mid-stage degeneration of the knee because they preserve more of the patient’s natural anatomy and result in less trauma to the patient. As a result, patients experience less tissue loss and faster recoveries. However, despite the potential clinical, quality of life and cost benefits of these procedures, standard instrumented partial knee resurfacing has achieved only limited adoption to date, in part, as a result of the following limitations that make performing these procedures very difficult:

|

|

|

| • | the restricted room to maneuver and impeded line of sight due to the smaller incision and minimally invasive nature of the procedures which make it difficult to insert, place and align the implant properly; and |

|

|

|

| • | the complex process of removing portions of the bone and resurfacing the knee joint in preparation for the implant. |

The difficulties in manually executing partial knee resurfacing procedures can result in inaccurate implant alignment, which can lead to reduced range of motion and premature implant failure. In light of the difficulties, many physicians choose not to recommend these procedures and many patients choose either to live with the osteoarthritic pain or to undergo standard total knee replacement surgery. According to an article published in theJournal of Engineering in Medicine in 2009, approximately 21% of patients who underwent total knee replacement surgeries had osteoarthritis in only one compartment of the knee, qualifying them as appropriate candidates for an unicompartmental procedure.

The Hip

Market for Osteoarthritis of the Hip

Similar to the knee joint, osteoarthritis, or OA, of the hip, as illustrated in the figure below, typically begins with degeneration of the hip joint caused by a local tear in the soft tissue surrounding the acetabulum, or hip socket, or an excessive load on the cartilage caused by impingement conditions between the femur and the acetabulum. The progression of osteoarthritis of the hip can take years, but even in the early stages, it can result in substantial pain for the patient and a reduction in the quality of life.

|

|

According to data from the Centers for Disease Control, there are currently more than 3 million people in the U.S. with osteoarthritis of the hip. As a result of this substantial clinical need, the market for orthopedic hip procedures in the U.S. is expected to experience continued growth. According to data compiled byMillennium Research Group, the U.S. hip implant market was approximately $2.7 billion in 2012 and is anticipated to grow to over $2.8 billion by 2016. In addition to the substantial costs of hip arthroplasty, other treatment options for osteoarthritis of the hip represent significant incremental costs to the healthcare system. These include costs associated with rehabilitation, medication, hospitalization and, over the long-term, costs incurred as a result of replacements or revisions that may be required due to wear or improper placement.

Current Orthopedic Hip Arthroplasty Approaches

The current treatments available for osteoarthritis in the hip joint consist of sports medicine procedures to treat soft tissue damage as well as more invasive procedures to treat impingement conditions. Conventional treatment for the replacement of the joint consists of a partial hip replacement where only one side of the joint is replaced (normally utilized for hip fractures), hip resurfacing, which is primarily indicated for male patients under the age of 65, and in late stage conditions, total hip arthroplasty. Total hip arthroplasty is a highly invasive surgical procedure in which a patient’s diseased hip joint is removed and replaced with an artificial replacement hip joint comprised of several components that attempt to mimic the normal function of the hip joint. The procedure requires a large incision ranging from six to twelve inches, which often results in significant pain and an extended recovery time. Unlike the knee joint, the hip joint is covered with significant muscle and fat tissue, preventing direct access to the joint without a large incision.

14

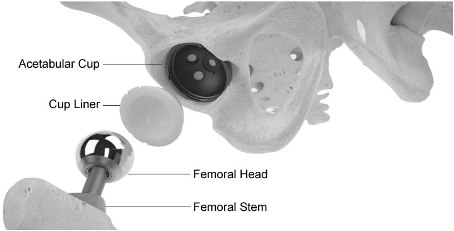

The traditional total hip replacement implant system consists of three main components:

|

|

|

| • | a metal cup and a plastic liner that together replace the acetabulum; |

|

|

|

| • | a metal stem inserted into the femoral canal that replaces the femoral neck; and |

|

|

|

| • | a highly polished metal ball that attaches onto the metal stem and replaces the femoral head. |

Despite its history as an established and effective orthopedic procedure, we believe that there are several limitations of traditionally instrumented total hip arthroplasty including malalignment of implant components, dislocation, differences in leg length, implant loosening, femoro-acetabular impingement and the eventual need for implant replacement or revision.

Dislocation, where the ball comes completely out of the replacement cup, is the most common reason for revision total hip surgery. According to an article published in theThe Journal of Bone and Joint Surgeryin 2003, the national average for dislocation of the hip joint within six months of the primary hip replacement procedure is approximately four percent, or approximately 14,000 procedures, annually. A study at Massachusetts General Hospital, which was presented at the 2010 Meetings of The Hip Society, found that fifty percent of the acetabular implant cups placed by the surgeons in the study using commonly used mechanical jigs were placed outside of the optimal zone for avoiding post-operative dislocation. Not all dislocations require a revision surgery to replace the existing implant, but according to an article published in theThe Journal of Bone and Joint Surgeryin 2009, each dislocation that requires a replacement of the existing implant costs a minimum of approximately $42,000 to the U.S. healthcare system.

Traditional surgical approaches to total hip arthroplasty may result in a leg length discrepancy, which clinical studies show may result in back pain, increased risk of nerve injury, dislocation, poor patient satisfaction, and the need for revision surgery. According to a study published inPhysiotherapy in 2009, a leg length discrepancy of ten millimeters or more is associated with a significantly poorer outcome in terms of the clinical benefits of surgery as well as more than twice the incidence of limping than patients with a leg length discrepancy of less than ten millimeters. One methodology currently used by surgeons to measure leg length involves using a ruler to measure anatomical landmarks on the hip before surgery to assess the patient’s preoperative leg length and then remeasuring the leg length with the implants in place following surgery to assess the change in the patient’s leg length. Another popular methodology used by surgeons requires the surgeon to line the patient’s legs up on the operating room table to assess the leg length before surgery and then to do the same thing with the hip implants in place after surgery. This method requires the legs to be in the exact same position at the time of both measurements and uses only the surgeon’s eyes and sense of touch to assess the change in leg length. We believe that limitations exist with respect to both of these methodologies.

OUR PRODUCTS

MAKOplasty procedures are enabled through our proprietary technology consisting of the following components: our RIO system, our joint specific MAKOplasty applications for the knee and hip, and our RESTORIS family of implant systems.

The MAKO RIO Robotic Arm Interactive Orthopedic System

The centerpiece of MAKOplasty is the RIO system, our proprietary robotic arm, interactive, orthopedic system, that provides both pre-operative and intra-operative guidance to the orthopedic surgeon, enabling tissue sparing bone removal and accurate implant insertion and alignment. The RIO system consists of two elements: a tactile robotic arm utilizing an integrated bone cutting instrument and a patient specific visualization component.

15

The figure below identifies the key components of the RIO system’s tactile robotic arm, stereo tracking system and instruments:

Tactile Robotic Arm System. The tactile robotic arm system consists of the key components identified in the figures above and incorporates the following specifications, features and benefits:

|

|

|

| • | Tactile Robotic Arm — The tactile robotic arm is designed to respond fluidly to movements initiated by the surgeon operating the bone cutting instrument. We have designed the robotic arm to achieve substantial dexterity and range of movement. The robotic arm helps enforce a tactile “safety zone” that is established by the patient specific visualization system by providing tactile resistance when the boundaries of the tactile “safety zone” are reached. This tactile resistance helps ensure that the surgeon does not move the bone cutting instrument outside the intended area. |

|

|

|

| • | Controller — The controller is the electronic hardware and firmware component of our computing system which interfaces with our proprietary surgical planning and execution software to allow the surgeon to safely guide the tactile robotic arm. The controller governs the basic, low-level functions of the tactile robotic arm, such as the tactile constraints and the safety circuit. |

|

|

|

| • | Stereo Tracking System Camera and Instruments — During a MAKOplasty procedure, the location of the tactile “safety zone” is updated continuously based on bone tracking data supplied to the computer system by an infrared stereo tracking system, which consists of a special camera that is directed toward a series of tracking arrays attached to the patient’s anatomy by bone pins. The tracking system assists the robotic arm system in locating and physically tracking the patient’s anatomy and coordinating its real time position with the cutting instrument of the robotic arm. It has a sufficient refresh rate to provide the robotic arm system with an adequate flow of information regarding movements of both the patient and the robotic arm to ensure optimal cutting and placement. Using the system, the surgeon can freely move the robotic arm within the defined space, but encounters tactile resistance as the boundaries of such space are reached. |

|

|

|

| • | End Effector — The end effector is the mechanical component by which the bone cutting instrument is attached to the tactile robotic arm. It is designed to ensure secure placement of the bone cutting instrument, while providing the flexibility necessary for the surgeon to manipulate the instrument. |

|

|

|

| • | Bone Cutting Instruments— The bone cutting instrument is integrated into the tactile robotic arm at the end effector. For MAKOplasty PKA procedures, this instrument is composed of a high speed motor and a component that houses a variety of single use bone cutting tips. The design of the bone cutting instrument allows the surgeon to grip it in a manner similar to holding a pen-like cutting tool, making it easy to manipulate the instrument in the patient’s anatomy. The cutting tip is the disposable end tip of the bone cutting instrument that makes contact with the joint and actually removes the bone for placement of the knee implant in accordance with the pre-operative surgical plan. In combination with our tactile robotic arm, the knee bone cutting instrument enables the smooth precision and accuracy necessary for MAKOplasty PKA procedures. For MAKOplasty THA procedures, the bone cutting instrument is a reamer (similar to a drill) to which hemispherical cutting baskets are attached. Surgeons currently use similar reamers and cutting tools for traditional hip replacement surgery. The tactile robotic arm in conjunction with the reaming instrument makes it possible for the surgeon to accurately and precisely prepare the bone to the pre-operative surgical plan. |

|

|

|

| • | Portable Base Console — The base component of our tactile robotic arm is a mobile unit that enables the portability of the tactile robotic arm from one operating room to another. The base console houses the controller and various electrical and mechanical components that help power the tactile robotic arm. Its design enables the console to be situated next to the patient during surgery and the tactile robotic arm to be conveniently positioned over the patient’s anatomy. |

16

The figure below identifies the key components of the RIO system’s patient specific visualization system:

Patient Specific Visualization System.Our patient specific visualization system is a vital part of our ability to deliver consistently reproducible precision. The surgeon uses our system pre-operatively to plan and intra-operatively to guide the surgical procedure. It consists of the key components identified in the figure above and incorporates the following specifications, features and benefits:

|

|

|

| • | Surgical Planning and Execution Software — Our surgical planning and execution joint specific application software, which is integrated into our patient specific visualization system, is used during the pre-operative surgical planning process to visualize and map the exact portion of bone to be removed, define the anatomical boundaries of the tactile “safety zone” and plan the optimal placement and alignment of our implants. During the procedure, the visualization system guides the surgeon through each specific, well defined surgical step and displays in real time each current and planned surgical activity, including soft-tissue balancing. The surgical plan is unique and individualized for each patient. |

|

|

|

| • | Tactile “Safety Zone” —The robotic arm enforces a tactile “safety zone” by providing tactile resistance when the boundaries of the tactile “safety zone” are reached, while our patient specific visualization system provides a visual representation of the tactile “safety zone” and provides additional visual and auditory cues when the boundaries of such tactile “safety zone” are reached. The combination of this tactile resistance and patient specific visualization helps ensure that the surgeon does not apply the bone cutting instrument beyond the intended area. |

|

|

|

| • | Instrument Locator — The instrument locator provides visual guidance on the position of the bone cutting instrument and other surgical instruments in relation to the patient’s anatomy. |

|

|

|

| • | Monitors — Prior to surgery, patients undergo a conventional CT scan that captures an image of the diseased joint. This CT image is uploaded to the patient specific visualization system for display as a 3-D volume in space. The surgeon can then virtually place the implants on the 3-D models of the patient’s bones. This patient specific visualization of our implant overlaid onto an image of the patient’s actual joint helps the surgeon to plan the procedure pre-operatively, by providing information that enables the surgeon to determine the optimal placement, alignment and sizing of the implant. The final planned placement of the implant establishes the boundaries of the tactile “safety zone” for surgery. During surgery, each monitor projects an active 3-D computer graphics visualization of the patient’s joint, showing the areas of the bone that are actually removed as the procedure progresses. The surgeon can also change the viewpoint and zoom level of the visualization as the procedure progresses to focus on different portions of the anatomy. |

|

|

|

| • | Mobile Base — The base component of our patient specific visualization system is a mobile unit that enables the portability of the patient specific visualization system from one operating room to another. It houses our computer hardware and our surgical planning and execution software and various electrical and mechanical components that help power the visualization system. |

The Current RIO System

The RIO system, which enables our MAKOplasty PKA application and MAKOplasty THA application, incorporates the following technical features which we believe allow us to expand the breadth of our clinical applications as well as implant offering and provide the benefits of MAKOplasty to more surgeons and patients:

17

|

|

|

| • | high dexterity and range of motion in the robotic arm enabled by the six degrees of freedom in the movement of the robotic arm; |

|

|

|

| • | increasingly more efficient physical configuration of the patient specific visualization system, robotic arm, customized bone cutting instruments and electronic components; |

|

|

|

| • | ability to perform a full range of partial knee arthroplasty procedures, including medial unicompartmental knee procedures, lateral compartment knee procedures, isolated patellofemoral knee procedures, and bicompartmental knee procedures, as well as total hip arthroplasty procedures; |

|

|

|

| • | intelligent implant planning features to aid surgeon efforts to achieve optimal patient specific alignments; |

|

|

|

| • | intelligence related to operating room workflow and configurations to reduce operating room set up times; |

|

|

|

| • | modular design of certain components for ease of manufacturability and assembly and to make them more accessible for service repairs; and |

|

|

|

| • | sophisticated industrial design, including enhanced system ergonomics, and state-of-the art user interface. |

The RIO system is a closed platform, as only our RESTORIS family of implant systems may be effectively used with our RIO system and MAKOplasty applications. In addition, users of the RIO system are contractually required to purchase all implants and disposable products used in MAKOplasty procedures from us.

We commercially launched the RIO system in the first quarter of 2009. In the third quarter of 2009, we launched version 2.1 of our RIO system, which reflected further refinement of the RIO platform and MAKOplasty PKA application. In the fourth quarter of 2009, we launched version 2.2 of our RIO system, which modified the MAKOplasty PKA application to enable surgeons to treat lateral compartment knee arthritis. We launched version 2.3 of our RIO system in the third quarter of 2010, version 2.4 in the second quarter of 2011, and version 2.5 in the third quarter of 2012, each of which further enhanced the RIO and associated applications to improve functionality, efficiency and ease of use. In the third quarter of 2011, we commercially introduced version 1.0 of our MAKOplasty THA application for the RIO system. We launched version 2.0 of our MAKOplasty THA application in the third quarter of 2012, which enabled the direct anterior approach for the MAKOplasty THA procedure, as well as the use of the MAKO RESTORIS PST Cup and Tapered Stem implant, designed in collaboration with Pipeline Orthopedics, as further described in the “MAKOplasty THA Products - The RESTORIS Family of Hip Implant Systems” section below.

MAKOplasty PKA Products

MAKOplasty PKA application

Unlike conventional knee replacement surgery, which requires extraction and replacement of the entire joint, our MAKOplasty PKA application enables surgeons to isolate and resurface just one or two specific diseased compartments of the joint through a minimally invasive incision, preserving significantly more soft tissue and healthy bone of the knee. The precision provided by our RIO system robotic arm and MAKOplasty PKA application makes such minimally invasive targeted treatment possible by eliminating the complex scaffold of cutting blocks and jigs that would otherwise be required to execute the blunt, planar bone cuts and insert the large implants involved in conventional total knee replacement surgery or a manually executed resurfacing procedure. Because of the minimally invasive nature of the MAKOplasty PKA procedure, smaller incisions are possible, which lead to less tissue damage and faster recoveries, thereby reducing the overall costs of rehabilitation, medication and hospitalization. In addition, because more of the patient’s natural anatomy is preserved and less trauma is inflicted on the knee, we believe that patients who undergo MAKOplasty PKA have the potential to experience better functionality and more natural knee movements, thereby achieving an improved post-operative quality of life. We believe that our MAKOplasty PKA application will make minimally invasive

18

orthopedic procedures, like unicompartmental and bicompartmental knee resurfacing, a viable option for a greatly expanded pool of patients and physicians.

The figure below illustrates a MAKOplasty PKA procedure.

The MAKOplasty knee resurfacing procedure is performed by the surgeon using the surgical planning and execution joint specific application software integrated into our patient specific visualization system. The figure below illustrates an actual MAKOplasty knee resurfacing procedure and the corresponding virtual representation of the MAKOplasty PKA application on the patient specific visualization system.

The RESTORIS Family of Knee Implant Systems

MAKOplasty PKA employs a knee implant system that is designed for insertion and cementation in a minimally invasive manner. Prior to the development and commercialization of the MAKO-branded, RESTORIS family of knee implant systems in late 2008, we provided our customers with off-the-shelf unicompartmental tibial inlay and tibial onlay implants from third-party suppliers. Currently, we offer the RESTORIS MCK unicompartmental and bicompartmental knee implant system for use with the RIO system and MAKOplasty PKA application.

The RESTORIS family of knee implant systems allows an orthopedic surgeon to treat early through mid-stage degenerative osteoarthritis of the knee with a modular implant system. We believe that modular components are key to the successful execution of minimally invasive knee surgeries because they can be more easily inserted into the knee joint through smaller incisions than a single, complete device. They can also be positioned independently to better accommodate the specific contours of the patient’s anatomy. Because of the technical design and programming, only the RESTORIS family of knee implant systems may be used effectively with our RIO system and MAKOplasty PKA application.

The RESTORIS onlay knee implant system is designed to accommodate patients who lack tibia sclerotic bone beds of sufficient quality. The metal support is placed horizontally on a planar surface prepared on the tibia using the RIO system, supported by the tibial cortical rim, rather than fitted into a pocket of the tibia. Some surgeons also prefer to utilize the tibial cortical rim support in all cases. Patients with relatively good tibial bone quality, including a sufficiently thick and appropriately located bed of hardened sclerotic tibial bone, are generally candidates for our RESTORIS inlay knee implant system.

The RESTORIS MCK unicompartmental and bicompartmental knee implant system offers an implant geometry to support the tissue and bone sparing goals of MAKOplasty PKA. Free from the limitations of manual instrumentation, RESTORIS MCK is designed to accurately mimic human anatomy, providing better coverage of diseased compartments while requiring less bone removal and tissue trauma than with traditional treatments.

The RESTORIS MCK system, depicted in the figures below, enables surgeons to treat patients suffering from osteoarthritis in any single compartment of the knee joint: the medial (inner), lateral (outer), or patellofemoral (sub-kneecap). The RESTORIS MCK system also enables bicompartmental treatment of the patellofemoral compartment in combination with the medial compartment. Utilizing a modular, bicompartmental system, a surgeon can use the pre- and intra-operative planning software in the RIO system to produce a patient specific implant plan, the result of which is the retention of a greater portion of the knee anatomy than patients treated with a total knee arthroplasty procedure. Surgeons are able to offer inlay and onlay implants medial configurations for both their unicompartmental and bicompartmental procedures. The product offering of the RESTORIS MCK system also features a patellofemoral component (under the kneecap), which is inset into the knee compartment between the medial and lateral (outer) compartments. Additionally, the surgeon has an array of patella “buttons” to affix to the back of the kneecap to replace the worn surface.

19

|

|

|

|

RESTORIS MCK Unicondylar | RESTORIS MCK Patellofemoral |

|

|

|

|

|

|

RESTORIS MCK Unicondylar | RESTORIS MCK Patellofemoral | RESTORIS MCK Lateral |

|

|

|

|

|

|

|

RESTORIS MCK Bicompartmental | RESTORIS MCK Bicompartmental |

MAKOplasty THA Products

MAKOplasty THA application

We believe our MAKOplasty THA application has the potential to add clinical and economic value in arthroplasty procedures in the hip joint. Our MAKOplasty THA application utilizes the RIO system’s tactile, visual and auditory feedback to assist the surgeon in preparing the acetabulum (hip socket) for optimal placement of the acetabular cup implant and femoral stem. The MAKOplasty THA application allows the surgeon to preoperatively plan the placement of the hip implants on a three dimensional image of a pre-operative CT scan, which we believe results in a plan that is optimized for each patient. The RIO system’s robotic arm then assists the surgeon in preparing the bone accurately to the pre-operative surgical plan, as well as in the positioning of the hip implant, which we believe may potentially decrease the likelihood and severity of implant impingement and dislocation that may result from the potential inaccurate placement of the acetabular cup with standard instrumented method of implant placement, which involves the use of mechanical jigs and visual alignment by the surgeon.

We believe our MAKOplasty THA application has the potential to provide a surgeon with the same consistently reproducible precision, accuracy, and dexterity as our MAKOplasty PKA application. In the same way that the cutting system of the RIO robotic arm allows for the precise resection of bone in the knee joint, we believe that surgeons will use the robotic arm to accurately plan and prepare the patient’s acetabulum for the cup implant and accurately plan and prepare the placement of the femoral stem. Moreover, unlike in MAKOplasty PKA, during the final insertion of the cup implant, the robotic arm assists the surgeon in positioning the cup at the orientation that was planned by the surgeon preoperatively. A study at Massachusetts General Hospital, which was presented at the 2010 Meetings of The Hip Society, found that fifty percent of the acetabular implant cups placed by the surgeons in the study using commonly used mechanical jigs were placed outside of the optimal zone for avoiding post-operative dislocation. We believe that our MAKOplasty THA application provides the surgeon with an accurate preoperative surgical plan, knowledge of the patient’s position on the operating room table and accurate implant sizing. We believe this information allows the surgeon to seat the implants according to the plan at a level of accuracy within plus or minus five degrees from the surgeon’s desired cup placement for both cup inclination and cup version. We believe this level of accuracy may result in optimal implant position to resist dislocation, which is difficult to accomplish manually. We also believe that the MAKOplasty THA application allows the surgeon to minimize leg length discrepancy to plus or minus three millimeters, which we believe is an improvement over the manual methodologies currently used by surgeons to measure leg length.

20

The figure below illustrates a MAKOplasty THA procedure.

The RESTORIS Family of Hip Implant Systems

The hip implant market, unlike the partial knee implant market, is based on multiple, differing implant philosophies, which results in most orthopedic companies offering a variety of hip implants options in order to satisfy the requirements of a majority of surgeons. In order to address these differing philosophies, we currently offer a variety of hip implant options for use with the RIO system and our MAKOplasty THA application. As was the case with early MAKOplasty PKA commercialization, our initial hip implant options included off-the-shelf hip implant systems from third-party suppliers pending the development and commercialization of a proprietary MAKO-branded RESTORIS family of hip implant systems in the fourth quarter of 2012.

In connection with the commercial release of the MAKOplasty THA application in 2011, we began to distribute a hip implant system manufactured by Corin PLC, depicted in the figures below, which we are marketing under the brand names RESTORIS Metafix for the femoral stem and the RESTORIS Trinity for the acetabular cup. The RESTORIS Metafix stem addresses a French implant philosophy based on the compaction, rather than the removal, of bone from the femoral canal, followed by the implantation of a fully hydroxyapatite-coated femoral stem into the femur. A stem representing this philosophy is listed in the Norwegian Joint Replacement Registry as one of the best for femoral stem survivorship.

We have also entered into a license and supply agreement with Total Joint Orthopedics, Inc. for the distribution of a second hip implant system, depicted in the figures below, which we commercially released in the first quarter of 2012 under the brand name RESTORIS Z. The RESTORIS Z hip implant system addresses the Zweymuller femoral stem philosophy, which is based on the implantation of a square peg in a round hole in order to gain immediate rigid fixation. The femur is prepared using square broaches and implanting a square stem. The Zweymuller philosophy is European-based and has a twenty-five year clinical track record with several long-term clinical studies supporting the use of its stem. We believe Zweymuller stems are one of the most frequently used stems worldwide.

As further described in the “Research and Development” section below, we entered into a Strategic Alliance Agreement with Pipeline Biomedical Holdings, LLC, or Pipeline, in October 2010 to develop and supply future advanced implant technologies for use with our RIO system including the development of a proprietary MAKO-branded RESTORIS family of hip implant systems for use with the MAKOplasty THA application. This collaboration resulted in the RESTORIS PST Cup and Tapered Stem implant system, depicted in the figures below, which was commercially released in the fourth quarter of 2012. The RESTORIS PST Cup and Tapered Stem implant system incorporates a modern blade stem design, novel, proprietary porous technology incorporated with the implant cup, and a vitamin E enhanced polyethylene liner. We believe this hip implant system is designed based on the broadest market philosophy for femoral implants in the United States.

|

|

|

|

|

|

RESTORIS Metafix and RESTORIS Trinity | RESTORIS Z Hip Implant System | RESTORIS Tapered Stem and PST |

We believe that the variety of hip implant options offered for use with the RIO system and our MAKOplasty THA application has the potential to address the requirements of a majority of orthopedic surgeons who perform total hip arthroplasty. Each of the above-described implant systems can be used for all types of bone quality and stages of joint disease.